Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

244 results about "Indigo dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indigo dye is an organic compound with a distinctive blue color (see indigo). Historically, indigo was a natural dye extracted from the leaves of certain plants, and this process was important economically because blue dyes were once rare. A large percentage of indigo dye produced today, several thousand tonnes each year, is synthetic. It is the blue often associated with denim cloth and blue jeans.

Stripping agent of indigo dyed pure cotton jean and stripping method thereof

ActiveCN102747622AGood peeling effectPromote environmental protectionDyeing processPolyethylene glycolALLYL SUCROSE

The invention discloses a stripping agent of indigo dyed pure cotton jean and a stripping method of the stripping agent, belonging to the technical field of jean stripping, wherein the stripping agent comprises following components by weight: 5-10% of a penetrating agent, 20-25% of a dispersant and the balance of water; the penetrating agent is an anionic surfactant; and the dispersant is any one of polyethylene glycol, polyether nonionic surfactant, polyvinylpyrrolidone, polyvinyl alcohol and polyacrylic acid. The stripping agent and the stripping method disclosed by the invention have good stripping effect and excellent environment protection performance, and are suitable for large-scale promotion in industrial application.

Owner:SHAOXING UNIVERSITY

Reducing agent for dyeing reduced dyes

The invention discloses a reducing agent for dyeing reduced dyes, belonging to the technical field of printing and dyeing technologies for textiles. The reducing agent consists of the following raw materials in percentage by mass: 5-10 percent of thiourea dioxide, 5-30 percent of sodium hydrosulfite 10-40 percent of reducing sugar type substances and 20-50 percent of salt. The reducing agent disclosed by the invention can effectively replace the sodium hydrosulfite to be used for dyeing of the reducer dyes and indigo dyes, the reduced dye leuco is long in existence time and slight in environment pollution, and the price of the dye leuco is superior to that of the sodium hydrosulfite. Moreover, the thiourea dioxide contained in the reducing agent for dyeing reduced dyes disclosed by the invention can be completely biodegraded, is high in reducing capacity, can effectively reduce the dyes into leuco, does not have a pungent smell and belongs to an environment-friendly substance; the reducing sugars refers to substances existing in the nature and have a certain reducing property, and the overall reducing capacity can be maintained and last for a long time; and moreover, according to salt substances, the stability of the components of the whole reducing agent can be enhanced.

Owner:濮阳圣恺环保新材料科技股份有限公司

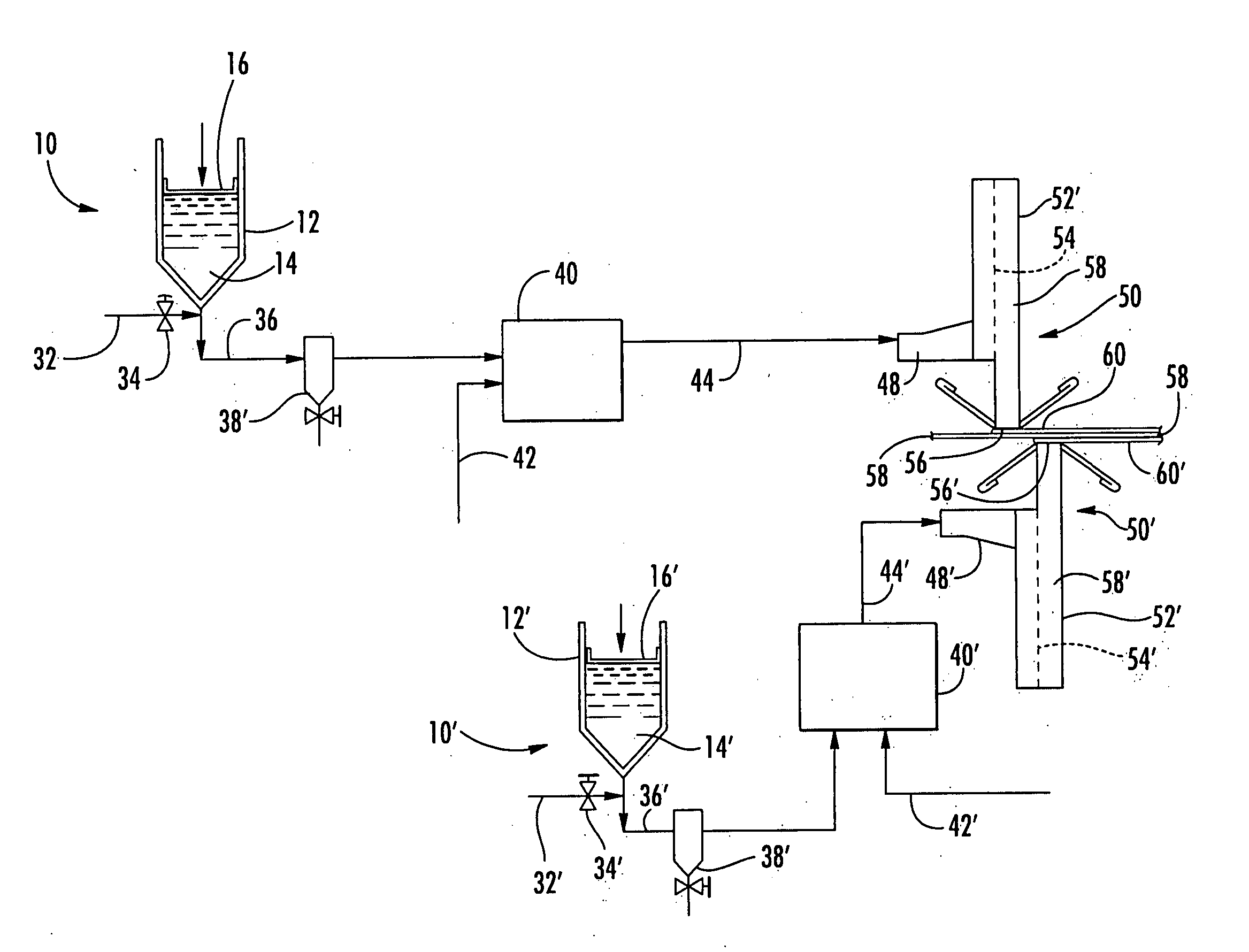

Method and apparatus for dyeing cellulosic textile substrates with an inert leuco state dye and dyed product

InactiveUS20050241078A1Textile treatment using short bath ratio liquorBleaching apparatusOxygenIndigo dye

Dyeing a cellulosic textile substrate with reduced indigo dye in a leuco state after foaming with an inert gas to maintain the dye isolated from oxidizing substances. Following application of the foam to the substrate, it is exposed to the adjacent atmosphere, with the oxygen in the atmosphere oxidizing the reduced indigo dye to regenerate it and cause it to affix to the textile substrate. A product can be produced using the method and apparatus of the present invention that has different dye characteristics on opposite surfaces of the substrate by applying the indigo dye foam to one surface and another dye, either an indigo dye or some other dye to the opposite surface.

