Alloy heating wire pay-off apparatus

A technology of pay-off device and heating wire, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of damage to the alloy heating wire, poor surface flatness of the heating wire, and poor ductility of the heating wire, and achieve the surface flatness High, good bending resistance, good ductility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

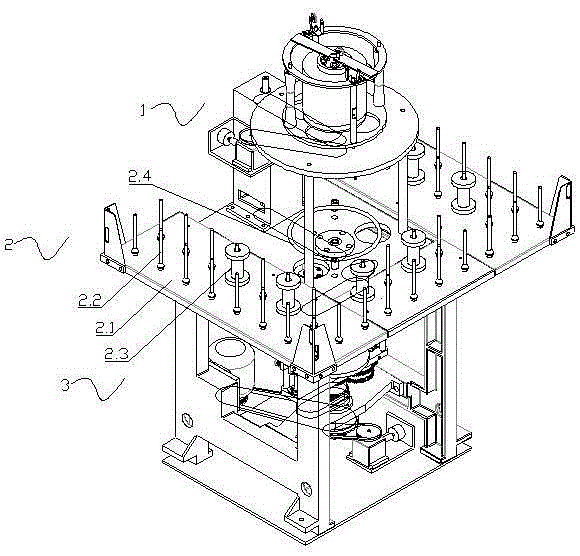

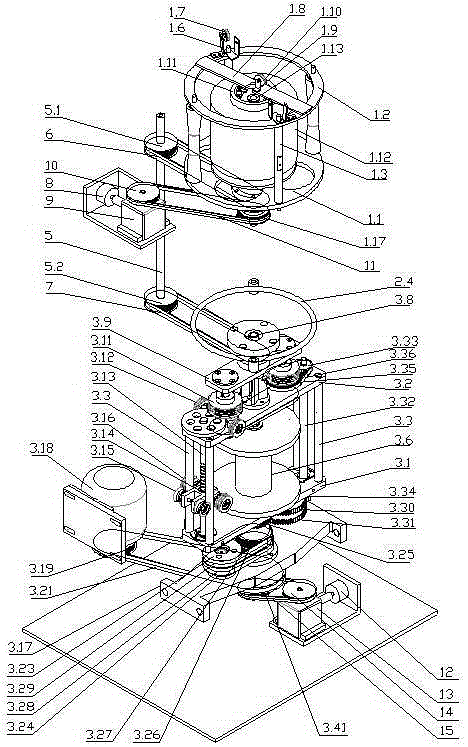

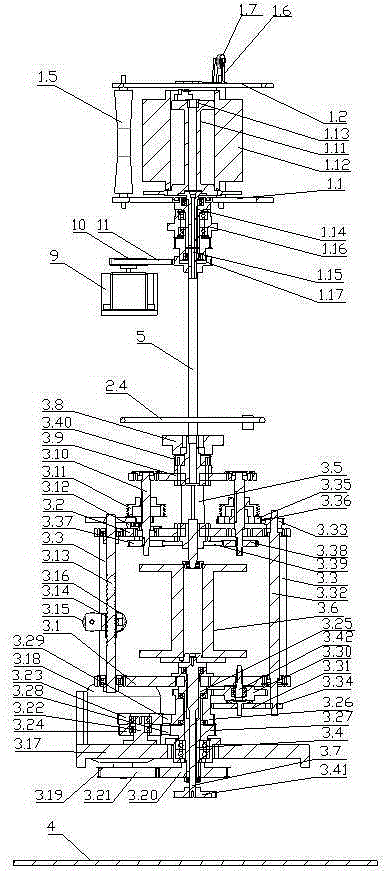

[0050] see Figure 1~Figure 16 , a kind of wire winding machine that the present invention relates to, it comprises frame 4, and described frame 4 is provided with bulletproof wire pay-off device 1, alloy heating wire pay-off device 2 and take-up device 3.

[0051] The bulletproof wire pay-off device 1 is arranged on the upper layer of the frame 4, and the bulletproof wire pay-off device 1 includes a bulletproof wire pay-off rotating frame, and the bulletproof wire pay-off rotating frame includes a support disc 1.1 at the bottom and a support ring 1.2 at the top , between the support disc 1.1 and the support ring 1.2 are evenly arranged two bulletproof wire pay-off rotating frame support rods 1.3 and two bulletproof wire pay-off guide roller support shafts, the bulletproof wire pay-off rotating frame support rods 1.3 The outer side is provided with the first guide wheel 1.4 of the bulletproof wire pay-off vertically arranged, the bulletproof wire pay-off guide roller support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com