Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

606 results about "Nickel electroplating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. The nickel layer can be decorative, provide corrosion resistance, wear resistance, or used to build up worn or undersized parts for salvage purposes.

Alkaline zinc-nickel alloy plating compositions, processes and articles therefrom

InactiveUS20050133376A1Easy to handleImprove ductilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingZinc ionNickel alloy

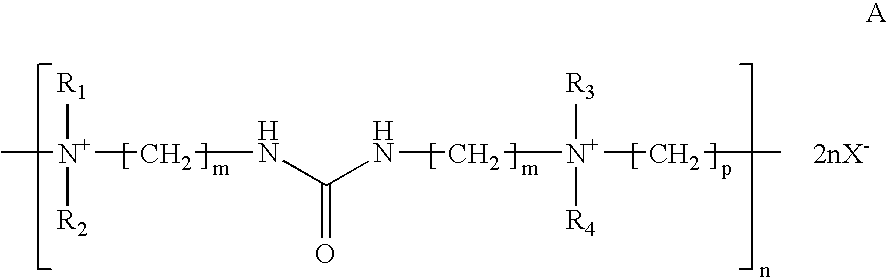

The present invention relates to an aqueous zinc-nickel electroplating bath, including water; nickel ion; zinc ion; at least one complexing agent; and at least one non-ionogenic, surface active polyoxyalkylene compound, wherein the bath has an alkaline pH. In one embodiment, the zinc ion, the nickel ion and the non-ionogenic surface active polyoxyalkylene compound are present at concentrations sufficient to deposit a zinc-nickel alloy comprising a substantially gamma phase.

Owner:ATOTECH DEUT GMBH

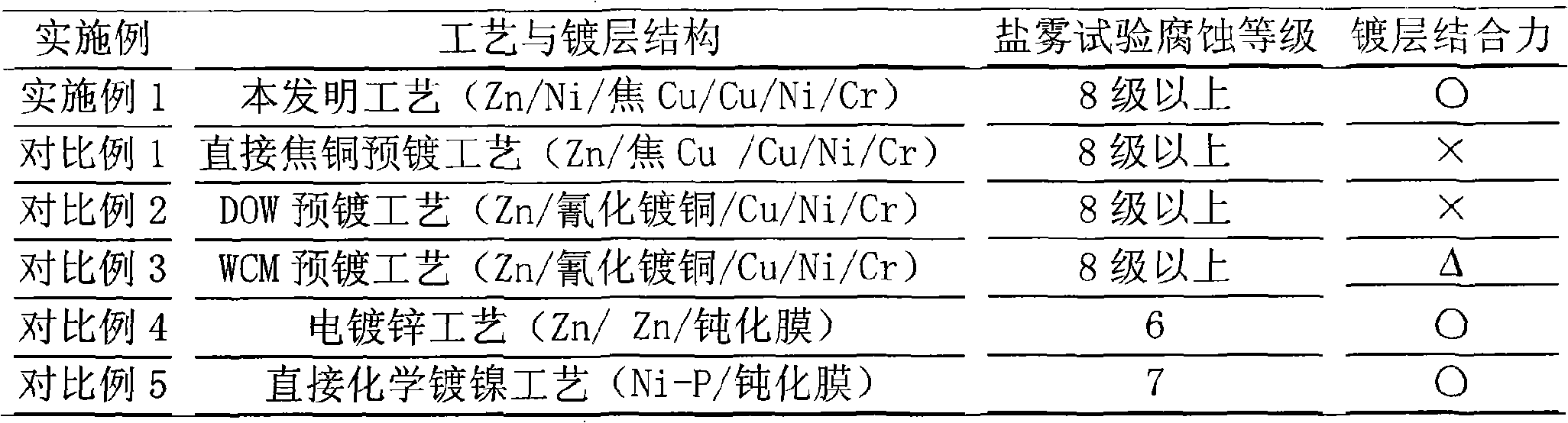

Electroplating process for surface of magnesium alloy motorcycle hub

InactiveCN101280445AHarm reductionReduce pollutionSolid state diffusion coatingLiquid/solution decomposition chemical coatingCyanidePyrophosphate

The invention relates to a combinational electroplating process on a magnesium alloy motorcycle wheel nave by adopting a non-cyanide and chrome free pre-plating treatment solution, electronickelling and pyrophosphate copper are adopted as dual-layer bottoming coat, then Cu / Ni / Cr combinational coat electroplating is performed, to obtain the Cu / Ni / Cr combinational metal coat with high corrosion resistance on the surface of the magnesium alloy motorcycle wheel nave. The binding force of the metal coat obtained on the surface of the magnesium alloy motorcycle wheel nave by adopting the process is strong, the corrosion resistance is high, and the combinational electroplating process has the prominent advantages that the personnel health is safeguarded, and the environmental pollution is avoided.

Owner:GCI SCI & TECH +1

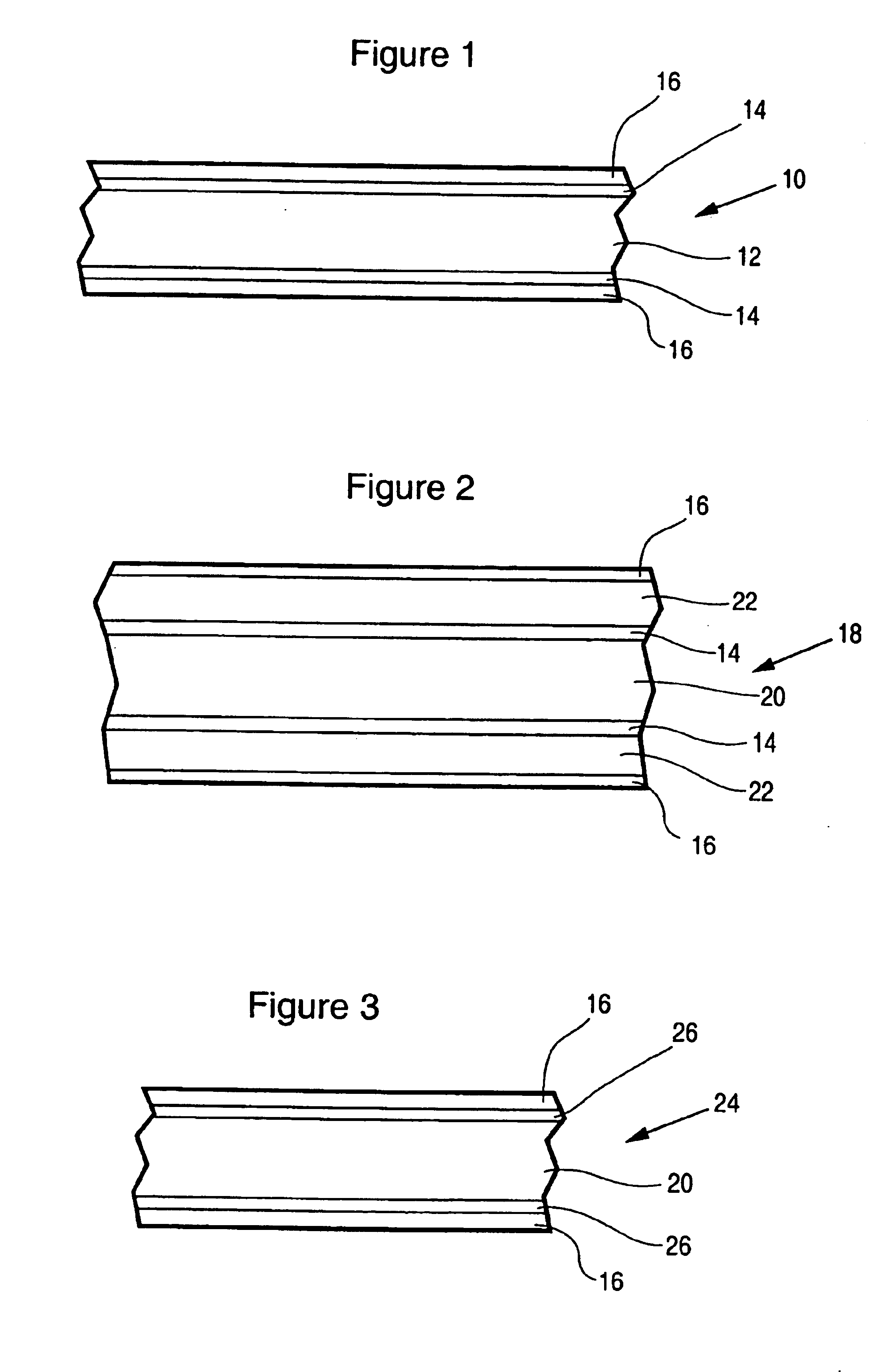

Electromagnetic shielding compound material made from three-dimensional braided nickel-plated carbon fiber and epoxy resin and method for preparing same

InactiveCN101531804AImprove performanceGood electromagnetic shieldingOther chemical processesFiberEpoxy

The invention relates to an electromagnetic shielding compound material made from three-dimensional braided nickel-plated carbon fiber and epoxy resin and a method for preparing same. The method comprises the following steps: carbon fiber surface treatment, carbon fiber nickel-electroplating, nickel-plated carbon fiber three-dimensional braiding, and compound material preparation on the basis of RTM (resin transfer molding) method and electromagnetic shielding effectiveness test. In the invention, the nickel-plated carbon fiber / epoxy resin braided compound material is prepared through the following steps: plating the carbon fiber with nickel, the metal; carrying out three-dimensional four-directional braiding; and then, compounding the nickel-plated carbon fiber braid and the epoxy resin. Owing to the good conductivity of the carbon fiber braid and the nickel-plated layer and the ferromagnetism of the nickel-plated layer, the braided compound material has good electromagnetic shielding performance. According to the test results based on the flange co-axial method, the electromagnetic shielding level of the braided compound material reaches 70dB to 80dB.

Owner:TIANJIN UNIV

Nickel cobalt boron ternary alloys

Disclosed are methods of electroplating a nickel cobalt boron alloy involving providing an electroplating bath comprising ionic nickel, ionic cobalt, ionic boron, and at least one brightener; and applying a current to the electroplating bath whereby a nickel cobalt boron alloy forms.

