Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3001 results about "Butt welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butt welding is a commonly used technique in welding that can either be automated or done by hand on steel pieces. Butt welding can also be done with brazing for copper pieces. It is used to attach two pieces of metal together such as pipe, framework in factories, and also flanges. A flange is something that either is internal or external that provided to strengthen a piece of material. In factories butt welding has shown how economical it can be for companies to use when building things out of metal. This is because if they wanted to make something out of metal without welding it together they would have to bend everything and reinforce the structure which costs more than welding the two pieces together. Butt welding is accomplished by heating up two pieces of metal, or applying pressure, or doing both of those. Penetration while welding the metal is important to maintain and with thin pieces of metal this is possible however, with thick pieces edge preparation may have to be done to prepare the metal. Full penetration butt welds are made when they are in the within the parent(bigger, stronger) metal. In butt welding the strongest welds will have the fewest imperfections. To achieve this the heat input is controlled, which decreases the size of the weld. In commercial welding when this is done it also reduces cost but in order to maintain the strength of the weld double butt welds will be used. In butt welding there are two types used to achieve the specific welds and then there are also a variety of joints considered to be butt joints.

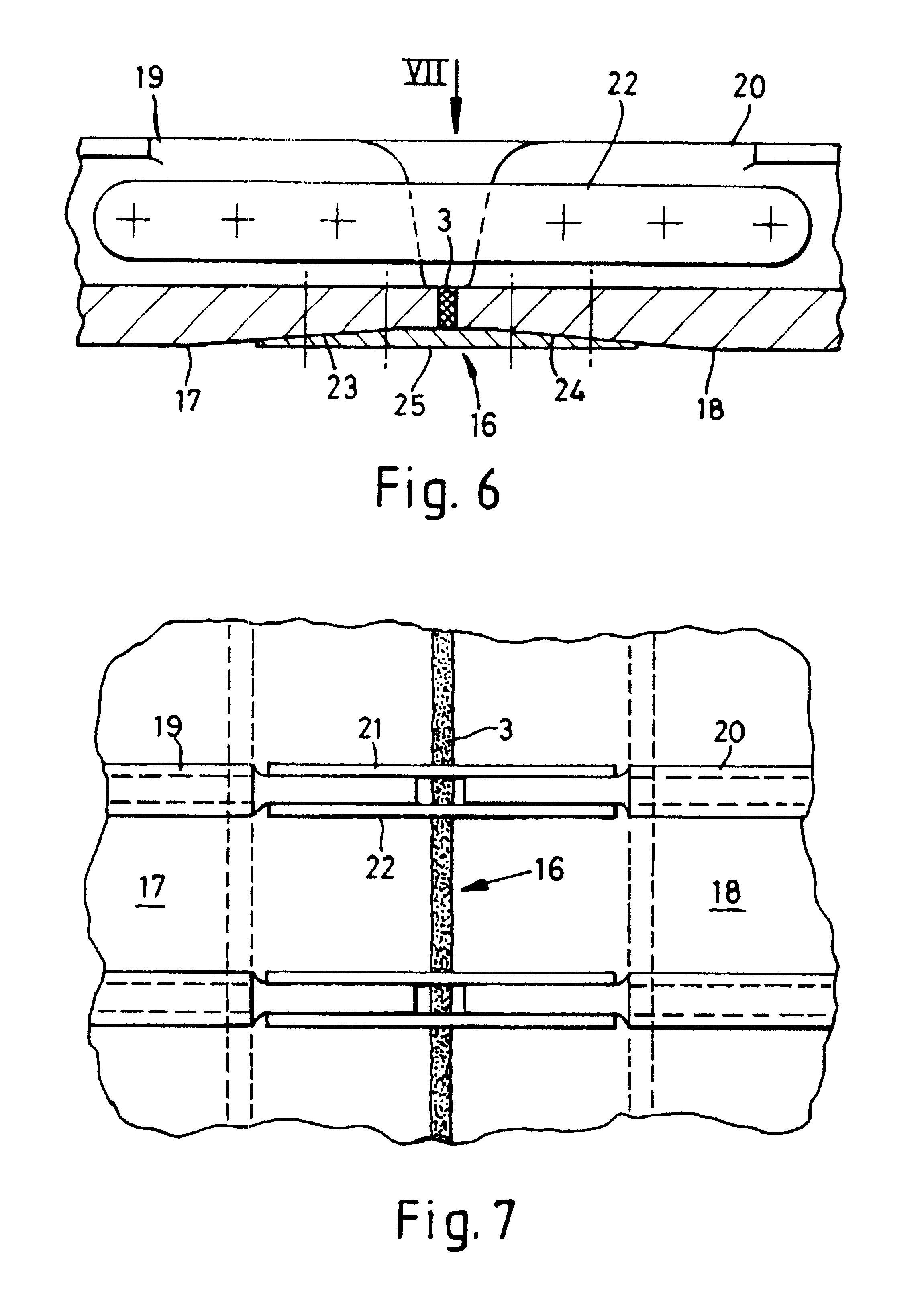

Friction welding metal components

InactiveUS6328261B1Additions can be avoidedPrevent skinFuselage framesWingsFriction weldingButt welding

A method of forming a structural airframe component for an aircraft and an airframe structural component The method includes placing at least two components (1,2) in abutting relationship with each other and joining them together by friction stir butt welding (3), and the structural airframe component comprises a component manufactured according to the method of the invention.

Owner:AIRBUS OPERATIONS LTD

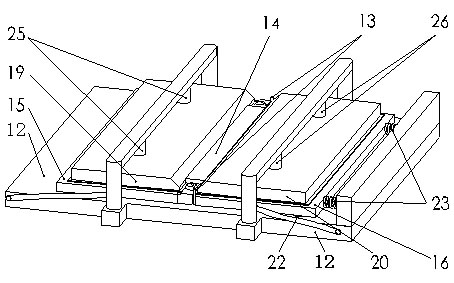

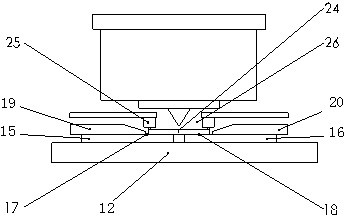

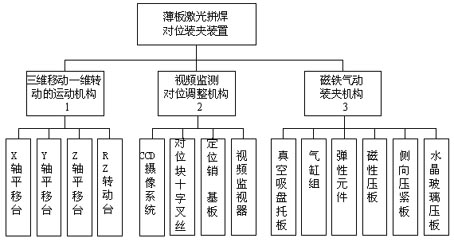

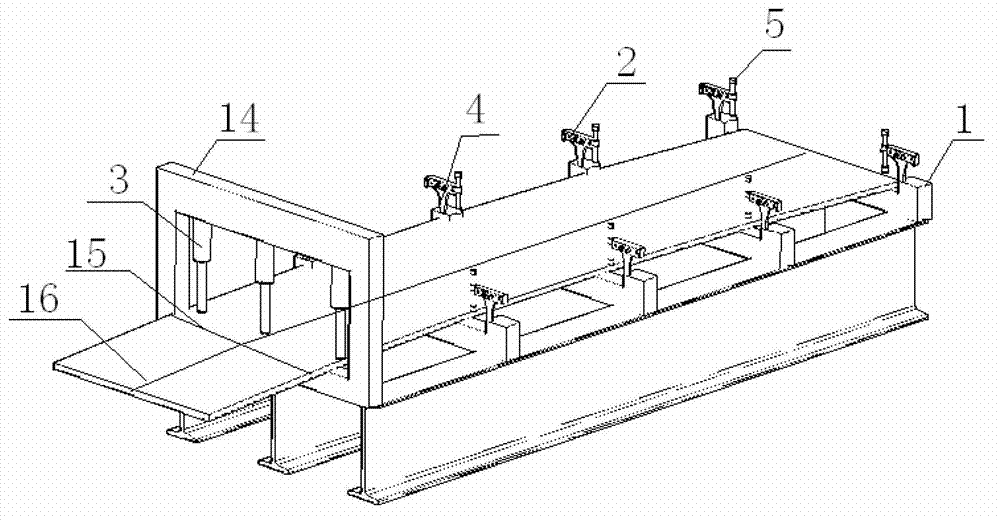

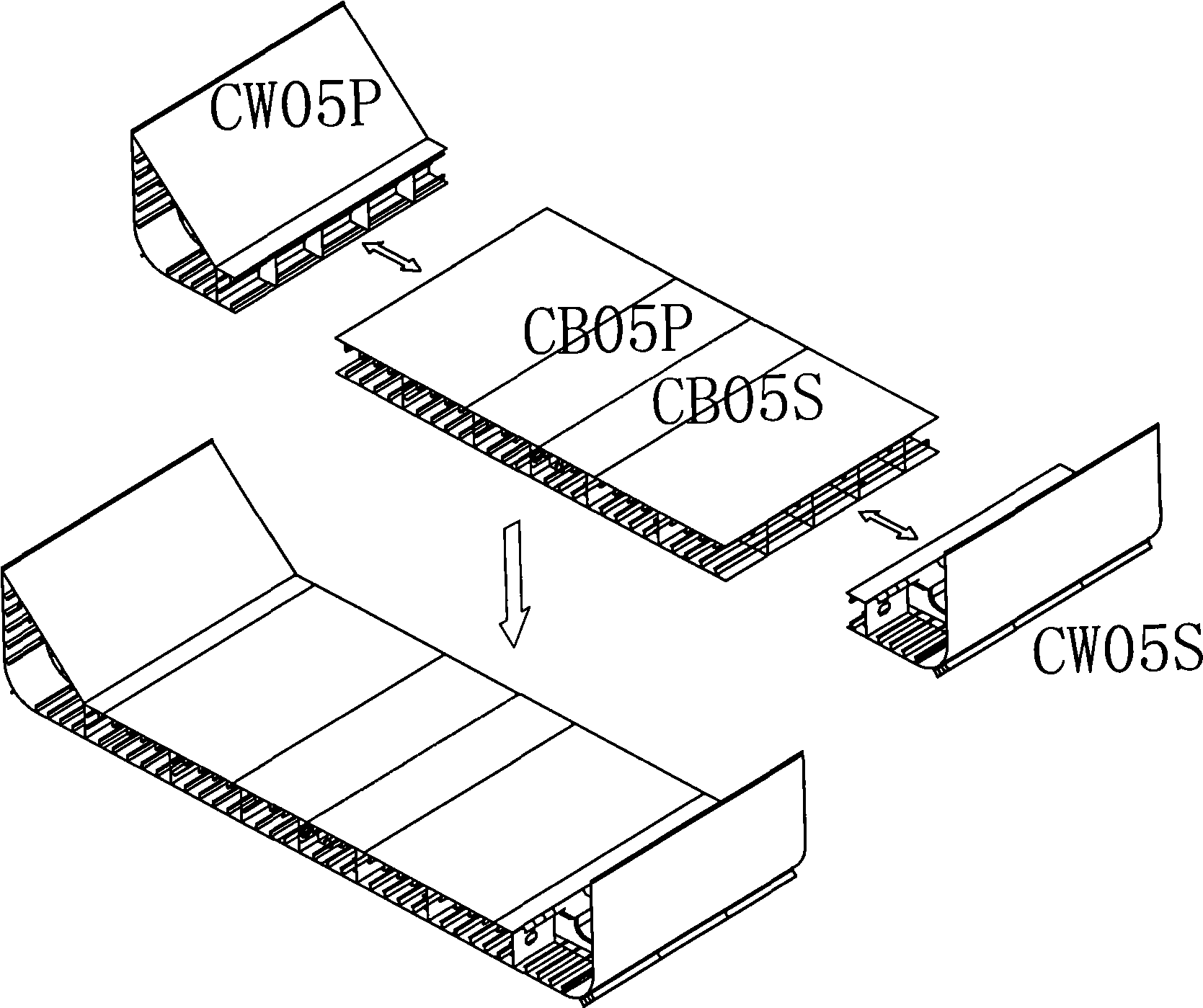

Stainless steel or nickel sheet laser tailor-welding alignment clamping device and method

ActiveCN101890576ARealize Tailored WeldingSolve the problem of difficult tailor welding of deformed thin platesWelding/cutting auxillary devicesAuxillary welding devicesVideo monitoringButt welding

The invention discloses a stainless steel or nickel sheet laser tailor-welding alignment clamping device and a method. The alignment clamping device comprises an XYZ three-dimensional translation RZ one-dimensional rotation motion mechanism, a video monitoring alignment regulating mechanism and a magnet pneumatic clamping mechanism, wherein the stainless steel or nickel sheet laser tailor-welding alignment clamping device can align and position sheets through the XYZ three-dimensional translation RZ one-dimensional rotation motion mechanism and the video monitoring alignment regulating mechanism, and then clamps and fixes the stainless steel or nickel sheets by the magnet pneumatic clamping mechanism to realize the laser tailor-welding of the stainless steel or nickel sheets. The invention can solve the problem of difficult welding of the stainless steel or nickel sheets smaller than 0.3mm in thickness in laser butt welding because the sheets are easy to deform owing to easy deformation property per se and thermal stress, and guarantees the quality of tailor-welded seams.

Owner:上海市激光技术研究所有限公司

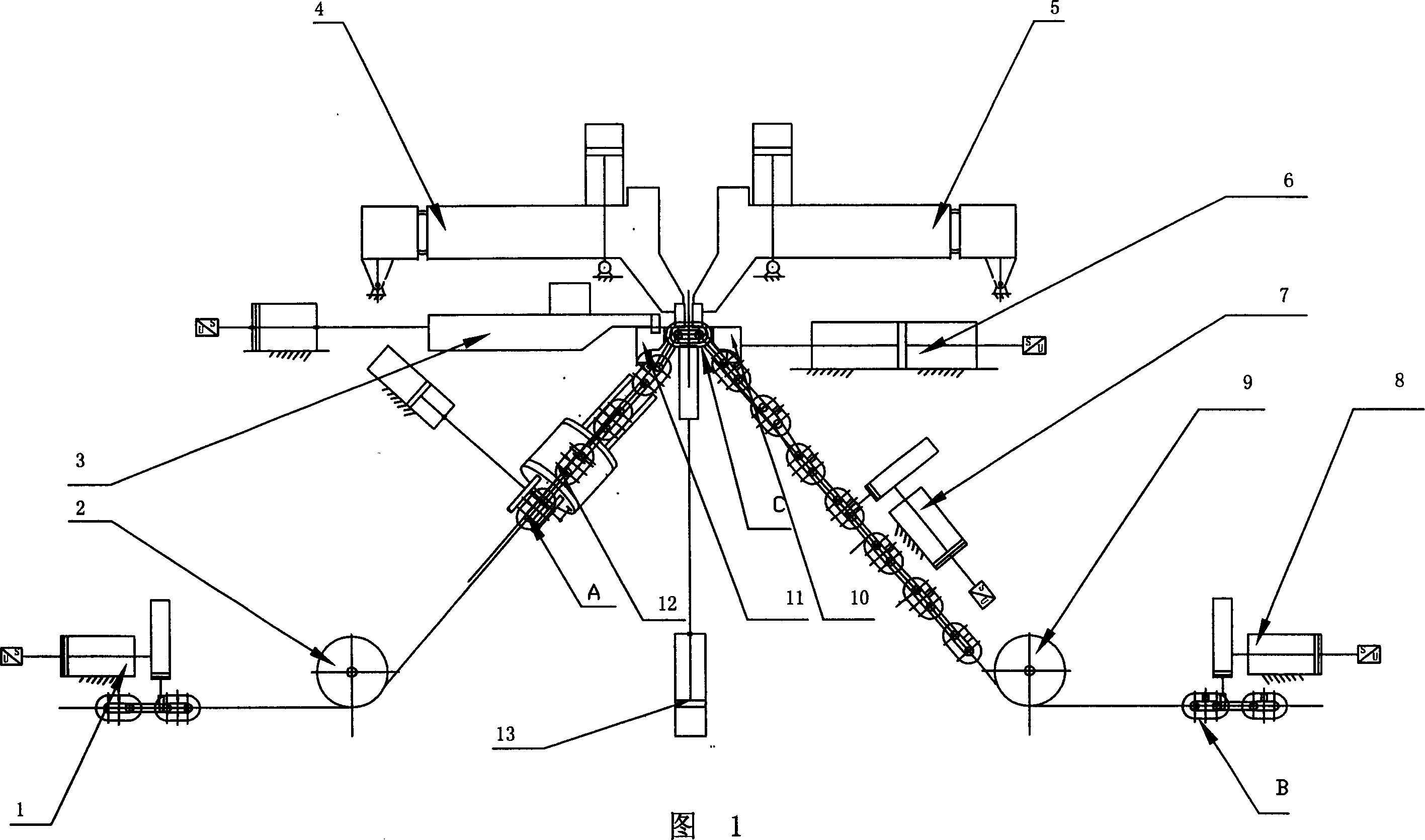

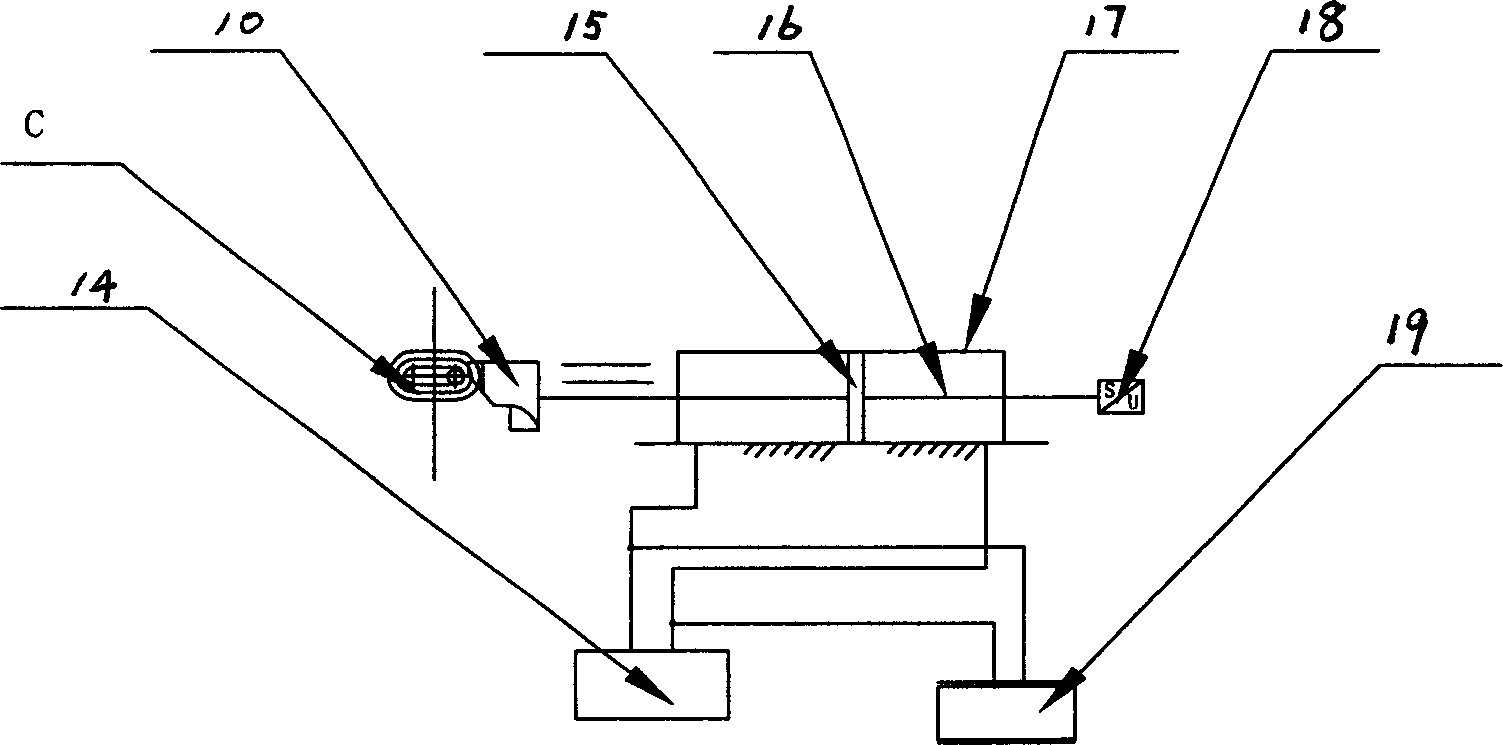

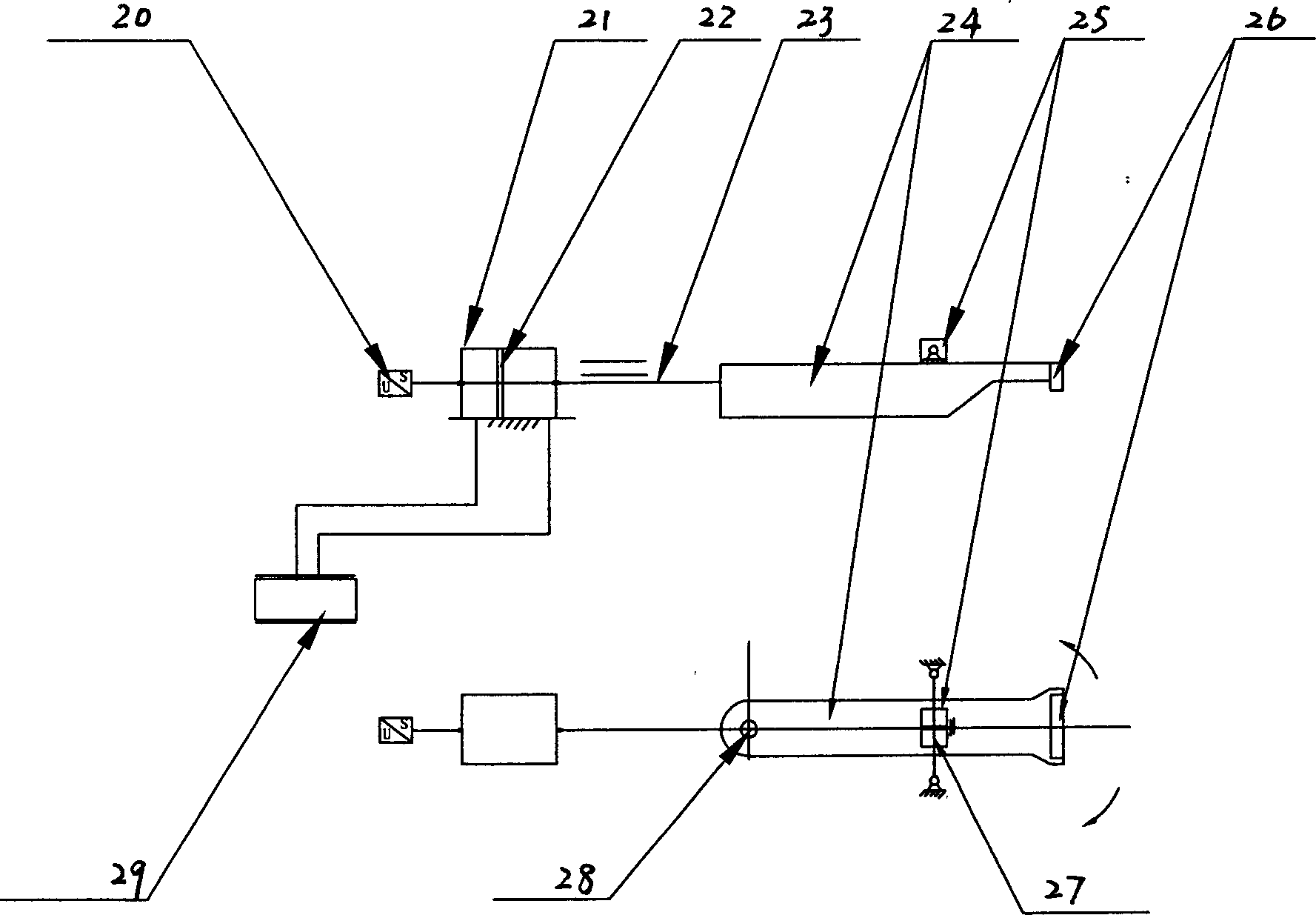

Full automatic hydraulic flash butt welding method of metal circular ring chain and apparatus thereof

ActiveCN1806992AHigh quality excisionFully automaticWelding/cutting auxillary devicesAuxillary welding devicesButt weldingTransducer

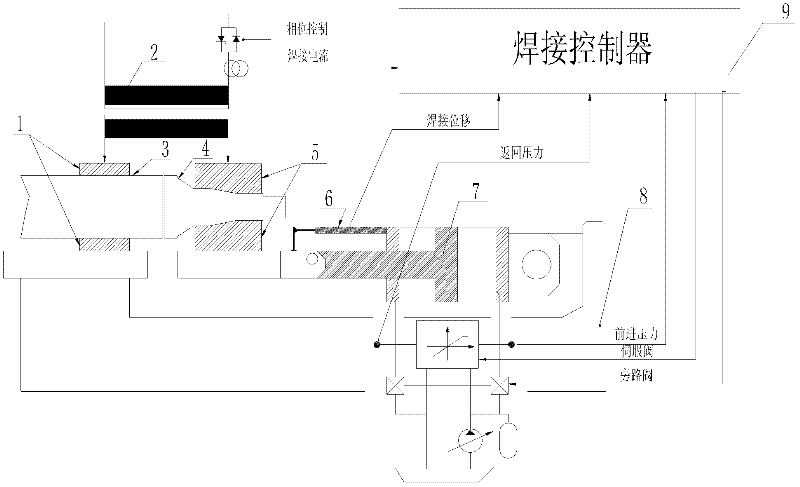

The invention relates the metallic bond full-automatic all-hydraulic flash butt welding method and device. The method is that the open of each chain link is automatically welded after the metallic bond is knitted to chain. The method comprises the following step: sending the chain link from left end of machine to position of welding under the combined action of main conveyer and subsidiary conveyer, controlling the hydraulic heading equipment with displacement transducer, servo valve and heading valve, preheating, burning, flashing and heading welding, auto removing the burrs, and exporting the finished chain link from the right end of machine. The whole process is the full-automatic all-hydraulic flash butt welding method. The invention possesses the characters of high automation level, high production efficiency, high product quality and high safe reliability. The said method and device will replace the national current fall behind electric milling cam type FBW method and device.

