Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2033 results about "Concrete composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

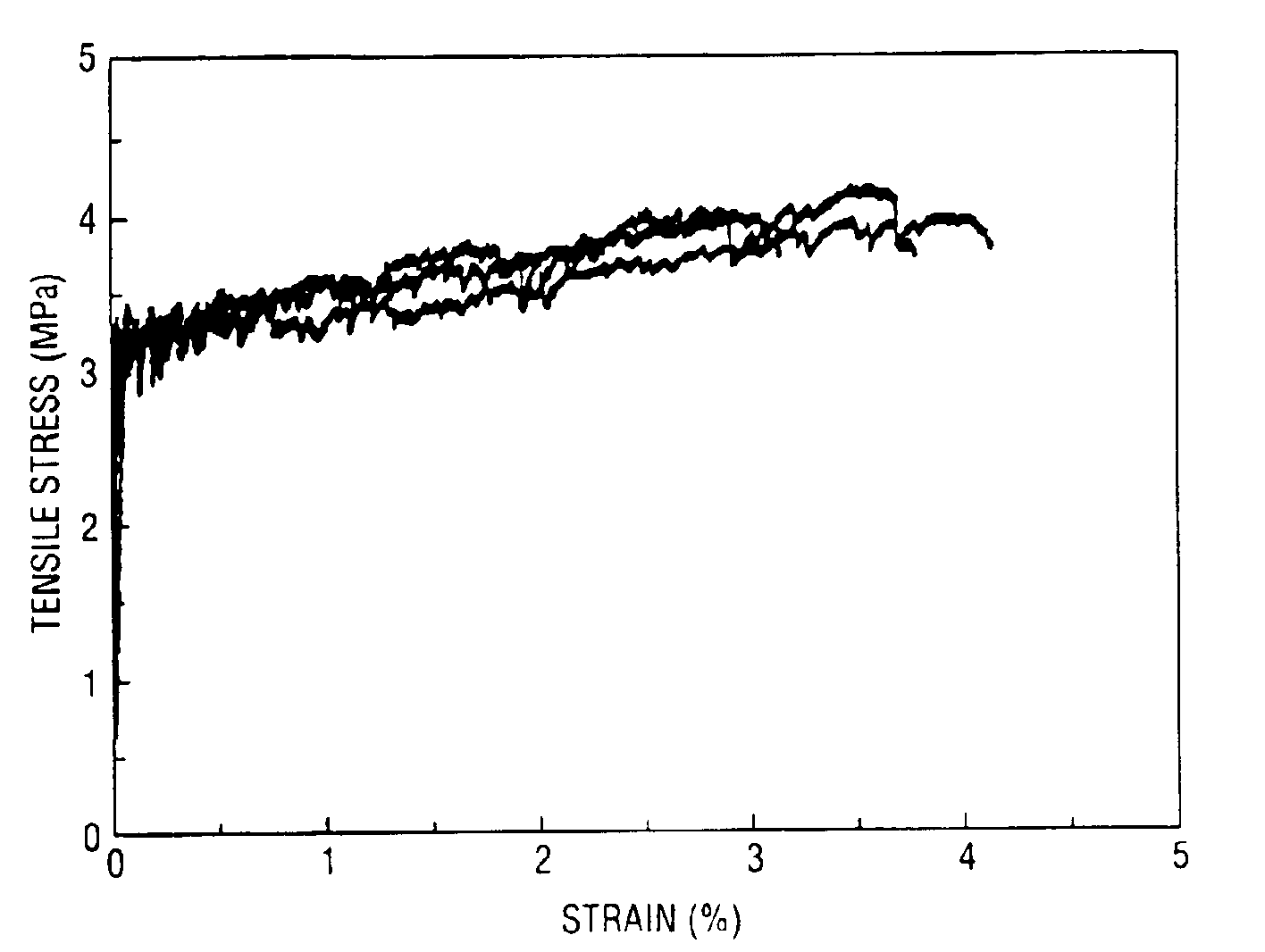

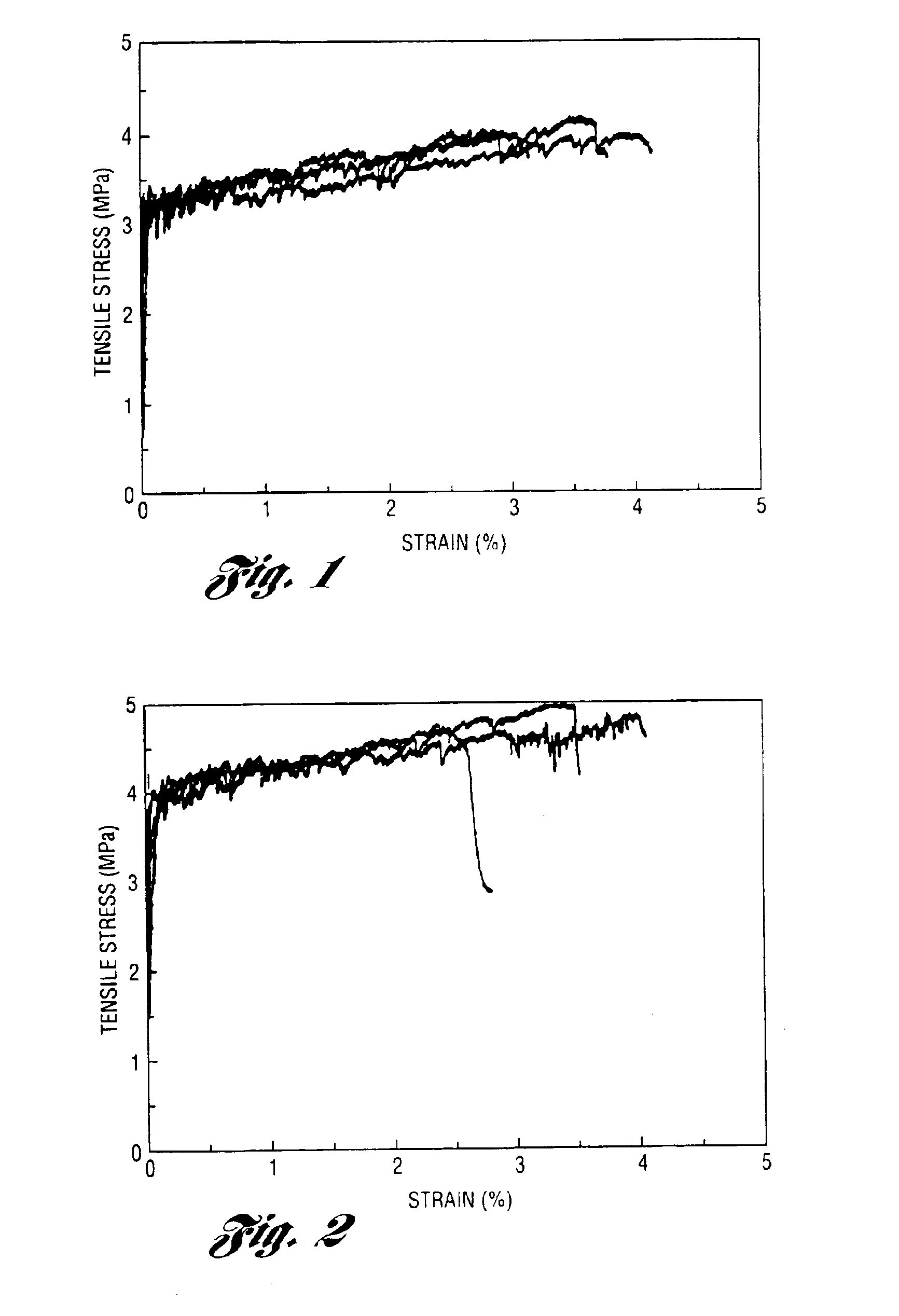

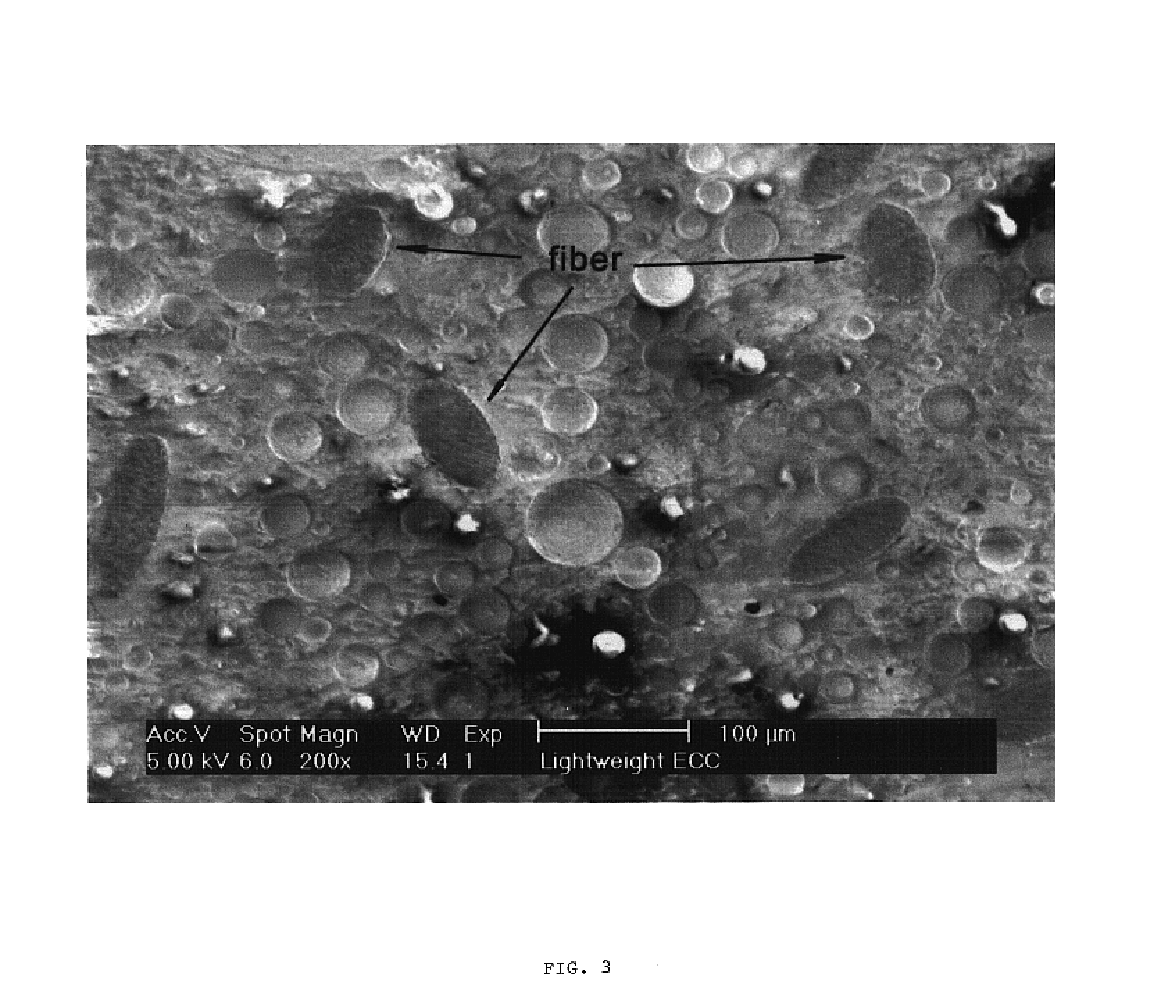

Lightweight strain hardening brittle matrix composites

Fiber reinforced lightweight concrete composites employ less than 4% by volume of reinforcing fibers in conjunction with small particulate lightweight aggregates or voids, and cure to composites which exhibit high tensile strain and strain hardening behavior. The composites are useful for numerous structures in civil engineering.

Owner:RGT UNIV OF MICHIGAN

Regenerative concrete composite material and method for making same

InactiveCN101139193ASolve processingSolve environmental problemsSolid waste managementEcological environmentLiving environment

The present invention discloses a regenerated concrete compound material, which is made of the following components according to weight ratio: 37-53 percent of regenerated aggregate prepared by the building waste residue, 14-30 percent of regenerated fine aggregate prepared by the building waste residue, 6-14 percent of industrial waste sand, 14-18 percent of common cement, 6-8 percent of water, additive and glue powder of waste tyre. The preparation method for the regenerated concrete is that: (1) the waste tyre is crushed and then is dipped in the coupling agent solution, and is to be dried; (2) the building waste residue is crushed, screened to obtain the regenerated coarse or fine aggregate; (3) the additive is added into the aggregate and the waste sand for mixing and blending evenly; (4) the regenerated aggregate, waste sand, cement, water and glue powder are milled evenly and then the regenerated concrete compound material can be obtained. The present invention can solve the problems that the building waste residue is difficult to be treated and the entironment is polluted and deteriorated greatly and so on. The building waste residue is to be used for replacing the natural aggregate that can decrease the consumptions to the natural aggregate in the building industry, solve the problems that the natural aggregates are increasingly lacked and the entironment is damaged by the exploitation of the sand stone. The present invention can protect the living environment for the human, guarantee the sustainable development for the society and accord to the requirement of the sustainable development.

Owner:云南华威废弃物资源化有限公司

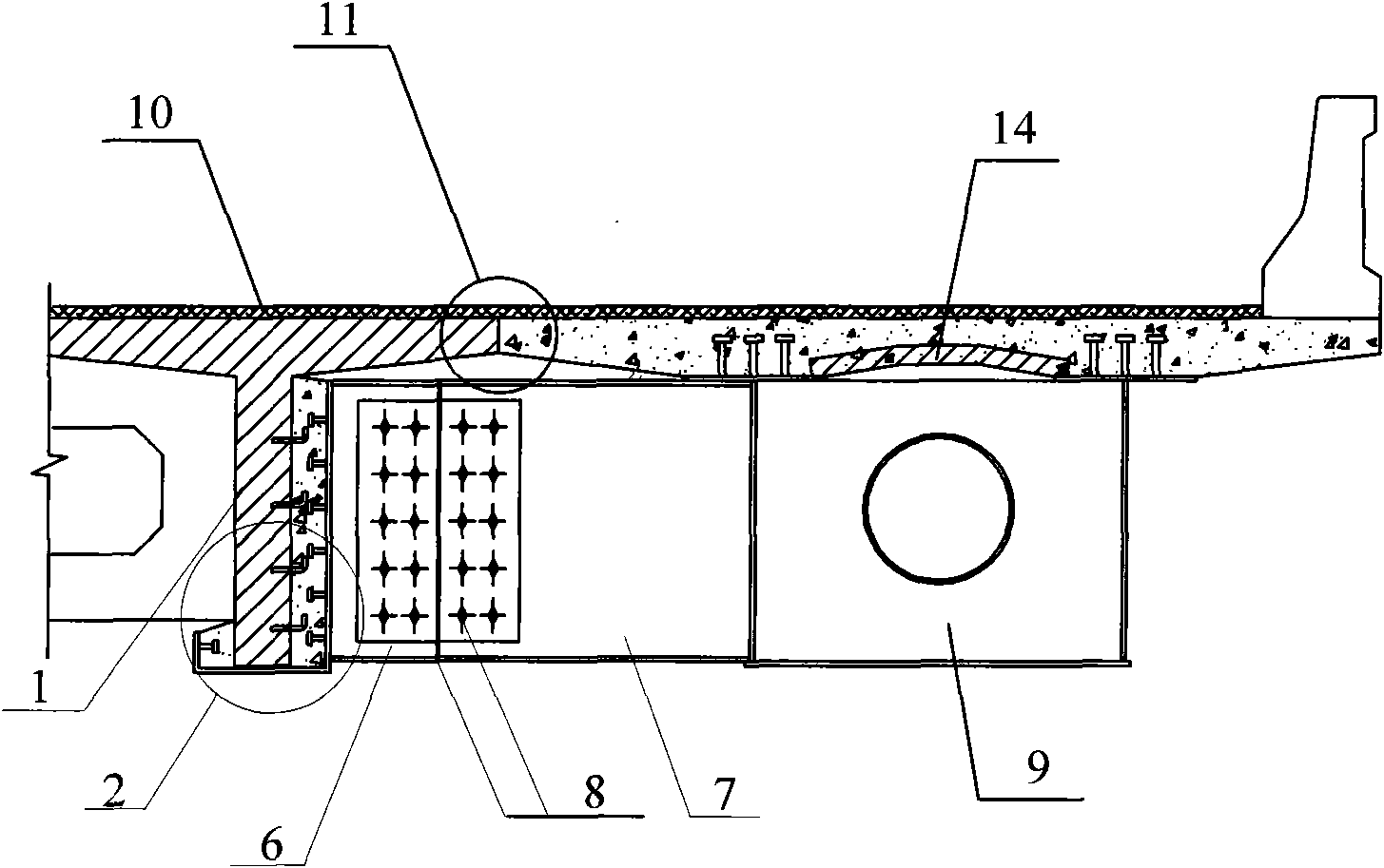

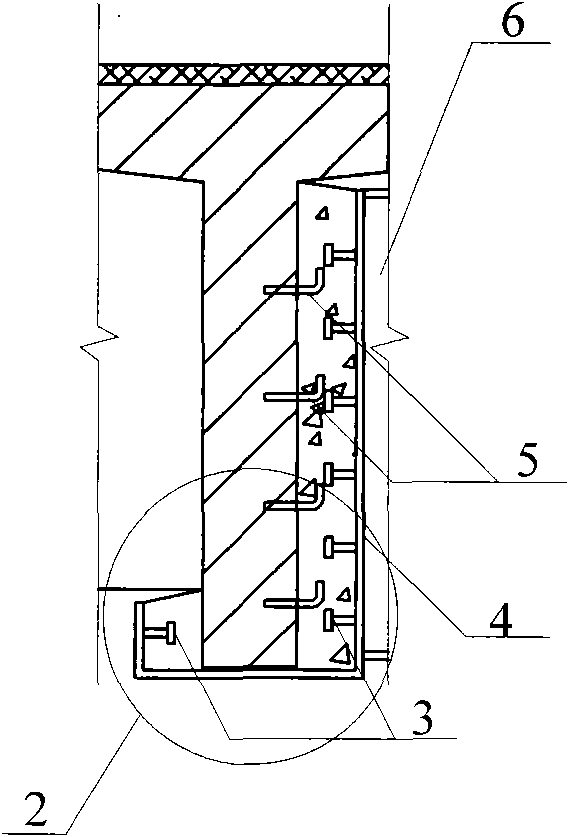

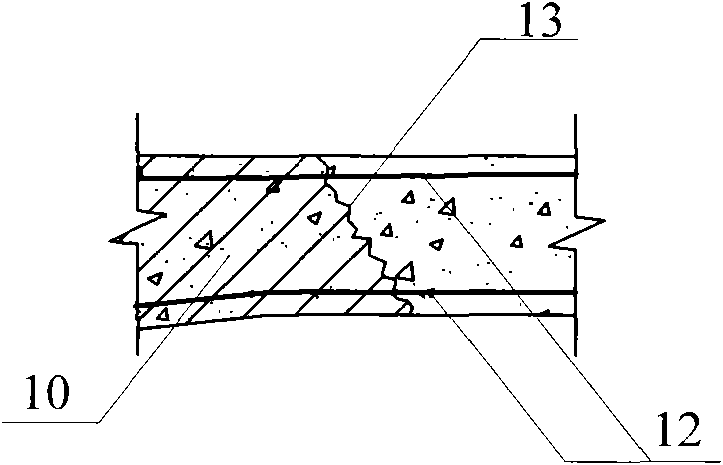

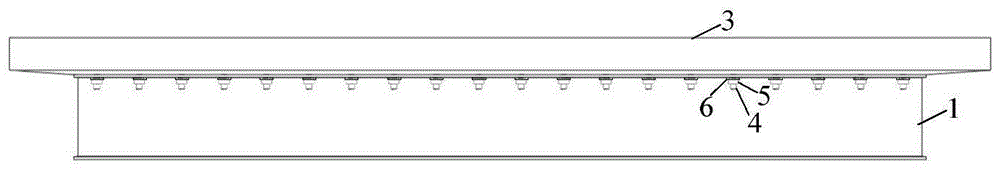

Steel-concrete composite beam adopting corrugated steel web and construction method thereof

The invention discloses a steel-concrete composite beam adopting a corrugated steel web, which relates to a corrugated steel web composite beam capable of being applicable to highway bridges and railway bridges. The beam comprises a top flange concrete composite plate, a corrugated steel web plate, a top flange steel plate, a box beam bottom plate and male pin connecting pieces, wherein the top flange comprises a precast concrete slab and a cast-in-place concrete layer; and the top flange concrete composite plate is connected with the top flange steel plate into a whole through the male pin connecting pieces welded on the top flange steel plate. By adopting the structure, the problems that the site workload and the construction difficulty for casting a bottom flange concrete slab of a traditional corrugated steel web composite beam are large, the construction quality is difficult to guarantee and the like are overcome on the premise that the quantity of steel is hardly increased, meanwhile, the tensile property of the steel plate is fully played, the bearing capacity, the rigidity and the cracking resistance of the structure are improved, and the durability of the structure is improved, therefore, the corrugated steel web composite beam has the advantages of simple structure, reasonable stress, quick and convenient construction, and good technical and economic benefits.

