Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

235 results about "Hard chromium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Description: Hard chromium or industrial chromium plating refers to relatively thick chromium deposits applied to a base material because of the hardness, wear resistance, and/or corrosion resistance of the chromium. Hard chromium may be applied to almost any metal.

Anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplate liquid thereof

The invention relates to an anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplates liquid thereof, which takes the nickel sulfate, sodium tungstate, phosphate as the main material, electrically depositing the Ni-WP amorphous mixture of amorphous or nanocrystalline alloy coating. The characteristics of the electroplate technique are following: corrosive solution is very small, the entire production of the use of cleaner production, less emissions, in line with the requirements of sustainable production. W of the coating for the content of 1-45wt%, P content of 0.1-5wt%, nickel is the residue. The plating layer is bright and dense; the hardness is 400-1100Hv, which is resistant to acid, alkali, salt and hydrogen sulfide corrosion, wear resistance is better than or equivalent to chrome plating, can not only replace decorative chromium or hard chromium is widely used, and can be used for oil field exploration equipment to deal with wear-resistant anti-corrosion.

Owner:湖南纳菲尔新材料科技股份有限公司

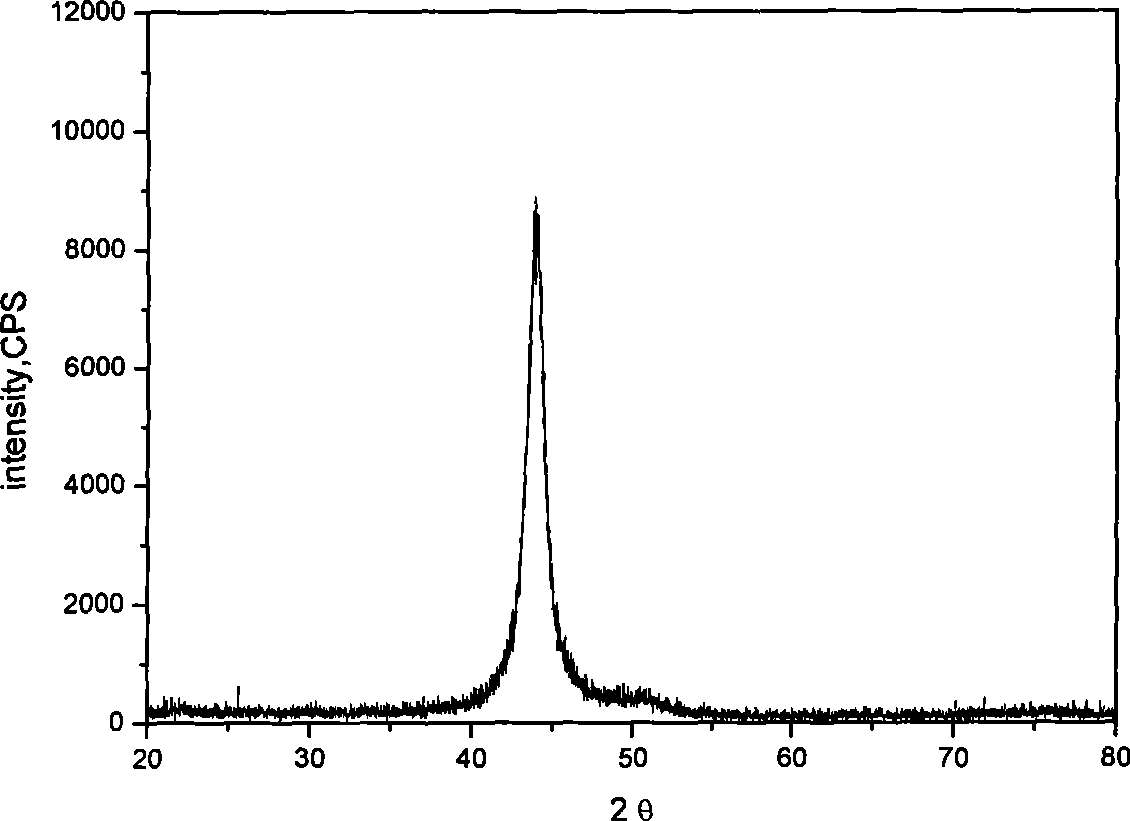

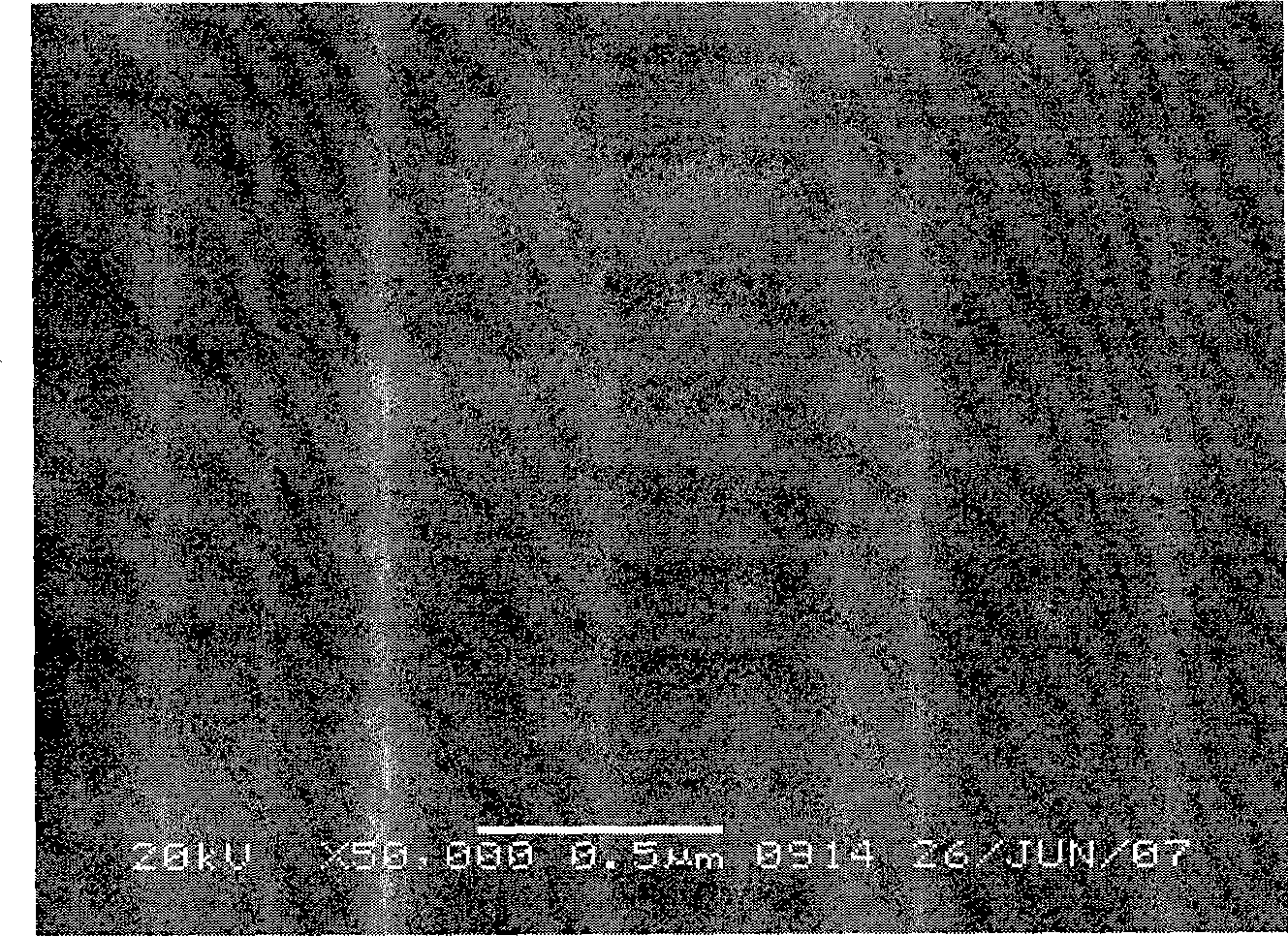

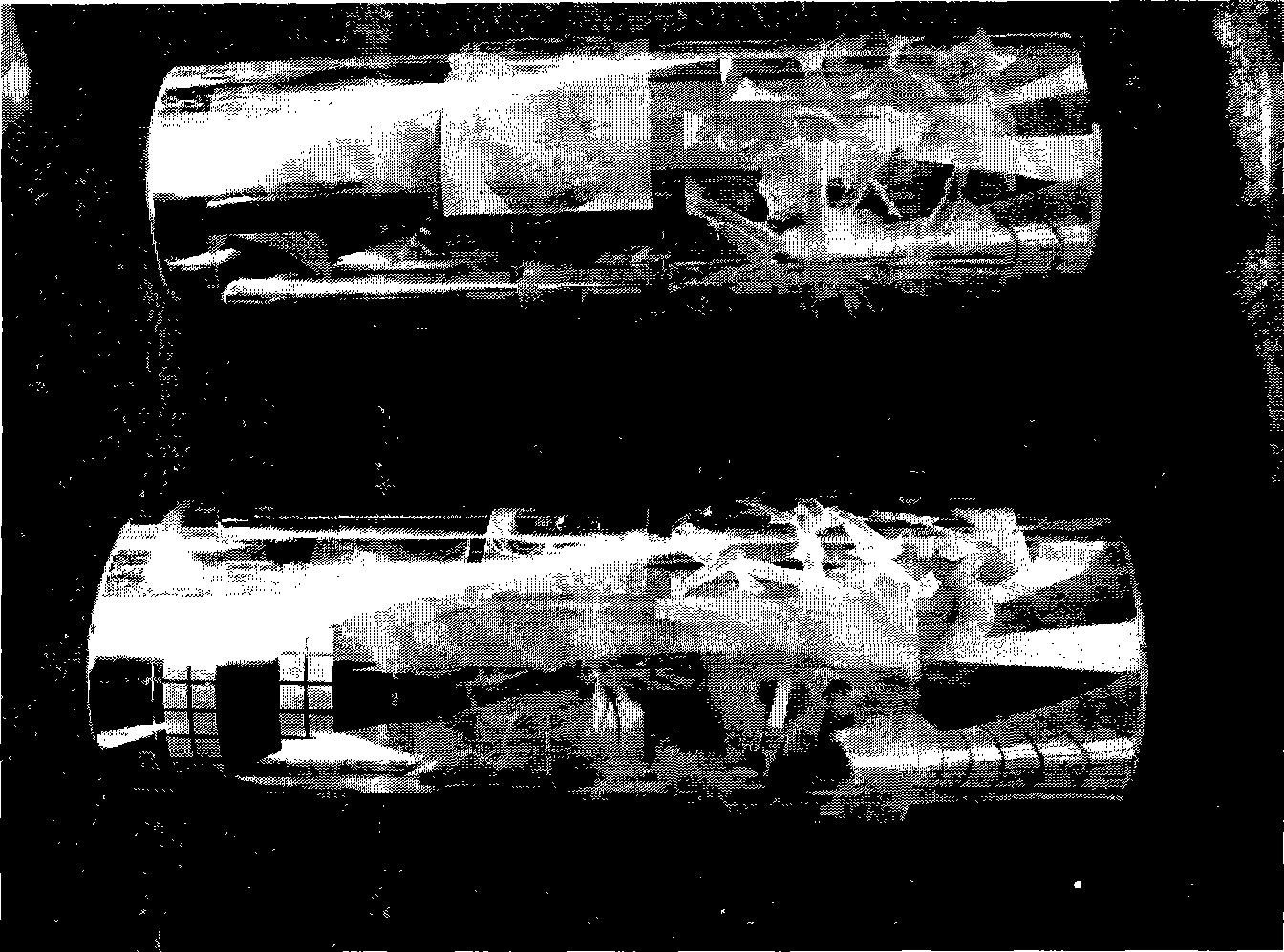

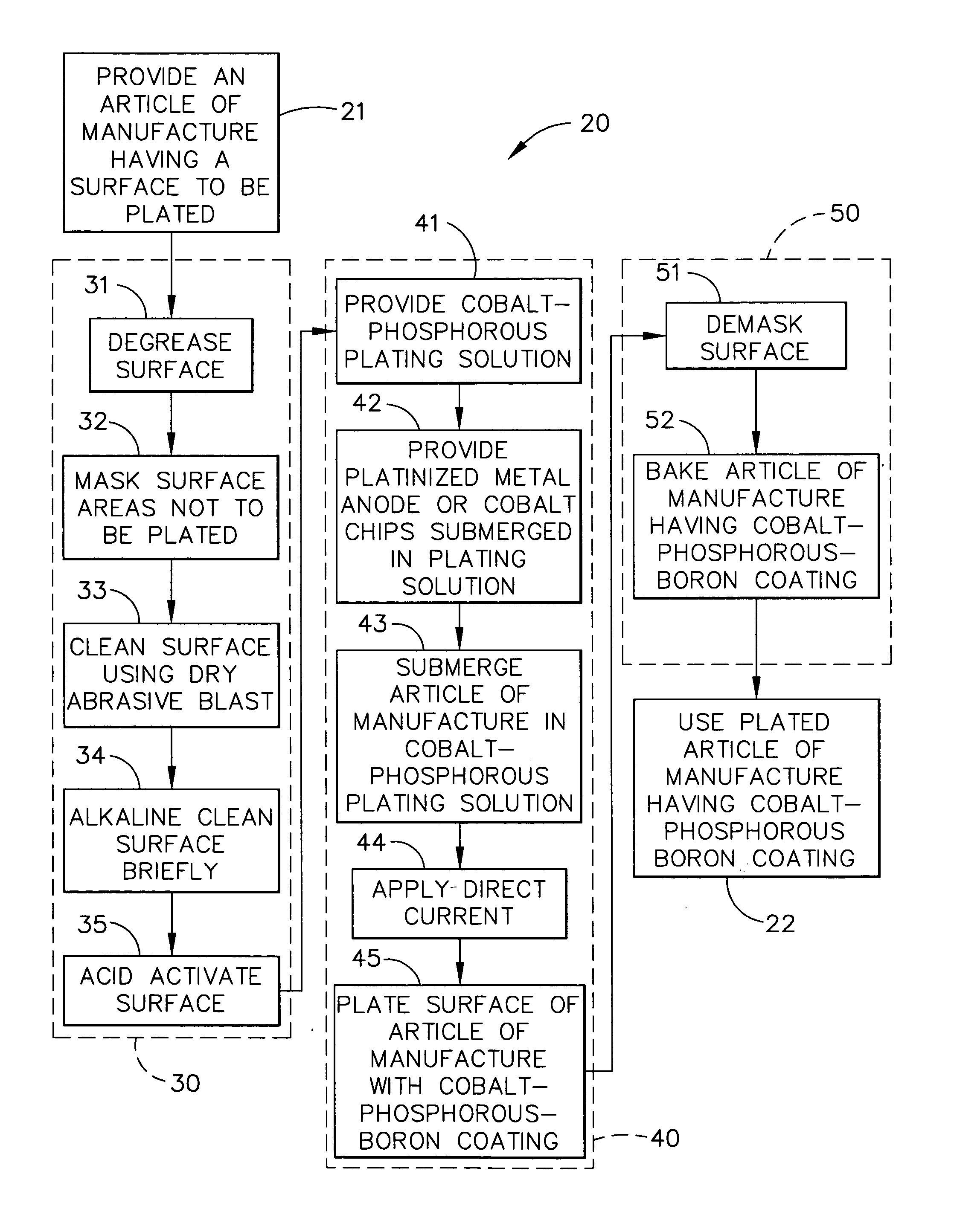

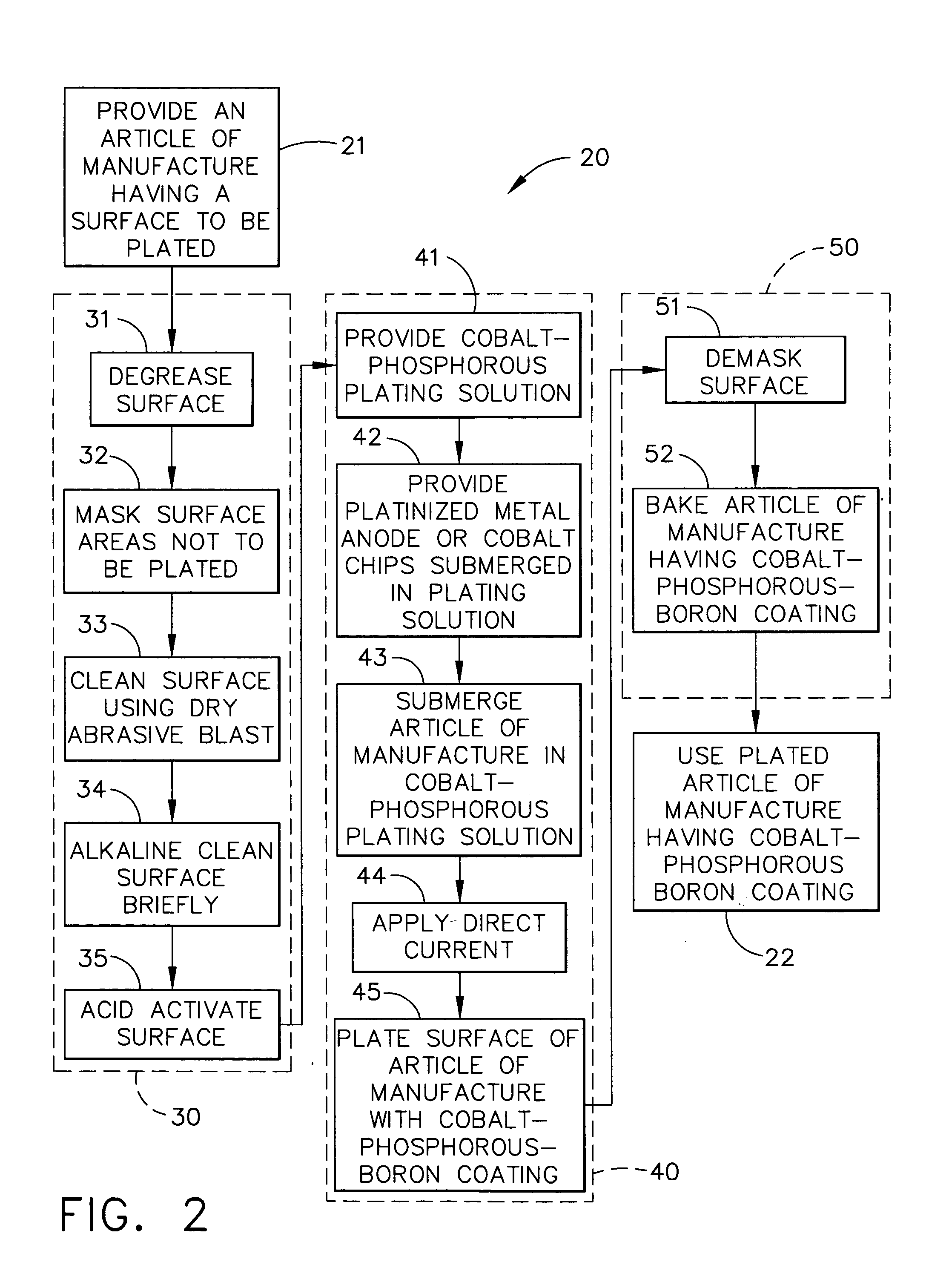

Cobalt-phosphorous-boron coating and process for plating

InactiveUS20050170201A1Anti-corrosive paintsLiquid/solution decomposition chemical coatingWear resistantCrack free

A cobalt-phosphorous-boron coating and a process for plating that is environmentally acceptable are provided. Furthermore, a cobalt-phosphorous plating solution is provided to deposit the cobalt-phosphorous-boron coating during the plating process on a surface of an article of manufacture. The cobalt-phosphorous plating solution does not contain chemicals presently restricted in use by the EPA. The cobalt-phosphorous-boron coating is a wear resistant coating with engineering properties, for example, low compressive residual stress, excellent adhesion to ferrous and nickel alloys, low fatigue debit, and a corrosion resistant crack-free structure, that meet or exceed the engineering properties of hard chromium plating intended for use in the aerospace industry. Furthermore, the cobalt-phosphorous plating process uses facilities and equipment that are comparable to those of the chromium plating process, and therefore, may be easily, readily, and economically introduced and implemented, for example, in the aerospace industry.

Owner:THE BOEING CO

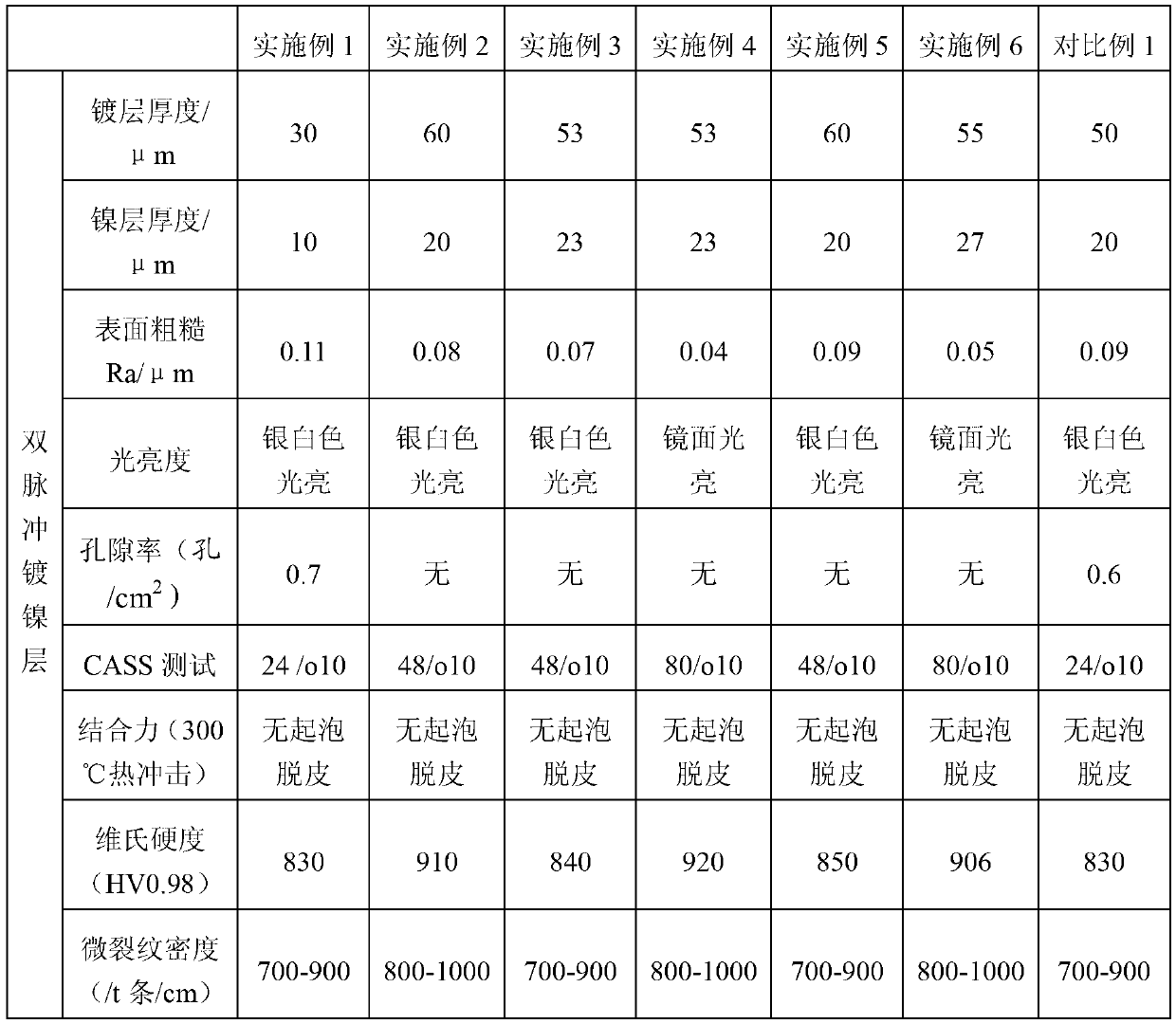

Wear-resistant worpiece and manufacturing method of wear-resistant coating thereof

