Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2840 results about "Block structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

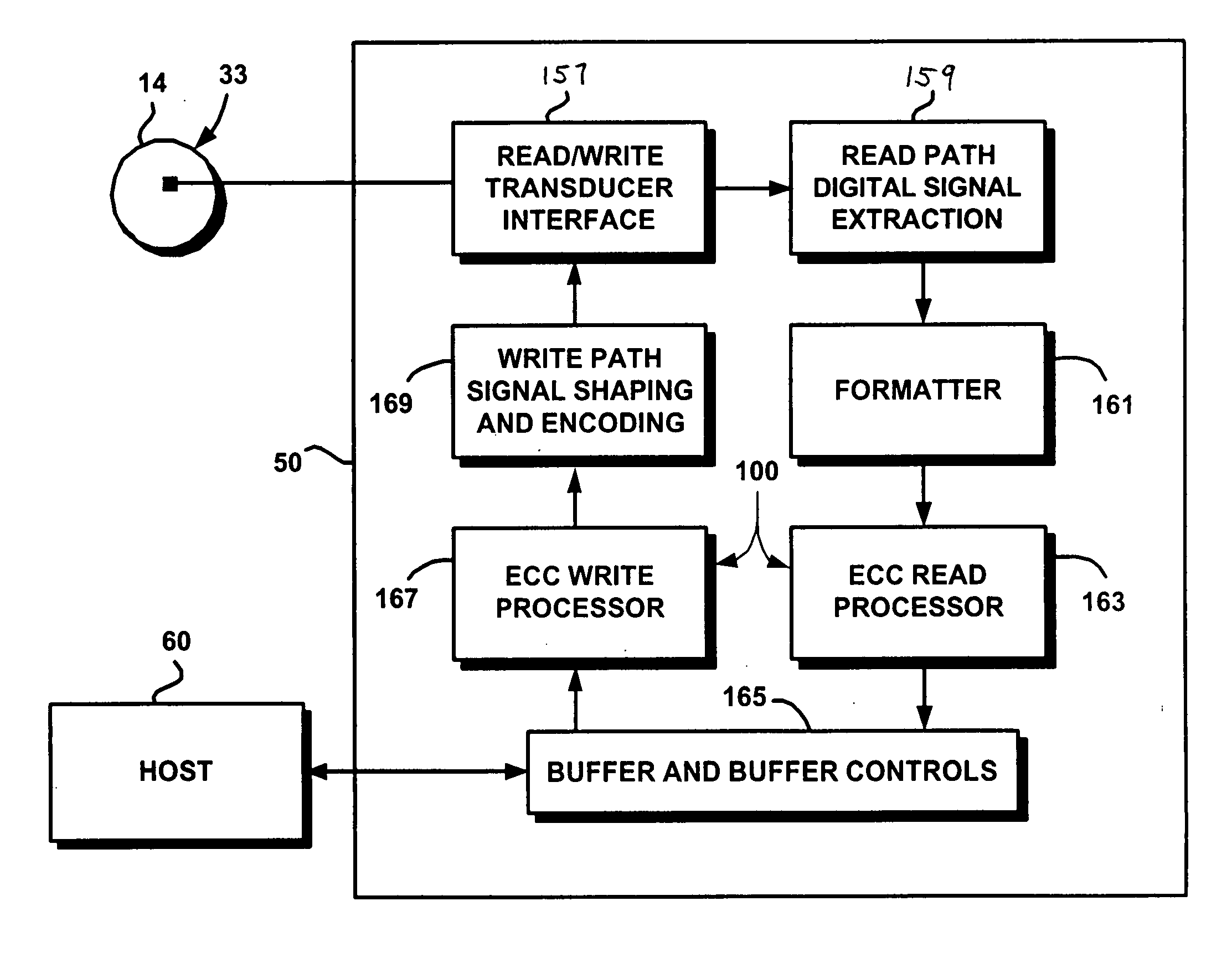

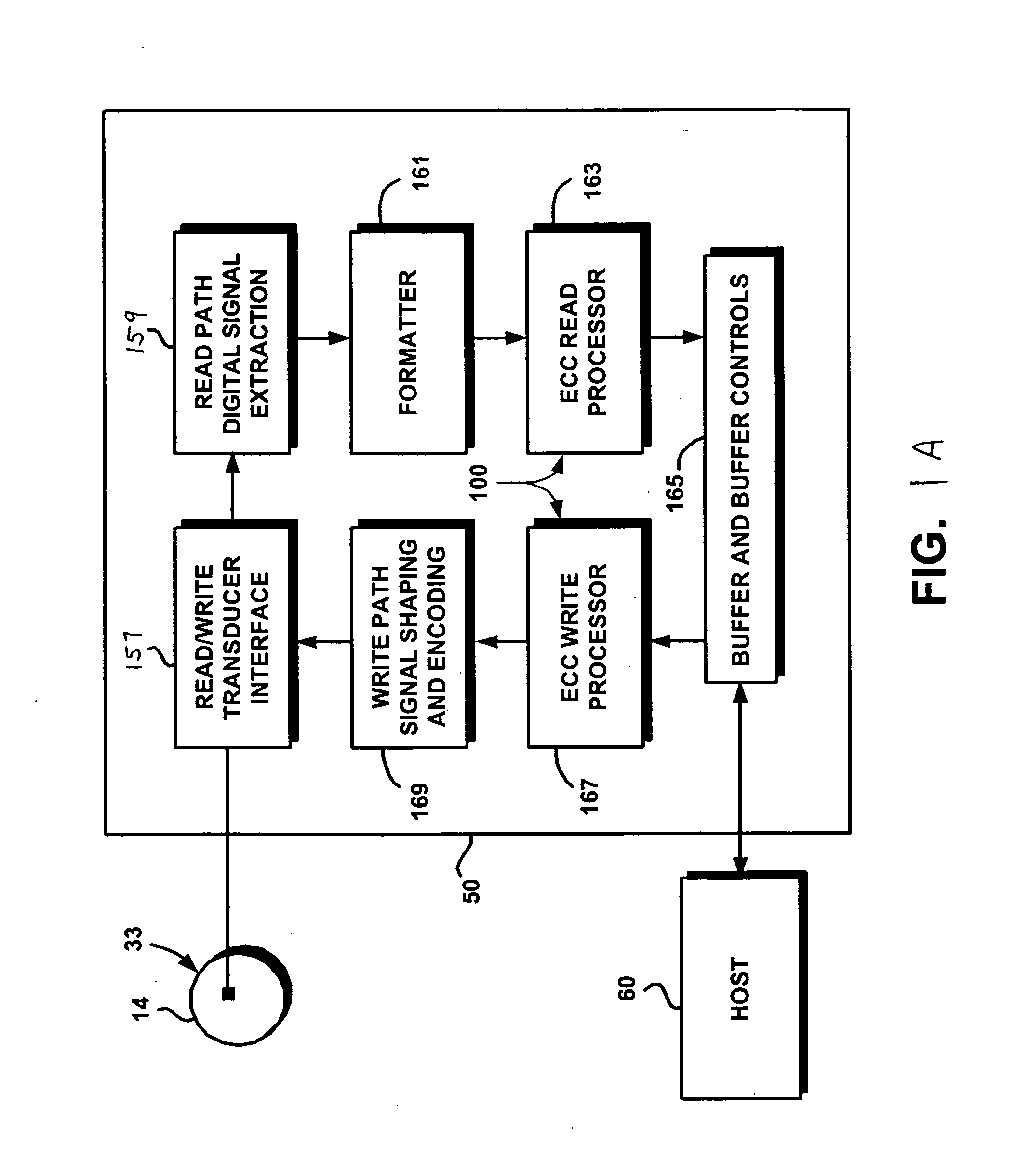

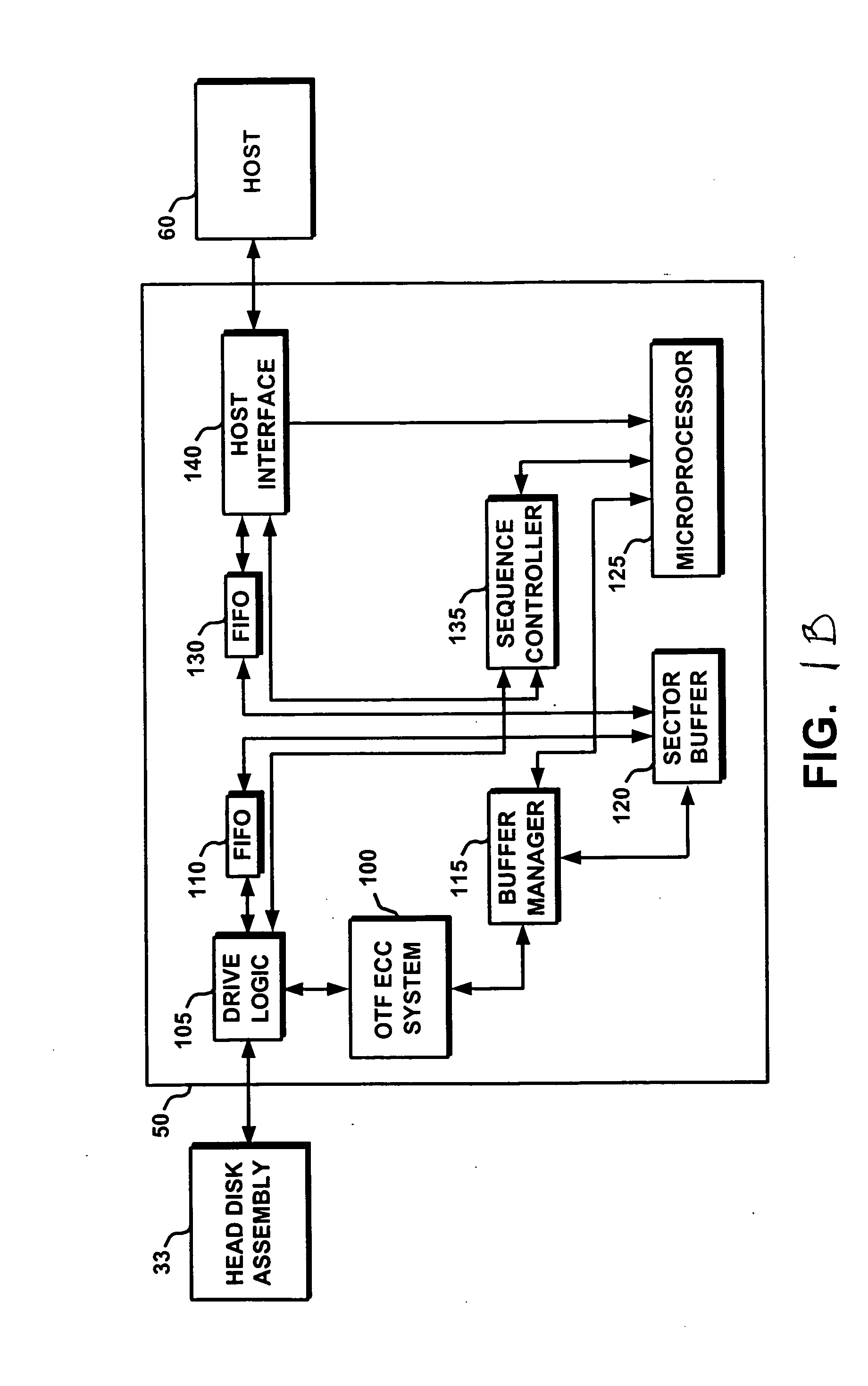

Techniques for detecting and correcting errors using multiple interleave erasure pointers

InactiveUS20050229069A1Correction capabilityTransmission systemsCode conversionBlock codeError location

Techniques for detecting and correcting burst errors in data bytes formed in a two-level block code structure. A second level decoder uses block level check bytes to detect columns in a two-level block code structure that contain error bytes. The second level decoder generates erasure pointers that identify columns in the two-level block structure effected by burst errors. A first level decoder then uses codeword check bytes to correct all of the bytes in the columns identified by the erasure pointers. The first level decoder is freed to use all of the codeword check bytes only for error byte value calculations. The first level decoder does not need to use any of the codeword check bytes for error location calculations, because the erasure pointers generated by the second level decoder provide all of the necessary error locations. This techniques doubles the error correction capability of the first level decoder.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV +1

