Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2166results about "Conjugated cellulose/protein artificial filaments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of core-shell structured synthetic polymer-natural polymer composite fiber

InactiveCN102817105ASimple and fast operationMild reaction conditionsConjugated cellulose/protein artificial filamentsFilament/thread formingFiberPolymer science

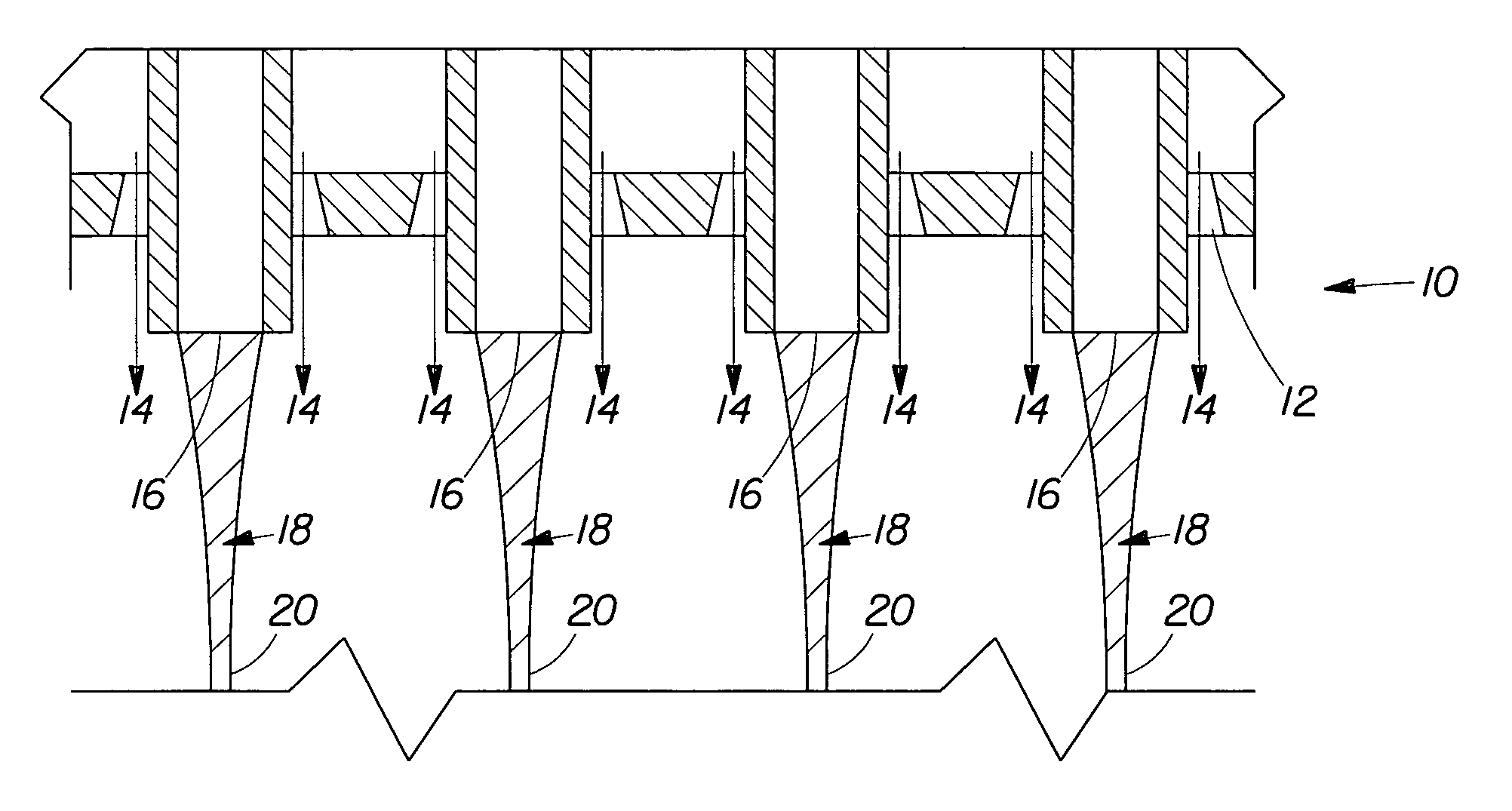

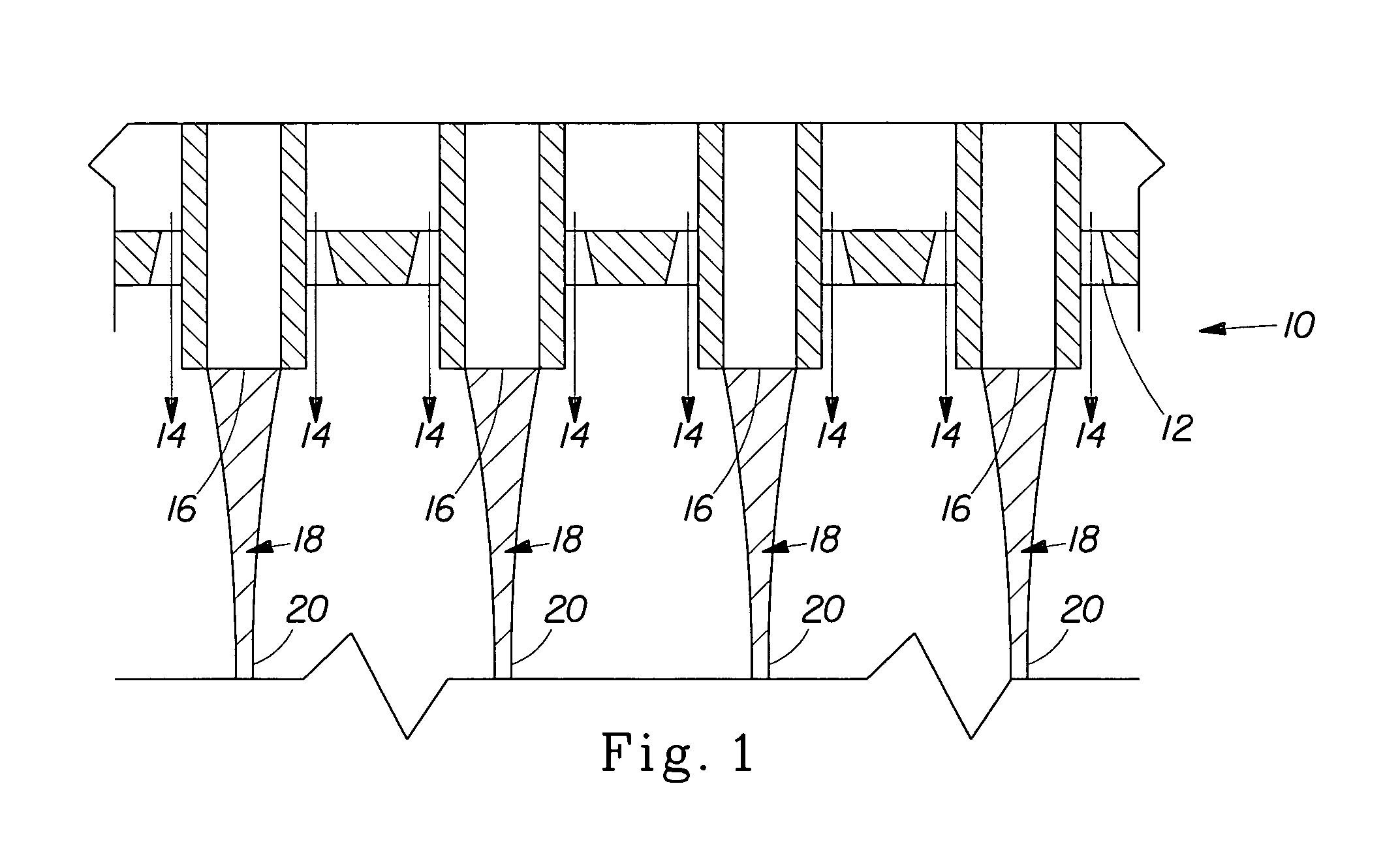

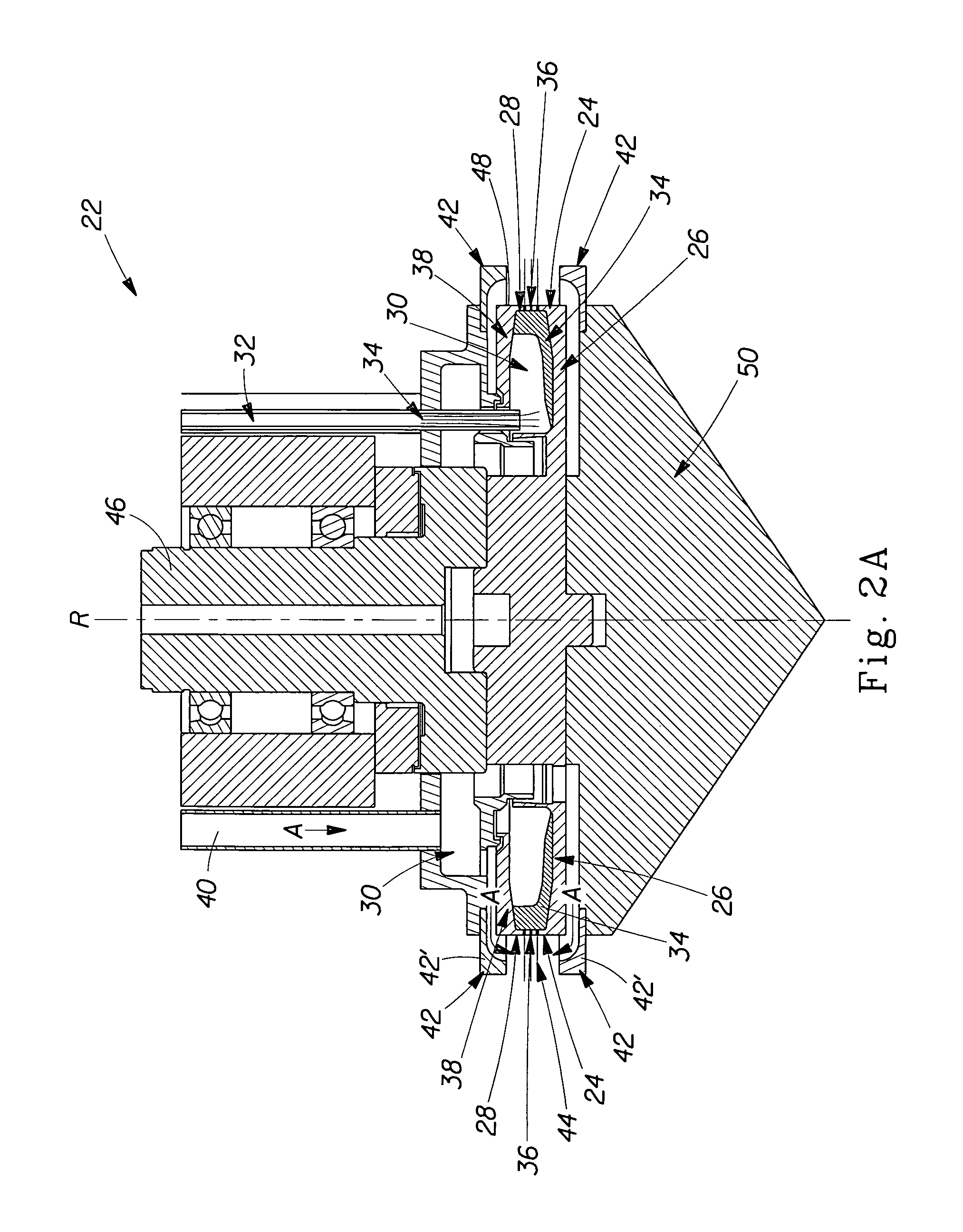

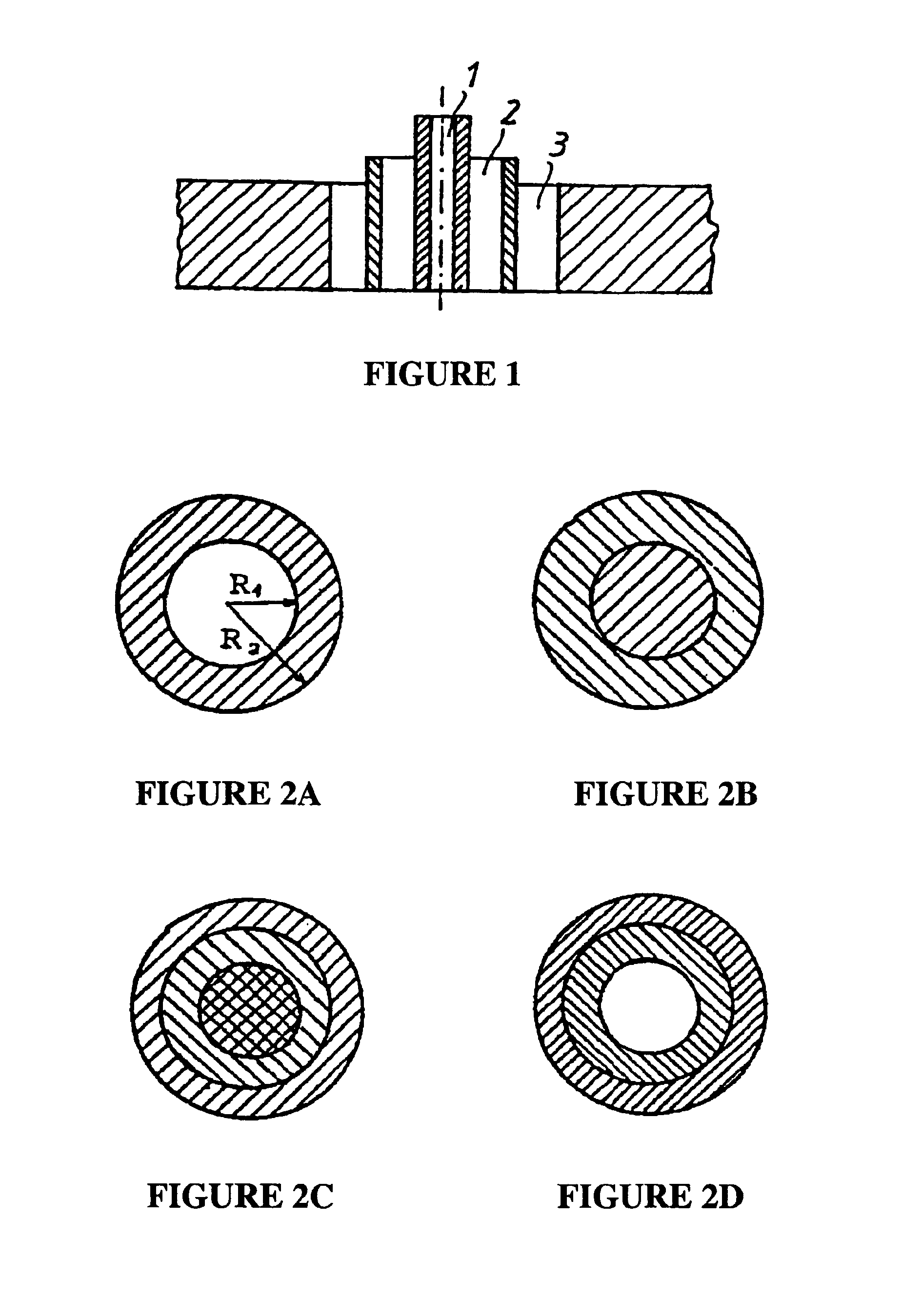

The invention discloses a preparation method of a core-shell structured synthetic polymer-natural polymer composite fiber, and the method comprises the steps of: (1) selecting one or several of synthetic polymers to dissolve in a solvent, and conducting stirring until complete dissolution; (2) selecting a natural polymer to dissolve in a solvent, or adding a spinning assistant, and carrying out stirring until complete dissolution; and (3) taking the solution prepared in step (1) as an outer tube