Owner:王洪军

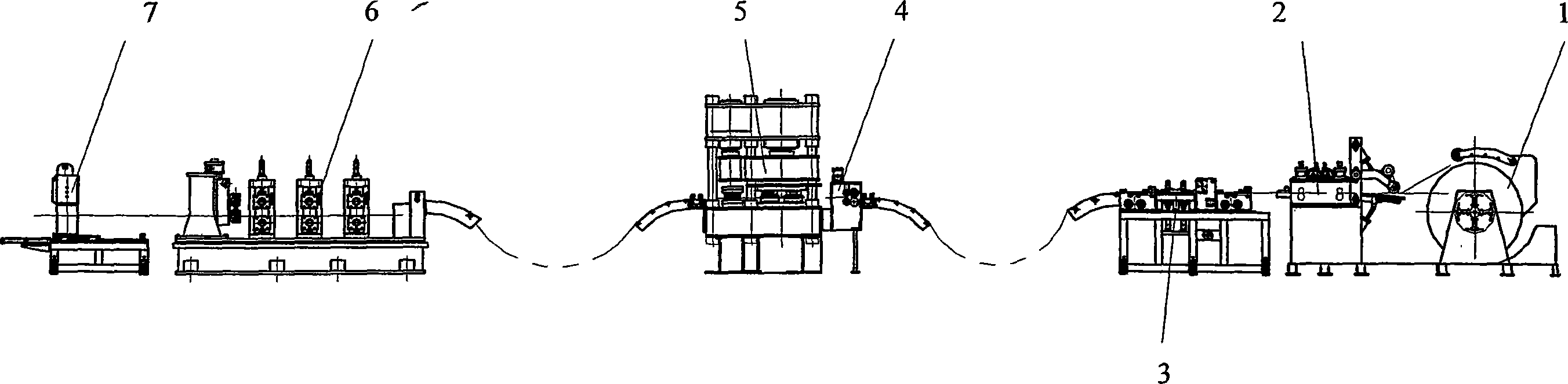

Stainless-steel band special apparatus for steel-aluminum composite contact rail

InactiveCN101028685AImprove performanceQuality improvementMetal-working feeding devicesOther manufacturing equipments/toolsButt weldingControl theory

Owner:南京赛彤铁路电气化有限公司

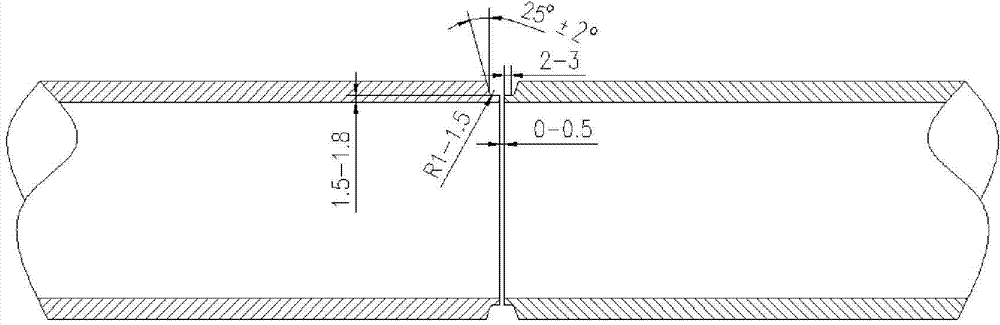

Girth welding technology for vacuum container

ActiveCN102357741AGuaranteed absolute penetrationAvoid the phenomenon of localized high temperatureArc welding apparatusWorkpiece edge portionsShielded metal arc weldingButt welding

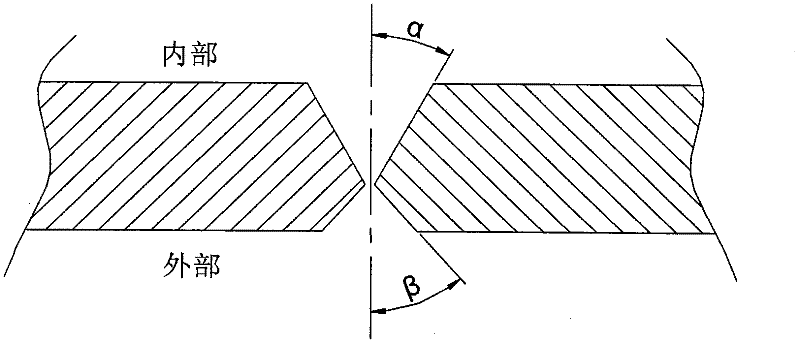

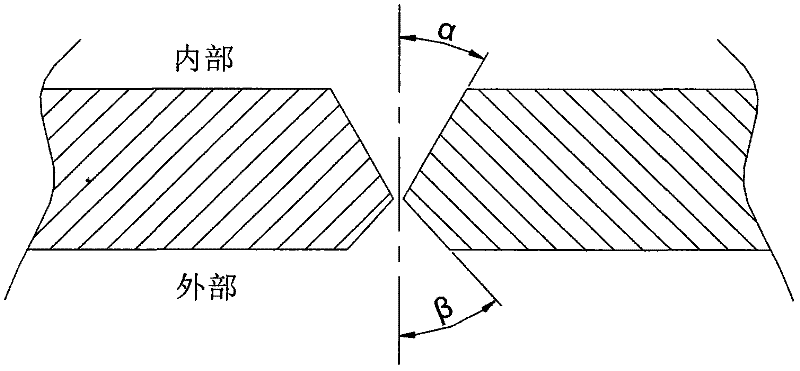

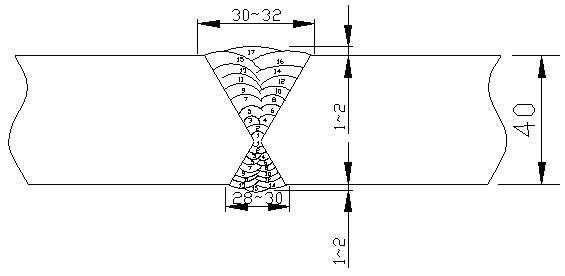

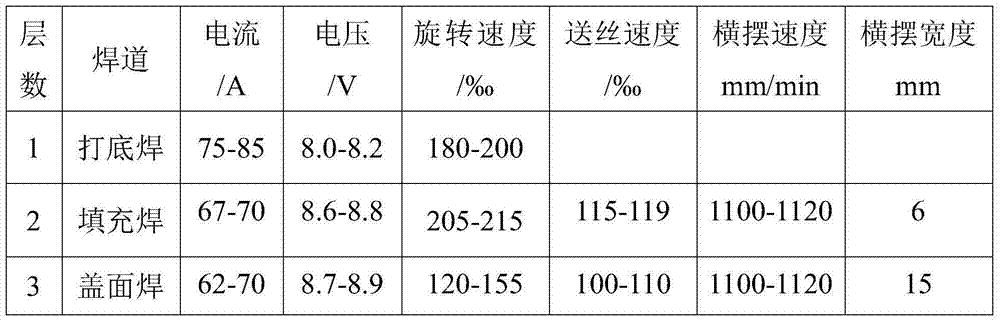

The invention discloses a girth welding technology for a vacuum container, which comprises the following steps: processing beveled edges, assembling and welding. In the step of processing the beveled edges, a 14mm thick 0Cr18Ni9 austenitic stainless steel material is selected as a cylinder base material, X-shaped beveled edges are adopted, an inside beveled edge is processed for 10mm with a single-side angle of 32.5 degrees, an outside beveled edge is processed for 4mm with a single-side angle of 35 degrees, and no truncated edge is left. In the step of assembling, reserved clearances of 2.0-2.5mm are assembled, argon tungsten-arc welding is adopted to position, a positioning welding length is 10-15mm, an interval is 200mm, and then a 'strut having a shape of Chinese character 'mi' which is used for adjusting the roundness of a cylinder is welded in the cylinder. In the step of welding, an argon arc welding double-gun butt-welding method is used for bottoming the interior of the cylinder, two layers are filled in an inner welding bead of the cylinder in the manner of manual arc welding, an external welding bead is covered in the manner of submerged-arc welding, and finally, the inner welding bead is covered in the manner of manual arc welding. The girth welding technology can be used for controlling the welding deformation and has the advantages that the method is simple and is easy to realize.

Owner:无锡市创新低温环模设备科技有限公司

Method for producing axle beam by using preheated flash butt welding

InactiveCN102500899AImprove reliabilityHigh dimensional accuracyResistance welding apparatusButt weldingEngineering

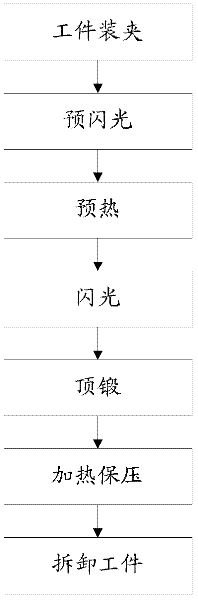

The invention discloses a method for producing an axle beam by using preheated flash butt welding, which comprises the following steps of: a workpiece clamping step, wherein an axle head and an axle pipe which are used as workpieces are respectively arranged in a shaft beam flash butt welding machine, are clamped by a hydraulic moving clamp and a fixed clamp, and align through an adjustment mechanism; a pre flash step, wherein a power supply is powered on, so that a moving clamp is pushed at a set constant speed, and further, flash can be generated between the workpieces and gradually shortens until the flash margin reaches a preset value; a preheating step, wherein the workpieces are preheated by preset preheated pulses; a flash step, wherein flash is carried out at set speed; an upsetting step, wherein upsetting is carried out immediately after flash; a heating and pressurizing step, wherein the workpieces are applied with preset pressure and are powered on to be heated; and workpiece disassembling step, wherein after welding, the workpieces are disassembled and taken out.

Owner:BPW (MEIZHO) AXLE CO LTD

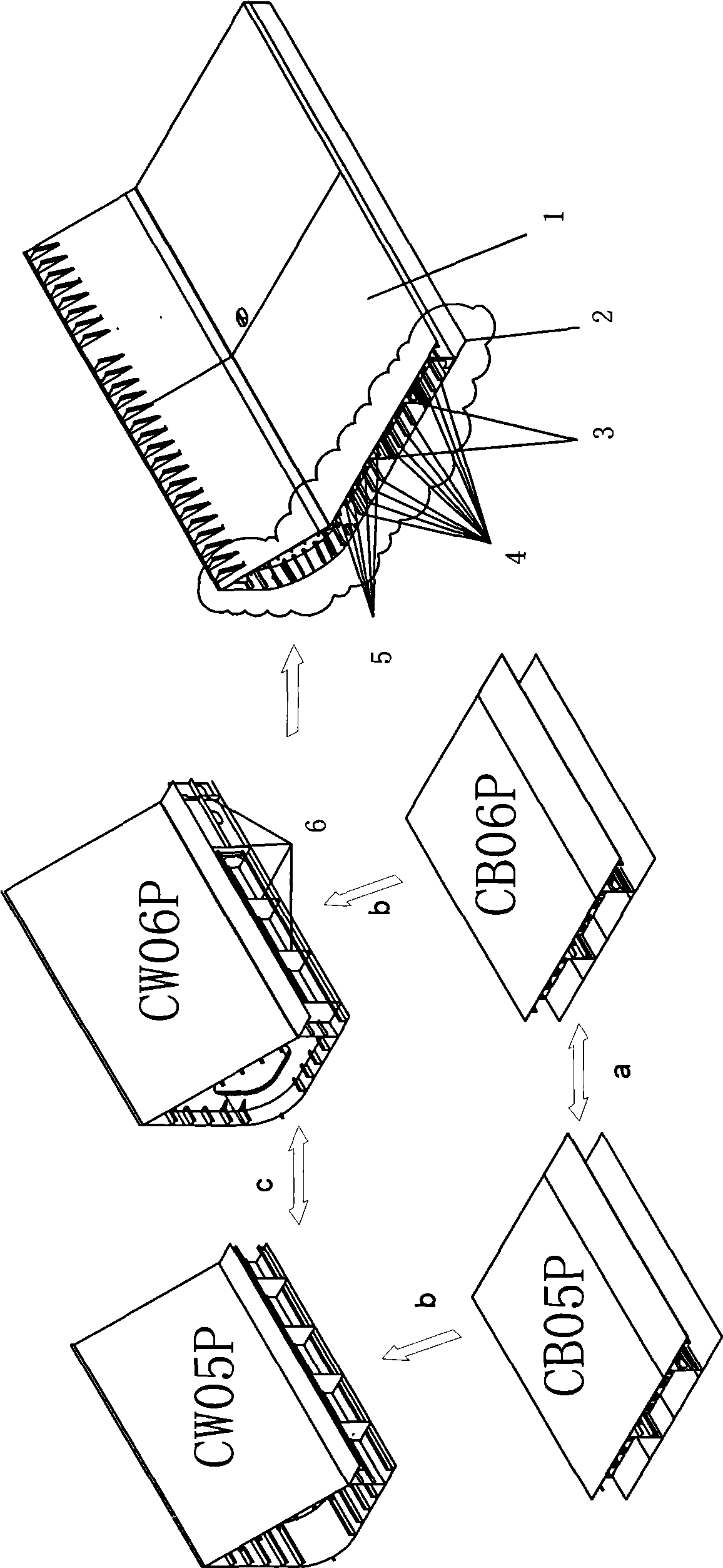

Method of laser machining of fiber-reinforced composite material and product made by the method

InactiveCN102438787AAvoid flyingWelding/soldering/cutting articlesLaser beam welding apparatusButt weldingLaser processing

A method of laser machining of a fiber-reinforced composite material of the present invention is characterized in that the fiber-reinforced composite material or composite ply material (ply material consisting of plates of metal or inorganic material and fiber-reinforced material) is cut using an ultra short pulse solid-state laser having a pulse-width ranging from 10 pico to 100 nano second and a pulse energy of 1mJ-500J, repeatedly irradiated to the material with the number of frequency ranging from 10Hz to 100kHz. According to the present invention, it is possible to work, e.g., cut, pierce, groove, or carve a fiber-reinforced composite material including CFRP, by removing materials by means of a laser with a high precision and good quality. It is also possible to form a fitting joint of proper shape so that a male-female joint may be available in a butt welding that has been hardly feasible. It is further possible to produce structural members such as a light weight panel or an H-column because the male-female joint can be used for a plate of any desired dimension (width, length and thickness).

Owner:沓名宗春

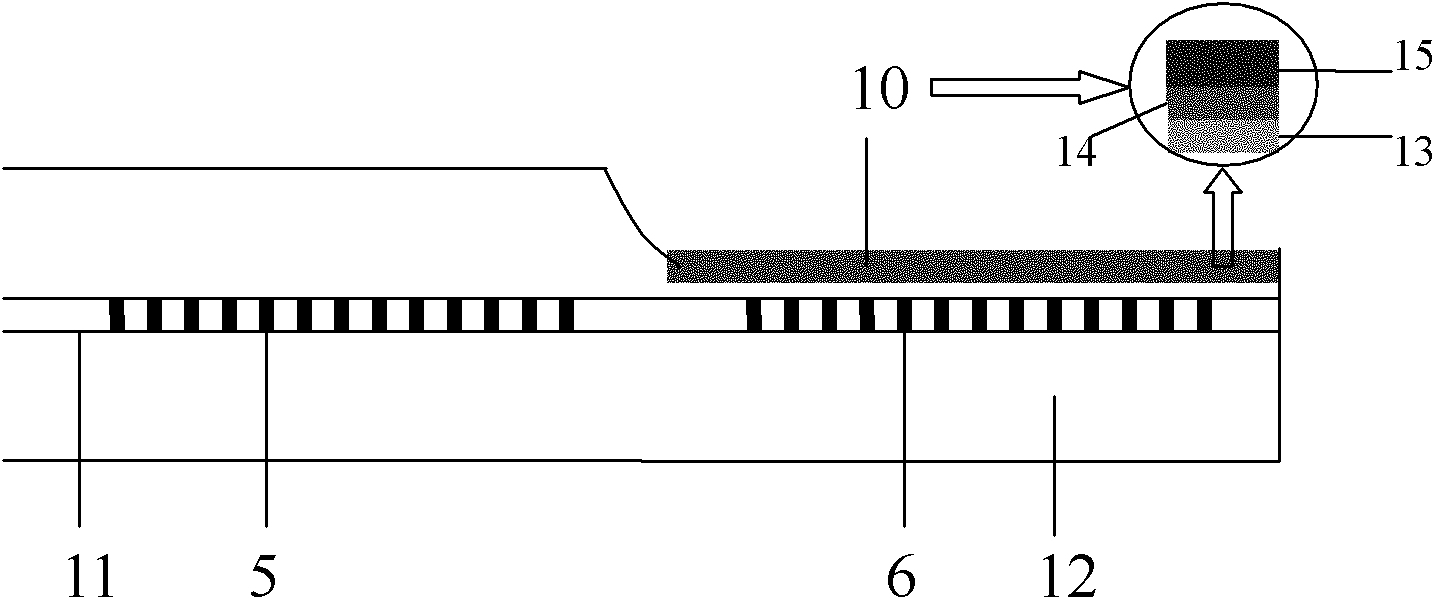

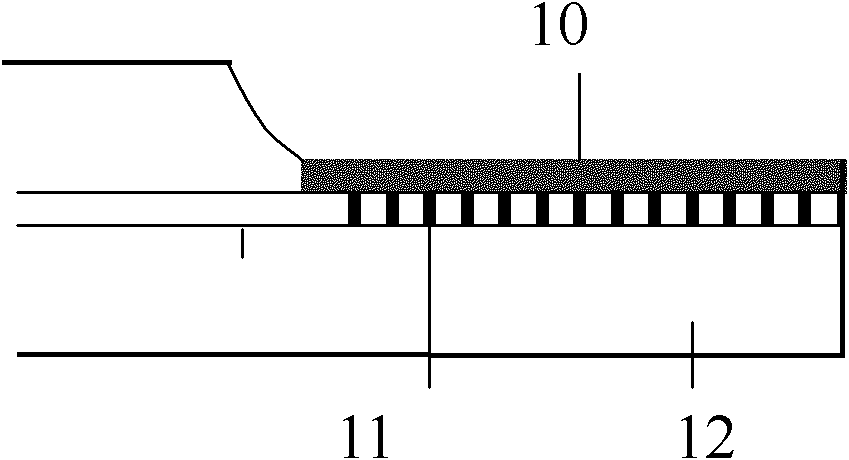

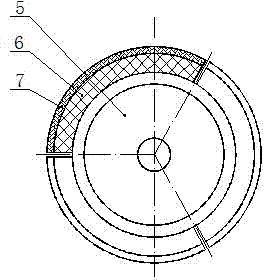

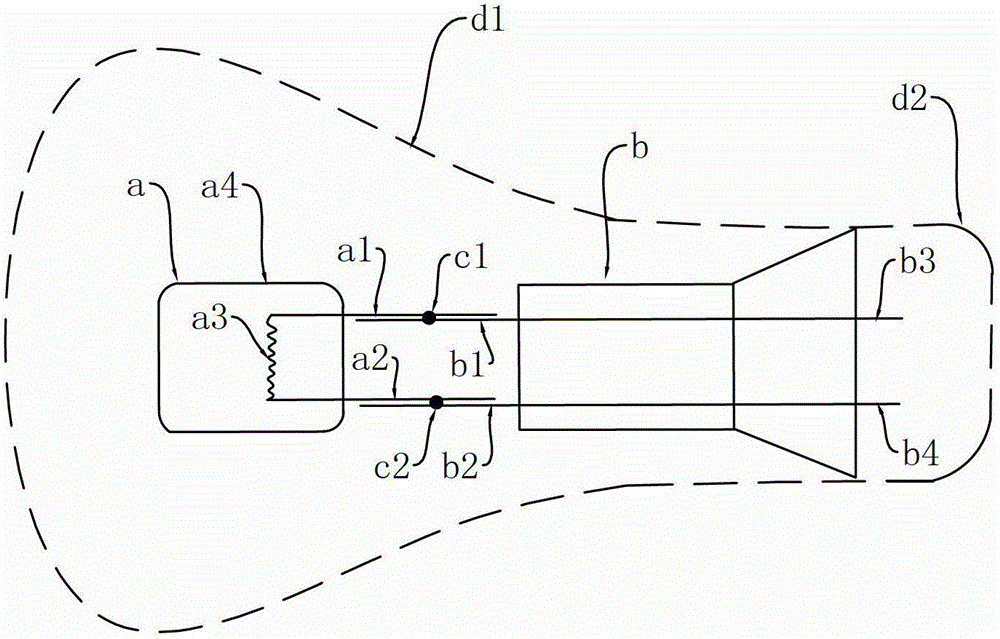

Multi-layer composite sensitive film optical fiber hydrogen sensing probe and manufacturing method thereof

ActiveCN102175619AHigh sensitivityVacuum evaporation coatingSputtering coatingSputteringButt welding

The invention discloses a multi-layer composite sensitive film optical fiber hydrogen sensing probe and a manufacturing method thereof. The probe is formed by the butt welding of a D-shaped fiber grating (6) coated with a hydrogen sensitive film (10) and a reference grating (5) which has the same central wavelength and is not coated with film, wherein the D-shaped fiber grating (6) coated with the hydrogen sensitive film (10) is prepared by performing magnetron sputtering coating of a SiO2 film (13), a SiO2-Pd mixed film (14) and a Pd film (15) on a fiber grating which is subjected to side polishing treatment; and the SiO2 film has the thickness of 1-100nm, the SiO2-Pd mixed film has the thickness of 1-100nm, and the Pd film has the thickness of 10nm to 20 mu m. The manufacturing method comprises a step of combining the hydrogen sensitive film with the anti-electromagnetic interference D-shaped fiber grating to form an optical fiber hydrogen sensing probe. Due to the adoption of magnetron sputtering, heat treatment and a temperature compensation technology, the accuracy and sensitivity of the sensor are greatly improved; moreover, the volume of the sensing probe is greatly reduced, and the probe contributes to implementing the miniaturization of an optical fiber hydrogen sensor.

