Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1687 results about "Vacuum circuit breakers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

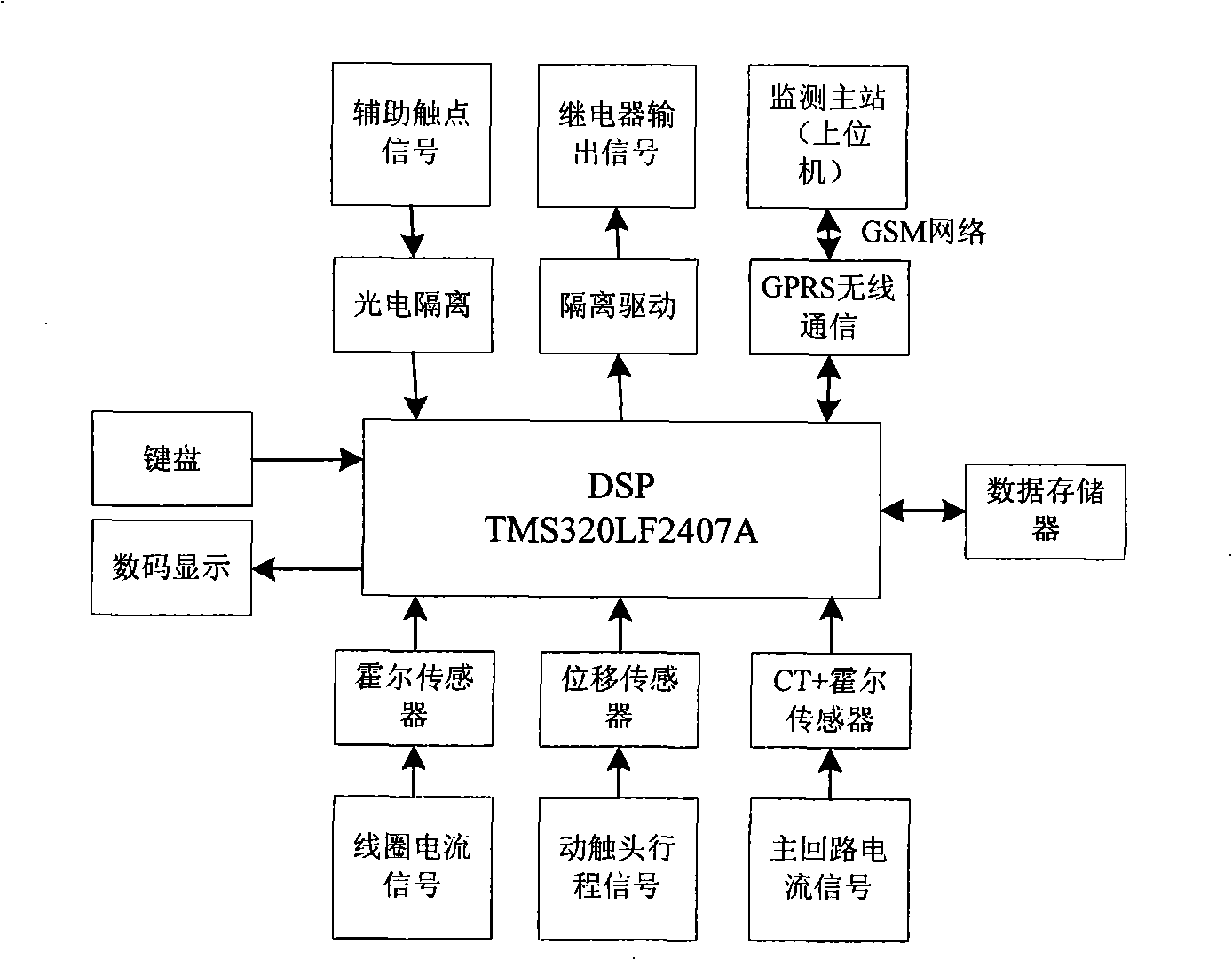

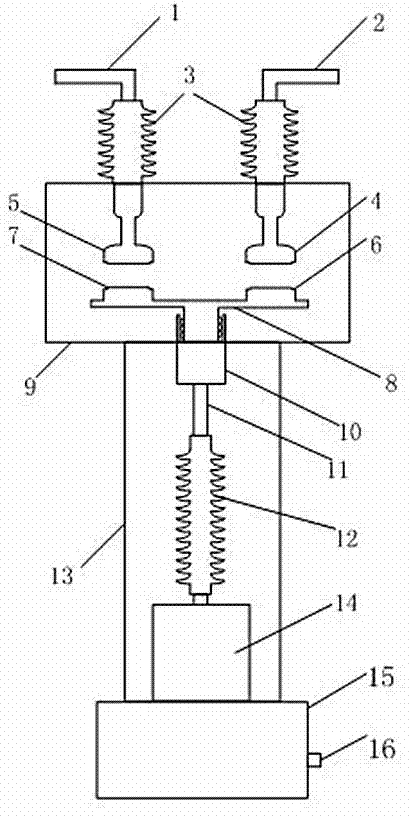

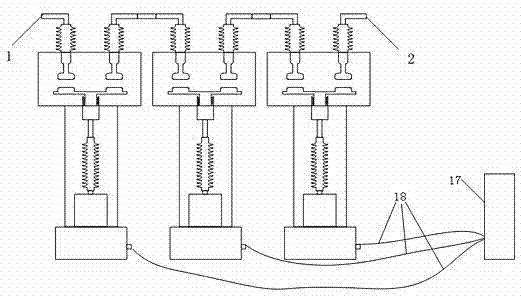

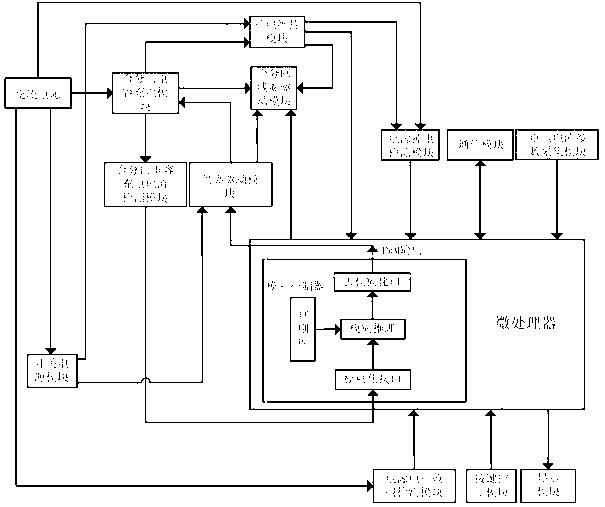

24KV high-voltage vacuum breaker mechanical features on-line monitoring method and monitoring device

InactiveCN101261192AEasy to analyzeSpeed upStructural/machines measurementHigh pressureSingle chip

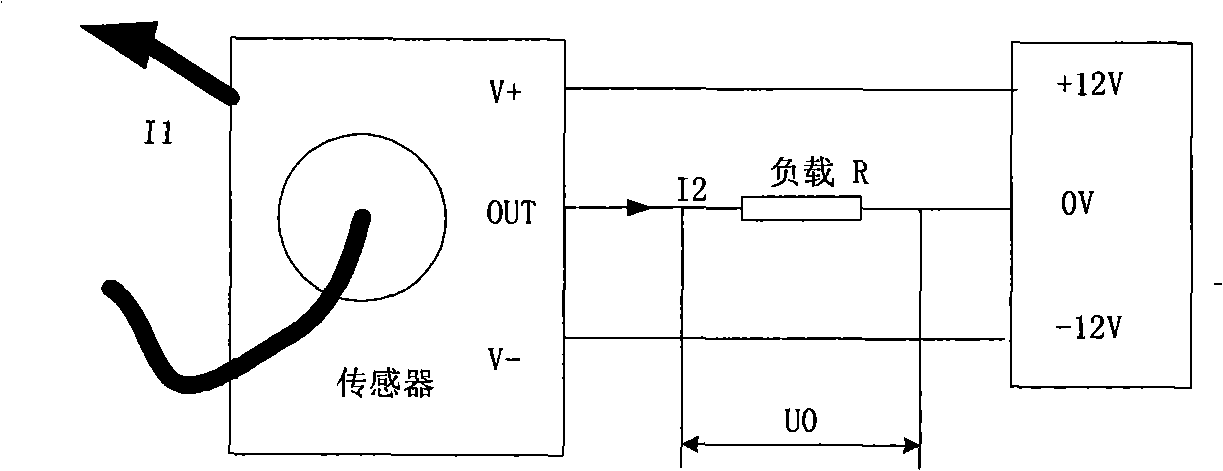

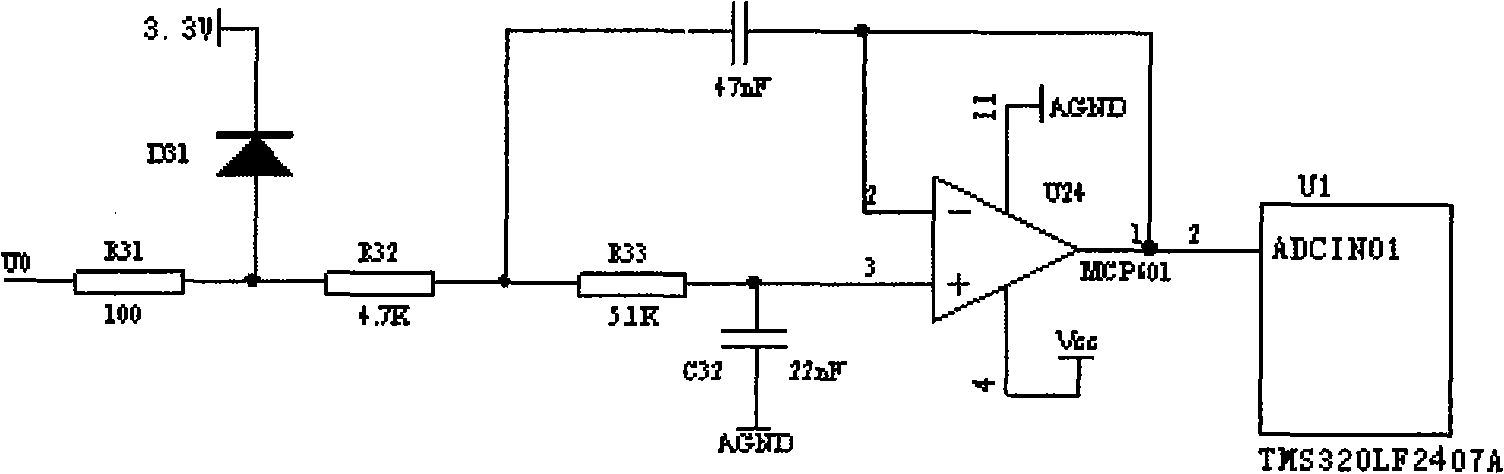

The invention provides a 24kV high-voltage vacuum circuit breaker mechanical characteristic online monitoring method in which the mechanical characteristic parameters of the vacuum circuit breaker are gained by monitoring the closing and opening switch coil current characteristic curve and the stroke characteristic curve of a moving contact when the vacuum circuit breaker acts; a corresponding monitoring device comprises a DSP single chip microprocessor, a circuit breaker coil current monitoring module, a circuit breaker movable contact stroke monitoring module, a circuit breaker main circuit current monitoring module, and a GPRS communication module. Compared with the existing circuit breaker mechanical characteristic online monitoring method and the device, the online monitoring method and the device of the invention adopt advanced sensing technique, signal processing technique, wireless communication technique, and computer technique, etc., realizes outdoor high voltage vacuum circuit breaker online monitoring; the online monitoring method and the device also display the real-time opening and closing coil current characteristic curve and the stroke characteristic curve of the moving contact by monitoring data when the vacuum circuit breaker acts, and calculates the mechanical characteristic parameters such as the closing and opening switch time of the vacuum circuit breaker, action speed, stroke of movable contact, and opening distance, etc., and can conveniently analyze the monitoring results.

