Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8126 results about "Construction aggregate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction aggregate, or simply "aggregate", is a broad category of coarse to medium grained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates. Aggregates are the most mined materials in the world. Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as reinforcement to add strength to the overall composite material. Due to the relatively high hydraulic conductivity value as compared to most soils, aggregates are widely used in drainage applications such as foundation and French drains, septic drain fields, retaining wall drains, and roadside edge drains. Aggregates are also used as base material under foundations, roads, and railroads. In other words, aggregates are used as a stable foundation or road/rail base with predictable, uniform properties (e.g. to help prevent differential settling under the road or building), or as a low-cost extender that binds with more expensive cement or asphalt to form concrete.

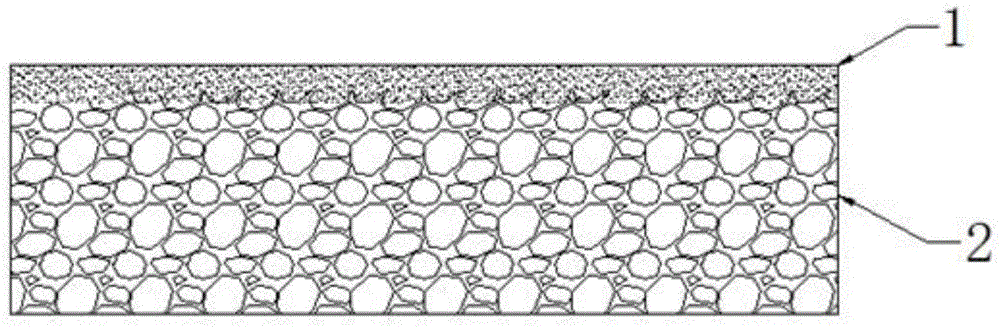

Composite water permeable brick

InactiveCN1966861AGood water permeabilityLow costSingle unit pavingsClimate change adaptationBrickAdhesive

A composite water permeable brick comprises water permeable surface and base closely combined together with aggregate and adhesive coating the aggregate, with the adhesive of the said water permeable surface including at least hydrophilicity adhesive. It can keep fine water permeability, with the brick surface fine and close and reduced in cost.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Anti-seepage burnon casting paint made from alcohol base or aqueous sand powder

InactiveCN1666828AExcellent anti-seepage and sticky sand effectSmall specific surface areaFoundry mouldsFoundry coresWater basedAlcohol

The invention relates to the melting coating of alcohol-base or water-base anti-penetrating sands, which uses the fireproofing bone materials, the floating agent, the felting agent, the reinforcing agent and the carrier as the preparing coating. The weight shares of the said coating are: 100,3-8,3-7,0.2-1.0 and 30-40. The invention uses chrome iron minerals as the main materials and is prior to any kinds of the traditional coating.

Owner:HUBEI UNIV OF TECH

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

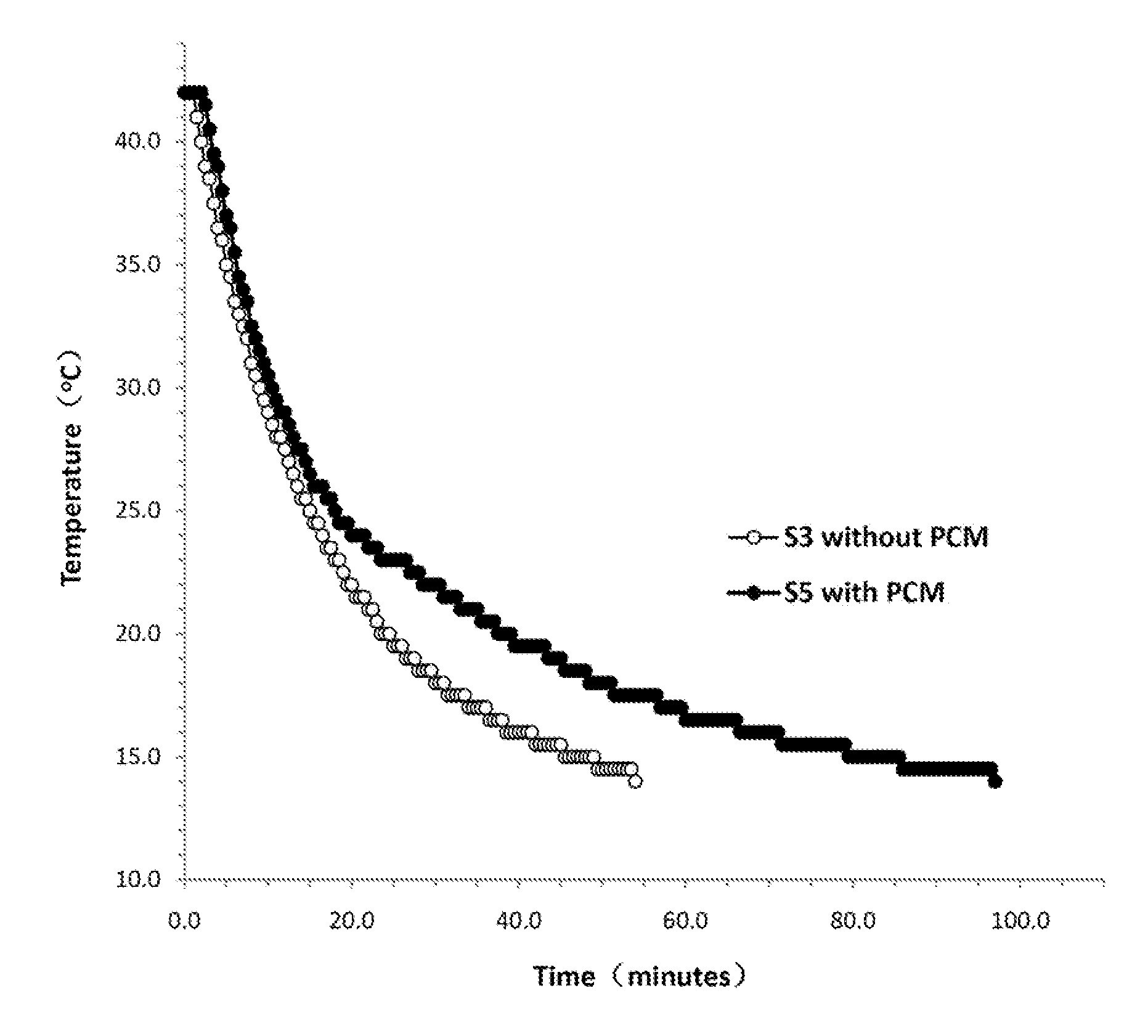

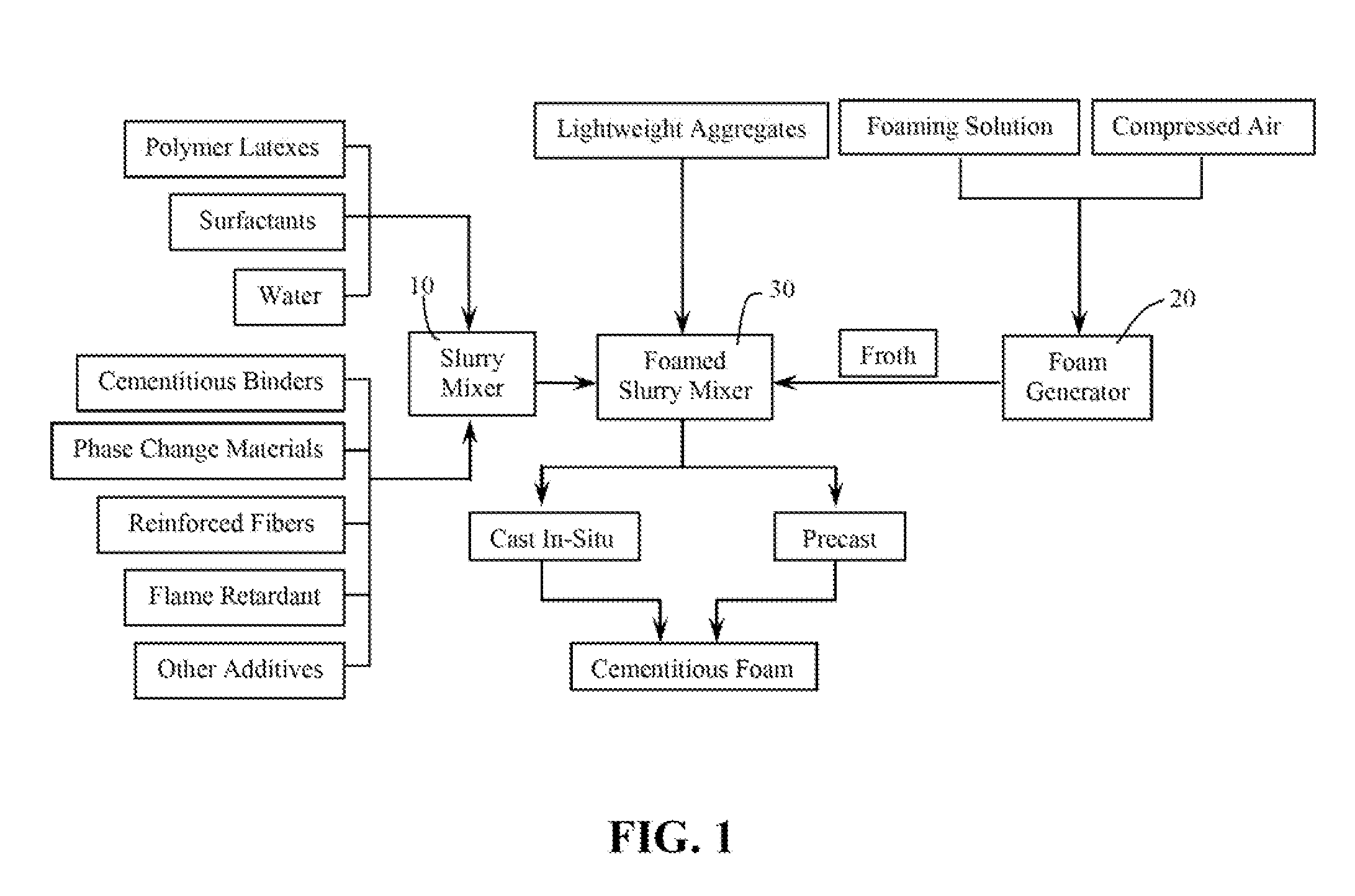

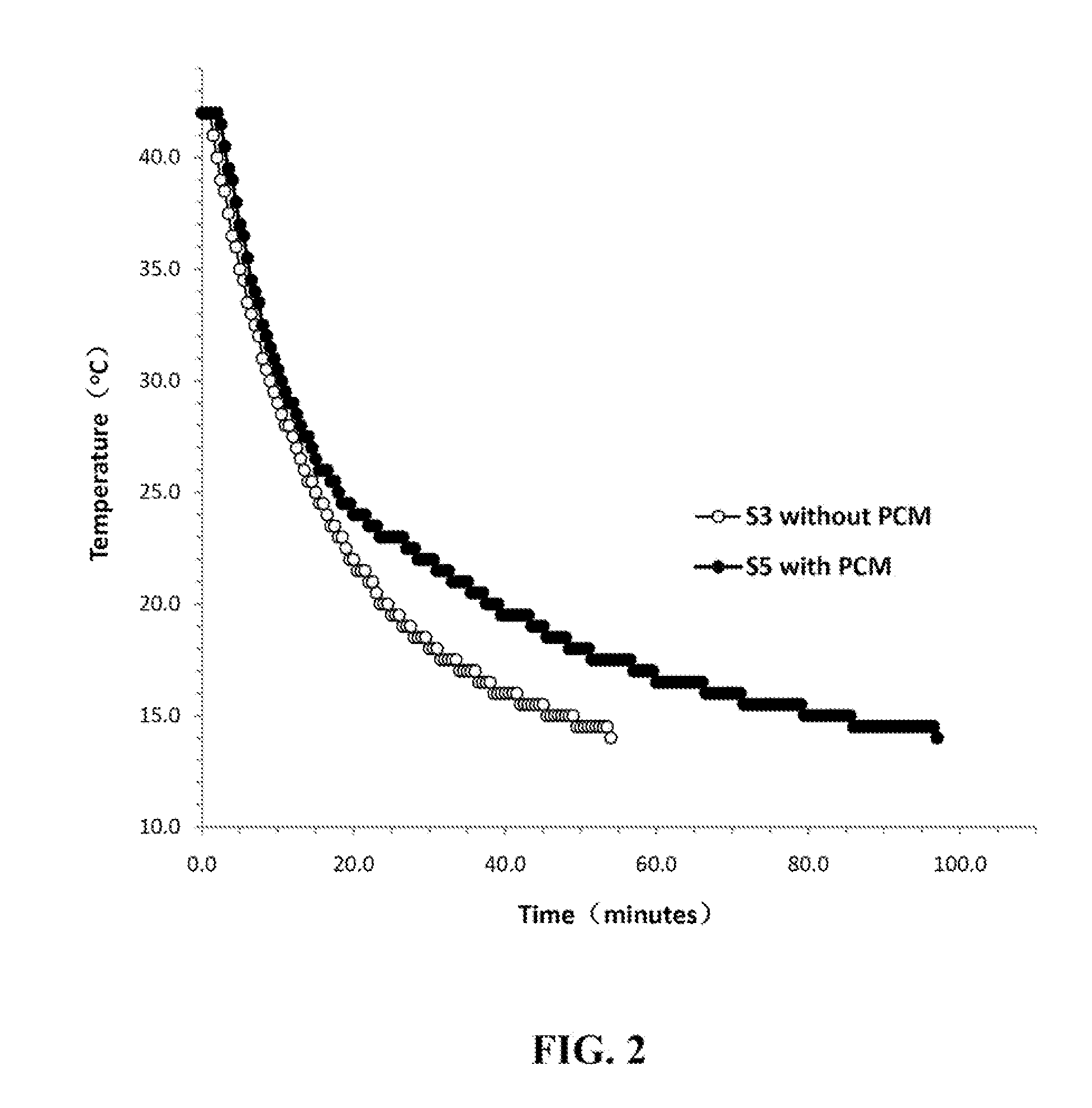

Fireproof insulating cementitious foam comprising phase change materials

ActiveUS8070876B1Improve fire resistanceImprove high temperature resistanceSolid waste managementSynthetic resin layered productsThermal energyThermal energy storage

A fireproof insulating foamed cementitious composition with thermal energy storage capacity is provided for use in producing wall insulation boards, fireproof claddings for steel structures, inner cores of fire resistant wall or door panels, and the like. The composition demonstrates improved energy efficiency in which phase change materials, such as microencapsulates, are used in conjunction with a cementitious mixture of calcined gypsum and hydraulic cement, lightweight aggregates, a polymer latex, and a foaming solution to create stable air bubbles inside the cementitious matrix. The calcined gypsum and the hydraulic cement are present in a weight ratio range from about 1:3 to about 3:1. The composition may further include reinforced fibers, surfactants, inorganic flame retardants, and other additives. The presence of the phase change material not only increases energy efficiency of the cured cementitious foam material, but also improves compatibility between calcined gypsum and cement during slurry mixing and hardening.

