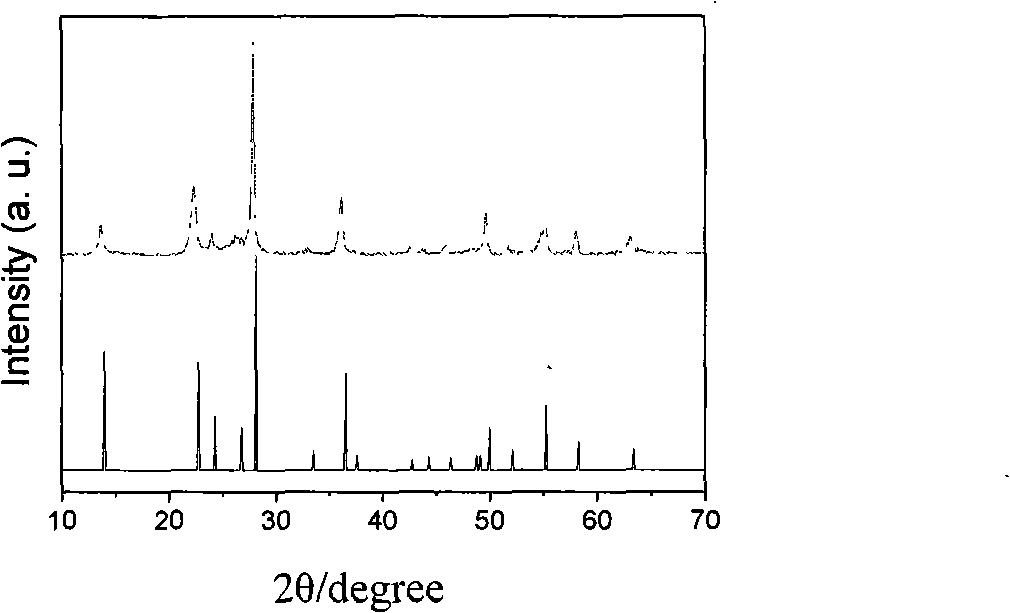

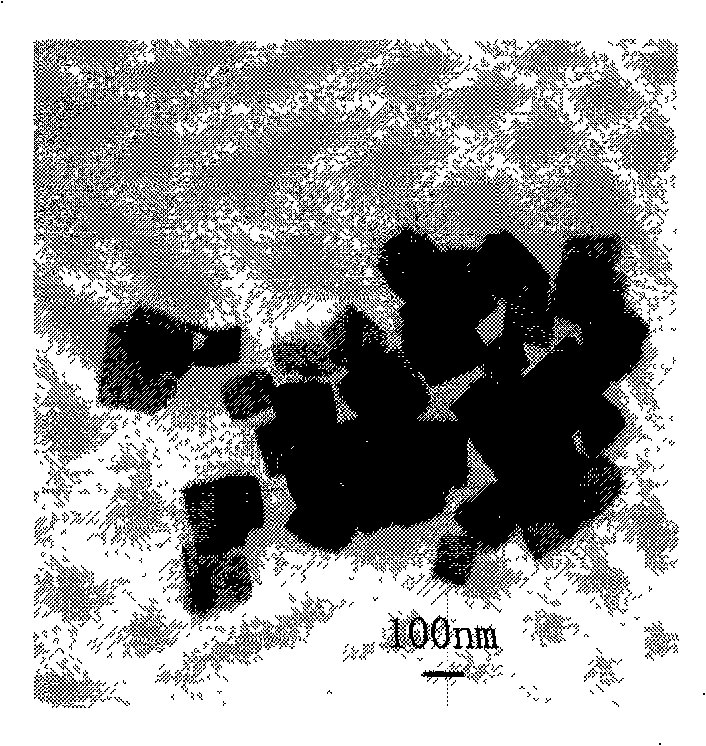

Method for synthesizing quadrangle tungsten oxide nano-powder

A nano-powder and square technology, which is applied in the field of preparation of square tungsten oxide nano-powder, can solve the problems of single shape, difficulty in large-scale promotion, high energy consumption, etc., and achieve the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 0.5g of sodium tungstate and 0.2g of citric acid in 10ml of water respectively, adjust the pH value to 1 with 6mol / L HCl after mixing. After ultrasonic treatment for 10 minutes, the resulting turbid solution was added to a polytetrafluoroethylene reactor lined with stainless steel (filling degree 80%), and reacted at 120° C. for 12 hours; the resulting product was washed with deionized water and ethanol, respectively, and washed The finished powder was kept at 60°C for 60 minutes to obtain tungsten oxide nanopowder.

Embodiment 2

[0024] Dissolve 0.5g of sodium tungstate and 0.2g of citric acid in 10ml of water respectively, adjust the pH value to 1 with 6mol / L HCl after mixing. After ultrasonic treatment for 10 minutes, the resulting turbid solution was added to a microwave reactor lined with polytetrafluoroethylene (filling degree 80%), and reacted at 120° C. for 0.5 h; the obtained product was washed with deionized water and ethanol respectively, After washing, the powder was incubated at 60° C. for 60 minutes to obtain tungsten oxide nanopowder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com