Owner:NANJING INTELLIGENT DISTRIBUTION AUTOMATION EQUIP

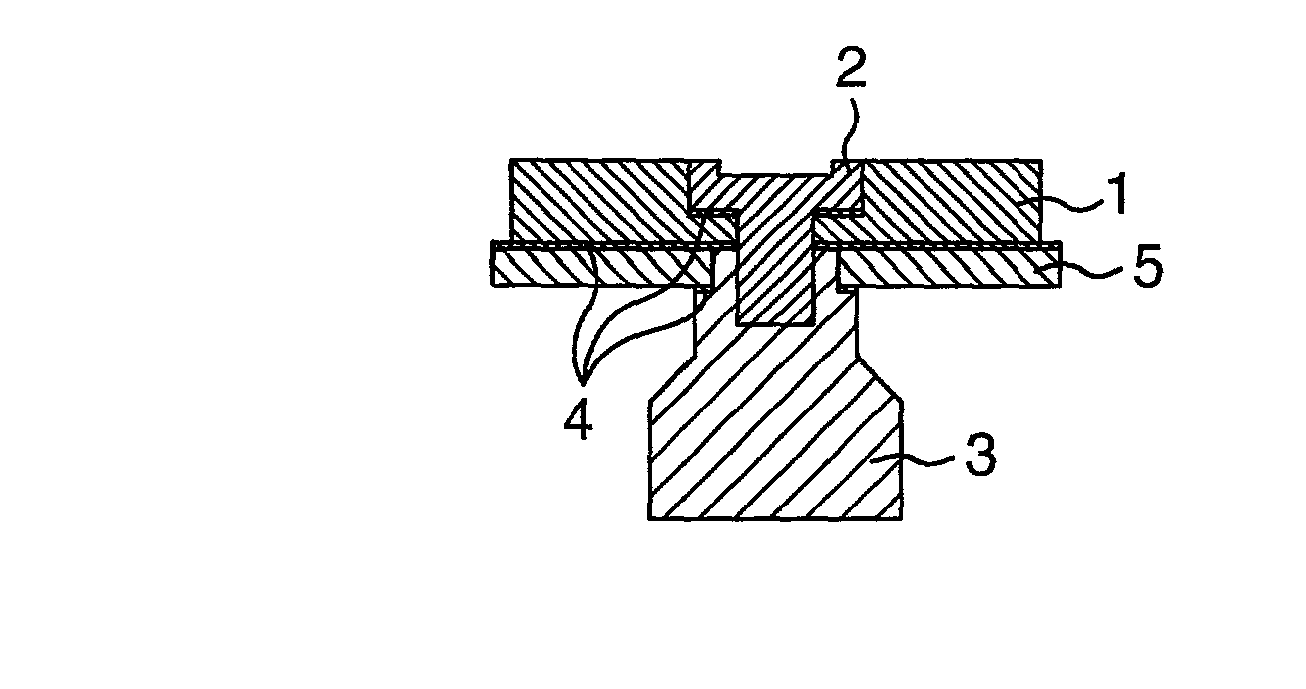

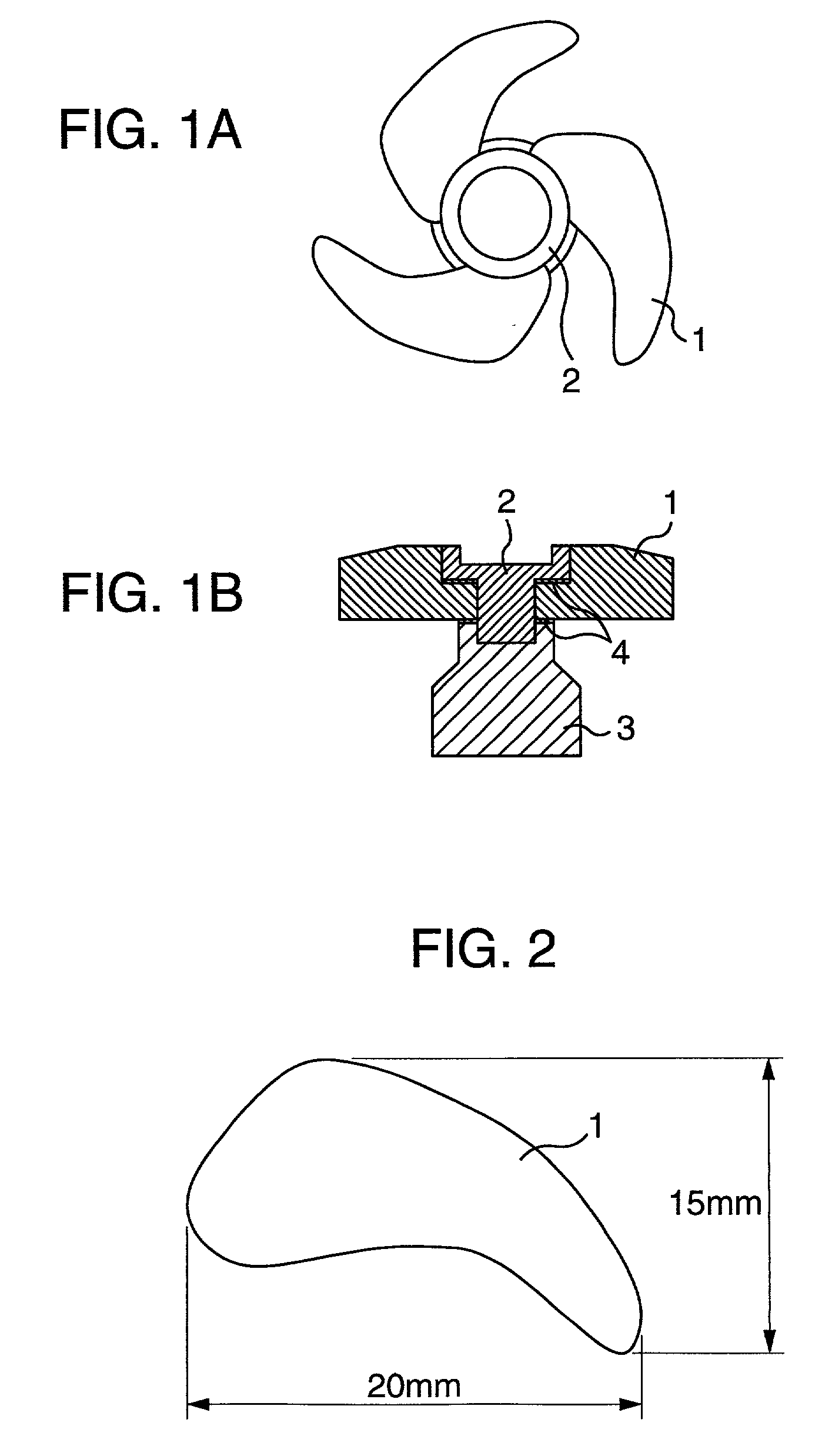

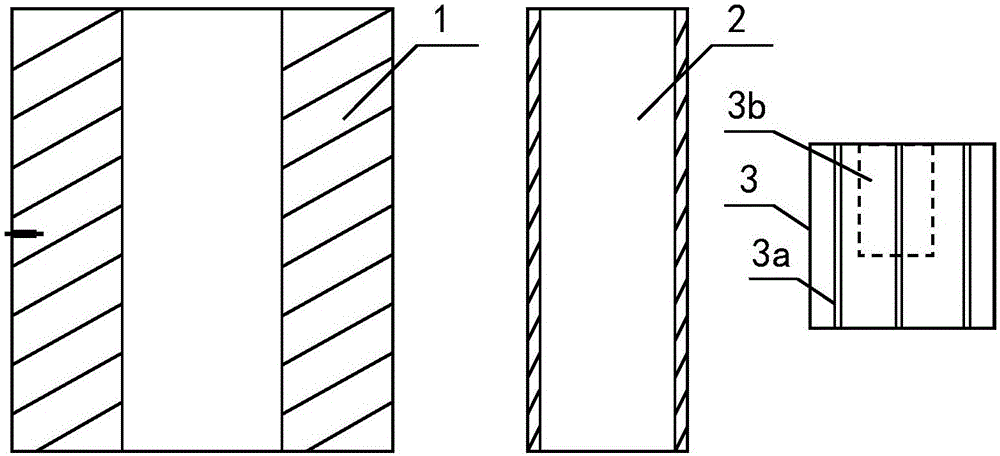

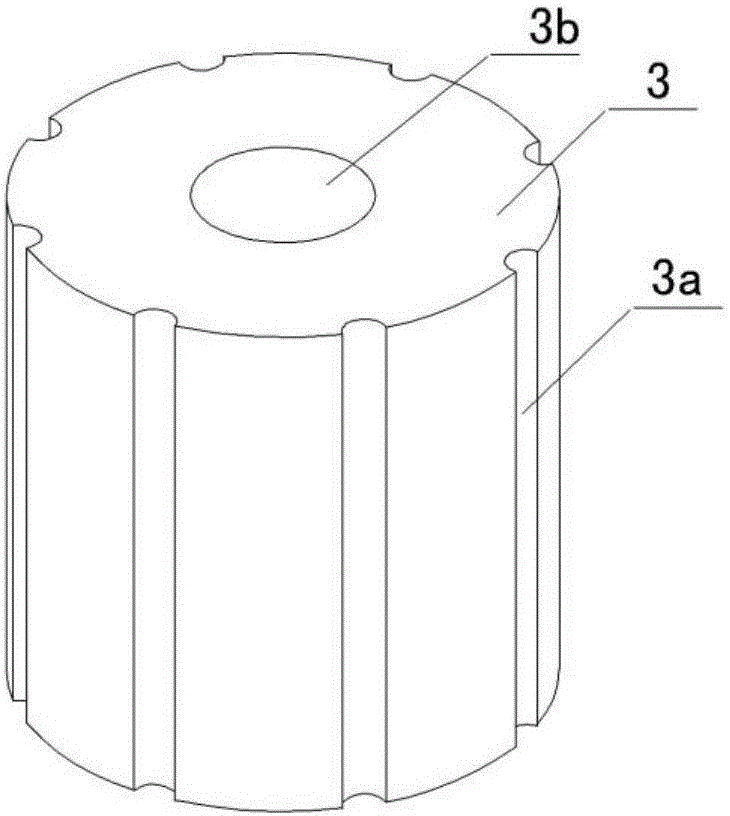

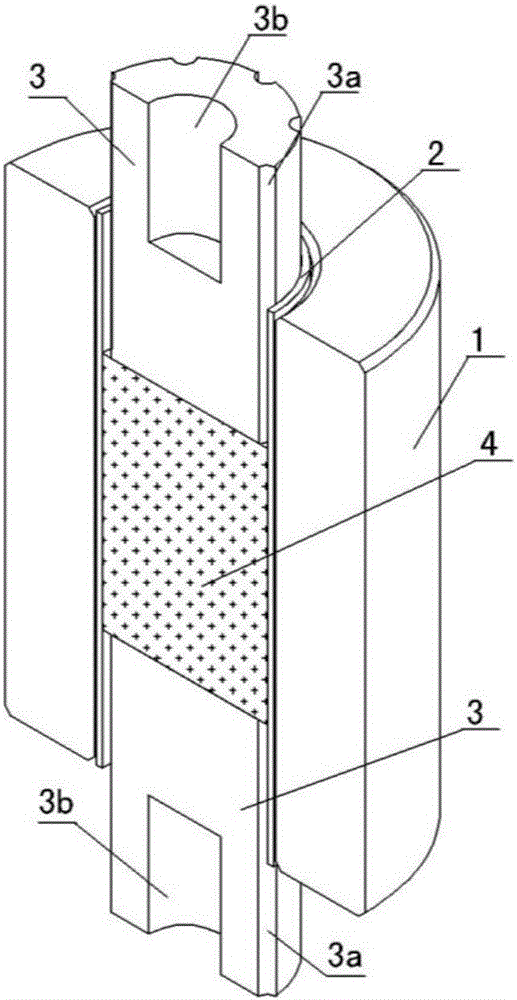

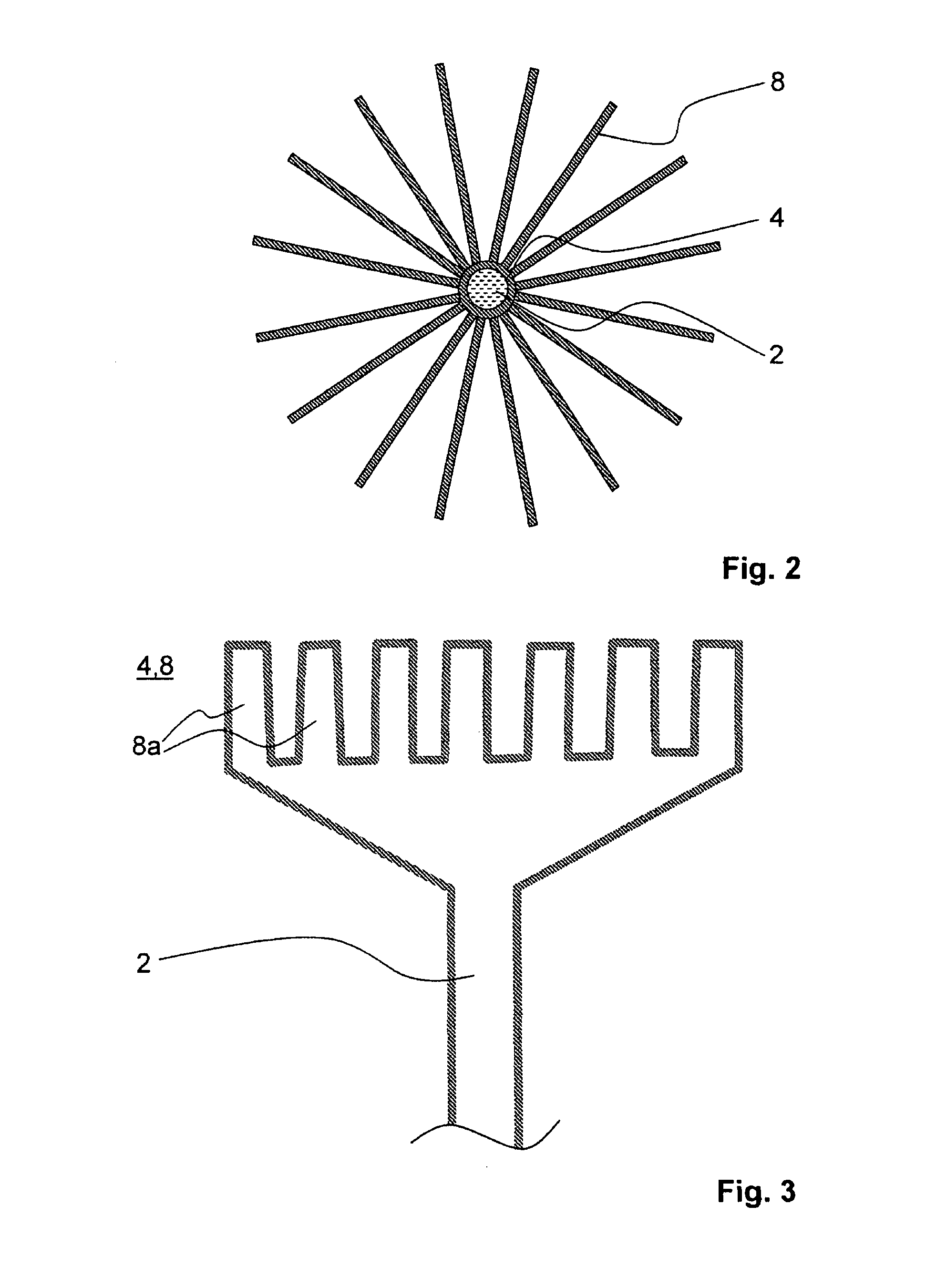

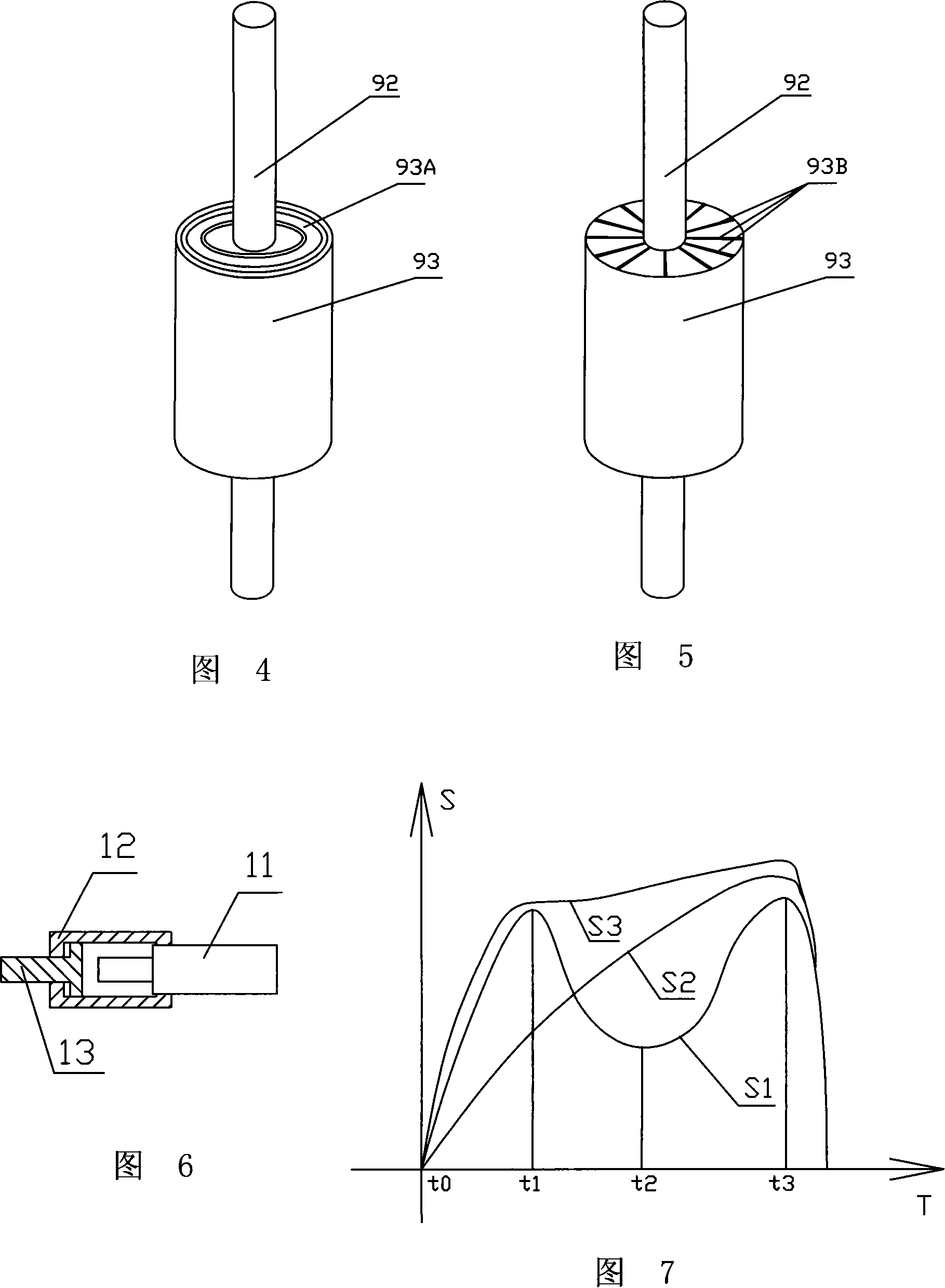

Electrode of a vacuum valve, a producing method thereof, a vacuum valve, a vacuum circuit-breaker and a contact point of the electrode

InactiveUS20020144977A1Improve circuit performanceWell formedContact materialsContact member manufacturingHigh conductivityMetal

The inventive electric contact point of a vacuum valve is made of a sintered alloy containing a heat-resistant metal and a high-conductivity metal. The contact point has at least three slit grooves which extend from the central region to the peripheral region of the contact point, and is soldered to an electrode rod which is connected to the contact point. The contact point includes at least three radially extending vane type contact point members each made of a sintered alloy containing a heat-resistant metal and a high-conductivity metal, and soldered to the electrode rod.

Owner:HITACHI LTD

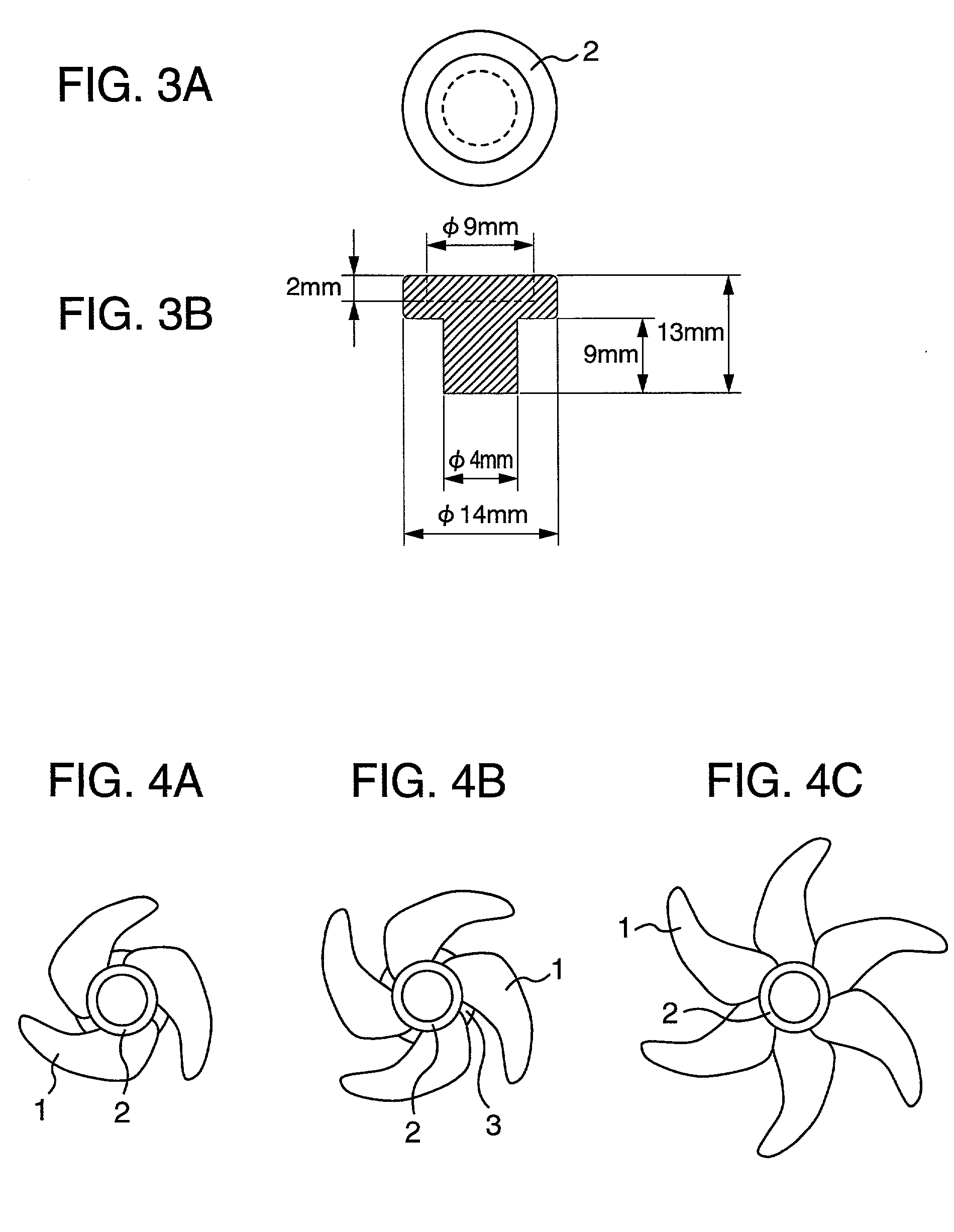

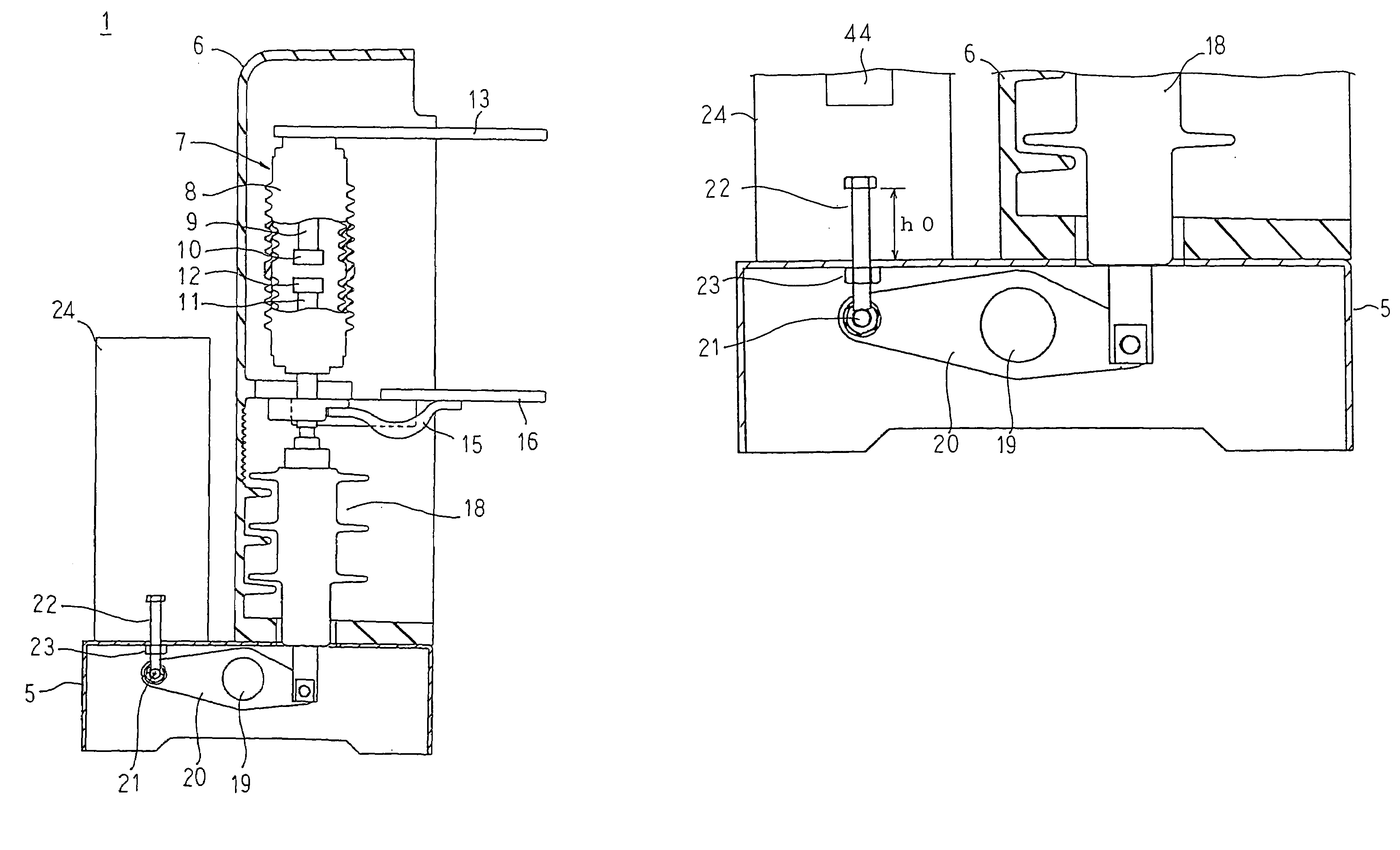

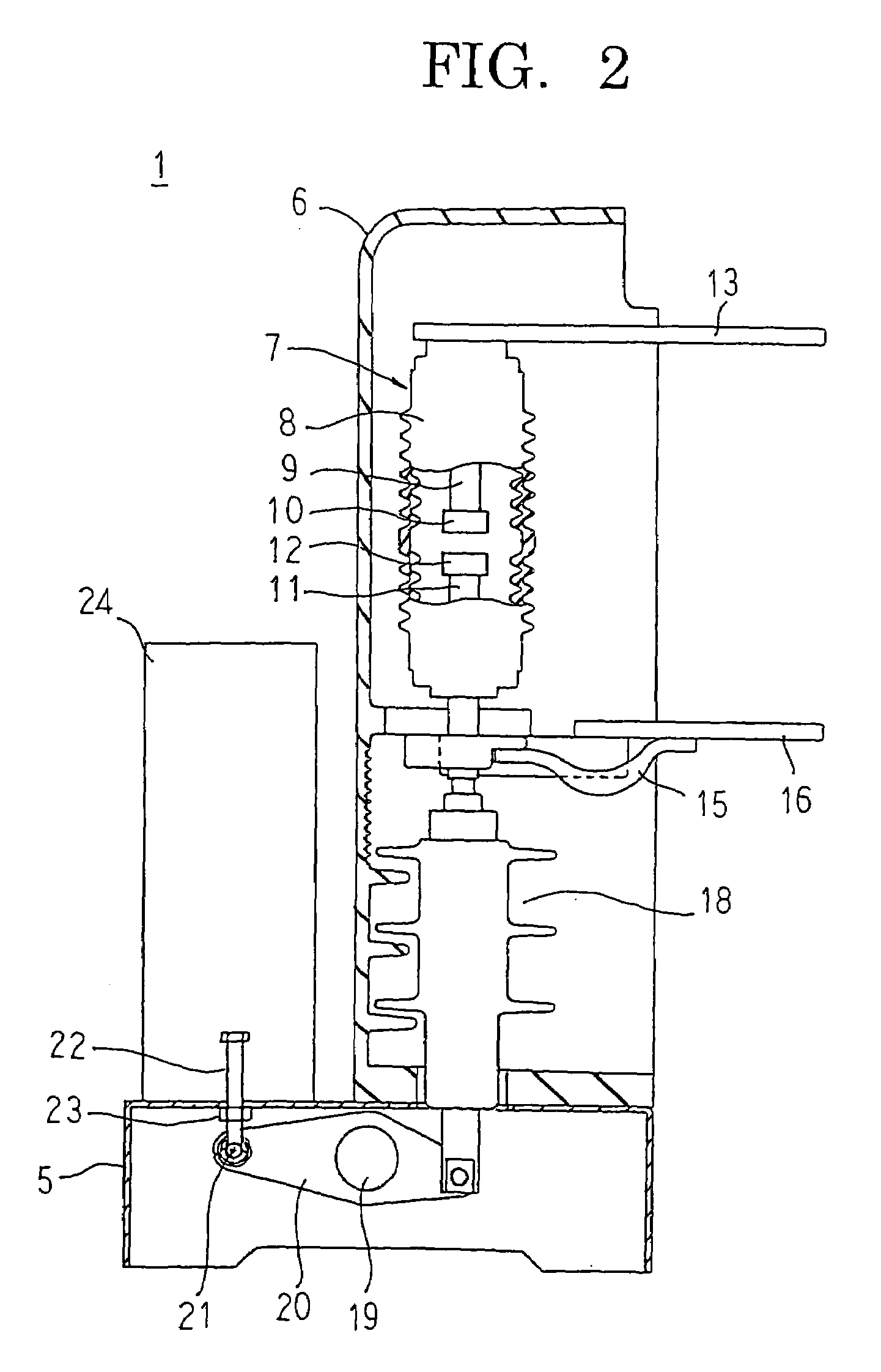

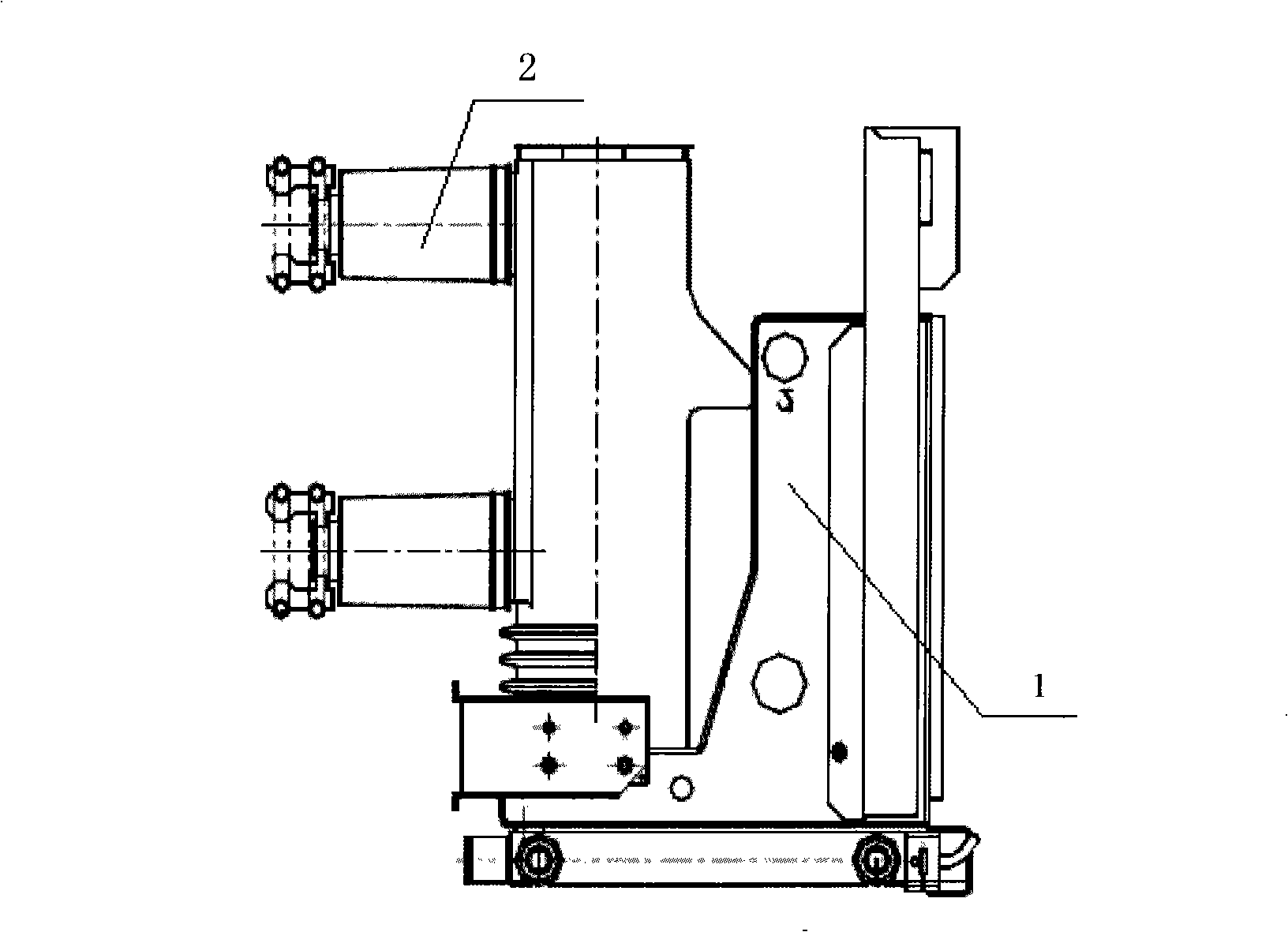

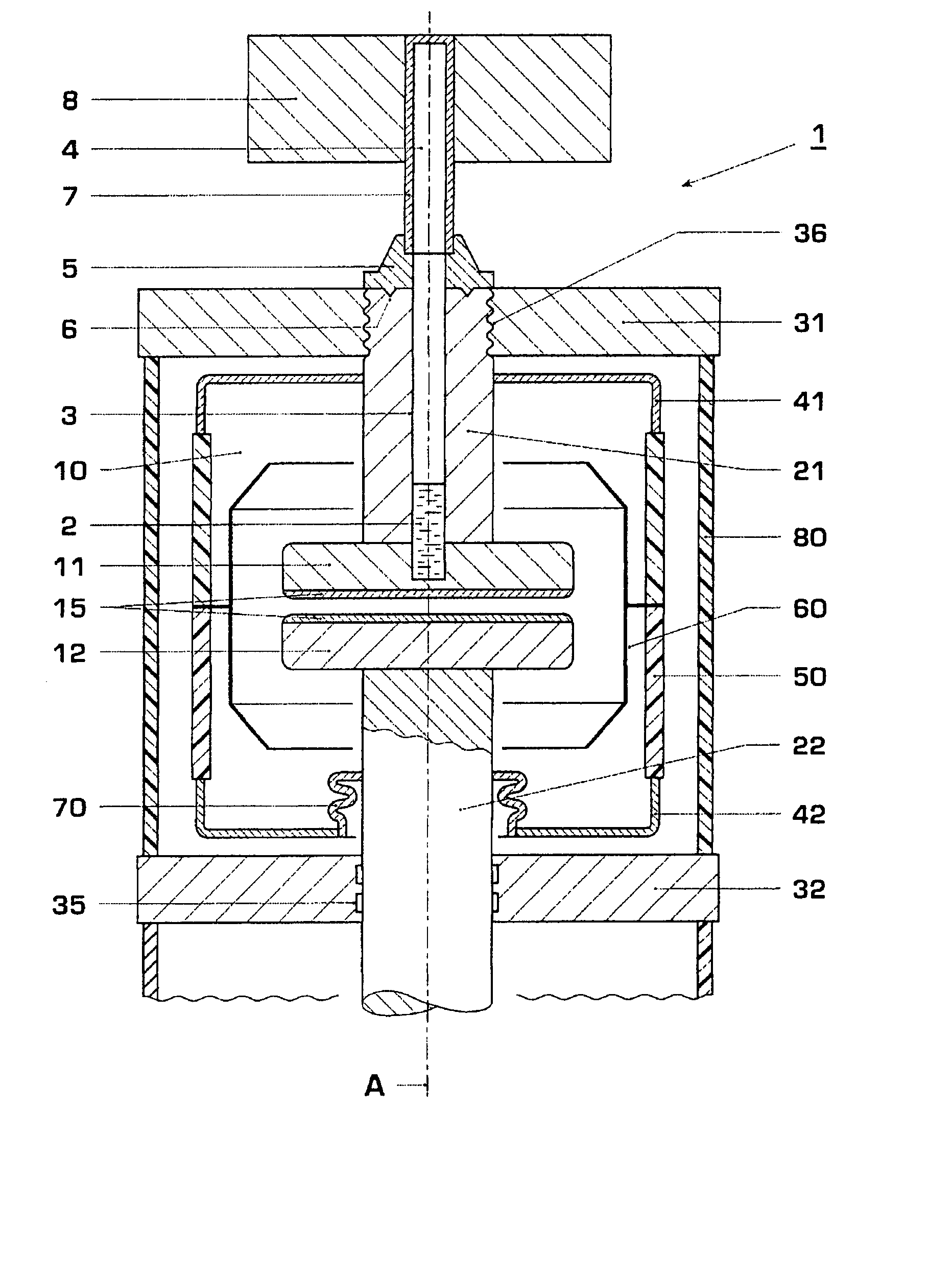

Vacuum circuit breaker, vacuum circuit breaker contact slow closing method, and contact erosion measuring method and contact gap length setting method using that slow closing method

ActiveUS7098418B1Accurate measurementMoved simply, slowly, and accuratelyContact mechanismsContact testing/inspectionEngineeringVacuum circuit breakers

An adjusting bolt is screwed into a nut attached to a dolly, and is disposed such that a central axis thereof is parallel to a closing and opening direction of a contact. A lever is attached to a shaft. An electrically-insulating rod is coupled to a first end of the lever, and a pin is mounted to a second end of the lever. The adjusting bolt is turned and lowered to lower the pin. The lever and the shaft are pivoted by the lowering of the pin, and the electrically-insulating rod is raised. Thus, a movable contact moves toward a fixed contact, moving the contact from an open state to a closed state.

