Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139results about How to "Improve color fixation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chinlon dyeing process adopting natural dye

InactiveCN104695241AReduce pollutionAvoid damageFibre typesHeating/cooling textile fabricsColour fastnessFiber

The invention provides a chinlon dyeing process adopting natural dye. The method comprises the steps of pretreatment, presetting, dyeing, soaping, fixation, softening treatment, drying, setting and rolling. The natural dye, alizarin, is adopted, rare earth chloride is adopted as dye mordant, the dyeing effect is better, the washability is greatly enhanced, and meanwhile dyed chinlon fibers have the good antibacterial property. The washing and fixation process is added, the dyeing firmness is good, environment-friendly formaldehyde-free TCD-R is adopted in the fixation process, chinlon is dried step by step after fixation, and the firmness of the chinlon is greatly improved. The softening treatment process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG TIANLONG CHEM FIBER

Flax fabric dyeing and finishing process

InactiveCN104988768AReduce pollutionAvoid damageUltrasonic/sonic fibre treatmentDyeing processInorganic saltsMontmorillonite

The invention discloses a flax fabric dyeing and finishing process including pretreatment, pre-sizing, modification treatment, dyeing, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment, and at the same time, the modification treatment step is added; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and an anti-yellowing reagent is used in the processes of pre-sizing, sizing and post-finishing, so that a final fabric does not easily turn yellow.

Owner:太仓市宝明化纤有限公司

Staining method for aramid fiber

ActiveCN104695239AReduce pollutionAvoid damageBiochemical fibre treatmentFibre typesColour fastnessAramid

The invention provides a staining method for aramid fiber. The staining method comprises the steps of preprocessing, preshaping, staining, reduction clearing, color fixing, soft processing, drying, shaping, calendaring and rolling. According to the staining method, DEET is added in to serve as a dye carrier, and the staining effect and efficiency are improved; meanwhile, substitute alkali is adopted to replace a conventional soda substance, and not only is the usage amount decreased, but also the color fixing effect is enhanced to enable the washability of the aramid fiber is further enhanced; the reduction clearing and color fixing processes are added, and therefore the staining fastness is good; green and environmental-friendly non-formaldehyde TCD-R is adopted in the color fixing process, the fiber is dried step by step after color fixing, and therefore the firmness of the fiber is greatly improved; the soft processing process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and therefore the fabric is fluffy and rich in elasticity.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

Matt color ink jet printer paper paint and preparation method thereof

InactiveCN101446055AImprove adsorption capacityLow costPaper coatingCoatingsRoom temperatureSilicon dioxide

The invention relates to matt color ink jet printer paper paint and a preparation method thereof. The preparation method is characterized in that the method comprises the following steps: adding dispersant into deionized water to be dissolved at the room temperature; adding modified bentonitic clay to the dissolved deionized water and dispersing at the room temperature; adding silicon dioxide to the modified bentonitic clay dispersion liquid for dispersion, and obtaining mixed dispersion liquid; adding an adhesion agent to the mixed dispersion liquid while stirring; adding a silicone antifoaming agent, PDMDAAC and carboxymenthyl cellulose in sequence, and obtaining paint liquid after evenly blending and stirring. Because the modified bentonitic clay is utilized as the pigment to prepare the paint for the matt color ink jet printer paper, good water absorption performance, good color fixation performance, high color density, good color reductibility and no infiltration of the matt color ink jet printer paper can be ensured, and the purpose of reducing the cost of the matt color ink jet printer paper can be achieved.

Owner:JIANGNAN UNIV

Dyeing and finishing process for modal fabric

InactiveCN104975499AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsProcess engineering

The invention discloses a dyeing and finishing process for modal fabric. The process comprises the procedures of pretreatment, pre-setting, modification treatment, dyeing, soaping, fixation, after-finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave, and a step of modification treatment is added; in the dyeing procedure, a base substituent SA is used, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedures of pre-setting, sizing and after-finishing, so that the final fabric cannot become yellow easily.

Owner:TAICANG CHENGLE CHEM FIBER

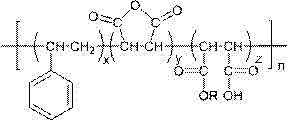

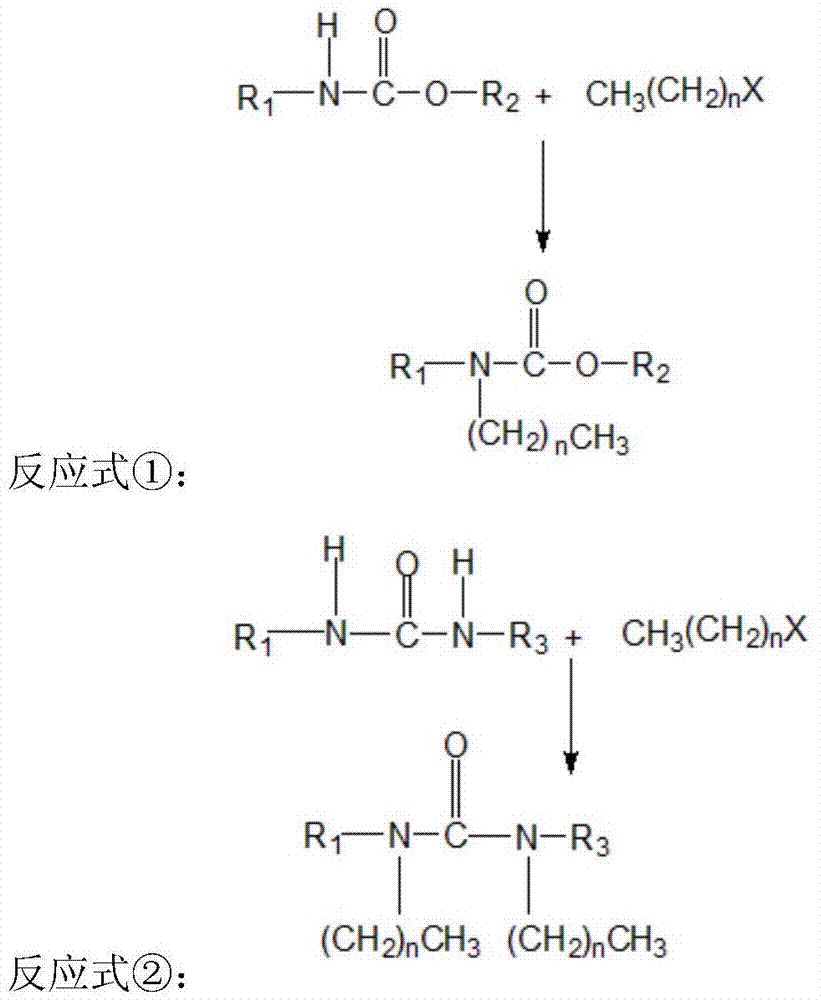

Preparation method for blocked waterborne polyurethane and application of blocked waterborne polyurethane to preparation of digital printing waterborne paint ink

ActiveCN106947049AImprove dispersion stabilityGood dispersionDyeing processFiberDispersion stability

The invention discloses a preparation method for blocked waterborne polyurethane. The method is characterized in that polyurethane is modified by synthesizing a partially-esterified styrene-maleic anhydride copolymer carrying hydroxyl, so that a polyurethane chain plays a role in strongly anchoring organic pigment particles, the dispersion stability of the organic pigment particles in waterborne polyurethane emulsion and the adhesion of a pigment by a waterborne polyurethane adhesive during inkjet curing are facilitated, and the friction resistance and washing fastness are improved. Meanwhile, the polyurethane is subjected to active blocking, so that an unblocked NCO group can react with an OH group on fiber during heating curing after digital printing waterborne paint ink prepared by taking the blocked waterborne polyurethane emulsion prepared by the method as an adhesive is directly jetted onto a fiber fabric, thereby remarkably improving the color fixing firmness and friction resistance. A printed pattern is bright in color, and is soft in handfeel.