Owner:GASTON SYST INC

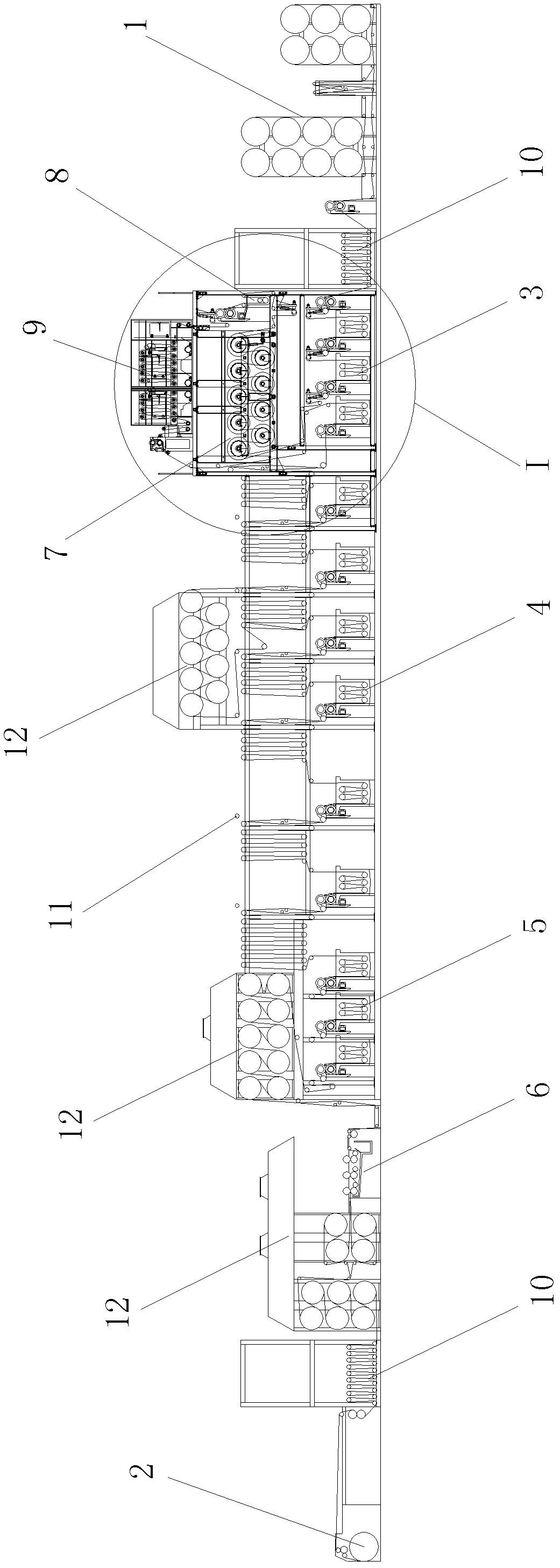

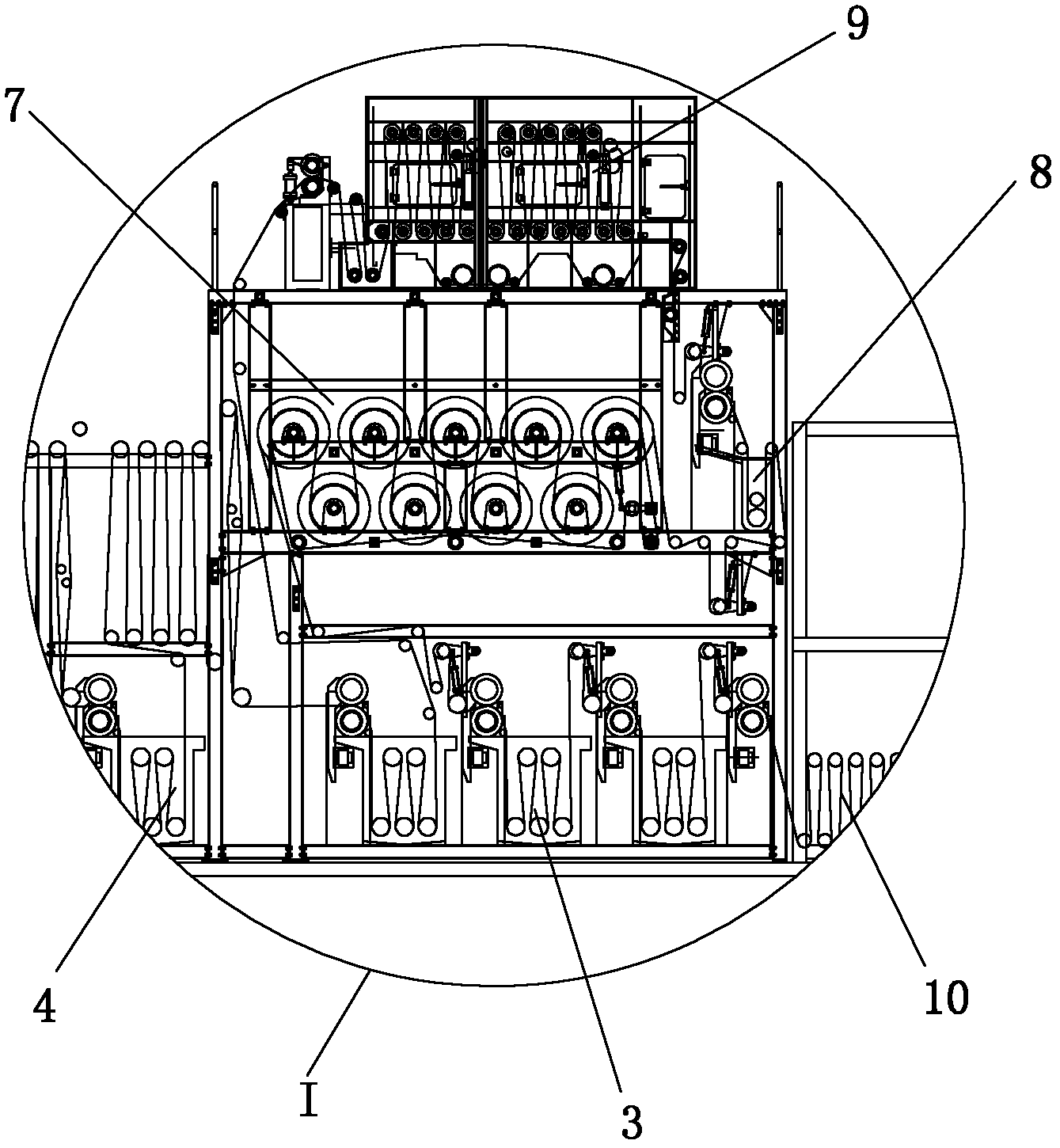

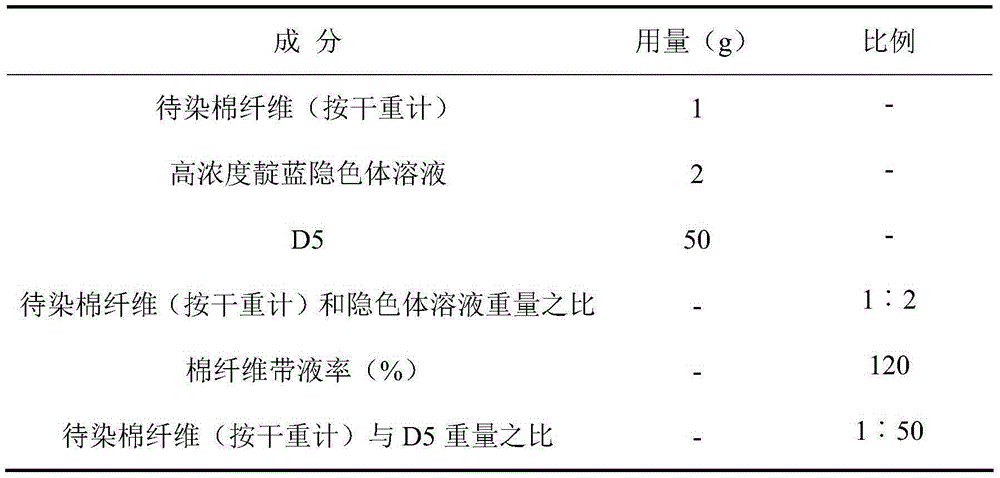

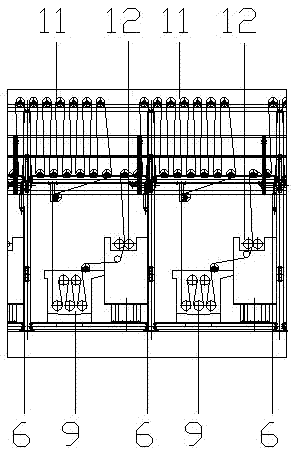

Multifunctional denim warp dyeing machine

InactiveCN102605582ARealize compound dyeingImprove dyeing effectSucessive textile treatmentsLiquid/gas/vapor removalPulp and paper industryPre treatment

