Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

374results about How to "High Young's modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-scratch-resistance abrasion-resistant coating material and preparation method thereof

InactiveCN106752923AIncrease elasticityAvoid scratch damageFireproof paintsAnti-corrosive paintsDispersityMechanical property

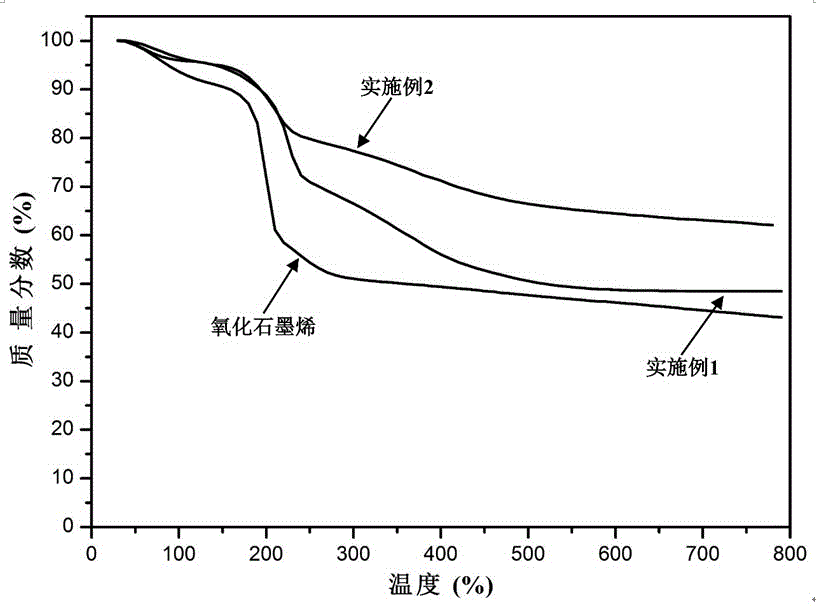

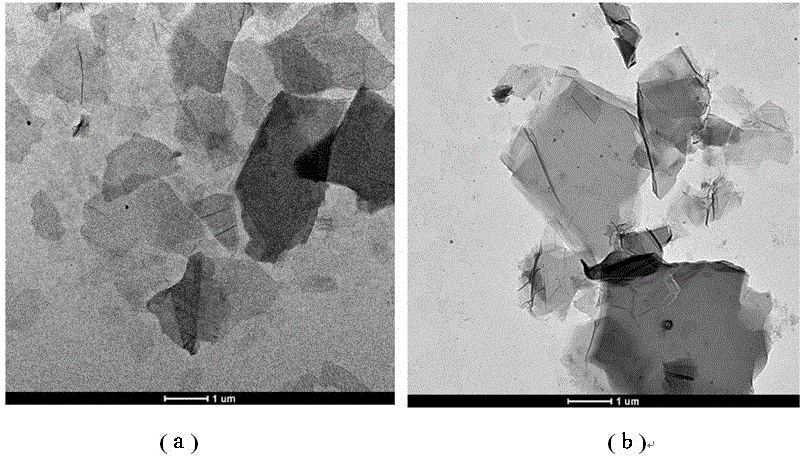

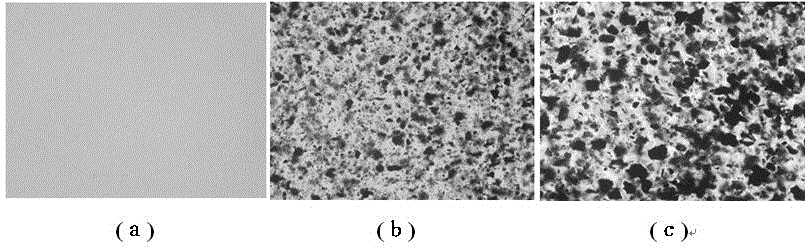

The invention provides a high-scratch-resistance abrasion-resistant coating material and a preparation method thereof. The preparation method comprises the following steps: modifying the graphene surface by using active groups by a chemical modification technique to obtain modified graphene, and blending the modified graphene with polysiloxane to obtain the high-scratch-resistance abrasion-resistant nano composite coating material. The surface modification is carried out to enhance the dispersity of the graphene and the interactions between the graphene and polysiloxane matrix, thereby enhancing the mechanical properties of the coating. No pigment or filler is added. The scratch resistance of the transparent graphene / polysiloxane composite coating is enhanced by 140% or above, and the abrasion loss is reduced by 60% or above. The transparent graphene / polysiloxane composite coating has excellent adhesion, heat resistance, weather resistance, flame retardancy and corrosion resistance. The graphene / polysiloxane composite coating can be used for surface protection and shielding of various metals, plastics, wood, concrete, glass and other substrates, and is applicable to the fields of automobile paints, photoelectric materials, precision instruments, marine heavy-corrosion protection, buildings and the like.

Owner:FUDAN UNIV

Optical glass

InactiveCN1450010AHigh coefficient of thermal expansionPrecise without migrationOptical elementsLithium oxideSilicic acid

The present invention relates to an optical glass using silicic acid group as main body, said optic glass has high expansion coefficient, high Young modulus, excellent weatherability and high transmissivity in the infrared wave zone. Said glass composition contains (mole%) 36-66% of silicon dioxide, 0-12% of aluminium oxide, 0-6% of boric oxide, 0-10% of magnesium oxide, 0-16% of calcium oxide, 0-16% of strontium oxide, 0-16% of baria, 0-8% of zinc oxide, 0-32% of lithium oxide, 0-25% of sodium oxide, 0-25% of potassium oxide, 0-20% of cesium oxide, 0-6% of phosphorus pentoxide, 0-8% of scandium oxide and others.

Owner:PICVUE OPTOELECTRONICS INT

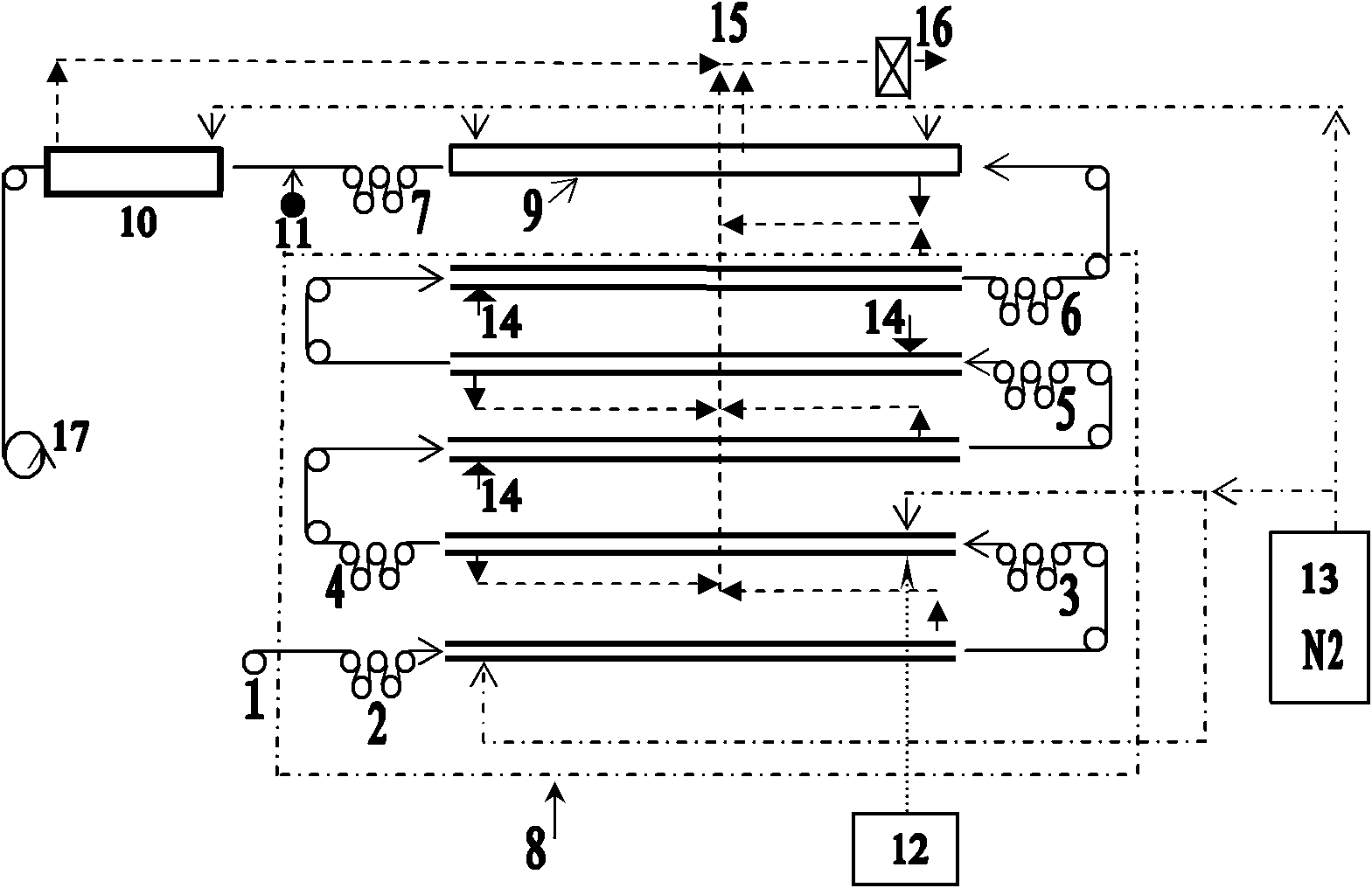

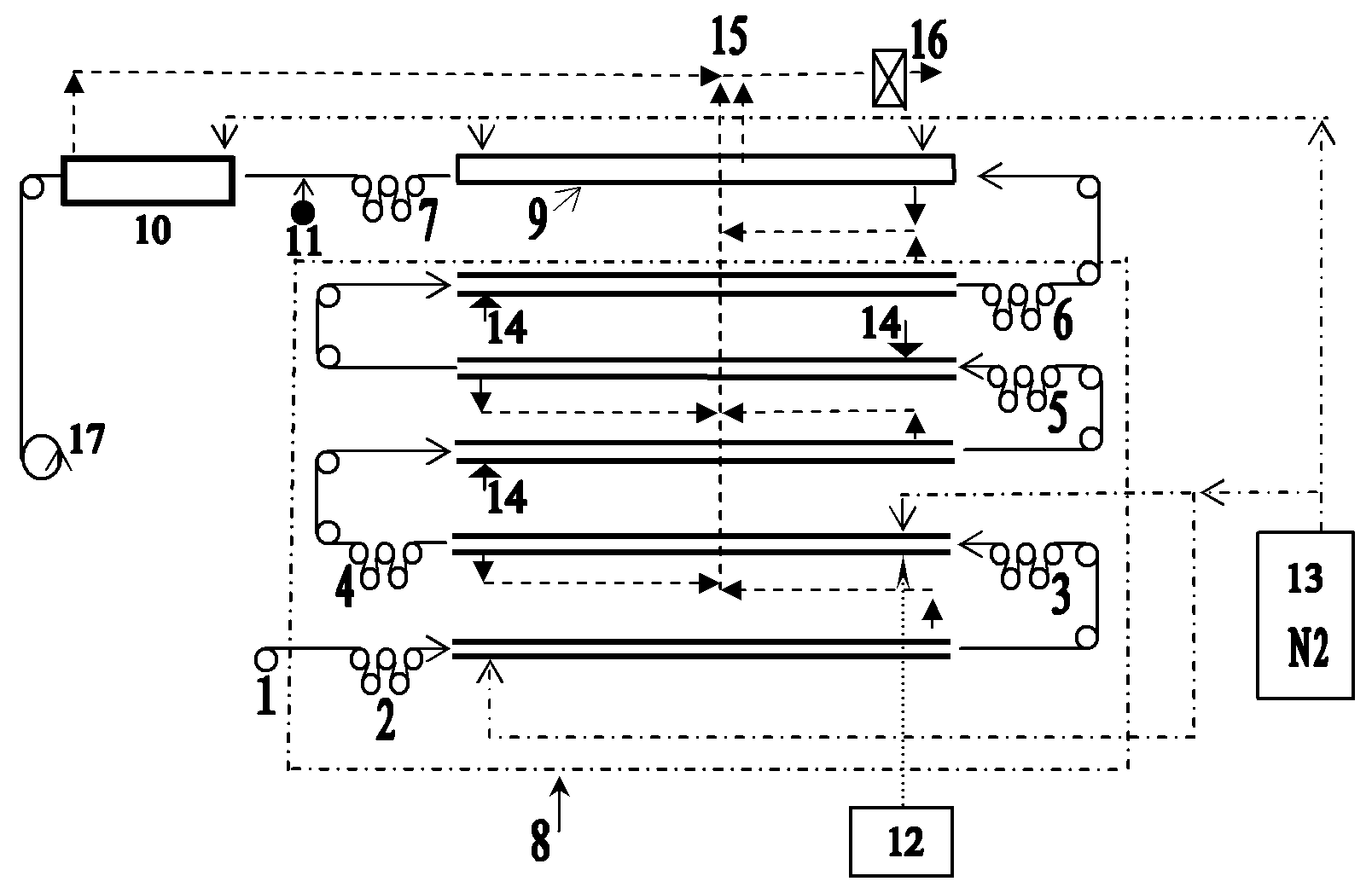

Curing treatment method of carbon fiber precursor polyacrylonitrile fiber

InactiveCN102181963AGood for cyclization reactionRaise the degree of orientationFibre chemical featuresAir atmosphereCarbon fibers

The invention relates to a curing treatment method of a carbon fiber precursor polyacrylonitrile fiber. The method comprises the following steps: pre-cyclizing the polyacrylonitrile fiber precursor in the atmosphere of inert gas; carrying out cyclizing and plastic drawing in the atmosphere of inert gas and water vapor; and carrying out oxidation crosslinking in the atmosphere of air, thus obtaining a pre-oxidized polyacrylonitrile fiber. The method has the following beneficial effects: carrying out heat treatment on the fiber in the inert atmosphere is beneficial to implementation of cyclization reaction in the molecules to form rigid ladderlike molecules with regular structure and strong heat resistance, and at the same time, a defined amount of water vapor is introduced to obtain a higher drawing ratio by enhancing the plasticity of the molecular chains in the fiber, thus improving the orientation degree of the rigid molecules along the fiber axis.

