Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5005results about How to "Improve bending resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

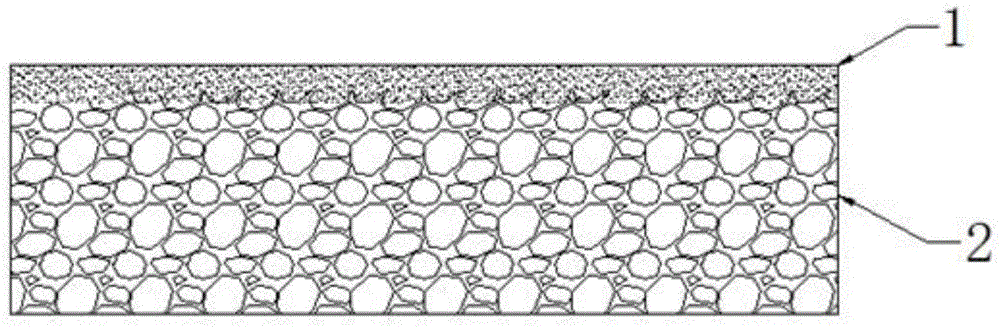

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

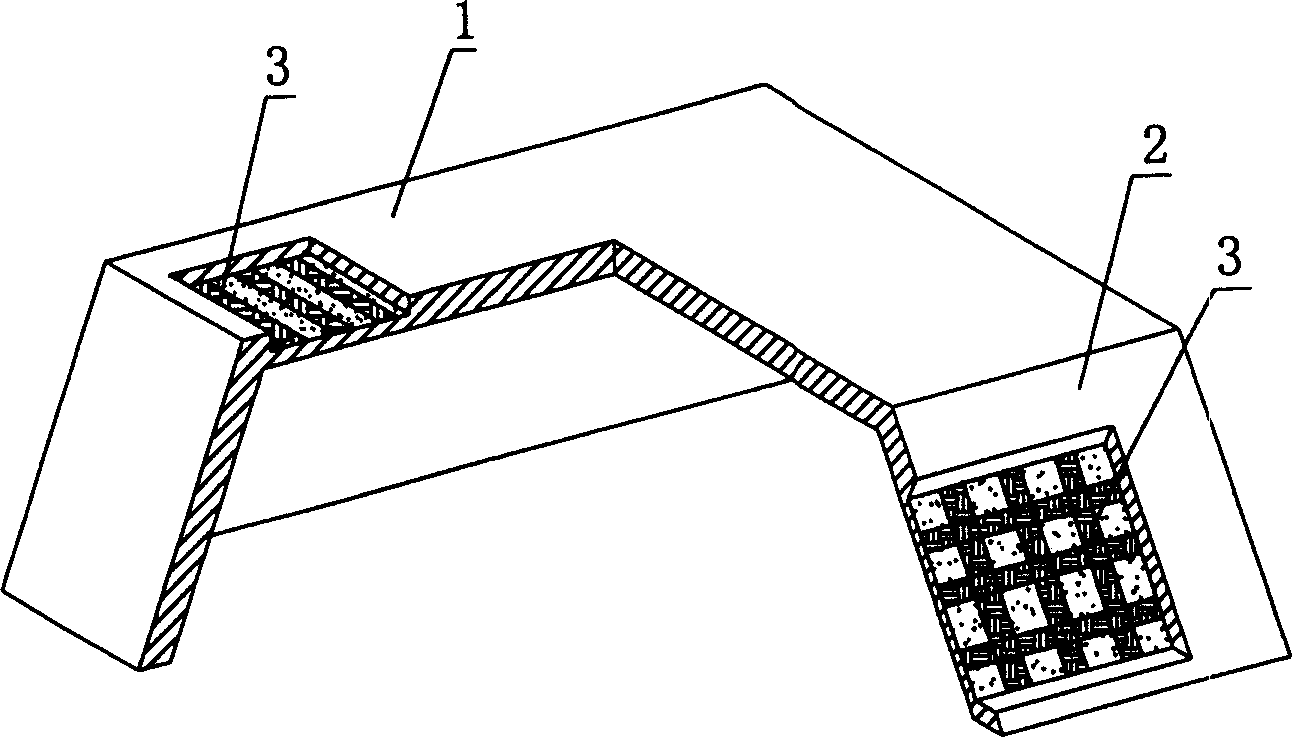

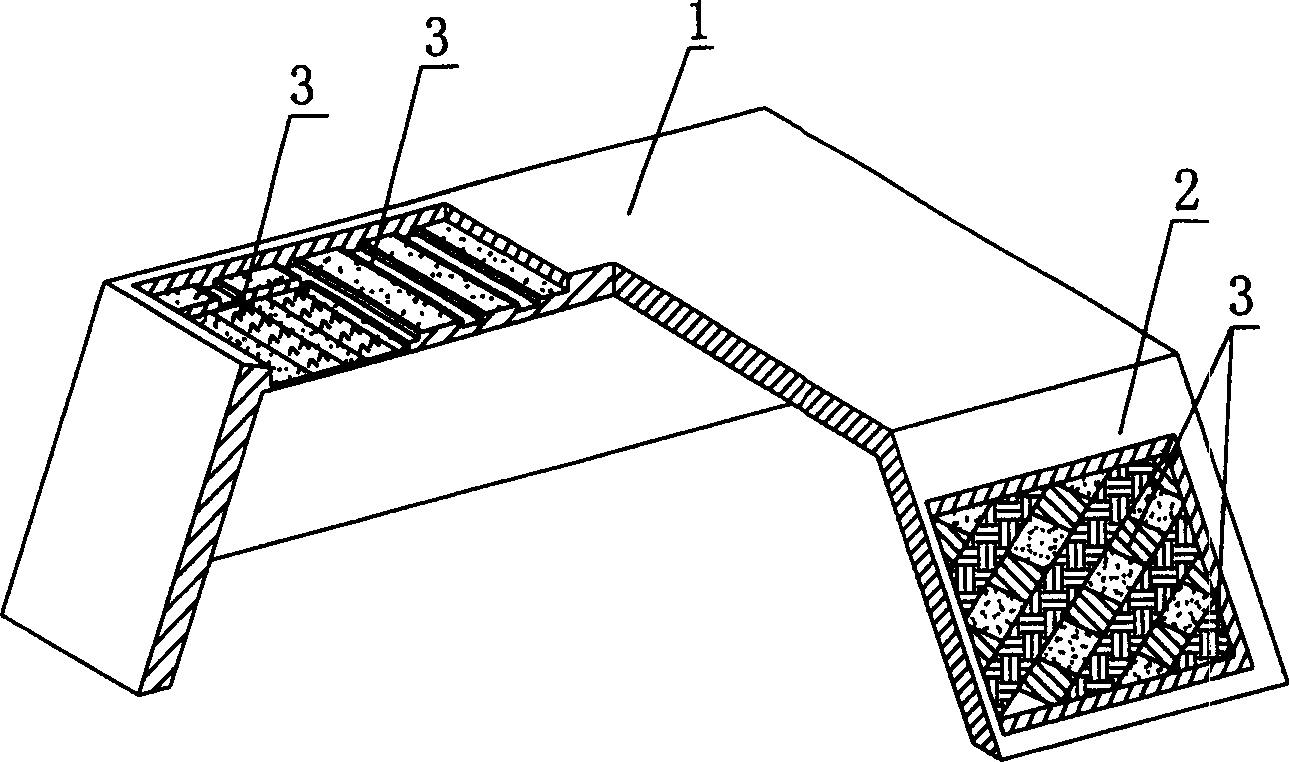

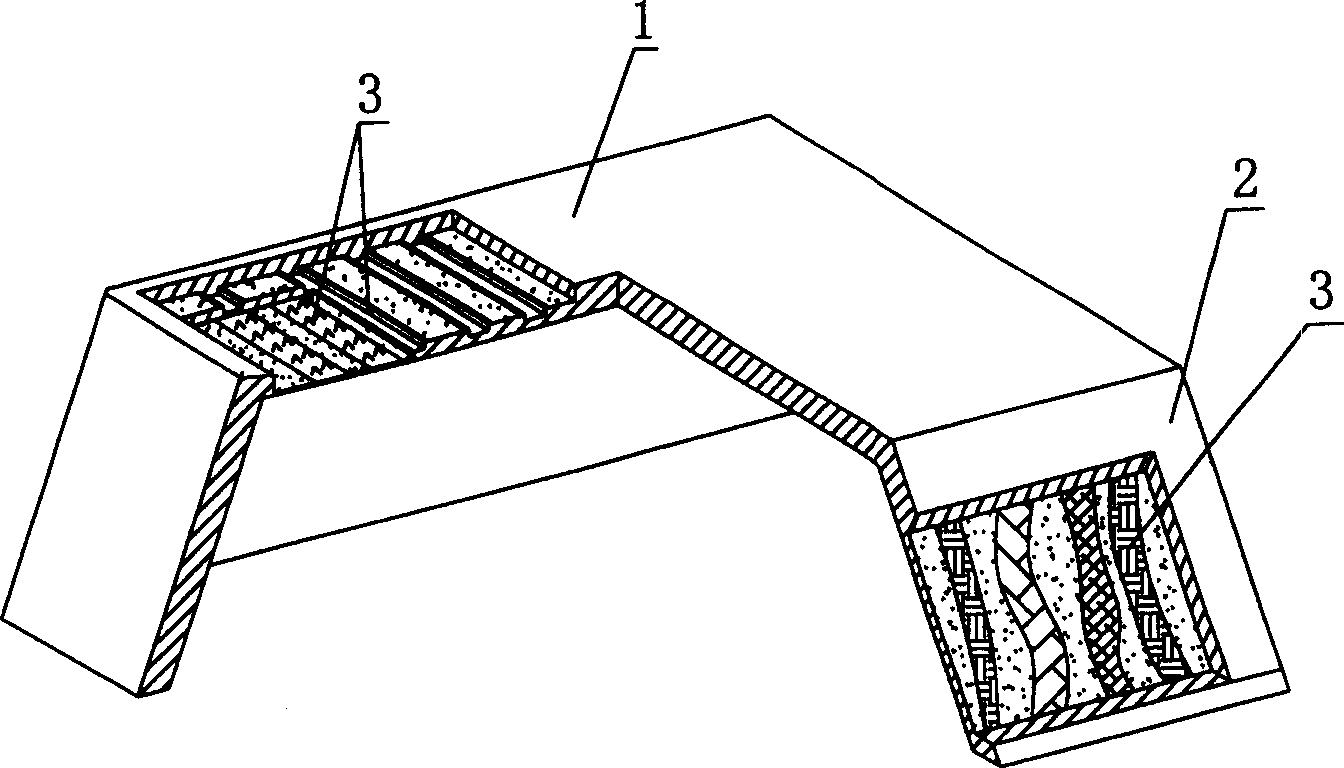

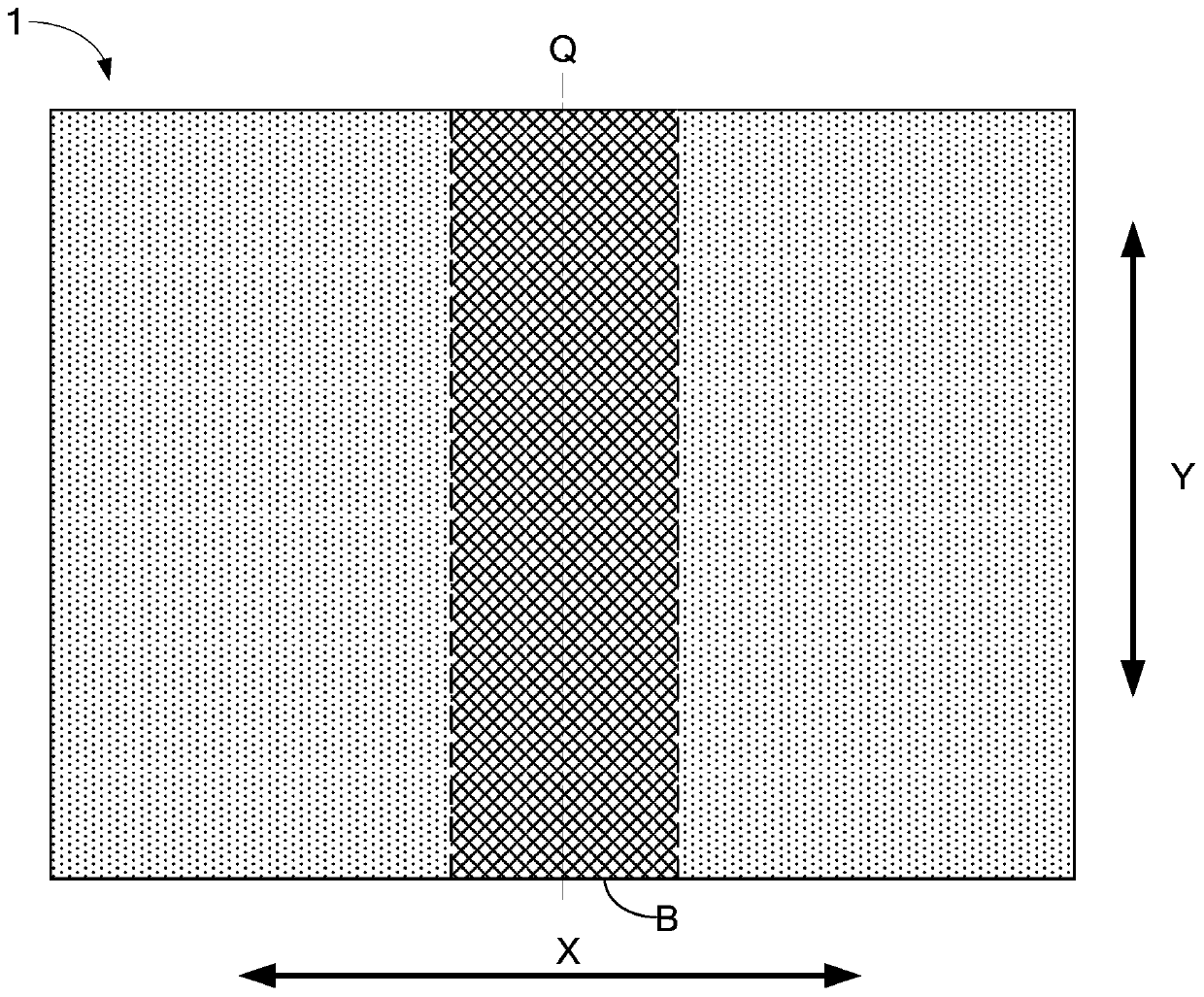

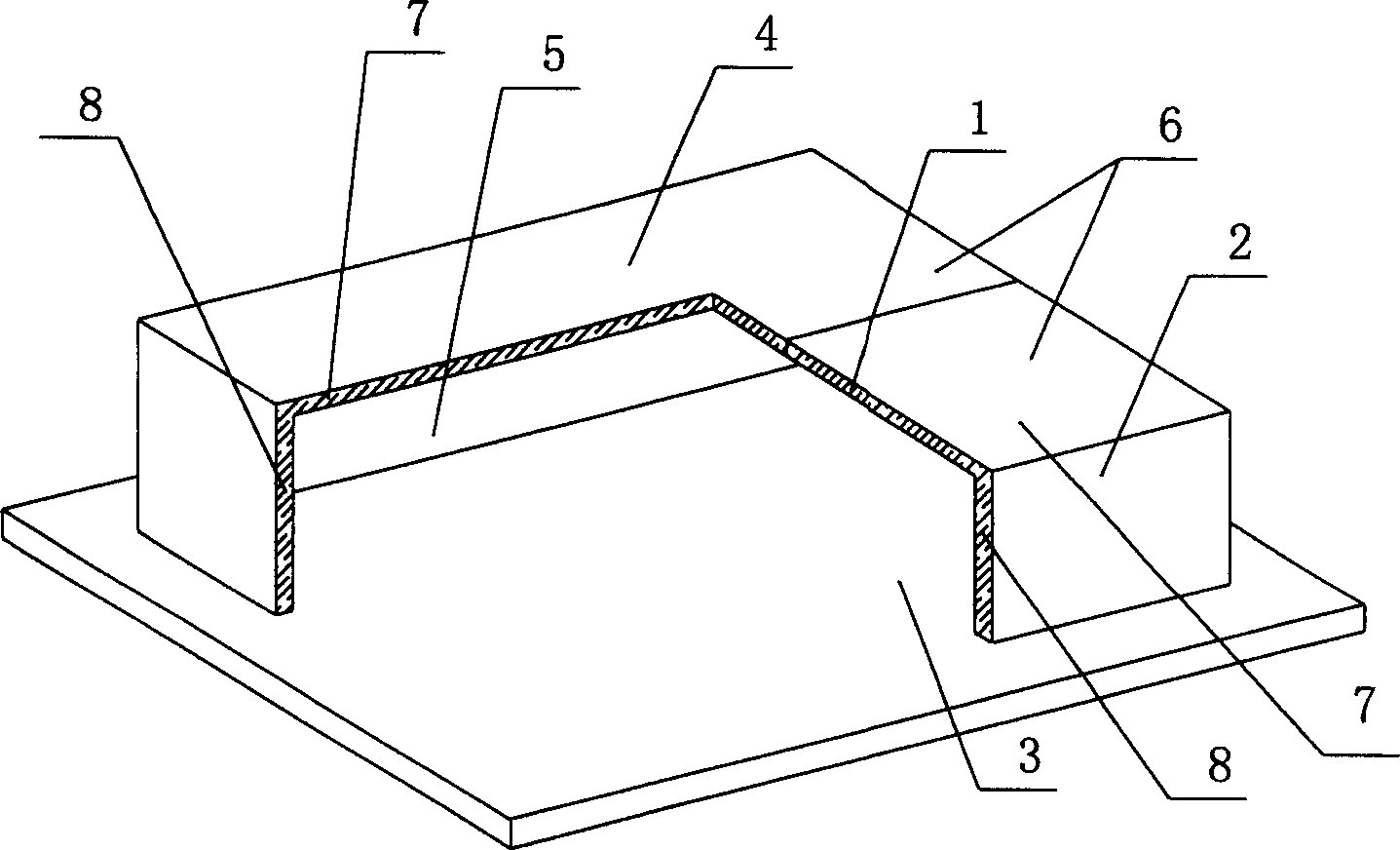

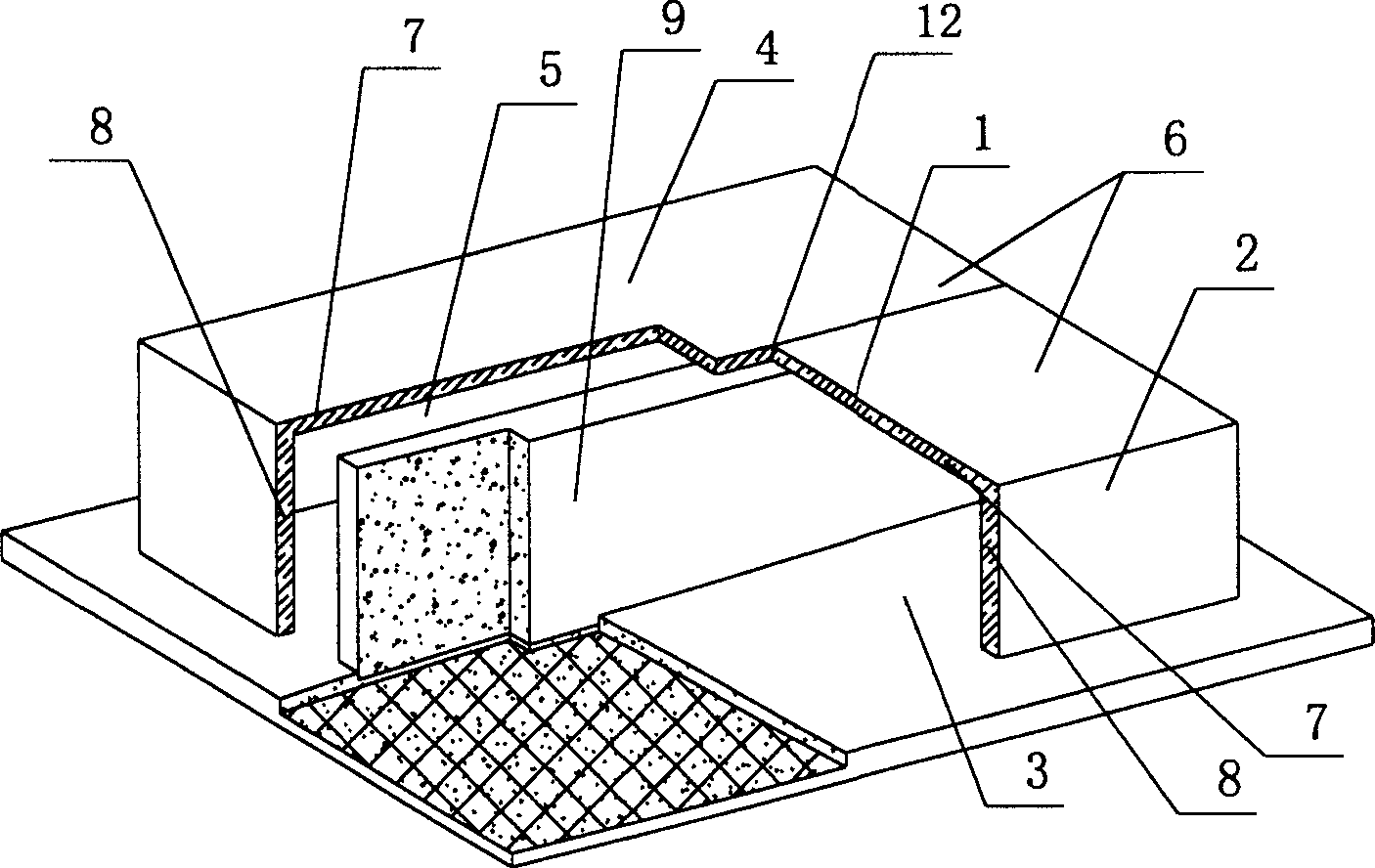

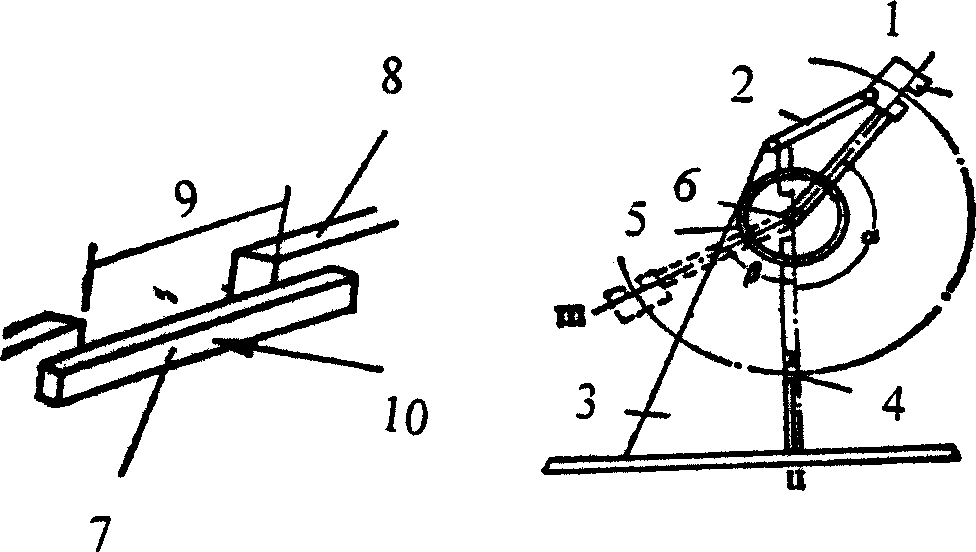

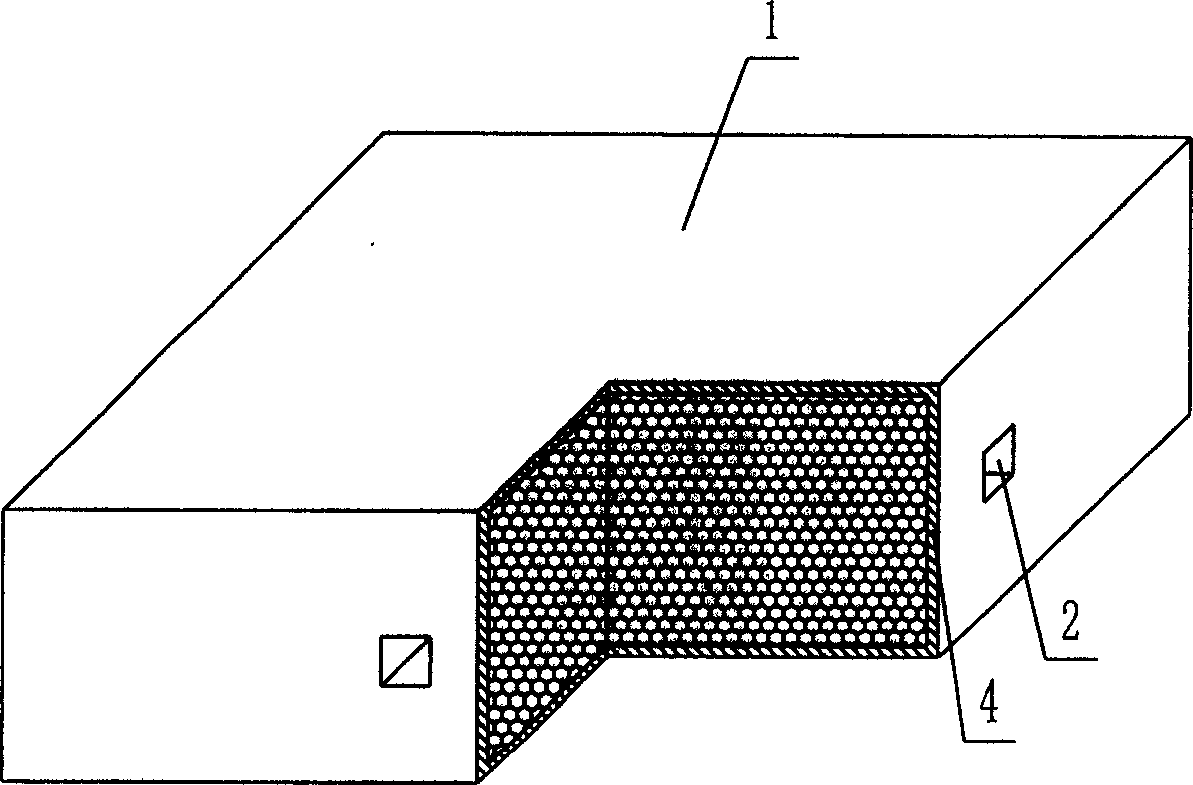

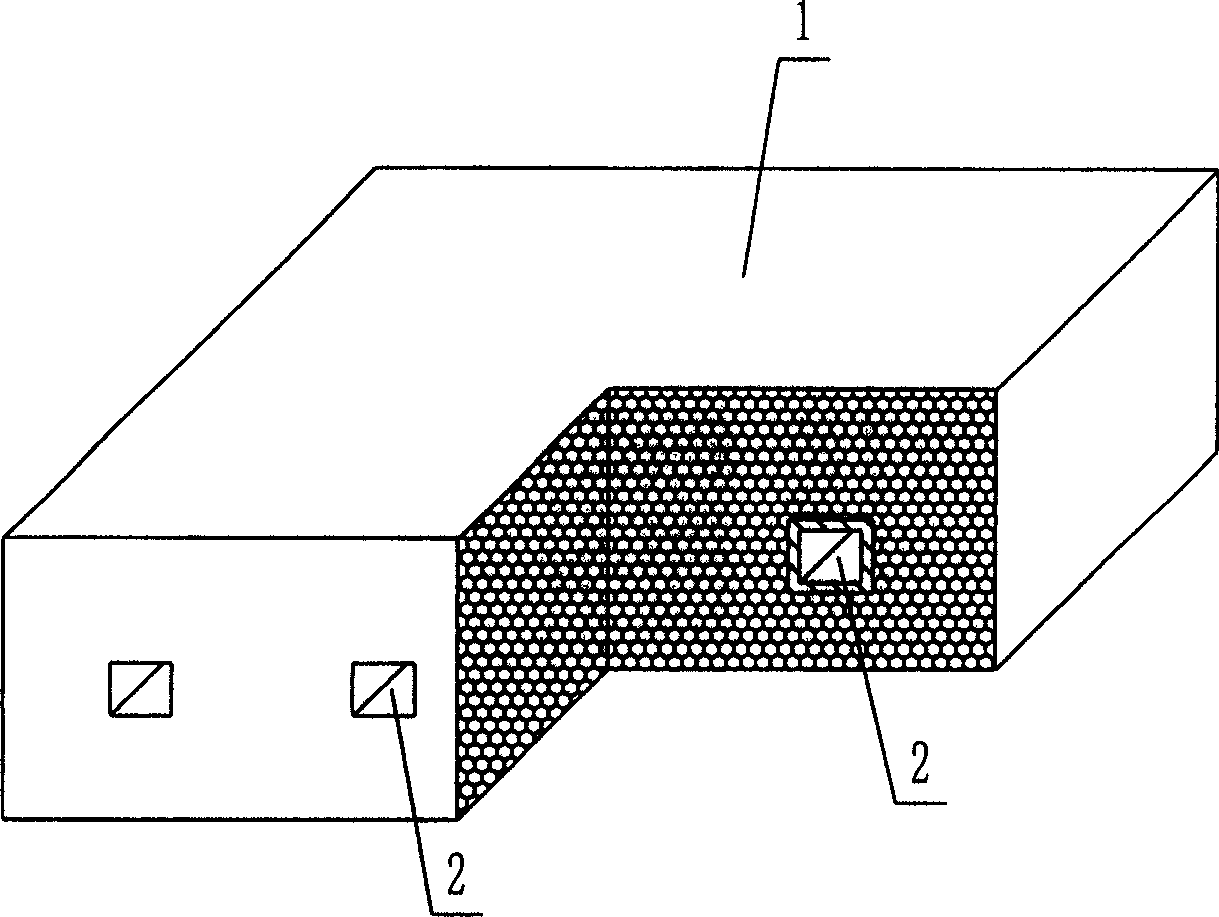

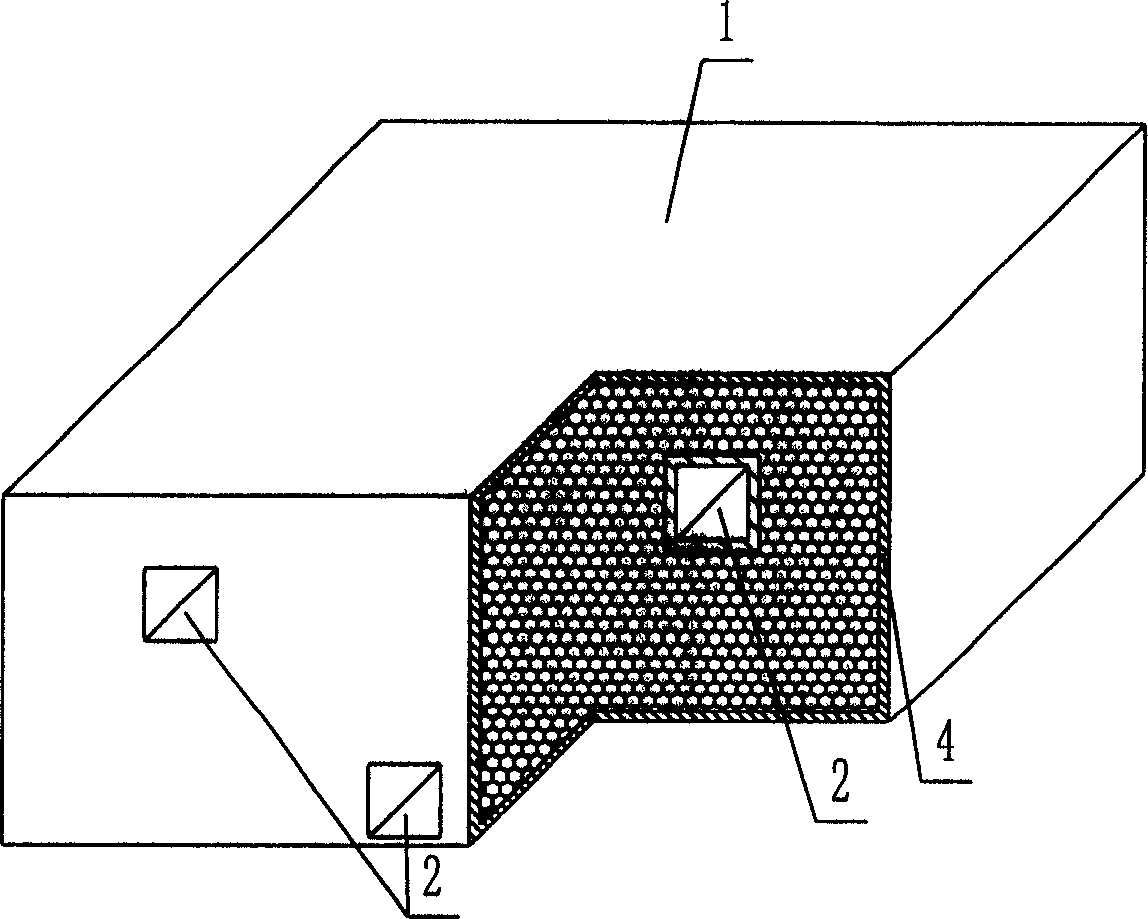

Thin-wall form member for hollowing out concrete

A thin-wall hollow form for concrete to in-situ pour hollow non-beam floor is composed of top plate, peripheral wall and bottom plate, and is characterized by that its bottom plate contains at least one thin strip for improving its resistance to impact and collision. Its advantages are simple structure, high strength, toughness and resistance to deformation and vibration, light weight and low cost.

Owner:湖南邱则有专利战略策划有限公司

Thin-wall form for filling concrete

A thin-wall form for filling concrete in it to in-situ pour hollow non-beam floor is composed of top plate and peripheral wall, and is characterized by that at least one of said top plate and peripheral wall contains at least one thin strip for improving its resistance to impact and collision. Its advantages are simple structure and high resistance to deformation and vibration.

