Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Vectran" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

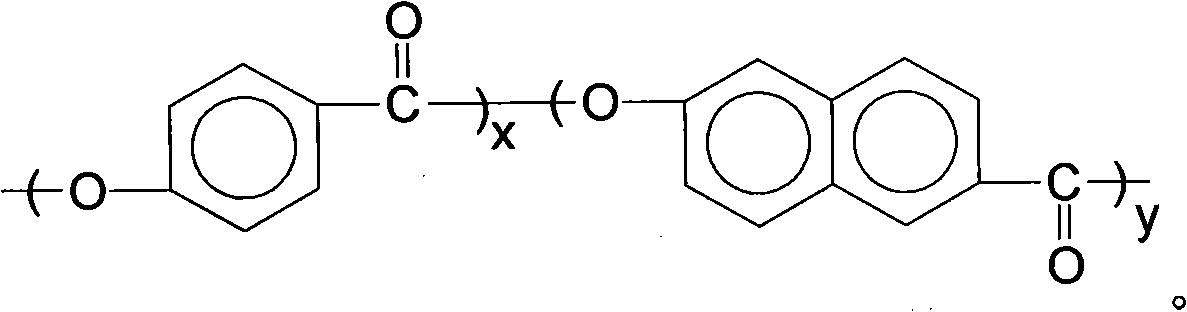

Vectran is a manufactured fiber, spun from a liquid-crystal polymer (LCP) created by Celanese Corporation and now manufactured by Kuraray. Chemically it is an aromatic polyester produced by the polycondensation of 4-hydroxybenzoic acid and 6-hydroxynaphthalene-2-carboxylic acid.

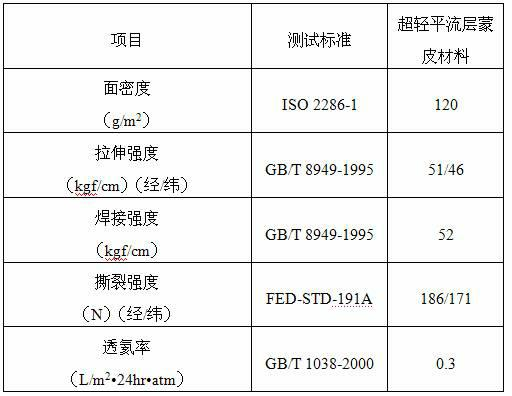

Ultra-light, weather-resistant and high-strength stratosphere skin material

InactiveCN101905557ALight in massGood weather resistanceSynthetic resin layered productsLighter-than-air aircraftPolyesterStratosphere

The invention provides an ultra-light, weather-resistant and high-strength stratosphere skin material which has high strength and weatherability, relating to skin materials. The ultra-light stratosphere skin material consists of a weather-resistant layer, a force bearing layer, a block layer and a heat sealing layer from outside to inside. Vectran fiber 200 Daniel plain woven fabric with ultra-high strength is selected and used as the force bearing layer, the Vectran fiber 200 Daniel plain woven fabric has the strength about 6 times as high as that of common polyesters, and the light weight of 54 g / m<2> and the thickness of 0.16 mm. The produced stratosphere skin material has ultra-light mass.

Owner:HARBIN INST OF TECH

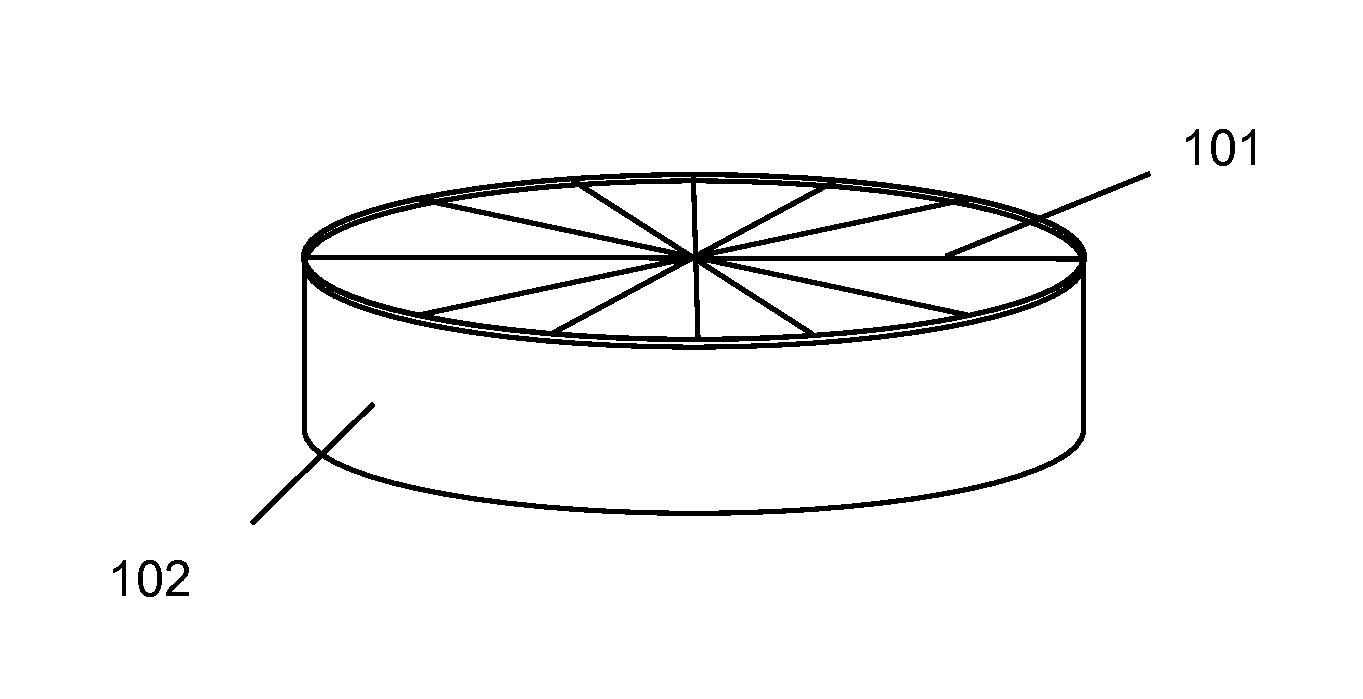

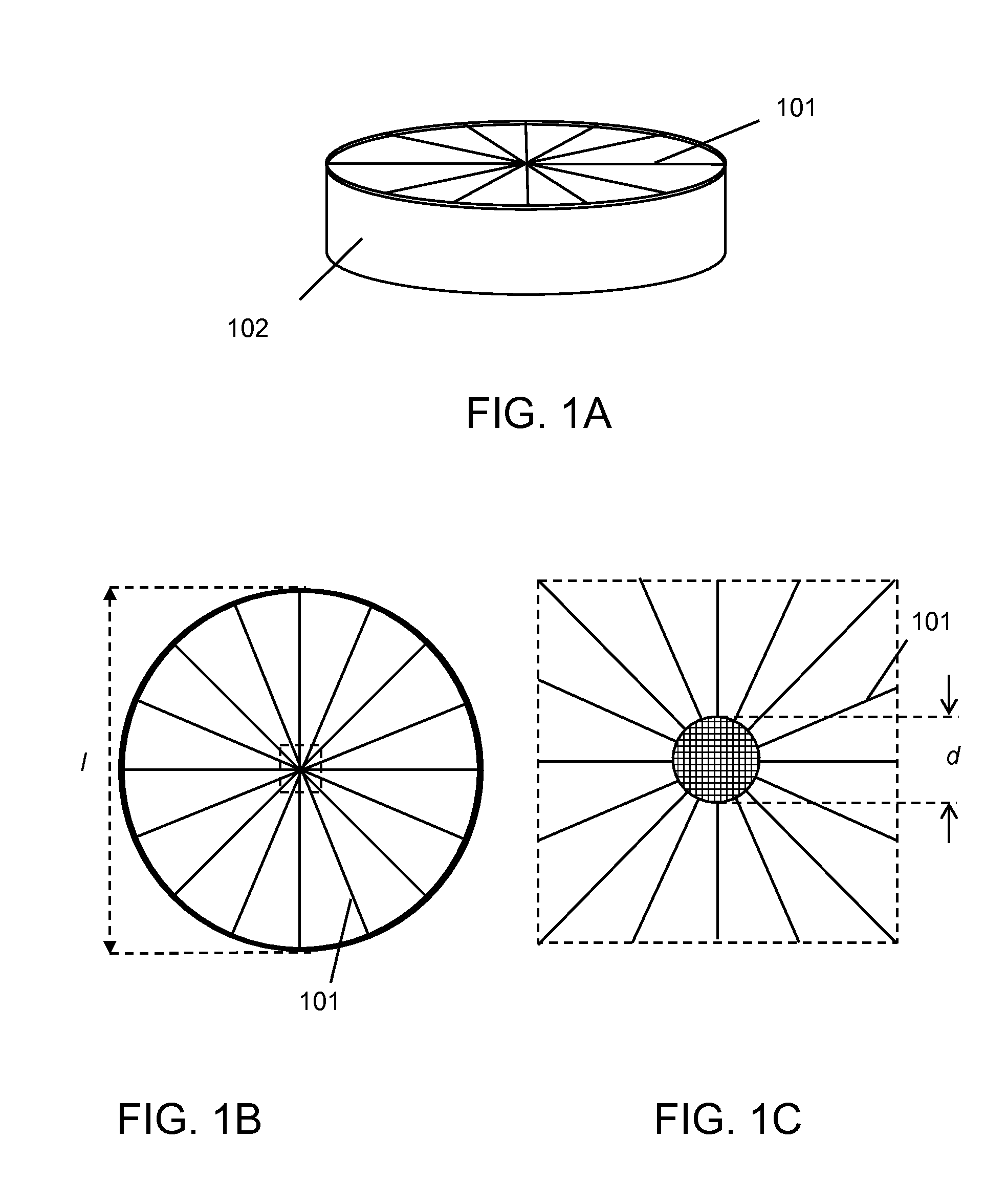

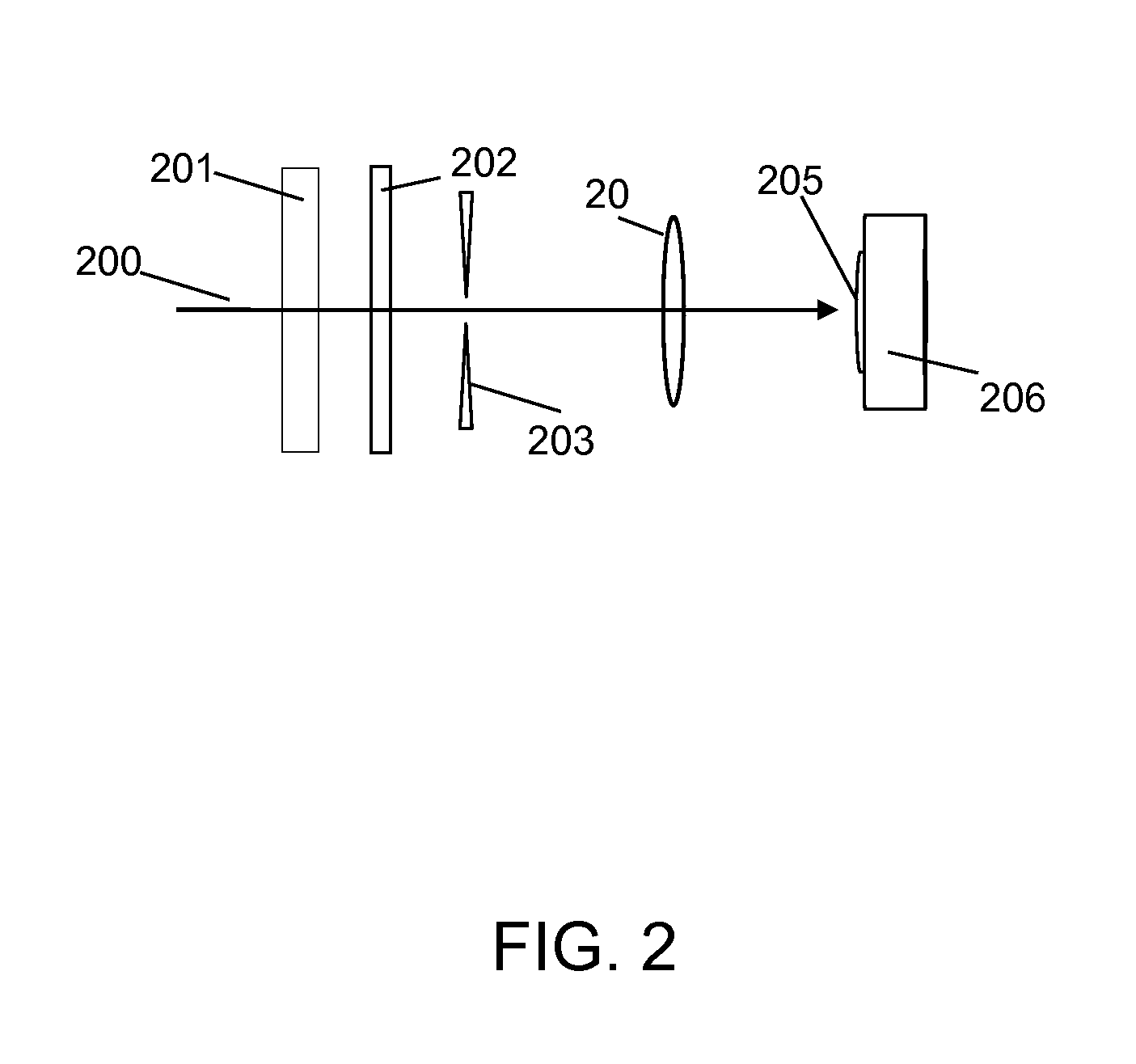

Vector vortex waveplates

ActiveUS20170010397A1Good optical performanceWide spectral rangePolarising elementsPretreated surfacesLiquid-crystal displaySpectral bands

Method for fabrication of vector vortex waveplates of improved quality due to reduced singularity size and widened spectral band, the method comprising creating a boundary condition for vortex orientation pattern of a liquid crystal polymer on a substrate using materials with reversible photoalignment, equalizing exposure energy over the area of the waveplate by redistributing the energy of radiation used for photoalignment from the center of the beam to its peripheries, and using vector vortex waveplate as a linear-to-axial polarization converter. Fabrication of spectrally broadband vector vortex waveplates further comprises two or more liquid crystal polymer layers with opposite sign of twist.

Owner:BEAM ENG FOR ADVANCED MEASUREMENTS

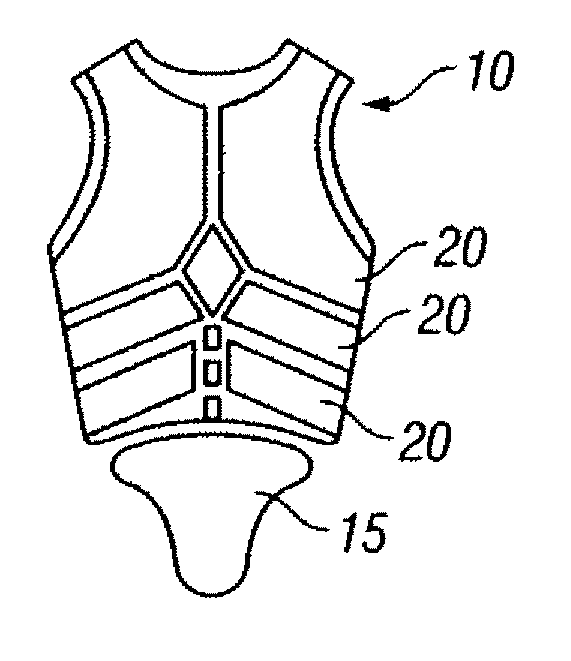

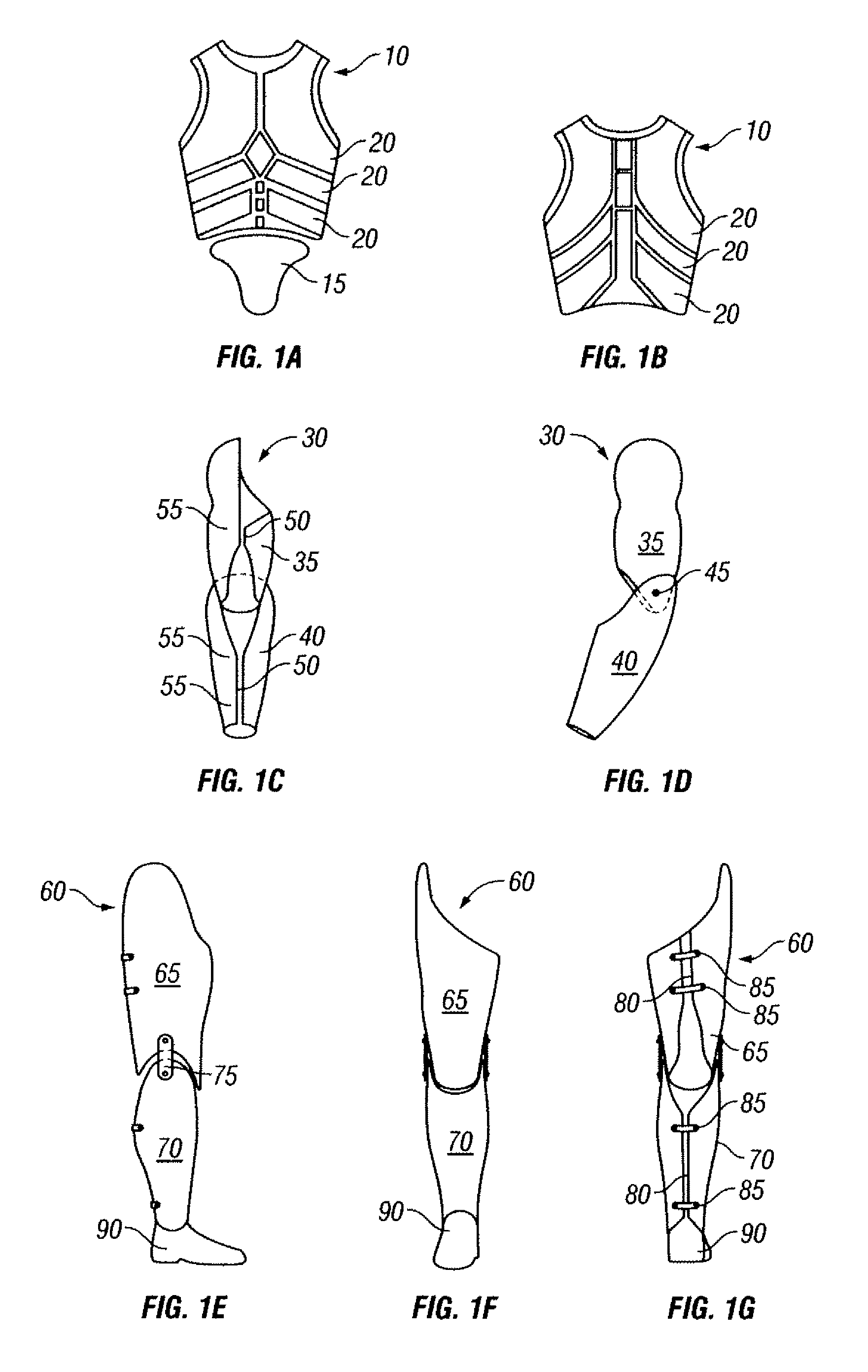

Wearable body armor

The present invention provides a wearable body armor suit, comprising a plurality of body armor components that are connected together by an impact-resistant material, wherein the impact-resistant material comprises Vectran™ or woven chain mail, and wherein the body armor components are formed of carbon fiber or liquid crystal polymer fiber that is woven or formed into a platen. The platen is molded or curved to accommodate the shape of a body part being covered by the body armor component, for localized and directed protection of strategically important body parts.