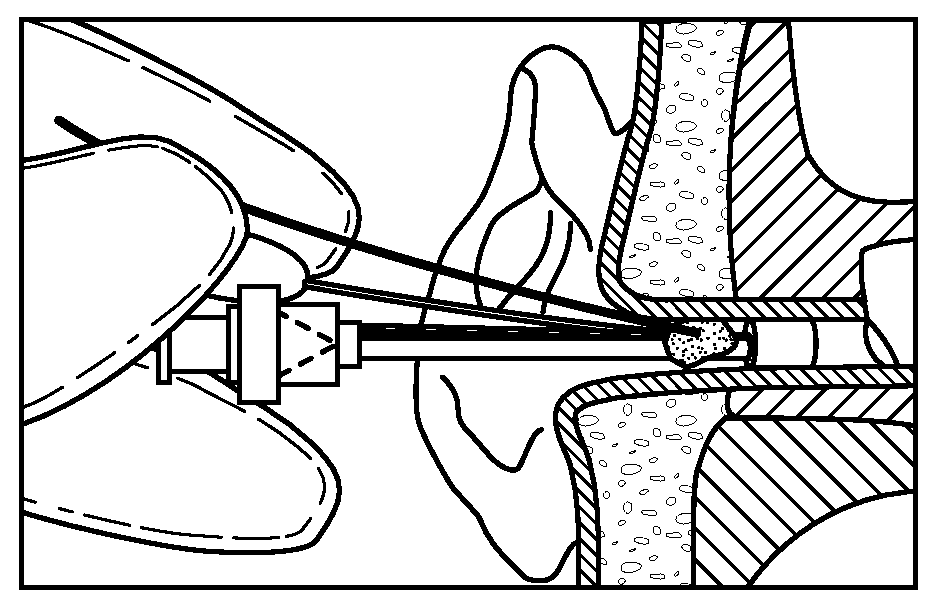

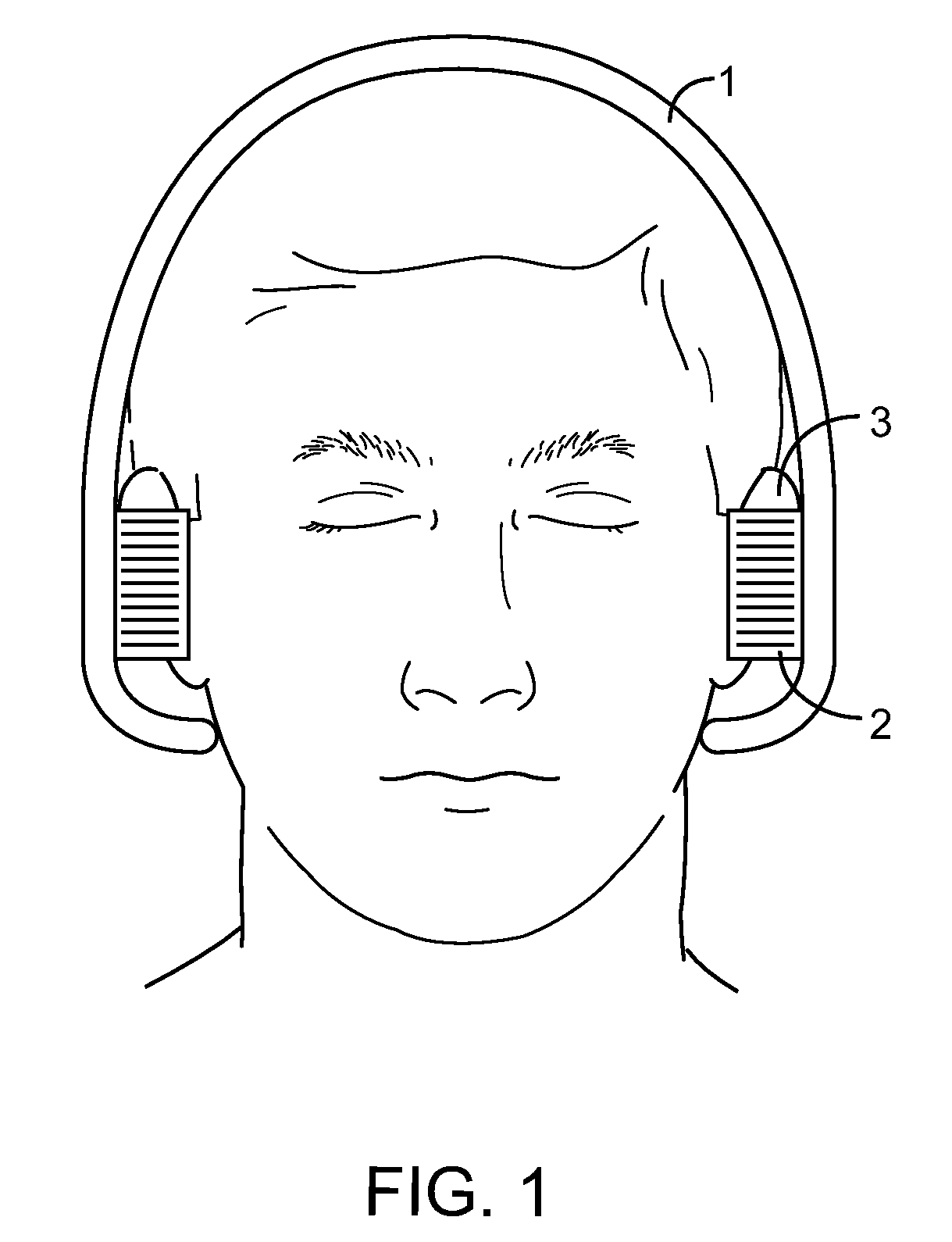

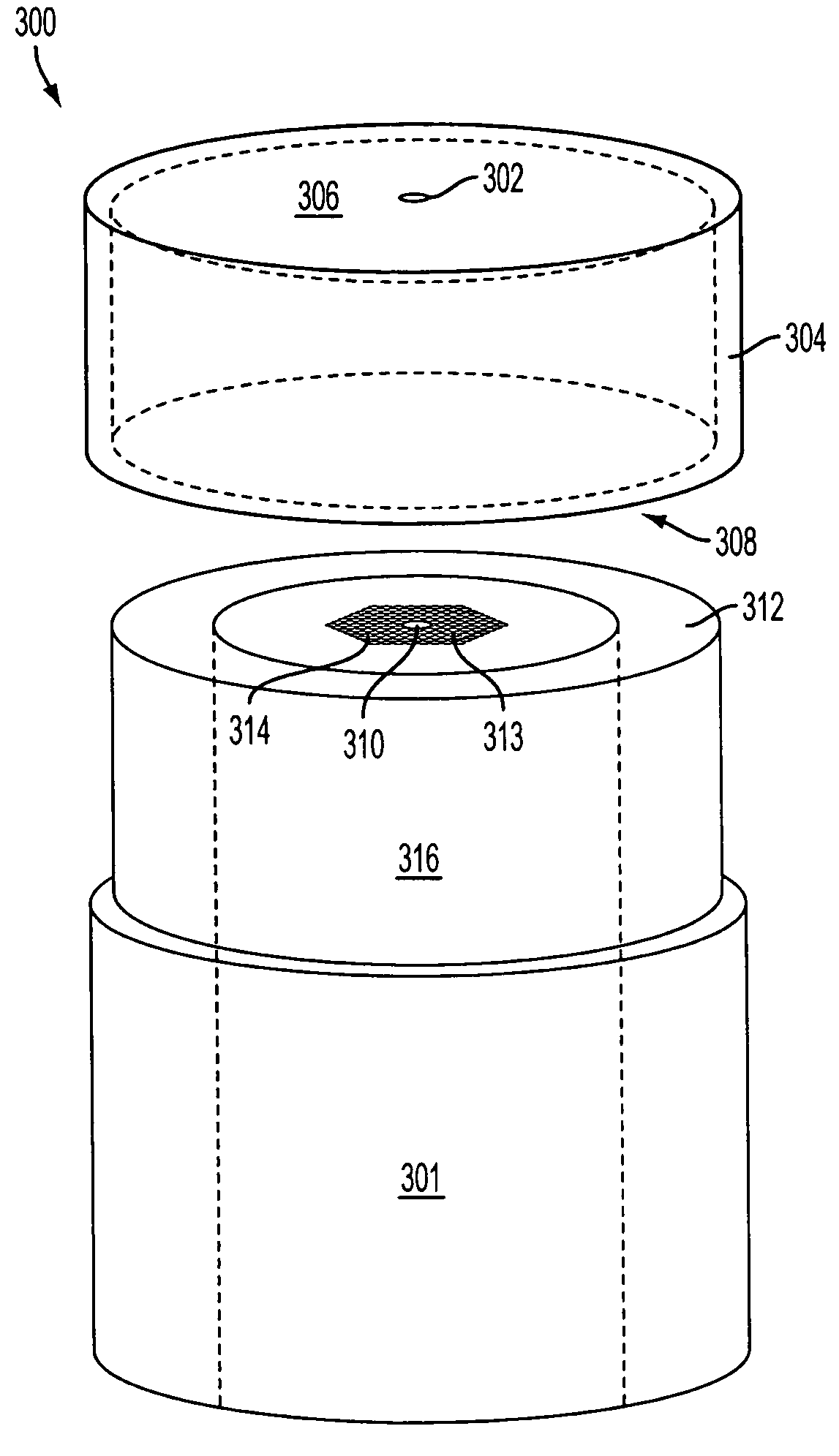

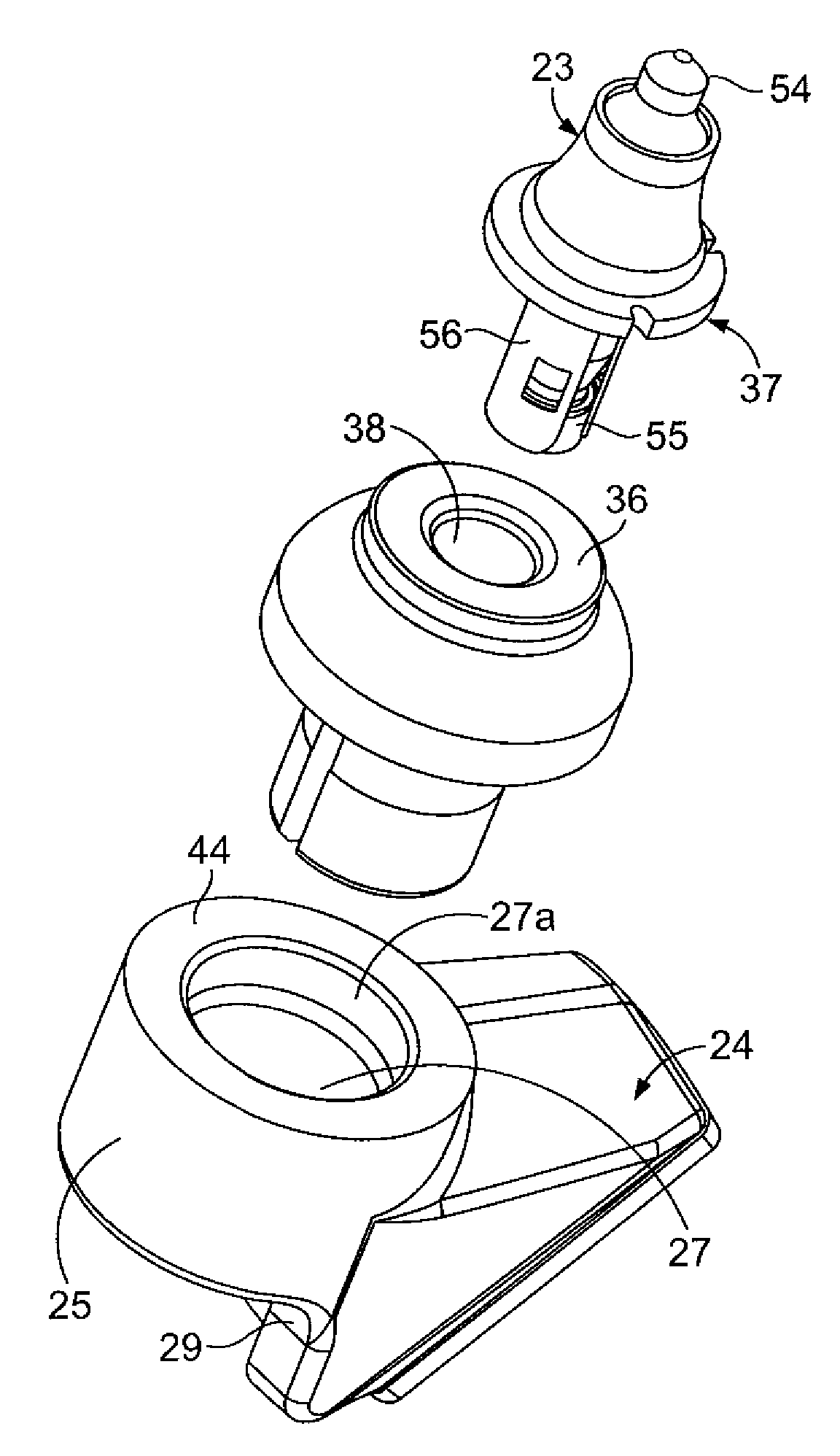

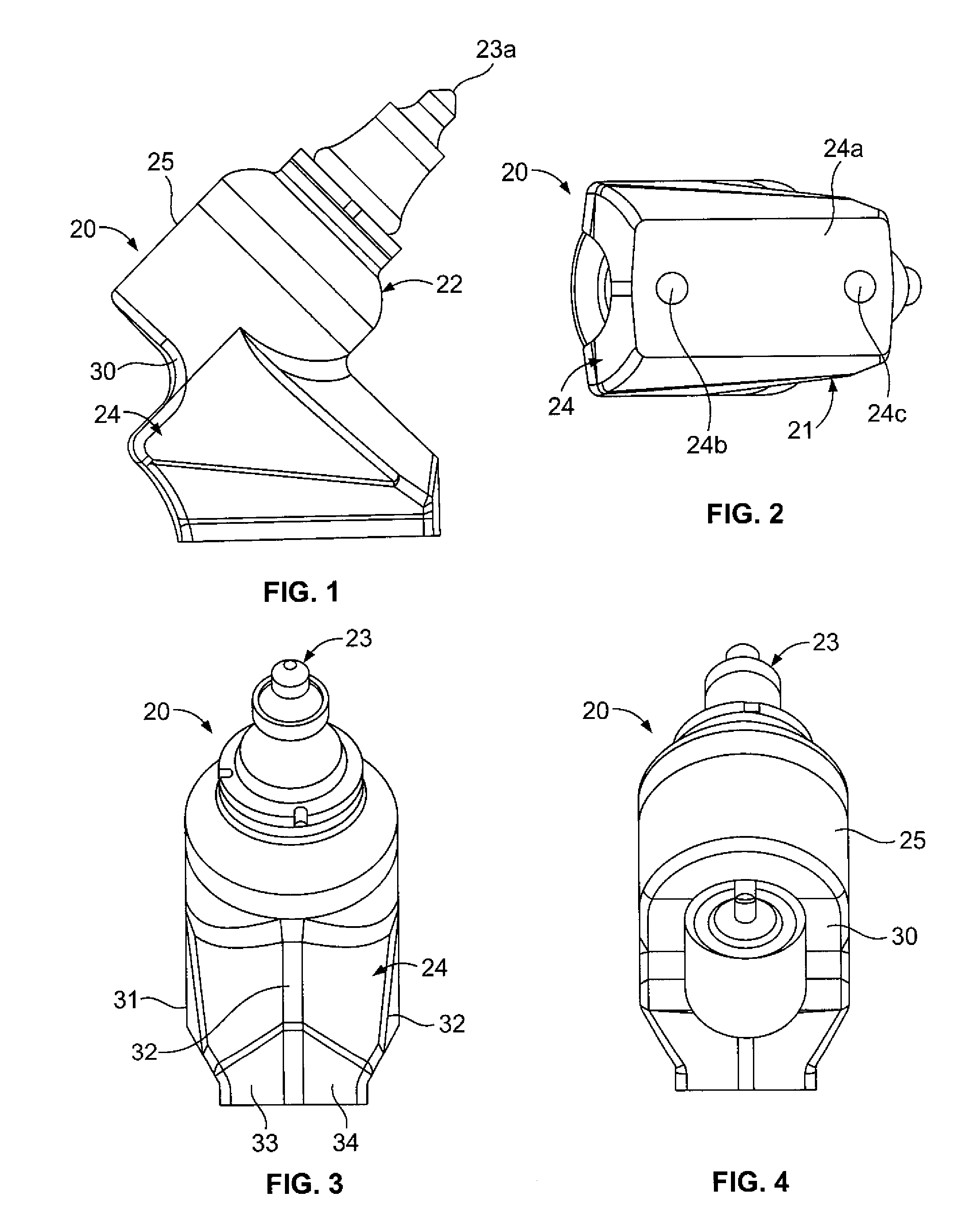

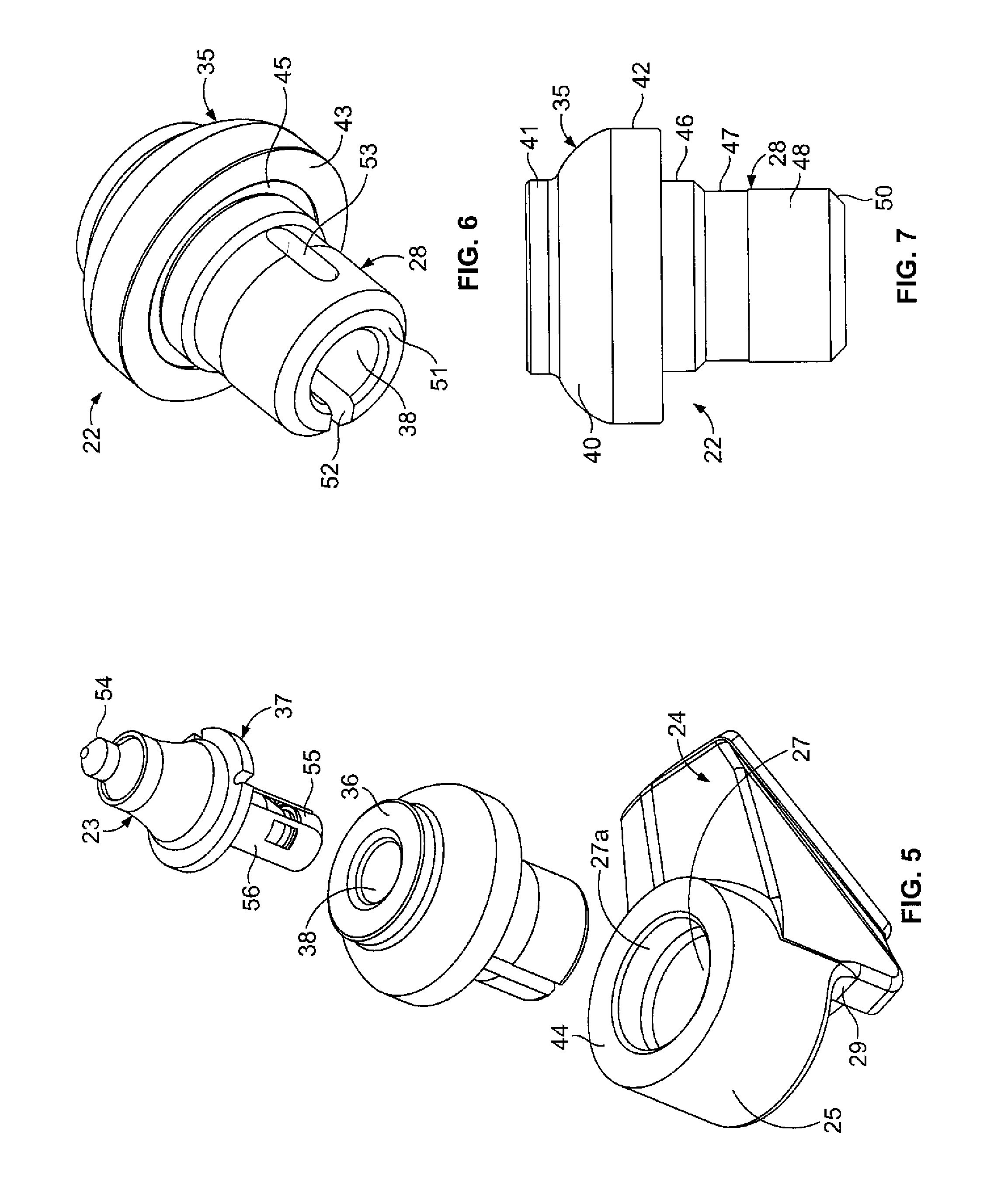

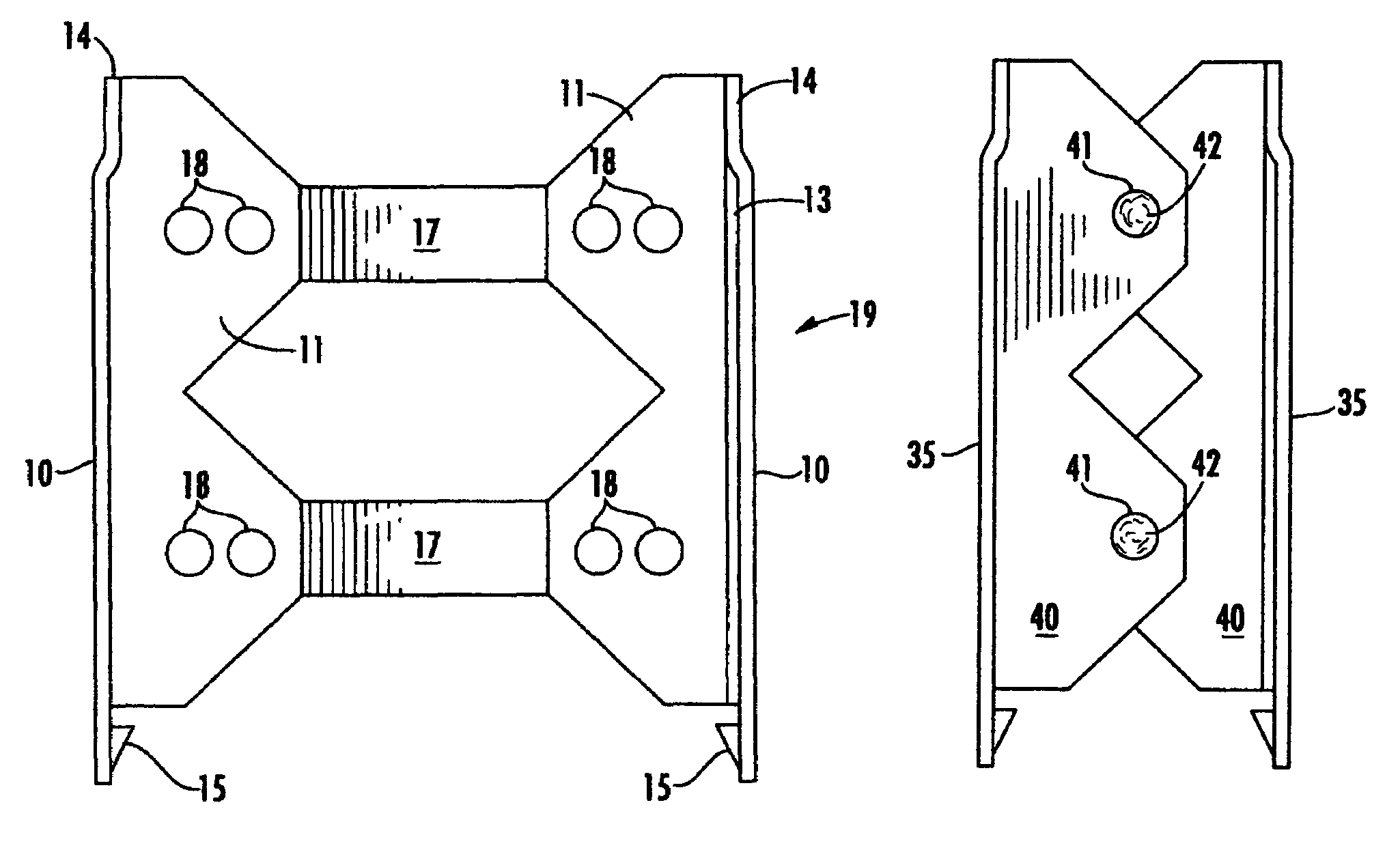

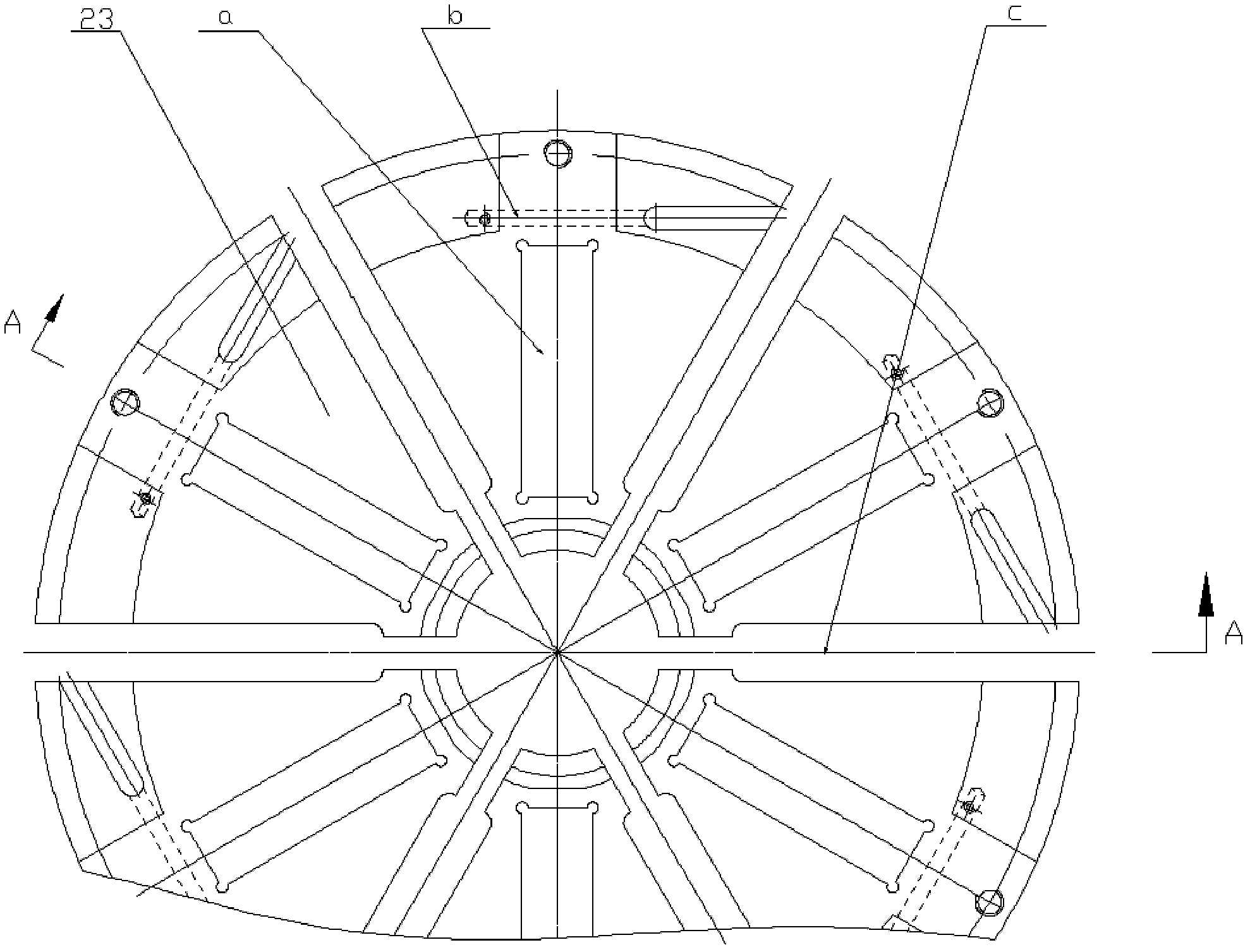

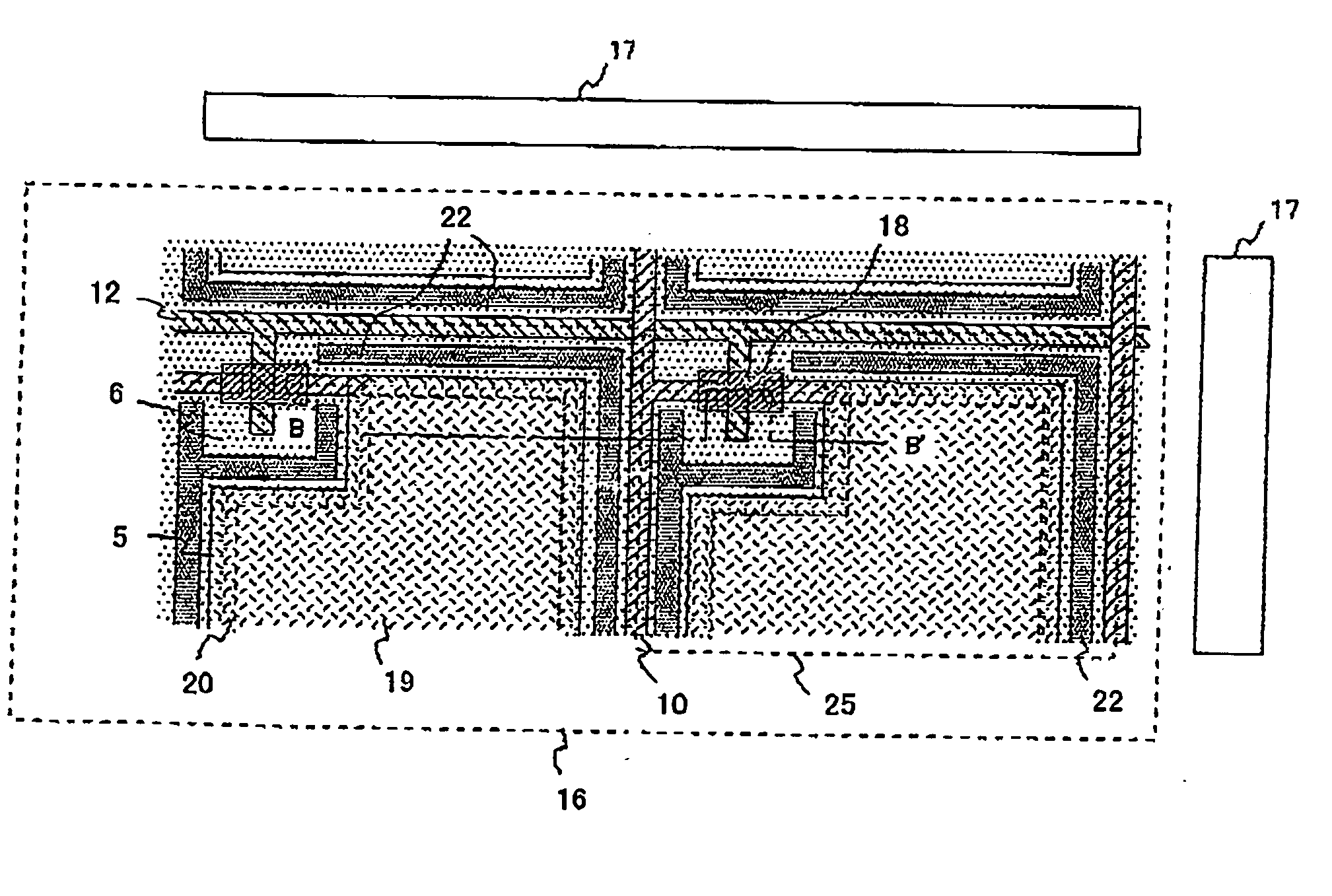

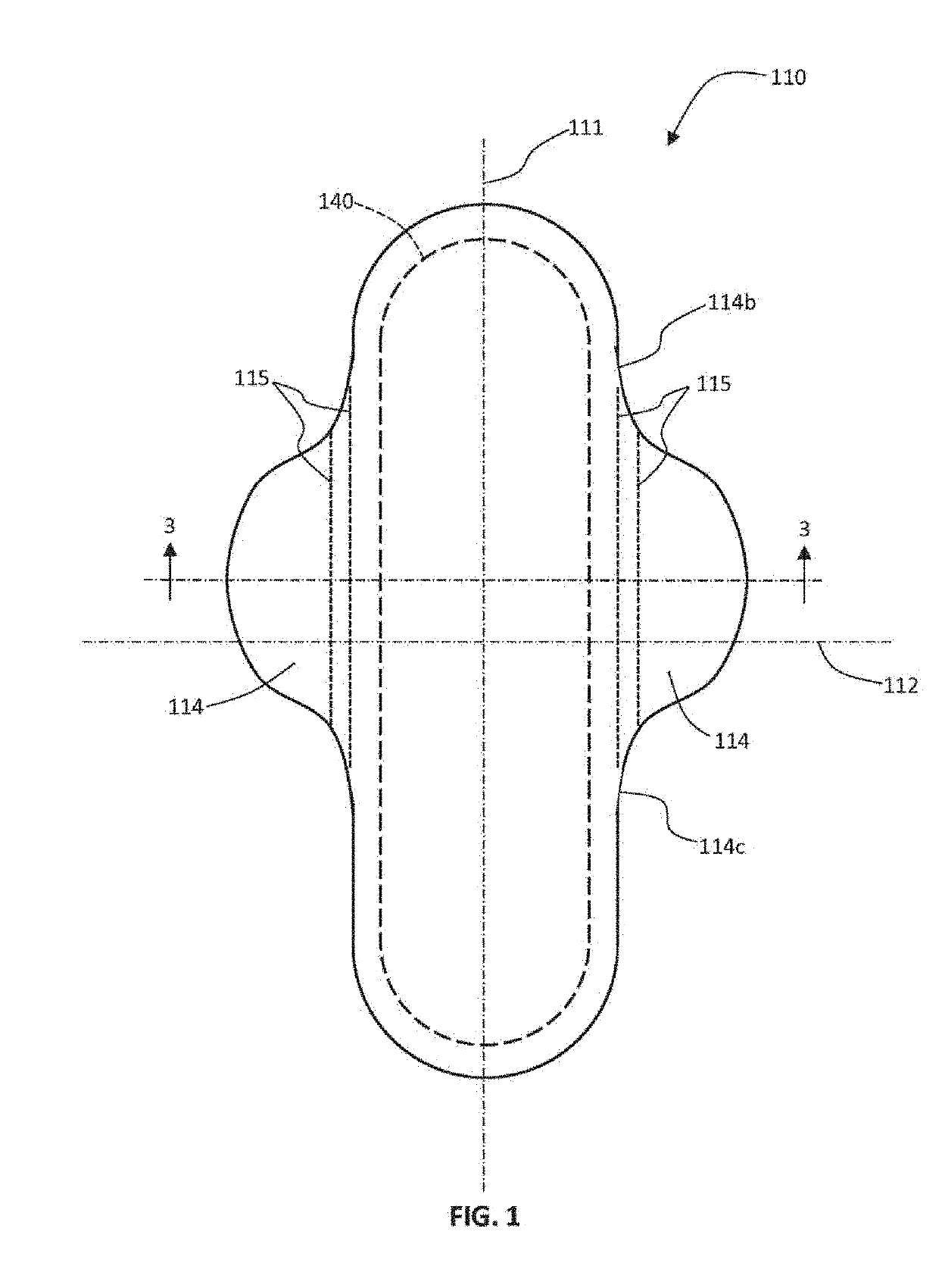

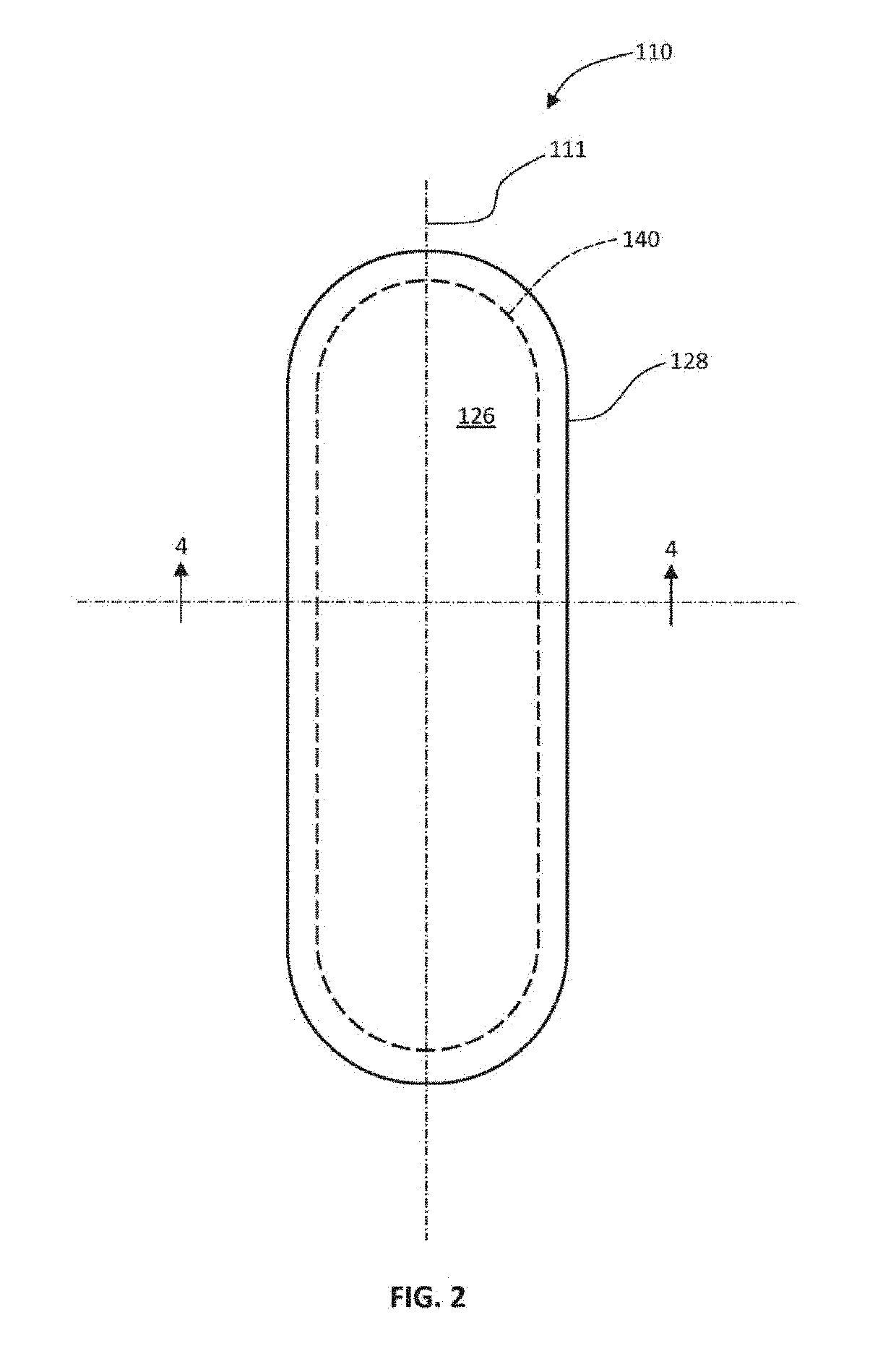

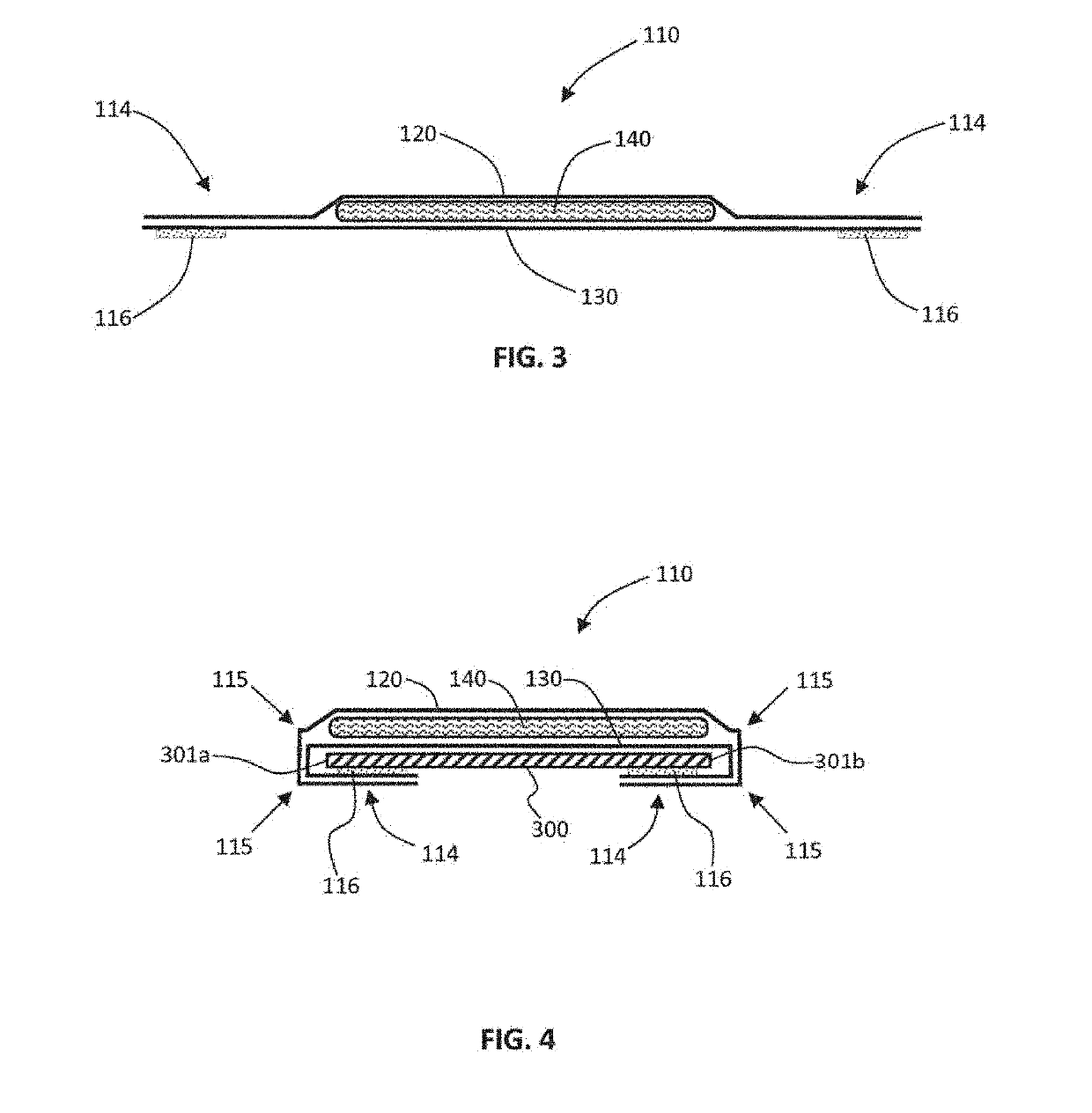

System and Method for the Simultaneous Bilateral Treatment of Target Tissues Within the Ears Using a Guide Block Structure

ActiveUS20080262468A1Facilitate visualFacilitate optical monitoringElectrotherapyEar treatmentSupporting systemMedicine

Systems and methods for treating a patient having a head with a first ear and a second ear, function by mounting a support structure to the head of the patient; aligning the support structure with a target tissue in an ear canal of the first ear; stabilizing the support structure relative to the target tissue by injecting a material into the canal and hardening the material; and actuating a device while the device is supported by the support system so that the device therapeutically remodels the target tissue of the first ear.

Owner:TUSKER MEDICAL

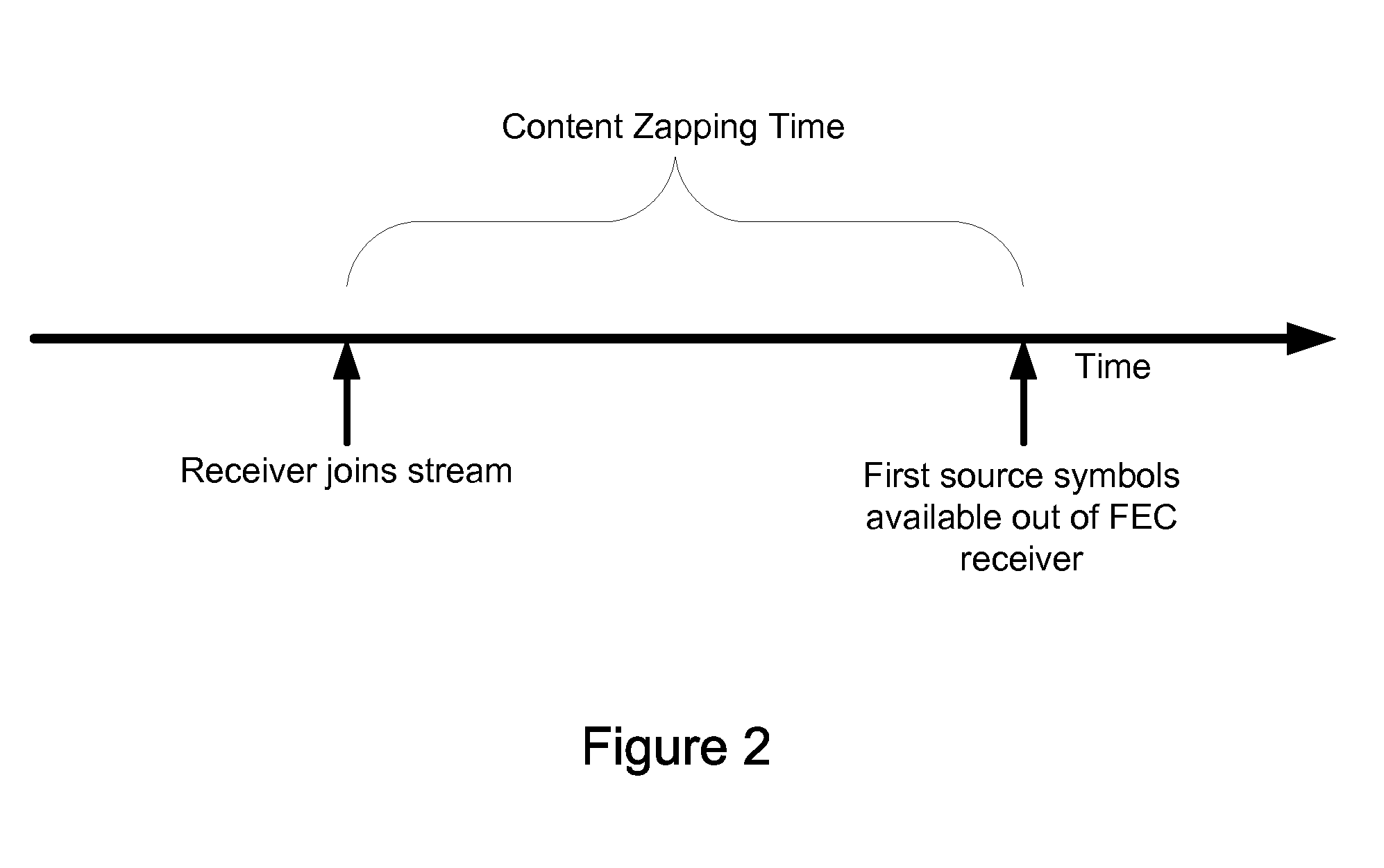

Dynamic stream interleaving and sub-stream based delivery

ActiveUS20080256418A1Convenient amountLoss of protectionFault responseCode conversionPacket lossCommunications system

A communications system can provide methods of dynamically interleaving streams, including methods for dynamically introducing greater amounts of interleaving as a stream is transmitted independently of any source block structure to spread out losses or errors in the channel over a much larger period of time within the original stream than if interleaving were not introduced, provide superior protection against packet loss or packet corruption when used with FEC coding, provide superior protection against network jitter, and allow content zapping time and the content transition time to be reduced to a minimum and minimal content transition times. Streams may be partitioned into sub-streams, delivering the sub-streams to receivers along different paths through a network and receiving concurrently different sub-streams at a receiver sent from potentially different servers. When used in conjunction with FEC encoding, the methods include delivering portions of an encoding of each source block from potentially different servers.

