Vacuum milling method for metal compound plate

A metal clad plate, vacuum rolling technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of energy consumption, non-compliance with strict standards for pressure vessel materials, affecting the quality and appearance of plates, etc. The effect of ensuring the quality of the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

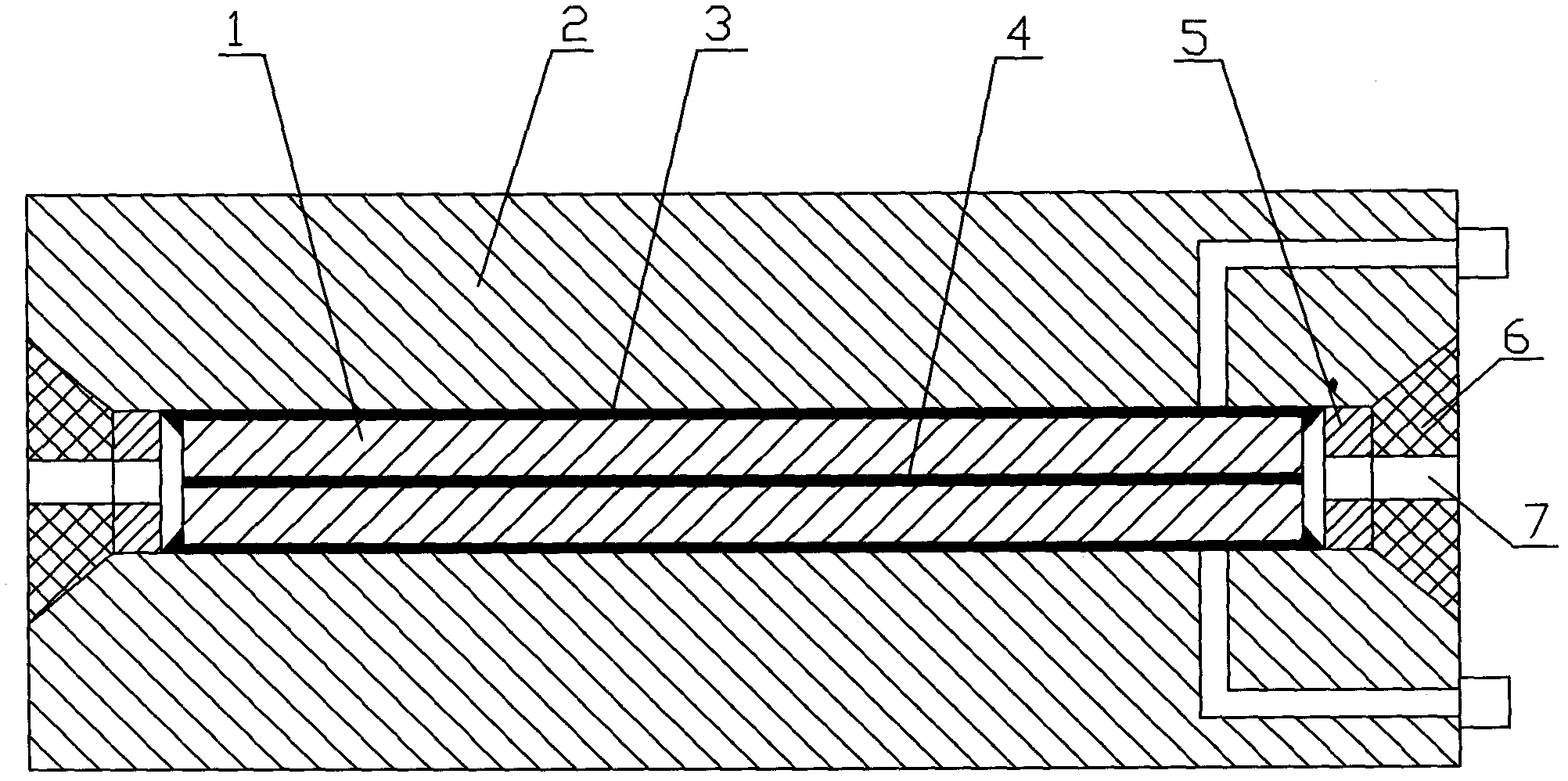

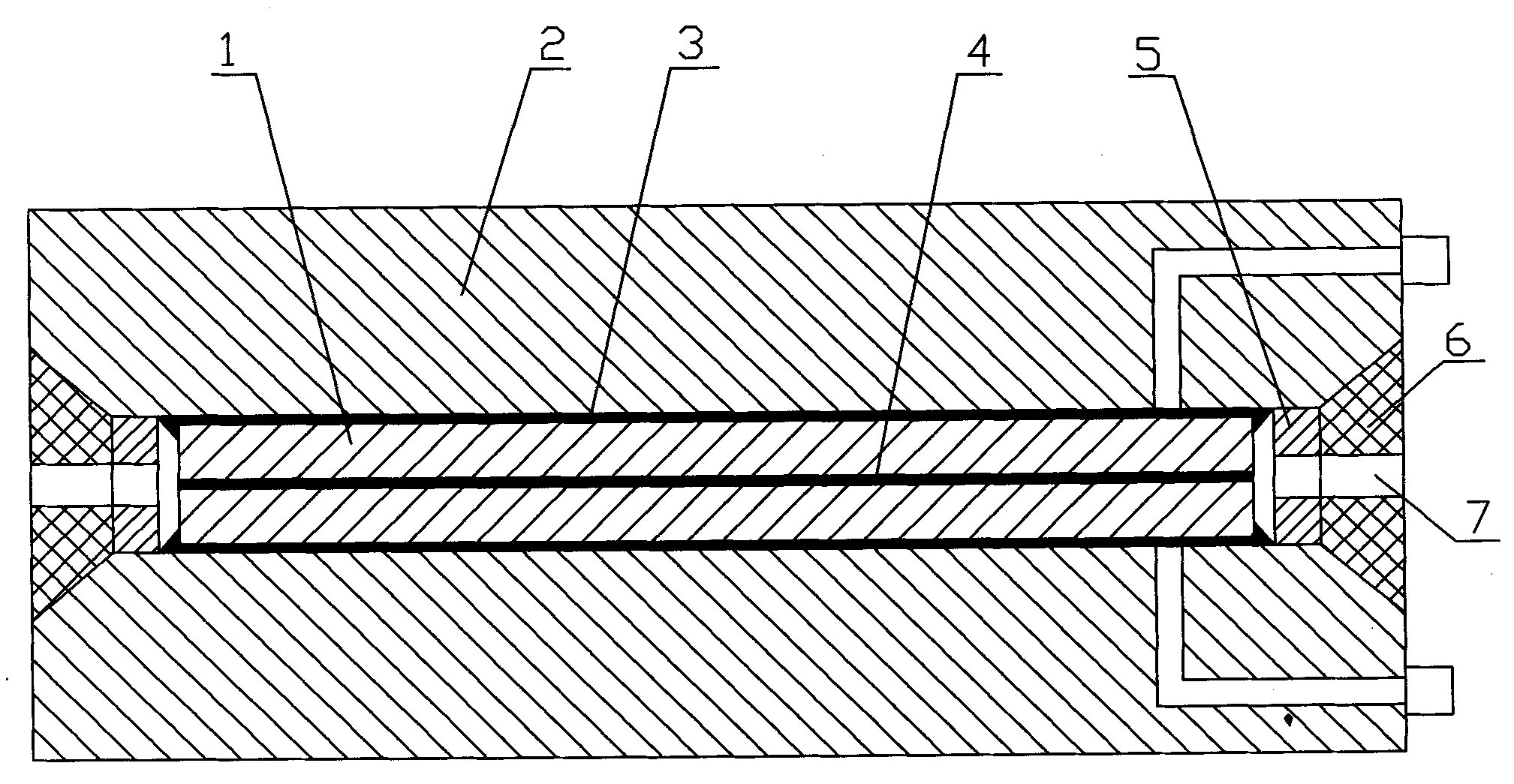

[0016] The present invention is characterized in that; Its steps are:

[0017] ① Use the plate for pressure vessel as the base plate 2, and process the circumferential chamfer bevel around one side of the base plate 2. The size of the periphery of the stainless steel plate 1 is smaller than the size of the circumferential chamfer bevel;

[0018] ② Drilling: Drill a right-angle hole between the two adjacent sides of the chamfer groove of the substrate 2 as a vacuum hole;

[0019] ③ Front butt welding: Spread the stainless steel plate 1 on the surface of the lead angle groove of the substrate 2, and spread the brazing flux layer 3 between the two, and then on the pressure platform, the periphery of the stainless steel plate 1 and the substrate 2 Circumferential seal welding at the joint to form the front blank;

[0020] ④ Vacuuming: Vacuuming through the right-angle hole of the substrate 2, and sealing the right-angle hole after pumping;

[0021] ⑤ Blanket sealing and welding:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com