Thermal expansibility microsphere and method for reducing residual monomers therein

A technology of heat-expandable microspheres and residual monomers, which is applied in the field of heat-expandable microspheres and the reduction of residual monomers, and can solve problems such as high cost, low production efficiency, and serious pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

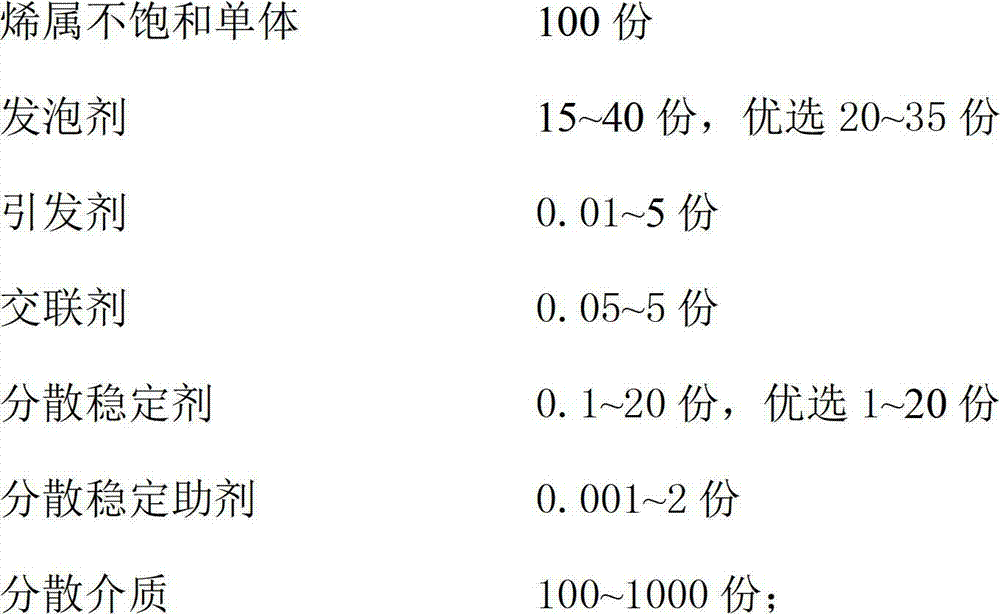

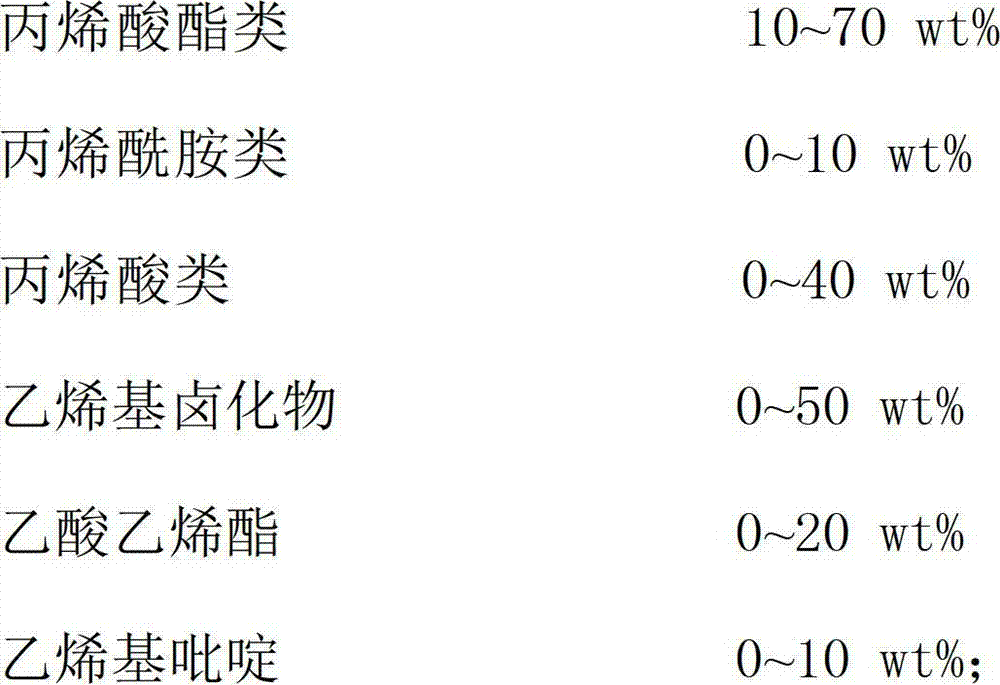

Method used

Image

Examples

Embodiment 1

[0064] By mixing 80 grams of acrylonitrile, 15 grams of methyl acrylate, 15 grams of methyl methacrylate, 90 grams of vinylidene chloride, 0.8 grams of ethylene glycol dimethacrylate, 1.2 grams of dicyclohexyl peroxycarbonate and 60 grams of Isobutane yields an oily phase for suspension polymerization.

[0065] Add 200 grams of deionized water, 20 grams of sodium hydroxide, 30 grams of sodium chloride and 0.15 grams of sodium lauryl sulfate into beaker No. 1 to fully dissolve; add 200 grams of deionized water, 60 grams of six Magnesium chloride hydrate, 20 grams of sodium chloride, and 0.01 grams of sodium nitrite are fully dissolved; the solution in the No. 1 beaker is first poured into a 1-liter three-necked flask with a stirring paddle, and then stirred at a speed of 1200 rpm, and then poured into the three-necked flask Slowly add the solution in the No. 2 beaker to the flask. After the addition was complete, the mixture was fully stirred for 15 minutes to obtain a suspens...

Embodiment 2

[0070] By mixing 100 g of acrylonitrile, 60 g of methacrylonitrile, 30 g of methyl methacrylate, 10 g of acrylic acid, 0.5 g of trimethylolpropane trimethacrylate, 1 g of benzoyl peroxide, 60 g of iso Octane gives a suspension polymerized oil phase.

[0071] In 400 grams of ion-exchanged water, add 45 grams of sodium chloride, 20 grams (active ingredient amount: 20% by weight) of colloidal silicon dioxide, 0.2 grams of polyvinylpyrrolidone and 0.02 grams of sodium nitrite, then adjust the pH to 2.4, uniform mixed as an aqueous dispersion medium.

[0072] The oil phase and the water phase were dispersed by stirring at 6000 rpm for 3 minutes with a homomixer to prepare a suspension solution. Immediately inject the suspension solution into a 1-liter high-pressure reactor, replace the air with nitrogen, and pressurize the reactor to reach an initial pressure of 0.3 MPa. Then, after polymerizing at 60-61°C for 15 hours, add 3 grams of potassium persulfate and 3 grams of sodium bi...

Embodiment 3-5

[0076] Except for changing the type and amount of monomers, crosslinking agents, initiators and blowing agents used, and the temperature of the polymer (see Table 1 for details), other conditions were the same as in Example 1, and different heat-expandable microspheres were prepared. Its performance is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com