Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improve color fastness to light" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional cotton fabric finishing agent and method for making same

The invention relates to a multifunctional cotton fabric finishing agent with anti-ultraviolet rays, improved fabric light fastness, antibacterial and wrinkle resistance and a preparation method thereof. The steps of the preparation method include: preparing a water phase; preparing an oil phase; preparing an emulsion; preparation. The invention solves the compatibility problem between functional components, the finishing agent has good stability, and there is a promotion effect between functional components, polycarboxylic acid, polycarboxylic acid and chitosan play the role of crosslinking agent, Improves the durability of various functions.

Owner:SOUTH CHINA UNIV OF TECH +1

Non-yellowing polyurethane memory cotton and preparation method thereof

ActiveCN110305289AImprove color fastness to lightGood resistance to phenol yellowingPolyolHigh activity

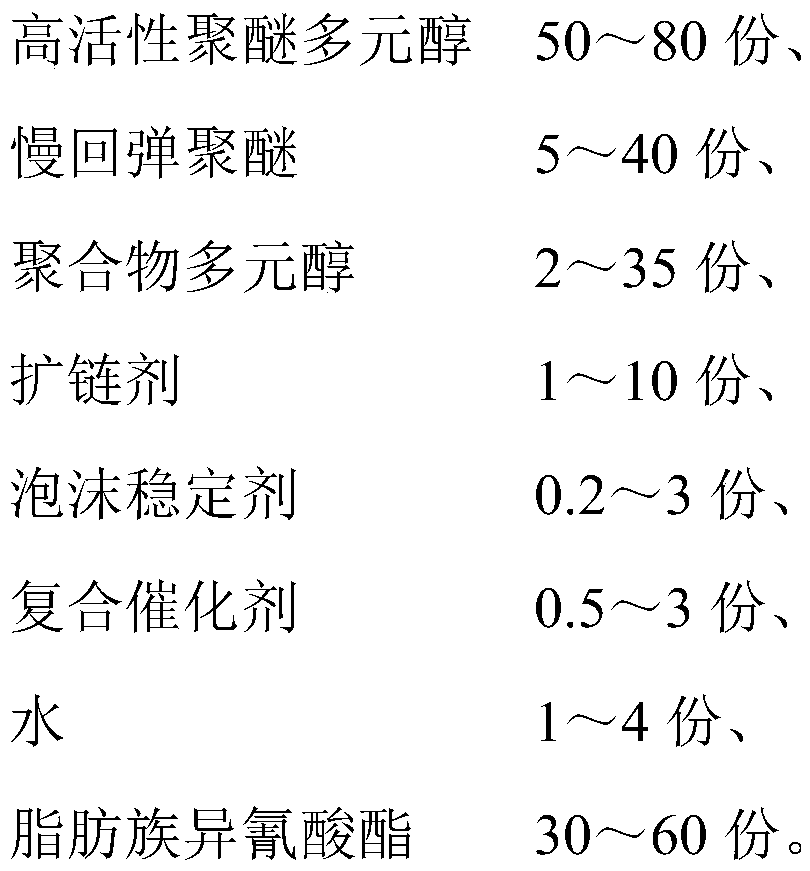

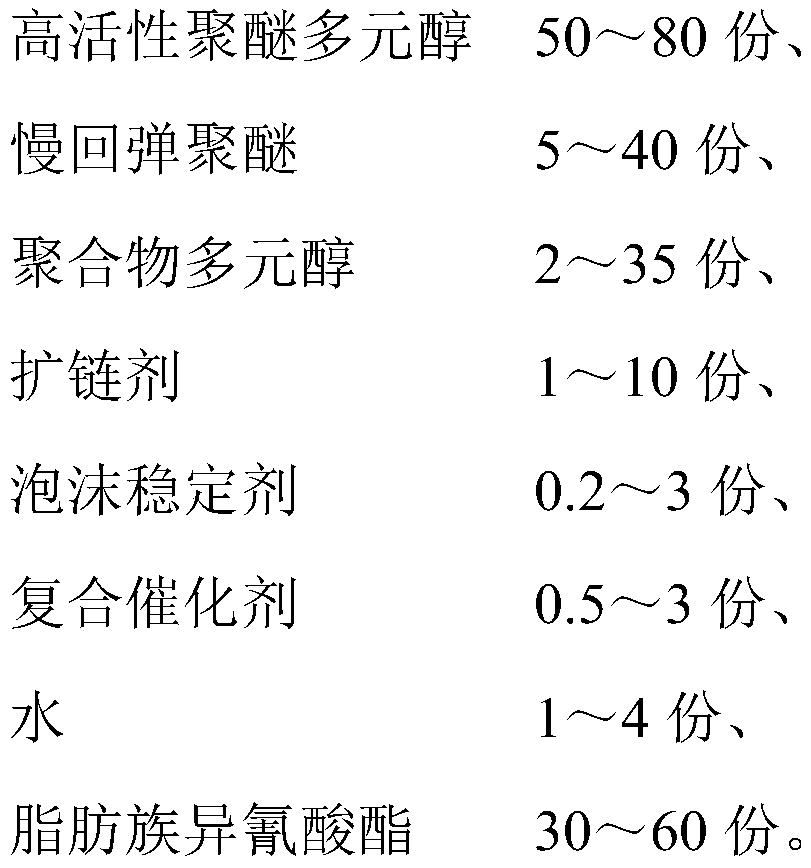

The invention discloses non-yellowing polyurethane memory cotton and a preparation method thereof. The non-yellowing polyurethane memory cotton is prepared from the following raw materials in parts byweight: 50-80 parts of high activity polyether polyols, 5-40 parts of slow rebound polyether, 2-35 parts of polymer polyols, 1-10 parts of chain extender, 0.2-3 parts of foam stabilizer, 0.5-3 partsof composite catalyst, 1-4 parts of water and 30-60 parts of aliphatic series isocyanate. The non-yellowing polyurethane memory cotton is composed of selected raw materials, the content of each raw material is optimized, the high activity polyether polyols, the slow rebound polyether, the polymer polyols, the chain extender, the foam stabilizer, the composite catalyst, the water and the aliphaticseries isocyanate are selected with proper proportions, respective advantages are given full play, mutual complementation and improvement are achieved, the quality stability of products is improved, the prepared non-yellowing polyurethane memory cotton is high in color fastness to light, good in phemol yellowing resistance, high in smoke resistance, long in slow rebound recovery time and low in falling sphere rebound rate.

Owner:FUJIAN GENEROUS SLEEP TECH CO LTD

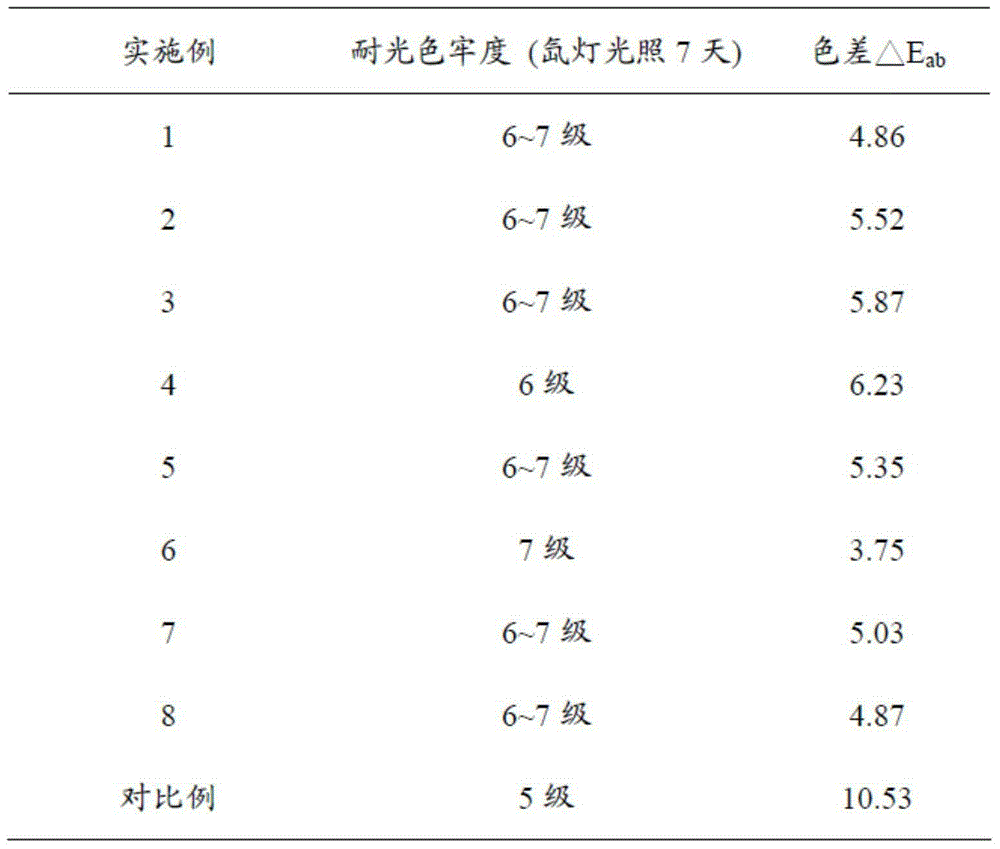

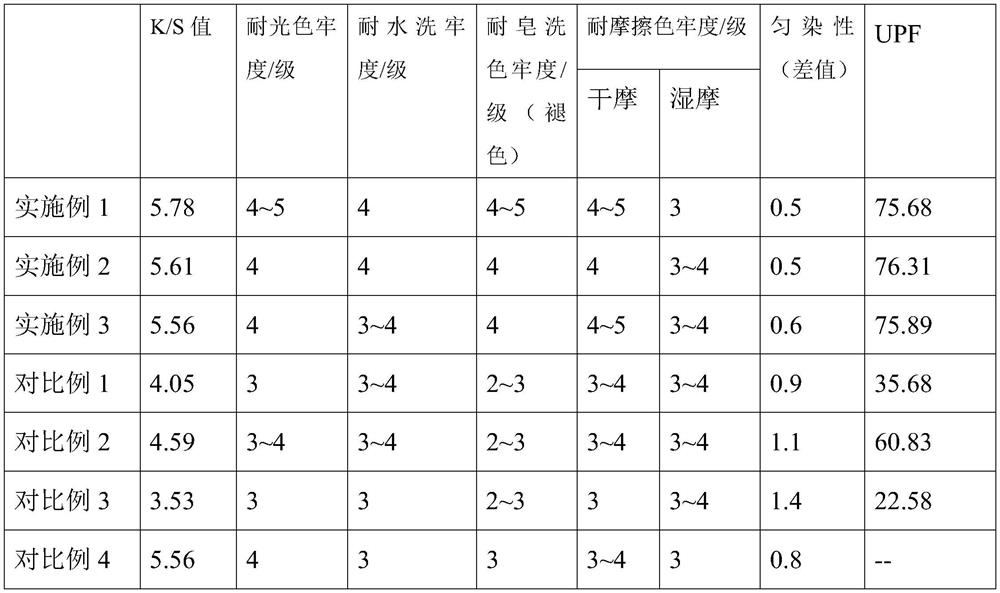

Dyeing method for improving color fastness to light of osier

InactiveCN107486908AImprove color fastness to lightEnhanced photooxidative stabilityRadiation/waves wood treatmentWood treatment detailsVolumetric Mass DensityBinding force

