Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167 results about "Sulfonated castor oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cotton fibers with antibacterial and insect-resisting effects and production method of cotton fibers

InactiveCN104278359AEasy to cleanNot easy to fluffConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCnidium monnieriFatty alcohol

The invention discloses cotton fibers with antibacterial and insect-resisting effects. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 21-24 parts of cotton fibers, 10-12 parts of apocynum venetum fibers, 6-8 parts of silk fibers, 7-9 parts of cashmere fibers, 9-11 parts of pineapple fibers, 4-7 parts of polypropylene fibers, 6-8 parts of taxus chinensis superfine micro-powder, 3-5 parts of ailanthus altissima leaf extracted powder, 1-3 parts of zeolite powder, 1.1-2.3 parts of chitosan, 0.5-0.7 part of magnesium nitride, 0.8-1.4 parts of N,N-dicyanoethylaniline, 5-7 parts of sulfonated castor oil, 15-18 parts of fatty alcohol alkoxy ether, 1-2 parts of mashed garlic, 1.3-2.5 parts of cnidium monnieri cuss, 2.1-3.6 parts of coptis chinensis, 90-95 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-100 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the cotton fibers, the taxus chinensis superfine micro-powder is added into raw materials by adopting an ultrasonic technology and a prepared cotton textile has a very good health effect and a useful pain-relieving effect on tumor patients and female symptoms; furthermore, the other active ingredients are added so that the good clothes properties of sweat absorption, breathability, softness, allergy prevention, easiness of washing, low probability of fuzzing and balling up and the like of natural cotton fibers are maintained, and the cotton fibers have good antibacterial and insect-resisting functions, a good electromagnetic radiation shielding function and the like.

Owner:ANHUI SWAN TECH IND GRP

Softening agent

InactiveCN105442324AGood flexibilityReduce the impactGrip property fibresPolyvinyl alcoholMethyl cellulose

The invention discloses a softening agent which is characterized by comprising the following components by weight: 15 parts of organic silicon, 10 parts of octamethyl-tetra-siloxane, 7.5 parts of sulfonated castor oil, 1.5 parts of hydroxy propyl methyl cellulose, 5 parts of polyvinyl alcohol, 5.5 parts of sodium tripolyphosphate, 2 parts of sodium dodecyl sulfate, 2 parts of magnesium chloride, 9 parts of calcium hydrophosphate, 1.5 parts of 2,3-dihydrobutanedioic acid, and 0.5 part of triethavolamine. The flexibleness of a fabric can be relatively high when a small quantity of the softening agent is used, so that the impact on environment is relatively low.

Owner:CHANGSHU MIAOQUAN SHENGDA AUX FACTORY

Printing ink cleaning agent

InactiveCN101492579APlentiful and cheapReduce manufacturing costChemical paints/ink removersNon toxicityPrinting ink

The invention discloses an ink cleaning agent which comprises the components with the weight percentage: 1-5% of alkyl phosphoester. 2-7% of oleic acid poly-ethanol ester, 0.1-1% of sulfonated castor oil, 0.2-1.5% of C5-6 and C18-23 synthetic fatty acid sodium soap, 0.2-1% of C10-16 synthetic fatty acid monoethanol amine, 0.5-5% of hexamethylene glycol, 10-56% of D-limonene and 23.5-56% of water. The invention aims at overcoming the defects in the prior art, and provides the ink cleaning agent which is produced by the D-limonene extracted from the waste citrus fruit peel and has the advantages of non-toxicity, innocuity, zero emission, low production cost and high efficiency.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC +2

Wear-resistant material workpiece quenching medium

The invention discloses a wear-resistant material workpiece quenching medium, relating to the technical field of heat treatment quenching. The wear-resistant material workpiece quenching medium comprises following raw materials based on weight percentage: 6-12% of sodium hydroxide, 6-8% of zinc chloride, 0.01-0.03% of sulfonated castor oil, 1-5% of polyamide polyethylene glycol, 2-5% of acrylic acid, 5-10% of acrylic ester, 0.1-2% of additive and the balance of water. In the wear-resistant material workpiece quenching medium, formula is reasonable, a quenching piece can achieve high and uniform hardness and can be directly subjected to quenching, residual forging heat quenching and induced spraying quenching, and the medium is particularly applicable for quenching of a large workpiece; the sodium hydroxide used in the invention can mutually react with oxide skin on the surface of the quenching piece to generate oxygen, so that the oxide skin is rapidly stripped off, and the surface of the quenching piece shows shiny silver ; the zinc chloride and the sodium hydroxide react to generate strong zinc oxide, the scabbing speed of a high-temperature region is faster than that of water, the cooling speed of a low-temperature region is slower than that of the water, the quenching piece is slightly deformed, is not easy to crack and has a shiny surface.