Owner:QUALCOMM INC

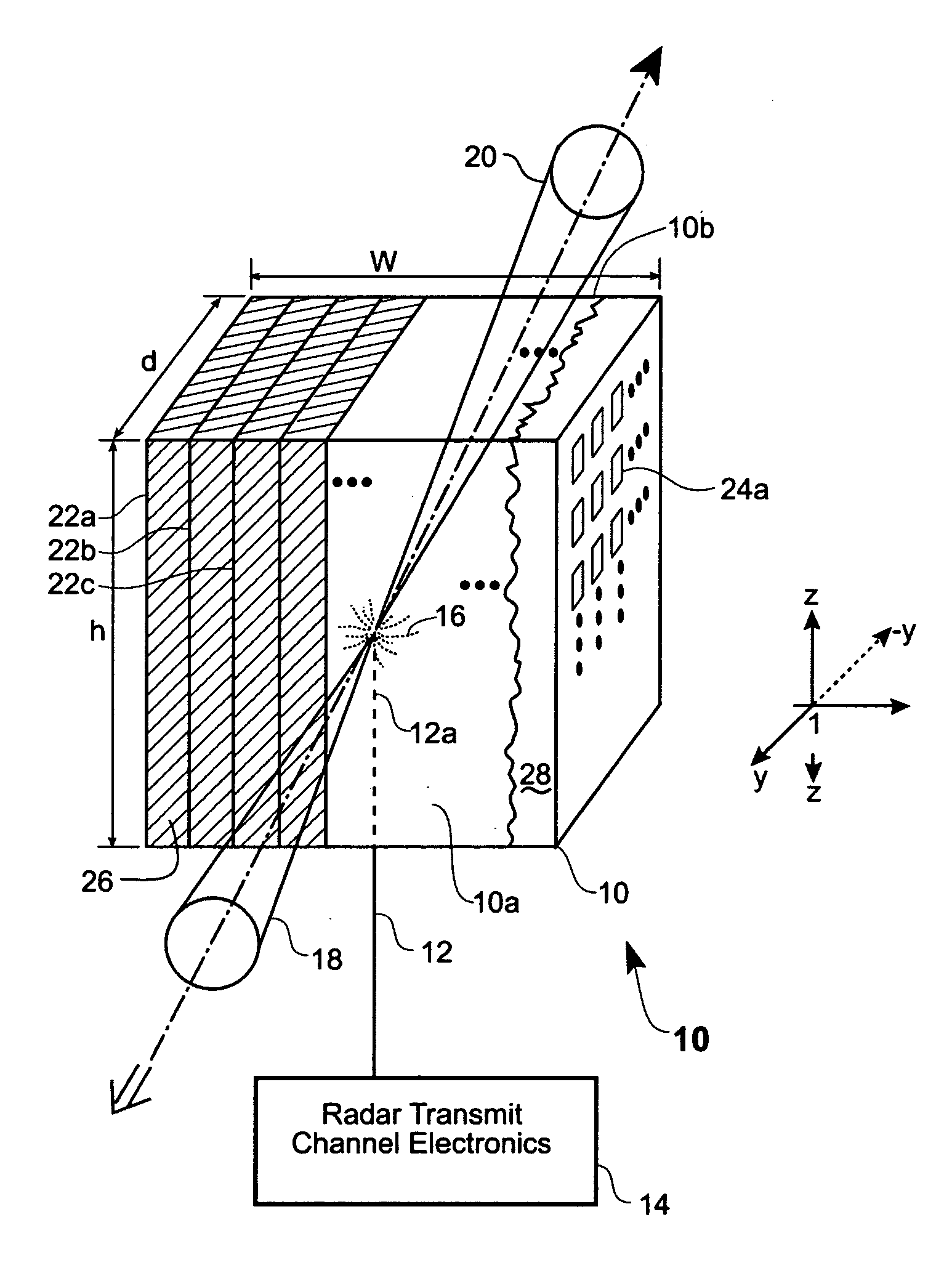

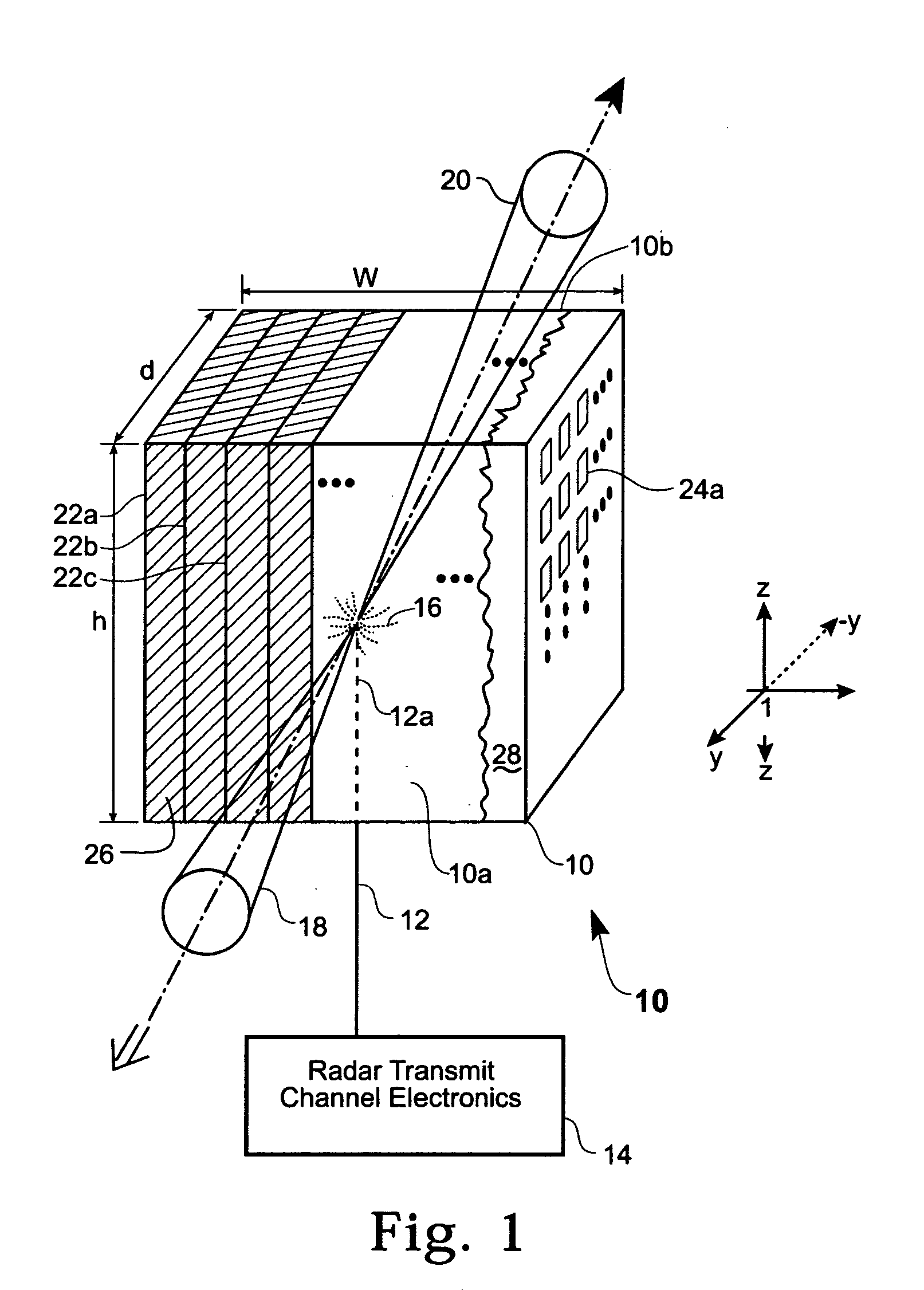

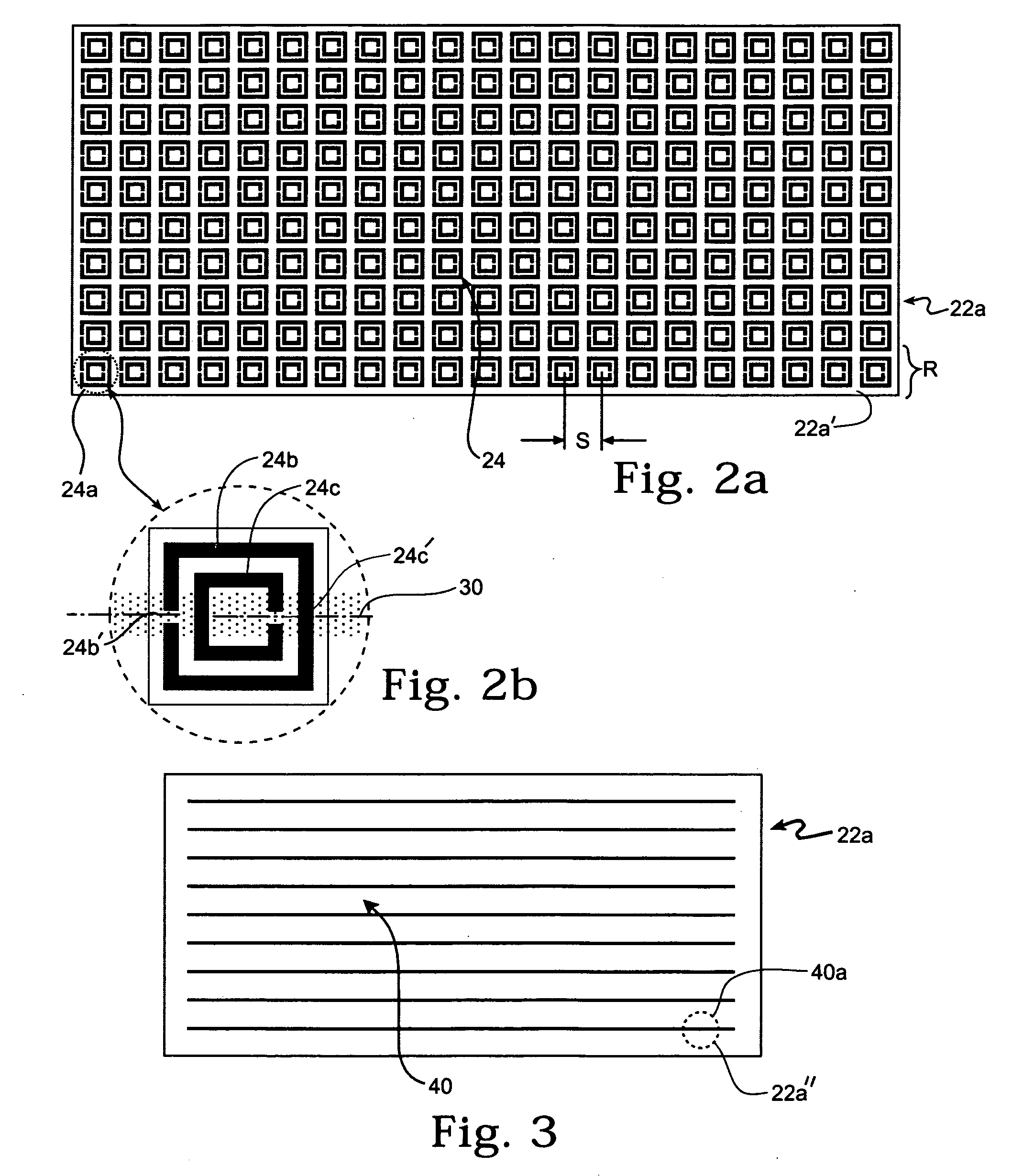

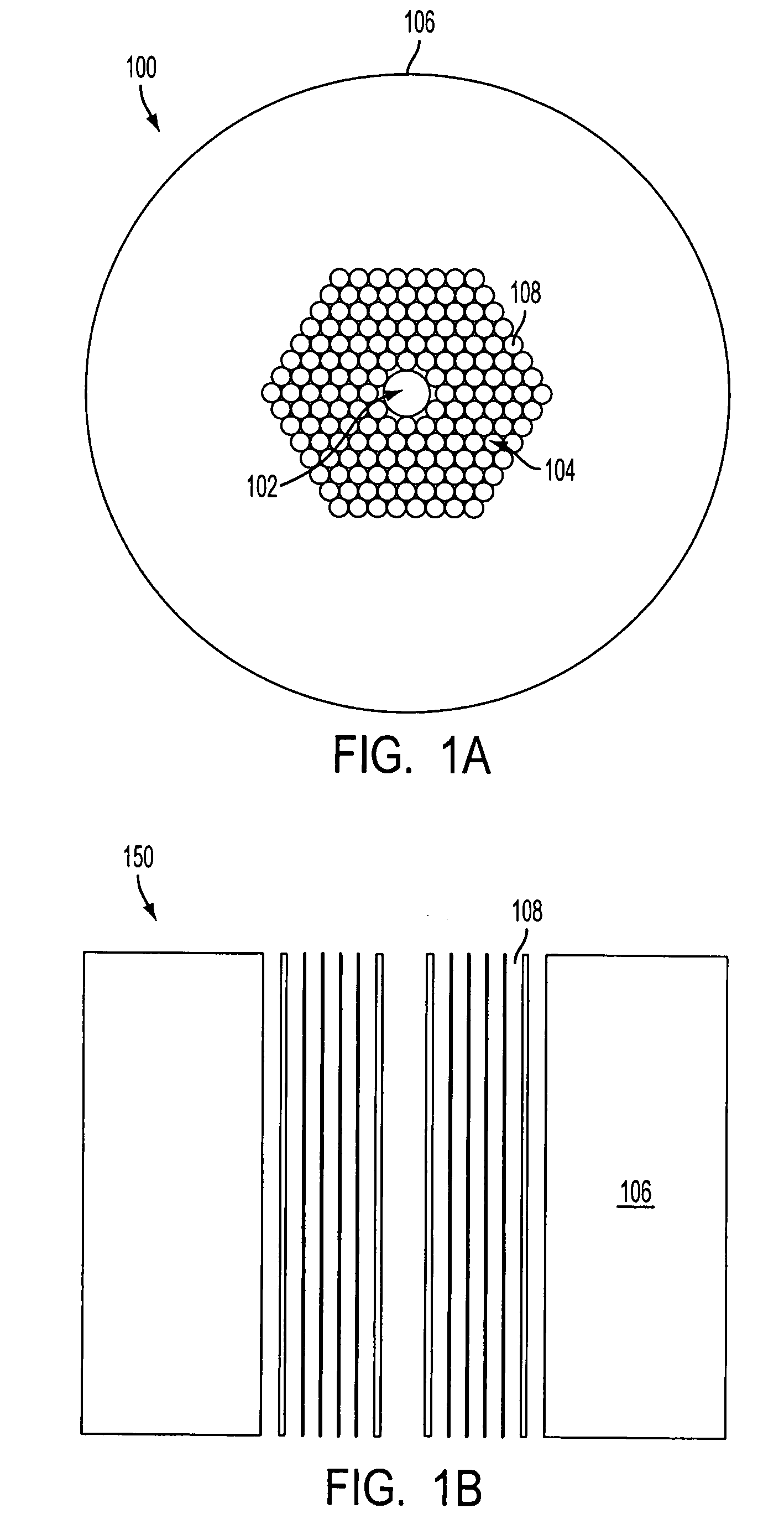

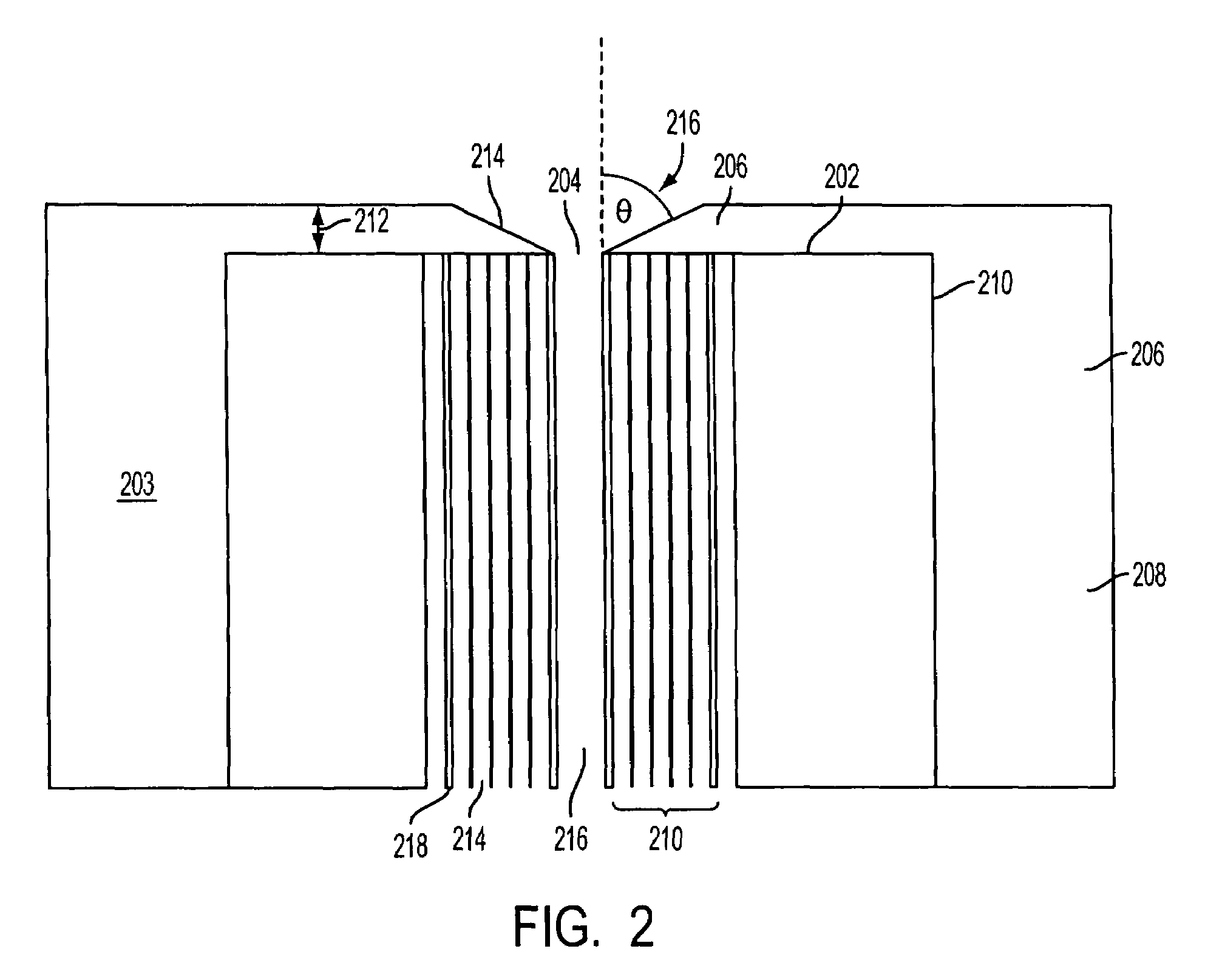

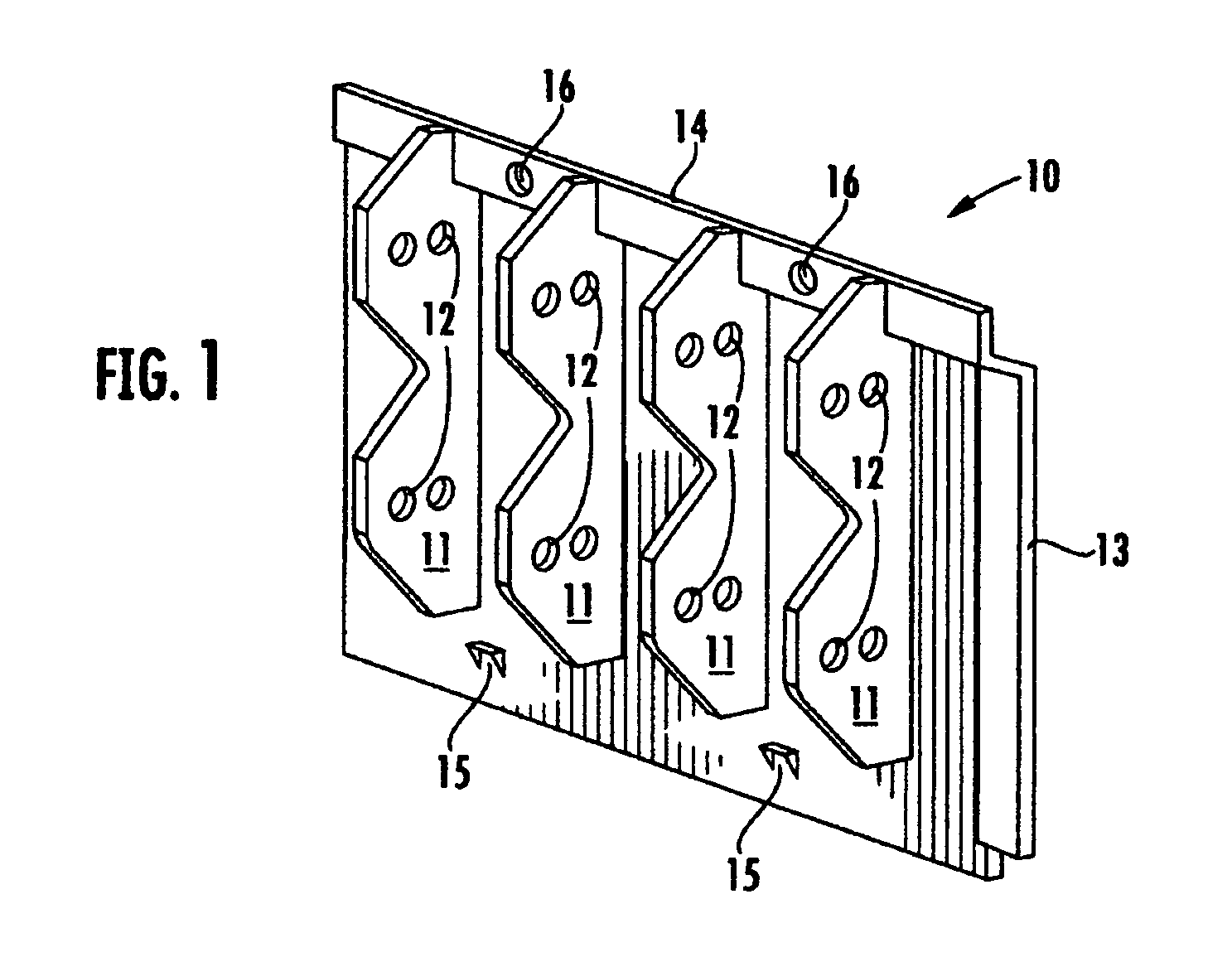

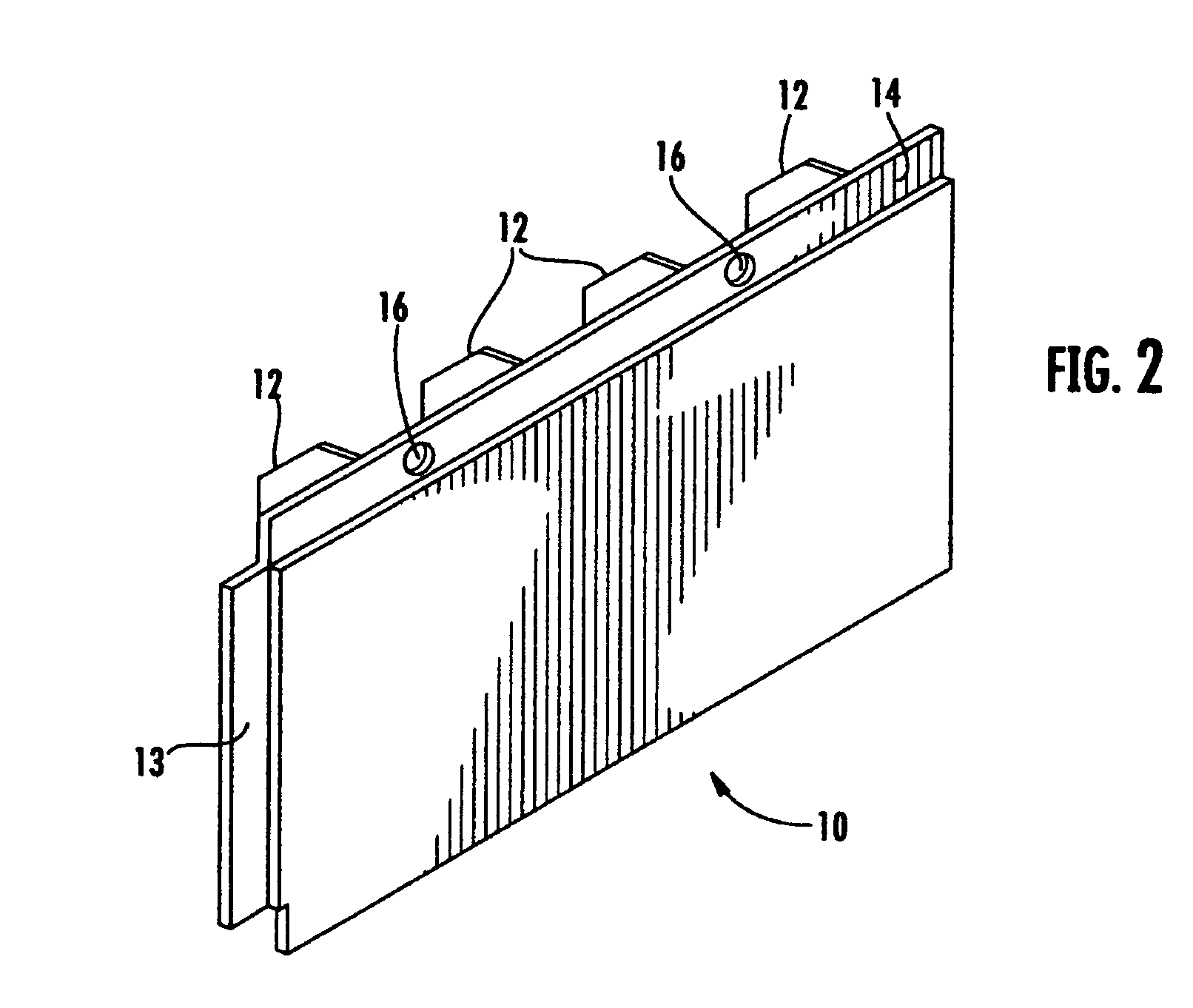

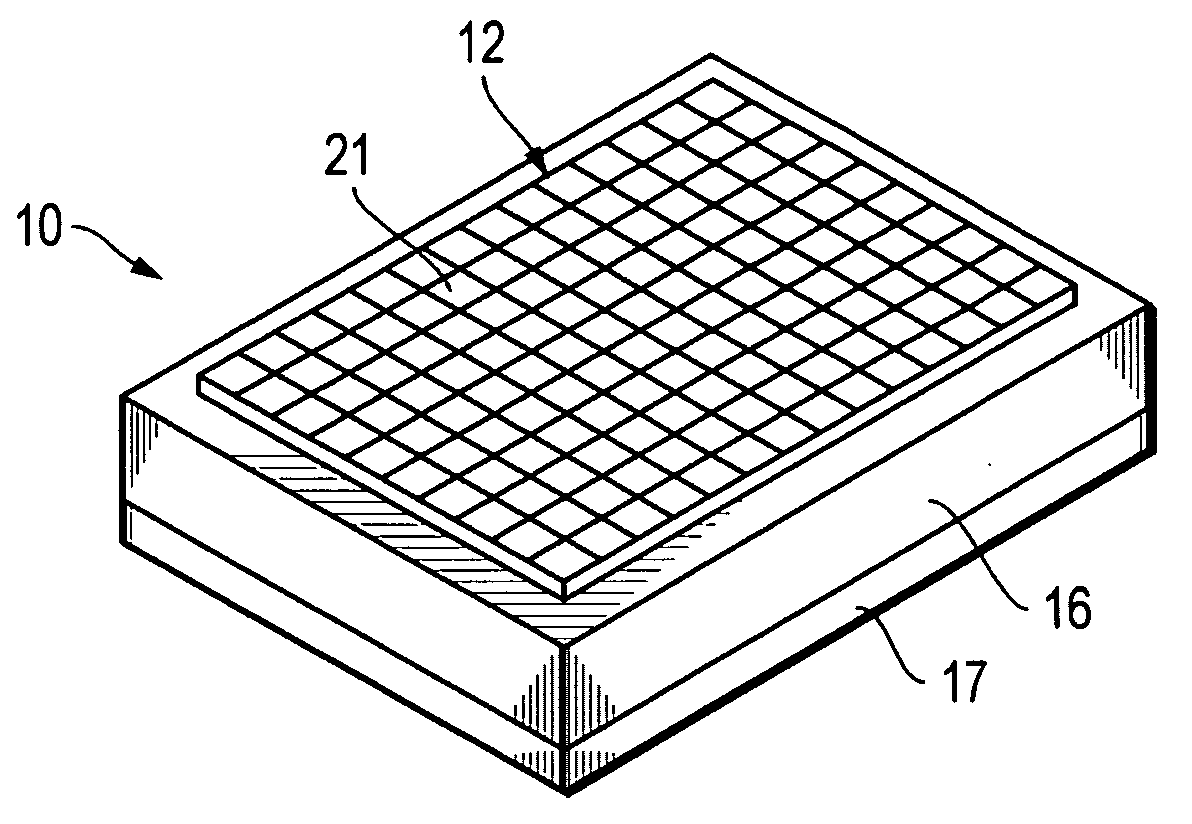

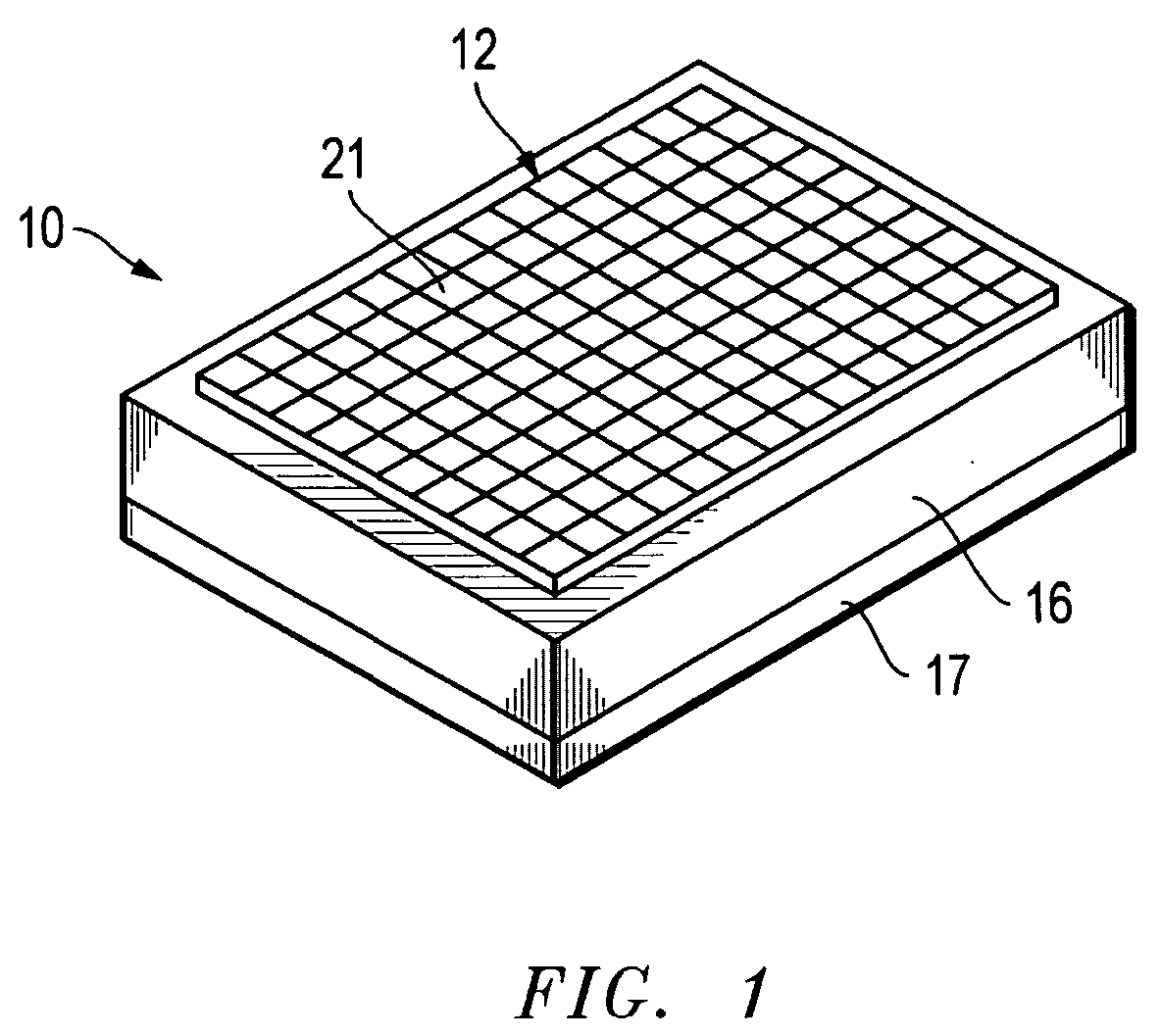

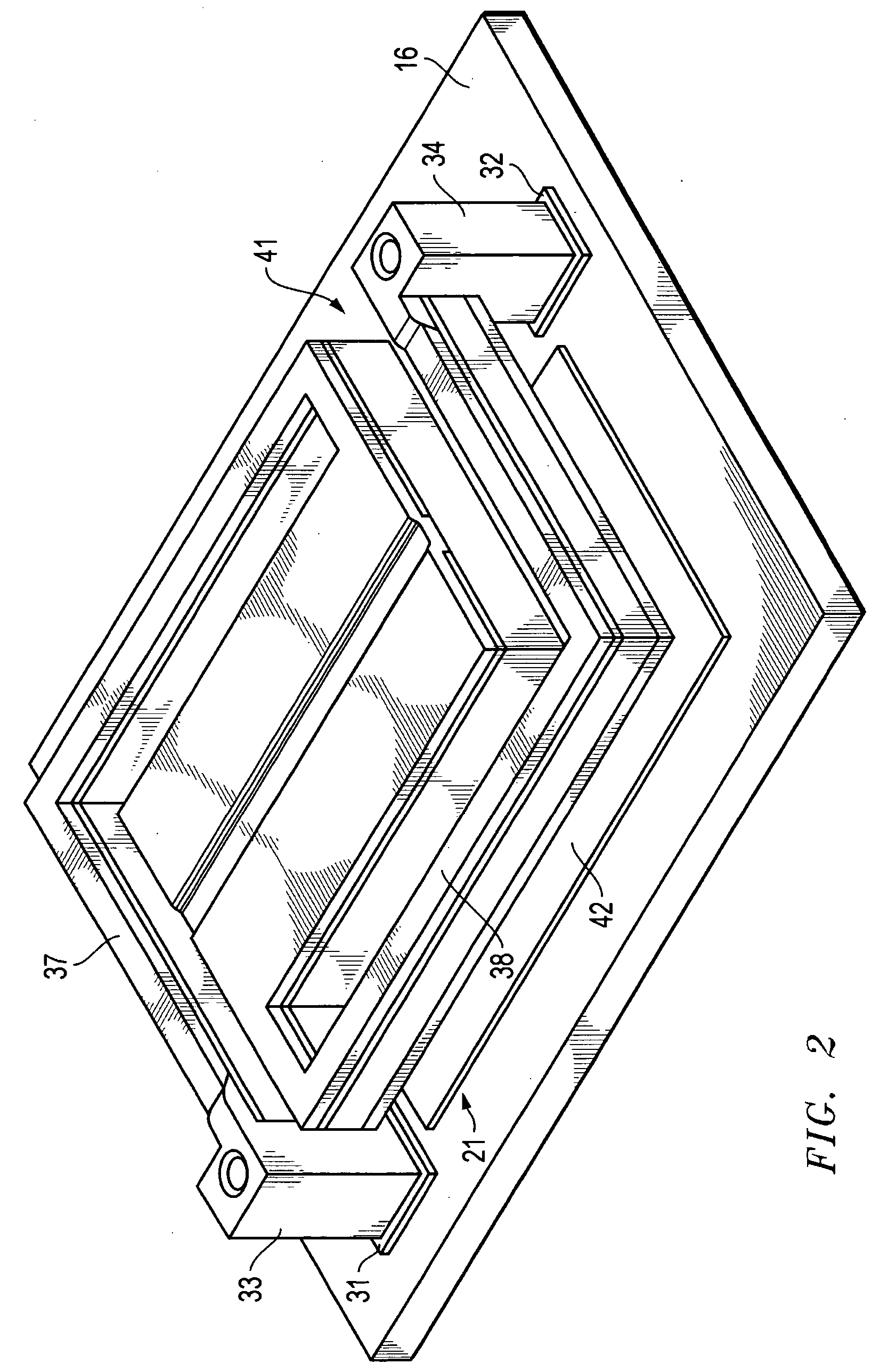

Antenna radiation collimator structure

ActiveUS20070164908A1Increase beam intensitySimultaneous aerial operationsRadiating elements structural formsBand shapeLight beam

An antenna radiation collimator structure is provided as including a number of resonator circuit boards oriented to form a block structure. A sheet of dielectric material is disposed between each of the number of resonator circuit boards to maintain a substantially uniform spacing between each of the resonator circuit boards. A plurality of conductive unit resonator cells may be disposed on first planar surfaces of each of the number of resonator circuit boards and a plurality of conductive strip lines may also be disposed on second planar surfaces of each of the number of resonator circuit boards. In this arrangement, radiation applied to a substantially central location of the block structure interacts with the plurality of conductive unit resonator cells and the plurality of conductive strip lines for redirecting the radiation out of front and rear facing surfaces of the block structure as respective first and second substantially collimated beams.

Owner:THE GOVERNMENT OF THE US SEC THE AIR FORCE

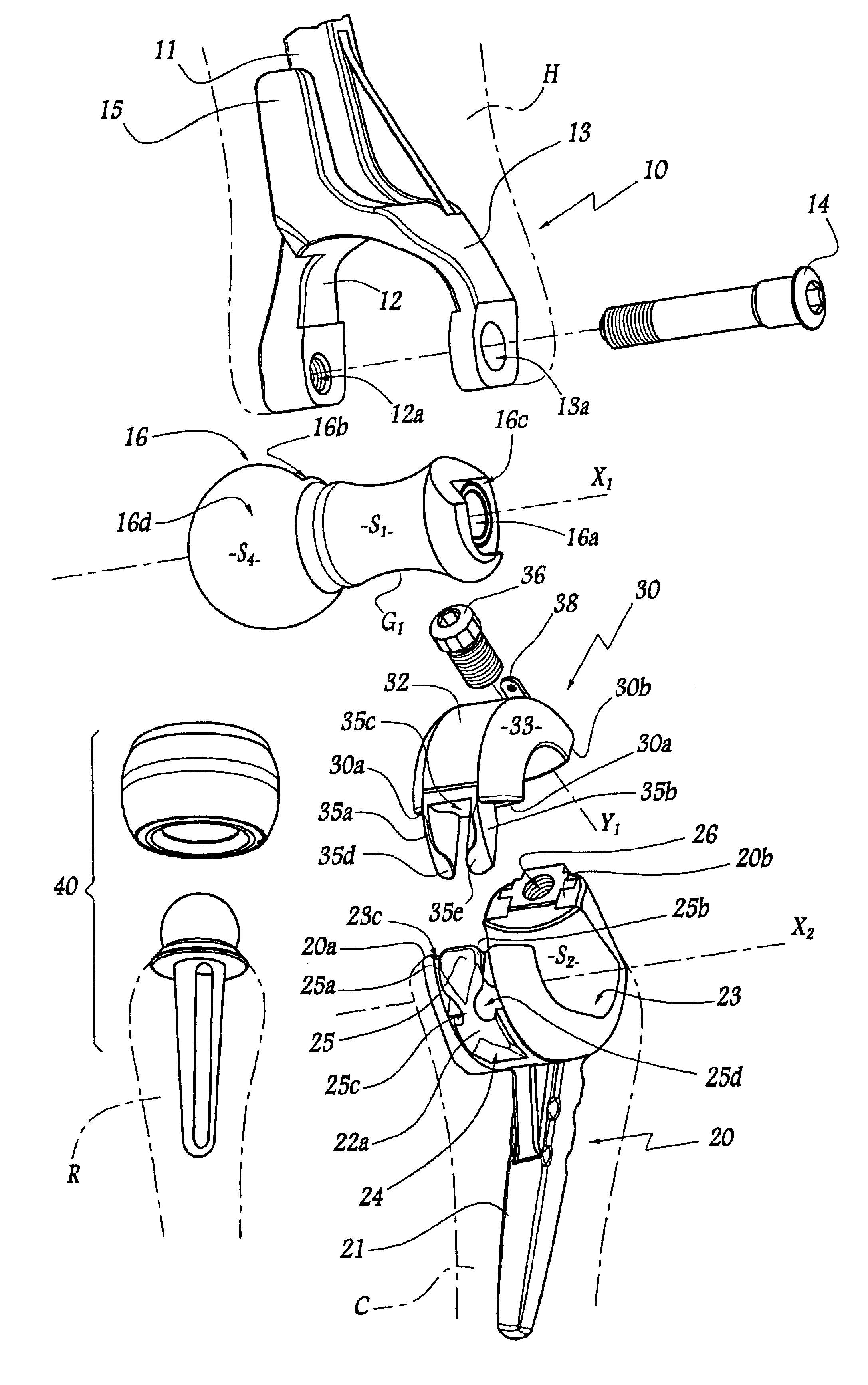

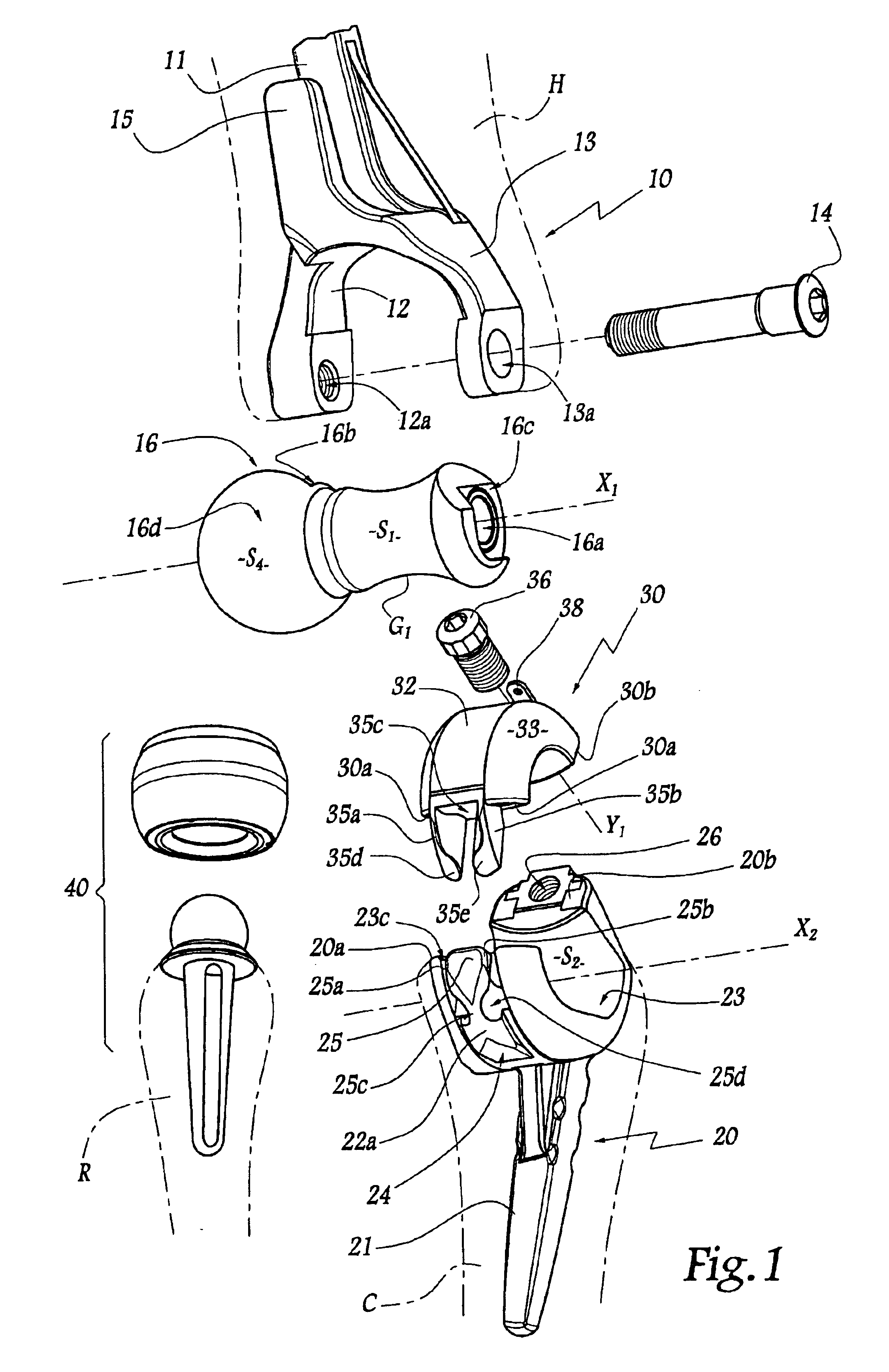

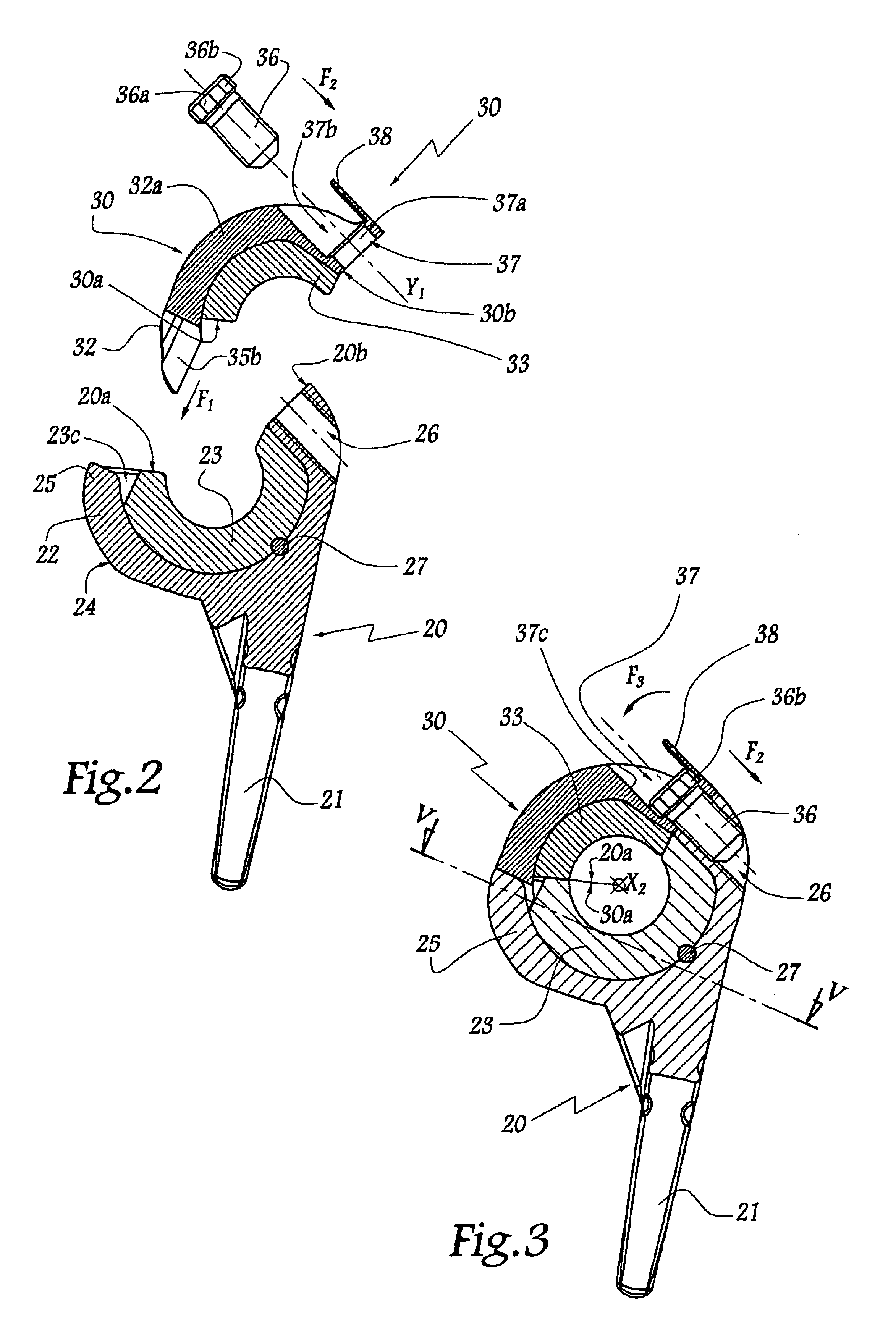

Elbow prosthesis

ActiveUS6890357B2Solve the lack of positioningEffectively fixedJoint implantsKnee jointsEngineeringHumerus

