Glass ceramics

A technology of glass-ceramics and subcrystalline phase, applied in the field of glass-ceramics, can solve problems such as easy milky and bluish glass, uneven glass, fluctuations in glass performance, etc., to achieve uniform internal quality, wide application value, high poplar The effect of the modulus

Active Publication Date: 2018-10-12

CDGM GLASS LLC

View PDF5 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] During the molding process of the original glass of glass-ceramics, the glass tends to be milky and blue, resulting in crystal nuclei or crystals of different sizes in the glass. After heat treatment, the size and distribution of crystals inside the glass are uneven, resulting in huge changes in glass performance. Fluctuation; especially when forming the initial glass of glass-ceramics with quartz solid solution and lithium disilicate as the main crystal phase, it is easy to milk and turn blue, resulting in uneven interior of the glass, and cannot be continuously and stably produced efficiently

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~10

[0087] Table 1 Examples 1-10 glass-ceramics

[0088]

[0089]

Embodiment 11~20

[0090] Table 2 Examples 11-20 glass-ceramics

[0091]

[0092]

Embodiment 21~30

[0093] Table 3 Examples 21-30 glass-ceramics

[0094]

[0095]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Login to View More

Abstract

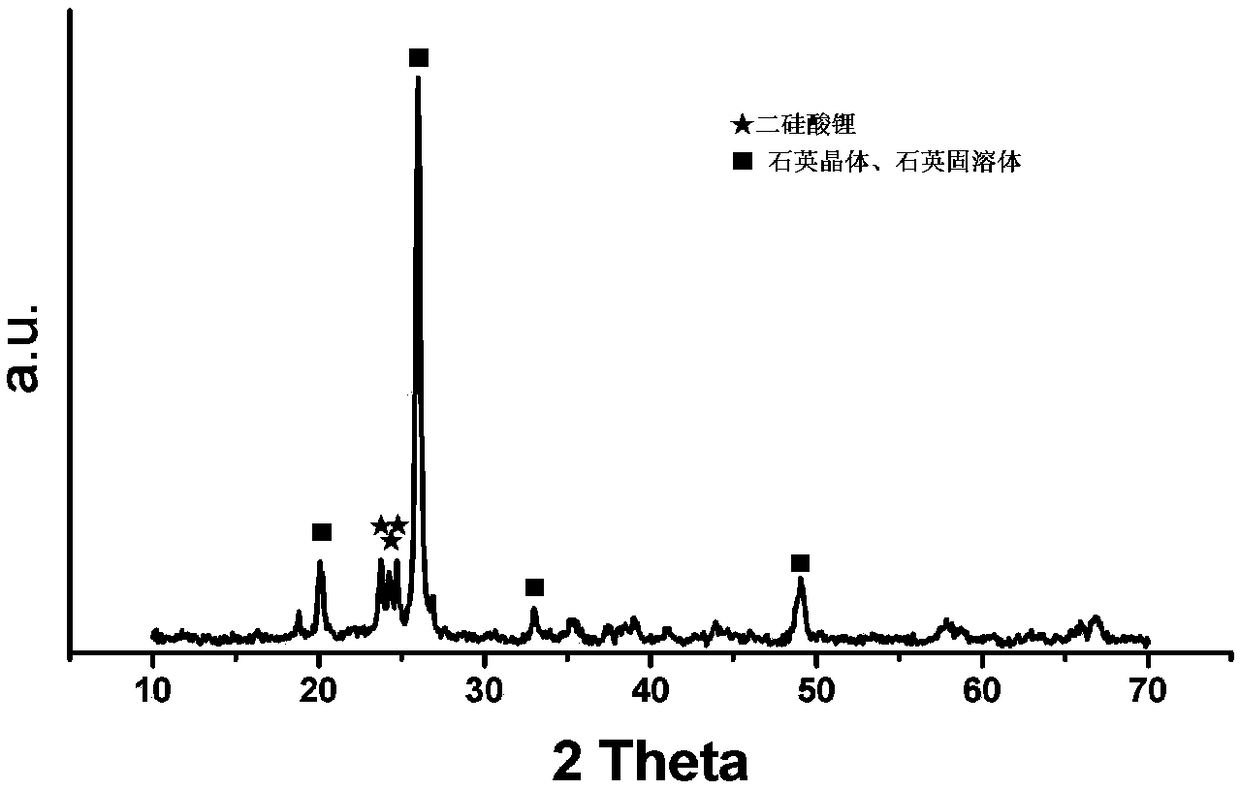

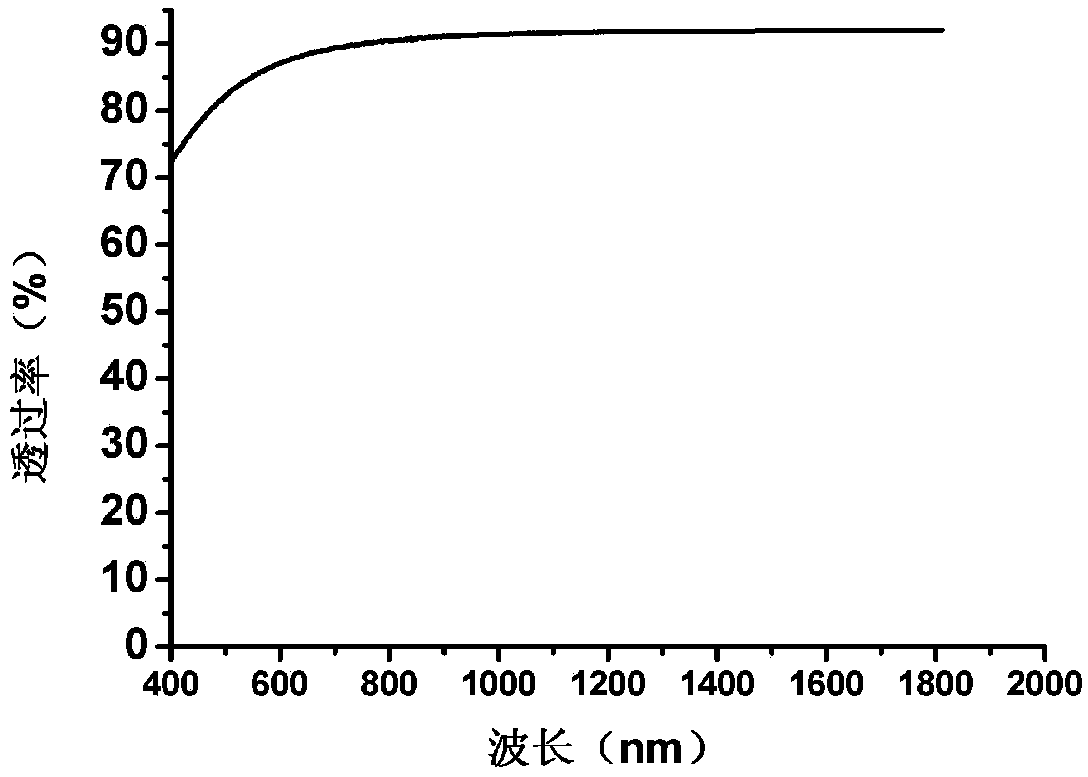

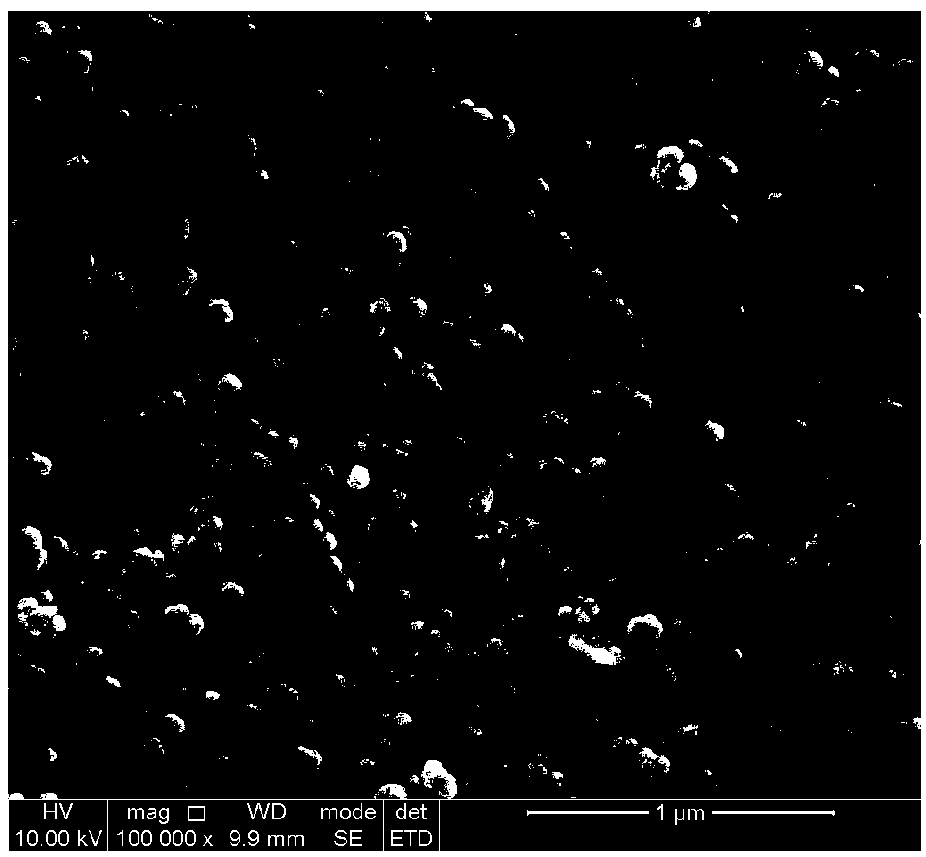

The invention discloses glass ceramics. The glass ceramics is prepared from the following components, in percentage by weight: 65-80% of SiO2, 0-3.5% of Al2O3, 7-12.5% of Li2O, 0.5-3% of K2O, greaterthan or equal to 3% and less than or equal to 10% of Y2O3, 1.5-4% of P2O5, 1-5% of ZrO2, 0.5-2% of MgO and 0.5-2% of ZnO. The glass ceramics solve problem of molding and opalescence presenting of theglass ceramics which take a quartz solid solution and lithium disilicate as main crystal phases by adjusting the components of the glass ceramics, the internal quality of the glass ceramics is uniform, the glass ceramics can be efficiently and stably produced, and the glass ceramics have the high hardness, the high Young modulus and the higher transmittance, and can be widely applied.

Description

technical field [0001] The invention relates to a glass-ceramic. Background technique [0002] Glass-ceramic with quartz solid solution and lithium disilicate as the main crystal phase has controllable thermal expansion coefficient, high hardness and mechanical strength, high thermal stability, good chemical stability and electrical insulation, and good The transparency of the filter can be used on the substrate of the dielectric film in the filter, the protective mirror, the disk substrate, etc. [0003] Glass-ceramic is a material that forms an irregular and uniform network structure through rapid cooling. When glass-ceramic is produced, it first needs to be cooled to become a uniform glass body, and then through subsequent heat treatment to achieve uniform distribution and controllable growth of crystals in the glass. At present, the heat treatment temperature of glass-ceramics is divided into two stages, the nucleation stage and the crystal growth stage. [0004] Duri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C10/14

CPCC03C10/0009

Inventor 原保平于天来何睿胡斌

Owner CDGM GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com