Manufacture method for double-curve H-shaped steel

A manufacturing method and H-beam technology, which are applied in the production field of hyperboloid H-beam, can solve the problems of long cycle and high cost, and achieve the effects of simple equipment, cost saving, and improvement of manufacturing efficiency and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

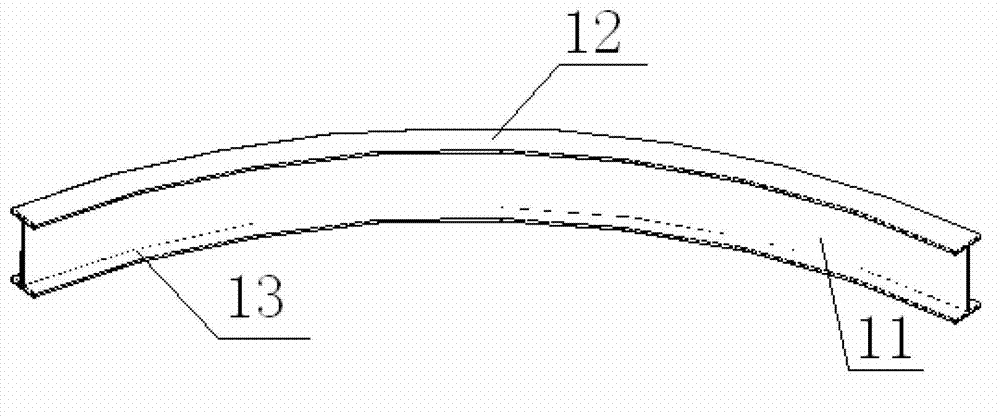

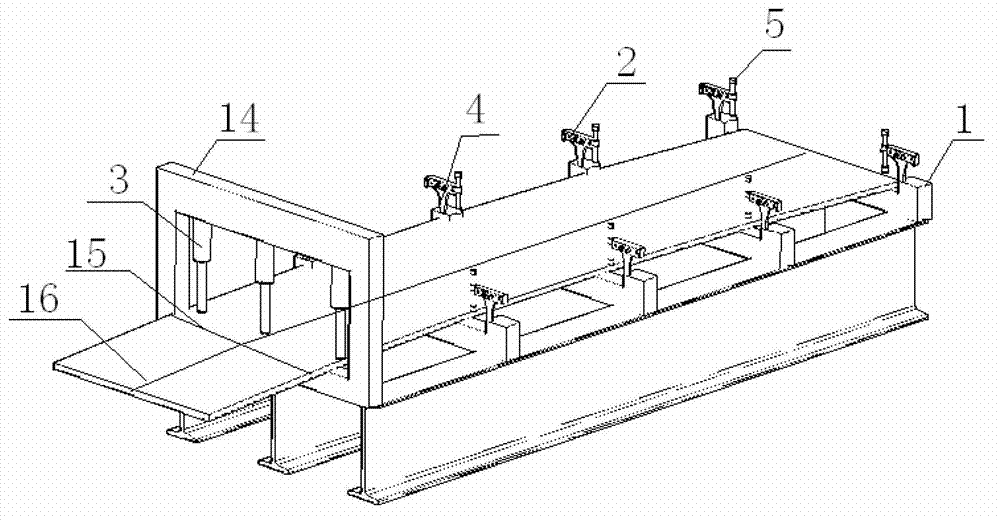

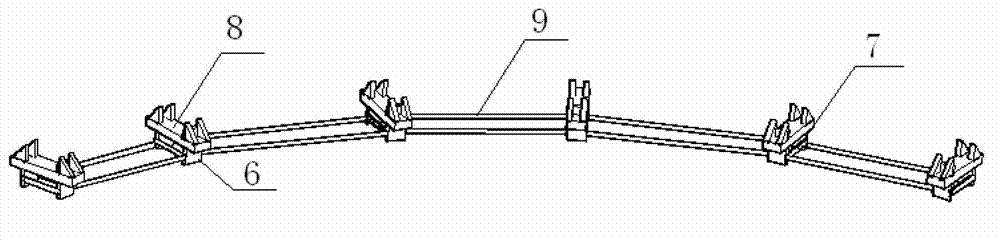

[0016] A method for making a hyperboloid H-shaped steel in this embodiment includes the following steps: 1) re-inspection of incoming materials for the horizontal plate, flat plate of the horizontal plate, and pretreatment; wired type, such as figure 1 as shown, figure 1 The middle web 11, the upper flange plate 12, and the lower flange plate 13; most of the straight H-shaped steels usually produced are assembled by the assembly machine, but this kind of H-shaped steel cannot be assembled on the assembly machine due to the complex and changeable line shape. Finish. 2) In order to ensure the manufacturing accuracy of hyperboloid H-shaped steel, computer CAD three-dimensional lofting is adopted to establish a three-dimensional coordinate system, and the web 11 and flange plates (upper flange plate 12 and lower flange plate 13) of the curved H-shaped steel are planar Expand; 3) Cut and blank the expanded flange plate (upper flange plate 12, lower flange plate 13) and web 11 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com