Owner:SUN YAT SEN UNIV +1

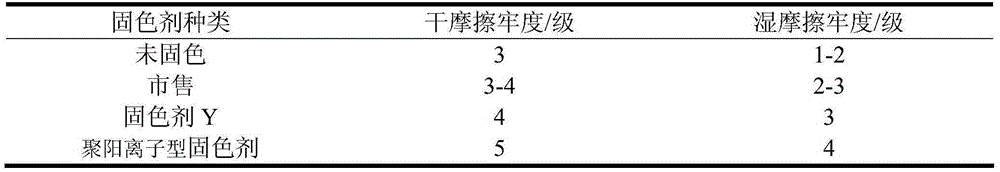

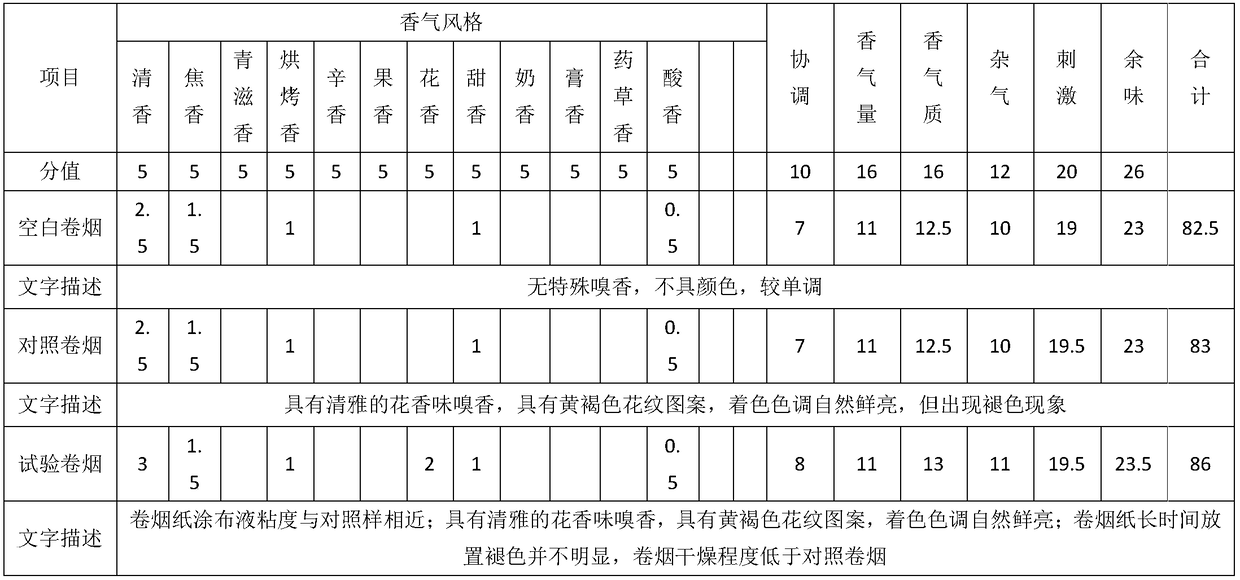

Poly-cation color fixing agent and preparation method thereof

InactiveCN105386347AImprove color fixation effectHigh quality color fixing effectDyeing processEpoxyDiethylene triamine

The invention discloses a poly-cation color fixing agent, which comprises the following components in parts by weight: 20 to 40 parts of diethylene triamine, 20 to 40 parts of epoxy chloropropane, and 10 to 20 parts of dimethyl diallyl ammonium chloride. The invention also discloses a preparation method of the poly-cation color fixing agent. The provided poly-cation color fixing agent can achieve an excellent color fixing effect. Moreover, the color fixing agent does not generate formaldehyde during the process of production and application, and the textiles processed by the color fixing agent will not give off formaldehyde either.

Owner:JIANGMEN CAIGE ENVIRONMENTAL PROTECTION TECH IND

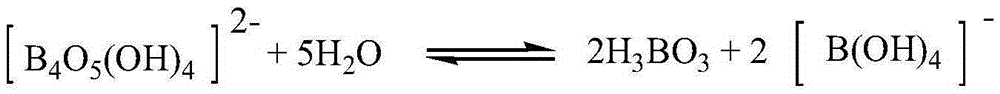

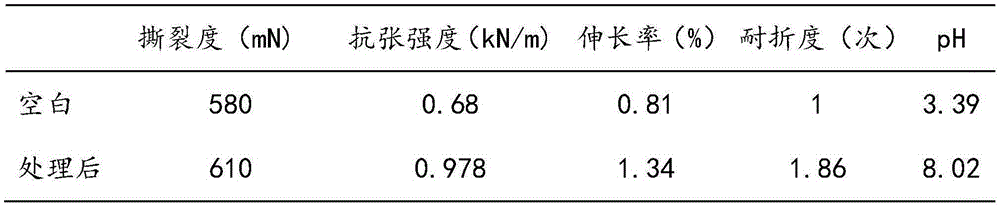

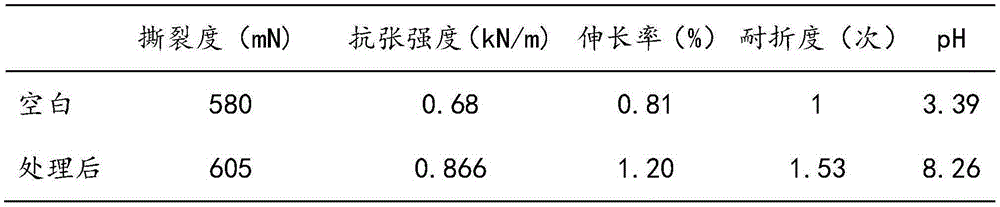

One-step paper deacidification strengthening and enhancing agent and method

InactiveCN105274900AHigh efficiency of deacidification and reinforcementShort processing timeOld paper after-treatmentReagentAmmonium

The invention discloses a one-step paper deacidification strengthening and enhancing agent and a method and aims at providing a paper deacidification strengthening and enhancing agent which is high in deacidification strengthening efficiency and short in processing time and a strengthening and enhancing method thereof. The one-step paper deacidification strengthening and enhancing agent is technically characterized by being prepared from cationic etherification starch and tetraborate. The method includes the steps that firstly, the paper deacidification strengthening and enhancing agent with 0.18-1.0g of quaternary ammonium type cationic starch and 4-6 g of tetraborate contained in each liter of reagents is prepared; secondly, paper needing to be processed directly makes contact with the paper deacidification strengthening and enhancing agent prepared in the first step and is processed for 10-120 min at the 25-60 DEG C; thirdly, the processed paper is taken out and stands still for 60-80 h.

Owner:GUANGDONG UNIV OF TECH

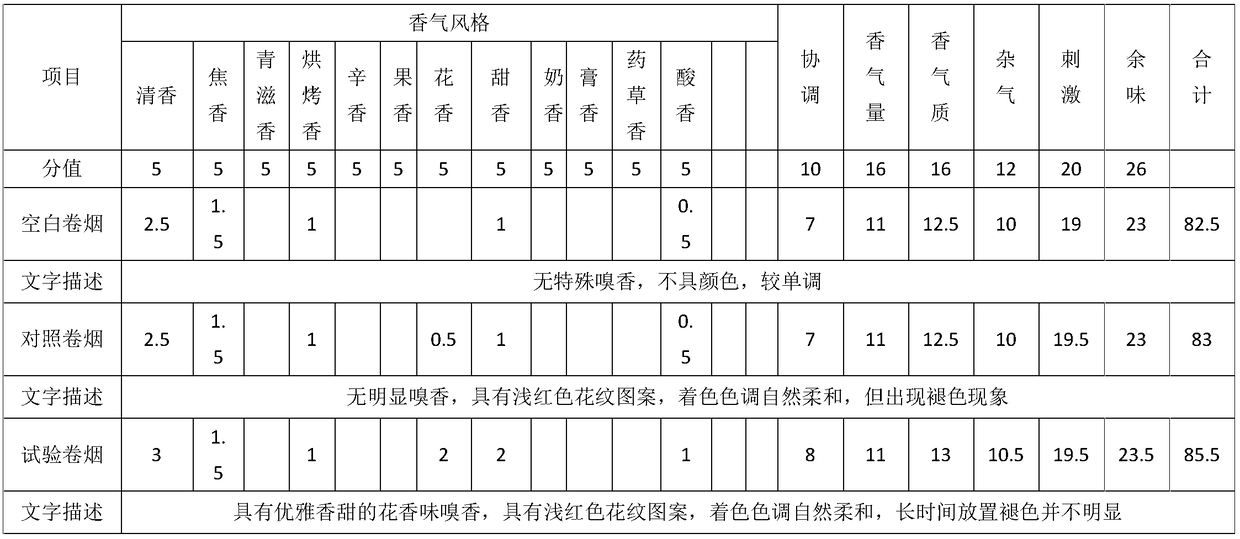

Colored cigarette paper coating solution with specific fragrance and application thereof