The invention belongs to the technical field of osier dyeing, in particular to a dyeing method for improving color fastness to light of osier. The method specifically comprises the following steps of (1) osier pretreatment and (2) osier dyeing. The permeation of a coloring agent is effectively improved, the degree of aggregation of dye molecules is higher, crosslinking binding between the dye molecules and the ingredients of osier is prompted, the binding force is high, leachability resistance is good, the electronic cloud density of azo group hydrogen atoms is reduced, the shielding effect on azo groups is achieved, the photooxidation resistance stability of the azo groups in the structure of the dye molecules is improved, and finally, the color fastness to light of a dye is improved; and furthermore, osier is evenly dyed and has good color fastness to water, the difference between the color of the interior and the color of the exterior of osier is small, osier is evenly dyed without stains, and is bright and glossy, and the quality of the wickerwork made of osier is effectively improved.

Owner:安徽阜南县万家和工艺品有限公司

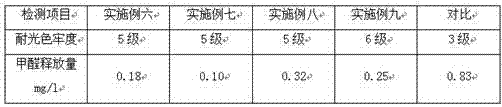

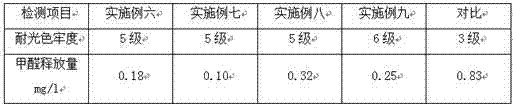

High-color-fastness environment-friendly ecological board and preparation method

ActiveCN105397873AImprove light resistanceReduce irradianceNon-macromolecular organic additionLaminationWood veneerAdhesive

The invention relates to a high-color-fastness environment-friendly ecological board and a preparation method, and belongs to the technical field of decorative materials. The high-color-fastness environment-friendly ecological board comprises a base board layer, buffer and balance layers and high-color-fastness facing layers. The level of the color fastness of the high-color-fastness facing layers reaches the fifth level or above. The upper surface and the lower surface of the base board layer are bonded to the buffer and balance layers through environment-friendly glue. The high-color-fastness facing layers are made of wood-grained paper soaked in melamine modified resin containing a light stabilizer. The high-color-fastness facing layers are bonded to the upper surfaces of the buffer and balance layers. The buffer and balance layers are made of poplar veneers or Eucalyptus veneers or technical wood veneers. The base board layer is made of multiply plywood or a core-board. A modified bio-based adhesive or a modified starch adhesive is used as the environment-friendly glue. A hindered amine compound is used as the light stabilizer. The high-color-fastness environment-friendly ecological board has the paint-free function and also has the performance of low formaldehyde emission and the high level of color fastness to light.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Large-scale production method of plant indigo dye for garment dyeing

ActiveCN110158329ASolve the problem that it cannot be applied on a large scale to modern garment dyeing machinesImprove color fastness to dry and wet rubbingDyeing processNitrogenEngineering

The invention relates to a large-scale production method of a plant indigo dye for garment dyeing. The plant indigo dye is used in the large-scale production method of garments, nitrogen is filled into a garment dyeing device to remove the air, or the garment dyeing device is vacuumed to form minus 0.05-minus 0.07MPa negative pressure, the garments are then dyed with the plant indigo dye in the garment dyeing device, the dyeing temperature is 26-70DEG C, and the dyeing time is 50-150 minutes. By the arrangement, the problem that the plant indigo dye cannot be applied to a modern garment dyeingmachine on a large scale can be solved, and dyeing times are greatly reduced from traditional 6-18 times repeated dyeing to 1-3 times; the dyeing temperature can be raised so as to improve dye-uptake, level-dyeing property and dye permeability, and the color fastness of dry and wet friction and light resistance of the plant indigo dye are improved.

Owner:苏州麻朵纺织科技有限公司

Fluorochrome monomer, copolymeric fluorescent polyurethane emulsion and fluorescent polyurethane-acrylic ester copolymer emulsion as well as preparation methods thereof

InactiveCN105601567ALittle impact on mechanical propertiesLow toxicityOrganic chemistryNaphthalimide/phthalimide dyesEmulsionFluorescence

The invention relates to a fluorochrome monomer, copolymeric fluorescent polyurethane emulsion and copolymeric fluorescent polyurethane-acrylic ester copolymer emulsion as well as preparation methods thereof. The dihydroxy-containing fluorochrome monomer is firstly synthesized, the dihydroxy-containing fluorochrome monomer is used as a chain extender and applied to a chain extension reaction of an aqueous polyurethane prepolymer, and after phase inversion, the copolymeric fluorescent polyurethane emulsion is prepared. In addition, the copolymeric fluorescent polyurethane emulsion and an alkene monomer are used for preparing the copolymeric fluorescent polyurethane-acrylic ester copolymer emulsion by emulsion grafting and copolymerization. A fluorescent chromophore group in the polymer emulsion is used as a side group and is bonded to a molecular chain; the polymer emulsion can be used as aqueous film forming resin, and widely applied to the fields of aqueous fluorescent paint, aqueous fluorescent ink, traffic sign, false proof mark, special clothes, leather, etc.

Owner:JIANGSU LIWENJIA CHEM +1

Printing method for improving color fastness to light of natural dye cotinus coggygria pigment

ActiveCN112252055AImprove color fastness to lightGood water solubilityUltrasonic/sonic fibre treatmentBiochemical treatment with enzymes/microorganismsTextile printerAmmonia nitrogen

The invention discloses a printing process for improving color fastness to light of natural dye cotinus coggygria pigment, and belongs to the technical field of plant dyeing. The preparation method comprises the following steps: firstly preparing a cotinus coggygria pigment dye mixed solution from cotinus coggygria pigment, nanometer titanium dioxide sol and dopamine hydrochloride, and preparing original printing paste with stable viscosity in cotinus coggygria pigment dye; then preparing color paste from the cotinus coggygria pigment dye mixed solution, the original paste and a color fixing agent (color fixing agent DS1315 and polyglutamic acid are mixed according to the mass ratio of 5:1) to dye real silk fabric. The indexes such as water-resistant color fastness, rubbing-resistant colorfastness, light-resistant color fastness and leveling property of the real silk fabric can be obviously improved. A metal ion mordant and a urea color fixing agent are not used, so that the emissionof ammonia-nitrogen wastewater is remarkably reduced, and environmental protection is facilitated.

Owner:GAOMI ZHONGHE GARMENT

Anti-ultraviolet PET colour master batches

InactiveCN106366581AImprove color fastness to lightMonocomponent polyesters artificial filamentArtifical filament manufactureColour fastnessPolyester

The invention relates to anti-ultraviolet PET colour master batches. The anti-ultraviolet PET colour master batches are prepared from the raw materials in parts by mass: 43 to 55 parts of polyethylene glycol terephthalate, 2 to 5 parts of a pigment, 3 to 6 parts of a dispersing agent, 1 to 3 parts of an antioxidant and 3 to 5 parts of nano-zinc oxide surface grafted powder. The anti-ultraviolet PET colour master batches provided by the invention are mainly used for colouring before spinning; polyester can be coloured; the colour fastness to light of existing polyester yarns can also be improved from grade 5 to grade 8.

Owner:绍兴协力新材料科技有限公司

High-weather-resisting type green recombined decorative veneer and preparation method thereof

PendingCN108045037AImprove wear resistance and weather resistanceReduce formaldehyde emissionWood treatment detailsMacromolecular adhesive additivesFormaldehyde freeEngineering

The invention relates to a high-weather-resisting type green recombined decorative veneer and a preparation method thereof. The high-weather-resisting type green recombined decorative veneer is prepared from a transparent abrasion-resisting adhesive film paper layer, a high-color-fastness recombined decorative veneer layer and a flexible enhanced material layer in sequence from top to bottom. Thepreparation method comprises the following steps: (1) manufacturing the high-color-fastness recombined decorative veneer layer: taking a rotatably-cut or sliced veneer as a main raw material; processing through procedures of dyeing by a high-color-fastness dyestuff, carrying out bionic assembling, coating an environment-friendly toughening adhesive, gluing and curing, so as to obtain a recombineddecorative limber batten; (2) coating one face of a flexible enhanced material with an environment-friendly formaldehyde-free adhesive and then compounding the flexible enhanced material on the back surface of the high-color-fastness recombined decorative veneer layer prepared by step (1), and carrying out hot pressing; (3) manufacturing the transparent abrasion-resisting adhesive film paper layer; (4) compounding the transparent abrasion-resisting adhesive film paper layer prepared by step (3) on the surface of the compound veneer prepared by step (2) and conveying the compound veneer into ahot pressing machine; carrying out hot pressing to obtain the high-weather-resisting type green recombined decorative veneer.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