Owner:JIANG HAIHONG

Magnetic biological carrier and preparation method thereof

InactiveCN102225806APromote recoveryRealize dynamic regenerationSustainable biological treatmentBiological water/sewage treatmentResource utilizationEngineering

The invention discloses a magnetic biological carrier and a preparation method thereof. The raw materials of the magnetic biological carrier comprise aggregate, iron oxide, a binder and a reducing agent. The preparation method of the magnetic biological carrier comprises the following steps of: mixing the aggregate, iron oxide and the reducing agent, crushing, screening with a 60-mesh sieve to obtain a mixed material, adding water which is 30-60% of the mixed material by weight to the binder, stirring for dissolving the binder to obtain a binder solution, then mixing the binder solution with the mixed material, uniformly stirring, granulating and shaping to obtain 2-10 mm granules, drying the granules till the water content of the granules is less than 10%, and calcining at the temperature of 350-1100 DEG C for 0.2-10 hours to obtain the magnetic biological carrier. The magnetic biological carrier provided by the invention can be applied to the deep treatment of secondary treatment water of domestic sewage, meets the requirements of landscape water replenishing and circulating cooling water treatment, and can be used for realizing the deep treatment and resource utilization of industrial wastewater.

Owner:HEFEI UNIV OF TECH

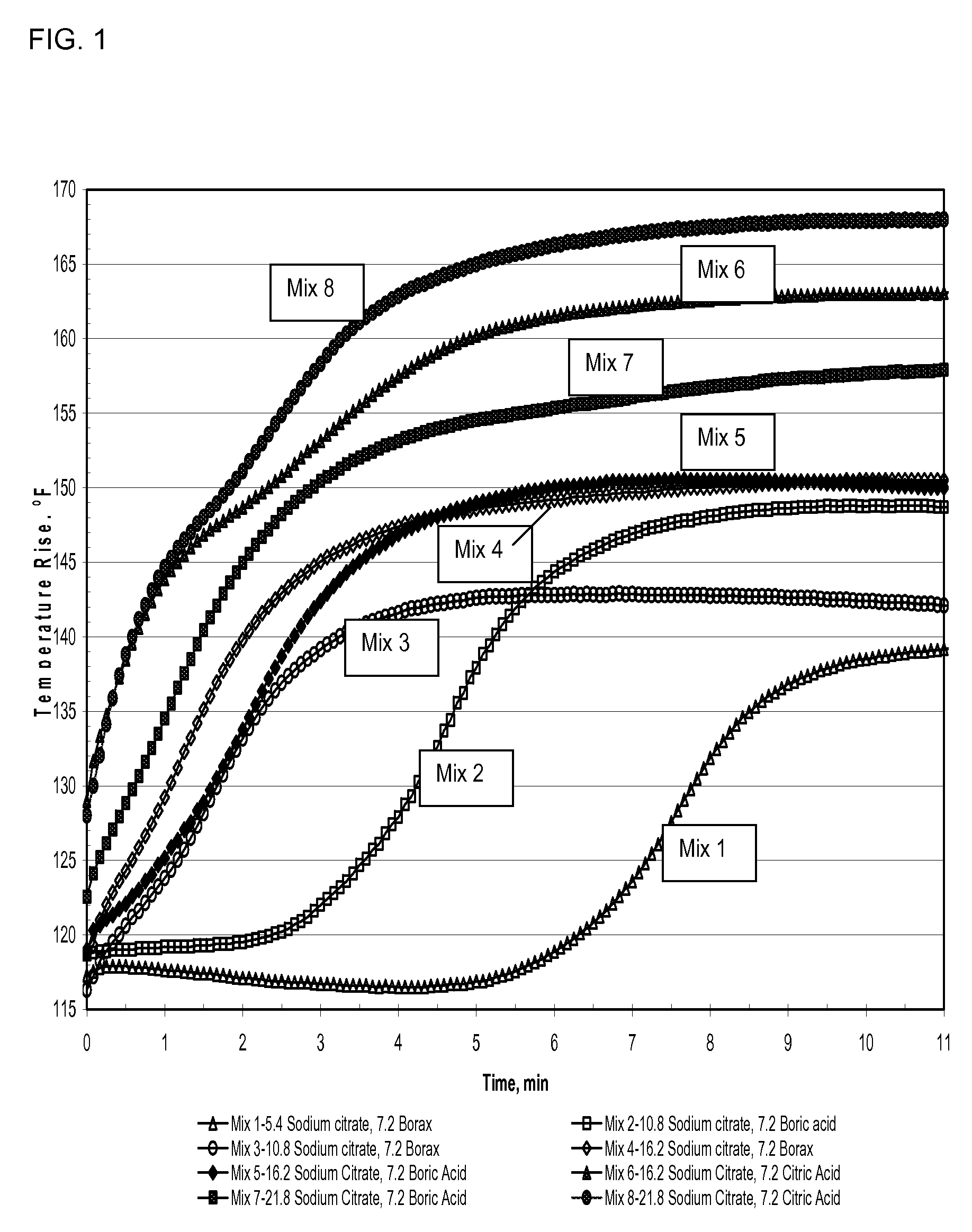

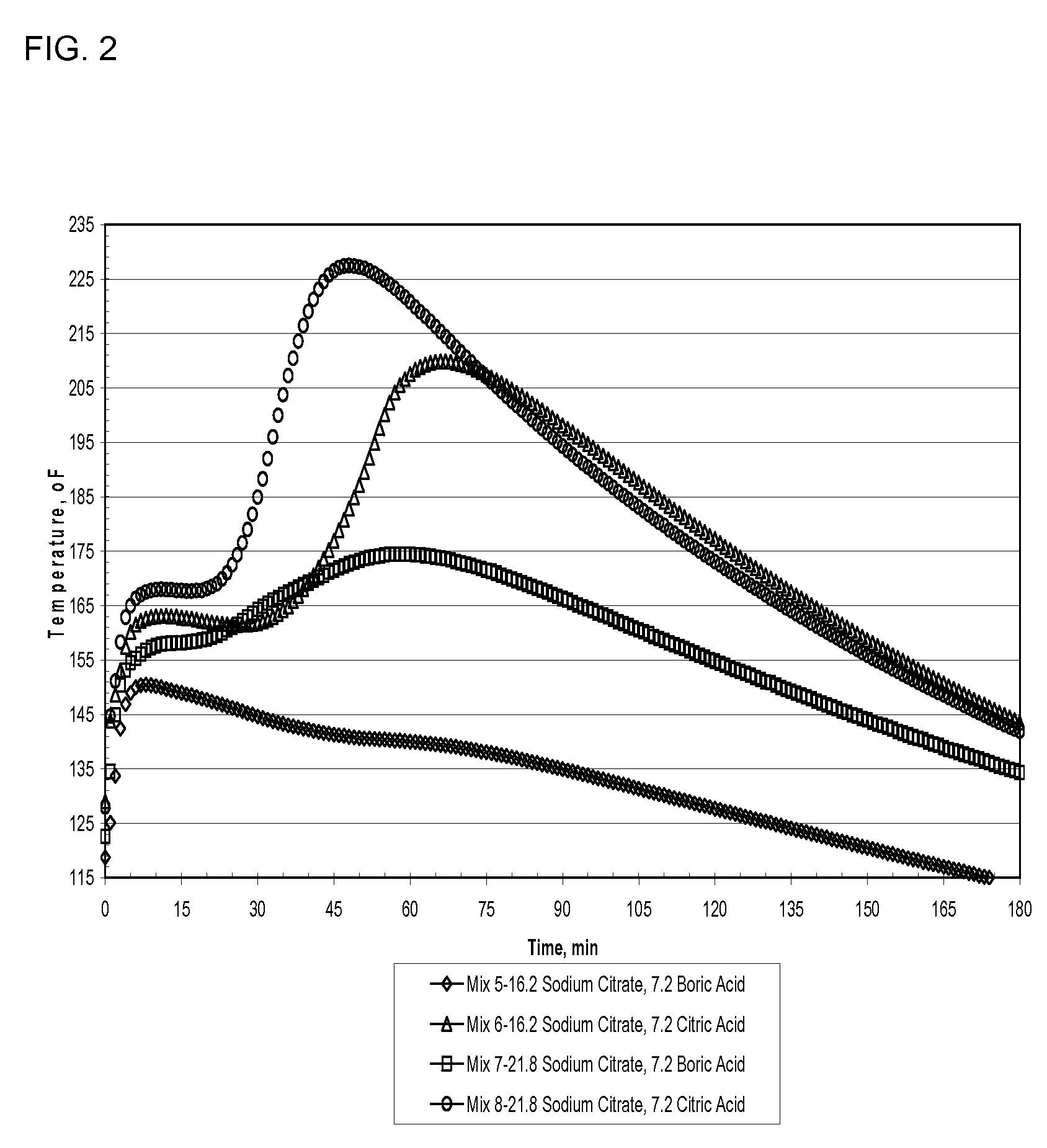

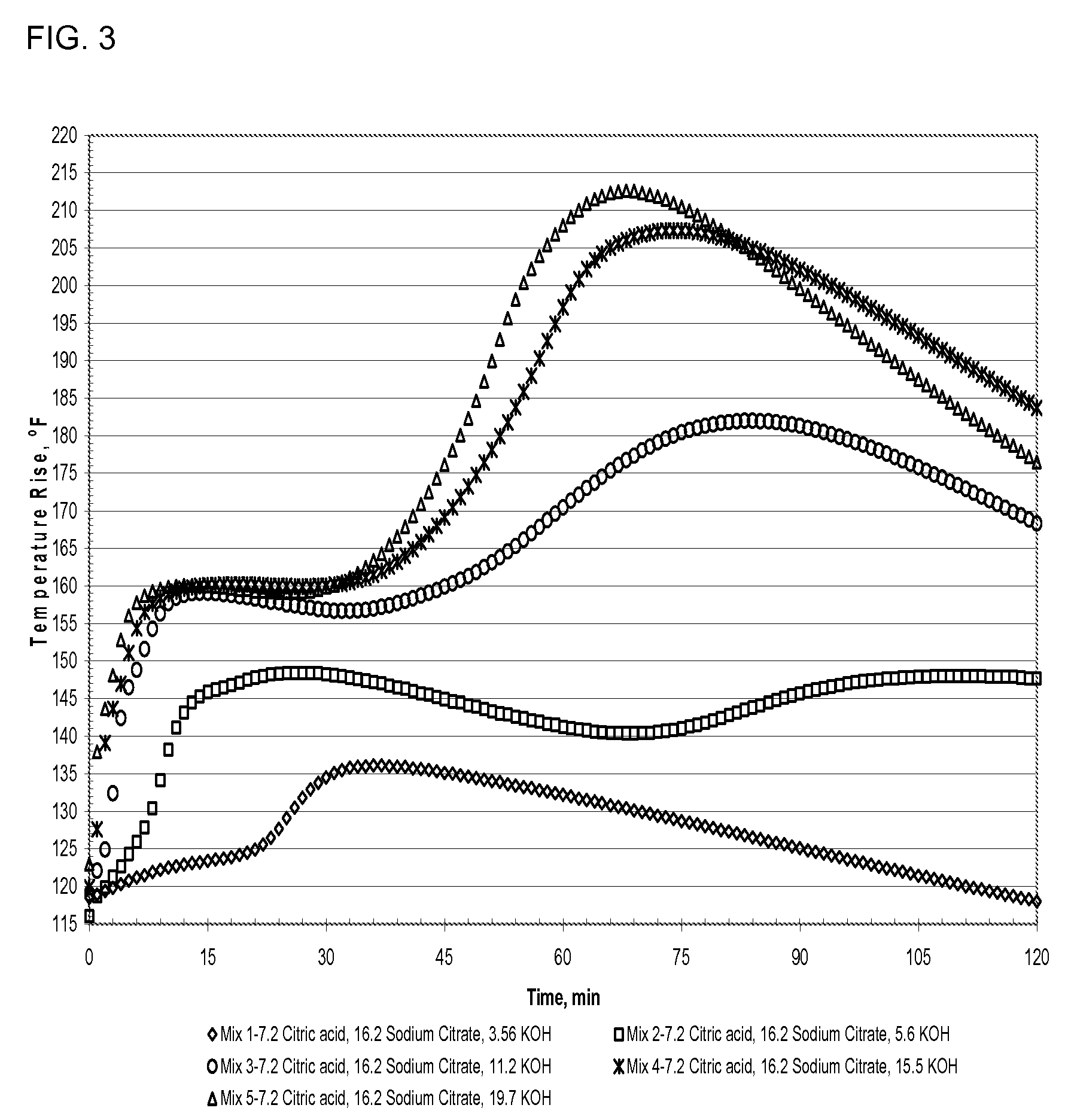

Fly ash based lightweight cementitious composition with high compressive strength and fast set

InactiveUS20100071597A1Quick SetupEnhanced early and final compressive strengthSolid waste managementPolymer scienceCompressive strength

A method of making a rapid setting lightweight cementitious composition with improved compressive strength for products such as boards is disclosed. The method mixes fly ash, alkali metal salt of citric acid and lightweight aggregate with water. Compositions which include fly ash, alkali metal salts of citric acid and lightweight aggregate are also disclosed.

Owner:UNITED STATES GYPSUM CO

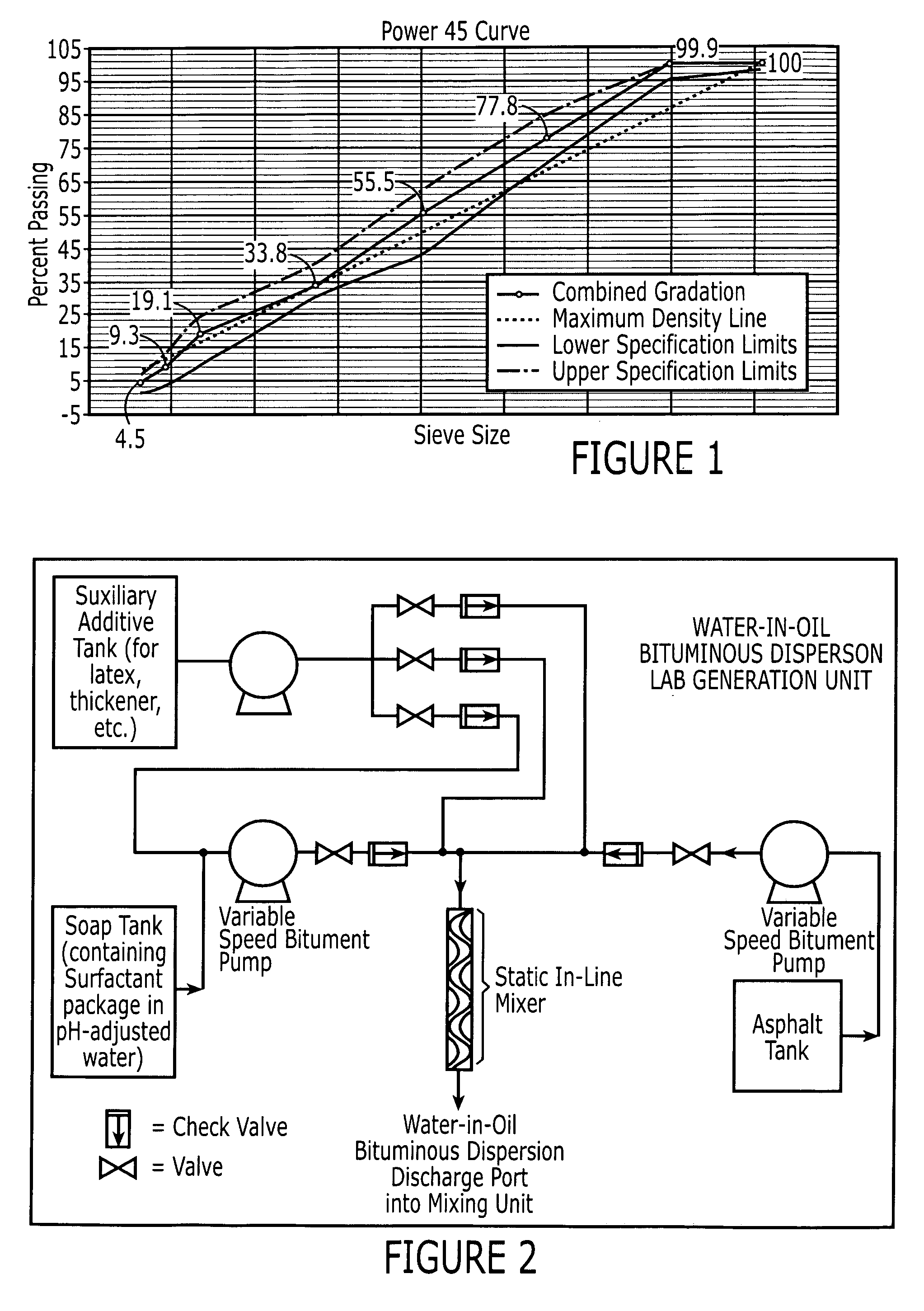

Water-in-oil bituminous dispersions and methods for producing paving compositions from the same