ActiveCN108797214APreserve the coloring functionAdjust colors flexiblySurface covering paperNon-fibrous pulp additionSocial benefitsEconomic benefits

The invention discloses a colored cigarette paper coating solution with specific fragrance and application thereof. The colored cigarette paper coating solution is prepared through the following steps: taking plants containing natural pigment as raw materials, and fermenting plant powder or pulp by sequentially using an aspergillus oryzae YNCA 9804 strain and a bacillus subtilis Van3 strain, thusforming an aroma component; carrying out solvent extraction and concentration purification; mixing the aroma component with coating solutions such as fungal polysaccharide, thus preparing a finished product. According to the colored cigarette paper coating solution disclosed by the invention, the characteristic of pleasant fragrance of the colored cigarette paper coating solution is given while acoloring function of the natural pigment is reserved; pigment powder with the fragrance obtained through treatment is independently compounded, mutually compounded or compounded with other natural pigment for use, so that the color of the colored cigarette paper coating solution can be flexibly regulated; synthetic pigment is replaced, dual sense experience on vision and olfaction can be obtainedby a cigarette product while the safety is improved, diversified color developing and fragrance increment of a tobacco paper base can be realized, and good social benefit and economic benefit are obtained.

Owner:CHINA TOBACCO YUNNAN IND

Alkali-resistant chlorine-resistant type aldehyde-free active dye color fixing agent and preparation method thereof

InactiveCN105755870AImprove wet fastnessGood alkali and chlorine resistanceFibre treatmentDyeing processIonCardanol

The invention discloses an alkali-resistant chlorine-resistant type aldehyde-free active dye color fixing agent which comprises the following components in parts by weight: 5-10 parts of an organic silicon monomer, 12-15 parts of acrylic acid, 8-13 parts of butyl acrylate, 6-10 parts of butyl diphenyl ether sodium disulfonate, 1-4 parts of cardanol polyoxyethylene ether, 7-10 parts of polyethylene glycol, 1.5-2 parts of carbon nanotubes, 2-3 parts of calcium silicate, 0.5-1 part of an initiator and 10-20 parts of deionized water. The invention further discloses a preparation method of the alkali-resistant chlorine-resistant type aldehyde-free active dye color fixing agent. The alkali-resistant chlorine-resistant type aldehyde-free active dye color fixing agent is good in alkali resistance, high in chlorine solidness and good in water scrubbing resistance, free of influence to appearance and property of a textile, free of toxic substance release in the preparation and use process, and beneficial to environment protection.

Owner:SUZHOU SANHE KAITAI COLORED THREAD WEAVING CO LTD

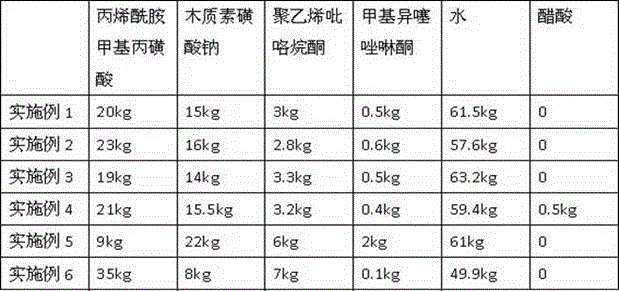

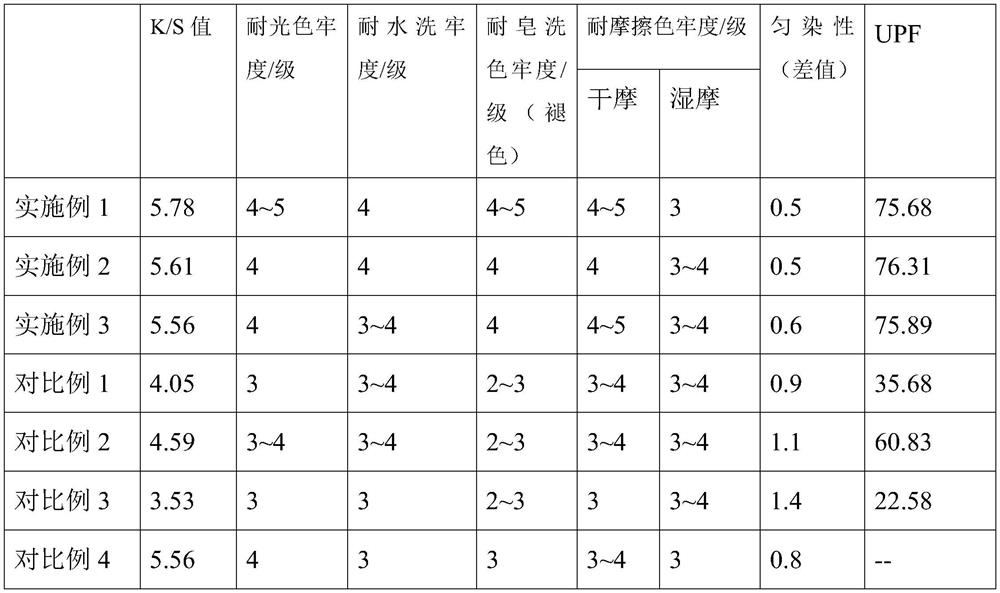

Acrylic color fixing agent and preparation method thereof

InactiveCN105926329AThe effect of removing floating color is obviousFloating effect is obviousDyeing processYarnFiber

The invention provides an acrylic color fixing agent, comprising the following components according to parts by weight: 10-30 parts of acrylamido methylpropanesulfonic acid, 10-20 parts of sodium lignosulfonate, 1-5 parts of polyvinylpyrrolidone, 0.2-1 part of methylisothiazolinone, and 40-70 parts of water. The invention also provides a preparation method of the acrylic color fixing agent, comprising: mixing well the components according to a matching ratio and reacting at high temperature. Fiber treated with the acrylic color fixing agent of the invention has high color fastness; the acrylic color fixing agent has high affinity to a dye not reacted with the fiber; the impact on color of yarn or fabric color-fixed with the acrylic color fixing agent is low; water can be effectively saved for a dyeing plant, and production efficiency can be effectively improved; the acrylic color fixing agent is a special surfactant and is free of bubbles.

Owner:广东博科纺织科技有限公司

Preparation method of spandex with reactive dye easy-dying function

ActiveCN105442083AImprove responsivenessImprove dyeing effect and color fixing effectMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePrepolymerUrea

The invention relates to a preparation method of spandex with a reactive dye easy-dying function. The method comprises steps as follows: 1), a modifying auxiliary is added to N,N-DMAC (dimethylacetamide), and the mixture is stirred to form a stable solution; (2), DMAC and PTMG (polytetramethylene ether glycol) are sequentially added to a prepolymerization tank, 4,4-MDI (diphenyl-methane-diisocyanate) is added according to the set proportion of NCO / OH, and sufficient prepolymerization is performed; (3), a prepolymerized product is transferred to a chain extension tank, a mixed amine solution is used for performing chain extension and chain termination reactions on the prepolymerized product, and a polyurethane urea solution is obtained; (4), a modifying auxiliary / DMAC solution is added to the prepared polyurethane urea solution, and the mixture is transferred to a stock solution storage tank after the complete reaction; (5), an antioxidant, a lubricating agent, an ultraviolet absorbent and the like are added to the polyurethane urea solution, and the mixture is stirred for dispersion; (6), a dry spinning system is used for drawing and drying of a spinning solution, and the spandex with the reactive dye easy-dying function is obtained through the further reaction of polymer with excessive modifying auxiliaries in a channel.

Owner:ZHEJIANG HUAFENG SPANDEX

Polyester fiber dyeing process

The invention discloses a polyester fiber dyeing process, which comprises following steps (1) pretreatment; (2) dyeing; (3) soaping; (4) color fixing; (5) coiling. The polyester fiber dyeing process is simple and convenient to operate and easy to realize, and improves adsorptivity of polyester fiber to dye and enhances a color fixing effect of the dye by a reasonable process design, and the prepared polyester fiber has the advantages of good mechanical properties, uniform dyeing, no color fading after washing and excellent comprehensive properties.