spinning solution, adopting the solution prepared in step (2) as an inner tube spinning solution, injecting them into the inner tube and the outer tube of a coaxial spinneret, and performing coaxial electrospinning at room temperature. The core-shell structured nano-fiber prepared by the invention selects the synthetic polymer as the shell layer, and can inhibit water molecules from penetrating the natural polymer as the core layer. The natural polymer as the core layer can more effectively encapsulate active substances to avoid inactivation of the active substances in the presence of an organic solvent, so that the core-shell structured composite fiber can play a good drug sustained release role in the drug carrier field, and an integral activity can be maintained.

Owner:SHANGHAI JIAO TONG UNIV +1

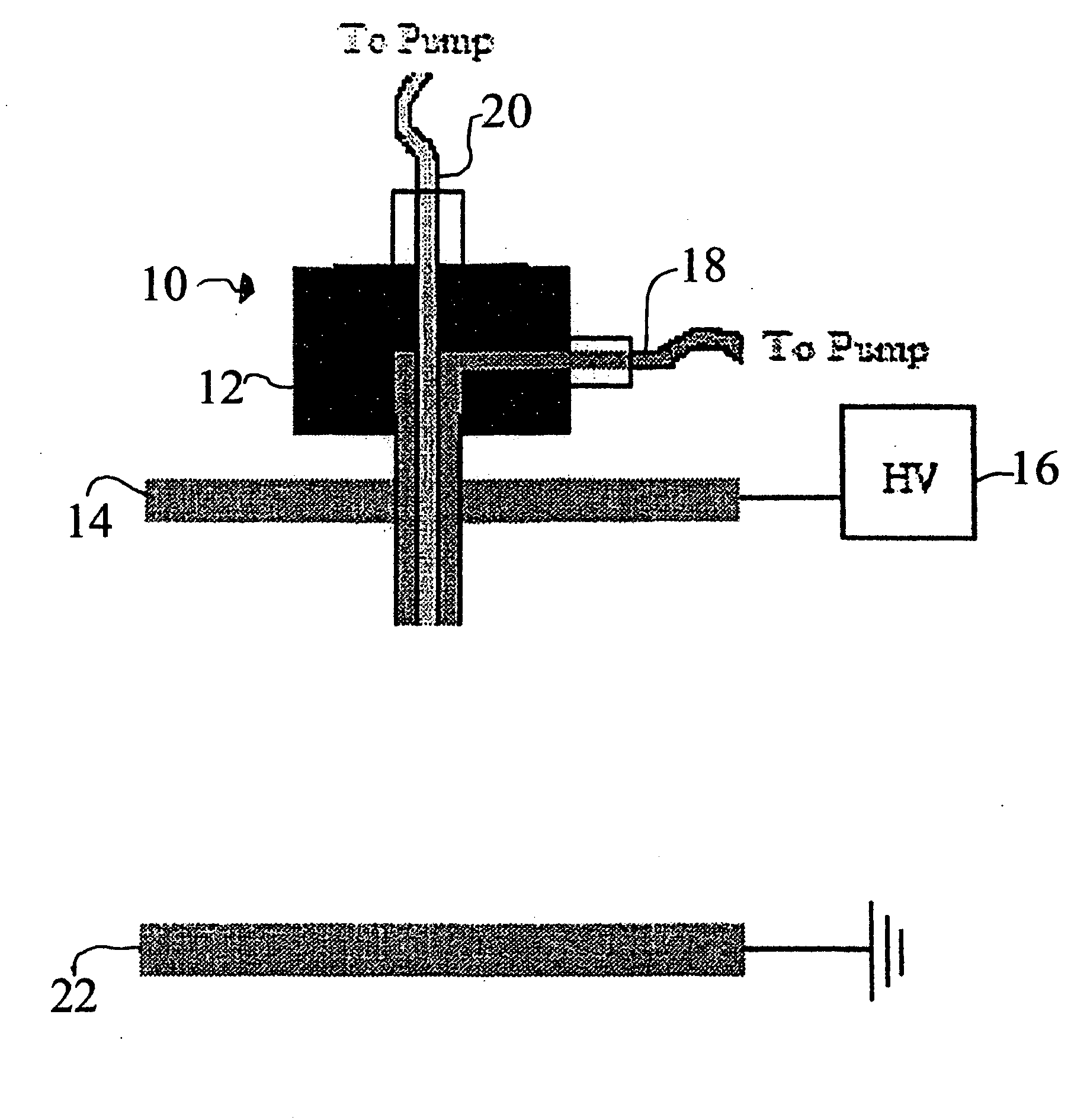

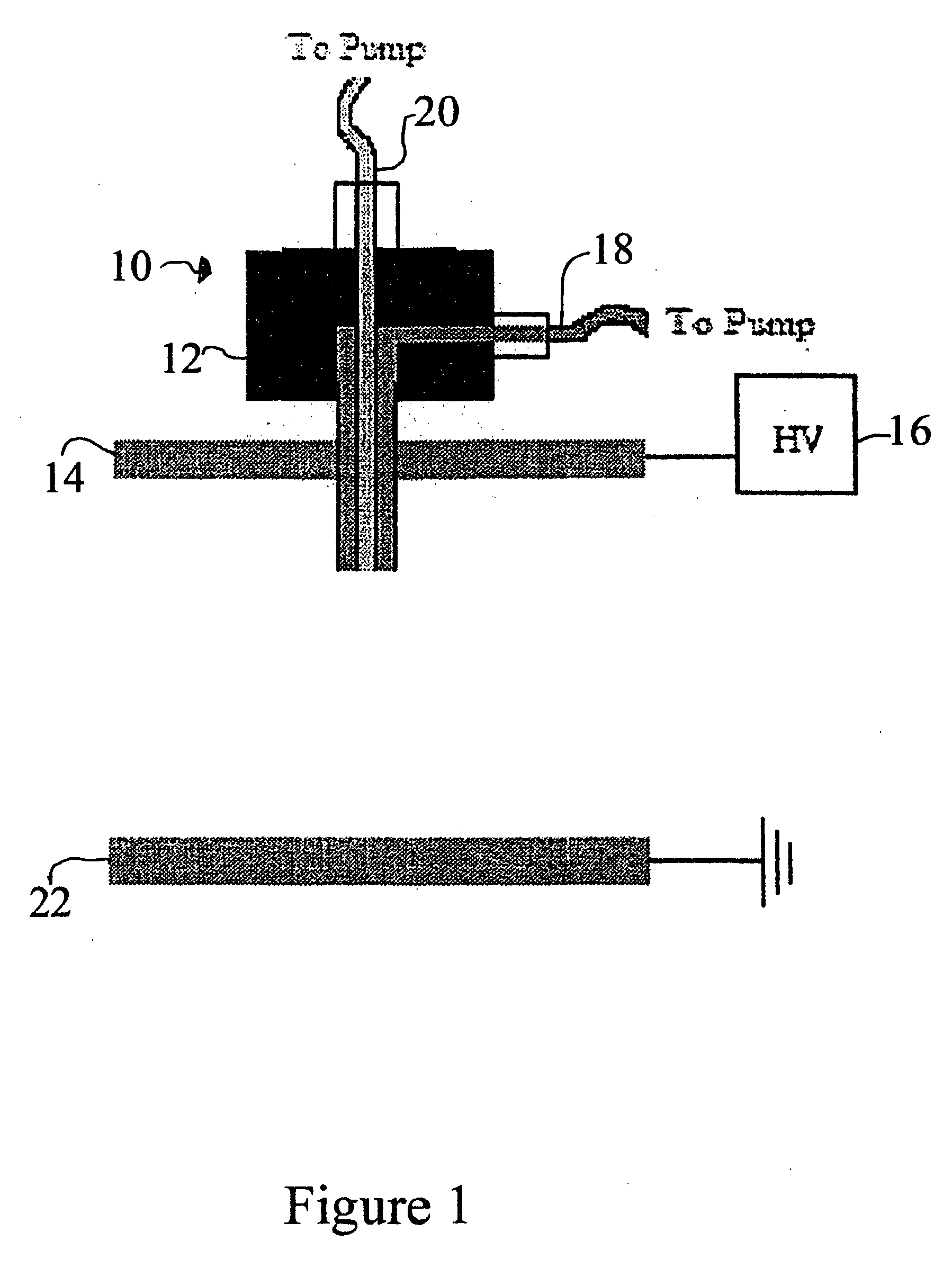

Production of submicron diameter fibers by two-fluid electrospinning process

InactiveUS20060213829A1Conjugated cellulose/protein artificial filamentsElectro-spinningHollow fibreNanowire

