Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1947 results about "Vacuum arc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vacuum arc can arise when the surfaces of metal electrodes in contact with a good vacuum begin to emit electrons either through heating (thermionic emission) or in an electric field that is sufficient to cause field electron emission. Once initiated, a vacuum arc can persist, since the freed particles gain kinetic energy from the electric field, heating the metal surfaces through high-speed particle collisions. This process can create an incandescent cathode spot, which frees more particles, thereby sustaining the arc. At sufficiently high currents an incandescent anode spot may also be formed.

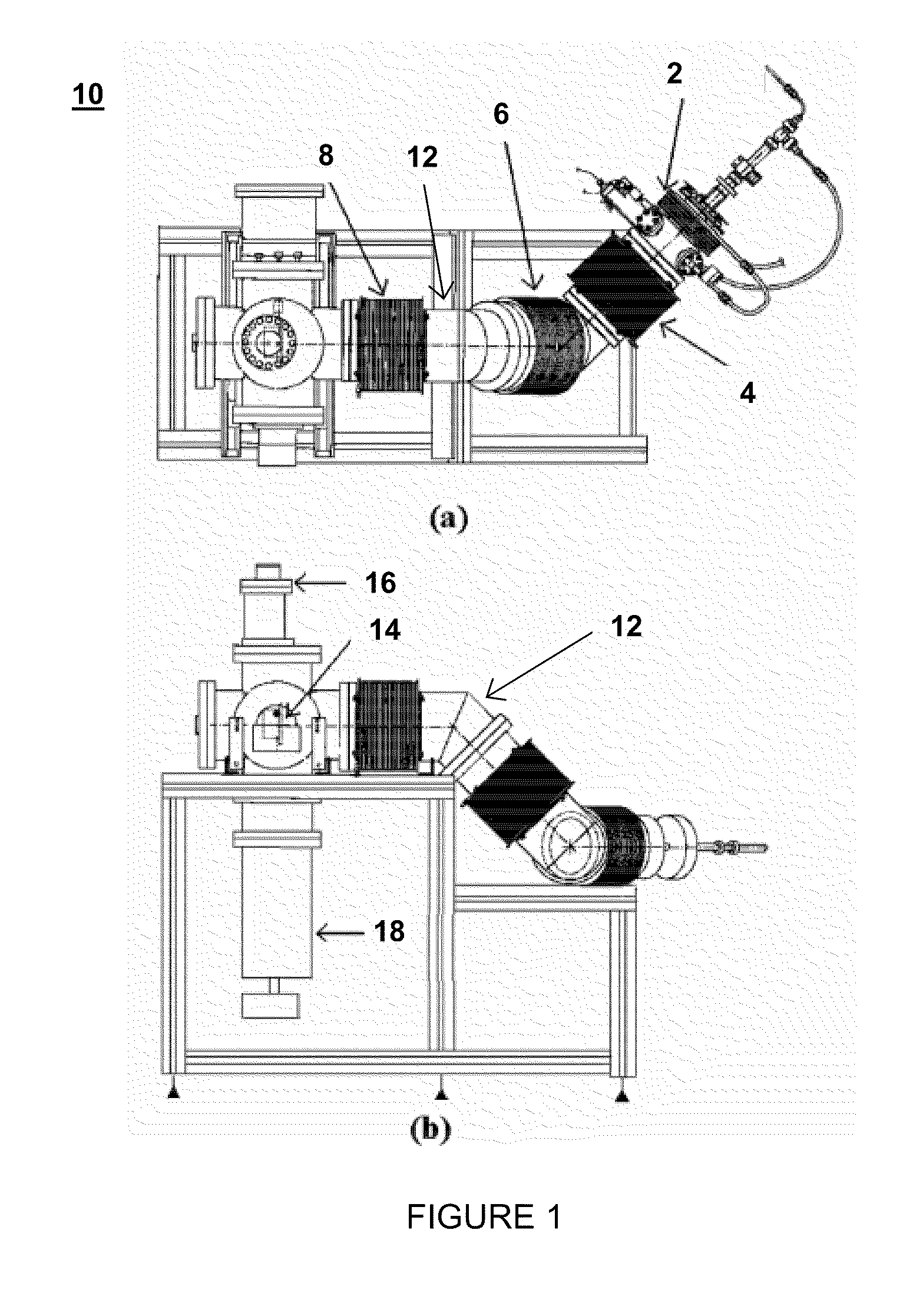

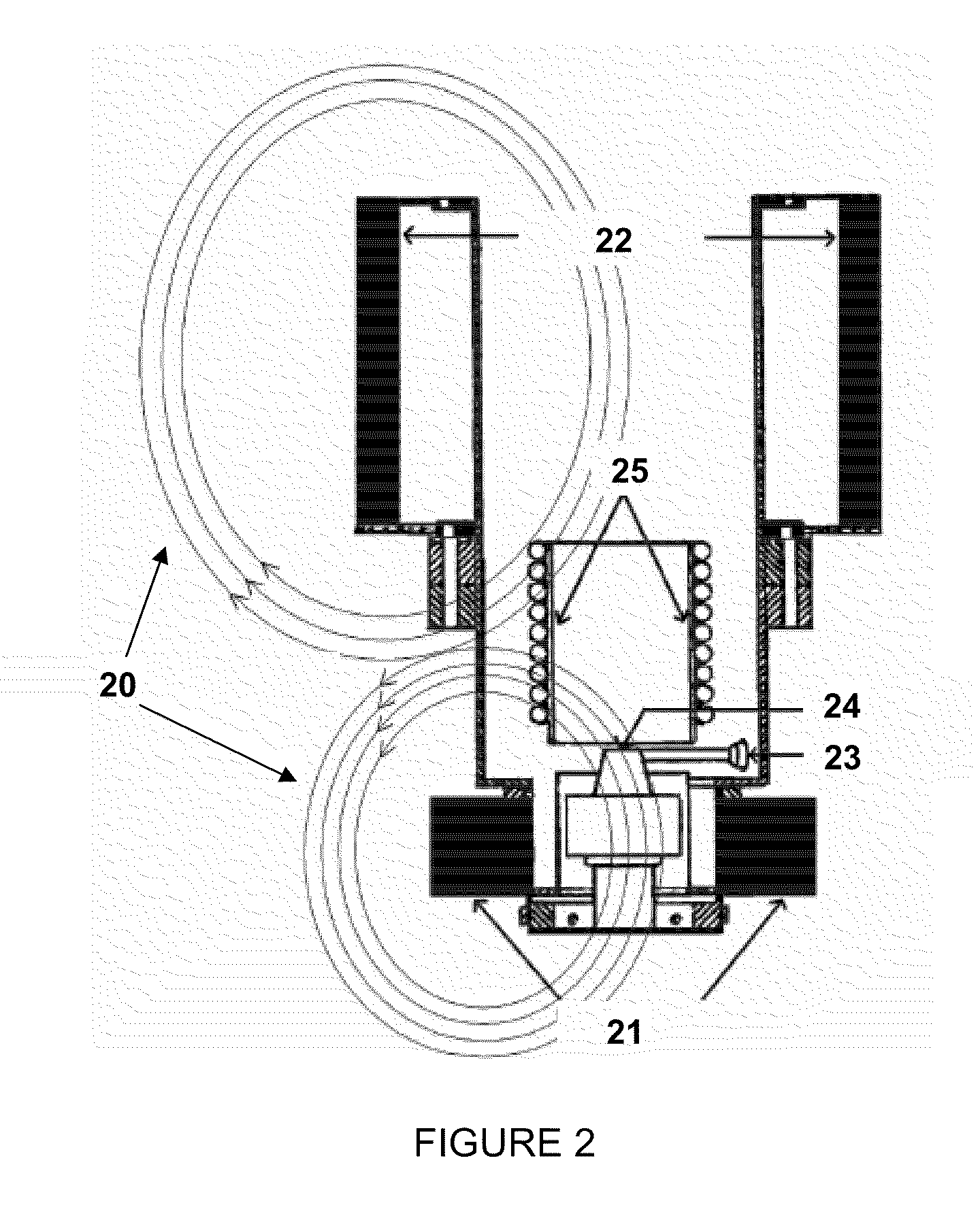

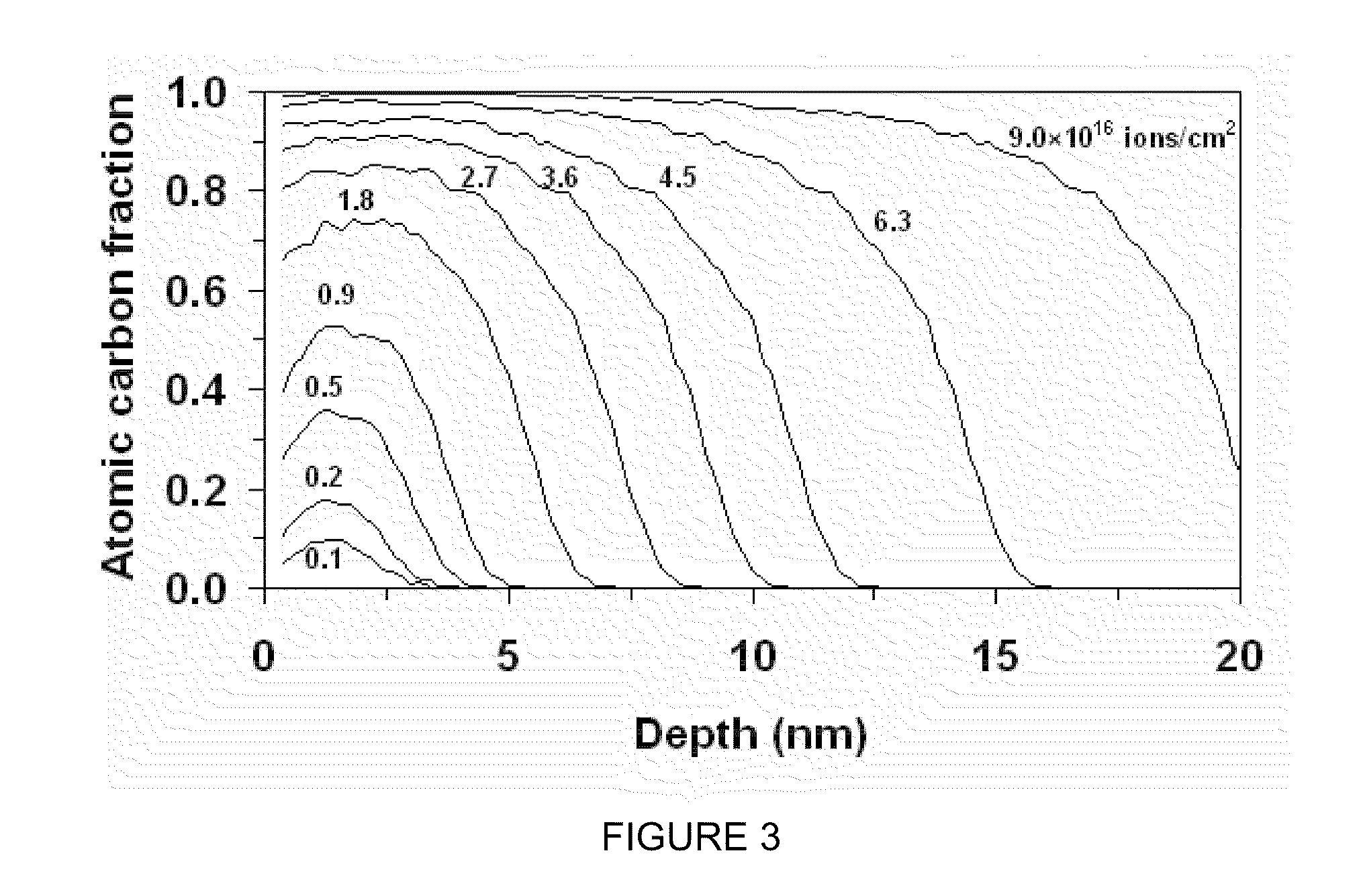

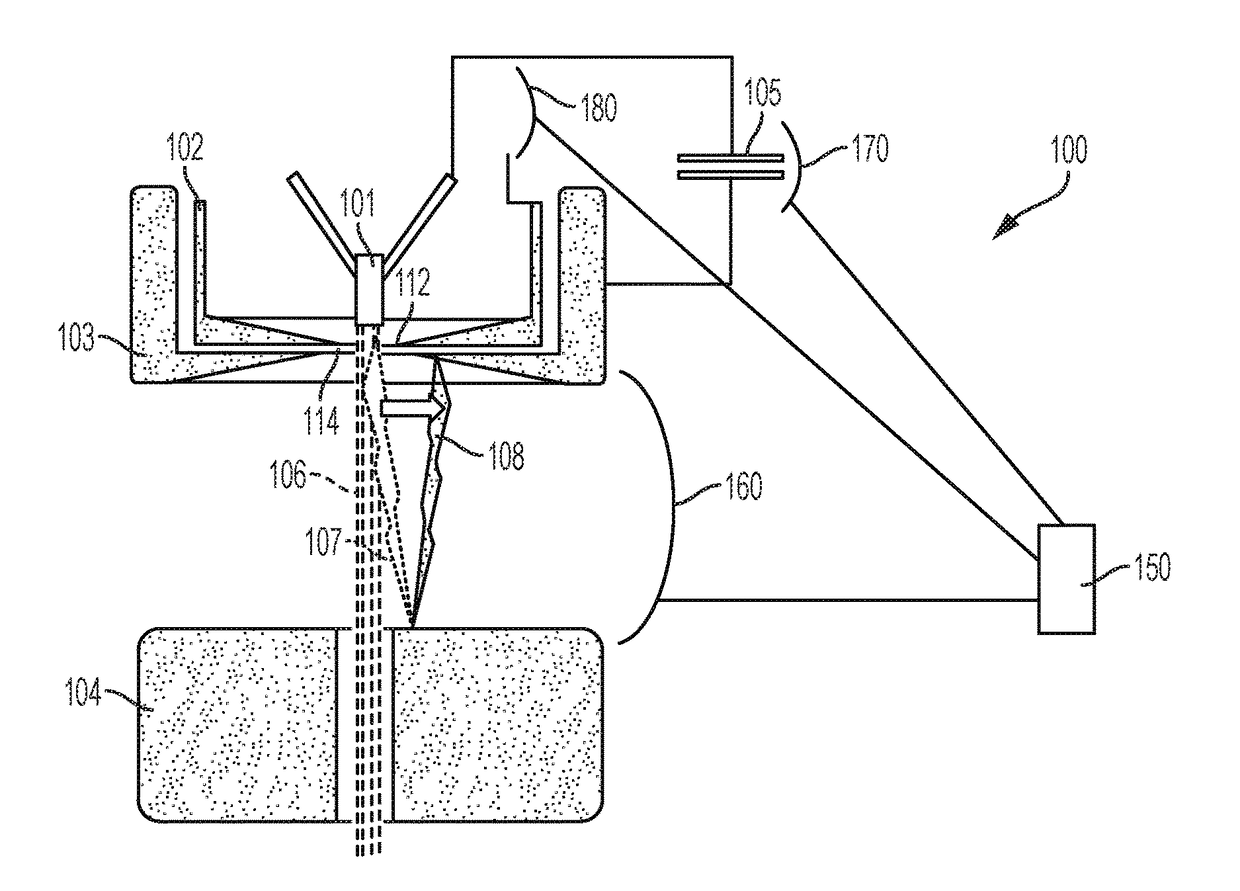

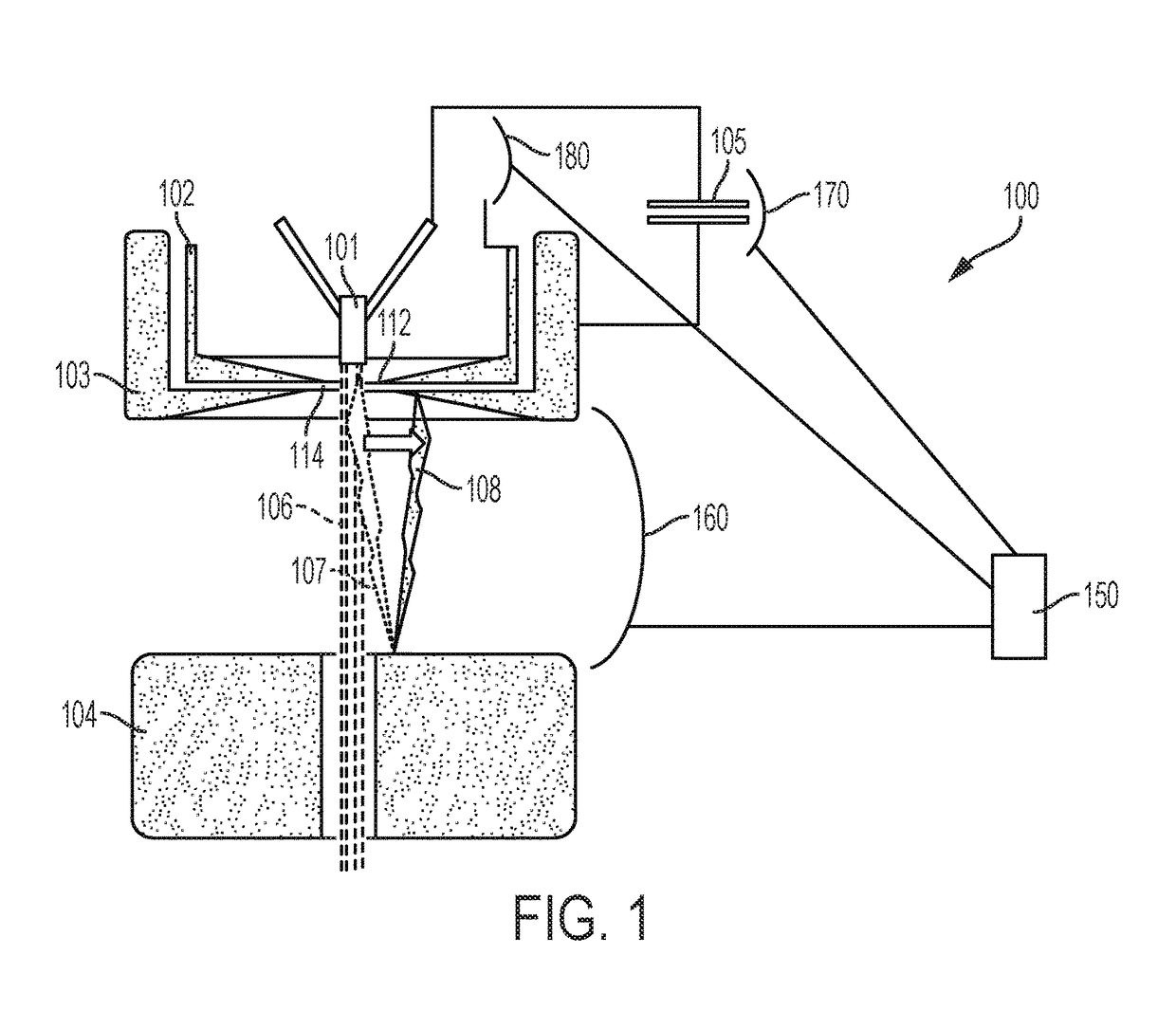

Systems and Methods for Surface Modification by Filtered Cathodic Vacuum Arc

InactiveUS20100190036A1Protective coatings for layersElectric discharge tubesSurface modificationMaterials science

Provided are filtered cathodic vacuum arc systems useful for modifying a surface of a substrate (e.g. depositing a thin film of a material onto a surface of a substrate and / or implanting a material into the near-surface region of a substrate). The systems are configured to stabilize a do arc discharge plasma from an arc source. Also provided are methods for modifying a surface of a substrate, which in some cases includes depositing a material onto a surface of a substrate, in some cases includes implanting a material into the near-surface region of a substrate, and in some cases includes both depositing a material onto a surface of a substrate and implanting a material into the near-surface region of a substrate using the subject cathodic arc systems. In addition, magnetic recording media produced by the subject systems and methods are provided.

Owner:NAT UNIV OF SINGAPORE +1

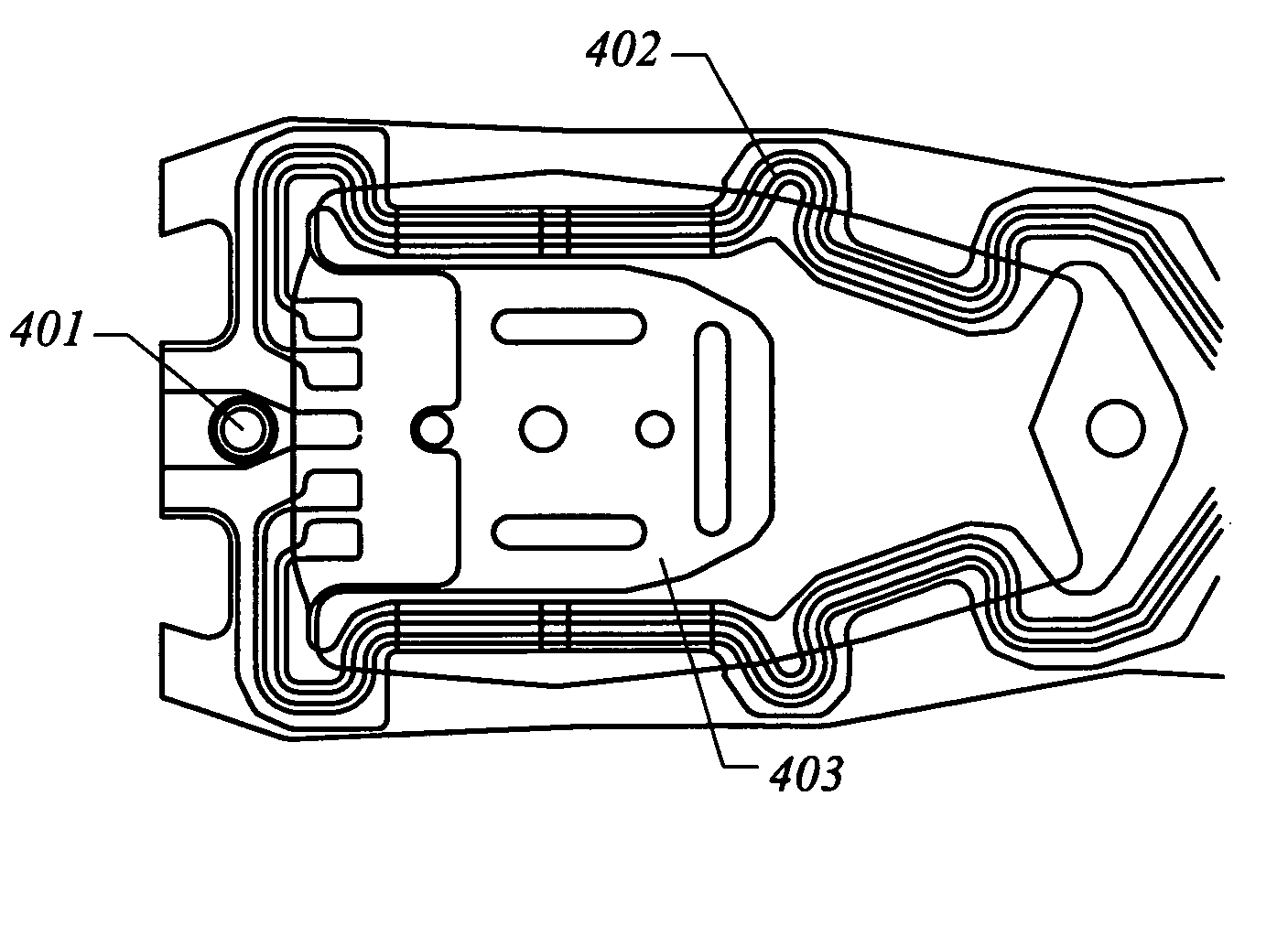

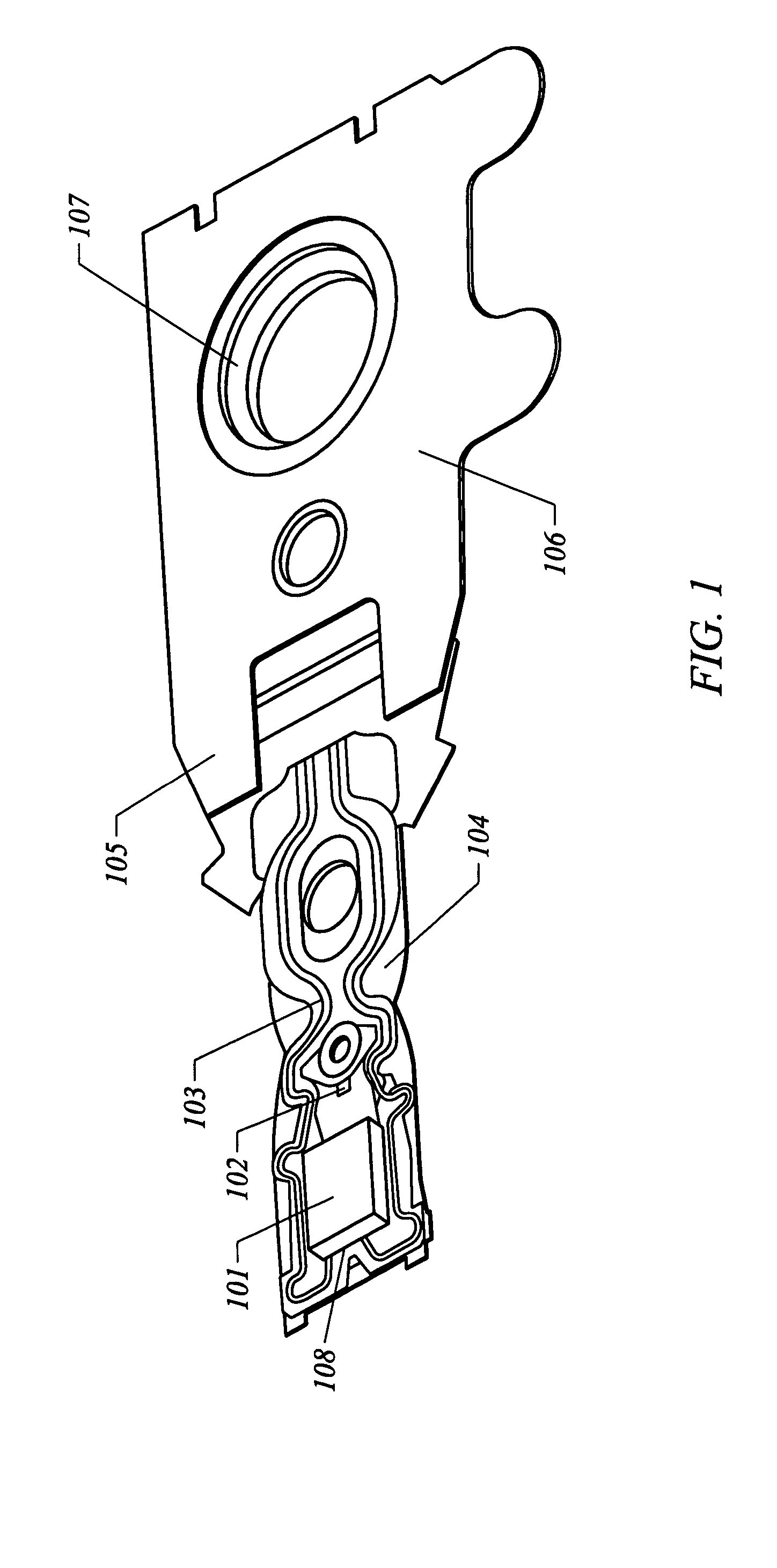

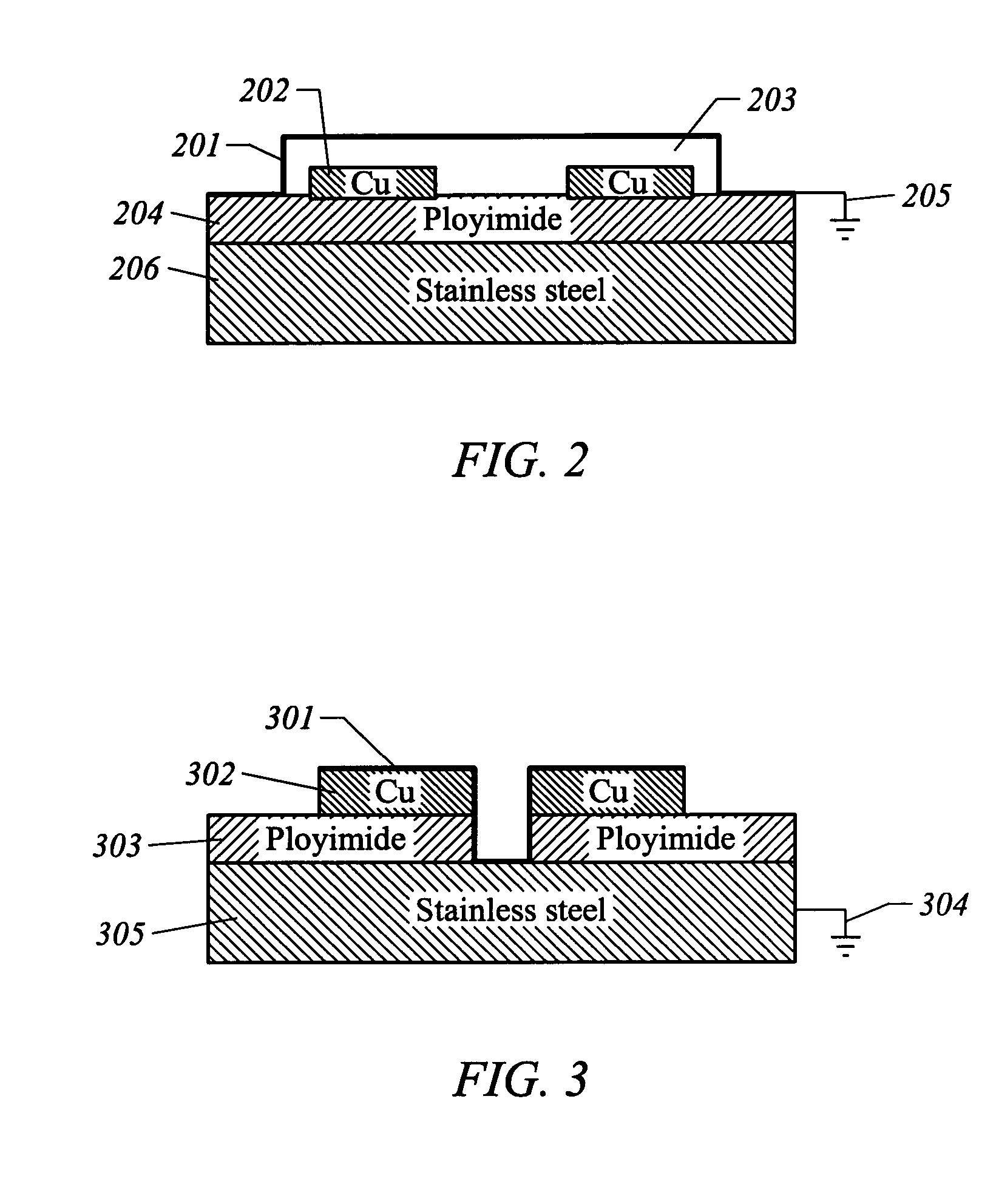

Method to form electrostatic discharge protection on flexible circuits

ActiveUS20050117257A1Avoid noisePreventing ESD damageSubstation/switching arrangement detailsRecord information storageFlexible circuitsIon deposition

Techniques for preventing electrostatic discharge (ESD) and circuit noise are provided. More particularly, the present invention provides a method to prevent ESD damage during the assembly of computer disk commonly called a hard disk for memory applications. The coating mainly involves a ion-deposition process. Merely by way of example, the present invention is implemented by using filtered cathodic vacuum arc (FCVA) with a dissipative crystalline and / or amorphous carbon base thin film coating on a flexible circuit to drain the potential electrostatic charges during circuit assembly and interconnect processes, yet it would be recognized that the invention has a much broader range of applicability on any electronic apparatus that is susceptible to electrostatic damage and static noise.

