Diffusion welding method of titanium or titanium alloy and stainless steel

A technology of titanium alloy and stainless steel, applied in the field of diffusion welding, which can solve the problems of high processing cost of micron-sized copper foil, high cost of intermediate layer, reduction of corrosion resistance and continuity of joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

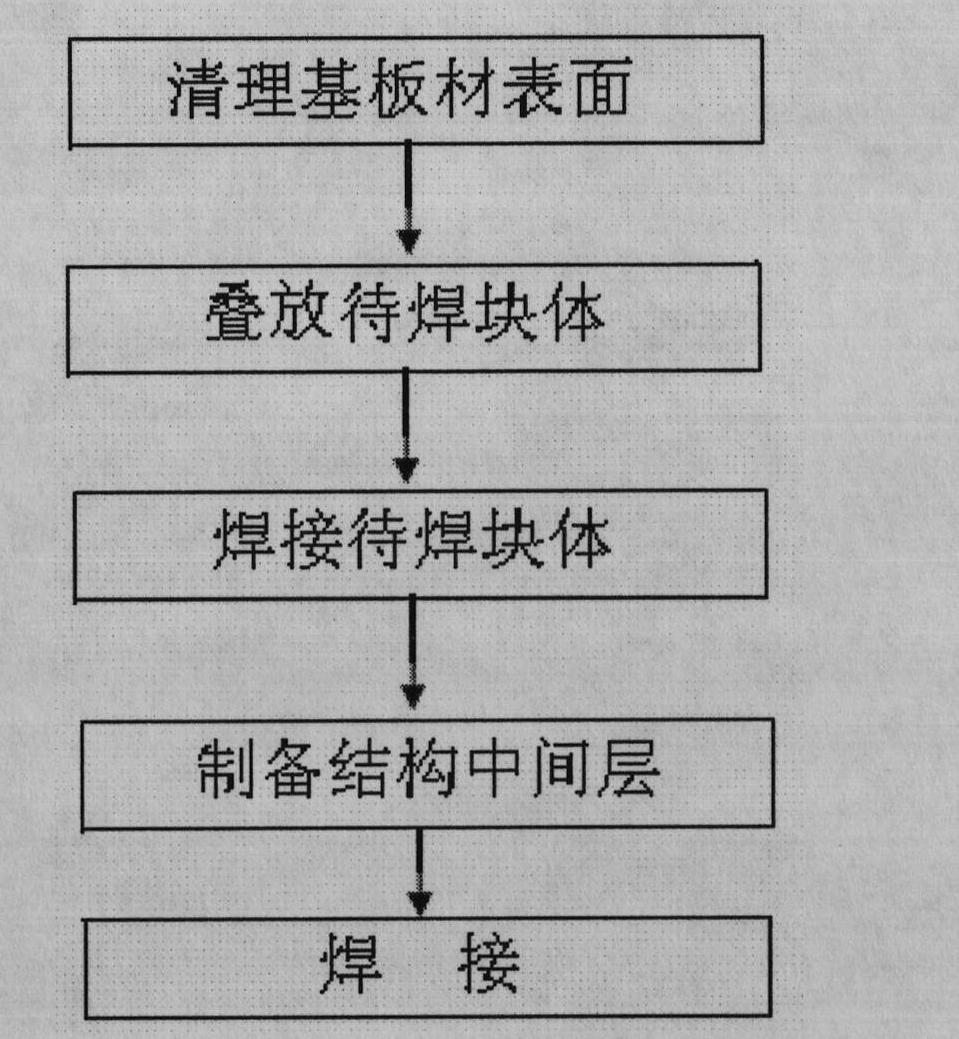

[0025] This embodiment is a method for diffusion welding of TA1 industrial pure titanium and 00Cr19Ni10 stainless steel, and its specific process includes the following steps:

[0026] Step 1, cleaning the surface of the plate; select several pieces of TA1 industrial pure titanium plate and 00Cr19Ni10 stainless steel plate with a thickness of 2mm as the raw materials for preparing the middle layer of the structure. Use metallographic sandpaper to polish the surface of the plate to make the surface roughness Ra≤1.6μm. Afterwards, immerse the processed plate in acetone for ultrasonic cleaning for 5 minutes, and dry it with cold air to obtain cleaned TA1 industrial pure titanium plate and 00Cr19Ni10 stainless steel plate. Ultrasonic power is 600W.

