Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

531 results about "Drawing ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The drawing ratio is a measure of the severity of the drawing operation and is the ratio of the initial blank diameter to the punch diameter. For a given material, the limiting drawing ratio (LDR) is a measure of that material’s deep drawability and is calculated from the largest blank that can be completely deep drawn for a given punch diameter.

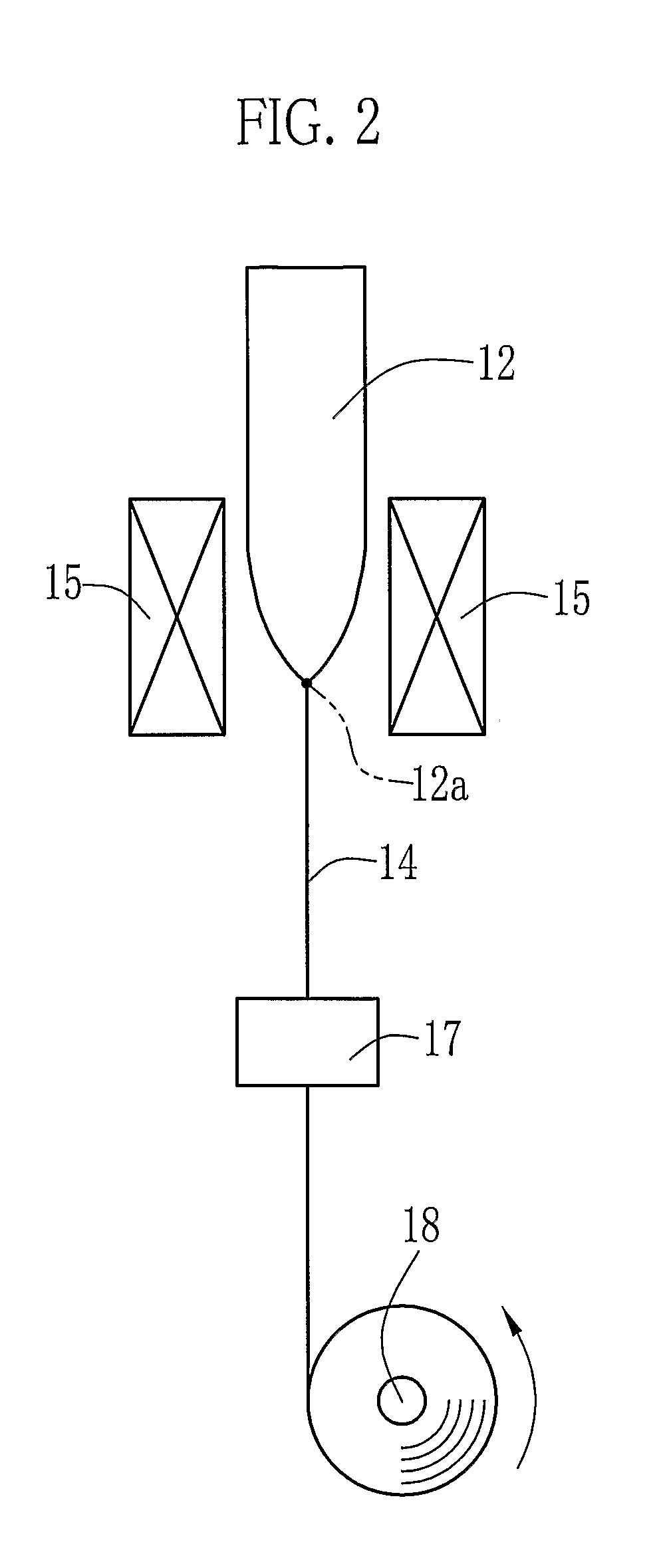

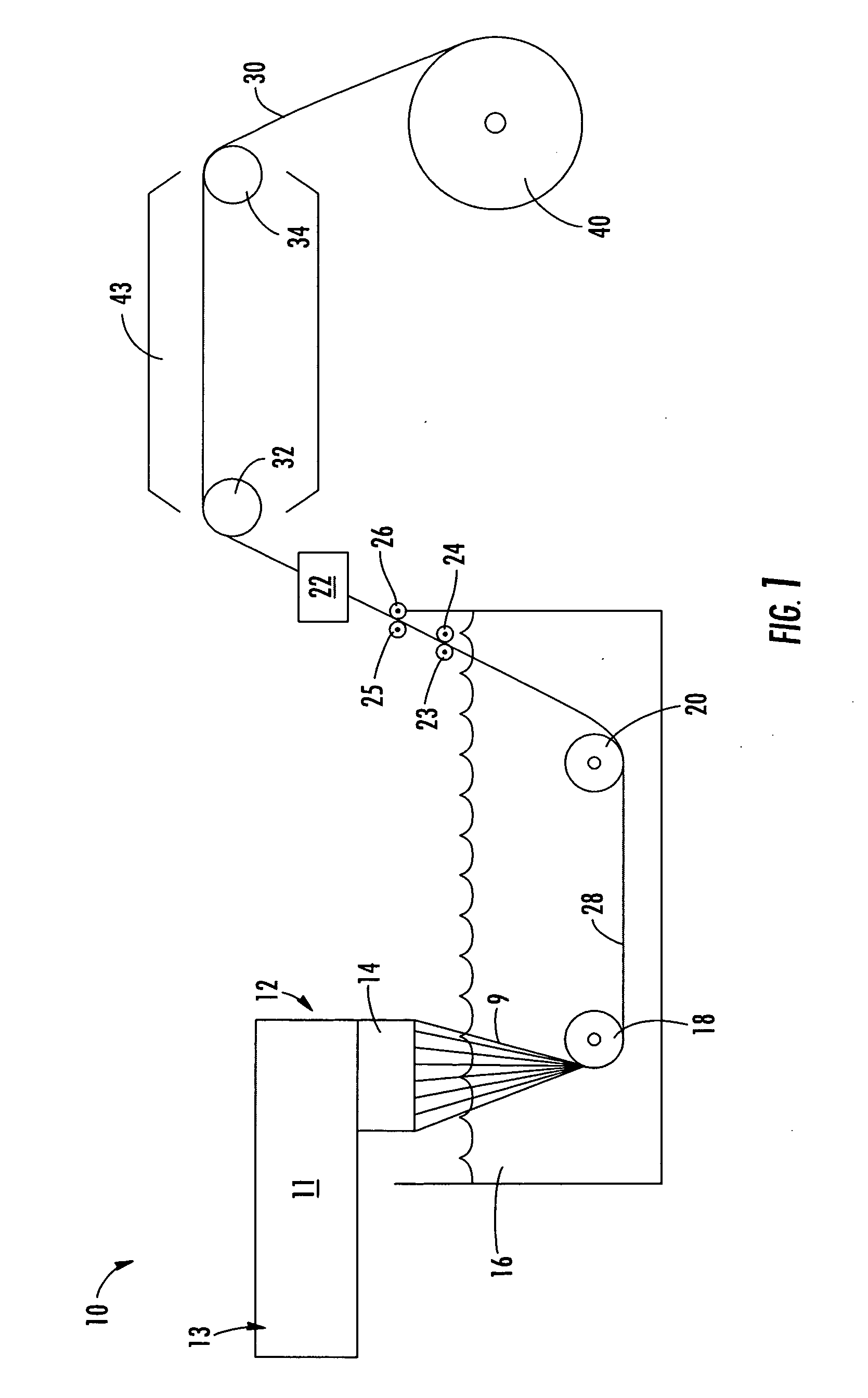

Process for drawing gel-spun polyethylene yarns

InactiveUS20050093200A1Domestic articlesMonocomponent polyolefin artificial filamentProduction rateForced convection

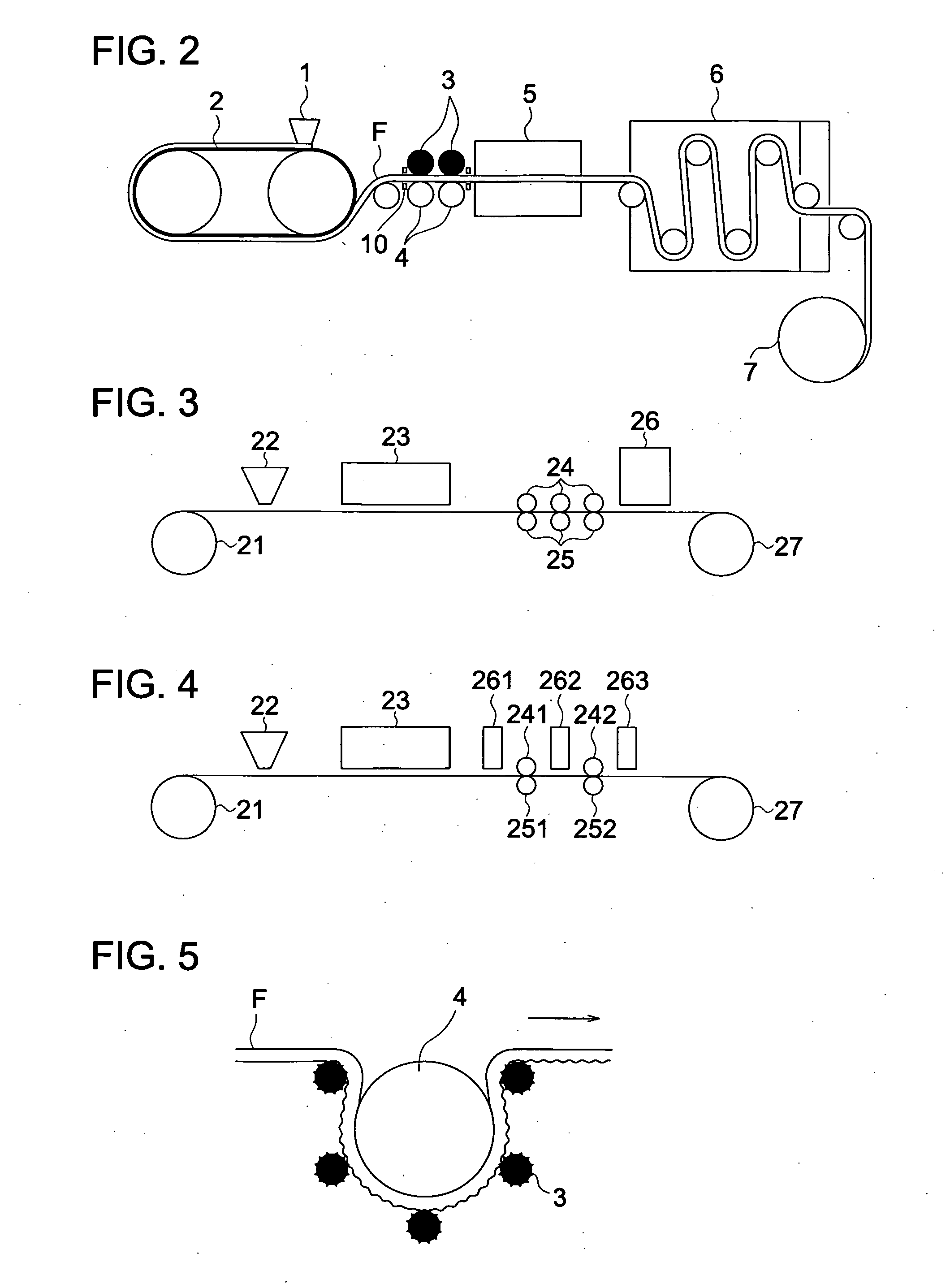

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

Process for drawing gel-spun polyethylene yarns

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

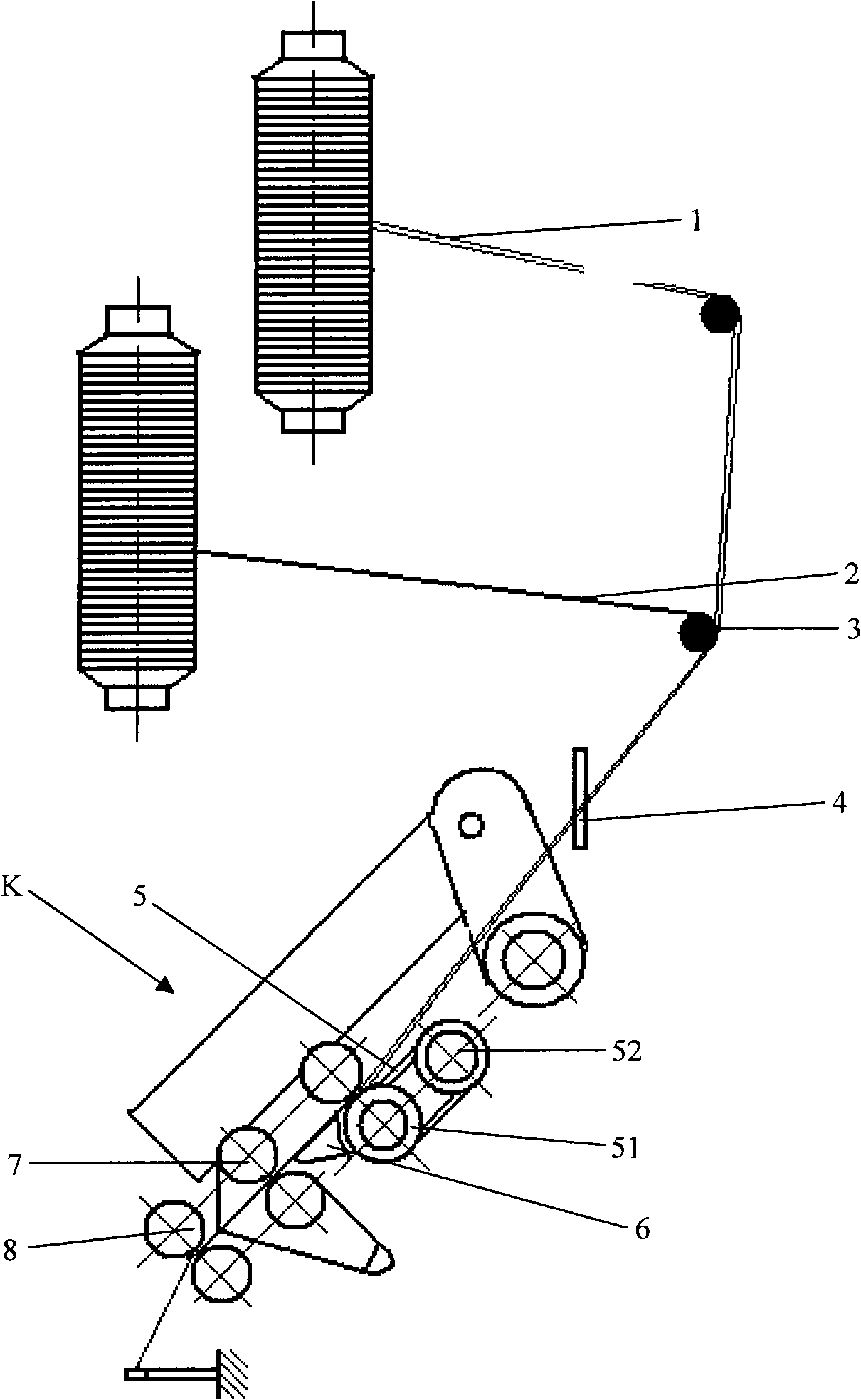

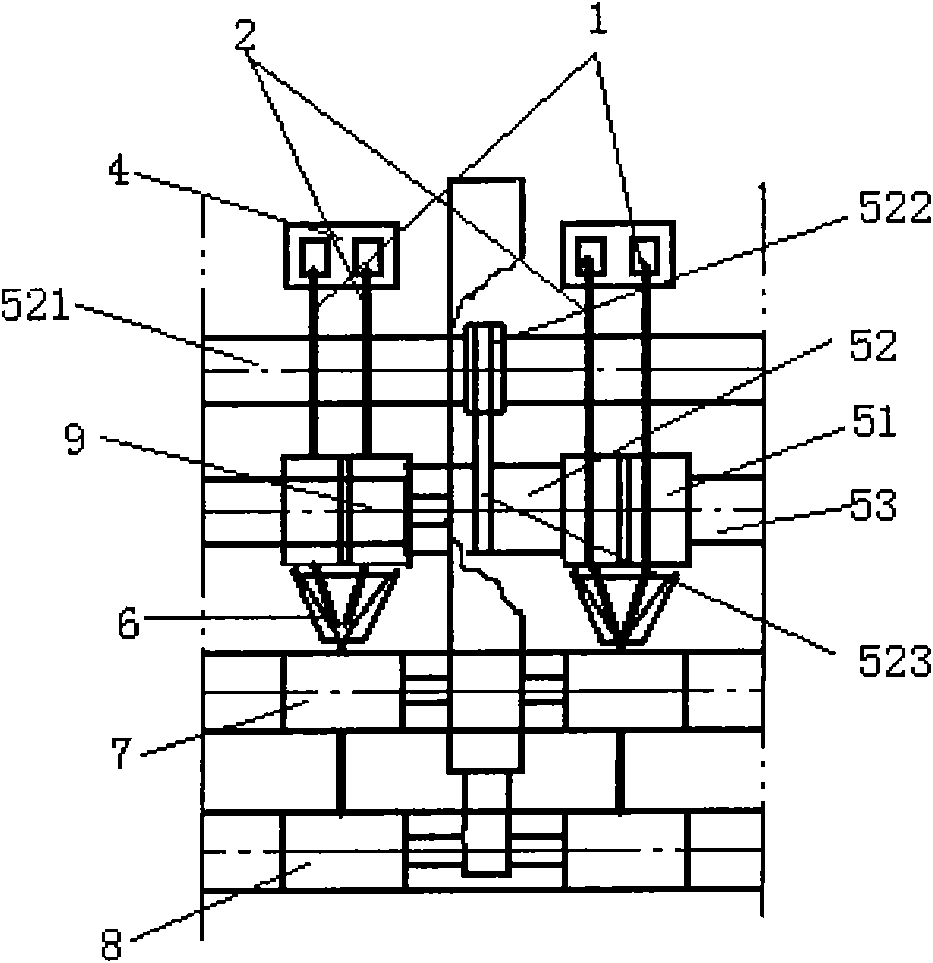

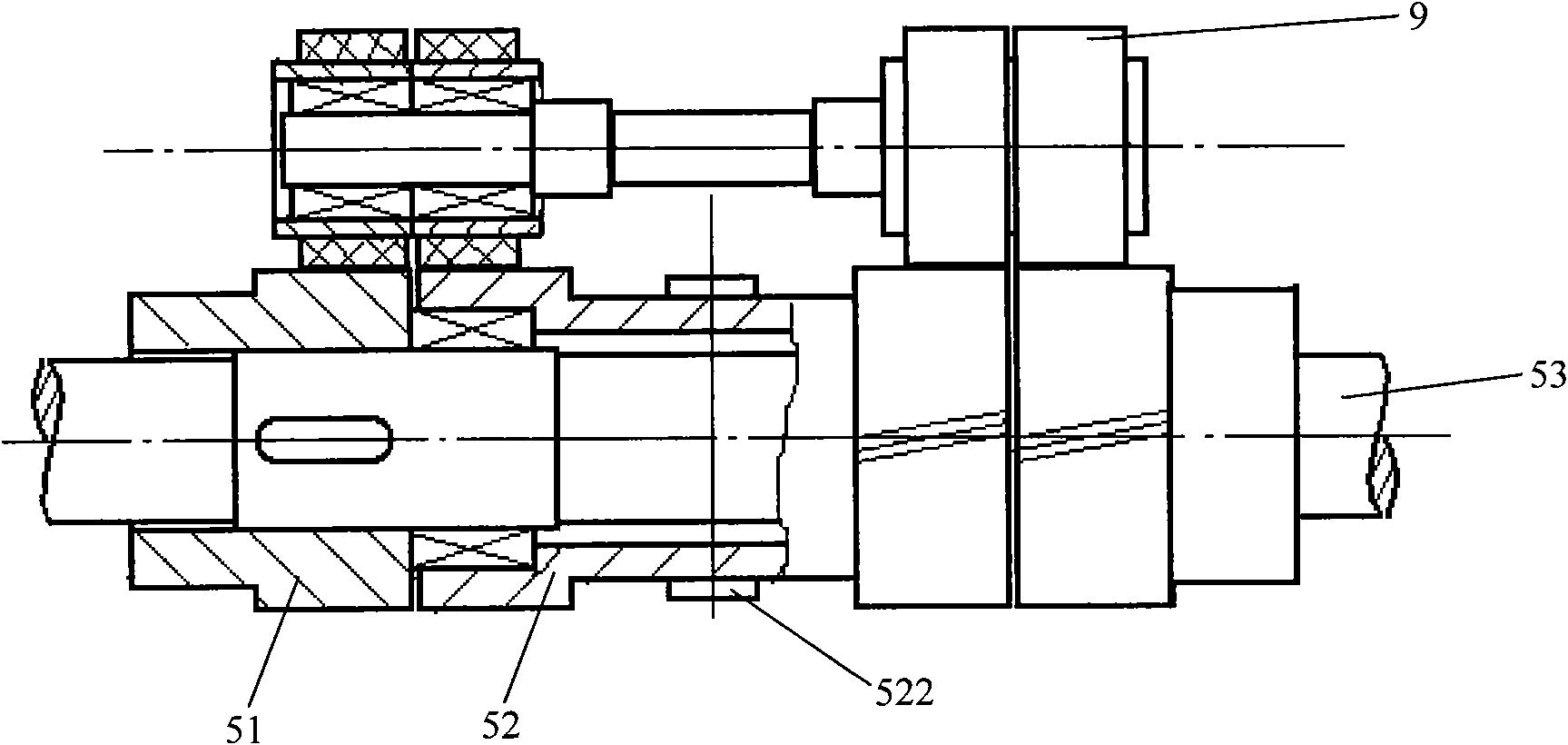

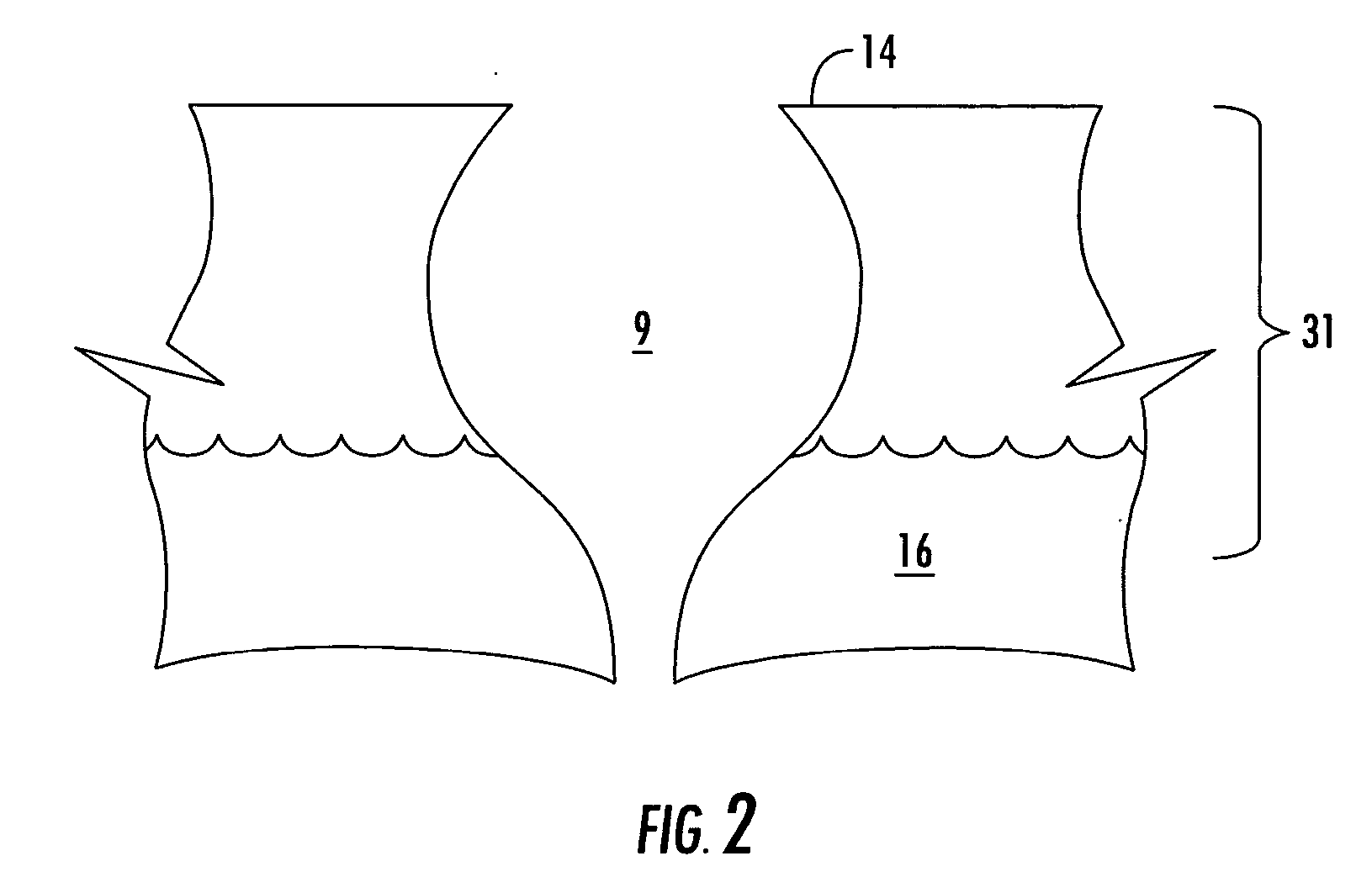

Ring spinning method and device of equi-linear density space dyed yarn

The invention relates to ring spinning method and device of equi-linear density space dyed yarn. The method comprises the following steps of: respectively feeding a fiber strip group (A) with the linear density tex T(A) and a fiber strip group (B) with the linear density tex T(B) into a fixed rear roller and a loop rear roller on a rear roller shaft through yarn guiding rods and grids; and feeding the fiber strip group (A) and the fiber strip group (B) with constant feeding quantity sum into a rear drawing region in any period of time under the process requirement that the feeding speeds of the fiber strip group (A) and the fiber strip group (B) vary with stages by adopting a speed coupling uniform feeding control method. After the strip collection of a strip collector, fiber strips are fed into a middle roller in different drawing ratios, converged in a front drawing region of a spinning machine, drawn and output by a front roller and twisted into equi-linear density space dyed yarn.