Owner:NEPTUNIC TECH

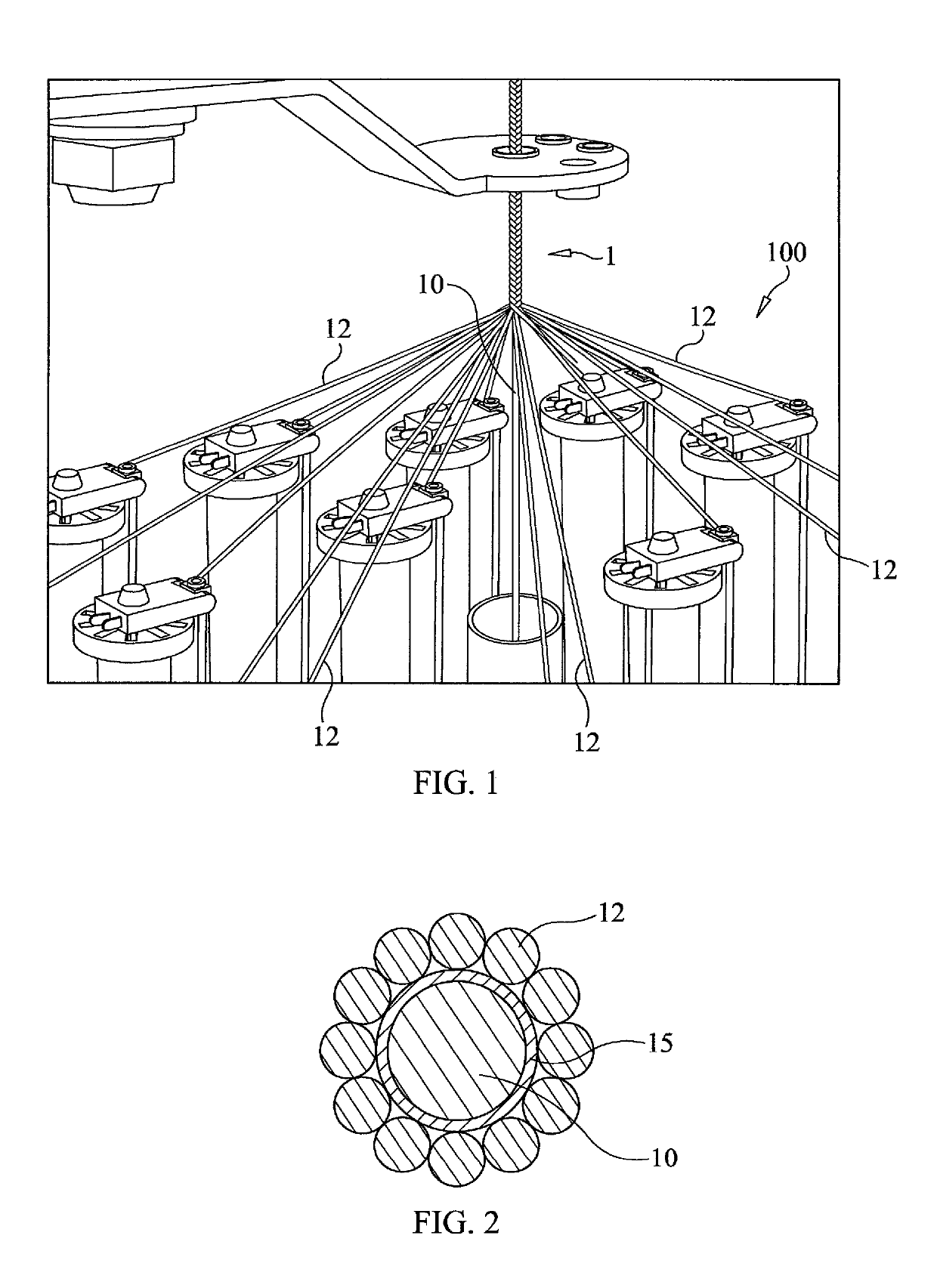

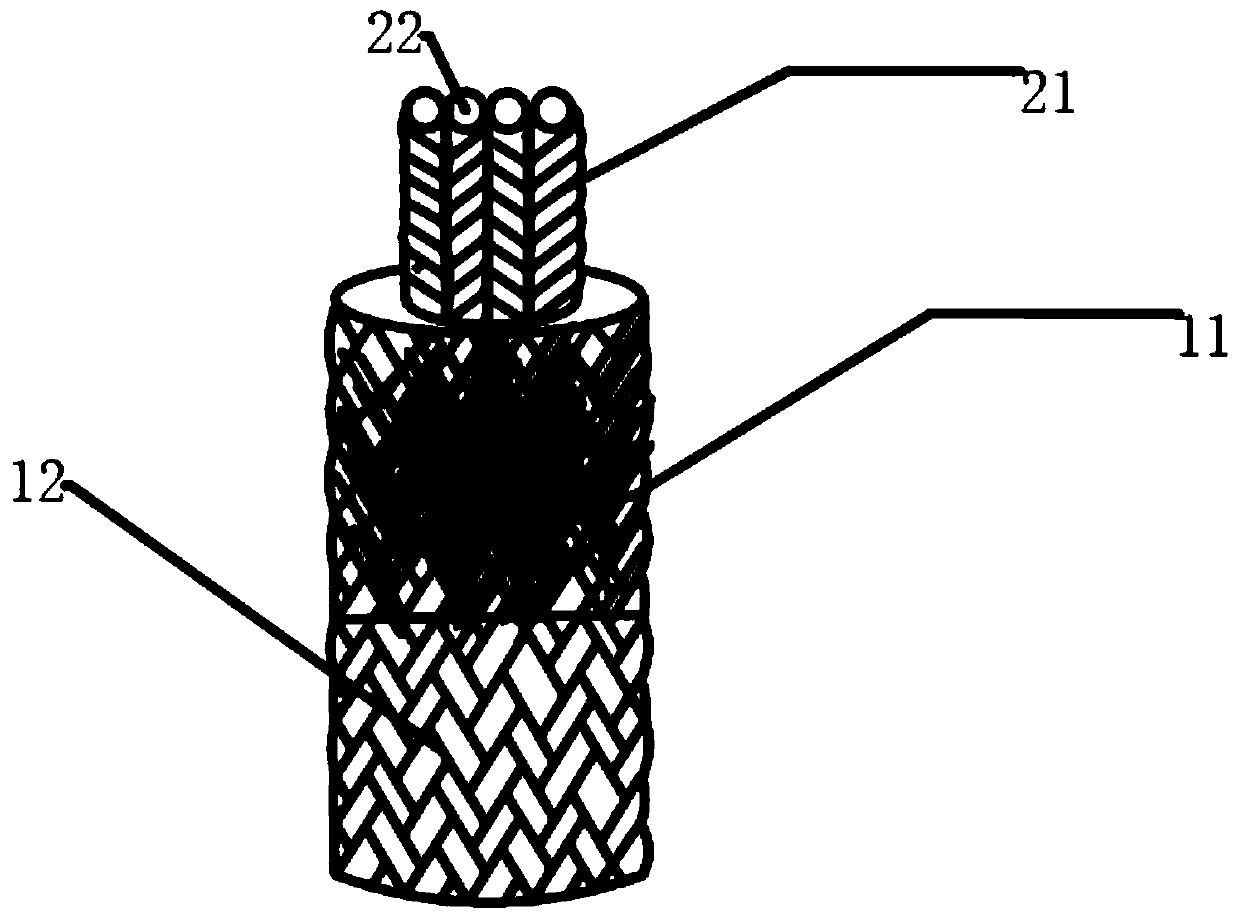

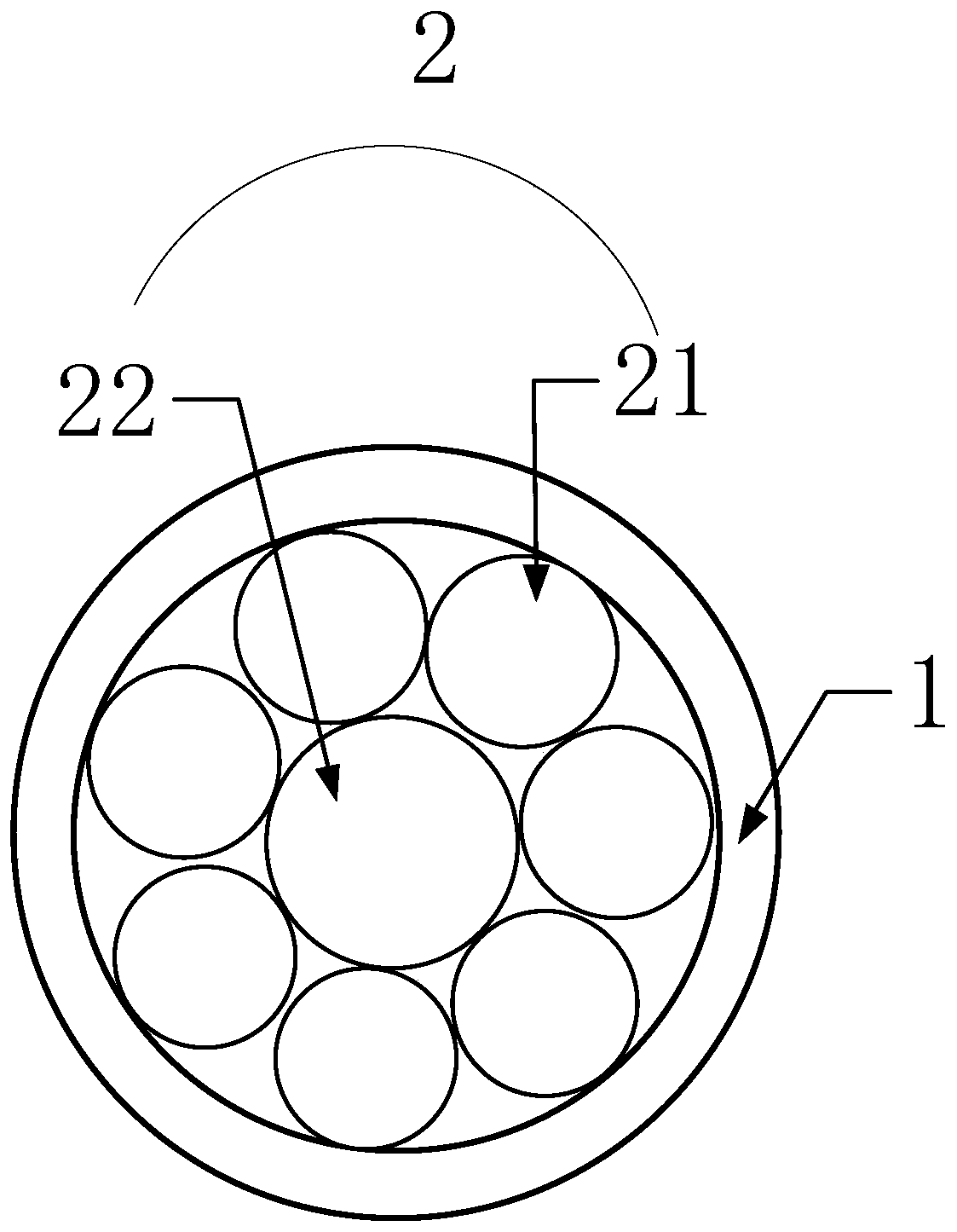

Wear-resisting high-strength cable and preparation method thereof

ActiveCN104762748AImprove performanceImprove breaking strengthRope making machinesCoatingsYarnPolyester

The invention discloses a wear-resisting high-strength cable produced by a non-single material and a preparation method of the wear-resisting high-strength cable. A cable body is an 8-strand structure core body which is prepared from ultra-high molecular weight polyethylene (UHMWPE) and high-strength polyester according to the amount ratio of 3 to 1; a high-toughness wear-resistant coating woven by adopting vectran fibers is arranged outside the core body; and a wear-resistant coating which is especially made of a wear-resistant material PTFE as a matrix coats the outer surface of the sleeve; the preparation method comprises the following steps: fabricating a cable body by the procedures of preparing roving, preparing rope yarns, infiltrating resin, preparing rope strands, braiding ropes, prestretching and drying; weaving a high-strength wear-resisting sleeve on the surface of the core body; and dipping and coating a wear-resisting coating which is especially prepared from PTFE as a matrix on the outer layer of the sleeve.

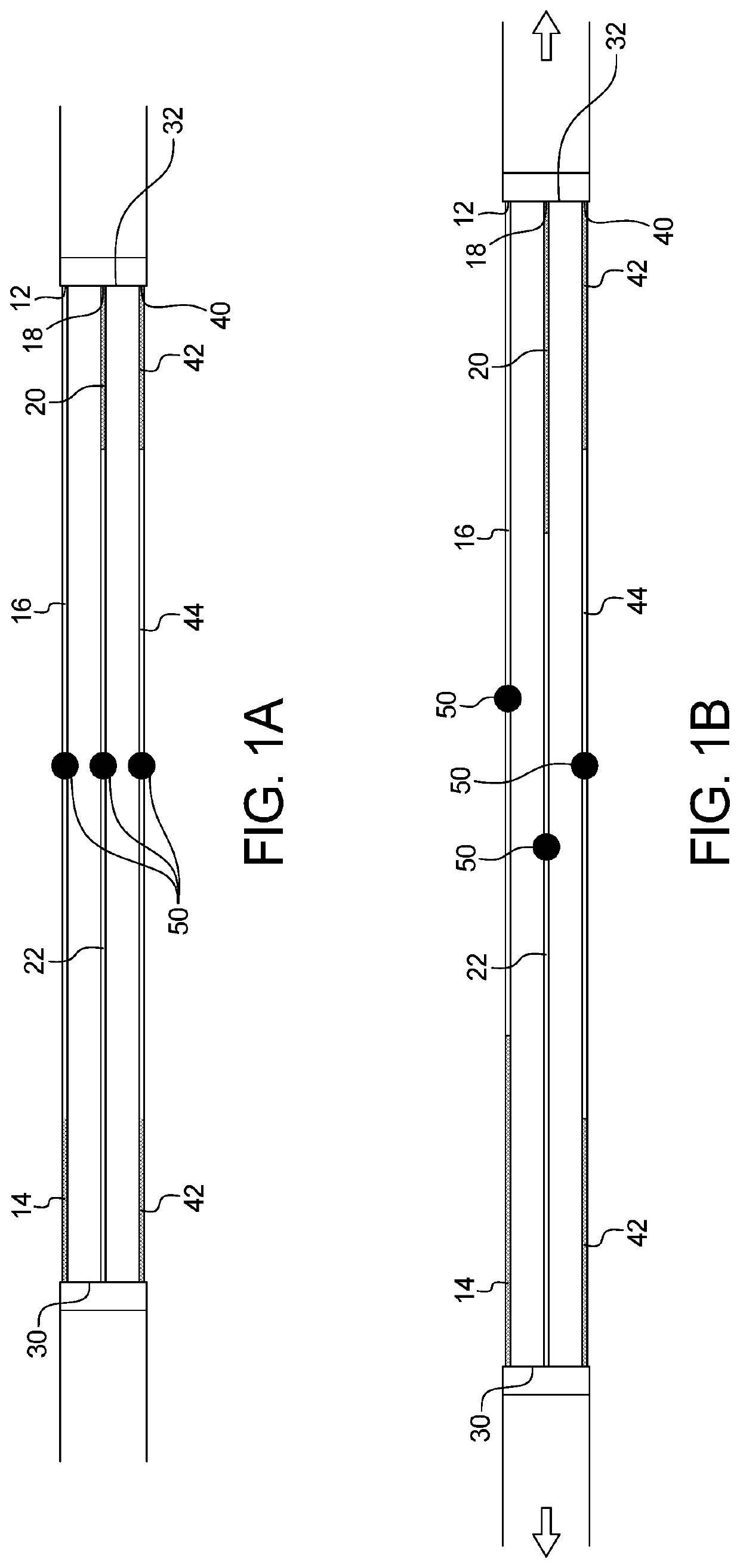

Apparatuses, systems, and methods for inhibiting the removal of cable from conduit

InactiveUS20090301777A1Prevent removalSnap fastenersPipe supportsElectrical resistance and conductanceAbove ground

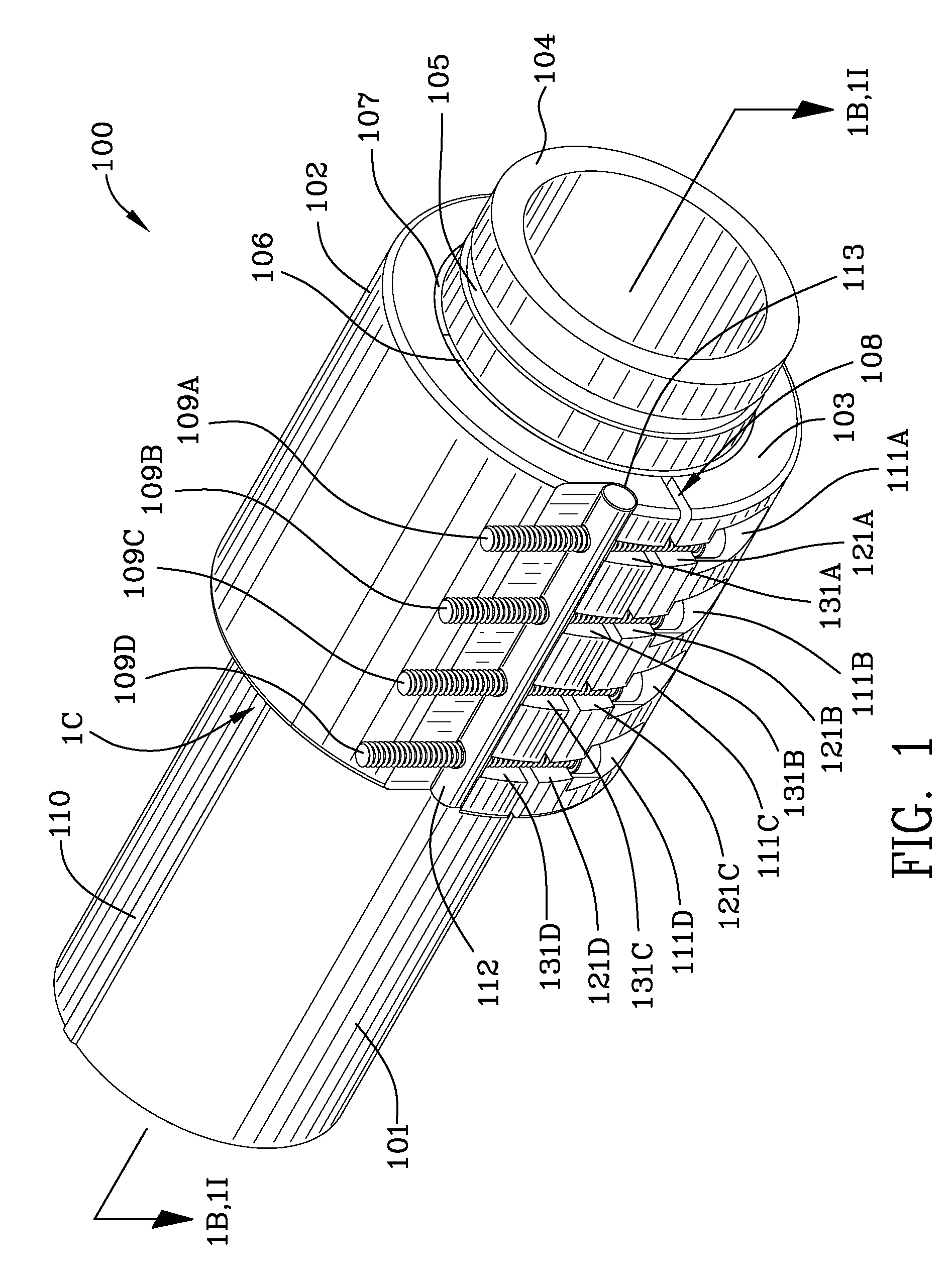

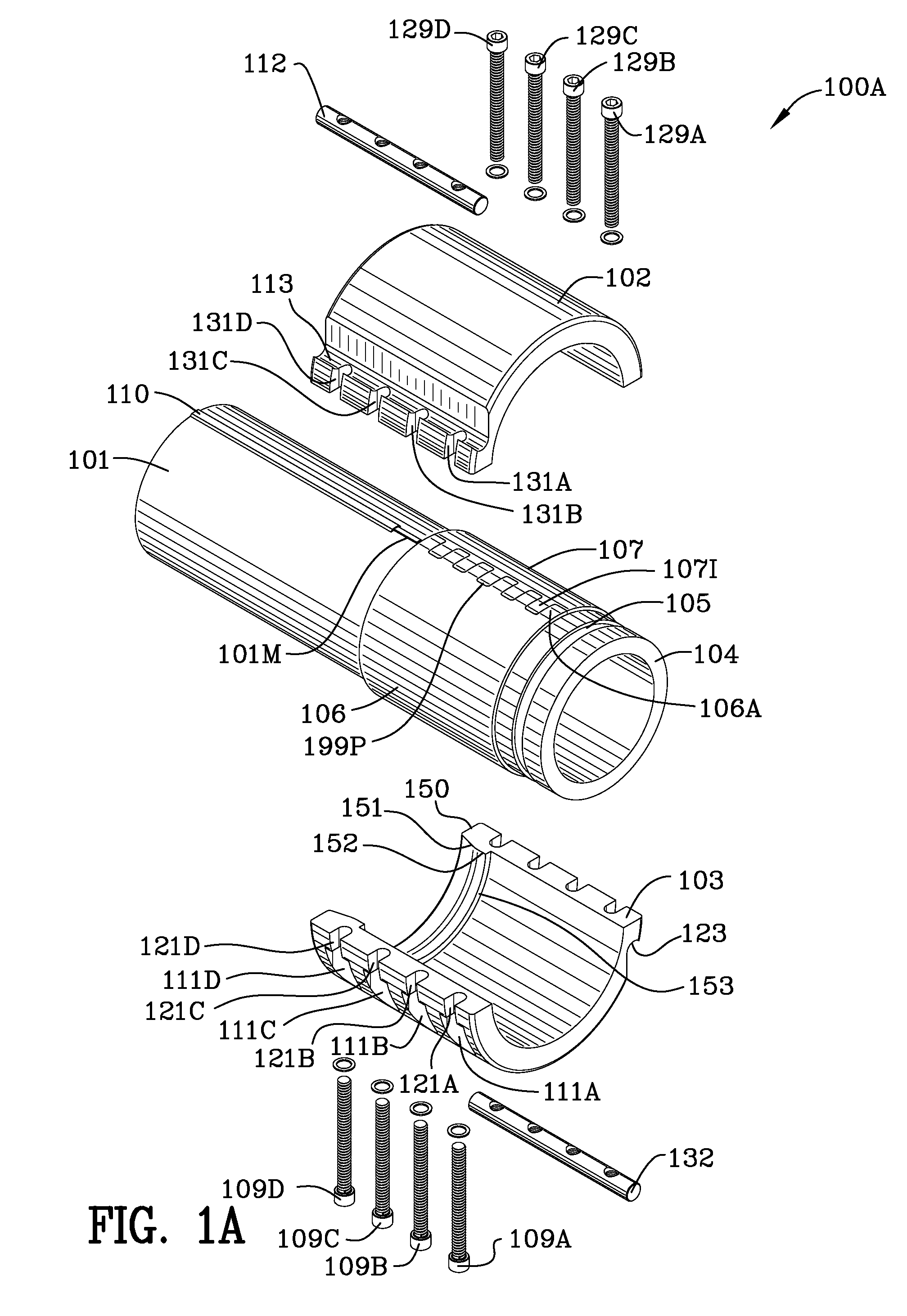

Apparatuses, systems, and methods for securing one or more wires or cables relative to a conduit, for example, an underground conduit, an above ground conduit, or a conduit disposed in a building. The inhibiting device can hinder or prevent the removal of such wires or cables from the conduit by compressing the wires or cables between a clamp and a portion of the inhibiting device and / or conduit at a location that is not co-axial with a central axis of the conduit. As a result, a resistive frictional load is applied to the wires or cables which has a vector generally parallel and opposite to a removal force and a vector generally perpendicular to the removal force. In some embodiments, the inhibiting device can include a bolt, fabric, nylon, polymer, or compression type clamp. In some embodiments, a system can include a plurality of clamps which are transversely and axially separated.