Owner:WUHAN UNIV OF TECH

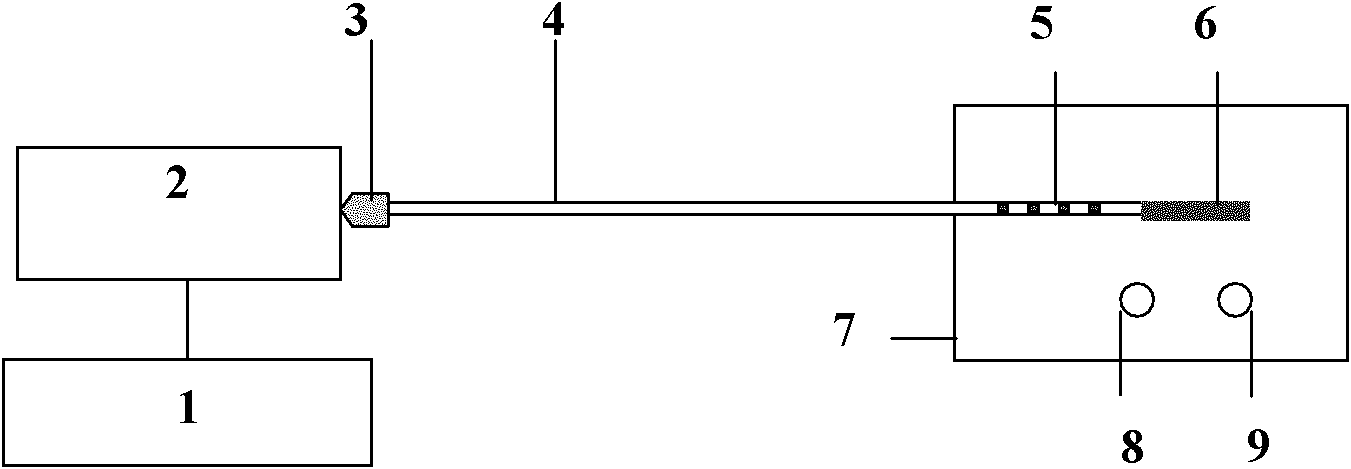

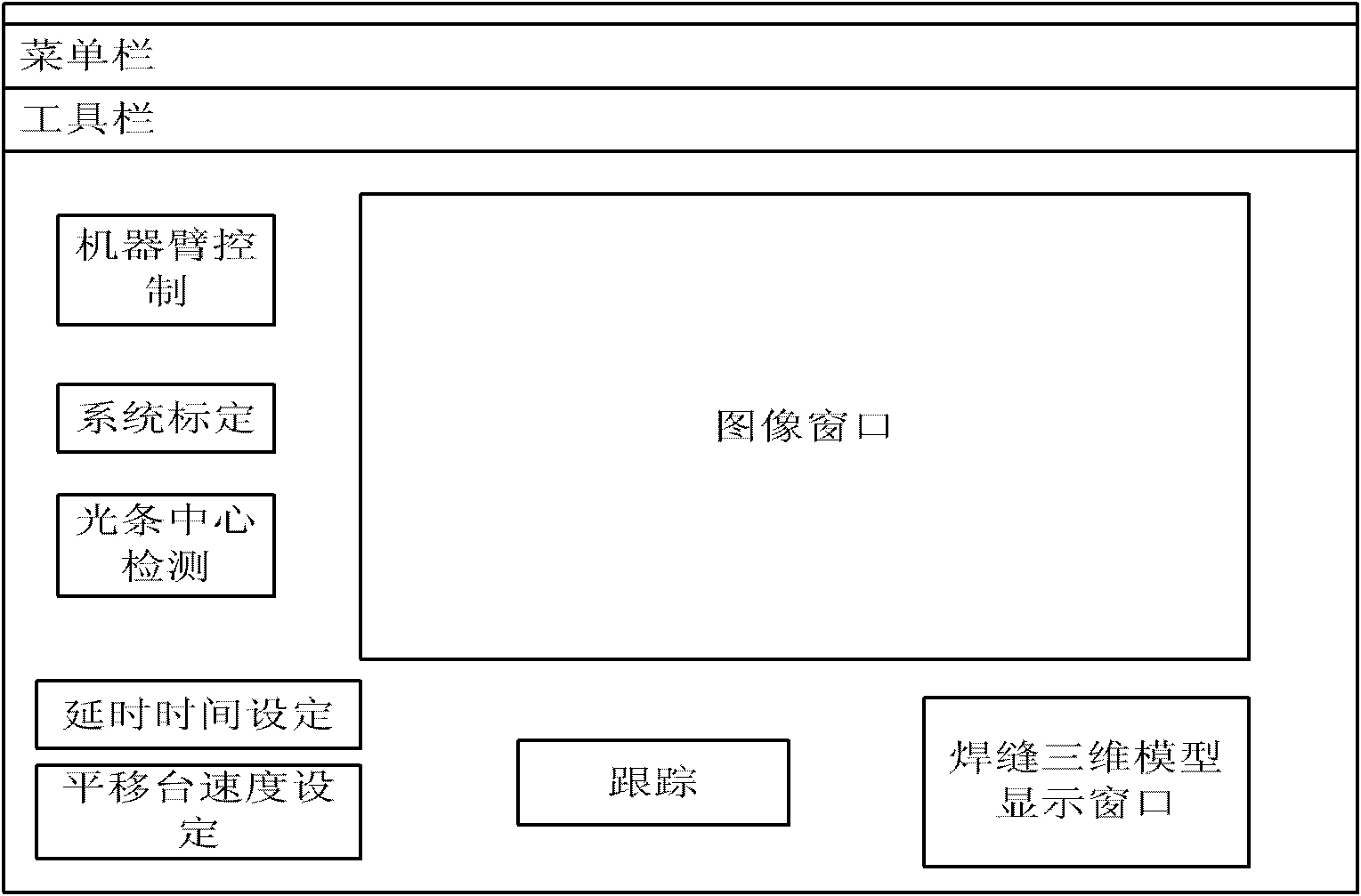

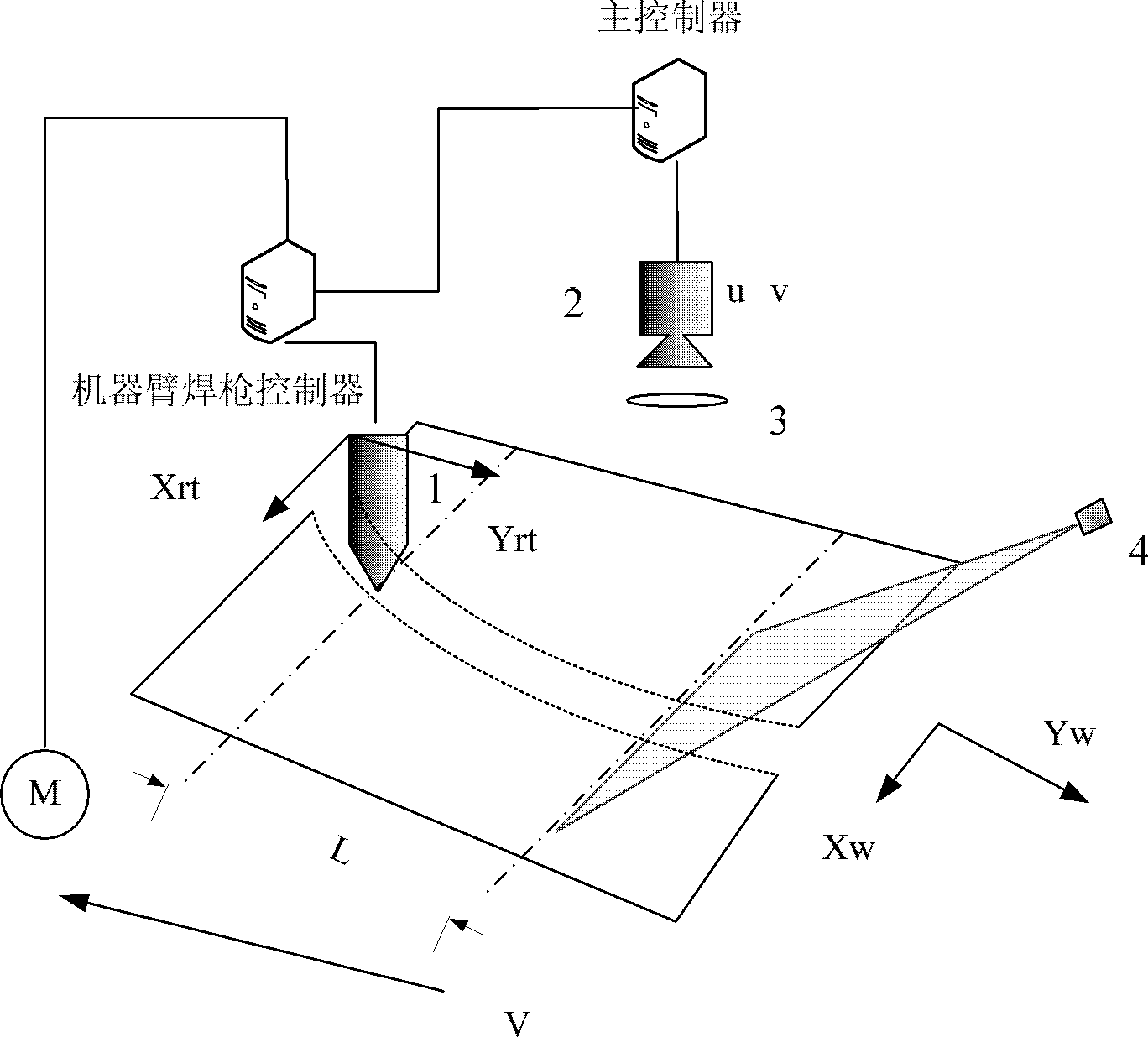

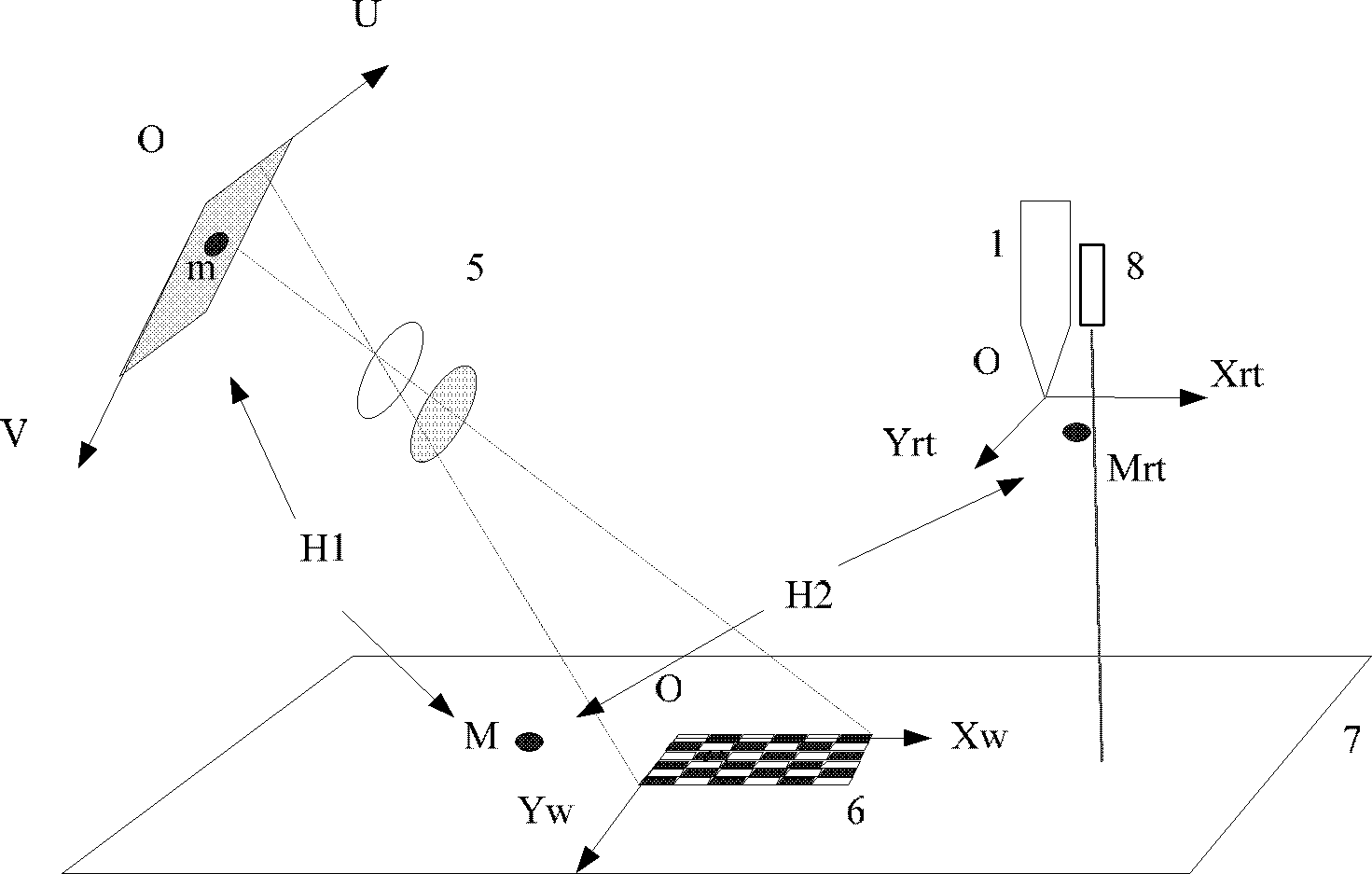

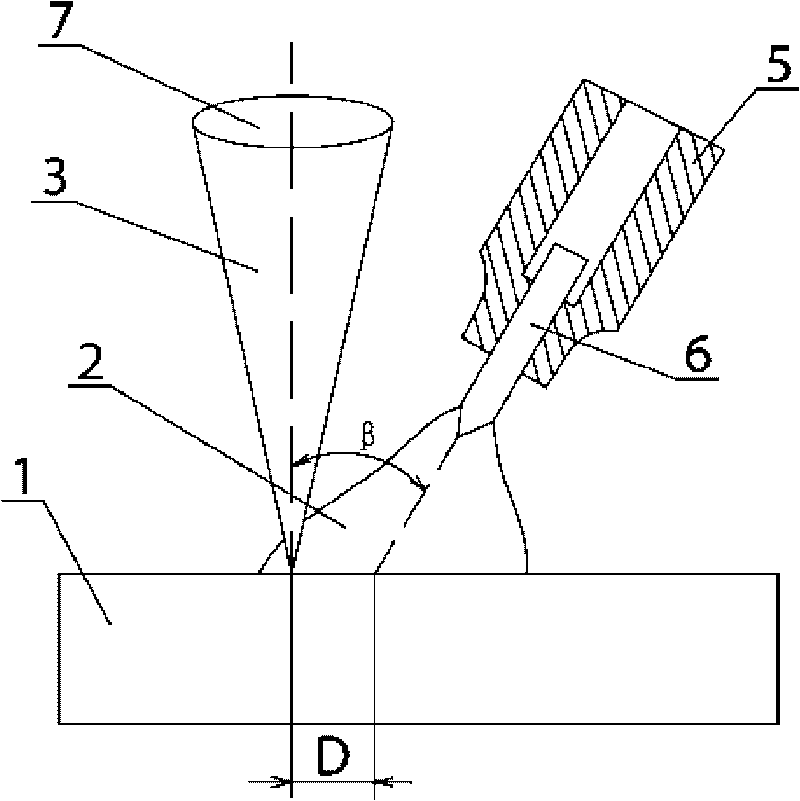

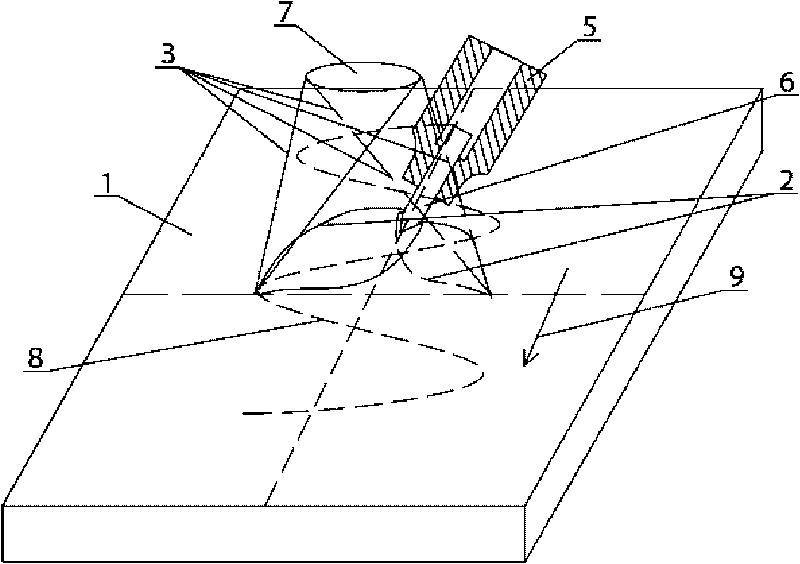

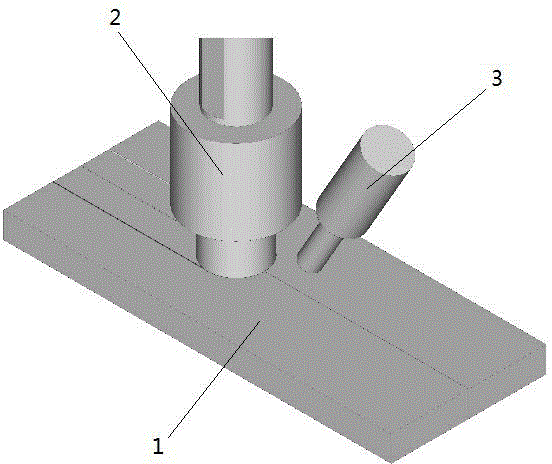

Method for visually tracking plane abut-jointed weld beam by linear laser

ActiveCN102303190AStable detectionResistance to microfracturesLaser beam welding apparatusClassical mechanicsWeld seam

The invention discloses a method for visually tracking a plane abut-jointed weld beam by a linear laser aiming at the complex condition of a welding site. The method comprises the steps of: building a weld beam tracking system, establishing a coordinate system model of each part of the weld beam tracking system, calibrating a system structure by adopting a checkerboard target and a point laser; passively scanning a weld beam by a linear laser, stable and accurately positioning a laser weld beam center by adopting a weld seam center detection technology; and flexibly changing the detection distance between a weld point and an image through setting delay time by a user. According to the method, the influence on the quality of the image by arc light and spattering can be effectively avoided, small breakage of a laser bar is effectively resisted, and automatic tracking of the plane abut-jointed weld beam is stably and accurately realized on line. The method has an important significance on realizing the welding automation.

Owner:JIANGNAN UNIV

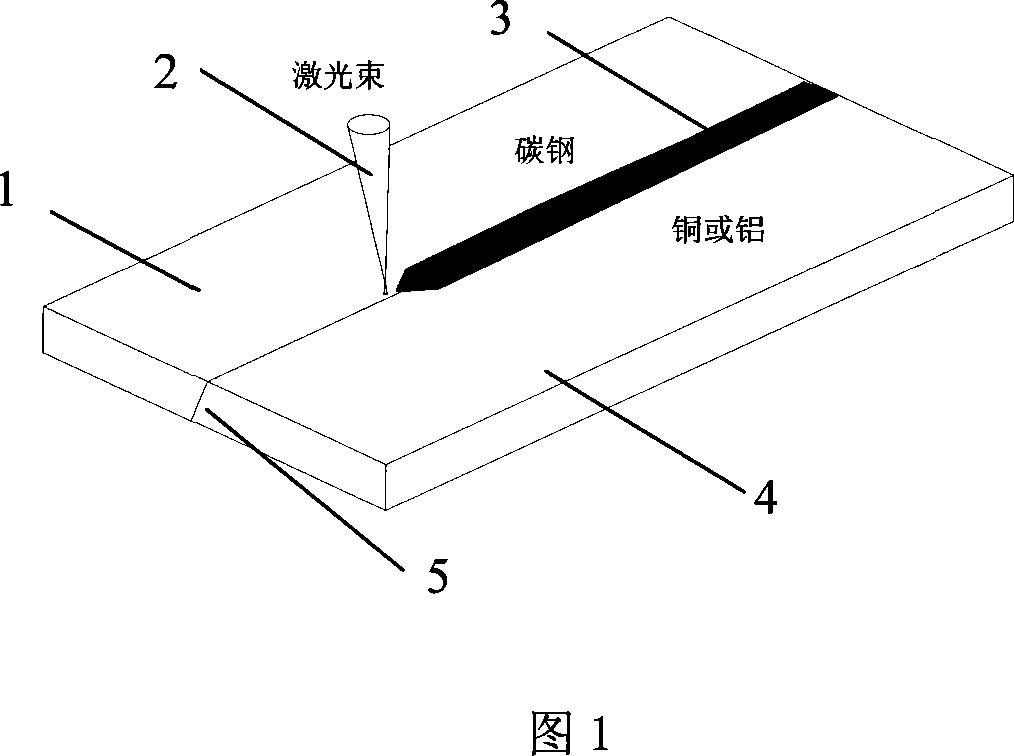

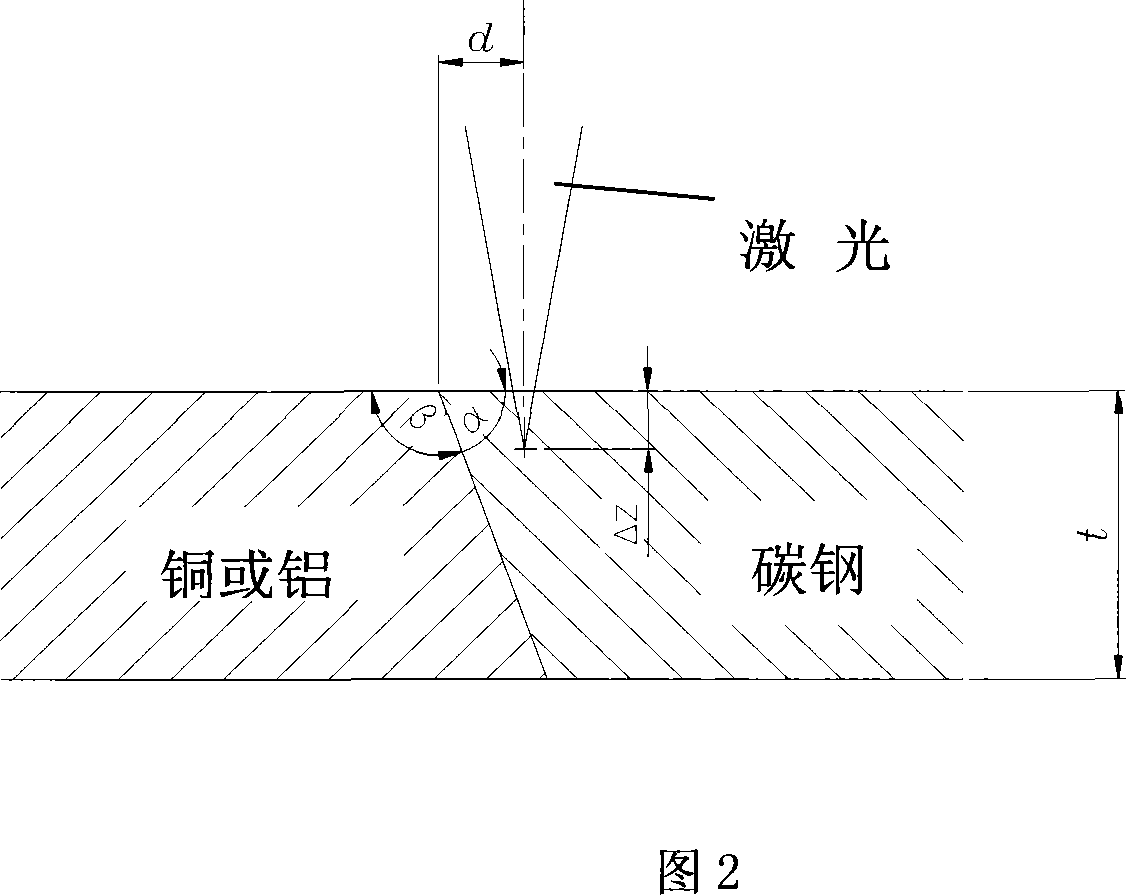

Method for laser butt-welding copper or aluminum and carbon steel

InactiveCN101073857AAchieve connectionNo crackWelding/soldering/cutting articlesWorkpiece edge portionsButt weldingSheet steel

The invention is concerned with the laser butt-joint welding method for copper or aluminum in heterogeneity metal joint technology field. It is: designs the joint between the copper or aluminum and the carbon-steel plate to be slanting end face joint mode without slope, adjusts the focus of the laser beam to the bottom of the welding working piece surface, biases the laser beam to one side of the carbon-steel plate with better absorptivity, in order that another side of the copper or aluminum is heated and melted.

