Ni-free low-Cu Ti-Zr-Cu-Co-Fe alloy brazing filler metal and preparation method thereof

A technology of alloy solder, ti-zr-cu-co-fe, applied in the direction of metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of low Cu content, reduce the strength of brazing joints, etc., and achieve low Cu content , Improve mechanical properties, avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The target composition is: 37.81 wt% Ti, 43.23 wt% Zr, 8.03 wt% Cu, 6.52 wt% Co and 4.41 wt% Fe. Converted to atomic percent expressed as Ti 50 Zr 30 Cu 8 co 7 Fe 5 .

[0056] Preparation of Ti by Melt Spin Quenching 50 Zr 30 Cu 8 co 7 Fe 5 The steps of alloy solder are:

[0057] Step 1, weigh each element

[0058] According to the target solder composition Ti 50 Zr 30 Cu 8 co 7 Fe 5 Weigh the metal elemental Ti, Zr, Cu, Co and Fe raw materials of corresponding quality for batching;

[0059] Step 2, melting the master alloy

[0060] Ti prepared in step 1 50 Zr 30 Cu 8 co 7 Fe 5 The raw materials are put into the vacuum arc melting furnace; the vacuum is pumped to make the vacuum degree in the furnace reach 8×10 -3 Pa; filled with argon, so that the pressure in the furnace is 0.05MPa; repeated smelting by arc heating for 4 times to ensure that the alloy composition is uniform, then cooled with the furnace, and the master alloy was taken out;

[00...

Embodiment 2

[0096] Target composition (wt%): Ti 33.03%, Zr 48.95%, Cu 3.90%, Co 8.13%, Fe 5.99%, converted to atomic percentage expressed as Ti 45 Zr 35 Cu 4 co 9 Fe 7 (at%).

[0097] Preparation of Ti by Melt Spin Quenching 45 Zr 35 Cu 4 co 9 Fe 7 The steps of alloy solder are:

[0098] Step 1, weigh each element

[0099] According to the target solder composition Ti 45 Zr 35 Cu 4 co 9 Fe 7 Weigh the metal elemental raw materials of corresponding quality for batching;

[0100] Step 2, melting the master alloy

[0101] Put the raw materials weighed in step 1 into the vacuum arc melting furnace; pump the vacuum to make the vacuum degree in the furnace reach 5×10 - 3 Pa; filled with argon, so that the pressure in the furnace is 0.05MPa; repeated smelting by arc heating for 5 times to ensure that the alloy composition is uniform, then cooled with the furnace, and the master alloy was taken out;

[0102] Vacuum arc melting parameters: electrode diameter 6mm, arc ignition vo...

Embodiment 2

[0108] Make the performance analysis of embodiment 2 alloy solder:

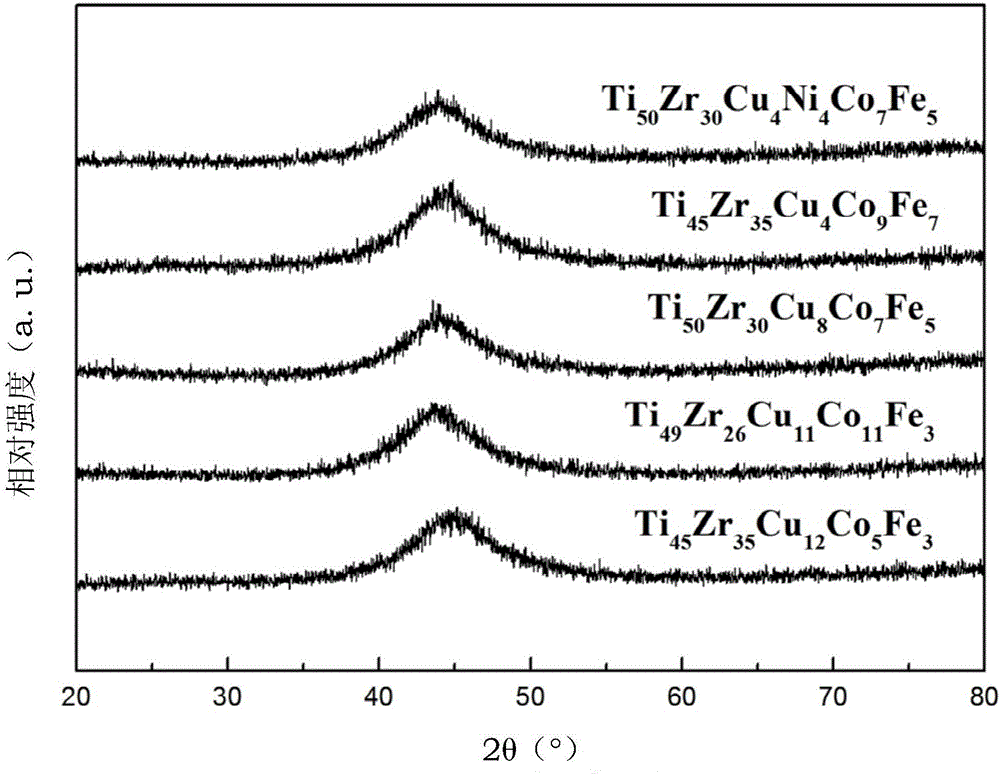

[0109] Depend on figure 1 From the XRD pattern shown, it can be seen that the thin strip of Example 2 prepared by the above method shows a single diffuse scattering peak through X-ray diffraction detection, and there is no obvious crystal diffraction peak, and it can be preliminarily determined to have an amorphous structure.

[0110] image 3 The displayed DSC curve represents the thermal performance of the amorphous alloy thin strip tested by a differential calorimetry scanner. It can be known that the solder liquidus temperature in Example 2 is 899°C.

[0111] The performance test of the brazed joint of embodiment 2:

[0112]The Ni-free alloy strip solder of embodiment 2 is brazed Ti in vacuum brazing furnace 3 Al (Ti-14Al-27Nbwt%), make a 30mm×10mm×2mm sample for vacuum brazing. The sample is polished with sandpaper from 60# to 2000#, and then ultrasonically cleaned with acetone and alcohol for brazin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com