Method for preparing titanium dioxide nanotube array photoelectrode

A nanotube array and titanium dioxide technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of low photocatalytic activity, toxic raw materials, complicated operation, etc., and achieve high photocatalytic activity and good stability , the effect of mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

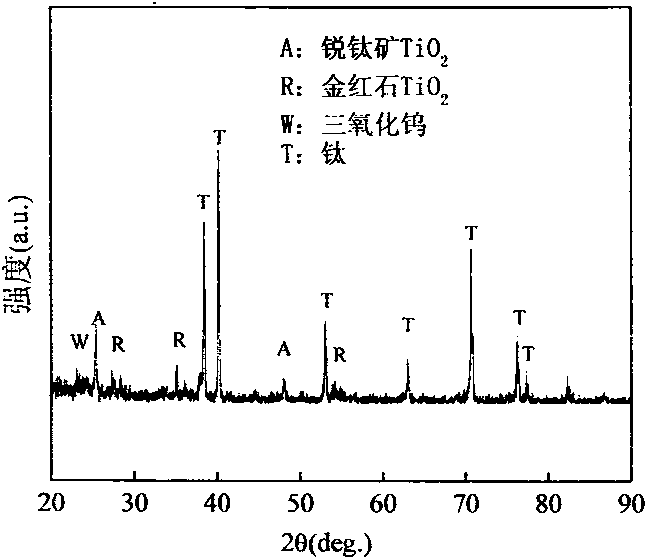

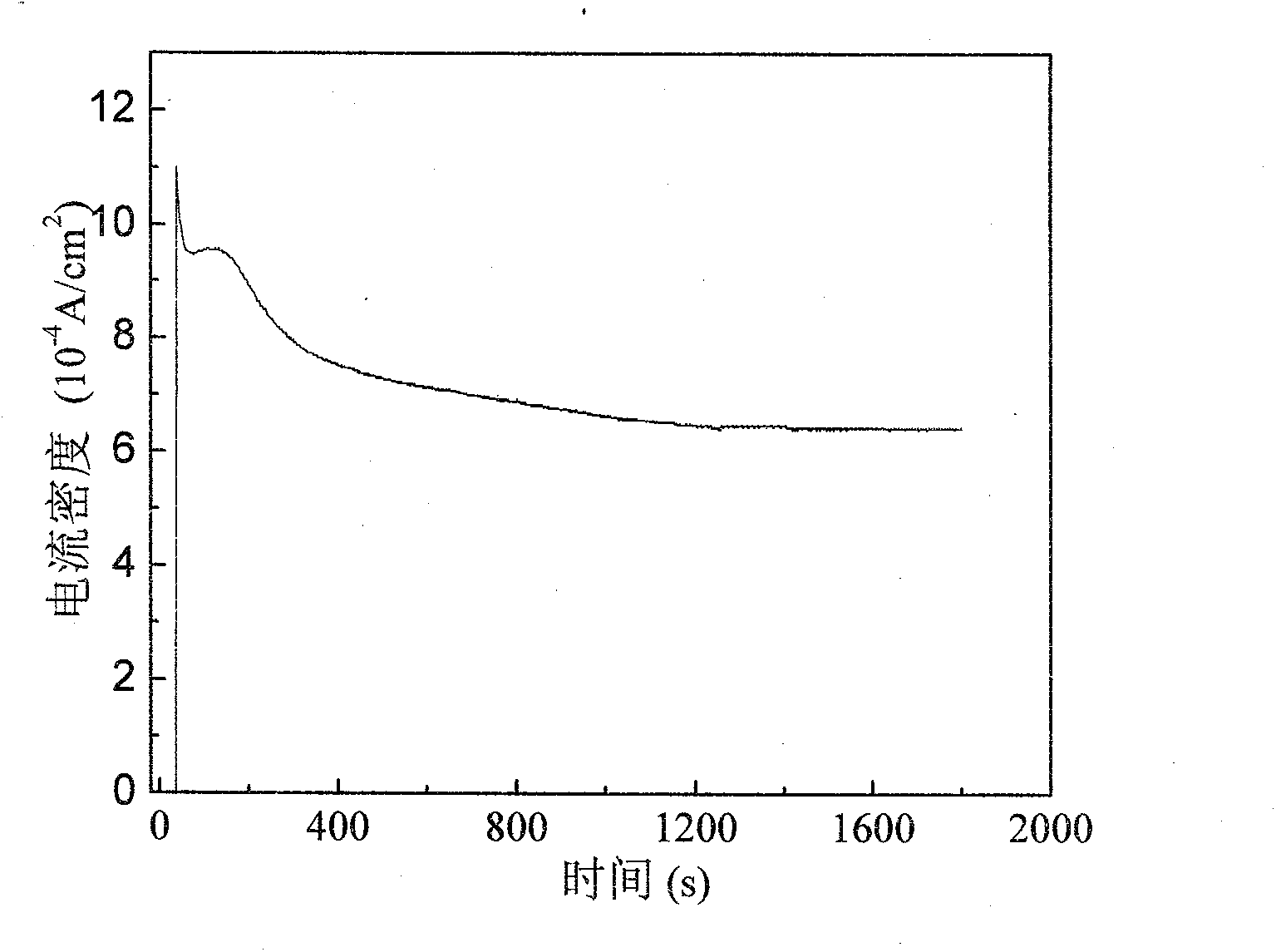

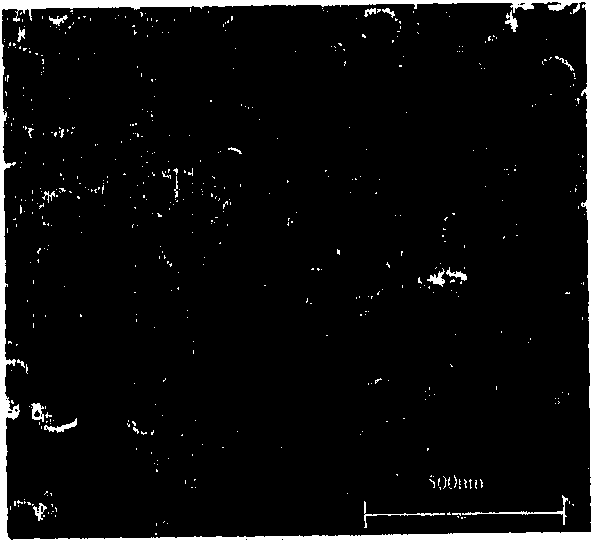

[0021] Such as figure 1 , 2 , The preparation method of the titanium dioxide nanotube array photoelectrode shown in 3, 4 is characterized in that, the steps are as follows:

[0022] 1) Cut pure titanium sheets (titanium > 99.9%) into 100×10×0.2mm strip-shaped foils, clean them with decontamination powder and hydrofluoric acid, and polish them with 1000-mesh sandpaper and 2000-mesh sandpaper, respectively. Acetone, ethanol and deionized water were ultrasonically cleaned for 5 minutes before use;

[0023] 2) Using the titanium sheet pretreated in step 1) as the substrate, the titanium dioxide nanotube array was prepared in situ by the constant current and constant voltage anodization method, and the electrolyte was 0.5% NaF and 1.0M Na 2 SO 4 Mixed solution, temperature 25°C, voltage 20V, current 0.004mA / cm 2 , oxidized for 2h, in situ generating titania nanotube arrays on the surface of the titanium sheet;

[0024] 3) calcining the nanotube array prepared in step 2) at 550...

Embodiment 2

[0029] 1) Cut pure titanium sheets (titanium>99.9%) into 100×10×0.2mm strip-shaped foils, clean them with decontamination powder and hydrofluoric acid, and polish them with 1000-mesh paper and 2000-mesh sandpaper. Acetone, ethanol and deionized water were ultrasonically cleaned for 5 minutes before use;