Owner:SHANGHAI JIAO TONG UNIV

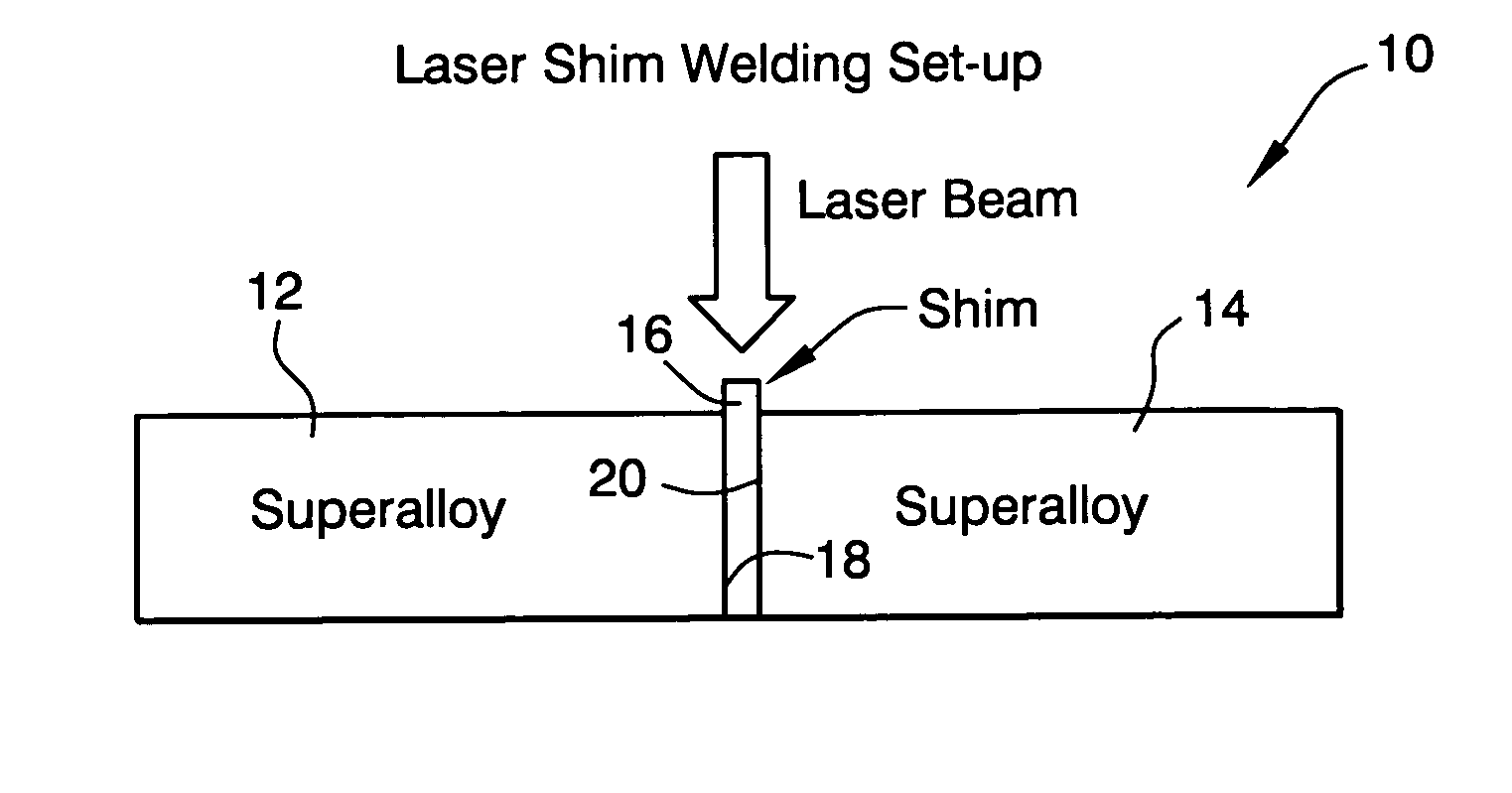

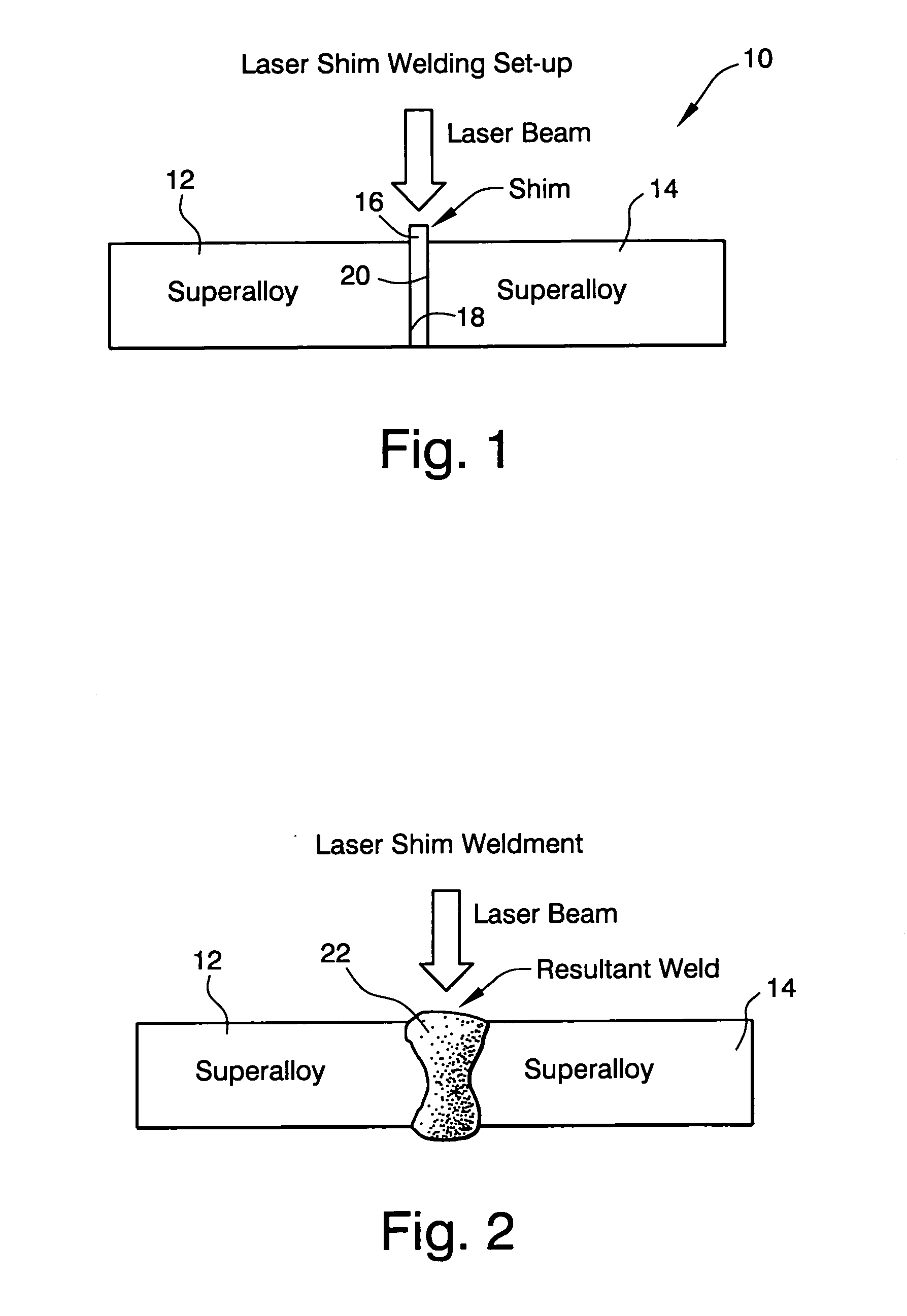

Shimmed laser beam welding process for joining superalloys for gas turbine applications

InactiveUS20070017906A1Improve developmentImproved low cycle fatigue lifeTurbinesEngine manufactureEngineeringSuperalloy

A method of laser beam welding at least two adjacent superalloy components includes (a) aligning the components along a pair of faying surfaces but without a backing plate; (b) placing a superalloy shim between the faying surfaces; (c) welding the components together using a laser beam causing portions of the superalloy components along the faying surfaces to mix with the superalloy shim; and cooling the components to yield a butt weld between the components.

Owner:GENERAL ELECTRIC CO

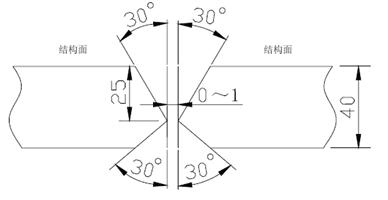

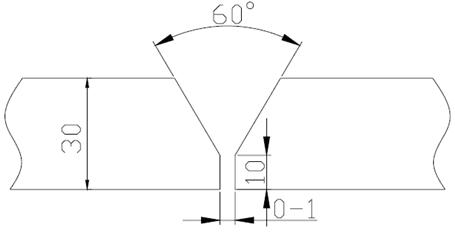

Plain butt welding process for high-strength hull structural steel

ActiveCN102019481AShorten the construction periodImprove labor efficiencyArc welding apparatusWorkpiece edge portionsHull structureCold treatment

The invention relates to a process for welding a high-strength hull structure steel, in particular to a plain butt welding process for a high strength hull structural steel plate (CCSE69040mm). The butt welding process is characterized in that effective specifications for bevel for welding, weld preheating, welding temperature, welding sequence, welding variables and after-welding cold treatment are provided. The plain butt welding process has the advantages of enabling the process of welding a super-thin high strength steel plate to be implemented smoothly, improving the operating efficiency, saving the raw materials, reducing the production cost, reducing the shipbuilding period, and filling a domestic technical blank on the welding of a high strength thick hull structural steel (CCSE69040mm).

Owner:WUCHANG SHIPBUILDING IND

Long continuous structural steel box beam or combination box beam construction method

InactiveCN101368373AReduce welding workloadSatisfy \"Light Large Span\"Bridge erection/assemblyBridge materialsButt weldingEngineering

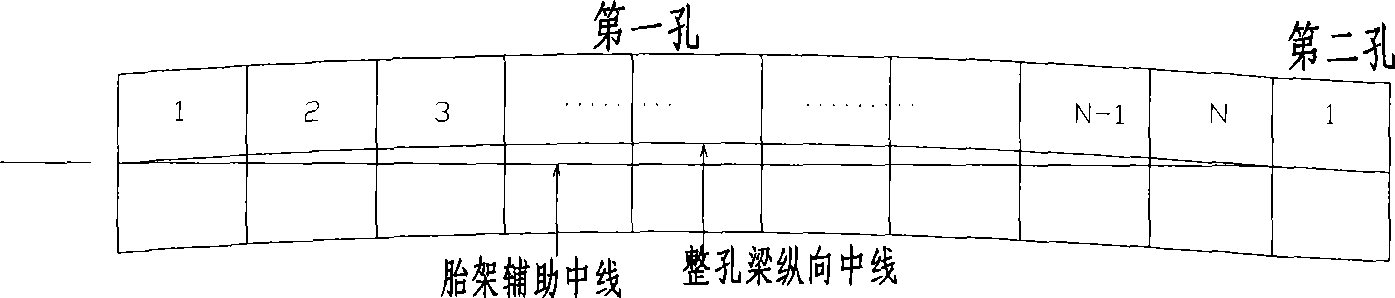

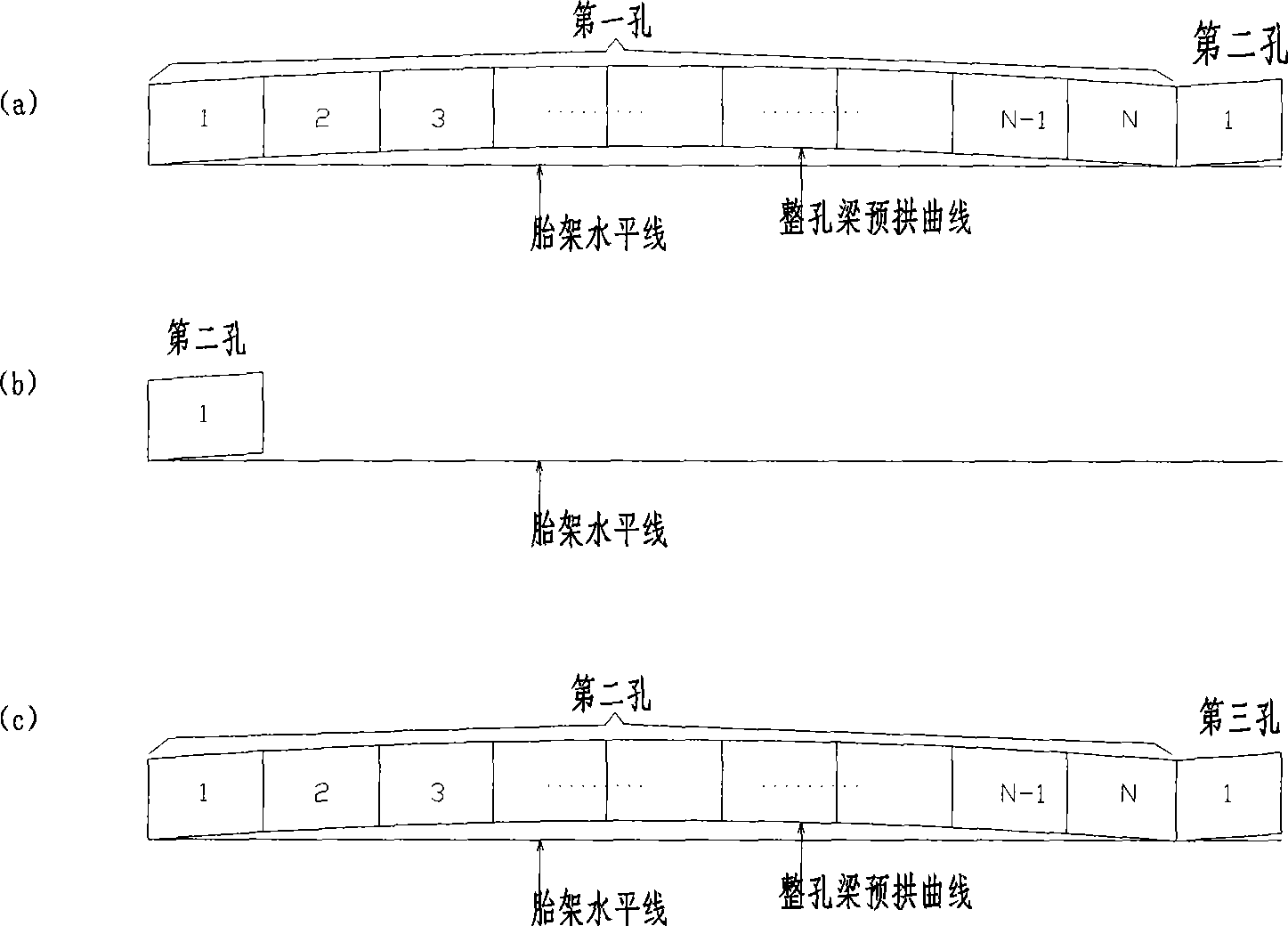

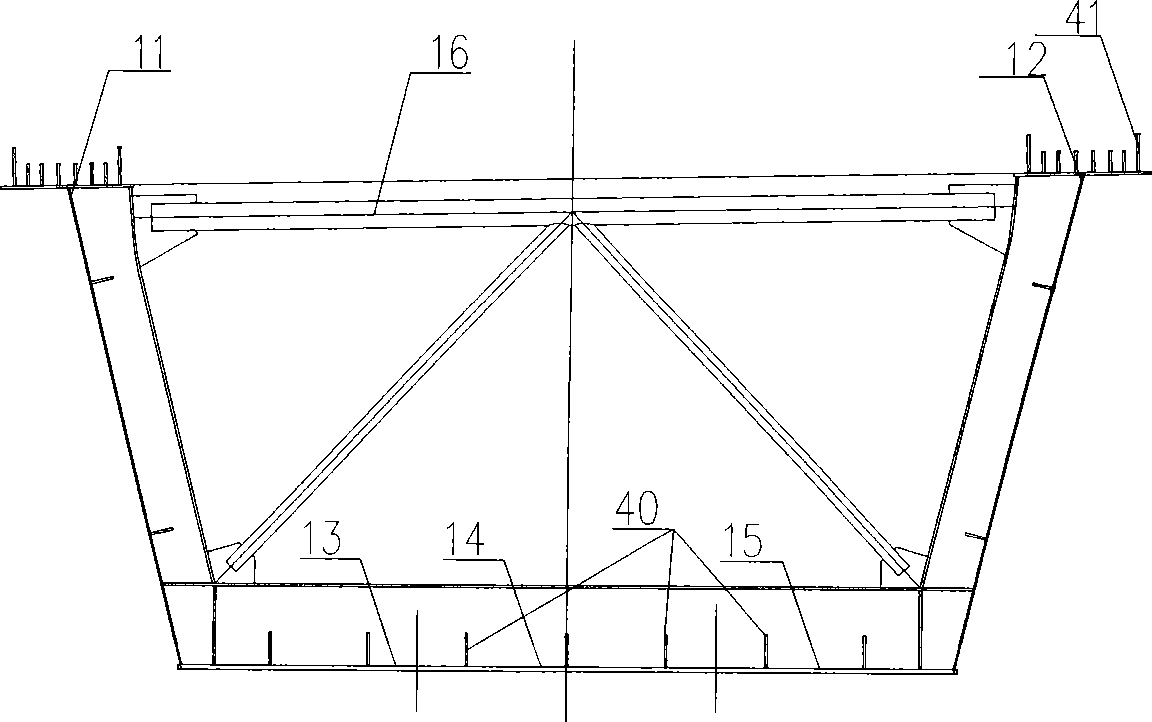

The invention discloses a long continuous steel box girder or combined box girder construction method, including the following steps: 1, segment division and plate unit division; 2, butt welding the fulcrum segmental box girders and standard segmental box girders at a prefabrication plant, namely, pre-splicing the segmental box girders of a full span box girder and the first box girder segment of the adjacent span box girder through long line method on a segmental box girder molding bed on which plane curves and pre-camber are arranged; marking the box girder segments, taking away the segmental box girders of the full span box girder, leaving the first box girder segment of the adjacent span box girder, and continuing to splice and weld the segmental box girders of the rest full span box girders; 3, generally assembling the full span box girders in the prefabrication plant. The invention adopts full span prefabrication and arrangement to construct a long continuous steel box girder or combined box girder, thus greatly reducing welding work load at the site. The invention ensures that the adjacent spans close smoothly after the steel girders are arranged and meets the requirements of light large span, precast assembly and quick construction.

Owner:CHINA MAJOR BRIDGE ENG

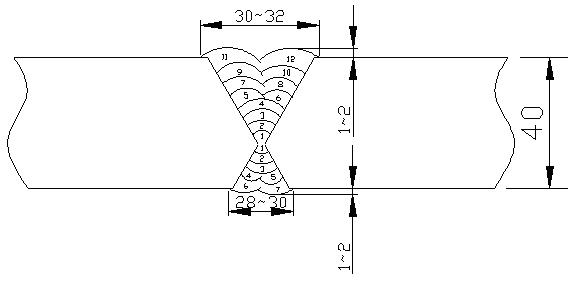

Downward and butt welding process for high strength steel for ship structure

ActiveCN102009256AShorten the construction periodImprove labor efficiencyArc welding apparatusCold treatmentButt welding

The invention in particular relates to a welding process for super thick high strength steel plates for ships and provides a downward and butt welding process aiming at downward and butt welding of EH36Z 100mm-thick high strength steel plates for a ship structure. By putting forward effective specifications for welding grooves, weld preheating, welding temperature, welding sequence, welding variables and cold treatment after welding, the welding process of the high strength steel for super thick plates can be smoothly implemented; and by using the welding process, the labor efficiency is improved, the raw materials is saved, the production cost is reduced, the ship building period is shortened, large scale practical application of the steel to the engineering is successfully implemented for the first time and the gap in the technical specifications in welding of the EH36Z 100mm-thick high strength steel for thick plates for the ship structure at home is filled in.

Owner:WUCHANG SHIPBUILDING IND

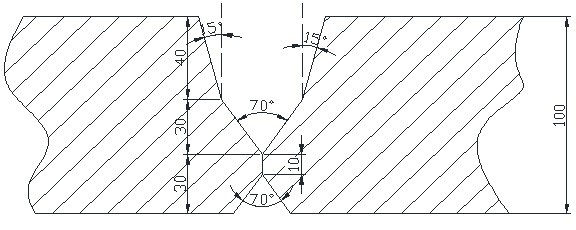

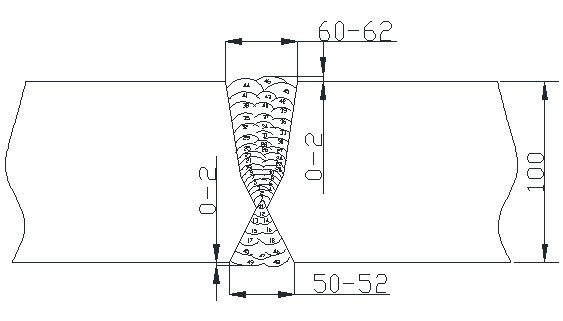

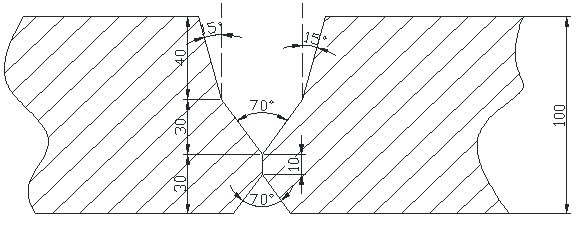

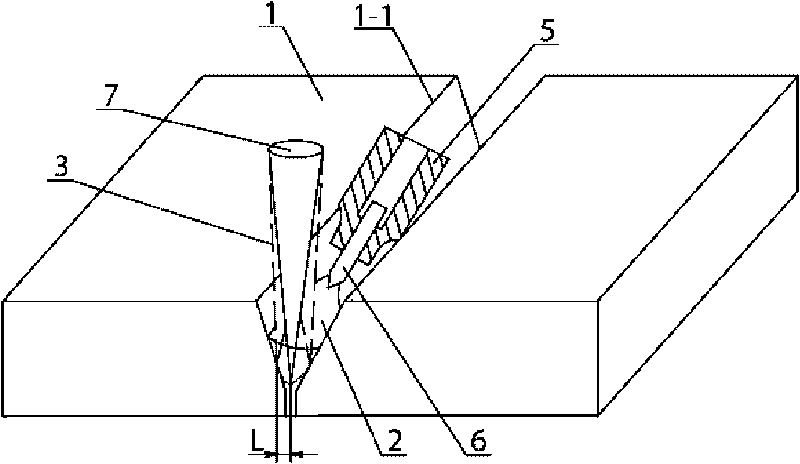

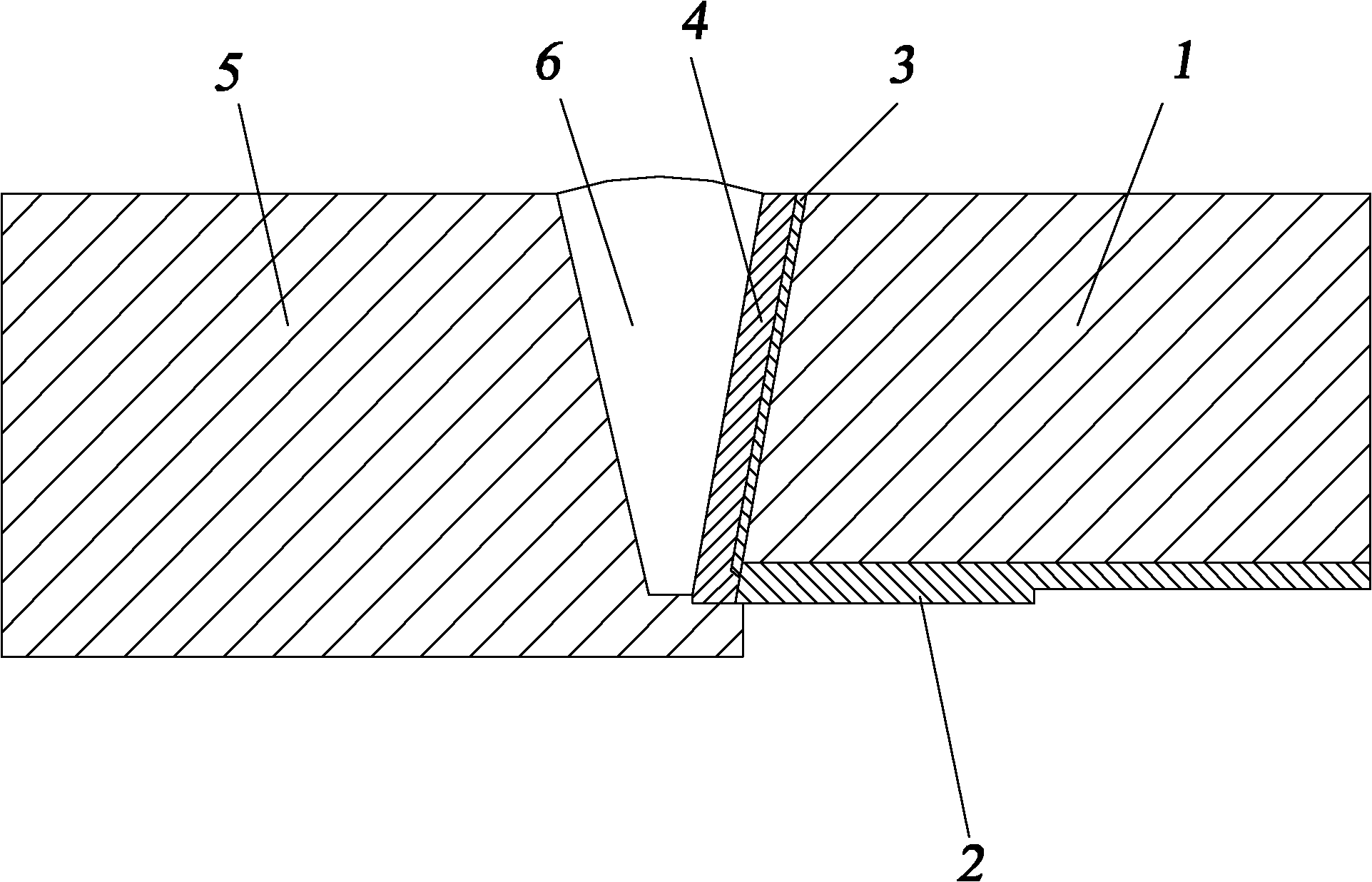

Method for realizing swing welding with laser-GMA electric arc hybrid welding device

The invention discloses a method for realizing swing welding with a laser-GMA electric arc hybrid welding device, relating to a laser-melting electrode gas metal arc welding hybrid welding method. The method solves the problem that the defects such as incomplete fusion, gas hole and included slag, and the like, are easily existed between a side wall and a layer when welding a moderate plate and a thick plate with the laser-GMA electric arc hybrid welding device. The method comprises the following steps of: 1. chamfering; 2. clamping a work piece to be welded; 3. ensuring the positions of an electric arc and a laser beam, wherein the laser beam is perpendicularly irradiated to the surface of the work piece to be welded, an included angle between the electric arc and the laser beam is 15-60 DEG C, and the distance between the laser beam and the sharp end of a GMA electric arc welding wire is 2-6mm; 4. setting a welding technology parameter; and 5. performing the welding, wherein an electric arc welding gun is kept to be immovable when welding, and a laser beam-focused wielding gun swinging welds in the shape of 'S'. The method is used for butt welding of a thick plate more than 10mm in national defense and civil use fields of shipbuilding, petroleum pipe lines, high-pressure vessels, fighting vehicles and nuclear devices, etc.