The invention discloses a wear-resistant workpiece and a manufacturing method of a wear-resistant coating thereof. The preparation method of the wear-resistant coating comprises the following steps: forming a preparation piece according to the structure of a required wear-resistant workpiece; coating nickel on the surface of the preparation piece through a double-pulse method, thus forming a nickel-coated transition piece; and coating a hard chromium layer on the surface of the nickel-coated transition piece, thus forming the wear-resistant coating on the surface of the preparation piece. For the manufacturing method of the wear-resistant workpiece, a step of coating nickel on the surface of the workpiece through a double-pulse nickel coating method is added; and the double-pulse nickel coating method is characterized in that the magnitude of current or voltage is regulated by an external control means, the current is additionally controlled by controlling the pulse switch-on time, the pulse switch-off time, the pulse duty factor, the pulse current density and the like, and corresponding variables are changed to respectively achieve the effects of increasing the cathode current density, inhibiting the generation of side reaction, reducing the impurity content in the coating, improving the current distribution and the like, thus improving the quality of the coated nickel layer and prolonging the service life of the wear-resistant workpiece.

Owner:HUNAN TELI HYDRAULIC +1

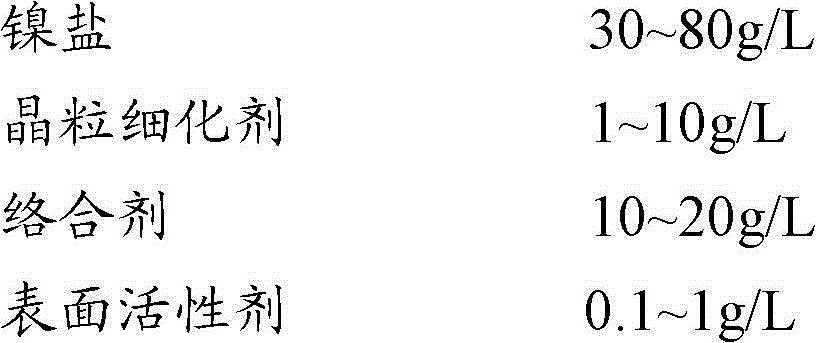

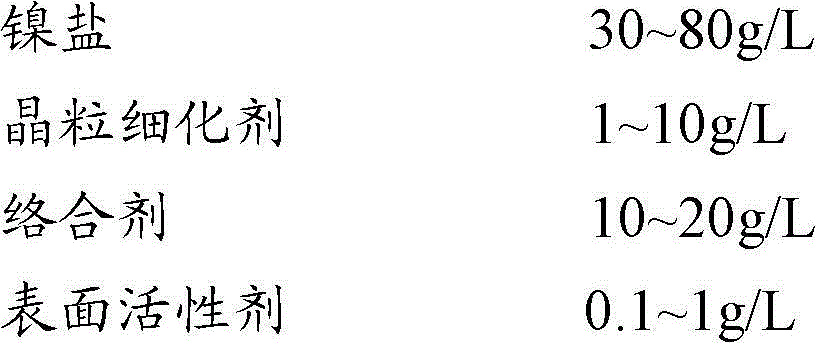

Electroplating solution for preparation of nanocrystalline nickel alloy plating and application thereof

The invention discloses an electroplating solution for preparation of a nanocrystalline nickel alloy plating. The electroplating solution comprises, in terms of mass concentration, 30 to 80 g / L of a nickel salt, 1 to 10 g / L of a grain-refining agent, 10 to 20 g / L of a complexing agent and 0.1 to 1 g / L of a surfactant. The invention also discloses an electroplating method for preparation of a nanocrystalline nickel alloy plating by using the electroplating solution and the prepared nanocrystalline nickel alloy plating which contains a certain amount of at least one inorganic element selected from the group consisting of nitrogen, carbon and boron besides the metallic element of nickel, wherein the inorganic element is introduced by the grain-refining agent. Compared with the prior art, the nanocrystalline nickel alloy plating prepared in the invention has a crystal grain size of less than 10 nm, a hardness of more than 800 Hv and good wear resistance; compared with conventional preparation methods for chromic acid plated hard chromium, the electroplating method provided by the invention has the advantages of simple equipment and process, easy operation, no pollution caused by hexavalent chromium and the like and has good market application prospects and research values.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