Owner:安徽新马铸造科技有限公司

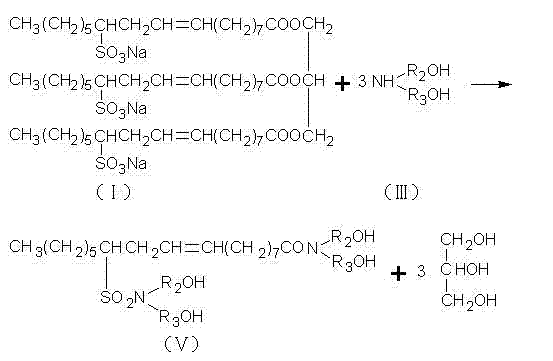

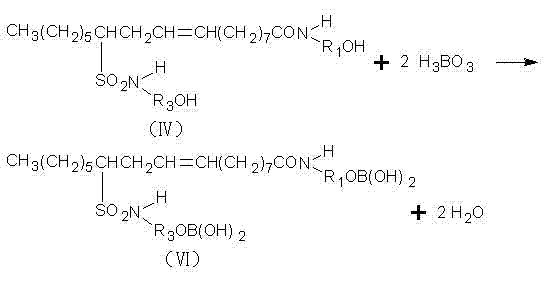

Method for preparing hydroxylated sulfonated castor oil borate

The invention discloses a method for preparing hydroxylated sulfonated castor oil borate. The method overcomes the defects in the prior art; sulfonated castor oil and alkanol amine undergo hydroxylation reaction by using a molecular design view, and water-soluble groups are introduced into molecules, so that water solubility, stability and emulsifying property of the molecules are enhanced; boric acid and hydroxy in the molecules undergo esterification reaction, so that stability, rust resistance, extreme pressure property and lubricating performance of the molecules are further enhanced, and a novel water-soluble hydroxylated sulfonated castor oil borate additive is synthesized; and the glycerol generated in the reaction process has a certain lubricating effect and is not required to be separated and removed, so that preparation and production are easy.

Owner:修建东

Fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing as well as preparation method thereof

The invention belongs to the technical field of metal processing and particularly relates to fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing as well as a preparation method thereof. The fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing comprises the following components in parts by weight: 5 to 25 parts of carboxylic acid ammonium salt composite antirust agent, 5 to 30 parts of sulfonated castor oil, 2 to 15 parts of water-soluble lubricating agent, 1 to 6 parts of monoacid, 0.5 to 2 parts of mildew-proof fungicide,0.02 to 1 part of defoaming agent and 20 to 55 parts of water. According to the fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing, which is provided by the invention, through compounding of the sulfonated castor oil and the water-soluble lubricating agent, high lubricating property is provided, and the fully-synthesized environmentally-friendly cutting liquidfor aluminum alloy processing serves as a cutting liquid product not containing oil and can replace semi-synthesized cutting liquid with low oil content under the same condition; in addition, throughcompounding of castor oil acid, organic acid and special alcohol amine, the protective effect that aluminum alloy is not liable to change color is achieved, and high lubricating requirement in the processing process of the aluminum alloy is met.

Owner:GUANGZHOU LANDNOK CHEM TECH

Metal spinning powder and preparation method thereof

ActiveCN104388155AEasy to cleanReduce friction damageLubricant compositionPotassium hydroxideHigh pressure

The invention discloses metal spinning powder and a preparation method thereof. The metal spinning powder is characterized by being prepared from the following raw materials in parts by weight: 100-300 parts of sodium carbonate or potassium carbonate, 1-5 parts of sodium benzoate, 300-600 parts of water, 10-60 parts of sulfonated castor oil, 5-30 parts of chlorcosane, 5-30 parts of tall oil, 2-15 parts of powdery sodium hydroxide or potassium hydroxide, and 5-30 parts of white carbon black. The invention also discloses the preparation method of the metal spinning powder. The metal spinning powder disclosed by the invention has the advantages of favourable lubricating property, corrosion resistance, high temperature resistance, high pressure resistance, lower cost and easy storage.