Owner:湖南邱则有专利战略策划有限公司

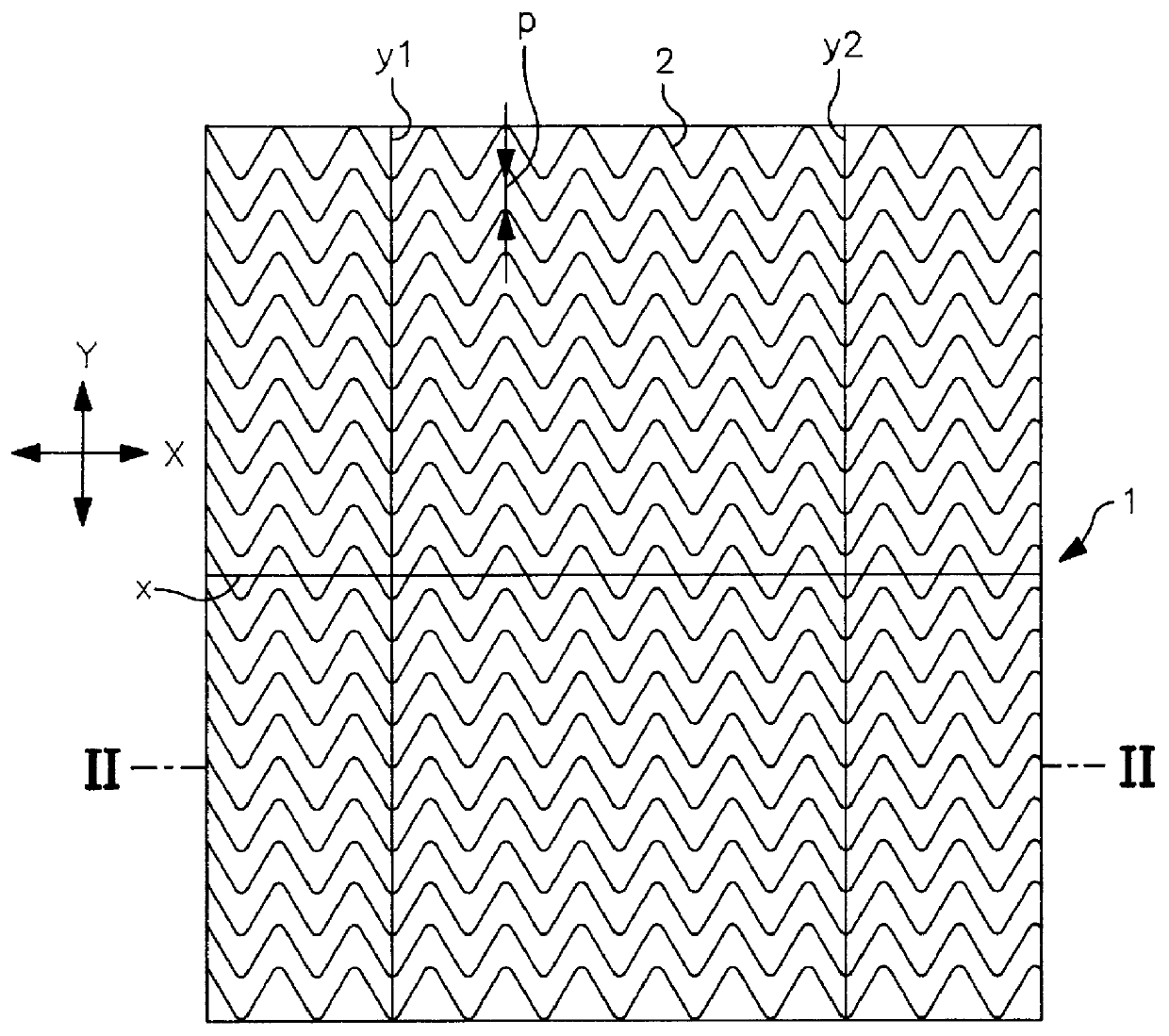

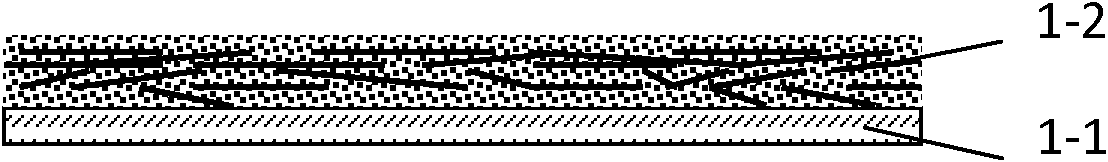

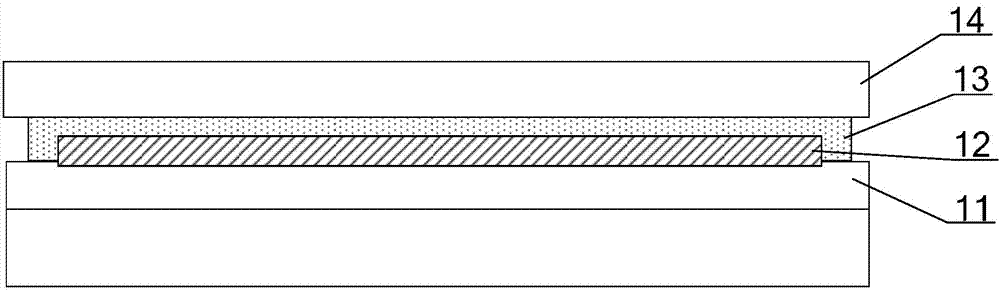

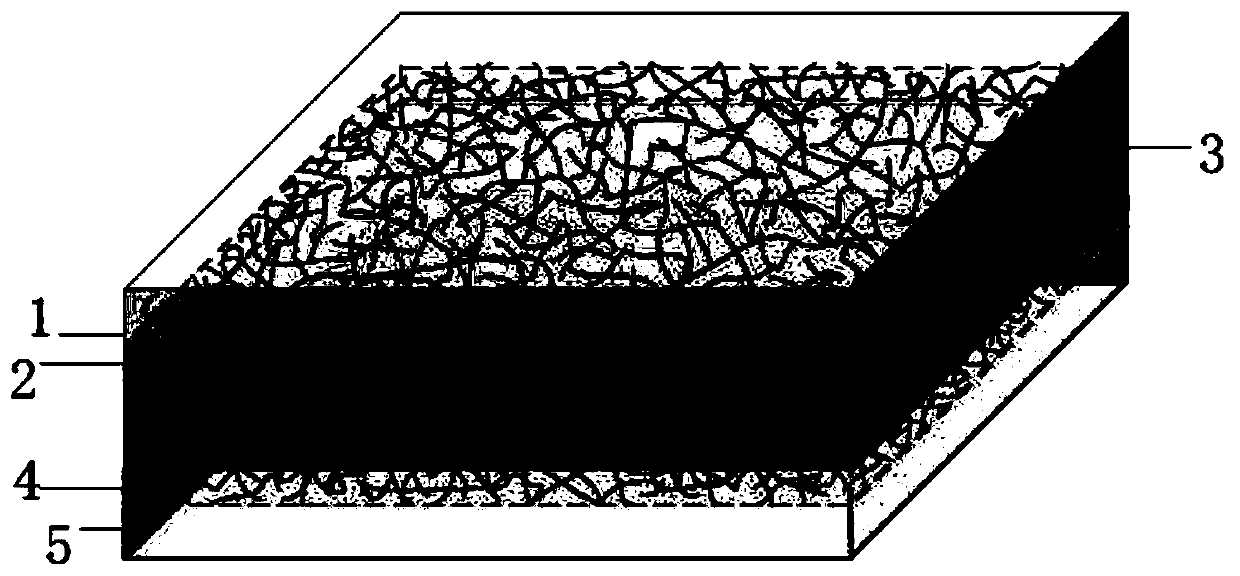

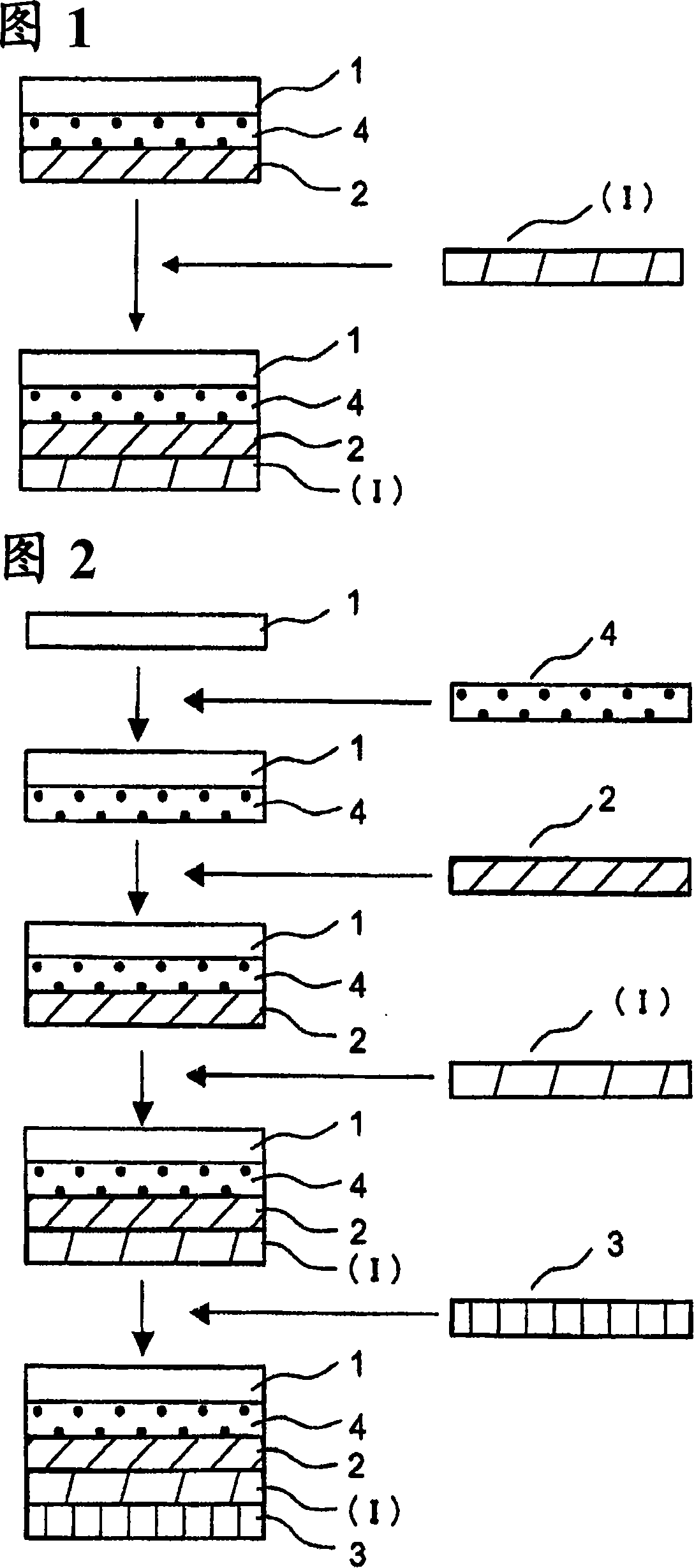

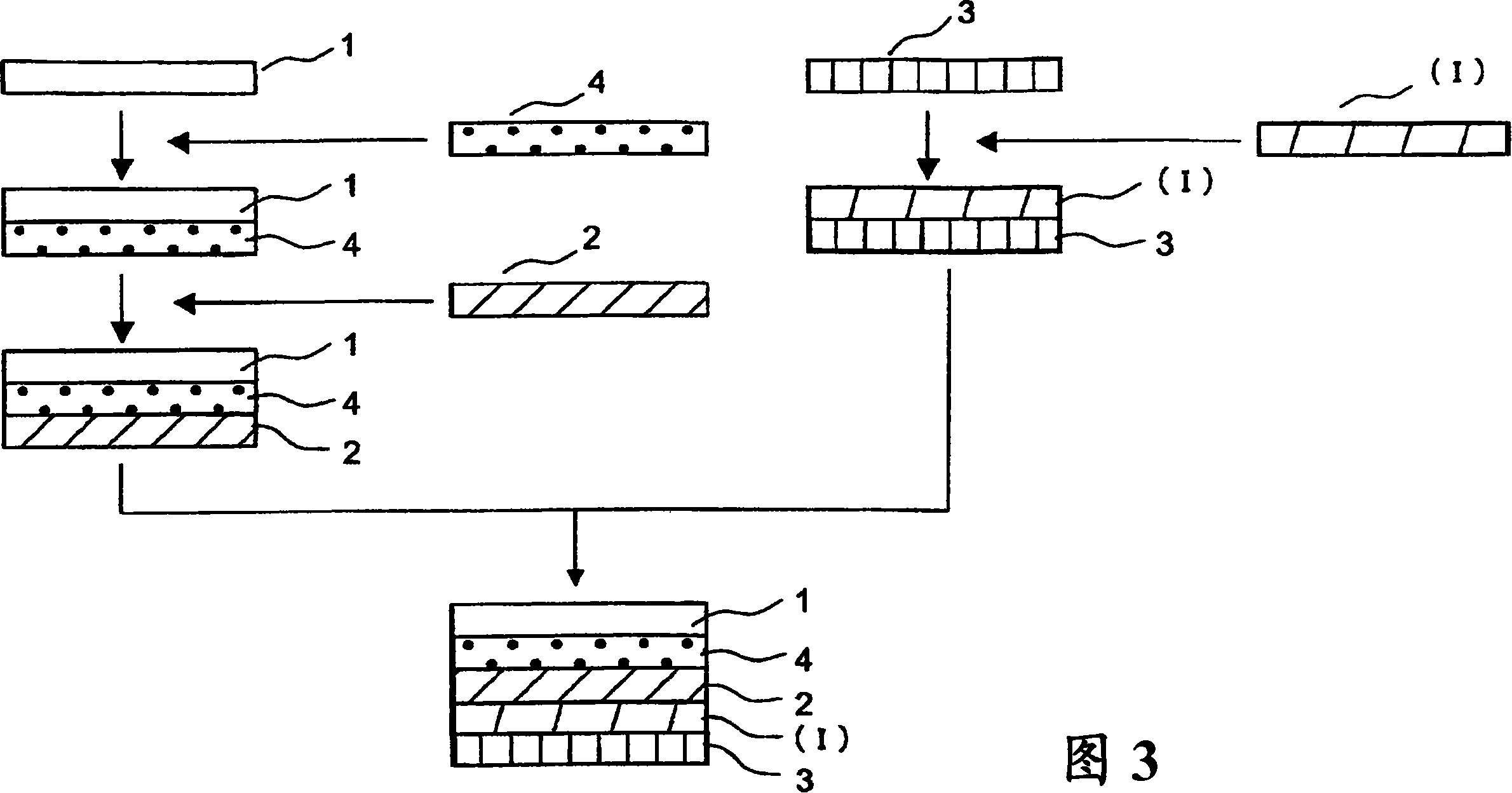

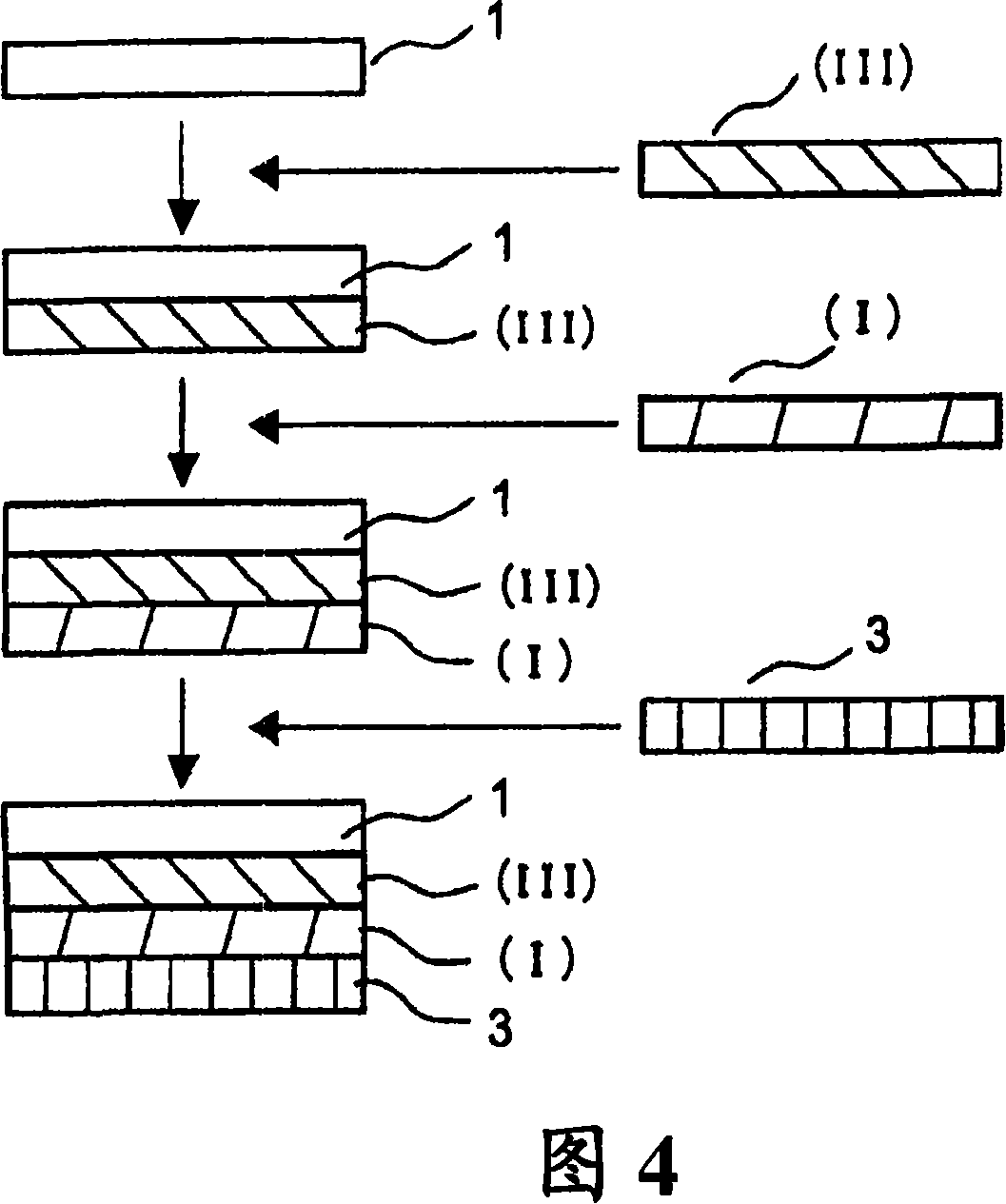

Wiping sheet

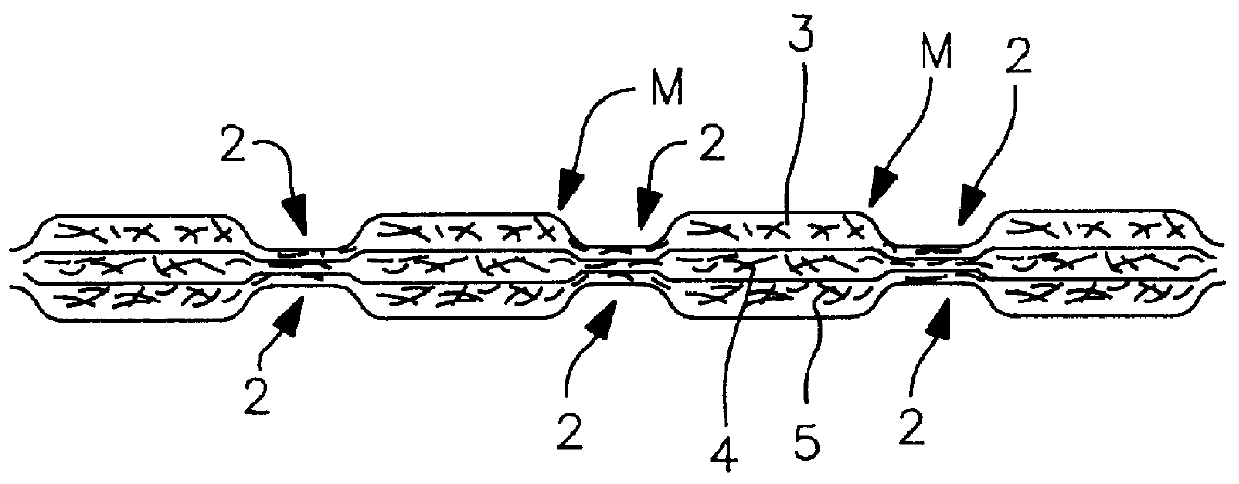

InactiveUS6013349AImprove bending resistancePromote recoveryCleaning machinesCleaning equipmentPolymer scienceNonwoven fabric

An absorbent core 4 composed of a nonwoven fabric containing an absorbent fiber at 20% by weight or more to 80% by weight or less and a hydrophobic fiber at 20% by weight or more to 80% by weight or less is interposed between a top sheet 3 and a bottom sheet 5, both the sheets being composed of a nonwoven fabric containing an absorbent fiber, such as rayon, at 30% by weight or more to 70% by weight or less and a hydrophobic fiber at 30% by weight or more to 70% by weight or less. Then, the top sheet 