Owner:陈伟雄

Optical Film, Method of Producing the Same and Image Displaying Apparatus Employing the Optical Film

InactiveUS20090286098A1Reduce in quantitySynthetic resin layered productsCellulosic plastic layered productsCellulose ester membraneOptical thin film

A method for producing an optical film, characterized by extruding a melt containing a cellulose ester resin from a casting die to thereby form a long length cellulose ester film at a draw ratio of 5 to 30, slitting both sides of the long length cellulose ester film and winding the same in roll form, and while unrolling the long length cellulose ester film from the roll, carrying out continuous coating of the surface hereof with an optical function layer.

Owner:KONICA MINOLTA OPTO

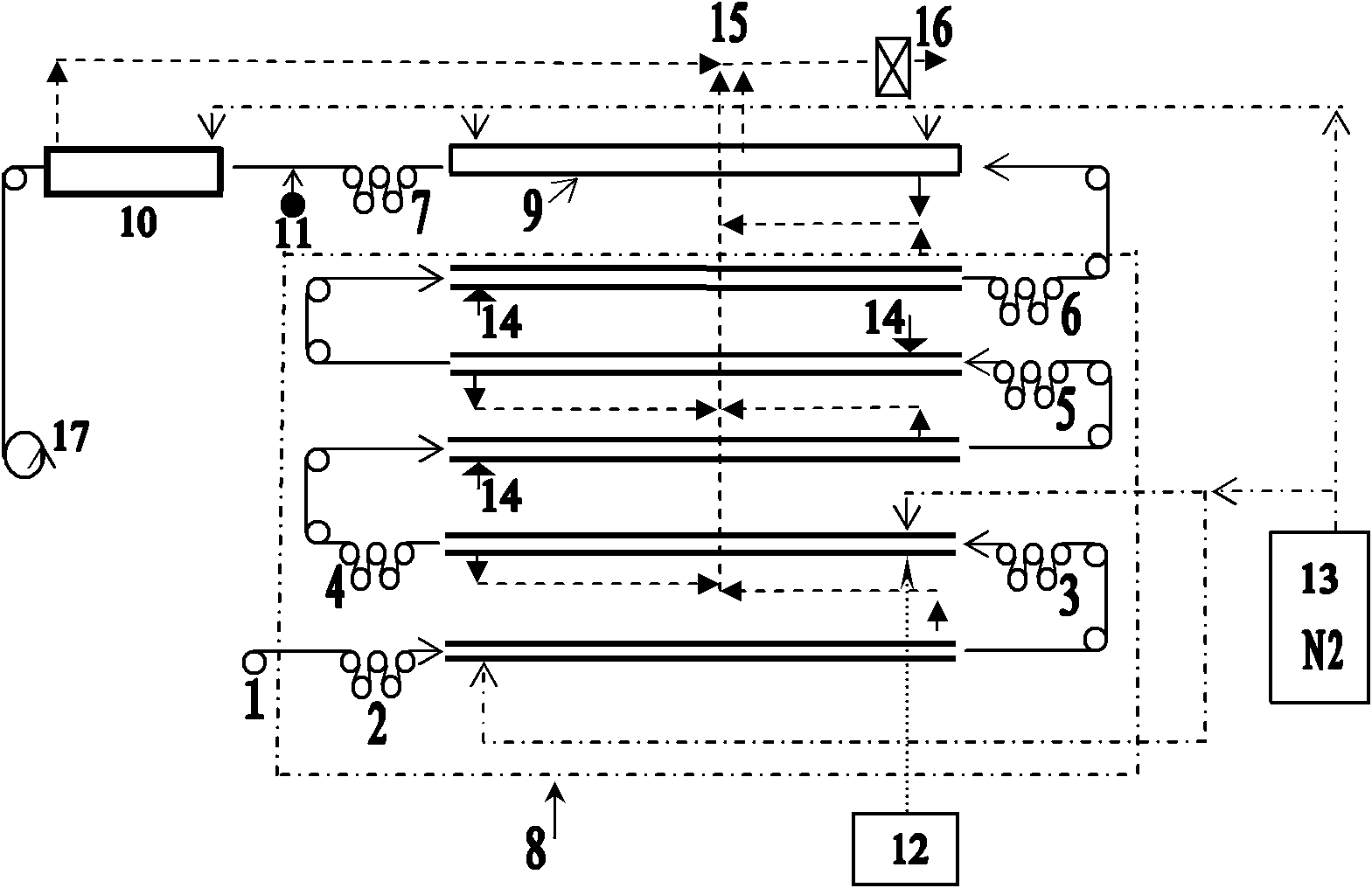

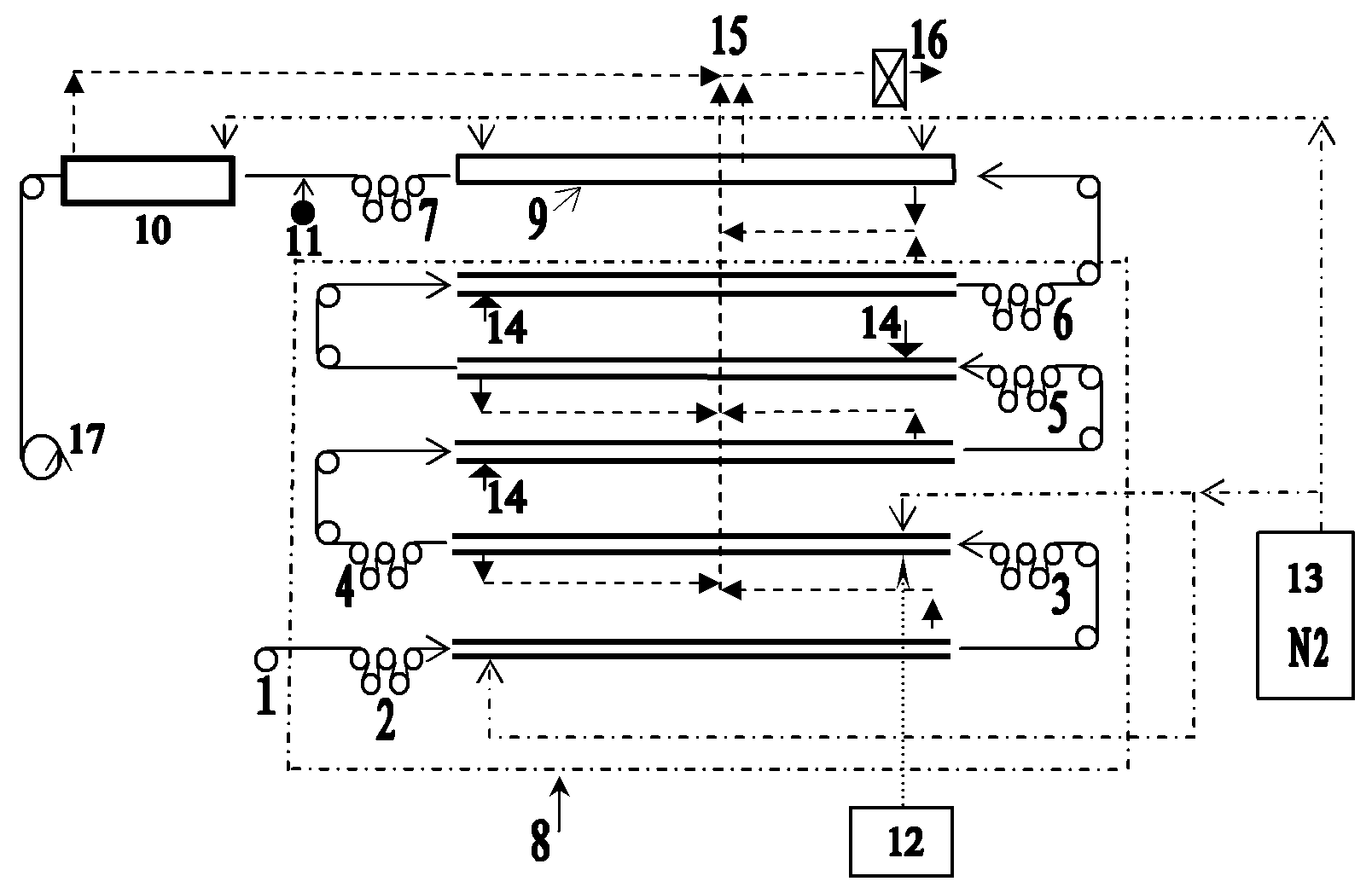

Curing treatment method of carbon fiber precursor polyacrylonitrile fiber

InactiveCN102181963AGood for cyclization reactionRaise the degree of orientationFibre chemical featuresAir atmosphereCarbon fibers

The invention relates to a curing treatment method of a carbon fiber precursor polyacrylonitrile fiber. The method comprises the following steps: pre-cyclizing the polyacrylonitrile fiber precursor in the atmosphere of inert gas; carrying out cyclizing and plastic drawing in the atmosphere of inert gas and water vapor; and carrying out oxidation crosslinking in the atmosphere of air, thus obtaining a pre-oxidized polyacrylonitrile fiber. The method has the following beneficial effects: carrying out heat treatment on the fiber in the inert atmosphere is beneficial to implementation of cyclization reaction in the molecules to form rigid ladderlike molecules with regular structure and strong heat resistance, and at the same time, a defined amount of water vapor is introduced to obtain a higher drawing ratio by enhancing the plasticity of the molecular chains in the fiber, thus improving the orientation degree of the rigid molecules along the fiber axis.

Owner:DONGHUA UNIV

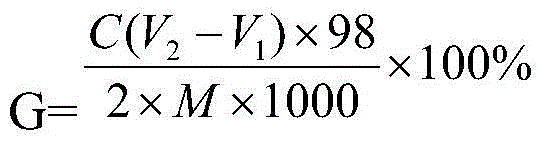

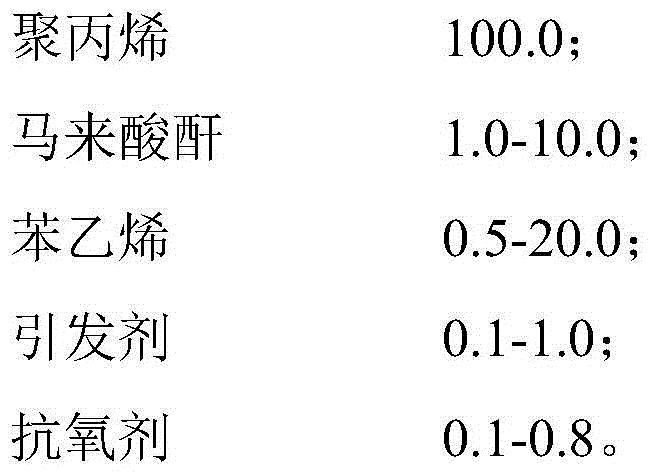

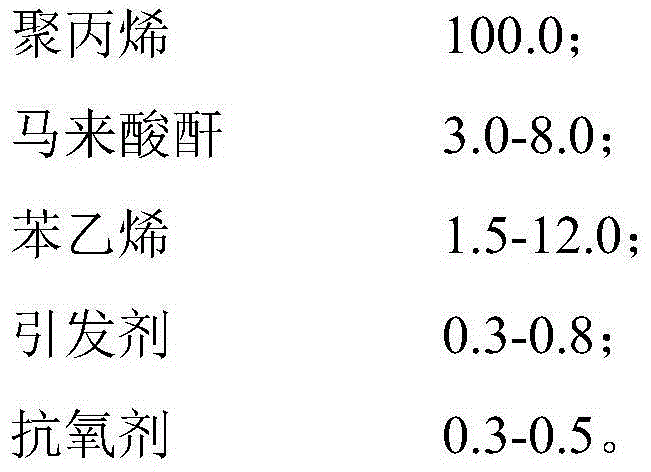

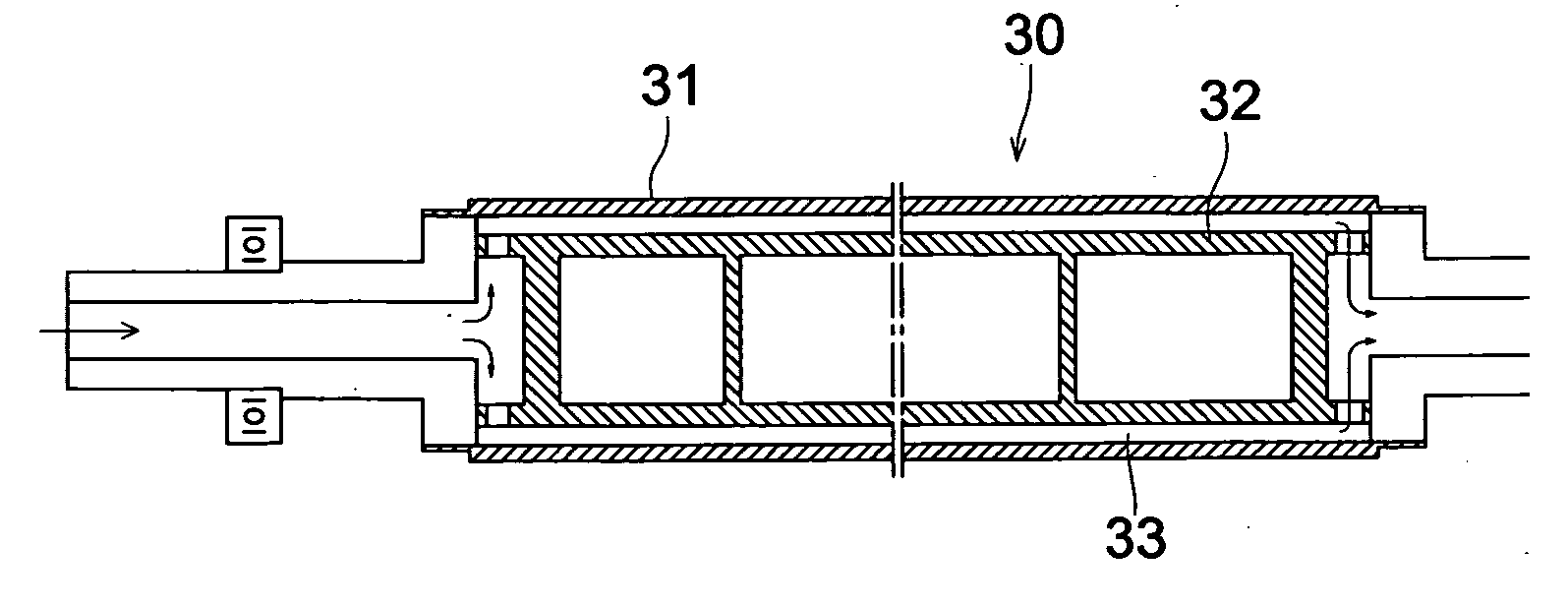

Preparation method of maleic anhydride grafted polypropylene

The invention provides a preparation method of maleic anhydride grafted polypropylene. According to the method, maleic anhydride is grafted to a polypropylene molecular chain through melting free radical grafting reaction. In the melting grafting reaction initiated by a peroxide initiator, the initiator and auxiliary monomer styrene are prepared into a solution, and the solution is continuously metered and input to a plurality of positions of different screw barrel sections of a double-screw extruder. The adopted extruder is the double-screw extruder of which the draw ratio is greater than or equal to 48: 1 or a double-order double-screw extruder. The usage of the maleic anhydride in raw materials is 1.0-10.0 weight percent of that of polypropylene. According to the preparation method, the functional maleic anhydride grafted polypropylene which is high in grafting rate can be obtained, and the molecular weight of the functional maleic anhydride grafted polypropylene is not obviously reduced compared with the molecular weight of the polypropylene in the raw materials.

Owner:EAST CHINA UNIV OF SCI & TECH

Method of Producing Polarizing Plate, Polarizing Plate, and Liquid Crystal Display

Disclosed is a method for producing a polarizing plate including the steps of: laminating a polarizing plate protective film A on one side of a polarizer; and laminating a polarizing plate protective film B on the other side of the polarizer, wherein the polarizing plate protective film B contains a noncrystalline polyolefin resin; and the polarizing plate protective film A is a solidified film produced in such a manner that a melted film prepared by extruding a melted substance containing a cellulose resin from a die is conveyed while pressed against a cooling roll by a touch roll so as to have a draw ratio of 10 to 30 and to be solidified on the cooling roll, provided that the touch roll has an outer metal cylinder, an inner metal cylinder and a space formed therebetween for accommodating a cooling medium.

Owner:KONICA MINOLTA OPTO

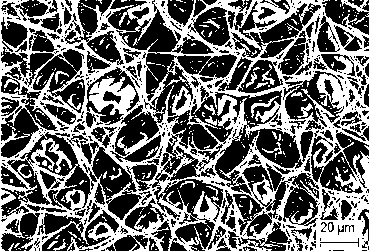

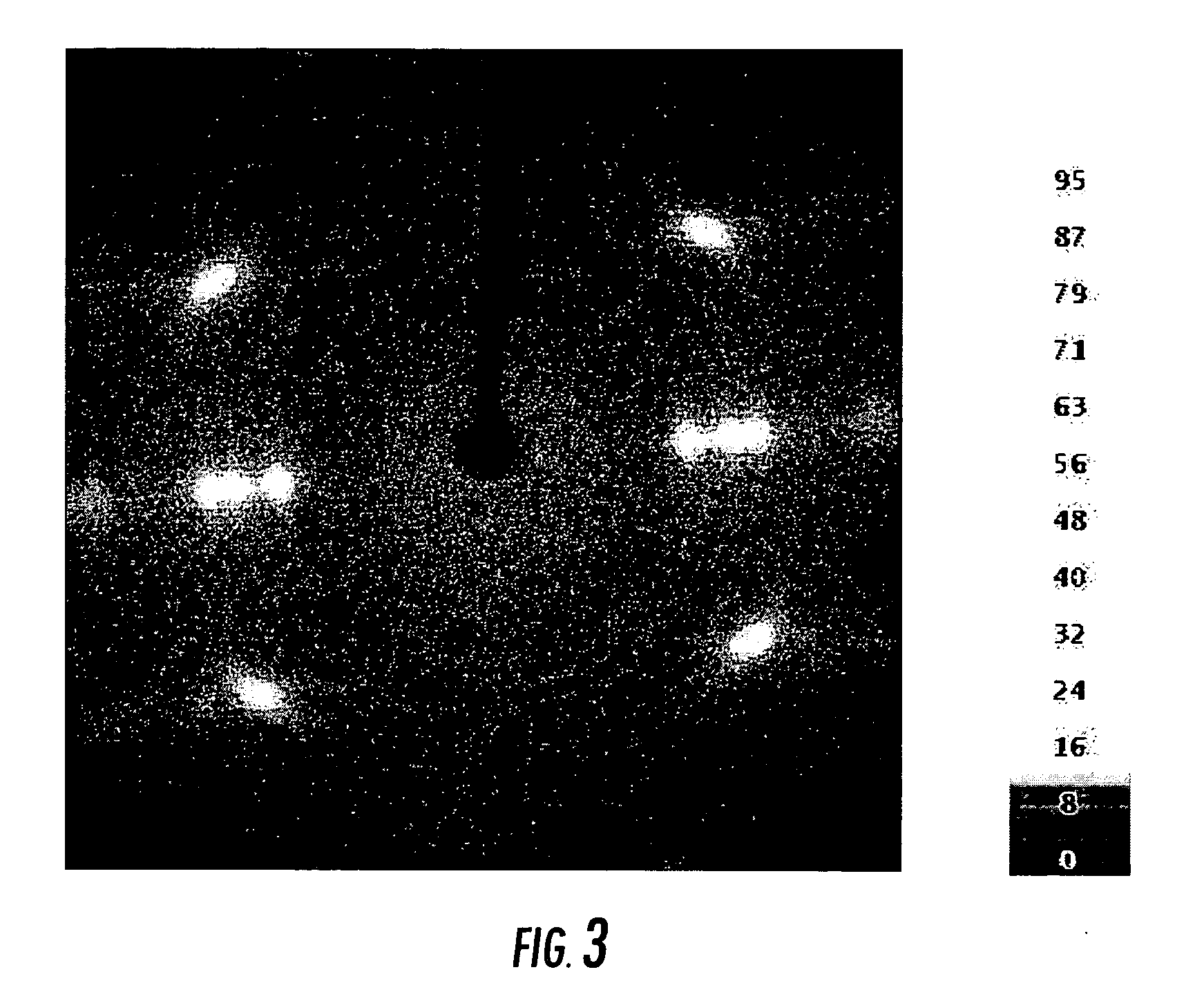

Non-fibrous high modulus ultra high molecular weight polyethylene tape for ballistic applications