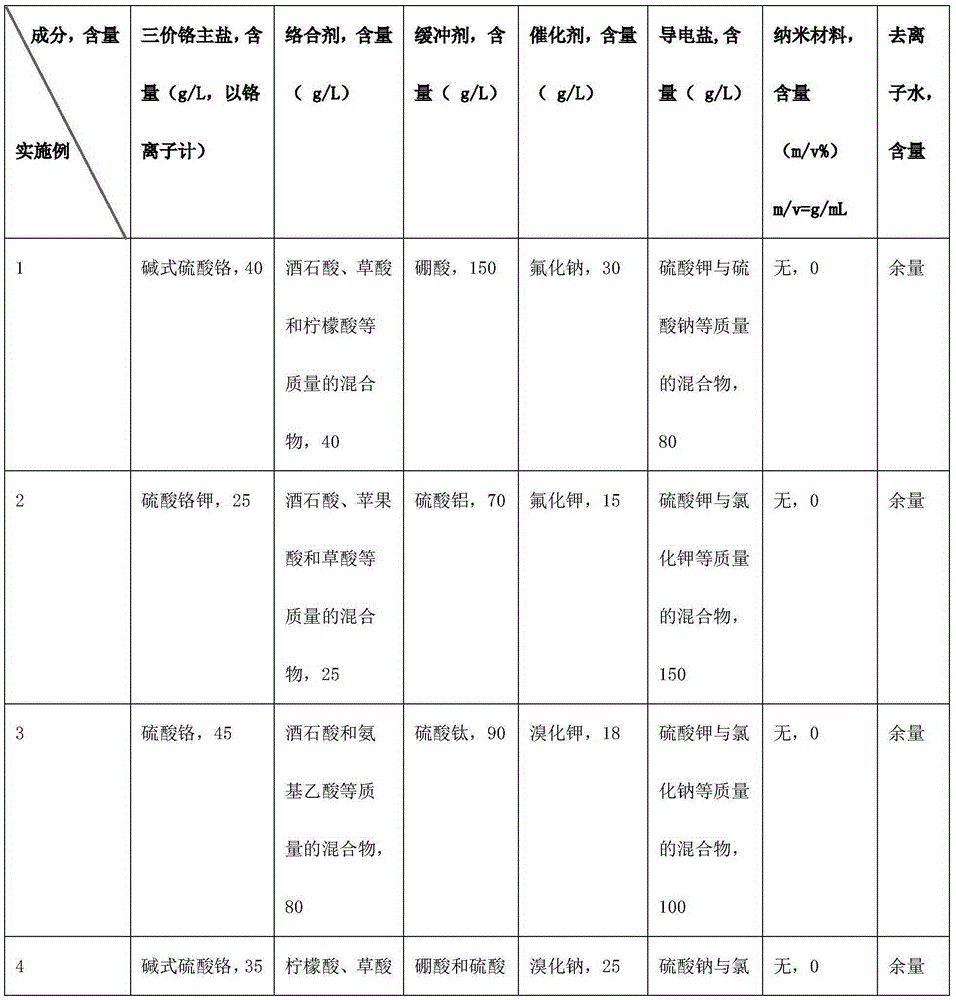

Trivalent chromium hard chromium electroplating solution and application of trivalent chromium hard chromium electroplating solution in hard chromium electroplating

The invention belongs to the technical field of metal surface treatment, and particularly relates to a trivalent chromium hard chromium electroplating solution and application of the trivalent chromium hard chromium electroplating solution in hard chromium electroplating. The electroplating solution is prepared from trivalent chromium main salt, a carboxylic acid or carboxylate complexing agent, a buffering agent, conducting salt and a catalyst. The deposition velocity reaches 2.5 micrometers / minute or above, the current efficiency reaches 36% or above, the thickness of an electroplating layer can reach 150 micrometers or above, each liter of the electroplating solution can be used for performing continuous electroplating for 900 ampere hours (an additive is supplemented during the process), high efficiency and high stability are maintained, the hardness of the electroplating layer reaches HV950 or above, and the electroplating layer has wear resistance the same as or similar to that of hexavalent chromium, has large binding force with steel, copper and copper alloy and is free of peeling or stripping or cracking in a 300 DEG C thermal shock test. As nanometer materials are added, corrosion resistance lasts for 150 h or longer in a neutral salt spray test. The trivalent chromium hard chromium electroplating solution has broad application prospects in the fields of rollers, hydraulic components, printing cylinders, shock absorbers, coal mine hydraulic supports and the like.

Owner:WUHAN DESYTEK ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

Double layer chromium electroplating processing process for conveying cylinder

The invention provides a bilayer-chromium electroplating machining process for transport cylinders. The process comprises the following steps of making a CrO3 solution and an H2SO2 solution into an electroplating solution according to a certain proportion, putting the electroplating solution into an electroplating bath, heating to a certain fixed value, placing and preheating a transport cylinder in the electroplating bath, removing impurities, plating the transport cylinder with 20 to 30 microns of milky white chromium at 15 to 25 A of current per dm<2>, cooling the transport cylinder to a certain temperature, adopting a stepped current raising method to raise the current to 35 to 45 A per dm<2> and plating the transport cylinder with 280 to 300 microns of hard chromium, so as to obtain the transport cylinder plated with bilayer-chromium. The transport cylinder manufactured through the process can effectively prevent chromium layers from falling off caused by corrosion or prevent burst caused by insufficient bonding strength, thereby greatly increasing the life span of the transport cylinder.

Owner:娄底市中兴液压件有限公司

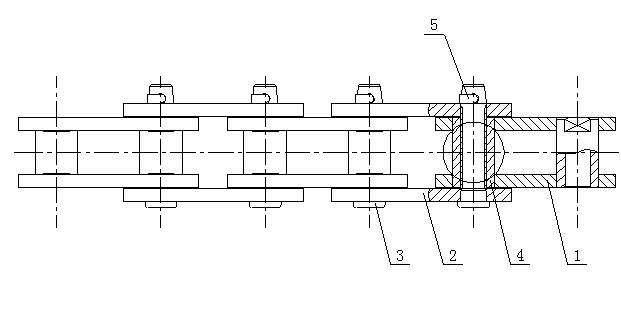

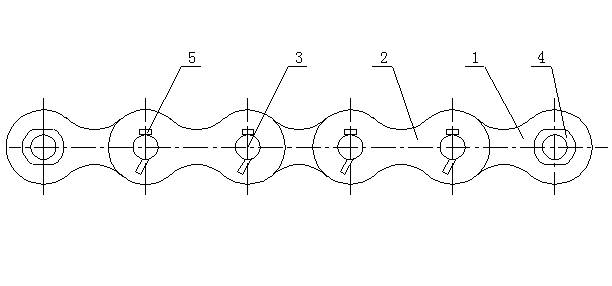

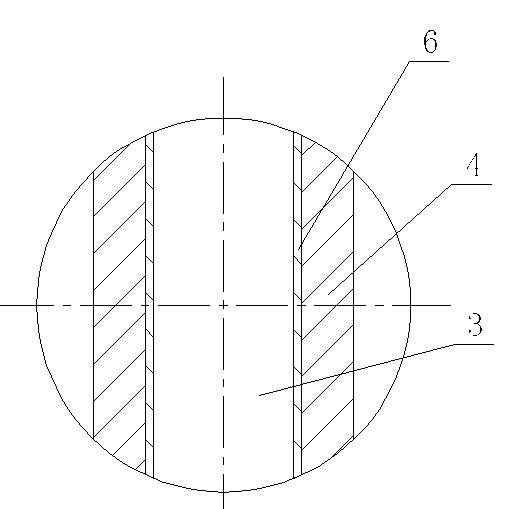

Wear-resistant chain

InactiveCN102537210AImprove corrosion resistanceReduce wearPivotal connectionsDriving chainsWear resistantEngineering

The invention discloses a wear-resistant chain. The chain comprises an inner chain plate, an outer chain plate, a pin shaft, a sleeve and a locking piece, wherein the inner chain plate is connected with the outer chain plate through the pin shaft; the sleeve is arranged outside the pin shaft; the locking piece for fixing the pin shaft is arranged outside the outer chain plate; and a wear-resistant layer is arranged on the surface of the pin shaft and is an alloy coating which is a hard chromium layer. According to the wear-resistant chain, the wear-resistant layer is arranged on the surface of the pin shaft, so the wear degree of the surface of the pin shaft, which is rolled by a high-hardness abrasive mixture, is greatly reduced, the corrosion resistance of the pin shaft is improved, the service life is prolonged, imported chains are not needed, and production cost is greatly reduced.

Owner:SUZHOU UNIVERSAL GRP TECH CO LTD

Method for plating hard chromium on surface of metallic material

InactiveCN1687486AReduce corrosionIncreased electrolyte transportChemical compositionMetallic materials

The present invention discloses a method of plating hard chromium on the surface of metal. The characteristic is that it concludes the following process: (1) Cleans and activates the surface of metallic material in common way; (2) plates hard chromium: plating hard chromium after the surface of the metal is cleaned and activated. The temperature of plating solution is 58 - 65 deg. C; Current density is 30 - 80 A / dm2; the proportion of cathode and anode area is 2 - 3:1; the component of plating solution (in one liter) is: Chromic anhydride is 220-280g; Sulfuric acid: 2.5 - 4.5 g; Cr (III): 1.5 - 7 g; the additive of organic compound LD-5660: 14 - 20 ml. This invention can increase current efficiency and speed of sedimentation. The coat is anti-corrosive.

Owner:CHONGQING JIANSHE MOTORCYCLE CO LTD

Production process of low-stress electroforming printing nickel screen

The invention relates to a production process of a low-stress printing nickel screen, which comprises the following steps of: (a) making a nickel screen die; (b) primarily coating the nickel screen; and (c) secondarily coating the nickel screen. The production process of the low-stress printing nickel screen is characterized in that a hard chromium layer is coated outside a bottom nickel layer of the die, electrolytes for coating nickel in the preparation of the die and the nickel screen are both nickel aminosulfonate with the concentration of 480-580 g / l and the working temperature of 43-47 DEG C, and vaseline with the concentration of 20 percent is adopted as a passivant for passivating the die. The nickel amino-sulfonate, instead of a traditional nickel sulfate, is used as the nickel-coating electrolyte, and the obtained nickel screen has low electric nickel layer stress and good toughness, elasticity and recovery. The original nickel sulfate electrolyte works at a temperature of 70 DEG C, but the nickel amino-sulfonate works at a temperature of 43-47 DEG C and saves electricity. Due to the hard chromium layer coated on the die, the wearing resistance of the die and the opening evenness of the nickel screen are improved. The die is passivated by the vaseline with the concentration of 20 percent so as to lessen the pollution and prolong the service life of the die.

Owner:金昌宇恒镍网股份有限公司

Crystallizer copper tube with transitional chromium coating and hard chromium coating and production process thereof

The manufacture technique for a crystallized copper tube with transient Cr-plating layer and hard Cr-plating layer comprises: cleaning the base copper tube to remove dust and oil; reverse nicking treatment before plating; preparing electroplate liquid; plating; cleaning; then, arranging transient plating layer with medium thermal-expansion coefficient and hardness between the base tube inner wall and surface hard plating layer. This invention ensures the tube resistance to high temperature, wear and corrosion, and endows the plating layer resistance peel, and has high yield efficiency with stable quality and low cost.

Owner:张喜成 +1

Method for preparing of low stress chromium nitride multilayer hard film

InactiveCN101338412AHarmonize internal stressReduce internal stressVacuum evaporation coatingSputtering coatingFilm baseNitrogen gas

The invention relates to a manufacturing method of a low-stress multi-layer hard chromium nitride film. Non-equilibrium magnetron sputtering equipment is used for processing. The method comprises procedures as follows: (1) cleaning is processed; (2) a chromium transition layer is deposited; (3) and a multi-layer chromium nitride film is deposited. High purity argon under the pressure of 0.65*<-1>Pa to 5*10<-1>Pa passes through a vacuum chamber; meanwhile, high purity nitrogen under the pressure of 0.65*<-1>Pa to 5*10<-1>Pa in the vacuum chamber is used as reaction gas. A work piece is put under the negative bias of -150 to 400V; the sputtering power of a chromium target is turned on to deposit a layer of compressive stress chromium nitride film; afterwards, the work piece is put under the negative bias of 0 to -100V; the sputtering power of the chromium target is turned on again to deposit a layer of pulling stress chromium nitride film; and the procures are repeated twice to forty times. The manufacturing method is easy to be operated and has low cost. The chromium nitride film manufactured by the method is thick and hard and has good film base bonding capacity, high consistency, smooth surface and strong corrosion resistance.

Owner:SOUTHWEST JIAOTONG UNIV

Composite coating for abrasion-resistance and anti-corrosion treatments on surface of machine components and preparation method

InactiveCN101746091AImprove corrosion resistanceImprove bindingVacuum evaporation coatingSputtering coatingGas phasePhysical vapor deposition

The invention discloses a composite coating for abrasion-resistance and anti-corrosion treatments on the surface of machine components and a preparation method thereof, which is characterized in that: the composite coating has a double layer structure, the surface layer of the double layer structure is a function layer, and a transition layer is arranged between the function layer and the surface of a component; the transition layer is a pure metal layer such as Cr layer, Ti layer or Ni layer; the function layer is a carbide layer MC, a nitride layer MN or a carbonitride layer MNC, wherein M is transition metal such as Ti, Al, Zr or Mo. The invention prepares the composite coating on the surface of the machine components under the requirements of abrasion-resistance and anti-corrosion by an unbalanced magnetron sputtering method of the physical vapor deposition. The composite coating has better performance in comparison with electrodeposited hard chromium, and has remarkable advantage in environment protection.

Owner:董志良 +1

Gantry-movable drilling, boring and milling compound machine tool

InactiveCN102862053AGuaranteed lubrication effectGuaranteed long-termOther manufacturing equipments/toolsLarge fixed membersNumerical controlThick wall

A gantry-movable drilling, boring and milling compound machine tool is guided by matching of typical cylinders and cylindrical sliding sleeves and adopts a stepless variable frequency speed regulation mechanism and a numerical control mode. Large-scale swing bearings are adopted for support and rotation of workbenches. In the material aspect, vertical column guide rails and cylindrical movable cutters are manufactured by structural alloy steel thick-walled seamless pipes and are subjected to grinding and hard chromium plating, and the workbenches are casted by ductile cast iron. The gantry movable drilling, boring and milling compound machine tool has the advantages that the machine tool can be used for drilling and boring and has functions of excircle, inner bore, section and curved surface turning, flat surface, inclined surface, curved surface and groove milling, thread tapping and the like, lubrication, dust prevention and durability of the guide rails are guaranteed, and long-term precision is maintained. Double gantries are movable, work efficiency can be improved by machining long and large pieces by the juxtaposed double gantries together, the large-scale rotating workbenches additionally arranged at two ends can be used as two numerical control lathes, equipment utilization rate is increased, and the gantry-movable drilling, boring and milling compound machine tool is simple in structure and can meet customer machining requirements particularly when parts are large in machining face and machining length.

