Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1087 results about "Material quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material quality definition, material quality meaning | English dictionary. material. 4 a person who has qualities suitable for a given occupation, training, etc.

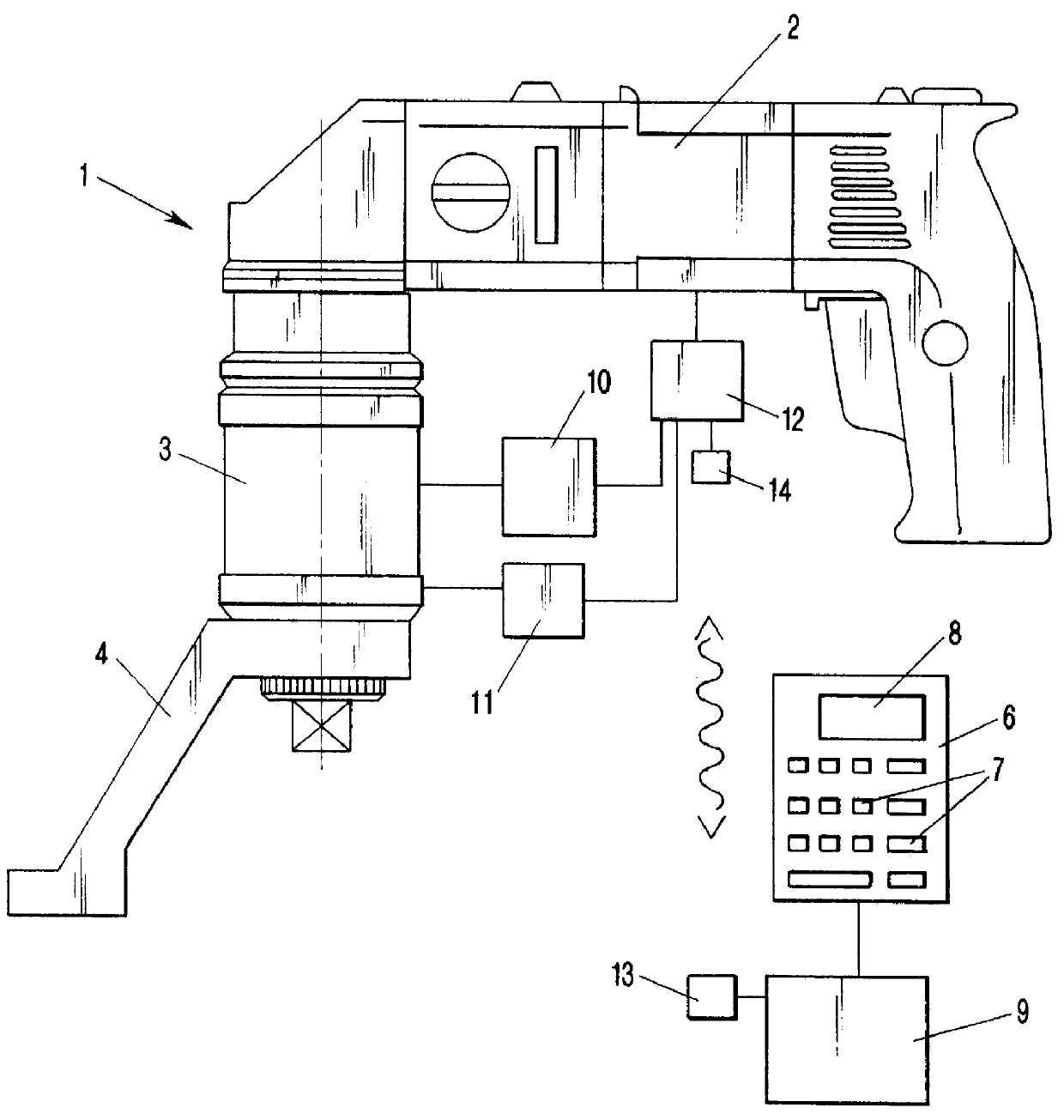

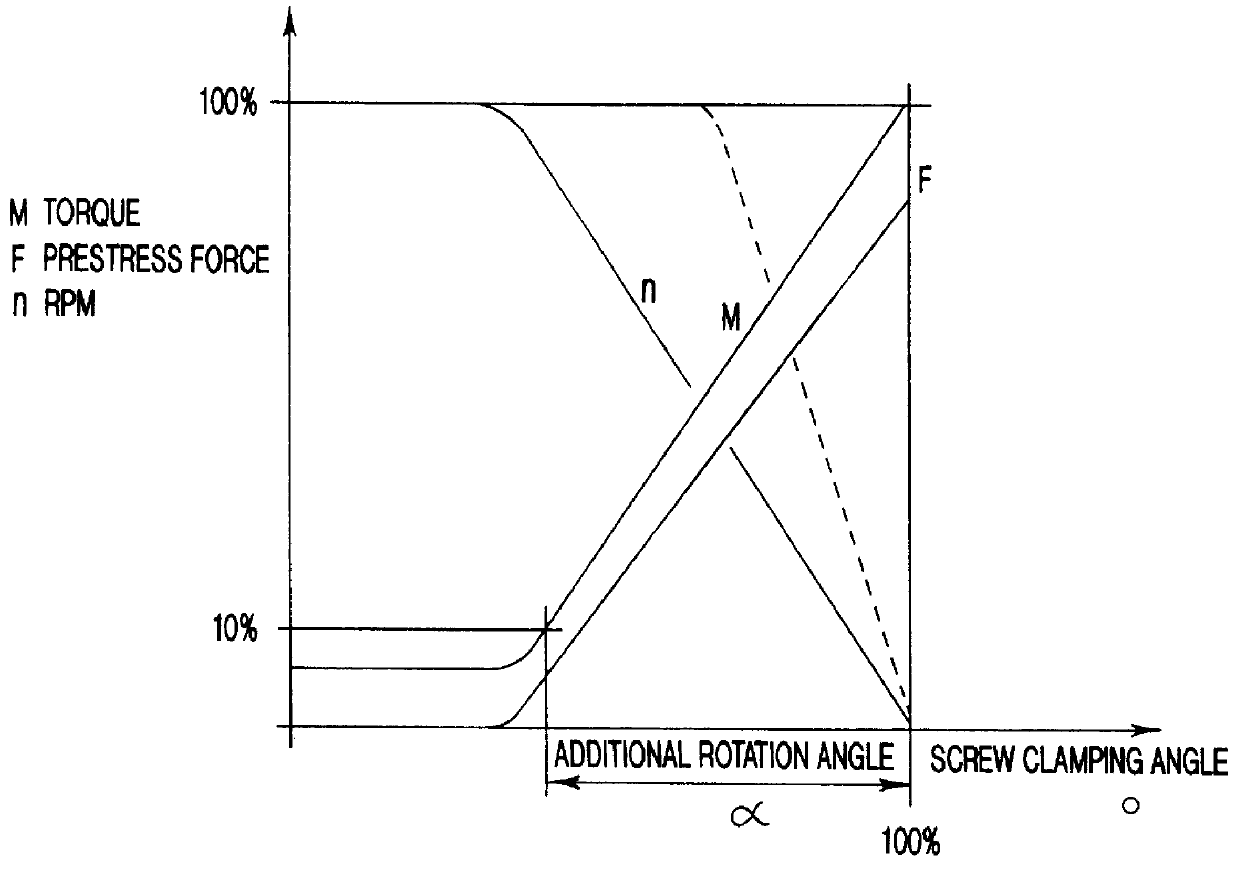

Power wrench

PCT No. PCT / EP97 / 05974 Sec. 371 Date Jul. 16, 1999 Sec. 102(e) Date Jul. 16, 1999 PCT Filed Oct. 29, 1997 PCT Pub. No. WO98 / 22263 PCT Pub. Date May 28, 1998A power screwdriver has a drive unit and an input circuit for inputting screw size, material quality, pitch, and clamping length of a screw. An evaluation circuit is provided for determining a nominal prestress force based on input screw size, material quality, and clamping length, for determining a nominal torque based on the nominal prestress force and the pitch, and for determining the screw clamping angle resulting from the nominal prestress force and the pitch. A sensing device for sensing the actual torque is provided, and a further sensing device for sensing the actual screw clamping angle is present. A control and switch-off device controls further rotation of the drive unit when the actual torque coincides with the nominal torque and switches off the drive unit when the actual screw clamping angle coincides with the nominal screw clamping angle. The nominal torque, based on which the additional rotation o f the drive unit is controlled until the nominal screw clamping angle is reached, is set to a value which is smaller than the torque corresponding to the nominal pretension force. An additional rotation angle of the drive unit, for reaching the nominal screw clamping angle corresponding to the nominal prestress force, is determined based on the difference between the nominal screw clamping angle and the adjusted screw clamping angle corresponding to the preset nominal torque and is used for switching off the drive unit.

Owner:HOHMANN JORG +1

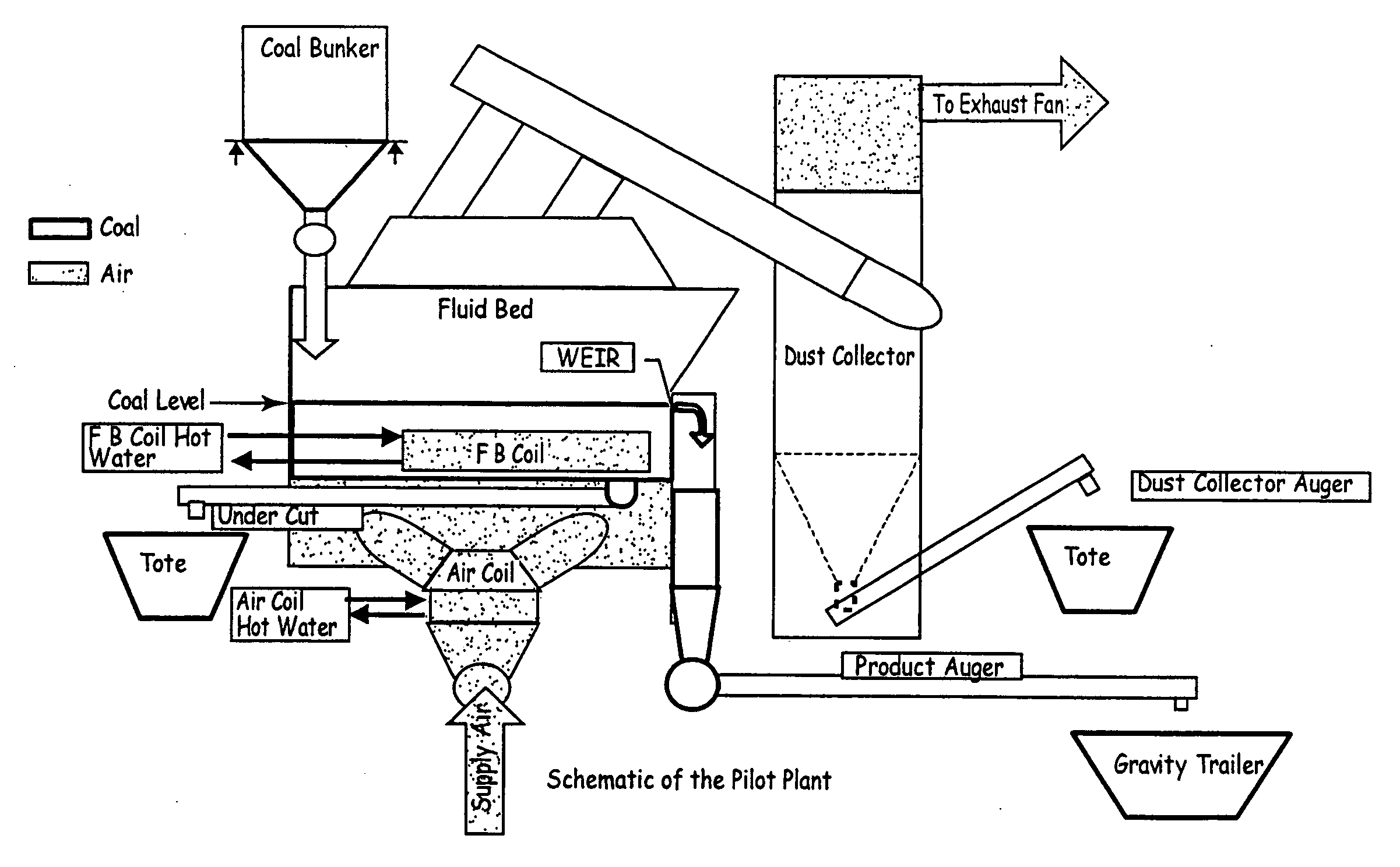

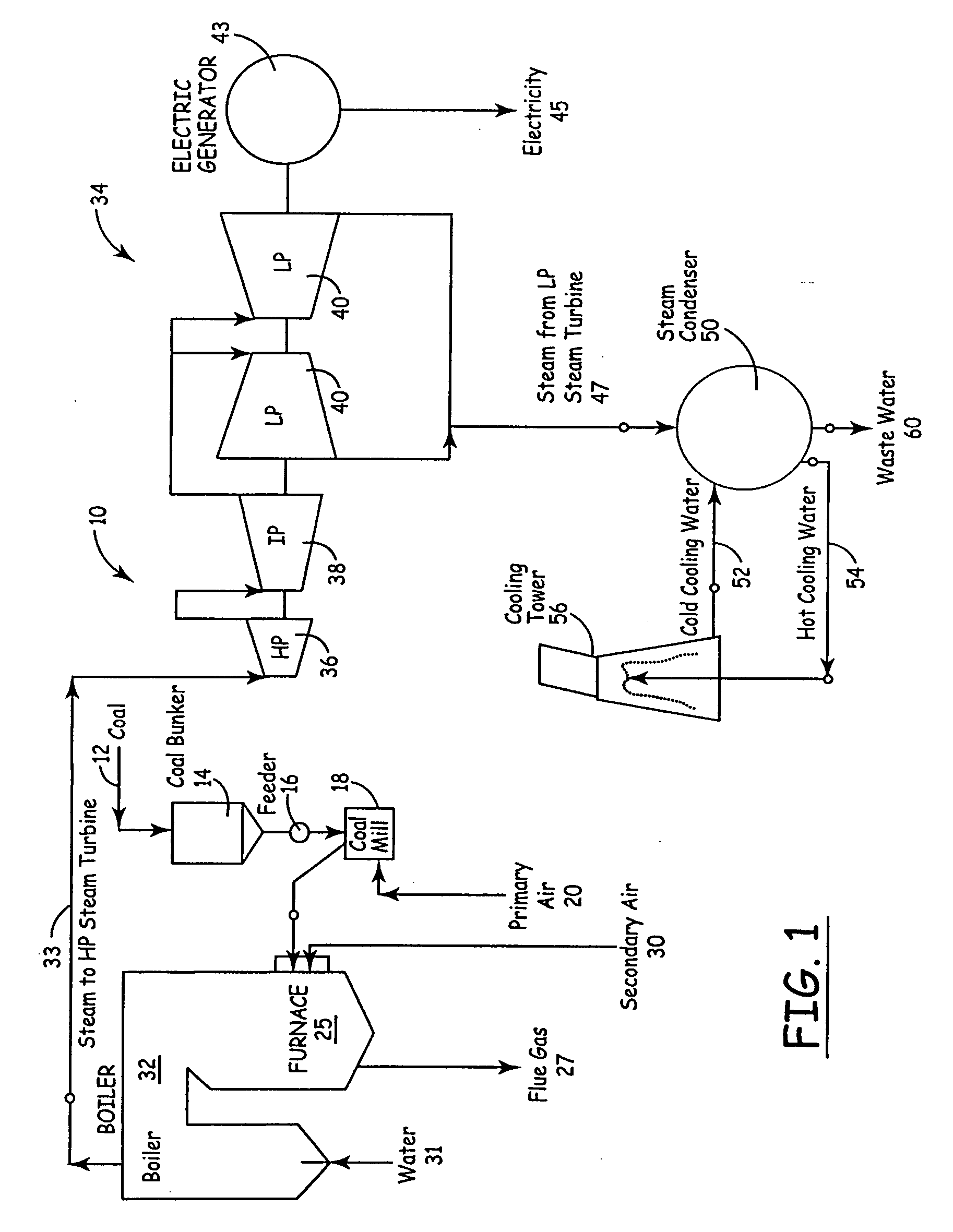

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

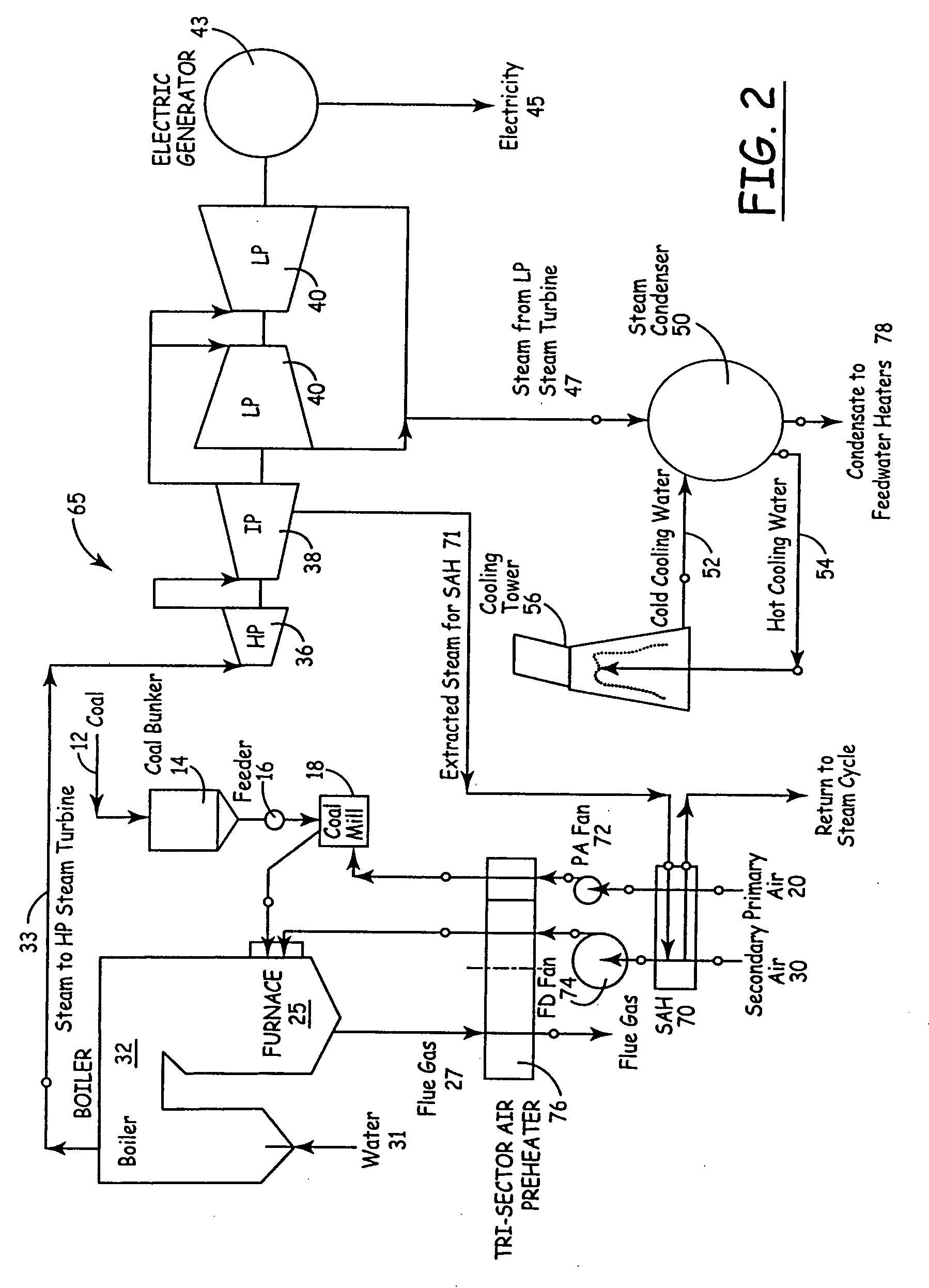

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

Quality controlled artificial eyelashes extension system

InactiveUS20070050207A1Reduce needFun and safeHair accessoriesData processing applicationsHuman useArtificial lashes

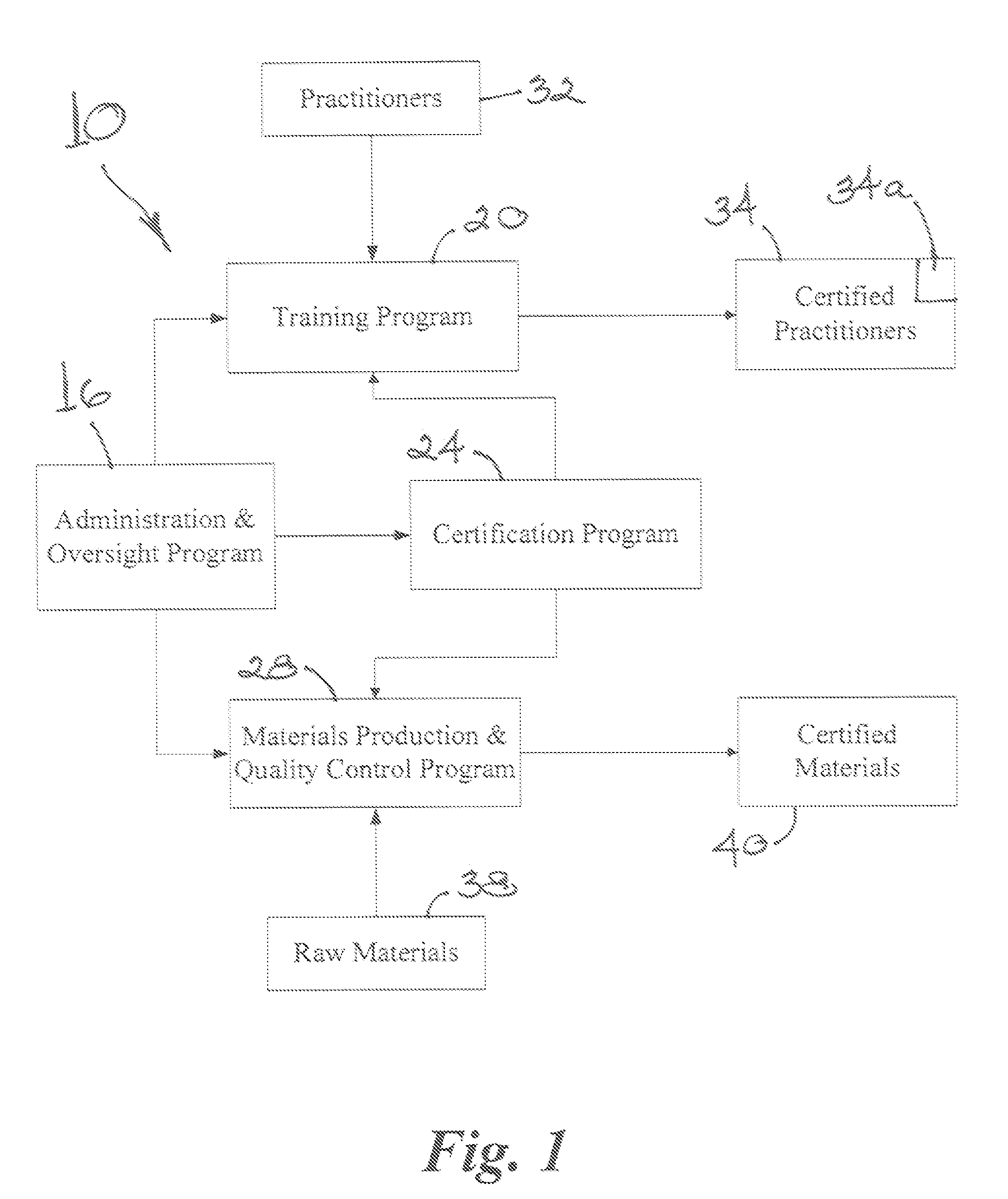

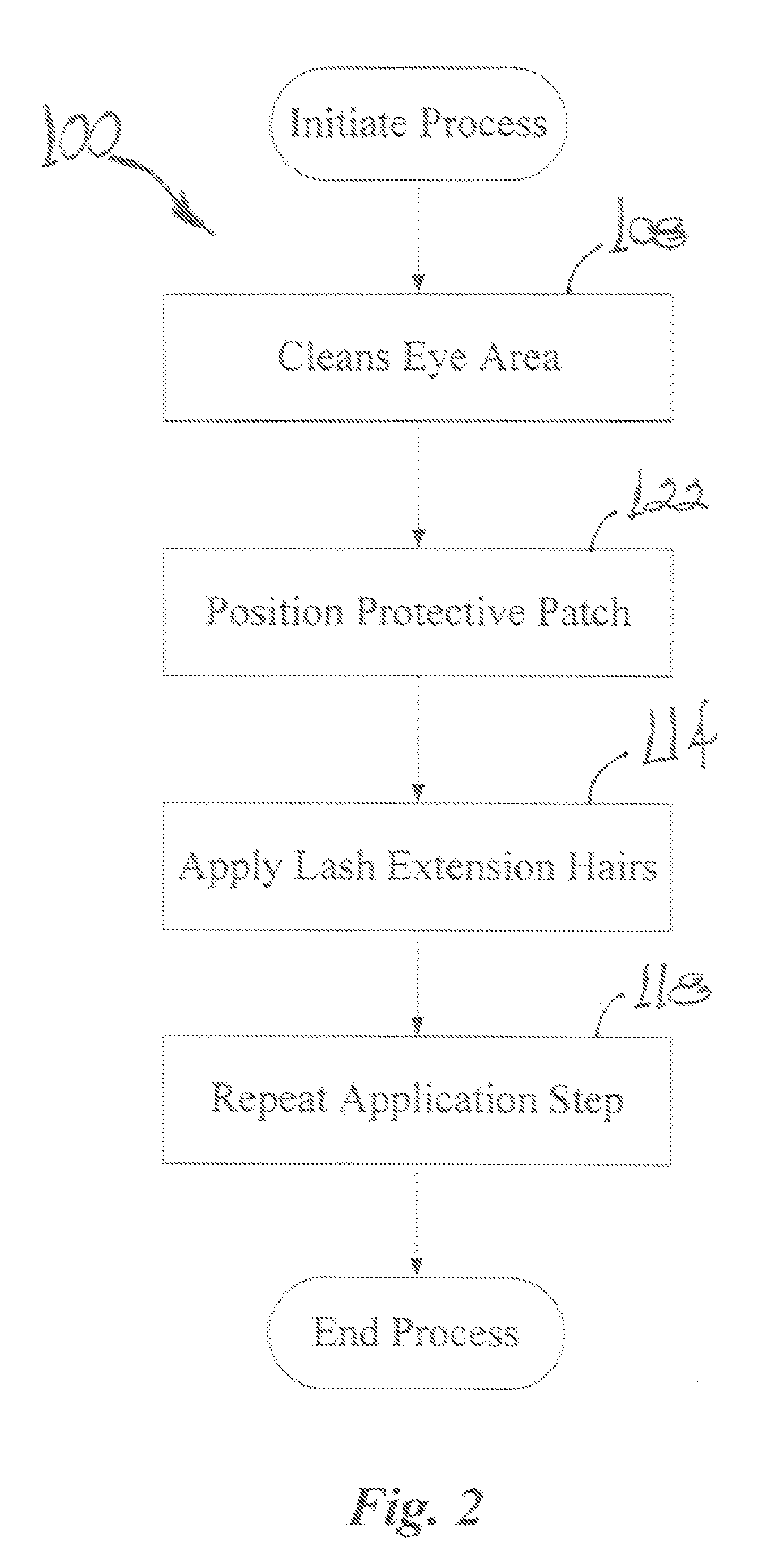

The present invention is a quality controlled artificial eyelashes extension system having two main features. One of the method and materials for the application of artificial lash hairs onto existing natural eyelashes of a human subject to extend the length of the natural eyelash. This feature provides the training and materials to attach the eyelash extensions on a hair-by hair basis to a subject's existing natural eyelash. The second is the quality control feature of the present lash extension system which provides for assuring that practitioners of the system are appropriately trained, and the consumable materials utilized by the system are safe for human use. Quality control assurance of practitioners and consumable materials is accomplished by having programs for practitioner training and certification, and for materials quality assurance which controls the quality of the system's consumable materials made available to practitioners.

