Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

784 results about "Sodium tungstate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium tungstate is the inorganic compound with the formula Na₂WO₄. This white, water-soluble solid is the sodium salt of tungstic acid. It is useful as a source of tungsten for chemical synthesis. It is an intermediate in the conversion of tungsten ores to the metal.

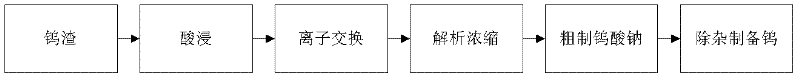

Tungsten slag treatment method

ActiveCN102212697ASolve the problem of secondary pollutionReduce recycling costsProcess efficiency improvementSlagFiltration

The invention discloses a tungsten slag treatment method. The tungsten slag treatment method comprises the following steps of: dissolving: mixing tungsten slag and 15 to 30 percent HCl solution of 50 to 65 DEG C, adding a tungsten stabilizing agent, and performing filtration after the reaction is finished to obtain acid solution; and reclaiming tungsten: adsorbing the tungsten in the acid solution by adopting weak alkali acrylic acid series anion exchange resin to obtain tail solution I, resolving the exchange resin by using sodium hydroxide solution to obtain sodium tungstate, and reclaimingthe tungsten from the sodium tungstate. By using the technical scheme, the tungsten slag is leached at a low temperature under normal pressure by adopting the HCl solution, and the tungsten is directly reclaimed by a one-step method under the acid condition; and the process is simple and low in reclamation cost.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

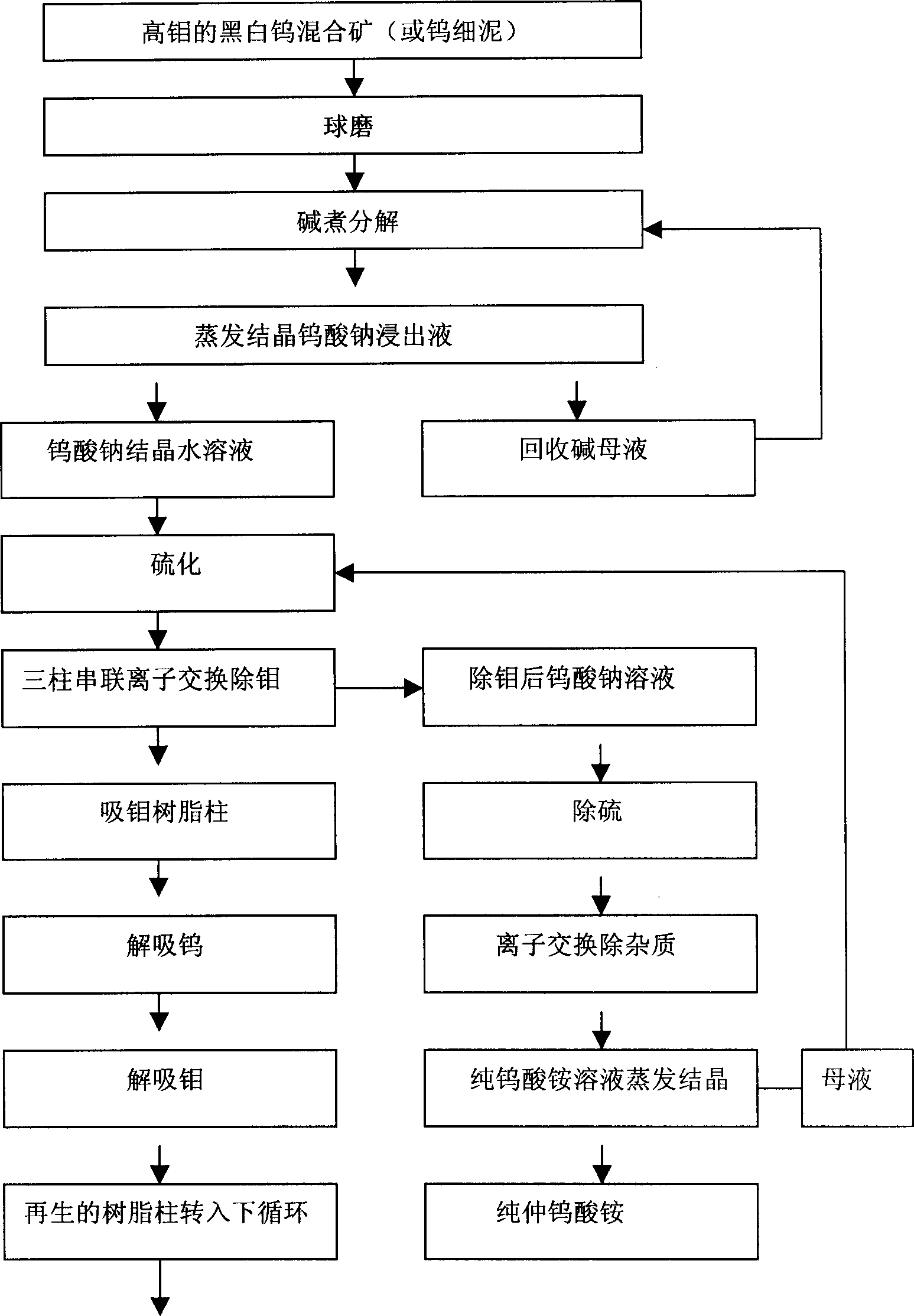

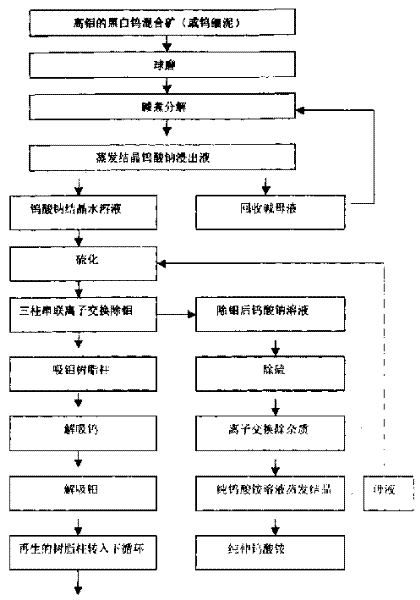

Process for preparing high purity ammonium para-tungstate using hihg-molybdenum tungsten ore

The present invention provides a method of treating high-molybdenum tungsten mineral or tungsten slime by means of three-ion column exchange molybdenum-eliminating technology so as to obtain ammoniumpara-tungstate with high purity at low cost. The treating process includes grinding, alkali leaching, filtering and concentration to obtain sodium tungstate crystal; water dissolving, filtering and sulfurizing sodium tungstate; ion exchange to eliminate molybdenum; desulfurizing sodium tungstate liquid; ion exchange to elimiante impurity and desorbing tungsten with ammonia water and ammonium chloride solution to prepare ammonium tungstate solution; and evaporation to obtain ammonium para-tungstate crystal. The present invention has low cost.

Owner:王旭升 +1

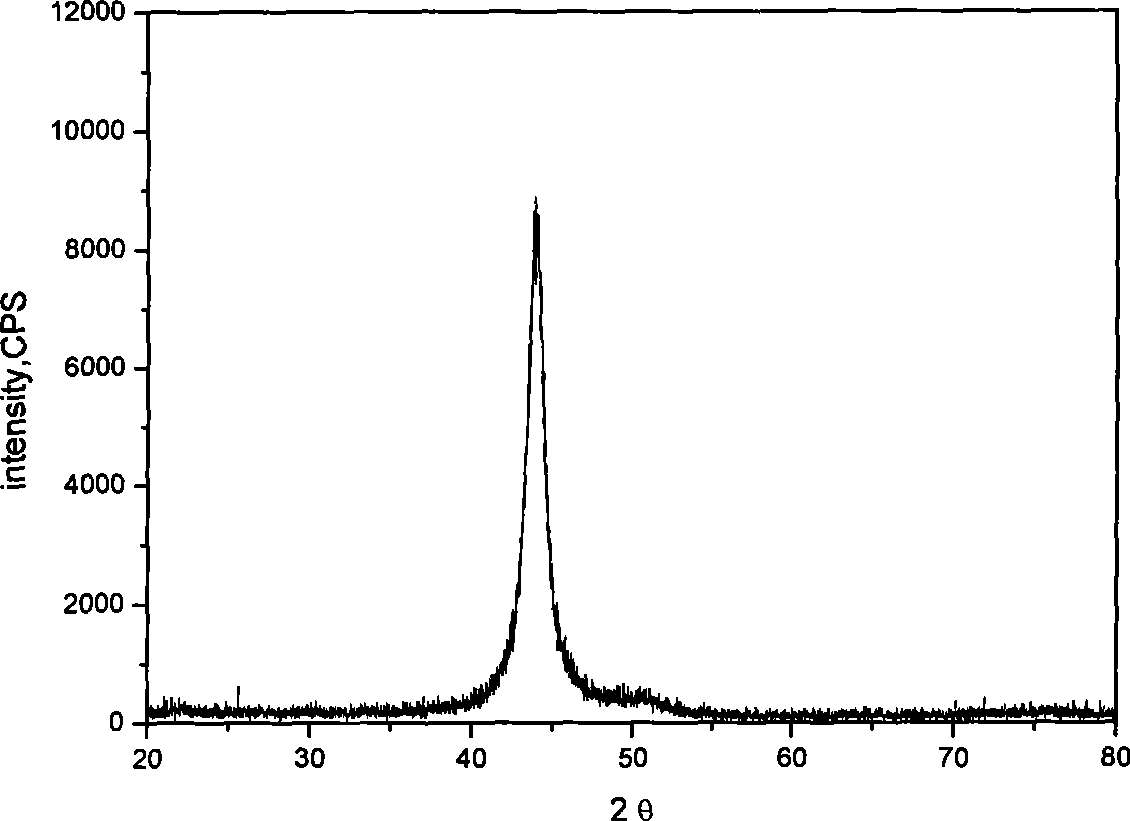

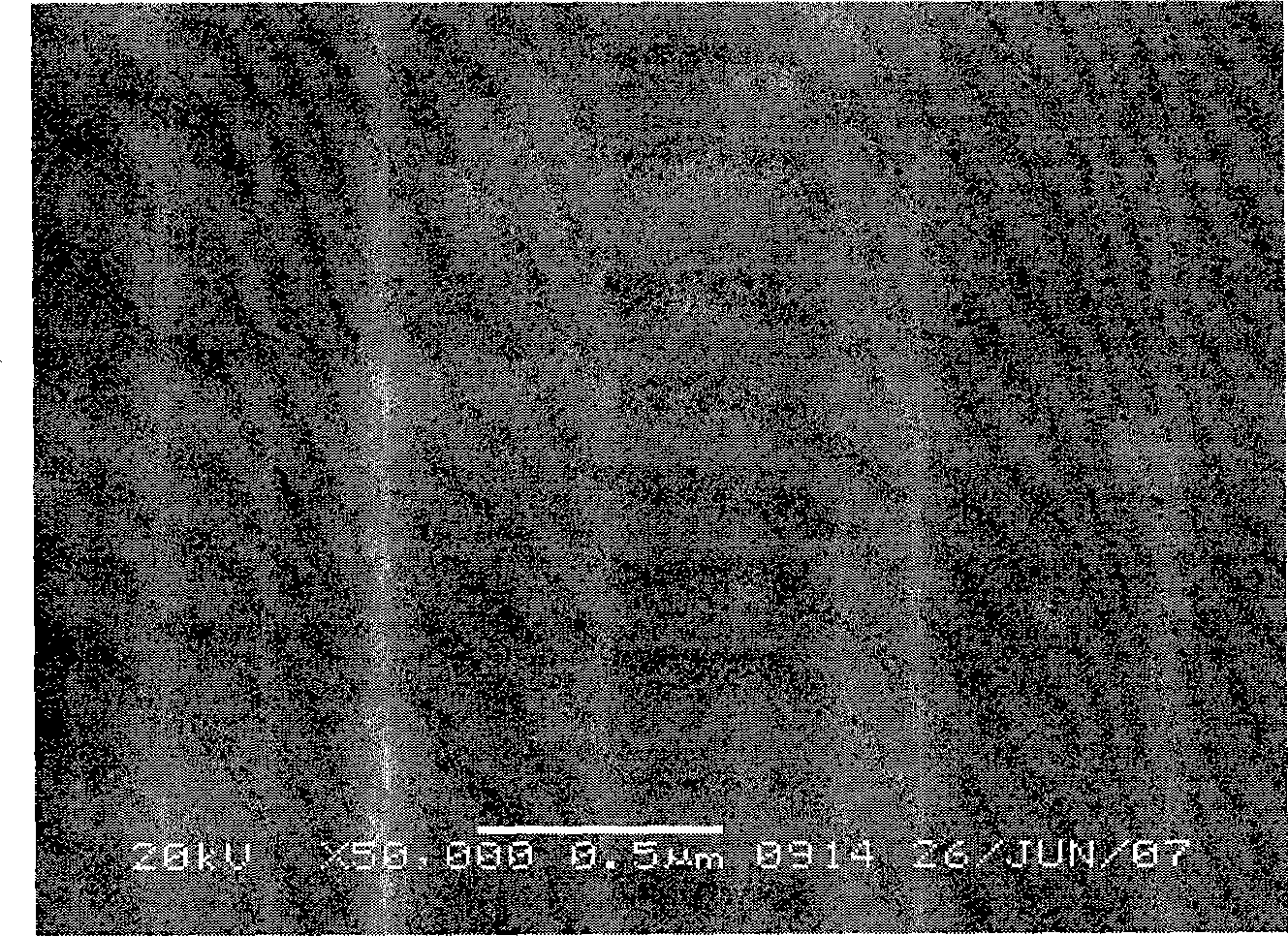

Anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplate liquid thereof

The invention relates to an anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplates liquid thereof, which takes the nickel sulfate, sodium tungstate, phosphate as the main material, electrically depositing the Ni-WP amorphous mixture of amorphous or nanocrystalline alloy coating. The characteristics of the electroplate technique are following: corrosive solution is very small, the entire production of the use of cleaner production, less emissions, in line with the requirements of sustainable production. W of the coating for the content of 1-45wt%, P content of 0.1-5wt%, nickel is the residue. The plating layer is bright and dense; the hardness is 400-1100Hv, which is resistant to acid, alkali, salt and hydrogen sulfide corrosion, wear resistance is better than or equivalent to chrome plating, can not only replace decorative chromium or hard chromium is widely used, and can be used for oil field exploration equipment to deal with wear-resistant anti-corrosion.