Owner:SHANDONG YIXIN HEAVY MACHINERY MFG

Hydraulic cylinder of carbon fiber composite material

InactiveCN103727092AGood mechanical propertiesHigh strengthFluid-pressure actuatorsFiberHydraulic cylinder

The invention discloses a hydraulic cylinder of a carbon fiber composite material. A cylinder body (2) is made of a high-strength carbon fiber precursor of which the strength is greater than or equal to 3500MPa as a reinforcing material and thermosetting resin as a substrate by adopting a technology of winding and molding carbon fiber into a carbon fiber composite material layer; a cylinder bottom (1), a piston (6) and a cylinder cover (10) are made of a high-strength aluminum alloy of which the strength is greater than or equal to 500MPa; a piston rod (9) is made of hard chromium-plated steel. Compared with a common hydraulic cylinder made of metal, the hydraulic cylinder has the significant advantage of weight reduction, and the weight-carrying capacity is obviously superior to that of an existing common hydraulic cylinder made of metal. Therefore, the hydraulic cylinder has a good application prospect in hydraulic drive and hydraulic control equipment in which water is used as a fluid medium.

Owner:WUHAN UNIV OF TECH

Steel and titanium alloy low-temperature pulse ion nitrocarburizing and cathode arc ion plating M/MN alternate plating thick-film technology

InactiveCN104862643AGood adhesionReduce distortionVacuum evaporation coatingSputtering coatingWear resistantStress relief

The invention discloses a steel and titanium alloy low-temperature pulse ion nitrocarburizing and cathode arc ion plating M / MN alternate plating thick-film technology, and belongs to the technical field of material surfaces. The technology is characterized in that the stress relief annealing is performed for a workpiece 3 by cold rolling or cold drawing; a nitrocarburizing layer and M / MN alternate composite thick-film layer with a mildly transitional hardness of a wear resistant layer on the surface of the workpiece is prepared to prevent the falling of a coating film; a transition layer with a thickness of 1-3 microns is formed between a modified layer and an ion plating M film layer to improve the adhesiveness of the coating film; ion plating M and MN alternate coating films are prepared; the ion plating M film can partially absorb the internal stress of the MN plating film; and the plating film is not liable to fall. The technology has the effects and benefits of solving low hardness and weak wear resistance of a titanium alloy, replacing electroplating hard chromium, having no environmental pollution, having no harm to human bodies and having wide application range, such as molds, machine tool parts, mine machinery, locomotives and piston rings.

Owner:DALIAN UNIV OF TECH

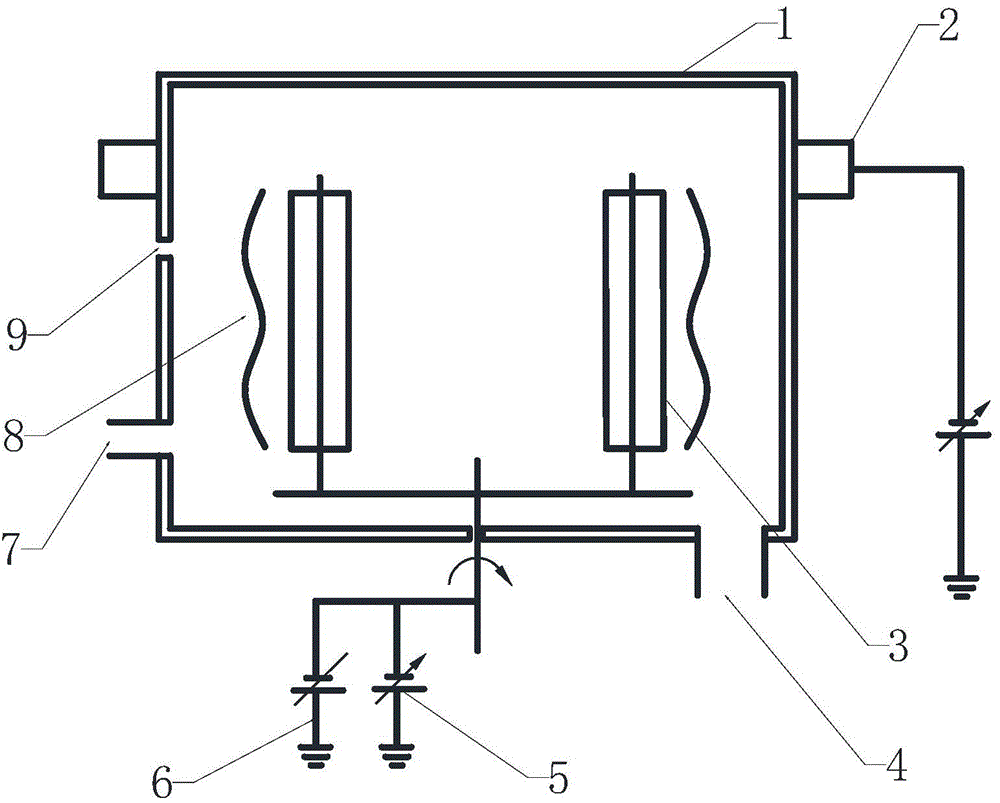

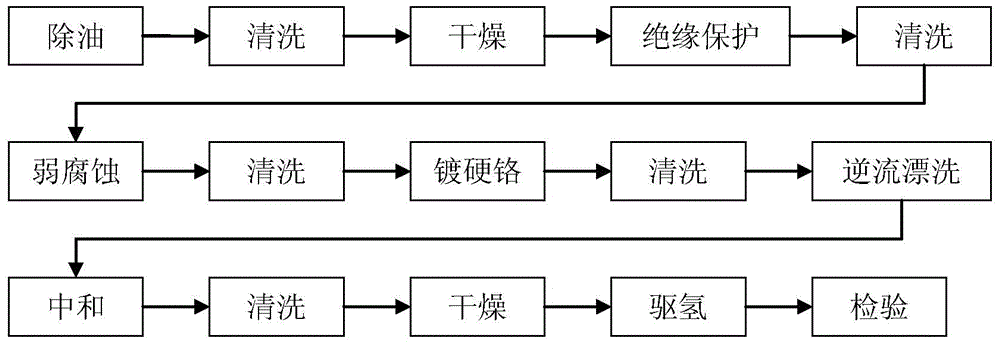

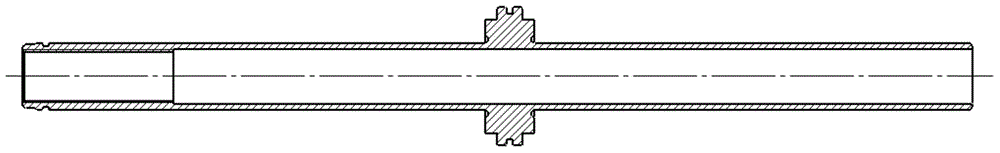

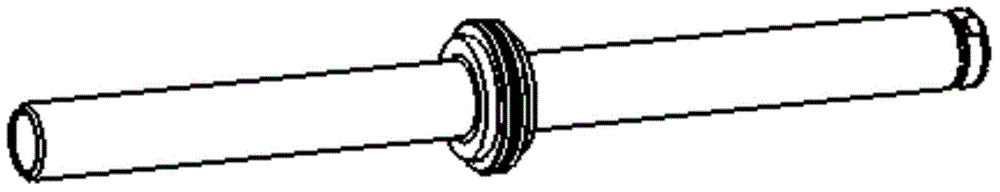

Hard chromium plating method and solution formula for piston rod class parts

The invention belongs to the field of chemical engineering and particularly relates to a hard chromium plating method and solution formula for piston rod class parts. The objective is to solve the problem that when a piston rod is produced, the quality of a hard chromium coating produced by a traditional electric chromium plating technology is not ideal, and the current efficiency is low. The method comprises the following steps: first, removing oil; then, washing, drying and carrying out insulation protection; after washing, carrying out weak corrosion; washing, and then, plating hard chromium; after washing, carrying out backflow bleaching, after neutralization, washing and drying; and after removing hydrogen, carrying out test. The hard chromium plating solution formula comprises 200-225g / L of CrO3, 2.3-2.5g / L of H2SO4 and 3-6g / L of Cr3+. The hard chromium plating method and solution formula are more suitable for piston rod class parts, particularly the production of hard chromium films of 30GrMnSiA materials. Moreover, the CrO3 content in the formula is reduced, so that the cost is reduced, and environmental pollution is reduced.

Owner:北京实验工厂有限责任公司 +1

Coating material for replacing hard chromium plating and laser-cladding preparation method thereof

ActiveCN103060707AImprove performanceMeet coating performanceMetallic material coating processesImpurityBond strength

The invention provides a coating material for replacing a hard chromium plating and a laser-cladding preparation method thereof and relates to the field of iron-base alloy super-hard coating materials. The coating material comprises the following components in percentage by mass: 0.8-1.0 wt% of C, 4.0-8.0 wt% of Cr, 2.0-3.0 wt% of Ni, 0.4-0.8 wt% of Si, 5.0-7.0 wt% of Mo, 6.0-10.0 wt% of W, 0.3-0.6 wt% of Mn and the balance of Fe. The preparation method comprises the following steps: using metal raw materials to prepare Fe-based powder by using a water atomization or gas atomization method; screening the Fe-based powder so as to obtain powder with a particle size range of 10-50 microns; selecting a part to be reinforced as a substrate; carrying out sand blasting treatment on a part area to be reinforced or repaired; removing particle impurities of the part by using compressed air; scrubbing the surface of the part by using alcohol; preparing a Fe-based coating on the surface of the part by using a laser-cladding process based on a synchronous powder feeding technology so as to reinforce or repair the part; and carrying out follow-up mechanical grinding machining on the Fe-based coating so as to machine the part with the part size and desired roughness. According to the invention, requirements of actual production on the performance, bonding strength and production efficiency of the coating are satisfied.