Owner:HENAN NORMAL UNIV

Acid dye leveling agent integrating uniform dyeing, color increasing and color fixing and preparation method thereof

ActiveCN105239425AGood level dyeingHigh tinting strengthDyeing processSulfonateSodium lignosulfonate

The invention provides an acid dye leveling agent integrating uniform dyeing, color increasing and color fixing and a preparation method thereof. The acid dye leveling agent comprises, by weight parts, 10-30 parts of sodium lignin sulfonate, 15-30 parts of sulfonated castor oil, 20-40 parts of fatty acid amine polyoxyethylene ether, 5-25 parts of nano-attapulgite and 20-50 parts of addition agents. The preparation method comprises the steps: (1) adding a PH modifier to a solvent, evenly stirring the solvent so that the PH of the solvent is stable, slowing adding sodium lignin sulfonate, sulfonated castor oil and fatty acid amine polyoxyethylene ether, evenly stirring the solvent to fully dissolve the solvent, and performing defoaming to obtain mixed solution; (2) adding dispersing agent and the PH modifier into the solvent, adjusting the PH of the solution, adding nano-attapulgite, performing high-speed stirring until the nano-attapulgite is dispersed fully, and obtaining nano-attapulgite solution; (3) linearly slowing adding the nano-attapulgite solution into the mixed solution, evenly stirring the mixed solution, and obtaining the acid dye leveling agent integrating uniform dyeing, color increasing and color fixing.

Owner:上海兴康超纤新材料有限公司

Rattan treatment method

ActiveCN104441155AIncrease anti-corrosion and insect-proof effectPrevent peelingWood treatment detailsReed/straw treatmentEngineeringBoric acid

The invention relates to a rattan treatment method, comprising the following steps: (1) carrying out air drying on placing rattans at sunshade ventilation sites for 3-5 days; (2) preparing a treating fluid; (3) soaking the rattans treated in step (1) in the treating fluid for 2-3 days, then taking out the rattans and carrying out air drying on the rattans to water content of 25-32%, and weaving the rattans. The treating fluid adopted in the invention is obtained by decocting a variety of traditional Chinese medicine, the rattans are soaked to increase the anticorrosion and anti-insect effects of the rattans, then boric acid, glycerol and sulfonated castor oil are added to effectively prevent the rattans from peeling, thus further improving the corrosion resistance of the rattans and increasing the beautiful appearance of wicker products.

Owner:阜南县猛发工艺品有限公司

Quenchant for medium carbon alloy steel abrasion-resistant material

The invention relates to the technical field of heat treatment quenching, and discloses a quenchant for medium carbon alloy steel abrasion-resistant material. The quenchant comprises, by weight, 6% to 8% of sodium hydroxide, 6% to 8% of zinc chloride, 1% to 5% of sodium chloride, 0.01% to 0.03% of sulfonated castor oil, 0.01% to 0.05% of antifoaming agents, 0.1% to 0.5% of soap, 0.1% to 0.4% of preservative, 0.1% to 0.5% of antirust agents, 0.1% to 0.5% of lubricants, 0.1% to 0.5% of sterilizing agents and the balance water. The quenchant is reasonable in formula, and a quenched piece can have high hardness and is even in hardness. Sodium hydroxide and oxide skin on the surface of the quenched piece can interact with each other to generate hydrogen, so that the oxide skin can be rapidly peeled off, and the surface of the quenched piece can be in a shining silver color. Zinc chloride and sodium hydroxide react to generate strong zinc oxide, and the cooling speed of a high temperature area is higher than the cooling speed of water while the cooling speed of a low temperature area is lower than the cooling speed of water, so that deformation of the quenched piece is small, the quenched piece is not prone to cracking, and the surface of the quenched piece is shining.

