Curing treatment method of carbon fiber precursor polyacrylonitrile fiber

A technology of polyacrylonitrile fiber and processing method, which is applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of failure to improve fiber molecular orientation, cost increase, lack of drafting means, etc., achieve good application prospects, improve Degree of Orientation, Effect of High Tensile Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

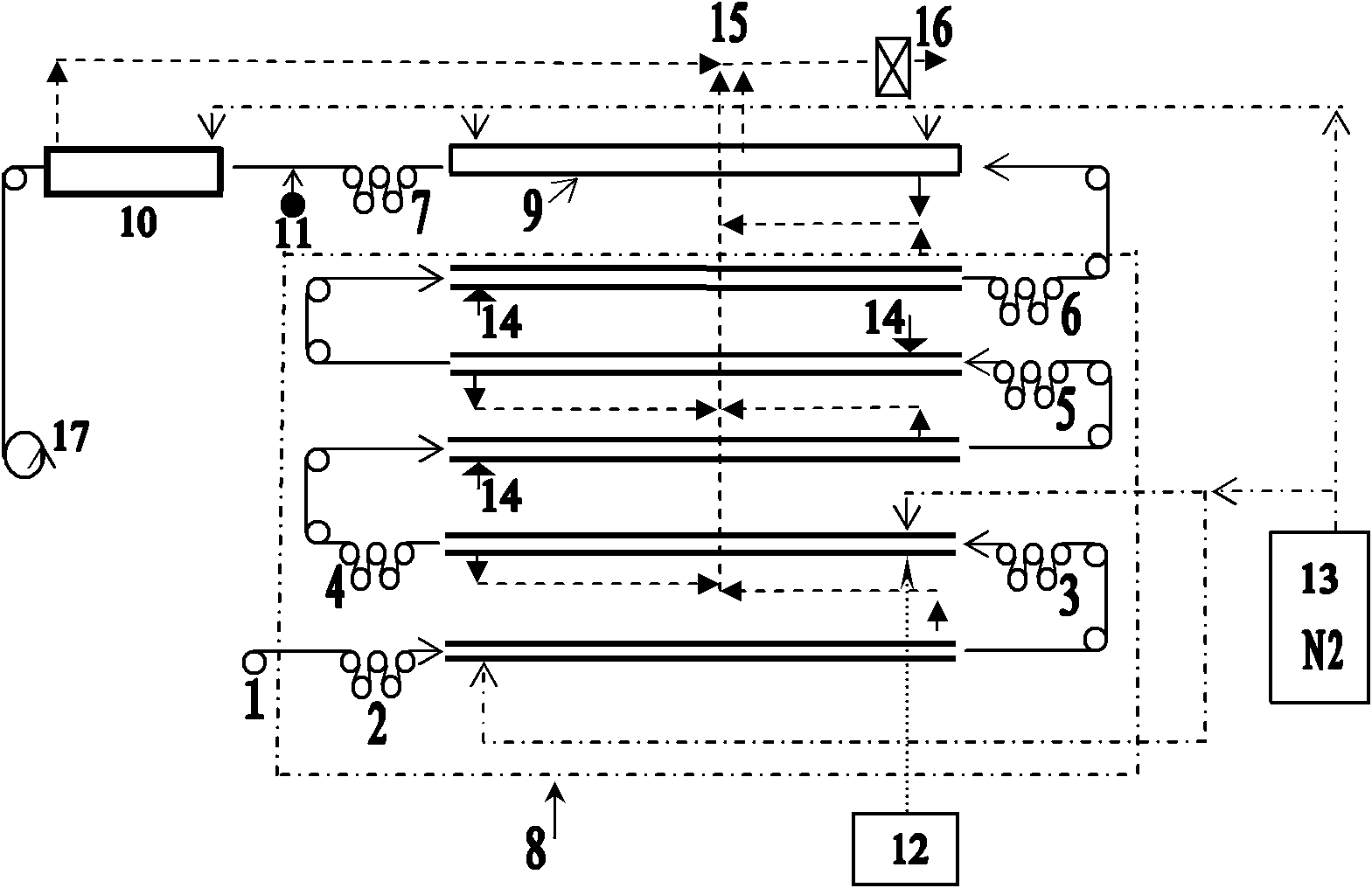

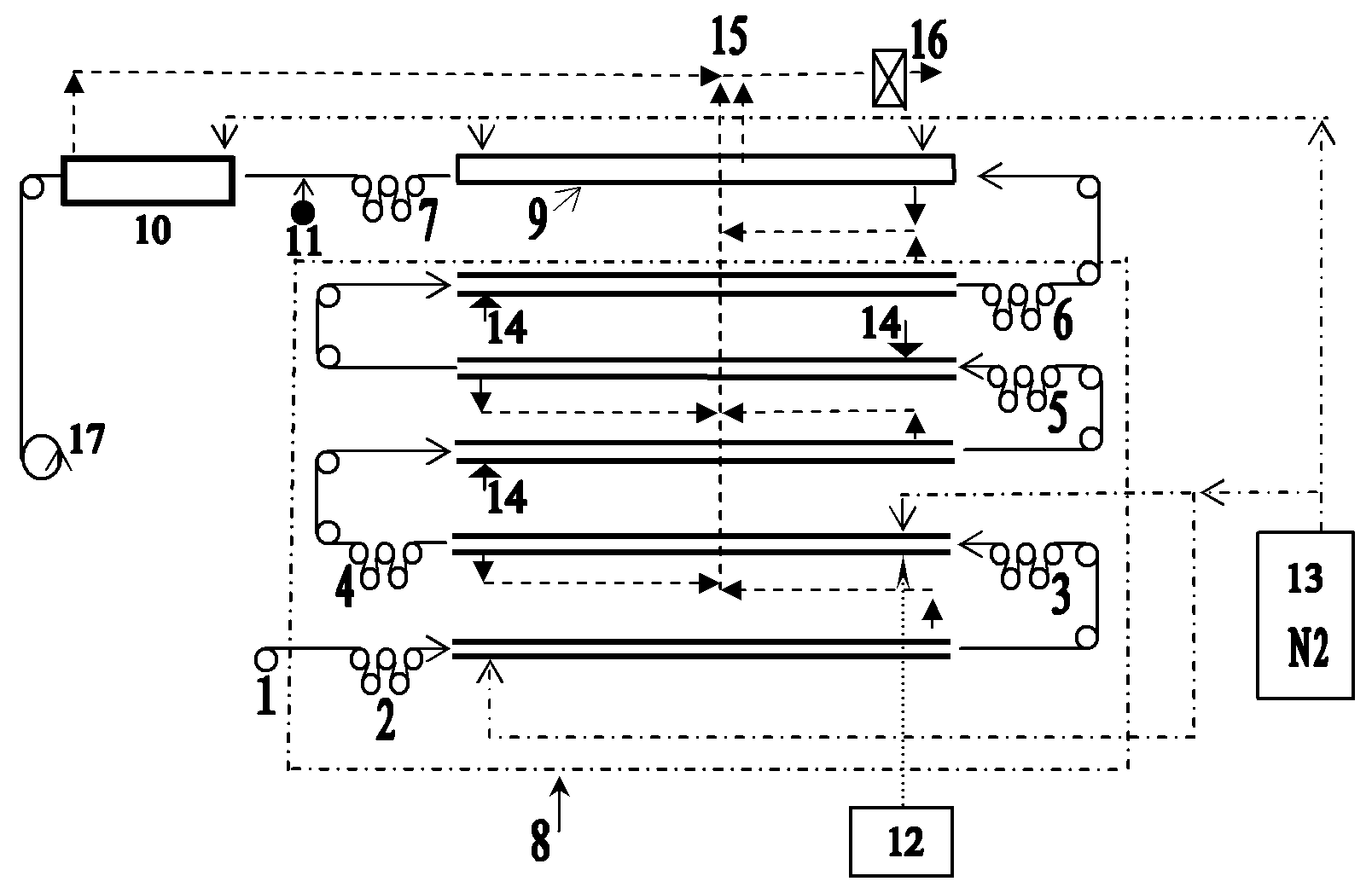

[0021] The polyacrylonitrile fiber precursors pass through five temperature zones in the continuous non-melting furnace successively under normal pressure conditions, the first temperature zone is the pre-cyclization stage, and the second temperature zone is the cyclization plastic drawing stage, the third, fourth, and fifth temperature zones are oxidation crosslinking stages. Then enter the carbonization furnace for carbonization treatment:

[0022] The first temperature zone is 190, 210°C, nitrogen gas is fed in, the tension is 16MPa, and the residence time is 15min; The ratio is 5%, the tension is 26MPa, and the residence time is 15min.

[0023] The third, fourth, and fifth temperature zones are respectively 200, 210°C, 230, 240°C, 260, and 280°C. Preheating air is introduced, and the tension of the fiber in the third temperature zone is 26MPa. The tension is 28MPa; the residence time of each temperature zone is 15min. The obtained bulk density is 1.38g / cm 3 , the degre...

Embodiment 2

[0027] The first temperature zone is 190, 210°C, nitrogen gas is fed in, the tension is 17MPa, and the residence time is 15min; The ratio is 10%, the tension is 33MPa, and the residence time is 15min.

