Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

677 results about "Natural sand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Premixing mortar with high moisture retention and production method thereof

The invention discloses pre-stirring mortar with high moisture retention and a production method thereof. The premixing mortar comprises the following components by weight ratio: 100 parts of cement with the high moisture retention, 1 to 900 parts of fine aggregate and 30 to 200 parts of water, wherein the cement with the high moisture retention contains a cellulose ether component and has the moisture retention above 90 percent; and the fine aggregate is natural sand or artificial sand obtain through screen sizing or removing harmful components, and has the maximum grain diameter of 1.18 mm to 2.36 mm. The production method comprises the following steps: arranging a mortar stirring machine on a construction site or nearby; adopting the cement with the high moisture retention and the fine aggregate to automatically meter and stir, enable mortar to be usable while stirring, and the like to ensure the mortar quality; and adopting a closed stirring mode, a dust-collecting mode and the like to reduce dust raise. The pre-stirring mortar can effectively improve and ensure the qualities of the mortar buildings, obviously improves the construction environment, greatly decreases the production cost of the pre-stirring mortar and solves the difficult problems that the prior pre-stirring mortar has over-high cost and are difficult to popularize and apply.

Owner:SOUTH CHINA UNIV OF TECH

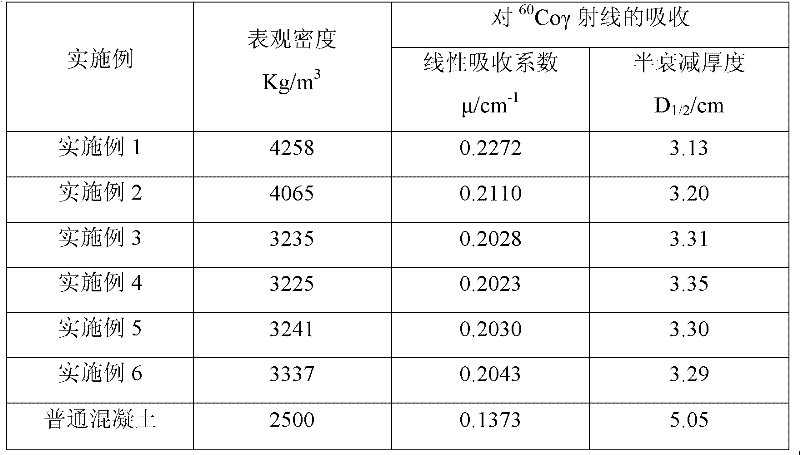

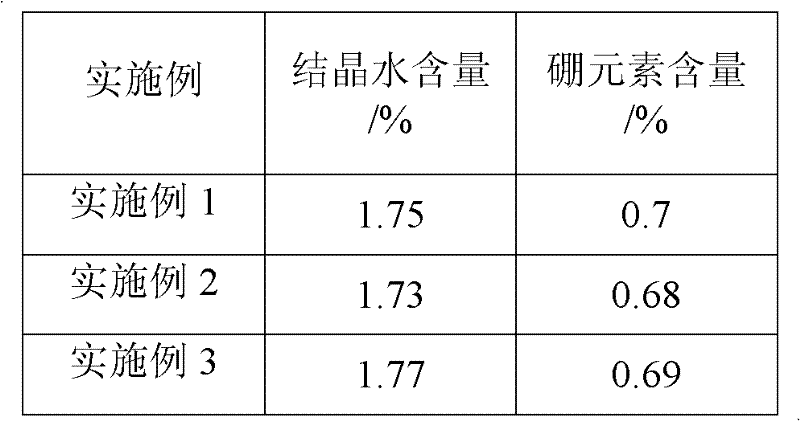

Radiation shield concrete and preparation method thereof

InactiveCN102219459AReduce water-cement ratioLow shrinkageSolid waste managementShieldingSlagSuperplasticizer

The invention relates to radiation shield concrete and a preparation method thereof. The radiation shield concrete is characterized by comprising a cementing material, coarse aggregates, fine aggregates, steel fibre, a high-efficiency slushing agent and water; the cementing material is composed of ordinary portland cement and inorganic mineral admixtures; the inorganic mineral admixtures are siliceous dust and coal ash; the fine aggregates are natural sand, boron glass powder and steel slag powder; the coarse aggregates are steel sections or a mixture of the steel sections and steel slag; the proportions of various types of components are as follows: 500 kg / m<3> of cementing material, 1400-2215 kg / m<3> of coarse aggregates, 750-950 kg / m<3> of fine aggregates, and 155-200 kg / m<3> of water; the high-efficiency slushing agent is 0.5-1.0% of the total weight of the cementing material by weight; and the steel fibre is 1.0-1.5% of the total volume of the concrete by volume. The radiation shield concrete has good mechanical property and lasting quality, good shielding effect on gamma rays, good effect on shielding neutron rays, can be used or comprehensively recycling wastes and has low cost.

Owner:WUHAN UNIV OF TECH

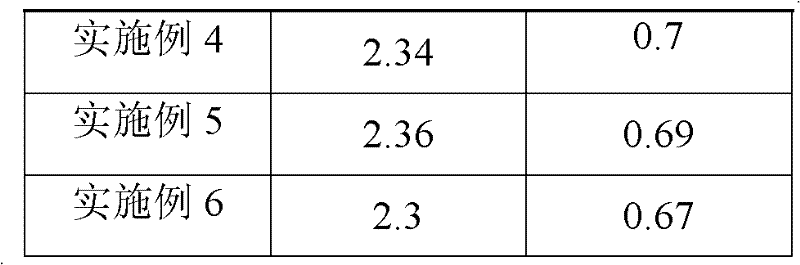

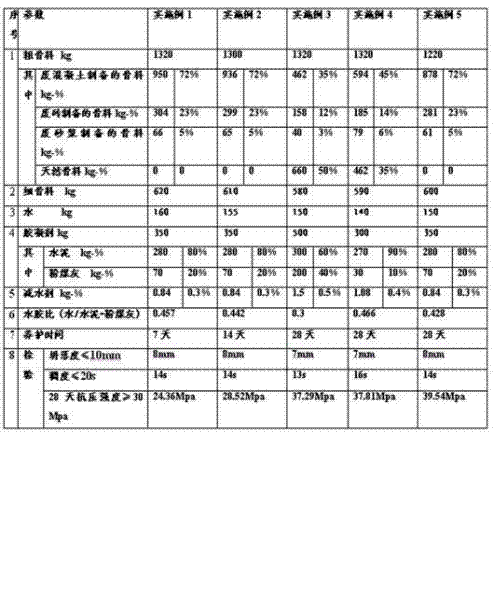

Recycled aggregate medium-dry hard concrete prepared by using building waste and preparation method of recycled aggregate medium-dry hard concrete

The invention discloses a recycled aggregate medium-dry hard concrete prepared by using building waste, which comprises the following raw materials of coarse aggregate, fine aggregate, a gelatinizing agent, a water reducing agent and water, wherein the gelatinizing agent comprises cement and coal ash, and the coarse aggregate comprises 50-100 percent of recycled coarse aggregate prepared from thebuilding waste. A preparation method of the recycled aggregate medium-dry hard concrete comprises the following steps of: pretreating the building waste, removing impurities, remaining waste concrete, waste bricks and the like; crushing and screening to prepare the recycled coarse aggregate; mixing the recycled coarse aggregate, natural sand, cement and water according to the proportion, adding the coal ash and the water reducing agent, stirring uniformly to obtain a mixture; and squeezing and forming the mixture, curing for 2 days to obtain the recycled aggregate medium-dry hard concrete. The invention solves the problems of worsening ecological environment and the like caused by difficulty in treating the building waste; and the building wastes are used for manufacturing the recycled aggregate for replacing natural aggregate, the increasingly deficient natural aggregate and damage degree to the ecological environment are reduced, and the living environment of human beings is protected. The recycled aggregate medium-dry hard concrete prepared by using the method has high strength and high abrasive resistance, and can be used for building base installations such as city roads, housing constructions and the like.

Owner:云南华威废弃物资源化有限公司

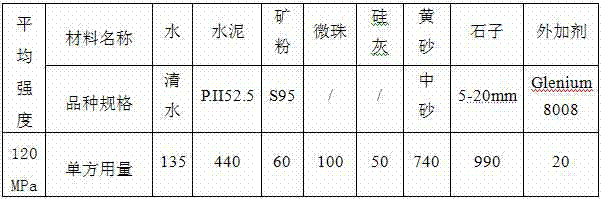

Low-viscosity easy-to-pump ultrahigh-strength concrete with average strength of 120MPa

ActiveCN103613348ALow viscosityEase of pumping performance requirementsHigh strength concreteMicrosphere

The invention relates to low-viscosity easy-to-pump ultrahigh-strength concrete with average strength of 120MPa. The concrete comprises the following components at single-prescription dosage ratio of kg / m<3>: 400-440 parts of cement, 40-60 parts of silica fume, 60-80 parts of slag micro powder, 100-120 parts of microspheres, 700-750 parts of natural sand with fineness modulus of 2.8-3.2, 980-1,000 parts of stone, 19.5-22.75 parts of additive and 130-135 parts of mixing water, wherein the additive is a polycarboxylate-type high-performance water reducing agent Glenium 8008 and has high water reducing rate, strong viscosity reducing property and high slump retaining property; the expansion degree of the ultrahigh-strength concrete is kept at 700+ / -50mm within 4 hours, the back taper time is controlled at 3-8 seconds, the viscosity is kept at 28-35Pa.s, and ultrahigh pumping of 300m and higher is easy to realize. The concrete provided by the invention can meet the performance requirements for ultrahigh concrete pumping of 500m and higher in terms of high slump retaining property, self-compaction property, strength property, low-viscosity property and the like.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +1

Recycled aggregate ecological water permeable brick and production method thereof

InactiveCN104628346AGood water permeabilityHigh water retentionSolid waste managementBrickResource utilization

The invention discloses a recycled aggregate ecological water permeable brick and a production method thereof. The raw material of the recycled aggregate ecological water permeable brick comprises a basic material, a surface material and water, the basic material comprises recycled aggregate, a gel material and additives, the gel material comprises cement, lime and coal ash, and the additives comprise a polycarboxylate superplasticizer and gelatine powder. The production method of the recycled aggregate ecological water permeable brick comprises the following steps: grading, extracting and preparing for discharging of the recycled aggregate, stirring the basic material, stirring the surface material, forming, curing and forming the finished product. The recycled aggregate ecological water permeable brick disclosed by the invention is produced by building wastes after resourceful treatment, which both promotes the resource utilization of the building wastes to improve the added value of products, and saves a large number of natural sand and stone resources; the produced recycled aggregate ecological water permeable brick has a high permeable rate, a high water-retention rate and high compressive strength, and the compressive strength reaches 30 MPa; and the permeation coefficient is 0.5 cm / s, which is 50 times as large as that of the existing national standard and much better than the properties of similar natural material products.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

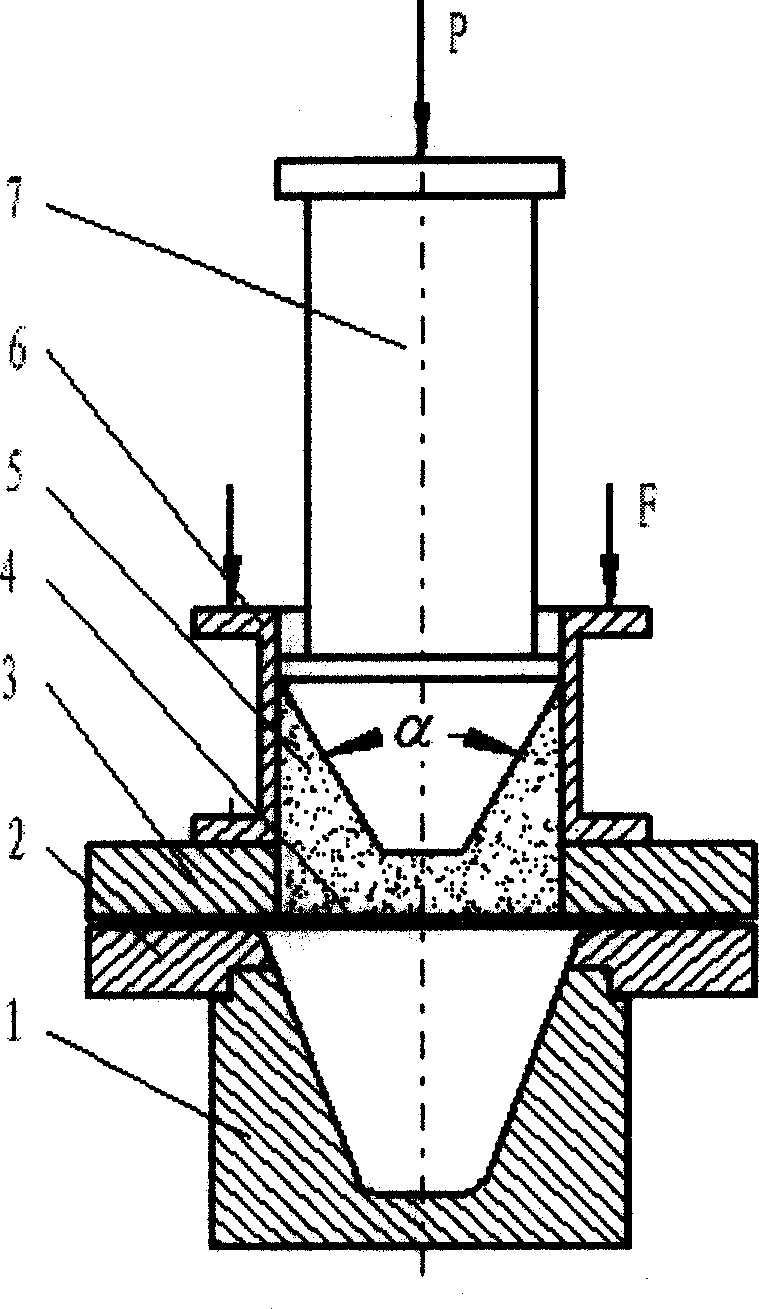

Half-mould forming process for metal plate material

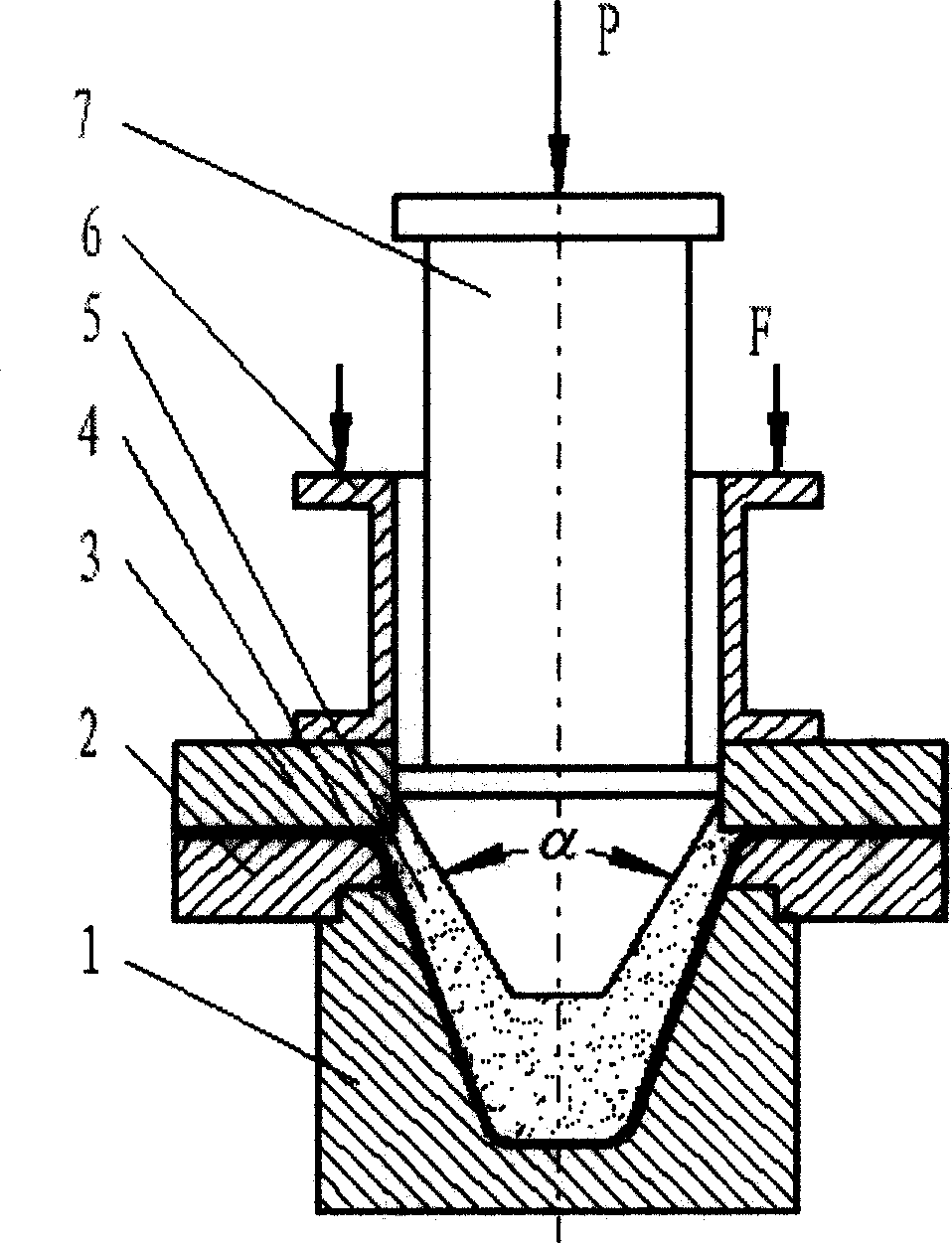

A half-mould shaping technology for metallic plate features that the solid particles are used to replace the rigid male mould. It includes such steps as providing high-hardness steel balls with diameter less than 4 mm or natural sand as force transfer medium, making a female mould, loading a metallic plate in it, adding said force transfer medium on the plate, and using a pressing head to press them for the plastic deformation of metallic plate.