Owner:TORNIER SA SAINT ISMIER

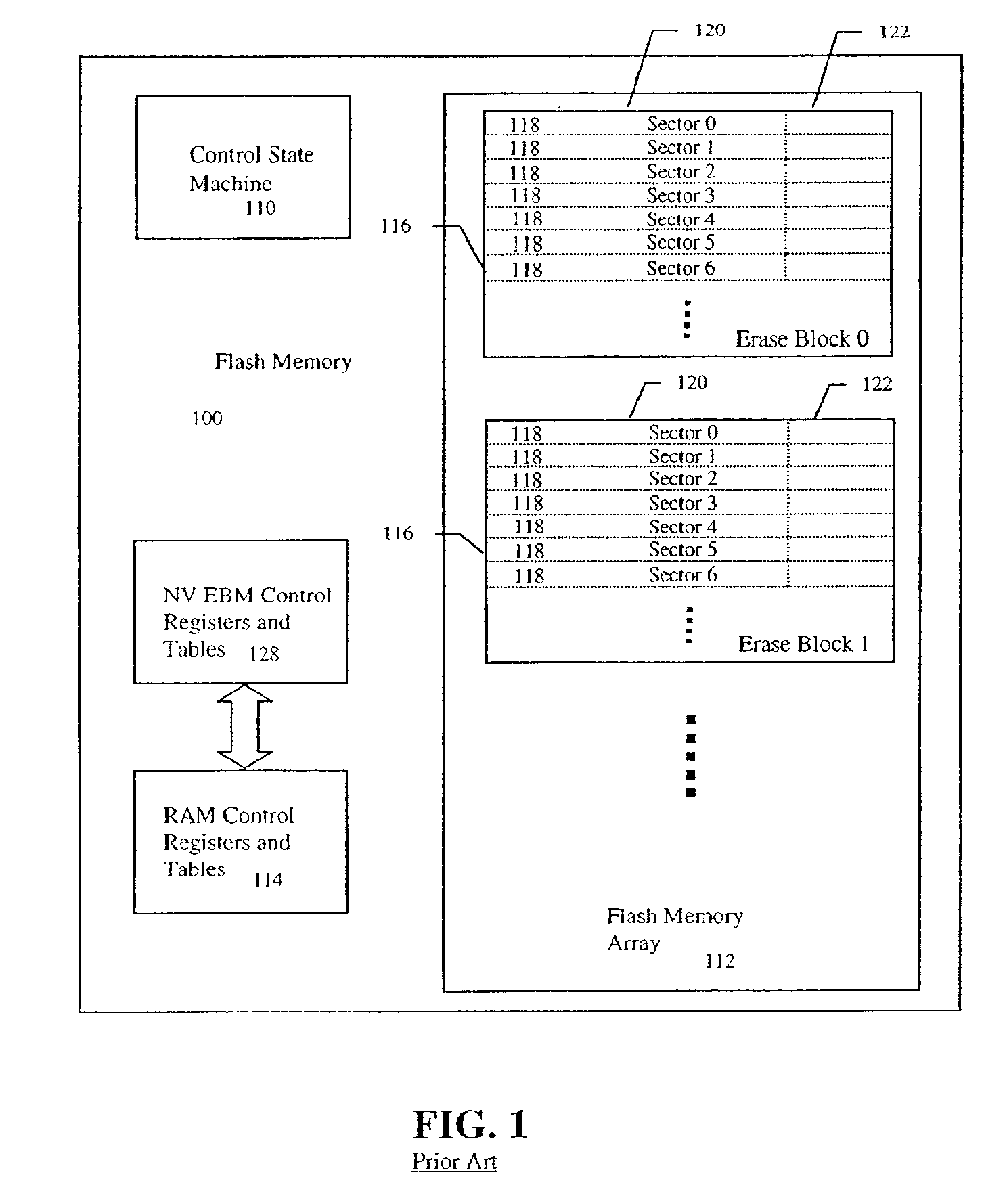

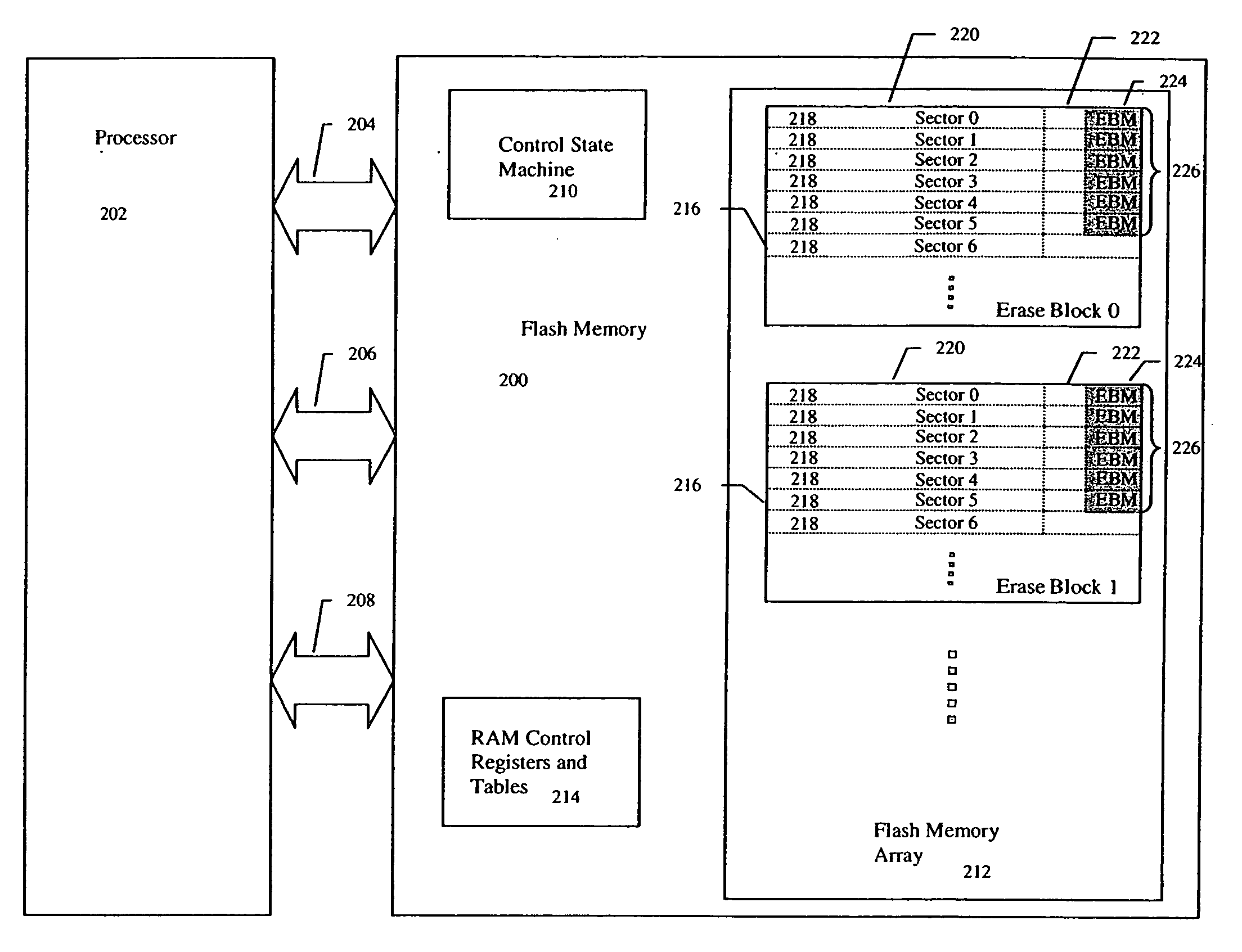

Erase block management

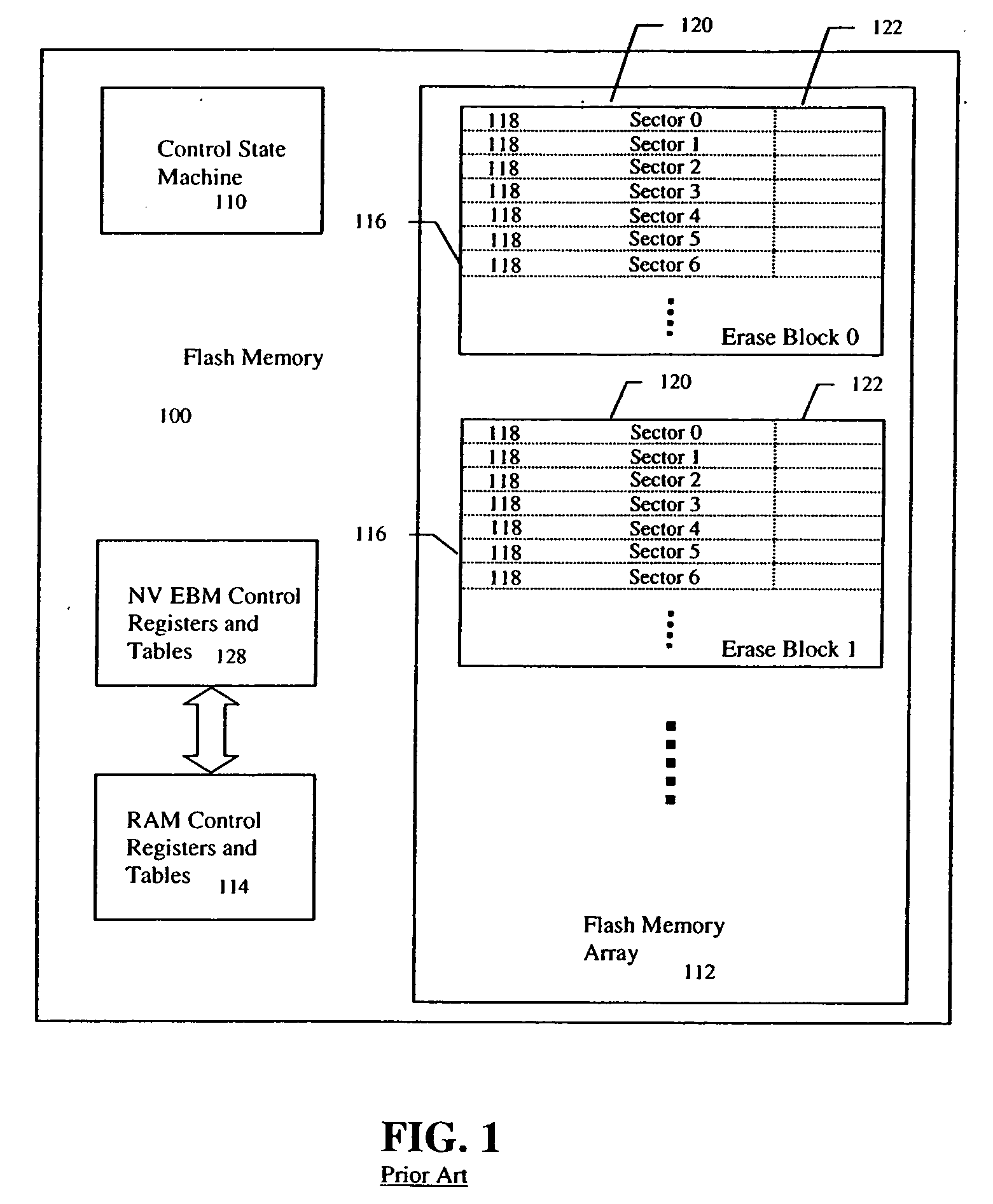

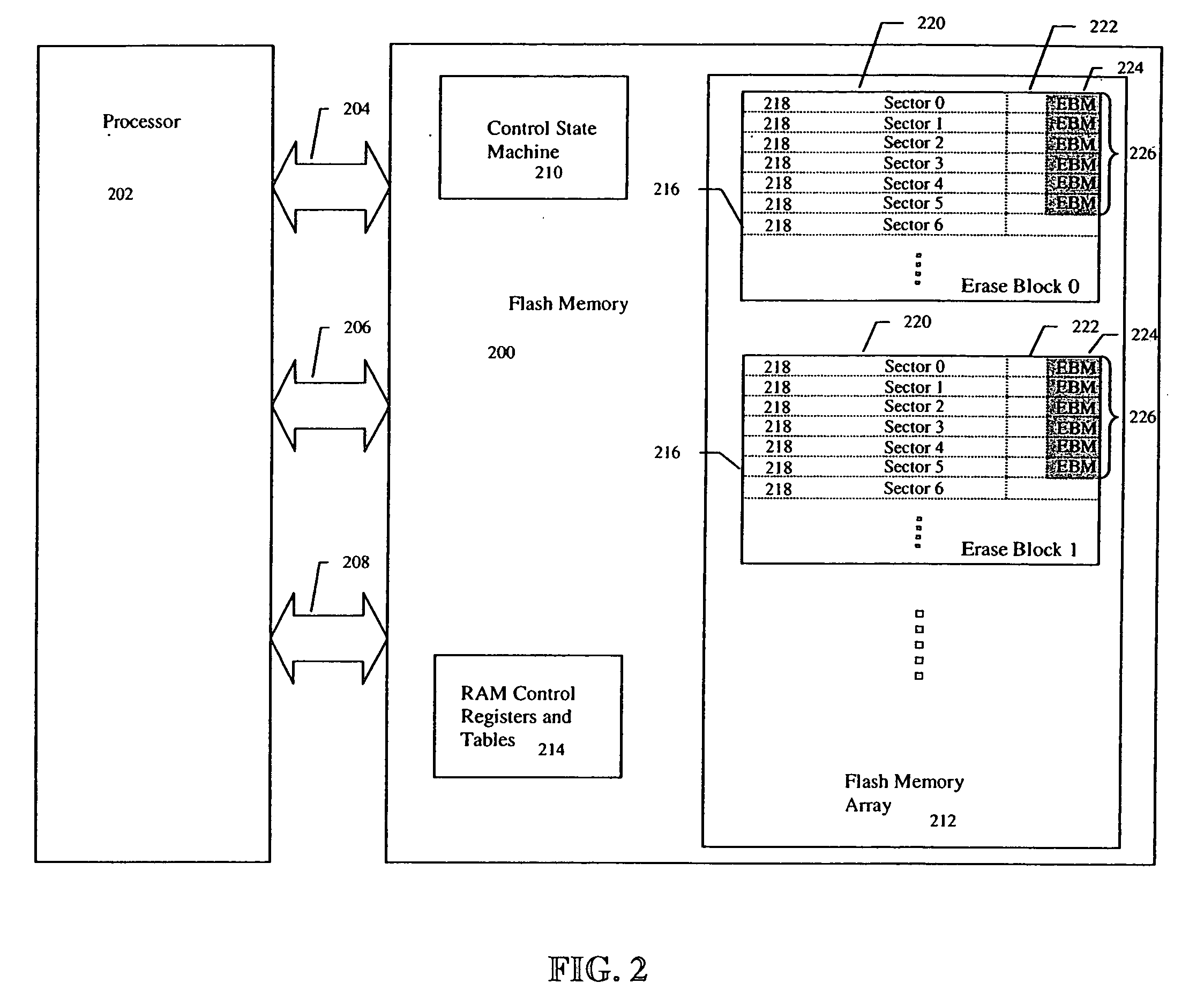

InactiveUS6948026B2Slowing overall Flash device operationMemory architecture accessing/allocationError detection/correctionData fieldControl data

An improved Flash memory device with a distributed erase block management (EBM) scheme is detailed that enhances operation and helps minimize write fatigue of the floating gate memory cells of the Flash memory device. In the prior art, erase block management of a Flash memory device, which provides logical sector to physical sector mapping and provides a virtual rewriteable interface for the host, requires that erase block management data be kept in specialized EBM data tables to keep the state of the Flash memory device in case of loss of power. This placement of EBM data in a separate erase block location from the user data slows the Flash memory operation by requiring up to two writes and / or block erasures for every update of the user data. Additionally, one of the goals of the EBM control is to minimize write fatigue of the non-volatile floating gate memory cells of the Flash memory device erase blocks by re-mapping and distributing heavily rewritten user data sectors in a process called load leveling so that no one erase block gets overused too quickly and reduce the expected lifespan of the Flash memory device. The EBM data structures, however, are some of the most heavily rewritten non-volatile floating gate memory cells in the device and thus, while helping to reduce write fatigue in the Flash memory device, are some of the data structures most susceptible to the process of fatigue. The Flash memory device of the invention combines the EBM data in a user data erase block by placing it in an EBM data field of the control data section of the erase block sectors. Therefore distributing the EBM data within the Flash memory erase block structure. This allows the Flash memory to update and / or erase the user data and the EBM data in a single operation, to reduce overhead and speed operation. The Flash memory also reduces the process of EBM data structure write fatigue by allowing the EBM data fields to be load leveled by rotating them with the erase blocks they describe.

Owner:MICRON TECH INC

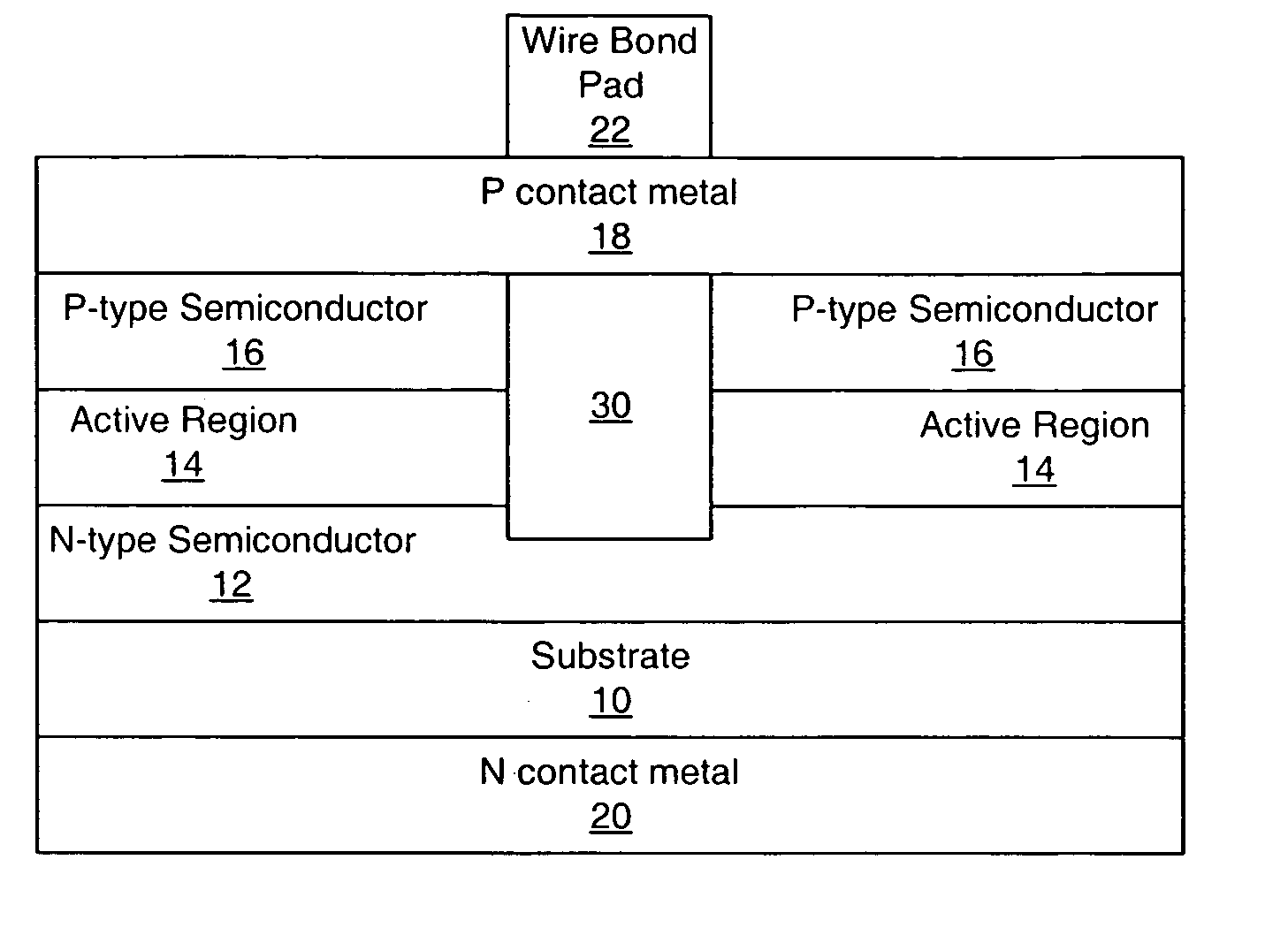

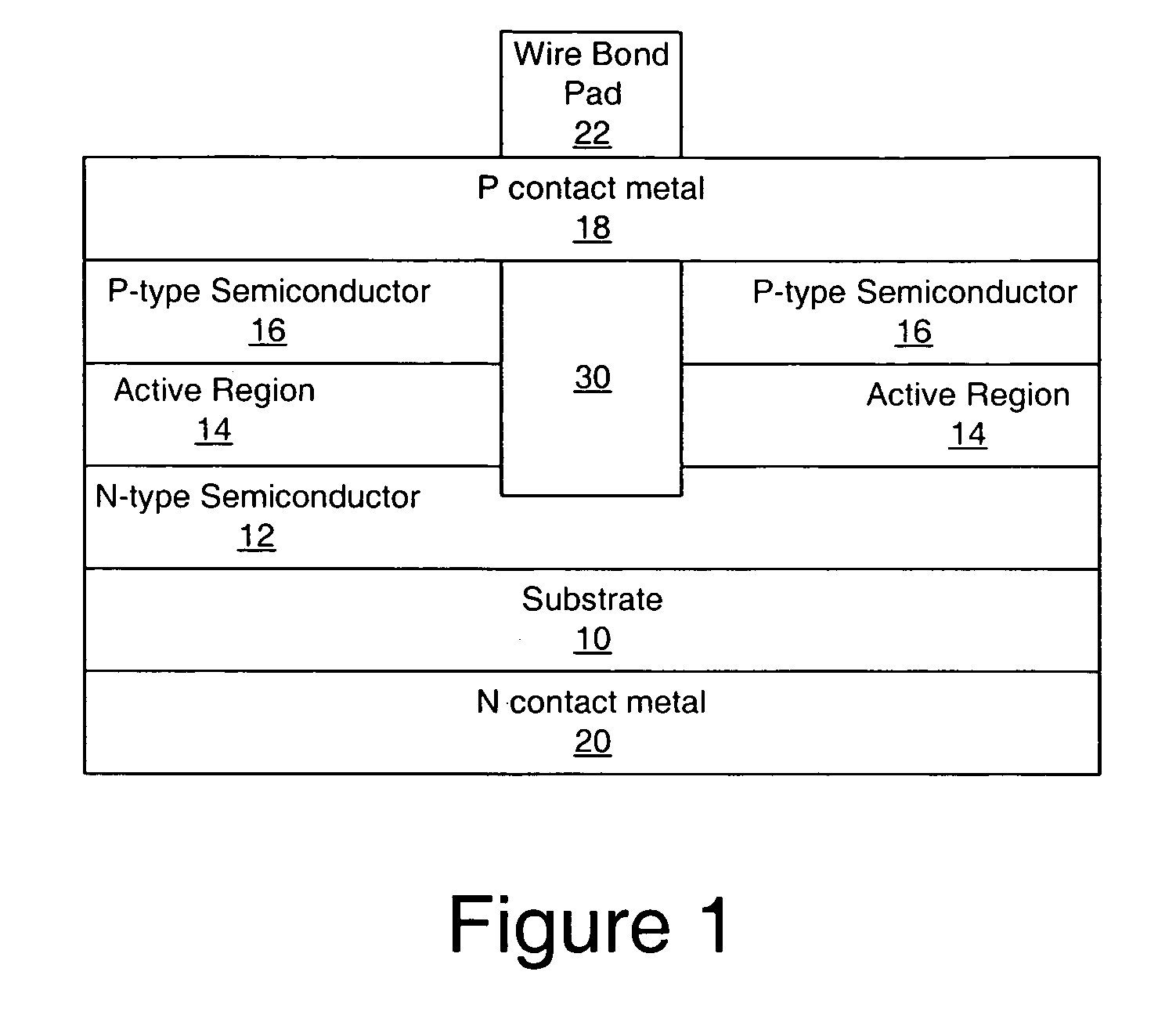

Light emitting devices having current blocking structures and methods of fabricating light emitting devices having current blocking structures

Light emitting devices and methods of fabricating light emitting devices having a current blocking mechanism below the wire bond pad are provided. The current blocking mechanism may be a reduced conduction region in an active region of the device. The current blocking mechanism could be a damage region of a layer on which a contact is formed. The current blocking mechanism could be a Schottky contact between an ohmic contact and the active region of the device. A semiconductor junction, such as a PN junction could also be provided between the ohmic contact and the active region.

Owner:CREE INC

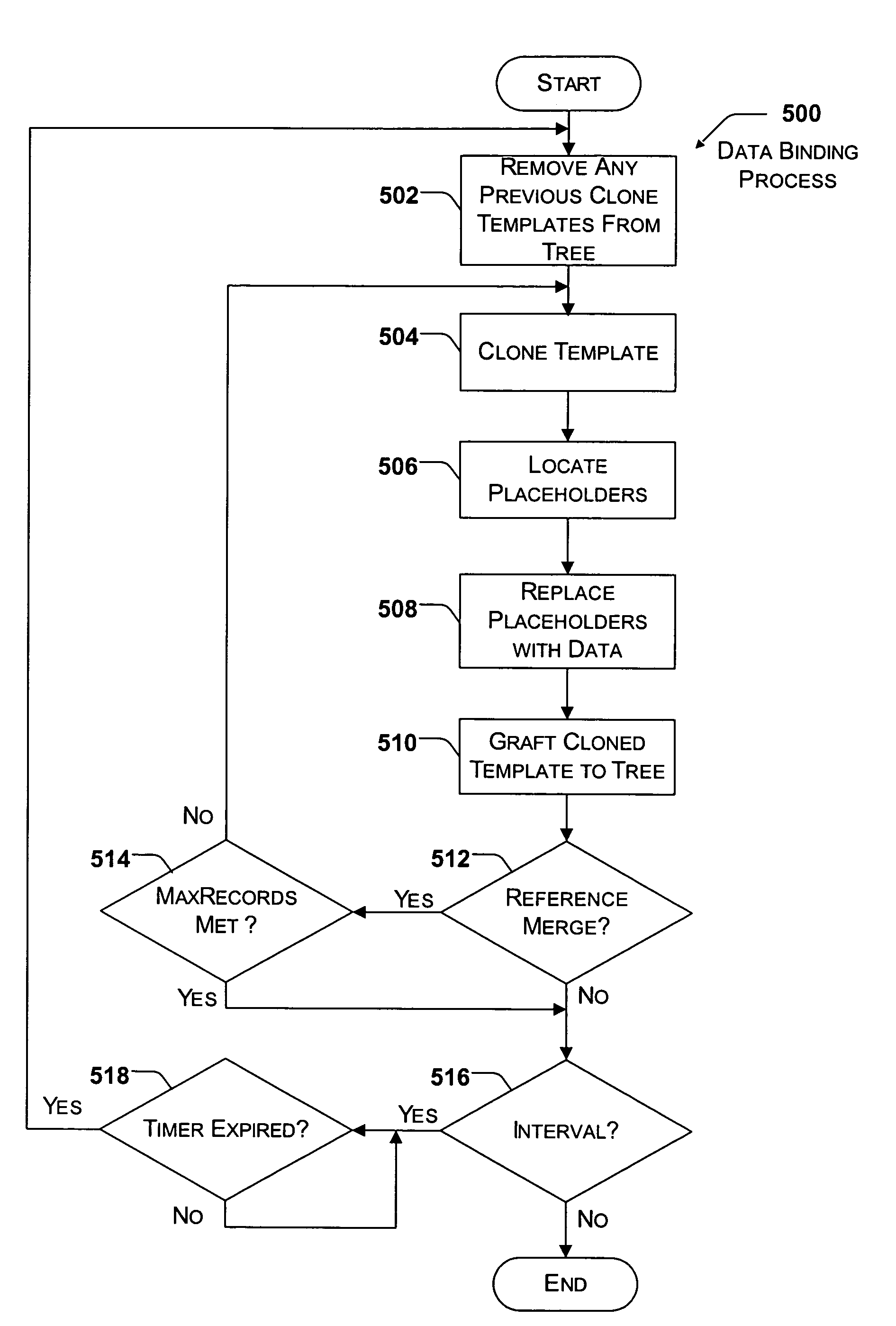

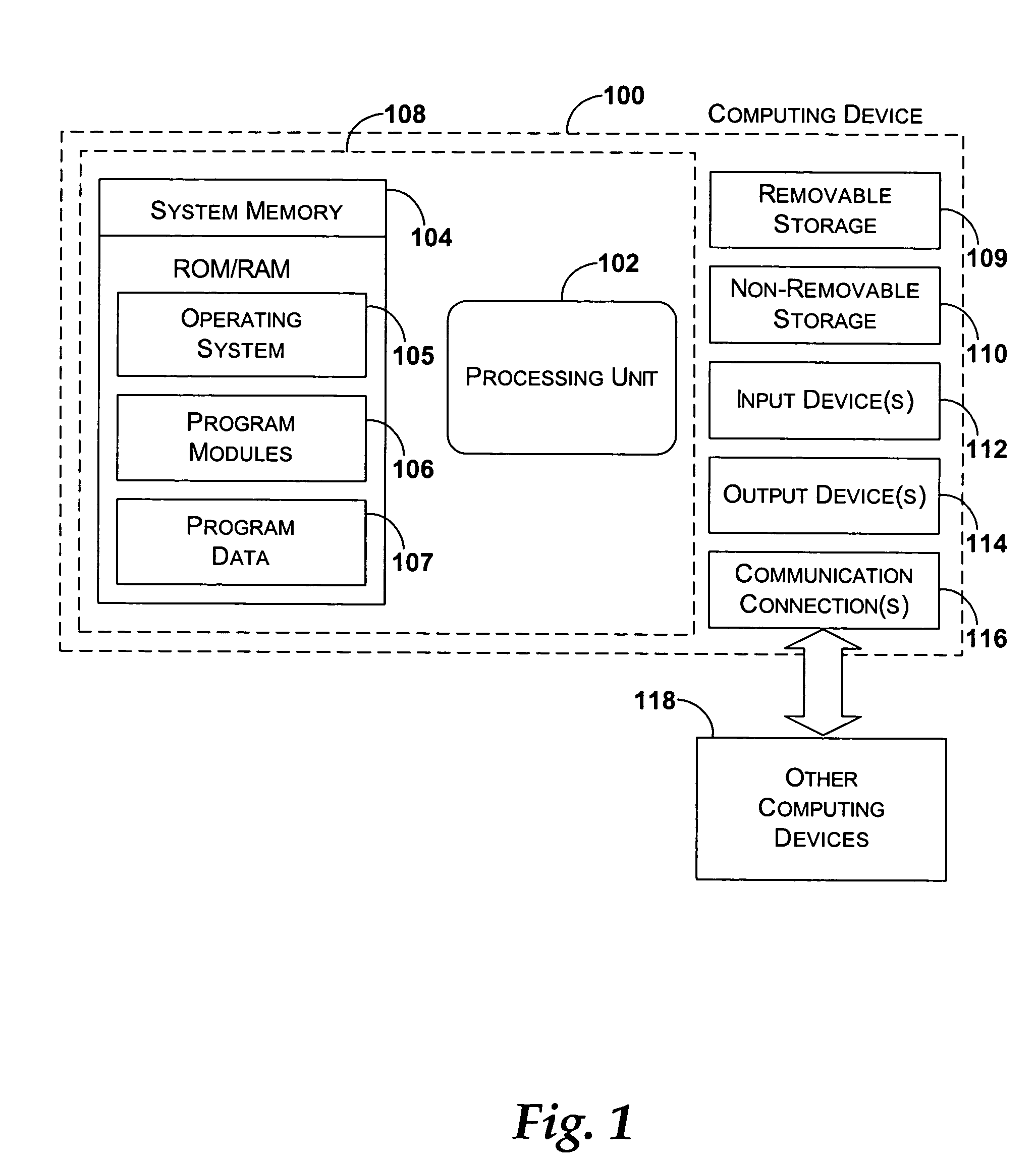

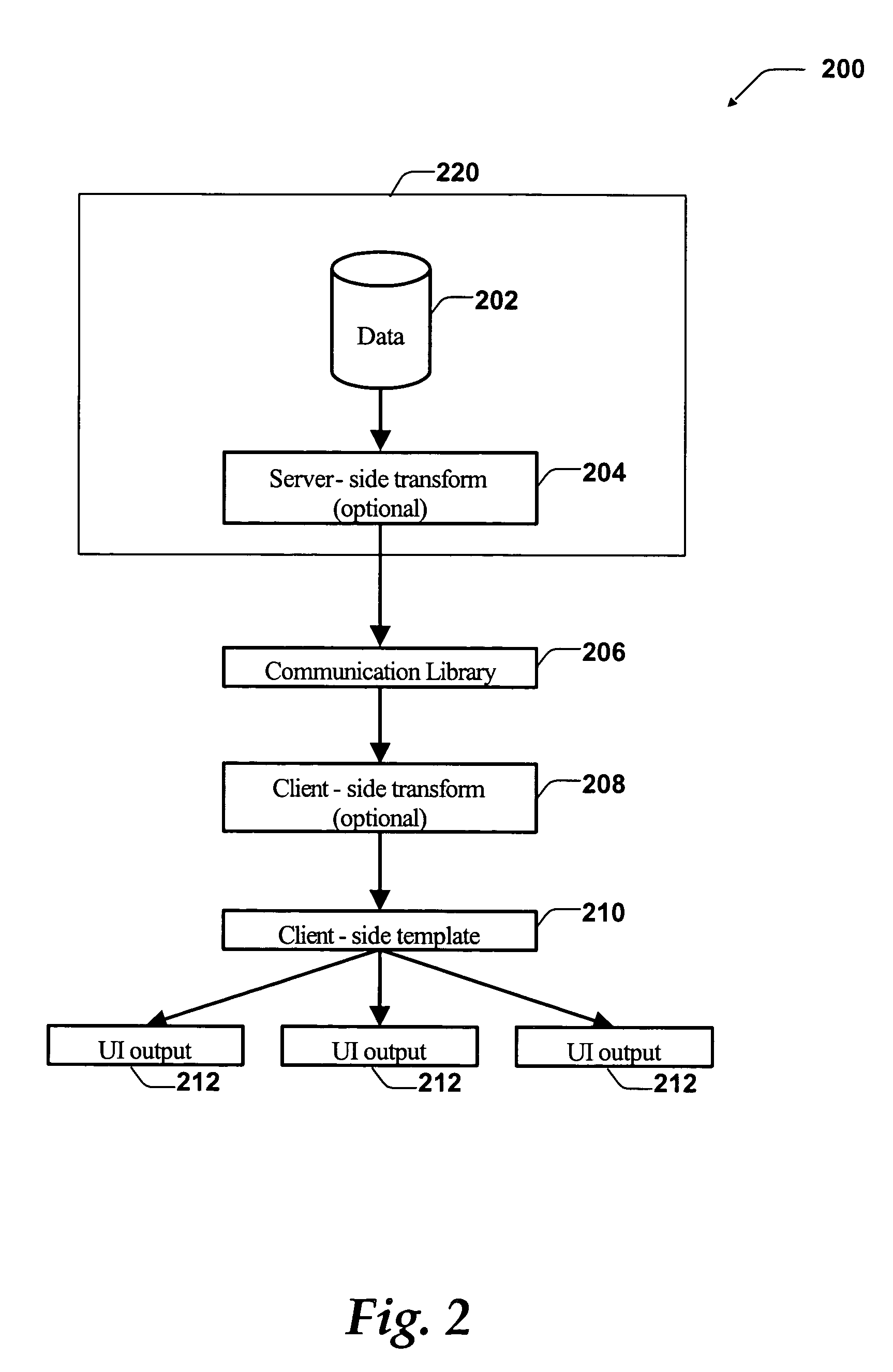

Method and system for data binding in a block structured user interface scripting language

InactiveUS7555707B1Natural language data processingSpecial data processing applicationsScripting languageBlock structure

A method and system is generally directed to retrieving data from an external source and binding the data to a structure used in executing a UI script. The external source may be on a local machine located across a network. The UI script is transformed to a tree structure. The relevant portions of the tree structure are cloned and manipulated to insert the data from the external source. The cloned portions of the tree structure are then grafted back into the tree. The tree structure is then used to display the UI corresponding to the UI script that includes the data from the external source.