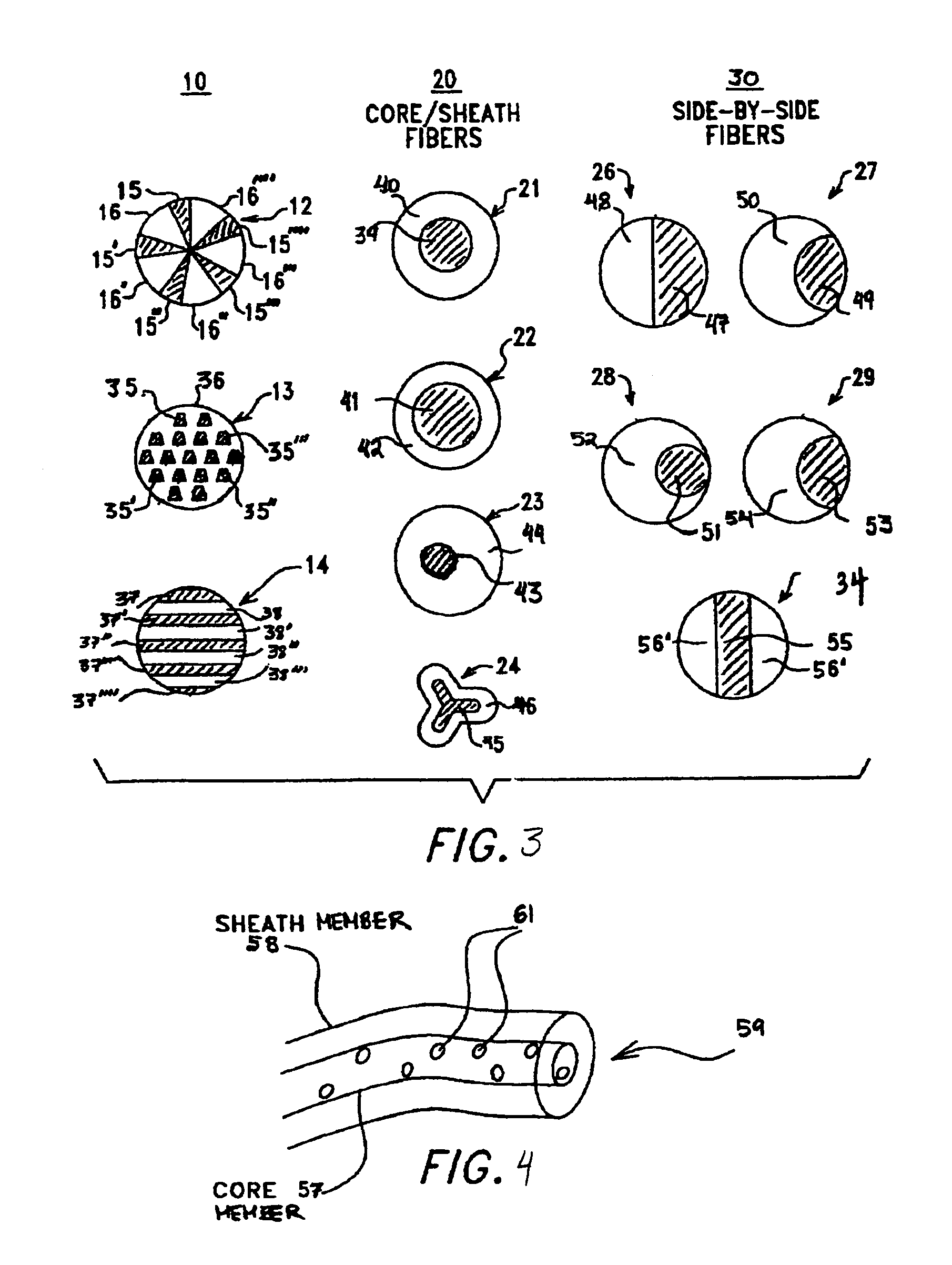

Electrospinning of materials that are difficult or impossible to process into nanofibers by conventional fiber-forming techniques or by electrospinning are prepared by an electrospinning procedure which uses an electrospinnable outer “shell” fluid around an inner “core” fluid, which may or may not be electrospinnable, to form nanofibers of the inner core fluid having a core / shell morphology. The resulting shell around the nanofiber can remain in place or be removed during post-processing with the core of the fiber remaining intact. The dual-fluid electrospinning process can produce core fibers having diameters less than 100 nm, insulated nanowires, as well as tough, bio-compatible silk fibers. Alternatively, the core can be removed leaving a hollow fiber of the shell fluid.

Owner:MASSACHUSETTS INST OF TECH

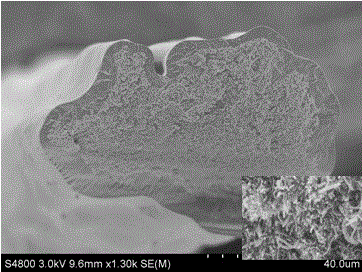

Method for preparing nano cellulose microfibril reinforced polymer composite material

ActiveCN102344685AUniform structureTransparent structureConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsSolubilityFiber

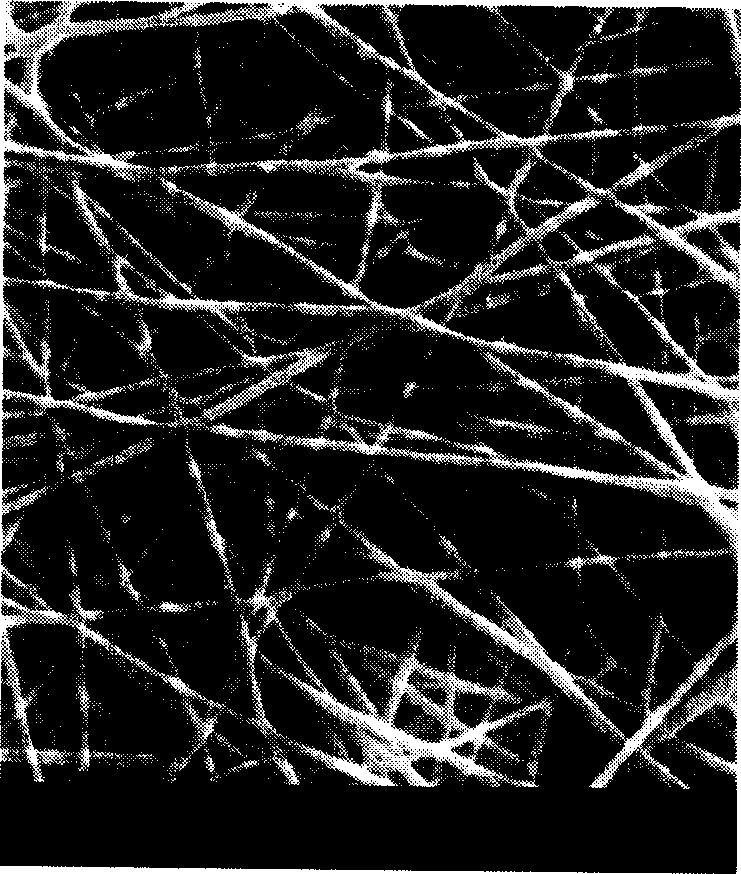

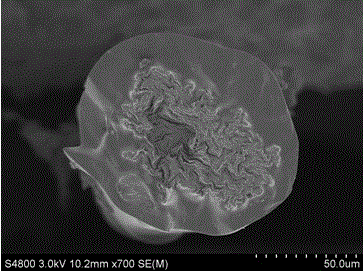

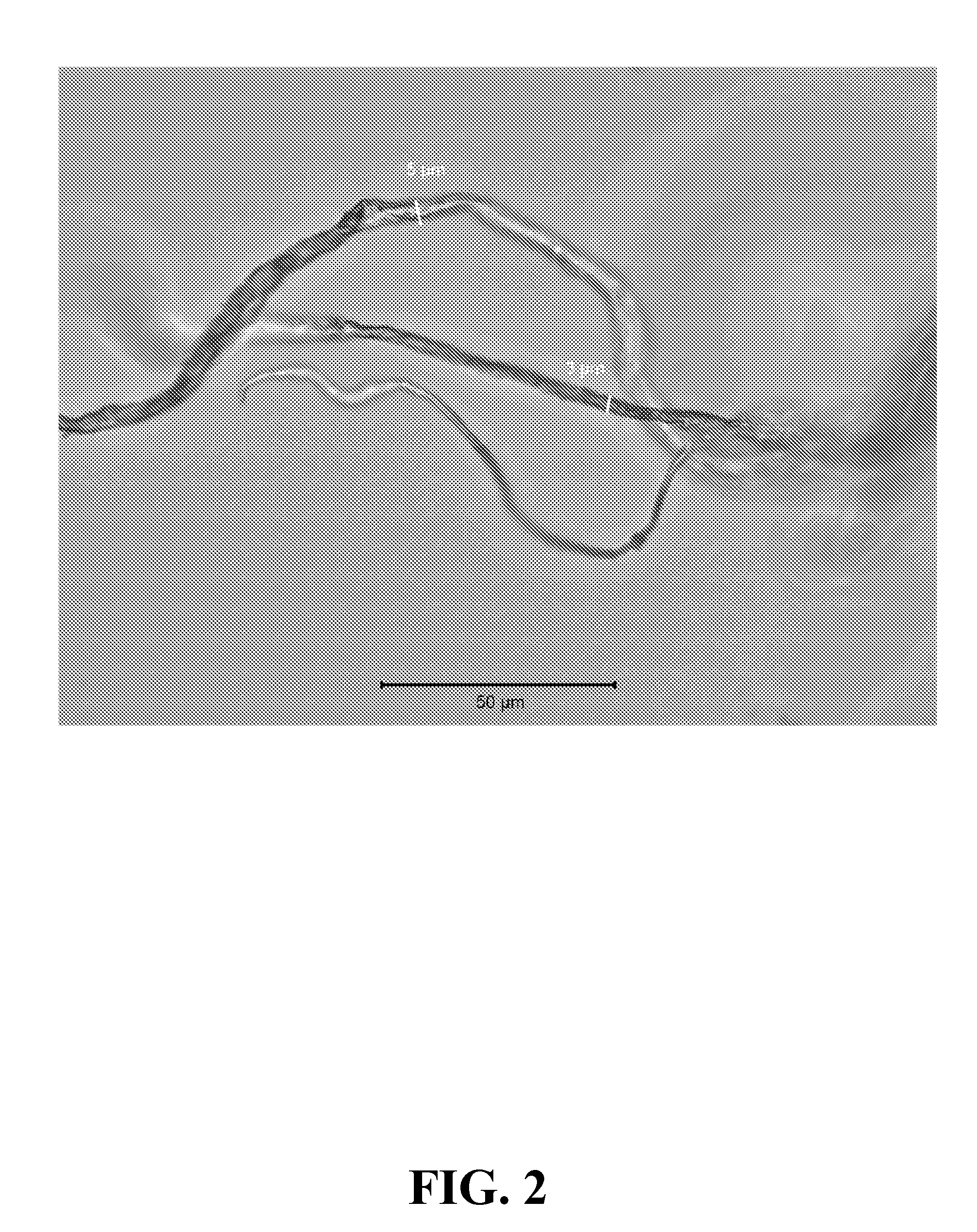

The invention discloses a method for in situ generating a nano cellulose microfibril reinforced polymer composite material, comprising the following steps: using ionic liquid as a primary solvent, dissolving cellulose, or mixing cellulose with other polymers via solution mixing, and controlling the solubility of the cellulosic material in the solvent to maintain naturally occurring nano cellulose microfibril in the cellulosic material, so as to in situ obtain the nano cellulose microfibril reinforced polymer composite material. The nano microfibril can be observed under a transmission microscope obviously, which is different from the completely dissolved cellulose solution. In the preparing process, the dissolving temperature is controlled within 30-150 DEG C, and stirring and vacuum deaeration are used as auxiliary. By controlling the dissolving time, solution concentration and ratio of mixing, a polymer solution containing cellulose microfibril with dimension of 5-300 nanometers can be obtained. The polymer solution can be used for preparing composite material fiber, hollow fibrous membrane, diaphragm, film, gel, porous material and other known applications of enhanced material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Cellulosic fibers having enhanced reversible thermal properties and methods of forming thereof

Cellulosic fibers having enhanced reversible thermal properties and methods of forming such cellulosic fibers are described. In one embodiment, a cellulosic fiber includes a fiber body formed of an elongated member. The elongated member includes a cellulosic material and a temperature regulating material dispersed within the cellulosic material. The temperature regulating material includes a phase change material having a transition temperature in the range of −5° C. to 125° C. The cellulosic fiber can be formed via a solution spinning process and can be used in various products where thermal regulating properties are desired. For example, the cellulosic fiber can be used in textiles, apparel, footwear, medical products, containers and packagings, buildings, appliances, and other products.

