Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Low liquidus temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite metal panel

InactiveUS20020086179A1Brazing can take place much more easilyReduce and avoid useConstruction materialWelding/cutting media/materialsTO-18Parallel plate

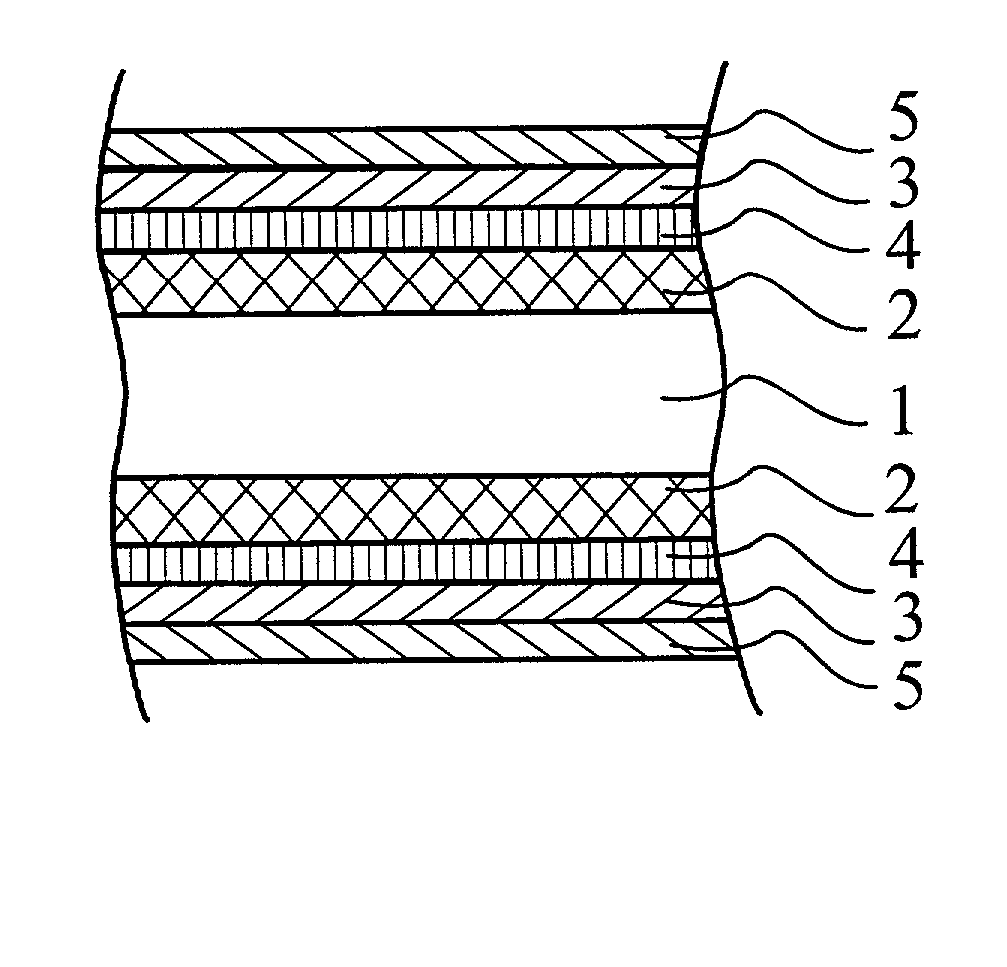

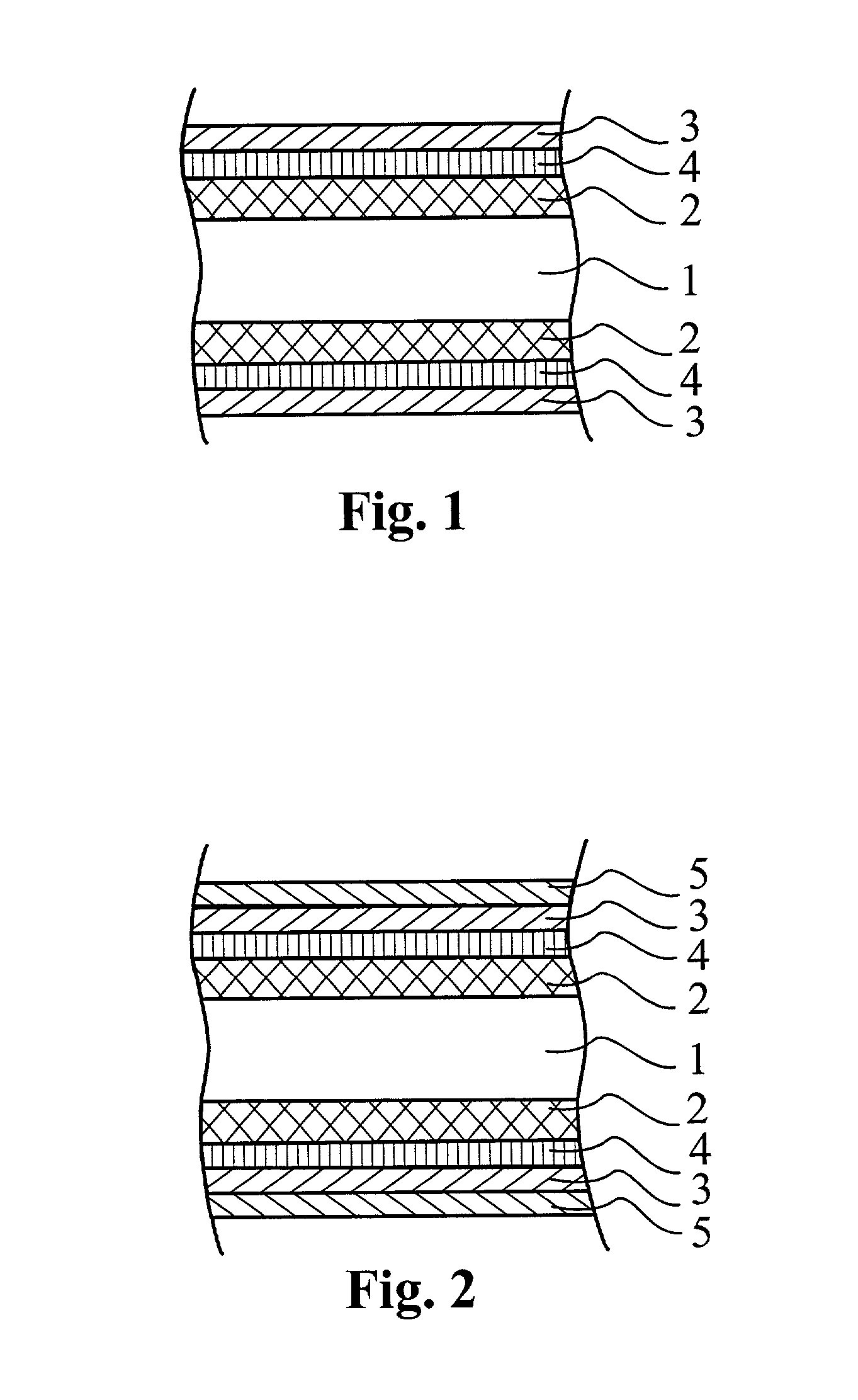

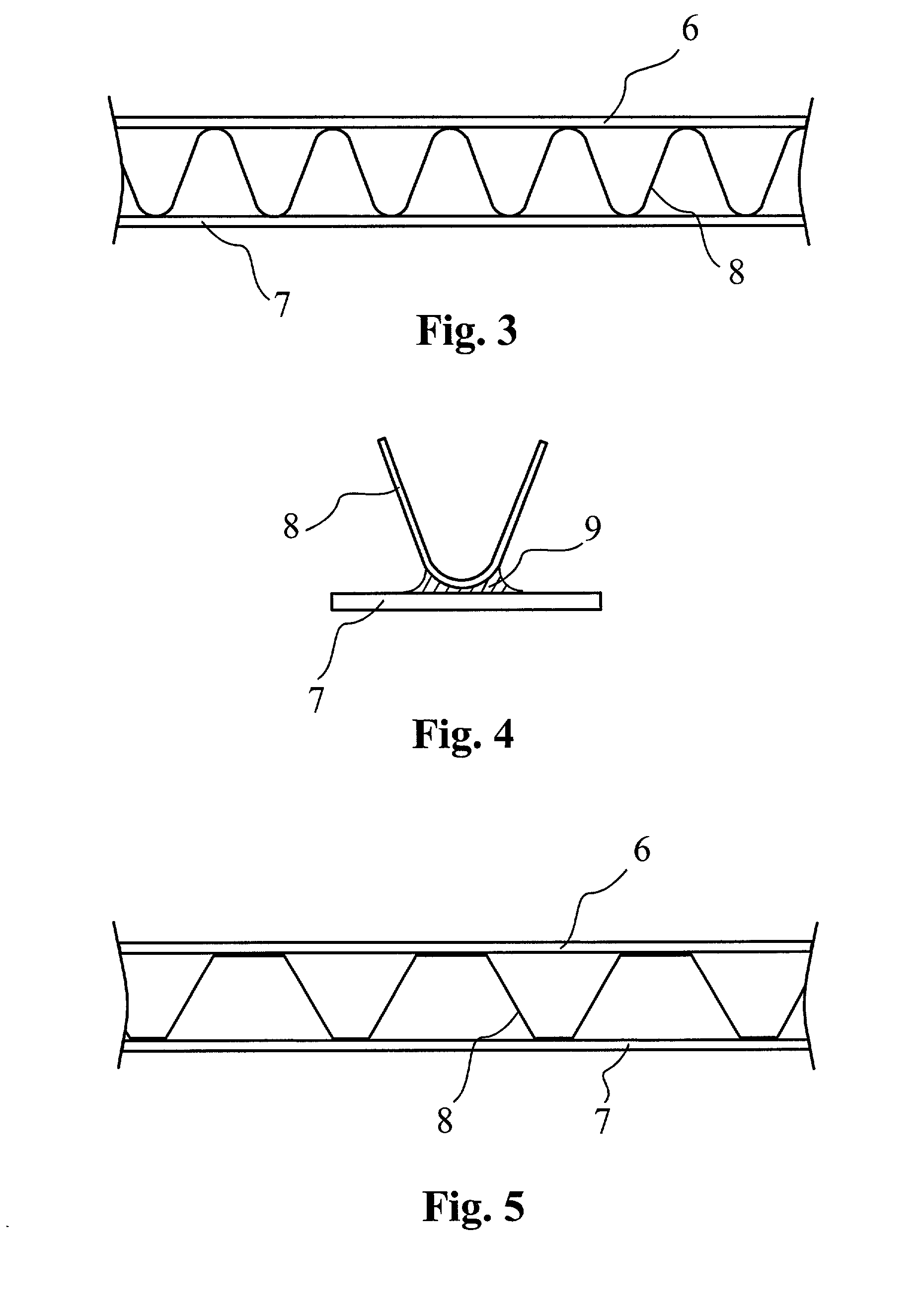

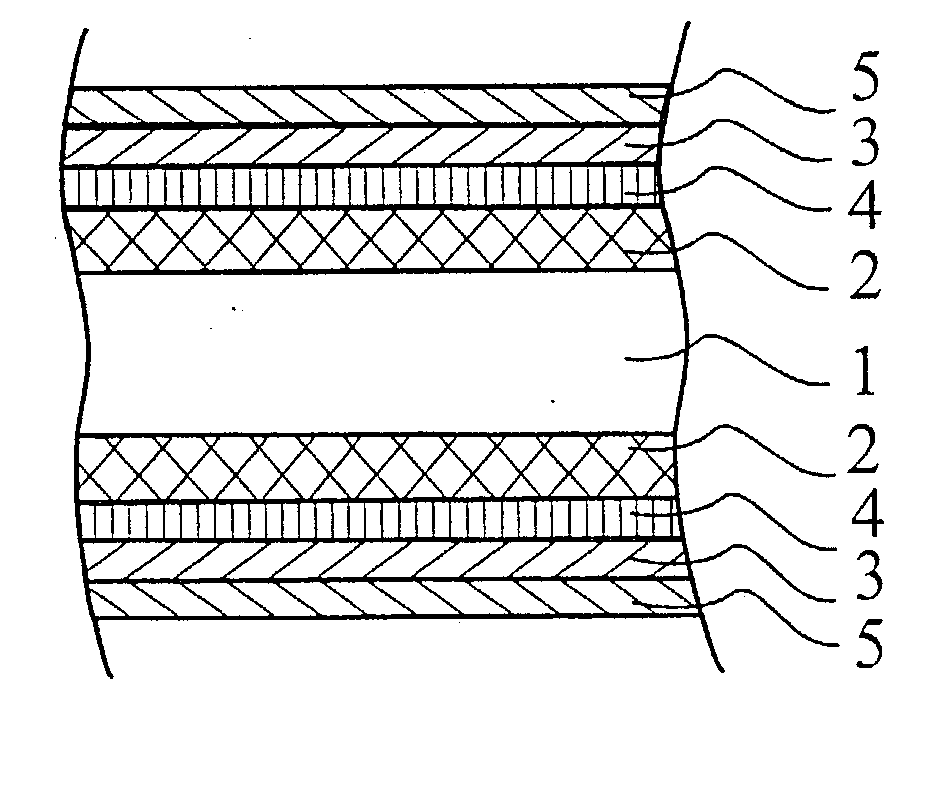

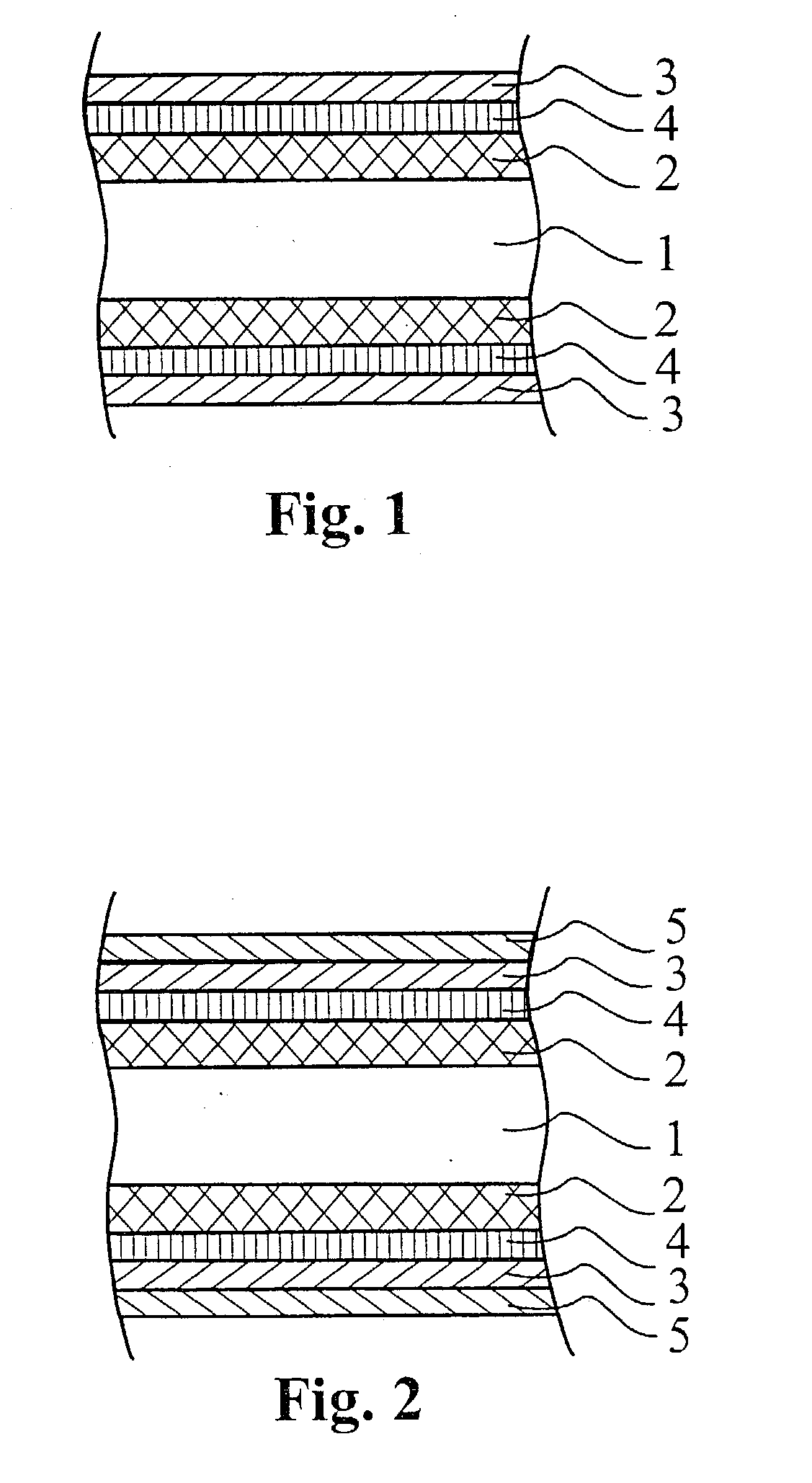

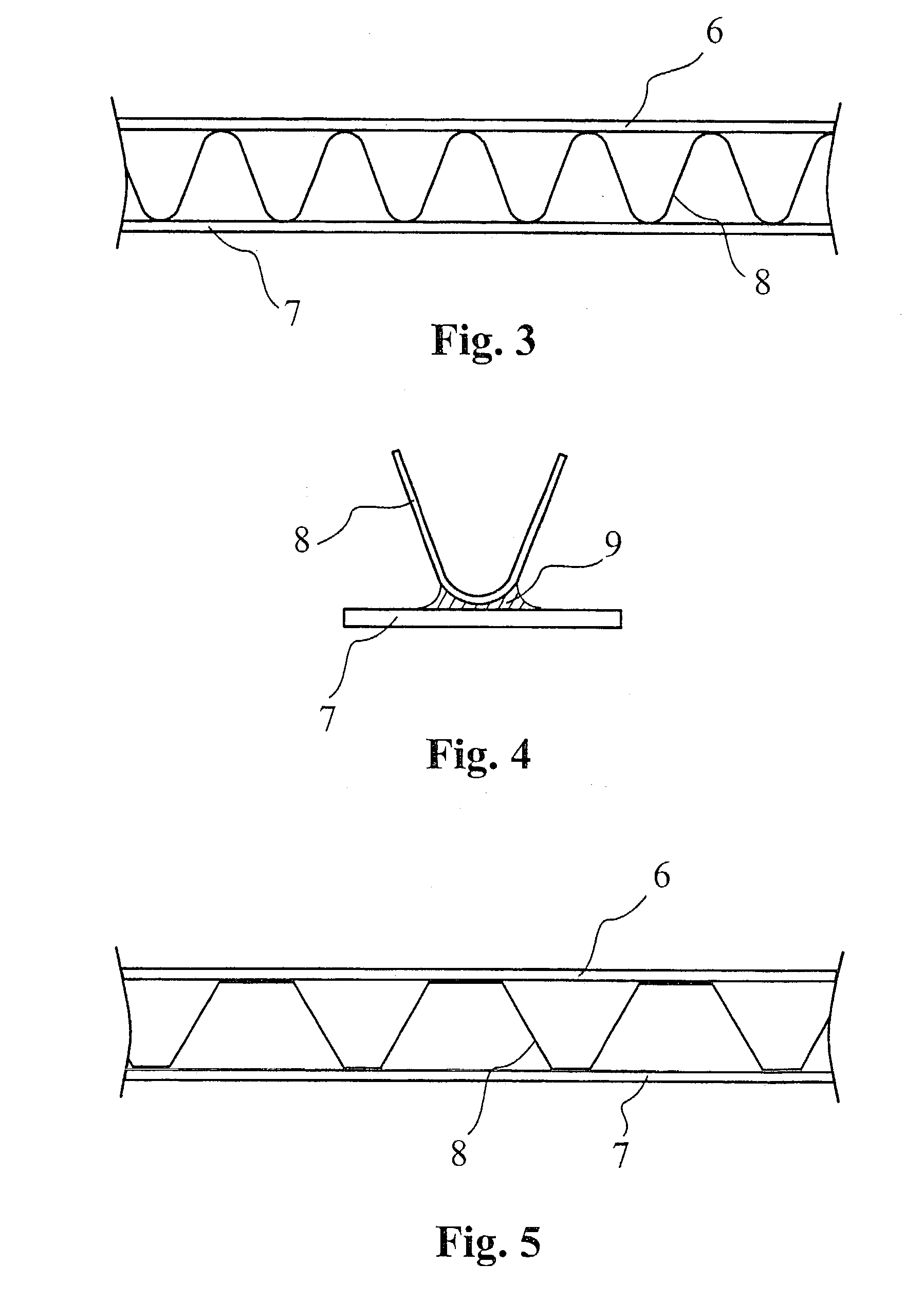

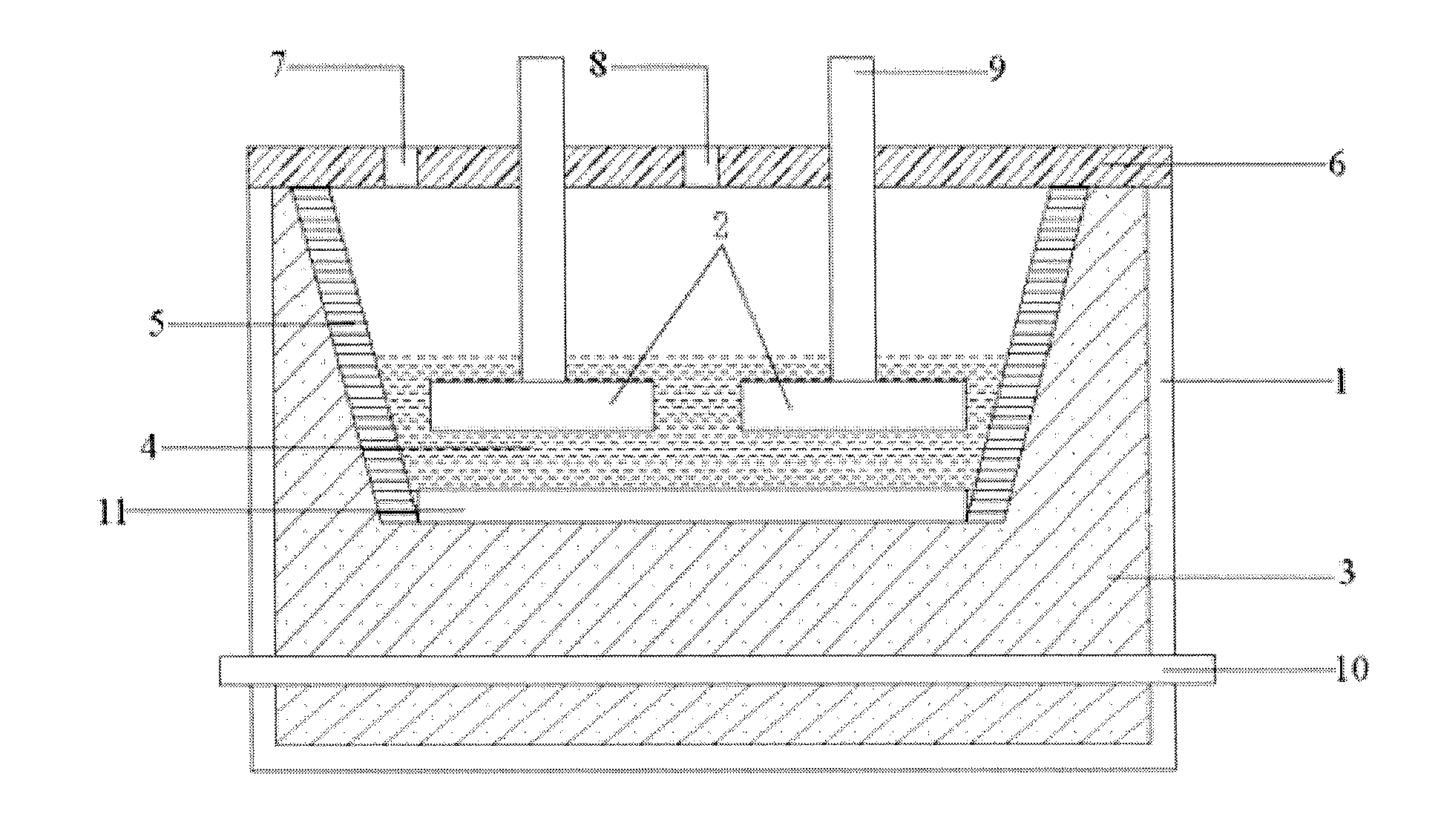

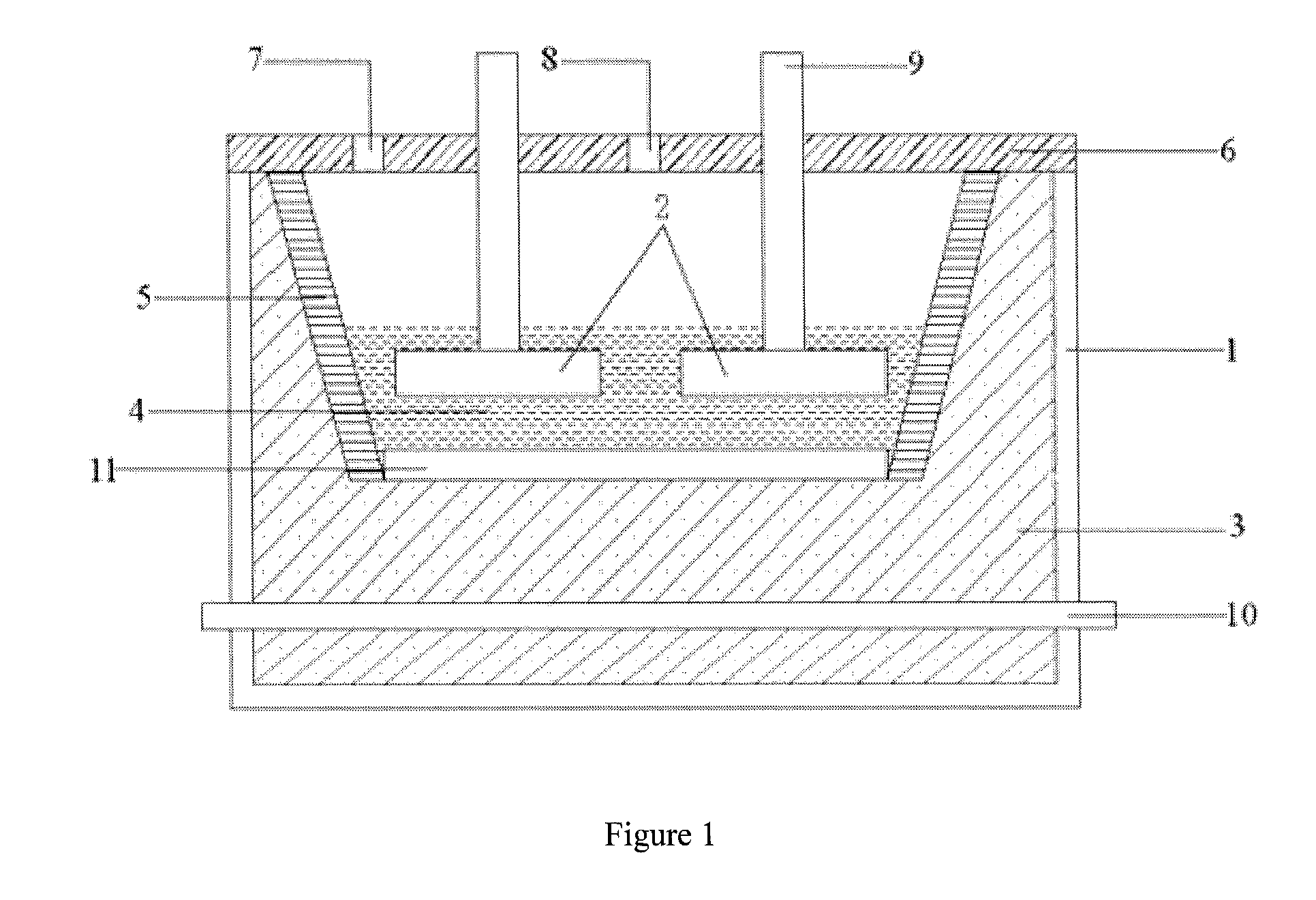

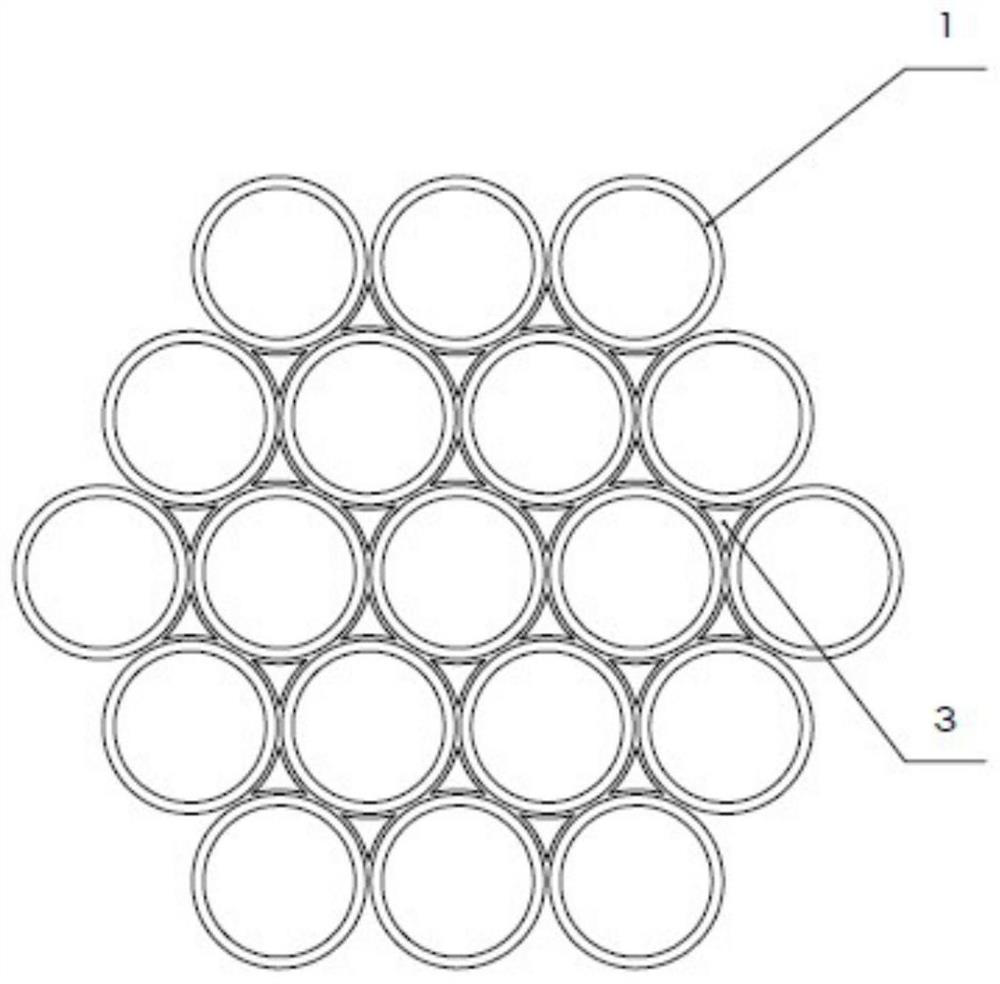

The invention relates to a rigid composite metal panel comprising at least two metal parallel plates and / or sheets secured to the peaks and troughs of a corrugated aluminium stiffener sheet arranged between the parallel plates and / or sheets, wherein the corrugated aluminium stiffener sheet is an aluminium brazing sheet product made from an aluminium brazing sheet product including a core sheet (1) made of an aluminium alloy having on at least one surface of the core sheet clad, and preferably on both sides, an aluminium clad layer (2), the aluminium clad layer being made of an aluminium alloy comprising silicon in an amount in the range of 2 to 18% by weight, preferably 5 to 14%, and a layer (3) comprising nickel on the outer surface of the aluminium clad layer. The invention further relates to a method of manufacturing thereof.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

Optical glass, preform for press molding and optical part

InactiveUS6977232B2High-temperature viscosityLower transition temperatureGlass pressing apparatusGlass press-moulding apparatusRefractive indexOptical glass

Provided is an optical glass that has high-refractivity and high-dispersion properties and can give preforms for press-molding, which are excellent in shapability at high temperatures and suitable for precision press-molding.The optical contains, as essential components, 25 to 45 mol % of B2O3, 2 to 20 mol % of SiO2, 5 to 22 mol % of La2O3, 2 to 20 mol % of