Owner:DONGHUA UNIV

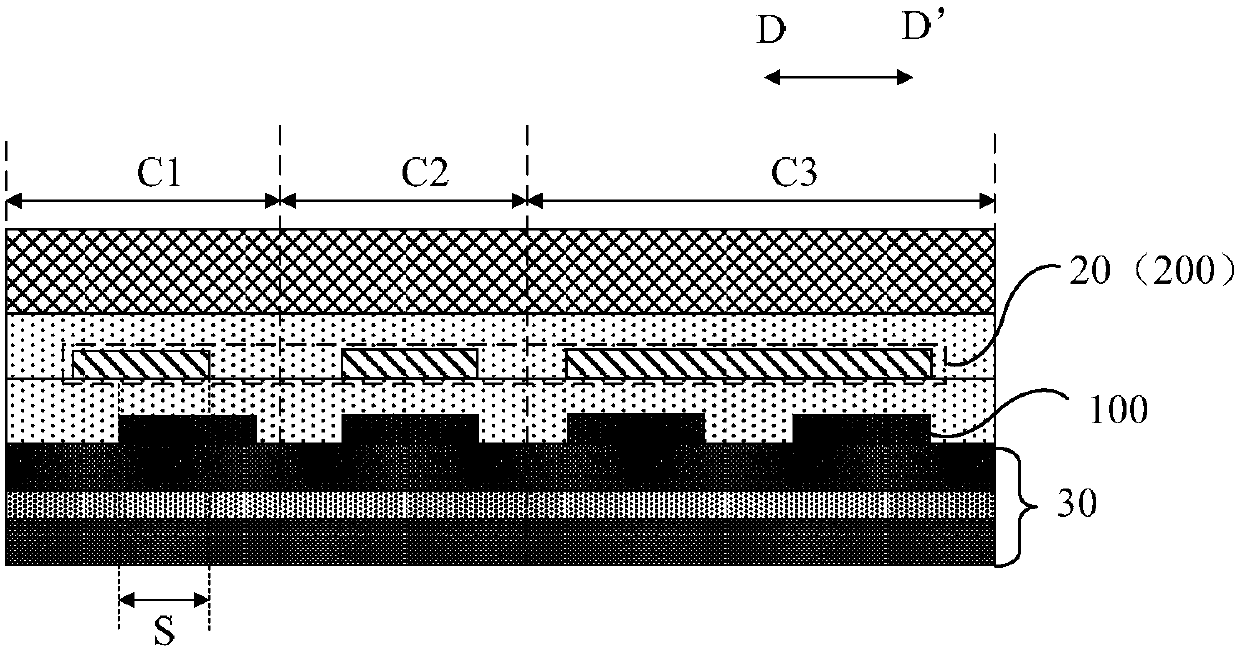

Flexible array substrate and preparation method thereof and display device

ActiveCN107634086AImprove stress uniformityReduce the chance of breakageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An embodiment of the invention provides a flexible array substrate and a preparation method thereof and a display device and relates to the display technical field. The probability of breakage of signal lines in a bending region due to bending can be reduced. The flexible array substrate comprises a display region and a wiring region. The wiring region comprises a bending region adjacent to the display region. The bending region comprises signal lines arranged on a substrate and a protection layer. The protection layer is arranged at one side, away from the substrate, of the signal lines; andthe orthographic projection of the protection layer on the substrate and the orthographic projection of the signal lines on the substrate have an overlapped region, and Young modulus of the protectionlayer is larger than or equal to Young modulus of the signal lines.

Owner:BOE TECH GRP CO LTD +1

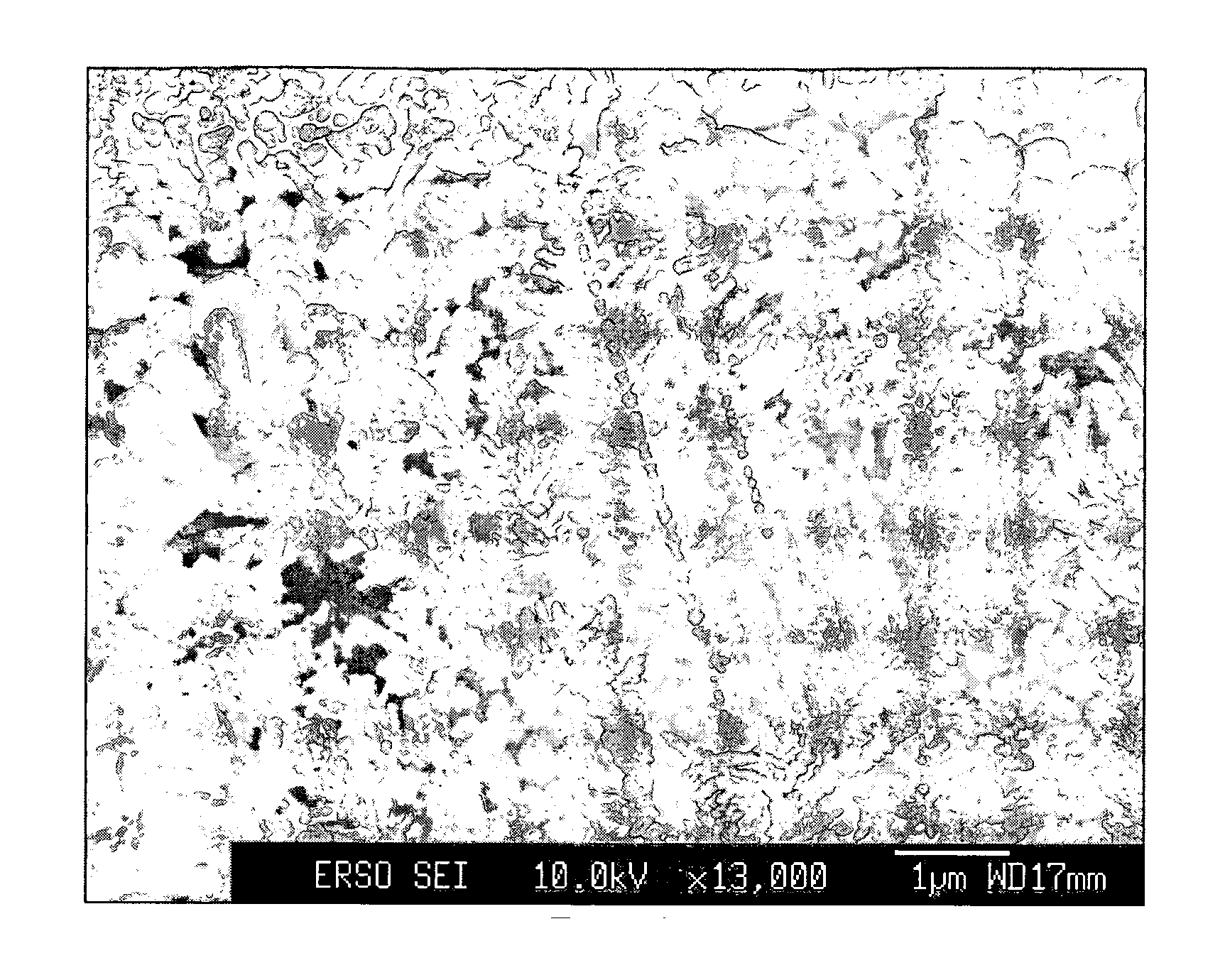

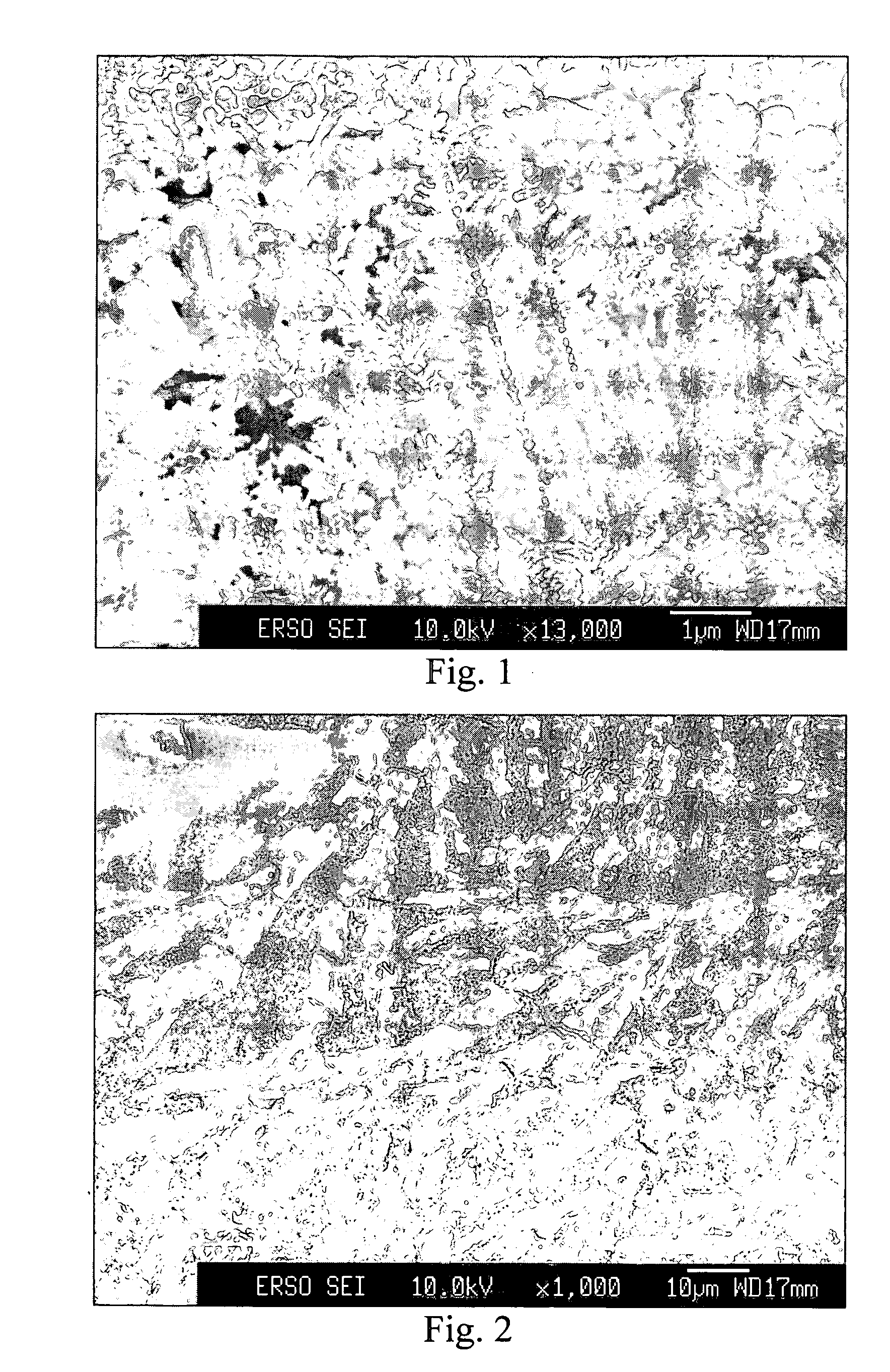

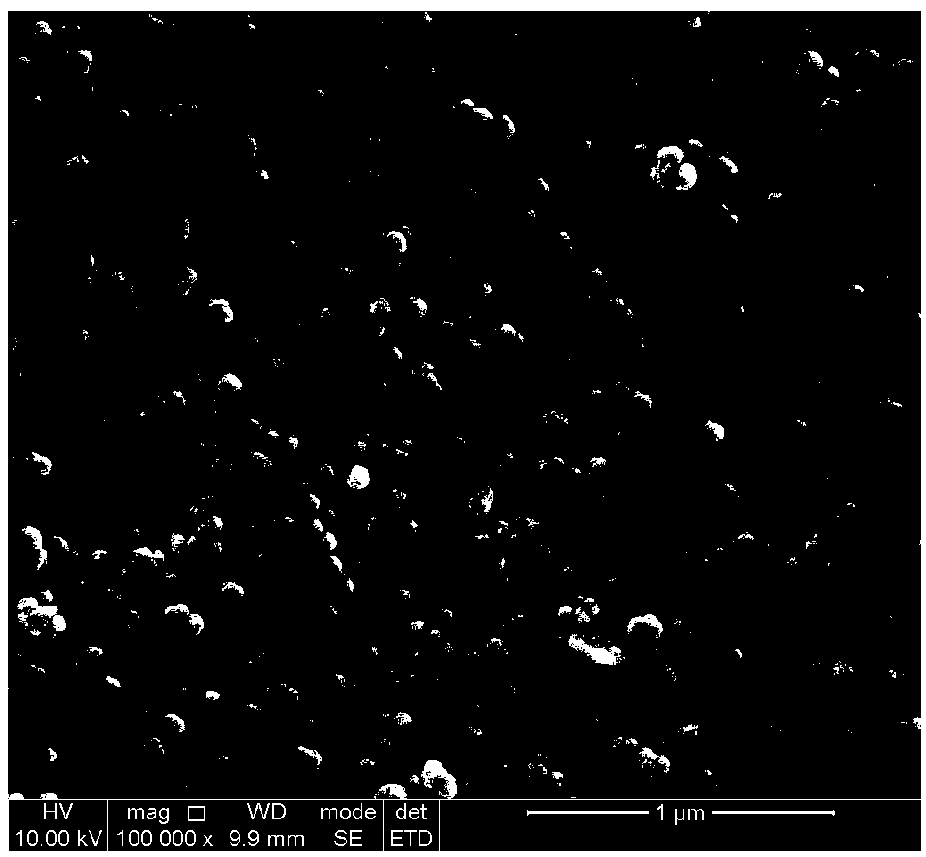

Method of making an electroplated interconnection wire of a composite of metal and carbon nanotubes

InactiveUS20070056855A1Increase current densityDegrade electromigration resistanceElectrolytic coatingsPrinted circuit manufactureOrganic solventCarbon nanotube

Method of making an electroplated interconnection wire of a composite of metal and carbon nanotubes is disclosed, including electroplating a substrate having a conductive baseline on a surface thereof in an electroplating bath containing a metal ion and carbon nanotubes, so that an electroplated interconnection wire of a composite of the metal and carbon nanotubes is formed on the conductive baseline. Alternatively, a method of the present invention includes preparing a dispersion of carbon nanotubes dispersed in an organic solvent, printing a baseline with the dispersion on a surface of a substrate, evaporating the organic solvent to obtain a conductive baseline, and electroplating the surface in an electroplating bath containing a metal ion, so that an electroplated interconnection wire of a composite of the metal and carbon nanotubes is formed on the conductive baseline.

Owner:IND TECH RES INST

Host-guest supramolecular hydrogel, and preparation method and application thereof

ActiveCN107652452AHigh mechanical strengthHigh Young's modulusProsthesisBandagesTissue repairUltraviolet lights

The invention discloses a host-guest supramolecular hydrogel, and a preparation method and an application thereof. The host-guest supramolecular hydrogel is prepared through initiating the copolymerization of free radicals by host-guest supramolecule and methacrylic anhydride gelatin (GelMA) under an ultraviolet light (UV ) condition, and has good mechanical strength and biocompatibility. The host-guest supramolecule is prepared through the host-guest coupling of acryloyloxyethyl isocyanate-modified beta-cyclodextrin (beta-CD) and allyl 1-bromoadamantane. Compared with pure GelMA hydrogel, thehost-guest supramolecular hydrogel has the advantages of good mechanical properties, control of the mechanical strength of the hydrogel by adjusting the concentration of the host-guest supramolecule,and good biocompatibility. The host-guest supramolecular hydrogel also has the advantages of simple preparation process, mild conditions, effective improvement of the mechanical strength, and good application prospect in the field of tissue repair engineering.

Owner:SOUTH CHINA UNIV OF TECH

Prepn of lateral hydroxyl group containing polyimide/SiO2 hybrid film

InactiveCN1436815AHigh molecular weightThe structure of the main chain is flexible and changeableEpoxyRoom temperature

The preparation process of lateral hydroxyl group containing polyimide / SiO2 hybrid film includes dissolving polyamido acid containing lateral hydroxyl group or polyimide in 1-1400 portions in solvent to compound 5-15 % concentration solution, adding silane coupling agent containing epoxy radical in 0-250 portions for reaction at 120-150 deg.c in the presence of catalyst in 0.1-10 portions of 2-4 hr; cooling to room temperature, adding n-silicate ester in 1-1000 portions through stirring for 6-24 hr, flow casting to form film, and processing at 0.1 atm negative pressure and 60 deg.c for 12 hr, and 160 deg.C for 2 hr, at 200 deg.c for 2 hr, at 260 deg.c for 1 hr and at 300 deg.c for 0.5 hr to obtain the lateral hydroxyl group containing polyimide / SiO2 hybrid film.