Owner:OUTLAST TECH GMBH

Rotary spinning processes for forming hydroxyl polymer-containing fibers

InactiveUS7655175B2Monocomponent protein artificial filamentElectric discharge heatingFiberMaterials science

Owner:THE PROCTER & GAMBLE COMPANY

Method for producing shaped bodies

InactiveUS6881361B1Monocomponent cellulose artificial filamentConjugated cellulose/protein artificial filamentsPolyvinyl alcoholSolvent

The invention relates to a method for producing shaped bodies, especially threads or foils, from at least one polymer of the groups consisting of polysaccharide, polysaccharide derivative or polyvinyl alcohol by forming a solution of the polymer that contains an additive in a solvent containing amine-N-oxide, extruding the solution and precipitating the extrudate by contacting with a coagulant. The invention is characterized in that at least two polymeric solutions are formed. At least one of the two polymeric solutions contains one or more finely distributed additives and the at least two polymeric solutions are simultaneously extruded forming a combined extrudate.

Owner:OSTTHURINGISCHE MATERIALPRUFGES FUR TEXTIL & KUNSTE

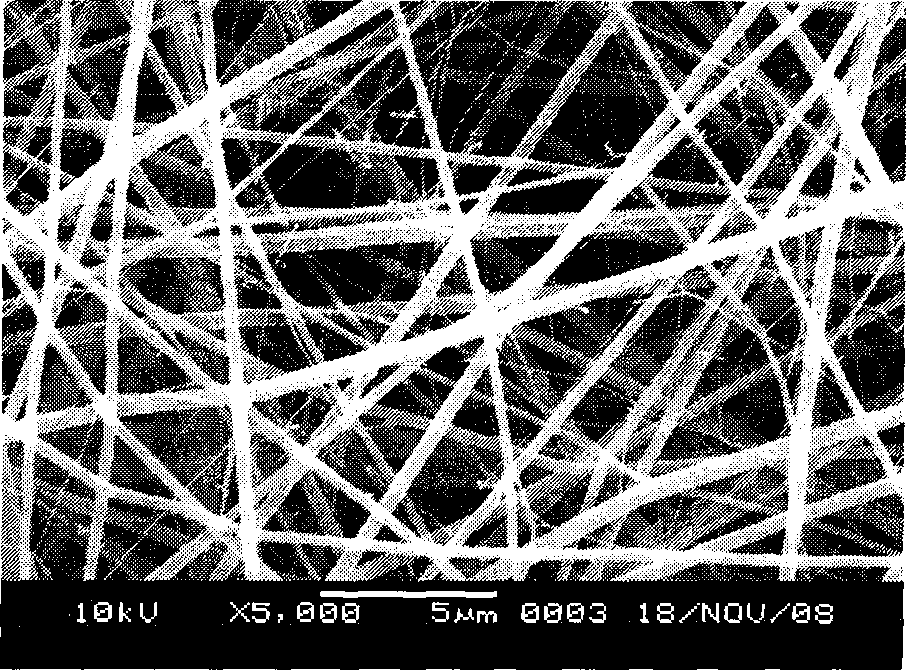

Nano fibrous tissue engineering blood vessel and preparation thereof

InactiveCN101214393APromote endothelializationMeet the mechanical requirementsConjugated cellulose/protein artificial filamentsBlood vesselsFiberCross-link

The invention relates to a tissue engineering material and a preparation method thereof, in particular to a nano fiber tissue engineering blood vessel and a preparation method thereof. The invention consists of a three-dimensional reticular non-woven film formed by an inner layer of nano fiber and an outer layer of nano fiber; the inner layer of the blood vessel is natural polymer, wherein, calculated by weight, 40 percent to 80 percent is fibroin, 20 percent to 50 percent is gelatine, 0 percent to 20 percent is extracellular matrix protein; while the outer layer of the blood vessel is synthetic polymer. The preparation method is that the natural polymer is dissolved in trifluroroethyl and other solution, while the synthetic polymer is dissolved in hexafluoroisopropanol and other solution, which are respectively prepared into spinning solution; the static electricity spinning technique is adopted to subsequently form the inner and the outer layers on a gather roller; cross-linked treatment is conducted after the inner and the outer layers are taken down, to prepare the nano fiber tissue engineering vessel. The inner layer can simulate the structure of the extracellular matrix, provide good environment for endothelial cells to grow, support adhesion, proliferation and differentiation of the cells, and is good for endothelization of the blood vessel; and the outer layer has good mechanical performance.

Owner:SUZHOU UNIV

Phase-change energy-storage fibre and method for making same

ActiveCN101041911AHigh phase change enthalpyFunction increaseConjugated cellulose/protein artificial filamentsMelt spinning methodsCelluloseWax

The invention discloses a phase-variable energy-storage fiber and relative production, which comprises that using cellulose slurry to prepare cellulose adhesive solution, to be mixed with phase-variable wax fused solution to prepare spinning dope to obtain the phase-variable energy-saving adhesive fiber. The functional fiber is mainly formed by cellulose and wax, while the wax content is 10-40% (relative to the cellulose content). And the inventive production has simple process, significantly reduced phase-variable material loss in the process, improve the phase-variable material content and improve the phase-variable energy-saving function and mechanical function.

Owner:潍坊欣龙生物材料有限公司

Silk fibroin and polyvinyl alcohol blending antibacterial nanometer fiber and its preparation method

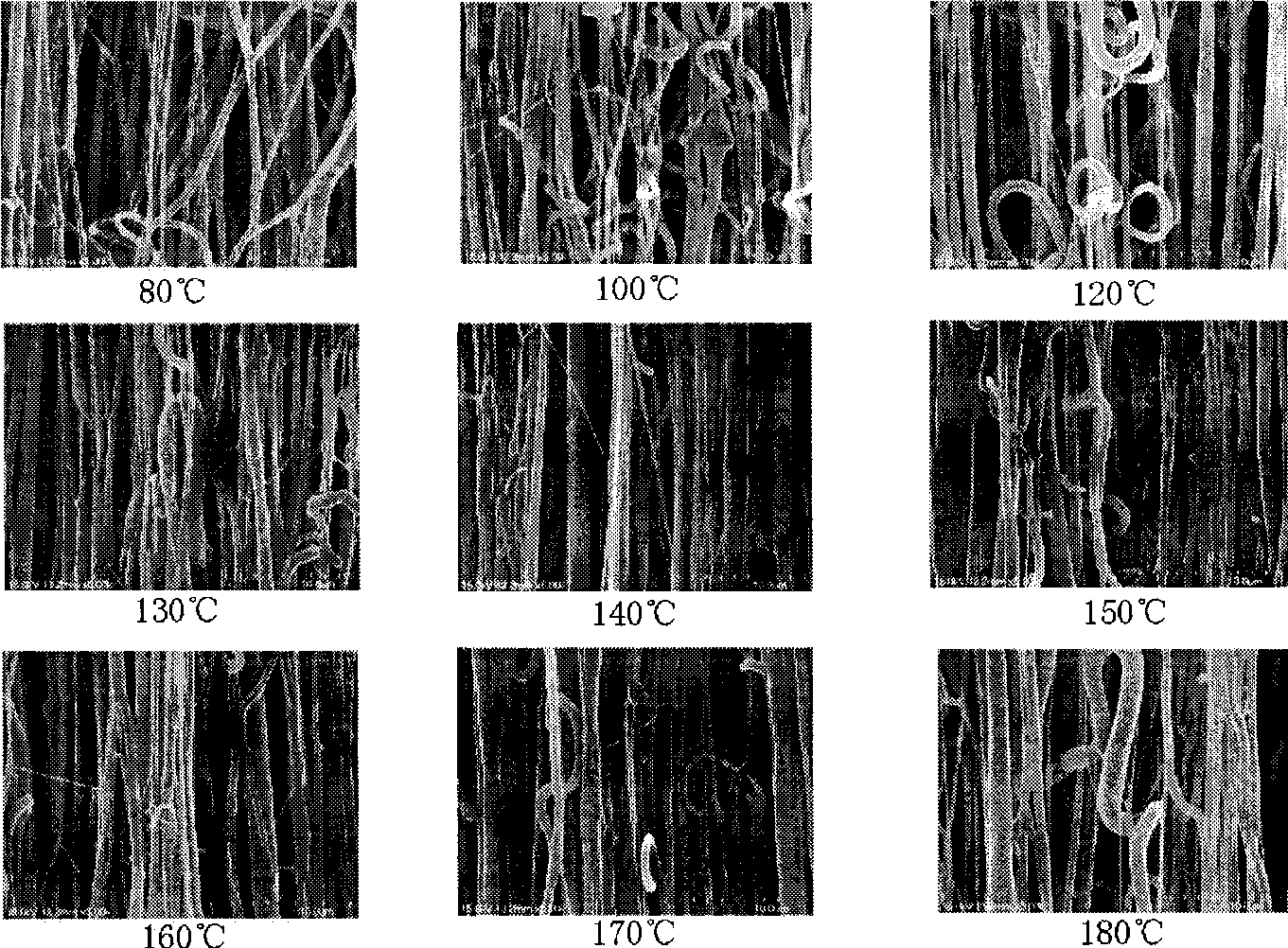

InactiveCN101187089AGood compatibilityHas a bactericidal effectFilament/thread formingConjugated cellulose/protein artificial filamentsElectrospinningChemistry

The invention discloses a nano-fiber and process for preparation, the components of the nano-fiber are silk fibroin, Argentine simple substance particles and polyvinyl alcohol, the process for preparation is that: a, after natural silk is unglued, dissolved, purified and dried, regenerated silk fibroin is obtained; b, the regenerated silk fibroin is dissolved in acidizing fluid, and regenerated silk acid solution is obtained; c, after polyvinyl alcohol is dissolved, polyvinyl alcohol solution is obtained; d, the two solutions are mixed. e, Ag-type inorganic salt is added; f, silver electrode is used to do electrostatic spinning, and blend nano fiber felt is obtained; g, the blend nano fiber felt is thermally treated for 2-5 minutes at the temperature condition of 100-150 DEG C and is treated by the radiation of ultraviolet light for 3-5 hours, and blend antibacterial nano fiber of the silk fibroin and the polyvinyl alcohol is obtained. The mechanical property of the fiber is better than pure silk fibroin fiber, the biocompatibility is excellent, the fiber has an antibacterial property, the fiber is suitable for bio-medical materials, in particular to tissue engineering scaffold materials.