Owner:MAGNECOMP

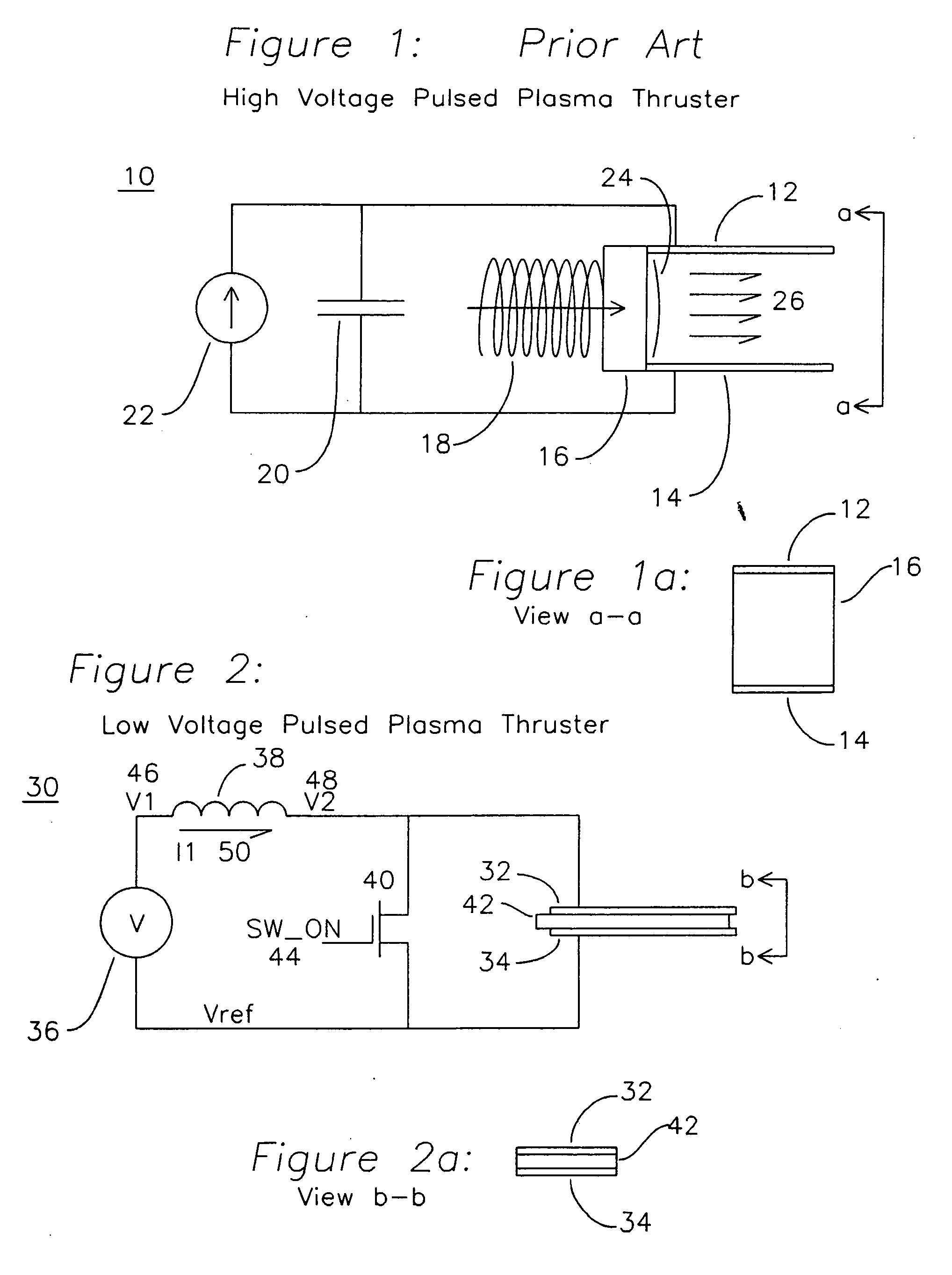

Vacuum arc plasma thrusters with inductive energy storage driver

InactiveUS20070045248A1Effective “ throttle ”High resistivityArc welding apparatusMachines/enginesVoltage spikeLow voltage

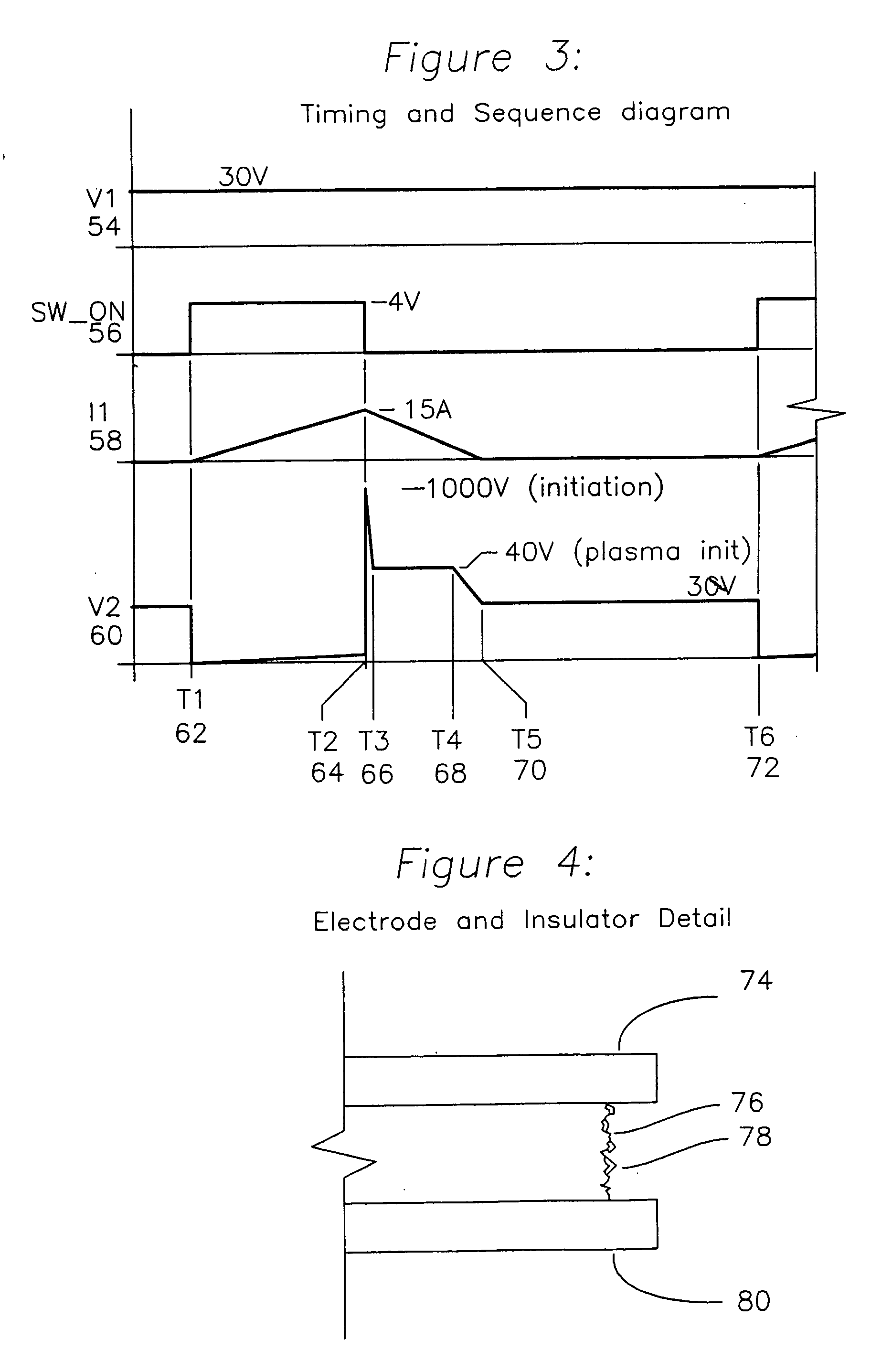

An apparatus for producing a vacuum arc plasma source device using a low mass, compact inductive energy storage circuit powered by a low voltage DC supply acts as a vacuum arc plasma thruster. An inductor is charged through a switch, subsequently the switch is opened and a voltage spike of Ldi / dt is produced initiating plasma across a resistive path separating anode and cathode. The plasma is subsequently maintained by energy stored in the inductor. Plasma is produced from cathode material, which allows for any electrically conductive material to be used. A planar structure, a tubular structure, and a coaxial structure allow for consumption of cathode material feed and thereby long lifetime of the thruster for long durations of time.

Owner:KRISHNAN MAHADEVAN

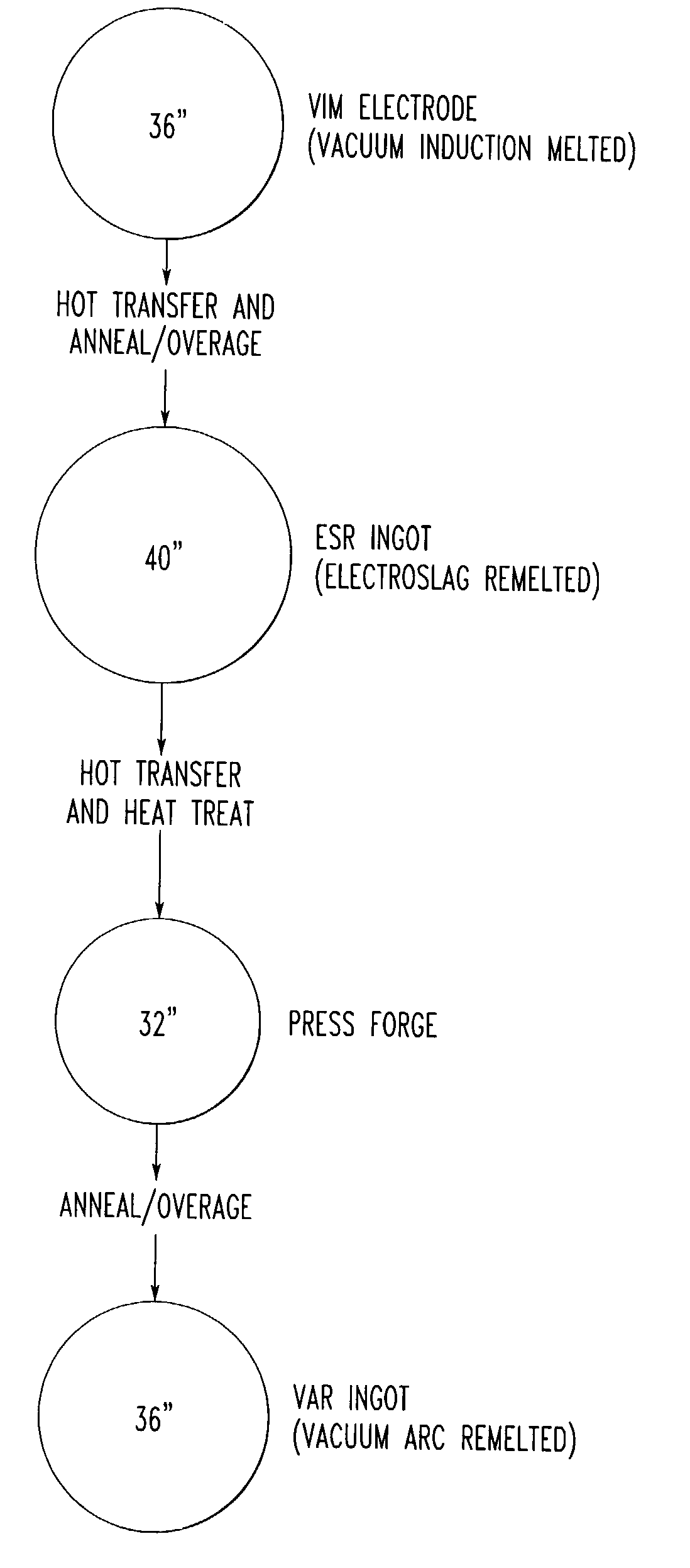

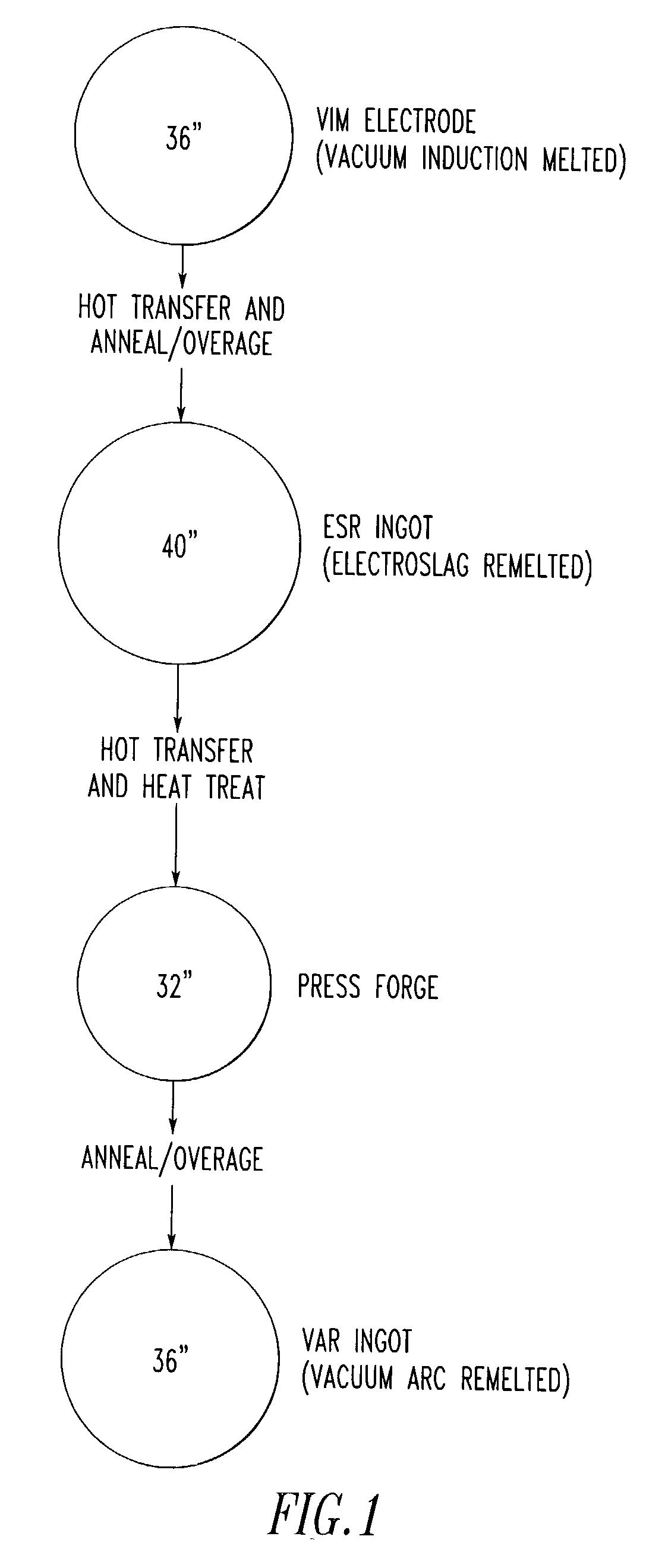

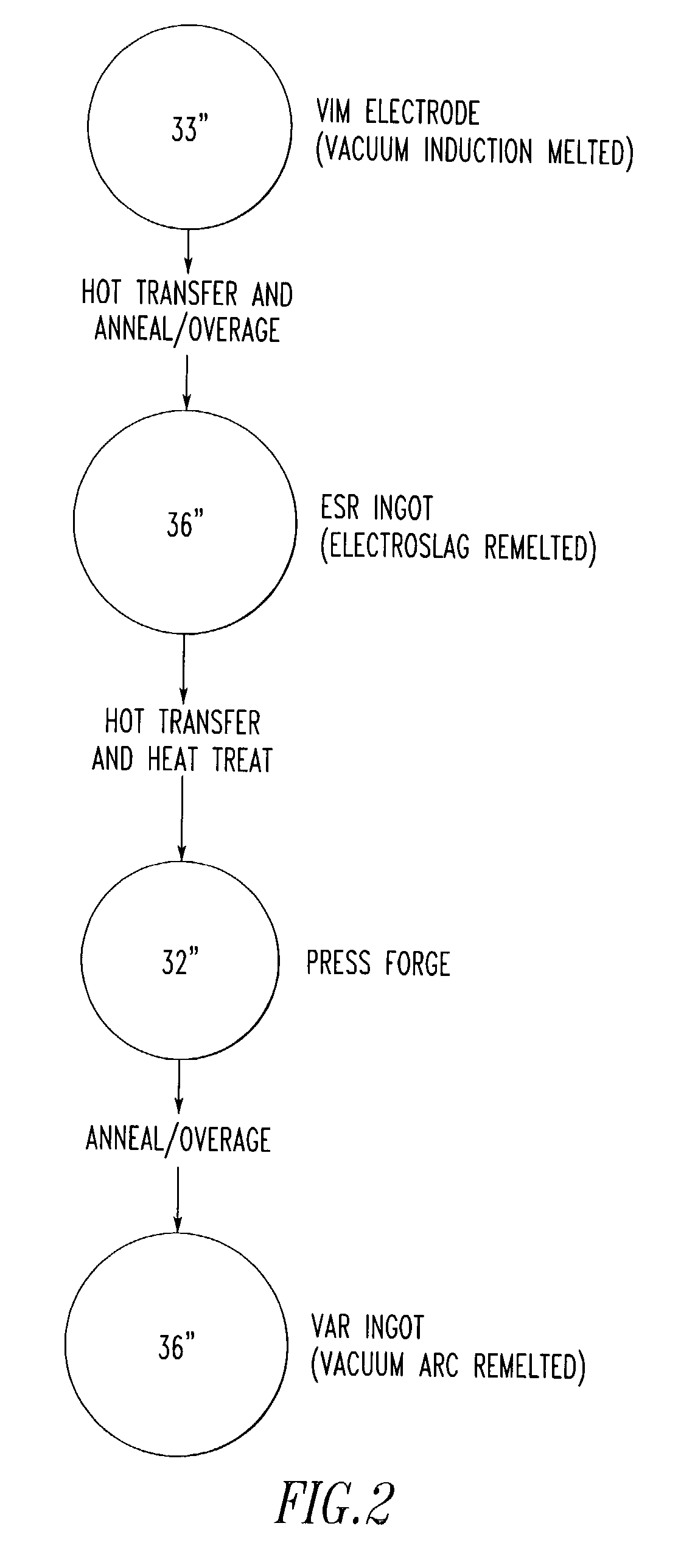

Method for producing large diameter ingots of nickel base alloys

InactiveUS6416564B1Inhibit thermal stressLarge caliberWelding/cutting media/materialsElectric furnaceCasting moldHeating furnace

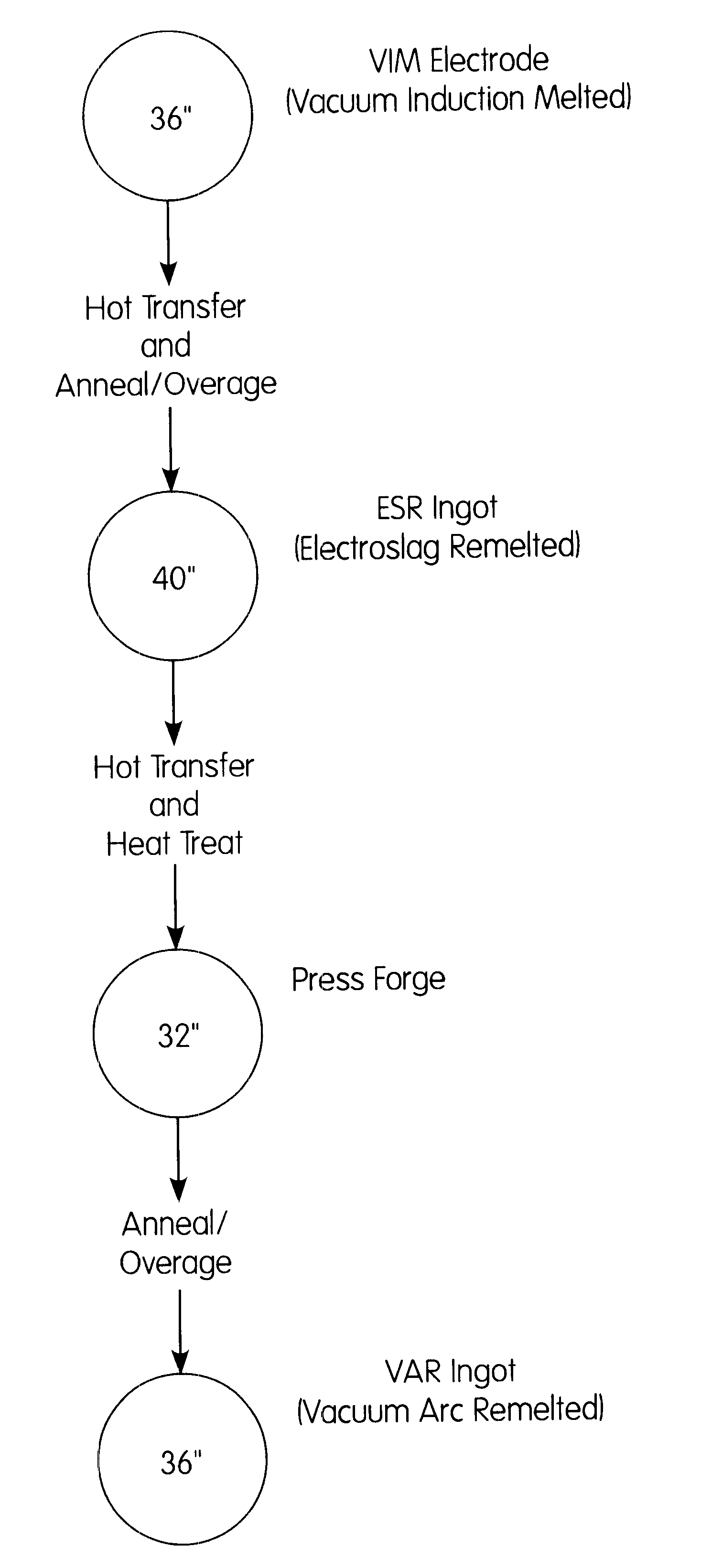

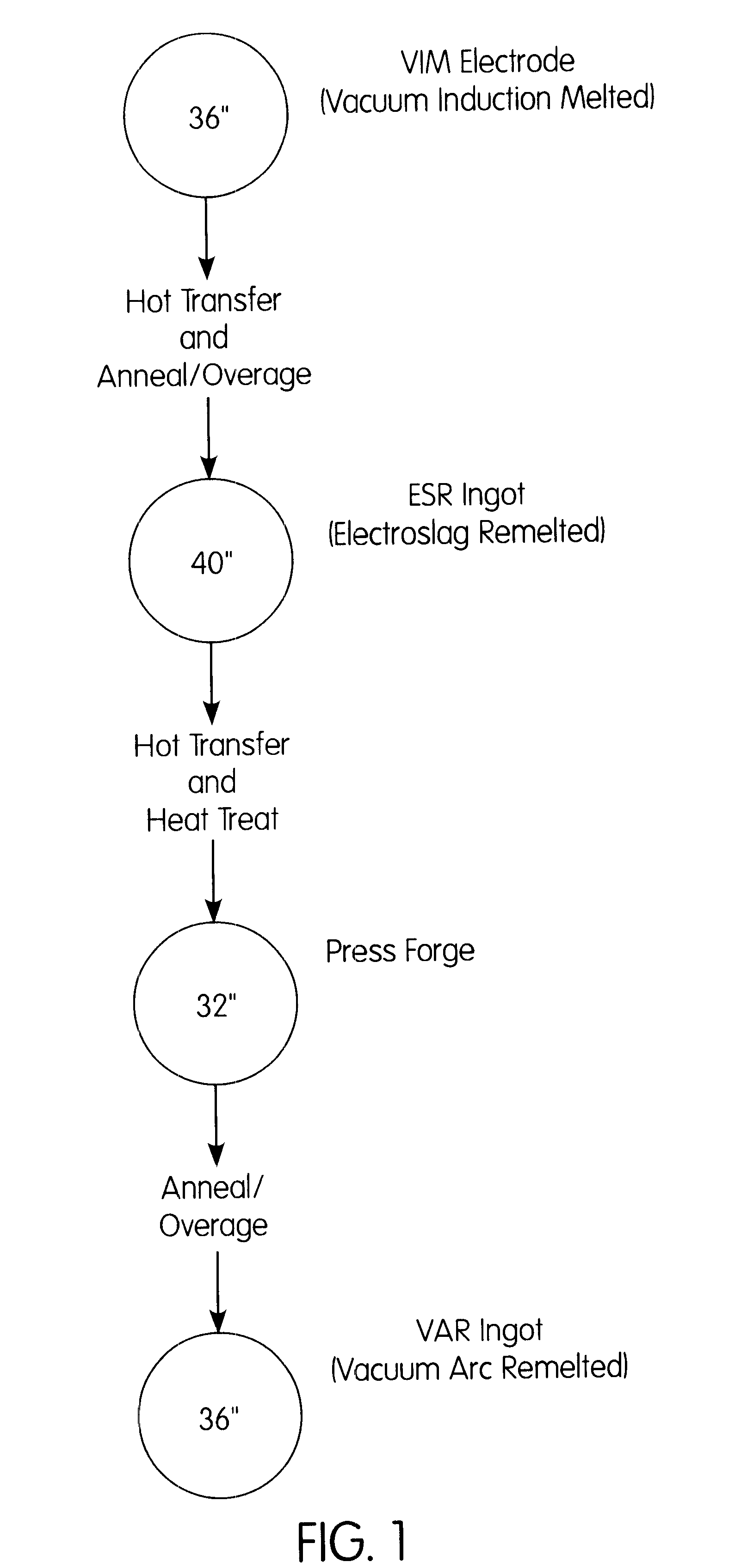

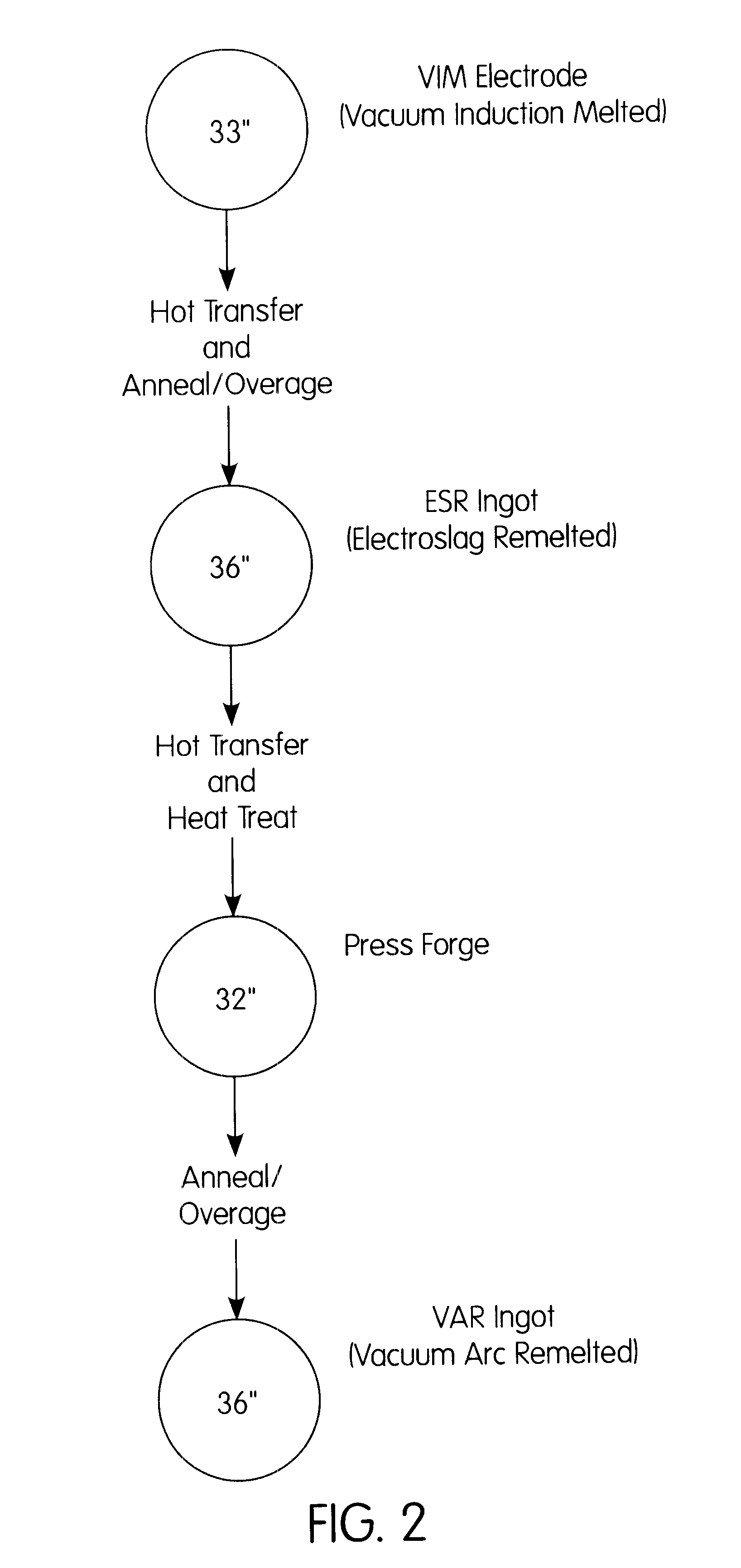

A method of producing a nickel base alloy includes casting the alloy within a casting mold and subsequently annealing and overaging the ingot at at least 1200° F. (649° C.) for at least 10 hours. The ingot is electroslag remeelted at a melt rate of at least 8 lbs / min (3.63 kg / mm.), and the ESR ingot is then transferred to a heating furnace within 4 hours of complete solidification and is subjected to a novel post-ESR heat treatment. A suitable VAR electrode is provided form the ESR ingot, and the electrode is vacuum arc remelted at a melt rate of 8 to 11 lbs / minute (3.63 to 5.00 kg / minute) to provide a VAR ingot. The method allows premium quality VAR ingots having diameters greater than 30 inches (762 mm) to be prepared from Alloy 718 and other nickel base superalloys subject to significant segregation on casting.