Owner:湖南纳菲尔新材料科技股份有限公司

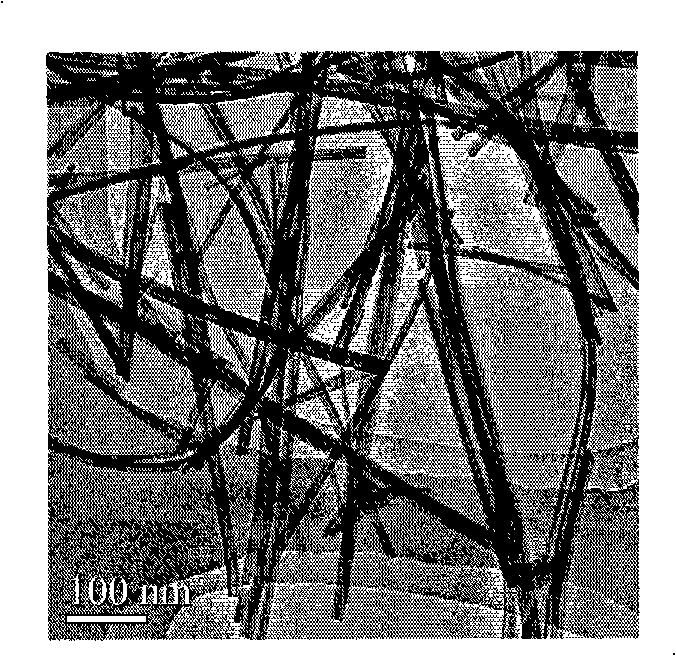

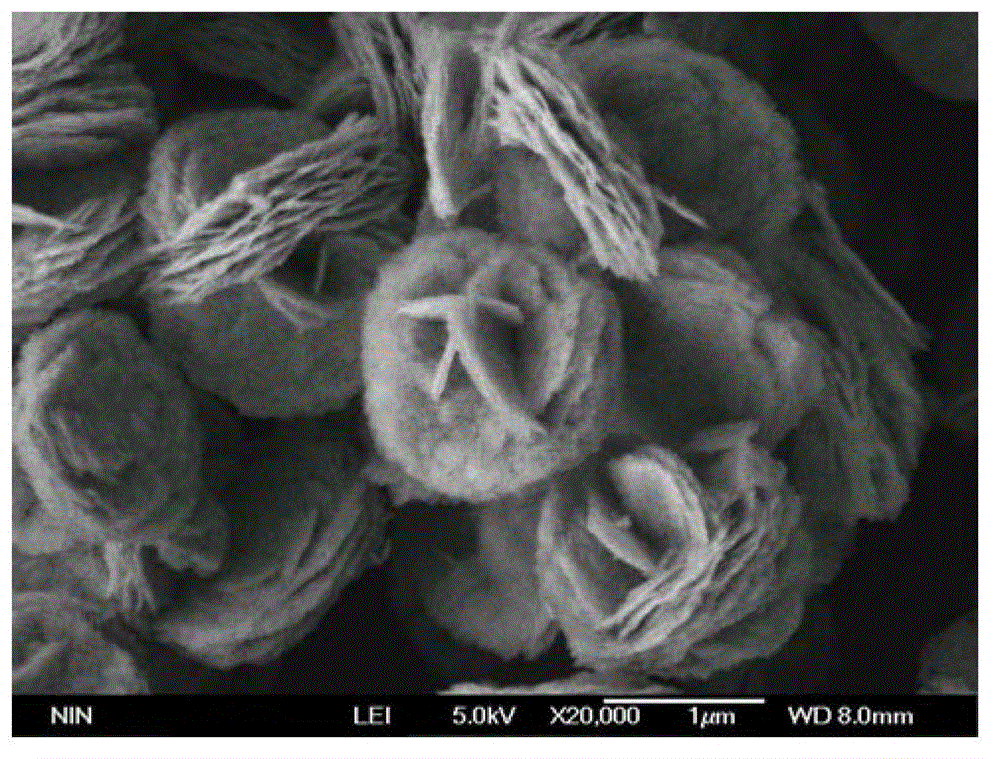

Tungstic oxide nano-wire and method for preparing tungstic oxide nano-wire gas-sensitive sensor

InactiveCN101318704AReduce consumptionLarge specific surface areaTungsten oxides/hydroxidesMaterial analysis by electric/magnetic meansAdhesiveMicellar solutions

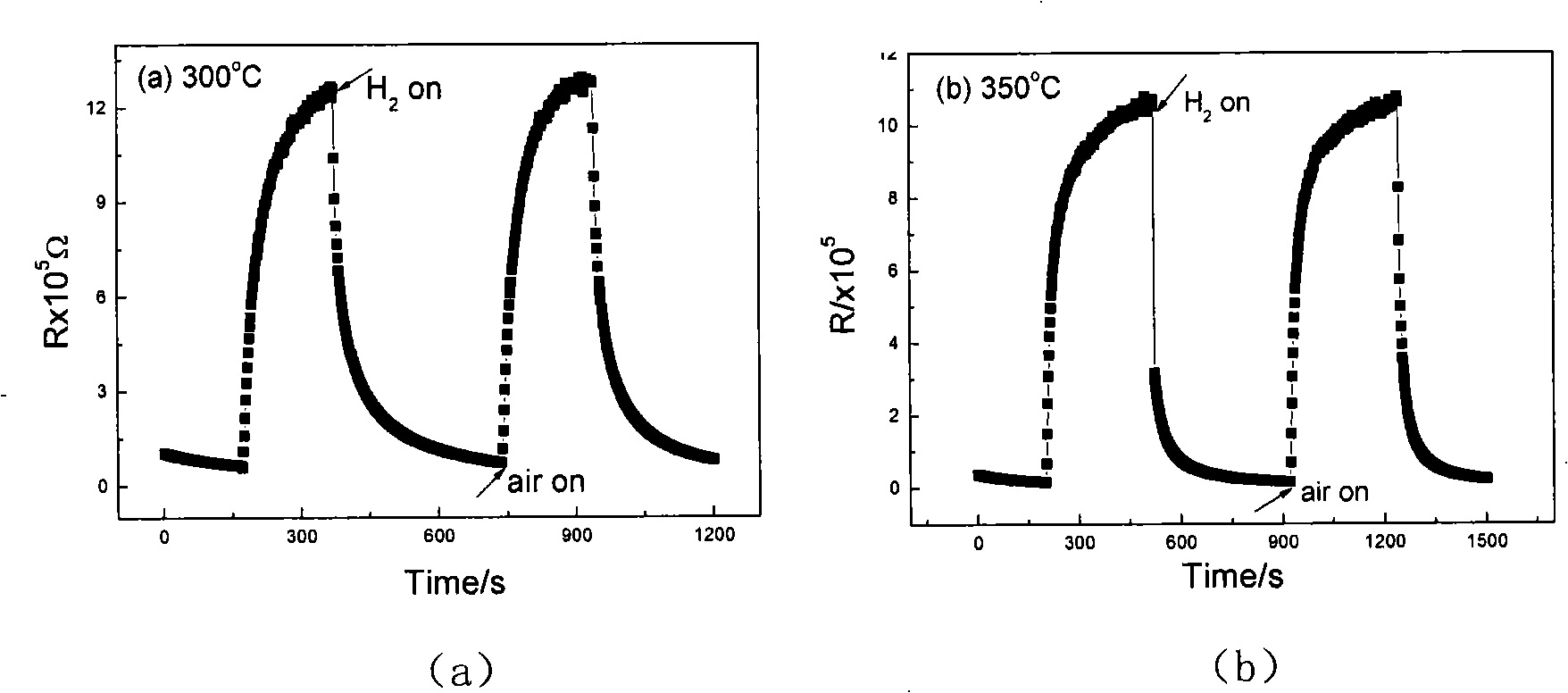

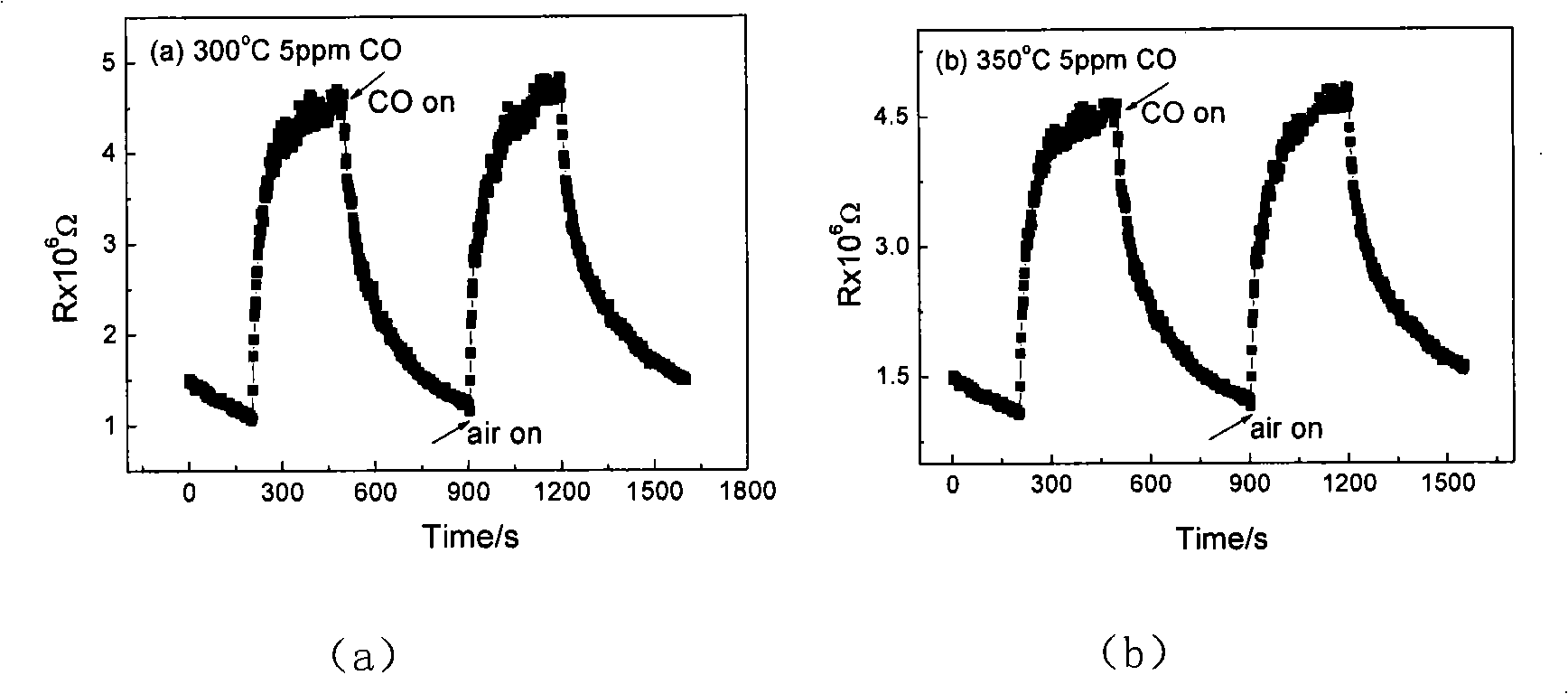

The invention relates to a method for preparing a tungsten oxide nano-wire and a tungsten oxide nano-wire ammonia-sensitive sensor, belonging to the one dimensional nano oxide material preparation and gas-sensitive technical field. The method comprises the following steps that: sodium tungstate is dissolved in deionized water to prepare a sodium tungstate solution; a hydrochloric acid is dripped slowly to prepare a flaxen micellar solution which is then centrifugally separated; products are uniformly dispersed in a potassium sulfate solution which is then transferred into a reaction kettle for hydrothermal reaction, and then the tungsten oxide nano-wire is prepared; adhesives and frit are added into the tungsten oxide nano-wire, and then the tungsten oxide nano-wire ammonia-sensitive sensor is prepared after element sintering and ageing. The method has simple steps, easily controlled technological parameters during the preparation process, and very low energy consumption during the whole preparation process; the tungsten oxide nano-wire prepared has a large specific surface area and high thermal stability; and the tungsten oxide nano-wire ammonia-sensitive sensor prepared has high sensitivity on low-concentration (between 1 and 100 pars per million) H2, CO and NH3, good repeatability and high stability.