Owner:SICHUAN UNIV

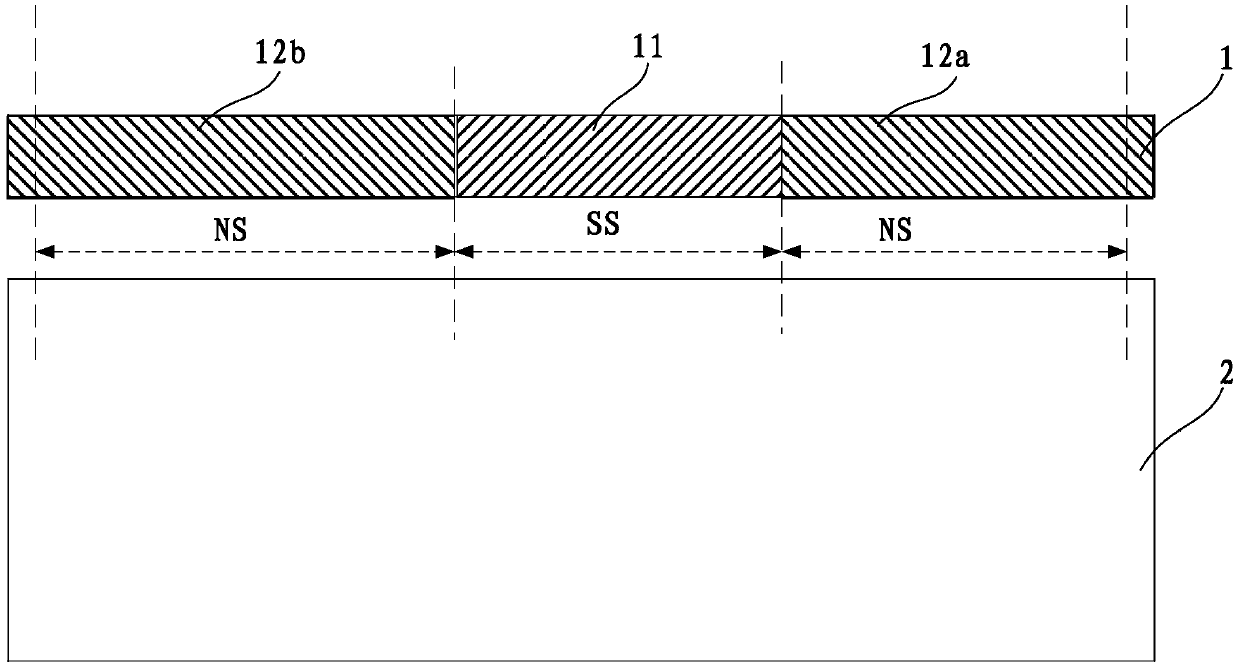

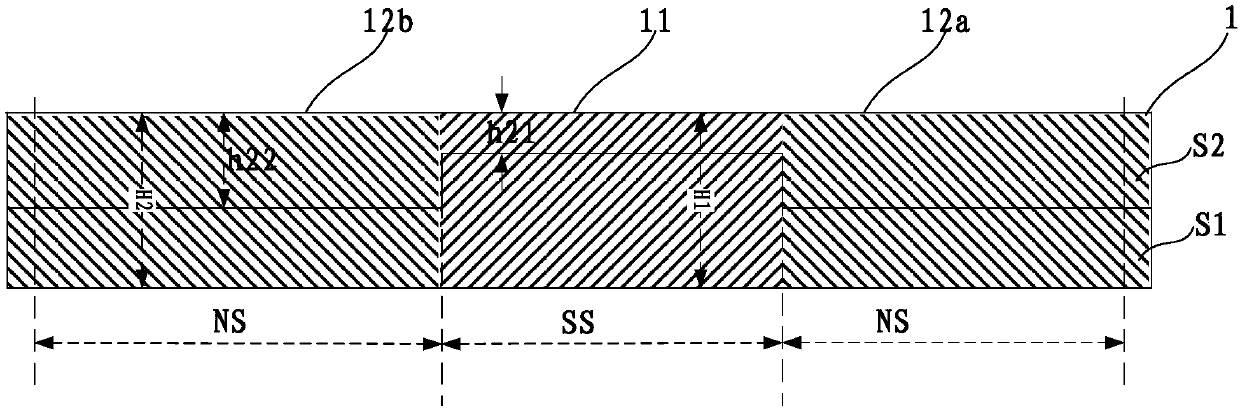

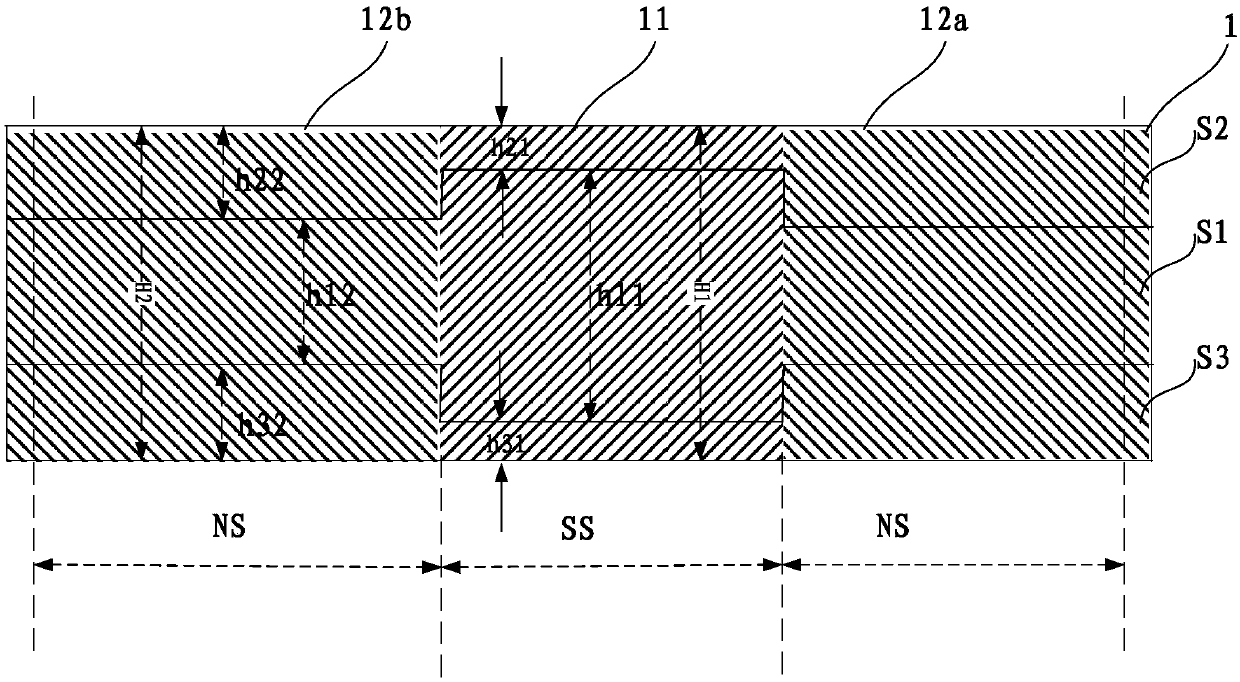

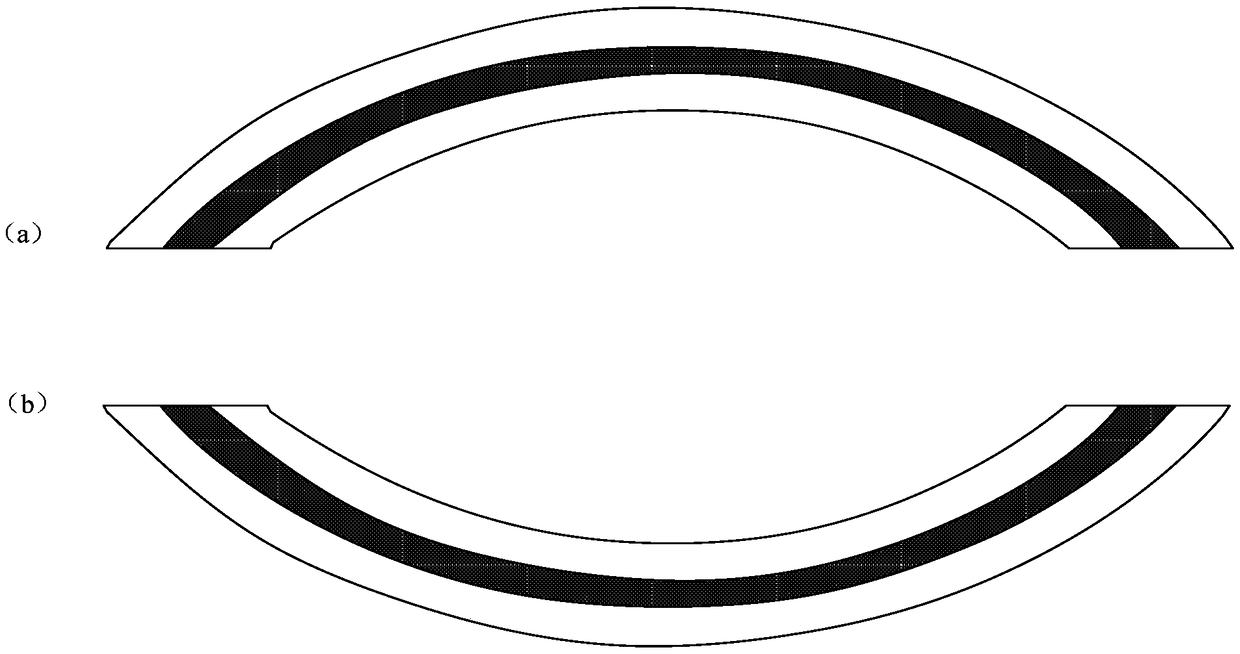

Protective cover plate and flexible display device

ActiveCN109671363ASolve technical problems that are difficult to pass the stress testLow Young's modulusIdentification meansYoung's modulusEngineering

The invention provides a protective cover plate and a flexible display device. The protective cover plate comprises a bending part and a non-bending part, wherein the bending part is located in a bending region, and the non-bending part is located in a non-bending region, and the Young modulus of the bending part is smaller than that of the non-bending part. In this way, since the bending part ofthe protective cover plate has the low Young modulus, the bending part can pass a bending test, meanwhile, the non-bending part has the high Young modulus and therefore can pass a pressure test, and the technical problem is solved that a non-bending part of an existing protective cover plate passes a pressure test with difficulty.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

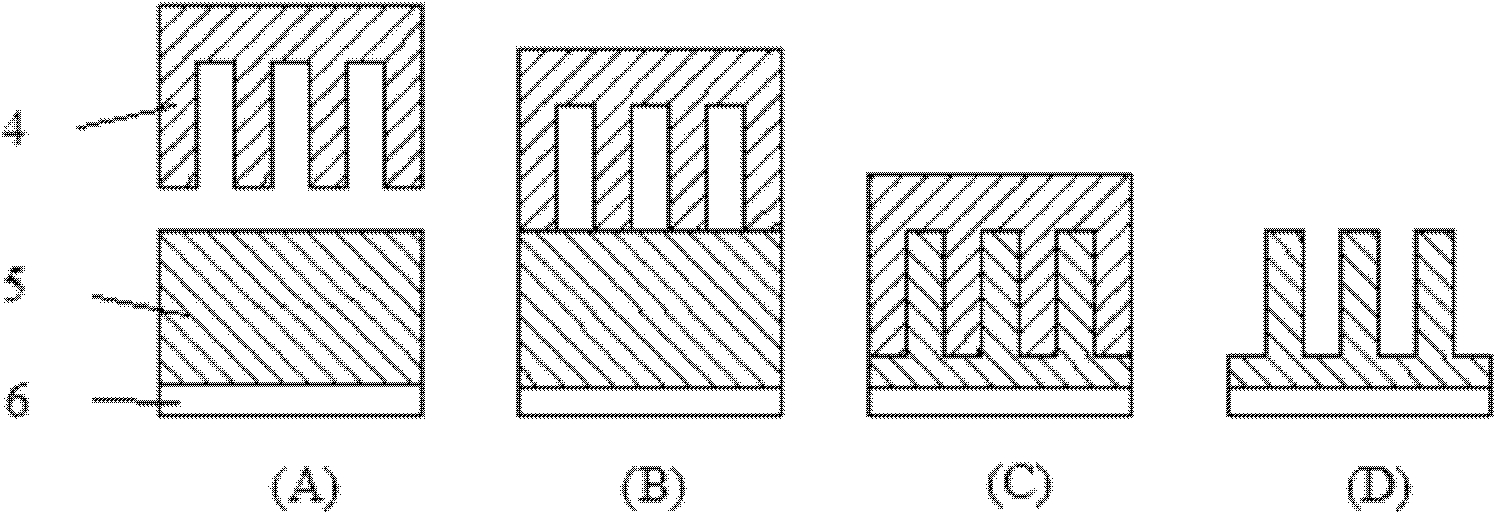

Method for preparing dry adhesive

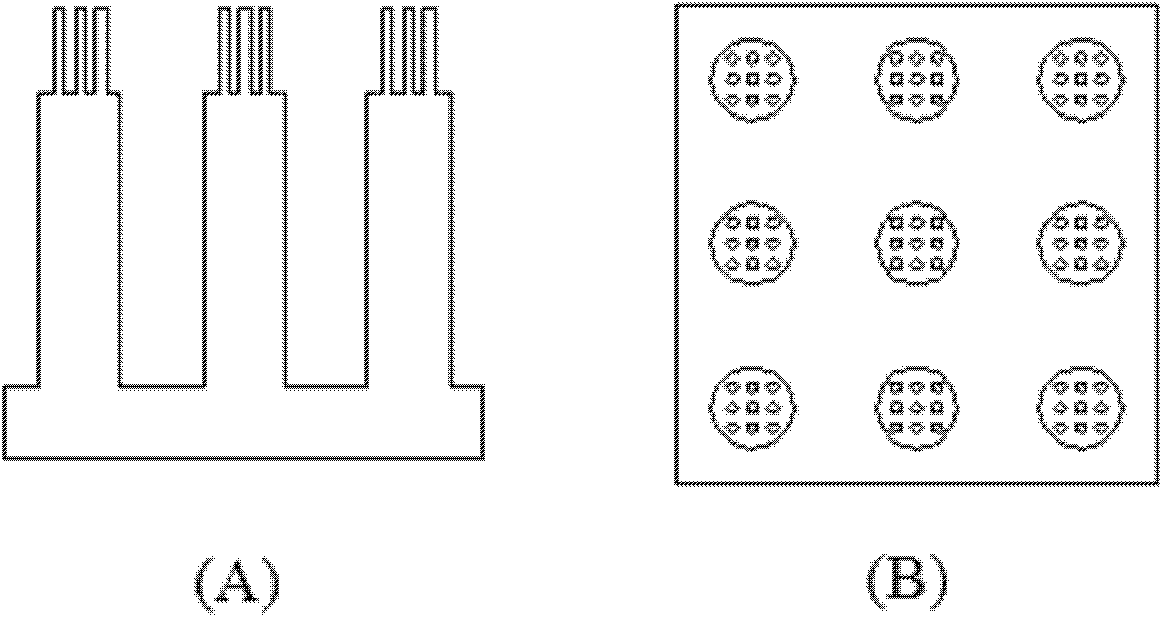

ActiveCN101837946AHigh Young's modulusModerate flexibilityNanostructure manufactureDecorative surface effectsFiberLevel structure

The invention provides a method for preparing a dry adhesive in order that the existing wet adhesive has the disadvantages that the wet adhesive is prone to deterioration, pollution, self-adhesion and non-reusability after being torn open. Based on the research into the structural characteristics of micron-level and nano-level foot hair of a gecko in the nature, micron-level and nano-level fiber arrays can be molded and drawn in a way that the fiber arrays are molded successively for twice, thus obtaining the micron-level and nano-level structure of the bio-mimetic gecko hair, which is characterized by powerful adhesion. The method of the invention comprises the following steps: preparing a micron-level silicon mother stamp; preparing a micron-level mold; preparing micron-level fiber arrays; preparing a nano-level silicon mother stamp; preparing a nano-level mold; and preparing nano-level fiber arrays. The method of the invention is capable of preparing the micron-level and nano-level structure with the parameters thereof being close to those of the foot hair of the gecko in the nature; and the prepared powerful dry adhesive is capable of being fitted with various surfaces and easily detached in an active manner.

