Stainless steel or nickel sheet laser tailor-welding alignment clamping device and method

A technology of laser tailor welding and clamping device, which is applied to laser welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of easy deformation of thin plates by heat, deformation of thin plate welding parts by heat, complicated image processing process, etc., and achieve clamping pressure. Uniform and reliable, improving quality and yield, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

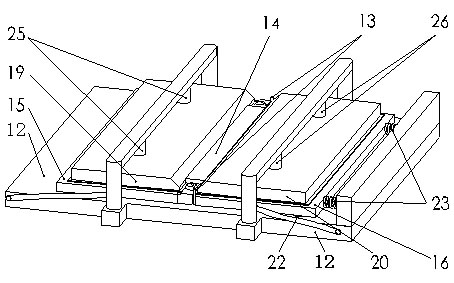

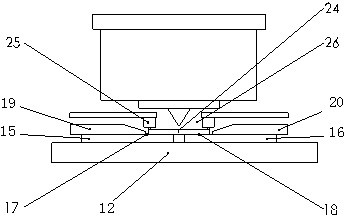

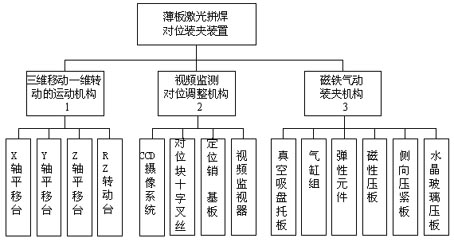

[0042] A counterpoint clamping device for laser tailor welding of stainless steel or nickel thin plates, consisting of figure 1 , figure 2 , Figure 4 , Figure 5 As shown, it includes a laser head 8, an XYZ three-dimensional translation RZ one-dimensional rotary motion mechanism 1, a video monitoring alignment adjustment mechanism 2 and a magnet pneumatic clamping mechanism 3. The XYZ three-dimensional translation RZ one-dimensional rotary motion mechanism 1 includes an X-axis Horizontal translation table 4, Y-axis horizontal translation table 5, Z-axis vertical translation table 6 and RZ rotary table 7 rotating around the Z-axis, the X-axis motion direction is the splicing direction of the first thin plate 17 and the second thin plate 18, Y The axis is perpendicular to the X axis, and the laser head 8 is connected to the Z vertical translation platform 6. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com