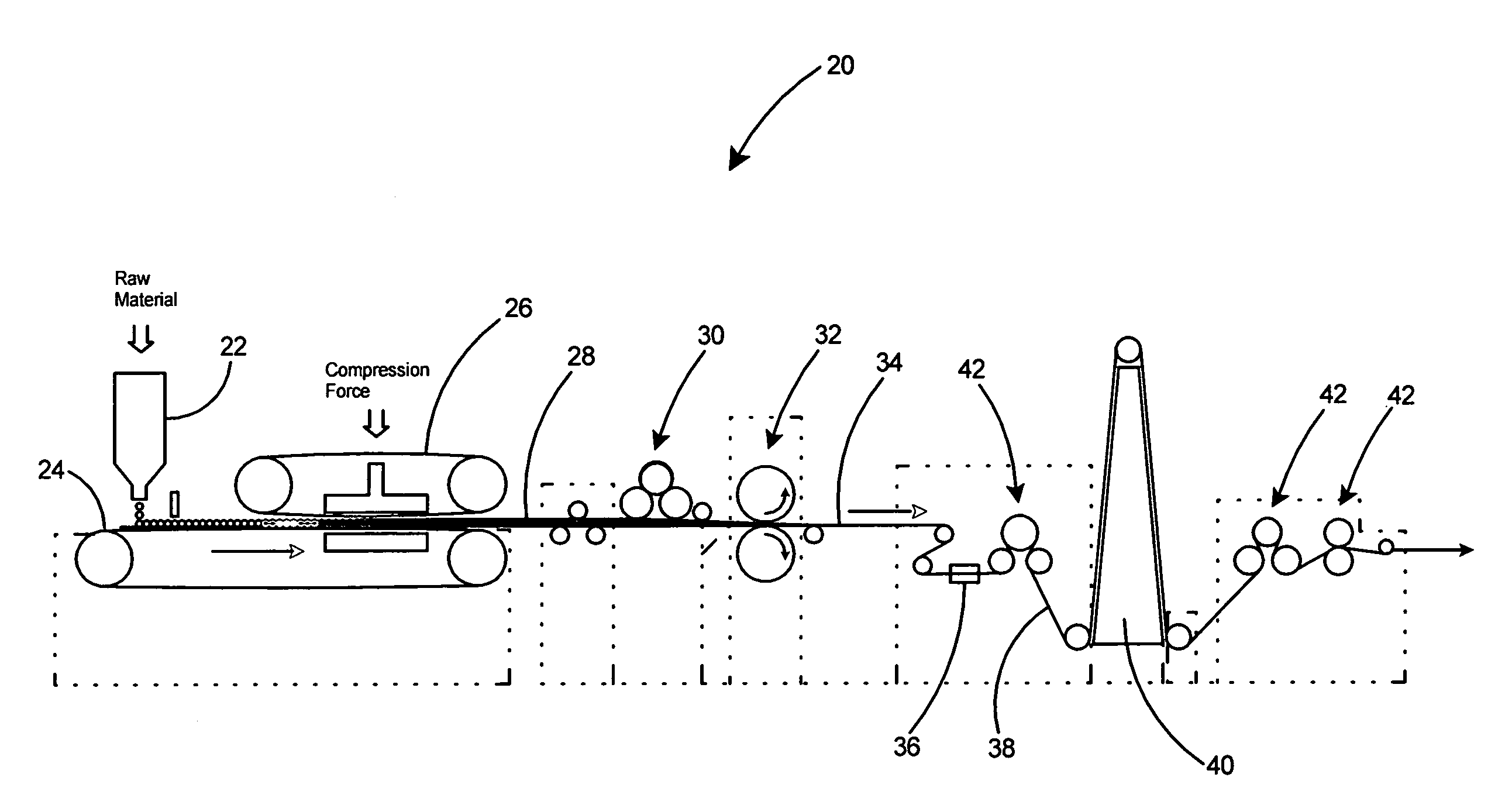

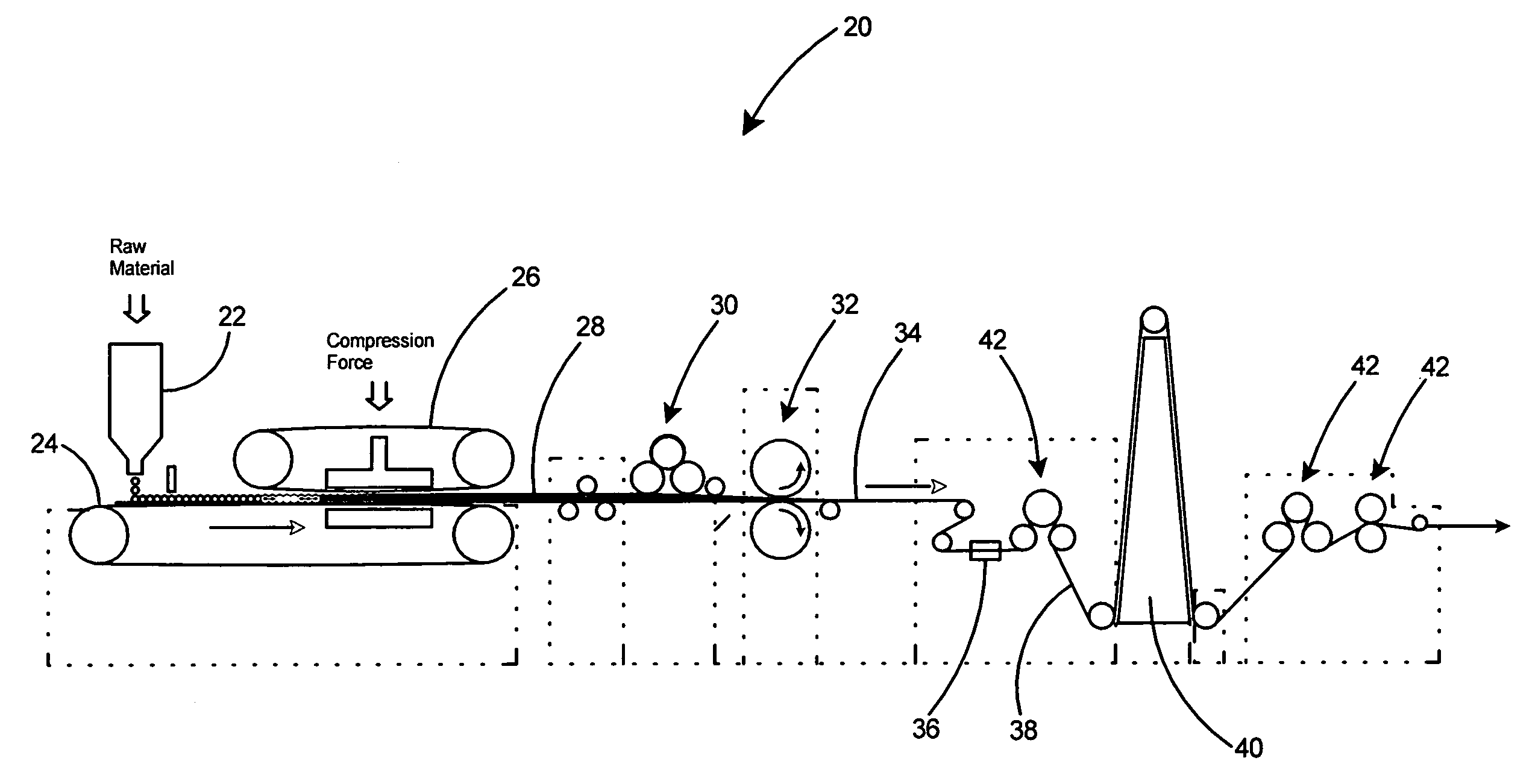

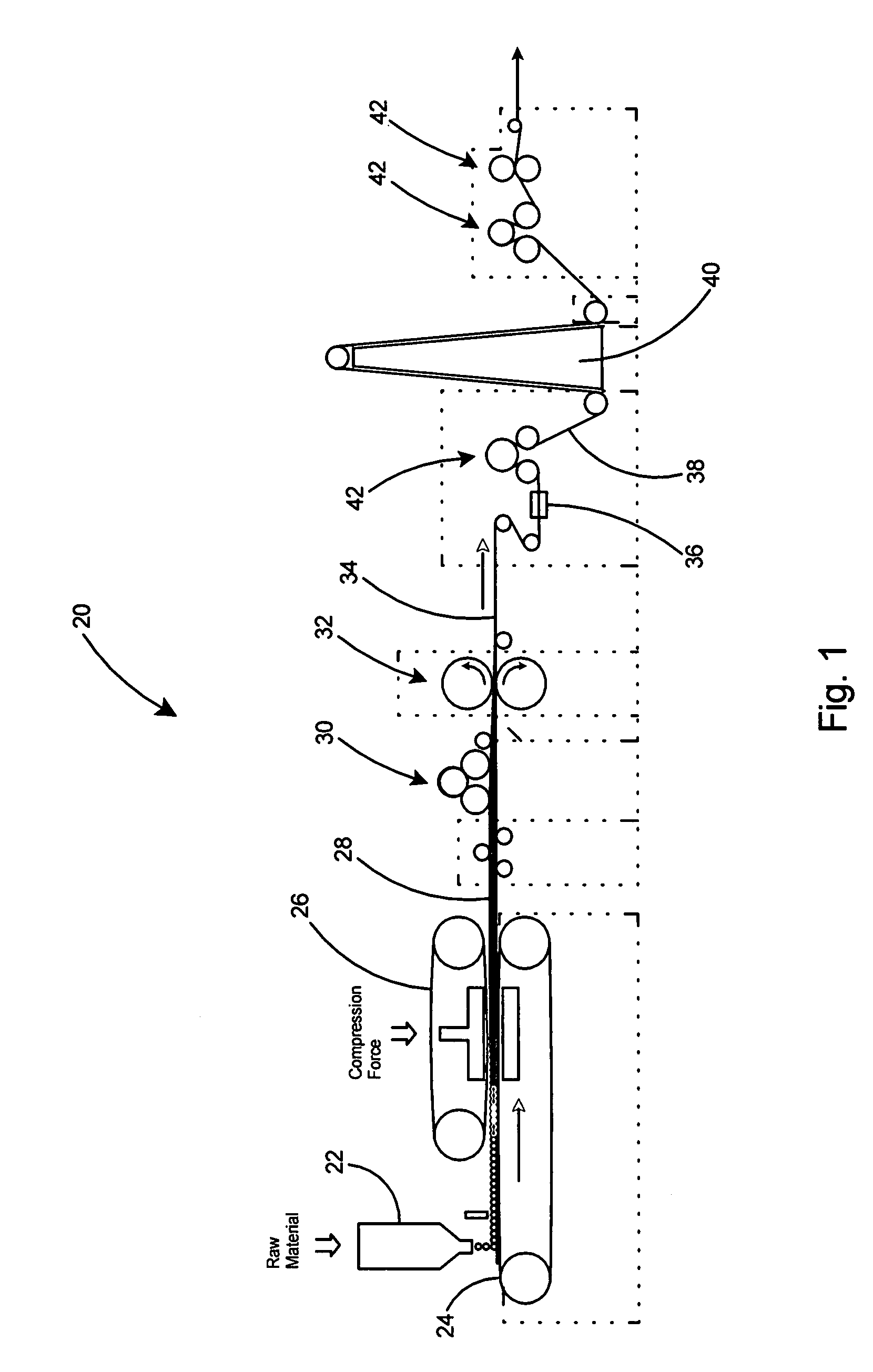

ActiveUS20080318016A1High propertySmall incidenceEngine sealsSynthetic resin layered productsStress concentrationFiber

A non-fibrous ultra high molecular weight polyethylene tape having a width of 1-inch or greater and a modulus of 1,400 grams per denier or greater. The non-fibrous UHMWPE tape is obtained by compression molding ultrahigh molecular weight polyethylene powder at a temperature below its melting point and then drawing and stretching the entire resultant compression molded UHMWPE sheet, with no slitting or splitting of the sheet, at a draw ratio of at least 100:1. The UHMWPE tape can be produced in weights of 6,000 to 90,000 denier or greater. The UHMWPE tape of the present invention minimizes the effect of stress concentrators that are prevalent with fibers and thereby enables the tape to be drawn at much higher draw ratios than is possible with fibrous UHMWPE. When used in ballistics panels, the high modulus high molecular weight polyethylene tape of the present invention improves ballistic performance by providing enhanced dissipation of the impact energy of a projectile.

Owner:DUPONT SAFETY & CONSTR INC

Non-fibrous high modulus ultra high molecular weight polyethylene tape for ballistic applications

A non-fibrous ultra high molecular weight polyethylene tape having a width of 1-inch or greater and a modulus of 1,400 grams per denier or greater. The non-fibrous UHMWPE tape is obtained by compression molding ultrahigh molecular weight polyethylene powder at a temperature below its melting point and then drawing and stretching the entire resultant compression molded UHMWPE sheet, with no slitting or splitting of the sheet, at a draw ratio of at least 100:1. The UHMWPE tape can be produced in weights of 6,000 to 90,000 denier or greater. The UHMWPE tape of the present invention minimizes the effect of stress concentrators that are prevalent with fibers and thereby enables the tape to be drawn at much higher draw ratios than is possible with fibrous UHMWPE. When used in ballistics panels, the high modulus high molecular weight polyethylene tape of the present invention improves ballistic performance by providing enhanced dissipation of the impact energy of a projectile.

Owner:DUPONT SAFETY & CONSTR INC

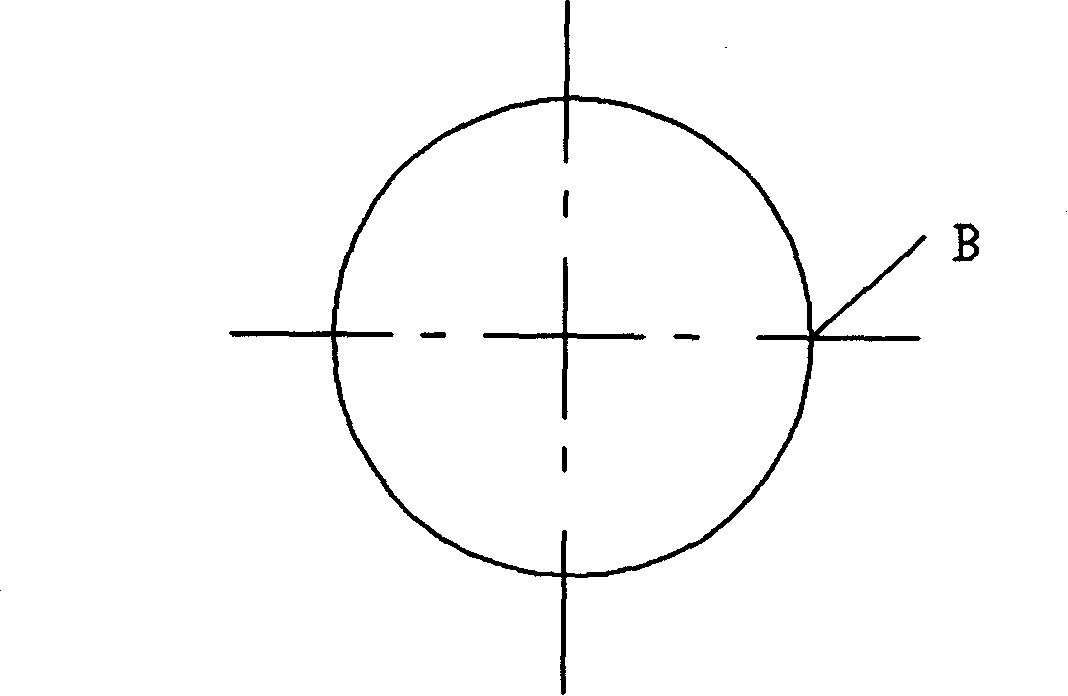

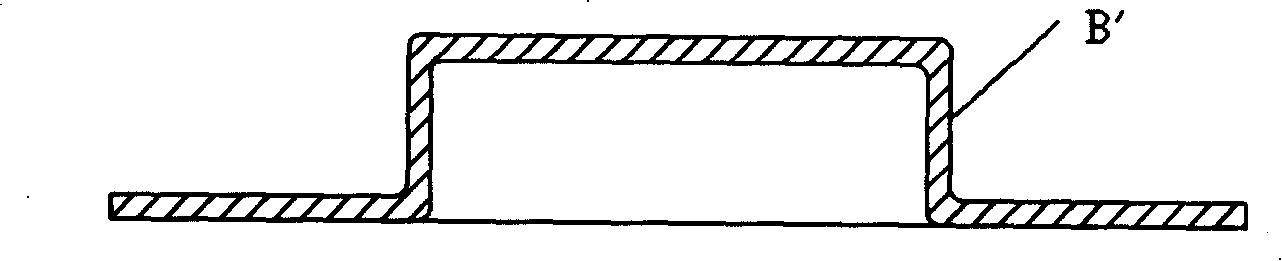

Method of preparing lining for cars

InactiveCN101209472ASolve concentrated stressSolve crackingMetal-working apparatusStress concentrationPunching

The invention relates to a manufacturing method of a vehicle bushing, comprising the following steps that: (1) blanking: a blanking die and a hydraulic device are used for blanking a steel plate EC, and a round material A is obtained; (2) drawing: the round material obtained by the step (1) is drawn by five times by drawing dies with different drawing ratio and the hydraulic device, and a cylindrical piece B with a flange edge is obtained; (3) punching: a cylinder bottom of the cylindrical piece B with a flange edge obtained by the step (2) is punched and cut by a punching die and the hydraulic device, and a part C is obtained; (4) shaping and trimming: the part C obtained by the step (3) is shaped by a shaping and trimming die, and the flange edge is punched and cut into the bushing with the dimension consistent with the demand. The invention solves the problems of a flanging technique that stress concentration and crack are existed at corners, thus improving the percent of pass and prolonging the service life of the parts.

Owner:上海德真工贸有限公司

Film

InactiveUS20100304062A1Easy to processIncrease chanceSynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The present invention provides a uniaxially oriented multilayer film comprising at least (i) a layer (A) and (ii) a layer (B), wherein said layer (A) comprises a linear low density polyethylene (LLDPE) comprising (e.g. selected from):—a multimodal LLDPE produced using a Ziegler Natta catalyst (znLLDPE), or—a LLDPE produced using a single site catalyst (mLLDPE) or—a mixture of a mLLDPE and a multimodal znLLDPE, said layer (B) comprises a multimodal LLDPE, and said multilayer film is in the form of a stretched film which is uniaxially oriented in the machine direction (MD) in a draw ratio of at least 1:3.

Owner:BOREALIS TECH OY

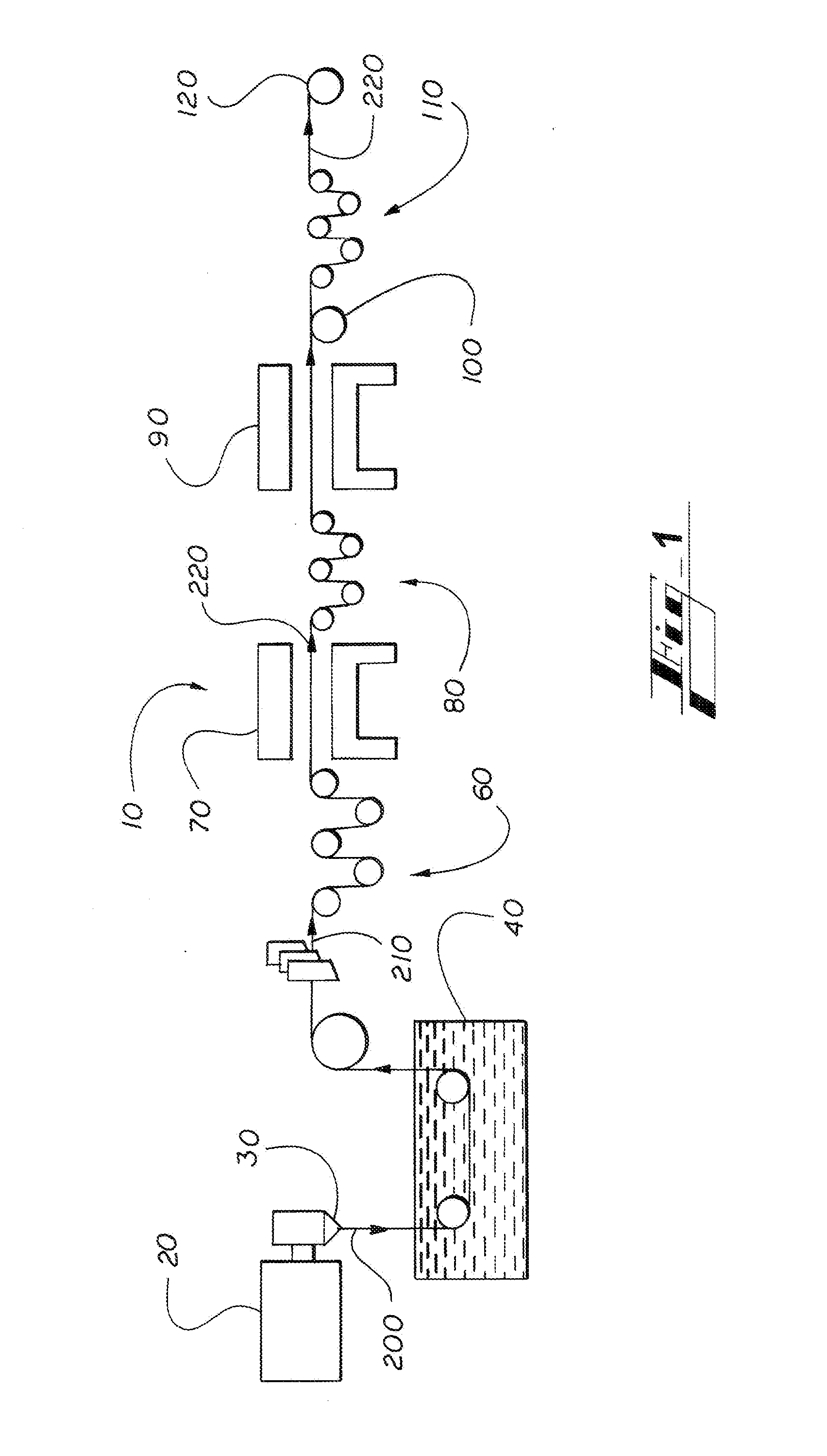

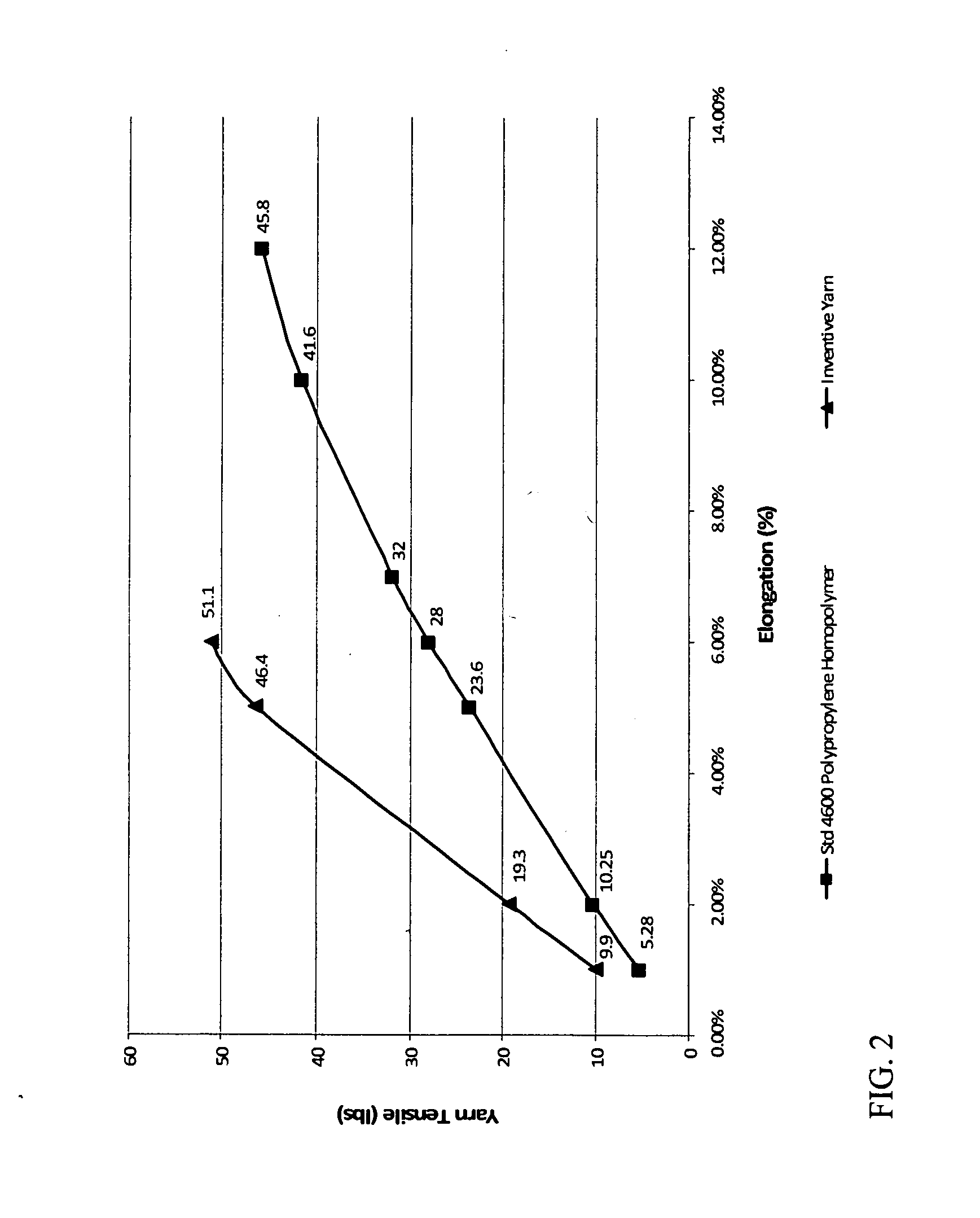

Polypropylene Yarn Having Increased Young's Modulus And Method Of Making Same

The present invention is directed to a monofilament, a yarn, a tape, or a staple fiber, each having 1 to 12,000 Denier per filament, a draw ratio of 2.5:1 to 25:1, and made of a polypropylene composition of a melt blended admixture of about 93% by weight of polypropylene, about 5% by weight of a polypropylene / ethylene copolymer, and about 2 wt. % of an additive. Also, a process for preparing the monofilament, yarn, tape, or staple fiber is disclosed.

Owner:NICOLON CORP

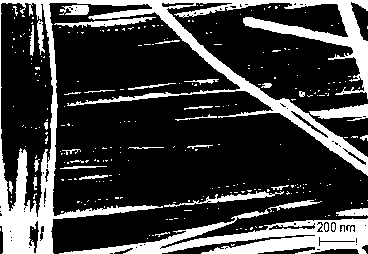

Mesophase-pitch-based carbon fiber and preparation method thereof

The invention discloses a mesophase-pitch-based carbon fiber and a preparation method thereof. The preparation method comprises the steps of conducting mesophase pitch polymerization, modification and visbreaking, conducting centrifugal spinning, conducting hot jetting drafting, conducting oxidation, carbonization and graphitization, and obtaining the mesophase-pitch-based carbon fiber. The diameter of the mesophase-pitch-based carbon fiber ranges from 120 nm to 2000 nm, the draw ratio is 500-20000: 1, the tensile strength is 1.5-4.0 GPa, the tensile modulus is 300-600 GPa, the electrical resistivity is less than 0.2 * 10 <-4> omega.cm, the thermal conductivity is 500-800 W / m.k, and the mesophase-pitch-based carbon fiber is low in fabrication cost and can be applied to fields such as static electricity resistance, heat dissipation, electromagnetic shielding and heat shielding.