Owner:HUAZHONG UNIV OF SCI & TECH

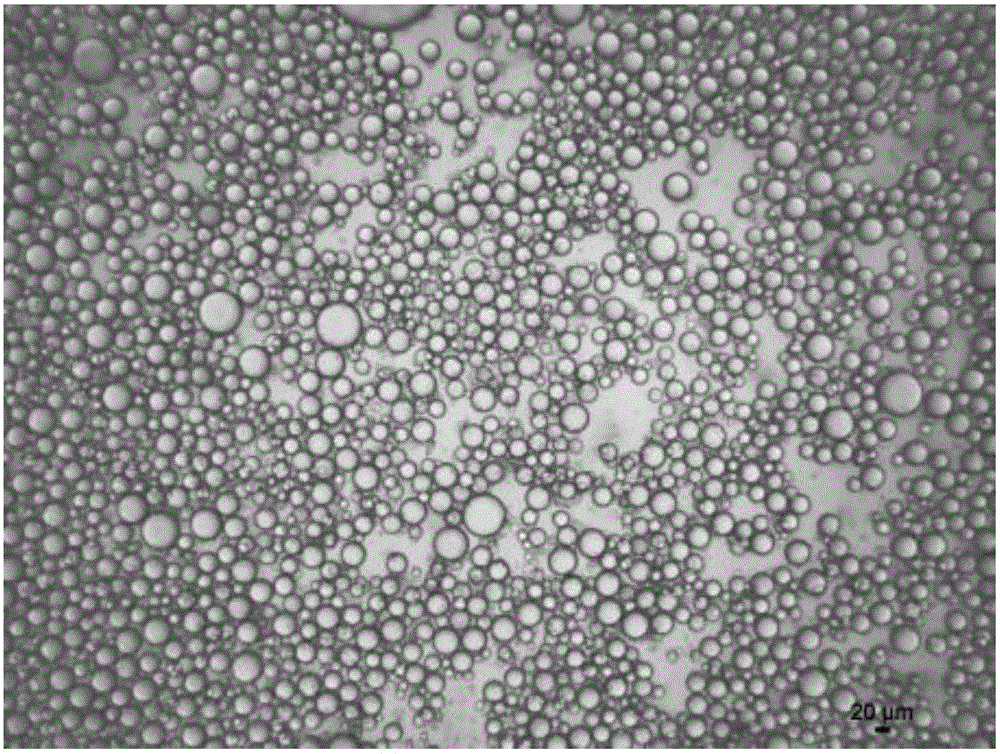

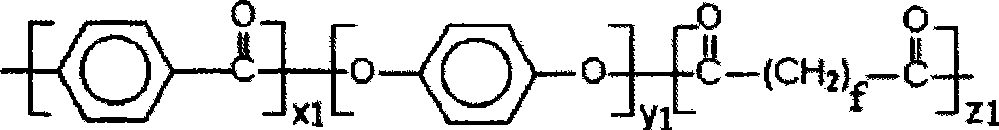

Method for preparing Pickering emulsion by utilizing modified nano-crystalline cellulose

The invention discloses a method for preparing Pickering emulsion by utilizing modified nano-crystalline cellulose. The method comprises the following steps: 1) taking the nano-crystalline cellulose modified with an amphiphilic segmented copolymer and grinding into powder, thereby acquiring the amphiphilic segmented copolymer modified nano-crystalline cellulose powder; 2) dispersing the amphiphilic segmented copolymer modified nano-crystalline cellulose powder acquired in the step 1) into deionized water, thereby forming modified nano-crystalline cellulose dispersion liquid; and 3) weighting an oily solvent, adding into the modified nano-crystalline cellulose dispersion liquid acquired in the step 2), and mixing and emulsifying, thereby forming stable Pickering emulsion. The method for preparing the Pickering emulsion by utilizing the modified nano-crystalline cellulose has the characteristics of less CNC dosage and low application cost.

Owner:SHAANXI UNIV OF SCI & TECH

Alkali-free glass substrate, method for producing it and liquid crystal display panel

ActiveUS20090176640A1High Young 's modulusLow linear expansion coefficientGlass rolling apparatusNon-linear opticsAlkali freeYoung's modulus

To provide an alkali-free glass substrate, which has a high Young's modulus, a low linear expansion coefficient, a high strain point and a low density, does not devitrify in the float forming process and is excellent in acid resistance.An alkali-free glass substrate, which contains neither alkali component nor BaO and consists essentially of, as represented by mol % based on oxide, from 57.0 to 65.0% of SiO2, from 10.0 to 12.0% of Al2O3, from 6.0 to 9.0% of B2O3, from 5.0 to 10.0% of MgO, from 5.0 to 10.0% of CaO and from 2.5 to 5.5% of SrO, provided that MgO+CaO+SrO is from 16.0 to 19.0%, MgO / (MgO+CaO+SrO)≧0.40, and B2O3 / (SiO2+Al2O3+B2O3)≦0.12; wherein Young's modulus ≧75 GPa; the linear expansion coefficient at from 50 to 350° C. is from 30×10−7 / ° C. to 40×10−7 / ° C.; the strain point ≧640° C.; the temperature T2 (the viscosity η satisfies log η=2)≦1,620° C.; the temperature T4 (the viscosity η satisfies log η=4)≦1,245° C.; the devitrification temperature ≦T4; and weight loss per unit area is at most 0.6 mg / cm2, when immersed in 0.1N HCl at 90° C. for 20 hours.

Owner:ASAHI GLASS CO LTD

Water-soluble three-dimensional network type electrode binding agent and preparation method thereof, electrode piece and preparation method thereof, and electrochemical devices

ActiveCN102142560ANo pollution in the processAdhesive retentionElectrode manufacturing processesElectrical batteryCross linker

The invention discloses a water-soluble three-dimensional network type electrode binding agent, comprising a water-soluble polymer polyelectrolyte. Molecular chains of the polyelectrolyte contain active groups; the molecular chains of the polyelectrolyte are cross-linked and bridged by a cross-linking agent to form a three-dimensional network type molecular structure. The invention also disclosesa preparation method of the binding agent, an electrode piece prepared by utilizing the binding agent, and electrochemical devices. In the water-soluble three-dimensional network type electrode binding agent disclosed by the invention, the water solubility is good, the viscosity is adjustable, and the tensile strength and the Young modulus are controllable; in the carbon electrode piece prepared by the electrode binding agent, the mechanical property is good, the phenomenon of common material falling of the electrode piece can be avoided, the irreversible capacity is low in the first chargingprocess, the reversible capacity is high, and electrochemical devices such as lithium-ion batteries and super capacitors and the like with excellent circulating performance can be manufactured.

Owner:SHENZHEN CAPCHEM TECH CO LTD

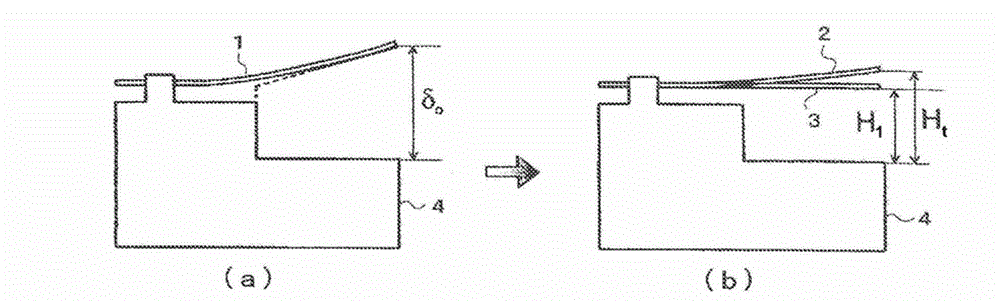

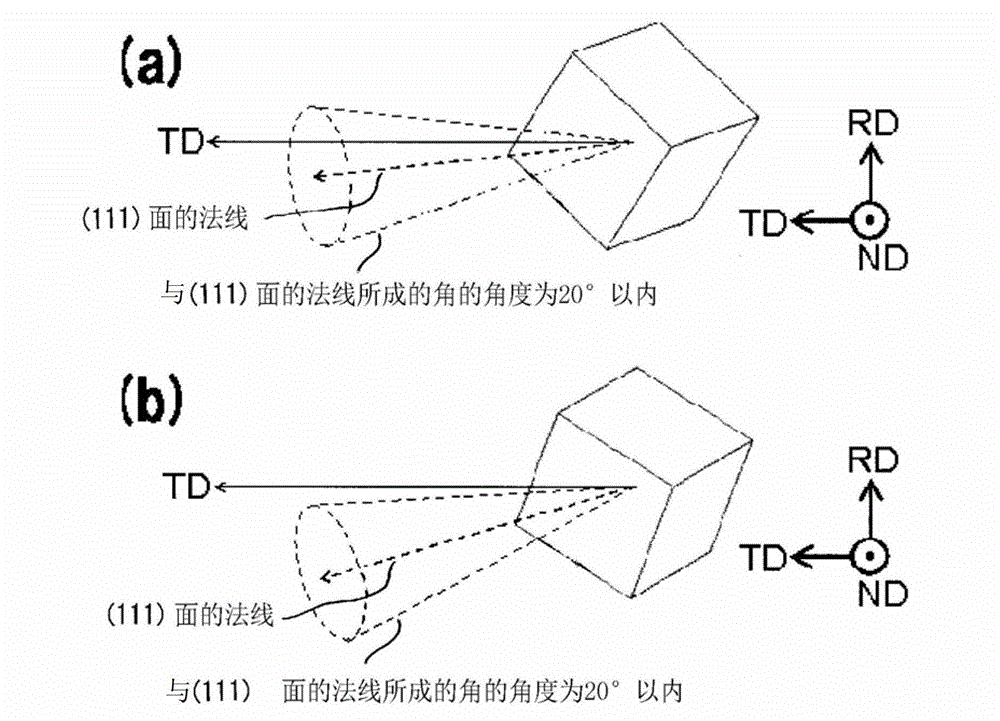

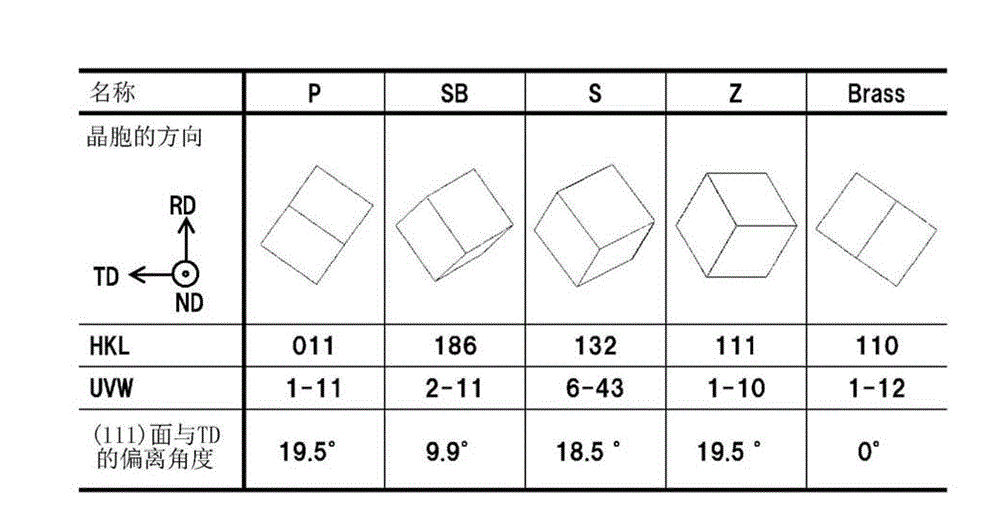

Copper alloy sheet and manufacturing method for same

ActiveCN103069025AHigh Young's modulusConductive materialCoupling contact membersIn vehicleCrystal orientation

Provided are a copper alloy sheet and a manufacturing method for the same, said sheet having a high Young's modulus and excellent strength, and being suited to electrical / electronic device lead frames, connectors, terminals and the like, and to in-vehicle connectors or terminals, relays or switches, etcetera. The sheet has an alloy composition which contains 0.05-1.0 mass% of one, two or three kinds among Cr, Zr and Ti, with the remainder being copper and unavoidable impurities,under crystal orientation analysis by means of EBSD, in relation to the accumulation in the atomic plane facing in the width direction (TD) of a rolled sheet, the surface area ratio of a region having an atomic plane wherein the angle formed by the TD and a normal line of a (111) surface is not greater than 20 DEG is at least 50%.

Owner:FURUKAWA ELECTRIC CO LTD

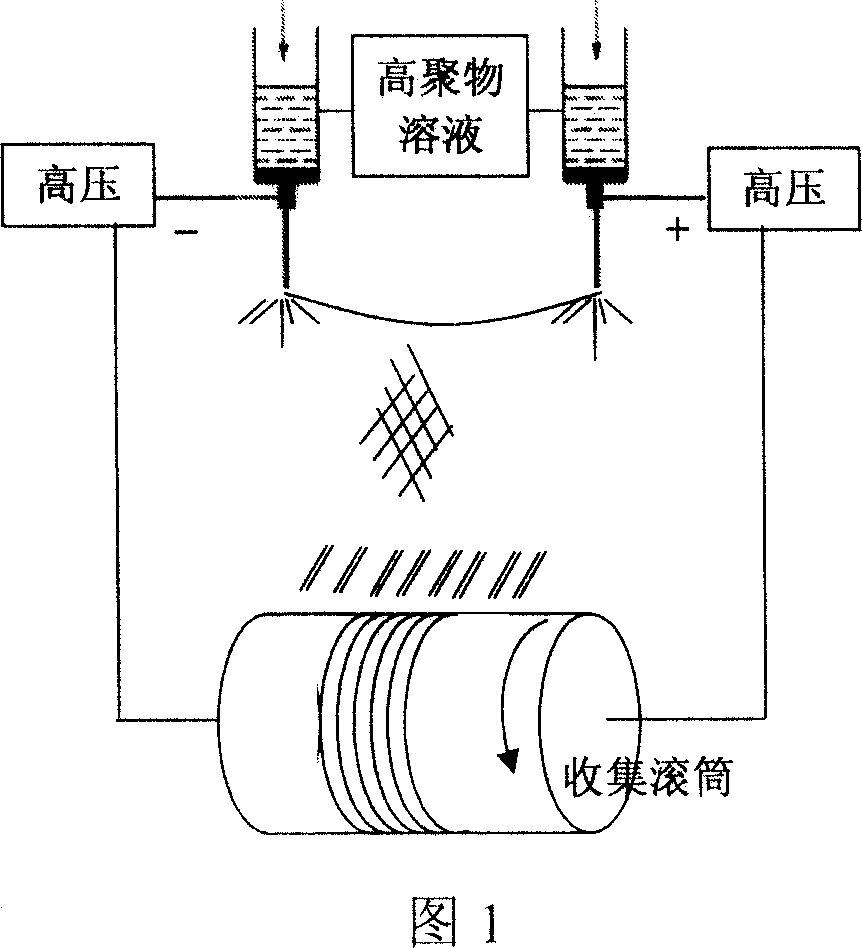

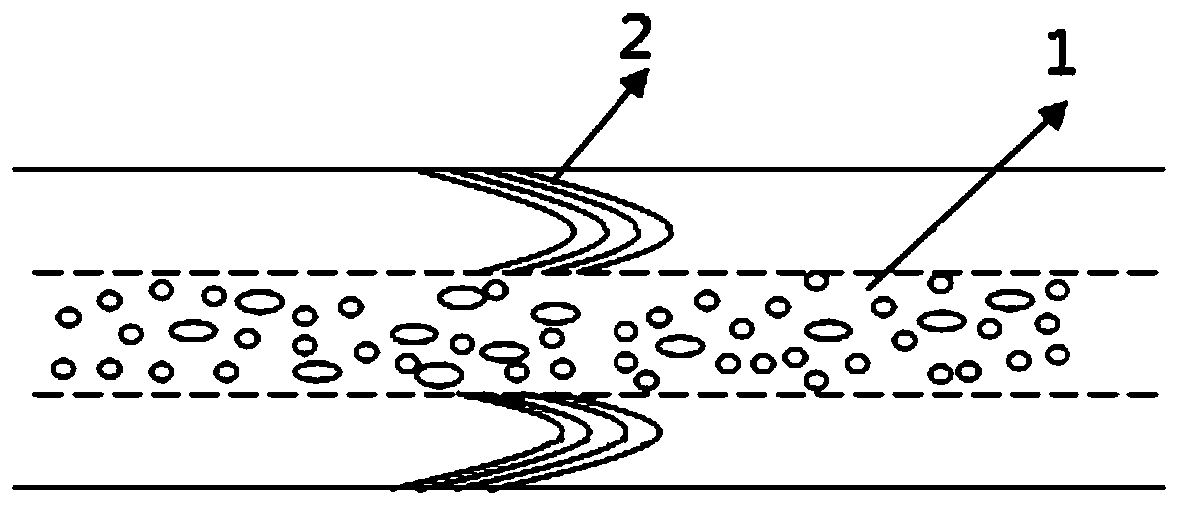

Complex type electrostatic spinning method with positive and negative electrodes in same electric field, and application

