Preparation method and application of ultrathin tungsten trioxide dihydrate nanosheet

A technology of tungsten trioxide and nanosheets, which is applied in the field of photoelectrochemical materials and photocatalysis, can solve the problems of low yield and achieve the effects of huge application potential, fast photocurrent response, and enhanced catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

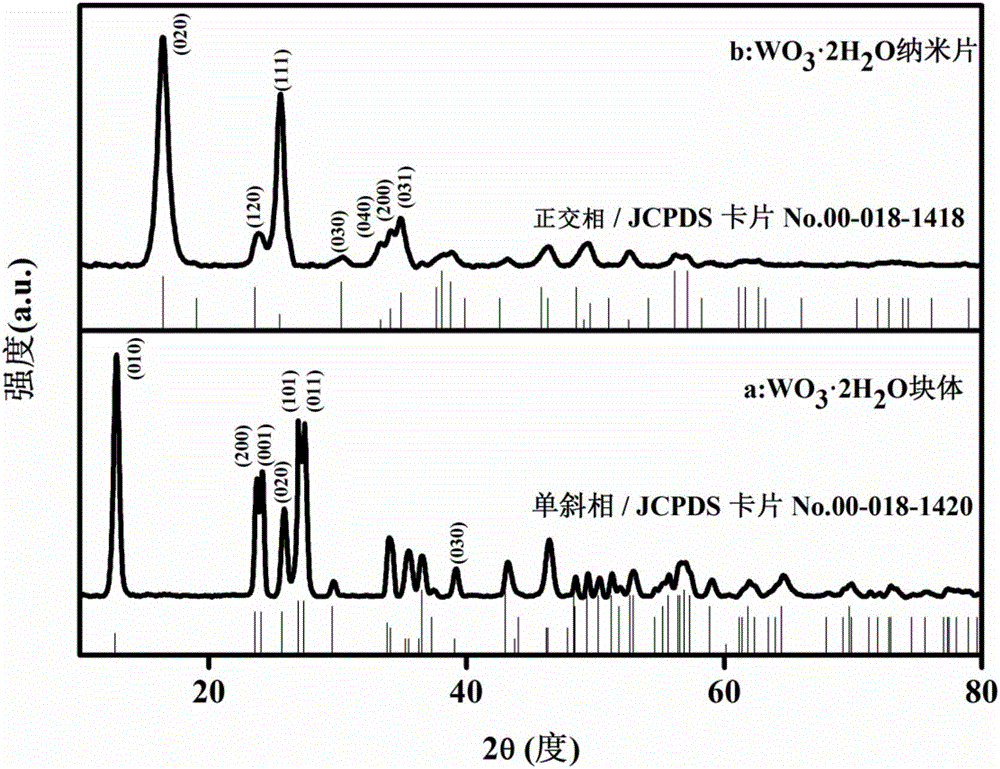

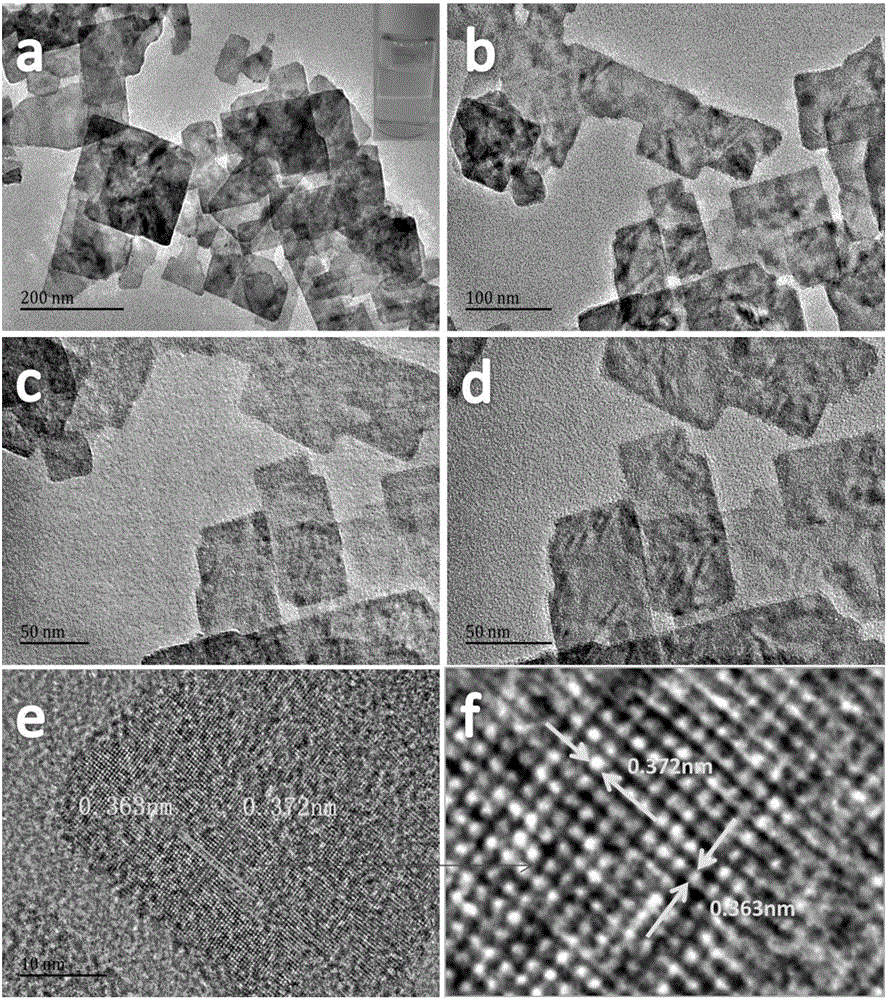

[0019] (1) Using the precipitation method, add 10mL of 1.0mol / L sodium tungstate solution to 90mL of 3.0mol / L hydrochloric acid solution, stir magnetically in an ice-water bath for 30 minutes, centrifuge the obtained product, and wash it with deionized water for 3 times. Then freeze-dry to obtain dihydrate tungsten trioxide block powder.

[0020] (2) Mix 0.2g of tungsten trioxide dihydrate bulk powder obtained in step (1) with 5mL of n-propylamine evenly, add it into a 25mL polytetrachlorethylene reaction kettle, react at 100°C for 3 days, and cool to room temperature naturally. The sample was centrifuged, washed with distilled water and ethanol three times successively, and then vacuum-dried at 60° C. to obtain an organic-inorganic hybrid intercalated with organic amines.

[0021] (3) Take 0.1 g of the organic-inorganic hybrid obtained in step (2) and add it to 15 mL of 3.0 mol / L acetic acid solution, stir it magnetically in an ice-water bath for 10 hours, and centrifuge for ...

Embodiment 2

[0025] (1) Using the precipitation method, add 10mL of 1.0mol / L sodium tungstate solution to 90mL of 3.0mol / L hydrochloric acid solution, stir magnetically in an ice-water bath for 30 minutes, centrifuge the obtained product, and wash it with deionized water for 3 times. Then freeze-dry to obtain dihydrate tungsten trioxide block powder.