Owner:TASKEM

Method for treating complexed chemical nickel electroplating wastewater

InactiveCN103833123AImprove processing efficiencyGood effectWaste water treatment from metallurgical processWater/sewage treatment by oxidationPotassium ferrateAdsorption effect

The invention provides a method for treating complexed chemical nickel electroplating wastewater and aims at the problem in the existing complexed chemical nickel electroplating wastewater treatment processes that the nickel ion removal efficiency is inadequate. The method comprises the main processes of firstly adding calcium hydroxide into the wastewater, adjusting the pH to 8-9 so as to form calcium phosphate precipitates, adding sulfuric acid into a supernatant liquid so as to adjust the pH of the liquid to 4-5, then, adding a potassium ferrate liquid with strong oxidizing power so as to decomplex in a strong oxidizing manner and change complexed nickel ions into free-state nickel ions, then, adding calcium hydroxide, adjusting the pH to 10-11 so as to enable the free-state nickel ions to form precipitates to be removed from the wastewater, enabling trivalent ferric ions with excellent flocculation function generated after oxidation of ferric acid radical ions to have flocculation with hydroxide precipitates with an adsorption effect, and finally, adding polyacrylamide (PAM) to coagulate and precipitate, thereby removing nickel ions from the electroplating wastewater. The method has the advantages that the condition that the nickel ions obtained after the complexed chemical nickel electroplating wastewater is treated reach the national standards can be effectively guaranteed, the treatment efficiency is high, and the requirements on emission are met.

Owner:陈瀚翔

Preparation method of electromagnetic shielding conductive fabric

InactiveCN101876140ALess investmentSmall plating resistancePhysical treatmentSuperimposed coating processPolyesterCopper plating

The invention discloses a preparation method of an electromagnetic shielding conductive fabric. In the preparation method, the electromagnetic shielding conductive fabric is prepared by sequentially carrying out pretreating, vacuum nickel plating, copper electroplating and nickel electroplating on a full polyester fabric, and then the obtained electromagnetic shielding conductive fabric is cured, wherein plasma glow discharge treatment is carried out in the pretreating step, a magnetron sputtering technology is adopted in the vacuum nickel plating step, and a vertical placement mode is adopted among conductive rods in the processes of copper electroplating and nickel electroplating. By adopting the technology combining the vacuum nickel plating with the copper electroplating and the nickel electroplating, the defects of high cost and difficult treatment of electroplating wastewater, caused by the adoption of an electroless copper and nickel plating technology in the traditional preparation method of the electromagnetic shielding conductive fabric, are avoided; and compared with the traditional preparation method of the electromagnetic shielding conductive fabric, which adopts a full vacuum copper and nickel plating technology, the method of the invention which adopts the technology combining the vacuum nickel plating with the copper electroplating and the nickel electroplating has smaller equipment investment and plating resistance, is more suitable for large-scale production, and can better adapt to market demands.

Owner:昆山市同福电子材料厂

Magnesium alloy with zinc and nickel compound plating layers and preparation method thereof

The invention discloses a magnesium alloy with zinc and nickel compound plating layers and a preparation method thereof. A zinc plating layer of the magnesium alloy is taken as a bottom layer with the width between 20 microns and 25 microns, a nickel plating layer is taken as a surface layer, and the total width of the zinc plating layer and the nickel plating layer is less than or equal to 40 microns. The method comprises the following steps: firstly, plating preliminary treatment, i.e. zinc is activated in an acid solution and then soaked in sulphate; secondly, zinc electrodeposition, i.e. after the zinc is soaked in the sulphate in the first step, the zinc layer of the magnesium alloy is electrodeposited; thirdly, nickel bright plating, i.e. the magnesium alloy which is nicely processed in the second step is brightly plated with nickel in a nickel plating solution; fourthly, sodium silicate water solution sealing. With the method, the obtained zinc plating layer is nicely combined with a base body, has uniform width and high corrosion resistance, can be taken as a protective plating layer to be singly used and can be also taken as a transition layer to carry out plating or chemical plating or other protective or decorative platings, and the nickel plating layer obtained from the zinc plating layer by plating is nicely combined with the zinc plating layer and is uniform, exquisite, bright and beautiful.

Owner:SOUTHEAST UNIV

Method of manufacturing an aluminum product

InactiveUS6383661B2High densityIncrease line speedLiquid surface applicatorsThin material handlingAlloyPre treatment

The invention relates to a method of manufacturing an Al or Al alloy workpiece, including the steps of (a) providing an Al or Al alloy workpiece, (b) pre-treating of the outersurface of the Al or Al alloy workpiece, and (c) plating a metal layer including nickel onto the outersurface of the pre-treated Al or Al alloy workpiece. During step (c) the metal layer including nickel is deposited by electroplating both nickel and bismuth using an aqueous bath comprising a nickel-ion concentration in a range of 10 to 100 g / l and a bismuth-ion concentration in the range of 0.01 to 10 g / l. The invention further relates to an aqueous plating bath for use in the method of this invention.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

Alkaline zinc-nickel alloy plating compositions, processes and articles therefrom

The present invention relates to a process for electroplating a zinc-nickel alloy on a substrate, including electroplating the substrate in an aqueous zinc-nickel electroplating bath, including water; nickel ion; zinc ion; at least one complexing agent; and at least one non-ionogenic, surface active polyoxyalkylene compound, wherein the bath has an alkaline pH. In one embodiment, the zinc ion, the nickel ion and the non-ionogenic surface active polyoxyalkylene compound are present at concentrations sufficient to deposit a zinc-nickel alloy comprising a substantially gamma phase.

Owner:OPASKAR VINCENT C +1

Method of manufacturing an aluminum product

InactiveUS20020012811A1High densityIncrease line speedLiquid surface applicatorsThin material handlingAlloyPre treatment

