Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1867 results about "Boiler water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler water is liquid water within a boiler, or in associated piping, pumps and other equipment, that is intended for evaporation into steam. The term may also be applied to raw water intended for use in boilers, treated boiler feedwater, steam condensate being returned to a boiler, or boiler blowdown being removed from a boiler.

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS6840251B2Reduce Microbial ContaminationReduce removalDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

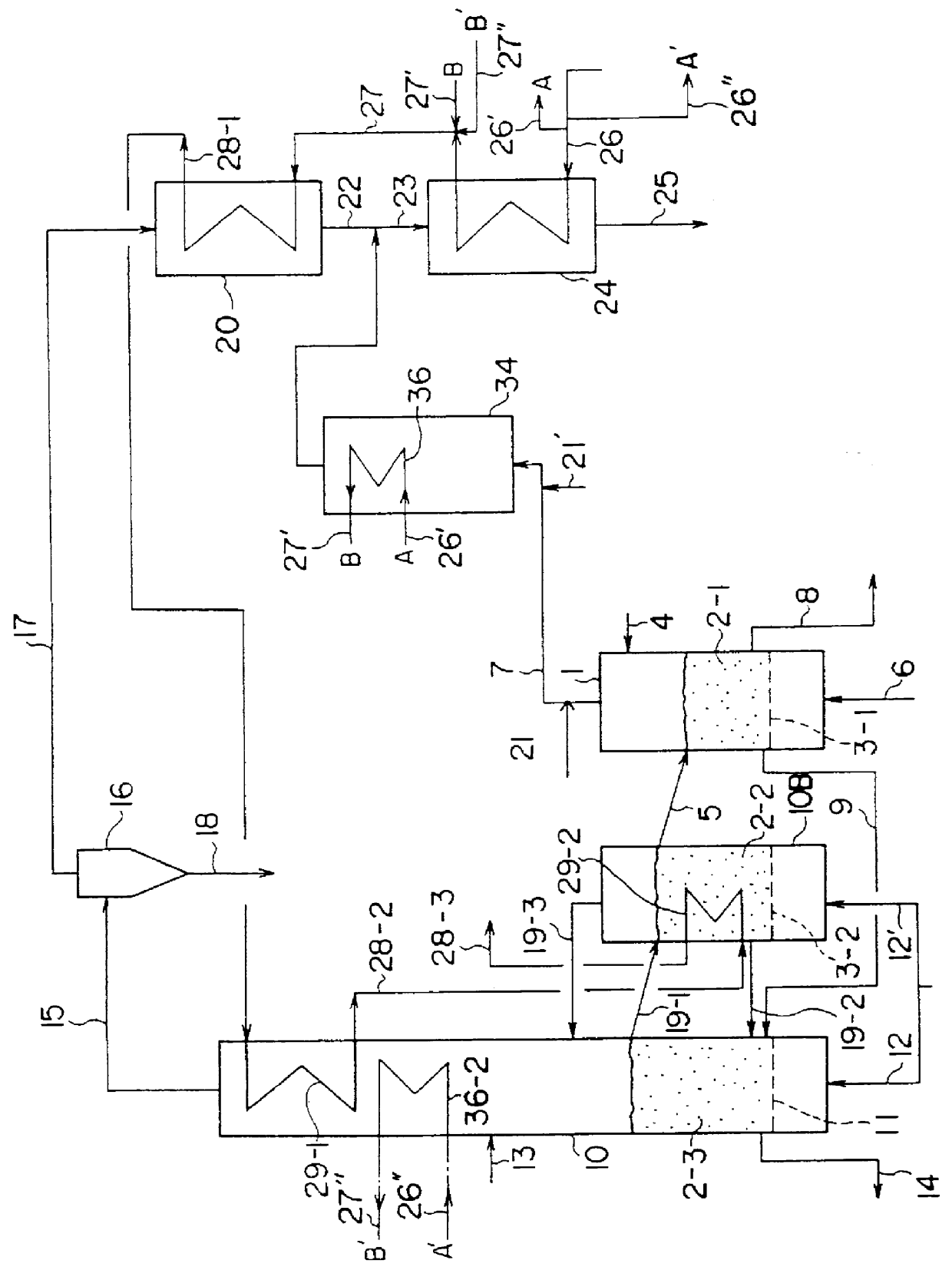

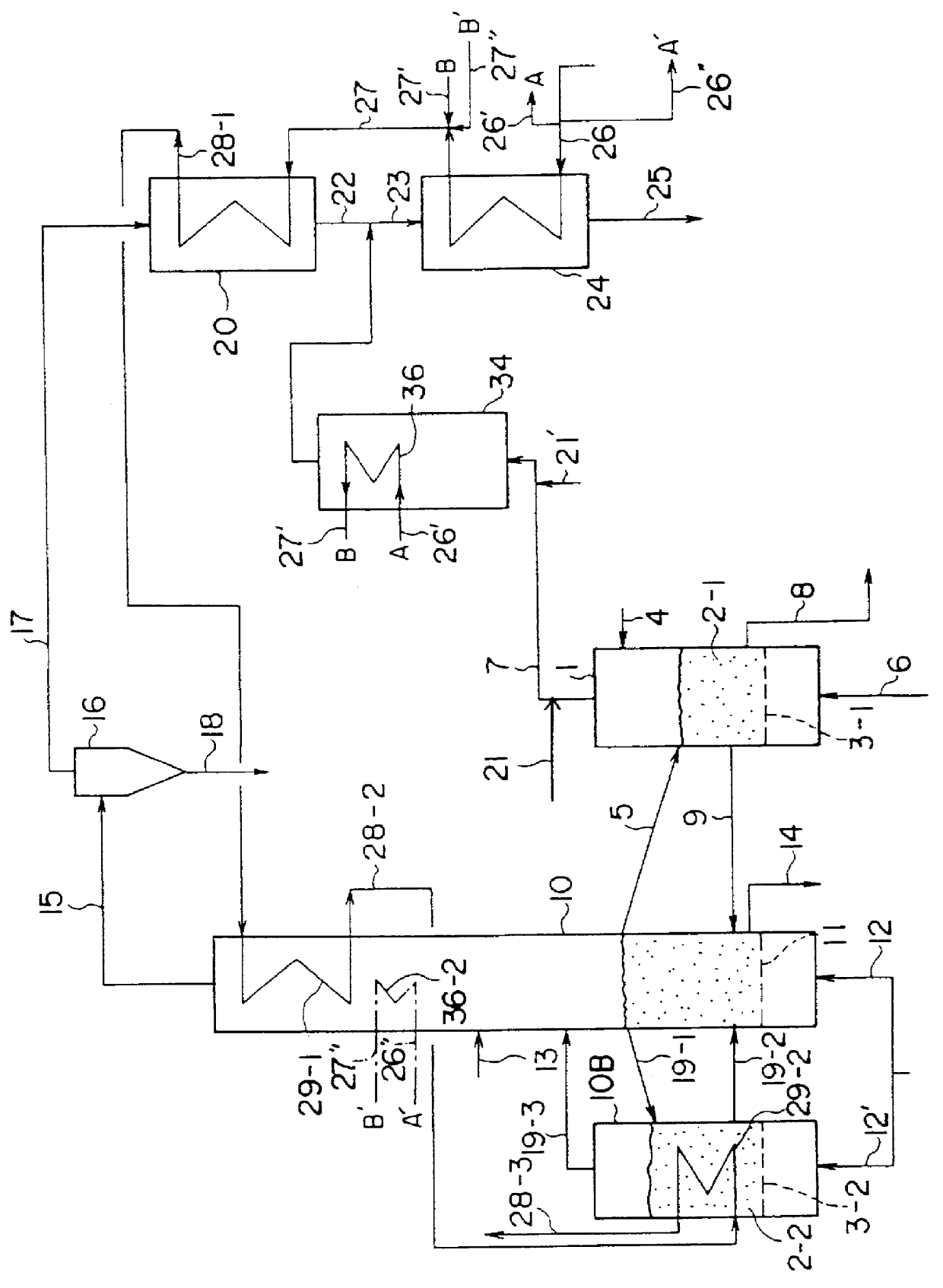

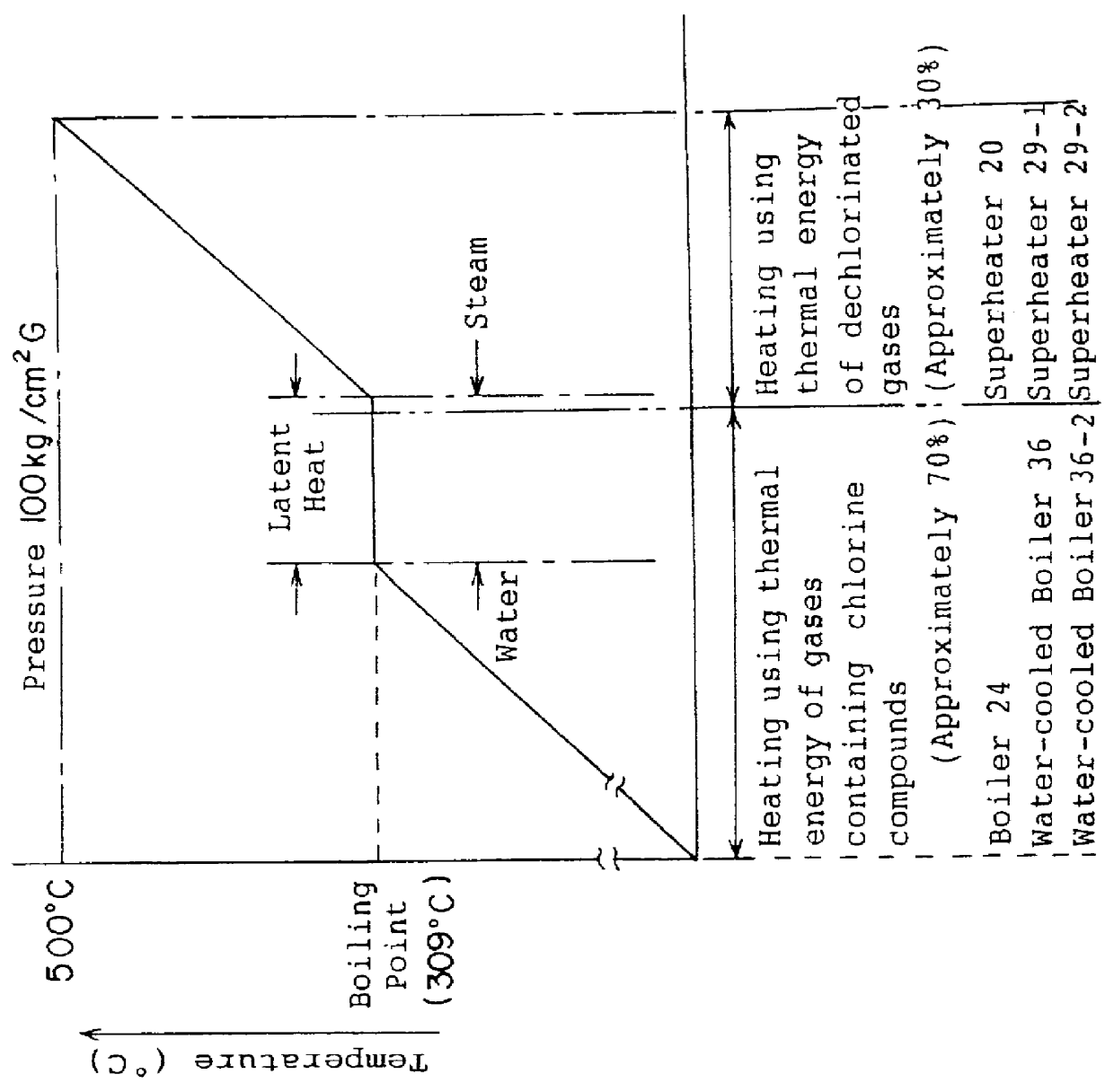

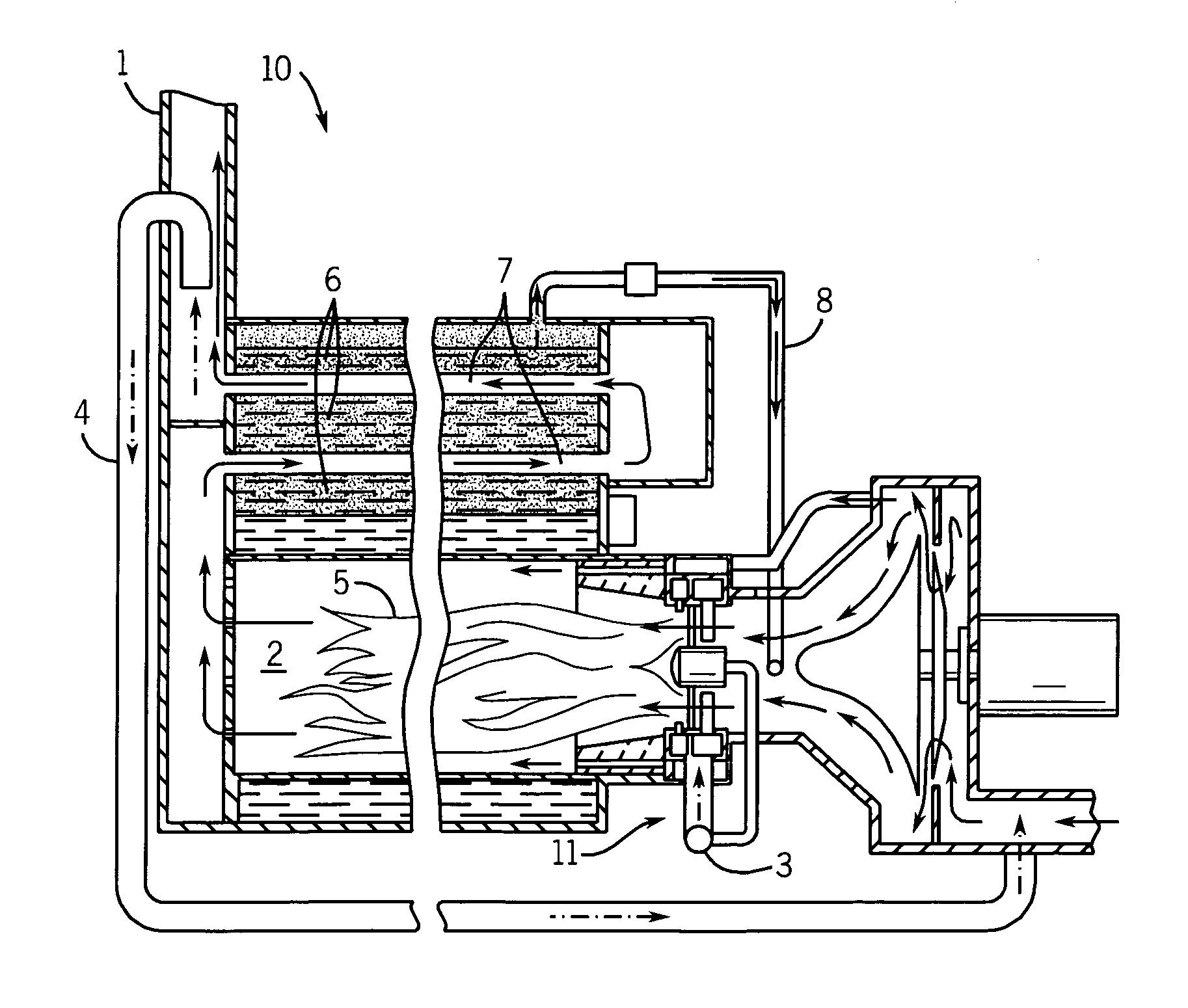

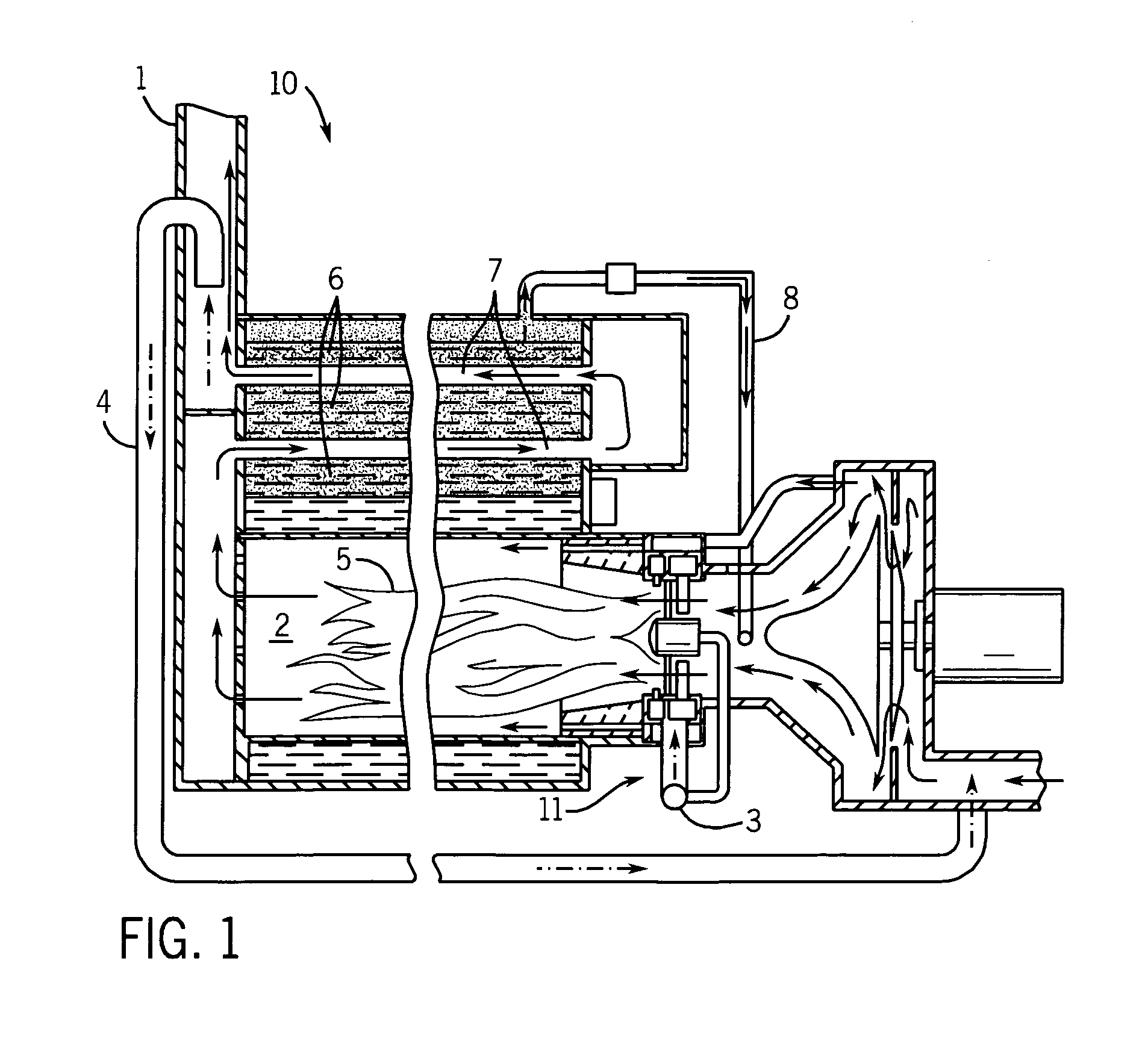

Method and apparatus for producing superheated steam using heat from the incineration of waste material

PCT No. PCT / JP97 / 00573 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 32161 PCT Pub. Date Sep. 4, 1997According to the present invention, boiler water is pressurized so that its boiling point is set at approximately 200 DEG C. to 320 DEG C. The boiler water is heated in at least two stages. Thermal energy of gases containing chlorine compounds is used to heat the water to its boiling point. Thermal energy of gases which do not contain chlorine compounds is used to heat the water from its boiling point until superheated steam of a given temperature is generated. The heating which uses the thermal energy of gases containing chlorine compounds is accomplished using the thermal energy from the combustion of pyrolysis gases obtained from a pyrolysis means in which waste material is supplied into a chamber containing a fluidized bed medium which has been heated to at least 300 DEG C., and a pyrolytic reaction is induced. The heating which uses the thermal energy of gases which do not contain chlorine compounds is accomplished using the thermal energy obtained from a char combustion means to combust char in which a char mixture consisting of unpyrolyzed residue and fluidized bed medium removed from the pyrolysis means is fluidized by a stream of air, and the unpyrolyzed residue is combusted.