[0030] 2) Using the titanium sheet pretreated in step 1) as a base, prepare a titanium dioxide nanotube array, and the preparation method is the same as that in Example 1.

[0031] 3) Calcining the nanotube array prepared in step 2) at 450° C. for 2 hours, and cooling in the furnace for later use;

[0032] 4) take graphite powder as raw material, prepare graphene oxide, and preparation method is with embodiment 1;

[0033] 5) Using the titanium dioxide nanotube array as the working electrode and the platinum electrode as the cathode, the three-electrode system was used for pulse deposition and reduction in different concentrations of sodium tungstate and graphene oxide solut...

Embodiment 3

[0036]1) Cut pure titanium sheets (titanium>99.9%) into 100×10×0.2mm strip-shaped foils, clean them with decontamination powder and hydrofluoric acid, and polish them with 1000-mesh sandpaper and 2000-mesh sandpaper. Use acetone, ethanol and deionized water after ultrasonic cleaning;

[0037] 2) Using the titanium sheet pretreated in step 1) as a substrate, prepare a titanium dioxide nanotube array, and the preparation method is the same as in Example 1;

[0038] 3) Calcining the nanotube array prepared in step 2) at 750° C. for 2 hours, cooling in the furnace and then standby;

[0039] 4) take graphite powder as raw material, prepare graphene oxide, and preparation method is with embodiment 1;

[0040] 5) Using the titanium dioxide nanotube array as the working electrode and the platinum electrode as the cathode, a three-electrode system was used to perform pulse deposition and reduction in different concentrations of sodium tungstate and graphene oxide solutions. Electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com