Owner:HARBIN INST OF TECH

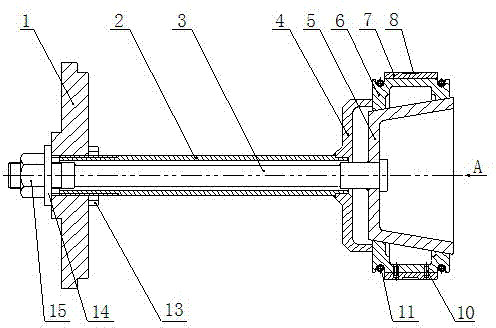

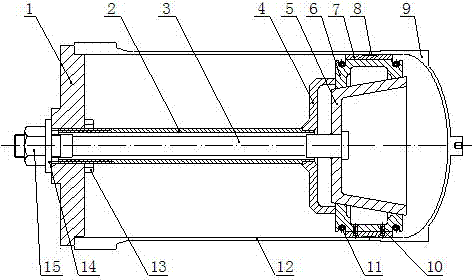

Butt welding positioning device for thin-walled cylinder with seal head

InactiveCN102416549ASolve the problem of joint positioningAccurate coaxial positioningWelding/cutting auxillary devicesAuxillary welding devicesButt weldingProcess equipment

The invention discloses a butt welding positioning device for a thin-walled cylinder with a seal head, and belongs to the technical field of process equipment. The device is mainly technically characterized by comprising a pressing plate, a pipe sleeve, a pull rod, a support body, a cone, a bulging block, a copper cushion block, a countersunk screw, a band spring, an adjusting nut, a gasket and a locking nut, wherein the pressing plate is adjusted by the adjusting nut to position a workpiece; the cone is pulled by the pull rod to jack and bulge the three-flap bulging block; the bulging block centers, bulges and clamps the workpiece to be welded; the taper of the inner wall of the bulging block is the same as that of the external surface of the cone; and a radial annular groove is formed on the surface of the copper cushion block. The assembly positioning problem of the thin-walled cylinder with the seal head and a thin-walled hollow cylinder during butt welding can be effectively solved, welding deformation is effectively reduced, and the device has the advantages that: the device has a simple structure, is convenient to assemble and disassemble and is operated and used reliably.

Owner:江南工业集团有限公司

Downward and butt welding process for high strength steel for ship structure

ActiveCN102009255AIncrease productivityReduce energy consumptionArc welding apparatusThick plateSheet steel

The invention in particular relates to a downward and butt welding process for high strength steel for a ship structure and provides a downward and butt welding process aiming at EH36 30mm-thick high strength steel plates for the ship structure. By putting forward effective specifications for welding grooves, weld preheating, welding temperature, welding sequence, welding variables and cold treatment after welding the welding process of the high strength steel for super thick plates can be smoothly implemented; and by using the welding process, the labor efficiency is improved, the raw materials are saved, the production cost is reduced, the ship building period is shortened and the gap in the technical specifications in downward and butt welding of the EH36 30mm-thick high strength steelfor the ship structure at home is filled in.

Owner:WUCHANG SHIPBUILDING IND

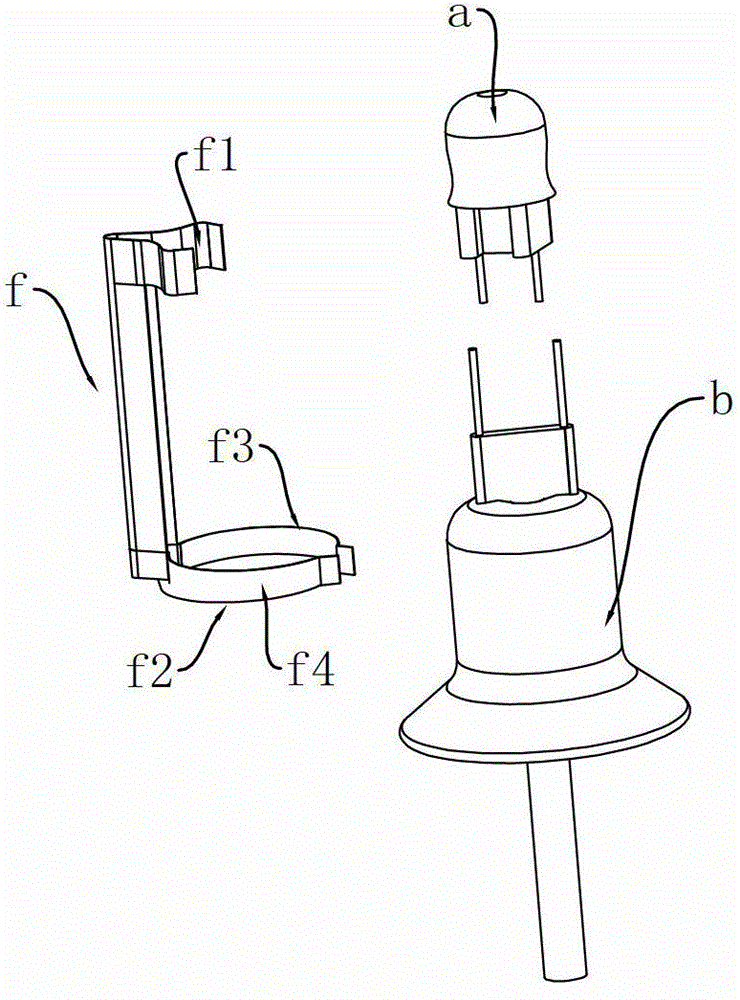

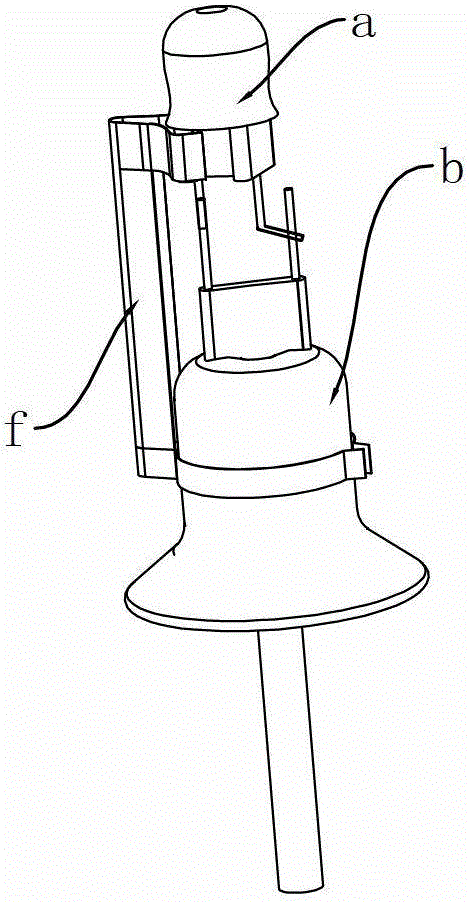

Light foot lead welding machine of bulb in bulb

InactiveCN102744508AReduce mistakesImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesButt weldingEngineering

A light foot lead welding machine of a bulb in a bulb comprises a bottom frame, a tray which is arranged on the bottom frame and can move forward step by step in the horizontal direction and a central controller for controlling the light foot lead welding machine to move in sequence. A plurality of clamping devices are evenly arranged on the tray, a feeding station capable of conveying lamp holders or core columns to the clamping devices, a welding station capable of welding a lamp foot lead and a finished product discharging station capable of discharging finished products from the clamping devices are sequentially arranged besides the tray, and each welding machine of the welding station at least comprises a pair of butt welding electrodes which move relatively in the vertical direction. The clamping devices comprise first clamping heads capable of clamping the lamp holders and second clamping heads capable of clamping the core columns, the first clamping heads and the second clamping heads are arranged in right and left mode in the horizontal direction, and welding spaces are reserved between the first clamping heads and the second clamping heads. Due to the fact that the light foot lead welding machine of the bulb in the bulb has the characteristics and the advantages, the light foot lead welding machine of the bulb in the bulb can be applied to production devices of the bulb in the bulb and other similar products.

Owner:佛山市南海佛阳照明有限公司

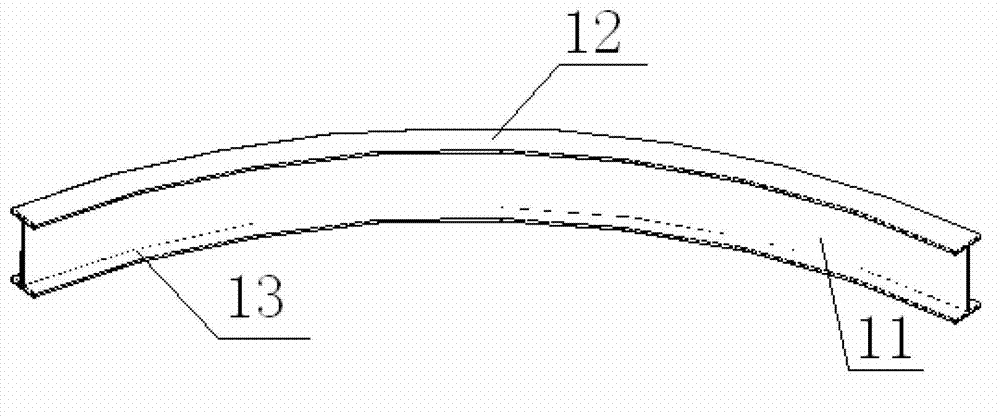

Manufacture method for double-curve H-shaped steel

The invention discloses a manufacture method for double-curve H-shaped steel. The manufacture method comprises the following steps of: 1) reviewing the material quality of a supplied horizontal plate, flattening the horizontal plate, and pre-processing; 2) three-dimensional lofting by a computer, and spreading in a plane; 3) cutting and blanking on a numeric control cutting machine; 4) opening a groove on an H-shaped steel web, and carrying out the butt welding; 5) marking a bending line and an assembly line on the web and a flange plate; 6) manufacturing a bending jig frame according to three-dimensional coordinates; 7) bending the web and the flange plate via the method of flame rectification assisting cold bending formation; 8) manufacturing a assembly jig frame; 9) combining position welding and spot-welding on an upper flange plate and a lower flange plate respectively assembled on an assembly jig frame group; 10) welding the soldering seam between the web and the lower flange plate; 11) lifting the component from the jig frame, and turning over the component to weld the soldering seam between the web and the upper flange plate; and 12) returning the jig for a repeated inspection, and carrying out the three-dimensional coordinates detection through a total-station instrument. According to the manufacture method, used equipment is simple, and efficiencies on manufacture and production are improved.

Owner:YINGDU BRIDGE STEEL STRUCTURE ENG

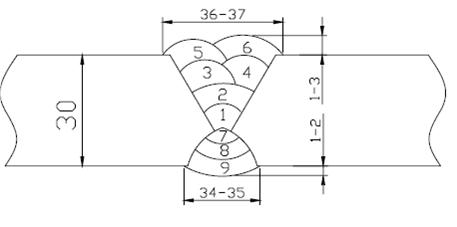

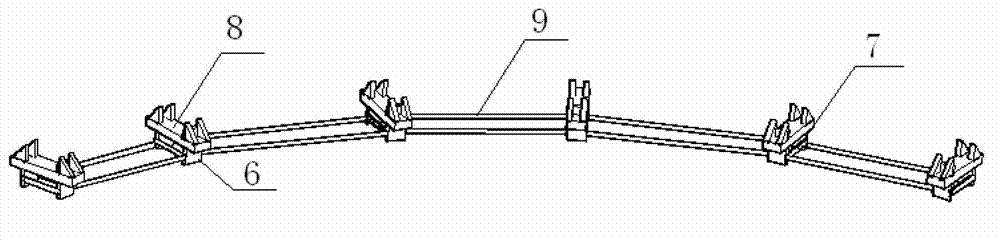

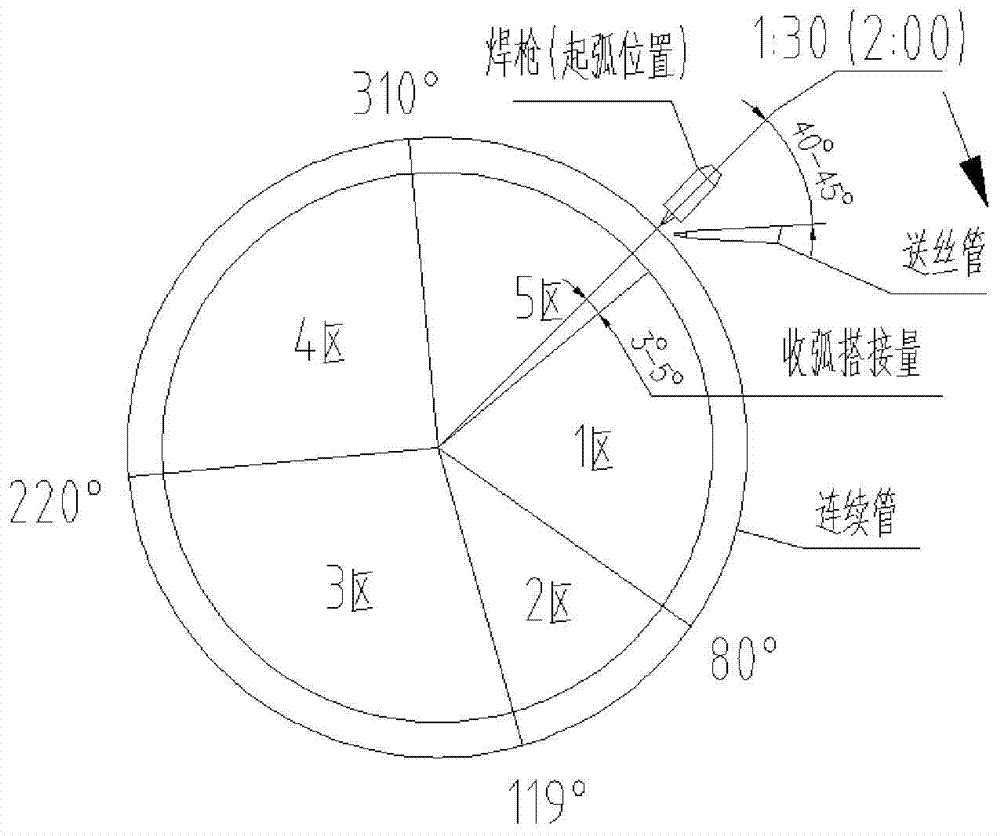

Automatic tube butt joint all-position TIG welding technology for coiled tubing

InactiveCN104741741ARealize dockingImprove performanceArc welding apparatusMetal working apparatusButt jointCoiled tubing

The invention provides an automatic tube butt joint all-position TIG welding technology for coiled tubing. The technology comprises the steps that the tube ends at the two sides of the coiled tubing are straightened, the tube ends of the two sides are subjected to V-shaped edge preparation or U-shaped edge preparation, the inner wall and the outer wall of a joint between the tube ends are cleaned, then the tube ends are assembled in a butt joint mode, a butt joint of the coiled tubing is subjected to non-wire-filling backing weld, filling weld and cosmetic weld through the automatic all-position TIG welding technology, when the butt joint is welded, the arc starting position of a welding gun is located at 1:30 or 2:00, and a separated section welding technology method is adopted for welding. By means of the welding technology, aiming at the tube butt joint welding of the coiled tubing, the traditional manual TIG welding is transferred into full-automatic TIG welding, the working efficiency is improved, the labor intensity is lowered, and the welding joint of the coiled tubing of great comprehensive performances is obtained.

Owner:XI'AN PETROLEUM UNIVERSITY

Method of drawing fiber continuously by butt welding optical fiber preforms

InactiveUS6098429AMitigates the above-described drawbacksSmall sizeCoupling light guidesGlass reforming apparatusButt weldingFiber drawing

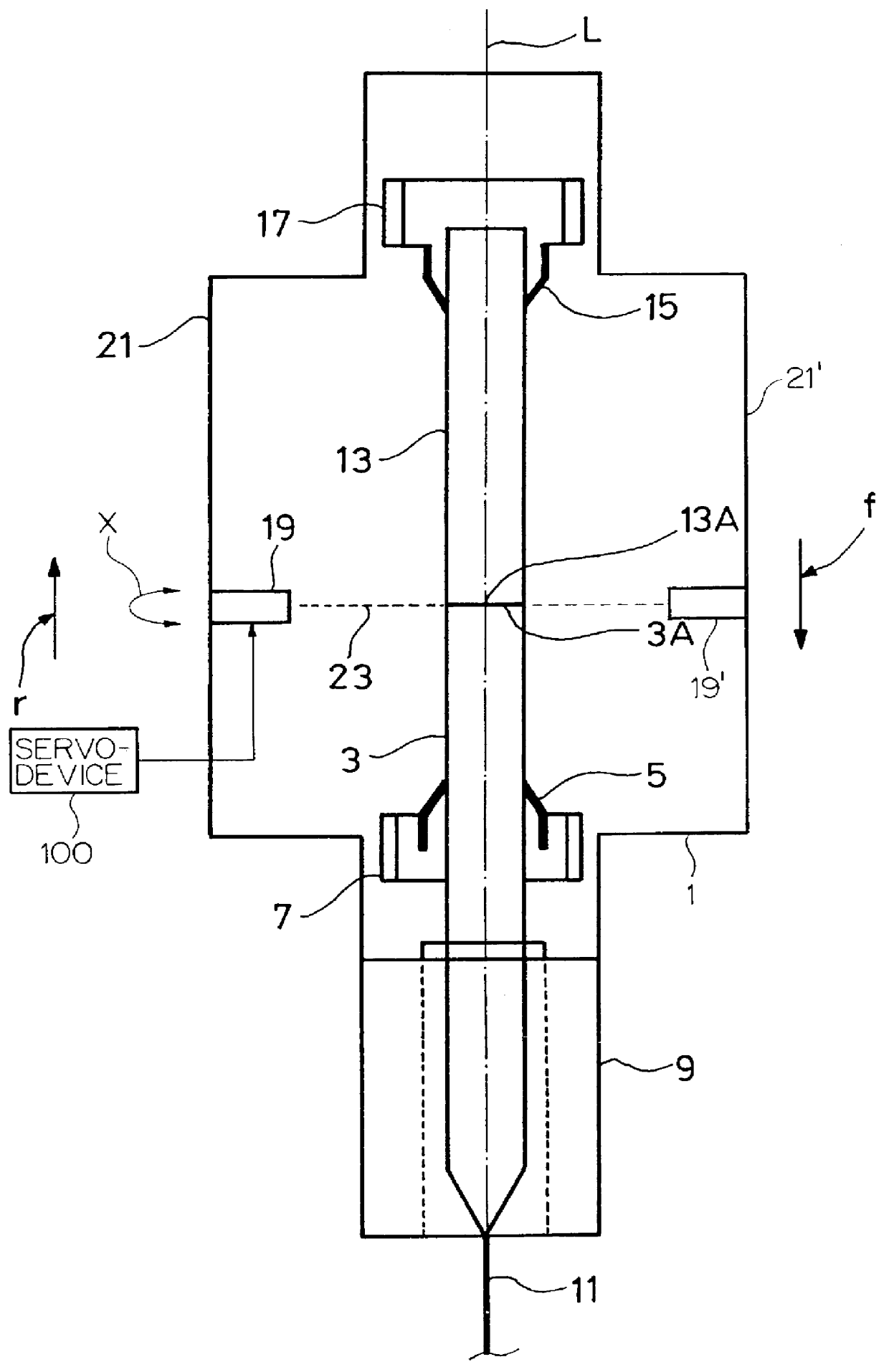

In the method of drawing fiber continuously from preforms for manufacturing an optical fiber, a first preform is displaced along a fiber-drawing axis and is drawn into an optical fiber through a fiber-drawing furnace disposed on the fiber-drawing axis, and a second preform is displaced along the fiber-drawing axis, which second preform is butt welded to the first preform so as to be drawn into an optical fiber following on from the first fiber. The two preforms are butt welded, i.e. they are welded together end-to-end, by displacing at least one power laser along the fiber-drawing axis, and by servo-controlling the displacement of said laser to the displacement of the two preforms so as to maintain a laser beam emitted by the power laser at the same height as the two ends to be welded together, thereby making it possible to reduce considerably the size of the zone affected by the welding, and to avoid polluting the side surfaces of the two preforms upstream and downstream from the weld.