Owner:响水源达轴承座制造有限公司

Normal-temperature cleaning anti-rust agent of cylinder body of host machine of iron-casting diesel engine and preparation method thereof

InactiveCN101660152ASave energySimple processMetallic material coating processesSolubilityPolyethylene glycol

The invention relates to a normal-temperature cleaning anti-rust agent of a cylinder body of a host machine of an iron-casting diesel engine and a preparation method thereof; the anti-rust agent has aformula as follows: 2-8 percent of sodium tripolyphosphate, 2-8 percent of sodium hexametaphosphate, 2-10 percent of metasilicate pentahydrate, 1-4 percent of sodium hydrogen carbonate, 8-12 percentof QYL-23, 3-6 percent of AEO, 0.1-1.2 percent of JFC, 4-6 percent of polyethyleneglycol, 3-5 percent of sulfonated castor oil, 0.2-2 percent of nekal BX, 3-5 percent of defoamer and remaining water;the preparation method is that: running water is added in a reaction kettle, the temperature is heated to 40-50 DEG C, and then the running water is stirred, and then the sodium tripolyphosphate, thesodium hexametaphosphate, the metasilicate pentahydrate, the sodium hydrogen carbonate, the nekal BX are sequentially added and are stirred until the temperature is reduced to below 30 DEG C, and thenthe QYL-23, the AEO, the JFC, the polyethyleneglycol and the sulfonated castor oil which are metered are sequentially added, until water-solubility liquid is formed. The anti-rust agent can be used at normal temperature and energy is saved; meanwhile, the anti-rust agent has the functions of rust protection, simple process and low cost; and the method can be easily operated and controlled.

Owner:DALIAN SANDAAOKE CHEM

Watersoluble chlorinated polypropylerie paint and method of producing the same

InactiveCN101429366ASimple preparation processRaw materials are cheap and easy to getEmulsion paintsWater basedToluene

The invention relates to a water-based chlorinated polypropylene paint and a preparation method thereof. The paint comprises the following components: 10 to 25 percent of chlorinated polypropylene, 20 to 30 percent of toluene, 0.5 to 1.5 percent of sodium dodecyl sulfate, 1.0 to 3.0 percent of sulfonated castor oil, and 50 to 60 percent of deionized water. The preparation method comprises the following steps: preparing materials according to the weight percentage, that is, firstly adding the chlorinated polypropylene into toluene solution, then adding the sodium dodecyl sulfate into the solution after the chlorinated polypropylene is fully dissolved, and stirring the mixture to dissolve the mixture fully; and then pouring the solution into a first container, dissolving the sulfonated castor oil into the deionized water, filling the solution into a second container and stirring the solution, dripping the solution in the second container into the first container, and stirring and emulsifying the solution to obtain water-based chlorinated polypropylene, wherein the emulsifying time is 4 hours.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Stainless steel wire drawing liquid and preparation method thereof

InactiveCN103614216AExtended service lifeImprove cooling effectLubricant compositionGlycerolSuccinic acid

The invention discloses a stainless steel wire drawing liquid and a preparation method thereof. The stainless steel wire drawing liquid and the preparation method thereof are characterized in that the wire drawing liquid comprises following raw materials by weight: 1-2 parts of sulfonated castor oil, 14-17 parts of castor oil, 32-34 parts of glycol, 1-2 parts of sodium petroleum sulfonate, 3-4 parts of linoleic acid, 1-2 parts of alkenyl succinic acid, 20-24 parts of propylene glycol, 4-5 parts of glycerin, 1-2 parts of nano-diamond, 1-2 parts of triethanolamine, 3-4 parts of isopropyl myristate, 1-2 parts of polydimethylsiloxane, 1-2 parts of 2-oxazolidinone, 10-14 parts of an antiwear agent and 1000 parts of water; nano aluminium nitride powder is added into the antiwear agent, thus promoting heat dissipation and enhancing film-forming property; the wire drawing liquid has characteristics of excellent lubricating property, good film-forming property, good stability, rapid heat transmission and good heat dissipation; and the wire drawing liquid has long service lifetime and is a wire drawing liquid with the long lifetime.

Owner:全威(铜陵)铜业科技有限公司

Ink

The present invention discloses ink. The ink consists of the following raw materials in parts by weight: 20-30 parts of titanium dioxide; 20-30 parts of vinyl chloride-vinyl acetate resin; 20-30 parts of lignin modified phenolic resin; 15-20 parts of saturated polyester resin; 35-40 parts of isoamyl acetate; 4-5 parts of starch phosphate; 20-25 parts of isopropanol; 10-15 parts of dipropylene glycol dimethyl ether; 2-3 parts of energy stone; 2-3 parts of magnet; 4-6 parts of hydrotalcite; 1-1.2 parts of sulfonated ricinoleic acid; 1-1.5 parts of polysorbate; 1-2 parts of butanone oxime; 1-2 parts of iron octylate; and 60-65 parts of water. The present invention also provides a preparation method for printing ink. The ink provided by the present invention has a relatively fast drying speed, good adhesion, and excellent heat resistance.