Owner:ANHUI HONGCHANG NEW MATERIAL CO LTD

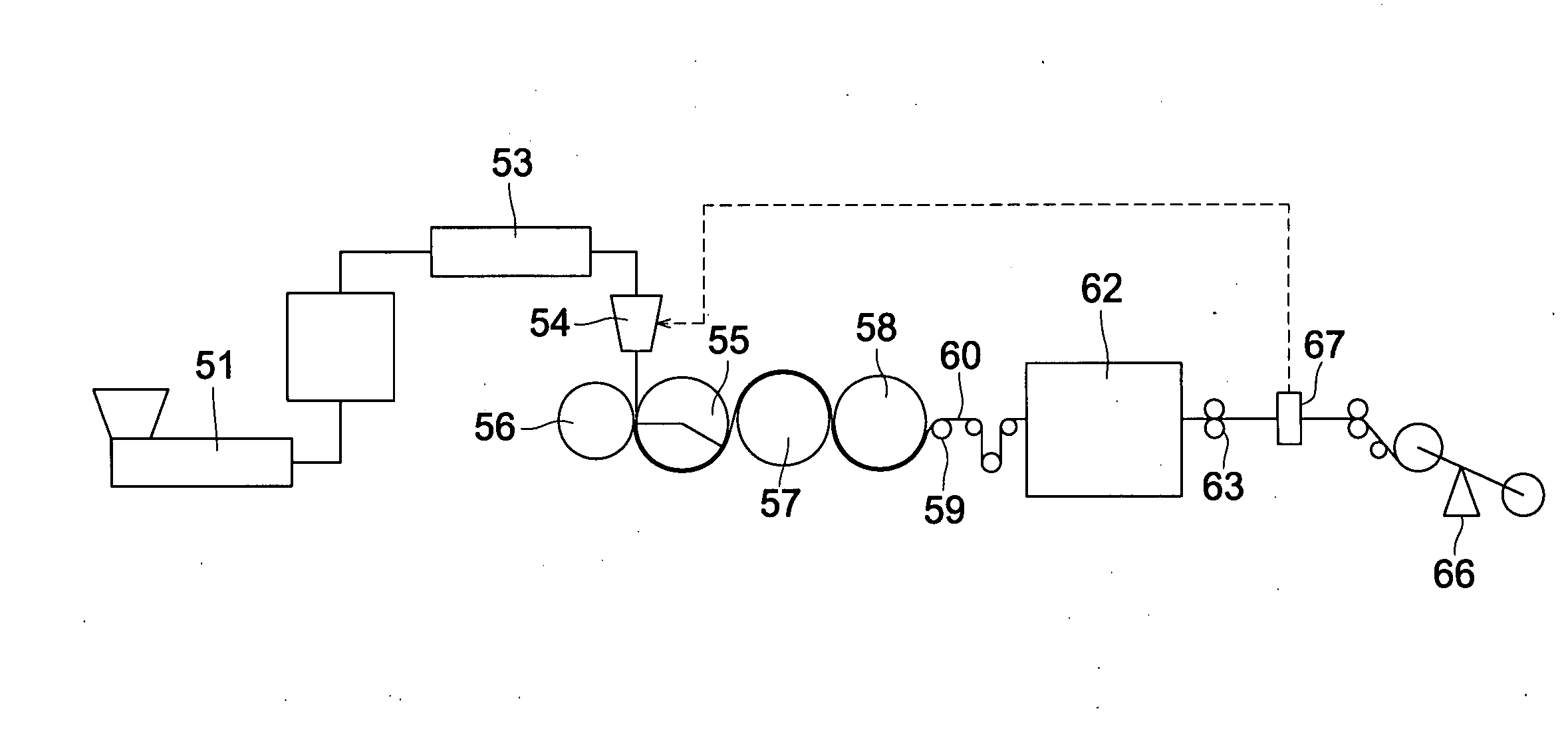

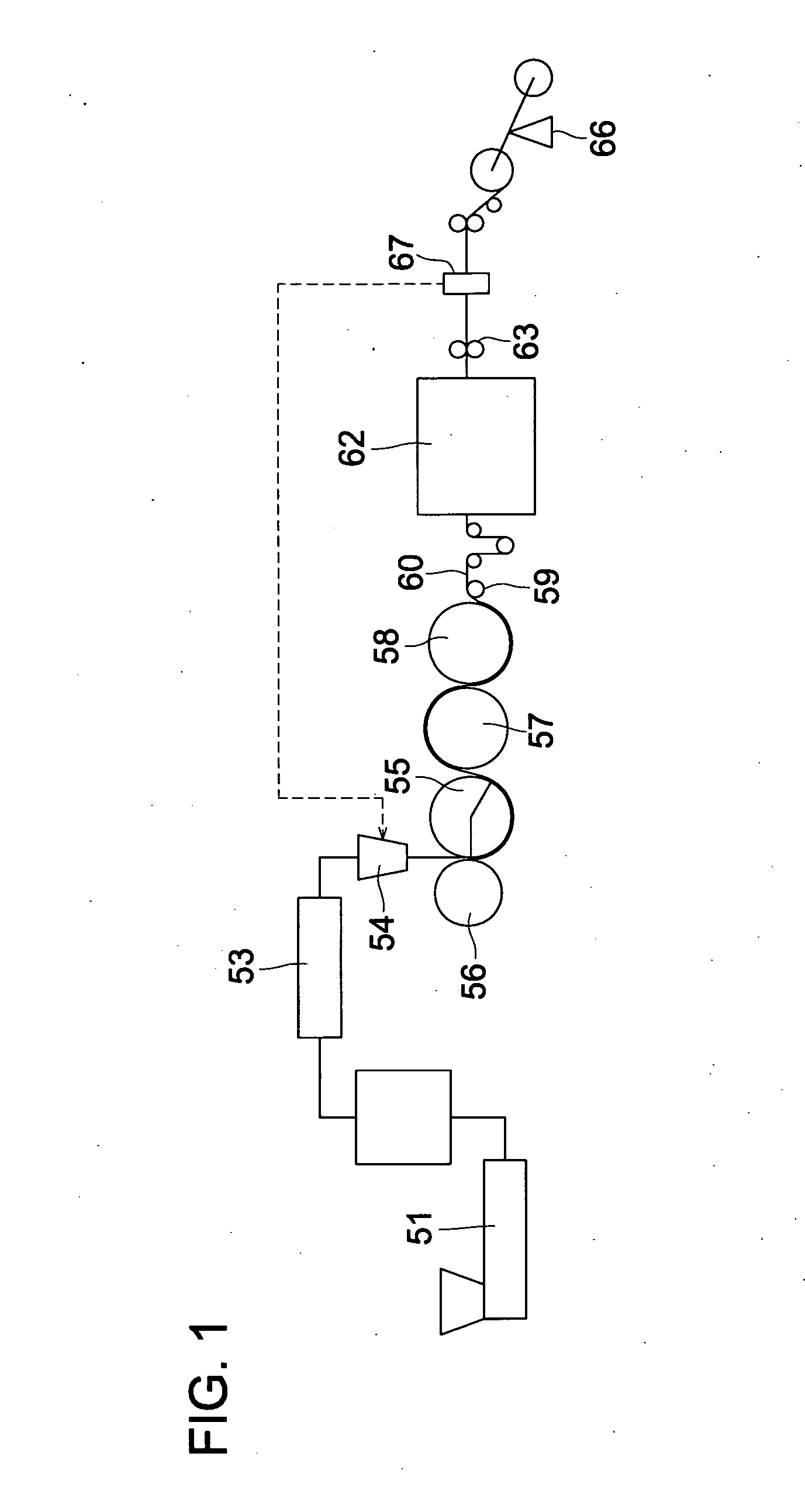

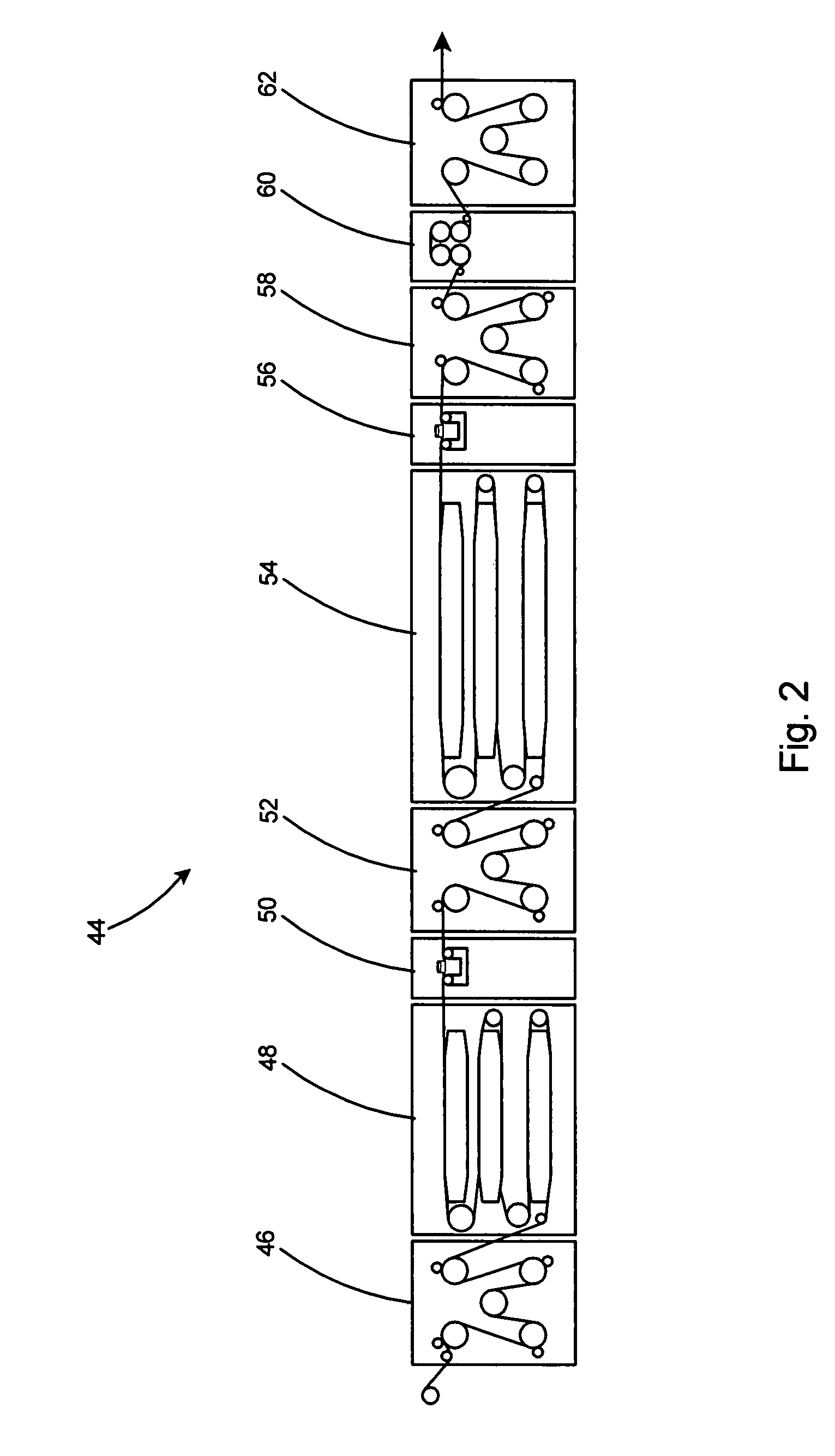

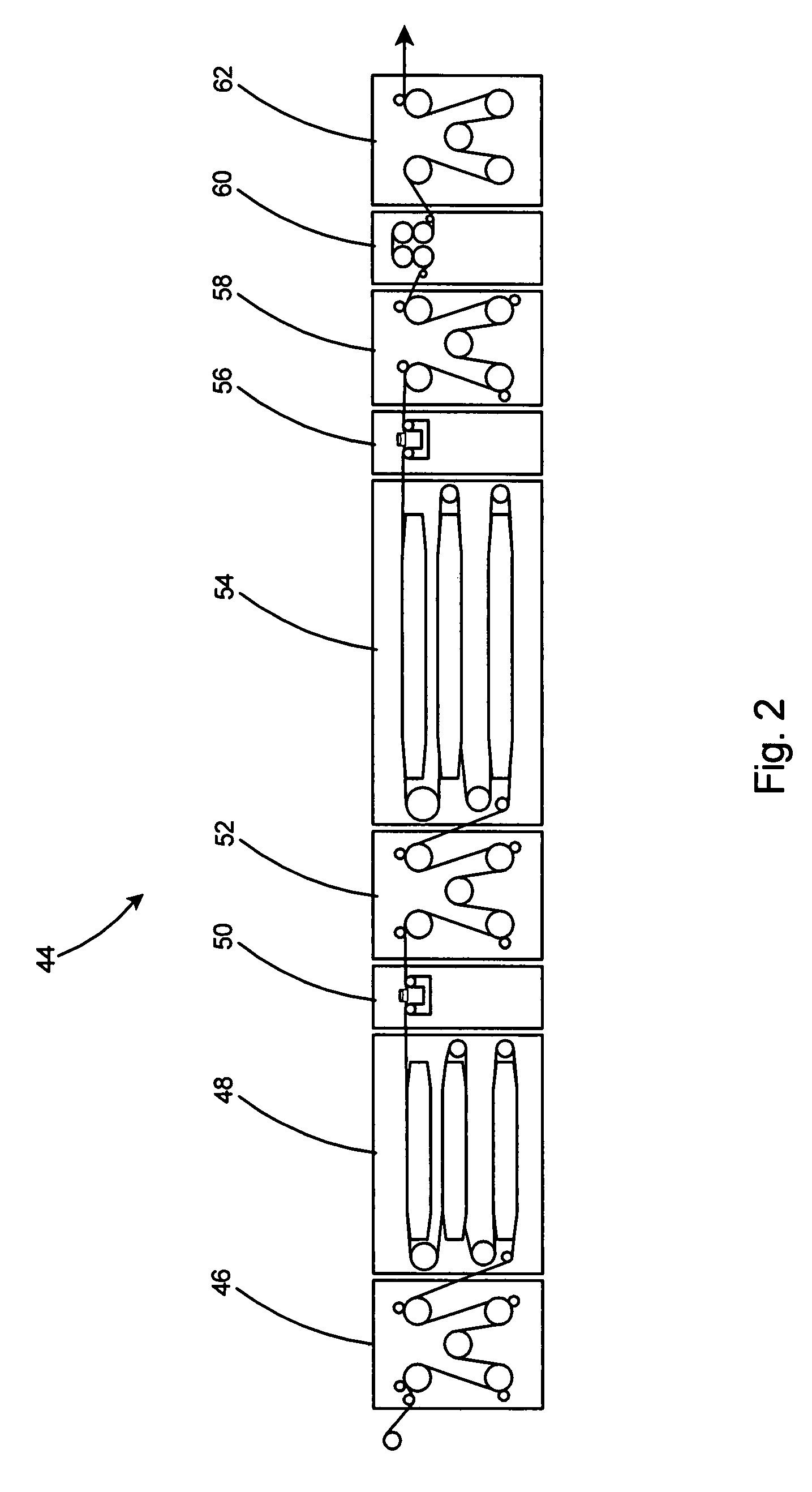

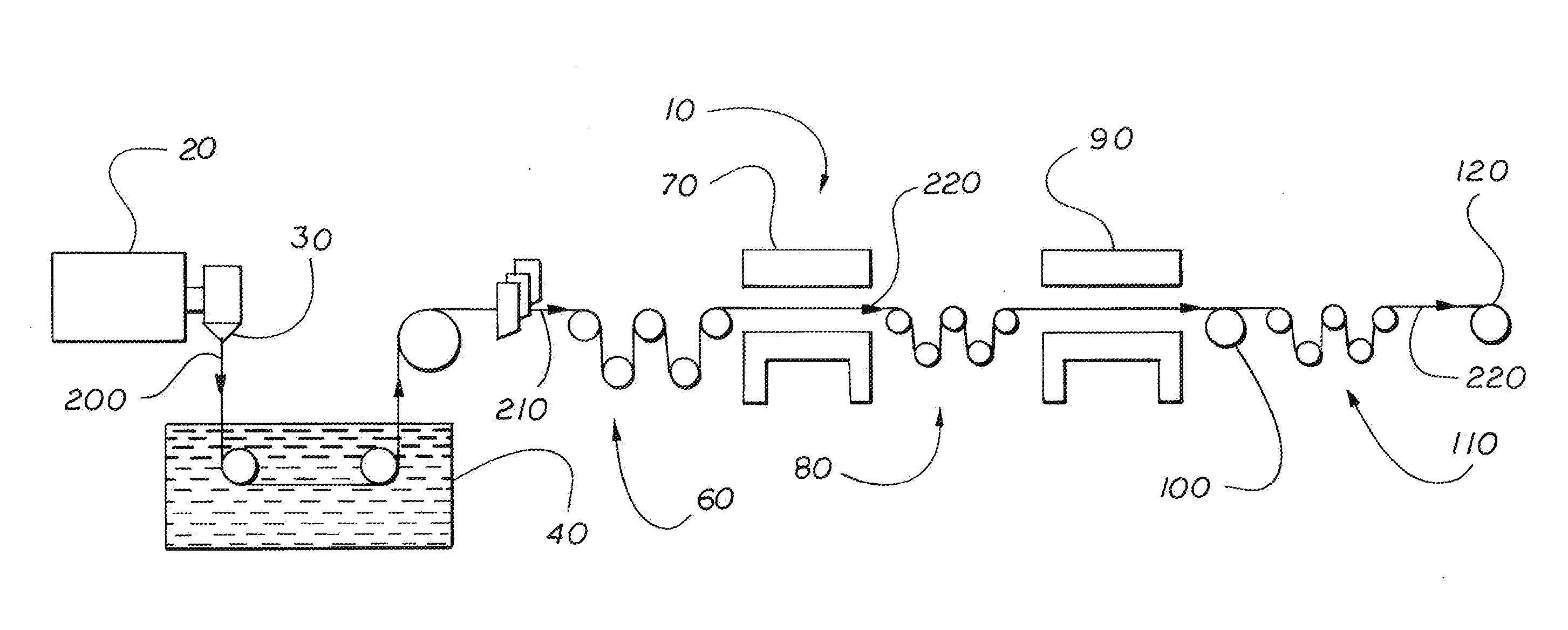

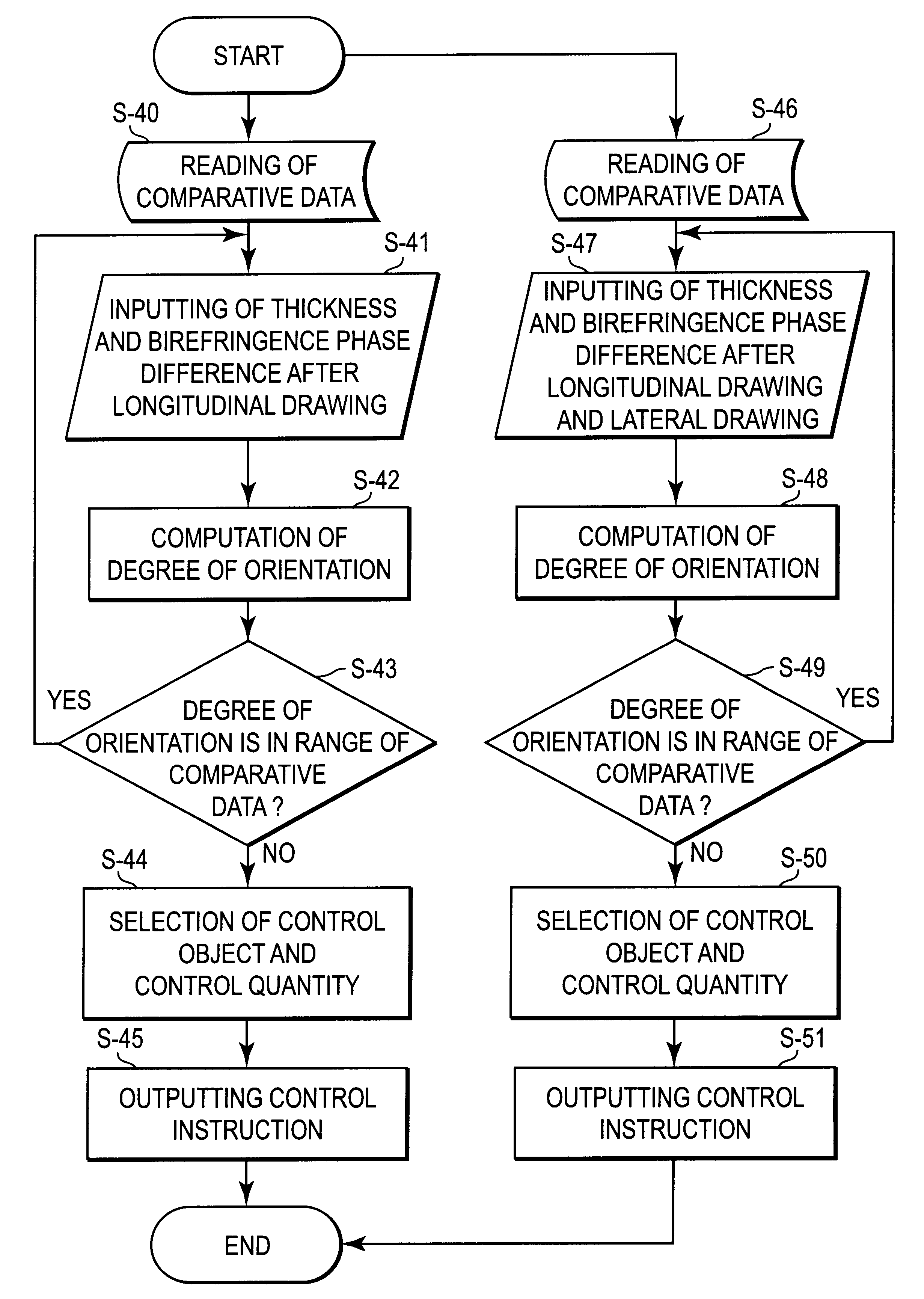

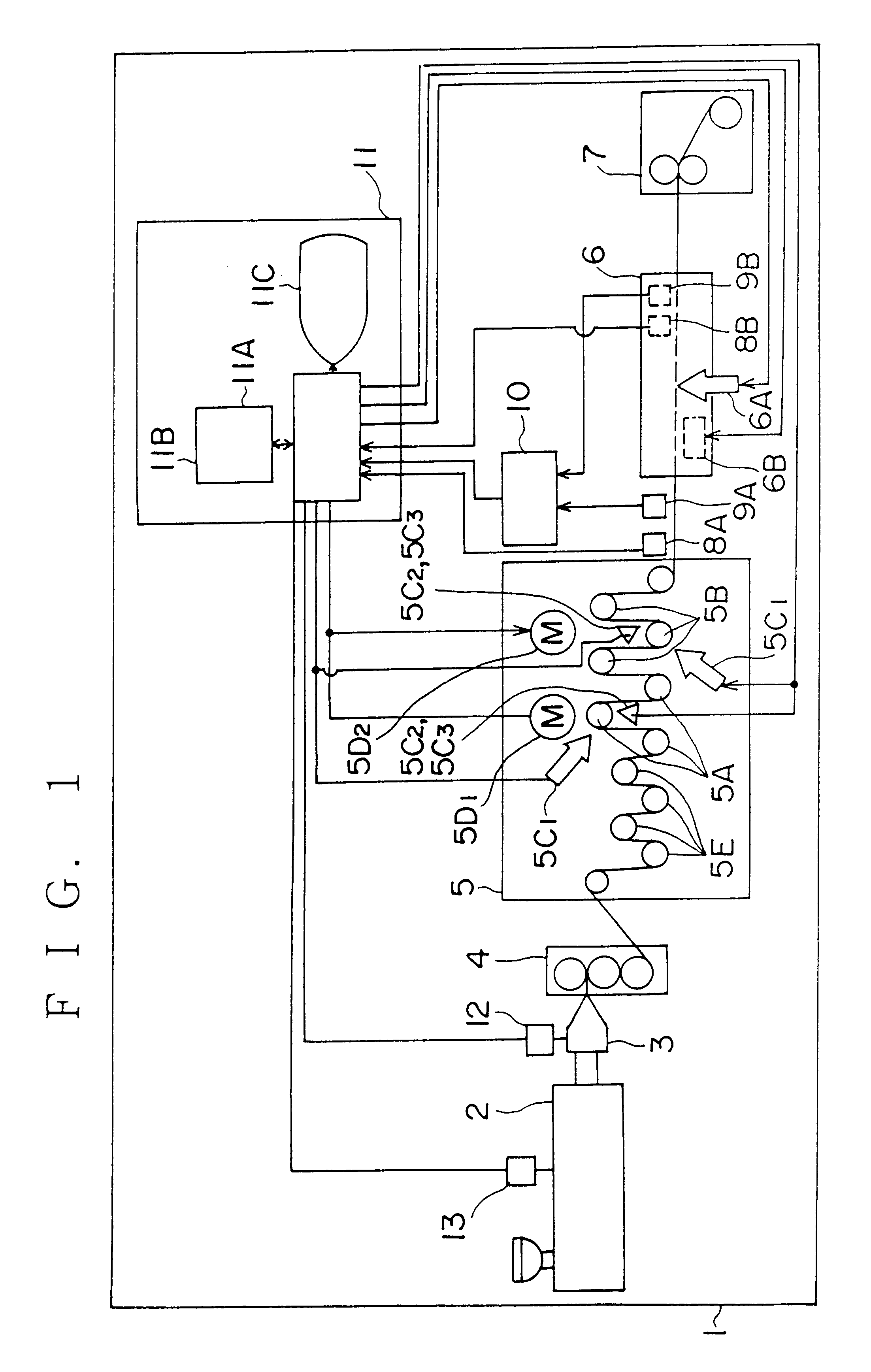

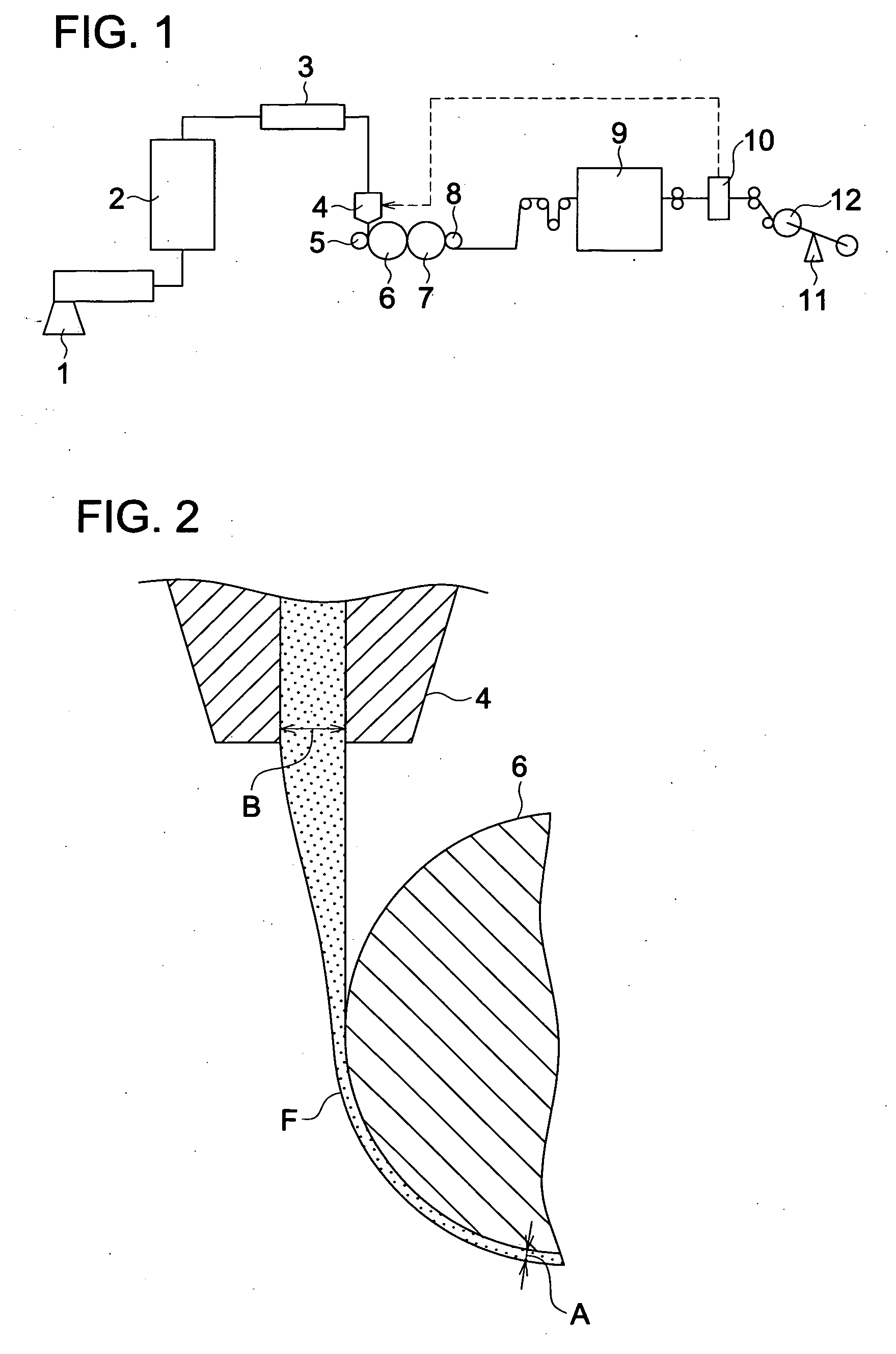

Oriented film producing facility with thickness and orientation control means

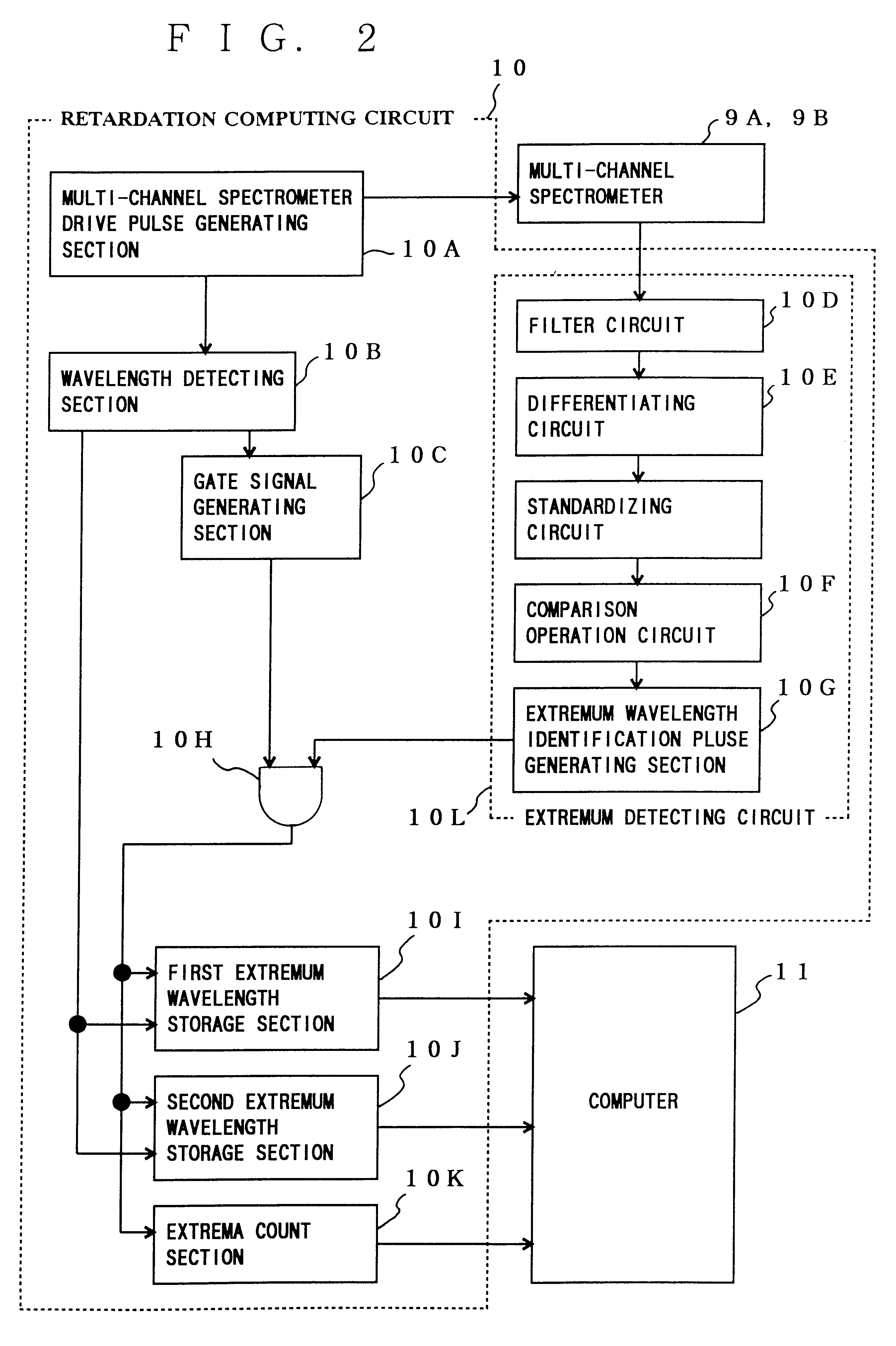

A drawing system in which a thickness and degree of orientation of an oriented film or the like is maintained in a uniform manner under a condition of a high speed, shortened is a time required from a time when a molding material is charged in an extruder and drawing started until a time when a film is taken up on a take-up apparatus, and a high quality film or the like is produced at a high speed and besides, a probability for a not-oriented or oriented film or the like to be broken down during drawing is reduced. A thickness and degree of orientation of a film are independently measured in thickness gauges and a film orientation measuring apparatus in a continuous manner after longitudinal drawing or lateral drawing and measured values are input to a computer. The computer input with the measured values respectively compares preset target values with the measured thickness and degree of orientation and a control operation to change a longitudinal draw ratio is conducted if the measured values are different from respective preset values based on results of comparison processing.

Owner:MITSUI CHEM INC +2

Method for manufacturing large silicon oxide ceramic sheet

The invention discloses a method for manufacturing a large silicon oxide ceramic sheet. The method comprises the following steps of: preparing blank soil particles serving as raw materials, preparing the green body of the large silicon oxide ceramic sheet, preparing the base body layer plain panel of the large silicon oxide ceramic sheet and preparing the large silicon oxide ceramic sheet finished product. The large silicon oxide ceramic sheet is prepared from the following raw materials in part by weight: 30 to 60 parts of needle-like wollastonite, 25 to 30 parts of clay, 15 to 20 parts of mullite, 15 to 20 parts of china clay, 10 to 20 parts of feldspar and 10 to 30 parts of bentonite; the needle-like wollastonite accounts for 28.57 to 36.36 percent based on the total weight of the raw materials; and the draw ratio of the needle-like wollastonite is (16.5-20):1. The method specifically comprises the following steps of: pressing blank soil particles serving as the raw materials to form the green body under the forming pressure of 6,000 to 7,000tons / m<2>; drying at the temperature of between 80 and 250 DEG C for 40 to 100 minutes; biscuitfiring the base body layer plain panel at the temperature of between 800 and 1,300 DEG C for 50 to 120 minutes; and glazing, printing, firing at the temperature of between 900 and 1,300 DEG C for 30 to 120 minutes to obtain the large silicon oxide ceramic sheet finished product. A rubber pad and redundant green body materials are completely recycled. The specification of the large silicon oxide ceramic sheet finished product is that: the ratio of length to width to thickness is 1,500-2,200mm to 800-1,500mm to 3-6mm.

Owner:山东德惠来装饰瓷板有限公司