Owner:TSINGHUA UNIV

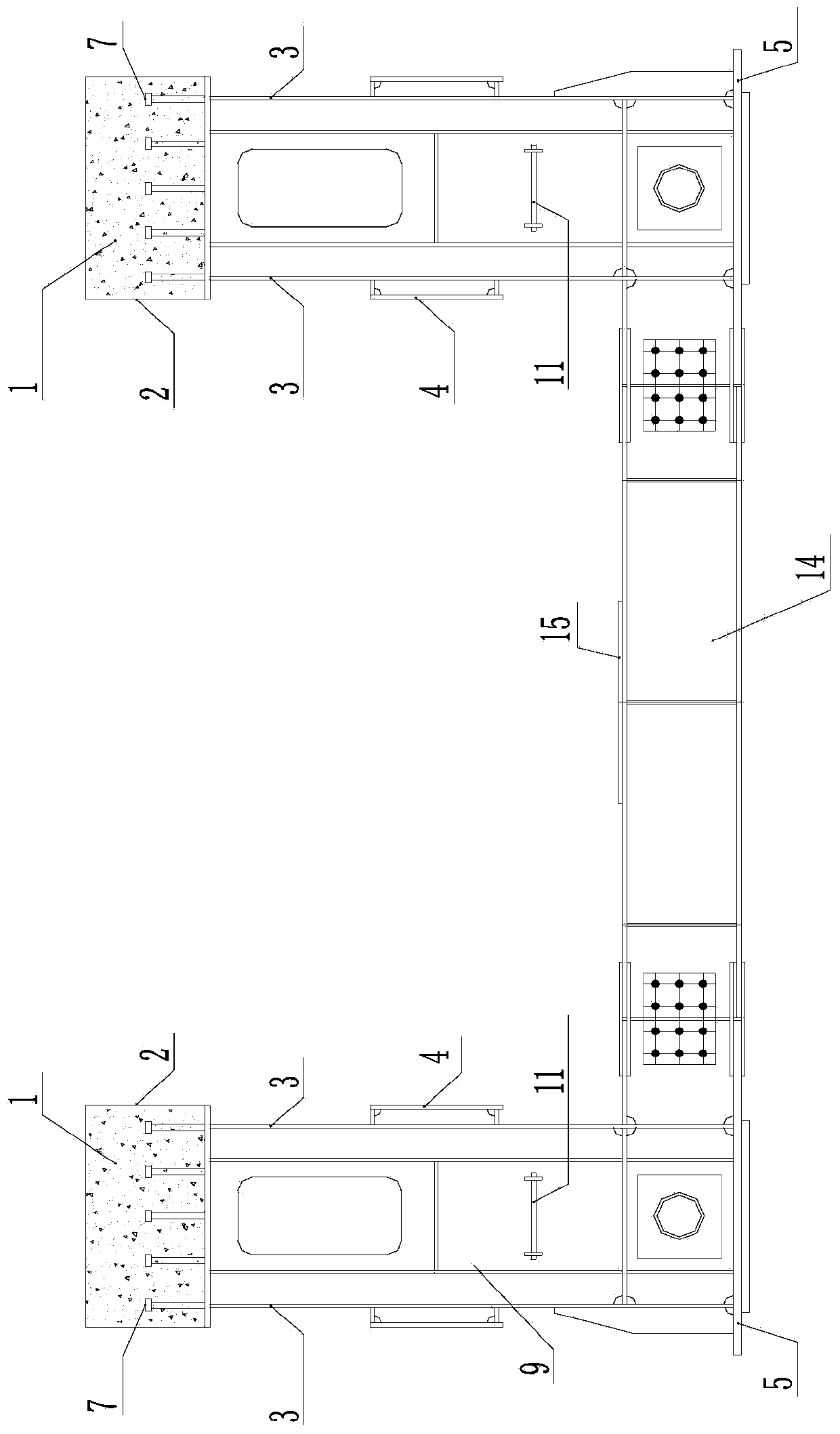

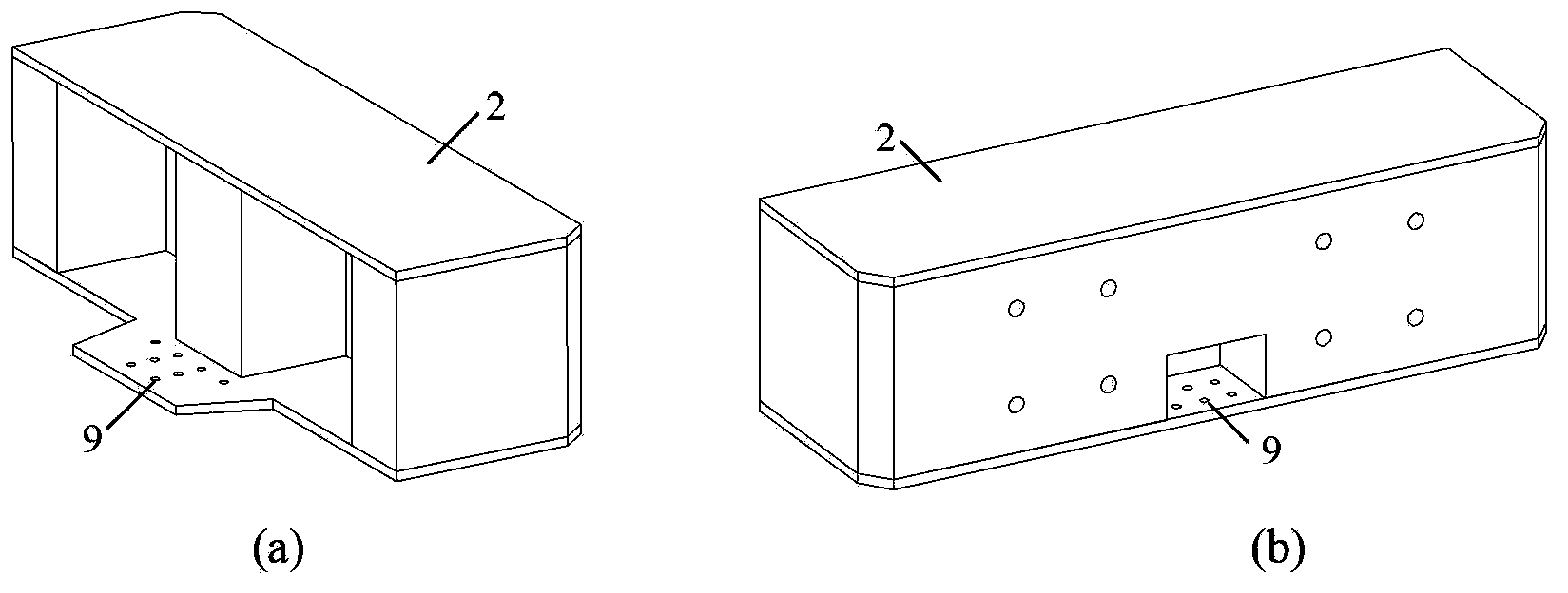

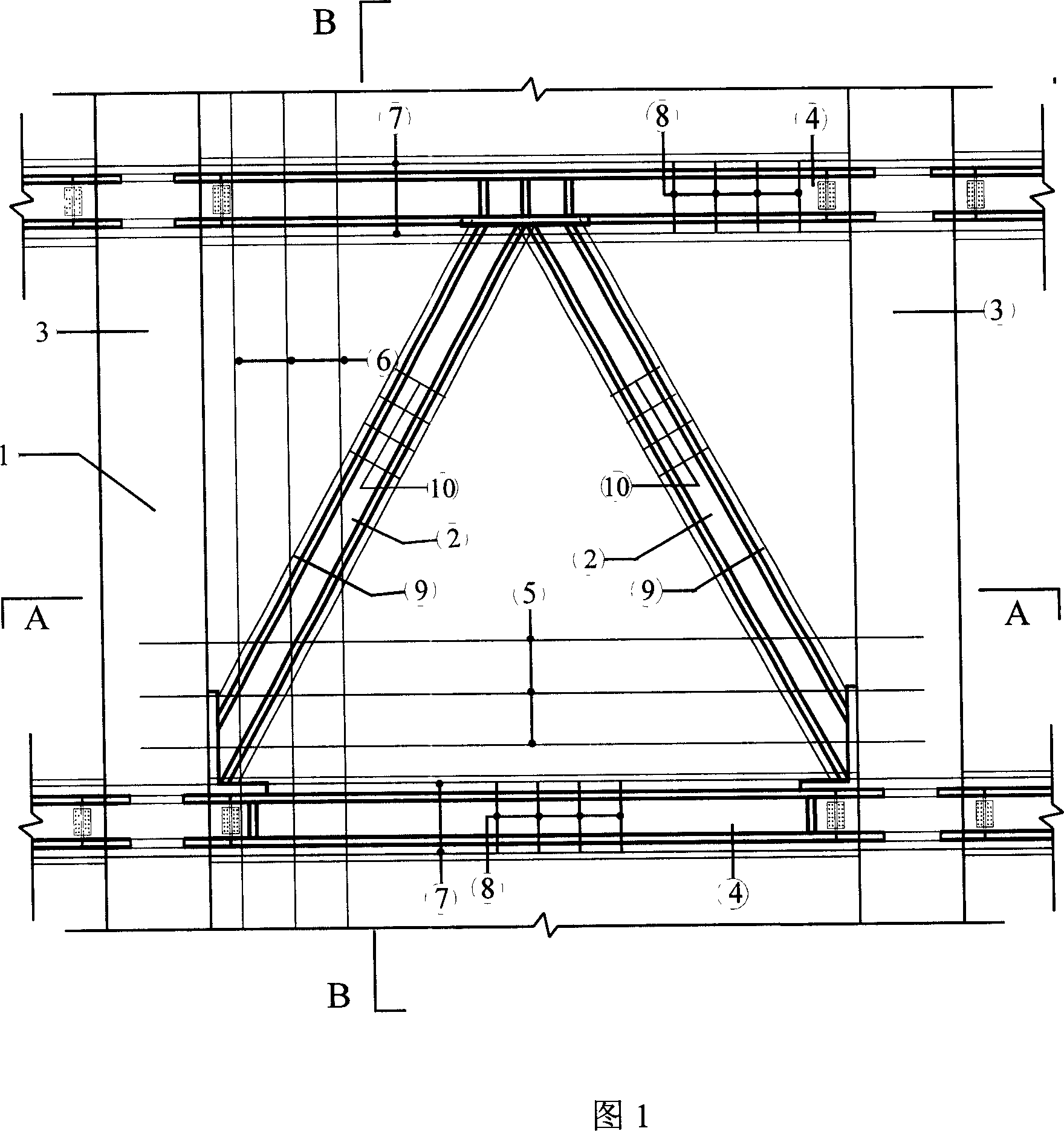

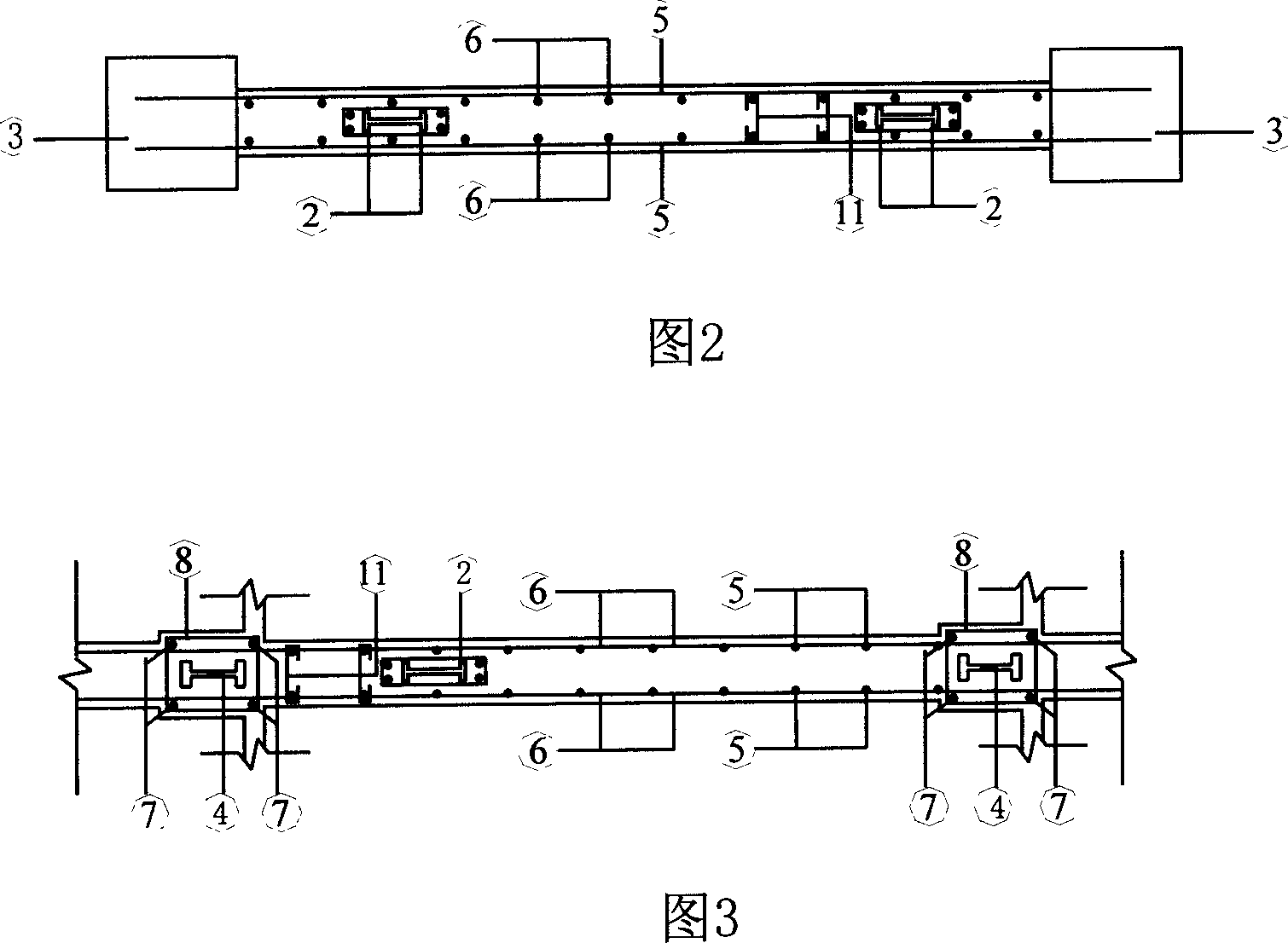

Straddle type single-track double-box rectangular steel-concrete composite track beam structure

InactiveCN104213477AImprove carrying capacityIncrease lateral stiffnessRailway tracksBridgesEngineeringSpandrel

The invention relates to the field of track beams, in particular to a straddle type single-track double-box rectangular steel-concrete composite track beam structure. The straddle type single-track double-box rectangular steel-concrete composite track beam structure comprises two steel-concrete track main beams parallel to each other; the two steel-concrete track main beams are connected through crossbeams below and a low plain longitudinal; each steel-concrete track main beam comprises a steel beam structure with a box-type cross section and a concrete cuboid structure with a rectangular cross section; each concrete cuboid structure is positioned above the corresponding steel beam structure and is connected with the steel beam structure through shear nails; the span of each steel-concrete track main beam is 30-80 meters; the cross beams are I beams and are in bolt connection with cross beam connecting plates of the steel-concrete track main beams; the low plain longitudinal is a diamond truss, and plain main rod piece parts are respectively connected with the steel-concrete track main beams and the cross beams. The straddle type single-track double-box rectangular steel-concrete composite track beam structure can be suitable for building double-line large-span track beams, and the double-line large-span track beams are large in span, high in transverse stiffness and high in transverse stress performance structurally.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

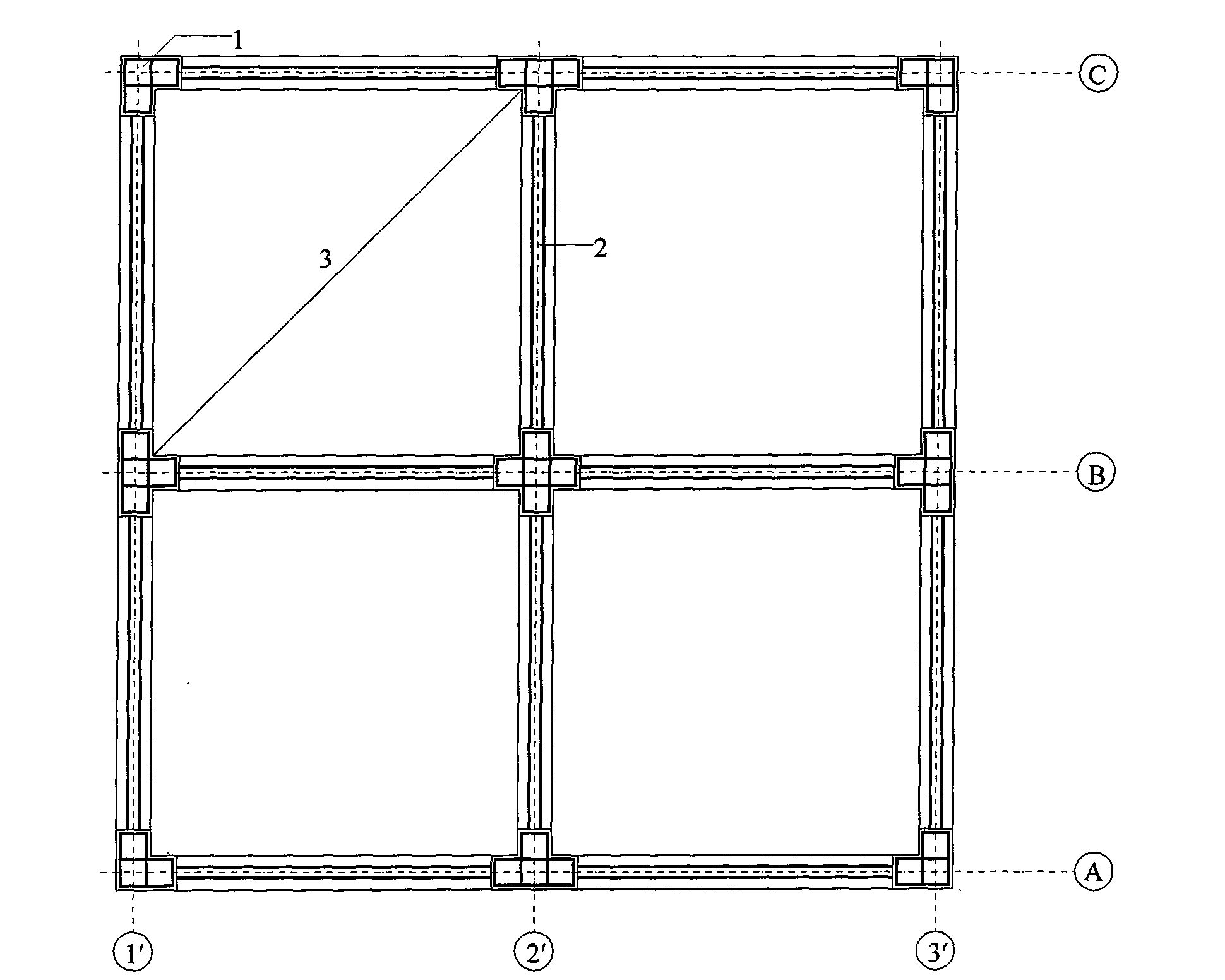

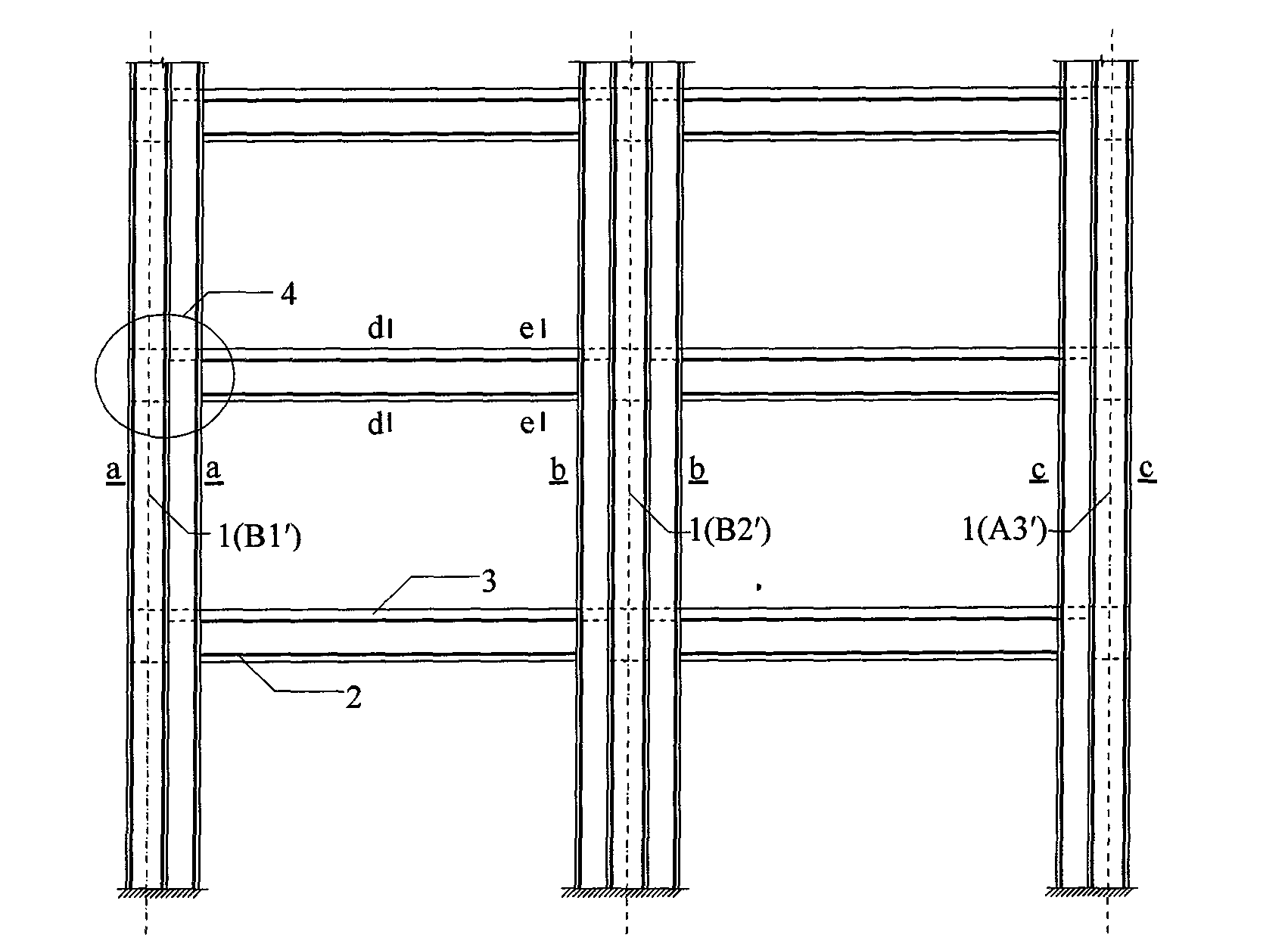

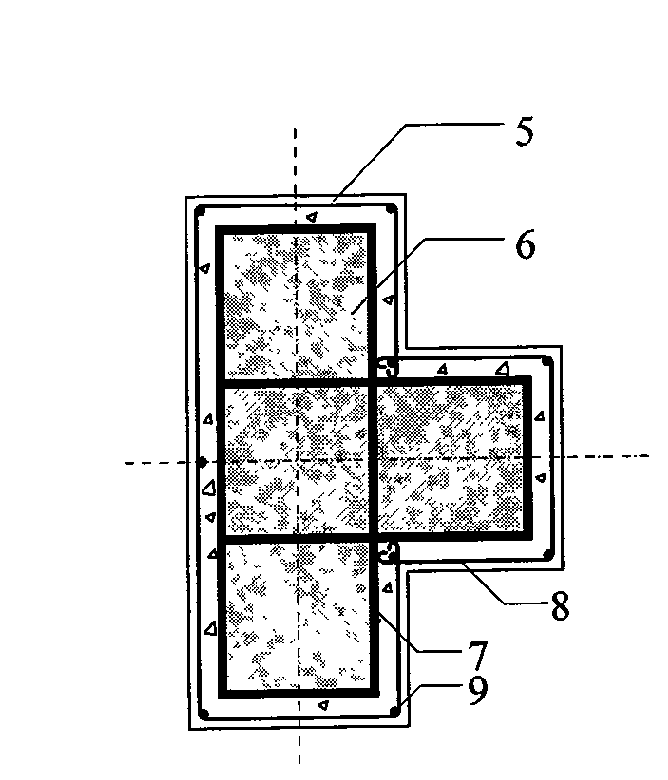

Mixed steel-concrete composite frame structure

ActiveCN101581115AEfficient use ofImprove structural fire resistanceBuilding constructionsFloor slabReinforced concrete