Owner:BEIJING UNIV OF TECH

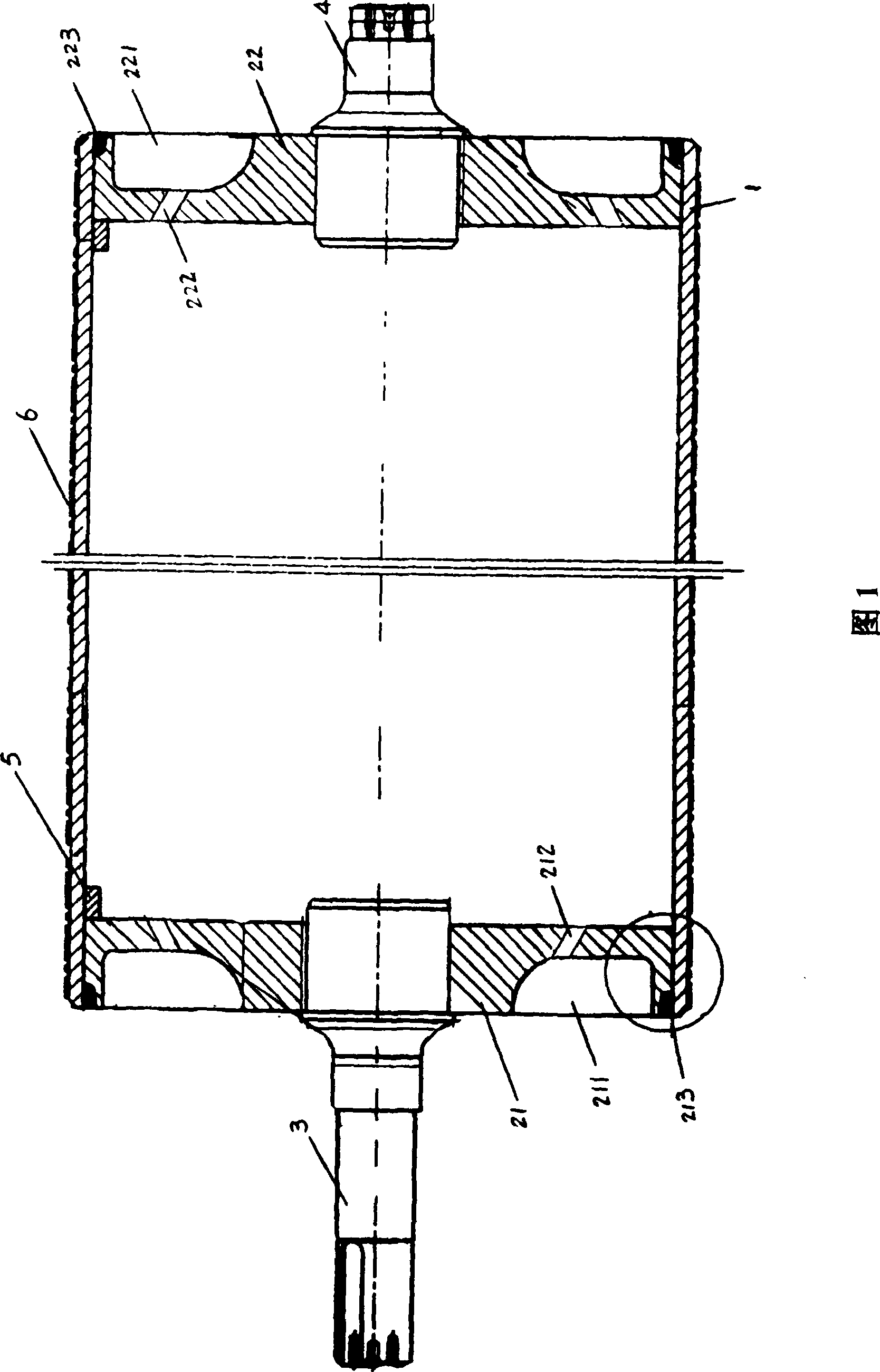

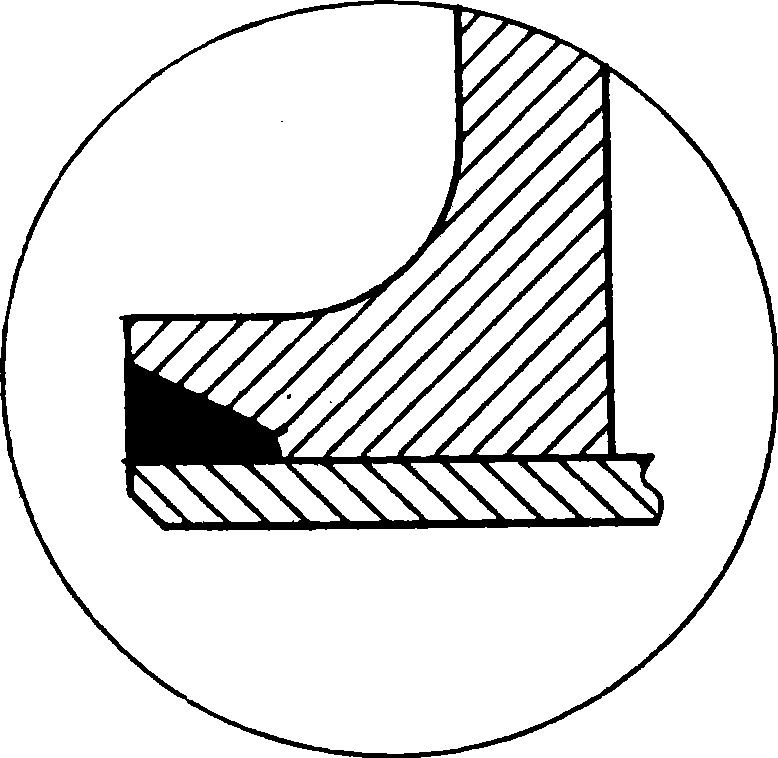

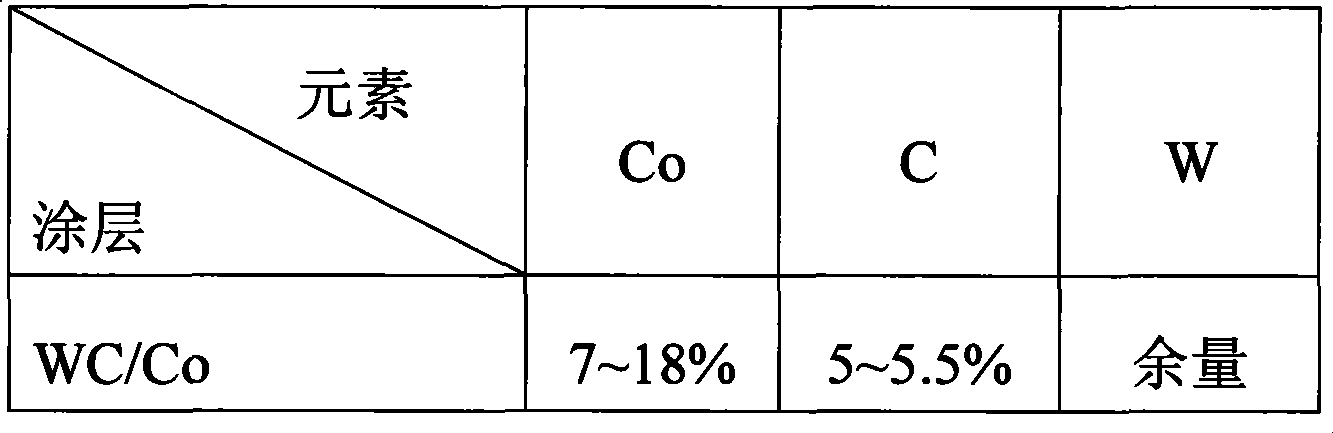

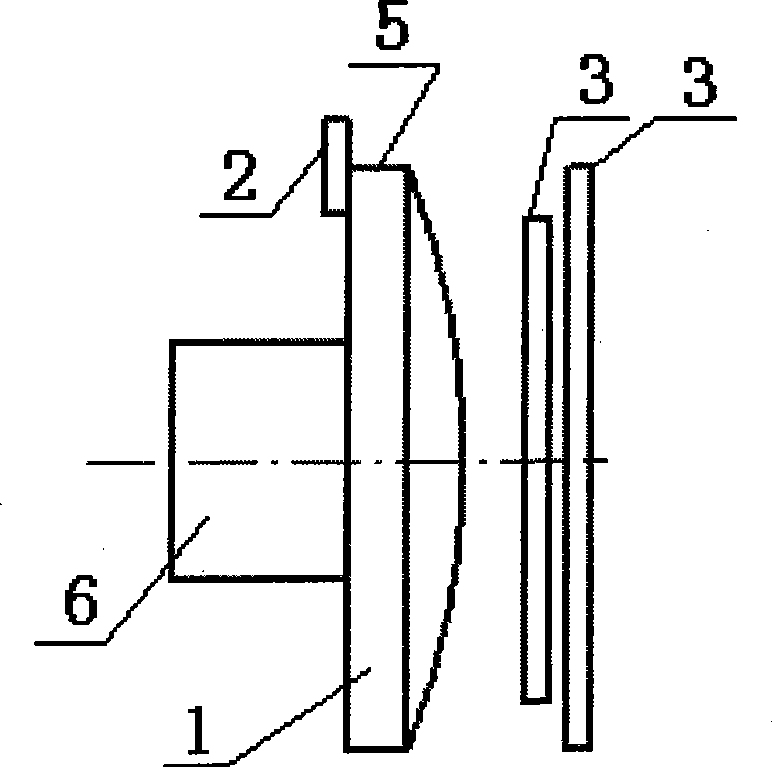

Intermediate-frequency quenching hard-surface strain roller and manufacture method thereof

ActiveCN101362152AReduce oxidationLow oxide contentMolten spray coatingFurnace typesProduction lineIntermediate frequency

The invention relates to a tension roller used in a cold rolling production line, in particular to a tension roller with a mid-frequency quenching hard surface, and a manufacturing method thereof. The tension roller comprises a roller and round side covers which are fixedly and closely covered at the openings of the two ends of the roller, and the circle centers of the two side covers are in coupling connection with a left axle head and a right axle head respectively. The tension roller is characterized in that: the outer surface of the roller is covered with a spaying layer, the outsides of the two side covers are provided with concave grooves in a surrounding way, the concave groove is internally provided with a through hole communicated with the interior of the roller; the spaying layer adopts the functional metal ceramic coating which is composed of compound metal ceramics of WC / Co metal ceramics and metal or alloy. The tension roller mainly solves the technical problems that the existing product roller surface is sprayed with hard chromium plating on the outer surface and is easy to be pressed into concave pits or protuberances by sundries such as ferric oxide, etc. When in use, drawing stamps or stains are formed on the surface of the finished product, the band steel, thus influencing the surface quality of the band steel, and the tension roller is beneficial to radiating the interior of the roller when in use.

Owner:SHANGHAI JUSN SURFACE TECH ENG

Trivalent hard chromium electroplating method

The present invention discloses an electroplating method for electroplating a trivalent hard chromium plating layer on iron and steel, wherein a DSA anode and a sulfuric acid system trivalent chromium solution are adopted, a temperature of about 50 DEG C and current density of 35-65 A / dm<2> are adopted, a soft starting process that change of current and a tank voltage is controlled during an electroplating process is adopted, and the pH value is maintained in the specified range (the pH value is 0.9-2.1) to obtain the trivalent chromium plating layer with a thickness of more than 80 mum, wherein the plating layer hardness achieves more than HV870, the current efficiency is more than 35%, the plating coating rate can be up to 2 mum / min, and the plating layer bonding force passes through the thermal shock test (200 DEG C heating, and salt water quenching). According to the present invention, the process method that the trivalent hard chromium electroplating replaces the sexvalent hard chromium electroplating with a characteristic of serious environment pollution is provided, and problems that the thick plating layer can not be obtained through the existing trivalent chromium electroplating technology, the plating layer and substrate bonding force is poor, and the like are solved.

Owner:WUHAN RES INST OF MATERIALS PROTECTION +2

Method for preparing silicon oxide ceramic coatings on steel member through electrophoretic deposition

InactiveCN102732936AImprove compactnessUniform compositionElectrophoretic coatingsCeramic coatingWear resistant

The invention discloses a method for preparing silicon oxide ceramic coatings on surfaces of Fe, Cu, Zn, Ni, Sn and their alloy through electrophoretic deposition. The method comprises the following steps: carrying out dark nickel electroplating or composite nickeling, or phosphorizing with above metals as electrophoretic silicon oxide coating matrixes, nickel sulfate as a main salt, nickel chloride as an anodic activator, boric acid as a buffering agent and Al2O3 as a powder body; carrying out electrophoretic deposition on the nickeled or phosphorized metal matrixes in a prepared silicon oxide sol; drying the matrixes; and sintering the matrixes to obtain the silicon oxide ceramic coatings. The method provided in the invention, which uses the electrophoretic deposition, has the characteristics of simple technology and no need of expensive or complex devices, and the prepared ceramic coatings have better compactness than pulled films, and have good performances and uniform components. The method can be used for preparing wear resistant coatings and high temperature oxidation resistant coatings on surfaces of metals especially common steel and above metals, can substitute hard chromium electroplating technologies with severe pollutions, and has the advantages of cleanness, no pollution and easy industrialization realization.

Owner:SHENYANG LIGONG UNIV

Process for deposition of crack-free and corrosion-resistant hard chromium and chromium alloy layers

An electrolytic plating composition and related plating process where the composition comprises chromium ions, a mineral acid, halogen oxoanion, alkylsulfonic acid, and a source of sulfoacetic acid for electrolytically coating a surface of a substrate with a chromium layer or a chromium alloy layer.

Owner:ENTHONE INC

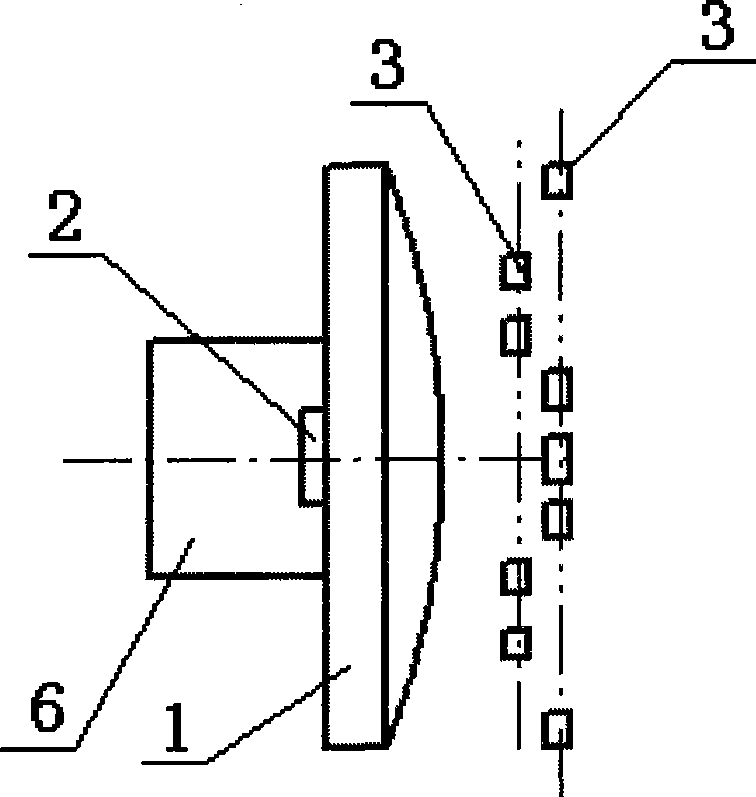

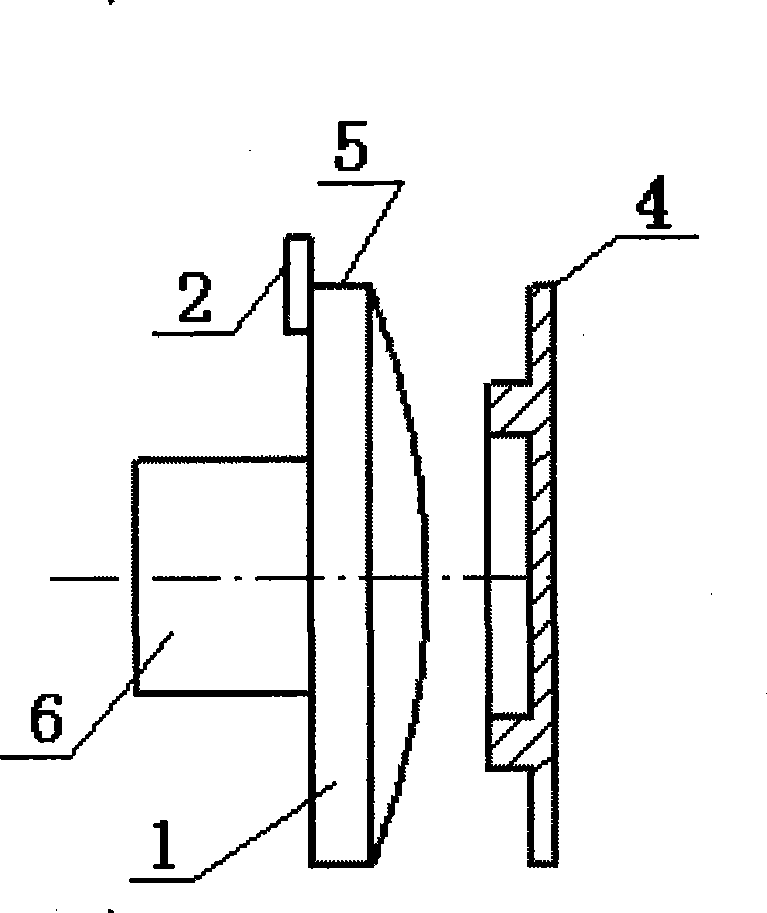

Chrome plating method for spherical crown surface of major diameter spherical crown workpiece

The invention provides a method for plating chromium on a spherical cap surface of a large-diameter spherical cap workpiece. In a step of immersing and positioning, the arrangement mode or structure of an anode strap or an anode plate is changed; in a step of plating chromium, opacified chromium is plated under the conditions that the temperature of the plating solution is 70 to 75 DEG C and the current density is 20 to 25A / decimeter<2>; and then, hard chromium is plated under the conditions that the temperature of the plating solution is 50 to 55 DEG C and the current density is 25 to 30A / decimeter<2>. The polishing processing is carried out on the spherical cap surface of the workpiece, which has the advantages of good evenness of chromium plated coating, defect prevention, high electroplating efficiency, fast speed of cladding deposit, high surface finish of the spherical cap surface after chromium is plated, and subsequent mechanical processing workload reduction.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