Owner:YRIBARREN RICHARD J

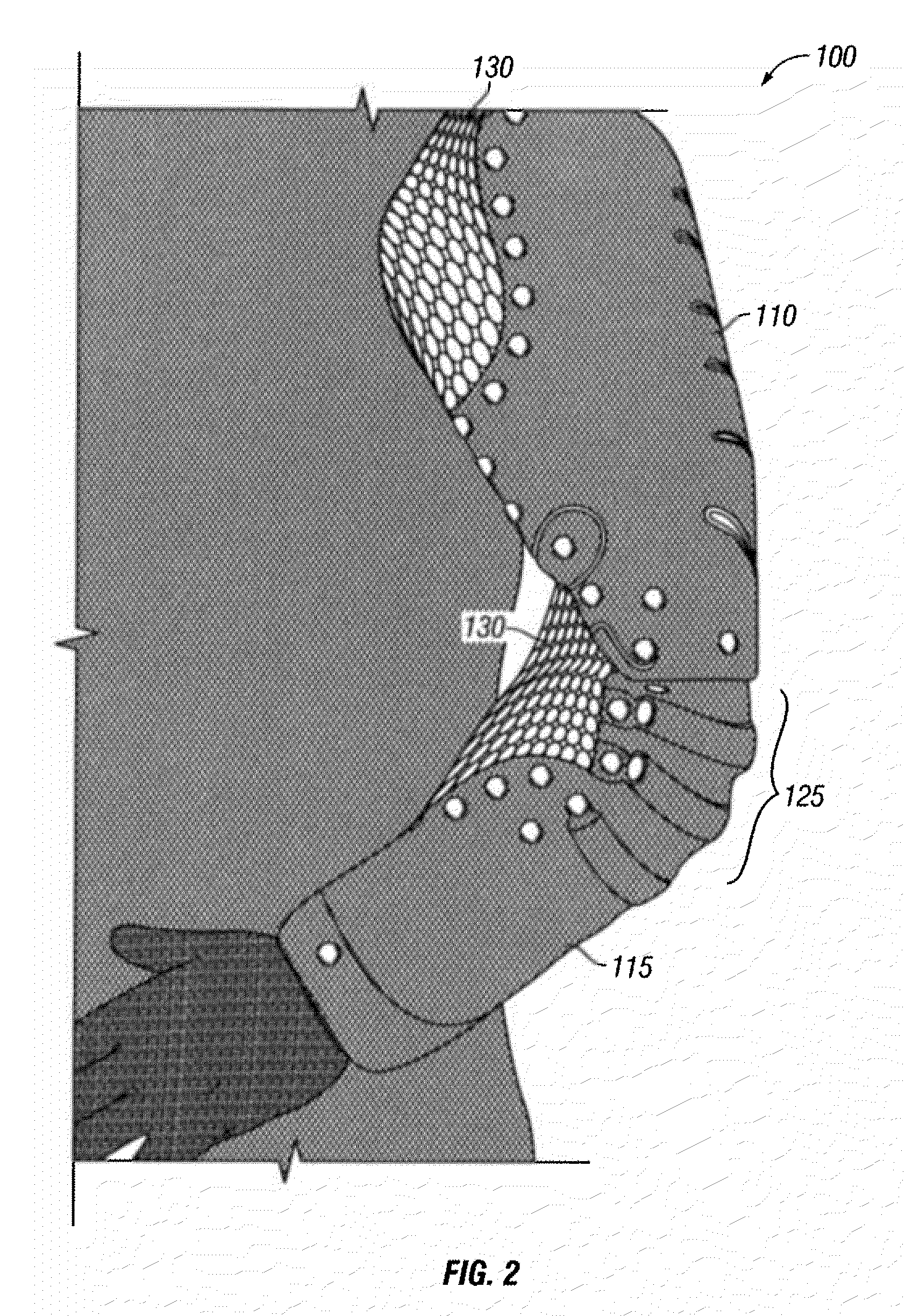

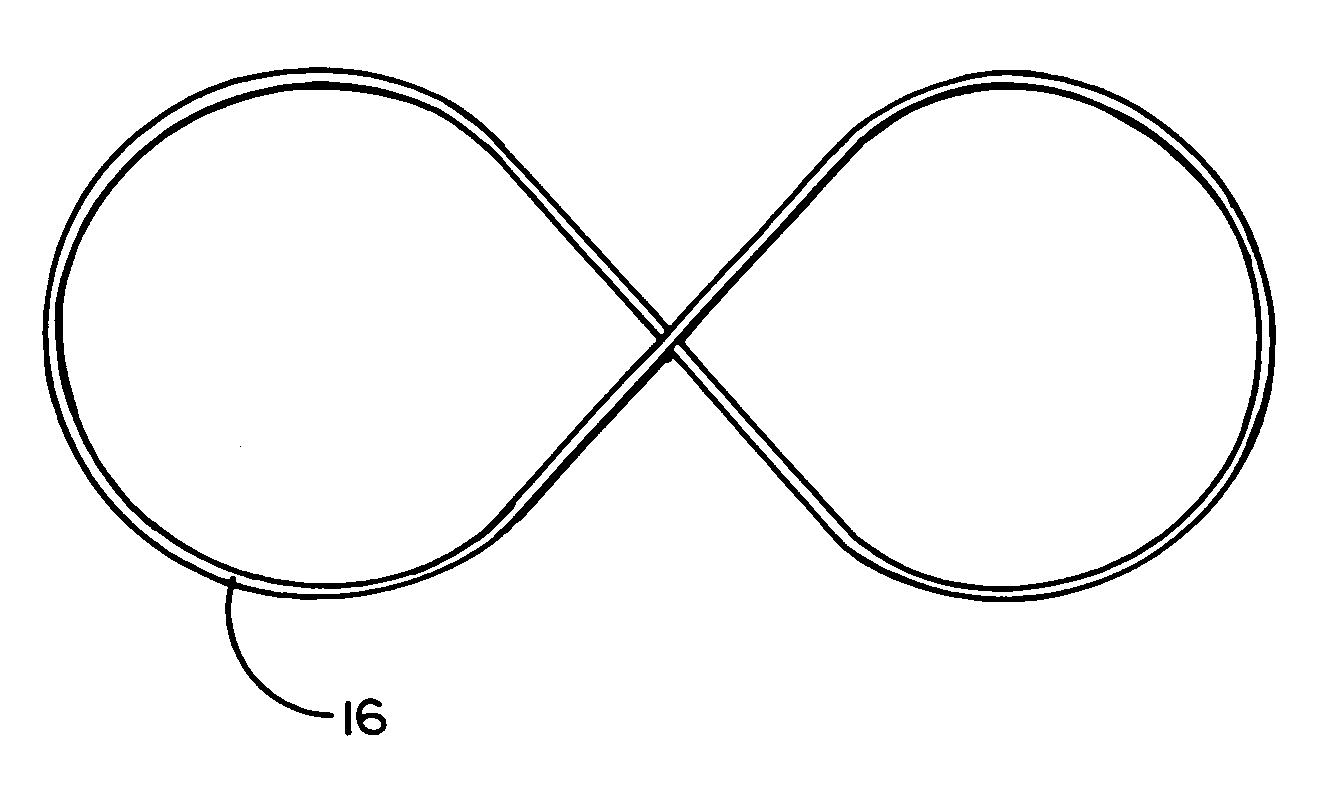

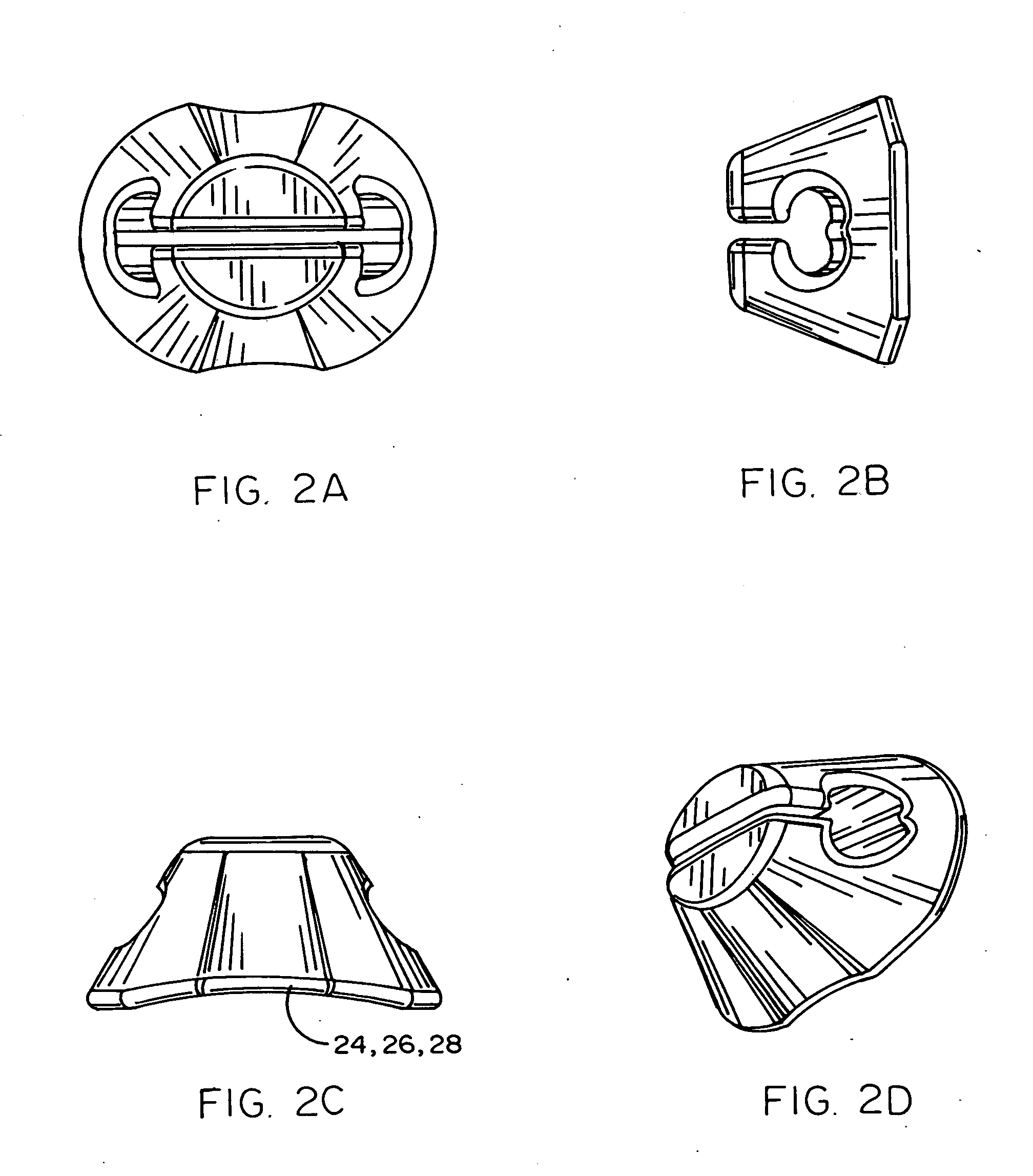

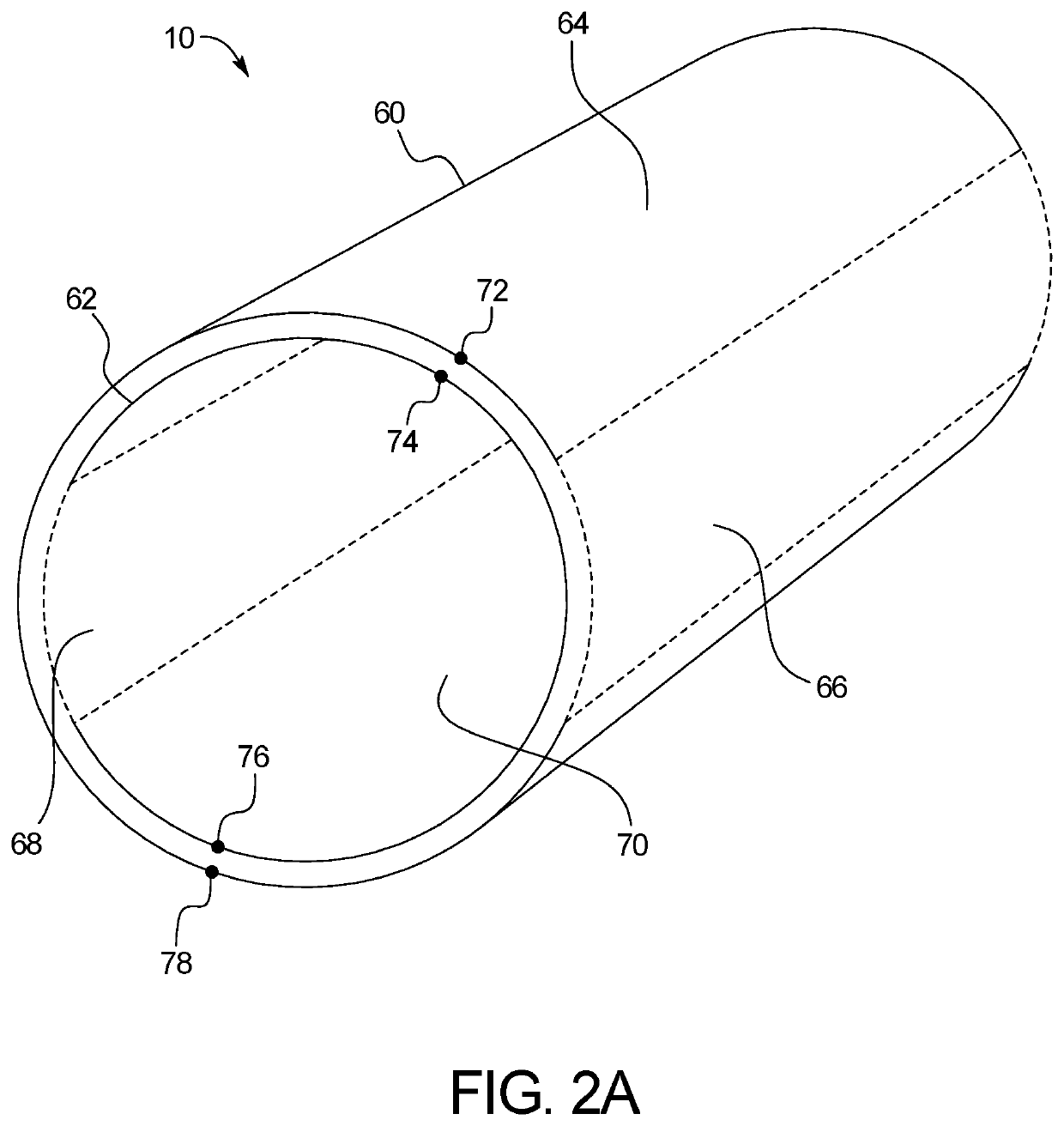

Adjustable oral appliance for treatment of snoring and sleep apnea

InactiveUS20110308531A1Open fullyStabilizes anterior positioningSnoring preventionNon-surgical orthopedic devicesPolyesterLocking mechanism

A mandibular advancement oral appliance for treatment of snoring and obstructive sleep apnea comprises upper and lower thermoformed co-polyester splints, custom fabricated to match the patient's dentition. The splints are interconnected by a thread cord or filament in a pre-fabricated continuous loop with no knot. The loop passes through guide tubes and around pulley's having openings to allow the thread to be forced into them. The thread is made up of braided liquid crystal polymer fiber (Vectran®). This appliance uses a locking device to keep the continuous loop from traveling along itself. This stabilizes the anterior positioning. The locking mechanism comprises an expansion clamp consisting of an oval expansion crank, oval casing and cap. The locking mechanism's function is to restrict movement of the loop, thereby locking the mandible in the desired forward location while the patient sleeps. The loop guide, pulleys and locking device are preferably affixed to the anterior-facing surfaces of the splints.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

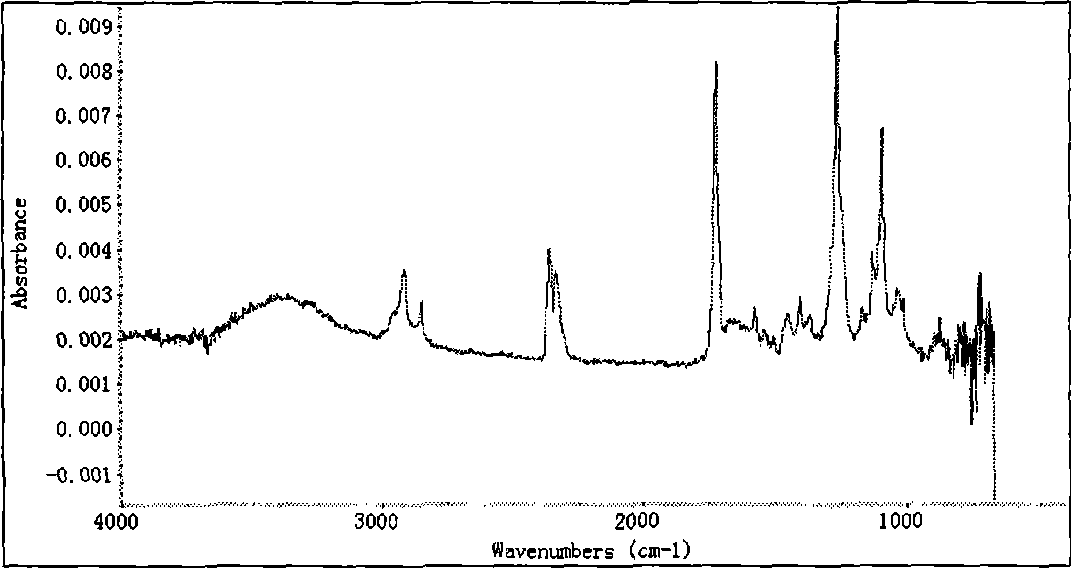

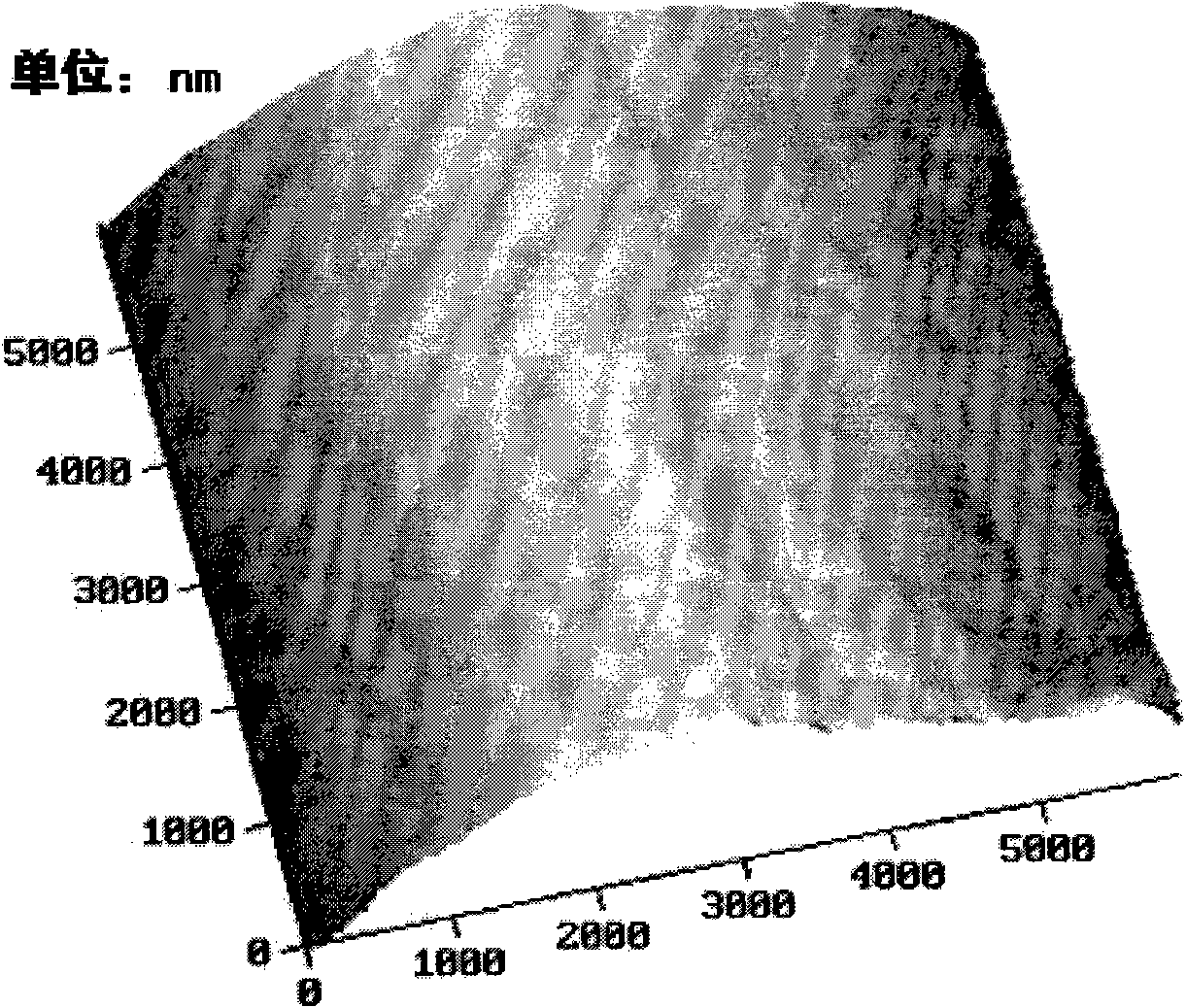

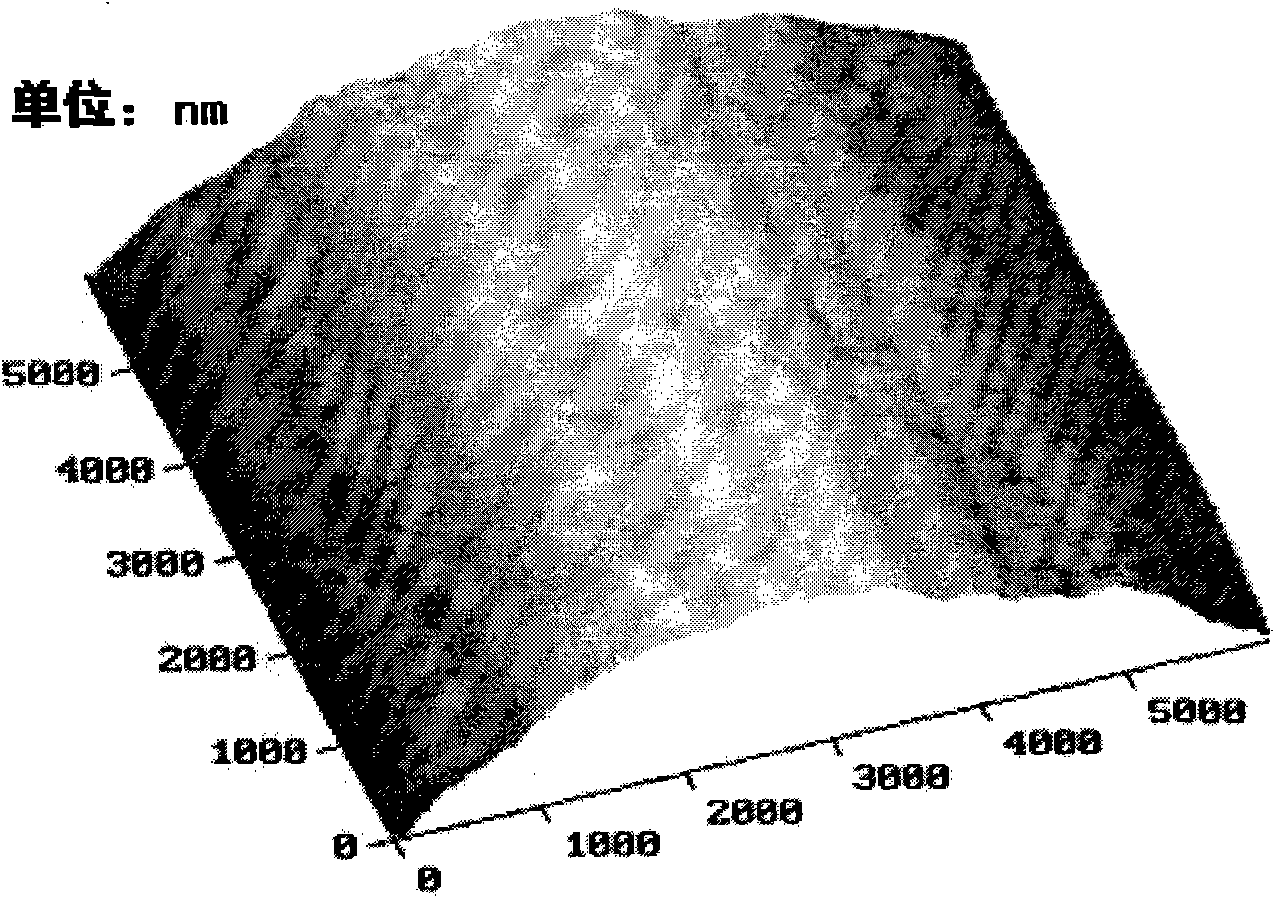

Method for Vectran carbon fiber surface modification of plasma coated with silicon dioxide colloidal sols by plasma treatment

InactiveCN101413211AImprove performanceImprove composite effectPhysical treatmentFibre typesTreatment effectSilicon dioxide

The invention relates to a method for modifying the surface of Vectran fiber coated with nano silicon dioxide sol through plasma treatment, which comprises the following steps: firstly, nano silicon dioxide is prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles and silicon dioxide nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the fiber and dried; and thirdly, the dried Vectran fiber is placed on a plasma transport unit and a plasma is sprayed on substances to generate modification, wherein the treating power is between 10 and 15,000 watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the fiber, improves the molded manufacturability and the overall properties of composite materials of the fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

Hose

InactiveUS8327887B2Avoid pinch problemsRelieve pressureLaminationLamination apparatusAdhesiveVectran

The hose includes an outer jacket which includes warp and weft fibers made of Vectran®. The process for making the hose, includes: forming an inner liner and coating the exterior thereof with adhesive; weaving, in a twill weave pattern, Vectran® yarn, in a repeating 2-4-2-4-2 pattern in both the warp and the weft directions; extruding polyurethane onto the woven vectran yarn, the polyurethane extending into pillars between the warp and weft yarn, forming an outer liner; inserting the inner liner coated with adhesive within the outer liner; and, pressurizing the inner liner with steam expanding the inner liner and the adhesive into engagement with the Vectran® yarn and polyurethane pillars of the outer liner.