Owner:CHANGSHU XIANGYING SPECIAL FIBER

Coating layer of high-gloss waterproof colorful ink-jet printing paper

InactiveCN103374856AHigh glossImprove color fixation effectCoatings with pigmentsPaper/cardboardWater basedAdhesive

The invention discloses a coating layer of high-gloss waterproof colorful ink-jet printing paper. The coating layer is characterized in that an ink coating layer with high absorbility is coated on manufacturing type wood pulp paper and mainly comprises nano aluminium hydrosilicate, a cationic dispersant and an adhesive and also comprises a water repellent agent, ultrafine aluminium hydrosilicate, wherein the weight ratio of the ultrafine aluminium hydrosilicate to the cationic dispersant to the adhesive is 100:(1-3):(5-15); the coating layer also comprises a defoaming agent, a flatting agent, a thickening agent, a whitening agent and a humidifying agent. By the mode, the coating layer can quickly absorb water-based ink, is high in gloss and high in color fixing capacity and can achieve an effect of silver salt picture quality.

Owner:常理企业服务(苏州)有限公司

Printing method for improving color fastness to light of natural dye cotinus coggygria pigment

ActiveCN112252055AImprove color fastness to lightGood water solubilityUltrasonic/sonic fibre treatmentBiochemical treatment with enzymes/microorganismsTextile printerAmmonia nitrogen

The invention discloses a printing process for improving color fastness to light of natural dye cotinus coggygria pigment, and belongs to the technical field of plant dyeing. The preparation method comprises the following steps: firstly preparing a cotinus coggygria pigment dye mixed solution from cotinus coggygria pigment, nanometer titanium dioxide sol and dopamine hydrochloride, and preparing original printing paste with stable viscosity in cotinus coggygria pigment dye; then preparing color paste from the cotinus coggygria pigment dye mixed solution, the original paste and a color fixing agent (color fixing agent DS1315 and polyglutamic acid are mixed according to the mass ratio of 5:1) to dye real silk fabric. The indexes such as water-resistant color fastness, rubbing-resistant colorfastness, light-resistant color fastness and leveling property of the real silk fabric can be obviously improved. A metal ion mordant and a urea color fixing agent are not used, so that the emissionof ammonia-nitrogen wastewater is remarkably reduced, and environmental protection is facilitated.

Owner:GAOMI ZHONGHE GARMENT

Novel color ink-jet printing paper coating formula

InactiveCN106337314AHigh glossImprove color fixation effectCoatings with pigmentsCoatingsPolyvinyl alcoholPrinting ink

The invention relates to the technical field of a color ink-jet printing paper, and especially relates to a novel color ink-jet printing paper coating formula. The color ink-jet printing paper coating formula comprises the following components in parts by mass: 20-30 parts of nano silica, 75-90 parts of deionized water, 8-15 parts of modified bentonite, 3-9 parts of an acrylic acid emulsion, 3.6-5.4 parts of modified alumina, 13-18 parts of carboxymethyl cellulose, 5.2-6.8 parts of polyvinyl alcohol, 1.8-2.6 parts of boric acid, and 5-10 parts of poly(diallyldimethylammonium chloride). By employing the formula, a novel color ink-jet printing paper coating can rapidly absorb the aqueous printing ink, has high luster and dye fixation capability, and can reach silver salt photograph quality; in addition, the color reductibility of the color ink-jet printing paper coating is good, and the cost of the matt color ink-jet printing paper is reduced.

Owner:魏忠

Direct dyeing process for chemical fiber

InactiveCN104762828AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsColour fastness

The invention provides a direct dyeing process for a chemical fiber. The direct dyeing process for the chemical fiber comprises the steps of pretreatment, pre-shaping, modification treatment, dyeing, soaping, color fixing, after-treatment, drying, sizing, calendaring and rolling. According to the direct dyeing process for the chemical fiber, the modification treatment is added, so that performances of a chemical fabric are subjected to the modification treatment basically, the dyeing degree of the fabric is increased, and the difficulty of a subsequent dyeing step is reduced; during dyeing, the mass utilization of inorganic salt is avoided; furthermore, substitute alkali is used for replacing a conventional sodium carbonate substance, so that the consumption is reduced, a color fixation effect is also improved, and the washing fastness of the chemical fiber is further improved; soaping and color fixing processes are added, so that the dyeing fastness is good; environment-protection formaldehyde-free TCD-R is utilized in the color fixing process, and color-fixed fibers are gradually dried, so that the firmness of the fibers is greatly improved; the post-treatment process is added, so that the color fastness and the flexibility of the fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and has high resilience.

Owner:TAICANG CHENGLE CHEM FIBER

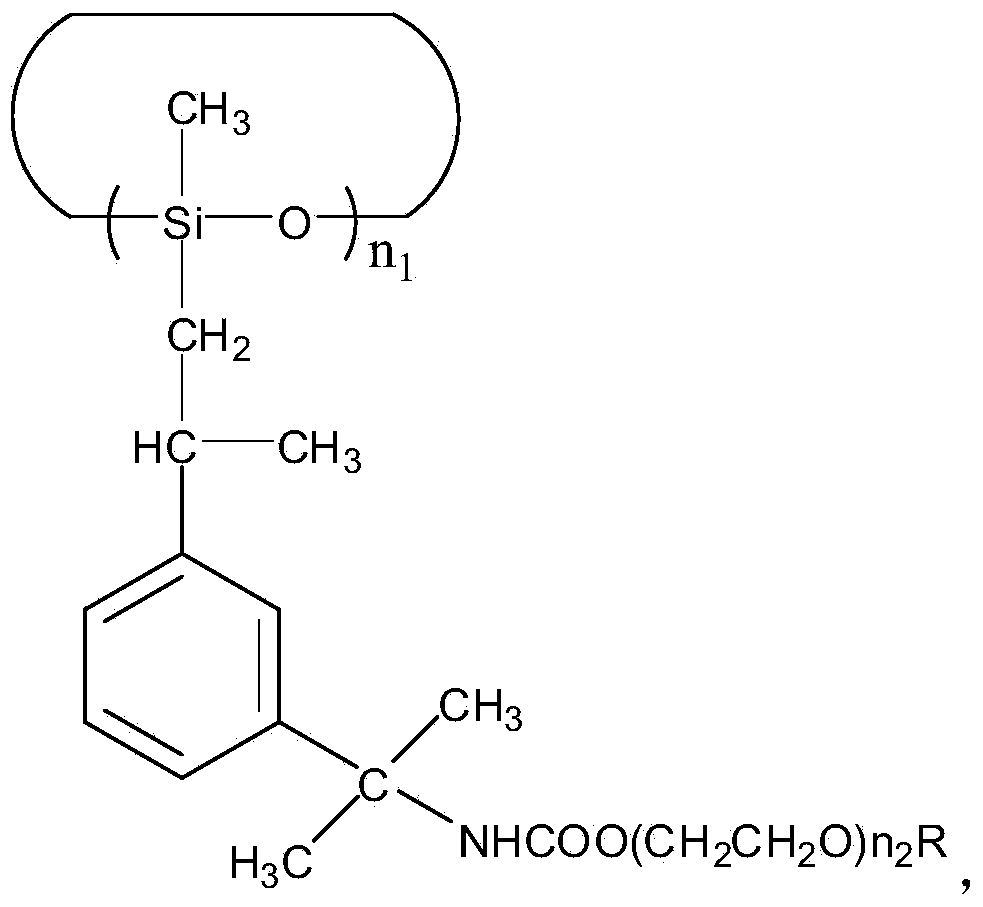

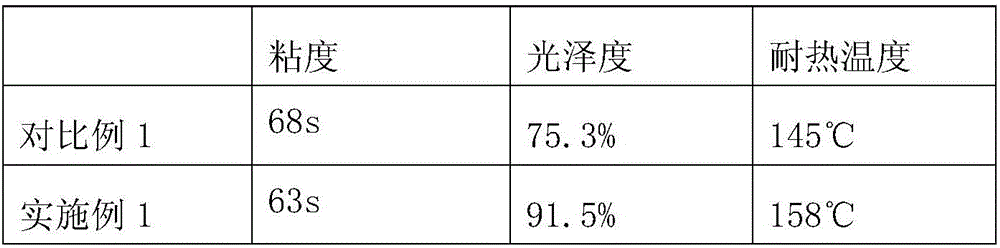

Water-based color ink-jet printing medium and production method thereof

ActiveCN104371411AImprove color fixation effectImprove waterproof performancePolyurea/polyurethane coatingsWater basedWater resistant

The invention discloses a water-based color ink-jet printing medium and a production method thereof. The water-based color ink-jet printing medium comprises a base material, wherein the base material is already subjected to corona treatment, at least one surface of the base material is coated with a base layer and an ink absorption layer, and the ink absorption layer contains an amphoteric star polymer. The water-based color ink-jet printing medium disclosed by the invention can be used for effectively improving the interaction of dye and pigment molecules which are contained in the ink absorption layer and ink, increasing the cohesive force of the ink absorption layer and enhancing the printing color density and the water resistant property by applying the amphoteric star polymer to a color ink-jet printing medium.