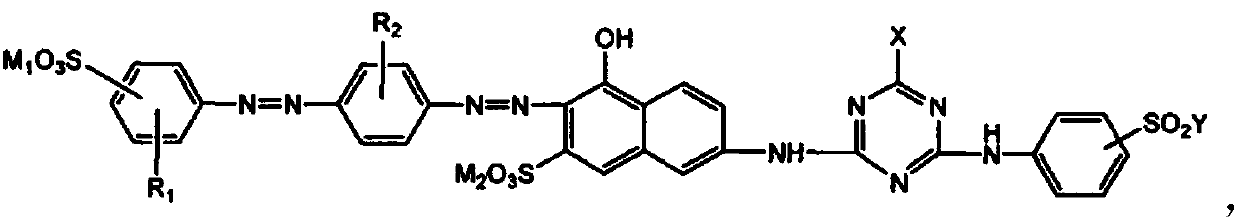

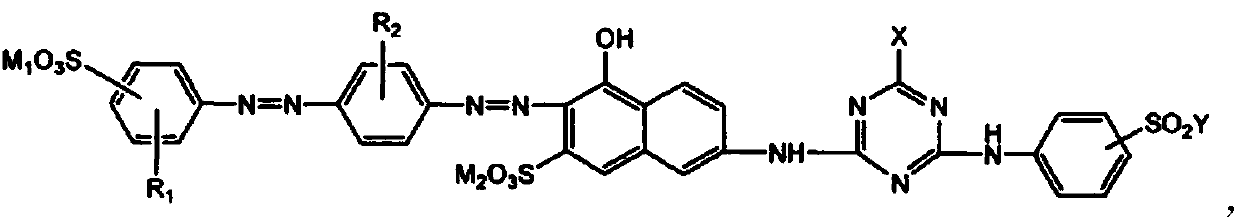

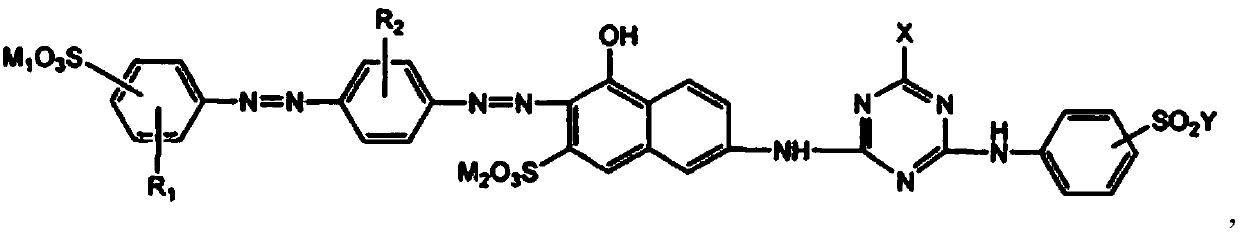

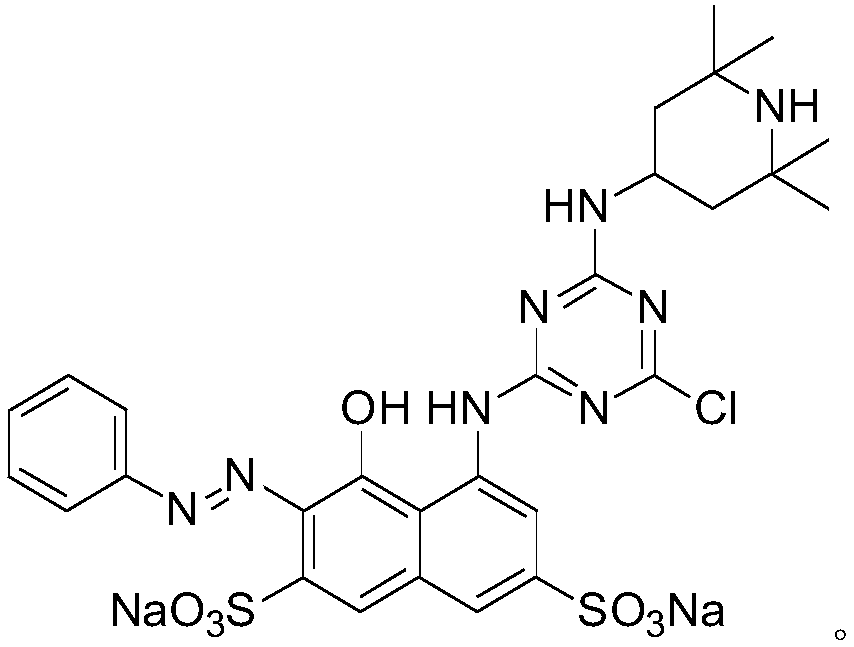

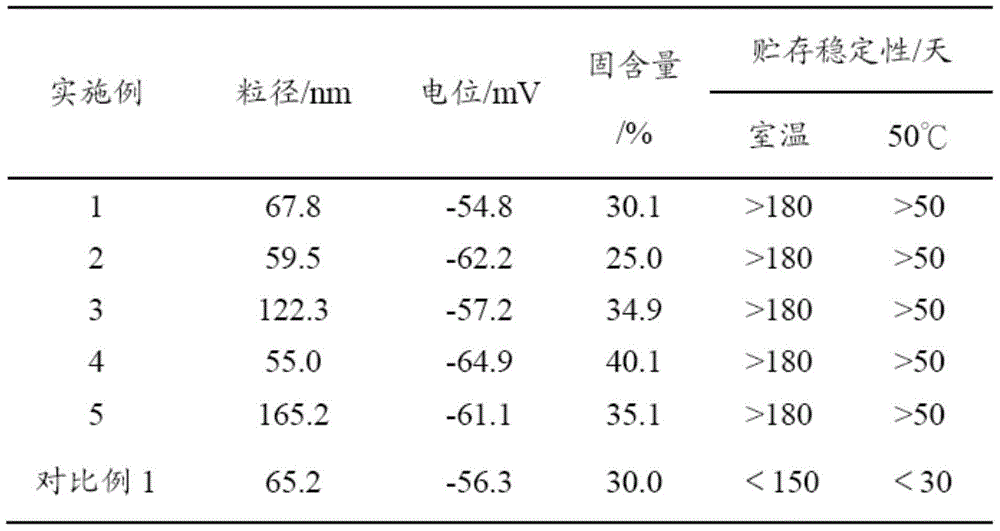

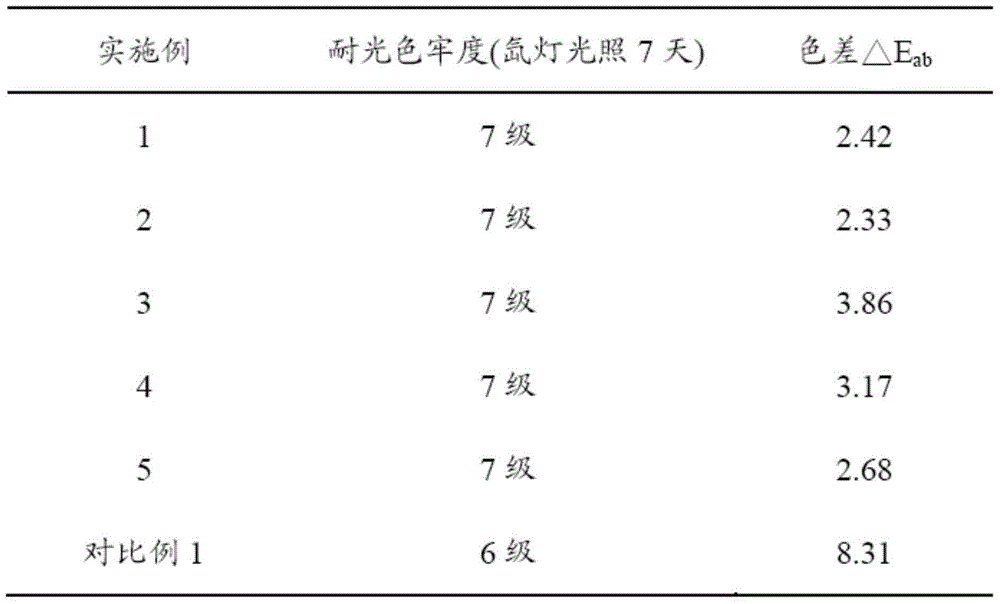

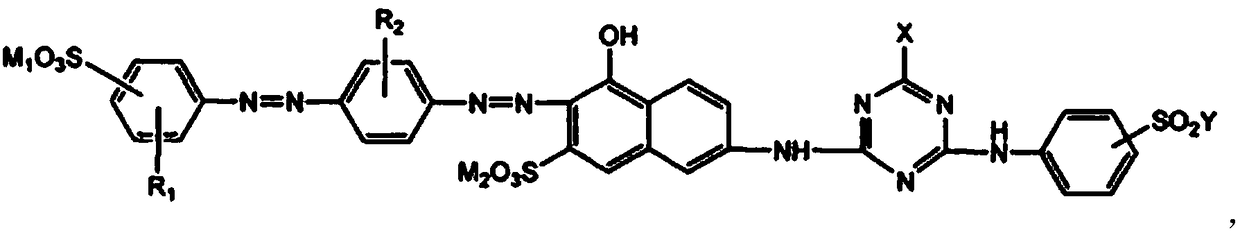

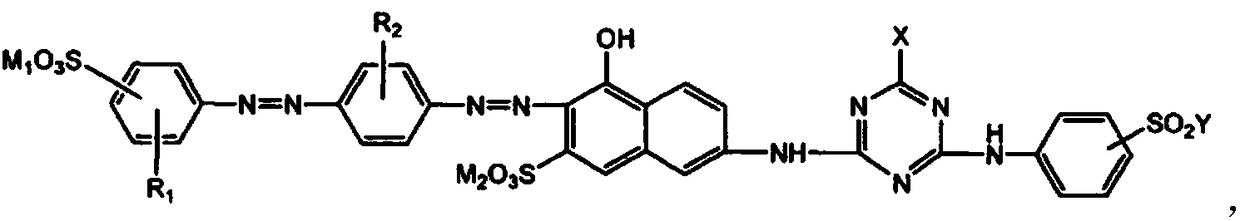

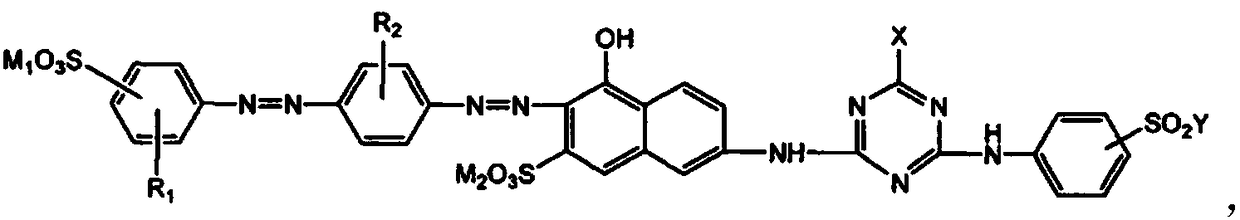

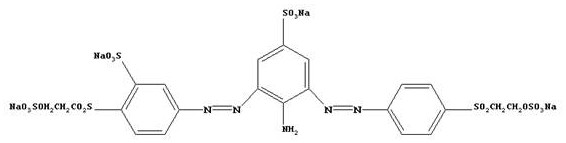

Red sunproof K-type active dye and preparation method thereof

ActiveCN108912735AImprove color fastness to lightImprove light resistanceReactive dyesFiberHindered amine light stabilizers

The invention discloses red sunproof active dye. The structural formula of the red sunproof active dye is shown in the description, wherein X is O or NH, Y is H or CH3, Z is H or SO3Na. Meanwhile, theinvention also discloses a preparation method of the red sunproof active dye. The preparation method comprises the following steps: adding hindered amine solution into active-dye aqueous solution, then adding potassium carbonate as an acid-binding agent, and reacting at a temperature of 40-50 DEG C; regulating pH of the obtained reaction liquid to be 1+ / -0.1 to generate precipitates; after filtering, carrying out acid pickling and drying on filter cakes and obtaining the red sunproof active dye. By adoption of the red sunproof active dye obtained by the invention, not only can the own light-resistant color fastness of the dye be improved, but also the light-resistant property of the dyed fiber can be improved.