Owner:TSINGHUA UNIV

Process for preparing high-purity ammonium paratungstate

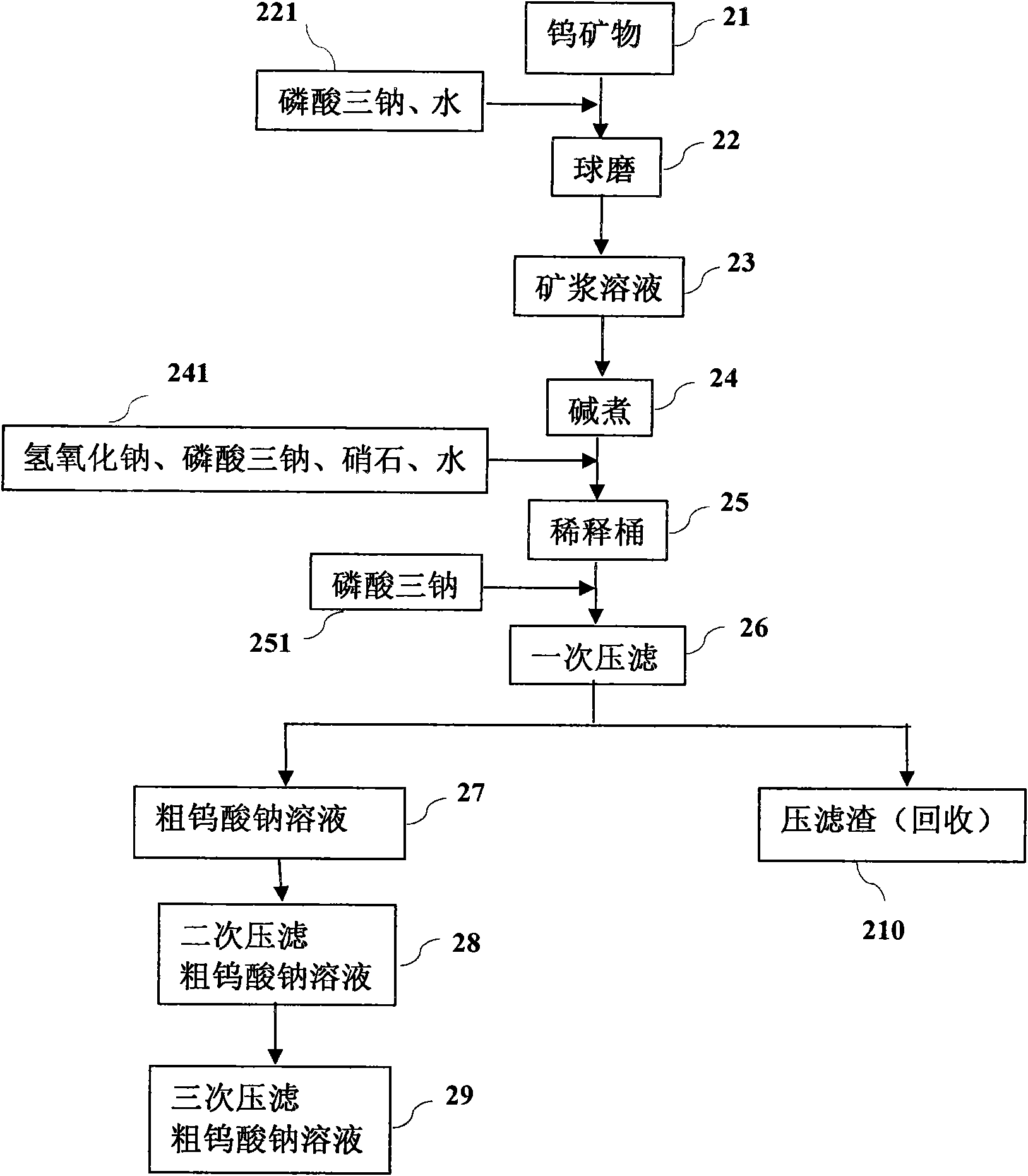

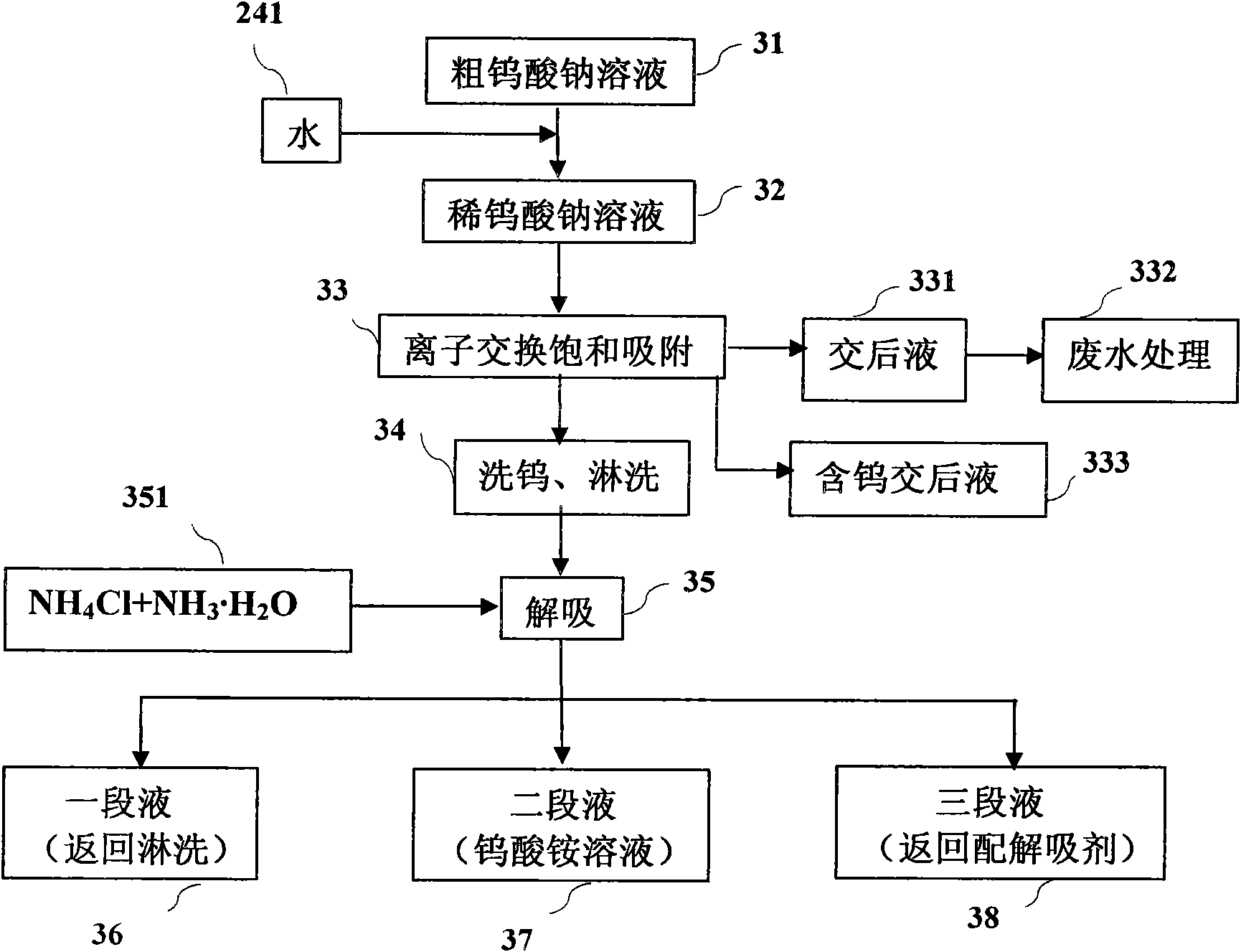

The invention relates to a process for preparing high-purity ammonium paratungstate, which can obtain a non-ferrous metal product, namely the ammonium paratungstate with low impurity content, whereinthe impurity content of the ammonium paratungstate is low and is lower than 70 ppm, and the ammonium paratungstate can be directly used for preparing deep processed products of tungsten, such as tungsten powder with low impurity content and the like. The process comprises the following four process steps: (1) a process step of preparing a sodium tungstate solution by using a tungsten concentrate (Fe, Mn)WO4, white tungsten (CaWO4) or a tungsten middling product as a raw material; (2) a process step of performing ion exchange on the sodium tungstate solution; (3) a process step of performing impurity removal and filtration by using an ammonium tungstate solution; and (4) a process step of performing crystallization, washing, drying and screening. The process for preparing the high-purity ammonium paratungstate optimizes the technological processes, improves the quality of a product, and reduces the preparation cost of the product.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

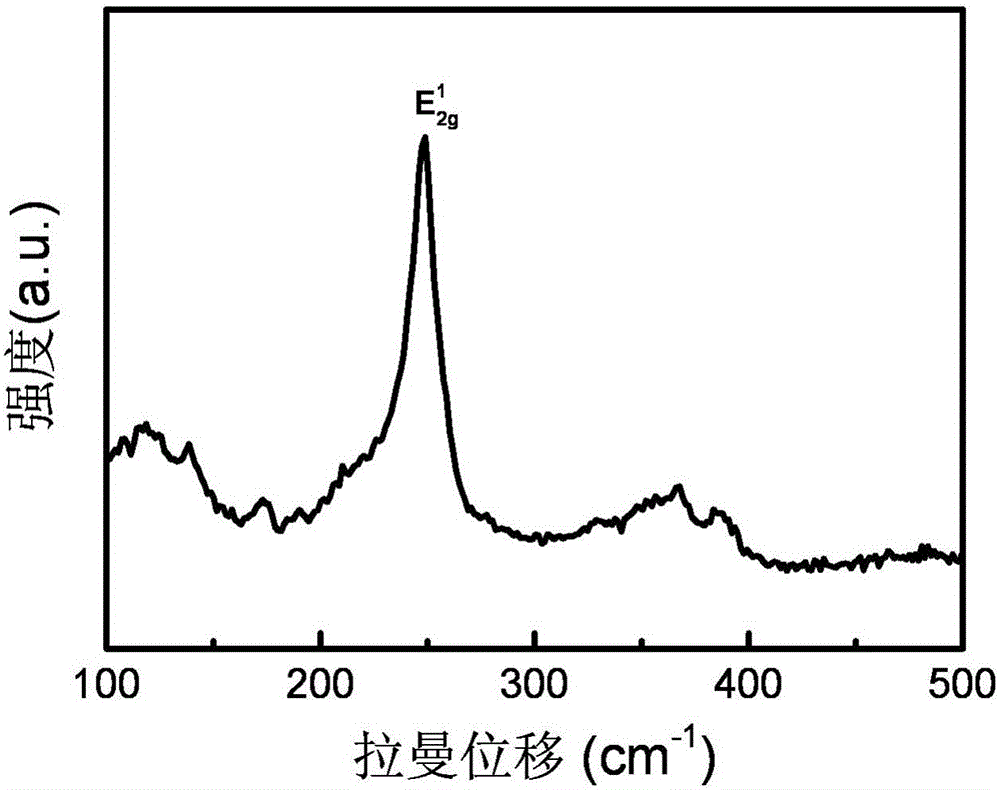

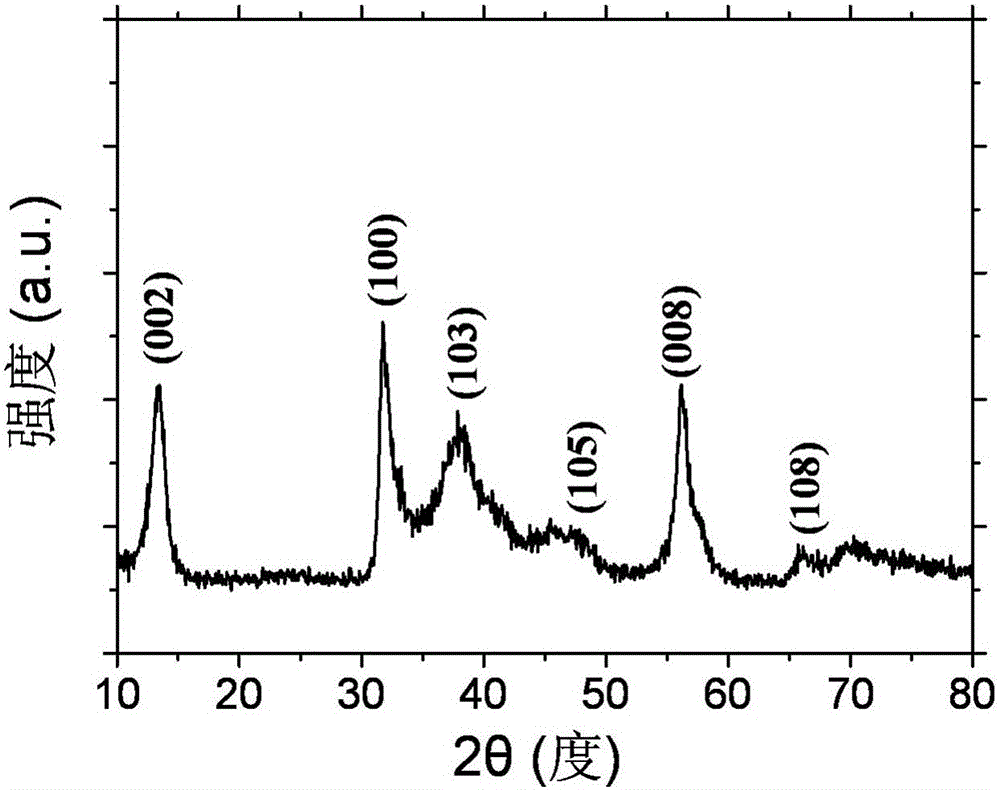

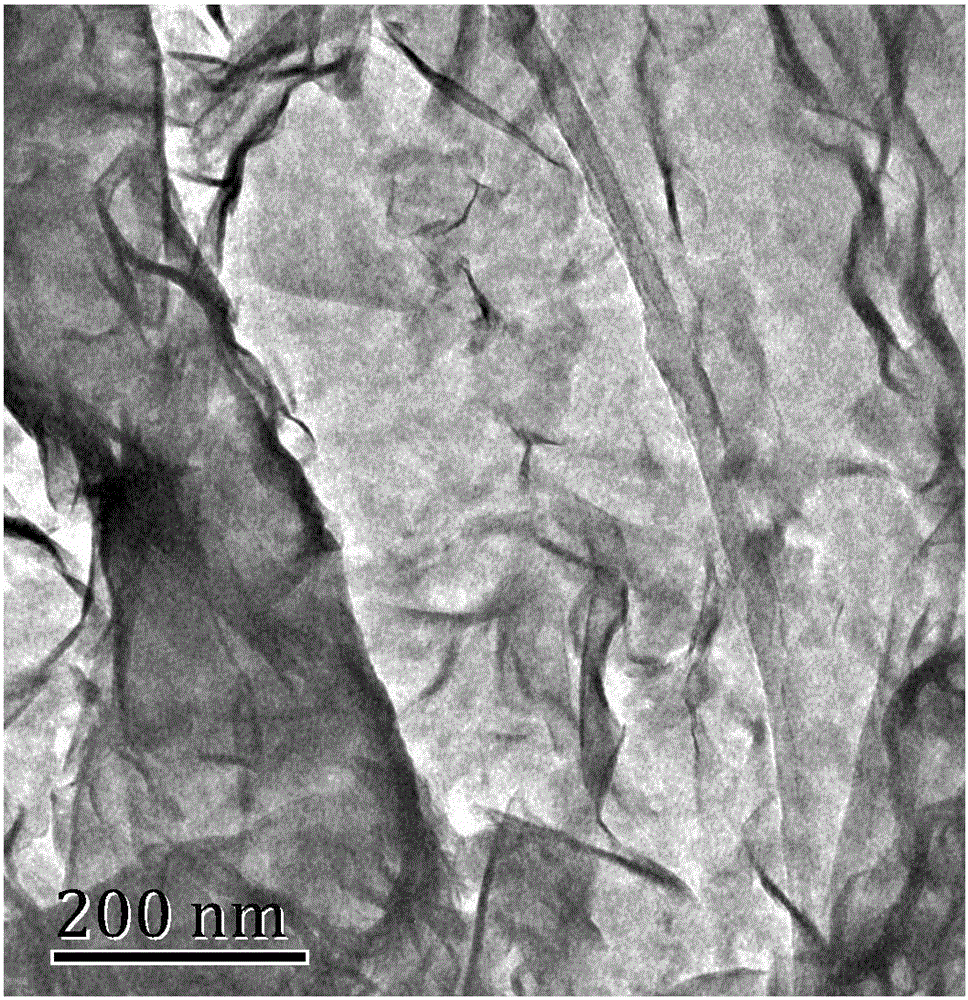

Preparation method of tungsten diselenide nanosheet

InactiveCN105776154AImprove crystal qualityLarge scaleNanotechnologyMetal selenides/telluridesFiltrationSolvent

The invention discloses a preparation method of a tungsten diselenide nanosheet, and belongs to the technical field of nanometer material preparation. The preparation method comprises the following steps of dissolving sodium borohydride into an organic solvent, and successively adding selenium powder and sodium tungstate to prepare a mixed solution; transferring the mixed solution to a reaction kettle, and performing reaction for 6 to 48 hours at 200 DEG C to 240 DEG C; after the temperature of the reaction kettle is naturally cooled to the room temperature, collecting black products through suction filtration; washing the product by deionized water and ethyl alcohol; freezing and drying the washed product to obtain the tungsten diselenide nanosheet. The invention provides the method for synthesizing the tungsten diselenide nanosheet in one step by a solvothermal method for the first time. The preparation method has the advantages that the raw materials are green and environment-friendly; the cost is low; the yield is high; the reaction condition is mild; the scale production can be realized. The high-crystallization tungsten diselenide nanosheet prepared by the method has the advantages that the size is great; the layer number is small; the distribution is uniform; the specific surface area is high; high application prospects are realized in the fields of catalysis, energy storage and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

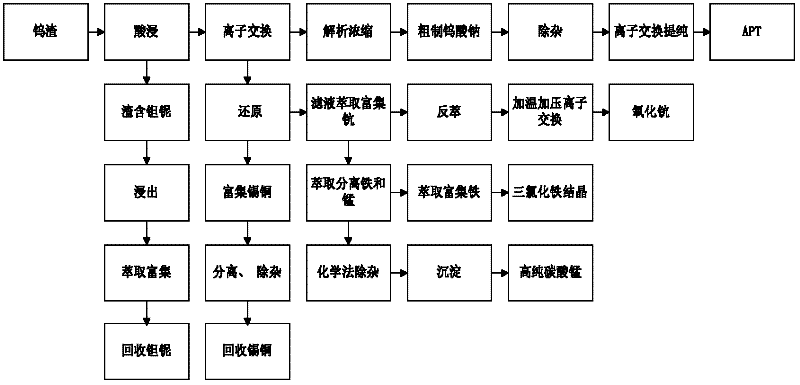

Method for separating and extracting metallic tungsten and molybdenum from molybdenum removal slag generated by smelting tungsten

InactiveCN101333598AReduce pollutionNo secondary pollutionProcess efficiency improvementSlagFiltration

The invention provides a novel wet separation method for separating and extracting metallic tungsten and molybdenum from molybdenum-removing slag produced by a sulfide method in the tungsten smelting, sequentially comprising: fully dissolving tungsten and molybdenum metallic elements by directly using (1-4)mol / L alkali solution under the conditions of agitation and temperature of 60 DEG C to 100DEG C to obtain an alkaline solution with a pH value of over 9 and then filter the alkaline solution; neutralizing the solution to have a pH value of 7.5 to 8.5 with (1-4)mol / L acid and filtering the solution; adjusting the acid to make the solution have a pH value of 2 to 3 at a temperature of under 60DEG C, then warming the solution to above 90DEG C and preserving the heat for 1 to 5 minutes, and cooling the solution to under 60DEG C for filtration, so as to obtain an acidulous tungstenic dilute solution and precipitation of molybdenum trisulfide; and gaining a sodium tungstate solution of (100-200)g / L by adopting the conventional process; and the method can effectively separate and extract valuable metals such as tungsten and molybdenum, and has advantages of stable and simple process and low treatment cost.