Gd2O3, 15 to 29 mol % of ZnO, 1 to 10 mol % of Li2O and 0.5 to 8 mol % of ZrO2, the optical glass having a B2O3 / SiO2 molar ratio of from 2 to 5.5 and having an La2O3 and Gd2O3 total content of 12 to 24 mol % and a ZnO and Li2O total content of 25 to 30 mol %, the optical glass having a refractive index (nd) of 1.75 to 1.85 and an Abbe's number (νd) of 40 to 55, or the optical glass contains, as essential components, B2O3, SiO2, La2O3, Gd2O3, ZnO, Li2O and ZrO2 and has a viscosity of at least 6 dPa·s at a liquidus temperature thereof, a glass transition temperature (Tg) of 600° C. or lower, a refractive index (nd) of 1.75 to 1.85 and Abbe's number (νd) of 40 to 55.

Owner:HOYA CORP

Lead-free solder alloys

InactiveUS6503338B1High bonding strengthAvoid heat damageWelding/cutting media/materialsSoldering mediaMelting temperatureLiquidus

A lead-free solder alloy which has a relatively low melting temperature and which is suitable for soldering electronic devices consists essentially of from 5 to 9 mass % of Zn, from 2 to 15 mass % of Bi, optionally from 0.001 to 1 mass % of P or from 0.001 to 0.1 mass % of Ge, and a balance of Sn. The solder alloy has a liquidus temperature of at most 220° C.

Owner:SENJU METAL IND CO LTD

Middle-temperature sharp-quenching aluminum solder and method of producing the same

InactiveCN101134273AFlat surfaceGood workmanshipWelding/cutting media/materialsSoldering media6063 aluminium alloyMelt temperature

The present invention belongs to the field of aluminum and aluminum alloy connecting material, relates to aluminum brazing material, and is especially one kind of fast cooled Al-Si-Cu-Zn brazing material for brazing aluminum and aluminum alloy and its preparation process. The Al-Si-Cu-Zn brazing material consists of Si 5.0-12.5 wt%, Cu 15.0-30.0 wt%, Zn 2.5-7.5 wt%, Sr 0.001-0.5 wt% and Al for the rest. The Al-Si-Cu-Zn brazing material is prepared through one single roll and fast cooling process. It has melting temperature of 500-525 deg.c and brazing temperature of 530-570 deg.c, and is suitable for brazing aluminum and aluminum alloy with solidus temperature over 530 deg.c.