ActiveUS20070082983A1Low viscosityAccelerated strength developmentProductsIn situ pavingsSolvent freeSURFACTANT BLEND

There is provided a method for making bituminous compositions comprising water-in-oil bituminous dispersion and aggregate by the steps of: preparing a solvent-free, water-in-oil bituminous dispersion comprising: (1) bitumen, in an amount from about 75.0% to about 95.0% by total weight of the bitumen dispersion; (2) a surfactant in an amount from about 0.05% to about 2.0% by total weight of the bitumen dispersion; and (3) water in an amount to complete the water-in-oil bituminous dispersion, and producing the bituminous composition having a temperature from about 50° C. to about 120° C. by mixing: (1) the water-in-oil bituminous dispersion of step (A), having a temperature from about 75° C. to about 95° C., in an amount from about 2.0% to about 10.0% by total weight of the bituminous composition, and (2) aggregate, having a temperature from about 60° C. to about 140° C., in an amount from about 90.0% to about 98.0% by total weight of the bituminous composition.

Owner:INGEVITY SOUTH CAROLINA

Hydrophobic granule and preparation method thereof, and waterproof breathable structure and forming method thereof

ActiveCN101838116AImprove hydrophobicityImprove water resistanceSolid waste managementSoil conditioning compositionsEpoxyPolyresin

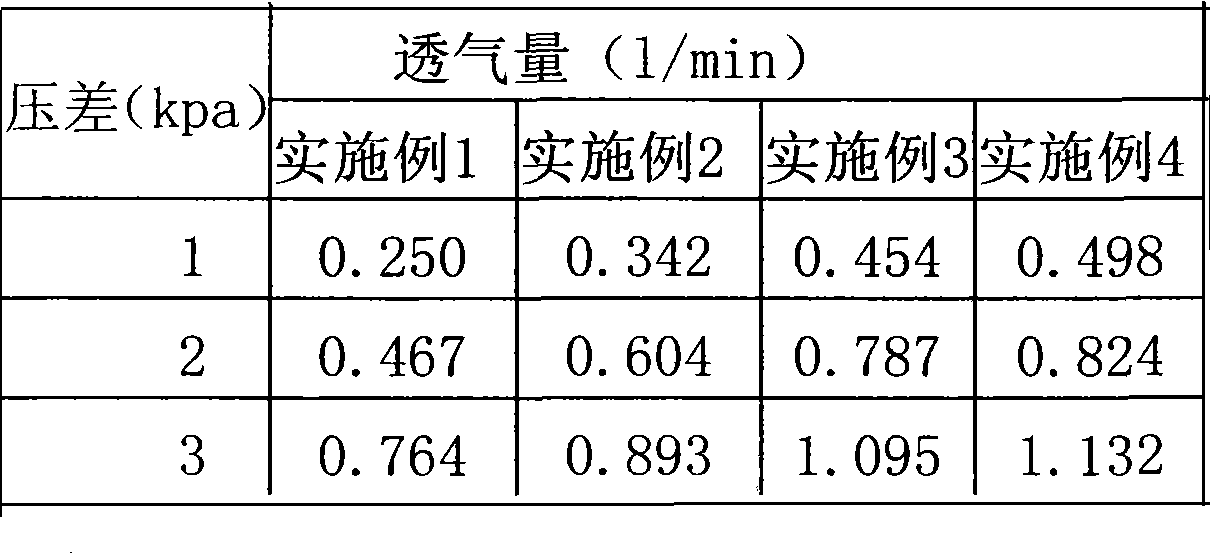

The invention relates to a hydrophobic granule and a preparation method thereof, and a waterproof breathable structure and a forming method thereof. The hydrophobic granule comprises aggregate and a hydrophobic resin film coated on the aggregate, wherein the aggregate size is 6-300 meshes, and the hydrophobic resin film is made of one or a plurality of hydrophobic epoxy resin, bakelite, polyurethane resin and silicone resin, and coated on the aggregate. The preparation method of the hydrophobic granule comprises the following steps: heating the aggregate to 50-400 DEG C; adding the hydrophobic resin, evenly stirring so that a film is coated on the aggregate surface; and cooling, crushing and screening to obtain the hydrophobic granules. The hydrophobic granule can be widely used as a waterproof breathable layer in desert planting, lake bottom seepage-proofing, river course seepage-proofing, landscape water system bottom seepage-proofing, and has favorable waterproof and breathable properties.

Owner:北京仁创科技发展有限公司

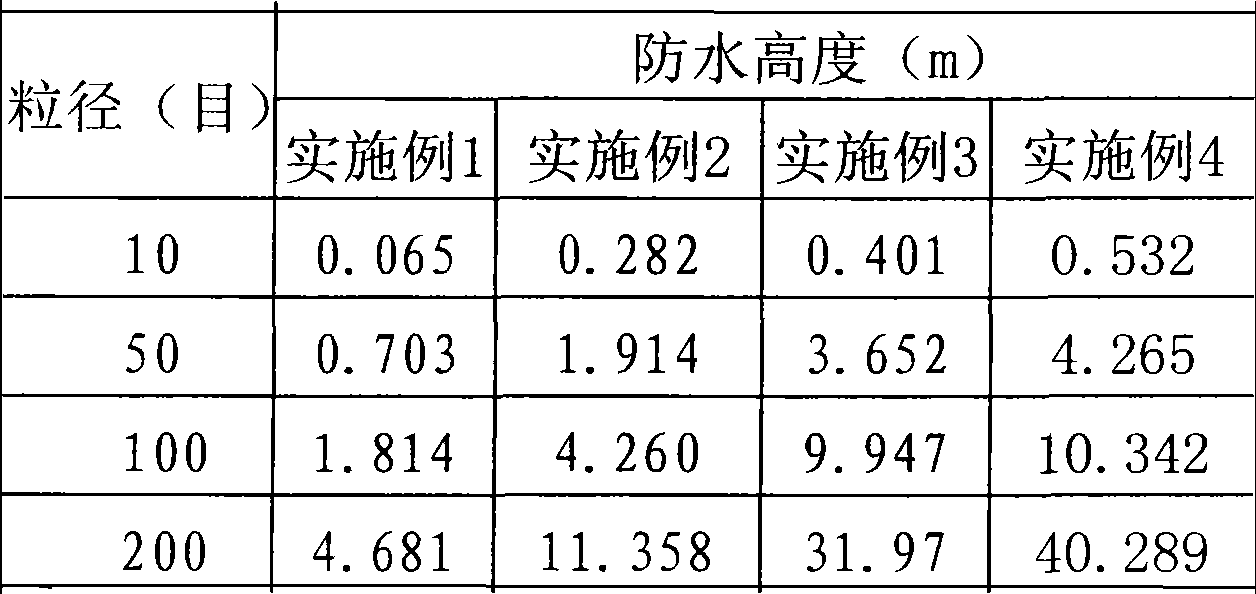

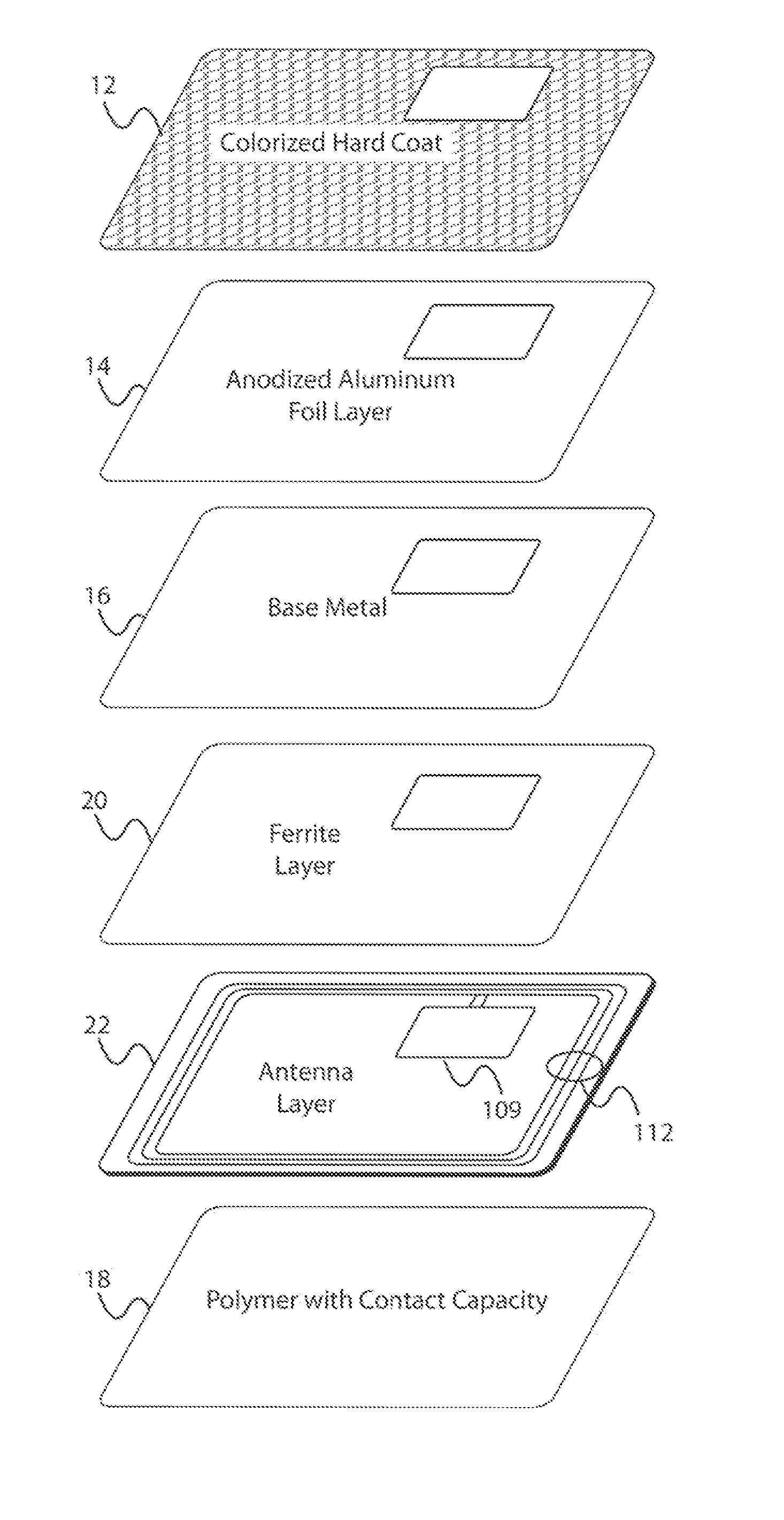

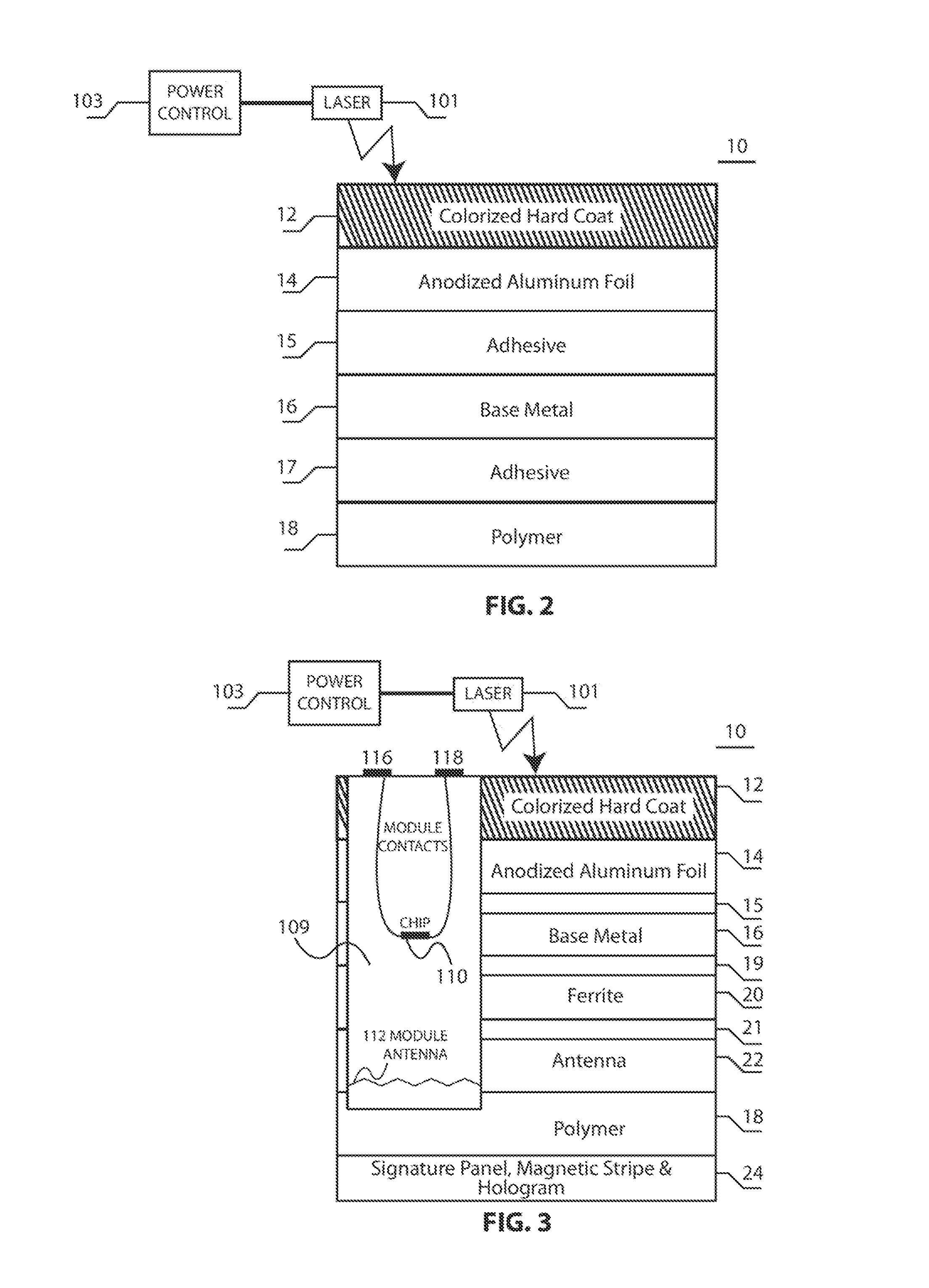

Transaction and id cards having selected texture and coloring

ActiveUS20150339564A1More costAvoid less flexibilityAnodisationWave amplification devicesEpoxyFinancial transaction

Cards made in accordance with the invention include a specially treated thin decorative layer attached to a thick core layer of metal or ceramic material, where the thin decorative layer is designed to provide selected color(s) and / or selected texture(s) to a surface of the metal cards. Decorative layers for use in practicing the invention include: (a) an anodized metal layer; or (b) a layer of material derived from plant or animal matter (e.g., wood, leather); or (c) an assortment of aggregate binder material (e.g., cement, mortar, epoxies) mixed with laser reactive materials (e.g., finely divided carbon); or (d) a ceramic layer; and (e) a layer of crystal fabric material. The cards may be dual interface smart cards which can be read in a contactless manner and / or via contacts.