Owner:ALL AMERICAN HOSE ACQUISITIONS LLC

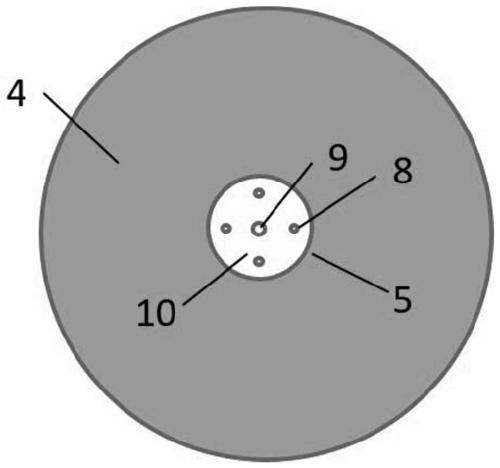

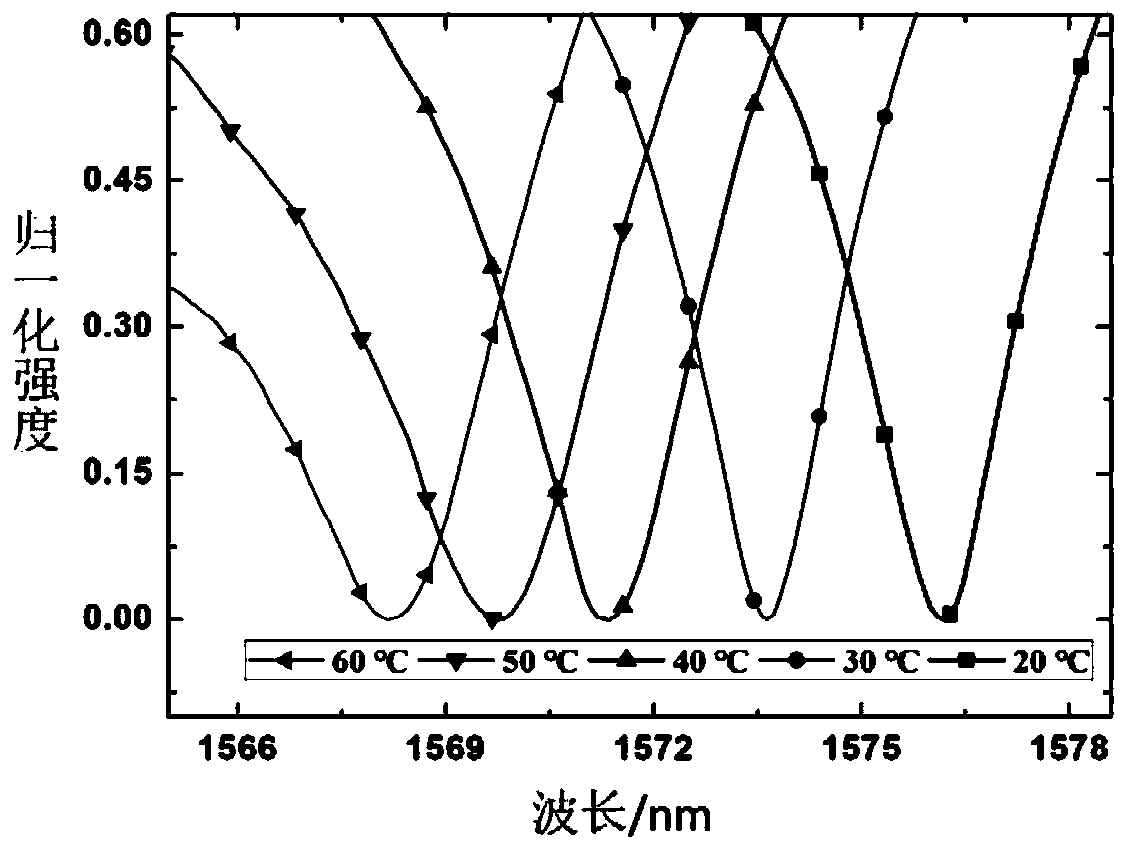

Vector stress meter based on micro-nano multi-core special optical fiber

ActiveCN111487000AEliminate cross-sensitivity effectsImprove reliabilityGlass optical fibreForce measurement by measuring optical property variationSpectrum analyzerMaterials science

The invention discloses a vector stress meter based on a micro-nano multi-core special optical fiber. A single-mode optical fiber A, a single-mode optical fiber B and the micro-nano multi-core specialoptical fiber are welded, the micro-nano multi-core special optical fiber is composed of four cladding fiber cores, a central fiber core and a multi-core optical fiber cladding, a surface is coated with a polymer, and the surface of the polymer is engraved with a grating. Light emitted by a broadband light source enters a fiber core A of the single-mode optical fiber A for total reflection transmission, and when the light reaches a welding point, a part of the light enters the micro-nano multi-core special optical fiber and is transmitted in the four cladding fiber cores, the central fiber core and the multi-core optical fiber cladding; and the other part of the light enters the polymer for transmission and is modulated by the grating in real time. And all optical signals return to a spectrum analyzer after passing through the single-mode optical fiber B and the fiber core B to obtain a transmission spectrum. The stress meter adopts an all-fiber structure design, has characteristics of high sensitivity, flexibility and easiness in packaging, can be used for wearable behavior monitoring and auxiliary equipment, and realizes sensing and interaction of a stress direction and magnitude.

Owner:NORTHEASTERN UNIV LIAONING

Method for preventing ultraviolet ageing of Vectran fibers

InactiveCN101851856AWith UV protectionImprove the protective effectFibre typesUltravioletUltraviolet absorption

The invention discloses a method for preventing ultraviolet ageing of Vectran fibers, which relates to a method for preventing ultraviolet ageing of coated fibers. The invention solves the problem of poor effect of preventing ultraviolet ageing of the existing Vectran fibers when a protective layer of an inorganic ultraviolet reflection agent or an organic ultraviolet absorbent is used independently. The method of the invention comprises the following steps: (1) preparing TiO2 hydrosol by a sol-gel method; (2) mixing the TiO2 hydrosol in the step (1) with organic solution of the organic absorbent to obtain a polymer paint; and (3) utilizing ultrasound effect to soak the polymer paint on the Vectran fibers, then airing the processed Vectran fibers and drying the Vectran fibers. The method has simple process and simple and easy operation and makes the Vectran fibers have protection functions of both ultraviolet reflection and ultraviolet absorption. The Vectran fibers obtained by the method are applied to a skin material of a high-altitude airship.

Owner:HARBIN INST OF TECH

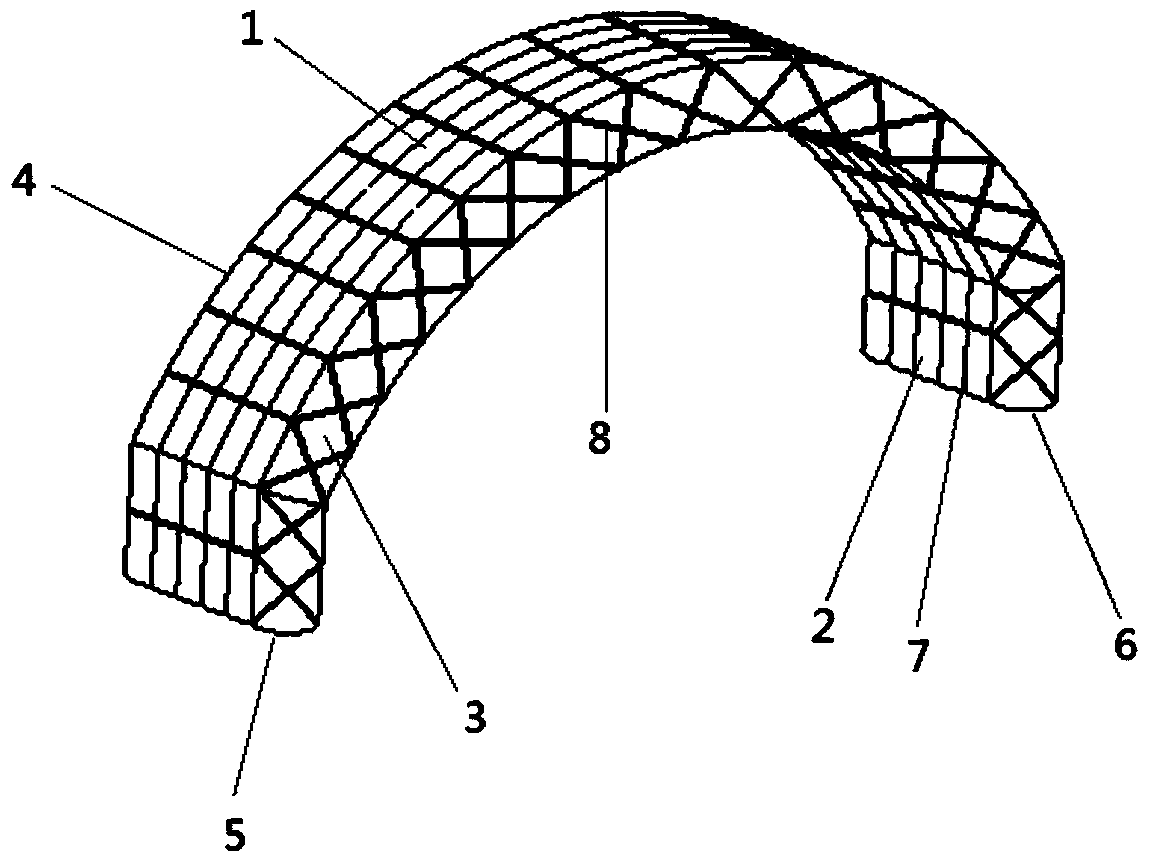

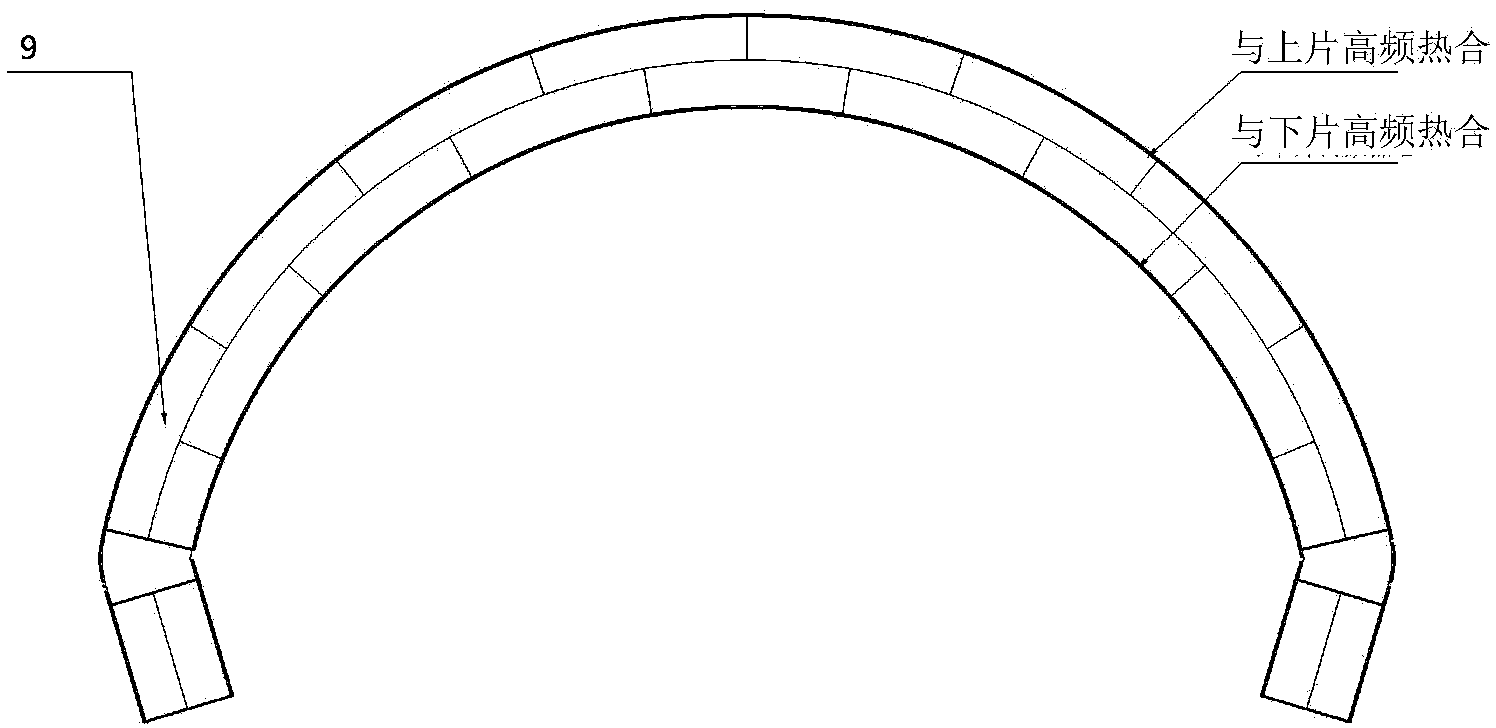

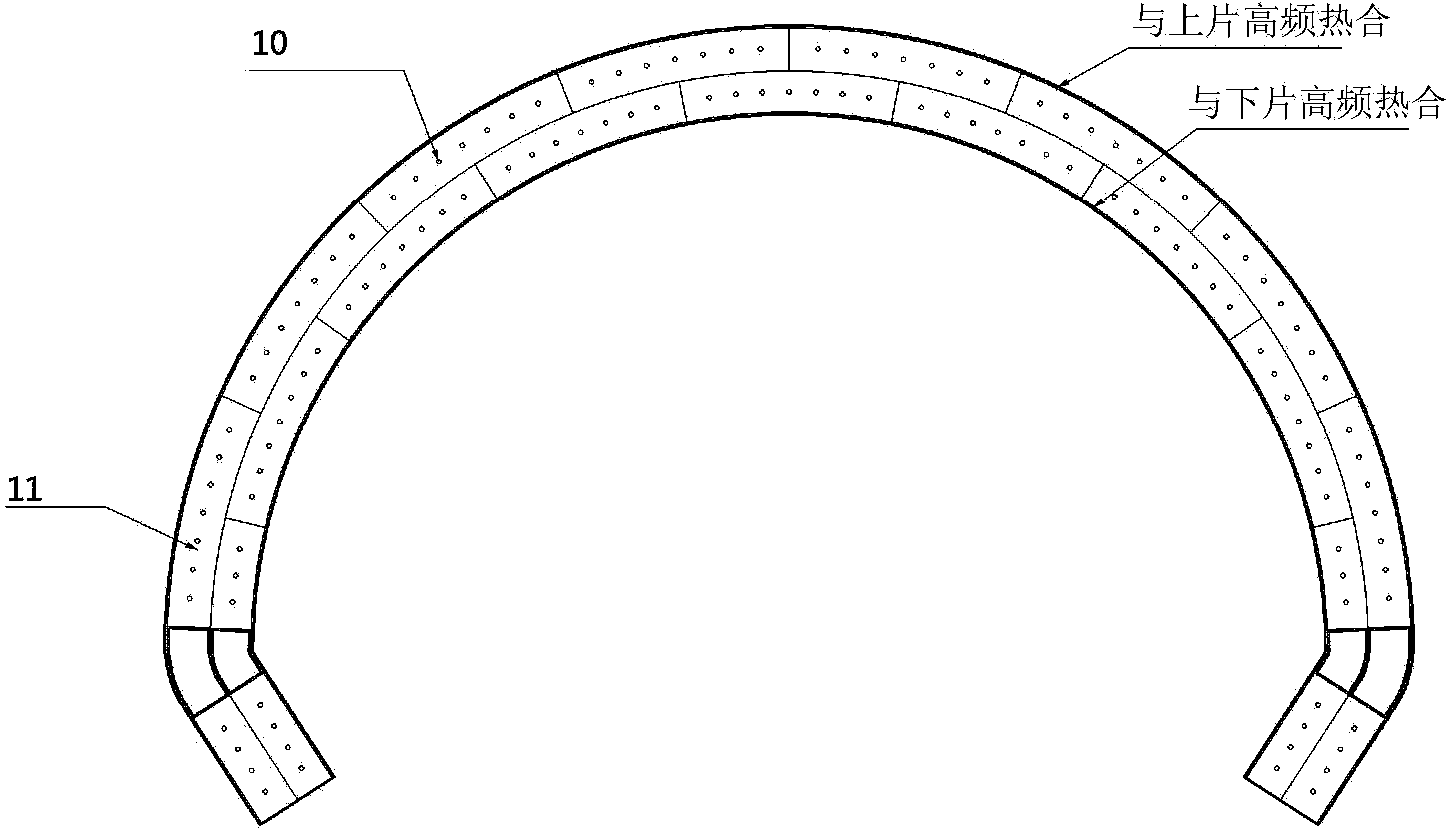

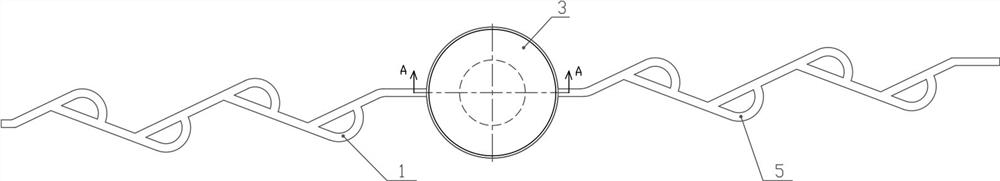

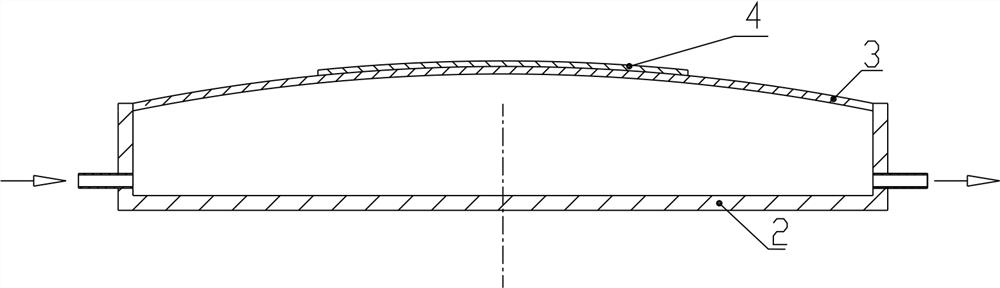

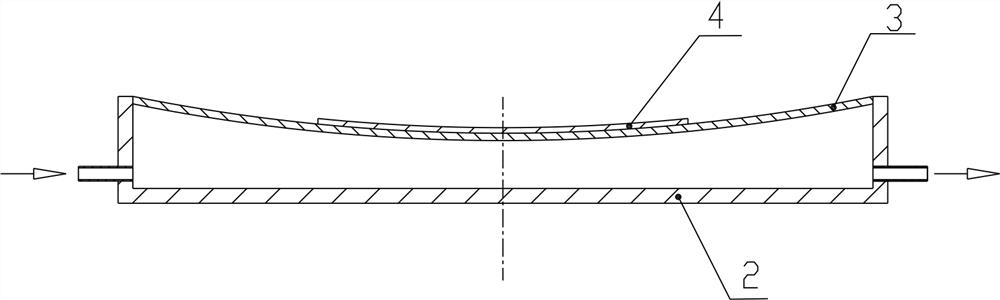

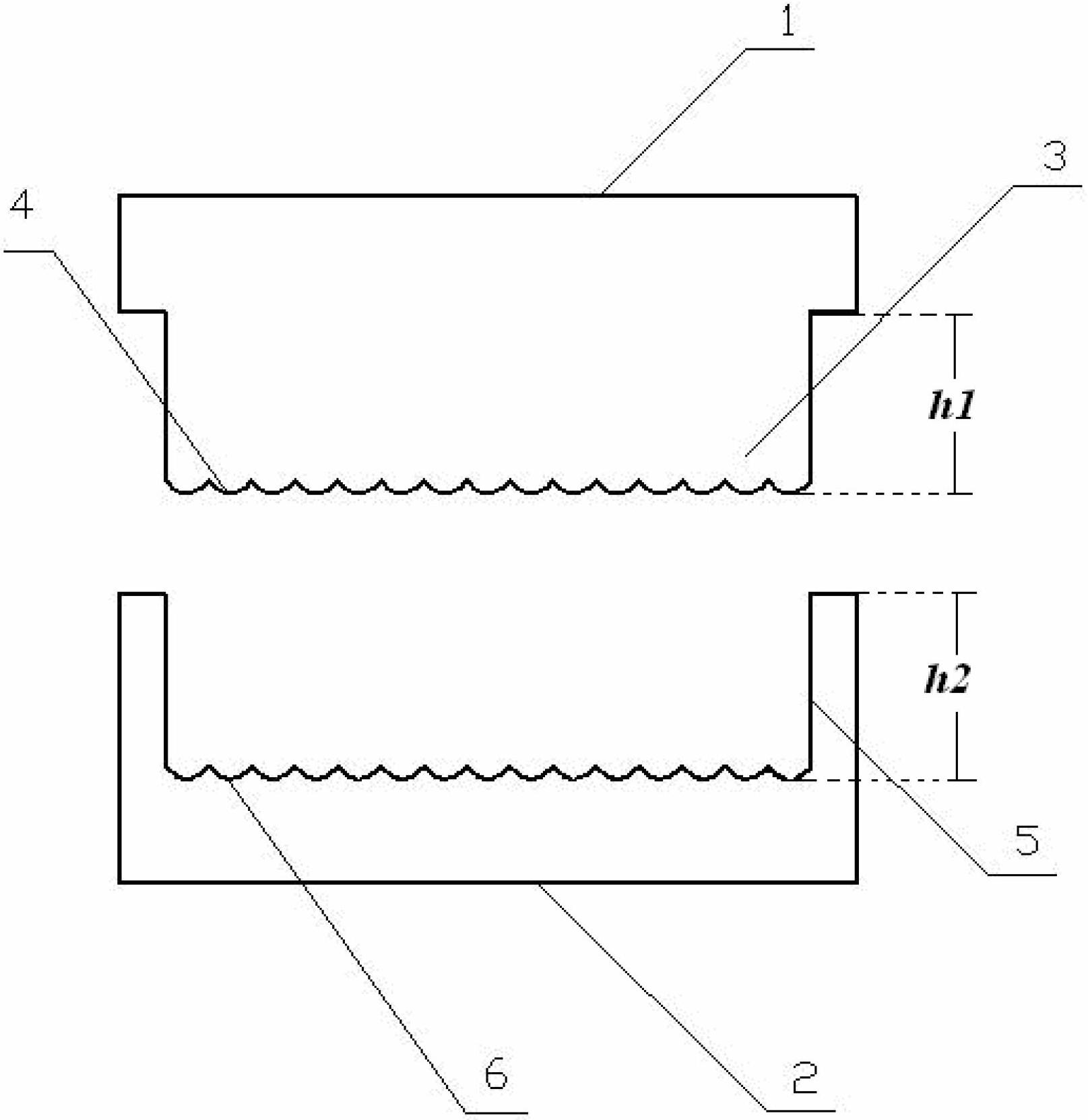

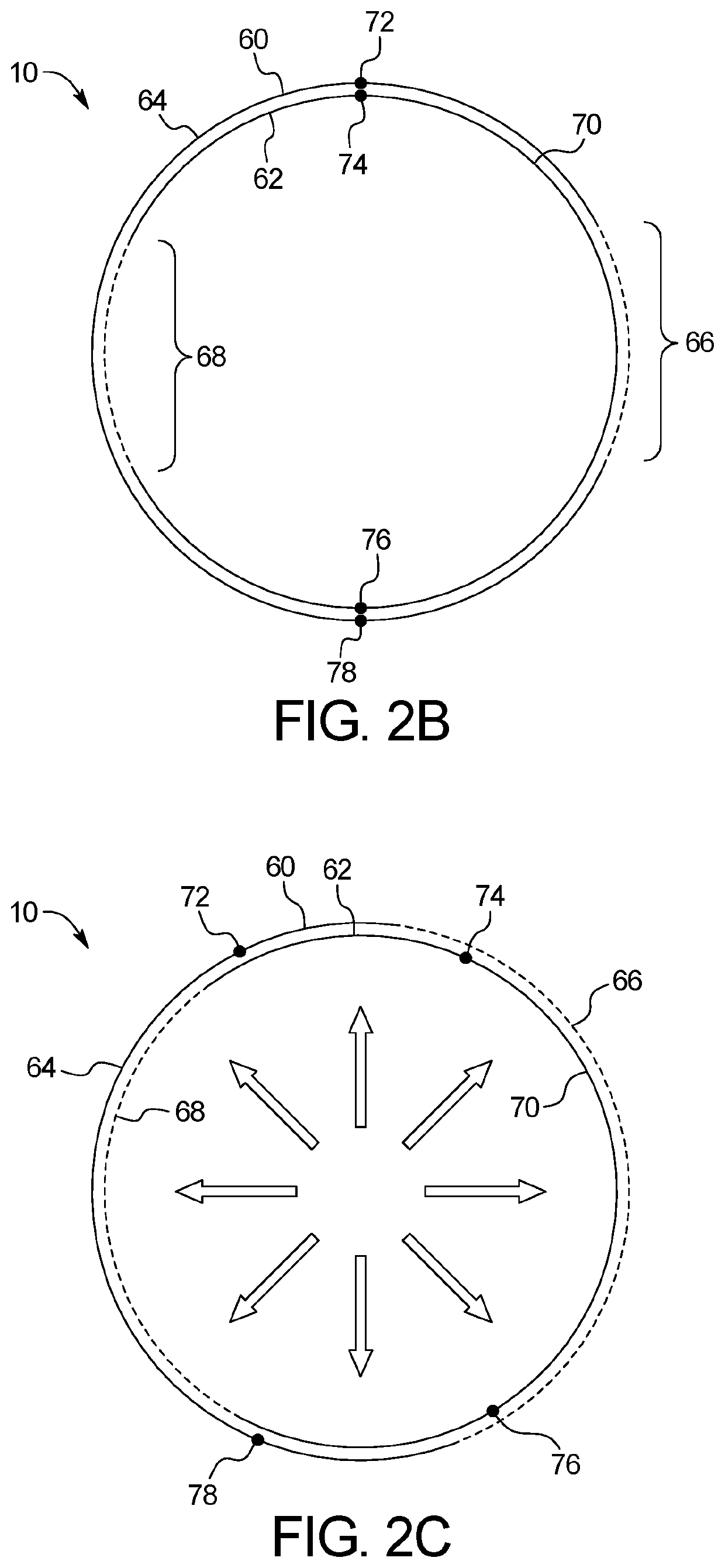

Gas rib suitable for large inflatable boat/hangar

ActiveCN104110156AEasy to shapeSuppression of the phenomenon of collapseTents/canopiesParkingsPolyesterInflatable boat