Owner:NOVALASH

Rendering engine, implementation method and producing tools for 3D web game

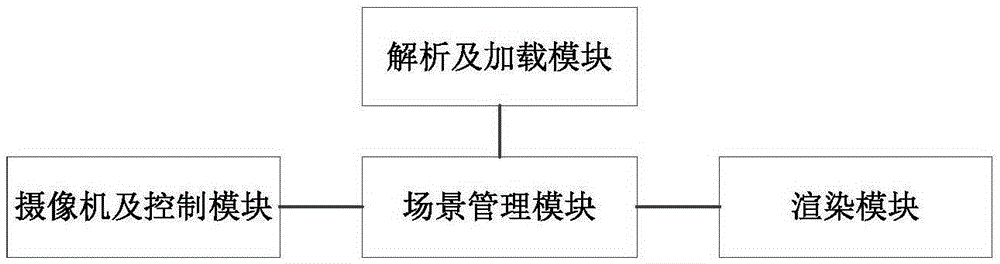

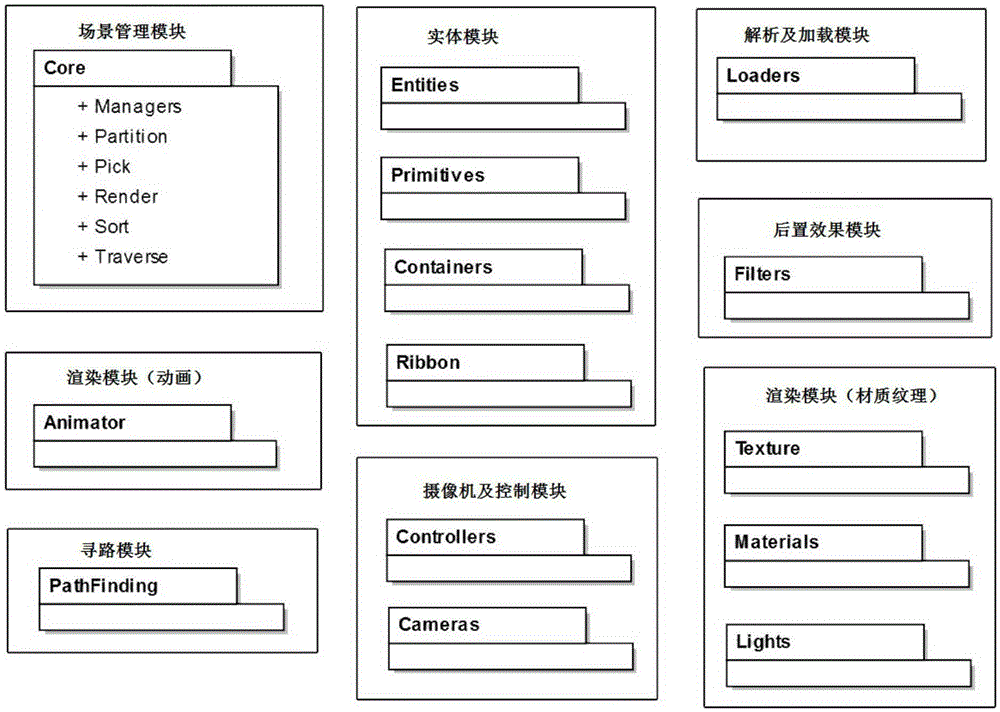

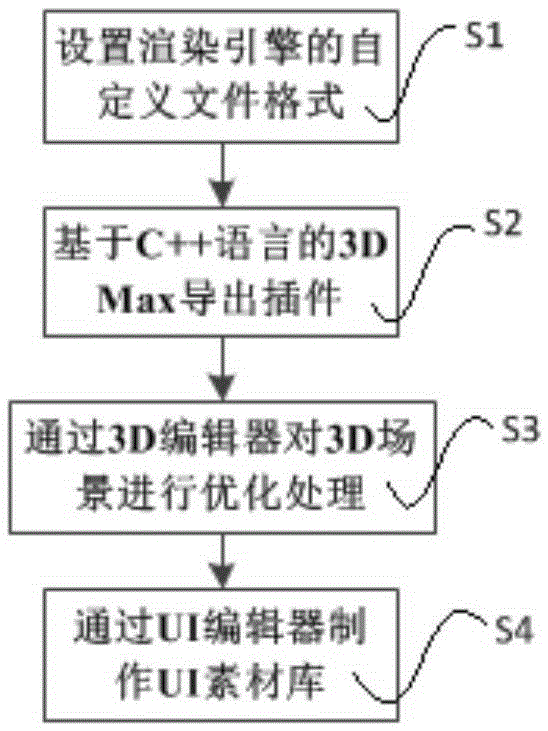

ActiveCN105354872AShorten the development cycleImprove good performanceAnimationViewing frustumParsing

The present invention provides a rendering engine, an implementation method and producing tools for a 3D web game. The rendering engine comprises: a parsing and loading module, which is used for reading, decompressing, and parsing a self-defined file format that is finally output by a workflow, to obtain information required by specific rendering, so as to implement non-blocked parsing; a scene management module, which is used for implementing view frustum culling, traversing and classifying objects in a scene, dispatching pickup and mouse events, and managing a rendering process; a camera and control module, which is used for scene roaming and camera animation; and a rendering module, which is used for rendering all information required by an object, which comprises renderings for geometry, material quality, animation and a transformation matrix. The producing tools comprise an export plug-in, a self-defined file format, a 3D editor, a special effect producing tool and a UI producing tool. The rendering engine, implementation method and producing tools provided by the present invention have good cross-platform performance and scalability, and can greatly shorten a game development period and lower a development threshold.

Owner:深圳墨麟科技股份有限公司

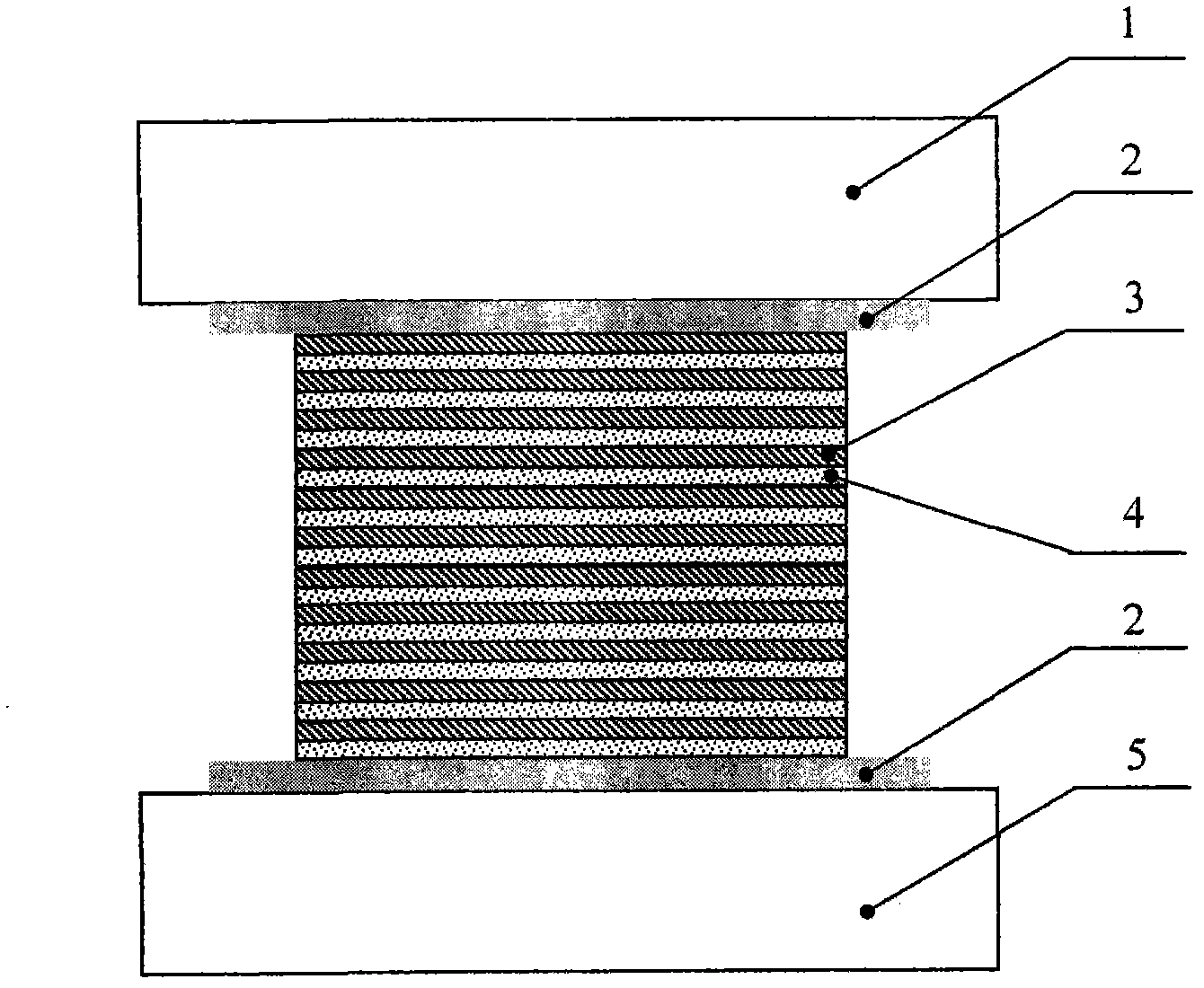

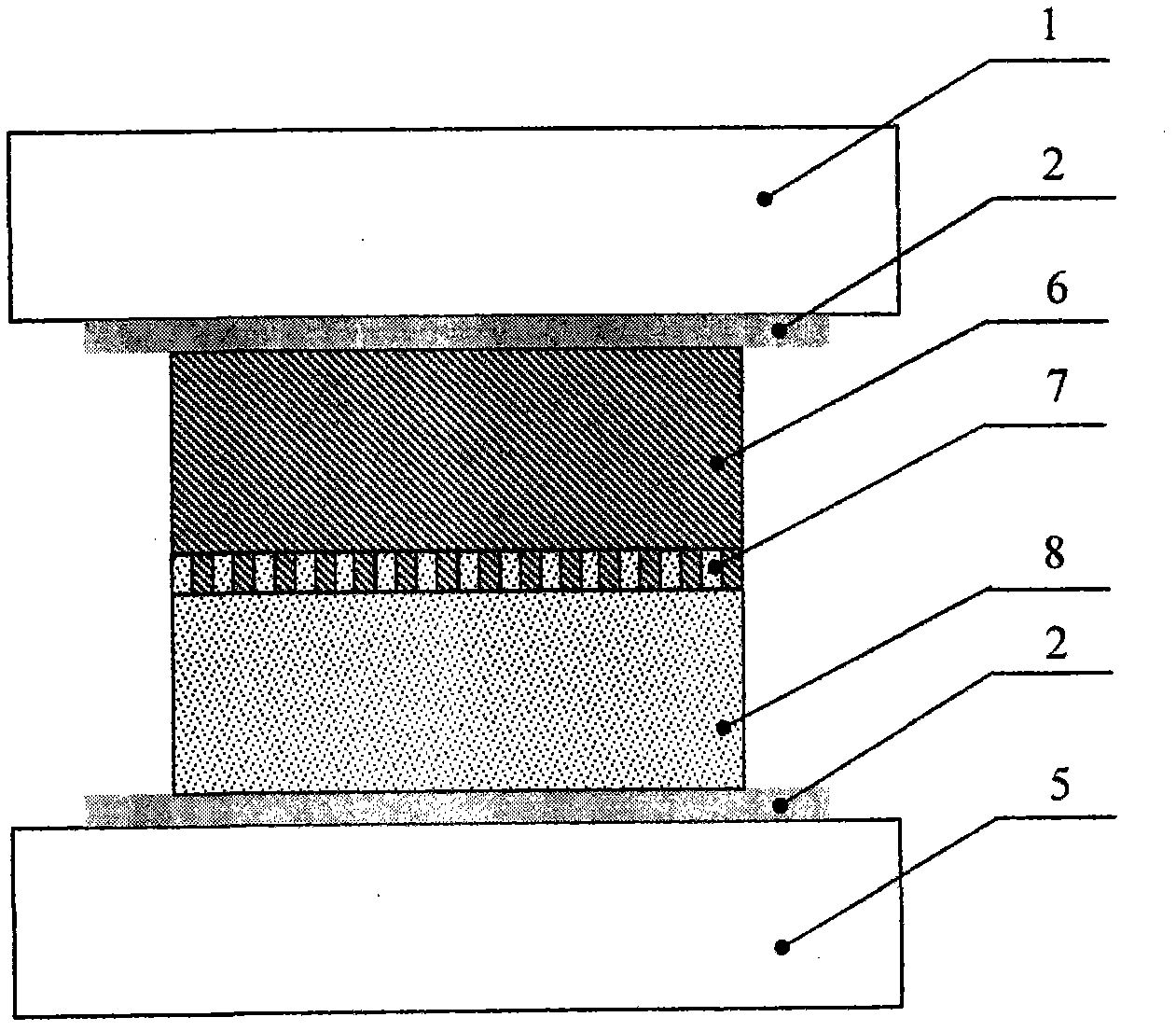

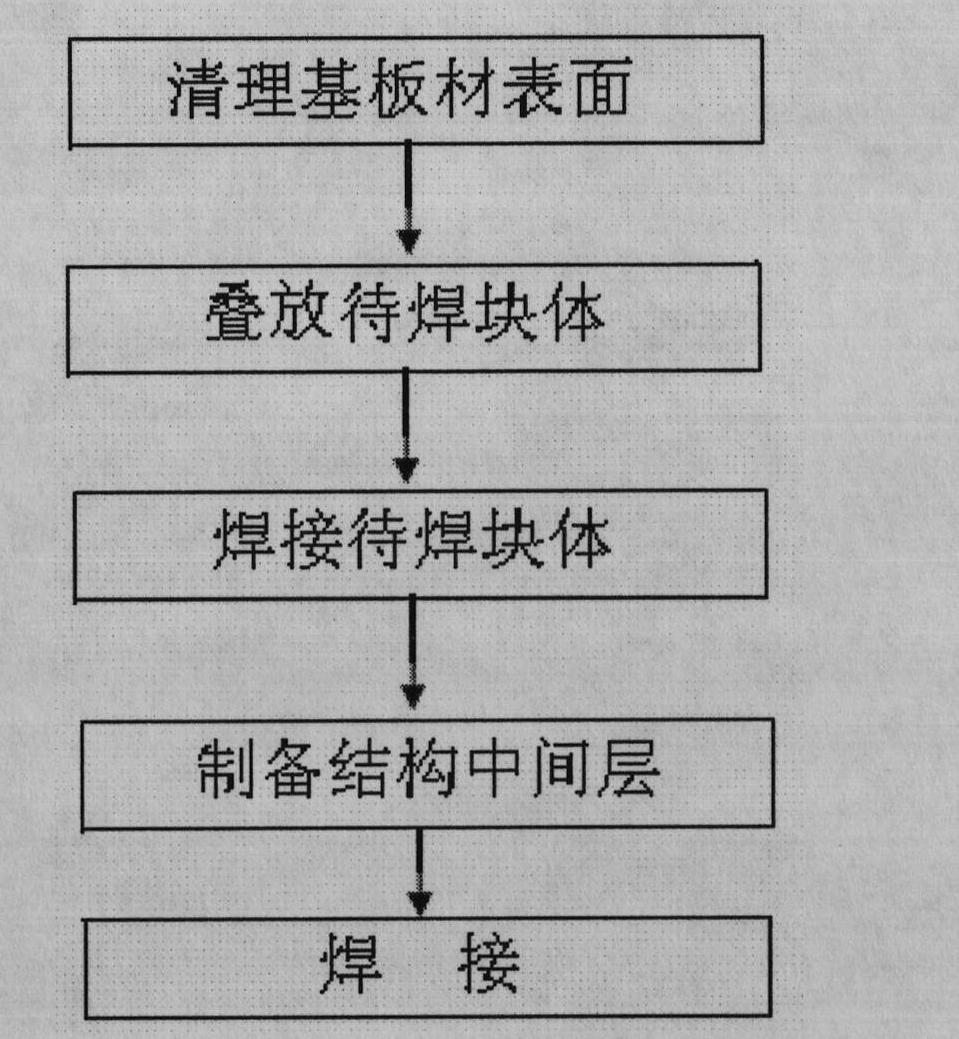

Diffusion welding method of titanium or titanium alloy and stainless steel

InactiveCN102218592AMeet service performance requirementsHigh-strength connectionNon-electric welding apparatusTitaniumHigh intensity

The invention discloses a diffusion welding method of titanium or titanium alloy and stainless steel. A plate pack having the same material quality with welded workpieces is welded into a block structure in advance. The plate pack is lengthways cut into slices along the block structure to form a structural middle layer 7. The middle layer is processed and then vertically arranged between the welded workpieces for diffusion welding. Because the middle layer having the same material quality with the workpiece is adopted, a joint heterogeneous interface combination mode is changed into a combination mode that half heterogeneous workpieces are directly combined and half heterogeneous workpieces are combined, and the titanium or titanium alloy and stainless steel workpieces are in high-intensity connection. In the diffusion welding method, the tensile strength of the joint is improved to above 80% from 50-70%(week side workpiece intensity) obtained by the direct diffusion welding technology, and various types of titanium or titanium alloy and stainless steel can be in high-intensity connection.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

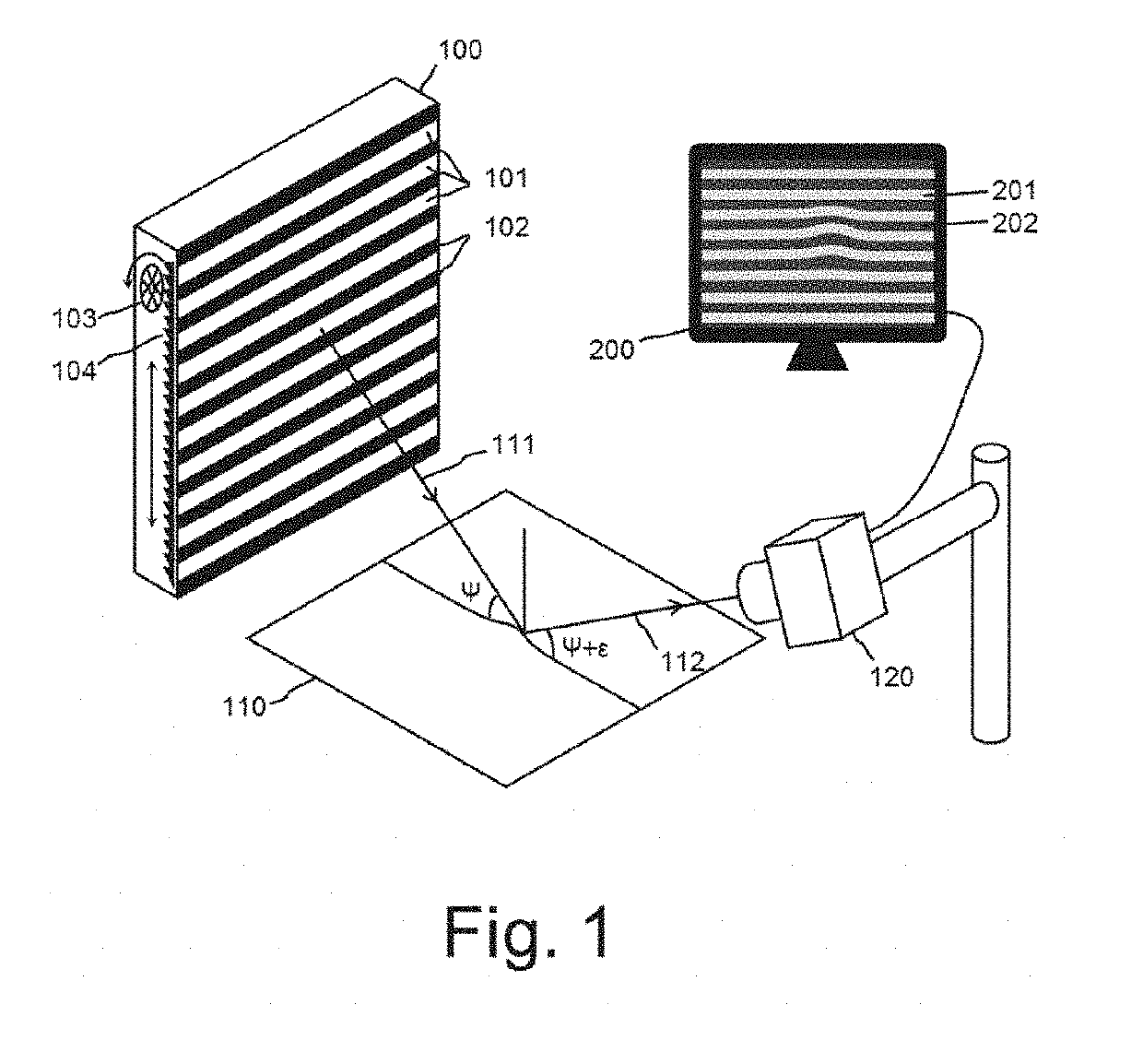

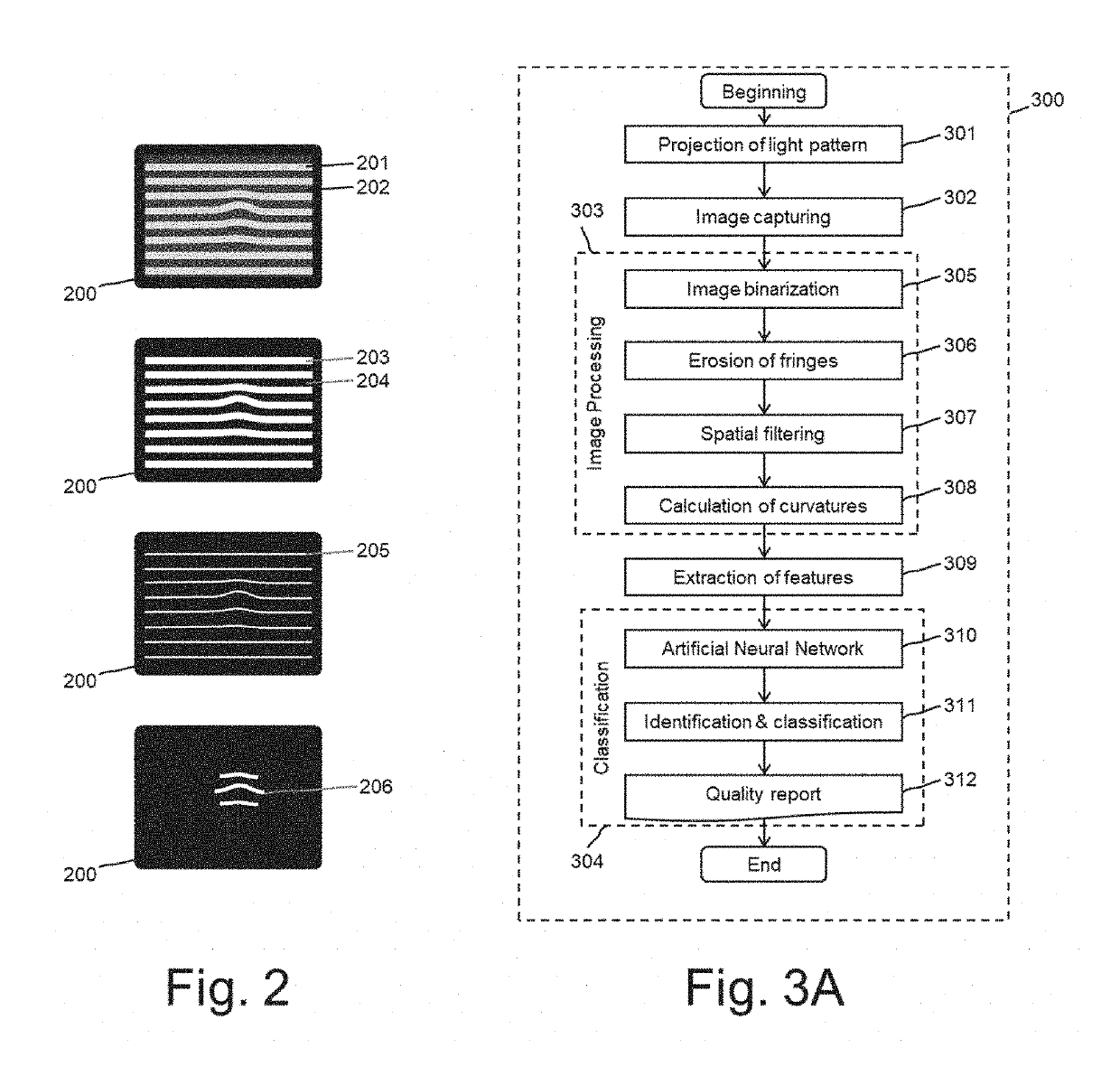

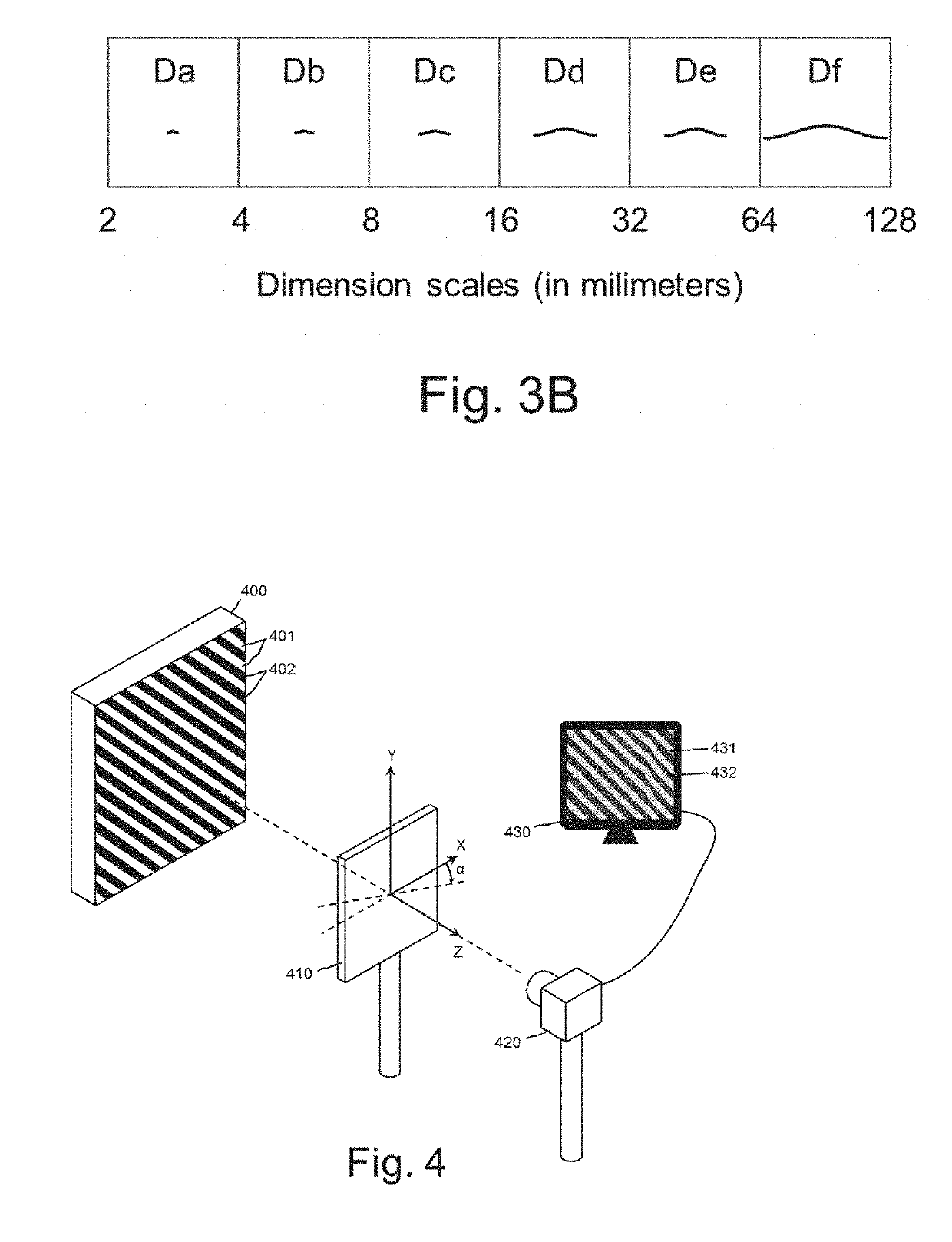

Method and system for automatic quality inspection of materials and virtual material surfaces

ActiveUS20190287237A1Improve objectivityGood reproducibilityImage enhancementImage analysisComputer visionDistortion

The present document describes methods and systems for the automatic inspection of material quality. A set of lights with a geometric pattern is cast on a material to be analyzed. Depending on the material being inspected, same may act as a mirror and the reflected image is captured by a capture device, or the light passes through the material being inspected and the image is captured by a capture device. Defects in the material can be detected by the distortion caused by same in the pattern of the reflected image or passing through. Finally, software is used to identify and locate these distortions, and consequently the defects in the material. This classification of defects is carried out using artificial intelligence techniques.