Owner:COMPOSECURE LLC

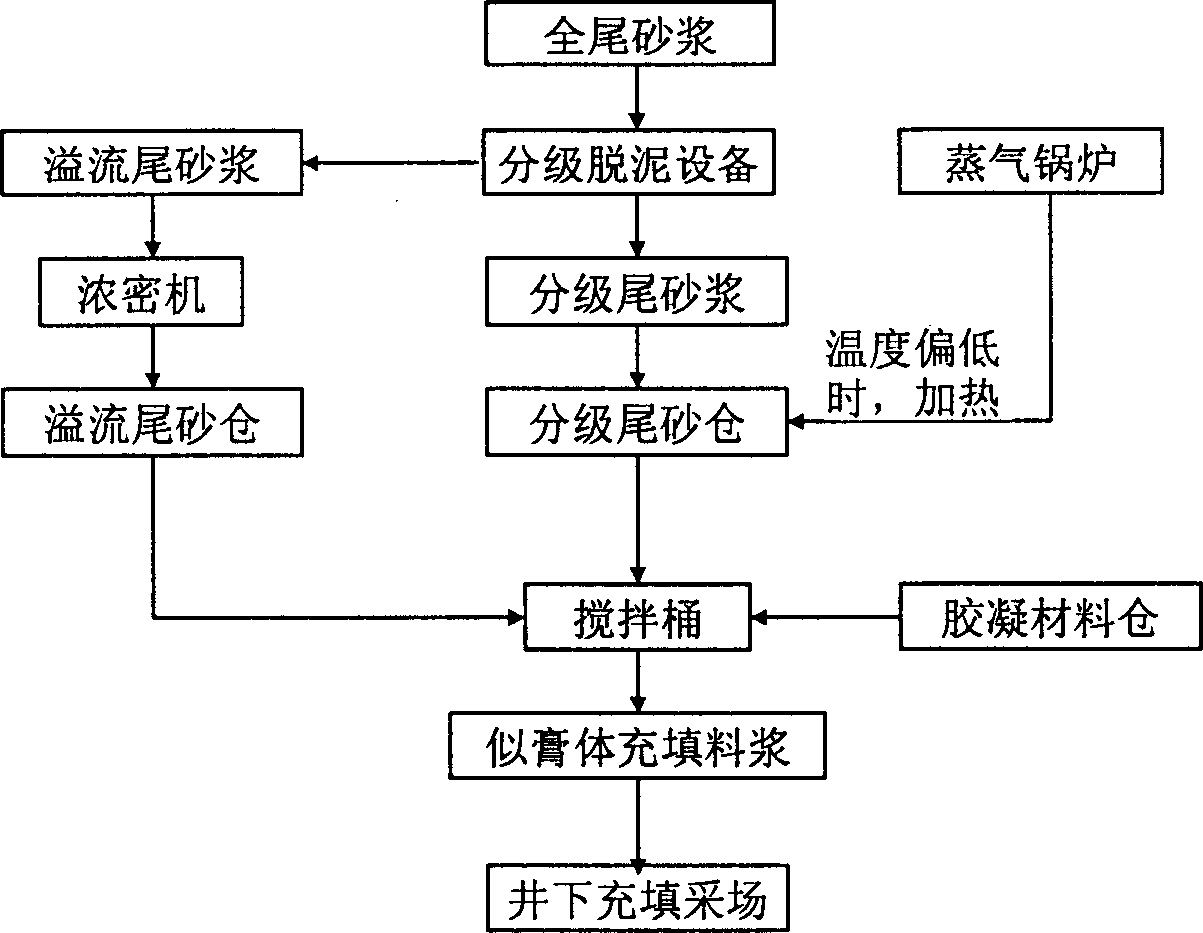

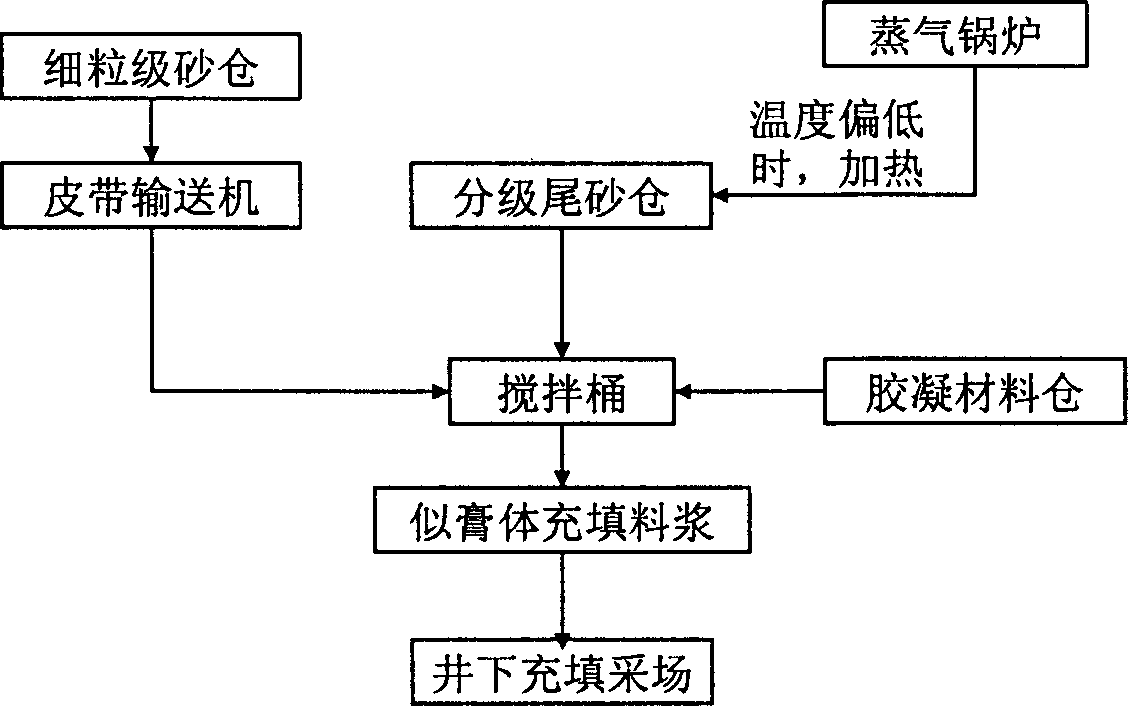

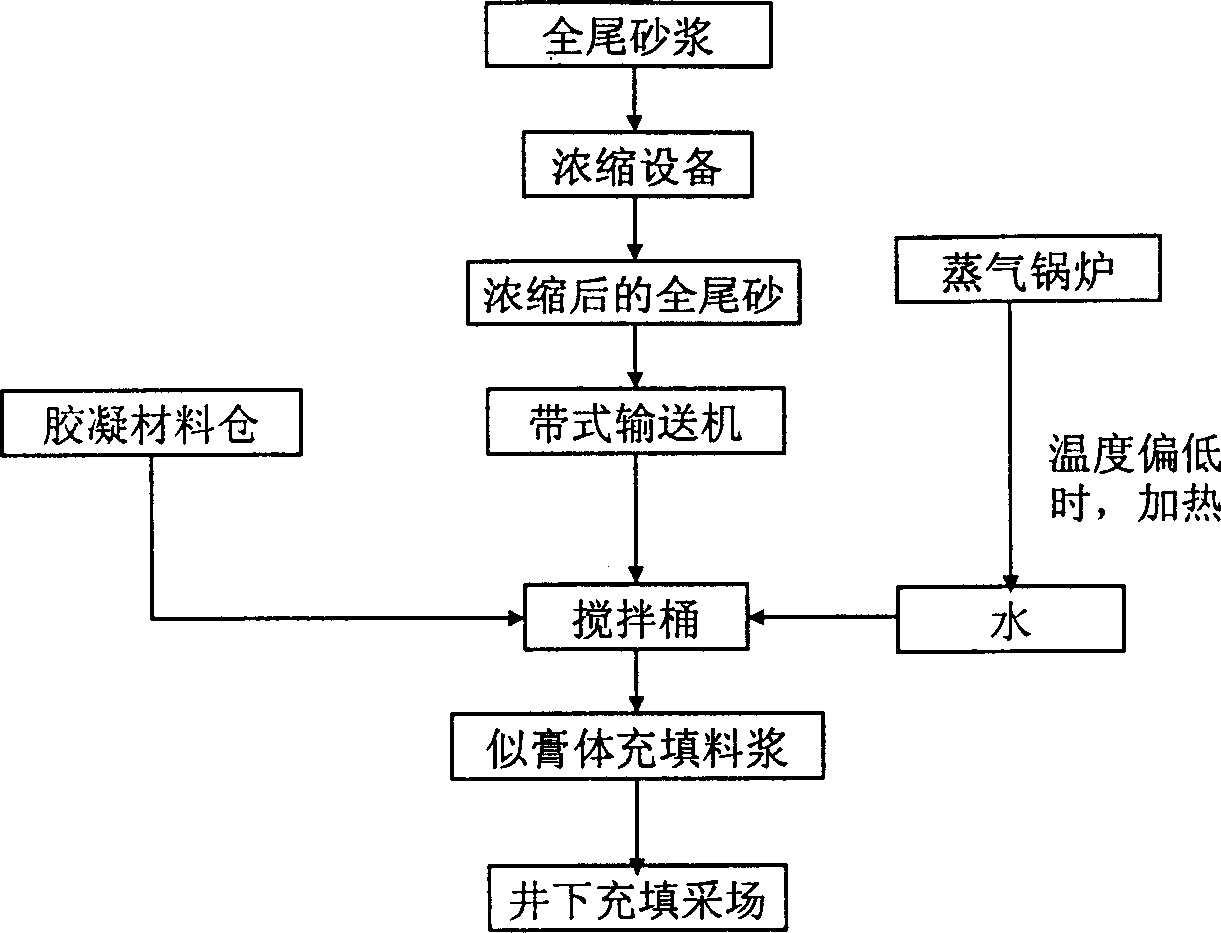

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

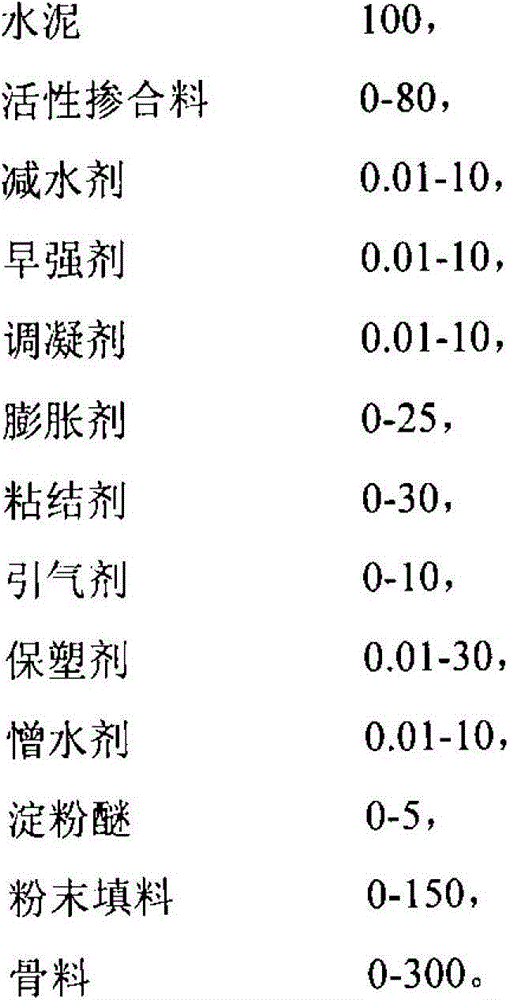

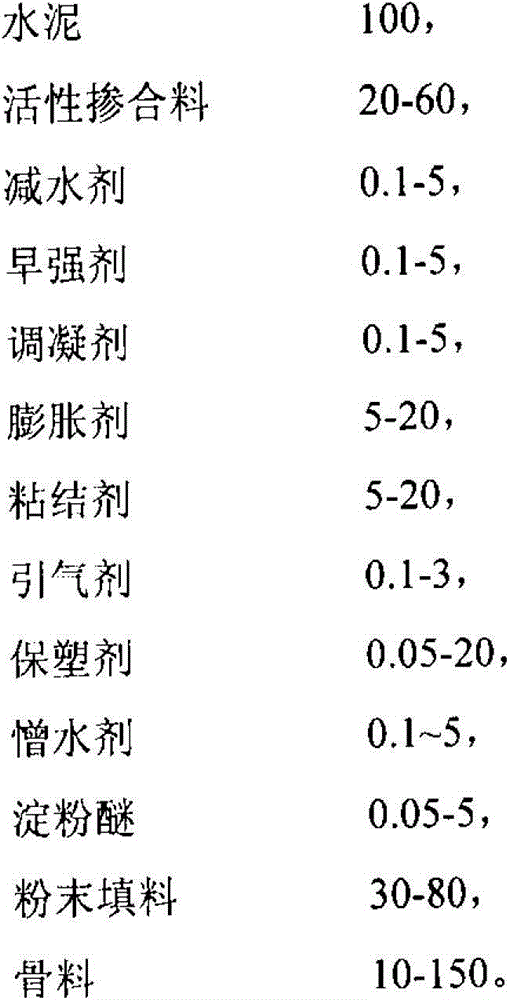

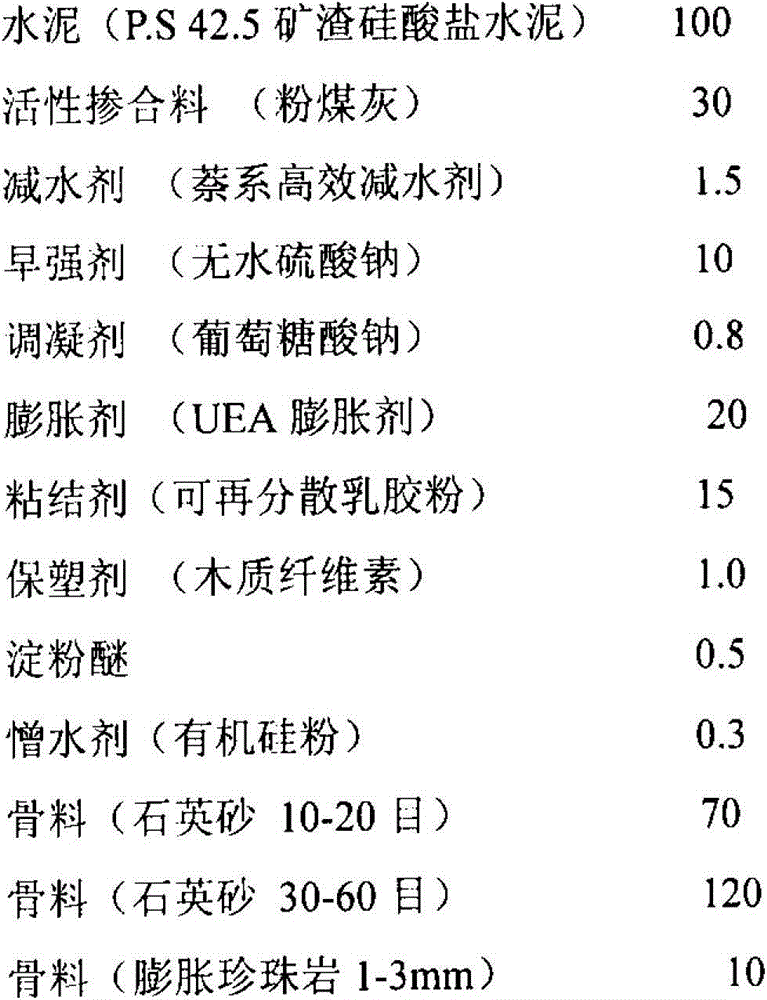

Cement-based shrinkage-free joint filling sealing mortar for doors and windows and preparation method and construction method thereof

