Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "Low residual monomer content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

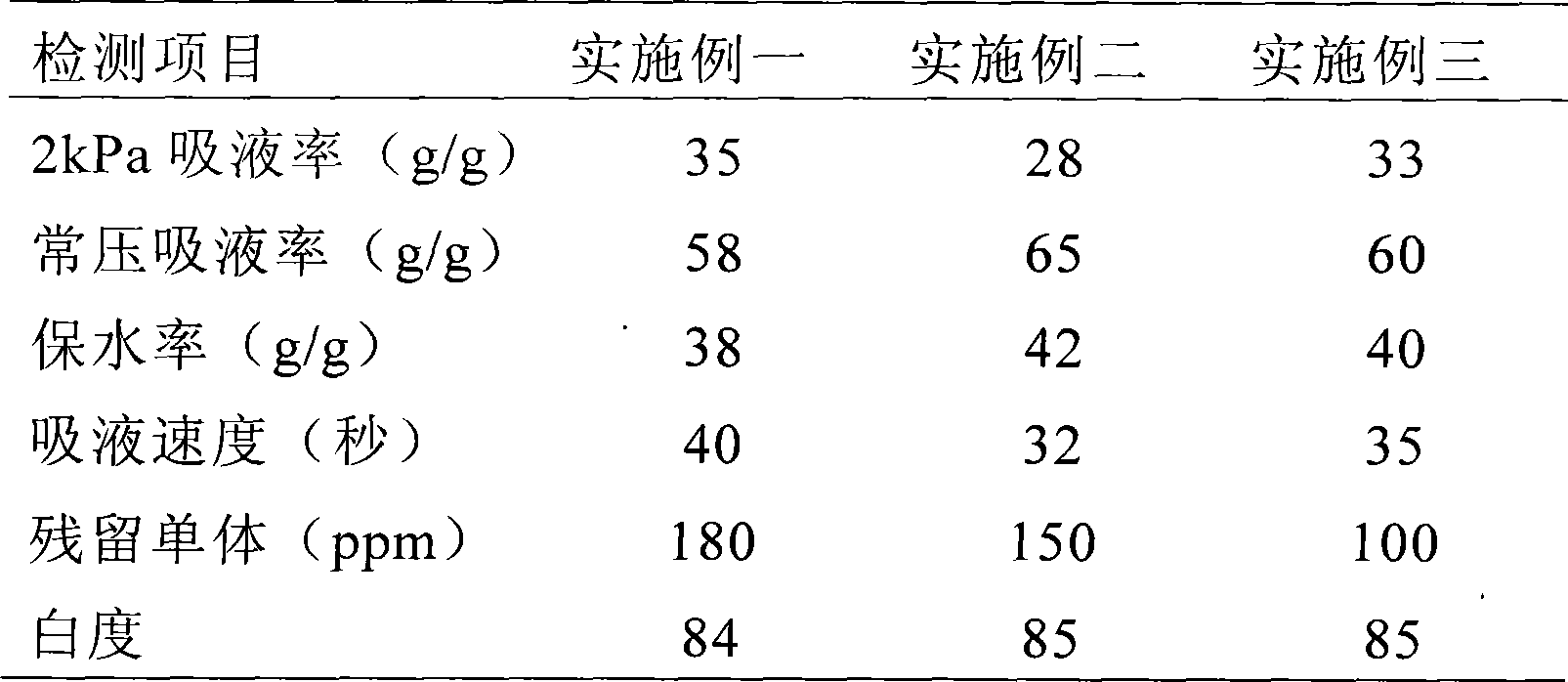

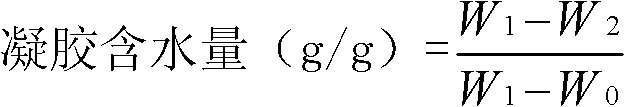

Production process for hydrophilic polymer

InactiveUS6207796B1Low residual monomer contentIncrease production capacityWater contentProduction rate

The present invention provides a production process to obtain a hydrophilic polymer, having a low residual monomer content, with good productivity while keeping the properties of a hydrogel polymer resultant from polymerization. In a drying process for a hydrogel polymer, the hydrogel polymer is dried under normal pressure at a material temperature of not higher than 90° C. until the water content of the hydrogel polymer reduces to 15~40 weight %, and then the hydrogel polymer is kept for not shorter than 10 minutes either in a state where the change of the water content of the hydrogel polymer is within 5 weight % and where the material temperature is in the range of 70~120° C. or in a state where the water content of the hydrogel polymer is in the range of 15~40 weight % and where the material temperature is in the range of 70~120° C., and then the hydrogel polymer is finish-dried.