Owner:YANSHAN UNIV

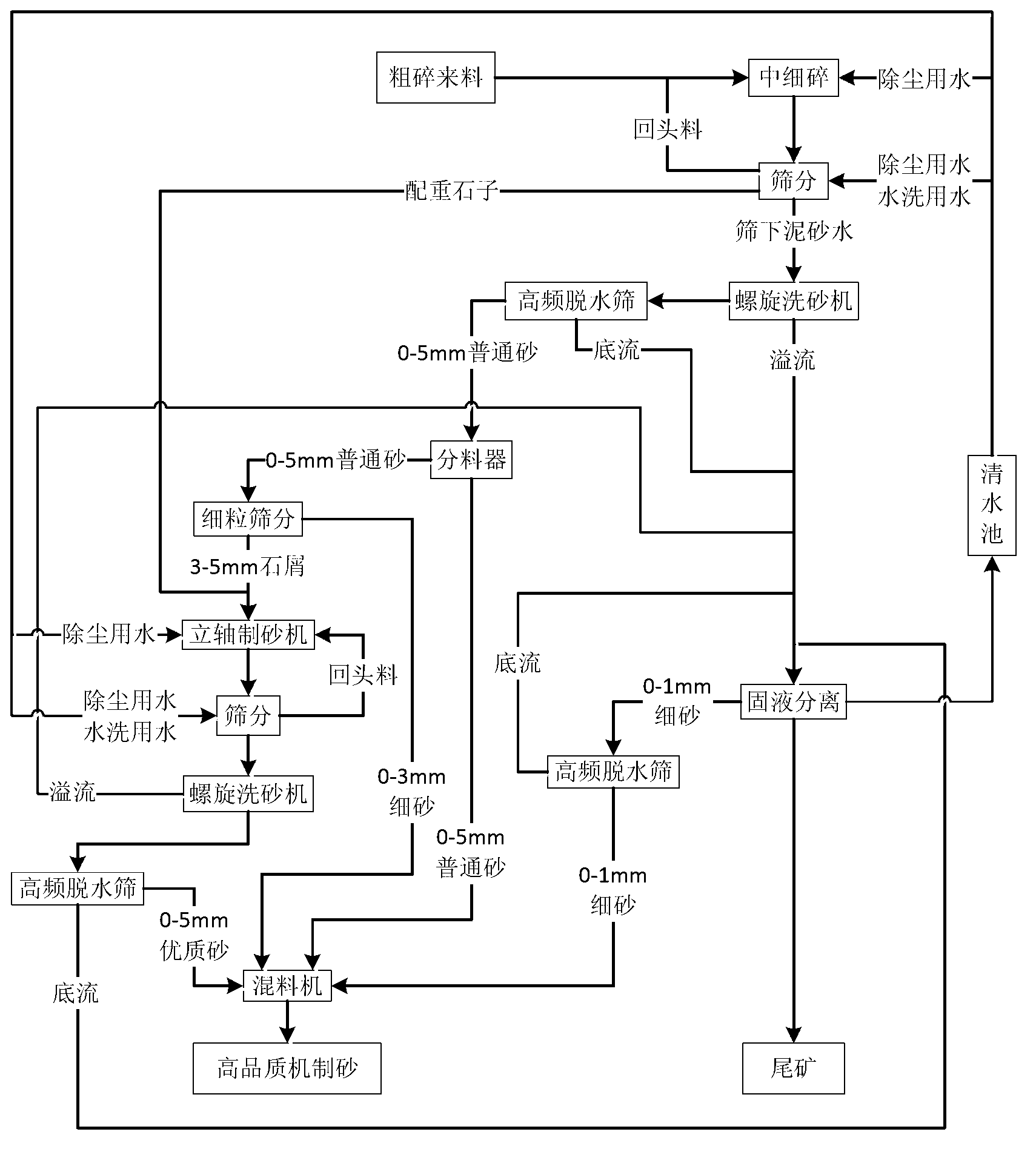

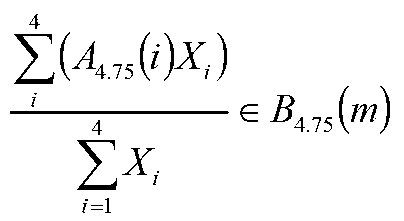

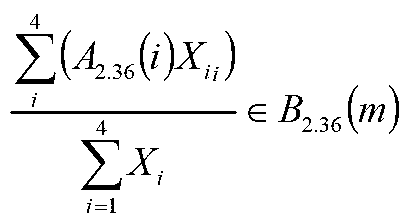

Preparation method of machine-made sand capable of replacing natural sand

The invention relates to a preparation method of machine-made sand capable of replacing natural sand. The machine-made sand is mixed by four or more than four kinds of sand in different specifications as semi-finished products under constraint of graduation, content of mountain flour, clay lump content and fineness modulus of sand for buildings. The method is helpful for recycling waste resources and has the advantages of low comprehensive cost, simpleness in operation, environment-friendly process, large-scale continuous production and the like. The technical quality of the product fully meets the standard of sand for buildings and can completely replace natural sand, so that the machine-made sand can be widely applied to the field of concrete for buildings such as bridges, roads, tubular piles and buildings.

Owner:NANJING UNIV OF TECH +1

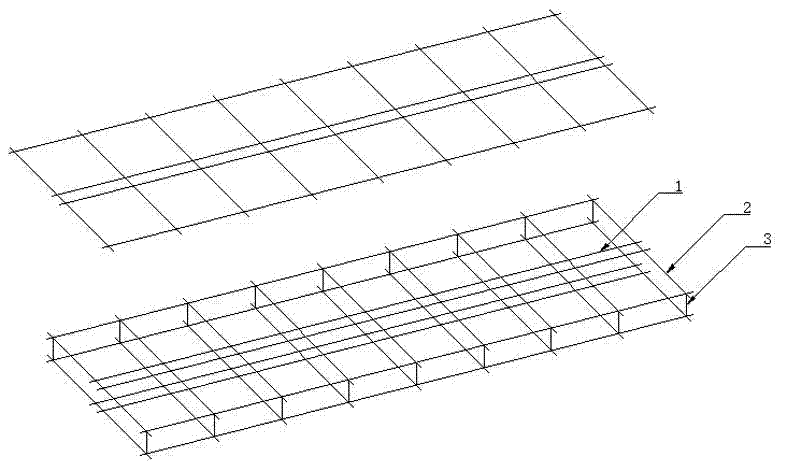

Precast concrete pile and manufacturing method thereof

The invention provides a precast concrete pile and a manufacturing method thereof. The precast concrete pile is obtained by mounting concrete into a mold mounted with a reinforcement cage framework, closing the mold, tensioning the mold, centrifugally shaping the mold, curing the mold by steam at a normal pressure; releasing the mold and curing the concrete by steam at a high pressure; raw materials of the concrete comprise a cementing material, a fine aggregate, a coarse aggregate, an admixture and water, wherein the fine aggregate is a machine-made sand or a mixture of the machine-made sand and a natural sand; the percentage of the machine-made sand in the fine aggregate by weight is 5-100%; the machine-made sand is obtained by mechanically crushing stone raw materials, such as mine tailings, industrial tailings and the like, screening the crushed stone raw materials in a graded way and removing dust from the screened stone raw materials; fineness modulus of the machine-made sand is 2.3-3.8; grain gradation of the machine-made sand meets requirements on an area 1 or an area 2 of a standard sand; and stone powder content of the machine-made sand is 2-8 wt%. According to the invention, the concrete cost is reduced and resource utilization rate is increased; and the used machine-made sand has the advantages of low silt content and controllable stone powder content, so that the performance of the precast concrete pile is improved.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

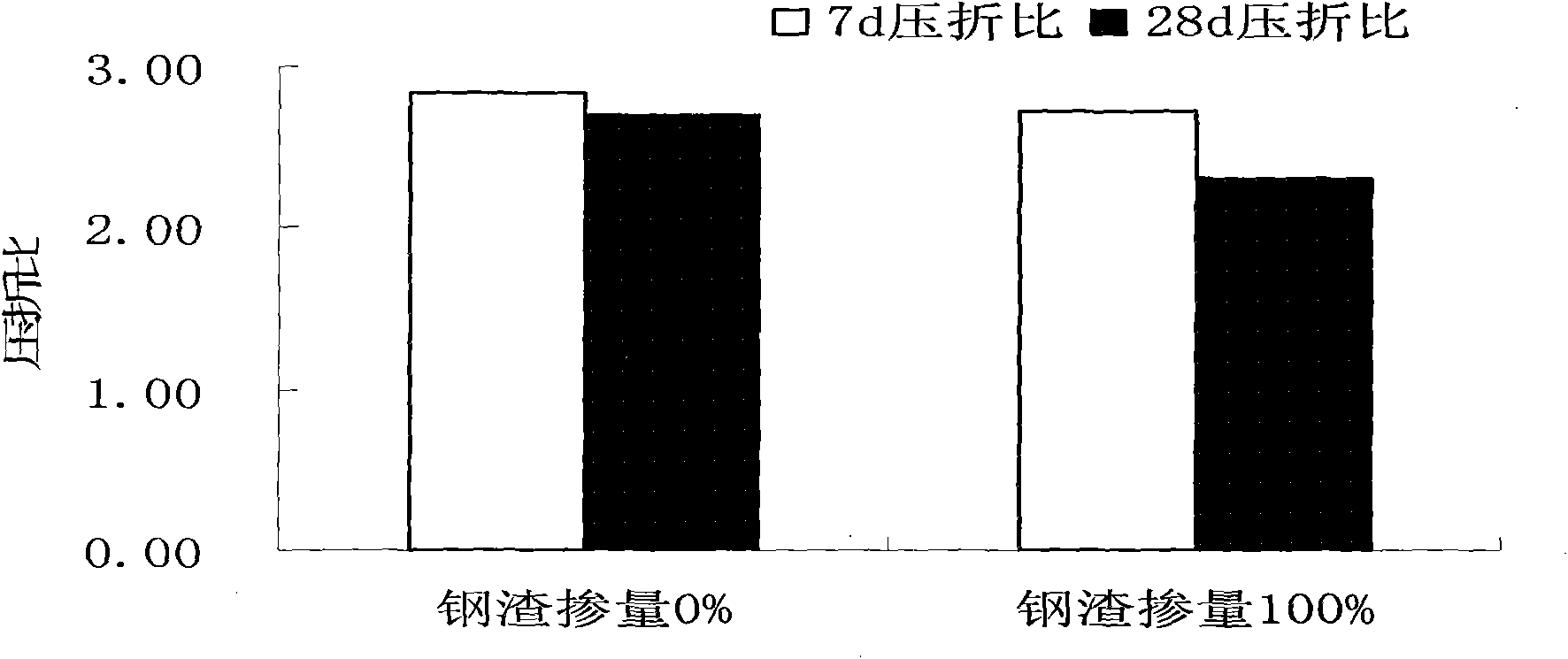

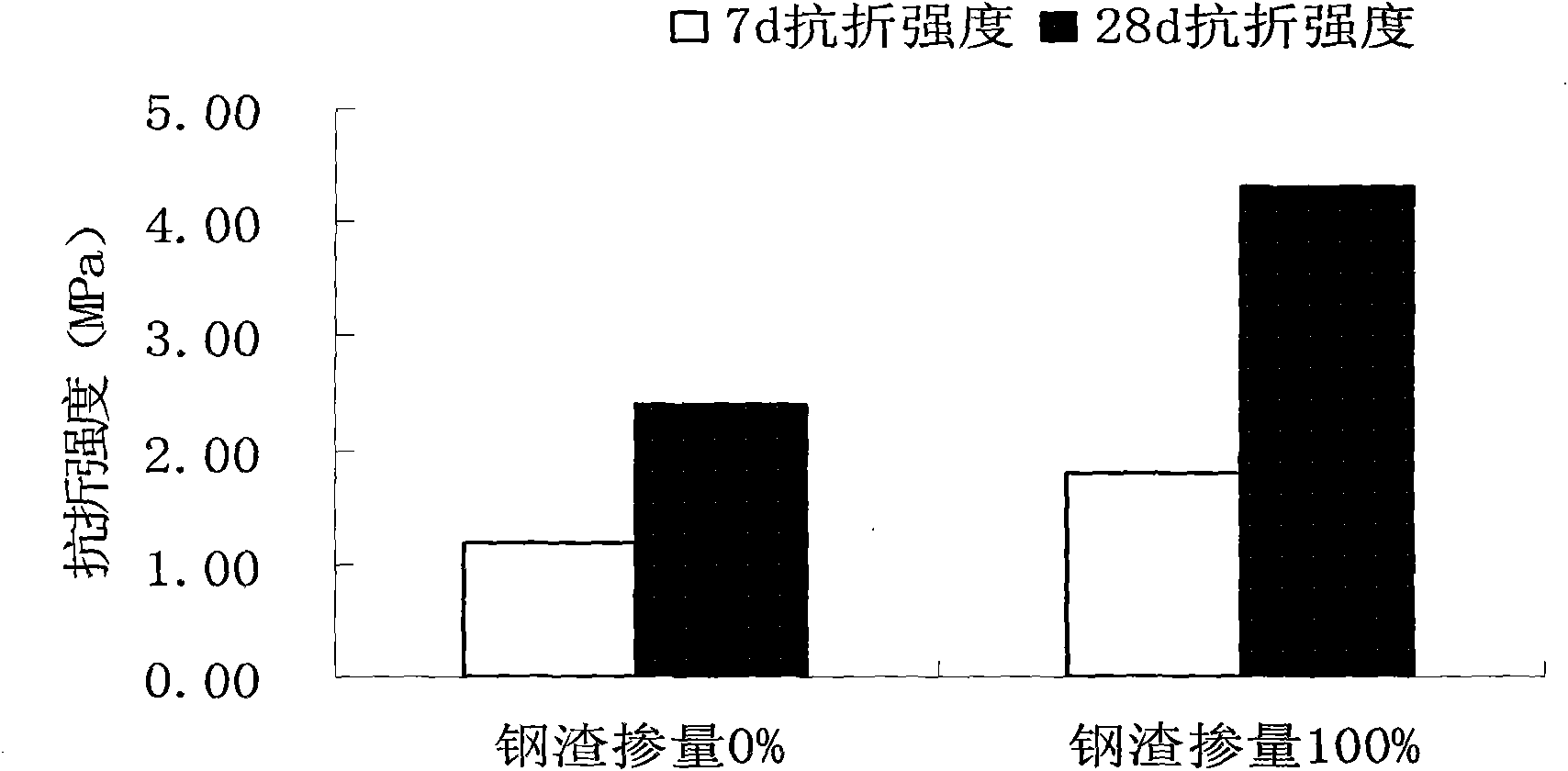

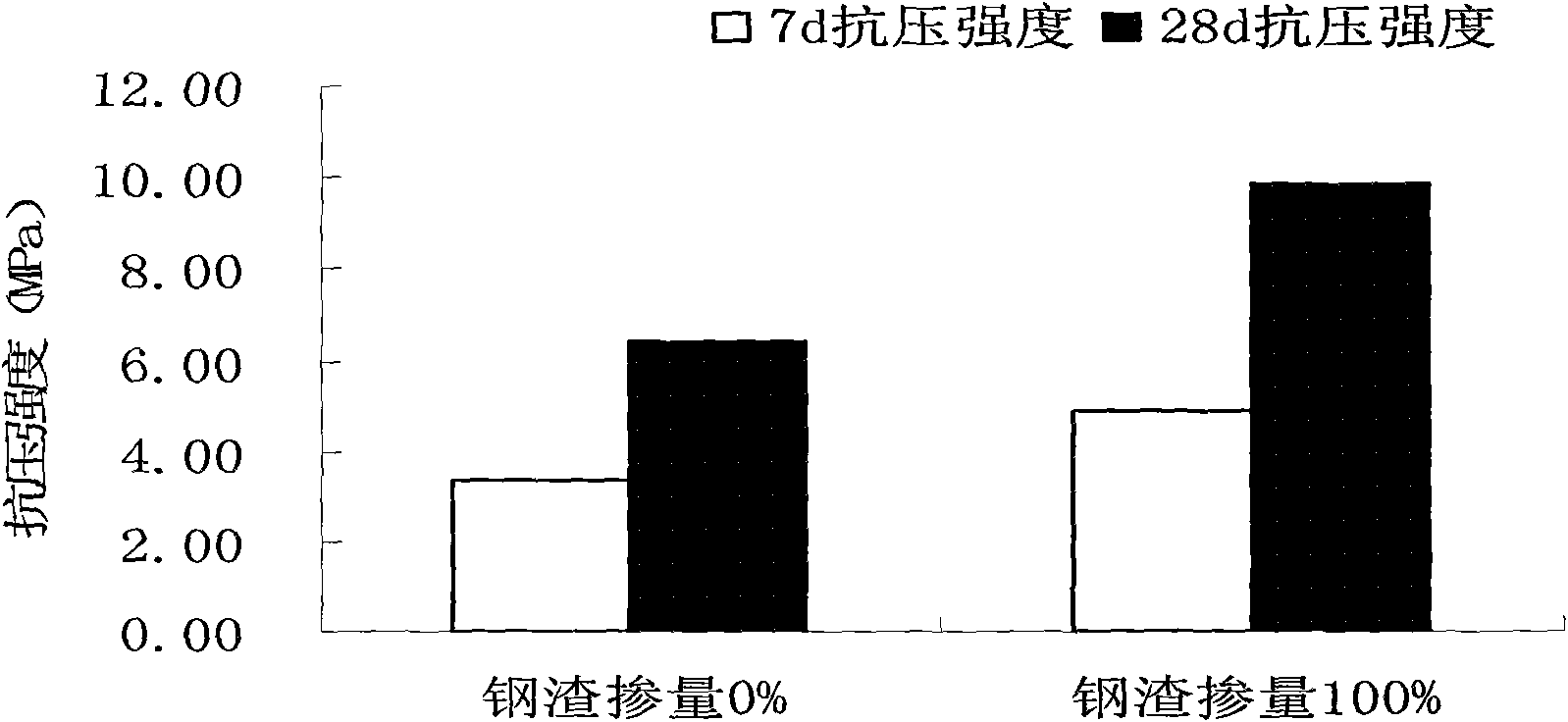

Waterproof and crack-resistant dry-mixed mortar of steel slag sand

InactiveCN101891435ACrack resistance and high efficiencyImprove mechanical propertiesSolid waste managementFiberCrack resistance