Owner:浙江理工大学上虞工业技术研究院有限公司 +2

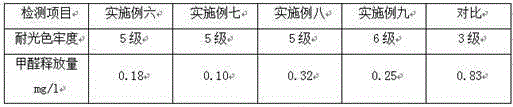

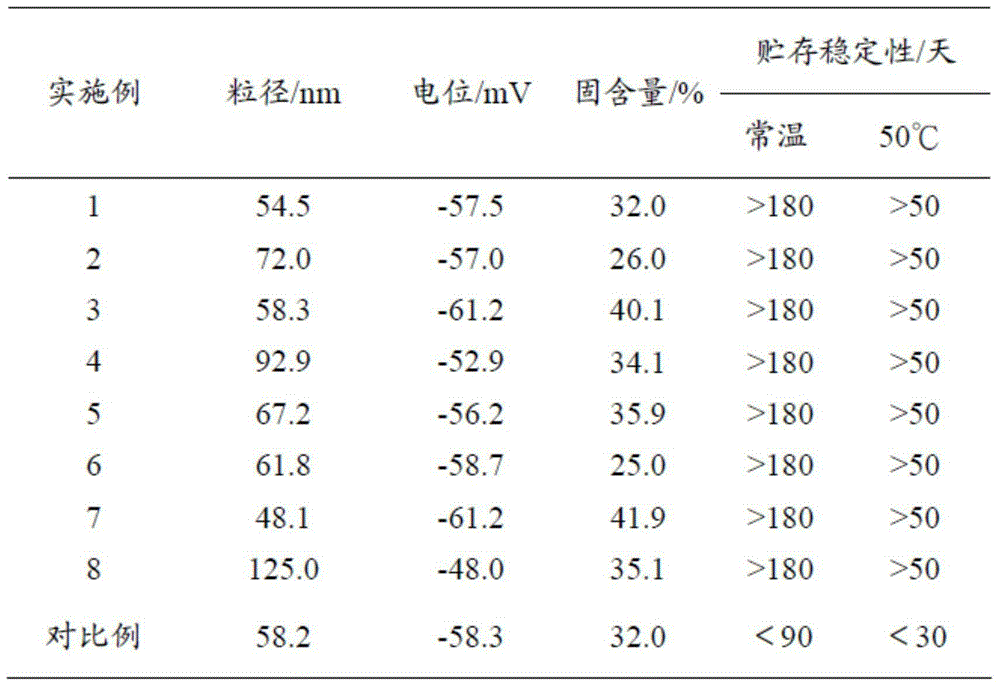

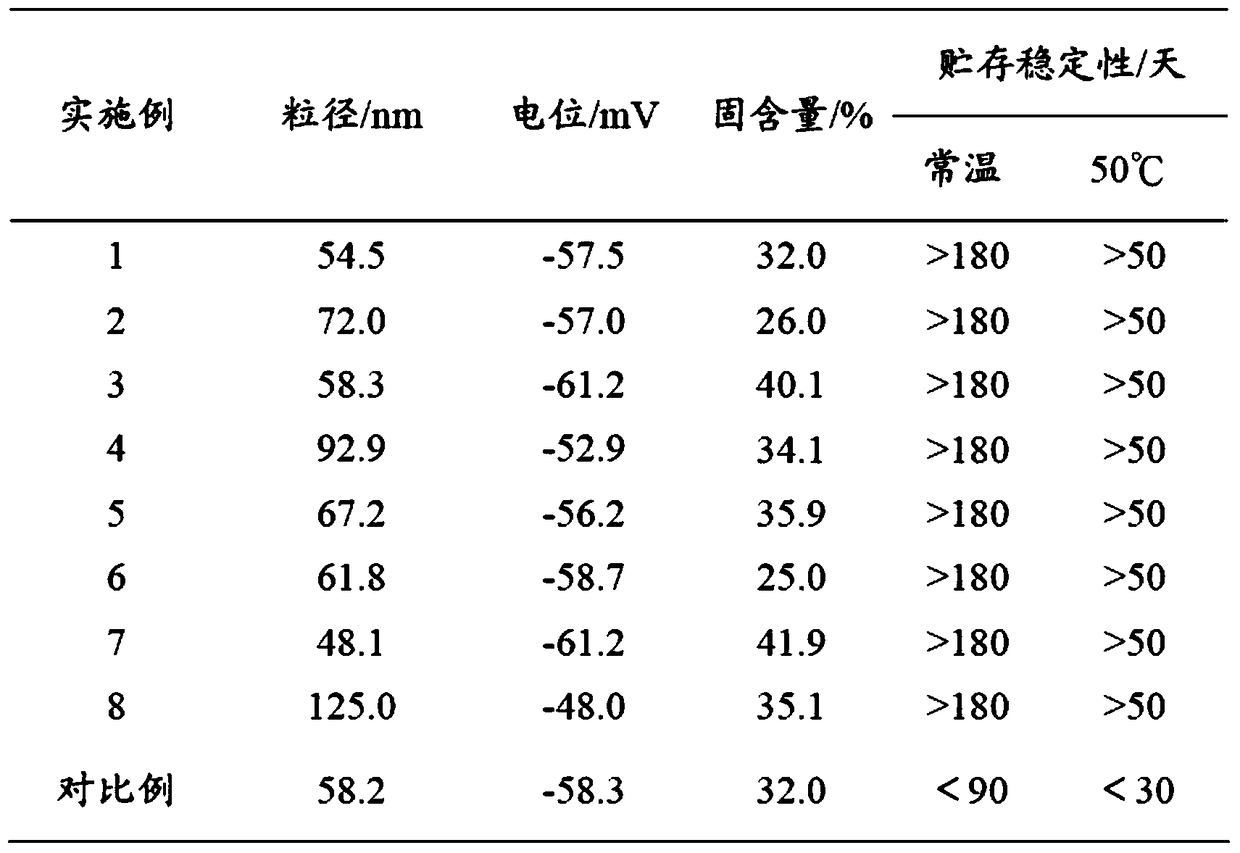

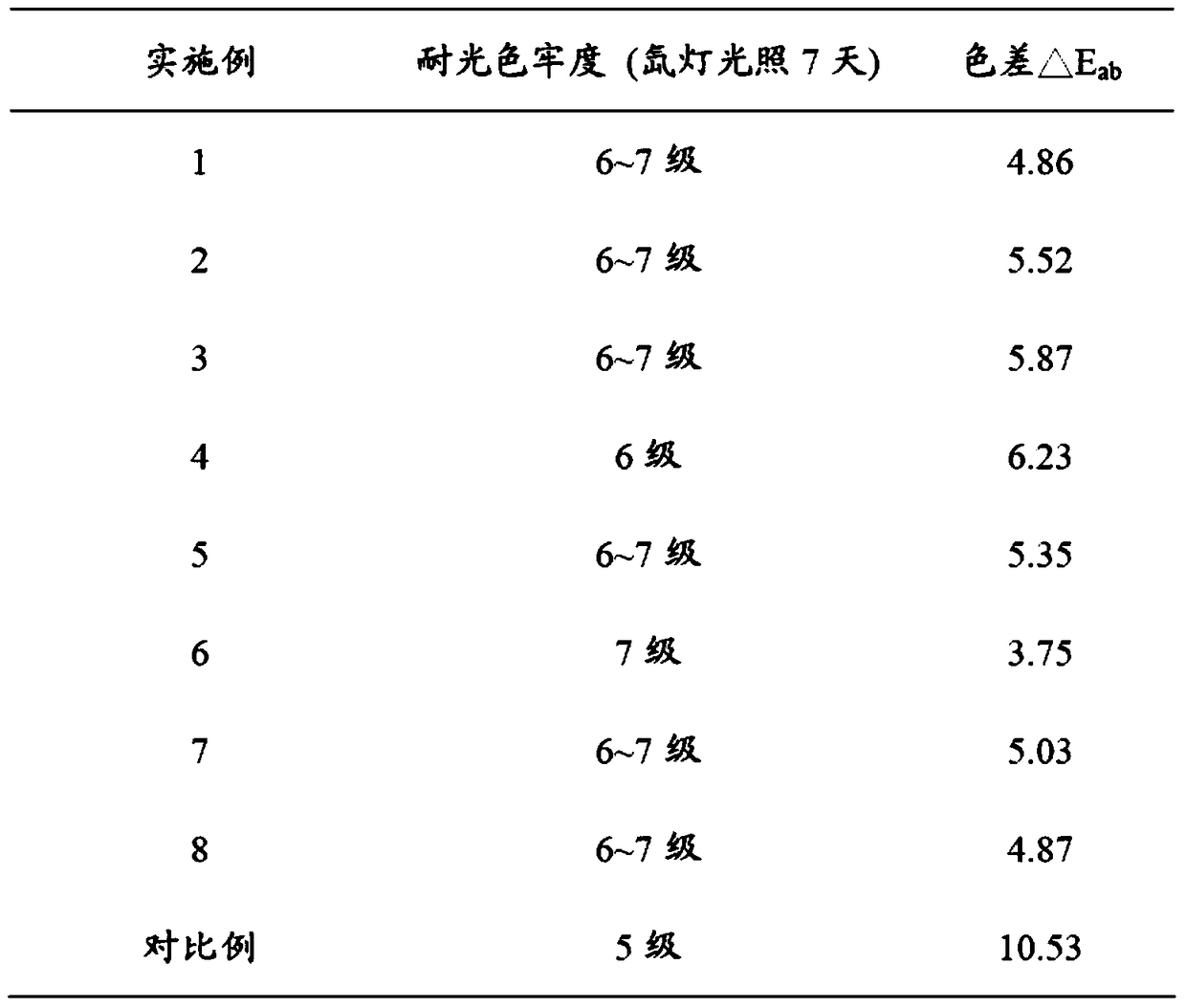

Color chain extender, co-polymerized color polyurethane emulsion, color polyurethane-acrylate copolymer emulsion, and preparation method thereof