Owner:AUTAZA TECH SA

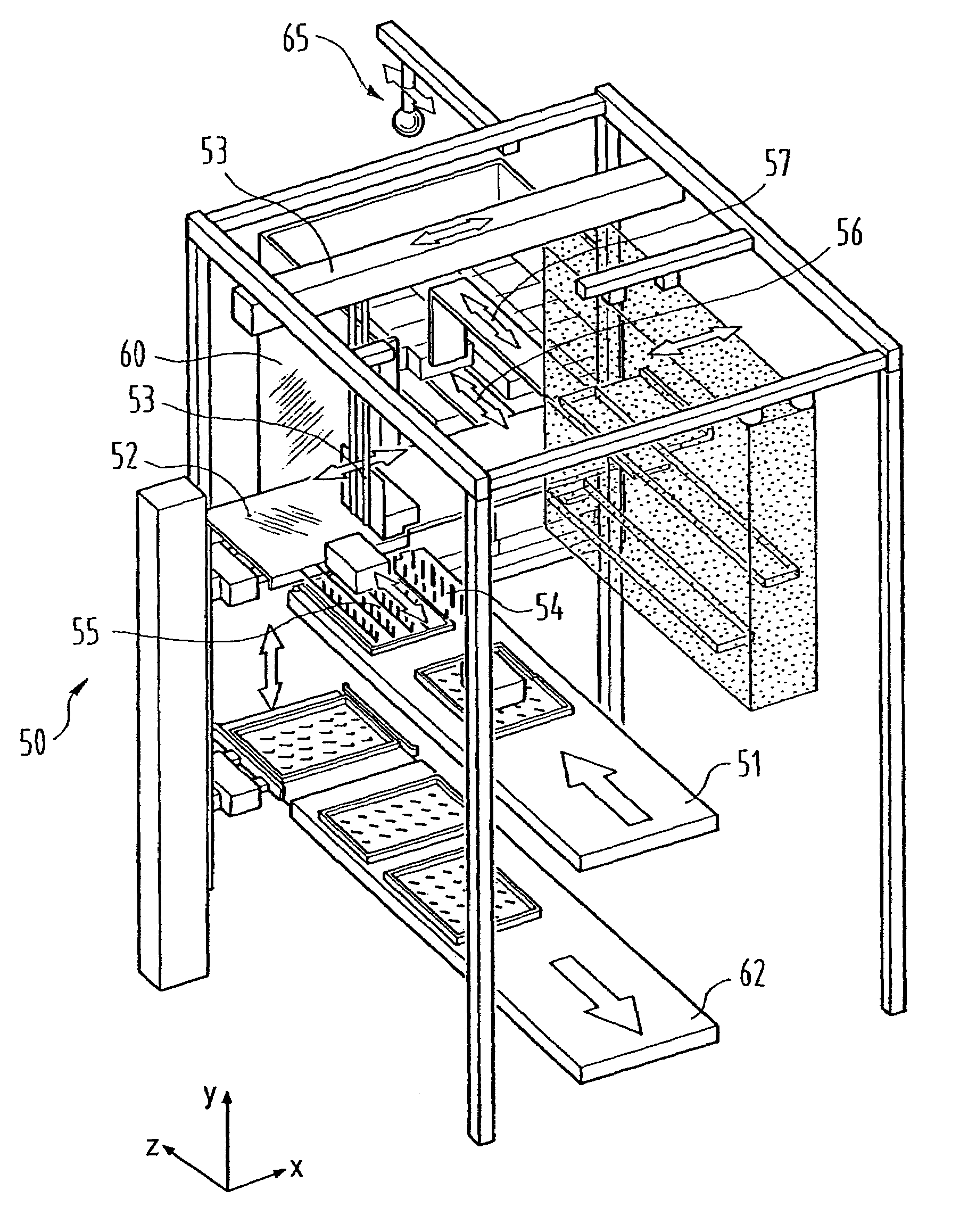

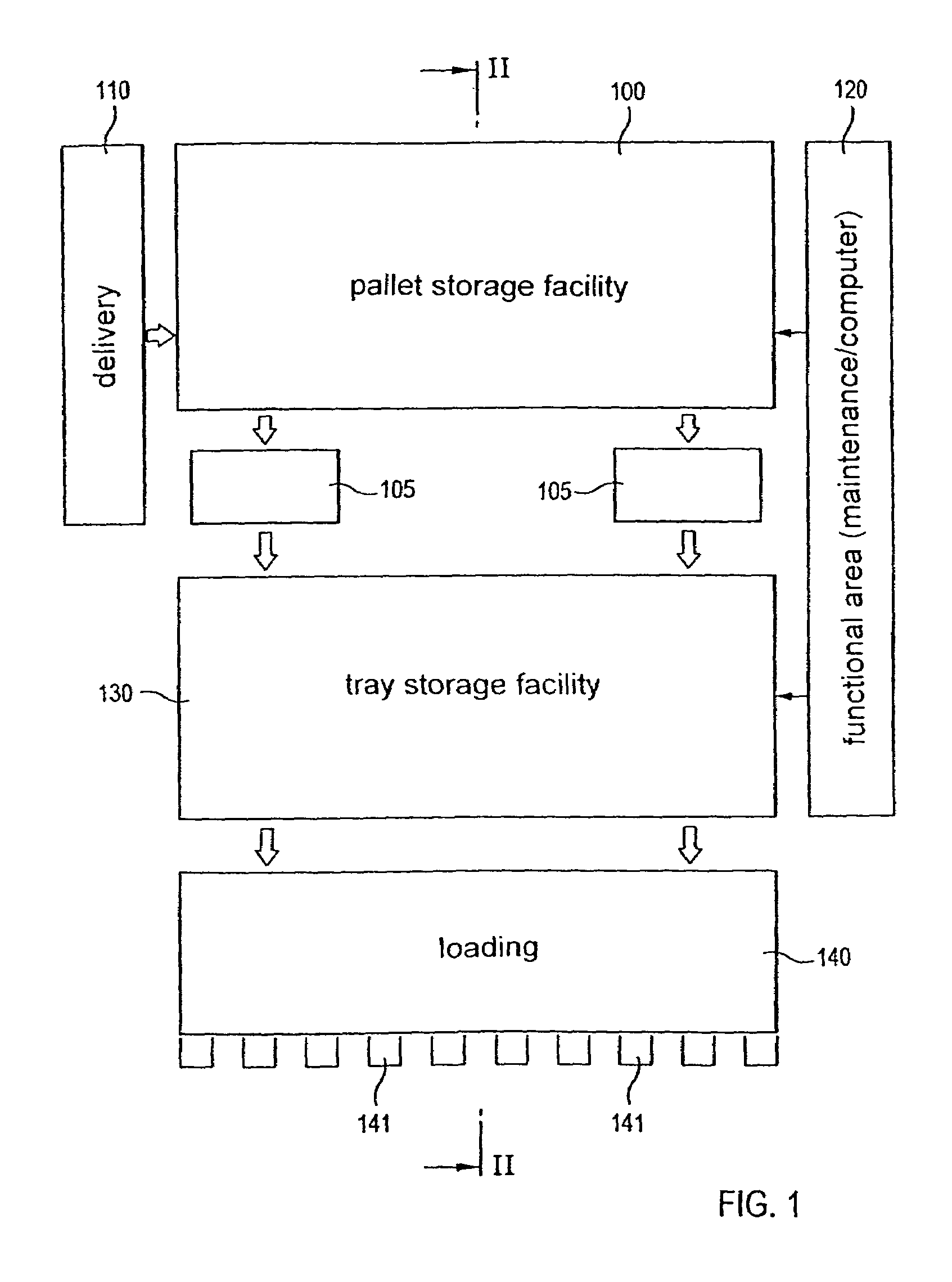

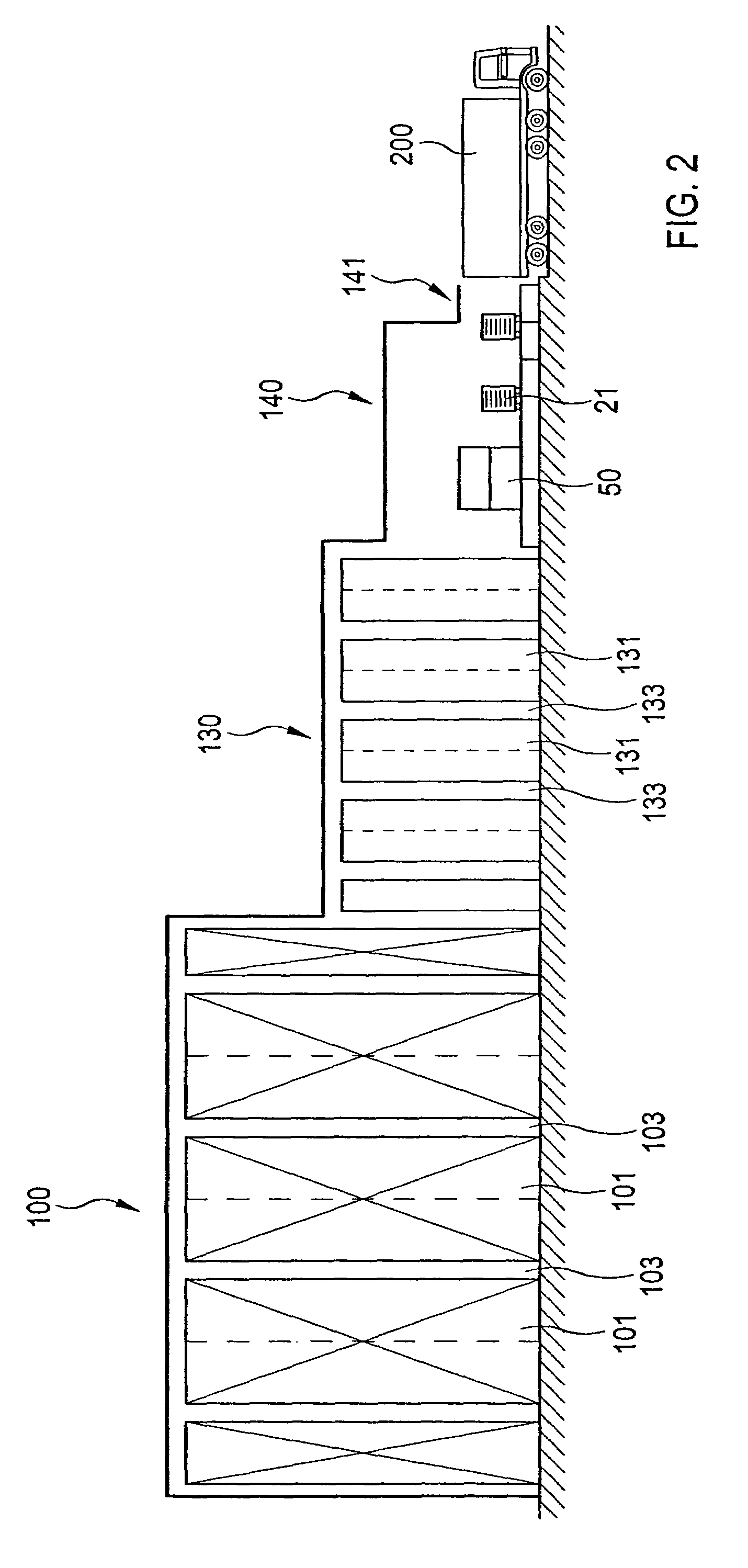

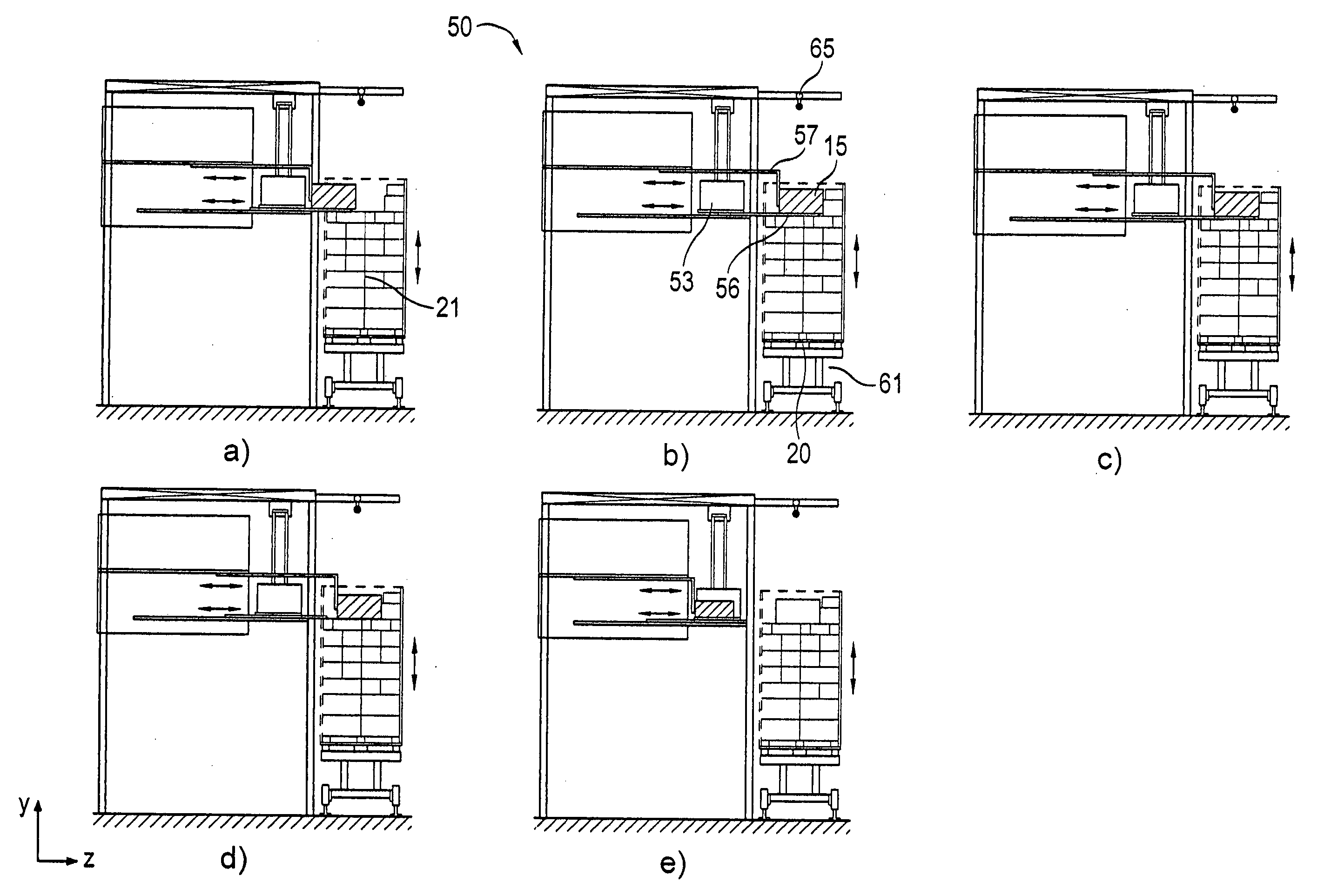

Apparatus for depositing a packing unit at a desired position on a load carrier

InactiveUS7047710B2Strong loadLoaded safely and reliablyWrappers shrinkageConveyorsEngineeringMaterial quality

A machine for loading a load carrier (20) such as a pallet with packing units (cardboard boxes, collis etc.), which form a load stack (21) on the load carrier, is presented. The machine includes handling and support mechanism (52–57), that allows a packing unit (15) to be loaded. The handling and support mechanism supports the load from below throughout the operation of loading from a feed device (51) onto the load stack. By virtue of the handling and support mechanism, the packing unit may be deposited at any selectable spatial position on the load stack. It is therefore possible to form an optimized load stack on the load carrier in which the packing units are always supported from below, with the result that the loading is not dependent upon the material quality of the packaging of the packing unit.

Owner:LOGISTIK INFORMATIK

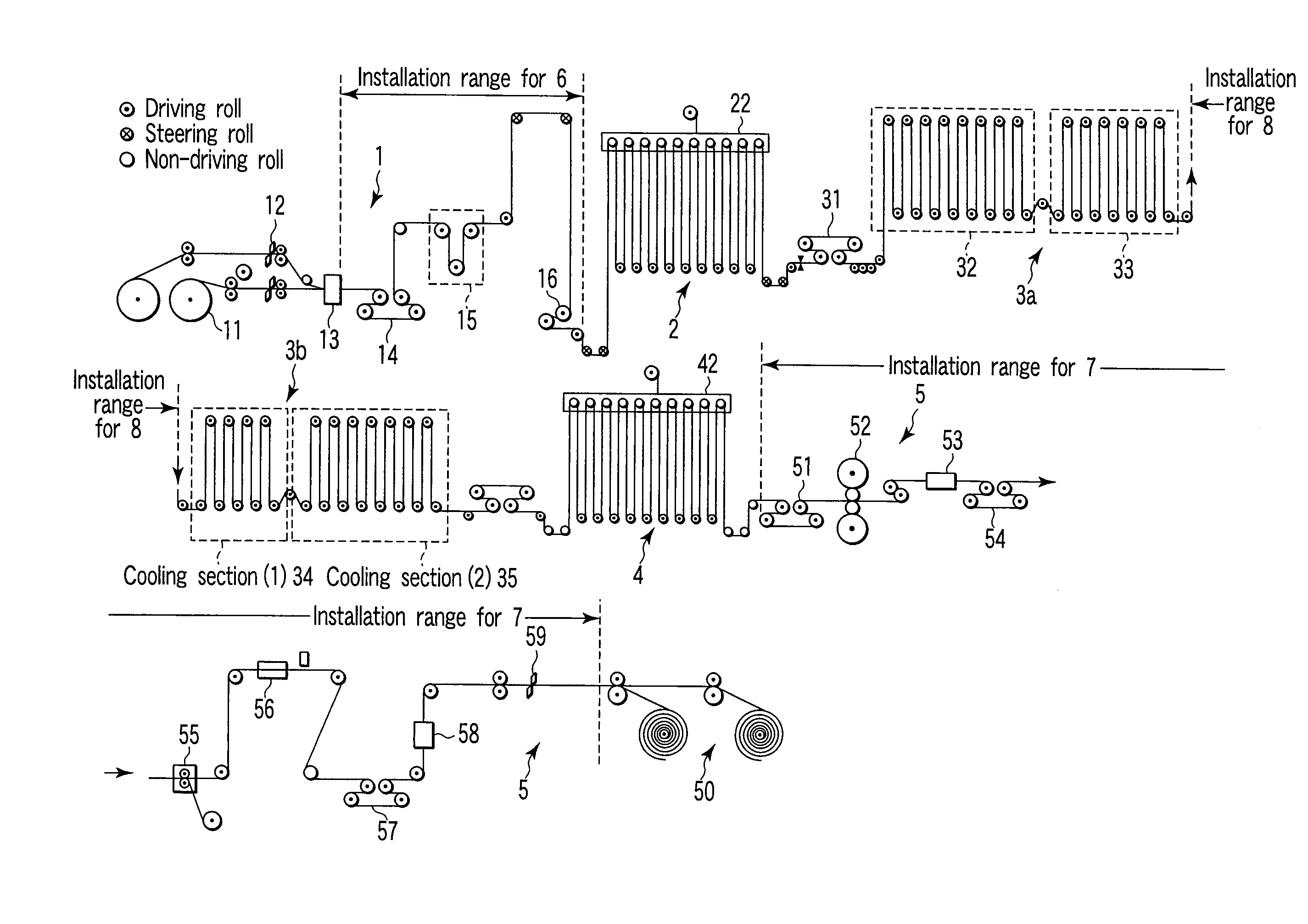

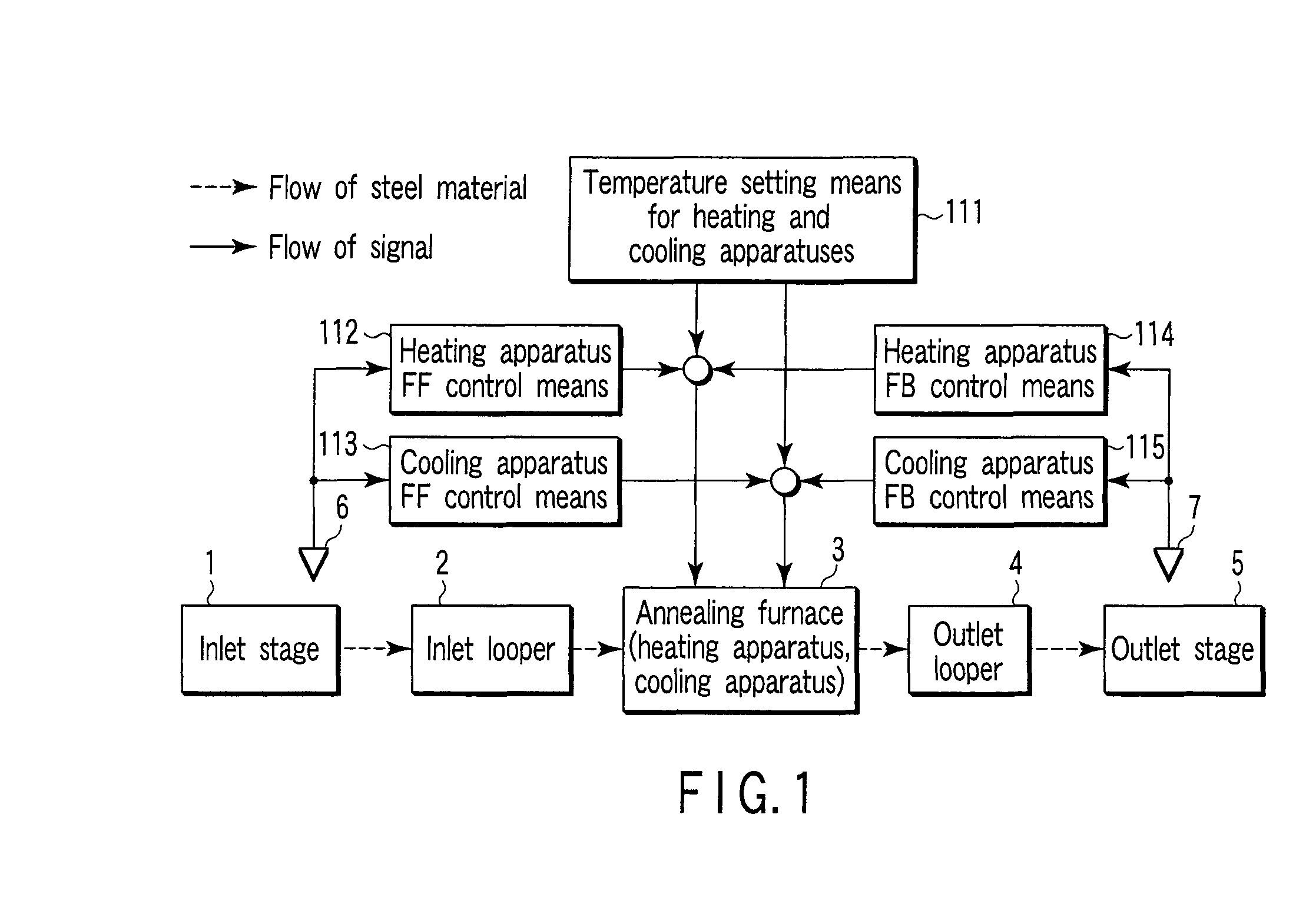

Process line control apparatus and method for controlling process line

InactiveUS20100219567A1Quality improvementHot-dipping/immersion processesFurnace typesProduction lineValue set

A process line control apparatus which controls a process line including an annealing furnace (3) including a heating process apparatus executing a heating process and a cooling process apparatus executing a cooling process, the heating and cooling processes being continuously executed on a steel material, the apparatus having feed forward control means (112, 113) for measuring quality of the steel material by a material quality measuring apparatus (6) installed in an inlet stage (1) preceding the heating process in the annealing furnace (3), and on the basis of measurement results, determining modifications for respective temperature set values set by temperature setting means (111) for the heating and cooling apparatuses in the annealing furnace (3), and feedback control means (114, 115) for measuring the quality of the steel material by a material quality measuring apparatus (7) installed in an outlet stage (5) succeeding the cooling process in the annealing furnace (3), and on the basis of measurement results, determining modifications for the respective temperature set values set by the temperature setting means (111) for the heating and cooling apparatuses in the annealing furnace (3).