Owner:ATI PROPERTIES

Process for preparing biomedical beta-titanium alloy

InactiveCN101724764AImprove performanceHigh strengthImpression capsFurnace typesMaterials processingQuenching

The invention discloses a process for preparing a biomedical beta-titanium alloy. The process comprises the following steps: A) alloy preparation; B) surface coating; C) hot forging and cogging; D) hot rolling; E) cold rolling and molding; and F) heat treatment. In the process, the material is manufactured to a 2mm plate after the beta-titanium alloy is subjected to high vacuum electric arc melting, repeated stirring, casting, phase transformation point measuring, homogenization under the protection of vacuum and argon, coating, hot forging, hot rolling, cold rolling, solid solution, water quenching, artificial aging and water cooling so as to prepare the biomedical beta-titanium alloy with excellent comprehensive performance. The process is a biomedical beta-titanium preparation process capable of improving the material strength, abrasion resistance and corrosion resistance, reducing the elasticity modulus of the material, and maintaining excellent manufacturing and molding performance of the material.

Owner:CENT SOUTH UNIV

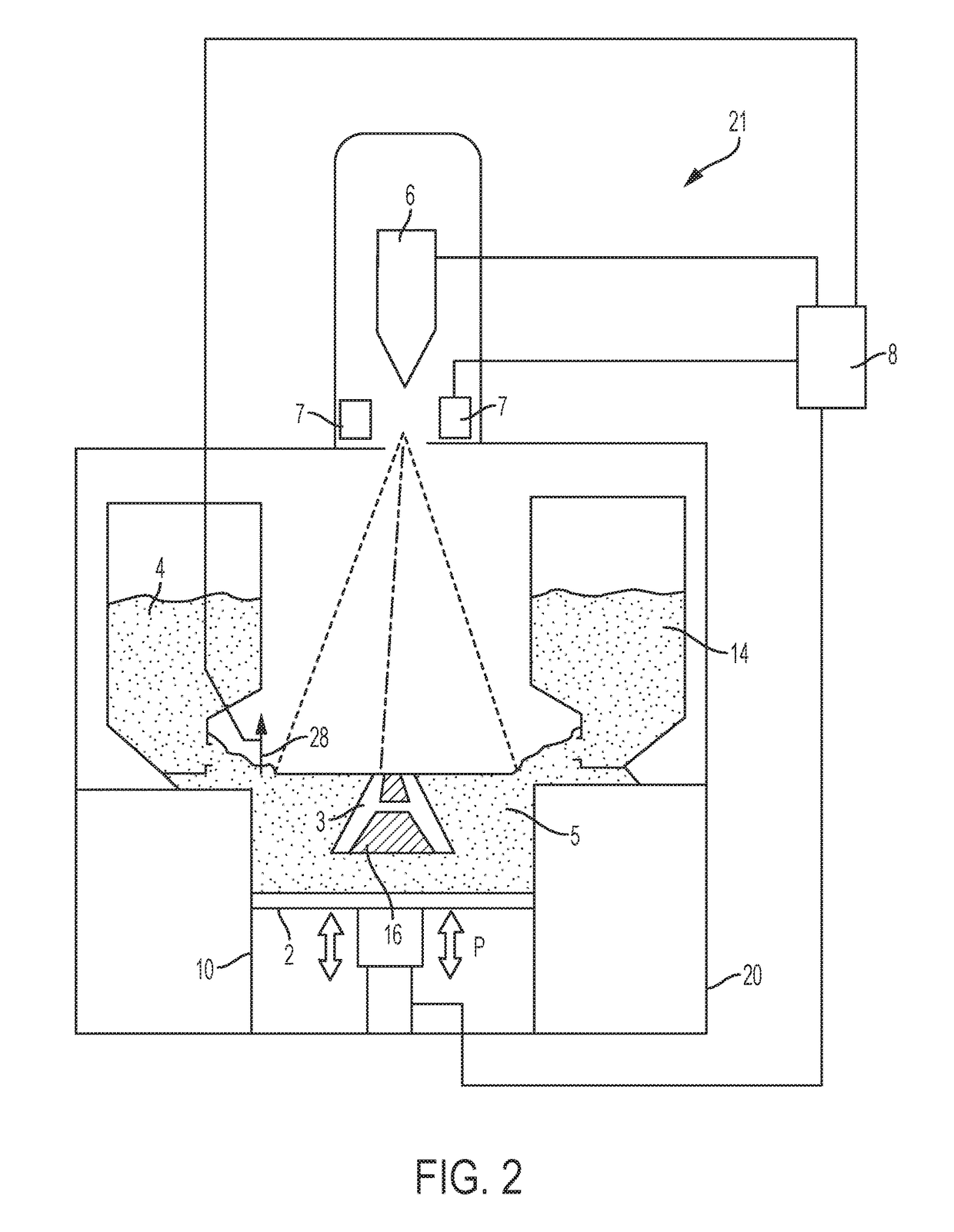

Additive manufacturing of three-dimensional articles

ActiveUS20170348791A1Improve reliabilitySimple and inexpensive implementationAdditive manufacturing apparatusElectric discharge tubesPower flowBeam source

A method is provided for forming a three-dimensional article through successively depositing individual layers of powder material that are fused together so as to form the article, the method comprising the steps of: providing at least one electron beam source emitting an electron beam for at least one of heating or fusing the powder material, where the electron beam source comprises a cathode, an anode, and a Wehnelt cup between the cathode and anode; providing a guard ring between the Wehnelt cup and the anode and in close proximity to the Wehnelt cup, where the guard ring is having an aperture which is larger than an aperture of the Wehnelt cup; protecting the cathode and / or the Wehnelt cup against vacuum arc discharge energy currents when forming the three-dimensional article by providing the guard ring with a higher negative potential than the Wehnelt cup and cathode.

Owner:ARCAM AB

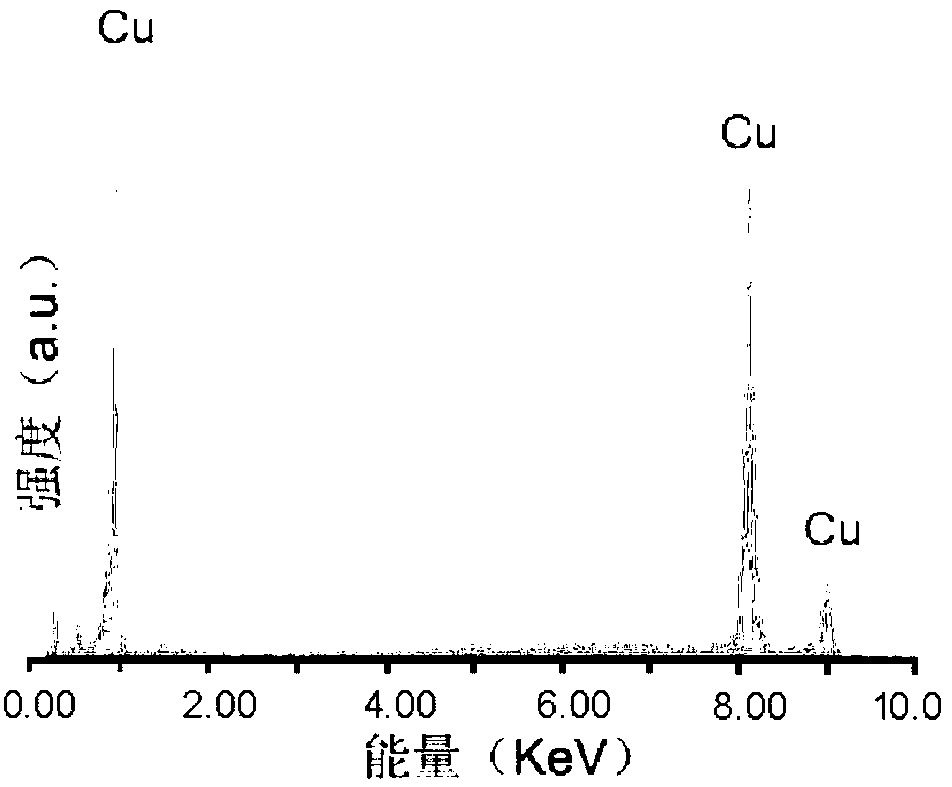

Method for preparing nano-porous copper

ActiveCN103343253AUniform and continuous nanoporous structureReduce complexityElectric arc furnaceIngot

The invention discloses a method for preparing nano-porous copper, which relates to manufacturing for metals with nanoscale porosity. The method comprises the following steps of: calculating the masses of the needed raw materials according to the atomic percent at. % of each element in a target alloy Cu (having an atomic percent of 50.00%)-Zr (having an atomic percent of 42.50-50.00%)(-Al (having the remainder atomic percent)), weighing copper sheets, zirconium grains and aluminium blocks, and mixing to obtain a mother alloy raw material; then smelting the mother alloy raw material in a vacuum arc furnace to prepare a Cu-Zr(-Al) alloy ingot; then preparing a Cu-Zr(-Al) amorphous alloy strip by smelting-spinning equipment; and then preparing a nano-porous metallic copper strip by one-step dealloying, cleaning, and then storing the cleaned nano-porous metallic copper strip in a vacuum chamber having a vacuum degree of 0.1 MPa for the later use, so as to avoid oxidation. With the adoption of the method, the defects of complex preparation process, high cost and inconvenience for industrialized large-scale production of the prior art are overcome.

