Cuprum aluminum socket connector for conductivity as well as manufacturing method and use thereof

A technology of connectors and manufacturing methods, which is applied in the design field of medium and high voltage conductive materials, can solve the problems of increasing overall resistance, increasing power transmission and transformation losses, and reducing power transmission efficiency, so as to achieve good wear resistance, reduce power transmission and transformation losses, The effect of improving power transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (Embodiment 1, copper-aluminum connector for conduction and application thereof)

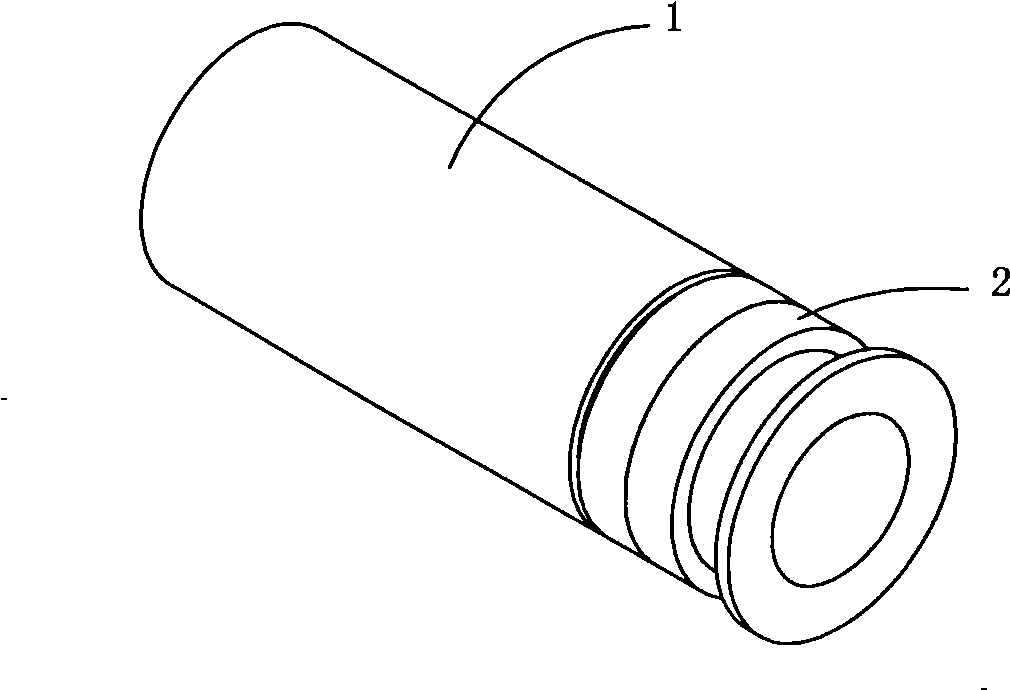

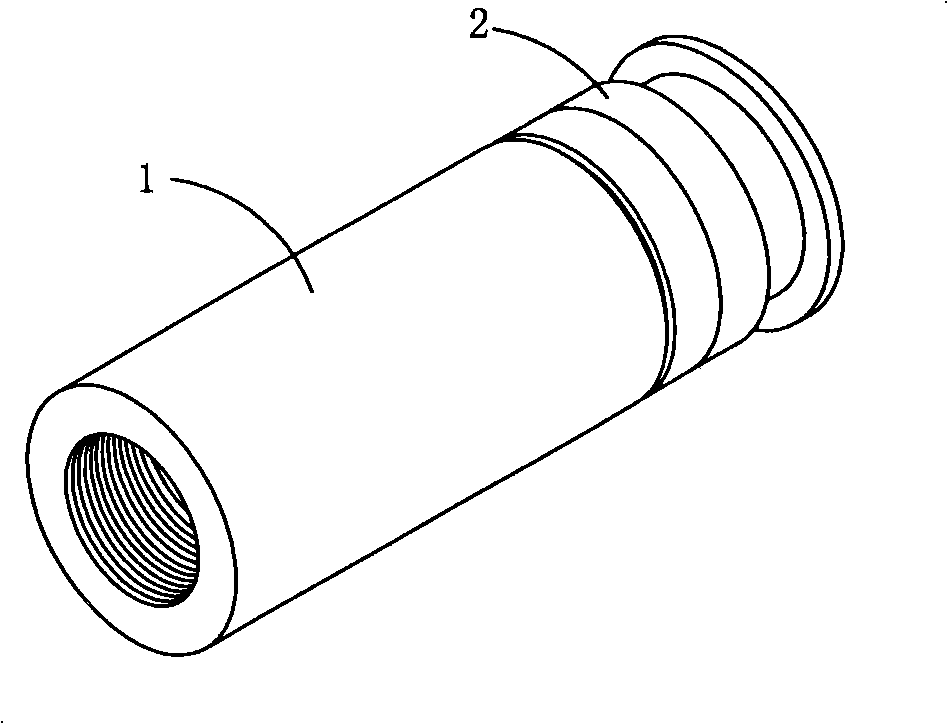

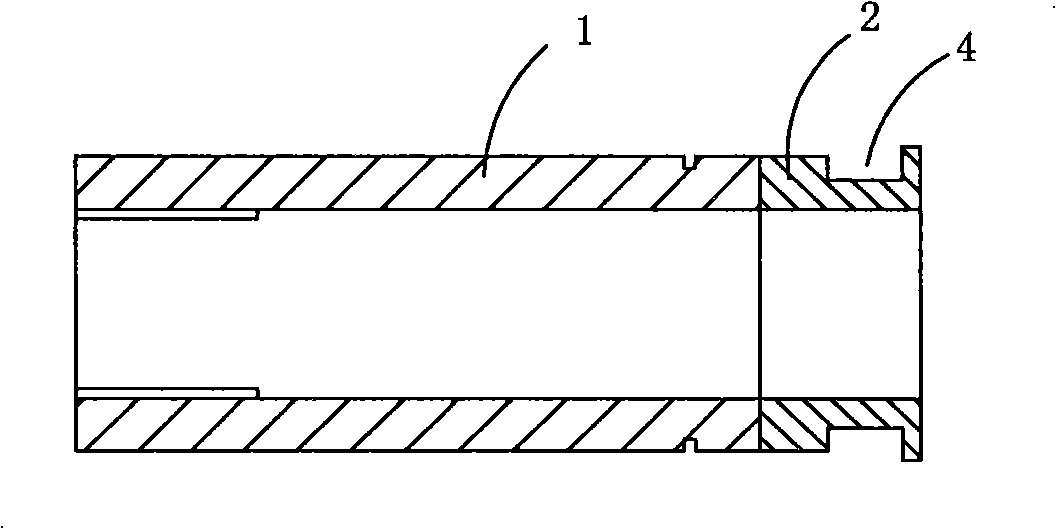

[0052] Figure 1 to Figure 3 A first embodiment of the invention is shown, in which figure 1 It is a schematic diagram of the three-dimensional structure of the first structure of the present invention; figure 2 yes figure 1 The schematic diagram of the three-dimensional structure of the copper-aluminum connector for electrical conduction when viewed from another angle; image 3 yes figure 1 The schematic diagram of the half-section structure of the copper-aluminum connector for electric conduction is shown.

[0053] This embodiment is a copper-aluminum connector for conduction, see Figure 1 to Figure 3 , comprising an aluminum main body 1 and a red copper plug 2 arranged at one end of the aluminum main body 1, the aluminum main body 1 and the red copper plug 2 are welded into one piece by flash butt welding. The basic shape of the aluminum main body 1 is tubular, and the basic sh...

Embodiment 2

[0056] (Embodiment 2, copper-aluminum connector for conduction and application thereof)