Owner:MITSUBISHI ELECTRIC CORP

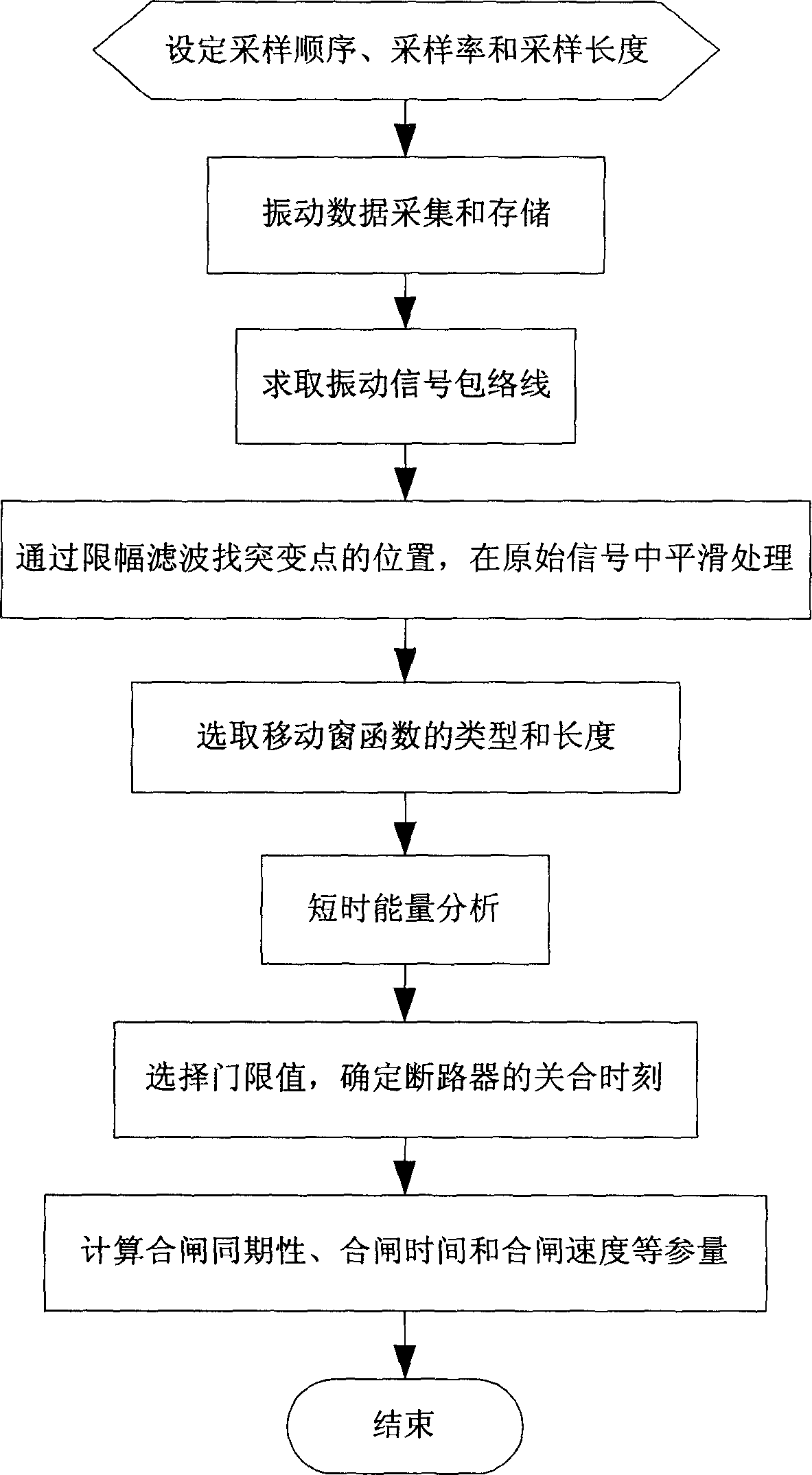

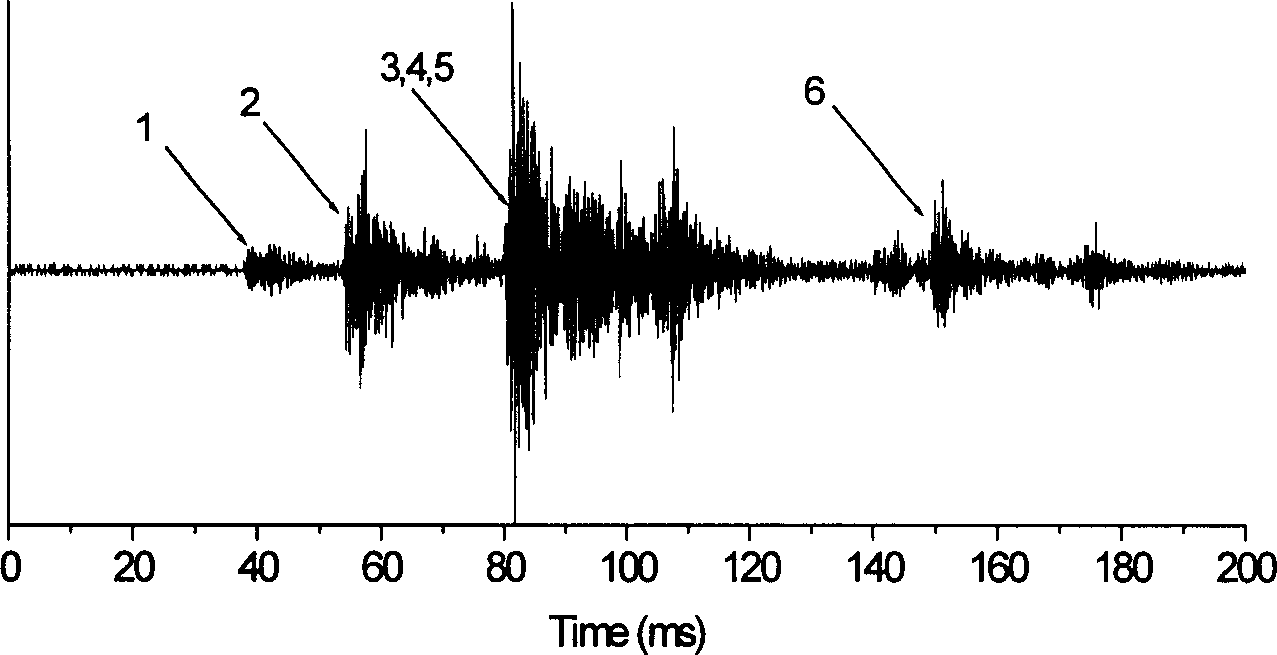

Online detection method for vacuum circuit breaker contact on-off time based on vibration analysis

InactiveCN1595188AExtension of timeImprove anti-interference abilityCircuit interrupters testingSample lengthFixed position

This invention discloses a vacuum breaker probes on or off moment on-line measurement method based on vibration analysis, which comprises the following steps: first to select the fix position and direction of the vibration sensor; second to set sample order, sample frequency, sample length and trigger means and to store the sample data; third to pre-process the vibration data; fourth to select moving window function type and length and adopt short-time energy calculation for further analysis; fifth to select threshold value to determine the on or off moments of triphase probes; sixth to calculate the closing term and closing time according to the on or off moments. This invention improves the affair resolution ability and anti-interference ability in the vibration signal analysis.

Owner:XI AN JIAOTONG UNIV

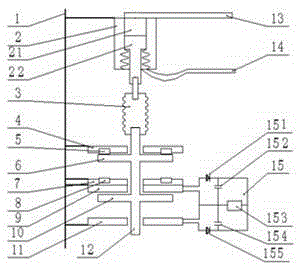

Intelligent self-diagnosis medium-pressure vacuum circuit breaker

ActiveCN101515520AExtended service lifeGuaranteed stabilityThermometers using electric/magnetic elementsUsing electrical meansElectric power systemComputer module

The invention relates to an intelligent self-diagnosis medium-pressure vacuum circuit breaker, which is characterized in that a left rib plate in the framework of the breaker is provided with a real time supervision and diagnosis system circuit, a separating brake loop, a tank circuit and a closing circuit are internally sheathed with hall sensors, an operational power supply is connected with two divider resistance in parallel, a first camera and a second camera are arranged above a second compartment and a fourth compartment of the breaker, an operating mechanism is provided with a displacement pickup, a touch arm is posted with the temperature pickup, the hall sensor, the divider resistance and the two cameras, the output end of the displacement pickup is electrically connected with the real time supervision and diagnosis system circuit by respective interface circuits, the output end of the temperature pickup is connected with the input end of a signal acquisition module, the output end of the signal acquisition module is connected with the input end of the real time diagnosis and supervision system circuit by a pair of wireless transceiving module. The breaker has the advantages of fault self-diagnostic function, reliably avoiding the occurrence of accidents and the worsening of problems and guaranteeing the stability of a power system.

Owner:上海南华兰陵电气有限公司 +1

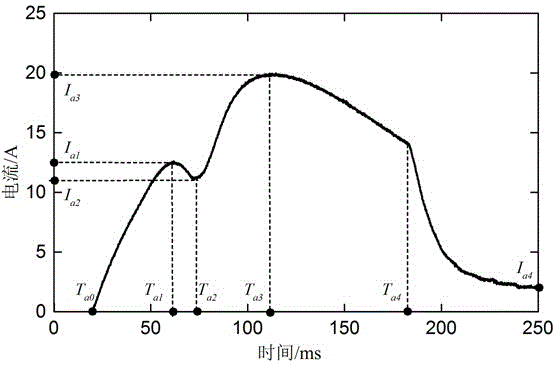

Permanent magnetic mechanism high voltage vacuum circuit breaker fault mode identification method

ActiveCN106199412AIncomplete solutionSolve the contradiction of information redundancy in multi-parameter monitoringCircuit interrupters testingClassification methodsHigh pressure

A permanent magnetic mechanism high voltage vacuum circuit breaker fault mode identification method comprises a fault condition information classification method, a condition information feature extraction method and a fault classification identification method. The fault information classification method is to classify permanent magnetic mechanism high voltage vacuum circuit breaker fault information into loop condition information, mechanical condition information and a vacuum extinction chamber condition information. The condition information feature extraction method is to carry out extraction in the time domain and the frequency domain for different kinds of condition information. The fault classification identification method is based on a method of support vector machine increment learning, draws on a fault sample training classification model, and continuously accumulates new samples to improve the classification identification accuracy. The invention solves problems that fault monitoring information acquisition is not comprehensive and the fault identification accuracy is low, effectively identifies common faults of a permanent magnetic mechanism high voltage vacuum circuit breaker, and has a guiding effect for breaker condition based maintenance and fault diagnosis.

Owner:TAIYUAN UNIV OF TECH

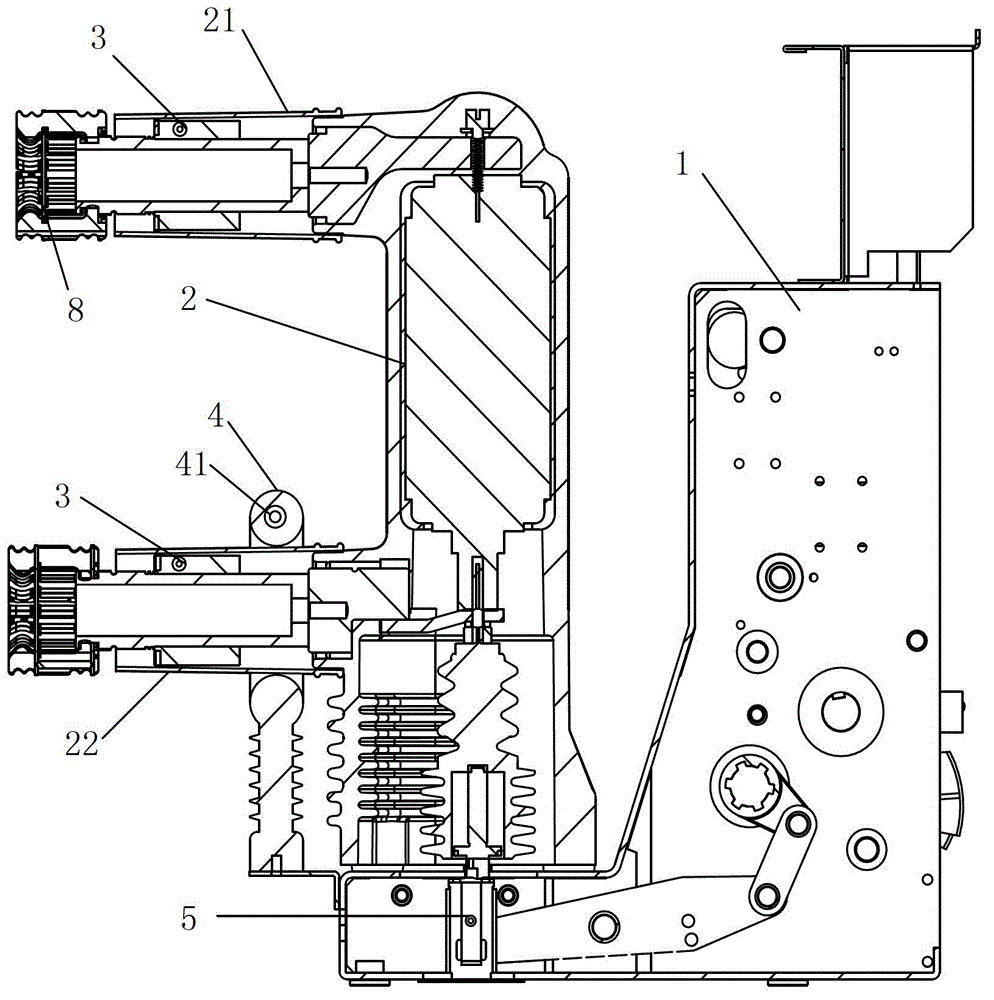

Vacuum circuit breaker based on T-shaped double break vacuum arc-extinguishing chamber

InactiveCN103050324AEnsure consistencyConducive to extinguishingHigh-tension/heavy-dress switchesAir-break switchesControl signalVacuum arc

The invention discloses a vacuum circuit breaker based on a T-shaped double break vacuum arc-extinguishing chamber, which can effectively reduce the cost, improves the voltage withstanding level of a single arc-extinguishing chamber, is easy to be in series connection to form an ultrahigh-voltage and superhigh-voltage vacuum circuit breaker. The vacuum circuit breaker comprises a vacuum arc-extinguishing chamber, an insulated ceramic column, an operating mechanism and a control case, a control signal input end is arranged on the control case, the insulated ceramic column is internally provided with an insulated connection rod which is connected with the operating mechanism, the upper end of the insulated connection rod is connected with a movable conducting rod in a guiding sleeve, the upper end of the movable conducting rod is connected with a movable contact connecting board which is arranged in the vacuum arc-extinguishing chamber, the transverse left end and the transverse right end of the movable contact connecting plate are respectively and correspondingly provided with a left movable contact and a right movable contact, a left static contact and a right static contact are correspondingly and fixedly arranged on the left movable contact and the right movable contact, the left static contact is connected with an incoming line, the right static contact is connected with an outgoing line, and bushings are sleeved on the incoming line and the outgoing line.

Owner:DALIAN UNIV OF TECH

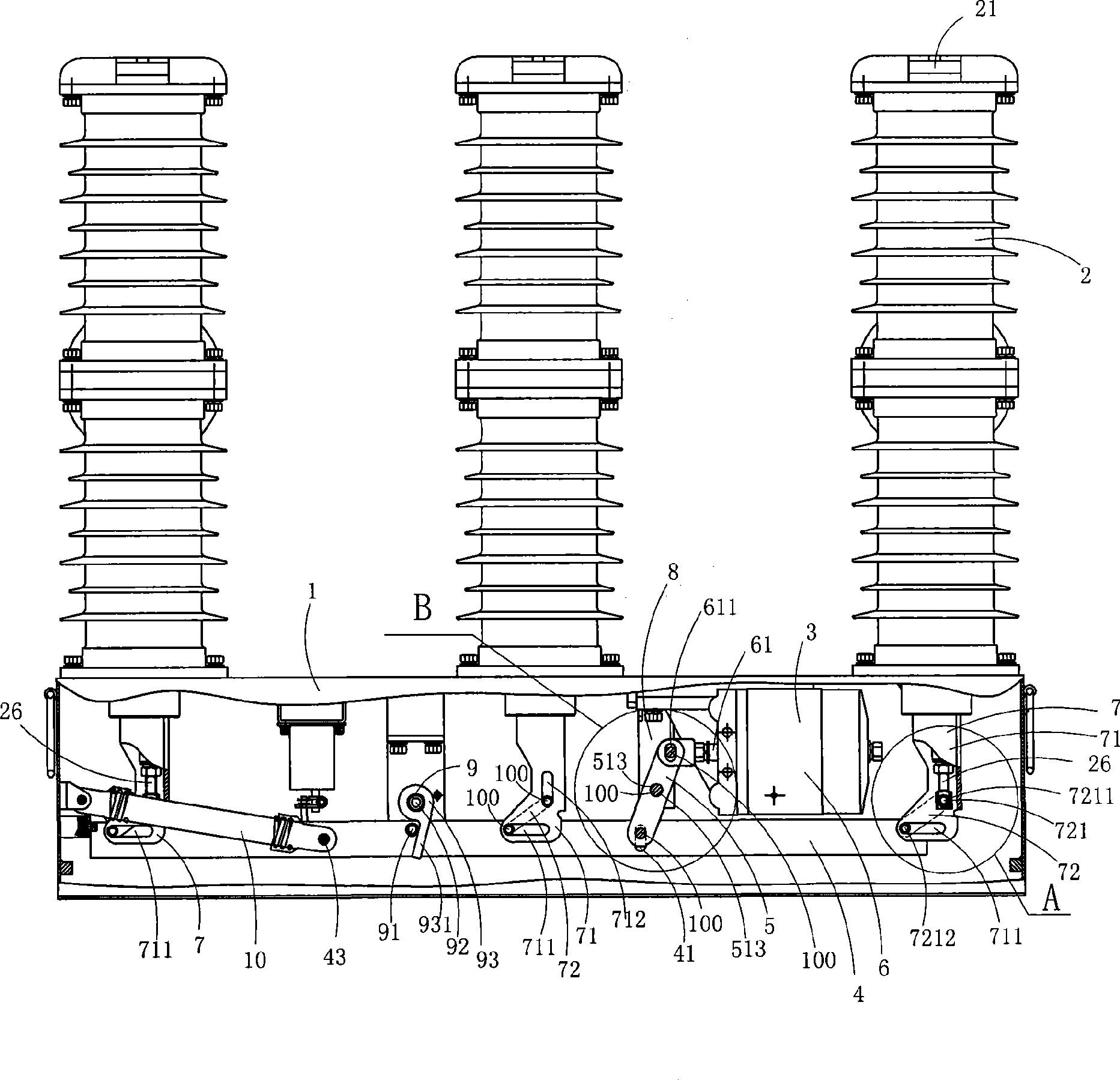

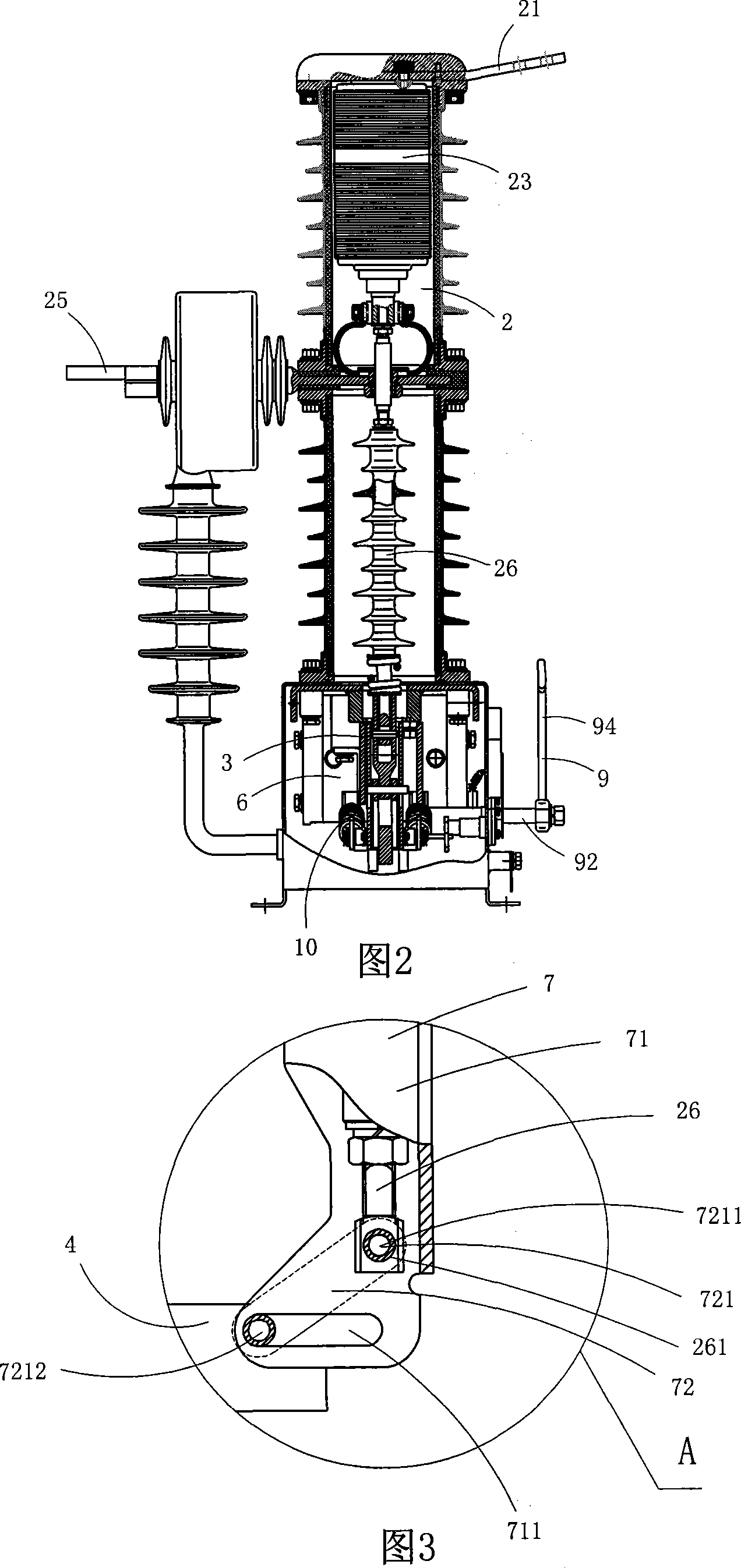

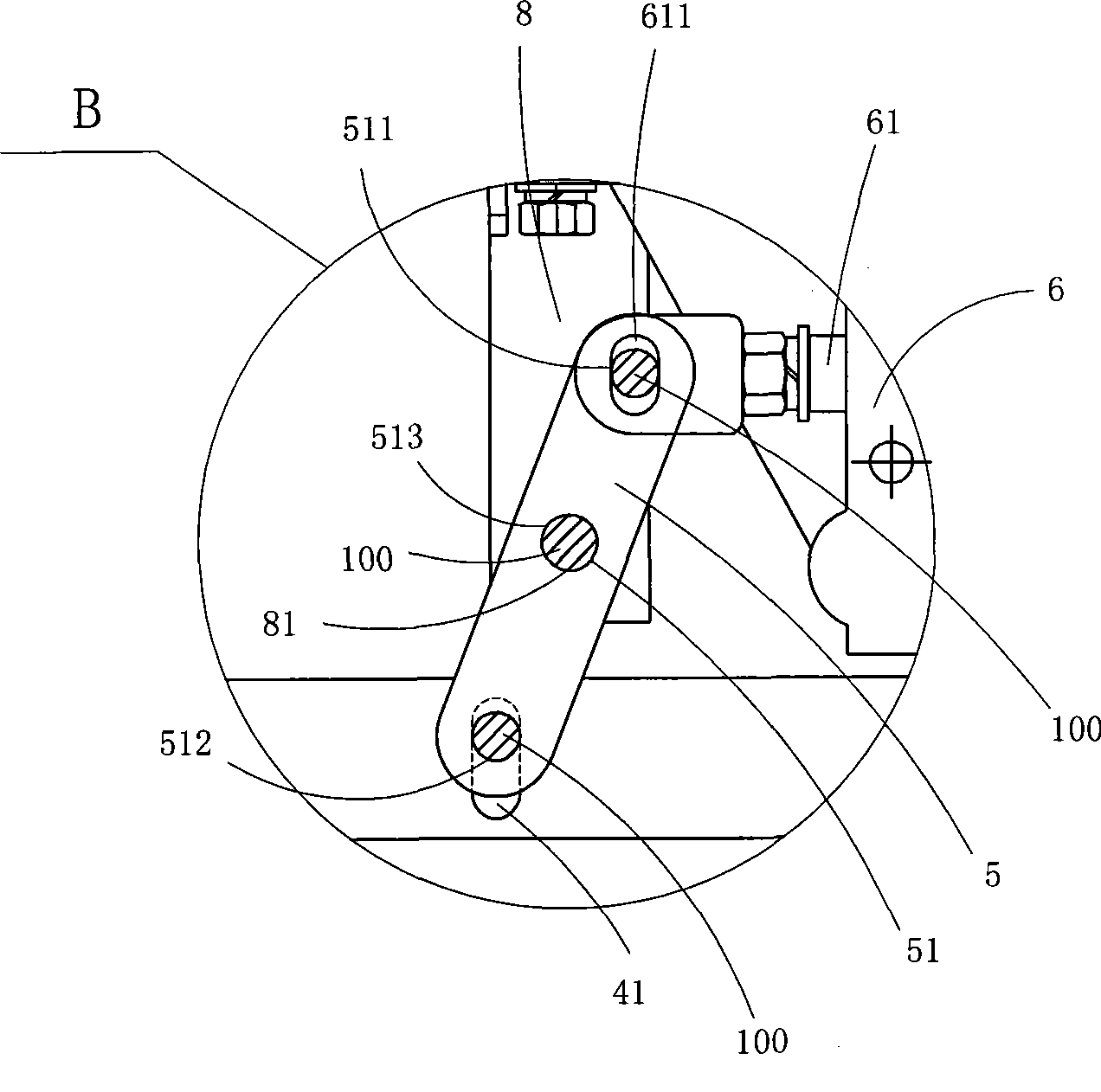

Outdoor high-voltage permanent magnet type vacuum circuit breaker

InactiveCN101430986AOpen smoothlyStable stateHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh pressure

The invention discloses an outdoor high-voltage permanent-magnetic vacuum circuit breaker; the permanent-magnetic operation mechanism comprises a driving rod which is arranged along the horizontal direction; the end of the driving rod is provided with a waist-shaped hole which extends along the vertical direction; the end of the driving rod is rotatablely connected with a driving arm by a position limit hole; a driving mainshaft hole is a waist-shaped hole which extends along the vertical direction; the other end of the driving arm is connected with a transmission mainshaft by a round shaft pin. The outdoor high-voltage permanent-magnetic vacuum circuit breaker can effectively ensure that the driving rod and the transmission mainshaft can do the horizontal movement or can not move wrongly due to the displacement of the rotation movement of the driving arm.