Owner:NIPPON SHOKUBAI CO LTD

Method for production of hydrophilic resin

Owner:NIPPON SHOKUBAI CO LTD

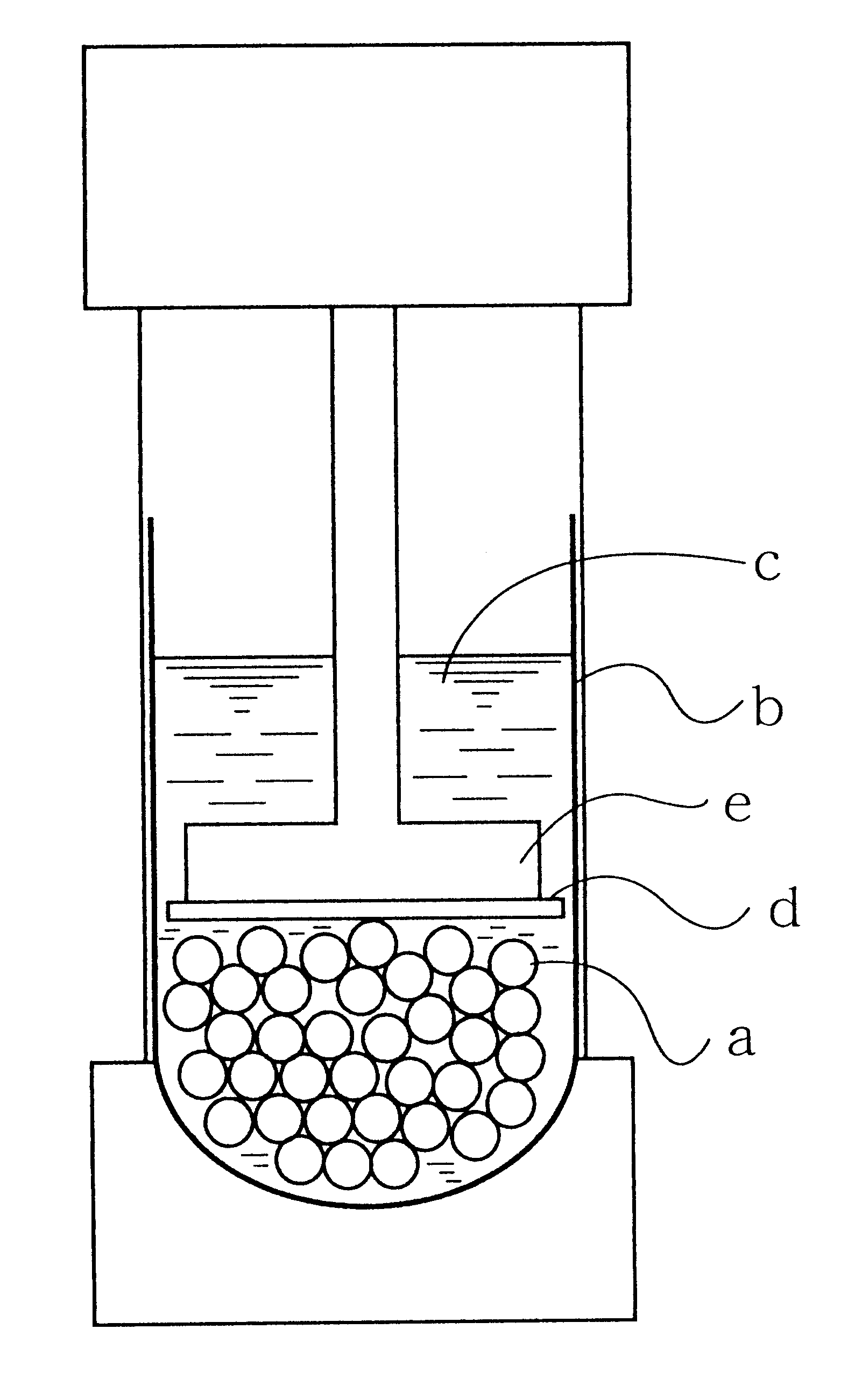

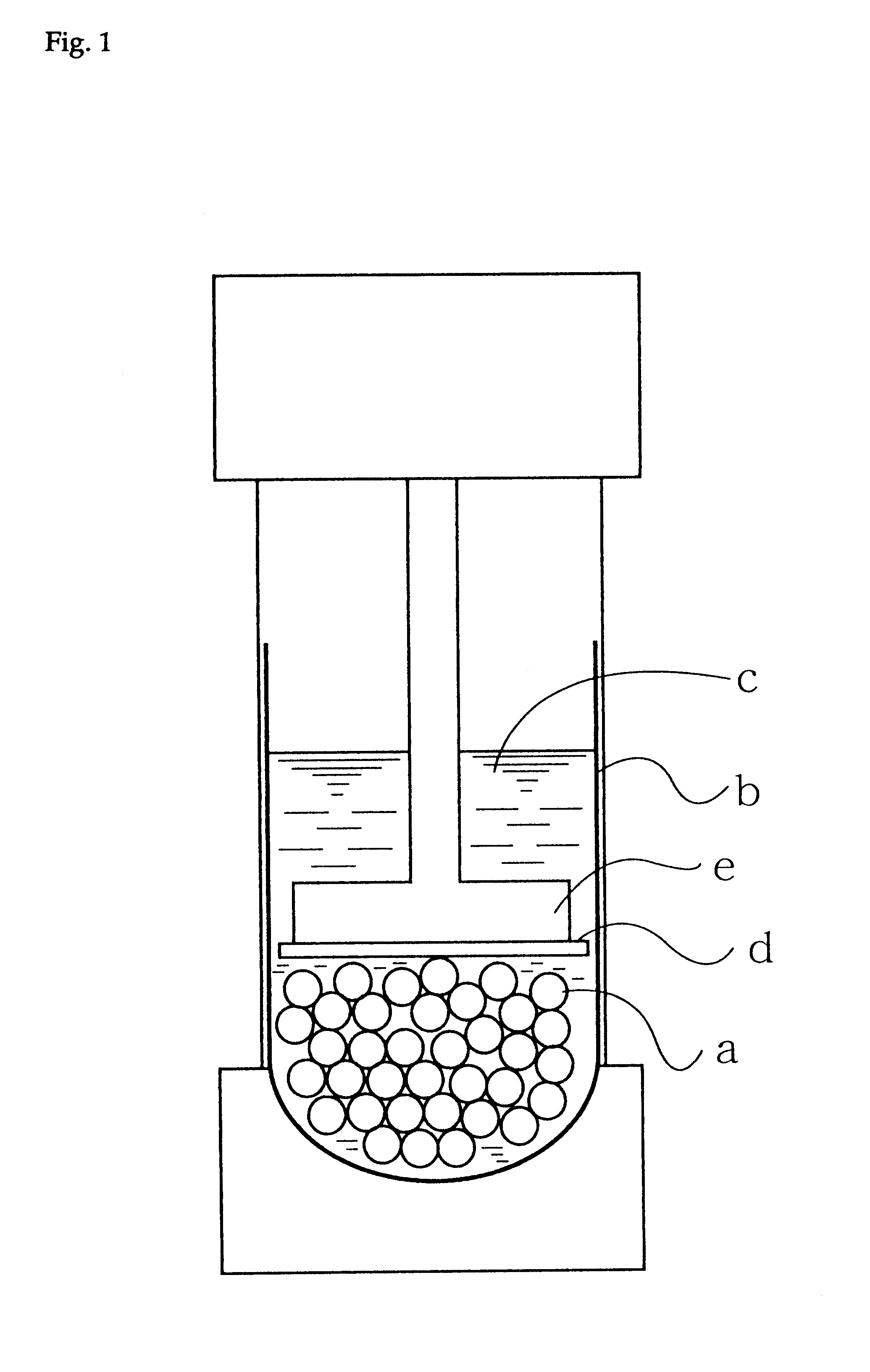

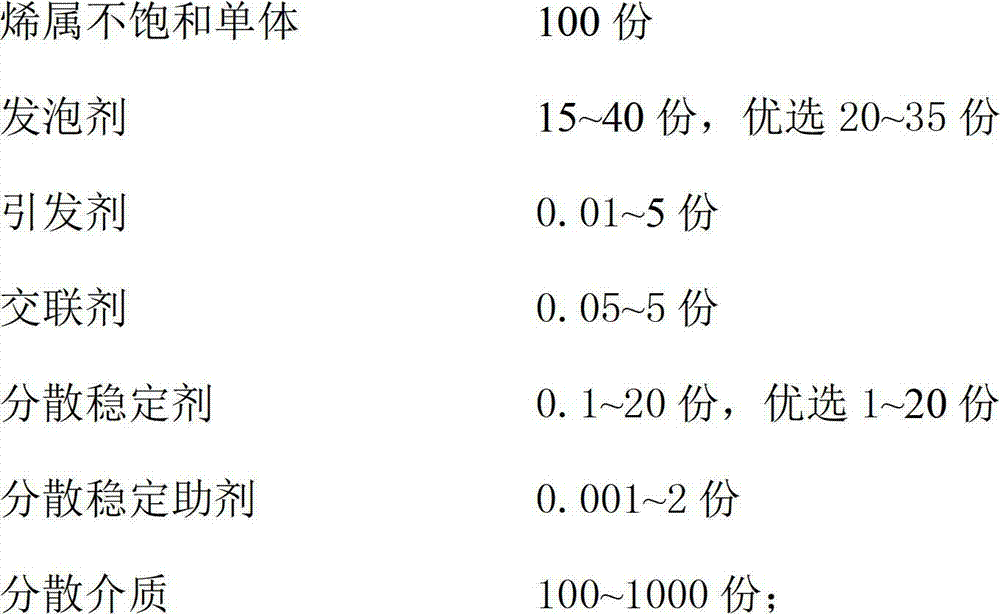

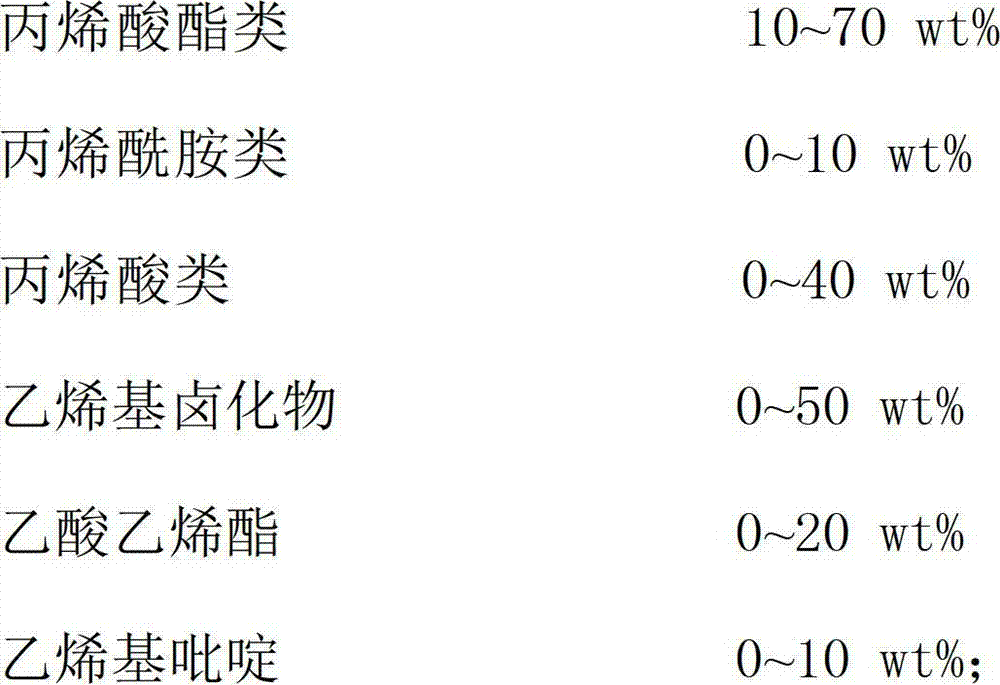

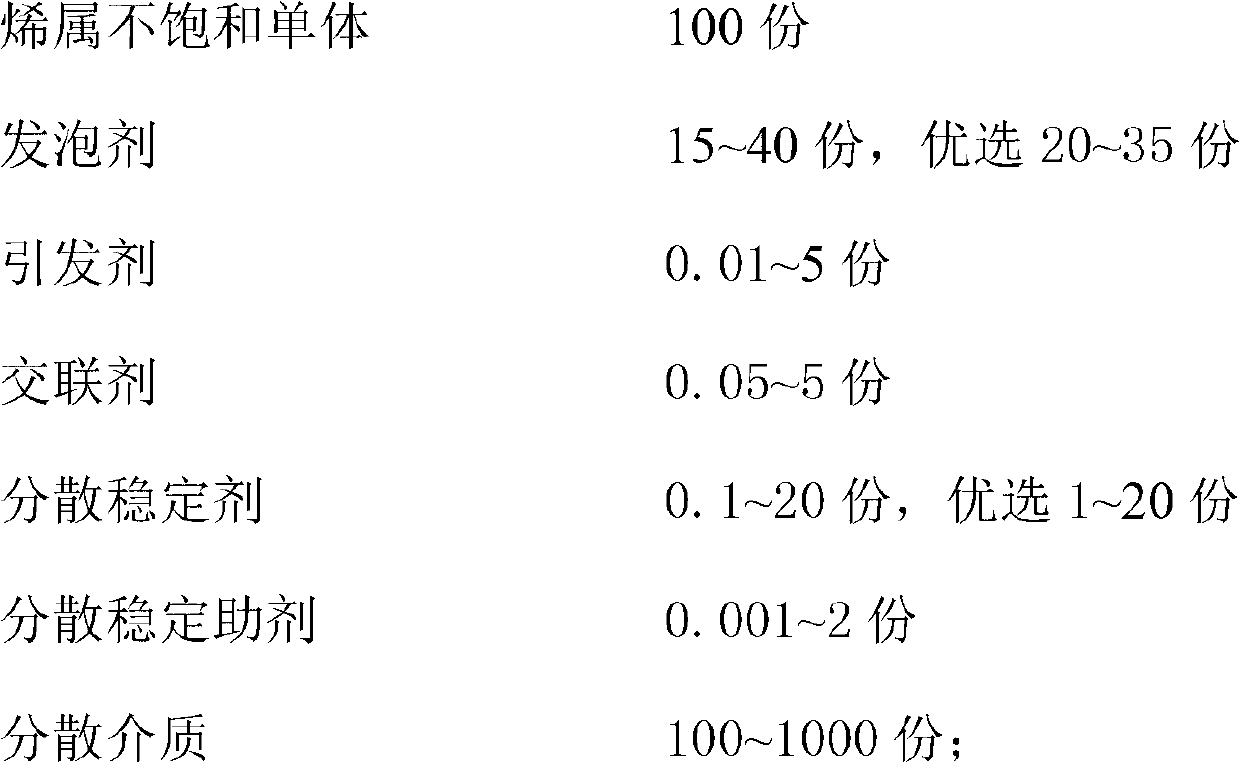

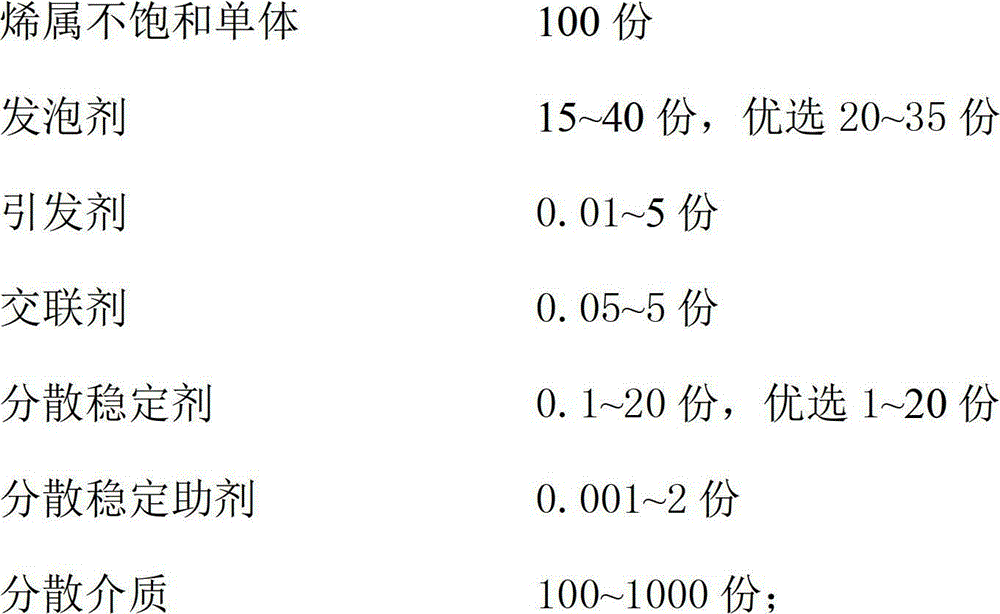

Thermal expansibility microsphere and method for reducing residual monomers therein

The invention provides a thermal expansibility microsphere and a method for reducing residual monomers therein. The method comprises a re-initiation step of supplementing an initiating agent of the residual monomers in a process of preparing the thermal expansibility microsphere by using a suspension polymerization method, wherein the initiating agent of the residual monomers is an oxidation reduction initiator system. The preparation method of the thermal expansibility microsphere, provided by the invention comprises the following steps: preparation of a water phase, preparation of an oil phase, suspension polymerization and residual monomer reduction. The technical scheme provided by the invention realizes quick reduction of the residual monomers under a low-temperature condition, is simple in production process, low in consumption and short in processing time, and simultaneously can efficiently reduce the content of the residual monomers in the thermal expansibility microsphere and a suspension reaction medium. The thermal expansibility microsphere prepared by using the method contains a little number of residual monomers and is small in pollution.

