Half-mould forming process for metal plate material

A technology of sheet metal and forming process, which is applied in the field of half-mold forming process of sheet metal, which can solve the problems of precise forming of difficult parts, increase of sheet thickness, complex control system, etc., and achieve good forming quality of parts and control of material thinning , The effect of simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

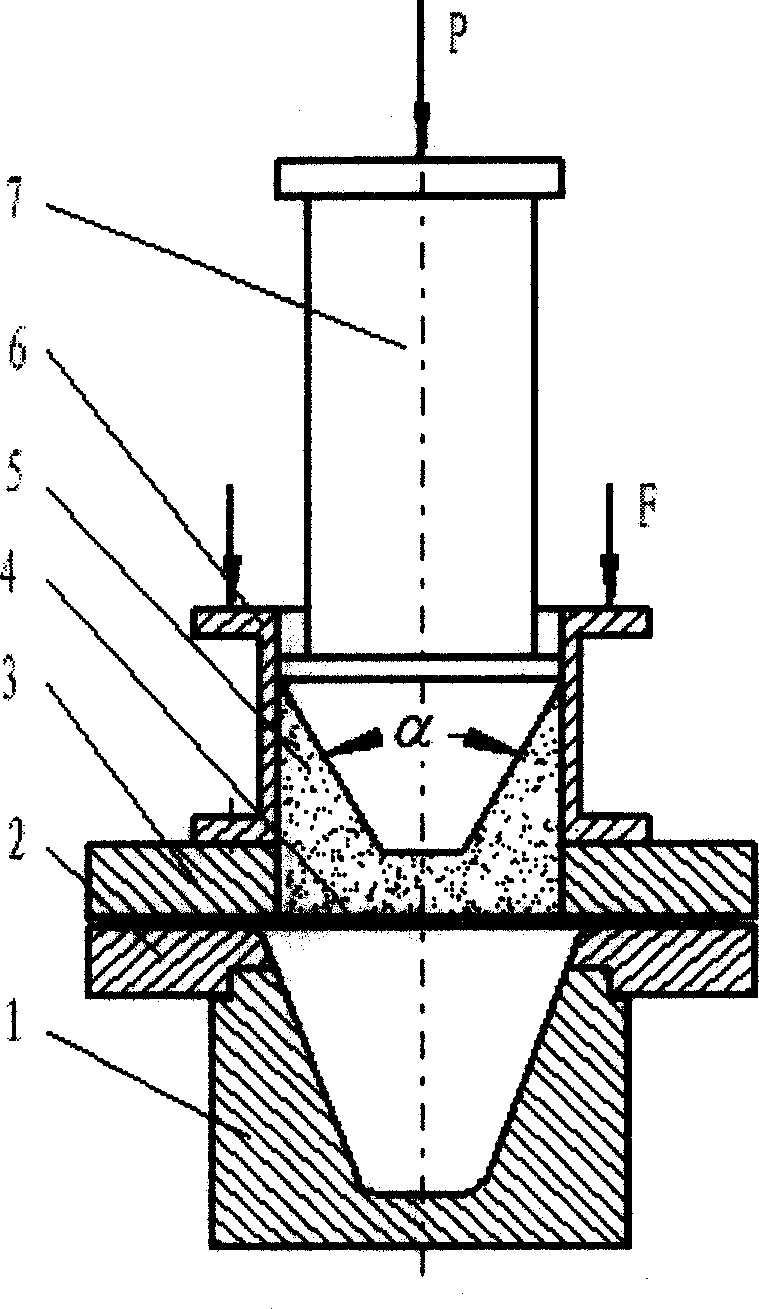

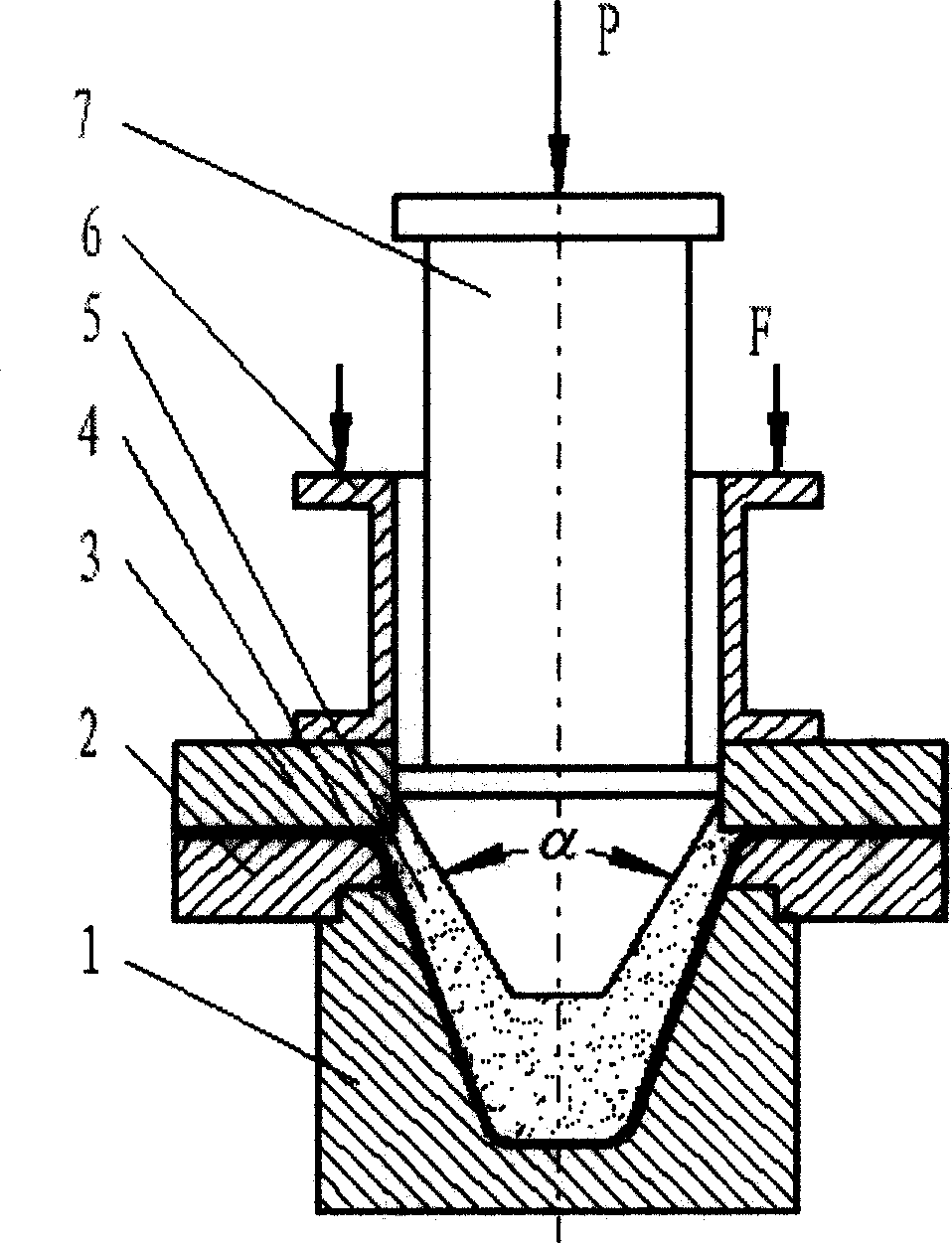

[0019] figure 1 It is the forming mold preparation stage. At this stage, the cavity of the die 1 is manufactured according to the shape of the workpiece to be processed. The parameters of the indenter 7 are: the cone angle of the indenter 7: α=70°, the fit between the indenter 7 and the storage cylinder 6 is clearance fit, and the diameter of the indenter 7 is 2mm smaller than the diameter of the workpiece. The solid particle pressure medium 5 used is natural sand. The sheet material 4 is placed between the upper binder ring 3 and the lower binder ring 2, and the solid particle pressure transmission medium 5 is filled in the storage cylinder 6, and a pressure F is applied to the upper binder ring 3 by a press, and the plate is pressed Material 4, to prevent the sheet material from wrinkling, and then apply a pressure P to the pressure head 7 through the press, so that the solid particle pressure transmission medium 5 generates a forming pressure, and the sheet material 4 is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com