Owner:SUZHOU UNIV

Anti bacteria natural silk composite nano-fiber material and its preparation method

InactiveCN1904159AGood tissue compatibilityNon-toxicConjugated cellulose/protein artificial filamentsWet spinning methodsTextile fiberResist

This invention discloses a compound antibacterial silk nanometer fibrous material, accounting for weight its component proportion are: Sericin protein 58-90%; chitosan or chitin 0-40%, antibacterial agent 0-5%, electric conduction 1-4%,crossing linking 1-4%. Its process is: dissolve the pure sericin protein, antibiotics separately in polar solvent, join electric conduction medicinal preparation and crosslinking agent, using the static electricity spinning technique, making the average aperture for 0.5-5.0 micron, factor of porosity 60-90%, the mean diameter is 40-100nm and the material is nanometer textile fiber adhesive-bonded membrane. This invention has good organization compatibility with human body, Antibiotics and sericin insoluble is in homogeneous solvent, massive holes among the nanometer textile fiber adhesive-bonded membrane, which has outstanding aqueous percolation permeability, antibacterial agent distributes evenly in the nanometer textile fiber, and the medicine release effect is perfect, so it can be a kind of ideal resist bacteria injured medical material.

Owner:SUZHOU UNIV

Preparation method of keratin complex fiber

InactiveCN104862818AReduce pollutionTime-consuming and laborious to solveConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberSolvent

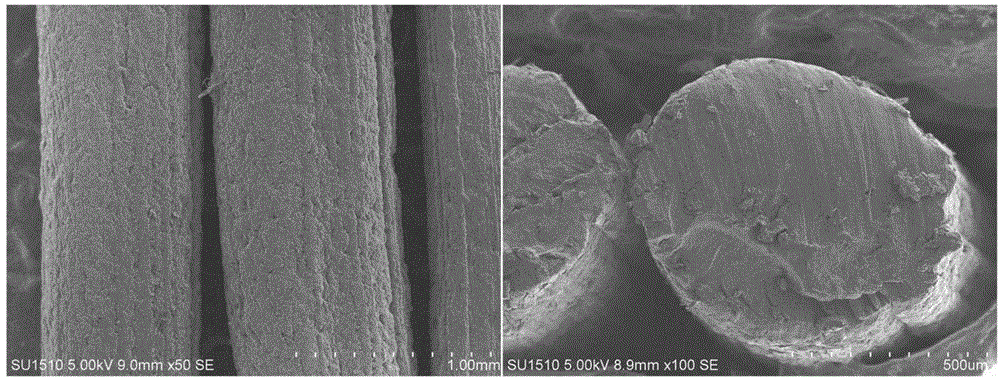

The invention relates to a preparation method of keratin complex fiber, which comprises the following steps: 1, mixing the dried keratin powder, high polymer for fiber forming, ionic liquid and the like, and mechanically stirring and dissolving to obtain a keratin complex solution at certain temperature; (2) preparing a keratin complex fiber by using a dry jet wet spinning process. According to the invention, the keratin used according to the invention comes from leftovers of processing industry such as chicken feather, drake feather, goose feather and wool, and as for the recycle of the waste, on one hand, the economic benefit is increased, on the other hand, the environment pollution can be reduced. The selected high polymer for fiber forming and keratin can dissolve together in the same ionic liquid, so that the characteristics of high efficiency, simpleness and convenience can be achieved. Compared with the pure keratin fiber, the strength and elongation at break of the spun regenerated keratin can be improved greatly, the practical use value can be increased; the keratin complex fiber has wide potential application in the fields of clothing, wig, tissue engineering and the like. In addition, the solvent ionic liquid can be completely recycled, can not pollute the environment and has the meaning of sustainable development.

Owner:JIANGNAN UNIV

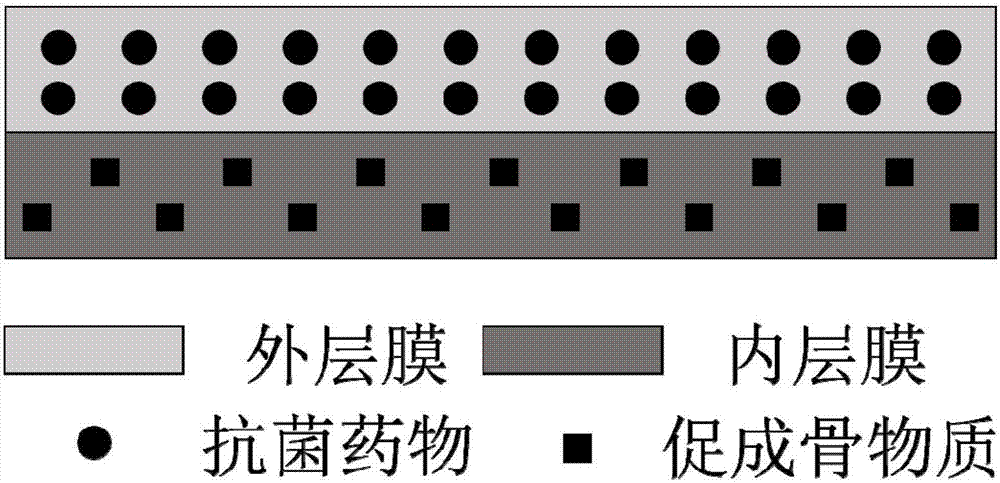

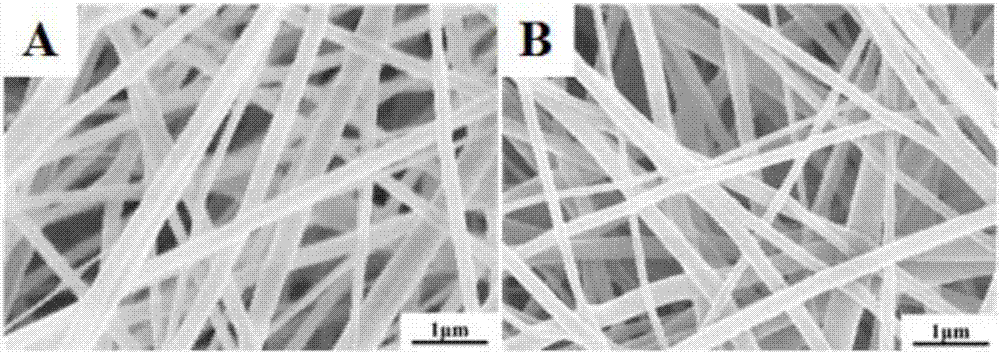

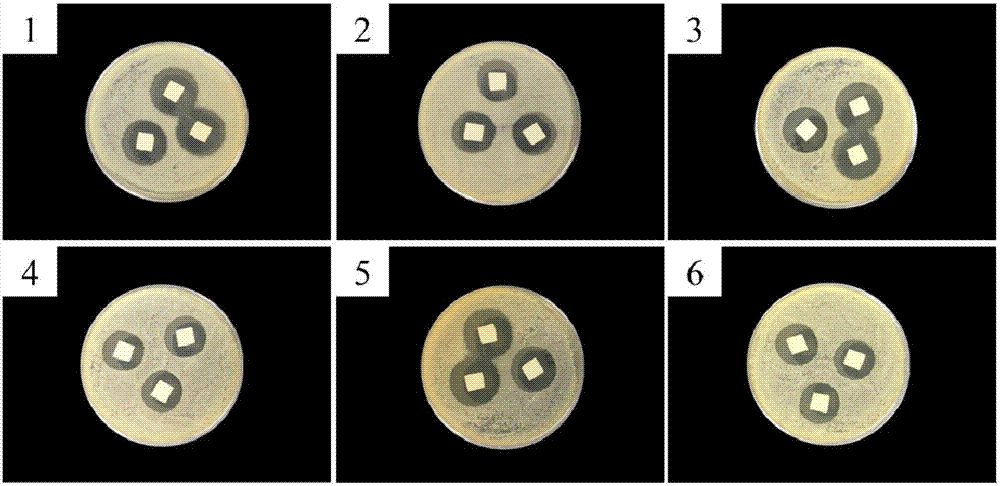

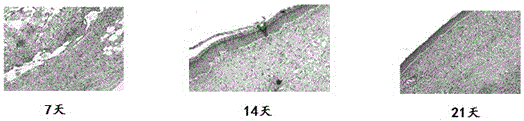

Double-layered bone repairing membrane material and preparation method thereof

InactiveCN106975106ACause targeted releasePromote repairConjugated cellulose/protein artificial filamentsElectro-spinningPolyesterBiocompatibility Testing

The invention provides a double-layered bone repairing membrane material and a preparation method thereof and in particular provides a bone repairing membrane material with antibacterial and inflammation-diminishing and bone promotion functions and belongs to the field of biological materials. The material takes biodegradable aliphatic polyester with biocompatibility and natural polymers as main raw materials and is prepared by adopting an electrostatic spinning method. The material has a double-layered membrane structure and comprises an outer layer added with an antibacterial drug and an inner layer added with a bone promotion substance. The material provided by the invention has excellent biocompatibility and a controllable and long-period medicine releasing performance; meanwhile, an outer-layer membrane of the double-layered membrane structure can be used for inhibiting bacterial infection and inflammation, which are easily caused after bone defects occur, and preventing bacteria from entering defected parts; an inner-layer membrane can be used for promoting the repairing of the bone defects. The material can be used for realizing controllable in-vivo degradation according to requirements and the material does not need to be taken out by a second surgery.

Owner:BEIJING UNIV OF CHEM TECH

Tissue induction biomedical material

InactiveCN106267341AConjugated cellulose/protein artificial filamentsTissue regenerationAcetic acidCollagen i

The invention discloses a tissue induction biomedical material, and particularly relates to a degradable active biological membrane / powder. The tissue induction biomedical material is prepared from, by weight, 0.1-99% of degradable medical polyurethane, 0-99.9% of polyhydroxyalkanoate, 0-99.9% of polylactic acid and 1-99.9% of collagen, wherein polyhydroxyalkanoate is one of PHA, PHB, PHBV, PHBHHx and P3HB4HB, polylactic acid is one of polyglycolic acid and polylactic acid-glycolic acid copolymer, and collagen is one or more of collagen I, collagen II, collagen VI, collagen IX, collagen X, collagen XI and other various in-vivo collagen. The ratio of all the components is adjusted according to the requirements of the implanting positions of different in-vivo tissue for material performance, degradation products and PH values, so better clinical service is provided.