Owner:NANOSPHERE SHANGHAI

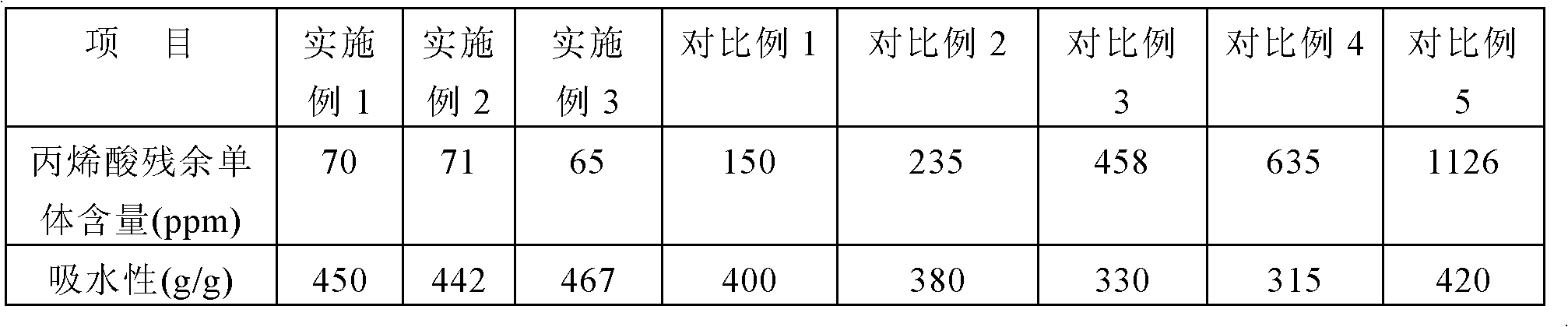

Method for preparing water-absorbing acrylic resin

The invention discloses a method for preparing water-absorbing acrylic resin, comprising the following steps: firstly, polymerizing acrylic acid monomer water solution with 60-90 mol percent of neutralization degree and polymerization reaction initiator; then adding whitening agent, cross linker and polymerization initiator into the polymerized product; drying the mixture by hot wind at the temperature between 110 and 200 DEG C, and crushing and screening the dried mixture; and after the mixture is packed and treated by the surface cross linker, heating the mixture to the temperature between 90 and 200 DEG C to carry out surface treatment, and adding inorganic salt into the mixture to form the water-absorbing acrylic resin. The water-absorbing acrylic resin has high and quick physiological-salt-absorbing ratio and good white content, and is suitable for sanitary product. The process can be continuously produced; and the product has little waste gas, powder layer and waste water.

Owner:浙江卫星新材料科技有限公司

Process for preparing urea-dione polyisocyanate with improved monomer stability

InactiveCN1334264ALow residual monomer contentImproved decomposition stabilityIsocyanic acid derivatives preparationOrganic compound preparationPolyurethane coatingPolymer chemistry

The invention relates to a process for the production of uretdione polyisocyanates with improved storage stability and their use as a starting component for polyurethane plastics, in particular as a crosslinker component for the production of two-component polyurethane coating compositions.

Owner:BAYER AG

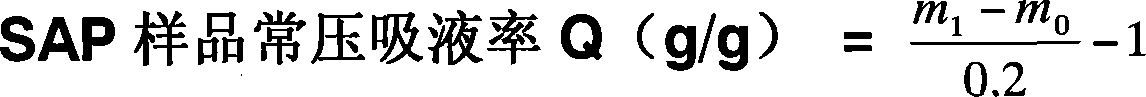

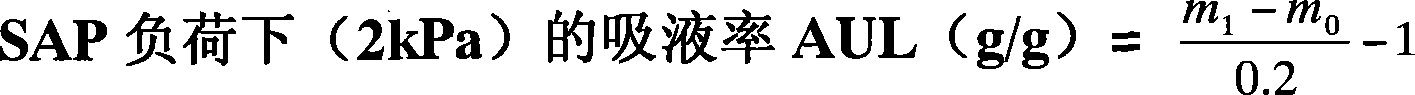

Method for fast preparing high water absorption resin

Preparation of SAP is carried out by taking acrylic acid as monomer, taking ion film base as neutralizer, heating to initial temperature, adding into cross-linking agent and oxidation reducing evocating agent, aqueous solution polymerizing, drying, crushing, screening and surface cross-linking treating. It has fast reactive speed and high normal saline absorptive rate. It can be used for sanitary products and continuous production.

Owner:SHANGHAI HUAYI NEW MATERIAL

Medium-high temperature thermal expansibility microsphere and method for reducing residual monomers therein

The invention provides a medium-high temperature thermal expansibility microsphere and a method for reducing residual monomers therein. The method comprises a re-initiation step of supplementing an initiating agent of the residual monomers in a process of preparing the thermal expansibility microsphere by using a suspension polymerization method, wherein the initiating agent of residual monomers is water soluble. The preparation method of the medium-high temperature thermal expansibility microsphere, provided by the invention comprises the following steps of: preparation of a water phase, preparation of an oil phase, suspension polymerization and residual monomer reduction. The thermal expansibility microsphere prepared provided by the invention contains a little number of residual monomers and is small in pollution; and the method for reducing the residual monomers is simple in production process, is low in consumption, and simultaneously can efficiently reduce the content of the residual monomers in the thermal expansibility microsphere and a suspension reaction medium.