Owner:GUANGDONG GLM DIGITAL TECH

Moisturizing light matte lip glaze and preparation method thereof

PendingCN113576948ALong-lasting color lockReduce heavinessCosmetic preparationsMake-upOil phaseComponents of crude oil

The invention discloses moisturizing light matte lip glaze and a preparation method thereof, and relates to the field of cosmetics. The matte lip glaze is prepared from the following raw material components: an oil-phase emulsifier, an oil-phase coalescing agent, an oil-phase coloring agent, an oil-phase emollient, an oil-phase thickening agent, an auxiliary agent and a water phase, the preparation method comprises the following steps: sequentially mixing the oil phase emulsifier, the oil phase emollient, the oil phase coloring agent and the oil phase thickener, adding the oil phase coalescing agent, heating to 60-65 DEG C, adding the preheated water phase material, homogenizing, cooling, adding the pre-dissolved auxiliary agent, and homogenizing to obtain the matte lip glaze. According to the lip glaze disclosed by the invention, a water-in-oil system is utilized, all the components are synergistically matched, a compact breathable film can be generated on lips, volatilization of moisturizing components in the system is reduced, a decorous feeling and a dry feeling brought in the volatilization process are reduced, and the lip glaze is moist and light, moisturized and moist and has lasting color locking effect.

Owner:广州花出见生物科技有限公司

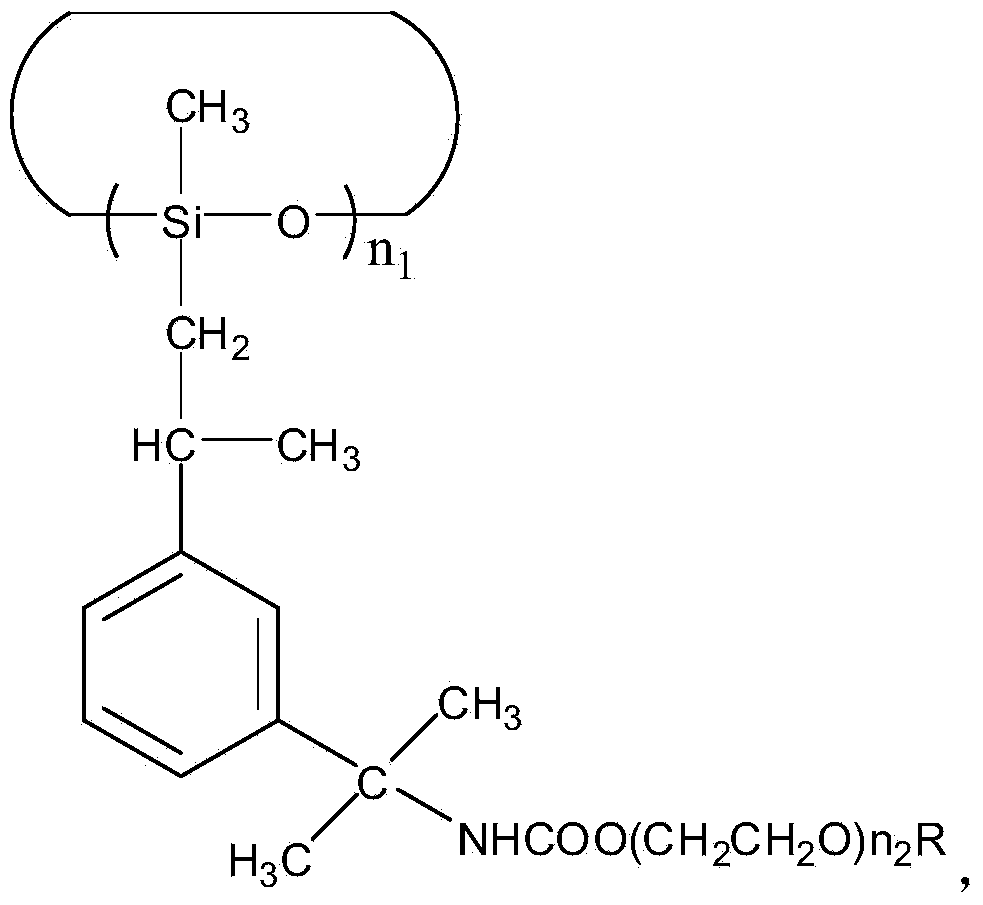

Preparation method of polyamide fiber applied to women's summer clothes

InactiveCN107151827AImprove crispnessImprove color fixing performanceSynthetic polymer filament chemical after-treatmentArtifical filament manufactureSurface modificationChemistry

The invention discloses a preparation method of a polyamide fiber applied to women's summer clothes. According to the method, attapulgite, graphene and antibacterial plant extract are added into polyamide fiber chips; adding graphene and attapulgite is beneficial to improvement of stiffness, smoothness and color fastness of the fiber; adding the antibacterial plant extract is beneficial to improvement of an antibacterial effect of the fiber, and the anti-ultraviolet performance of the fiber is also improved to some extent; after nano ground calcium carbonate is sprayed to the surface of the polyamide fiber to realize surface modification of the polyamide fiber, the anti-ultraviolet performance of the fiber is further improved.

Owner:长兴博美纺织有限公司

Method for improving ink adhesion in plastic printing product

ActiveCN106480416AFastGood response controllabilityVacuum evaporation coatingSputtering coatingEpoxyDimethylaniline N-oxide

The invention belongs to the field of printing machining and particularly relates to a method for improving ink adhesion in a plastic printing product. The method includes the following steps of (1) pretreatment of the plastic product and (2) printing. An ion sputtering method is adopted to conduct oxidation treatment on the surface of the plastic product, energy can be rapidly transferred to a special functional group on the plastic surface, and purposes of even heating and even oxidization are achieved; printing ink is prepared in the manner that based on ordinary ink, microcrystalline wax, N, N-dimethylaniline, lignin-based epoxy resin and a surface active agent are added, and consistency and permeability of the ink and the plastic product are increased. The plastic printing product prepared through the method has the advantages that adhesion between the plastic product and the ink is high, and friction resistance is achieved.

Owner:义乌市双杰日用品有限公司

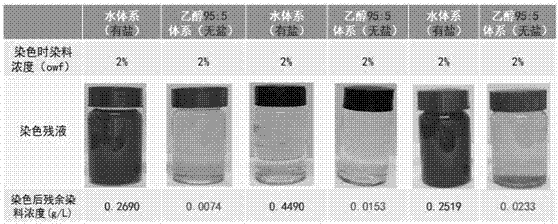

Ethyl alcohol dyeing accompanying technology

InactiveCN106868893APlay a role in promoting dyeingRelieve pressureLiquid/gas/vapor removalDyeing processInorganic saltsSocial benefits

The invention discloses an ethyl alcohol dyeing accompanying technology. The ethyl alcohol dyeing accompanying technology is characterized in that the dyeing is completed by 5% to 10% dissolving dyeing material, and 90% to 95% of water and inorganic salt are replaced by the ethyl alcohol. The ethyl alcohol dyeing accompanying technology has the advantages that by adopting a salt-free dyeing technique under an ethyl alcohol system, the usage amounts of salt and water are obviously reduced, and the economic and social benefits are obvious; compared with the traditional technology, the usage amount of water for dyeing is reduced by 90% to 95%, the ethyl alcohol can be recycled, and the zero drainage of dyeing is basically realized; the dyeing time is shortened by 50%, the dyeing temperature is reduced by 10 to 20 DEG C, the energy is saved by 30% or above, and the problem of sewage in the textile industry is solved by the zero-drainage plan.