Owner:TSINGHUA UNIV

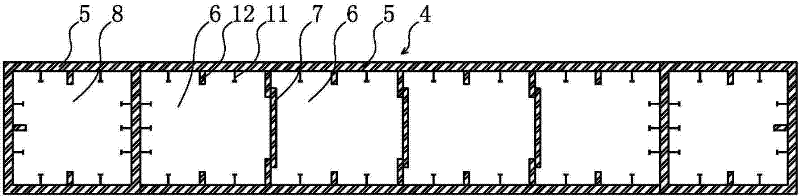

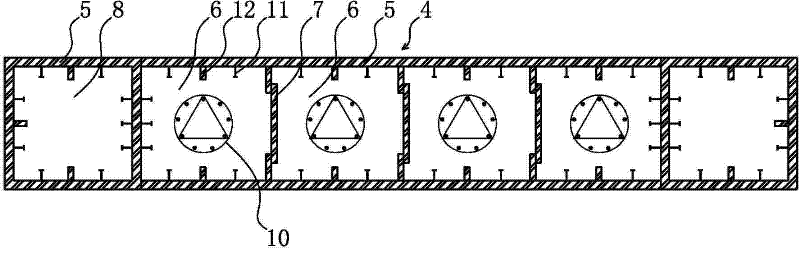

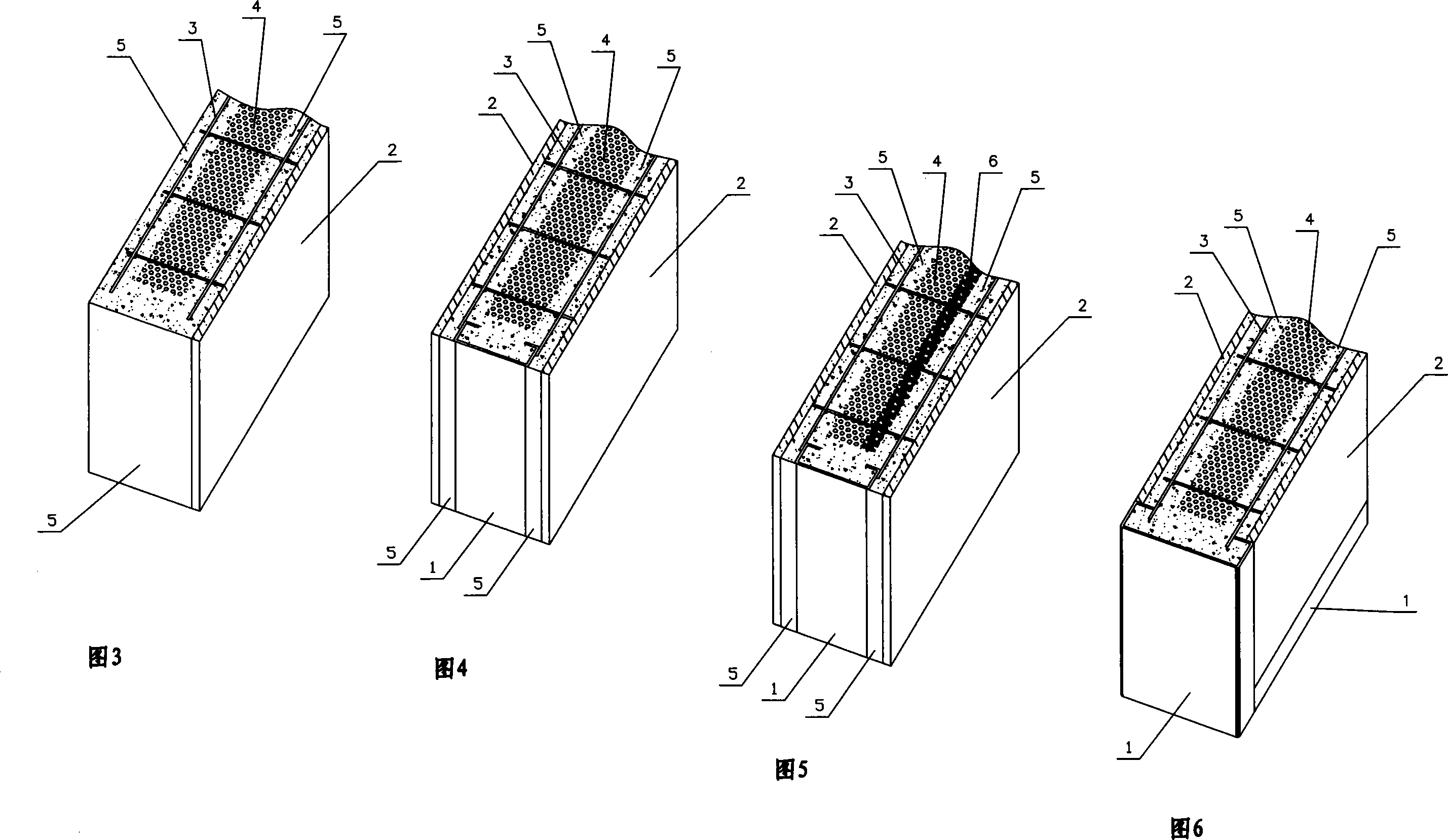

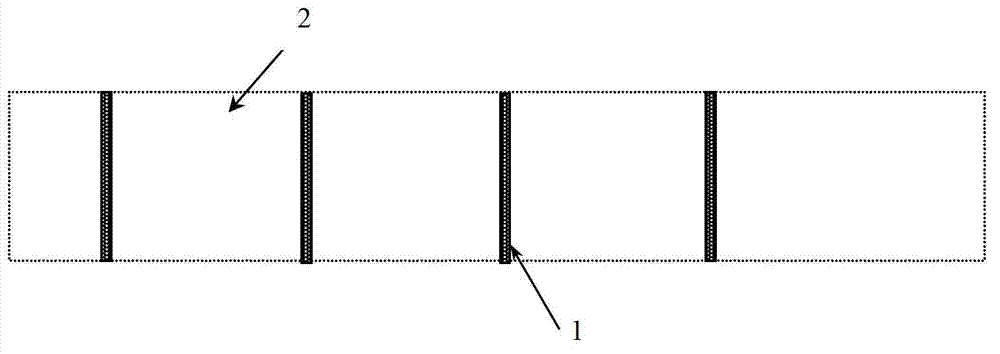

Double layer sandwich foamed concrete composite solid wall plate

InactiveCN1987008AShort demoulding timeIncrease productivityConstruction materialSolid waste managementFiberFoam concrete

A dual-layer sandwich-type solid wall slab is composed of two surficial thin cement slabs and a foam concrete core layer. It is proportionally made of fast hardening sulphoaluminate cement, powdered coal ash, river sand, fibers, hydrogen peroxide as foaming agent, and stabilizer. Its advantages are light weight, high surface strength and high insulating effect.

Owner:贵州华骏集团节能环保材料有限公司

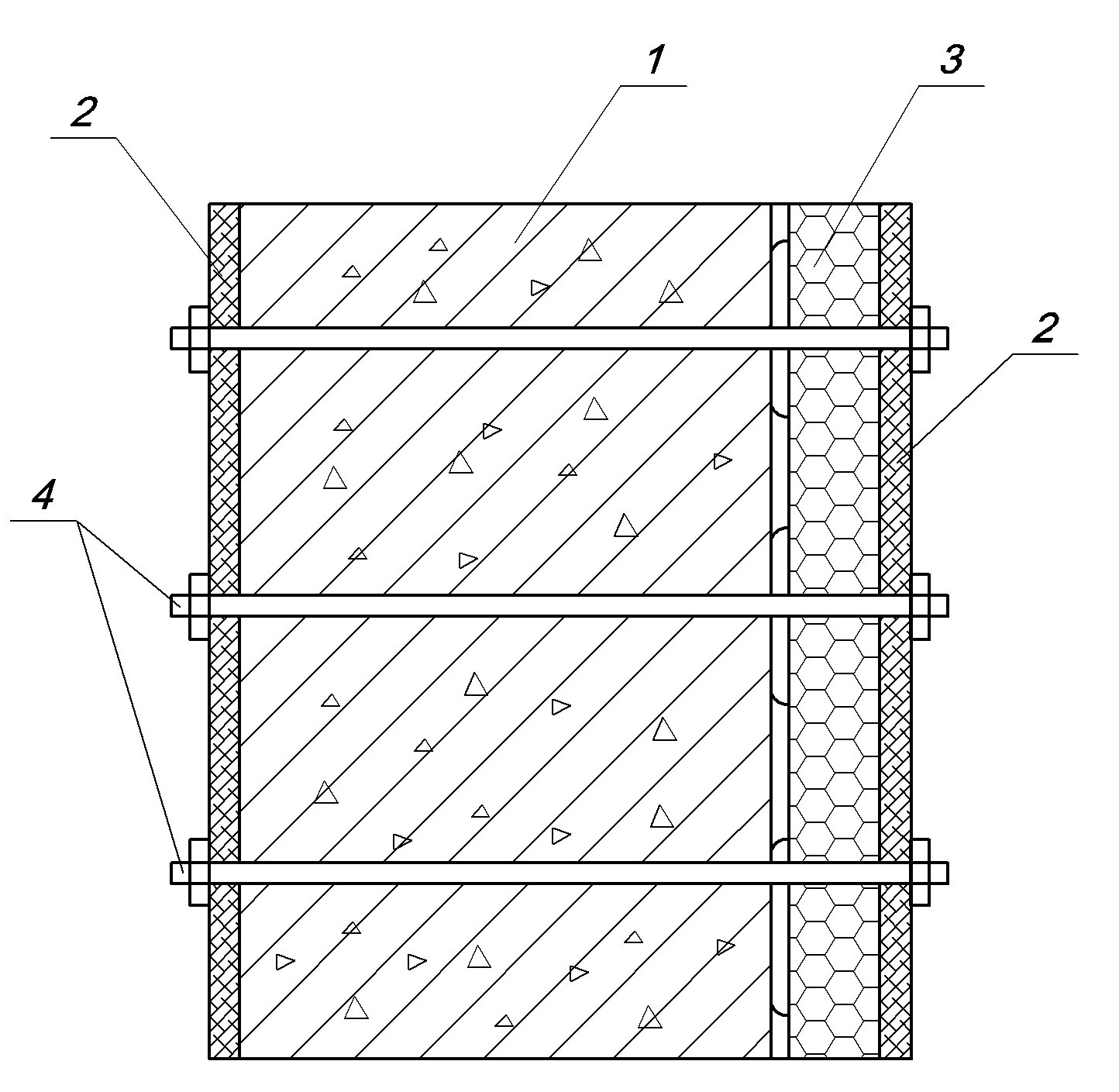

Fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and exterior wall heat-preservation construction process

InactiveCN102071797AMeet flatness requirementsReduce thicknessWallsBuilding material handlingInsulation layerReinforced concrete

The invention relates to a fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and an exterior wall heat-preservation construction process. The heat-preservation template is formed by compounding an expandable polystyrene (EPS) aggregate layer on the surface on one side of a fiber concrete plate. The process comprises the following steps that: a fiber concrete template and a fiber concrete composite heat-preservation template are vertically fixed on the two sides of the position of a pre-built wall body respectively, wherein the fiber concrete template and the fiber concrete composite heat-preservation template are fixed together through pull bolts; and reinforcements are arranged and concrete is poured between the fiber concrete template and the fiber concrete composite heat-preservation template, so that a reinforced concrete bearing wall body is formed. The integrated permanent dismantle-free heat-preservation template meets the requirements on heat preservation of an exterior wall and flatness of a plaster layer in place of the exterior wall template, an outer heat-preservation layer and the plaster layer. In the process, the template is not required to be removed, the heat preservation, heat insulation and water proofing performance are good, the thickness of the wall body is reduced, a great amount of materials and labor are saved, the construction period can be shortened, and the energy conservation requirement and the requirements on adhesion between the permanent template and a basic layer and flatness of a surface layer can be met. The template is suitable for high-rise and small high-rise buildings; the dwelling environment can be improved; the building function quality is improved; the building development benefit is improved; and the template has a wide application prospect.

Owner:ZHENGZHOU UNIV +2

Concrete composite wall panel

A composite wall panel for exterior walls of a structure includes a polymeric foam core having a C-stud framing system embedded therein and an exterior and / or interior facing formed of a reinforced concrete bonded to the core surface and mechanically attached to the studs thereby providing increased strength, insulation and resistance to environmental conditions.

Owner:RUBIO EDWARD

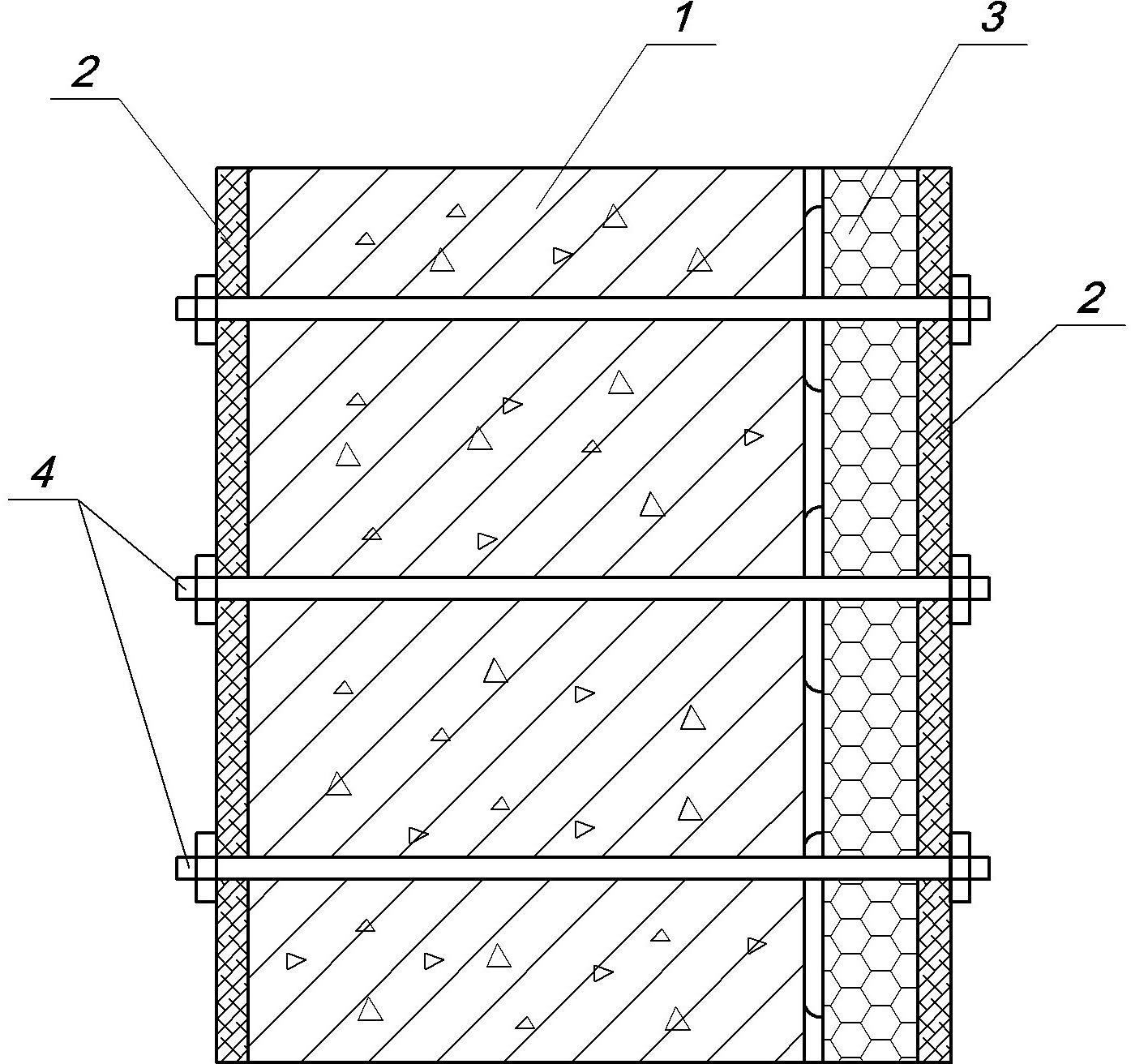

Outsourcing multi-cavity steel plate concrete composite shear wall and its construction method

InactiveCN102296723AReasonable structureImprove performanceWallsBuilding material handlingHigh riseCantilever

Owner:广州容柏生建筑结构设计事务所(普通合伙)