Owner:NANOSPHERE SHANGHAI

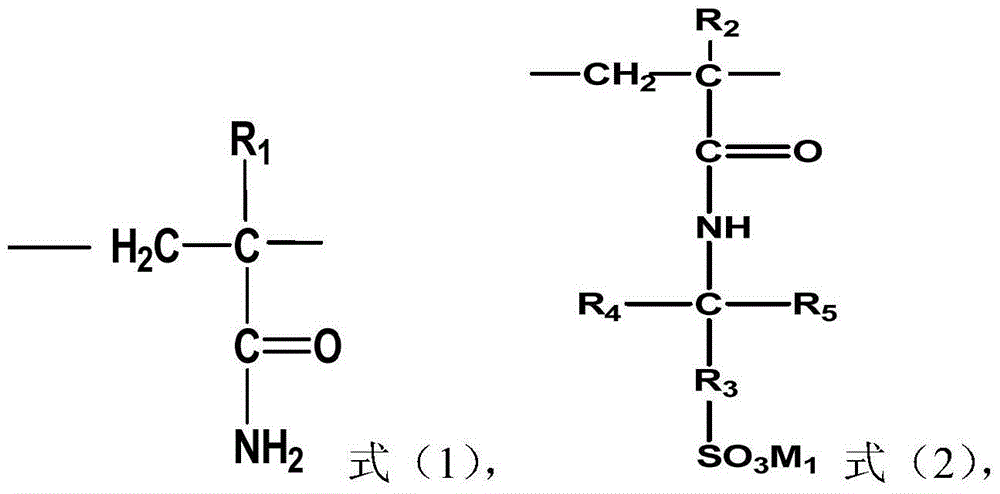

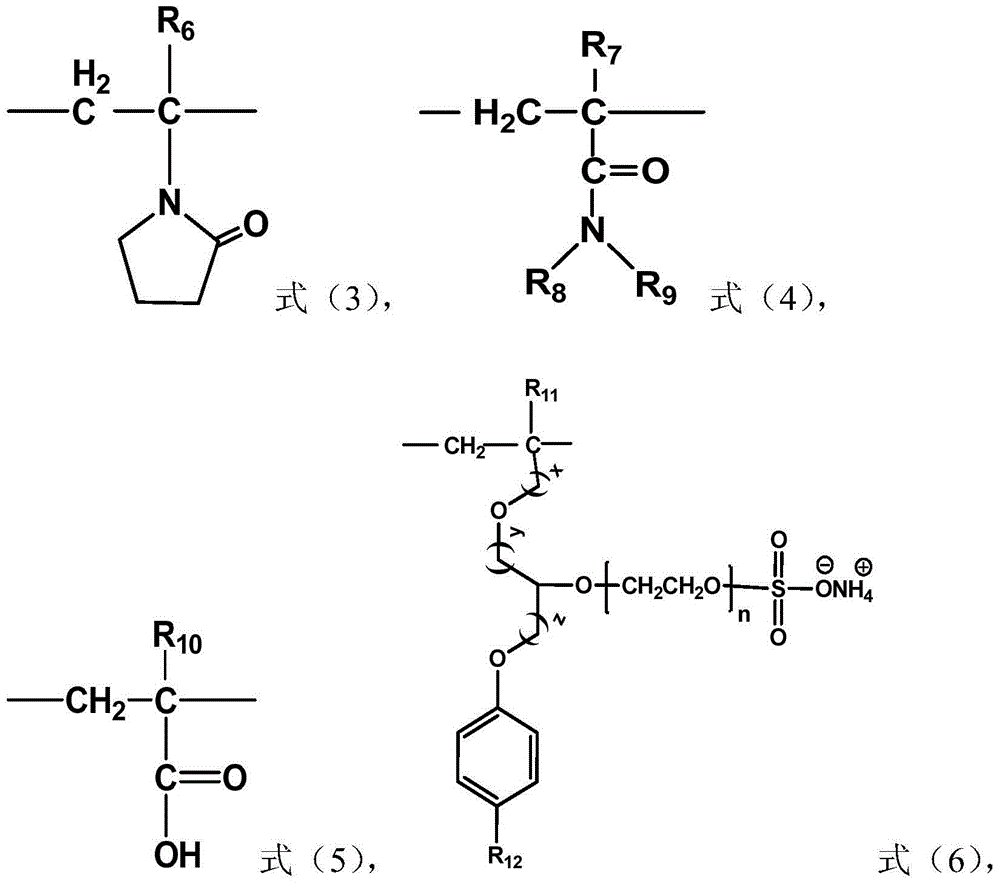

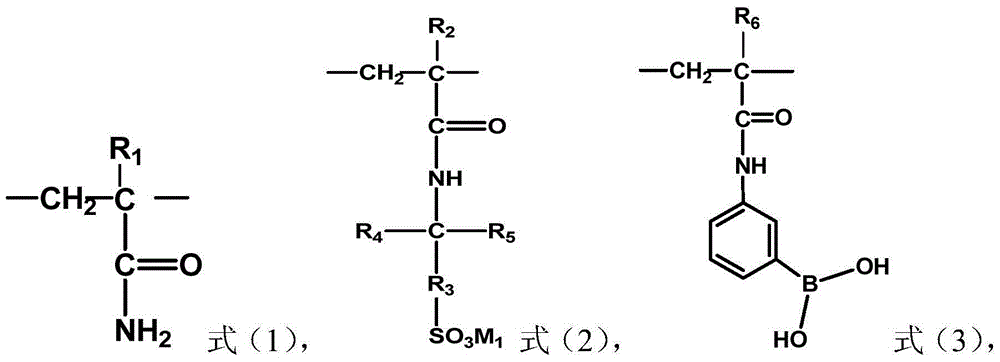

Acrylamide copolymer and its preparation method and use

ActiveCN104650301AGood water solubilityLow residual monomer contentDrilling compositionApparent viscosityPolymer science

The invention discloses an acrylamide copolymer. The acrylamide copolymer contains a structural unit A, a structural unit B and a structural unit C. The structural unit A has a structure shown in the formula (1). The structural unit B has at least one structure shown in the formulas (1), (2), (3), (4) or (5). The structural unit C has a structure shown in the formula (6). A mass ratio of the structural unit A, B to C is 1: 0.001-3: 0.001-0.5. The viscosity-average molecular weight of the acrylamide copolymer is in a range of 27 million to 32 million. The acrylamide copolymer has high molecular weight and apparent viscosity and can be used as a high-temperature high-salt oil reservoir tertiary recovery oil displacement agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

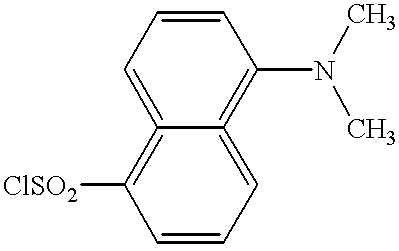

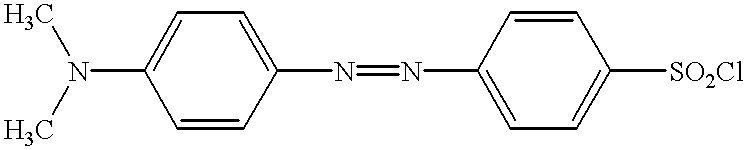

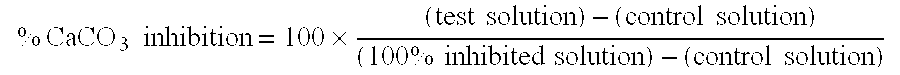

Colorimetric or fluorometric-detectable polymers containing pendant amine groups

InactiveUS6218491B1Minimize contaminationLow residual monomer contentOrganic detergent compounding agentsScale removal and water softeningThiolFluorescence

Polymers having amine-thiol terminal moieties are provided. The amine-thiol terminal moieties are imparted by using amine-thiols as chain transfer agents in aqueous addition polymerizations.The polymers are useful as mineral dispersants, as water-treatment additives for boiler waters, cooling towers, reverse osmosis applications, sugar refining, paper production, geothermal processes and oil wells, and as detergent additives acting as builders, anti-filming agents, dispersants, sequestering agents and encrustation inhibitors.

Owner:ROHM & HAAS CO

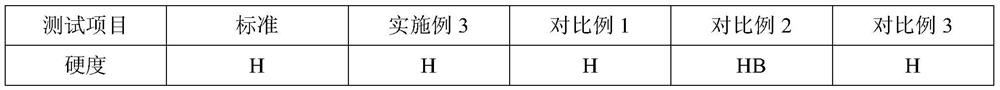

Small-particle latex compositions based on waterborne alkyd seeds

InactiveUS20050004272A1Small particle sizeImprove film formationEmulsion polymerizationLatex particle

Aqueous latex polymer dispersion compositions are disclosed characterized by their small particle size. The compositions are prepared by emulsion polymerization of one or more ethylenically unsaturated monomer in the presence of an alkyd seed containing sulfonate groups. Coatings based on these latex dispersions have improved advantages in film forming, gloss, hardness, low residual monomer content, less yellowing, and low VOC. The latex dispersions, having average particle sizes of 60-140 nm, are prepared by using a small ratio (i.e. about 2-15 wt. %) of an aqueous alkyd dispersion as the seed for latex particle growth. The waterborne alkyds are based on 5-sodiosulfo-isophthalic acid and either unsaturated or saturated fatty acids. The latex polymer dispersions thus obtained have improved film forming properties as well as low residual monomer content. The latexes are capable of forming clear, hard films at room temperature in the absence of external coalescents. Moreover, the resultant films are essentially non-yellowing. Thus, the latexes of this invention could be formulated into zero- or low-VOC paints for a variety of coating applications.

Owner:EASTMAN CHEM CO

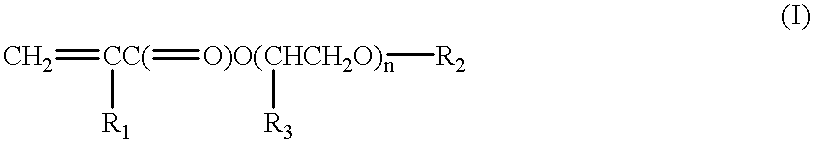

Amphiphilic polymer composition

Polymer compositions derived from selected monoethylenically unsaturated (C3-C6)carboxylic acid monomers, (C1-C4)alkyl (meth)acrylate ester monomers and alkoxylated (meth)acrylate monomers used in certain weight ratios to provide enhanced detergent and cleaning performance are disclosed. Polymer compositions containing from 5 to 40% of monoethylenically unsaturated (C3-C6)carboxylic acid monomer, from 35 to 65% of (C1-C4)alkyl (meth)acrylate ester monomer and from 20 to 60% of alkoxylated (meth)acrylate monomer provide improved cleaning performance in laundry detergent formulations relative to conventional polymer compositions.

Owner:ROHM & HAAS CO

Method for producing high absorptive resin

A process for preparing high-hydroscopicitiy resin includes prepolymerization between monomers to be polymerized, trigger, system and cross-linking agent, and polymerizing to obtain gel-state solid product. Its advantages are high hydroscopicity (500-2000 g / g for deionized water), high water absorbing speed (less than 10 S) and high gel strength after the water is absorbed by it.

Owner:KEYUAN PRODIVE POWER PROMOTION CENT OF PETROCHEM IND SHANDONG

ADHESIVES, UV-CROSSLINKABLE PSAs AND BONDING AGENTS WITH UV-CROSSLINKED PSAs

InactiveUS20150299530A1Good technical adhesive propertyIncreased free volumeFibre treatmentSynthetic resin layered productsPressure sensitivePolymerization

Adhesives and pressure-sensitive adhesives comprising polymerization products of acrylates, the adhesives being meltable and comprising polymerization products of esters of (meth)acrylic acid and (meth)acrylic acid, the polymerization product having a molecular weight Mn of greater than 50 000 g / mol and Mw of greater than 500 000 g / mol.

Owner:TESA SE

Method for production of hydrophilic resin

InactiveUS20050113542A1Sacrifice in costSacrifice in productivityAbsorbent padsEmulsion paintsPropanoic acidWater soluble

In the production of an acrylate polymer by the steps of preparing a water-soluble unsaturated monomer having a ratio of neutralization in the range of 30 to 100 mol % and containing 50 to 100 mol % of an acrylate and then polymerizing the monomer, a method for the production of a hydrophilic resin which comprises using a water-soluble unsaturated monomer having a β-hydroxy propionic acid (salt) content of not more than 1,000 ppm. The hydrophilic resin obtained by this method exhibits excellent physical properties and has only a small residual monomer content. Further, a residual monomer content neither occurs nor increases in any using conditions.

Owner:NIPPON SHOKUBAI CO LTD

Water absorbent resin and method for production thereof

ActiveCN101120038AGood physical propertiesLow residual monomer contentAqueous solutionOxidizing agent

According to the present invention, a balance between lowering of the fine powder generated during the production, and lowering of the amount of residual monomer in the resulting water absorbent resin can be achieved. More particularly, according to the present invention, a water absorbent resin which includes a small amount of residual monomer and has a favorable physical property can be obtained while effectively reutilizing the fine powder generated in the production step of the water absorbent resin, without increasing using amount of an additive (at least one selected from the group consisting of thermal initiators, oxidizing agents and reducing agents) for reducing the residual monomer. In other words, the method for production of a water absorbent resin of the present invention is a method in which the residual monomer can be efficiently reduced, and in addition, an effect in terms of the production cost, i.e., recycling of the fine powder, can be also achieved similarly to conventional recycling methods of fine powder through agglomeration.

Owner:NIPPON SHOKUBAI CO LTD

Method for production of hydrophilic resin

InactiveUS7078458B2Low costDecrease productivityAbsorbent padsEmulsion paintsPropanoic acidWater soluble

In the production of an acrylate polymer by the steps of preparing a water-soluble unsaturated monomer having a ratio of neutralization in the range of 30 to 100 mol % and containing 50 to 100 mol % of an acrylate and then polymerizing the monomer, a method for the production of a hydrophilic resin which comprises using a water-soluble unsaturated monomer having a β-hydroxy propionic acid (salt) content of not more than 1,000 ppm. The hydrophilic resin obtained by this method exhibits excellent physical properties and has only a small residual monomer content. Further, a residual monomer content neither occurs nor increases in any using conditions.