3, the absorbent core 4 and the bottom sheet 5 are bonded together on bonding lines 2. These individual layers are water retentive because of the absorbent fiber therein, and the resulting sheet has good slip properties because of the hydrophobic fiber contained therein. The absorbent core 4 works to enhance the bending resistance.

Owner:UNI CHARM CORP

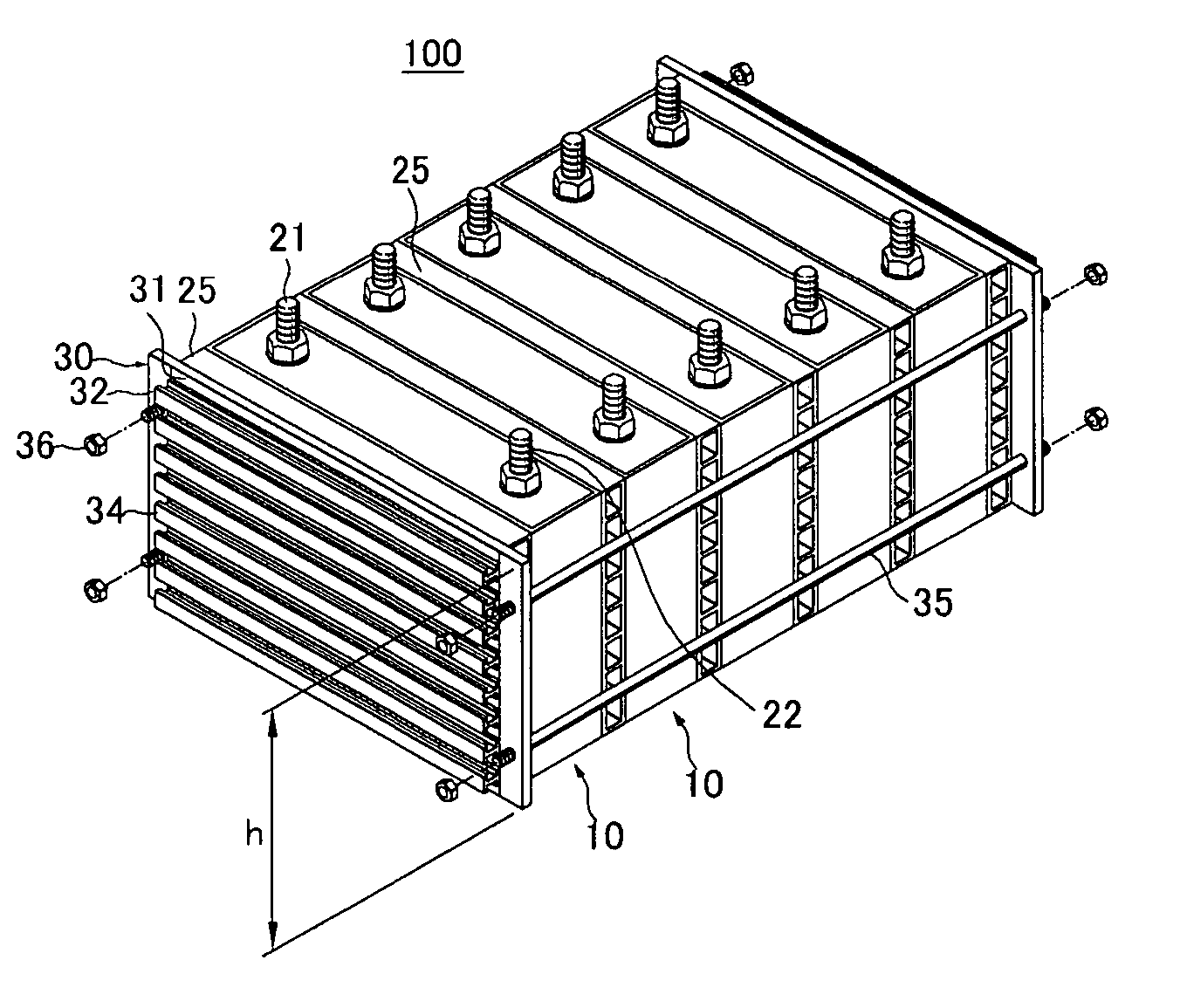

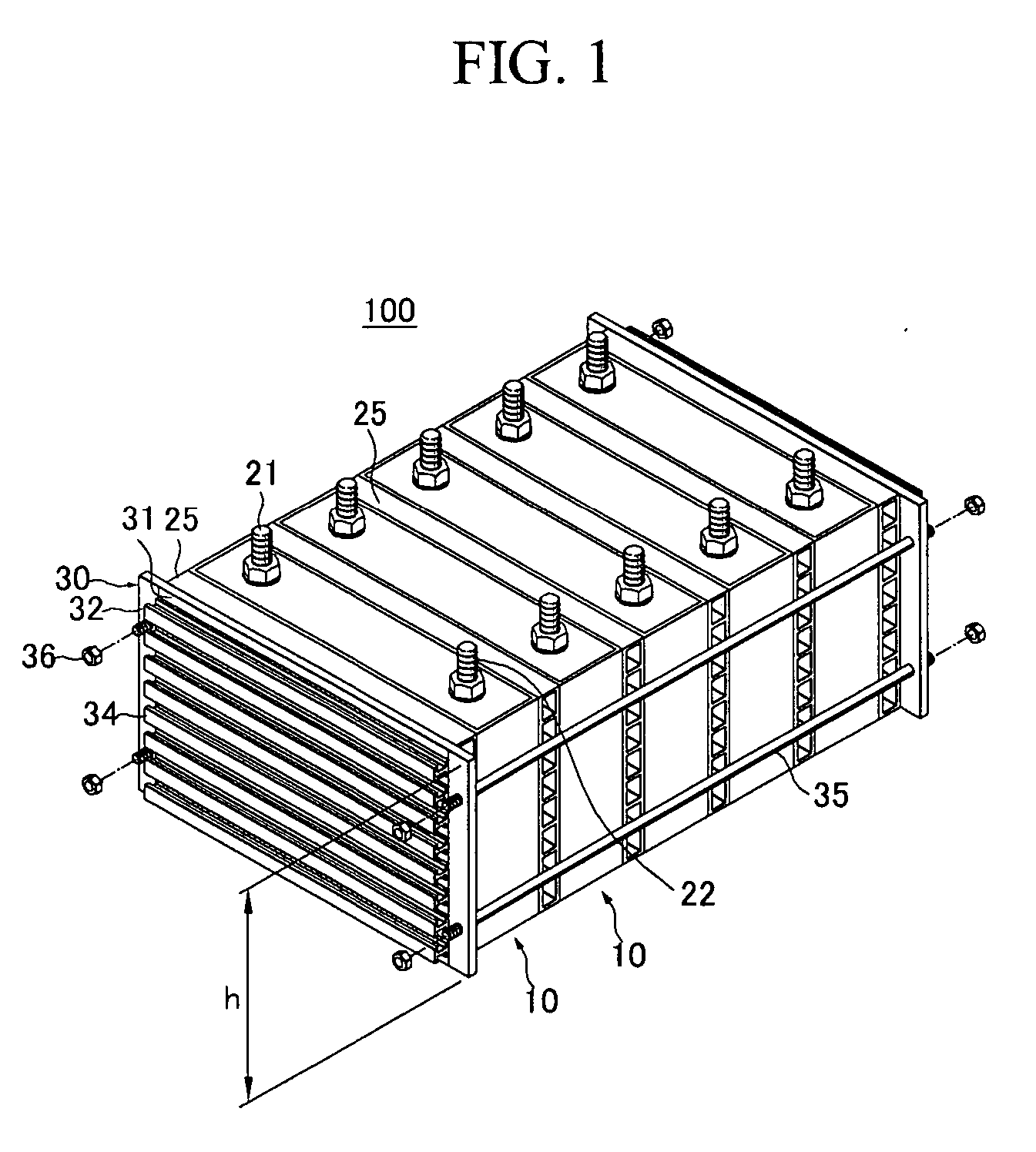

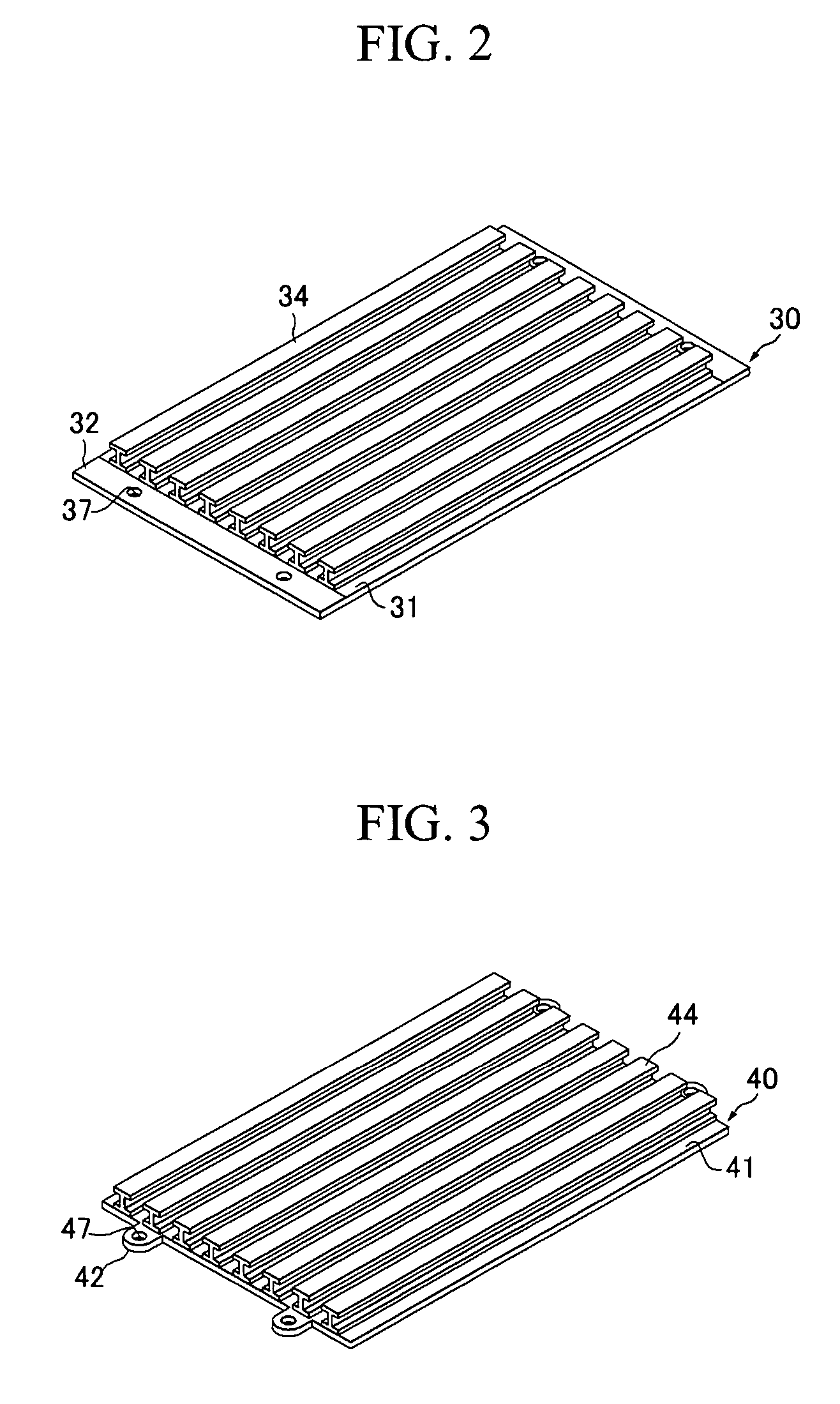

Battery module

InactiveUS20070026305A1Improve bending resistancePrimary cell to battery groupingCell component detailsElectrical and Electronics engineering

Owner:SAMSUNG SDI CO LTD

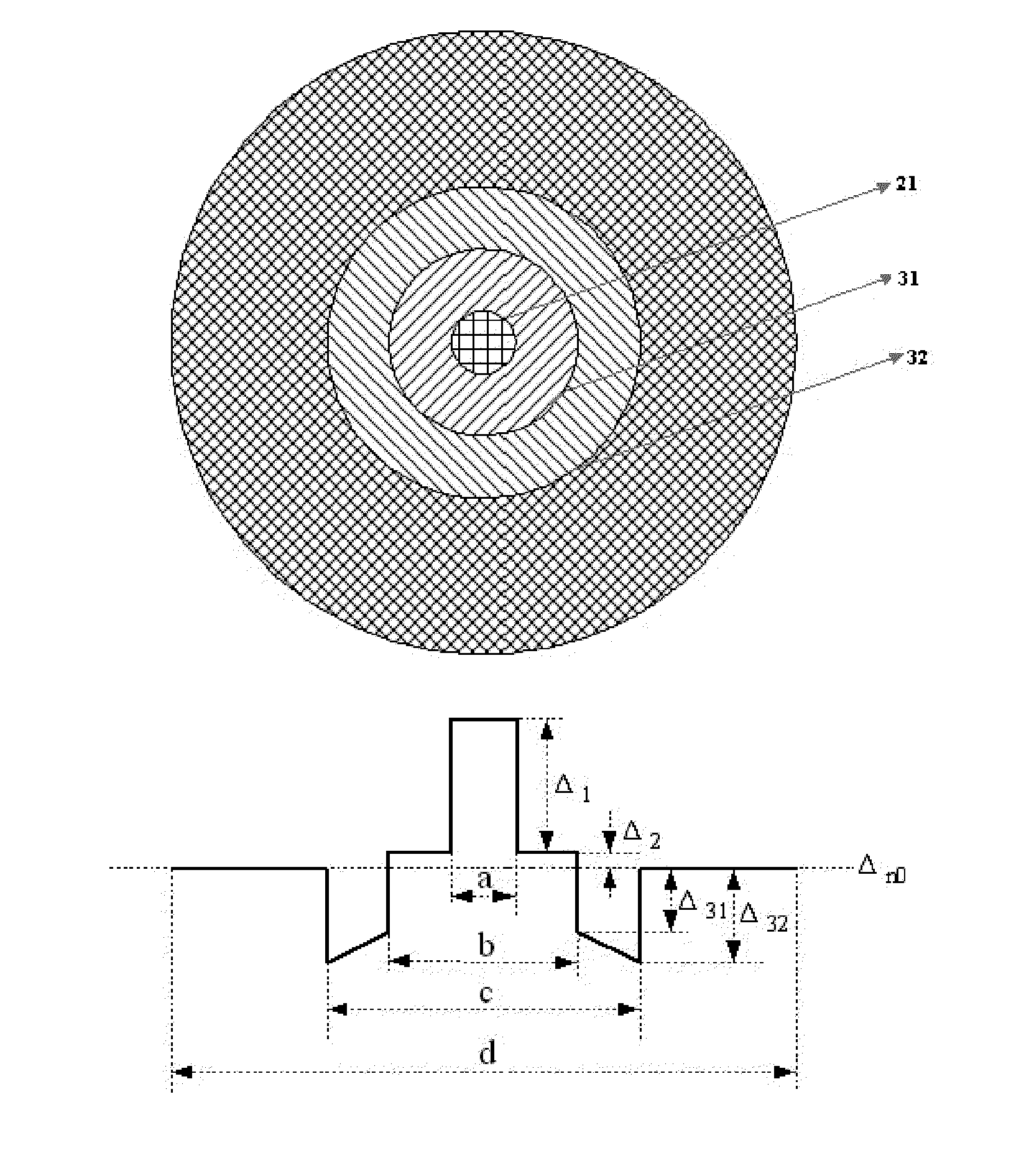

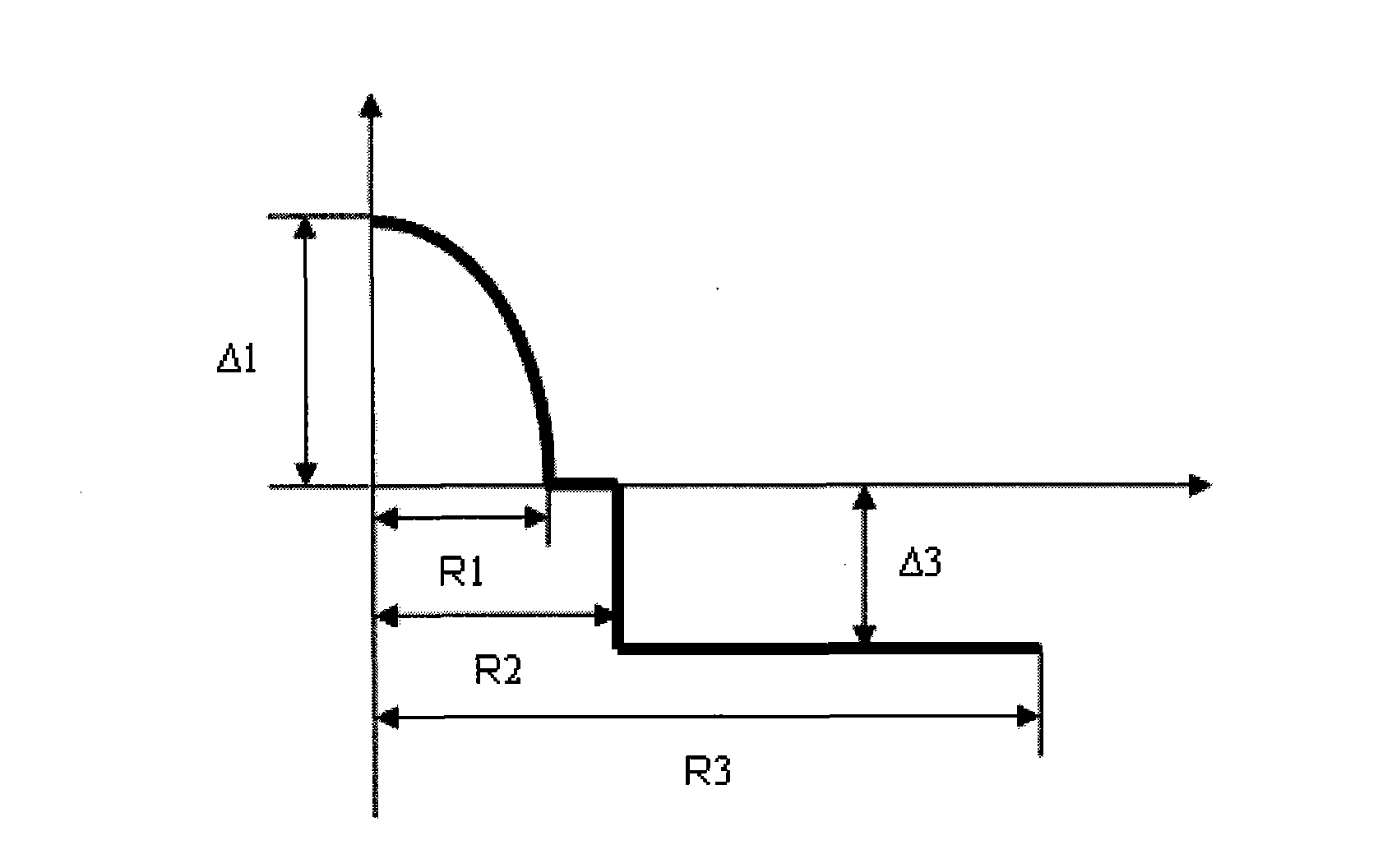

Single-mode fiber and production method thereof

ActiveUS20110058780A1Prevent viscosity being lowIncrease refractive indexGlass making apparatusOptical fibre with graded refractive index core/claddingSingle-mode optical fiberUltrasound attenuation