Owner:HONGXIU ELECTRIC

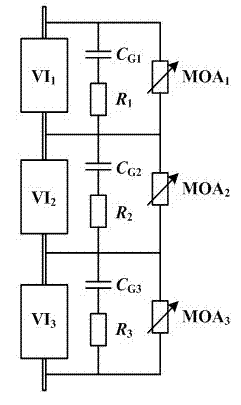

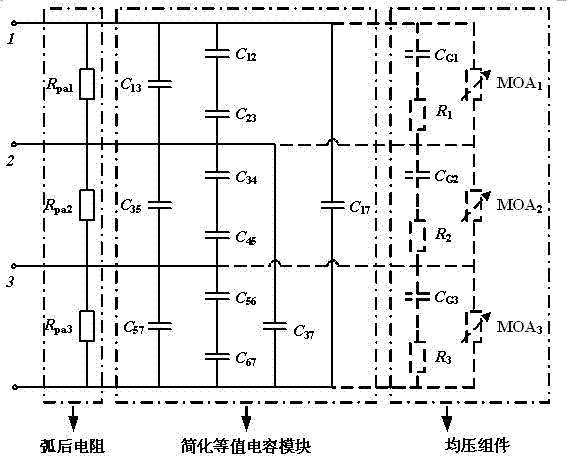

Dynamic voltage sharing device of multi-break vacuum circuit breaker and parameter selection method for dynamic voltage sharing device

InactiveCN102364655AReduce reburn rateImprove breaking capacityHigh-tension/heavy-dress switchesAir-break switchesCapacitanceCurrent limiting

The invention provides a dynamic voltage sharing device of a multi-break vacuum circuit breaker and a parameter selection method for the dynamic voltage sharing device. A voltage sharing capacitor, a current limiting resistor and a zinc oxide arrester are used as a dynamic voltage sharing component of a multi-break serial vacuum circuit breaker; and the voltage sharing capacitor is connected in series with the current limiting resistor and then is connected in parallel with the zinc oxide arrester. The optimal value of relative parameters is selected in combination with vacuum arc model-based electromagnetic transient simulation according to a synthesis test. According to the technical scheme, reliable switch-off of a plurality of vacuum arc extinguish chambers during serial operation can be ensured, and the vacuum circuit breaker can be applied in the voltage range of 110kV and more than 110kV.

Owner:WUHAN UNIV +1

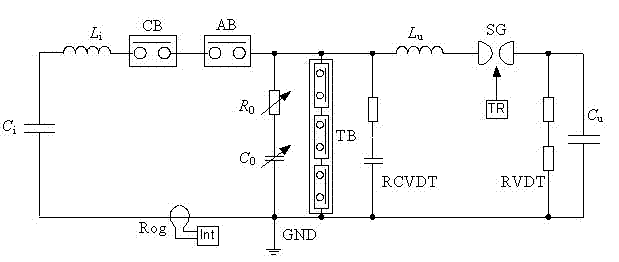

Zero-loss depth current-limiting protection device

InactiveCN104821563AReduce the amplitudeForecast exact timeEmergency protective arrangements for limiting excess voltage/currentElectric power systemTransformer

A zero-loss depth current-limiting protection device relates to the technical field of over-voltage absorption in a power system. The protection device is characterized in that the device comprises a Rogowski coil, a measurement and control unit, a high-speed switch and a depth current-limiting reactor 1, wherein the measurement and control unit is connected with the Rogowski coil and the high-speed switch, and the two ends of the depth current-limiting reactor 1 are connected with the two ends of the high-speed switch respectively. The device is fast in speed, high in breaking capacity and good in current-limiting effect, not only can protect electrical equipment of a transformer and a motor and the like in a system, but also improves service life of a load vacuum circuit breaker at a short circuit point.

Owner:SOLVE AIR HEFEI

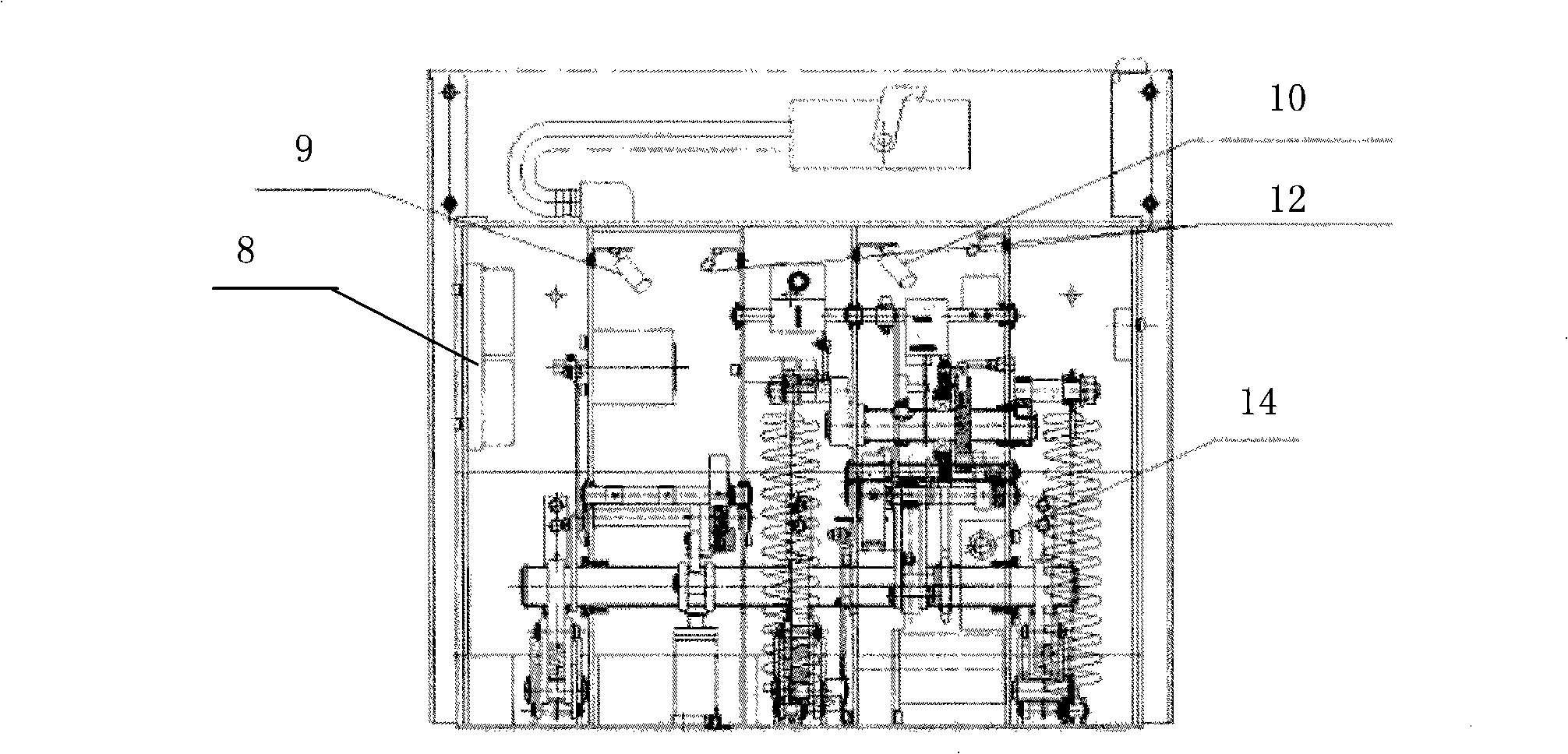

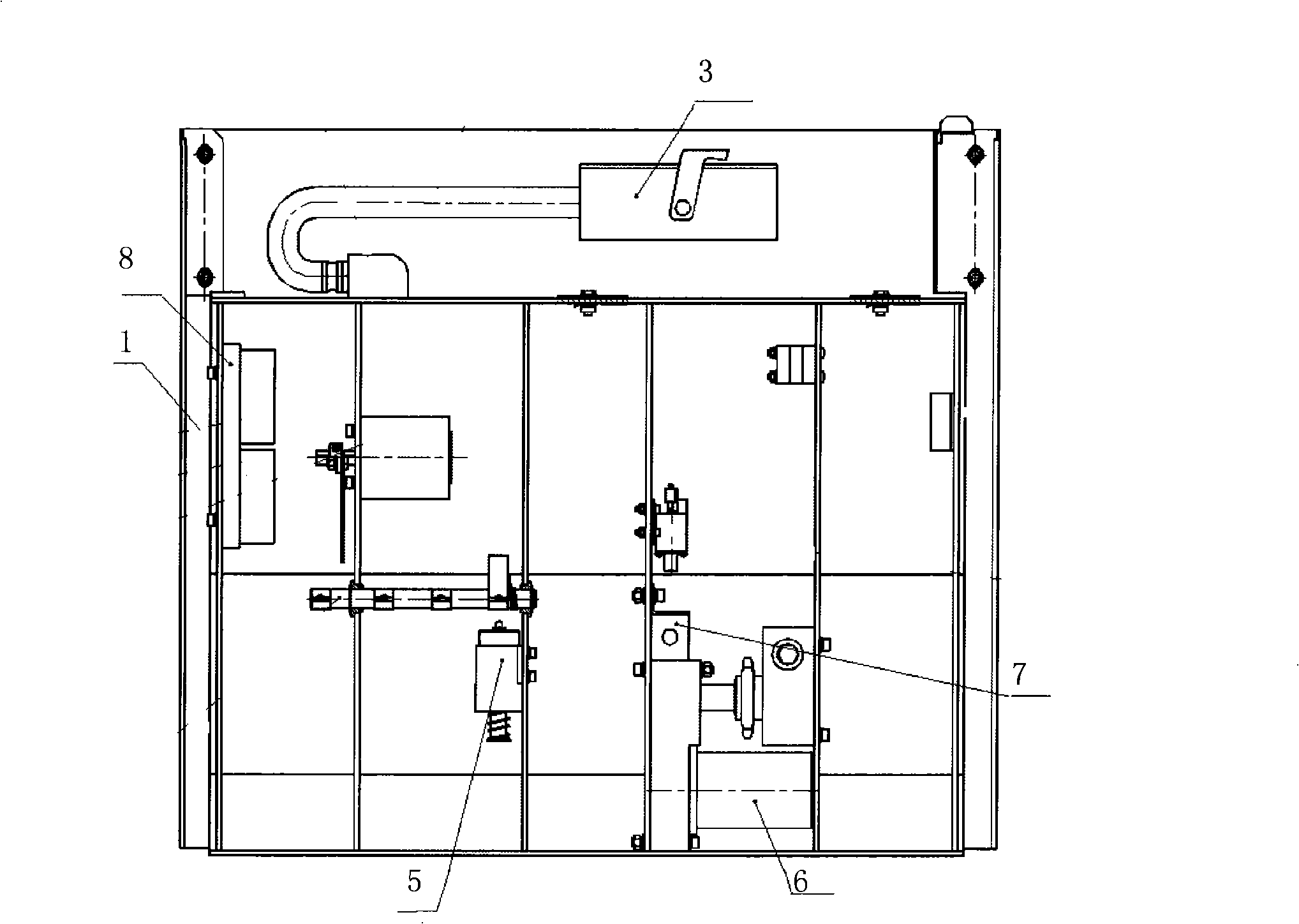

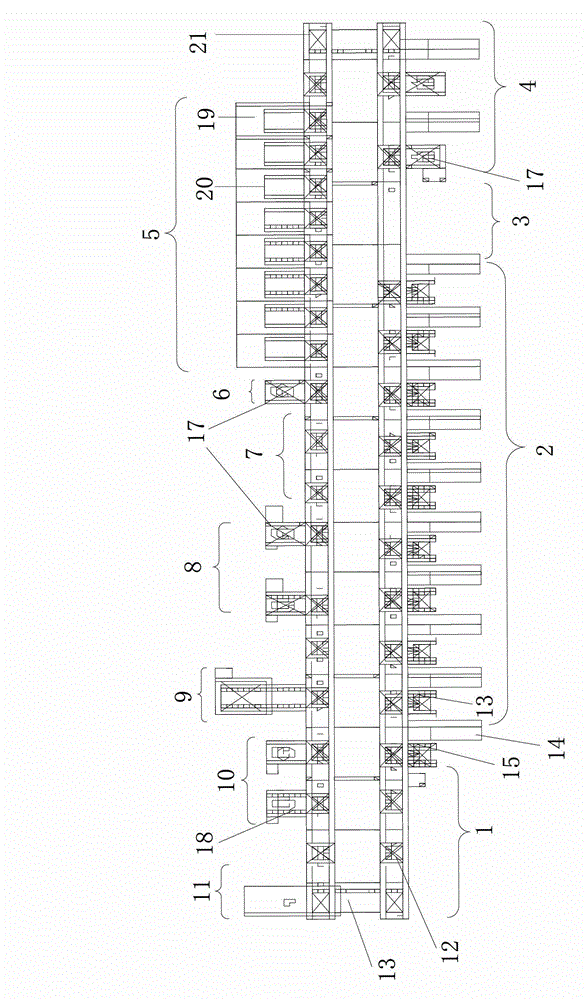

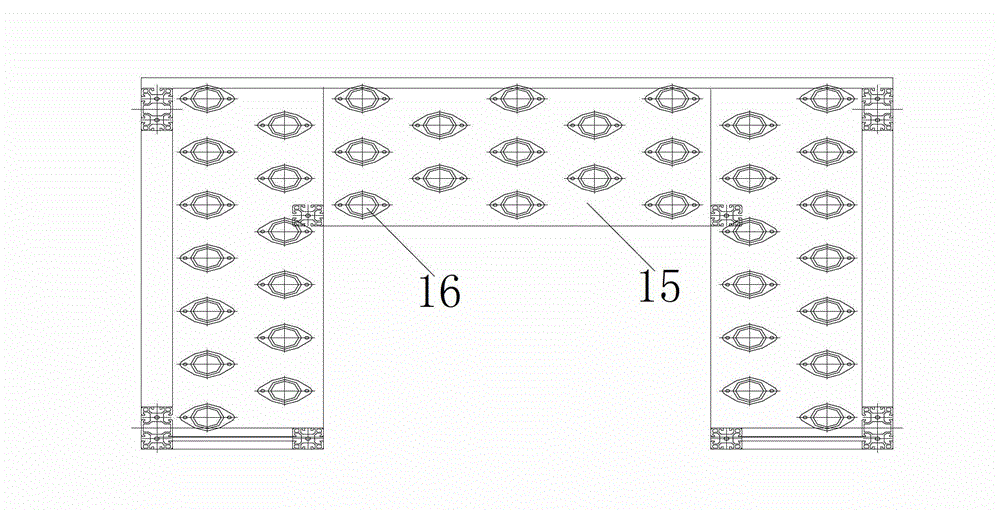

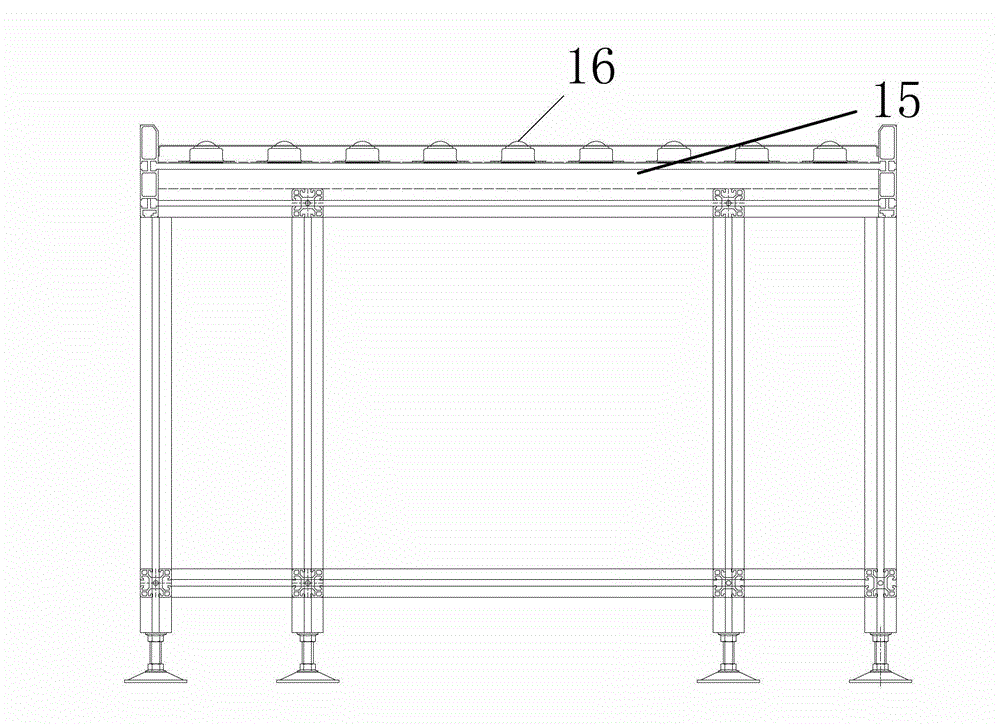

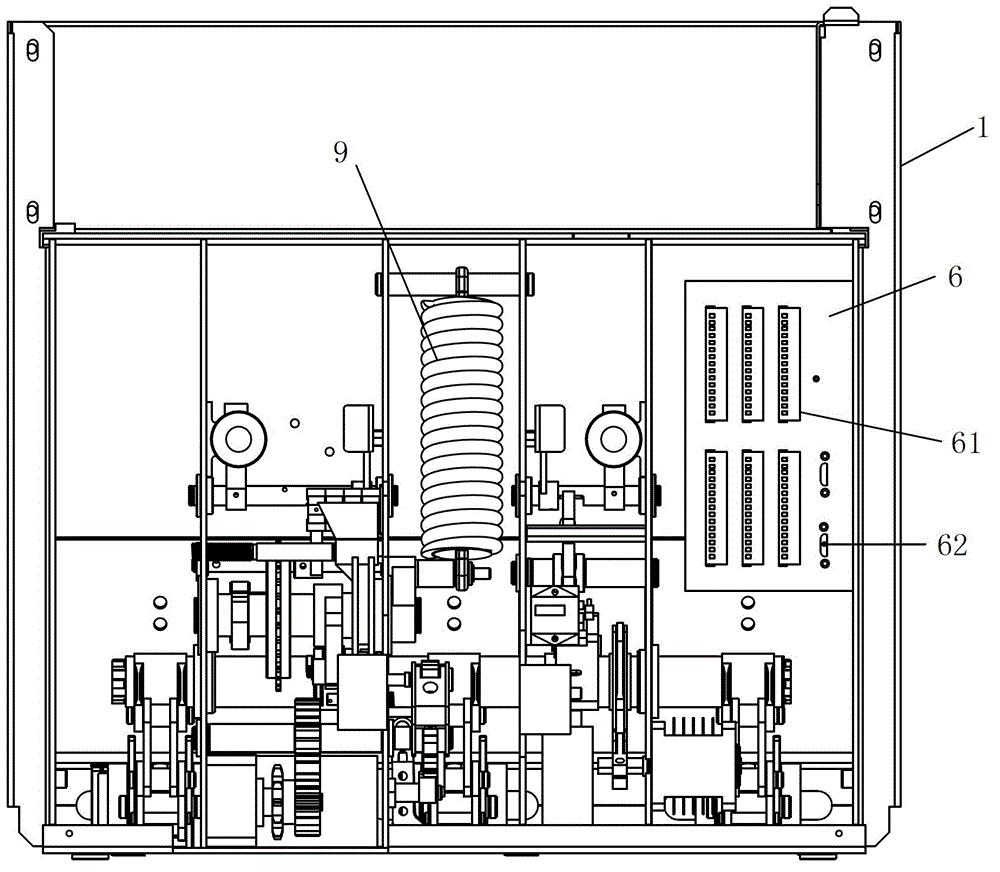

Production line for vacuum circuit breakers

InactiveCN102751120ARealize automatic cycleAvoid manpower lossElectric switchesProduction lineEngineering

The invention relates to a production line for vacuum circuit breakers. The production line comprises a loading area, a mechanism assembly area, a first transition area, an insulation barrel assembly area, a running-in area, a reworking area, a second transition area, a mechanical characteristic test area, a chassis vehicle assembly area, a contact arm assembly area and an unloading area; the production line takes a tooling plate as a carrier; the unloading area is connected with the loading area through a translation mechanism; and the tooling plate is controlled to move on the production line through a controller. The unloading area and the loading area are connected through the translation mechanism to form the circular production line, the tooling plate is controlled to move on the production line through the controller, when the vacuum circuit breakers are unloaded in the unloading area, the tooling plate is controlled through the controller and automatically moves to the loading area through the translation mechanism, thereby avoiding the manual labor loss caused by the loading and unloading of the tooling plate, realizing the automatic circulation of the production line and effectively increasing the assembly concordance rate and production efficiency in the production process of the products.

Owner:JIANGSU SENYUAN ELECTRICAL

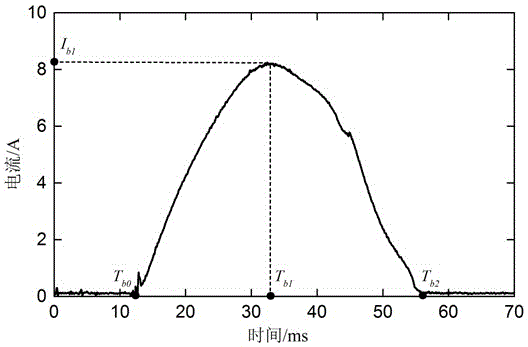

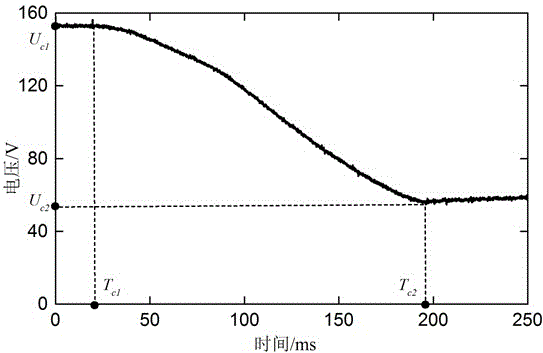

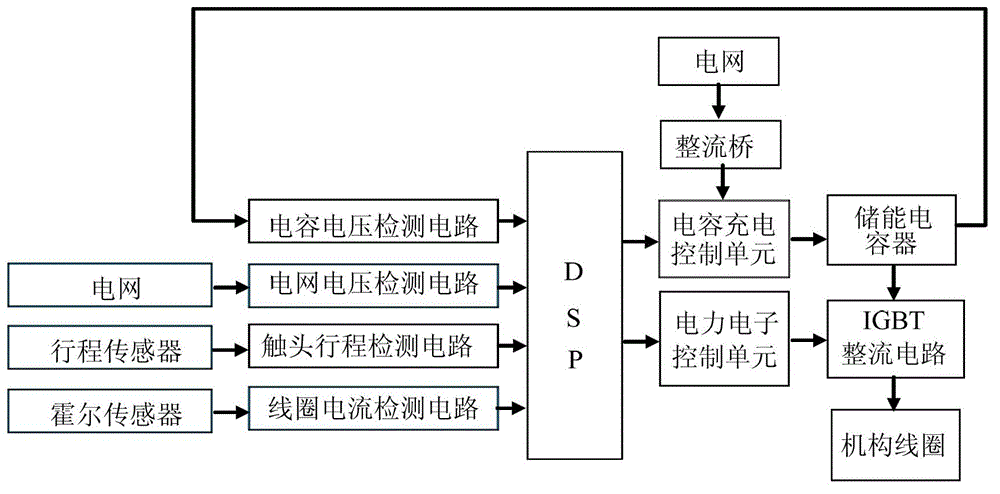

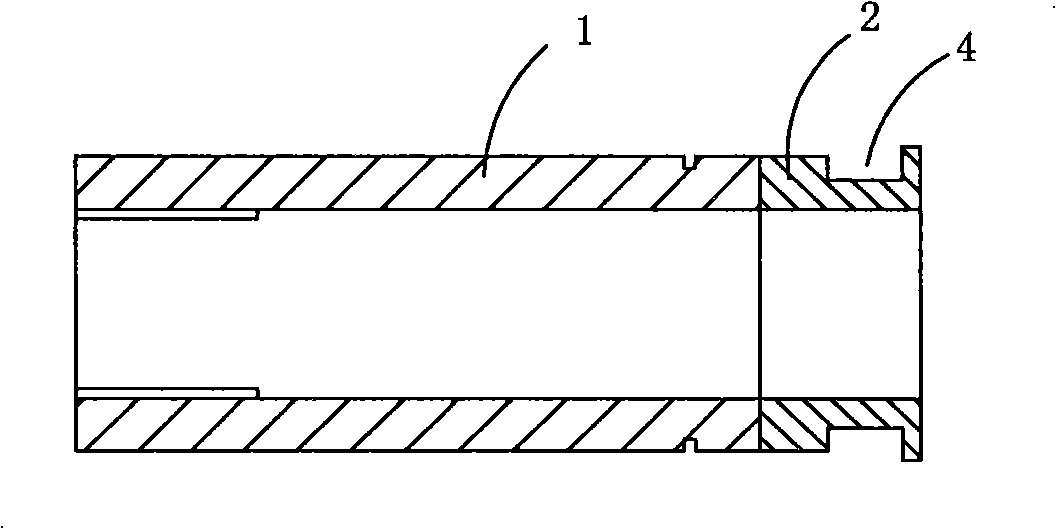

Control device and method for vacuum circuit breaker permanent magnetic mechanism based on double signal tracking

ActiveCN103336474AImprove reliabilityExtended service lifeProgramme controlComputer controlAutomatic controlElectric power system

The invention provides a control device and method for a vacuum circuit breaker permanent magnetic mechanism based on the double signal tracking, and belongs to the field of the automatic control of electrical equipment. According to the invention, a double closed-loop PID control algorithm is adopted to enable a vacuum circuit breaker permanent magnetic operating mechanism contact terminal with movement characteristics to be in a controlled state, so as to improve the robustness and control precision of a control system; field coil electric current of a current sensor measurement mechanism in the control device is utilized to enable the field coil electric current to be subjected to whole-course control, so as to avoid the possibility of coil burning down; a contact terminal journey dynamic curve is selected to reduce the impulsive force of a moving contact reaching an extreme position, so as to improve the reliability of the mechanism action and prolong the service life of the mechanism; the divide-shut brake voltage is improved, and the contact terminal journey curve is selected to reduce energy loss of the contact terminal caused by collision, so as to achieve the energy-saving effect, enable the circuit breaker to complete brake reclosing operation for more times under the same application condition, effectively prolong the service life of the circuit breaker, and improve the stability of an electric power system simultaneously.