Owner:MICROSOFT TECH LICENSING LLC

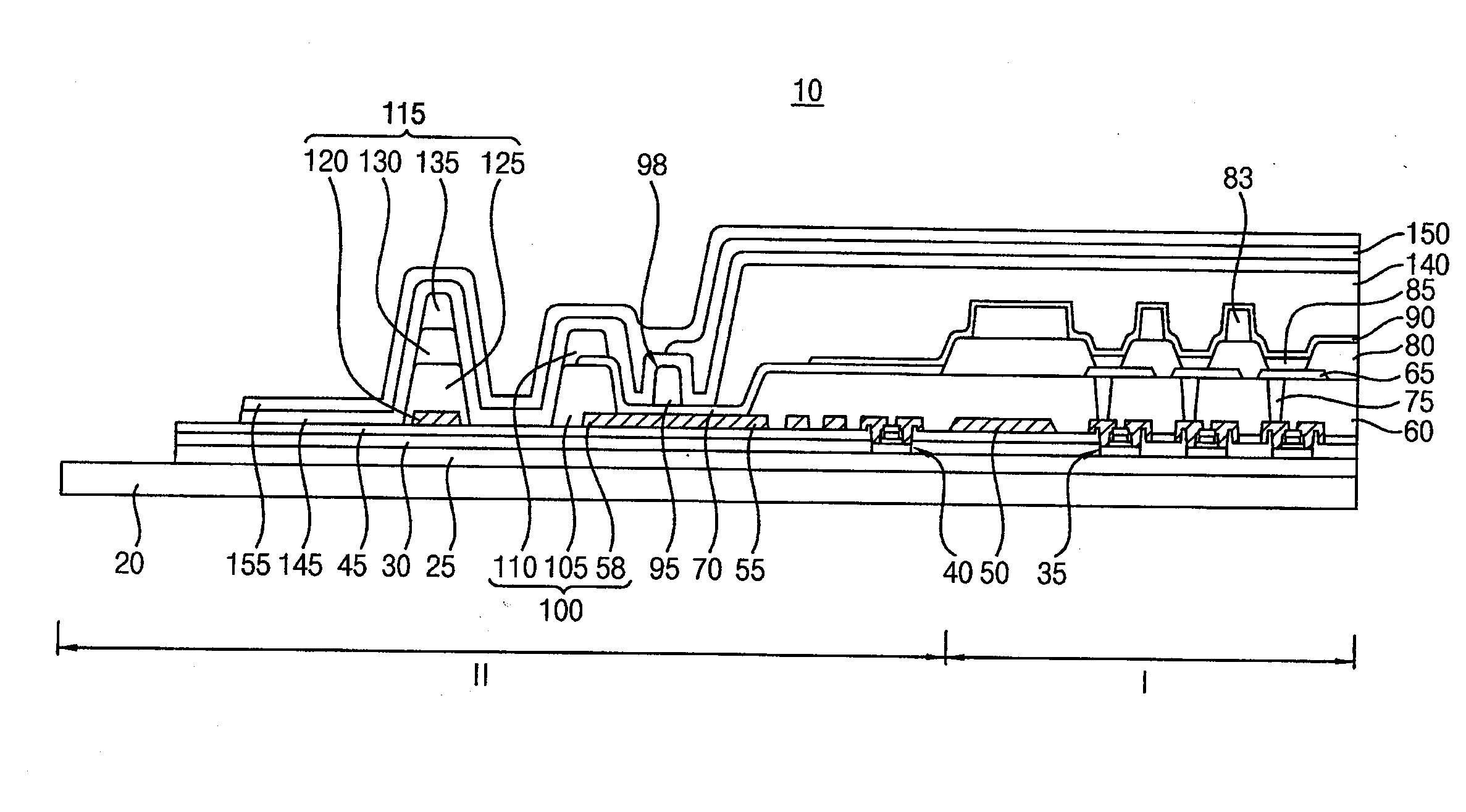

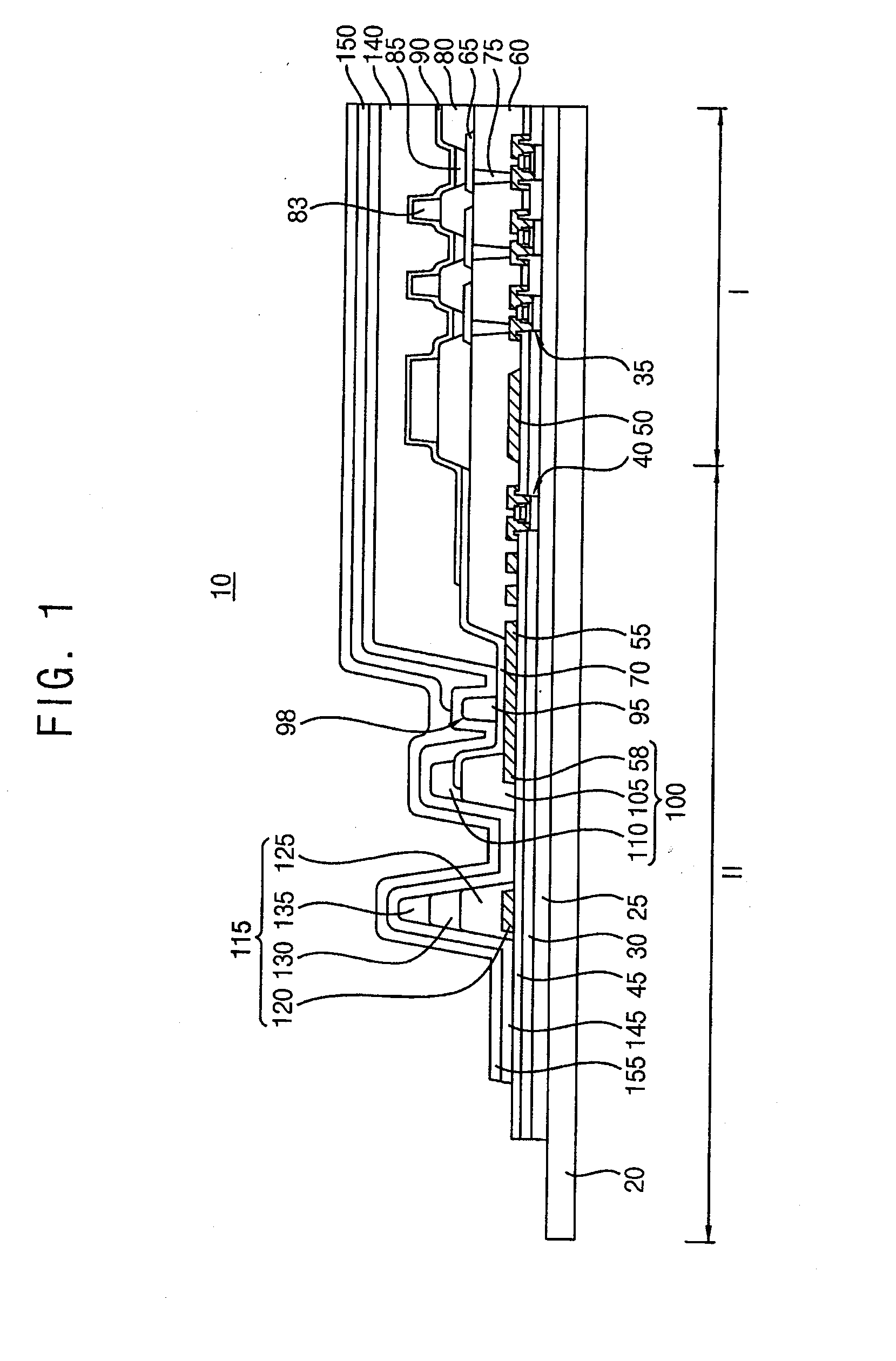

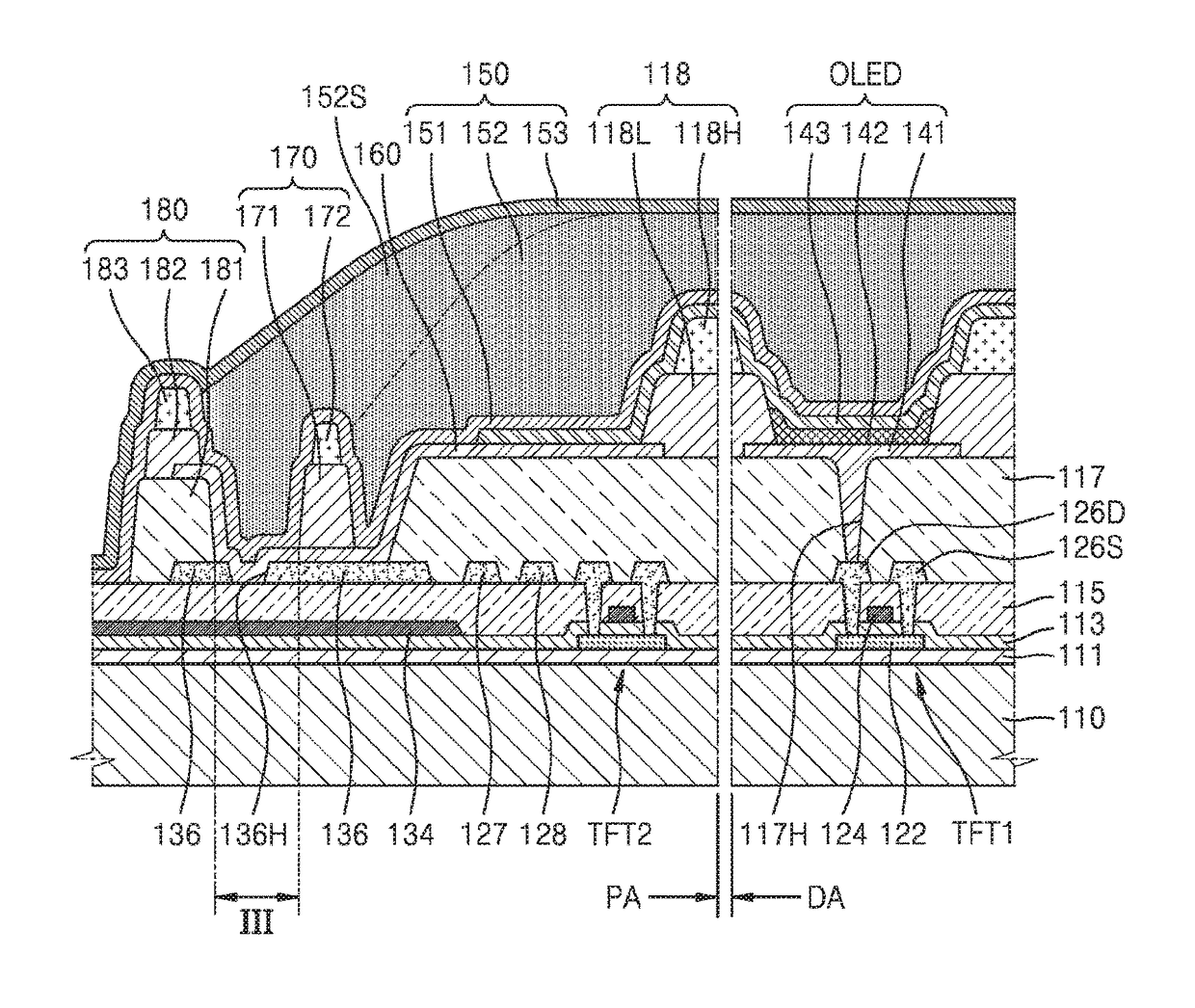

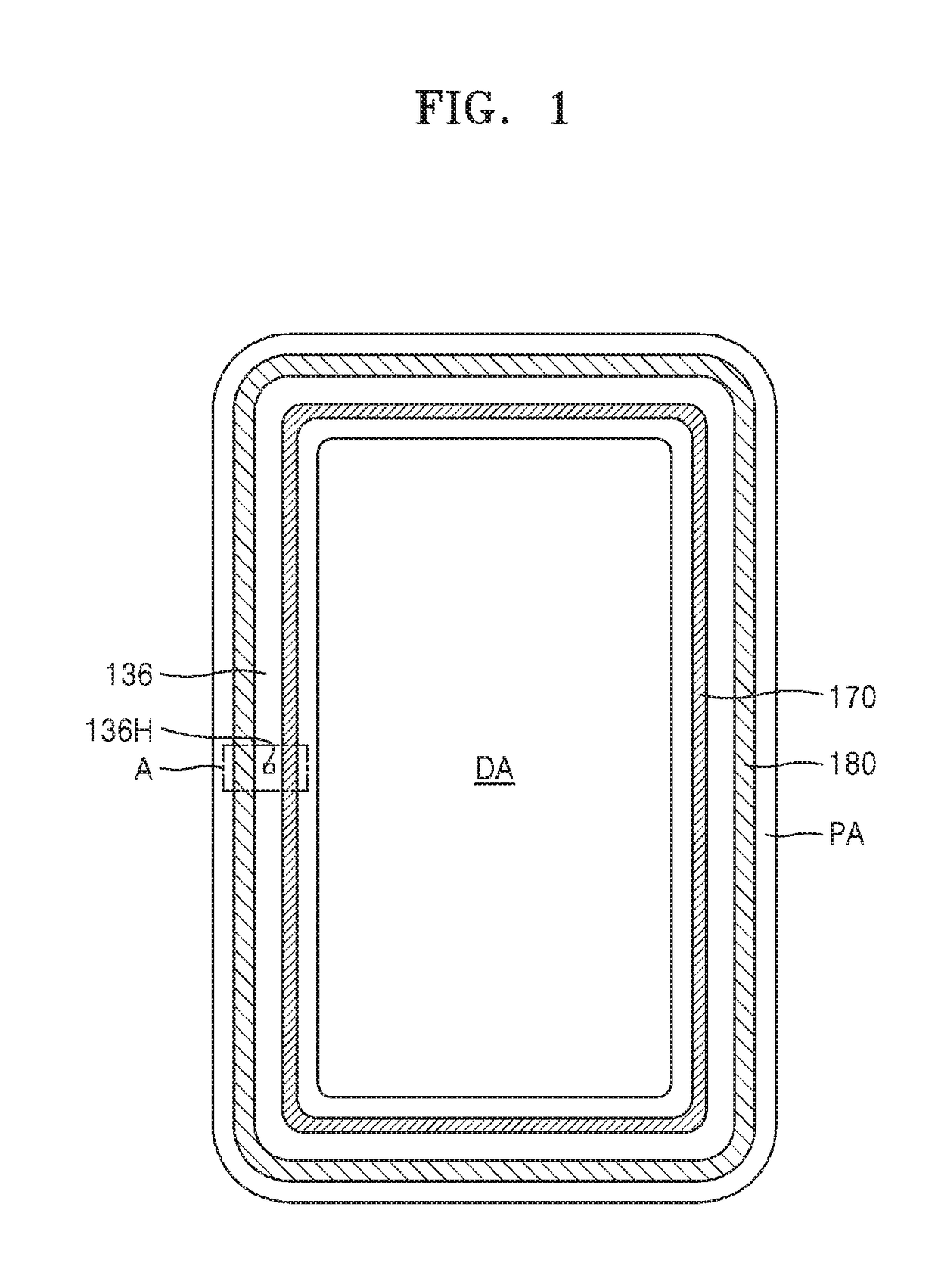

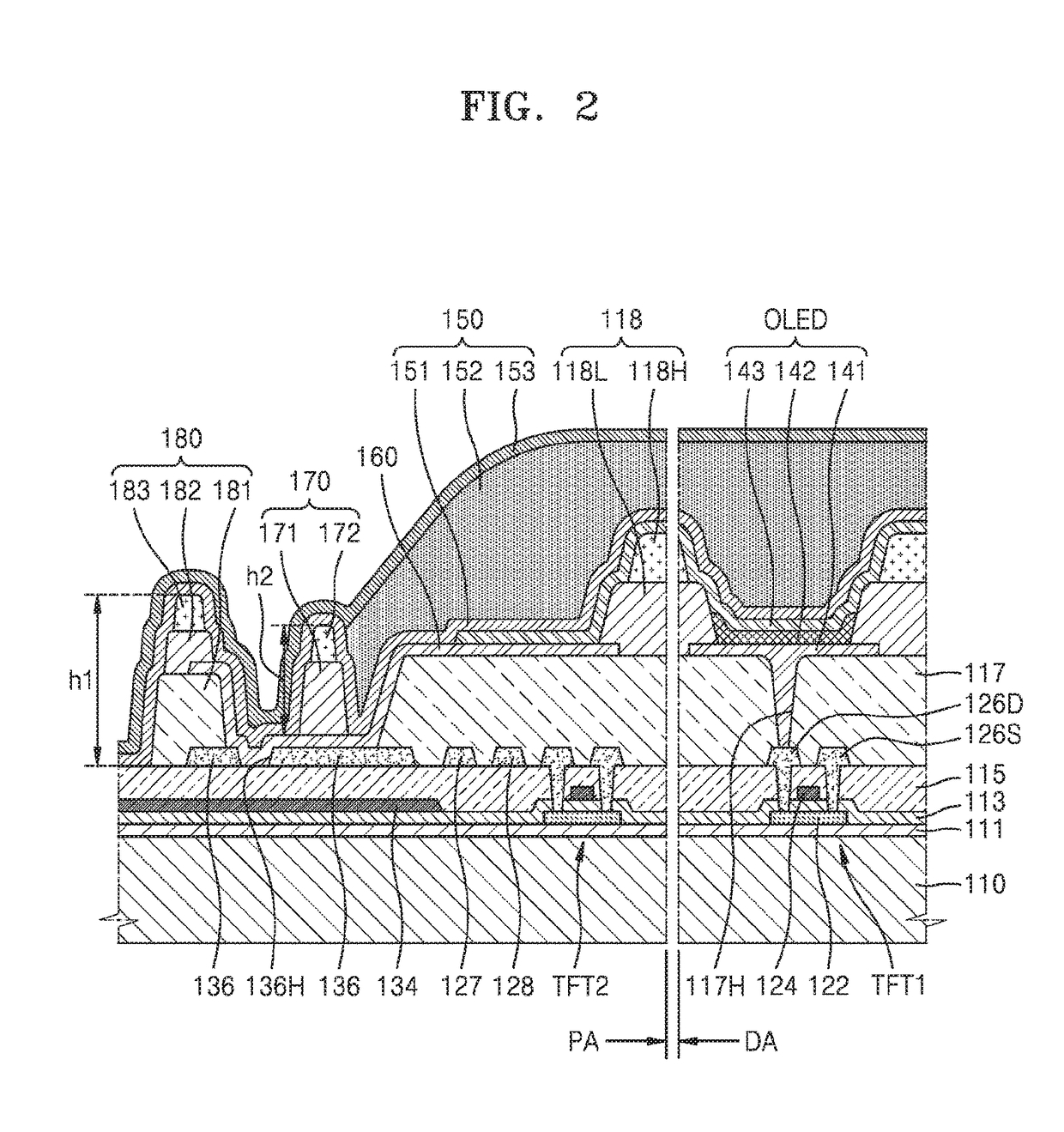

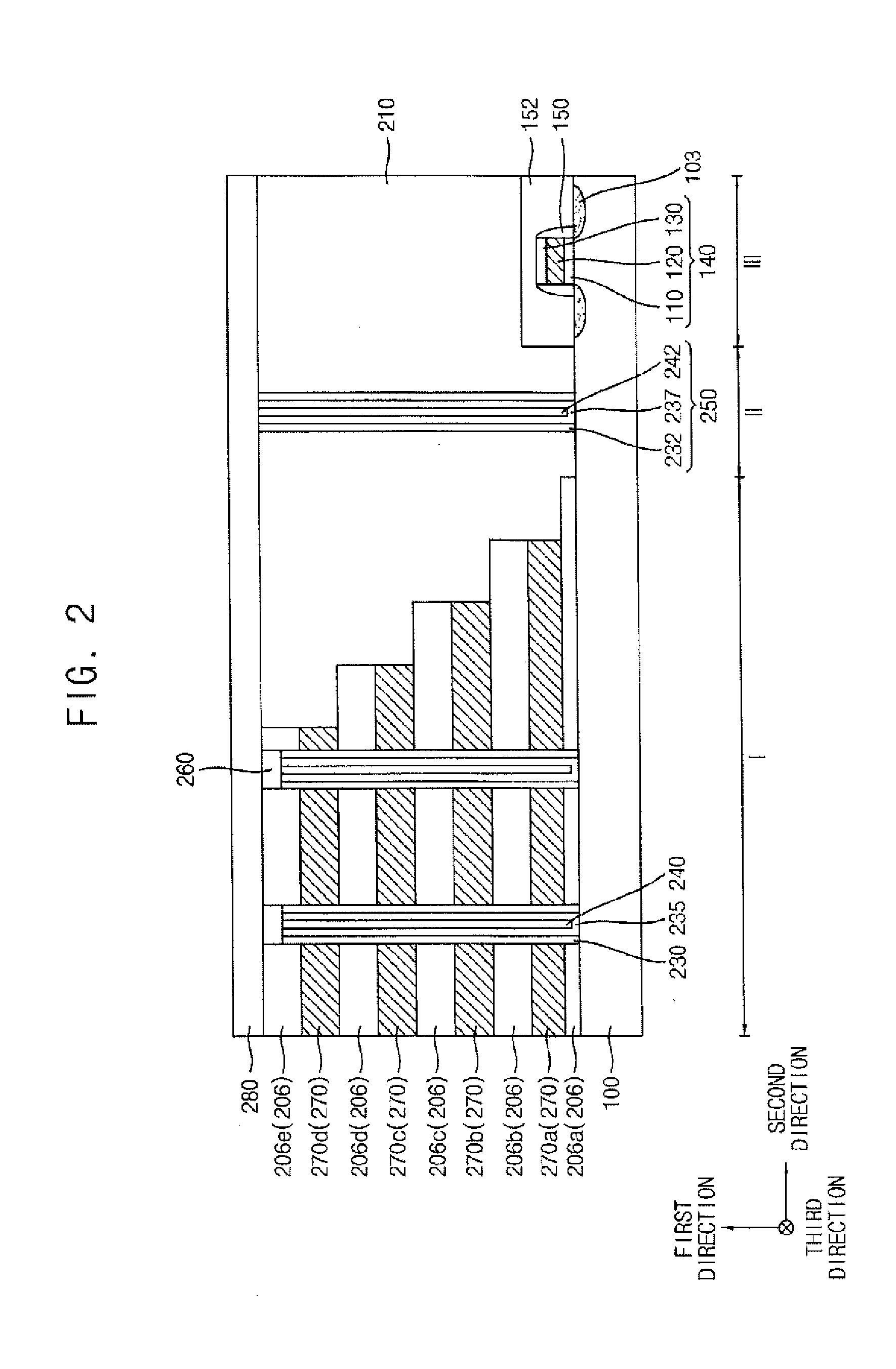

Display devices and methods of manufacturing display devices

ActiveUS20150091030A1Increased durabilityImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsBlock structure

A display device includes a substrate including a display region and a peripheral region, display structures at the display region of the substrate, a plurality of blocking structures at the peripheral region of the substrate wherein the blocking structures have heights different from each other, an organic layer on the display structures and the blocking structures, and an inorganic layer on the organic layer.