[0028] The third, fourth, and fifth temperature zones are respectively 200, 210°C, 230, 240°C, 260, and 280°C. Preheating air is introduced, and the tension of the fiber in the third temperature zone is 29MPa. The tension is 28MPa; the residence time of each temperature zone is 15min. The obtained bulk density is 1.38g / cm 3 , the degree of orientation is 76.2%, and the cyclization rate is 85.0% of the preoxidized fiber.

[0029] The pre-oxidized fiber enters the low-temperature carbonization furnace, and performs low-temperature carbonization treatment on the temperature distribution gradient of 350°C, 500°C, 650°C, and 900°C. The time is 15 minutes, and the tension is controlled at 12MPa; finally, it enters the high-temperature carbonization furnace at 1300°C. For high-temp...

Embodiment 3

[0032] The first temperature zone is 190, 210°C, nitrogen gas is fed in, the tension is 18MPa, and the residence time is 15min; The ratio is 5%, the tension is 27MPa, and the residence time is 15min.

[0033] The third, fourth, and fifth temperature zones are respectively 205, 215°C, 230, 240°C, 260, and 280°C. Preheating air is introduced, and the tension of the fiber in the third temperature zone is 26MPa. The tension is 28MPa; the residence time of each temperature zone is 15min. The obtained bulk density is 1.38g / cm 3 , the degree of orientation is 75.3%, and the cyclization rate is 85.2% of the preoxidized fiber.

[0034] The pre-oxidized fiber enters the low-temperature carbonization furnace, and performs low-temperature carbonization treatment on the temperature distribution gradient of 350°C, 500°C, 650°C, and 900°C. The time is 15 minutes, and the tension is controlled at 12MPa; finally, it enters the high-temperature carbonization furnace at 1300°C. For high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com