Owner:MITSUBISHI HEAVY IND LTD

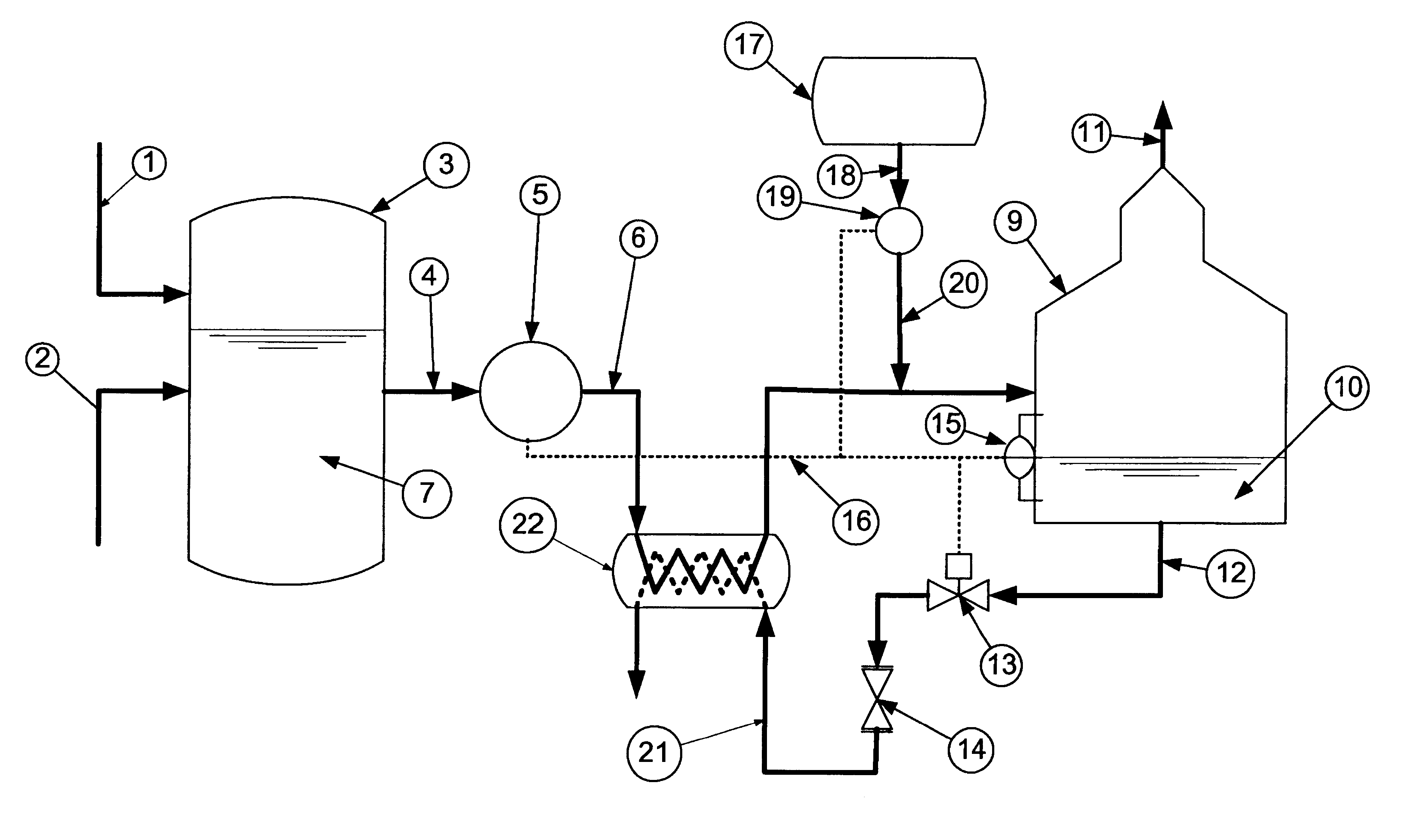

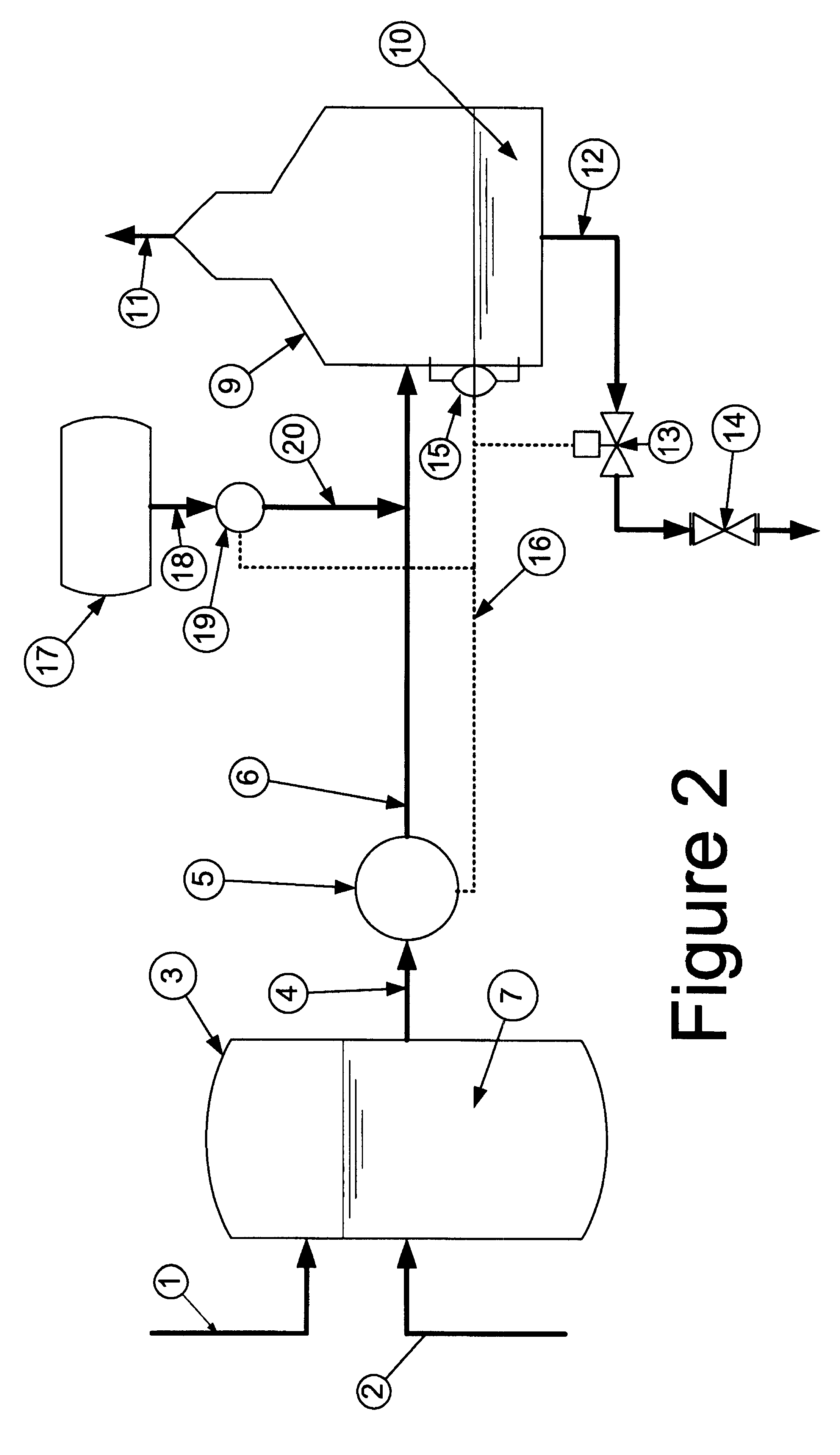

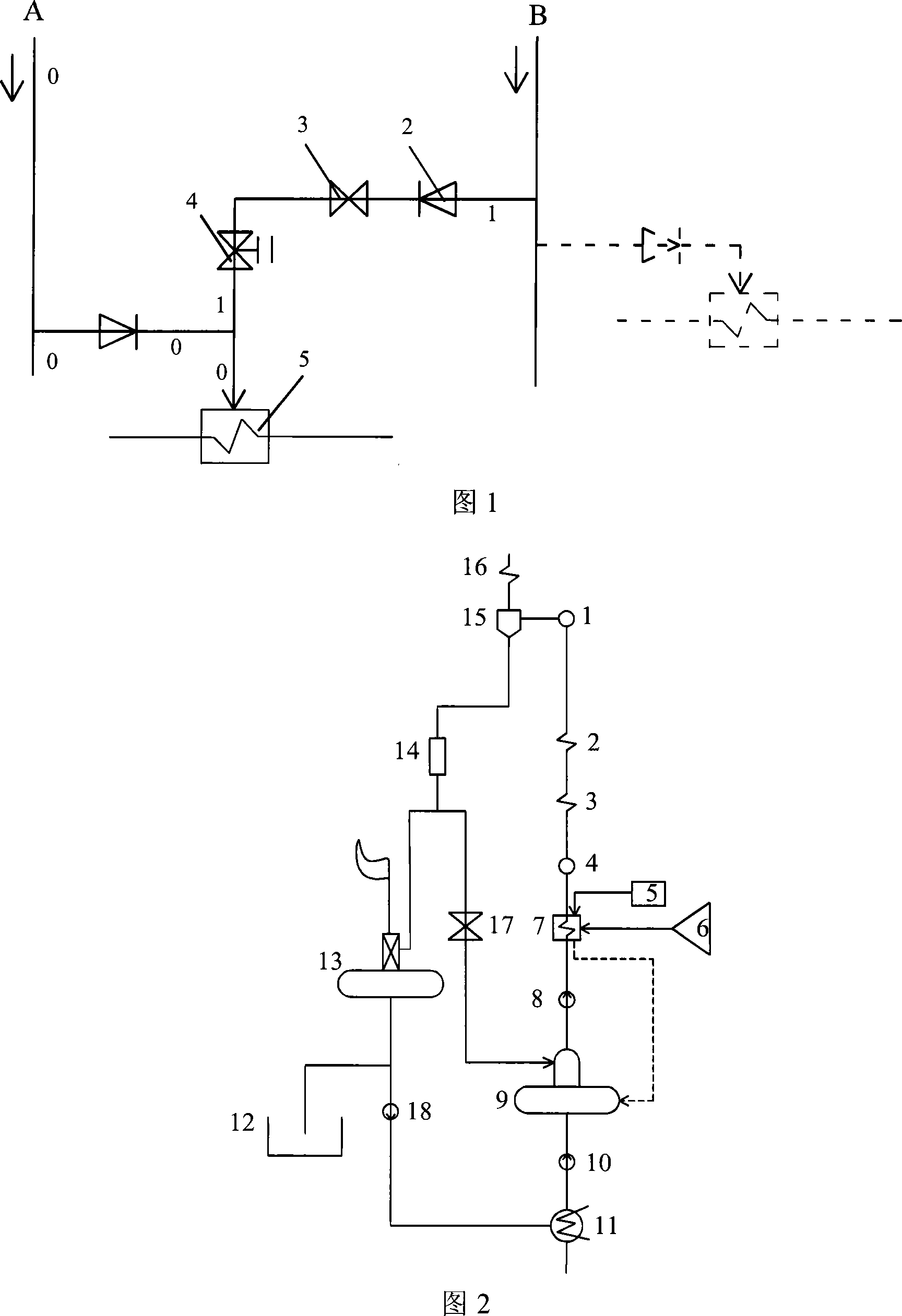

Boiler water blowdown control system

InactiveUS6655322B1Constant flowThe process is simple and accurateBoiler cleaning apparatusMachines/enginesControl systemEngineering

The present invention relates to a method for automatically maintaining the concentration of scale forming minerals in boiler water for boiler systems utilizing bimodal feedwater pumps that deliver a substantially constant feedwater flow to the boiler drum when activated. According to the present invention, the feedwater supply pump and blowdown rate control valve are synchronized to remove boiler water at a predetermined rate when the feedwater pump is activated. The present invention thereby provides a simplified and less expensive method for controlling the concentration of dissolved solids in boiler water despite variations in the steam loads and / or other boiler operation parameters.