[0026] (2) Mix 0.2g of tungsten trioxide dihydrate powder obtained in step (1) with 10mL of n-butylamine in the liner of a polytetrachlorethylene reactor, react at 120°C for 2 days, cool to room temperature naturally, and centrifuge the sample , successively washed with distilled water and ethanol for 3 times, and then vacuum-dried at 60°C to obtain an organic-inorganic hybrid intercalated with organic amines.

[0027] (3) Get 0.1g step (2) gained organic-inorganic hybrid, join in the tartaric acid solution of 15mL1.0mol / L, after ice-water bath magnetic stirring 6 hours, centrifuge 5 under the rotating speed of 5000 rev / mins with centrifuge ...

Embodiment 3

[0029] (1) Using the precipitation method, add 10mL of 1.0mol / L sodium tungstate solution to 90mL of 3.0mol / L hydrochloric acid solution, stir magnetically in an ice-water bath for 30 minutes, centrifuge the resulting product, and wash it with deionized water for 3 times. Then freeze-dry to obtain dihydrate tungsten trioxide block powder.

[0030] (2) Mix 0.2g of blocky tungsten trioxide dihydrate powder obtained in step (1) and 8mL of n-octylamine evenly, add it to a polytetrachlorethylene reactor, react at 150°C for 2 days, and cool it down to room temperature naturally. The sample was centrifuged, washed three times successively with distilled water and ethanol, and then vacuum-dried at 60°C to obtain an organic-inorganic hybrid intercalated with organic amines.

[0031] (3) Get 0.1g of the organic-inorganic hybrid obtained in step (2), add it to 15mL of 1.5mol / L citric acid solution, stir it magnetically in an ice-water bath for 8 hours, and centrifuge it at a speed of 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com