[0057] Figure 4 to Figure 6 shows the second specific embodiment of the present invention, wherein Figure 4 is a perspective view of the second structure of the present invention; Figure 5 is a copper-aluminum connector for electrical conduction shown in Figure 4 observed from another angle Figure 6 is a schematic diagram of the half-section structure of the conductive copper-aluminum connector shown in Figure 4.

[0058] This embodiment is a conductive connector, which can be used specifically as a conductive contact arm in a vacuum circuit breaker or a high and low voltage switchgear, as shown in Figures 4 to 6, including an aluminum body 1 and a copper connector 2. The main body 1 made of aluminum and the plug 2 made of red copper are welded into one piece by flash butt welding. The basic shape of the aluminum main body 1 is tubular, and the copper connector 2 is a copper tube matched...

Embodiment 3

[0061] (Embodiment 3, copper-aluminum connector for conduction and application thereof)

[0062] Figure 7 to Figure 9 A third embodiment of the invention is shown, in which Figure 7 It is a three-dimensional structural schematic diagram of the third structure of the present invention; Figure 8 yes Figure 7 The schematic diagram of the three-dimensional structure of the copper-aluminum connector for electrical conduction when viewed from another angle; Figure 9 yes Figure 7 The schematic diagram of the half-section structure of the copper-aluminum connector for electric conduction is shown.

[0063] This embodiment is a conductive connector, which can be used specifically as a conductive contact arm in a vacuum circuit breaker or a high and low voltage switchgear, see Figure 7 to Figure 9 , comprising an aluminum main body 1 and a red copper plug 2 arranged at one end of the aluminum main body 1, the aluminum main body 1 and the red copper plug 2 are welded into one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com