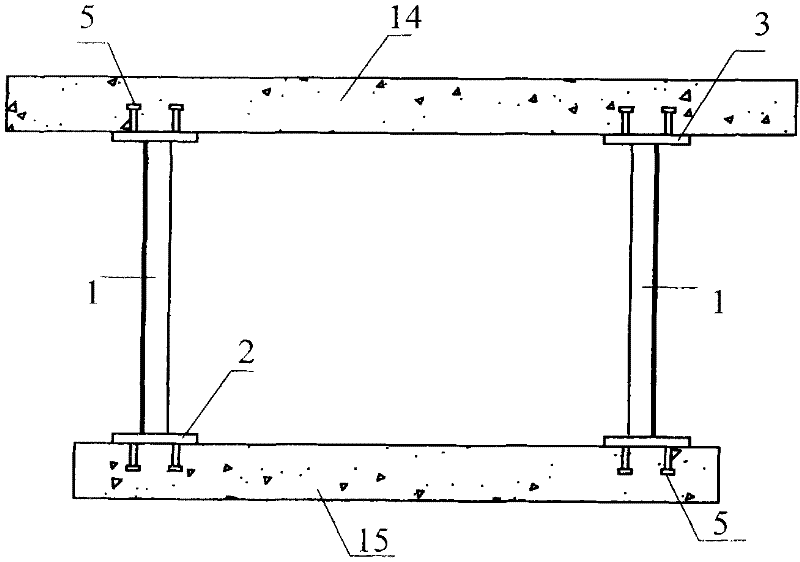

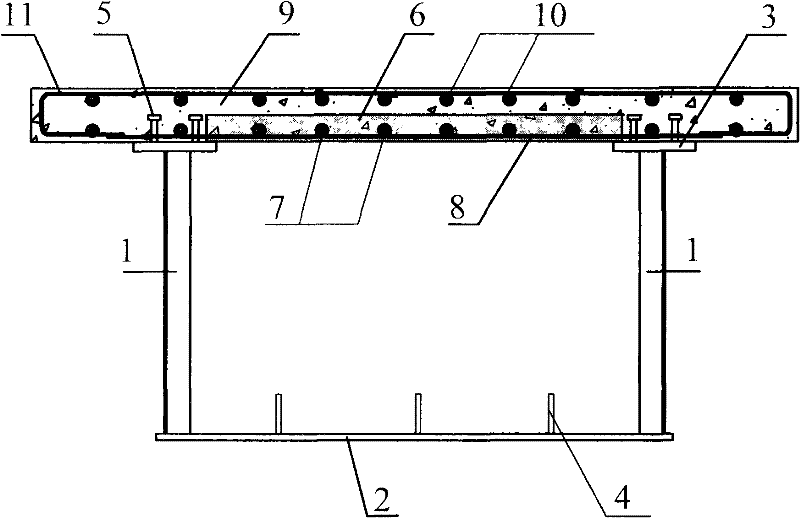

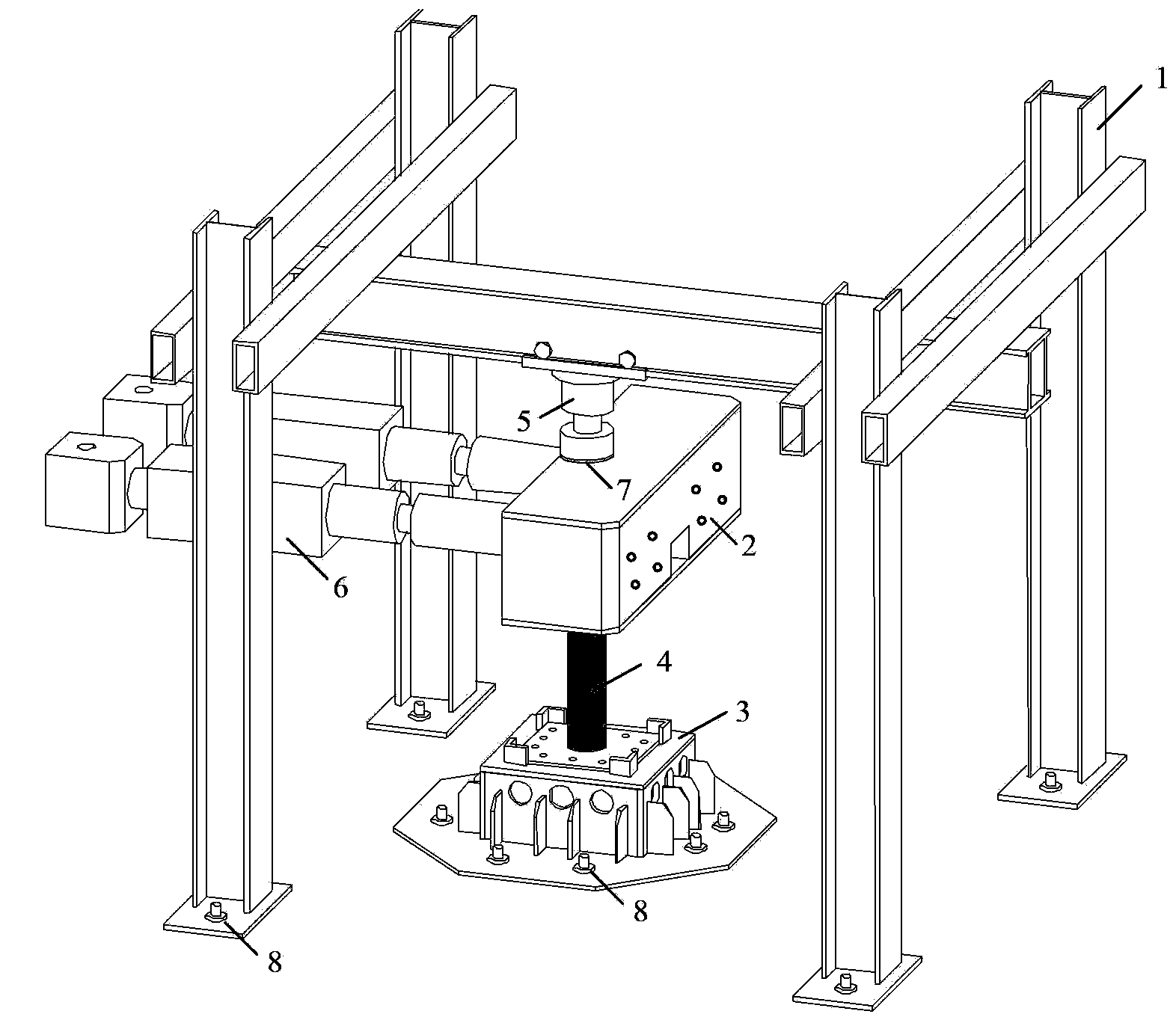

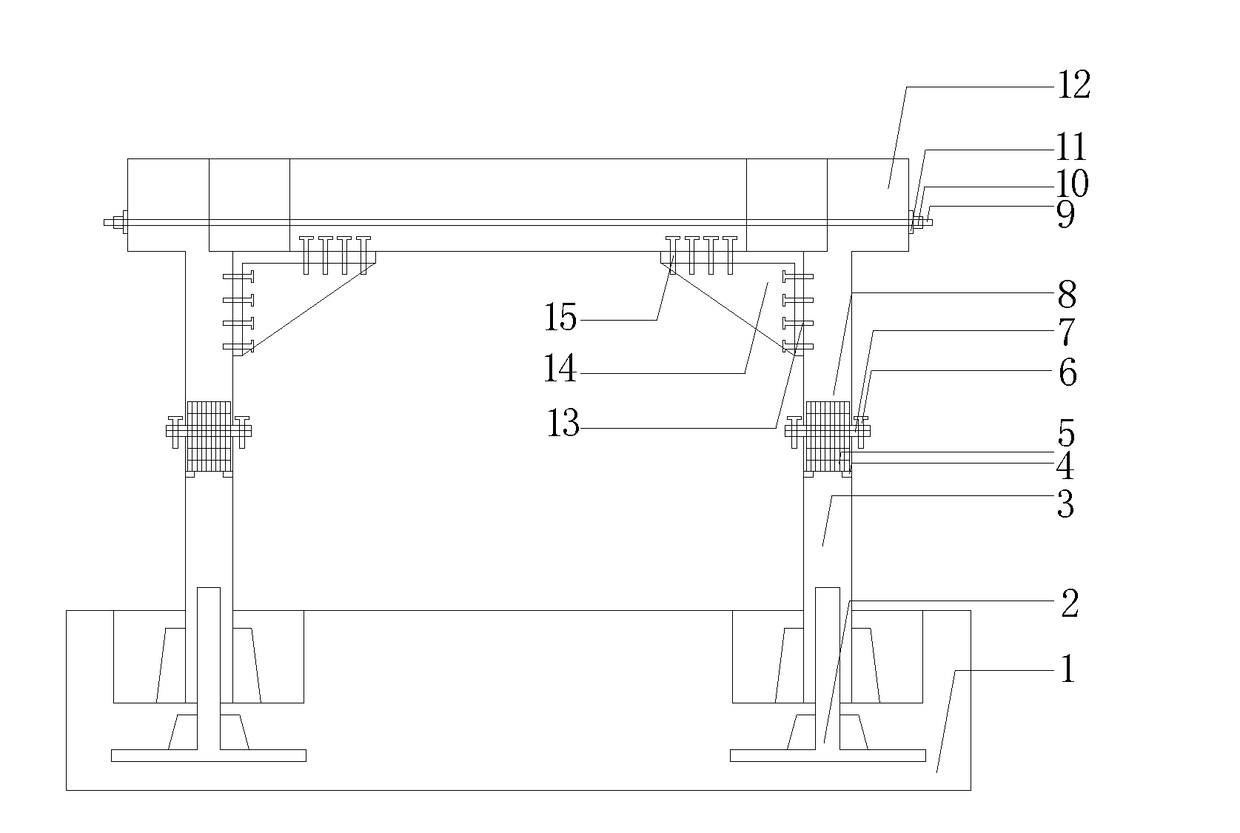

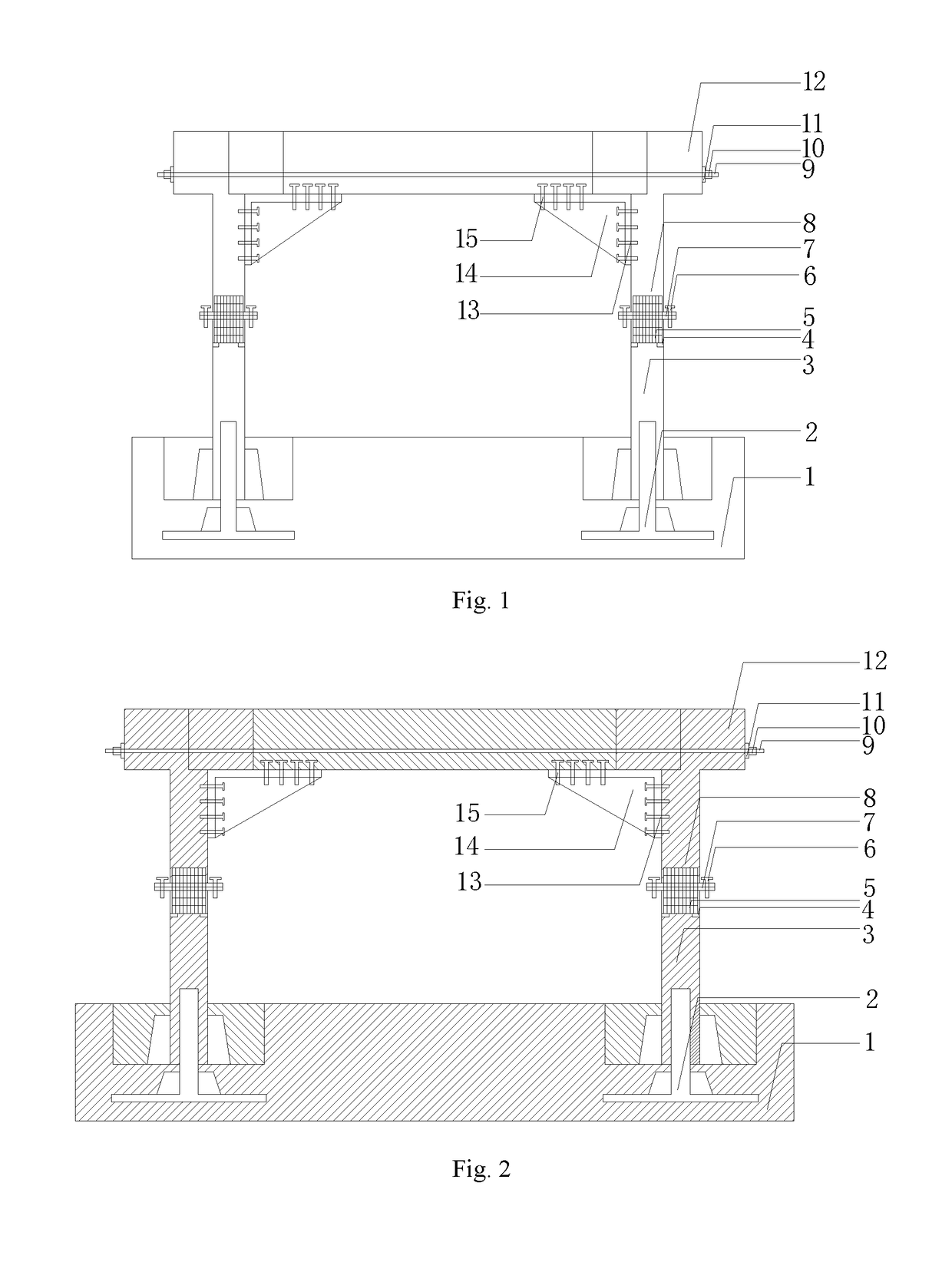

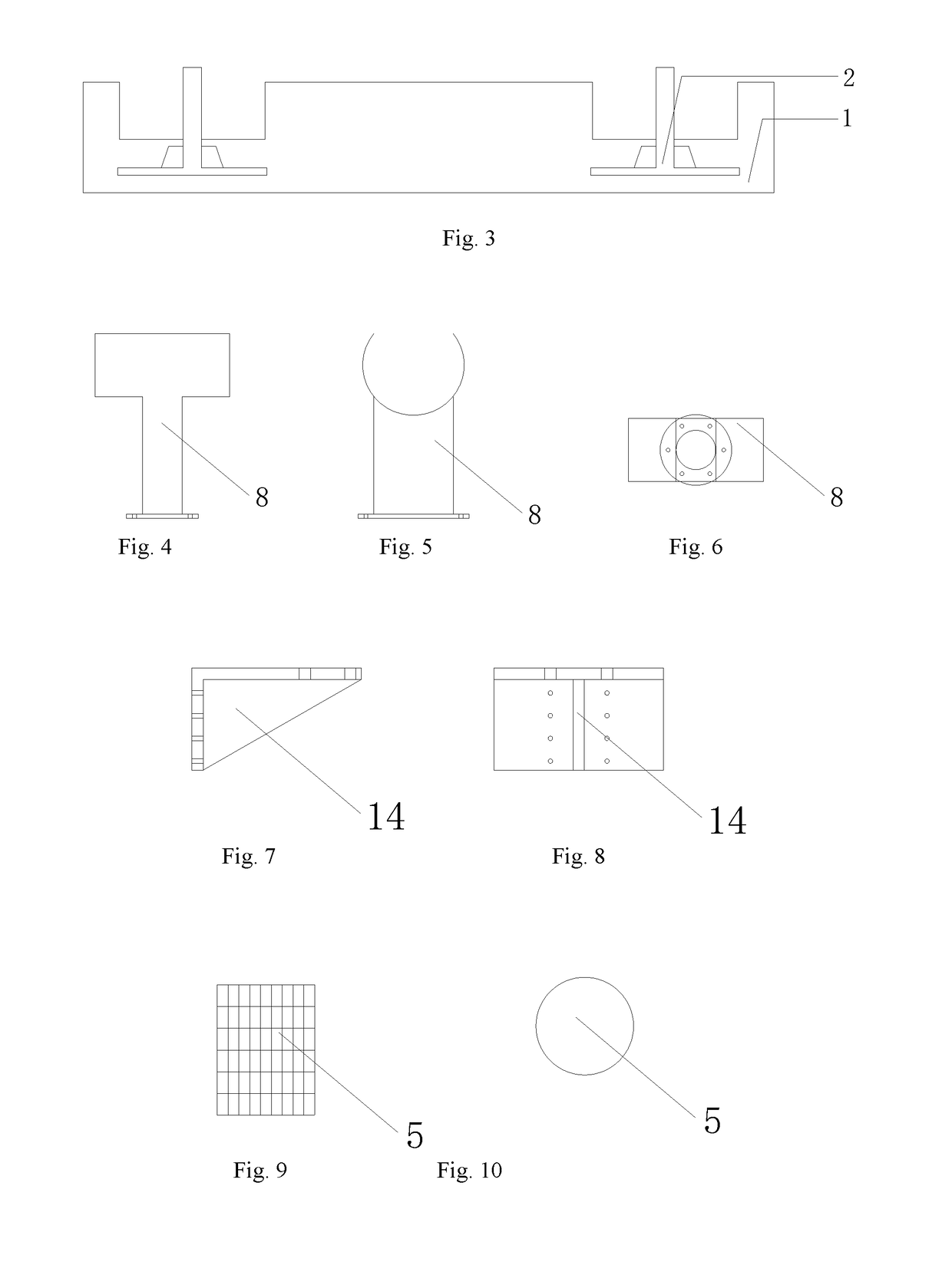

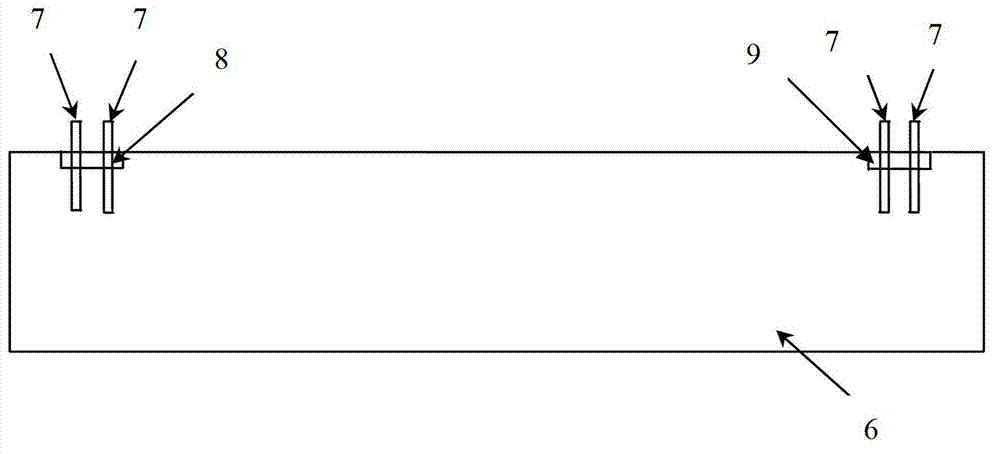

Steel-concrete composite column anti-seismic anti-torsion test loading device and manufacturing method thereof

InactiveCN103398908AGuaranteed to twist freelyFor quick replacementMaterial strength using steady bending forcesServo actuatorTorsion test

The invention relates to a steel-concrete composite column anti-seismic anti-torsion test loading device and a manufacturing method thereof, and belongs to the technical field of structure engineering. The steel-concrete composite column anti-seismic anti-torsion test loading device comprises a loading frame, a top beam, a base, an antifriction plate, a thrust jack, and two electro-hydraulic servo actuators. The loading frame is obtained by welding steel plates. All column bases of the loading frame are provided with bolt holes and are fixedly connected to the ground by ground anchor bolts. The top beam is obtained by welding steel plates. The bottom of the top beam is provided with bolt holes and is fixedly connected to a top steel plate of a test piece by bolts. The base is obtained by welding steel plates. The top of the base is provided with bolt holes and is connected to a bottom steel plate of the test piece by bolts. An upper end of the thrust jack is connected to the loading frame by a rolling bearing. The antifriction plate is horizontally arranged in the center of the top of the top beam. The electro-hydraulic servo actuators are arranged horizontally and are fixedly connected to the top beam. The steel-concrete composite column anti-seismic anti-torsion test loading device solves the problem of the prior art, has a simple structure, is convenient for use, has strong universality, can be used for anti-seismic anti-torsion tests on various steel-concrete composite columns, and has wide application prospects.