Owner:ALCATEL LUCENT SAS

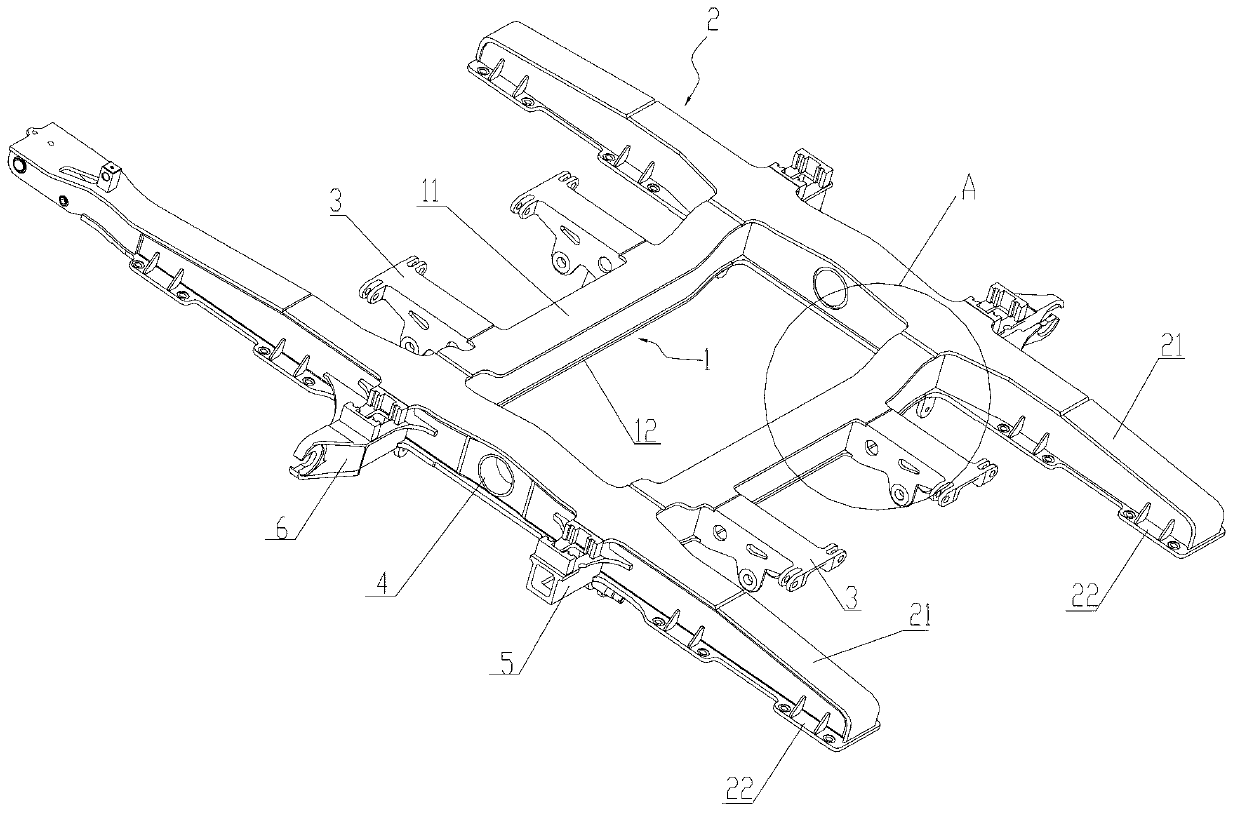

Bogie frame and manufacturing method thereof

ActiveCN103128457AImprove structural strengthImprove fatigue resistanceBogiesWelding apparatusBogieButt welding

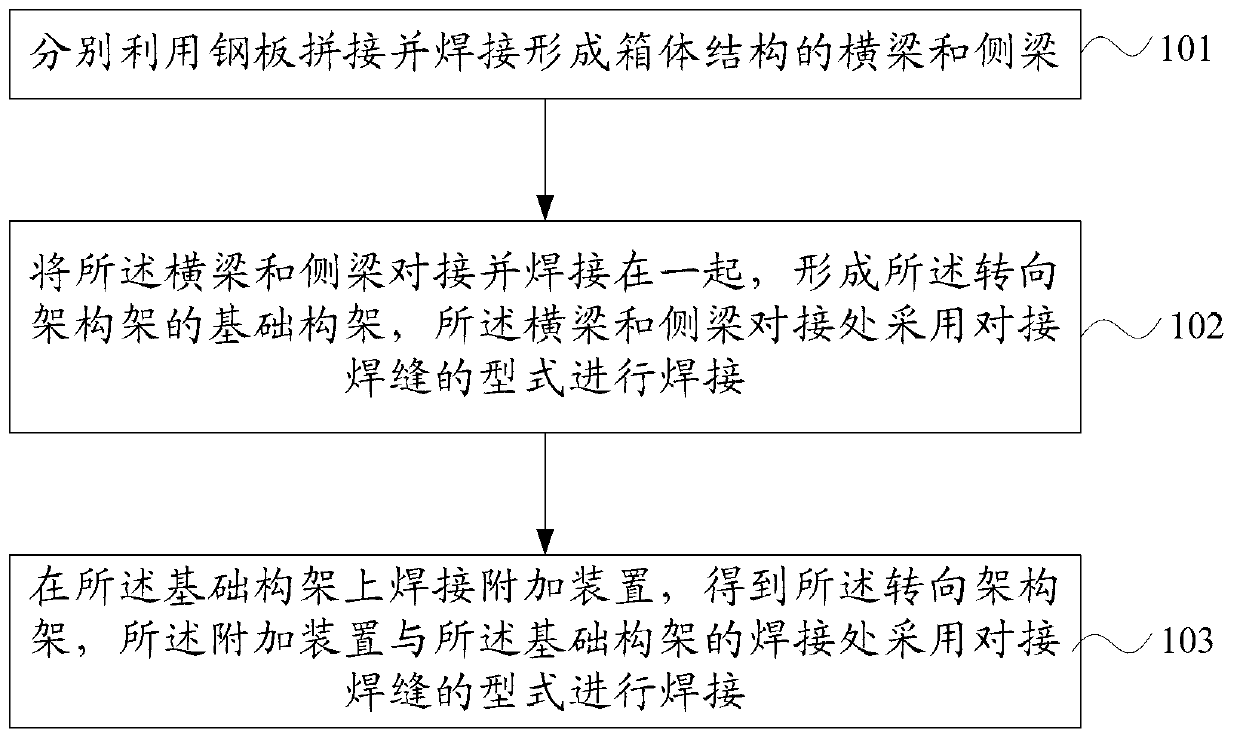

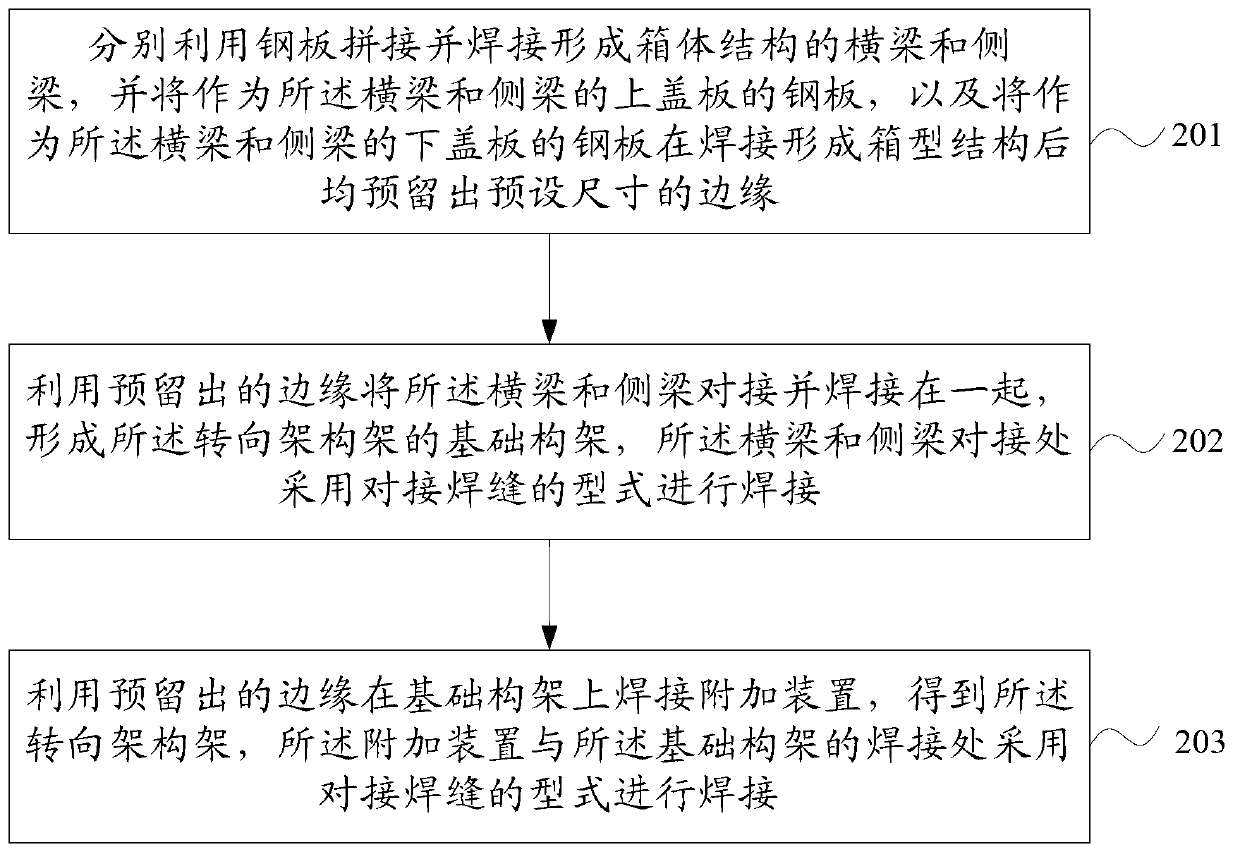

The invention provides a bogie frame and a manufacturing method thereof. The manufacturing method includes the steps: respectively splicing and welding steel plates to form beams and side beams of a box structure; butting and welding the beams and the side beams together to form a base frame of the bogie frame, and welding butt joints of the beams and the side beams by a butt-jointed seam type; and welding additional devices on the base frame to obtain the bogie frame, and welding welds of the additional devices and the base frame by the butt-jointed seam type. The bogie frame and the manufacturing method thereof can overcome the shortcomings that profiling quality of the beams and the side beams manufactured by pressing with dies is unstable, and the surfaces of the steel plates are easily scratched. The welds of the beams and the side beams and the welds of the base frame and the additional devices are welded by the butt-jointed seam type, a large stress area can be avoided, and the structural strength and the fatigue resistance of the bogie frame are improved.

Owner:CRRC TANGSHAN CO LTD

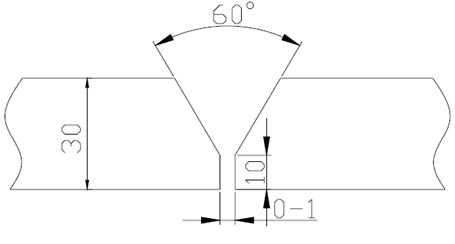

Method for combined welding of austenitic stainless steel moderate thickness plate

InactiveCN104858557ALittle thermal impactNo crackWelding/soldering/cutting articlesWelding apparatusButt weldingButt joint

The invention relates to a method for combined welding of an austenitic stainless steel moderate thickness plate. The method comprises the steps of opening a V-shaped groove at the position of the to-be-welded butt joint surface of austenitic stainless steel; polishing and cleaning the surface of a to-be-welded workpiece and the position of the V-shaped groove; performing gapless tight fixed assembly of the workpiece, performing spot welding fixation on a run-on plate, an arc blowout plate and a test plate; pre-leading in protective gas prior to butt welding, guaranteeing that sufficient protective atmosphere is formed on the surface of the stainless steel groove and the bottoms of the weld joints; adopting pulsed plasma arc welding to perform bottoming welding; adopting low carbon welding wires to perform cosmetic welding of pulse wire filling argon tungsten-arc welding, performing the bottoming welding of the pulsed plasma arc welding and cosmetic welding of the pulse wire filling argon tungsten-arc welding simultaneously, and cooling the workpiece while performing the welding. The PC-PAW bottoming welding is adopted, the micropore effect is utilized to achieve one-side welding and double-sided free forming of the moderate thickness plate, the backs of the weld joints are smoothly formed and are free of cracks and edge snapping defects, the process is stable and easy to achieve, and the quality is reliable.