Owner:JIANGSU UNIV OF SCI & TECH

Composite metal panel

InactiveUS20030091856A1Brazing can take place much more easilyReduce and avoid useConstruction materialElectron beam welding apparatusParallel plateAluminium alloy

The invention relates to a rigid composite metal panel comprising at least two metal parallel plates and / or sheets secured to the peaks and troughs of a corrugated aluminium stiffener sheet arranged between the parallel plates and / or sheets, wherein the corrugated aluminium stiffener sheet is an aluminium brazing sheet product made from an aluminium brazing sheet product including a core sheet (1) made of an aluminium alloy having on at least one surface of the core sheet clad, and preferably on both sides, an aluminium clad layer (2), the aluminium clad layer being made of an aluminium alloy comprising silicon in an amount in the range of 2 to 18% by weight, preferably 5 to 14%, and a layer (3) comprising nickel on the outer surface of the aluminium clad layer. The invention further relates to a method of manufacturing thereof.

Owner:DANA CANADA CORP

Glass plate

InactiveUS20130115422A1Improved denitrification resistanceEasily formed into glass sheetRecord information storageMagnetic recordingPolymer scienceAlkali metal oxide

Provided is a glass sheet, comprising, as a glass composition in terms of mass %, 40 to 80% of SiO2, 0 to 30% of Al2O3, 0 to 15% of B2O3, 0 to 25% of an alkali metal oxide (one kind or two or more kinds of Li2O, Na2O, and K2O), and 0 to 15% of an alkaline earth metal oxide (one kind or two or more kinds of MgO, CaO, SrO, and BaO), and being used as a viewing zone control member for covering partially or wholly a two-dimensional display.

Owner:NIPPON ELECTRIC GLASS CO LTD

LCD sheet glass

The invention discloses a base plate glass with rare-earth element to dope liquid crystal display device (TFT-LCD), which is characterized by the following: comprising glass basic oxide, lanthanum oxide, cerium oxide, neodymium oxide and or yttrium oxide; setting the mass ratio at (60. 5-195):(0. 003-28) of the glass basic oxide and all rare-earth oxide; adding at least three rare-earth oxide; improving the fusion of the glass; accelerating clarification and equalization in the course of formation; preventing glass crystallizer; decreasing the liquid phase temperature; delaying devitrification speed of the glass; fitting for productive technology of float glass; improving chemical stability of the glass; decreasing the expansion coefficient; fitting for large scale float glass procession.

Owner:CHINA BUILDING MATERIALS ACAD

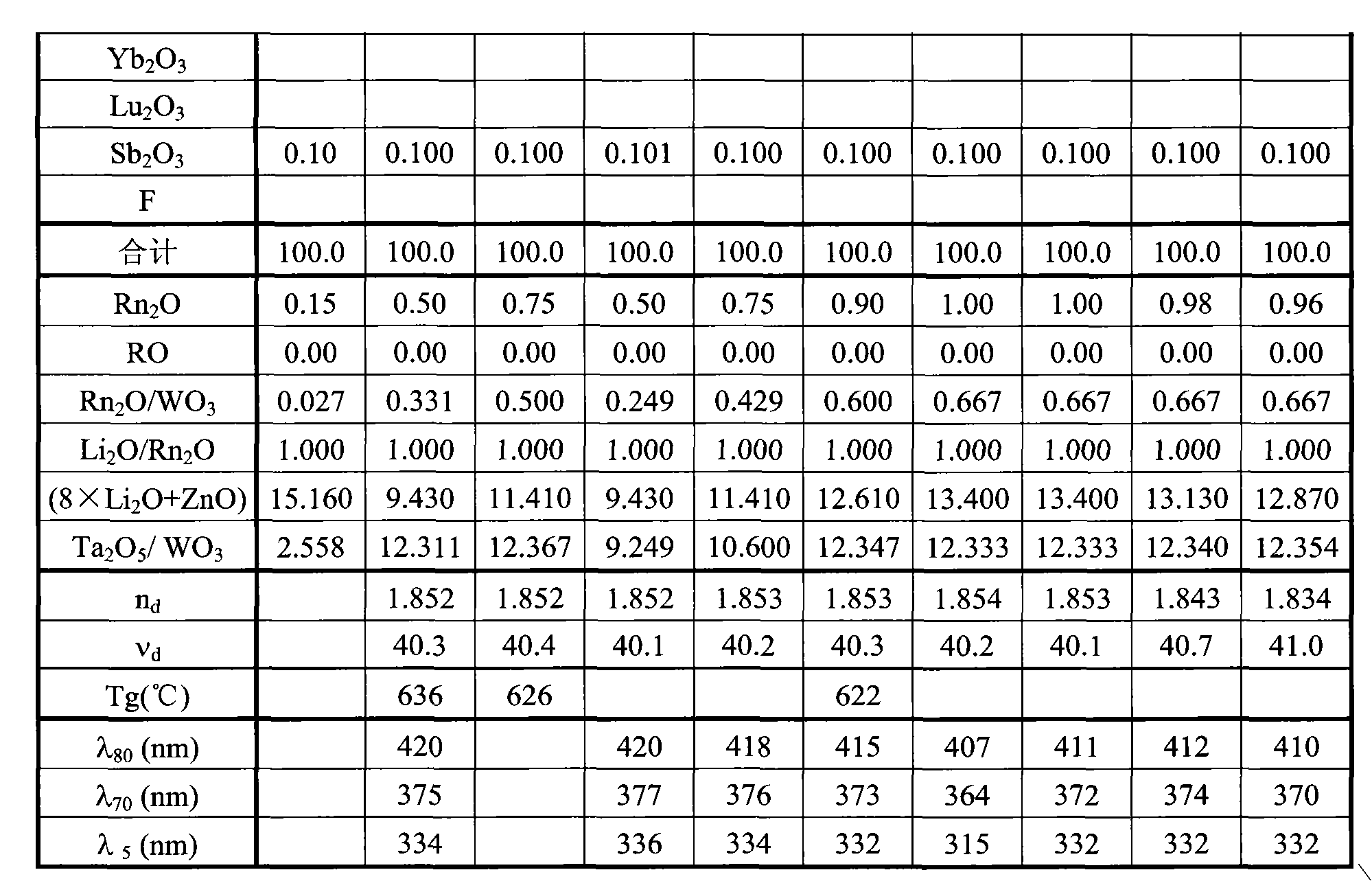

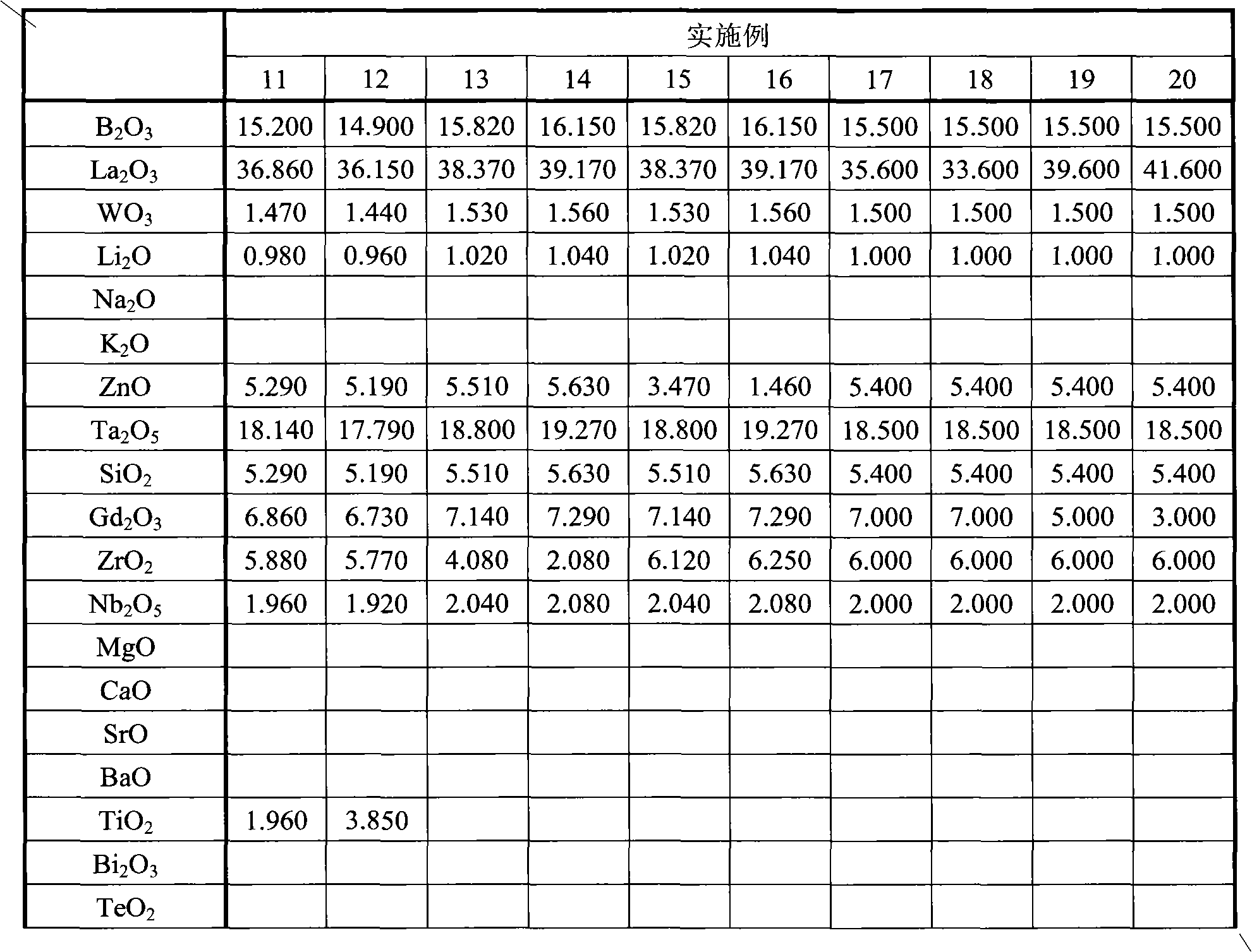

Optical glass, preforming material and optical element

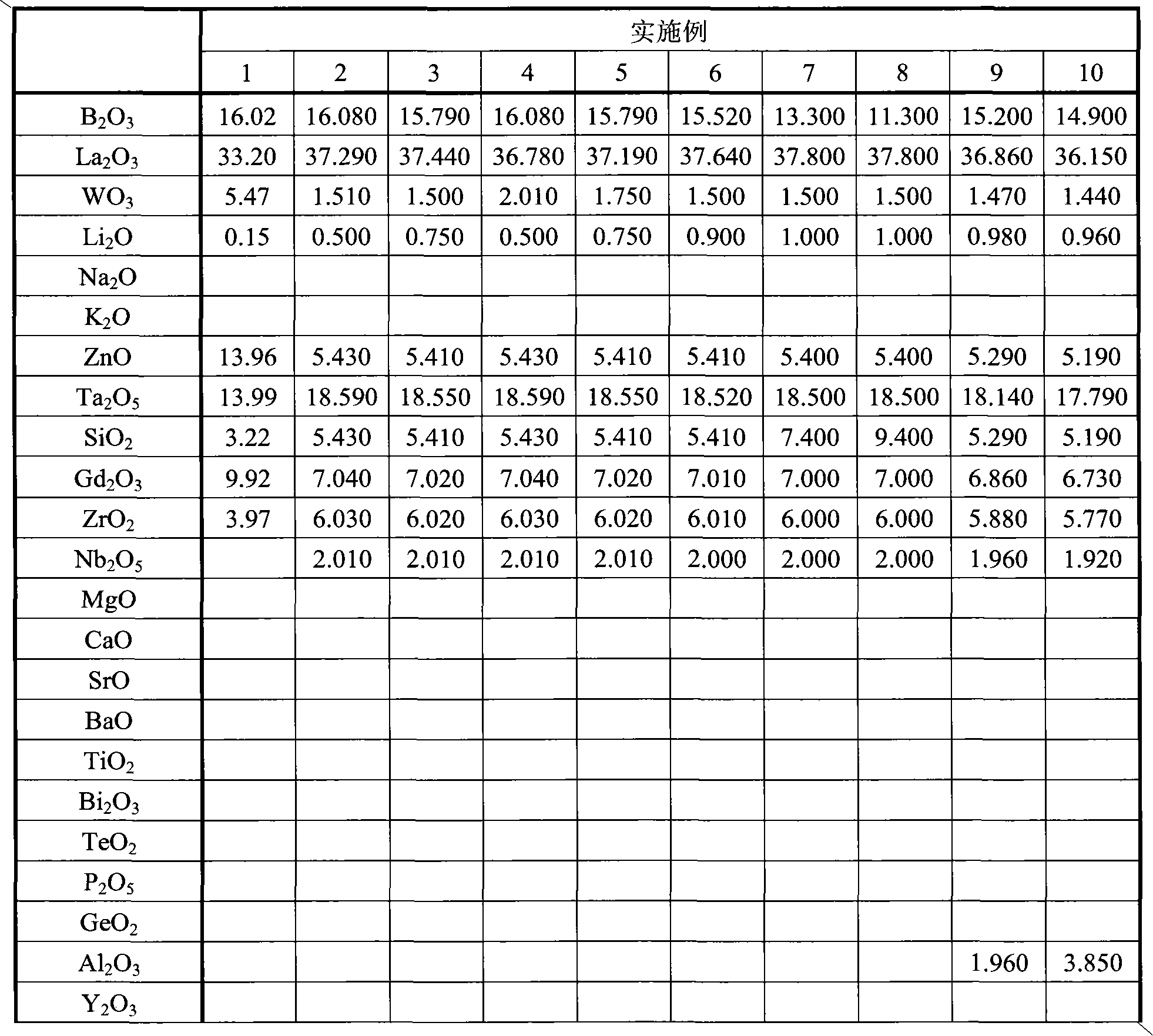

ActiveCN101935164ALow liquidus temperatureHigh viscosityOptical elementsDevitrificationRefractive index

The present invention provides an optical glass which refractivity (nd) and Abbe number (vd) are all located in an expectation range, has less veins and is difficult to bring devitrification, and can be used to form a great-diameter preforming material, a preforming material using the optical glass and an optical element. The optical glass, relative to a gross mass of the glass scaled based on oxide by weight percentage, contains 5.0-35.0% of B2O3, 15.0-50.0% of La2O3, less than 10.0% of Rn2O (Rn is selected from more than one of Li, Na, K) AND 1.0-15.0% of WO3.