The invention relates to a cement-based shrinkage-free joint filling sealing mortar for doors and windows and a preparation method and a construction method thereof. The sealing mortar is prepared by the components in parts by weight as follows: 100 parts of cement, 0-80 parts of active admixture, 0.01-10 parts of water reducer, 0.01-10 parts of early strength agent, 0.01-10 parts of thickening time control agent, 0-25 parts of expanding agent, 0-30 parts of binder, 0-10 parts of air entraining agent, 0.01-30 parts of plastic retaining agent, 0.01-10 parts of moisture repellent, 0-5 parts of starch ether, 0-150 parts of powder filler and 0-300 parts of aggregate. Compared with the prior art, the mortar provided by the invention has the advantages of no shrinkage, strong binding power, no falling, good anti-permeability, simpleness in construction, efficiency and the like, and can adequately fill joints of doors and windows to ensure the sealing property around the doors and windows, and water is prevented from being seeped into the doors and windows.

Owner:TONGJI UNIV

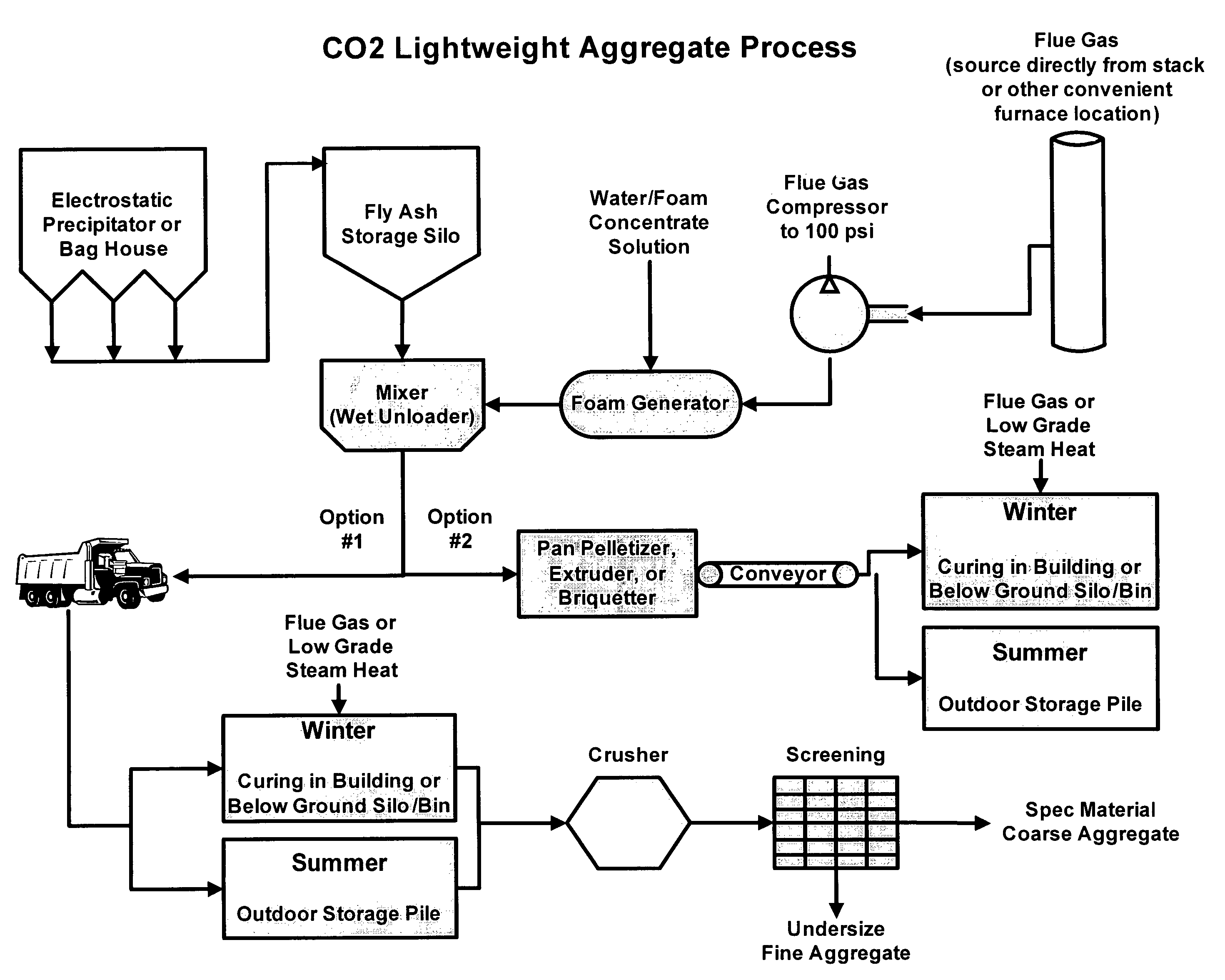

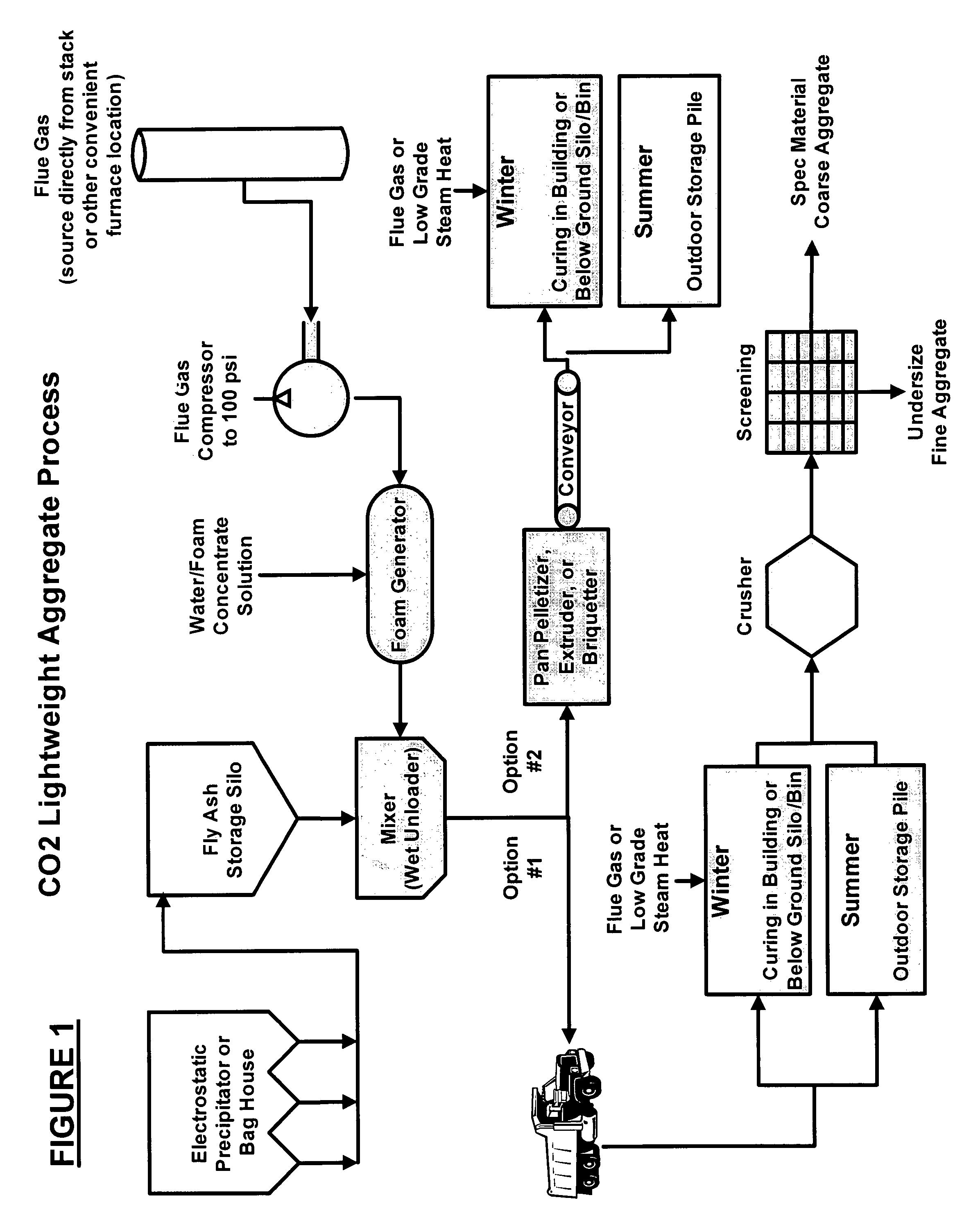

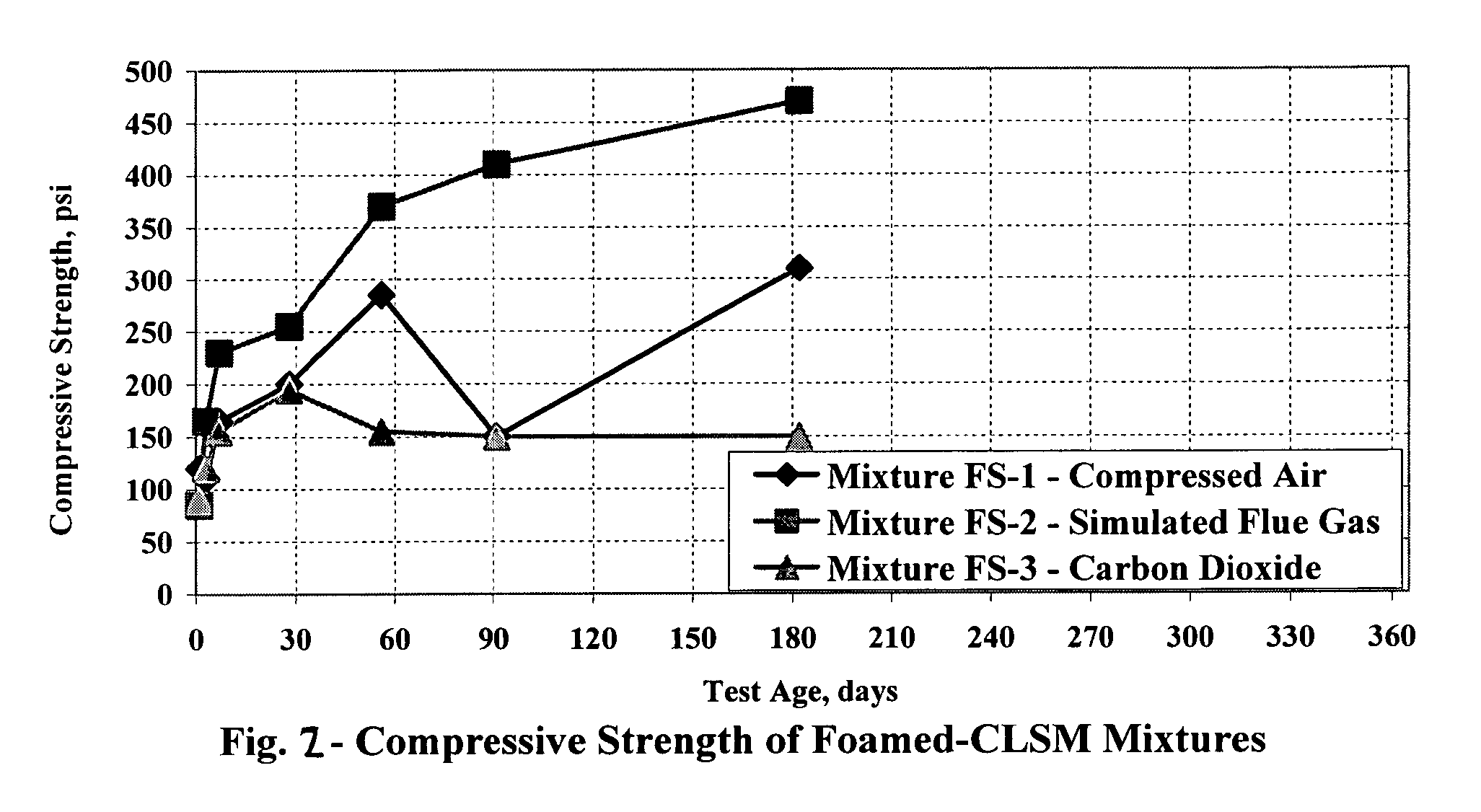

Carbon dioxide sequestration in foamed controlled low strength materials

A process for sequestering carbon dioxide from the flue gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the flue gas is formed, and the foam is added to a mixture including a cementitious material (e.g., fly ash) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the flue gas and waste heat reacts with hydration products in the controlled low-strength material to increase strength. In this process, the carbon dioxide is sequestered. The CLSM can be crushed or pelletized to form a lightweight aggregate with properties similar to the naturally occurring mineral, pumice.