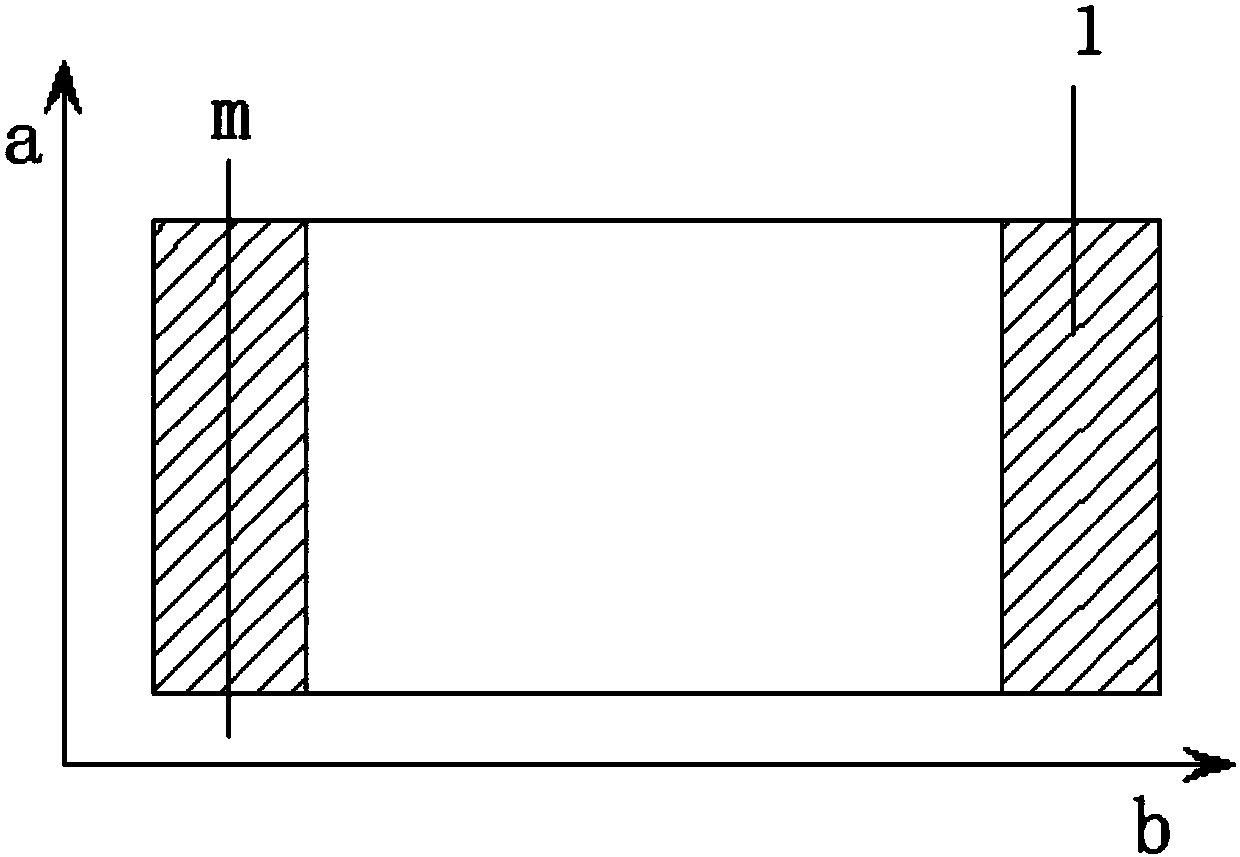

A single mode fiber having a core, an inner cladding, a depressed cladding, and an outer cladding composed of pure silica glass. The core is surrounded in sequence with the inner cladding and the depressed cladding. The core has silica glass doped with germanium and fluorine, with a diameter (a) of 8.0-8.8 μm, a relative refractive index difference (Δ1) of 0.35-0.38%, and the contribution of fluoride (ΔF) is −0.09±0.02%. The inner cladding has silica glass doped with germanium and fluorine, with a diameter (b) of 18-21 μm and a relative refractive index difference (Δ2) of 0±0.02%. The depressed cladding has silica glass doped with fluorine, with a diameter (c) of 26-36 μm and a relative refractive index difference (Δ32) at the external interface thereof is between −0.22 and −0.35%, and a relative refractive index difference (Δ31) at the internal interface thereof is between −0.20 and −0.35%, and Δ32≦Δ31. The fiber has a good bending resistance, good mechanical properties, and extended service lifetime, and prevents the additional stresses generated by bending from passing on to the core, thereby reducing attenuation.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Environmental-friendly waterproof polymer mortar

InactiveCN101560084AImprove adhesionStrong bondSolid waste managementSilicate CementConstruction aggregate

The invention relates to environmental-friendly waterproof polymer mortar, which comprises the following components in portion by weight: 50 to 230 portions of low-clinker silicate cement, 200 to 450 portions of quartz sand, 80 to 120 portions of fly ash, 1 to 18 portions of re-dispersible polyethylene vinyl acetate latex powder, 1 to 10 portions of dispersible polyvinyl acetate vinyl versatate latex powder, 0.2 to 0.6 portion of water reducing agent, 0.05 to 0.3 portion of antifoaming agent, and 0.25 to 2.25 portions of polypropylene fibers. A gel material prepared from steel slag, tailings and the fly ash replaces silicate cement and partial aggregate in the prior mortar; the modified waterproof polymer mortar has the advantages of excellent impermeability, good mechanical property and construction property, simple production technology, and easy manufacture, greatly consumes industrial and mining wastes, controls the ecological environment, and lowers the cost; and the product has reliable quality and wide market; and the environmental-friendly waterproof polymer mortar can be popularized and applied in large area.

Owner:黑龙江省学府环艺雕塑有限公司

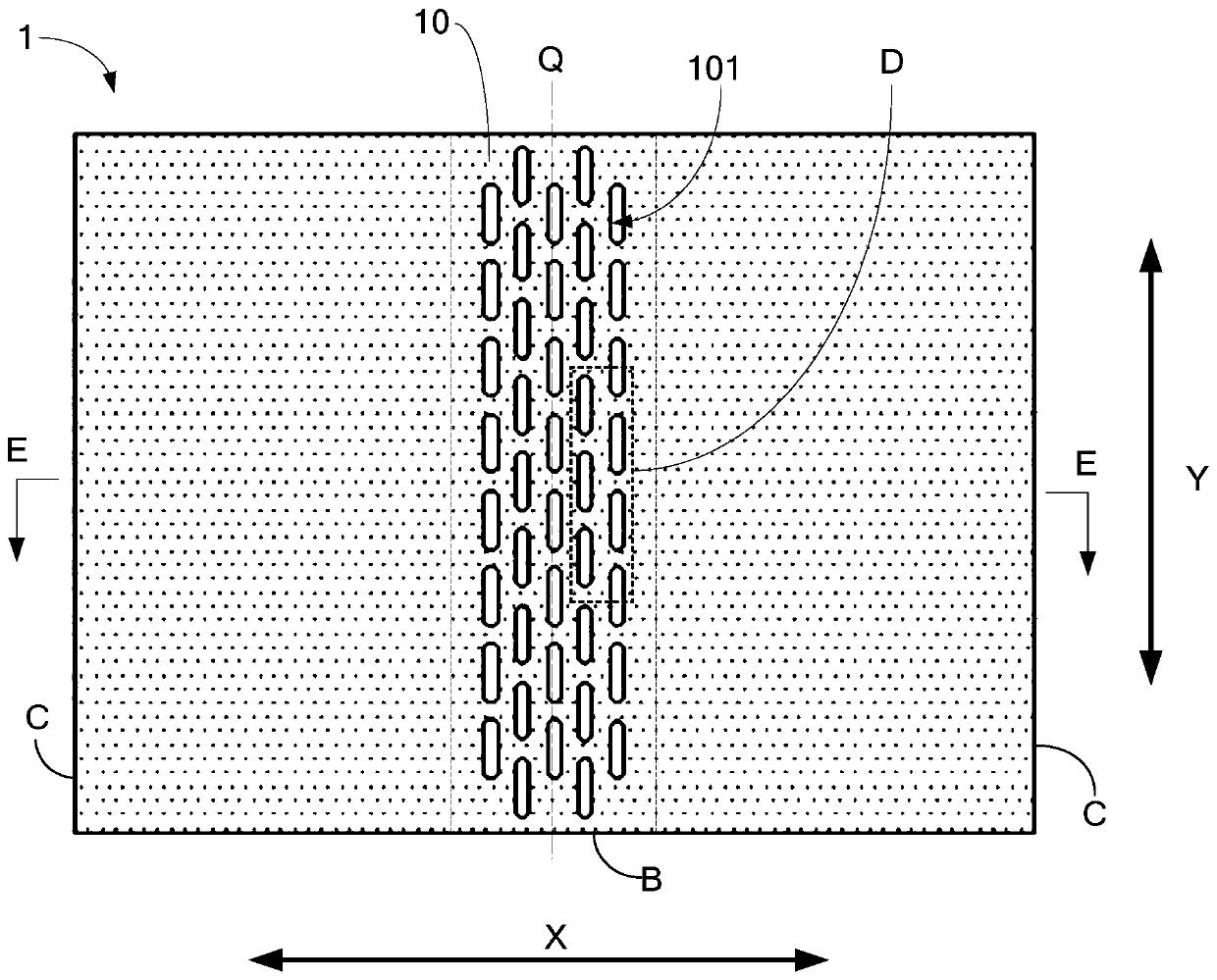

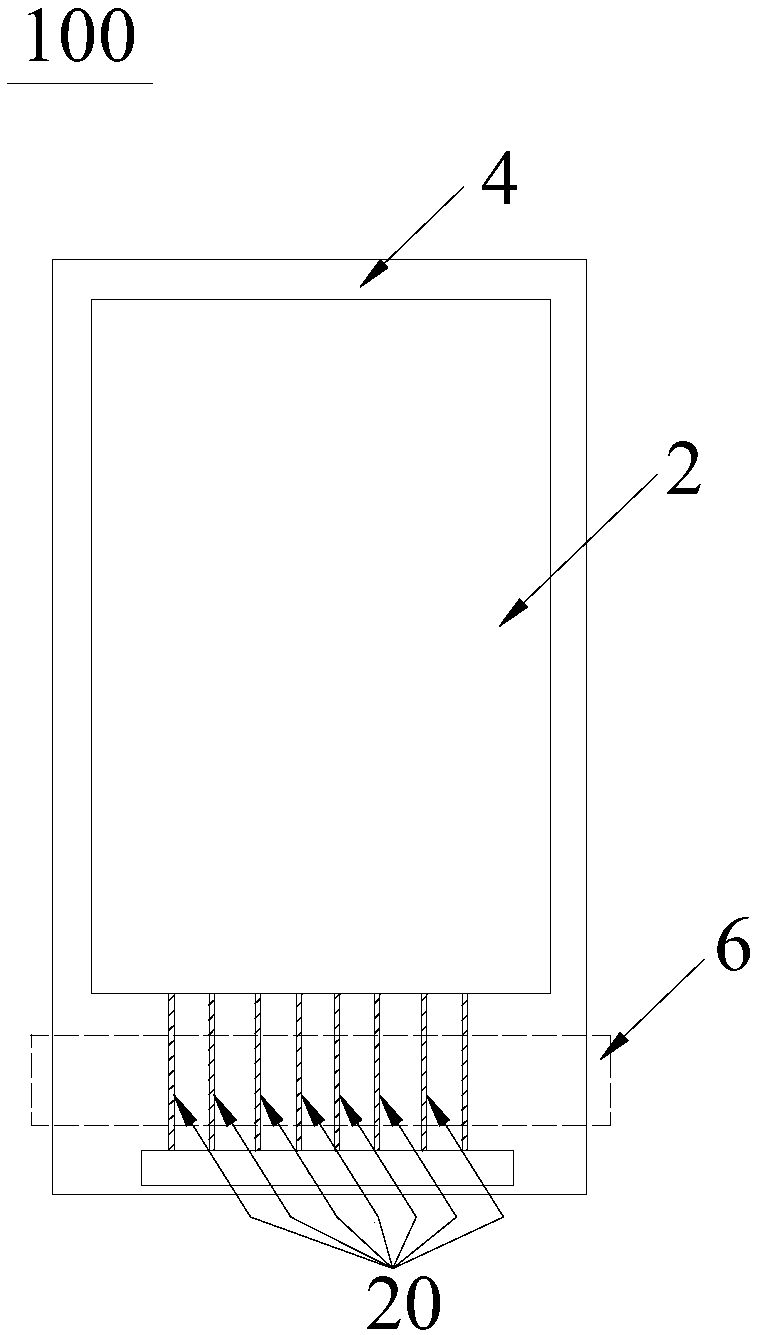

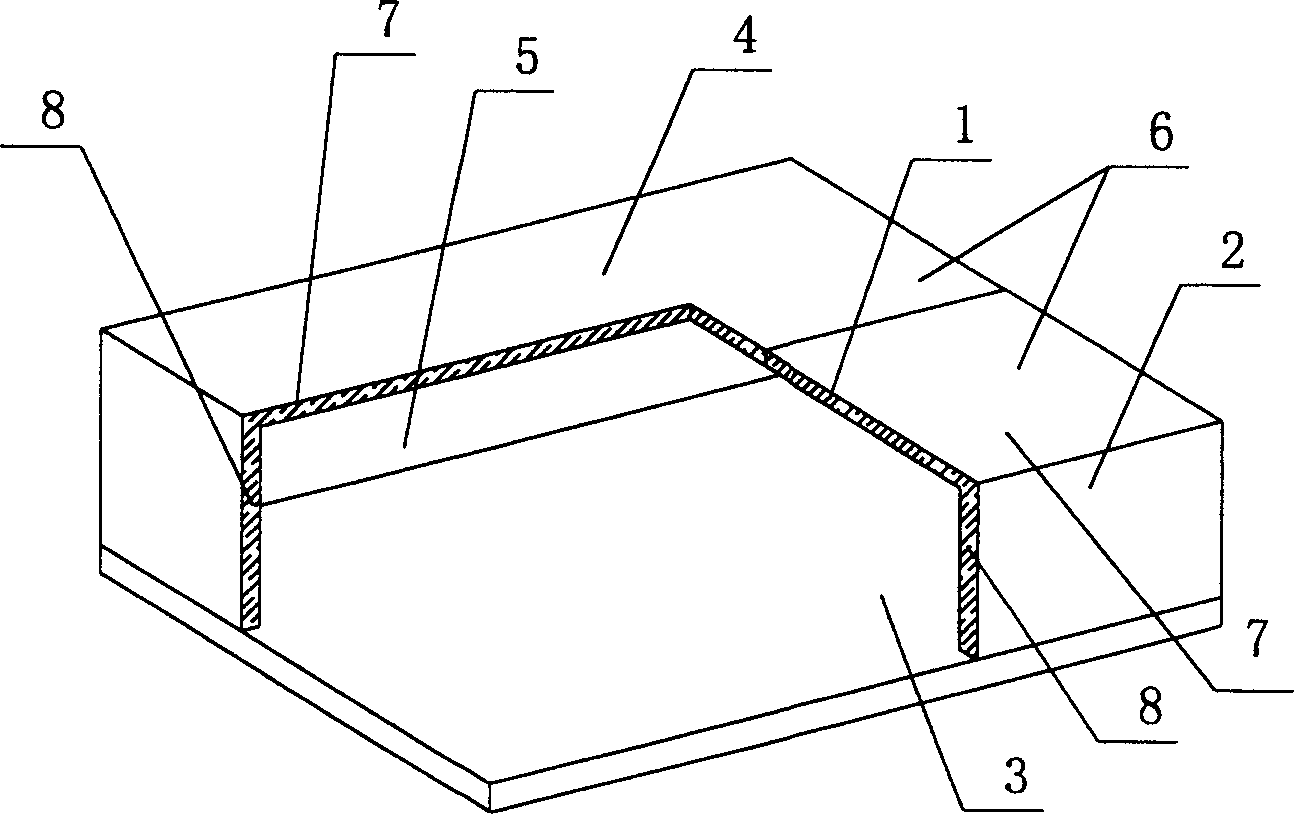

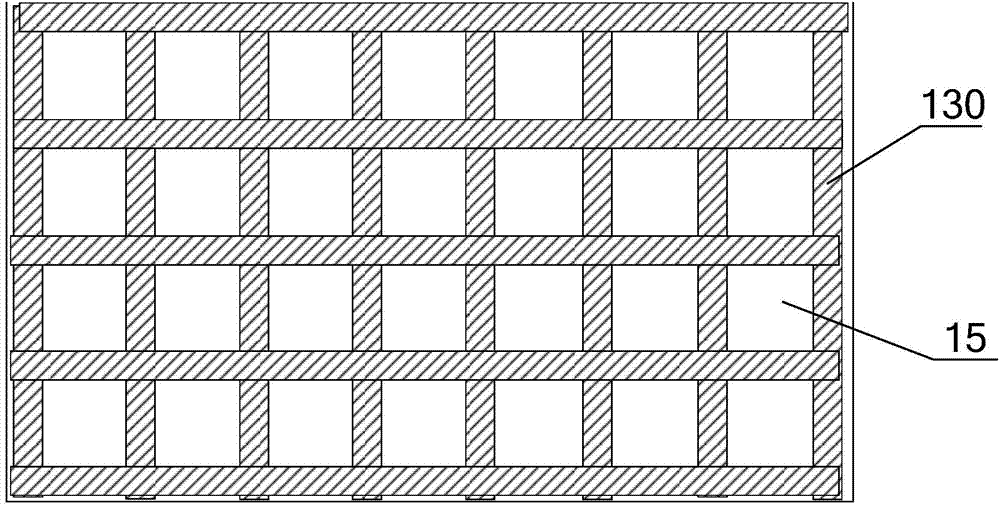

Supporting structure and display device

ActiveCN110767096AImprove bending resistanceBending Resistance GuaranteeCasings with display/control unitsPhotovoltaic energy generationDisplay deviceEngineering

The application relates to a supporting structure and a display device. The supporting structure is arranged at one side of a flexible display panel, the flexible display panel comprises a bendable area, a bending axis corresponding to the bendable area extends on a first direction, wherein the supporting structure comprises a hollow-out area with a positive projection capable of completely covering the bendable area on the display panel, the hollow-out area comprises a first part formed with multiple first hollow-out holes, second parts located at two opposite sides of the first part on the first direction, wherein multiple second hollow-out holes are formed on the second parts; a specific value of the total area of multiple second hollow-out holes and the total area of the second parts is different from that of the total area of multiple first hollow-out holes and the first part, thereby guaranteeing the structure stability of the supporting structure and enhancing the shock resistance and bending resistance of the flexible display panel.

