Method for preparing fluorine-mixed bismuth tungstate powder through microwave hydrothermal method

A microwave hydrothermal and bismuth tungstate technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of low activity, small specific surface area, large particles, etc., and achieve high reaction activity, low reaction temperature, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

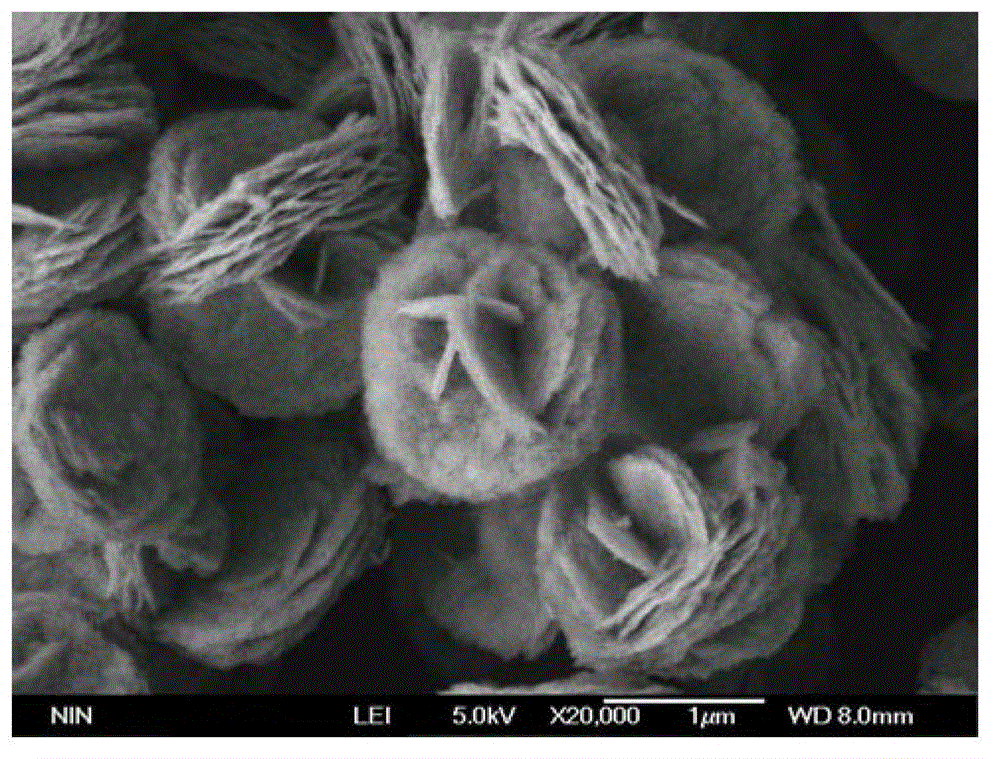

Image

Examples

Embodiment 1

[0015] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O, Na 2 WO 4 2H 2 O and NH 4 Put F into a beaker, add deionized water to prepare a mixed solution, in which Bi(NO 3 ) 3 ·5H 2 O concentration is 0.1mol / L, Na 2 WO 4 2H 2 O concentration is 0.05mol / L, NH 4 F concentration is 0.025mol / L;

[0016] Step 2: Stir magnetically at room temperature for 30 minutes to mix the raw materials evenly to obtain a precursor solution for microwave hydrothermal reaction;

[0017] Step 3: Put the precursor solution obtained in step 2 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power to 300W, and set the temperature at 180°C Stop reaction after reacting for 60mins;

[0018] Step 4: After the reaction temperature drops to room temperature, take out the precipitate in the reactor;

[0019] Step 5: washing the precipitate with water and absolute ethanol to neutrality;

[0020] Step 6: Dry at 80°C for 12 hours, take it out...

Embodiment 2

[0022] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O, Na 2 WO 4 2H 2 O and NH 4 Put F into a beaker, add deionized water to prepare a mixed solution, in which Bi(NO 3 ) 3 ·5H 2 O concentration is 0.1mol / L, Na 2 WO 4 2H 2 O concentration is 0.05mol / L, NH 4 F concentration is 0.05mol / L;

[0023] Step 2: Stir magnetically at room temperature for 30 minutes to mix the raw materials evenly to obtain a precursor solution for microwave hydrothermal reaction;

[0024] Step 3: Put the precursor solution obtained in step 2 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power to 300W, and set the temperature at 160°C Stop reaction after reacting for 60mins;

[0025] Step 4: After the reaction temperature drops to room temperature, take out the precipitate in the reactor;

[0026] Step 5: washing the precipitate with water and absolute ethanol to neutrality;

[0027] Step 6: Dry at 80°C for 12 hours, take it out ...

Embodiment 3

[0029] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O, Na 2 WO 4 2H 2 O and NH 4 Put F into a beaker, add deionized water to prepare a mixed solution, in which Bi(NO 3 ) 3 ·5H 2 O concentration is 0.1mol / L, Na 2 WO 4 2H 2 O concentration is 0.05mol / L, NH 4 F concentration is 0.075mol / L;

[0030] Step 2: Stir magnetically at room temperature for 30 minutes to mix the raw materials evenly to obtain a precursor solution for microwave hydrothermal reaction;

[0031] Step 3: Put the precursor solution obtained in step 2 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power to 300W, and set the temperature at 240°C Stop reaction after reacting for 60mins;

[0032] Step 4: After the reaction temperature drops to room temperature, take out the precipitate in the reactor;

[0033] Step 5: washing the precipitate with water and absolute ethanol to neutrality;

[0034] Step 6: Dry at 80°C for 12 hours, take it out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com