Owner:SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD

Chemical fiber dyeing technology with ultraviolet protection function

InactiveCN104695240AReduce pollutionAvoid damageFibre treatmentHeating/cooling textile fabricsFiberAnti bacteria

The invention provides a chemical fiber dyeing technology with the ultraviolet protection function. The chemical fiber dyeing technology comprises pretreatment, pre-shaping, dyeing, washing, soaping, color fixing, softening treatment, drying, shaping and rolling. The natural dyestuff of sophora flower bud is adopted, aluminum potassium sulfate dodecahydrate is used as a mordant, the dyeing effect is better, and the washability is greatly enhanced; meanwhile, due to the performance of the sophora flower bud, dyed chemical fiber has the good ultraviolet protection performance and the antibacterial and oxidation resistance; the washing technology and the color fixing technology are added, the dyeing firmness is good, green and environment-friendly and aldehyde-free TCD-R is adopted in the color fixing technology, and the chemical fiber obtained after color fixing is dried step by step, so that the firmness of the chemical fiber is greatly improved; the softening treatment technology is added, the fabric color firmness and flexibility are improved, the fabric roughness is lightened, and the fabric is fluffy and full of elasticity.

Owner:TAICANG TIANLONG CHEM FIBER

Preparation method of tea dyed costume fabric

InactiveCN106367957AImprove permeabilitySpeed up entryDyeing processVegetal fibresHigh resistanceBenzoic acid

The invention discloses a preparation method of a tea dyed costume fabric. By the use of fatty alcohol-polyoxyethylene ether, sodium citrate, hydroxypropyl methylcellulose, ethyl maltol and 2-hydracrylic acid, permeation of water is accelerated, so that tea polyphenol can quickly enter water, and the extraction time is shortened; 2-phosphonic acid butane-1,2,4-tricarboxylic acid sodium salt, sodium tetraphenylboron, 1,2,3,4,5,6-cyclohexanehexacarboxylic acid, sorbitol, ethanediol di(2-aminoethyl ether)quadrol enhance tea even dyeing, so that the dyeing is uniform and consistent, and the resistance to wet rubbing fastness of tea leaves is improved; hydroxypropyl guar gum trimethyl ammonium chloride, trehalose, glucosamine sulfate, 2,4,6-trichlorine benzoic acid and 4-hydroxy phenethylamine enhance the antibacterial property of chitosan, and the dyeing firmness is facilitated; ethylene diamine tetraacetic acid, L-cysteine, 4-hydroxyphenyl boronic acid, methoxyphenylboronic acid and hexamethylol melamine enhance the fixation effect of a tea dye, and the color fastness is enhanced; the costume fabric has high resistance to washing fastness, antibacterial property and resistance to dry and wet rubbing fastness.

Owner:SICHUAN VOCATIONAL COLLEGE OF SICHUAN

Environment-friendly dyeing agent for textile fabrics and preparation method thereof

InactiveCN110424169APromote degradationReduce fadingDyeing processRare-earth elementEnvironmental resistance

The invention discloses an environment-friendly dyeing agent for textile fabrics and a preparation method thereof. The environment-friendly dyeing agent is prepared by mixing well a dyestuff and a mordant in the weight ratio of (3.5-4.5):1. Dyeing components of the dyestuff are extracted from dyestuff plants; the dyeing components extracted from the plants have good degrading effect. The mordant is prepared mainly with cerite and tannic acid, is free of heavy metal particles, such as iron, copper and hexavalent chromium, and is more environmentally friendly and better in safety; a nano additive dispersed evenly in the dyeing agent has good ultraviolet resistance and antibacterial property, and fading of the dyestuff after dyeing can be retarded effectively; nano titania and nano zinc oxidehave good color-fixing effect, so that the natural dyestuff has better dyeing effect; in the preparation of the mordant, cerite containing various rare-earth elements can provide good mordanting effect.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

Environment-friendly mordant for natural dye and preparation method of environment-friendly mordant

ActiveCN106120382AImprove reaction efficiencyImprove responseDyeing processOrganic acidRare-earth element

The invention discloses an environment-friendly mordant for natural dye and a preparation method of the environment-friendly mordant. The mordant with good effects is prepared by adopting allanite and organic acid to cooperate with graphene, and the color fixing effect of the natural dye can be effectively improved; meanwhile, rare earth elements contained in allanite do not need to be chemically extracted in the preparing process, therefore, the usage amount of various chemical reagents is greatly decreased, environmental pollution is reduced, and the healthy and environment-friendly requirements of the state on textile industry are met.

Owner:湖州新嘉怡丝织印花有限公司

One-bath dyeing technology for polyester-cotton blended fabric by natural vegetable dye

The invention discloses a one-bath dyeing technology for polyester-cotton blended fabric by natural vegetable dye. The one-bath dyeing technology has the advantages that the polyester-cotton blended fabric is subjected to low-temperature treatment and then a one-bath treatment technology, and boiling-off, bleaching and dyeing are completed once, so that a technological process is shortened, wastewater discharge amount is decreased, energy consumption is reduced, and the environment-friendly requirements of China on the textile industry, involving energy conservation, consumption reduction, wastewater reduction and waste gas emission, are satisfied; organic solvents are avoided in a whole dyeing process, so that human bodies and the environment are hardly endangered; one-bath treatment liquid is reusable, so that the wastewater discharge amount can be decreased; dyeing promoters are added into the one-bath treatment liquid and then gelatin is added into a subsequent sodium silicate solution, so that the dye uptake is increased, color difference is reduced and fixation effects are enhanced; since the sodium silicate solution is used for fixation after one-bath treatment, excellent fixation effects are achieved, the dye uptake can be above 95%, and the fixation rate can be also above 90%.

Owner:长兴锦桥纺织有限公司

Production method for high-color-fastness polyester-cotton drawing yarn

The invention discloses a production method for high-color-fastness polyester-cotton drawing yarn. The polyester-cotton blended yarn is obtained after blending positive-ion modified polyester fibers and combed cotton; the production method includes the following specific steps of A, opening picking; B, cotton carding; C, pre-dyeing; D, drawing; E, roving; F, dyeing; G, spinning. The polyester-cotton blended yarn has the advantages of being even in evenness, small in the number of hairiness, soft in hand feeling and the like; in the technology, short fiber card slivers are pre-dyed, and are subjected to drawing, then roving is conducted, dyeing is conducted, and the color fastness of the yarn is improved through secondary dyeing, and can reach level 3 to level 4.