Owner:BOE TECH GRP CO LTD

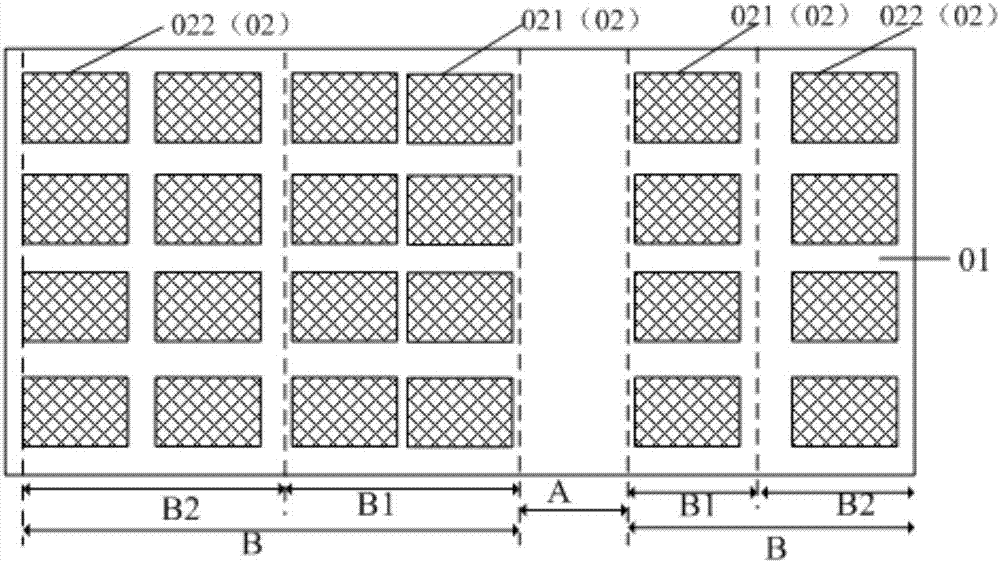

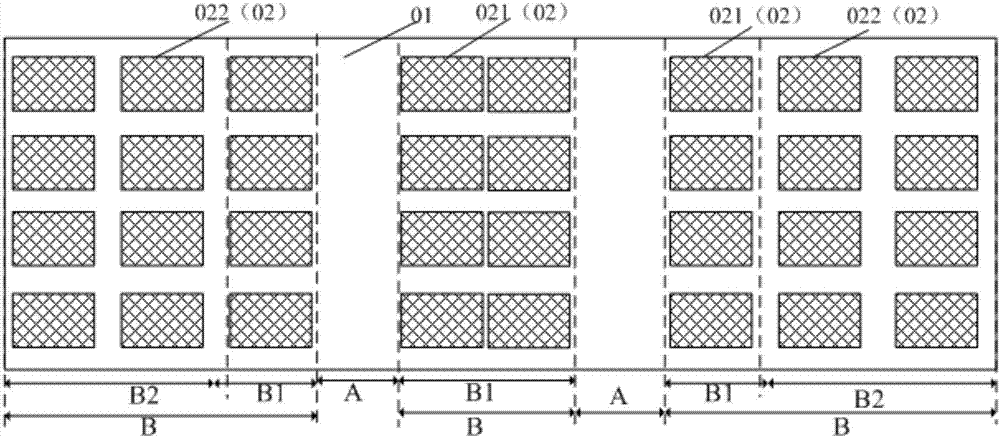

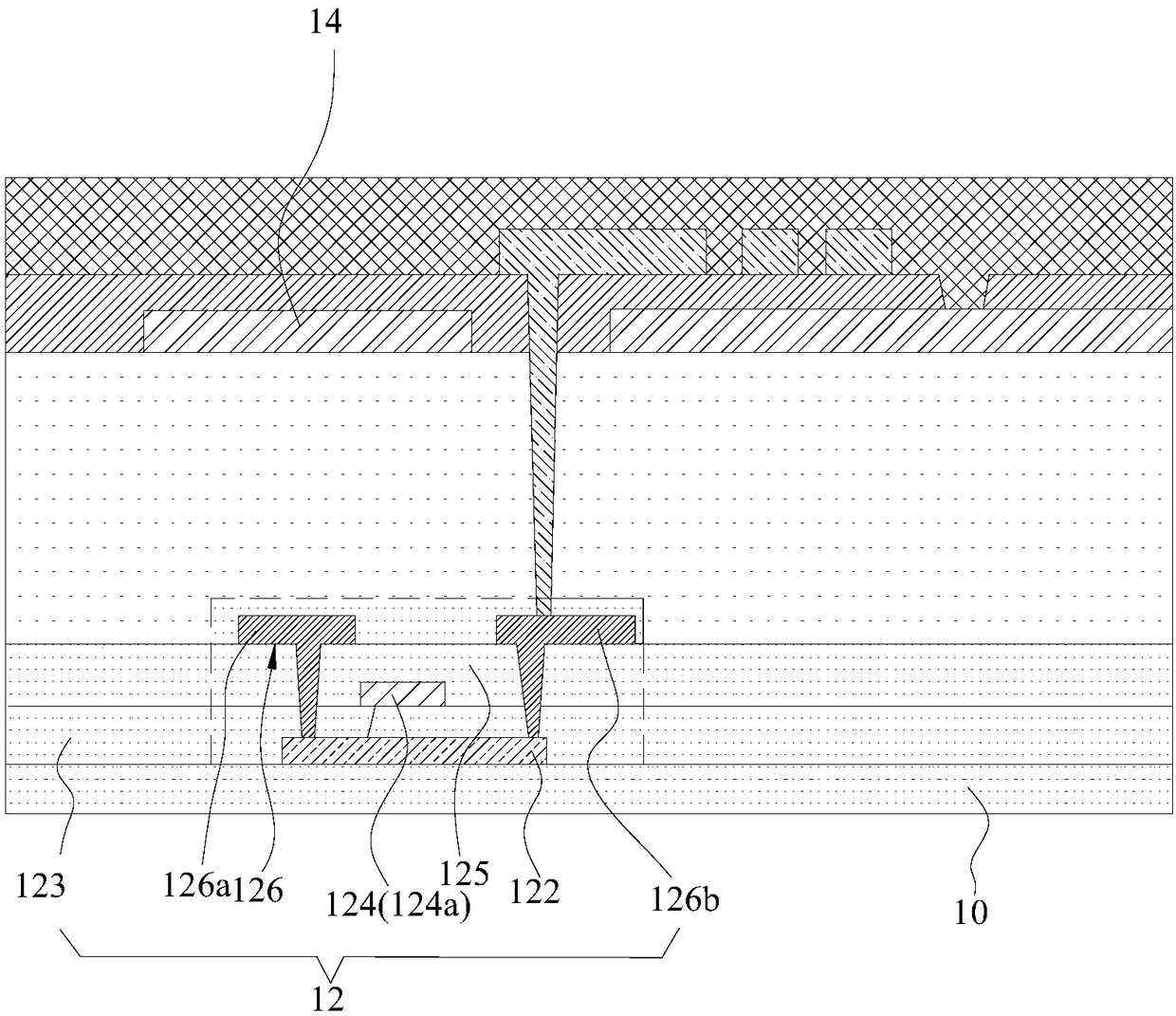

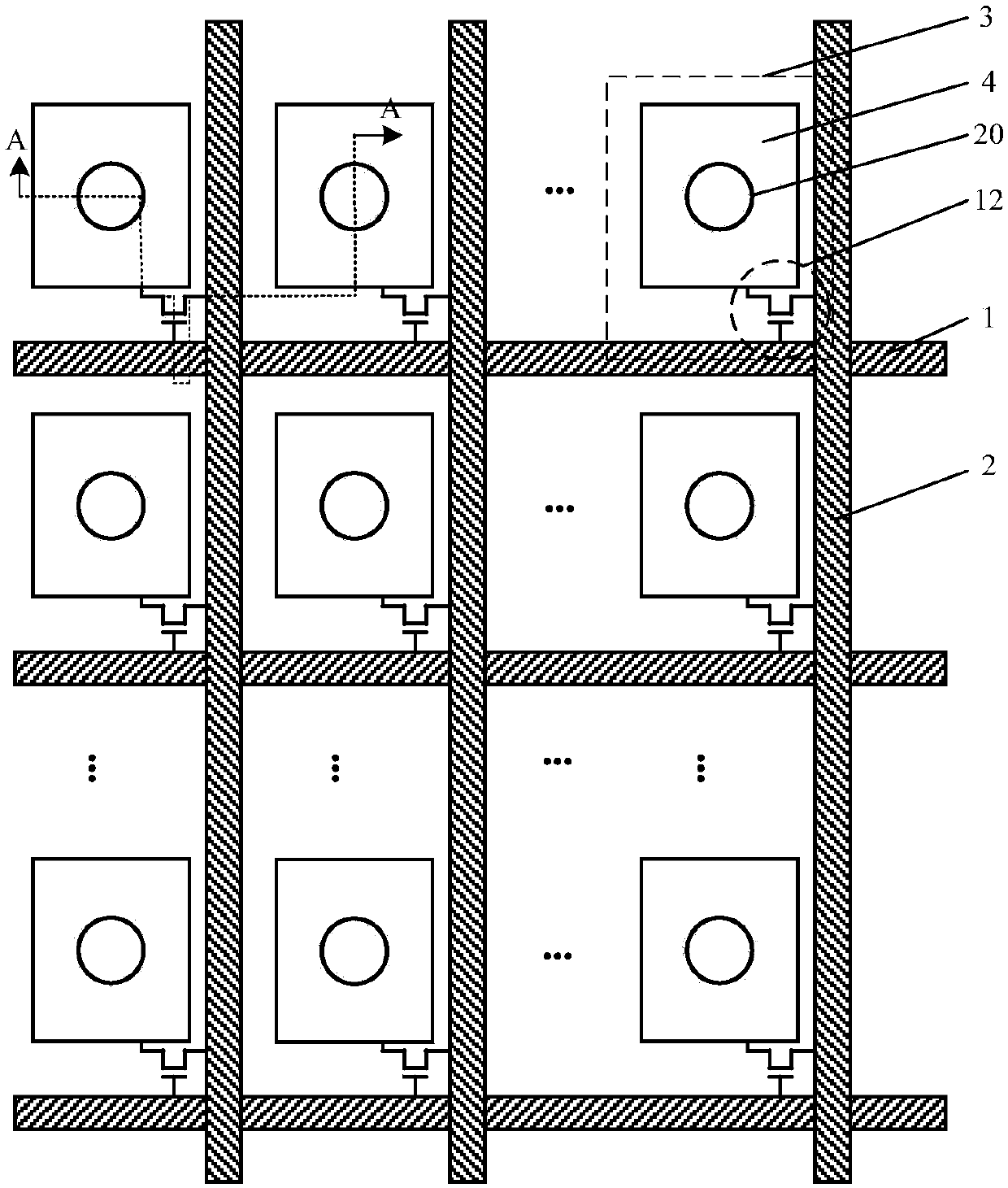

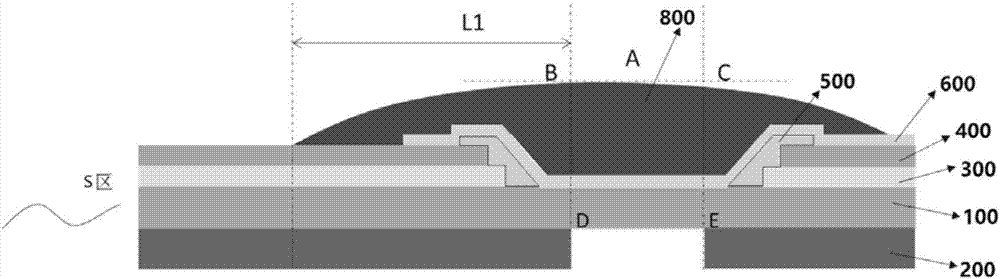

Display panel and display device

ActiveCN107293570ADoes not affect the display effectImprove bending resistanceStatic indicating devicesSolid-state devicesDisplay deviceVolumetric Mass Density

The present invention discloses a display panel and a display device. The invention aims to improve the bending resistance of the display panel without affecting the display effect of the display panel. The display panel is divided into at least one folding region and at least one non-folding region adjacent to the folding region; and the display panel comprises a substrate, a plurality of light emitting devices and a plurality of pixel circuit units, wherein the pixel circuit units are located on the substrate and are all arranged in the non-folding regions, wherein each non-folding region comprises at least one first region and at least one second region; each of the first regions and the second regions includes a plurality of pixel circuit units arranged in an array; the first regions are adjacent to the folding regions; the second regions are located at one side of each of the first regions which is far away from the folding regions; and the distribution density of the pixel circuit units in the first regions is greater than or equal to the distribution density of the pixel circuit units in the second regions.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

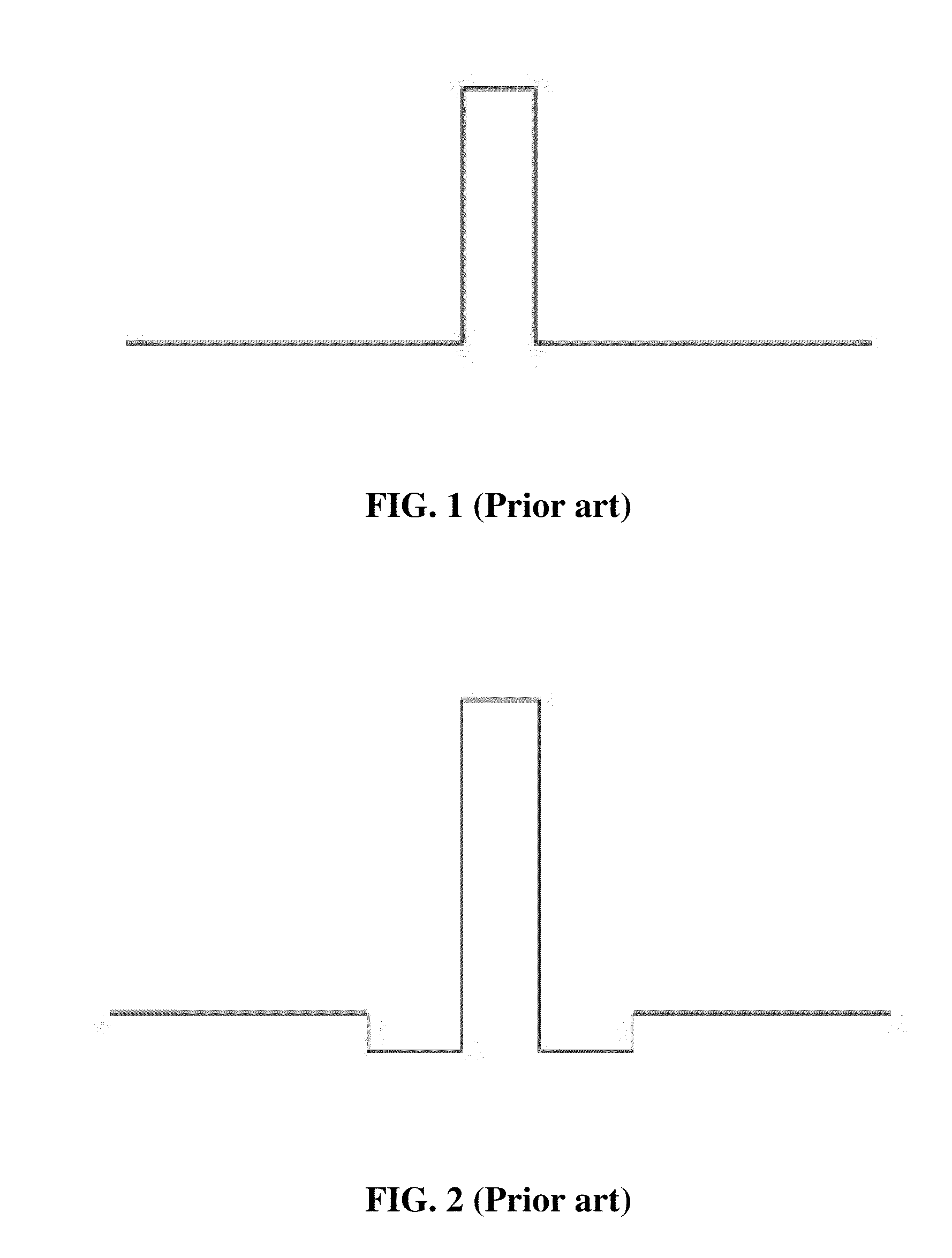

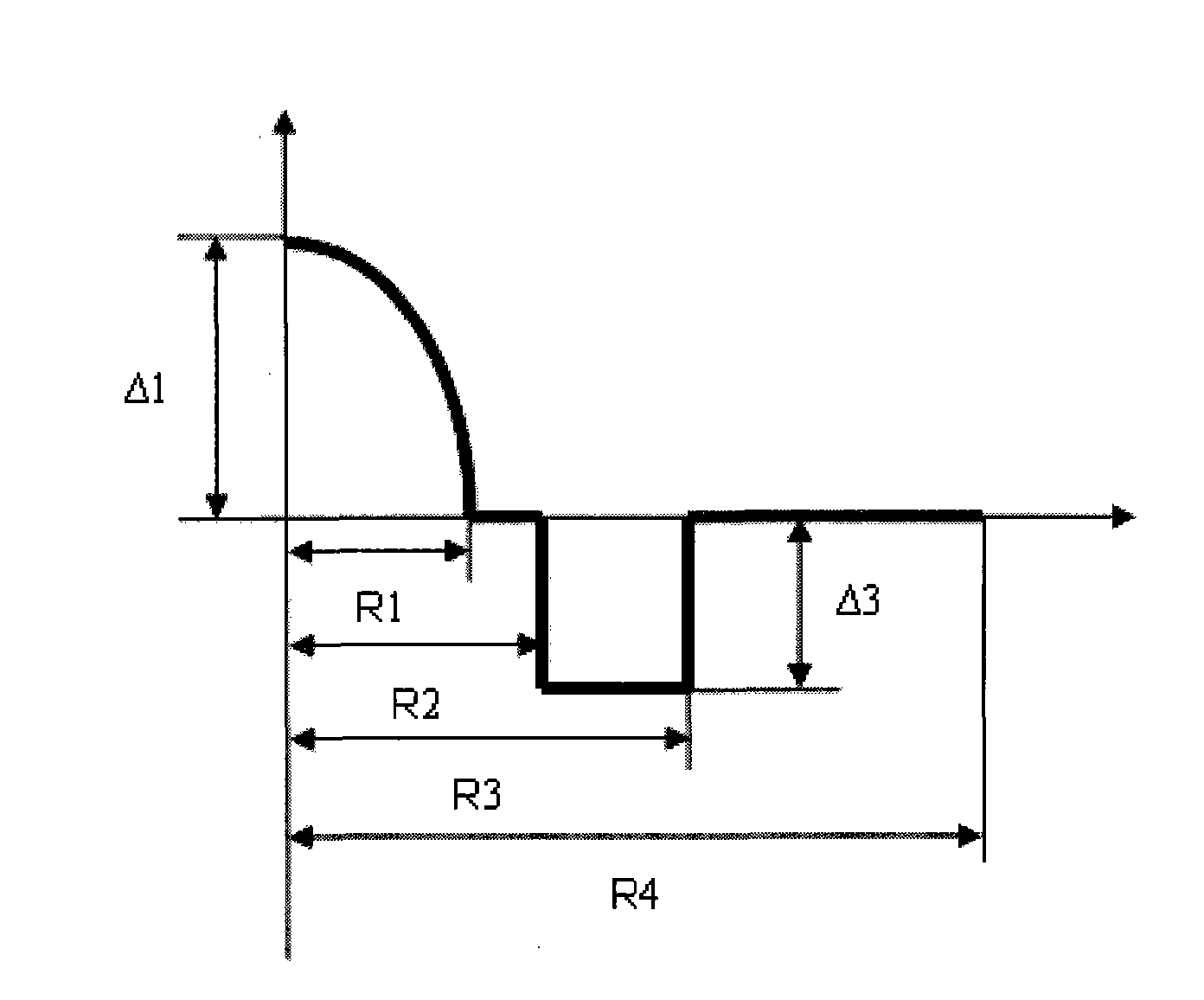

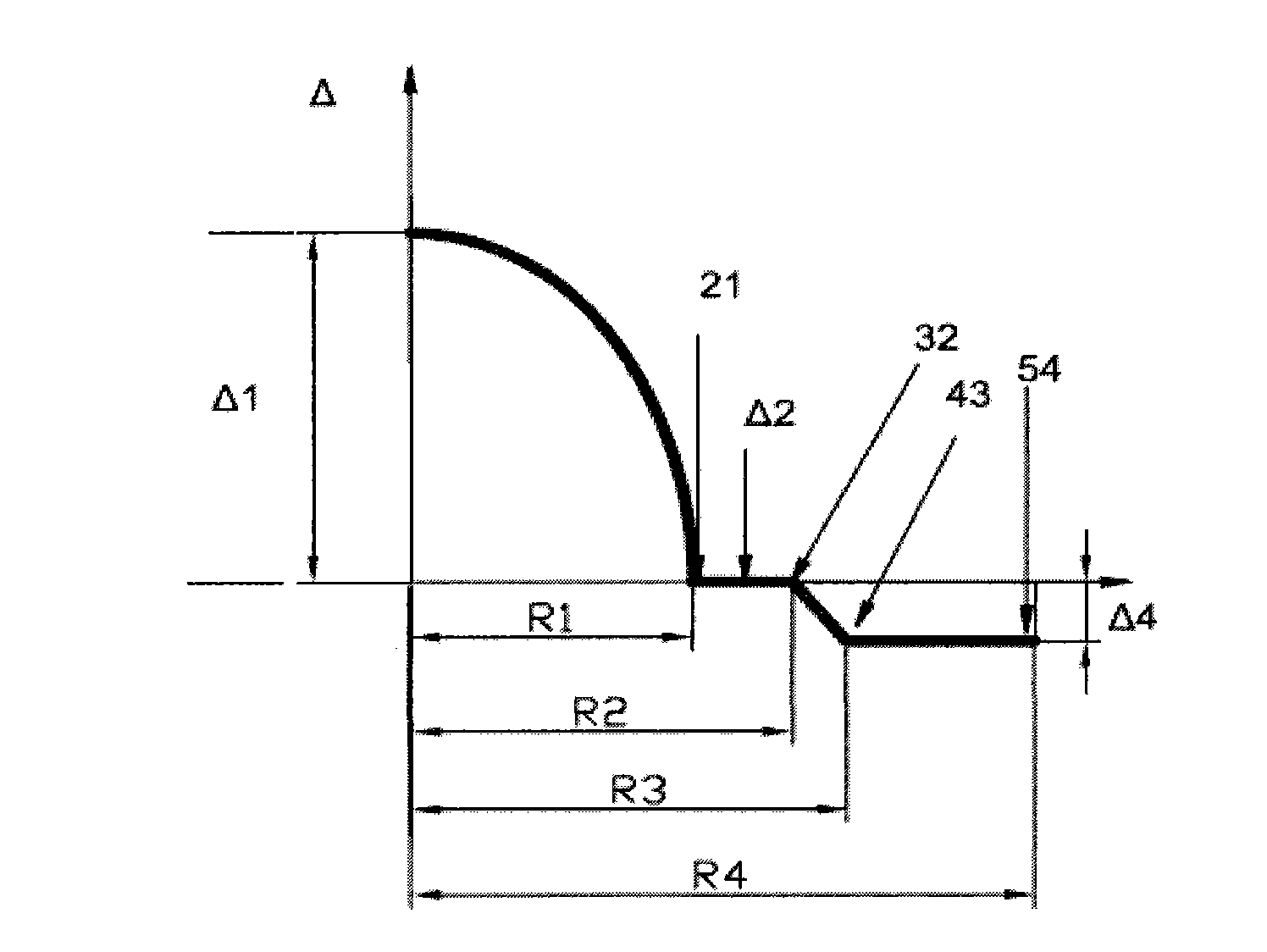

Anti-bending multimode fiber and manufacturing method thereof

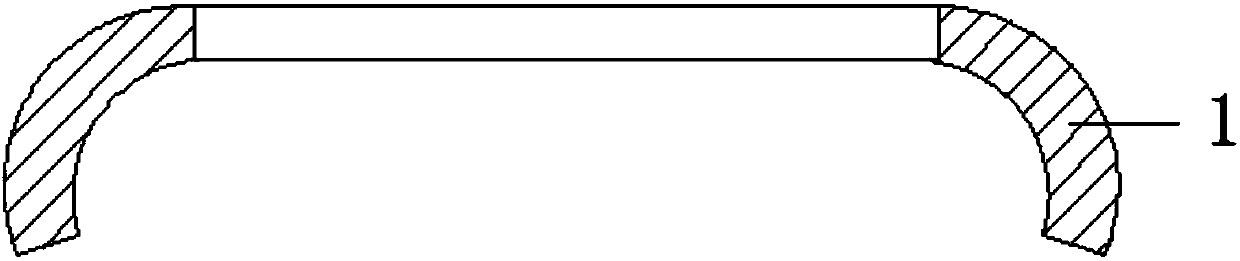

ActiveCN101634728AReduce bend add-on attenuationImprove bending resistanceGlass making apparatusOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

The invention relates to an anti-bending multimode fiber and manufacturing method thereof. The fiber comprises a core and a cladding and is characterized in that the radius of core R1 is 24-26 microns, refractive index section of the core is like a parabola, refractivity maximum delta1 is 0.9-1.1%, the cladding outside the core is composed of three parts, the radius of inner cladding R2 is 1.04-1.6 times of the radius of core R1, delta2 is minus 0.01-0.01%, intermediate cladding is gradually changed in refractive index, the radius of intermediate cladding R3 is 1.06-1.8 times of R1, refractivity is gradually changed into delta4 from delta2, the radius of outer cladding R4 is 2.38-2.63 times of R1, and delta4 is minus 0.20% to minus 0.40%. The invention reduces fiber bending additional attenuation and improves anti-bending performance of fiber but also basically eliminates inner stress of fiber, greatly improves mechanical properties of fiber, and service life of fiber operating in minor radius for a long time also can be guaranteed. The manufacturing method of the invention is simple, convenient and effective and is applicable to mass production.

Owner:EVERPRO TECH COMPANY

Sneaker sole material with high wear resistance and low hardness and preparation method thereof

The invention discloses a sneaker sole material with high wear resistance and low hardness and a preparation method thereof, particularly a method for preparing a sneaker sole material which is suitable for middle and high-grade sneaker soles with higher requirements on wear resistance and comfort. The sneaker sole material comprises the following components: butadiene rubber (BR), natural rubber (NR), styrene butadiene rubber (SBR), softening oil, a reinforcing agent, an activating agent, a coupling agent, a vulcanizer, a vulcanization accelerator, a tackifier and an anti-aging agent. A series of sole material with high wear resistance (DIN abrasion is less than or equal to 40mm<3>, and the length of grinding marks is 3.0 to 4.0mm) and low hardness (ShoreA 60-66) is prepared by screening the proportion of rubber composition, the coupling agent, the accelerator, and the activating agent and reasonably controlling a process on the basis of the rubber, the softening oil and the reinforcing agent. The material has the advantages that: (1) the total weight of a sneaker sole is expected to be reduced, namely the thickness of a rubber outer sole of a sneaker can be reduced under the condition that the material has the wearing life which is the same as that of the conventional sneaker sole, so that the total weight of the sole is reduced; (2) the humidity and slip resistance is improved, namely the hardness of the sole is lower and the sole is easy to distort under the condition of stress, so that the contact area of the sole and the ground is increased, and the aim of improving the humidity and slip resistance of the sole is fulfilled; and (3) the comfort is improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Ultraviolet-cured hydrophilic coating composition and preparation method thereof

InactiveCN102585691AHigh content of hydrophilic substancesCreate pollutionPolyurea/polyurethane coatingsPolyether coatingsHydrophilic coatingPolymer science

The invention relates to a highly-hydrophilic transparent ultraviolet-cured coating composition and a preparation method thereof. The ultraviolet-cured hydrophilic coating composition comprises light-cured resin, a polymerization monomer, a reactive diluent, a light initiator, an auxiliary and pigment. The preparation method comprises accurately weighing the light-cured resin according to a formula and pouring the light-cured resin into a mixing kettle, sequentially adding the polymerization monomer, the reactive diluent and the auxiliary into the mixing kettle, and stirring the mixture for 20-45 minutes; adding the light initiator into the mixing kettle, mixing for 15-35 minutes to obtain ultraviolet-cured hydrophilic coating, and storing the ultraviolet-cured hydrophilic coating away from the light; and when the ultraviolet-cured hydrophilic coating is used, adding the pigment and performing even mixing. The ultraviolet-cured hydrophilic coating composition can be coated on base materials of plastic, metal, glass and the like. An ultraviolet-cured coating has excellent hydrophilcity and good physical performance, adhesive force, hydrolytic resistance, salt fog resistance and alkali resistance.