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

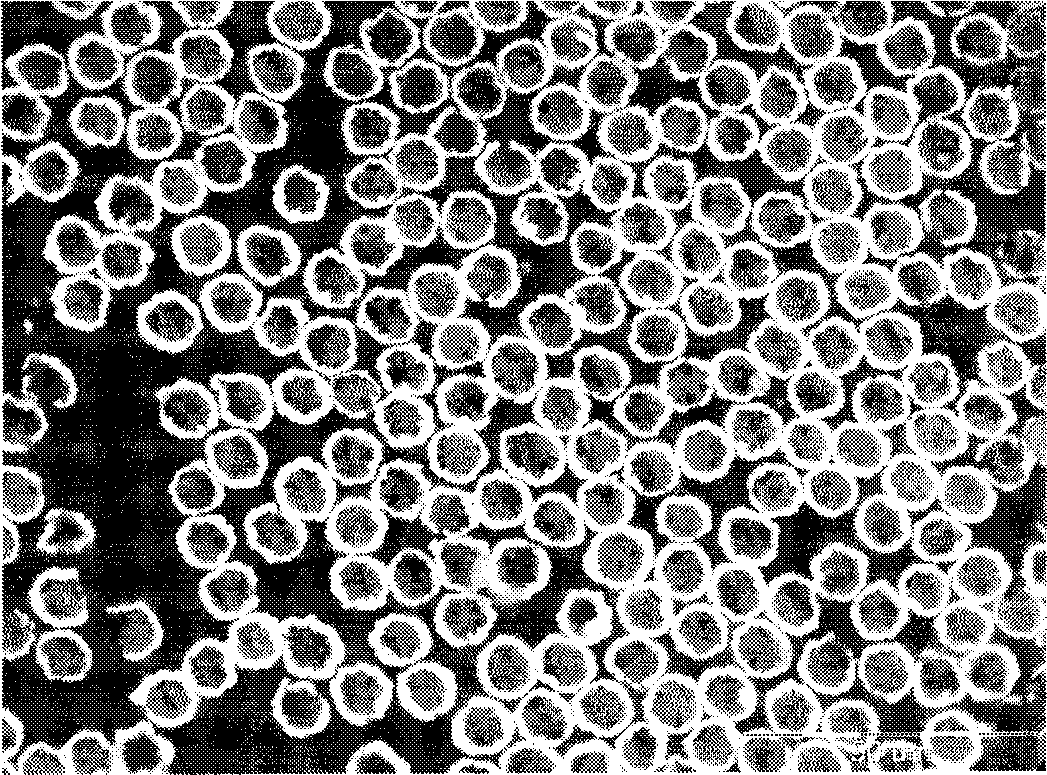

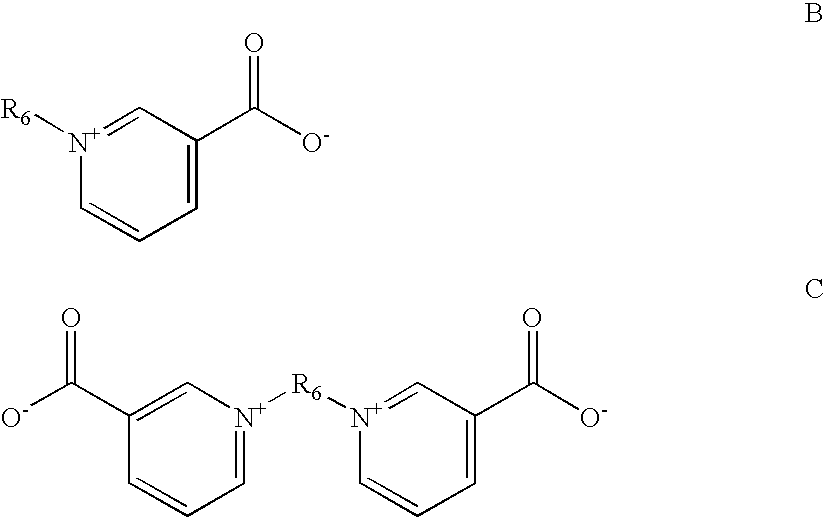

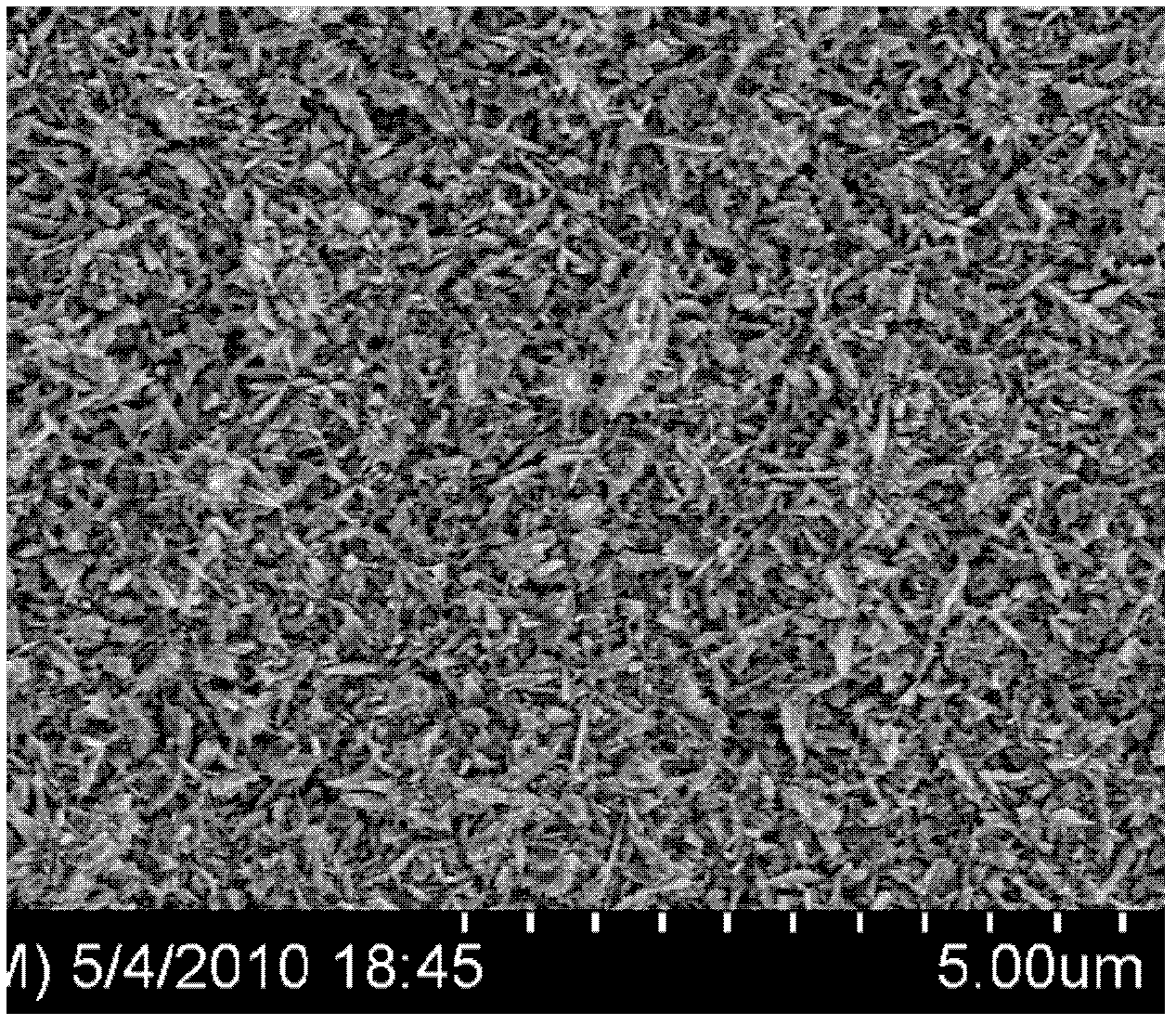

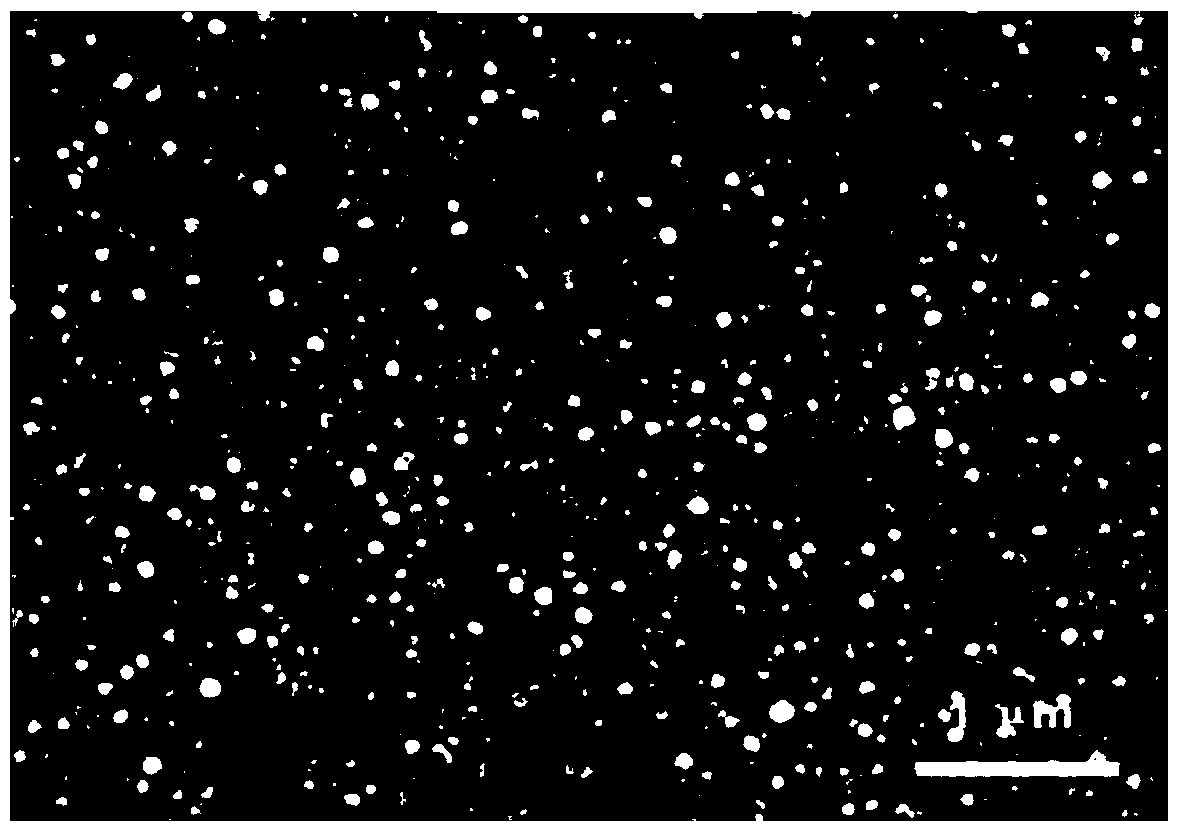

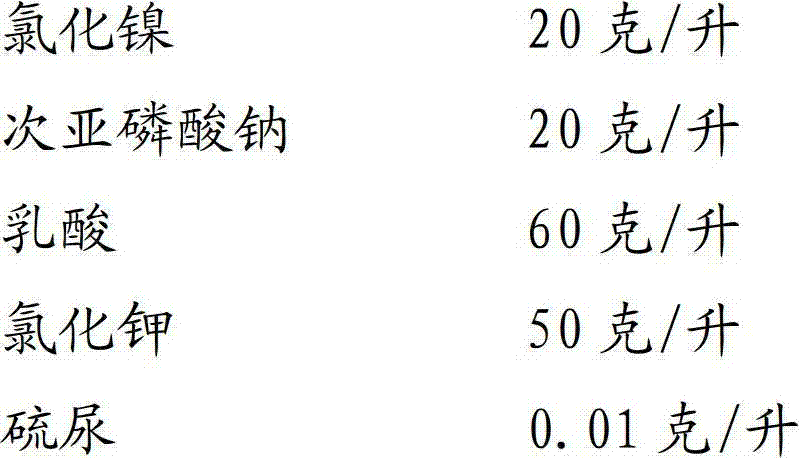

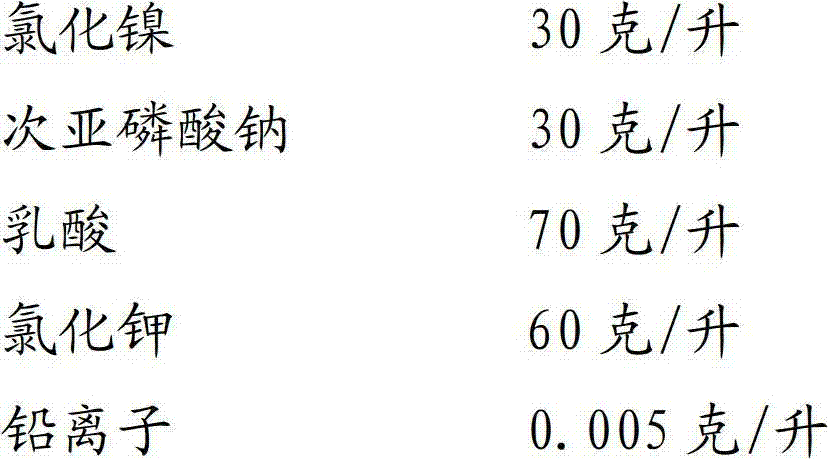

Nickel electroplating liquid, and preparation method for super-hydrophobic nickel plating layer using same

The invention discloses a nickel electroplating liquid, and a preparation method for a super-hydrophobic nickel plating layer using the same. The nickel electroplating liquid is composed of a choline-chloride-based ionic liquid used as a solvent and NiCl2.6H2O or NiCl2 used as a solute, wherein the mol concentration of the solute is 0.1-3 mol / L. The preparation method for the super-hydrophobic nickel plating layer using the nickel electroplating liquid comprises the following step of electroplating in the nickel electroplating liquid with pure nickel as an anode and the workpiece to be electroplated as a cathode at the temperature of the nickel electroplating liquid from room temperature to 200 DEG C and electroplating voltage of 0.2-2 V. The nickel electroplating liquid provided by the invention has simple components, is convenient to prepare and is environmentally-friendly. The preparation method for the super-hydrophobic nickel plating layer using the nickel electroplating liquid has the advantages of simple and controllable process, no corrosive substances and no vapor discharge during the electroplating process, and is beneficial to mass production. More prominent characteristics are that the obtained nickel plating layer has super-hydrophobic property, a contact angle larger than 160 degrees and a sliding angle smaller than 2 degrees.

Owner:ZHEJIANG UNIV

Al3O3 ceramic substrate metallization process

InactiveCN103319208AAchieve metallizationMicrocosmic coarse particles fineChemical platingCopper plating

The invention relates to a technical field of ceramic material metallization production, and specifically relates to an Al3O3 ceramic substrate metallization process. According to the invention, the Al3O3 ceramic substrate is sequentially subjected to a coarsening treatment, a sensitization and activation treatment, a chemical plating treatment, and a metal or alloy electroplating treatment, such that a metal or alloy film is formed on the surface of the substrate. With the process method provided by the invention, the surface of the ceramic substrate is uniformly coarsened. Microscopic coarse particles are small and have high adsorption capacity. Therefore, reducing cores can be well absorbed during the subsequent sensitization and activation treatment, and chemical plating can be finally realized. The coarsened ceramic substrate can be subjected to the sensitization and activation treatment with a subsequent silver ammonia solution, and can be provided with a copper plating layer with the chemical copper plating process. Also, the substrate can be subjected to the sensitization and activation treatment with colloidal palladium, and can be subjected to a nickel plating process, such that a chemical nickel plating layer can be obtained. Copper, nickel, or other metal or alloy can be electroplated, and ceramic substrate metallization can be realized.

