Electroplating solution for preparation of nanocrystalline nickel alloy plating and application thereof

A nanocrystalline and nickel alloy technology, applied in the field of nickel alloy coating preparation, can solve the problems of insufficient wear resistance, limitation, and low hardness of nickel coating, and achieve high wear resistance and hardness, compact structure, and fine grain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

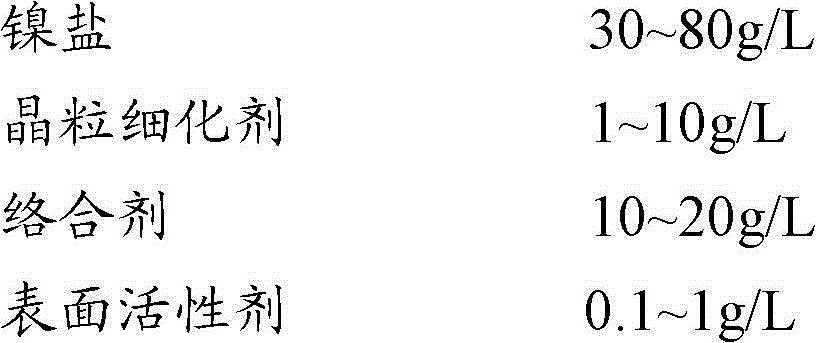

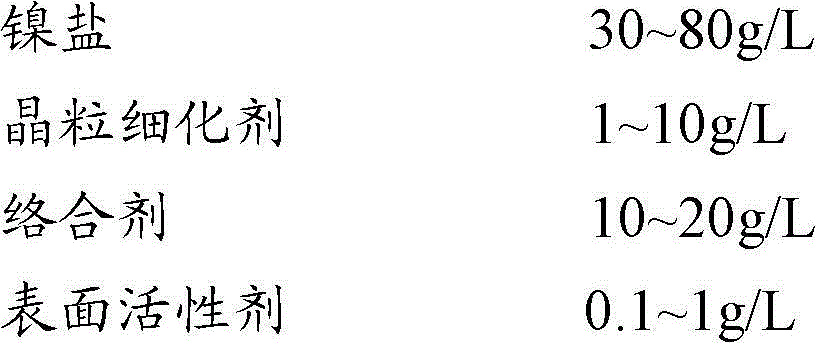

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of electroplating solution: use deionized water as solvent, prepare nickel sulfate with mass concentration of 30g / L, boric acid 10g / L, hydrazine hydrate 1g / L, hydroxylamine hydrochloride 9g / L, 2-ethylhexyl sodium sulfate 0.1g / L L's plating solution.

[0027] 2. Degreasing: Add sodium lauryl sulfate to a NaOH solution with a concentration of 5% by mass to obtain a mixed solution (the concentration of sodium lauryl sulfate is about 2g / L), which will be used as the low carbon steel of the metal substrate (3.14cm 2 Discs) were put into the mixed solution, and washed at 40° C. for about 10 minutes.

[0028] 3. Oxidation film removal treatment: use mechanical polishing and chemical polishing to perform surface oxidation film removal treatment on the degreased metal substrate in step 2.

[0029] 4. Preparation of nanocrystalline nickel alloy coating: use ammonia water to adjust the pH value of the electroplating solution obtained in step 1 to 3.5, use the pure...

Embodiment 2

[0031] 1. Preparation of electroplating solution: use deionized water as solvent, prepare nickel chloride with a mass concentration of 35g / L, sodium citrate 20g / L, formaldehyde 1g / L, hydroxylamine hydrochloride 9g / L, sodium ethylhexyl sulfate 0.2g / L L's plating solution.

[0032] 2. Degreasing: Add sodium lauryl sulfate to NaOH solution with a mass percentage concentration of 20% to obtain a mixed solution (the concentration of sodium lauryl sulfate is about 2g / L), which will be used as the low carbon steel of the metal substrate (3.14cm 2 disk) into the mixed solution, and washed at 70° C. for about 3 minutes.

[0033] 3. Oxidation film removal treatment: use mechanical polishing and chemical polishing to perform surface oxidation film removal treatment on the degreased metal substrate in step 2.

[0034] 4. Preparation of nanocrystalline nickel alloy coating: use ammonia water to adjust the pH value of the electroplating solution obtained in step 1 to 6, use the pure nicke...

Embodiment 3

[0036] 1. Preparation of electroplating solution: use deionized water as solvent, prepare basic nickel carbonate nickel 50g / L, sodium potassium pyrophosphate 10g / L, sodium hypophosphite 1g / L, hydroxylamine hydrochloride 1g / L, dodecane Sodium base sulfate 0.1g / L electroplating solution.

[0037] 2. Degreasing: Add sodium lauryl sulfate to NaOH solution with a concentration of 20% by mass to obtain a mixed solution (the concentration of sodium lauryl sulfate is about 2g / L), which will be used as the low carbon steel of the metal substrate (3.14cm 2disk) into the mixed solution, and washed at 70° C. for about 3 minutes.

[0038] 3. Oxidation film removal treatment: use mechanical polishing and chemical polishing to perform surface oxidation film removal treatment on the degreased metal substrate in step 2.

[0039] 4. Preparation of nanocrystalline nickel alloy coating: use ammonia water to adjust the pH value of the electroplating solution obtained in step 1 to 5, use the pure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com