Owner:SAMSUNG DISPLAY CO LTD

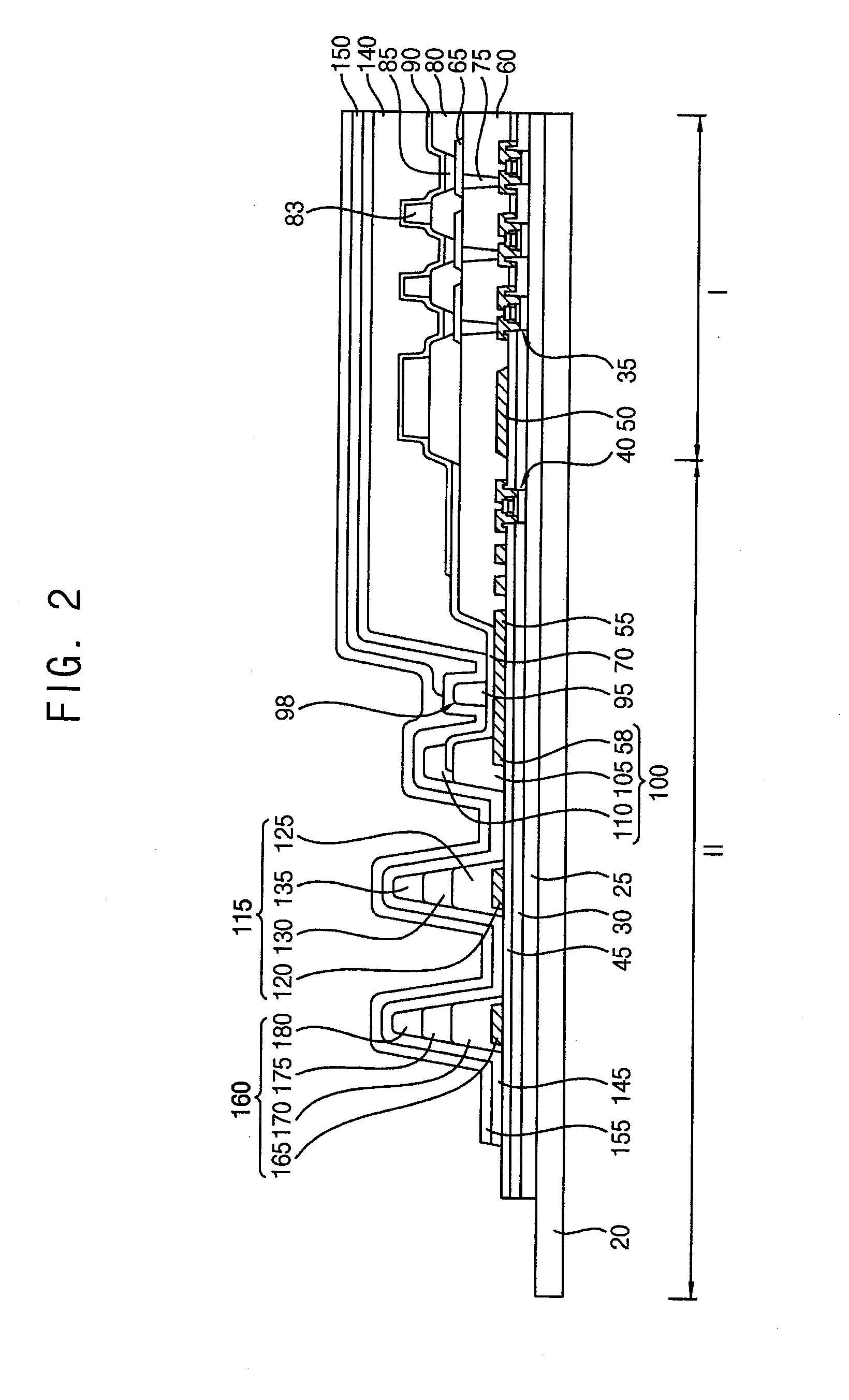

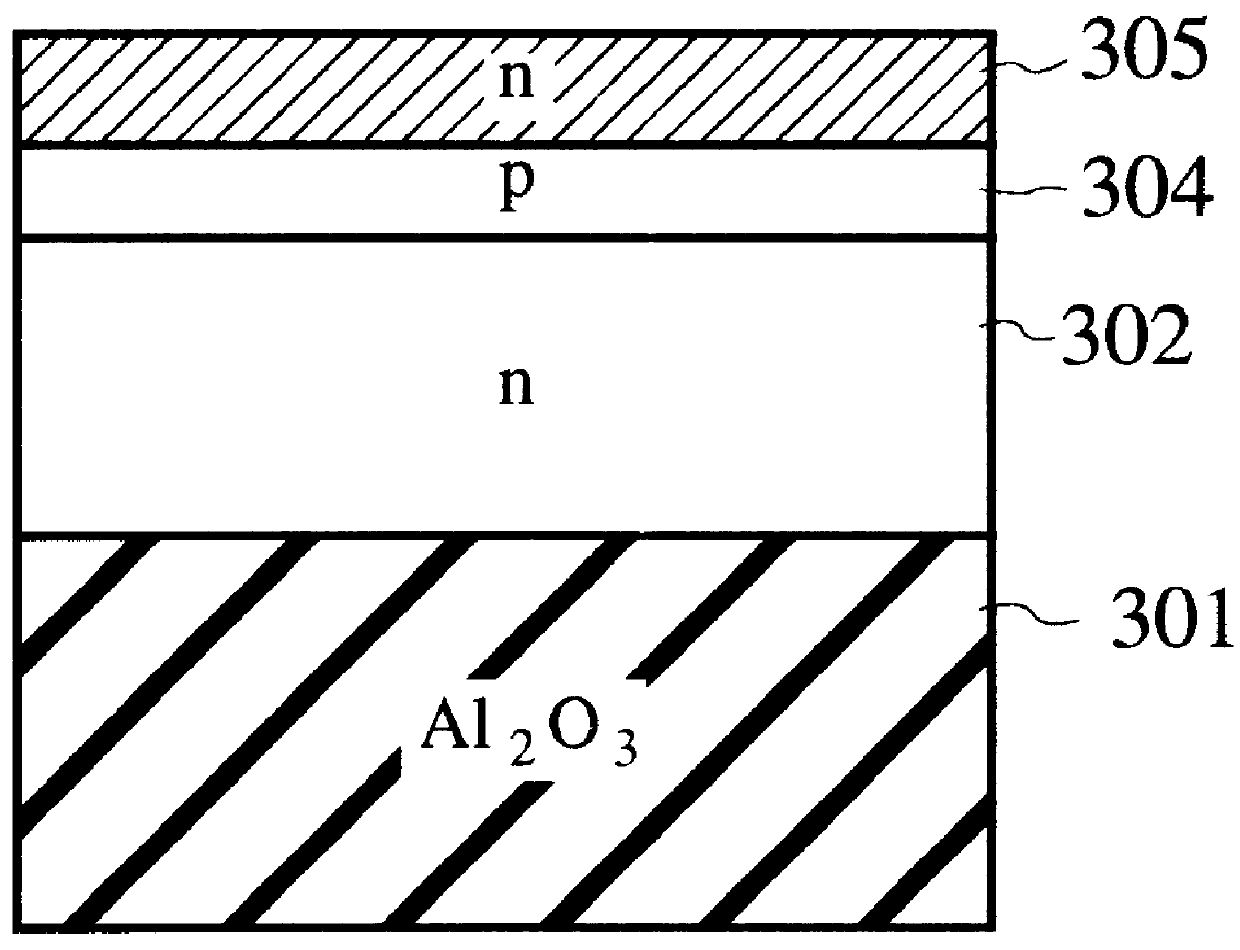

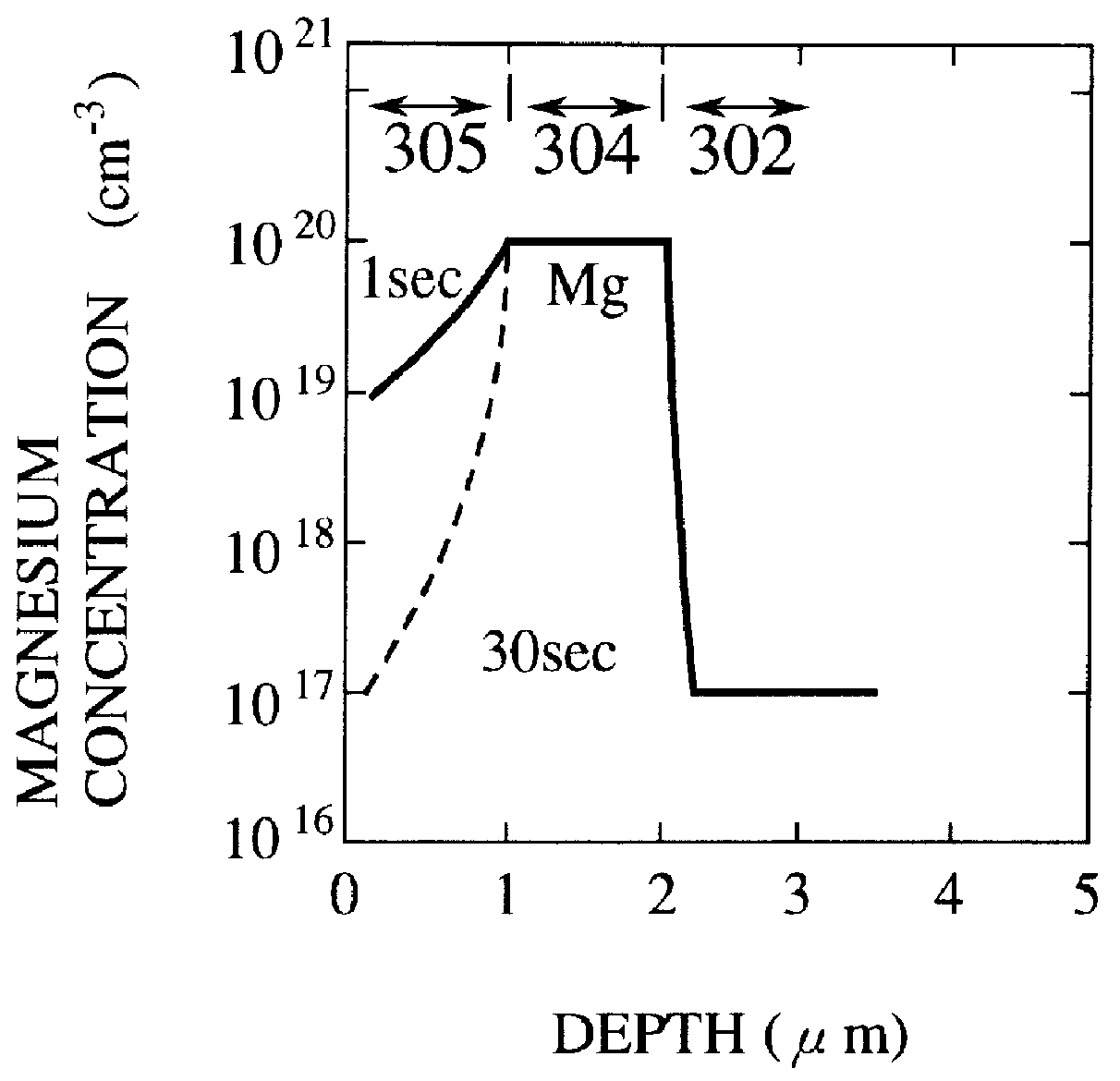

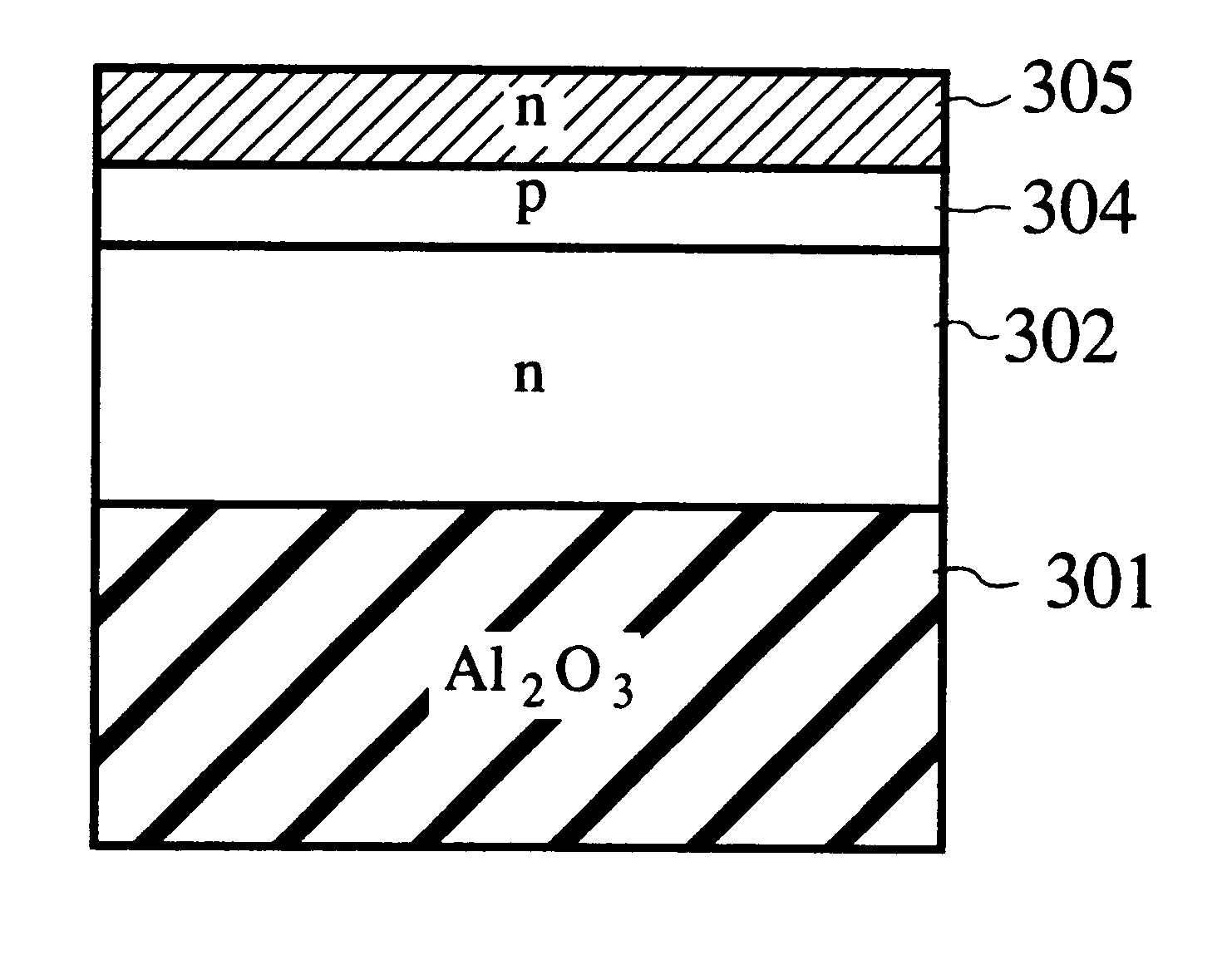

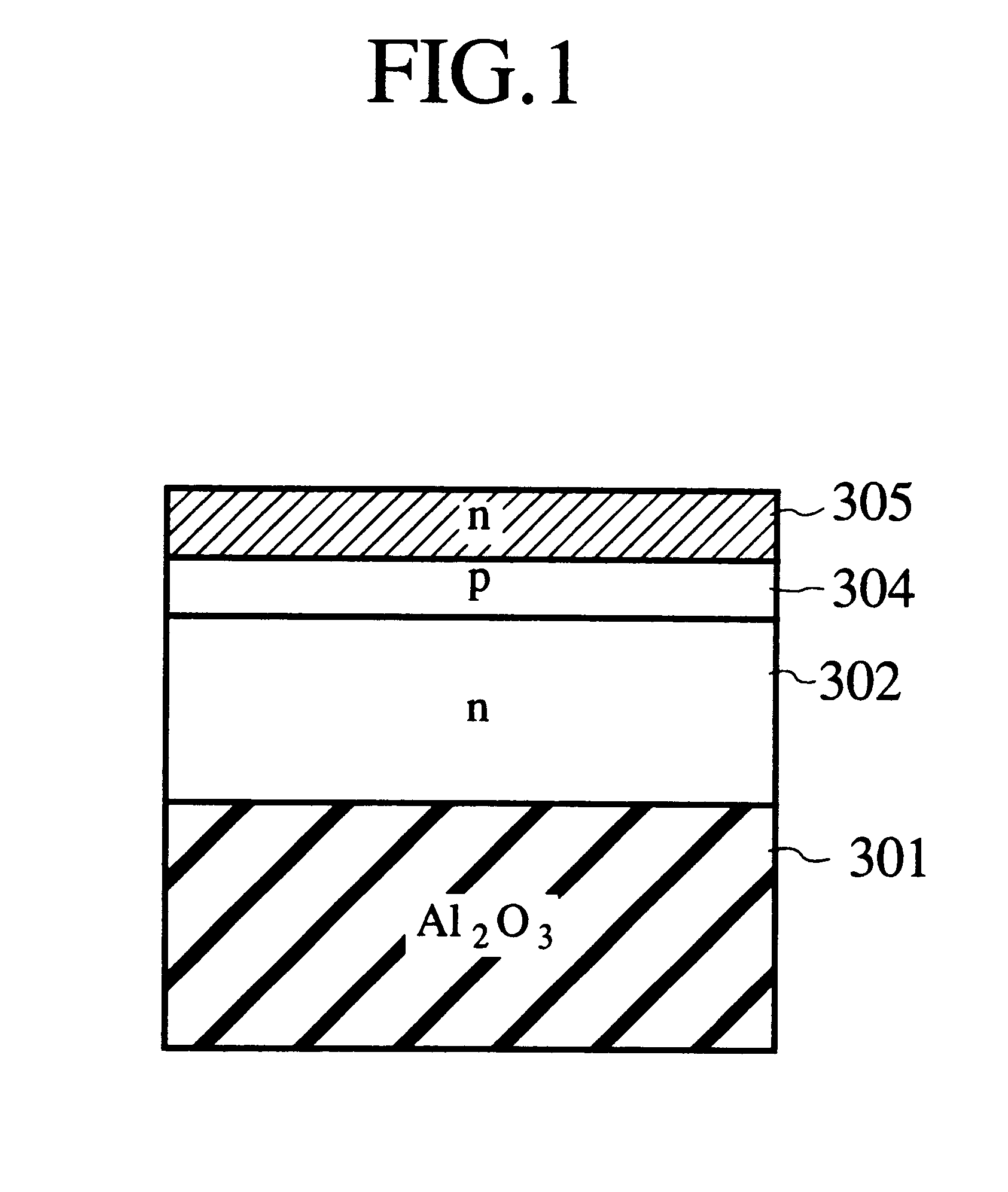

GaN based optoelectronic device and method for manufacturing the same

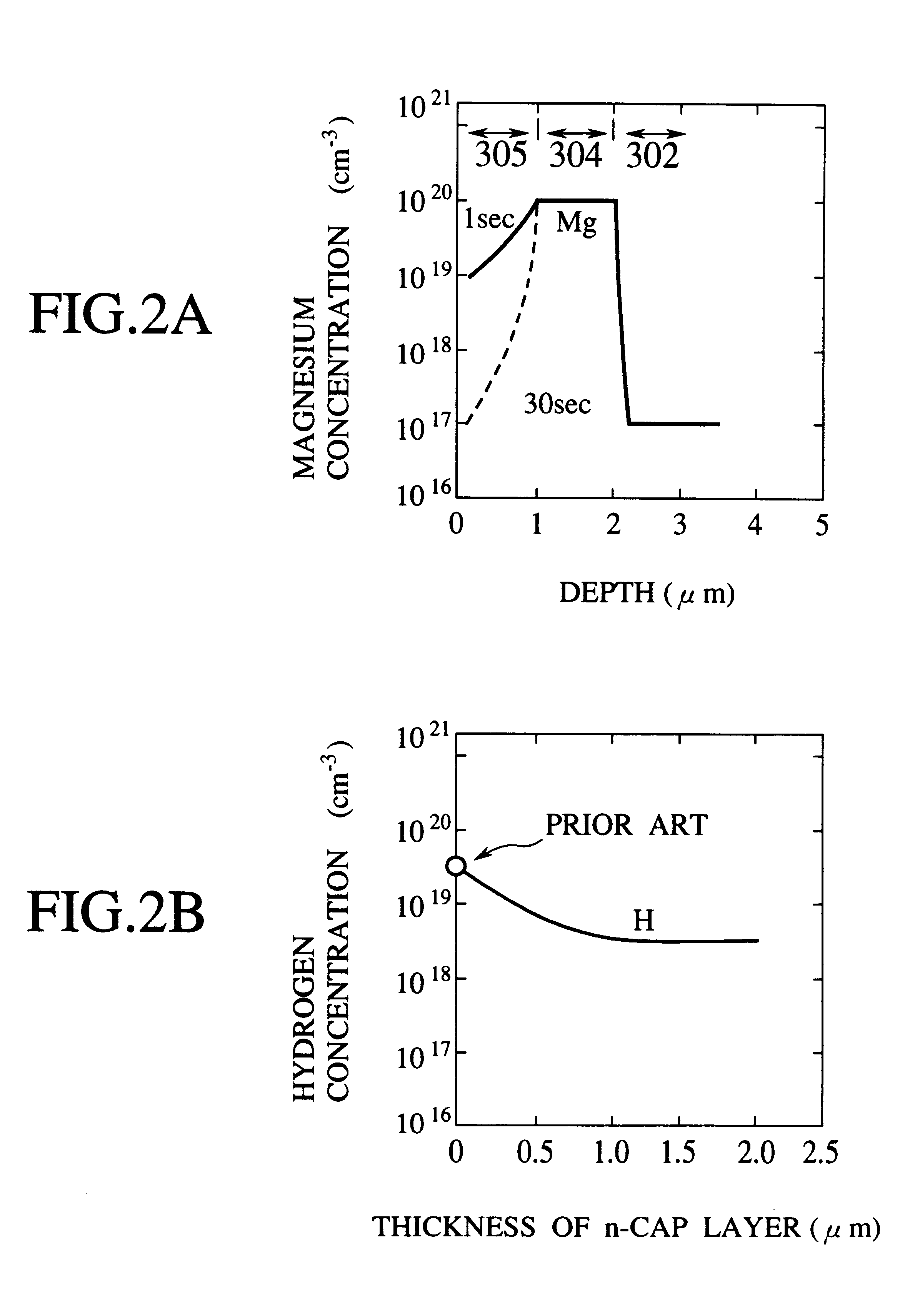

InactiveUS6020602AImprove extraction efficiencyImprove luminous performanceLaser detailsLaser active region structureCharge carrierAcceptor impurity

An n-cap layer is formed on a top surface of p-type clad layers, the p-type clad layer is a top layer of a stacked structure having a pn-junction for emitting carriers into light-emitting region of a GaN based light-emitting device, thus increasing the activation ratio of acceptor impurities in the p-type clad layers. The n-cap layer is used also as a current blocking layer, thereby constructing a current-blocked structure. The n-cap layer should preferably be made of InuAlvGa1-u-vN (0<u, v<1) deposited as thick as 1.0 micron or more. The present invention will easily provide a high luminous efficiency GaN based semiconductor light-emitting device without using any complicated processes such as electron-beam irradiation or thermal annealing.

Owner:KK TOSHIBA

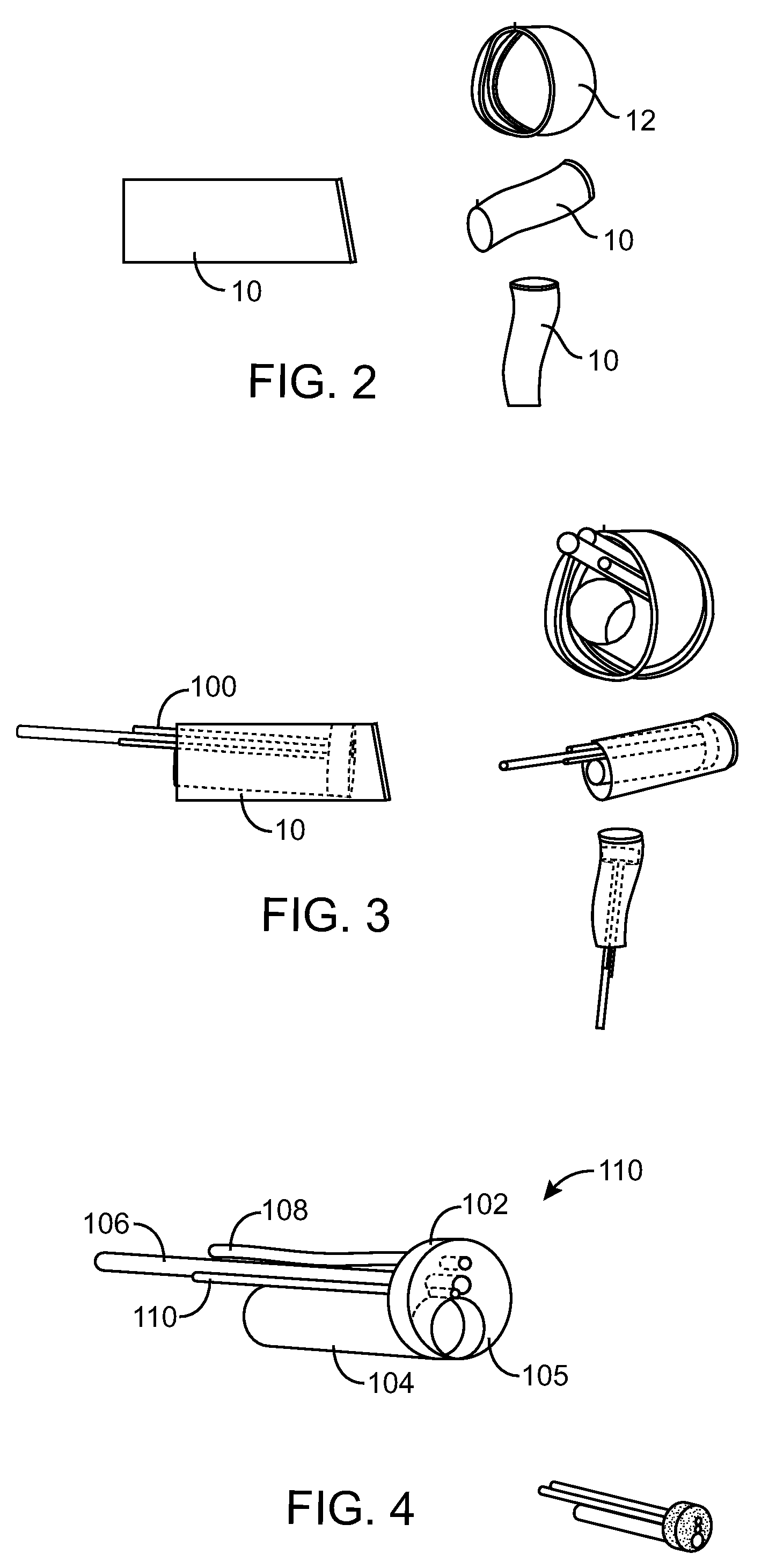

Optical fiber clad-protective terminations

This invention pertains to fiber termination combination which includes an optical fiber having a fiber core for transmitting a highly energetic optical signal that can damage the fiber and a structured region around the core for directing the optical signal into the core, the structured region being characterized by multiple channels of smaller internal diameter than the core defined by thin walls disposed around said core; a ferrule, with an opening therein for locating said fiber, at the end of said fiber enveloping said fiber extremity which cooperates with said blocking structure to block the optical signal from impinging on said microstructured region of said fiber; and a blocking structure disposed over the end of said fiber with an opening mating with said fiber core, said blocking structure blocking the optical signal from impinging on said microstructured region of said fiber.

Owner:NAVY U S A AS REPRESENTED BY THE SEC OF THE THE

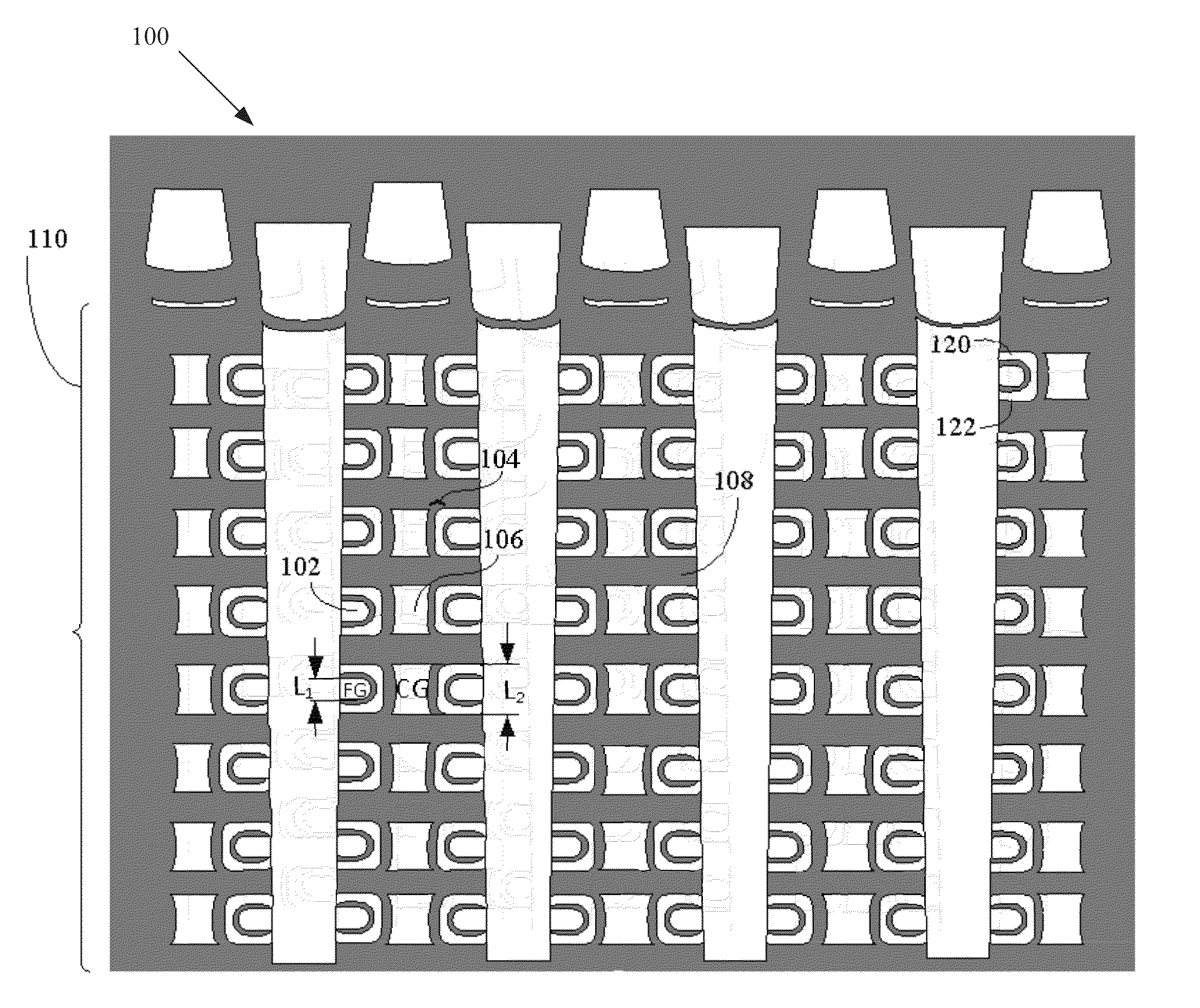

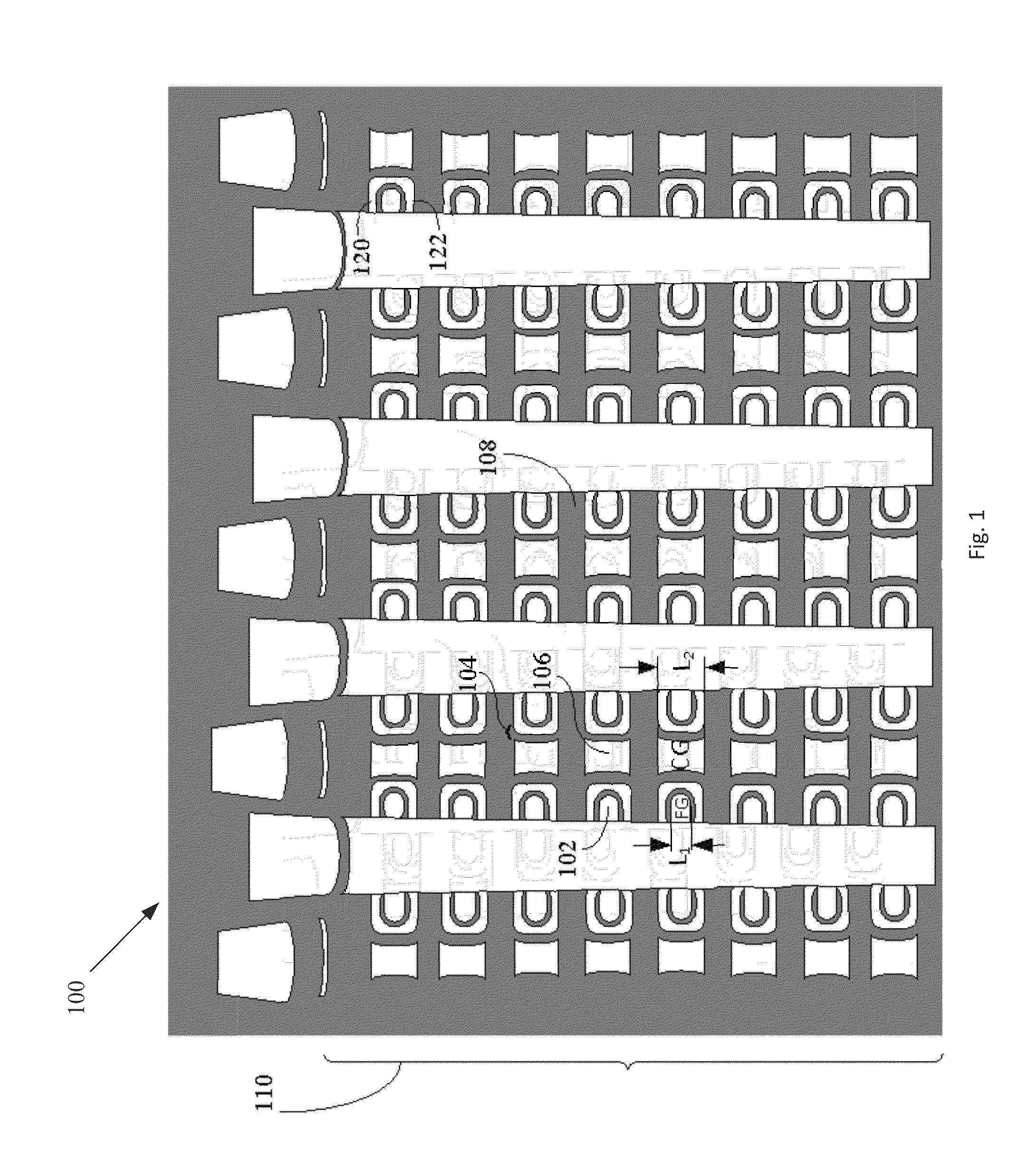

Floating gate memory cells in vertical memory

Floating gate memory cells in vertical memory. A control gate is formed between a first tier of dielectric material and a second tier of dielectric material. A floating gate is formed between the first tier of dielectric material and the second tier of dielectric material, wherein the floating gate includes a protrusion extending towards the control gate. A charge blocking structure is formed between the floating gate and the control gate, wherein at least a portion of the charge blocking structure wraps around the protrusion.

Owner:MICRON TECH INC

Bit Holder Shank and Differential Interference Between the Shank Distal Portion and the Bit Holder Block Bore

Improved bit holder / bit holder block structure provides increased access to the rear of the assembly allowing bit holder blocks to be mounted closer to each other for micro-milling operations. Shortened bit holder shanks are reconfigured from prior art to provide increased holding power between the bit holder shank and bit holder block bore.

Owner:THE SOLLAMI COMPANY

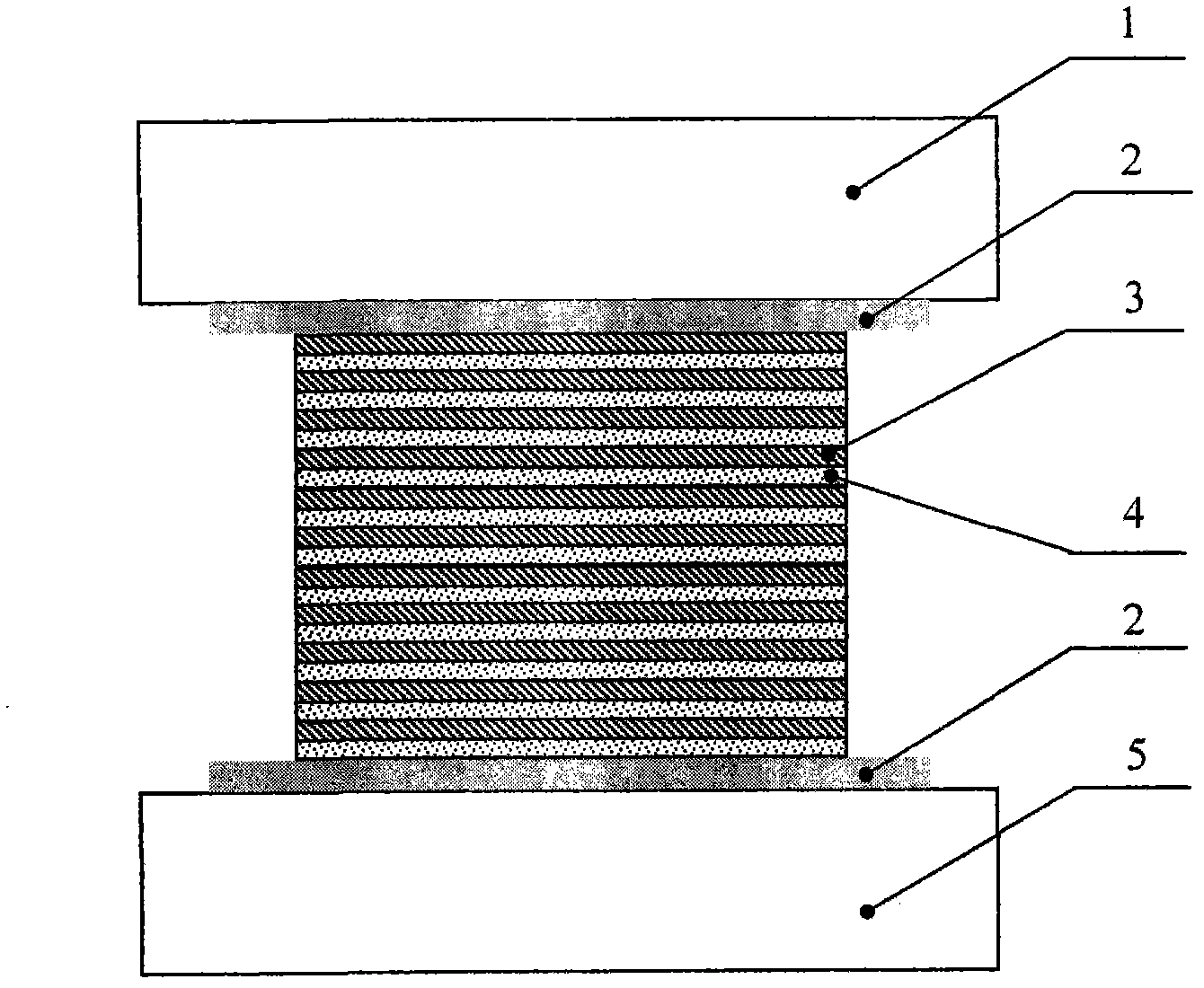

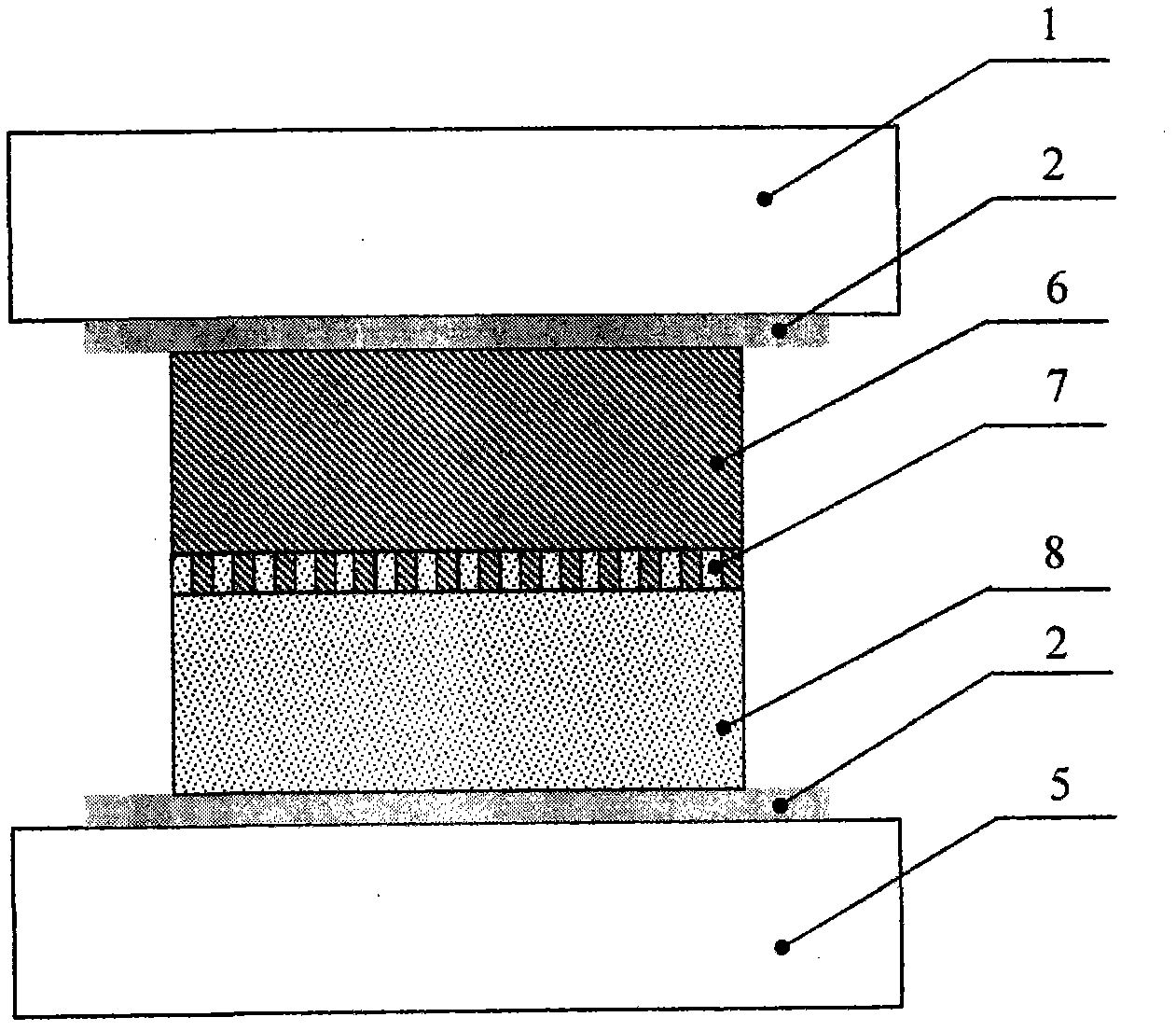

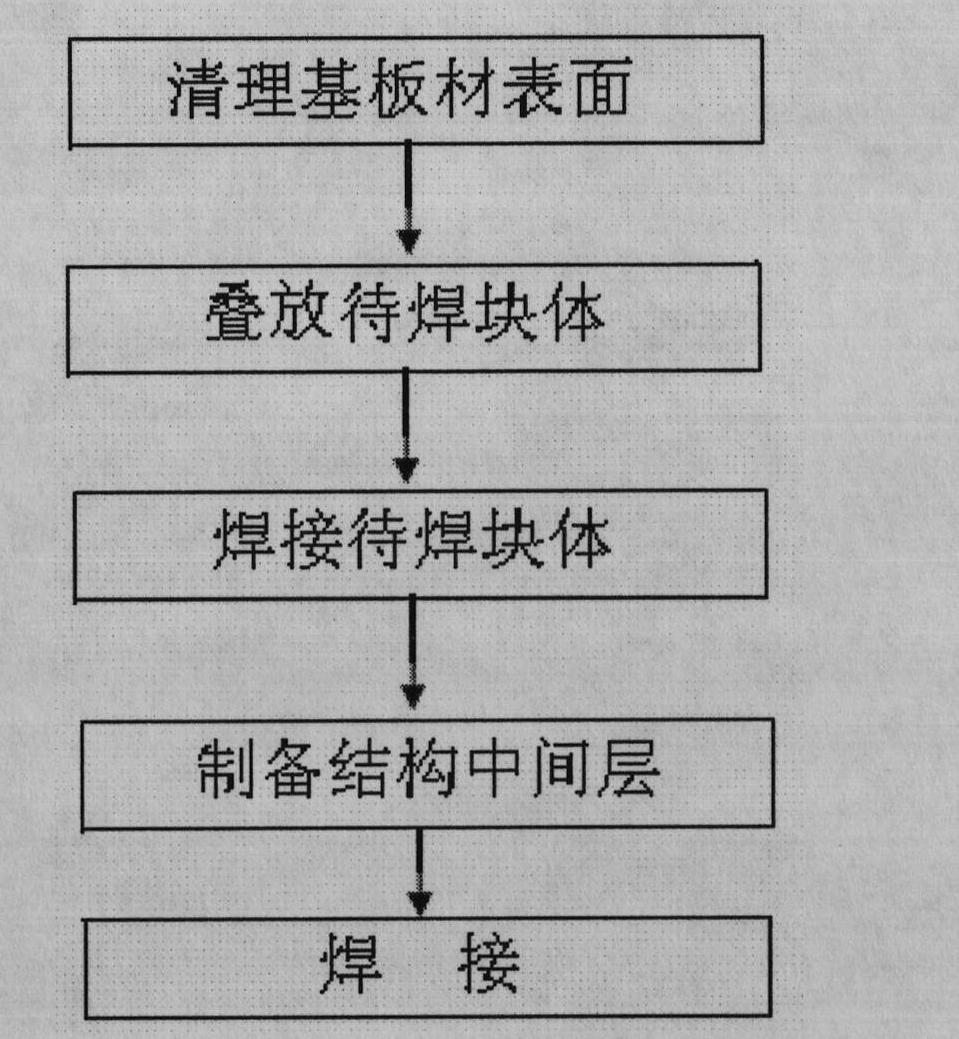

Diffusion welding method of titanium or titanium alloy and stainless steel

InactiveCN102218592AMeet service performance requirementsHigh-strength connectionNon-electric welding apparatusTitaniumHigh intensity

The invention discloses a diffusion welding method of titanium or titanium alloy and stainless steel. A plate pack having the same material quality with welded workpieces is welded into a block structure in advance. The plate pack is lengthways cut into slices along the block structure to form a structural middle layer 7. The middle layer is processed and then vertically arranged between the welded workpieces for diffusion welding. Because the middle layer having the same material quality with the workpiece is adopted, a joint heterogeneous interface combination mode is changed into a combination mode that half heterogeneous workpieces are directly combined and half heterogeneous workpieces are combined, and the titanium or titanium alloy and stainless steel workpieces are in high-intensity connection. In the diffusion welding method, the tensile strength of the joint is improved to above 80% from 50-70%(week side workpiece intensity) obtained by the direct diffusion welding technology, and various types of titanium or titanium alloy and stainless steel can be in high-intensity connection.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Wall construction

Owner:MULTI FORM DEV CORP

Organic light-emitting display device and method of manufacturing the same

ActiveUS20170345881A1Reduce defective rateStatic indicating devicesFinal product manufactureInter layerDisplay device

An organic light-emitting display apparatus includes: a substrate including a display area and a peripheral area at an outer side of the display area; a pixel electrode disposed in the display area of the substrate; a pixel-defining layer disposed on the pixel electrode and exposing at least a portion of the pixel electrode; an intermediate layer disposed on the pixel electrode; an opposite electrode disposed on the intermediate layer; a first conductive layer disposed in the peripheral area of the substrate and including at least one opening; a first block structure and a second block structure disposed on the first conductive layer and separated from each other with the at least one opening therebetween; and an encapsulation structure disposed on the opposite electrode in the display area and the peripheral area.