The invention provides a multifunctional denim warp dyeing machine, which comprises a to-be-dyed warp rack and a dyed warp reel. A warp pretreatment tank, a warp dyeing groove, a washing tank and a slashing tank are successively arranged between the to-be-dyed warp rack and the dyed warp reel, wherein the warp pretreatment tank is used for removing impurities of warps and washing the warps, the warp dyeing tank is used for dyeing the warps by indigo dyes or sulfur dyes, the washing tank is used for washing the dyed warps, a combined drying barrel, a small colorful dyeing tank and a steaming box are successively disposed between the warp pretreatment tank and the warp dyeing tank, the combined drying barrel is used for colorfully dyeing the warps, and the small colorful dyeing tank dyes the warps by reduced dyes. The problems that when warps are dyed, a color selection range is narrow, color fastness is poor, and the warps cannot be dyed by bright-colored dyes are resolved; after the dyed warps are woven into denim, the characteristics that the warps of the denim are colorful while wefts of the denim are white can be kept; composite dyeing by the aid of the indigo dyes or the sulfur dyes can be realized, and a dyeing effect is good.

Owner:HAINING DENIM WEAVING CO LTD

Indigo paste industrial preparation method

ActiveCN102690529ASolve the troublesome problem of manual preparationReduce pollutionNatural dyesWater filterSettling basin

The invention discloses an indigo paste industrial preparation method, comprising a first step of raw material preparation, wherein mature indigo stems and foliages are cut into small parts by using a guillotine or a fiber cutter; a second step of raw material soaking, wherein the small parts are placed in a fermentation tank, fresh water is added for immersion, lime milk or industrial base is further added and thoroughly evenly stirring is carried out; a third step of sealed fermentation, wherein the fermentation tank is covered with a thin film for the sealed fermentation; a fourth step of impurities removal and standing, wherein after fermentation, fermentation broth is continuously turned and stirred, residue of the stems and foliages is then removed by filtering, and an indigo solution in the fermentation tank is discharged into a settlement tank for standing; and a fifth step of water filtering, wherein the indigo paste is obtained after a precipitate in the bottom of the settlement tank undergoes the water filtering. The method utilizes natural plant resources to prepare dye material through an industrial method, and the problem that the indigo dye preparation is troublesome is solved. With the method of the invention, the product has good and stable quality, treatment of three wastes is centralized, environmental pollution is reduced, and product cost is reduced. The method lays a foundation for batik product development.

Owner:GUIZHOU DANZHAI NINGHANG BATIK

Novel soft shape-maintenance knitted denim fabric production process

ActiveCN107419559AHigh color fastnessComply with color fastness standardWeft knittingBiochemical fibre treatmentColour fastnessEngineering

The invention discloses a novel soft shape-maintenance knitted denim fabric production process, which comprises the following steps: selecting fabric, performing pretreatment, dyeing, performing aftertreatment, performing final finishing sizing and washing with water. According to the invention, the advantage of good color fastness of reactive-based indigo dye is strengthened, and the prepared fabric feels similar to reactive dye. Meanwhile, the advantages of being comfortable and elastic and maintaining the shape of knitted fabrics are combined. The production process disclosed by the invention enables the color fastness of the knitted denim fabric to meet the requirements of the latest national standard GB31701-2015 Technical Code for Safety of Infants and Children Textile Products.

Owner:广州锦兴纺织漂染有限公司

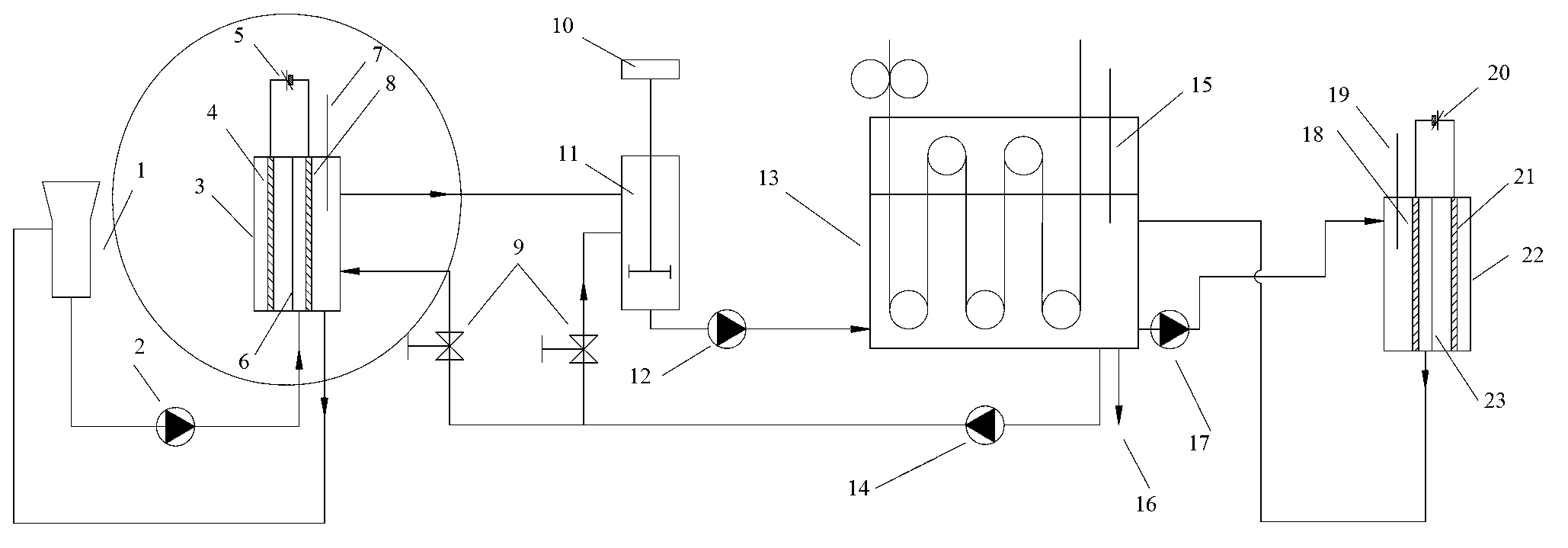

Continuous indigo blue electrochemistry reduction dyeing process

InactiveCN103255642AReduce concentrationIncrease concentrationDyeing processHigh concentrationElectrochemical response

The present invention discloses a continuous indigo blue electrochemistry reduction dyeing process, which is sequentially and continuously performed according to the following steps that: 1, under a low concentration medium condition, high concentration indigo blue is subjected to electrolysis reduction in a first electrochemistry reactor, the electrolyte is input into a leuco body dilution tank after 80-98% of the indigo blue is reduced into the leuco body, and concurrently the indigo blue and a dyeing liquid are added so as to maintain a indigo blue concentration in the first electrochemistry reactor; 2, the dyeing liquid is adopted to dilute the leuco body in the electrolyte into a required dyeing concentration in the leuco body dilution tank; 3, the diluted electrolyte in the step 2 is input into a dyeing machine, and a second electrochemistry reactor is adopted to control an electric potential of the dyeing liquid in the dyeing machine so as to completely convert the indigo blue into the leuco body; 4, the dyeing machine is opened after the electric potential of the dyeing liquid in the dyeing machine is stabilized so as to absorb the leuco body by cotton yarns; and 5, a filtration treatment is performed on the dyeing liquid used in the step 4, and recycling is performed. With the present invention, media loss can be reduced, dyeing work efficiency can be increased, and dyeing quality can be ensured.