Owner:OHARA

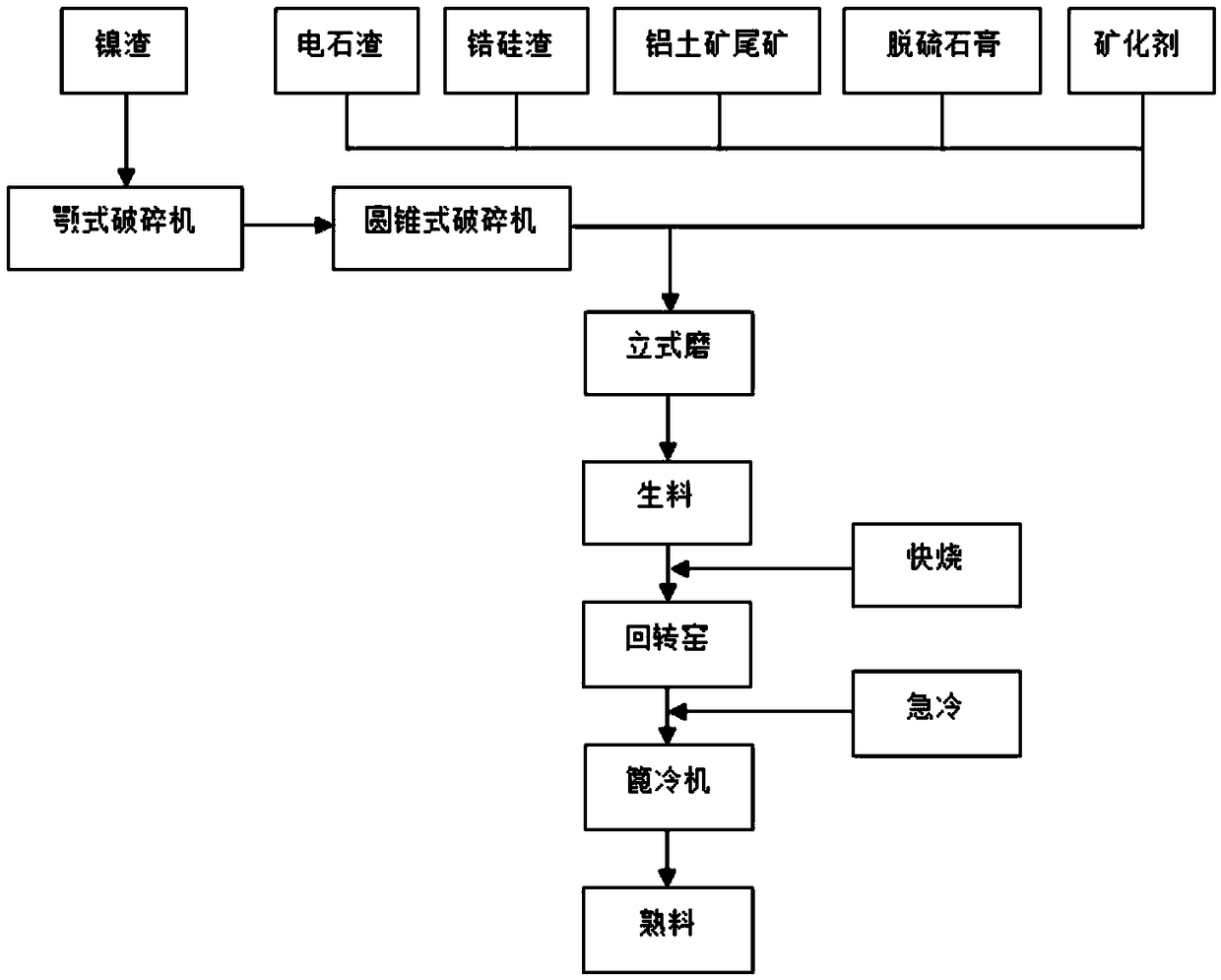

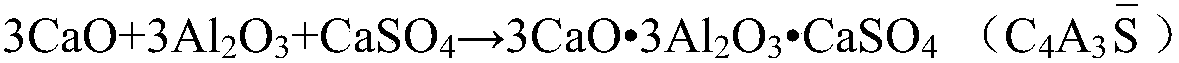

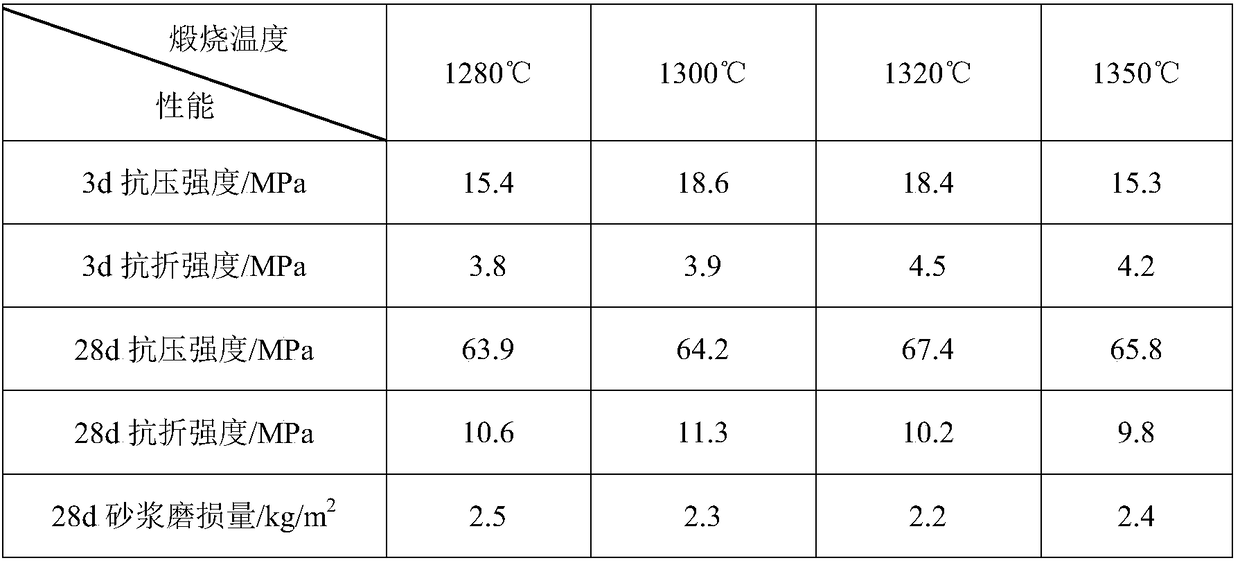

Road silicate cement clinker on basis of industrial waste residues and method for preparing road silicate cement clinker

ActiveCN109081615AStrong mechanical propertiesReduce consumptionCement productionSlagToxic industrial waste

The invention discloses road silicate cement clinker on the basis of industrial waste residues and a method for preparing the road silicate cement clinker. The road silicate cement clinker comprises nickel slag, calcium carbide residues, zirconium-containing silica residues, bauxite tailing, desulfurization gypsum and mineralizers. The method includes mixing, grinding and homogenizing the nickel slag, the calcium carbide residues, the zirconium-containing silica residues, the bauxite tailing, the desulfurization gypsum and the mineralizers to obtain cement raw materials; preheating the cementraw materials, then calcining the cement raw materials under the condition of the temperature of 1280-1350 DEG C for 30-35 min and then carrying out cooling to obtain the road silicate cement clinker.The road silicate cement clinker and the method have the advantages that the 28 d compressive strength of the road silicate cement clinker can reach 63.9-75.2 MPa, the strength grade of the road silicate cement clinker can reach 62.5 grade, the 28 d breaking strength of the road silicate cement clinker can reach 9.8-18.2 MPa, the 28 d mortar abrasion loss of the road silicate cement clinker is lower than 2.5 kg / m<2>, cement is high in stability, and the road silicate cement clinker is high in abrasion resistance and excellent in work performance; the method is simple, complicated working procedures can be omitted, and the road silicate cement clinker and the method are low in cost.

Owner:哈尔滨太行兴隆水泥有限公司

Magnesium alloy and smelting and heat treatment processes thereof

The invention provides a magnesium alloy, which comprises the following components in percentage by weight: 0.5-1.5% of calcium, 0.5-2.5% of zinc, and the balance of magnesium, wherein the sum of weight percentages is 100%. The invention also provides a melting process of the magnesium alloy, which comprises the following steps: (1) slicing magnesium ingots and removing impurities, and weighing zinc and calcium for standby; (2) preheating a crucible and a die; (3) putting the magnesium slices into the crucible, putting the crucible in a furnace, and after an operation of vacuumizing is completed, feeding mixed gas into the furnace; (4) heating the furnace until the magnesium slices are completely molten, and heating and stirring the obtained product; (5) wrapping metal calcium with an aluminum foil, adding the obtained object in the bottom of molten magnesium, then adding zinc slices, carrying out stirring and slag removal on the obtained mixture, and after the obtained product is heated, carrying out heat preservation on the obtained product; and (6) cooling molten liquid, carrying out heat preservation on the molten liquid, opening the furnace, taking the die, pouring the molten liquid into the die, and waiting. The invention also provides a heat treatment process of the magnesium alloy, which comprises the following steps of (1) homogenized annealing; and (2) solid solution treatment. The magnesium alloy disclosed by the invention has the advantages that the mechanical properties of the alloy are improved, the casting performance is improved, and the creep resistance of the alloy is increased.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

Precisely pressed optical glass

ActiveCN1772671AExcellent devitrification resistanceImprove transmittanceDevitrificationRefractive index

The present invention provides one kind of precisely pressed optical glass. The optical glass consists of SiO2 8-30 wt%, B2O3 6-25 wt%, ZnO 8-30 wt%, Nb2O5 0.5-19 wt%, BaO 5-26 wt%, Li2O 0.5-7 wt% and ZrO2 1-6 wt% chemically. The optical glass of the present invention has refractivity of 1.65-1.74, Abbe number of 36-45, conversion temperature lower than 500 deg.c, high chemical stability, low liquid phase temperature, high devitrification resistance, high light permeability and low specific weight, and is especially suitable for precise mold pressing to form aspherical lens, spherical lens and other optical elements.

Owner:CDGM OPTICAL GLASS

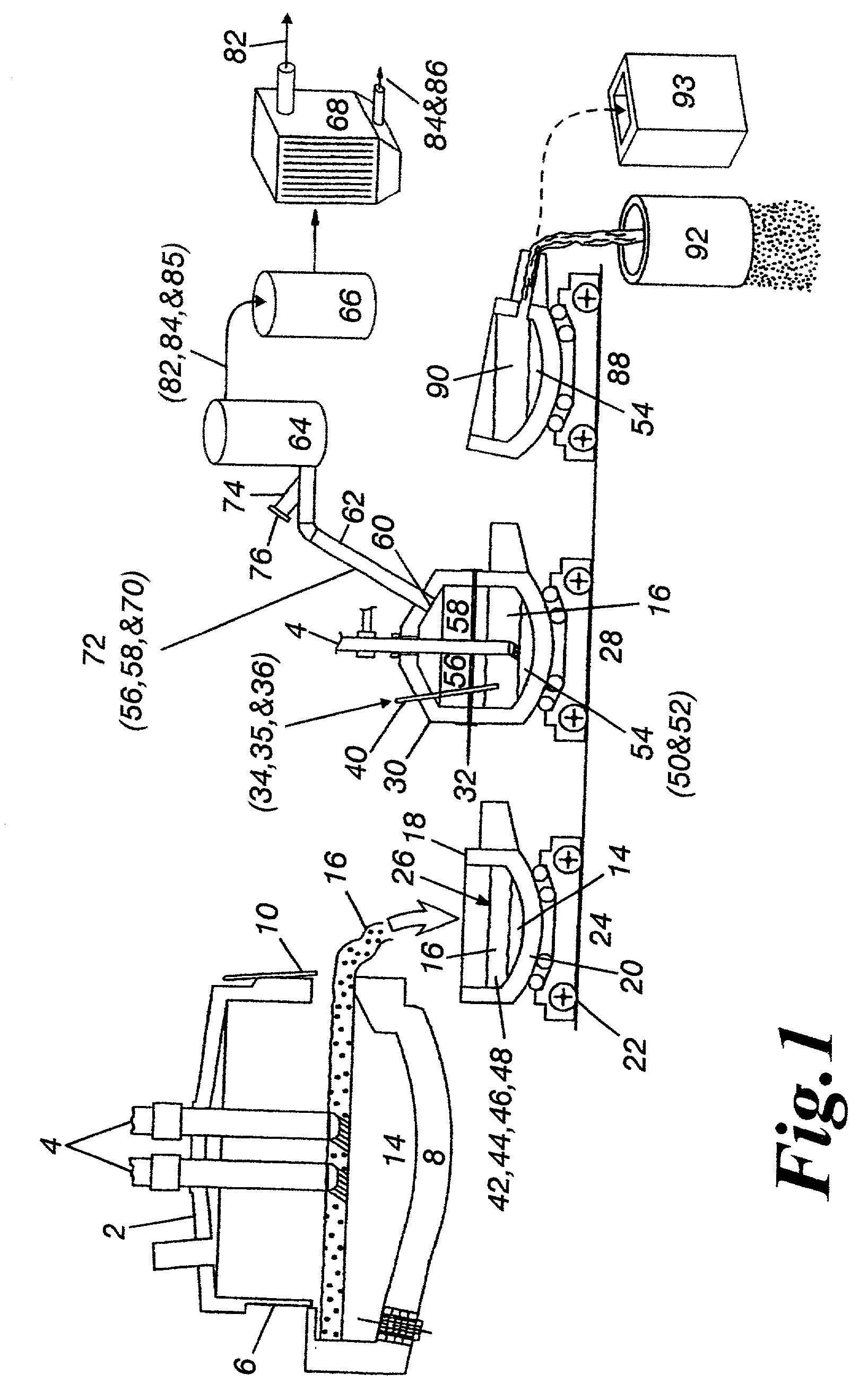

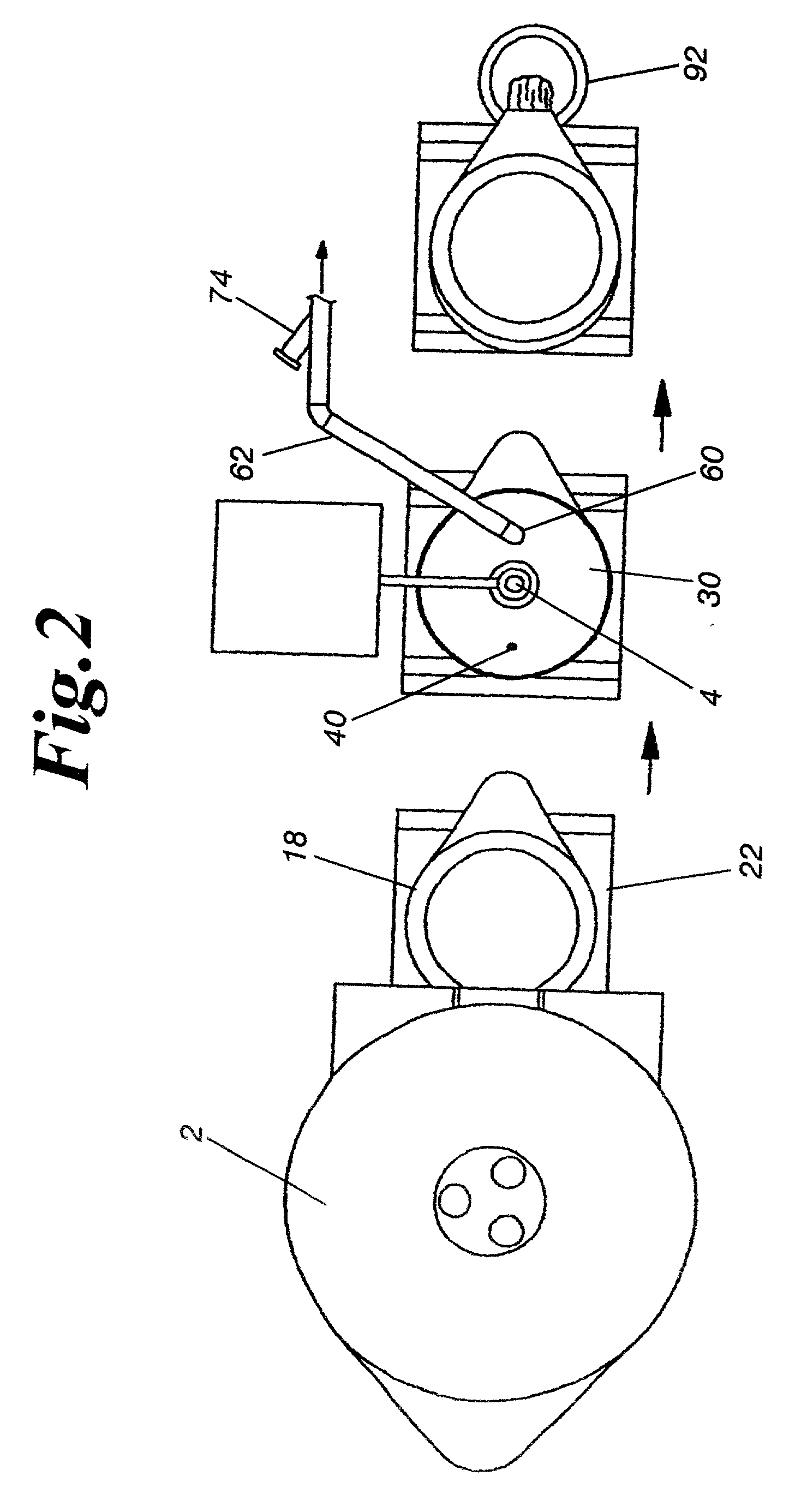

Method and apparatus for recovering metal values from liquid slag and baghouse dust of an electric arc furnace

InactiveUS20010046251A1Reduce disposal costsLow cost of treatmentSolid waste disposalCharge composition/stateSteelmakingElectric arc furnace

An apparatus and method for processing liquid slag and baghouse dust from a steelmaking furnace such as an EAF to recover valuable metals from the slag and dust includes a treatment vessel having a movable lower shell portion for receiving liquid slag and an upper shell portion that couples with the movable lower shell portion during heat activation of the treatment vessel. The slag is combined with silicon dioxide, a reducing agent, baghouse dust, and an inert gas before being heated to between approximately 1400° C. and 3000° C. The heat treatment results in a molten reduced iron and manganese metallic material, a treated slag layer, and an off-gas containing lead, zinc, and carbon monoxide. The off-gas is combusted, cooled, and solidified, resulting in lead oxide and zinc oxide. The slag layer is tapped, cooled, and solidified. The metallic layer is tapped for recycle in the steel making process.