The invention relates to a color chain extender, a co-polymerized color polyurethane emulsion, a color polyurethane-acrylate copolymer emulsion, and a preparation method thereof. The method includes the steps of: 1) preparing the color chain extenders having the three base colors: red, yellow blue, through polymerizable modification of dye molecules; 2) performing a chain extension reaction of polyurethane with the color chain extenders as a component in a chain extender, and performing a subsequent phase-reversal emulsification process to prepare the co-polymerized color polyurethane emulsion; and 3) performing grafted emulsion copolymerization to a copolymerization-type color polyurethane prepolymer and a vinyl monomer to prepare the co-polymerized color polyurethane-acrylate copolymer emulsion. Because a chromophoric group is bonded to the molecular chain of the polymer as a side group, so that the copolymer emulsion can be directly used for producing a color aqueous polymer product without addition of a dye or a pigment. The copolymer emulsion can be widely used in the fields of aqueous coatings, paints and ink as an aqueous film-forming resin.

Owner:TSINGHUA UNIV

Ternary compound dye and method for preparing high-color-fastness veneer layer by adopting dye

PendingCN108162112AHigh application valueGood health effectsElectric wood treatmentWood treatment detailsHindered amine light stabilizersBiomass

The invention relates to ternary compound dye and a method for preparing a high-color-fastness veneer layer by adopting the dye. The ternary compound dye is formed by a biomass nanofiber solubilizer,a hindered amine light stabilizer and acid bisazo dye according to the mass ratio of 1:(15-30):(100-300) in a compound manner. The method for preparing the high-color-fastness reconstituted decorativeveneer layer is characterized by comprising the following steps that a rotary-cut or sliced veneer is adopted as a main raw material, a reconstituted decorative material batten is processed through the procedures of dyeing, simulation assembly, environment-friendly toughening glue smearing, gluing and maintenance of the ternary compound dye, and then the batten is manufactured into a reconstituted decorative veneer with the thickness ranging from 0.15 mm to 1.0 mm through slicing. The compound dye has a good sterilization and antibacterial effect, the service life is prolonged, meanwhile, thedye has pleasant fragrances, and the dye is green and environment-friendly.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

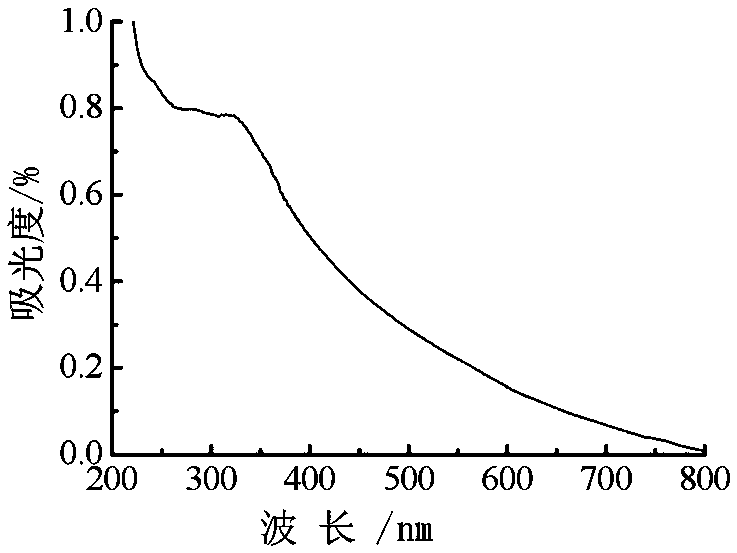

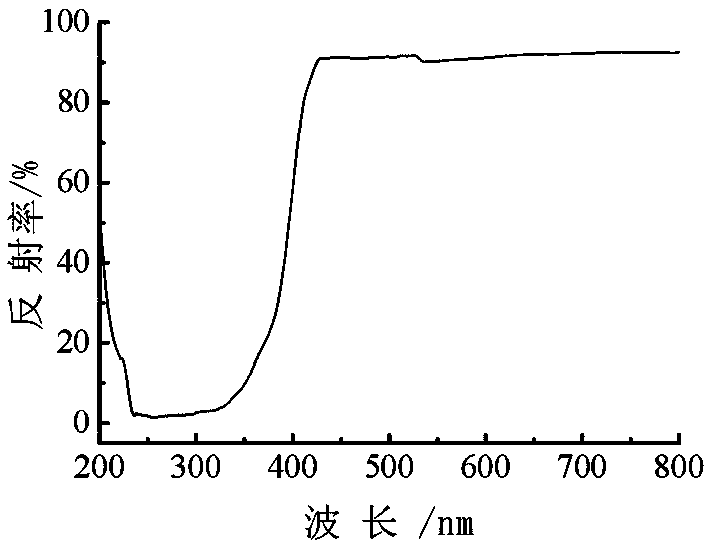

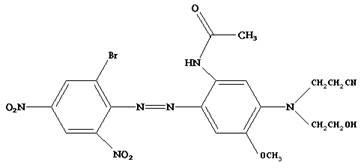

Protein material capable of absorbing ultraviolet ray and preparation method thereof

InactiveCN102408572AEmission reductionImproves UV resistanceVegetal fibresAnimal fibresOrtho-nitroanilineProtein molecules

The invention discloses a protein material capable of absorbing ultraviolet ray and a preparation method thereof. According to the invention, an arylamine compound containing an ortho-nitroaniline structure is subjected to diazotization and then to a coupling reaction with the ortho-position hydroxyl groups of side groups of p-hydroxybenzmethylene in tyrosine residue in protein molecules and produces a structure containing an azo bond with macro-molecular side groups of proteins, and an ortho-hydroxyphenyl-benzotriazole structure is produced through loop closure between the azo bond and ortho-nitro group of an aromatic ring after further treatment with a reducing agent. The ortho-hydroxyphenyl-benzotriazole structure connected with macro-molecular chain of protein has the capability of absorbing ultraviolet ray, which enables a prepared protein material to have the capability of ultraviolet resistance and effectively enhances the functions of ultraviolet resistance and aging resistance of the protein material.