Owner:HANGZHOU SAILONG CHEM IND +1

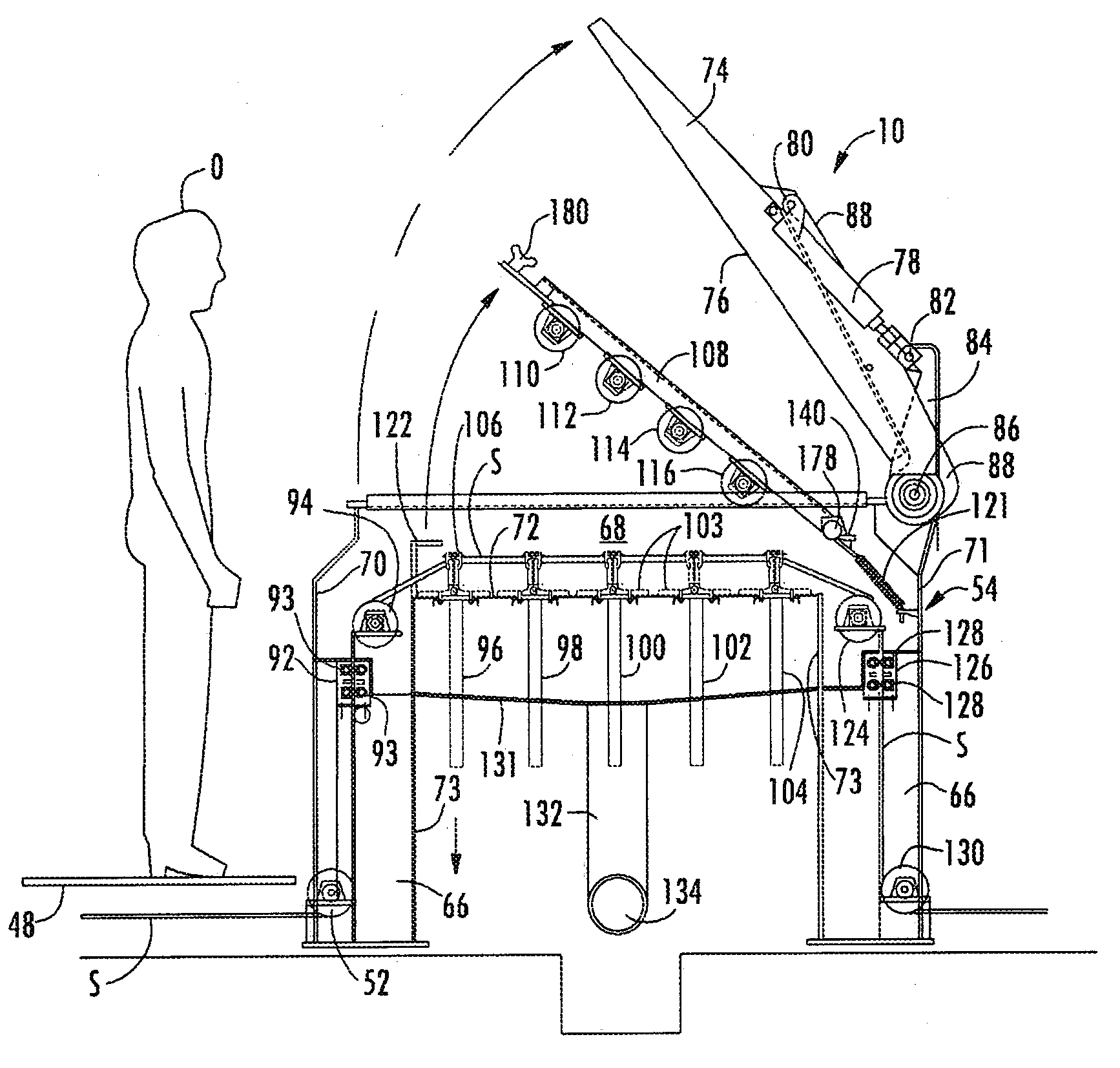

Apparatus for dyeing textile substrates with foamed dye

ActiveUS7913524B2Increases the amount of inert nitrogen in the chamber environmentReduce tensionTextile treatment containersOther washing machinesEngineeringIndigo dye

An apparatus for dyeing a textile substrate using a plurality of applicators that each apply an increment of a total dye application. In one form a reduced indigo dye in a leuco-state is applied in an inert atmosphere substantially isolated from oxidizing substances. In another form the foamed dye is applied while open to the atmosphere. In both forms holddown rollers or inverted applicators are located between applicators at decreasing depths to minimize increases in tension as the substrate travels over successive applicator faces.

Owner:GASTON SYST INC

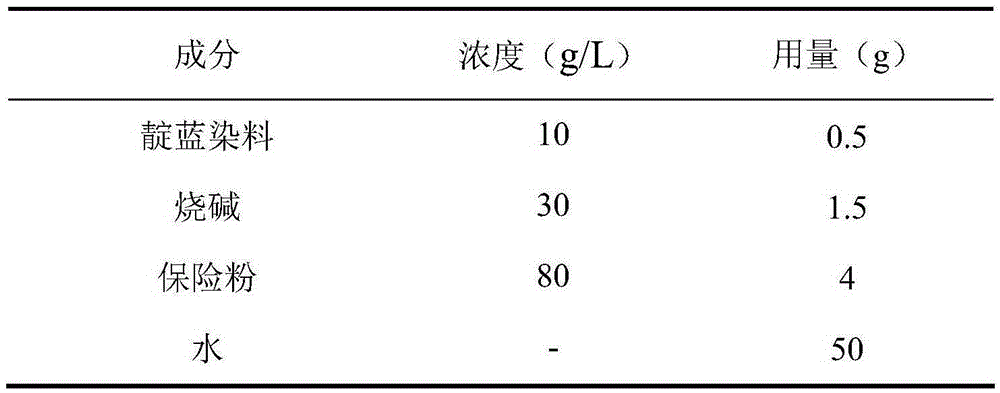

One-time deep dyeing method for cotton fiber employing indigo dye

ActiveCN105401463AImprove dye uptakeAchieve a deep color effectDyeing processHigh concentrationFiber

The invention discloses a one-time deep dyeing method for a cotton fiber employing an indigo dye. The method is a process of finishing dyeing of the cotton fiber with the indigo dye in a non-aqueous medium of decamethyl cyclopentasiloxane (D5). The method comprises the following steps: (1) refining, washing and dewatering the cotton fiber, and controlling the final take-up rate for dyeing; (2) preparing a high-concentration indigo leuco body; (3) firstly, adding a proper amount of high-concentration indigo leuco body to the D5 to prepare a dye liquor, and then putting the cotton fiber with certain take-up rate into a non-aqueous dye liquor for dyeing; and 4) after dyeing, carrying out oxidation treatment, and then carrying out soap boiling to remove the surface floating color. The cotton fiber is dyed in the D5 by the indigo dye; oxidation of the indigo leuco body in the dyeing process and invalid decomposition of sodium hydrosulfite can be effectively suppressed; the one-time deep dyeing effect is reached; the dyeing procedure is greatly simplified; the dyeing time is shortened; the work efficiency is improved; the cost is saved; and dyeing wastewater emission is significantly reduced.

