Secondary peak aging method for high-vacuum die-casting high-speed gearbox shell containing rare earth aluminum-silicon alloy

A peak aging and vacuum die-casting technology, which is applied to transmission parts, mechanical equipment, belts/chains/gears, etc., can solve thin-wall remelting, it is difficult to meet the porosity requirements of drawings, and the porosity of cylinder blocks cannot be met, etc. Problems, to achieve the effect of improving tensile strength, reducing quality, and appropriate time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

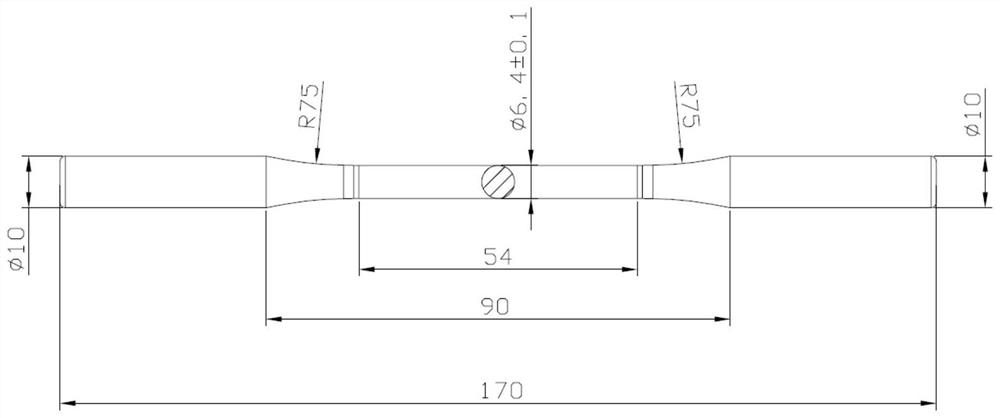

[0012] The tensile test bar of this embodiment meets GB / T 13822, such as figure 1 shown. The raw material of the aluminum alloy adopts EN1706-ENAC-43400, AlSi10Mg(Fe), the mass fraction of Fe is controlled to be ≤0.65%, and low-cost lanthanum-cerium mixed rare earth with a mass fraction of ≤0.1% is added.

[0013] In the lanthanum-cerium mixed rare earth: the mass fraction of lanthanum is 70%, and the mass fraction of cerium is 30%.

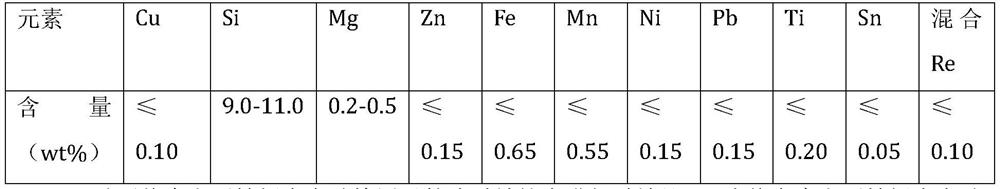

[0014] The specific composition of AlSi10Mg (Fe) is shown in Table 1.

[0015] Vacuum die-casting adopts Toyo V3-350T vacuum die-casting machine, the vacuum degree is controlled at 50-100mbar, and the water is quenched immediately after the test rod is released from the mold. The water temperature is 60-75°C, and the maximum supersaturated solid solution is retained as much as possible.

[0016] Table 1 AlSi10Mg (Fe) chemical composition

[0017]

[0018] Then the vacuum die-casting aluminum alloy test rods were placed in a box-type aging f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com