Owner:WISCONSIN ELECTRIC POWER

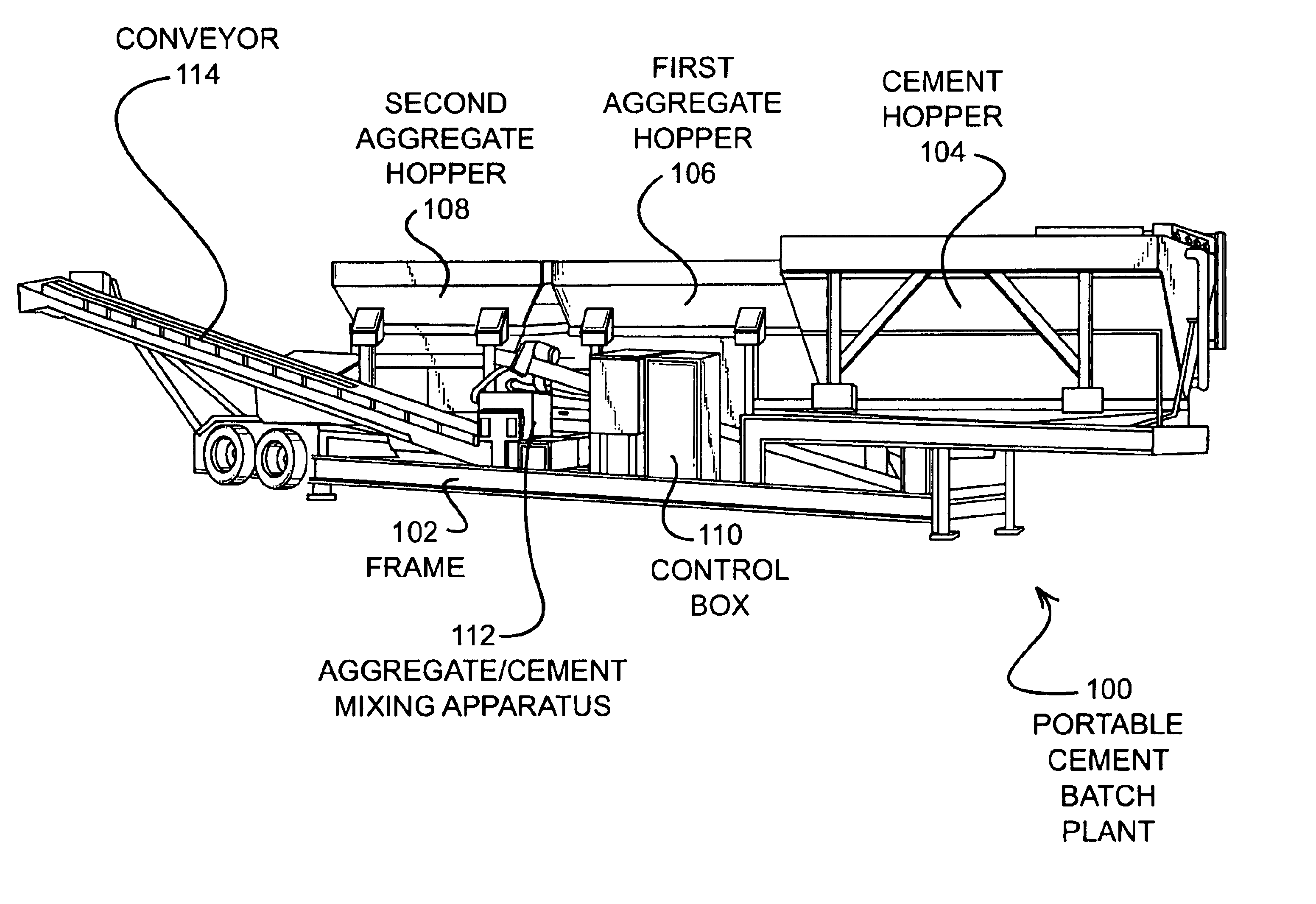

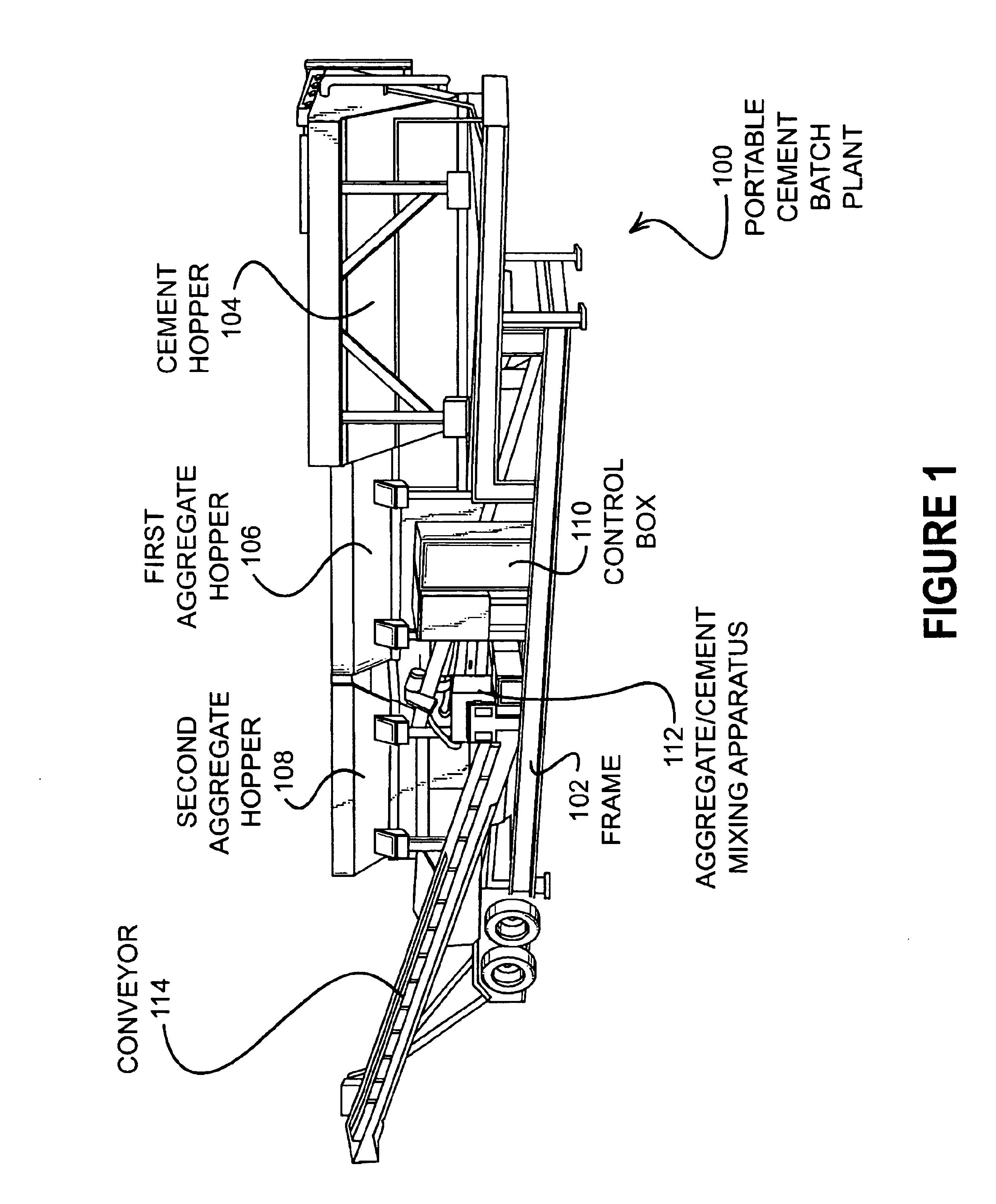

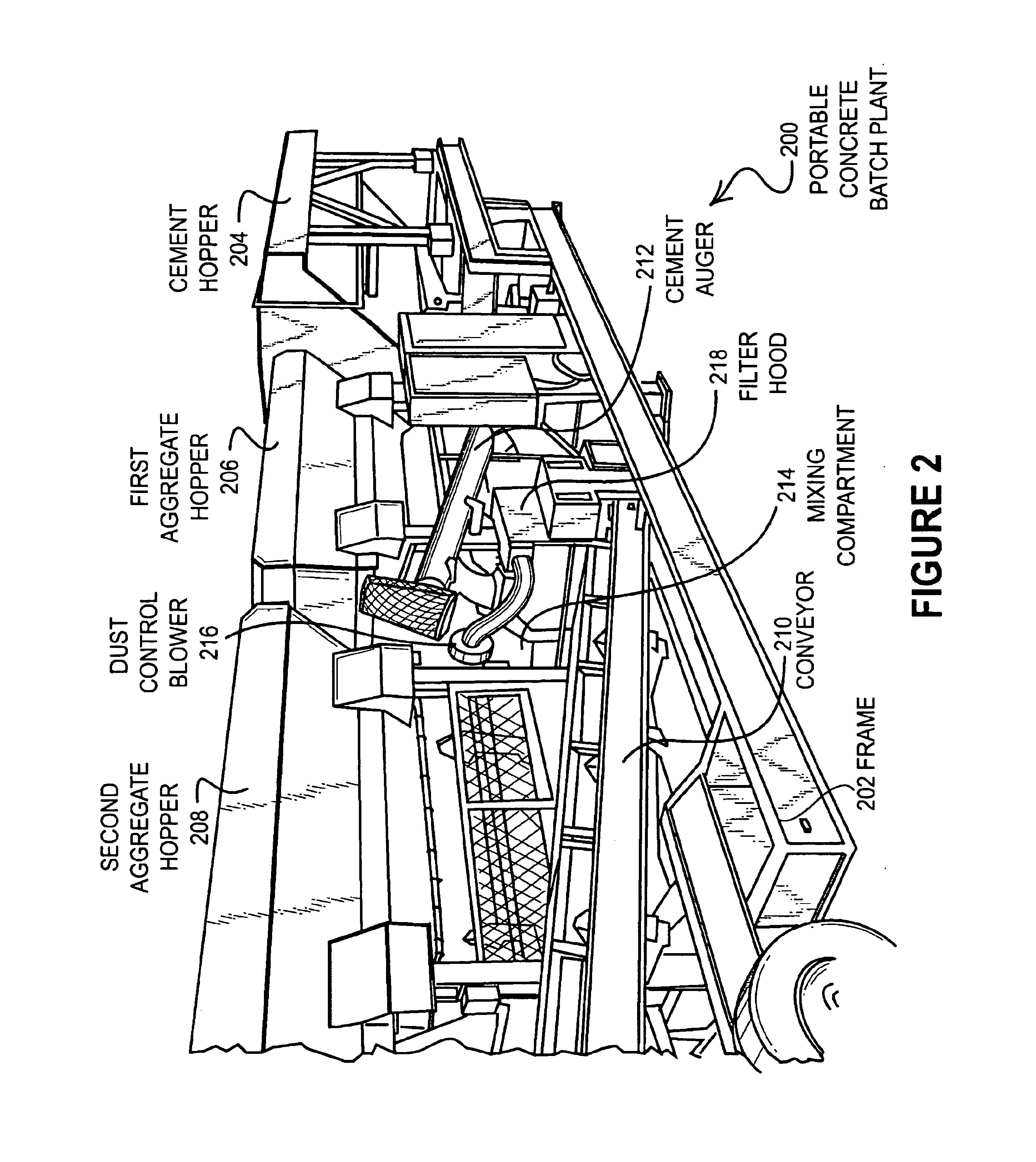

Portable concrete plant dispensing system

ActiveUS6876904B2Dispensed more accuratelyGood repeatabilitySampled-variable control systemsDischarging apparatusDistribution controlControl system

A computer controlled pumping and measuring system is used to dispense chemicals into a concrete mix. The redundant use of positive displacement pumps and flow meters ensure that any problems with the chemical dispensing are immediately caught. The computerized control system may be operable to control exact batch configurations of concrete and aggregate in conjunction with the chemical dispensing, as well as provide precise mixture control and recording of the various components.

Owner:PORT A POUR

Heat insulation wall integral pouring material and construction method

InactiveCN101376582AImprove insulation effectEarly benefitsSolid waste managementFiberCrack resistance

The invention discloses an insulation wall body integral-casting material and a construction method thereof. The insulation wall body integral-casting material is characterized in that the ratio of a binder, an insulation aggregate and an additive is 1000:(5-5000):(0-300); the binder is a cement-based binder or a gypsum-based binder; the constitutes of the cement-based binder are 300-1000 parts of cement, 0-200 parts of silica fume, 0-400 parts of fly ash, 0-700 parts of slag powder, 0-300 parts of zeolite powder, 0-200 parts of ash-calcium powder and 0-40 parts of gypsum; the constituent of the gypsum-based binder is 1000 parts of gypsum; and the constituents of the insulation aggregate are 0-100 parts of expanded polystyrene granules, 0-1500 parts of expanded perlite, 0-1500 parts of expanded vermiculite, 0-1500 parts of expanded vitrified microspheres, 0-5000 parts of expanded ceramisite and 0-200 parts of sepiolite fibers. The invention also comprises the construction method. The wall bodies casted by the insulation wall body material have good insulating and thermal performances, higher strength, and good water resistance, crack resistance and permeability resistance performances, as well as good compatibility and good security towards the subsequent decorating process.

Owner:湖南江盛新型建筑材料有限公司

Lightweight wall plaster

InactiveCN101691292AReduce lossWith thermal insulationSolid waste managementPlasterworkThermal insulation

The invention discloses a lightweight wall plaster which comprises the following components by weight percent: 65-90% of inorganic cementing material, 5-30% of lightweight aggregate, 0-30% of filler and 0-10% of functional additive, wherein the inorganic cementing material is a desulfurized plaster or a building plaster. The lightweight wall plaster is a single-component dry mixed material produced by a factory and can be used on a construction site by only adding water for stirring, the lightweight wall plaster has a certain thermal insulation function and excellent fire prevention performance, the bonding performance is good, and the compressive strength is high, thereby being capable of replacing the traditional plastering mortar to be plastered on inner sides of external walls, partition walls, room separating walls, ceilings and other occasions and further improving the thermal insulation performance of wall bodies.

Owner:谢日清

Crack self-remediation regenerated concrete based on urease production microorganism mineralization deposition and preparation method

ActiveCN106699026AStrong adaptability to high alkaline environmentAdaptableOn/in inorganic carrierWater reducerMechanical property

The invention discloses crack self-remediation regenerated concrete based on urease production microorganism mineralization deposition and a preparation method. The crack self-remediation regenerated concrete comprises components, namely, expanded perlite carried with urease production microorganisms, cement, stone, sand, silica fume, water, urea, calcium chloride, a urease production microorganism suspension and a water reducing agent. The urease production microorganisms are adopted as a concrete crack remediation agent, urease can be generated through metabolism through the urease production microorganisms, and the urea can be decomposed into NH4<+> and CO3<2+>, and furthermore the calcium carbonate can be mineralized and deposited to remedy cracks. In the preparation process, a part of the crack remediation agent is directly mixed with the concrete, then cracks and holes in regenerated crude aggregate self and weak adhesion areas between regenerated aggregate and a new cement stone base can be remedied, and thus the mechanical property of the regenerated concrete can be improved; meanwhile, the other part of the crack remediation agent is firstly adsorbed into an expanded perlite carrier and is further mixed into the concrete, then the crack self-remediation property of the regenerated concrete in the service period can be improved, and thus the anti-penetrability performance and the durability of the regenerated concrete can be improved.

Owner:TAIYUAN UNIV OF TECH

Heat preservation and energy saving type lightweight, gas filled wall bricks, and preparation method

This invention relates to a method for preparing heat-insulating and energy-saving lightweight aerated wall bricks, which are prepared from aggregate, gelation agent, aeration agent, heat-insulating material and water. The aggregate is composed of slag or river sand, glass microbeads, floating beads, closed perlite, and expanded perlite. The gelation agent is composed of cement, gypsum and lime. The aeration agent is Al powder. The fiber heat-insulating material is composed of high-Al powder, tripolite, ceramic fibers, mineral wool, sepiolite, expanded vermiculite, glass cotton and palygorskite. The wall bricks have such advantages as high compressive strength, low heat conductivity, high heat-insulating performance, high fireproof and damp-proof performances, rapid and convenient construction, and no need for composite heat-insulating layer.

