A double-spoke turbine disk pressure welding method

A technology of pressure welding and turbine discs, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of difficult welding process, inability to reprocess, and deformation of parts, etc., and achieve a simple structure and easy realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

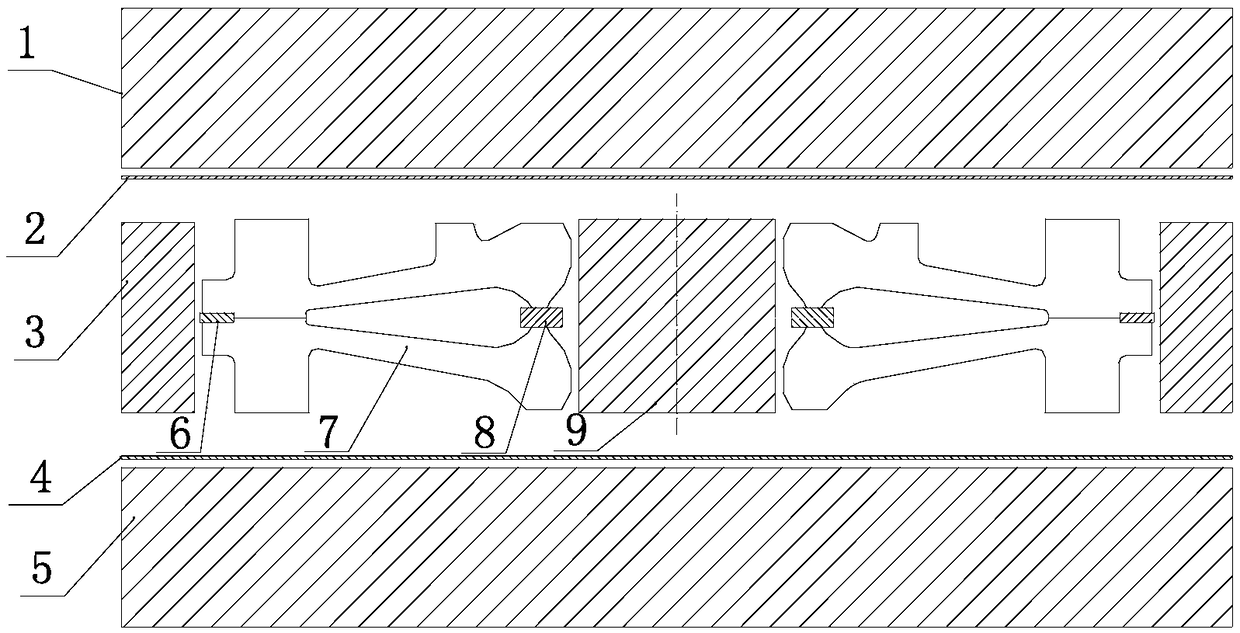

[0022] Concrete a kind of pressure welding method of double spoke plate turbine disc, such as figure 1 As shown, in the method, a graphite indenter 1, an upper backing plate 2, a graphite bearing column 3, a lower backing plate 4, a plurality of graphite bases 5, a graphite bearing block and a double-spoke turbine disc blank 7 are used;

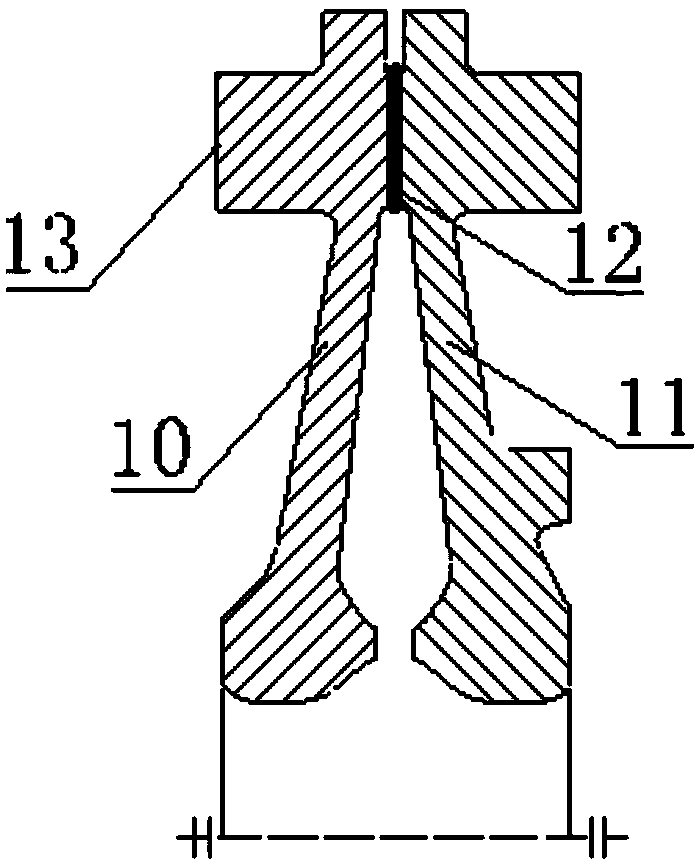

[0023] The structure of the double-spoke turbine disk blank 7 is as follows: figure 2 As shown, the double-spoke turbine disk blank is two vertically symmetrical blank disks; both blank disks include an annular welding part 12, a pressure application part 13 and non-welding easy-to-deform parts 10, 11;

[0024] Described method comprises the steps:

[0025] Step 1. Place the graphite base 5, a plurality of graphite bearing columns 3 and the lower backing plate 4 in a pressure welding furnace, so that the lower backing plate 4 is covered on the graphite base, and the plurality of graphite bearing columns 3 are placed on the lower backing On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com