Owner:CHANGSHA YUANPENG CHEM TECH

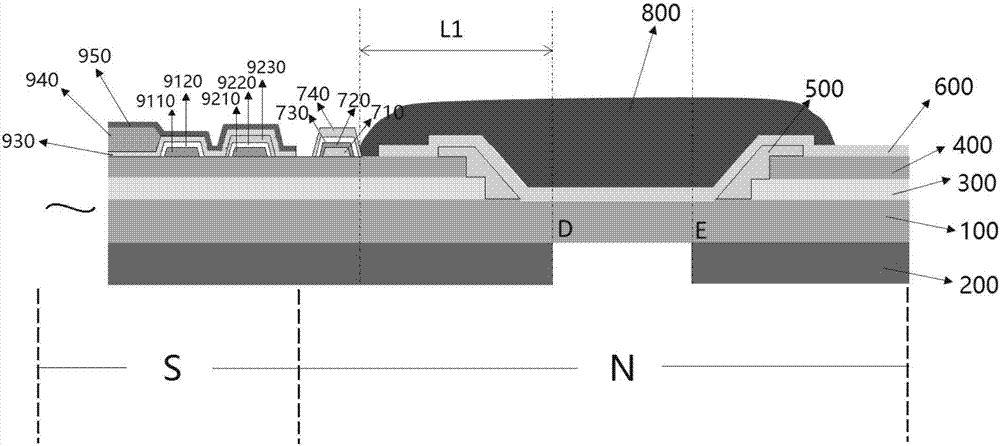

Flexible display panel

ActiveCN108389869AImprove display qualityImprove reliabilitySolid-state devicesPhotovoltaic energy generationLine BreakTransmission line

The invention relates to a flexible display panel and a flexible display device. The display panel comprises a display region and a non-display region, and a bending region is arranged between the display region and the non-display region. The display panel further comprises a flexible substrate, a thin film transistor (TFT) layer, a touch control layer and a signal transmission line; the TFT layer is arranged on the flexible substrate, and in the direction far from the flexible substrate, the TFT layer comprises a semiconductor layer, a grid insulating layer, a grid layer, an interlayer insulating layer and a source-drain metal layer stacked successively; the touch control layer is arranged in the side, far from the flexible substrate of the TFT layer, and comprises a first touch controlmetal layer and a second touch control metal layer; and the signal transmission line comprises two conductor wires arranged in parallel at least, and the conductor wires are arranged in the same layerwith at least two selected from the source-drain metal layer, the first touch control metal layer and the second touch control metal layer. The flexible display panel is less possible of line breaking during bending.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

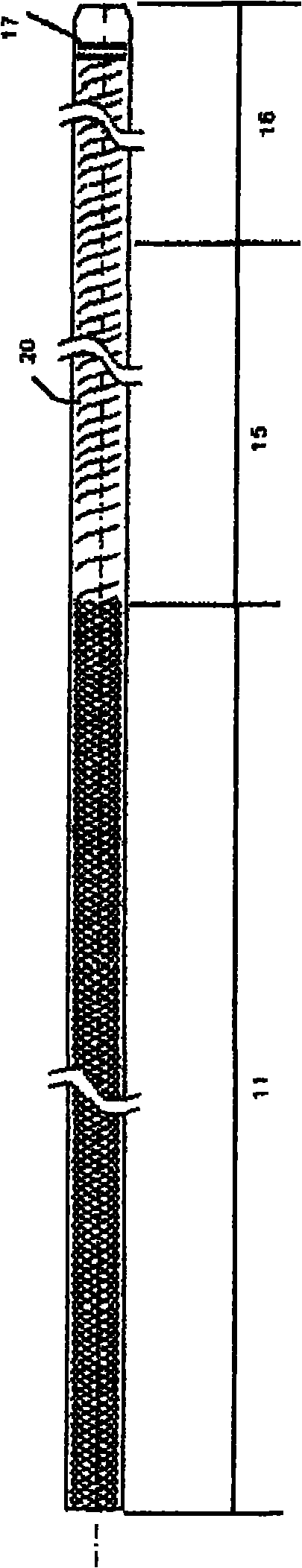

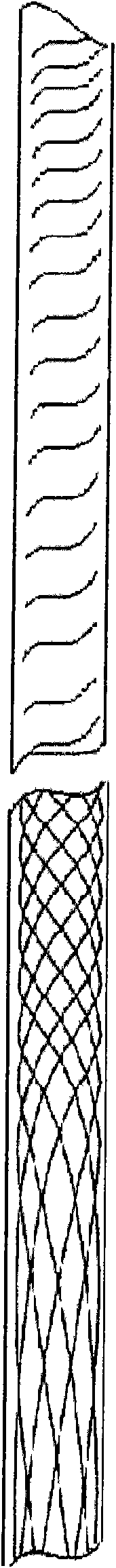

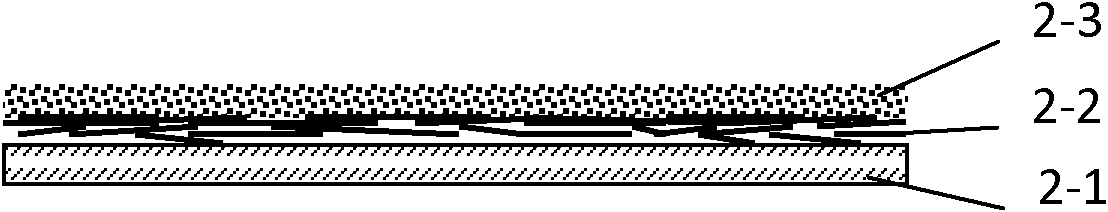

Mciro-catheter

ActiveCN101933821ASafe and smooth crossingImprove flexibilitySurgeryMedical devicesBlood vesselPolymer

The invention relates to a catheter. A catheter wall thereof sequentially comprises a smooth layer, a strengthened layer and a jacket layer from inside to outside, wherein the smooth layer and the jacket layer are both formed by compounding polymer materials, and the strengthened layer is a support layer and is respectively connected with the smooth layer and the jacket layer, therefore, every two layers of the catheter are connected. The catheter also sequentially comprises a proximal end part and an extension part along the direction from the near to the distance. In addition, the strengthened layer is in a braided structure at the proximal end part and is in a spiral structure at the extension part. The invention has the advantages that the structure can enhance the flexibility, the torsional resistance, the tracing property, the supporting property and the anti-fold property of the catheter when reducing the size of the catheter, and therefore, the catheter is suitable for penetrating through a distal vessel in a cranium.

Owner:MICROPORT NEUROTECH SHANGHAI

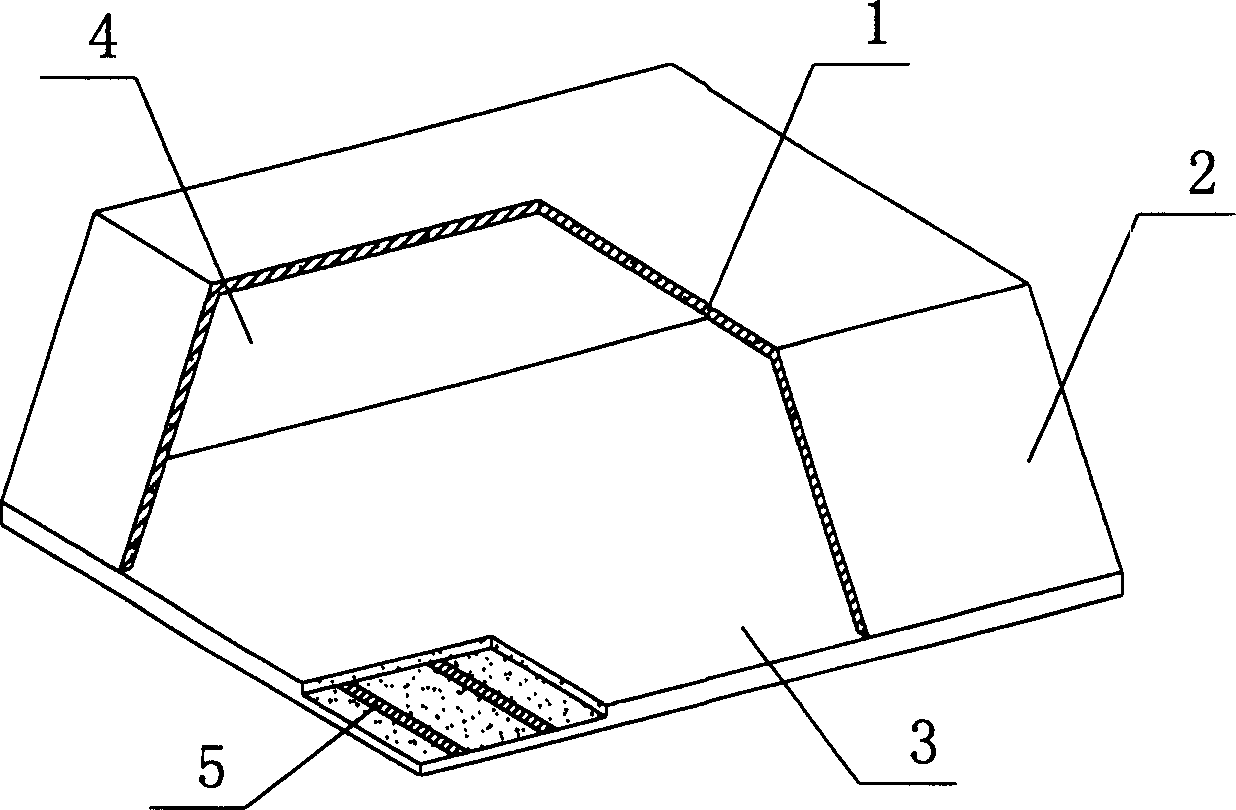

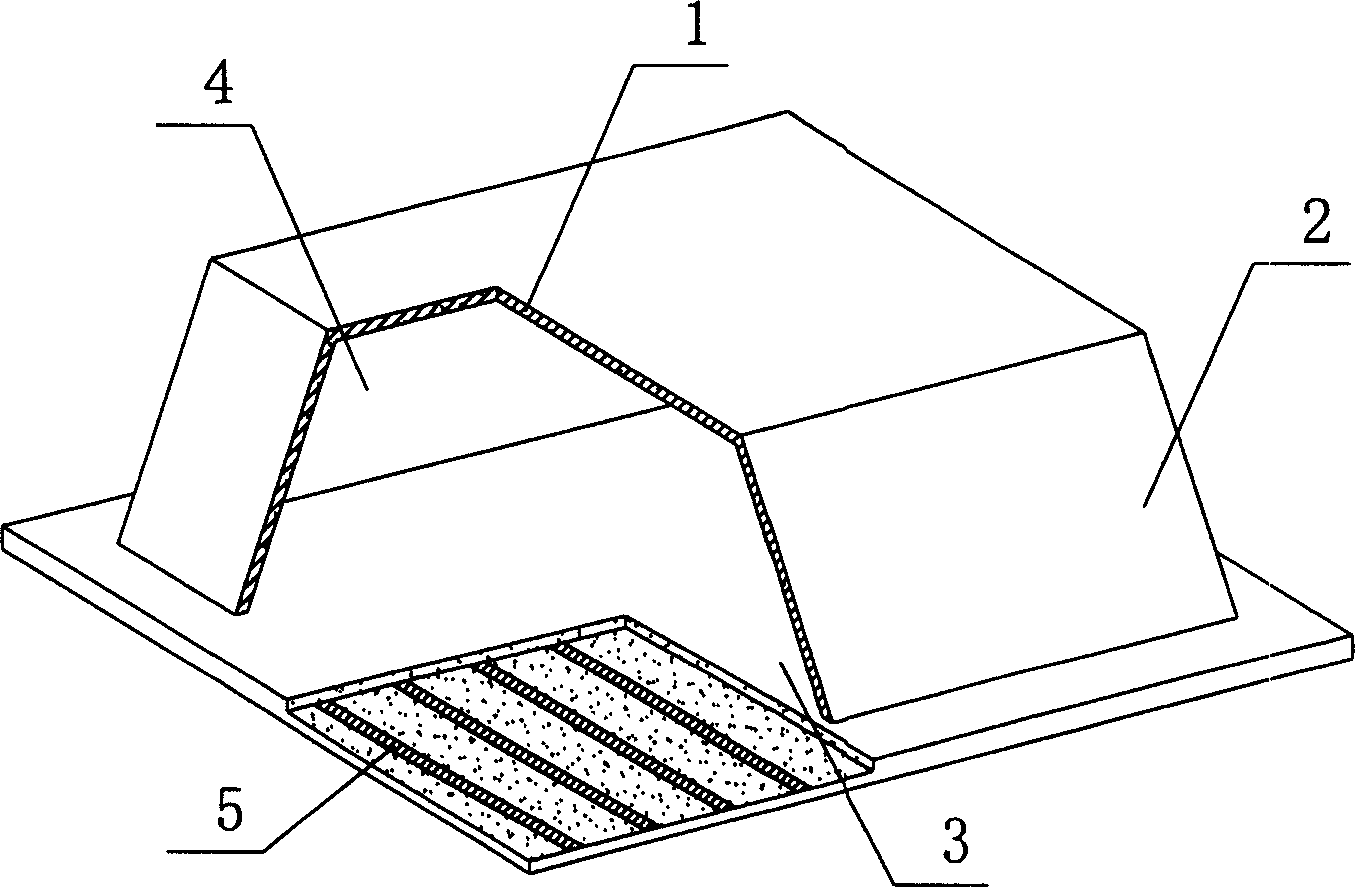

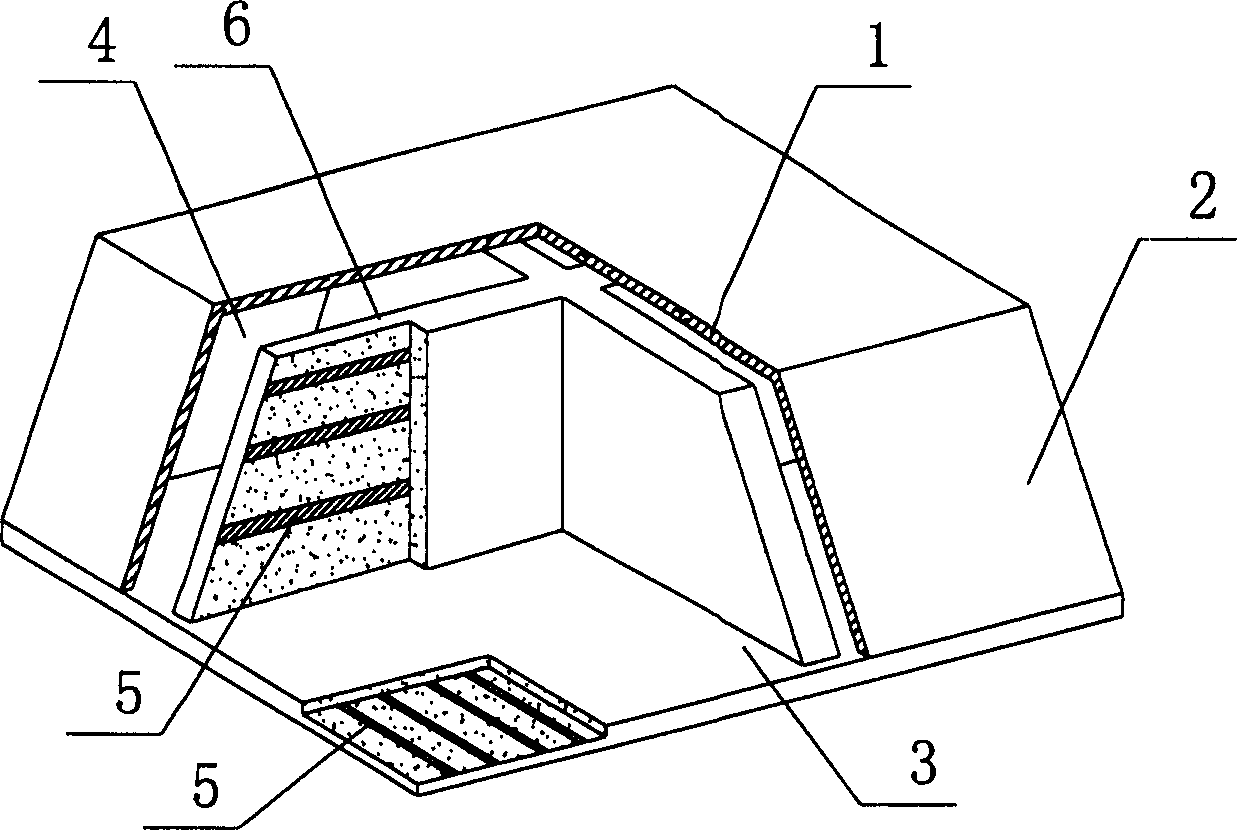

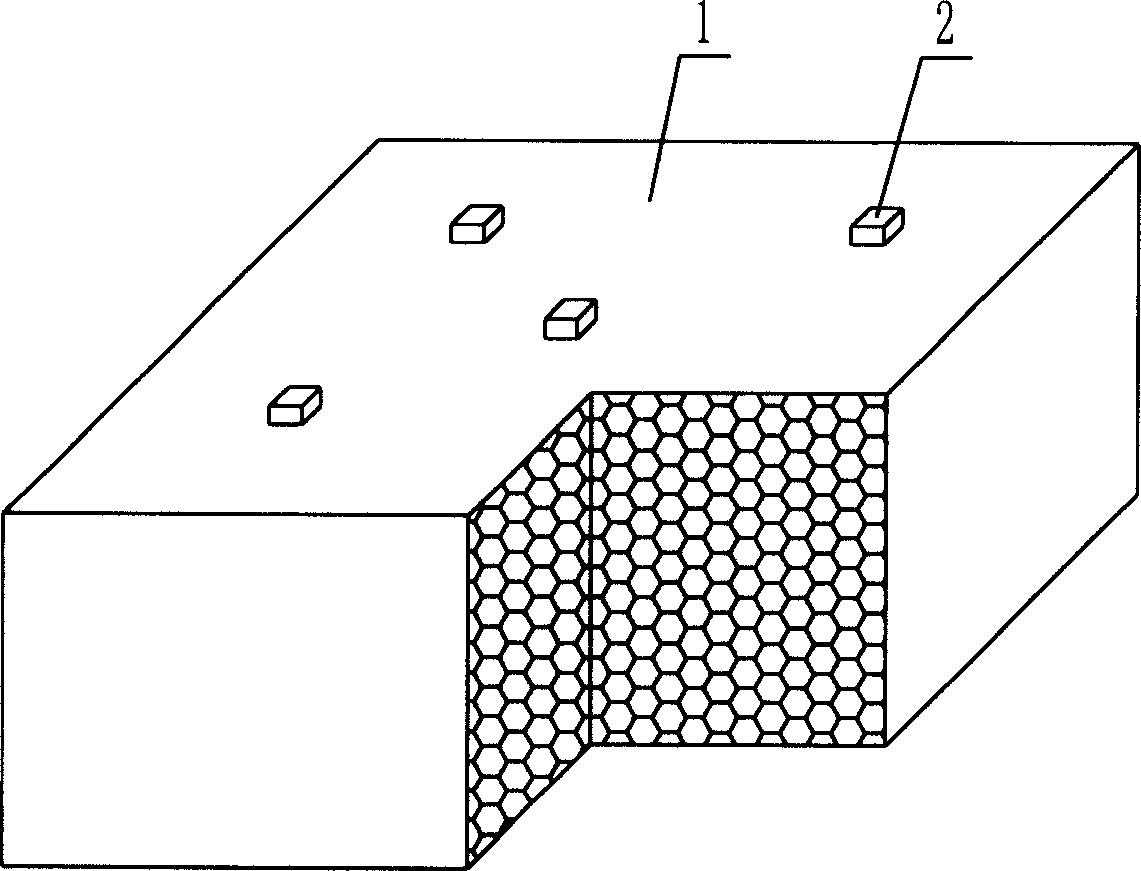

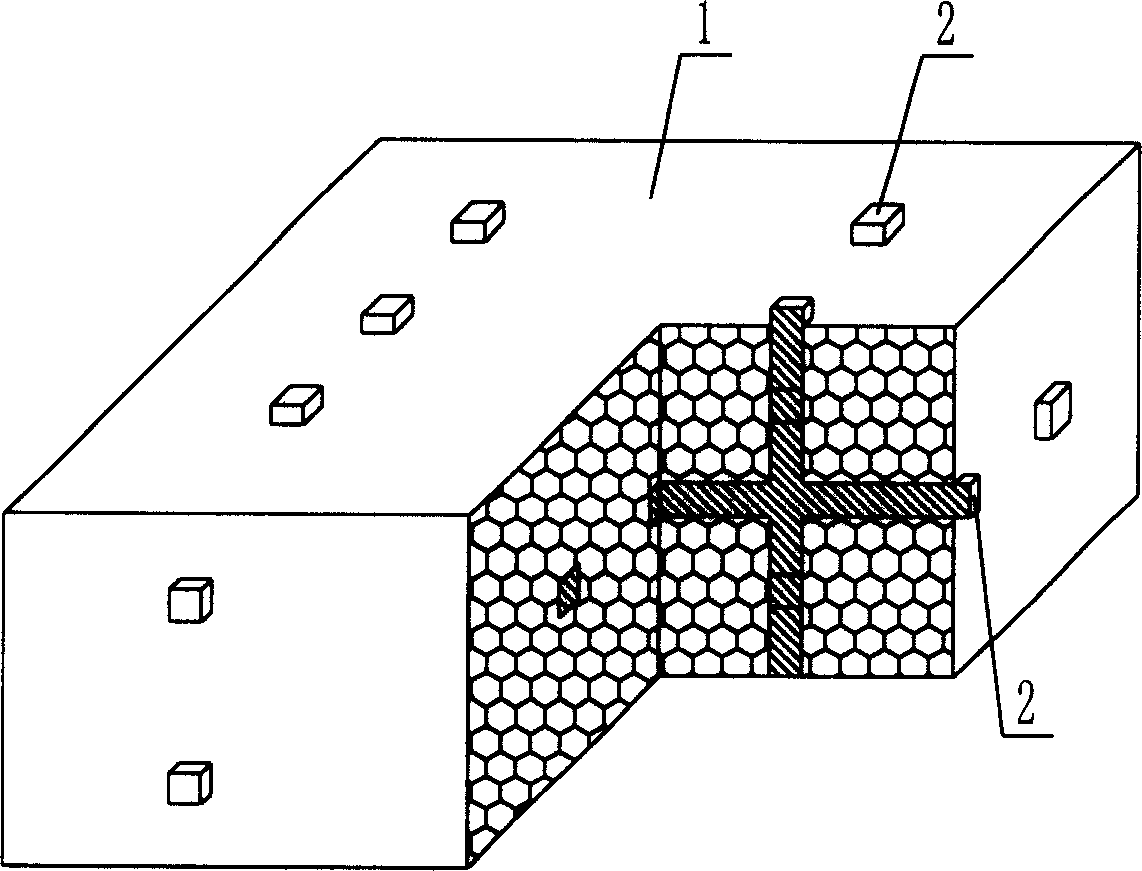

Component of light stuffing mould for concrete poured-in-situ

InactiveCN1598205AIt is convenient to obtain materials nearbyReduce manufacturing costFloorsSolid lightPre stress

A light mould component for concreting, which includes a polyhedron solid light material component, its character lies in: the mentioned polyhedron solid light material component contains at least one strengthening pole. Because of the strengthening pole, the intensity of the component is high, the rigidity is large, and it is not apt to be damaged; additionally, it has characters of simple structure, high intensity, deformation and vibration resisting, easy producing, low cost, and convenient construction. And the applications of the component are wide.

