Nuclear island primary device connection tube safe end dissimilar metal welding technology

A technology for dissimilar metals and welding processes, which is applied in the field of dissimilar metals welding process for the main equipment of nuclear island to take over the safety end, can solve the problems of easy occurrence of pores, high cost, and lack of fusion, so as to ensure successful welding, reduce welding costs, and ensure reliable welding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

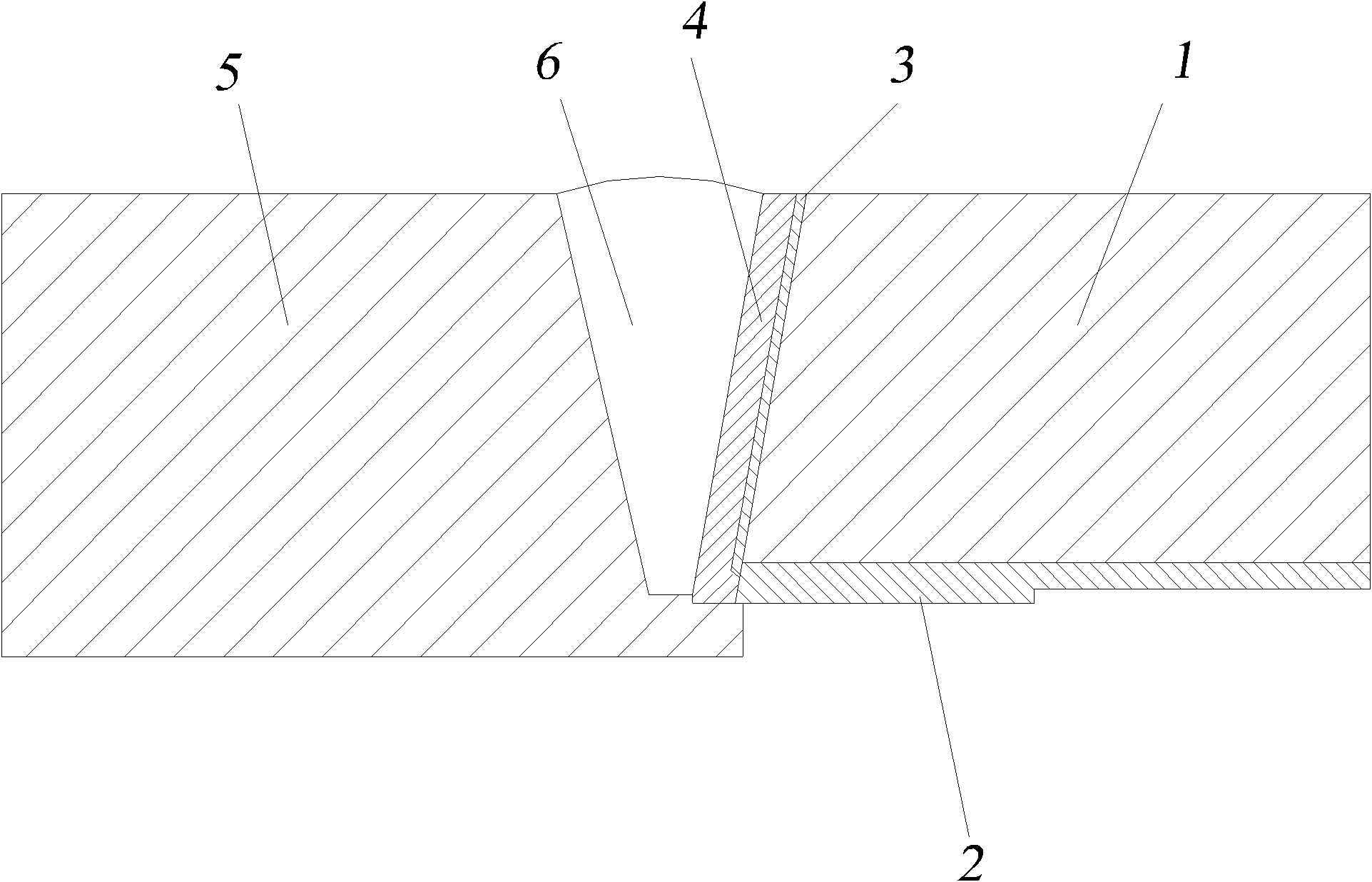

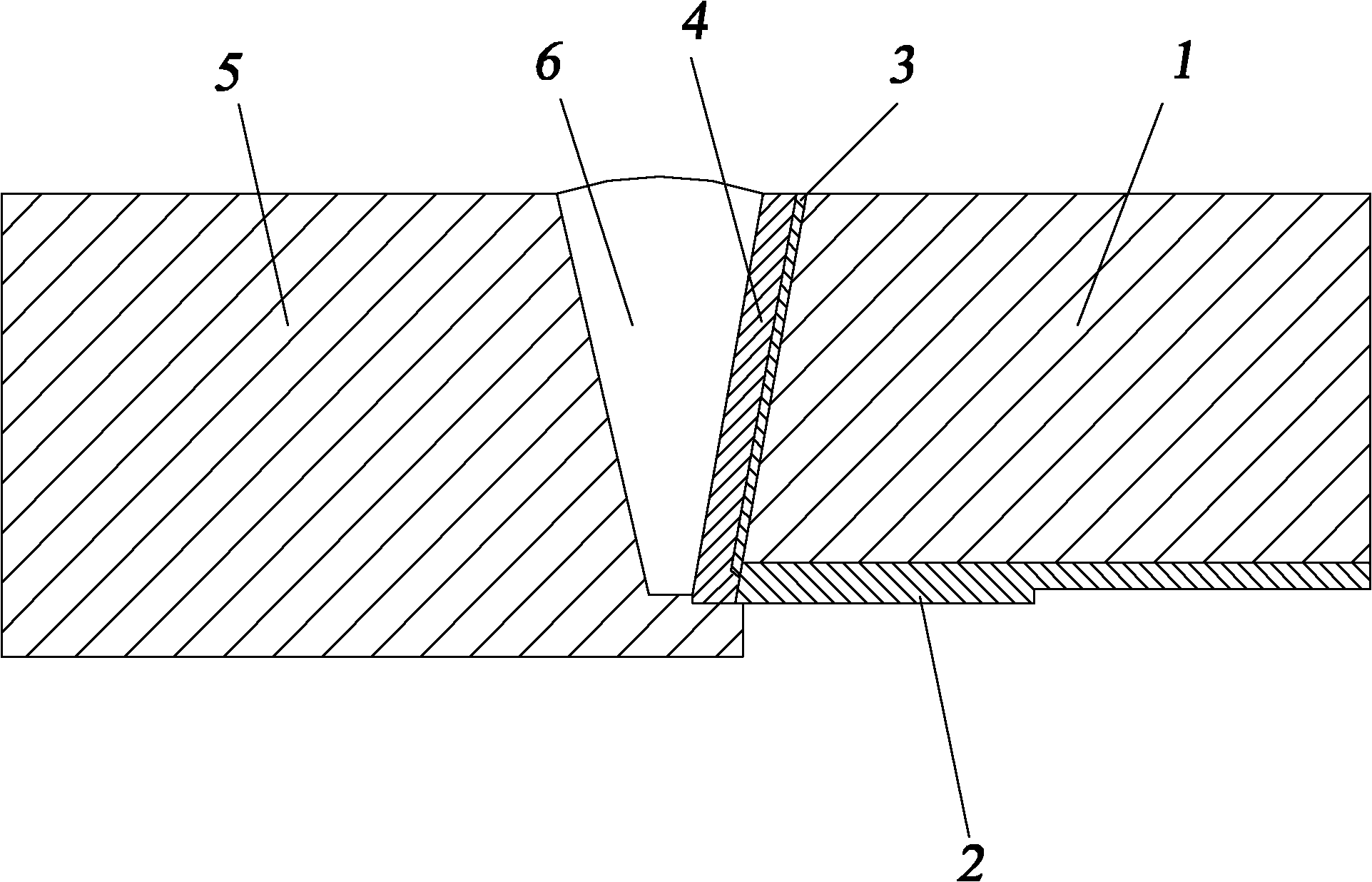

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] see figure 1 , the present invention, that is, a nuclear island main equipment to take over the safety end dissimilar metal welding process, it includes the following steps:

[0018] In the step of selecting the welding groove form, select the groove form of the main equipment connection 1 as a single-sided groove form, and the material of the main equipment connection 1 is 16MND5 low-alloy steel;

[0019] In the stainless steel surfacing step, the stainless steel corrosion-resistant layer 2 is surfacing on the inner wall of the main equipment connecting pipe 1; specifically, before performing the surfacing stainless steel step, it is necessary to clean up the oil, rust oxides, etc. on the inner wall of the main equipment connecting pipe 1 that affect welding quality dirt, and preheated to above 100°C, and then use stainless steel with a width of 25-40mm and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com