Owner:ZHEJIANG SCI-TECH UNIV

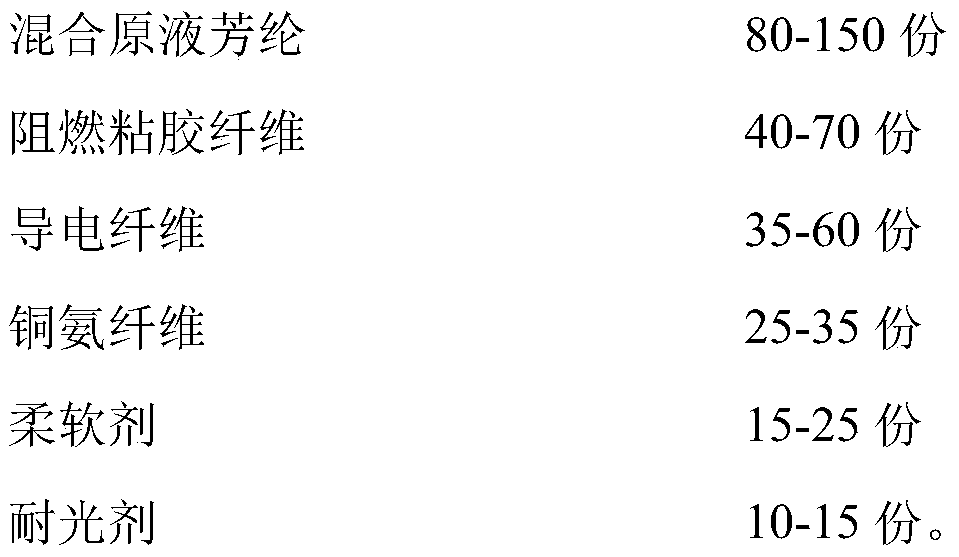

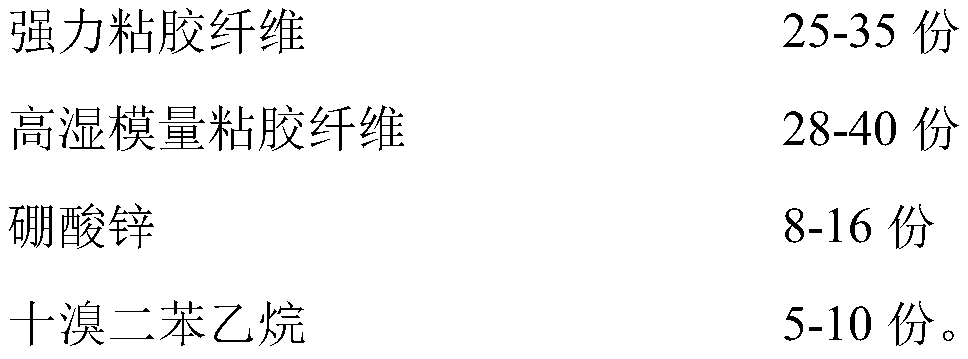

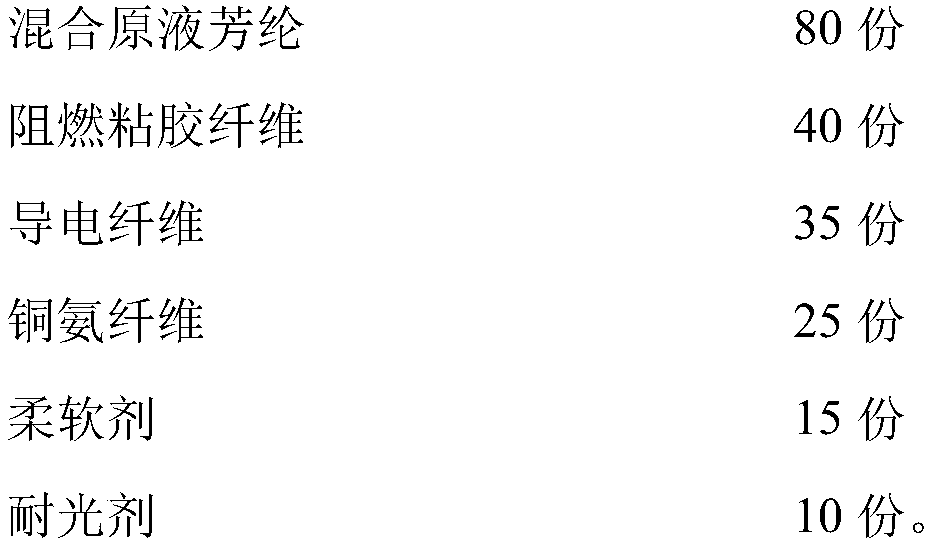

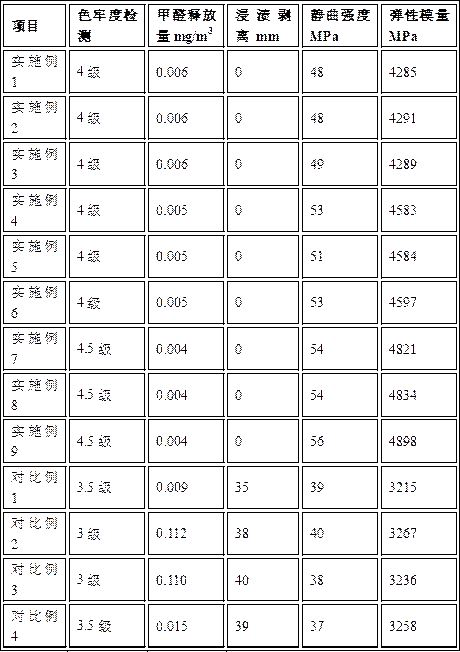

A kind of high soft flame retardant fabric

ActiveCN110004554BNatural and permanent flame retardantGood flexibilityArtificial filaments from viscoseYarnPolymer scienceZinc borate

The invention discloses a high-softness flame-retardant fabric. The high-softness flame-retardant fabric is prepared from, by weight, mixed solution aramid, flame-retardant viscose fibers, conductivefibers, copper ammonia fibers, a softening agent and a light-resistant agent. The mixed solution aramid is made from para-aramid and meta-aramid in a mass ratio of 1:(18-20) by blending. A flame-retardant viscose fiber preparation method includes steps: S1, subjecting strong viscose pulp and high-wet-modulus viscose pulp to mixed pulp feeding, impregnating, pressing, crushing, aging, yellowing andgrinding sequentially to obtain a mixed viscose fiber precursor; S2, adding zinc borate and decabromodiphenyl ethane into a ball mill, and performing mixed grinding for 1-2h until uniform dispersoidpowder is obtained; S3, subjecting the mixed viscose fiber precursor to post-dissolving, mixing, filtering, defoaming, filtering and short fiber spinning to obtain mixed viscose fibers, wherein addingtheh dispersoid powder in the step of post-dissolving according to the corresponding parts by weight to obtain flame-retardant viscose fibers. The fabric is comfortable, soft and efficient and durable in flame retardation.

Owner:杭州澳品纺织有限公司

Efficient application method of isatis root plant dye in loose fiber dyeing

InactiveCN110804882AImprove color fastness to lightEffective protectionDyeing processFiberMelting tank

The invention discloses an efficient application method of isatis root plant dye in loose fiber dyeing, which comprises the steps of 1, preparing nitrogen; 2, mounting a stainless steel valve above working liquid level, and a check valve at the top; 3, dyeing loose fiber plants for the first time, and filtering to obtain residual dye liquor after dyeing; 4, adding the residual dye liquor; 5, introducing the nitrogen through the stainless steel valve; 6, carrying out continuous vat dyeing on the loose fiber plants, filtering to obtain residual dye liquor, and then carrying out oxidation fixation on the loose fiber plants needing color fixation; and 7, adding the residual dye liquor in the step 6 into an empty loose fiber dyeing machine or an empty melting tank or an empty storage tank or anempty dyeing auxiliary vat, and returning to the step 5. According to the invention, the light fastness of the blue plant dye is improved, the blue plant dye can be applied to large-scale industrialproduction to replace part of chemical dyes for dyeing, so that the plant dye is greatly saved, water is saved, the environment is protected, and the isatis root plant dye can be efficiently used.

Owner:杭州彩润科技有限公司

Dyeing method of lyocell fibers

InactiveCN111379040AImprove color fastness to lightImprove stabilityMonocomponent cellulose artificial filamentDye addition to spinning solutionCelluloseFiber

The invention relates to a dyeing method of lyocell fibers. According to the dyeing method of the lyocell fibers, vegetable dye is directly added into a spinning solution of the lyocell fibers, so that the purposes of environmental protection and dyeing avoiding are achieved; and the light color fastness of the vegetable dye is improved by utilizing the natural light shielding effect and excited state electron quenching effect of graphene. Meanwhile, lanthanum nitrate or cerium nitrate and the like are used as sources of rare earth ions, and the action of the grapheme is used in cooperation, so that the vegetable dye is firmly combined to the edge of an amorphous region and even a crystallization region to form firm multi-element combination with cellulose molecules, and the color fastnessand the stability of the natural dye are improved. The method has an obvious effect on improving colored light and performance, saves the dyeing process, and is energy-saving and environment-friendly.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Energy-saving decorative plate and preparation method thereof

ActiveCN113787790AImprove stabilitySmooth connectionCovering/liningsLamination ancillary operationsPolymer sciencePolyvinyl chloride

The invention relates to the field of wood processing, in particular to an energy-saving decorative plate and a preparation method thereof, and the prepared decorative plate is energy-saving, environment-friendly and high in color fastness to light. The decorative plate comprises a decorative surface layer and a base plate layer arranged below the decorative surface layer, the base plate layer is a high-color-fastness-to-light veneer layer, the thickness of the decorative surface layer is 1.2-1.5 mm, and the decorative surface layer comprises a PVC surface layer; and the PVC surface layer contains polyvinyl chloride resin powder and calcium carbonate powder. The preparation method of the energy-saving decorative plate comprises the following steps: preparing the decorative surface layer: firstly preparing the PVC surface layer, and then sequentially pressing and pasting the color film layer and the transparent surface layer on the PVC surface layer to obtain the decorative surface layer; preparing a substrate layer; and allowing the decorative surface layer and the base plate layer to be subjected to hot pressing, and then coating the transparent skin layer with UV light-resistant paint.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Method for improving fluorescence dye color fastness of brocade/spandex blended fabrics

ActiveCN105421098AImprove washing resistanceImprove color fastness to rubbingFibre typesUltrasonic/sonic fibre treatmentFluorescenceVacuum chamber

The invention relates to a method for improving the fluorescence dye color fastness of brocade / spandex blended fabrics, and belongs to the technical field of fabric printing and dyeing. The method for improving the fluorescence dye color fastness of brocade / spandex blended fabrics comprises the following steps: preprocessing the brocade / spandex blended fabrics by using mixed plasma including O2 and NH3 in a vacuum chamber; carrying out fluorescence dyeing treatment on the preprocessed brocade / spandex blended fabrics; and post-processing the fluorescence dyed brocade / spandex blended fabrics. The fluorescence dyeing method can substantially improve the dyeing effect of disperse fluorescence dyes in brocade, spandex and brocade / spandex blended fabrics, allows the dyes to be closely combined with the fabrics, and can substantially improve the water washability, the color fastness to rubbing and the color fastness to light of the brocade / spandex blended fabrics.