Owner:SHANDONG UNIV

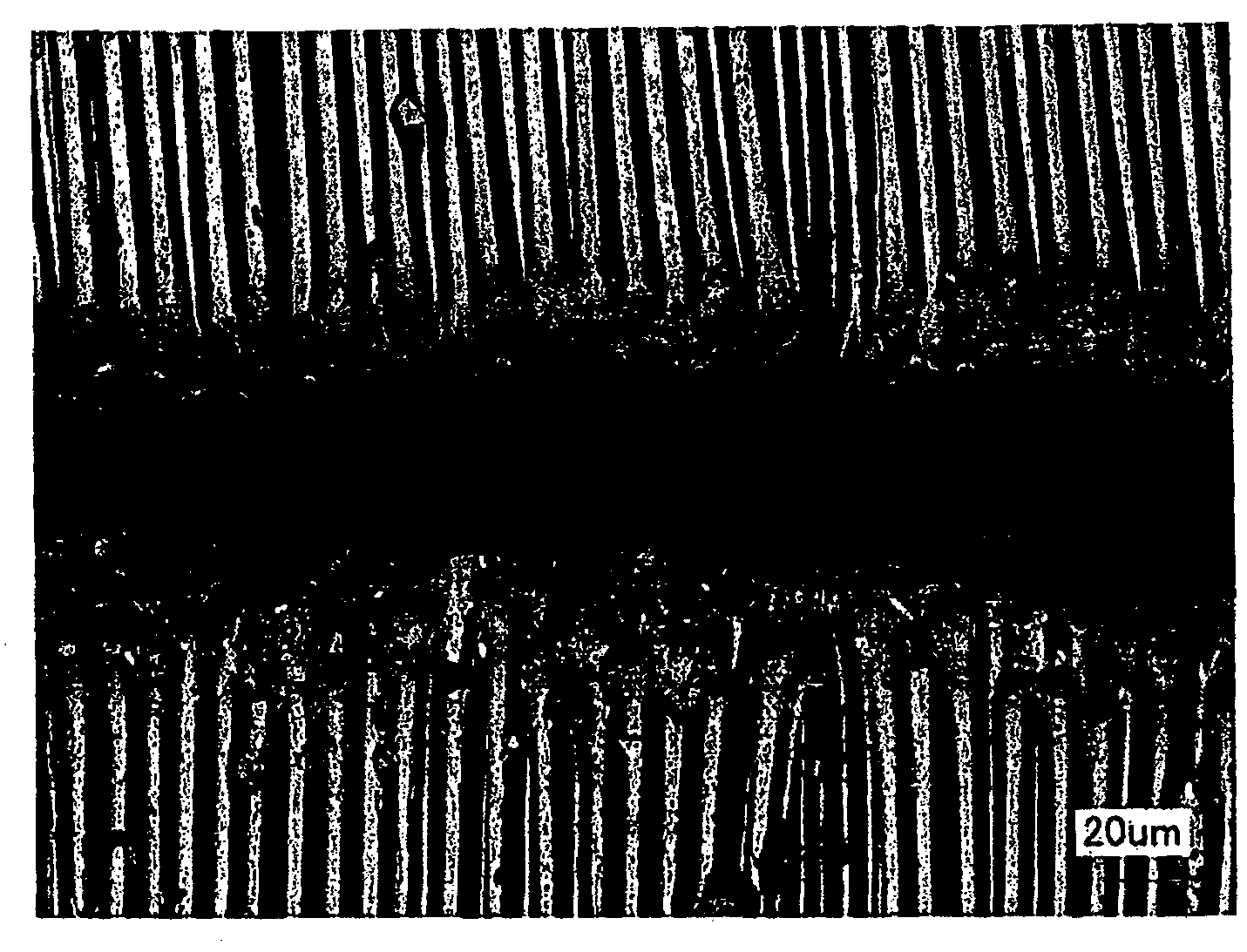

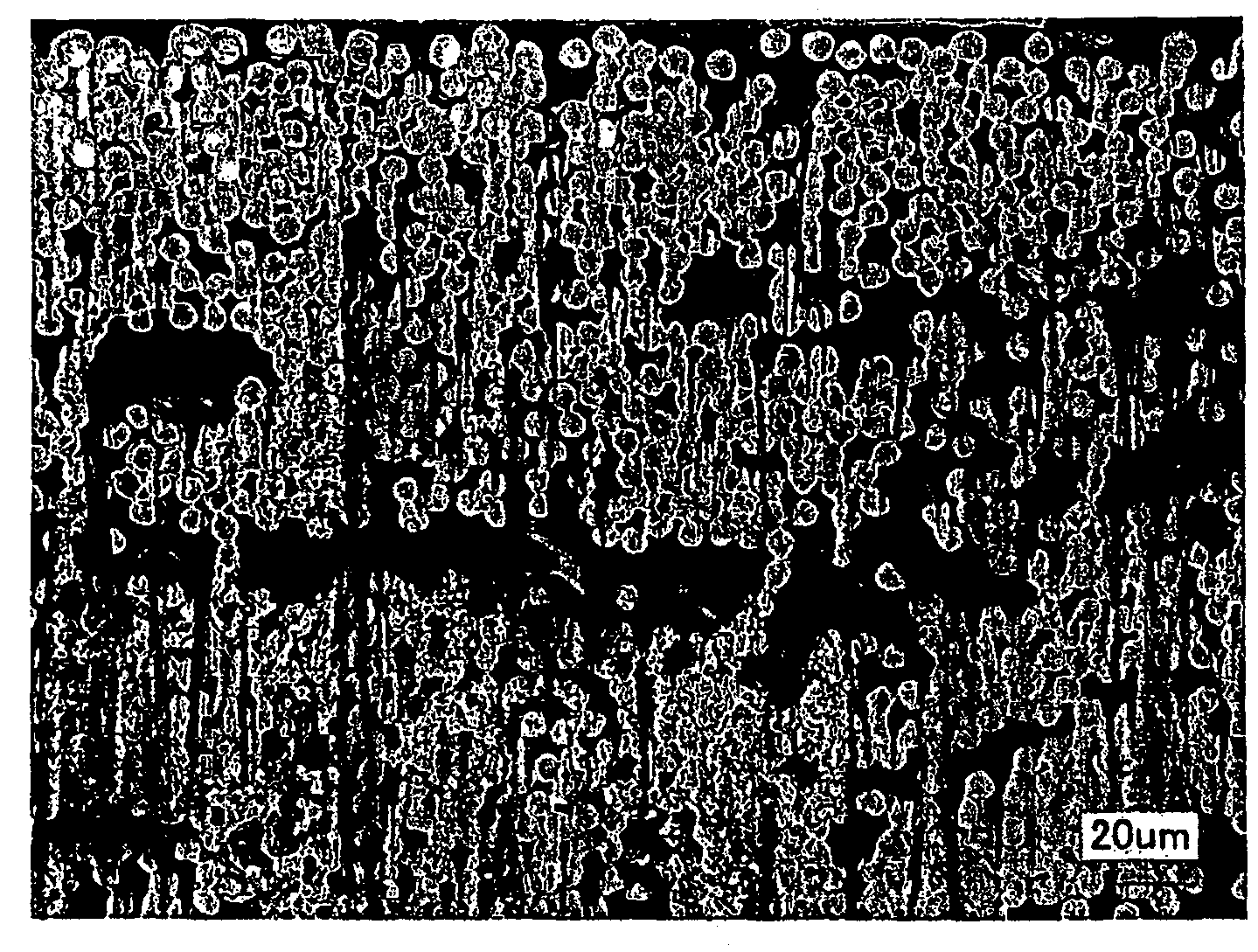

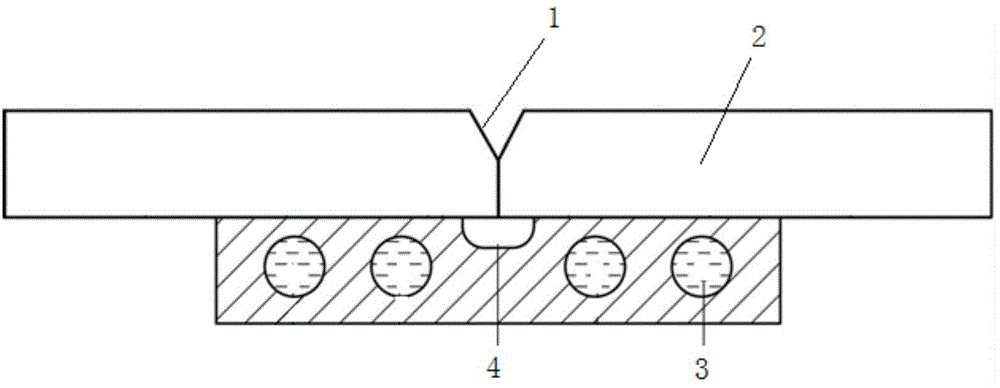

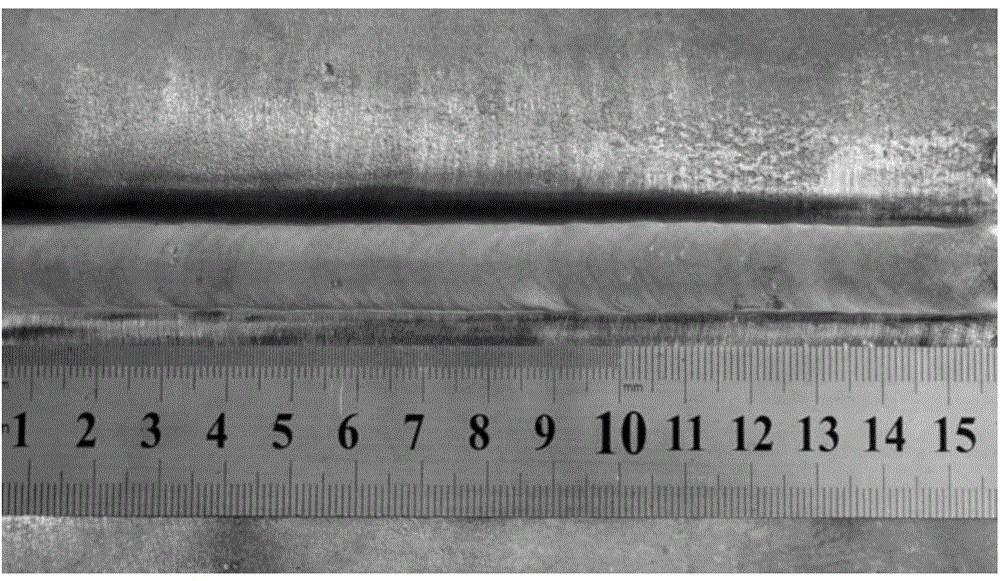

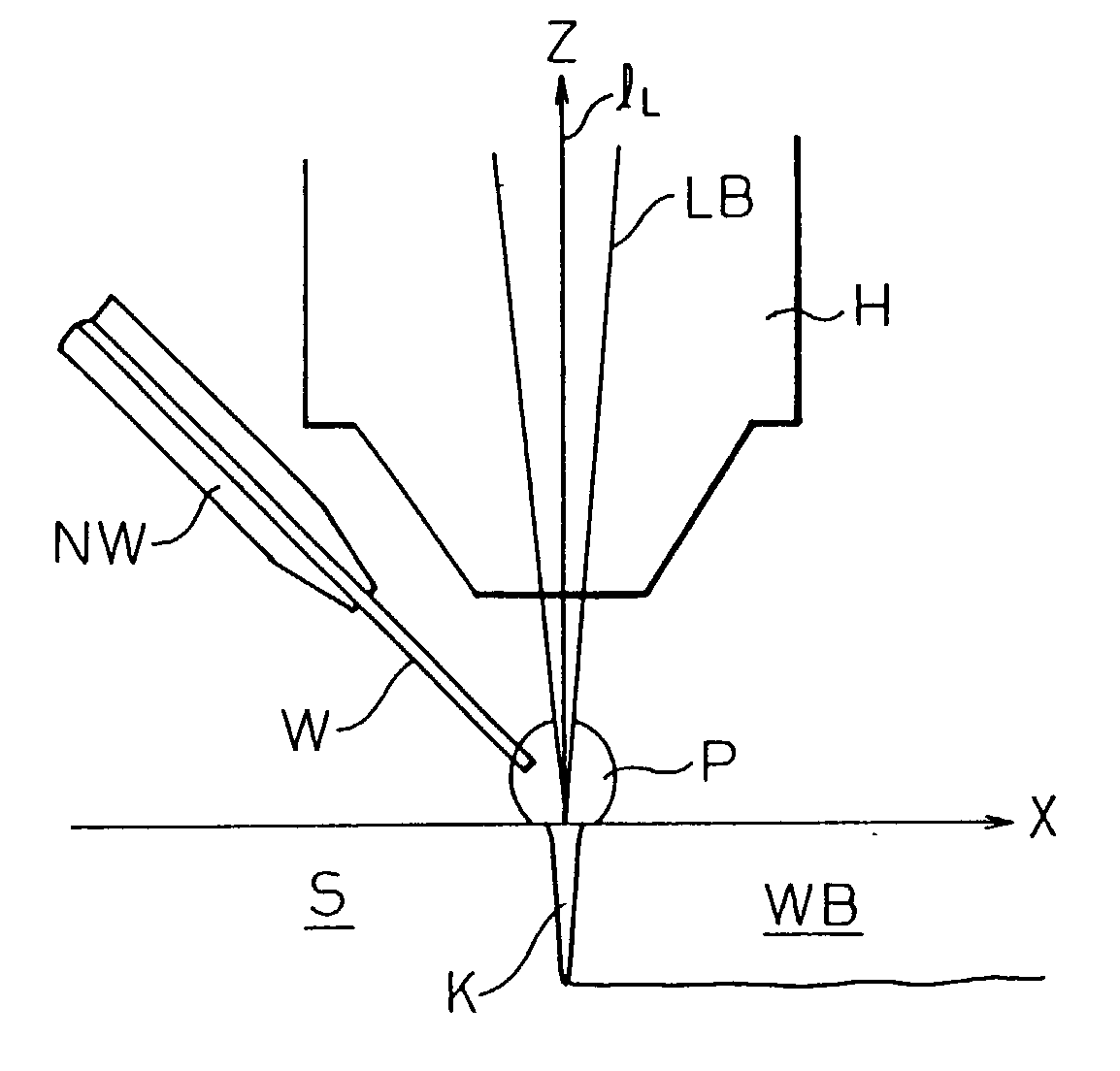

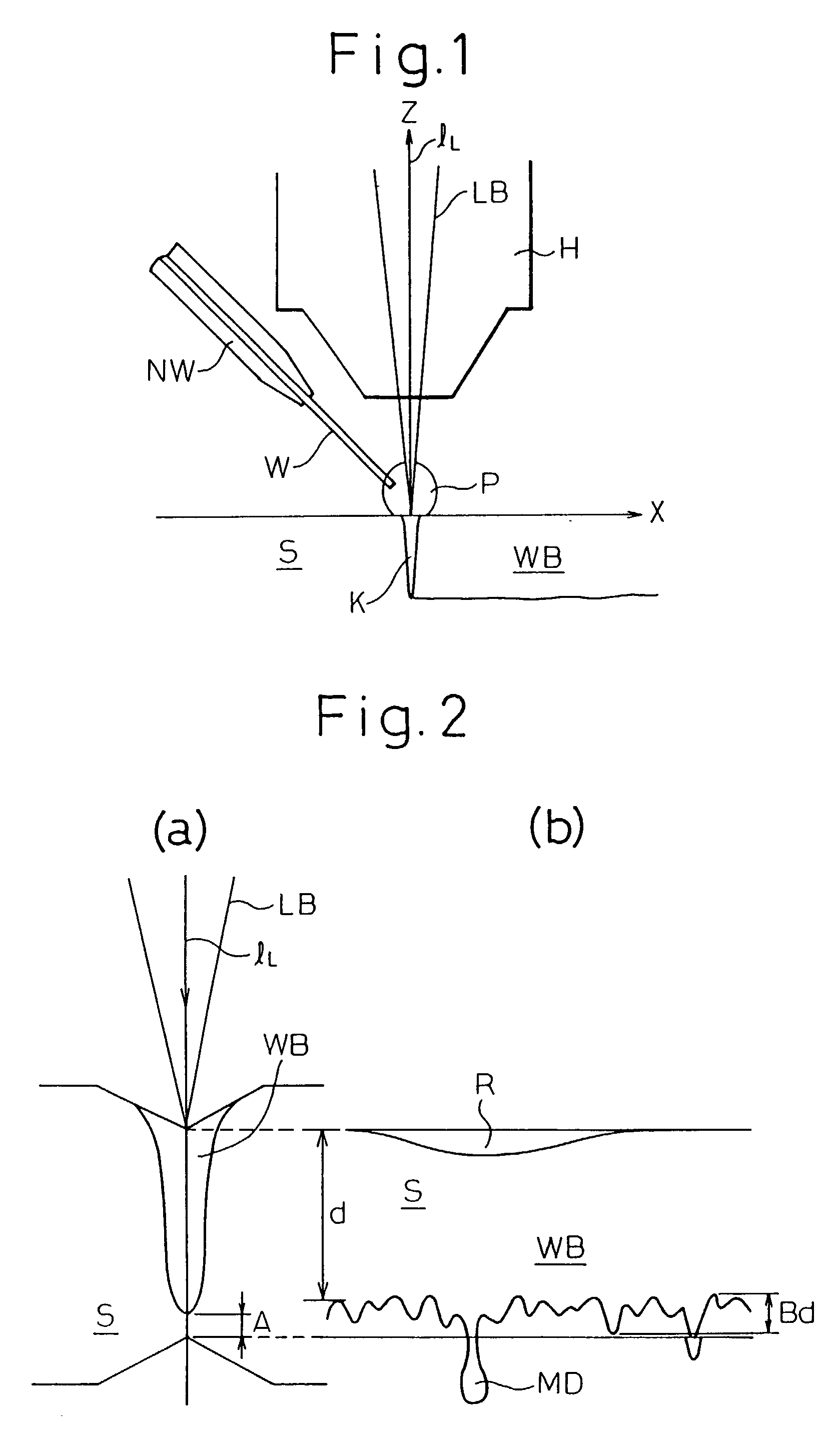

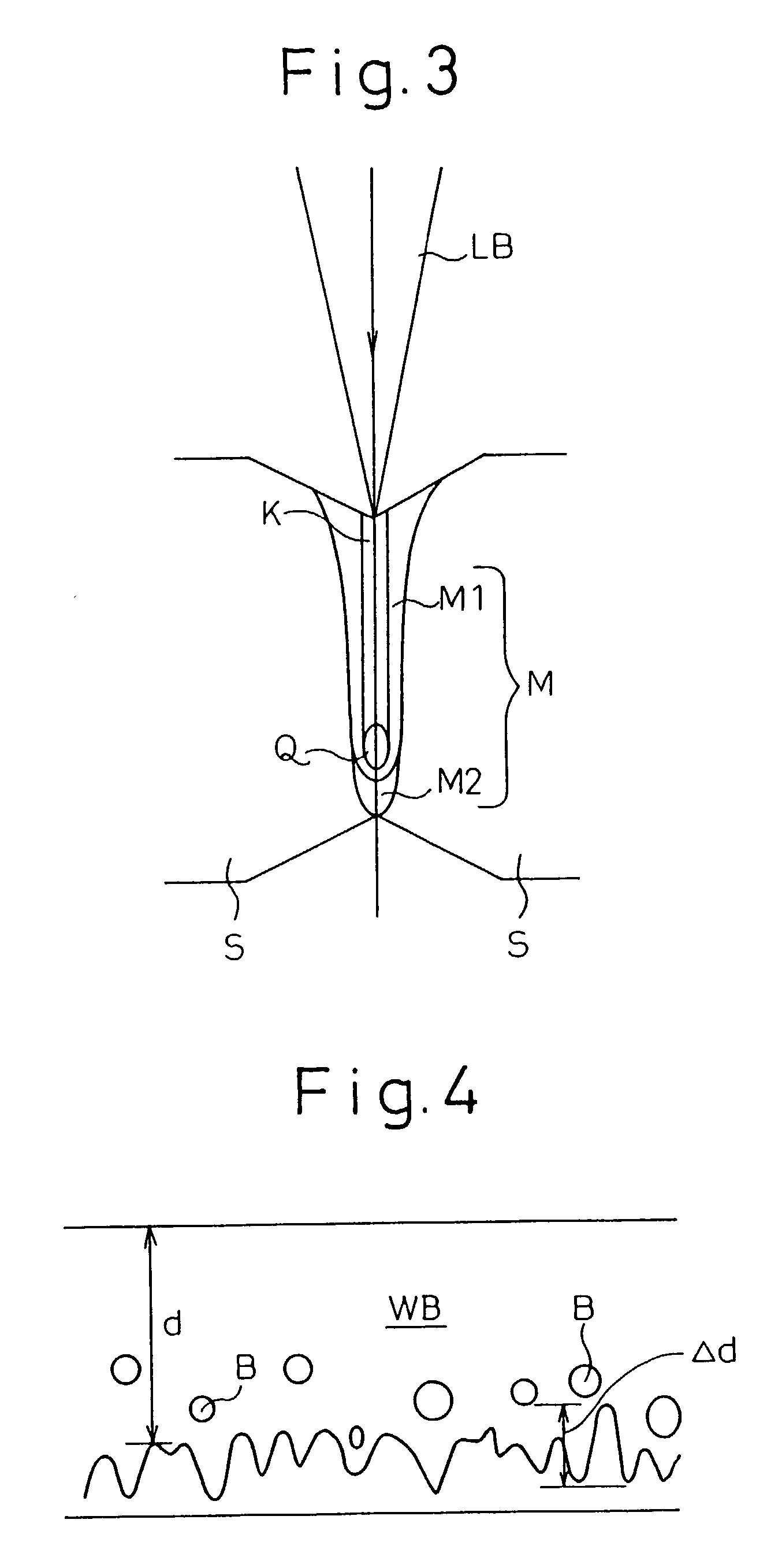

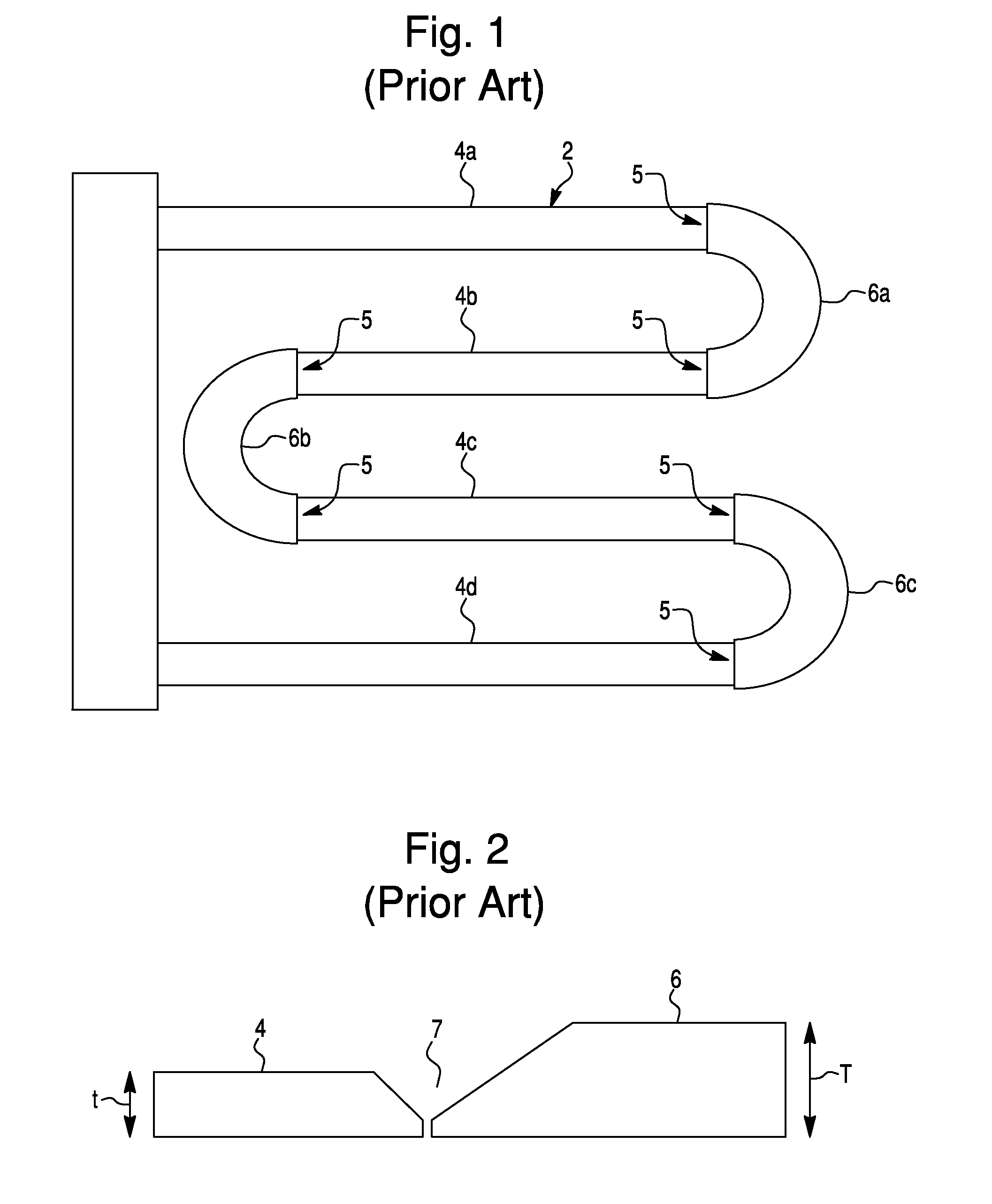

Method of butt-welding hot-rolled steel materials by laser beam and apparatus therefor

InactiveUS20030038120A1Inhibition formationSufficient reducing abilityWelding/cutting media/materialsWelding/soldering/cutting articlesButt weldingManganese

In order to make the depth of penetration in the weld bead portion uniform and obtain a bead shape having a flat bottom without spiking and meltdown during continuous hot rolling by bonding a plurality of hot-rolled steel materials using a laser beam, the following methods are employed: (A) a method of butt welding wherein center gas is blown against the welding portion symmetrically to the optical axis of the laser beam while side gas is being blown thereagainst from the side, the method comprising conducting welding while the center of laser-induced plasma is shifted in the welding direction from the center of the laser beam by a distance 0.2 to 0.5 times as much as a reference plasma diameter determined from the laser output and the beam diameter, and the type and flow rate of the center gas; or (B) a method comprising scanning the butt line with the laser beam during the laser welding at a speed of 2 to 10 m / min, and simultaneously oscillating the laser beam in the direction vertical to the butt line at a frequency of 40 to 80 Hz at an amplitude of 0.4 to 1.0 mm. Alternatively, (C) in order to prevent formation of blow holes in the weld bead, to make the depth of penetration in the weld bead portion uniform, and to obtain a bead shape having a flat bottom without spiking and excessive penetration, laser welding is conducted while a filler wire of an iron series base material, containing from 0.05 to 3% of one or at least two elements selected from aluminum, silicon, titanium and manganese, is being supplied to the welding portion. Moreover, (D) in order to stably supply a filler wire to the butt portion with high supply accuracy, the filler wire W is passed through a wire supply nozzle having a curved portion, and the filler wire is supplied toward the welding point along the welding line.

Owner:NIPPON STEEL CORP

Method for half-breadth double-span total assembling and building in shipbuilding

ActiveCN101544268AReduce upwarping deformationReduce welding distortionVessel partsButt weldingButt joint

The invention relates to a method for half-breadth double-span total assembling and building in shipbuilding, which comprises the following steps: firstly, dividing the half-breadth building at the bottom of a cargo area of a ship into four sections including two double-layer bottom sections and two bottom edge water camber sections; secondly, using one of the double-layer bottom sections as a reference, performing normal total assembling on the two double-layer bottom sections; and thirdly, aligning and welding the two bottom edge water camber sections with the corresponding double-layer bottom sections first, and then performing butt welding on the two adjacent bottom edge water camber sections so as to form a half-breadth type total section. The building method is advantageous for the structural completeness of a shipway, and can speed up the structural submission progress. The pitch point control at a bilge round-turning part can be performed at the total assembling in advance, thus the number of butt joints at the round-turning part of an upper shipway is reduced, the shipway and a total assembling platform are used reasonably, and the utilization rate of the total assembling platform is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

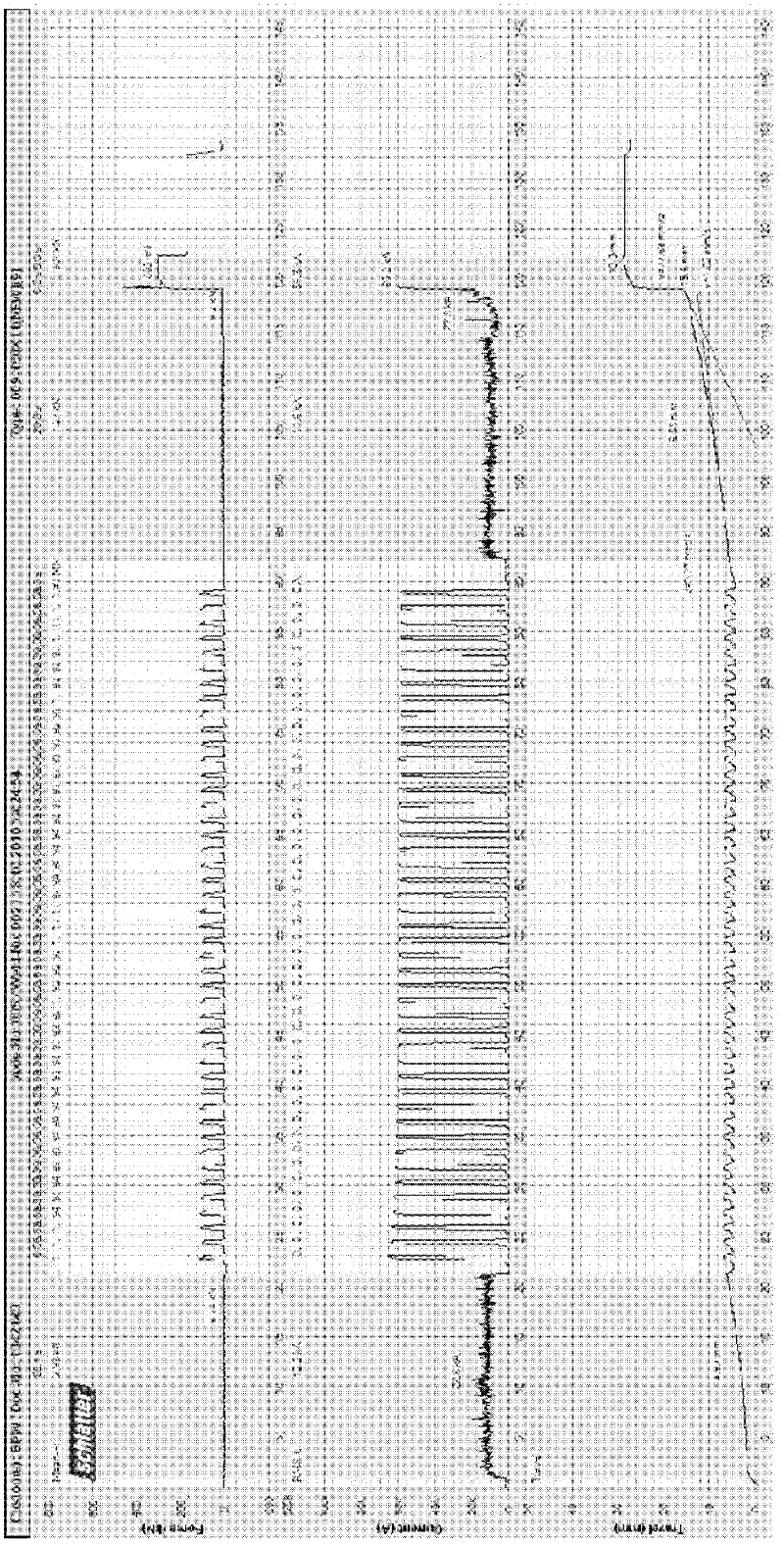

Pulsed switch-on preheating flash butt welding process for steel rims of heavy trucks

InactiveCN102107320ANo crack defectHigh degree of automationResistance welding apparatusButt weldingEngineering

The invention discloses a pulsed switch-on preheating flash butt welding process for steel rims of heavy trucks, which belongs to the technical field of welding, and comprises the steps of blanking, reeling, flattening, welding condition setting, fitting, pulsed flash preheating, continuous flash, charged upsetting, pressure maintaining, clamp loosening, deburring, and the like. The process is characterized by comprising the controlled process parameters as follows: the overhanging length is 20-50mm; the flash allowance is 5-12mm; the upset allowance is 5-10mm; the upset force is (2-3)*105 N; the clamp force is (3-6)*105 N; the pulsed switch-on preheating process is (4-10) times*(0.5-1.2) s, (0.1- 0.2) s per pulse; the preheating and welding voltage is 10.8-14.6 V; the flash time is14-30s; and the upset charged time: 0.3-2s. The process disclosed by the invention has the advantages that the degree of automation is high; the process is suitable for welding steel rims (thickness: 3-8mm, width: 300-400mm) of heavy trucks, and after the welded steel rims are sequentially subjected to trimming, flaring, roll shaping and expanding, the welded joints have no crack defect.