Owner:HUIZHOU CITY SHUNFENG PRINTING MATERIAL TECH CO LTD

Micro-emulsion cutting liquid with good oil removal performance

InactiveCN102757851AImprove oil discharge effectGuaranteed anti-rustLubricant compositionFatty alcoholPetroleum

The invention discloses a micro-emulsion cutting liquid with a good oil removal performance. The cutting liquid is composed of the components in percentage by weight as follows: 5-7% of diethanol amine, 4-6% of triethanolamine, 7-9% of boric acid, 5-7% of 60% petroleum sodium sulfonate and 6-8% of fatty alcohol-polyoxyethylene ether with the hydrophile-lipophile balance of 2-4, 5-7% of sulfonated monopol soap, 8-10% of polyalcohol oleate, 3-5% of vulcanized aliphatic ester, 10-12% of naphthenic oil with kinematic viscosity of 10-32 mm<2> / s at 40 DEG C, 0.3-0.5% of benzotriazole, 0.2-0.4% of silicone emulsion and the balance of water.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Pipe fitting processing lubricant

InactiveCN103602460AReduce roughnessExtended service lifeLubricant compositionPipe fittingBenzotriazole

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Lubricant for high-speed fine wiredrawing of copper wire and preparation method thereof

InactiveCN103351920AImprove drawing speedImprove the lubrication effectAdditivesCopper wireMaterials science

The invention provides a lubricant for high-speed fine wiredrawing of copper wire and a preparation method thereof. The lubricant is characterized by comprising the following raw materials by weight parts: 10-12 parts of machine oil, 2-3 parts of isopropanolamine, 3-4 parts of sulfonated castor oil, 2-3 parts of petroleum sulfonate, 1-2 parts of tricresyl phosphate, 1-2 parts of an antifoaming agent T901, 5-8 parts of propylene glycol, 2-3 parts of aminopropyl triethoxysilane, 1-2 parts of dimethicone, 1-2 parts of triethanolamine, 1-2 parts of boric acid, 1-2 parts of benzotriazole, 2-3 parts of a film forming auxiliary agent and 120-125 parts of water. According to the invention, the machine oil is used as a lubricating component to improve a lubricating effect, thereby increasing a wiredrawing speed of the copper wires; by using the triethanolamine, the boric acid and the benzotriazole, the lubricant is enabled to have a relatively good corrosion inhibiting effect; the wiredrawn copper wire can remain bright for a long time, and does not rust.

Owner:安徽富华电子集团有限公司

Wear-resistant low-cost cable material

InactiveCN106800702AGood acid and alkali resistanceIncrease spacingPlastic/resin/waxes insulatorsWear resistantAntioxidant

The invention discloses a wear-resistant low-cost cable material which is prepared from the following raw materials in parts by weight: 15-25 parts of polyethylene, 10-20 parts of polyvinyl chloride, 35-45 parts of polypropylene, 1.5-2.5 parts of cyanoethylated diethylenetriamine, 4-8 parts of modified montmorillonite, 6-10 parts of mica sheet, 1.5-2.5 parts of glass microsphere, 2-4 parts of lactose, 3-5 parts of microcrystalline cellulose, 2-4 parts of sulfonated castor oil, 2-4 parts of dioctyl terephthalate, 2-4 parts of tall oil, 2-4 parts of ointment, 2-6 parts of fatty acid, 0.3-0.9 part of color master batch, 1-2 parts of phosphite, 2-4 parts of antistatic agent and 2-4 parts of antioxidant. The wear-resistant low-cost cable material has the advantages of excellent light resistance, excellent heat resistance, excellent aging resistance, high mechanical strength, favorable wear resistance and low cost.