Owner:海盐县于城丝绸印染股份有限公司

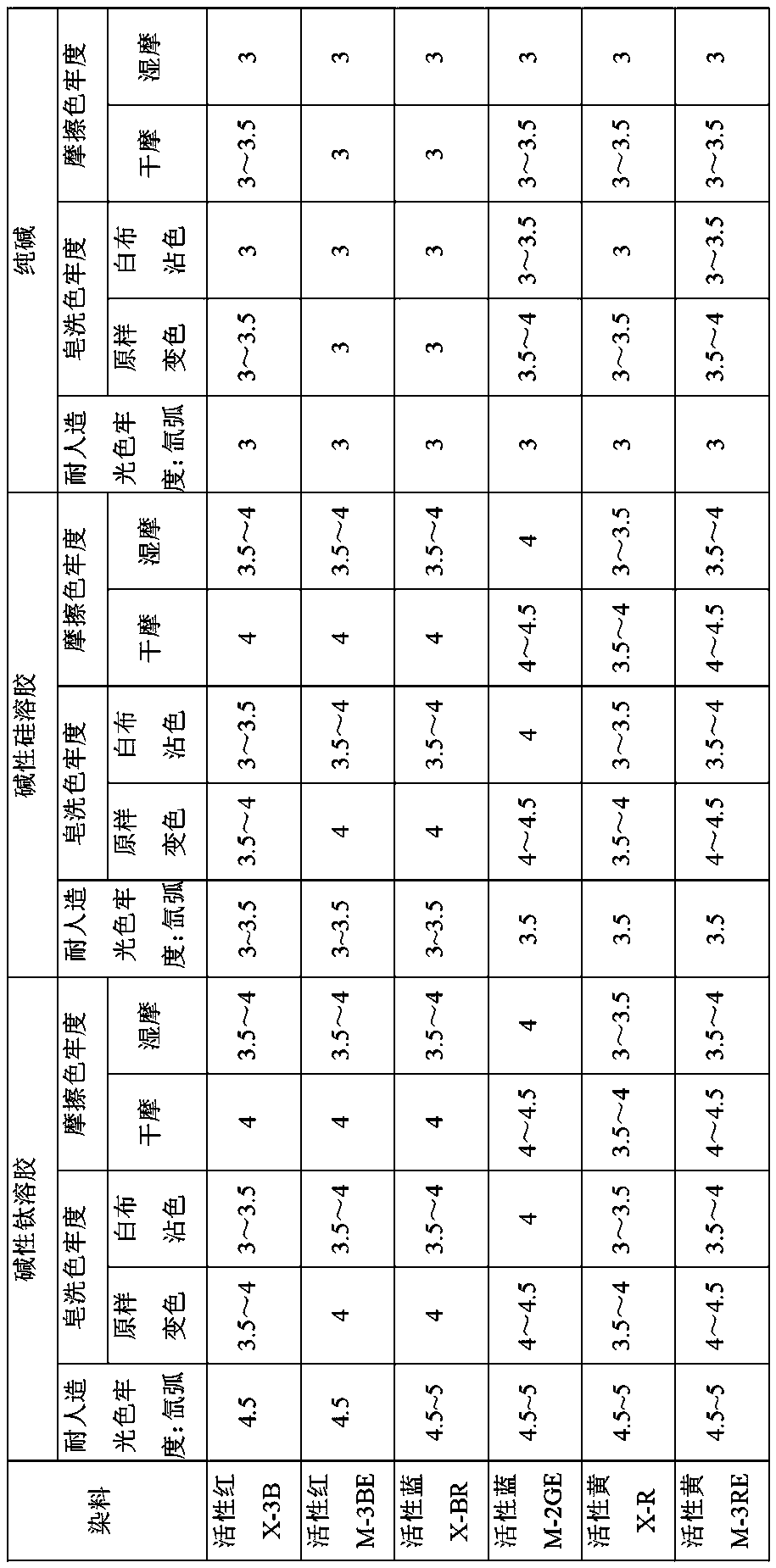

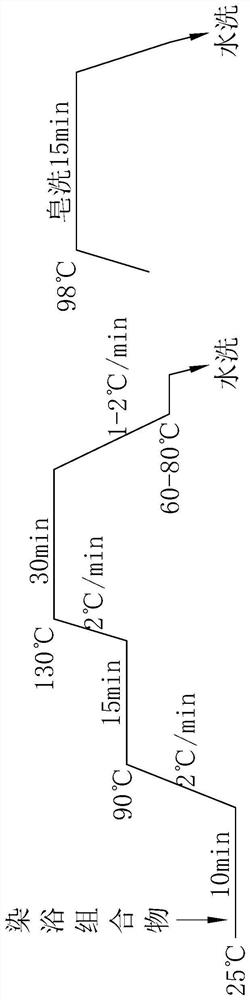

Basic titanium sol dye-fixing agent as well as preparation method and application thereof

The invention provides a basic titanium sol dye-fixing agent. The basic titanium sol dye-fixing agent is prepared through sol-gel reaction on butyl titanate, water, alcohol, a catalyst and a silane coupling agent serving as raw materials according to a molar ratio of (1 to 3) to (8 to 16) to (18 to 25) to (2.0 to 3.5) to (0.001 to 0.01). The invention also provides a preparation method of the basic titanium sol dye-fixing agent. The basic titanium sol dye-fixing agent and the preparation method of the basic titanium sol dye-fixing agent disclosed by the invention have the advantages that the colour fastness to light of woods can be obviously improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Pure-cotton double-layer jacquard home textile dyeing and finishing method

InactiveCN108130754ASimple production processIncrease lifting powerDyeing processTextile dyeingSulfone

The invention discloses a pure-cotton double-layer jacquard home textile dyeing and finishing method, and belongs to the technical field of pure-cotton fabric dyeing. The method is characterized by comprising the following preparation steps: with a dyeing liquid formula, namely an active dye with two active groups of ethylene sulfuryl and hydroxyl ethylene sulfone sulfate in a main liquid, putting20-50% in percentage by mass of a dye liquid into a dyeing tank, and performing dyeing once; adding the rest dyeing liquid, and performing dyeing once again; adding sodium sulfate, and performing dyeing once; adding alkali powder, and performing dyeing once; adding a soaping agent SN-45, increasing the temperature, and performing dyeing for three times; washing with cold water, adding a neutralization acid, and performing dyeing for three times; performing acid pickling, and discharging a fabric roll. The inventor improves a cotton double-layer jacquard fabric dyeing process, and together with the selected active dye with two active groups of ethylene sulfuryl and hydroxyl ethylene sulfone sulfate in the main liquid, factors such as the soaping fastness, the lifting power of the dye, thedyeing velocity and the curve of the dye, the matching property of the dye, and the like are improved.

Owner:ZIBO DARANFANG SILK GRP

Black dye composition as well as application and dyeing method thereof

PendingCN114149694AObvious synergistic effectImprove dyeing effectOrganic dyesDyeing processPolyesterPolymer science

The invention relates to the field of textile dyes, and particularly discloses a black dye composition as well as application and a dyeing method thereof. The black dye composition comprises one or more compounds represented by a general formula (I), one or more compounds represented by a general formula (II), one or more compounds represented by a general formula (III), one or more compounds represented by a general formula (IV) and one or more compounds represented by a general formula (V). General formula (I); general formula (II); general formula (III); general formula (IV); general formula (V); the black dye composition is applied to polyester-cotton blended fabric dyeing. The black dye composition disclosed by the invention has good dyeing performance and various color fastness, and can be used for simultaneously dyeing polyester and cotton under a one-bath process, so that the dyeing process is simplified, and the dyeing efficiency is improved.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Multifunctional cotton fabric finishing agent and method for making same

The invention relates to a multifunctional cotton fabric finishing agent with anti-ultraviolet rays, improved fabric light fastness, antibacterial and wrinkle resistance and a preparation method thereof. The steps of the preparation method include: preparing a water phase; preparing an oil phase; preparing an emulsion; preparation. The invention solves the compatibility problem between functional components, the finishing agent has good stability, and there is a promotion effect between functional components, polycarboxylic acid, polycarboxylic acid and chitosan play the role of crosslinking agent, Improves the durability of various functions.

Owner:SOUTH CHINA UNIV OF TECH +1

High-temperature-resistant flame-retardant electrostatic flocking fabric and preparation method thereof

InactiveCN109281191AGood flame retardant effectImprove flocking fastnessLiquid surface applicatorsCoatingsFinenessPolyimide

The invention provides a high-temperature-resistant flame-retardant fiber electrostatic flocking fabric and a preparation method thereof, wherein the flocking fabric comprises a fluff layer, an adhesive layer and a base cloth layer; the fluff layer adopts one or more of aramid fiber 1313, polyimide, polyphenylene sulfide, polysulfonamide, polyacrylonitrile or viscose pre-oxidized yarns, polyether-ether-ketone, poly (p-phenylene benzobisoxazole), basalt fiber, ceramic fiber and glass fiber as fluff fiber, and the length of the fluff is 0.5-3 mm, and the fineness is 0.8-50 D. The flocking fabrichas remarkable flame-retardant properties: the flame-retardant effect is good, the permanent flame-retardant effect is achieved, and the flame-retardant grade can reach A-grade flame retardancy according to GB / T5455.

Owner:山东领潮新材料有限公司 +2

A kind of preparation method of environmental protection ecological board

ActiveCN105291540BImprove light resistanceReduce irradianceLaminationLamination apparatusSingle plateEnvironmental engineering

The present invention involves a preparation method of an environmentally friendly ecological board, which is a technical field of decorative materials.It includes the following steps: (1) Divide the blocked amine light stabilizer in the melamine modified resin, and then the first impregnation treatment, the first drying, the second impregnation treatment, the second immersion treatment, the second immersion treatment,The second drying system is high -colored, the fairy decoration layer; the scattered process of the light stabilizer includes: ① 100 parts of melamine modified resin according to the quality portion, 5 to 20 copies of the light stabilizer; ② in the melamine modified resinAdd an optical stabilizer while mixing; (2) compose the high -color target surface layer and the buffer balance layer of the single board for heat pressure;The formation of the plate is composed of the upper and lower surfaces of the substrate layer of the environmentally friendly plastic.The invention decorative board has the performance of low formaldehyde release and high level of light resistance.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Fluorescent dye monomer, fluorescent copolymer emulsion and preparation method thereof

InactiveCN105601567BLittle impact on mechanical propertiesLow toxicityOrganic chemistryNaphthalimide/phthalimide dyesEmulsionFluorescence

The invention relates to a fluorochrome monomer, copolymeric fluorescent polyurethane emulsion and copolymeric fluorescent polyurethane-acrylic ester copolymer emulsion as well as preparation methods thereof. The dihydroxy-containing fluorochrome monomer is firstly synthesized, the dihydroxy-containing fluorochrome monomer is used as a chain extender and applied to a chain extension reaction of an aqueous polyurethane prepolymer, and after phase inversion, the copolymeric fluorescent polyurethane emulsion is prepared. In addition, the copolymeric fluorescent polyurethane emulsion and an alkene monomer are used for preparing the copolymeric fluorescent polyurethane-acrylic ester copolymer emulsion by emulsion grafting and copolymerization. A fluorescent chromophore group in the polymer emulsion is used as a side group and is bonded to a molecular chain; the polymer emulsion can be used as aqueous film forming resin, and widely applied to the fields of aqueous fluorescent paint, aqueous fluorescent ink, traffic sign, false proof mark, special clothes, leather, etc.

Owner:JIANGSU LIWENJIA CHEM +1

A kind of cowboy anti-oxidative yellowing finishing agent and its manufacturing process

ActiveCN104532590BObvious anti-oxidative yellowing effectImprove durabilityFibre treatmentFatty alcoholPOLYOXYETHYLENE ETHER

The invention relates to a denim anti-oxidant yellowing finishing agent and a preparation process thereof. The denim anti-oxidant yellowing finishing agent is prepared by mixing a component A and a component B in a weight ratio of 1 to 1, wherein the component A comprises the following components in percentage by weight: 10%-15% of alcohol amine, 8%-12% of dodecyl dimethyl amine ethyl lactone, 5%-10% of fatty alcohol-polyoxyethylene ether, 10%-30% of distilled water, 10%-20% of benzotriazole and the balance of water; the component B comprises the following components in percentage by weight: 8%-10% of fatty acid amide, 50%-60% of distilled water, 1%-3% of glacial acetic acid, 1%-2% of a calcium chloride solution, 15%-30% of a polyamine compound and the balance of water. Compared with the prior art, the denim anti-oxidant yellowing finishing agent has the advantages of being lasting in yellowing resistance, and the like.