Owner:YUANRONG BIOLOGICAL PHARMA WUXI CO LTD

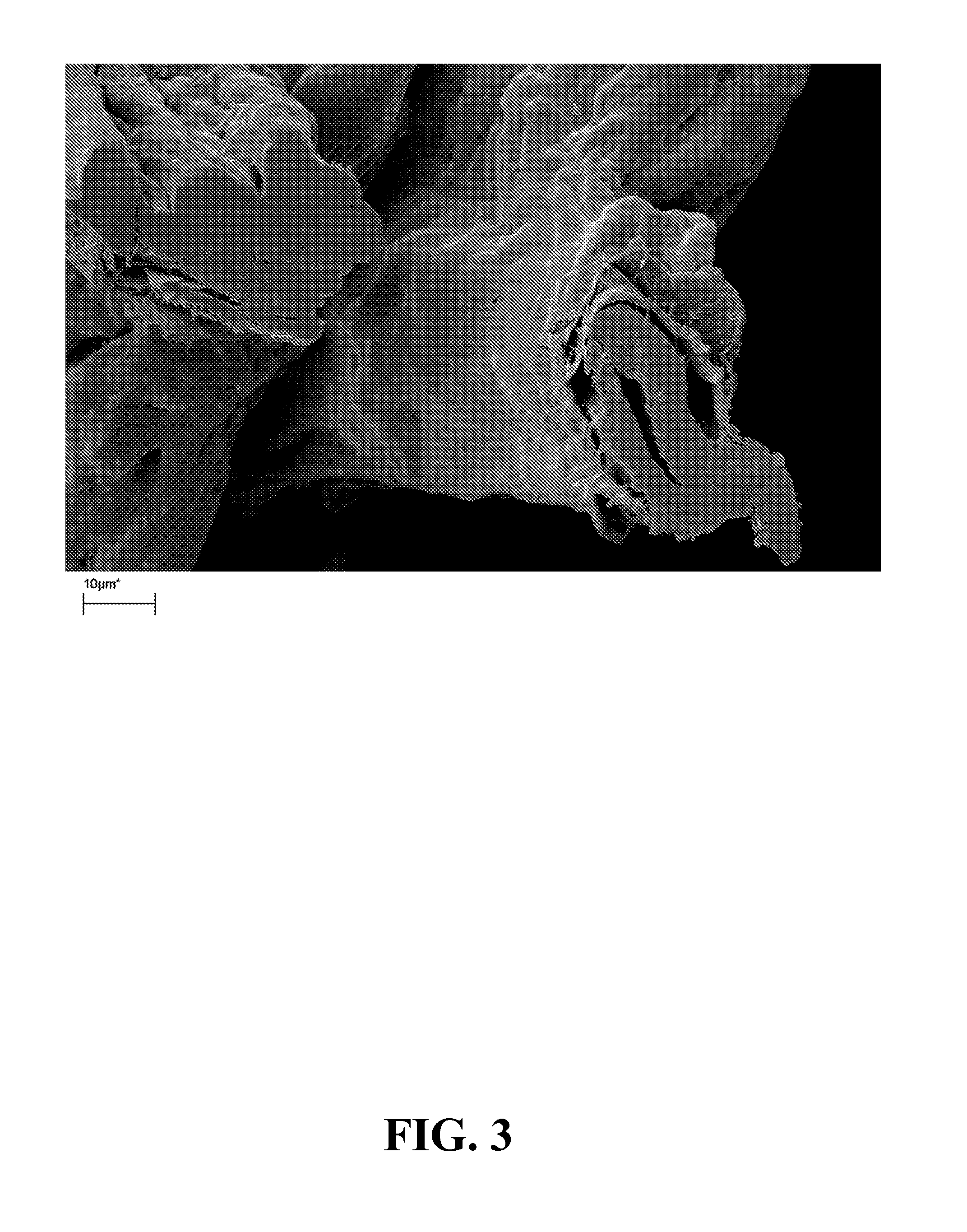

Biomimetic preparation method of high-strength regenerated silk protein fiber

ActiveCN103498210AHigh crystallinityHigh strengthConjugated cellulose/protein artificial filamentsWet spinning methodsMechanical propertyProtein fiber

The invention discloses a biomimetic preparation method of a high-strength regenerated silk protein fiber. The method takes high crystallization degree, high strength, high modulus nano cellulose whiskers with a large length-diameter ratio to simulate the beta-fold microcrystal in the natural silk fiber, then mixes the nano cellulose whiskers with a regenerated silk fibroin solution, and finally prepares the high-strength regenerated silk protein fiber through a wet spinning method. The characteristic that a large amount of hydroxyl groups in the molecular chains of the rigid nano cellulose whiskers can form intermolecular hydrogen bonds with polar groups such as carboxyl groups, amino groups, and the like, in the molecular chains of silk protein is utilized to achieve the structural bionics of the regenerated silk protein fiber, and thus improves the mechanical properties of the regenerated silk protein fiber. The preparation method is simple, and does not pollute the environment. The mechanical properties of the obtained regenerated silk fiber are equal to or even better than those of natural silk, and the regenerated silk fiber has the similar micro-structure and configuration as the natural silk.

Owner:浙江枫翎新材料科技有限公司

Spider silk protein/polylactic acid composite nano fibre yarn and preparation method thereof

InactiveCN101418472AAvoid difficultiesHigh breaking strengthConjugated cellulose/protein artificial filamentsFilament/thread formingYarnFiber

The invention discloses a method for preparing spider silk protein / polylactic acid composite nano-fiber yarn. The method comprises the following steps of preparing a spinning solution, preparing a bath solution and then adopting an improved electrostatic spinning method to guide, heat, wind and shape bunched fibers, so as to obtain the spider silk protein / polylactic acid composite nano-fiber yarn. The composite nano-fiber yarn of the invention can be continuously spun for more than 10 hours and have no broken ends, and a certain amount of spider silk protein effectively reduces the diameter of the fibers and improves the strength of the yarn. In addition, the fracture strength and flexibility of the composite nano-fiber yarn can be further improved through secondary stretching and combined twisting, so that the composite nano-fiber yarn can be applied in biomedical materials and other fields better.

Owner:SUZHOU UNIV

Conductive fiber with scabbard type structure and preparation method thereof

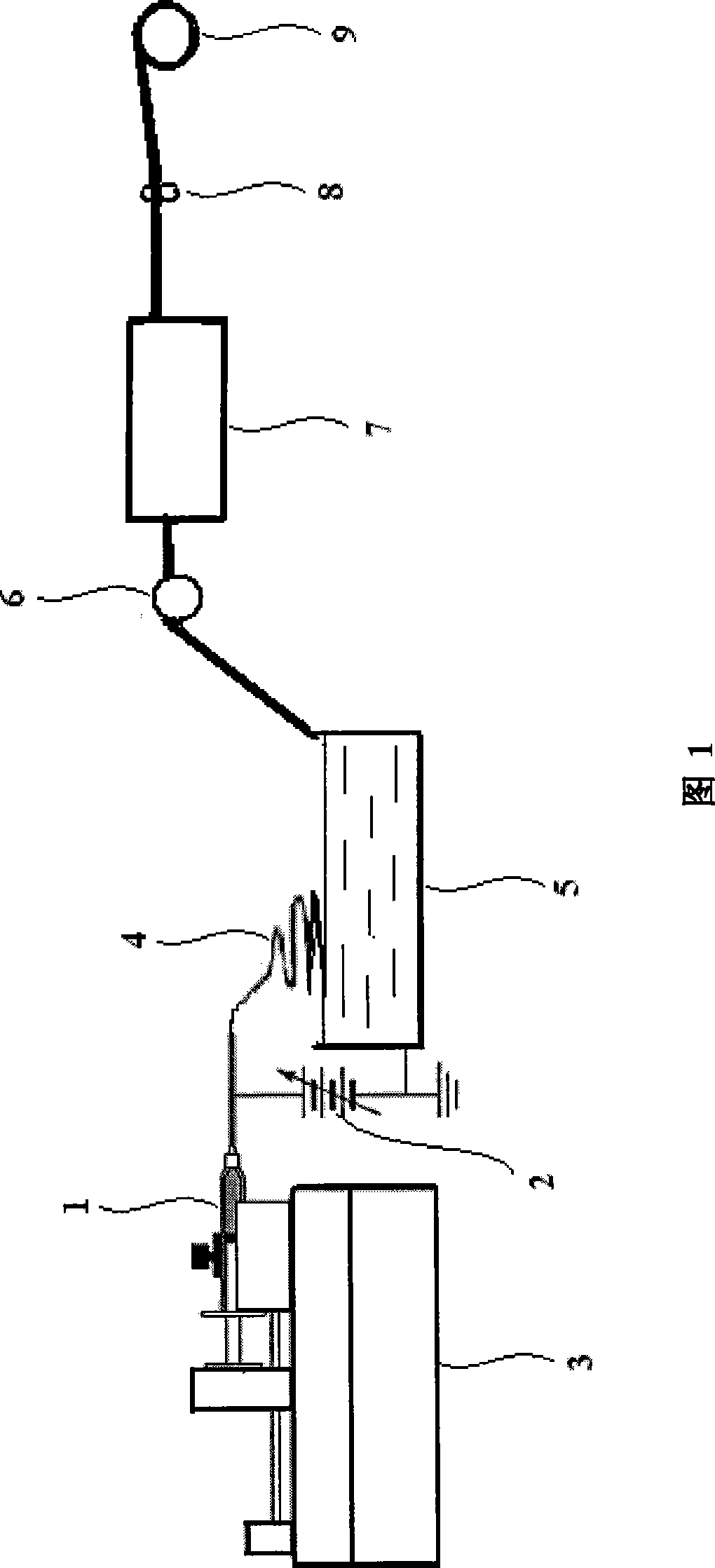

ActiveCN103603088AEasy to makeLow costConjugated cellulose/protein artificial filamentsFilament/thread formingFiberPolymer science

The invention discloses a conductive fiber with a scabbard type structure and a preparation method thereof. The preparation method comprises the following steps: 1) preparing a carbon nano material into a solution 1; 2) preparing the polymer into a solution 2; 3) passing the solution 1 through an inner pipe of a coaxial spinning needle head at a certain speed, at the same time, passing the solution 2 through an outer pipe of the coaxial spinning needle head at a certain speed, extruding the two into a coagulation bath, so as to form a gel fiber with scabbard type structure preliminarily; 4) transferring the gel fiber to a solution containing a reducing agent and conducting chemical reduction at a certain temperature; and 5) cleaning the gel fiber subjected to reduction in the step 4 with a solvent, drying and collecting the gel fiber to a roller, so as to obtain the conductive fiber with scabbard type structure. The invention has the advantages of simpleness, low cost and strong applicability, and is suitable for large-scale industrial production; and the produced fiber with scabbard type structure has excellent electrical and mechanical properties and can be used in the fields of power transmission, antistatic fabrics and engineering materials, etc.

Owner:杭州德烯科技集团有限公司

Cotton fibers with antibacterial and insect-resisting effects and production method of cotton fibers

InactiveCN104278359AEasy to cleanNot easy to fluffConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCnidium monnieriFatty alcohol

The invention discloses cotton fibers with antibacterial and insect-resisting effects. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 21-24 parts of cotton fibers, 10-12 parts of apocynum venetum fibers, 6-8 parts of silk fibers, 7-9 parts of cashmere fibers, 9-11 parts of pineapple fibers, 4-7 parts of polypropylene fibers, 6-8 parts of taxus chinensis superfine micro-powder, 3-5 parts of ailanthus altissima leaf extracted powder, 1-3 parts of zeolite powder, 1.1-2.3 parts of chitosan, 0.5-0.7 part of magnesium nitride, 0.8-1.4 parts of N,N-dicyanoethylaniline, 5-7 parts of sulfonated castor oil, 15-18 parts of fatty alcohol alkoxy ether, 1-2 parts of mashed garlic, 1.3-2.5 parts of cnidium monnieri cuss, 2.1-3.6 parts of coptis chinensis, 90-95 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-100 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the cotton fibers, the taxus chinensis superfine micro-powder is added into raw materials by adopting an ultrasonic technology and a prepared cotton textile has a very good health effect and a useful pain-relieving effect on tumor patients and female symptoms; furthermore, the other active ingredients are added so that the good clothes properties of sweat absorption, breathability, softness, allergy prevention, easiness of washing, low probability of fuzzing and balling up and the like of natural cotton fibers are maintained, and the cotton fibers have good antibacterial and insect-resisting functions, a good electromagnetic radiation shielding function and the like.

Owner:ANHUI SWAN TECH IND GRP

Regenerated animal micropowder protein cellulose fiber and preparation method thereof

ActiveCN102493020AStrong sense of silkSoft touchConjugated cellulose/protein artificial filamentsArtificial filaments from viscoseViscose fiberTextile processing

The invention discloses a regenerated animal micropowder protein cellulose fiber and a preparation method thereof. The preparation method comprises the following steps of: adding nanoscale animal micropowder protein into a dispersant solution, stirring the mixture uniformly, filtering to obtain 20 to 35 weight percent of animal micropowder protein liquid; preparing viscose by using cellulose pulp as a raw material, adding denaturant in the dissolution step to obtain modified viscose; adding the animal micropowder protein liquid into the modified viscose in a weight ratio of animal micropowder to the finished fiber of (1-30):100, uniformly stirring to obtain animal micropowder compounding viscose; and defoaming and filtering, spinning molding by introducing a coagulating bath, and then drawing filament and performing aftertreatment to obtain the animal micropowder protein viscose fiber. The fabric made of the regenerated animal micropowder protein cellulose fiber is low in density, and is light; the hygroscopicity, the air permeability and the thermal insulating property of the fabric are further improved; the fiber textile processing and wearability are good; and the production process is pollution-free.