The invention relates to waterproof and crack-resistant mortar for buildings prepared from steel slag. The waterproof and crack-resistant mortar comprises the following components in weight percentage: 55-80% of steel slag with granularity of not more than 4.75 mm, 15-40% of silicates cements, 0.5-5% of acrylic acid gelatine powder, 0.05-5% of water-retaining agent, 0.1-1.0% of wood fiber, 0-0.5% of water reducing agent and 0-0.5% of organosilicon water repellent. Compared with the prior art, the waterproof and crack-resistant dry-mixed mortar for buildings is prepared from the steel slag which partially or totally replaces natural sand, thereby protecting natural ecology and environment, comprehensively utilizing the steel slag and improving additional values thereof and having the advantages of high waterproof efficiency, overall crack resistance, excellent impact resistance and flexibility, favorable construction and workability, energy saving, consumption reduction, stable performance and simple construction; and the mortar does not contain poisonous and harmful substances.

Owner:武汉钢铁有限公司

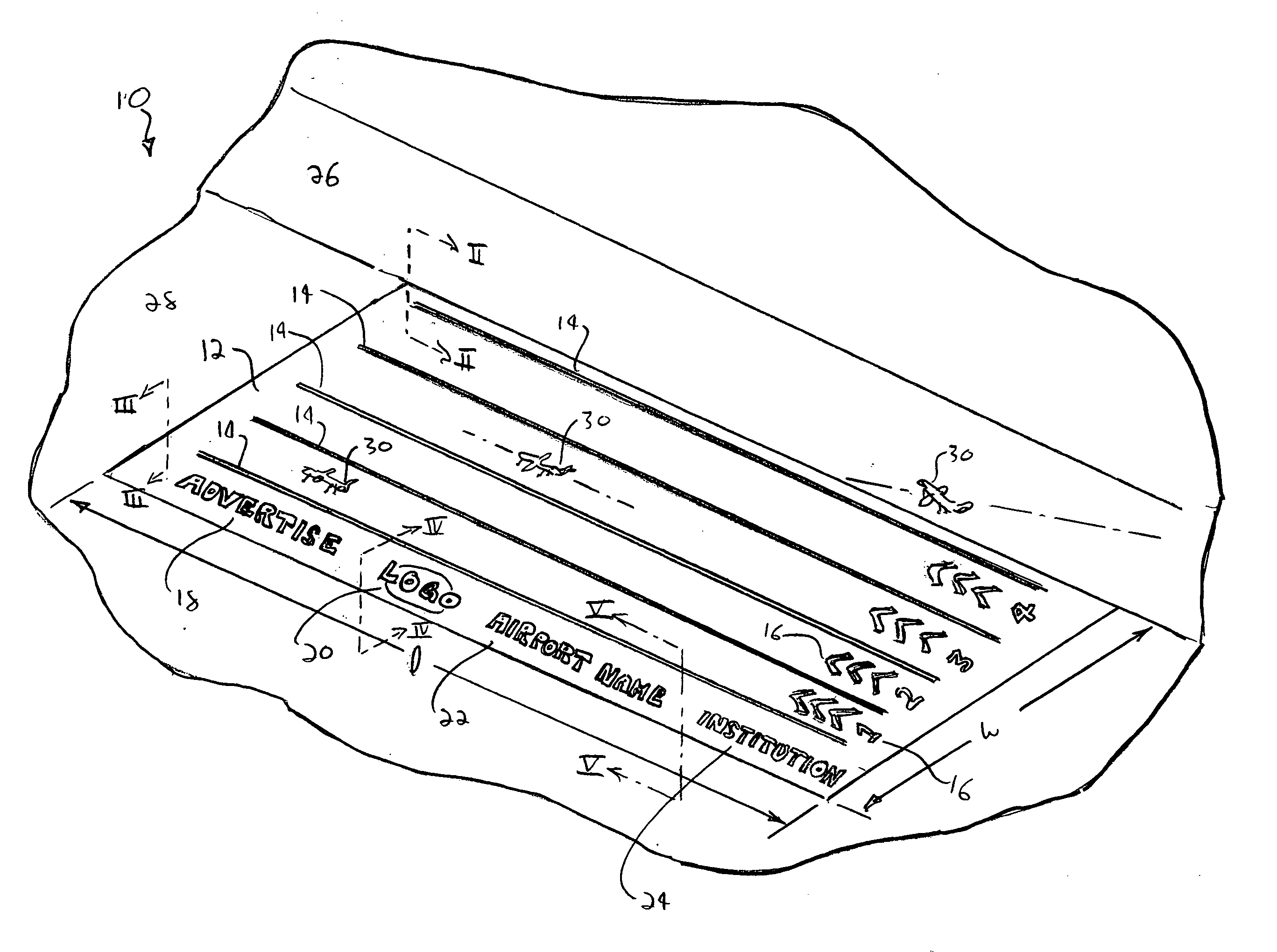

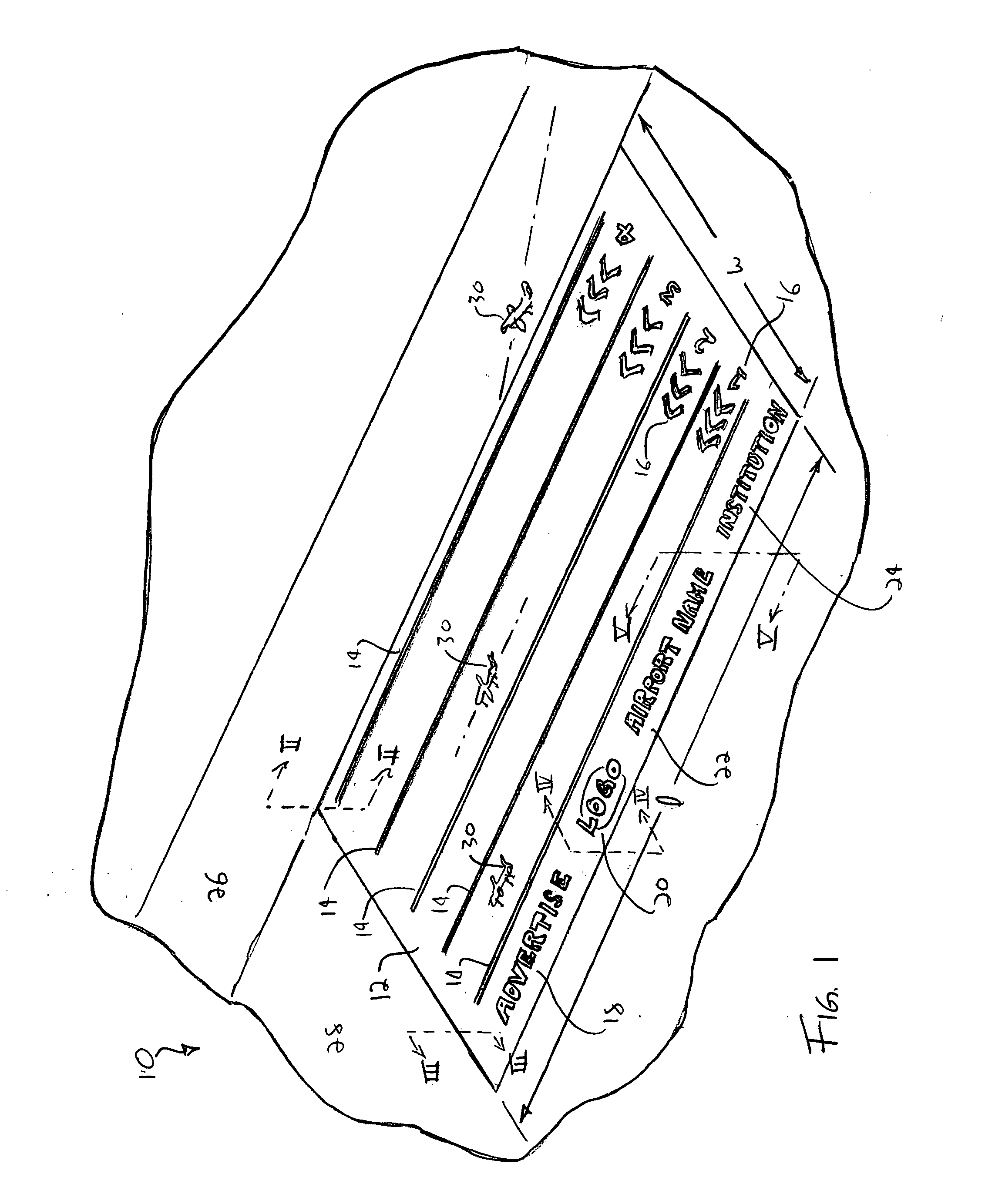

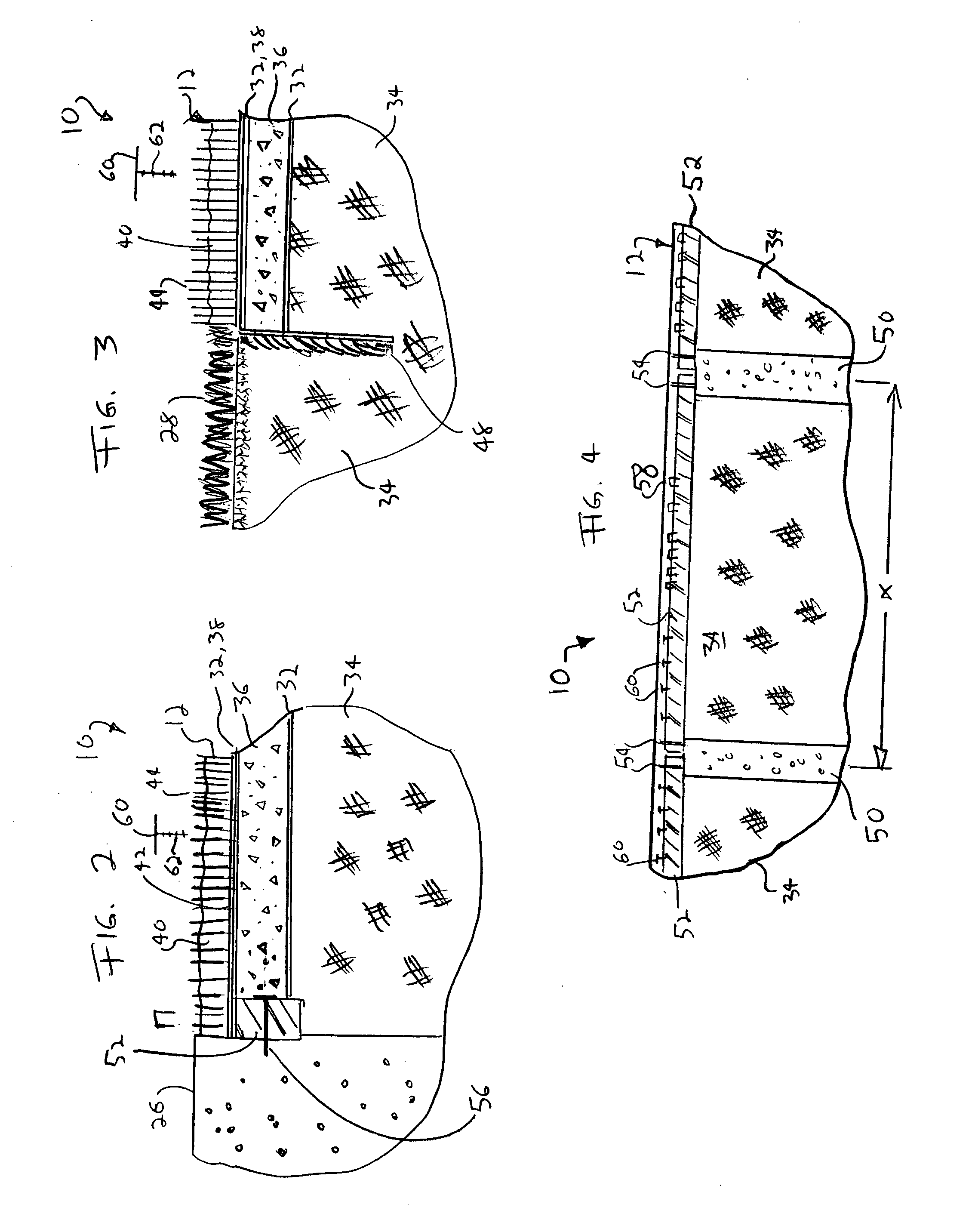

Synthetic runway surface system

ActiveUS20050129903A1Reduce the possibilityMinimize fire damageDead plant preservationArtificial flowers and garlandsArtificial turfIngested food

The present invention provides an artificial turf runway surface suitable for supporting take off, landing and taxiing of aircraft. The turf system cures many of problems and pitfalls associated with natural sand or grass systems, such as rutting, bare spots, erosion, unevenness, standing water as well as other problems associated with natural grass airstrips. The synthetic surface also removes nesting materials and food and thereby dissuades birds and other animals from landing and congregating thereon. The system includes a synthetic covering, such as an artificial turf covering, one or more sheeting or flow through membranes, a compacted rock base suitable for supporting the aircraft when landing, tacking off and taxiing.