Owner:FIBER CHEM BIOLOGICAL CHEM

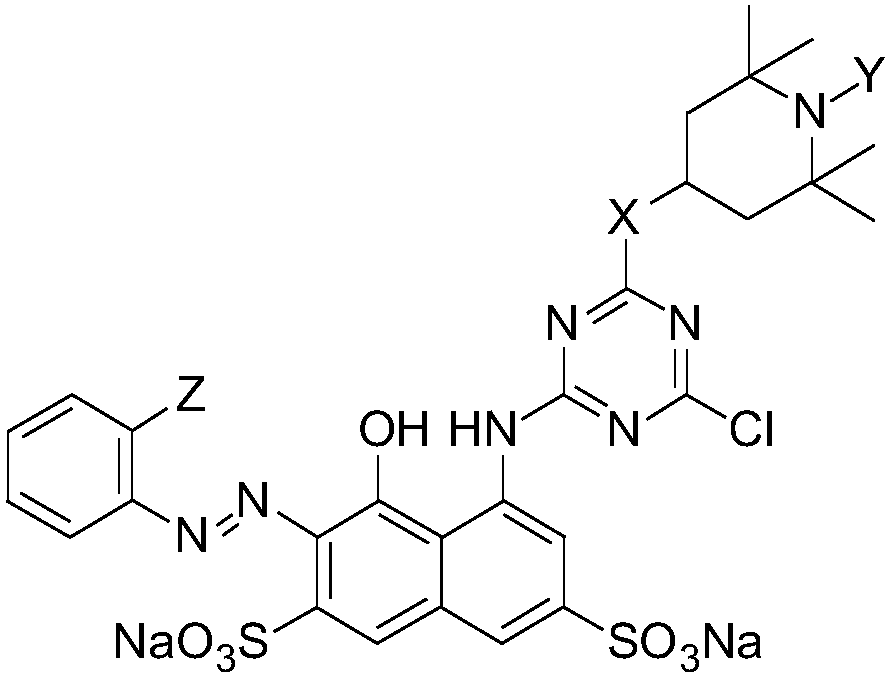

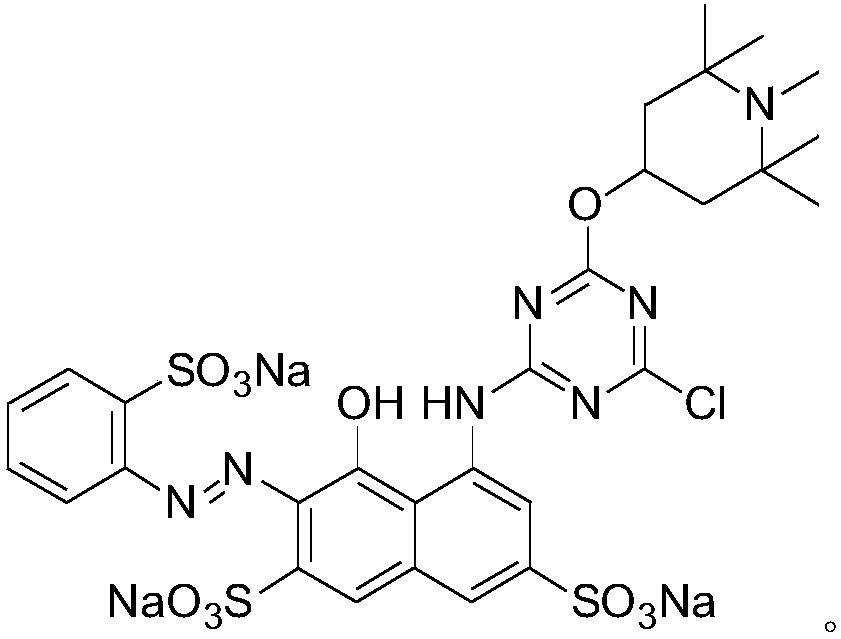

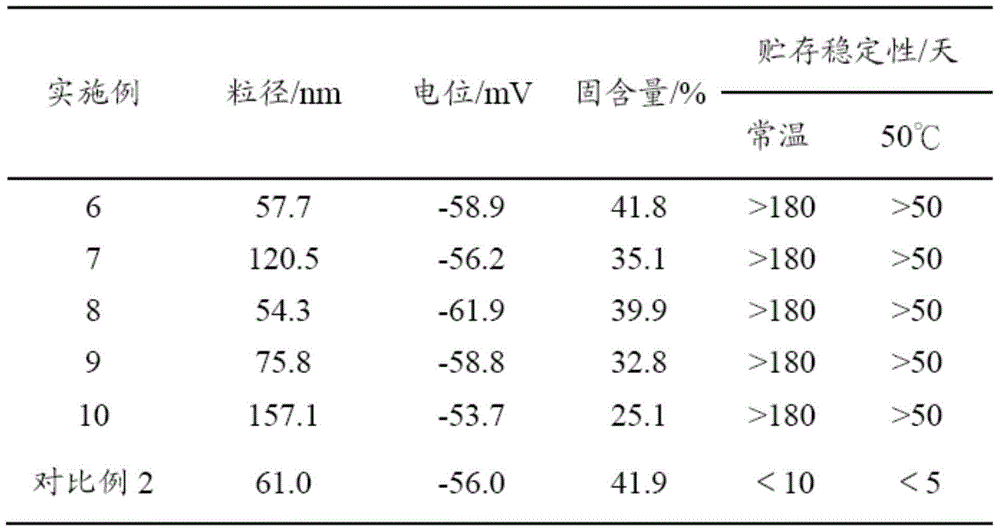

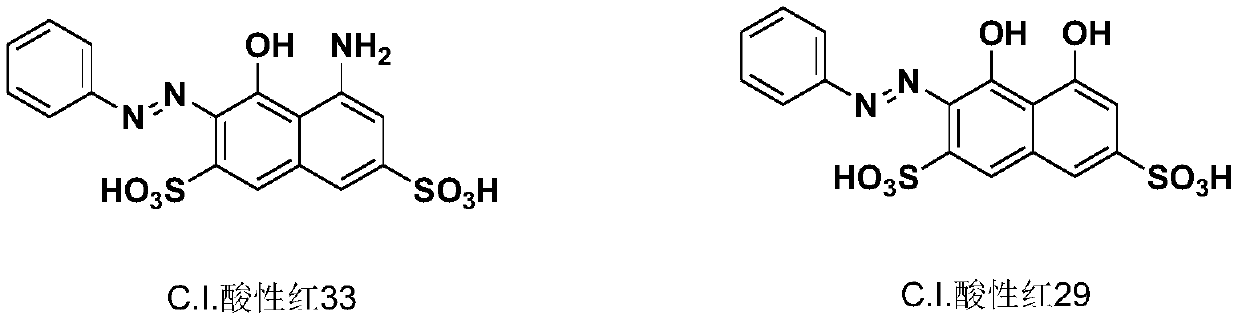

A kind of red sunfast acid dye and preparation method thereof

ActiveCN109439016BAvoid applicability problems for compound useImprove light resistanceMonoazo dyesDyeing processAcid dyeLightfastness

The invention discloses red sun-proof acidic dyestuff. The structural formula of the red sun-proof acidic dyestuff is as shown in specification, and X is NH or O. The invention further discloses a preparation method of the dyestuff. The dyestuff not only has excellent light resistance, but also has light stabilizing effect on dyed fibers, and has good application prospect.

Owner:浙江金塔克斯科技有限公司

Protein material capable of absorbing ultraviolet ray and preparation method thereof

InactiveCN102408572BEmission reductionImproves UV resistanceOrganic chemistryVegetal fibresOrtho-nitroanilineProtein molecules

The invention discloses a protein material capable of absorbing ultraviolet ray and a preparation method thereof. According to the invention, an arylamine compound containing an ortho-nitroaniline structure is subjected to diazotization and then to a coupling reaction with the ortho-position hydroxyl groups of side groups of p-hydroxybenzmethylene in tyrosine residue in protein molecules and produces a structure containing an azo bond with macro-molecular side groups of proteins, and an ortho-hydroxyphenyl-benzotriazole structure is produced through loop closure between the azo bond and ortho-nitro group of an aromatic ring after further treatment with a reducing agent. The ortho-hydroxyphenyl-benzotriazole structure connected with macro-molecular chain of protein has the capability of absorbing ultraviolet ray, which enables a prepared protein material to have the capability of ultraviolet resistance and effectively enhances the functions of ultraviolet resistance and aging resistance of the protein material.

Owner:ZHEJIANG SCI-TECH UNIV

A kind of high color fastness environmental protection ecological board and preparation method

ActiveCN105397873BImprove light resistanceReduce irradianceNon-macromolecular organic additionLaminationEnvironmental resistanceWood veneer

The invention relates to a high-color-fastness environment-friendly ecological board and a preparation method, and belongs to the technical field of decorative materials. The high-color-fastness environment-friendly ecological board comprises a base board layer, buffer and balance layers and high-color-fastness facing layers. The level of the color fastness of the high-color-fastness facing layers reaches the fifth level or above. The upper surface and the lower surface of the base board layer are bonded to the buffer and balance layers through environment-friendly glue. The high-color-fastness facing layers are made of wood-grained paper soaked in melamine modified resin containing a light stabilizer. The high-color-fastness facing layers are bonded to the upper surfaces of the buffer and balance layers. The buffer and balance layers are made of poplar veneers or Eucalyptus veneers or technical wood veneers. The base board layer is made of multiply plywood or a core-board. A modified bio-based adhesive or a modified starch adhesive is used as the environment-friendly glue. A hindered amine compound is used as the light stabilizer. The high-color-fastness environment-friendly ecological board has the paint-free function and also has the performance of low formaldehyde emission and the high level of color fastness to light.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Method for Improving the Color Fastness of Fluorescent Dye of Nylon/Ammonia Blended Fabric

ActiveCN105421098BImprove washing resistanceImprove color fastness to rubbingFibre typesUltrasonic/sonic fibre treatmentFluorescenceAmmonia

The invention relates to a method for improving the fluorescence dye color fastness of brocade / spandex blended fabrics, and belongs to the technical field of fabric printing and dyeing. The method for improving the fluorescence dye color fastness of brocade / spandex blended fabrics comprises the following steps: preprocessing the brocade / spandex blended fabrics by using mixed plasma including O2 and NH3 in a vacuum chamber; carrying out fluorescence dyeing treatment on the preprocessed brocade / spandex blended fabrics; and post-processing the fluorescence dyed brocade / spandex blended fabrics. The fluorescence dyeing method can substantially improve the dyeing effect of disperse fluorescence dyes in brocade, spandex and brocade / spandex blended fabrics, allows the dyes to be closely combined with the fabrics, and can substantially improve the water washability, the color fastness to rubbing and the color fastness to light of the brocade / spandex blended fabrics.

Owner:海盐县于城丝绸印染股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com