Owner:NIPPON SHOKUBAI CO LTD

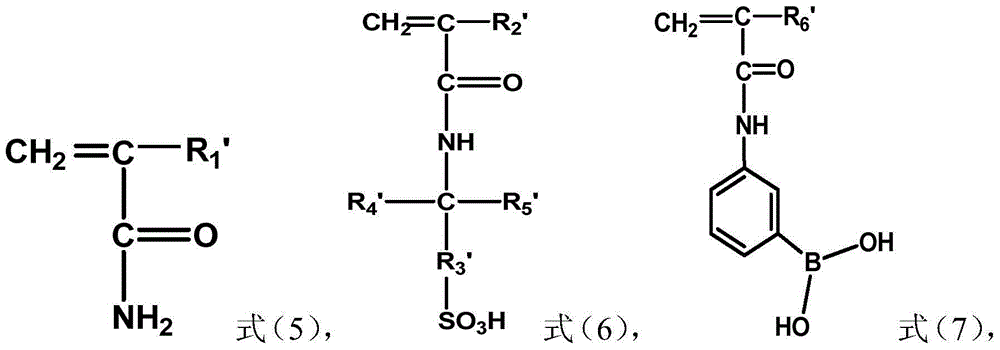

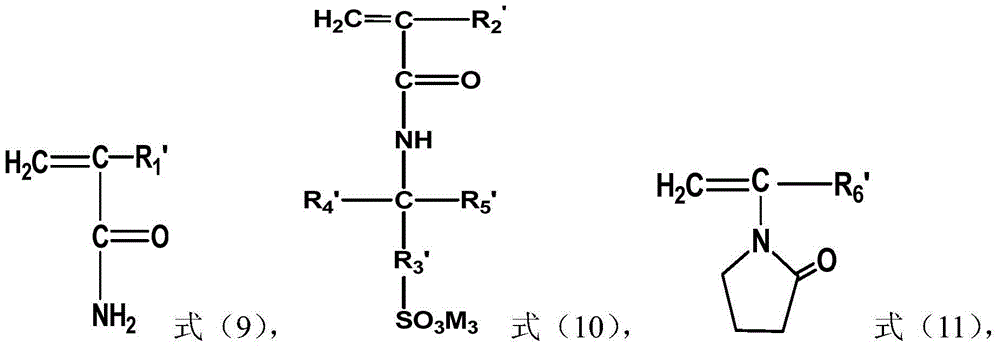

Acrylamide copolymer, as well as preparation method and application thereof

ActiveCN104628940AHigh molecular weightHigh apparent viscosityDrilling compositionApparent viscosityPolymer science

The invention discloses an acrylamide copolymer, as well as a preparation method and an application thereof. The acrylamide copolymer comprises a structural unit as shown in a formula (1), a structural unit as shown in a formula (2) and a structural unit as shown in a formula (3) in a mass ratio of 1:(0.001-3):(0.0001-0.5), preferably 1:(0.01-1.5):(0.001-0.2); and the viscosity-average molecular weight of the acrylamide copolymer is 28-35 millions. The acrylamide copolymer has high apparent viscosity and oxidation resistance, and can be used for achieving an excellent oil dispelling effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low viscosity allophanates containing actinically curable groups

ActiveUS20060052526A1Low residual monomer contentUrea derivatives preparationOther chemical processesAllophaneZinc

The present invention relates to a process for preparing radiation-curing binders containing allophanate groups by reacting at temperatures of ≦130° C. A) one or more compounds containing uretdione groups with B) one or more OH-functional compounds which contain groups which react, with polymerization, with ethylenically unsaturated compounds on exposure to actinic radiation (radiation-curing groups), C) optionally NCO-reactive compounds other than B), in the presence of D) a catalyst containing at least one zinc compound, to form allophanate groups by opening the uretdione ring. The present invention also relates to the binders obtained by the process of the invention and to coating compositions containing these binders.

Owner:ALLNEX NETHERLANDS BV +1

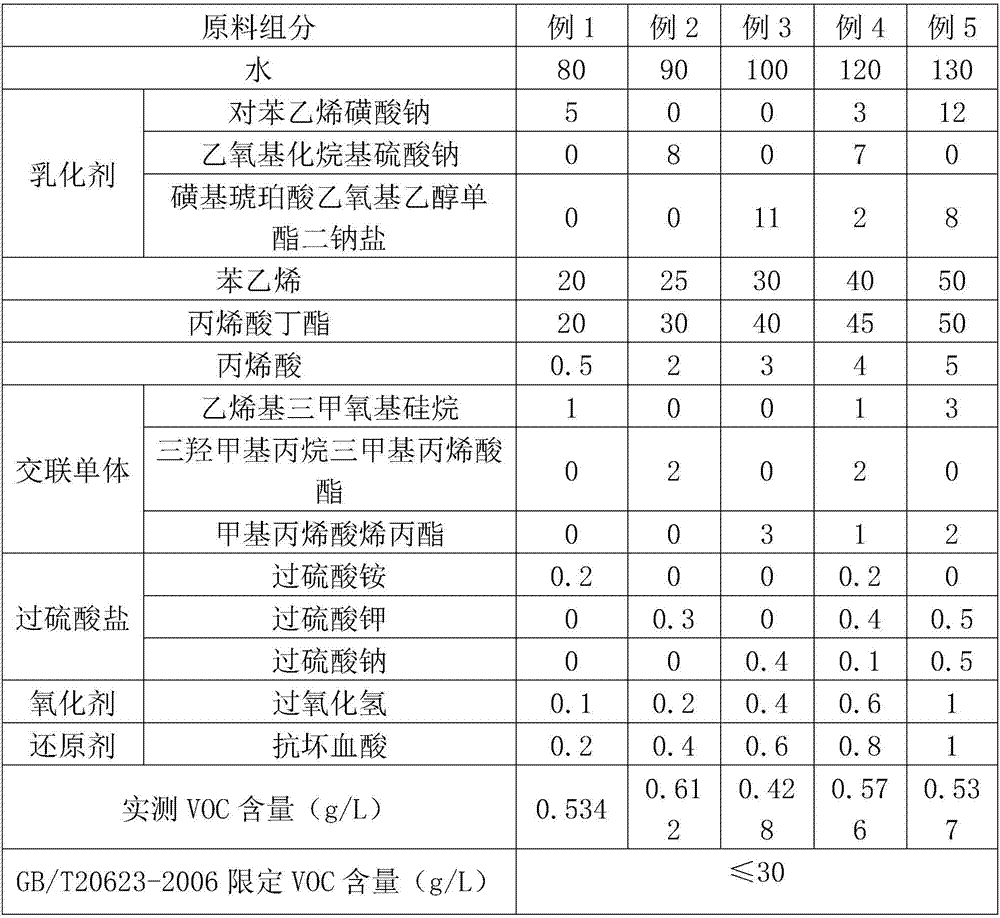

Styrene acrylic emulsion containing ultralow VOC content and preparing method thereof

The invention discloses styrene acrylic emulsion containing ultralow VOC content. The styrene acrylic emulsion containing ultralow VOC comprises, by mass, 80-130 parts of water, 5-20 parts of emulsifier, 20-50 parts of styrene, 20-50 parts of butyl acrylate, 0.5-5 parts of acrylic acid, 1-5 parts of cross-linking monomer, 0.2-1 part of persulfate, 0.1-1 part of oxidizing agent, and 0.2-1 part of reducing agent. The styrene acrylic emulsion containing the ultralow VOC content is environmentally friendly and pure in smell, and the VOC content is extremely low.

Owner:佛山市顺德区巴德富实业有限公司

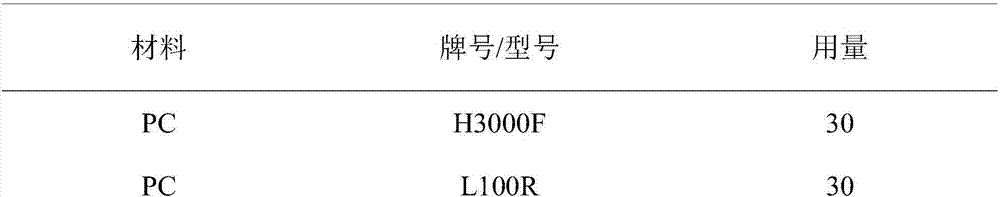

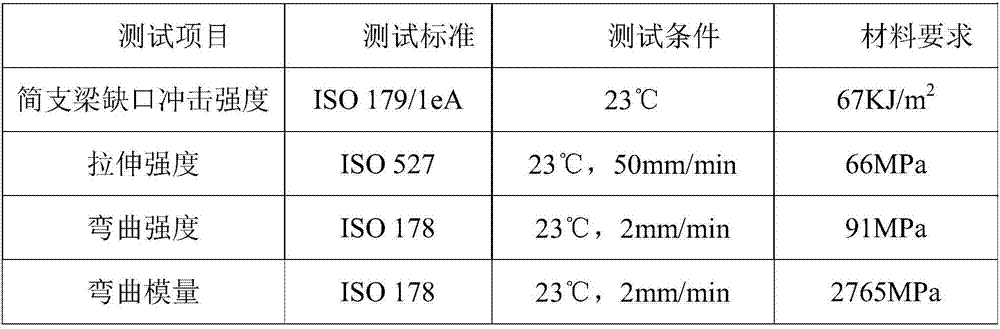

Low-odor spray-coating-free PC/ABS (polycarbonate/acrylonitrile butadiene styrene) material and preparation method thereof

The invention discloses a low-odor spray-coating-free PC / ABS (polycarbonate / acrylonitrile butadiene styrene) material and a preparation method thereof. The material is prepared from the following ingredients including 40 to 80phr of PC, 20 to 60phr of ABS, 5 to 10phr of AS, 0 to 1phr of lubricating agents, 1 to 1.5phr of deodorants, 0.5 to 1phr of heat stabilizers, 0.5 to 1phr of color masterbatch, 0 to 10phr of compatibilizers, 0 to 5phr of processing auxiliary agents, 0.1 to 0.5phr of antioxidants and 0 to 5phr of ultraviolet light absorbers. The material has the low odor and spray-coating-free appearance requirements; the odor grade is lower than or equal to 3.0; the appearance luster is good; the blackness is high; the thermal stability is high; the defects of flowing marks, melting and connecting wires, silver silks and the like cannot be easily generated; the spraying work procedure is omitted; the good spray-coating-free effect is achieved; through the creative selection on raw materials and auxiliary agents and the process innovation, a low-odor spray-coating-free PC / ABS material is produced, and is obviously superior to similar products in the market.