Owner:CHEMTREAT

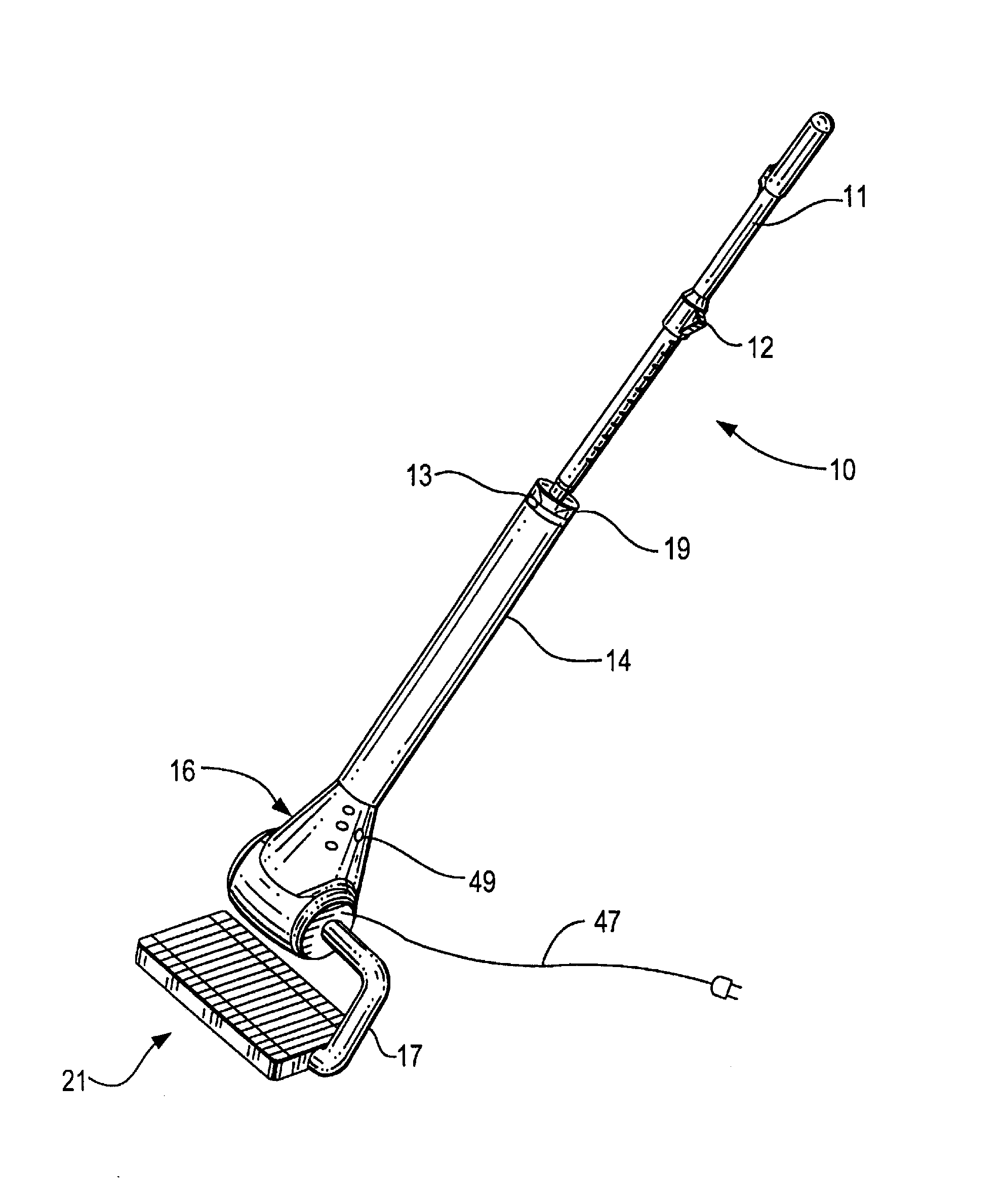

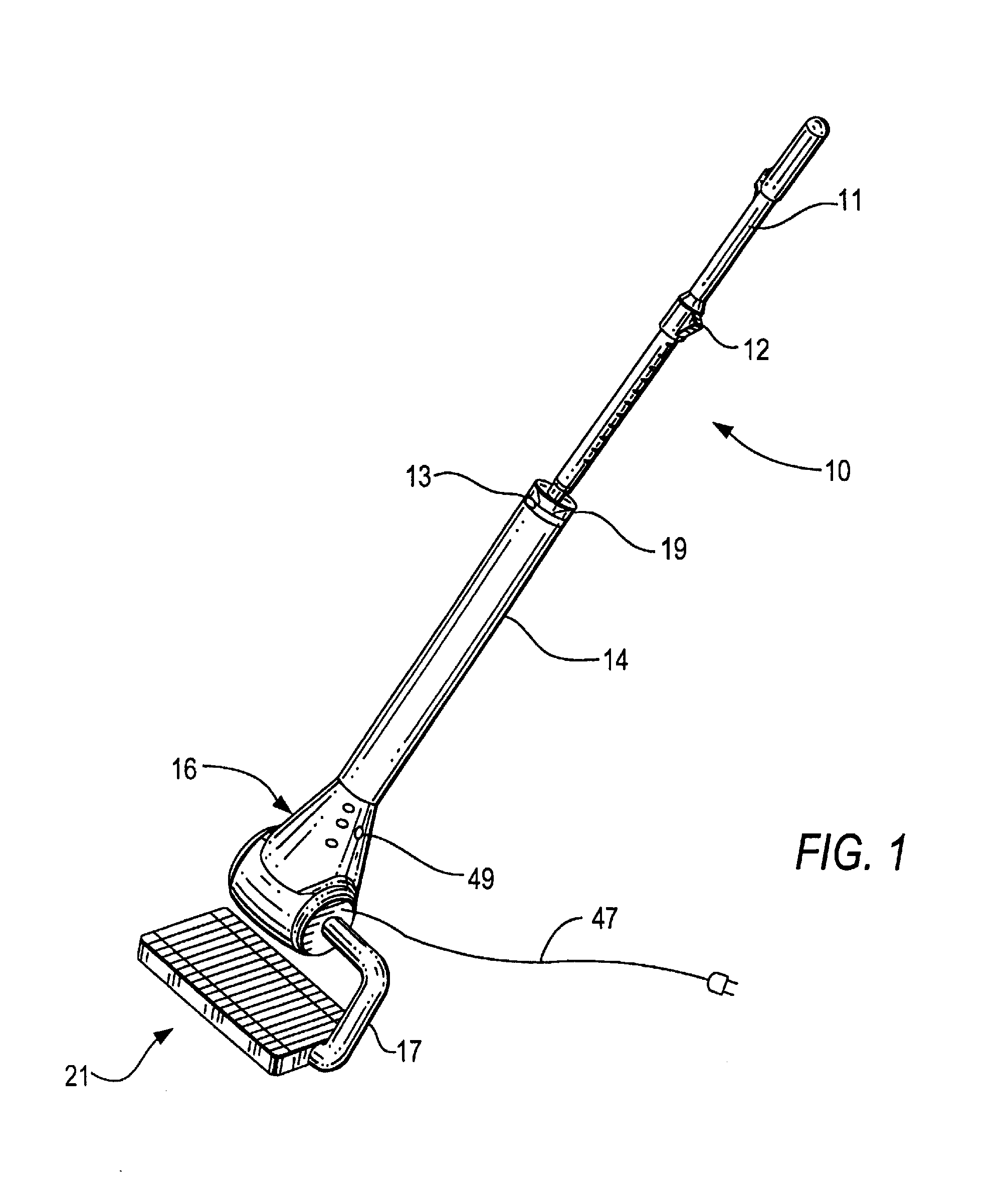

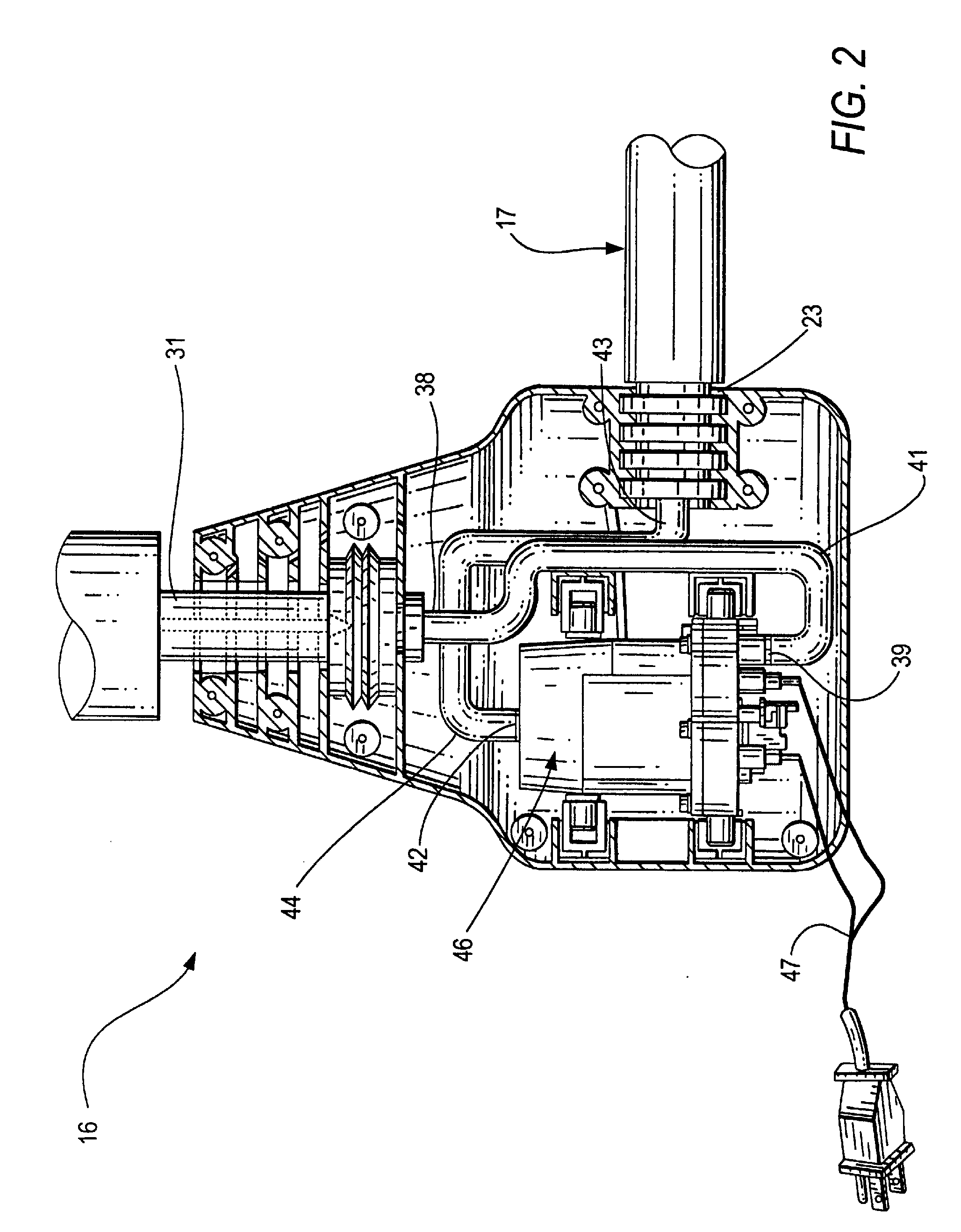

Steam mop

InactiveUS20080236635A1Clean surfaceEasy to useSteam generation heating methodsCarpet cleanersSteam mopEngineering

A steam mop having a main body with a boiler, a water container, a mechanical water pump between the boiler and container and at least one side arm connecting the boiler steam outlet to a fabric steam pocket frame. The water pump is actuated by movement of the mop when cleaning to send water to the boiler. The steam pocket frame is substantially rectangular with a plurality of baffles to distribute steam disposed substantially perpendicular to a steam channel having openings to distribute steam between the baffles. A replaceable fabric pocket fits snugly over the frame to distribute cleaning steam to the surface to be cleaned.

Owner:EURO PRO OPERATING

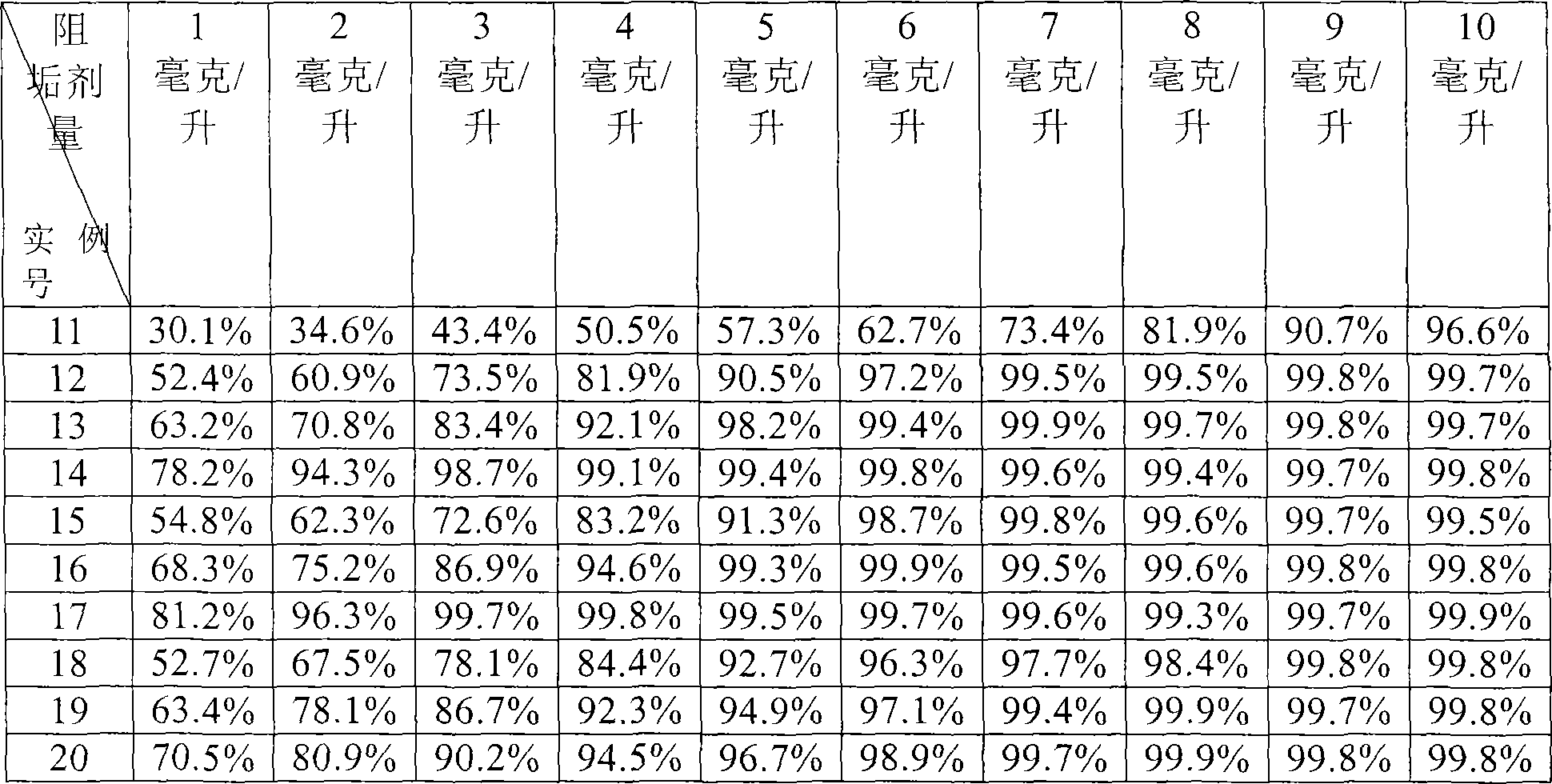

Preparation method for highly effective maleic anhydride series polymer antisludging agent

ActiveCN101041516AImprove solubilityHigh molecular weightScale removal and water softeningChemical industryEthylene Homopolymers

The invention discloses a preparing method of effective maleic anhydride system polymeric compound antisludging agent belonging to chemical industry technical and water disposal domain, which comprises the following steps: adding overdraw multi-double bond monomer in the maleic anhydride series antisludging agent synthetic course; proceeding polymerization; increasing molecular weight and combination property of maleic anhydride homopolymer. This invention can be applied to recycle cooling water system, boiler water, oil field water, paper making and seawater desalinization.

Owner:HAISO TECH

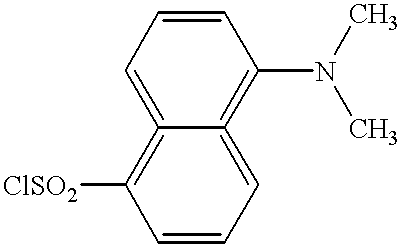

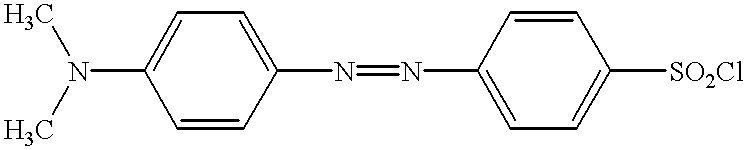

Use of disulfonated anthracenes as inert fluorescent tracers

InactiveUS20050025659A1Quantity minimizationDetection of fluid at leakage pointSamplingAnthraceneSteam line

The use of an isomer of anthracene disulfonic acid as an inert fluorescent tracer is described and claimed. The utility of this type of inert fluorescent tracer in boiler systems to trace unwanted carryover of boiler water into a steam line is also described and claimed.

Owner:ECOLAB USA INC

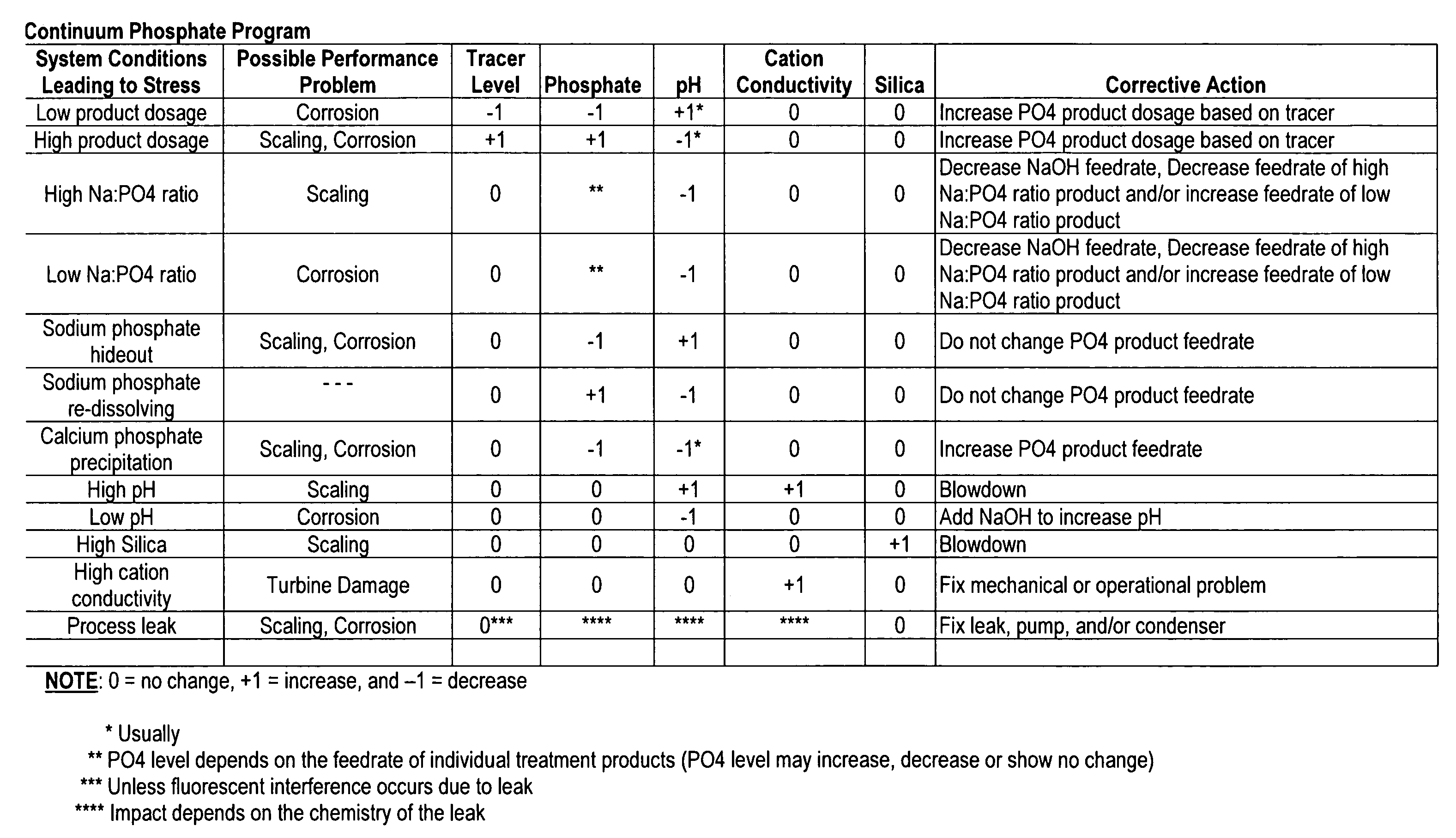

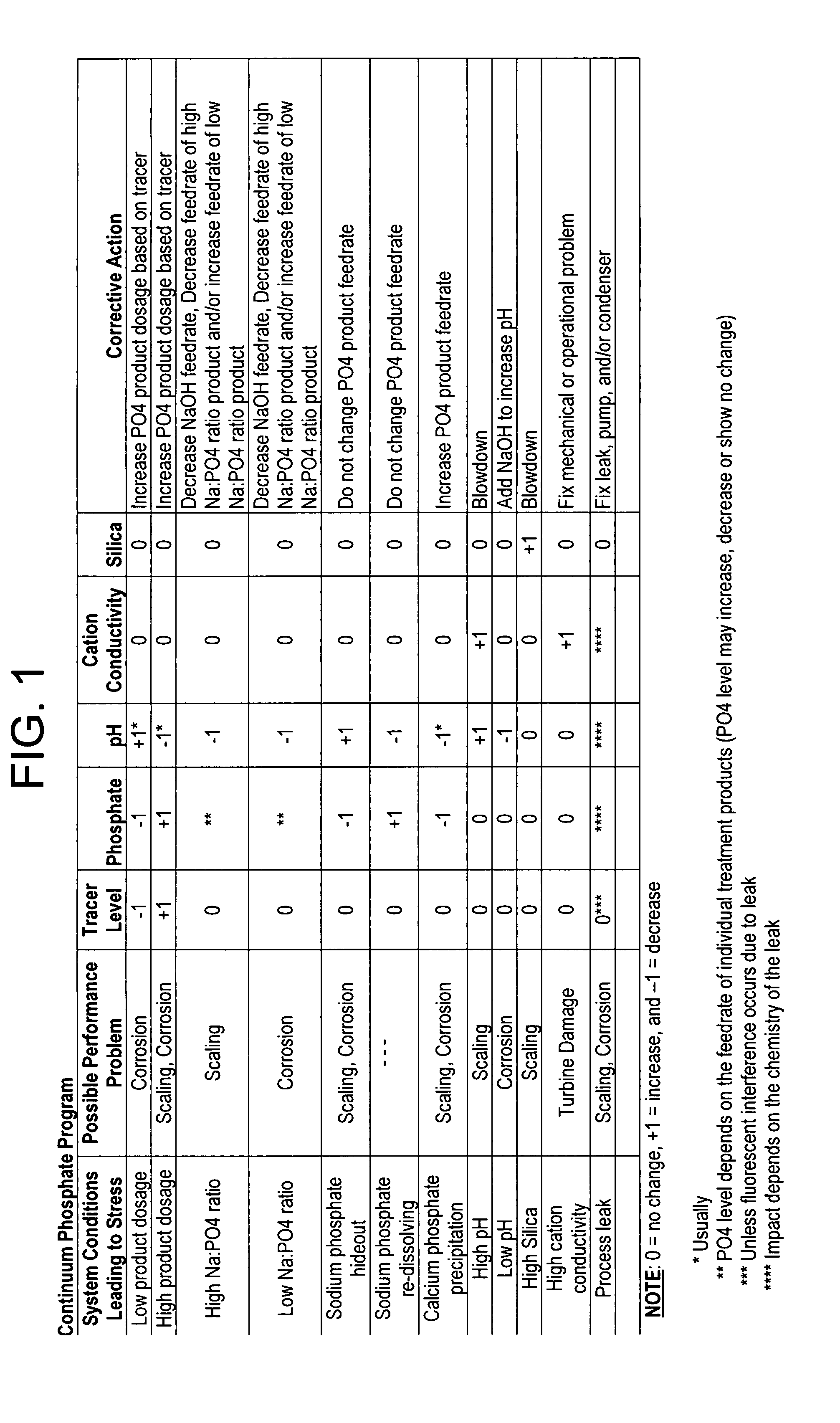

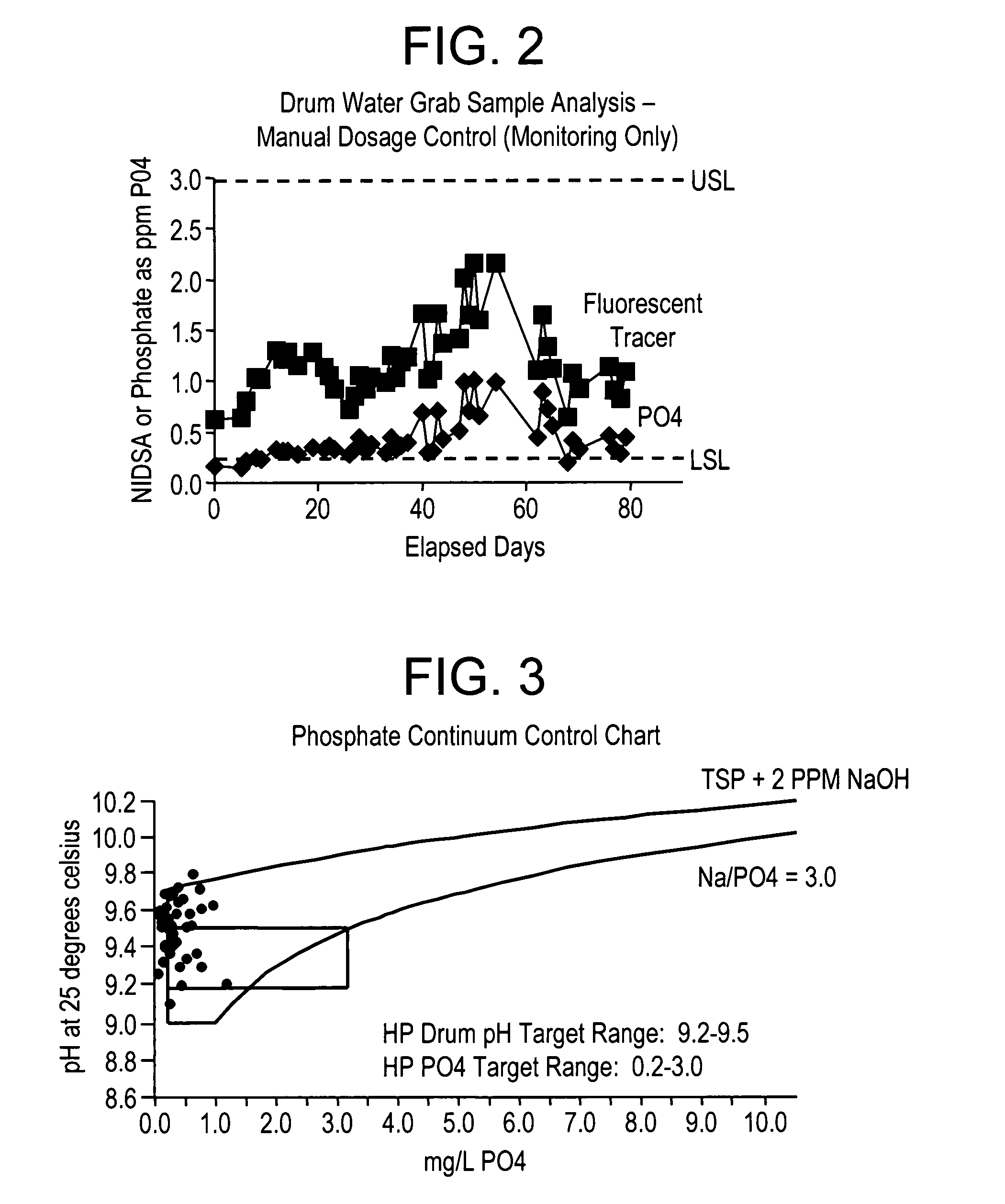

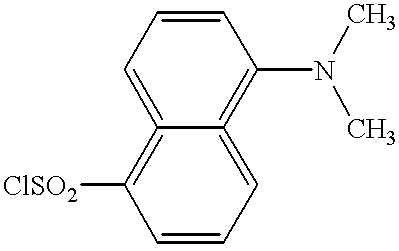

Very high-temperature fluorescent tracer and automation for boiler water applications

A method of fluorometrically monitoring dose control and leak detection, as well as boiler water system programs that occur in industrial systems containing boilers that operate between about 1500 psig and 2600 psig, and at pH from about 7.6 to 11.5.

