Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

336 results about "Expandable microsphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

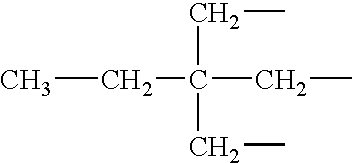

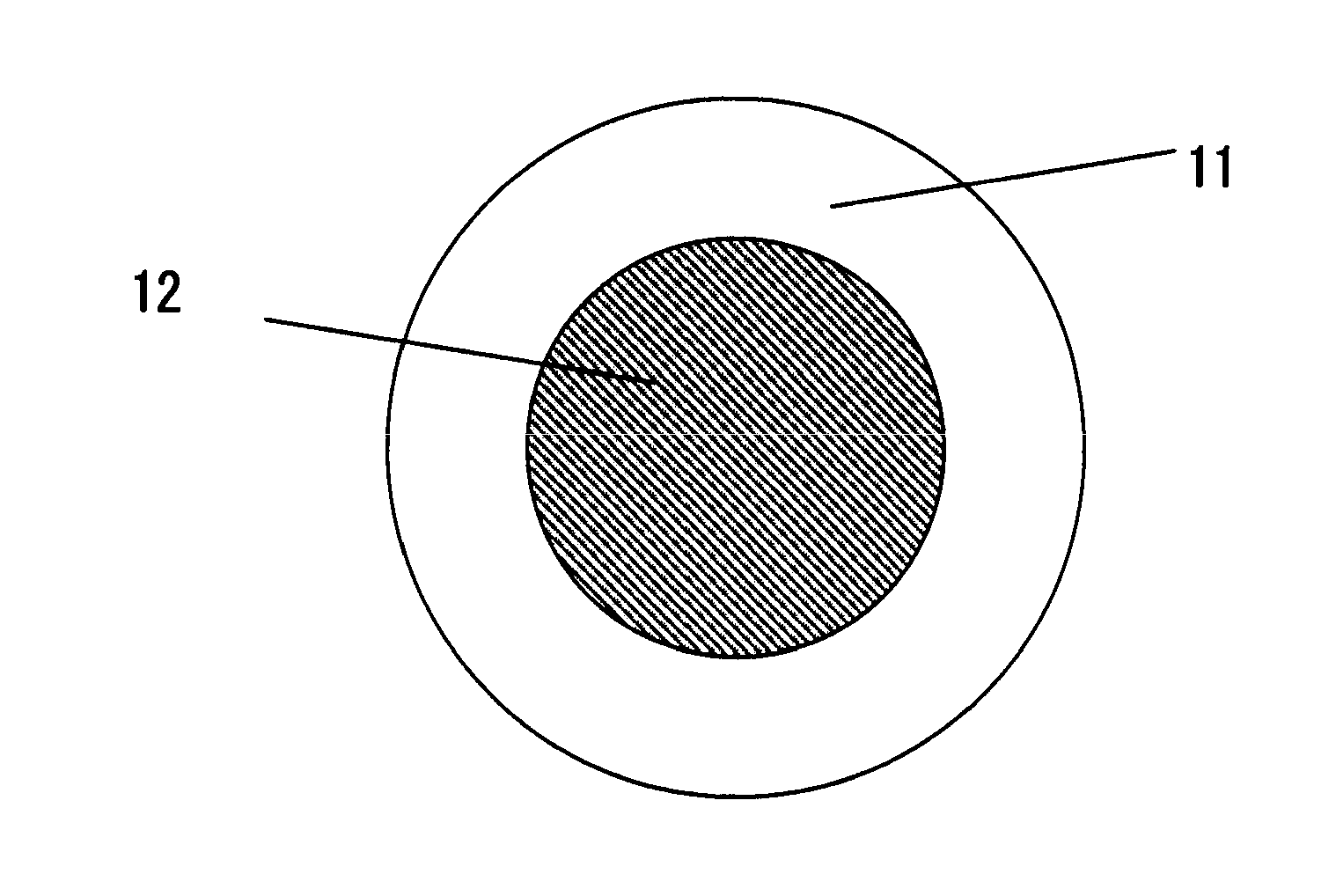

Expandable microspheres are microscopic spheres comprising a thermoplastic shell encapsulating a low boiling point liquid hydrocarbon. When heated to a temperature high enough to soften the thermoplastic shell, the increasing pressure of the hydrocarbon will cause the microsphere to expand. The volume can increase by 60 to 80 times.