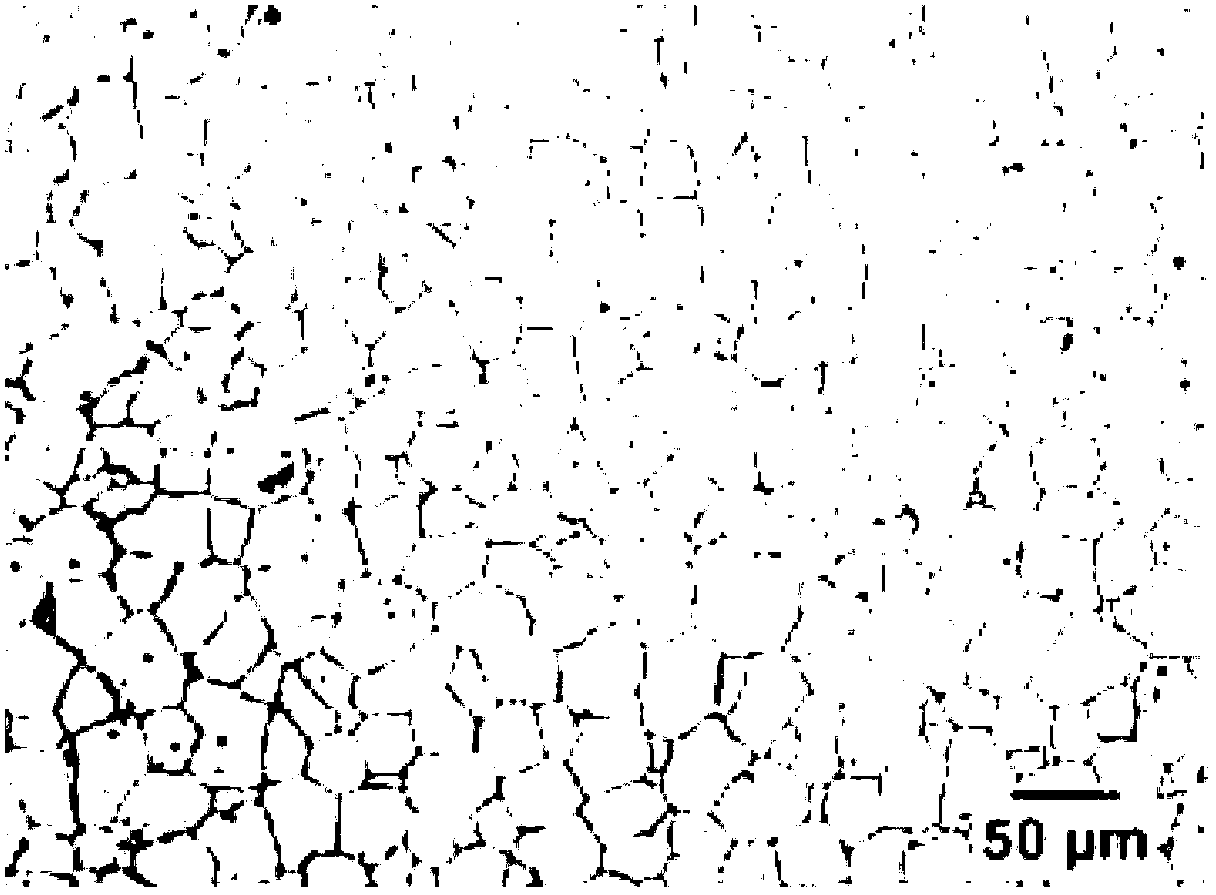

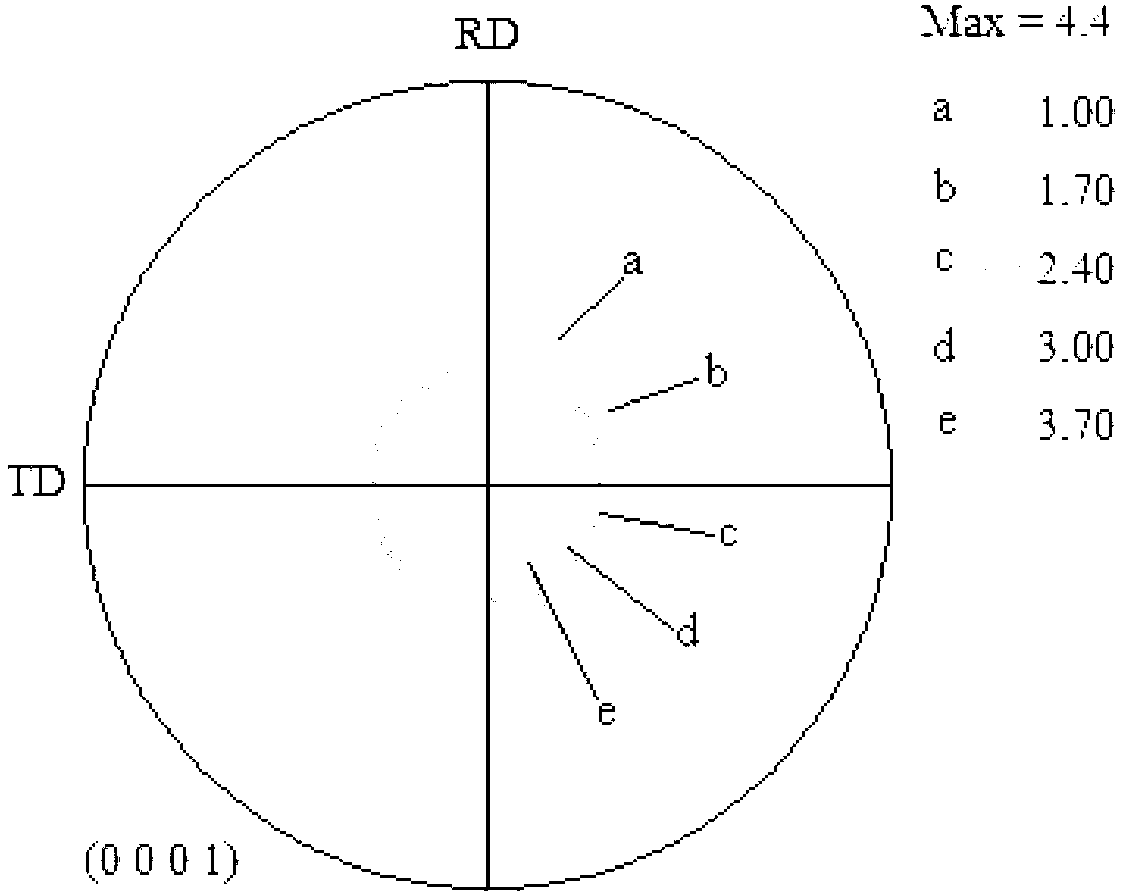

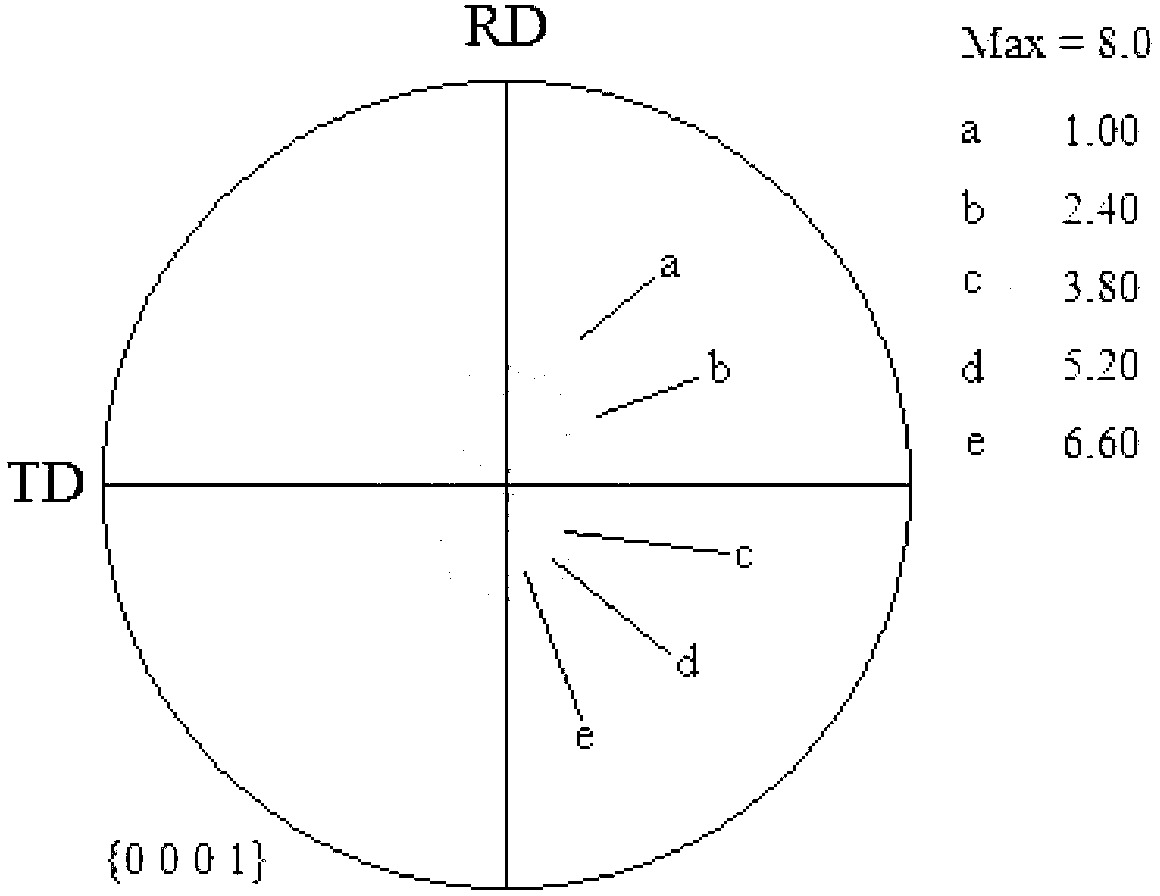

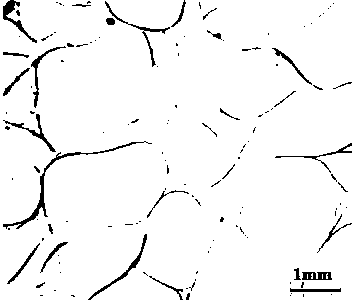

Low-cost fine-grain weak-texture magnesium alloy sheet and manufacturing method thereof

ActiveCN103255329AChanges in mechanical propertiesMeet the requirements of different componentsChemical compositionRoom temperature

The invention discloses a Mg-Ca-Zn-Zr magnesium alloy sheet which comprises the following chemical components in percentage by weight: 0.5-1.0% of Ca, 0.4-1.0% of Zn, 0.5-1.0% of Zr and the balance of Mg and unavoidable impurities, wherein the average grain size of the magnesium alloy sheet is less than or equal to 10 microns, the texture strength of the base surface is less than or equal to 5, and after annealing at 250-400 DEG C, the texture structure of the base surface is less than or equal to 3; the room-temperature ultimate draw ratio is higher than AZ31; the grain size is obviously less than the average grain size of the AZ31B sheet manufactured under the same conditions; and the sheet texture is obviously weakened. According to the magnesium alloy sheet disclosed by the invention, the magnesium alloy has simple composition without precious alloy elements, the technology is widely applicable, the production cost is low, and the magnesium alloy sheet can be used as a plate of components such as an automobile door inner plate, an engine cover inner plate, a trunk lid inner plate, an interior plate, a rail transit vehicle body, a 3C product shell and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Magnesium alloy plate working method and special apparatus

The present invention relates to magnesium alloy preparation technique, in the concrete, it is a processing method of magnesium alloy plate material and its special-purpose hot stamping equipment. Said invention adopts plate stamping technology to form magnesium alloy shell moulded component, and includes the following steps: preheating mould to 200-500 deg.C, heating magnesium alloy plate material to 200-350 deg.C, applying lubricant on plate material and placing said plate material into the mould, controlling drawing ratio in the range of 1.5-3, and its drawing speed is 50-80 mm / min. Said invention can improve the workability of the material, can raise product quality and can raise production efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

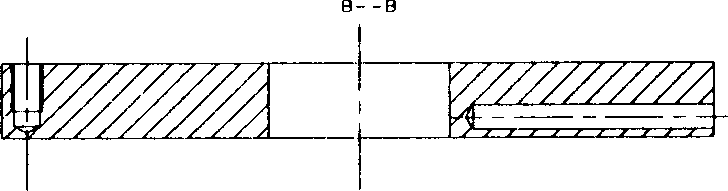

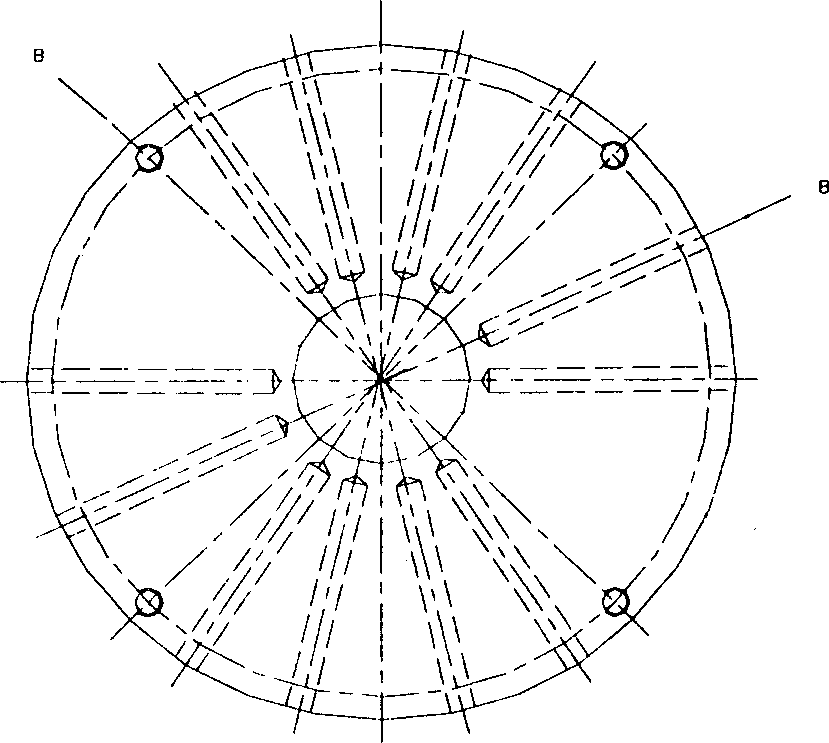

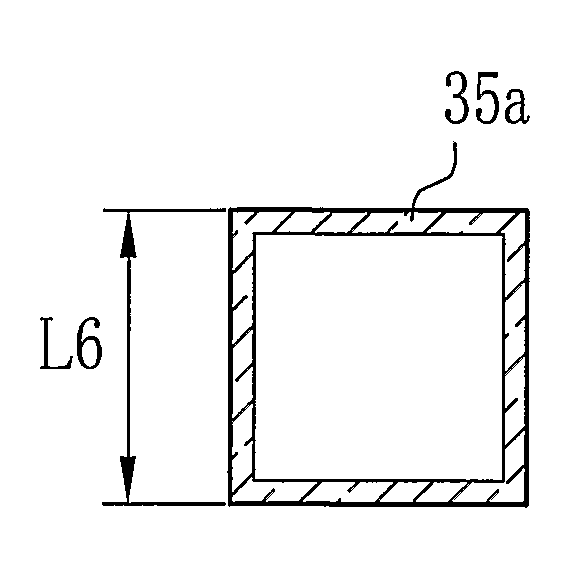

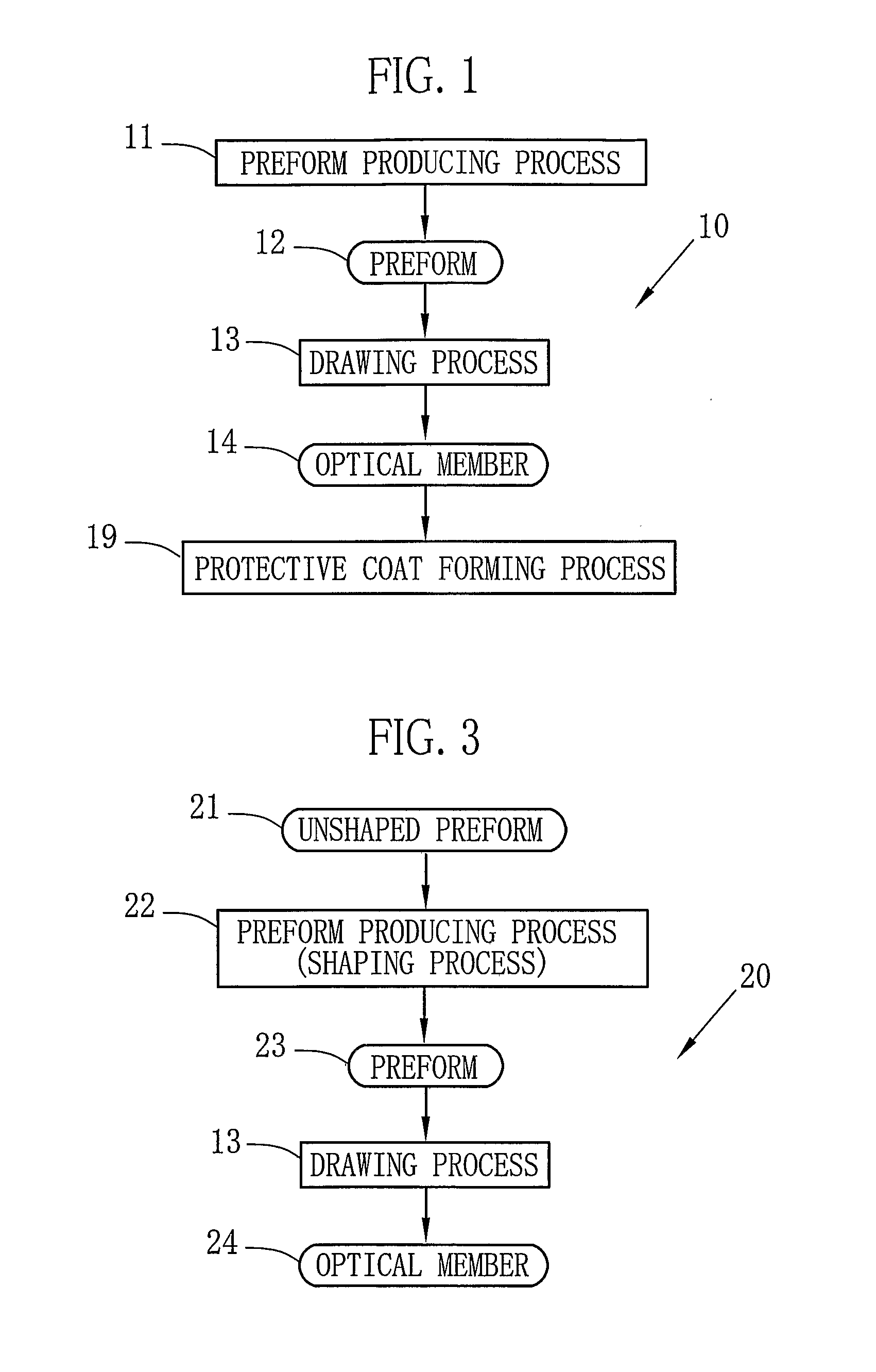

Plastic Optical Member and Producing Method Thereof

InactiveUS20080205840A1Easy to produceSimple structureOptical fibre with multilayer core/claddingOptical articlesSquare cross sectionMelt extrusion

A clad pipe (70) is produced by heating PVDF to 180° C., and then this PVDF being extruded from a melt-extrusion device. The clad pipe (70) has a square cross-section whose sides L1 are 20 mm length, and in a center thereof, there is a square hole. In the square hole, a core (72) mainly includes PMMA is formed. Accordingly, a preform (12) having a clad (71) of PVDF and the core (72) of PMMA is obtained. The preform (12) is heat-soften-drawn at 210° C. A drawing ratio is 1600. Finally, an optical member (14) having a 0.5 mm square cross-section is obtained.