Owner:SHENYANG POLYTECHNIC UNIV

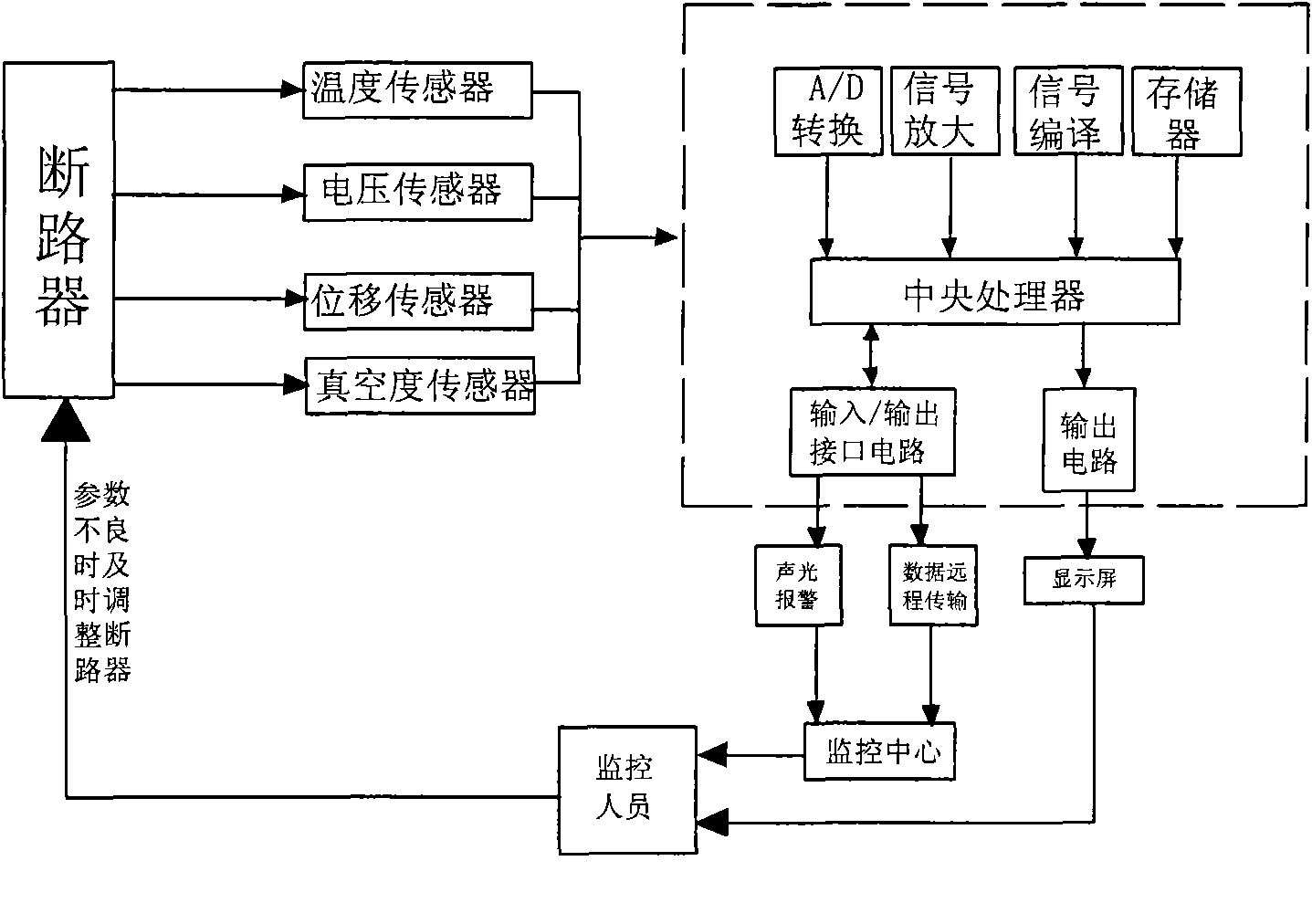

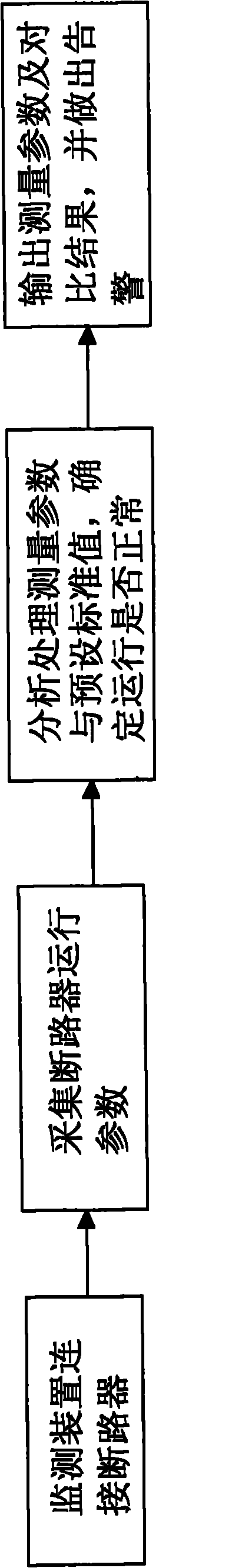

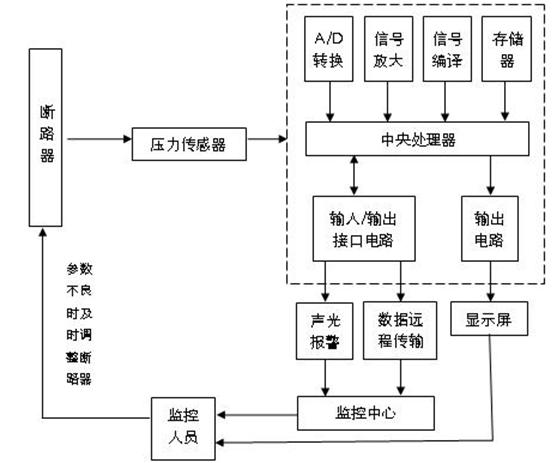

Intelligent vacuum circuit breaker online monitoring method

InactiveCN101825684AReduce work intensityImprove reliabilityHigh-tension/heavy-dress switchesAir-break switchesElectric power systemComputer module

The invention relates to the monitoring technical field of the vacuum circuit breaker, in particular to an intelligent vacuum circuit breaker online monitoring method, which comprises the following steps that: a. an intelligent vacuum circuit breaker online monitoring device is connected with a vacuum circuit breaker, and a sensor of the online monitoring device is arranged inside the vacuum circuit breaker; B. the senor instantly collect the running parameter information of the vacuum circuit breaker and transmits the running parameter information to a control module; C. the control module analyzes and compares the running parameter information of the vacuum circuit breaker and performs the conversion treatment of the running parameter information; D. the information after being processed is directly fed back to the online monitoring device in an acousto-optic way. A plurality of measurement parameters are obtained through a plurality of sensors of different types so as to instantly monitor the running state of the vacuum circuit breaker and to improve the examination pertinence, so the automatic treatment of the online monitored information is realized, the reliability of the electric power system is remarkably improved, and the work intensity of the personnel is greatly reduced.

Owner:CHANGZHOU MECAN ELECTRIC TECH DEV

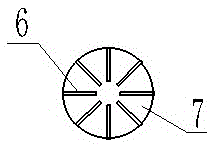

Vacuum arc-extinguishing chamber, vacuum arc-extinguishing chamber contacts and direct current vacuum circuit breaker

ActiveCN105551881ARestoration of insulation propertiesRealization of openingHigh-tension/heavy-dress switchesAir-break switchesHigh-voltage direct currentVoltage drop

The invention relates to a vacuum arc-extinguishing chamber, vacuum arc-extinguishing chamber contacts and a direct current vacuum circuit breaker. The direct current vacuum circuit breaker comprises an operating mechanism and the vacuum arc-extinguishing chamber, wherein the vacuum arc-extinguishing chamber comprises a moving contact and a fixed contact; arc-extinguishing gate pieces are arranged on the end plane, facing to the fixed static, of the moving contact, or the end plane, facing to the moving contact, of the fixed contact; the arc-extinguishing gate pieces are extended in the radial direction of the moving contact or the fixed contact, and are uniformly distributed in the circumferential direction; and the direct current vacuum circuit breaker also comprises a magnetic field apparatus used for generating a transverse magnetic field for enabling electric arc to rotate along the axial line of the vacuum arc-extinguishing chamber. When a switch-off action is implemented, the electric arc is sent to the gaps of the arc-extinguishing gate pieces under magnetic blowing force generated by the transverse magnetic field in the electric arc movement process, and the electric arc is cut into multiple series-connected short arcs under the function of the arc-extinguishing gate pieces; the electric arc is stretched, and meanwhile, a series of proximal-polar voltage drops occur on the surfaces of the gate pieces; and in addition, the electric arc is further cooled by the gate pieces, so that the electric arc is extinguished rapidly, and disconnection for the high voltage direct current is realized.

Owner:XUJI GRP +1

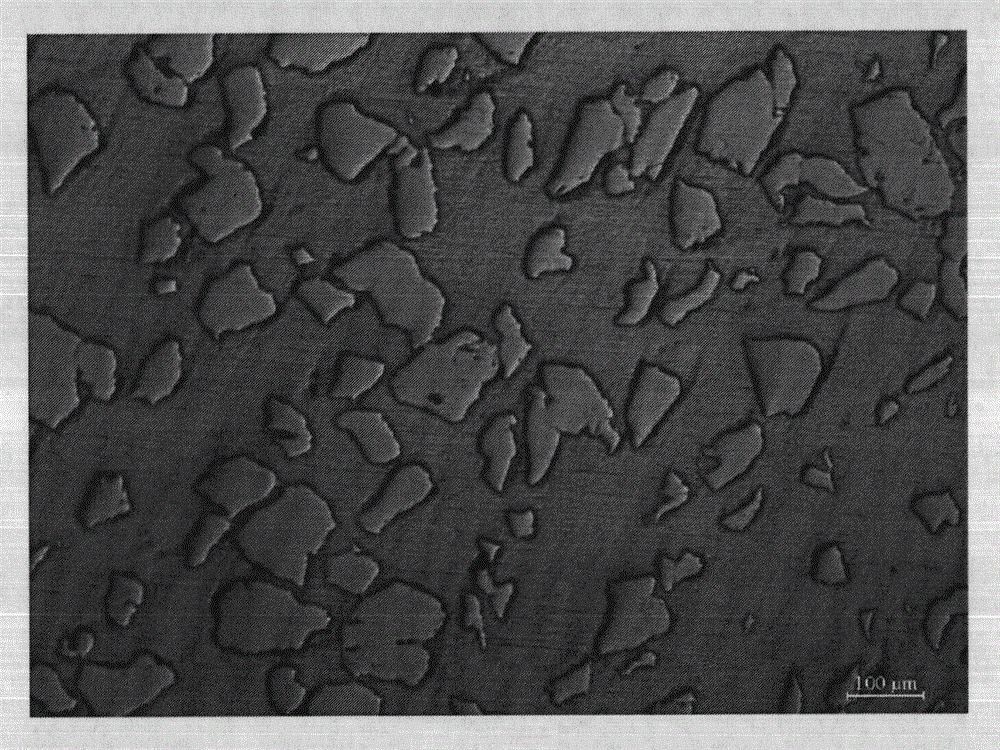

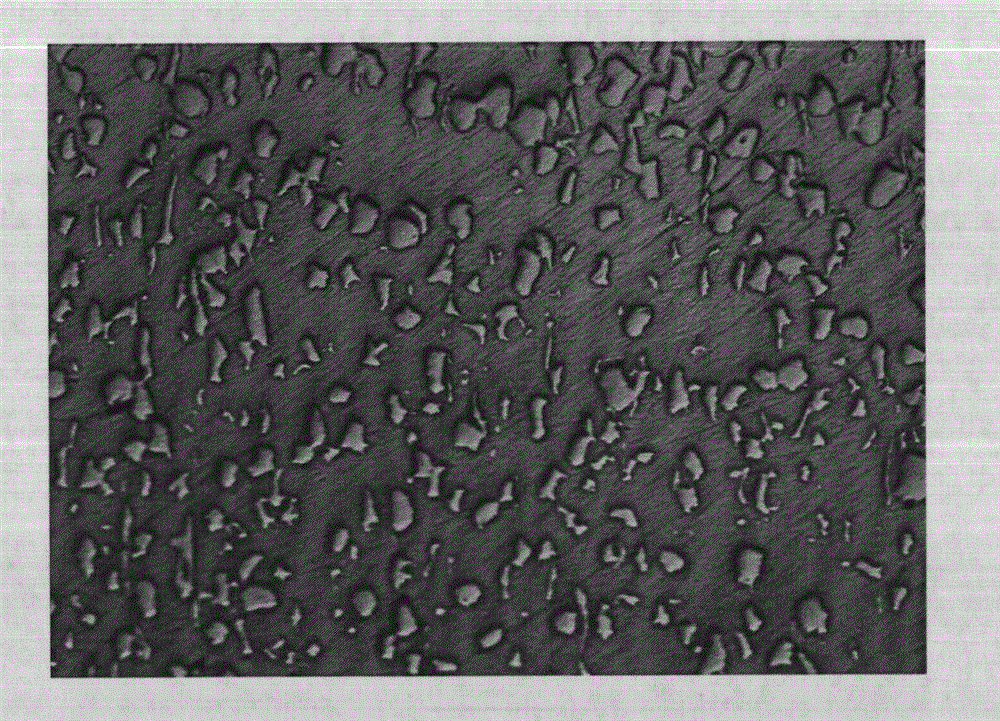

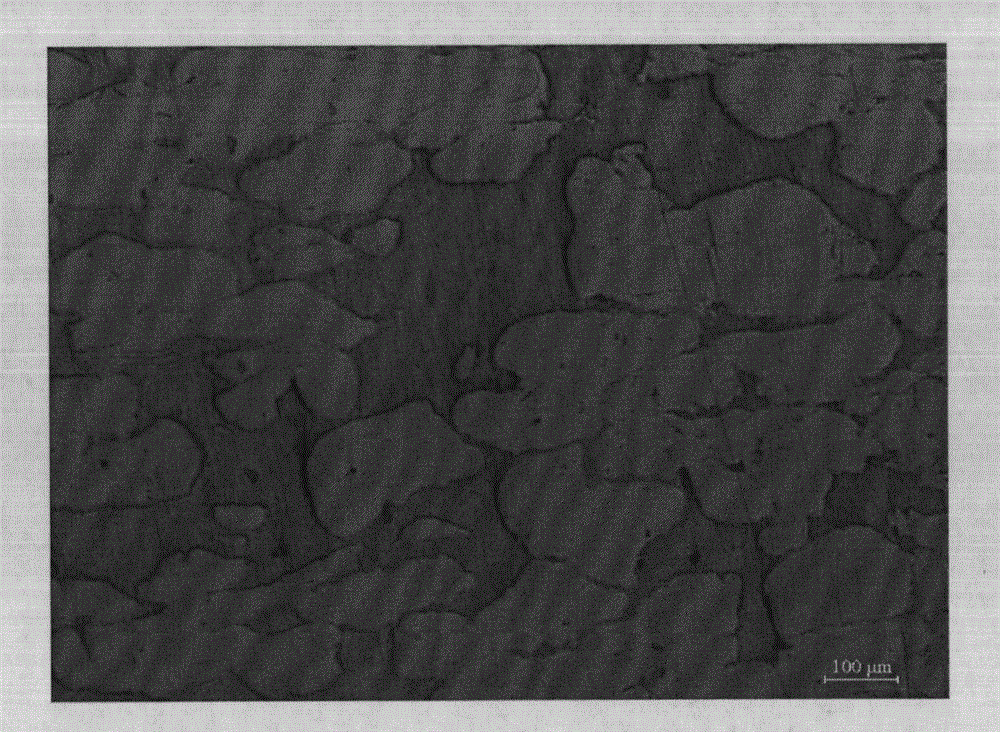

Manufacturing method for large-size high-density high-uniformity CuCr alloy

The invention discloses a manufacturing method for a large-size high-density high-uniformity CuCr alloy. The manufacturing method is characterized in that CuCr mixed powder is solidified and formed through discharge plasma sintering, by optimizing a sintering die structure, the temperature is increased to 800 DEG C to 880 DEG C through a step heating manner at 10 DEG C / min to 50 DEG C / min and then kept for 2 minutes to 8 minutes while axial mechanical pressure is applied, and a sintered cylinder ingot with the diameter not smaller than 50 mm, the long diameter ratio of 0.04-1.0, the density larger than 99.0%, axial and radial fluctuation less than 1% and an uniform component structure can be obtained. According to the manufacturing method, different sintering conditions can be selected according to the size demand of the CuCr alloy, the process is simple, the period is short, the production efficiency is high, and the obtained CuCr alloy can be made into a finished product through a small amount of subsequent machining and then used as a part of a vacuum circuit breaker in large-power transmission and transformation equipment.

Owner:HEFEI UNIV OF TECH +1

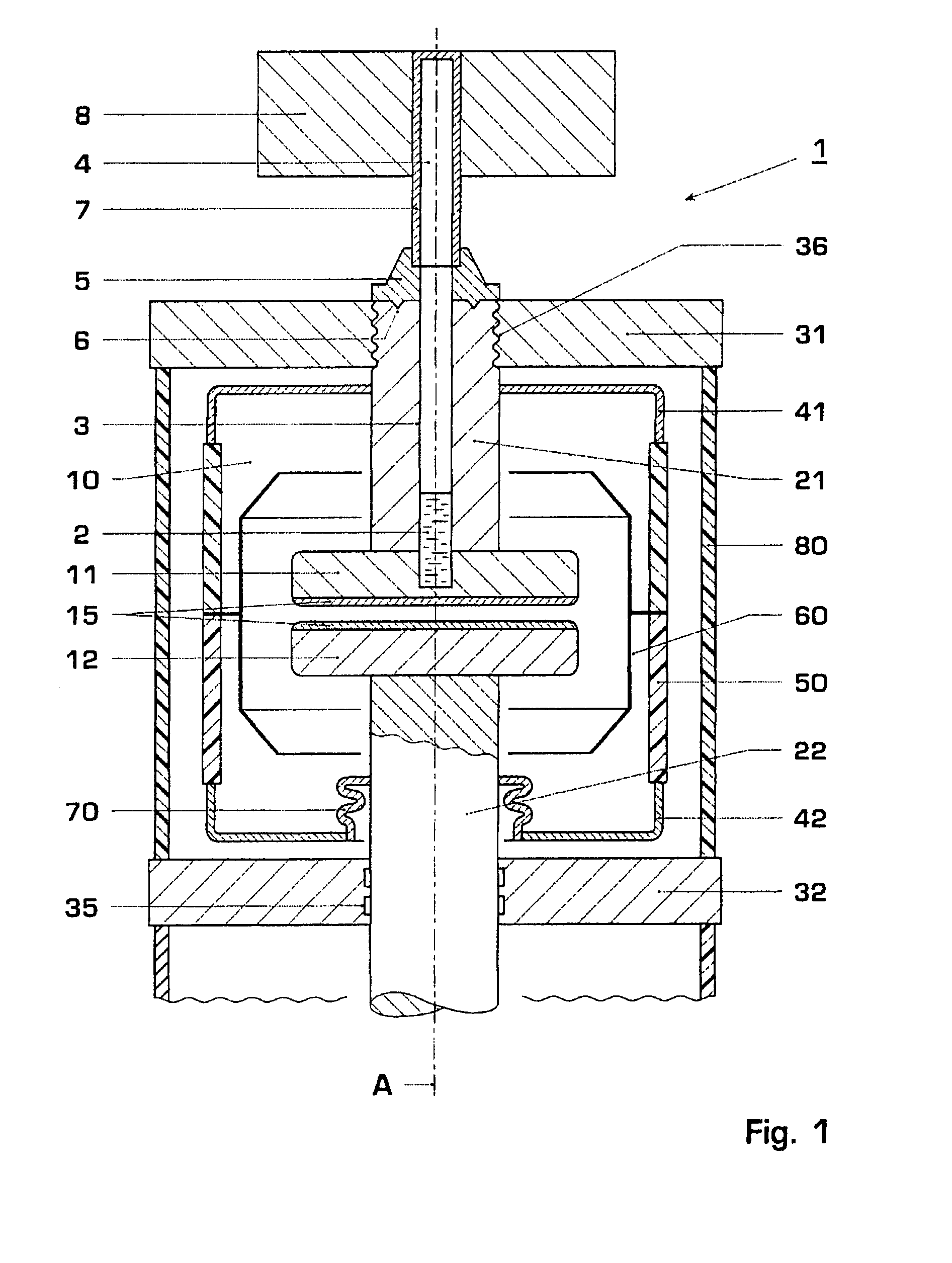

Vacuum circuit breaker having a high current-carrying capacity

InactiveUS20080000879A1Effective coolingImprove current carrying capacityIndirect heat exchangersHigh-tension/heavy-dress switchesCarrying capacityEngineering

The vacuum switching chamber has two contact pieces and is provided with at least one heat pipe for dissipating heat. The heat pipe contains a working medium for dissipating the heat by evaporating the working medium in a section, referred to as the evaporator, of the heat pipe and condensing the working medium in a section, referred to as the condenser, of the heat pipe. Advantageously, the evaporator is in close thermal contact with at least one contact piece, and, in particular, at least part of the evaporator is integrated in the first contact piece or the second contact piece. Advantageously, the condenser has a cooling rib arrangement.