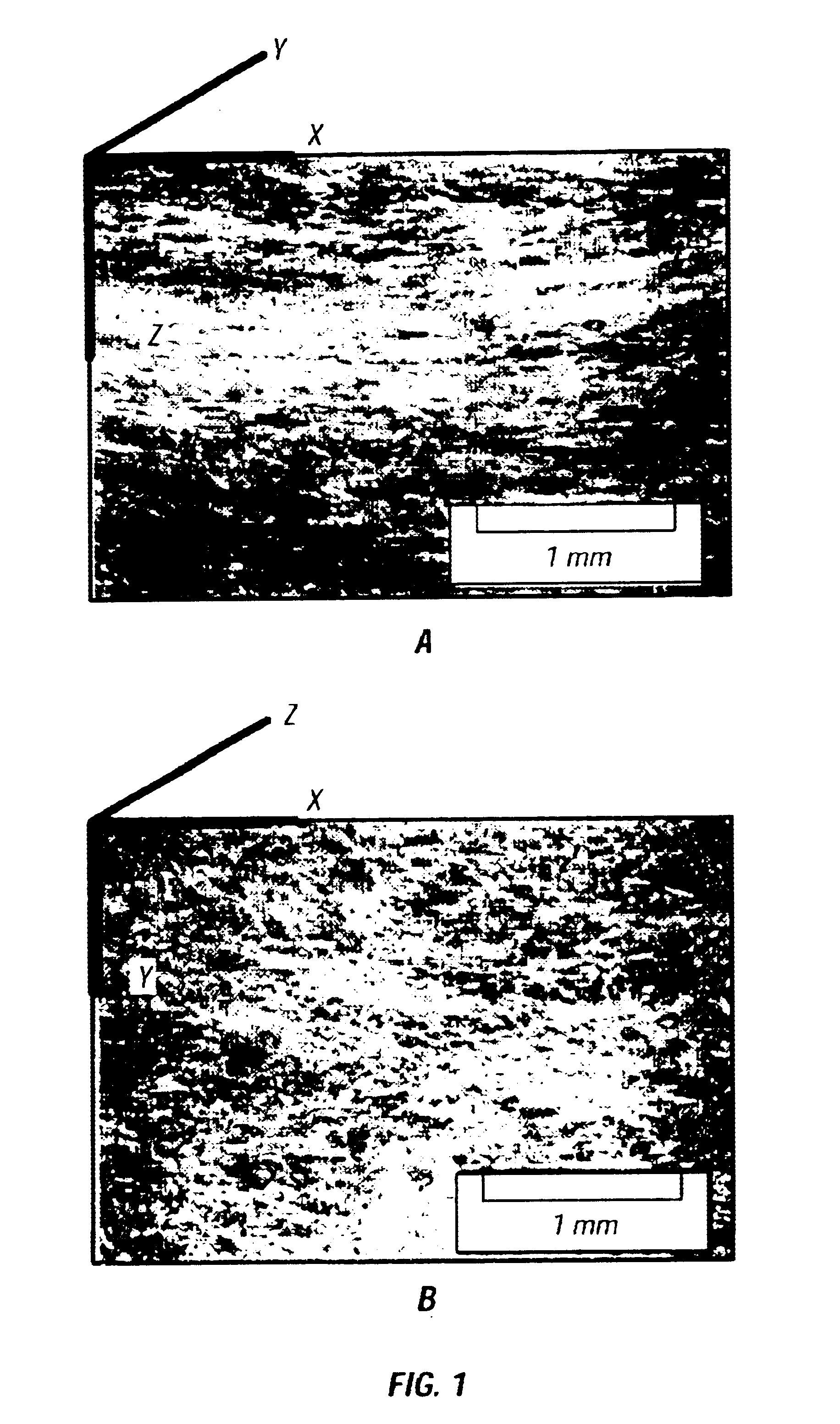

Bulk enhanced paperboard and shaped products made therefrom

An improved paperboard has been bulk enhanced by retaining a substantial portion of bulk-enhanced additives including expandable microspheres in a suitable distribution within the paperboard. The cellulosic paperboard web has an overall fiber weight (w) of at least 40 lbs. / 3000 square feet and at a fiber density of 3, 4.5, 6.5, 7, 8.3, and 9 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inch respectively, has a GM Taber stiffness of at least about 0.00716 w2.63 grams-centimeter / fiber mat density1.63 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inch, and a GM tensile stiffness of at least about 1890+24.2 w pounds per inch. The high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The resulting paperboard has better GM Taber stiffness values and GM tensile stiffness than prior art paperboards. The paperboard also has increased strain to failure and is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