Owner:ACT GLOBAL HLDG LLC

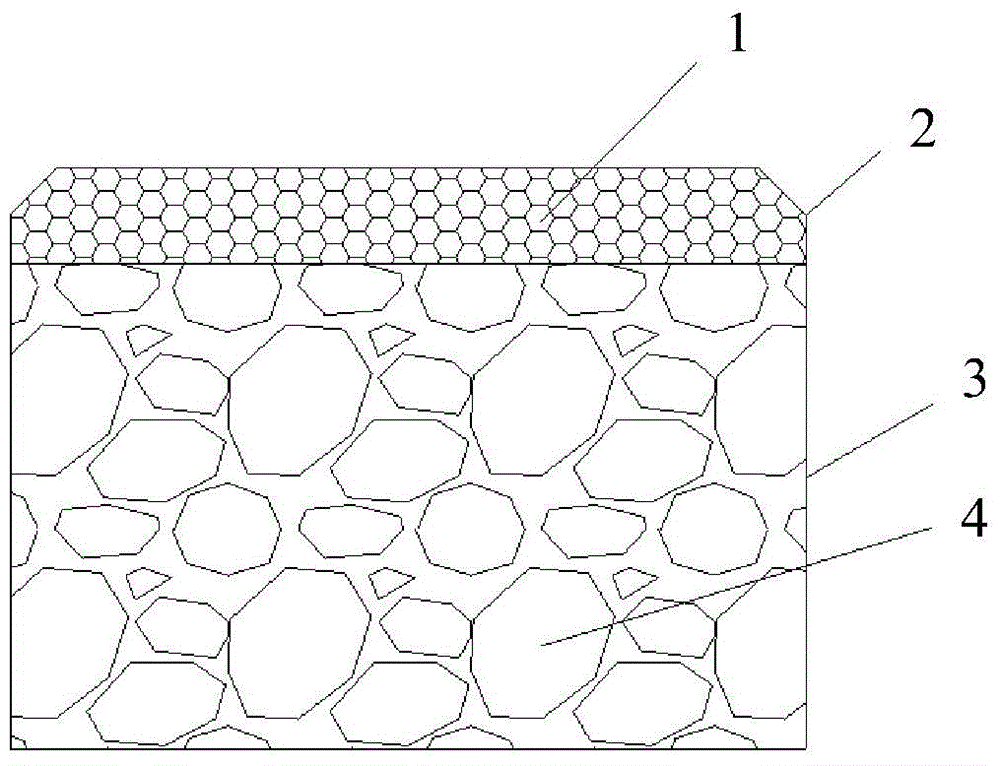

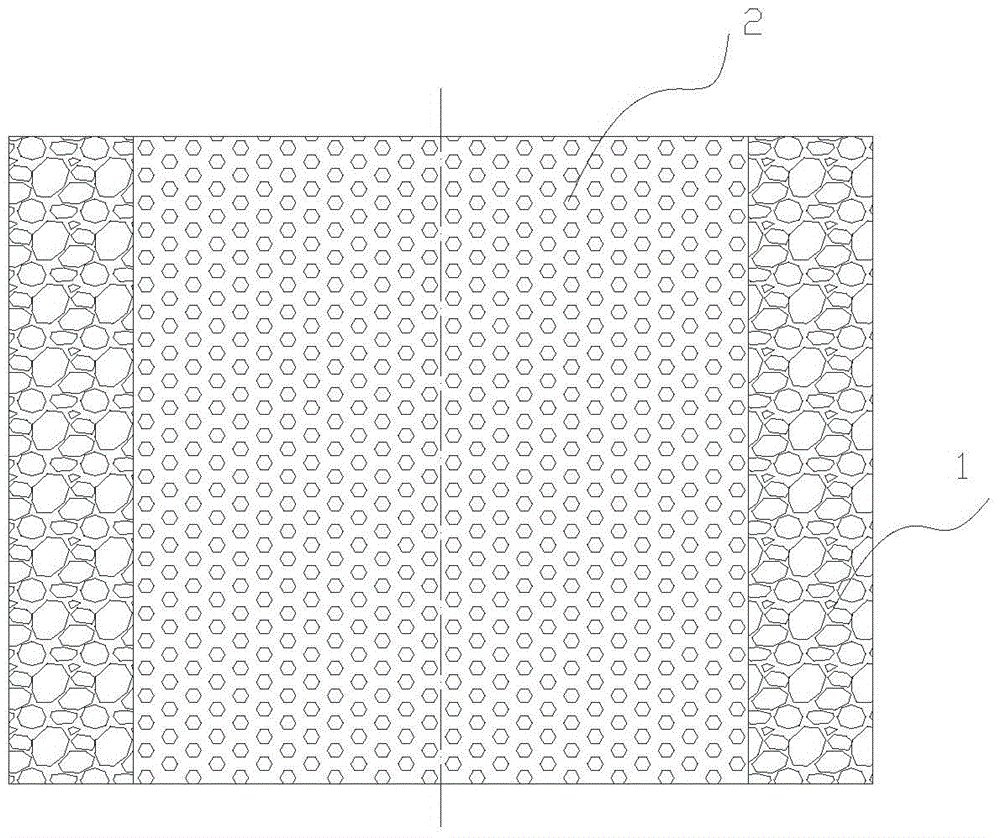

Double-layer baking-free permeable brick and manufacturing method thereof

InactiveCN101956357ASolve pollutionGuaranteed water permeabilitySolid waste managementSingle unit pavingsBrickAdhesive

The invention discloses a double-layer baking-free permeable brick and a manufacturing method thereof. The permeable brick consists of a face layer and a base layer, wherein the face layer mainly comprises 3 to 5 weight parts of mountain flour and 2.2 to 4.4 weight parts of adhesive; the base layer mainly comprises 2 to 4 weight parts of sand stone and 1.2 to 2.4 weight parts of adhesive; the sand stone are small stones made of natural sand and crushed scraps from stone processing; and the thickness ratio of the face layer to the base layer is 1:10-20. The manufacturing method comprises that: the face layer is prepared by mixing and stirring the mountain flour, cement, polymerizer, water and paint in a ratio, filling the mixture in a forming mold, and compacting by vibration; the base layer is prepared by mixing and stirring the sand stone, cement, polymerizer and water in a ratio, uniformly filling the prepared base layer material in the mold after the face layer material is solidified initially and compacting by vibration; and removing the mold after the face layer and the base layer are solidified, maintaining at normal temperature for 10 to 20 days, and obtaining the double-layer baking-free permeable brick.

Owner:建德市新世纪装饰材料有限公司

Method for producing concrete mixture by using machine-made sand to substitute natural sand

The invention relates to a production method of a concrete mixture, in particular to a method of producing concrete mixture by using machine-made sand instead of natural sand. The machine-made sand and gravel after being measured are fed into a stirrer to be stirred uniformly, then 70-80 percent of water of the total water is added into the mixture, which is stirred again so as to lead the mixture to become wet; measured cementing materials are put into the stirrer, and the residual water of the total water and concrete additive are added into the stirrer to be stirred uniformly. The concrete mixture prepared by the invention overcomes the defects existed in the concrete mixture which is prepared by employing machine-made sand instead of natural sand with the existing traditional technology, thus improving the property of the concrete mixture which is produced by adopting machine-made sand.

Owner:CHONGQING DAYE CONCRETE

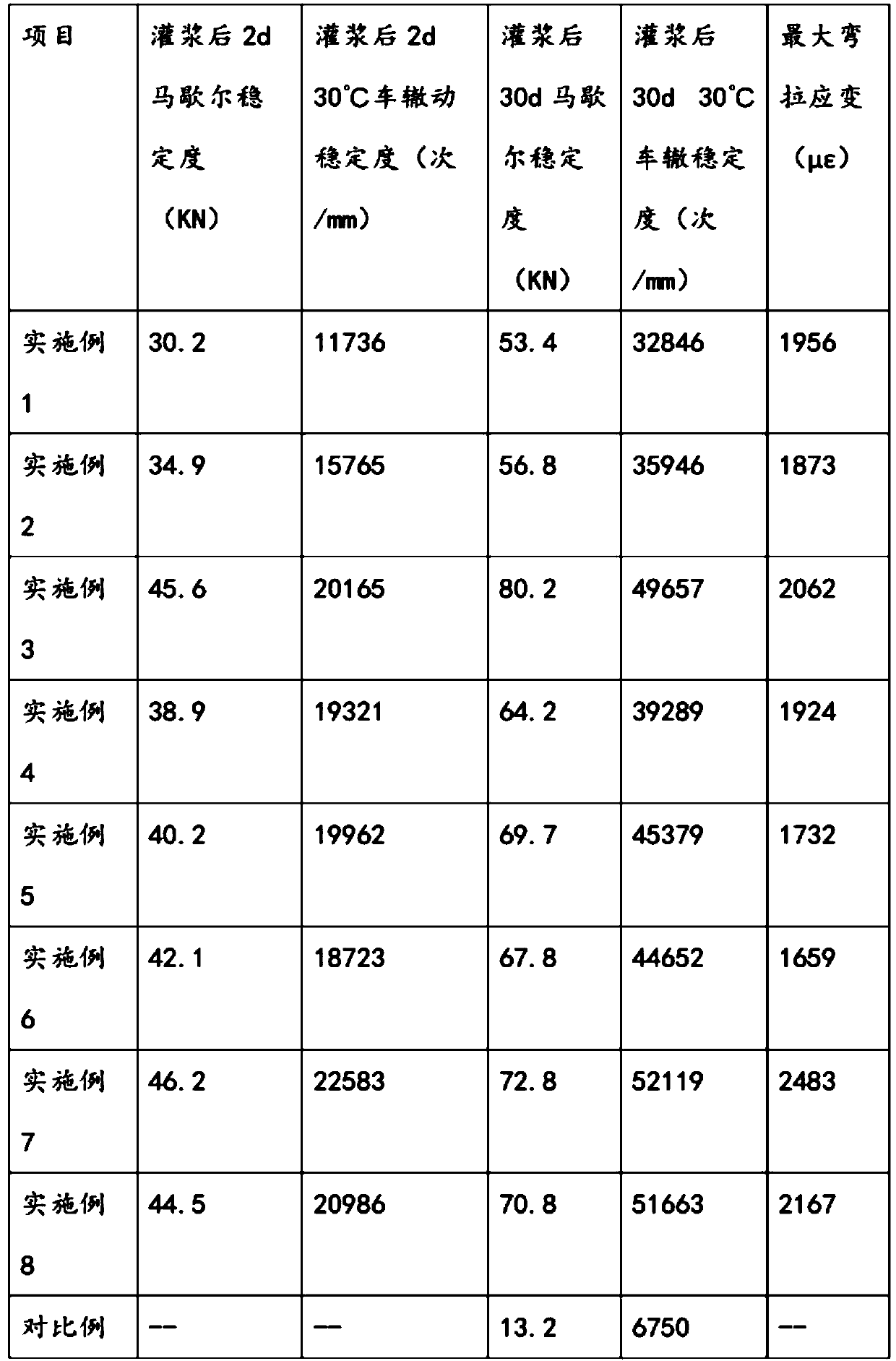

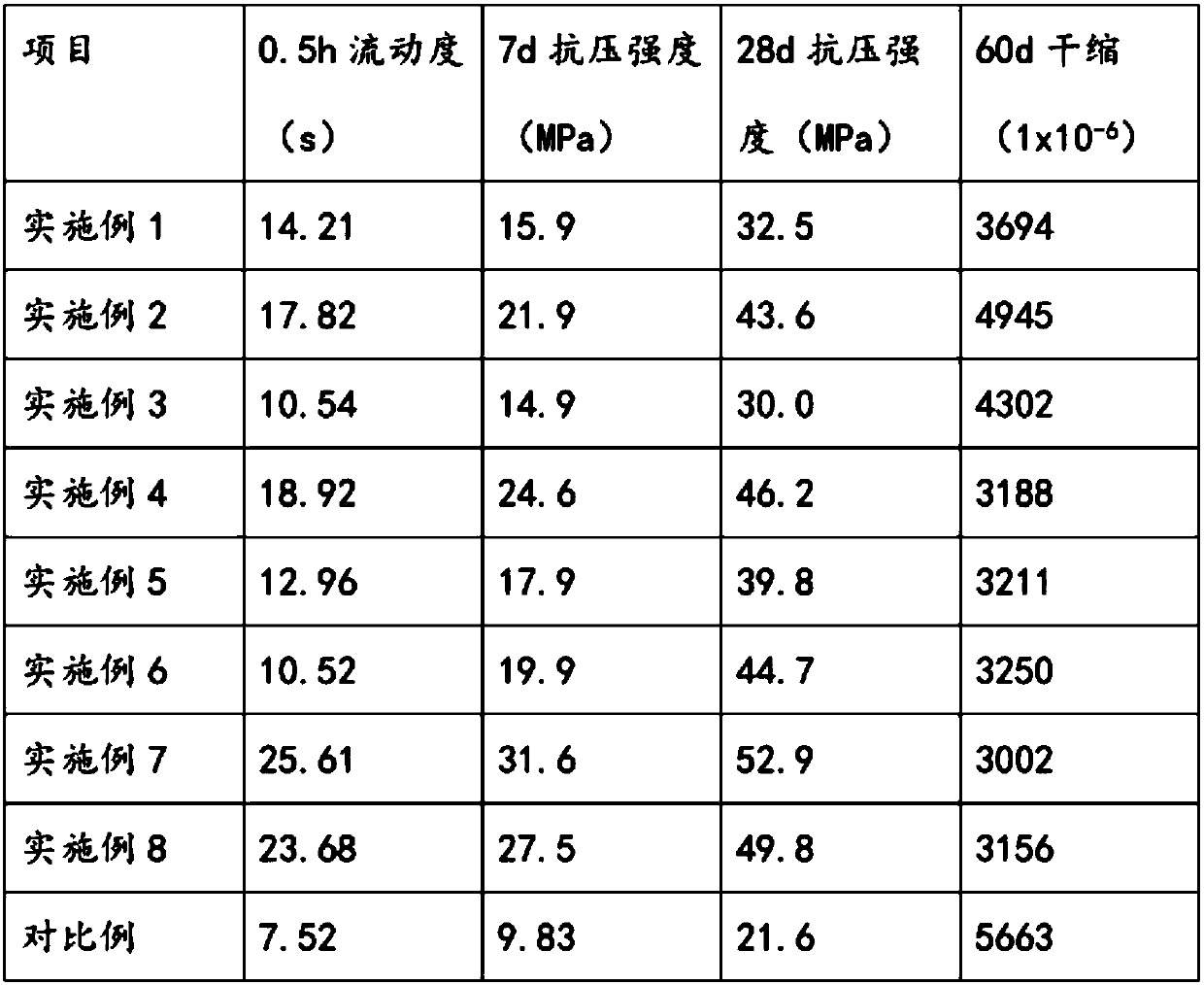

Semi-flexible pavement material and pavement construction method thereof

ActiveCN107915427AFlexibleExtended service lifeIn situ pavingsCeramicwarePolyvinyl alcoholRoad surface

The invention discloses a semi-flexible pavement material and a pavement construction method thereof. According to key points of the technical scheme, components of the semi-flexible pavement materialinclude an asphalt mixture serving as a large-pore matrix and cement slurry serving as a filler, wherein a weight percentage of the asphalt mixture is 70-80%; a weight percentage of the cement slurryis 20-30%; the asphalt mixture contains the following components in parts by weight: 1-2 parts of SBS modified asphalt, 4-5 parts of coarse aggregate, 0.5-0.8 part of fine aggregate, 0.2-0.3 part ofwater, 0.4-0.5 part of limestone dust and 0-0.005 part of a lithium salt composite early strength agent; the coarse aggregate is natural sand with a particle size of 13.2-16mm; the fine aggregate is natural sand with a particle size of 4.5-9mm; and the cement slurry contains the following components in parts by weight: 0.5-1.5 parts of Portland cement, 0.2-0.3 part of super-fine sand, 0.05-0.2 part of fly ash, 0.4-0.9 part of water, 0.05-0.09 part of a UEA expanding agent, 0.2-0.6 part of a water reducing agent, 0.01-0.05 part of polyvinyl alcohol and 0-0.5 part of BD emulsion. The aim of prolonging the service life of the semi-flexible pavement is achieved.