Owner:TSINGHUA UNIV

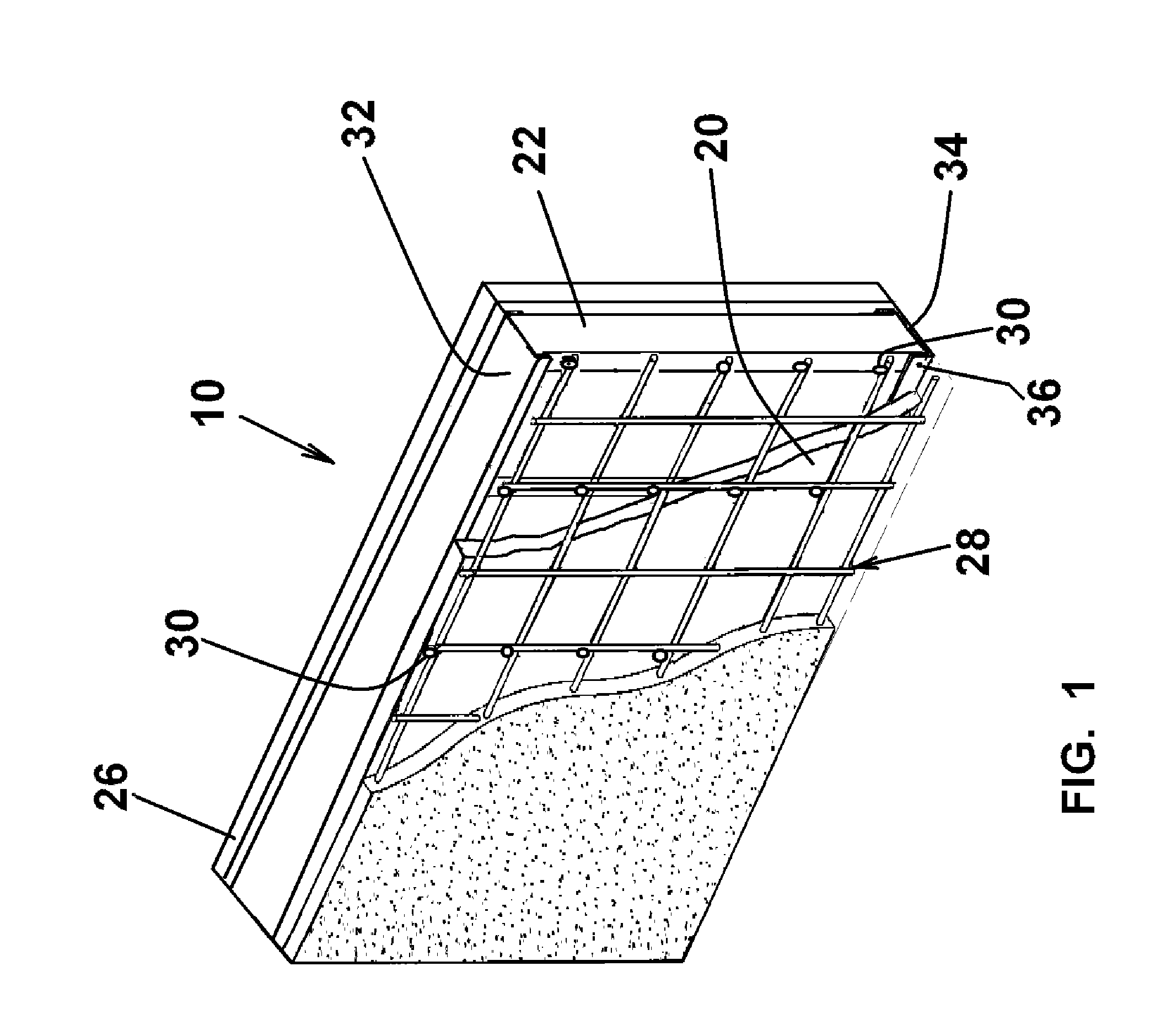

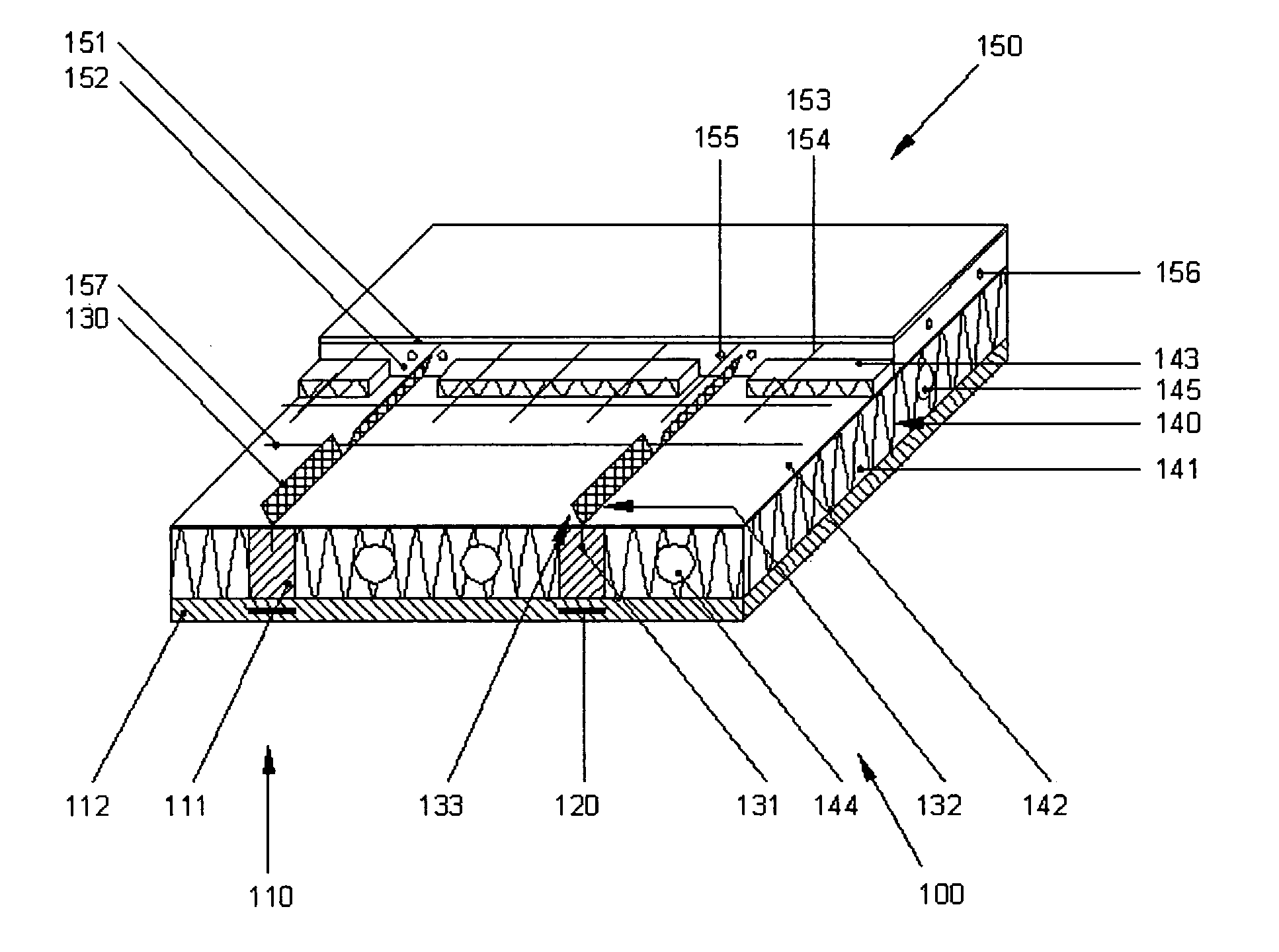

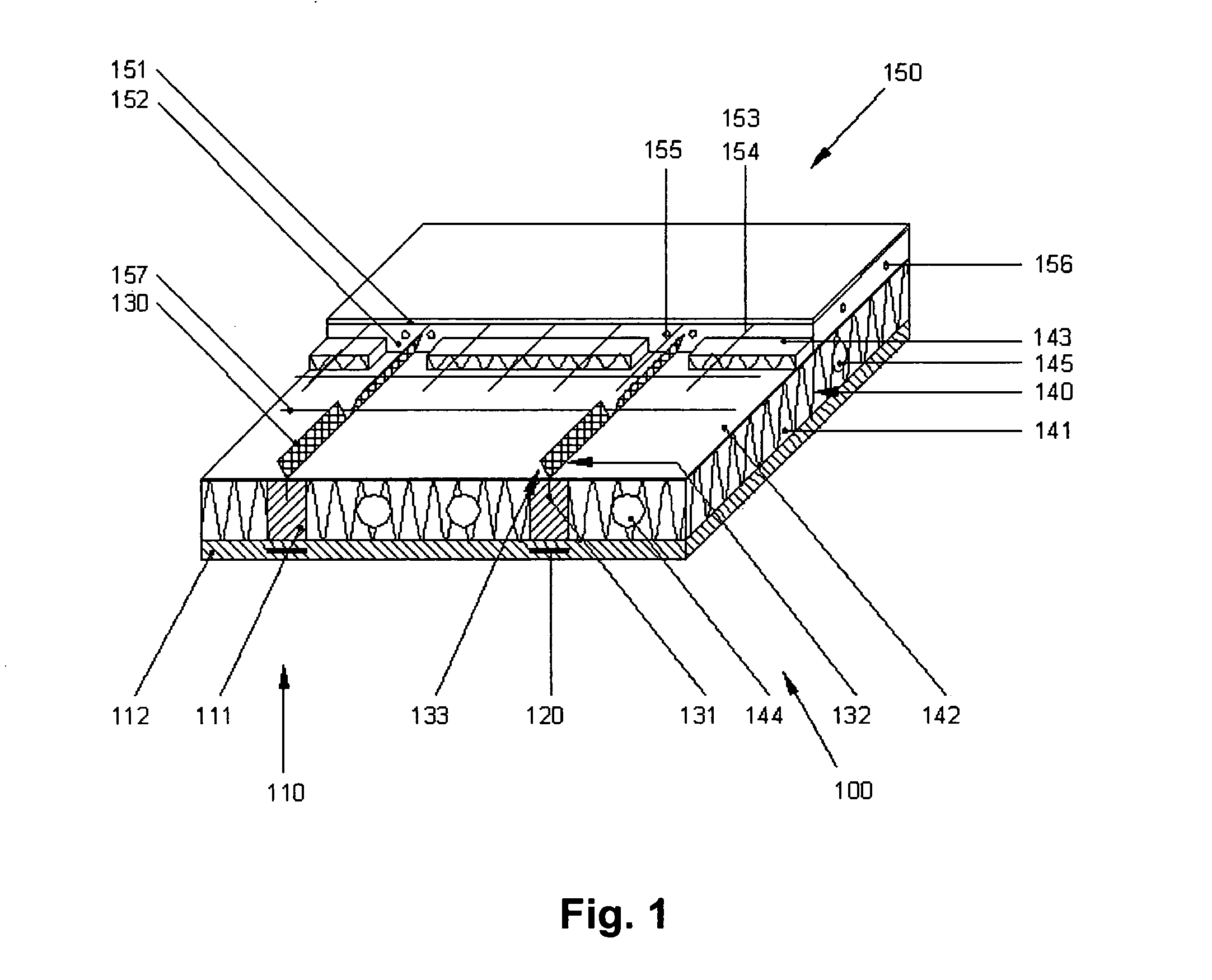

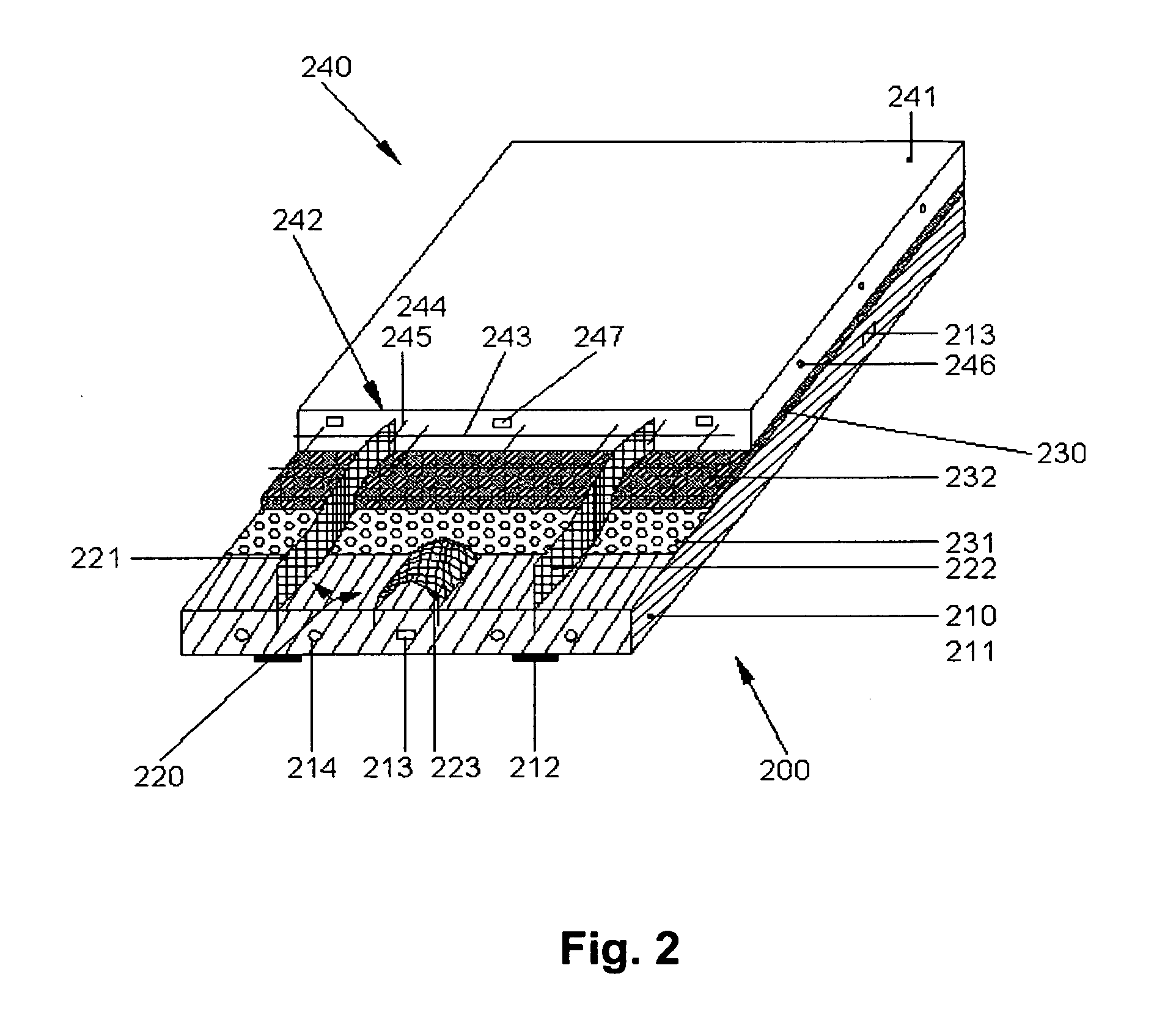

Wood-concrete-composite systems

InactiveUS20050086906A1Composite action can evenImprove connection stabilityArched girdersConstruction materialStructural componentConcrete composites

A wood concrete composite system (100,200) has a wood construction component (110, 111, 112, 210, 211), at least single intermediate layer (140, 141, 142, 143, 230, 231, 232) and a concrete construction unit (150, 151, 152, 240, 241). The concrete construction unit (150, 151, 152, 240, 241) faces at least with one side towards the wood construction component (110, 111, 112, 210, 211). The at least single intermediate layer (140, 141, 142, 143, 230, 231, 232) creates at least a partial uncoupling between the wood and concrete.

Owner:BATHON TOBIAS +1

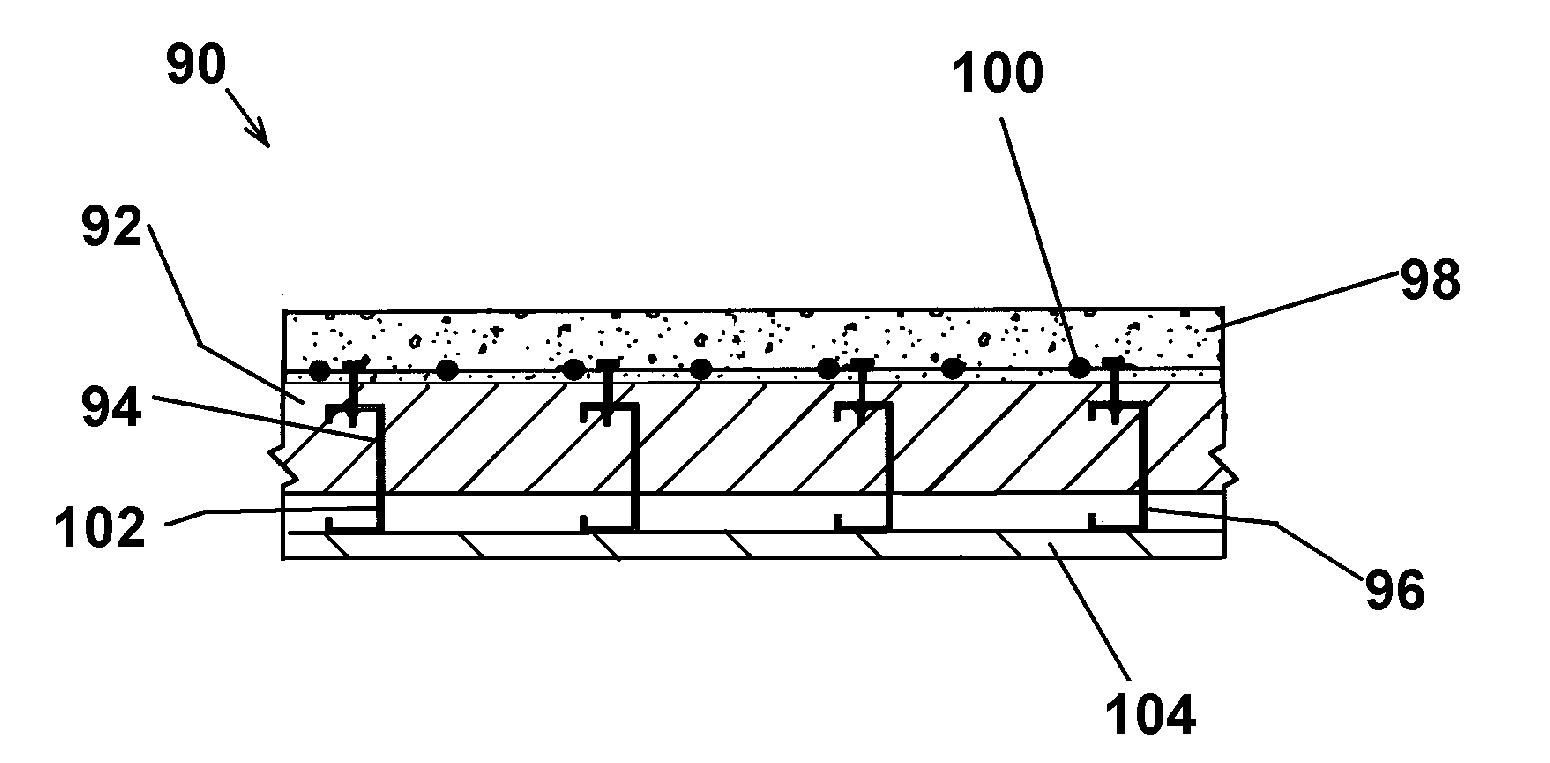

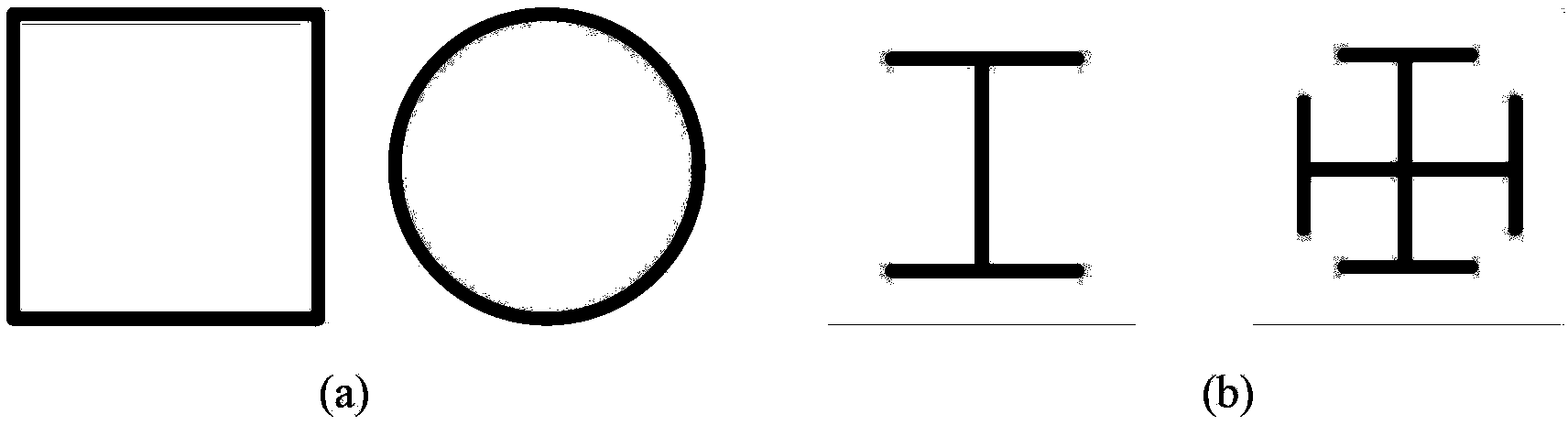

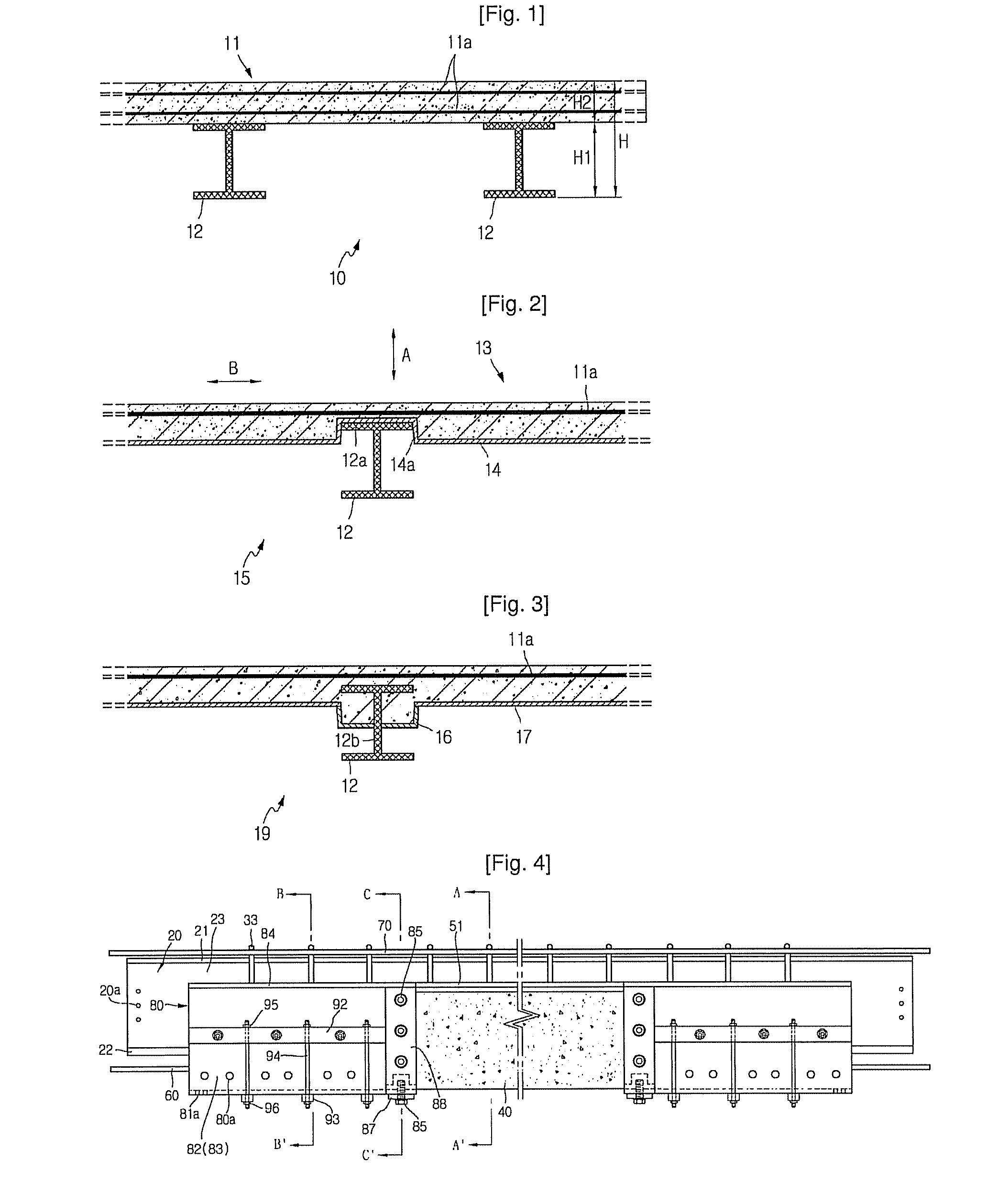

Mold-Concrete Composite Crossbeam and Construction Method Using the Same

InactiveUS20080282644A1Reduce the overall heightEfficient reductionFloorsBuilding repairsEngineeringRebar

A mold-concrete composite crossbeam includes a H-steel composed of upper and lower flanges and a web connecting them; a concrete member formed in a length direction of the H-steel to expose the upper flange out but bury the lower flange and the web partially; deck plate supports installed to both upper side edges of the concrete member to support a deck plate placed thereon; a reinforcing steel bar installed around the H-steel; a mold including a bottom detachably coupled to a lower end surface of the concrete member, and sidewalls formed in parallel to both sides of the bottom and detachably coupled to both end sides of the concrete member; a lateral reinforcing member coupled across both sidewalls; a side reinforcing member installed to an outer side of the sidewalls in a length direction; and bottom reinforcing members installed across a lower surface of the bottom.