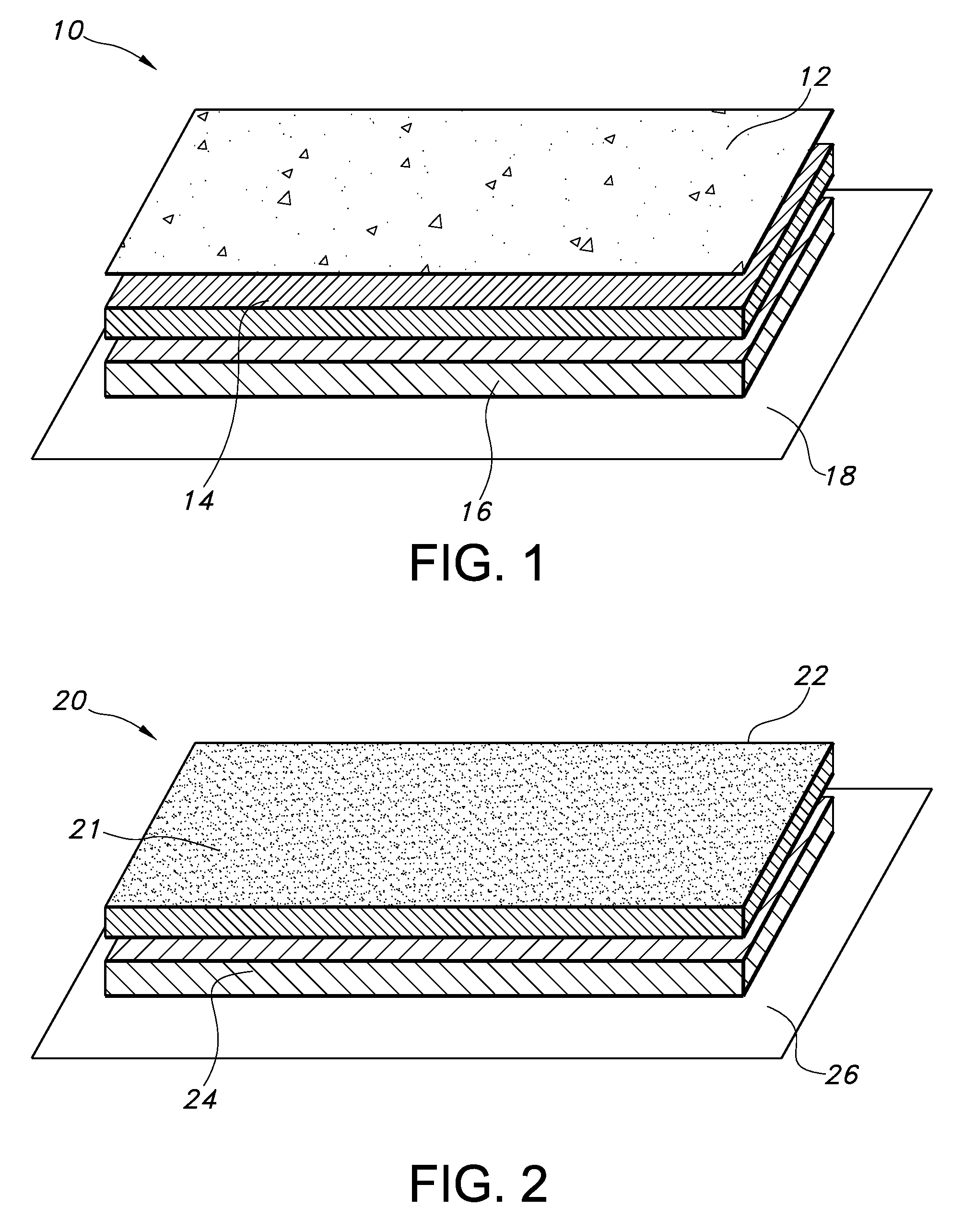

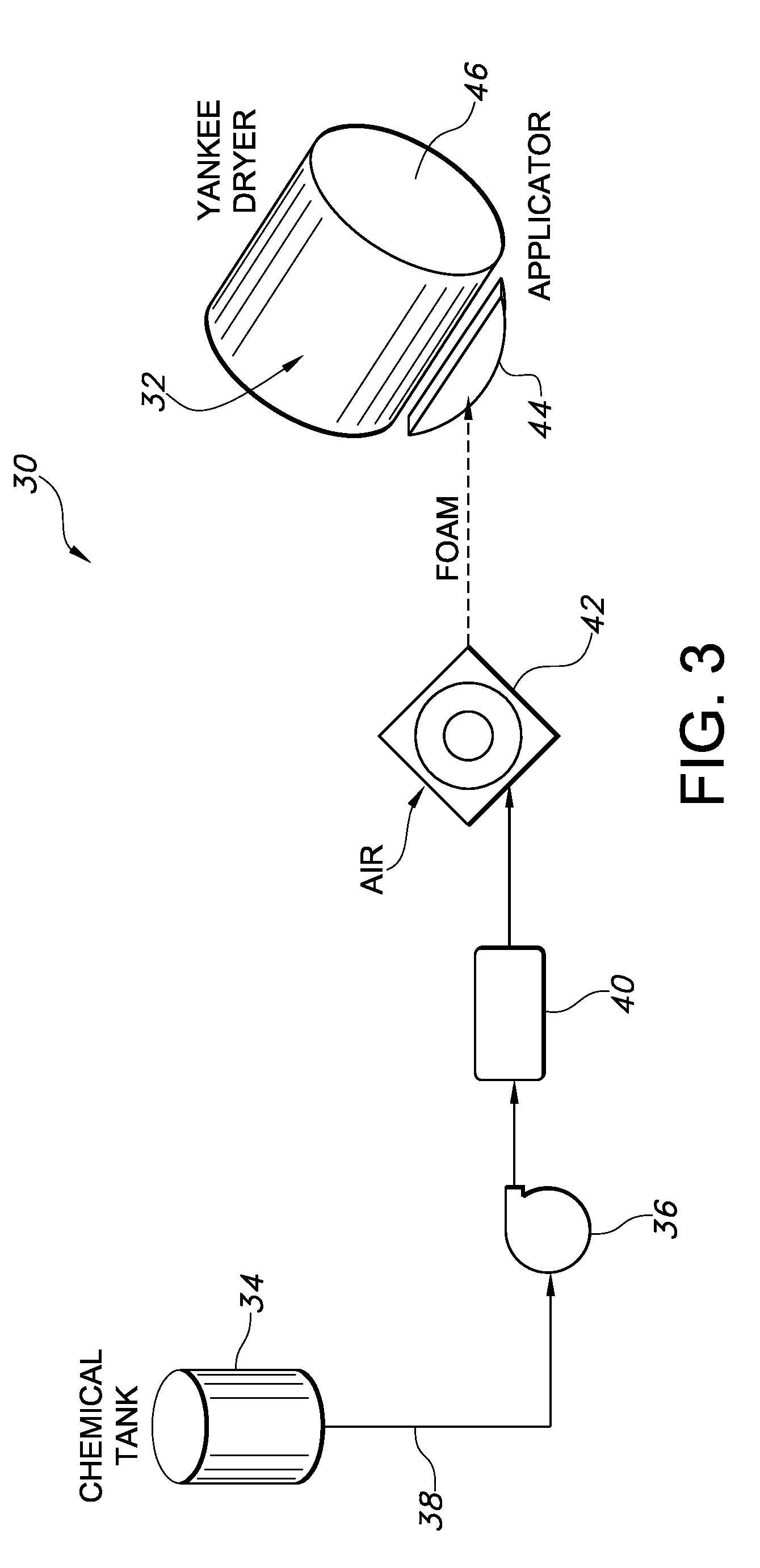

Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

InactiveUS6919111B2Quality improvementImprove insulation performanceNon-fibrous pulp additionWrappersPaperboardEngineering