Owner:VALLOMY JOHN A

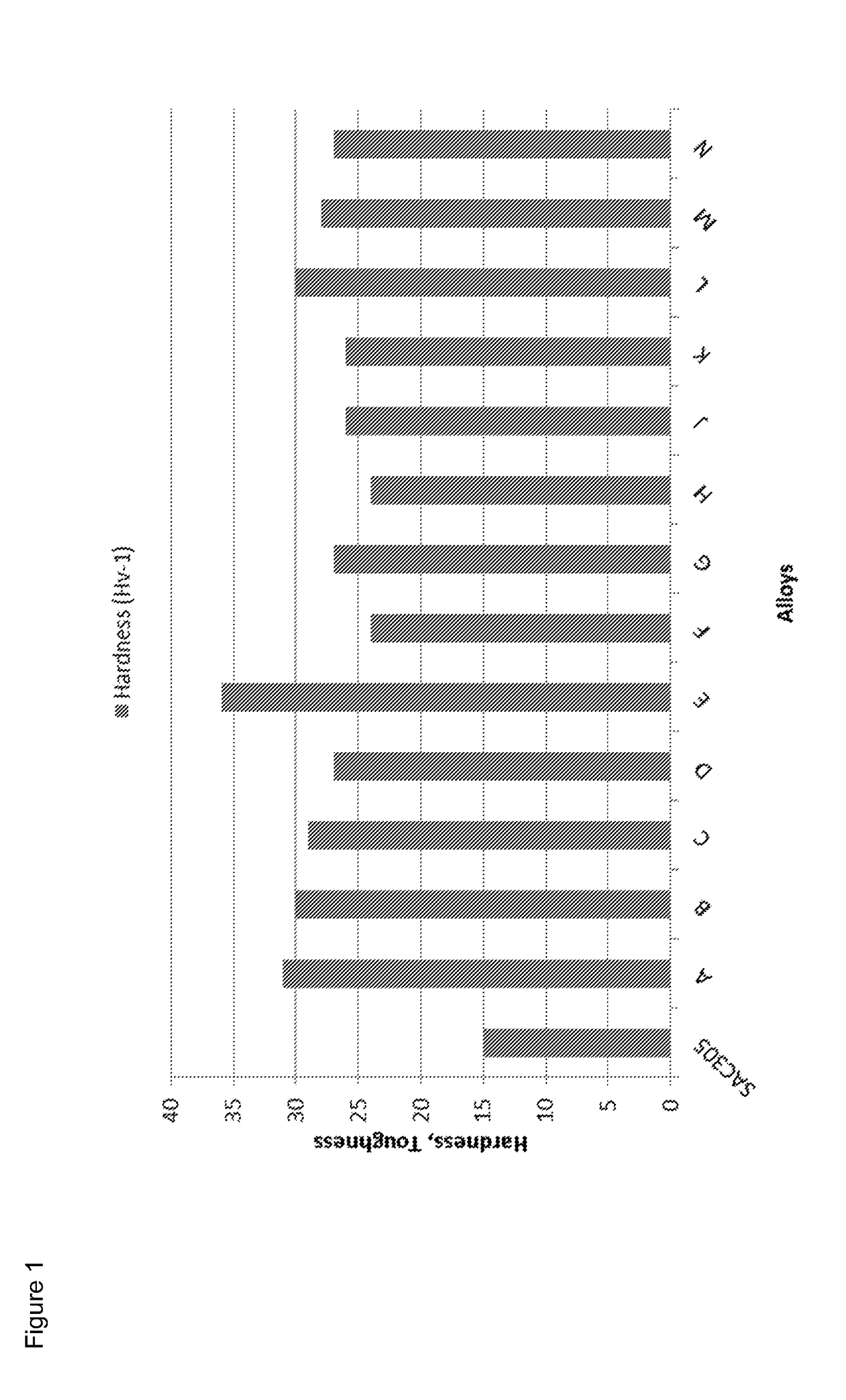

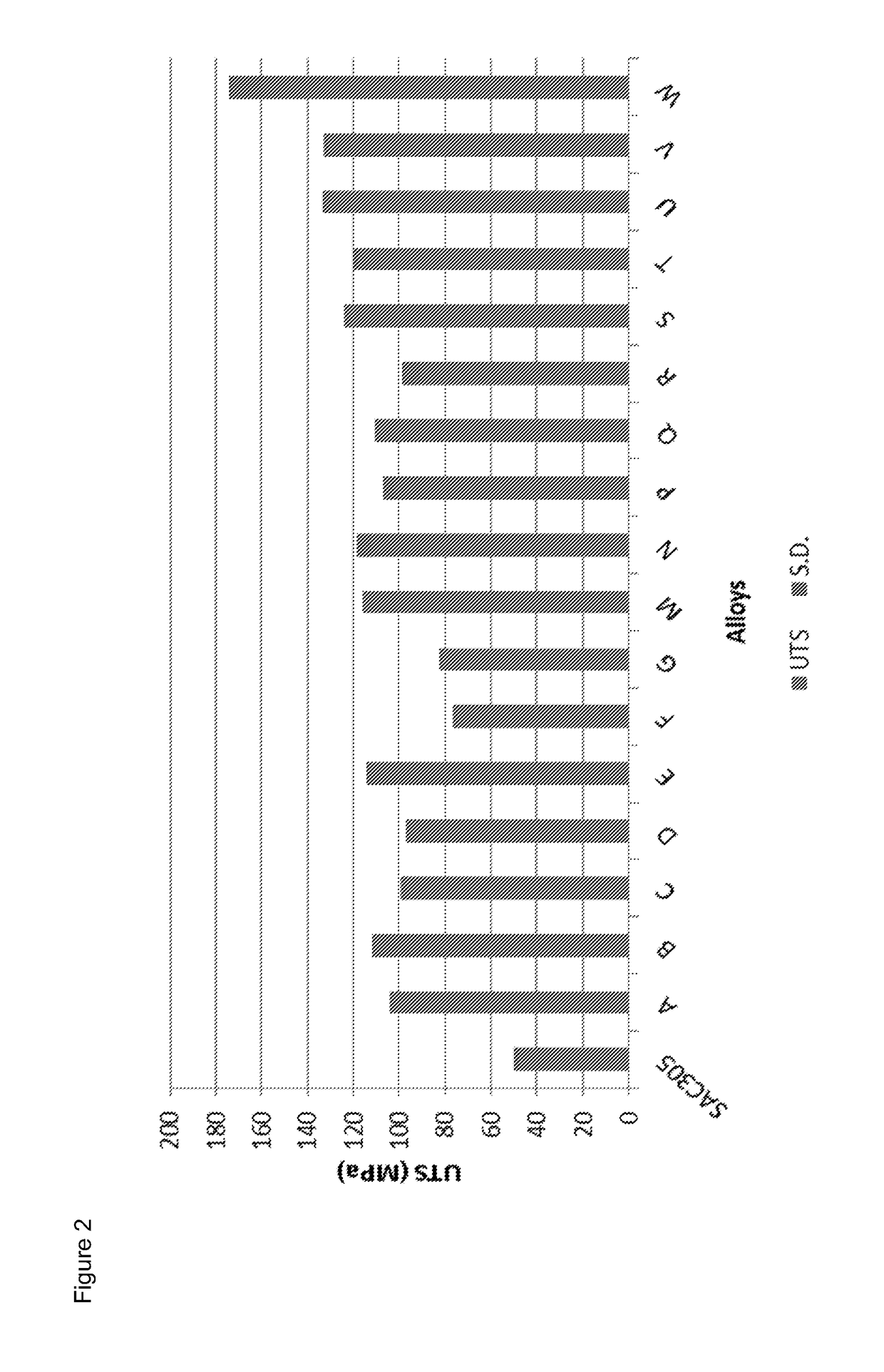

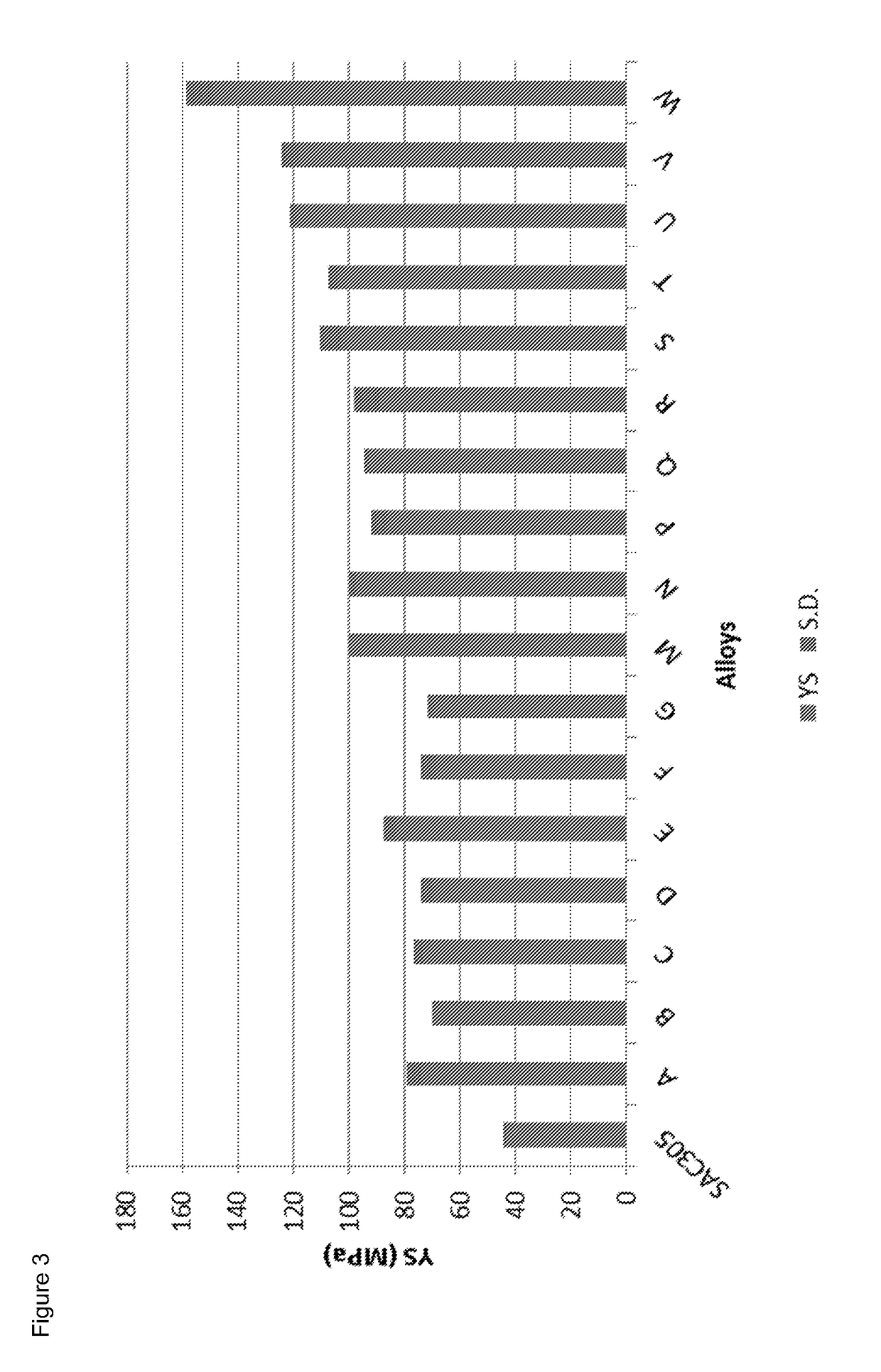

Low Temperature High Reliability Alloy for Solder Hierarchy

ActiveUS20170197281A1Improve high temperature reliabilityLow liquidus temperatureSemiconductor/solid-state device detailsSolid-state devicesIndiumCopper

A lead-free, antimony-free solder alloy_suitable for use in electronic soldering applications. The solder alloy comprises (a) from 1 to 4 wt. % silver; (b) from 0.5 to 6 wt. % bismuth; (c) from 3.55 to 15 wt. % indium, (d) 3 wt. % or less of copper; (e) one or more optional elements and the balance tin, together with any unavoidable impurities.

Owner:FRY S METALS INC

Alkali-free silicate glass and preparation method and application thereof

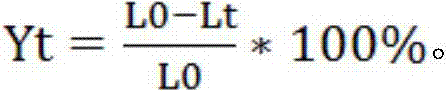

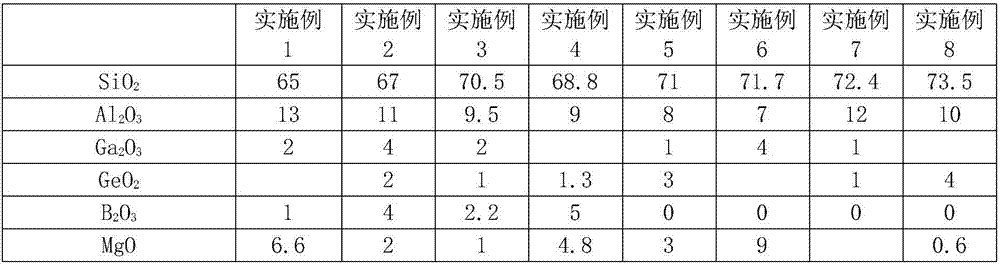

ActiveCN107382052AHelps to reduce weightHigh expansion coefficientGlass shaping apparatusGlass productionAlkali freeSilicate glass

The invention relates to the field of glass and particularly relates to alkali-free silicate glass and a preparation method and application thereof. The alkali-free silicate glass comprises, by mole, 65-75 mol% of SiO2, 11-17 mol% of Al2O3, Ga2O3 and GeO2, 0-8 mol% of B2O3, 0-15 mol% of MgO, 2-10 mol% of CaO, 0.5-14 mol% of SrO and BaO, 0-10 mol% of TiO2, 0.01-2 mol% of Ta2O5 and 0.01-0.5 mol% of Tl2O3. The alkali-free silicate glass has high thermal stability and dimensional stability, a high strain point, a high specific modulus, a low melting temperature, a low liquidus temperature and low density and is suitable for large-scale industrial production.

Owner:ZHENGZHOU UNIV

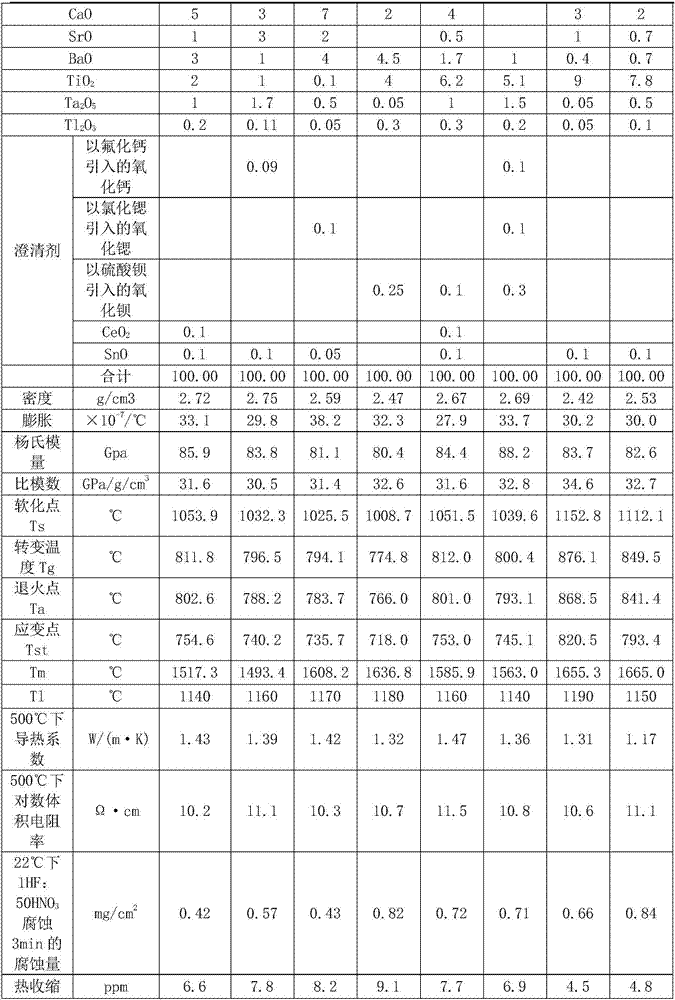

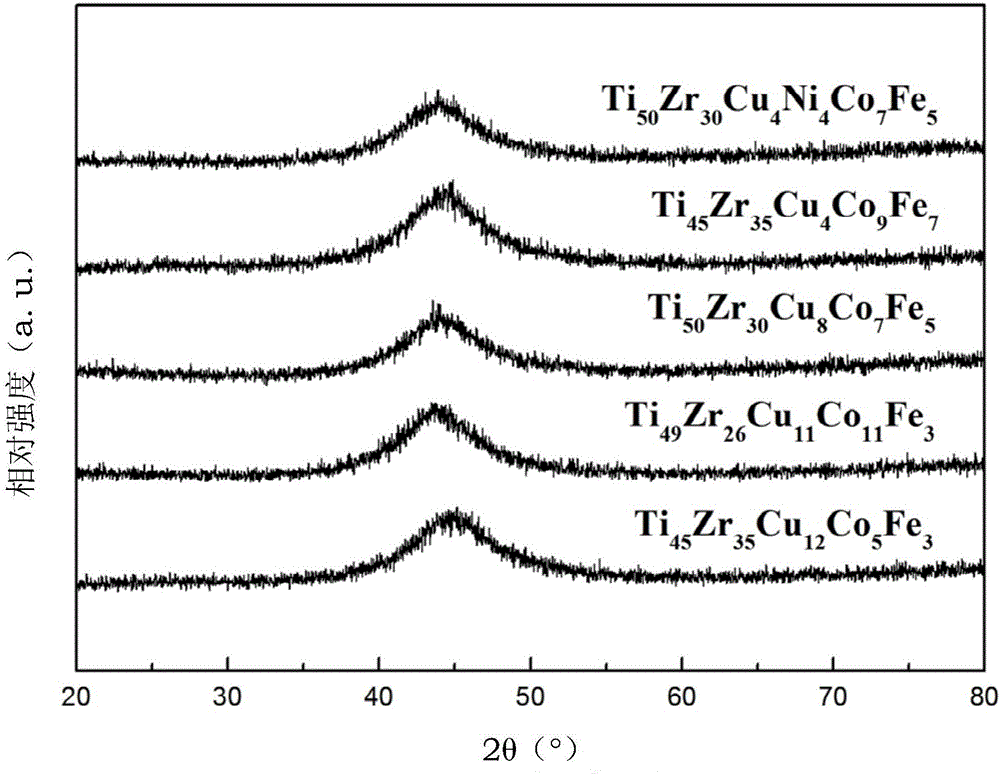

Ni-free low-Cu Ti-Zr-Cu-Co-Fe alloy brazing filler metal and preparation method thereof

ActiveCN106736037AAvoid generatingLow Cu contentWelding/cutting media/materialsSoldering mediaTitaniumNi element

The invention discloses Ni-free low-Cu Ti-Zr-Cu-Co-Fe alloy brazing filler metal and a preparation method of the Ni-free low-Cu Ti-Zr-Cu-Co-Fe alloy brazing filler metal. The brazing filler metal comprises 2-14wt% of Cu, 3-13wt% of Co, 1-9wt% of Fe and 35-50wt% of Zr and the balance Ti. The amorphous or amorphous / nanocrystalline thin-belt-shaped alloy brazing filler metal with the thickness being 20-60 micrometers is obtained through a melt rotary quenching method. Compared with existing titanium-based brazing filler metal or titanium and zirconium-shaped brazing filler metal, the brazing filler metal contains no Ni element, so that production of a fragile Ti-Ni intermetallic compound in a brazed joint is completely eradicated, the Cu content is not higher than 14wt%, the melting point is low, and the Ni-free low-Cu Ti-Zr-Cu-Co-Fe alloy brazing filler metal has the advantages that a brazed joint is good in performance, high in reliability and the like, and is applicable to welding of titanium alloy and titanium aluminide intermetallic compounds, steel, ceramic and other special materials.