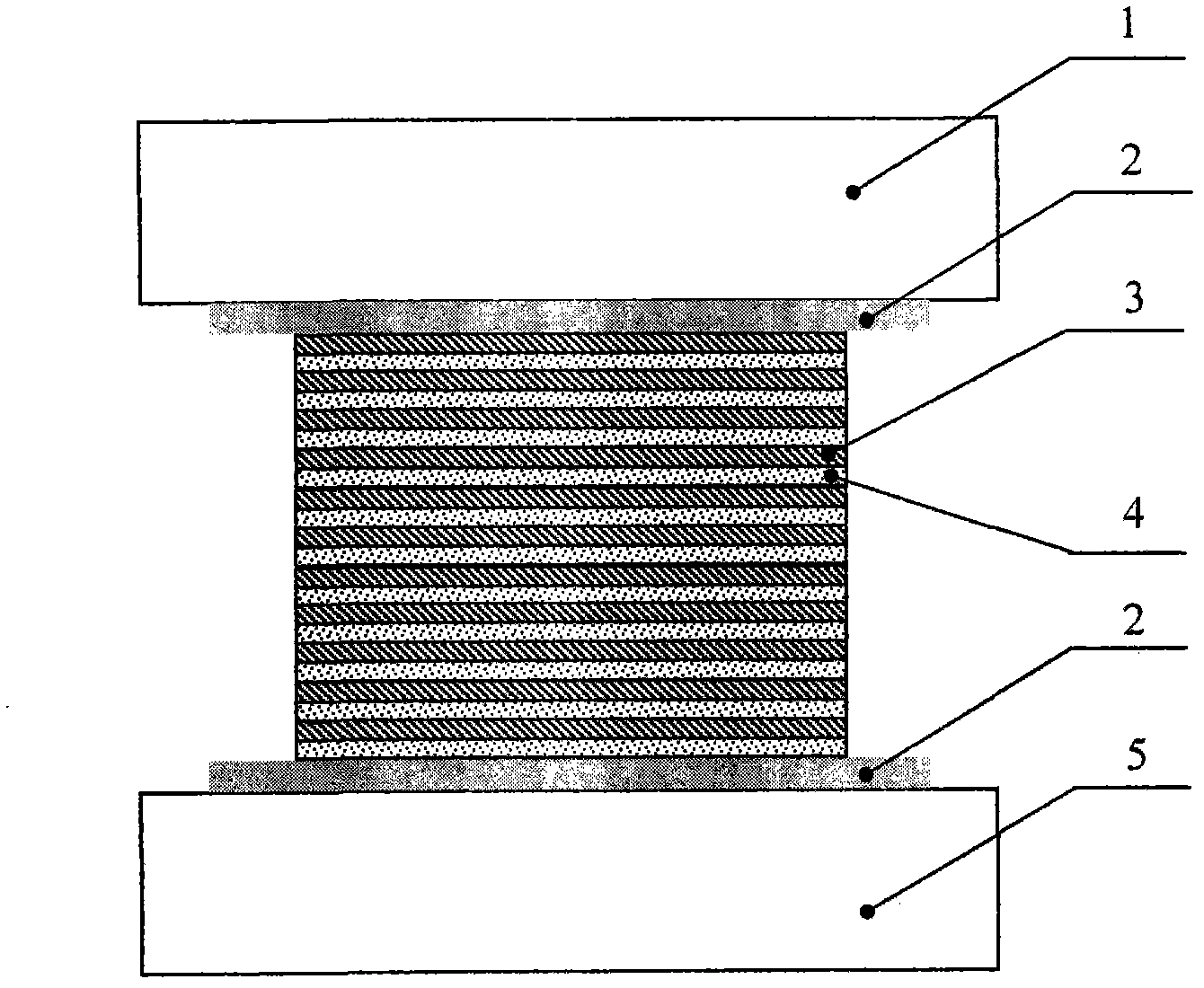

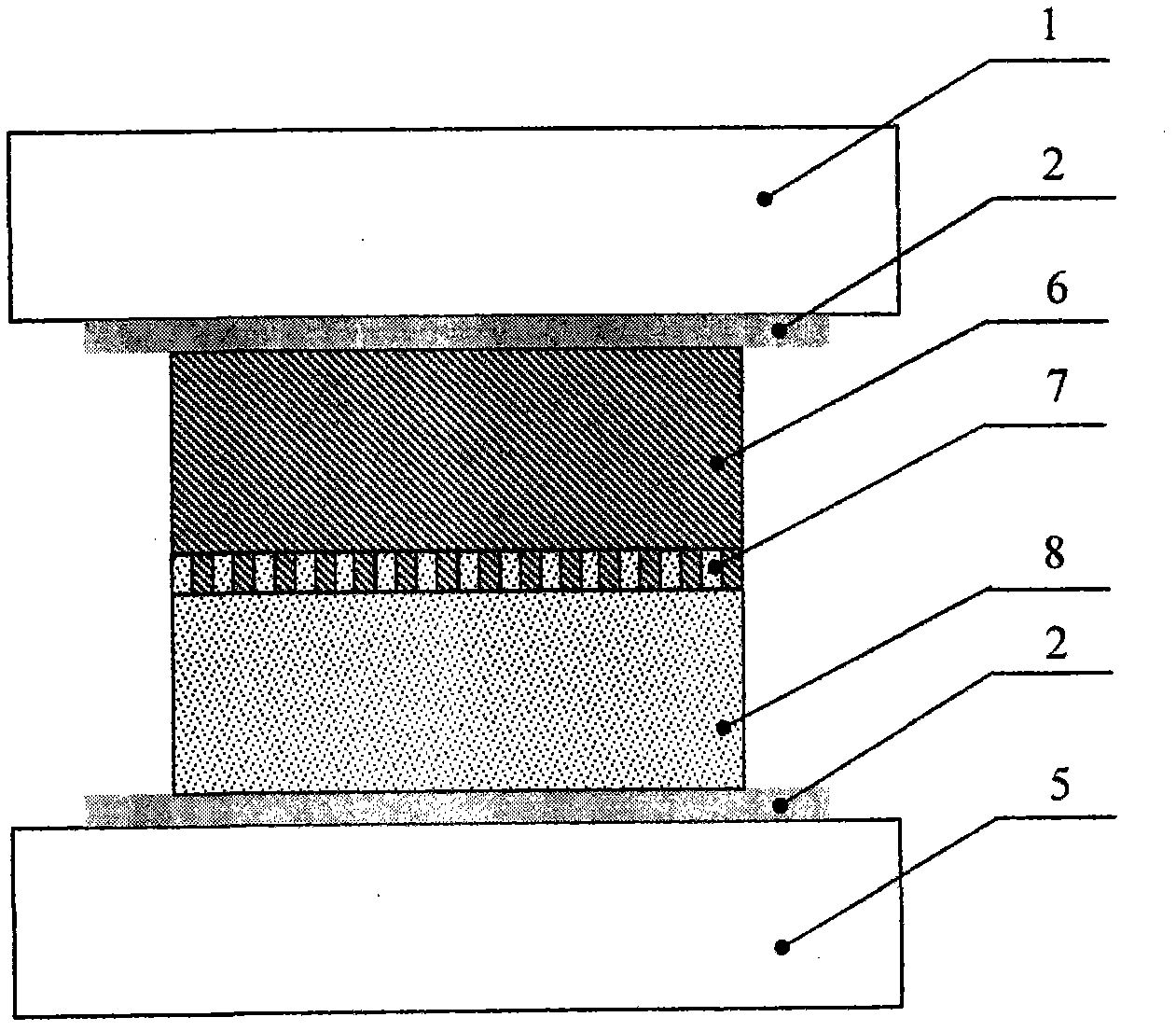

[0027] Step 2, stacking the block body to be welded; stacking the treated TA1 industrial pure titanium plate 3 and 00Cr19Ni10 stainless steel plate 4 alternately in the manner of one TA1 industrial pure titanium plate, one 00Cr19Ni10...

Embodiment 2

[0033] Present embodiment is a kind of method of TA2 industrial pure titanium and 1Cr18Ni9Ti stainless steel diffusion welding, and its specific process comprises the following steps:

[0034] Step 1, cleaning the surface of the plate; select several pieces of TA2 industrial pure titanium plate and 1Cr18Ni9Ti stainless steel plate with a thickness of 3mm as the raw materials for preparing the structural middle layer. Use metallographic sandpaper to polish the surface of the plate to make the surface roughness Ra≤1.6μm. Afterwards, immerse the processed plate in acetone and ultrasonically clean it for 5 minutes, and dry it with cold air to obtain cleaned TA2 industrial pure titanium plate and 1Cr18Ni9Ti stainless steel plate. Ultrasonic power is 600W.