An improved paperboard has been bulk enhanced by retaining a substantial portion of bulk-enhanced additives including expandable microspheres in a suitable distribution within the paperboard. The cellulosic paperboard web has an overall fiber weight (w) of at least 40 lbs. per 3000 square feet and, at a fiber density of 3, 4.5, 6.5, 7, 8.3, and 9 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inches, has a GM Taber stiffness of at least about 0.00246 w2.63 grams-centimeter / fiber mat density1.63, and a GM tensile stiffness of at least about 615+13.18 w pounds per inch. The high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The resulting paperboard has better GM Taber stiffness values and GM tensile stiffness than prior art paperboards. The paperboard also has increased strain to failure and is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

Expandable microspheres for foam insulation and methods

InactiveUS20050079352A1Use in some applicationHigh of encapsulationLiquid surface applicatorsGlass/slag layered productsPolymer scienceFoaming agent

Hollow thermoexpandable particles or microspheres are provided that contain hydrocarbon blowing agents and have a shell polymer that can be softened at the onset of the expansion temperature and solidified at a higher temperature (thermoset) in an expanded state. Preferably, the microspheres have a shell of thermally expandable and thermally crosslinkable polymer and a hollow interior that contains a hydrocarbon liquid that boils at a temperature below the heat activated crosslinking temperature of the polymer shell. The crosslinking of the shell polymer during or after expansion, which is heat activated at an elevated temperature, can solidify the shell polymer and, then, maintain the expanded volume of the microspheres. The thermoexpandable thermoset polymer particles are useful in insulation, packaging, for making foam materials such as polyurethane or polyisocyanurate rigid foams. The invented thermoset microspheres can substantially improve the close cell percentage and compressive strength of the foam materials and make the foam manufacturing less hazardous.

Owner:IP RIGHTS +1

Enhanced personal care absorbent articles

The present invention relates to a personal care absorbent article comprising at least two substrates each having an internal and external surface, wherein at least one substrate is a fluid permeable bodyside substrate selected from spunbond, meltblown, coform, airlaid, bonded-carded web, spunlace materials and combinations thereof; at least one substrate is an impermeable backsheet; and an absorbent core disposed in between said substrates; wherein at least the external surface of at least one substrate has applied to it a benefit agent selected from an additive composition wherein said additive composition is a polymer dispersion selected from polyolefin dispersions, polyisoprene dispersions, polybutadiene-styrene block copolymer dispersions, latex dispersions, polyvinyl pyrrolidone-styrene copolymer dispersions, polyvinyl alcohol-ethylene copolymer dispersions, and combinations thereof; an enhancement component selected from microparticles, expandable microspheres, fibers, additional polymer dispersions, scents, anti-bacterials, moisturizers, medicaments, soothers and combinations thereof; and combinations thereof.

Owner:KIMBERLY-CLARK WORLDWIDE INC

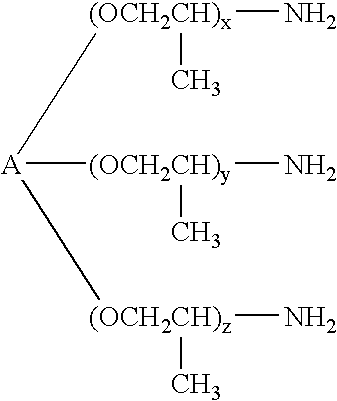

Epoxy adhesive having improved impact resistance

InactiveUS20030196753A1Polyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyphenolExpandable microsphere