Owner:HEBEI UNIV OF TECH

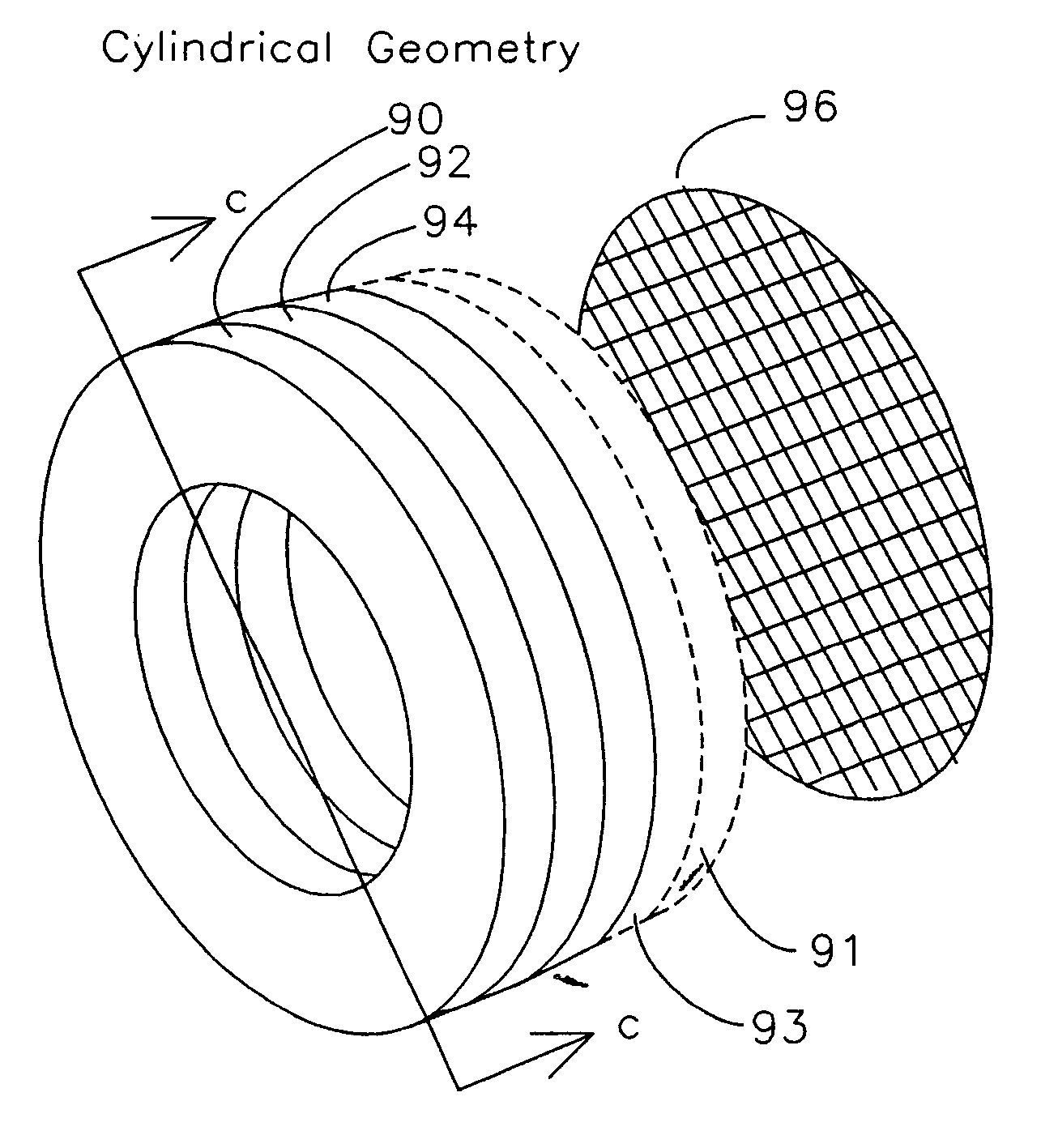

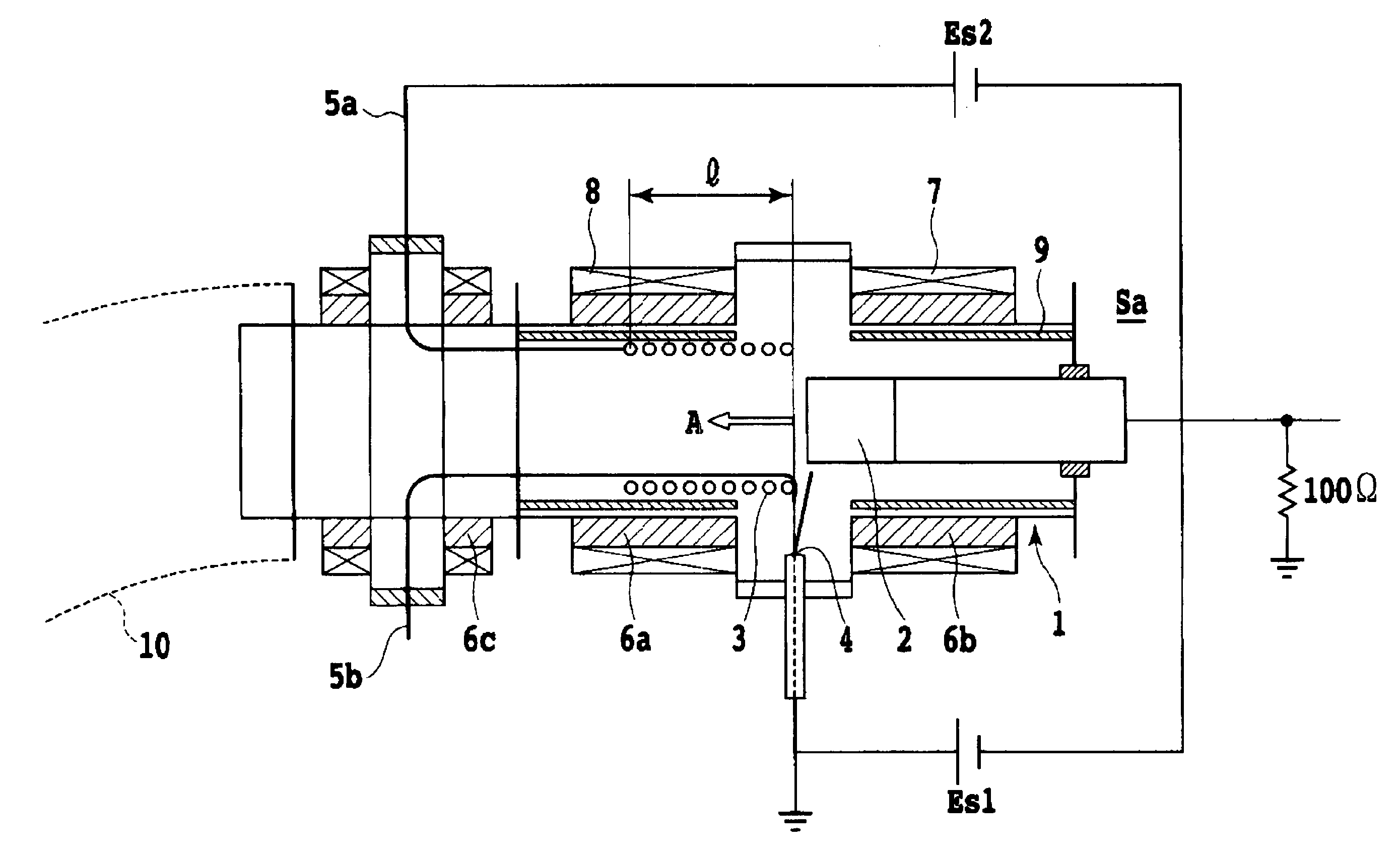

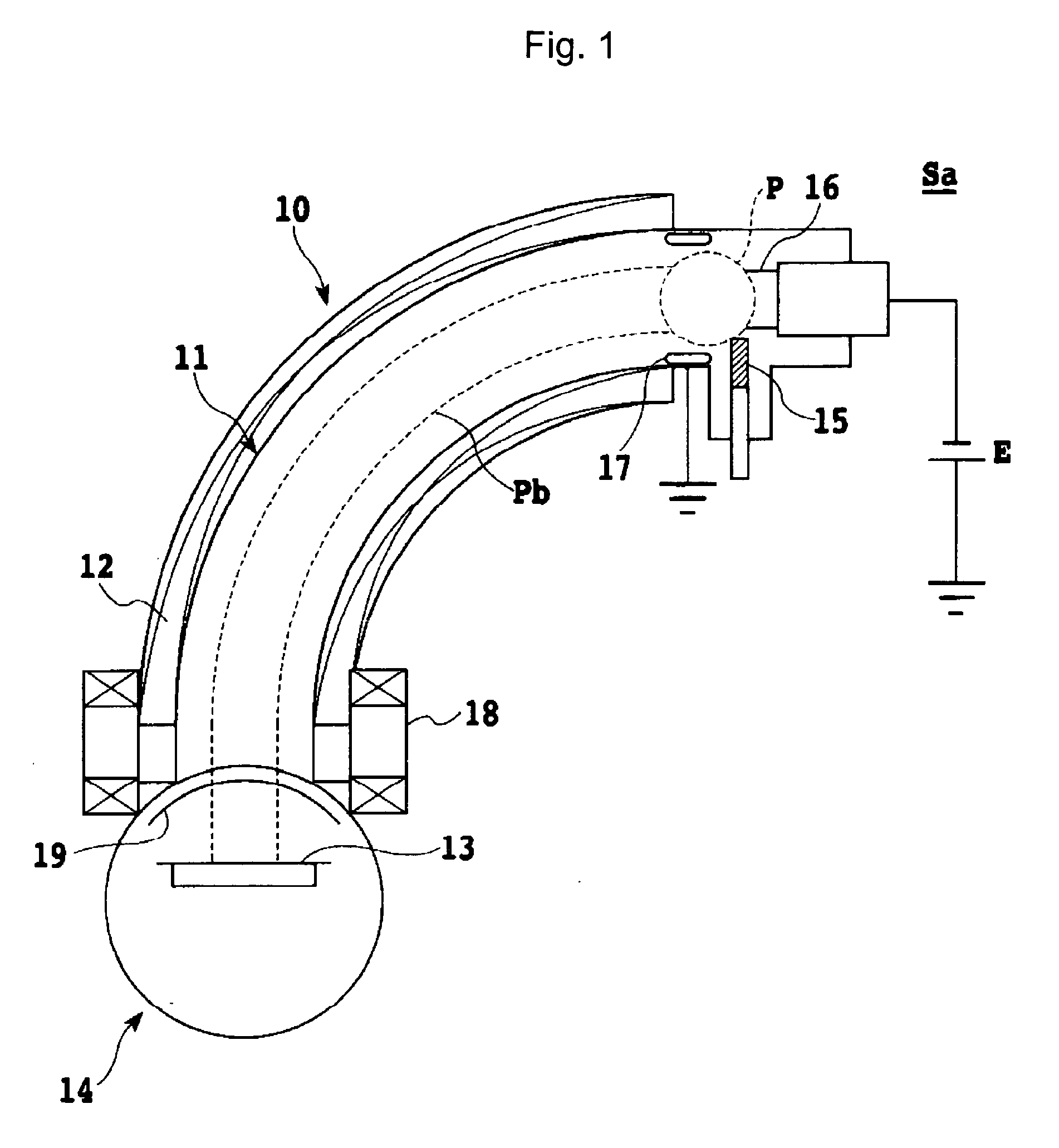

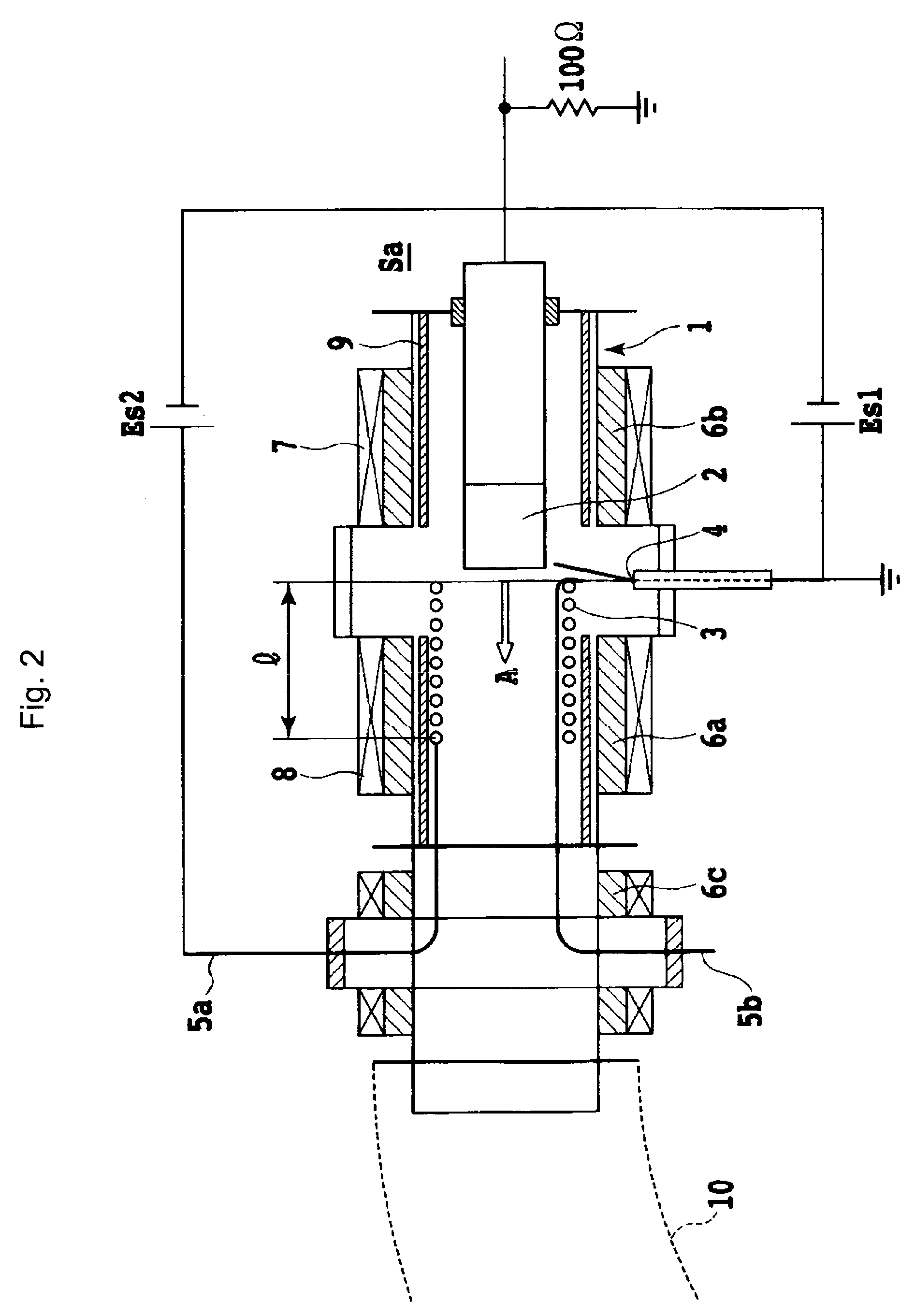

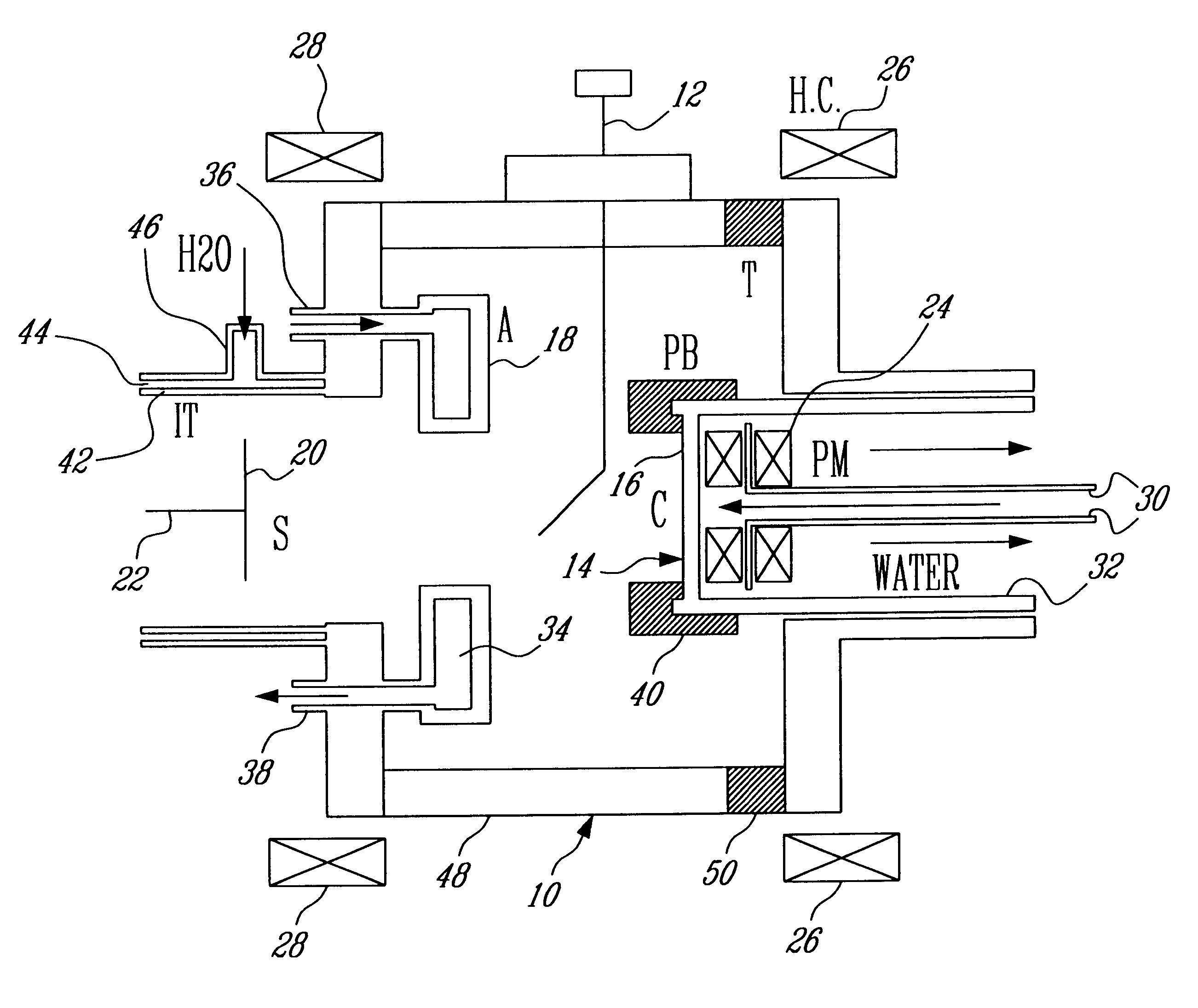

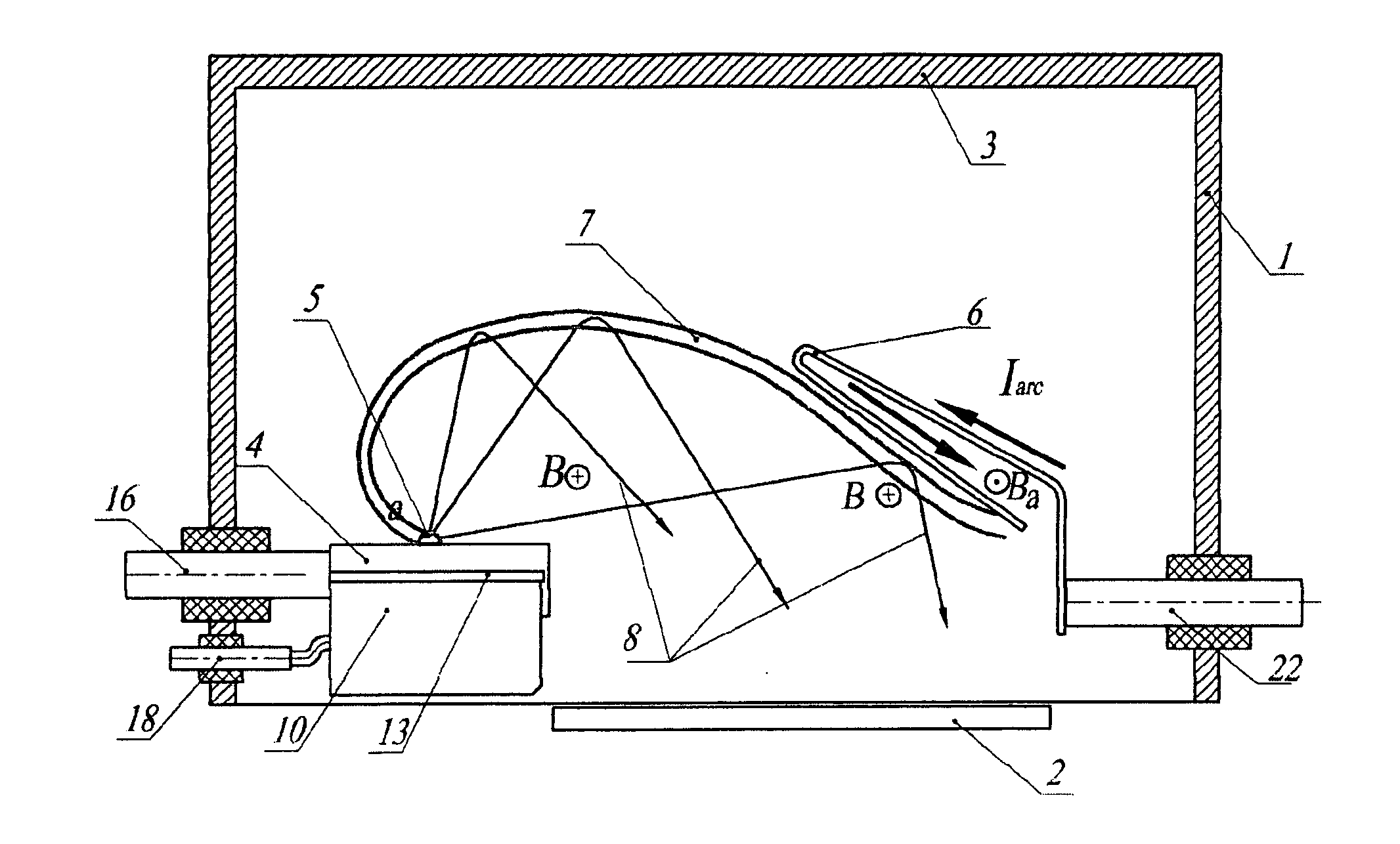

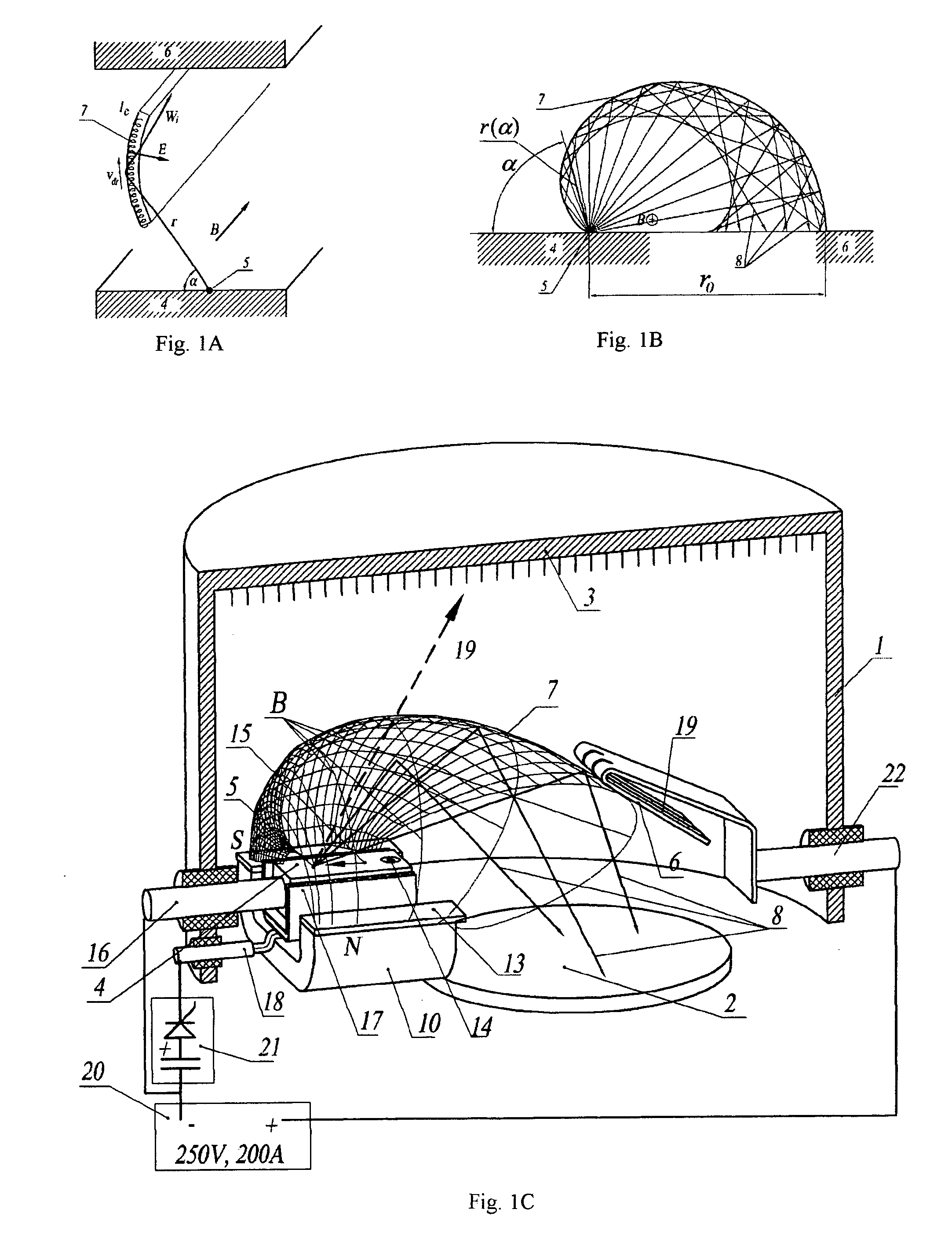

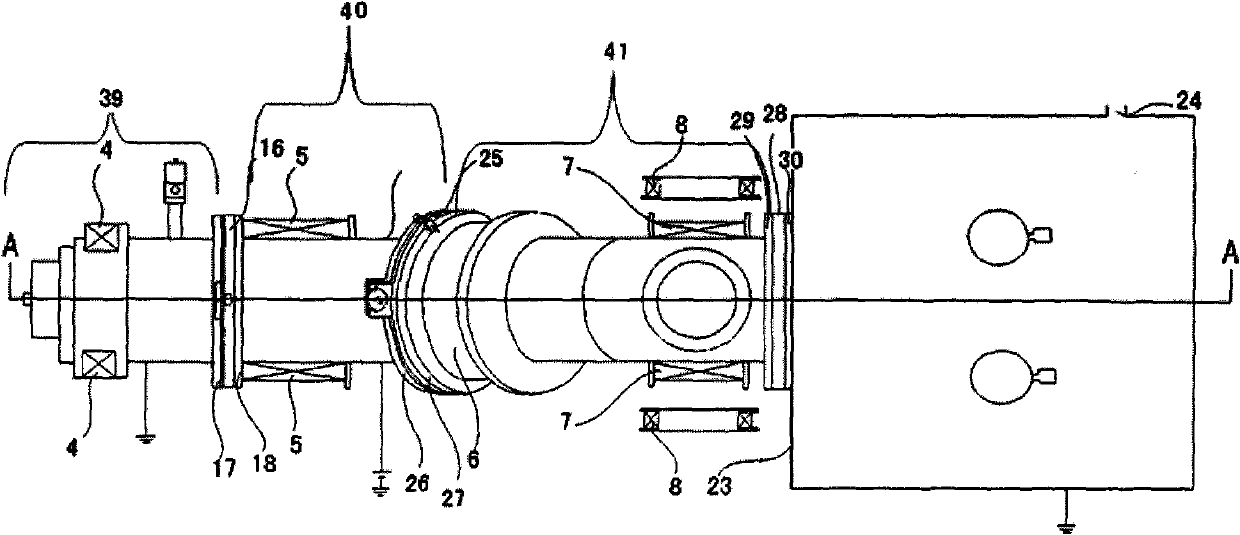

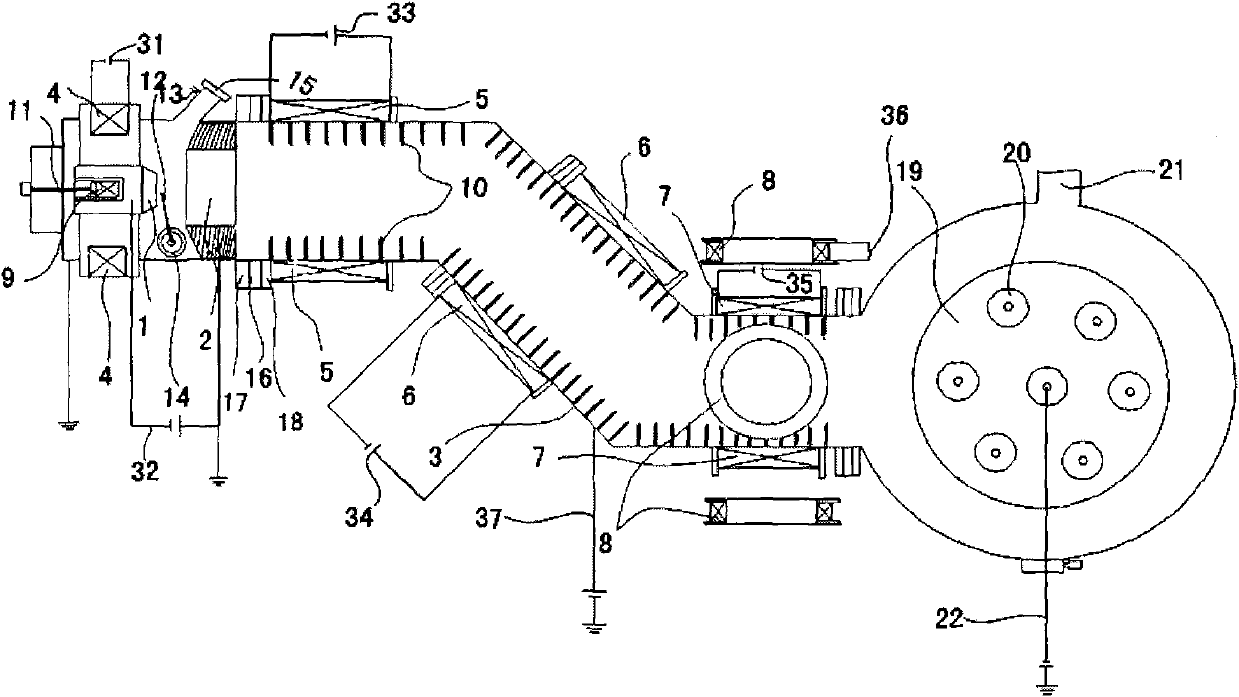

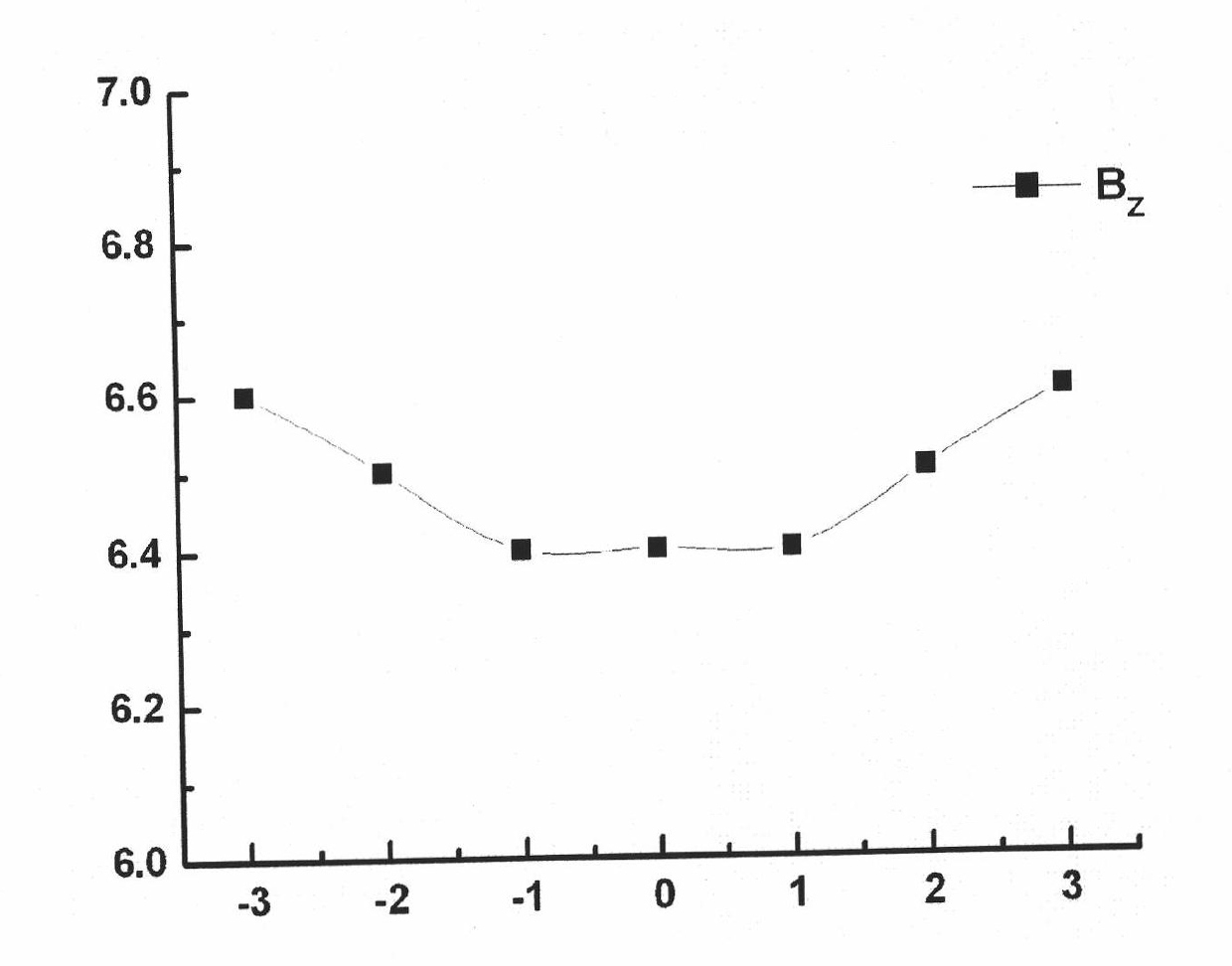

Vacuum arc evaporation apparatus and method, and magnetic recording medium formed thereby

In a vacuum arc evaporation apparatus, to stably maintain vacuum arc discharge at an arc source when depositing a cathode material on a substrate, namely a magnetic recording medium, an ungrounded anode of a coil-type tube is placed inside an arc source discharge vacuum chamber. A DC arc power supply is connected between the cathode and the anode to cause an arc current to flow in the anode to generate a first magnetic field in one direction, from the cathode toward the anode. A second magnetic field is generated in the opposite direction, from the anode to the cathode by feeding a specified current to an external coil positioned around the discharge chamber. The external coil includes an around-cathode coil and an around-anode coil. The arc discharge can be started by operating a striker to carry out the deposition.

Owner:FUJI ELECTRIC DEVICE TECH CO

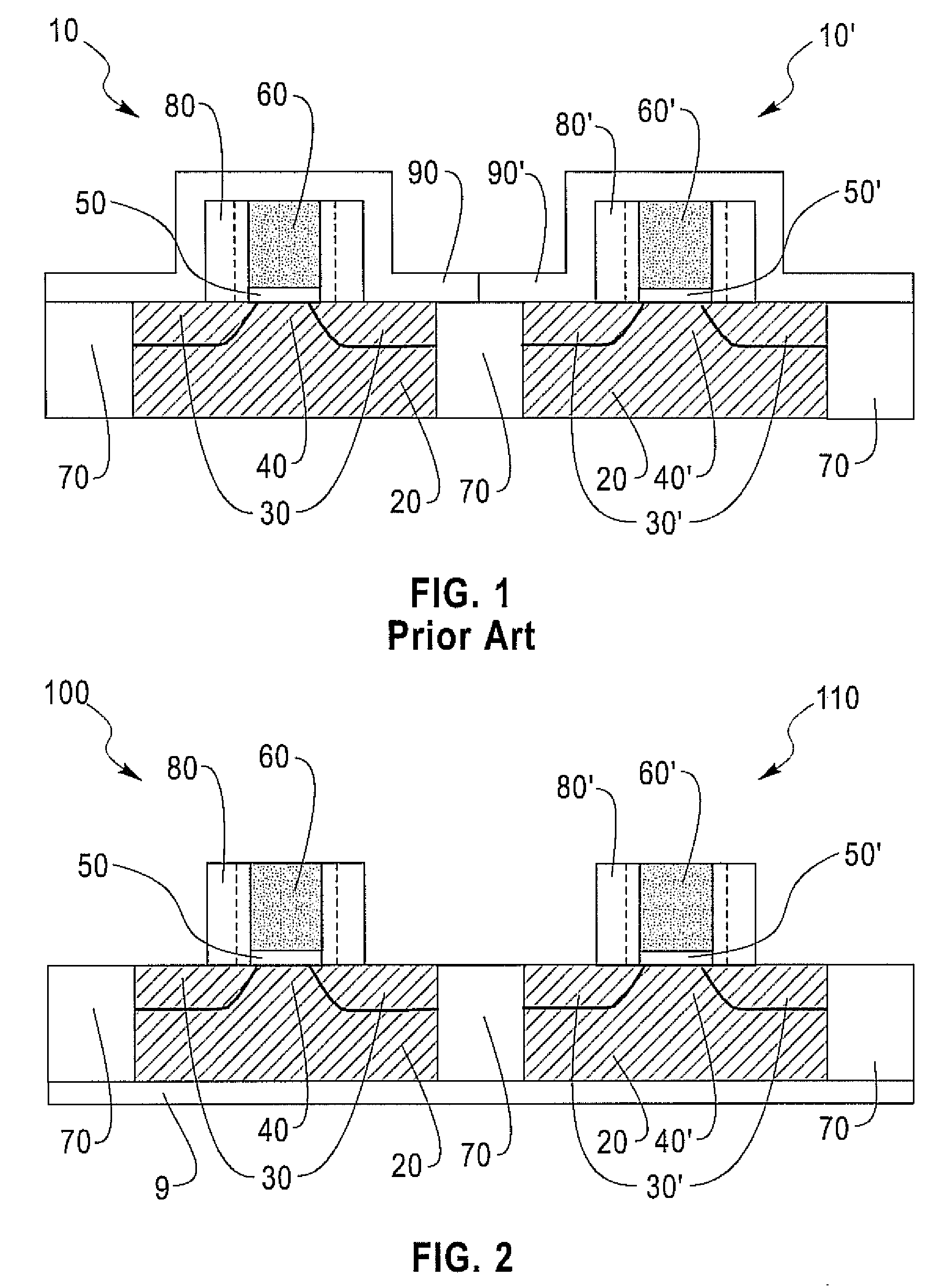

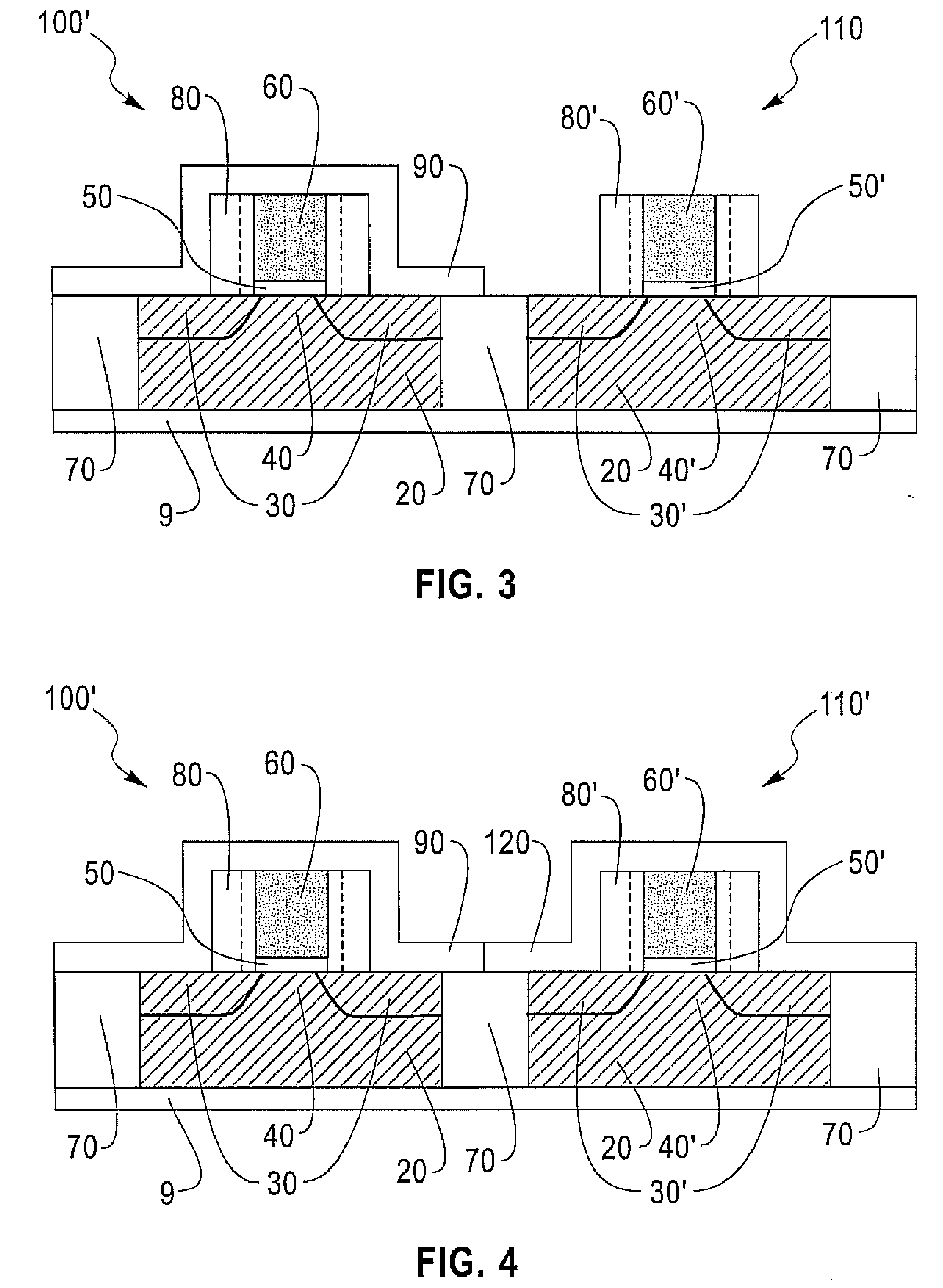

Field effect transistor using carbon based stress liner

InactiveUS20080303068A1Increase compressive stressTransistorSemiconductor/solid-state device manufacturingSemiconductor materialsHydrogen

A stress liner for use within a semiconductor structure that includes a field effect device has a dielectric constant less than about 7 and a compressive stress greater than about 5 GPa. The stress liner may be formed of a carbon based material, preferably a tetrahedral amorphous carbon (ta-C) material including at least about 60 atomic percent carbon and no greater than C about 40 atomic percent hydrogen. The carbon based material may be either a dielectric material, or given appropriate additional dielectric isolation structures, a semiconductor material. In particular, a ta-C stress liner may be formed using a filtered cathodic vacuum arc (FCVA) physical vapor deposition (PVD) method.