Owner:HEFEI UNIV OF TECH

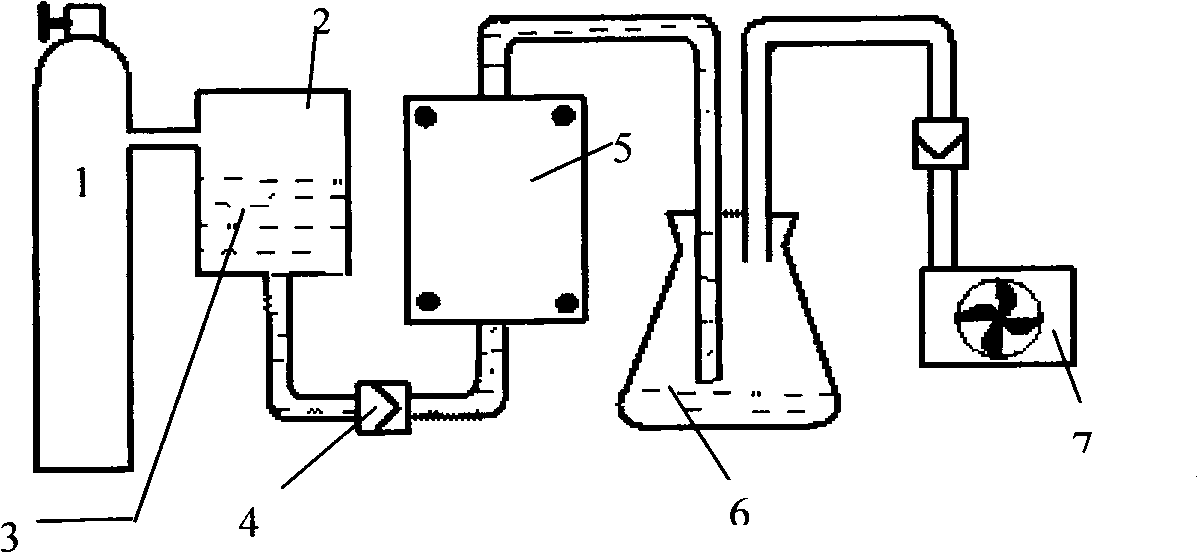

Production process for electroplated abrasive material on surface of metal wire

InactiveCN102191525AImprove adsorption capacityUniform adsorptionElectrolytic coatingsSulfamic acidMaterials science

The invention relates to a production process for electroplated abrasive material on the surfaces of a metal wire. The production process comprises the following steps: 1. carrying out chemical nickel plating treatment on the surface of a diamond; 2. preparing impactive nickel electroplating solution; 3. preparing sulfamic acid nickel plating solution and nickel-plated diamond mixed electroplating solution; 4. cleaning; 5. carrying out impactive nickel electroplating; 6. electroplating the nickel-plated diamond on the surface of the metal wire; 7. reinforcing nickel-plated diamond granules; and 8. carrying out post-electroplating treatment. The invention employs the diamond and the metal wire the surfaces of which are chemically nickel-plated as raw materials, and realizes high-speed production by using sulfamic acid nickel plating solution. The binding of the nickel-plated diamond and a nickel plating layer is identical nickel-material binding, and belongs to identical nickel-metal atomic force binding, so that the diamond has high firmness, long service life and high sawing capability.

Owner:NV BEKAERT SA

Nickel electroplating bath designed to replace monovalent copper strike solutions

A nickel electroplating bath is disclosed which is suitable for plating, a base layer of nickel over zinc or zinc alloy parts. Subsequent plating onto this base layer can be achieved with copper, chromium or bright nickel with good adhesion and appearance. The nickel electroplating solution proposed comprises an additive package comprising (i) sulphonic acid or sulphonic acid salts, (ii) sulfonated alkoxylate and (iii) organic acid selected from the group consisting of tolylacetic acid, salicylic acid, hydroxy-benzoic acid, benzyloxyacetone and mixtures of the foregoing.

Owner:MACDERMID INC

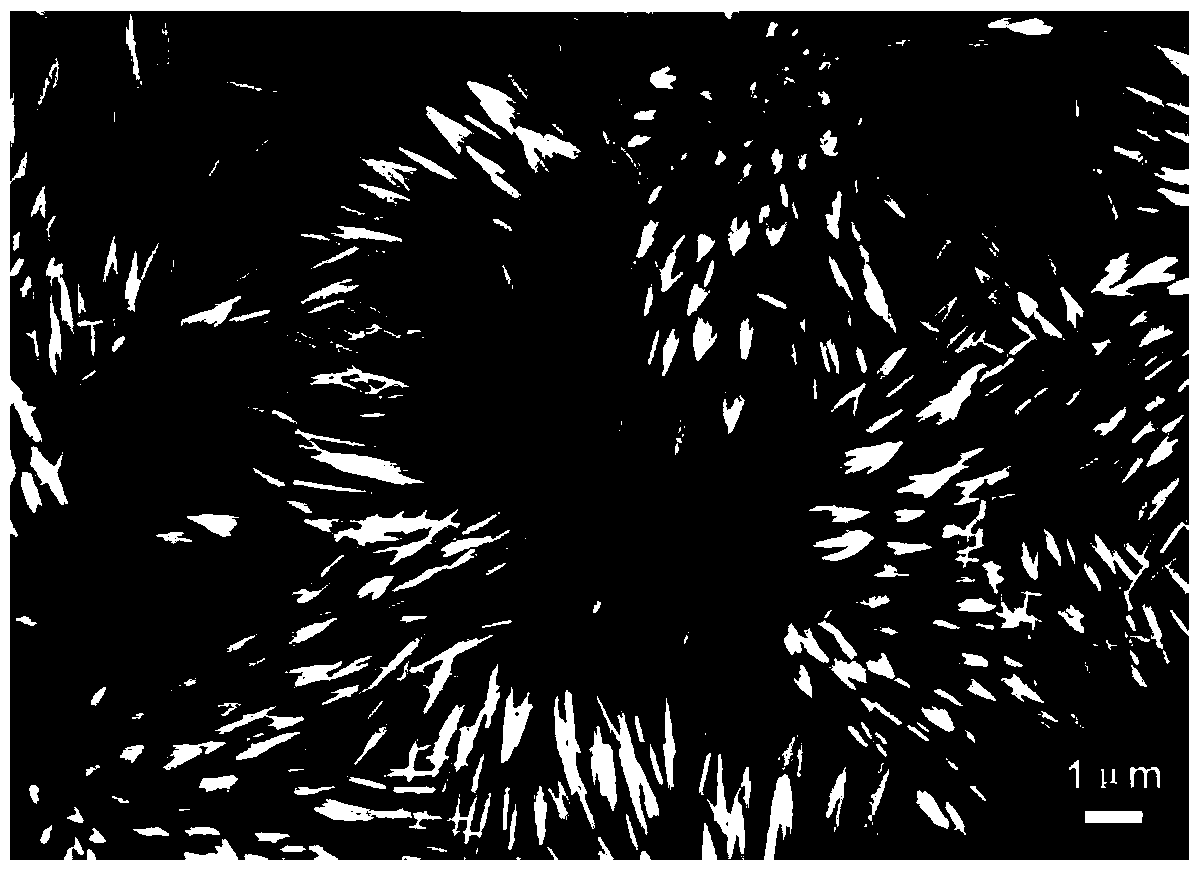

Method for synthesizing nanometer Ni2O3/Co3O4 cathode material on copper sheet current collector through two-step method

InactiveCN104009208AIncrease capacityGood capacity valueElectrode carriers/collectorsSecondary cellsAdhesiveLithium-ion battery

The invention discloses a method for synthesizing a nanometer Ni2O3 / Co3O4 cathode material on a copper sheet current collector through a two-step method. According to the method, a nanowire array directly grows on the current current collector matrix, so that the process treatment is greatly simplified, and an adhesive and a conductive additive are not used in the electrode. The method comprises the following steps: electroplating a nano-scale granular nickel layer on a copper matrix subjected to acid treatment to serve as a seed, generating a nano array through a hydrothermal reaction, and preparing a final product through high-temperature calcining. The proper nickel electroplating time is selected, the combination degree between the substrate and the material is improved, and the nickel is hard to drop, so that the cycling stability of the lithium ion battery is improved. Meanwhile, compared with a nickel plating-free pure Co3O4 array, the Ni2O3 / Co3O4 array has the advantages that the capacity value of unit area is improved. When the electrochemical performance is tested, the prepared cathode material reflects high charging and discharging capacity and long cycle life.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for electroplating plastic base material

The invention provides a method for electroplating a plastic base material and relates to a plastic surface processing method. The invention provides the method for electroplating the plastic base material, which can realize a surface metallization of a plastic material, simplifies an electroplating process flow, greatly reduces a discharging amount of waste water, reduces pollution to the environment and the human, and is suitable for various plastic surface requirements. The method comprises the following steps of: pre-treating the plastic base material; carrying out physical vapor deposition metallization on the treated plastic base material and sequentially carrying out physical vapor deposition plasma modification, and plating a metal bottom layer, a metal transition layer and a metal conducting layer; directly electroplating copper on the treated plastic base material or electroplating copper and electroplating nickel on the treated plastic base material; carrying out drawing treatment on the surface of an electroplated copper layer of the treated plastic base material or carrying out the drawing treatment on the surface of an electroplated copper and electroplated nickel layer of the treated plastic base material; and after hanging the treated plastic base material into a PVD (Physical Vapor Deposition) furnace to carry out plasma treatment, depositing a chromium layer or carrying out dry type dust removal and static removal on the treated plastic base material and then carrying out organic coating protection treatment on the treated plastic base material.