Owner:苏州三创路面工程有限公司

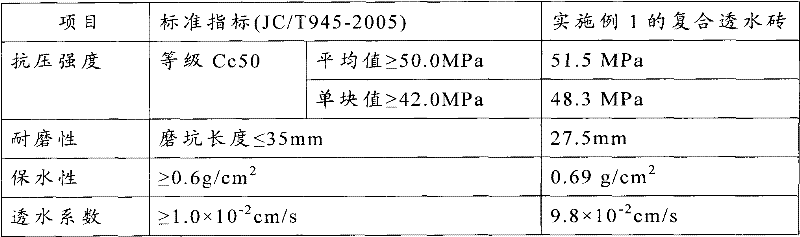

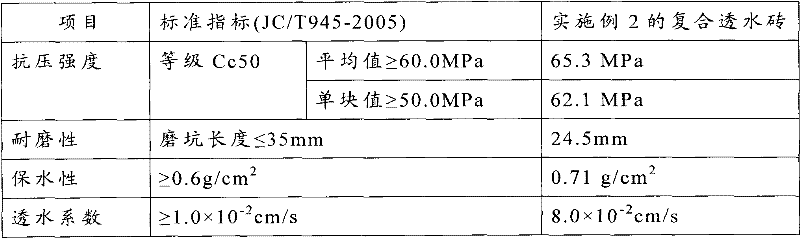

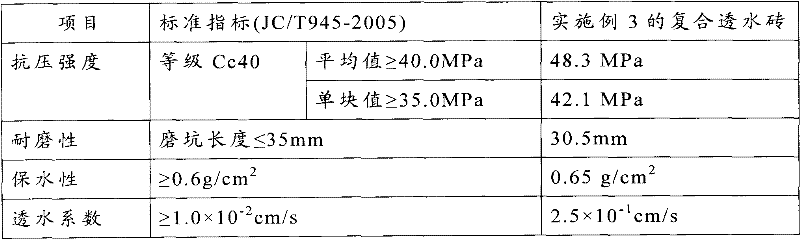

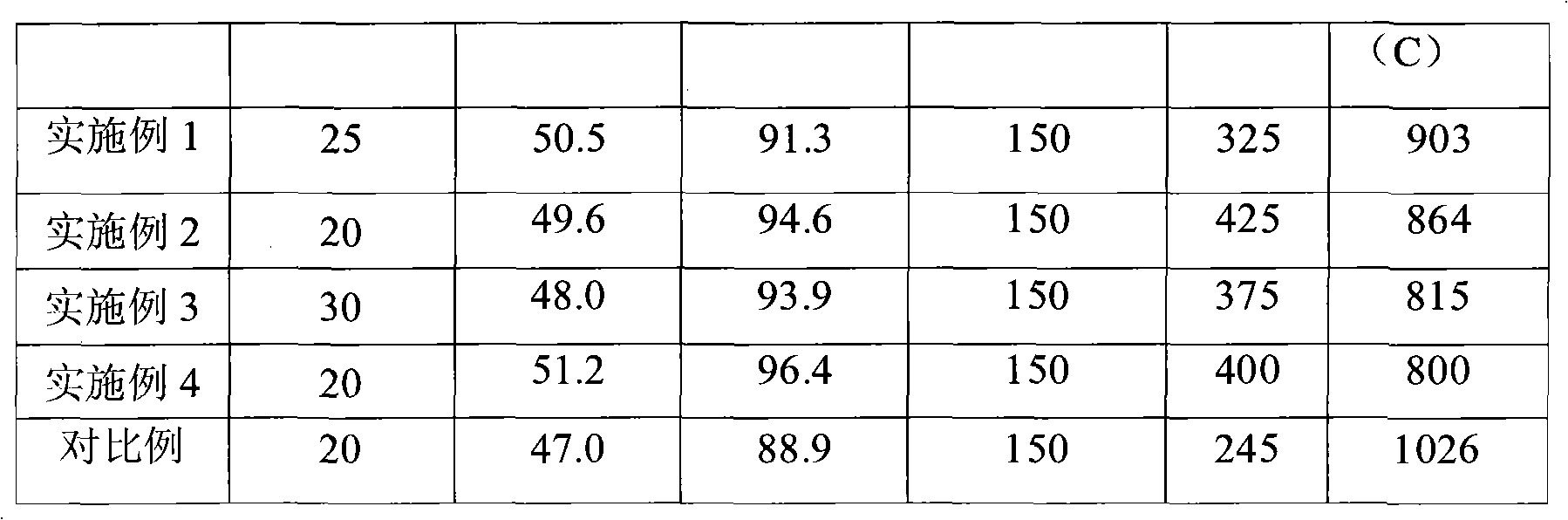

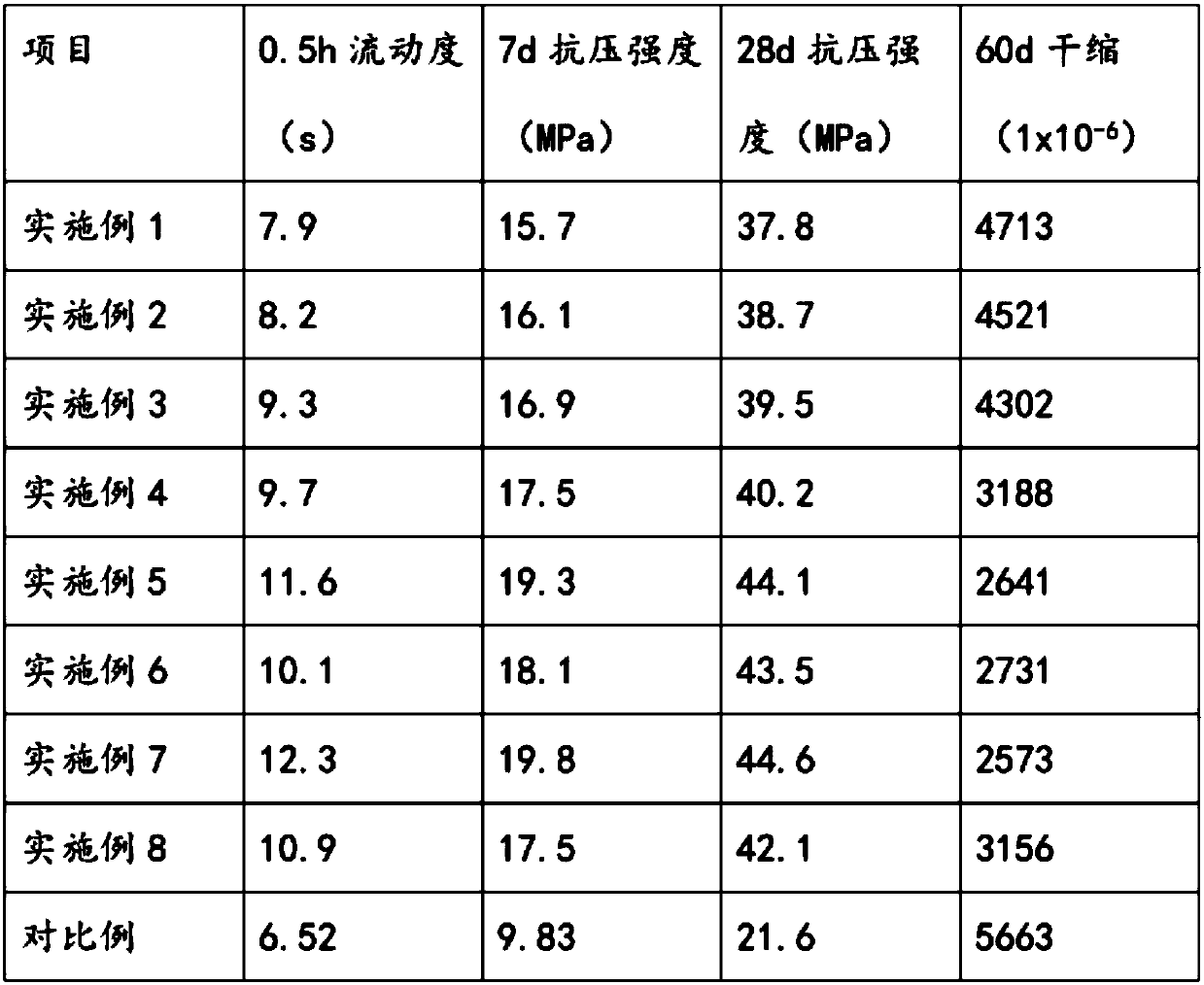

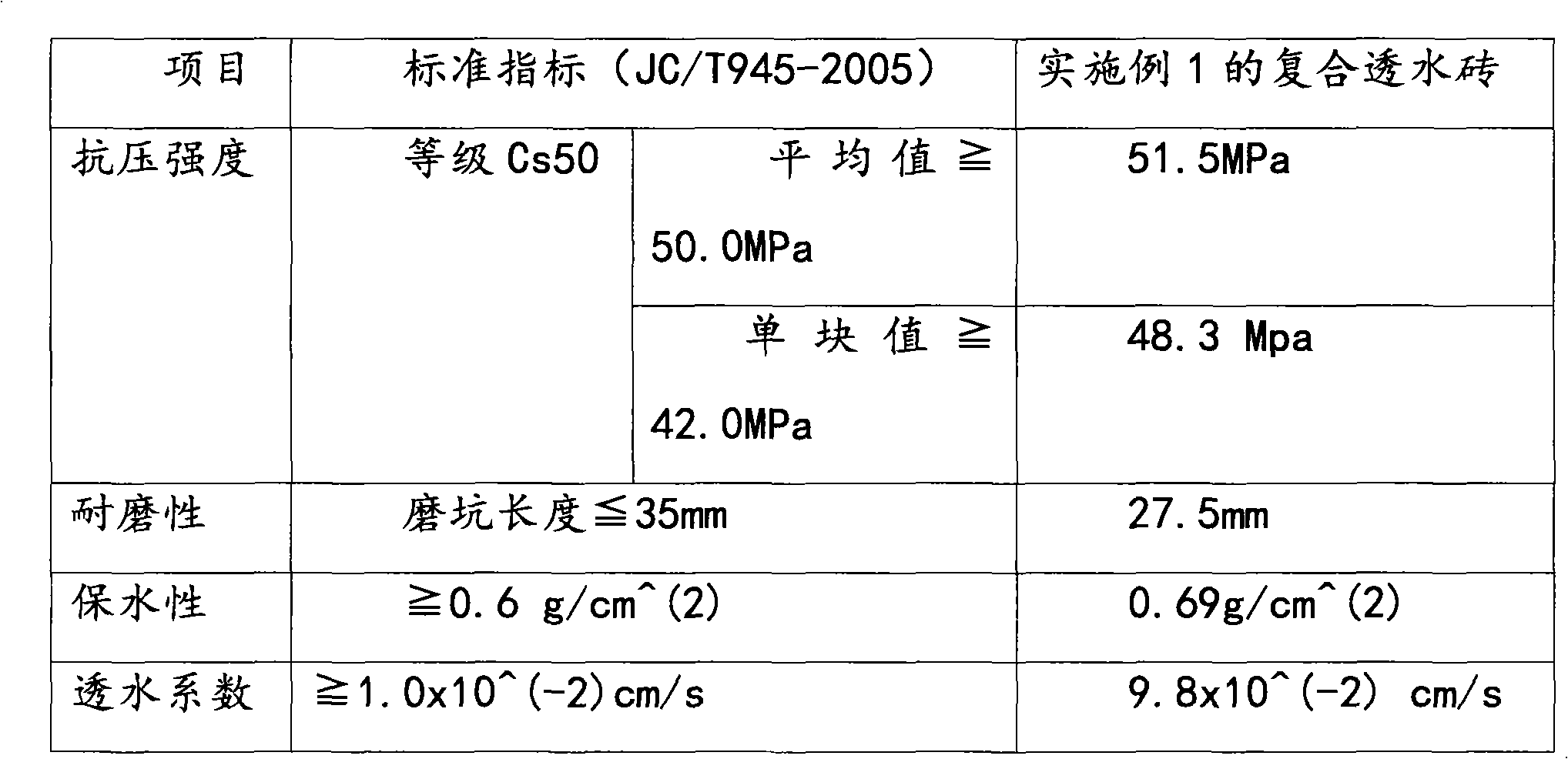

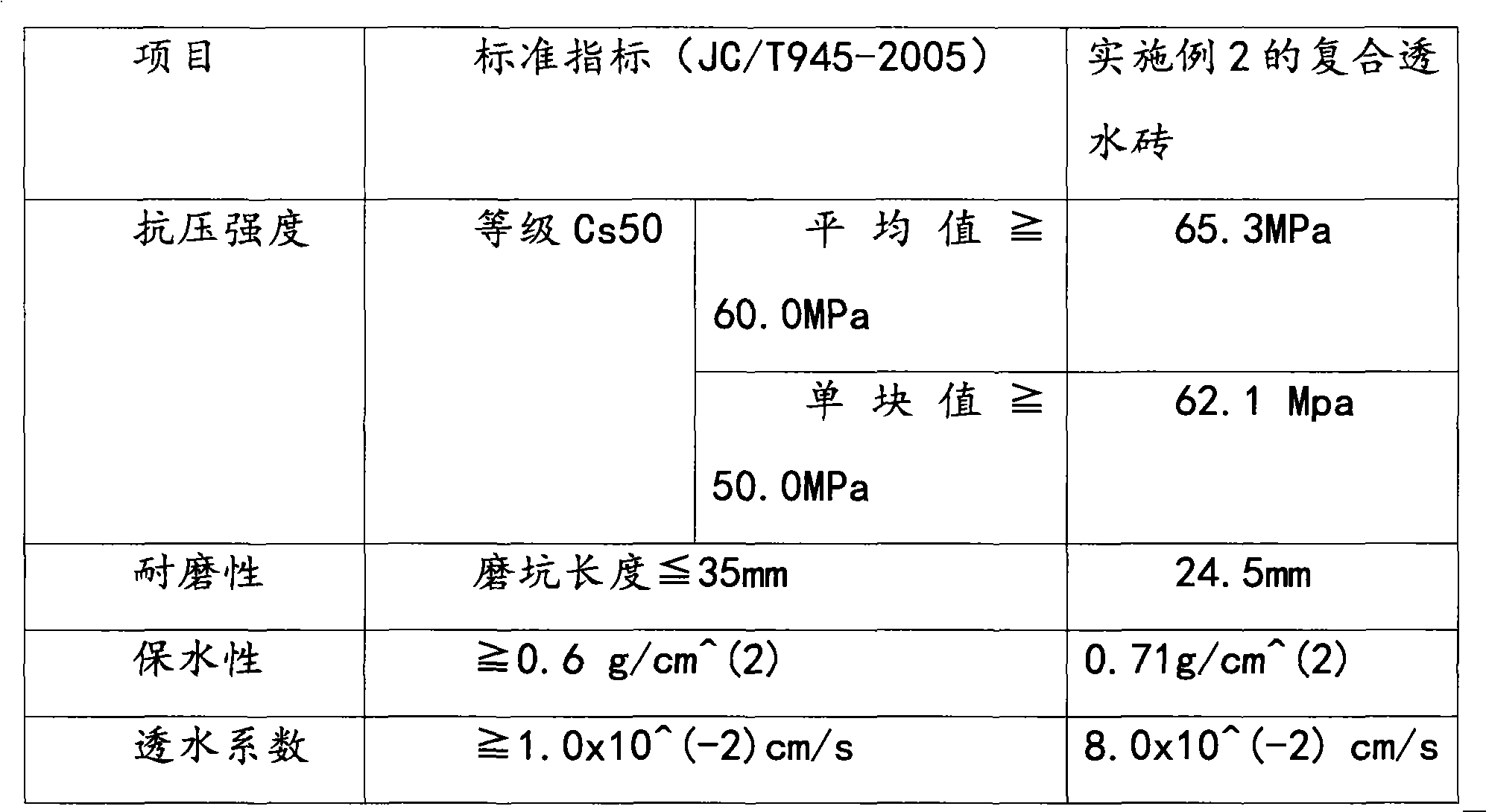

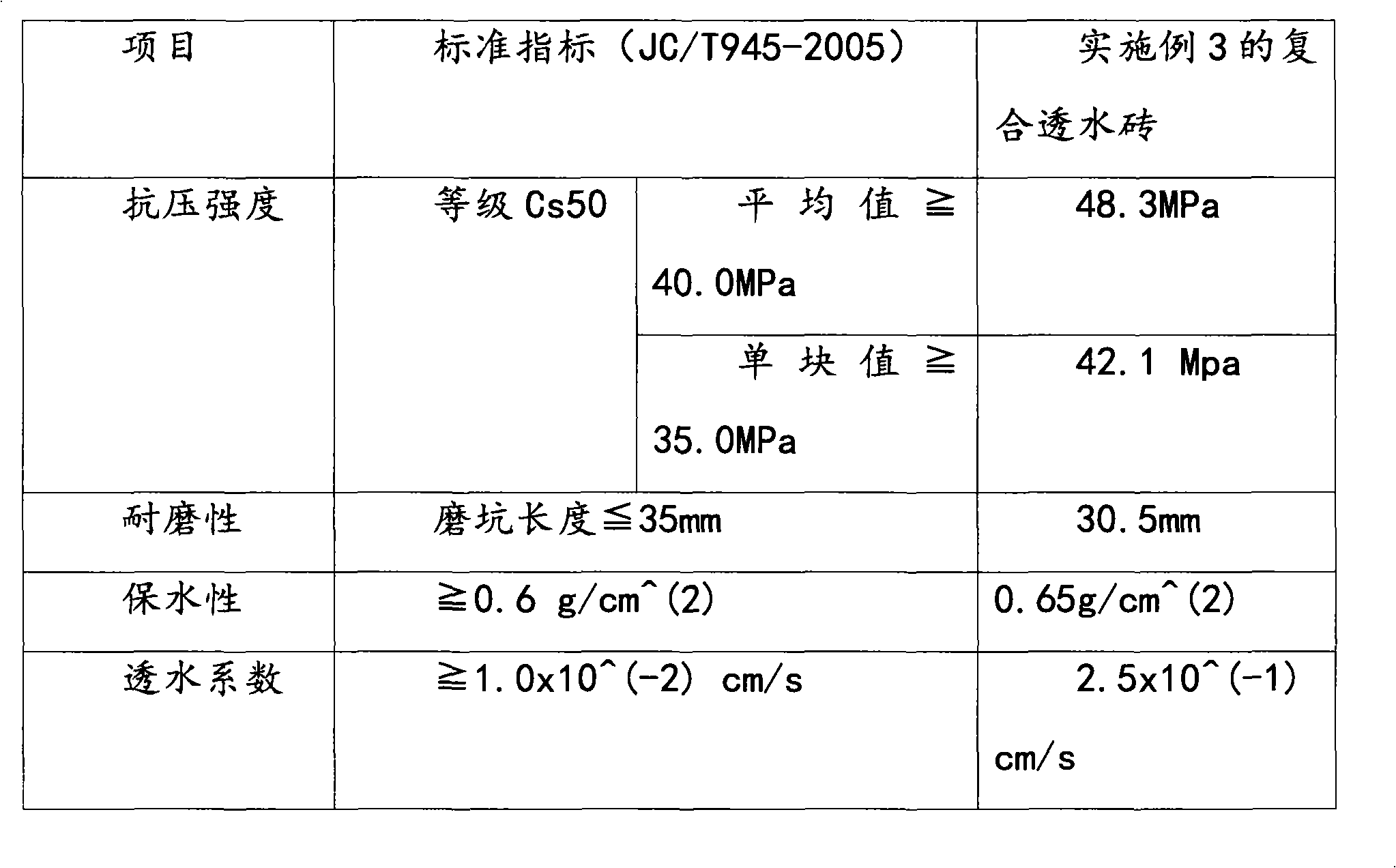

Pre-coated new sand, preparation method thereof and composite permeable brick

The invention provides pre-coated new sand, a preparation method thereof and a composite permeable brick. The pre-coated new sand comprises natural sand, pre-coated resin, a pre-coated curing agent, a coupling agent and a lubricating agent, wherein the pre-coated resin is weather-resistant alicyclic epoxy resin; the pre-coated curing agent is modified alicyclic amine. The composite permeable brick comprises a sandy surface layer and a concrete bottom layer, wherein the sandy surface layer contains pre-coated new sand and a fabric adhesive; the pre-coated new sand is the pre-coated new sand provided by the invention; the concrete bottom layer comprises a crushed stone aggregate, cement, coal ash, a water reducer and water. According to the pre-coated new sand provided by the invention, the composite permeable brick prepared by the pre-coated new sand has the characteristics of being high in strength and good in water permeability, and the composite permeable brick is simple in molding technology and low in cost.