Owner:CHENZHOU DIAMOND TUNGSTEN PRODS

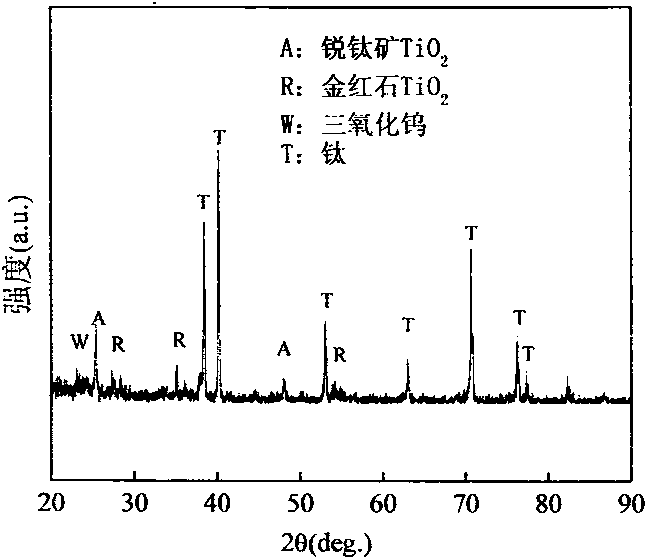

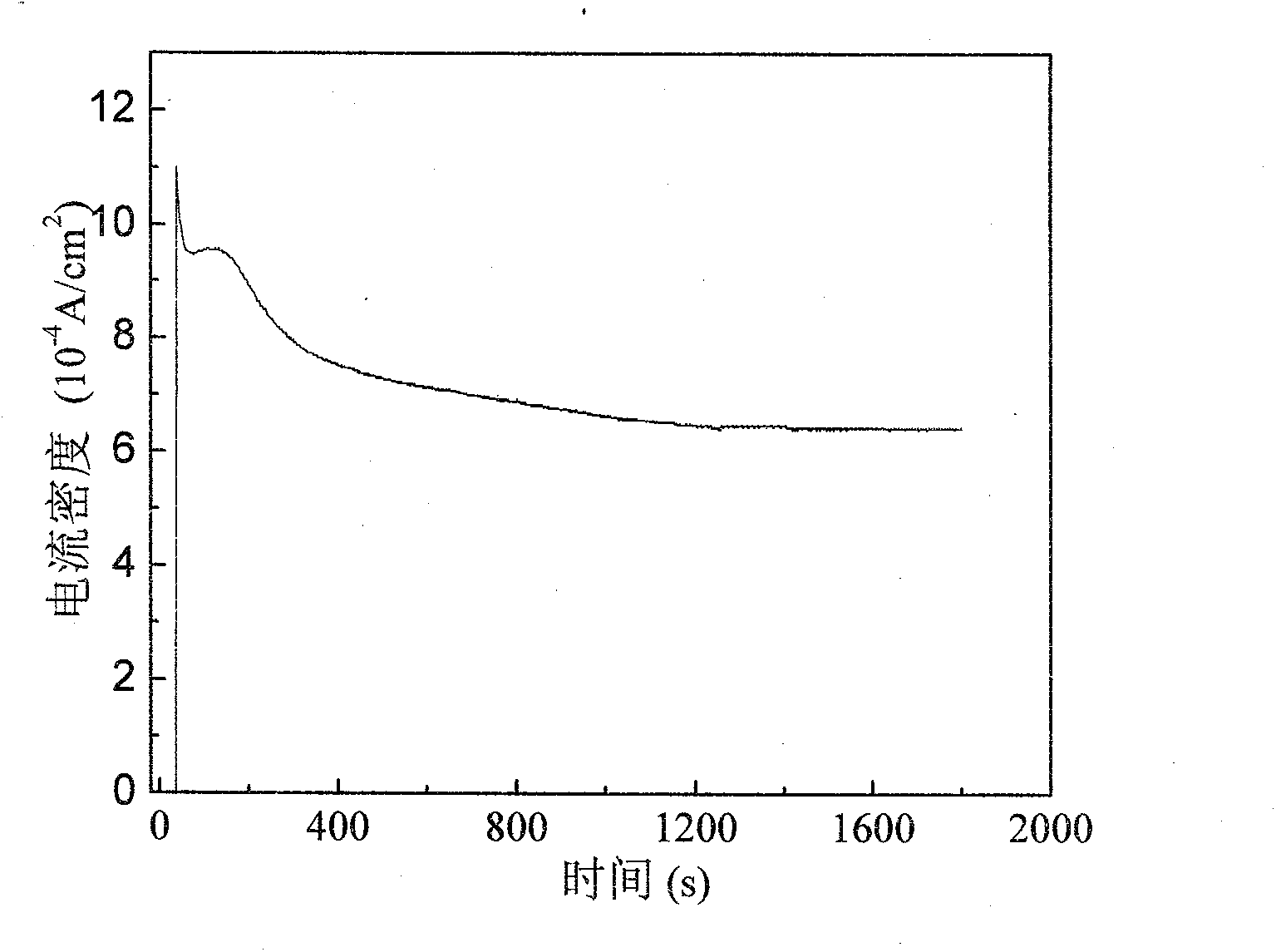

Method for preparing titanium dioxide nanotube array photoelectrode

ActiveCN103361689ANo pollution in the processImprove stabilitySurface reaction electrolytic coatingSolubilityVisible light photocatalytic

The invention discloses a method for preparing a titanium dioxide nanotube array photoelectrode. The method comprises the following steps of: 1, pretreating a titanium sheet; 2, by taking the pretreated titanium sheet as a substrate, preparing a titanium dioxide nanotube array by employing a constant current constant voltage anodic oxidation method; 3, calcining and cooling the titanium dioxide nanotube array, and obtaining a titanium dioxide nanotube array with different crystal structures; 4, by taking graphite powder as a raw material, preparing oxidized graphene with water solubility; 5, by taking the titanium dioxide nanotube array in the step 3 as a working electrode, taking a platinum electrode as a counter electrode, performing pulse deposition reduction in sodium tungstate and oxidized graphene solutions of different concentrations by utilizing a three-electrode system; 6, calcining the prepared photoelectrode under the vacuum condition of 100-300 DEG C to prepare graphene and tungsten trioxide modified titanium dioxide nanotube array photoelectrode. The raw materials in the preparation process are non-toxic, the preparation conditions are mild, the prepared electrode has high stability, the photocatalytic activity is high, and the electrode is environmentally-friendly and has high visible-light catalytic activity.

Owner:QINGDAO AGRI UNIV

Treatment method of black hard microarc oxidation ceramic membrane on surface of magnesium alloy

InactiveCN102021631AUniform colorImproved color stabilityAnodisationElectrolysisPlasma electrolytic oxidation

The invention belongs to the treatment technology of a black hard ceramic membrane on the surface of magnesium alloy, in particular relating to a treatment method of a black hard microarc oxidation ceramic membrane on the surface of magnesium alloy. The invention mainly solves the technical problems that the colour of a ceramic membrane treated by magnesium alloy microarc oxidation is white or grey white mostly and the deep colour and even black ceramic membranes can not be obtained in the prior art. The method provided by the invention comprises the steps that sodium phosphate, sodium fluoride, sodium hydroxide, sodium molybdate, potassium carbonate, sodium tungstate, copper sulphate and potassium dichromate are added into water and prepared into an alkaline electrolytic solution, and the solution is stirred for later use; and then magnesium alloy and a stainless steel plate are immersed into the alkaline electrolytic solution, the magnesium alloy is taken as an anode, the stainless steel plate is taken as a cathode, and microarc oxidation treatment is carried out until a compact black hard ceramic membrane grows in situ on the surface of the magnesium alloy.

Owner:杭州意来客电器设备有限公司

Super-wide-temperature-range nickel-hydrogen battery and manufacturing method therefor

ActiveCN105390755AImprove conductivityLower ohmic resistanceCell seperators/membranes/diaphragms/spacersFinal product manufacturePotassiumNickel electrode

The invention discloses a super-wide-temperature-range nickel-hydrogen battery. The battery comprises an iron shell as well as a nickel electrode, a hydrogen electrode, a diaphragm and an electrolyte solution mounted in the iron shell, wherein the nickel electrode takes foam nickel as a substrate material; the space in foam nickel is filled with a positive electrode active substance Ni(OH)2, a conductive agent, an additive and a binder; the hydrogen electrode takes a porous nickel-plated steel belt, a copper net or foam nickel as a substrate material; the porous nickel-plated steel belt, the copper net or foam nickel is coated with a negative electrode active substance, namely, hydrogen storage alloy powder, the conductive agent, the additive or the binder; and the electrolyte solution is a mixture of a potassium-rich alkaline aqueous solution and sodium tungstate or tungstic acid crystals. The invention furthermore discloses a manufacturing method for the super-wide-temperature-range nickel-hydrogen battery. According to the super-wide-temperature-range nickel-hydrogen battery disclosed by the invention, the ratio of 0.2C discharge capacity to normal-temperature capacity maximally can reach 70-80% in an environment with the temperature of -45 DEG C; and the ratio of 0.2C discharge capacity to normal-temperature capacity of the nickel hydrogen battery maximally can reach 85-95% in an environment with the temperature of 70 DEG C. Moreover, the manufacturing method is simple and suitable for large-scale production.

Owner:HENGYANG BST POWER

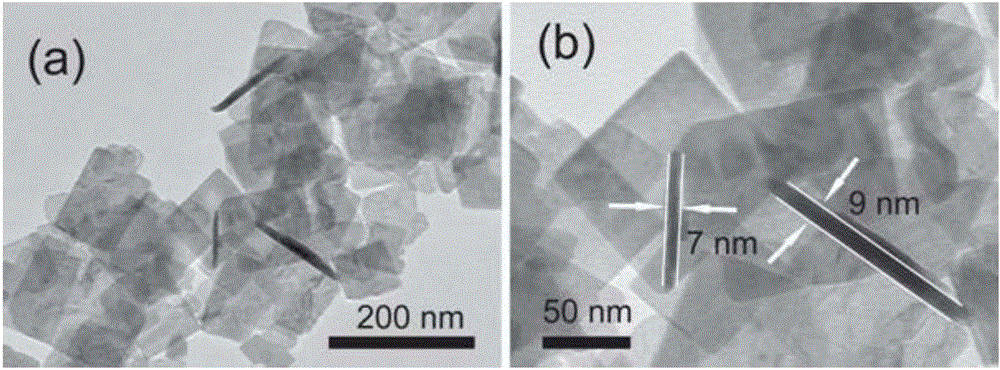

Silver-modified bismuth tungstate composite photocatalyst, its preparation method and application thereof