Owner:安徽新立电缆材料有限公司

Mineral oil defoaming agent for waterborne coating and preparation method of mineral oil defoaming agent

The invention discloses a mineral oil defoaming agent for a waterborne coating and a preparation method of the mineral oil defoaming agent. The mineral oil de-foaming agent for the waterborne coating comprises the following components in percentage by weight: 5-15 percent of modified organic polyether, 5-25 percent of white oil, 10-25 percent of wax, 15-40 percent of octyl alcohol, 30-55 percent of sulfonated castor oil, 2-10 percent of an emulsifying agent, 0.1-0.2 percent of a catalyst, 0.1-0.3 percent of a sterilizing agent and 0.6-0.8 percent of a dispersing agent. The mineral oil de-foaming agent for the waterborne coating is formed by refining an organic polyether ester, mineral oil and alcohol composite product through a special process. The mineral oil de-foaming agent has the performance such as self-emulsification, easy dispersion, strong universality, good de-foaming, and lasting foam inhibition; the surface defect cannot be generated or the film-forming property cannot be affected; the mineral oil de-foaming agent has a special effect on the waterborne coating.

Owner:广东中联邦精细化工有限公司

Water-based lubricating oil and production method

ActiveCN101255374AImprove the lubrication effectHigh melting pointLubricant compositionWater basedIsothiazolinone

The invention discloses a water-based lubricant oil which is good in lubricate and cooling effect, low in cost, and meets environmental protection requirement, wherein the weight percentage of raw material is polyethyleneglycol 10-14%, glycyl alcohol 16-20%, ethandiol 1-3%, sulfonated castor oil 3-5%, benzotriazole 0.4-0.6%, industrial alcohol 2-3%, 2-methyl-3(2H)-isothiazolone 0.05-0.15%, deionized water 60-62%. The production process is dissolving benzotriazole with industrial alcohol of computed amount, standing by for service; adding deionized water, polyethyleneglycol, glycyl alcohol, ethandiol of computed amount sequentially into reactor, starting agitator, adjusting rotational speed to 200 rotates / min and stirring for one hour; adding standby prepared in step a, sulfonated castor oil and 2-methyl-3(2H)-Isothiazolone into reactor, heating to 50-60 DEG C and stirring for 2 hours; then cooling to normal temperature.

Owner:DALIAN SANDAAOKE CHEM

Wicker treating agent

ActiveCN104308926AEasy to prepareImprove anti-corrosion performanceReed/straw treatmentWood impregnation detailsMedicineDodecyl sulfate

The invention relates to a wicker treating agent. The wicker treating agent is prepared from water, sulfonated castor oil, glycol, boric acid, paroline, sodium dodecyl sulfate, radix sophorae flavescentis, asarum, agaro-oligosaccarides, ginger, fructus forsythia, corn stigma and bamboo leaves. A preparation method of the wicker treating agent is simple, the obtained treating agent is nontoxic, and wicker treated by use of the treating agent is excellent in corrosion resistance; besides, the treating agent is capable of softening the wicker and facilitating wicker processing; besides, a wicker product produced by use of the treated wicker does not deform and crack in the use process.

Owner:安徽宏润工艺品有限公司

Automobile clutch disk hub special-purpose water-based milling liquid and production method

The invention discloses a water-based broaching liquor for automobile clutch disk hub which can reduce broaching temperature and force to maximum extent, improves processing efficiency of broaching, ensures broaching precision and surface quality, prolongs life of cutting tool, reduces cost, satisfies environmental protection requirement. Raw materials of specialized water-based broaching liquor and corresponding weight percentage are phytic acid 1.2-1.8%, sodium benzoate 3-5%, triethanolamine 5.5-6.5%, sodium carbonate 1,8-2.2%, hyposulfite of soda 0.8-1.2%, polyethyleneglycol 7-9%, glycyl alcohol 9-11%, sulfonated castor oil 2.5-3.5%, oleic acid 1.5-2.5%, alkyl phenol polyethenoxy ether 1.5-2.5%, 2-methyl-3(2H)-isothiazolone 0.4-0.6%, de-ionized water 56-62%. The production method is synthesis with stirring under normal temperature - medium temperature - normal temperature.