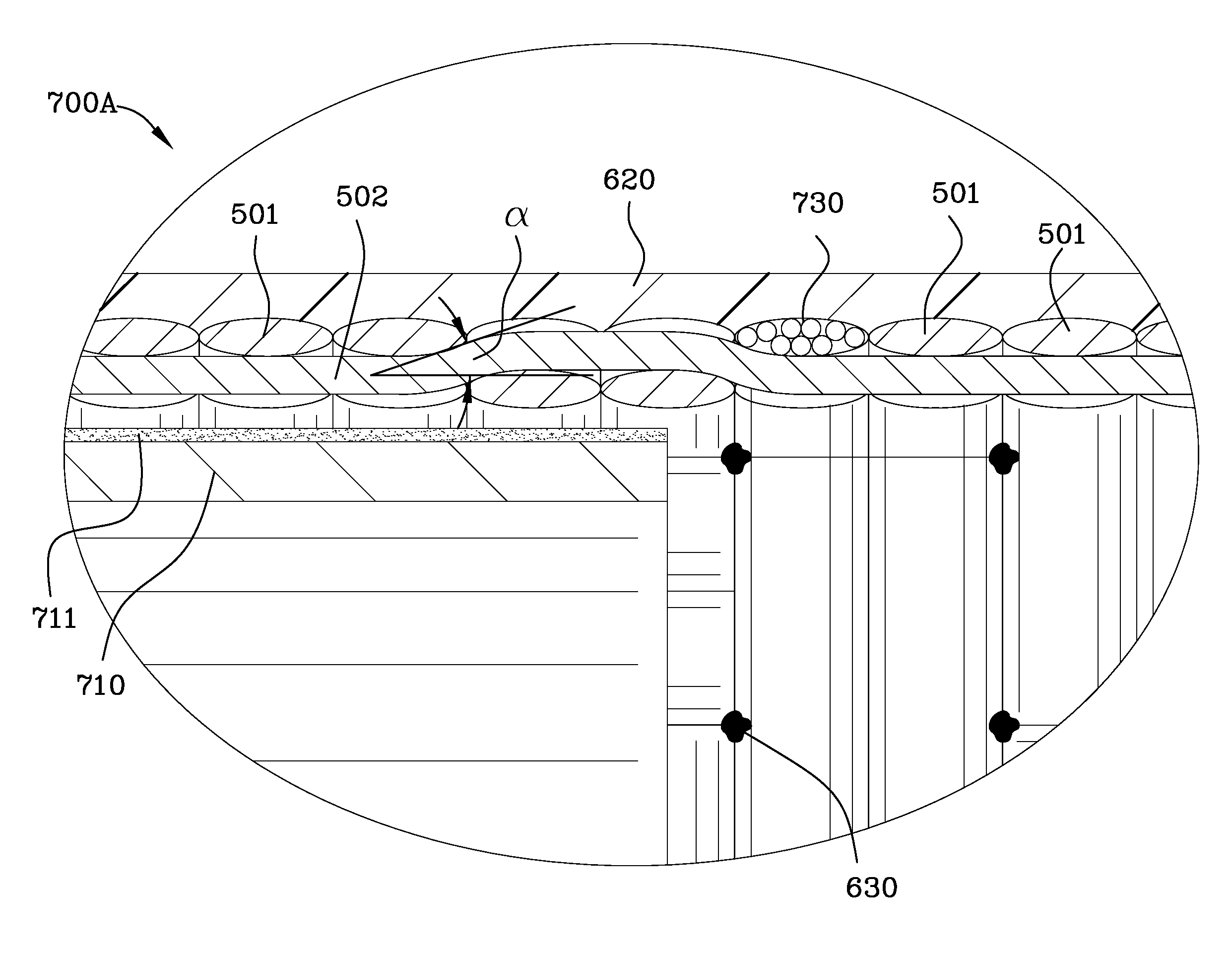

The invention provides a gas rib suitable for a large inflatable boat / hangar. The technique mainly includes three aspects of designing of the cutting manner of a middle strengthening pulling belt and gas rib cut pieces, selecting of the middle strengthening pulling belt and gas rib materials and designing of a reinforcing net outside the gas rib. The gas rib is formed by mutually welding a front end face, a rear end face, an upper piece, a lower piece and two bottom faces in a high frequency mode. The middle of the gas rib is provided with the strengthening pulling belt. The front end face and the rear end face are respectively formed by welding a plurality of end face cut pieces in a high frequency mode, and the strengthening pulling belt is formed by welding a plurality of pulling belt cut pieces in a high frequency mode. The end faces, the upper pieces and the two bottom faces of the gas rib are made of polyester / PVC composite film materials, and the lower piece of the gas rib and pilling belt bodies composing the strengthening pulling belt are made of Vectran / PVC composite film materials. The end face cut pieces and the pulling belt cut pieces are cut in a specific manner than inflated and formed bearing layer fabric materials are subjected to the maximum acting force in the longitude direction and the latitude direction. A reinforcing net is arranged on the outer portion of the gas rib.

Owner:EAGLES MEN AERONAUTIC SCI & TECH GRP

Wear-resisting high-strength mooring rope and manufacturing method thereof

The invention discloses a wear-resisting high-strength mooring rope, and relates to the field of industrial mooring rope manufacturing. The mooring rope comprises a core body, a high-tenacity wear-resisting sleeve and a wear-resisting coating, wherein the core body is manufactured from novel polyester and ultrahigh molecular weight polyethylene on the basis that the quantity relative ratio is 1:3to form an eight-ply structure, wear-resisting material Vectran fiber is knitted through a dual-layer rope braiding machine at a time to form a high-tenacity wear-resisting sleeve, and the high-tenacity wear-resisting sleeve wraps the core body. The outer surface of the high-tenacity wear-resisting sleeve is soaked and coated with a specially-made wear-resisting coating adopting a novel wear-resisting material PTFE as a base body. The mooring rope with high strength, low weight, low creeping and high wear resistance is manufactured through the unique technology.

Owner:钱飞

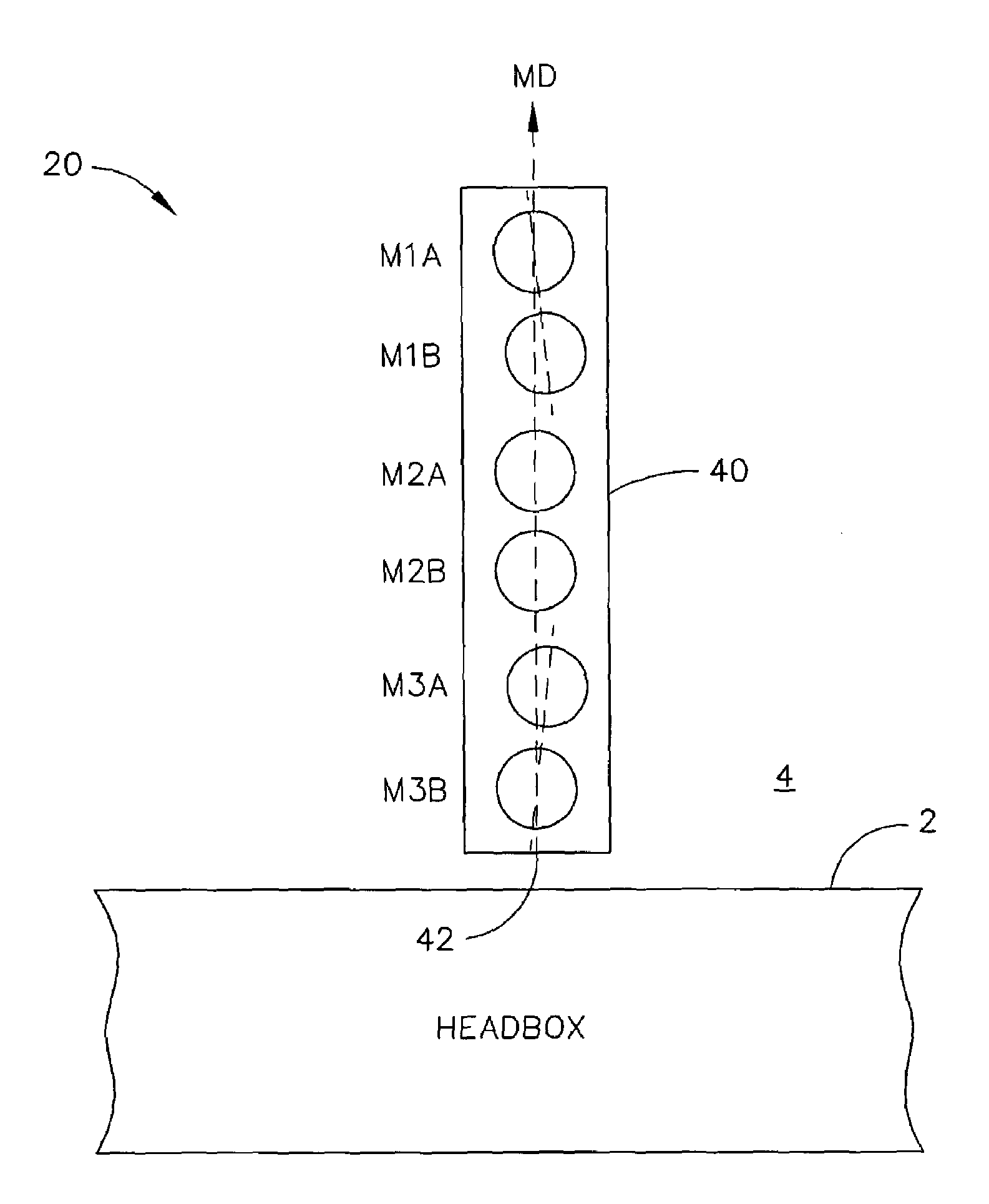

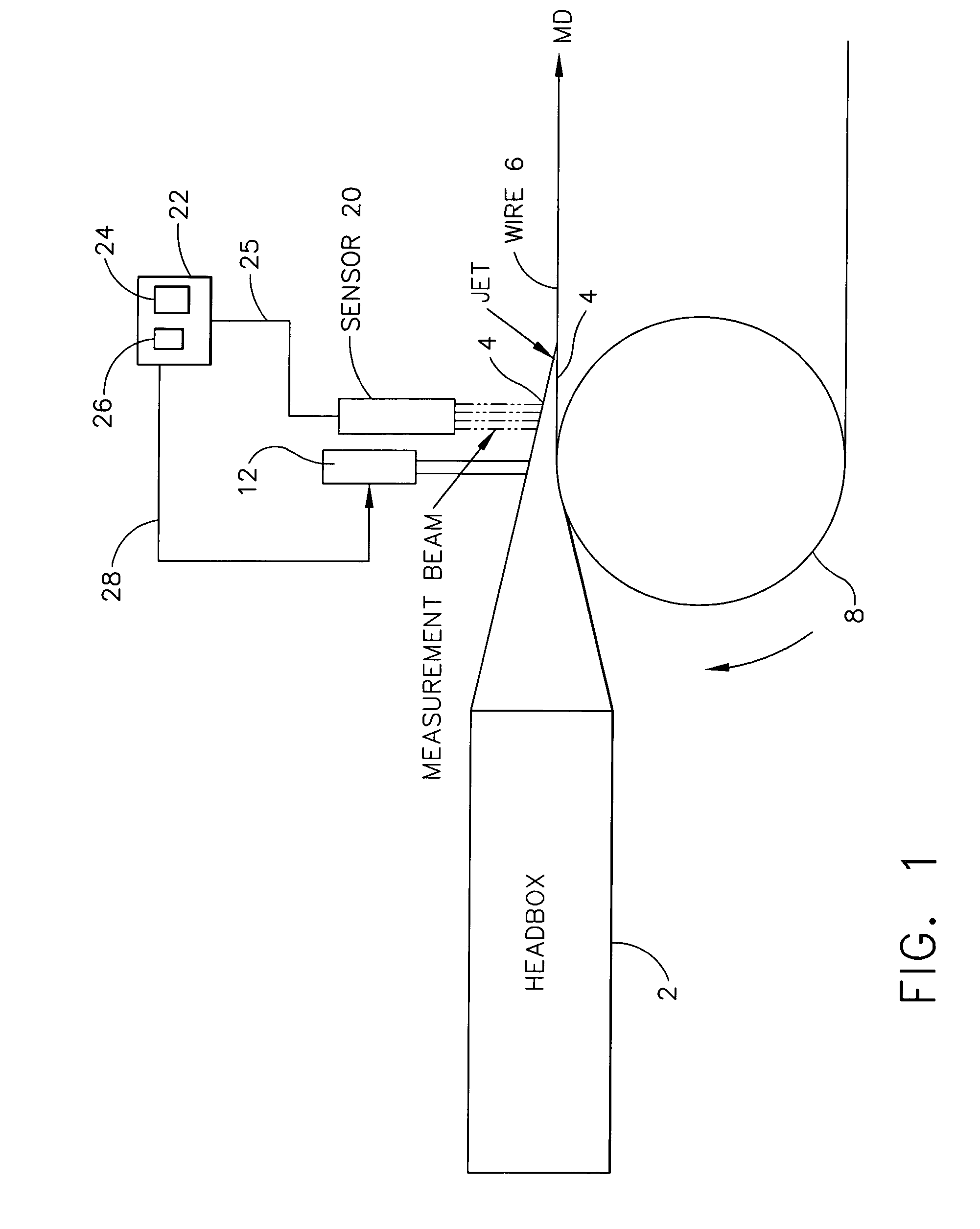

Jet velocity vector profile measurement and control

ActiveUS7399380B2Quickly and accurately determineIncrease speed of resultMachine wet endPaper/cardboardVectranFiber orientation

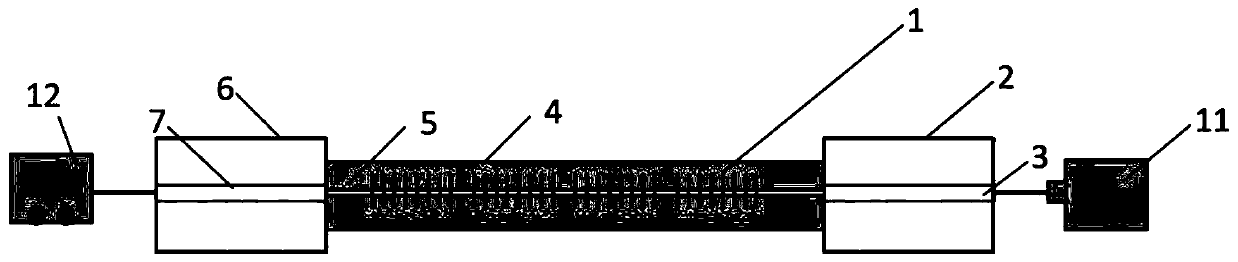

In a papermaking system having a headbox to dispense a jet of liquid and paper forming fibers, an improvement comprising at least one sensor arrangement for simultaneously or sequentially measuring in at least one location the jet velocity or jet flow correlation of the jet at plural known angles relative to the machine direction. The measured data is analyzed to generate a velocity vector profile or velocity direction profile of the jet, and hence to determine the profile of fiber orientation angles laid down in the sheet formed of the jet.

Owner:HONEYWELL INT INC

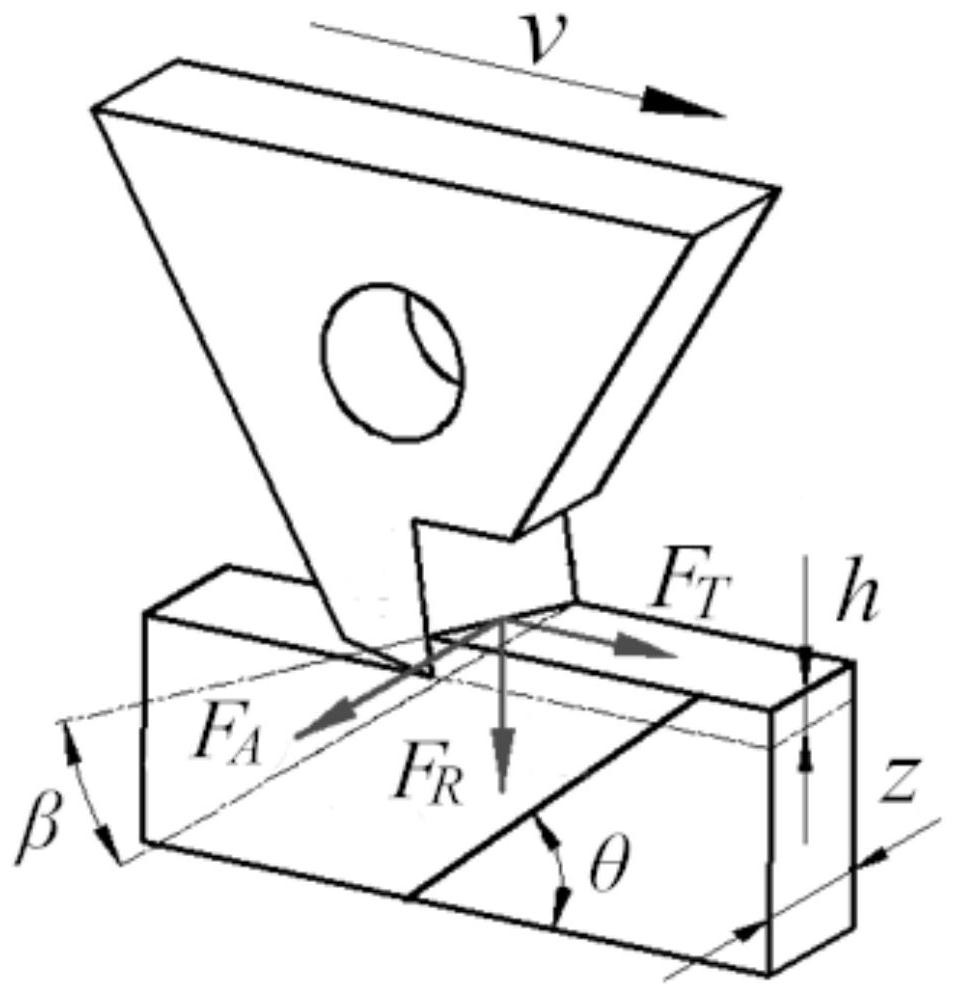

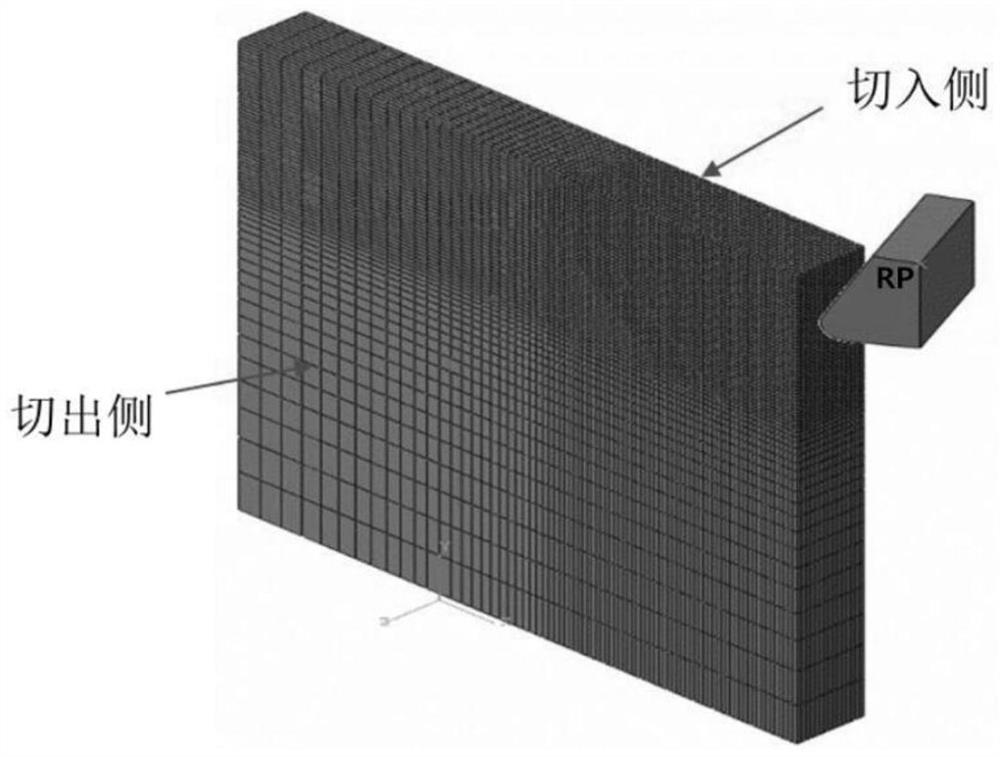

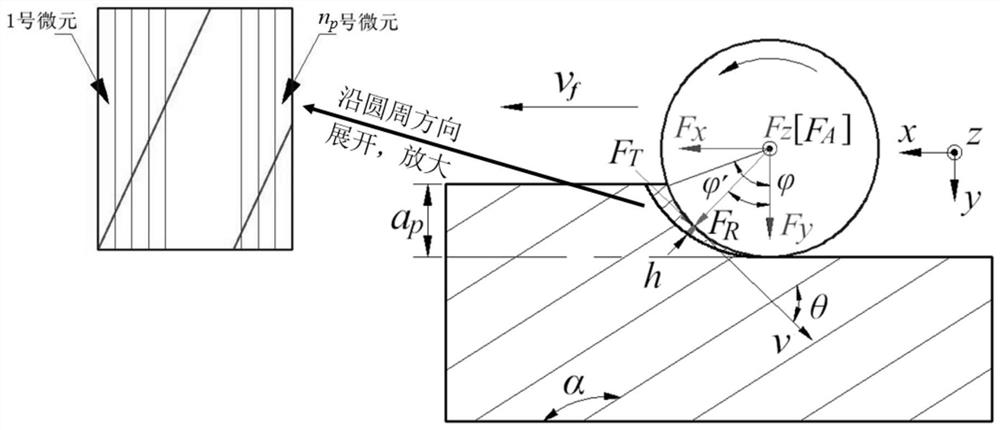

Method for calculating instantaneous milling force of carbon fiber reinforced composite material by considering changes of fiber cutting angle and cutting depth

ActiveCN111666640AIndirect estimated qualityGeometric CADDesign optimisation/simulationMilling cutterVectran

The invention discloses a method for calculating instantaneous milling force of a carbon fiber reinforced composite material by considering changes of a fiber cutting angle and a cutting depth. The method comprises the following steps: firstly, simulating cutting processes with different fiber cutting angles and different cutting depths to acquire a data sample about cutting force, substituting the acquired data sample into an agent model, and establishing a prediction model in which input variables are the fiber cutting angle and cutting depth and output variables are the cutting force, so that the cutting force under other different fiber cutting angles and cutting depths can be predicted. When the instantaneous milling force is calculated, each instantaneous spiral milling cutter cutting edge is dispersed into a plurality of infinitesimal elements along the circumferential direction of the spiral milling cutter cutting edge; the infinitesimal cutting process is approximately regarded as a right-angle cutting process or an oblique-angle cutting process; the cutting force of each section of infinitesimal element is independently calculated according to different fiber cutting angles and cutting depths of the position where each section of infinitesimal element is located; and finally the cutting force of all the infinitesimal elements is added through a coordinate transformation and vector superposition method, so that the milling force of each moment is calculated.