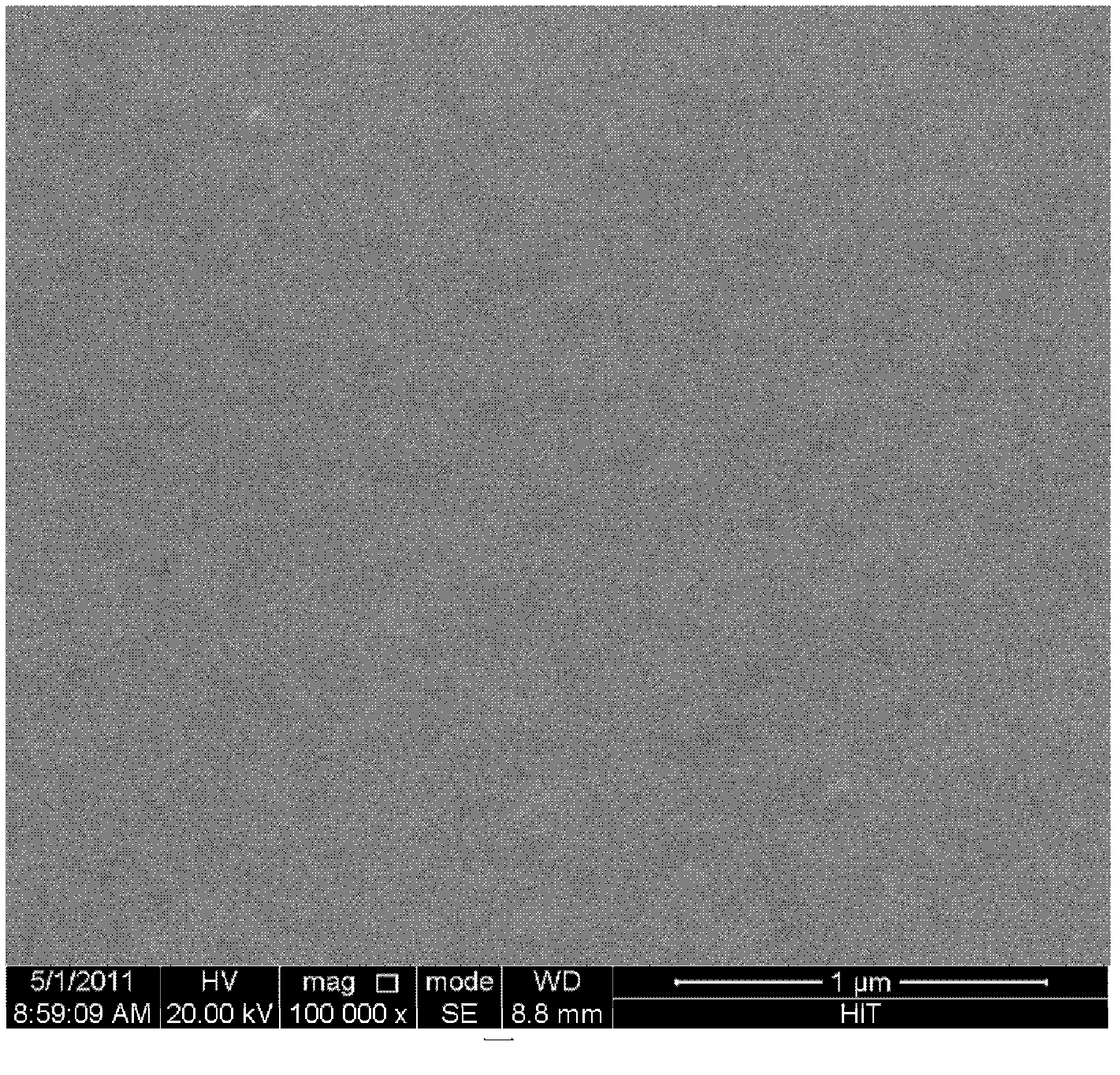

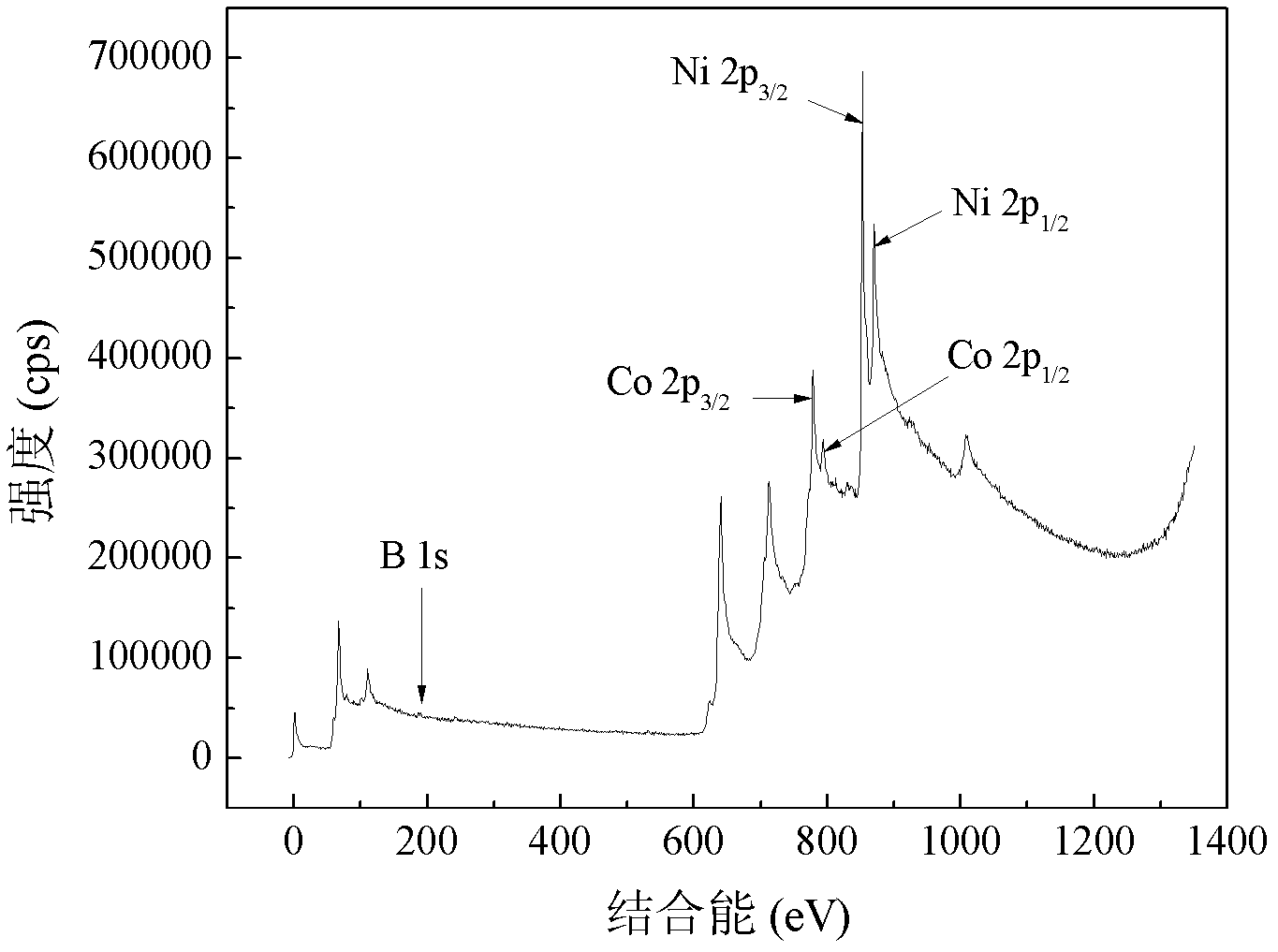

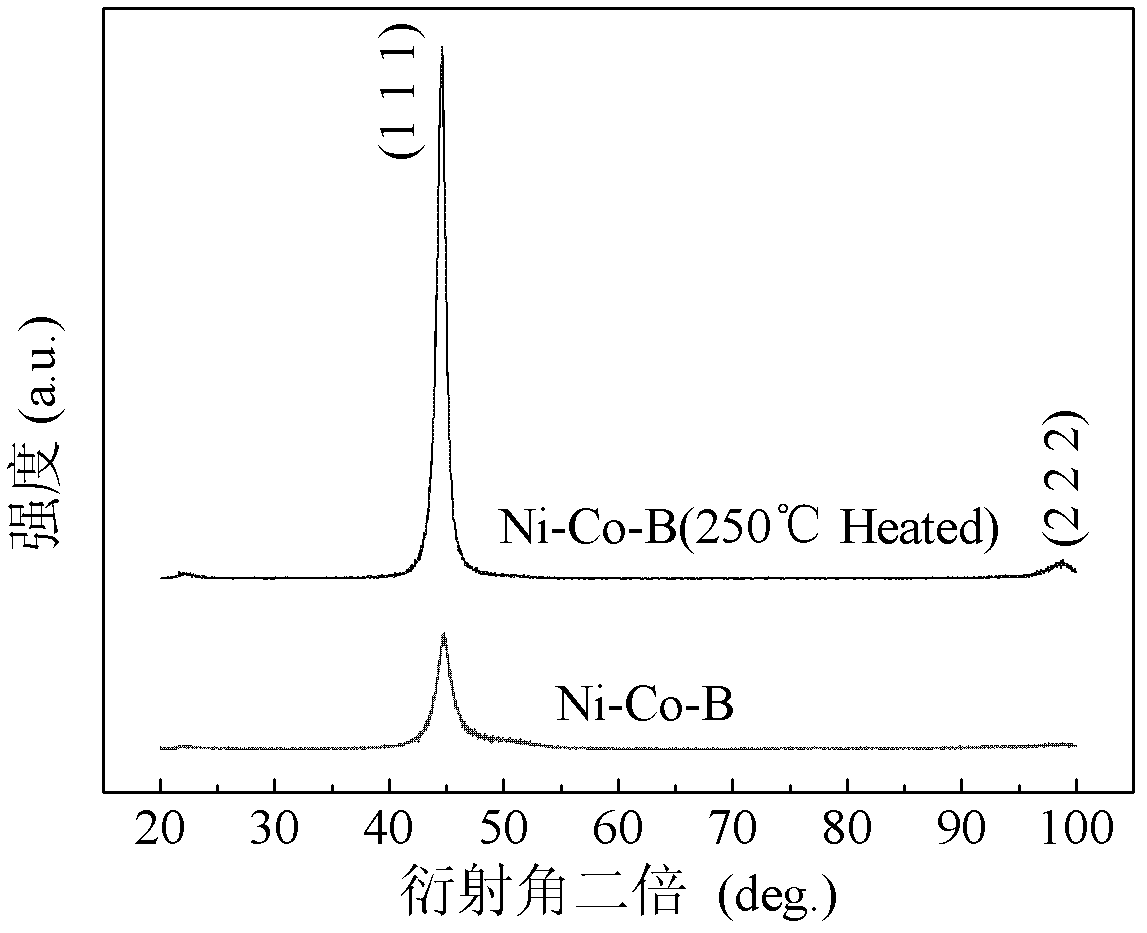

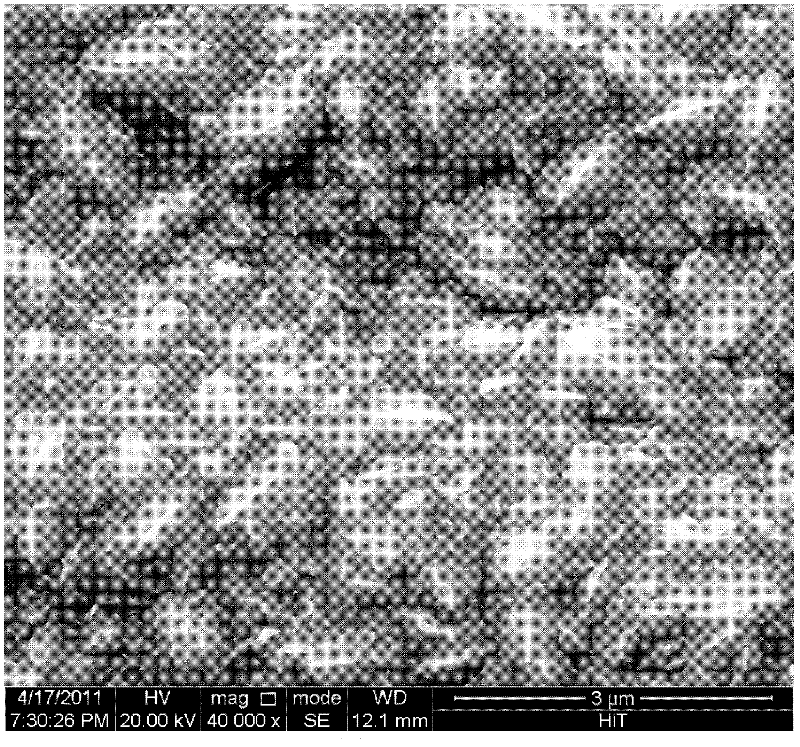

Electric deposition preparation method of Ni-Co-B alloy substituted hard chromium plating

The invention provides an electric deposition preparation method of a Ni-Co-B alloy substituted hard chromium plating, relating to a preparation method of the Ni-Co-B alloy substituted hard chromium plating. The method 1 comprises the following steps of: taking nickel salt, cobalt salt, nickel chloride, boric acid, amine boride, NI3<#> fast high-level nickel-plating glazing agent A and lauryl sodium sulfate; preparing an alloy plating solution; and plating a processed plated part. The method 2 comprises the following steps of: taking nickel chloride, cobalt salt, boric acid, amine boride, NI3<#> fast high-level nickel-plating glazing agent A and lauryl sodium sulfate; preparing an alloy plating solution; and plating a processed plated part. In the invention, a Ni-Co-B alloy plating with uniform brightness, hardness of 770-800HV50 as well as good corrosion resistance and bonding force is obtained at a deposition rate higher than 60mu m / h. In the plating process, the cathode current efficiency is higher than 96%; and after the plating is subjected to heat treatment at 150-400 DEG C for 1-3 hours, the hardness of the plating can be increased to 1055-1108HV50.

Owner:HARBIN INST OF TECH +1

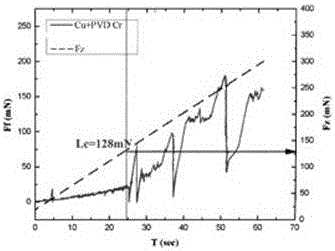

PVD coating on surface of airspeed head and preparing method of PVD coating

InactiveCN105803412AFast depositionImprove deposition efficiencyVacuum evaporation coatingSputtering coatingSputteringChromium coating

The invention relates to a PVD coating on the surface of an airspeed head and a preparing method of the PVD coating, and belongs to the technical field of material surface treatment. The non-balance magnetron sputtering physical vapor deposition method is adopted, equipment is provided with a single chromium metal target, a single layer of hard chromium is deposited on the surface of the airspeed head subjected to chromium removing and polishing, and the thickness of the PVD coating is about 2 microns-6 microns. By means of the preparing method, the bright airspeed head surface coating can be obtained, meanwhile, precise elements in the airspeed head cannot be damaged, and the using performance of the airspeed head can be guaranteed. In addition, the binding force between the PVD chromium coating and a base body of the airspeed head is good, and the abrasion resistance and corrosion resistance are good. No pollution is caused to the environment, and no harm is done to the human body.