Owner:桐乡市隆亿纺织有限公司

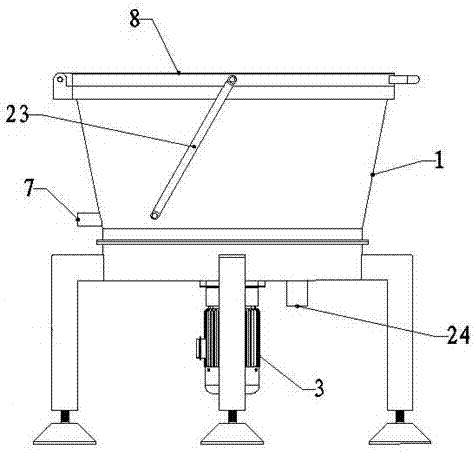

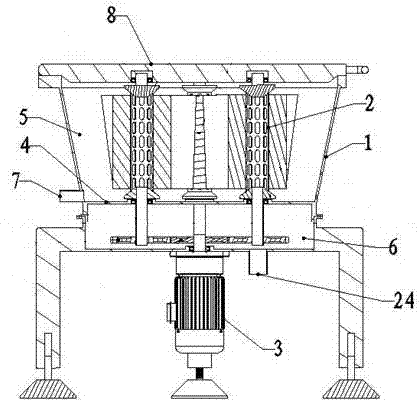

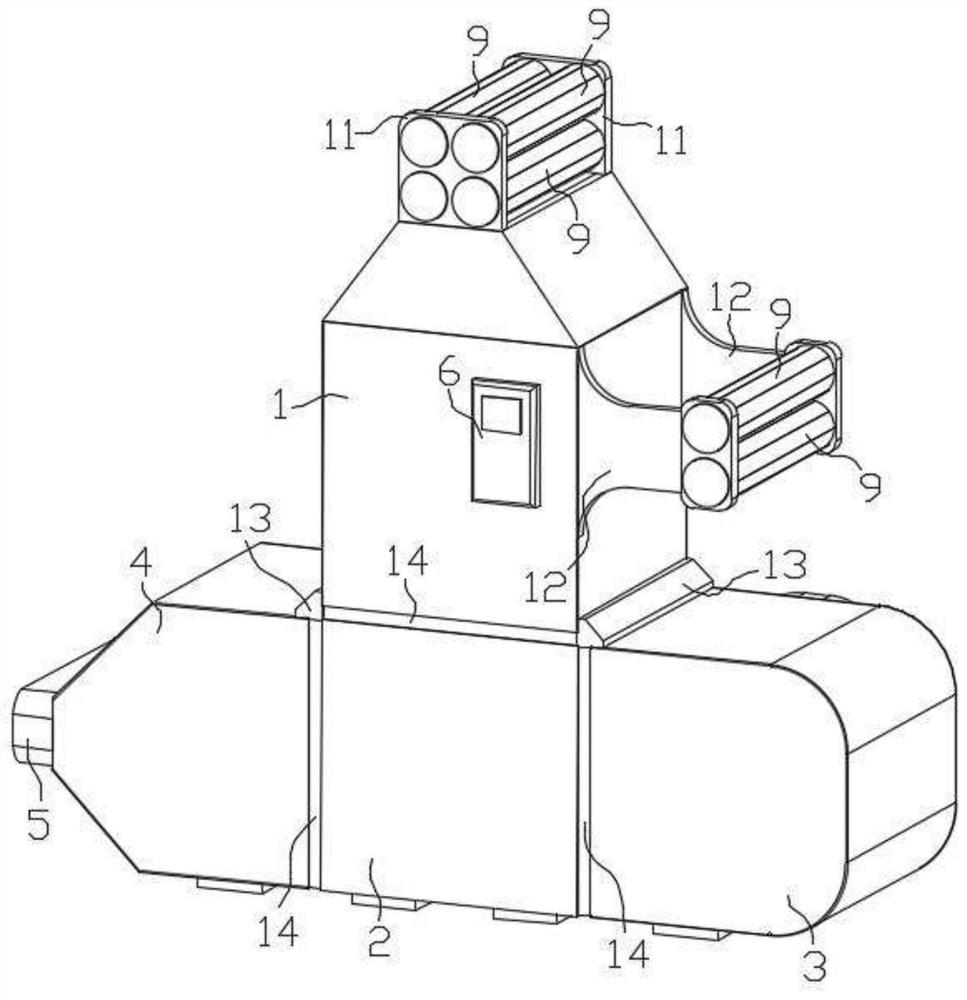

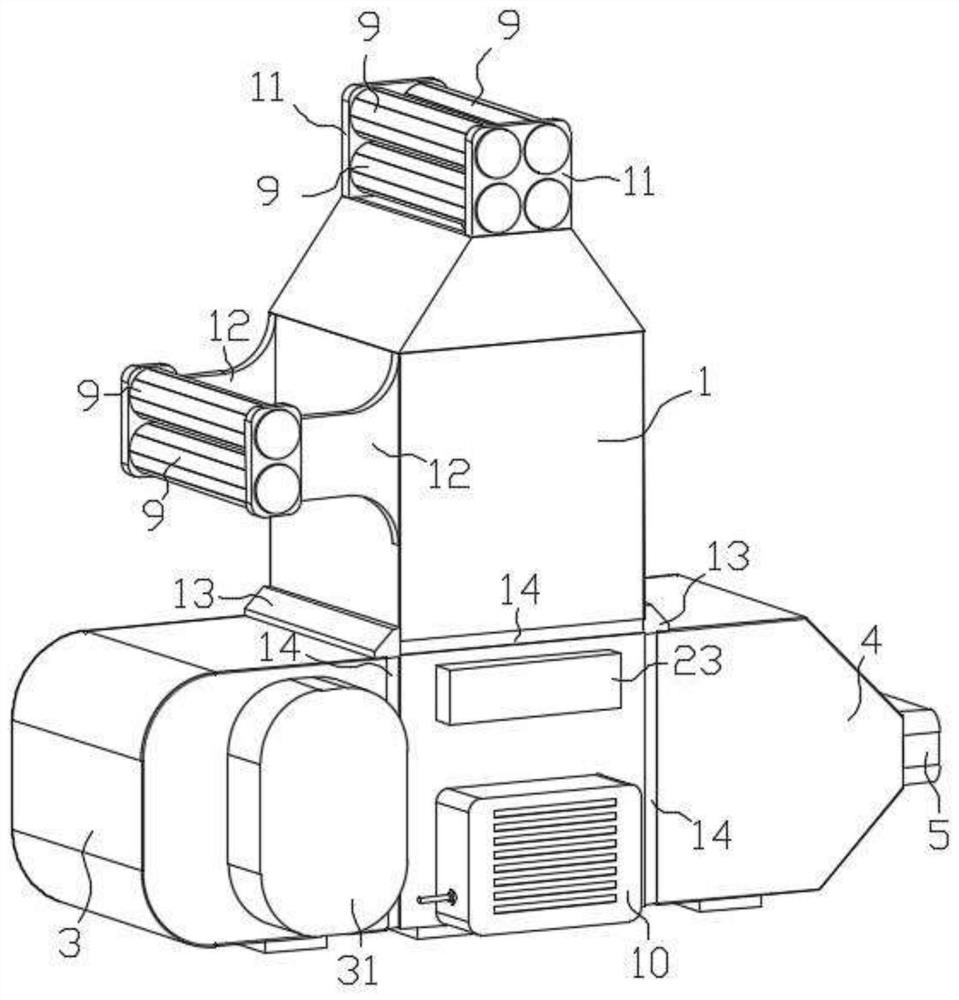

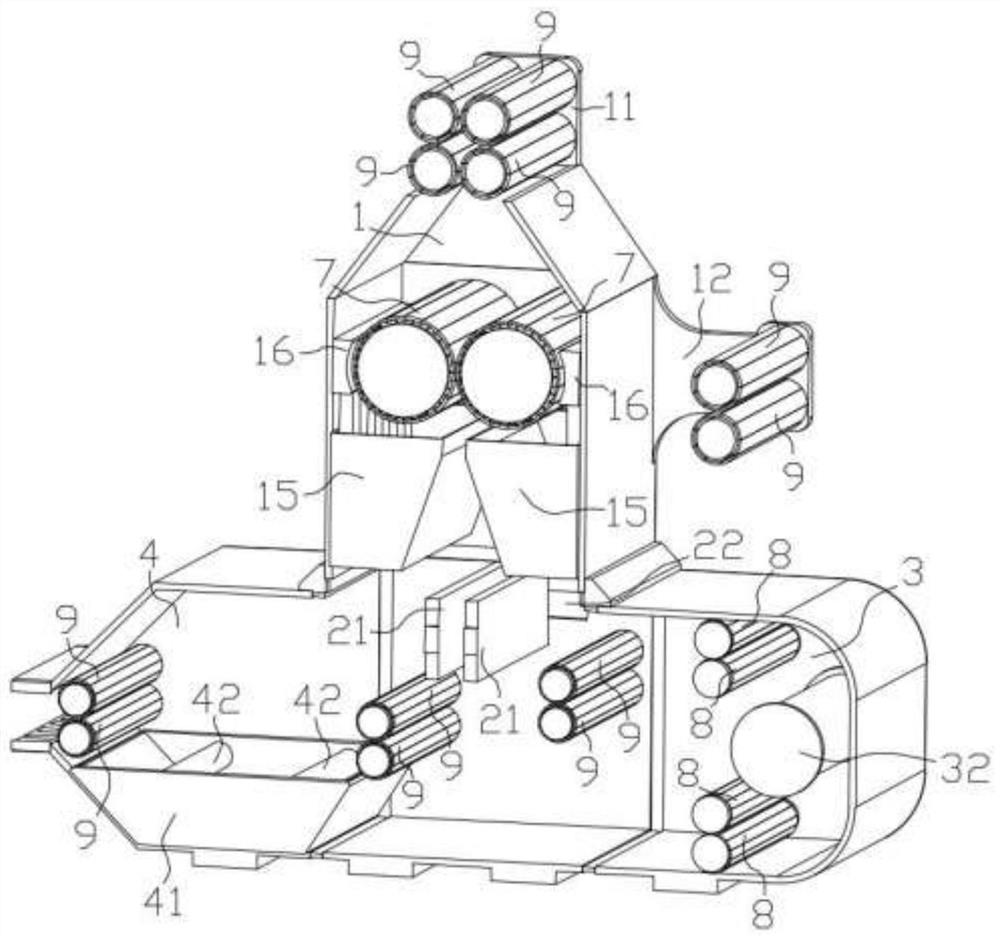

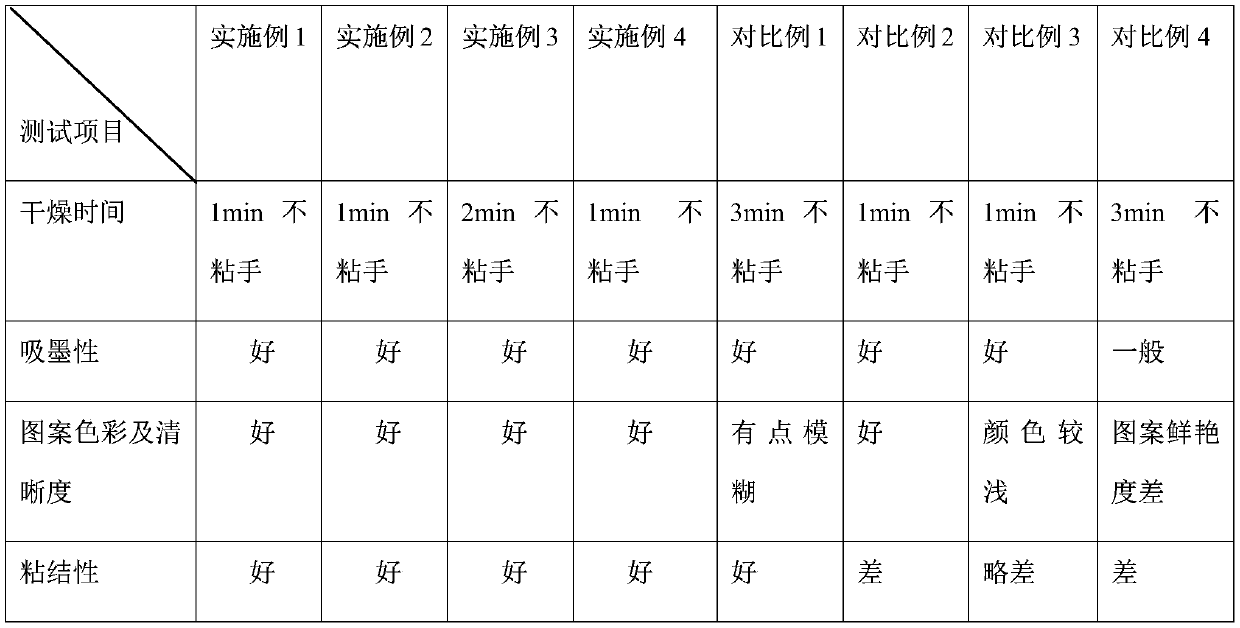

Printing and dyeing production process and device for all-cotton antibacterial double-sided cloth

ActiveCN112342717AImprove efficiencyEasy to handleSucessive textile treatmentsTextile treatment machine arrangementsPolymer scienceColor printing

The invention discloses a printing and dyeing production process and device for all-cotton antibacterial double-sided cloth. The production process comprises the following steps that S1, dye color paste is prepared, and magnetization treatment is conducted on the dye color paste; S2, double-sided color printing is conducted on the all-cotton antibacterial double-sided cloth by using the productiondevice and the magnetized dye color paste obtained in the step S1, and then drying is conducted; and S3, steaming and color fixing are conducted on the treated all-cotton antibacterial double-sided fabric by using a prepared color fixing solution, and washing and shaping are conducted to obtain the all-cotton antibacterial double-sided printed and dyed fabric. The production device comprises a printing and dyeing bin, a drying bin, a color fixing bin and a washing bin. According to the double-sided printing and dyeing process and device, simultaneous double-sided printing and dyeing treatmentcan be conducted on the all-cotton antibacterial double-sided cloth, the printing and dyeing efficiency is effectively improved, the printing and dyeing effect can be effectively improved, and therefore the problems of printing and dyeing fading or insufficiency and the like can be avoided.