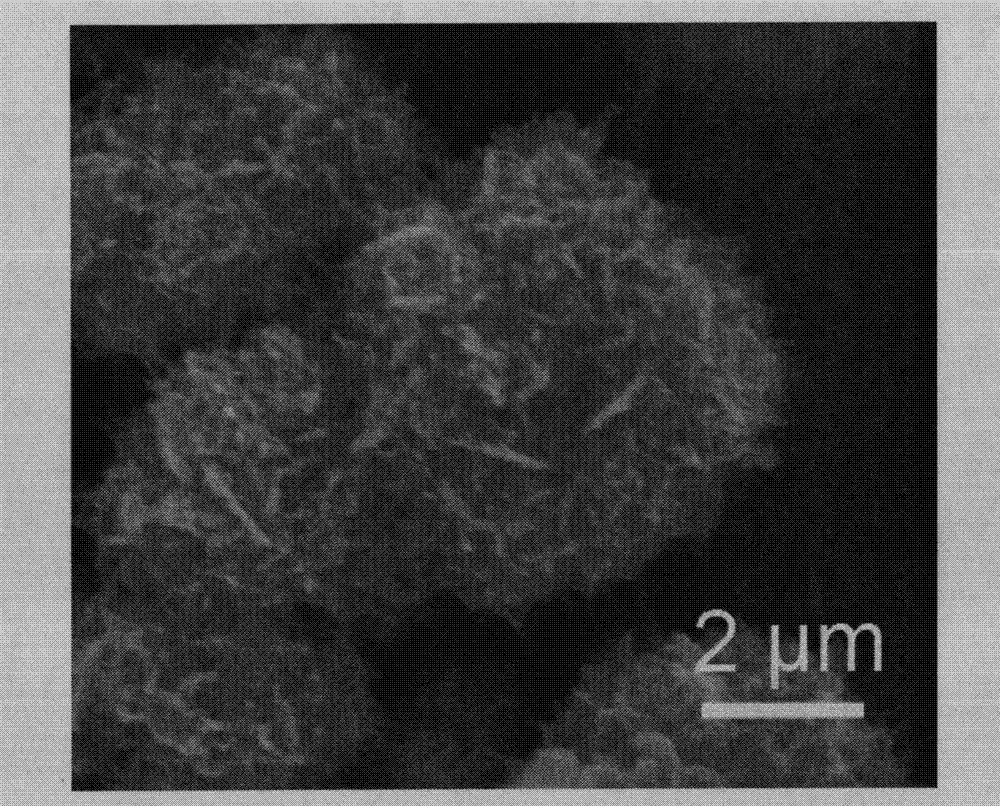

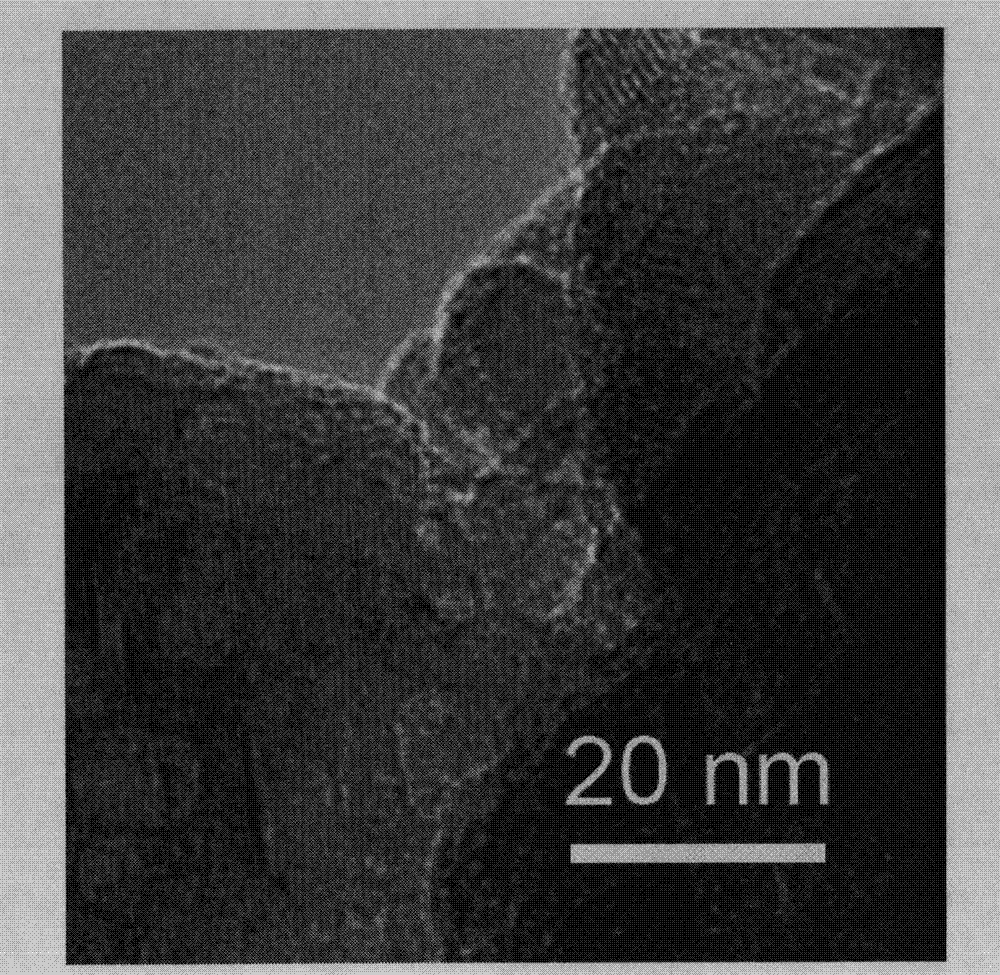

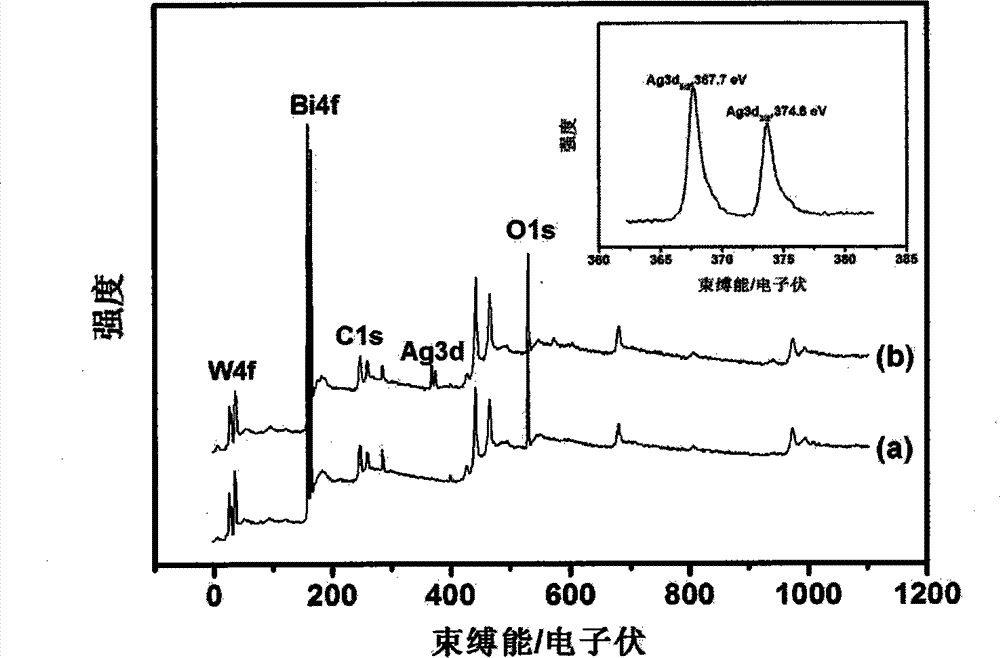

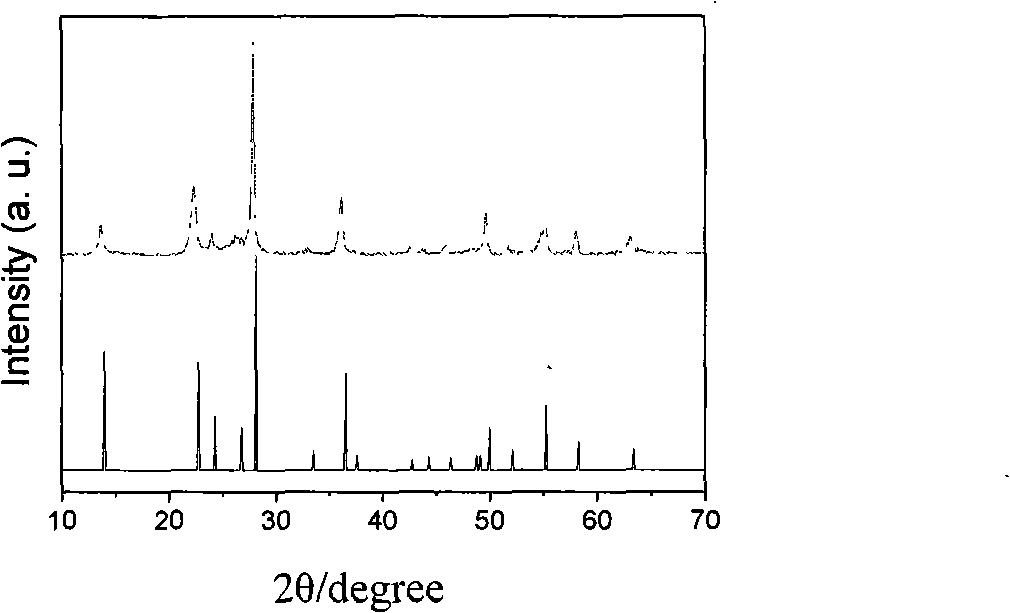

InactiveCN102764653ALarge specific surface areaImprove stabilityWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsTungstatePhotodegradation

The invention discloses a silver-modified bismuth tungstate composite photocatalyst, its preparation method and an application thereof. Bismuth tungstate in the catalyst is granules with the particle size being 0.5-3 microns and the catalyst is composed of bismuth tungstate pieces, the length of which is 30-100 nm and the thickness of which is 5-10 nm. Silver granules with the particle size being 5-40 nm are modified on the bismuth tungstate pieces. The specific surface area of the catalyst is 10-30 m<2> / g. The preparation method comprises the following steps of: respectively adding bismuth nitrate into a nitric acid solution with stirring to obtain a bismuth nitrate solution and adding polyvinylpyrrolidone into a sodium tungstate solution with stirring to obtain a mixed solution, adding the bismuth nitrate solution into the mixed solution, placing in an enclosed state, keeping warm at 160-180 DEG C for 20-24 h, centrifuging, washing, drying to obtain a bismuth tungstate powder, adding the bismuth tungstate powder into a silver nitrate solution, stirring, drying, grinding into a powder, and roasting the powder to prepare the target product. The product can be used in water polluted by organic matters or heavy metal ions to perform visible light photodegradation.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

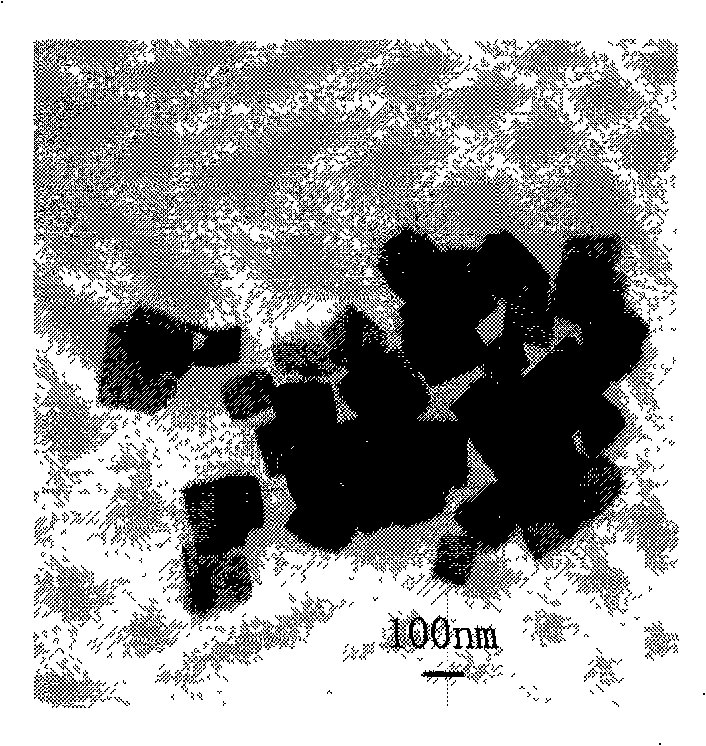

Method for synthesizing quadrangle tungsten oxide nano-powder

InactiveCN101407339AUniform sizeNo reunionNanostructure manufactureTungsten oxides/hydroxidesMetallic materialsHigh pressure

The invention relates to a preparation method of square tungsten oxide nano powder, belonging to the field of inorganic non-metallic materials. The content thereof is as follows: tungstenic acid deposition obtained by the reaction of sodium tungstate and hydrochloric acid is used as a precursor, citric acid is used as an auxiliary reagent, hydrochloric acid is used to adjust pH value and nano tungsten oxide is grown in a high-pressure autoclave by heating. Heating mode can be microwave heating and resistance wire heating, and the nanocrystalline grown is square. The characteristic of the square tungsten oxide powder material is that: the size of the square tungsten oxide is between 80 and 150nm. The advantages of the method are that: the process is simple, the cost is low and the shape and size of the tungsten oxide crystal are hydrothermally controlled by the citric acid auxiliary.

Owner:XINJIANG UNIVERSITY

Blackening liquid for chromium-free titanium-zinc panel surface and using method of blackening liquid

InactiveCN103849868ASimple compositionStrong corrosion resistanceMetallic material coating processesAluminium chlorideChromium free

The invention discloses blackening liquid for a chromium-free titanium-zinc panel surface and a using method of the blackening liquid. Raw materials of the blackening liquid comprise a main salt, auxiliary components, a complexing agent, a pH conditioning agent and water, wherein the main salt is one or several of molybdate with the massic volume concentration of 5-40g / L or sodium tungstate with the massic volume concentration of 0.5-10g / L or copper sulfate with the massic volume concentration of 0.5-20g / L or silver nitrate with the massic volume concentration of 5-40g / L; the auxiliary components comprise nickel sulfate with the concentration of 1.0-4g / L, sodium sulfite with the concentration of 0.5-4g / L, sodium thiosulfate with the concentration of 1.0-5g / L, aluminium chloride with the concentration of 2.0-5g / L, zinc chloride with the concentration of 2.0-5g / L and fluoric acid with the concentration of 0-40g / L. A black protective layer of a titanium-zinc panel is obtained by a series of treatment of the titanium-zinc panel workpiece. The black protective layer of the titanium-zinc panel is compact, uniform, pitch-black and glossy and has the characteristics of being low in cost, chromium-free, environmental-friendly and the like, the performances of the titanium-zinc panel can reach the level of foreign products, and therefore, the titanium-zinc panel has relatively strong application prospect and market competitiveness.

Owner:ZHEJIANG UNIV OF TECH +1

Composite water treatment agent

InactiveCN103663738AImprove protectionGood corrosion and scale inhibition effectTreatment using complexing/solubilising chemicalsCarboxylic acidCarboxylate

The invention discloses a composite water treatment agent which comprises the following components in parts by mass: 15-45 parts of sodium tungstate, 5-25 parts of polyaspartic acid, 1-5 parts of zinc salt, 2-15 parts of sodium benzoate and 2-25 parts of carboxylate, wherein sodium tungstate is a corrosion inhibitor which is non-toxic, causes no environmental hazard and can generate the synergic corrosion inhibition function with polyaspartic acid. With addition of other assistants, the composite water treatment agent becomes a green composite water treatment agent which has excellent corrosion inhibition and scale inhibition effects, lower in cost, non-phosphorus, easily biodegradable and beneficial to environmental protection. In China, tungsten reserves and yield are abundant, so that the sufficient tungsten compounds can be provided, and the cost of the treatment agent is greatly lowered.

Owner:QINGDAO BAIZHONG CHEM TECH

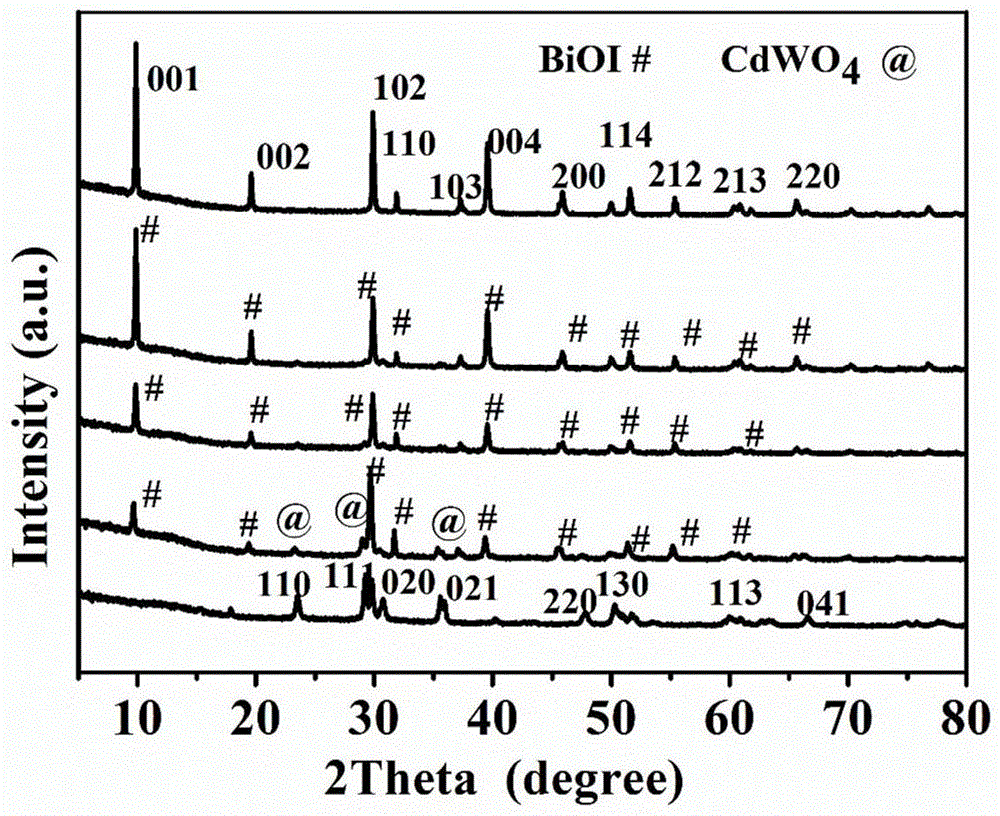

Method for preparing BiOI / CdWO4 heterojunction photocatalyst

InactiveCN105642316APhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionTungstate

The present invention relates to a transition metal tungstate, and in particular to a method for preparing a BiOI / CdWO4 heterojunction composite photocatalyst. The method uses bismuth nitrate, sodium tungstate, potassium iodide and chromium acetate as raw materials for preparing the BiOI / CdWO4 heterojunction composite photocatalyst. The prepared nano-composite photocatalyst has excellent visible light catalytic activity, especially a sample supplemented with 1.5mmol of bismuth nitrate has the best activity in degradation of rhodamine B, and reaches degradation rate of 90% after 90min of visible reaction, and has higher degradation activity than pure BiOI and CdWO4.

Owner:JIANGSU UNIV

Method for treating hard alloy grinding material

The invention relates to a method for treating a waste hard alloy and particularly relates to a method for treating a waste hard alloy grinding material, mainly solving the problems of long nickel-cobalt leaching time, high oxidizing agent consumption, high equipment requirement, long process, high separation difficulty of cobalt and tungsten which are contained in the waste hard alloy grinding material and low purity of an obtained tungsten product in the prior art. The method comprises the following steps of: (a) soda calcination: mixing tungsten carbide filter residues with sodium carbonate and sodium nitrate, and then calcining to obtain a material I; (b) caustic soda leaching: leaching the material I by using liquid caustic soda with [OH-] of 0.5-2.0 mol / l to obtain a sodium tungstate-containing solution and cobalt-nickel-containing filter residues; (c) cobalt-nickel leaching: leaching the cobalt-nickel filter residues by using an acid solution with [H+] of 0.5-2.0 mol / l to obtain a cobalt-nickel-containing solution used for cobalt-nickel recovery; (d) tungsten recovery: adding acid to the sodium tungstate-containing solution to regulate the pH value to 5.0-8.0 to obtain a high-purity tungstic acid precipitate, and washing, drying and calcining to obtain high-purity tungsten trioxide. The method disclosed by the invention can be used for well solving the problems and is worthy of being applied and popularized.