Owner:BEIHANG UNIV

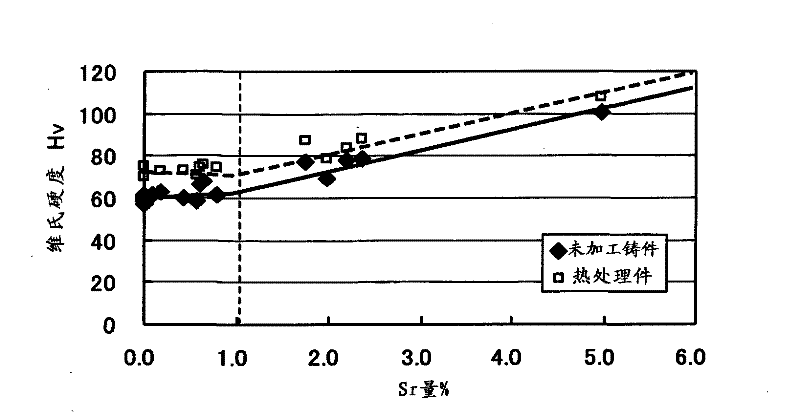

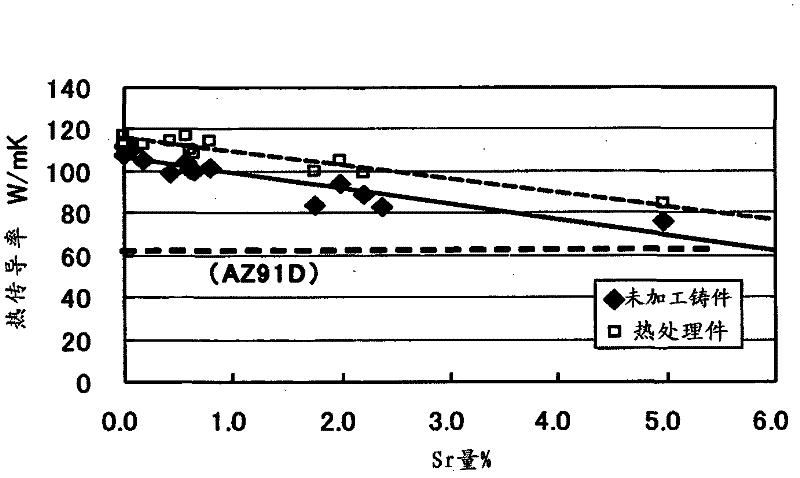

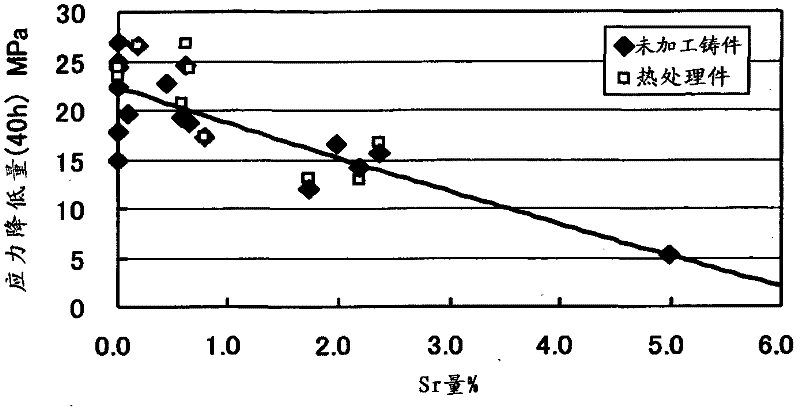

Magnesium alloy and magnesium alloy casting

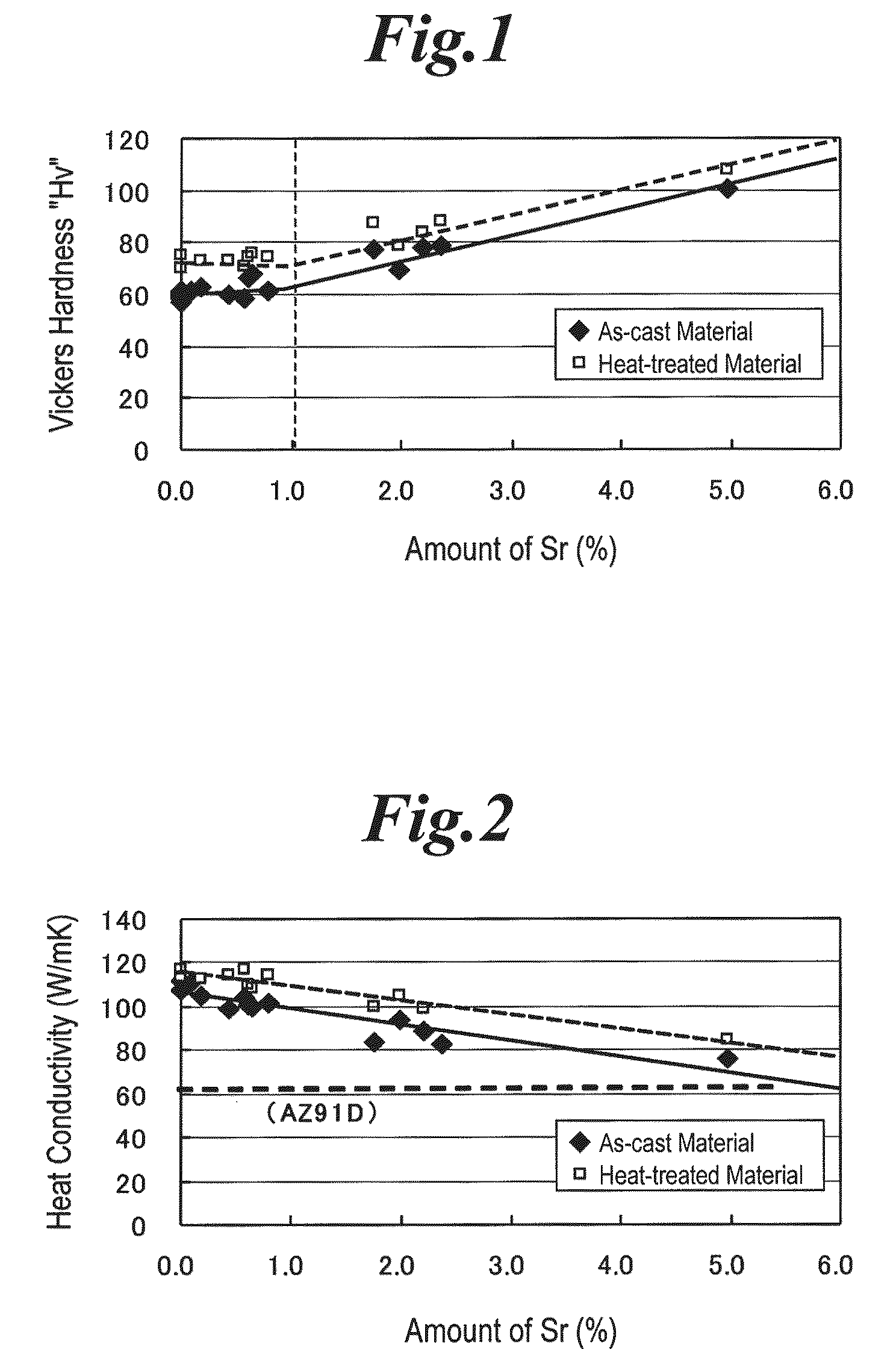

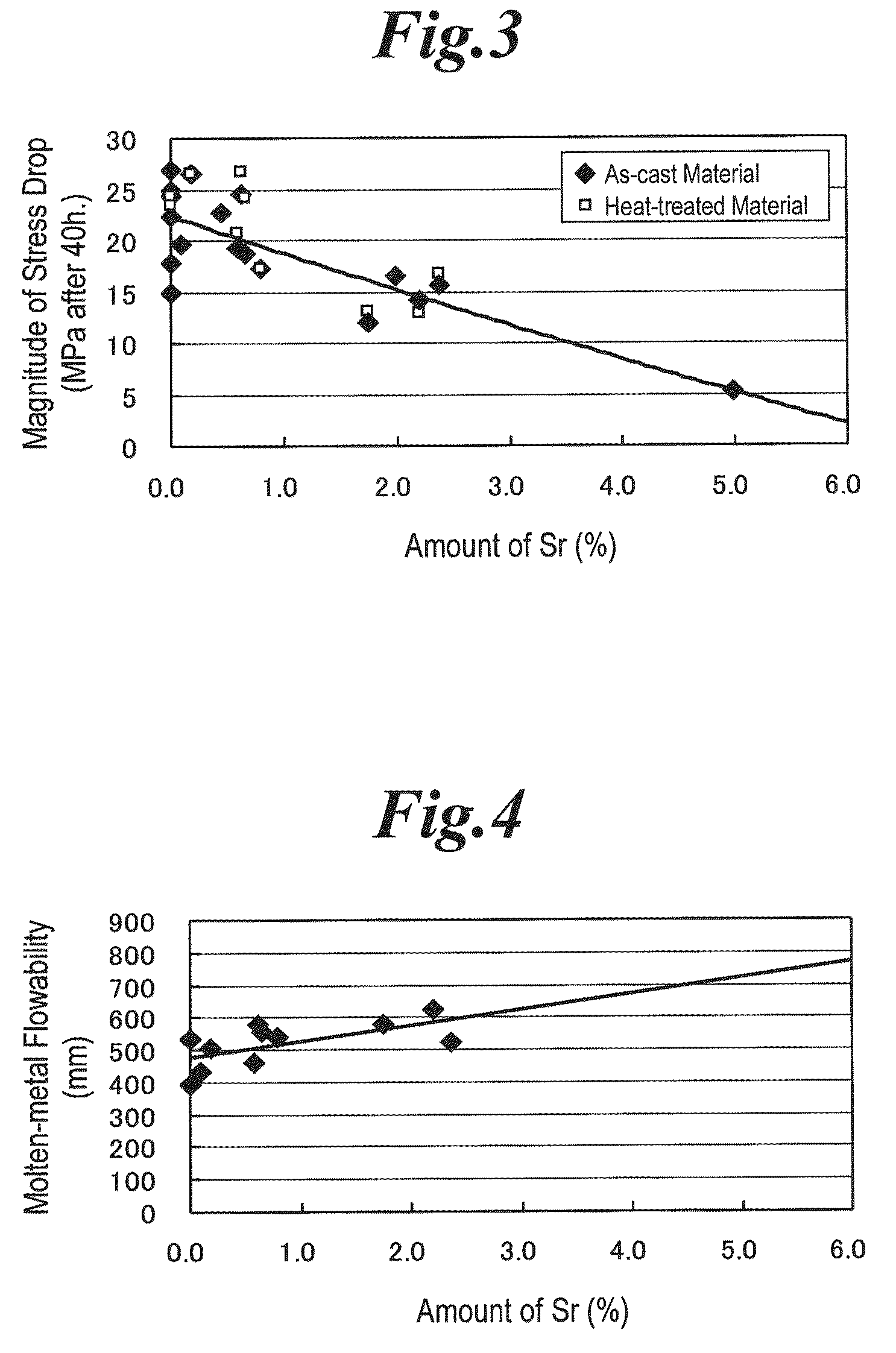

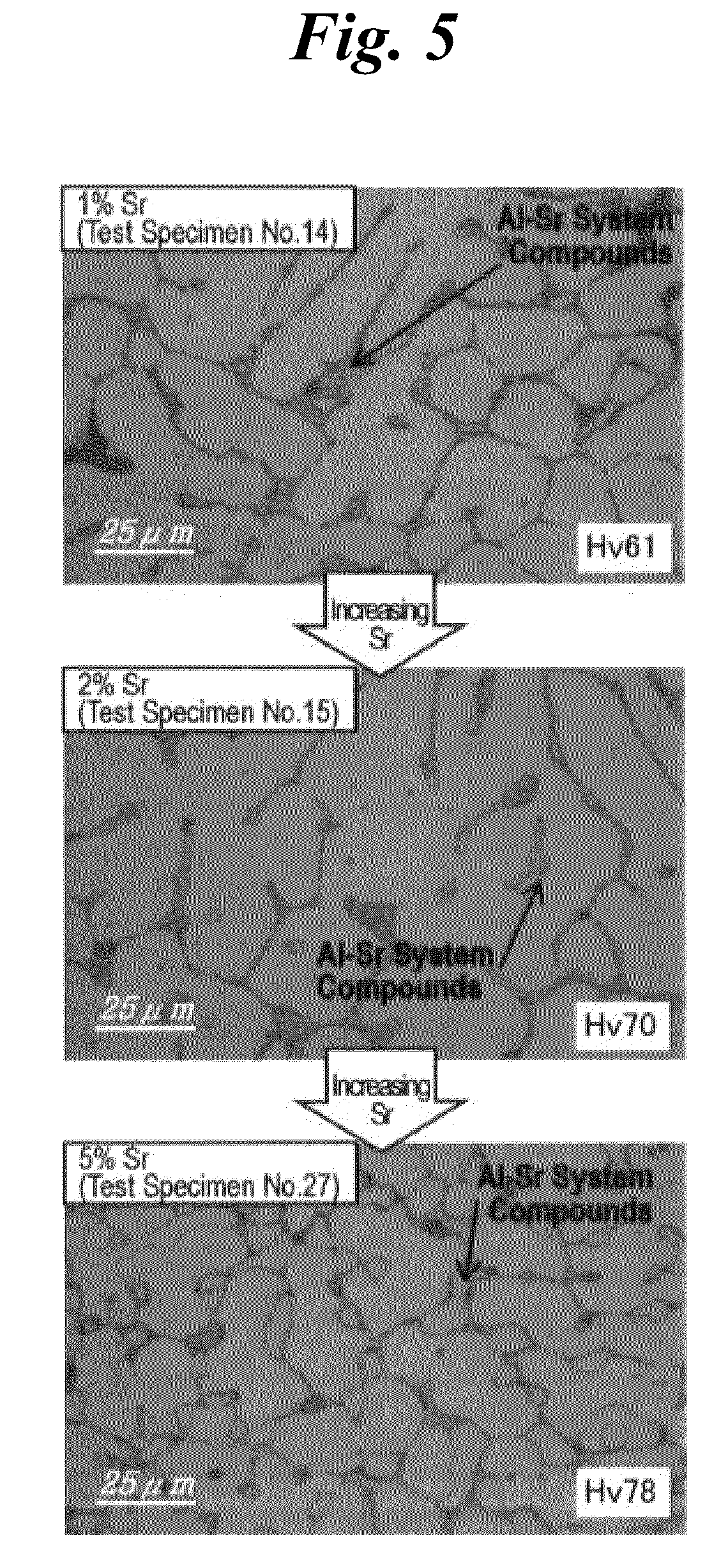

InactiveCN102197153AGood high temperature characteristicsGood castabilityImpurityThermal conductivity

The Mg alloy comprises 2-6% of Al, Ca at a composition ratio (Ca / Al) of 0.5-1.5, 0.1-0.7% of Mn, 1-6% of Sr, and the remainder Mg and inevitable impurities and / or modified elements, when the total is 100 wt%. With this, an Mg alloy with excellent normal-temperature characteristics as well as creep resistance and high-temperature characteristics, such as thermal conductivity, was obtained.