Owner:GLOBALFOUNDRIES INC

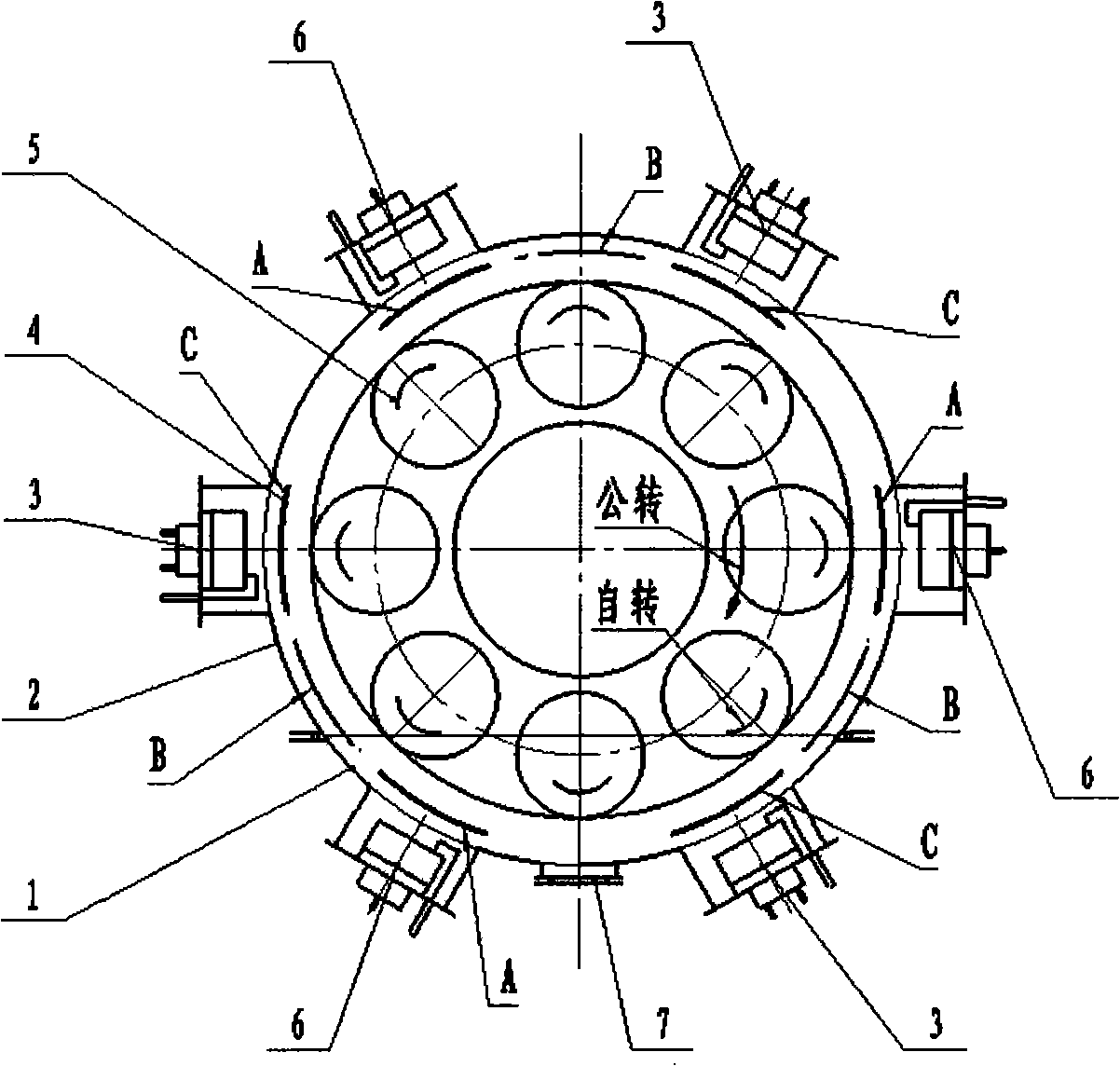

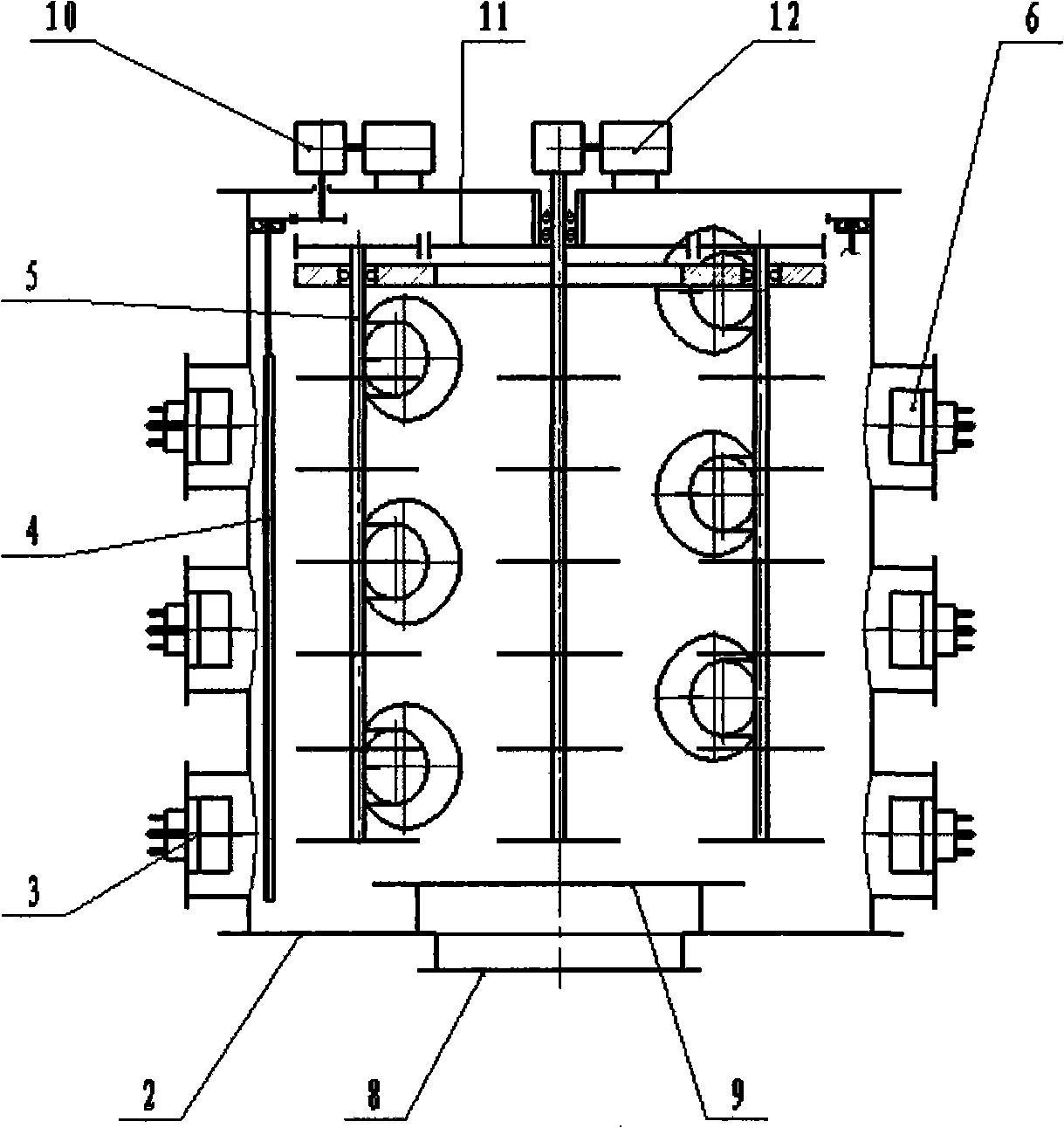

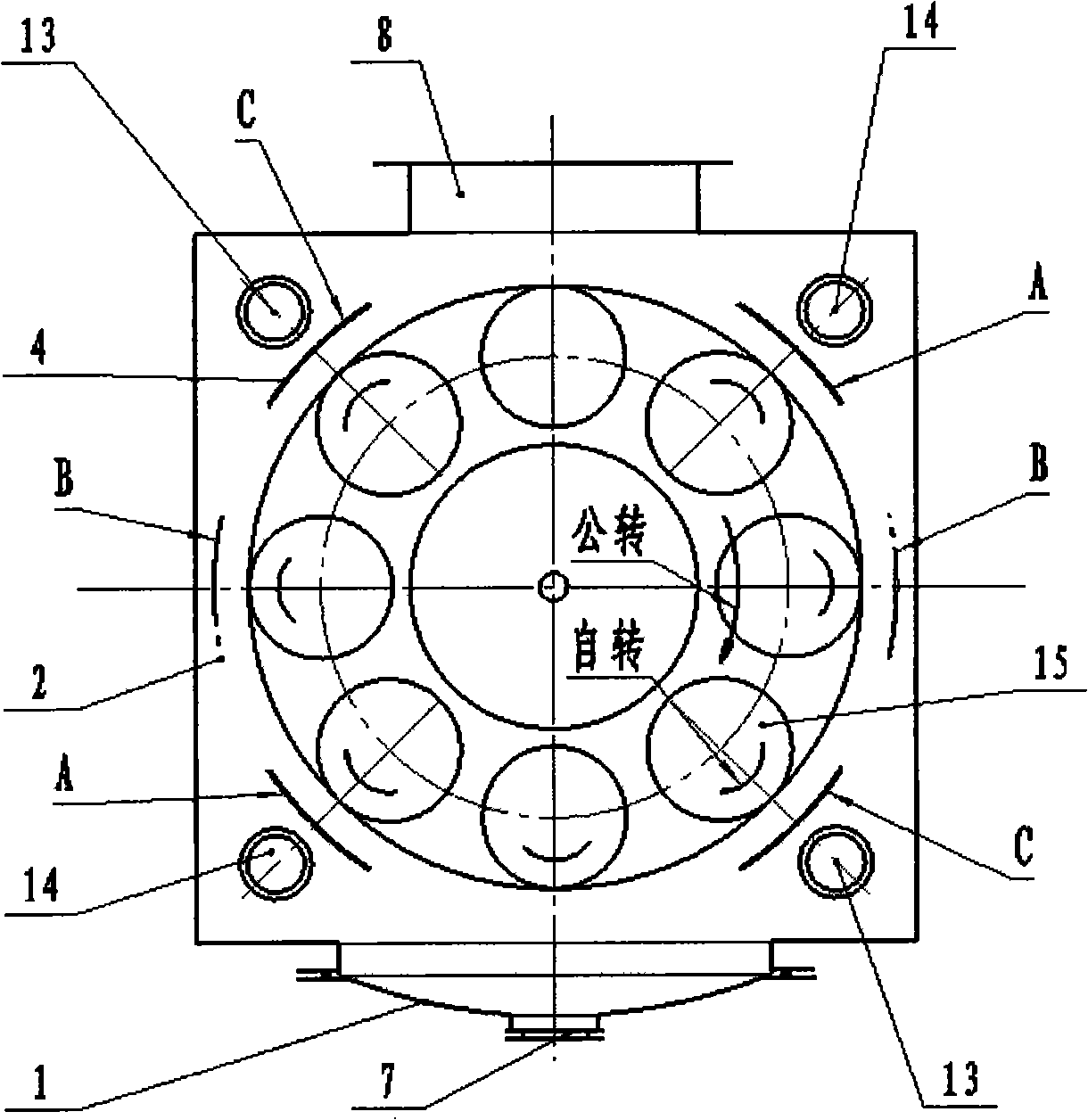

Equipment and method for producing nichrome composite plate with vacuum arc ion plating

InactiveCN101294270ACorrosion protectionHigh surface hardnessVacuum evaporation coatingSputtering coatingComposite plateVacuum chamber

The invention relates to a device for manufacturing a nickel-chromium composite plate by using vacuum arc ion plating to replace electroplating and a method thereof, and is characterized in that the device of the vacuum arc ion plating and the method are utilized to replace water electroplating to sequentially prepare the nickel-chromium composite plate composed of a pure nickel film, a nickel-chromium gradient transition film and a pure chromium film on a copper substrate; the device for manufacturing the nickel-chromium composite plate by using the vacuum arc ion plating is of a vertical cylindrical shape or a regular polygon; arc target sources are evenly distributed around a vacuum chamber wall; a controllable mechanical baffle plate is arranged in front of each target source; a planetary type work rest with rotation and revolution is arranged in the middle part of a vacuum chamber; the technical process of a filming operation comprises three stages that are preliminary treatment, the filming operation and post treatment. The device and the method simplify the process flows and the operation links, increase the work efficiency, fully replace the traditional electroplating technology to coat a wearproof anticorrosion decoration coating on a coppery water heating component, and thoroughly eliminate the environmental pollution problems in the electroplating.

Owner:辽阳市弓长岭区光辉铁矿石加工厂

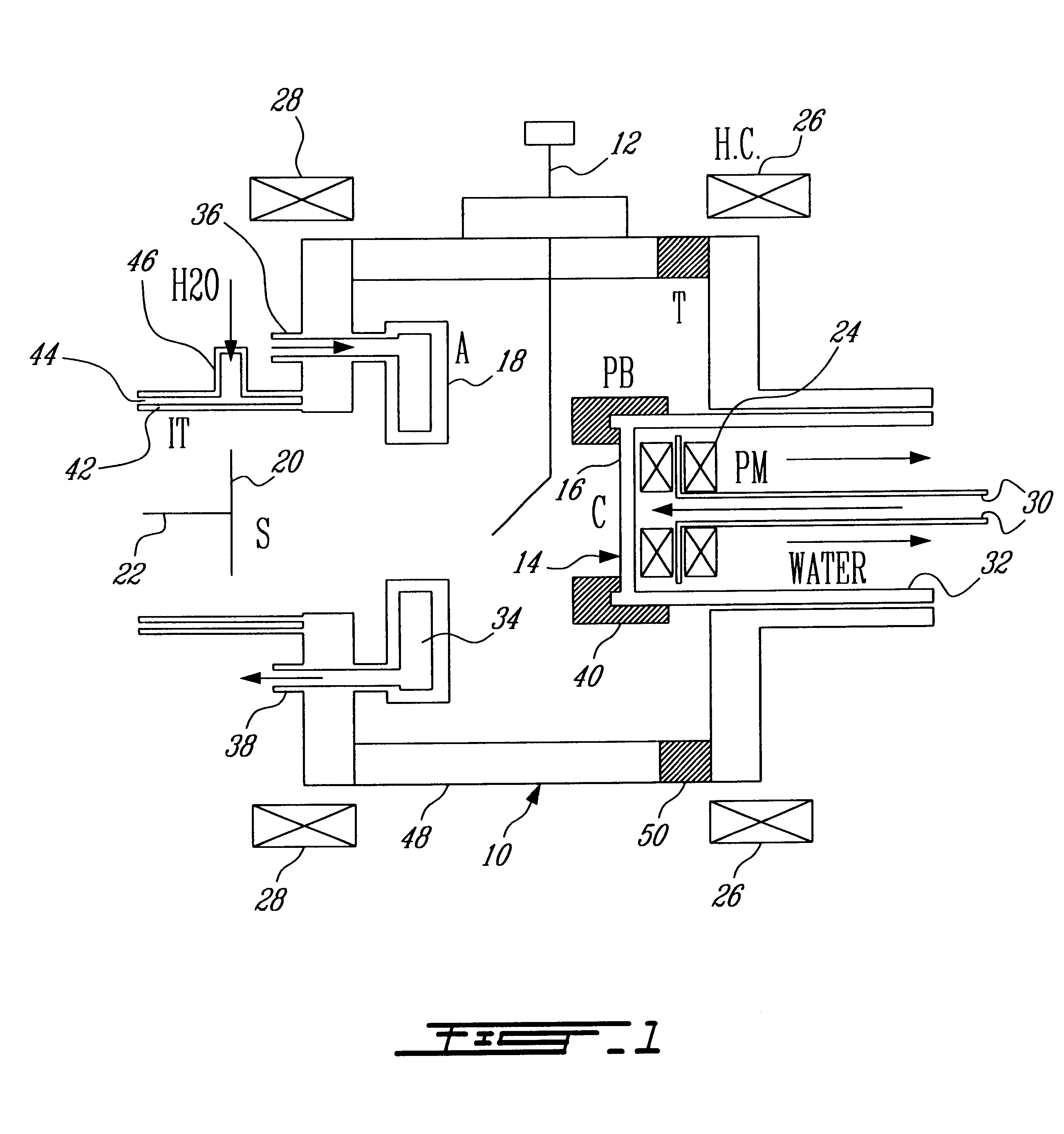

Particle-free cathodic arc carbon ion source

A method and apparatus for vacuum arc deposition of carbon on a substrate inhibits or eliminates emission of contaminating carbon particles in the ion plasma by maintaining an elevated local plasma pressure at the cathode or target surface, thereby minimizing the role of heat conduction in the creation of the particles and strongly increasing the electron emission cooling effects.

Owner:MCGILL UNIV

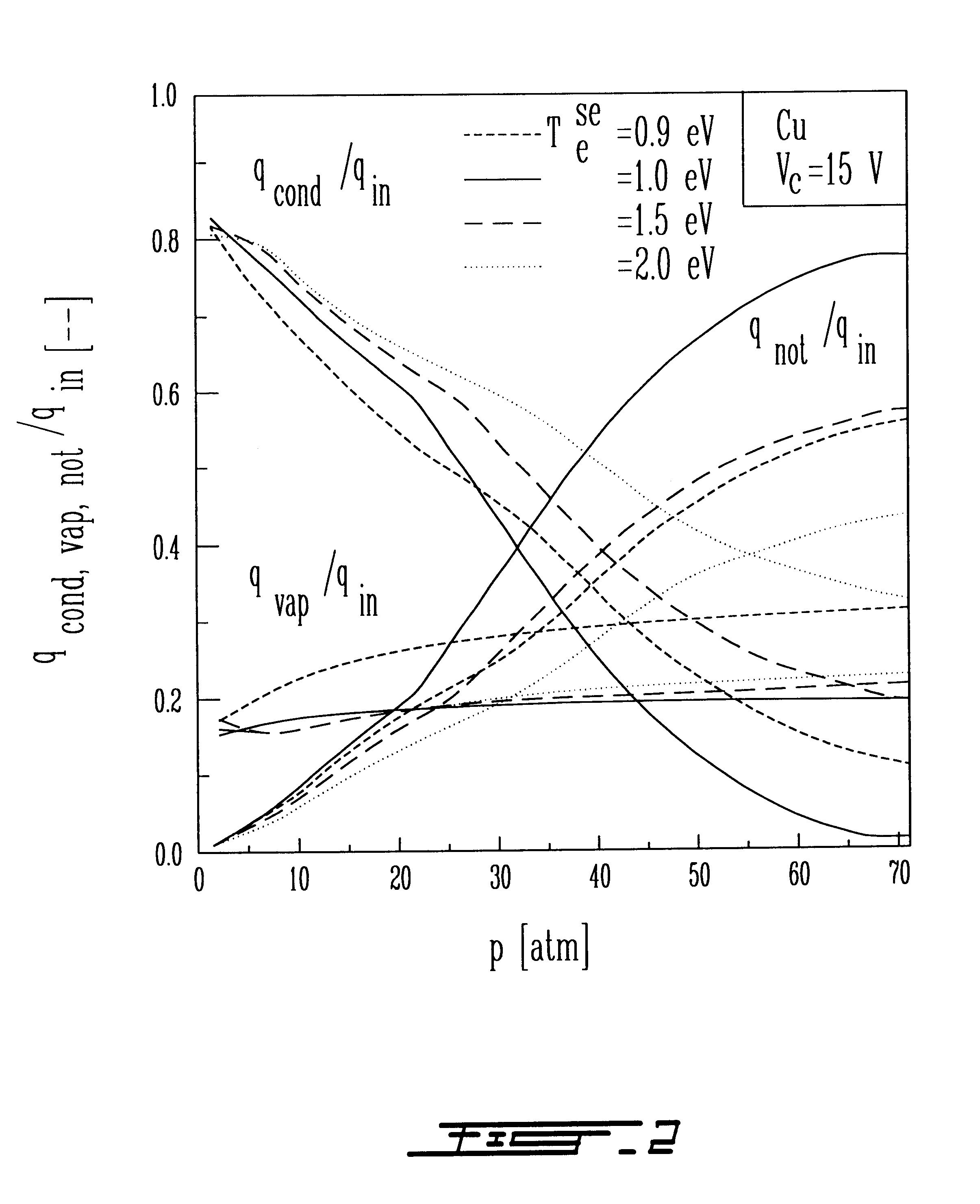

High-entropy amorphous alloy material and preparation method thereof

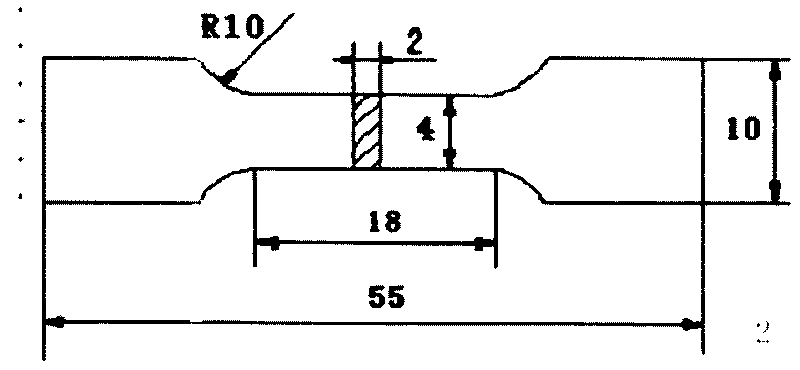

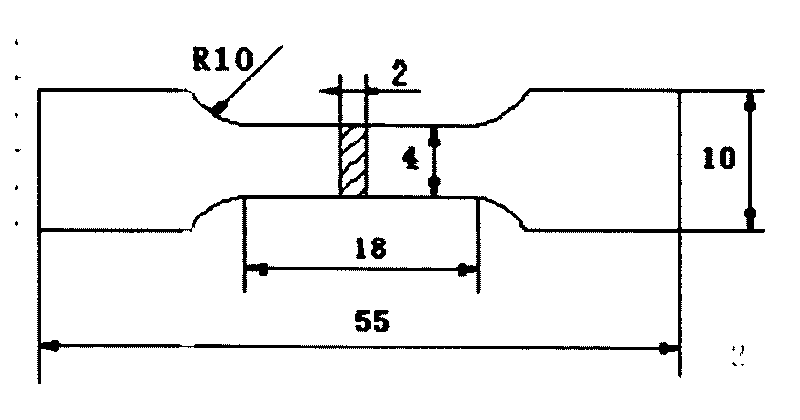

The invention discloses a high-entropy amorphous alloy material and a preparation method of the high-entropy amorphous alloy material, and belongs to the technical field of an amorphous alloy material and a preparation method of the amorphous alloy material. The high-entropy amorphous alloy material, which comprises a plurality of blocks and strips synthesized from 5 or more alloy elements, is prepared by melting using a vacuum arc furnace, wherein the atomic percents of all the components of the alloy or the atomic percents of most components of the alloy are equal. The mechanical performance data of a tested sample proves that the obtained high-entropy amorphous alloy material has excellent performances of high strength, high hardness, high wear resistance, high corrosion resistance and the like, which are beyond the reach of some traditional crystalline alloys.

Owner:TSINGHUA UNIV

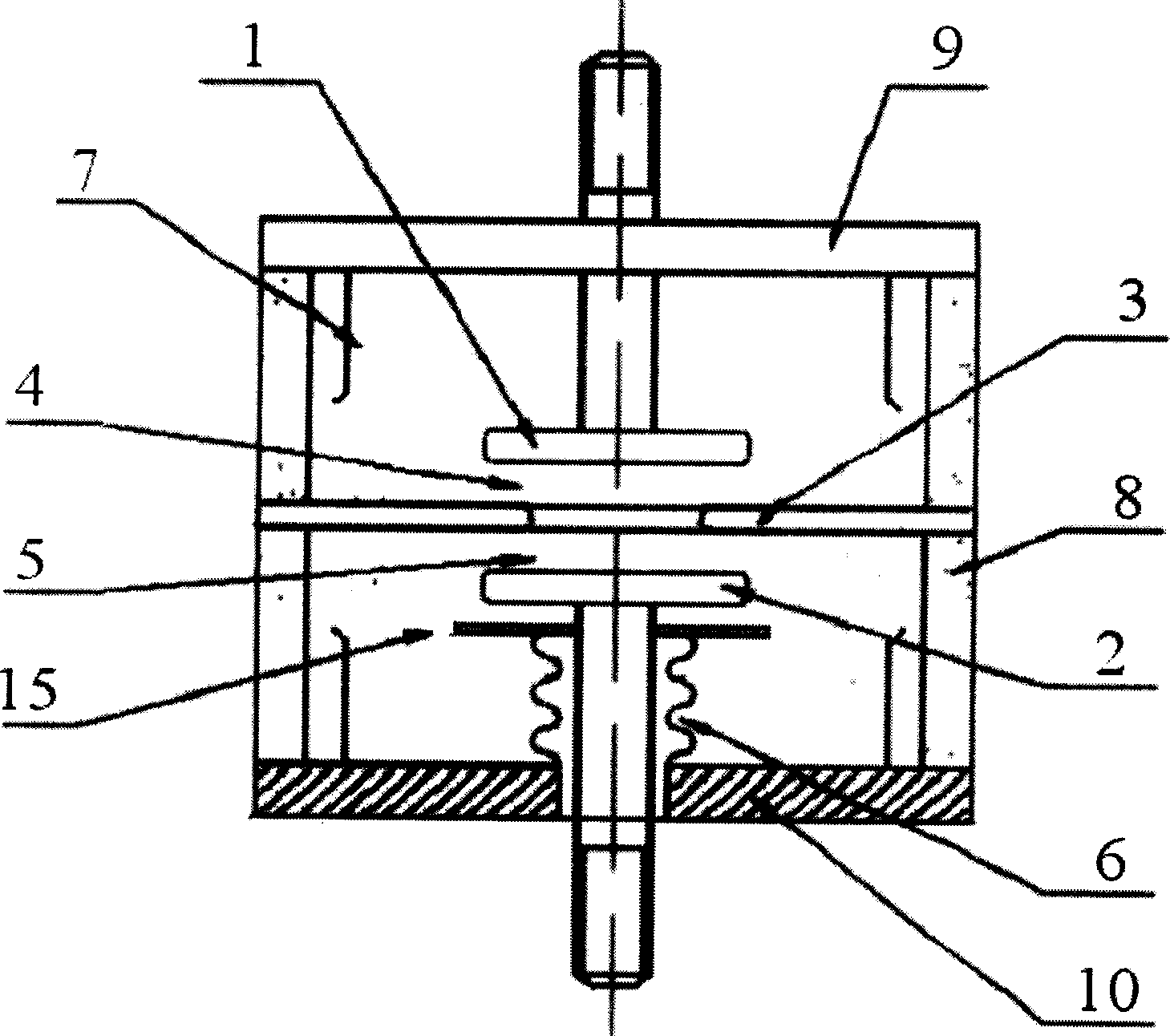

Controllable discharge switch of high-energy impulse in three electrodes under vacuum environment

InactiveCN1697107AReduce ablation rateDiffusion fastSpark gaps with auxillary triggeringHigh-tension/heavy-dress switchesElectricityHigh energy

The disclosed discharge switch includes upper and lower electrodes setup inside insulated case. Pressure inside the air locked shell body formed by the insulated case and flanges at two ends of the case is 10 -3 - 10 -4 Pa. At least one of the upper and lower electrodes is a movable electrode. Trigger electrode is inlaid inside the fixed electrode or setup between the upper and lower electrodes. Since being air locked in vacuum environment, the upper and lower electrodes possess tremendous ability of ducting transient current in high energy. Moreover, operation reliability of pulse switch is raised because vacuum environment is not interfered from outside. Features are: raised reliability, very low ablation rate of electrode, and wide range of stable operation voltage.

Owner:XI AN JIAOTONG UNIV

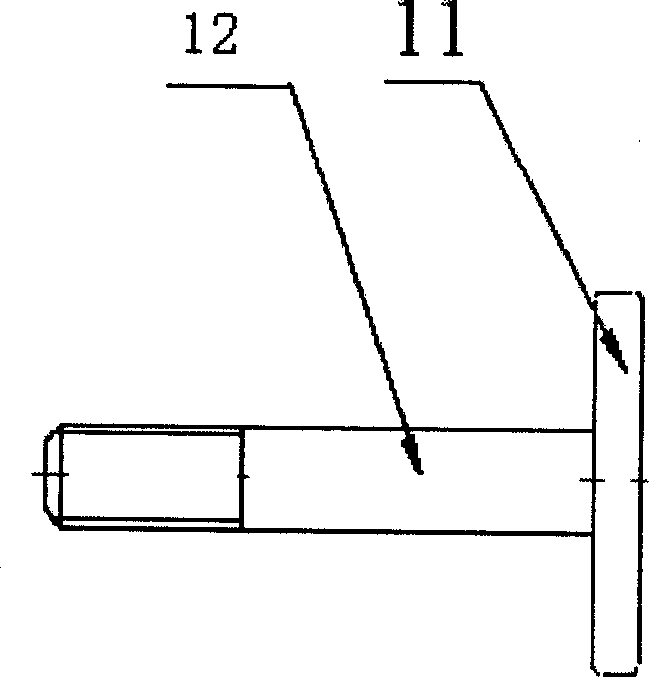

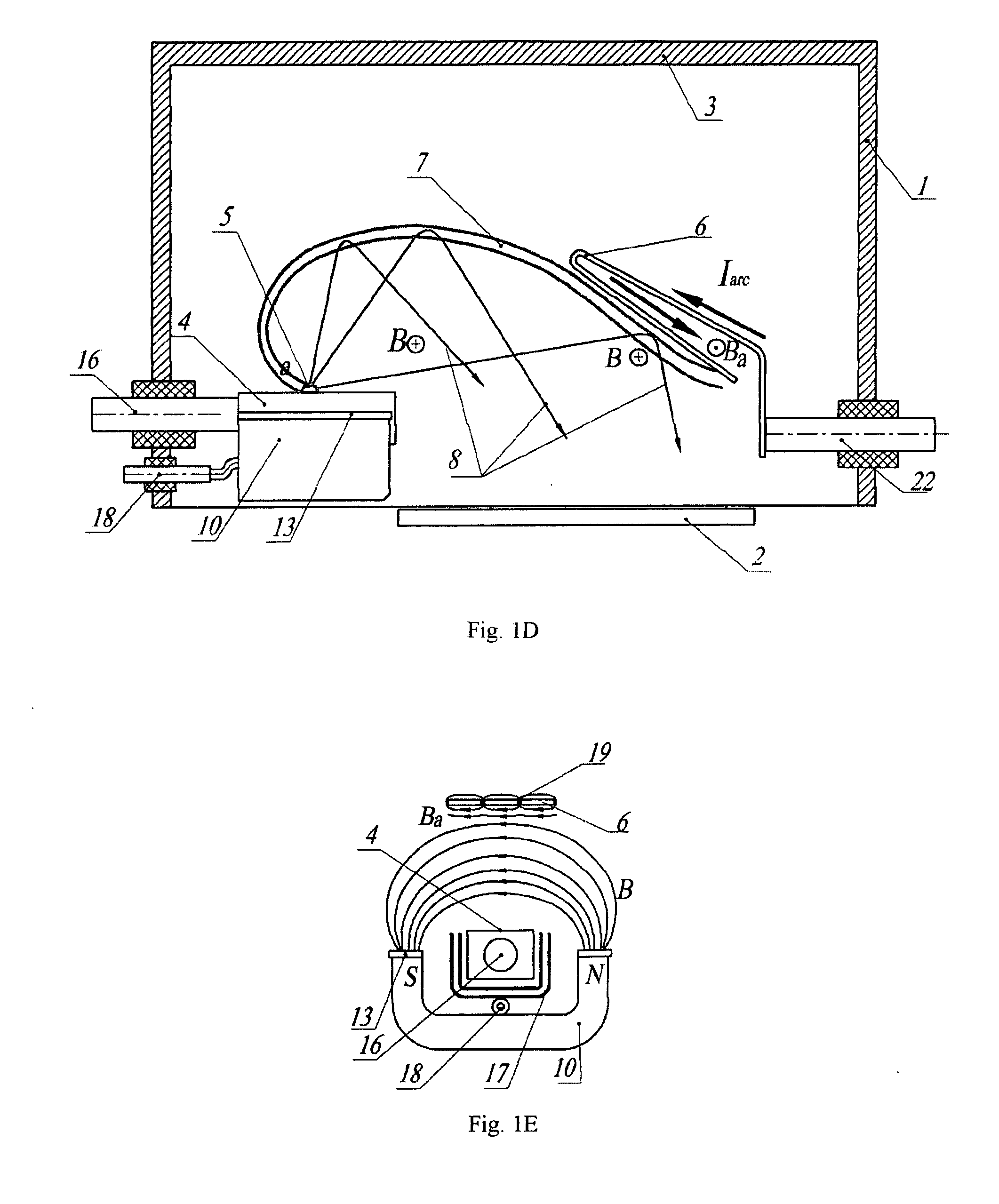

Cathode-arc source of metal/carbon plasma with filtration

InactiveUS20070034501A1Improve transportation efficiencyIncrease the number ofCellsElectric discharge tubesStationary conditionsCurrent sheet

The a cathode-arc source of metal plasma with filtration, used, in particular, for deposition of DLC, utilizes the effect of fast ions reflection from the Hall stratum in a transversal arched magnetic field to filtrate vacuum arc plasma arc from contaminating macroparticles and vapor. Various embodiments for producing maximal plasma flux at the source outlet, in particular, a pulse source with more the one cathode units for deposition of coating inside pipes / cavities, for deposition of coating in a stationary / quasi-stationary condition are offered. The cathode is made of a consumable material and is exposed to poles of magnets on both ends of cathode for creating a transversal magnetic field of an arched configuration in a discharge gap between the cathode and the anode. The anode geometry adequate to the mechanism of the arc current passage through a transversal magnetic field is offered. To avoid longitudinal and transverse short circuits of the current layer, an installation of non-conducting surfaces at ends or sectioned shields under a floating potential at the cathode sides is provided. The method of creating the Hall stratum in said transversal magnetic field of arched configuration is offered.