Owner:ECOLAB USA INC

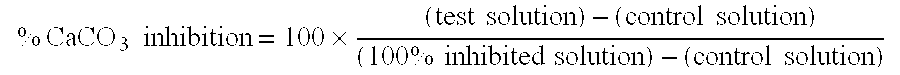

Scale inhibition agent and method for using same

InactiveUS6162391APrevent scalingPrevent adhesionOther chemical processesWater softeningSilicon dioxidePolymer

An agent for preventing scale formation and a method for preventing scale formation include a polymer which has at least 50% of N-vinyl formamide units or N-vinyl acetamide units and a phosphorus compound added to water in a cooling water system, a boiler water system, or the like. The scale preventing agent and scale preventing method of the present invention are effective in preventing the adherence of various types of scales which are generated in cooling water systems, boiler water systems, and the like. In particular, the present invention is effective in preventing the adherence of silica and calcium scale.

Owner:KURITA WATER INDUSTRIES LTD

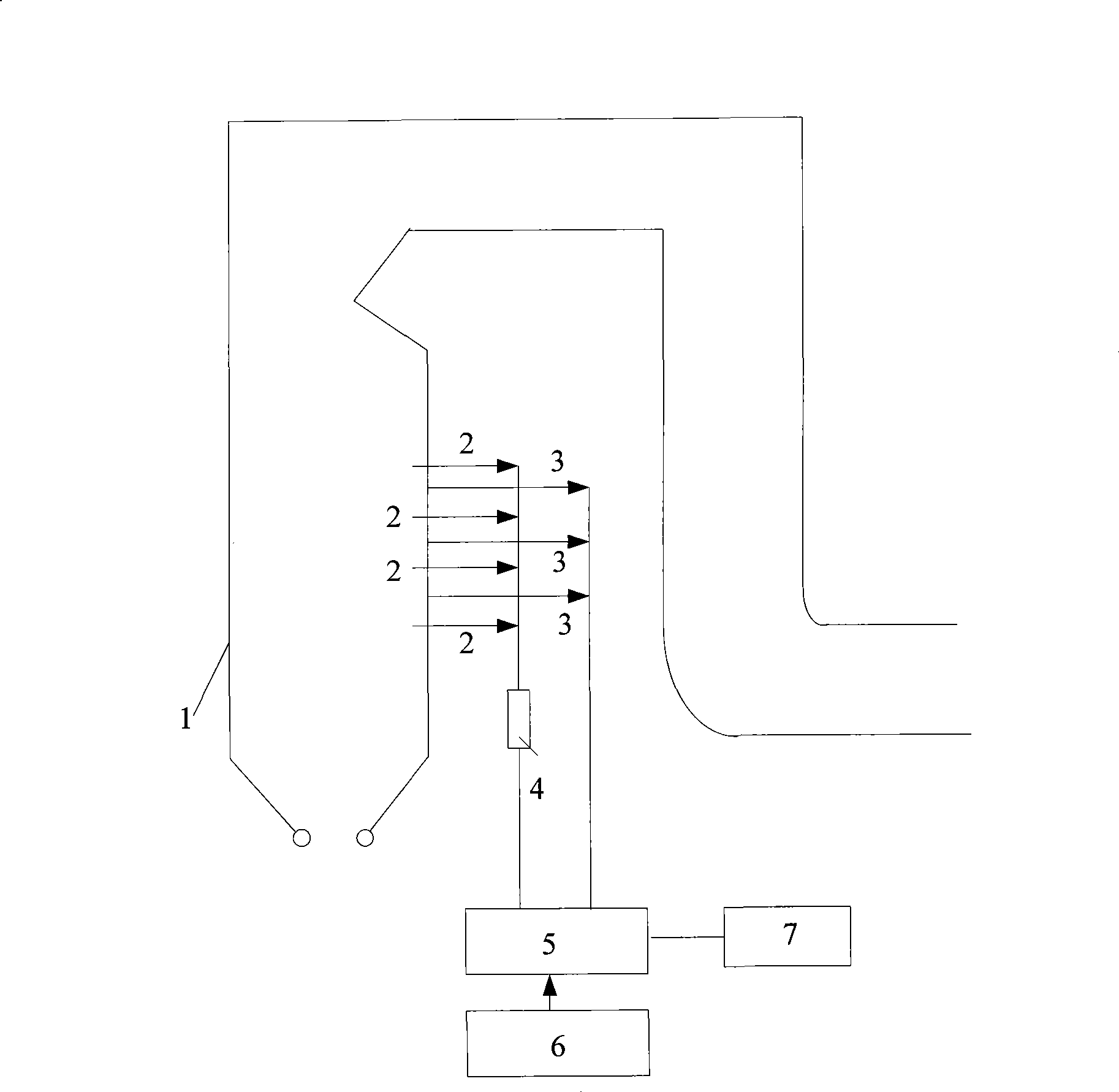

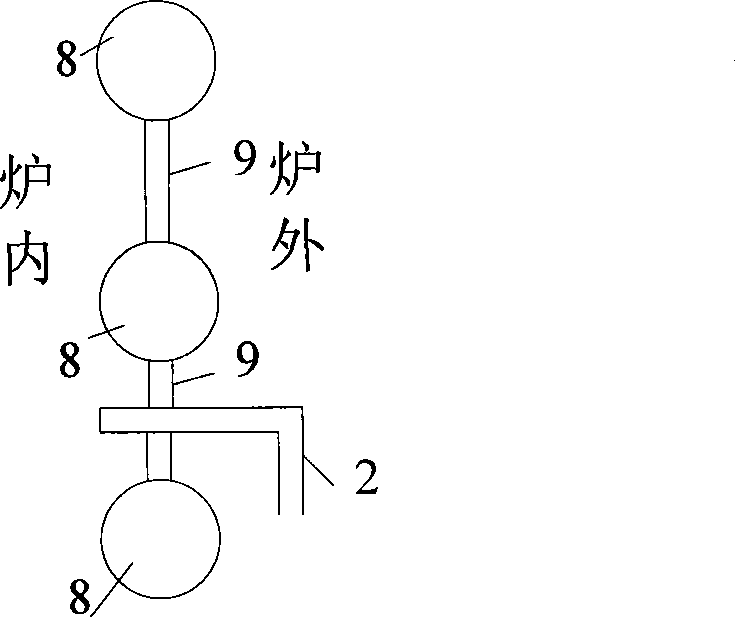

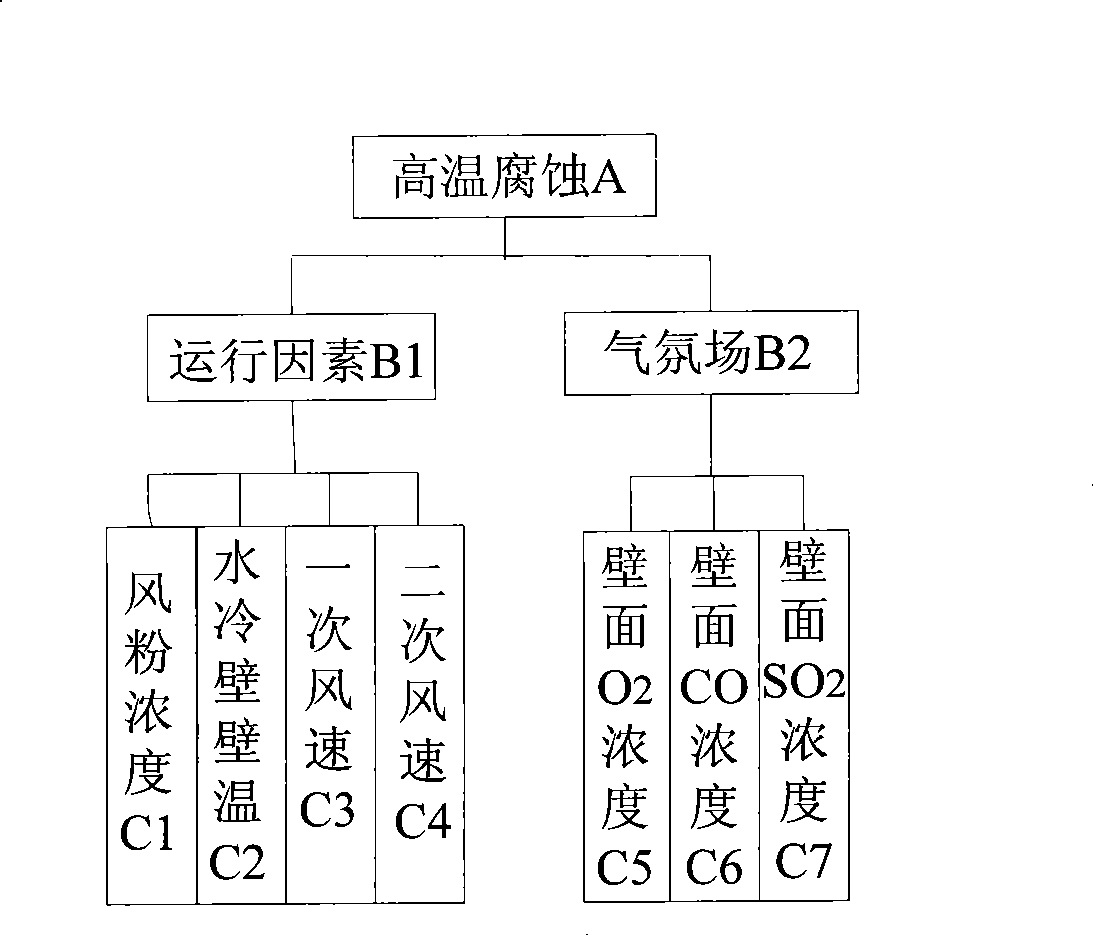

Boiler water-cooling wall high-temperature corrosion on-line monitoring device and method thereof

The invention provides a boiler water wall high-temperature corrosion on-line monitoring device and a method thereof. The device comprises a flue gas sampling pipe, a flue gas analyzer, an industrial computer, a high temperature thermocouple and a monitor. The method comprises the following steps: opening holes of the connection plate between the pipes on the membrane water wall; arranging 1 to 5 layers of measuring points in the height direction of a furnace; sucking flue gas by the flue gas sampling pipe; measuring the concentrations of CO, O2 and SO2 in the flue gas by the flue gas analyzer; and measuring the wall temperature of the wall of the water wall by combining the high temperature thermocouple; and transmitting the measured data to the industrial computer. Meanwhile, the industrial computer receives the data of the primary air speed, the secondary air speed and the air powder concentration of the Oracle database of the MIS system of a power plant, analyzes by modified intangible analytical hierarchy process, calculates the weight of the prior high-temperature corrosion influencing factor, carries out ordering on a real-time basis according to the weight, display the result on the picture of the monitor in a user-friendly manner, and gives a relevant diagnosis suggestion, and requires the line personnel to adjust timely.

Owner:XI AN JIAOTONG UNIV

Detectable polymers and methods for detecting polymers in Aqueous systems

InactiveUS6251680B1High molecular weightDecrease in levelAnalysis using chemical indicatorsOrganic detergent compounding agentsThiolPaper production

Polymers having amine-thiol terminal moieties are provided. The amine-thiol terminal moieties are imparted by using amine-thiols as chain transfer agents in aqueous addition polymerizations. The polymers are useful as mineral dispersants, as water-treatment additives for boiler waters, cooling towers, reverse osmosis applications, sugar refining, paper production, geothermal processes and oil wells, and as detergent additives acting as builders, anti-filming agents, dispersants, sequestering agents and encrustation inhibitors.

Owner:ROHM & HAAS CO

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS20050150520A1Reduced pHDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

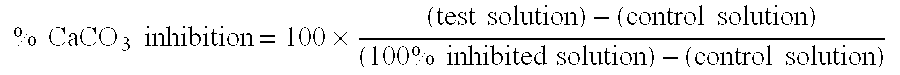

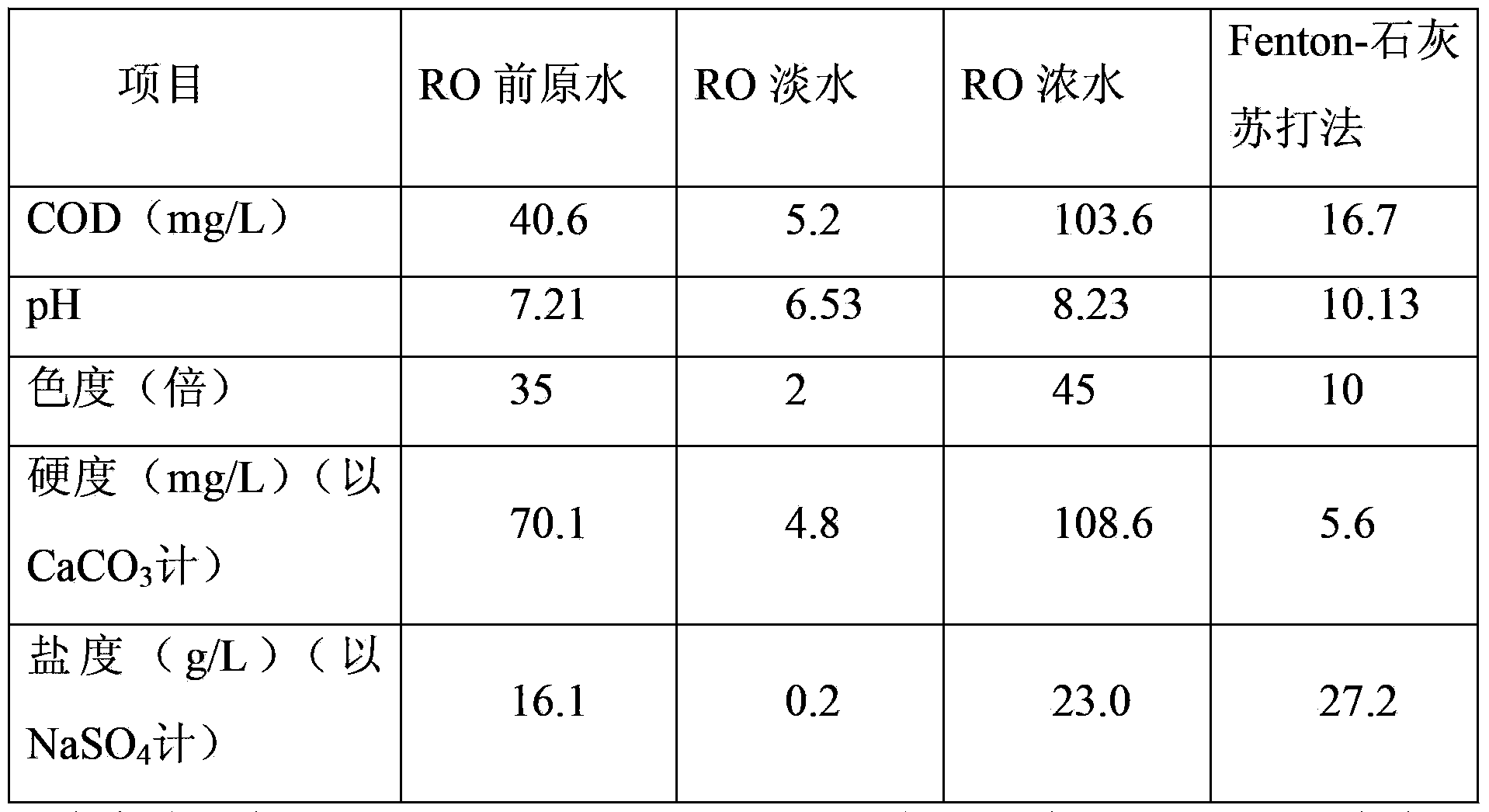

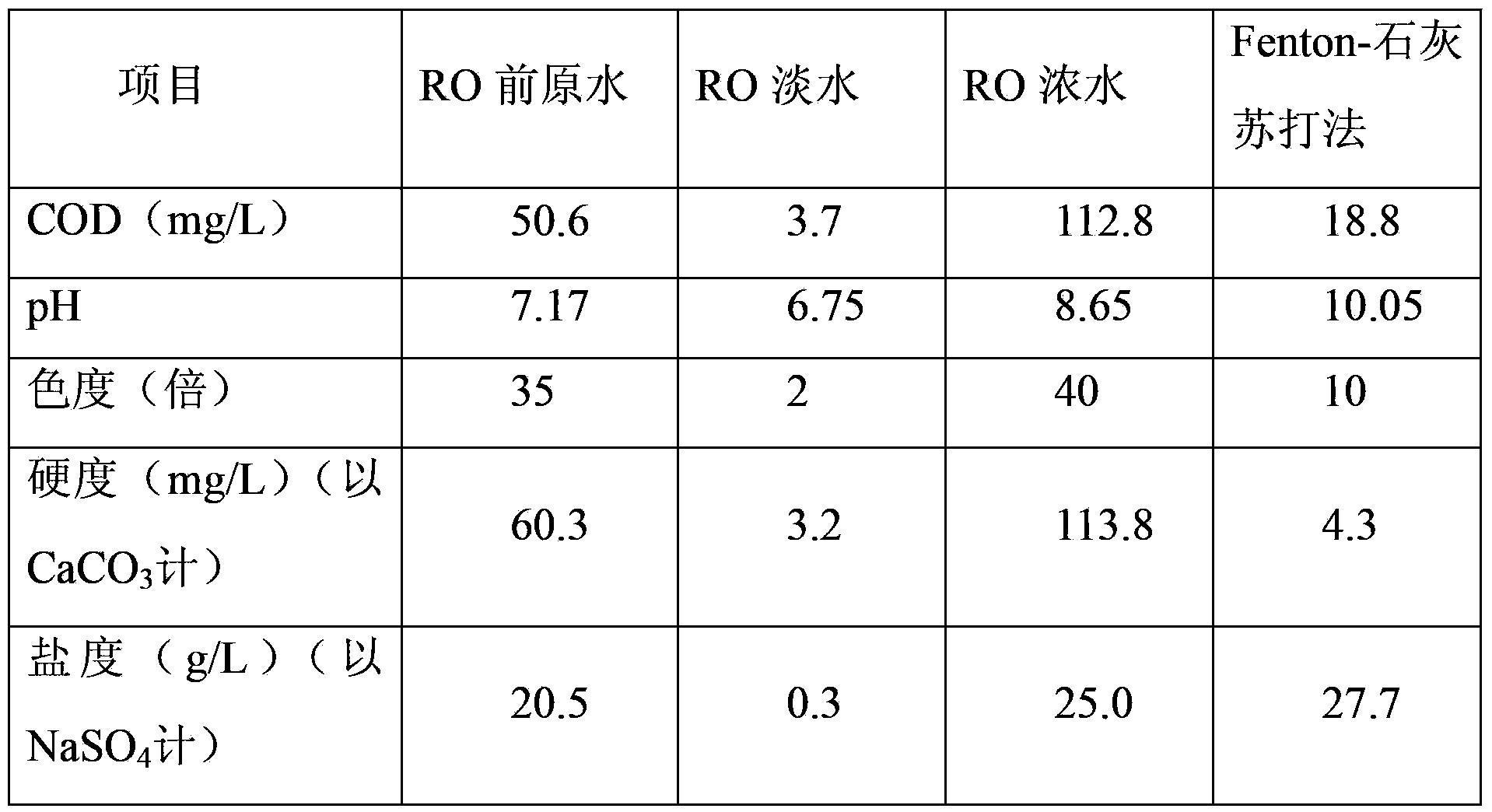

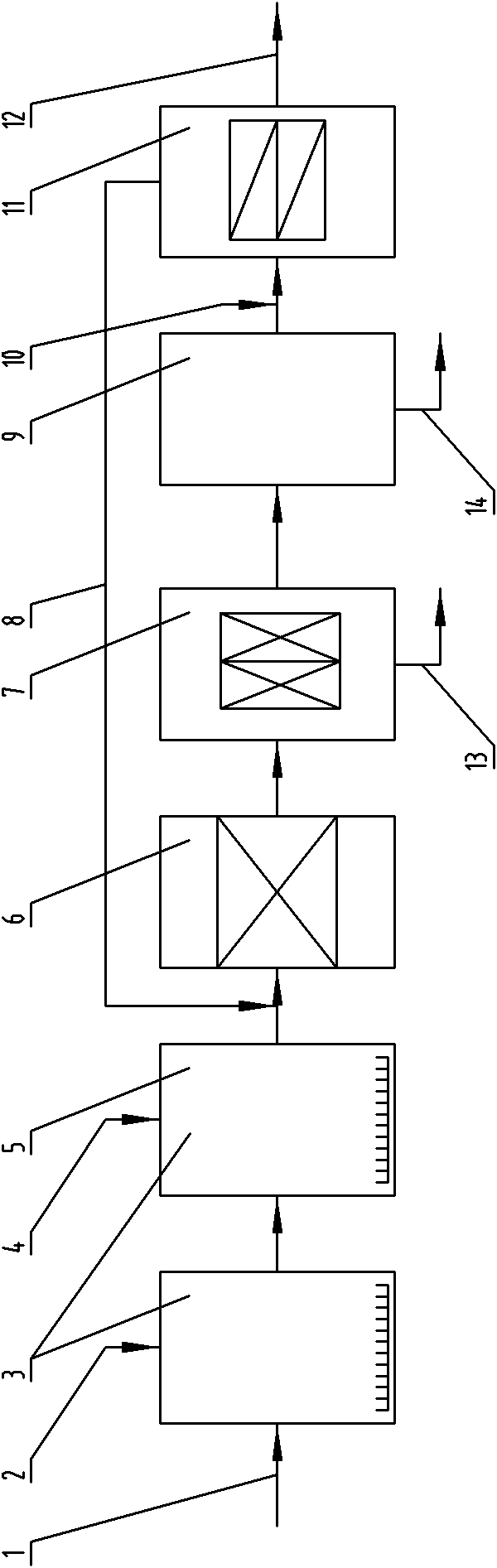

Treatment method for realizing zero emission of printing and dyeing wastewater

ActiveCN103359878AReduce energy consumptionNo secondary pollutionMultistage water/sewage treatmentWaste water treatment from textile industryEcological environmentUltrafiltration