Owner:DALIAN UNIV OF TECH

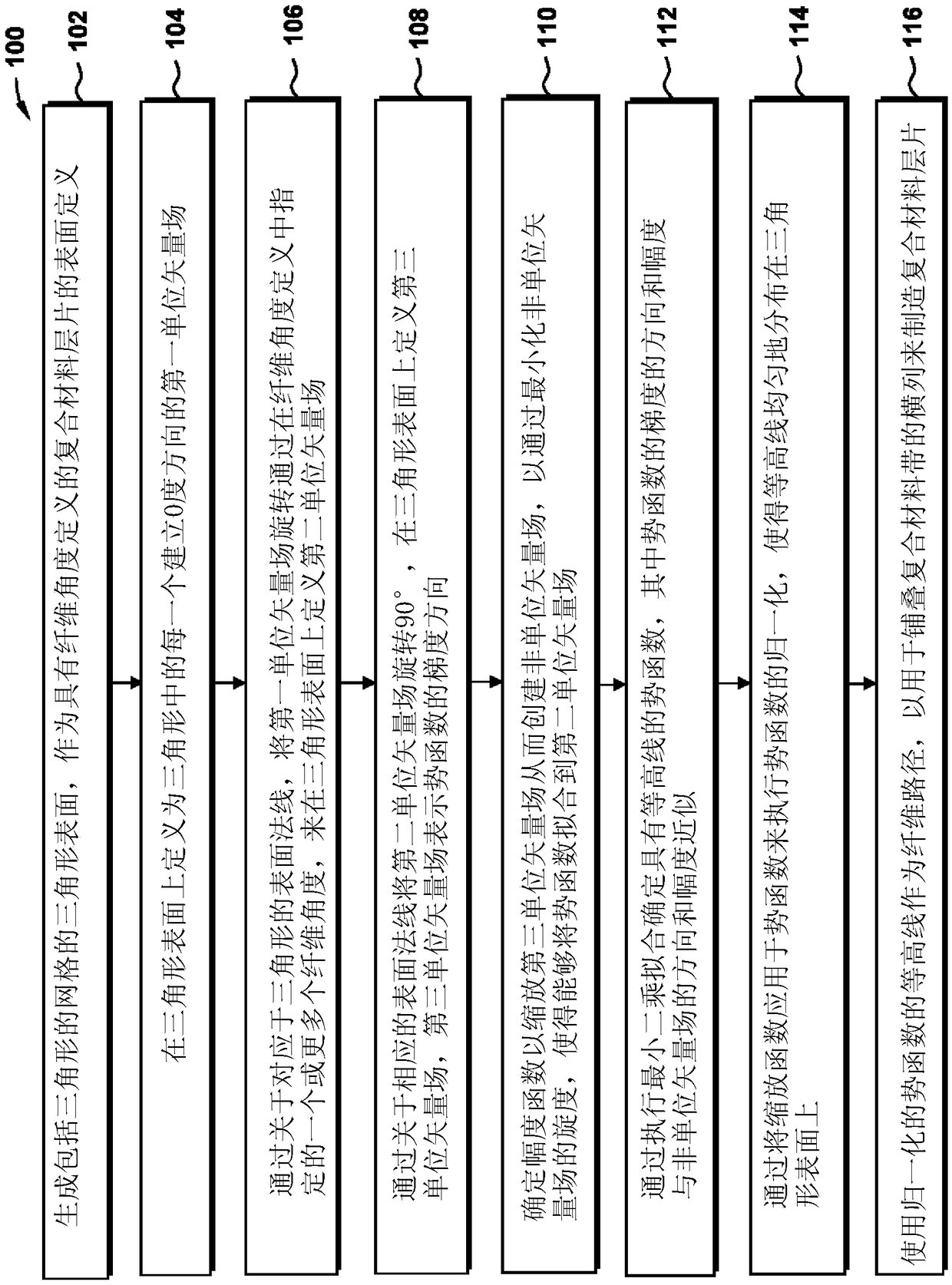

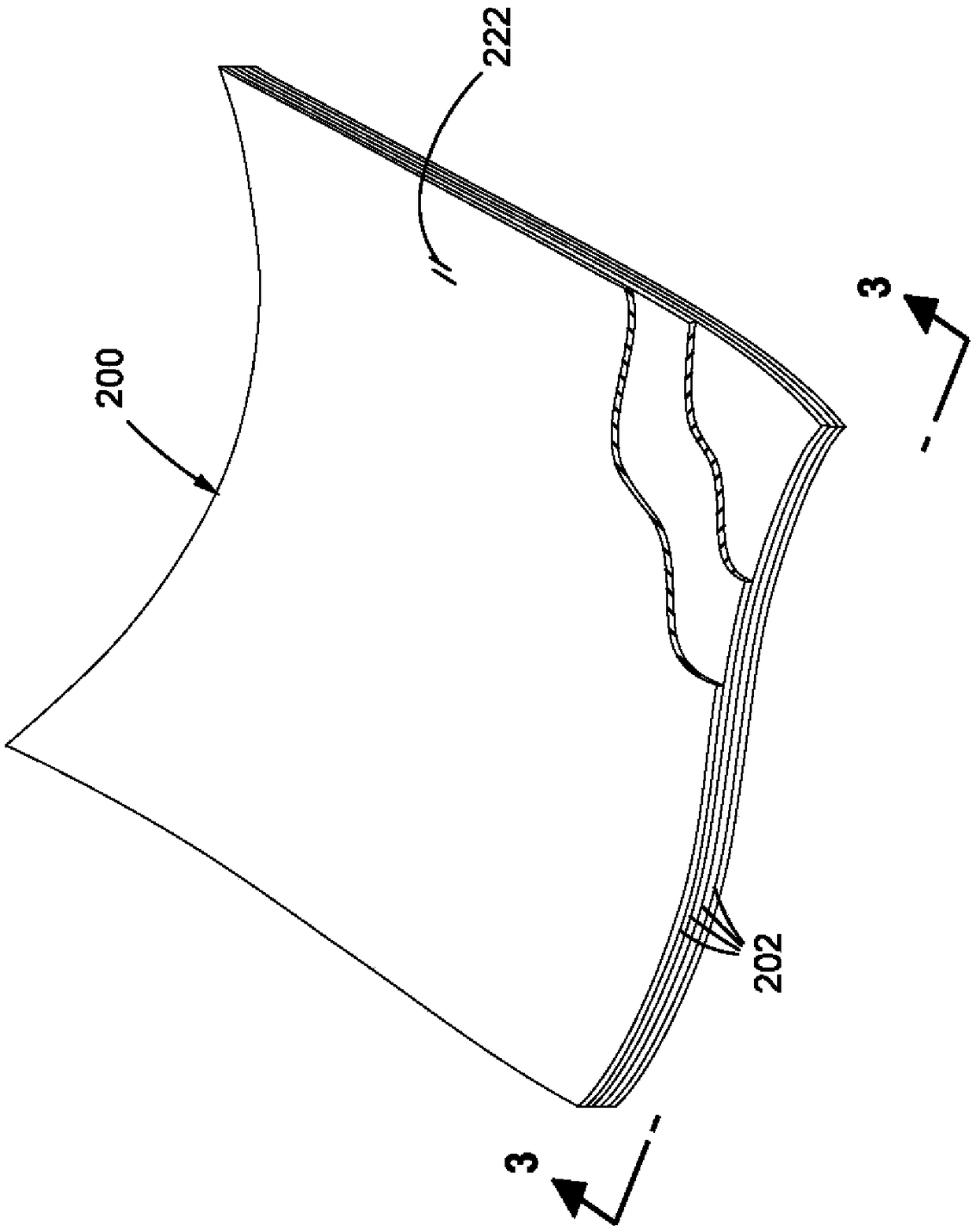

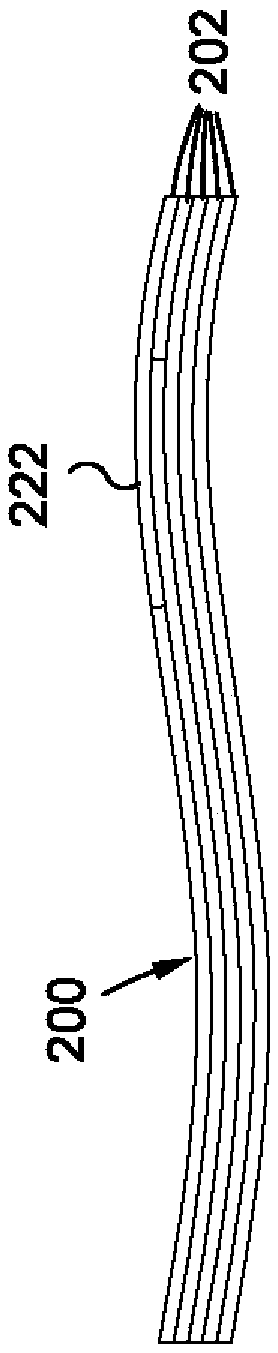

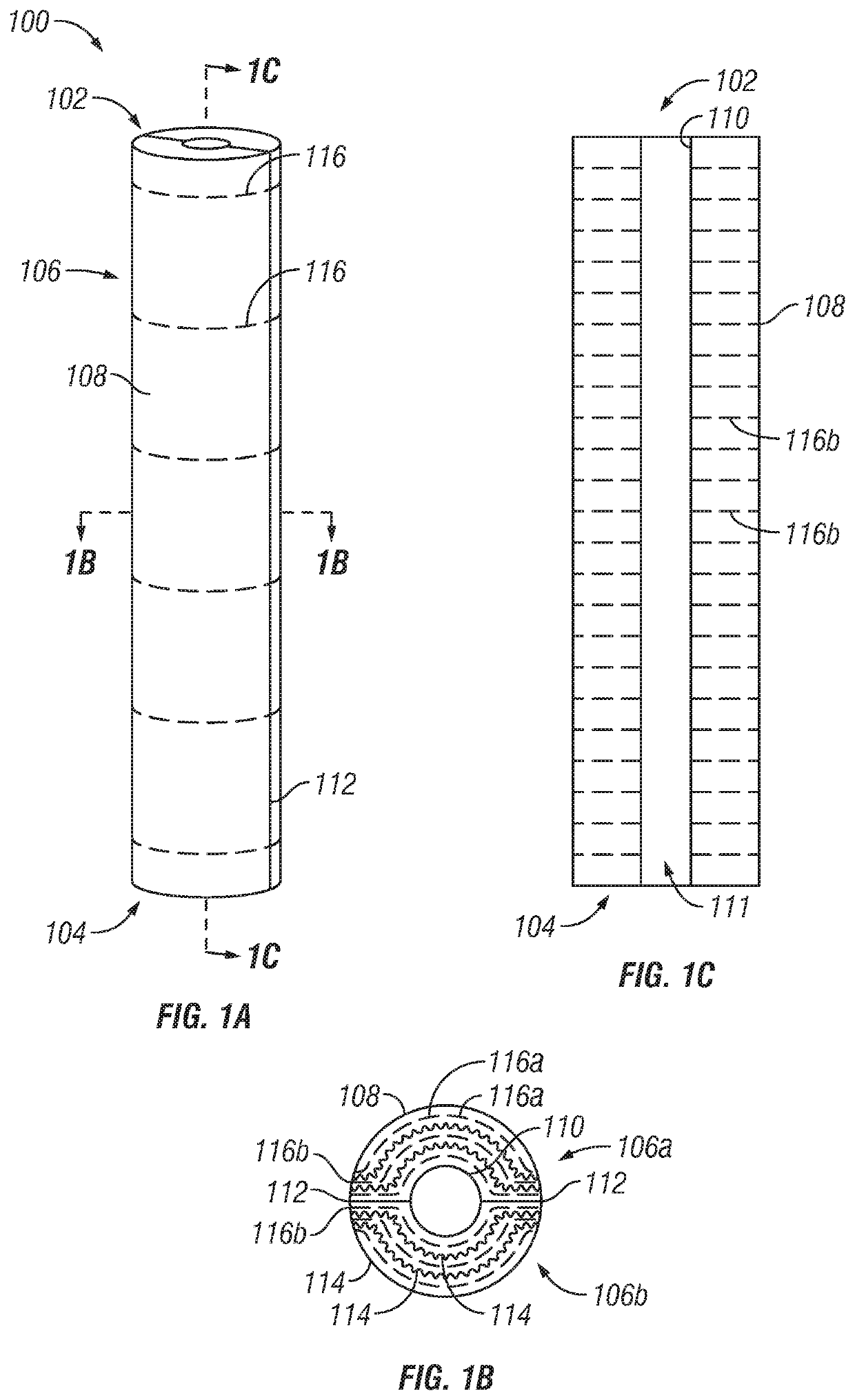

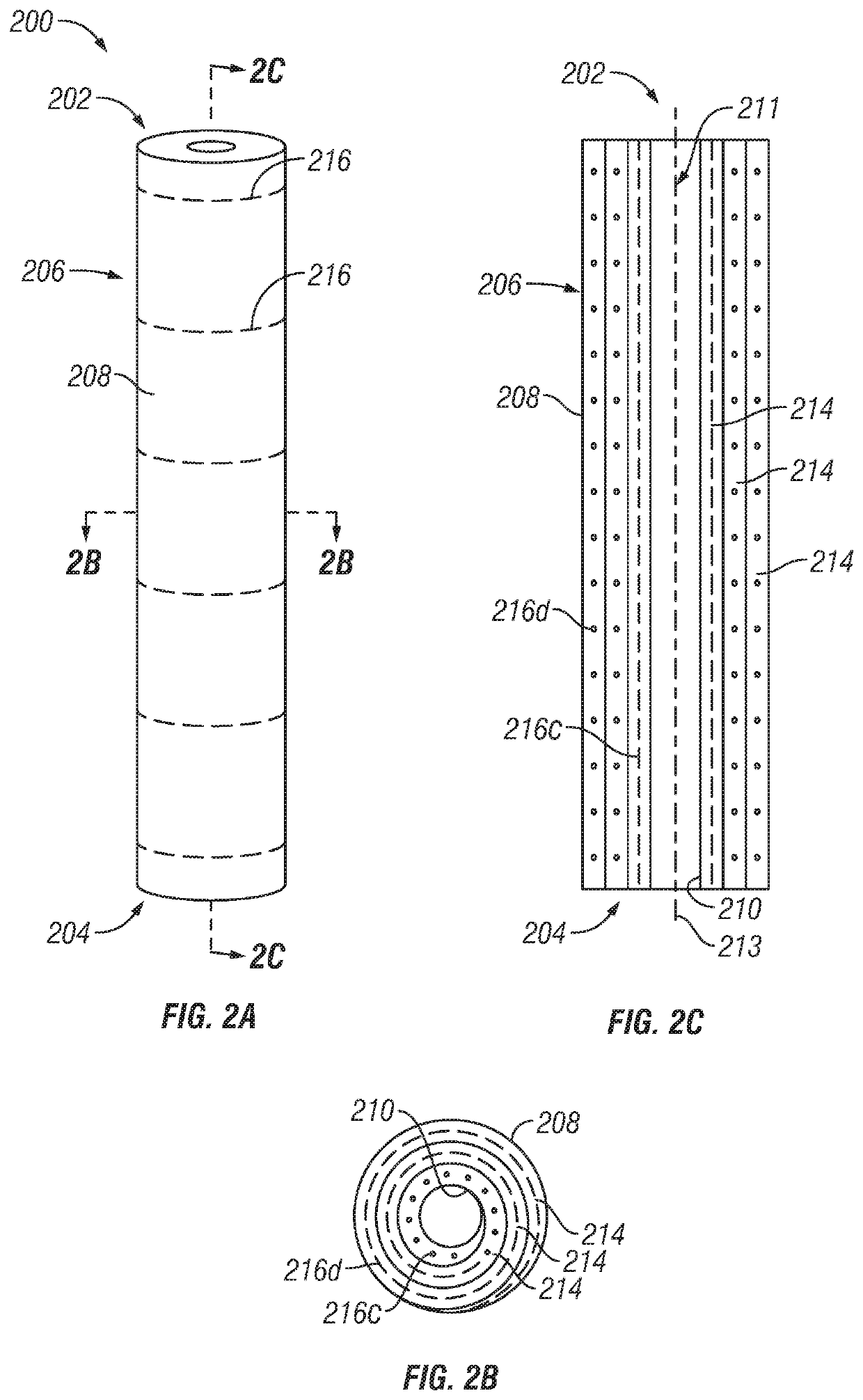

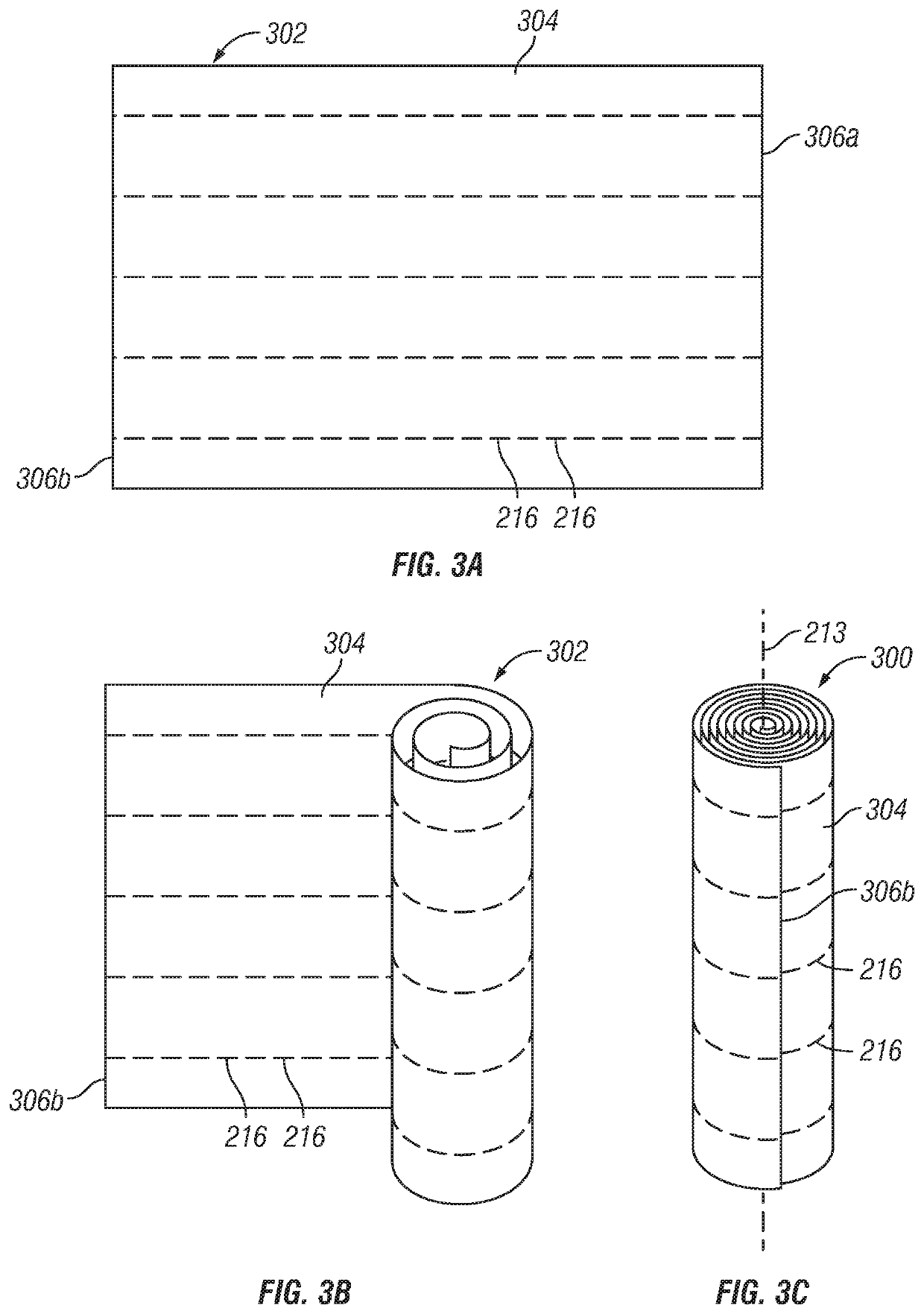

System and method for determining the direction and spacing of fiber paths for a composite ply

A method (100) of determining fibers paths (314) for a composite material layer sheet (202) includes generating a triangulated surface (218) of the composite material layer sheet (202), and defining afirst unit vector field establishing a 0-degree direction (302) for the triangulated surface. A second unit vector field (306) is defined by rotating, through specified fiber angles measured relativeto the 0-degree direction, the first unit vector field about surface normals of the triangulated surface. A third unit vector field representing a gradient direction (308) of a potential function isdefined by rotating the second unit vector field over 90D about the respective surface normals. The third unit vector field is scaled to create a non-unit vector field, and a first potential functionis determined by performing a least-squares fit such that the direction and magnitude of the gradient best approximate the direction and the magnitude of the non-unit vector field. A normalization ofthe potential function uniformly distributes contour lines of the potential function across the triangulated surface. The contour lines are used as fiber paths for laying up courses of composite material to fabricate the composite material layer sheet (202).