Owner:BENDER EFIM

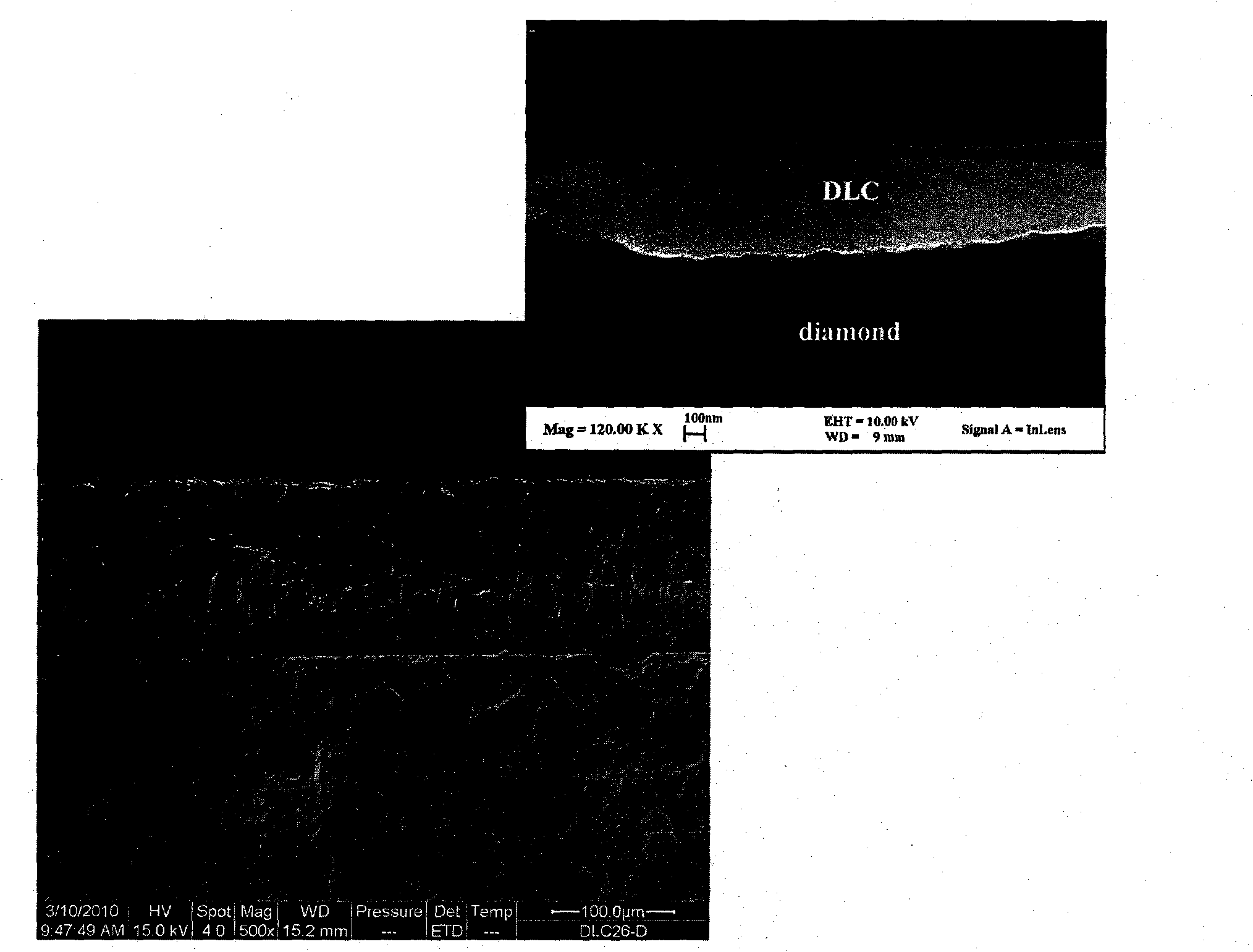

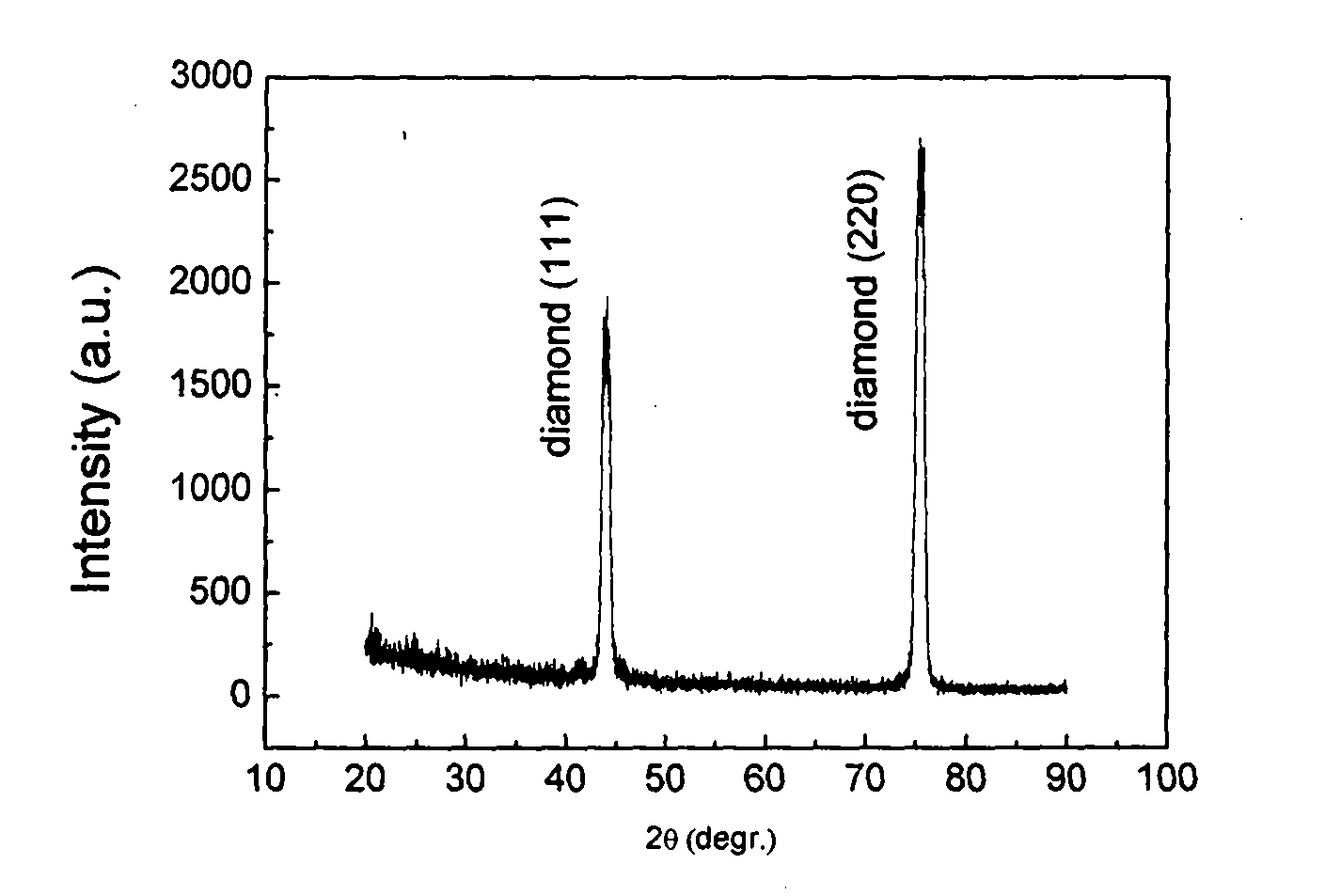

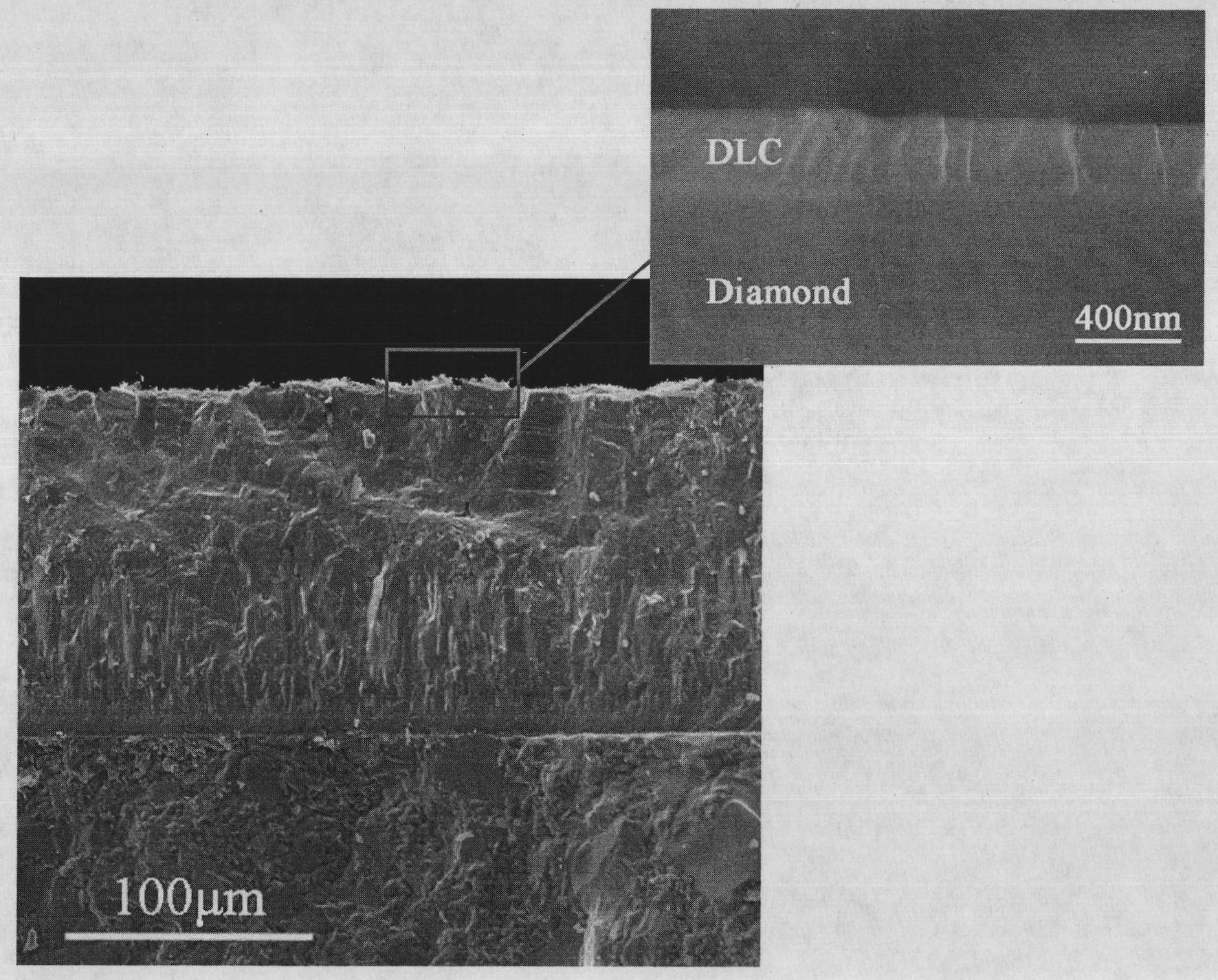

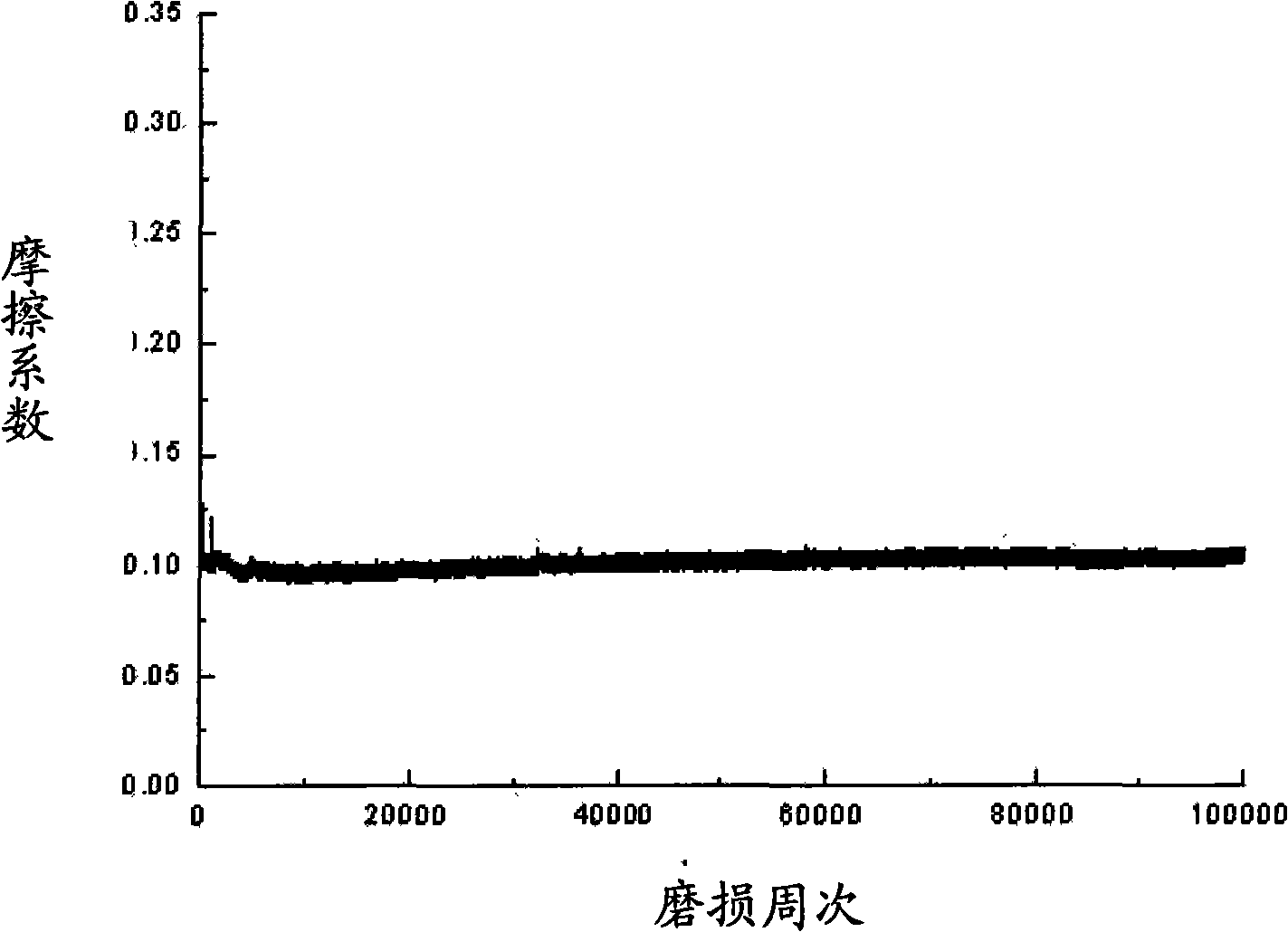

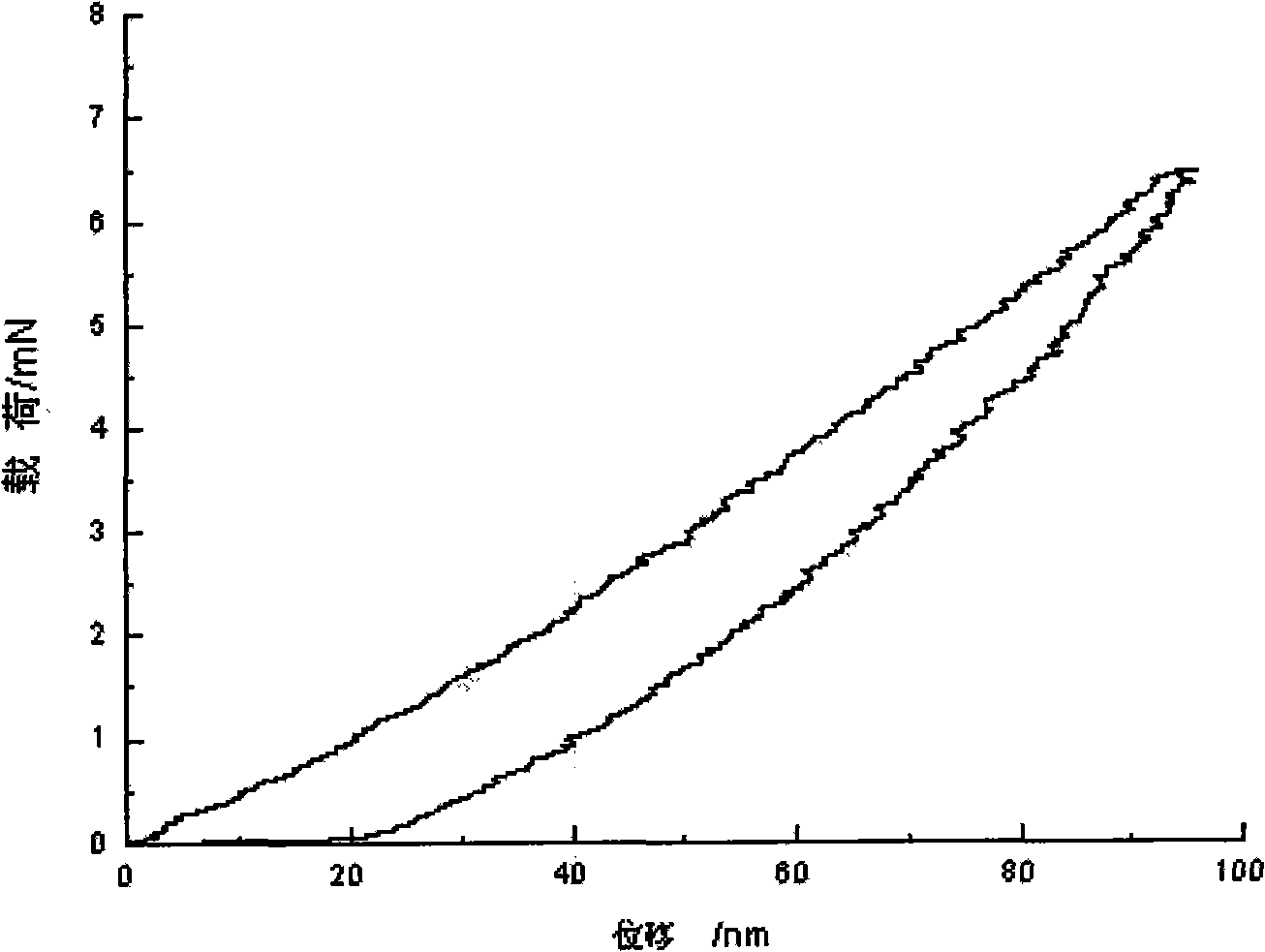

Super-hard self-lubricating diamond/diamond-like composite laminated coating material and preparation method thereof

ActiveCN101818332AThe process steps are simplePrecise and controllable synthesis conditionsChemical vapor deposition coatingPolymer scienceMagnetic filtration

The invention relates to a tool coating material and a preparation method thereof, and belongs to the technical field of material preparation and application. The material is a diamond / diamond-like composite laminated coating material with super-hard self-lubricating property. The method for preparing the diamond / diamond-like composite laminated coating material is characterized by comprising the following steps of: firstly, pretreating a matrix by using mixed solution of acid and alkali respectively; secondly, synthesizing diamond with ultrahigh hardness and good crystalline form on the matrix, which serves as the main body of the composite coating, by adopting hot filament chemical vapor deposition; and finally, depositing a high-hardness diamond-like thin film on the main body of the diamond, which serves as a self-lubricating surface layer, by using magnetic filtration cathodic vacuum arc. In order to improve the binding force between the diamond thin film and the matrix and between the diamond-like thin film and the diamond thin film, a transition layer is coated between adjacent layers respectively. The method has the advantages of simple process, precise and controllable synthesis conditions, high film-forming quality, high product yield, low cost, and the like. The obtained diamond / diamond-like composite laminated coating material has ultrahigh hardness, extremely low friction factor and extremely low wear rate, shows excellent self-lubricating friction and wear resistance, and has significance for application of tools or molds under rigorous service conditions.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

Preparation of high-hardness diamond-like multi-layer film

InactiveCN101298656AIncreasing the thicknessReduce hardnessVacuum evaporation coatingSputtering coatingVacuum chamberVacuum arc

The invention discloses a preparation method of a multilayer diamond-like film with high hardness, which comprises the following steps: a substrate is sputter cleaned, the diamond-like film is deposited by a depositing method with magnetic filtering and cathode vacuum arc, and the depositing method comprises steps of closing a vacuum chamber, vacuumizing the vacuum chamber to the pressure of 10<-3> Pa, turning on a pot lead cathode arc source, exerting negative bias voltage from minus 50 V to minus 200 V on the substrate and simultaneously and periodically letting in argon of 99.99 percent; furthermore, a control period lasts for 120 to 600 seconds, the time for letting in the argon is 10 to 50 percent of the control period, and the argon pressure in the vacuum chamber during argon inletting is 0.01 to 0.1 Pa; time for shutting off the argon is 90 to 50 percent of the control period, and the vacuum degree of the vacuum chamber at the time is 10<-4> to 10<-3> Pa; the number of the control periods is 3 to 50. The preparation method of the multilayer diamond-like film with high hardness has simple technique, low cost, produced films with strong bonding force, high hardness, large thickness, small stress and excellent mechanical and tribology performance; as well as wide application space in the industrial application field.

Owner:SOUTHWEST JIAOTONG UNIV

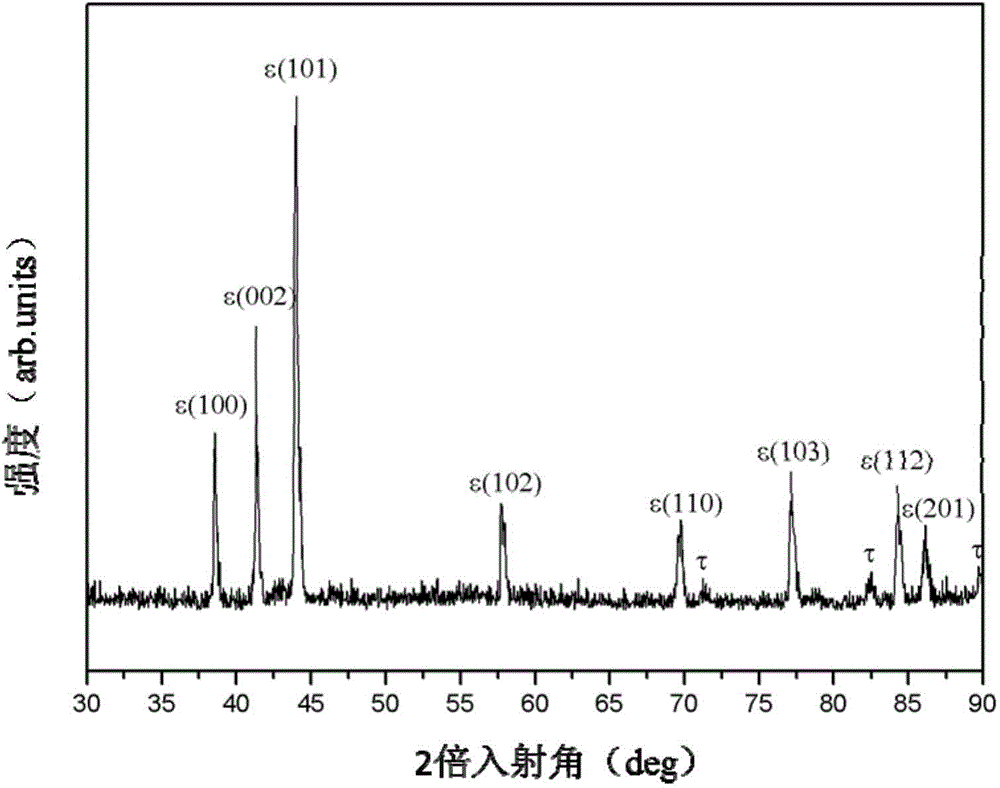

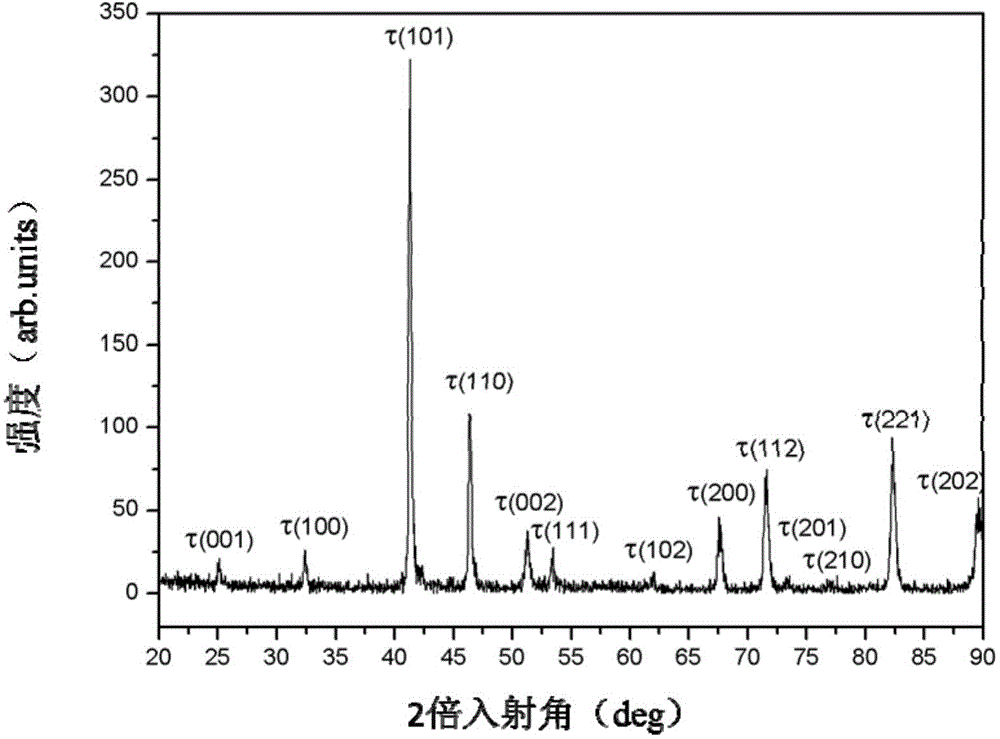

Preparation method of non-rare earth MnAl permanent magnetic alloy

InactiveCN104593625AEasy to processAccelerated corrosionMagnetic materialsElectric arc furnaceRare earth

The invention relates to a preparation method of a non-rare earth MnAl permanent magnetic alloy. The preparation method comprises the following steps: (1) preparing the compositions of a master alloy sample: preparing master alloy raw materials with Mn60-xAl40+x as a nominal composition according to the atom percentage, wherein x is equal to 0-10; (2) smelting the master alloy: adopting a non-self-consumable electric arc furnace, putting the prepared master alloy raw materials into a water cooling copper crucible, and repeatedly smelting the alloy for 3-5 times to obtain a MnAl alloy ingot with uniform compositions; (3) preparing an MnAl alloy ribbon by the MnAl alloy ingot by adopting a single-roller rapid quenching method; (4) carrying out vacuum heat treatment: carrying out vacuum heat treatment on the MnAl alloy ribbon obtained in the third step to obtain a tau-phase MnAl alloy; and (5) mechanical ball milling: ball milling the tau-phase MnAl alloy obtained in the fourth step to obtain tau-phase MnAl alloy powder, namely the non-rare earth MnAl permanent magnetic alloy with high coercivity. Compared with the prior art, according to the preparation method disclosed by the invention, the cost is low, the preparation process is simple, and the obtained MnAl permanent magnetic alloy is good in permanent magnetic property and high in coercivity.