Owner:FUJIFILM CORP

Melt-spun multifilament polyolefin yarn formation processes and yarns formed therefrom

Owner:QUANTUM MATERIALS LLC

Preparation method of tensile transparent conductive membrane material

The invention provides a preparation method of tensile transparent conductive membrane material. Concretely, the invention employs an emulsion method to arrange metal nano wires of high draw ratio, in order to construct an ordered tensile transparent conductive network structure, and solve a caking problem of polymer, thereby the ordered grid structure of the metal nano wires is controllable, and can not be destroyed in a stretching state, and can be combined better with polymers. The light transmittance of the metal nano wire grid is 50-90%, and the diamond resistor is 10-100 ohm / sq, and the number of wire in a grid controllable, and the size of a unit grid is controllable between 50-500 nm; the membrane material can be stretched for more than 1000 times, and the elongation is 5-150%, and the rate of conductivity change is 5-50%.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Polarizing Plate Protective Film, Film Producing Method, Polarizing Plate, and Liquid Crystal Display

Disclosed is a method for production of a film, which comprises the steps of: extruding a molted material containing a cellulose resin on a cooling roll from a die in a film-like form at a draw ratio ranging from 10 to 30 inclusive; pressing the extruded molted film on the cooling roll with a touch roll; and transferring the molted film while solidifying the film on the cooling roll, wherein the touch roll has a metal-made outer cylinder, an inner cylinder, and a space for accommodating a cooling medium between the metal-made outer cylinder and the inner cylinder and also has a touch roll linear pressure ranging from 1 to 15 kg / cm inclusive during pressing with the touch roll.

Owner:KONICA MINOLTA OPTO

Synthetic resin heat-resistant bottle type container

ActiveUS7552834B2Stretch smoothlyNot adversely affect heat resistanceBottlesLarge containersBlow moldingHeat resistance

A slender synthetic resin heat-resistant bottle type container having a circumferential draw ratio of 2.8 or less, for example, comprises at least one pressure reduction absorbing panel (5) provided at a container body part, wherein the pressure reduction absorbing panel is provided with at least one convex portion (6) having a width larger at a lower side than at an upper side as viewed in a circumferential direction of the container. Alternatively, each pressure reduction absorbing panel has a border line bulged toward a container bottom part. This causes a resin to be smoothly stretched even at mold surface portions corresponding to concave and convex portions of a container body part surface upon blow molding. These avoid a defective appearance of the container and do not adversely affect heat resistance thereof.

Owner:YOSHINO KOGYOSHO CO LTD

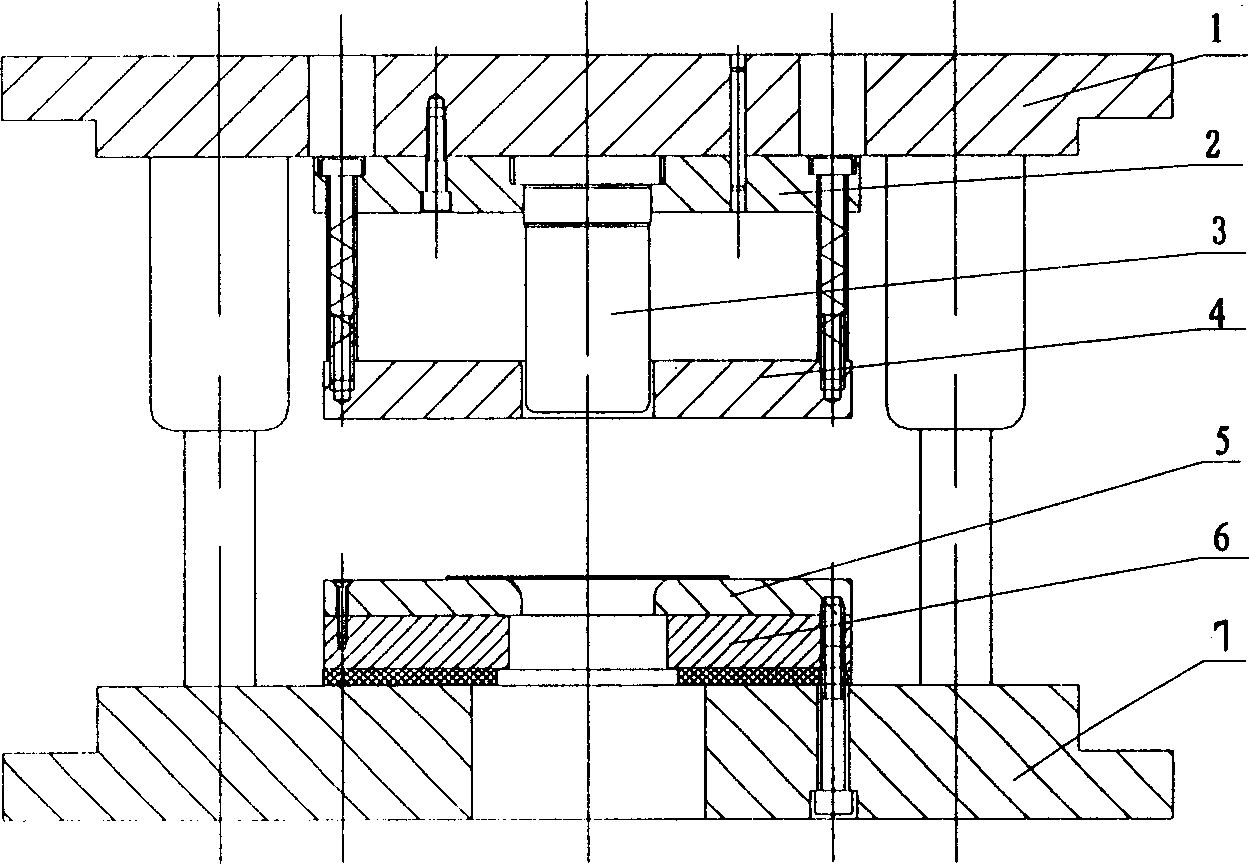

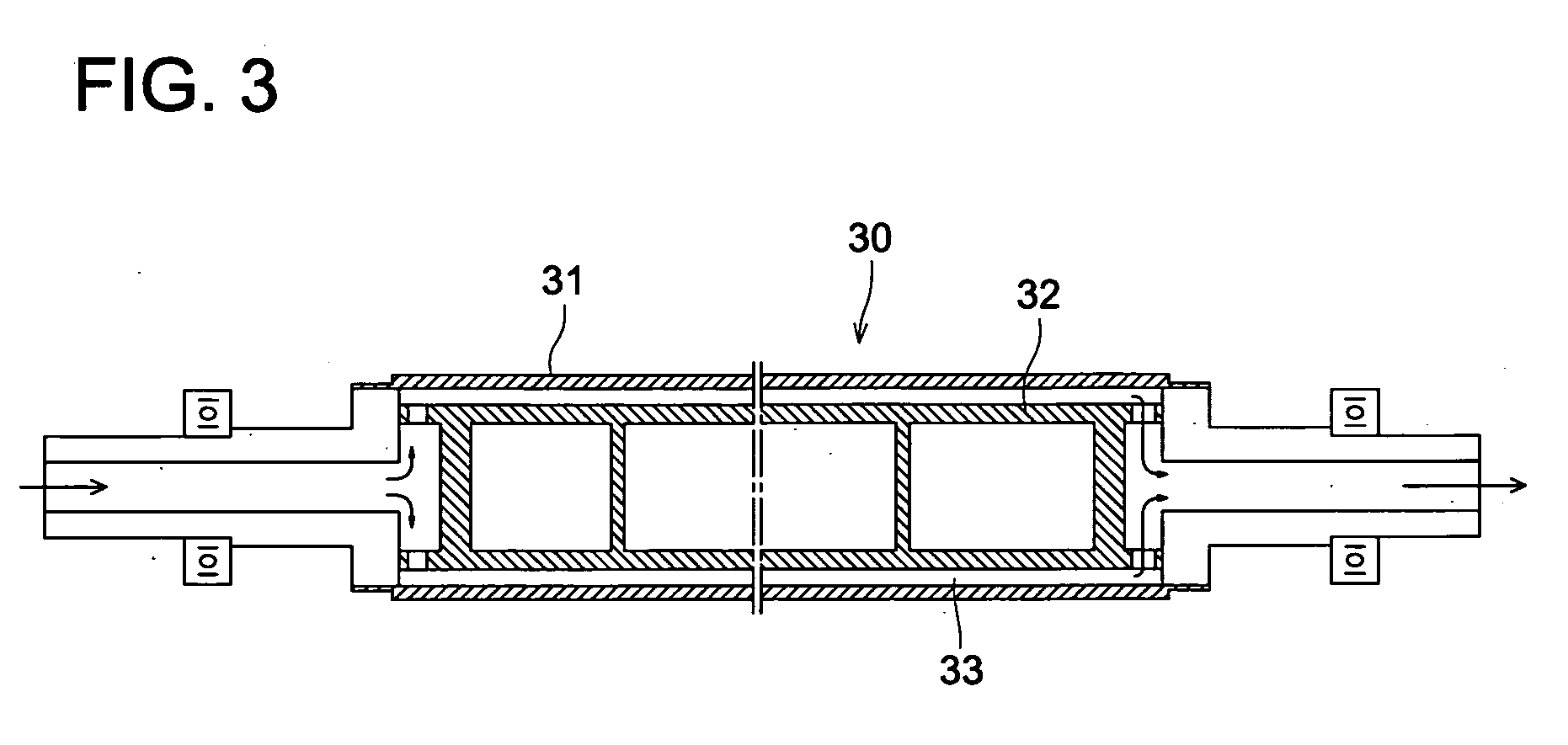

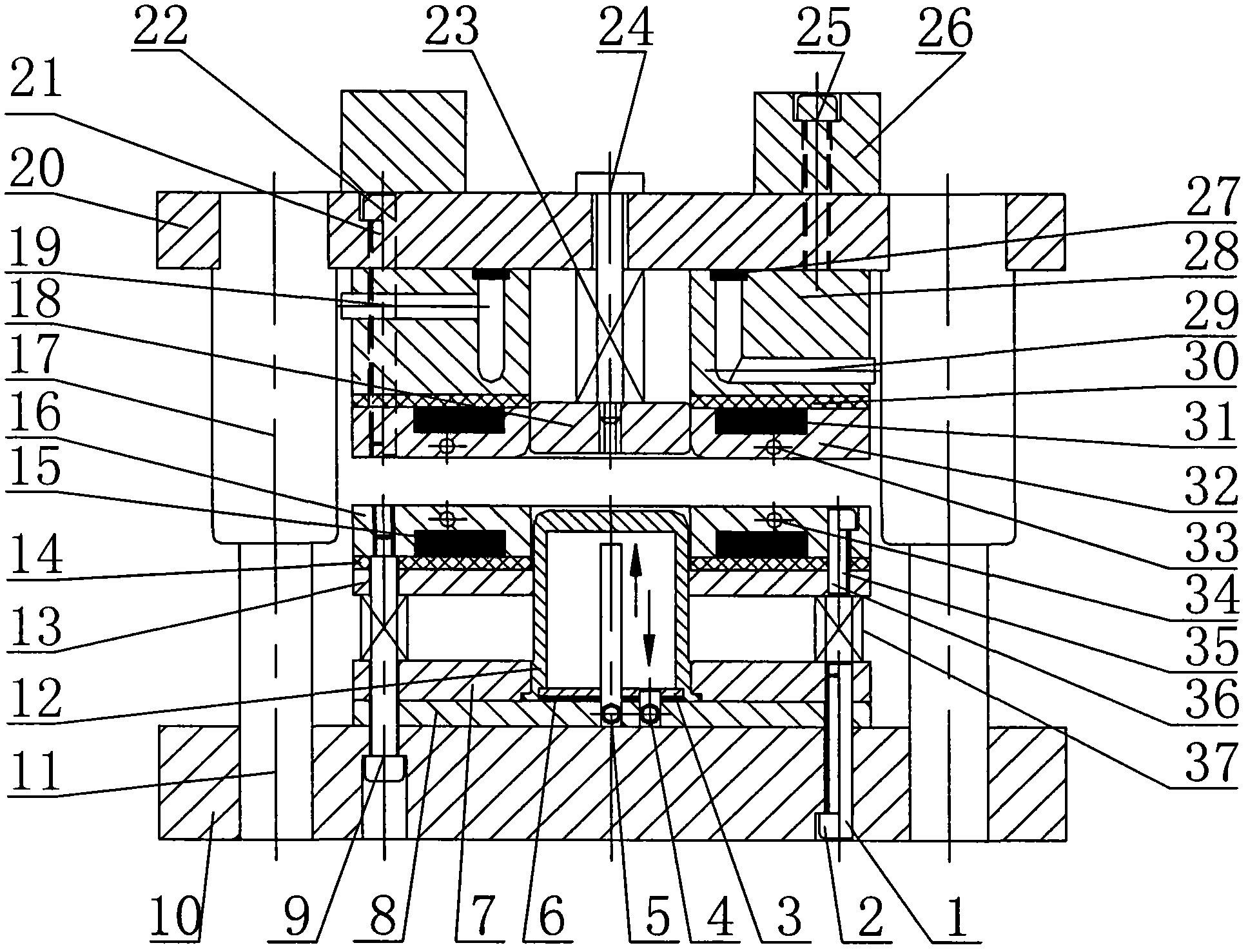

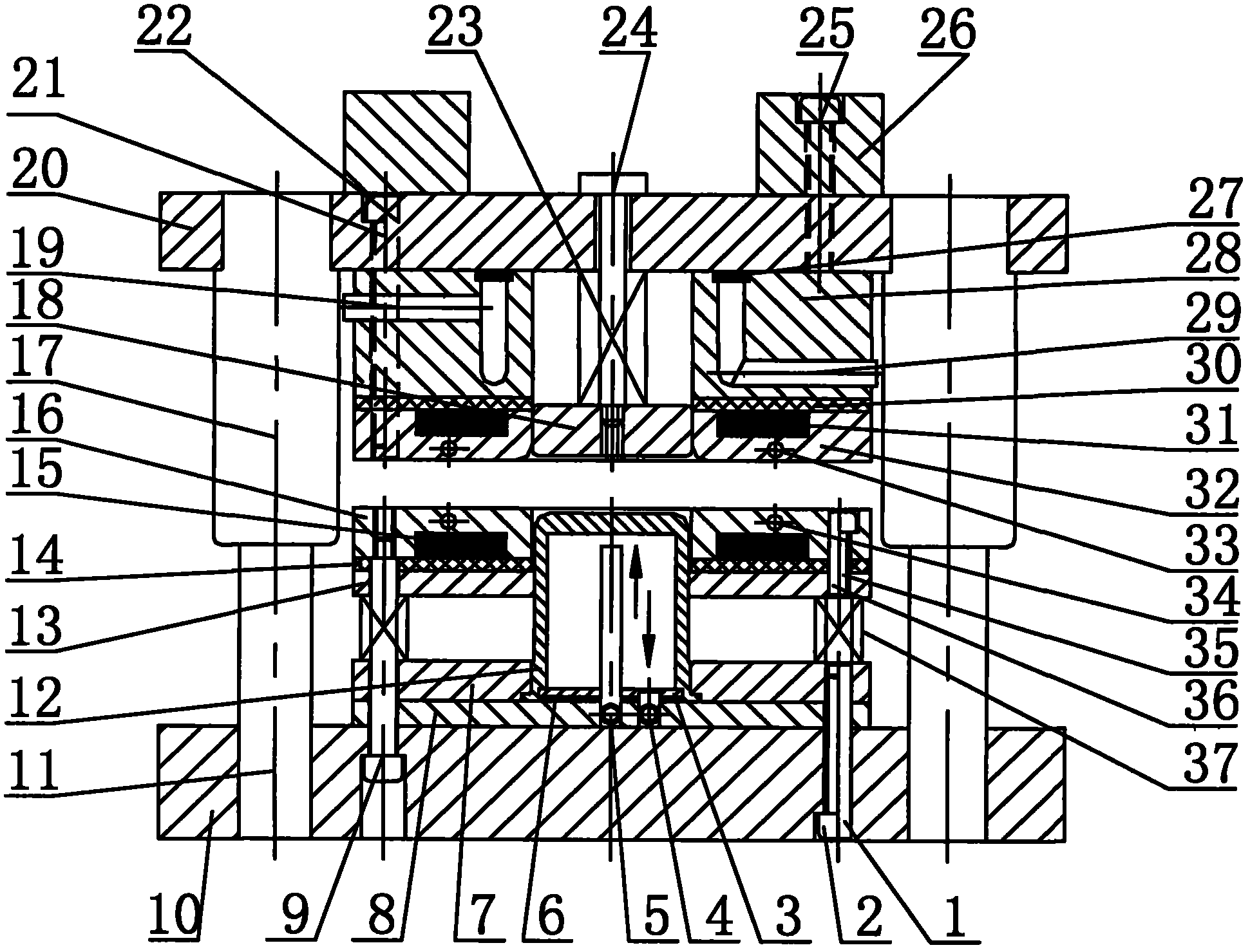

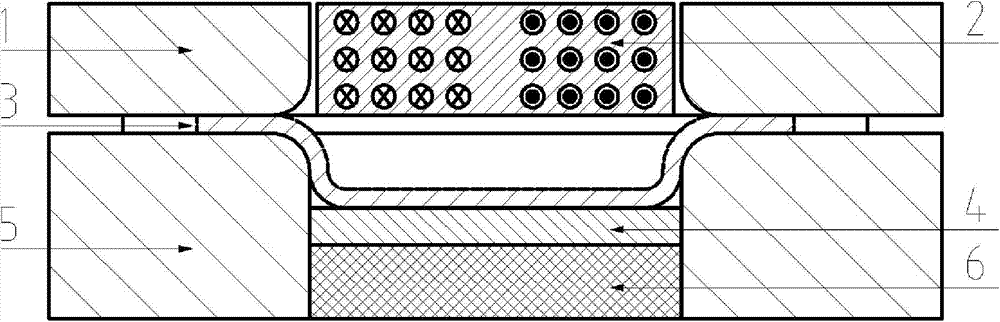

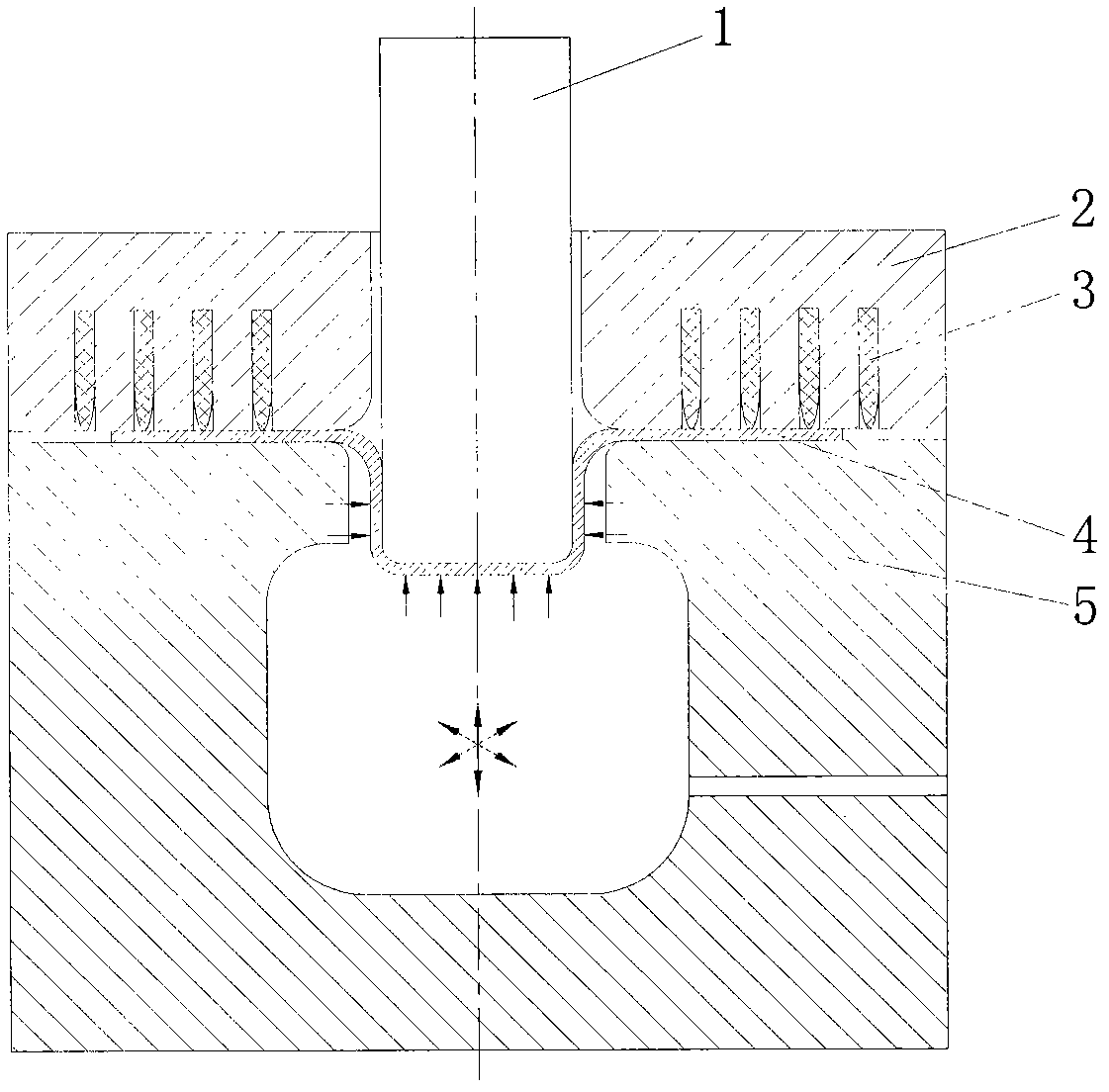

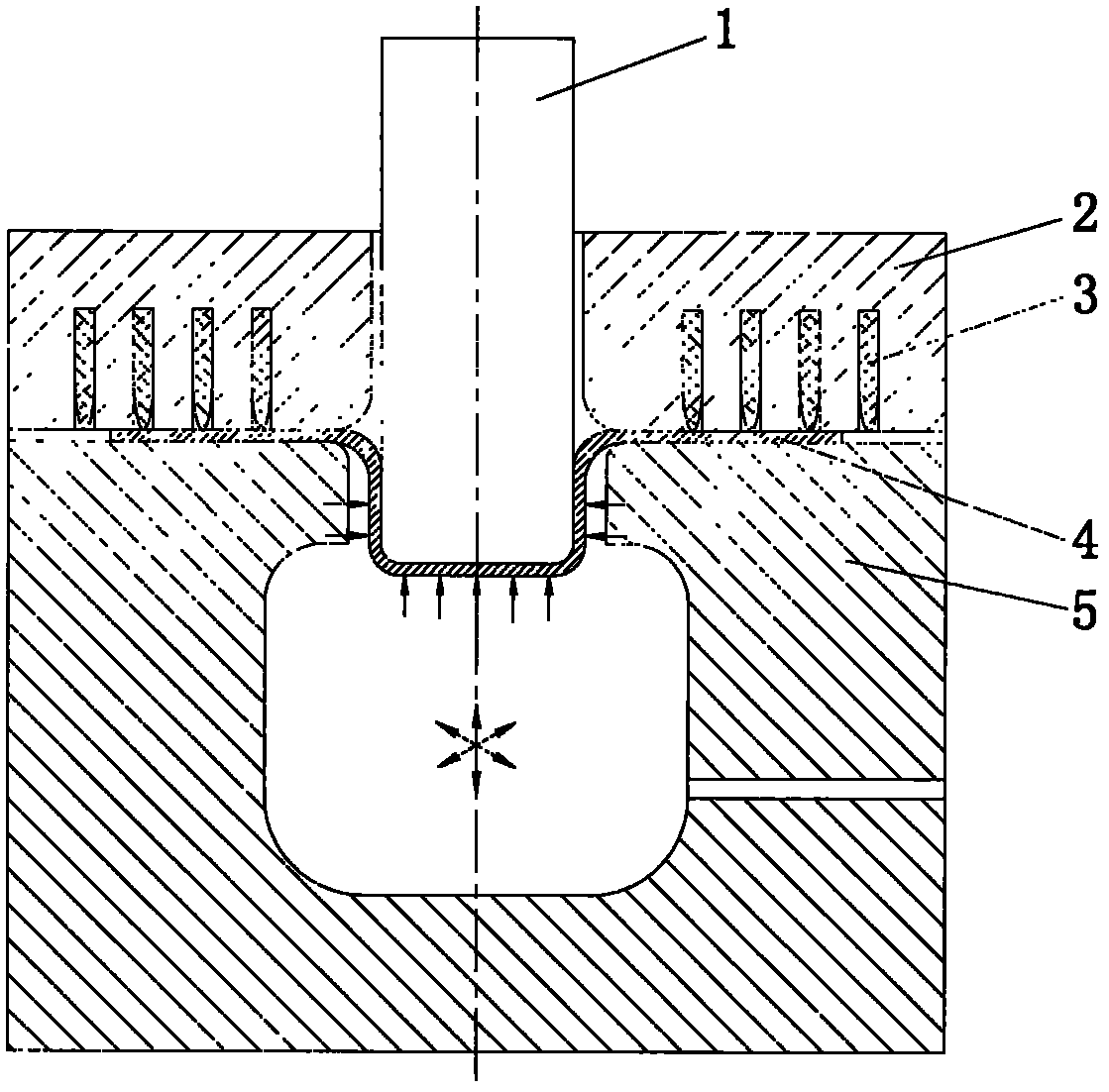

Magnesium alloy sheet different temperature drawing mold

InactiveCN102554040AReasonable temperature differenceIncrease the limit drawing ratioShaping toolsSurface roughnessTemperature difference