InactiveCN101003917AIncrease spinning speedOvercome the defects of single productsFilament/thread formingArtificial filaments from cellulose derivativesComplex typeElectrospinning

Owner:CIVIL AVIATION UNIV OF CHINA

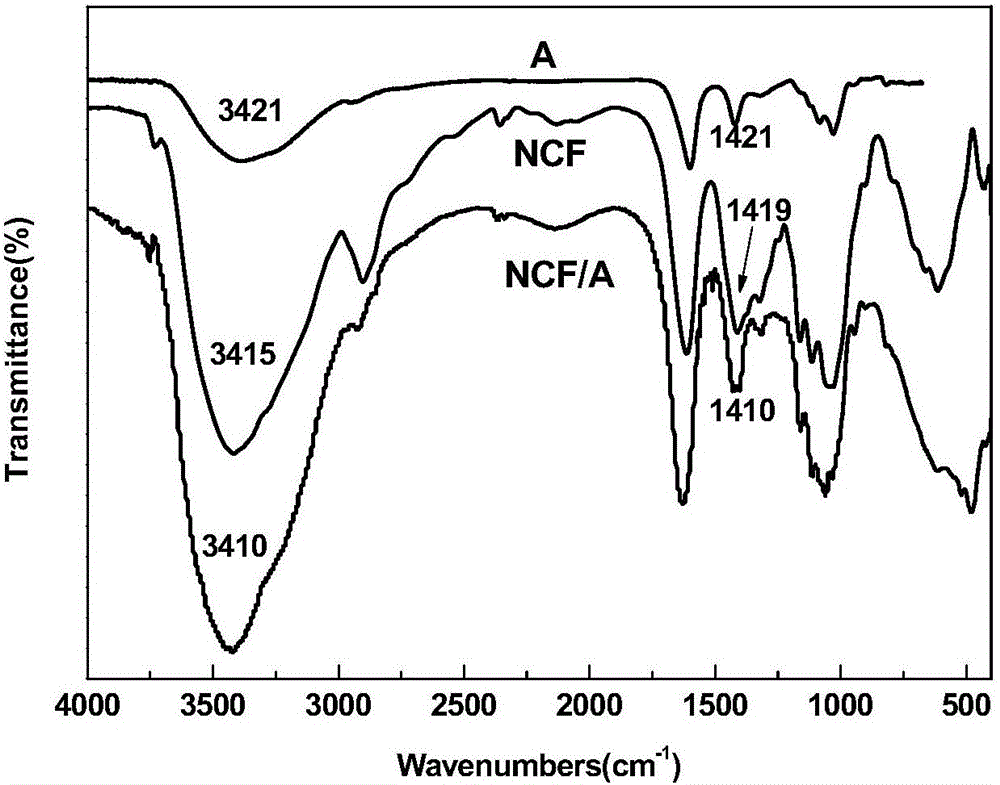

Preparation method of composite fiber of cellulose nanometer fibrils/alginate

ActiveCN106521706ALarge specific surface areaHigh crystallinityConjugated cellulose/protein artificial filamentsArtifical filament manufactureCelluloseFiber

The invention discloses a preparation method of composite fiber of cellulose nanometer fibrils / alginate. The method includes steps of evenly dispersing cellulose nanometer fibrils under ultrasound wave function, and preparing aqueous suspension; then evenly mixing with alginate solution and obtaining the mixed solution of cellulose / sodium alga acid as spinning raw liquid; spinning by wet method and obtaining the composite fiber of cellulose nanometer fibrils / alginate. The preparation method is simple and easy to operate, the technique is green and environmental-friendly; the prepared composite fiber of cellulose nanometer fibrils / alginate is an environment-friendly recycled material, and has the same excellent biocompatibility and biological degradability as the pure alginate fiber; the oriental controllability of cellulose nanometer fibrils is enhanced, and the cellulose nanometer fibrils and the base alginate are formed to be an interpenetrating polymer network structure, thereby effectively improving the intensity and flexibility of composite fiber and greatly improving the adaptation of alginate fiber in textile and garment and medical treatment health domain.

Owner:QINGDAO UNIV

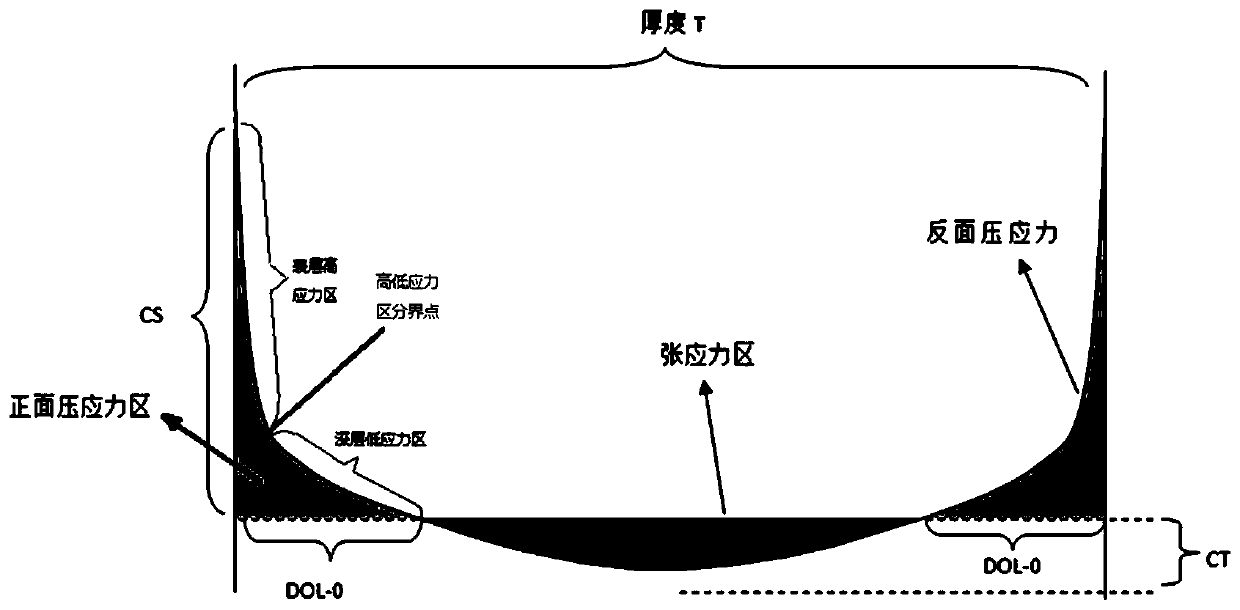

Lithium aluminum silicon glass, lithium aluminum silicon chemically strengthened glass and preparation method and application thereof

The invention discloses lithium aluminum silicon glass, lithium aluminum silicon chemically strengthened glass and a preparation method and application thereof. The molar content of oxide components contained in the lithium aluminum silicon glass satisfies the following relationship: the SiO2 content is at least 66.5 mol%, and the total amount of an alkali metal oxide usable for ion exchange is not more than 14 mol%; (Na2O+Li2O) / (SiO2+Al2O3) is 0.09-0.22; Na2O / Li2O is 0.4-1.2; MgO / SiO2 is 6%-18%; (Na2O+Li2O+0.3*MgO) / Al2O3 is 0.7-1.4; and 0.5%<P2O5+ZnO+SnO2+K2O+ZrO2+TiO2<7%. The lithium aluminum silicon chemically strengthened glass is formed by chemically strengthening the lithium aluminum silicon glass as basic glass.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

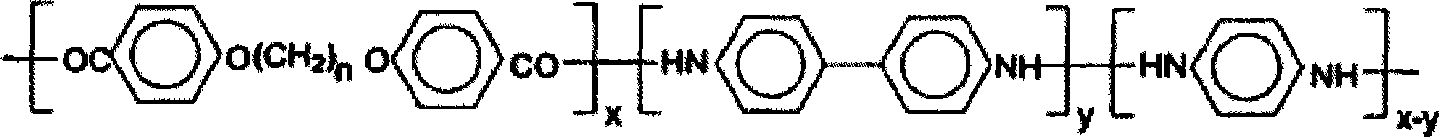

Polyphenyl thioether / thermotropic liquid crystal complex fiber and preparation thereof

InactiveCN101440536AImprove performanceImprove mechanical propertiesMonocomponent synthetic polymer artificial filamentArtifical filament manufactureWater bathsDry heat

The invention discloses a polyphenylene sulfide / thermotropic liquid crystal composite fiber and a method for preparing the same. The polyphenylene sulfide / thermotropic liquid crystal composite fiber comprises 100 portions of polyphenylene sulfide slice or powder material and 0.5 to 5 portions of thermotropic liquid crystal. The method for preparing the polyphenylene sulfide / thermotropic liquid crystal composite fiber comprises the following steps: drying the polyphenylene sulfide slice or the powder material and the thermotropic liquid crystal through a vacuum rotary drum dryer respectively, and mixing the materials evenly; performing melt spinning on the obtained mixture in a screw spinning device to obtain a fused body which is spouted out from a spinneret plate, passes through a annealing device, and then is cooled naturally and solidified into a fiber; and coiling the cooled fiber after the fiber is oiled and clustered, and performing hot water bath first-stage stretching, dry heat second-stage stretching and a one-step heat-setting treatment on the coiled fiber so as to obtain the polyphenylene sulfide / thermotropic liquid crystal composite fiber. The polyphenylene sulfide / thermotropic liquid crystal composite fiber has the advantages that the mechanical property and the processing performance of the polyphenylene sulfide fiber can be improved, the equipment is simple, and the operation is easy.

