Titanium carbonitride based metal ceramic based on high-entropy alloy binder phase and preparation method of metal ceramic

A high-entropy alloy, titanium carbonitride technology, applied in the field of titanium carbonitride-based cermet materials based on high-entropy alloy binder phase and its preparation, to improve the comprehensive mechanical properties, achieve the matching of hardness and toughness, The effect of easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The raw materials used in this embodiment and the processing steps are as follows:

[0034] Weigh 97gTi(C 0.5 , N 0.5 ) powder and 3g high-entropy alloy binder phase raw material powder, wherein the high-entropy alloy binder phase raw material powder component and proportioning are iron, cobalt, nickel, samarium metal elemental powder, according to the molar ratio of iron, cobalt, nickel, samarium element 1:1:1:1 formulation. Then put the above powders into the ball mill jar together, put the balls into the ball according to the ratio of ball to material of 8:1, and pour 100ml of alcohol, and ball mill for 24 hours to get the mixed powder, after drying, add rubber in the proportion of 1wt% to form Agent, sieved, granulated. Then the mixed raw materials are weighed to a certain weight and loaded into the mold cavity for compression molding. Then put the prepared sample into a low-pressure sintering furnace for sintering. The sintering system is: vacuumize to 1×10 -1...

Embodiment 2

[0036] The raw materials used in this embodiment and the processing steps are as follows:

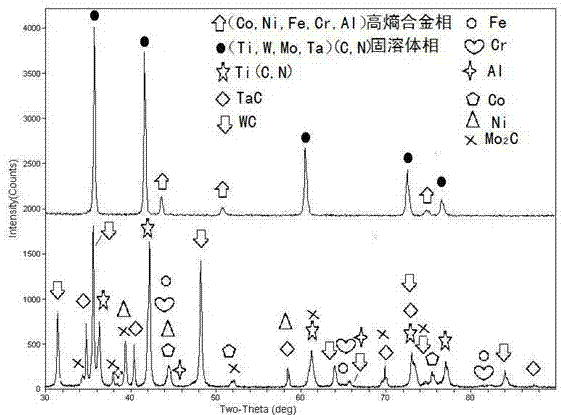

[0037] Weigh 66gTi(C 0.7 , N 0.3 ) powder, 10gWC powder, 5gTaC powder, 4gMo 2 C powder, 15g high-entropy alloy binder phase raw material powder, wherein the high-entropy alloy binder phase raw material is nickel-aluminum alloy powder, iron-chromium alloy powder, cobalt powder, and according to the molar ratio of iron, cobalt, nickel, chromium, and aluminum elements 1 :1:1:1:1 formulation. Then put the above powders into the ball mill jar together, put the balls into the balls according to the ball-to-material ratio of 8:1, pour 150ml of acetone, and ball mill for 24 hours to get the mixed powder, dry it and add rubber in the proportion of 1wt% to form Agent, sieved, granulated. Then the mixed raw materials are weighed to a certain weight and loaded into the mold cavity for compression molding. Then put the prepared sample into a low-pressure sintering furnace for sintering. The sin...

Embodiment 3

[0039] The raw materials used in this embodiment and the processing steps are as follows:

[0040] Weigh 59g Ti(C 0.3 , N 0.7 ) powder, 30g (Ti, 15W, 5Mo, 0.2V) (C 0.5 , N 0.5 ) solid solution powder, 2gWC powder, 0.2gVC powder, 0.8gCr 3 C 2 powder and 8g of high-entropy alloy binder phase raw material powder, wherein the high-entropy alloy binder phase raw material is metal elemental powder of iron, cobalt, nickel, chromium, dysprosium, and europium, according to the elements of iron, cobalt, nickel, chromium, dysprosium, and europium The molar ratio is 1:1:1:1:0.5:0.5. Then put them into the ball mill jar together, put the balls into the balls according to the ratio of ball to material of 8:1, and pour 150ml of alcohol into the ball mill for 24 hours to get the mixed powder, after drying it, add the rubber molding agent according to the ratio of 1wt%, Sieve, granulate. Then the mixed raw materials are weighed to a certain weight and loaded into the mold cavity for com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com