Owner:ABB RES LTD

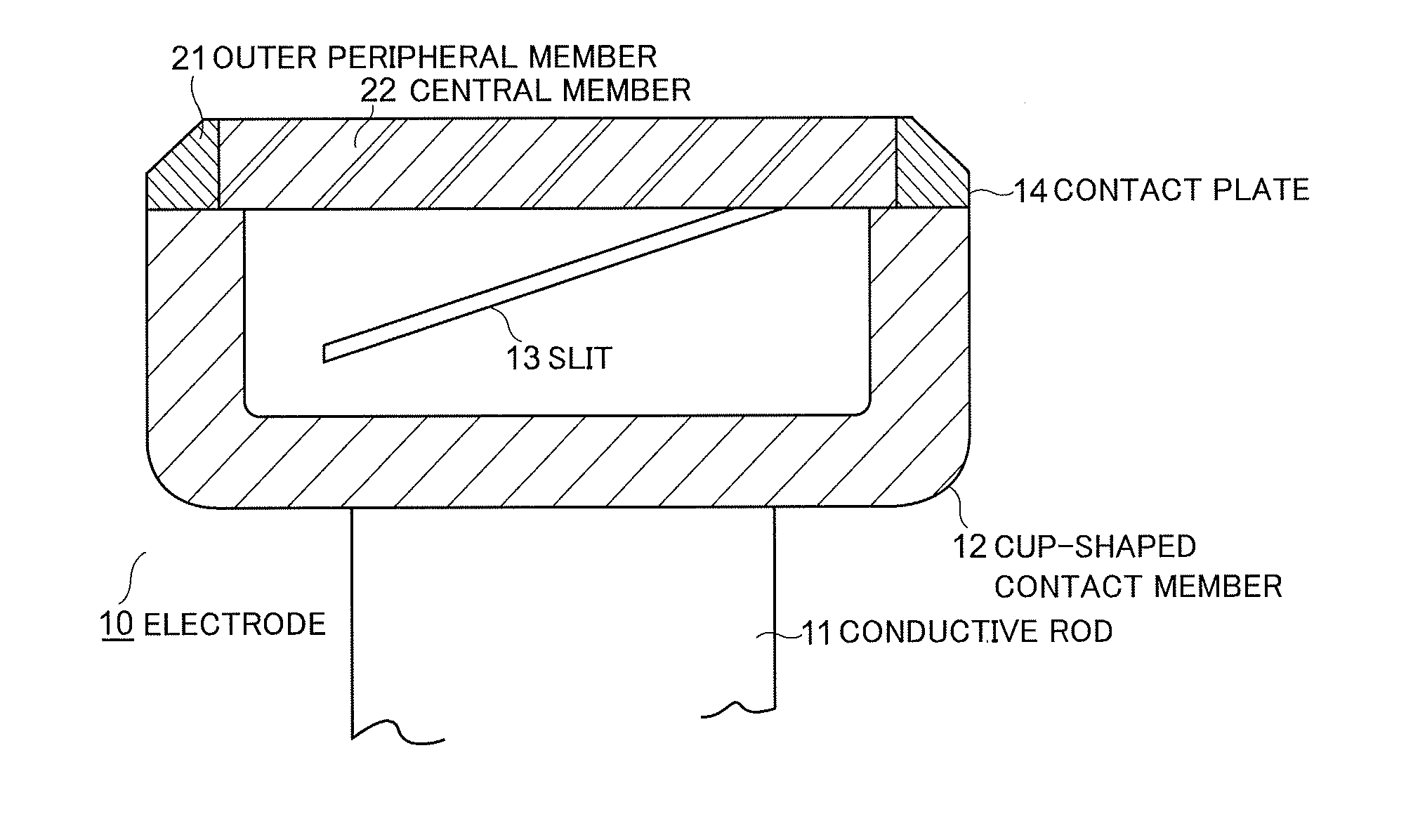

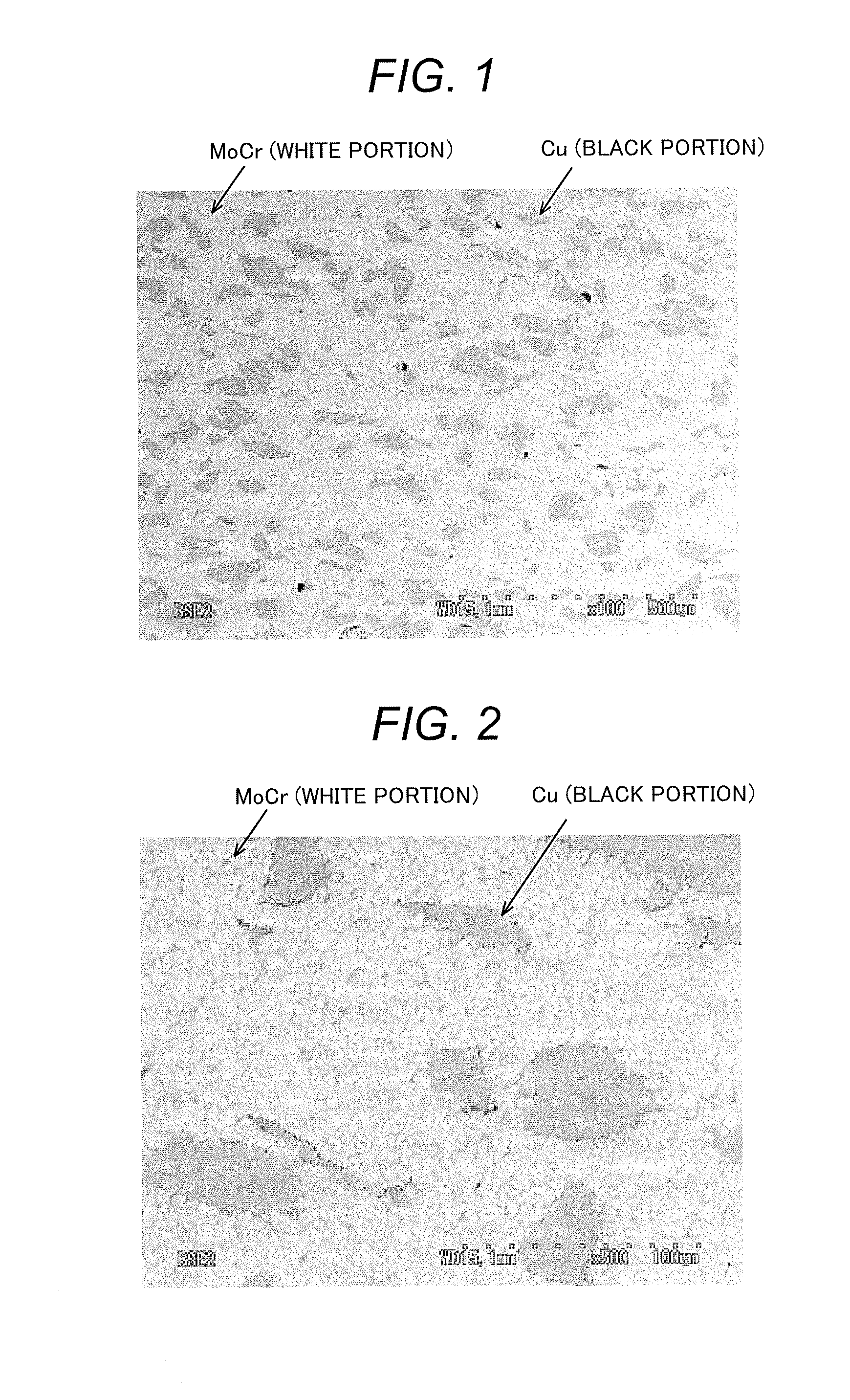

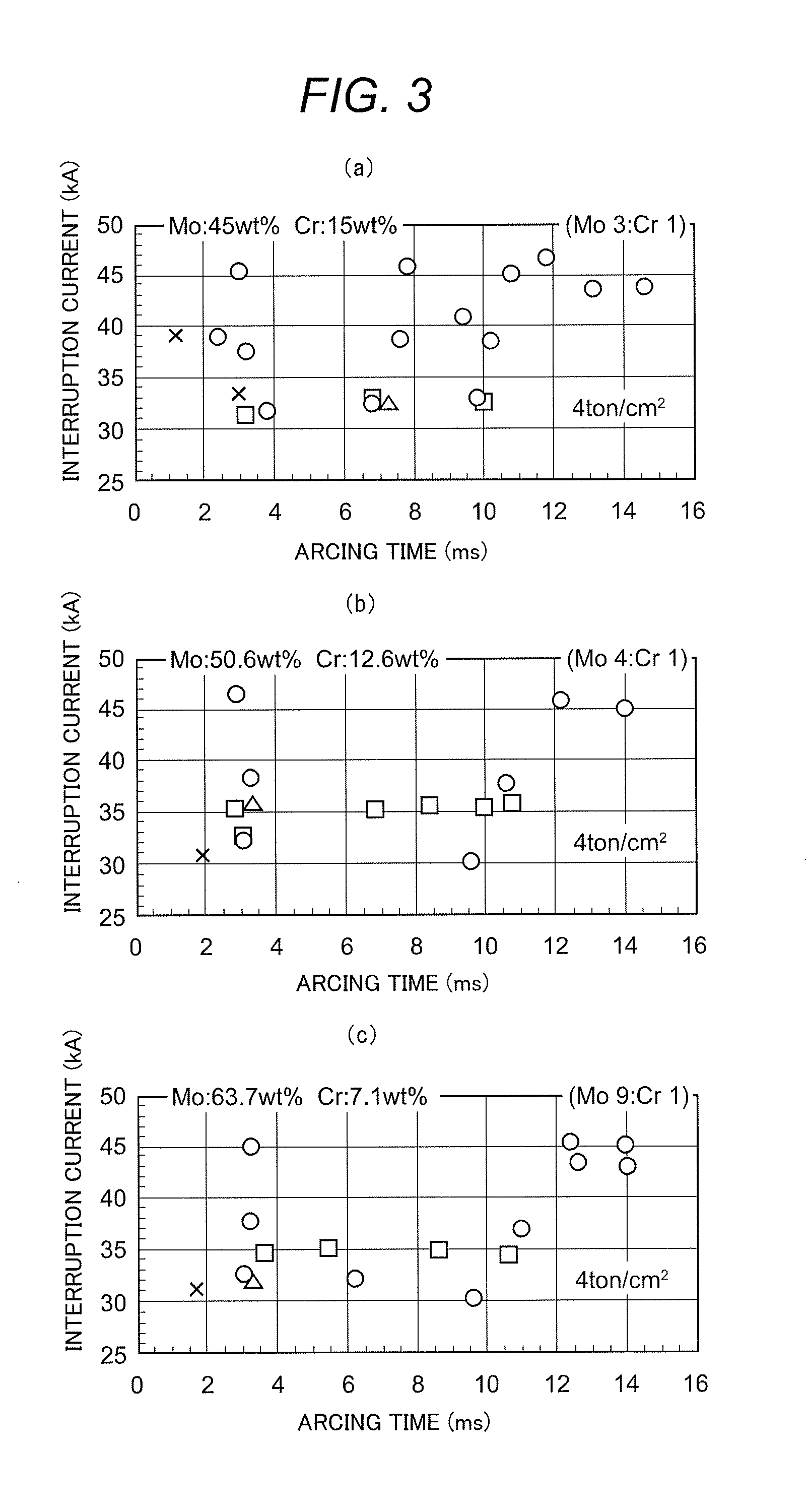

Method for Producing Electrode Material for Vacuum Circuit Breaker, Electrode Material for Vacuum Circuit Breaker and Electrode for Vacuum Circuit Breaker

ActiveUS20130199905A1Easy to produceHigh hardnessContact materialsContact surface shape/structureEngineeringHeating furnace

Provided are: a method for producing an electrode material for a vacuum circuit breaker, whereby withstand voltage, high current interruption performance and capacitor switching performance can be improved; an electrode material for a vacuum circuit breaker; and an electrode for a vacuum circuit breaker.The electrode material for a vacuum circuit breaker is produced by a method comprising a mixing step, a press sintering step, and a Cu infiltration step. In the mixing step, an Mo powder having a particle diameter of 0.8 to 6 μm is homogeneously mixed with a thermite Cr powder having a particle diameter of 40 to 300 gm in such a manner as giving a mixing ratio (Mo:Cr) of 1:1 to 9:1 and satisfying the weight relation Mo≧Cr. In the press sintering step, the resultant mixture is pressure molded under a press pressure of 1 to 4 t / cm2 to give a molded article. Next, said molded article is sintered by maintaining the same at a temperature of 1100 to 1200° C. for 1 to 2 hours in an heating furnace to give a partially sintered article. In the Cu infiltration step, a thin Cu plate is placed on said partially sintered article and maintained at a temperature of 1100 to 1200° C. for 1-2 hours in a heating furnace so that Cu is liquid-phase sintered and infiltrated into the partially sintered article. A contact material of an electrode for a vacuum circuit breaker has an integral structure consisting of a central member and a Cu—Cr outer peripheral member, said central member having been produced as described above and comprising 30 to 50 wt % of Cu of a particle diameter of 20 to 150 μm and 50 to 70 wt % of Mo—Cr of a particle diameter of 1 to 5 μm, while said outer peripheral member being formed of a material, which is highly compatible with the central member, shows excellent interruption performance and had high withstand voltage, and being provided outside the central member and fixed thereto.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

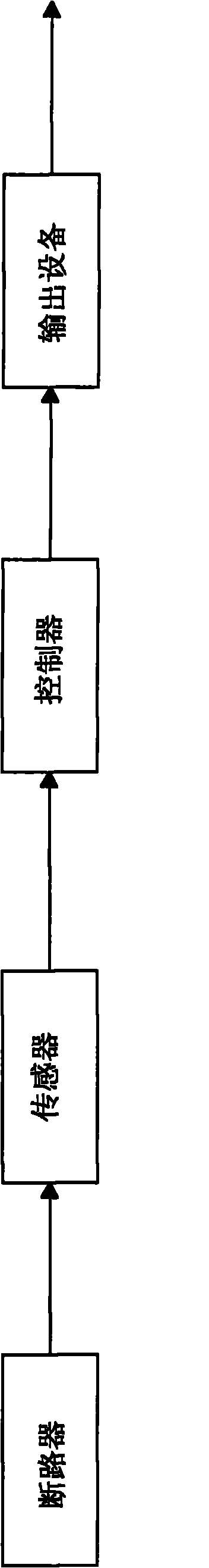

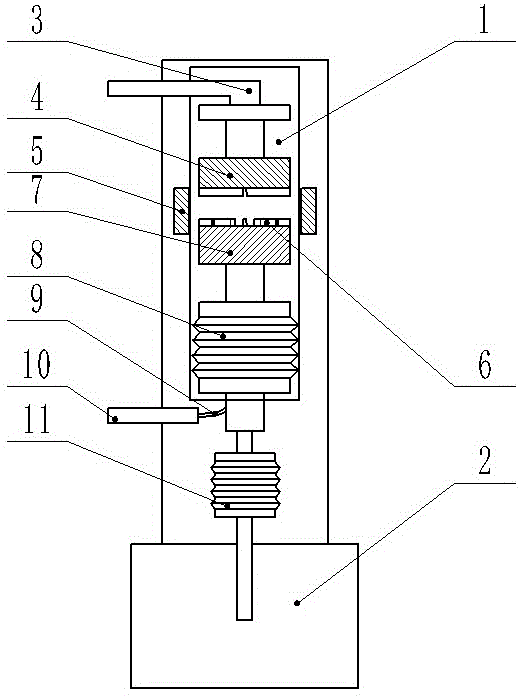

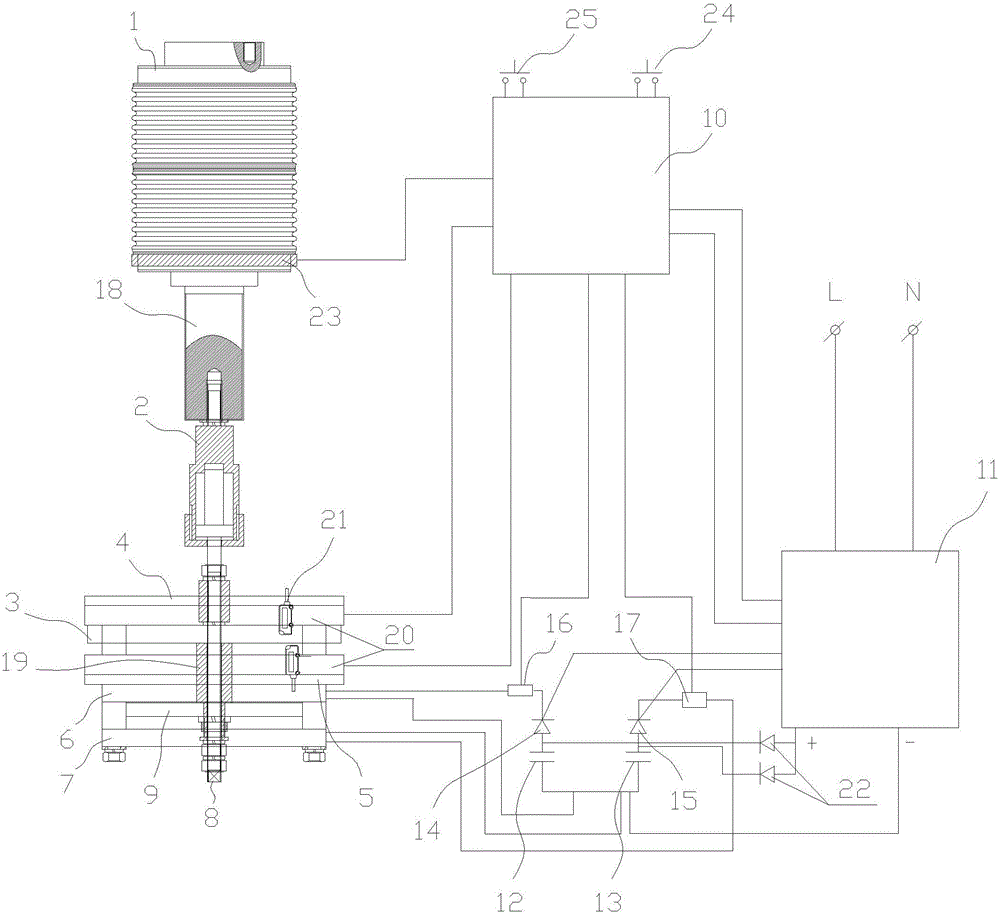

Intelligent device and method for monitoring switch-on spring performance of vacuum circuit breaker

InactiveCN102592878AKeep abreast of work statusImprove reliabilityMachine part testingHigh-tension/heavy-dress switchesElectric power systemSpring force

The invention relates to the field of monitoring technologies for vacuum circuit breakers, in particular to intelligent device and method for monitoring switch-on spring performance of a vacuum circuit breaker. The device comprises a circuit breaker, a sensor, a controller and output equipment, wherein the sensor is used for monitoring operational parameters of the circuit breaker and sending an acquired real-time modeling signal to the controller; the controller is used for receiving the operational parameters output by the sensor and processing the acquired parameters to calculate out a corresponding switch-on spring force value which is transmitted out through the output equipment; the sensor is a pressure sensor; and the operational parameters of the sensor are force value parameters of the sensor. According to the invention, whether the switch-on spring of the vacuum circuit breaker is fatigued or not can be timely and accurately judged, so that the working state of the circuit breaker can be timely known, untimely or unnecessary power failure test and maintenance can be reduced, maintenance workload is also reduced, maintenance cost is saved, and the reliability and economical efficiency of an electric power system are both obviously improved.

Owner:CHANGZHOU MECAN ELECTRIC TECH DEV

Closing holding device for vacuum circuit breaker

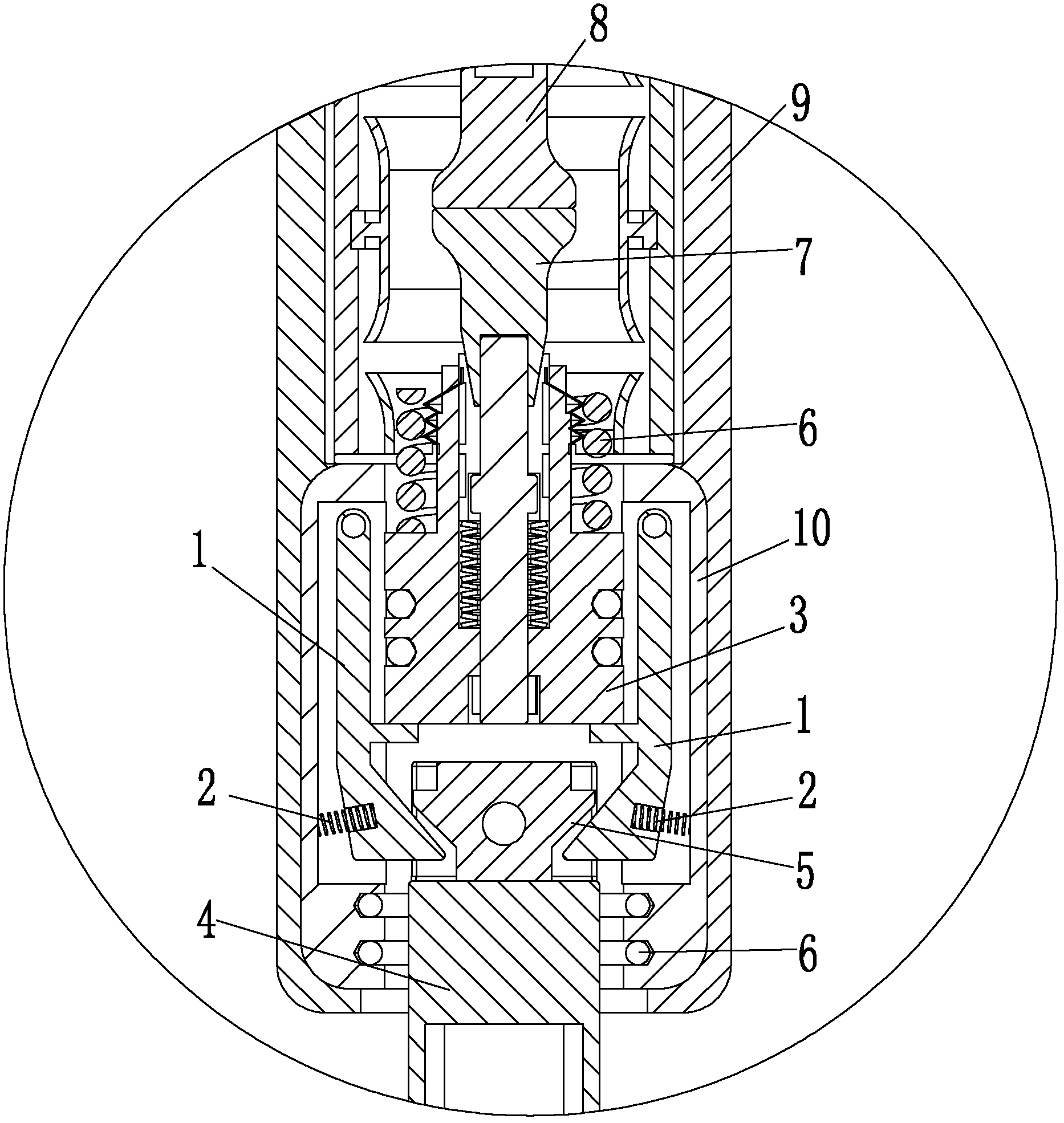

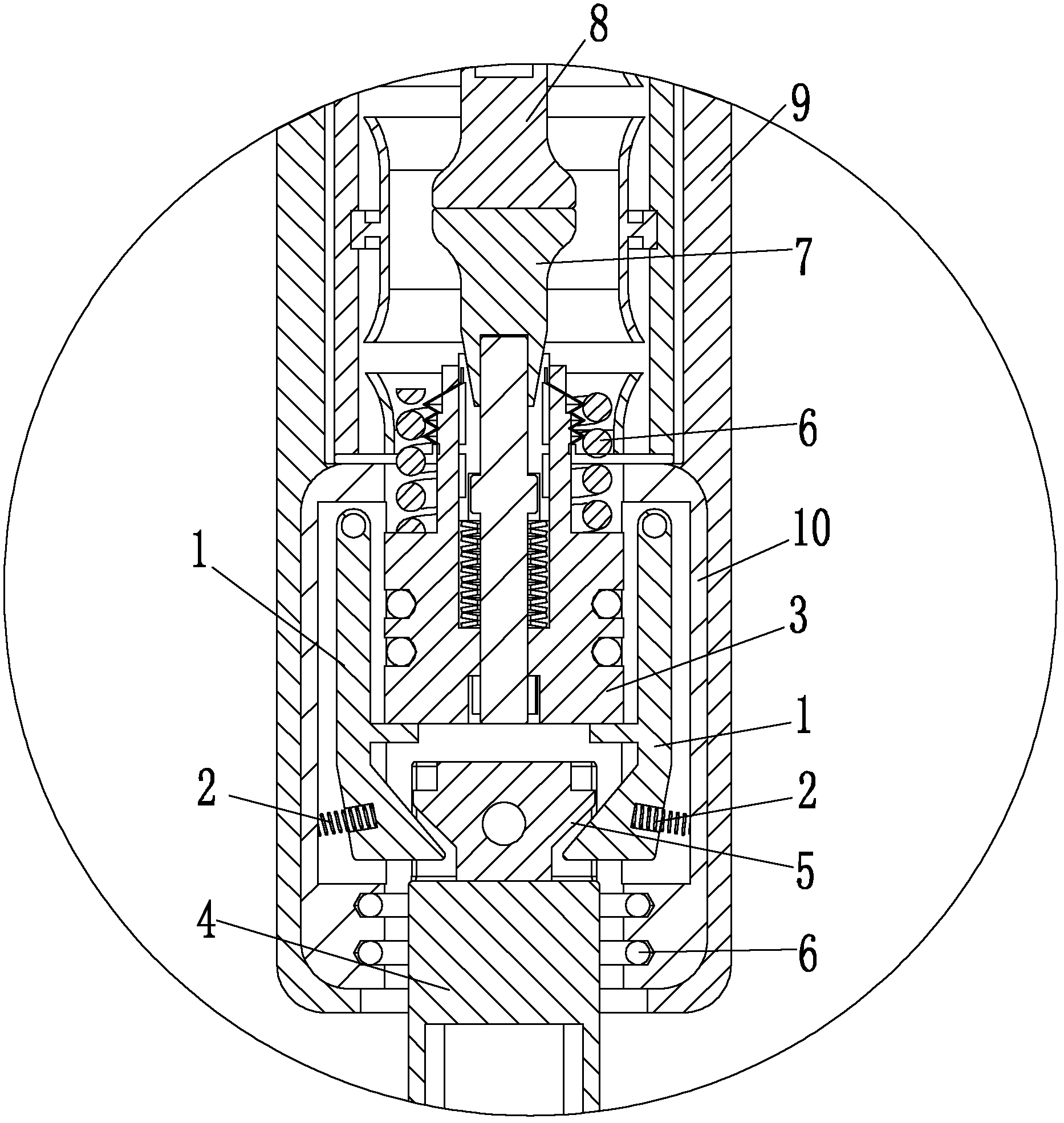

InactiveCN102543561AEasy to operateSimple structureHigh-tension/heavy-dress switchesAir-break switchesStructural engineeringVacuum circuit breakers

The invention discloses a vacuum circuit breaker with a closing holding device. A hollow cavity is formed in a housing; switch-off springs are sleeved on a movable conductor pole, and arranged in the middle of the cavity in the housing; a movable contact is connected with an ejector rod at the top part of the movable conductor pole; a static contact is fixed at the top part of the cavity and is separated from the movable contact; paired closing holding pawls are arranged at the lower part of the movable conductor pole; pressure springs are arranged between the side parts of the lower ends of the closing holding pawls and the inner wall of the cavity; protrusions are arranged at the middle parts of the closing holding pawls and clamped at the bottom of the movable conductor pole when the movable contact and the static contact are in contact; inclined planes are arranged at the lower parts of the closing holding pawls; the inclined planes of one pair of closing holding pawls form an erect V-shaped structure; a closing holding unlocking block is arranged in the V-shaped structure; and an isolating switch movable contact is arranged at the lower part of the closing holding unlocking block so as to push the closing holding unlocking block to perform up-and-down motion. The vacuum circuit breaker with the closing holding device provided by the invention is convenient to control.