The invention discloses a treatment method for realizing zero emission of printing and dyeing wastewater. The treatment method comprises the following steps: performing physicochemical and biochemical treatments on printing and dyeing wastewater stoste; performing such advanced treatments on the discharged water as sand filtration, ultrafiltration and security filtration, and then, conveying the discharged water into a nanofiltration or reverse osmosis membrane treatment system to perform membrane treatment, thus obtaining fresh water and concentrated water through the membrane treatment, wherein the fresh water is low-COD and low-hardness ionized water and is used as process water to be directly recycled in dyeing procedure, boiler water addition, general washing or circulating cooling water. The concentrated water is high-salinity and high-hardness wastewater containing organic pollutants, the concentrated water is treated by a Fenton oxidation coupling lime soda method, the concentrated water becomes low-COD and low-hardness water with high salinity, and salt is directly added in the concentrated water according to dyeing process requirements so as to recycle the concentrated water in the dyeing procedure. The treatment method provided by the invention can be used for completely recycling the treated wastewater to realize zero emission of printing and dyeing enterprises and save the cost, and the treatment method is free of secondary pollution, thereby protecting the ecological environment and recycling the printing and dyeing wastewater.

Owner:SOUTH CHINA UNIV OF TECH

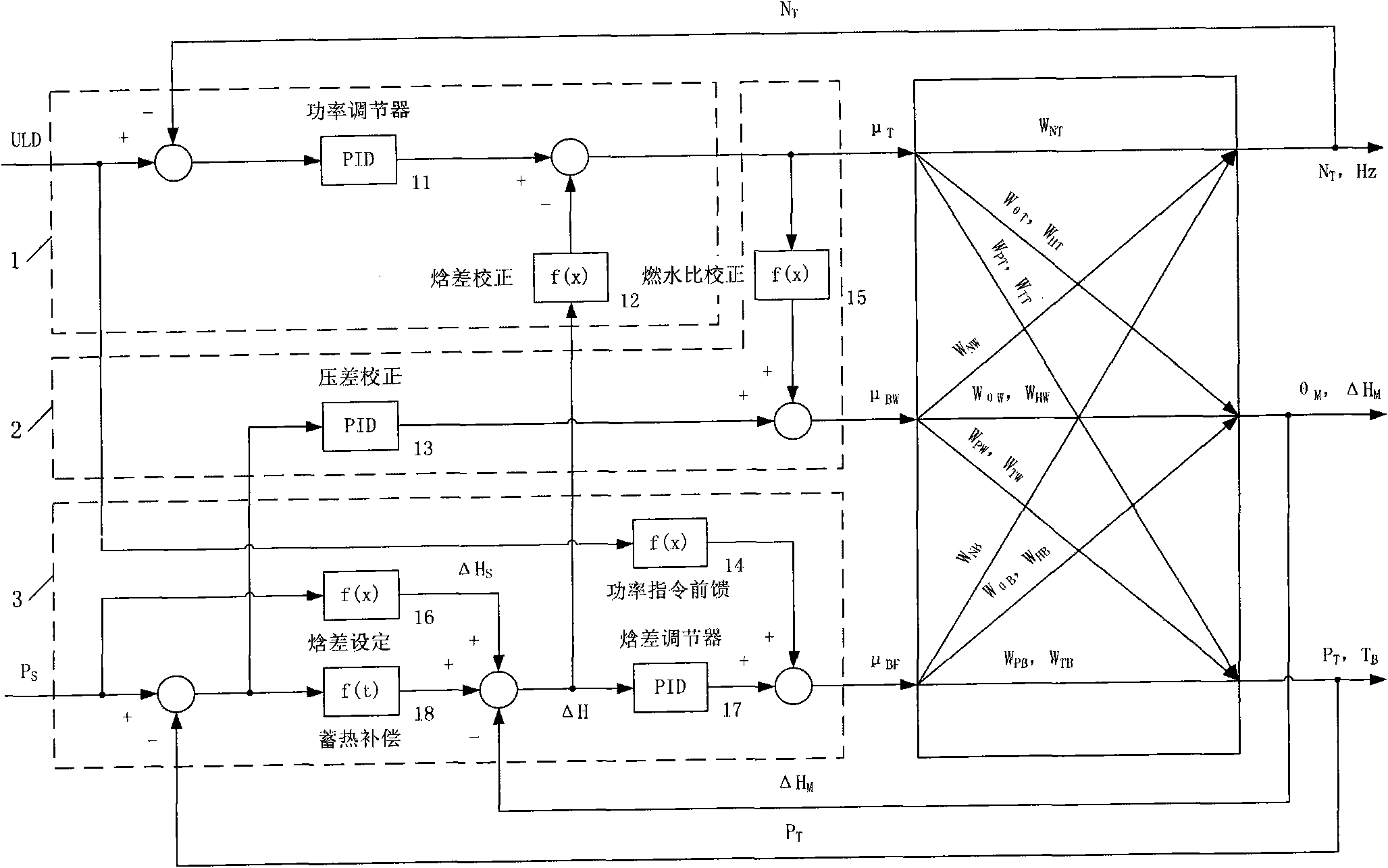

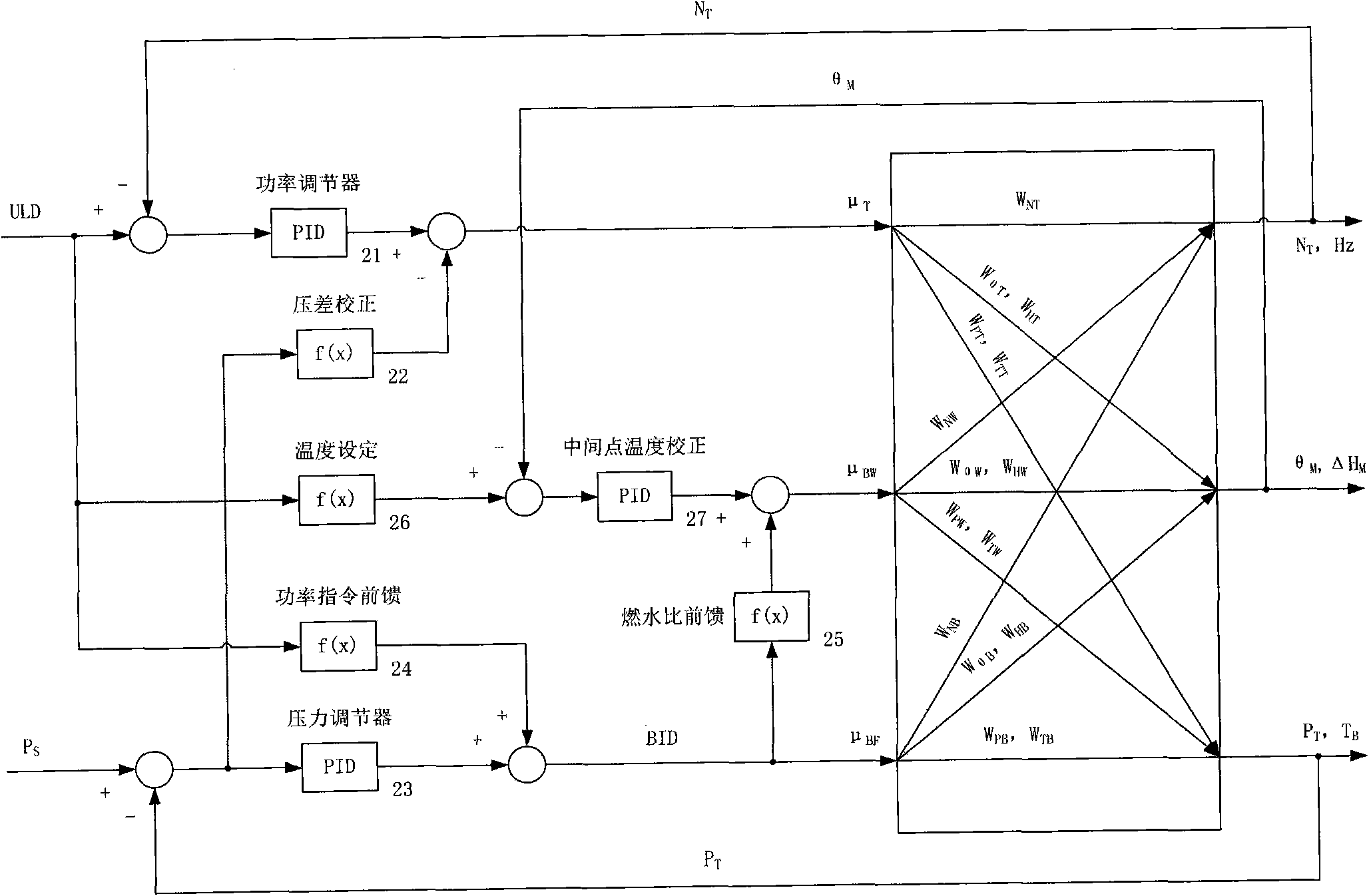

Direct mass balancing and coordinating control system of direct current boiler unit

ActiveCN102323748AImprove dynamic response characteristicsImprove stabilityEngine componentsSteam engine plantsEnergy balancingEvaporation

The invention respectively adopts a direct energy balancing mechanism to realize the dynamic decoupling between a steam turbine power regulating loop and a boiler burning regulating loop and a direct mass (flow) balancing mechanism to realize the dynamic decoupling between a steam turbine power regulating loop and a boiler water supply regulating loop, and decouples a usual direct current boiler unit 3*n multi-variable parallel control system onto a decoupling control loop in a hierarchical control structure. The boiler burning regulating loop cancels an usual front side pressure series regulator, and takes the enthalpy increased deviation of an evaporation heated surface of a boiler as the control input; and the boiler water supply regulating loop is designed into fuel-water ratio regulation with a steam turbine power instruction as the input; and the dynamic compensation between boiler burning and water supply is designed. The method best eliminates the coupling impact among all the regulating loops, so that the adjustment is convenient, and the control quality of the direct current furnace unit coordinating control system under the working conditions of variable pressure and variable load is improved.

Owner:BEIJING GUODIAN ZHISHEN CONTROL TONGDY

Preparation method of nickel base alloy coating on boiler water wall

InactiveCN104264102AAccelerated corrosionImprove wear resistanceMolten spray coatingCompound structureAlloy coating

A preparation method of a nickel base alloy coating on a boiler water wall is characterized in that a compound coating is formed on the surface of a tube panel of the boiler water wall and adopts a double-layer compound structure coating which is formed by coating a bonding base layer on the tube panel of the boiler water wall by supersonic-speed electric arc spraying equipment and coating a nickel base alloy coating resistant to the high-temperature corrosion and abrasion on the combined base layer. According to the preparation method of the nickel base alloy coating on the boiler water wall, the service life of the boiler water wall can be greatly prolonged, the process is simple, the production cost is low, the controllability is good, the influence on a substrate is small, the bonding strength of the coating is high, the service life of the boiler water wall can be effectively prolonged, and the boiler water wall has excellent corrosion and abrasion resistance.

Owner:XI'AN PETROLEUM UNIVERSITY

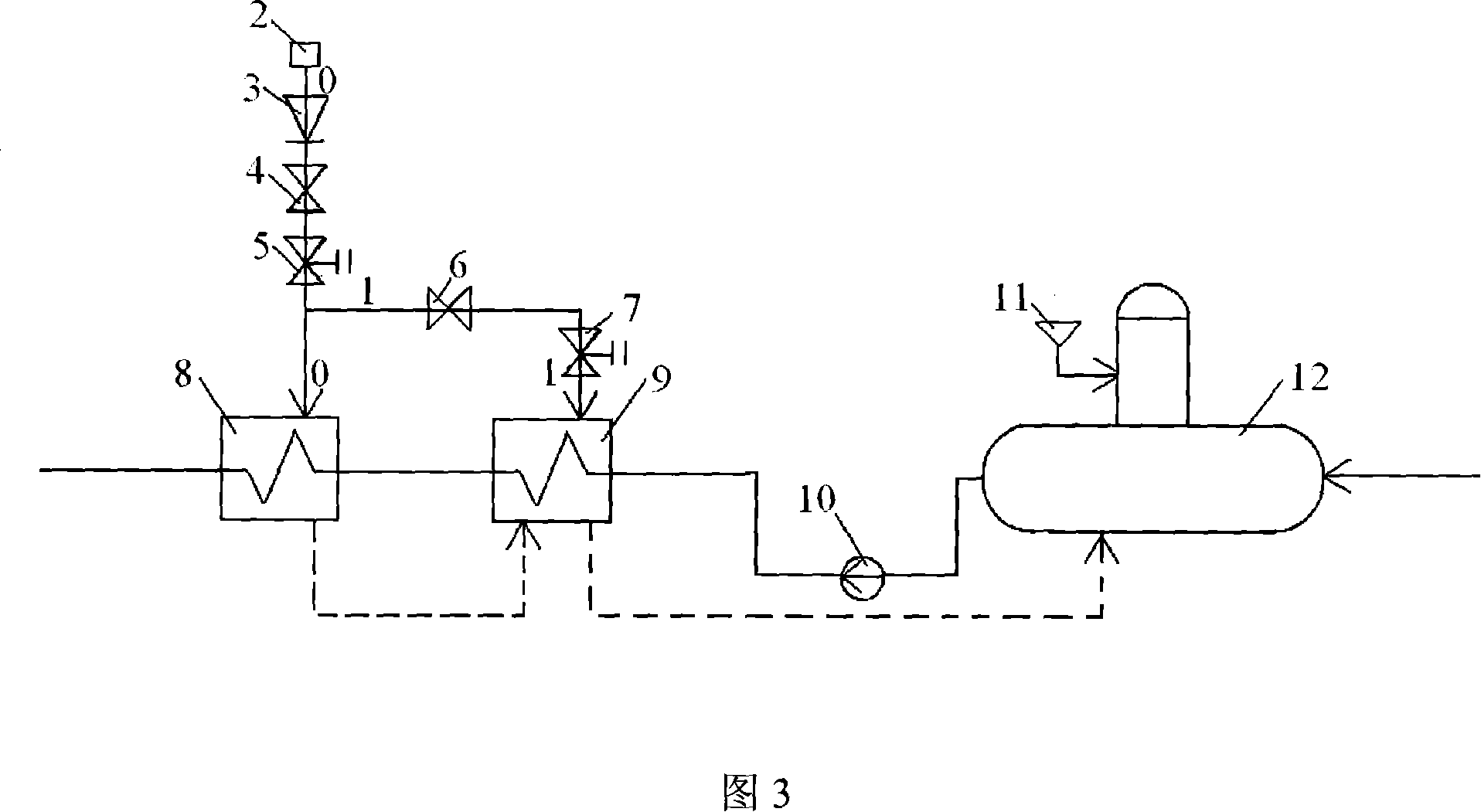

Start-up method with circulating-stove-water pump monotube boiler near steam heating boilers

ActiveCN101135433AShorten oiling timeReduce fuel consumptionSteam generationEngineeringHigh pressure

This invention declares a starting process of once-through boiler with by neighboring steam heating in which the high pressure heater is connected by the pipeline receiving exogenous heating steam. The mentioned process includes: heating the water in the unit boiler with the exogenous steam through the high pressure heater, heating the heat delivery surface of the boiler indirectly when starting up at cold, warm or hot status, starting the boiler water circulating pump and air-gas system when the temperature is close to the saturation temperature of the exogenous steam, ignition of the boiler, increasing the thermal load with bypass system after the is started, switching off the fuel when the thermal load of the coal exceeds the minimum oil-break thermal load and switching to the general starting process; when starting at the extreme hot status, ignition of the boiler after purging, after the coal pulverizing system is started, switching off the fuel when the thermal load of the coal exceeds the minimum oil-break thermal load and switching to the general starting process. The starting process will shorten the starting duration, and save fuel, coal and water.

Owner:冯伟忠

Use of disulfonated anthracenes as inert fluorescent tracers

InactiveUS7220382B2Quantity minimizationDetection of fluid at leakage pointSamplingAnthraceneSteam line

The use of an isomer of anthracene disulfonic acid as an inert fluorescent tracer is described and claimed. The utility of this type of inert fluorescent tracer in boiler systems to trace unwanted carryover of boiler water into a steam line is also described and claimed.

