Production technology for solid sealing electrode pole of high voltage vacuum breaker

A technology of vacuum circuit breakers and solid-sealed poles, which is applied to high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., to achieve the effects of strong adaptability to the environment, simple process and reliable operation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

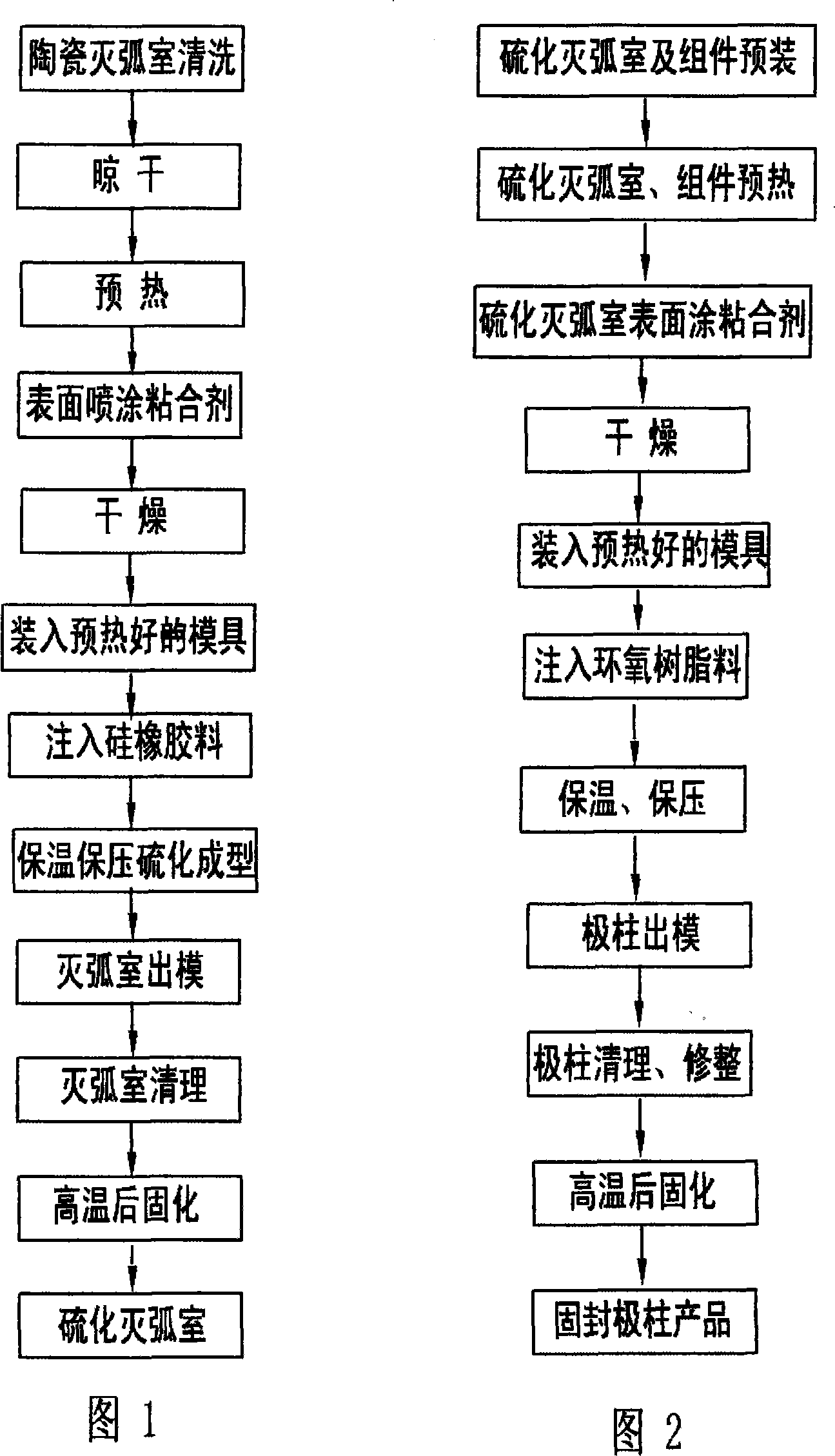

[0009] The invention adopts high-temperature vulcanized silicone rubber as the transition material between the epoxy resin and the ceramic shell of the vacuum interrupter, and evenly sprays the adhesive on the joint surface of the silicon rubber and the ceramic shell of the arc extinguisher, and the joint surface of the silicone rubber and the epoxy resin Material. The process is divided into two parts: first, the arc extinguishing chamber of the high-voltage vacuum circuit breaker's solid-sealed pole is made by the vulcanization process, and then the high-voltage vacuum circuit-breaker's solid-sealed pole is integrally formed by the APG epoxy resin injection process. Silicone rubber is directly molded on the outer surface of the vacuum interrupter by vulcanization technology, which serves as a transition layer between the epoxy resin of the solid-sealed pole and the ceramic shell of the interrupter. Adhesive is evenly sprayed on the bonding surface between the silicone rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com