Owner:THE BOEING CO

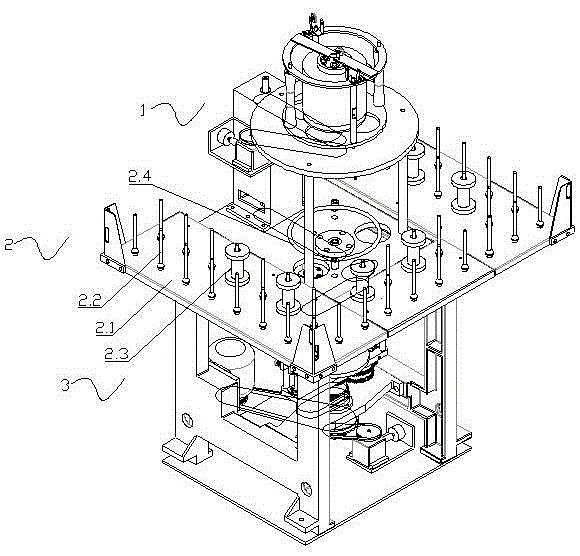

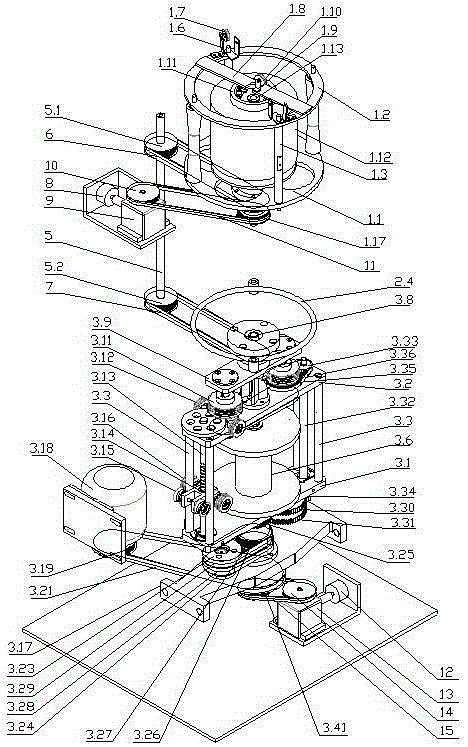

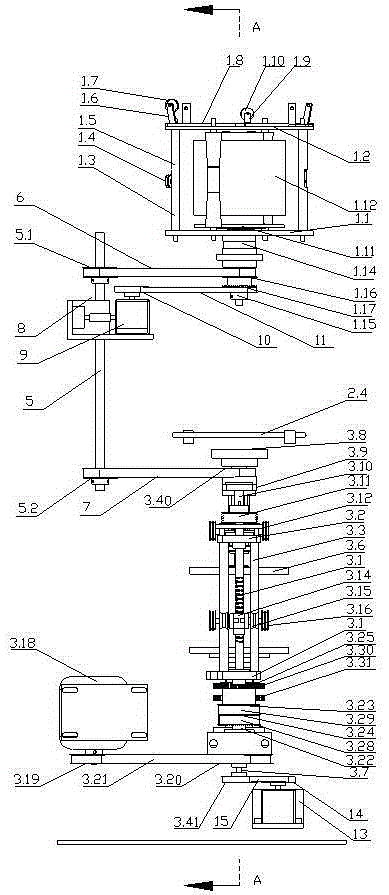

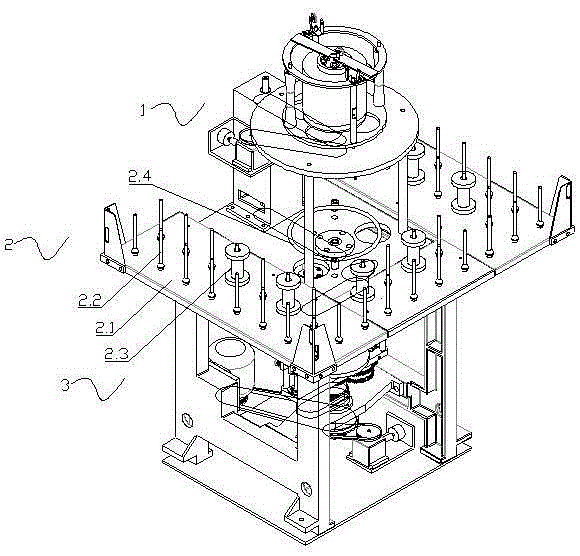

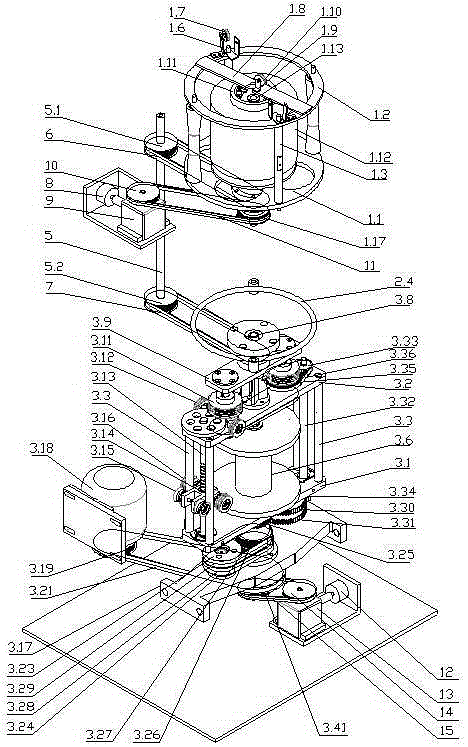

Take-up apparatus

ActiveCN105336442AImprove ductilityImprove bending resistanceCable/conductor manufactureExtensibilityVectran

The invention relates to a take-up apparatus. The take-up apparatus is characterized by comprising a take-up frame, the take-up frame is internally provided with an I-shaped wheel (3.6), an upper rotation wheel (3.5) is successively provided with a take-up die head (3.8) and a support plate (3.9) from top to bottom, vertical top plate support shafts (3.10) are arranged between the two ends of the support plate (3.9) and a top plate (3.2), the two top plate support shafts (3.10) are each fixedly provided with a take-up wheel, a base plate (3.1) at the front side and the rear side of the take-up wheel at the left is each provided with a fixation wire guide roller (3.12), and a wire arrangement apparatus is also arranged between the base plate (3.1) and the left end of the top plate (3.2). The take-up apparatus is used for assembling a wire-coiling machine, and a die head is not extruded when an alloy heating wire is wound on the surface of vectran. Therefore, a finally wound product is good in extensibility, high in surface flatness and good in anti-folding performance.

Owner:江阴神辉电工材料有限公司

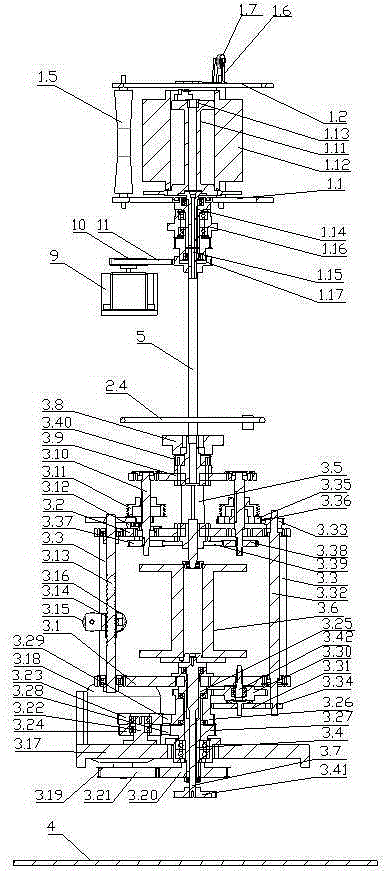

Alloy heating wire pay-off apparatus

ActiveCN105336443AImprove ductilityImprove bending resistanceCable/conductor manufactureExtensibilityVectran

The invention relates to an alloy heating wire pay-off apparatus. The apparatus is characterized by comprising a support bench (2.1), the support bench (2.1) is provided with multiple vertically arranged vertical rods (2.2), the vertical rods (2.2) are sleeved by alloy heating wire pay-off cylinders (2.3), a guide ring spacing collar (2.4) is arranged at the center of the support bench (2.1), and the guide ring spacing collar (2.4) is provided with multiple alloy heating wire guide rings. The alloy heating wire pay-off apparatus is used for assembling a wire-coiling machine, and a die head is not extruded when an alloy heating wire is wound on the surface of vectran. Therefore, a finally wound product is good in extensibility, high in surface flatness and good in anti-folding performance.

Owner:江阴神辉电工材料有限公司

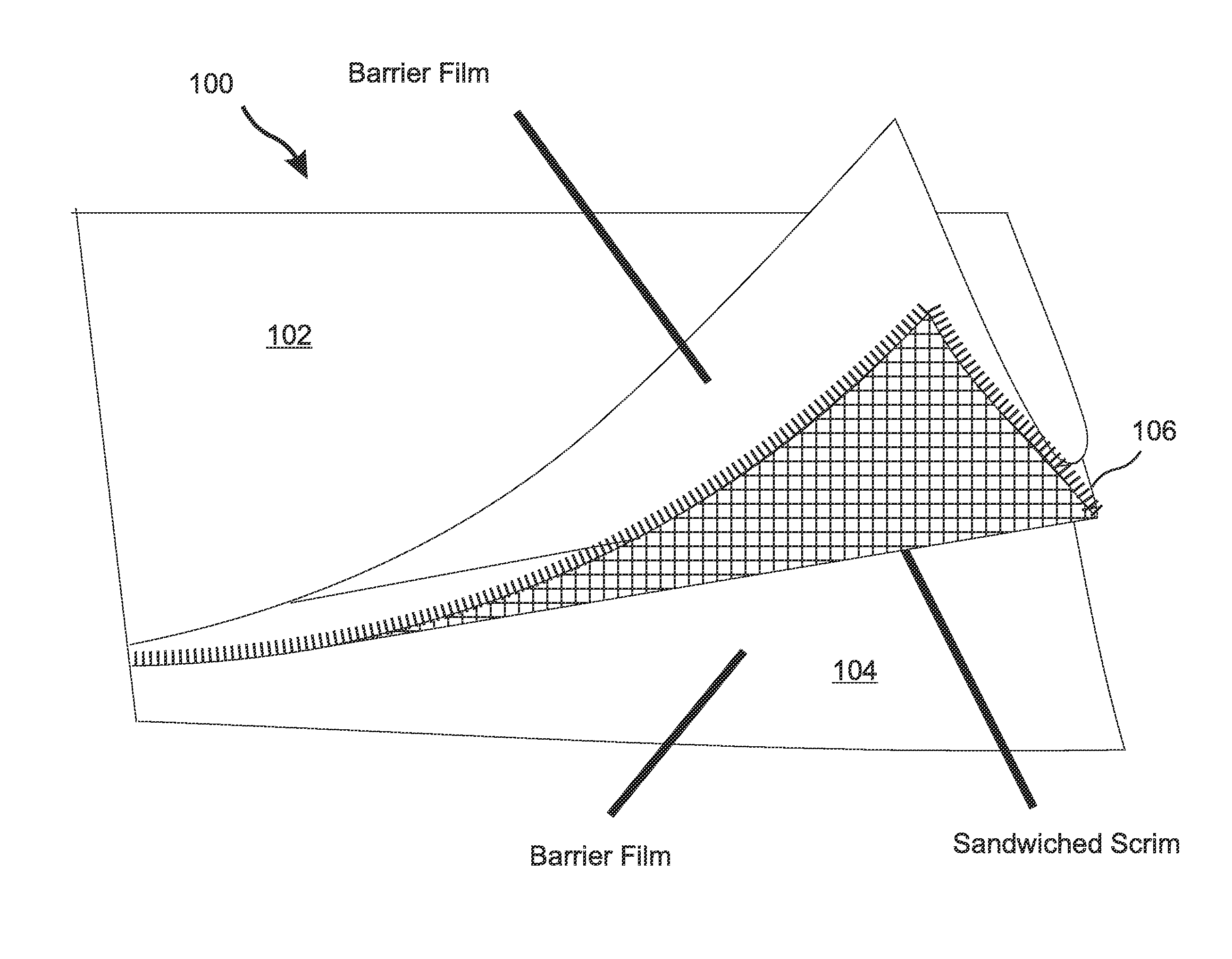

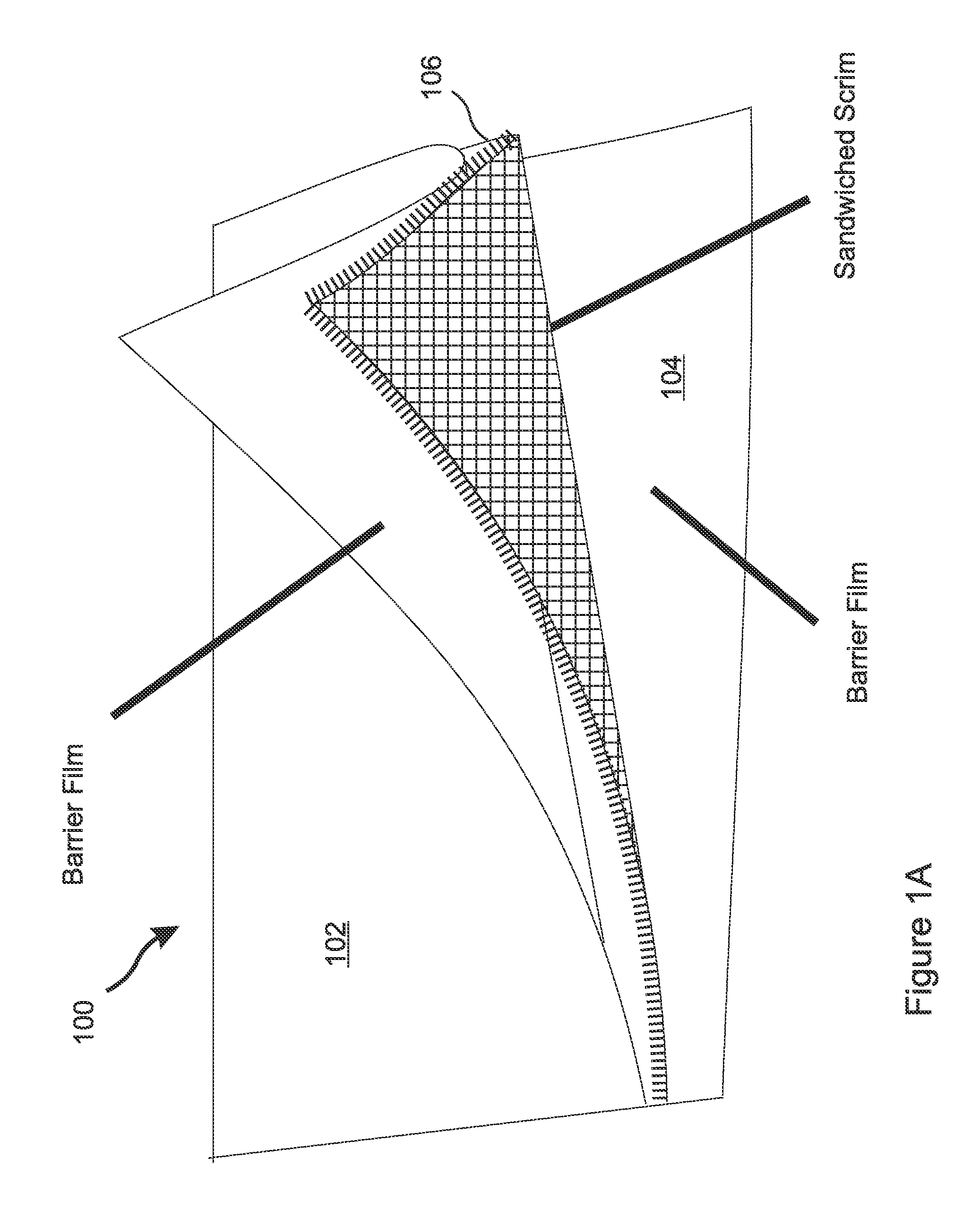

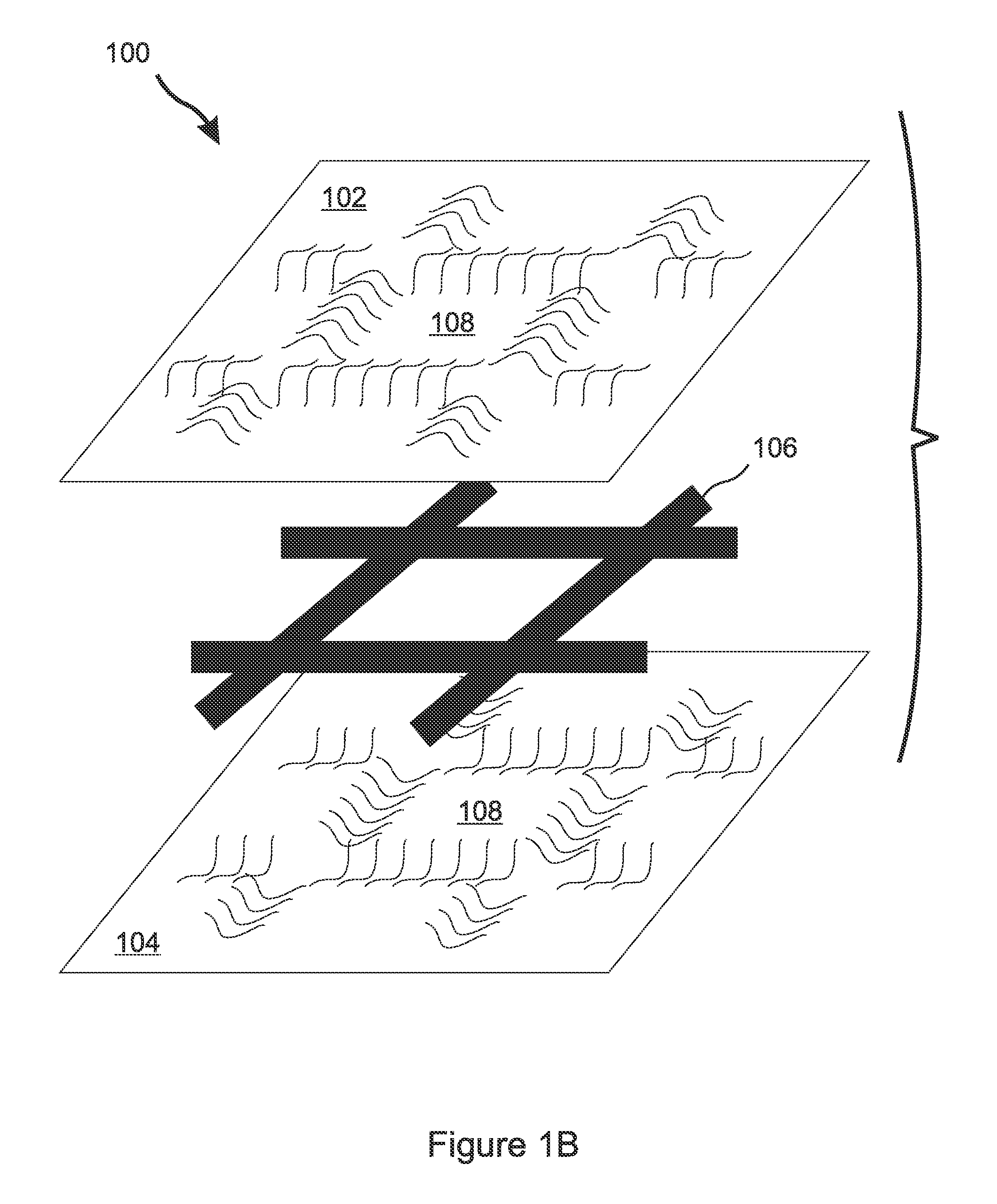

Multi-layer chemical and biological protection fabric for mobile shelters

ActiveUS20140030483A1High tensile strengthMinimizing bulkChemical protectionAdhesive processesYarnWeather resistance

A lightweight, low bulk, mobile CB shelter fabric includes a high tensile strength woven scrim laminated between two thin CB-impenetrable polymer films. Laminate adhesives can include isocyanate adhesion promotors. Coatings can be applied to the films for camouflage, increased light opacity, increased CB protection, sun, fire, and weather resistance. Lamination heat and pressure can cause the films to conform and bond through the scrim, while a pre-applied coating does not flow and remains uniform in thickness. The resulting fabric weight can be approximately 50% of conventional CB fabrics. The films can be hard-drawn polymers. A coating of hammer milled kaolin clay can provide increased light opacity. The films can be 1 micron thick, and can be nylon, aliphatic nylon, urethane, or poly-ether. The scrim can be a 1500 denier vectran with a 4.5 ends-per-inch warp and a 3.5 ends-per-inch fill. The scrim yarns can be flattened bundles of untwisted fiber.

Owner:WARWICK MILLS INC

Concrete structure protective textile weaving

InactiveCN101187097AResolve primary cracksAvoid damageCeramic shaping apparatusWoven fabricsYarnSocial benefits

The invention provides a novel weaving idea of protecting concrete structure grid fence type fabric and process, wherein high strength high mole fabric such as filaments of Vectran and Zylon and the like and high strength nylon fiber are blended into 20-40 yarns, grid fence type fabric whose yarn density is less than 20 lines / 10cm is weaved, thereby being capable of improving the brittle failure characteristics of concrete, reducing the shrinkage crack of the concrete, increasing the toughness and impact resistant wear resistance of the concrete, simultaneously, and being capable of improving the characteristics of the concrete such as anti-permeability and antifreezing and the like. The production cost is low, the weaving process is simple, and the economic and social benefits are excellent.