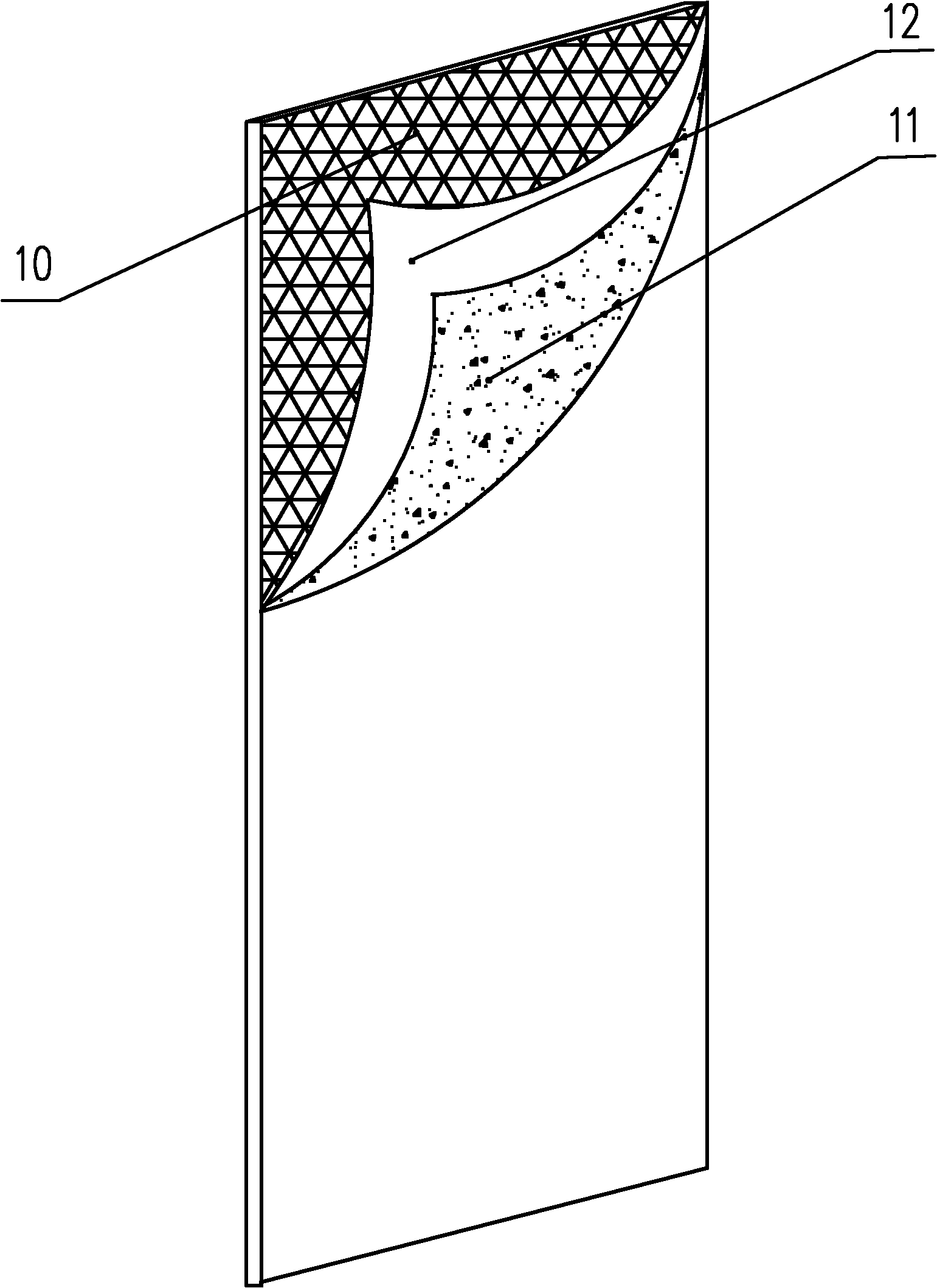

The invention discloses a magnesium alloy sheet different temperature drawing mold. The mold is of inverted type, i.e. a drawing terrace mold (12) and a blank holder (1) are installed at a lower mold of the mold; a concave mold (32) is installed at the upper mold of the mold; a resistance annular heating coil and a temperature measuring element thermal coupler are embedded in the concave mold (32) and the blank holder (1); the upper mold and the lower mold are guided by a ball guide pillar (11) and a guide sleeve (17); and a drawing piece is pushed out from the concave mold (32) by a spring and a hitting plate (18) in the upper mold. A mode of different temperature drawing mold structure is adopted, i.e. a contact part of the blank holder and the concave mold with a blank deformation area is heated, and the cylindrical walls of the concave mold and the terrace mold are cooled, so that the plate blank is provided with a rational temperature difference during the drawing process. The mode of different temperature drawing mold structure is adopted and the surface roughness value of the working surface of the drawing terrace mold is larger than the surface roughness value of the working surface of the blank holder, so that the limiting drawing ratio of AZ31B is improved greatly.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

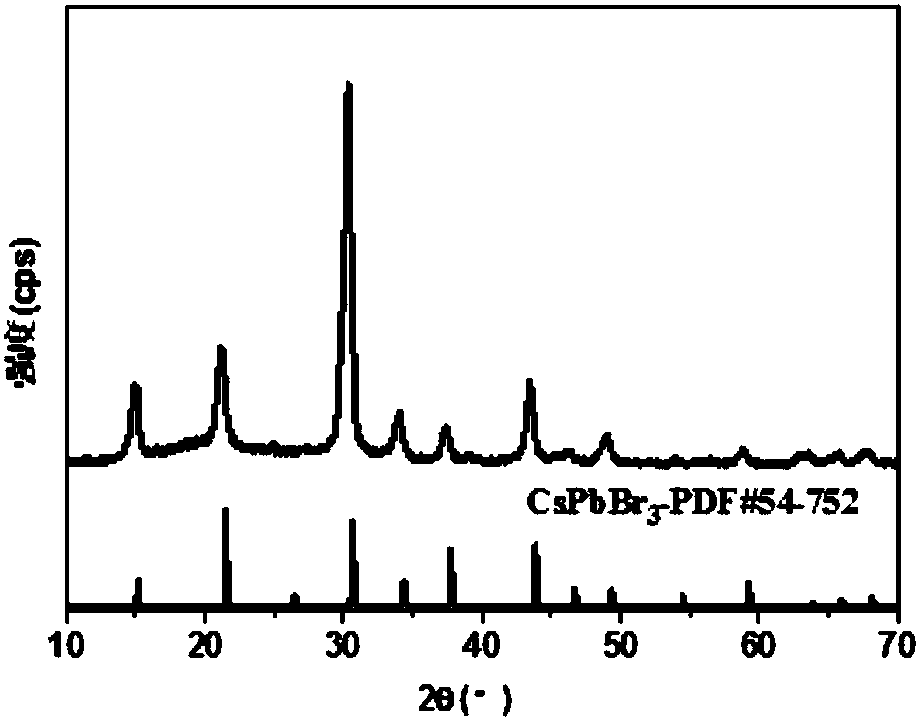

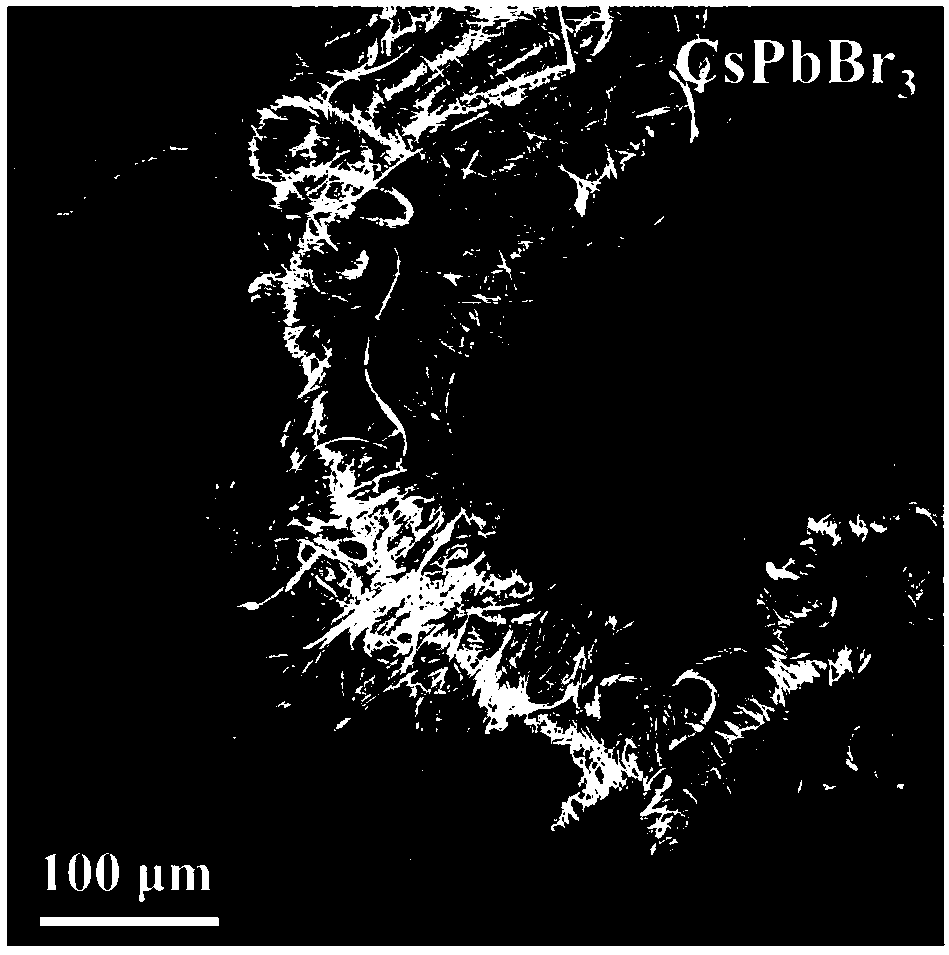

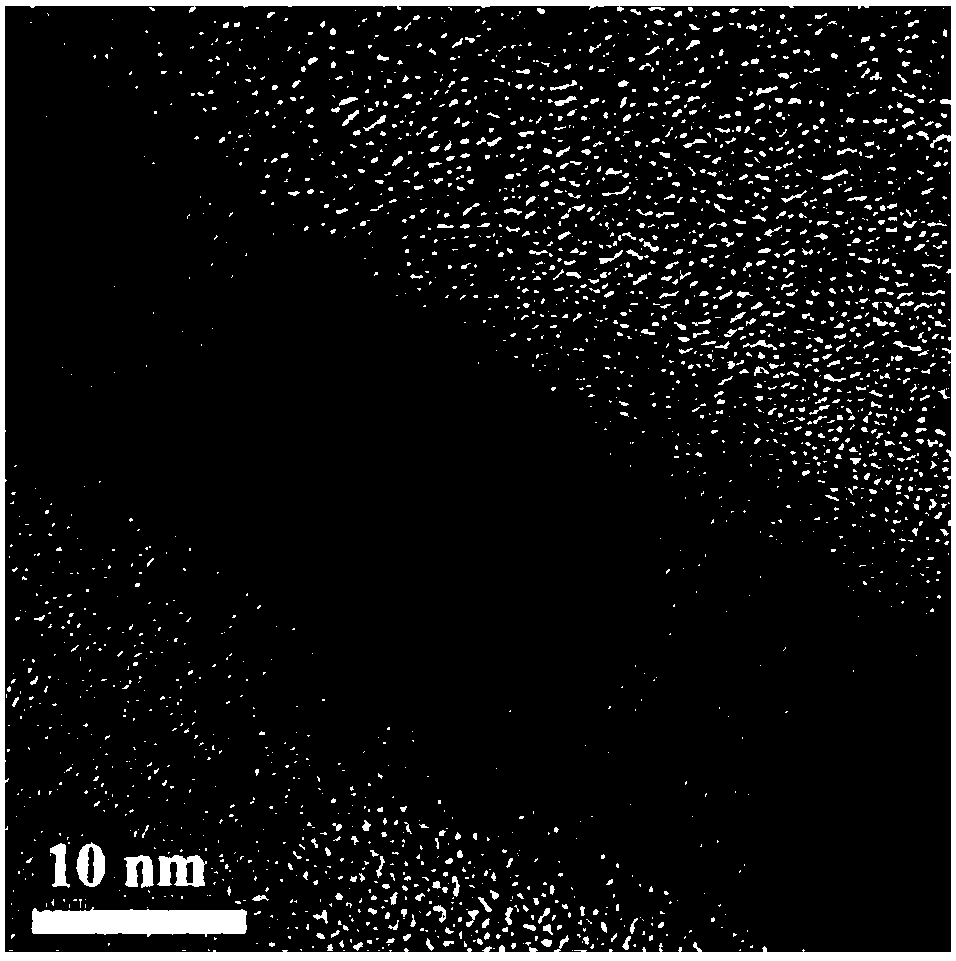

Method for synthesizing inorganic perovskite nanowires

ActiveCN108502918ALow reaction temperatureHigh yieldLuminescent compositionsLead compoundsDrawing ratioIon exchange

The invention discloses a method for synthesizing inorganic perovskite nanowires. According to the method, a CsPbBr3 nanowire which has a length of several millimeters, a diameter of only about 10 nmand an ultrahigh draw ratio is prepared at a low temperature by utilizing a solvothermal method and an anion exchange method, and nanowires CsPbI3 and CsPbCl3 are obtained by virtue of a simple anionexchange process. The method has a great effect of promoting industrial large-scale preparation of inorganic perovskite nanowires and is expected to further realize application in various aspects suchas photoelectric detection, laser and solar cells and the like. The method disclosed by the invention is simple, controllable, high in yield, uniform in morphology, low in reaction temperature and suitable for large-scale production.

Owner:HEBEI UNIV OF TECH

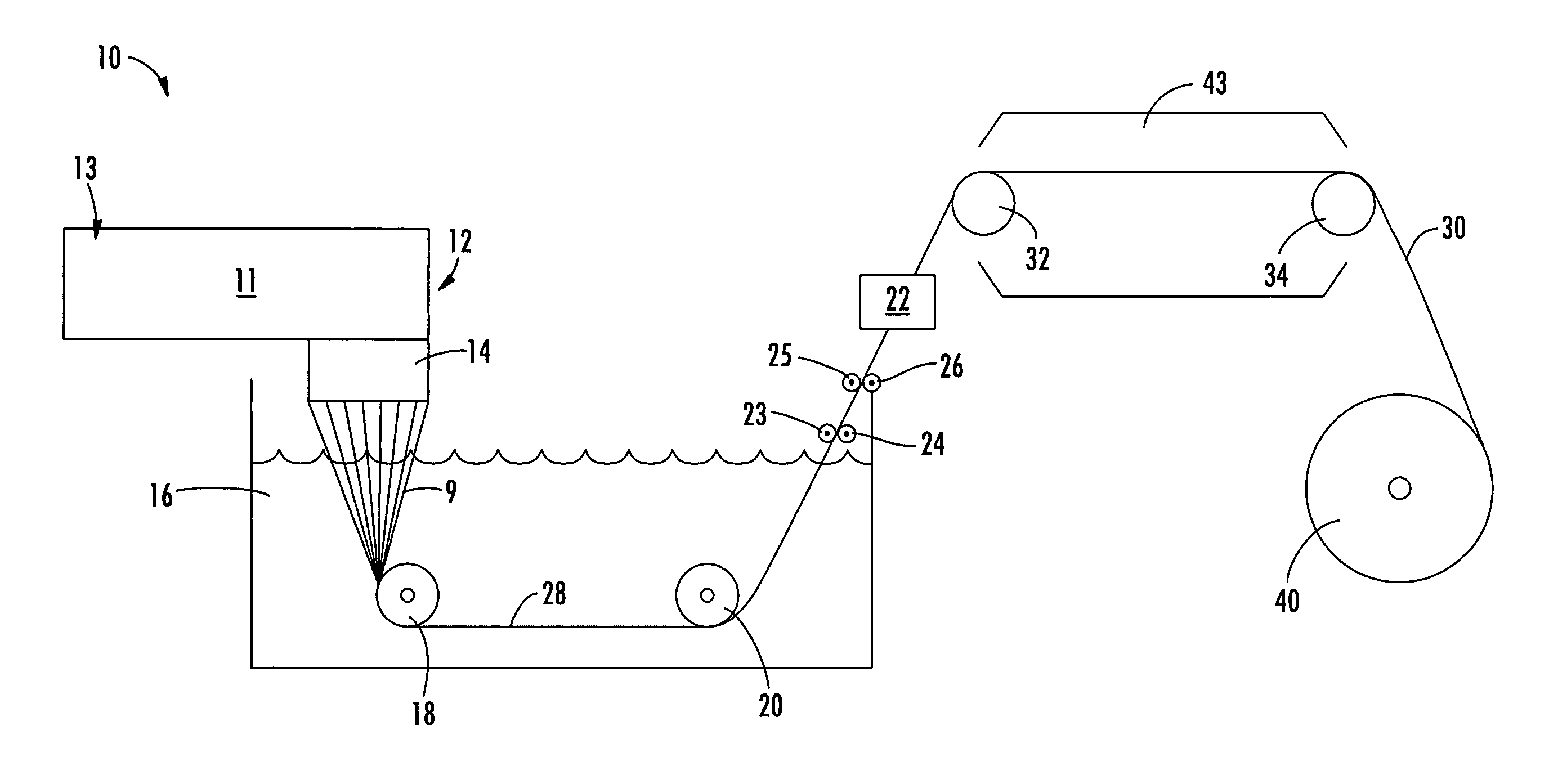

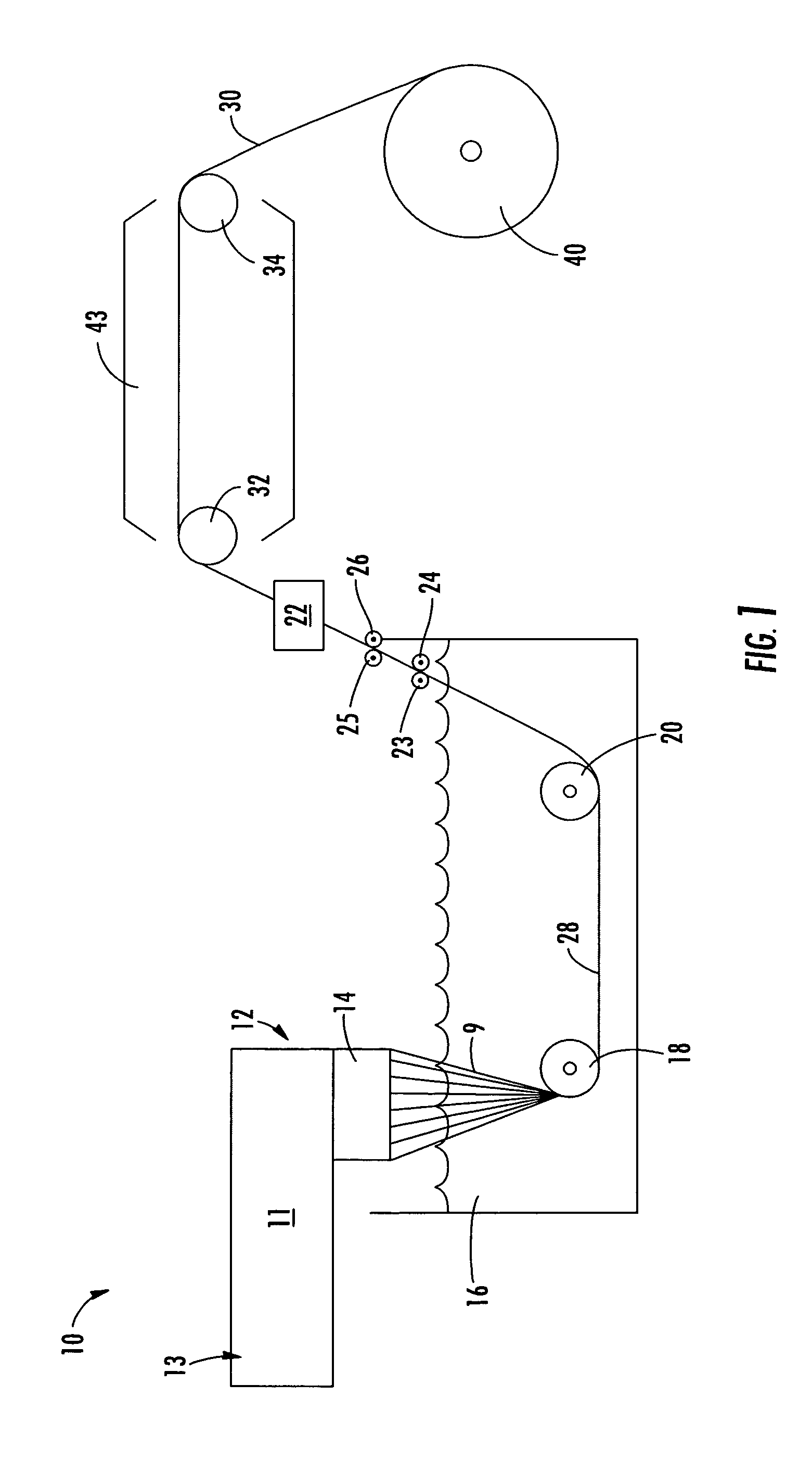

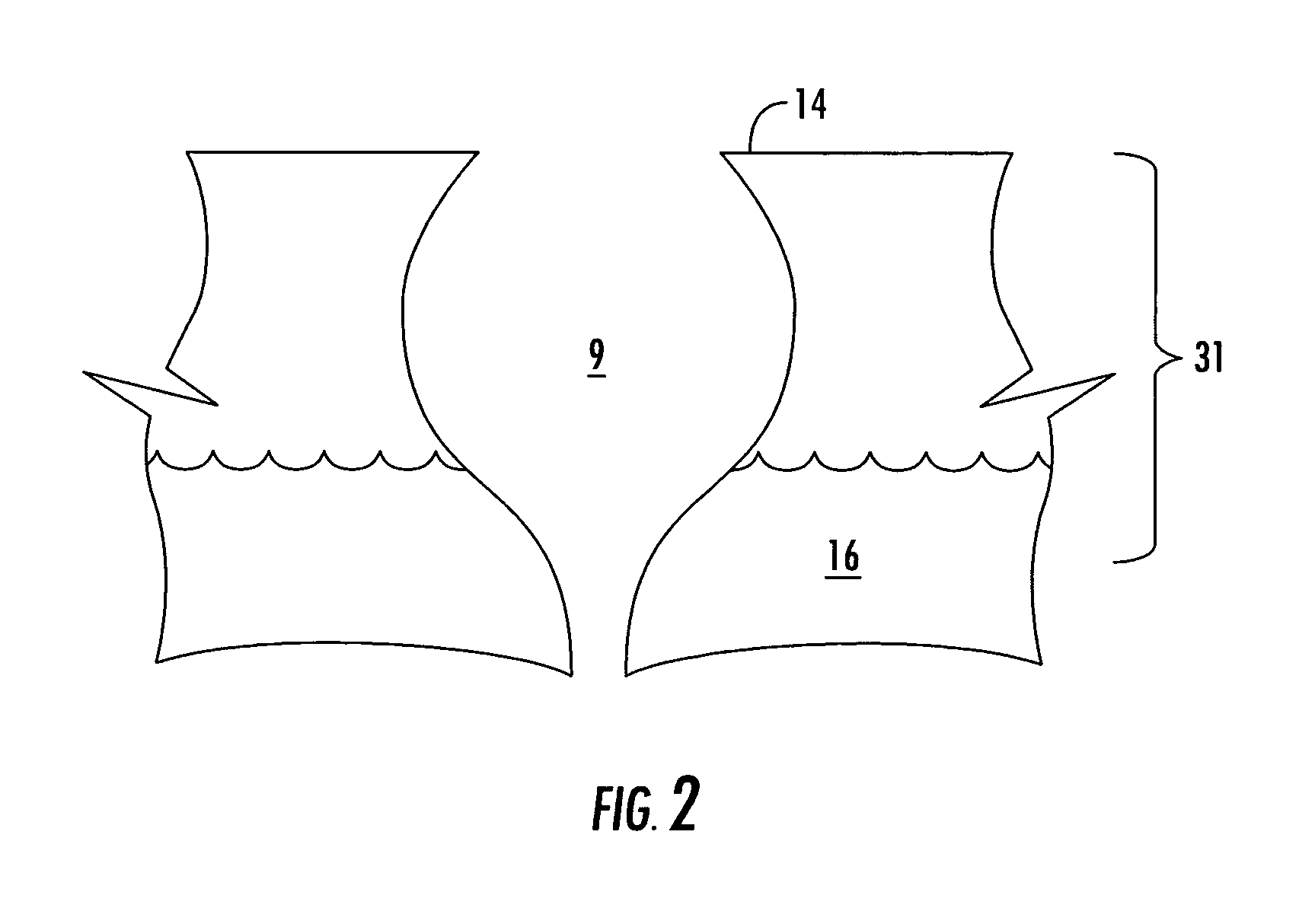

Melt-spun multifilament polyolefin yarn formation processes and yarns formed therefrom

ActiveUS20060099415A1Increase temperatureFilament/thread formingMonocomponent polypropylene artificial filamentYarnPolymer science

Disclosed is a method of forming multifilament polyolefin yarns and yarns formed according to the disclosed method. The yarns can be polypropylene yarns and can exhibit any of a high modulus, high tenacity, and a unique crystalline structure for multifilament polyolefin yarns. The process can generally include extruding a polymeric melt including the polyolefin at a relatively high throughput and low spinline tension and quenching the filaments in a liquid bath prior to drawing the fiber bundle at a relatively high draw ratio, for example greater than 10, in some embodiments.