Owner:TONGJI UNIV

High-strength low-elasticity modulus TiZrNbHf high-entropy alloy and preparation method thereof

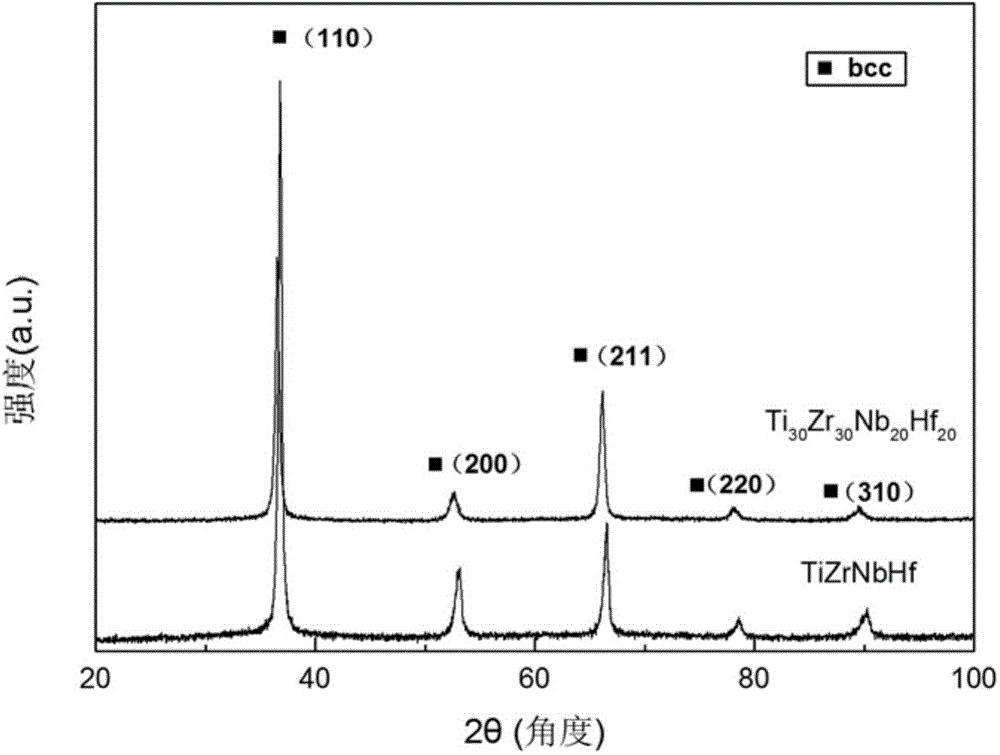

ActiveCN103602874ALow Young's modulusExcellent structural stabilityHigh entropy alloysYoung's modulus

The invention relates to a high-strength low-elasticity modulus TiZrNbHf high-entropy alloy and a preparation method thereof; the component of the high-entropy alloy is TiaZrbNbcHfd, wherein a is not less than 20 and not more than 35, b is not less than 20 and not more than 35, c is not less than 20 and not more than 35, and d is not less than 20 and not more than 35. The preparation method of the alloy comprises the following steps: descaling metallurgy raw materials (Ti, Zr, Nb and Hf metals), precisely weighing and proportioning according to a mole ratio for smelting alloy; smelting the alloy by using a non-consumable vacuum arc furnace or a cold crucible suspension furnace, smelting the alloy in a water-cooling copper crucible, suction casting or pouring the alloy in a copper mold through vacuum suction casting or metal mold equipment so as to obtain high-entropy alloy rod or platy material. The high-entropy alloy has high strength, low Young modulus, and excellent structure property stability at a high temperature, the alloy element is non-toxic to human body or low in toxicity; and therefore, the high-entropy has good application prospect on biomedical and high-temperature components.

Owner:UNIV OF SCI & TECH BEIJING

TiZrHfNb based high-entropy alloy with nitrogen and oxygen alloyed together and preparation method thereof

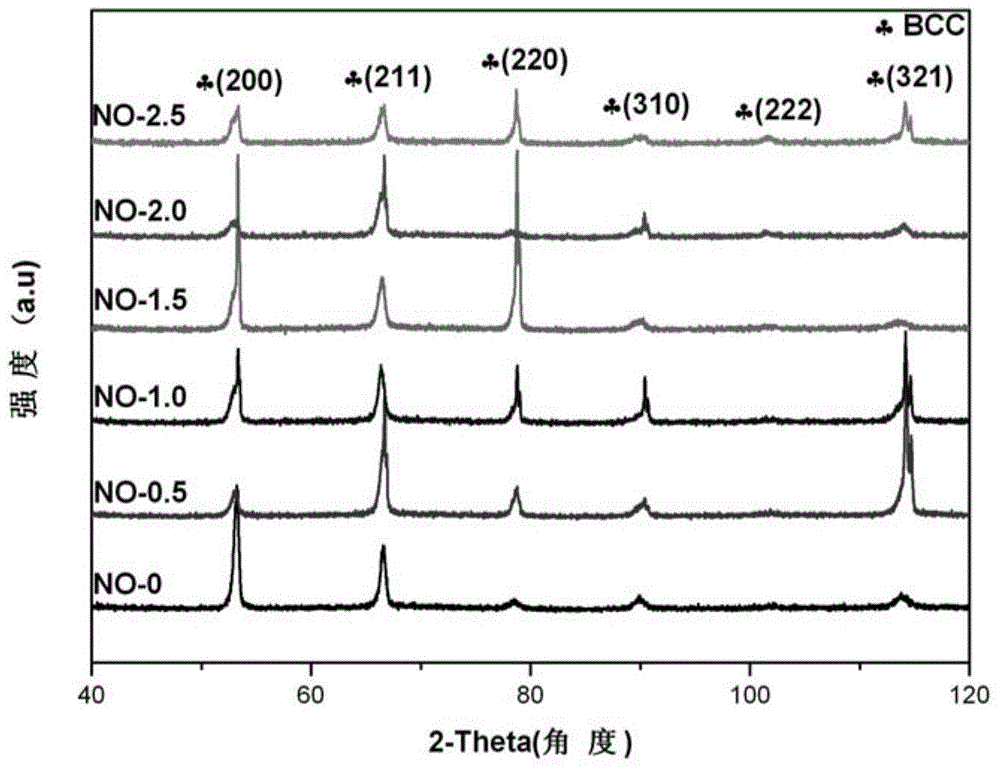

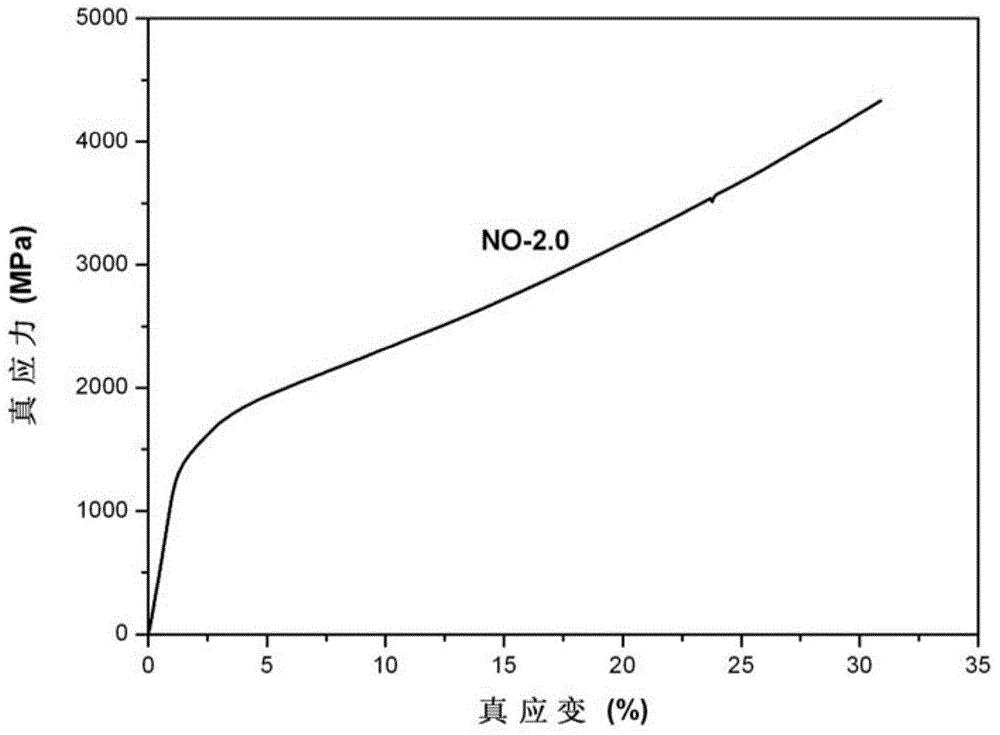

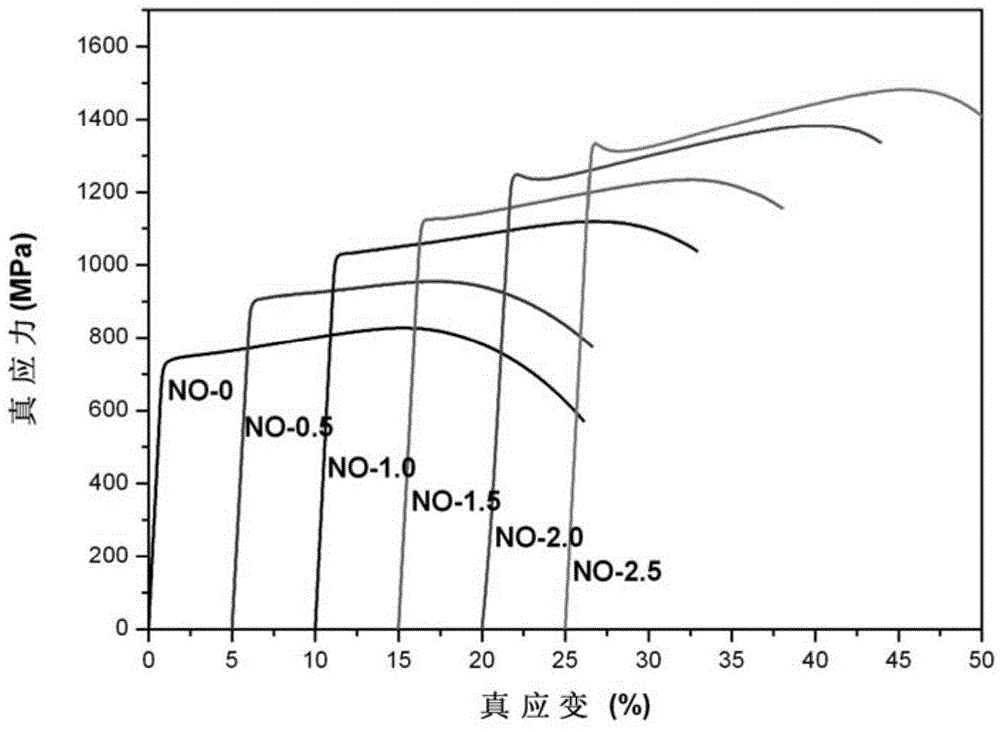

ActiveCN105671404AWide range of ingredientsWide range of preparation conditionsHigh entropy alloysOxygen

The invention relates to TiZrHfNb based high-entropy alloy with nitrogen and oxygen alloyed together and a preparation method thereof. Particularly, the tensile strength and tensile ductility of the alloy are remarkably improved by simultaneously microalloying N and O elements. The preparation method includes the following steps that metal raw materials of Ti, Zr, Hf and Nb are accurately weighed according to the molar ratios after oxide skin is removed; other added elements are accurately weighed according to the molar ratios after oxide skin is removed and the elements are washed with alcohol; the N element is added in the form of nitride, and the O element is added in the form of oxide; and target alloy is smelted in a nonconsumable vacuum arc furnace or cold crucible shower furnace, and the alloy is obtained through vacuum suction casting or casting equipment. The tensile property of the high-entropy alloy is improved remarkably by simultaneously adding the N and O elements, the tensile strength of (TiZrHfNb)97.5(NO)2.5 based high-entropy alloy reaches 1300 MPa, meanwhile, the tensile ductility exceeds 15%, the work-hardening rate is low, and the comprehensive tensile property is excellent.

Owner:UNIV OF SCI & TECH BEIJING

Cathodic vacuum arc source film depositing device and method for depositing film

ActiveCN101792895AIncrease deposition rateCompact structureVacuum evaporation coatingSputtering coatingEngineeringLarge particle

The invention discloses a cathodic vacuum arc source film depositing device which comprises a magnetic filtering part capable of transferring plasma at high speed and effectively filtering macro-large particles, wherein the magnetic filtering part comprises a tube body and a magnetic field generator which is arranged at the external periphery of the tube body; the tube body comprises an inlet end surface of the tube body and an outlet end surface of the tube body, at least one bent tube is arranged between the inlet end surface of the tube body and the outlet end surface of the tube body, and an included angle between the axial lines of the tube body at two sides of the bent tube is 135 degrees; and the introducing amount of inert gases in the device is 10-50sccm, and the vacuum degree is 1.0*10-5 to 5.0*10-5Torr after the device is vacuumized. Compared with the prior art, the cathodic vacuum arc source film depositing device of the invention can realize the purposes of effectively filtering macro-large particles and simultaneously transferring plasma at high speed, thereby improving the quality and the deposition rate of the film. The method of the invention can be used for depositing the film at high speed, the deposited film has compact structure, smooth surface and large uniform region area, and the method can be used for depositing high-performance ta-C films.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

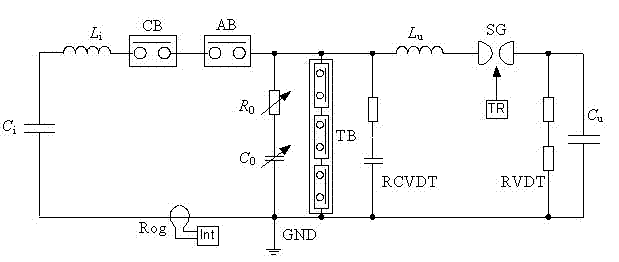

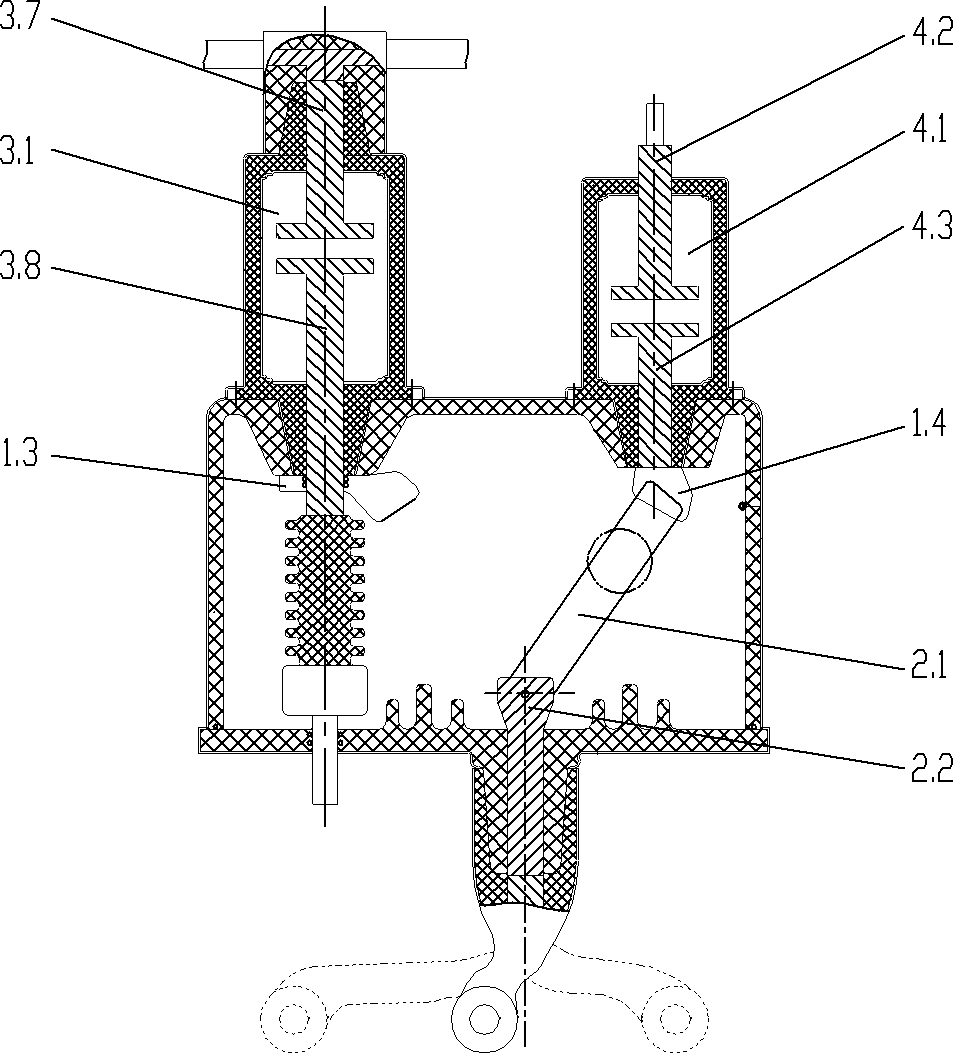

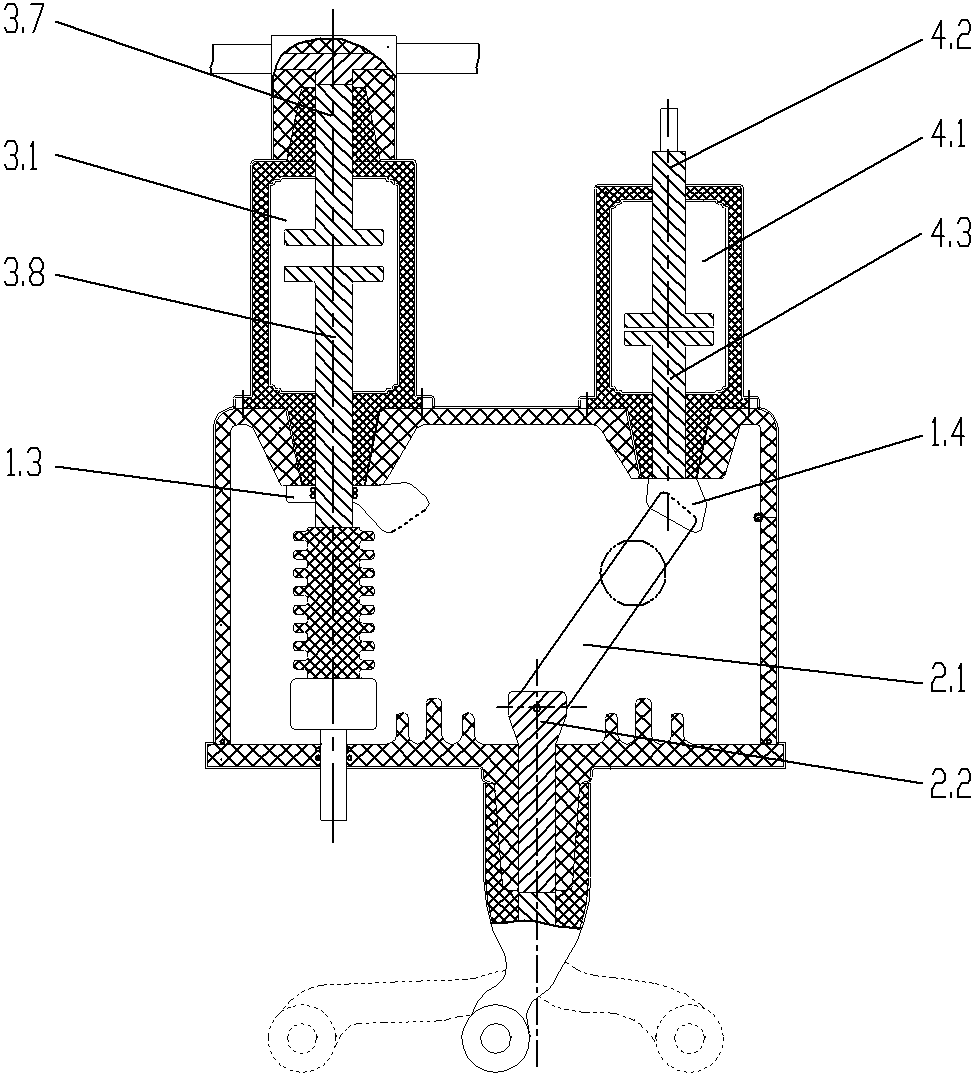

Vacuum circuit breaker based on T-shaped double break vacuum arc-extinguishing chamber

InactiveCN103050324AEnsure consistencyConducive to extinguishingHigh-tension/heavy-dress switchesAir-break switchesControl signalVacuum arc

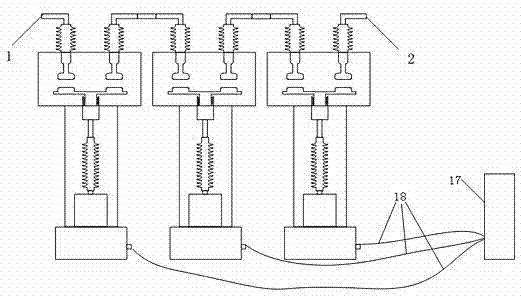

The invention discloses a vacuum circuit breaker based on a T-shaped double break vacuum arc-extinguishing chamber, which can effectively reduce the cost, improves the voltage withstanding level of a single arc-extinguishing chamber, is easy to be in series connection to form an ultrahigh-voltage and superhigh-voltage vacuum circuit breaker. The vacuum circuit breaker comprises a vacuum arc-extinguishing chamber, an insulated ceramic column, an operating mechanism and a control case, a control signal input end is arranged on the control case, the insulated ceramic column is internally provided with an insulated connection rod which is connected with the operating mechanism, the upper end of the insulated connection rod is connected with a movable conducting rod in a guiding sleeve, the upper end of the movable conducting rod is connected with a movable contact connecting board which is arranged in the vacuum arc-extinguishing chamber, the transverse left end and the transverse right end of the movable contact connecting plate are respectively and correspondingly provided with a left movable contact and a right movable contact, a left static contact and a right static contact are correspondingly and fixedly arranged on the left movable contact and the right movable contact, the left static contact is connected with an incoming line, the right static contact is connected with an outgoing line, and bushings are sleeved on the incoming line and the outgoing line.

Owner:DALIAN UNIV OF TECH

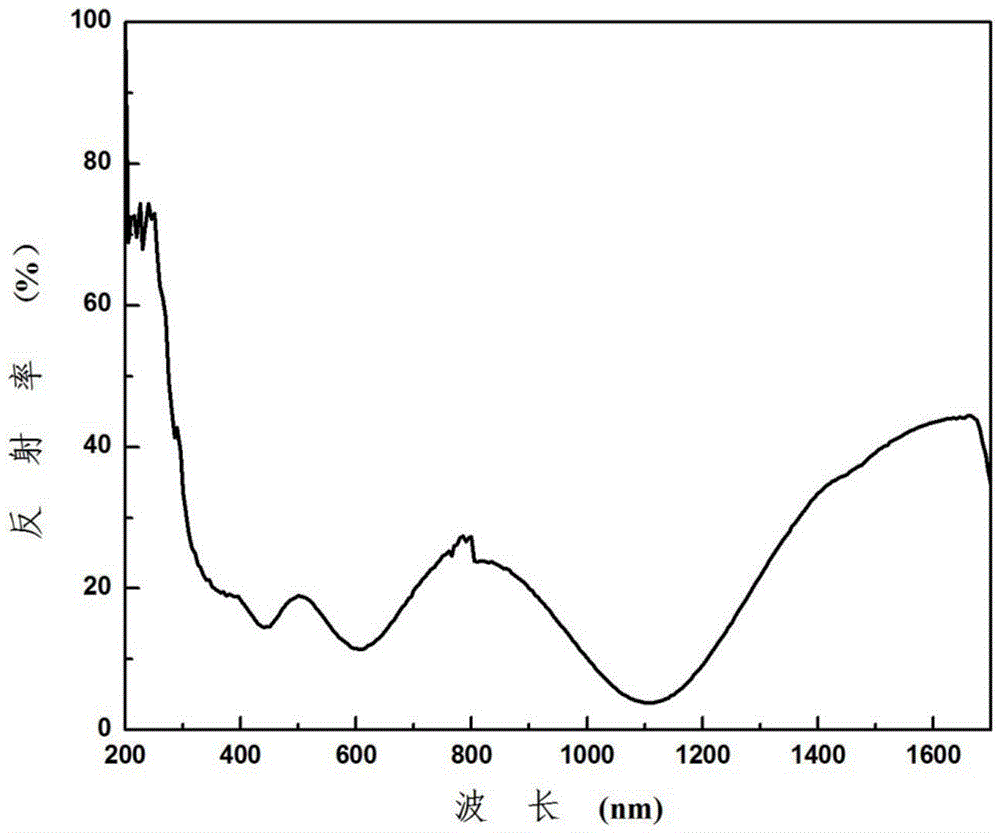

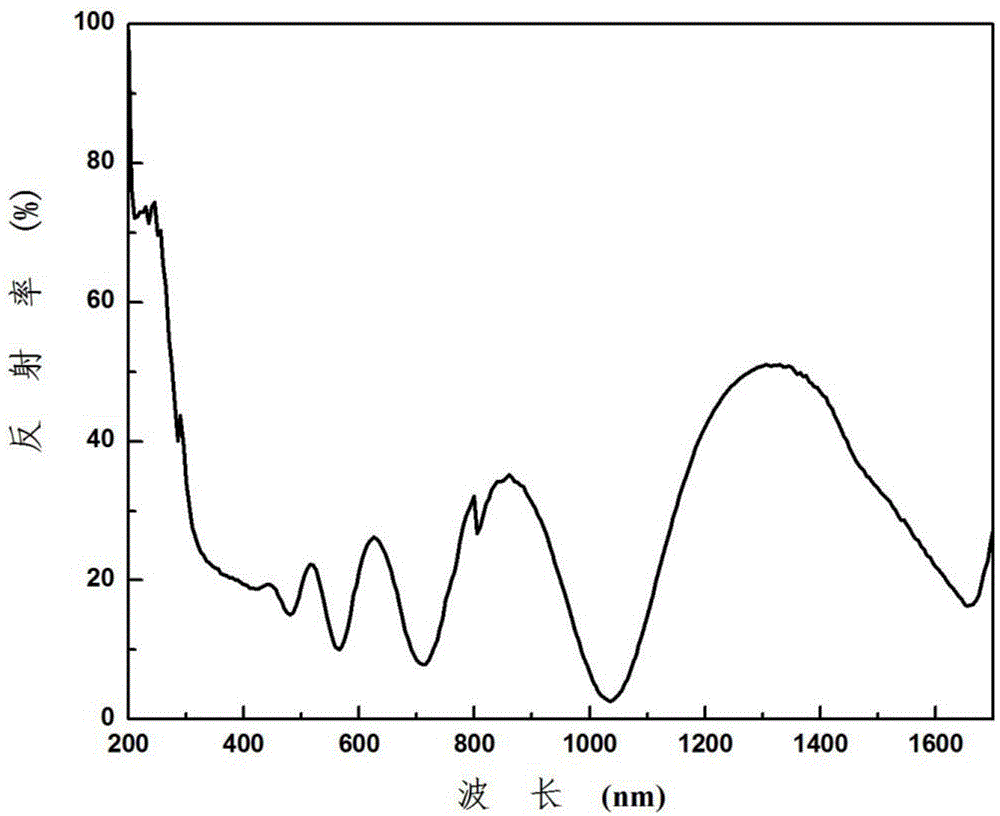

High-property optothermal transformation multiple-element alloy nitride film and preparation method thereof

ActiveCN104630706AEasy to prepareEasy to operateVacuum evaporation coatingSputtering coatingHigh absorptionHeat stability

The invention relates to a high-property optothermal transformation multiple-element alloy nitride film and a preparation method thereof. The preparation method comprises the following steps of successfully preparing a multiple-element alloy sputtering target material by adopting a powder metallurgic method and a vacuum arc melting method; preparing multiple-element alloy nitride films with different thicknesses by adopting a vacuum magnetron sputtering film coating process and changing sputtering time and working air pressure so as to provide a new material for a solar spectrum selective-absorption coating, wherein the typical structure of the solar spectrum selective-absorption coating is of a sandwich structure which includes an infrared reflecting layer, a dual-absorption layer and an anti-reflection layer, and the solar spectrum selective-absorption coating has higher absorption rate and heat stability. According to the preparation method, a single-layer multiple-element alloy nitride film is sputtered on a polished stainless steel substrate, the single-layer multiple-element alloy nitride film is detected to have higher absorption rate of 79.82% compared with other single-layer optothermal transformation films within a solar spectrum range, and the obtained multiple-element alloy nitride film is uniform in thickness and has good combining capacity and high-temperature resistant property with the substrate. The high-property optothermal transformation multiple-element alloy nitride film disclosed by the invention is suitable for a high-temperature vacuum heat-collecting pipe and has wide application prospect in the field of solar optothermal.

Owner:安徽科鑫光热技术有限公司

Large diameter ingots of nickel base alloys

InactiveUS20020170386A1Difficult to extractIncrease the diameterWelding/cutting media/materialsElectric furnaceCasting moldHeating furnace

A method of producing a nickel base alloy includes casting the alloy within a casting mold and subsequently annealing and overaging the ingot at at least 1200° F. (649° C.) for at least 10 hours. The ingot is electroslag remelted at a melt rate of at least 8 lbs / min. (3.63 kg / min.), and the ESR ingot is then transferred to a heating furnace within 4 hours of complete solidification and is subjected to a novel post-ESR heat treatment. A suitable VAR electrode is provided form the ESR ingot, and the electrode is vacuum arc remelted at a melt rate of 8 to 11 lbs / minute (3.63 to 5.00 kg / minute) to provide a VAR ingot. The method allows premium quality VAR ingots having diameters greater than 30 inches (762 mm) to be prepared from Alloy 718 and other nickel base superalloys subject to significant segregation on casting.