Owner:GUANGXI UNIV

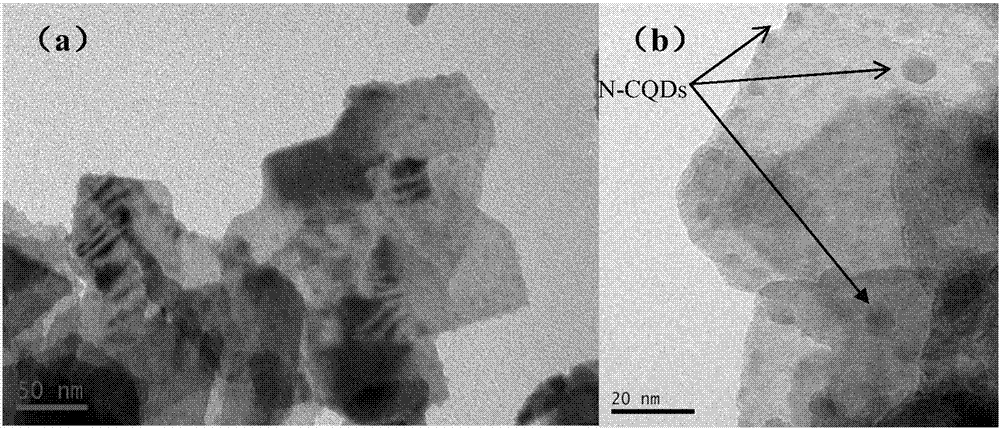

Bismuth tungstate composite photocatalyst modified by nitrogen-doped carbon quantum dot and preparation method and application thereof

InactiveCN107224990AImprove light absorption efficiencyImprove separation efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationTungstateModified carbon

The invention discloses a bismuth tungstate composite photocatalyst modified by a nitrogen-doped carbon quantum dot and a preparation method and application thereof. The composite photocatalyst is characterized in that bismuth tungstate is taken as a carrier, and is modified with the nitrogen-doped carbon quantum dot. The preparation method comprises the following steps: mixing bismuth nitrate, sodium tungstate and water, and stirring the mixture to obtain a bismuth tungstate precursor solution; mixing the bismuth tungstate precursor solution with a nitrogen-doped carbon quantum dot solution, and stirring the mixture to obtain a mixed solution; performing a hydrothermal reaction to obtain the bismuth tungstate composite photocatalyst. The composite photocatalyst has the advantages of environmental friendliness, high photo-induced electron-hole separating efficiency, high light absorbing efficiency, high photocatalysis activity, high photocatalysis stability and high corrosion resistance; the preparation method has the advantages of simple preparation process, low raw material cost, and easiness in controlling operation conditions. The composite photocatalyst is used for catalyzing degradation of antibiotic wastewater, and has the advantages of simple application method, high degrading efficiency and high repeatability, and has a very good practical application prospect.

Owner:HUNAN UNIV

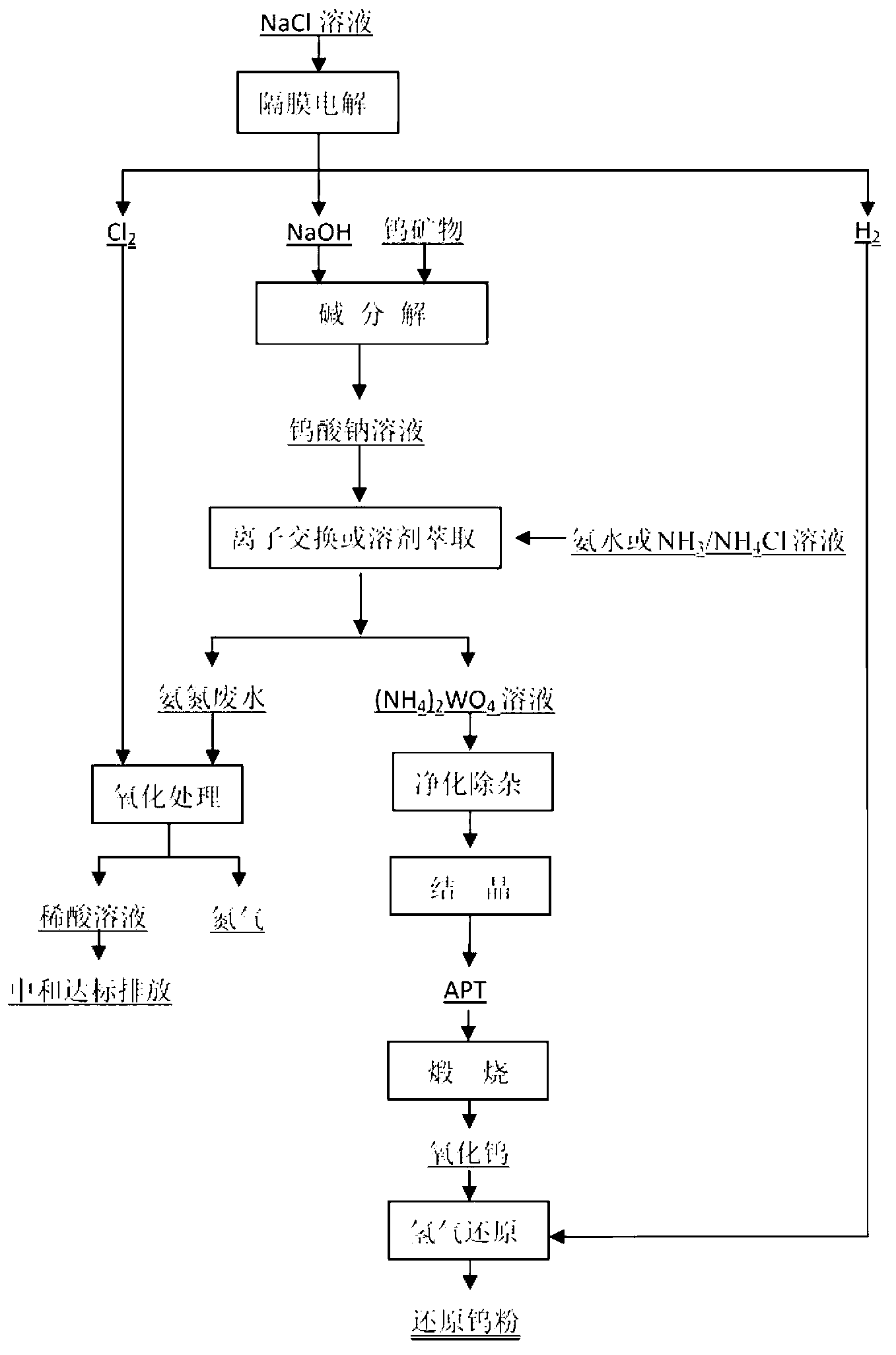

High-efficiency and clean tungsten smelting method

ActiveCN103266231ALow costAchieving zero emissionsElectrolysis componentsProcess efficiency improvementElectrolysisTungstate

The invention provides a high-efficiency and clean tungsten smelting method. The method comprises the steps of: carrying out electrolysis on an NaCl solution to obtain NaOH and H2 from a cathode chamber and obtain Cl2 from an anode chamber; leaching a tungsten mineral raw material by the NaOH solution obtained by electrolysis to prepare a sodium tungstate solution; treating and transforming the obtained sodium tungstate solution by the existing technology to obtain a ammonium tungstate solution; oxidizing and removing ammonia nitrogen in waste smelting water by the Cl2 obtained by electrolysis; and reducing a tungsten oxide by the H2 obtained by electrolysis, thereby preparing tungsten powder. The method can be used for efficiently treating the tungsten mineral raw material to prepare the tungsten powder; and the method can save cost and no ammonia-nitrogen waste water is discharged.

Owner:CENT SOUTH UNIV

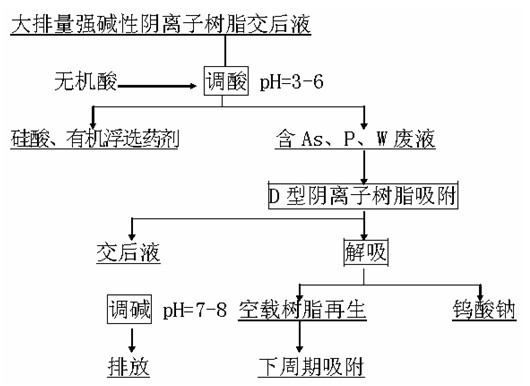

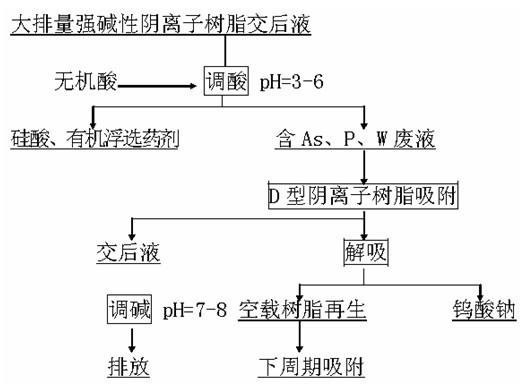

Method for removing arsenic and recycling tungsten from tungsten smelting wastewater

InactiveCN101985692AAvoid pollutionWater contaminantsWaste water treatment from metallurgical processLiquid wasteSlag

The invention discloses a method for removing arsenic and recycling tungsten from tungsten smelting wastewater, which comprises the following steps of: 1, adding inorganic acid into waste liquor after sodium tungstate solution is subjected to strongly basic anion resin exchange to adjust the waste liquor to be faintly acid, namely pH=3-6, and simultaneously adding a trace amount of flocculating agent; 2, injecting the faintly acid wastewater from which suspended matters are filtered out into an exchange column filled with D313 or D314 type anion resin, and adsorbing all arsenic and phosphorus in the wastewater by using the D type anion resin; and 3, desorbing the resin by using caustic soda solution, making 90 percent of tungsten crystallized and separated out in a form of Na2WO4.2H2O, reacting most harmful elements with an additive, and removing a slag phase. The method has the advantages that: the resin can thoroughly adsorb the tungsten and arsenic, so that the harmful element arsenic in the discharged production wastewater is reduced to less than 0.05mg / L from 1.5mg / L; the metal recovery rate is improved to 96-97 percent from 93-94 percent; and the tungsten detection in the in-process control process is saved, so the operation is simplified, the product quality is ensured, and the consumption of a NH4Cl strippant and water can be reduced.

Owner:江西修水湘赣有色金属有限公司

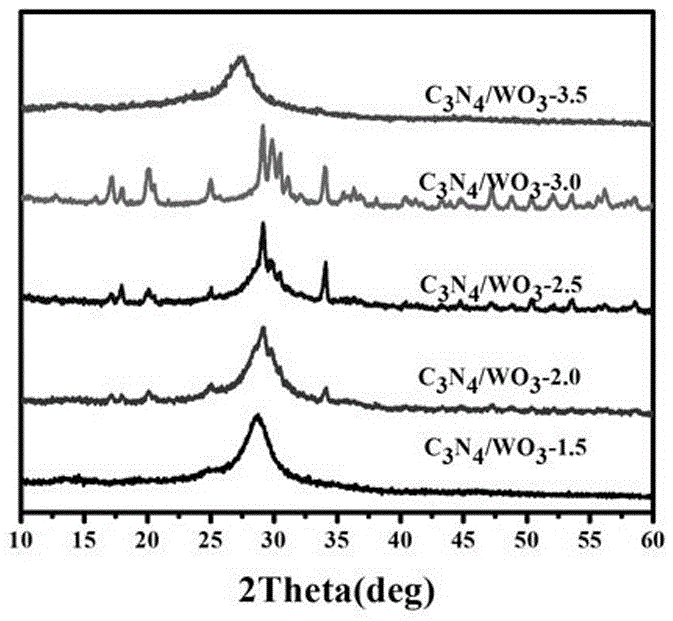

Method for preparing morphology and constitution controllable WO3 nano sheet/g-C3N4 nano composite material

InactiveCN106824248AImprove stabilityGood catalyticPhysical/chemical process catalystsWater/sewage treatment by irradiationNano compositesSodium tungstate

The invention discloses a method for preparing a morphology and constitution controllable WO3 nano sheet / g-C3N4 nano composite material, and belongs to the field of photocatalysts. The nano composite material is of a structure that WO3 nano sheets are uniformly distributed on layered g-C3N4 nano sheets. The nano composite material is simple in preparation process and is prepared by using a one-step method. The method comprises the following steps: by taking sodium oleate as a surfactant, firstly, dissolving the surfactant into a dilute nitric acid solution at certain temperature, adding g-C3N4, sufficiently dispersing the g-C3N4, slowly adding a sodium tungstate solution, and performing reaction for 120 minutes at 60 DEG C, thereby obtaining the WO3 nano sheet / g-C3N4 nano composite material. The nano composite material can be used as a photocatalyst for degrading MO, and has good catalysis effects and stability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

United decomposition technology of tungstite, wolframite alkali decomposition

InactiveCN1410562AIncreased alkali decomposition rateReduce alkali consumptionProcess efficiency improvementAlkalinityDecomposition

A process for alkaline decomposition of both scheelite and wolframite includes such steps as grinding and pressure-digestion of the two ores in NaOH solution respectively at 140-200 deg.C and under 0.3-1.1 MPa for 1-6 hr, diluting and filtering the decomposed scheelite to obtain a solution of sodium tungstate, and directly using it to decompose the wolframite while adding additive containing PO4 ions. Its advantages are high decomposition percentage (99%), and reduced pollution and low alkali consumption.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Synthesizing method of heteropolyacid imidazolium salt catalyst

ActiveCN103357434AHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsChemical synthesisPhosphoric acid

The invention relates to a synthesizing method of a heteropolyacid imidazolium salt catalyst. The method belongs to the technical field of chemical synthesis. According to the invention, sodium tungstate and phosphoric acid are adopted as raw materials. Through the steps such as phosphotungstic acid synthesis, sodium ion removing, phosphotungstic acid imidazolium salt preparation, filtering, and spray drying, heteropolyacid imidazolium salt is obtained. The ionic liquid heteropolyacid imidazolium salt catalyst synthesized with a liquid synthesis route has catalytic activity substantially better than that of a heteropolyacid catalyst prepared with a traditional method. At least, the catalyst has an excellent performance in a reaction for synthesizing PTMEG through tetrahydrofuran polymerization.