Owner:ZHEJIANG SCI-TECH UNIV

Manual technique for fabricating blue printed true silk, and protection sgainst dyeing paste dedicated to manual blue printing

An indigo dyeing technology for the white silk fabric includes such steps as laminating 10-20 layers of tough paper with tung oil, drying in the air, fixing the 2-3 gummed plate together, drawing pattern, chiselling to become through pattern, grinding, putting the chiselled plate on white silk fabric, coating anti-dyeing slurry, drying the fabric in the sun, immersing in warm water at 30-50 deg.C for softening it, dyeing with plant indigo by immersion method, rinsing, drying and rolling. Said anti-dyeing slurry is prepared from soybean powder, lime powder, water and soybean oil.

Owner:吴莹

Method for willow artwork dyeing through natural indigo pigment

ActiveCN107253249AGood colorGood spotlightRadiation/waves wood treatmentWood treatment detailsSteepingDistillation

The invention discloses a method for willow artwork dyeing through a natural indigo pigment. The method comprises the following aspects that (1) indigo extraction is conducted, specifically, a plant raw material is subjected to crushing, fermentation, water soluble extraction and low-temperature drying, and the indigo pigment is prepared; (2) acid-alkali steeping is conducted, specifically, a hydrochlric solution with the concentration being 0.3-0.4% and a sodium hydroxide solution with the concentration being 0.25-0.3% are used to steep a willow artwork correspondingly; (3) cooking for impurity removal is conducted, specifically, impurities in the willow artwork is removed through cooking; (4) steaming for dyeing is conducted, specifically, the indigo pigment with the mass being 11-13% that of distillation boiler water is added, and steam dyeing is conducted; (5) low-temperature drying is conducted, specifically, the dyed willow artwork is dried; (6) infrared color fixing is conducted, specifically, the willow artwork is wrapped through mixed slurry and placed under infrared lamplight with the illumination intensity being 470-520 lux for color fixing; (7) ultraviolet inspection is conducted, specifically, the willow artwork subjected to color fixing is placed under an ultraviolet lamp, and the color fixing condition is inspected; and (8) tung oil layer coating is conducted, specifically, the willow artwork qualified after inspection is coated with tung oil, and after drying, the willow artwork with the natural indigo pigment is prepared.

Owner:阜南县宏达工艺品厂

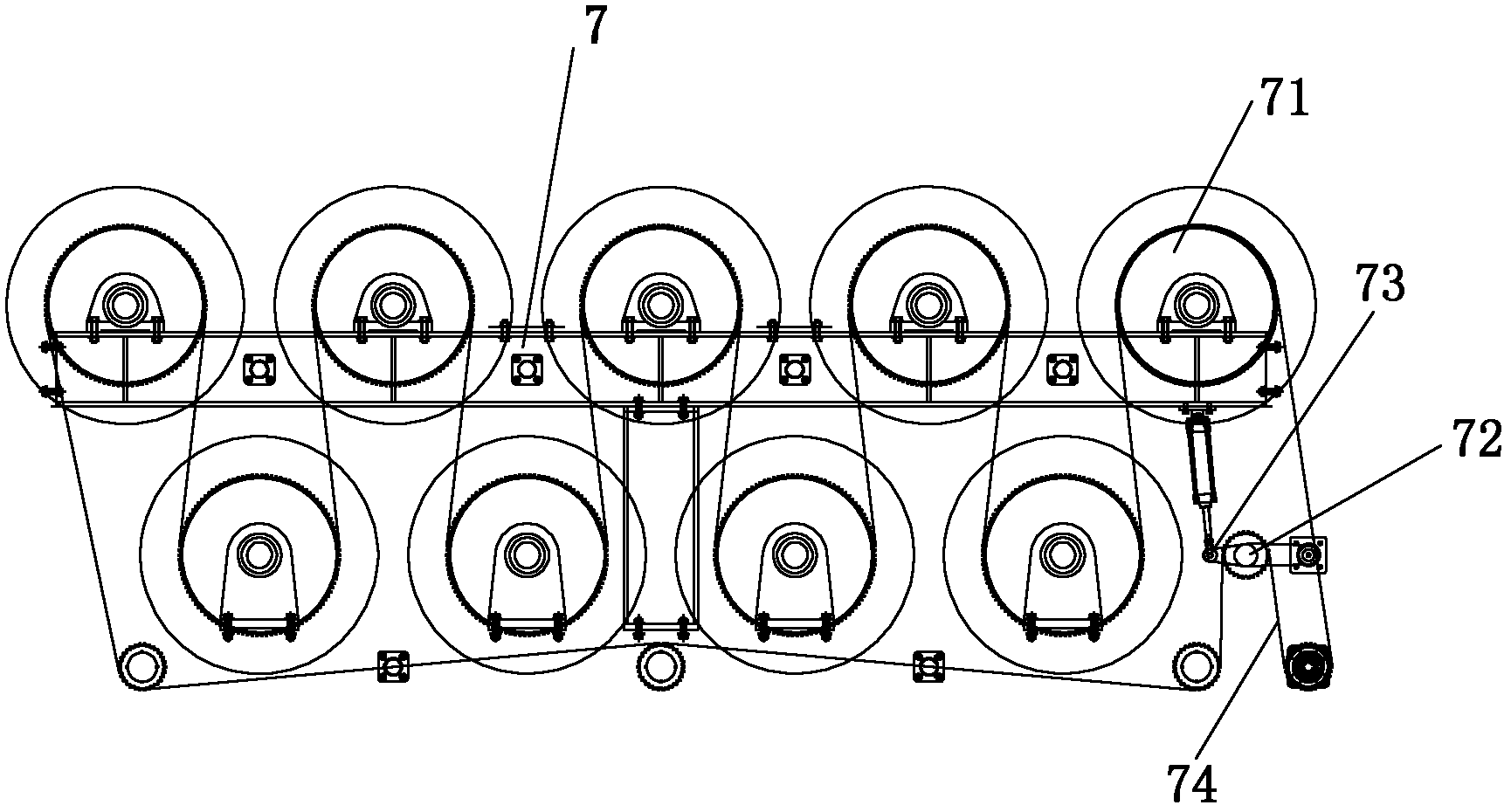

Indigo-blue jean dyeing machine

InactiveCN105442224ARealize large-scale productionSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersSurface coolingPulp and paper industry

The invention relates to an indigo-blue jean dyeing machine. The indigo-blue jean dyeing machine comprises a cloth feeding device, a cloth surface washing system, a cloth surface dyeing system, a cloth surface drying system, a cloth surface cooling system and a cloth discharging device, wherein the cloth surface dyeing system is composed of a continuous pad dyeing oxidization system and a level dyeing oxidization system; the pad dyeing oxidization system is composed of three groups of cloth surface dyeing grooves, two dyeing solution rollers and a cloth surface oxidization frame; the level dyeing oxidization system is composed of five groups of cloth surface dyeing grooves, a dyeing solution uniform roller and a cloth surface oxidization frame. The indigo-blue jean dyeing machine provided by the invention creates conditions for large-scale production of jeans of indigo-blue in longitude and latitude directions.

Owner:HAINING DENIM WEAVING CO LTD

Method of preparing hydroxyl acetonitrile in industrial scale from acrylonitrile apparatus by-product formonitrile

InactiveCN1907963AReduce manufacturing costSimple processPreparation by hydrogen cyanide additionAcrylonitrileGlycin

This invention involves an industrial scale preparation method for hydroxyacetonitrile by using acrylonitrile production byproduct hydrocyanic acid through a synthesis reaction with acetonitrile at the presence of catalyst. The method is characterized by (1) taking acrylonitrile production byproduct hydrocyanic acid as the raw material with content of 95% or above, (2) controlling a molar ratio of hydrocyanic acid : formaldehyde : catalyst at 1 : 1.0~1.5 : 0.001~ 0.015, (3) adding catalyst in formaldehyde while stirring, adding hydrocyanic acid at 0-20DEG C, and reacting at 0~40DEG C for 1~6 h, and (4) adjusting pH of 6 or below with inorganic acid to obtain hydroxyacetonitrile. The invention has the advantages of low cost, product content of 50% or above, simplified aftertreatment, no wastes discharge, and product with formaldehyde and hydrocyanic acid content less than 0.05%. Hydroxyacetonitrile can be used as the intermediates of glycin, malononitrile, and indigo dye to solve transport inconvenience of hydrocyanic acid and geographical limitation of production.