Owner:SHANGHAI HAI YING MECHANICAL FACTORY +1

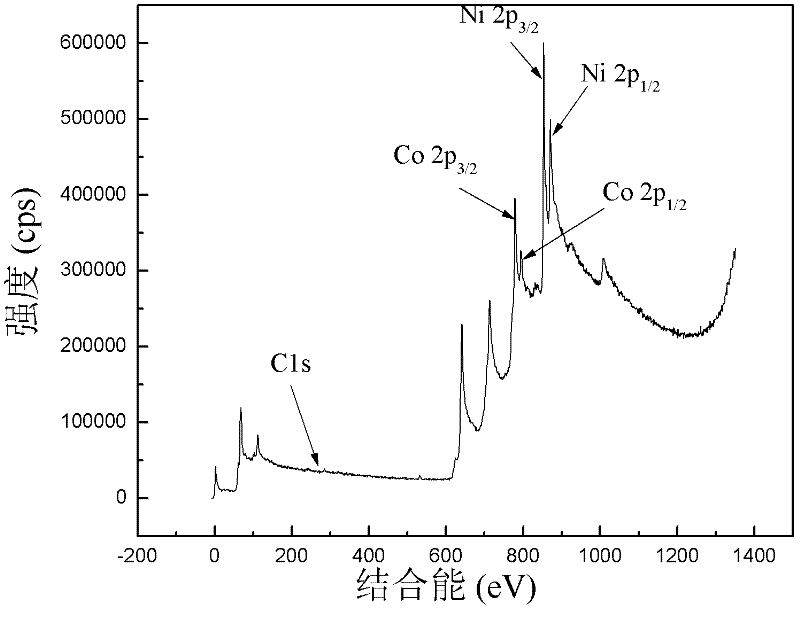

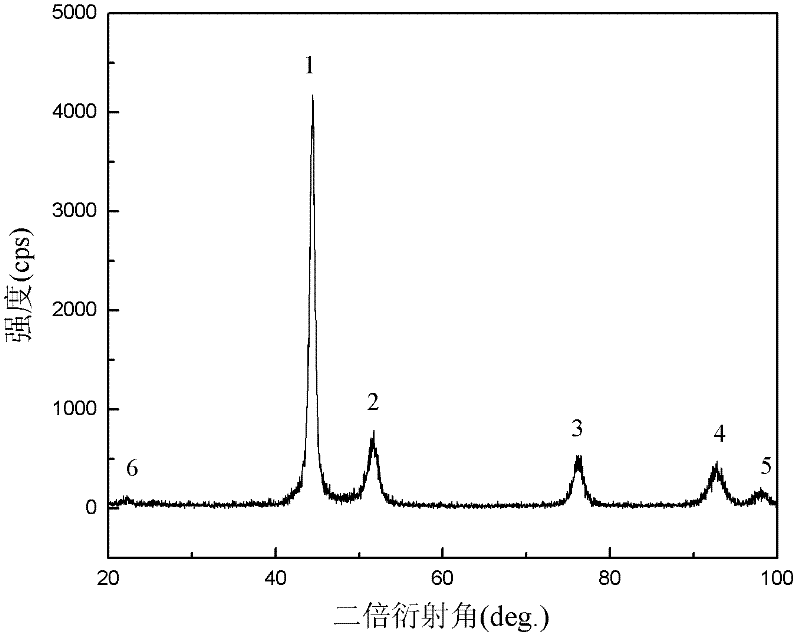

Electro-deposition preparation method of Ni-Co-C alloy substitute hard chromium plating

The invention discloses an electro-deposition preparation method of Ni-Co-C alloy substitute hard chromium plating, which relates to the preparation method of Ni-Co-C alloy substitute hard chromium plating. The method one comprises the steps of: taking nickel salt, cobalt salt, NiC12.6H2O, boric acid, ammonium citrate, a carbon-containing compound, an N13# rapid high-leveling nickel plating glossing agent A and a stress relieving agent; preparing plating solution; and carrying out electroplating on a plated part. The method two comprises the steps of: taking NiC12.6H2O, cobalt salt, boric acid, ammonium citrate, a carbon-containing compound, an N13# rapid high-leveling nickel plating glossing agent A and a stress relieving agent; preparing plating solution; and carrying out electroplating on a plated part. In the invention, the Ni-Co-C alloy plating with uniform brightness, hardness of 690-770HV50 and favorable corrosion resistance is obtained at a deposition speed of 32 microns per hour; in the electroplating process, the cathode current efficiency is higher than 60%; and the hardness of the plating can be improved to 1000-1100HV50 after undergoing heat treatment for 1-3h at a temperature between 150-400DEG C.

Owner:HARBIN INST OF TECH +1

Method for processing multilayer Cr based network embedded superhard wear-proof particle plating layer piston ring

The invention includes the following steps of preparing the bath (g / l): CrO3 100-400, analytically pure sulfate 1-4, potassium fluosilicate 8-20 and the rest is ionic water; putting the piston ring in the bath and striking forward current to make a hard chromium coating cover on the cylindrical surface; striking backward current make the hard chromium coating on the surface of the piston ring be backcut; adding the supperhard particle into the bath to mix to make it be filled in the network crack on the chromium coating surface of the piston ring; electroplating forward to close the network crack, in order to fix the supperhard particle; repeating the steps 2-5 until the coating thickness can reach the request.

Owner:NANJING FAYN PISTON RING

Hard chromium electroplating method

The invention provides a hard chromium electroplating method. The method comprises the following steps: A, carrying out surface roughening treatment on a part to be plated; B, connecting the part to be plated to an electroplating system, and carrying out pre-charging on the surface of the part to be plated, so that an integral chromium layer is deposited on the whole surface of the part to be plated; and C, carrying out chromium plating on the surface of the part to be plated, so that the chromium layer achieves a specified thickness, wherein in the process of pre-charging in the step B, the current density is 30-50 A / dm<2> larger than the current density in the process of chromium plating in the step C. According to the hard chromium electroplating method provided by the invention, through plating a chromium layer on the surface of a part to be plated, the bonding force of the plated chromium layer and a substrate of the part to be plated is ensured, and the plated chromium layer can be uniform and complete.

Owner:CHINA HANGFA SOUTH IND CO LTD

Method for barrel-plating copper and chromium on surface of cold-rolled sheet tinned conductive roller

The invention relates to a method for barrel-plating copper and chromium on the surface of a cold-rolled sheet tinned conductive roller. The method is characterized by comprising the following steps of: (1) pretreatment before plating: wiping the conductive roller by using rust removing liquid to activate the conductive roller, and wiping the surface of the roller by using cyanation copper plating bath electrolyte to prevent rusting; (2) copper pre-plating: stopping pre-plating when the thickness of a copper coating reaches 20 microns; (3) thick copper barrel-plating: plating copper by using sulfate electrolyte till the thickness of the coating reaches 1 to 3 millimeters; (4) roughing and peak clipping treatment: wiping a roughed layer by using peak clipping liquid at normal temperature to remove burrs; and (5) hard chromium plating. The method has the advantages that: by adopting the two-step copper plating process of copper pre-plating and thick copper barrel-plating and improving the formula of the copper plating liquid, the copper layer is well combined with the steel without loosening or foaming, the coating crystal is delicate and uniform, and the thickness is improved to HV120 from HV60; the copper layer is plated with the hard chromium after the peak clipping treatment, the plated chromium is firmly combined with the copper matrix, the hardness HV is more than or equalto 950, and the conductive roller has no burrs and is abrasion-resistant and anticorrosive; and the produced conductive roller has stable quality and long service life which reaches over 6 months.