Owner:XIAMEN RUNNER IND CORP

Zinc-zinc nickel electroplating method of neodymium iron boron magnet

InactiveCN106835209ASolve the corrosion resistanceNo increase in demagnetization lossSuperimposed coating processBiological activationBinding force

The invention provides a zinc-zinc nickel electroplating method of a neodymium iron boron magnet. The method comprises the steps of grinding and chamfering-deoiling-acid pickling-ultrasonic cleaning-galvanizing (acid)-activation-nickel alloy galvanizing-bright dipping-trivalent chromium passivation-drying. A neodymium iron magnet is prepared by the zinc-zinc nickel electroplating method of the neodymium iron boron magnet; a zinc layer is 2-5 microns; a zinc nickel layer is 5-10 microns; the corrosion resistance is achieved under the neutral salt mist environment for 2h and the environment of 40 DEG C and 90% of humidity for 168h; the binding force of the neodymium iron boron magnet can satisfy the requirement of falling by 1.8 m*30 times; the magnetic reducing loss is not increased (not more than 6%); the hexavalent chromium problem is solved (hexavalent chromium is not more than 1000 ppm); and the cost is lower than that of nickel electroplating of copper nickel.

Owner:BEIJING JINGCI ELECTRIC TECH CO LTD

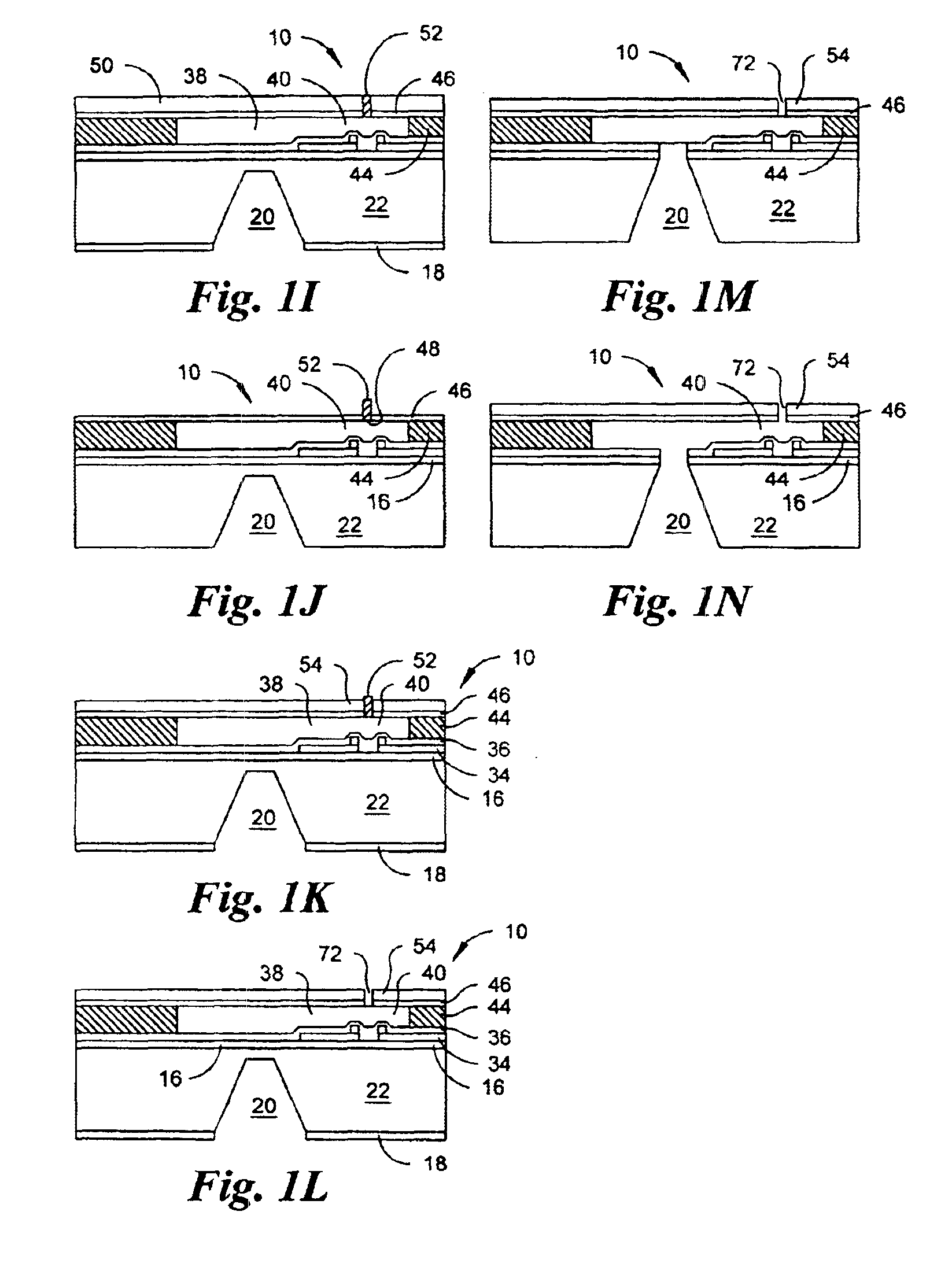

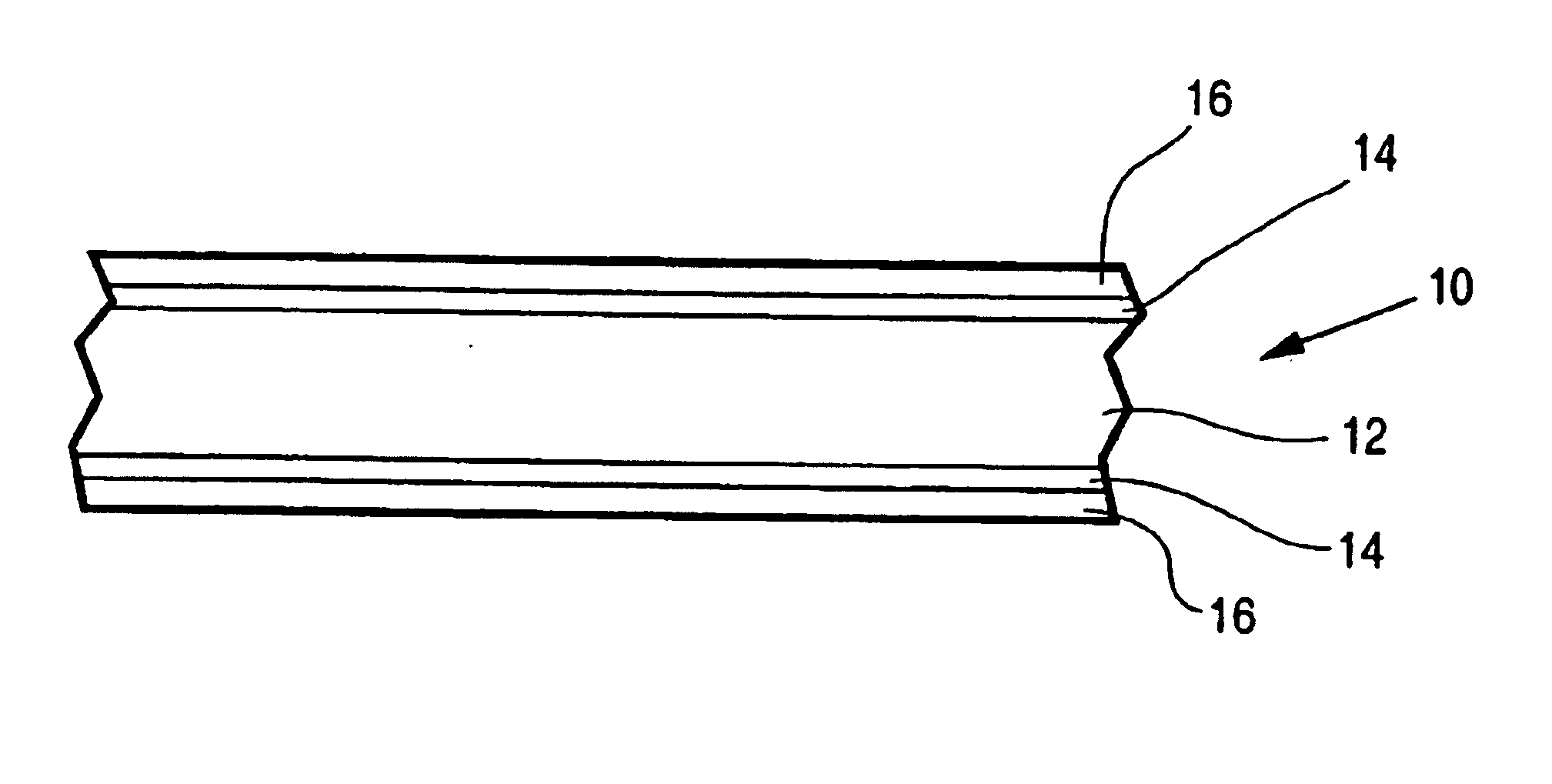

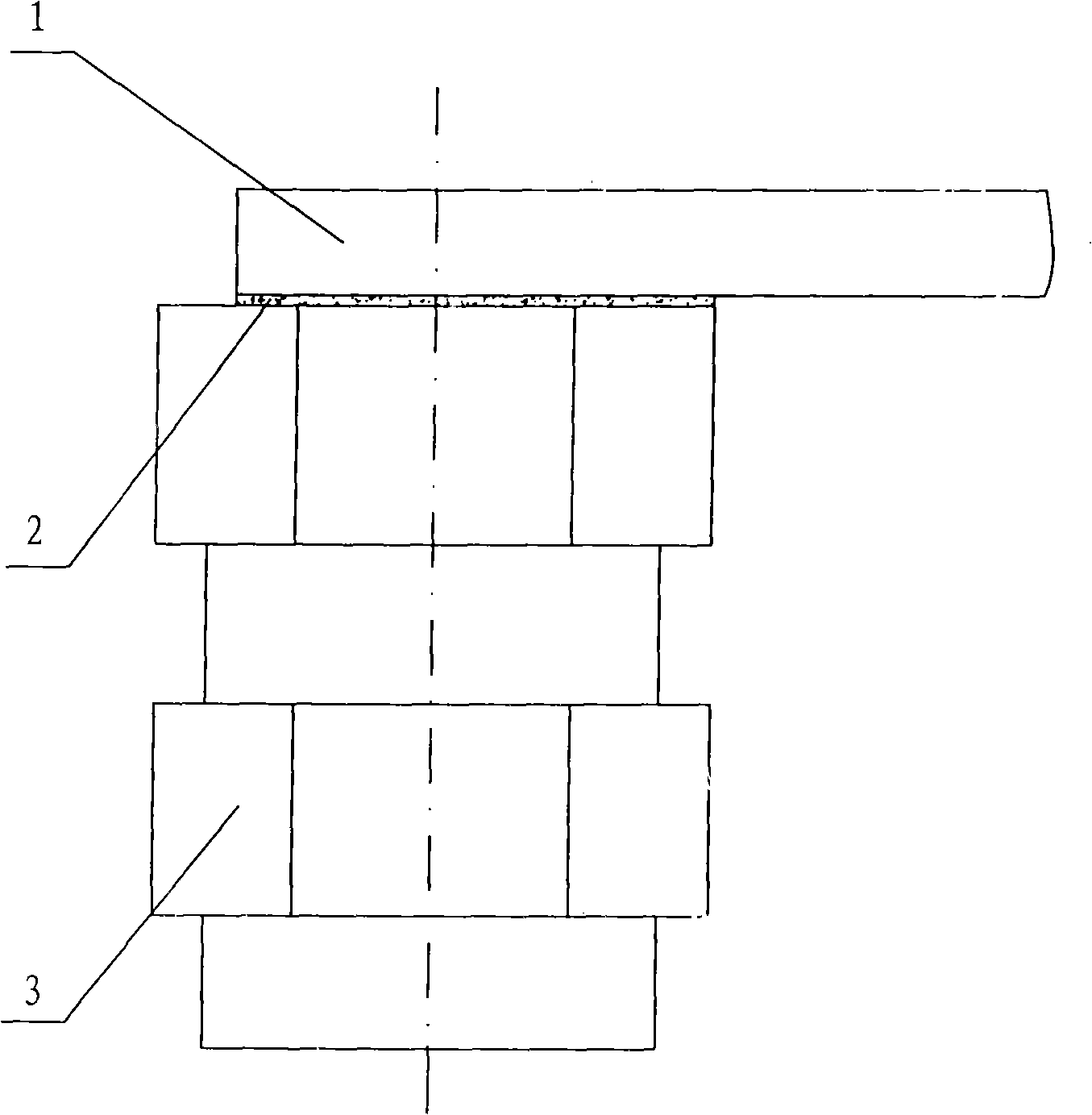

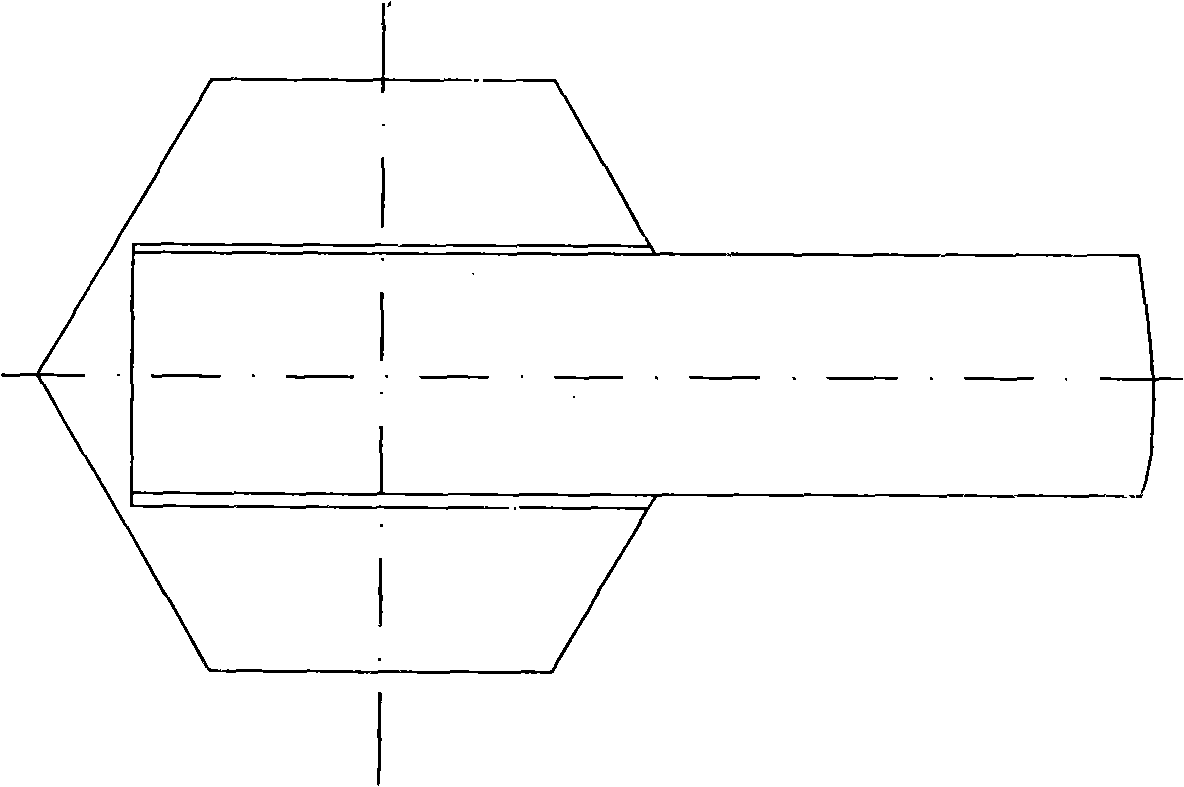

Integrated micro-droplet generator

A method for fabricating a thermal inkjet head equipped with a symmetrical heater and the head fabricated by the method are provided. The method incorporates two thick photoresist deposition processes and a nickel electroplating process. The first thick photoresist deposition process is carried out to form an ink chamber in fluid communication with a funnel-shaped manifold and an injector orifice. The second thick photoresist deposition process forms a mold for forming an injector passageway that leads to the injector orifice. The nickel electroplating process provides an orifice plate on top of the inkjet head through which an injector passageway that leads to the injector orifice is provided for injecting ink droplets.

Owner:IND TECH RES INST

Alloy composition and method for low temperature fluxless brazing

InactiveUS6913184B2Low liquidus temperatureMetallic material coating processesWelding/cutting media/materialsThermal sprayingBraze alloy

A family of low temperature brazing alloys wherein the alloy is utilized in the form of a filler metal or shim and consists of electroplated nickel on zinc shimstock, wherein the zinc shimstock includes zinc, aluminum and silicon, with or without a small amount of lead, tantalum or bismuth. The use of the brazing alloys for joining aluminum parts together or an aluminum part to a part of another metal, such as brass. Further, metallic coating could be thermally spray coated and powder metals could be utilized as the filler materials with equally acceptable brazing techniques. Using these techniques, the brazing could be accomplished at a temperature in the range of 750 to 1050° F.