Owner:湖南邱则有专利战略策划有限公司

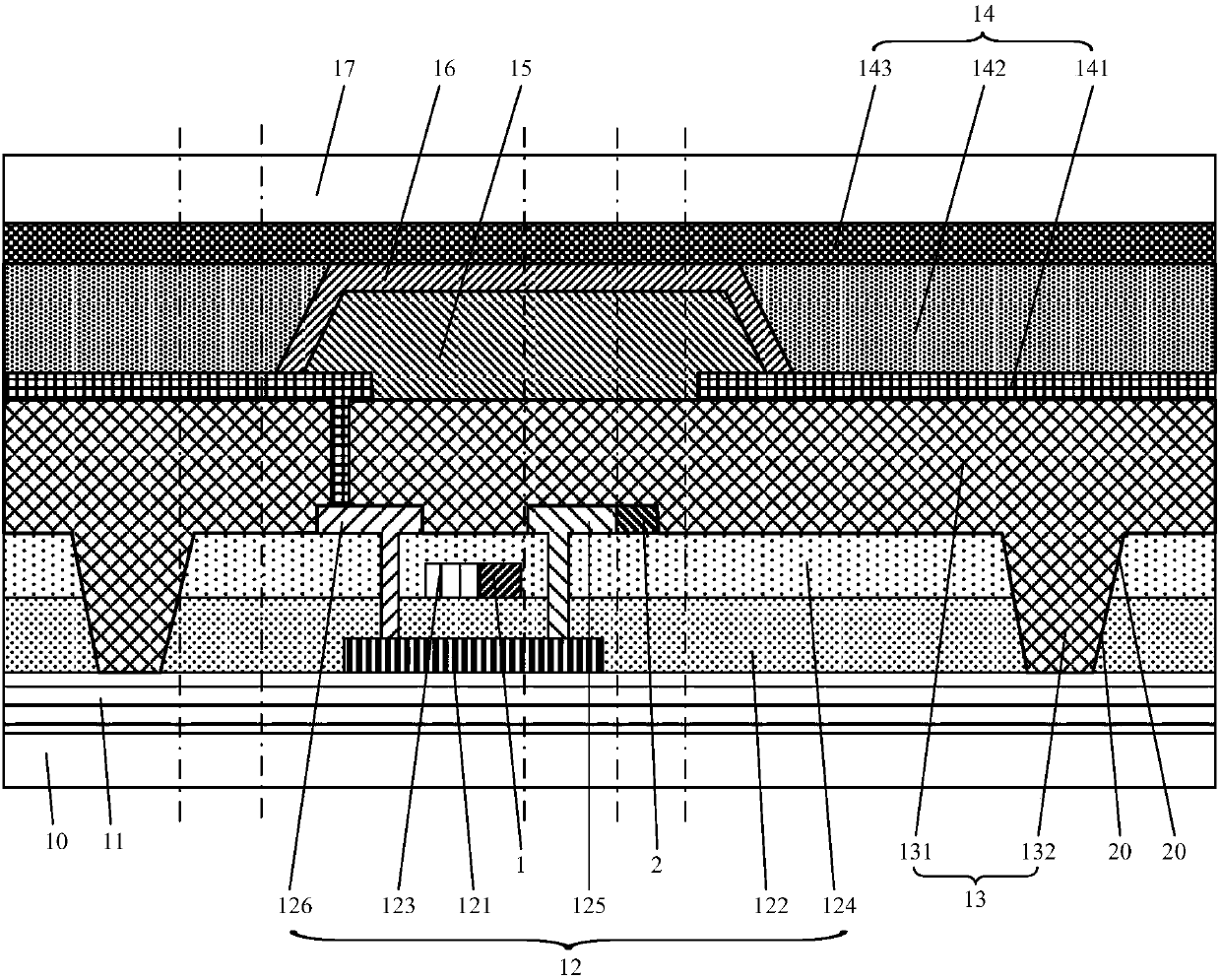

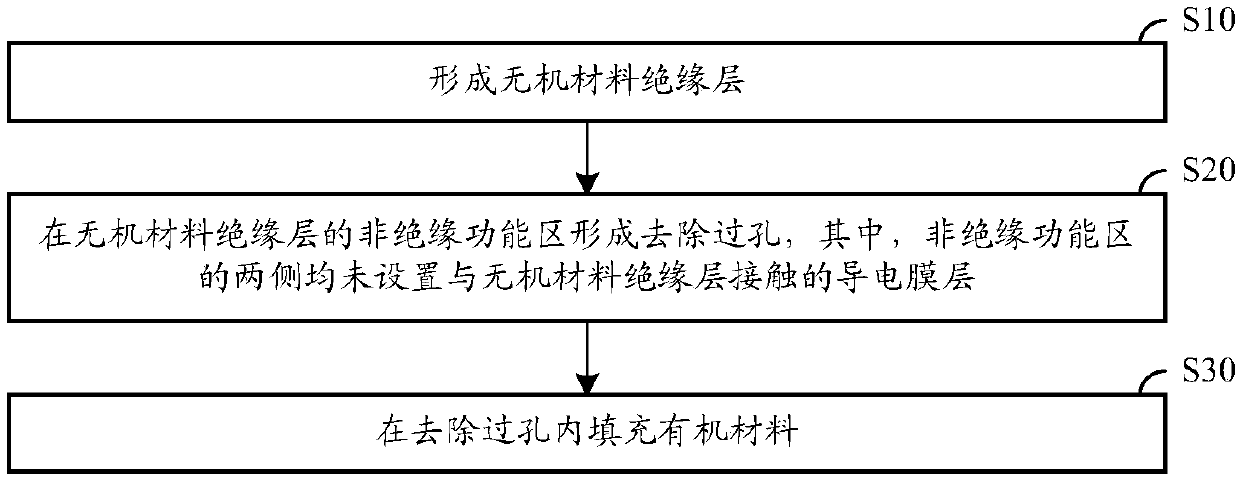

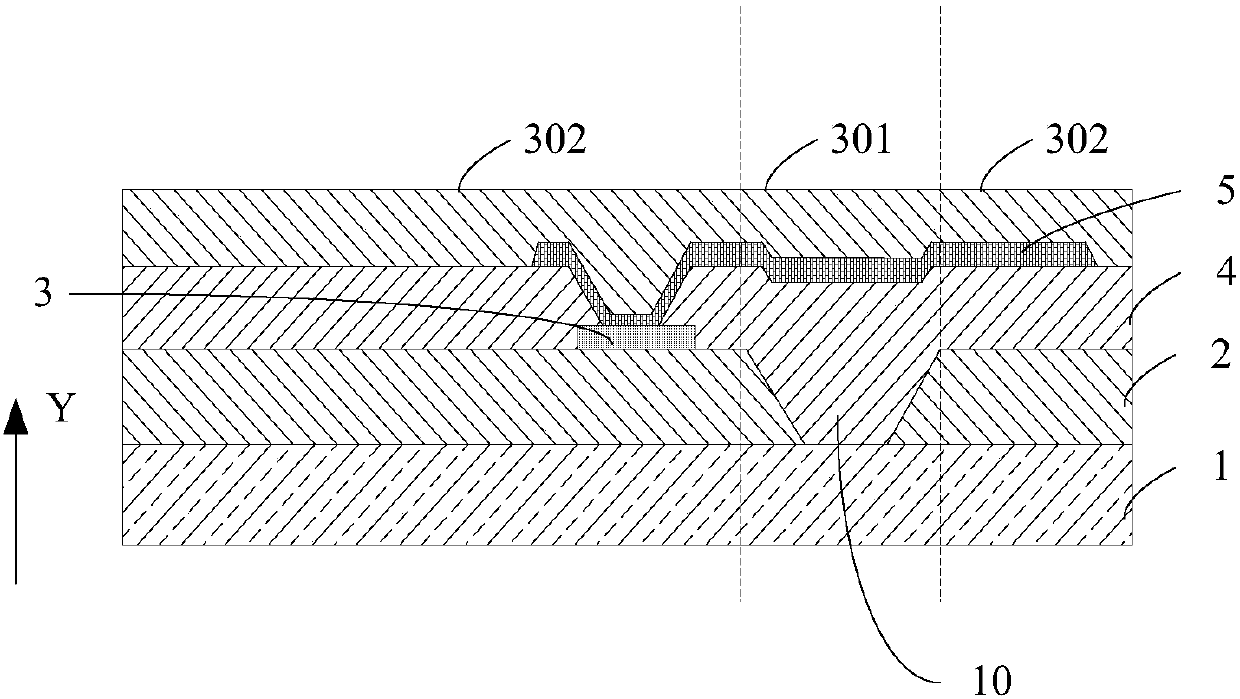

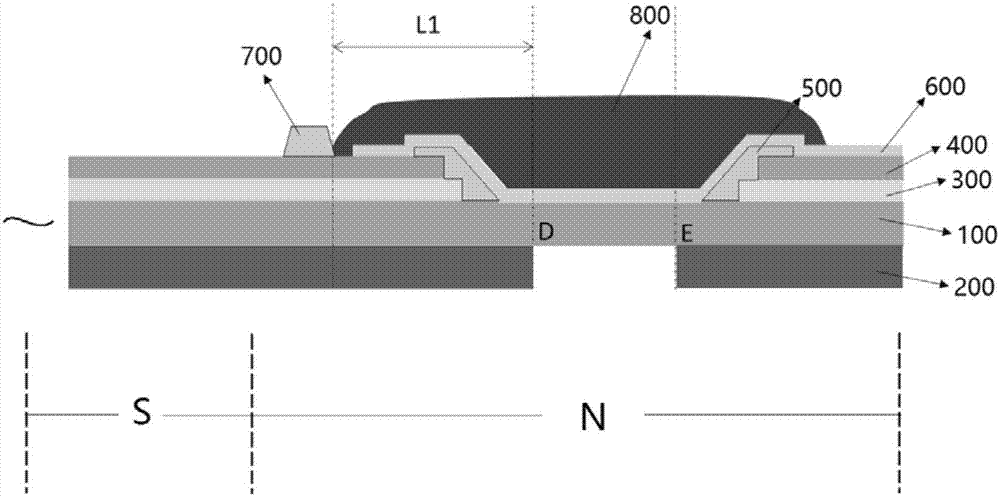

Flexible display panel and manufacturing method thereof and flexible display device

PendingCN107658333AReduce coverage areaImprove bending resistanceFinal product manufactureSolid-state devicesInorganic materialsFlexible display

The invention discloses a flexible display panel and a manufacturing method thereof and a flexible display device, and relates to the technical field of display. Quality declining and even failure ofthe flexible display device caused by cracks and even fractures of an inorganic material insulating layer because of the stress can be prevented. The flexible display panel comprises the inorganic material insulating layer. The inorganic material insulating layer comprises a non-insulating functional area. The non-insulating functional area is internally provided with removing through holes for removing the inorganic material insulating layer in the non-insulating functional area so as to remove the organic material filled in the through holes. The two sides of the non-insulating functional area are not provided with a conductive film layer contacted with the inorganic material insulating layer. The coverage area of the inorganic material insulating layer can be reduced without influencingthe insulation function of the inorganic material insulating layer, and the removing through holes are filled by using the organic material so that the probability of the cracks and even the fractures of the inorganic material insulating layer can be reduced, and quality declining and even failure of the flexible display device can be prevented.

Owner:BOE TECH GRP CO LTD

Method for preparing Wood-plastic composite material by modified wood powder and waste and old plastics

The invention relates to a preparation technique of a wood plastic composite material, in particular to a method for preparing a wood plastic composite material by using modified wood powder and waste plastics. The method is characterized in that: (1) discarded agriculture and forestry wastes are crushed, milled and dried, and three different surface modification agents are added in sequence and mixed with the waste power one after another in a high-speed mixer to produce the modified water powder; and (2) waste plastics are washed and crushed into granules with the grain size of 2mm to 12mm and then dried; the modified waste powder, the waste plastic granules, a lubricant, a vesicant and a blowing promoter are mixed by weight percentage and put into the high-speed mixer for high-speed mixing and then cooled to the temperature lower than 55 DEG C for discharging so as to prepare a special premix. The composite material has super high strength and anti-bending and anti-impact capacity, wherein, the obvious enhancement of the anti-impact strength causes the great enhancement of the processing capacity of the product, thus causing products to meet different demands and ensuring an extremely wide application range.

Owner:FUJIAN NORMAL UNIV

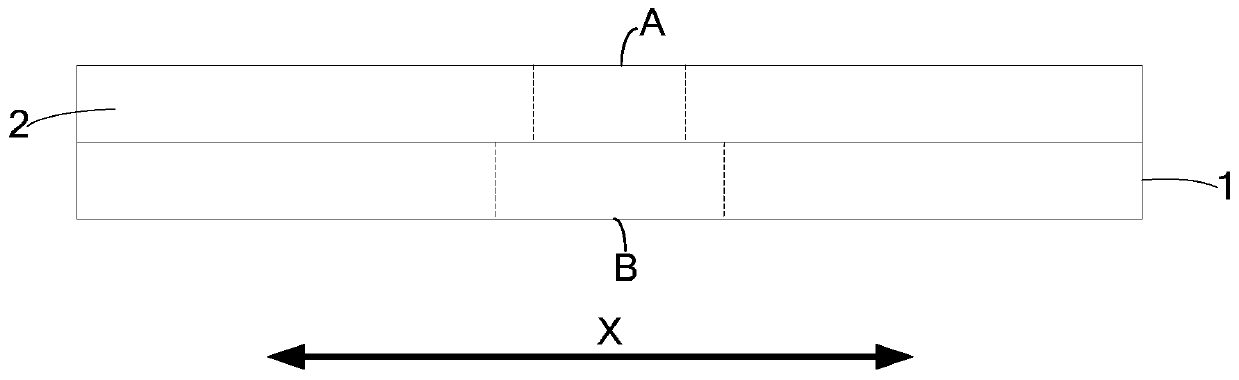

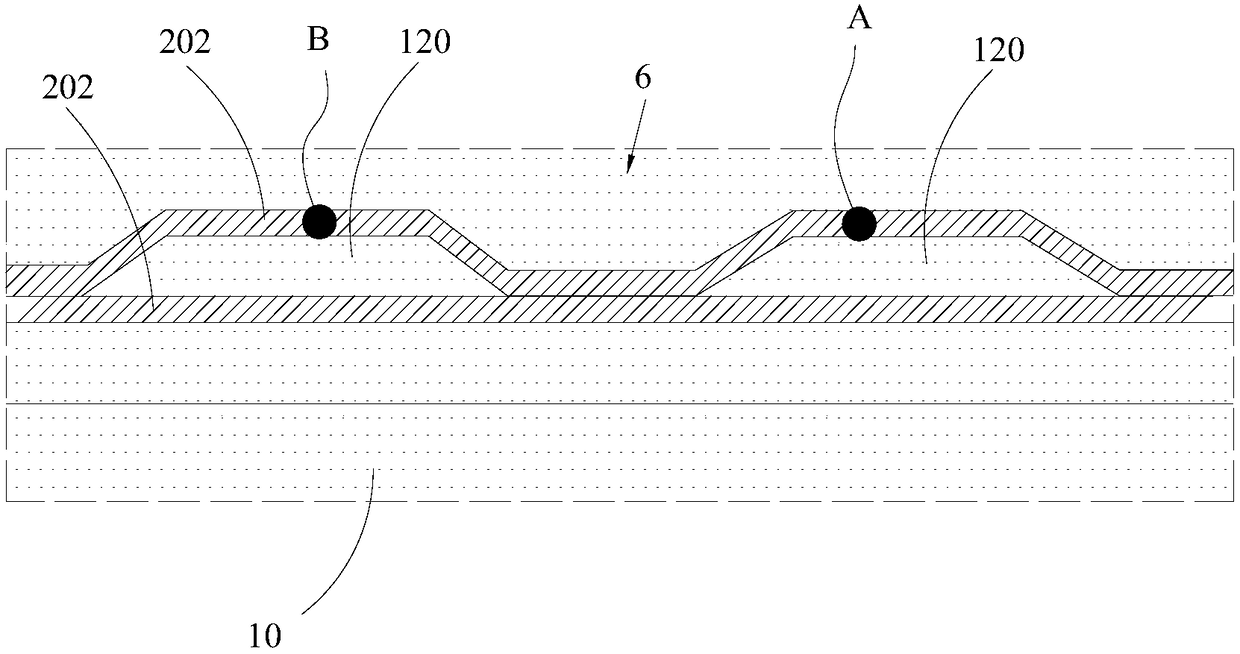

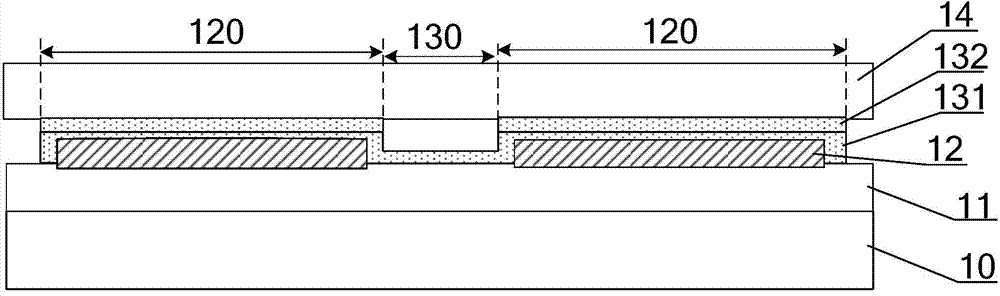

Flexible display panel, display device and making method of flexible display panel

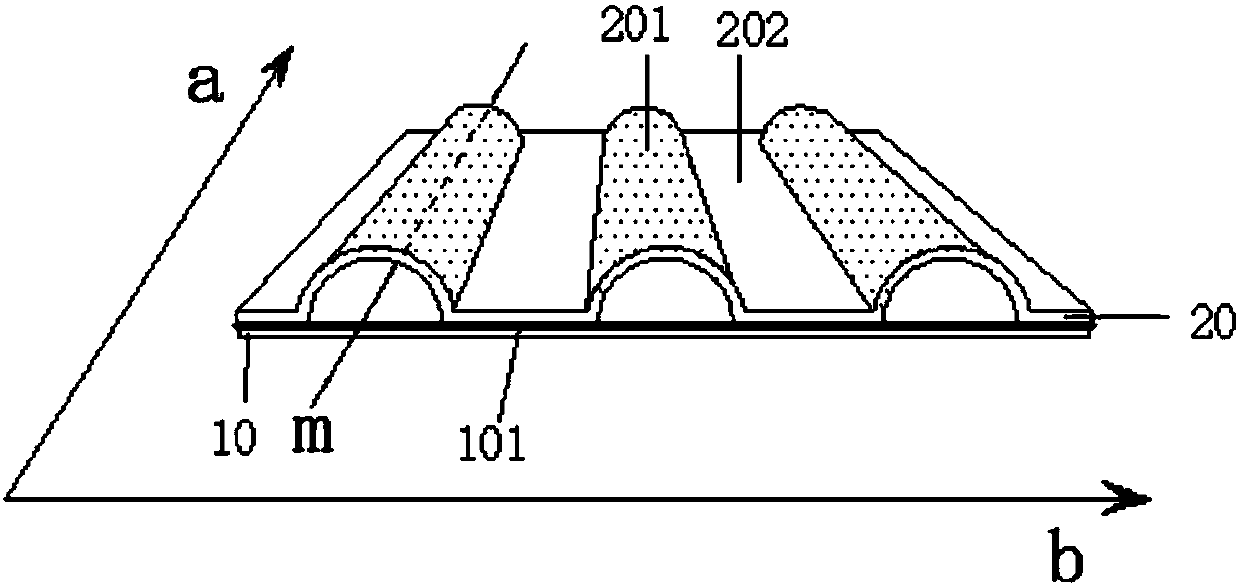

ActiveCN107564415AExtend your lifeImprove bending resistanceIdentification meansDisplay deviceEngineering

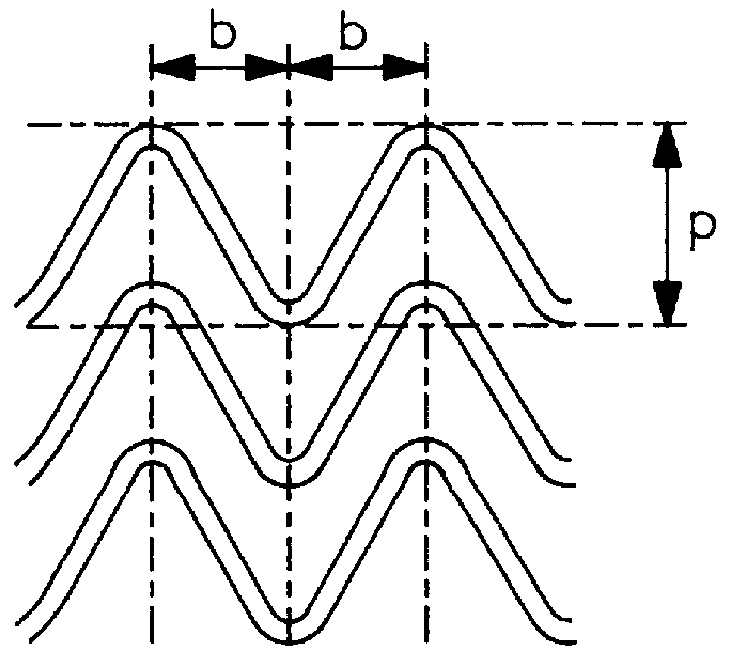

The invention discloses a flexible display panel, a display device and a making method of the flexible display panel. A bending shaft in a bendable area of the flexible display panel extends in the first direction, and the flexible display panel comprises a support membrane and a flexible display module which is arranged on the first surface of the support membrane, wherein in the bendable area, the flexible display module comprises a plurality of crinkled parts and fixed parts, the crinkled parts and the fixed parts are sequentially arranged in the second direction in an alternated mode, thecrinkled parts extend in the first direction, the fixed parts are fixed to the first surface, and the first direction is perpendicular to the second direction. When the bendable area is in a flattenedstate, the crinkled parts are in a crinkled state, and when the bendable area is in a bending state, the crinkled parts can be flattened. According to the flexible display panel, when the flexible display module of the bendable area is divided into the crinkled parts and the fixed parts, the fixed parts are fixed to the first surface of the support membrane, and the states of the crinkled parts are changed along with the state of the bendable area, the bending stress is absorbed, the bending resistance and the tension resistance of the flexible display module are enhanced, and the service life of the flexible display panel is prolonged.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Hollow form member of cast-in-place concrete

A hollow form for in-situ pouring concrete is composed of the form unit and bottom plate, and is characterized by that form unit consists of top plate and peripheral wall and is divided into two halves. Its advantages are simple structure, high strength, low cost and easy manufacture.