Owner:ATI PROPERTIES

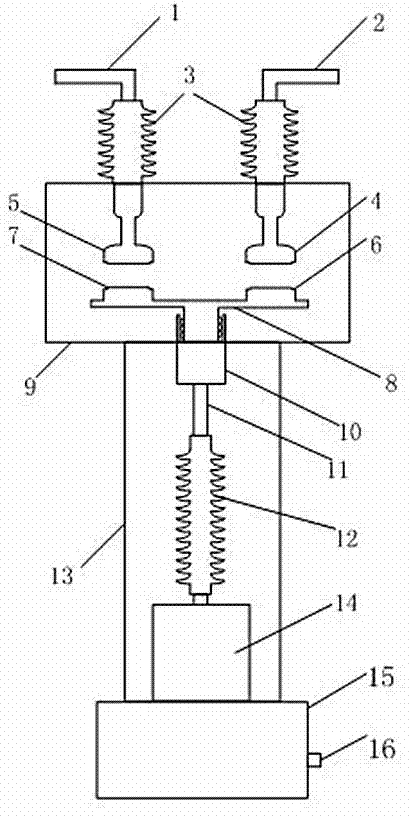

Quick high-voltage switch

InactiveCN105470041ACurb riseSafe and stable operationHigh-tension/heavy-dress switchesAir-break switchesHigh pressureMultiple fractures

The invention proposes a quick high-voltage switch. The switch comprises N vacuum arc-extinguishing chambers, N electromagnetic repulsion operation mechanisms and one energy storage and trigger unit, wherein the N vacuum arc-extinguishing chambers are connected in series; each vacuum arc-extinguishing chamber is connected with one electromagnetic repulsion operation mechanism; and the N electromagnetic repulsion operation mechanisms are controlled to be switched on or off by the energy storage and trigger unit. According to the quick high-voltage switch, multiple fractures are connected in series, so that the opening travel of the insulated fractures is increased and a higher voltage can be withstood; and only one energy storage and trigger unit is used for control, so that the switch-on and switch-off synchronicity is high and the integral switch-on and switch-off time is unchanged.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

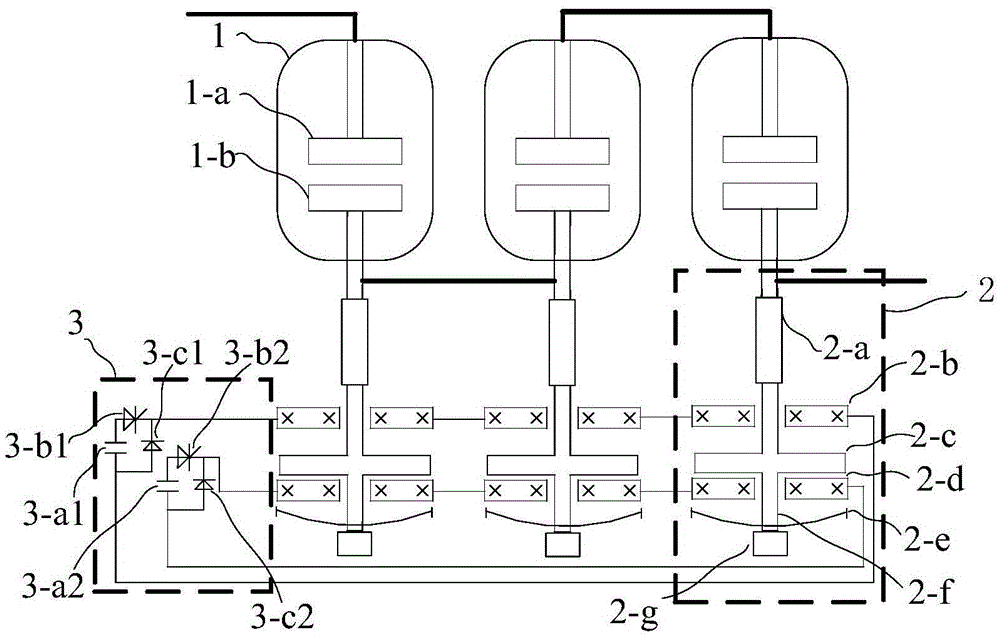

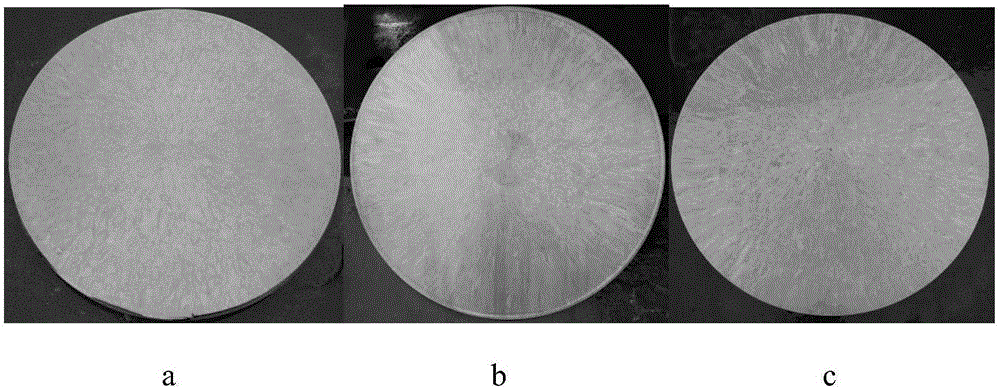

Method for controlling solidification structure of large-size TC4-DT titanium alloy ingot

The invention discloses a method for controlling a solidification structure of a large-size TC4-DT titanium alloy ingot. The method particularly comprises the steps that batching is conducted on sponge titanium and intermediate alloy according to the proportion required by the GB / T3620.1, the materials are pressed into an electrode block after being mixed, the electrode block is subjected to vacuum plasma welding and then subjected to vacuum arc furnace smelting, the arc stabilizing current and the arc stabilizing period are strictly controlled when third-time smelting is conducted in the smelting process, and lastly the finished ingot product is obtained after surface machining is conducted. According to the method, VAR three-time smelting is conducted, the solidification structure of the TC4-DT titanium alloy ingot is uniformized by adopting an appropriate arc stabilizing parameter technology when third-time smelting is conducted, and therefore the problem that grain crushing is difficult in the forging process due to the fact that the solidification structure of an existing large-size (ranging from phi 720 mm to phi 1,000 mm) TC4-DT titanium alloy ingot is thick and big is solved.

Owner:西部超导材料科技股份有限公司

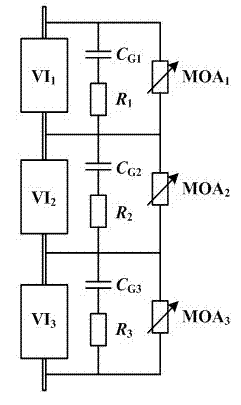

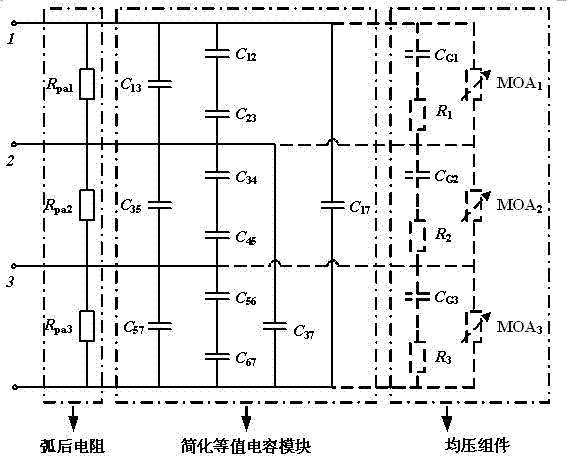

Dynamic voltage sharing device of multi-break vacuum circuit breaker and parameter selection method for dynamic voltage sharing device

InactiveCN102364655AReduce reburn rateImprove breaking capacityHigh-tension/heavy-dress switchesAir-break switchesCapacitanceCurrent limiting

The invention provides a dynamic voltage sharing device of a multi-break vacuum circuit breaker and a parameter selection method for the dynamic voltage sharing device. A voltage sharing capacitor, a current limiting resistor and a zinc oxide arrester are used as a dynamic voltage sharing component of a multi-break serial vacuum circuit breaker; and the voltage sharing capacitor is connected in series with the current limiting resistor and then is connected in parallel with the zinc oxide arrester. The optimal value of relative parameters is selected in combination with vacuum arc model-based electromagnetic transient simulation according to a synthesis test. According to the technical scheme, reliable switch-off of a plurality of vacuum arc extinguish chambers during serial operation can be ensured, and the vacuum circuit breaker can be applied in the voltage range of 110kV and more than 110kV.

Owner:WUHAN UNIV +1

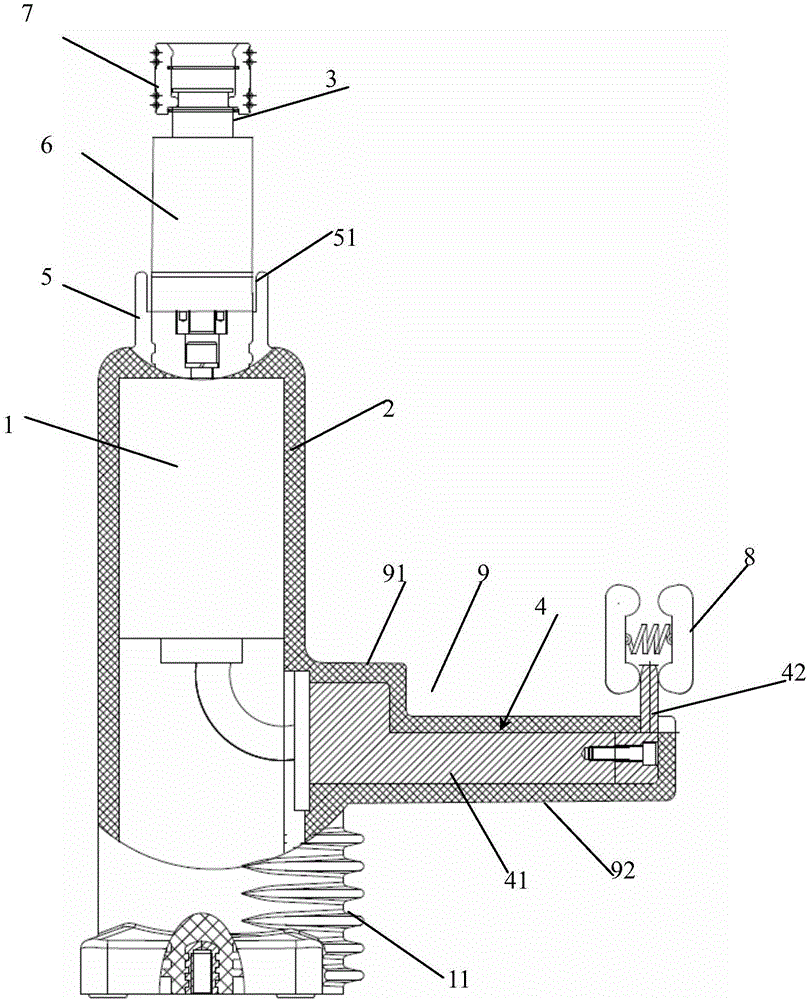

Side line outgoing type vacuum post terminal and handcart type side-mounted circuit breaker

InactiveCN106024499ASimple structureOperational securitySwitchgear with withdrawable carriageHigh-tension/heavy-dress switchesElectricityElectrical conductor

The invention discloses a side line outgoing type vacuum post terminal which comprises an insulation barrel with a vacuum arc-extinguishing chamber inside, an upper line outgoing conductor and a lower line outgoing conductor. The upper line outgoing conductor and the lower line outgoing conductor are electrically connected with the vacuum arc-extinguishing chamber respectively. The upper line outgoing conductor is arranged in the axial direction of the insulation barrel. The lower line outgoing conductor comprises an inclined section and a vertical section, wherein the inclined section keeps an included angle with the axial direction of the insulation barrel, and the vertical section is parallel to the axial direction of the insulation barrel. The high-medium pressure side outgoing type vacuum post terminal is simple in overall structure and safe and reliable in operation, the arrangement way of the lower line outgoing conductor is changed, the overall size is smaller so that the side line outgoing type vacuum post terminal can be applicable to a side-mounted circuit breaker, meanwhile, handcart operation can be achieved, and the advantages of the side-mounted circuit breaker are brought into full play.

Owner:天津市先智电气设备有限公司

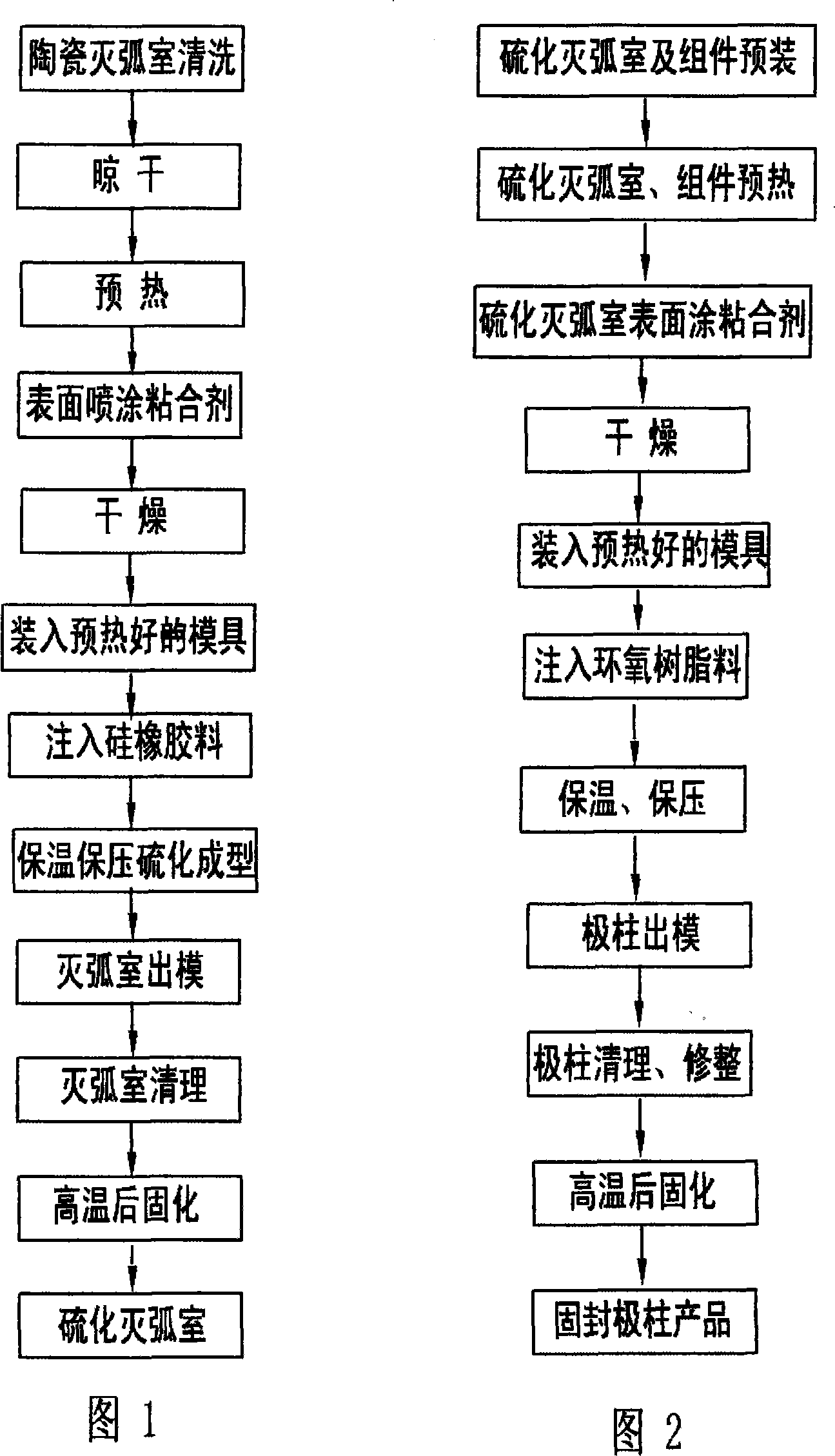

Production technology for solid sealing electrode pole of high voltage vacuum breaker

ActiveCN101127280ASimple processImprove insulation performanceHigh-tension/heavy-dress switchesAir-break switchesEpoxyAdhesive

The utility model relates to a production process for a xerogel of high voltage vacuum circuit breaker, which is characterized in that a high temperature vulcanizing silicone rubber is adopted as a transitional material between epoxy resin and a porcelain housing of the a vacuum interrupter chamber, and adhesive is applied evenly on the connecting planes between the vulcanizing silicone rubber and the porcelain housing of the vacuum arcing chamber and between the vulcanizing silicone rubber and the epoxy resin. The process comprises two parts: first, the arcing chamber of the high voltage vacuum breaker xerogel is made by using vulcanizing process, second, the integration formation of the high voltage circuit breaker xerogel is made by utilizing an APG expoy resin winding injection process. The utility model has advantages of simple process, good insulation and reliable operation and strong acclimation capability of the produced product. The utility model is applicable to the production enterprises of the xerogel vacuum circuit breaker.

Owner:GUANGXI YINHE DECOM ELECTRIC

Solid insulation ring main unit

ActiveCN103368096AReduce control precision requirementsGuaranteed to workSwitchgear arrangementsHigh-tension/heavy-dress switchesEngineeringVacuum switch

The invention discloses a solid insulation ring main unit, comprising a high-voltage switch unit; the high-voltage switch unit comprises a vacuum arc-extinguishing chamber and an isolation grounding switch device comprising an insulation cavity body; a line outlet end, a grounding end and a line inlet end electrically connected with a conductive rod are arranged on the insulation cavity body; a vacuum switch tube for grounding is fixedly arranged inside or outside the insulation cavity body; the static contact of the vacuum switch tube for grounding is electrically connected with the grounding end while the movable contact is provided with a grounding wiring part; the movable contact of the vacuum switch tube for grounding is in transmission connection with a grounding operative mechanism; an isolation disconnecting link is arranged in the insulation cavity body; one end of the isolation disconnecting link is a hinging end hinged to the line outlet end while the other end is a contact end; and a driving mechanism is connected onto the isolation disconnecting link in a transmission way. The isolation grounding switch is positioned in different work conditions by controlling the swinging of the isolation disconnecting link and the connecting / disconnecting states of the static and movable contacts in the vacuum switch tube.

Owner:STATE GRID CORP OF CHINA +2

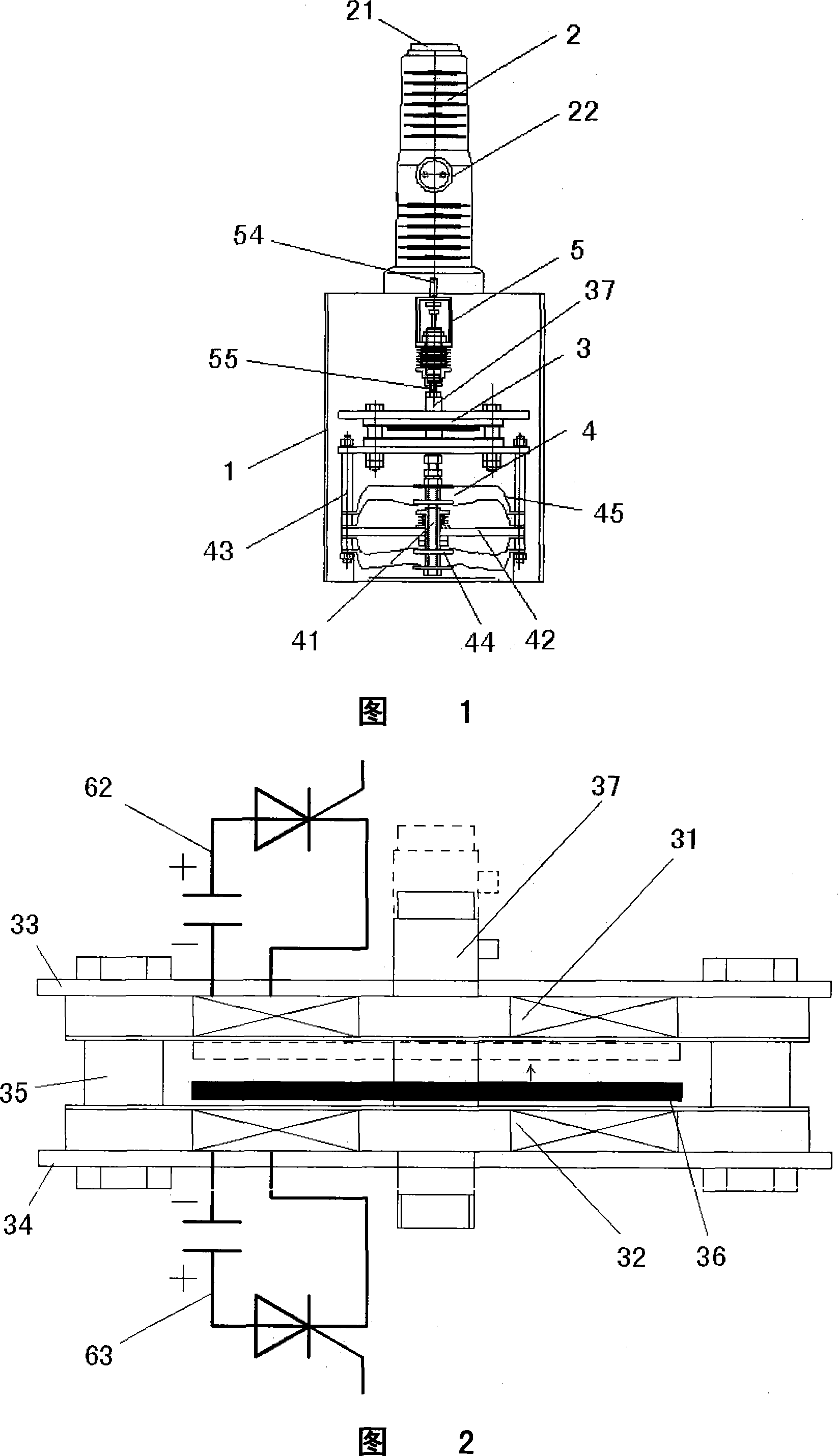

AC high voltage vacuum breaker

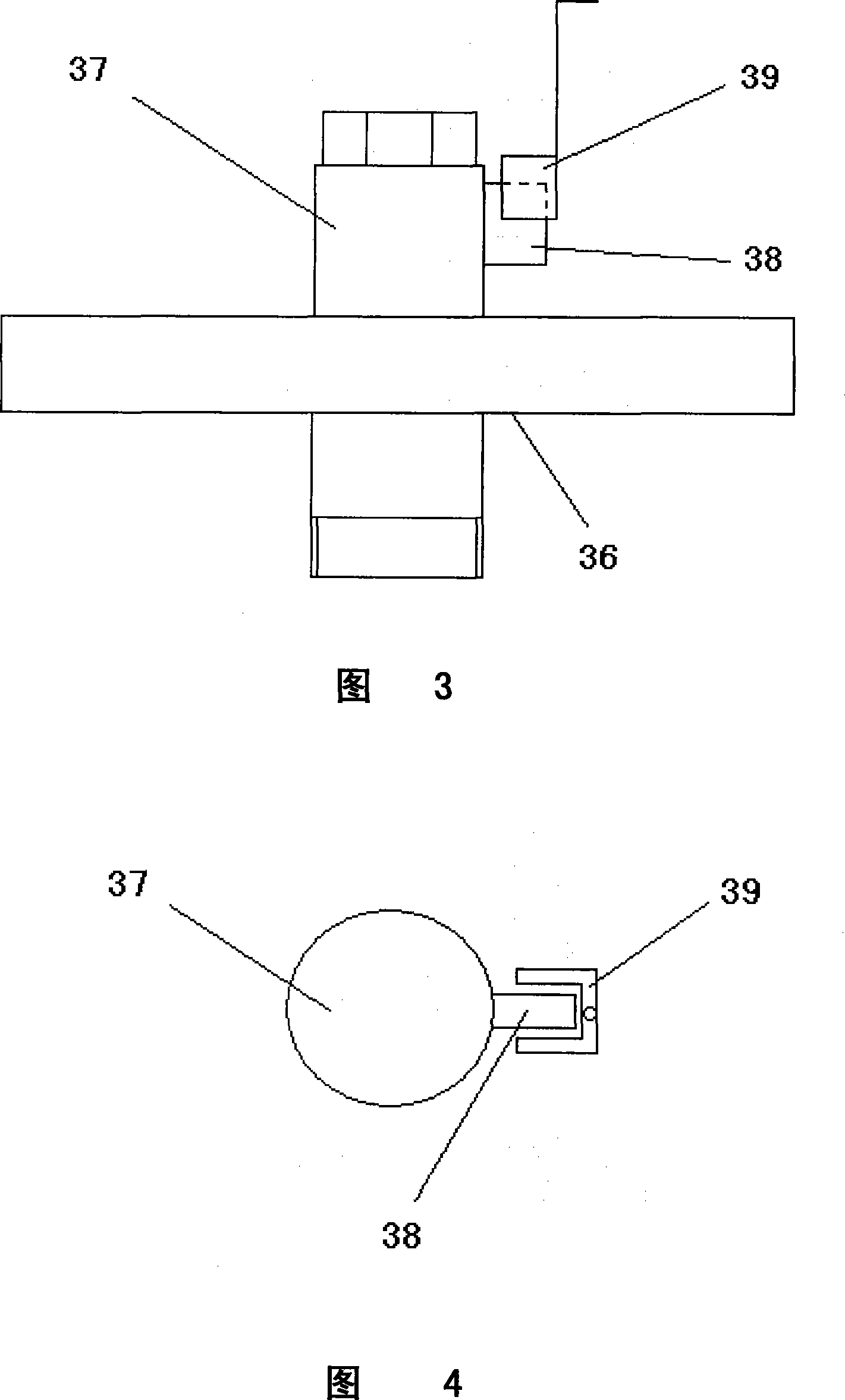

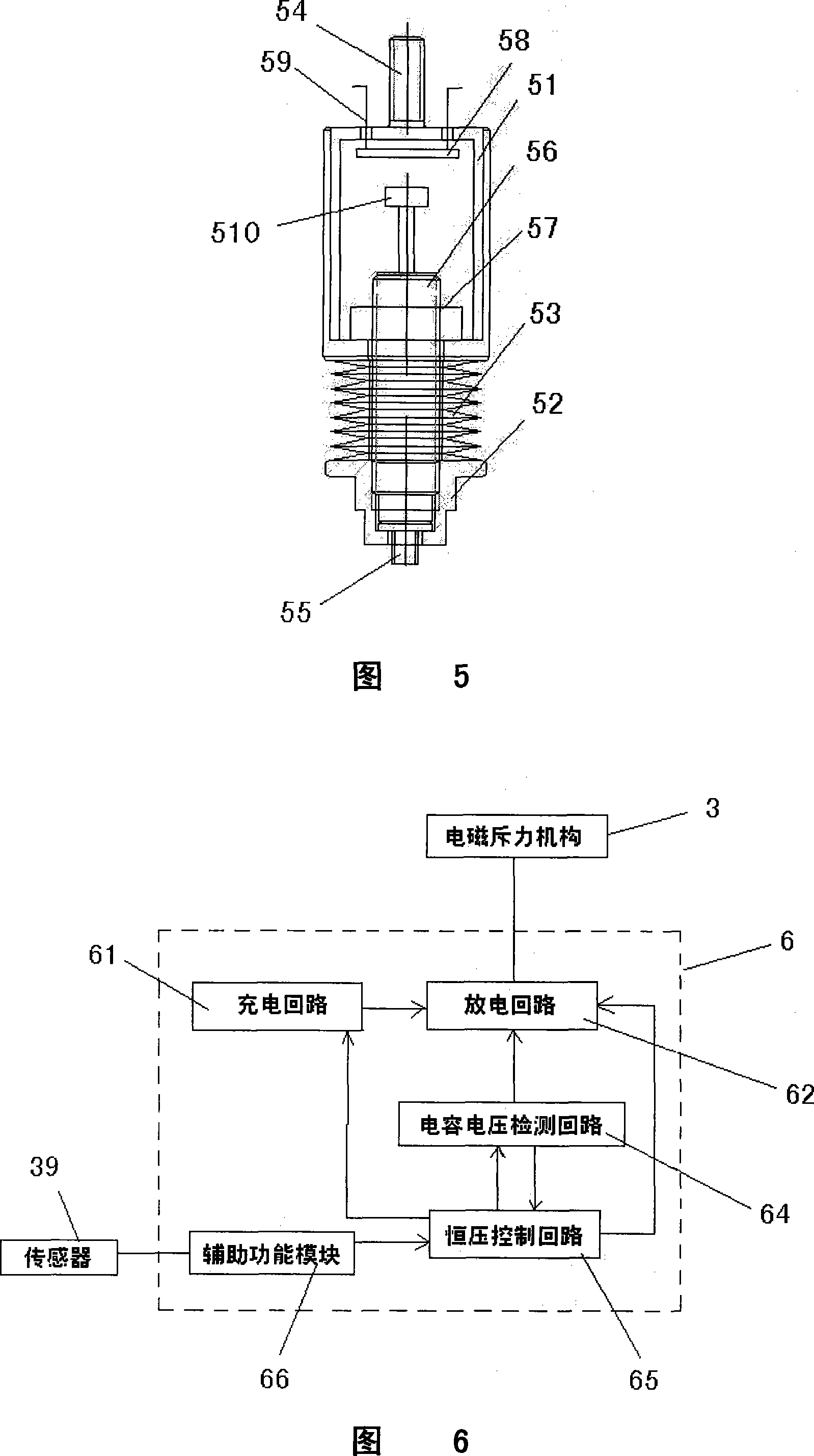

ActiveCN101226847AUndisturbedMove quicklyHigh-tension/heavy-dress switchesAir-break switchesForce structureFault current limiter

The invention relates to an alternating current high-voltage vacuum circuit breaker, which is characterized in that the invention comprises a case body, a vacuum arc extinguish chamber is seated and connected to the case body, an electromagnetic repulsive force mechanism is disposed in the case body, the mechanism comprises an open coil and a close coil which form a fixed gap, a repulsion disk arranged in the gap, a repulsion rod which is fixedly penetrated by the equipped repulsion disk, a retention capacity rod of a composite disc spring retention force structure connected with the lower end of the repulsion rod, a catch spring fixed on the retention force rod and at least two pieces of disc springs top-arranged on the catch spring. The upper end of the electromagnetic repulsive force is connected with a closing buffer gear which comprises a spring frame structure and a hydraulic cylinder, further, the closing buffer gear comprises an intelligent pulse generator. Because the invention employs the electromagnetic repulsive force mechanism, employs bi-stable composite disc springs to retain, employs the closing hydraulic pressure buffer gear to inhibit closing bouncing, and employs a photoelectric sensor to realize position returning, thereby belonging to the advanced design at home and abroad, therefore, the invention can be widely applied to the field of fault current limiters, phase selection switches, solid change-over switches and the like.

Owner:CHINA ELECTRIC POWER RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com