Owner:DANA CANADA CORP

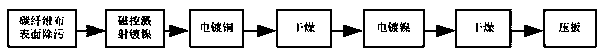

Method for producing nickel-plated carbon fiber board having electromagnetic shielding property

The invention discloses a method for producing a nickel-plated carbon fiber board having electromagnetic shielding property. The method includes the steps: step 1, carbon fiber cloth surface treatment; step 2, magnetron sputtering nickel plating of the carbon fiber cloth surface; step 3, copper electroplating of the carbon fiber cloth surface; step 4, nickel electroplating of the carbon fiber cloth surface; step 5, drying; and step 6, board pressing. The nickel-plated carbon fiber plate has the electromagnetic shielding effectiveness of more than 40 dB in a 150 kHz-18 GHz electromagnetic field, and the stability of the electromagnetic shielding effect of carbon fiber cloth can be effectively improved through the nickel-copper-nickel three-plating-layer structure design; and through the composite material molding, a resin layer on the nickel-plated carbon fiber surface improves the corrosion resistance of the product.

Owner:SYST EQUIP CO LTD OF THE 28TH RES INST LI YANG

Method for producing goldfinger via twice electroplating

InactiveCN102638945ASolve the problem of short circuitShorten the timeConductive pattern reinforcementPrinted element electric connection formationScreen printingNanotechnology

The invention discloses a method for producing a goldfinger via twice electroplating, comprising the following steps: B, carrying out screen printing on dielectric gold oil ink on the lead part of the goldfinger; C, pasting a dry film on the line graph area of a circuit board for protection and exposing the goldfinger part; D, carrying out electronickelling processing on the goldfinger part, forming a nickel layer on the goldfinger, then electroplating flash gold and forming a flash gold layer on the nickel layer; and E, electroplating heavy gold on the goldfinger part and forming a heavy gold layer on the flash gold layer. According to the invention, the nickel layer, the flash gold layer and the heavy gold layer are successively electroplated on the goldfinger, so that the time for electroplating the goldfinger is greatly shortened, the gold leakage caused by contacting with the electroplate liquid for a long time is avoided and therefore the problem of short circuit of the goldfinger caused by gold leakage is solved. In comparison with the prior art, the method disclosed by the invention has high efficiency and short time in electroplating the heavy goldfinger, effectively improves the production efficiency and ensures the quality of the product.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