Owner:YINGKOU YINGXIN CHEM TECH CO LTD

Preparation of red mud-based polymer catalyst and application of catalyst in organic dye degradation

InactiveCN103537270ASimple processNo waste dischargePhysical/chemical process catalystsWater/sewage treatment by irradiationRed mudOrganic dye

The invention discloses a preparation of a red mud-based polymer catalyst and an application of the catalyst in organic dye degradation. A preparation method respectively takes industrial solid waste red mud of different producing areas as raw materials to prepare the red mud-based polymer catalyst under the excitation of sodium silicate, and the preparation of the red mud-based polymer catalyst has the advantages that the red mud raw materials can be completely utilized and no three wastes are discharged. The red mud-based polymer catalyst is applied to the degradation reaction of an indigo dye wastewater solution under ultraviolet irradiation, the degradation rate of the red mud-based polymer catalyst reaches 100%, the degradation efficiency is high, dye molecules are completely degraded into CO2 and H2O, secondary pollution cannot be generated, and moreover, dual purposes of using waste to treat waste are achieved. The preparation and dye degradation of the red mud-based polymer catalyst are simple in reaction technology, so that the practical application of large-scale preparation and dye degradation can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

UV photocuring blue nail polish

InactiveCN104027261AModerate adhesionMeet the attachment effectCosmetic preparationsToilet preparationsOrganic solventNail lacquer

The invention relates to the technical field of printing ink and particularly relates to UV photocuring blue nail polish. The UV photocuring blue nail polish comprises the following components in percentage by weight: 35-55% of polyurethane acrylate, 20-35% of trimethylolpropane triacrylate, 15-20% of epoxy acrylate, 3-5% of a photoinitiator, 1-5% of an indigo dye and 0.5-1% of a flatting agent. The UV photocuring blue nail polish provided by the invention is moderate in adhesive force, can satisfy the adhering effect on nails and can be easily stripped from the nails, and assistant stripping due to addition of an organic solvent is avoided, so that the damage of a stripping solution on the nails is effectively prevented.

Owner:ZHANGJIAGANG MAOAN TRADING

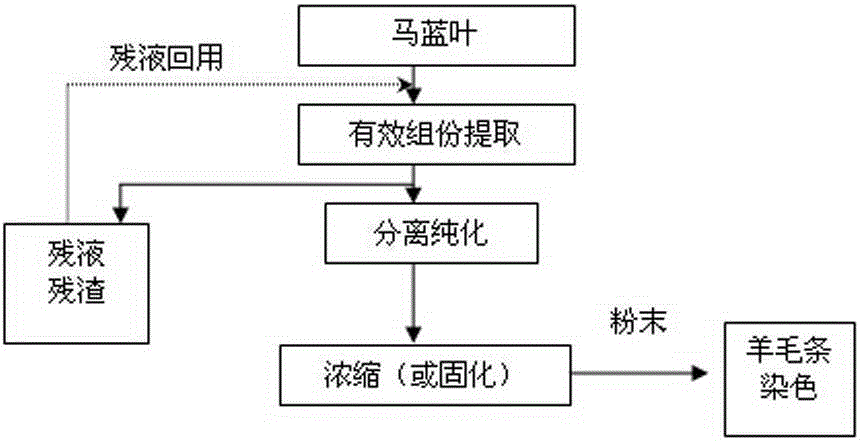

Technological method for dyeing wool tops through plant indigo dye

The invention discloses an extraction technology of extracting plant indigo from baphicacanthus cusia bremek leaves and a dyeing technology of top dyeing of wool fiber tops through the plant indigo. The technology comprises the steps that collected baphicacanthus cusia bremek leaves are cleaned thoroughly, impurities are removed, after natural airing or drying at low temperature is conducted, the baphicacanthus cusia bremek leaves are smashed in a pulverizer, and baphicacanthus cusia bremek leaf plant powder dregs are obtained; a mixed solution of ethyl alcohol and water is poured into the baphicacanthus cusia bremek leaf plant powder dregs, and a plant indigo extracting solution is obtained through ultrasonic treatment; high-speed centrifugation is conducted on the extracting solution, vacuum concentration and drying are conducted after the impurities are removed, and plant indigo powder is obtained; the plant indigo powder is dissolved in soft water, caustic soda and sodium hydrosulfite are sequentially added, the mixture is stirred evenly and added into a top dyeing dye vat, and wool tops to be dyed are completely immersed; the temperature rises to start dyeing, and after heat preservation is conducted for a certain period, the wool tops are taken out of dye liquor to be dewatered; the wool tops are moved into an air blower rapidly, and oxidation is conducted on the wool tops through air which flows at a high speed till the wool tops turn blue from yellow green; the wool tops are put back into the dye vat, soaping is conducted, washing is conducted through clear water after soaping, drying is conducted, and the the wool tops dyed through the plant indigo are obtained.

Owner:JIANGSU DANMAO TEXTILE

Method for processing wool jean plus material

InactiveCN101215745AGuaranteed rendering effectFix color problemsFibre treatmentSingeingPolymer scienceThermal water

The invention discloses a process for preparing wool denim fabric, which solves the problem that the existing wool fiber can not be used in the manufacture of denim fabric. The invention has simple method, convenient operation, and uses wool fiber in the manufacture of denim fabric. The method comprises first, taking shrinkproof top wool as raw material, second, adopting indigo dyes to dye chaine, steps comprise preprocessing under the temperature of 50-70 DEG C, washing in hot water under the temperature of 35-45 DEG C, washing in cold water in normal temperature, dipping for times, oxygenizing, dipping in acid whose PH value is 11.2-11.3, washing in water, carrying out soft process under the temperature of 50-70 DEG C, drying under the temperature of 80-100 DEG C, third, sizing on chaine, steps comprise reeling off through shaft, sizing, the temperature is 50-70 DEG C, wet splitting, drying, the temperature is 80-90 DEG C, dry splitting, and reeling, fourth, weaving denim cloth, fifth, post finishing wool denim cloth: genapping, diagonal tensioning, full-width scouring, full-width crabbing, relaxedly steam preshrinking, full decatizing and doffing cloth, finally obtaining finished product, namely wool denim fabric.

Owner:LINYI AOTAI TEXTILE

Method for recycling bipseudoindoxyl dye from indigo dyeing waste water

ActiveCN101376747ALess investmentReduce chromaMultistage water/sewage treatmentWater/sewage treatment by neutralisationFiberMicrofiltration membrane

The invention discloses a method for recycling an indigo dye from the indigo waste coloring water. In the method, a proper filtration fabric is selected first for filtering the fibers and impurities in the waste water; then an acid liquid is added into the waste water the fibers and impurities of which are removed to adjust the pH value between 2 and 7; air is blown for oxidation to oxidize sodium salt of a water-soluble indigo leuco body into an insoluble solid indigo dye; finally the indigo dye and a condensed liquid which is rich in the dye are obtained through a microfiltration membrane device. The method has the advantages of less investment and simple device; the recycled indigo dye and the recycled condensed liquid can be recycled for coloring a fabric; besides, after the indigo waste coloring water is treated by the membrane, the chroma, the turbidity and the COD, and the like, are greatly reduced. The removing rate of effluent color dilution after the membrane treatment is larger than 98 percent; the turbidity is reduced by more than 97 percent and the COD removing rate is larger than 30 percent.