Owner:太仓市华鼎塑料有限公司

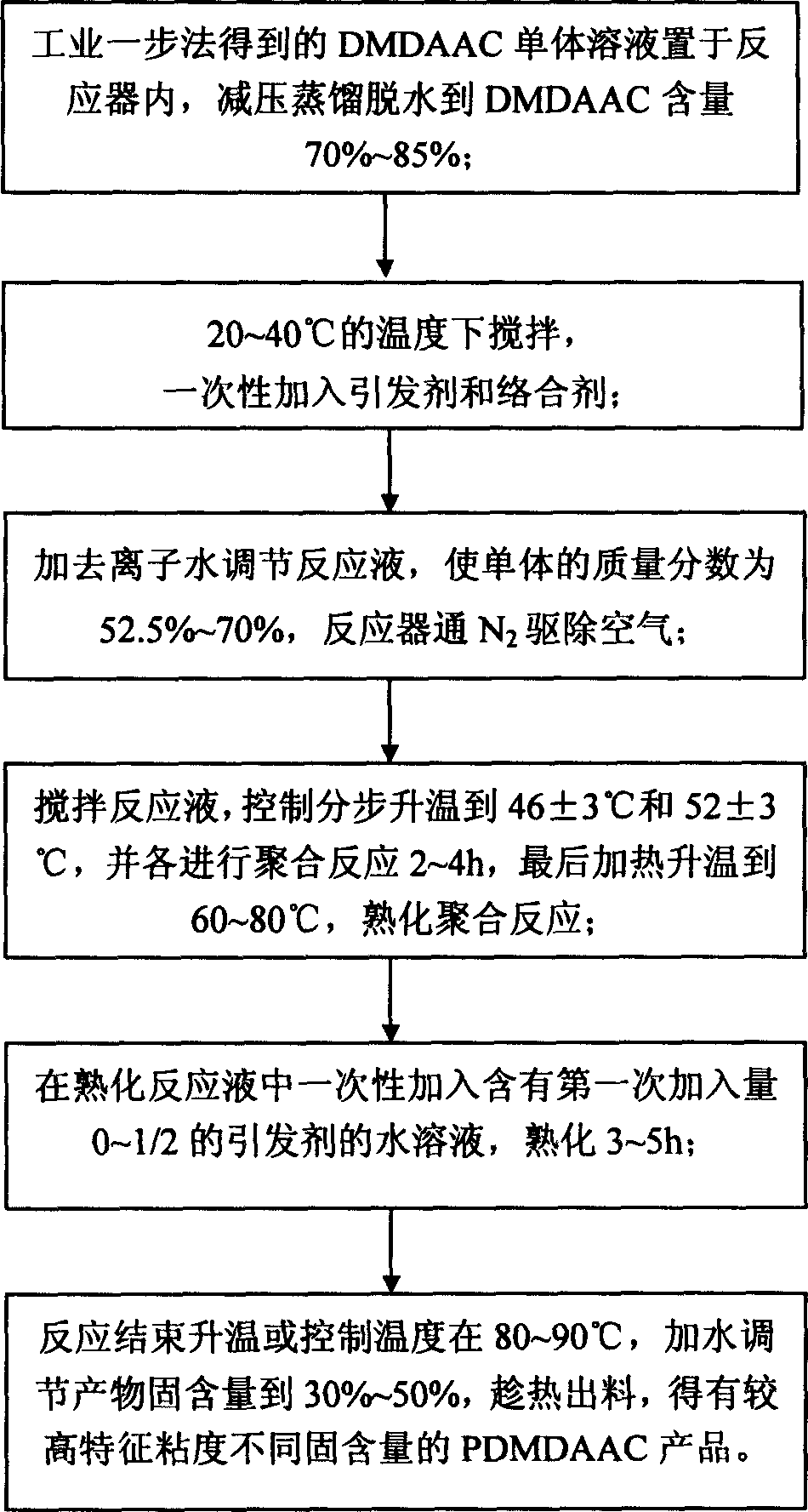

Preparation method of poly dimethyl allyl ammonium chloride

The present invention discloses preparation process of polyammonium dimethyldiallyl chloride. By using the water solution of industrial cation monomer DMDAAC as material, and through once adding persulfate as initiator and Na4EDTA as complexing agent, controlling reaction temperature under stirring, stepped temperature raising for controlling the reaction rate, initiating the polymerization of DMDAAC monomer at relatively low temperature for high polymerization degree and high molecular weight, adding small amount of water solution of initiator in the late stage to raise the monomer converting rate and controlling the diluting water amount to regulate solid content in the product, polyammonium dimethyldiallyl chloride with relatively high molecular weight is prepared. The process has high economic performance, good industrial foundation, mild reaction condition, low production cost and other advantages, and the product has various uses.

Owner:NANJING UNIV OF SCI & TECH

Fast-dissolving cationic polyacrylamide and preparation method thereof

The invention discloses fast-dissolving cationic polyacrylamide and a preparation method thereof. The method comprises the following steps: mixing a polyacrylamide solution, a cationic monomer solution, a weakly polar monomer, deionized water, disodium ethylenediamine tetraacetate, polyethylene oxide and urea to prepare a solution A; adding a photoinitiator into a chain transfer agent, performinguniform dissolution under stirring to prepare a solution B; uniformly mixing the solution A and the solution B under stirring to obtain a reaction solution; and adjusting the pH of the reaction solution to 3-6, introducing nitrogen for deoxygenation, performing irradiation under a short-wave ultraviolet lamp, performing irradiation under a long-wave ultraviolet lamp, cutting the prepared rubber block, performing granulation, performing drying, and performing crushing to obtain the fast-dissolving cationic polyacrylamide. The method provided by the invention greatly shortens the dissolution time of the cationic polyacrylamide, improves the use efficiency of the cationic polyacrylamide in industries such as water treatment, sludge dewatering, mineral dressing by washing, oil and gas extraction and papermaking, and has huge potential application value.

Owner:JIANGSU FEYMER TECH

Thermal expansibility microsphere and method for reducing residual monomers therein

The invention provides a thermal expansibility microsphere and a method for reducing residual monomers therein. The method comprises a re-initiation step of supplementing an initiating agent of the residual monomers in a process of preparing the thermal expansibility microsphere by using a suspension polymerization method, wherein the initiating agent of the residual monomers is an oxidation reduction initiator system. The preparation method of the thermal expansibility microsphere, provided by the invention comprises the following steps: preparation of a water phase, preparation of an oil phase, suspension polymerization and residual monomer reduction. The technical scheme provided by the invention realizes quick reduction of the residual monomers under a low-temperature condition, is simple in production process, low in consumption and short in processing time, and simultaneously can efficiently reduce the content of the residual monomers in the thermal expansibility microsphere and a suspension reaction medium. The thermal expansibility microsphere prepared by using the method contains a little number of residual monomers and is small in pollution.

Owner:NANOSPHERE SHANGHAI

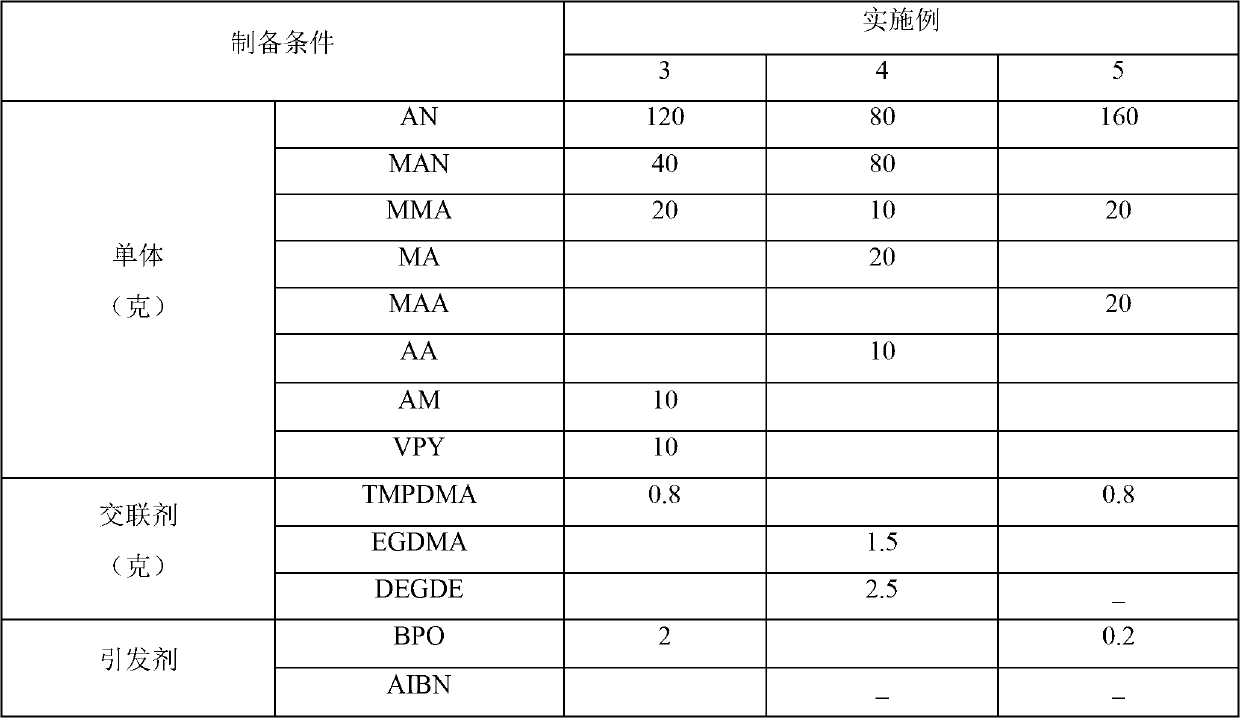

Preparation method of narrow-distribution polyacrylonitrile-based carbon fiber spinning solution

ActiveCN110684149AImprove mass transfer efficiencyImprove heat transfer efficiencyFibre chemical featuresPolymer scienceCarbon fibers

The invention relates to a preparation method of a narrow-distribution polyacrylonitrile-based carbon fiber spinning solution. The preparation method of the narrow-distribution polyacrylonitrile-basedcarbon fiber spinning solution mainly solves the problems of wide molecular weight distribution of polyacrylonitrile, high residual monomer content and long polymerization reaction time in the priorart. The preparation method of the narrow-distribution polyacrylonitrile-based carbon fiber spinning solution includes the following steps that (1) polymerization raw material acrylonitrile, a comonomer 1 and / or a comonomer 2, a solvent and an initiator are added into a reactor, a thermostatic reaction is started under the protection of inert gas to the reaction materials, and a reaction temperature is controlled to 60-65 DEG C; (2) when the conversion rate exceeds T1, the temperature is increased by 5-10 DEG C; (3) when the conversion rate exceeds T2, the temperature is increased by 5-10 DEGC; and (4) when the conversion rate reaches T3, the reaction is finished, and preparation of the spinning solution is completed. According to the technical scheme, the problems of wide molecular weight distribution of polyacrylonitrile, high residual monomer content and long polymerization reaction time are well solved, and the preparation method can be used in the industrial production of the polyacrylonitrile-based carbon fiber spinning solution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-based two-component coating for rail transit vehicle interiors and preparation method thereof