Owner:TOYOTA IND CORP

Lead-free solder alloys

InactiveUS20030021719A1High bonding strengthAvoid heat damageWelding/cutting media/materialsSoldering mediaMelting temperatureMaterials science

Owner:SENJU METAL IND CO LTD

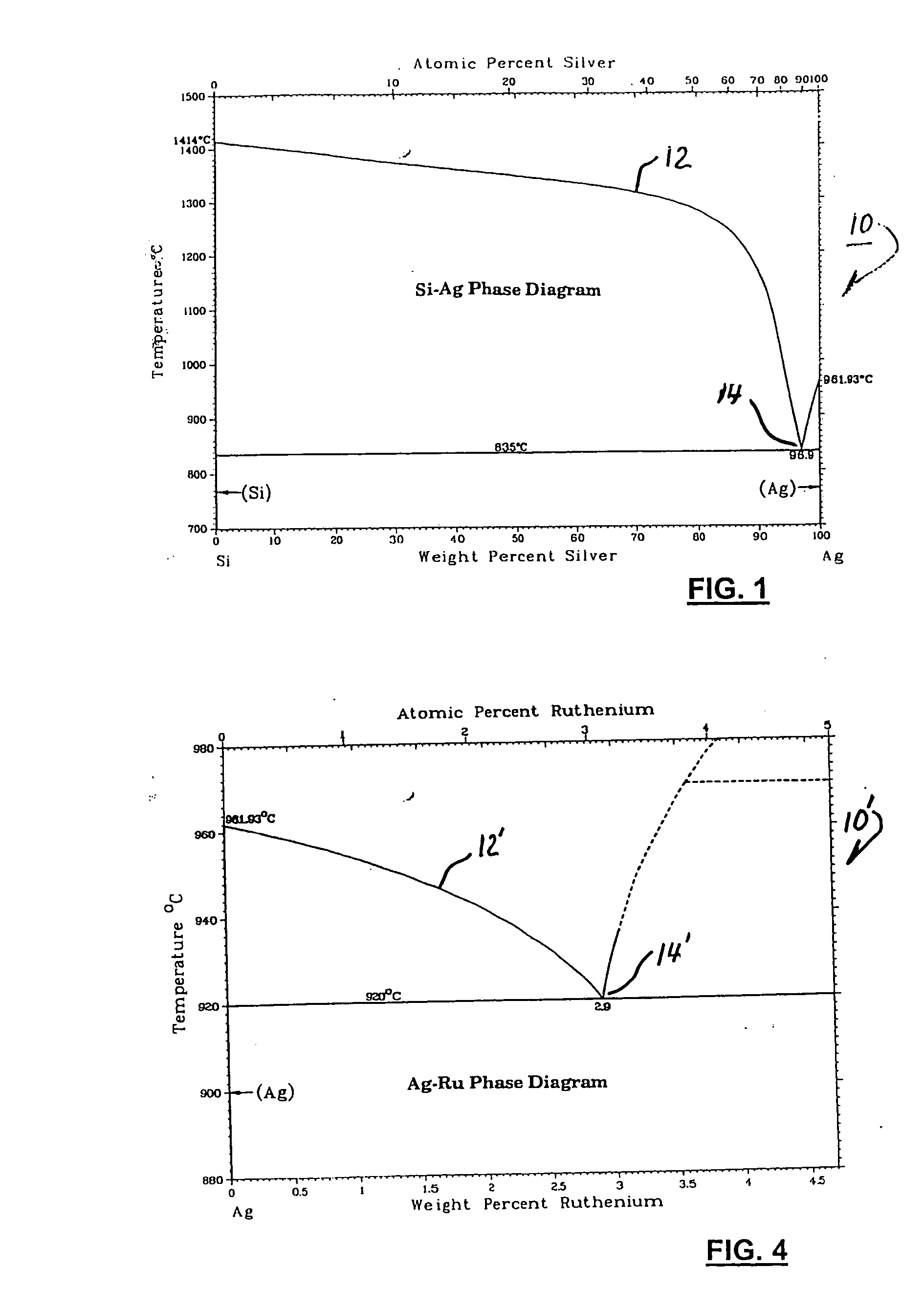

Low melting temperature silver braze alloy

InactiveUS20060045791A1Low liquidus temperatureWelding/cutting media/materialsSoldering mediaSilicon alloyBraze alloy

A brazing alloy comprising elemental silver alloyed with elemental silicon in a silver / silicon ratio between about 95 / 5 and 99 / 1, preferably about 97 / 3. Small amounts of silicon alloyed with silver depress the alloy liquidus curve significantly, the liquidus temperature of a silver and silicon eutectic alloy being about 837° C. Brazing alloys in accordance with the invention are useful in bonding ceramics to ceramics, ceramics to metals, and metals to metals. Copper, vanadium, or other oxygen-reactive surface bonding elements may also be included. Silver / silicon alloys are useful in applications such as assembly of components of solid oxide fuel cells. A variety of silver / silicon alloy brazes can be used within the same fuel cell so that subsequent brazing can be performed without reliquifying a previous braze. A brazing alloy comprising elemental silver and ruthenium in a silver / ruthenium ratio between 97 / 3 and 99 / 1 is also included.

Owner:DELPHI TECH INC

Magnesium alloy casting and preparation method thereof

The invention discloses a magnesium alloy casting. The magnesium alloy casting is characterized by being composed of, by weight, 2.6%-4.2% of Si, 0.85%-1.5% of Cu, 1.3%-6% of Al, 0.2%-0.8% of W, 0.1%-0.5% of Mn, 2%-5% of Y, 0.1%-0.2% of Pr, 0,1%-0.15% of Ti, 0.05%-0.08% of Zr, 0.3%-0.7% of Nd, and the balance Mg and inevitable impurities. According to the magnesium alloy casting, magnesium oxidation can be avoided, the overall hardness, tensile strength, yield strength and elongation of Mg alloy are greatly improved by adding function salt and melt in the magnesium alloy casting.

Owner:NANJING LONGCHAO METAL MFG TECH

High modulus glass fibre composition, and glass fibre and composite material thereof

The present invention provides a high-modulus glass fiber composition, a glass fiber and a composite material therefrom. The glass fiber composition comprises the following components expressed as percentage by weight: 55-64% SiO2, 13-24% Al2O3, 0.1-6% Y2O3, 3.4-10.9% CaO, 8-14% MgO, lower than 22% CaO+MgO+SrO, lower than 2% Li2O+Na2O+K2O, lower than 2% TiO2, lower than 1.5% Fe2O3, 0-1.2% La2O3, wherein the range of the weight percentage ratio C1=(Li2O+Na2O+K2O) / (Y2O3+La2O3) is greater than 0.26. Said composition can significantly increase the glass elastic modulus, effectively inhibit the crystallization tendency of glass, decrease the liquidus temperature, secure a desirable temperature range (ΔT) for fiber formation and enhance the fining of molten glass, thus making it particularly suitable for production of high-modulus glass fiber with refractory-lined furnaces.

Owner:JUSHI GRP CO

High-modulus glass fiber composition, glass fiber and composite material therefrom

The present invention provides a high-modulus glass fiber composition, a glass fiber and a composite material therefrom. The glass fiber composition comprises the following components expressed as percentage by weight: 55-64% SiO2, 13-24% Al2O3, 0.1-6% Y2O3, 3.4-10.9% CaO, 8-14% MgO, lower than 22% CaO+MgO+SrO, lower than 2% Li2O+Na2O+K2O, lower than 2% TiO2, lower than 1.5% Fe2O3, 0-1.2% La2O3, wherein the range of the weight percentage ratio C1=(Li2O+Na2O+K2O) / (Y2O3+La2O3) is greater than 0.26. Said composition can significantly increase the glass elastic modulus, effectively inhibit the crystallization tendency of glass, decrease the liquidus temperature, secure a desirable temperature range (ΔT) for fiber formation and enhance the fining of molten glass, thus making it particularly suitable for production of high-modulus glass fiber with refractory-lined furnaces.

