Gas rib suitable for large inflatable boat/hangar

A technology of inflatable boats and air ribs, which is applied in the direction of building types, tents/canopies, buildings where cars are parked, etc., to achieve the effect of restraining deformation, improving overall rigidity, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A kind of air rib applicable to the large inflatable boat / hangar of the present invention will be further described below in conjunction with the accompanying drawings and a specific embodiment, so as to help understand the content of the present invention.

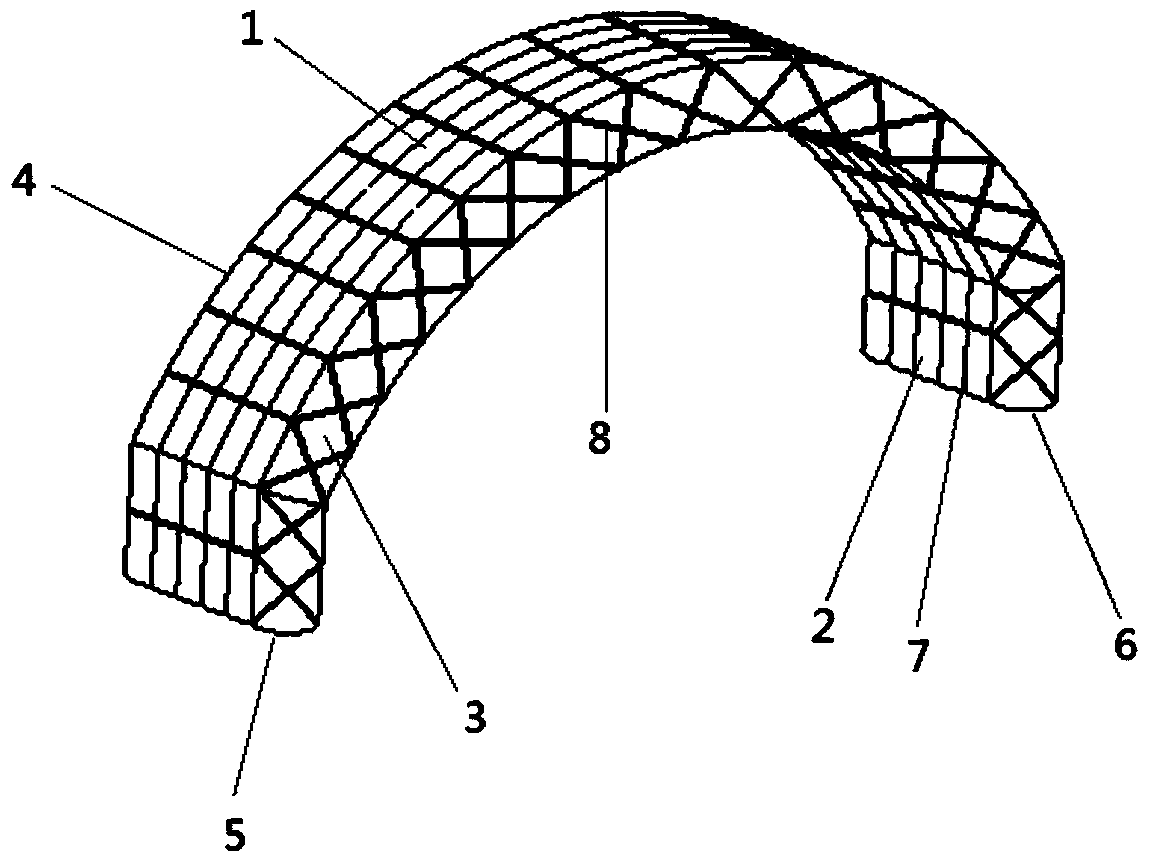

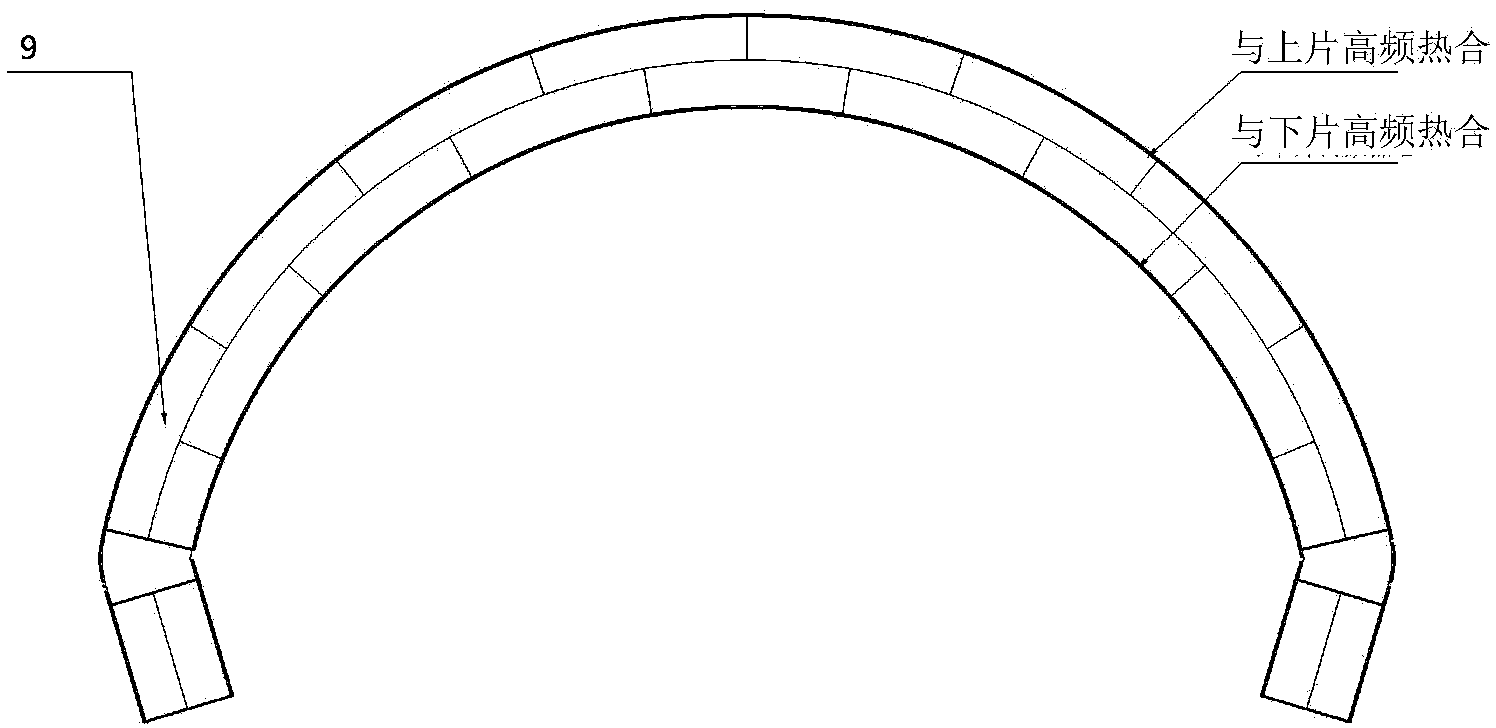

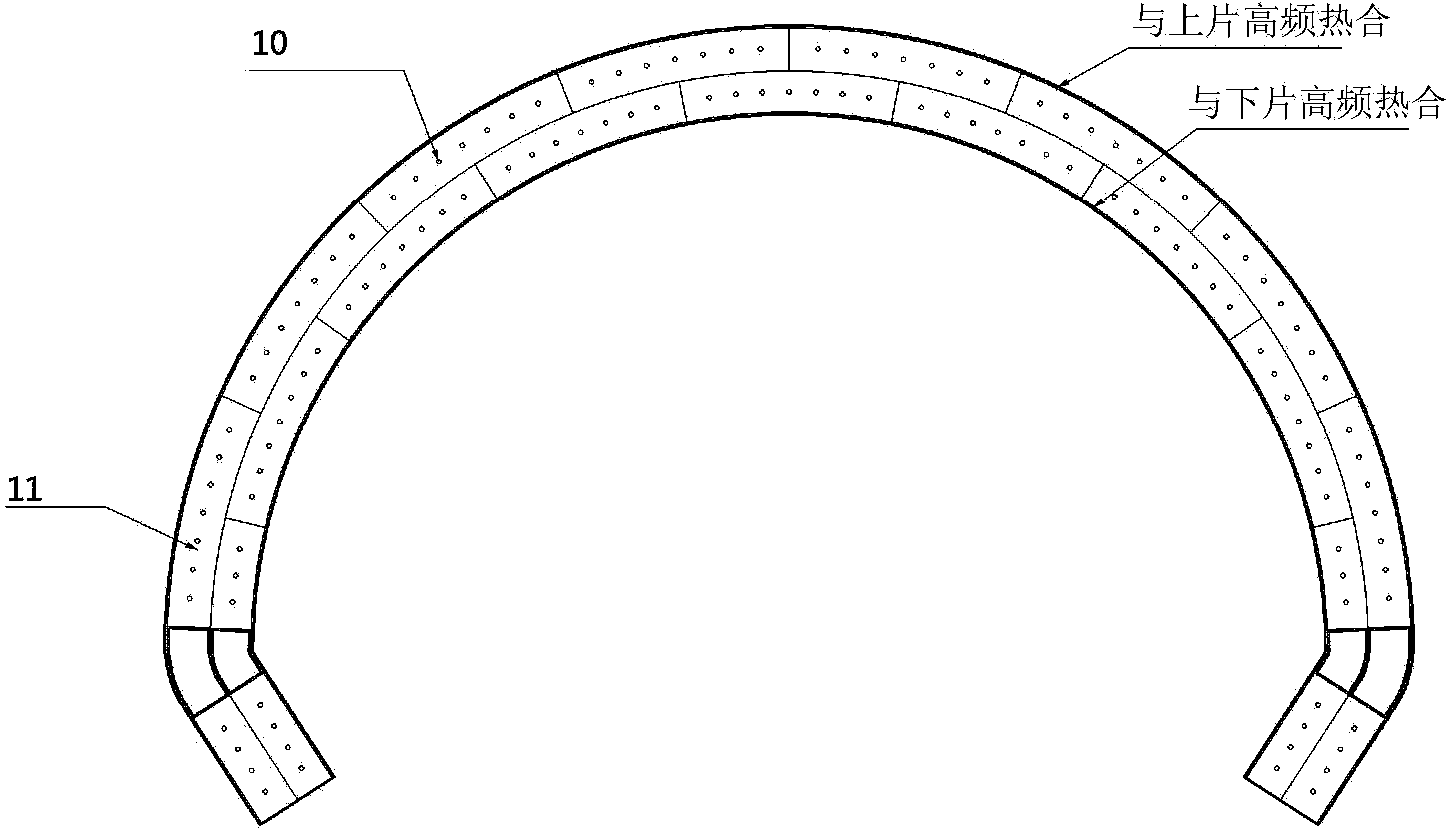

[0029] Such as figure 1 As shown, the air ribs suitable for large inflatable boats / hangars are welded by the front face 3, the rear face 4, the upper piece 1, the lower piece 2 and two bottom surfaces (left bottom surface 5 and right bottom surface 6) , the front end surface 3 is opposite to the rear end surface 4, the upper piece 1 is opposite to the lower piece 2, the front end surface 3, the rear end surface 4, the upper piece 1 and the lower piece 2 form an arched cavity, and the two A bottom surface closes the arched cavity; the air rib is provided with a reinforced drawstring 7, and a reinforced mesh 8 is arranged on the outside, and the reinforced mesh 8 is formed by interlacing and fixing aramid belts, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com