Owner:徐振飞

Method for treating and regenerating reuse building waste

ActiveCN101099974AAvoid excessive cement slurry contentAvoid Excessive Water DemandSolid waste managementSolid waste disposalPrillBrick

The present invention discloses building waste treating and reusing process, which includes the following steps: classifying building wastes into waste concrete, waste stone material, waste ceramic, waste sintered brick and waste lime-sand brick; crushing separately into coarse grains and eliminating metal, timber and other impurity; milling into 5 mm below regenerated fine aggregate; sorting 0.15 mm below high quality fine aggregate and milling into regenerated fine powder material of 250-600 sq m / kg specific surface area; and preparing mortar, concrete, asphalt concrete and other building material with the regenerated fine aggregate and the regenerated fine powder.

Owner:SOUTH CHINA UNIV OF TECH

Lightweight leveling mortar

The invention discloses a lightweight leveling mortar material for a variety of wall surfaces and floors inside and outside buildings, and the lightweight leveling mortar material comprises the following components by weight percent: 65-90% of inorganic cementing material, 5-30% of lightweight aggregate, 0-30% of filler and 0-10% of functional additive. The lightweight leveling mortar material is a single-component dry-mixed material produced by a factory and can be used on a construction site by only adding water for stirring. The lightweight leveling mortar has a certain thermal insulation function and excellent fire prevention performance, the bonding performance is good, and the compressive strength is high, thereby being capable of replacing the traditional mortar to be plastered on a variety of wall surfaces and floors of buildings and further improving the thermal insulation performance of wall bodies.

Owner:谢日清

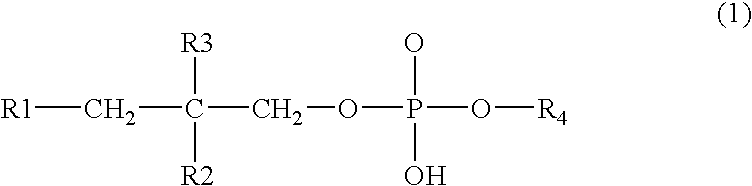

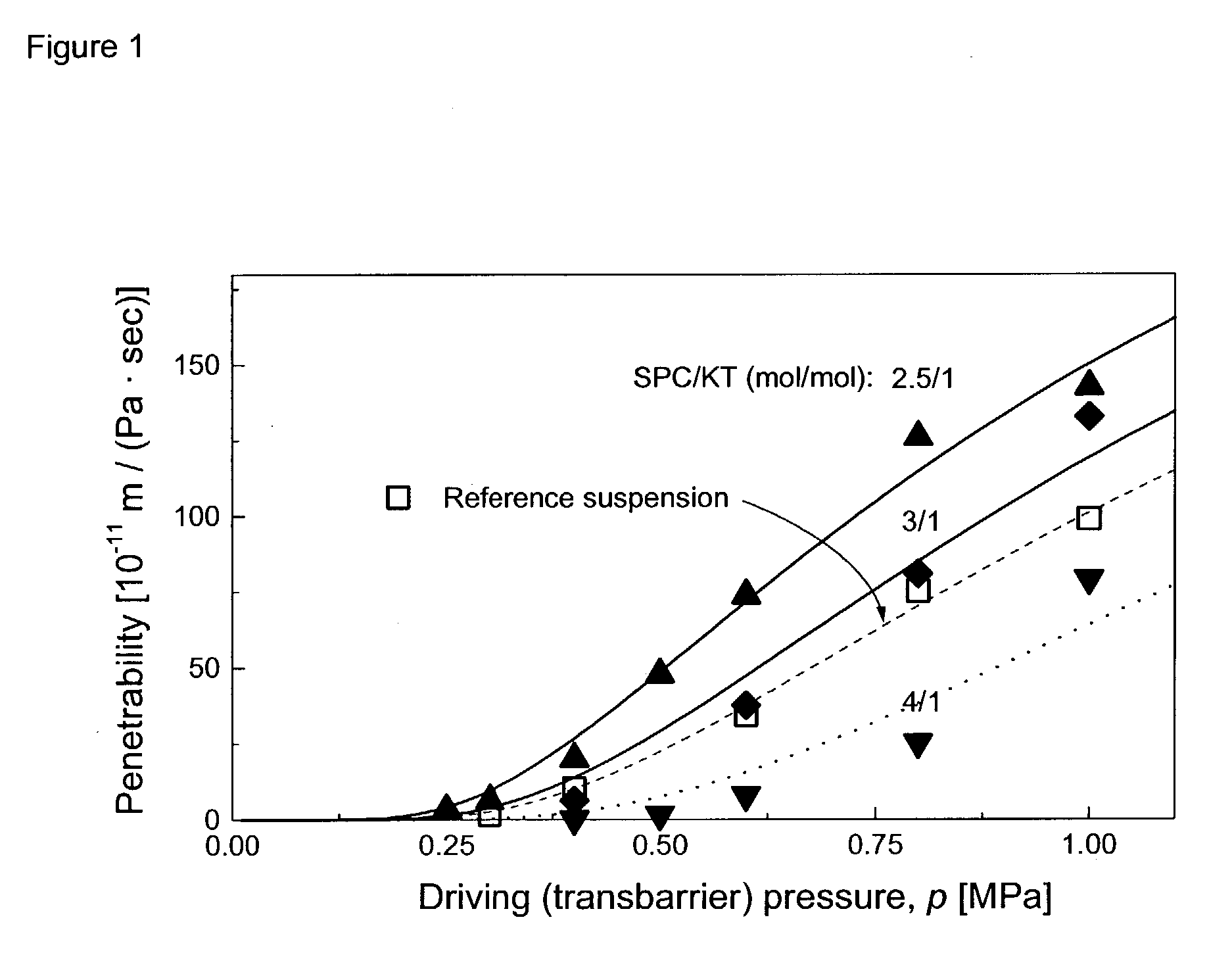

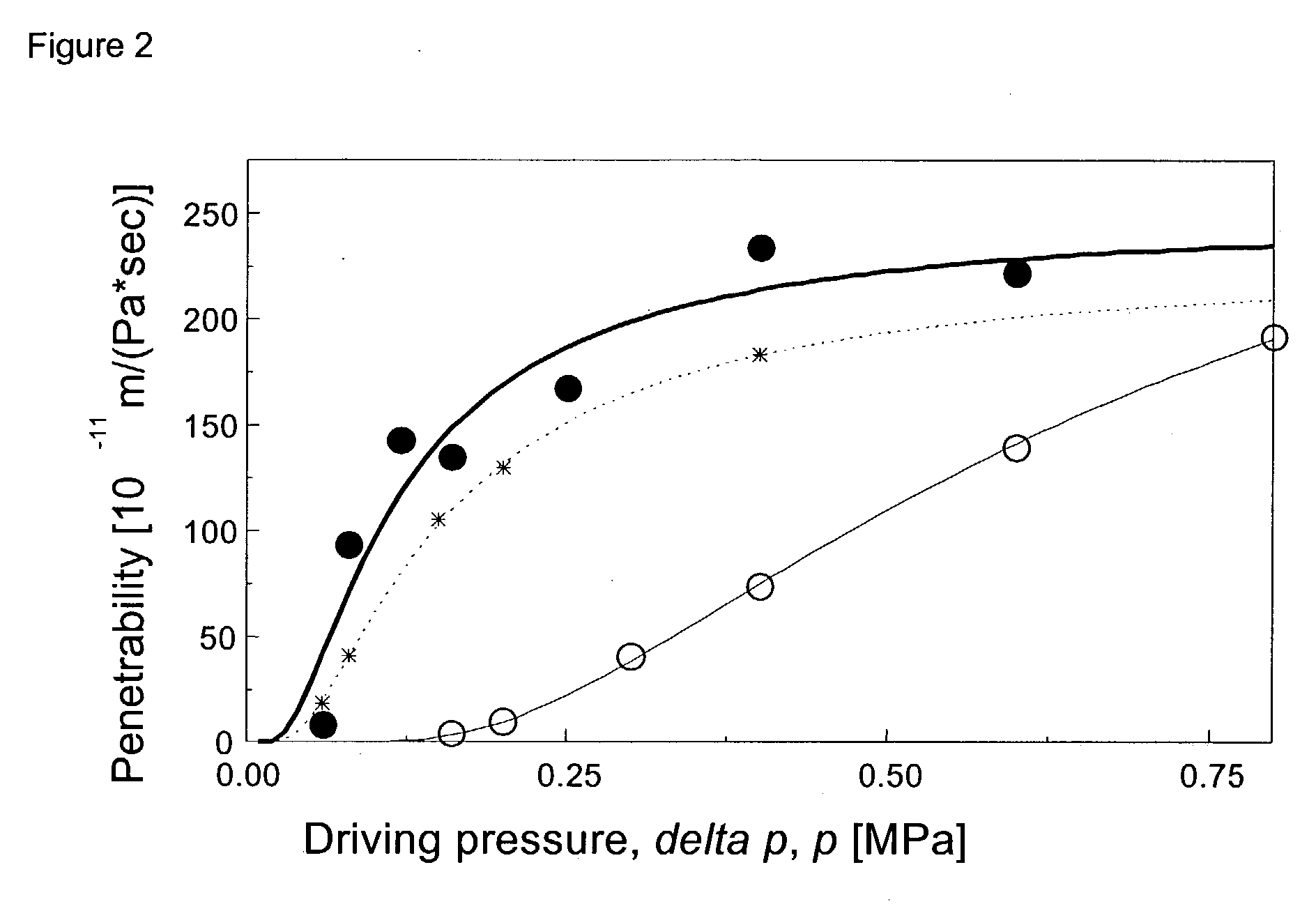

NSAID formulations, based on highly adaptable aggregates, for improved transport through barriers and topical drug delivery

The invention describes novel formulations of nonsteroidal anti-inflammatory drugs (NSAIDs) based on complex aggregates with at least three amphipatic components suspended in a suitable, e.g. pharmaceutically acceptable, polar liquid medium. A suitably ionised NSAID is one of the two, amongst said three, components that tends to destabilise lipid membranes, the other system component with such activity being typically a surfactant. In contrast, the remaining amongst said at least three amphipatic components typically forms a stable lipid membrane on it's own. An essential characteristics of the resulting, relatively large, aggregates is an improved ability to penetrate pores, in a semi-permeable barrier, at least 30%, and often much smaller than the average diameter of the complex aggregate. This enables said aggregates to mediate NSAID transport through semi-permeable barriers including mammalian skin. As a result of the skin penetration by NSAID loaded large aggregates, the drug delivered transcutaneously with such carriers gets deeper into the tissue than the corresponding NSAID from a solution on the skin surface. This is believed to be due to the special ability of suitable large carriers to bypass the local sink of blood capillaries at the epidermal-dermal junction in the skin. The carrier-mediated delivery of locally applied NSAIDs thus allows therapy of deep tissues under the drug administration site, which is medically highly desirable.

Owner:IDEA AG

Permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste and preparation

The invention discloses permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste and preparation. The permeable recycled aggregate and ceramsite concrete doped with industrial and agricultural solid waste is characterized in that recycled coarse aggregates and ceramsites are taken as coarse aggregates of concrete, an appropriate amount of pretreated industrial and agricultural solid waste such as industrial waste, agricultural waste, household garbage and the like is taken as an admixture, a cementing agent is prepared from cement, water, a superplasticizer and a reinforcement material, and the materials are mixed with a preset stirring process and preparation method, so that ecological concrete with good mechanical property, permeable property and durability is produced. According to the concrete, the waste utilization rate is up to about 80%, the concrete is environment-friendly, locally available materials can be used, the economic benefit is remarkable, ceramist pore is smaller, and sewage can be continuously and stably treated, so that the concrete is commonly used in water environment comprehensive improvement engineering; and besides, the concrete has light weight, high strength and good water permeability and can be also used in permeable pavement engineering such as a sidewalk, a parking lot and the like as well as plant engineering such as ecological riverway slope protection, roof landscape planting and the like.

Owner:YANGZHOU UNIV

Isotropic graphite product and preparation method thereof

The invention relates to an isotropic graphite product and a preparation method thereof. The materials consist of caking agent and skeletal material. The mass ratio of the caking agent and the skeletal material is (0.30-0.70) to 1, wherein the weight of the rarefied natural crystallite graphite is 30 to 100% of that of the skeletal material, and the other materials are one or more than two of thegraphite returning charge, the pitch coke, the refinery coke, the secondary coke and the intermediate carbon sphere. The preparation method comprises the steps of uniformly mixing the caking agent andthe skeletal material, molding, baking, dipping, secondarily baking, and graphitizing. With rich materials, low cost, small limitation for molding, high capability of prepared isotropic graphite product, the invention can be widely applied in the field of preparing graphite product.