Owner:SHOUGANG CORPORATION +1

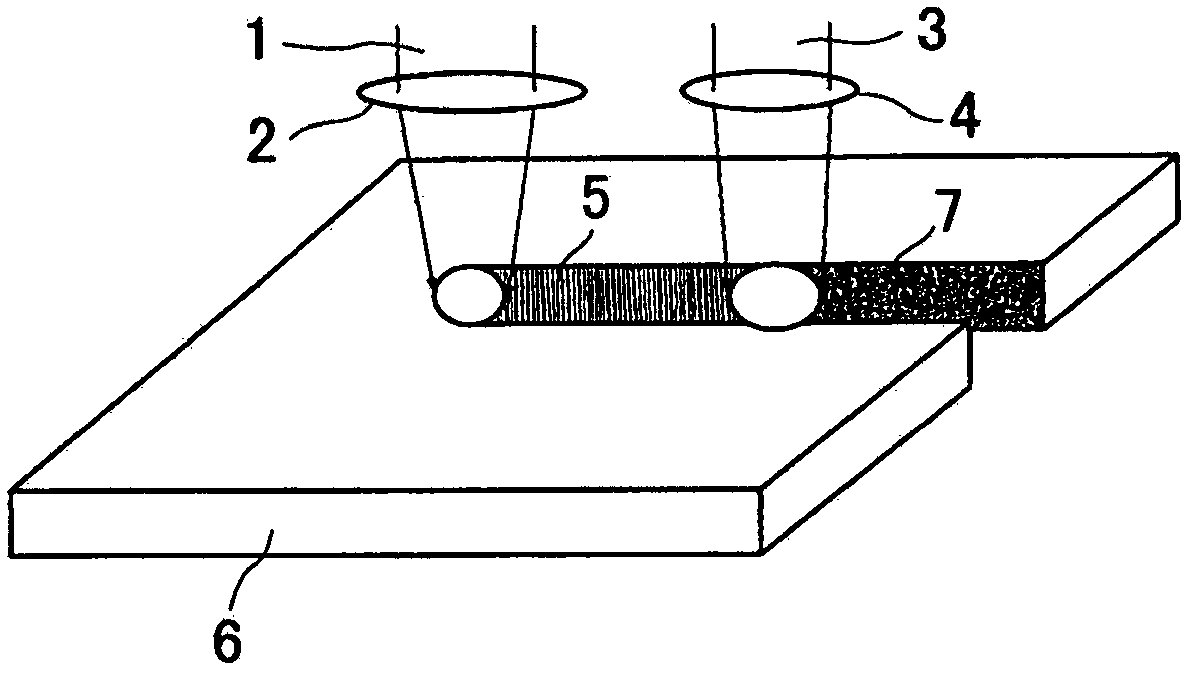

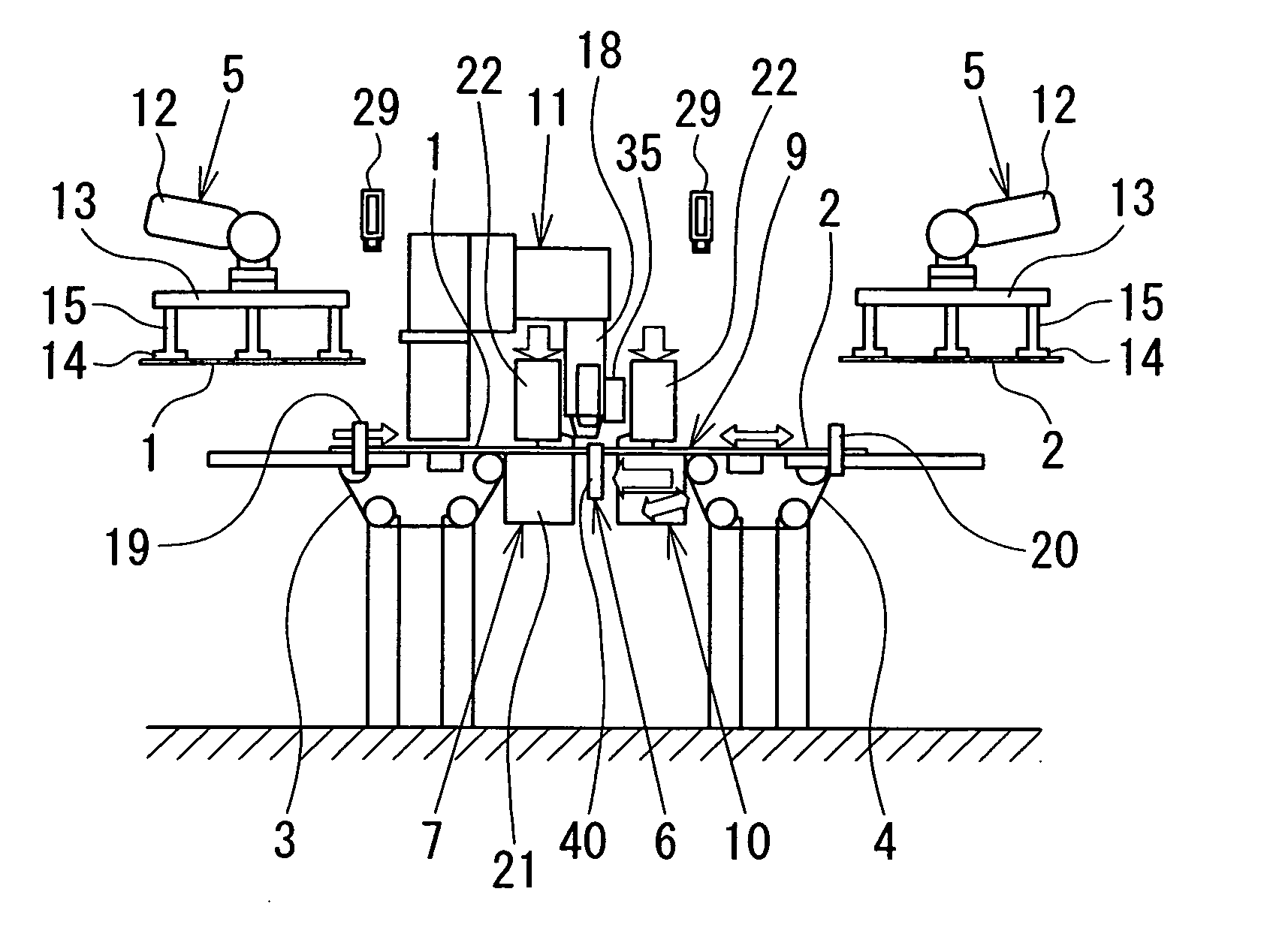

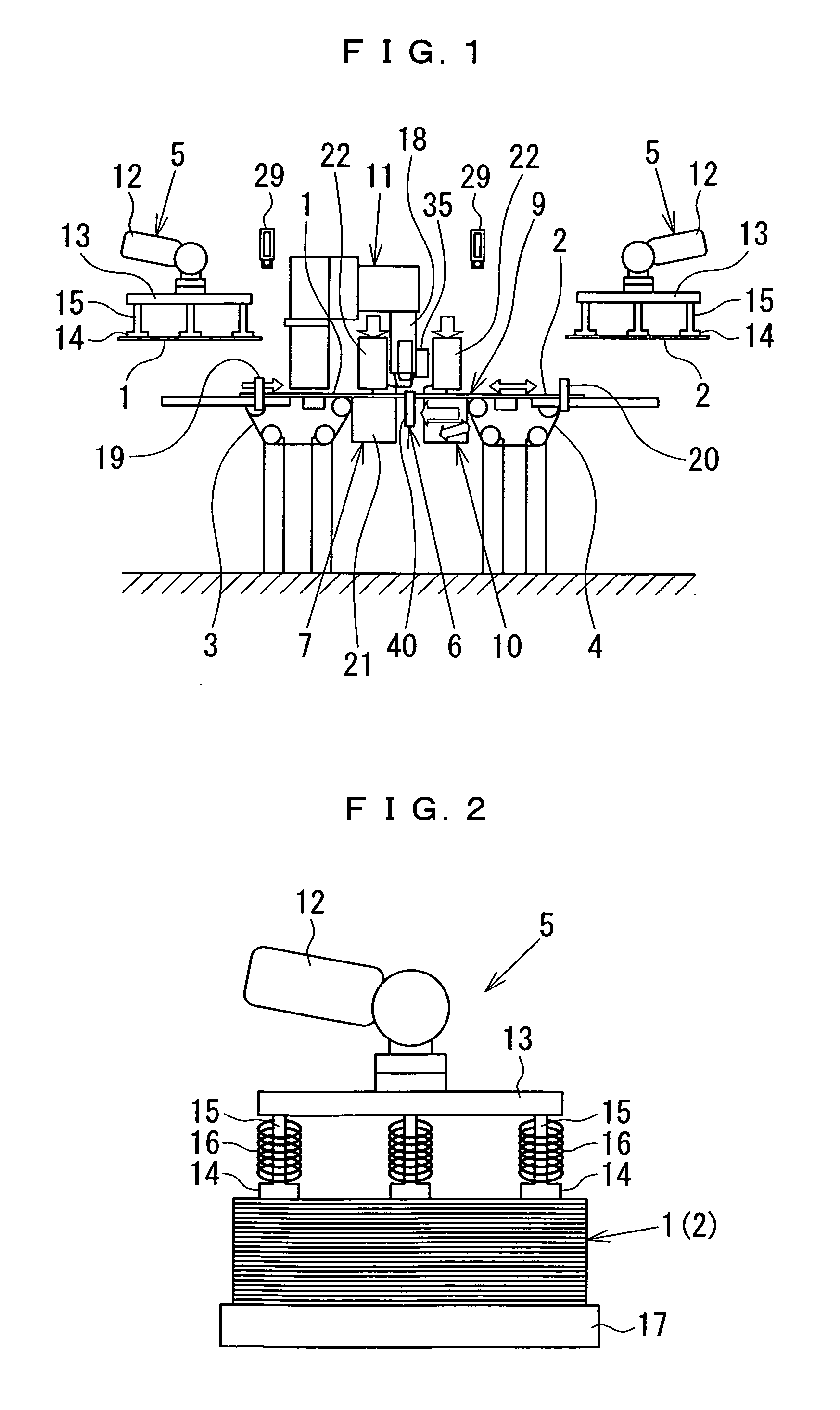

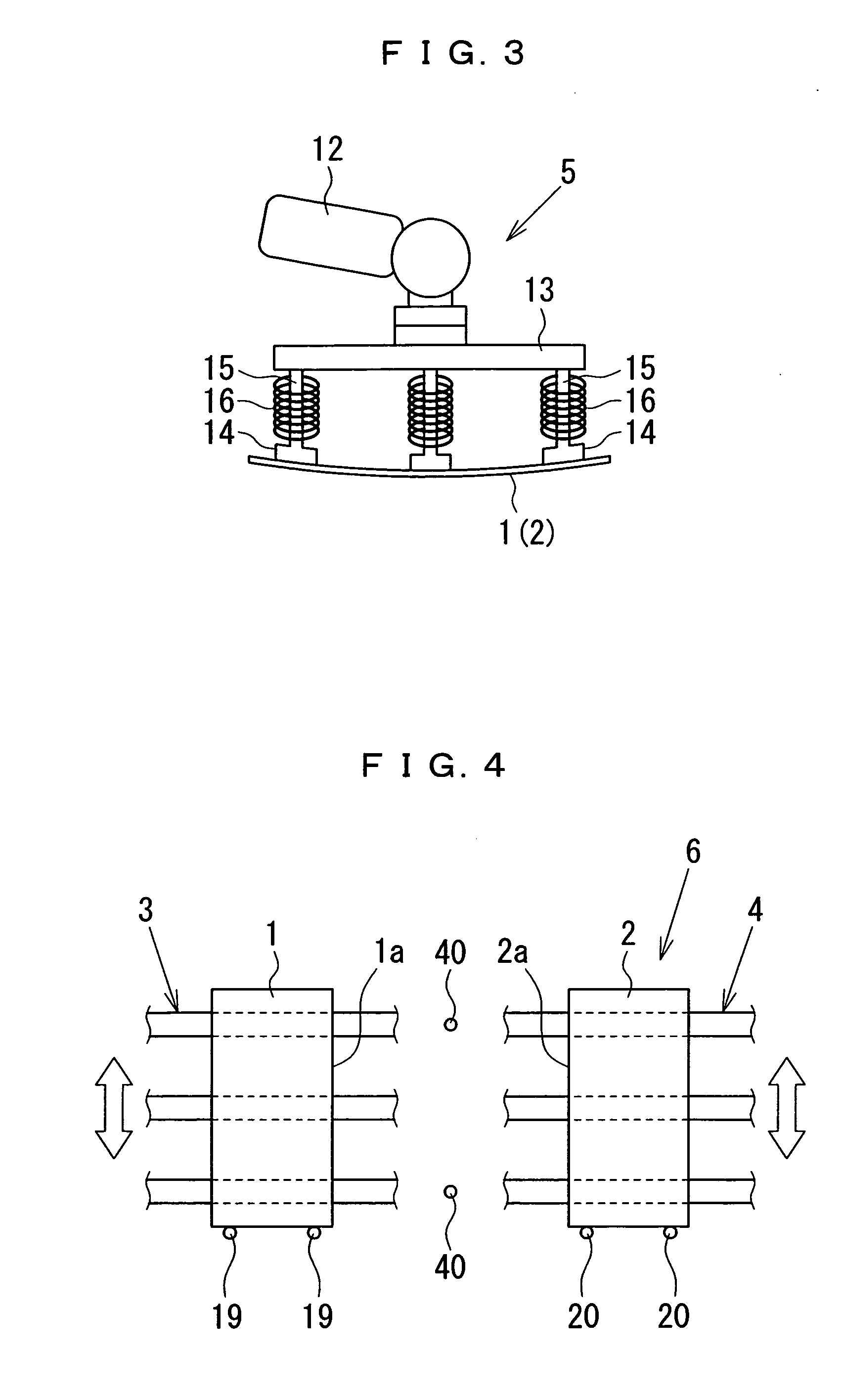

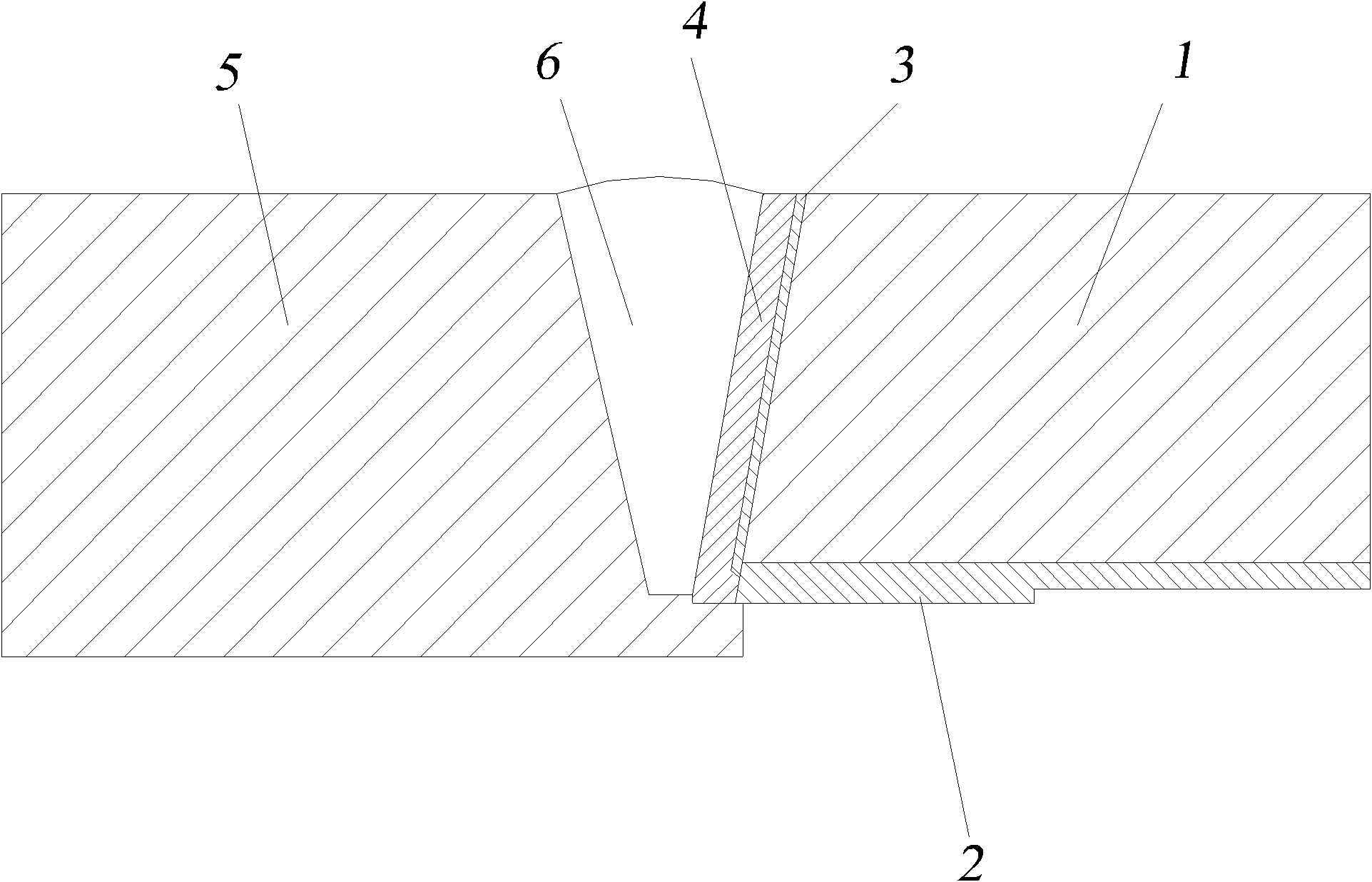

Butt Welding System of Steel Plate and Butt Welding Method of Steel Plate

InactiveUS20090159579A1Guarantee product qualityEnsure qualityWelding/cutting auxillary devicesAuxillary welding devicesButt weldingSheet steel

A butt welding system and a butt welding method of steel plate by which the quality of a product can be ensured. Butting portions of blank members (1,2) to be joined together are butted and a predetermined butting load is applied to the butting portion, wherein the blank members (1,2) are moved relatively in the direction of the welding line thus matching the butting portions. Protrusions and recesses formed on each butting portion of each blank member (1,2) are flattened, whereby linear precision at each butting portion of each blank member (1,2) is enhanced as compared with a case where the butting portions are not matched. Since the gap is reduced extremely at the butting portion, welding is facilitated at the butting portion. Good welding beads are thereby obtained at the butting portion and the quality of a product is ensured.

Owner:TOYOTA JIDOSHA KK

Nuclear island primary device connection tube safe end dissimilar metal welding technology

ActiveCN101890562AMake sure the welding is successfulTake over reliableArc welding apparatusButt weldingSurface layer

The invention relates to a nuclear island primary device connection tube safe end dissimilar metal welding technology which comprises the following steps: selection of form of a welding groove: selecting a single groove form as the groove form of a primary device connection tube; overlay welding of stainless steel: overlay-welding a stainless steel anti-corrosion layer on the inner wall of the primary device connection tube; overlay welding of isolating layer: overlay-welding an isolating layer on the end face of the primary device connection tube by carrying out TIG overlay welding with hot wire to obtain a transition layer and carrying out submerged arc overlay welding to obtain a surface layer; butt welding: butting the safe end with the surface layer at the end face of the primary device connection tube in a submerged arc welding mode; and postweld heat treatment. The invention reduces the welding cost and the labor intensity of welders, and ensures the successful welding of the safe end structure, thereby laying foundation for reliable welding of the safe end and the primary device connection tube.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

FSW (Friction-stir Welding) method assisted by heat source

InactiveCN104551379AFast welding speedSolve the longevity problemNon-electric welding apparatusFriction weldingButt welding

The invention discloses an FSW (Friction-stir Welding) method assisted by a heat source. The method comprises the following steps of: A, splicing and fixing to-be-welded materials, preheating to-be-welded regions by an auxiliary heat source until the welded materials are in a plasticized or alloyed state; and B, enabling the auxiliary heat source and a friction-stir head to be positioned on same pair of butt welding wires, and after the welded materials are heated to be in the plasticized state, enabling the friction-stir head to advance along the heating path of the auxiliary heat source so as to perform friction welding. The invention provides a composite welding method which is reasonable in cost, long in service life of stir head, capable of realizing high high-melting-point metal and dissimilar metal welding speed, and high in welding quality. According to the welding method, the service life problem of the stir head of high-melting-point metal FSW and the problem of dissimilar metal FSW welded seam alloying are successfully solved, the welding cost of the high-melting-point metal and the welding cost of the dissimilar metal are greatly lowered and the welding quality is improved.

Owner:董春林

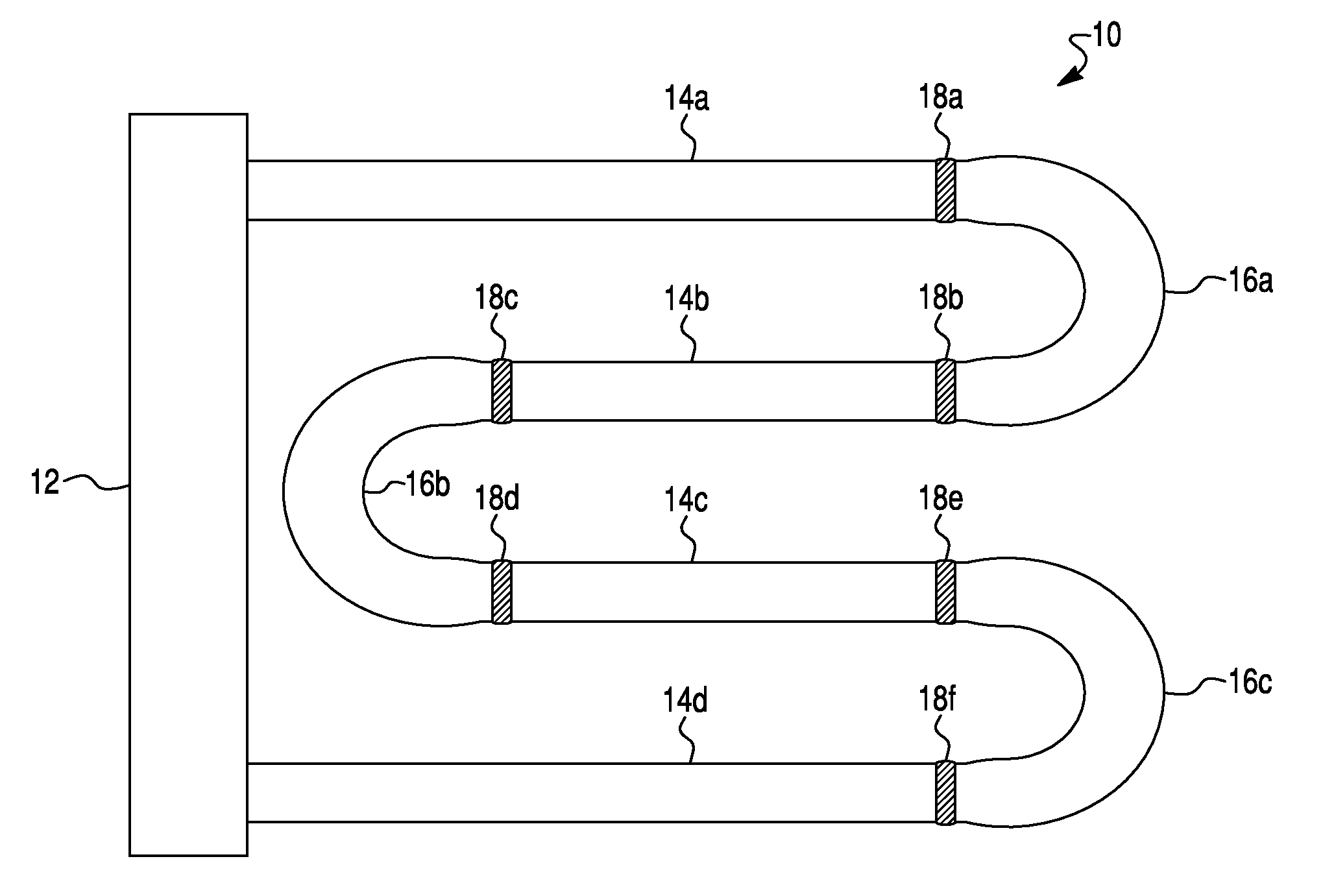

Nickel-base radiant tube and method for making the same

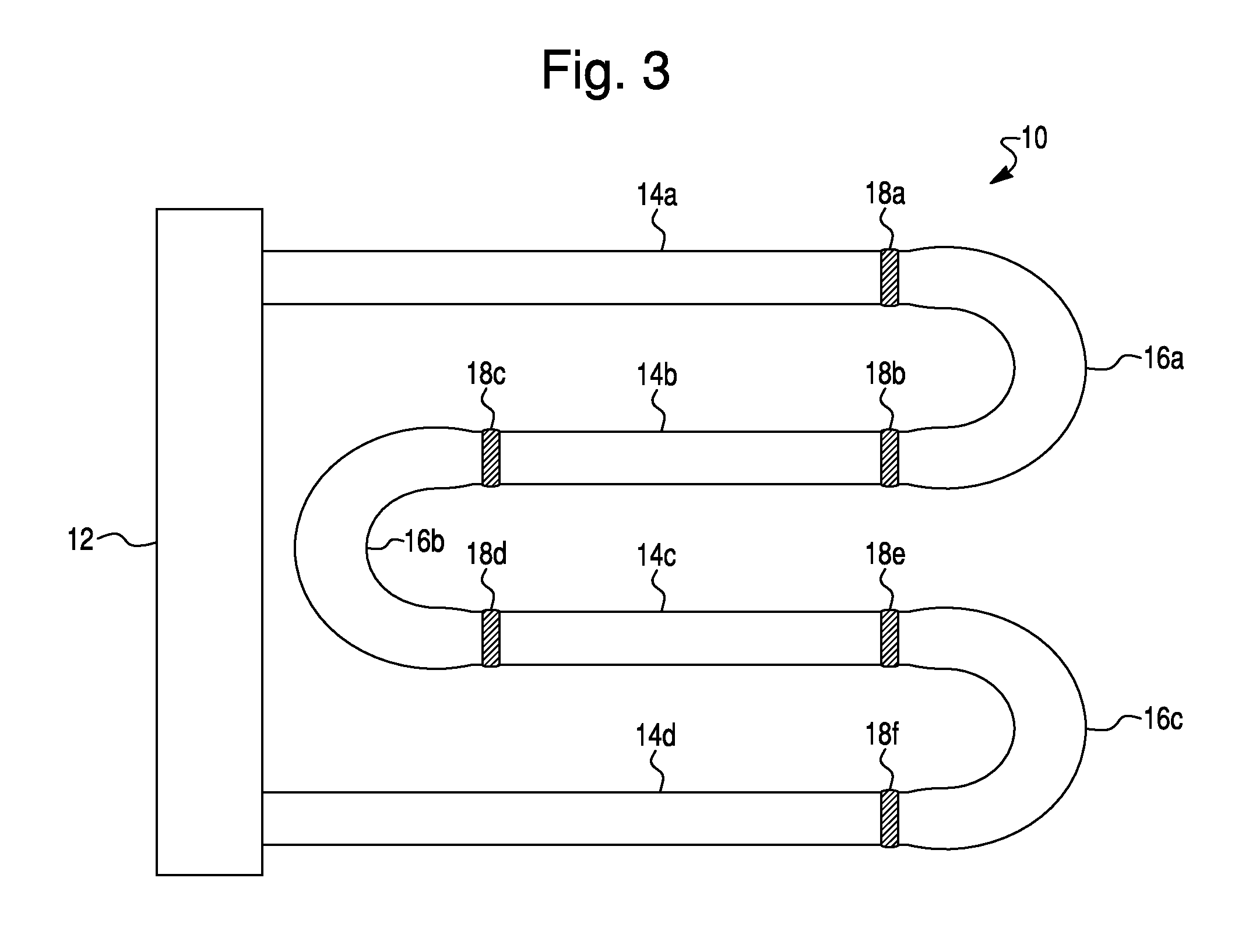

ActiveUS20110316271A1Reduce stress concentrationReduce the cost of the whole machineThermal non-catalytic crackingArc welding apparatusButt weldingStraight tube

Nickel-base radiant tube includes straight and curved elbow tube sections. The straight tube section has constant inner and outer radii. The elbow tube section has a constant inner radius and variable outer radius. The inner diameter of the elbow tube section is equal the inner radius of the straight tube section. Mating end portion of the elbow tube section has an outer radius equal to the outer radius of the straight tube section. Method for making the radiant tube comprises the steps of positioning a mating end portion of the straight tube section adjacent to and aligned with the mating end portion of the elbow tube section so that end faces of the straight and elbow tube sections face each other to define a circumferentially extending weld groove, and butt welding the mating end portions of the straight and elbow tube sections together at the weld groove.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com