Owner:李国辉

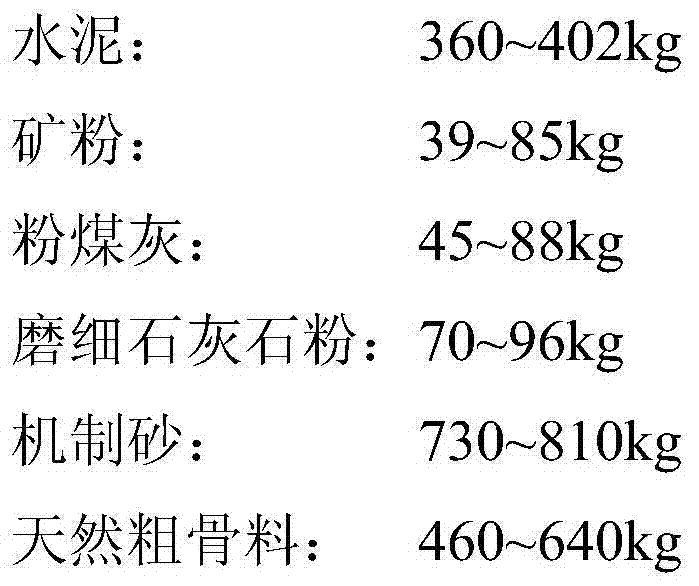

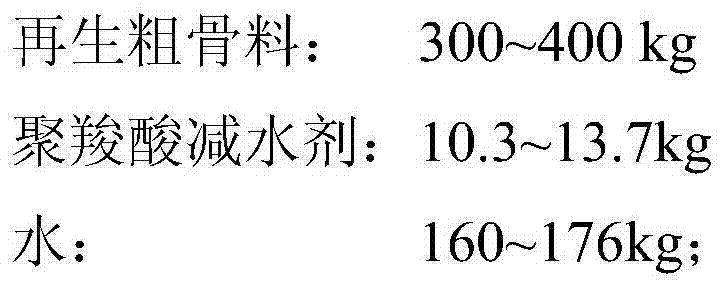

Ground limestone powder full-manufactured sand high-strength recycled self-compacting concrete and application thereof

ActiveCN104724989AHigh strengthImprove workabilitySolid waste managementSuperplasticizerUltimate tensile strength

The invention discloses ground limestone powder full-manufactured sand high-strength recycled self-compacting concrete and application thereof. Per cubic meter of concrete contains 360-402kg of cement, 39-85kg of mineral powder, 45-88kg of fly ash, 70-96kg of ground limestone powder, 730-810kg of manufactured sand, 460-640kg of natural coarse aggregate, 300-400kg of recycled coarse aggregate, 10.3-13.7kg of polycarboxylate superplasticizer and 160-176kg of water. According to the full-manufactured sand high-strength recycled aggregate self-compacting concrete prepared from three additives including the ground limestone powder, the fly ash and the mineral powder, the fine aggregate is totally manufactured sand, and 31-46% of recycled coarse aggregate is added to the coarse aggregate, so that an effective path is provided for reducing exploitation and utilization of natural sand and sufficiently recycling concrete wastes, and a technical reference is provided for preparing the ground limestone powder full-manufactured sand self-compacting concrete.

Owner:华润水泥技术研发(广西)有限公司

Surface pretreating method of dry method spray sand type neodymium iron boron permanent magnetic material

ActiveCN101373650AImprove bindingImprove adhesionInductances/transformers/magnets manufactureMagnetic materialsEthylenediamineCopper plating

The invention provides a surface preprocessing method of a dry-process sand-spraying type NbFeB permanent magnet material. The method comprises the following steps: chamfering, polishing, spraying sand, and chemical plating. Under the condition of room temperature, a natural sand blasting material is adopted to apply sand blasting on the surface of the NbFeB permanent magnet material; the pressure of a sand blasting machine is 0.16 to 8MP; the partial pressure of a spray gun is 0.16 to 6MP; and the sand blasting angle is 10 degree to 60 degree. A copper plating bath comprises copper sulfate of 0.03-0.5m / L, sulfite of 0.10-0.3m / L, fluoride of 0.05-0.7m / L and one or more components selected from EDTA, sodium citrate, potassium sodium tartrate and quadrol. The pH of 6.5-8.0 is achieved through adjustment, and the copper plating temperature is 10-65DEG C. The invention improves the binding force of a plating layer and a substrate, changes the roughness of the plating layer and improves the cohesive force of the plating layer.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

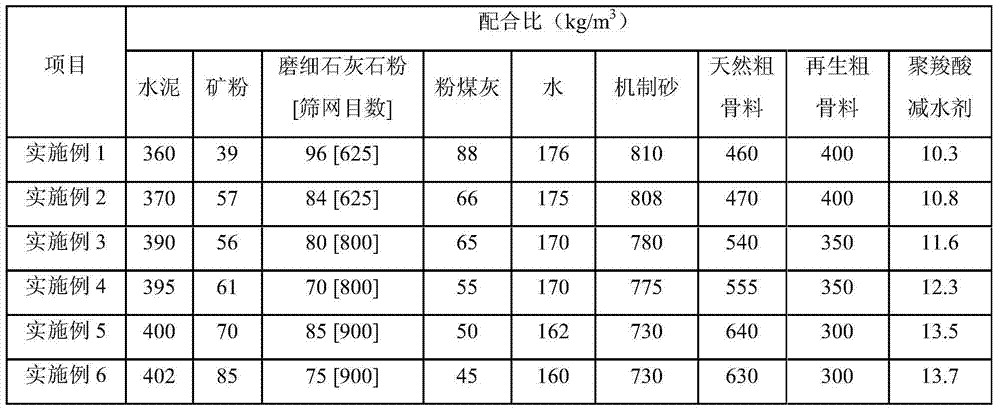

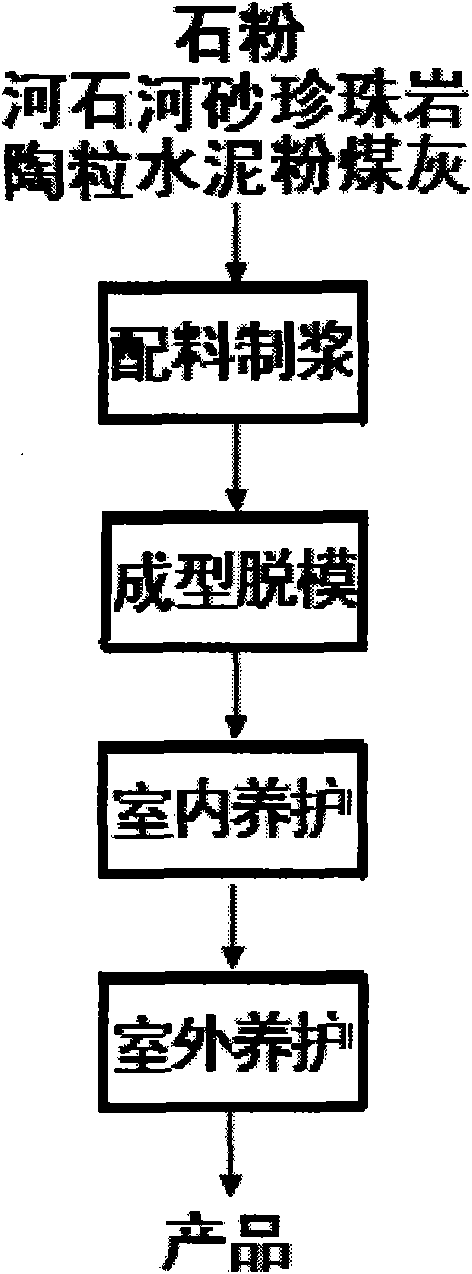

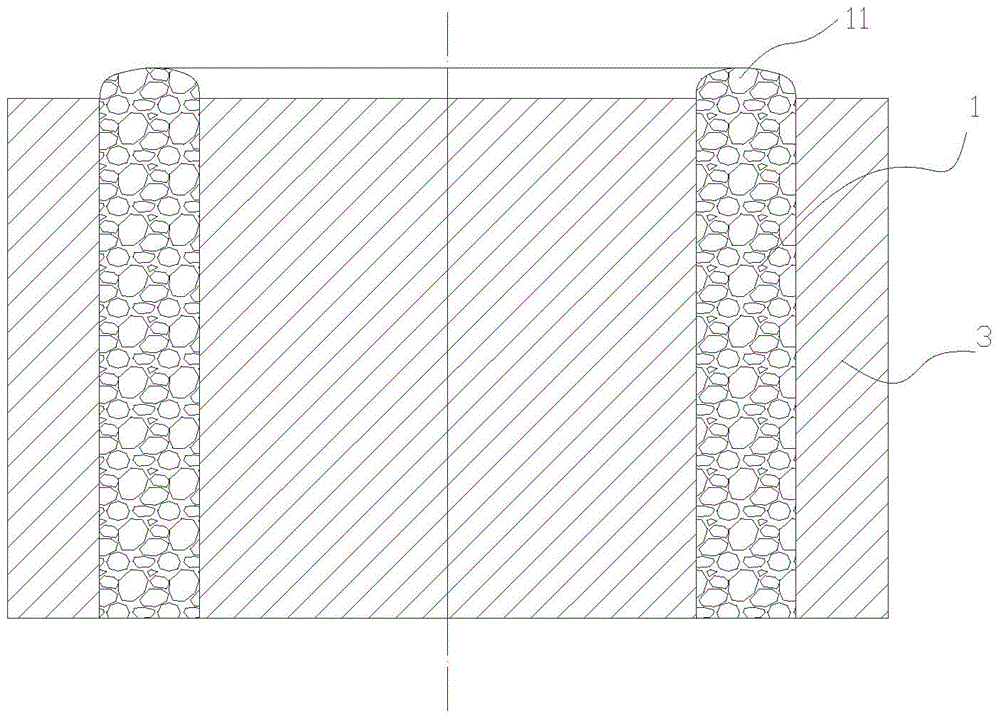

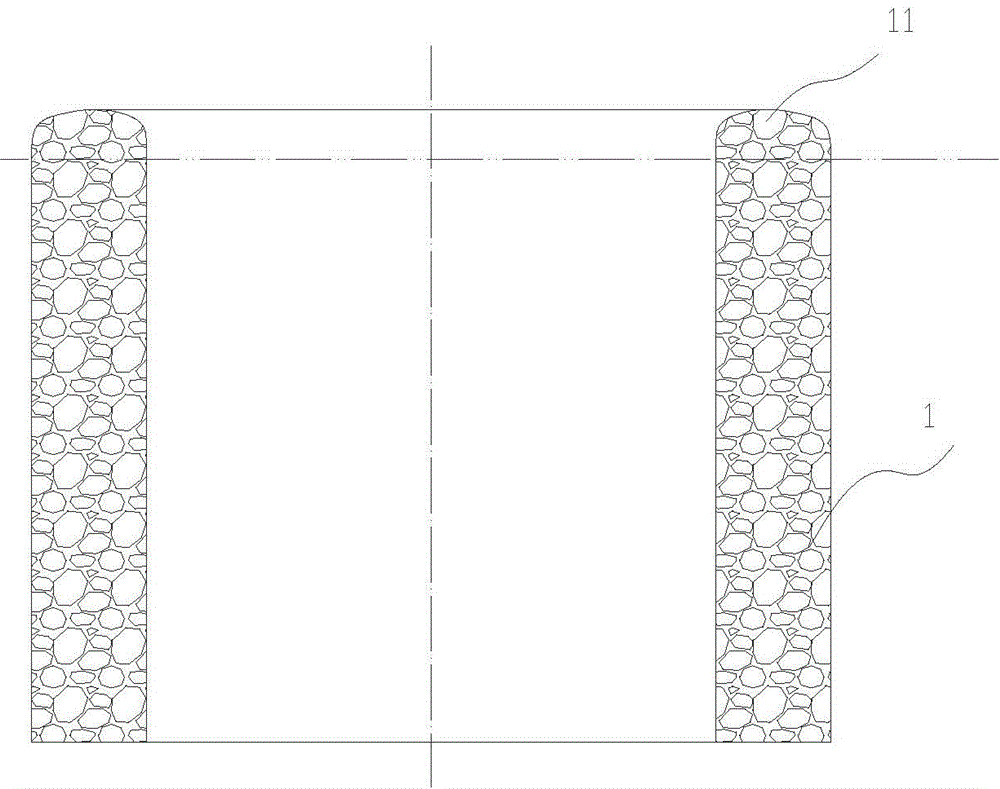

Baking-free hollow thermal insulation blocks and preparation method thereof

The invention discloses baking-free hollow thermal insulation blocks and a preparation method thereof. The baking-free hollow thermal insulation blocks are characterized by being prepared from the following raw materials in part by weight: 100 to 115 parts of waste ceramsite, 110 to 130 parts of cement, 90 to 100 parts of flyash, 23 to 27 parts of pearlstone, 190 to 210 parts of mountain flour, 170 to 190 parts of rive stone, 170 to 190 parts of river sand and 39 to 41 parts of water. Waste ceramic is adopted to be prepared into the waste ceramsite to replace partial natural sandstone, and the flyash replaces partial natural sand and cement, so that the damage to natural resources is reduced. The pearlstone is adopted to serve as fine aggregate of concrete to regulate the porosity of mortar and improve construction workability. The product has good mechanical properties and durability, also has good thermal insulation property, improves the thermal insulation capacity of buildings, and is suitable for various thermal insulation projects. The use and construction of the baking-free hollow thermal insulation blocks are same as that of a common block construction method. The technical scheme has the advantages that: the process is easy to operate, the raw materials are readily available and cheap, the production cost is lower, and the economic and social benefits are better.

Owner:HUALAN DESIGN GRP CO LTD

Processing method for building waste foamed concrete composite heat preservation building blocks

InactiveCN104153512AImprove surface structureHigh bonding strengthConstruction materialSolid waste managementFoam concreteMixed materials

The invention discloses a processing method for building waste foamed concrete composite heat preservation building blocks. The invention provides a processing method for the building waste foamed concrete composite heat preservation building blocks. By virtue of the processing method, the performance of a recycled material can be optimized to the maximum extent, so that the compression strength, the shear strength and the heat preservation performance of a finished product can be guaranteed. Each building block comprises a base body and a heat preservation core body. A building block preparation process comprises base body forming, core body preparation, maintaining and drying working procedures; each base body comprises cement, an active mixed material, a modifier and a recycled aggregate. A processing method for the recycled aggregate comprises the steps of (1) classifying and initially sorting building waste; (2) roughly crushing building waste to prepare granular recycled coarse aggregates of which the dimension is smaller than 10mm; (3) performing mechanical enhancement on the recycled coarse aggregates, adding natural sand into the recycled coarse aggregates according to a weight ratio of 1:(0.2 to 1), and taking fine sand, which has the particle size of 0.25-0.5 mm, in the mechanically enhanced aggregates for later use. According to the method, the building blocks are high in bonding strength and uniform, the water absorption property of a single unit is reduced, the production cost is lowered, and the production technology is simple and feasible.