Owner:潍坊欣龙生物材料有限公司

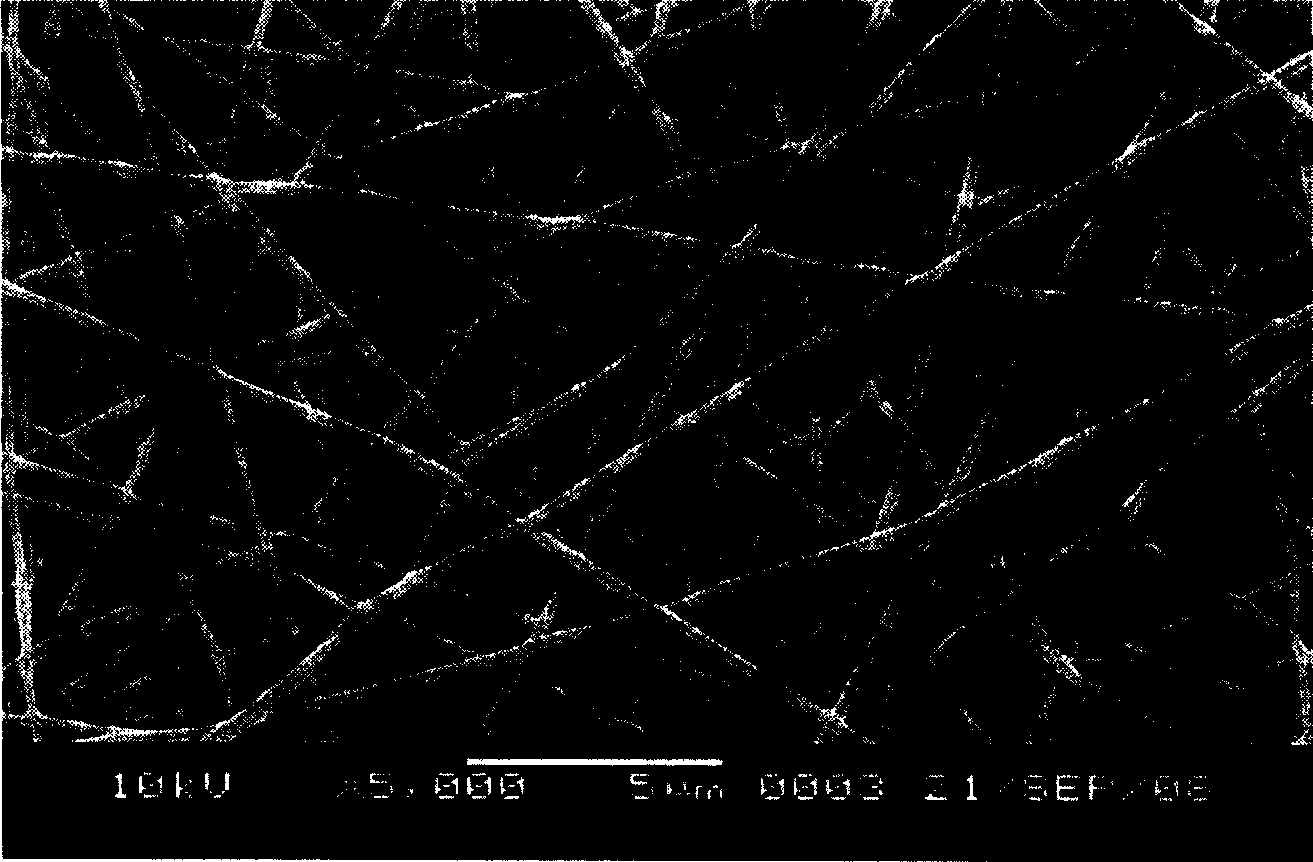

Method for preparing bionic extracellular matrix silk fibroin/chitosan composite nanometer fibre

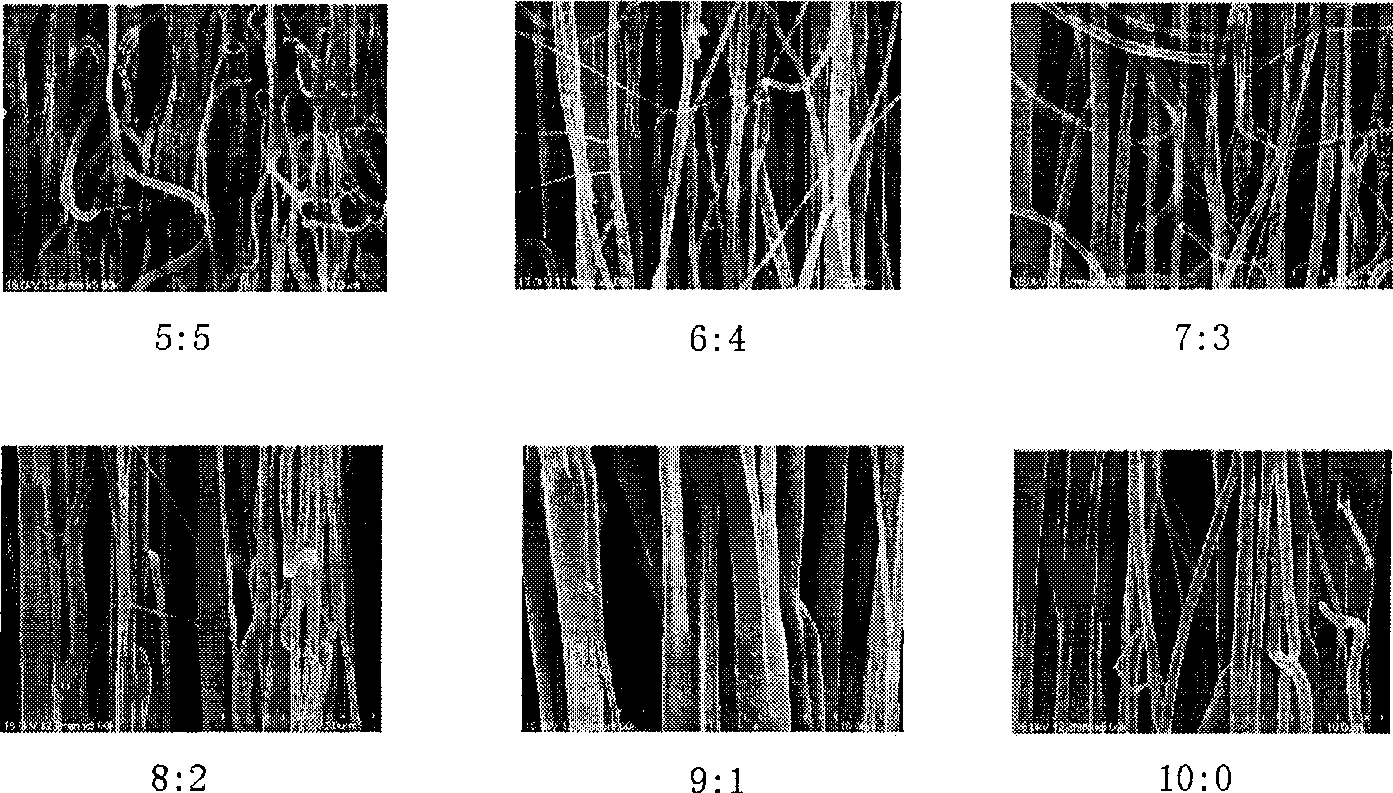

InactiveCN101445971AImprove mechanical propertiesPromote degradationConjugated cellulose/protein artificial filamentsFilament/thread formingElectrospinningPorous solids

The invention relates to a method for preparing a bionic extracellular matrix silk fibroin / chitosan composite nanometer fibre. The method comprises the steps as follows: (1) cocoons without pupas are cooked in Na2CO3 solution for three times, are cleaned and dried at the temperature of 45 DEG C and are dissolved in ternary solvent to be hydrolyzed, dialyzed and freeze-dried to obtain loose porous solid silk fibroin; (2) the silk fibroin is dissolved in hexafluoroisopropanol to obtain silk fibroin solution; (3) chitosan is dissolved in mixed solvent of HFIP and TFA to obtain chitosan solution; (4) the silk fibroin solution and the chitosan solution are mixed and stirred uniformly to obtain blended electrostatic spinning solution; and (5) the mixed solution is carried out electrostatic spinning to obtain silk fibroin / chitosan composite nanometer fibre. The silk fibroin / chitosan composite nanometer fibre has good mechanical property and degradation behavior and provides best bionic physiological environment for cell growth and tissue regeneration, and the preparation method is simple and easy for implementing and is easy for realizing industrialized production.

Owner:DONGHUA UNIV

Protein cellulose viscose and preparing method thereof

ActiveCN101298708AGood protein contentImprove spinnabilityConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentSpinningPROTEIN S HEERLEN

The invention relates to a protein viscose fiber and a preparation method thereof, belonging to the textile field and aiming at solving a technical problem about how to provide a method for adopting different animal and plant proteins as materials to prepare the protein viscose fiber. The preparation method of the protein viscose fiber includes the following steps: 1. the animal and plant proteins are degreased, decolored and deodorized to obtain animal-plant protein powder; 2. alkalization: the animal-plant protein powder is dissolved in alkaline liquor to obtain protein alkaline solution; 3. cross-linker is added into the protein alkaline solution to obtain a protein spinning liquor; 4. the protein spinning liquor is blended with a glue to be spun to obtainprotein filaments; 5. the protein filaments are washed by peroxide solution and are oiled, dried and formed into cylinder form to get the protein viscose fiber. The protein viscose fiber preparation method of the invention does not adopt any acetalation treatments to the protein filaments after spinning so as to avoid the remaining of methanal, etc. harmful matters, the technique steps are simple and can be easily operated and the manufacturing can be realized with the existing viscose fiber preparation equipment.

Owner:YIBIN GRACE GROUP CO LTD

Method for preparing protein modified cellulose fibre

InactiveCN101113535AImprove protectionGood for healthConjugated cellulose/protein artificial filamentsWet spinning methodsYarnCellulose fiber

The invention relates to a preparation method of a protein modified cellulose fiber, comprising the steps that: (1) a protein and a cellulose are dissolved in ion solution to prepare homogeneous mixing spinning solution; (2) the spinning solution is deaerated, filtered, measured, and extruded out through spinning jet to form spinning rills, and the spinning rills pass through a wet air layer and enter into a solidification bath to be solidified and molded; (3) the yarn is extended, cleaned by water, dried and heat molded, and formed into fiber to prepare the protein modified cellulose fiber. The method has the advantages of environmental protective, low cost, fast spinning speed and high production efficiency, and the prepared fiber has the advantages of comfort and health care, etc.

Owner:DONGHUA UNIV

Wool fibre fabric sweat shirt (pants) with functions of powerful antibiosis, cancer prevention and life prolonging by utilizing nano silver, selenium and germanium

InactiveCN101703319AReduce permeationAnti-electromagnetic wave shieldingMonocomponent protein artificial filamentHeavy metal active ingredientsSe elementHuman immunodeficiency virus (HIV)

The invention provides a wool fibre fabric sweat shirt (pants) with functions of powerful antibiosis, cancer prevention and life prolonging by utilizing nano silver, selenium and germanium, belonging to the technical field of healthy wool textile fibre fabrics clothes production. In the real life of people, various germs, viruses and fungi are contacted unavoidably, in particular, various bird flu and HIV discovered currently seriously threaten the health of human beings. Nano silver can kill 650 types of pathogens; far-infrared rays are almost absorbed by the skin of human body completely to lead the surface temperature of the skin to rise; heat energy impels the blood vessel to expand, improves blood circulation and microcirculation; the electromagnetic wave is colorless, tasteless and formless, can easily cause pollution to human body and is a potential killer. The anions in the air are vitamins and longevity elements in the air and are beneficial to human body; selenium and germanium are important elements to prevent and resist cancer; and the mixture of bee series can comprehensively supplement a plurality of nutrient active components required by human body. After nano treatment, the efficacy of anti-aging traditional Chinese medicine can be improved to 100 times.