Owner:TSINGHUA UNIV +1

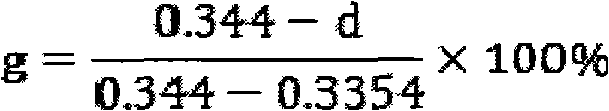

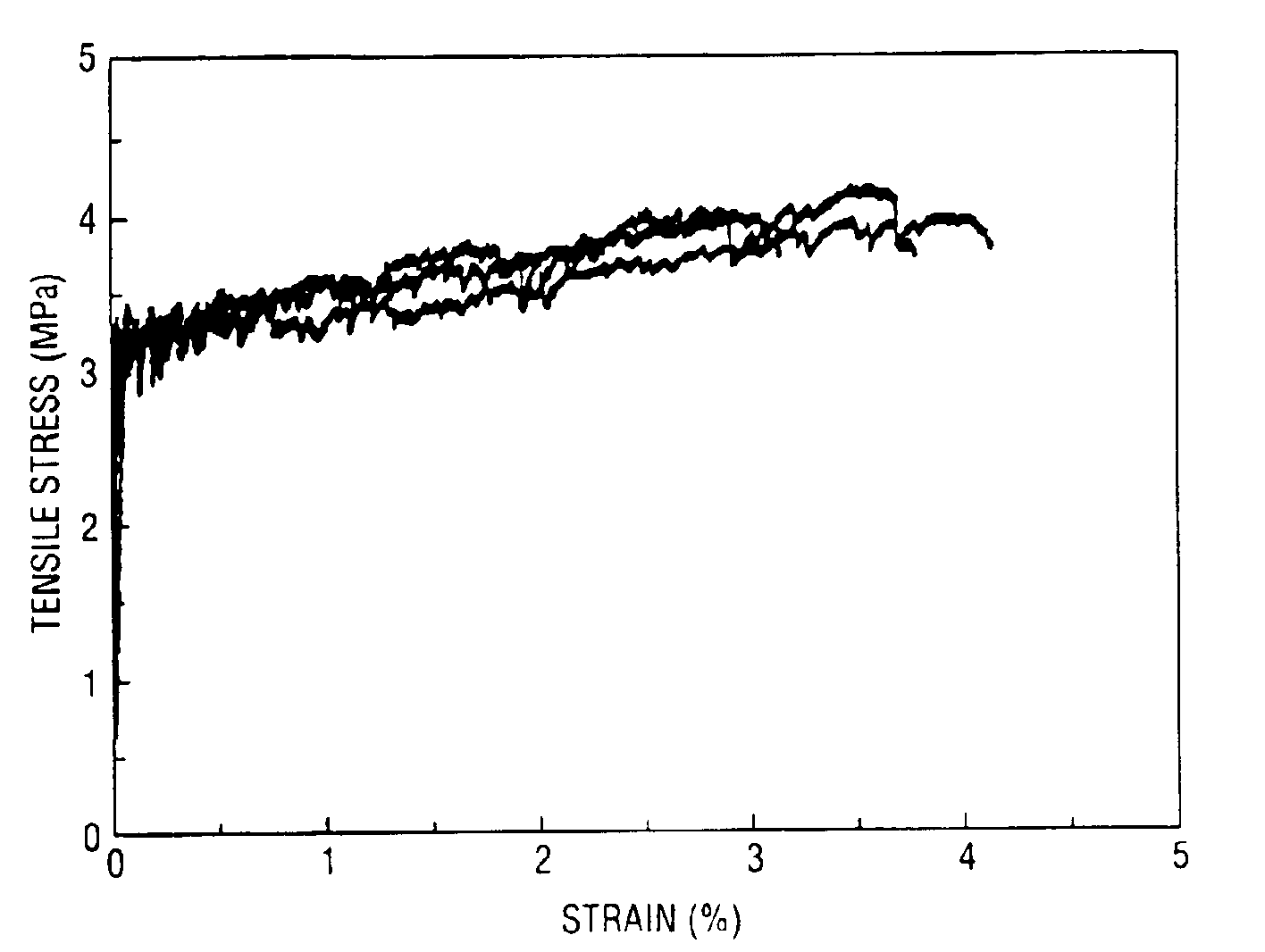

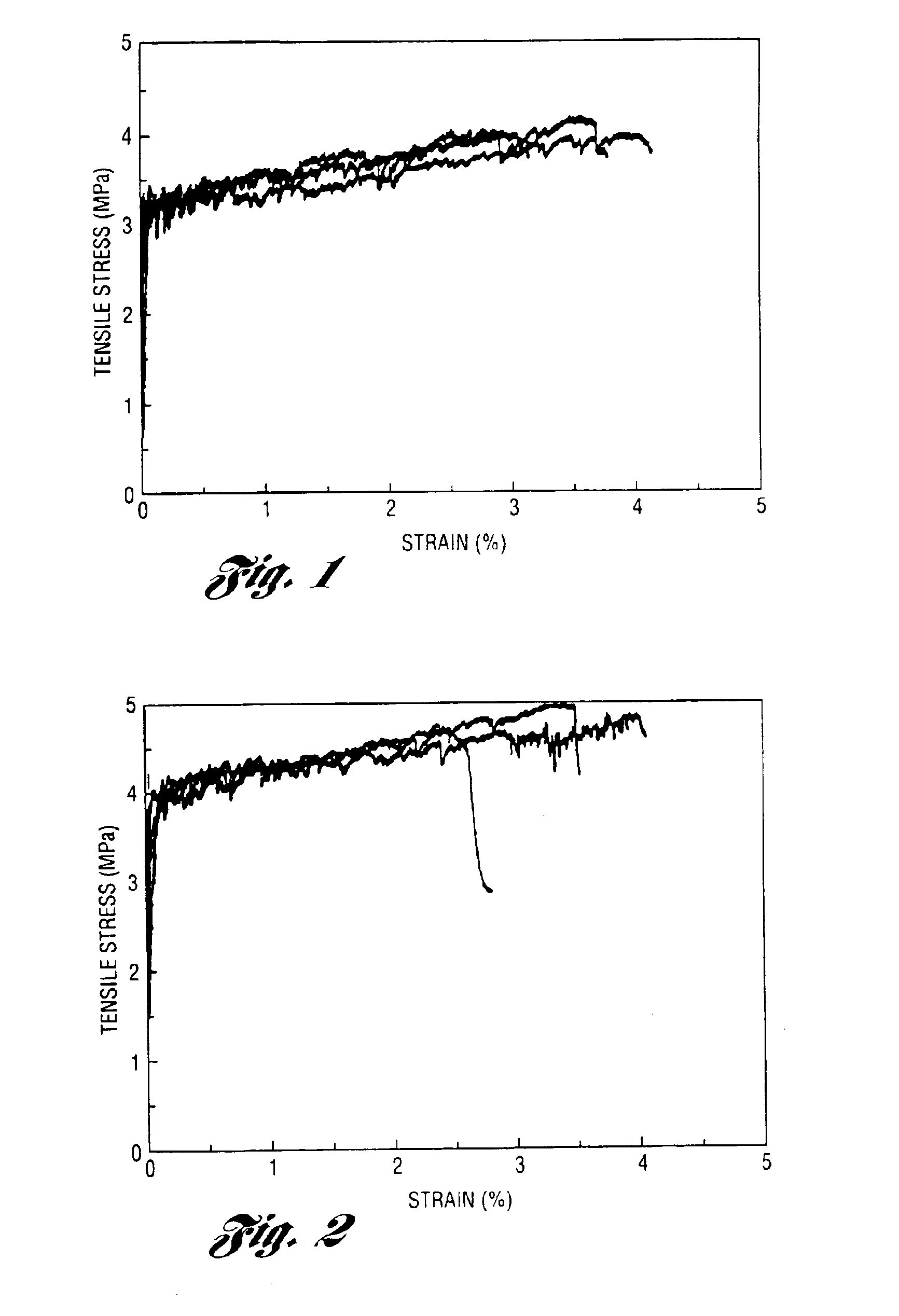

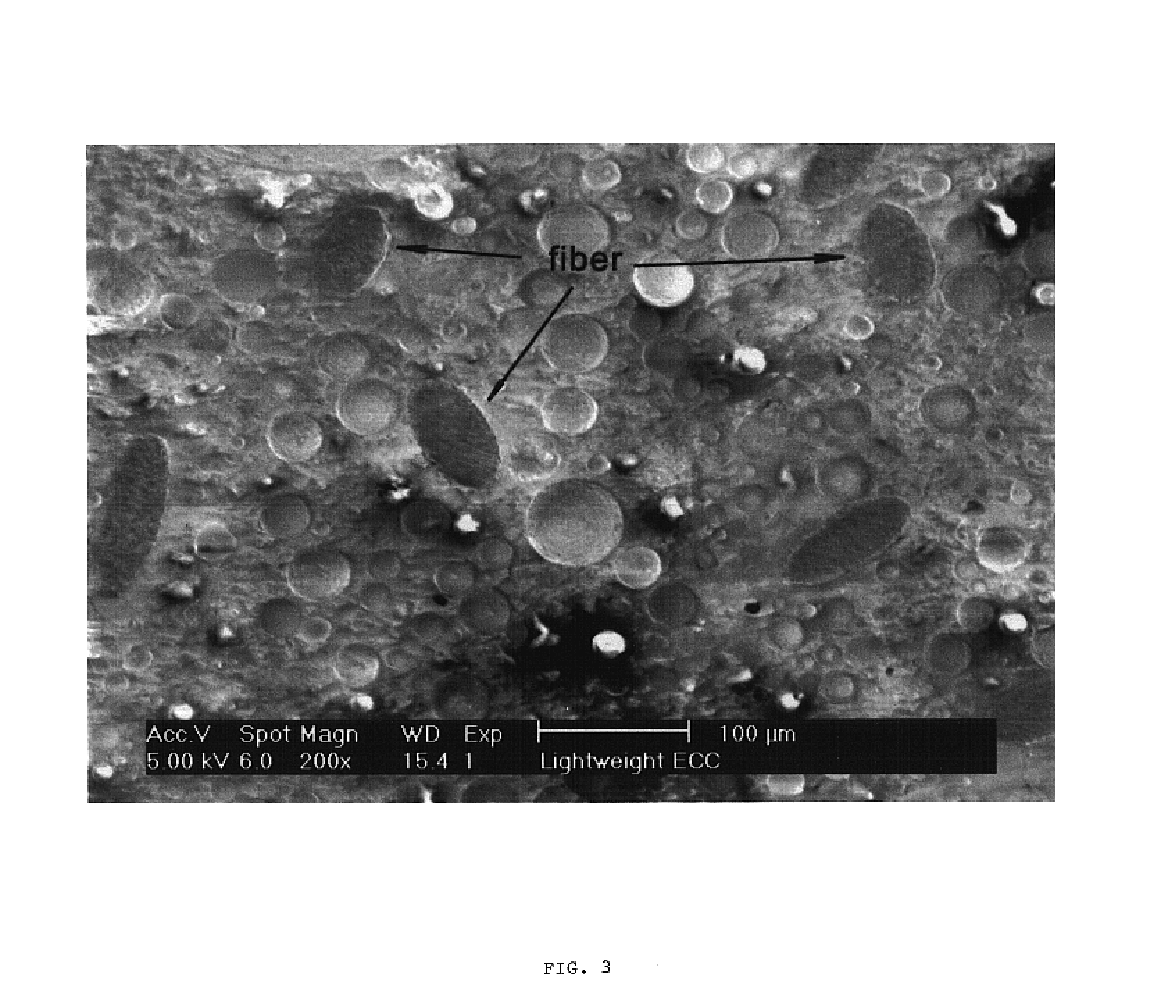

Lightweight strain hardening brittle matrix composites

Fiber reinforced lightweight concrete composites employ less than 4% by volume of reinforcing fibers in conjunction with small particulate lightweight aggregates or voids, and cure to composites which exhibit high tensile strain and strain hardening behavior. The composites are useful for numerous structures in civil engineering.

Owner:RGT UNIV OF MICHIGAN

Slag concrete manufactured aggregate

Embodiments of the invention provide a slag manufactured aggregate suitable for inclusion in one or more of concrete, precast concrete, cellular concrete, or precast cellular concrete. Concretes, precast concretes, cellular concretes, and precast cellular concretes comprising the slag manufactured aggregate are also included in embodiments of the invention. Methods of making the foregoing aggregates and concretes are also included herein.

Owner:EXCELL TECH

Self-suspended propping agent and preparation method thereof

InactiveCN104946234AReduce pollutionLow costFluid removalDrilling compositionPolymer scienceFracturing fluid

The invention belongs to the field of fluid mineral product exploration such as petroleum, natural gas and shale gas, and provides a self-suspended propping agent which is prepared by wrapping or partially wrapping a granular framework with a water-soluble high polymer material; the framework consists of solid granules which are sufficient in mechanical strength for bearing crack closing stress and are selected from one or multiple of quartz sand, ceramsite, metal granules, spherical glass granules, sintered monohydrallite, sintered alumina, sintered zirconium oxide, synthetic resin, precoated sand and crushed fruit shell granules; the amount of the water-soluble high polymer material accounts for 0.1-5wt% of that of the framework. The self-suspended propping agent provided by the invention does not need to be fractured by using fracturing fluid which is added with organic macromolecules and is high in cost, and can be fractured by using natural water which can be obtained at any place directly, so that pollution is reduced, and the cost can be lowered. By adopting the self-suspended propping agent provided by the invention, friction resistance of the fracturing fluid can be reduced, and a fracturing support system adopting the self-suspended propping agent has properties which are generally identical to those of conventional fracturing fluid, and is easy to convey and discharge backwards.

Owner:BEIJING RECHSAND SCI & TECH GRP

Composite water permeable brick and composition for producing the same

The invention disclosed a composite permeable brick comprising a permeable surface layer and a permeable base layer. The surface layer and the permeable base layer, which respectively comprise an aggregate and a binder adhering to the aggregate, are closely combined together. The binder in the permeable surface layer at least comprises a hydrophilic binder. The permeable brick according to the invention has a good permeability and is of low cost, because of the compact and permeable surface of the brick. The invention also discloses a mixture for preparing the composite permeable brick, comprising an aggregate and a binder adhering to the aggregate. The binder at least comprises a hydrophilic binder, and the binder / aggregate ratio is from 1:100 to 20:100 by mass. The composite permeable brick and the mixture of the invention may be used for road surfacing, water circulation, water filtration and water purification, promoting the full utilization of rainwater resources and improving the urban water circulation.

Owner:BEIJING RECHSAND SCI & TECH GRP

Preparation method of self-suspension proppant for natural hydrofracturing construction

The invention provides a preparation method of a self-suspension proppant for natural hydrofracturing construction, which comprises the following steps: by using 6-200-mesh granules as aggregate, adding an adhesive solution accounting for 10-30 wt% of the aggregate into the aggregate, and adding a water-soluble high polymer material accounting for 0.1-5 wt% of the aggregate; and stirring uniformly, drying and screening. The optimal selection of the raw materials and technological conditions greatly enhances the mechanical properties of the proppant. The obtained proppant has the advantages of small friction resistance and high strength, can be suitable for high-temperature conditions, and can be easily recovered; and the used coating material can not cause environmental pollution.

Owner:BEIJING RECHSAND SCI & TECH GRP

Weatherable water-permeable material and its uses

The invention discloses a weatherability permeable material, which consists of aggregate and adhesive, wherein the aggregate is one of natural quartz sand, coal ash, melt slag, artificial quartz sand or their random composition with diameter at 0.07mm-1. 6mm; the adhesive is one of epoxide resin, polyurethane resin and acroleic acid resin or their composition with good weatherability; the optical stabilizer, anti-oxidizer and adhesive are added in the raw material, which improves weatherability obviously; the permeable resin is added in the aggregate as well as inorganics, which improves permeability effectively.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Technological process for preparing active powder concrete by using iron tailing

A technological process for preparing active powder concrete by using iron tailing is characterized by performing screening and mechanical-chemical activation to iron tailing, using partial iron tailing after screening as fine aggregate of the active powder concrete, using activated tailing as component of the active powder concrete, and preparing the active powder concrete. The invention substitutes partial cement, quartz powder and silica fume with mechanically-activated iron tailing and fly ash or slag, and quartz sand or river sand with screened iron tailing fine aggregate, and prepares high-strength active powder concrete under standard curing or high-temperature high-pressure curing condition; and compared with conventional method, the invention reduces raw material cost, improves iron tailing comprehensive utilization rate, reduces natural resource consumption amount, and promotes development of ecological environment protection and circular economy promotion.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Refractory spray coating with high steel fiber content and spraying method thereof

The invention discloses a refractory spray coating with high steel fiber content and a spraying method thereof, which belong to the technical field of refractory materials. The method comprises the following step of: 1, pneumatically conveying the refractory spray coating to a nozzle, adding water onto the nozzle, and spraying and bonding the coating on a wall; or 2, adding water or a liquid bonding agent into the refractory spray coating, stirring the mixture into mortar, conveying the mortar to the nozzle by a pumping method, spraying the mortar out of the nozzle by using high-pressure air,and bonding the mortar on the wall. The refractory spray coating comprises the following ingredients in part by weight: 30 to 80 parts of refractory aggregate, 30 to 50 parts of refractory powder, 5 to 20 parts of bonding agent, 0.5 to 15 parts of additive and 3 to 80 parts of steel fiber. The invention has the advantages that: by spraying the refractory spray coating on a blast furnace cooling wall, spraying on a blast furnace throat steel brick, spraying on various refractory linings with cold faces and hot faces and repairing, the service life of the refractory material for the inner wall of a blast furnace can be greatly prolonged, and the effects of protecting the environment, saving energy and reducing consumption are achieved.

Owner:北京联合荣大工程材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com