Owner:杭州师恩科技有限公司

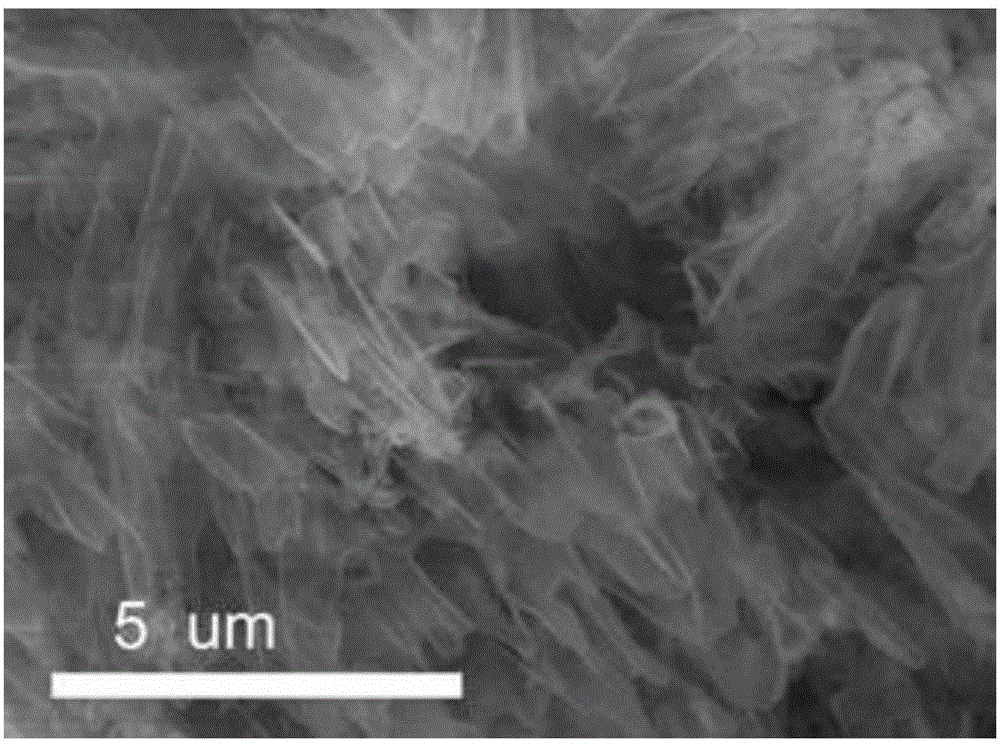

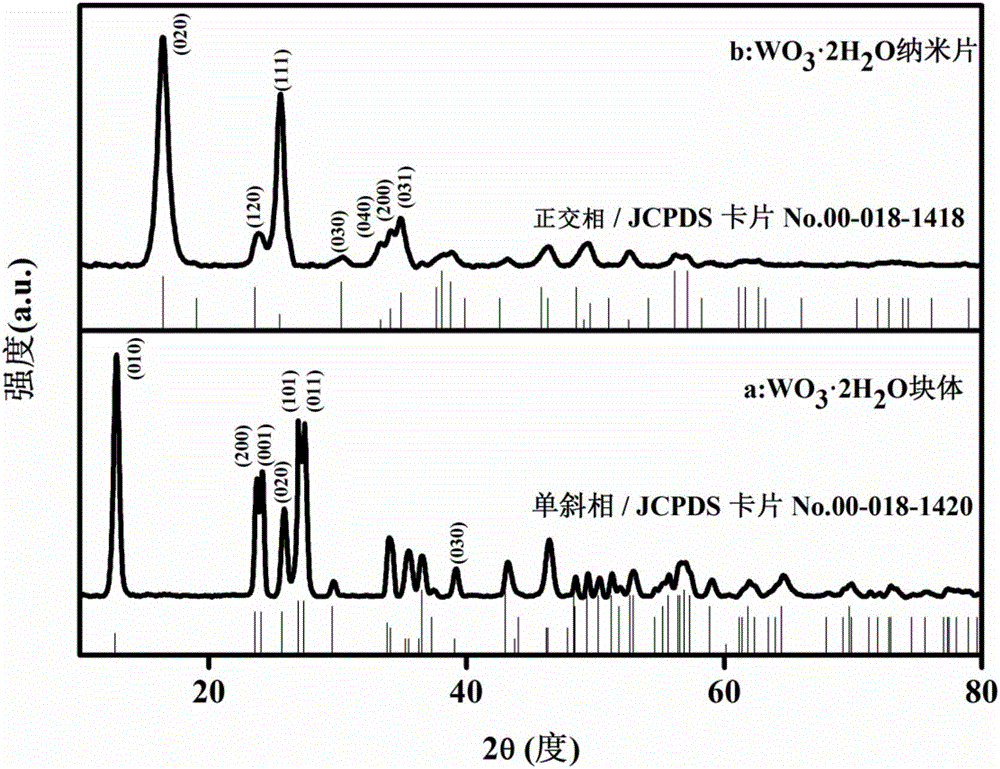

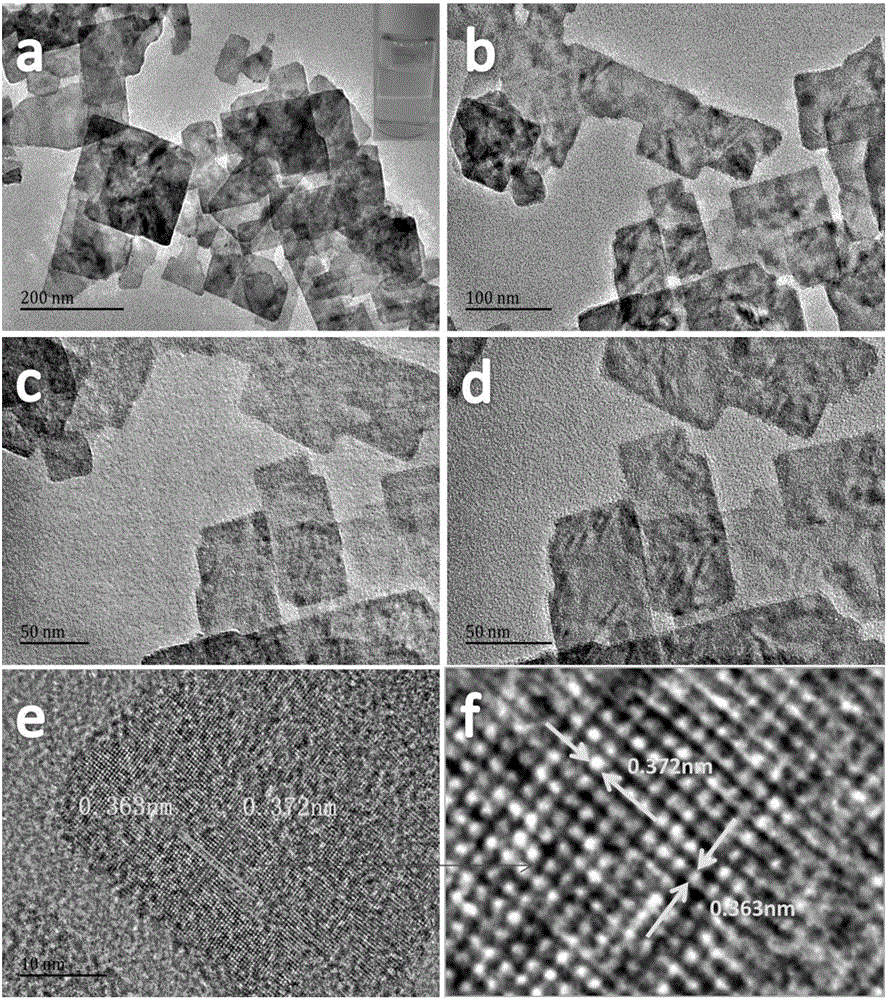

Preparation method and application of ultrathin tungsten trioxide dihydrate nanosheet

ActiveCN106563442APromote absorptionImprove catalytic performanceTungsten oxides/hydroxidesNanotechnologyOrganic acidTungsten trioxide

The invention discloses a preparation method of an ultrathin tungsten trioxide dihydrate nanosheet photocatalyst. The preparation method is characterized in that an organic-inorganic hybrid of an organic amine intercalation is prepared through solvothermal reaction. The preparation method comprises the steps of mixing 10 mL of a sodium tungstate solution of which the concentration is 1.0 mol / L with 90 mL of a hydrochloric acid solution of which the concentration is 3.0 mol / L for reaction, so as to obtain tungsten trioxide dihydrate block powder; mixing tungsten trioxide dihydrate powder with organic amine for reaction for 2 to 3 days at the temperature of 100 DEG C to 150 DEG C, so as to obtain the organic-inorganic hybrid of the organic amine intercalation; then, forming the tungsten trioxide dihydrate ultrathin nanosheet through organic acid liquid phase peeling; and mixing tungsten trioxide dihydrate of the organic amine intercalation with an organic acid solution, and carrying out liquid phase ultrasonic peeling to obtain the tungsten trioxide dihydrate ultrathin nanosheet. The method is simple and convenient in use and easy to operate, and the prepared tungsten trioxide dihydrate ultrathin nanosheet has relatively high photocatalytic activity.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

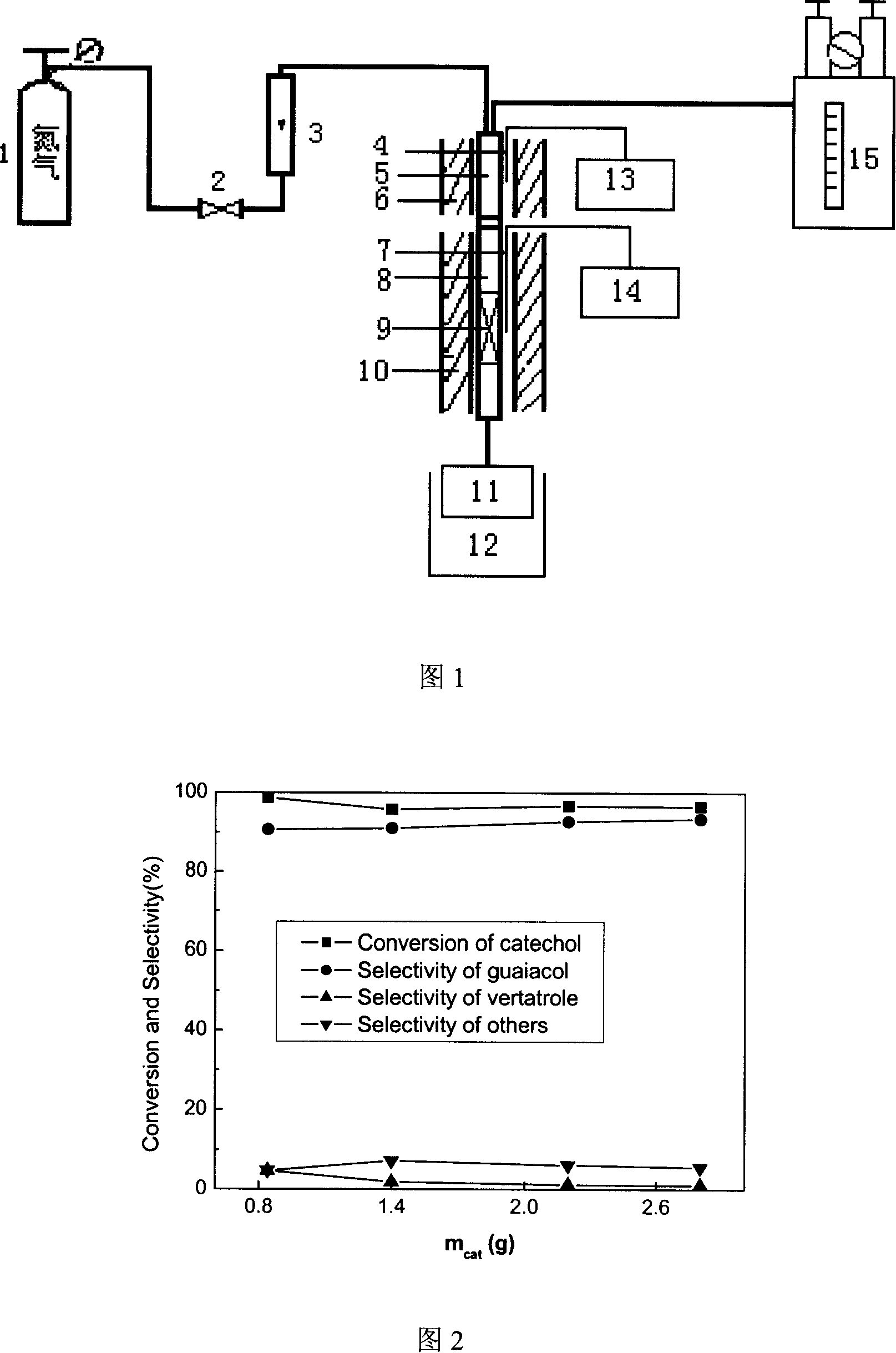

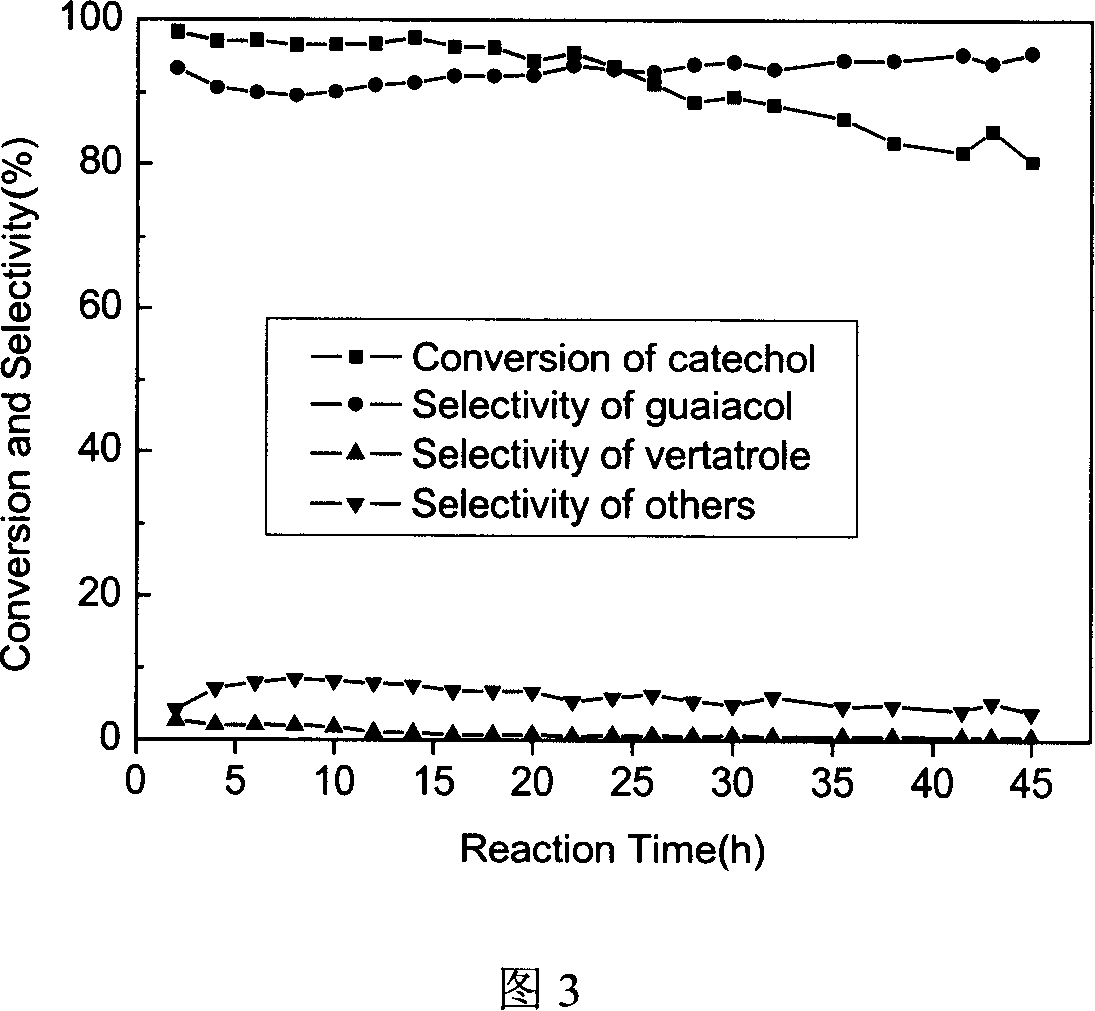

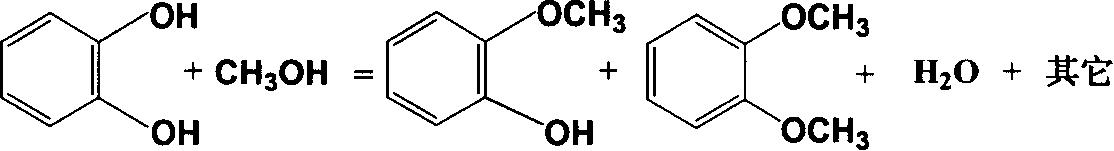

Method for synthesizing guaiacol

ActiveCN101081805AHigh activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsEther preparation by compound dehydrationReaction temperatureGuaiacol

The present invention is process of synthesizing guaiacol, and relates to the application of catalyst in catalytically synthesizing guaiacol through the solid phase alkylation reaction between catechol and methanol. The catalyst has active component of ammonium metatungstate, sodium tungstate, ammonium molybdenum, ammonium biphosphate, ammonium phosphate, ammonium chromate or silicotungstic acid; and carrier of active carbon, SiO2, ZnO, Al2O3, TiO2, BaCO3 or CaO; and active component supporting amount of 2.1-30.2 wt%. The process of synthesizing guaiacol has catalytic reaction temperature of 533-573 K, the molar ratio between catechol and methanol of 1 / 7-1 / 2.5, and catalyst amount of 0.84-2.8 weight portions. During the process, the mixed solution of catechol and methanol is fed to the pre-heater in the flow rate of 0.3-2ml / hr, gasified and reacted catalytically at the temperature of 533-573 K.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Zinc coat environmental-friendly passivation solution and use method thereof

InactiveCN101886259ASolve pollutionCorrosion resistance is equivalentMetallic material coating processesSodium molybdateSalt spray test

The invention discloses a zinc coat environmental-friendly passivation solution and a use method thereof. The passivation solution is formed by dissolving a solute consisting of a plurality of materials into deionized water, wherein the solute in the solution comprises the following components: 80-120g / L of sodium molybdate, 20-30g / L of sodium tungstate, 2-7g / L of titanyl sulfate, 5-10g / L of phytic acid, 15-50g / L of acrylic acid and 20-40g / L of hydrogen peroxide, wherein the pH value of the solution is regulated to 1.5-2.5 by using dilute acid. It is found that the zinc coat environmental-friendly passivation solution contains no chromium ions and thoroughly solves the problem of environment pollution brought by chromating; through salt spray test examination, a zinc coating plate passivated by the passivation solution has corrosion resistance approximately consistent with that of the traditional passivation solution; meanwhile, the use method is simple and easy.