Owner:成钢

Mixed polymer superabsorbent fibers containing cellulose

InactiveUS20080082065A1Conjugated cellulose/protein artificial filamentsBaby linensPolymer compositesGalactomannan

Owner:WEYERHAEUSER NR CO

Protein and cellulose composite fiber and manufacturing method thereof

InactiveCN101660215AConjugated cellulose/protein artificial filamentsWet spinning methodsCelluloseNatural fiber

The invention discloses a protein and cellulose composite fiber, which is the regenerative protein composite fiber containing 5-50% of natural protein, 50-95% of natural cellulose and 0-30% of alginate, and the fiber is prepared by the technical processes of stock solution preparation, wet spinning, crosslinking finishing and the like. The fiber has the advantages of good hygroscopicity, antistatic property, good dyeing property and complete biodegradability, and the alginate is added in the fiber for leading the fiber to have good flame-retardant performance, thereby being a real green raw material for ecological textiles. The fiber has soft and smooth hand feeling, thereby being applicable to underwear processing, bedroom supplies, sanitary and health care supplies and the like of the textiles.

Owner:陈福库

Production process of wool protein compound viscose fiber

ActiveCN102560735AAvoid joiningReflect the superiority of environmental protectionConjugated cellulose/protein artificial filamentsWet spinning methodsPolymer scienceSpinning

The invention provides a production process of wool protein compound viscose fiber, which belongs to the technical field of viscose fiber. The process comprises the steps of preparing a wool protein spinning solution, blending the wool protein spinning solution with a viscose spinning solution, spinning, solidifying and curing and performing aftertreatment to obtain the wool protein compound viscose fiber. In the invention, the addition of toxic substances is avoided, the obtained finished product is more suitable for manufacturing the textile products with high safety, such as intimate apparels and the like, and shows the advantages in environmental friendliness.

Owner:CHENGDU GRACE FIBER +1

Protein synthetic fiber and its production method

InactiveCN1515710AGood air permeability and moisture conductivityGood skin affinityConjugated cellulose/protein artificial filamentsPolyvinyl alcoholMoisture permeability

The present invention discloses a protein synthetic fibre. It is formed from plant protein, animal protein and polyvinyl alcohol. The ratio of total weight of two proteins in fibre weight is: from 1% to less than 20% to from 20% to 40% of from greater than 40% to 99%, the rest is polyvinyl alcohol, and when the ratio of total weighto f two proteins in the fibre weight is from 20% to 40%, the ratio of one of them in the total weight of proteins is from 1% to 25% or from 75% to 99%. It also discloses the production method of said fibre. The fibre is good in breathable moisture permeability, and has the flexible and good dermophilic property of cashmere.

Owner:李官奇

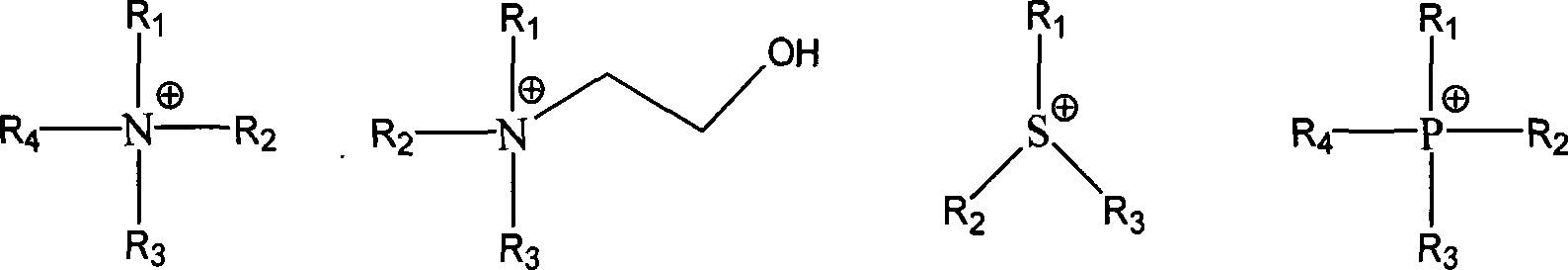

Biological protein hair fiber preparation method by dissolving animal hair and cellulose material mixture

InactiveCN1884642AReduce lossesReduce direct lossesConjugated cellulose/protein artificial filamentsCelluloseAdjuvant

The invention discloses a biological protein wool fiber preparing method, which comprises the following steps: blending animal fur and fiber to produce soluble liquid in the ion liquid with positive and negative ion of fusing condition at 100 deg.c and positive ion to form salt; solidifying in the water, carbinol, alcohol, cyanoethyl or (NH4)2SO4 solution; adding adjuvant in the soluble liquid; solidifying in the water, carbinol, alcohol, cyanoethyl or 30 percent (NH4)2SO4 solution; evolving biological protein fur fiber.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

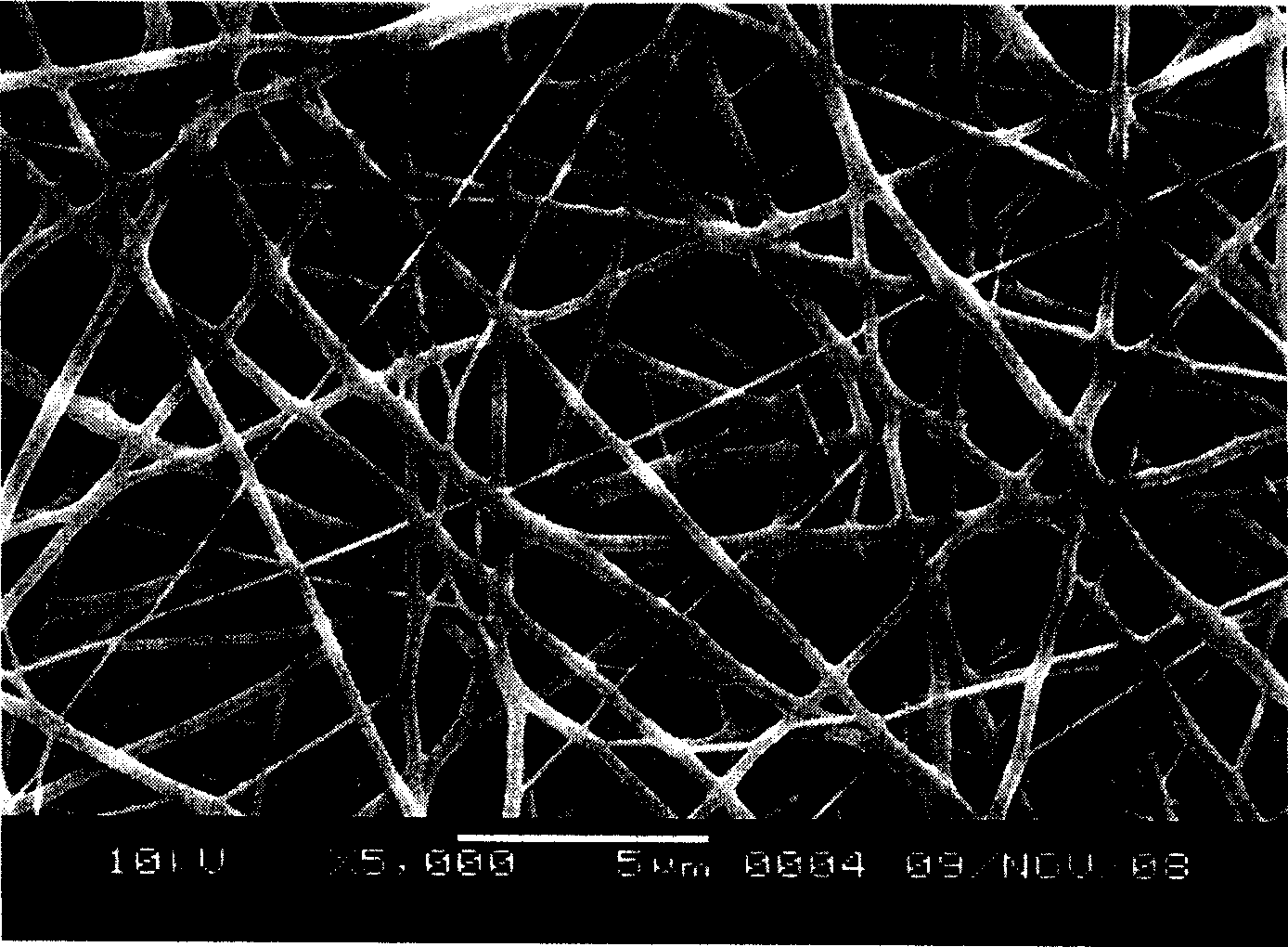

Method for preparing silk fibroin/ P(LLA-CL) compound nano fiber structure repair stand

ActiveCN101502671AAbundant resourcesSimple manufacturing methodConjugated cellulose/protein artificial filamentsFilament/thread formingProtein solutionPorosity

The invention relates to a method for preparing fibroin protein / P(LLA-CL) compound nanofiber tissue repair bracket, comprising : (1) boiling silkworm cocoon with pupa removed in 0.5% of Na2CO3 aqueous solution, then cleaning and drying the boiled silkworm cocoon; then dissolving the boiled silkworm cocoon in ternary solvent, carrying out hydrolysis at constant temperature, dialyzing for 70-72 hours, carrying out prefreezing, then carrying out freezing and drying at the temperature of minus (45-58) DEG C; (2) dissolving the fibroin protein in hexafluoroisopropanol, stirring to dissolve the protein; (3) dissolving the P(LLA-CL) in hexafluoroisopropanol, stirring to dissolve the fiber; (4) mixing the fibroin protein solution with P(LLA-CL) solution, stirring the solution evenly; (5) carrying out electrostatic spinning on blending electrostatic spinning liquid and obtaining the fibroin protein / P(LLA-CL) compound nanofiber. The preparation method of the invention is easy and feasible, the raw materials are abundant and the industrialized production is easy to be realized; in addition, the obtained compound nanofiber features fine biocompatibility, good mechanical property and relatively high porosity factor.

Owner:DONGHUA UNIV

Bamboo pupa protein fiber long-short yarn and method for making same

ActiveCN101117737AConjugated cellulose/protein artificial filamentsStaple fibre formationYarnCellulose

The present invention belongs to the spinning field and provides a long or short filament of bamboo pupa protein fiber. The long or short filament comprises 10-40wt percent silkworm pupa protein spinning liquid and 60-90wt percent bamboo cellulose viscose as the raw materials. The present invention also provides a method for preparing of the long or short filament. With bamboo cellulose as the raw material, the present invention can still meet the quality standard. Since bamboo cellulose can be acquired easily, the present invention provides a new choice for spinning product-pupa protein fiber.

Owner:YIBIN GRACE

Collagen-base PEG composite fibre and spinning technique thereof

InactiveCN101215733AGive full play to the advantages of biological performanceTechnology transfer is feasibleConnective tissue peptidesFibre typesFiberBiocompatibility Testing

The invention provides a novel collagen protein-based PEG composite fiber and spinning technology, comprises extracting collagen protein, preparing collagen protein-PEG blending spinning original liquid, spinning composite fiber, preparing coagulating liquid and fixing fiber, and carrying out acetalation process of composite fiber and the like, wherein collagen protein is extracted through alkali method or enzymatical method from chrome leather scraps, and can be also extracted from raw hide or heel tendon of healthy animals through enzymatical method. PEG is high molecular polymer which has biocompatibility. Spinning fluid which has certain concentration and viscosity is prepared through mixing collagen protein 100 parts and PEG 5-30 parts according to weight by parts, then composite fiber is prepared through wet spinning, and collagen protein-based composite fiber which is used in fabric needs carrying out acetalization and stretching and the like to improve intensity, swellability, water-absorbing quality and the like of composite fiber. The collagen protein-based PEG composite fiber which is disclosed by the invention can be both used in fabric material and in biological medical material.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com