Owner:KH HOUSING SOLUTIONS

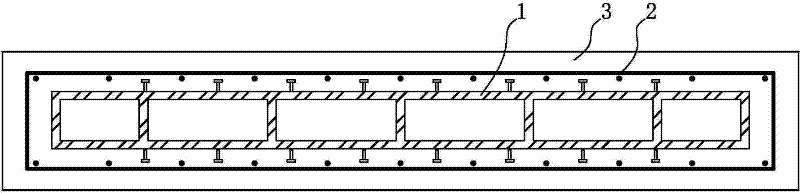

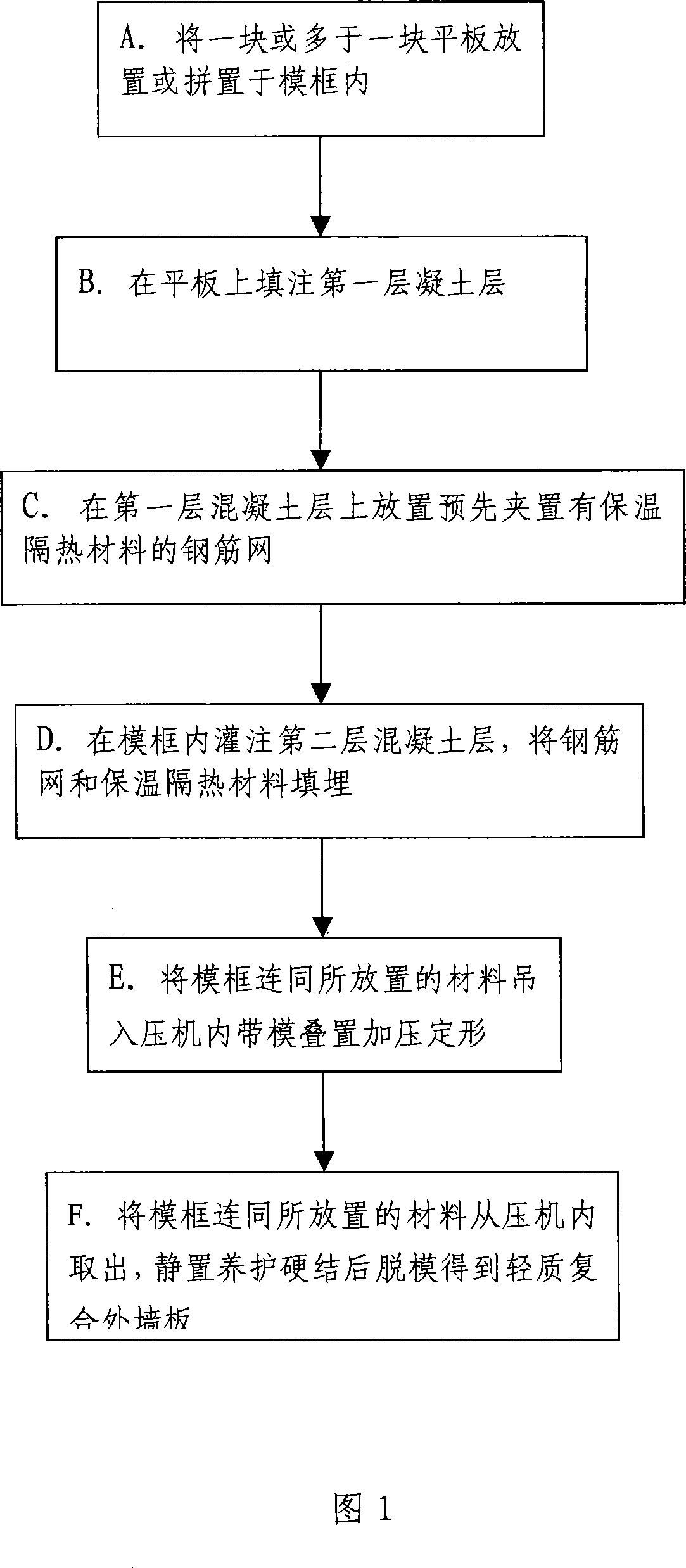

Method for manufacturing light concrete composite wall plate, building plate and road sound barrier plate

ActiveCN101100887AHighlight substantiveSignificant progressBuilding componentsSound barrierFloor slab

A construction method for light weight concrete wall, floor plate and sound screen on road follows the steps as: A. put plate into a module frame; B. fill in a premier layer of concrete on the plate; C. on the premier concrete layer put a steel web pre-inserted with heat preservation material and connected to the frame; D. grout a secondary layer of concrete filling into the steel web or put plate on it; E. modeling press. F. standing and harden.

Owner:广州益群板业有限公司

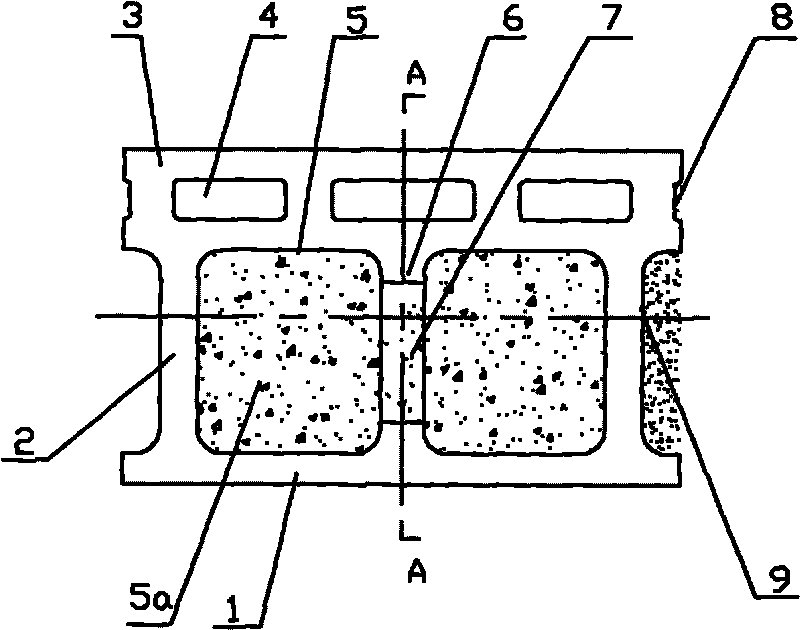

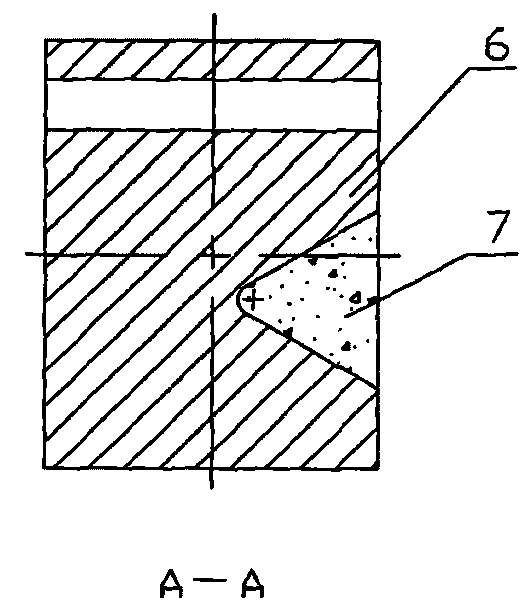

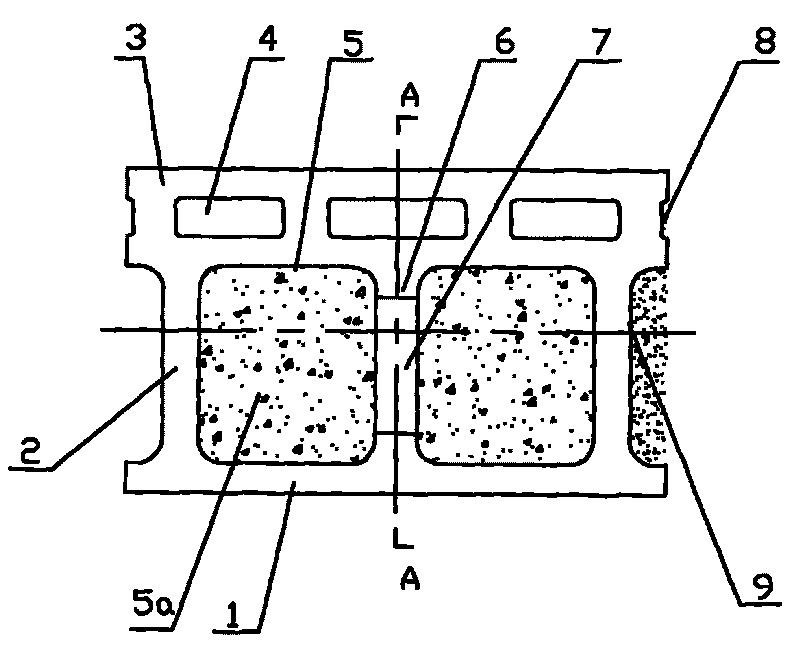

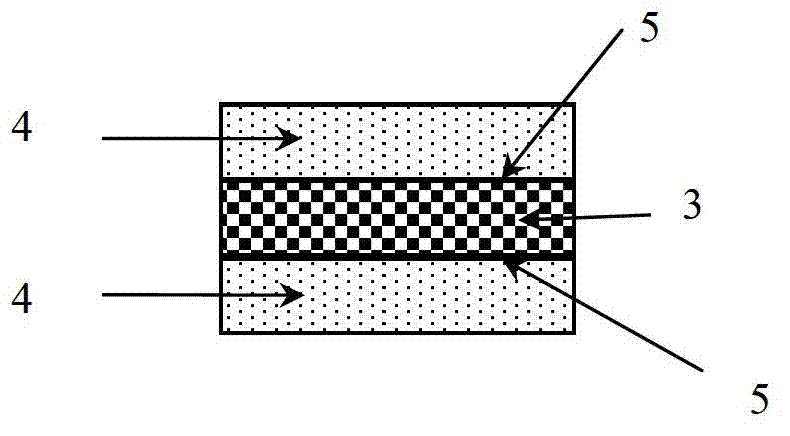

Non-homogeneous concrete composite automatic heat insulation building block

InactiveCN101694117AImprove insulation effectHigh void rateConstruction materialThermal engineeringBrick

The invention relates to a composite heat insulation building block which comprises a rectangular building block body, and is characterized in that one side of the rectangular building block body is provided with a group of parallel thermal insulation water-proof chamber (4); the middle part of the rectangular building block is provided with at least one heat insulation chamber (5) which is internally provided with heat insulation fillers (5a); the middle part of the rectangular building block is provided with two parallel heat insulation chambers (5); a leveling groove (7) used for leveling the heat insulation fillers are arranged on a rib plate (6) formed between the heat insulation chambers (5); and the connecting ends at two sides of the rectangular building block are respectively provided with an opening slit building groove (9) and an opening slit building groove (8). The composite heat insulation building block has the advantages of high void content (more than 60%), good heat insulation effect and high strength, and the produced composite heat insulation building brick has light weight, high strength, low water absorption rate, small air shrinkage rate, and good thermal engineering performance, and can meet the design requirement that building energy conservation rate can reach 65%.

Owner:金波

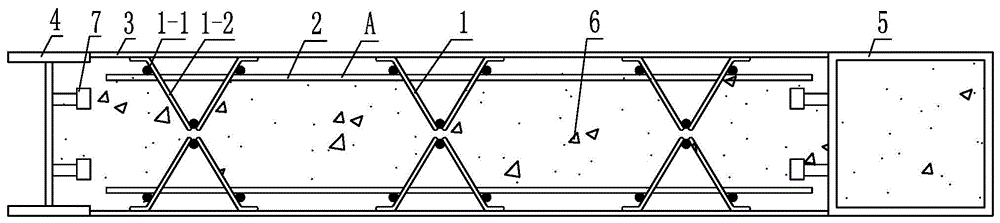

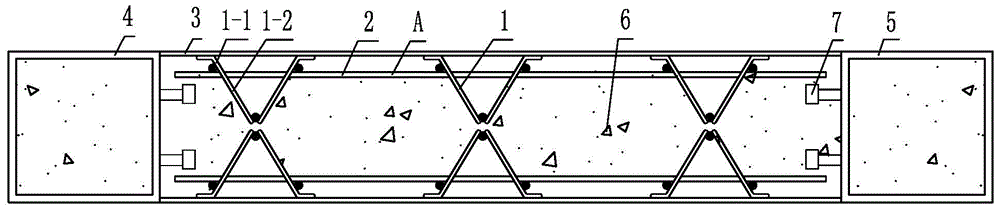

Steel bar truss stiffened steel concrete composite shear wall

InactiveCN104929281AImprove bearing capacityIncreased shear capacityWallsSheet steelReinforced concrete

The invention discloses a steel bar truss stiffened steel concrete composite shear wall, relates to a shear wall and belongs to the field of building structures. The steel bar truss stiffened steel concrete composite shear wall aims to solve the problems that an existing steel concrete shear wall is poor in anti-seismic property, prone to crack and complex in construction when connected with steel members. The steel bar truss stiffened steel concrete composite shear wall comprises a second stiffening member, concrete, a first stiffened steel body and a plurality of shearing-resistant connecting keys. The first stiffened steel body comprises a first stiffening member, two steel plates, a plurality of transverse steel bars and a plurality of steel bar trusses. Each steel bar truss comprises two erection steel bars and three longitudinal steel bars, wherein the three longitudinal steel bars are arranged in a triangular shape, and the steel bar trusses are arranged in parallel between the two steel plates in the horizontal direction. The erection steel bars are connected to the steel plates. The transverse steel bars are horizontally arranged between the two steel plates, and the transverse steel bars are connected with the steel bar trusses. The first stiffening member and the second stiffening member are provided with the shearing-resistant connecting keys, and the concrete is poured on the first stiffening steel body and the second stiffening member.

Owner:HARBIN INST OF TECH

Concrete composite containing silicon micro powder and preparation method thereof

InactiveCN102001845AReduce temperature shrinkage crackingHigh strengthSolid waste managementMixing operation control apparatusSiliconMaterials science

The invention discloses a concrete composite containing silicon micro powder and a preparation method thereof. The concrete composite is mixed and prepared from gelled material, additive, coarse aggregate, fine aggregate and water, wherein the dosage range of the gelled material in the concrete is 250 kg / m3-700 kg / m3, the gelled material contains 10 kg / m3-200 kg / m3 of silicon micro powder, and the balance is the admixture of cement and mineral. By using the concrete composite and the preparation method, concrete hydration temperature rise can be obviously reduced, the possibility of concrete cracking is reduced and the durability of concrete is effectively improved. The concrete composite and the preparation method can be prepared into concrete suitable for various purposes.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Integral type thermal insulation building

ActiveCN101684671AReduce indoor temperature fluctuationsReduce the weight of the structureConstruction materialSolid waste managementThermal insulationFly ash

The invention discloses an integral type thermal insulation building, which belongs to the technical field of building engineering. The problem to be solved is to provide the integral type thermal insulation building. The adopted scheme is that the integral type thermal insulation building at least uses one of an inorganic thermal insulation structure layer and an inorganic thermal insulation layer, wherein the inorganic thermal insulation structure layer is formed by combining one or two of inorganic thermal insulation load-bearing concrete and inorganic thermal insulation load-bearing building blocks; and the inorganic thermal insulation load-bearing concrete comprises the following components in a mixing weight ratio (kg / m<3>) of concrete composite light bone admixture to cement to sandto stone to porcelain granule to fly ash to water to concrete admixture of (6-225):(200-800):(300-700):(500-1,600):(150-650):(10-600):(80-400):(0.1-200). The integral type thermal insulation buildingcan be widely applied to the technical field of buildings.