Owner:DALIAN SANDAAOKE CHEM

Dyeing assistant for pure-cashmere products

The invention relates to the field of dyeing assistants, in particular to a dyeing assistant for pure-cashmere products. The dyeing assistant is prepared from, by mass, 5-8 parts of carboxymethyl chitosan, 3-10 parts of sodium sulfate, 1-4 parts of linear alcohol ethoxylates, 2-3 parts of sulfonated castor oil, 10-15 parts of polyacrylamide, 10-12 parts of sodium polyacrylate, 8-10 parts of dodecyl dimethyl betaine, 2-5 parts of alkylphlhalimide, 4-6 parts of diethylenetriamine, 5-10 parts of acetic acid and 40-60 parts of water. The dyeing assistant for the pure-cashmere products and dye are added at the same time according to a certain proportion in the dyeing process, in this way, the color fastness can be effectively improved in pure-cashmere dyeing, damage to the pure-cashmere can be avoided, and the dyeing performance can be improved.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

Fully-synthetic environment-friendly cutting fluid for magnesium aluminum alloy

InactiveCN104031731AEasy to handleLong processLubricant compositionSodium PyrithionePolyethylene glycol

The invention provides a fully-synthetic environment-friendly cutting fluid for a magnesium aluminum alloy. The cutting fluid is basically characterized by comprising, by weight, 1 to 3% of isothiazolinone, 0.5 to 3% of pyrithione, 1 to 6% of sulfonated castor oil, 0.5 to 5% of calcium carbonate, 3 to 8% of pyrazinecarboxamide, 0.5 to 4% of polyethylene glycol, 0.5 to 3% of molybdenum disulfide, 0.5 to 3% of acrylate and 0.5 to 3% of synthetic fat, with the balance being water. A preparation method for the cutting fluid is simple and has low cost. The prepared cutting fluid has a longer service life and a wider application scope, does not have odor changes, is harmless to the human body, accords with higher environmental protection requirements, enables treating process of a waste liquid to be simple, can maintain the strength of a cutter for a long time, has more long-lasting cooling performance and a protruding cleaning effect, improves machining efficiency and allows a processed product to have better fineness.

Owner:黎灼添

Quick-drying spray antirust oil for automobile cast iron engine workpieces

InactiveCN103992842AFast film formationGood rust protectionLubricant compositionKeroseneSodium bisulfate

The invention discloses a quick-drying spray antirust oil for automobile cast iron engine workpieces. The quick-drying spray antirust oil comprises, by weight, 60-67 parts of No.120 gasoline, 20-24 parts of 0# light diesel oil, 10-14 parts of 2402 resin, 3-5 parts of barium petroleum sulfonate, 3-5 parts of industrial castor oil, 4-10 parts of dewaxed kerosene, 0.8-2 parts of sodium bisulfate, 1-2 parts of hydroxyethyl ethylene bisstearamide, 2-3 parts of 2,6-di-tert-butyl-p-cresol, 0.8-3 parts of zinc dialkyl dithiophosphate, 2-3 parts of sulfonated castor oil and 6-10 parts of a film forming assistant. The antirust oil has a fast film forming speed, can completely form a dry film on the surface of a workpiece 3min after the antirust oil is sprayed on the surface, has an antirust period reaching above 2 years, is especially suitable for being used on automobile cast iron engine workpieces, has a very good antirust protection effect on an engine and prolongs the service life of the engine.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Nontoxic printing ink cleaning agent and preparation method thereof

InactiveCN107418294AEfficient removalEasy to cleanChemical paints/ink removersPolyethylene glycolPrinting ink

The invention discloses a nontoxic printing ink cleaning agent and a preparation method thereof. The nontoxic printing ink cleaning agent is prepared from, by weight, 10-20 parts of polyethylene glycol octylphenol ether, 5-15 parts of tea saponin, 2-6 parts of algae powder, 2-8 parts of titanium dioxide, 4-12 parts of sorbitol fatty acid ester, 5-16 parts of a corrosion inhibitor, 4-12 parts of modified sodium disilicate, 10-20 parts of nano metal oxides, 4-10 parts of sulfonated castor oil and 10-30 parts of purified water. The preparation method is simple, and the prepared ink cleaning agent is capable of effectively clearing ink on machines and rubber rollers without corrosion and oxidation of the machines and the rubber rollers and is harmless to human bodies.