Owner:DONGHUA UNIV

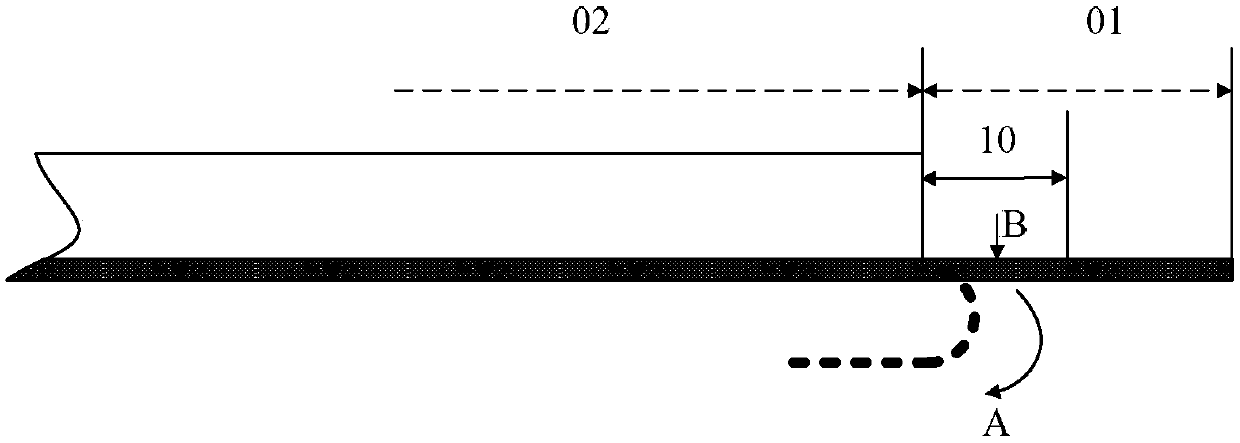

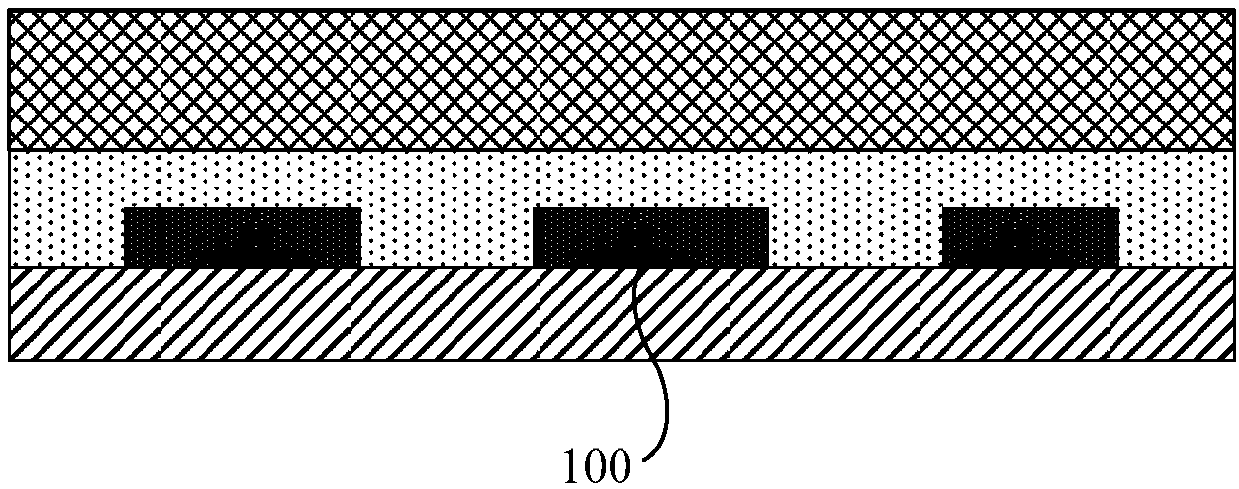

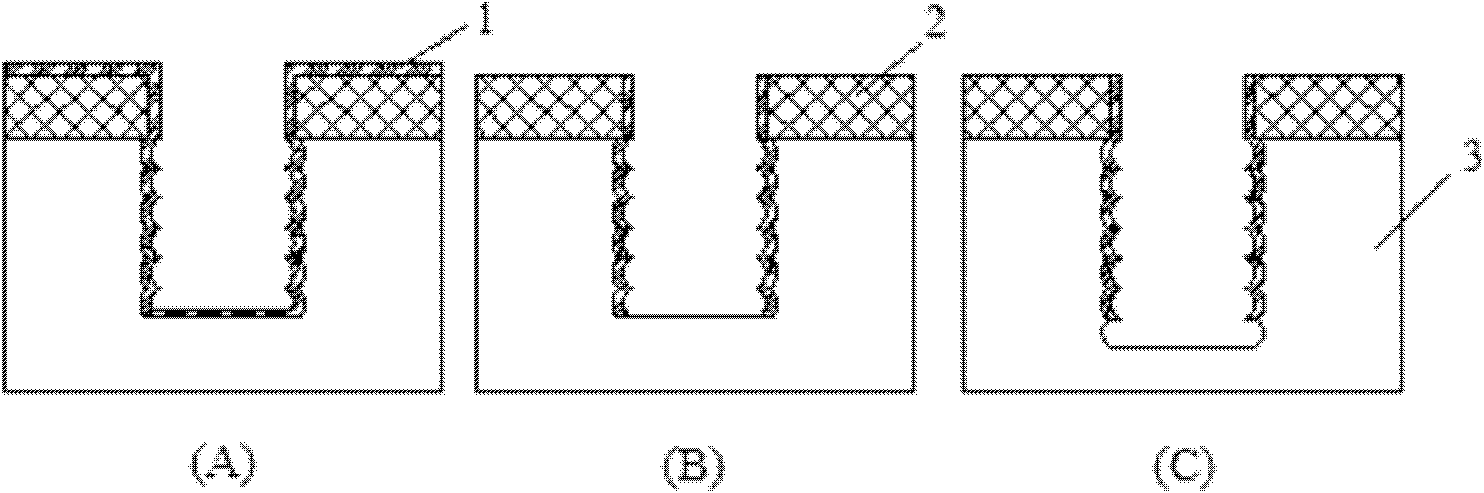

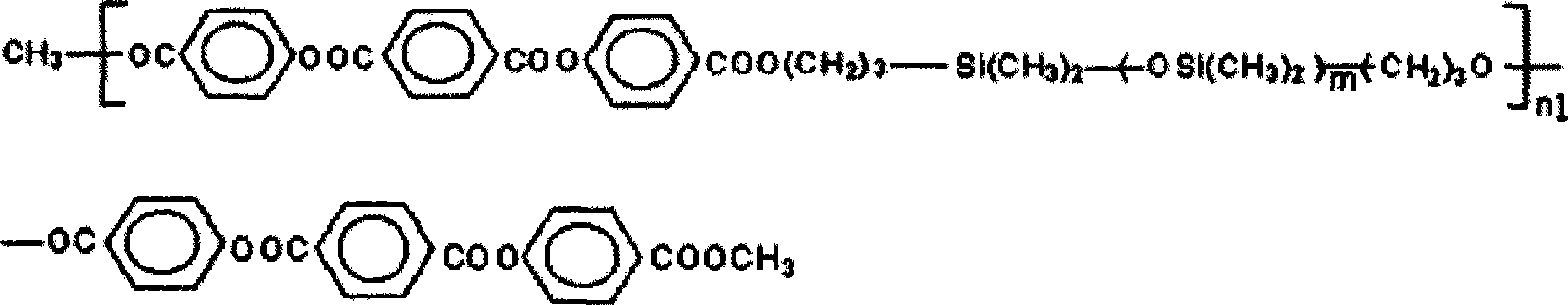

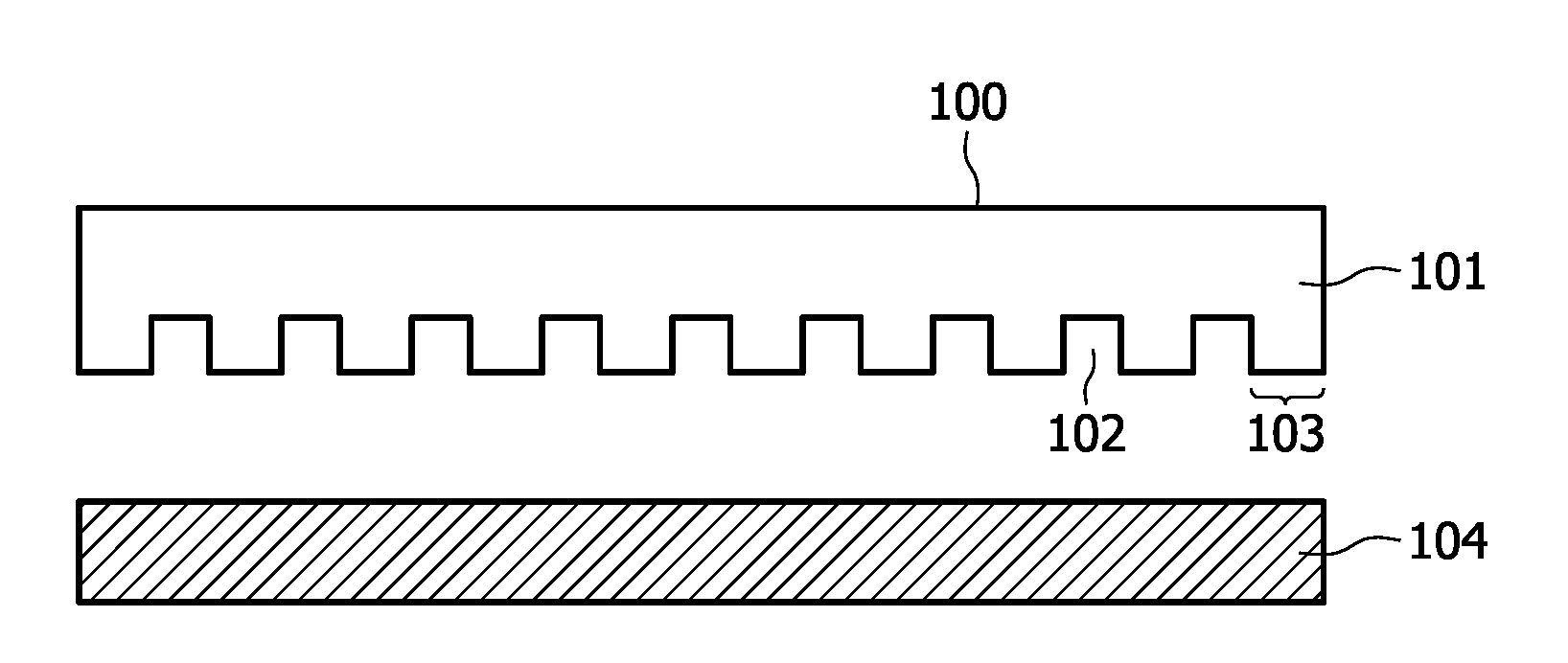

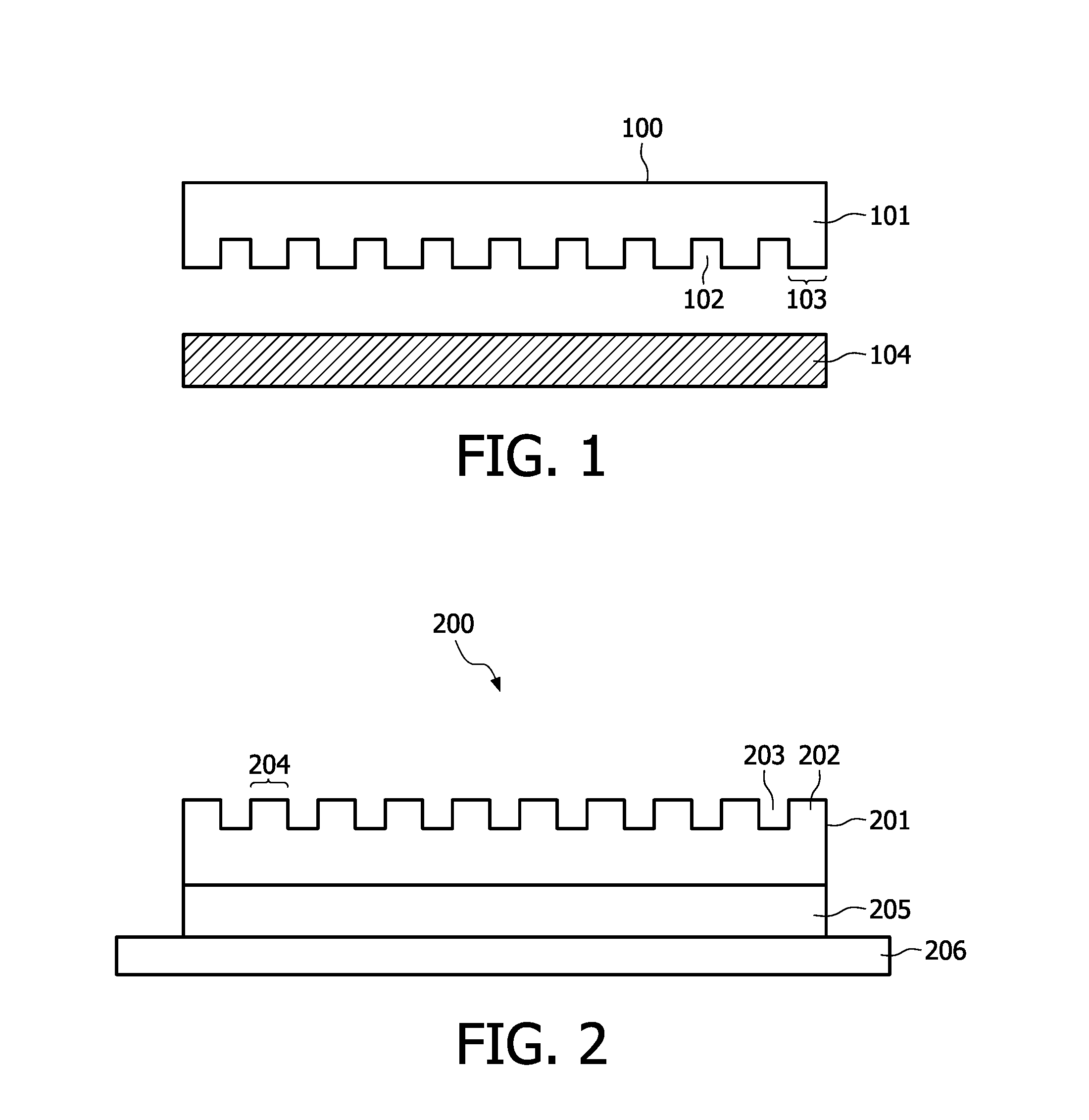

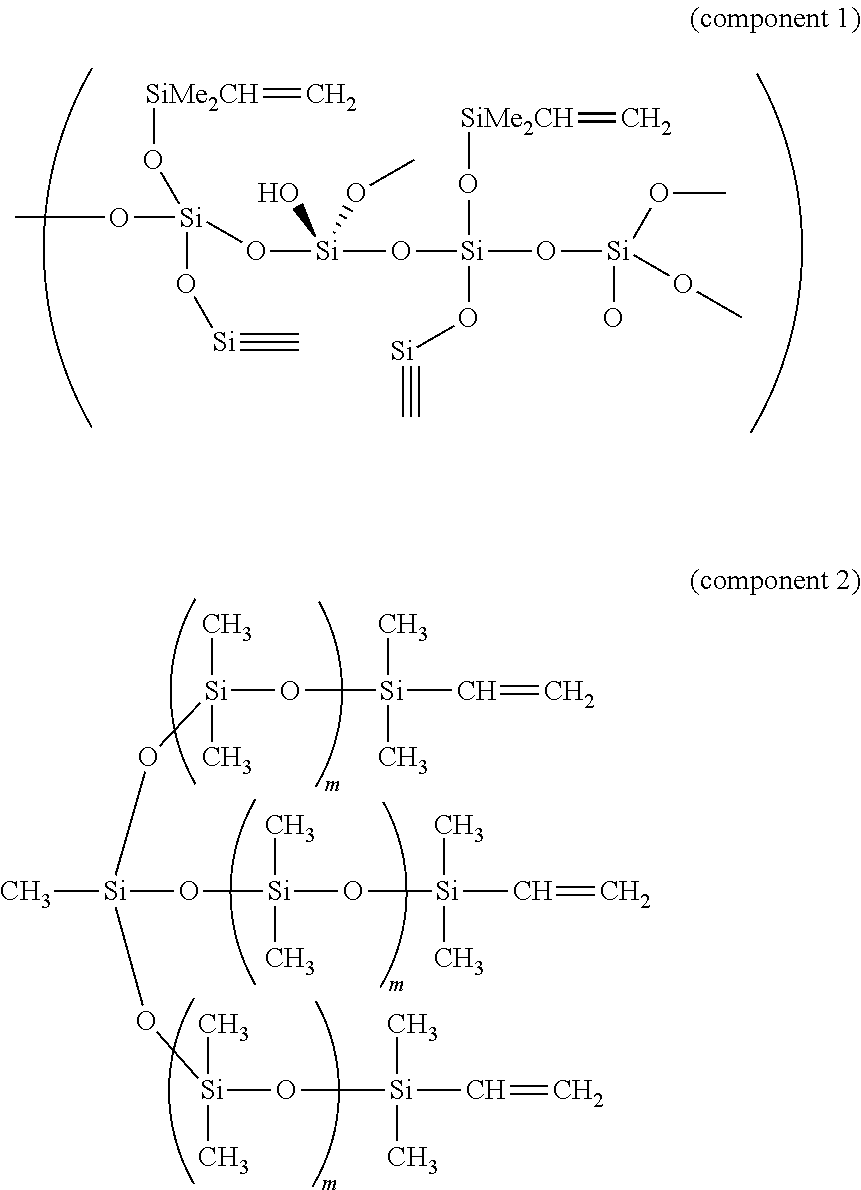

Silicone rubber material for soft lithography

ActiveUS20110094403A1High incubation temperatureHigh incubation temperature is avoidedPlaten pressesDuplicating/marking methodsPolymer scienceLithography process

The present invention relates to a silicone rubber like material and a printing device including a stamp layer (100;201) comprising such a material. The material is suitable for use in soft lithography as it enables stable features having mensions in the nanometer range to be obtained on a substrate, and also allows for the accommodation onto rough and non-flat substrate surfaces. The invention also relates to methods for manufacturing the silicone rubber like material and stamp layer (100;201) and use thereof in lithographic processes.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Acetylated cellulose nanocrystalline composite modified biomass-based polyester material and preparation method thereof

The invention belongs to the field of natural high polymer materials and particularly relates to an acetylated cellulose nanocrystalline composite modified biomass-based polyester material and a preparation method thereof. The acetylated cellulose nanocrystalline composite modified biomass-based polyester material is prepared from acetylated cellulose nanocrystalline and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) in the weight ratio being (3-30):100 through compositing. The preparation method comprises steps as follows: poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and an acetylated cellulose nanocrystalline solution are mixed and put into a polytetrafluoroethylene mold for film casting, a solvent is evaporated at the room temperature, and the acetylated cellulose nanocrystalline composite modified biomass-based polyester material is obtained after vacuum drying. The tensile strength and the Young modulus of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) are remarkably improved after composite modification by acetylated cellulose nanocrystalline, the strength and the rigidity of the material are improved, and the application range of the material is effectively broadened.