Owner:WUHAN IRON & STEEL (GROUP) CORP

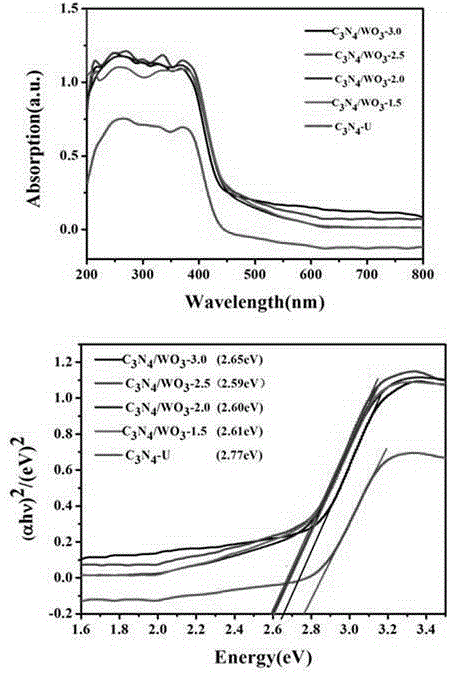

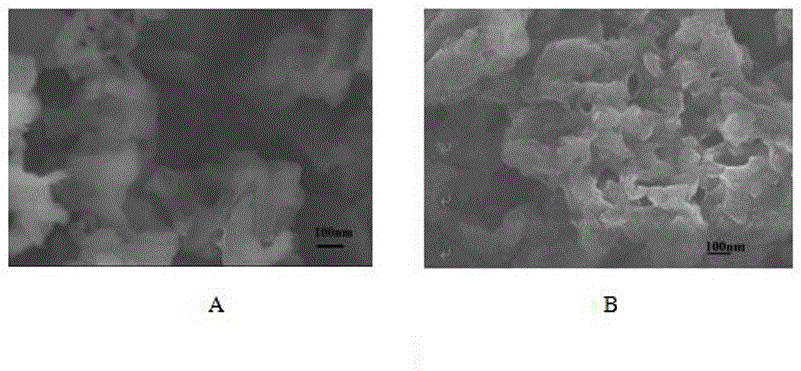

Carbon nitride/tungsten trioxide nano composite material and preparation method and application thereof

InactiveCN105536842AThe method is simple and controllableSolve the problem of low photoelectrochemical activityElectrophoretic coatingsMetal/metal-oxides/metal-hydroxide catalystsAlcoholCarbon nitride

The invention provides a preparation method of a carbon nitride / tungsten trioxide nano composite material. The preparation method comprises the following steps: (1) mixing and fusing deionized water and absolute ethyl alcohol, then stirring, adding sodium tungstate, stirring to dissolve at room temperature, adding a carbon nitride precursor, stirring, precipitating to obtain crystals, drying the crystals, grinding the crystals, and thus obtaining a white powder, wherein the carbon nitride precursor comprises urea and dicyandiamide; (2) calcining the white powder obtained in the step (1) to obtain a yellow solid, grinding the yellow solid, and collecting a yellow powder; (3) stirring the yellow powder obtained in the step (2) with HCl; and swashing away impurities, then filtering, drying, and grinding to obtain a yellow powder; and (4) calcining the yellow powder obtained in the step (3). The invention also provides the carbon nitride / tungsten trioxide nano composite material prepared by the method and an application thereof. The method is simple and easy to control, and friendly to the environment; the obtained nano composite material has high dispersion and high catalytic performance; and an electrode prepared from the nano composite material has high sensitivity.

Owner:NORTHWEST NORMAL UNIVERSITY

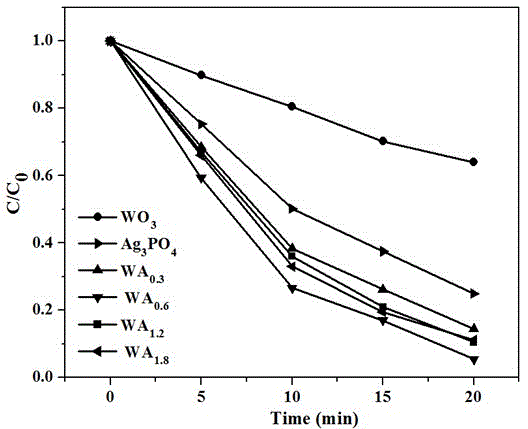

Heterojunction nanosheet photocatalyst and preparation method and application of heterojunction nanosheet photocatalyst

The invention belongs to the technical field of photocatalytic materials, and particularly relates to a heterojunction nanosheet photocatalyst and a preparation method and application of the heterojunction nanosheet photocatalyst. A visible light responsive heterojunction photocatalytic material is prepared from silver nitrate, disodium hydrogen phosphate, nitric acid, ammonia water, and sodium tungstate as raw materials by utilizing a hydrothermal method and a precipitation method. The photocatalyst is made from a silver phosphate / tungsten oxide heterojunction photocatalytic material formed by tungsten oxide and silver phosphate, tungsten oxide is in a nanosheet shape, silver phosphate is in a particle shape, the silver phosphate nano-particles uniformly grow on the surfaces of the tungsten oxide nanosheets, and the molar ratio of tungsten oxide to silver phosphate is 1 to (0.3-1.8). The visible light responsive heterojunction photocatalytic material prepared by the method is used for degrading a methylene blue trihydrate dye, and the degradation rate can reach 97% after the degradation is carried out for 20 minutes.

Owner:JIANGSU UNIV

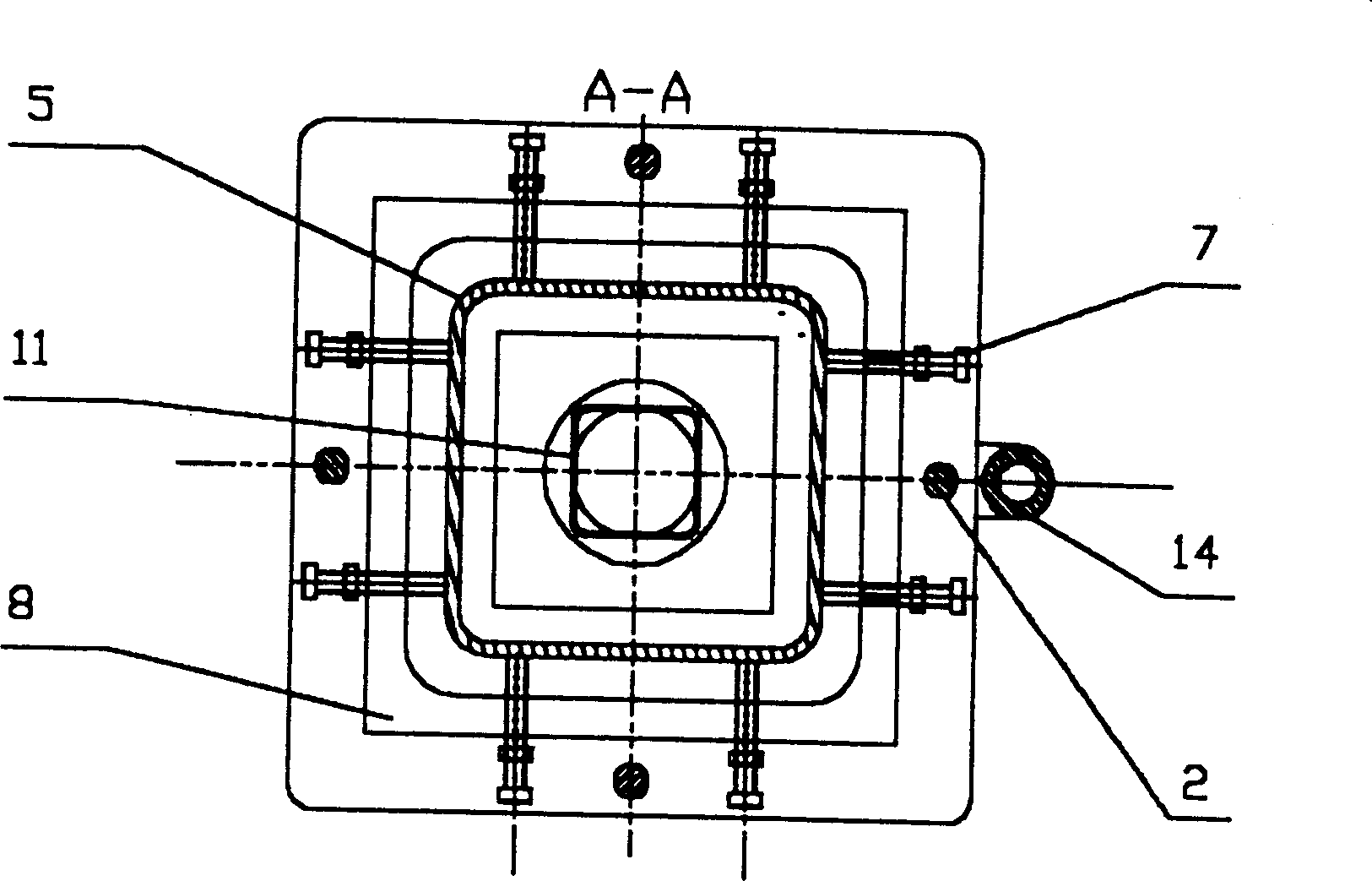

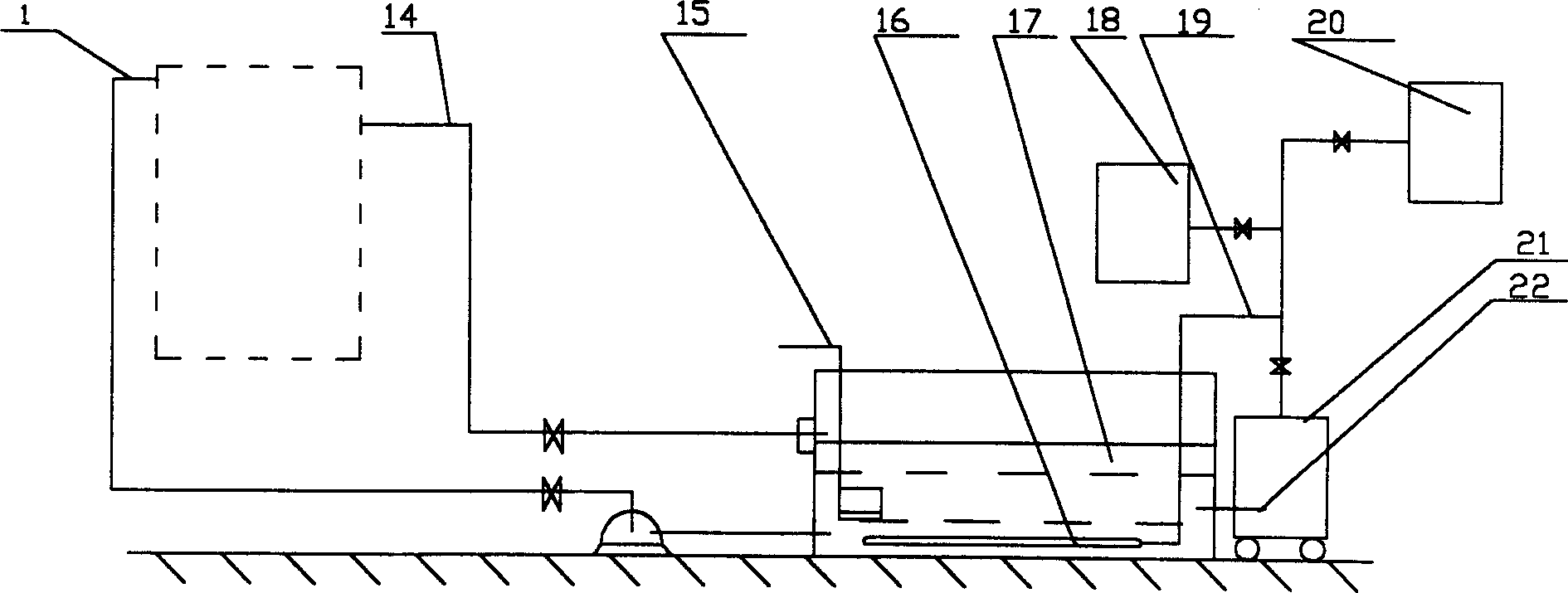

Galvanization apparatus and process of tube-type crystallizer

The present invention provides one kind of electroplating apparatus for electroplating inner wall of copper tube for tubular crystallizer and the corresponding electroplating process. The electroplating apparatus includes electroplating solution storing tank, filter, relevant controller and pipeline; and the electroplating bath has tubular crystallizer copper tube as electroplating cathode, fixture sealing cover and anode titanium basket. The electroplating process includes the deoiling treatment of the inner surface of the crystallizer; and electroplating with W-Co electroplating solution comprising cobalt sulfamate, sodium tungstate, HCl, boric acid, lauryl sodium sulfate and AD486 to form coating of 0.1-1 mm thickness. The electroplating process can obtain W-Co alloy coating with small friction coefficient, high wear resistance, heat expansion coefficient near that of copper and no peeling off and production process produces easy-to-process effluent and no harmful gas.

Owner:鞍山冶金集团工业有限公司鞍山一炼钢分公司

Waste hard alloy grinding material recovery treatment method

The invention relates to a waste hard alloy grinding material recovery treatment method, wherein problems of low process, high equipment requirements, high cobalt-tungsten separation difficulty in a grinding material, and low recovery rate in the existing technology are mainly solved. The technical scheme of the waste hard alloy grinding material recovery treatment method comprises: a) mixing a waste hard alloy grinding material, a sulfuric acid solution and an oxidant I, carrying out a reaction, and filtering to obtain tungsten carbide filter residue and a cobalt-nickel-iron-containing solution; b) mixing the tungsten carbide filter residue, sodium carbonate and sodium nitrate, and calcining to obtain a material I; c) immersing the material I in hot water to obtain a solution containing sodium tungstate, and carrying out concentration evaporation crystallization on the solution containing sodium tungstate to obtain a sodium tungstate crystal; and d) adding an oxidant II to the cobalt-nickel-iron-containing solution under a condition of the pH value of 2-5, carrying out a reaction to obtain iron precipitate and a nickel-cobalt-containing solution, and treating the nickel-cobalt-containing solution to obtain a cobalt-nickel salt crystal. According to the present invention, with the technical scheme, the problems in the prior art are well solved, and the method can be used for the waste hard alloy grinding material recovery treatment in the industrial production.

Owner:SINOPEC SHANGHAI ENG +1

Method for preparing fluorine-mixed bismuth tungstate powder through microwave hydrothermal method

The invention provides a method for preparing fluorine-mixed bismuth tungstate powder through a microwave hydrothermal method. The method comprises the steps as follows: with bismuth nitrate pentahydrate, sodium tungstate dehydrate and ammonium fluoride as raw materials, dissolving Bi(NO3)3.5H20 and Na2WO4.2H2O into deionized water according to the mole ratio of Bi:W of 2:1, adding a certain amount of NH4F, magnetically stirring the raw material at a room temperature to make the raw material be uniformly mixed so as to obtain a precursor solution for microwave hydrothermal reaction, transferring the precursor solution into a reaction kettle, adopting the microwave hydrothermal method to react the precursor solution at the temperature of 160 DEG C to 240 DEG C, and controlling the time for heat preservation for 60 minutes so as to obtain the fluorine-mixed bismuth tungstate powder. The method provided by the invention has the advantages of simple device, low temperature (about 200 DEG C), high efficiency (the reaction time is about 60 minutes), high powder reacting activity, simple technology, high efficiency, low energy consumption, low cost, environment protection and the like.

Owner:盐城青墩津邦水务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com