Owner:CHINA BUILDING MATERIALS ACAD

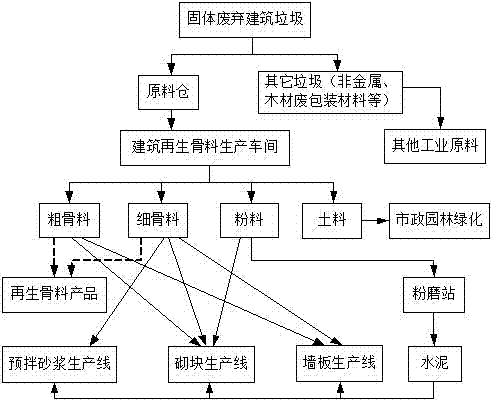

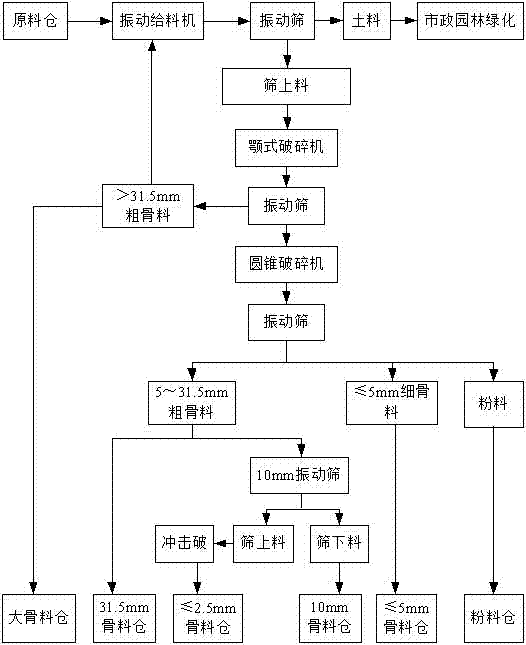

Construction waste recycling technology

InactiveCN104261715AImprove land occupationAvoid pollutionConstruction waste recoveryWaste processingMixed materialsRenewable resource

The invention discloses a construction waste recycling technology. The technology comprises an aggregate production technology, a premixed mortar production technology, a building block production technology, and a wallboard production technology. The construction wastes are graded, grinded, and sieved to produce aggregate that can replace the natural sand and stones. Part of the aggregate can be used to produce premixed mortar, cement mixed material, and concrete products. The residual aggregate is packed as commercial aggregate for sale, and can be used in concrete mixing plants, premixed mortar plants, and road structural foundation backfilling. The produced powder can be used to product concrete products, and the produced soil can be directly used as greening soil. The construction wastes are graded, removed, or grinded, and then subjected to a series of technological procedures, so that the wastes are converted into renewable resources and reutilized, and the economic profit is prominent. The sprayed dusts and sands which cause severe environmental pollution during the transportation and storage process are avoided. Solved is the problem that plants cannot grow on the soil that is used to bury construction wastes.

Owner:GUANGDONG XINGU TECH

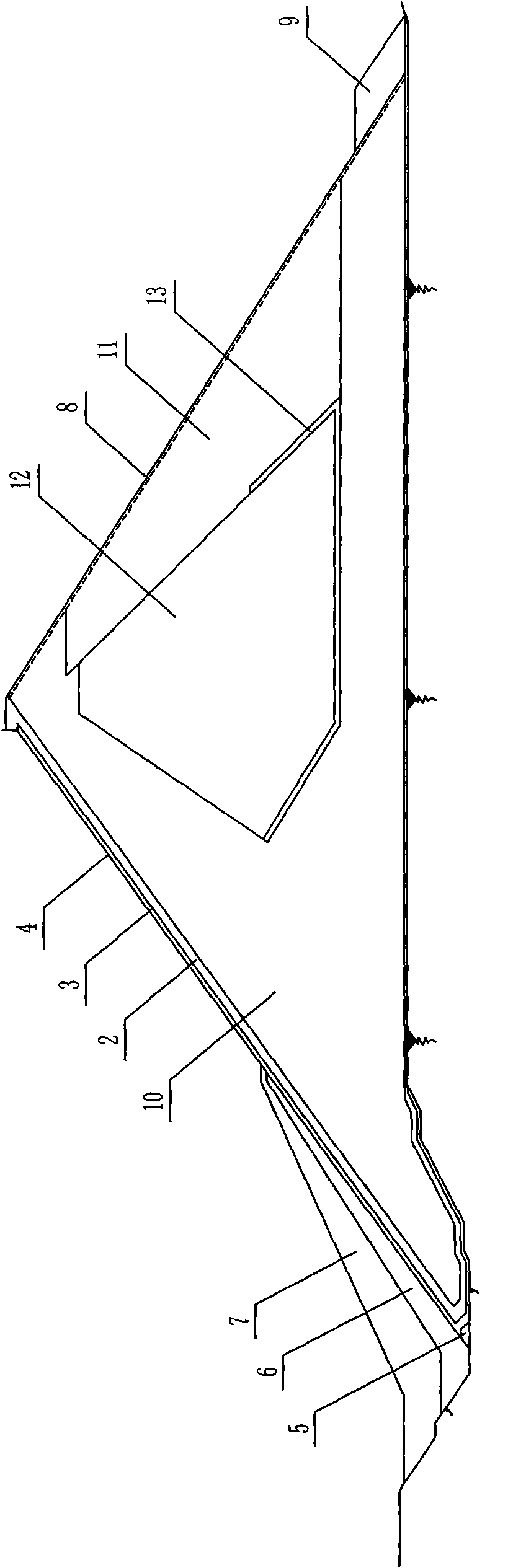

Face plate rock-fill dam structure of reasonably utilizing sand gravel material and construction method thereof

InactiveCN101672026AReduce settlementReduce the volume of fillingEarth-fill damsRock-fill damsFilling materialsEngineering

The invention relates to a face plate rock-fill dam structure of reasonably utilizing sand gravel material and a construction method thereof. The invention aims at providing a face plate rock-fill damstructure of reasonably utilizing sand gravel material and a construction method thereof; a sand gravel material near a dam site is put in a drying area of the middle part of a dam body so as to avoid additionally open up a rock-fill material field and protect the biological environment. The face plate rock-fill dam structure of reasonably utilizing sand gravel material is provided with a dam main body; the upstream side of the dam main body is sequentially laid with a transition layer, a cushion layer and a face plate from inside to outside; a special cushion layer is arranged below the cushion layer; a dam base of the upstream side of the main body is provided with a rock ballast backfill area and a silt backfill area, the downstream side of the main body is provided with a dry stone pitching, and a downstream dam base is provided with an oversize stone pressing stone area; and the main body comprises a main rock-fill area and a secondary rock-fill area, a sand gravel area positioned above a seepage line is arranged in a hollow cavity surrounded by both the main rock-fill area and the secondary rock-fill area, and the bottom part of the sand gravel area and the low altitude position of a downstream surface are provided with inverted filter protection layers. The invention is used in face plate dam engineering of the natural sand gravel material near the dam site.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

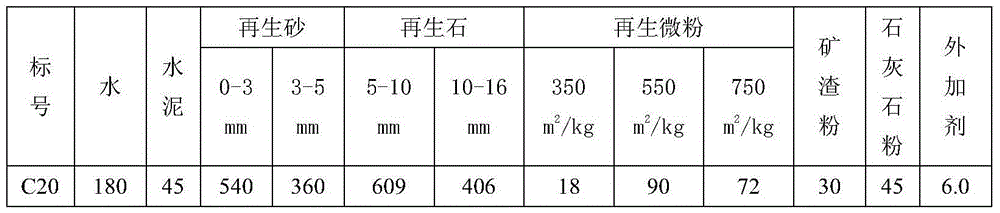

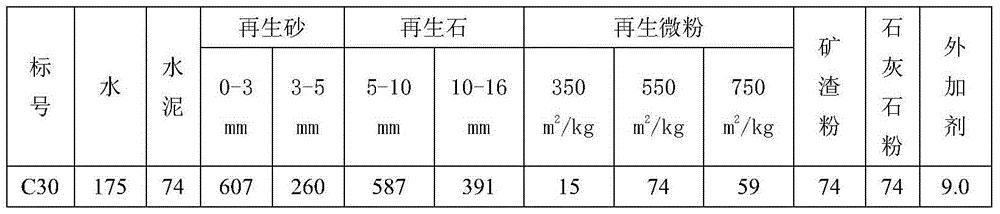

Recycled green concrete with low cement content and preparation method thereof

ActiveCN103553395AOvercoming small dosageOvercoming the drawbacks of high cement contentSolid waste managementSlagNatural sand

The invention relates to recycled green concrete with low cement content. The recycled green concrete is the concrete prepared through reclaimed sand and recycled stone instead of natural sand and stone, and recycled micro powder, slag and limestone powder instead of most of the cement, wherein the reclaimed sand and recycled stone are obtained by treating construction wastes taking waste concrete as major by cleaning, crushing, grading and mixing in a certain proportion.

Owner:北京联绿技术集团有限公司

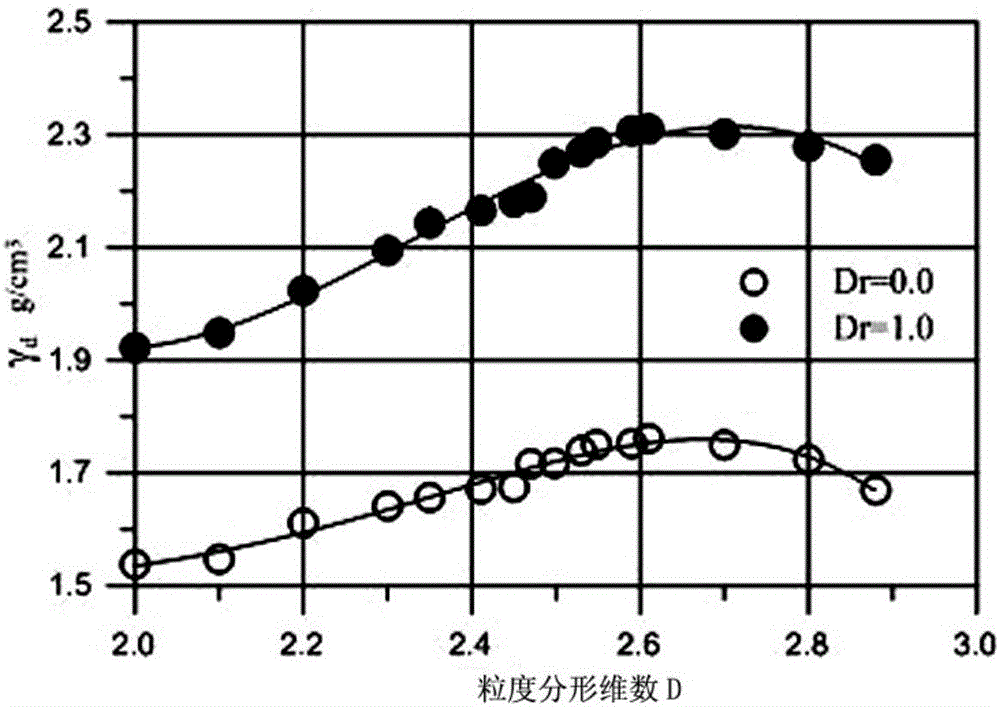

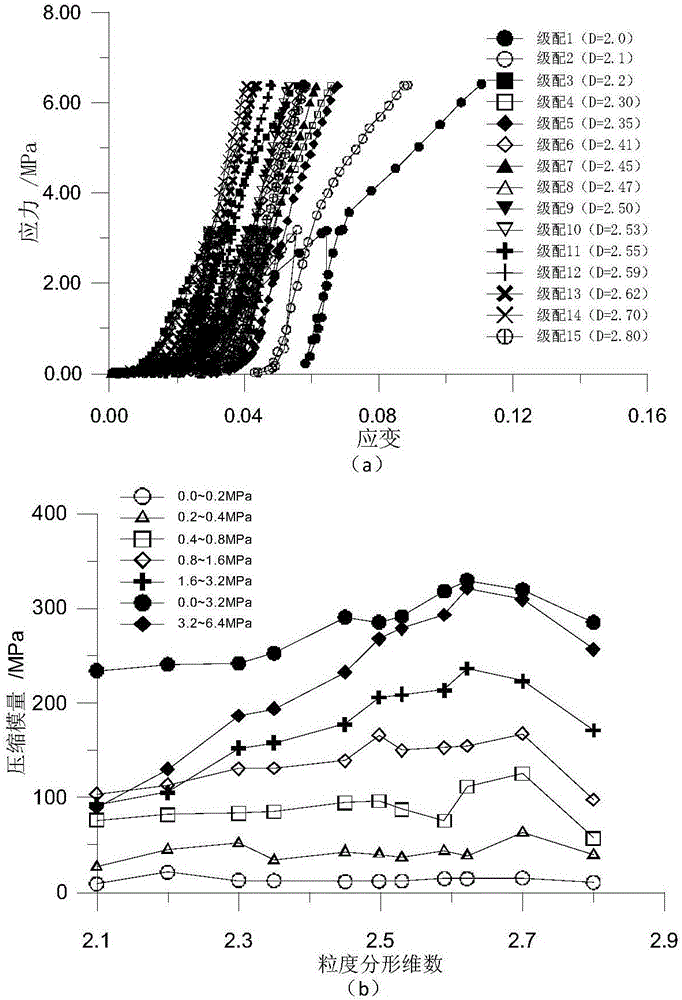

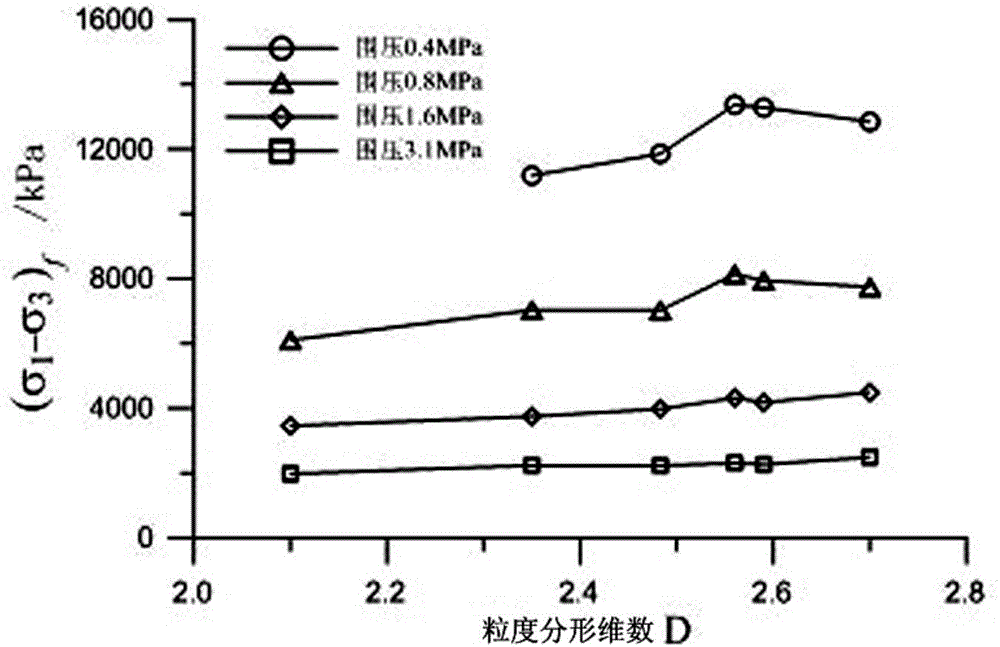

Earth and stone material grading optimization method based on fractal theory and physical mechanics test

The invention provides an earth and stone material grading optimization determining method which comprises the following steps of: changing granularity fractal dimension of earth and stone materials for the earth and stone materials with particle distribution meeting fractal distribution characteristics; preparing a grading earth and stone material sample with different particle size distribution functions; establishing a function relationship of extreme value dry density, modulus of compression, shearing strength and grading granularity fractal dimension through a field or indoor test; and regulating the granularity fractal dimension to obtain earth and stone material grading with a better filling relationship, easier compactness, higher modulus and strength. The earth and stone material grading optimization determining method can be used for a particle grading optimization design of rockfill materials and natural sand gravel materials.

Owner:HOHAI UNIV

Non-steamed reactive powder concrete

InactiveCN101781107ALow costReduce molding maintenance costsSolid waste managementFiberReinforced concrete

The invention belongs to concrete materials and in particular relates to reactive powder concrete which can be maintained at room temperature. The non-steamed reactive powder concrete of the invention is prepared by mixing cement, superfine steel slag powder, natural sand, steel fiber, water reducing agent and water in a mass ratio of 1: 0.10-0.25: 1.25-1.45: 0-0.25: 0.01-0.04: 0.15-0.28. In the invention, natural sand replaces quartz sand, the 200-grade reactive powder concrete is prepared by maintenance at room temperature, so raw material cost and concrete maintenance cost can be obviously reduced; a great amount of industrial residues are used, so the non-steamed reactive powder concrete has the advantages of low cost, sources conservation, waste recycling, environment protection and the like. The maintenance process of the non-steamed reactive powder concrete needs no high temperature or high pressure, so the production and construction processes are simplified. The non-steamed reactive powder concrete is applicable to production of thin-wall products or elongated members and can be used for producing reinforced concrete members such as plates, blocks and the other structure forms, so the market application prospect is promising.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Autoclaved aerated concrete plate produced by using Yellow River sand, and production method thereof

ActiveCN103693928AMeet the requirements of new building materialsProtect the ecologyConstruction materialCeramicwareRebarBiology

The present invention relates to an autoclaved aerated concrete plate produced by using Yellow River sand. The base material components of the concrete plate billet comprise 2450-3500 kg of Yellow River sand, 480-700 kg of cement, 420-620 kg of quick lime, 30-120 kg of slaked lime, 42-50 kg of desulfurized gypsum, 37-50 kg of magnesite, 4.0-4.5 kg of aluminum powder paste, and 0.05-0.1 kg of a foam stabilizer. According to the present invention, the Yellow River sand is adopted to replace the ordinary natural sand so as to be adopted as the siliceous material, and the prepared ALC plate has characteristics of high compressive strength, high stiffness, low deflection value, high bonding strength between the billet and the steel bar, good flatness, substantially-improved construction efficiency, project cost reduction, and broad market prospects.