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

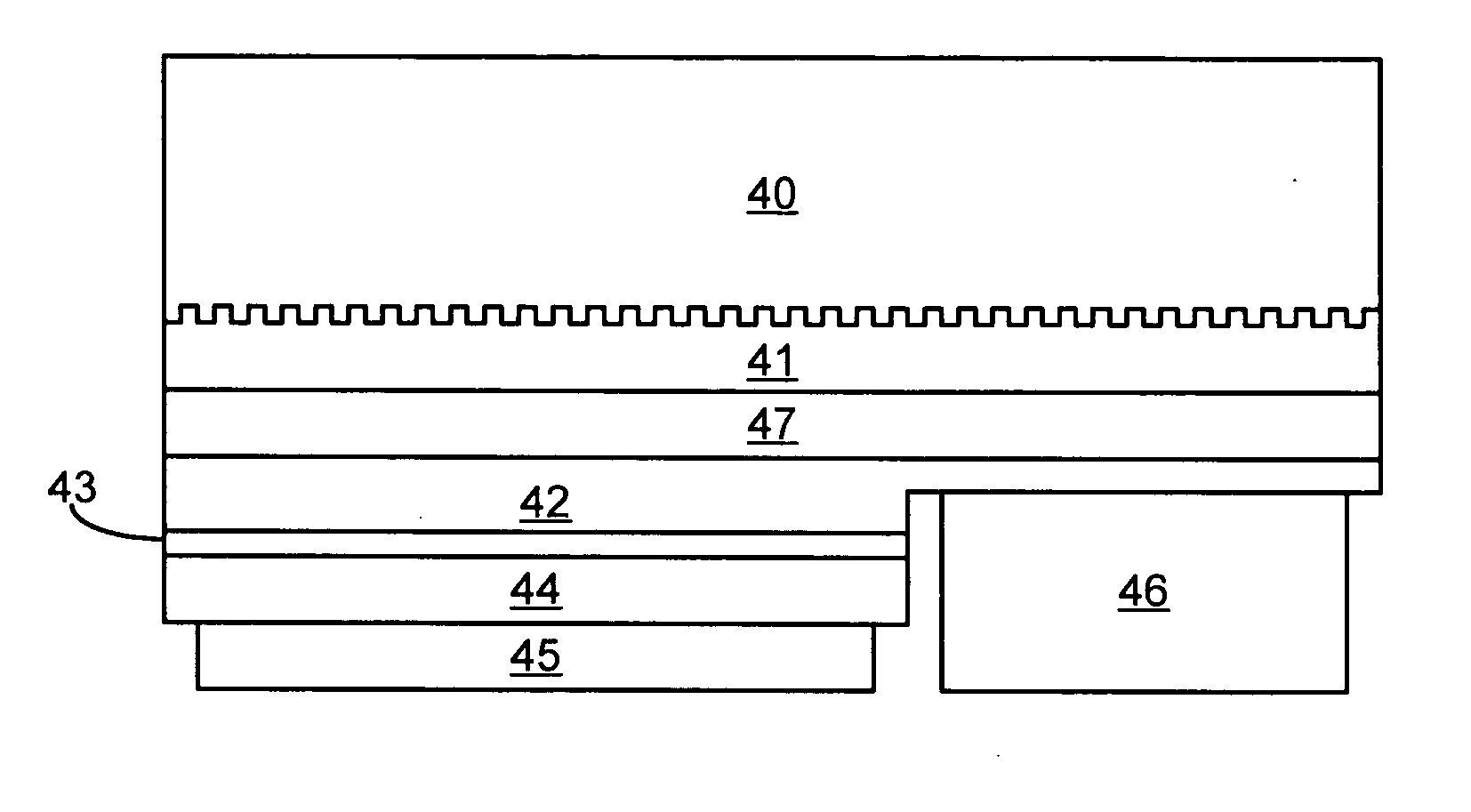

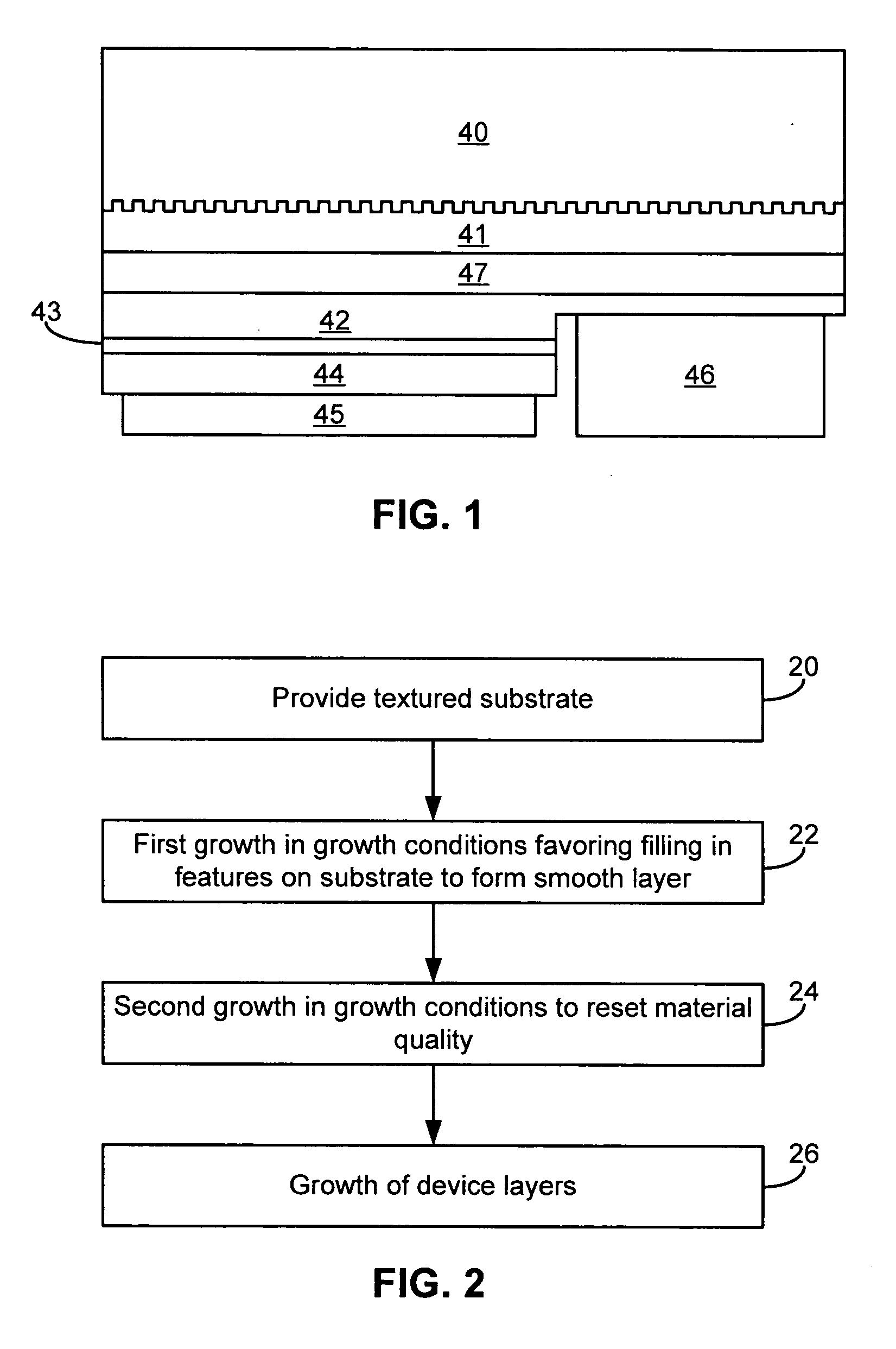

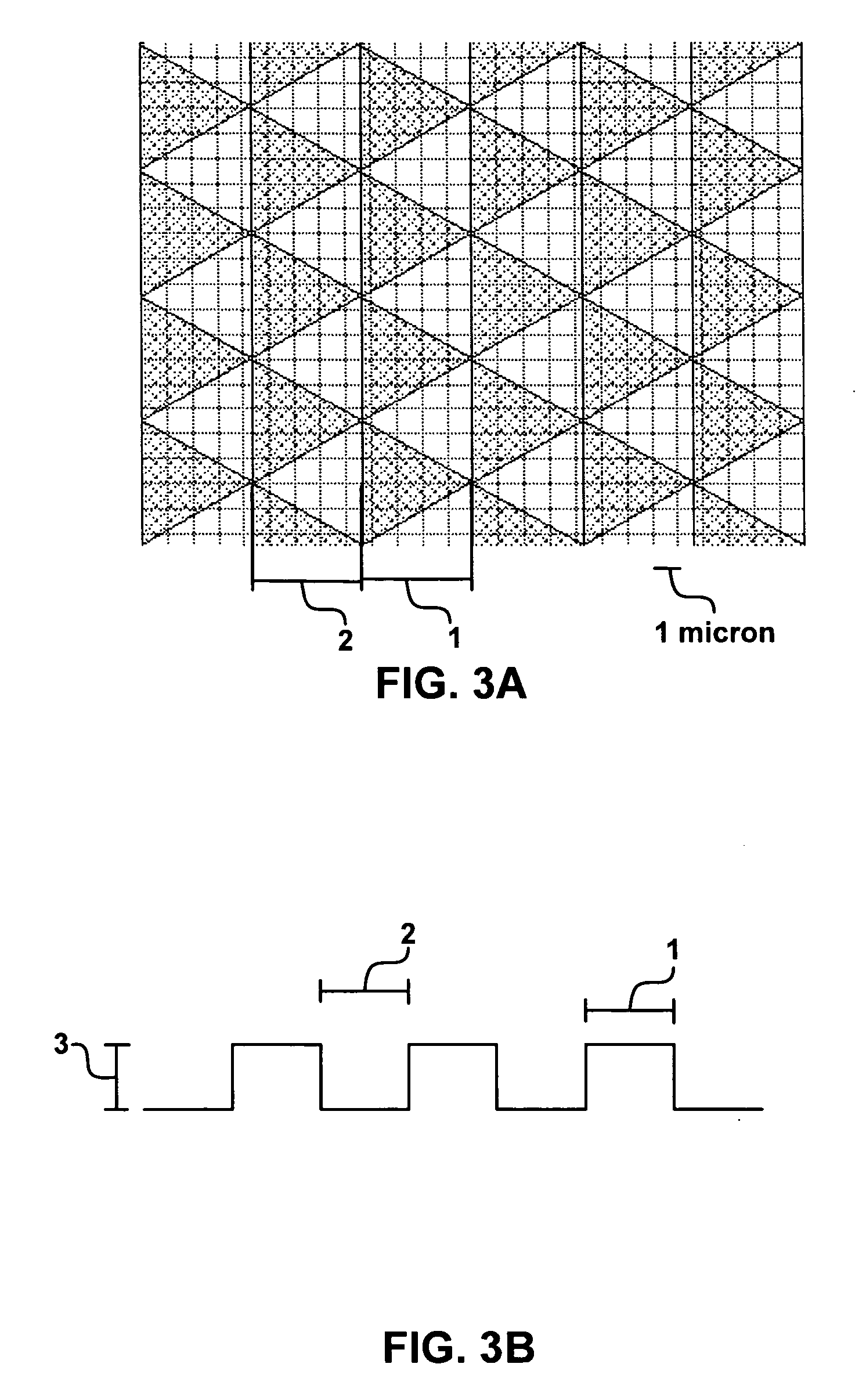

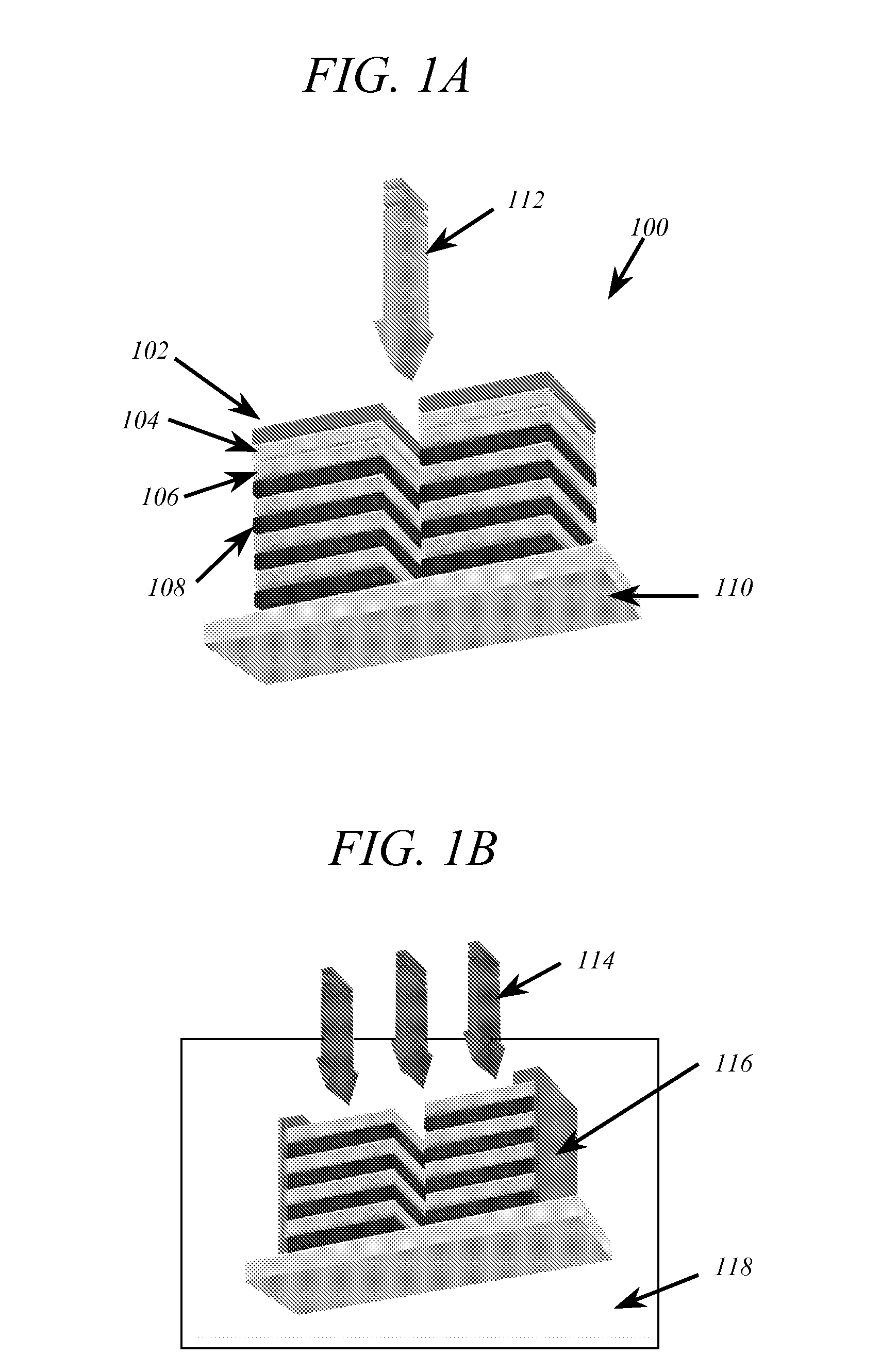

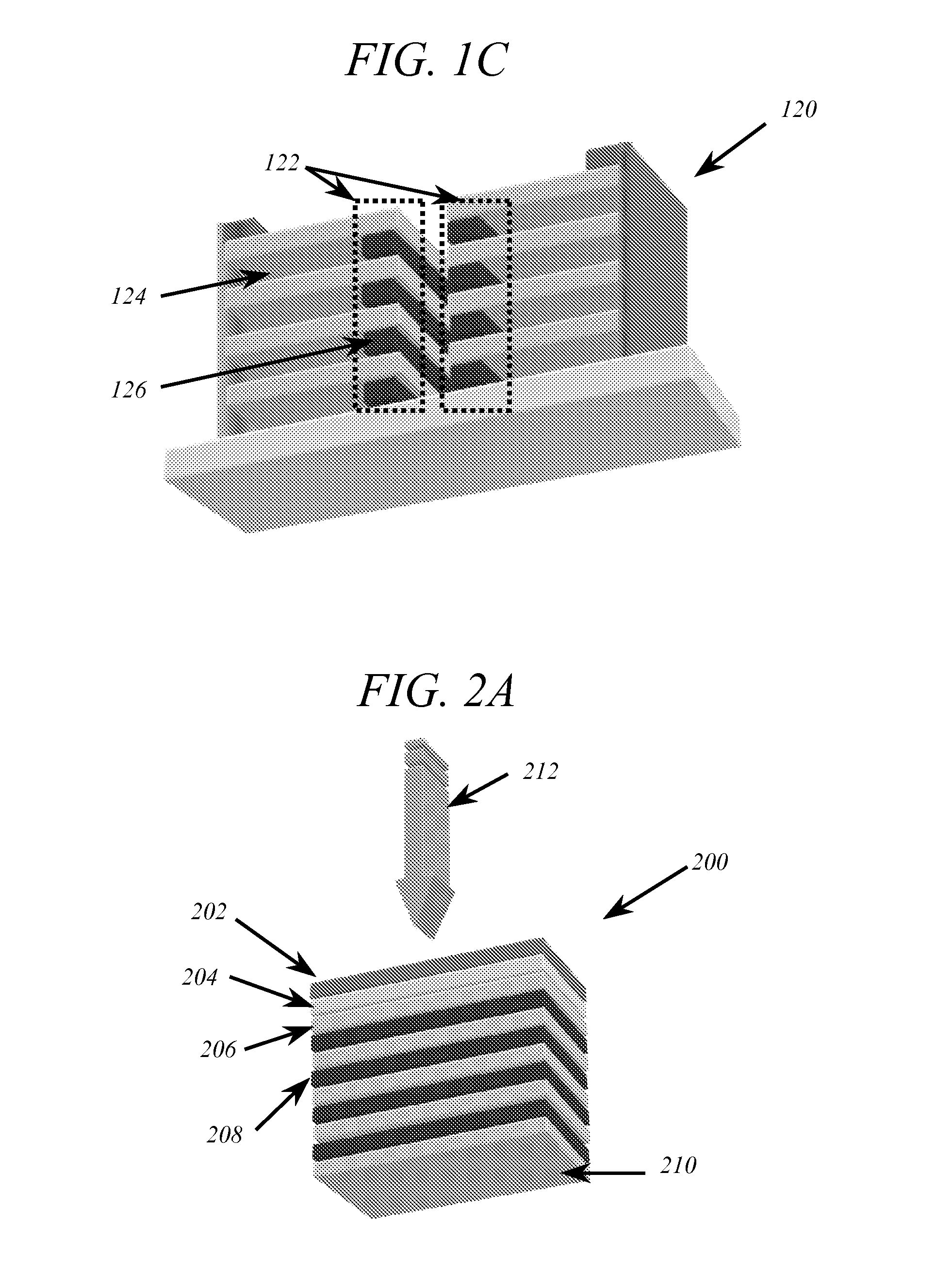

Growth of III-nitride light emitting devices on textured substrates

ActiveUS20060060888A1Reduce the amount requiredImprove material qualitySemiconductor/solid-state device manufacturingSemiconductor devicesTotal internal reflectionNitride

A III-nitride light emitting device is grown on a textured substrate, in order to reduce the amount of total internal reflection at the interface between the substrate and the III-nitride layers. In some embodiments, the device includes a first growth region substantially free of voids, and a second growth region that improves the material quality such that high quality layers can be grown over the first and second regions.

Owner:LUMILEDS

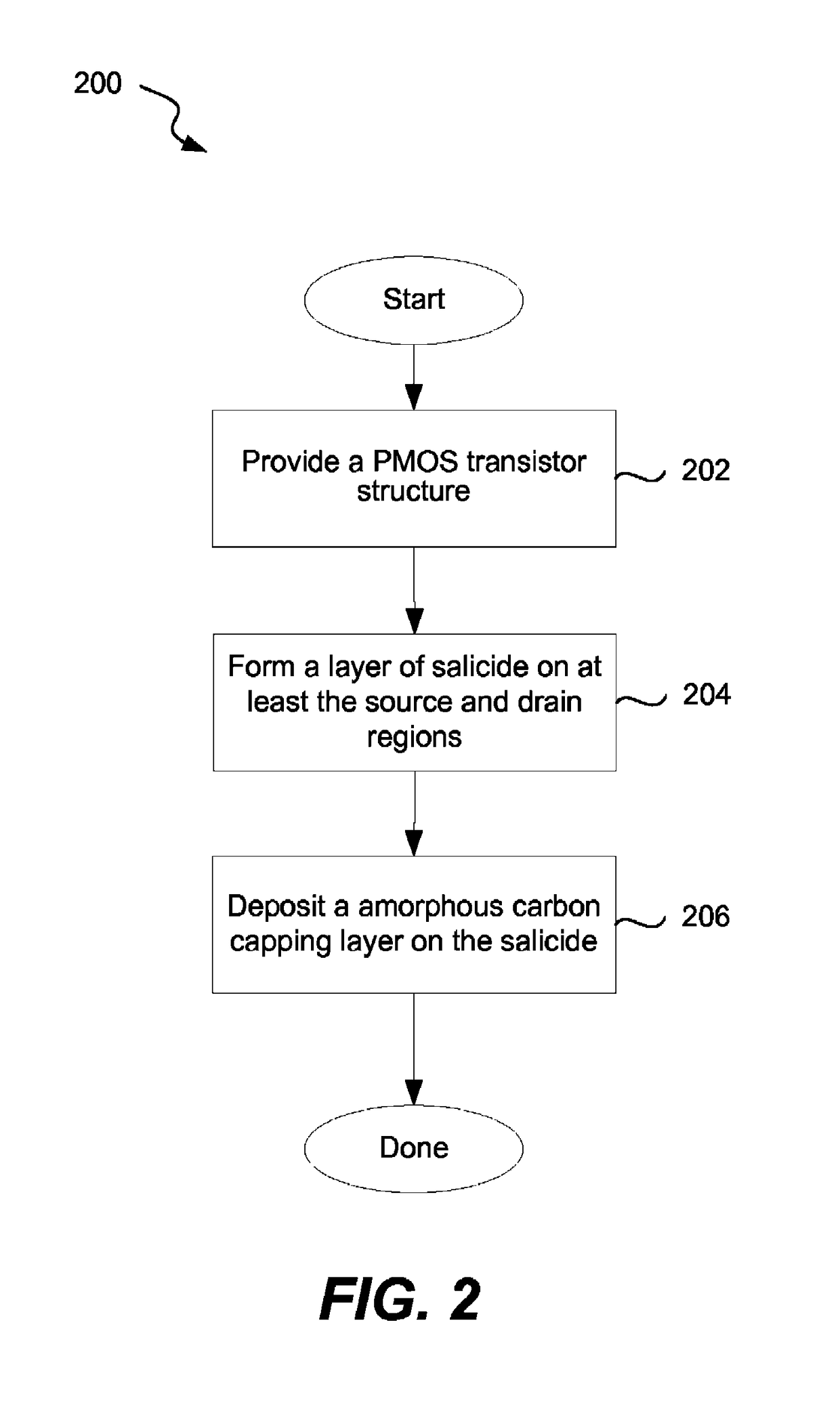

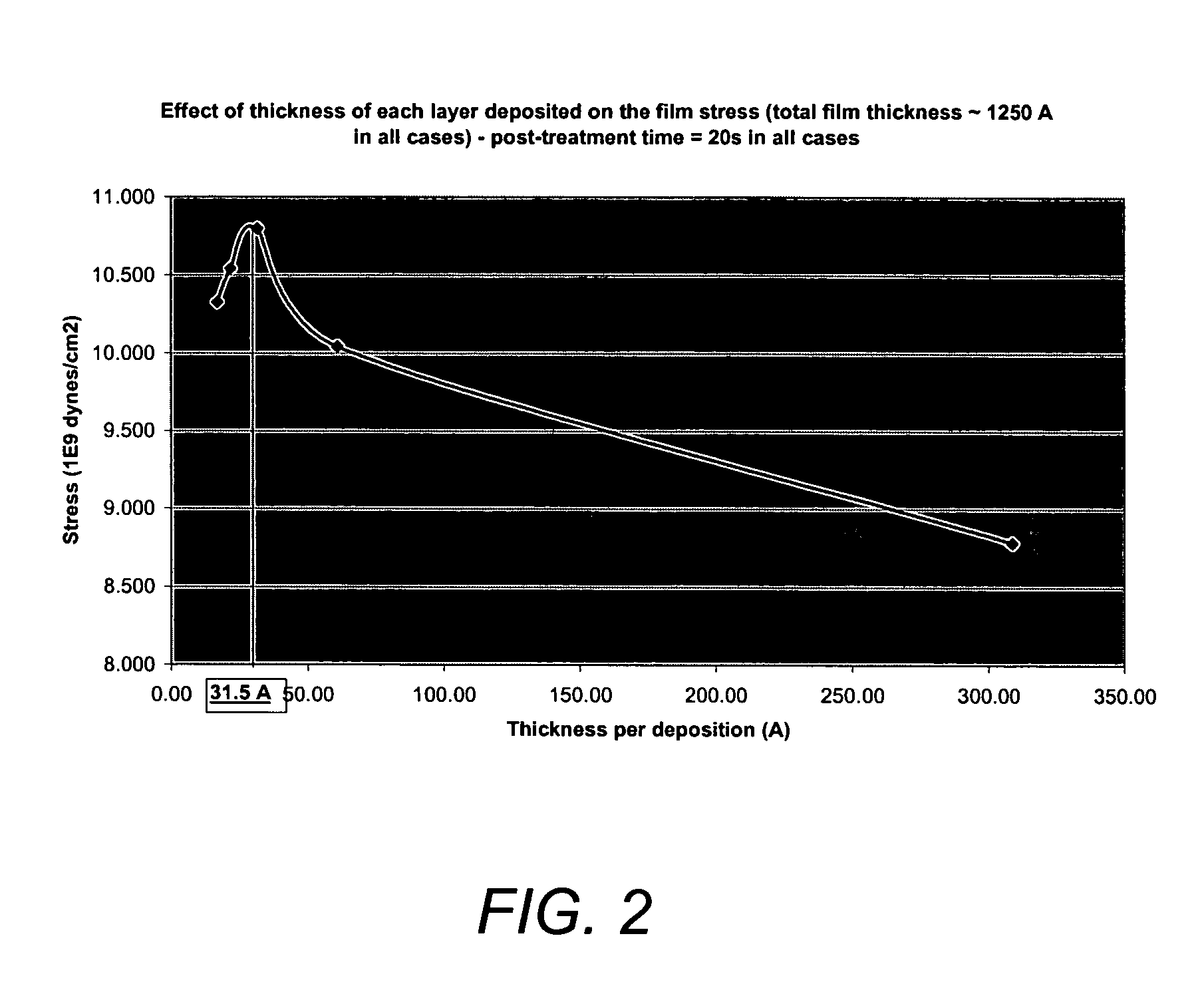

High compressive stress carbon liners for MOS devices

InactiveUS7906817B1Improve performanceGuaranteed preservation qualitySemiconductor/solid-state device manufacturingSemiconductor devicesSalicideEngineering

Transistor architectures and fabrication processes generate channel strain without adversely impacting the efficiency of the transistor fabrication process while preserving the material quality and enhancing the performance of the resulting transistor. Transistor strain is generated is PMOS devices using a highly compressive post-salicide amorphous carbon capping layer applied as a blanket over on at least the source and drain regions. The stress from this capping layer is uniaxially transferred to the PMOS channel through the source-drain regions to create compressive strain in PMOS channel.

Owner:NOVELLUS SYSTEMS

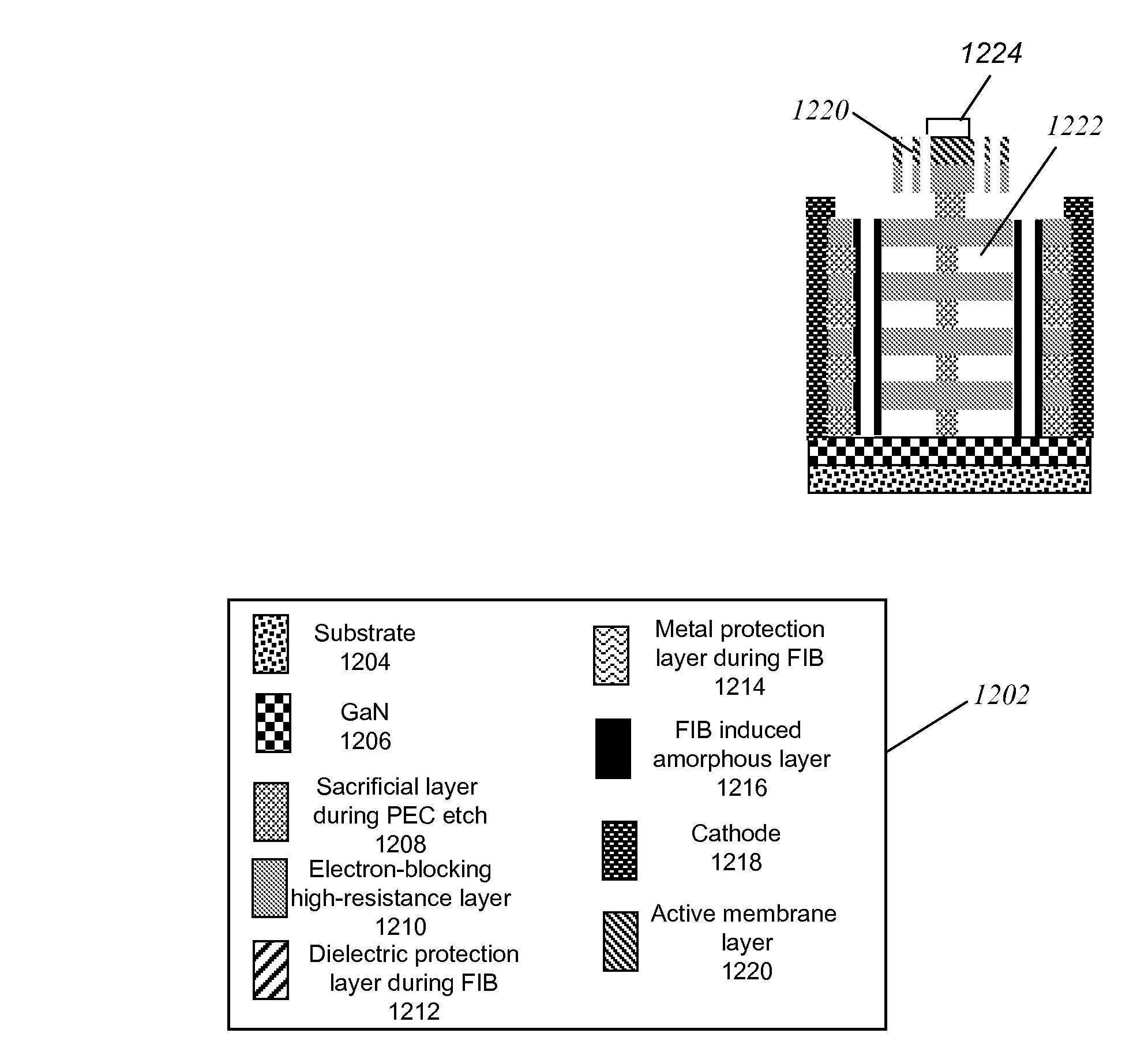

Ion beam treatment for the structural integrity of air-gap iii-nitride devices produced by the photoelectrochemical (PEC) etching

InactiveUS20080182420A1Avoid damageSemiconductor/solid-state device manufacturingSemiconductor devicesPhotoelectrochemical etchingPhotonics

A method for ensuring the structural integrity of III-nitride opto-electronic or opto-mechanical air-gap nano-structured devices, comprising (a) performing ion beam implantation in a region of the III-nitride opto-electronic and opto-mechanical air-gap nano-structured device, wherein the milling significantly locally modifies a material property in the region to provide the structural integrity; and (b) performing a band-gap selective photo-electro-chemical (PEC) etch on the III-nitride opto-electronic and opto-mechanical air-gap nano-structured device. The method can be used to fabricate distributed Bragg reflectors or photonic crystals, for example. The method also comprises the suitable design of distributed Bragg reflector (DBR) structures for the PEC etching and the ion-beam treatment, the suitable design of photonic crystal distributed Bragg reflector (PCDBR) structures for PEC etching and the ion-beam treatment, the suitable placement of protection layers to prevent the ion-beam damage to optical activity and PEC etch selectivity, and a suitable annealing treatment for curing the material quality after the ion-beam treatment.