Owner:SUZHOU LONGER ELECTRIC CO LTD

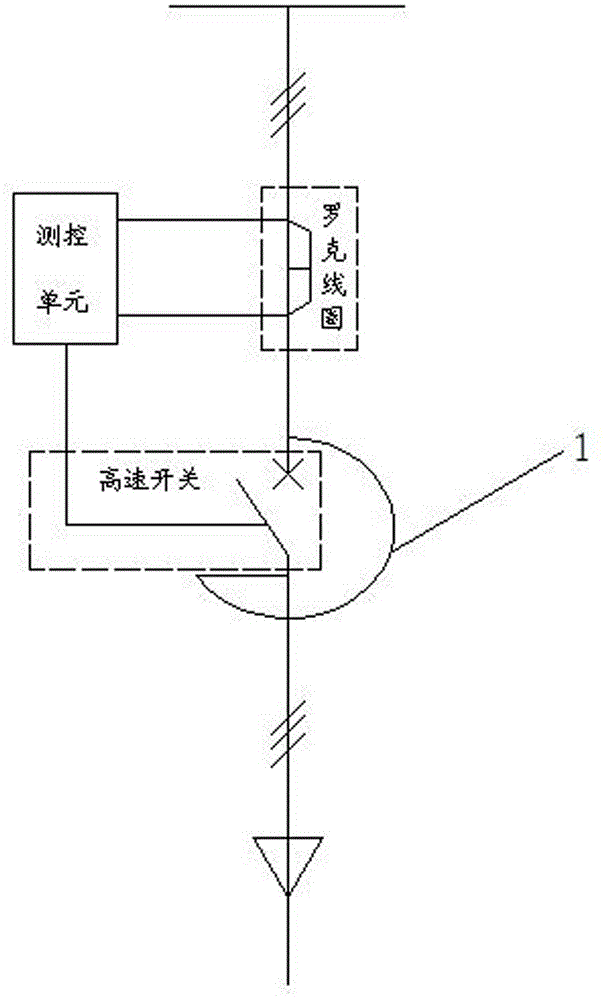

Adaptive smart synchronous high-speed switching device

ActiveCN106024500AGuaranteed anti-interference abilityGuaranteed accuracyHigh-tension/heavy-dress switchesAir-break switchesEngineeringVacuum circuit breakers

The invention provides an adaptive smart synchronous high-speed switching device. The amplitude, phase angle and zero-crossing point during short circuit can be calculated through current and voltage parameters when a sampling system is short-circuited. Balanced dynamic control of coil driving magnetic flux during a moving transient process is realized, the opening speed of the switch is adjusted automatically according to the short circuit state to satisfy requirements of different short circuit states on opening time. A Rogowski coil on a vacuum circuit breaker explosion chamber mounting base conducts sampling, monitoring and controlling of a current loop, and smart control and phase-splitting control of the switch and synchronous switching are realized.

Owner:ANHUI HEKAI ELECTRICAL TECH CO LTD

High-performance copper chromium contactor material and preparing method thereof

The invention relates to a high-performance copper chromium contactor material and a preparing method thereof. The copper chromium contactor material is composed of, by weight, 10-50% of Cr and the balance Cu. The preparing method of the copper chromium contactor material comprises the steps of raw material selecting, powder mixing, cold isostatic pressing, vacuum covering, heating and hot extruding. According to the high-performance copper chromium contactor material and the preparing method thereof, the special covering, heating and extruding technology is adopted, so that the special requirement for a press and a die by a large-specification contactor and high Cr content in the cold pressing process is greatly lowered, and mass production can be carried out through existing conventional equipment; furthermore, by means of high-temperature extruding, powder can be densified as much as possible in the solid phase, and air holes in texture can be reduced and even eliminated. The prepared high-performance copper chromium contactor material is used in a middle-high pressure vacuum circuit breaker, due to the fact that the contactor material prepared through the technology has the beneficial effects of being high in density and even in texture, the issues that in an existing technology, electric conductivity and heat conductivity are poor, and the air releasing amount is large can be easily relieved, and meanwhile good melting-welding resistance is maintained.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

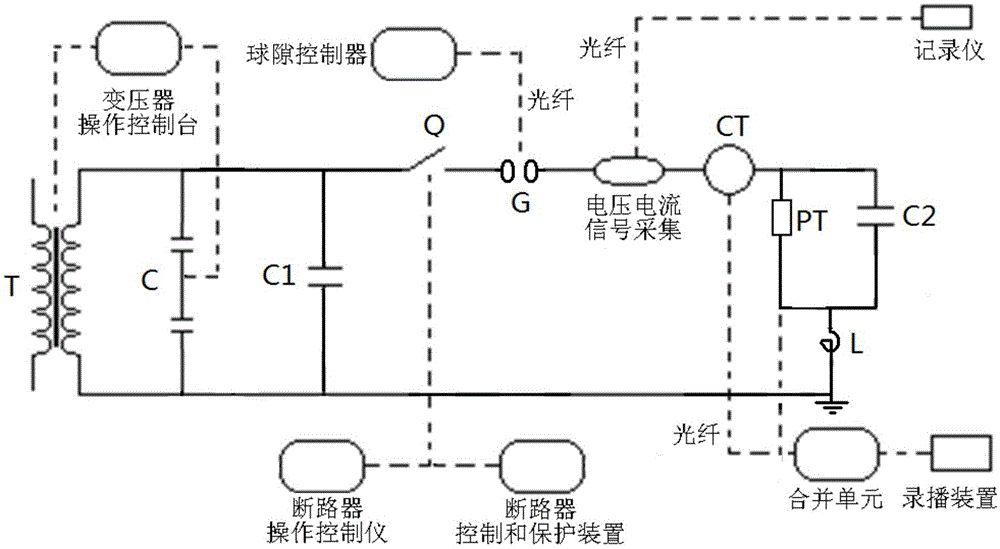

Simulated electromagnetic disturbance source for isolating switch

ActiveCN105137135AHigh precisionEasy to assembleElectrical measurement instrument detailsElectrical testingCapacitanceCapacitive divider

The invention discloses a simulated electromagnetic disturbance source for an isolating switch. The simulated electromagnetic disturbance source comprises a testing transformer, a capacitive divider, an adjustable grounding capacitor, a power supply side analog capacitor, a vacuum circuit breaker switch, a discharging sphere gap and a load side analog capacitor. The original side of the testing transformer is connected with a power supply, and the auxiliary side is serially connected with the capacitive divider. The power supply side analog capacitor is parallelly connected with the capacitive divider. The anode of the power supply side analog capacitor is successively connected with the vacuum circuit breaker switch, the discharging sphere gap, the load side analog capacitor and a grounding capacitor in series. The cathode of the power supply side analog capacitor is grounded. The simulated electromagnetic disturbance source can truly simulate an electromagnetic disturbance process and a ground potential increase process in a switching-on process and a switching-off process of the isolating switch and can output a 1.1MHz high-strength electromagnetic field. Furthermore the simulated electromagnetic disturbance source for the isolating switch has advantages of convenient assembling, simple operation, high testing safety and high precision.

Owner:STATE GRID CORP OF CHINA +2

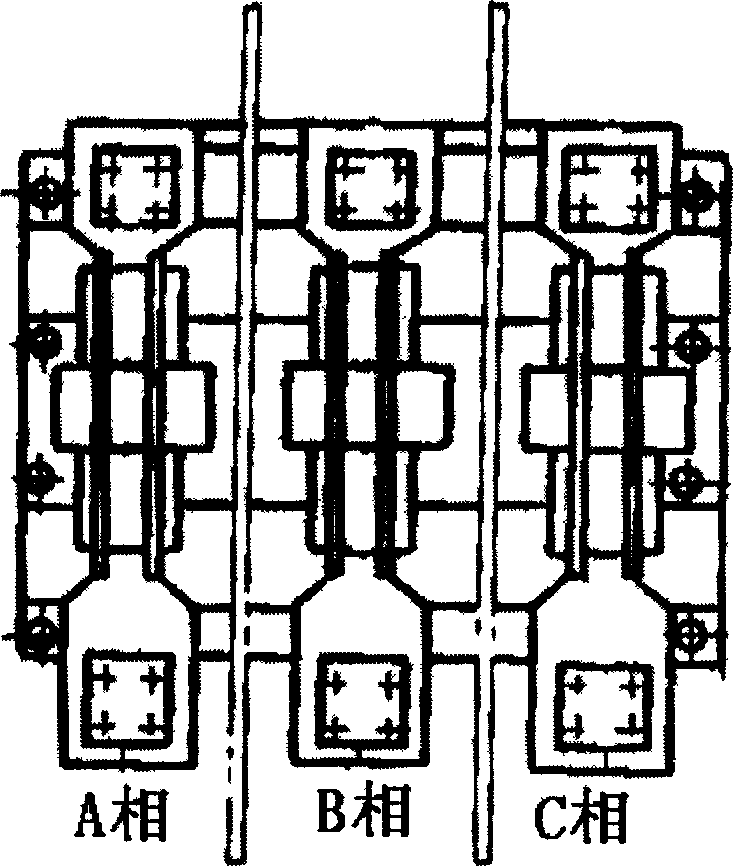

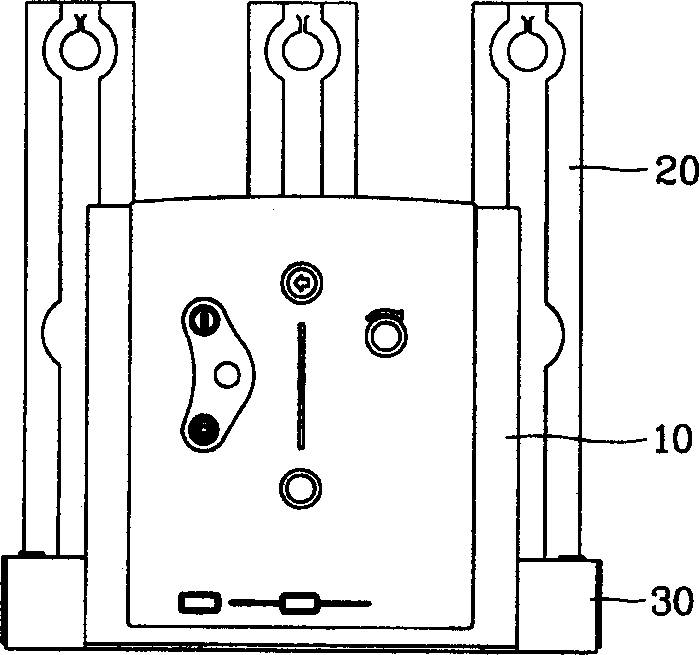

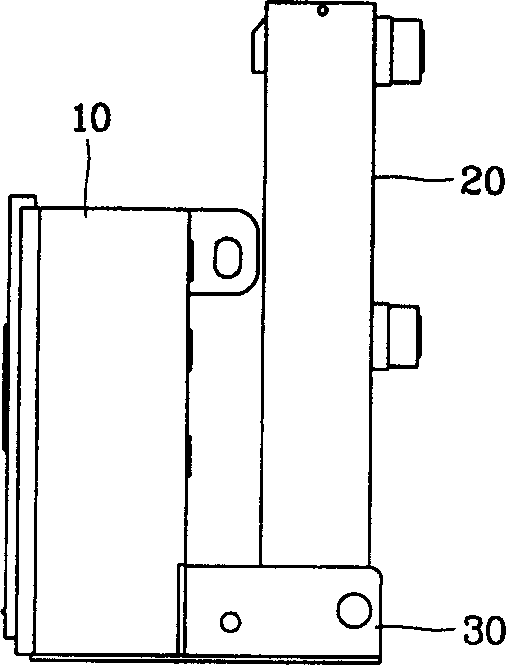

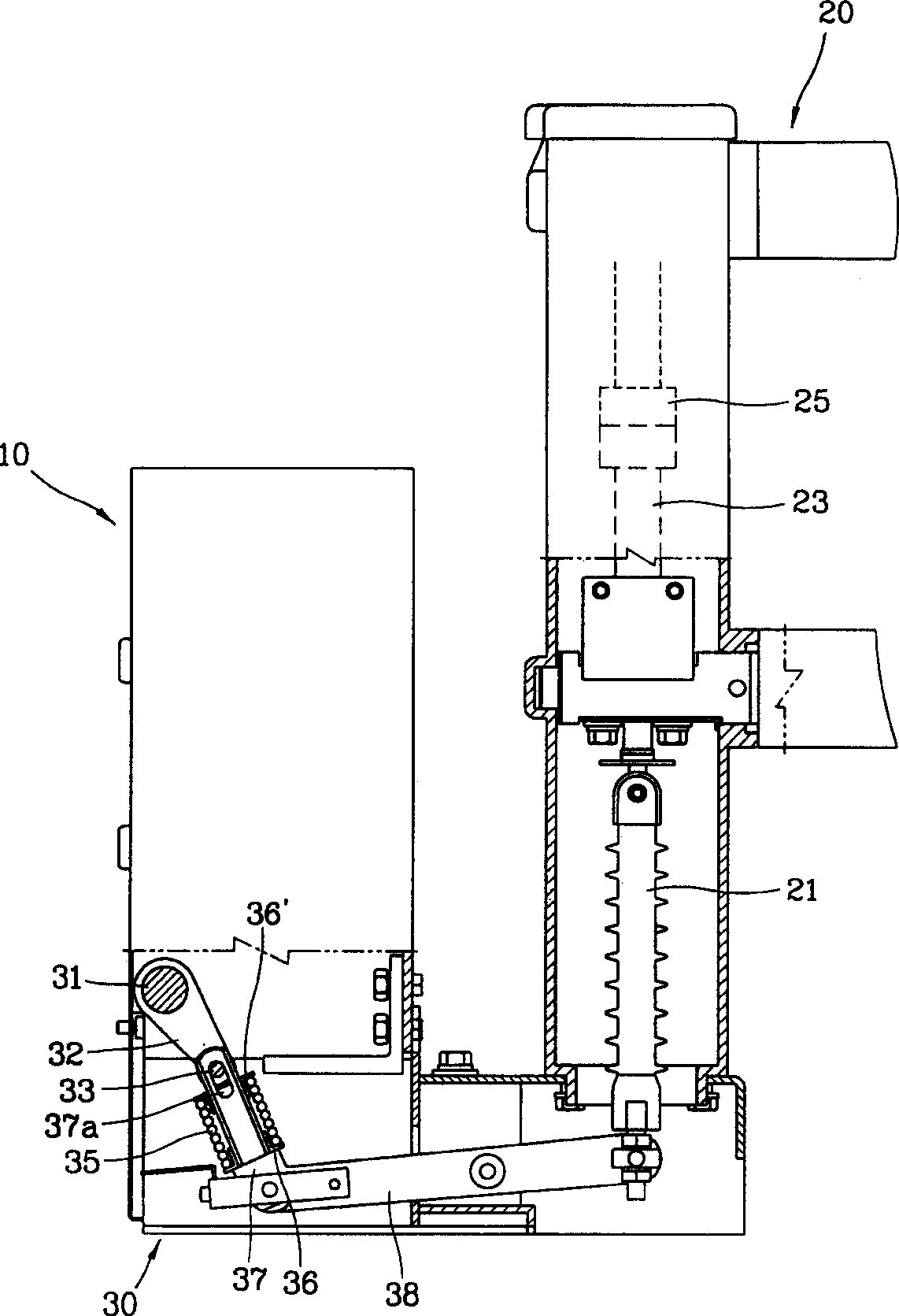

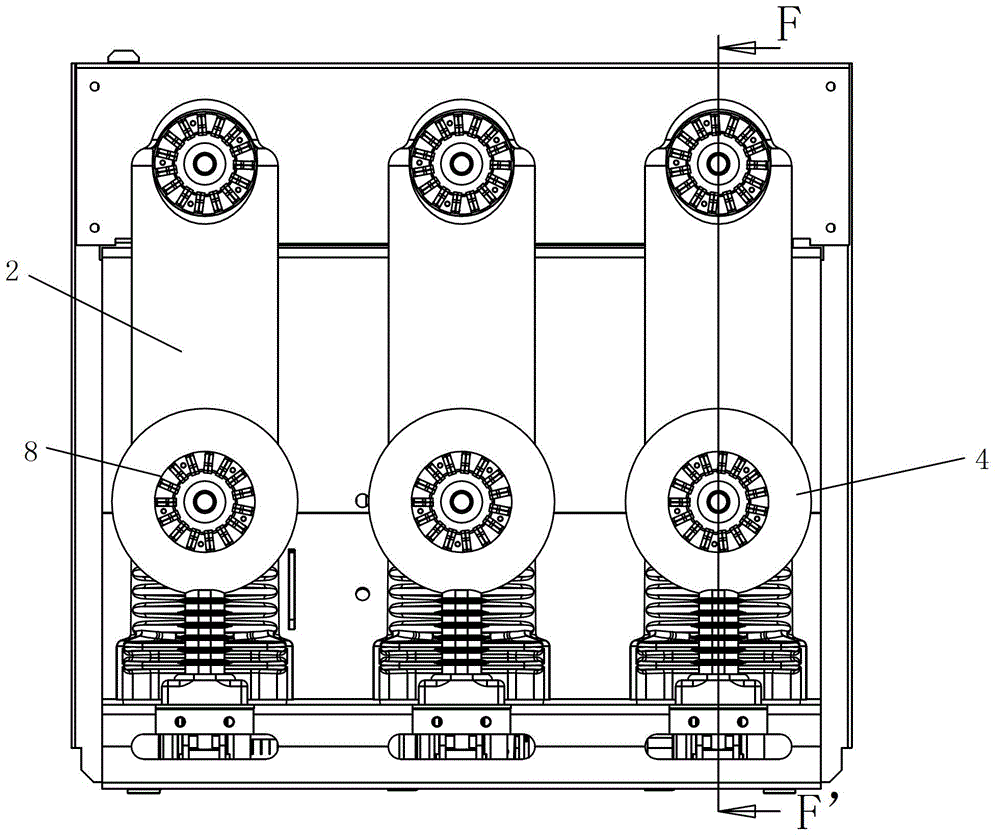

Vacuum disconnector

InactiveCN1357902AEasy to installEffective maintenanceSubstation/switching arrangement detailsHigh-tension/heavy-dress switchesEngineeringActuator

A vacuum circuit breaker comprises: a plurality of switching mechanism units having movable contacts and stationary contacts for connecting / breaking an electric circuit between an electric source and an electric load respectively, and disposed in lengthwise direction; an actuator unit including at least one rotary shaft for providing the movable contacts with dynamic power so as to move to positions contacting to the stationary contacts or to positions separating from the stationary contacts; a supporting frame for fixing and supporting the switching mechanism units and the actuator unit; and a transfer link unit for transferring rotating movement of the rotary shaft to a plurality of vertical movements, whereby the vacuum circuit breaker can be easily installed in a power distributing cabinet and a power of the actuator unit can be evenly transmitted to the plurality of switching mechanism units.

Owner:LG IND SYST CO LTD

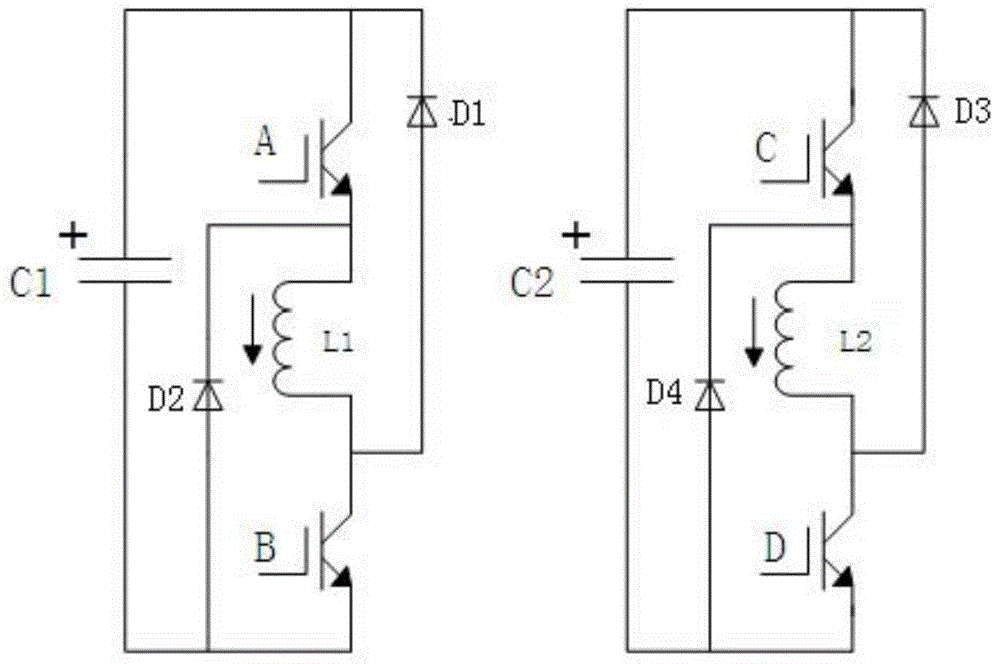

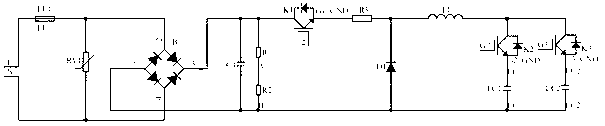

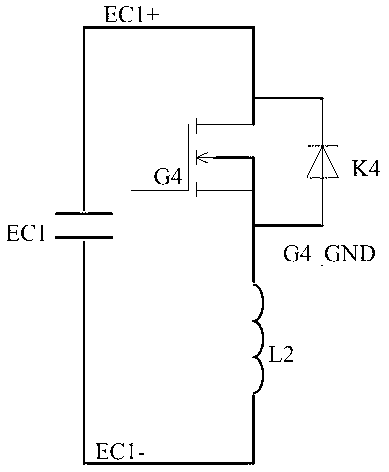

Control device and method of bistable permanent-magnet vacuum circuit breaker rapid divide-shut brake

InactiveCN104157509ASmall pressure dropAvoid generatingHigh-tension/heavy-dress switchesAir-break switchesCapacitancePeak current

The invention discloses a control device and method of a bistable permanent-magnet vacuum circuit breaker rapid divide-shut brake. The method comprises the following steps that a freewheeling diode is utilized for enabling the coils to be supplied with follow current, so that the coils can discharge to a corresponding discharge capacitor when switch tubes on the two sides of an opening coil or a closing coil are all turned off, and at the same time, the induced voltage generated by mutual inductance is counteracted with the negative voltage, namely, the voltage of a non-discharge voltage. According to the control device and method, the problem of the conventional bistable operating mechanism that the voltage drop of the capacitor is too big and the operation is influenced by the induced current is solved, the control voltage is reduced, the discharging peak current is reduced, the movement speed can be adjusted by the PWM drive control module according to requirements and the contact bounce is reduced, so that the operating characteristic is more in accordance with the arc resistance of the circuit breaker.

Owner:SOUTHEAST UNIV

Intelligent vacuum circuit breaker

InactiveCN102751130AEasy opening and closing controlEasy maintenanceHigh-tension/heavy-dress switchesAir-break switchesPower flowLiquid-crystal display

The invention discloses an intelligent vacuum circuit breaker, which comprises a case and a pole connected with the case and also comprises temperature detection modules, a current measuring device, a mechanical characteristic detection device, an intelligent control unit and a liquid crystal touch display, wherein an upper contact arm and a lower contact arm are arranged on the pole; the temperature detection modules are arranged on the upper contact arm and the lower contact arm; the current measuring device is arranged on the lower contact arm; the mechanical characteristic detection device is arranged at the bottom of the pole; the intelligent control unit is arranged in the case; the liquid crystal touch display is arranged on the case; and the intelligent control unit is connected with the temperature detection modules, the current measuring device, the mechanical characteristic detection device and the liquid crystal touch display. The working parameters of the circuit breaker are acquired through the temperature detection device, the current measuring device and the mechanical characteristic detection device, are sent to the intelligent control unit in real time and are finally transmitted to the liquid crystal touch display, a worker monitors an operating state of the circuit breaker through the liquid crystal touch display, so that problems are conveniently found in real time to perform switching on / off control and maintenance on the circuit break, and intelligent control is facilitated.