Owner:SHENGHONG GRP CO LTD

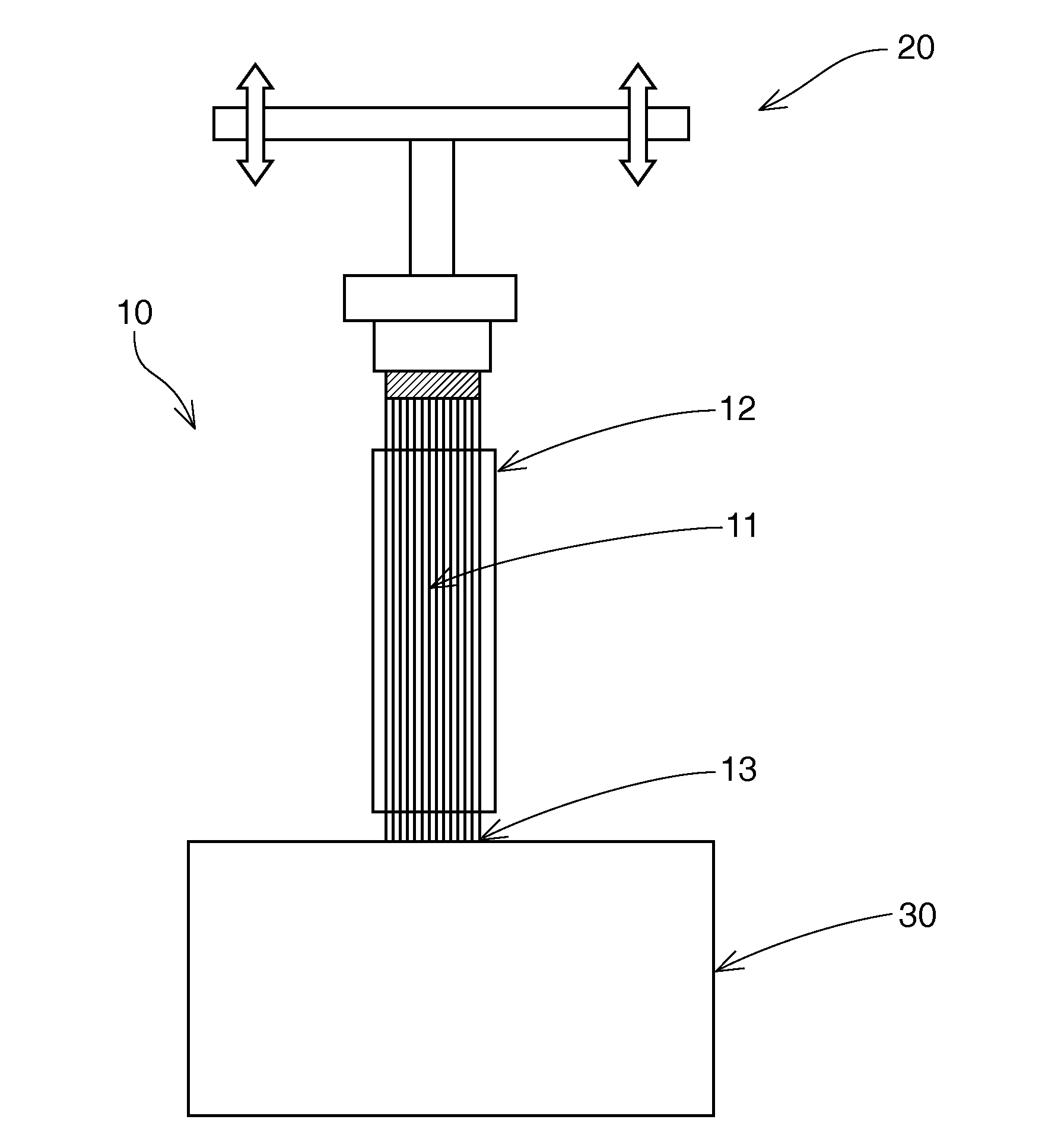

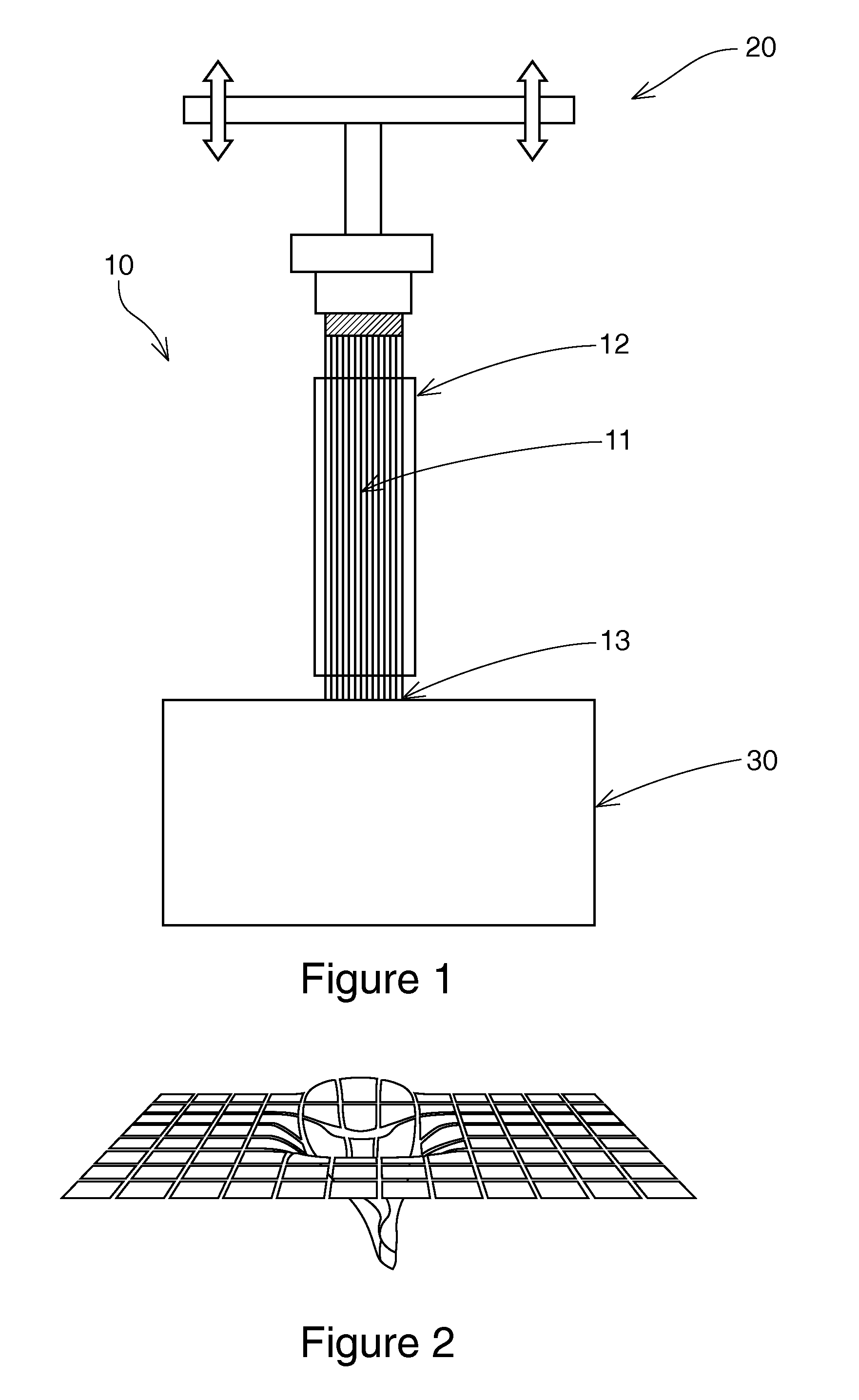

Method for assessment of force properties generated by the fiber tip

InactiveUS8607629B2Reduce stimulationData processing applicationsDiagnostic recording/measuringFiberTactile sensor

A method for assessment of force properties generated by the fiber tip of one or more fibers, comprising the steps of: (a) providing a fiber sample of one or more fibers, the fiber sample having a free portion and an end; (b) suspending the fiber sample over a tactile sensor at least 0.1 mm away in the vertical direction from the tactile sensor; wherein the fiber sample or the tactile sensor is connected to a means for vertically moving either the fiber sample or the tactile sensor toward each other; (c) surrounding the free portion of the fiber sample with a cover which surrounds the free portion over some length of the free portion and stably positioned; wherein the cover guides the direction of the free portion in a more or less vertical orientation through the steps hereof; (d) vertically moving the fiber sample or the tactile sensor such that the end of the fiber sample contacts the tactile sensor; (e) providing the tactile sensor with means for measuring the distribution of force vectors generated by the contact of the end of the fiber sample; and (f) assessing the force properties based on the distribution of force vectors.

Owner:PROCTER & GAMBLE CO

Fluid thrust vector exciter

InactiveCN113955088AReasonable designLight in massDrag reductionAir-flow influencersGas compressorFlight vehicle

The invention relates to the technical field of flow lift enhancement and drag reduction of aircrafts, and particularly discloses a fluid thrust vector exciter which comprises a machine body, a bistable diaphragm, an excitation piece and two Tesla one-way valves, the machine body is provided with a cavity with an opening, and the cavity is provided with a fluid inlet and a fluid outlet; the bistable diaphragm is fixedly sealed at the opening of the cavity; the excitation piece is a piezoelectric composite fiber membrane, is attached to the bistable membrane, and drives the bistable membrane to realize modal transformation under the action of alternating voltage, so that the volume of fluid in the cavity is changed; the two Tesla one-way valves are respectively communicated with the fluid inlet and the fluid outlet; the fluid thrust vector exciter has the advantages of being light, thin and compact in structure, free of mechanical connecting rod moving parts and the like, can be flexibly arranged in the rear edge of the wing, changes local lifting resistance of the wing, forms pitching or rolling torque, forms fluid thrust vector control, can also play a role of the gas compressor and can be used for blowing and sucking gas in a boundary layer.

Owner:中国空气动力研究与发展中心设备设计与测试技术研究所

Preparation method for fiber composite material reinforcing strip

The invention provides a preparation method for a fiber composite material reinforcing strip and relates to a preparation method for an inflating extending arm reinforcing strip. By the preparation method, the problems that the elastic reinforcing steel strip in the conventional charging extending arm is magnetized easily and the unit mass is high are solved. The preparation method for the fiber composite material reinforcing strip comprises the following steps of: 1, paving bottom layer Vectran fiber cloth; 2, brushing epoxy resin glue on the surface of the bottom layer Vectran fiber cloth; 3, paving interlayer carbon fiber cloth; 4, brushing epoxy resin glue on the surface of the interlayer carbon fiber cloth; 5, paving upper layer Vectran fiber cloth; 6, placing the three layers of composite fiber cloth into a special die, placing into a constant-temperature chamber, heating and curing; and 7, cutting the cured three layers of composite fiber cloth to obtain the fiber composite material reinforcing strip. The preparation method for the fiber composite material reinforcing strip has a simple process. The reinforcing strip has corrosion resistance, ageing resistance, light weight, high straightness and high tensile strength and bending rigidity, and is not magnetized. The fiber composite material reinforcing strip is applied to the charging extending arm.

Owner:HARBIN INST OF TECH

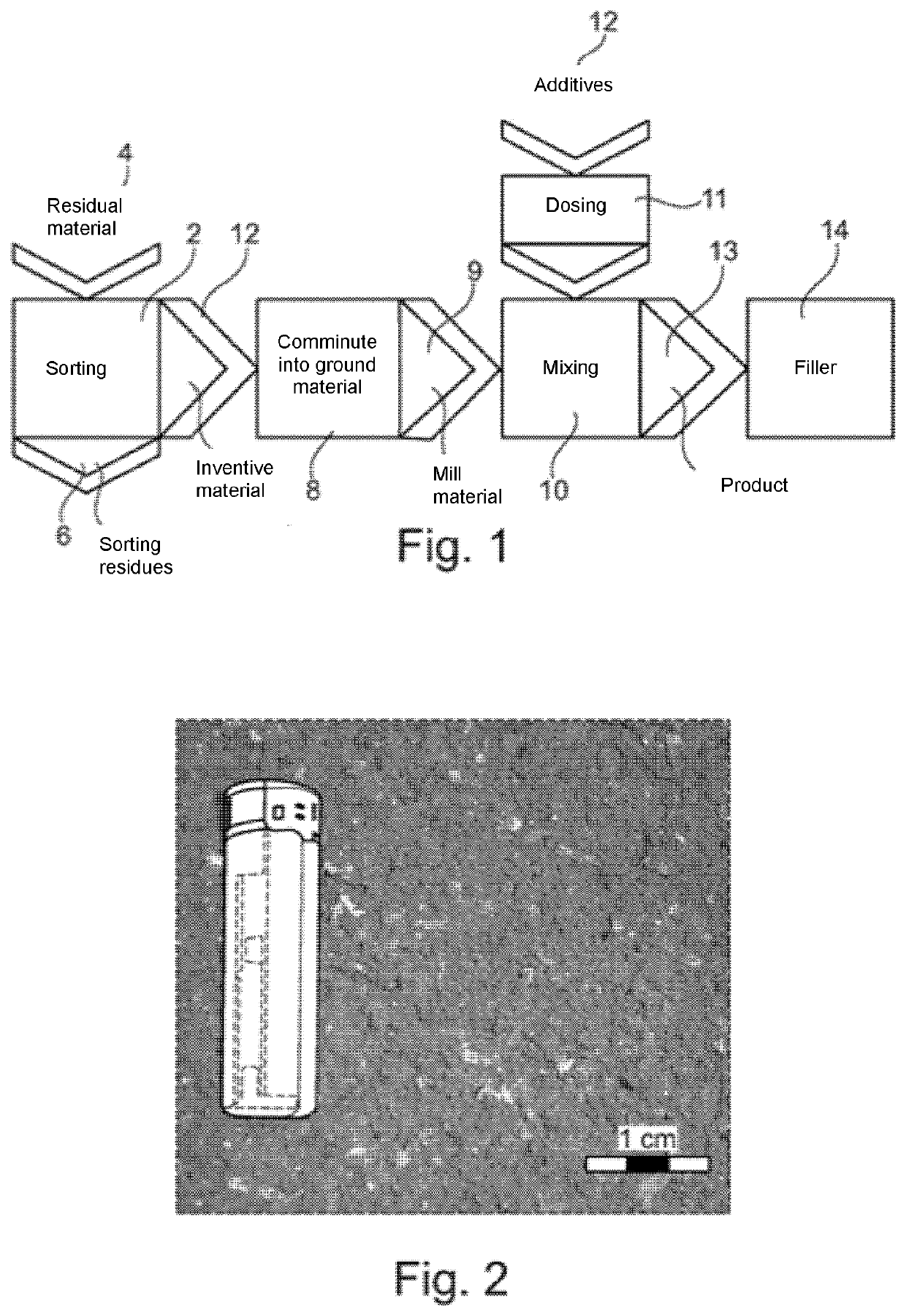

Filler Made from Sorted Waste Materials for the Production of Cement-bound Shaped Bodies

PendingUS20210340064A1Reduced oxygen partial pressureAvoid spreadingSolid waste managementAuxillary shaping apparatusPaperboardProcess engineering

A filler for production of cement-bound shaped bodies, comprising a material group mixture of comminuted and sorted waste materials, conditioned with chemical reagents / compounds in the presence of water, wherein the material group mixture is composed of comminuted and sorted waste materials, selected from the following material groups:PPK: paper, paperboard, cardboardplasticsinert materialtextileswoodwhich are mixed according with a mass-related material group vector and then comminuted.

Owner:TERION

Visually dynamic multi-layer elastomeric materials

ActiveUS20200079048A1Large capacityImprove utilizationTransportation and packagingSynthetic resin layered productsRelative motionVectran

The present disclosure provides a multi-layer system including at least two or more parallel layers of thin material unconnected within a layer but joined together by at least two opposing edges that are in series with an anticipated vector of mechanical force. Each layer includes two or more materials of different elasticities that are arranged in series with respect to the two fixed ends of the material. Each layer can possess a unique spatial arrangement of the different elastic segments. The relative movement of the material layers provides patterns within one or more of the layers that reveal colors, spaces, or patterns in the underlying layers depending on the amount of tension across the material. This allows for the dynamic change in outward appearance of the material with the increase and decrease of force.

Owner:DOW ELIOT

Wave-absorbing heat-conducting gasket and preparation method thereof

ActiveCN114525036AExcellent thermal conductivity and absorbing performanceChemical industrySynthetic resin layered productsPolymer scienceSucrose

The invention discloses a heat-absorbing and heat-conducting gasket and a preparation method thereof, and the heat-absorbing and heat-conducting gasket is prepared by constructing a 3D heat-conducting channel in a liquid nitrogen directional freezing manner to prepare aerogel and then pouring liquid silicone rubber. The heat-conducting filler main body is h-BN with good heat-conducting property, the wave-absorbing filler main body is rGO, and the h-BN and the rGO are combined together through chemical bonds; h-BN and cane sugar have hydroxyl groups on the surface after ball milling, rGO has carboxyl groups on the surface after being treated by H2SO4, and the hydroxyl groups and the carboxyl groups are combined together through chemical bonds after reacting. The wave-absorbing and heat-conducting gasket shows excellent heat-conducting and wave-absorbing properties in the direction perpendicular to the gasket under the condition of extremely low filler filling amount (15wt%). Tests are carried out according to the ISO 22007-2 standard, the heat conductivity coefficient of the wave-absorbing heat-conducting gasket is larger than or equal to 2.0 W / m.K, the effective absorption bandwidth (RL is smaller than or equal to-10 dB) of the wave-absorbing heat-conducting gasket can reach 7.5 GHz when the thickness of the wave-absorbing heat-conducting gasket is 2 mm through testing of a vector network analyzer, and the wave-absorbing heat-conducting gasket shows excellent heat-conducting and wave-absorbing performance.

Owner:南京冠旭新材料科技有限公司

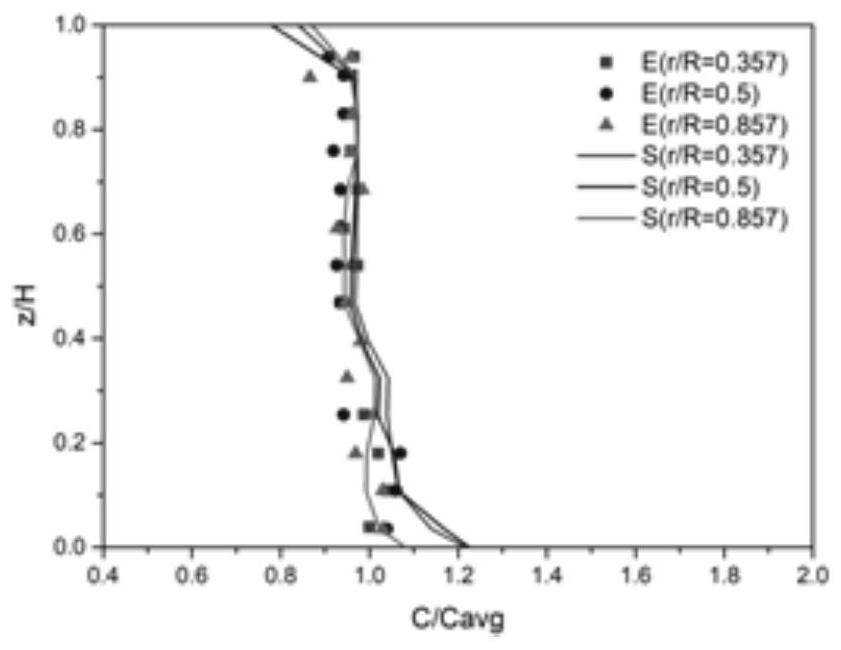

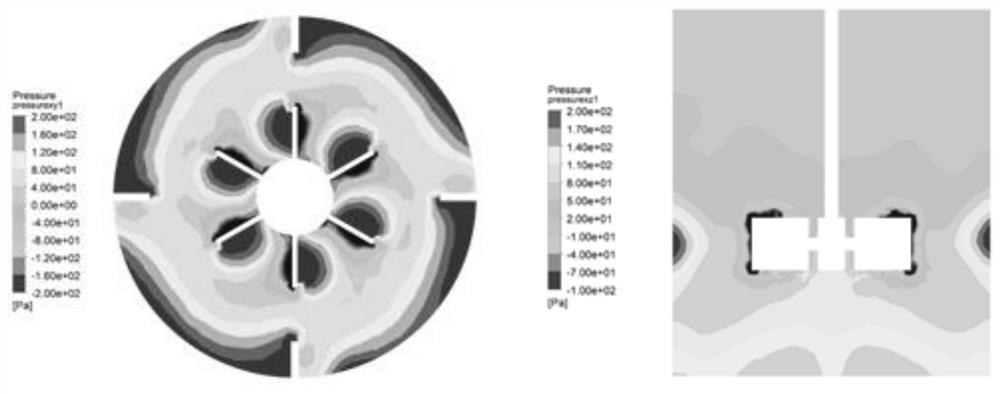

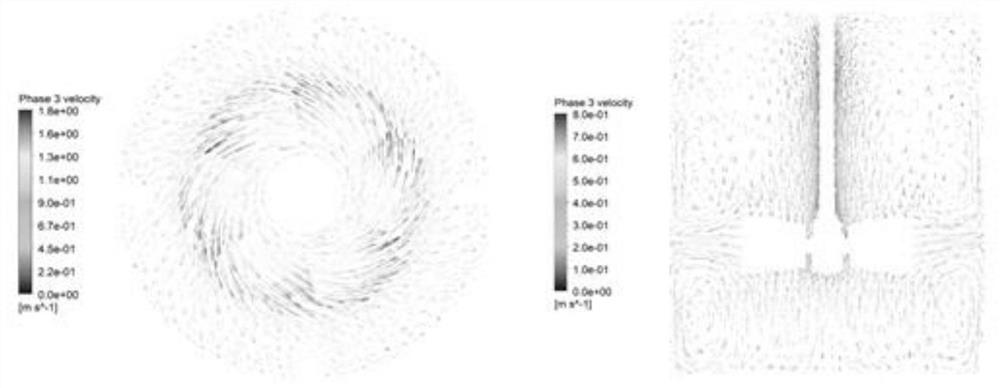

Method for adding particles in composite material and particle adding device

ActiveCN113627057APrevent regurgitationAvoid particle cloggingDesign optimisation/simulationSpecial data processing applicationsInternal pressureMaterials preparation

The invention relates to the technical field of composite material preparation, in particular to a method for adding particles in a composite material and a particle adding device. The method comprises the following steps: obtaining a velocity vector distribution result and a pressure field distribution result in a mixing device for mixing the base material and the particles through numerical simulation calculation; selecting an area which simultaneously meets the conditions (1) and (2) as an inlet for particles to enter the mixing device, wherein (1) refers to that the internal pressure of the mixing device is a negative value; and (2) refers to an area with a relatively high shearing speed. According to the method, the particles can smoothly enter the mixing device, the contact time of the particles and air can be shortened, and the problem of oxidation slag inclusion is solved; and the problems of suck-back and particle blockage of the mixing device at the outlet of the pipeline for transporting the particles can be effectively avoided. In addition, the particles entering the mixing device can be subjected to a strong shearing effect, and dispersion of the particles is promoted.

Owner:GUANGDONG INST OF NEW MATERIALS

High strength racquet string

A high strength racquet string includes a monofilament core and a plurality of strands braided around the monofilament core in opposite directions. The same number of strands are braided clockwise as braided counterclockwise. The plurality of strands are not bonded to the monofilament core along a length thereof, but are bonded to each other at opposing ends to prevent unraveling of the plurality of strands. A coating is not applied to the high strength racquet string. A cross-sectional shape of the monofilament core and the plurality of strands is preferably round or substantially round. The monofilament core is preferably fabricated from nylon, polyester, polyethylene or any other suitable material. The plurality of strands are preferably fabricated from Spectra, Vectran or any other suitable material. An outside diameter of the high strength racquet string preferably ranges from 1.0 mm to 1.5 mm.

Owner:LAMBO ANTHONY P

Preparation method of alpha-Fe2O3 conductive polyaniline composite material

The invention provides a preparation method of an alpha-Fe2O3 conductive polyaniline composite material. The preparation method comprises the following steps: by using ferric chloride hexahydrate, sodium acetate, ethylene glycol and the like as main raw materials, synthesizing granular alpha-Fe2O3 by using a hydrothermal method, and compounding the granular alpha-Fe2O3 with conductive polyanilineto prepare the composite material with microwave and infrared wave-absorbing properties. An XRD performance test proves that the synthesized material has high crystallinity. The morphology characterization of the material is carried out through SEM, and a characterization result proves that the synthesized alpha-Fe2O3 is granular, and the alpha-Fe2O3 conductive polyaniline compound is of a core-shell structure. A wave-absorbing performance test is carried out on the compound through a vector network instrument, and it is proved that the compound has good wave-absorbing performance in microwaveand infrared bands and has high practical application value. The alpha-Fe2O3 conductive polyaniline composite material has good application prospects in the fields of microwave and infrared absorption materials, electromagnetic protection and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

Light wear-resistant multifunctional composite power single rope and manufacturing method thereof

An embodiment of the invention discloses a light wear-resistant multifunctional composite power single rope. The power single rope comprises a composite rope core and a rope skin which wraps the outside of the composite rope core, wherein the composite rope core is formed by compounding a first rope core fiber and a second rope core fiber, and the rope skin is formed by combining the first rope skin and the second rope skin at intervals in the axial direction of the power single rope. The first rope core fiber is a polyamide fiber, the second rope core fiber is a high-strength low-elongation fiber, and the first rope core fiber and the second rope core fiber are parallel, plied and compounded or braided and compounded to obtain the composite rope core; the rope skin is formed by weaving composite fiber strands, the first rope skin is formed by weaving with the pitch of 25-30 mm, and the second rope skin is formed by weaving with the pitch of 32-40 mm; the composite fiber strands are formed by compounding the polyamide fiber with the high-strength low-elongation fiber according to the number ratio of 4: 1; and the high-strength low-elongation fiber comprises one or a combination ofmore than one of ultra-high molecular weight polyethylene fiber, Vectran fiber, aramid fiber, carbon fiber and glass fiber.

Owner:SHANDONG ROPE TECH CO LTD +1

Molded tool and a method of manufacture

A molded tool is formed from a compression mold material and a corresponding method of manufacture is disclosed. The molded tool has a first end, a second end separated from the first end by a sidewall formed from a heat-sensitive polymeric matrix. The sidewall has an interior surface with a first strength and an exterior surface with a second strength, the first strength being greater than the second strength. Further, the molded tool is formed by a method that includes exerting an expansive force within an interior of the compression mold material, the expansive force having a directional vector along the central axis.

Owner:WELLS FARGO BANK NAT ASSOC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com