Owner:RGT UNIV OF CALIFORNIA

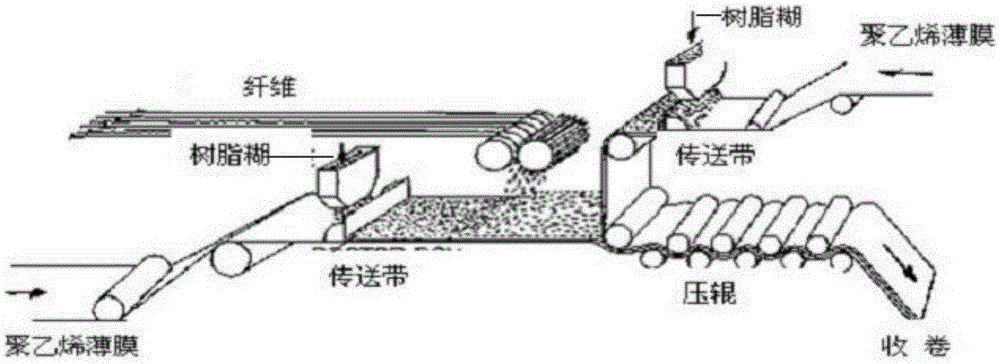

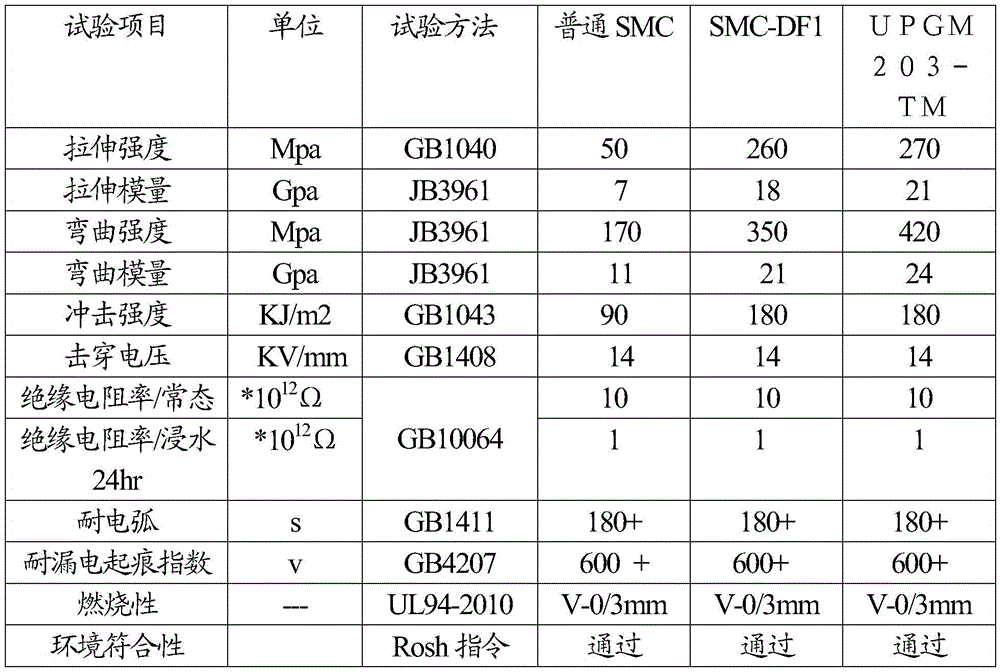

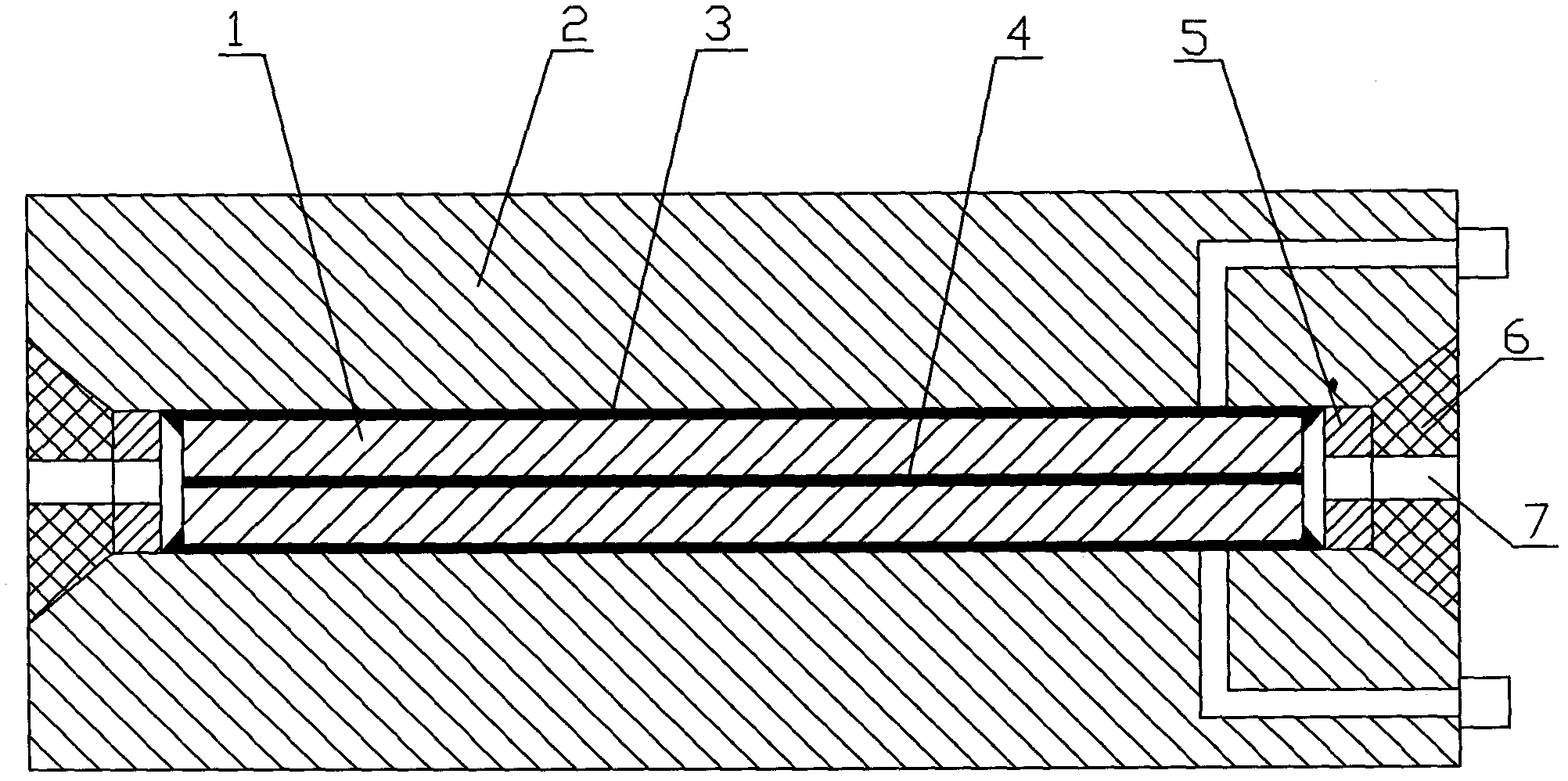

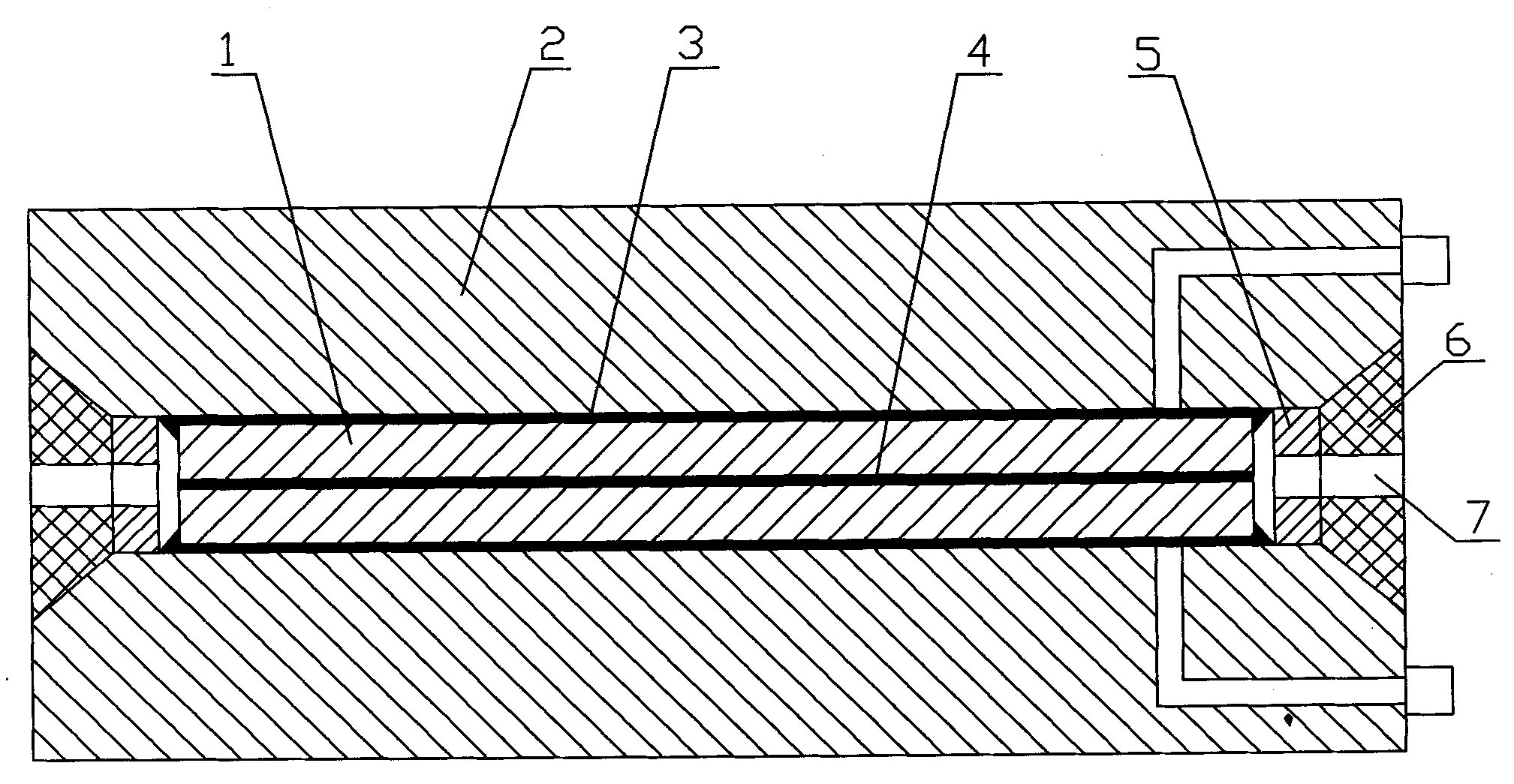

Unsaturated polyester resin fiber reinforced sheet-shape molding compound and preparation method thereof

The invention discloses an unsaturated polyester resin fiber reinforced sheet-shape molding compound, comprising unsaturated polyester resin, a low shrinkage agent, a filler, a curing agent, a thickener, a mold release agent, a reinforcing material, a colorant and an additive. The unsaturated polyester resin is characterized by comprising one or more of o-phenylene resin, m-phenylene resin and vinyl ester resin in mixing; the filler is modified aluminium hydroxide; the reinforcing material is made of one or more selected from the group containing alkali-free chopped glass fiber, alkali-free untwisted continuous glass fiber rove, high silica glass fiber and Kevlar fiber. The molding compound combines light weight, high strength, retardance, corrosion resistance and insulation, has the advantages of high weight percentage of reinforced material, good electrical properties, significantly improved mechanical properties, tensile strength of not less than 100Mpa, bending strength of not less than 300Mpa, impact strength not less than 260 KJ / m<2>, dielectric strength of not less than 12KV / mm, flame retardance of UL94V-0 and product thickness of up to 60mm, and can be used for compression molding of electrical insulation structural parts.

Owner:SICHUAN D&F ELECTRICAL TECH

Vacuum milling method for metal compound plate

The invention provides a vacuum milling method for a metal compound plate, which relates to a compound plate production method and comprises the following steps that: 1, circumference lead angle beveled edges are processed on the circumference of the single side of a base plate, and the circumference dimension of a stainless steel plate is smaller than the dimension of the circumference lead angle beveled edges; 2, a right-angle hole is drilled between the lead angle beveled edges; 3, the stainless steel plate is flatly paved on the lead angle beveled edges side of the base plate, in addition, a soldering flux layer is flatly paved between the stainless steel plate and the base plate, and the circumference sealing welding is carried out on a pressure platform; 4, the vacuum pumping is carried out through the right-angle hole of the base plate, and the sealing and plugging is carried out after the vacuum pumping; 5, the two prepositive blank stainless steel surfaces are combined, in addition, a high-temperature adhesion-prevention agent layer is flatly paved between the two prepositive blank stainless steel surfaces, then, separation plates with the same circumference lengths are in dot welding on the circumference, and next, submerged arc welding sealing welding is carried out between the two lead angle beveled edges and the separation plates; 6, a plurality of vent holes are drilled on a sealing and welding ring frame and the separation plates, 7, the hot milling is carried out; and 8, the edge milling separation is carried out. The vacuum milling method has the advantages that the prepositive blank processing and the vacuum pumping are firstly carried out, then, air holes are drilled, excessive air can be exhausted during the milling, and the plate material quality is ensured.

Owner:SANMING TIANZUN STAINLESS STEEL CLADDING TECH

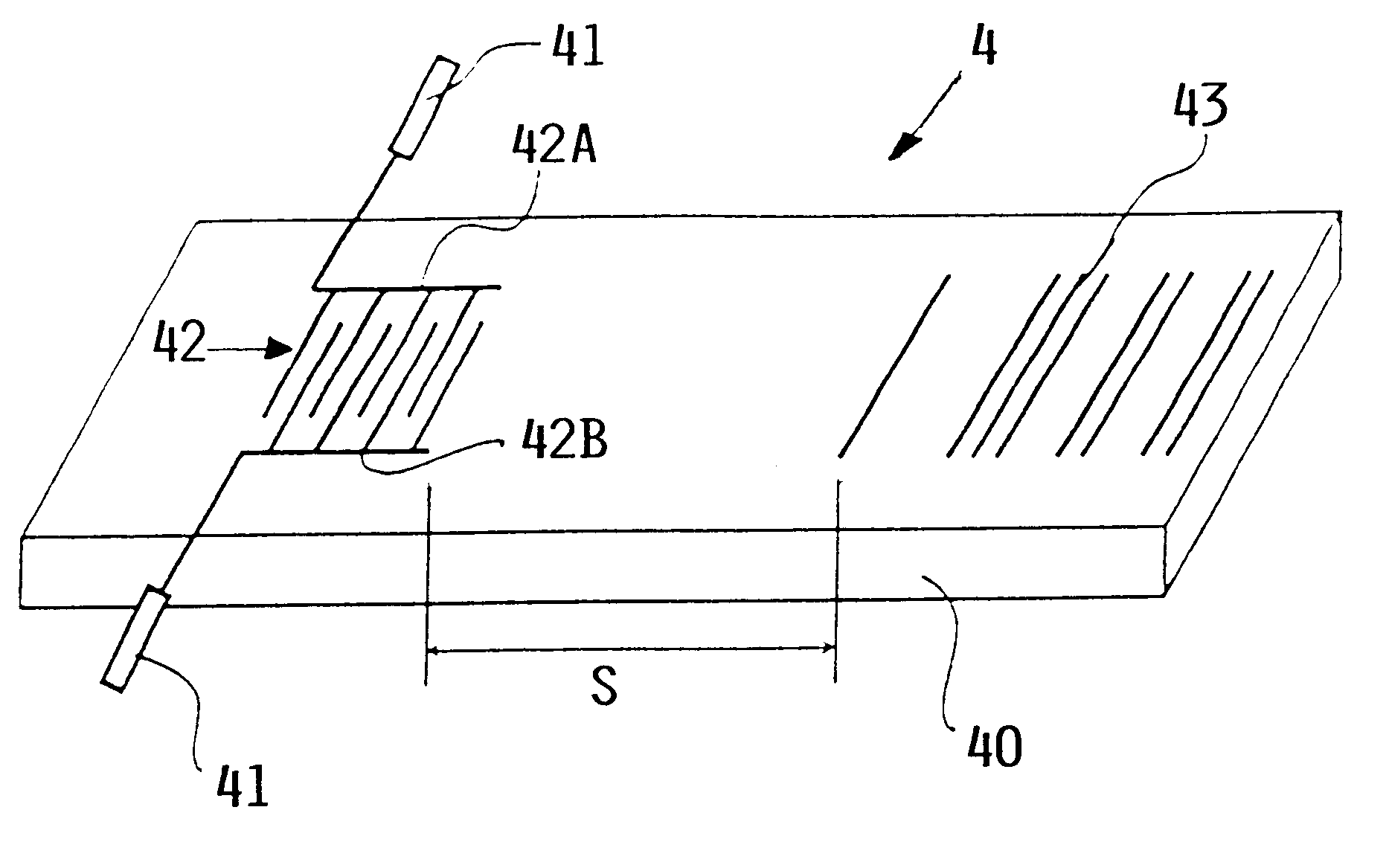

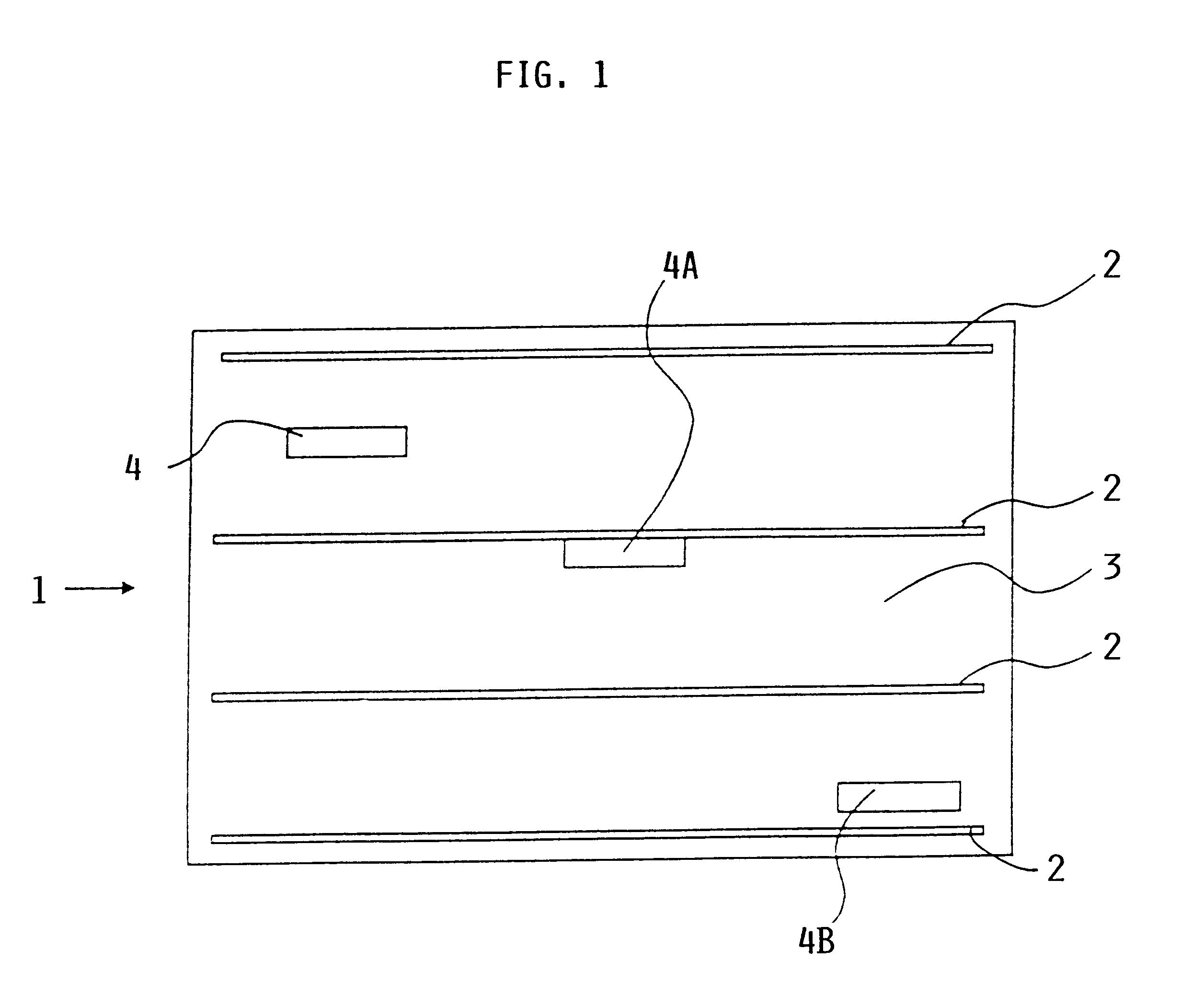

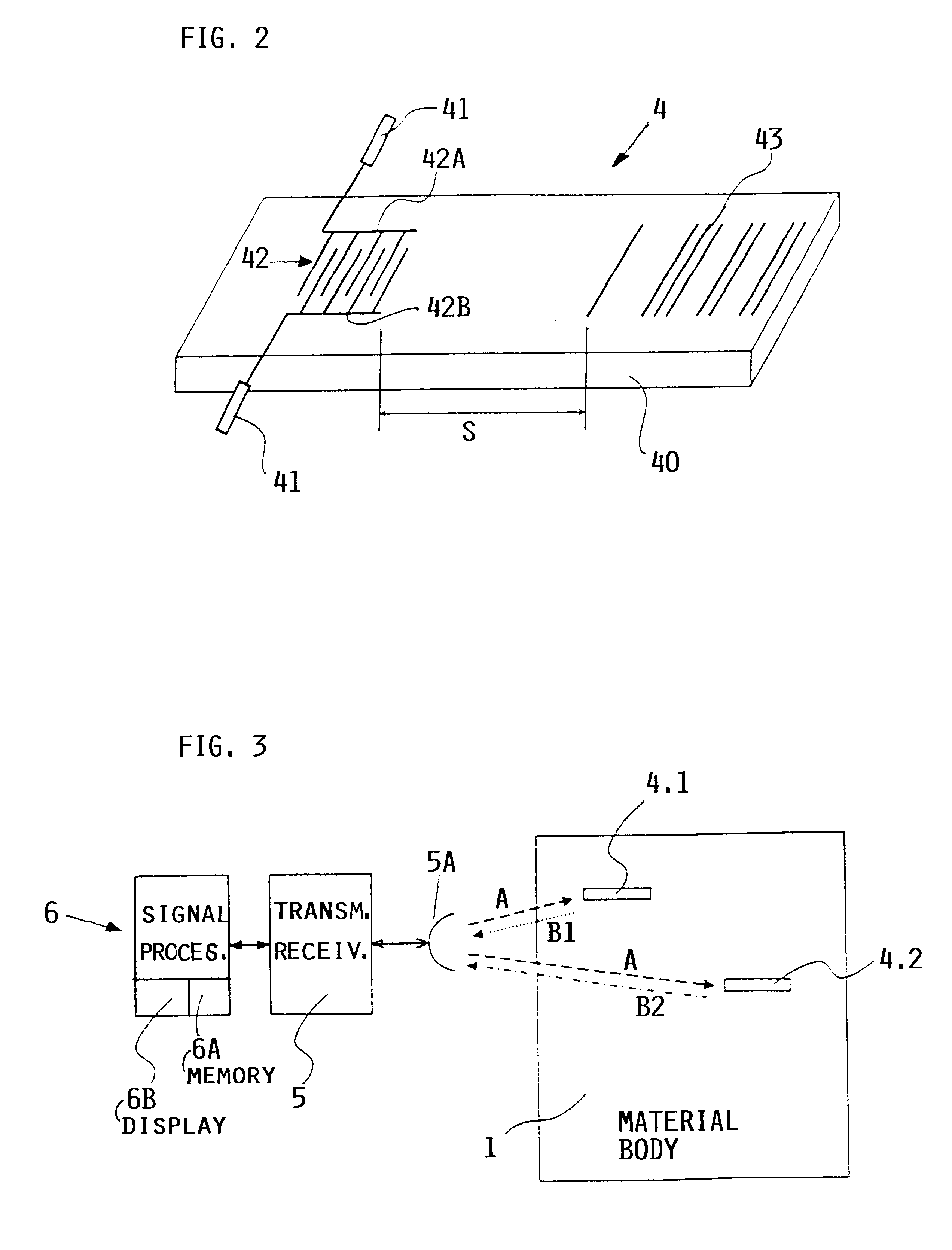

System and method for material testing, material suitable for such testing and method for producing such material

InactiveUS6260415B1Easy to testEasy assessment processAnalysing solids using sonic/ultrasonic/infrasonic wavesConverting sensor ouput using wave/particle radiationMaterial under testSurface acoustic wave

A material, such as a fiber composite material, has embedded inside at least one, preferably more, surface acoustic wave filters of piezoelectric material for receiving testing energy in a wireless manner and for retransmitting a material quality signal in a wireless manner which is evaluated in a system that has a wireless transmitter for sending testing energy into a material and a wireless receiver for receiving the material quality signal which is then processed and evaluated by a respective processor of the testing system. An output of the processor provides information regarding the nature and quality of the material tested and of the presence and location of any material faults that may be displayed on display screen.

Owner:DAIMLER AG

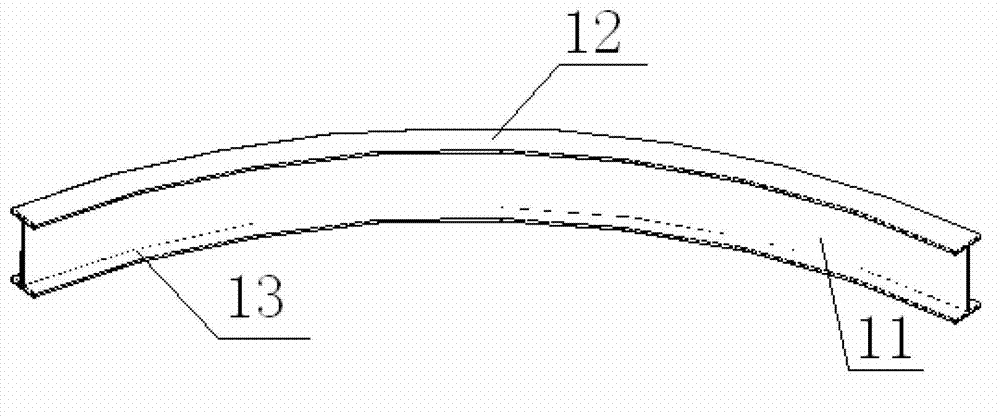

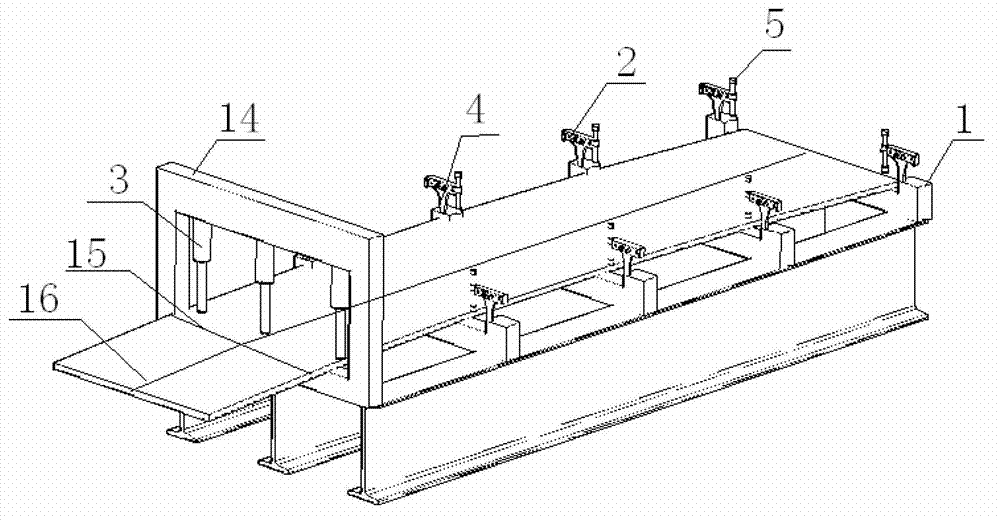

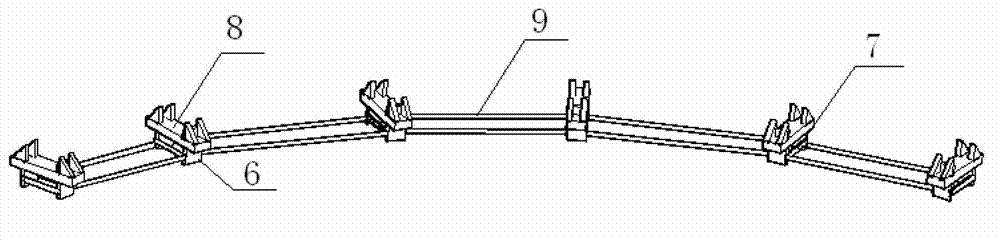

Manufacture method for double-curve H-shaped steel

The invention discloses a manufacture method for double-curve H-shaped steel. The manufacture method comprises the following steps of: 1) reviewing the material quality of a supplied horizontal plate, flattening the horizontal plate, and pre-processing; 2) three-dimensional lofting by a computer, and spreading in a plane; 3) cutting and blanking on a numeric control cutting machine; 4) opening a groove on an H-shaped steel web, and carrying out the butt welding; 5) marking a bending line and an assembly line on the web and a flange plate; 6) manufacturing a bending jig frame according to three-dimensional coordinates; 7) bending the web and the flange plate via the method of flame rectification assisting cold bending formation; 8) manufacturing a assembly jig frame; 9) combining position welding and spot-welding on an upper flange plate and a lower flange plate respectively assembled on an assembly jig frame group; 10) welding the soldering seam between the web and the lower flange plate; 11) lifting the component from the jig frame, and turning over the component to weld the soldering seam between the web and the upper flange plate; and 12) returning the jig for a repeated inspection, and carrying out the three-dimensional coordinates detection through a total-station instrument. According to the manufacture method, used equipment is simple, and efficiencies on manufacture and production are improved.

Owner:YINGDU BRIDGE STEEL STRUCTURE ENG

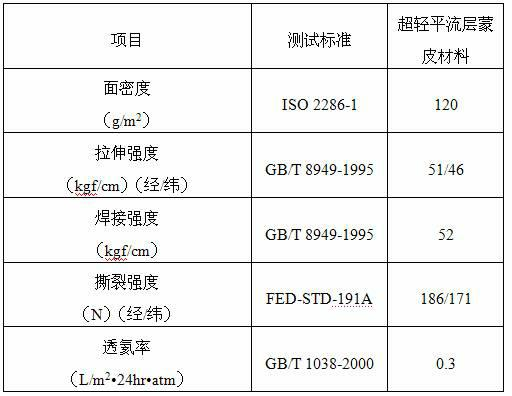

Ultra-light, weather-resistant and high-strength stratosphere skin material

InactiveCN101905557ALight in massGood weather resistanceSynthetic resin layered productsLighter-than-air aircraftPolyesterStratosphere

The invention provides an ultra-light, weather-resistant and high-strength stratosphere skin material which has high strength and weatherability, relating to skin materials. The ultra-light stratosphere skin material consists of a weather-resistant layer, a force bearing layer, a block layer and a heat sealing layer from outside to inside. Vectran fiber 200 Daniel plain woven fabric with ultra-high strength is selected and used as the force bearing layer, the Vectran fiber 200 Daniel plain woven fabric has the strength about 6 times as high as that of common polyesters, and the light weight of 54 g / m<2> and the thickness of 0.16 mm. The produced stratosphere skin material has ultra-light mass.

Owner:HARBIN INST OF TECH

Eight-treasure spicy chili sauce and manufacturing thereof

InactiveCN101897428APrevent cardiovascular diseaseHigh in proteinFood preparationMonosodium glutamateLycium barbarum fruit

The invention relates to an eight-treasure spicy chili sauce and manufacturing thereof. The eight-treasure spicy chili sauce has the main functions of edibility and nutrition, and also combines the functions of helping digestion, darkening the hair, beautifying the face, moistening the intestine, clearing heat, dispelling fire and building the body. The chili sauce can be eaten together with rice or bread. The chili sauce is characterized by choosing clean walnut seeds, pine seeds, peanut seeds, coix seeds, barbary wolfberry fruit, raisin, bamboo shoots and dried hawthorn as raw materials, and clean chili, cooked beef, catchup, thick broad-bean sauce, honey, white granulated sugar, cooked sesame seeds, pepper, salt, gourmet powder, dried chrysanthemum leaching liquid, wine, onion and ginger oil and edible oil are compounded. The chili sauce has high material quality, fine processing, red color, fragrant flavor and good taste.