Owner:JUSHI GRP CO

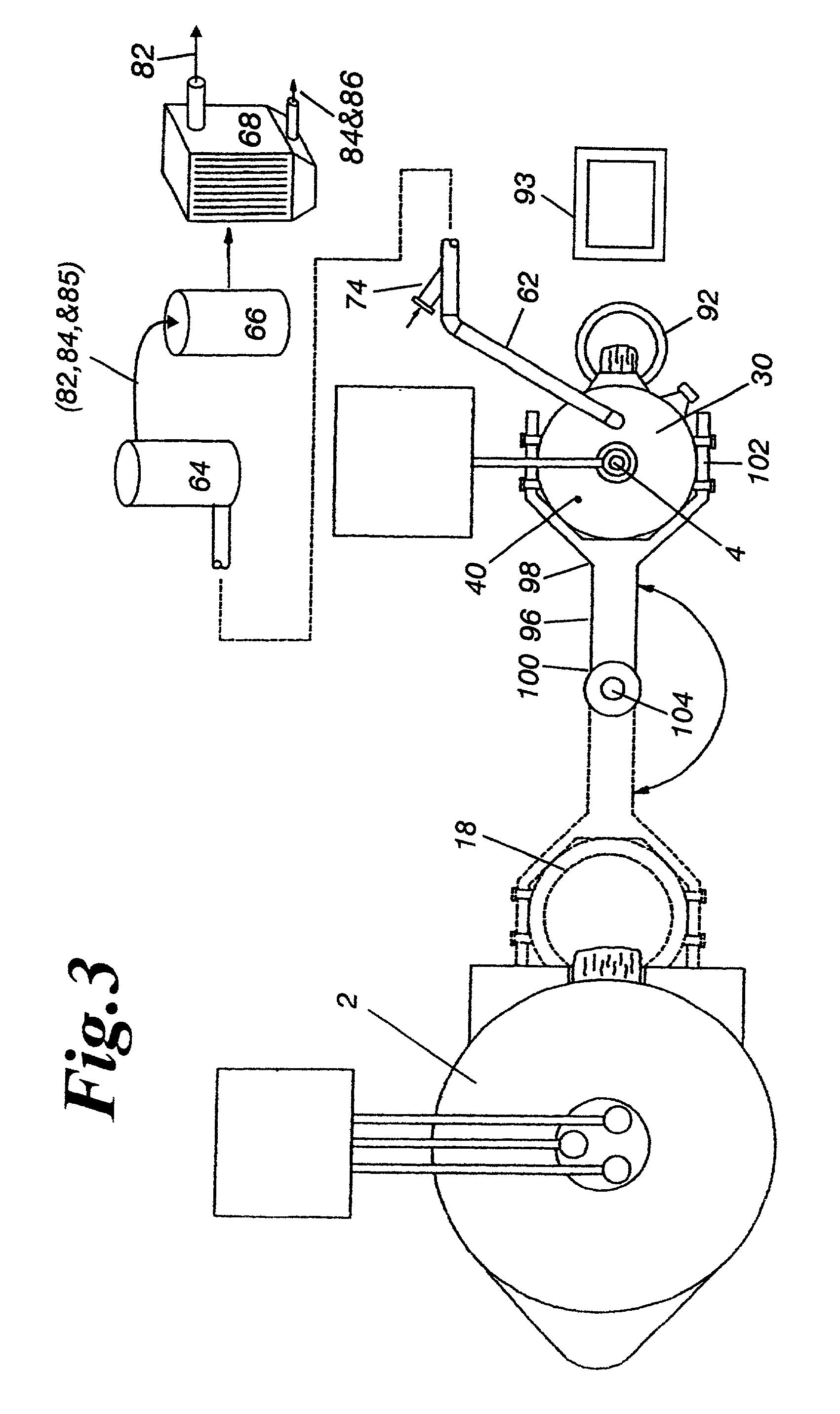

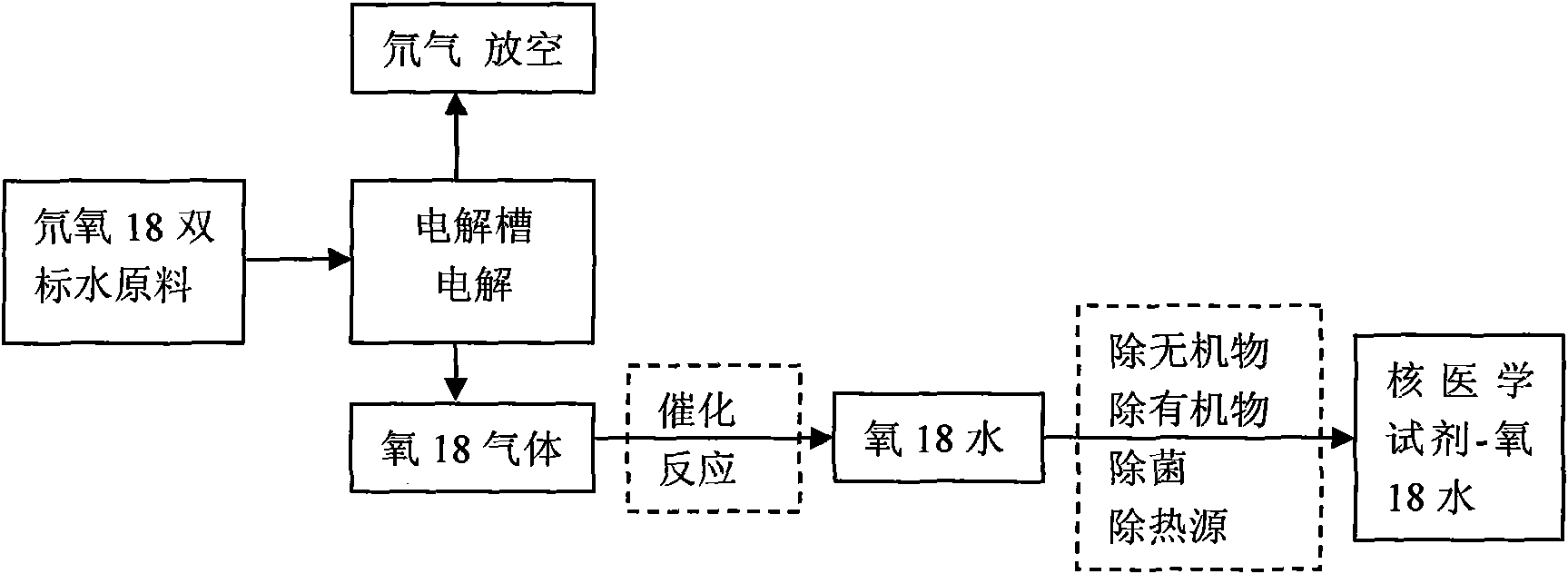

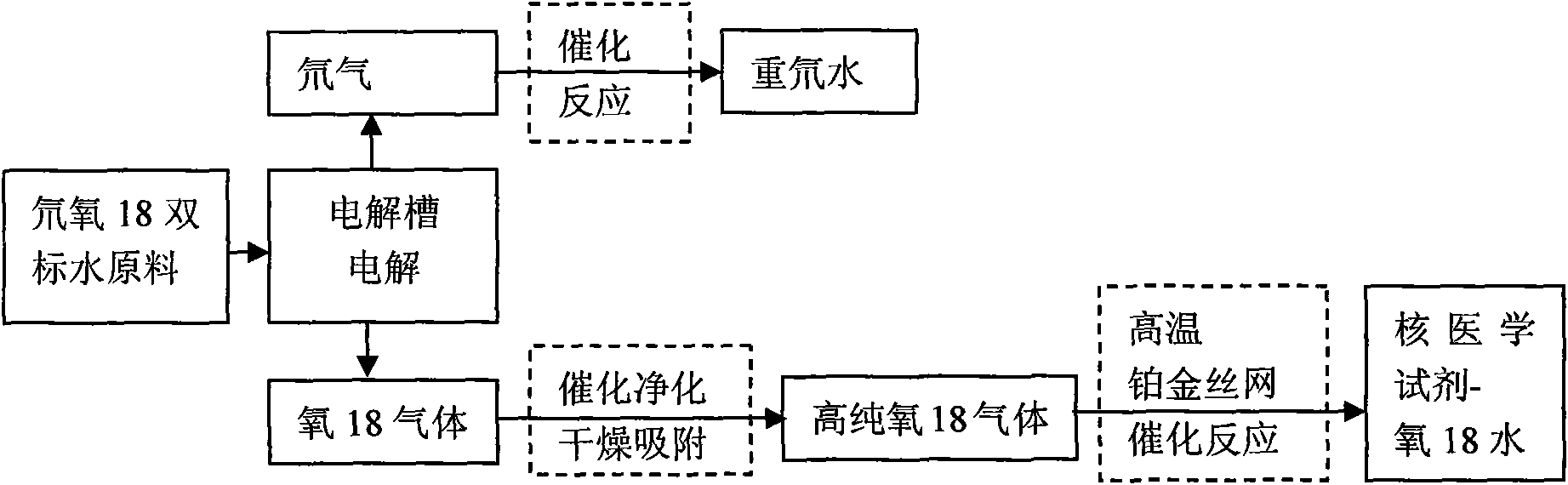

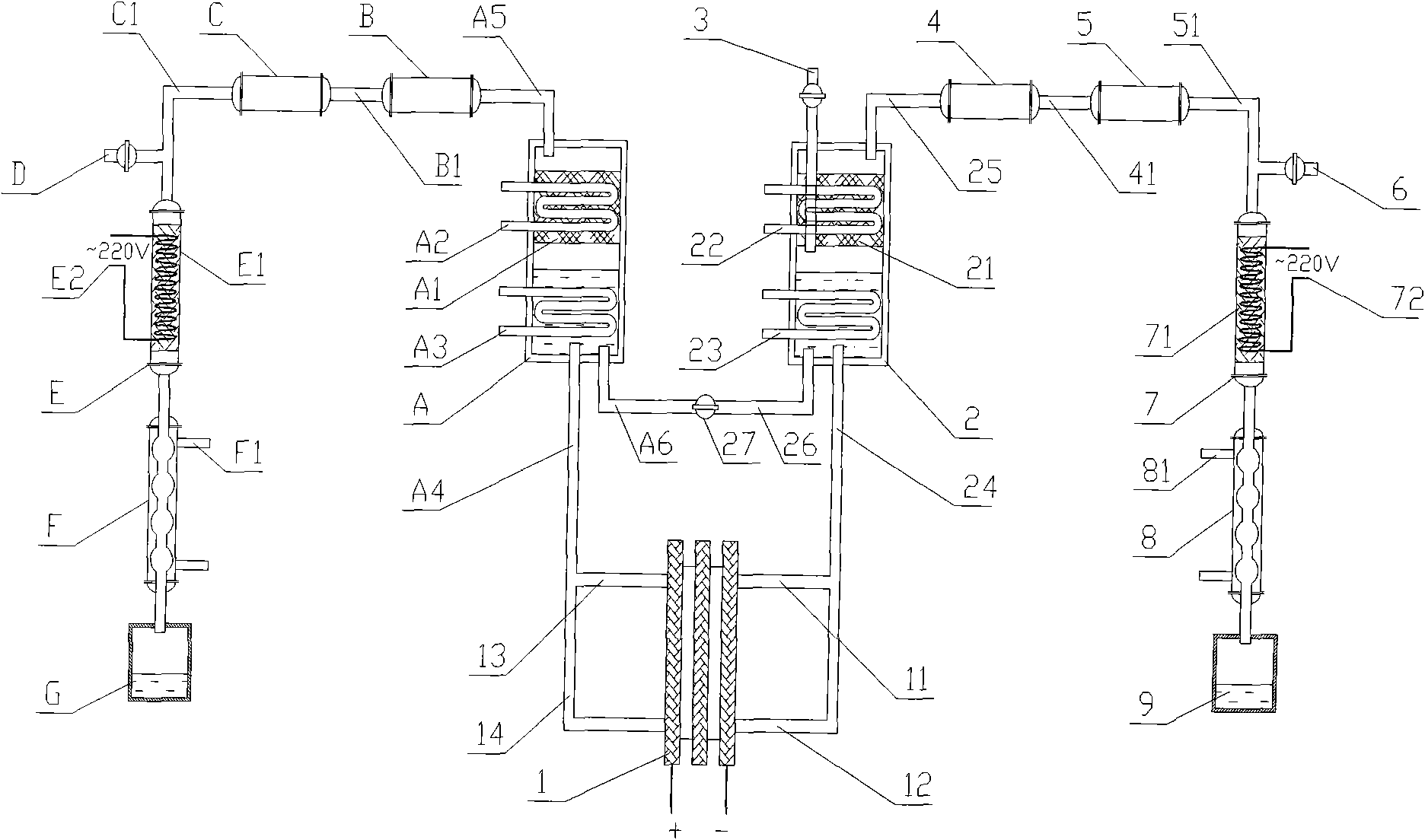

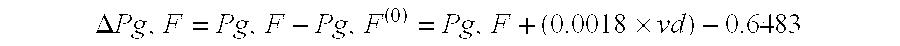

Method for preparing nuclear medicine diagnostic reagent oxygen-18 water and device thereof

ActiveCN101575086AImprove gas purityReduce running lossElectrolysis componentsWaterProduct gasRadiochemistry

The invention relates to a method for preparing nuclear medicine diagnostic reagent oxygen-18 water and a device thereof. The method comprises the steps of: utilizing an oxygen isotope water industrial rectifying separation device to obtain deuterium oxygen 18 doubly-labelled water as material; carrying out steps of electrolysis, purification and filtering to obtain high-purity deuterium and high-purity oxygen-18 gas; adopting a high-temperature platinum mesh to carry out catalyzing so as to lead the high-purity deuterium to react with the high-purity oxygen-18 gas at high temperature to generate deuterium water; and adopting the high-temperature platinum mesh to carry out catalyzing to lead the high-purity oxygen-18 gas to directly react with high-purity hydrogen to obtain the highly-purified oxygen-18 water adopted as the diagnostic reagent of nuclear medicine. Compared with the prior art, the invention which not only can make full use of the deuterium oxygen 18 doubly-labelled water to prepare the nuclear medicine diagnostic reagent oxygen-18 water and utilize by-product deuterium to prepare deuterium water but also can reduce process steps, enhance quality and yielding of oxygen-18 water of nuclear medicine and reduce product cost really has simple process and better effect.

Owner:SHANGHAI RES INST OF CHEM IND +1

Optical glass, preform for precision press molding, optical element, and method for manufacturing optical element

ActiveUS8609560B2Stable productionLittle tendencyGlass reforming apparatusGlass severing apparatusRefractive indexOptical glass

Owner:HOYA CORP

Solder alloy, solder powder, solder paste, and a solder joint using these

InactiveUS20210245305A1Easily brokenLow tensile strengthWelding/cutting media/materialsPrinted circuitsSolder pasteAlloy composition

A solder alloy having an alloy composition including at least one of As: 25 to 300 mass ppm, Pb: more than 0 mass ppm and 5100 mass ppm or less, and Sb: more than 0 mass ppm and 3000 mass ppm or less, and moreover Bi: more than 0 mass ppm and 10000 mass ppm or less, as well as a balance including Sn, wherein expression (1) and expression (2) below are satisfied:275≤2As+Sb+Bi+Pb (1)0.01≤(2As+Sb) / (Bi+Pb)≤10.00 (2)where in the expression (1) and the expression (2), As, Sb, Bi, and Pb each represent a content (mass ppm) in the alloy composition.

Owner:SENJU METAL IND CO LTD

Electrolysis tank used for aluminum electrolysis and electrolysis process using the electrolyzer

InactiveUS20150122664A1Improve conductivityReduce overvoltageIsotope separationOxygenMaterials science

An electrolytic cell for aluminum electrolysis includes a cell body, in which an anode and a cathode are arranged inside the cell body, the cell body is filled with an electrolyte, and at least a part of the anode is immersed in the electrolyte; the anode is arranged above the cell body, the cathode is arranged at the bottom of the electrolytic cell and is covered by aluminum liquid, the electrolyte is located between the anode and the cathode and covers the aluminum liquid; and an insulating layer is arranged on the inner sidewall of the cell body for isolating oxygen or the electrolyte from a carbon block. The anode contains Fe and Cu as primary components; and the electrolyte is composed of 30-38 wt % of NaF, 49-60 wt % of AlF3, 1-5 wt % of LiF, 1-6 wt % of KF and 3-6 wt % of Al2O3, and the molar ratio of NaF to AlF3 is 1.0-1.52.

Owner:INNER MONGOLIA UNITED IND

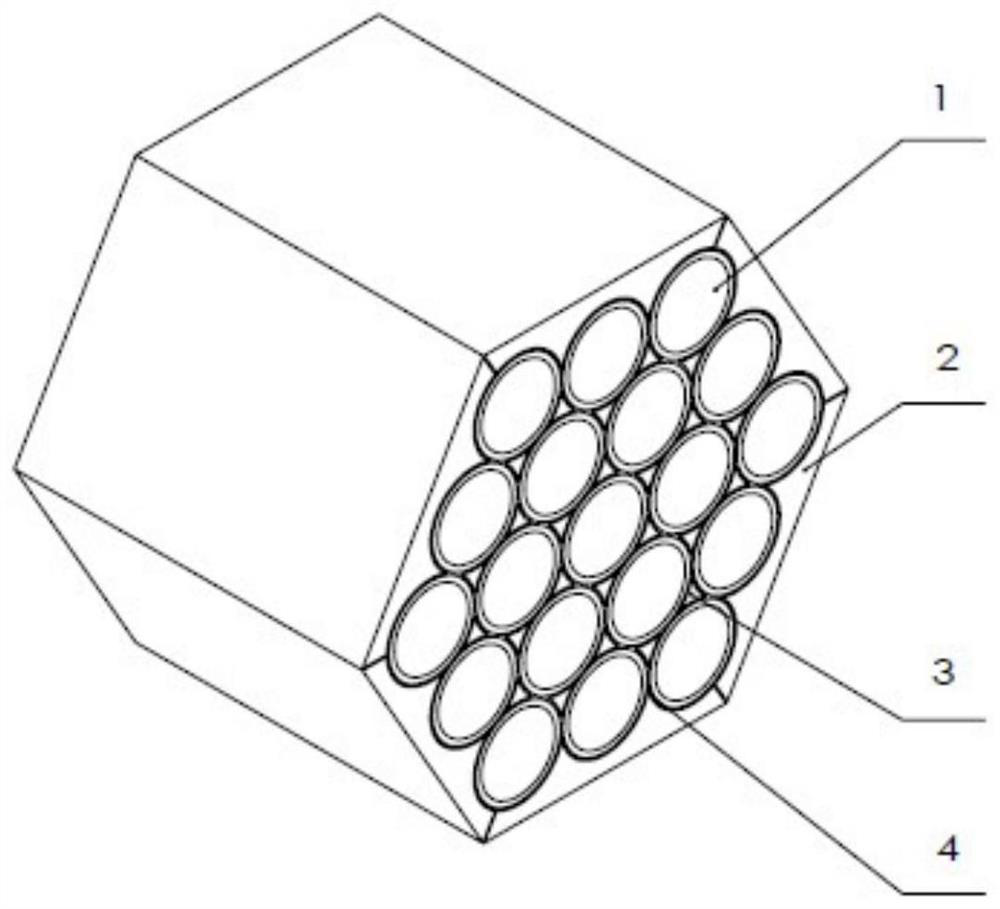

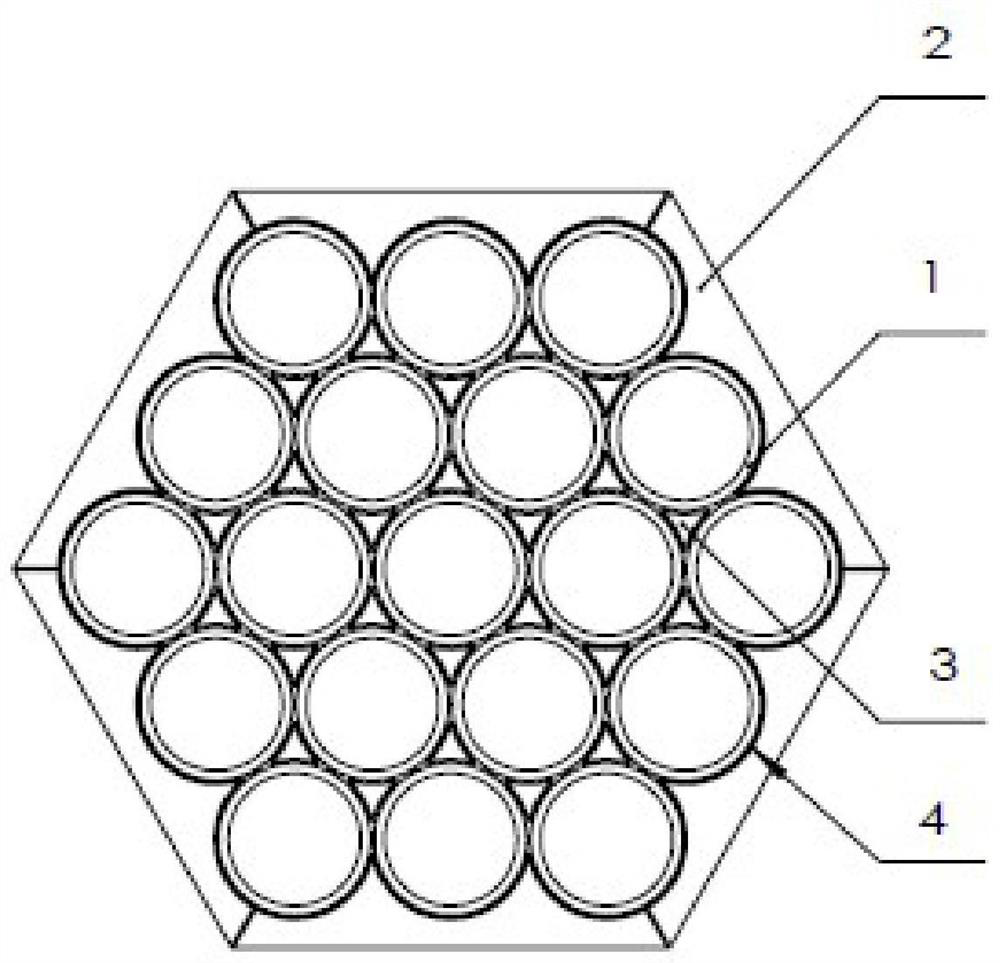

Stainless steel honeycomb type heat exchanger and vacuum brazing method thereof

InactiveCN112775512AImprove structural strengthIncrease profitStationary conduit assembliesHeat exchanger casingsHoneycombHeat conservation

The invention discloses a stainless steel honeycomb type heat exchanger and a vacuum brazing method thereof.The brazing method comprises the steps: firstly, cleaning surfaces of heat exchanger components; secondly, coating the surfaces of all the components with brazing filler metal and then assembling the same by an assembly tool; and then putting the components into a vacuum furnace to be subjected to heat preservation and preheating so as to obtain good welding conditions, so that heat input in the welding process is ensured to be uniform and stable, finally brazing is conducted, and furnace cooling is conducted to the room temperature; the stainless steel honeycomb type heat exchanger is formed by splicing stainless steel profiles, so that the material utilization rate is high, and the cost is saved. The honeycomb type heat exchanger is formed through vacuum brazing fixing with small parts, so that the overall structure is simple. The round pipes and the triangular prisms are positioned and assembled through a tool after the outer frame is welded, vacuum one-time brazing forming is achieved, and the production efficiency is high; and brazing seam tissues are uniform, and the component structural strength is high.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Ni-Cr Based Alloy Brazing Material Containing Trace Amount of V

ActiveUS20200048740A1Grown rapidly in demandLow costVehicle componentsWelding/cutting media/materialsNichromeBraze alloy

Disclosed is a Ni—Cr-based brazing alloy including, on the basis of mass %: 15%<Cr<30%; 3%<P<12%; 0%<Si<8%; 0.01%<C<0.06%; 0%≤Ti+Zr<0.1%; 0.01%<V<0.1%; 0%≤Al<0.01%; 0.005%<O<0.025%; 0.001%<N<0.050%; 0%≤Nb<0.1%; and the balance being Ni and incidental impurities. Inequality (1): 0.2≤0.24V % / C %≤1.0 is satisfied if the alloy contains no Nb, and Inequality (2): 0.2≤(0.24V %+0.13Nb %) / C %≤1.0 is satisfied if the alloy contains Nb. Also disclosed is an inexpensive Ni—Cr-based brazing alloy containing a trace amount of V for use in the production of stainless steel heat exchangers and other steel articles. The alloy has a low liquidus temperature and high corrosion resistance, and achieves high brazing strength.

Owner:SANYO SPECIAL STEEL COMPANY

Optical glass

InactiveCN106467357AHigh resistance to devitrificationLow liquidus temperatureRare earthRefractive index

The invention provides optical glass with high refraction power and low chromatic dispersion. The optical glass comprises, by weight, 1 to 30% of B2O3, 0 to 20% of SiO2, 25 to 55% of La2O3, 5 to 40% of Gd2O3, 0 to 25% of Y2O3, 0 to 10% of Yb2O3, 0 to 10% of Ta2O5, 1 to 30% of Nb2O5, 0 to 10% of TiO2, 0.5 to 20% of ZrO2, 0 to 10% of WO3, 0 to 10% of Al2O3, 0 to 10% of GeO2 and 0 to 10% of Bi2O3. The optical glass does not contain ZnO and has a refractive index of 1.80 to 1.95 and an Abbe number of 33 to 45. The optical glass with excellent transmittance, high refraction power and low chromatic dispersion is obtained by reducing the content of Ta2O5 in the composition of the glass, introducing a proper amount of rare earth oxides with high refraction power and low chromatic dispersion and optimizing the ratio of the components.

Owner:CDGM OPTICAL GLASS

Magnesium alloy and magnesium-alloy cast product

A magnesium alloy according to the present invention comprises: Al in an amount of from 2 to 6%; Ca in an amount making a compositional ratio (i.e., Ca / Al) being from 0.5 to 1.5; Mn in an amount of from 0.1 to 0.7%; strontium (Sr) in an amount of from 1 to 6%; and the balance being magnesium (Mg), and inevitable impurities and / or a modifying element; when the entirety is taken as 100% by mass. By means of this setting, Mg alloys, which are also good in terms of high-temperature characteristics, such as creep resistance and heat conductivity, in addition to ordinary-temperature characteristics, are obtained.

Owner:TOYOTA IND CORP

High modulus glass fibre composition, and glass fibre and composite material thereof

The present invention provides a high-modulus glass fiber composition, a glass fiber and a composite material therefrom. The glass fiber composition comprises the following components expressed as percentage by weight: 55-64% SiO2, 13-24% Al2O3, 0.1-6% Y2O3, 3.4-10.9% CaO, 8-14% MgO, lower than 22% CaO+MgO+SrO, lower than 2% Li2O+Na2O+K2O, lower than 2% TiO2, lower than 1.5% Fe2O3, 0-1.2% La2O3, wherein the range of the weight percentage ratio C1=(Li2O+Na2O+K2O) / (Y2O3+La2O3) is greater than 0.26. Said composition can significantly increase the glass elastic modulus, effectively inhibit the crystallization tendency of glass, decrease the liquidus temperature, secure a desirable temperature range (ΔT) for fiber formation and enhance the fining of molten glass, thus making it particularly suitable for production of high-modulus glass fiber with refractory-lined furnaces.

Owner:JUSHI GRP CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com