Owner:李珠 +1

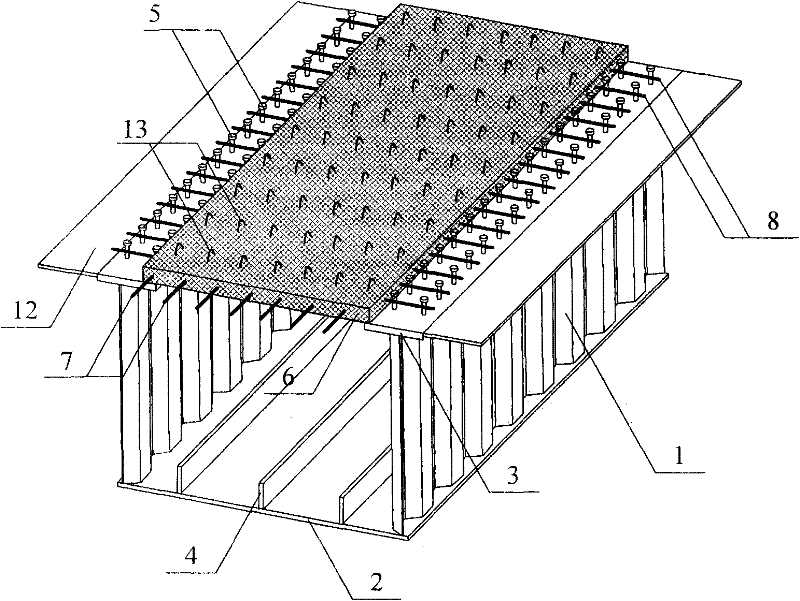

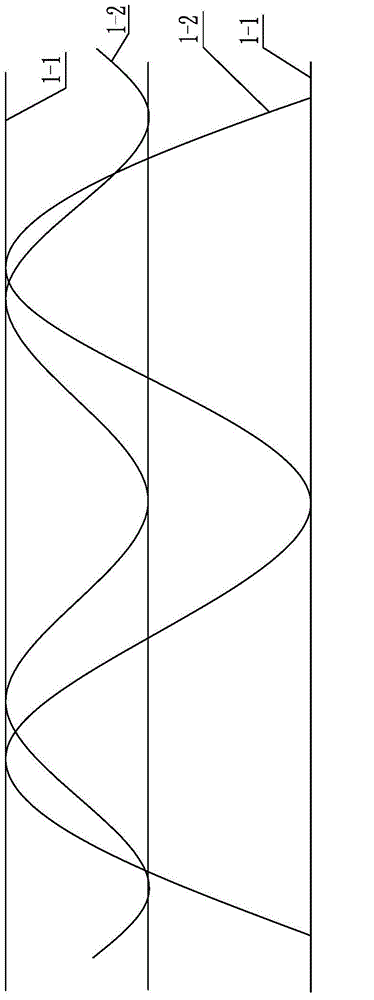

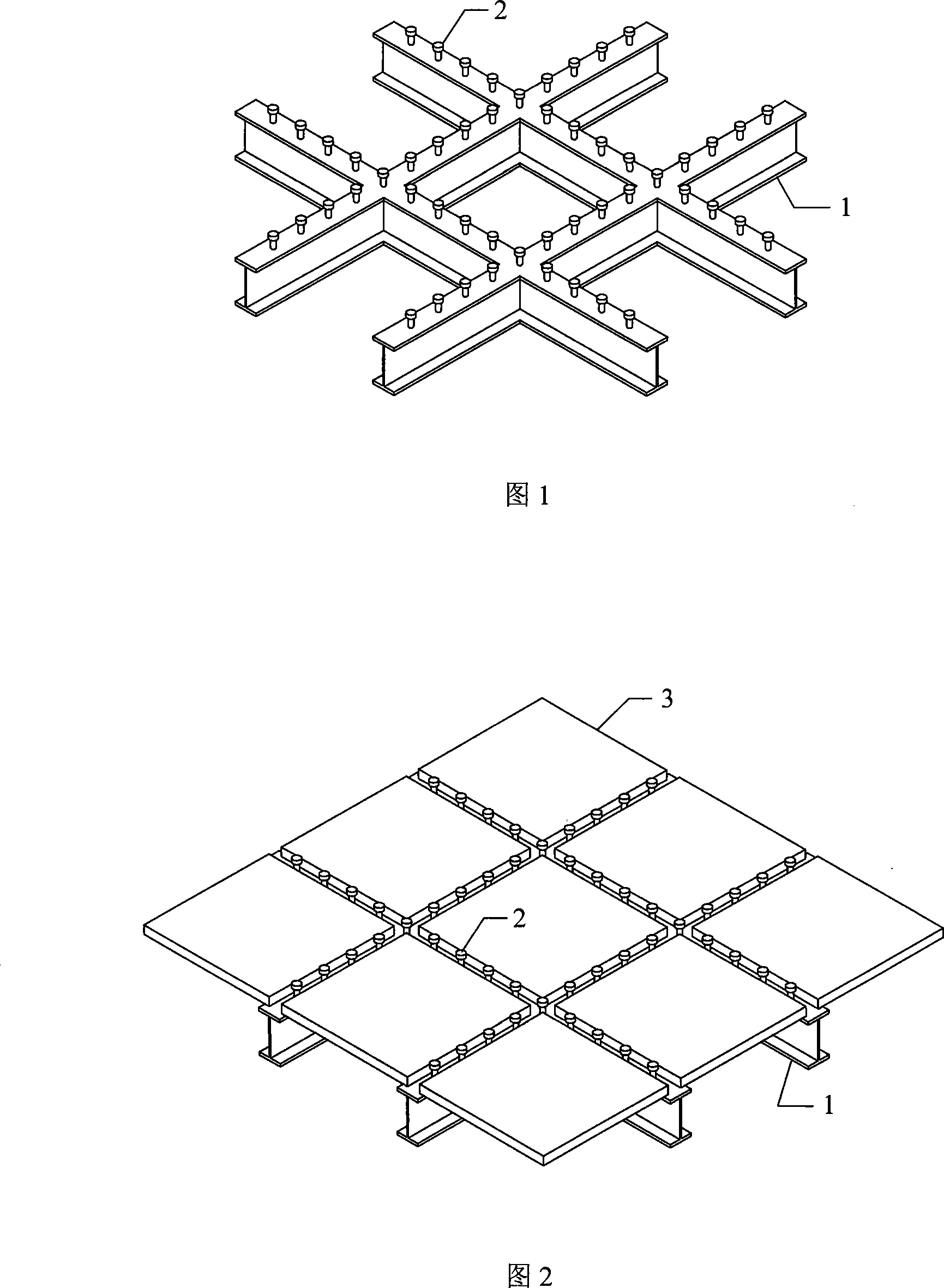

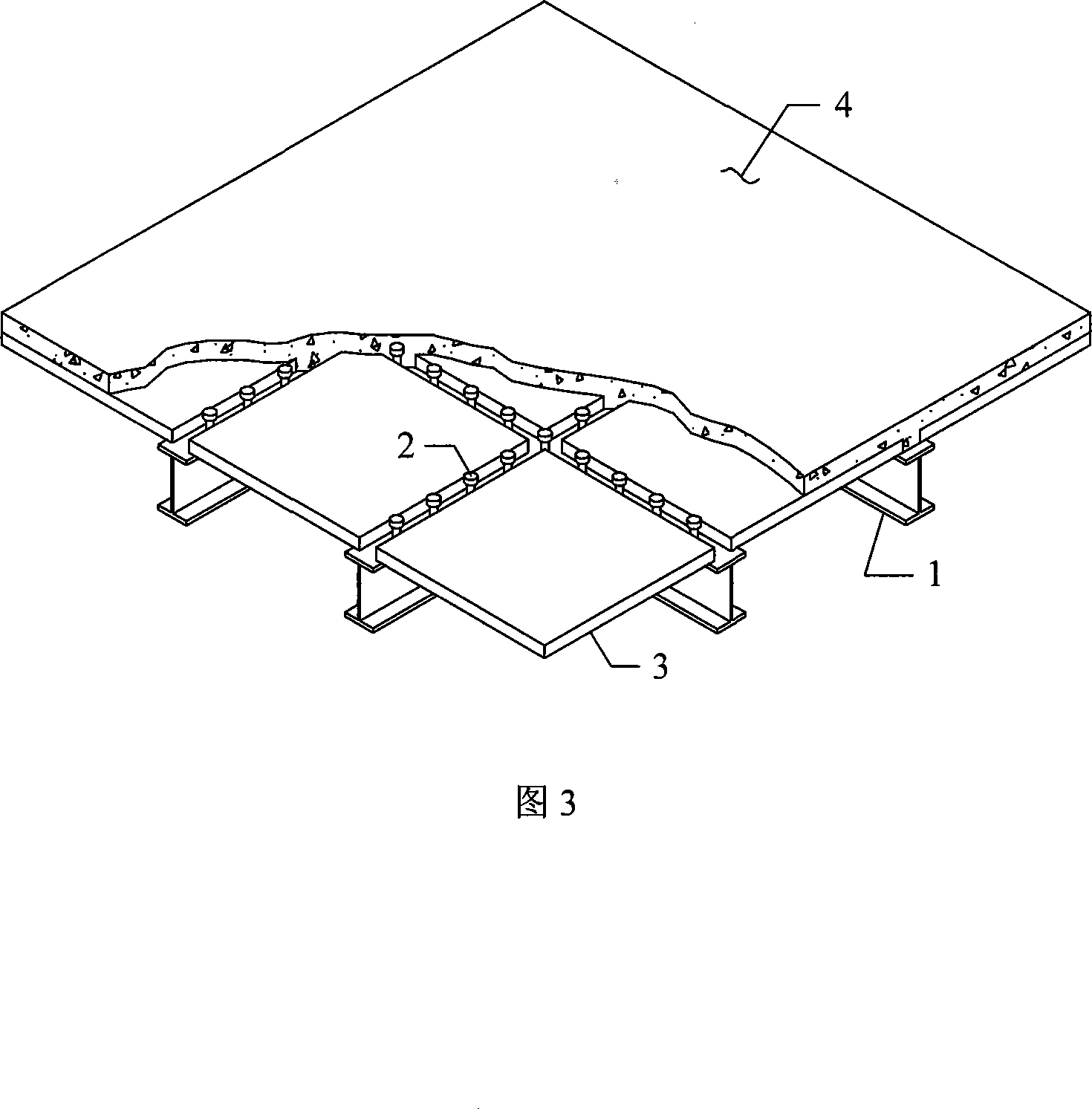

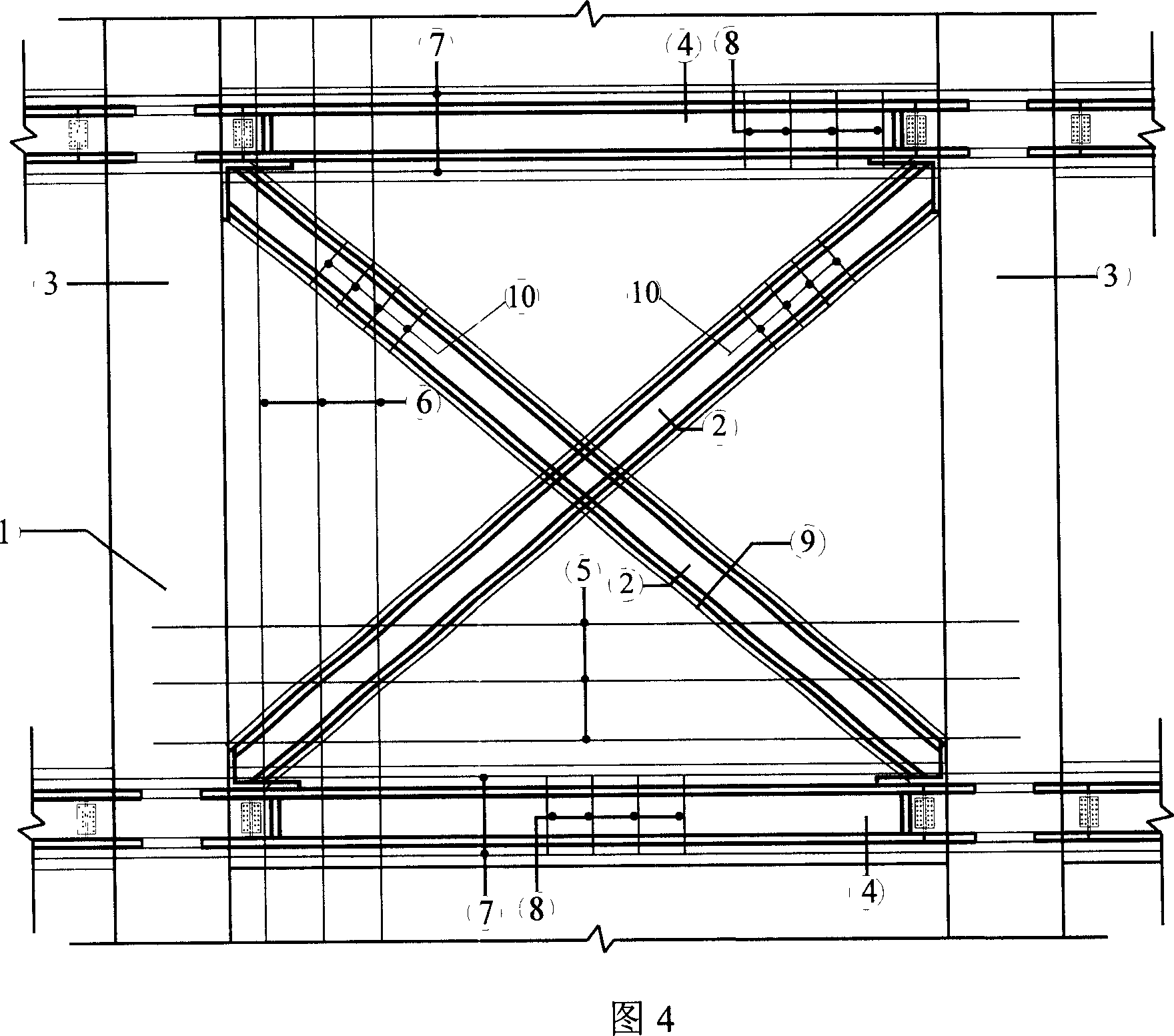

Bidirectional steel-stacked plate concrete composite building roof

The invention relates to a dual-way steel-laminated slab concrete composite floor, belonging to a new large span floor structure, comprising a cross steel beam, a prefabricated slab and a later pouring concrete layer, wherein the cross steel beam is an I shaped cross section or box section steel beam; the prefabricated slab, a common reinforced concrete slab or a prestressed concrete slab, is held on the cross steel beam and covered on the grids between the steel beams; the later pouring concrete layer is concrete poured on the prefabricated slab and the steel beam. The invention has the advantages of low structure height, high bearing capacity, stiffness, bilateral support effect, saved forming procedure and formwork, reduced the wet work amounts of site concrete, favorableness to the three-dimensional construction, and shortened construction period.

Owner:TSINGHUA UNIV

Assembled type pier column member with steel-concrete composite structure

InactiveUS20170356144A1Improve construction progressReasonable and convenient to constructBridge structural detailsBridge erection/assemblyPile capPre stress

A segment-assembled type pier column member with a steel-concrete composite structure includes a reinforcement tube embedded in a pile cap, wherein the reinforcement tube is connected with a bottom of a lower segment of a hollow steel tube pier and is poured with concrete, and pier columns in upper and lower segments are reinforced by means of segment connecting and being embedded with local reinforcing meshes. A steel cross beam is connected with an upper segment of the hollow steel tube pier in an assembled way. A pre-stressed tensioning duct is reserved between the steel cross beam and the pier column in the upper segment.

Owner:HOHAI UNIV

Lightweight concrete composite blocks

A lightweight concrete composite is utilized to form blocks. The lightweight concrete composite includes polystyrene, cement, water, and glass. The blocks are advantageous for building retaining structures in the form of walls, enclosed areas, raised gardens, flower beds, and the like because the blocks are lightweight, easily cut and stacked, and more importantly do not introduce harmful chemicals into the environment.

Owner:AMAZON FORMS ONE

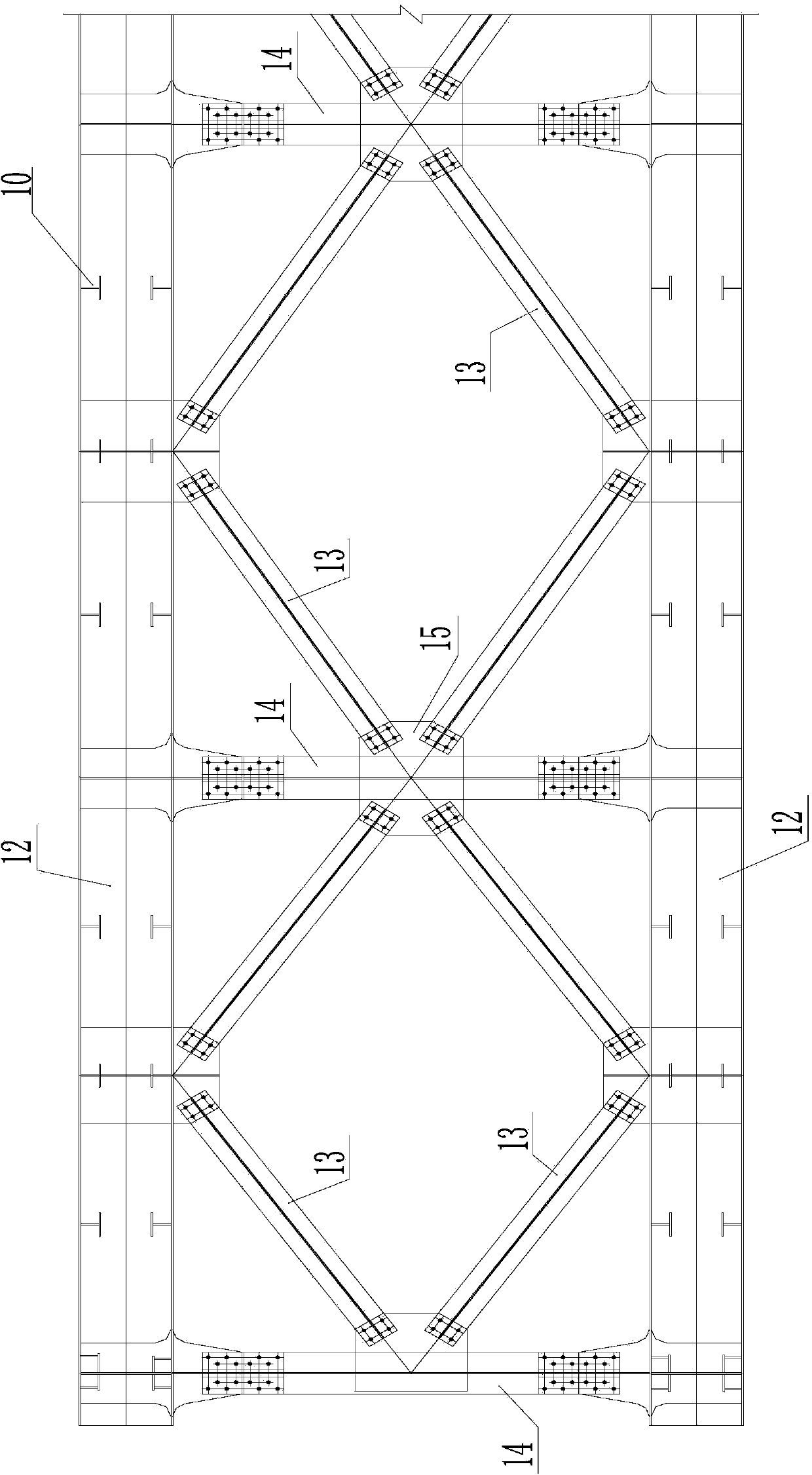

Steel pipe concrete frame-steel truss-concrete combined shear wall and its manufacture method

InactiveCN1995579AReduce the axial pressure ratioReduce thicknessWallsShock proofingSteel barSteel frame

The invention relates to a steel-tube concrete frame-steel frame-concrete composite shear wall and the manufacturing method, belonging to a shear wall and the manufacturing method. The shear wall comprises frame and shear wall board. Steel bar mesh made by steel bar group in transversal and longitudinal directions is made in shear wall board. Linked rib (11) is set between steel bar meshes. Between two rows of steel bar meshes concealed section steel support (2) and concealed steel bar (9) support are set. Section steel beam (4) is set in frame beam and steel tube concrete frame columns (3) are set at two ends of shear wall. The combination of section steel beam (4), steel tube concrete frame column (3), concealed section steel support (2) and concealed steel bar support (9) is set in shear wall and steel frame (1) is set in the concrete shear wall. The concealed support can be combined in BA-shape, X or V-shape. The shear wall in invention is provided with large initial rigidity, high load capacity, slow attenuation of load capacity and rigidity, good total aseismic consumed energy behavior, relative stability of later aseismic performance and lessened damage of bottom shear slip.

Owner:沧州市建筑设计研究院有限公司 +1

Intelligent FRP (Fiber Reinforce Plastic)-concrete composite structure and manufacturing method thereof

The invention discloses an intelligent FRP (Fiber Reinforce Plastic)-concrete composite structure and a manufacturing method of the intelligent FRP-concrete composite structure. The intelligent composite structure comprises an intelligent FRP layer, a reinforced concrete core and an anchoring device, wherein the intelligent FRP layer is formed by carbon fibers or carbon fiber mixed with other fibers and impregnated by resin, and in the composite structure, the intelligent FRP layer both serves as structural material and plays a sensing function. The intelligent FRP layer is wrapped on the stressed side of the reinforced concrete core, certain prestress is applied on the intelligent FRP layer to better play the high strength property of the FRP, and the intelligent FRP layer is connected with the reinforced concrete core through resin adhesion and mechanical connection of anchorage device. The intelligent FRP-concrete composite structure not only has high carrying capacity, self sensing function, excellent corrosion resistance and high durability, but also has strong designability of performance and structure.

Owner:SOUTHEAST UNIV

Method for widening steel-concrete combination

ActiveCN101613997AReduce crackingReduce adverse effectsBridge structural detailsBridge erection/assemblySheet steelWhole body

The invention relates to a method for widening a steel-concrete combination, which is a technological method for widening an original concrete bridge. The method widens the original concrete bridge by adopting an integrally and jointly stressed steel-concrete composite beam comprising a concrete bridge deck and a steel beam. The method comprises the following steps: firstly roughening and reinforcing bar loading treatments are carried out on the main beam of the original bridge, a steel plate-concrete composite anchoring and connecting piece is arranged to connect the main beam with the transverse connecting steel beam of the original bridge; the main beam of the original bridge is connected with the steel-concrete composite beam into a whole body through the transverse connecting steel beam; roughening and transverse connecting reinforcing bar loading are carried out on the bridge deck of the original bridge, the bridge deck of the original bridge is extended to the upper bridge deck area of a widened beam, and the widened bridge deck is concreted to form a whole body. Compared with a traditional widening method, the method has the advantages that the structural height can be reduced, the structural dead weight can be reduced, and the lower structural cost can be reduced. Meanwhile, the composite beam is convenient to be produced, the installation quality is high, the construction is economic, convenient and fast, the influence to the normal traffic of the current bridge is small, and the deficiency of the method for widening the traditional concrete beam is overcome.

Owner:TSINGHUA UNIV

High strength concrete and preparation method thereof

InactiveCN105367026AHigh strengthSolution to short lifeSolid waste managementHigh strength concreteAggregate (composite)

The invention discloses high strength concrete and its preparation method, and relates to the technical field of building materials. 1 m<3> of the high strength concrete comprises the following ingredients: 200-300 kg of ordinary Portland cement, 40-50 kg of mineral powder, 15-30 kg of rubber particles, 500-800 kg of fine aggregate, 600-900 kg of coarse aggregate, 20-60 kg of a concrete composite additive, 50-100 kg of polypropylene fiber, 100-200 kg of water, 45-90 kg of phosphorous slag powder, 2-3 kg of a corrosion inhibitor, 5-10 kg of a water reducing agent, and 10-20 kg of a reinforcing agent. According to the prepared concrete product, compressive strength is remarkably raised, cracks are minimized, and life of concrete structures is prolonged. In addition, the preparation method is simple, and production efficiency is high.

Owner:张进

Prefabricated assembled steel-concrete composite beam connected by adopting high-strength bolt

InactiveCN105239720AImprove assembly efficiencyWork lessLoad-supporting elementsBridgesRebarPrecast concrete

The invention discloses a prefabricated assembled steel-concrete composite beam connected by adopting a high-strength bolt. The composite beam main comprises a steel beam, a prefabricated reinforced concrete slab and a shearing resistant bolt connection pair, wherein reasonable structural measures are reserved on the steel beam and the prefabricated concrete slab, and the shearing resistant bolt connection pair is adopted to connect the steel beam with the prefabricated concrete slab, so that compared with a situation that the beam-slab connection part is in rigid connection and the shear capacity is not substantially reduced, strong ductility and deformability can be obtained. When a prefabricated slab needs to be replaced, by detaching the nut of the shearing resistant bolt, the prefabricated slab is separated from the steel beam, so as to realize detaching and replacement of the prefabricated slab. All components adopted in the invention are assembled and connected on site, so that field welding work and template engineering can be reduced, the industrial assembly efficiency of buildings is improved, the function of detaching, separating and replacement of the beam-slab main body structure of the assembled composite structure can be achieved, and the novel architectural concept of capability of detachment and energy conservation and environment protection of building components can be embodied.