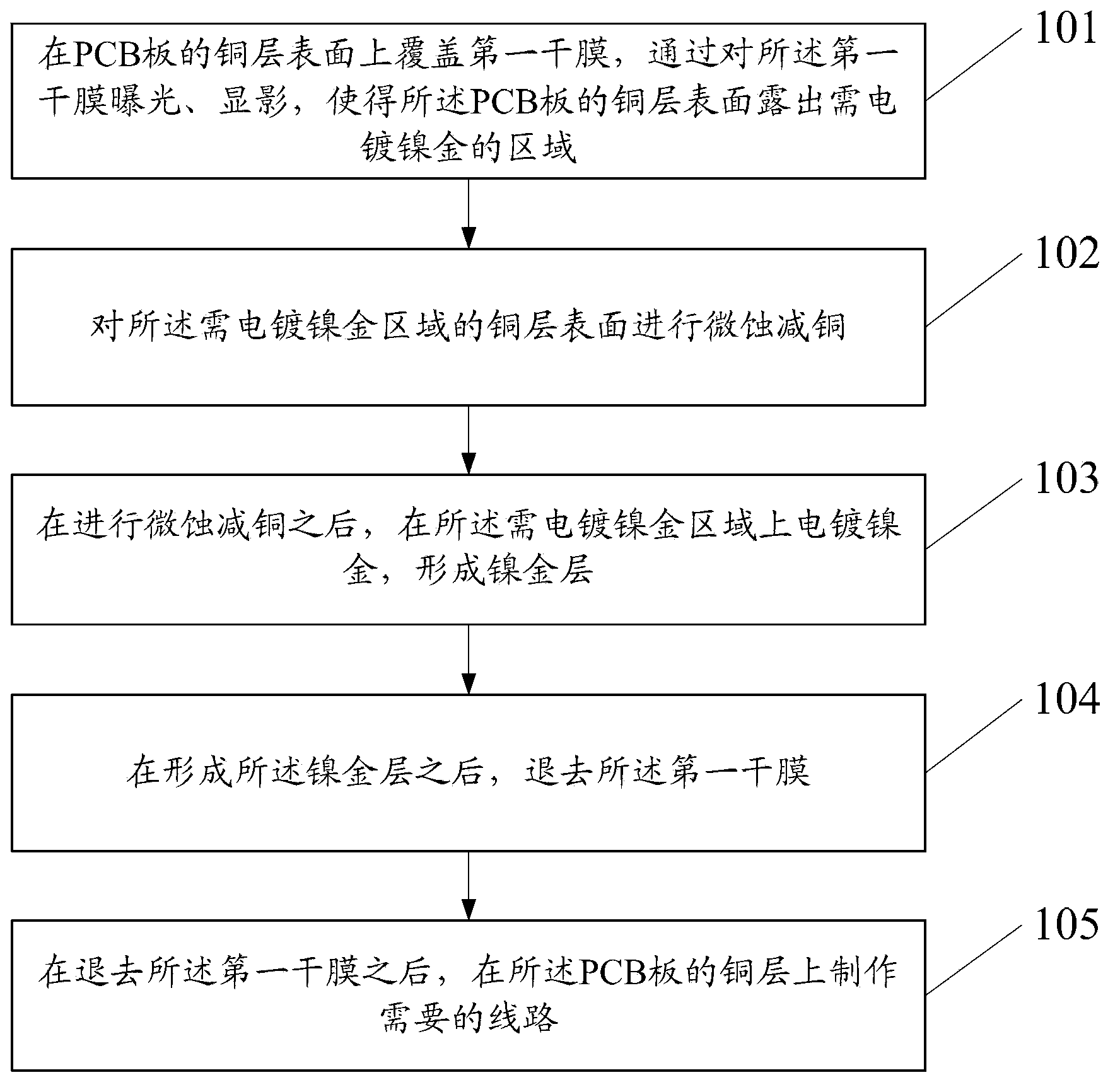

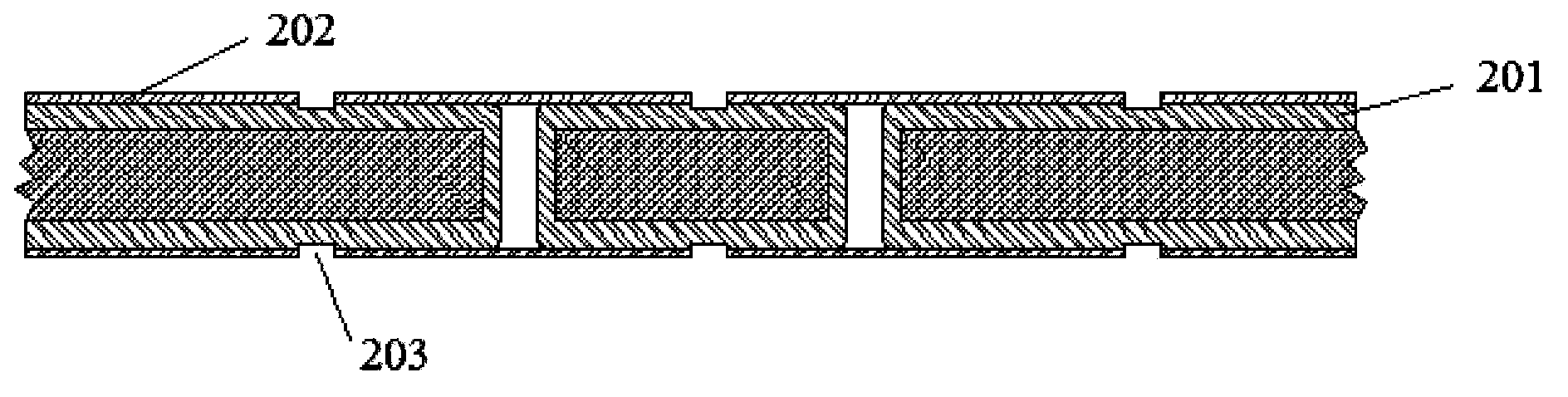

Selective nickel and gold plating method, PCB and device

ActiveCN104105350AReduce height differenceImprove bindingConductive material chemical/electrolytical removalConductive pattern reinforcementEtchingHeight difference

The invention discloses a selective nickel and gold plating method comprising the steps that a first dry film is covered on the surface of a copper layer of a PCB, and a area requiring nickel and gold plating is exposed out of the surface of the copper layer of the PBC via exposure and development; micro-etching and copper reduction are performed on the copper layer of the area requiring nickel and gold plating; and then nickel and gold are plated on the copper layer of the area requiring nickel and gold plating, then the first dry film is removed, and a required line is manufactured on the copper layer of the PCB. According to the method, nickel and gold are firstly plated on the surface of the copper layer of the PCB, and then the line is manufactured so that a lead wire for plating does not need to be manufactured in the overall implement process, and a problem of difficulty in nickel and gold plating on the PCB caused by the fact that the lead wire for plating cannot be manufactured on the PCB is solved. Besides, micro-etching and copper reduction are performed on the copper layer of the area requiring nickel and gold plating so that height difference between the nickel and gold surface of the nickel and gold area and the surface of the line without nickel and gold plating is reduced, and thus combination force of the dry film and the surface of the PCB in the subsequent dry film covering technology is enhanced.

Owner:SHENNAN CIRCUITS

Nickel electroplating solution and electroplating method thereof

The invention provides nickel electroplating solution and an electroplating method thereof. The nickel electroplating solution comprises main salt, stabilizer, complexing agent, conducting salt and reducing agent, wherein the content of the reducing agent is 10-40g / liter. The electroplating method adopting the nickel electroplating solution comprises the following steps of: firstly, putting the metal nickel into nickel electroplating solution to serve as an anode; putting a workpiece into the nickel electroplating solution to serve as a cathode; and finally, introducing a direct-current power supply, wherein the cathode current density is 0.5-5 amperes / square centimtre, the electroplating solution temperature is 40-55DEG C, and the electroplating time is 1-10 minutes. According to the invention, the technical problems existing in the traditional electronickelling and chemical nickel-plating are solved. Reducing agent is added into the electroplating solution to obviously improve the plating solution coverage capability and the corrosion-resistant capability of a nickel layer, and the electroplating solution has the advantages of strong corrosion-resistant capability and good coverage capability.

Owner:GUANGZHOU HKS SURFACE TREATMENT CO LTD

Plating method of magnesium and magnesium alloy

InactiveCN101638790AImprove corrosion resistanceImprove bindingLiquid/solution decomposition chemical coatingChemical platingCopper

A plating method of magnesium and magnesium alloy comprises the following steps: providing a magnesium or magnesium alloy substrate, pretreating the substrate to clean the surface of the substrate; alligatoring the cleaned magnesium or magnesium alloy substrate to ensure that the surface of the substrate is rough; activating the treated magnesium or magnesium alloy substrate; plating nickel to theactivated magnesium or magnesium alloy substrate by using chemical plating; finally electroplating nickel, electroplating copper, electroplating nickel again and electroplating chromium to the obtained magnesium or magnesium alloy substrate in turn.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Preparation method for electricity conductive cloth, and electricity conductive cloth

ActiveCN102817232AReduce internal stressReduce stressFibre treatmentElectricityElectrical resistance and conductance

The present invention discloses a preparation method for an electricity conductive cloth and the electricity conductive cloth. The preparation method comprises the following steps: carrying out a catalytic treatment, wherein an ionic palladium solution is adopted to carry out a pretreatment on the surface of an original cloth; carrying out chemical copper plating, wherein chemical copper plating is performed on the surface of the original cloth; carrying out copper electroplating, wherein copper electroplating is performed on the original cloth, and a thickening treatment is performed on the copper layer of the original cloth; and carrying out nickel electroplating, wherein a nickel layer is electroplated on the surface to provide protection for the copper layer. With application of the method of the present invention to produce the electricity conductive cloth, equipment investment is less, and a copper electroplating layer is adopted to carry out thickening on the copper layer of the product, such that a cost of the copper electroplating process is less than a cost of a complete chemical copper plating process, and the resulting product has characteristics of low electric resistance, low internal stress of the plating layer, and good ductility so as to provide advantages of low cost, high yield, low electric resistance of the product, excellent adhesion and the like.

Owner:SHENZHEN FRD SCI & TECH

Sofc-conduction

ActiveUS20160099476A1Reduce gradientStable temperatureFuel cell auxillariesElectrolytesThermal energyCombustion chamber

A solid oxide fuel cell (SOFC) system included high thermal conductivity materials such as copper to increase thermal energy transfer by thermal conduction. The copper is protected from oxidation by nickel electroplating and protected from thermal damage by providing Hastelloy liners inside combustion chambers. Monel elements are used in the incoming air conduits to prevent cathode poisoning.

Owner:UPSTART POWER INC

Brazing method of aluminum electromagnetic wire and brass

InactiveCN101537521AMeet welding requirementsGood resistance to temperature changesCellsMetallic material coating processesCopper atomPotassium

The invention relates to a brazing method of an aluminum electromagnetic wire and brass. The method comprises the following steps: an aluminum electromagnetic wire and a brass connector are included; firstly nickel electroplating treatment or chemical nickel plating treatment is performed on the surface of the brass connector to enhance the connection strength of a solder and a brass connecting piece and the corrosion resistance of a copper aluminum connector; the nickel plating layer can isolate aluminum atoms from copper atoms to prevent the mutual diffusion and to form a compound layer between friable metals, thus reducing the strength of the copper aluminum connector; and then flux-cored Al-Si hard solders are adopted, the solders adopt non-corrosive potassium fluoroaluminate soldering flux, and the nickel plating surfaces of the aluminum electromagnetic wire and the brass connecting piece are partially lapped and brazed through gas brazing. During the braze welding, the mass percents of the main components of the flux-cored Al-Si hard solders are 9.0 to 13.0 percent of Si, less than 4.70 percent of Cu, and less than 0.20 percent of Zn in sequence. In the aluminum electromagnetic wire and the connector of the brass connecting piece which are welded by adopting the method, the tensile strength of the connector is approximately equal to that of the aluminum electromagnetic wire.