Owner:HENAN XIAN NEW BUILDING MATERIALS

Recycled high-performance concrete and preparation method thereof

InactiveCN104446175AConvenience to workIncreased durabilitySolid waste managementRoad engineeringToughening

The invention relates to recycled high-performance concrete and a preparation method thereof. The recycled high-performance concrete is prepared from recycled coarse aggregates, made from crushed construction waste, as a raw main raw material, and added with natural sand, cement, coal ash, aluminum dross, an admixture, graphene and water in a stirring manner. According to the preparation method, a micropore of a cement-based composite material is filled with a nanometer material, namely graphene, so that the effects of reinforcing, toughening, and reducing the shrinkage are achieved. The aluminum dross produced in the electrolytic aluminum production process is adopted as the admixture; and aluminite powder in the aluminum dross expands in water, so as to play a shrinkage-compensating role. The concrete is small in shrinkage besides good working performance, durability and relatively high strength, and can be widely applied to road engineering, structure engineering and the like.

Owner:NANCHANG UNIV

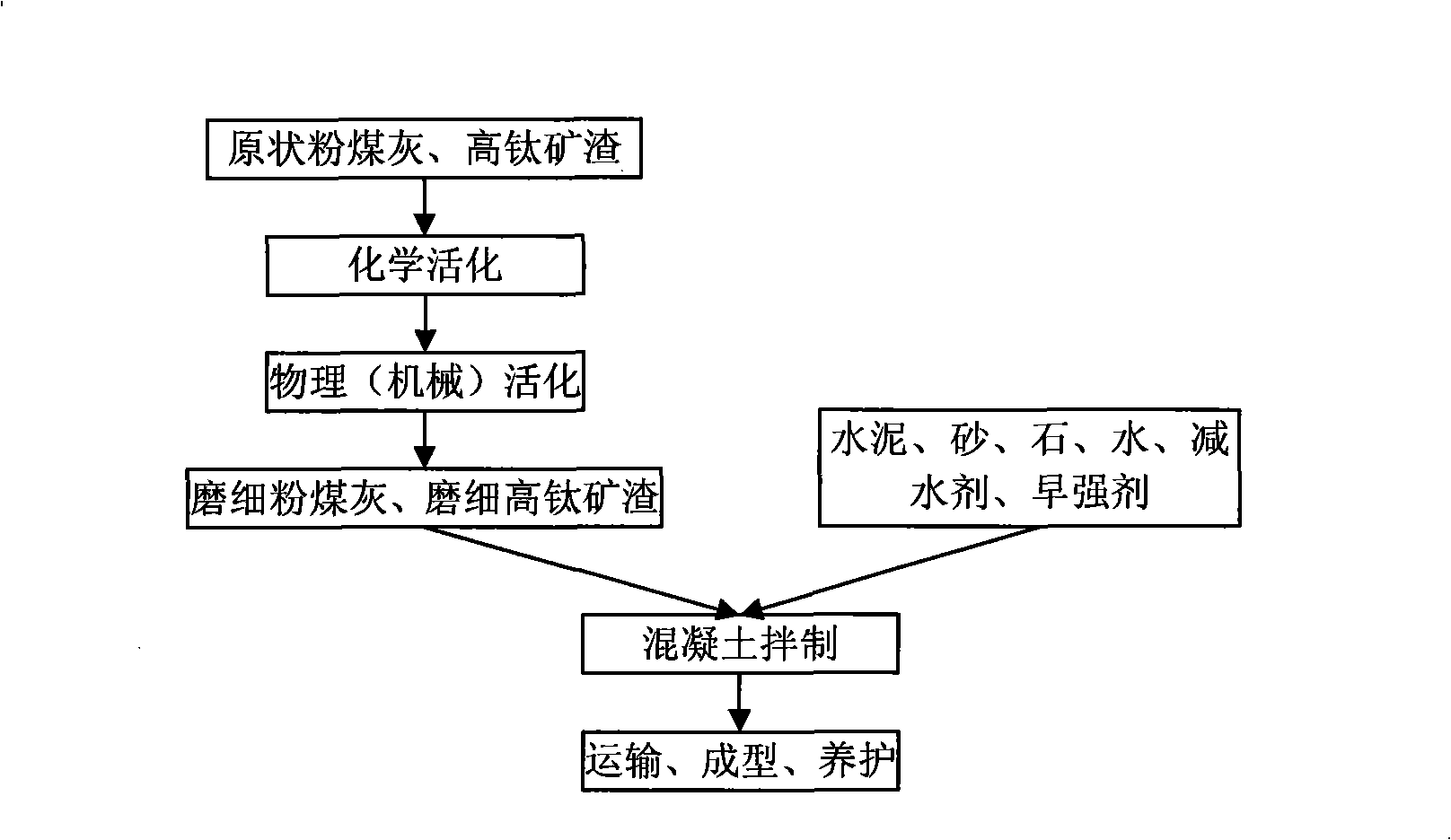

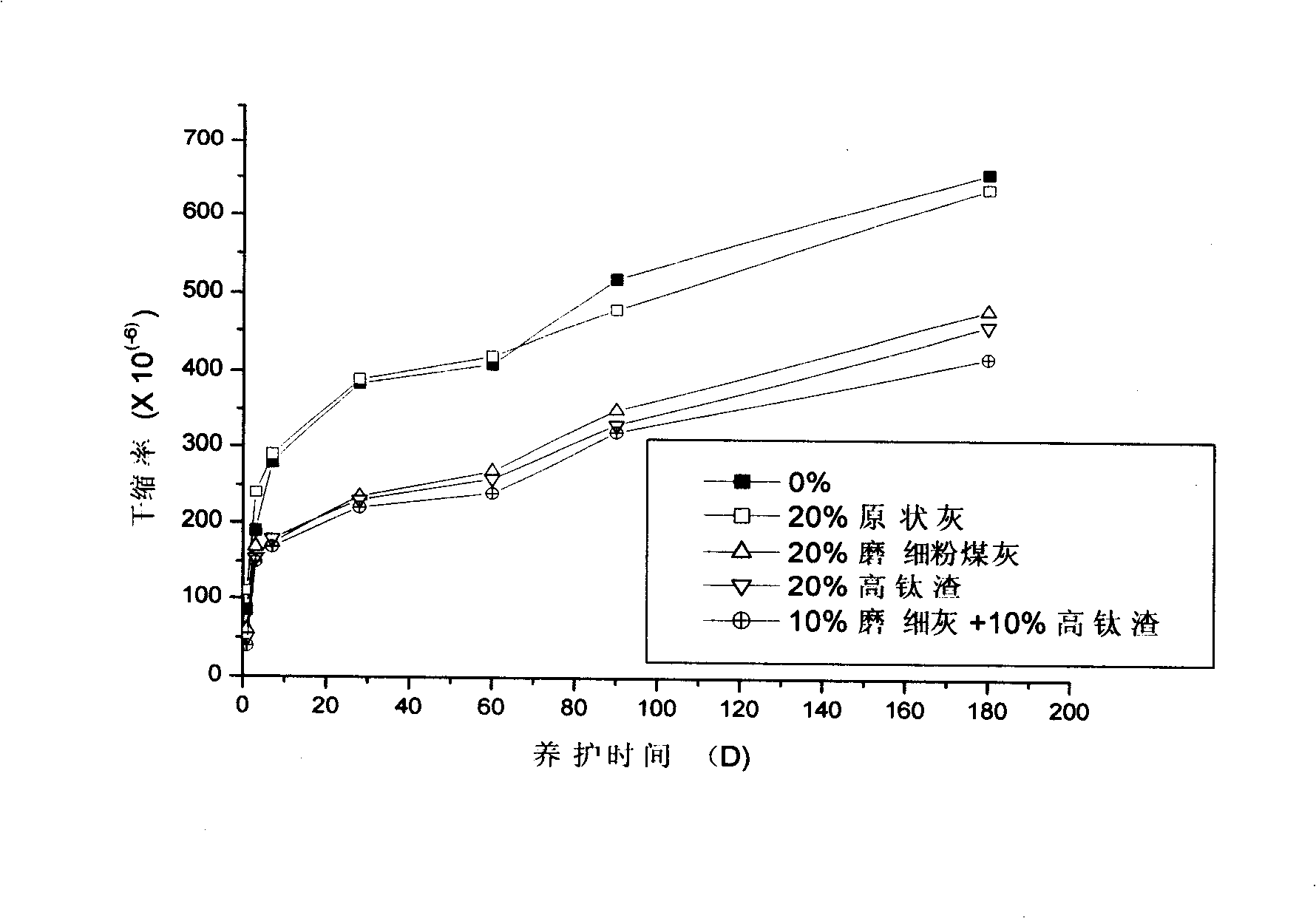

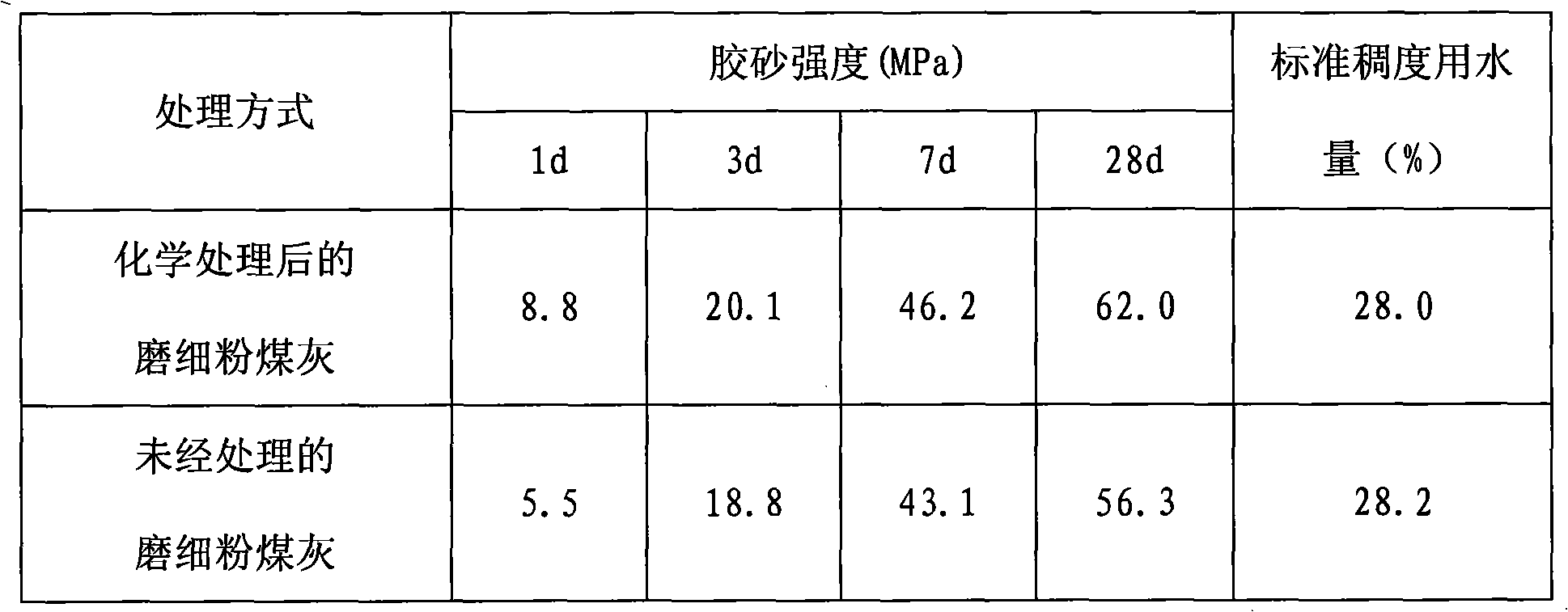

Finely ground high-titanium slag and fly ash composite high-performance concrete

InactiveCN101514088AIncrease profitEasy constructionSolid waste managementSuperplasticizerBiological activation

The invention discloses concrete, which is prepared by mixing cement, sand, stone and water which are mixed in common concrete, as well as finely ground high-titanium slag, fly ash, high-efficiency water reducing agent and hardening accelerator. The prepared concrete has high workability, durability, volume stability and excellent physical and mechanical performance. The concrete is activated by using mechanical (physical) activation and chemical activation and is used as excellent active additive to replace 10 to 25 percent of cement equally, so the workability and durability of the concrete are improved obviously without influencing the later strength of the concrete. The concrete has the advantages of improving the comprehensive utilization rate of high-titanium slag and fly ash, providing a high-performance concrete convenient in construction and high in quality, reducing construction cost and exploitation of natural sand and stone, and protecting environment.

Owner:陈加耘 +2

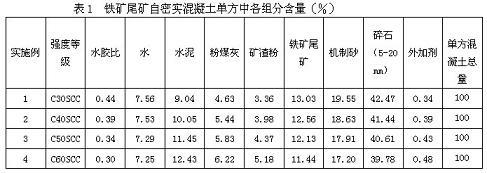

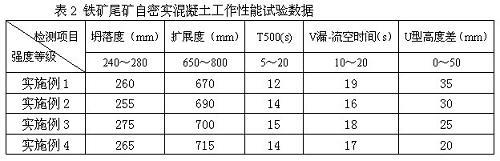

Self-compacting concrete prepared from iron ore tailings, and preparation method thereof

The present invention discloses a self-compacting concrete prepared from iron ore tailings, and a preparation method thereof. The self-compacting concrete is prepared through adding 38.00-46.00% of a coarse aggregate, 23.00-37.00% of a fine aggregate, cement, 15-24% of a cementing material and 0.30-0.48% of an additive to water. The coarse aggregate is prepared through mixing crushed stones with particle sizes of 5-20 mm. The fine aggregate is the mixed sands prepared from iron ore tailings and machine-made sands or natural sands, wherein the mixed sands meet the technical requirements of thesands in the region II, preferably that a mass ratio of the iron ore tailings to the machine-made sands or the natural sands is 3:7-7:3. The cementing material is a mixture, wherein the mixture comprises cement, fly ash and ground slag powder. A mass ratio of the water to the cementing material is 0.30-0.50. The additive is a mixture, wherein the mixture comprises a water reducing agent and a tackifier, the water reducing agent is a polycarboxylic superplasticizer, the tackifier comprises a cellulose polymer or an amide polymer. With the present invention, the damage to the ecology environment due to the natural sand mining is reduced; the damage to the environment due to the iron ore tailings is reduced; the waste can be utilized; a purpose of reutilization of the resource is achieved; with adopting the iron ore tailings, the concrete cost can be substantially reduced, and significant social benefits and economic benefits are provided.

Owner:CHINA MCC17 GRP

Strength controllable coal ash-based polymer concrete and preparation method thereof

The invention provides a strength controllable coal ash-based polymer concrete. The polymer concrete comprises a mixed solid phase and a mixed liquid phase, wherein the weight ratio of the mixed solid phase and the mixed liquid phase is 11:1, the mixed solid phase comprises the following components in parts by weight: 45-55 parts of coarse aggregate gravel, 13-33 parts of fine aggregate natural sand, 19-27 parts of coal ash, 0-8 parts of silica fume, and 0.05-0.12 part of sodium tripolyphosphate, and the mixed liquid phase comprises the following components in parts by weight: 67-75 parts of liquid sodium silicate for industrial use, and 25-33 parts of 10-18mol / L of sodium hydroxide solution. A preparation method for the coal ash-based polymer concrete is simple, has no toxicity and no contamination, and has low cost, and the raw material spreads all over the world and is expected to be used in fields such as corrosion resistant concrete construction, utilization of industrial wastes, rapid patching materials, high-strength high performance materials and the like. Furthermore, according to the coal ash-based polymer concrete, large amount of industrial waste coal ash can be efficiently used, so that the coal ash-based polymer concrete has great significance to conservation of energy and resources and environment protection. The invention also provides the preparation method of the coal ash-based polymer concrete.

Owner:WENZHOU UNIVERSITY

Steam-curing-free durable concrete containing metakaolin and construction method of segments

ActiveCN103951351AImprove mechanical propertiesIncreased durabilitySolid waste managementCrushed stoneIntermediate stage

The invention discloses high-performance steam-curing-free durable concrete containing metakaolin and a construction method of segments. The steam-curing-free durable concrete containing metakaolin is characterized by comprising the following components in parts by weight: 100 parts of silicate cement, 10-50 parts of pulverized fuel ash, 5-20 parts of metakaolin, 180-280 parts of natural sand, 300-370 parts of broken stone, 0.6-1.0 part of polycarboxylate water reducer, and 37-45 parts of mixing water. Concrete segments with the designed size and shape, which are prepared by the construction method disclosed by the invention, have the characteristics of good operation performance, achievement of rapid turnaround of a mold without steam curing, low energy consumption, high early-stage, middle-stage and later-stage mechanical properties, excellent durability and good volume stability.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com