Owner:SAMSUNG DISPLAY CO LTD

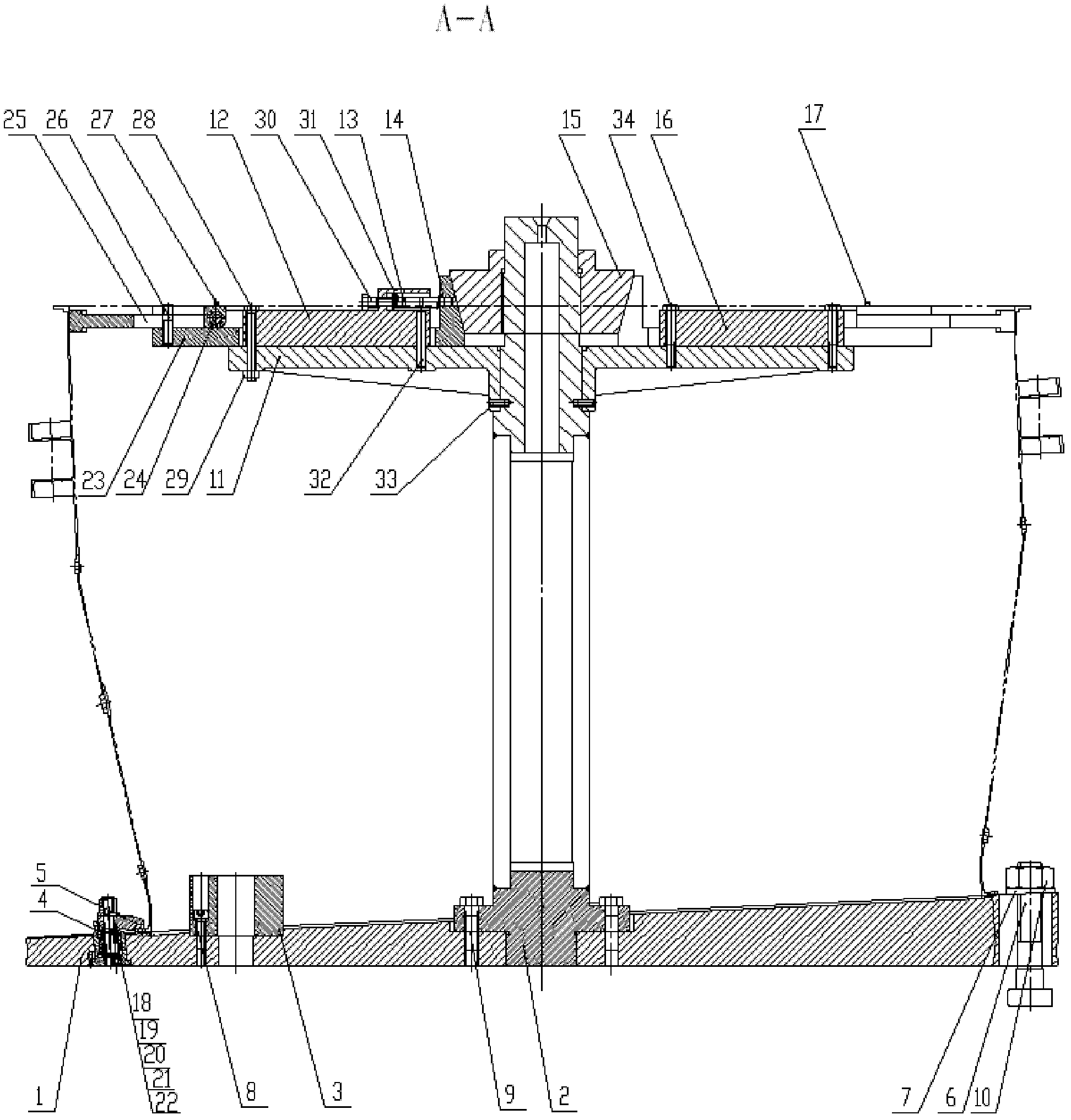

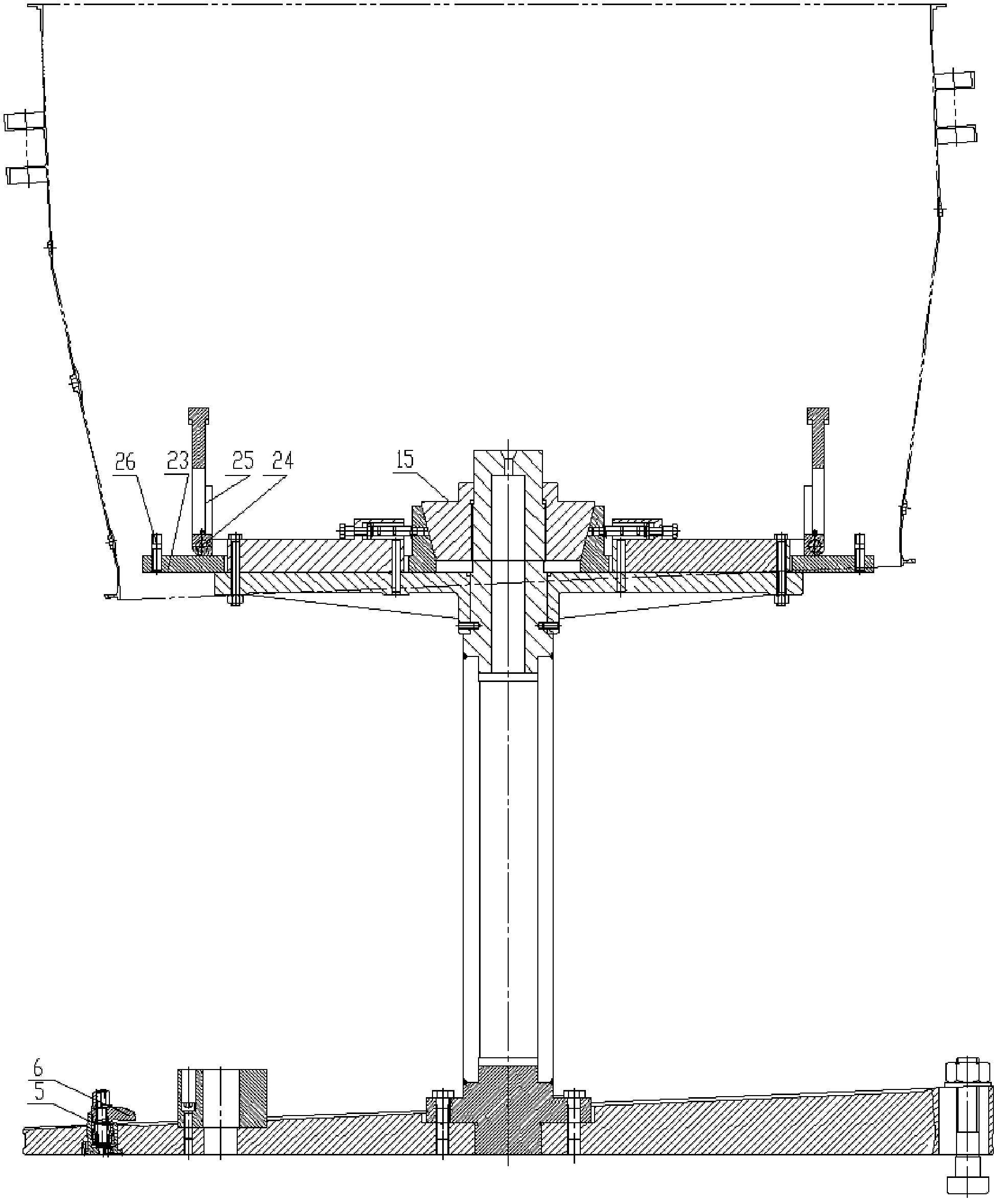

Method for positioning and clamping welding receiver lathing installation edges and device

ActiveCN102423858AImprove assembly accuracyImprove processing efficiencyPositioning apparatusMetal-working holdersBlock structureMachining

The invention provides a method for positioning and clamping welding receiver lathing installation edges and a device. In the method, according to the principle of the same basis, a large and a small installation edge positioning and clamping structures are designed into a whole; expansion of the installation edge on a large-diameter end is realized by adopting a partially rotatable structure; assembly, expansion and co-axis of the large and small installation edges are realized by applying the condition that the same basis is used for a whole clamp; in the whole clamp, the clamp expansion part of a conventional structure is designed into an expansion block structure capable of rotating, locking and releasing; the expansion block structure and a positioning block are matched for realizing positioning and expansion of the installation edges of a part on the large and the small ends; machining requirements of the installation edges are satisfied; the problems of assembly errors and low efficiency of positioning, clamping and aligning processes due to use of a traditional splitting clamp in thin wall welding receiver lathing installation edges are solved; part assembly precision and processing efficiency are enhanced; and a production period is shortened.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

GaN based optoelectronic device and method for manufacturing the same

InactiveUS6221684B1Improve extraction efficiencyImprove luminous performanceLaser active region structureSemiconductor/solid-state device manufacturingCharge carrierAcceptor impurity

An n-cap layer is formed on a top surface of p-type clad layers, the p-type clad layer is a top layer of a stacked structure having a pn-junction for emitting carriers into light-emitting region of a GaN based light-emitting device, thus increasing the activation ratio of acceptor impurities in the p-type clad layers. The n-cap layer is used also as a current blocking layer, thereby constructing a current-blocked structure. The n-cap layer should preferably be made of InuAlvGa1-u-vN (0<u, v<1) deposited as thick as 1.0 micron or more. The present invention will easily provide a high luminous efficiency GaN based semiconductor light-emitting device without using any complicated processes such as electron-beam irradiation or thermal annealing.

Owner:KK TOSHIBA

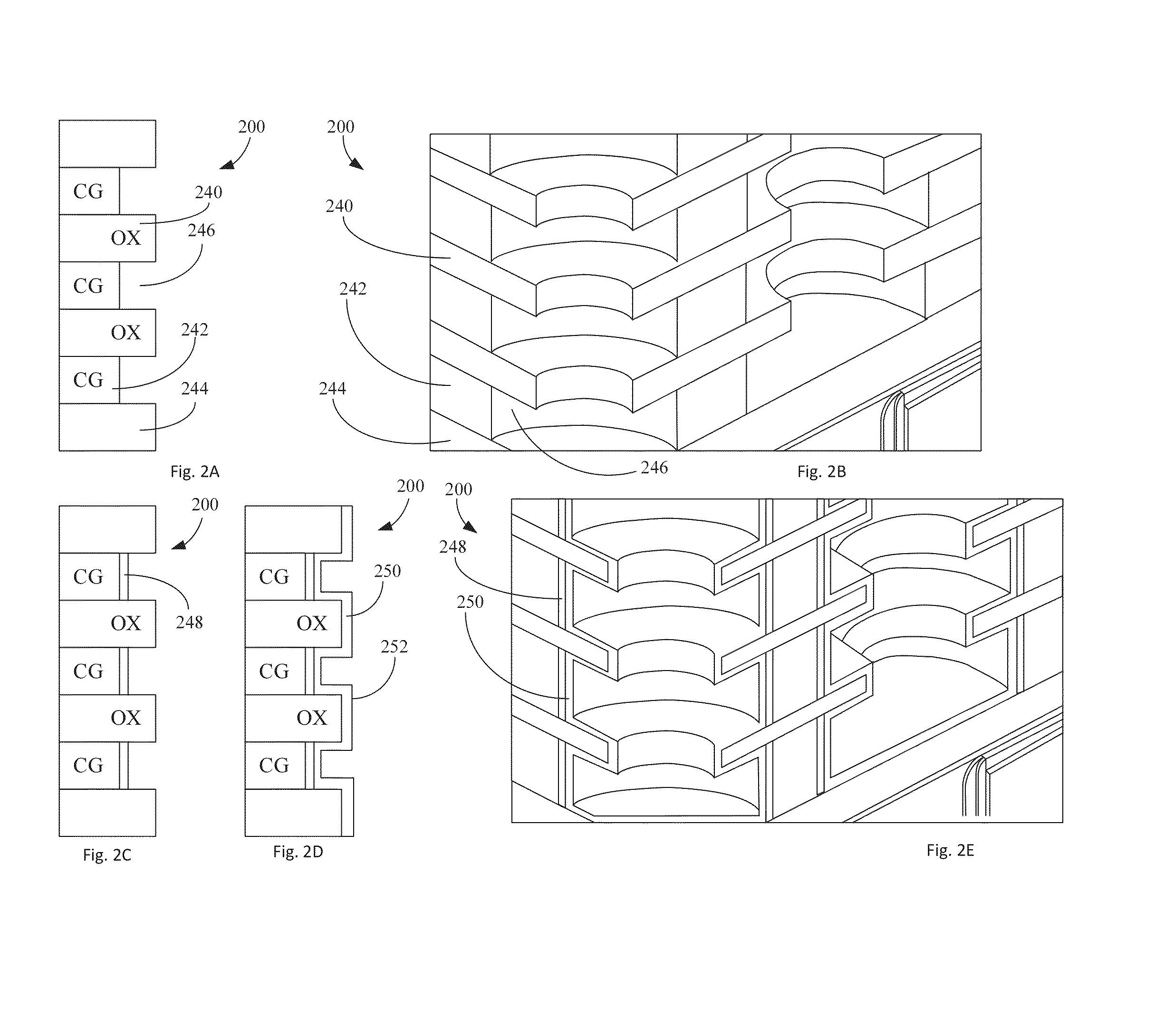

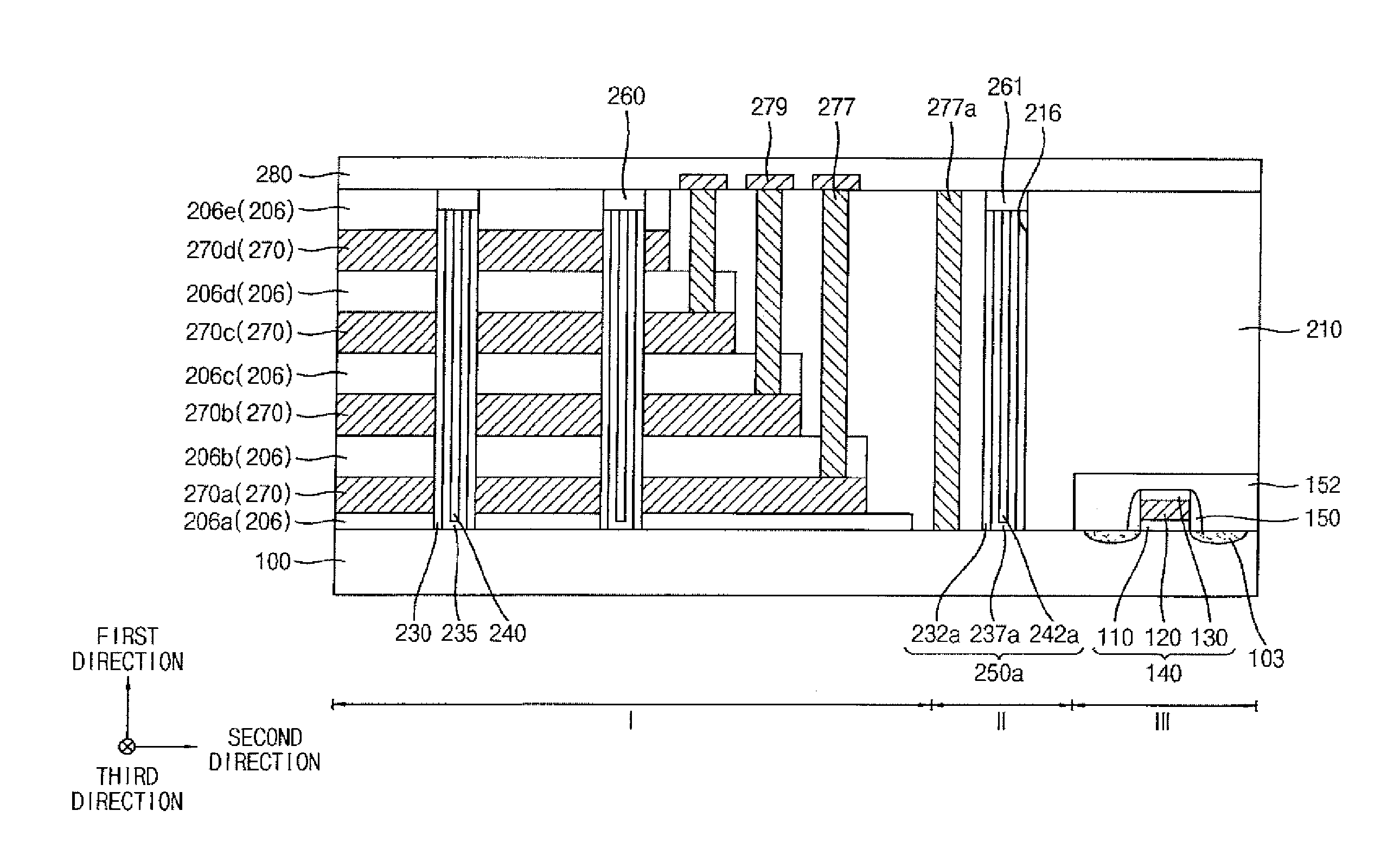

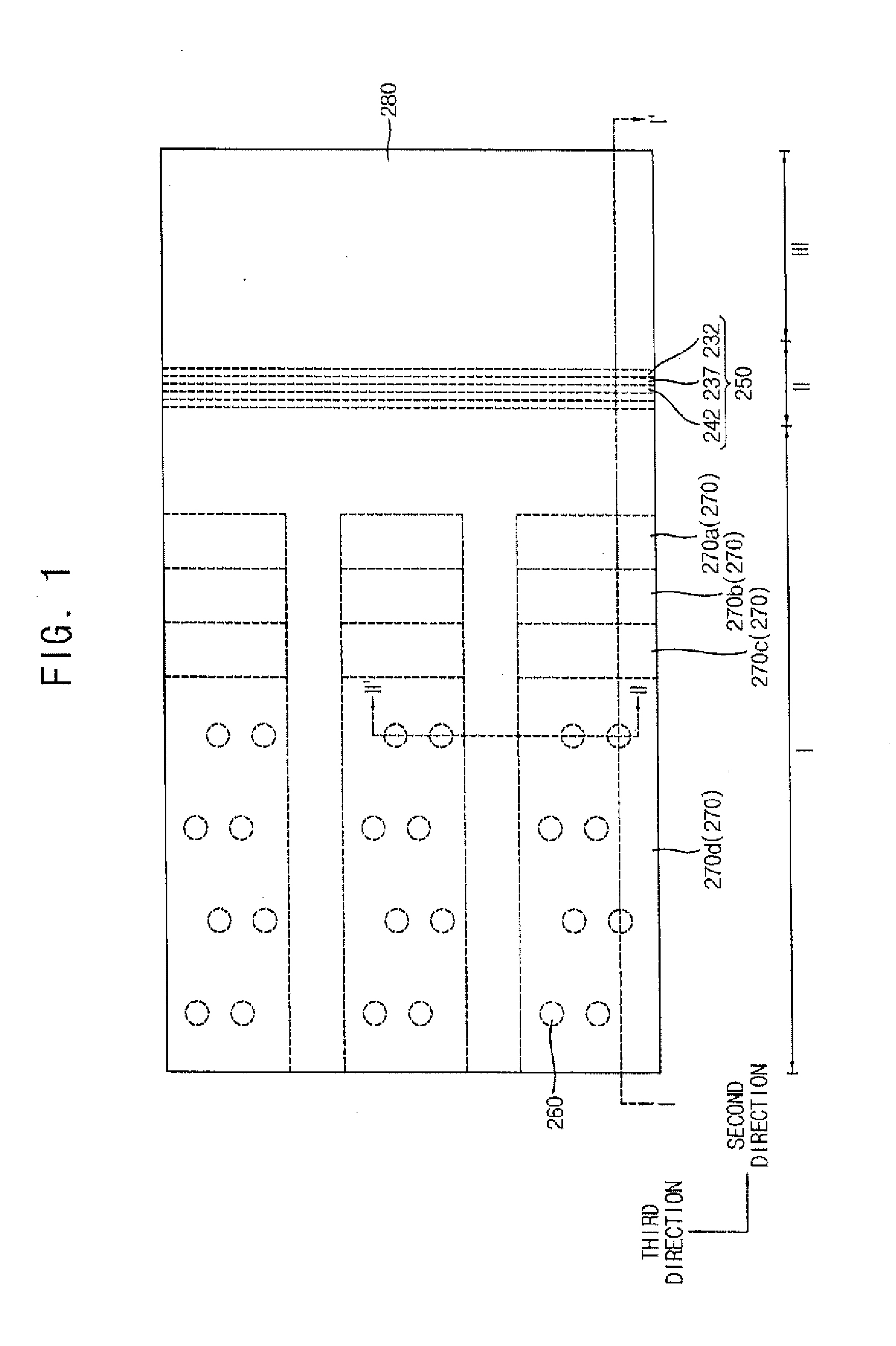

Vertical memory devices

ActiveUS20150303214A1Improve structural stabilityImproved operational reliabilitySemiconductor/solid-state device detailsSolid-state devicesPeripheralBlock structure

A vertical memory device includes a substrate including a cell region and a peripheral circuit region, the peripheral circuit region including a gate structure comprising a transistor, a plurality of channels on the cell region, each of the channels extending in a first direction that is vertical with respect to a top surface of the substrate, a plurality of gate lines stacked in the first direction and spaced apart from each other, the gate lines surrounding outer sidewalls of the channels, and a blocking structure between the cell region and the peripheral circuit region, wherein a height of the blocking structure is greater than a height of the gate structure in the peripheral region.

Owner:SAMSUNG ELECTRONICS CO LTD

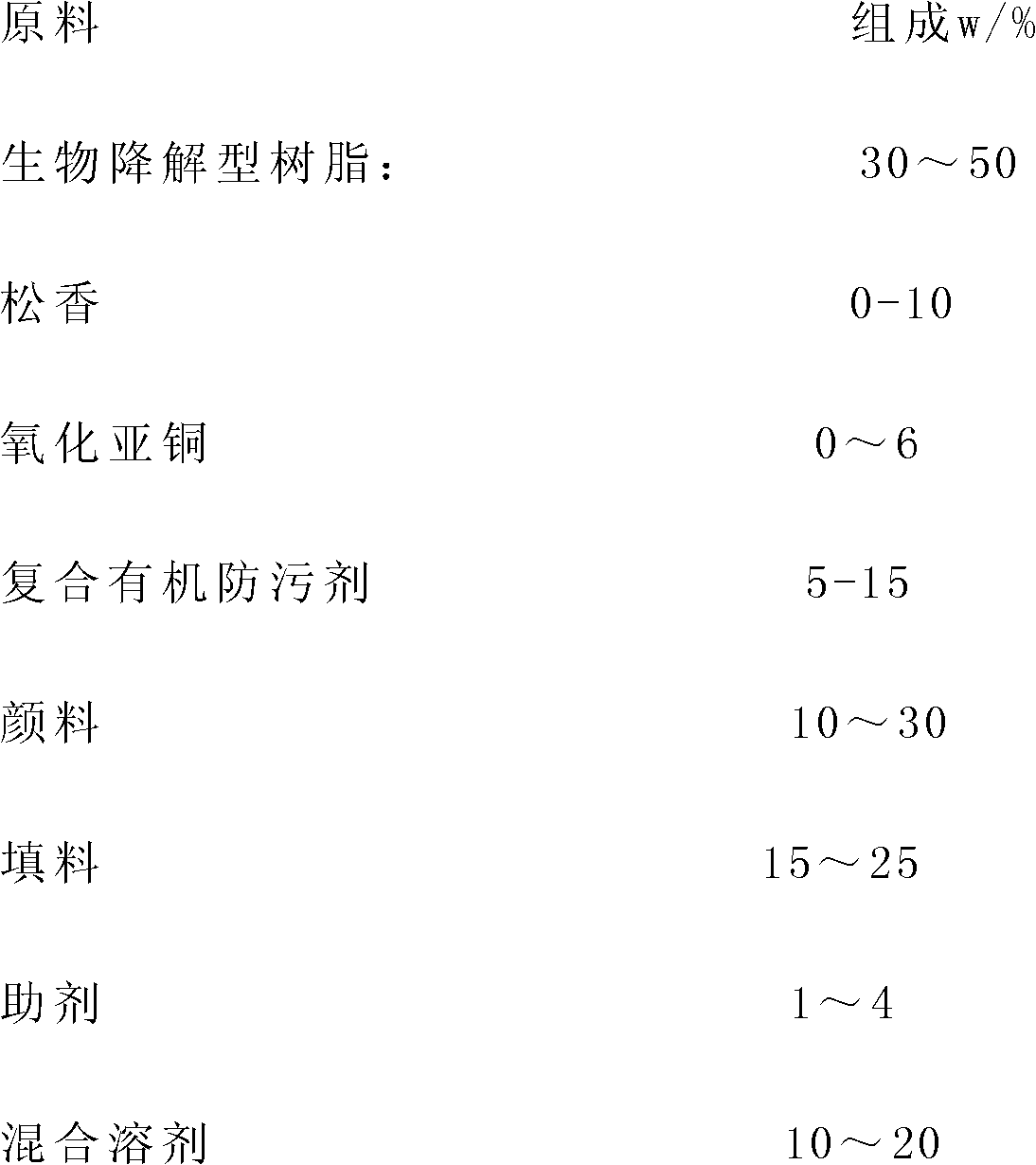

Resin for biodegradable anti-fouling paint, synthetic method of the same, and anti-fouling paint composition containing the same

ActiveCN102432802AReduce dosageHigh requirements for reaction conditionsAntifouling/underwater paintsPaints with biocidesCompound organicEnvironmental resistance

The invention provides a resin for a biodegradable anti-fouling paint. The resin for the biodegradable anti-fouling paint is a polymer containing a multi-block structure, characterized in that: the resin is prepared by polymerizing by polylactic acid oligomer, flexible segments, polyisocyanates under the effect of catalysts, wherein, the polylactic acid oligomer is prepared by carrying out reflux reaction on lactic acid having a monomer content of 80-85 % and aromatic solvents under negative pressure or normal pressure until no water generates; the flexible segments comprises polyols or / and polyester polyols; and the amount of the flexible segments accounts for 5-30 % of the weight percentage of the lactic acid raw material; and the amount of polyisocyanates accounts for 10-30 % of the weight percentage of the lactic acid raw material. The invention further provides a biodegradable anti-fouling paint composition containing the resin as a matrix resin. The anti-fouling paint contains composite organic antifouling agent and contains no or little cuprous oxide, and has the advantages of low toxicity, environmental protection, and good anti-fouling effect.

Owner:MARINE CHEM RES INST CO LTD

Luminescence display apparatus and method for fabricating the same

InactiveUS20050168135A1Few defectExcellent gradation controllabilityTransistorDischarge tube luminescnet screensActive matrixBlock structure

A luminescence display apparatus including a light blocking structure having a function of reflecting light propagating through the dielectric layer and / or of attenuating light propagating through the dielectric layer, that surrounds a EL element for separating a pixel driving TFT from the EL element. Self-emitted light or external light be attenuated before reaching the TFT by using the light blocking structure to reduce the photo leakage of the TFT to provide the active matrix organic EL display apparatus having the less defects and the excellent gradation controllability.

Owner:NEC CORP

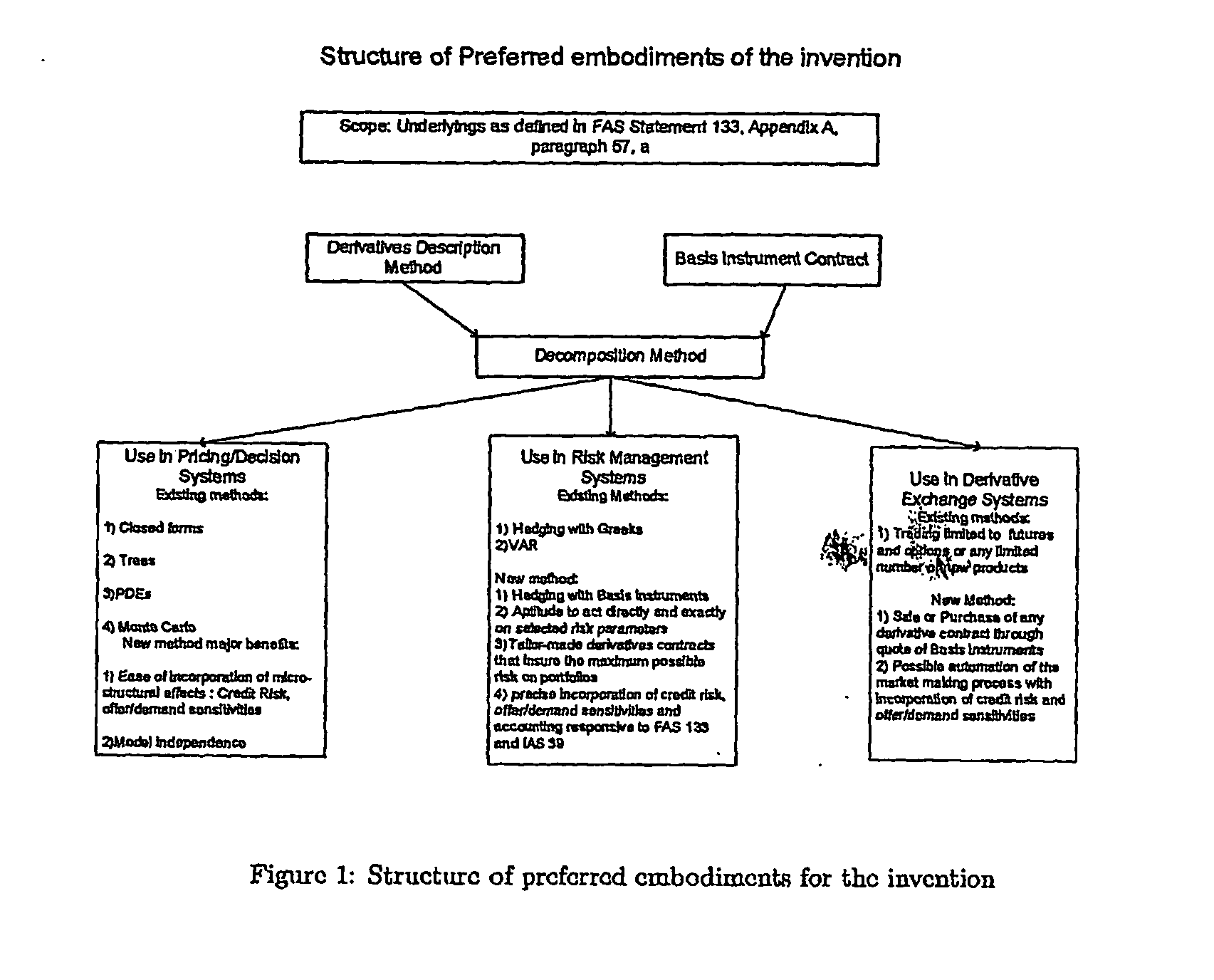

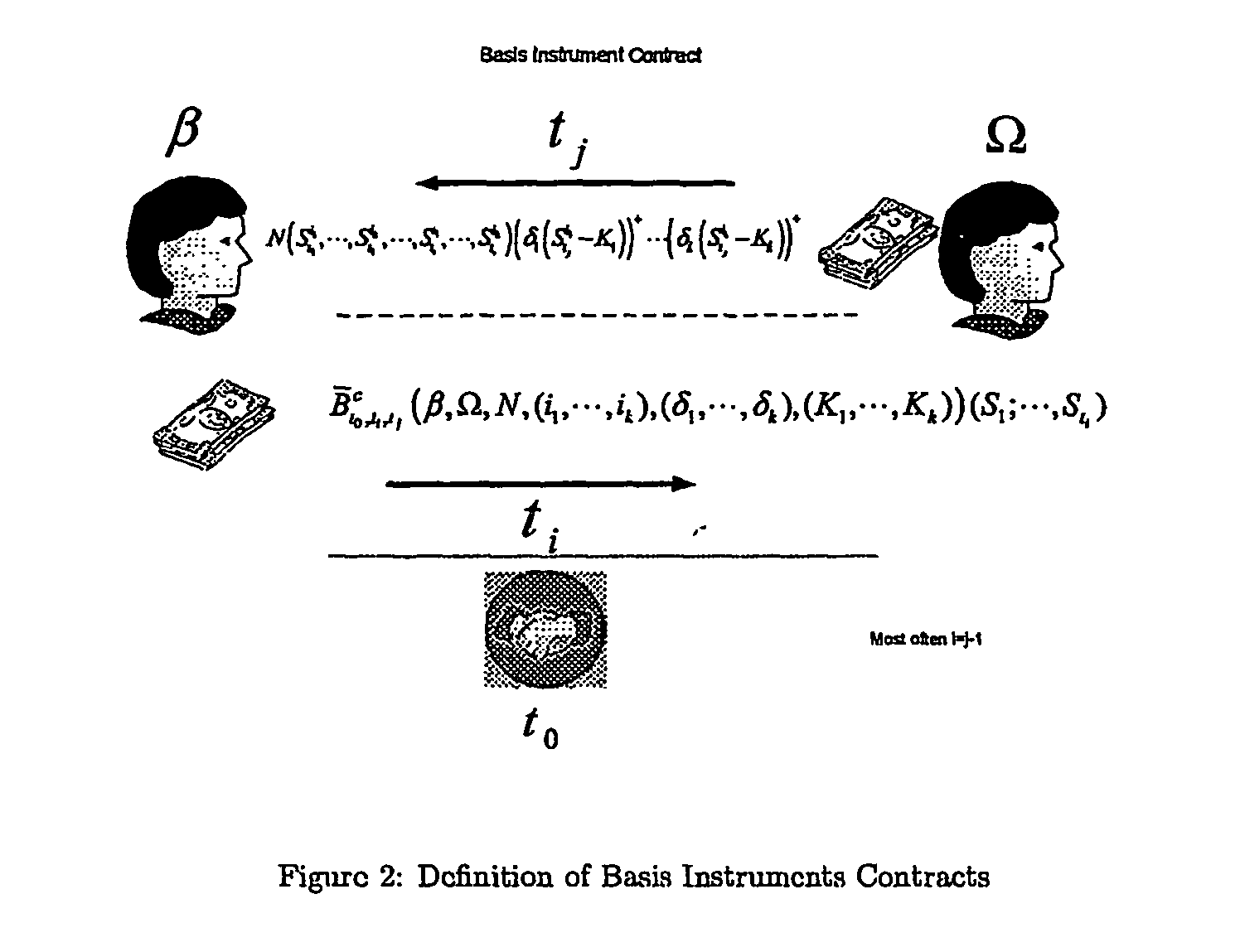

Methods, systems and computer program products to facilitate the formation and trading of derivatives contracts

InactiveUS20070162373A1Reduce computing timeCalibration of the credit risk model is facilitatedFinanceDecompositionBlock structure

This invention relates to methods, systems and computer programs to facilitate the formation trading and risk management of derivatives on one or more underlying. It innovates in the following areas: 1. The decomposition of any derivatives contract into fundamental building block structures called basis instruments in a multi-period, multi-securities market. 2. The incorporation of supply and demand price sensitivities in the pricing of derivatives contracts. 3. The incorporation of credit risk in the pricing of derivatives. 4. The development of methods, systems or computer program products for the accounting of derivatives contracts in compliance with FAS 133 or IAS 39. 5. The development of methods, systems or computer program products for the C pricing of derivatives. 6. The development of methods, systems or computer program products for the risk management of derivatives. 7. The development of methods, systems or computer program products for the trading of derivatives whether in organized exchanges or in over-the-counter (OTC) markets.