Owner:林戈非

Hydrophobic and ultraviolet radiation proof transparent film and preparation thereof

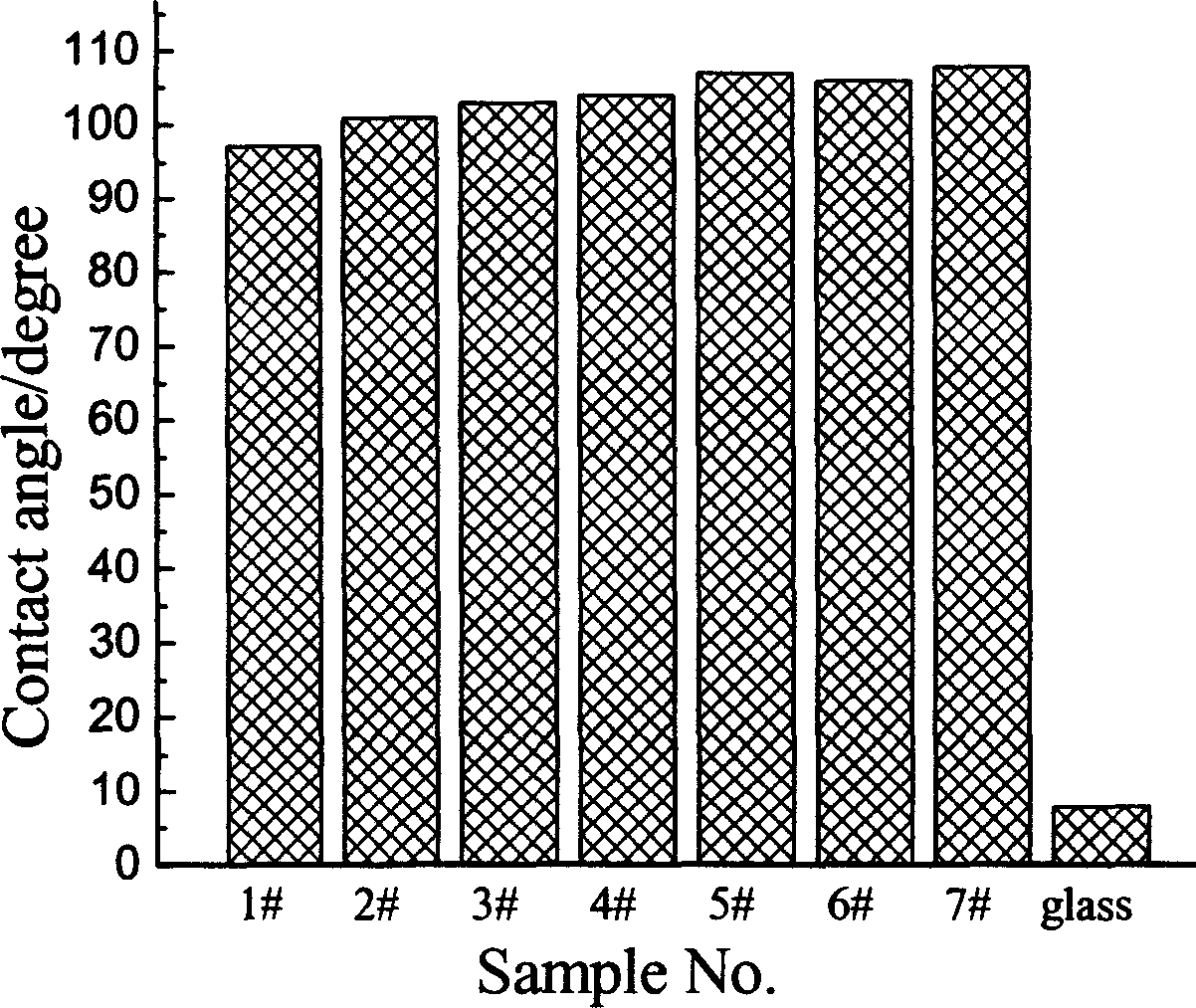

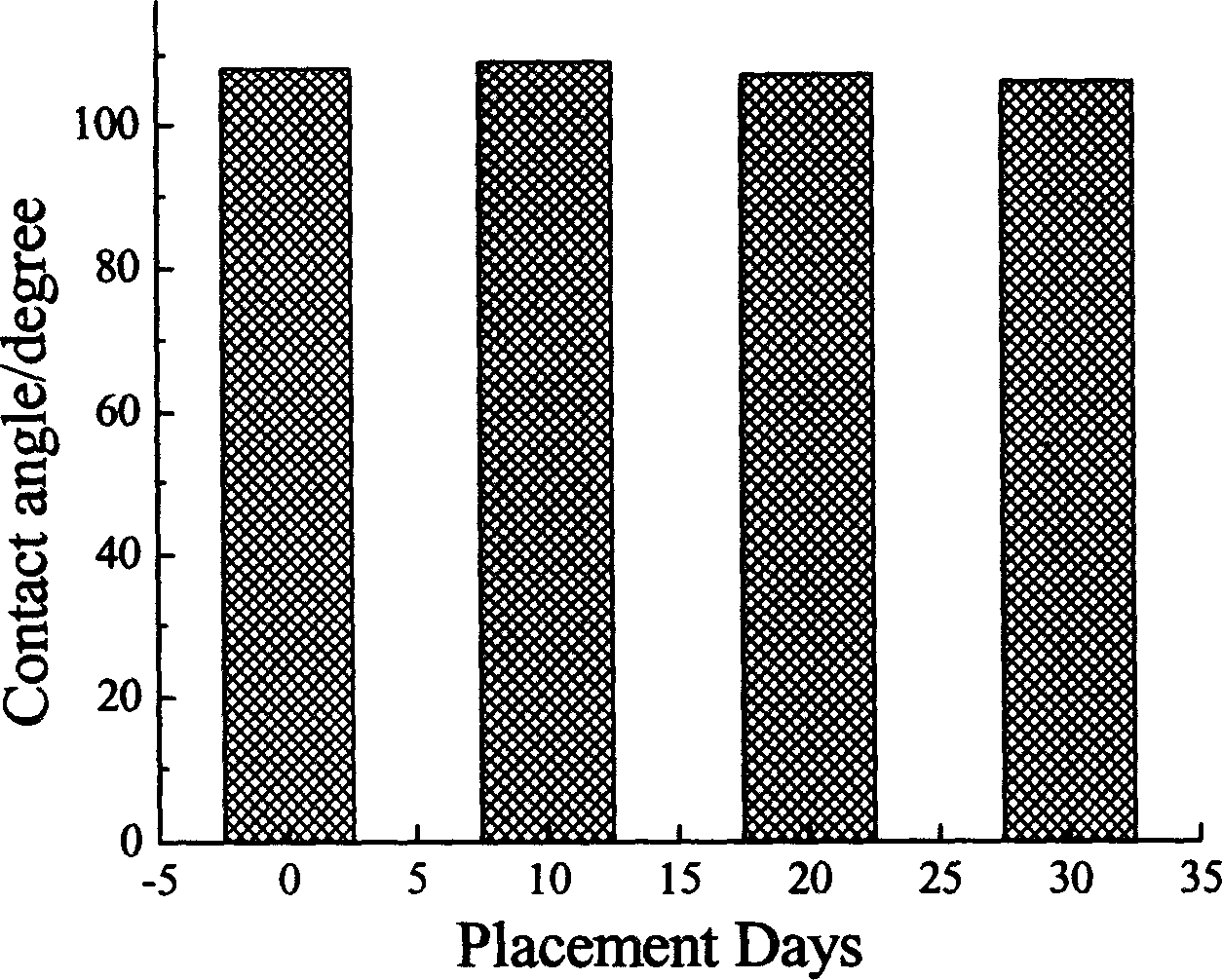

InactiveCN1594646AImprove hydrophobicityThe cutoff wavelength increasesVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringUltraviolet

The invention relates to a nitrogen doped titanium dioxide film of hydrophobicity and ultraviolet resistance, and its preparation. The character of film lies in that nitrogen exists in titanium dioxide crystal lattice in substitution and clearance mode, still a portion of Ti exist in Ti<3+> ion mode. film crystallization may be red schorl, anatase and amorphism. Titanium dioxide film prepared using direct current and radio-frequency magnetron sputtering method has good hydrophobic effect. Contact angle of film to distilled water is 97-110 DEG, ultraviolet cut-off wavelength is above 390nm, and visible light average transmittance is 70%-80%. Hydrophobicity of film is not influenced by film exposition time in air. The invention is easily operated, and the film thickness and composition can be controlled. Nitrogen doped hydrophobic film can be prepared for sample of different specification, material quality, and shape.

Owner:WUHAN UNIV OF TECH

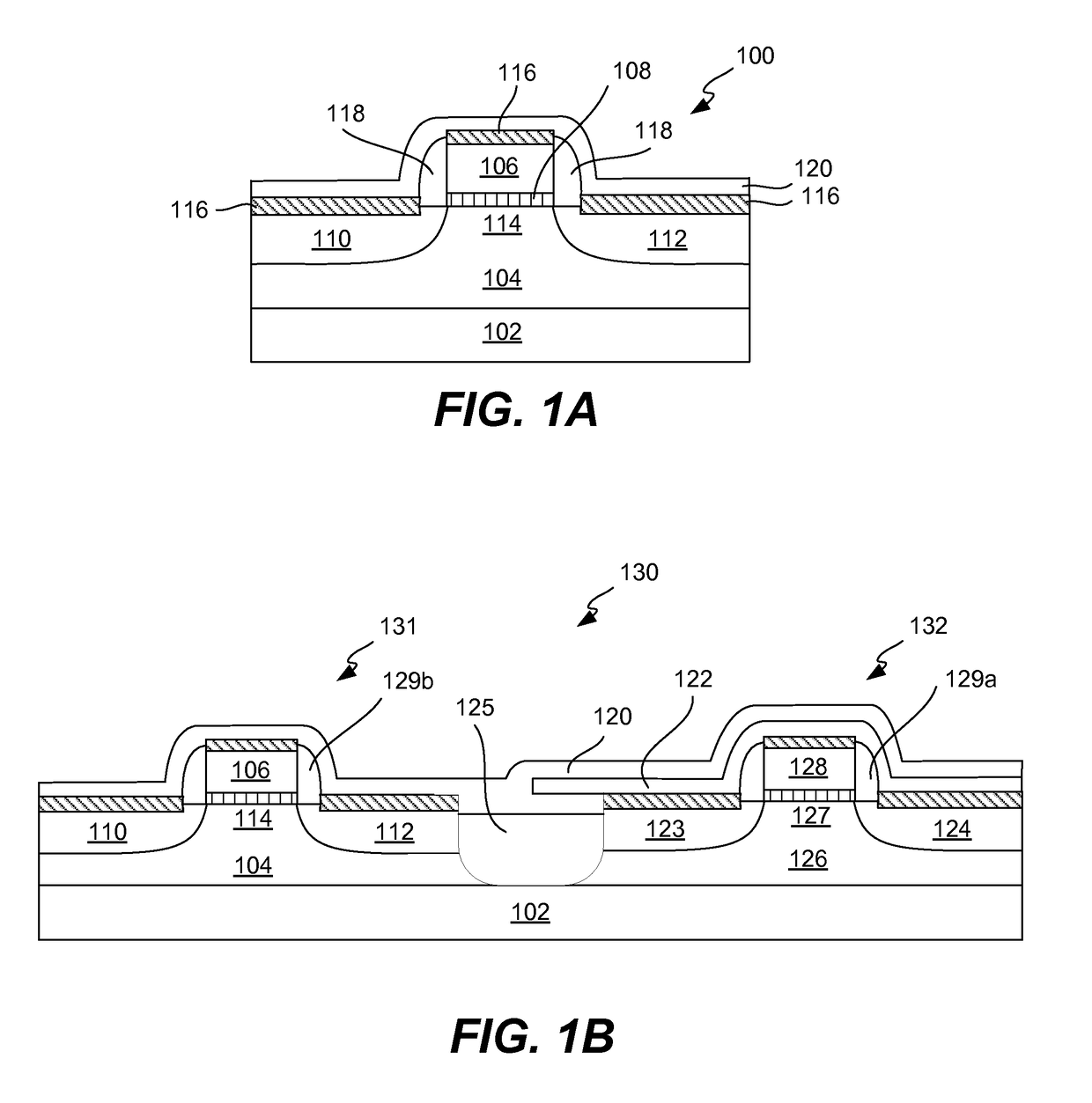

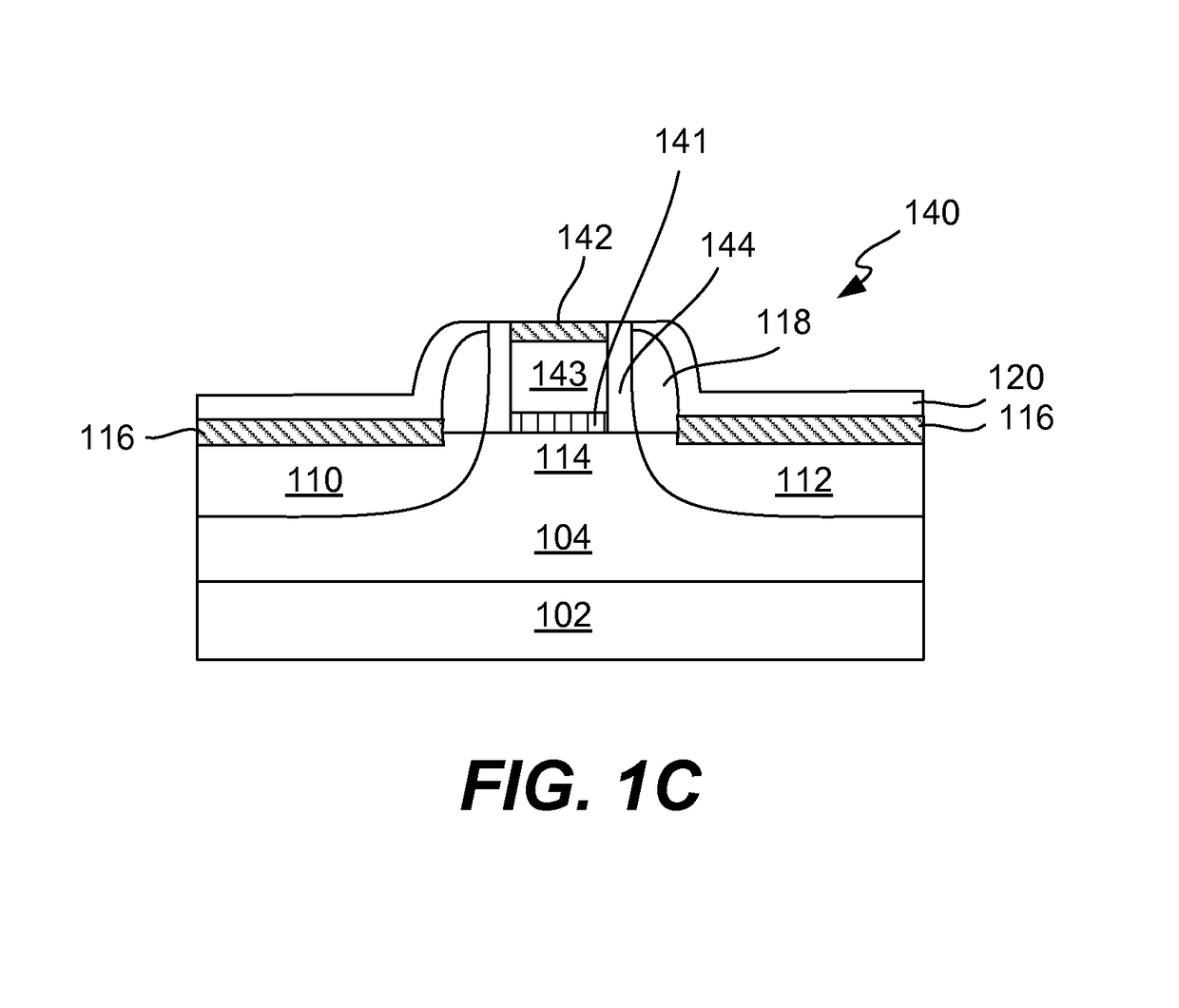

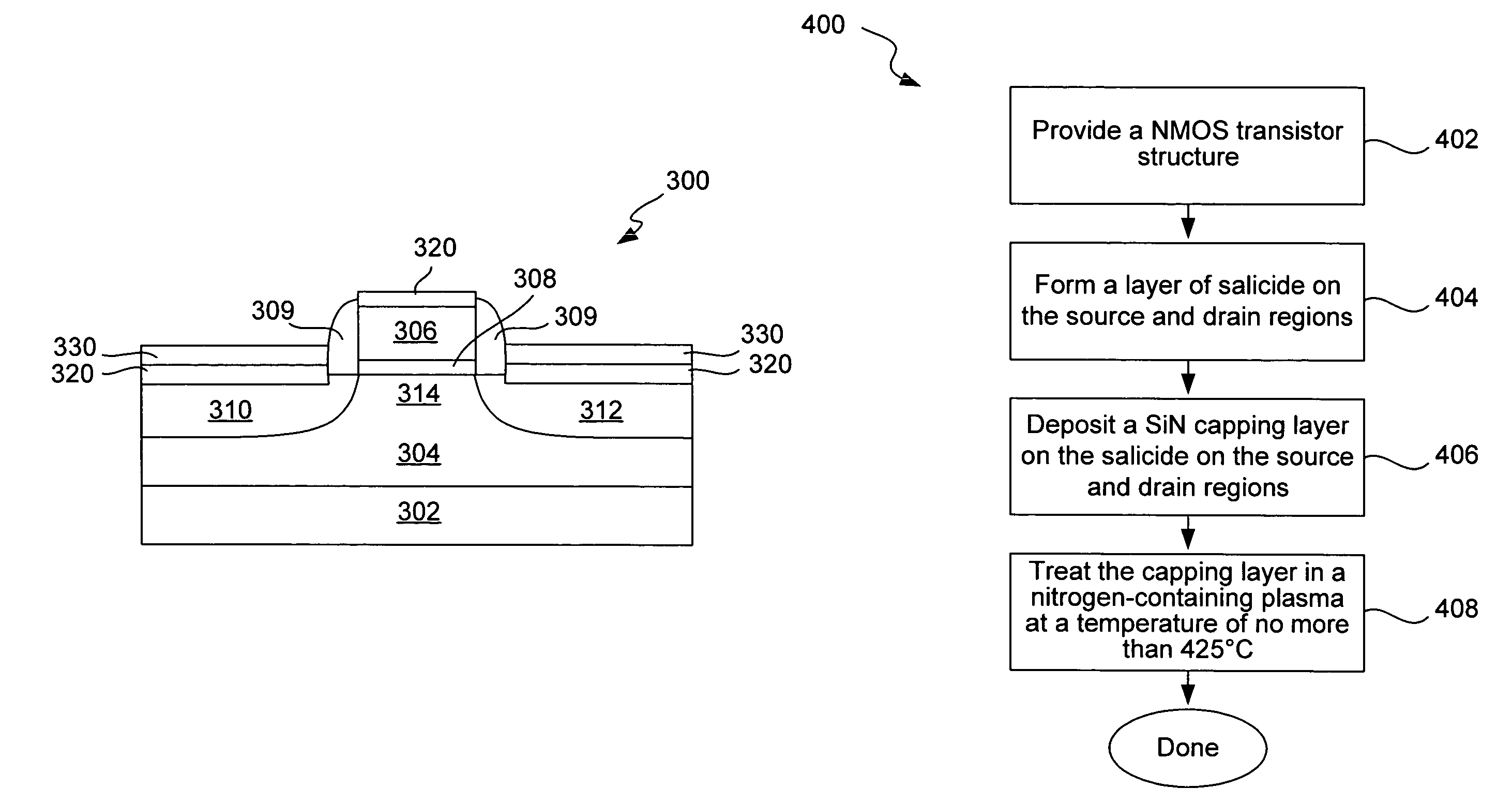

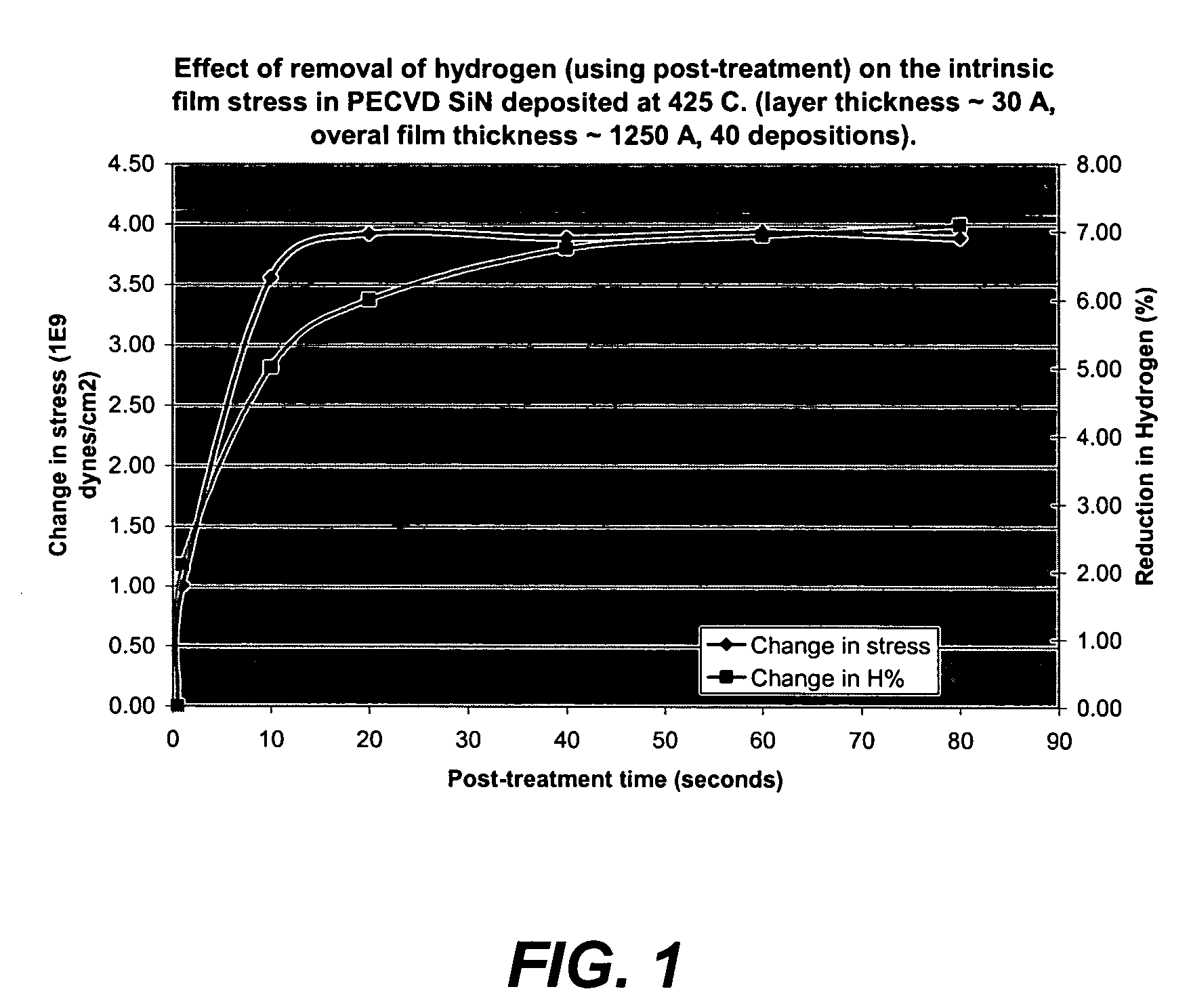

Strained transistor architecture and method

ActiveUS7041543B1Preserving material qualityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesTensile strainSalicide

Transistor architectures and fabrication processes generate channel strain without adversely impacting the efficiency of the transistor fabrication process while preserving the material quality and enhancing the performance of the resulting transistor. Transistor strain is generated is NMOS devices using a highly tensile post-salicide silicon nitride capping layer on the source and drain regions. The stress from this capping layer is uniaxially transferred to the NMOS channel through the source-drain regions to create tensile strain in NMOS channel.

Owner:NOVELLUS SYSTEMS

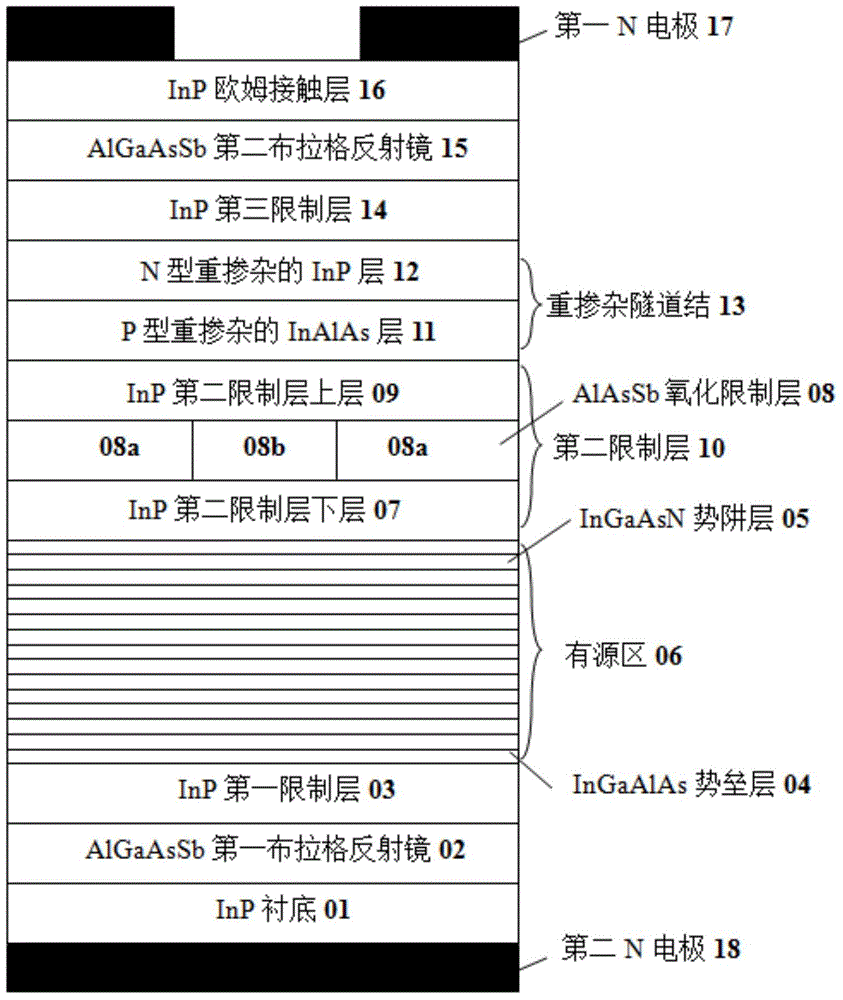

Vertical-cavity surface-emitting laser and manufacturing method thereof

InactiveCN104577711AHigh gainEffective limitLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserPotential well

The invention discloses a vertical-cavity surface-emitting laser which comprises a substrate, a first Bragg reflector, a first limiting layer, an active region, a second limiting layer, a second Bragg reflector and an Ohmic contact layer which are arranged in a laminated manner, wherein the active region adopts a quantum well structure, a potential barrier layer is made of InGaAlAs, and a potential well layer is made of InGaAsN; a heavily-doped tunnel junction and a third limiting layer are also arranged between the second limiting layer and the second Bragg reflector; an oxidized limiting layer is also arranged in the second limiting layer. The invention also provides a preparation method of the laser. The laser has the advantages that the laser uses an InGaAsN / InGaAlAs material system as the active region, has large conduction band order ratio and can effectively limit injected carriers, so that the threshold current is reduced, and the laser gain is improved; on an isometric wavelength band of 1550 nm, the content of N required by an active region material is lower, and devices with high material quality are easy to obtain.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

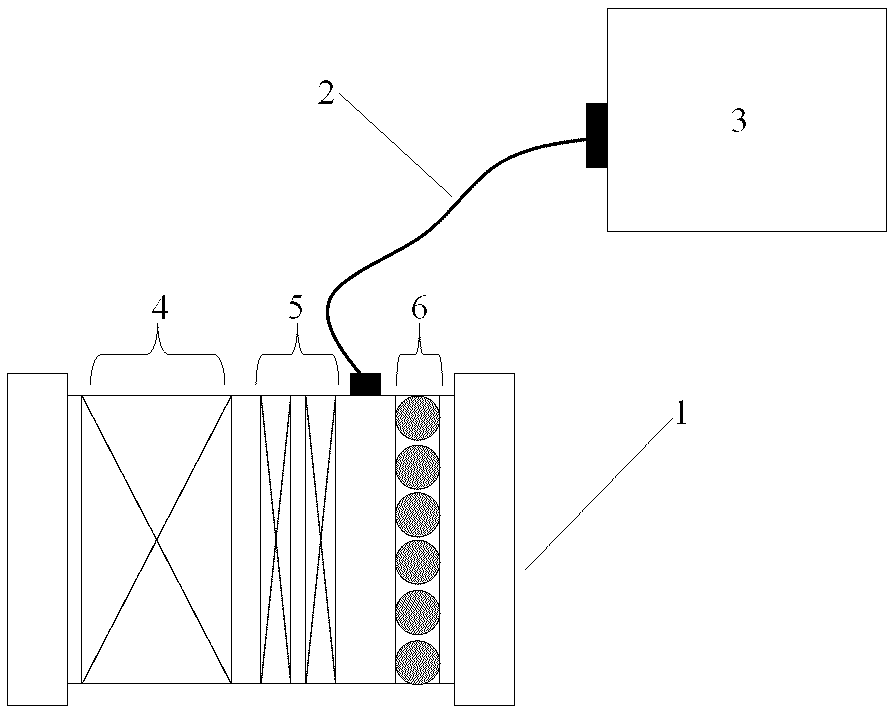

Method and device of improving online monitoring accuracy of engine oil metal abrasive particles

ActiveCN102818754AEliminate potential safety hazardsReal-time monitoring of working statusMaterial analysisEngineeringCopper

The invention discloses a method and a device of improving online monitoring accuracy of engine oil metal abrasive particles, designing a detection device capable of improving the online monitoring accuracy of the metal abrasive particles in engine oil and integrating an absolute electromagnetic detection technology, a differential motion electromagnetic detection technology and an array electromagnetic detection technology. According to the method and the device disclosed by the invention, online dynamic detection is carried out on the metal abrasive particles in the engine oil by adopting an integrated combination detection mode of absolute electromagnetic detection, differential motion electromagnetic detection and array electromagnetic detection, so that antijamming capability, monitoring accuracy and monitoring sensitivity of the device are improved, quality of the metal abrasive particles which pass through an oil return pipeline of an engine can be effectively measured in real time, and material quality is simultaneously separated by utilizing the characteristics that magnetic conductivity and electric conductivity of metal abrasive particles of copper abrasive particles, aluminum abrasive particles, iron abrasive particles and the like are different, so that the abrasion condition of the engine is judged, and alarm is sent out when abrasion loss reaches a preset upper limit threshold value, thereby timely eliminating safety hidden dangers due to abrasion of the engine and ensuring normal work of the engine.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD

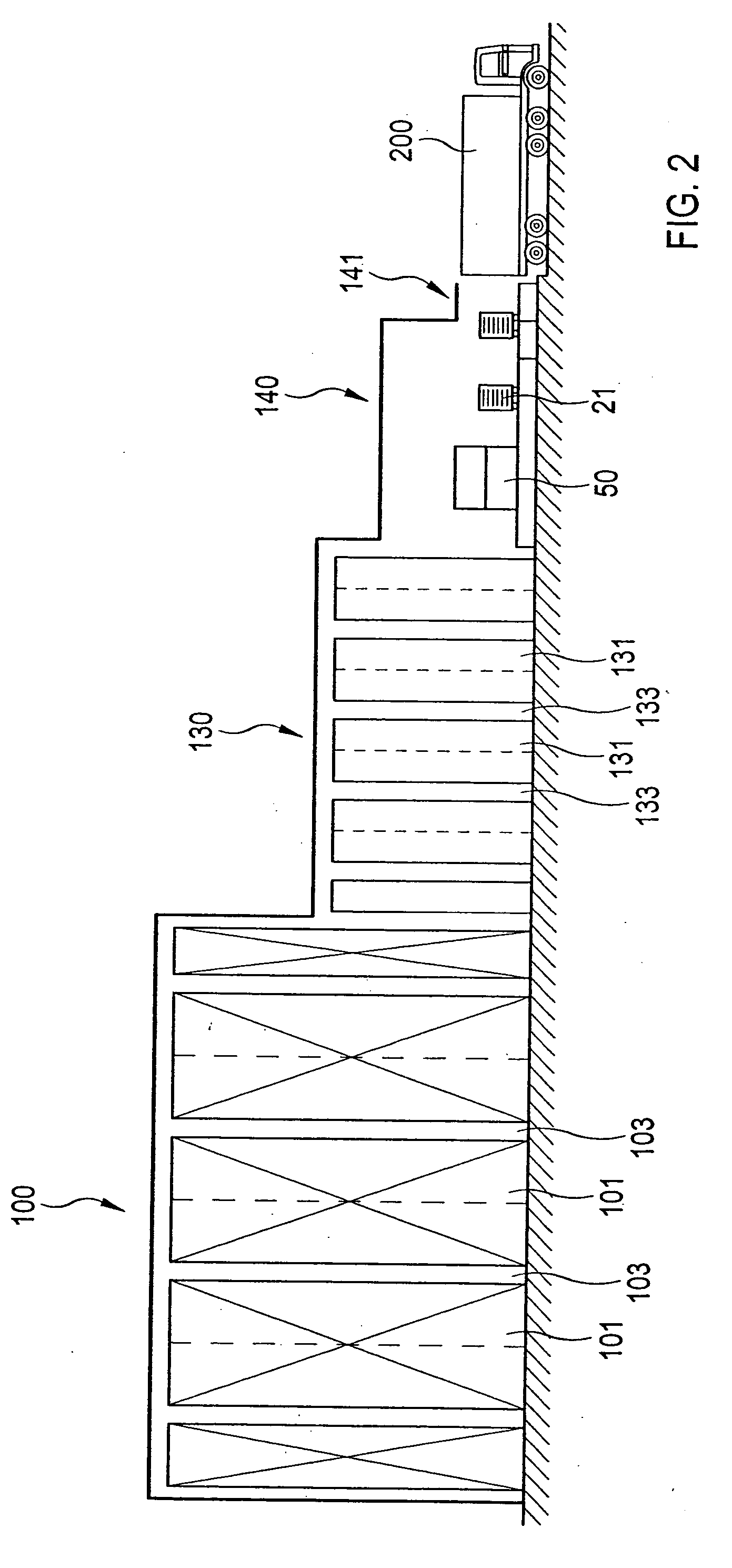

Load-carrier loading apparatus

ActiveUS20040191049A1Strong loadLoaded safely and reliablyWrappers shrinkageConveyorsMaterial qualityPallet

A machine for loading a load carrier (20) such as a pallet with packing units (cardboard boxes, collis etc.), which form a load stack (21) on the load carrier, comprises handling and support means (52-57), by means of which a packing unit (15) to be loaded is supported from below throughout the operation of loading from a feed device (51) onto the load stack. By virtue of the handling and support means the packing unit may be deposited at any selectable spatial position on the load stack. According to the invention it is therefore possible to form an optimized load stack on the load carrier, wherein the packing units are always supported from below, with the result that the loading is not dependent upon the material quality of the packaging of the packing unit.