[0035] Step 2, stacking the block body to be welded; the processed TA2 industrial pure titanium plate 3 and 1Cr18Ni9Ti stainless steel plate 4 are stacked alternately in the manner of a 1Cr18Ni9Ti stainless steel plate, a TA2 i...

Embodiment 3

[0041] Present embodiment is a kind of method of TA7 titanium alloy and 0Cr18Ni9 stainless steel diffusion welding, and its specific process comprises the following steps:

[0042] Step 1, cleaning the surface of the plate; selecting several TA7 titanium alloy plates and 0Cr18Ni9 stainless steel plates with a thickness of 2mm as the raw materials for preparing the structural middle layer. Use metallographic sandpaper to polish the surface of the plate to make the surface roughness Ra≤1.6μm. After that, immerse the processed plate in acetone for ultrasonic cleaning for 5 minutes, and dry it with cold air to obtain cleaned TA7 titanium alloy plate and 0Cr18Ni9 stainless steel plate. Ultrasonic power is 600W.

[0043] Step 2, stacking the block body to be welded; stacking the treated TA7 titanium alloy plate 3 and 0Cr18Ni9 stainless steel plate 4 alternately in the manner of one TA7 titanium alloy plate, one 0Cr18Ni9 stainless steel plate, and one TA7 titanium alloy plate to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com