Owner:WUHAN UNIV OF TECH

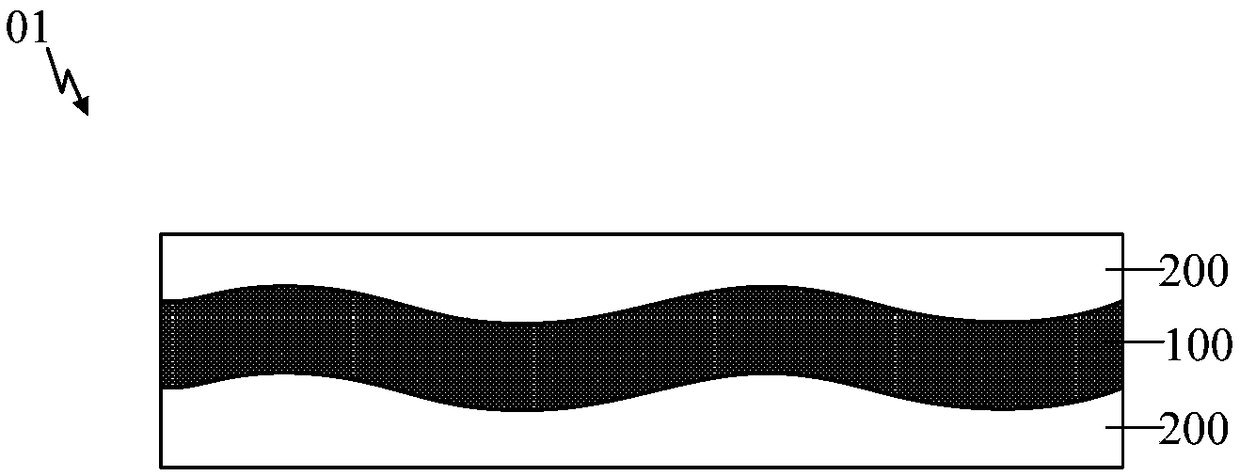

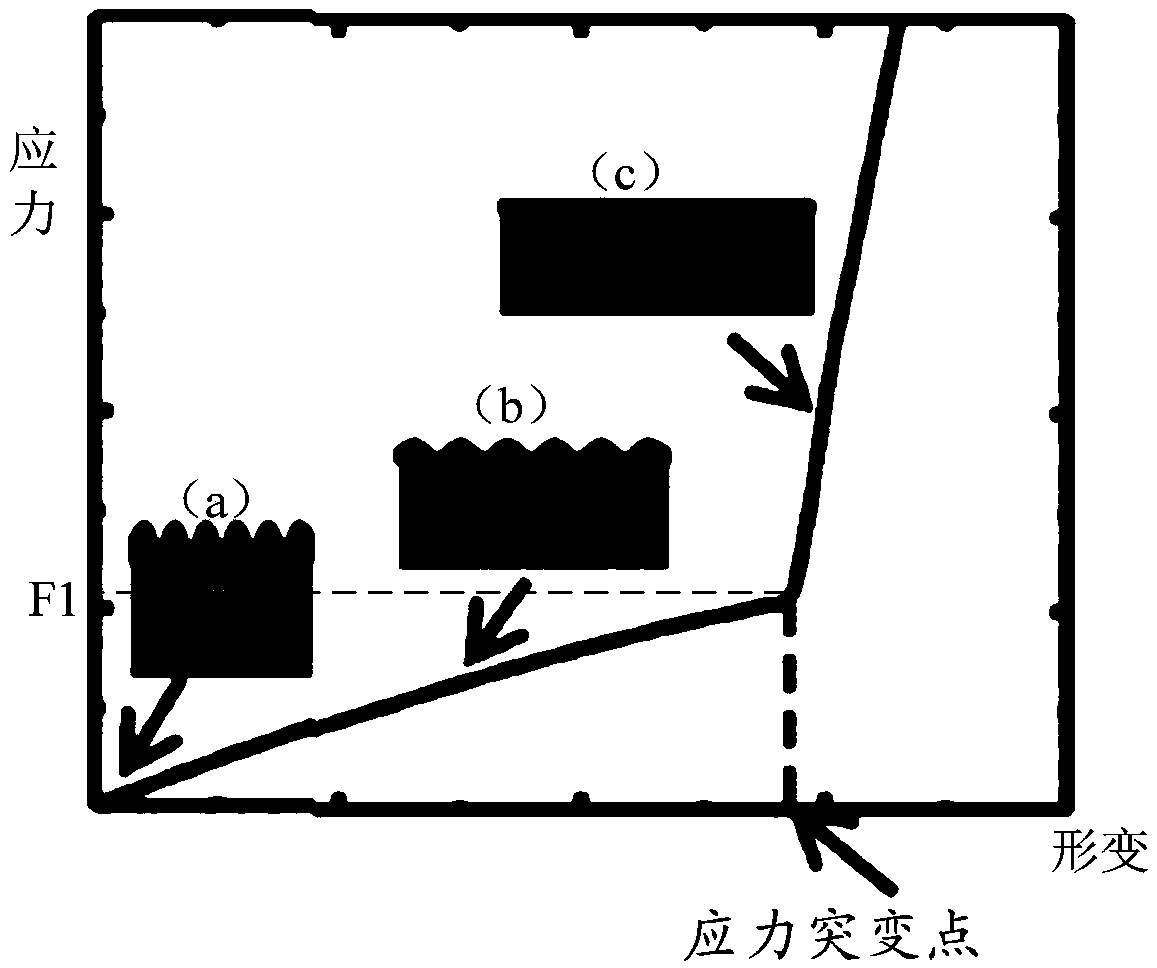

Flexible display component and manufacturing method thereof and display device

ActiveCN109326564AIncreased stretch rangeAvoid failureSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneDisplay device

An embodiment of the invention relates to the technical field of displaying, provides a flexible display component and a manufacturing method thereof and a display device and avoids the problem of damages caused by exceeding of a stretching range of a flexible display panel. The flexible display component comprises a stretchable flexible display panel and protective films on the top surface and / orthe bottom surface of the stretchable flexible display panel; the Young modulus of the protective films is larger than that of the stretchable flexible display panel; stress of the protective films at stress sudden change points is smaller than a maximum effective deformation stress of the flexible display panel. When not external force is applied to the flexible display component, the stretchable flexible display panel is in a contracted state under resilience force of the protective films.

Owner:BOE TECH GRP CO LTD

Alkali-free glass substrate, method for producing it and liquid crystal display panel

ActiveUS7754631B2High Young 's modulusLow linear expansion coefficientGlass rolling apparatusNon-linear opticsAlkali freeYoung's modulus

To provide an alkali-free glass substrate, which has a high Young's modulus, a low linear expansion coefficient, a high strain point and a low density, does not devitrify in the float forming process and is excellent in acid resistance.An alkali-free glass substrate, which contains neither alkali component nor BaO and consists essentially of, as represented by mol % based on oxide, from 57.0 to 65.0% of SiO2, from 10.0 to 12.0% of Al2O3, from 6.0 to 9.0% of B2O3, from 5.0 to 10.0% of MgO, from 5.0 to 10.0% of CaO and from 2.5 to 5.5% of SrO, provided that MgO+CaO+SrO is from 16.0 to 19.0%, MgO / (MgO+CaO+SrO)≧0.40, and B2O3 / (SiO2+Al2O3+B2O3)≦0.12; wherein Young's modulus ≧75 GPa; the linear expansion coefficient at from 50 to 350° C. is from 30×10−7 / ° C. to 40×10−7 / ° C.; the strain point ≧640° C.; the temperature T2 (the viscosity η satisfies log η=2)≦1,620° C.; the temperature T4 (the viscosity η satisfies log η=4)≦1,245° C.; the devitrification temperature ≦T4; and weight loss per unit area is at most 0.6 mg / cm2, when immersed in 0.1N HCl at 90° C. for 20 hours.

Owner:ASAHI GLASS CO LTD

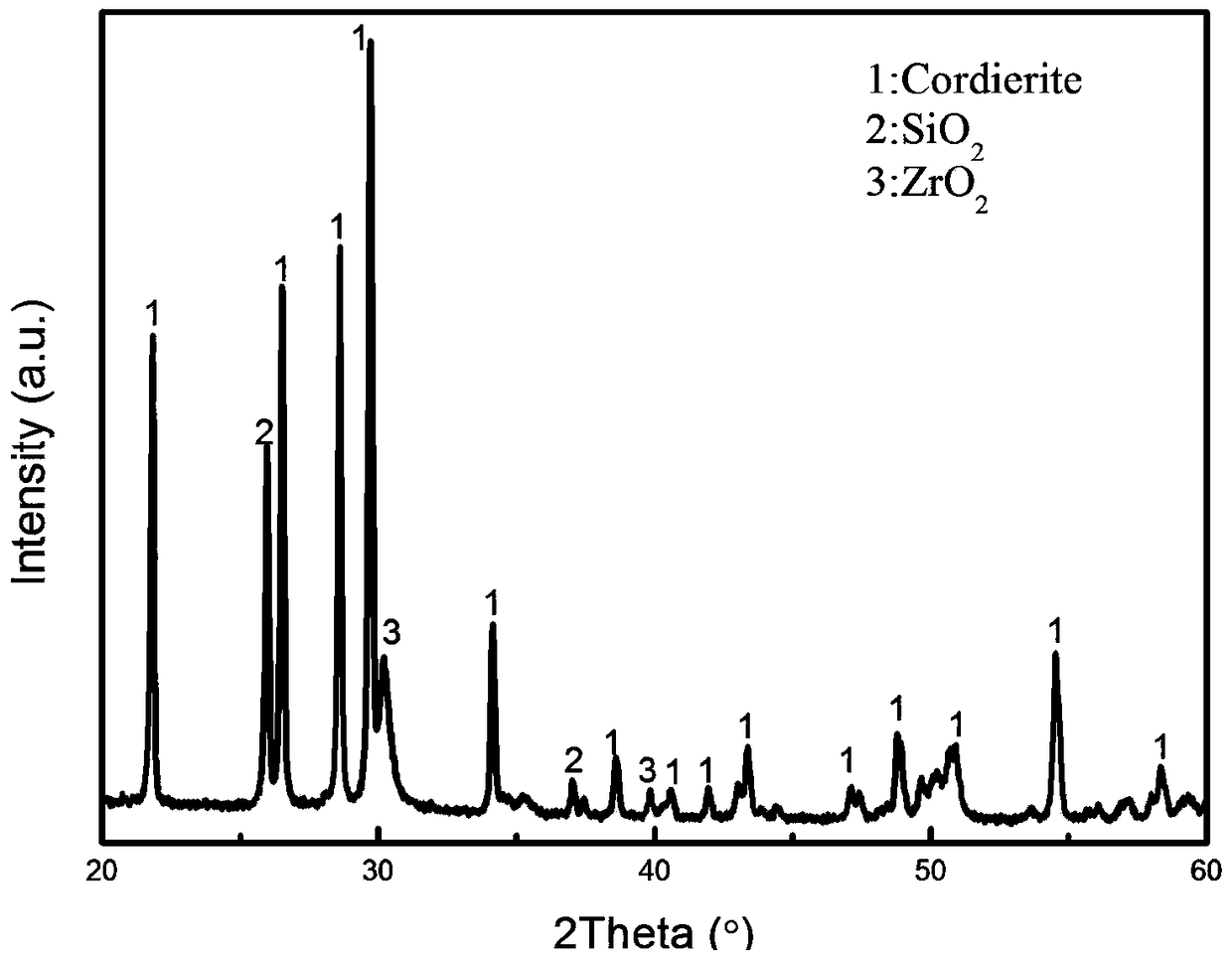

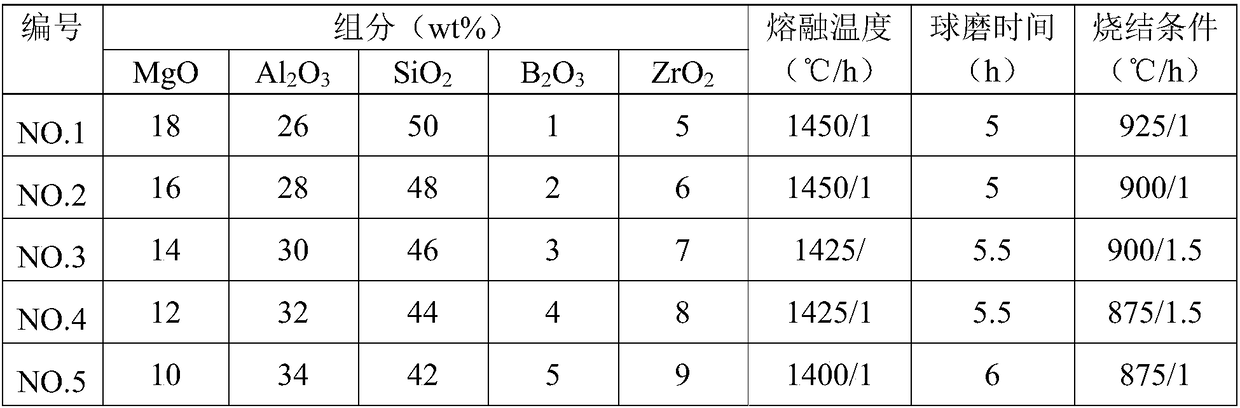

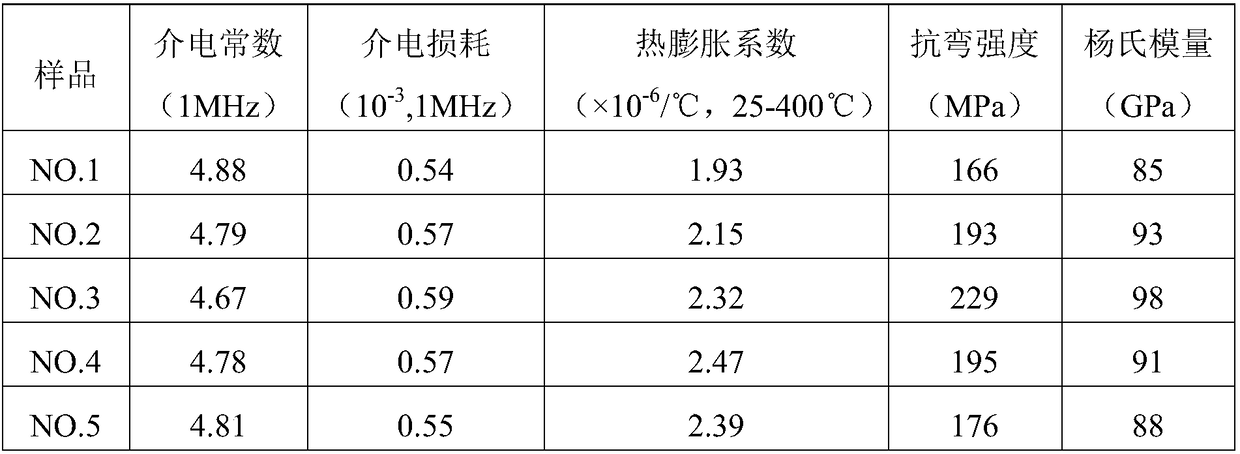

Cordierite-based microcrystalline glass material and preparation method thereof

InactiveCN108947257ARich sourcesSmall coefficient of thermal expansionFlexural strengthYoung's modulus

Belonging to the field of electronic ceramic materials, the invention provides a cordierite-based microcrystalline glass material and a preparation method thereof, and overcomes the problem of poor matching with silicon chips caused by large thermal expansion coefficient, low flexural strength, high dielectric constant, high dielectric loss and the like of existing ceramic materials. The cordierite-based microcrystalline glass material provided by the invention belongs to a magnesium-aluminum-silicon system, the principal crystalline phase is cordierite, the density is high, the flexural strength is up to 230MPa, the Young's modulus is 80-100GPa high, the thermal stability is good, the thermal expansion coefficient is 1.5-2.5*10<-6> / DEG C (20-600DEG C) low, and the cordierite-based microcrystalline glass material can form good match with silicon chips. At the same time, the dielectric constant can be adjusted to 4.5-5.0, the dielectric loss is tan Delta is less than 0.6*10<-3>, the signal transmission speed is greatly improved, and the power consumption is greatly reduced. In addition, in the preparation process, the temperature is lowered from the 1100DEG C or above in the traditional sintering process to 900DEG C or below, under the premise of improving the performance, the sintering temperature is further reduced and the production cost is saved. Moreover, the whole preparation technology has the characteristics of simple process, abundant raw material sources and energy consumption reduction, thus being of important significance for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Soy bean protein/aluminium hydrate nano composite material, its prepn. and uses

This invention relates to a kind of soybean protein / aluminium hydroxide nano-composites, its preparation method and application. This kind of materials basically comprises 1~30wt% aluminium hydroxide and 70~99wt% soybean protein and a certain amount of glycerol is also permitted. The preparation method is that, soybean protein (SPI) is dispersed in aqueous aluminium chloride solution by fierce stirring and ammonia is slowly dropped in. the gel-like complex is centrifugated and dried so as to obtain SPI / aluminium hydroxide nano-composites. This kind of materials is mixed with glycerol and thermo compressed to obtain SPI / aluminium hydroxide plastic plates. It has the advantages of simple production, environmental friendliness and good mechanical properties. Therefore, it can be potentially used as a kind of biodegradable green materials.