Owner:ECOLAB USA INC

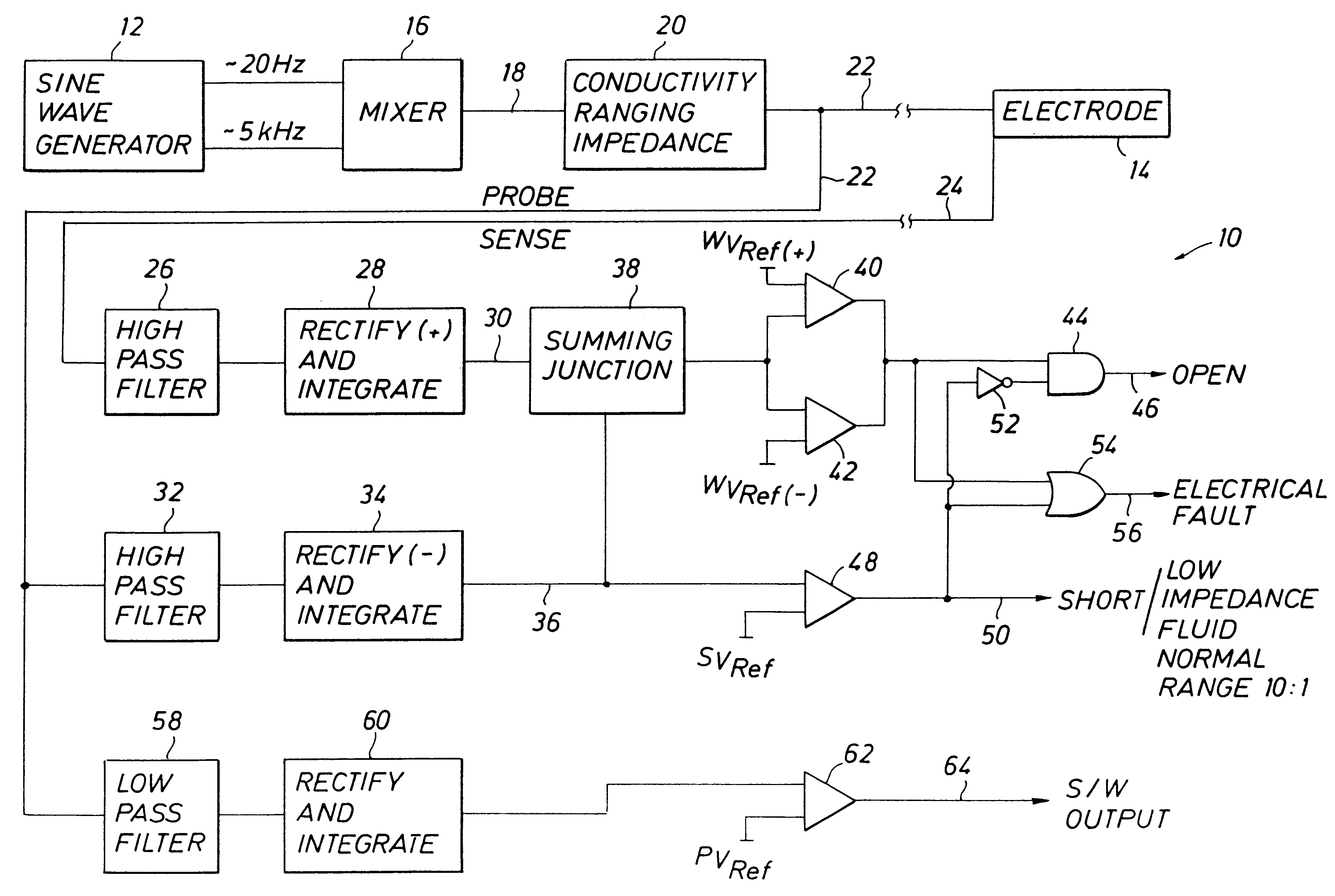

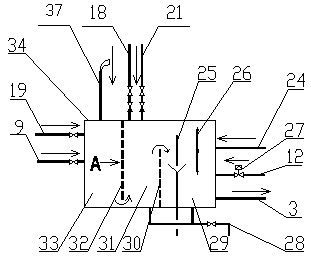

Method and apparatus for circuit fault detection with boiler water level detection system

InactiveUS6650128B2Rule out the possibilityTesting/calibration apparatusResistance/reactance/impedenceDual frequencyAc components

A fault detection circuit in a boiler-water level system includes a dual-frequency signal generator which develops two AC components with no associated DC component. The two frequencies are mixed and sent through an impedance matching circuit to match the impedance of the signal generating portion of the system with the impedance of the boiler water under measurement. The impedance-matched signal is then directed to two legs, one leg directed through one of a plurality of electrode probes and then to a first filter circuit, and the other leg is directed a second set of filters. In combination, the filters pass either the higher or the lower of the two frequencies to determine an open or short condition in the level sensing circuitry, as well as a steam vs. water condition.

Owner:TYCO VALVES & CONTROL INC

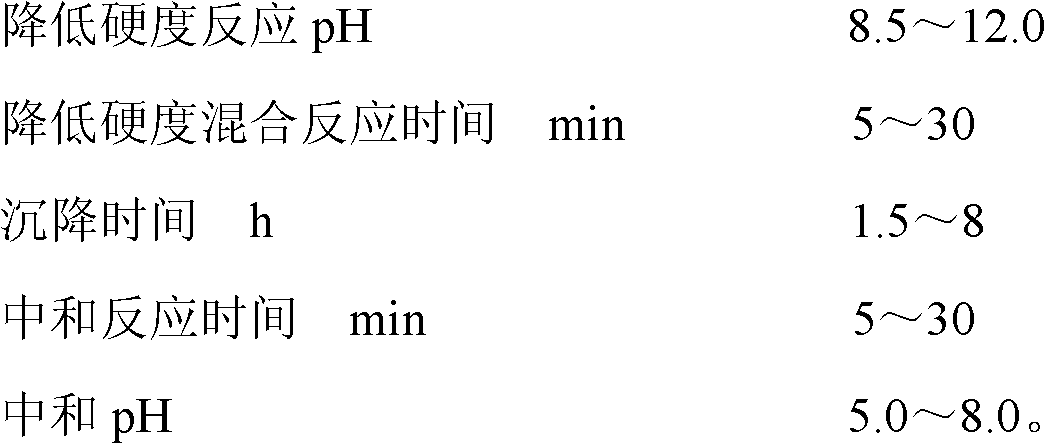

Deep stage treatment method for industrial wastewater

ActiveCN102616962AInfluent water quality requirements are lowReduce energy consumptionDispersed particle separationWater softeningWater qualityReverse osmosis

The invention discloses a deep stage treatment method for industrial wastewater. The method comprises the following steps of: 1, primarily reducing hardness, settling, and neutralizing; 2, filtering; 3, performing electro-adsorption to appropriately remove salt; and 4, performing reverse osmosis to deeply remove salt. According to deep stage treatment method for the industrial wastewater, the water quality application range is wide, a process can run stably, salt can be deeply removed by the method, and a small amount of sewage which is produced by a treatment system and meets the standard is discharged, and secondary pollution is avoided; and the treated industrial wastewater can be used as industrial circulating water, industrial circulating cooling water, and boiler water. The problems that a reverse osmosis membrane is easy to pollute, and reverse osmosis concentrated water which does not meet standard is discharged, and the problem of low running stability are solved; all the discharged sewage which is discharged meets the standard; and the produced water has various water qualities, and the recycling range is widened.

Owner:CHINA PETROLEUM & CHEM CORP

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS7252096B2Detergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

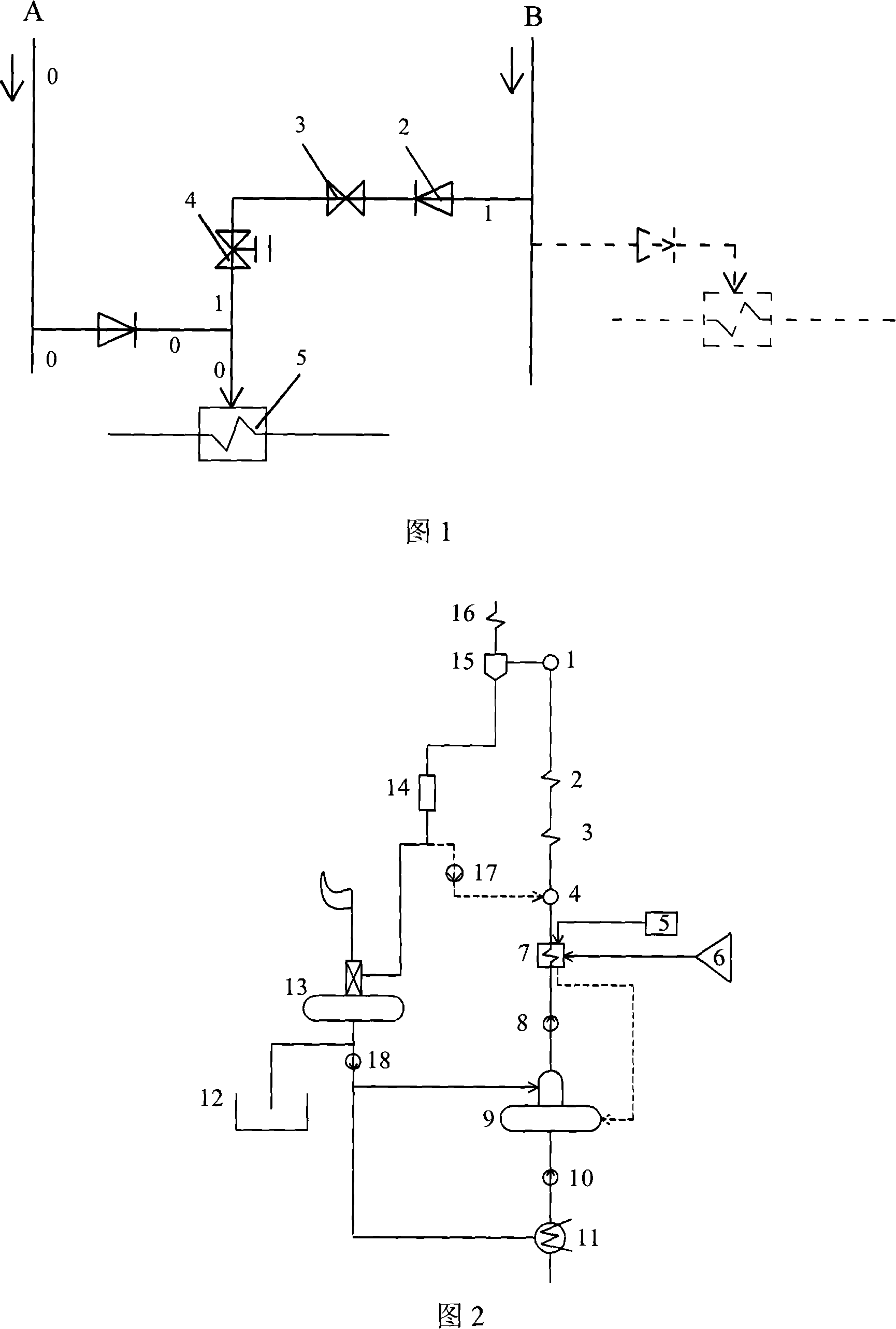

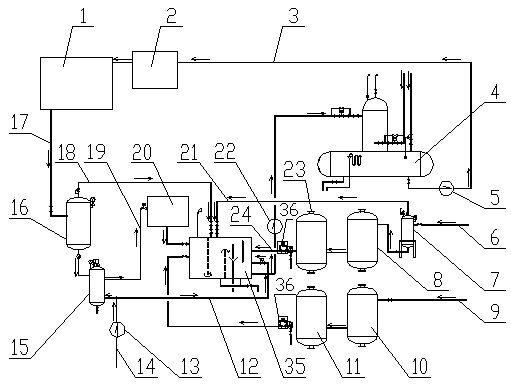

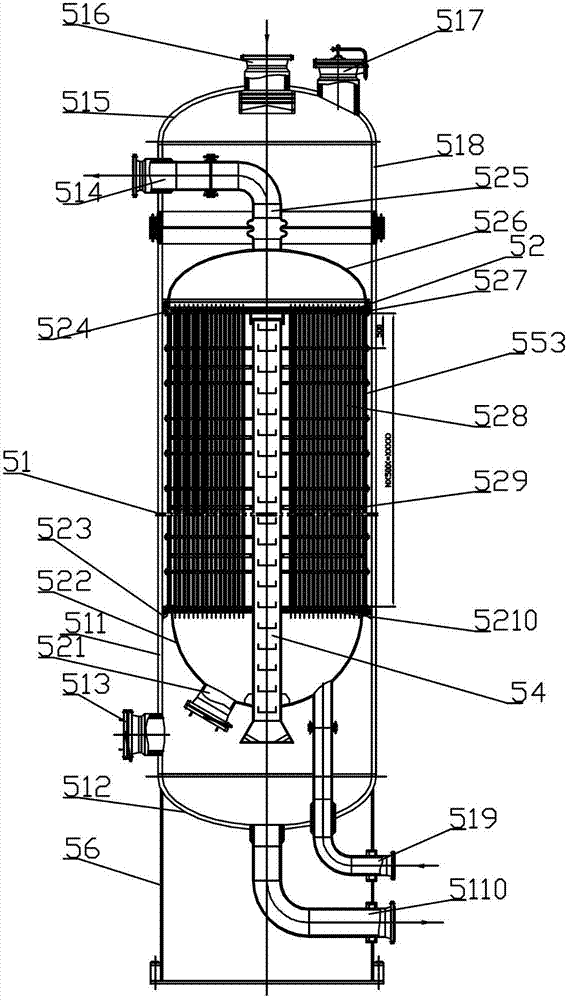

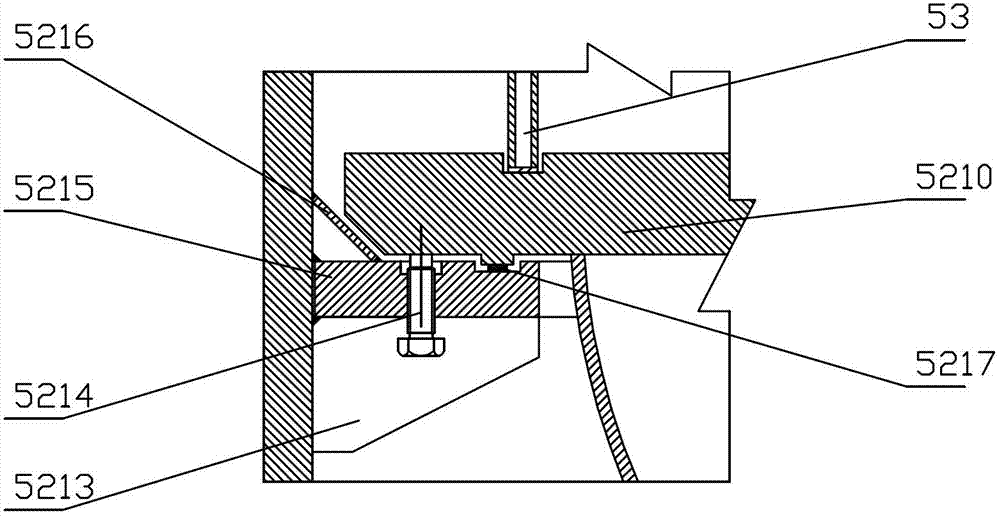

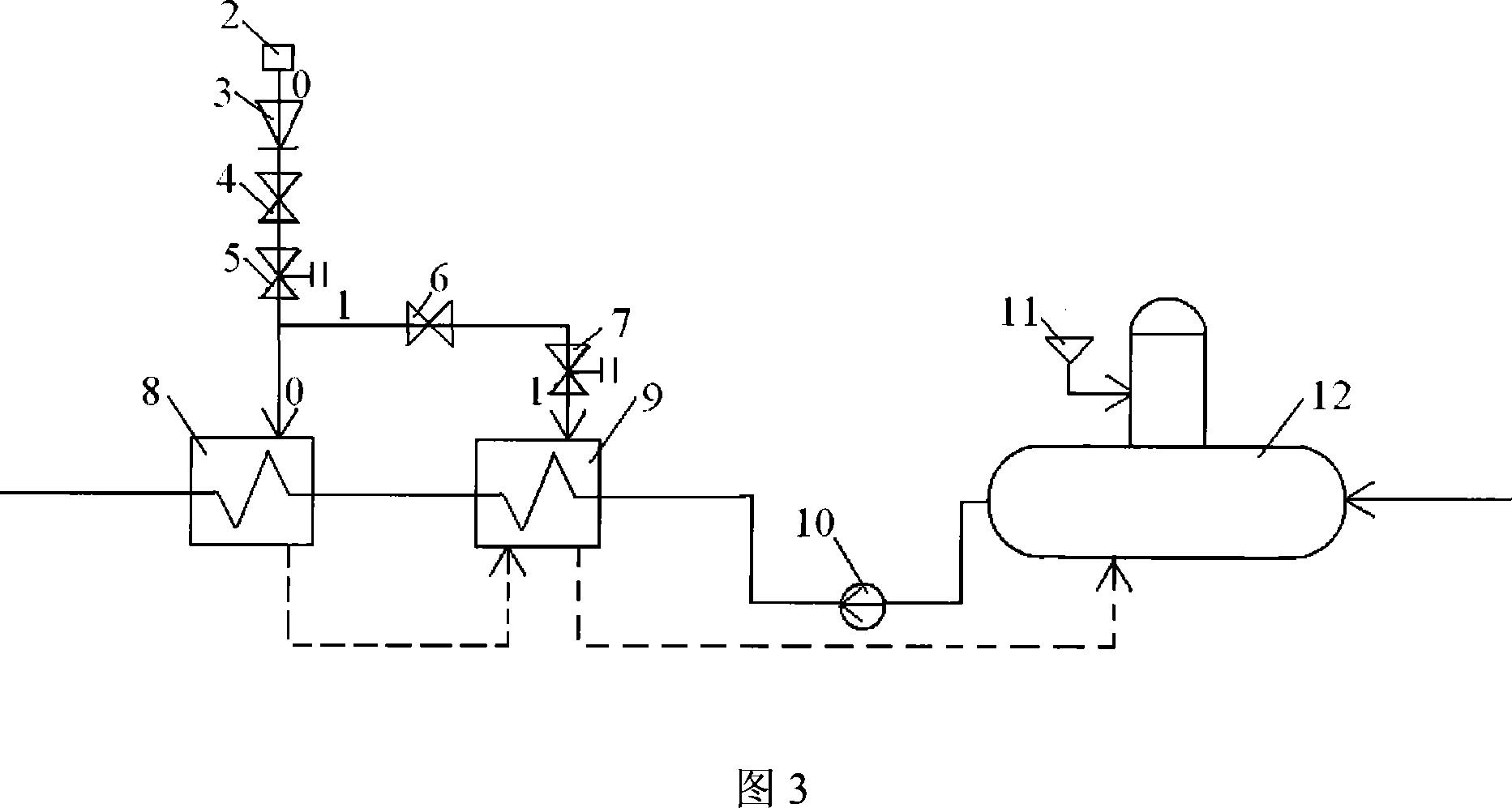

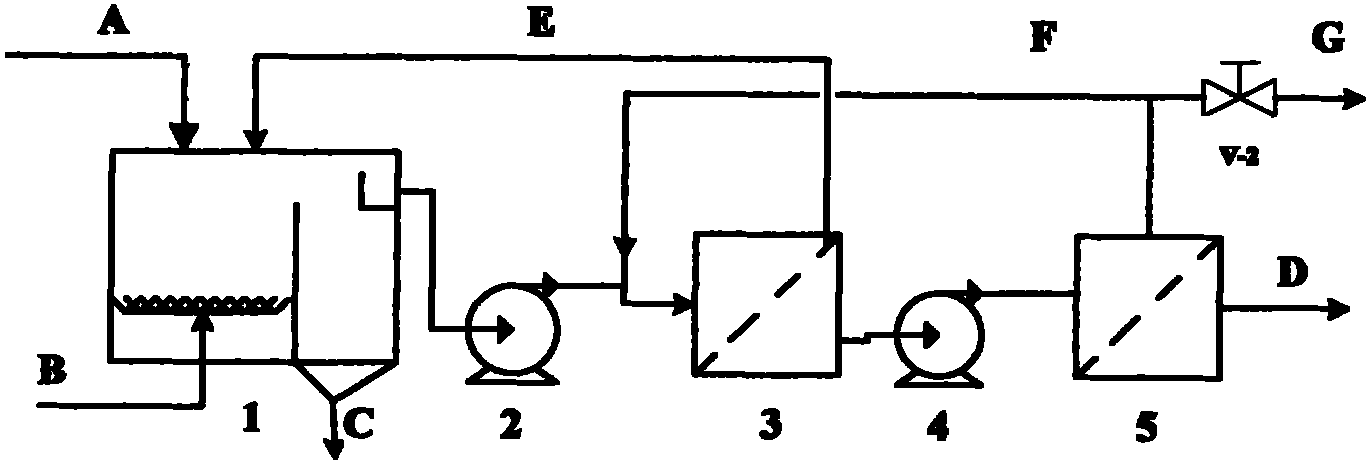

Boiler water replenishing system capable of collecting waste heat and condensed water

ActiveCN102607014AHydration does not affectReduce consumptionFeed water supplyExpansion tankBoiler blowdown

The invention discloses a boiler water replenishing system capable of collecting waste heat and condensed water. A boiler blowdown pipe of a boiler is connected with a blowdown expansion tank, a steam outlet of the blowdown expansion tank is connected into a hot water tank through a blowdown flash steam pipe, a blowdown water pipe of the blowdown expansion tank is connected into a continuous-discharge heat exchanger which is further connected with a softened water feeding pipe, the softened water feeding pipe is connected with a water softening station through a water supply pump, the softened water feeding pipe for the continuous-discharge heat exchanger is connected with a boiler secondary energy saver prior to being connected into the hot water tank, and the hot water tank is connected with a hot water outlet pipe which is sequentially connected with a circulating pump, a heat deaerator and a boiler water feeding pump prior to being connected into a boiler water inlet. The boiler water replenishing system has the advantages that centralized use of the waste heat and the condensed water is achieved, steam consumption of the deaerator is reduced, waste heat absorption effect is enhanced, connection of the deaerator is simplified, pollution of the heat and the condensed water to the environment is reduced, and water replenishing for the boiler is unaffected when heat exchange equipment fails.