Owner:MAANSHAN SONGHAK INFORMATION TECH CO LTD

BE230 ester-soluble environment-friendly composite printing ink

The invention relates to a BE230 ester-soluble environment-friendly composite printing ink. The printing ink is prepared from, by weight, 25-35 parts of titanium dioxide, 20-30 parts of polyurethane resin, 20-30 parts of lignin modified phenolic resin, 15-20 parts of saturated polyester resin, 35-40 parts of isoamyl acetate, 4-5 parts of starch phosphate, 20-25 parts of isopropanol, 10-15 parts ofdipropylene glycol dimethyl ether, 2-3 parts of energy stone, 2-3 parts of magnets, 4-6 parts of hydrotalcite, 1-3 parts of acetic acid-n-propyl ester, 1-1.2 parts of sulfonated ricinoleic acid, 1-1.5 parts of polysorbate, 1-2 parts of diacetylmonoxime, 0.8-1.5 parts of an adhesion promoter, 1-2 parts of iron 2-ethylhexanoate and 60-65 parts of water. The obtained printing ink has high drying speed, good adhesive force and excellent heat resistance, particularly, the energy stone, magnets and hydrotalcite are adopted for filler, the characteristics of the obtained printing ink are better thanthose of a calcium carbonate filler printing ink, and the printing ink is even and bright in color, good in glossiness, levelling property, anti-static performance and printing adaptability, high intransitivity, excellent in overprinting effect, high in compounding strength, extremely good in solvent release performance and capable of achieving a small quantity of residual solvent.

Owner:陕西奥华油墨科技有限公司

Novel stamping emulsified oil and production method thereof

InactiveCN104711092AWill not cause sticking to the moldPrevents chafing and wearAdditivesChlorinated paraffinsPetroleum

The invention discloses a novel stamping emulsified oil. The novel stamping emulsified oil comprises following raw materials, by mass, 4 to 6% of sulfide cottonseed oil, 8 to 12% of chlorinated paraffin, 4 to 6% of sulfonated castor oil, 10 to 13% of petroleum sodium sulfonate, 10 to 13% of barium petroleum sulfonate, 2 to 4% of oleic acid, 4 to 8% of triethanolamine, and the balance No.45 transformer oil. A production method comprises following steps: weighed No.45 transformer oil is delivered into a reaction vessel, and is heated to 48 to 52 DEG C; a stirrer is turned on, and rotating speed is controlled to be 60r / min; weighed sulfide cottonseed oil, chlorinated paraffin, sulfonated castor oil, petroleum sodium sulfonate, barium petroleum sulfonate, oleic acid, and triethanolamine are delivered into the reaction vessel successively with stirring; and after 2 to 3h of stirring, an obtained solution is cooled to room temperature, and is collected and packaged.

Owner:DALIAN SANDAAOKE CHEM

Environment-friendly high-efficient brass passivating treatment technology

ActiveCN104294266ASolution fell intoExtended use timeMetallic material coating processesAlcoholSalt spray test

The invention relates to an environment-friendly high-efficient brass passivating treatment technology. The passivating treatment technology comprises the following steps: (1), deoiling and passivating: soaking a brass piece in a passivating solution for passivating for 1-20 min; (2), sealing and film forming: soaking the brass piece passivated in the step (1) in a sulfonated castor oil solution for 0.1-20 min, spin-drying and cooling, wherein the passivating solution comprises mercaptobenzothiazole salt and sodium alcohol ether sulphate, the dosage of mercaptobenzothiazole salt is 0.02-50 g / l, the dosage of sodium alcohol ether sulphate is 0.5-20 g / l, and the dosage of sulfonated castor oil is 0.5-500 ml / l. The passivating treatment technology does not relate to heavy metals of chromic acid and the like, and is free of the procedures of separate deoiling, acid washing, washing and the like, environment-friendly and safe; meanwhile, the anti-neutral salt spray test can be realized for 168 hours or above, and corrosive resistance of the passivating treatment technology is remarkably superior to that of the conventional various passivating treatment technologies.

Owner:杭州东方表面技术有限公司

High-strength absorbable suture and preparation method thereof

The invention discloses a high-strength absorbable suture and a preparation method thereof. The suture is composed of the following components in parts by mass: 39-51 parts of chitosan, 7-16 parts of zinc acetate, 2-11 parts of glutaraldehyde, 11-26 parts of polyhydroxybutyrate, 2-8 parts of Ca5(OH)(PO4)3, 13-24 parts of sulfonated castor oil, 9-17 parts of polyglycolide acid, and 1-8 parts of itaconic anhydride. According to the prepared suture disclosed by the invention, tensile strength can be improved, elongation is increased, moreover, complete absorption is realized and the suture can be widely applied to clinical treatment.

Owner:温州嘉钮知识产权代理服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com