InactiveCN111621220AImprove performanceStrong adhesionFireproof paintsPolyurea/polyurethane coatingsAcrylic resinFire retardant

The invention relates to the technical field of paint for interior decoration, in particular to a water-based two-component coating for rail transit vehicle interiors and a preparation method thereof.The coating comprises a component A and a component B in a weight ratio of 10: 1, wherein the component A comprises water-based hydroxyl acrylic resin, water-based hydroxyl polyurethane hand feelingresin, a water-based hydroxyl organic silicon hand feeling auxiliary agent, pigment and filler, an environment-friendly flame retardant, sand streak wax, extinction powder, a water-based dispersing agent, a water-based wetting agent, a water-based defoamer, a water-based leveling agent, a water-based thickener and water, and the component B comprises water-based polyisocyanate resin and a solvent.The preparation method comprises preparation of the component A and preparation of the component B. The coating provided by the invention adopts a two-component cross-linking curing technology and ismatched with a water-based hydroxyl organic silicon hand feeling auxiliary agent, so that the hand feeling of the coating can be kept stable for a long time, the VOC content and the residual monomeramount are low, formaldehyde, benzene series and the like are not contained, and the coating is suitable for human body contact and is very suitable for interior coating of rail transit vehicles.

Owner:山东七维新材料有限公司

Production method of acrylic polymer resin and products produced thereby

The invention discloses a production method of acrylic polymer resin. The production method includes the steps of forming bulky hydrogel of acrylic polymer, granulating and drying. The production method is characterized in that by weight of the bulky hydrogel of acrylic polymer, 6-7% of initiator solution is added to obtain gel granules 15-25mm in diameter; the drying step includes two drying stages, drying in the first stage is at 50-110 DEG C for the duration of 5-20 minutes, and drying the second stage is at 110-180 DEG C for the duration of 10-30 minutes. The invention further discloses products produced by the production method and applications thereof.