Owner:INNEGRITY LLC

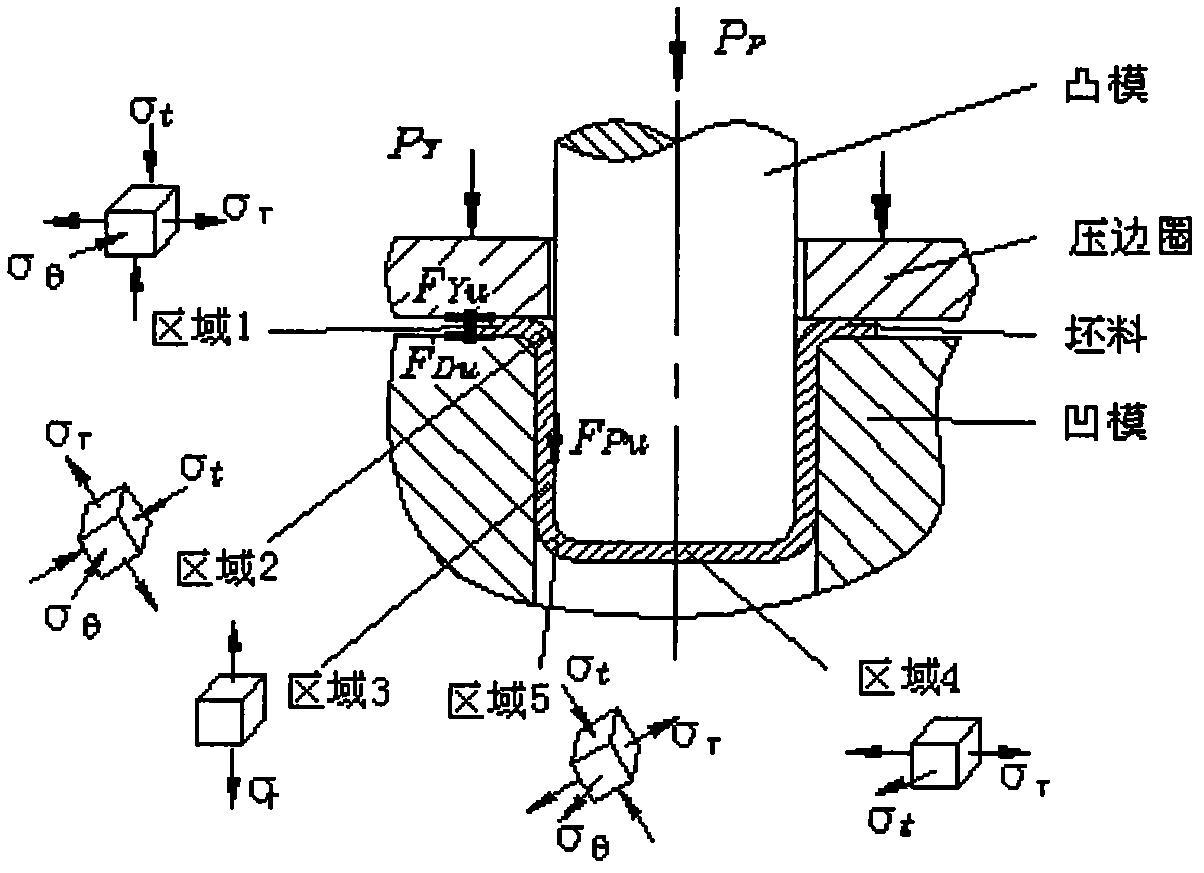

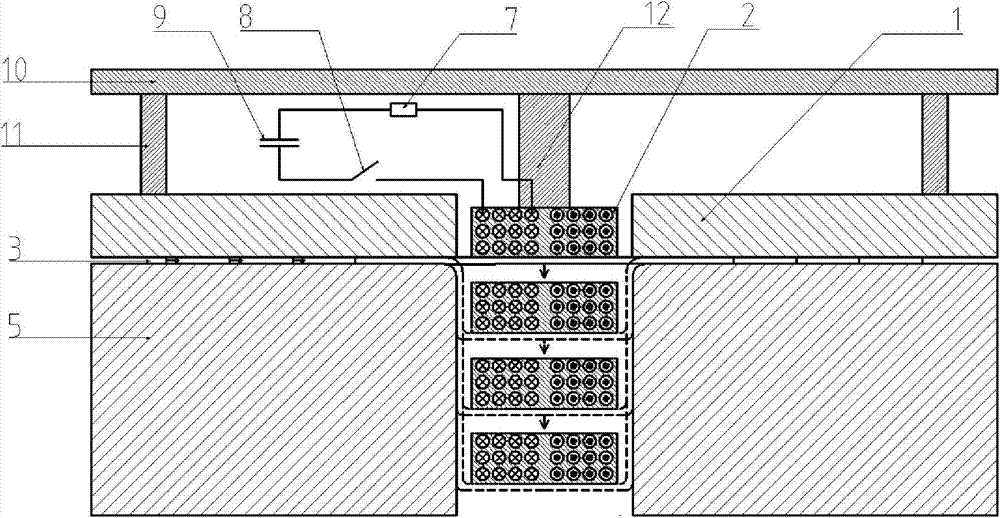

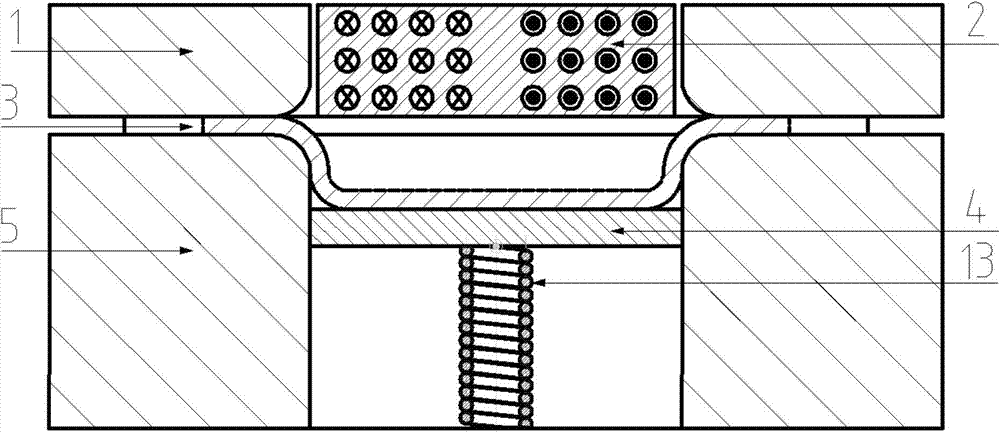

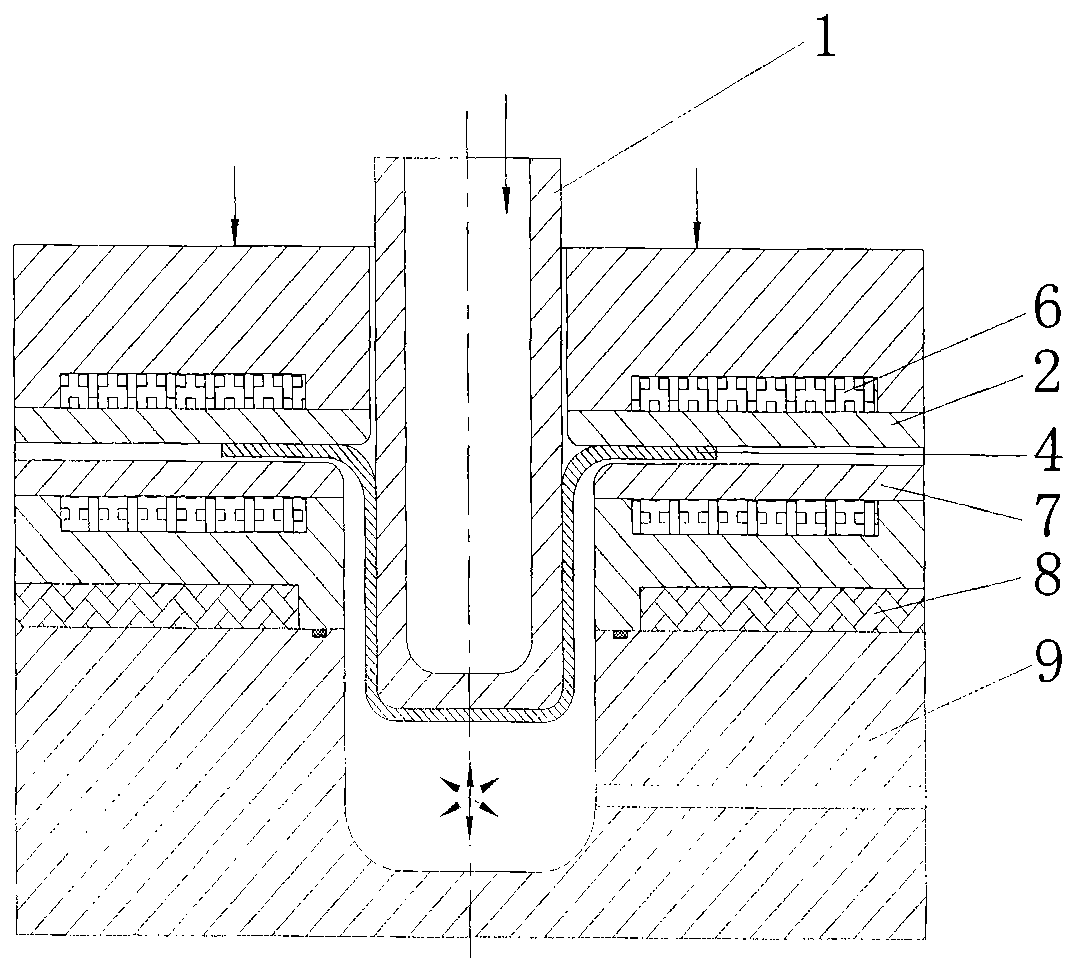

Electromagnetic forming method for deeply punched member

The invention provides an electromagnetic forming method for a deeply punched member. The method comprises the first step of placing a sheet to be formed in a female die, the second step of placing a coil on the sheet to be formed, the third step of allowing the sheet to be formed to be just in contact with a stop block of the female die, the fourth step of driving the coil to descend to the position where the coil is just in contact with the sheet to be formed, the fifth step of performing charging and discharging so as to generate pulse current in the coil to make the sheet to be formed be deformed at a high speed, the sixth step of performing heat treatment of annealing on the sheet to be formed, the seventh step of placing the sheet to be formed after the heat treatment of annealing back onto the female die and pressing the sheet to be formed tight through a drawing ring, and the eighth step of repeating from the second step to the seventh step until electromagnetic forming with a high depth-diameter ratio is completed. Deep drawing of the sheet to be formed (such as an aluminum alloy sheet) is achieved through the electromagnetic forming method of one-time discharging plus one-time annealing, and electromagnetic forming with the high depth-diameter (forming depth to the diameter of a final part) ratio larger than two to one is achieved; compared with common drawing at constant temperature, the extreme drawing ratio can be enhanced obviously.

Owner:HUAZHONG UNIV OF SCI & TECH

Manufacturing technology for far-infrared polyester short fibers

InactiveCN102560732ALow costPromote environmental protectionHollow filament manufactureArtificial filament heat treatmentPolyesterManufacturing technology

The invention discloses a manufacturing technology for far-infrared polyester short fibers, which takes recycled PET (Polyethylene Terephthalate) as a raw material, and the recycled PET is processed sequentially through pretreatment, rotating drum drying, melt spinning, cooling formation, winding, drawing, curling, oil application, cutting and heat setting, so as to obtain finished products, wherein in the rotating drum drying step, the recycled PET is dried for 5.5 to 6.5 hours firstly, then far-infrared master batches are added, the final mass fraction of the far-infrared master batches ranges from 5 to 7 percent, the total drying time ranges from 9.5 to 10.5 hours, and far-infrared ceramic powders account for 19 to 21 percent in the far-infrared master batches; in the melt spinning step, the temperatures of a screw bolt and a spinning box body of a screw bolt extruder range from 268 to 278 DEG C, and cooling formation is carried out through circular air blow; in addition, the total drawing ratio is 3.0 to 3.5, the heat setting temperature ranges from 162 to 168 DEG C, and the heat setting time ranges from 8 to 12 minutes. The manufacturing technology can save cost and is beneficial to environmental protection, and the prepared finished products achieve good warmth retention and health protection properties.

Owner:HANGZHOU BEST CHEM FIBER

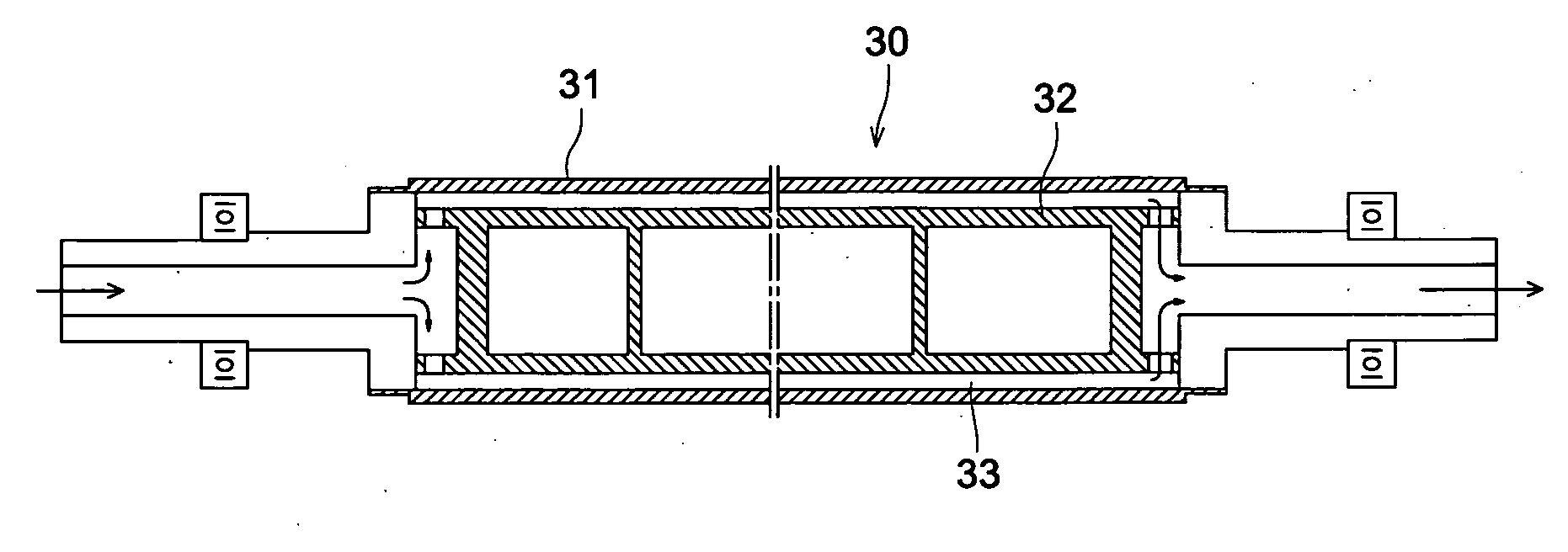

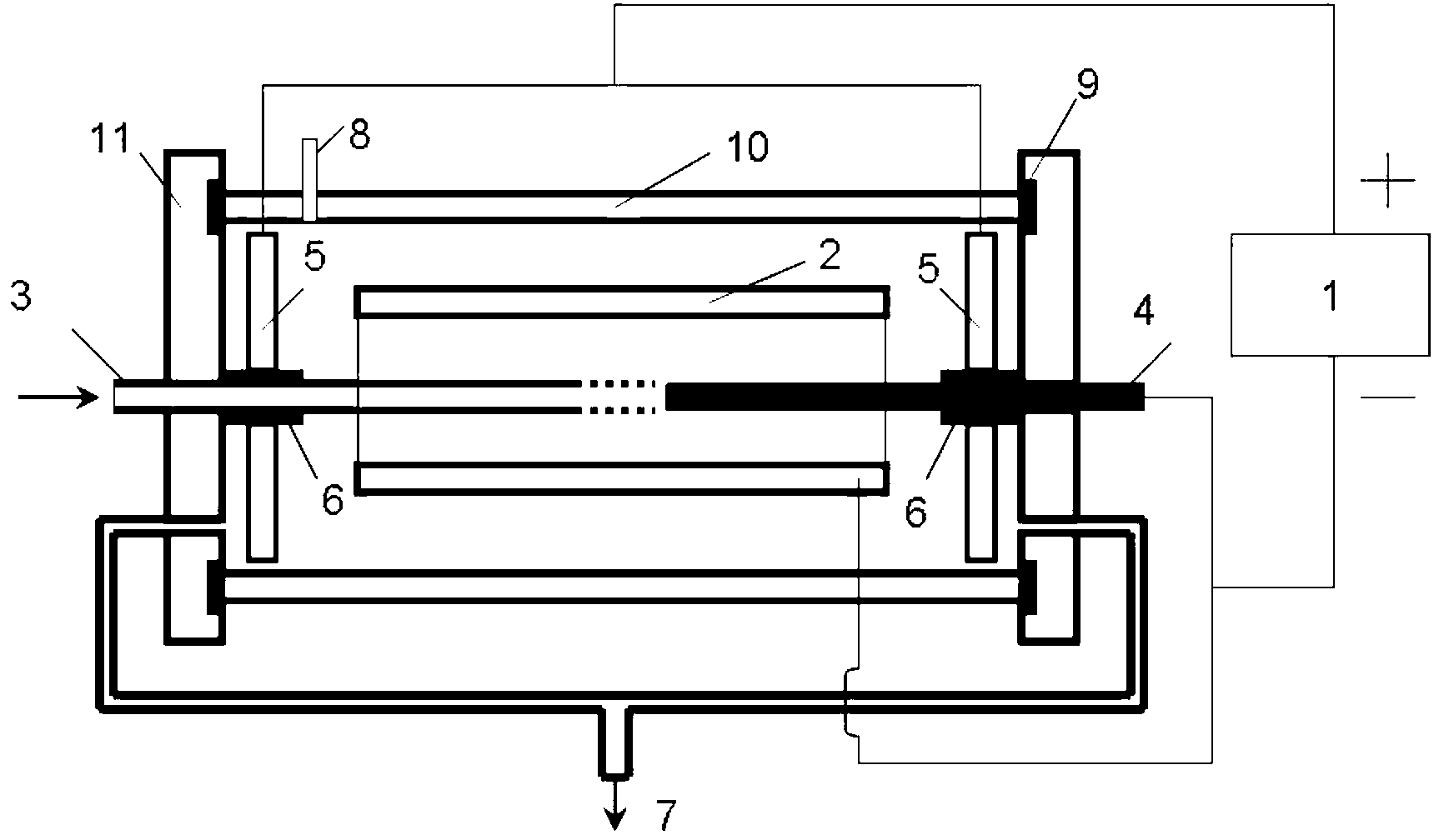

Metal inner surface modification device and method

InactiveCN103320772AAchieve chemical permeationImprove surface modification efficiencySolid state diffusion coatingChemical vapor deposition coatingDiamond-like carbonNitrogen gas

The invention discloses a metal inner surface modification device and method and belongs to the technical field of plasma surface modification. The method is characterized by comprising the following steps: generating plasmas on a metal inner surface by utilizing the principle of hollow-cathode discharge, and nitriding or depositing diamond like carbon, so as to improve the hardness, the wear resistance and the corrosion resistance of the metal inner surface; by taking a treated piece as a cathode, arranging the cathode inside, adjusting the distance and the vacuum degree between a workpiece and the cathode to reach the discharge condition, arranging an anode at the periphery of a cathode cavity, and adding a direct current pulse power supply between the anode and the cathode, wherein reaction gas is nitrogen or ammonia gas and carrier gas is argon gas during the nitriding, and the reaction gas is methane or acetylene and the carrier gas is argon gas in the process of depositing a hard carbon film. The method has the effects and advantages of simple process, low cost and high efficiency and is particularly suitable for treating the metal inner surface and pipe fittings of large draw ratios.

Owner:DALIAN UNIV OF TECH

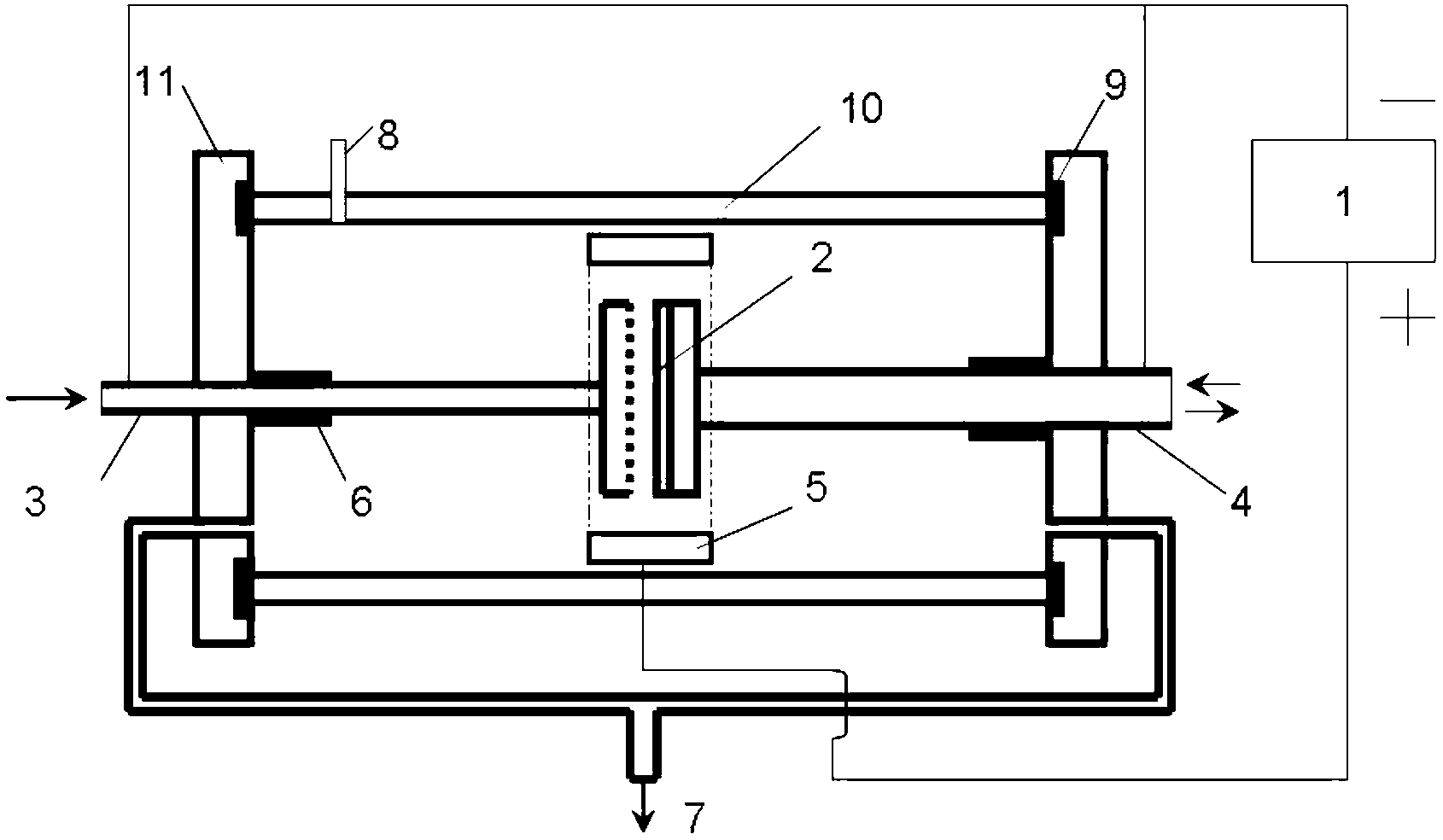

Thermal hydro-mechanical drawing forming method for dot matrix self-impedance electrical heating plates

InactiveCN102139304ARealize controllable flexible heatingRaise the forming limitShaping toolsOhmic-resistance heating detailsDot matrixEngineering

The invention relates to a thermal hydro-mechanical drawing forming method for dot matrix self-impedance electrical heating plates, and belongs to the technical field of the thermal hydraulic forming of the plates. The method comprises the following steps of: fully filling liquid into a cavity of a female die serving as a liquid pond; when the plates are driven by a male die to enter the female die, forming the plates by reverse pressure generated when the liquid is compressed; embedding pin type electrodes inside pressure plates according to the distribution of dot matrixes, and performing self-impedance electrical heating on flanges of the plates by using contact resistors between the electrodes and the plates; adjusting the distribution of temperature fields of the flanges by changing the distribution law of the dot matrixes of the electrodes and adjusting the heating current of each heating electrode; adjusting the flow stress of heating points by changing the temperature of each mass point on the flanges so as to control the flow of metal by the asynchronous flow of the metal mass points on the flanges; and coordinating the deformation process of the metal by the asynchronousdeformation of each mass point on the flanges due to the temperature to fulfill the aim of improving the limit drawing ratio of the plates. The method has the advantages that: the heating speed is high, the effect is good, the plates can be heated controllably and flexibly, and the forming limit of the plates is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Process for making a monofilament-like product

ActiveUS8022171B2Pleasant touchPleasant feelCeramic shaping apparatusMonocomponent polyolefin artificial filamentFiberPolyolefin

The invention relates to a process for making a monofilament-like product from a precursor containing a multitude of continuous polyolefin filaments, comprising exposing the precursor to a temperature within the melting point range of the polyolefin for a time sufficient to at least partly fuse adjacent fibers and simultaneously stretching the precursor at a draw ratio of at least 2.8. With the process according to the invention a monofilament-like product can be made that shows improved tensile properties; making it very suitable for application as e.g. fishing line.

Owner:PURE FISHING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com