Owner:溧阳常大技术转移中心有限公司

Indigo reduction deep dyeing promoter

The invention discloses an indigo reduction staining deep dyeing promoter which is a high performance deep dyeing promoter for denim indigo dyeing reduction. The invention is prepared mainly by dispersant, sodium polyacrylate, anionic surfactant, industrial salt, at least one kind of C8-C18 fatty alcohol ethoxylate and at least one kind of rare earth sulfonate. When the deep dyeing promoter is used for indigo dyeing reduction for denim, depth and fastness of the dyeing denim are obviously improved, degree of dyeing is further improved, and using amount of toxic dye indigo and dyeing period are reduced.

Owner:江门市科恒实业有限责任公司

Discharge printing process of fibers dyed with indigo dye and/or sulfide dye

InactiveUS20070050914A1Stable discharge printingBright colorationDetergent compounding agentsDyeing processFiberSulfide

The object of the invention is to provide a discharging agent for fibers dyed with an indigo dye and / or a sulfide dye, which enables stable discharge printing treatment to give the fibers soft texture, bright coloration and contours, which also enables printing. The object was achieved by the following: (1) A discharging agent for a fiber dyed with an indigo dye and / or a sulfide dye, consisting of chlorite and a viscosity-increasing nonionic surfactant, (2) a discharging agent according to the item (1), wherein the viscosity-increasing nonionic surfactant is a nonionic surfactant having HLB of 15 or higher, (3) a discharge printing process of a fabric or a sewing product dyed with an indigo dye and / or a sulfide dye, characterized in that a discharging agent having an adjusted pH of 7-12 and consisting of chlorite and a viscosity-increasing nonionic surfactant is printed on or applied to the fabric or the sewing product, followed by the application of a heat treatment, and (4) a discharge printing process according to the item (3), wherein the discharge printing treatment is performed simultaneously with, before, or after a coloring treatment.

Owner:MATSUI SHIKISO KAGAKU INDSHO

Recovered mixed alkali solution from production of indigo, and recovering method and use thereof

InactiveCN102127307AReduce manufacturing costGood GreenIndigoid dyesRecovery methodPotassium hydroxide

Owner:梅剑平

Cellulase complexes and preparation method thereof

InactiveCN101586060AUnique nostalgic styleImprove performanceNon-surface-active detergent compositionsBleaching apparatusPhosphateEther

The present invention belongs to a biologic enzyme complexes technical field, especially relates to a novel cellulase complexes and a preparation method thereof, including the following raw materials be weight percent: neutral cellulase 5%-30%, ammonium dibasic phosphate: 20%-40%, ammonium dihydrogen phosphate 5%-20%, fatty alcohol polyethenoxy ether 2%-15%, Na[2]SO[4]: 25%-50%, cornstarch :2%-15%, color paste: 0.1-0.2%. The invention replaces the traditional ellulase preparation, has a global performance, non dusting, a high catalytic activity, a rapid rocket, a very low back staining phenomenon, and is environmental protection, is used for indigo dye rinsing of bronchobuster clothing with a good rinsing effect, and the prepared bronchobuster clothing has a special reminiscence style.

Owner:东莞市广利行洗涤原料有限公司

Distressed processing method for colored fabric

ActiveCN101748601AAdd cationic modificationEvenly colored surfaceFibre treatmentDyeing processRing dyeingTreatment effect

The invention discloses a distressed processing method for colored fabric, which is characterized in that a cation modification technology of yarn is added before the traditional yarn dyeing processing technology, so that the whole processing technology comprises the following steps in sequence: yarn preparation, cation modification of yarn, yarn dyeing processing, sizing, preshrinking, washing and finished products. The distressed processing method has the advantages that the surface layer of the yarn colors up uniformly, and the inner layer of the tarn maintains the original white core, so a clear skin - core effect is formed; the processed fabric has uniform ring dyeing and a uniform distressed treatment effect; by the combination application of a cation modifier and reactive dyes, the dyed fabric achieves the effect which sulfur dyes or indigo dyes can just achieve; and the distressed processing method greatly reduces energy consumption, reduces environmental pollution, ensures the stability and the production efficiency of dyeing, and enhances the quality of products.

Owner:浙江盛泰服装集团股份有限公司

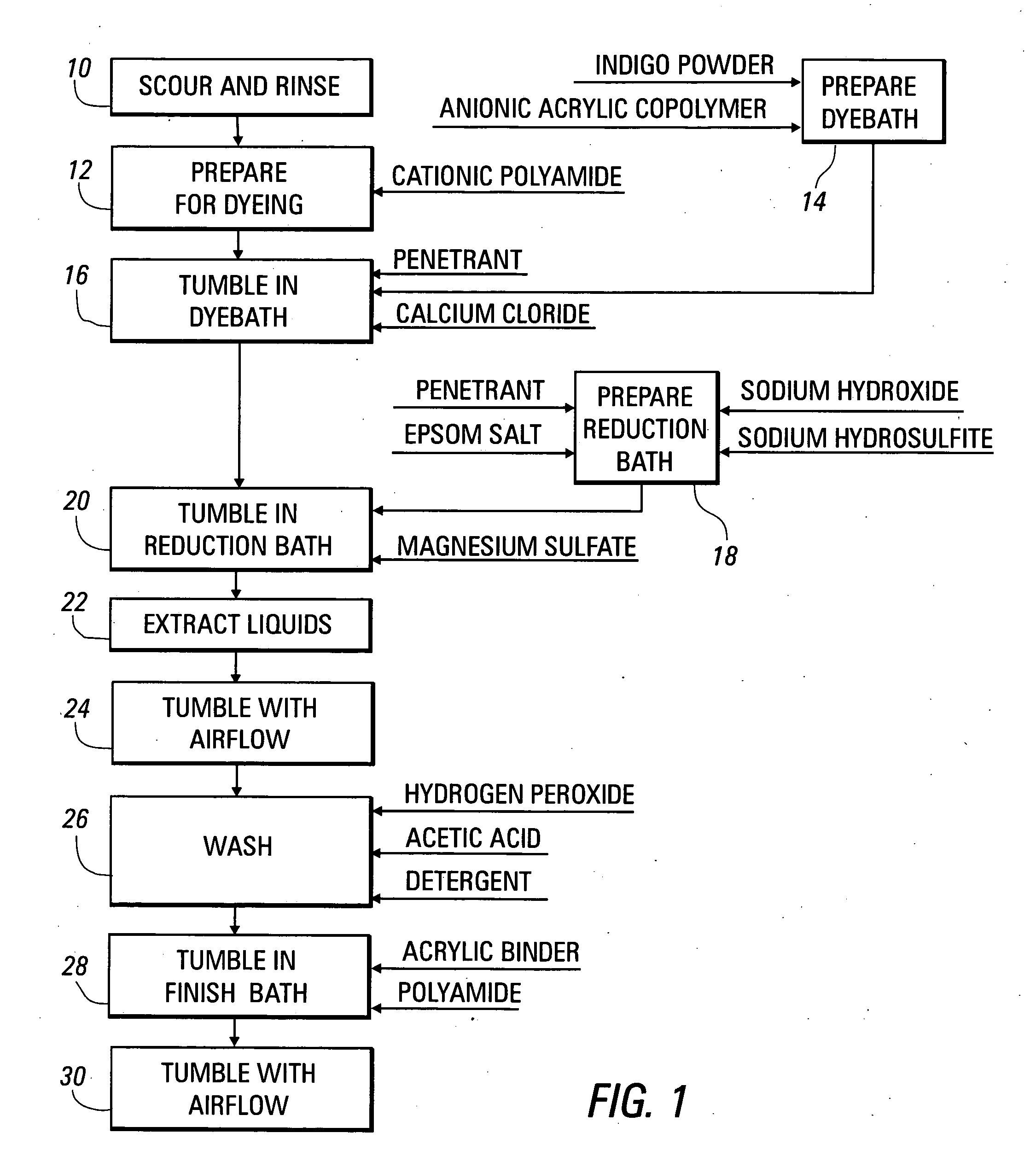

Method for dyeing fabric materials with indigo, other vat dyes, and sulfur dyes

A method for surface dyeing a range of textile materials, in the form of yarn, fabric, or garments, includes: a) preparing a dyebath including dye particles and an additive, such as an anionic acrylic copolymer, causing the particles to become charged; b) preparing the textile material by applying an additive, such as a cationic polyamide, forming a substrate with a charge attracting the particles, c) immersing the textile material in the dyebath; d) chemically reducing the dye particles retained on the textile material to a leuco form; and e) oxidizing the dye material.