Owner:KONGTCHEU PHILIBERT F

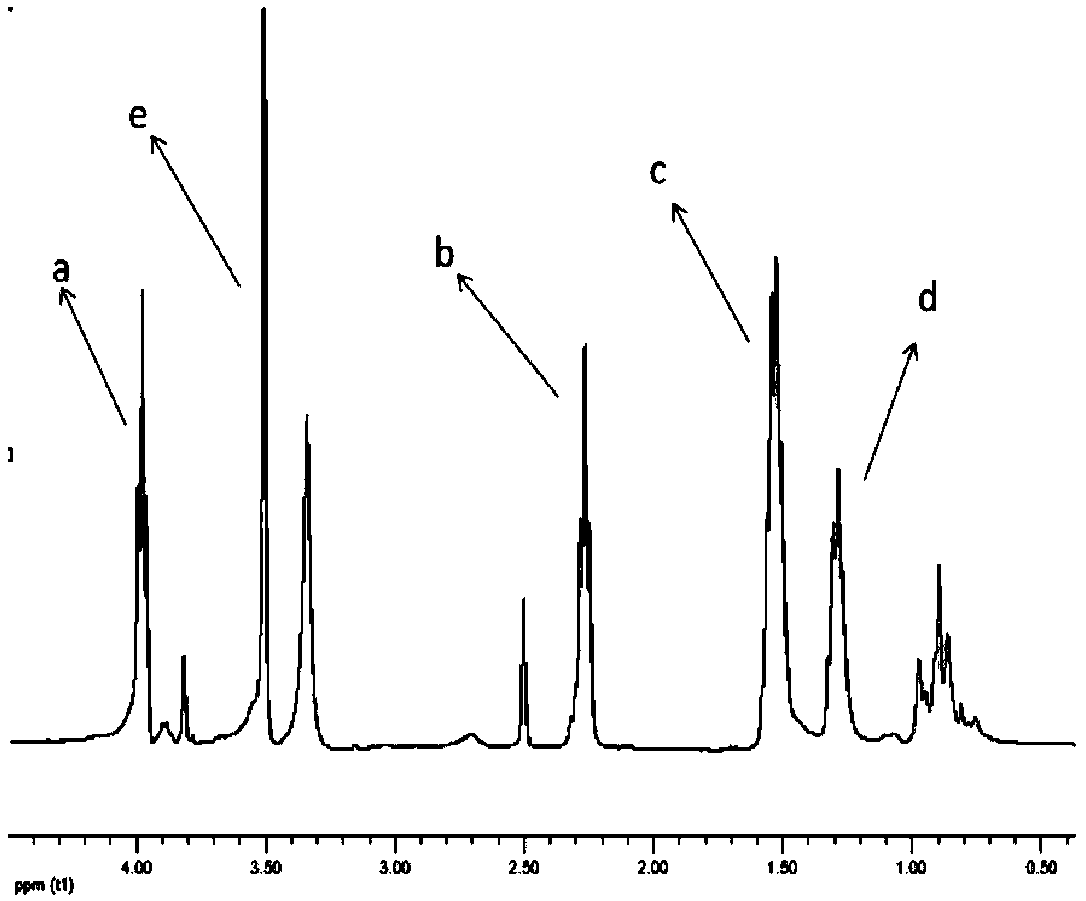

Biquaternary ammonium salt-containing diamine or diol monomer, preparation method of monomer, water-based non-toxic antibacterial polyurethane emulsion prepared by monomer, and preparation method of emulsion

ActiveCN103420868AImprove antibacterial propertiesMeet different antibacterial needsOrganic compound preparationCarboxylic acid amides preparationWater basedBiocompatibility Testing

The invention discloses a biquaternary ammonium salt-containing diamine or diol monomer with the following structural general formula, and also discloses a preparation method of the monomer, water-based non-toxic antibacterial polyurethane emulsion prepared by the monomer, and a preparation method of the emulsion. The biquaternary ammonium salt-containing diamine or diol monomer disclosed by the invention can easily serve as a chain extender with an antibacterial function to be introduced into polyurethane, so the antibacterial effect of the polyurethane is greatly improved; the biquaternary ammonium salt-containing diamine or diol monomer disclosed by the invention also can be introduced quantitatively as required so as to meet different antibacterial requirements; the water-based non-toxic antibacterial polyurethane emulsion disclosed by the invention has a unique multi-block structure and a suspended group with an excellent antibacterial effect, and can form a stable emulsion in water; the structure and the performance of the water-based non-toxic antibacterial polyurethane emulsion are easy to regulate and control; the water-based non-toxic antibacterial polyurethane emulsion has excellent biocompatibility, adhesion resistance, biomembrane formation resistance and antibacterial performance, and can be widely applied to antibacterial treatment in the fields of textile, plastic, food packaging, daily necessities, water treatment, medical treatment and public health and the like; and the preparation process of the water-based non-toxic antibacterial polyurethane emulsion is simple, mature in process, easy to control and convenient to industrialize.

Owner:SICHUAN UNIV

Optically blocked reference pixels for focal plane arrays

ActiveUS20060124831A1Minimize divergenceIncreasing scene temperature temperatureRadiation pyrometrySemiconductor/solid-state device detailsThermal isolationBlock structure

Methods for making optically blind reference pixels and systems employing the same. The reference pixels may be configured to be identical to, or substantially identical to, the active detector elements of a focal plane array assembly. The reference pixels may be configured to use the same relatively longer thermal isolation legs as the active detector pixels of the focal plane, thus eliminating joule heating differences. An optically blocking structure may be placed in close proximity directly over the reference pixels.

Owner:DRS NETWORK & IMAGING SYST

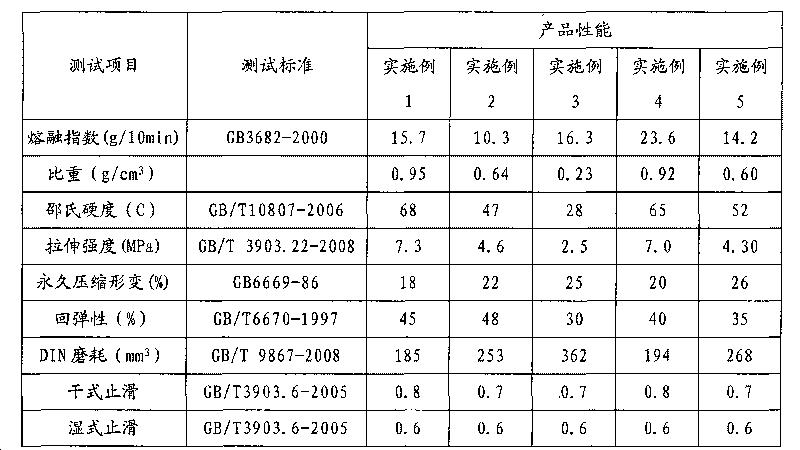

Styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, preparation method and application method thereof

The invention discloses a styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, a preparation method and an application method thereof. The preparation method takes styrene-butadiene copolymer mixing random structure with block structure as base material, and adds flow modifier or softener to regulate the fluidity of rubber. Rubber compositions manufactured by the method have good fluidity and can be molded directly through injection. Chemical foaming agents added reduces product density and effectively achieves the aim of obtaining lightweight material. Post partial chemical crosslinking can be performed so as to improve the stress cracking resistance and wear resistance of the material. Meanwhile, as the partial physical crosslinking of the styrene-butadiene copolymer allows the material to overcome the defect that all-chemical crosslinked rubber cannot be regenerated, the material can be recycled and regenerated.

Owner:浙江仕峰实业有限公司

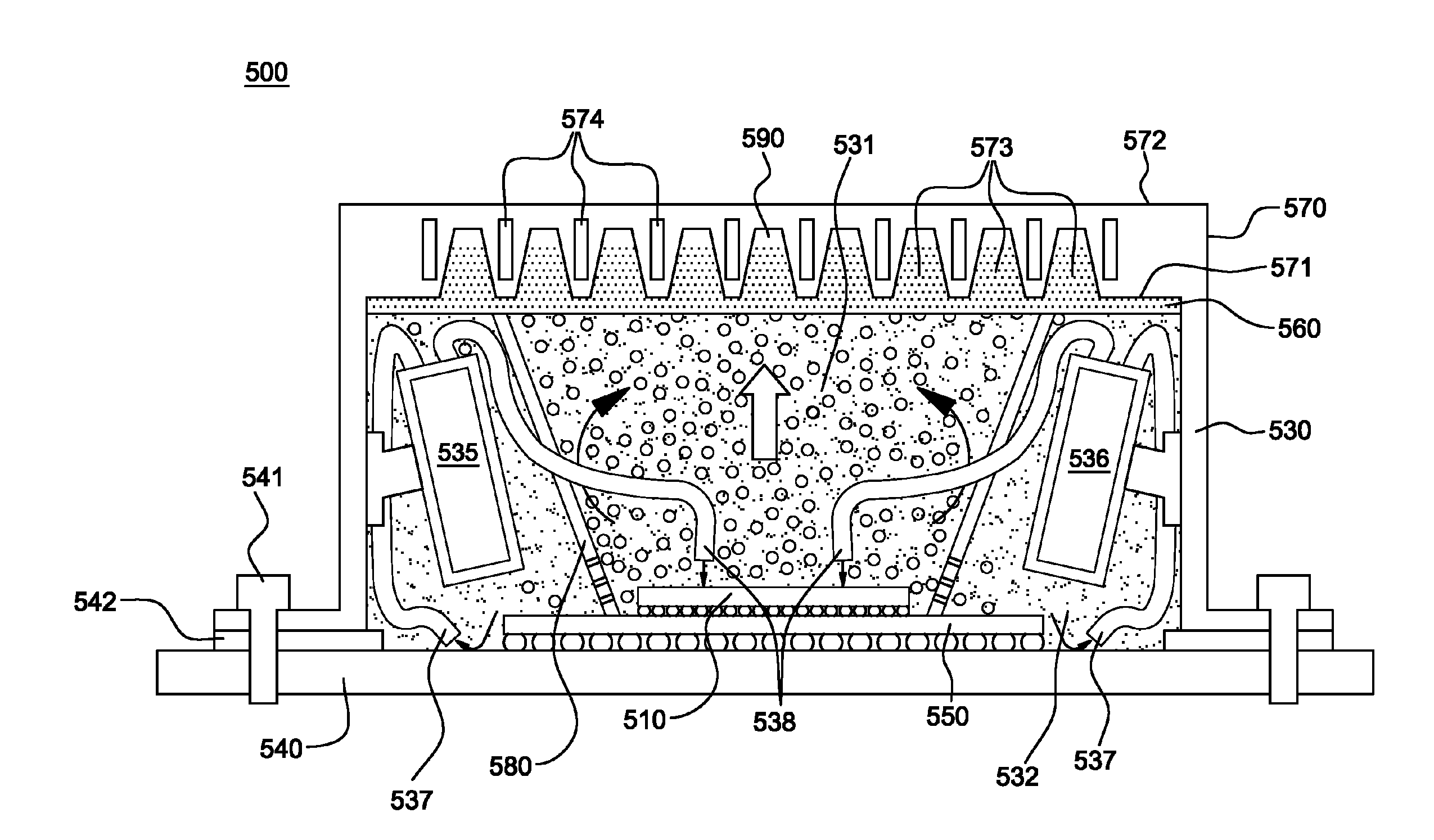

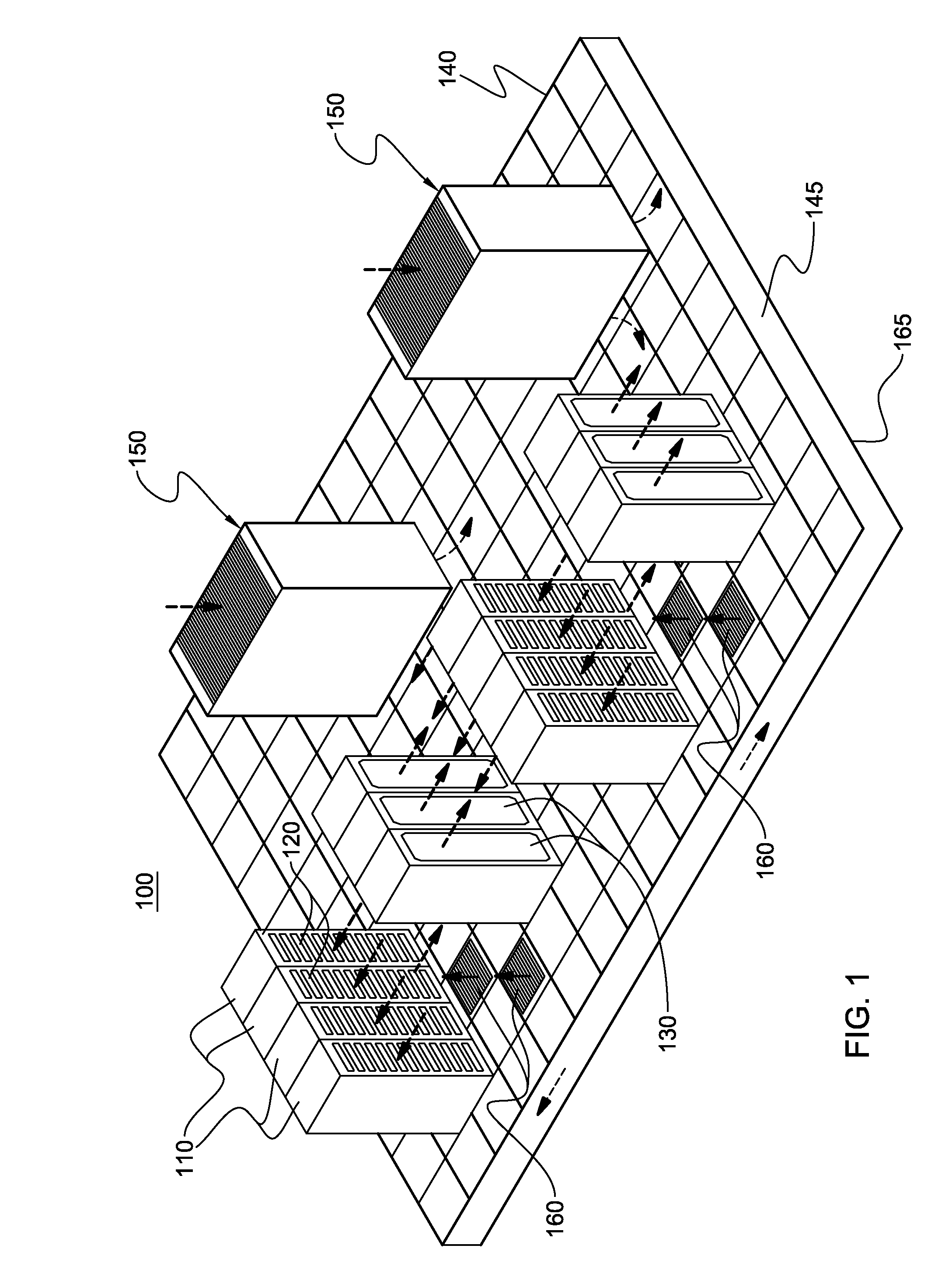

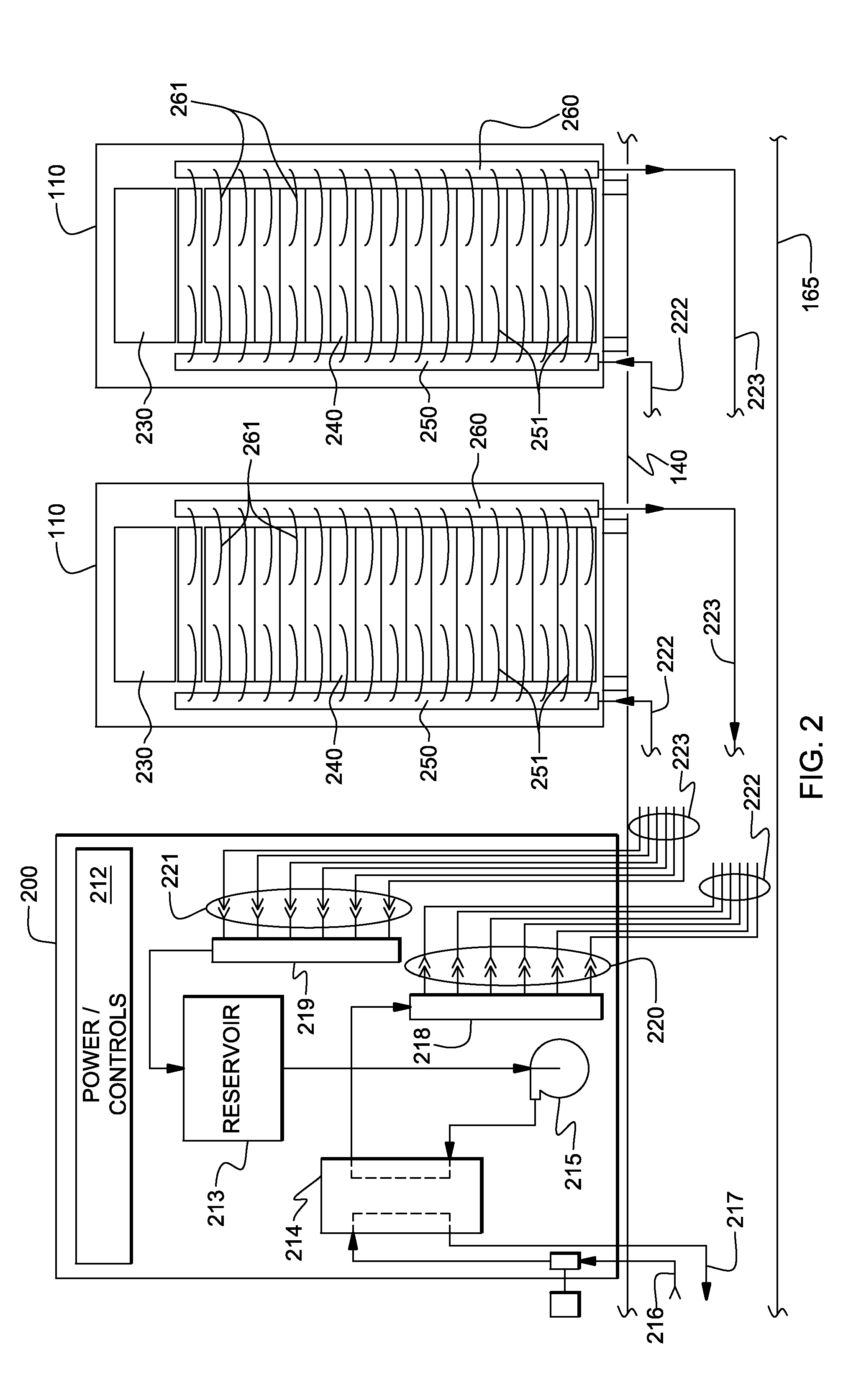

Condenser block structures with cavities facilitating vapor condensation cooling of coolant

InactiveUS8059405B2Improve cooling effectIncrease surface areaDigital data processing detailsIndirect heat exchangersSteam condensationCondensation heat transfer

Condenser structures and cooling apparatuses are provided which facilitate vapor condensation heat transfer of a coolant employed in cooling an electronic device. The condenser structure includes a thermally conductive condenser block with multiple exposed cavities therein extending from a first main surface towards a second main surface. The condenser block is a monolithic structure, and the first main surface is a coolant vapor condensate formation surface when the condenser structure is operationally facilitating cooling of an electronic device. The exposed cavities extend from the first main surface into the condenser block to increase a condensation surface area of the condenser block, thereby facilitating coolant vapor condensate formation on the condenser block, and thus cooling of the electronic device using a two-phase coolant. The condenser structure also includes coolant-carrying channels for facilitating cooling of the condenser block, and thus vapor condensate formation on the condenser block.

Owner:IBM CORP

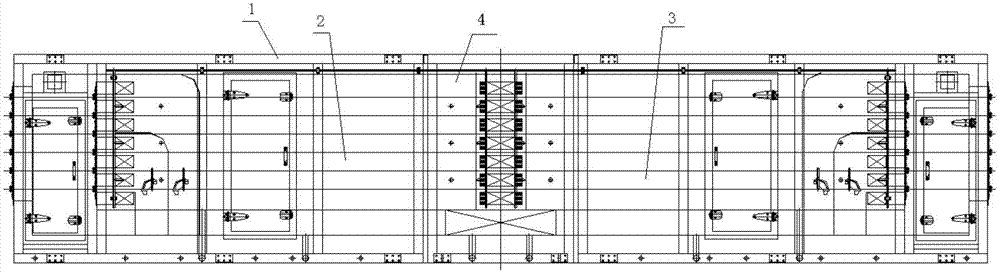

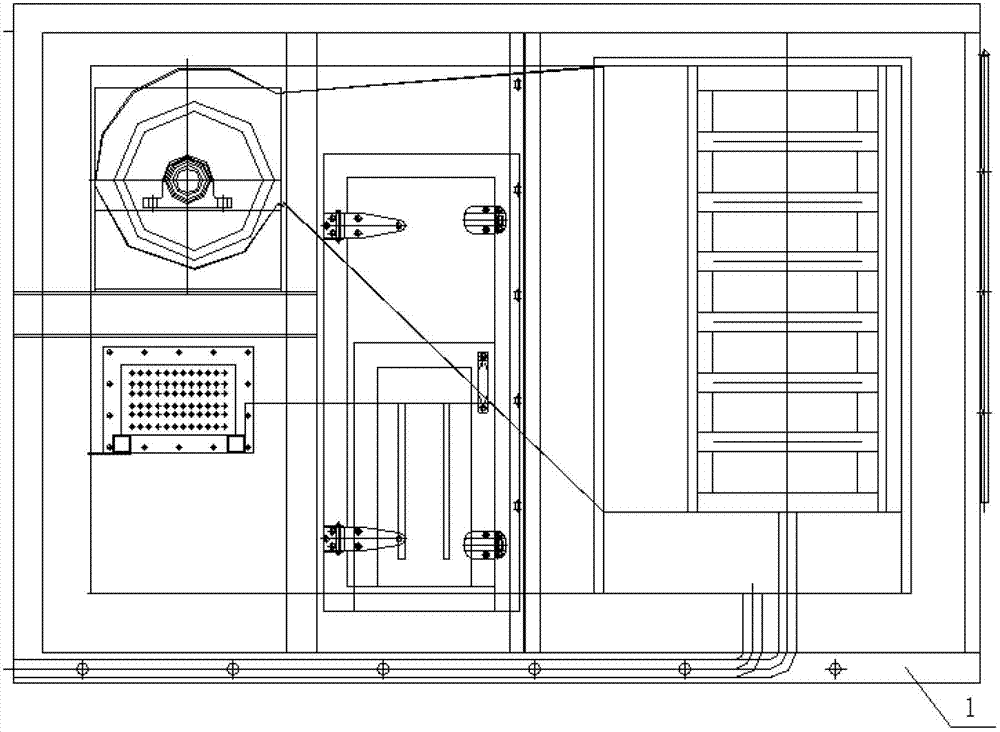

High-performance carbon fiber pre-oxidation furnace

ActiveCN102758270AAvoid burnsPrevention of legitimate discharge problemsFibre chemical featuresFiberCarbon fibers

The invention discloses a high-performance carbon fiber pre-oxidation furnace which is specially designed for carrying out heat treatment on a high-performance carbon fiber material at a temperature below 350 DEG C. A furnace body is designed into a building block structure and is convenient to assemble and disassemble. For the design of the furnace, the requirements of a preparation process of the high-performance carbon fiber material are fully considered and understood and the key special requirements of the preparation process of the high-performance carbon fiber material are met to the greatest extent. According to the requirements of the preparation process of the material, a circulating hot air heating mode is adopted for the pre-oxidation furnace; for a circulating air traveling mode, air is blown to two ends of the furnace body from the middle of the furnace body; and a plurality of heat treatment cavities are connected in series and in parallel to form a system with a certain temperature gradient. An anticorrosion stainless steel structure is adopted for an inner hearth totally; a full-fiber superlight material is adopted as a heat insulating material to carry out heat insulation; a PLC (Programmable Logic Controller) temperature control module is used for temperature control and has the characteristics of high temperature control accuracy, high temperature stability and the like; and according to the pre-oxidation furnace, in a pre-oxidation process, the problems of low heat treatment efficiency, inaccurate temperature control and unideal temperature uniformity in the heat treatment cavities are solved, protofilament combustion is prevented, sufficient supplementation of the oxygen content in the hearth is realized and waste gas is reasonably discharged. The integral high-performance carbon fiber pre-oxidation furnace has relatively low energy consumption and is durable.

Owner:HEFEI RISINE HEATEK

Absorbent article with function-formed topsheet, and method for manufacturing

Methods for manufacturing topsheets for absorbent articles are disclosed. The methods may include: providing a cycling forming belt that includes an air-permeable substrate and an ordered arrangement of airflow blocking structures thereon; directing air flow with entrained fibers and / or filaments to a working location through which the belt cycles; drawing the air flow through airflow permeable regions of the belt as they cycle through the working location, and thereby drawing the fibers / filaments to the belt such that they accumulate thereon to form a batt having an arrangement of built-up regions and attenuated regions corresponding with the arrangement of blocking structures, wherein the structures are arranged in individualized single-topsheet configurations that repeat along the machine direction, each configuration being adapted to form a section of web material for a topsheet and to impart a desired formation thereto including channel portions, hinge portions and / or pattern(s) of discrete low bulk portions.

Owner:THE PROCTER & GAMBLE COMPANY

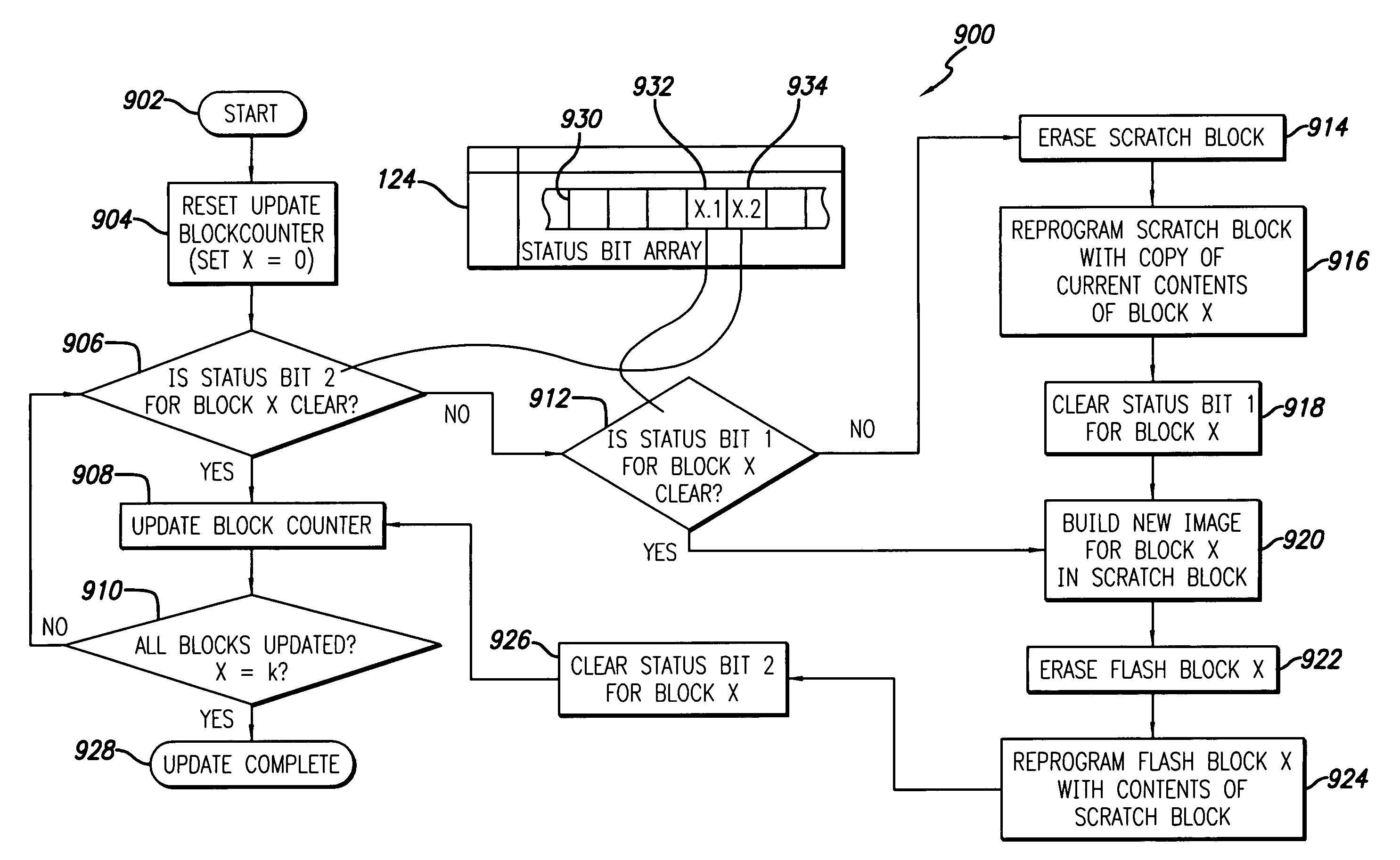

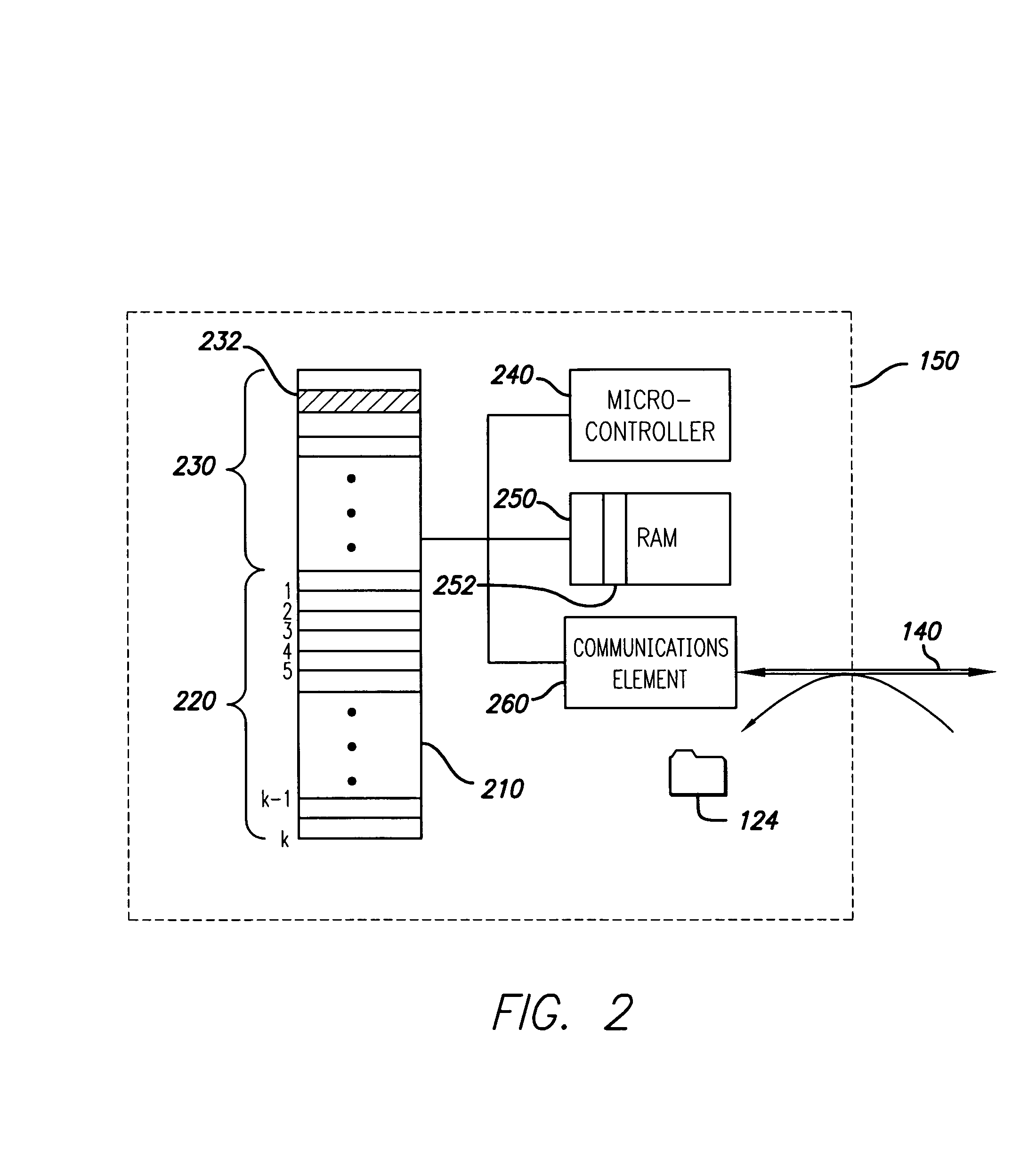

Efficient system and method for updating a memory device

ActiveUS7210010B2Removal costResolution problemData processing applicationsMemory loss protectionBlock structureCopying

A system and method for updating a binary image stored across a block-structured memory device, such as a flash memory device. From comparison of original and new images, an update package is generated which includes an encoded instruction set comprising COPY and ADD operations instructing the copying of source data from locations in the memory device and adding other data provided in the update package. The instruction set comprises SETBLOCK operations that direct updating of the memory blocks in an order that optimizes the COPY and ADD operations required and resulting update package size. The instruction set further comprises SETCOPYOFFSET operations to toggle between copy-offset modes thereby allowing for improved efficient encoding of COPY operations. The update package further includes an array of status bits corresponding to the memory blocks to be updated, thereby allowing for reliable restarting of the update process following power loss or other interruption.

Owner:INSIGNIA SOLUTIONS

Erase block management

InactiveUS20050273551A1Memory architecture accessing/allocationMemory adressing/allocation/relocationData fieldControl data

Owner:MICRON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com