Owner:WUHAN UNIV

Capacitive pressure sensor and preparation method thereof

ActiveCN104677528AIncrease the capacitance change valueHigh Young's modulusForce measurementFluid pressure measurement using capacitance variationCapacitive pressure sensorOptoelectronics

The invention discloses a capacitive pressure sensor. The capacitive pressure sensor comprises a plate capacitor, and further comprises a conductive monocrystal silicon substrate and a conductive supporting structure, wherein the plate capacitor comprises a conductive monocrystal silicon movable electrode plate and a metallic fixed electrode; the conductive supporting structure is arranged between the conductive monocrystal silicon movable electrode plate and the conductive monocrystal silicon substrate; a closed cavity is defined by the conductive monocrystal silicon movable electrode plate, the conductive monocrystal silicon substrate and the conductive supporting structure; the metallic fixed electrode is arranged on the conductive monocrystal silicon substrate inside the closed cavity; the conductive monocrystal silicon substrate comprises a plurality of conductive monocrystal silicon blocks which are insulated from each other; the conductive monocrystal silicon blocks are not simultaneously connected with the conductive monocrystal silicon movable electrode plate and the metallic fixed electrode, but at least one of the conductive monocrystal silicon blocks is connected with the conductive monocrystal silicon movable electrode plate and the metallic fixed electrode respectively. The capacitive pressure sensor disclosed by the invention is high in change value of capacitance, simplified in circuit, high in Young modulus of structure, accurate in measuring result, and not prone to be subjected to influence from the external environment.

Owner:NO 24 RES INST OF CETC

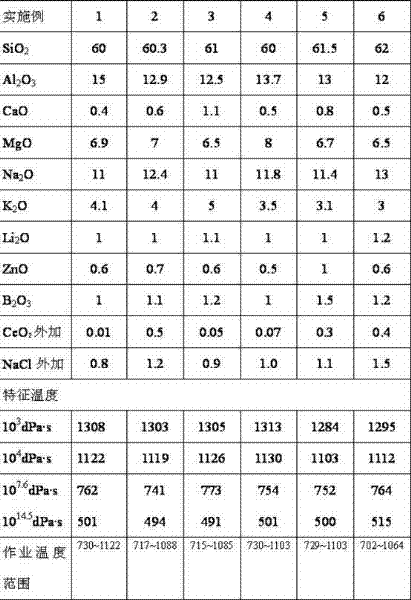

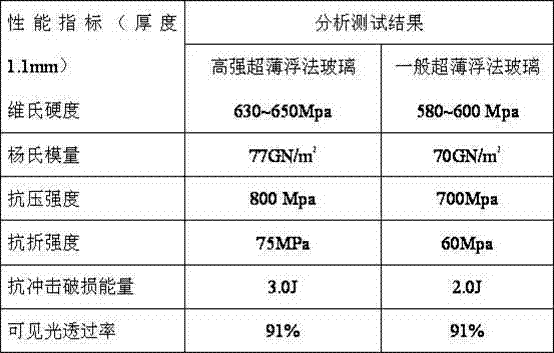

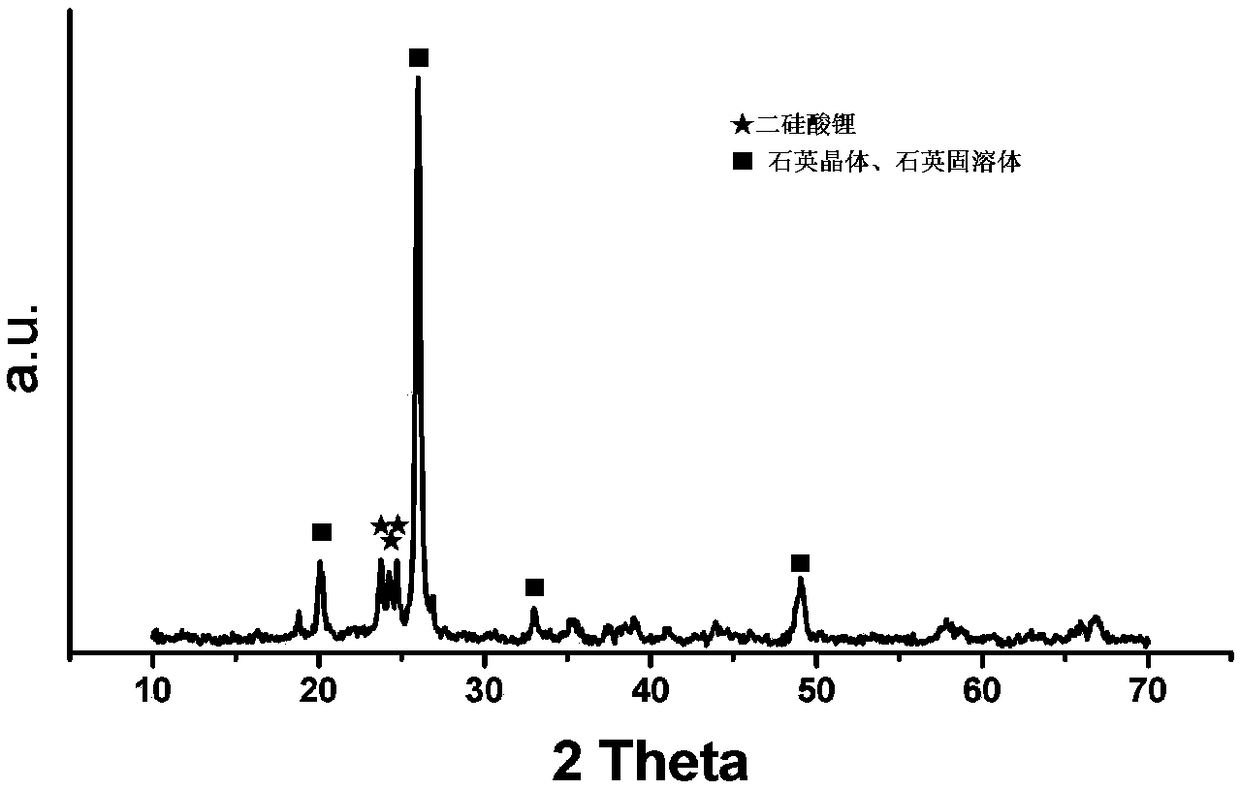

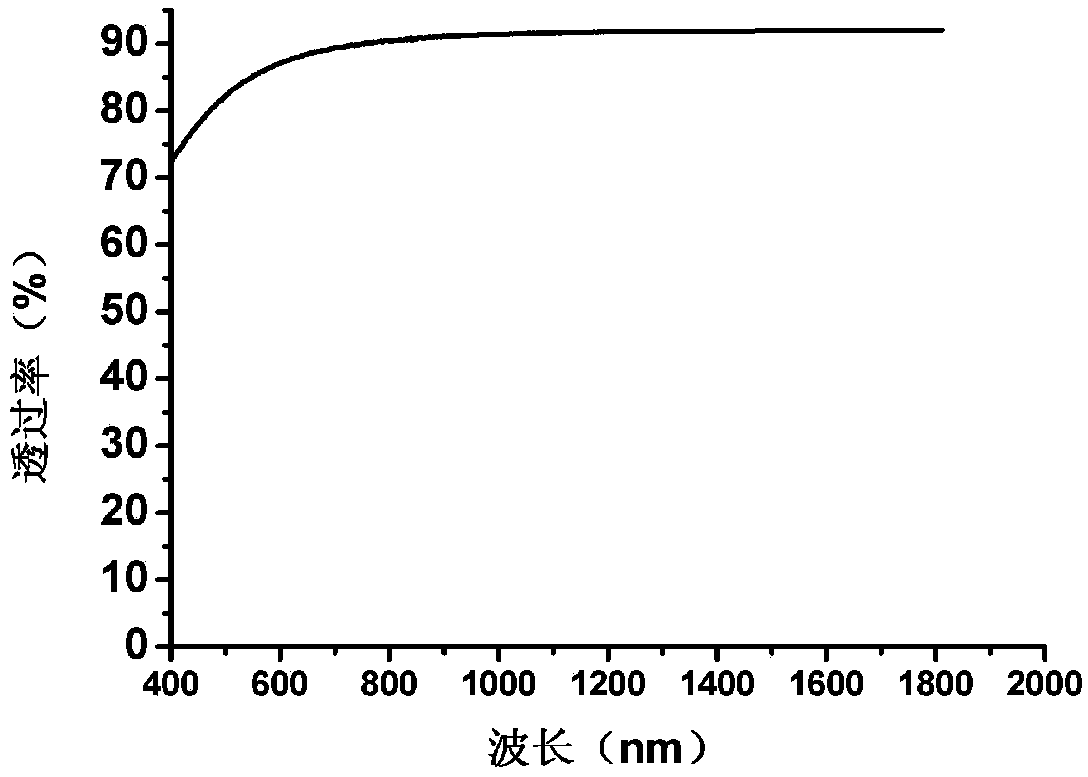

High strength ultrathin float glass

Owner:CLFG LONGHAI ELECTRONICS GLASS

Glass ceramics

The invention discloses glass ceramics. The glass ceramics is prepared from the following components, in percentage by weight: 65-80% of SiO2, 0-3.5% of Al2O3, 7-12.5% of Li2O, 0.5-3% of K2O, greaterthan or equal to 3% and less than or equal to 10% of Y2O3, 1.5-4% of P2O5, 1-5% of ZrO2, 0.5-2% of MgO and 0.5-2% of ZnO. The glass ceramics solve problem of molding and opalescence presenting of theglass ceramics which take a quartz solid solution and lithium disilicate as main crystal phases by adjusting the components of the glass ceramics, the internal quality of the glass ceramics is uniform, the glass ceramics can be efficiently and stably produced, and the glass ceramics have the high hardness, the high Young modulus and the higher transmittance, and can be widely applied.

Owner:CDGM GLASS LLC

Method for preparing carbon nano tube modified bipolar membrane with anion groups

InactiveCN102580549AGood compatibilityHigh water dissociation efficiencySemi-permeable membranesCell component detailsCelluloseAcetic acid

The invention relates to a method for preparing a carbon nano tube modified bipolar membrane with anion groups. The method comprises the following steps of: preparing a sodium carboxymethylcellulose (CMC) aqueous solution or a sodium alginate (SA) aqueous solution by using sodium carboxymethylcellulose or sodium alginate, adding a carbon nano tube with the anion groups, stirring and defoaming under reduced pressure to obtain viscous membrane liquid; casting the viscous membrane liquid in a smooth culture dish to prepare a cation exchange membrane; stirring and dissolving chitosan in 1 to 10 mass percent of acetic acid aqueous solution to prepare 1 to 10 mass percent of chitosan acetic acid aqueous solution, dripping 2.5 volume percent of glutaraldehyde solution slowly with stirring, and defoaming under the reduced pressure to obtain a chitosan (CS) anion membrane liquid; and forming a membrane of the CS anion membrane liquid, fixing the membrane to a prepared cation membrane layer, and airing at room temperature to obtain the bipolar membrane. Due to the adoption of the carbon nano tube modified cation membrane layer with the anion groups, the bipolar membrane has the characteristics of high water dissociation efficiency, small membrane impedance, low tank voltage, high compatibility of two membrane layers and the like.

Owner:FUJIAN NORMAL UNIV

High-purity alumina fiber and preparation method thereof

The invention discloses a preparation method of a high-purity alumina fiber. The alumina fiber takes anhydrous aluminium chloride and aluminium micro powder as raw materials and acetic acid or lactic acid as a stabilizer and a spinning auxiliary and is added with an oxide second phase (MgO, SiO2, Y2O3, ZrO2 and the like) with mass fraction of 0-2%, so that mechanical properties of the alumina fiber at room temperature and high temperature are improved. An alumina fibreboard is composed of alumina fibers, an inorganic binder, an organic binder and an additive in a mass ratio of (30-40) to (55-65) to (0-1) to (4-5). A preparation method of the alumina fibreboard is characterized by comprising the following steps: preparing colloid, carrying out centrifugal spinning, preparing alumina fibers, preparing a wet blank, carrying out high temperature treatment, and machining, so that the alumina fibreboard finished product is obtained. The high-purity alumina fiber product has excellent thermal insulation properties and mechanical properties, and an operating temperature is increased, so that an operating temperature range of a similar product is expanded.

Owner:南京理工宇龙新材料科技股份有限公司

Synthetic polymer and natural extracellular matrix composite material, artificial blood vessel and preparation method thereof

PendingCN110201223AGood biocompatibilityImprove biological activityProsthesisCell-Extracellular MatrixVascular tissue

Owner:NANKAI UNIV

Bacteria cellulose pervaporation membrane and uses thereof

InactiveCN101234299ASolve the problem that the thickness uniformity is difficult to controlAddressing Chemical StabilityDistillationCulture fluidMicrobiology

The invention provides a bacterial cellulose pervaporation membrane, which is characterized in that the preparation method is as follows: Acetobacter xylinum DT4.2 strain of the active wood fermentation is put into the seed culture fluid and shaking cultured at constant temperature of 25 to 32 DEG C for 8 to 24 hours; the seed solution is put into the fermentation culture solution to be evenly shaken; and then the fermentation culture solution is moved to the container for culturing for 7 to 15 days at the constant temperature of 25 to 32 DEG C; pellicle membrane formed on the surface of the fermentation solution is taken out and then is processed by the alkali liquor with the quality concentration of 1 to 20 percent; the residual alkali liquor in the membrane is washed to neutrality by the deionized water to prepare into the membrane after drying. The invention also discloses the application of the membrane. The preparation method of the membrane has the advantages of simple preparation, good mechanical and chemical property, excellent heat stability, strong hydrophilicity, high separation choice to the water in the organic water solution at lower temperature, long service life; moreover, the membrane material itself can be biodegradation which is a environmental friendly material.

Owner:许春元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com