Owner:SHANGHAI HUAYI ACRYLIC-ACID CO LTD

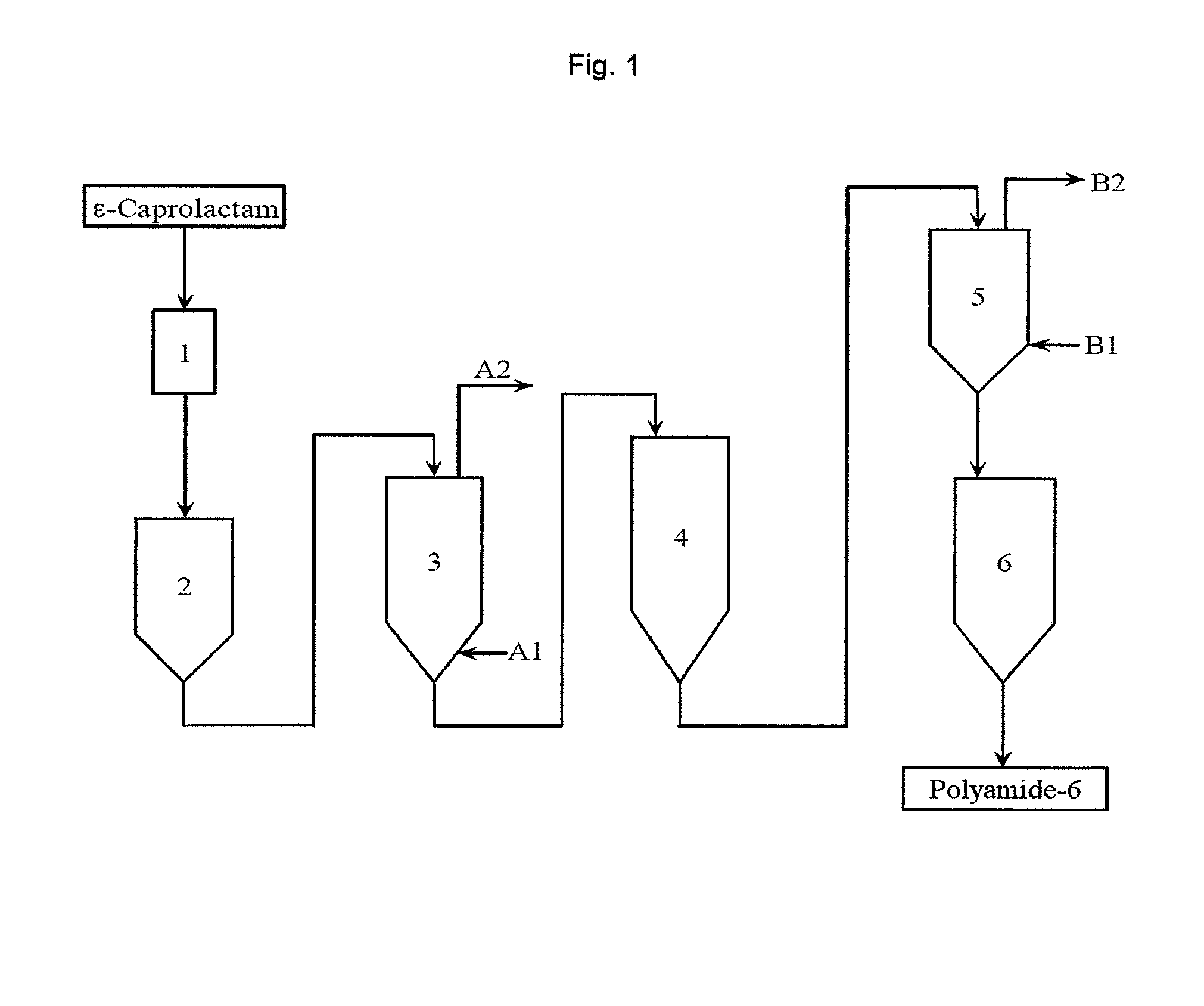

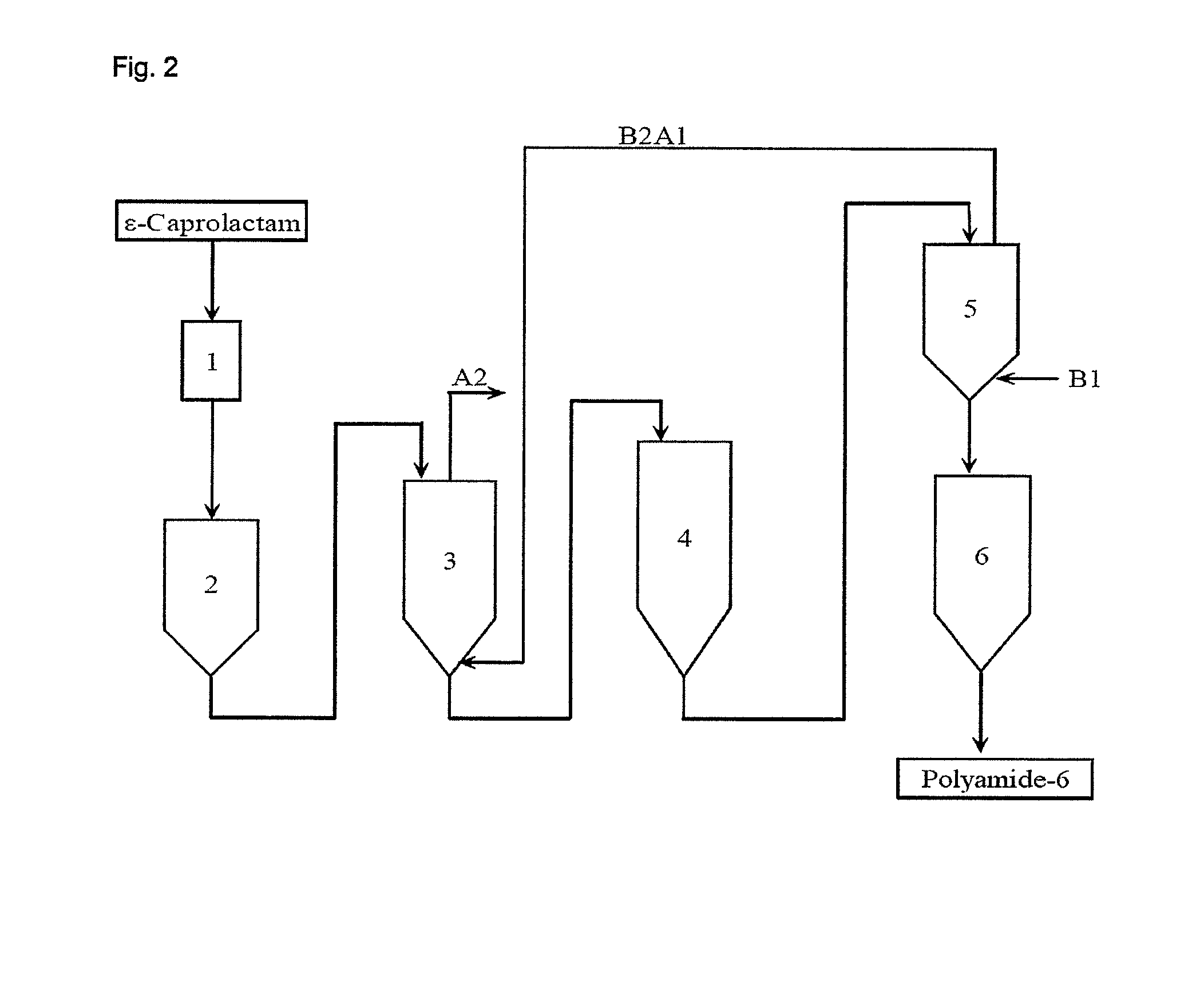

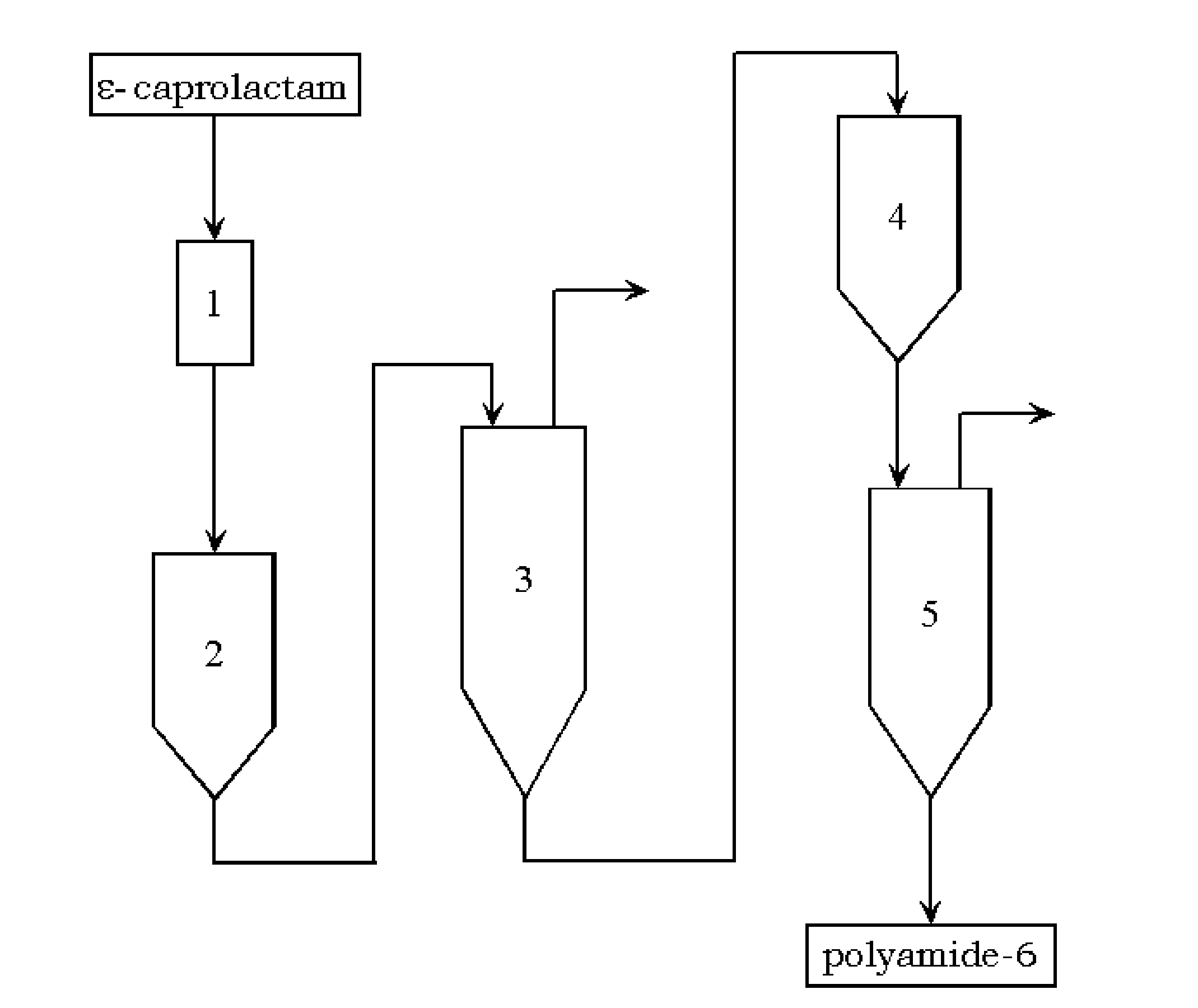

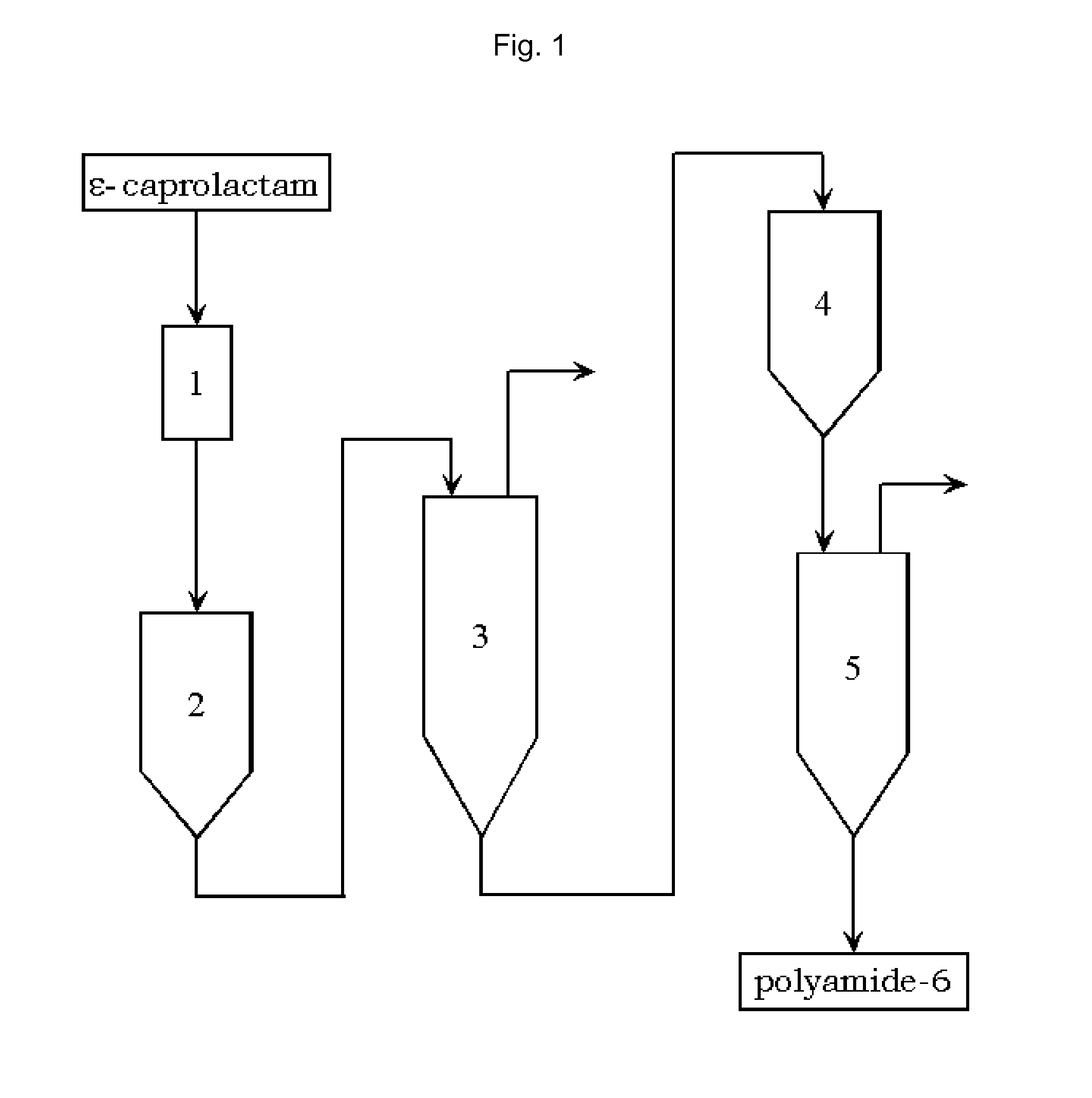

Preparation of polyamides by hydrolytic polymierization and multiple extraction

The present invention relates to a process for preparing polyamides, comprising a hydrolytic polymerization and at least two extraction steps which are not in immediate succession.

Owner:BASF AG

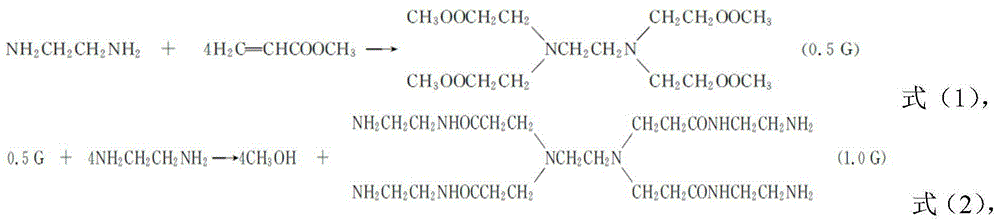

Structure-oriented composite initiator system and acrylamide polymer and preparation method and application thereof

ActiveCN105566515AHigh molecular weightImprove shear resistanceDrilling compositionPolymer scienceReducing agent

The present invention discloses a structure-oriented composite initiator system and an acrylamide polymer and a preparation method and application thereof. The structure-oriented composite initiator system contains a redox system initiator, the redox system initiator comprises oxidizing and reducing agents, wherein the structure-oriented composite initiator system further comprises a polyamide-amine dendritic macromolecule. The acrylamide polymer has a higher molecular weight, higher shear resistance, better anti-aging properties, and good water-soluble and other advantages, and the acrylamide polymer has high apparent viscosity in high temperature and high salinity water, and can be used as a high temperature and high salinity oil reservoir tertiary oil recovery oil displacement agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylamide copolymer, as well as preparation method and application thereof

ActiveCN104628943AGuaranteed water solubilityGood temperature and salt resistanceDrilling compositionSalt resistanceSalinity

The invention provides an acrylamide copolymer, as well as a preparation method and an application thereof. The copolymer comprises a structural unit A, a structural unit B and a structural unit C, wherein the structural unit A is a unit having a structure as shown in a formula (1), the structural unit B is at least one unit having a structure as shown in formulae from (2) to (5), and the structural unit C is a unit having a structure as shown in a formula (6); the mass ratio of the structural unit A to structural unit B to structural unit C is 1:(0.001-3):(0.001-0.5); and the viscosity-average molecular weight of the acrylamide copolymer is 30-35 millions. A temperature-endurance salt-resistance product of the acrylamide copolymer has the characteristic of high molecular weight; and the acrylamide copolymer has an advantage of greatly thickening, and can be used as an oil-displacing agent for tertiary recovery of a high temperature and high salinity reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

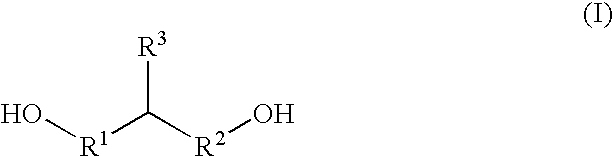

Preparation of polyamides by hydrolytic polymerization, postpolymerization and subsequent extraction

InactiveUS20160009869A1Low residual monomer contentPrevent reformationMonocomponent polyamides artificial filamentPolymer sciencePolyamide

The present invention relates to a process for preparing polyamides, comprising a hydrolytic polymerization, a postpolymerization and an extraction.

Owner:BASF AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com