Owner:ALPERT MELVIN

One-step method jean jacket manufacturing technology

InactiveCN105063872AReduce processing stepsReduce lossSucessive textile treatmentsWeft knittingYarnBobbin

The invention discloses a one-step method jean jacket manufacturing technology. The technology includes the following steps that a, cotton yarn is sorted out through a beam warping machine to complete warping; b, the cotton yarn subjected to warping is conveyed into a dyeing machine for indigo dyeing; c, the cotton yarn subjected to indigo dyeing is conveyed into a yarn dividing machine for yarn dividing; d, the divided cotton yarn is conveyed into a bobbin making machine for a shaft, and the cotton yarn is manufactured into bobbins through the bobbin making machine for the shaft; e, the manufactured bobbins are placed in an automatic knitting machine, and the cotton yarn is knitted into a jean jacket through the automatic knitting machine. By means of the design of the processing steps, in the jean jacket making process, jean does not need to be cut or sewn, the cotton yarn manufactured into the bobbins can be directly made into the jean jacket through the automatic knitting machine, that is, the processing procedures of the jean jacket can be effectively shortened through the one-step method jean jacket manufacturing technology, and loss can be effectively reduced.

Owner:GUANGDONG FORWARD DENIM

Two-component complexing system indirect electrochemical reduction method and system for indigo dye and preparation method of system

InactiveCN106868533AReduce consumptionPlay a synergistic roleElectrolysis componentsElectrolytic organic productionPower flowShielding gas

The invention belongs to the technical field of indigo dye reduction dying and particularly relates to a two-component complexing system indirect electrochemical reduction method and system for an indigo dye and a preparation method of the system. The preparation method comprises the steps that 1, under the alkaline condition, Fe(II / III) salt is fully mixed with triethanolamine, so that a complexing system is obtained; and 2, gluconate is added to the complexing system obtained in step 1, so that a two-component complexing system is obtained. The indirect electrochemical reduction method comprises the step that under protection of protective gas, the two-component complexing system serves as a medium, indirect electrochemical reduction is conducted on the indigo dye in an electrolytic cell at the temperature of 25-75 DEG C and under the alkaline condition. According to the two-component complexing system indirect electrochemical reduction method and system for the indigo dye and the preparation method of the system, the mixed medium of a certain condition is jointly formed by gluconic acid and iron-triethanolamine, and the synergistically-reinforcing effect can be achieved; the current required in the energized reduction process is reduced, reduction time is shortened, and thus current efficiency is improved; and energy consumption is remarkably lowered, and cost is saved.

Owner:WUHAN TEXTILE UNIV

Method for dyeing denim yarn with natural indigo blue

ActiveCN109098011AImprove color vividnessImprove staining reproducibilityDyeing processYarnRoom temperature

The invention discloses a method for dyeing denim yarn with natural indigo blue. The method comprises the following steps: dyeing denim cotton yarns by using a leuco body multi-time padding oxidationmethod, carrying out vatting reduction at 40-50 DEG C, and dyeing denim yarns according to processes of pre-dyeing treatment, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation and aftertreatmenet with 0.5-2g / L of natural indigo blue, 1.5-4.5g / L of sodium hydroxide, 0.75-1.8g / L of sodium hydrosulfite, 0.25-0.6g / L of a sodium hydrosulfite stabilizer, 10-15g / L of a dyeing acceleration agent sodium chloride or sodium sulfate and 2g / L of a penetrant JFC2. By adopting the dyeing method of multiple times of padding, rolling and oxidation,the dyeing fastness of the denim yarns can be improved, dyeing and oxidation can be both carried out under a room temperature condition, no heating is needed, energy conservation and environment protection can be achieved, reduction is carried out by using a sodium hydrosulfite method, a high reduction velocity can be achieved, and a stable dyeing effect can be achieved.

Owner:鹤壁新歌源丹宁科技有限公司

Indigo dye and preparation method thereof

The invention discloses an indigo dye and a preparation method thereof, and belongs to the technical field of dyes. The dye comprises the following components in parts by weight: 100 parts of water, 5-10 parts of indigo, 1-1.5 parts of a wormwood ash water solution and 0.5-1 part of arrack. The invention further discloses the preparation method for the dye. The preparation method particularly comprises three steps of indigo preparation, wormwood ash water solution preparation and dye preparation; defects that a prepared indigo dye is hard to color, the color of dyed cloth is not bright, the dyed cloth is likely to fade, and a preparation technology is complex in the prior art are effectively overcome; the dye has the benefits that the coloring effect is better, the color of the dyed cloth is bright, the dyed cloth is unlikely to fade, raw materials are easy to obtain, the preparation process is simple, and the operation is convenient.

Owner:莫玉明

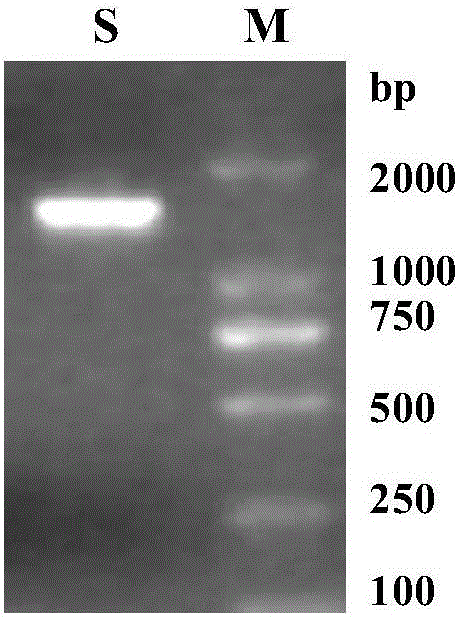

Bacillus subtilis ZNXH1 sourced bacterial laccase gene, bacterial laccase and application thereof

The invention provides a bacillus subtilis ZNXH1 sourced bacterial laccase gene, bacterial laccase and application thereof, belongs to the technical field of biology, and particularly relates to a bacillus subtilis ZNXH1 sourced bacterial laccase gene cahh1, bacterial laccase CAHH1 expressed by the gene and application of the bacterial laccase CAHH1 in the fields of textile industry, environmental protection and the like. Compared with traditional laccase, the bacterial laccase CAHH1 has the advantages of remarkable application stability and broad spectrum effect, mainly including that (1) the bacterial laccase CAHH1 has better pH stability in a range of 3-9; (2) the bacterial laccase CAHH1 has better temperature stability in a range of 30-90 DEG C; and (3) the bacterial laccase CAHH1 has a strong decolorizing effect on indigo dye, azo dye and triphenylmethane dye. The bacterial laccase can be used for decolorizing industrial dye, has wide application prospects, can easily realize engineering preparation and has higher practical values.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com