Owner:湖南邱则有专利战略策划有限公司

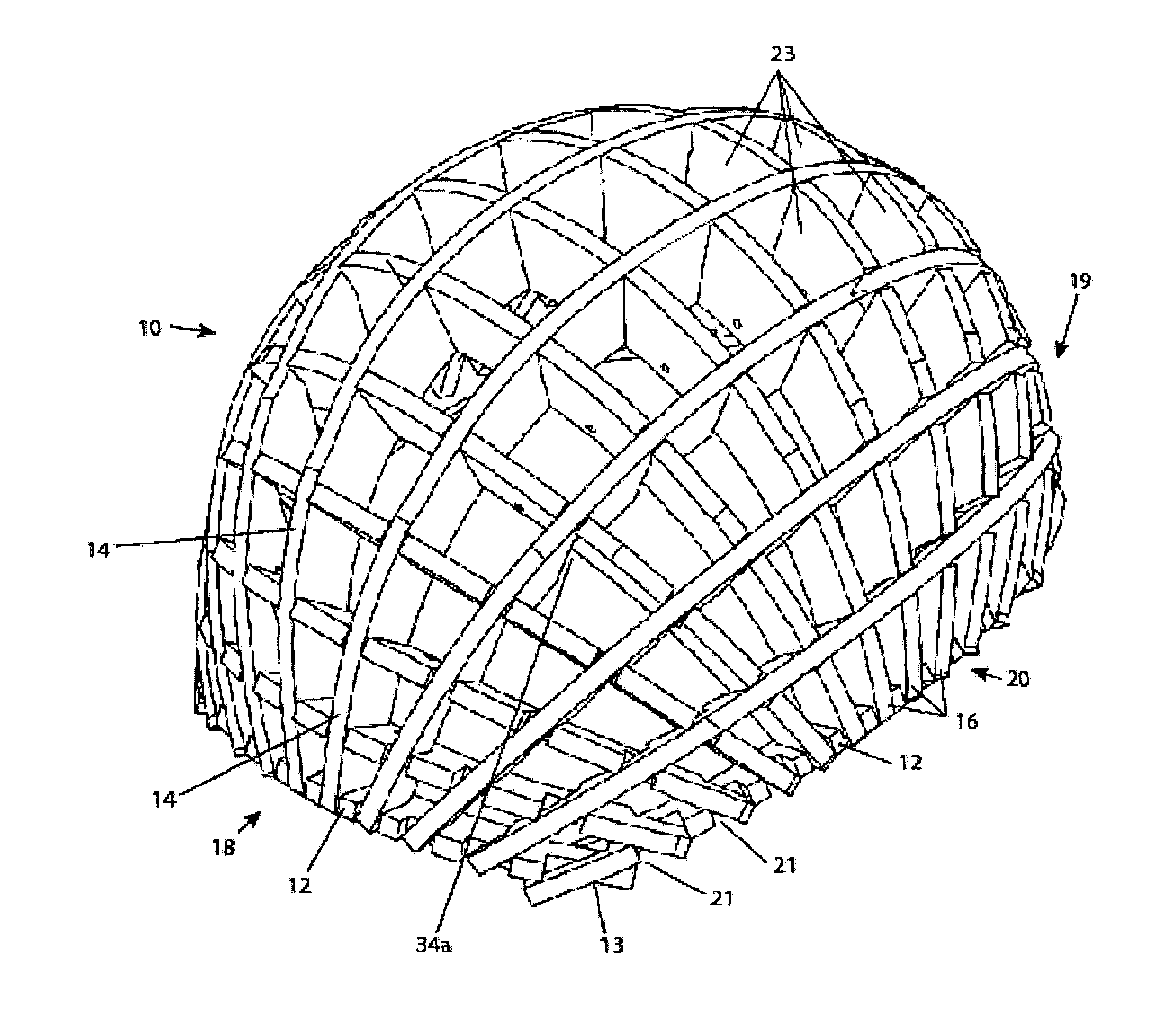

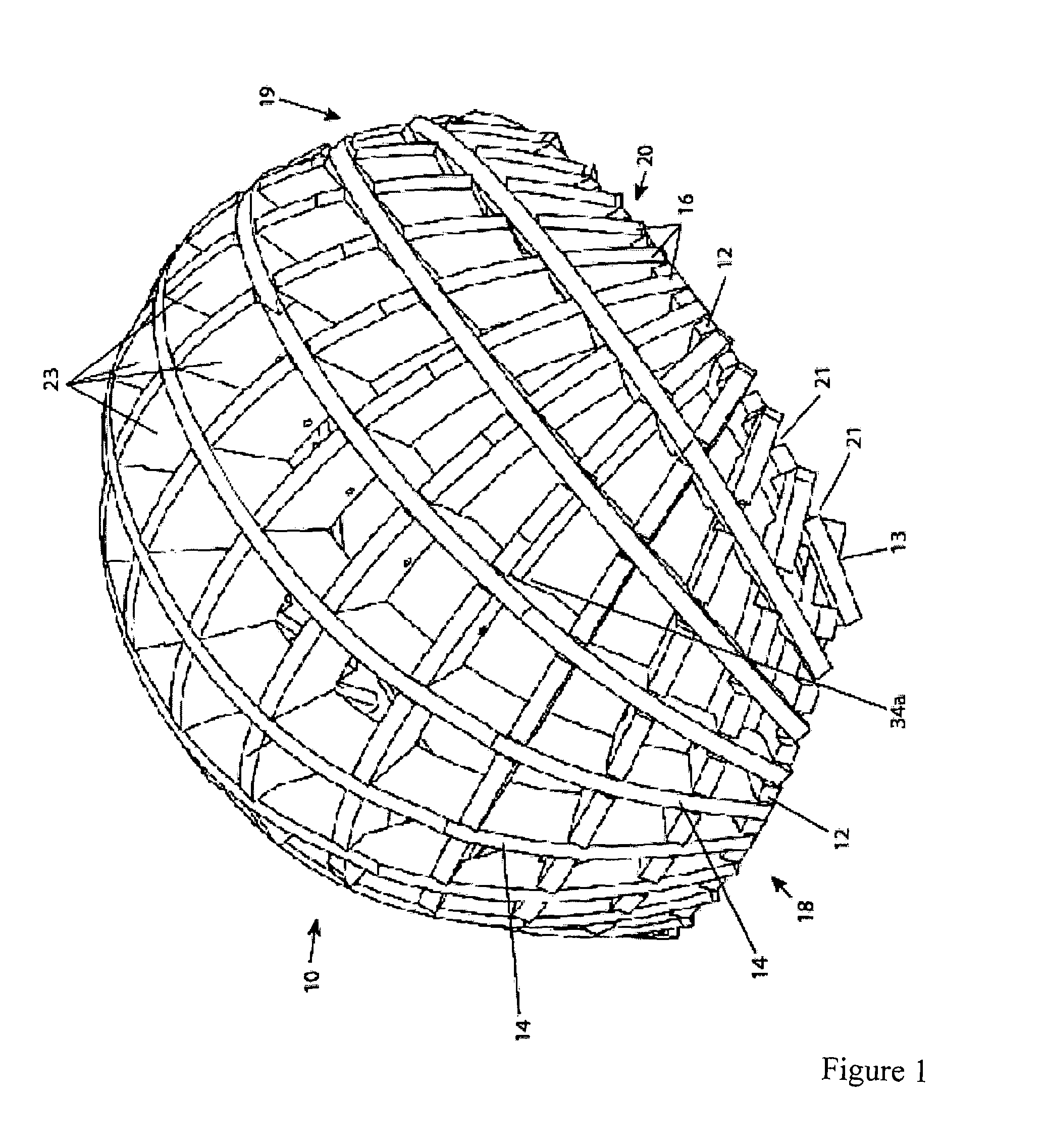

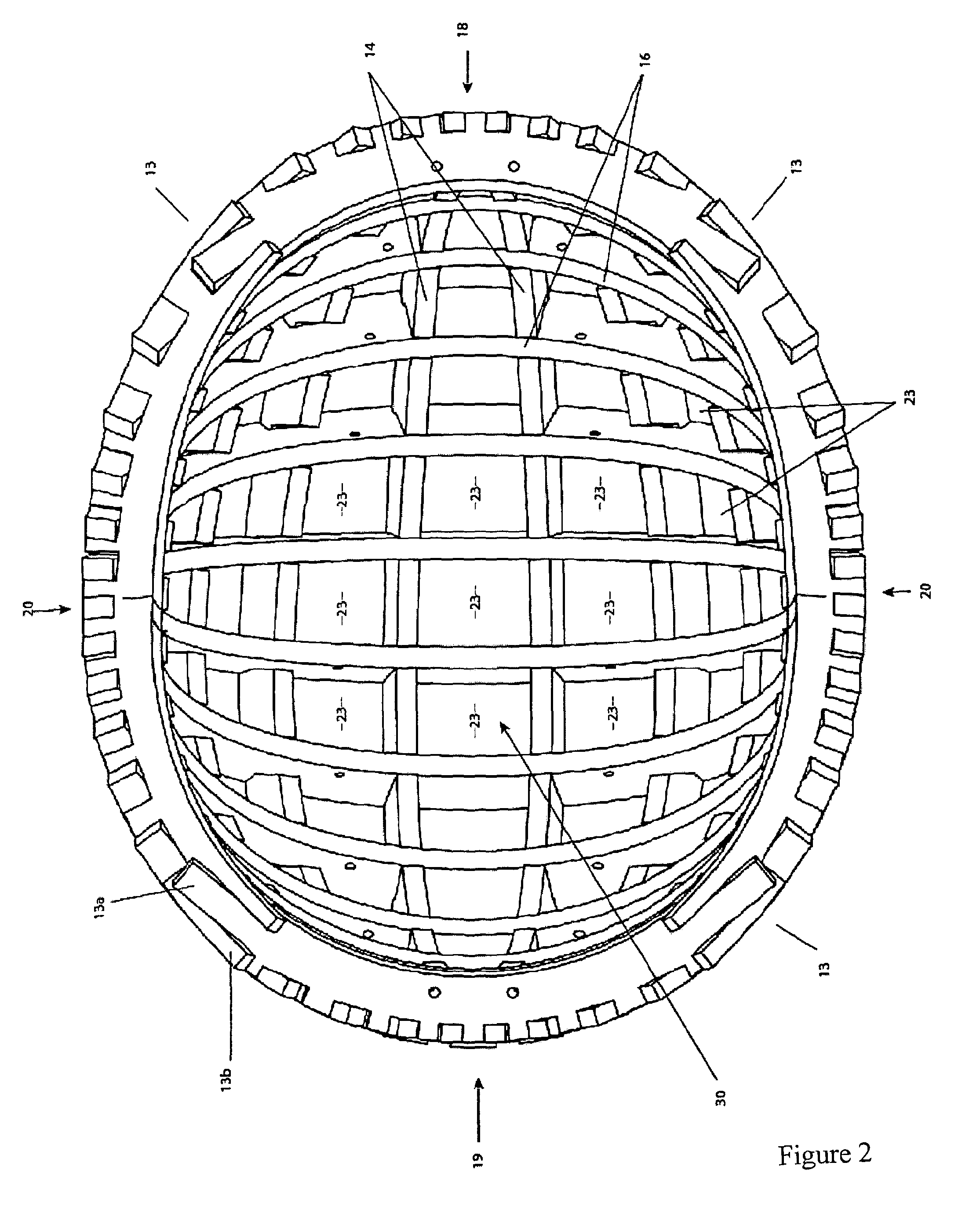

Helmet

InactiveUS20130305435A1Easy to detect triggeringImprove bending resistanceHelmetsHelmet coversEngineeringMechanical engineering

A head protection helmet comprises an impact resistant shell comprising a cavity for accommodating a user's head and an array of crushable bodies having a hollow closed configuration, e.g. flutes in corrugated material. The crushable bodies each having an axis that extends outwardly from the cavity to absorb impact forces exerted along the direction of the axis.

Owner:KRANIUM SPORTS

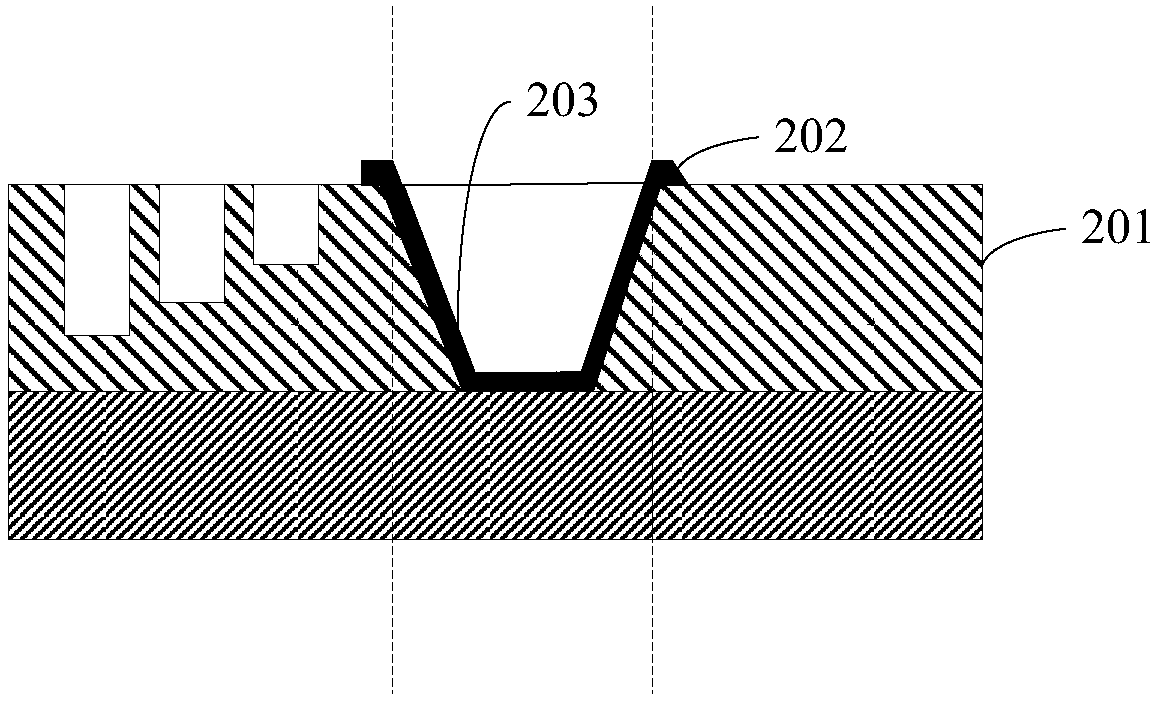

Flexible display device and manufacturing method thereof

InactiveCN107833906ANot prone to short circuitNot easy to produce semiconductor glue residueSolid-state devicesSemiconductor devicesSlope angleFlexible display

The present invention provides a flexible display device and a manufacturing method thereof. The flexible display device is characterized by firstly arranging an inorganic layer on a flexible substrate, then arranging a groove on the inorganic layer in a bending area, and filling a planarization layer in the groove. A first metal routing is arranged in a non-bending area, wherein the first metal routing is located between the inorganic layer and the planarization layer, and then a second metal routing is arranged on the planarization layer, and the second metal routing and the first metal routing are connected electrically and are at least located in the bending area. According to the scheme, the second metal routing is used as the metal routing of the bending area, is not located in the groove and does not have a larger slope angle, so that the photoresist residual is not easy to generate, and further the short circuit between the metal routings is not easy to occur.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Composite waterproof plate, ad its manufacturing method and use

InactiveCN1640640AImprove waterproof performanceImprove corrosion resistanceWood working apparatusDomestic articlesPolymer scienceAdhesive

The present invention relates to a composite water-proof material. It is made up by using (by weight portion) 20-70 portions of plant fibre, 10-60 portions of flyash and 5-40 portions of adhesive through the processes of mixing them, die-pressing and polymerization. The described adhesive is formed from maleic anhydride, phthalic anhydride, polyalcohol, styrene or mixture of their homologous compounds, also can include trimeric cyanamide, acrylic acid or rosin and dicyclopentadiene. Its raw material composition also can include 10-40 portions of new and old plastics. Said plate material has strong strength and good water-proof property, so that it has extensive application range.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

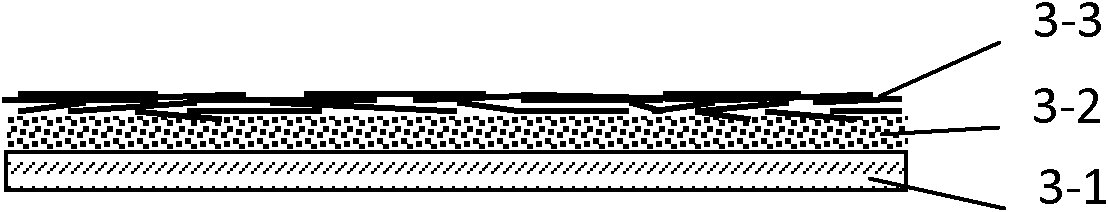

Transparent conductive film and preparation method of transparent conductive film

InactiveCN102568654AGood light transmissionImprove conductivityConductive layers on insulating-supportsSolid-state devicesTransparent conducting filmGraphite

The invention provides a transparent conductive film, which is characterized in that the transparent conductive film comprises a transparent substrate layer and a conductive layer attached onto the substrate layer. The conductive layer contains graphene and metal oxide, and has a sheet resistance of 0.1-5000 Omega / sq, and light transmittance of 60-95% in a visible light region. The inventive graphene and metal oxide-based transparent conductive film has better light transmittance and conductivity compared with a single graphene-based transparent conductive film, has better bending resistance compared with a single metal oxide-based transparent conductive film, and can be used as a flexible transparent electrode.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Flexible array substrate as well as manufacturing method and flexible display thereof

ActiveCN107123667ANarrow widthImprove thickness uniformitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a flexible array substrate as well as a manufacturing method and a flexible display thereof. The flexible array substrate comprises a flexible substrate, a display region arranged on one side of the flexible substrate, a non-display region arranged at the periphery of the display region, a protective layer used for covering a source and drain electrode layer of the non-display region and a protective layer block wall arranged on one side, close to the display region, of the non-display region and used for limiting a width of the protective layer. According to the flexible array substrate provided by the invention, the protective layer block wall is arranged on one side, close to the display region, of the non-display region and can limit a glue material from flowing toward a light emitting region when the protective layer of a bending region is manufactured, so that the width of the protective layer can also be limited while the uniformity of the coating thickness of the protective layer is guaranteed, a climbing region can be effectively shortened, and realization of the narrow frame effect is facilitated.

Owner:BOE TECH GRP CO LTD

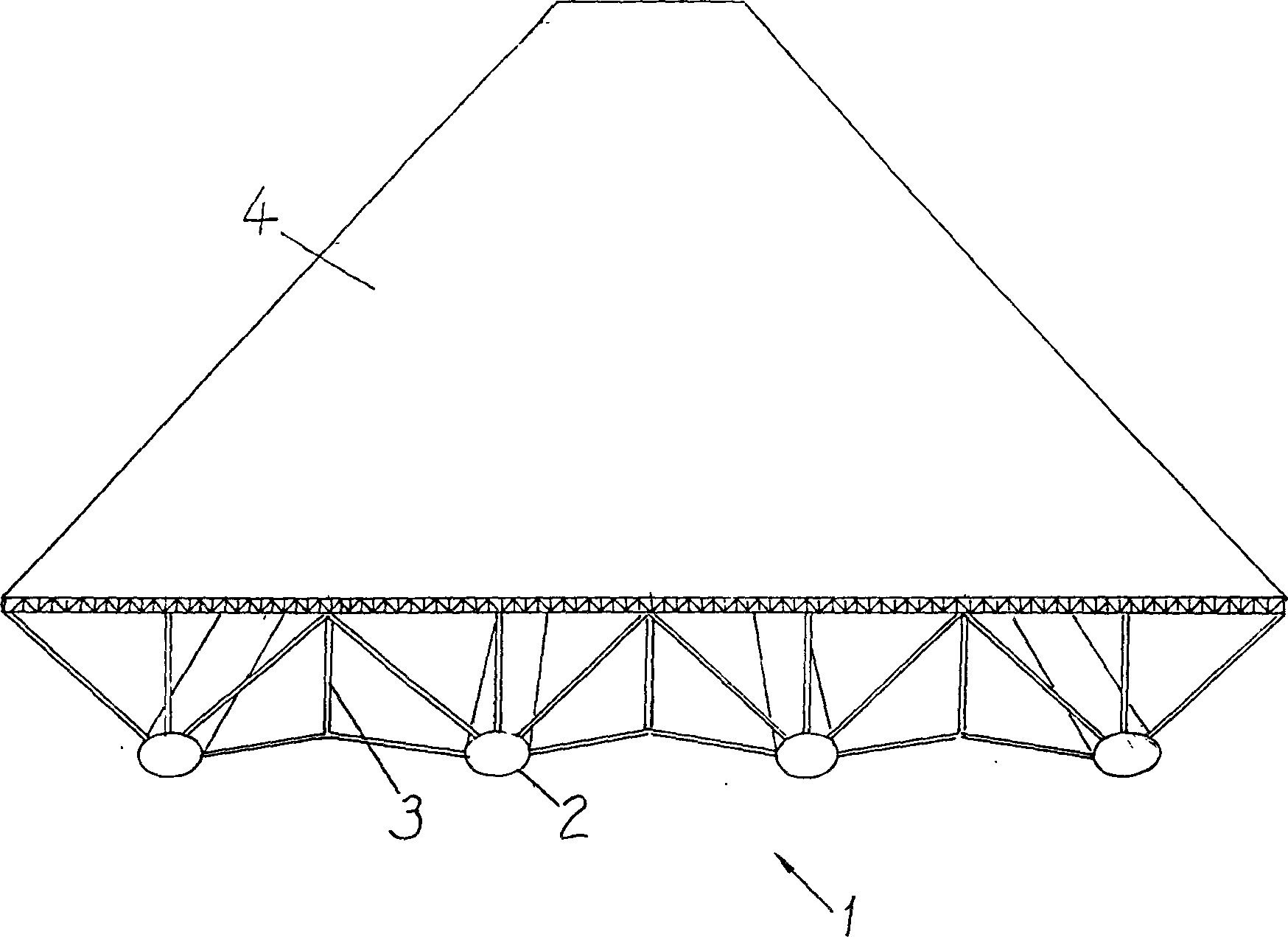

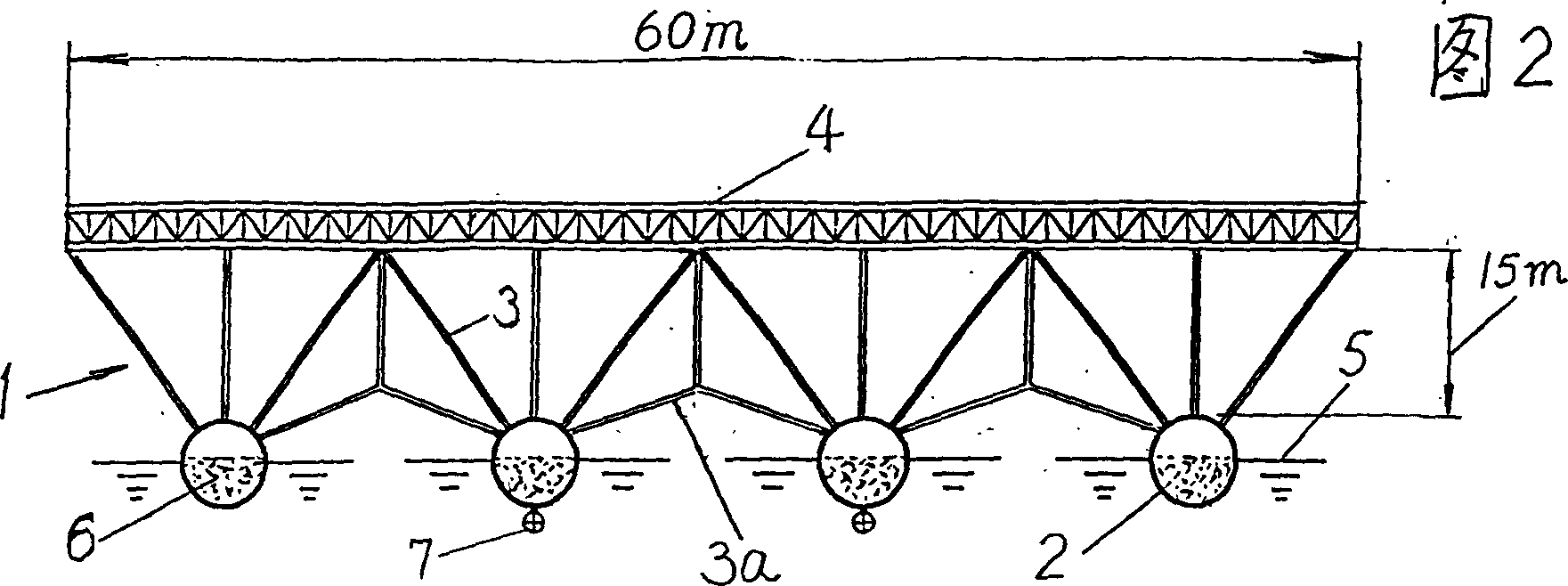

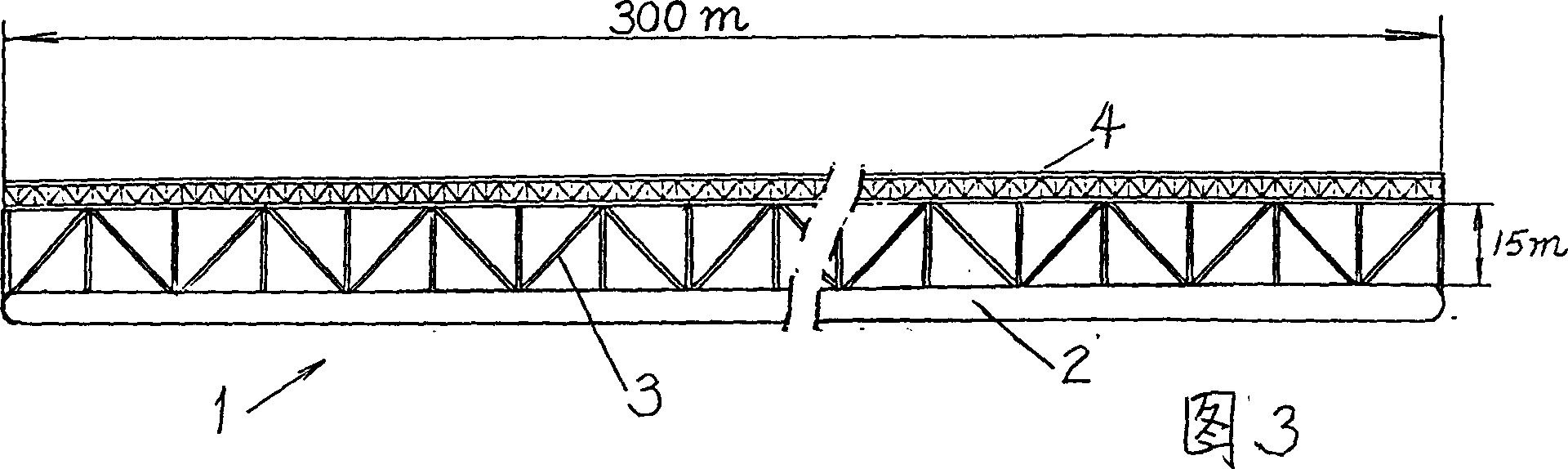

Super large truss type floating maine platform

An ultra-large truss type floating marine platform is composed of floating drums dispersed on water surface, a working platform above water surface, and connecting rods. Its advantage is high stability.

Owner:TANGSHAN REMOVABLE ISLAND MARINE HEAVY IND CO LTD

Component of light stuffing mould for concrete poured-in-situ

A light mould component for concreting which includes a polyhedron solid light weight material component, its character lies in: the polyhedron solid light weight material component is arranged with at least one transverse aperture penetrating the surface of the component. When it is applied to the construction, because that the apertures penetrates the around side surfaces of the component, and the concrete is poured into the aperture cavities, after they are solidified, there forms concreting poles, thus a stressing and bearing component is formed in the light weight tire matrix component, the mechanical performance is upgraded greatly; at the same time, the light weight tire matrix component has characters of low cost, convenient construction and quick.

Owner:湖南邱则有专利战略策划有限公司

Modified composite material of woods and plastics as well as its usage and manufacturing method

A modified wood-plastics composition is prepared from wood flour, plastic, assistant, and grafting agent through graft modifying of wood flour and plastics, and continuous extruding out. Its advantage is high tension strength, bending strength and impact strength.

Owner:BEI JING NEW BUILDING MATERIALGRP

Flexible display device and packaging method thereof

ActiveCN103943788AImprove bending resistanceAvoid crackingConstructionsSolid-state devicesEngineeringOxygen

The embodiment of the invention discloses a flexible display device and a packaging method of the flexible display device, and relates to the field of display. The problem that cracks easily occur in an existing packaging film layer can be solved, and bending resistance of the flexible display device can be improved. The flexible display device comprises an OLED, and a protective layer arranged on a cathode of the OLED. The protective layer comprises a water and oxygen blocking area and a multifunctional area. The multifunctional area has dual functions, namely, the water and oxygen blocking function and the stress cut-off function, and the thickness of the film layer of the multifunctional area is smaller than that of the film layer of the water and oxygen blocking area; or the film layer of the multifunctional area is looser than the film layer of the water and oxygen blocking area; or the thickness of the film layer of the multifunctional area is smaller than that of the film layer of the water and oxygen blocking area, and meanwhile the film layer of the multifunctional area is looser than the film layer of the water and oxygen blocking area.

Owner:BOE TECH GRP CO LTD

Flexible capacitive sensor fabricated by employing silver nanowire flexible electrode and fabrication method of flexible capacitive sensor

InactiveCN110455443AGood flexibilityHigh sensitivityMaterial nanotechnologyForce measurementSignal responseThin layer

The invention relates to a flexible capacitive sensor fabricated by employing a silver nanowire flexible electrode. The flexible capacitive sensor comprises an upper-layer flexible electrode plate, alower-layer flexible electrode plate and an intermediate flexible dielectric layer, wherein each flexible electrode comprises a flexible substrate, a silver nanowire electrode thin film layer, and thesilver nanowire electrode thin film layer is arranged in the flexible substrate. A fabrication method of the electrode employs a transfer printing method, the silver nanowire electrode thin film layer is fabricated in an electrode template, a flexible polymer is injected for curing, so that the silver nanowire conductive thin film layer is transferred to the flexible substrate. The flexible dielectric layer is divided into two types comprising a thin film structure and a porous structure, the thin film structure is fabricated by uniformly coating a flexible polymer prepolymer on a silicon wafer to form a thin layer, the porous structure is fabricated by a template method, the flexible polymer prepolymer is uniformly mixed with salt, a film formation structure is fabricated and cured, andthe porous dielectric layer structure is obtained after salt removal. The flexible capacitive sensor is simple in fabrication method and has favorable signal response.

Owner:BEIHANG UNIV

Electromagnetic-wave-shielding adhesive film, process for producing the same, and method of shielding adherend from electromagnetic wave

ActiveCN101120627AHeat resistanceImprove bending resistanceMagnetic/electric field screeningSemiconductor/solid-state device detailsIsocyanatePrepolymer

An electromagnetic-wave-shielding adhesive film which comprises a base film and a curable conductive adhesive layer (I), wherein the curable conductive adhesive layer (I) comprises: a polyurethane-polyurea resin (A) prepared by reacting a polyamino compound (e) with a urethane prepolymer (d) having an isocyanate group at an end and obtained by reacting a carboxylated diol compound (a), a polyol (b) which has a number-average molecular weight of 500-8,000 and is not a carboxylated diol compound, and an organic diisocyanate (c); an epoxy resin (B) having two or more epoxy groups; and a conductive filler.

Owner:TOYO INK SC HOLD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com