Owner:JIANGSU SENYUAN ELECTRICAL

Intelligent controller of bistable permanent-magnet vacuum circuit breaker

ActiveCN103123882ARealize constant current chargingExtended service lifeHigh-tension/heavy-dress switchesAir-break switchesCapacitanceLow voltage

The invention discloses an intelligent controller of a bistable permanent-magnet vacuum circuit breaker and belongs to the technical field of intelligent low-voltage apparatus. The intelligent controller comprises a microprocessor, an isolating driving module, a switching-on / off brake coil driving module, a power supply failure detection module, a power supply voltage range detection module, a switching power supply module, a switching-on / off brake capacitor charging module, a switching-on / off brake capacitor charging current detection module and a power failure maintenance module. By the aid of the intelligent controller, constant-current charging of a switching-on / off brake capacitor is achieved, the service life of the capacitor is prolonged, simultaneously, a circuit of the power failure maintenance module and a circuit of the power supply failure detection module in the intelligent controller can guarantee the effective utilization of energy and the reliable switching-off of a circuit breaker under the power failure condition, circuits are simplified, the reliability of the whole intelligent controller is further improved, and the safety of power supply is guaranteed.

Owner:CHUZHOU UNIV

High-speed vacuum circuit breaker based on eddy current drive

InactiveCN105390330ASimple structureLow costHigh-tension/heavy-dress switchesAir-break switchesEddy currentContact position

The present invention relates to a high-speed vacuum circuit breaker based on eddy current drive. The high-speed vacuum circuit breaker comprises a shell as well as a vacuum arc extinguish chamber, an operating mechanism and a control circuit which are mounted on the shell; a fixed static conductive contact and a movable conductive contact positioned right below the static conductive contact are arranged in the vacuum arc extinguish chamber; a lower end of the movable conductive contact extends out of the vacuum arc extinguish chamber and is fixedly connected to a connecting rod by an insulating tension pole; leading-out terminals which extend towards the outside of the shell and are used for connecting a bus are formed at end parts of the static conductive contact and the movable conductive contact; and an operating mechanism apparatus for enabling the movable conductive contact to move up and down by a magnetic flux force so as to reach a switching-off or switching-on position and the control circuit for controlling the operating mechanism apparatus to execute the switching-off or switching-on action are arranged on the connecting rod. The vacuum circuit breaker disclosed by the present invention has a simple structure and low costs, and switching-on and switching-off of the vacuum circuit breaker are controlled by an induced magnetic field and the control circuit, so that switching-on and switching-off speeds and stability of the vacuum circuit breaker are improved.

Owner:ANHUI HUIDIAN SCI & TECH

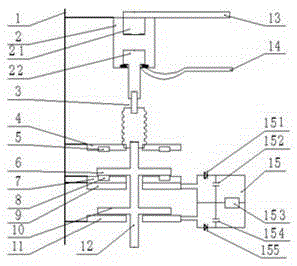

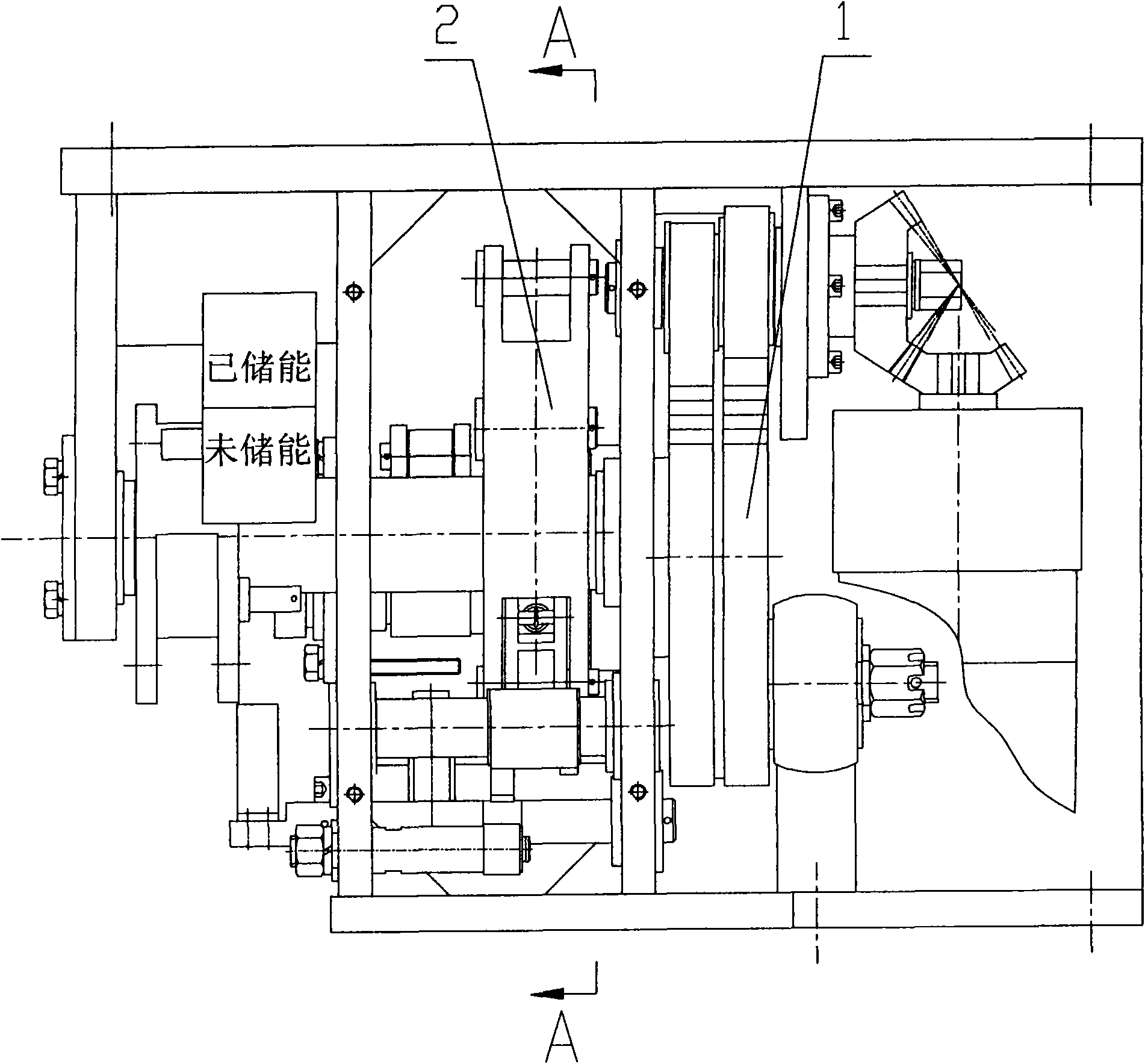

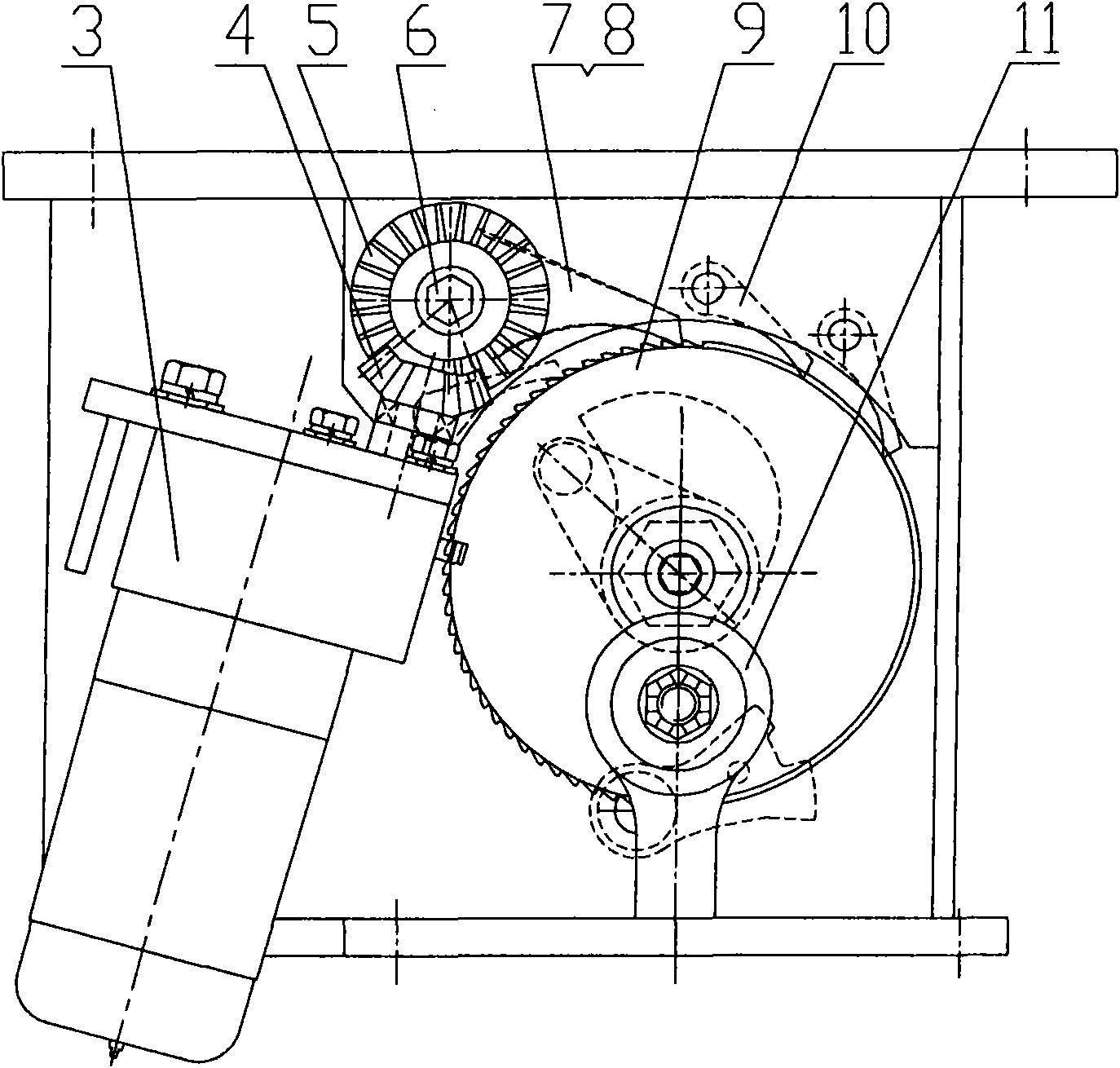

Energy storing part and switching-off and switching-on part combining device and method of spring operating mechanism

InactiveCN101814382AReasonable designSimple structureSwitch power arrangementsHigh-tension/heavy-dress switchesUltra high voltageHigh energy

The invention relates to energy storing part and switching-off and switching-on part combining device and method of a spring operating mechanism. The device comprises an energy storing part and a switching-off and switching-on part. The device has the design key point that the energy storing part and the switching-off and switching-on part are respectively two module units; and the energy storing part is connected with a switching-on crank arm of the switching-off and switching-on part and a cam by a large hexagonal shaft. In the operating method, the spring operating mechanism needs less external driving force in the process of switching-on energy storage; the stored high energy can meet the energy needed when an ultrahigh pressure alternating current vacuum circuit breaker is switched on, and is safe and reliable; and when the spring operating mechanism is in a state to be switched on and switched on, a switching-off and switching-on buckling plate has less pressure on a switching-on and switching-off half shaft, which is beneficial to releasing the switching-on and switching-off half shaft and ensures reliable switching-on and switching-off. The spring operating mechanism has the output characteristics matched with the loading characteristics of the ultrahigh pressure alternating current vacuum circuit breaker, therefore, the mechanical characteristic parameter of the ultrahigh pressure alternating current vacuum circuit breaker is met and the technical problem that the current domestic ultrahigh pressure alternating current vacuum circuit breaker is not provided with a special spring operating mechanism is solved.

Owner:张文炎

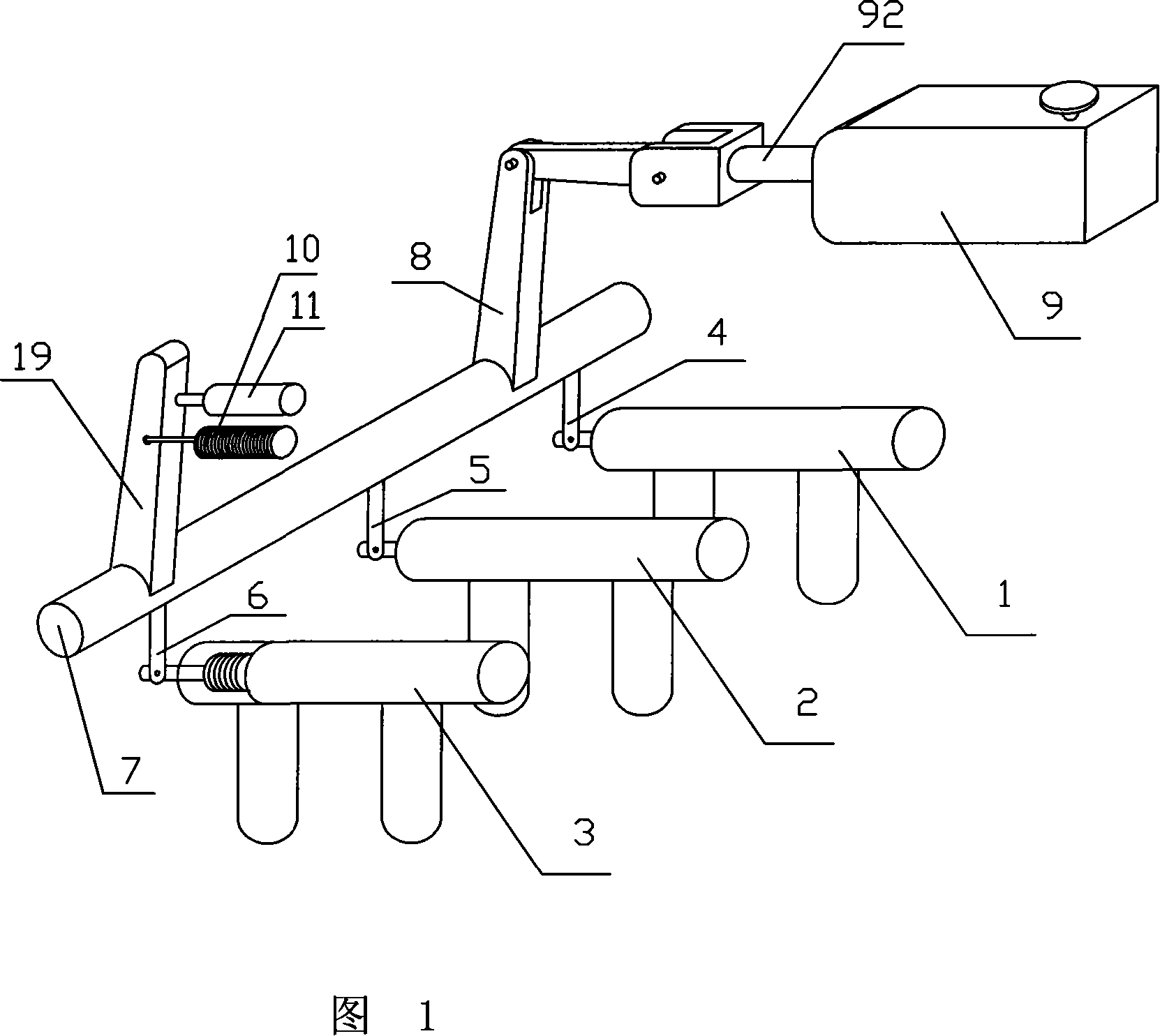

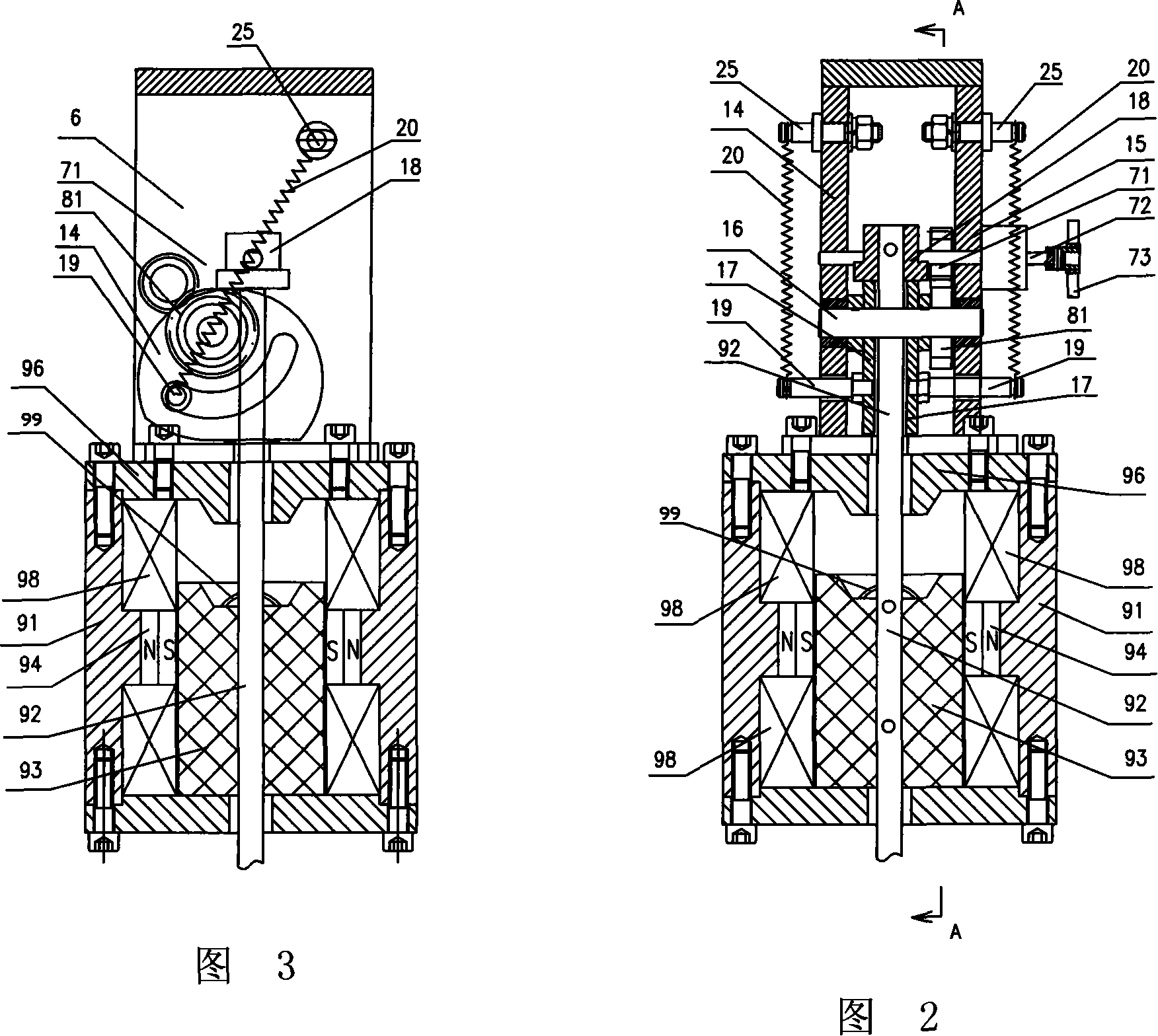

A vacuum breaker for dual stabilized permanent magnetic machine

InactiveCN101127281APlay a buffer roleAvoid collisionSwitch power arrangementsHigh-tension/heavy-dress switchesMechanical impactVacuum circuit breakers

The utility model relates to a vacuum circuit breaker with bi-stable permanent magnetic mechanism, comprising a breaking device connected with each cable respectively, wherein a control end of the breaking device is hinged with a driven arm respectively, each driven arm is fixedly connected with the same rotating shaft, the driving arm is also fixedly connected with the rotating shaft, the driving arm is connected with a bi-stable permanent magnet switch mechanism, an output shaft is positioned in a housing of the bi-stable permanent magnet switch mechanism and passes through the two end covers at both ends of the casing and extended out, wherein one end is hinged with the driving arm, an iron core is fixedly arranged on the output shaft inside the housing, a permanent magnet is positioned outside the iron core and fixedly connected with the inner wall of the housing, two groups of pulse coil are positioned between both ends of the permanent magnet and the end covers; a opening boosting spring of the breaker is also connected with the driving arm. The utility model has the advantages of steady opening speed of the circuit breaker and small mechanical impact force.

Owner:王光顺

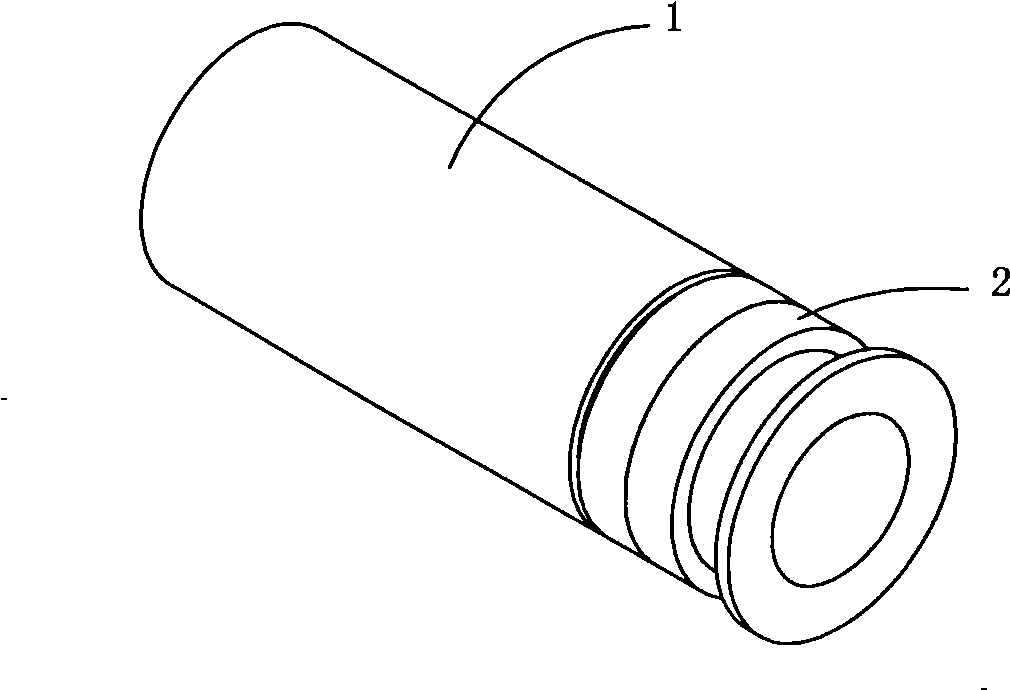

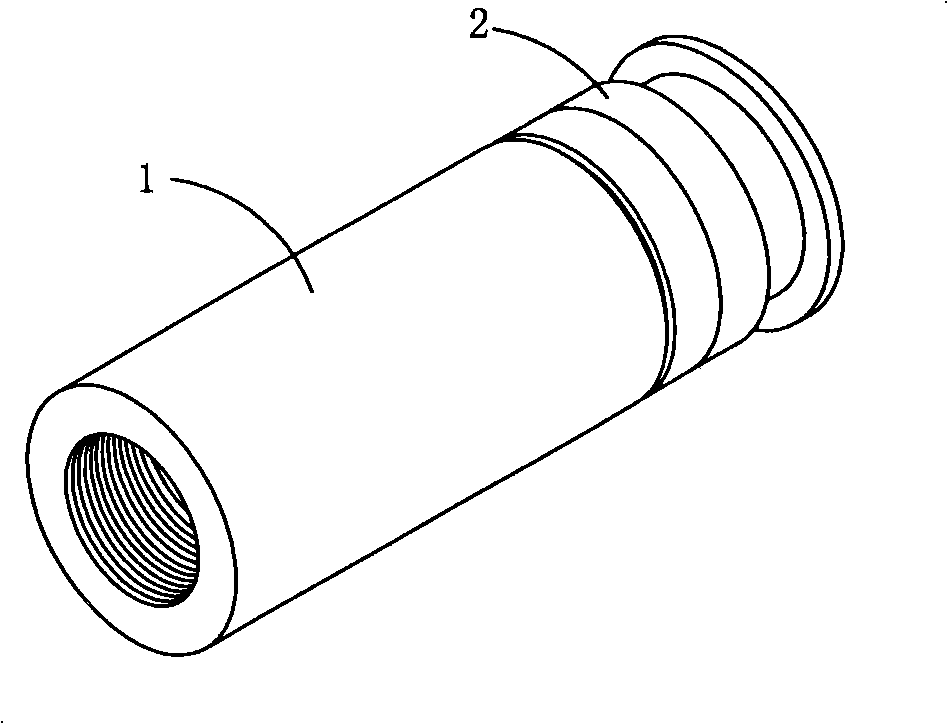

Cuprum aluminum socket connector for conductivity as well as manufacturing method and use thereof

InactiveCN101330174AHigh strengthImprove wear resistanceContact materialsContact member manufacturingElectrical resistance and conductanceLow voltage

The invention discloses a copper-aluminum socket connector for the electric conduction, the preparation method thereof and the application thereof. The socket connector comprises an aluminum body and a copper plug integrated into a whole by welding. The preparation method comprises the following steps: (1) manufacturing the molded aluminum body and the copper plug, and cleaning the welding surfaces of both the aluminum body and the copper plug; and (2) welding the aluminum body and the copper plug into an integrated part by adopting a flash welder or a spin friction welder to obtain the copper-aluminum socket connector semi-product for the electric conduction. The socket connector is mainly applied to a moving contact, a static contact or a conductive contact arm in a high and low voltage switch cabinet or a vacuum circuit breaker. The socket connector has the advantages of non-contact resistance, no galvanic corrosion, smaller resistance, less current conveyance loss, improved current transmission efficiency and reduced power transmission and transformation loss.

Owner:梁楚欣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com