Owner:顺特电气设备有限公司

Process method for electroplating nickel on aluminum-copper composite material component

The invention discloses a process method for electroplating nickel on an aluminum-copper composite material component. The process method can be utilized to obtain a nickel-coated layer with good binding force on the surface of the aluminum-copper composite material component. The process method is realized by the following steps: (a), alkaline corrosion; (b), bright dipping, wherein a clean basal body is obtained by primary bright dipping and secondary bright dipping; (c), zinc immersion, wherein a layer of zinc is uniformly immersed and coated for the aluminum-copper composite material component in sodium hydroxide, zinc oxide, tartrate, ferric trichloride and sodium nitrate solution; and (d), nickel plating, wherein an uniform nickel layer is deposited on the surface of the aluminum-copper composite material component in citrate solution by using an aluminum-copper composite material as a cathode and galvanizing with cathode current. According to the process method disclosed by the invention, the nickel-plating liquor is stable in component, good in dispersing capability, small in corrosion to aluminum base of the aluminum-copper composite material and capable of effectively avoiding corrosion of the aluminum-copper composite material in an nickel-electroplating process, so that a problems of corrosion to aluminum layer substrate and the aluminum-copper composite part and poor binding force with a coating when the aluminum-copper composite material is electroplated with nickel are solved.

Owner:成都泛华航空仪表电器有限公司

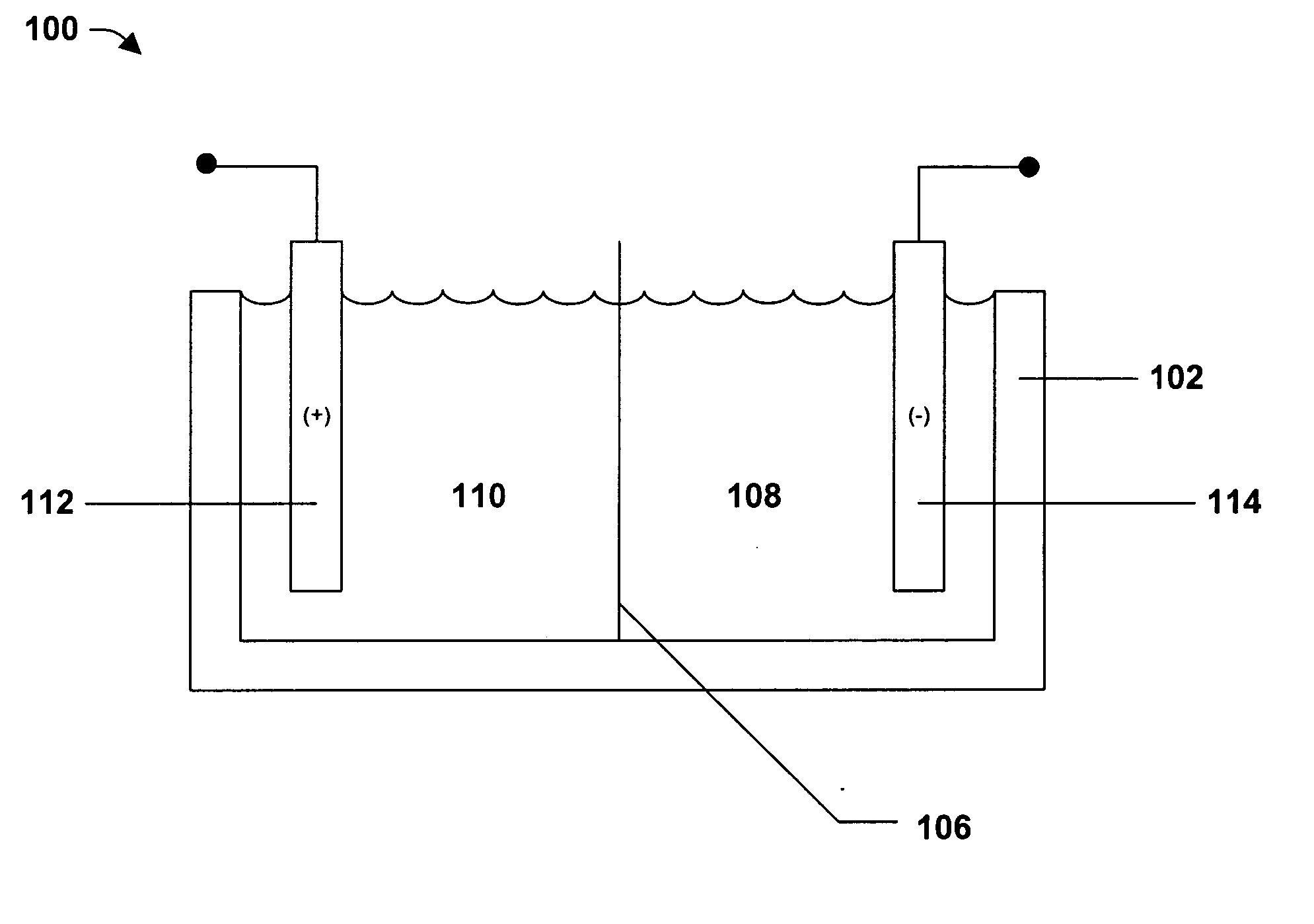

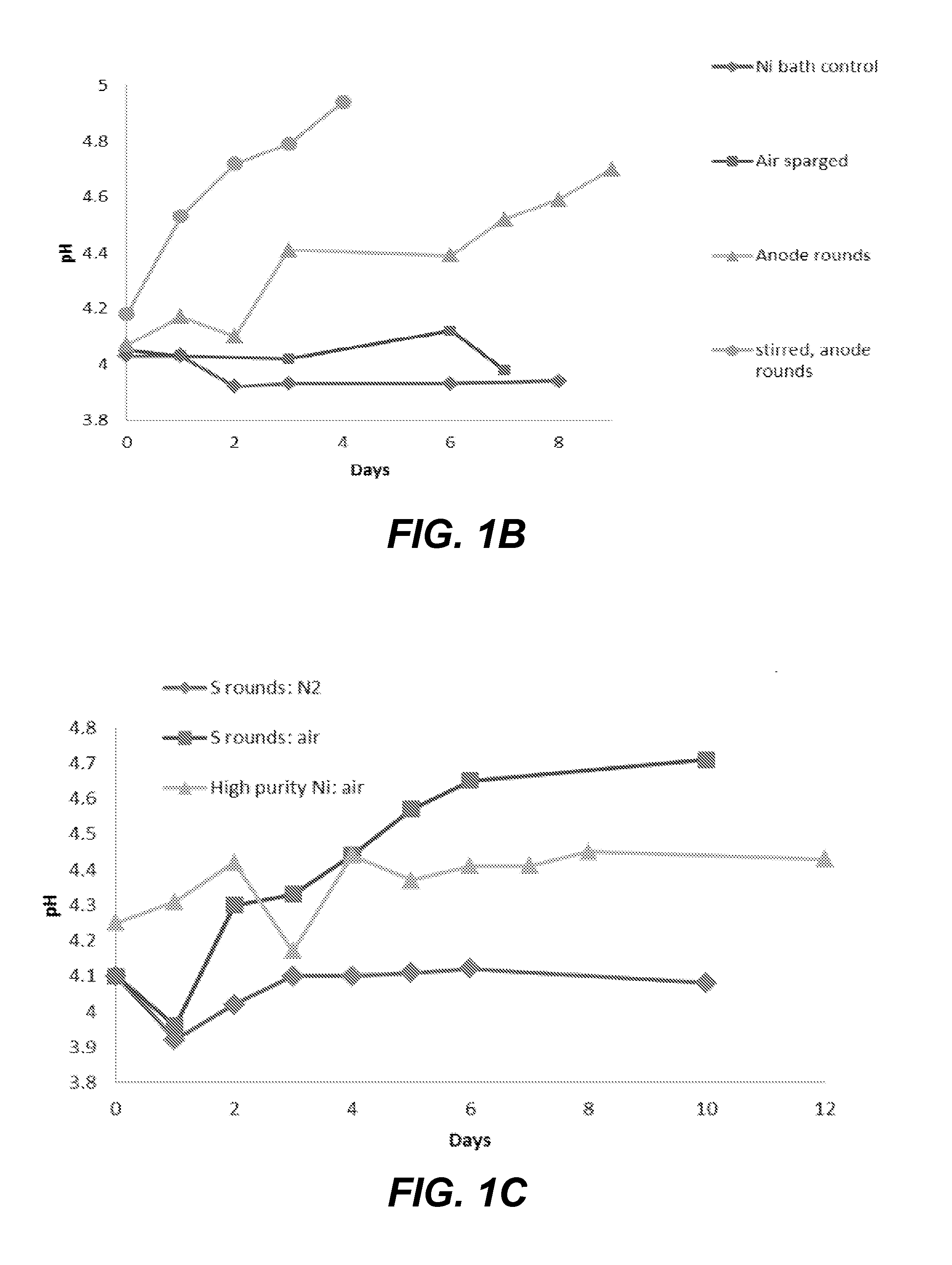

Apparatuses and methods for maintaining ph in nickel electroplating baths

ActiveUS20150041327A1Reduce oxygen concentrationCellsSemiconductor/solid-state device manufacturingIdle timeOxygen

Disclosed herein are electroplating systems for electroplating nickel onto a semiconductor substrate having an electroplating cell for holding an electrolyte solution during electroplating which includes a cathode chamber and an anode chamber configured to hold a nickel anode, and having an oxygen removal device arranged to reduce oxygen concentration in the electrolyte solution as it is flowed to the anode chamber during electroplating and during idle times when the system is not electroplating. Also disclosed herein are methods of electroplating nickel onto a substrate in an electroplating cell having anode and cathode chambers, which include reducing the oxygen concentration in an electrolyte solution, flowing the electrolyte solution into the anode chamber and contacting a nickel anode therein, and electroplating nickel from the electrolyte solution onto a substrate in the cathode chamber, wherein the electrolyte solution in the cathode chamber is maintained at a pH of between about 3.5 and 4.5.

Owner:LAM RES CORP

Matrix for electroplating diamond products and electroplating process thereof

The invention relates to a matrix of a diamond product and a plating process thereof. The matrix is characterized in that the matrix consists of electroplated iron or iron-nickel alloy. Electroplating solution adopted by the plating process comprises ferrous sulfate and other sulphates, ferrous chloride and other chlorides, or nickel sulfate, the ferrous sulfate and the chloride. The matrix has the beneficial effects that all of the electroplated iron, the iron-nickel alloy containing 30 to 60 percent of iron and other ferroalloy have higher hardness (HRC35-50) and good bezel setting property for the diamond. Though the matrix is worse than electroplated nickel in wear-resisting property, the matrix is in favor of the exposure of the diamond product and improves the sharpness of the diamond product. Therefore, the matrix is especially suitable for manufacturing the drill pit and the sharper of the diamond. As the cheap iron replaces the expensive nickel, the manufacturing cost of the electroplated diamond product is greatly reduced.

Owner:兰桥昌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com