Owner:LOGISTIK INFORMATIK

Processable full sea-depth buoyancy material and manufacture method

The invention provides processable full sea-depth buoyancy material and manufacture method, which can solve the problem that the processable buoyancy material with 11000m is difficult to manufacture in the prior art. The buoyancy material comprises the following components in part by mass: 100 parts of preprocessed matrix epoxy resin, 170-220 parts of glass cenosphere, 4-6 parts of aramid short fibre, 2-3 parts of silane coupling agent and 40-75 parts of curing agent. Experiments show that the processable full sea-depth buoyancy material has service water depth capable of reaching 11000m, uniform and consistent material quality and comprehensive property indexes remarkably superior to that of the prior art, and can be subjected to the appearance mechanical processing according to the requirements.

Owner:MARINE CHEM RES INST

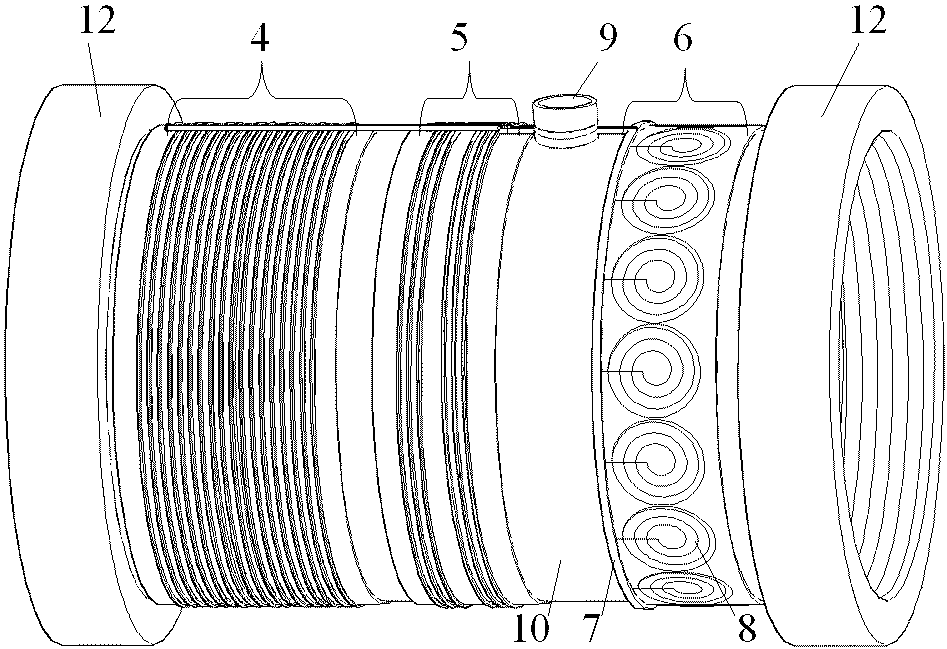

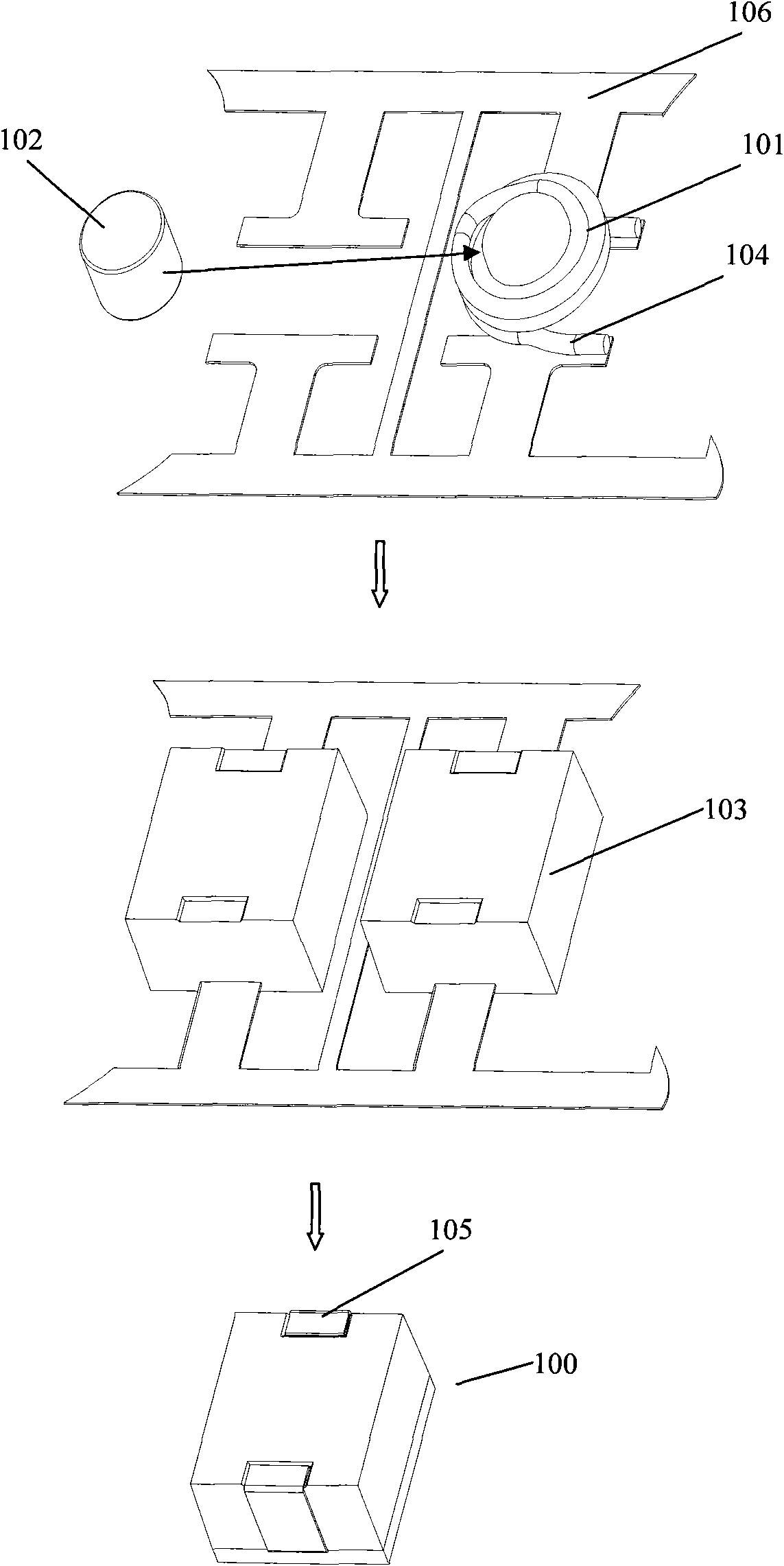

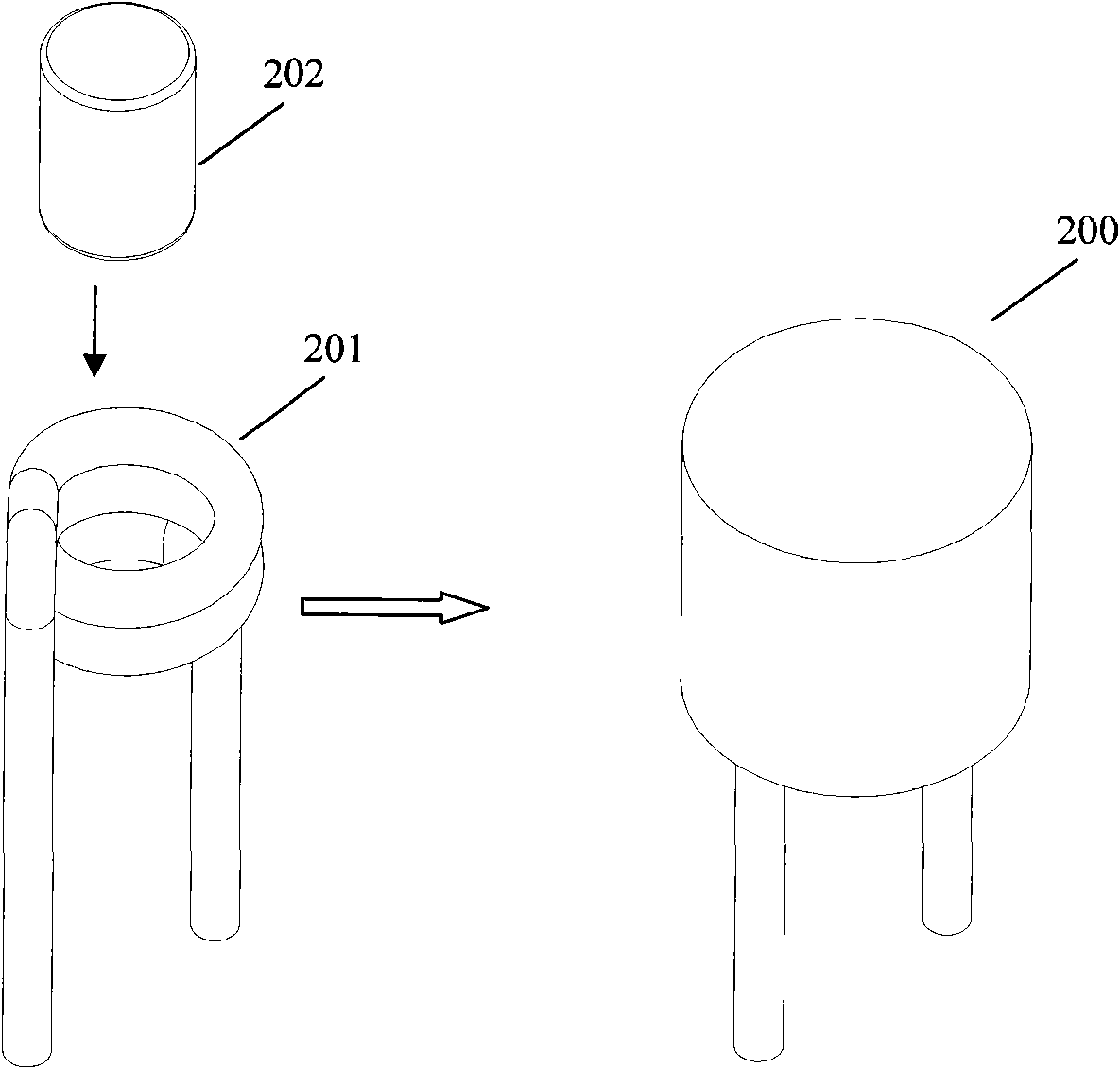

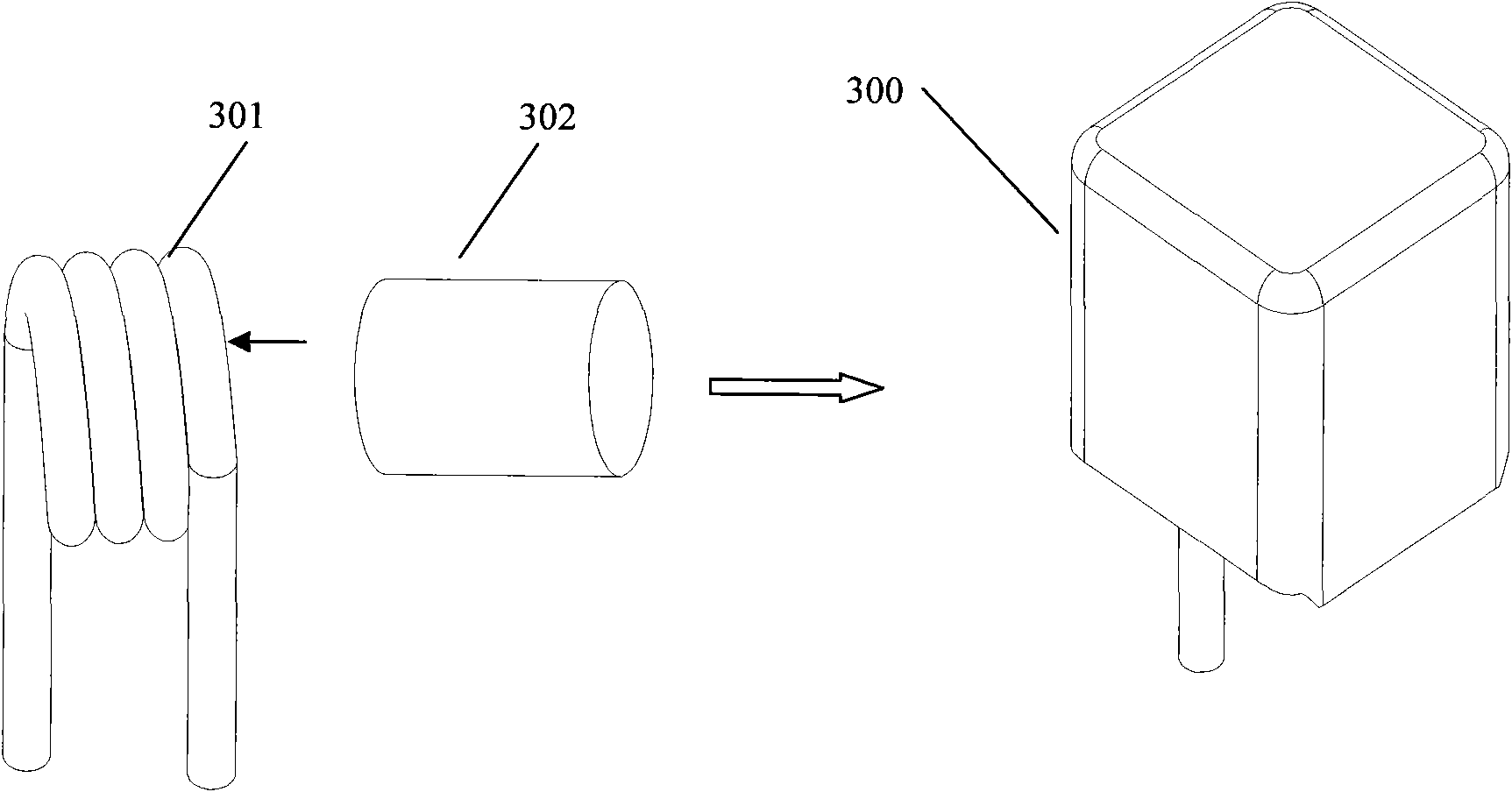

Metal powder injection molding inductor and processing method thereof

InactiveCN101552091AImprove mechanical propertiesImprove featuresTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureElectrical performanceInductor

The invention relates to a metal powder injection molding inductor and a processing method thereof, which aim at solving the problems of poor electrical performance consistence and high production cost and the like of the traditional power inductors; the method comprises the following steps of: firstly installing a magnetism-conducting core in a hollow cavity of a coil body of an enameled wire, later installing the coil with the magnetism-conducting core in an injection mold; then taking the composite material which mainly comprises ferromagnetic metal powder as flowing feeding and injecting the composite material into the injection mold until the cavity of the injection mold is completely filled; and finally obtaining a patch type inductor or a plug-in inductor which is molded by the injection of metal powder after curing and demolding. The inductor product has consistent appearance size and electrical performance, can select magnetism-conducting cores of various shapes and material qualities to meet different inductance performance demands, and can also greatly improves the production efficiency; in addition, the placement direction of the internal coil of the product can be designed freely and the whole product is consistent with the development direction of elements towards shortness and thinness.

Owner:深圳感通科技有限公司

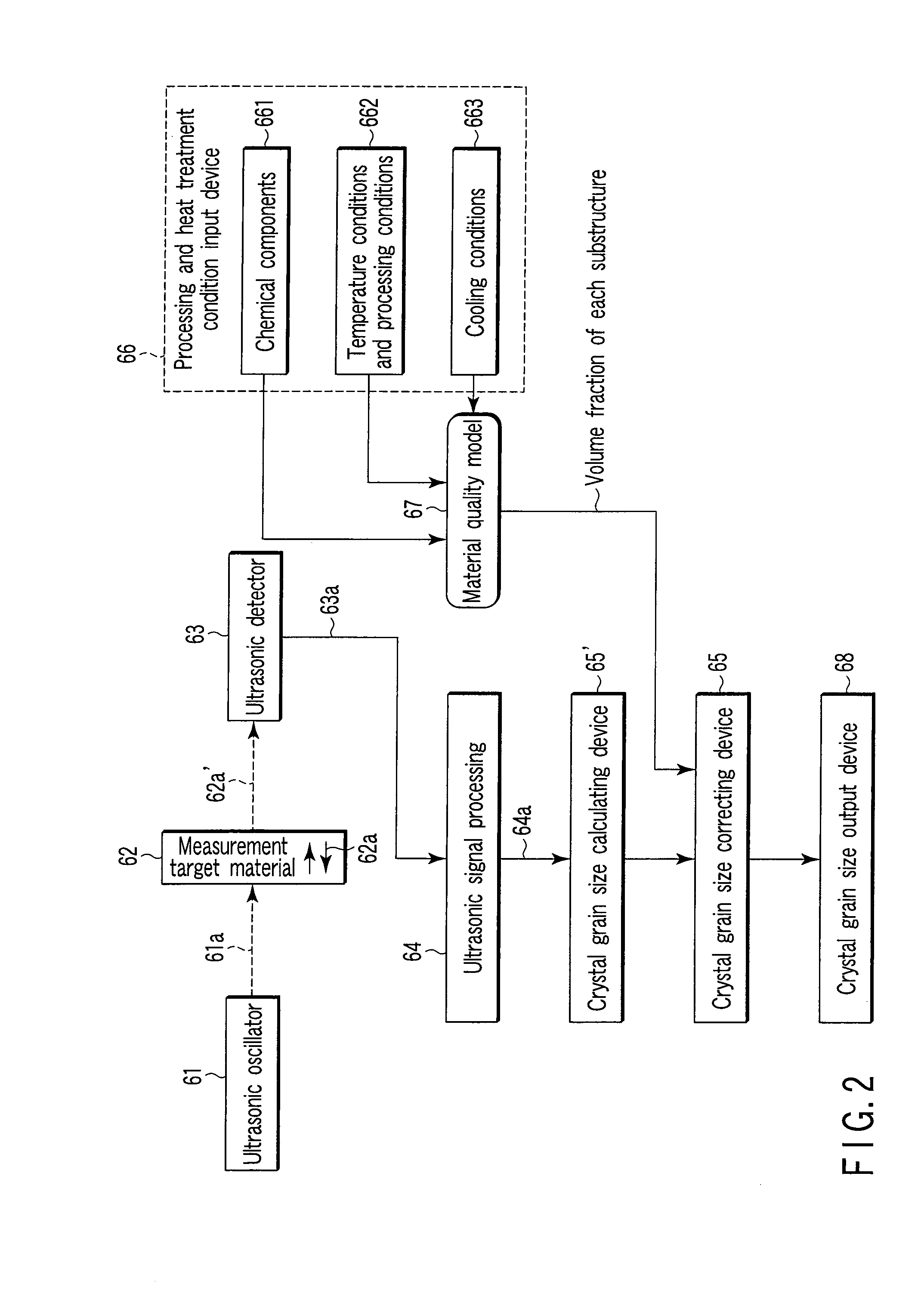

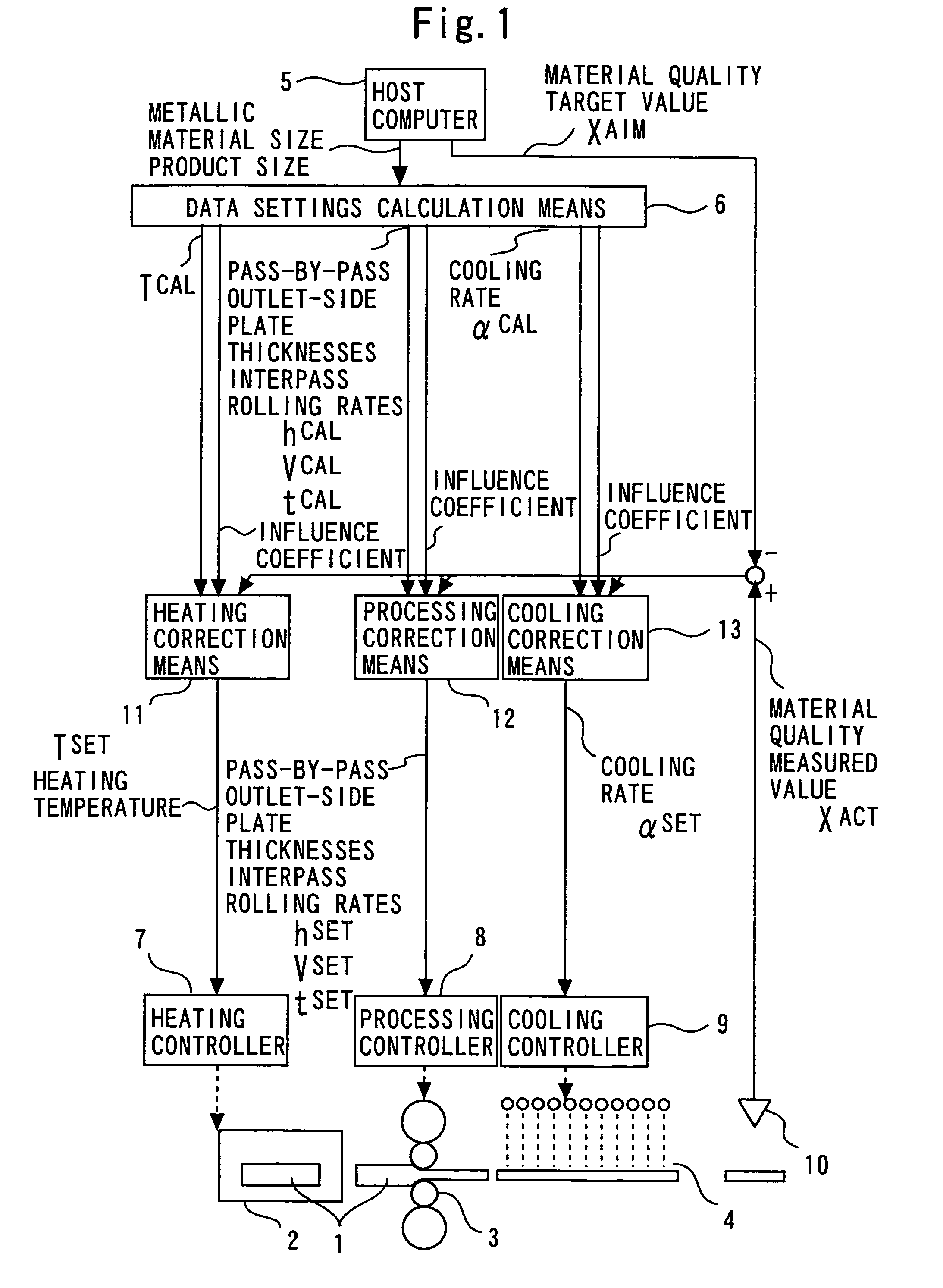

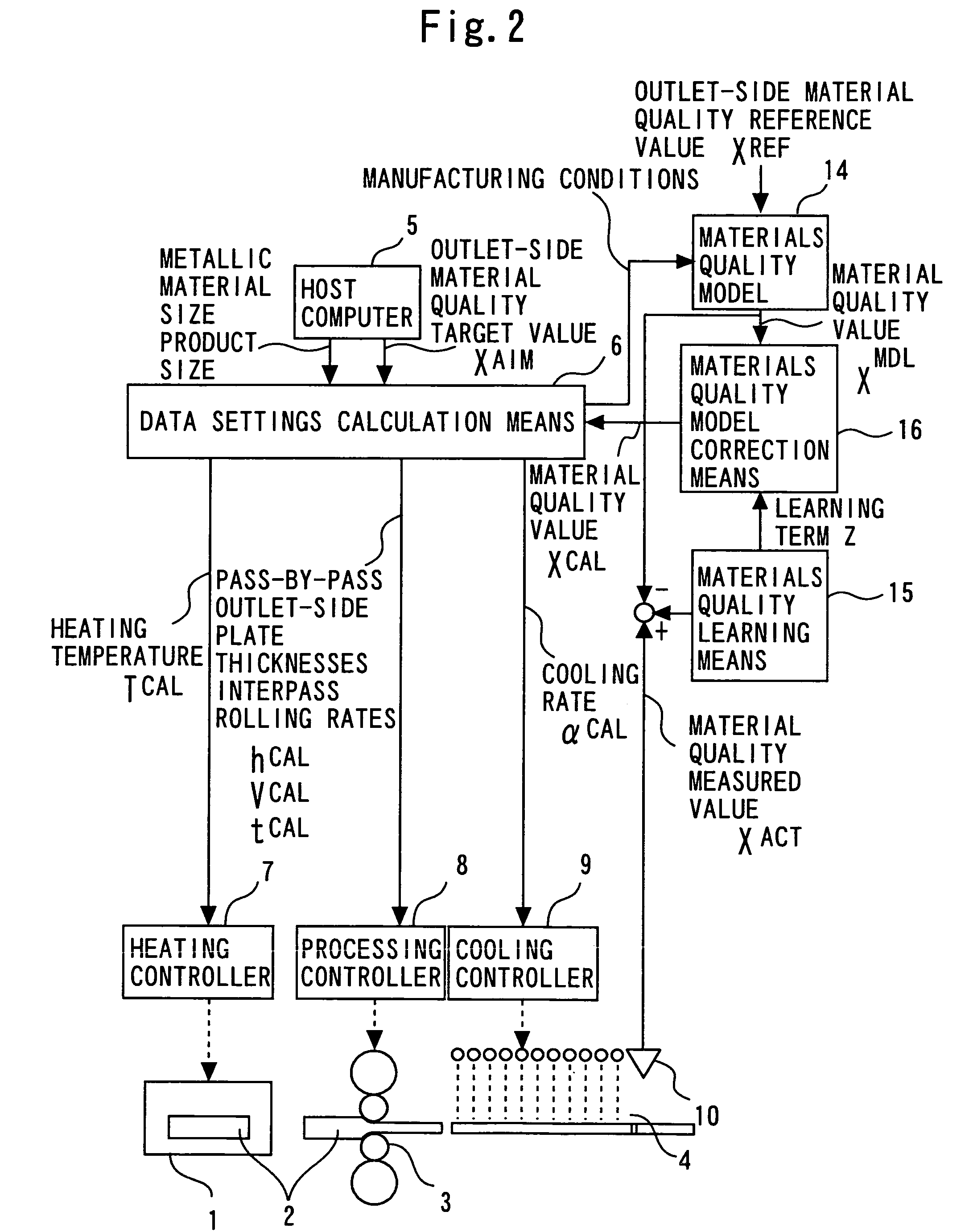

Method and apparatus for controlling materials quality in rolling, forging, or leveling process

ActiveUS20070151635A1Avoid it happening againConstant material qualityShaping toolsEnvelopes/bags making machineryManufacturing lineMaterial quality

The invention matches the material quality of a product to target data, even when a materials quality model is insufficient in prediction accuracy. Heating a metallic material, rolling, forging, or leveling the metallic material, and cooling the metallic material are each conducted at least once. Prior to manufacture of a metallic product of a desired size and shape, qualitative data of the metallic material are measured at a position by materials, quality sensor in a manufacturing line, and modifications based on measured data are made to heating, processing, or cooling conditions in at least one of the steps, upstream of the materials measured data sensor so that the quality of the metallic material at the measuring position agrees with target data.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