Owner:无锡迈克斯纺织品有限公司

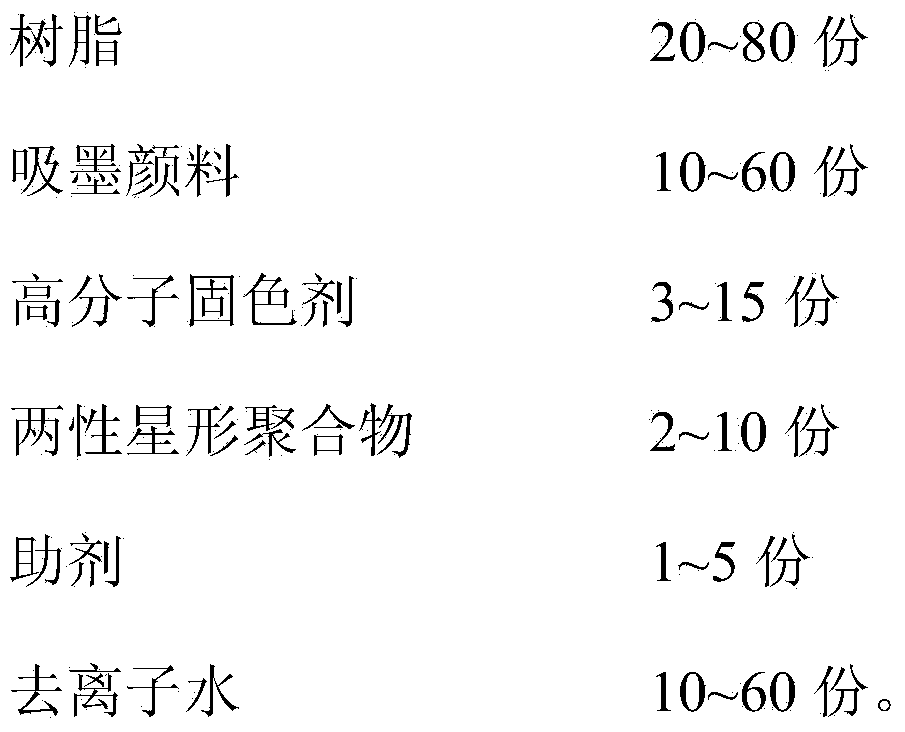

Prime coating liquid suitable for aqueous pigment ink printed non-absorptive printing medium, and preparation method and applications thereof

InactiveCN110804381AImprove color fixing abilityHigh resolutionPolyurea/polyurethane coatingsProtein coatingsDefoaming AgentsPrinting ink

The invention discloses a prime coating liquid suitable for an aqueous pigment ink-jet-printing ink printed non-absorptive printing medium. The prime coating liquid comprises following components in percentage by weight: 10 to 70% of a pigment adsorbent, 5 to 15% of a highly swelling polymer, 5 to 25% of cationic emulsion polymer, 2 to 15% of a color fixing agent, 0.05 to 1% of a base material wetting agent, 0.05 to 1% of an anti-foaming agent, 0.1 to 1% of a sterilizing agent, and the balance being deionized water. Moreover, the invention also discloses a preparation method of the prime coating liquid and a method of applying the prime coating liquid on a non-absorptive printing medium. The provided prime coating liquid is applied on a non-absorptive printing medium and can effectively improve the ink absorbing performance, color fixing performance and binding force of an aqueous pigment ink on a non-absorptive printing medium such as polyvinyl chloride.

Owner:HONGSAM DIGITAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com