Owner:CHINA TOBACCO HENAN IND

Boiler water level monitoring and control system

A software-based water level monitoring and control system, preferably for use with conventional steam boilers, is disclosed. The system includes software for monitoring and recording system functions, safety features, diagnostic testing histories, and other functions. The water level system is employed to monitor and / or regulate one or more operating parameters of the boiler, such as water levels within the boiler. In response to the boiler system testing of low-water cut-off, auxillary low-water cut-off, and pressure vessel float operation and functionality, the software builds histories and other data compilations. The extensive electronic information permits a user that accesses the water level control system to, for example, view the data compilations and to monitor the status of the system. In this manner, real-time information, as well as the historical data, are available to accomplish the regulation of key parameters in the boiler.

Owner:CLEAVER BROOKS INC

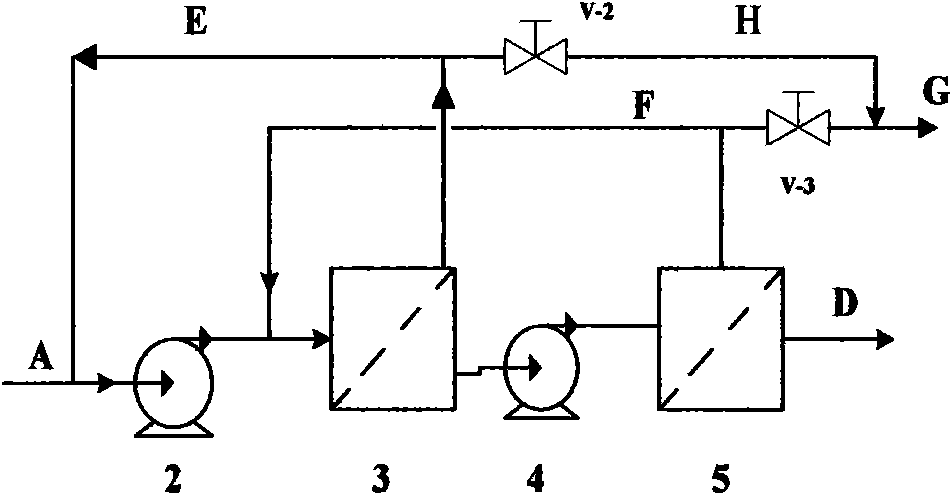

Saturation tower/isothermal furnace series/heat isolation furnace CO transformation technology

ActiveCN102888252ASmall pressure dropSave compression workHydrogen separationCombustible gas catalytic treatmentState of artSystem pressure

Owner:CHINA PETROCHEMICAL CORP +2

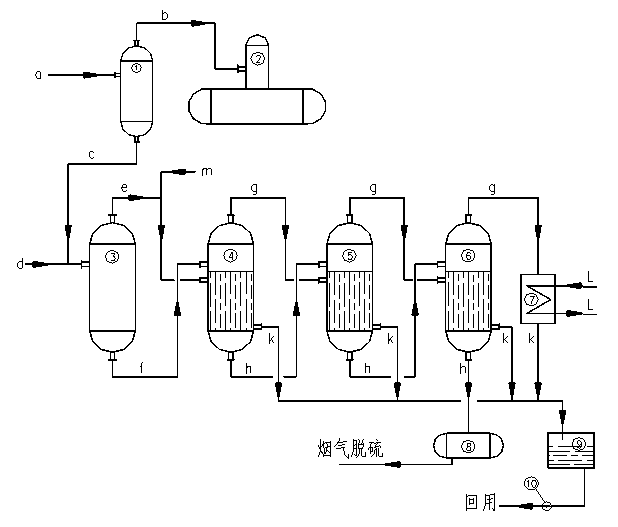

Comprehensive utilization method of thermal power plant boiler wastewater

The invention provides a comprehensive utilization method of thermal power plant boiler wastewater. The comprehensive utilization method comprises the following process steps: (1) continuous boiler wastewater goes into a continuous blowdown flash tank for reduced-pressure flashing; secondary steam generated after flashing is guided out of the upper part of the continuous blowdown flash tank and into a deaerator; (2) the hot wastewater at the bottom of the continuous blowdown flash tank is guided into a boiler periodic blowdown flash tank for further reduced-pressure flashing together with regular boiler wastewater; (3) the secondary steam generated by flashing from the periodic blowdown flash tank serves as a heat source and is guided into a low-temperature multiple-effect evaporator group, and bottom salt-containing wastewater also goes into the low-temperature multiple-effect evaporator group as the evaporated liquid; (4) the condensed water generated by the low-temperature multiple-effect evaporator group and the steam condensed water out of a cooler are collected to a condensed water tank by use of a condensation header and then fed into a boiler water supply system by use of a condensed water pump to be recycled; a thickened liquid generated by performing multiple-effect evaporation on the salt-containing wastewater is recycled into a thickened liquid recovery tank and then fed into a wet boiler flue gas desulphurization system used as a desulfurizing agent for desulphurization.

Owner:CHINA CEC ENG

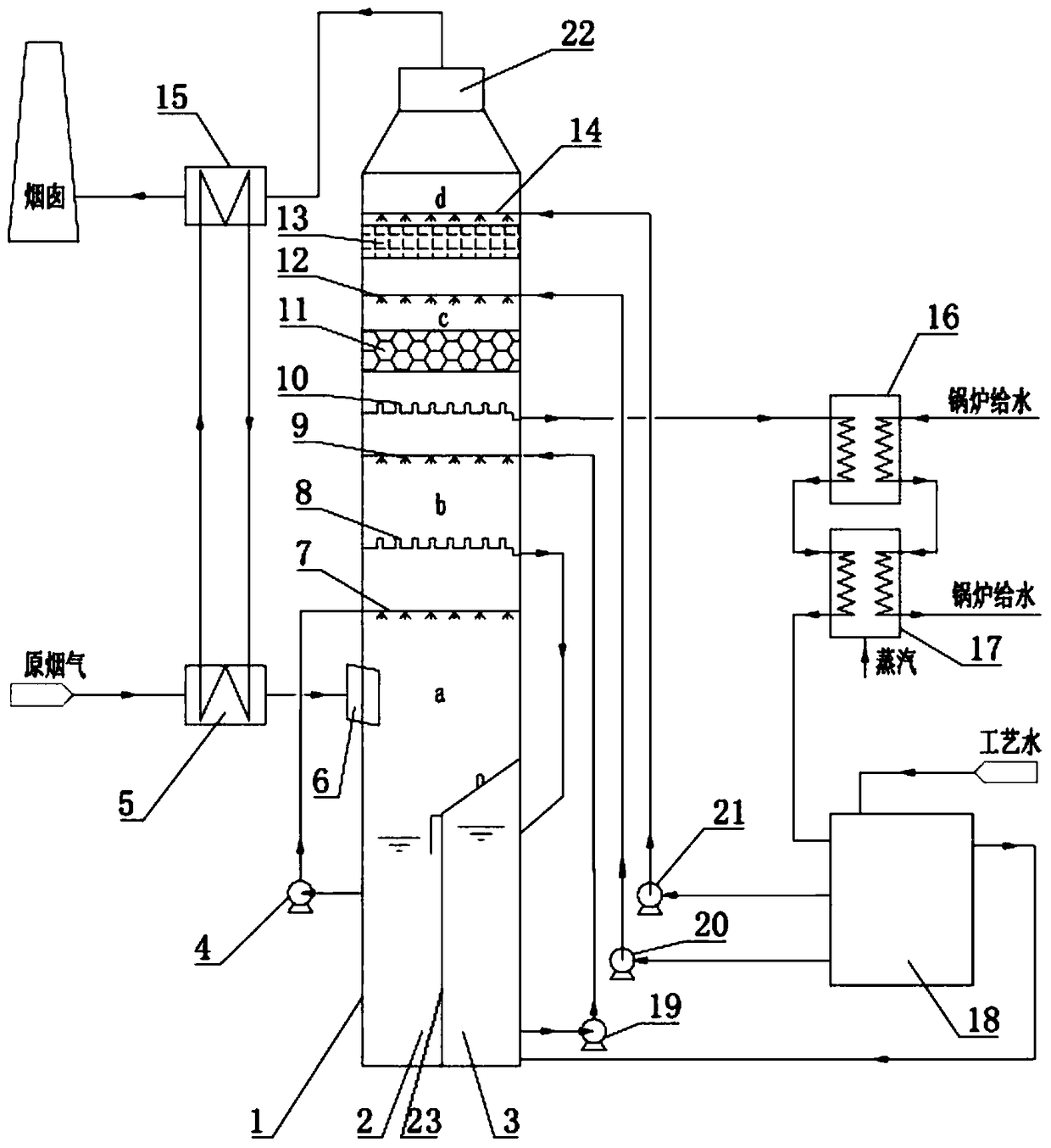

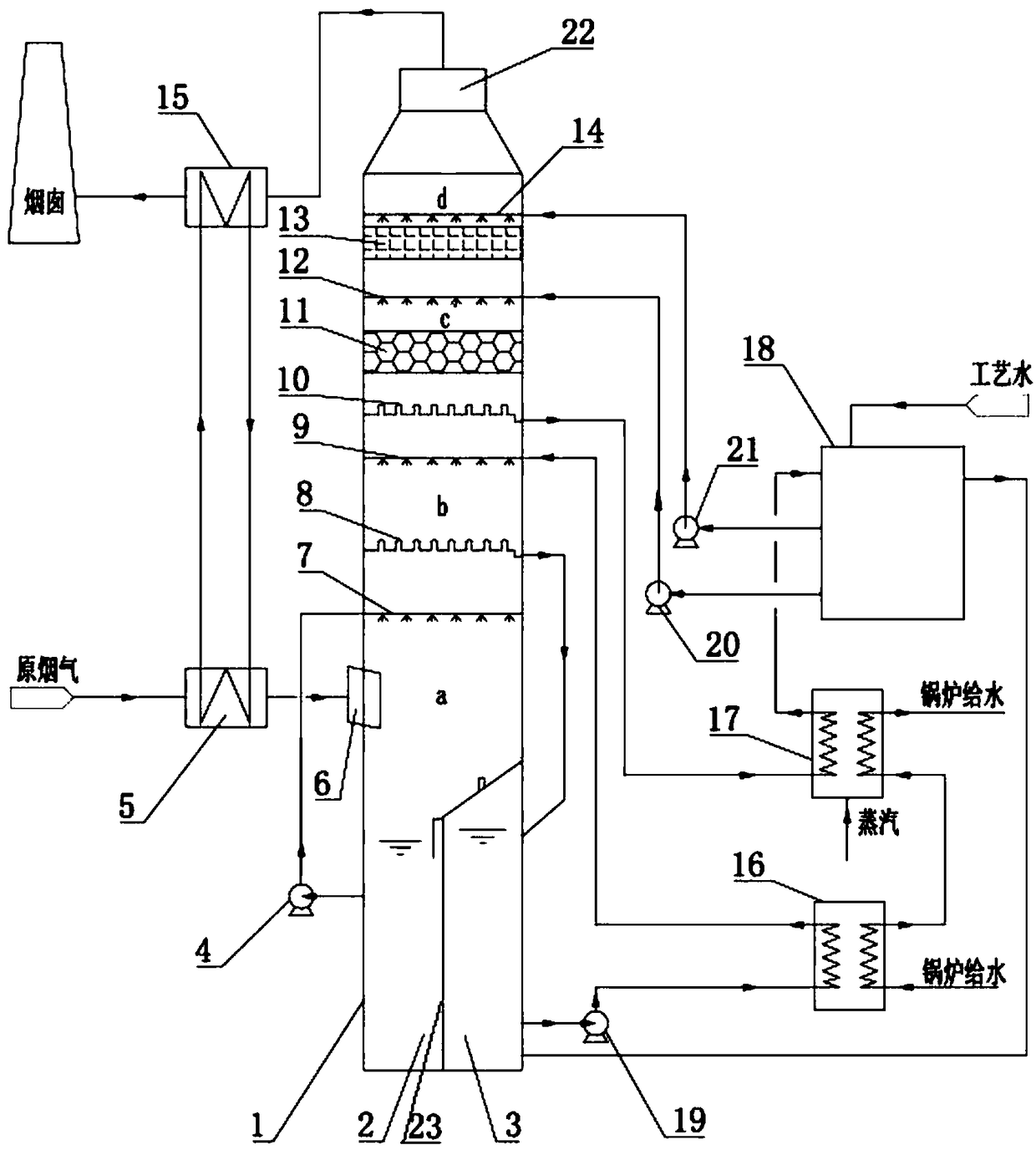

System for desulfurization, white smoke elimination and deep waste heat recovery based on ammonia process, and application

PendingCN109045976AImprove desulfurization efficiencyImprove cleanlinessGas treatmentDispersed particle separationRecuperatorAbsorption heat pump

The invention relates to a system for desulfurization, white smoke elimination and deep waste heat recovery based on an ammonia process. The system comprises a desulfurization tower, a circulating water tank, a heat exchanger, an absorption heat pump unit, a flue gas cooling section, a flue gas heating section, an inlet flue and an outlet flue; the desulfurization tower above a concentration tankis coaxially provided with a concentration section, a desulfurization section, a water washing section and a defogging section from the top to bottom in sequence; the inlet flue is arranged on the desulfurization tower between the concentration tank and the concentration section in a communicated mode; the outlet flue is arranged at the top of the desulfurization tower above the defogging sectionin a communicated mode; the heat exchanger and the absorption heat pump unit can perform two-stage cooling on circulating water, and can perform two-stage heating on supplemented boiler water; the supplemented boiler water can flow through the heat exchanger and the absorption heat pump unit to achieve two-stage heating. The system has the advantages of high desulfurization efficiency and high heat recycling rate, and flue gas desulfurization, white smoke elimination and deep waste heat recovery can be simultaneously realized.

Owner:AEROSPACE ENVIRONMENTAL ENG

Start-up method of dewatering capacity-enlarging start-up monotube boiler near steam heating boilers

ActiveCN101140059AShorten oiling timeReduce fuel consumptionSteam generation using hot heat carriersFeed-water heatersValue setTemperature difference

The invention discloses a starting method for an adjacent steam heating boiler of a drainage expansion starting once-through boiler; wherein a high-pressure heater of a starting unit is communicated with a pipeline for receiving the heating steam; the steam makes a unit boiler increase the temperature for water through the high-pressure heater; when starting in the cold, warm or hot state, the boiler heating surface is indirectly heated; when the temperature of the boiler heating surface is close to the saturation temperature of the steam, the feedwater flow is added up to the lowest ignition flow or above; a wind and smoke system is started, and the boiler is ignited; after starting a powder making system, the heat load is increased as soon as possible through a bypass system; the oil burning is cut off after the coal burning heat load is higher the lowest oil cut-off heat load in order to enter the conventional starting mode; when starting in the hot state and after finishing blowing, the feedwater flow is added up to the lowest ignition flow or above when the temperature difference of the cold wall of the feedwater and the boiler water is smaller than the value set by regulations, and the boiler is ignited; the oil burning is cut off after the coal burning heat load is higher the lowest oil cut-off heat load in order to enter the conventional starting mode. The method provided in the invention has the energy saving effects.

Owner:冯伟忠

Method for high temperature wastewater treatment and reuse in MTO process

ActiveCN101962235AImprove filtration throughputHigh removal rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentThermal energyWastewater

The invention relates to a method for treating and reusing high-temperature stripping purified wastewater produced in the process of transferring oxygenated compounds into olefins by using a high-temperature separation membrane. The combination process can effectively remove the impurities such as metal ions and organic micro-molecules and the like in stripping purified water, and the treated purified water in a tower kettle can meet the quality requirements of makeup water for middle and low-pressure boilers or the quality requirements of the makeup water in the MTO process. The invention effectively overcomes the defects exiting in the method for treating and reusing the stripping purified water without condensation in the MTO process, and lowers or reduces the consumption of circulating cooling water in the process of cooling firstly and then treating, thereby saving a large amount of boiler water and recycling the thermal energy of produced high temperature wastewater, and providing a stable and efficient way for high temperature wastewater treatment and reuse of relevant enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

