Plain butt welding process for high-strength hull structural steel

A technology of structural steel and welding technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of imperfect welding standards of high-strength steel, insufficient welding technology, and immature application, so as to reduce the ship construction cycle , Saving raw materials and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Using carbon dioxide gas shielded welding:

[0044] 1. The welding materials are as follows: welding wire GFR-110K3 (E761T1-K3C) Φ1.2mm, carbon dioxide gas purity ≥ 99.5%.

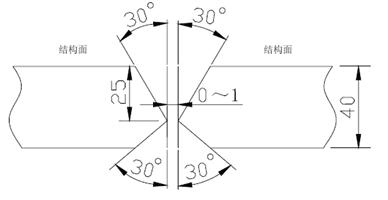

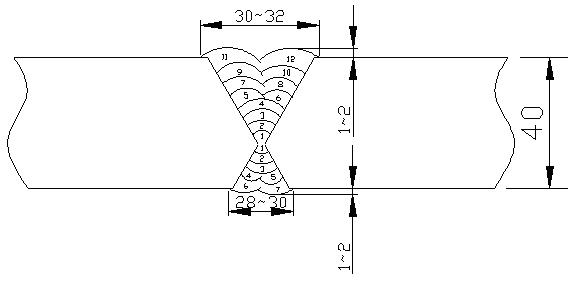

[0045] 2. Welding sequence and groove size such as figure 2 shown.

[0046] 3. The welding specification parameters are shown in the following table 1:

[0047] Table 1 Carbon dioxide gas shielded welding

[0048]

Embodiment 2

[0050] Welding with manual arc welding:

[0051] 1. The welding materials are as follows: electrode CHE807RH (E8015-G) Φ4mm.

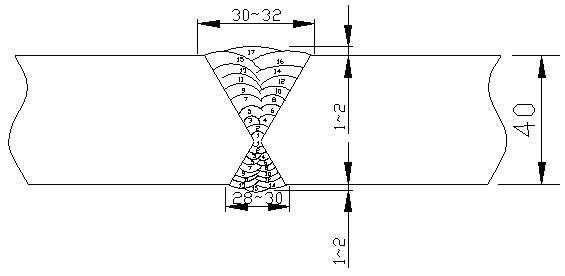

[0052] 2. Welding sequence and groove size such as image 3 shown.

[0053] 3. The welding specification parameters are shown in the following table 2:

[0054] Table 2 arc manual welding

[0055]

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com