Owner:HUNAN UNIV

Silica micropowder-containing concrete composite admixture and preparation method thereof

InactiveCN102001839ASolve application problemsSolve temperature shrinkage crackingSolid waste managementEnergy conservationMaterials science

The invention discloses a silica micropowder-containing concrete composite admixture and a preparation method thereof. The silica micropowder-containing concrete composite admixture consists of 10 to 95 weight percent of silica micropowder and 5 to 90 weight percent of mineral powder, wherein the silica micropowder is prepared from natural quartzite through crushing, grinding and other technology. The preparation technology comprises the following steps of: grinding the quartzite into superfine powder and uniformly mixing with other mineral powder according to a ratio. The prepared composite admixture can replace 5 to 80 percent of cement, the concrete cement consumption and water consumption can be greatly reduced when the composite admixture is prepared into high-performance concrete, and the composite admixture has the characteristics of resource and energy conservation and environment friendliness.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

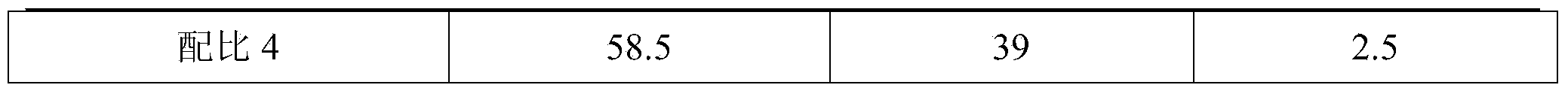

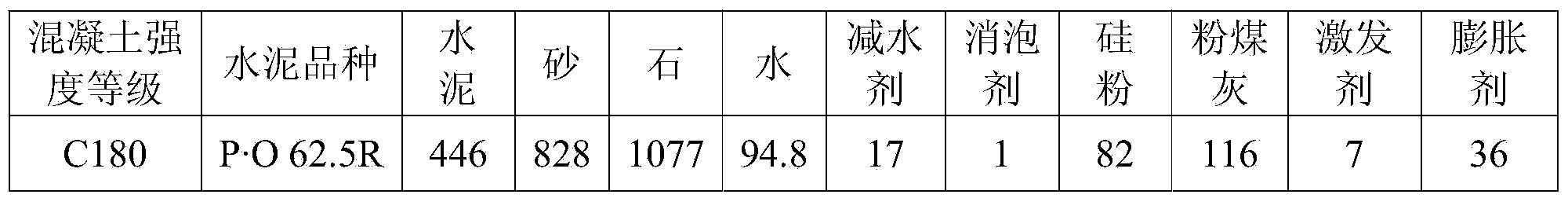

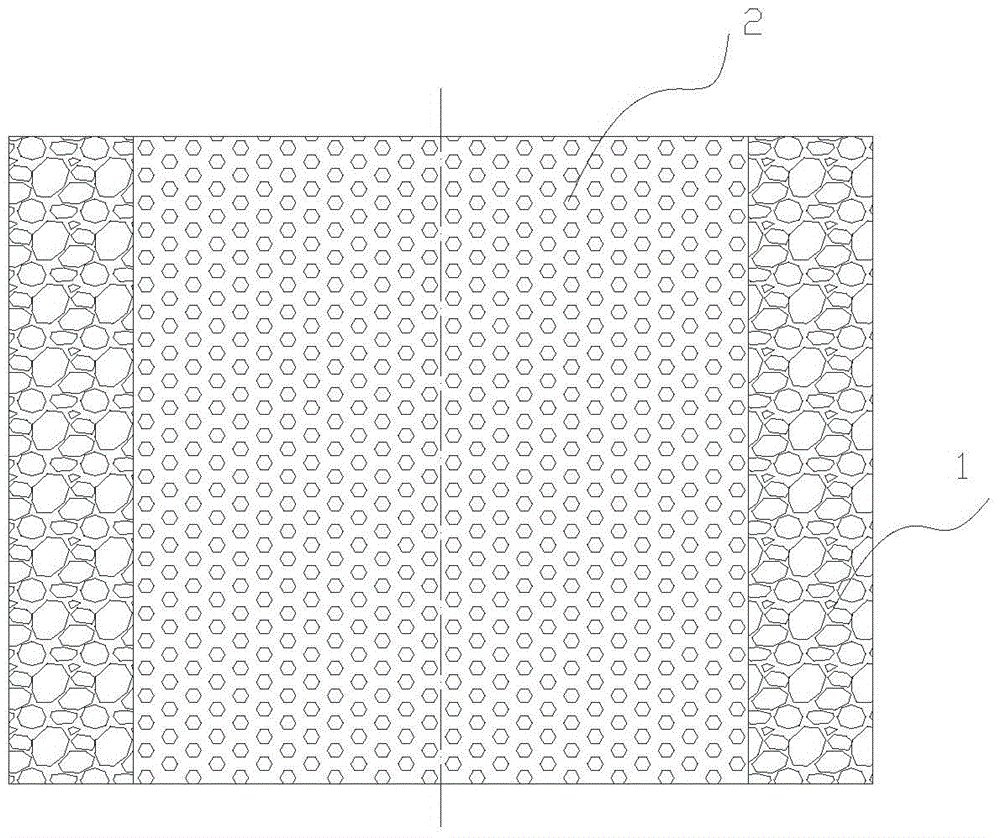

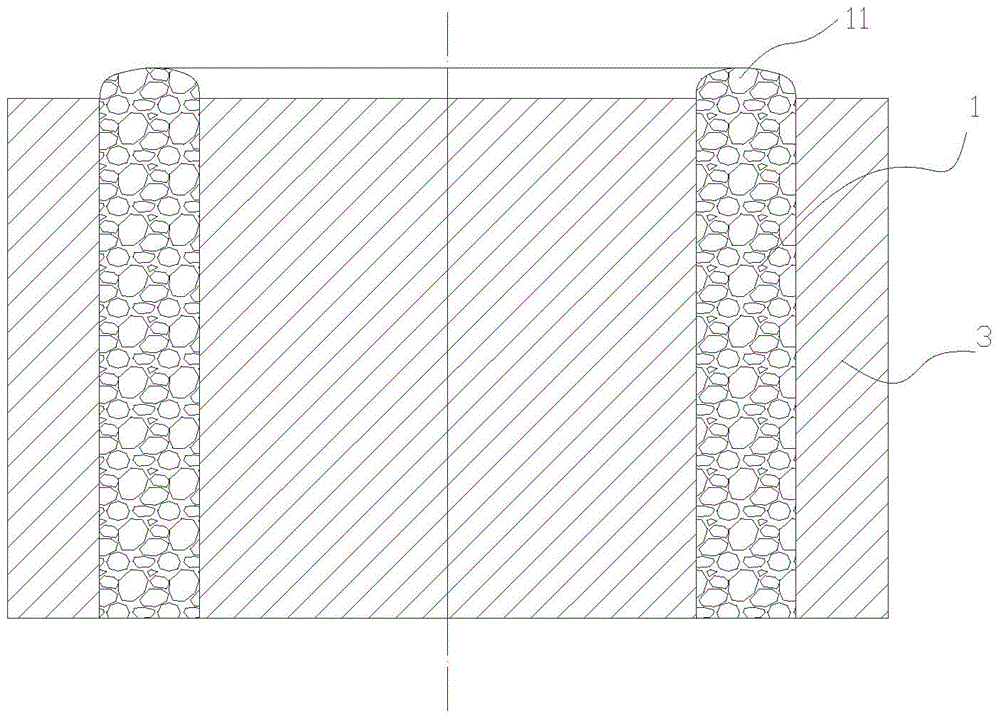

C180 strength-grade concrete for formed steel concrete composite structure

The invention discloses a C180 strength-grade concrete for a formed steel concrete composite structure, which is composed of 446 parts of cement, 828 parts of fine aggregate, 1077 parts of coarse aggregate, 94.8 parts of water, 17 parts of concrete superplasticizer, 1 part of defoaming agent, 82 parts of silicon powder, 116 parts of expanding agent, 7 parts of activator and 36 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Processing method for building waste foamed concrete composite heat preservation building blocks

InactiveCN104153512AImprove surface structureHigh bonding strengthConstruction materialSolid waste managementFoam concreteMixed materials

The invention discloses a processing method for building waste foamed concrete composite heat preservation building blocks. The invention provides a processing method for the building waste foamed concrete composite heat preservation building blocks. By virtue of the processing method, the performance of a recycled material can be optimized to the maximum extent, so that the compression strength, the shear strength and the heat preservation performance of a finished product can be guaranteed. Each building block comprises a base body and a heat preservation core body. A building block preparation process comprises base body forming, core body preparation, maintaining and drying working procedures; each base body comprises cement, an active mixed material, a modifier and a recycled aggregate. A processing method for the recycled aggregate comprises the steps of (1) classifying and initially sorting building waste; (2) roughly crushing building waste to prepare granular recycled coarse aggregates of which the dimension is smaller than 10mm; (3) performing mechanical enhancement on the recycled coarse aggregates, adding natural sand into the recycled coarse aggregates according to a weight ratio of 1:(0.2 to 1), and taking fine sand, which has the particle size of 0.25-0.5 mm, in the mechanically enhanced aggregates for later use. According to the method, the building blocks are high in bonding strength and uniform, the water absorption property of a single unit is reduced, the production cost is lowered, and the production technology is simple and feasible.

Owner:CHINA BUILDING MATERIALS ACAD

Reinforcement method of deep layer soft soil foundation

InactiveCN1948632AEliminate settlementIncrease the bearing capacity of the foundation soilBulkheads/pilesSoil preservationEngineeringElectron system

This invention discloses a deep soft soil reinforce method. Its construction steps includes:(1)the vacuum well point declines water (2) vacuum electricity declines a water : vertically plugs electricity tube in a vacuum tube wells inside, installs electric system for vacuum tube wells and electron system the cathode connecting, electron and electron pipe system connecting to form the anode DC circuit; (3) low-energy strong ramming; (4) vibrating roll, flat ground; (5) adding concrete-pile : machine drills hole, adapting tube pump concrete for the construction technology-concrete composite construction of the foundations; (6) lays cushion : concrete pile in the top layer structure and the site uses static compaction cushion construction. This invention by vacuum precipitation and-concrete pile combination of approaches to achieve the reinforcement of the deep soft ground, breakthroughs in the tradition of deep soft soil to use reinforced concrete piles in the traditional concept and reduces the construction cost.

Owner:杨静明 +2

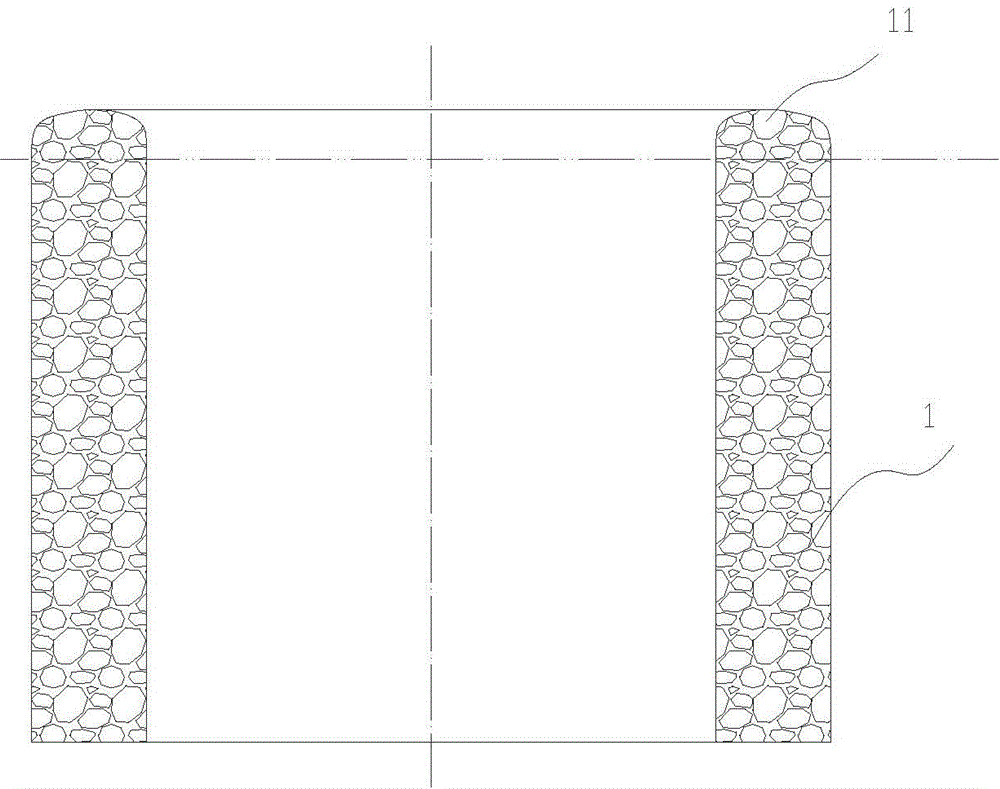

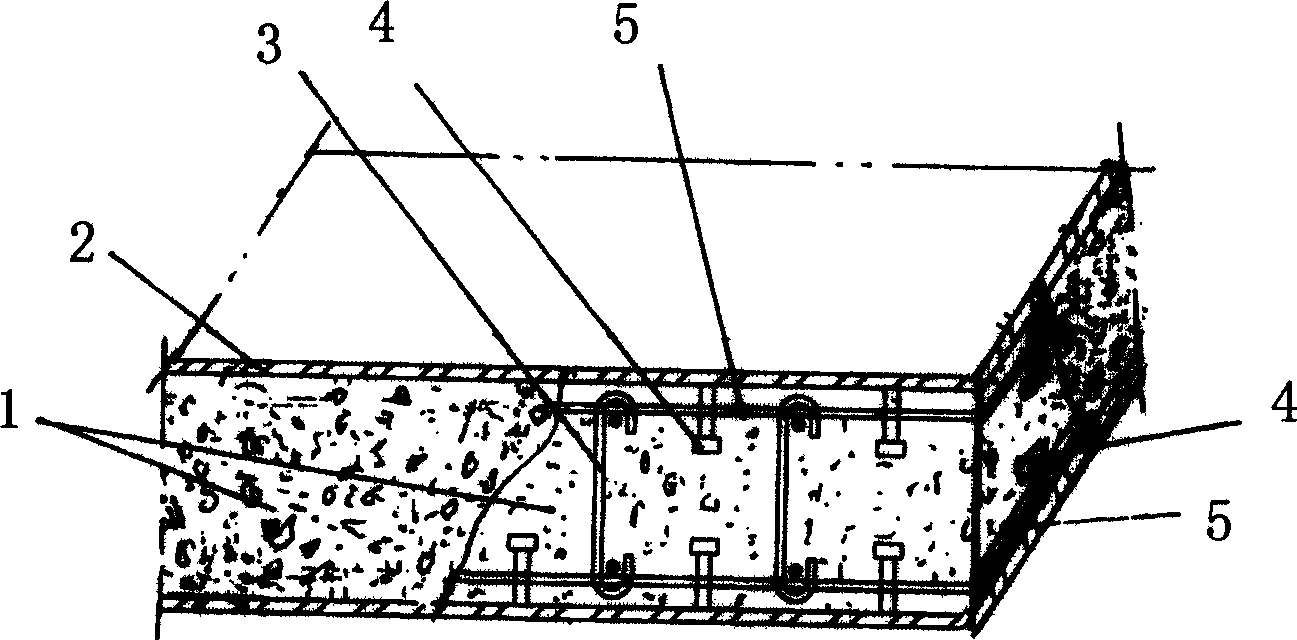

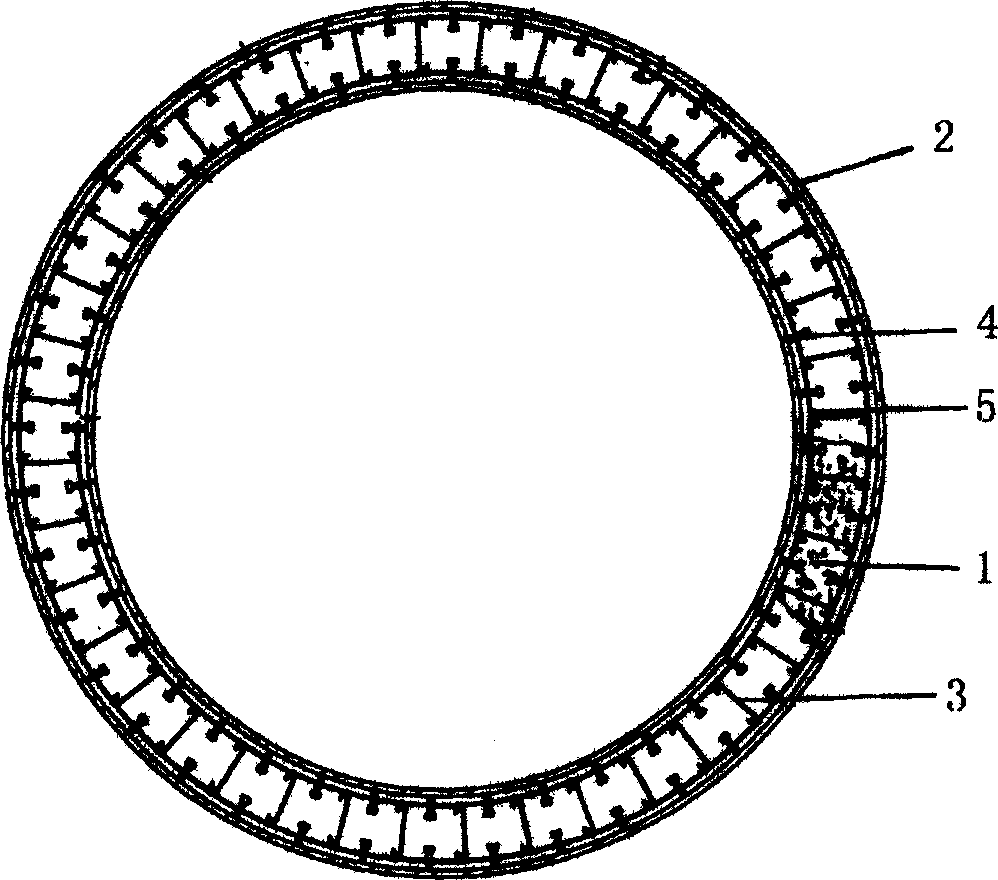

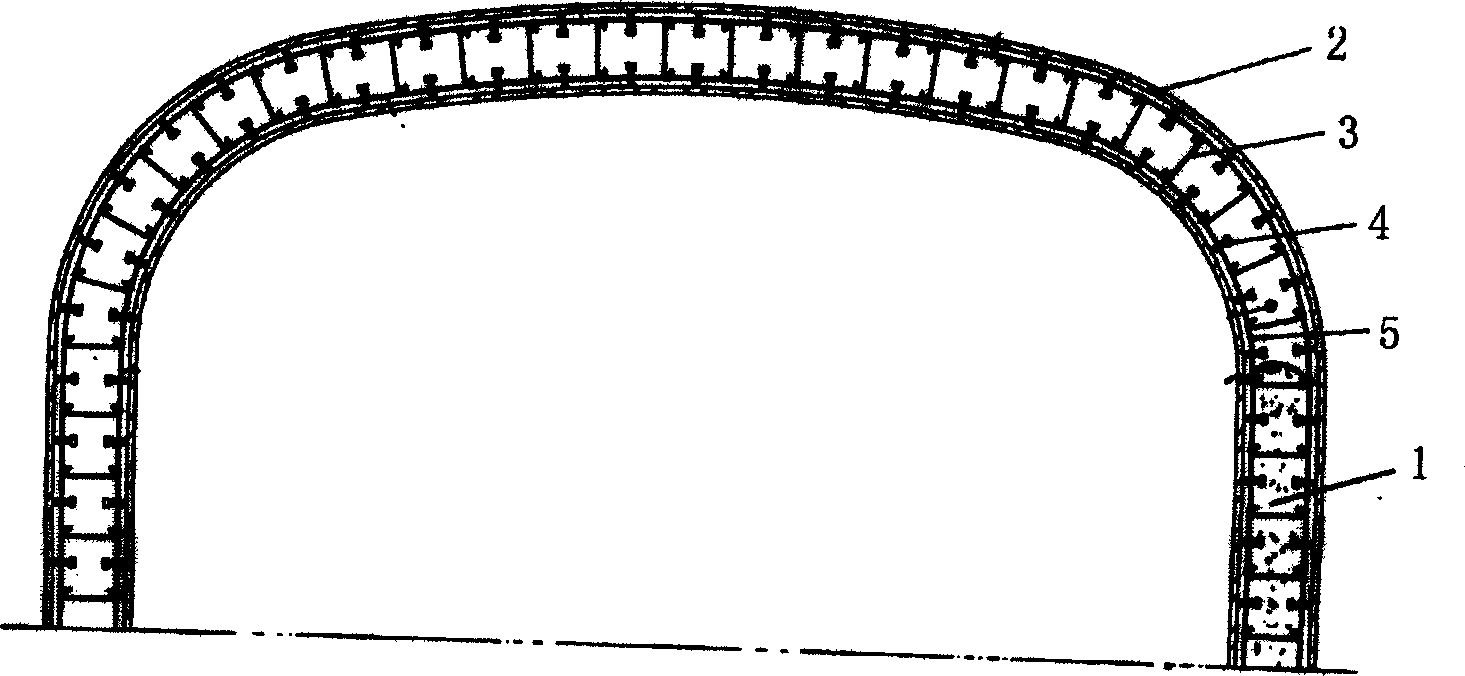

Steel plate-concrete composite lining

InactiveCN1594833AImprove mechanical propertiesLarge bearing capacityUnderground chambersTunnel liningShotcreteSheet steel

The present invention disclose a steel plate-concrete composite lining which combines support and water proof and belongs to tunnel safe support device range. It can be applied for construction of new tunnel with high force bearing and water proof requirement and the reinforcement of existing structures, and includes a circular cross section tunnel, an arched section tunnel or various section shape tunnels or saps. The lining is generally formed in a way of first forming a lining frame by two anti-cut connection elements melted with studs, a reinforcing steel net banded by reinforcing steels and a steel plate and then spraying concrete into the frame. The invention combines the steel plate, the sprayed concrete to a whole structure to bear force, has improved bearing ability and stability than single reinforcing steel concrete lining, can be as support for new tunnel and as the reinforcement device for similar structure. The invention has the advantages of easy in quality guaranty, simple and quick in construction and high in synthetic effect.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com