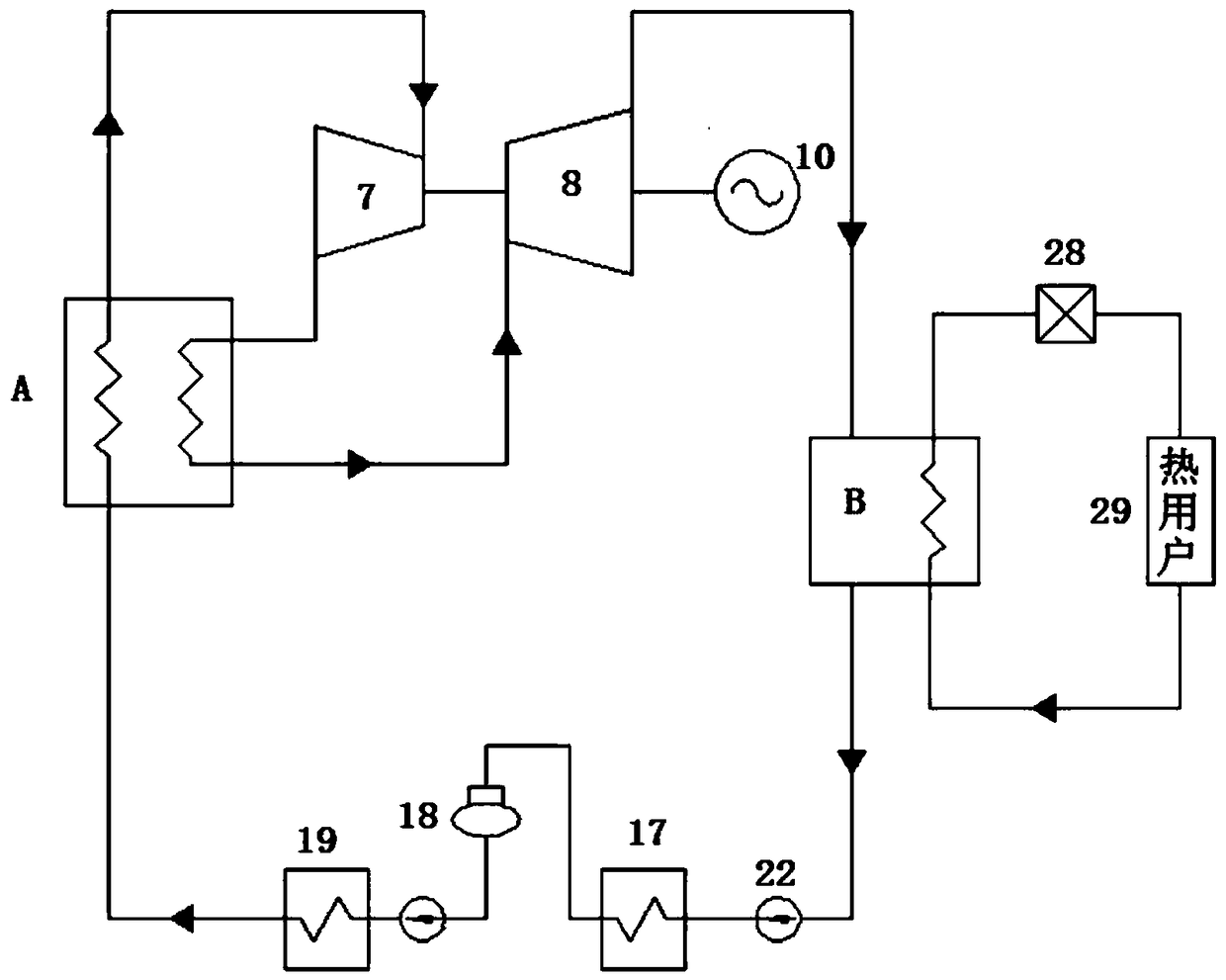

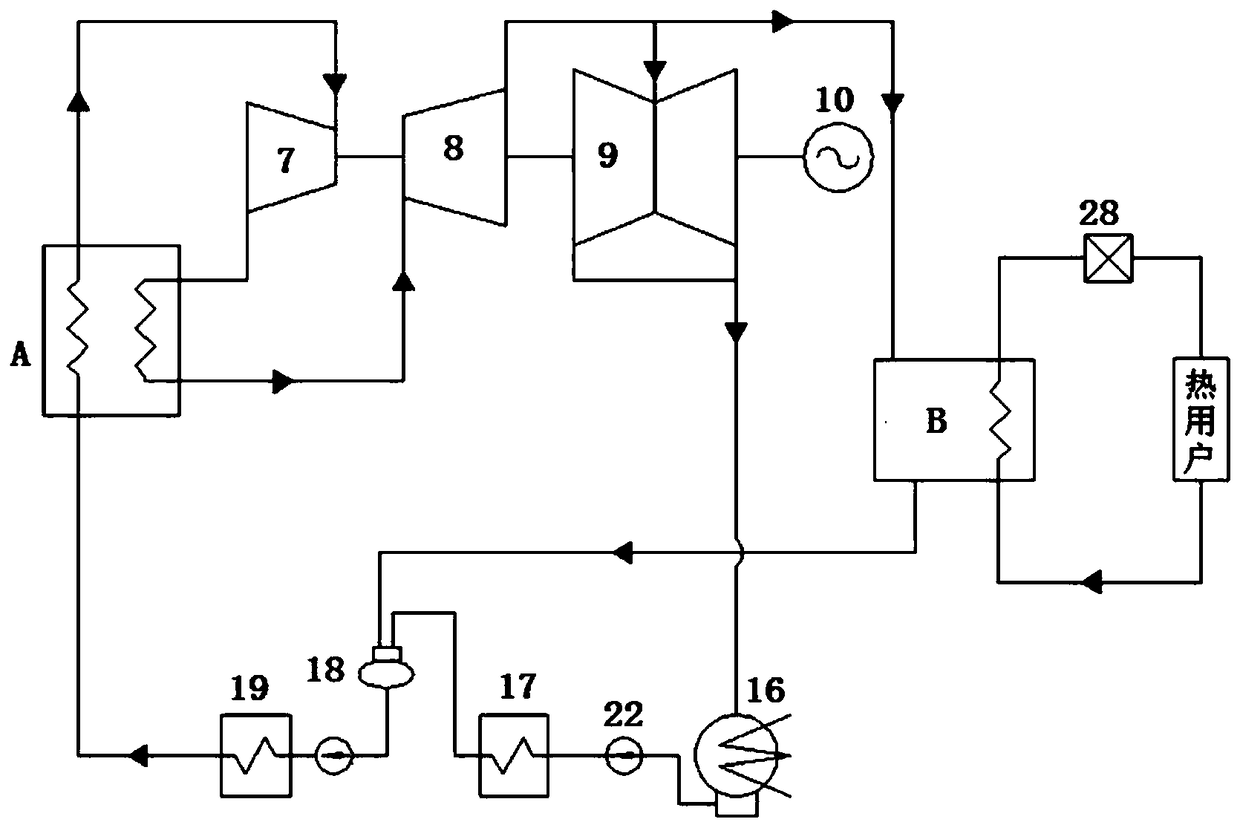

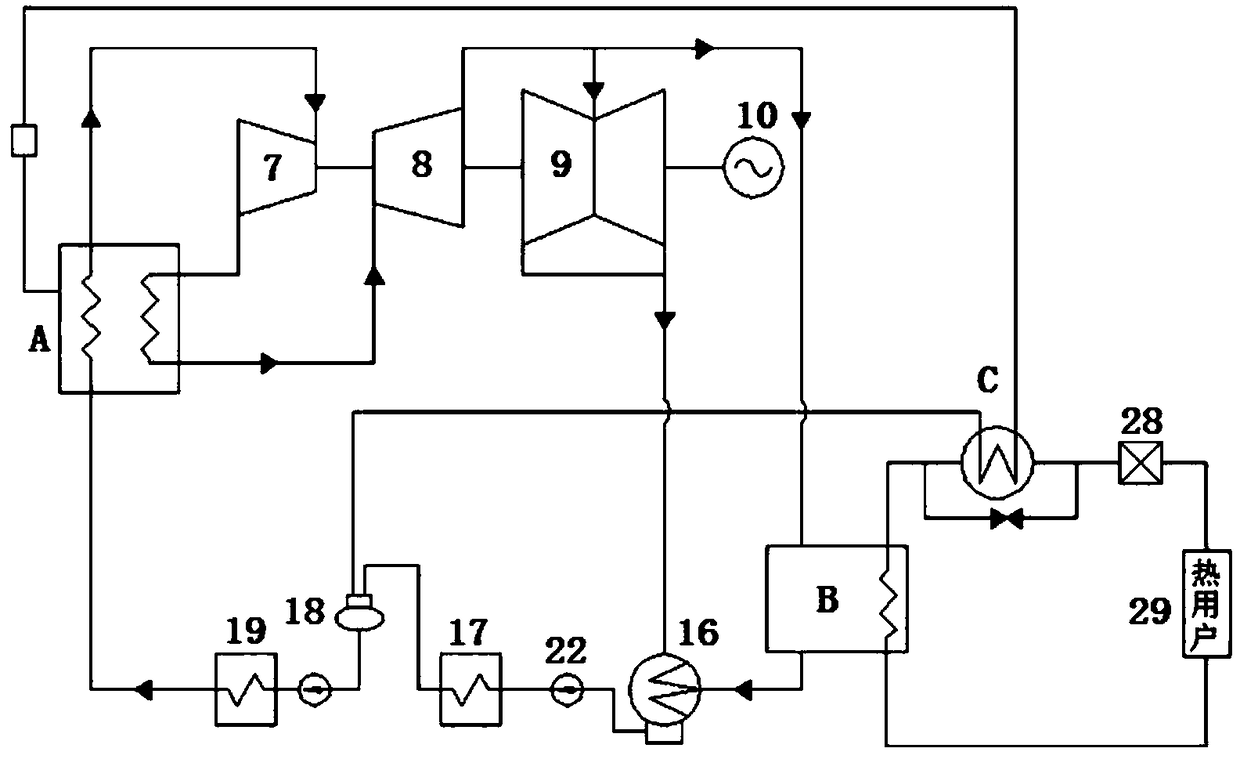

Thermodynamic system for improving heat supply unit electric output adjusting capacity

The invention relates to a thermodynamic system for improving heat supply unit electric output adjusting capacity. The thermodynamic system is characterized in that main steam or reheating section steam is subject to temperature and pressure reduction to directly serve as heat source steam for industrial heat users; an absorption heat pump 23 of a first-stage heat exchange device serves as a heatsource of a first-stage heat exchange station 25 in the heating period to supply heat to heat users 29 and supplies cold to the users in the non-heat supply period; a high-pressure electric boiler 24of a second-stage heat exchange device improves the boiler water feeding temperature, reduces heat absorbed by boiler fed water in an economizer 4, accordingly improves the boiler tail smoke discharging temperature, and guarantees normal running of an SCR denitration device 5; and according to a three-stage heat exchange device, exhaust steam of a turbine intermediate pressure cylinder 8 serves asheat source steam of a third-stage heat exchange station 27, the unit heat load is guaranteed, and the heat using requirement of the heat users 29 is met. The electric output adjusting capacity of the heat supply unit can be improved, it is guaranteed that the unit heat supply capacity is not decreased under the low load running working conditions, pyroelectric decoupling is achieved, and the electric output adjusting capacity of the heat supply unit is improved.

Owner:NORTHEAST DIANLI UNIVERSITY +2

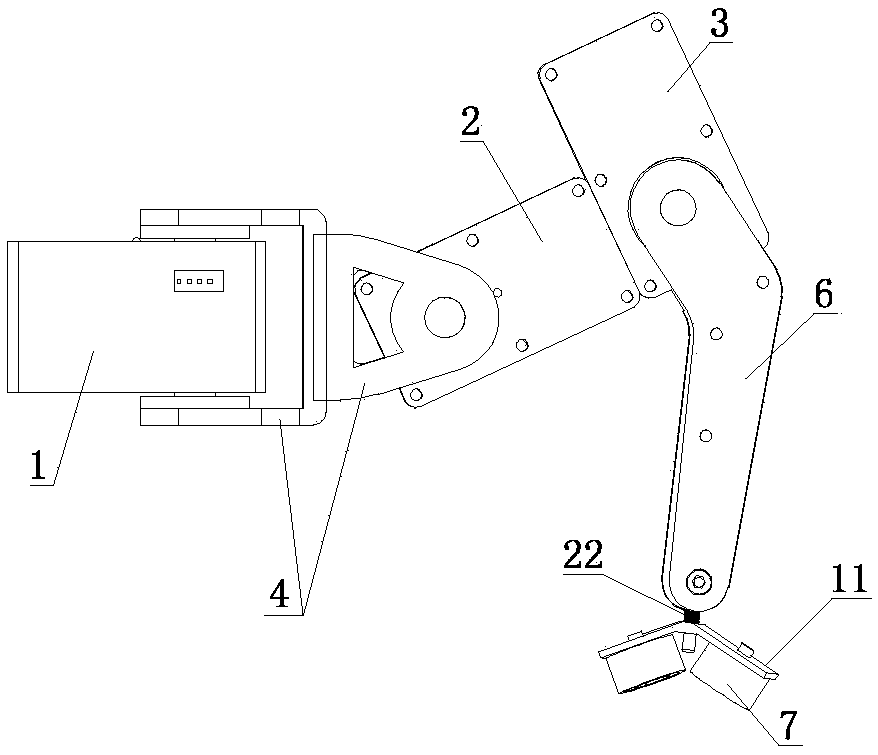

Hexapod bionic power plant boiler water wall inspection and maintenance climbing wall robot

ActiveCN109131621APrevent the situation that falls out to avoidReduce loadHydro energy generationVehiclesElectricityFree rotation

The invention relates to a hexapod bionic power plant boiler water wall inspection and maintenance climbing wall robot comprising a robot body and a plurality of mechanical legs arranged on both sidesof the body, ach mechanical leg consists of three large torque steering gears, thighs, calves, leg root parts, and magnetic feet, and an elastic adaptive device is arranged between the leg root partsand the magnetic foot. Each joint of the mechanical leg is pivotally connected and can rotate freely. The angle of each steering gear is controlled by gait algorithm, and hexapod insects are imitatedto walk, so that the robot can walk flexibly. A light supplement lamp, a camera and a flexible manipulator are arrange on that robot body, and the front end of the flexible manipulator can be equipped with an ultrasonic thickness measuring probe, a water wall welding device and a water wall cutting device, which are use for detecting and repairing the water wall of a boiler. The magnetic feet adopts the electromagnetism that cut off electricity to absorb type, can avoid dropping off the robot caused by the abnormal power cut. The invention has the advantages of strong load capacity, flexiblemovement, strong wall adaptability, almost complete coverage and no dead angle inside the boiler, and good application prospect.

Owner:洛阳清展智能科技有限公司

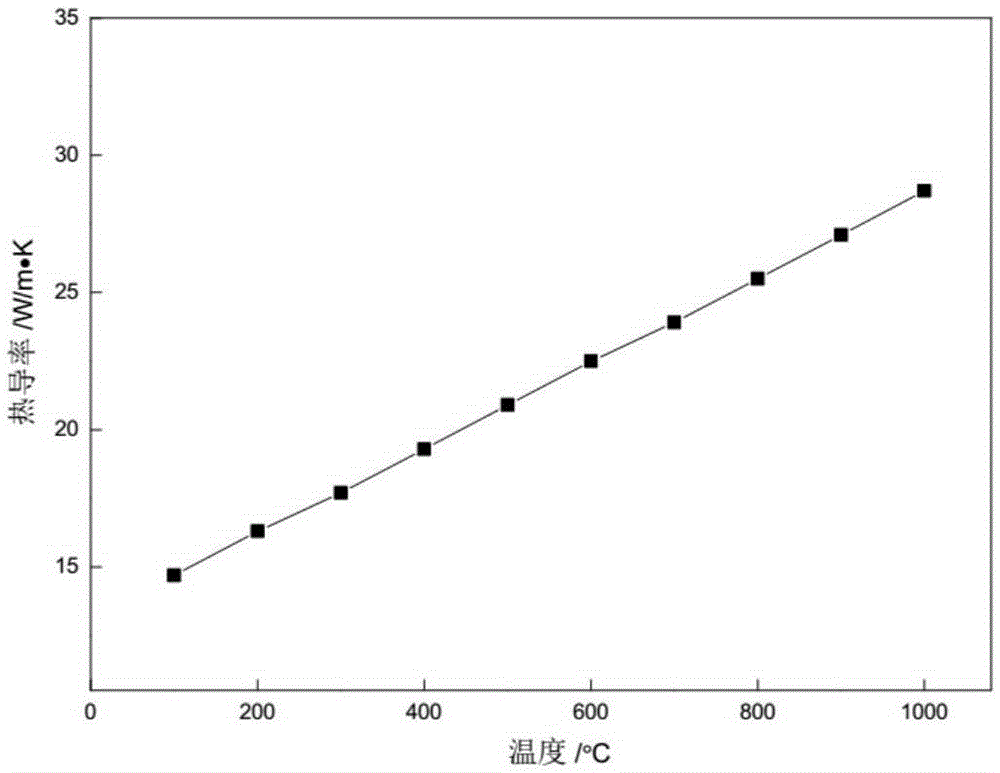

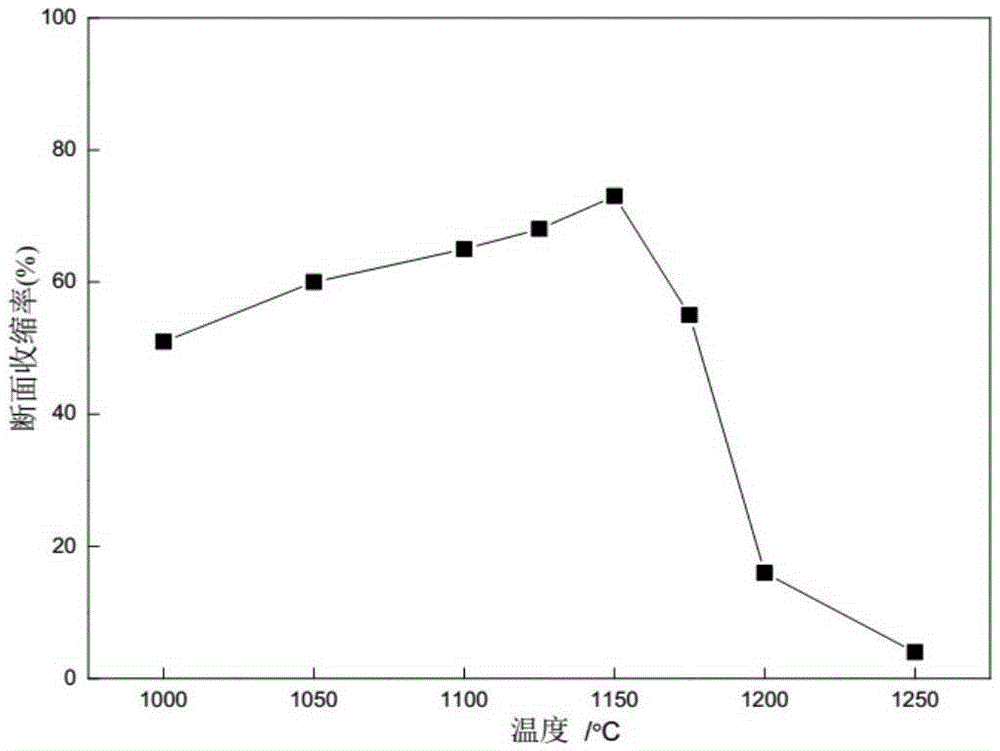

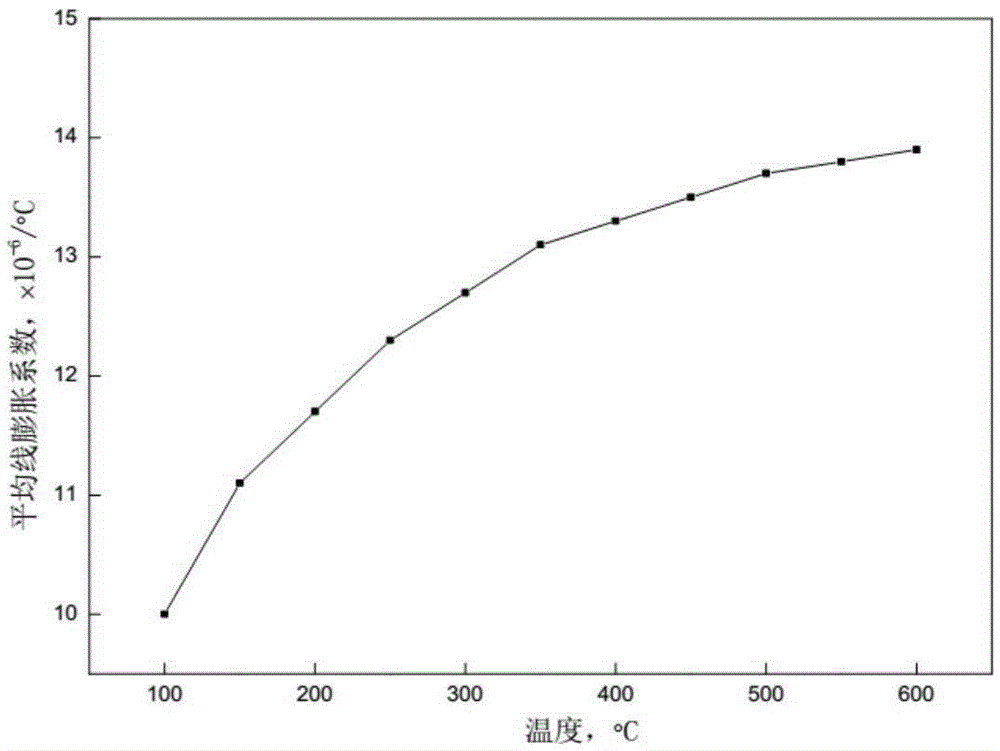

Heat-resisting alloy for 700-DEG C ultra-supercritical boiler water-cooling wall and tubing manufacturing method

ActiveCN105420638ASimple designMeet service environment requirementsSupercritical steam generatorAlloy

The invention provides a heat-resisting alloy for a 700-DEG C ultra-supercritical boiler water-cooling wall and a tubing manufacturing method, and belongs to the technical field of heat-resisting alloys. The alloy comprises the following chemical components in percentage by weight: 0.03 to 0.05% of C, 22 to 24% of Cr, 12 to 14% of Co, 8.3 to 8.8% of Mo, 0.5 to 1.0% of W, 0.003 to 0.005% of B, 0.05 to 0.12% of Zr, less than 0.1% of Mn, less than 0.05% of Si, not greater than 0.15% of Cu, not greater than 0.002% of P, not greater than 0.001% of S, not greater than 0.01% of N, not greater than 0.01% of O, not greater than 0.01% of Ca, not greater than 0.001% of Pb, not greater than 0.001% of Sb, not greater than 0.001% of Sn, not greater than 0.0001% of Bi, not greater than 0.001% of As, and the balance Ni and inevitable impurity elements. The manufacturing method comprises the following steps: smelting; homogenizing; cogging; thermally extruding; performing cold rolling; performing solid solution heat treatment. The alloy and the manufacturing method have the advantages that the endurance strength extrapolation number of a produced tubing under 600 DEG C and 105 hours is not less than 130MPa, which is far more than that of a T92 material, thus the requirement of a service environment of the 700-DEG C ultra-supercritical boiler water-cooling wall can be met, and postweld heat treatment is avoided.

Owner:CENT IRON & STEEL RES INST

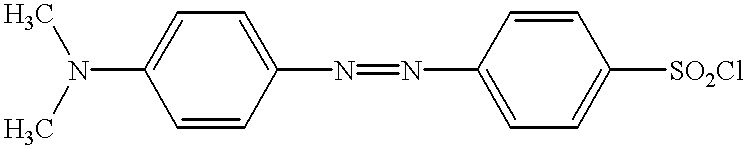

Colorimetric or fluorometric-detectable polymers containing pendant amine groups

InactiveUS6218491B1Minimize contaminationLow residual monomer contentOrganic detergent compounding agentsScale removal and water softeningThiolFluorescence

Polymers having amine-thiol terminal moieties are provided. The amine-thiol terminal moieties are imparted by using amine-thiols as chain transfer agents in aqueous addition polymerizations.The polymers are useful as mineral dispersants, as water-treatment additives for boiler waters, cooling towers, reverse osmosis applications, sugar refining, paper production, geothermal processes and oil wells, and as detergent additives acting as builders, anti-filming agents, dispersants, sequestering agents and encrustation inhibitors.

Owner:ROHM & HAAS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com