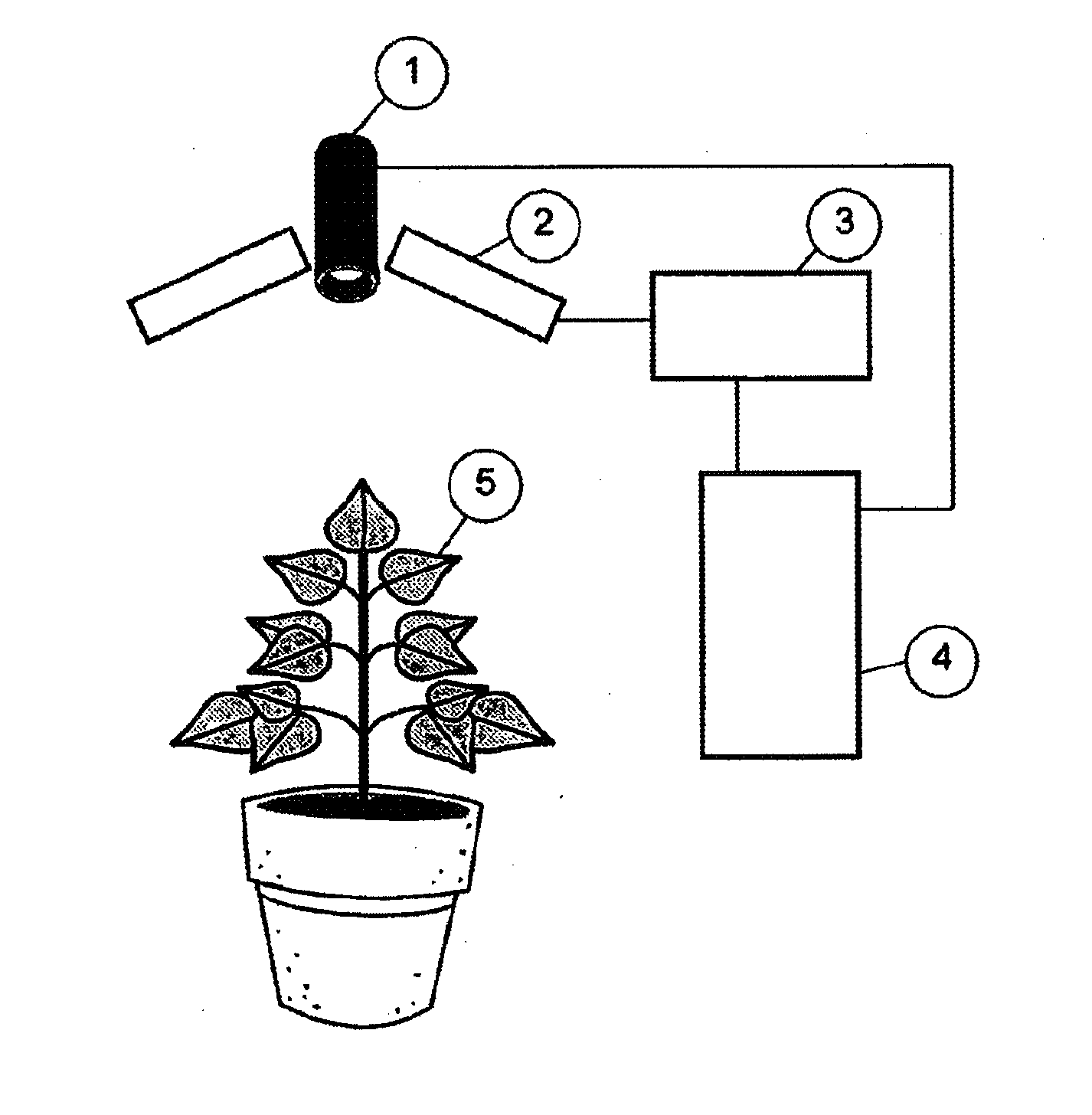

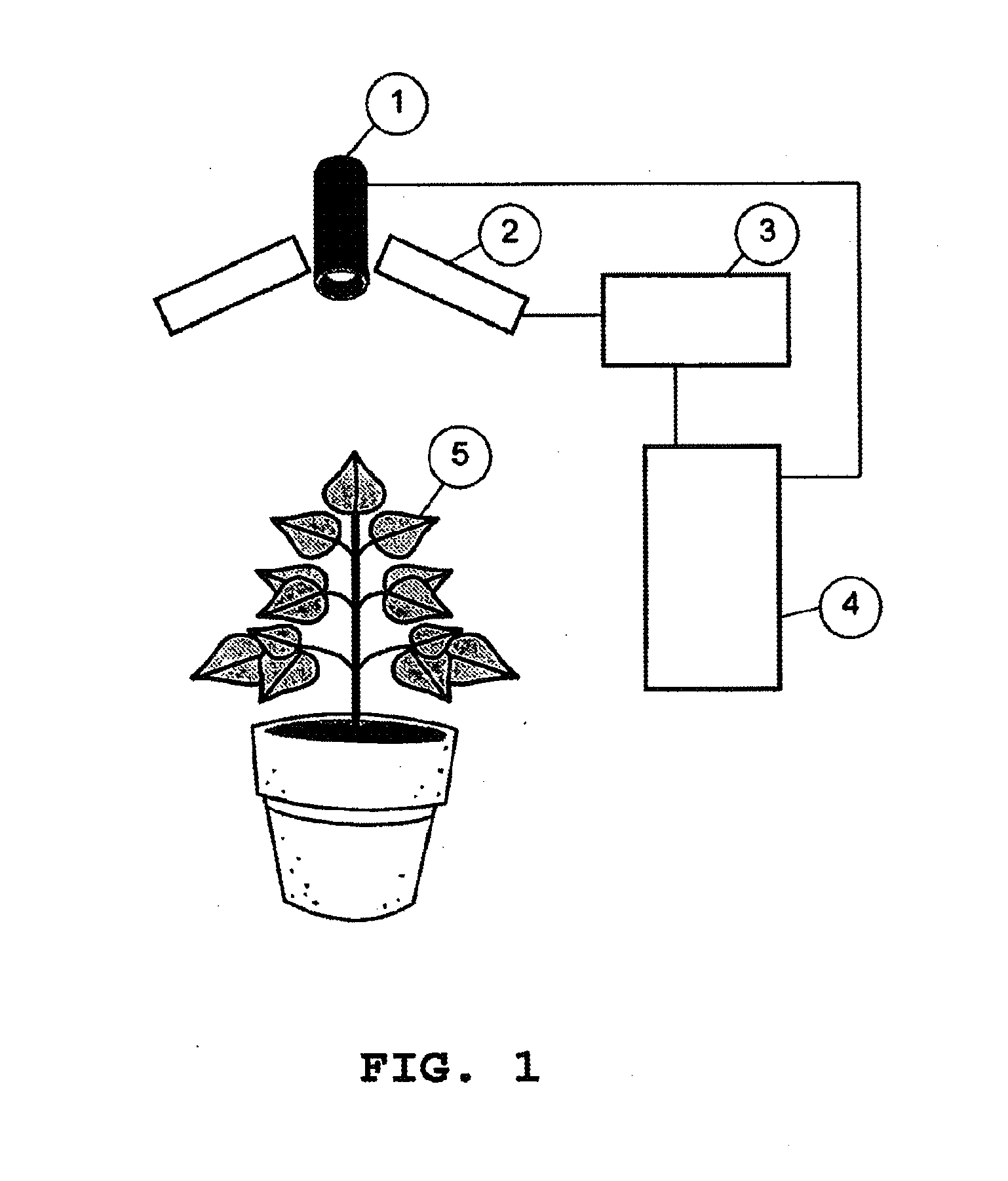

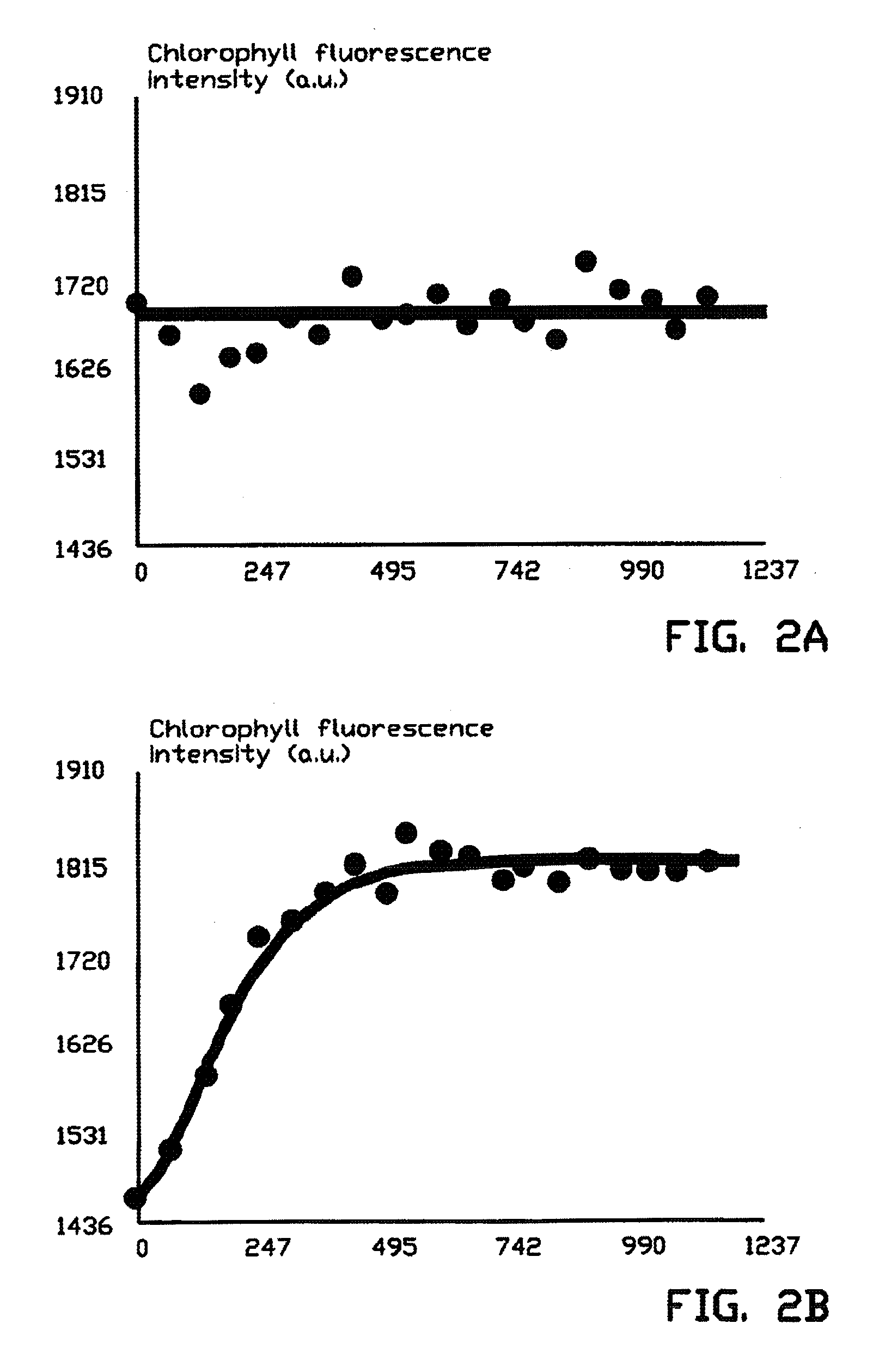

Method and device for determining plant material quality using images containing information about the quantum efficiency and the time response of the photosynthtic system

The present invention relates to a method for determining the quality of plant material by irradiating said plant material with a beam consisting of several consecutive light pulses of electromagnetic radiation comprising one or more such wavelengths, that at least a part of the chlorophyll present is excitated by at least a part of the radiation, and for each light pulse measuring the fluorescence radiation originating from the plant material and associated with the chlorophyll transition with an imaging detector for obtaining the chlorophyll fluorescence images. The invention also relates to calculating characteristic chlorophyll fluorescence images from the chlorophyll fluorescence images that contain information about the quantum efficiency and the time response of the photosynthetic activity of the photosynthetic system of the plant material. The invention further relates to a device for recording and processing the chlorophyll fluorescence images and to methods and devices for sorting and separating plant material.

Owner:STICHTING DIENST LANBOUWKUNDIG ONDERZOEK

Enzyme beverage and preparation method thereof

InactiveCN105533377AImprove permeabilityHigh content of bioactive substancesFood ingredient functionsSocial benefitsRipening

The invention discloses an enzyme beverage. The enzyme beverage is prepared from a raw material, a leavening agent and deuterium-depleted water. The mass ratio of the deuterium-depleted water to the raw material is (1-10):1. The leavening agent comprises saccharomycetes and lactic acid bacteria, the use amount of the saccharomycetes accounts for 5% to 10% of the volume fraction of the inoculated raw material, and the use amount of the lactic acid bacteria accounts for 1% to 3% of the mass of the inoculated raw material. The invention further discloses a preparation method. The preparation method comprises the following steps of 1 raw material pretreatment, 2 saccharomycete fermentation, 3 lactobacillus fermentation and 4 ripening. The enzyme stock solution obtained after ripening can be directly orally taken, and can also be taken after being diluted by 1-10 times with deuterium-depleted water. The enzyme beverage and the preparation method have the advantages that the deuterium-depleted water is adopted as fermentation water, the characteristics that the deuterium-depleted water is high in permeability and the reaction activity of biological enzymes is enhanced are fully utilized, the fermentation period can be obviously shortened, the bioactivator content of the obtained enzyme product is high, the production method is simple in process and suitable for large-scale production, and high economic and social benefits are achieved.

Owner:SHANGHAI JINWEIZI BIOTECH CO LTD

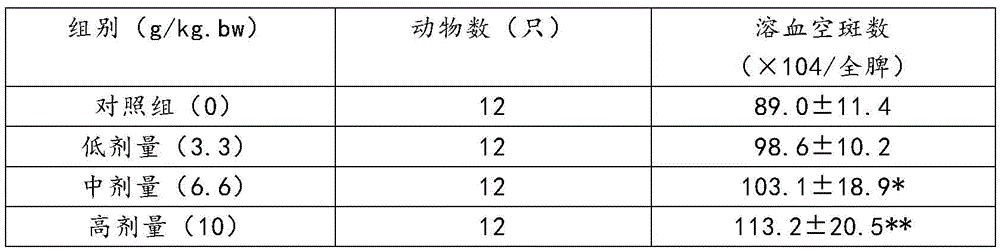

Entity material quality replacement method based on three-dimensional virtual platform

InactiveCN103035024AInstant renderingReduce program operation timeGeometric image transformation3D-image renderingThumbnailVirtual camera

The invention discloses an entity material quality replacement method based on a three-dimensional virtual platform. The entity material quality replacement method based on the three-dimensional virtual platform comprises the following steps that a three-dimensional render engine is initialized, an initial position of a virtual camera in a scene is set, the size of a viewport is set, after a user selects the scene, scene data is read from scene organization files, entity data is read from material files, an illumination effect of the scene is loaded, a software interface is initialized, a texture mapping menu which comprises a plurality of various thumbnails of texture mappings is displayed, wherein the thumbnails can be dragged, a user selects a texture mapping from the texture mapping menu, and drags the texture mapping to the scene, software confirms a three-dimensional coordinate of the scene of a needed position through drag operation of the user, material quality need replacing is confirmed through the three-dimensional coordinate, when the material quality is confirmed, the texture mapping in the entity texture mapping is carried out with appropriate scaling by the selected texture mapping in the texture mapping menu and is replaced by the selected texture mapping in the texture mapping menu, and the scene is saved. The entity material quality replacement method based on the three-dimensional virtual platform achieves immediate render.

Owner:NANJING HOMEJOY DIGITAL TECH

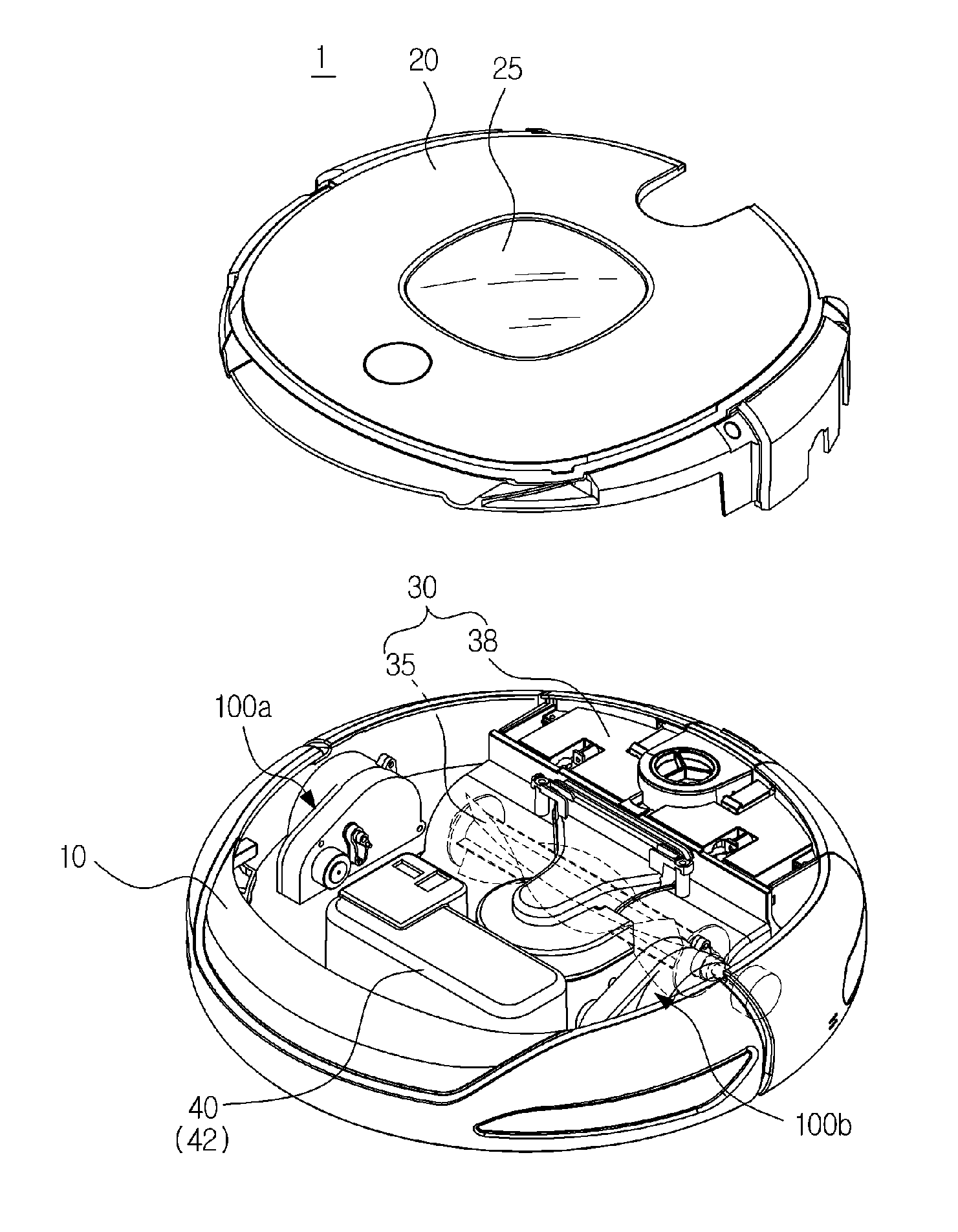

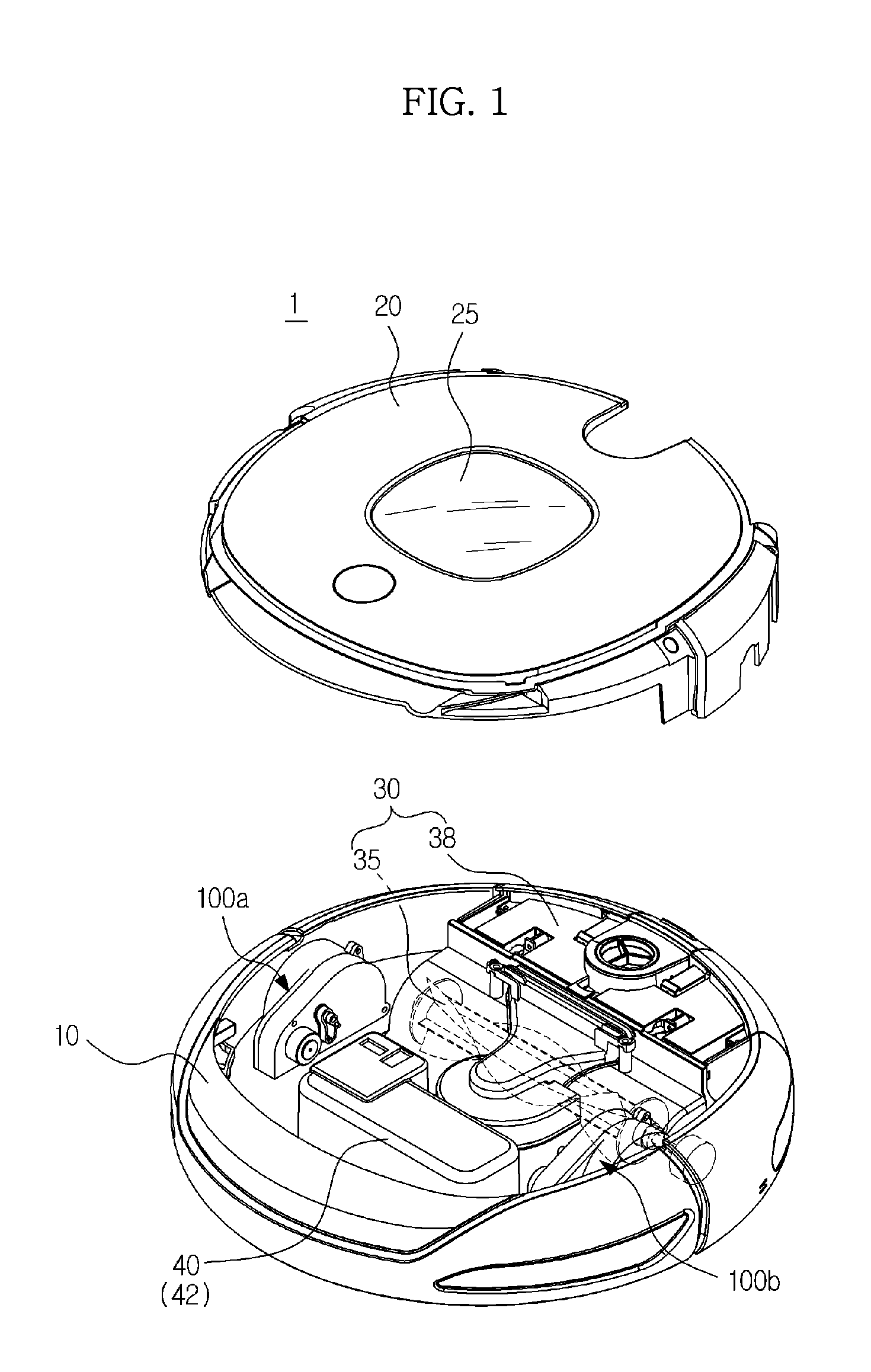

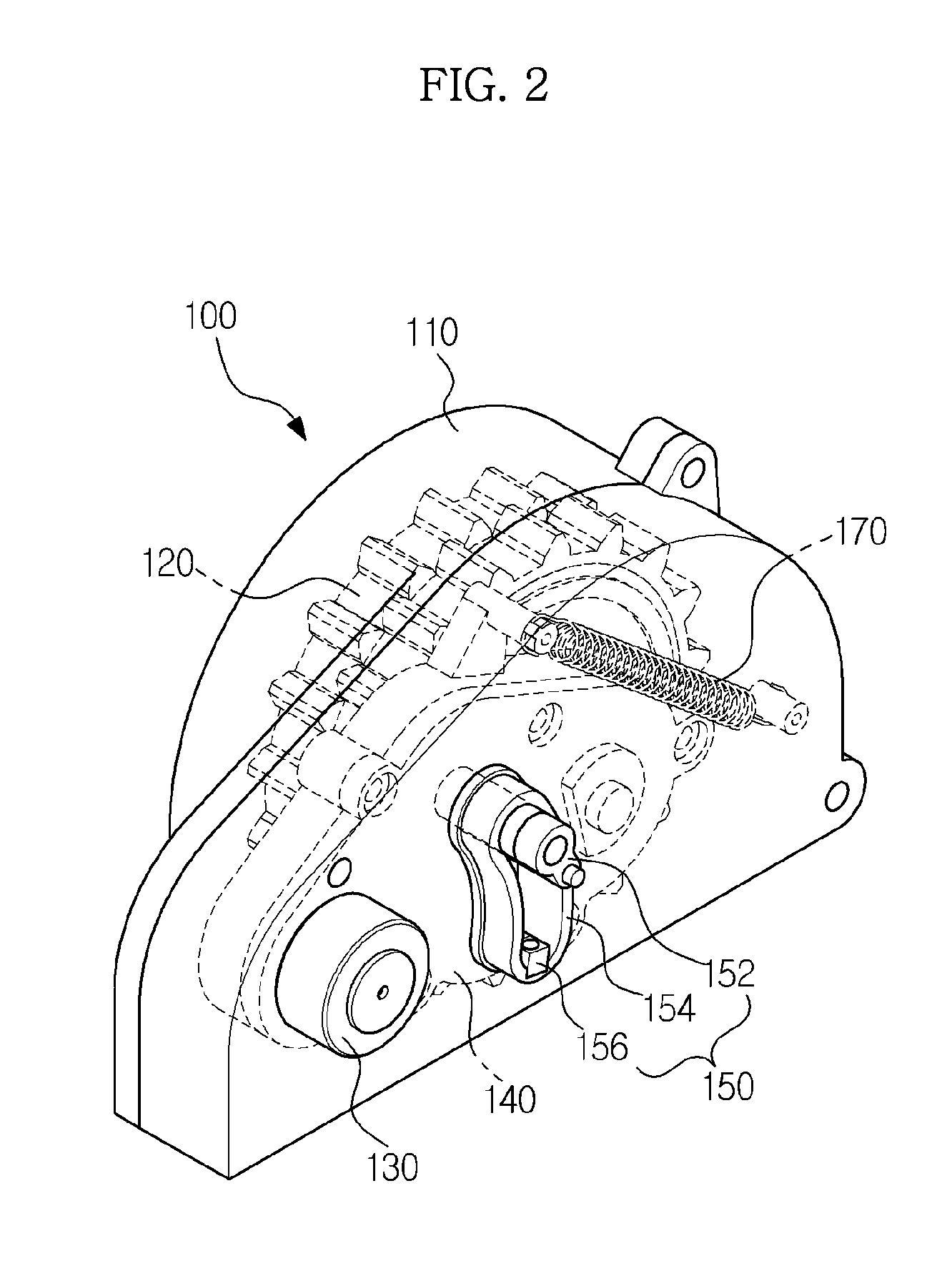

Autonomous cleaner and method of controlling the same

ActiveUS20130054022A1Simple structureAutomatic obstacle detectionTravelling automatic controlDrive wheelEngineering

An autonomous cleaner has an enhanced structure capable of conducting an efficient cleaning task according to the material quality or the condition of the floor surface of a cleaning space.The autonomous cleaner includes a body, a driving wheel to drive the body, a driving wheel assembly having the driving wheel, and a control unit. The control unit detects a displacement of the driving wheel corresponding to a reference position by sensing a sensor target, determines material quality or condition of a floor surface according to the displacement of the driving wheel, and controls the driving of the autonomous cleaner according to the determined material quality or the condition of the floor surface.

Owner:SAMSUNG ELECTRONICS CO LTD

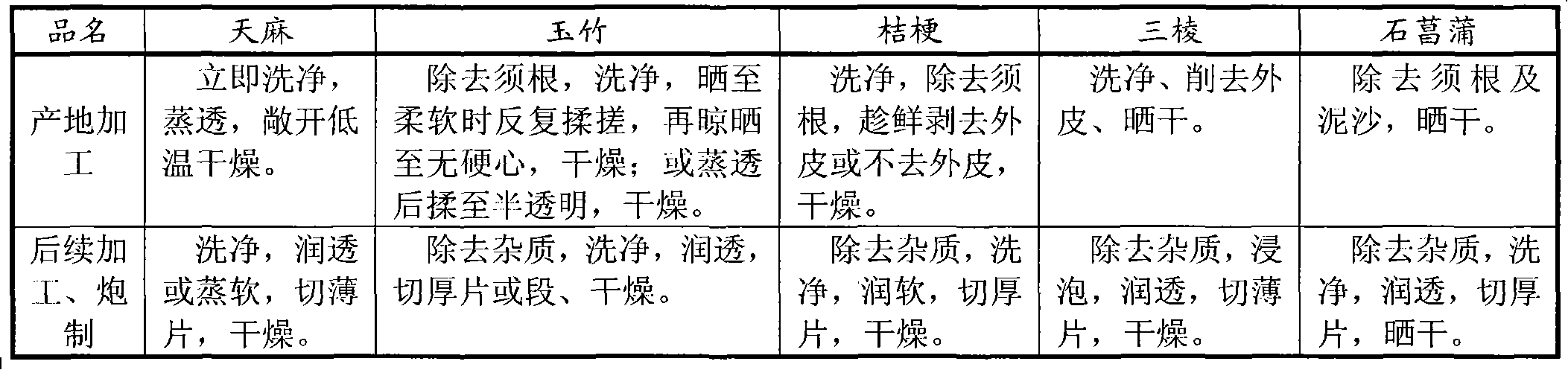

Fresh processing technology of traditional Chinese plant medicine at producing site

InactiveCN102000119AQuality improvementGuaranteed curative effectPlant ingredientsSocial benefitsBiology

The invention relates to the filed of traditional Chinese plant medicine processing technologies at the producing site, in particular to a fresh processing technology of a traditional Chinese plant medicine at the producing site. The technology comprises the following steps of: harvesting, cleaning, cutting, inactivating and drying the medicinal material, or harvesting, cleaning, cutting and drying the medicinal material. The multiple and repeated procedures of cleaning and drying the medicinal material at the producing site and cleaning, softening, cutting and drying the medicinal material at a medicine piece plant of the prior art are directly changed into the process of cleaning, cutting and drying at the producing site. Thus, the invention achieves the purposes of simplifying the processing, subsequent processing and preparing procedures of the traditional Chinese medicinal material at the producing site, saving energy consumption, reducing comprehensive production cost, ensuring medicinal material quality and increasing peasant incomes and has obvious economical and social benefits.

Owner:HANGZHOU HAISHAN PHARMA EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com