Owner:上海通乐冶金设备工程有限公司

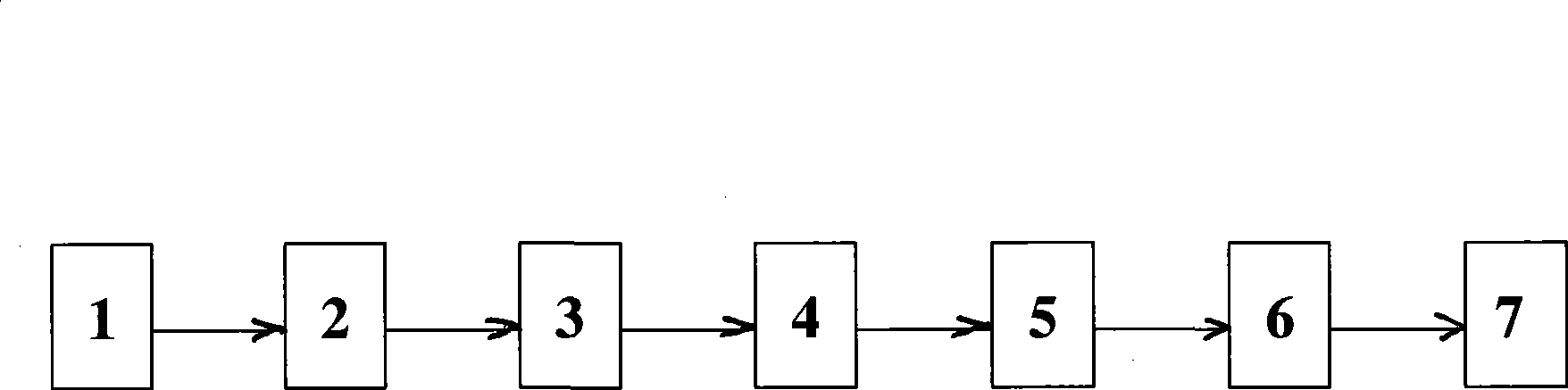

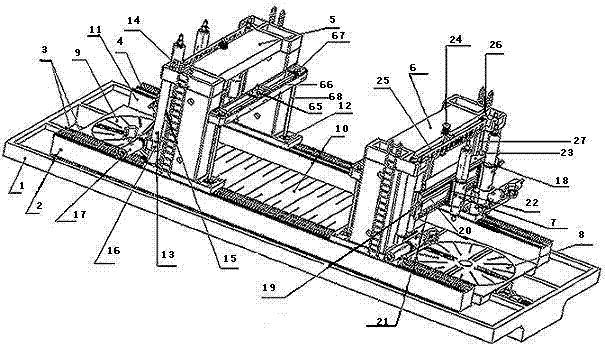

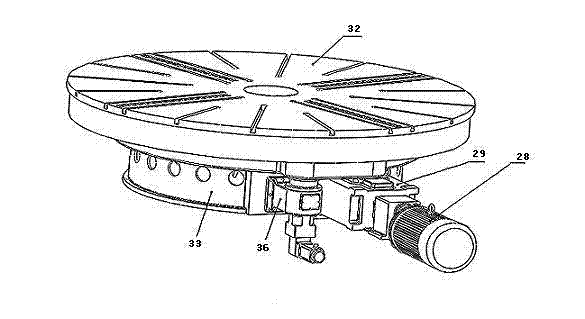

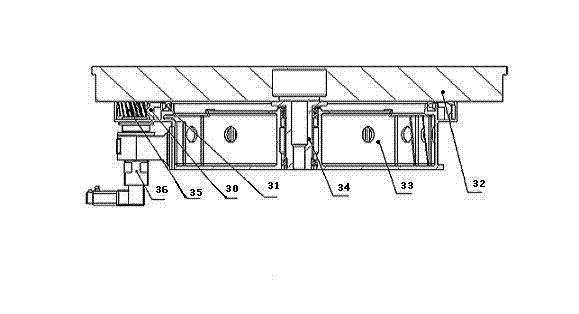

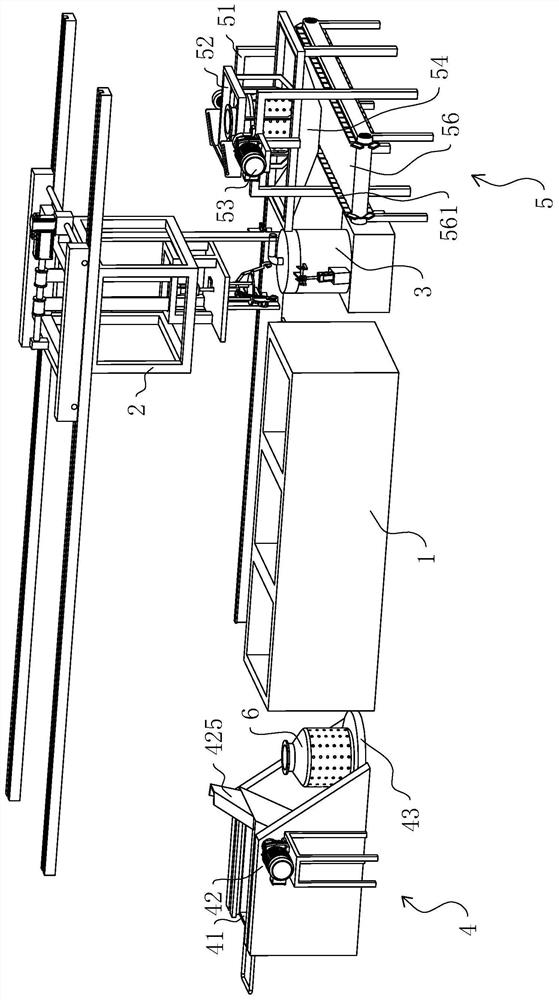

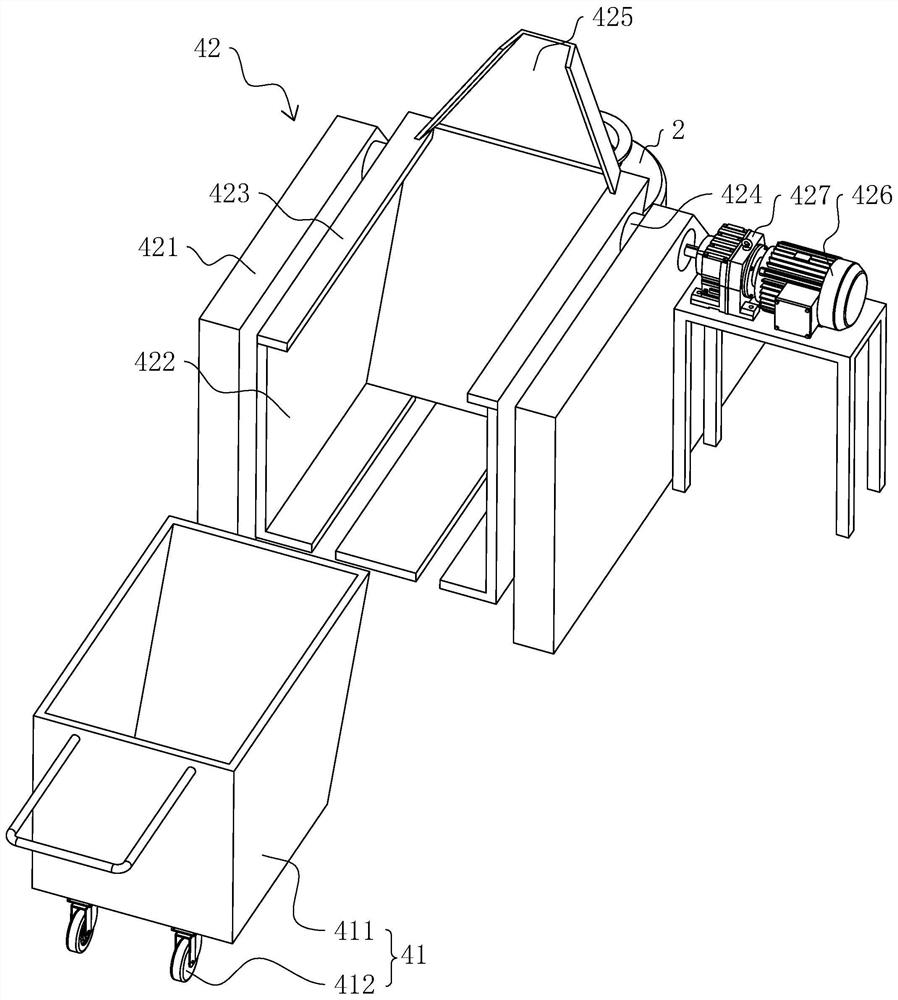

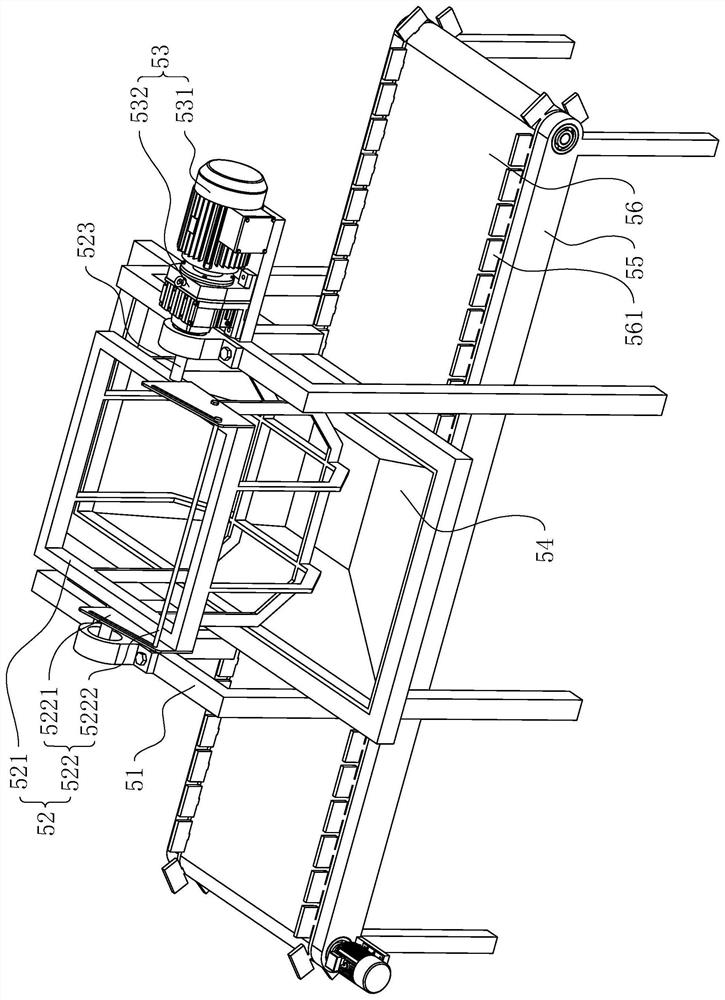

Hard chromium barrel plating production line for aluminum alloy and production process thereof

ActiveCN112064099ARealize automatic feeding processIncrease productivityElectrolysis componentsProduction lineEngineering

The invention relates to the technical field of aluminum alloy electroplating, in particular to a hard chromium barrel plating production line for aluminum alloy and a production process thereof. Thehard chromium barrel plating production line for the aluminum alloy comprises an electroplating pool, a drying machine arranged on the side of the tail end of the electroplating pool, a barrel and a joist barrow arranged above the electroplating pool; the starting end of the electroplating pool is provided with an automatic feeding device; one side of the drying machine is provided with an automatic discharging device; the automatic feeding device comprises a material vehicle, a containing table and a feeding mechanism located on one side of the containing table; and the automatic dischargingdevice comprises a second supporting frame, a fixing mechanism and a driving mechanism. Aluminum alloy parts are placed in the material vehicle in a centralized mode, the feeding mechanism can transfer the parts in the material vehicle into the barrel, and automatic feeding is achieved. The driving mechanism can drive the fixing mechanism and the barrel to turn over, and automatic discharging is achieved. The automatic feeding device and the automatic discharging device can effectively reduce the physical labor intensity of workers, and therefore the production efficiency of the barrel platingproduction line is improved.

Owner:太仓市新惠电镀有限公司

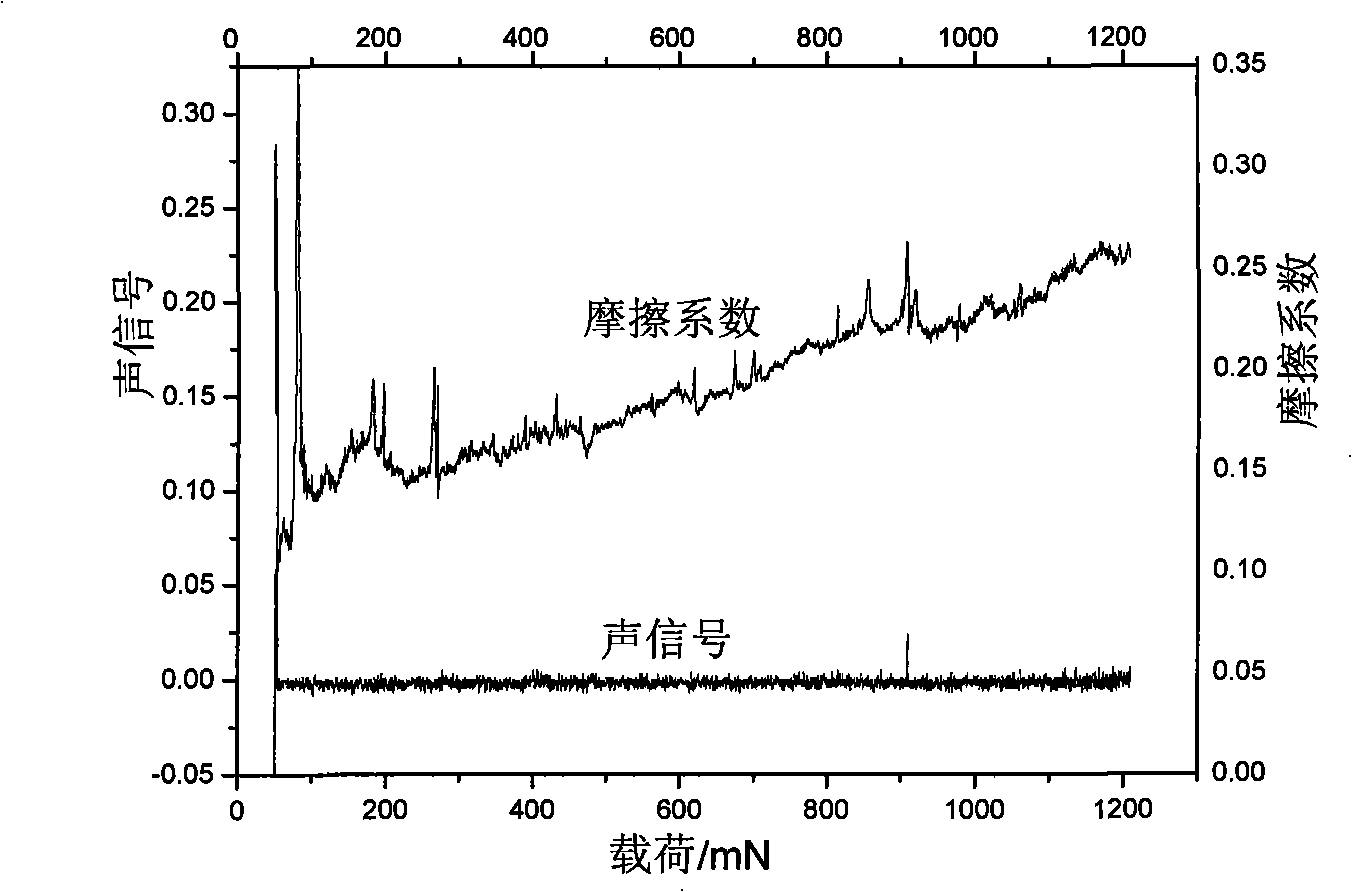

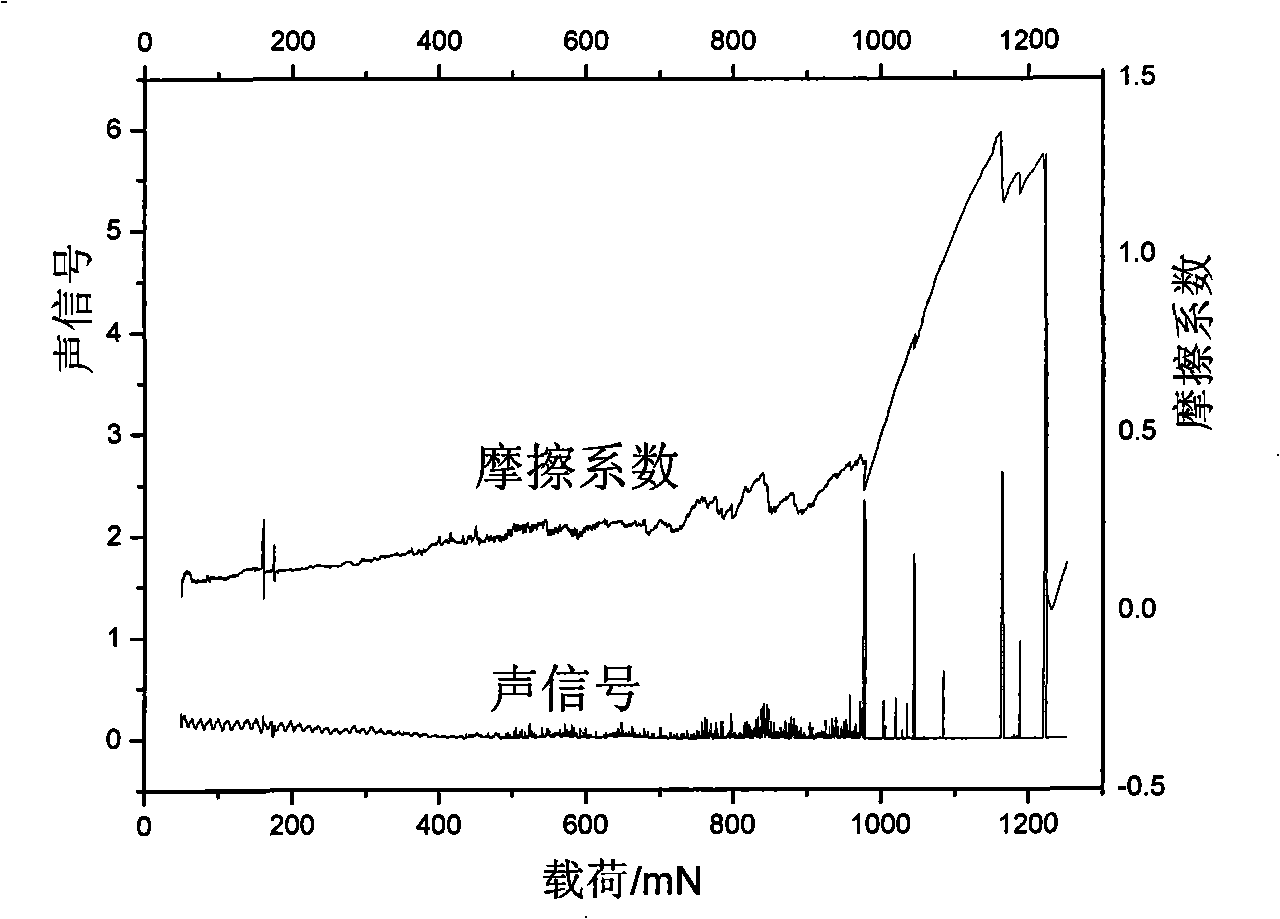

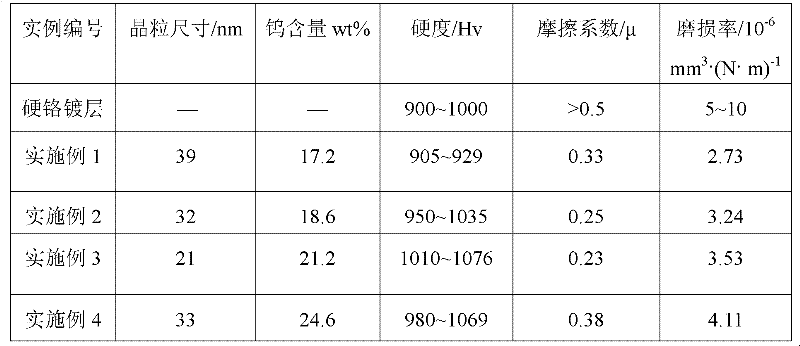

Cobalt-tungsten nanometer alloy plating layer and preparation method thereof

InactiveCN102337569AHigh hardnessImprove wear resistanceCellsMaterial nanotechnologyFriction reductionSodium sulfate

The invention discloses a preparation method of a cobalt-tungsten nanometer alloy plating layer, which comprises steps of electroplating by using a platinum titanium or cobalt-tungsten alloy as an anode and a workpiece to be plated as a cathode and using a mixed solution as electrolyte, wherein the mixed solution contains 100-200 g / L of cobaltous sulfate, 10-70 g / L of sodium tungstate, 50-150 g / L of g / L of sodium sulfate, 15-50 g / L of boracic acid, 1-4 g / L of saccharin sodium salt, 0.01-0.1 g / L of surfactant and 40-120 g / L of complexing agent; the alloy plating layer is of a nanometer crystal structure, and the dimension of a crystalline grain is 20-40 nm; and the tungsten content in the nanometer alloy plating layer is 13.2-25.1 wt%. The invention has the advantages that the preparation method of the plating layer is simple, and the plating layer not only has the hardness of a hard chromium plating layer, but also has better wearing resistance and friction reduction performance than the hard chromium plating layer. The plating layer is suitable for components with high hardness, high wearing resistance and low friction coefficients and has an extensive application range.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com