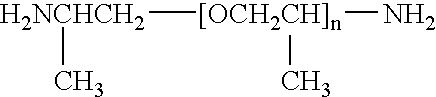

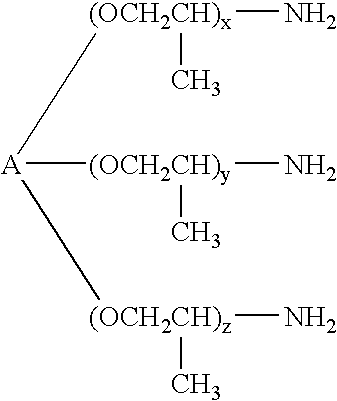

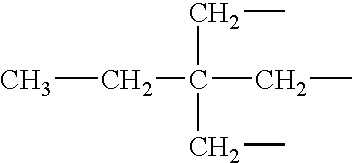

In the preparation of an improved adhesive composition, an epoxy-based prepolymer is obtained by the reaction of one or more epoxy resins with amino-terminated polyethers and / or carboxyl-terminated butadiene-nitrile rubbers. In one embodiment of the invention, both a solid epoxy resin and a liquid epoxy resin, each of which is a diglycidyl ether of a polyphenol such as bisphenol A, are used. The epoxy-based prepolymer is mixed with an acrylate-terminated urethane resin (preferably, one based on a polyol having a number average molecular weight of at least about 400) and a heat-activated latent curing agent to make an adhesive composition which can be pumpable at room temperature. Curable adhesives capable of expansion to about 100% with high impact resistance after curing may be obtained by inclusion of expanding agents such as expandable microspheres.

Owner:HENKEL KGAA

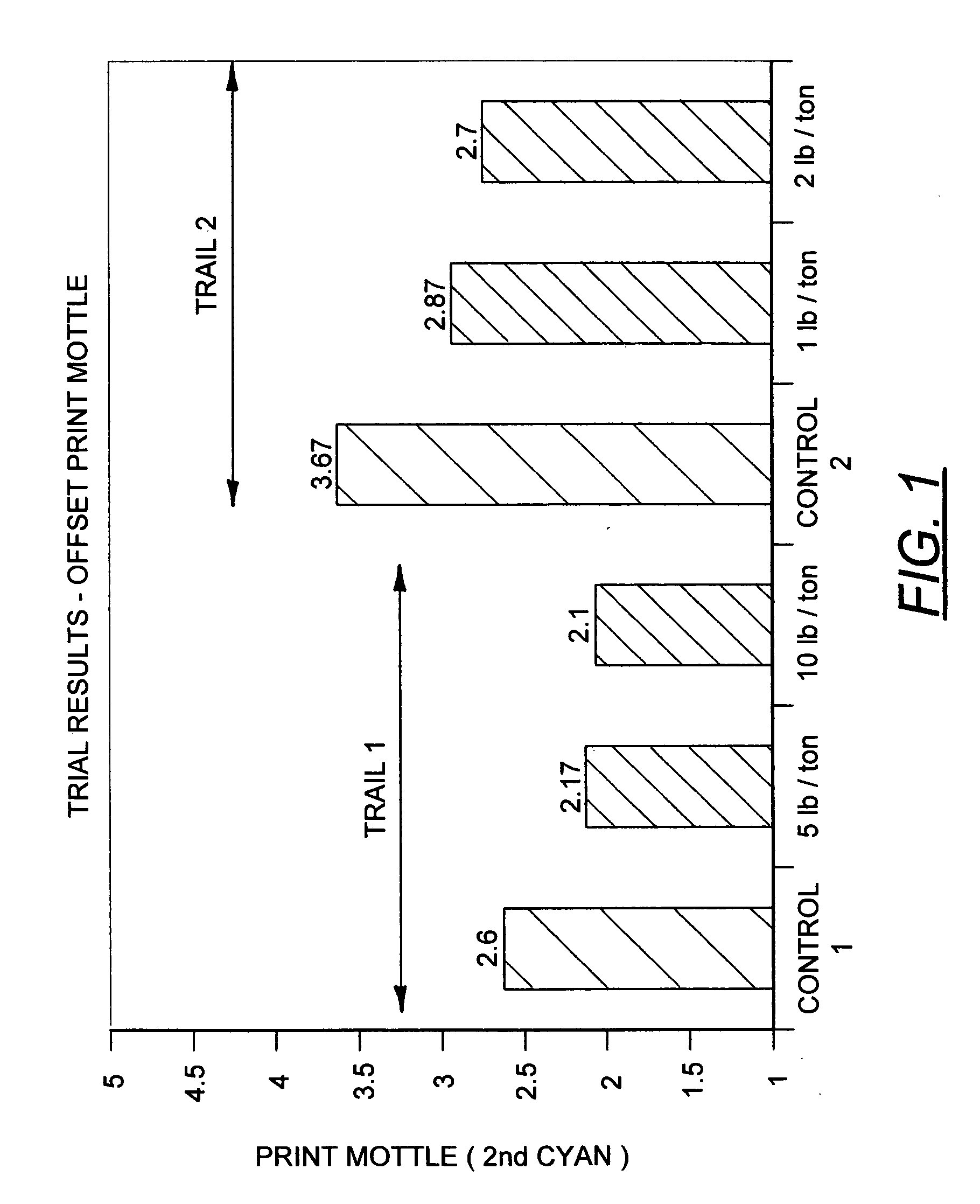

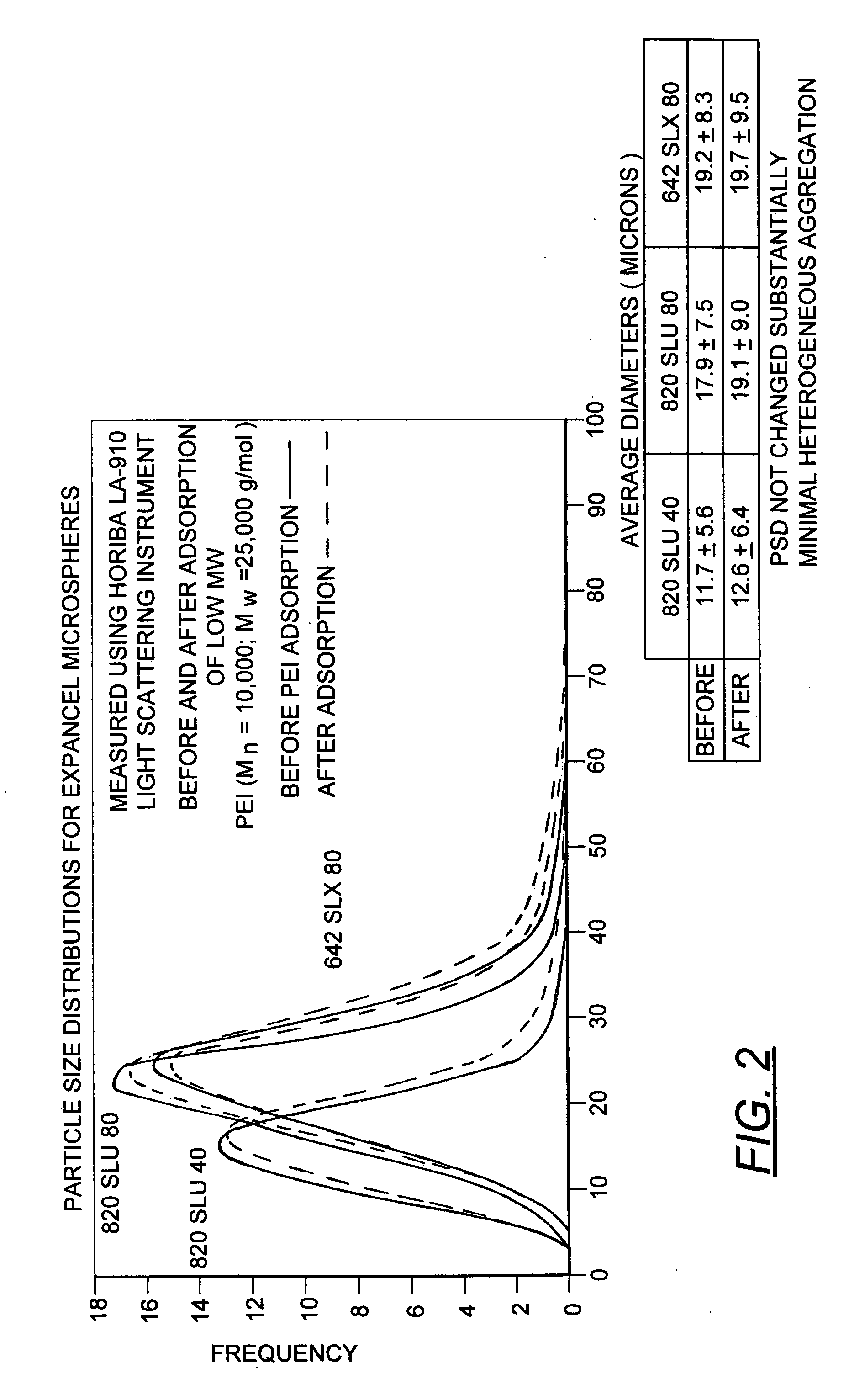

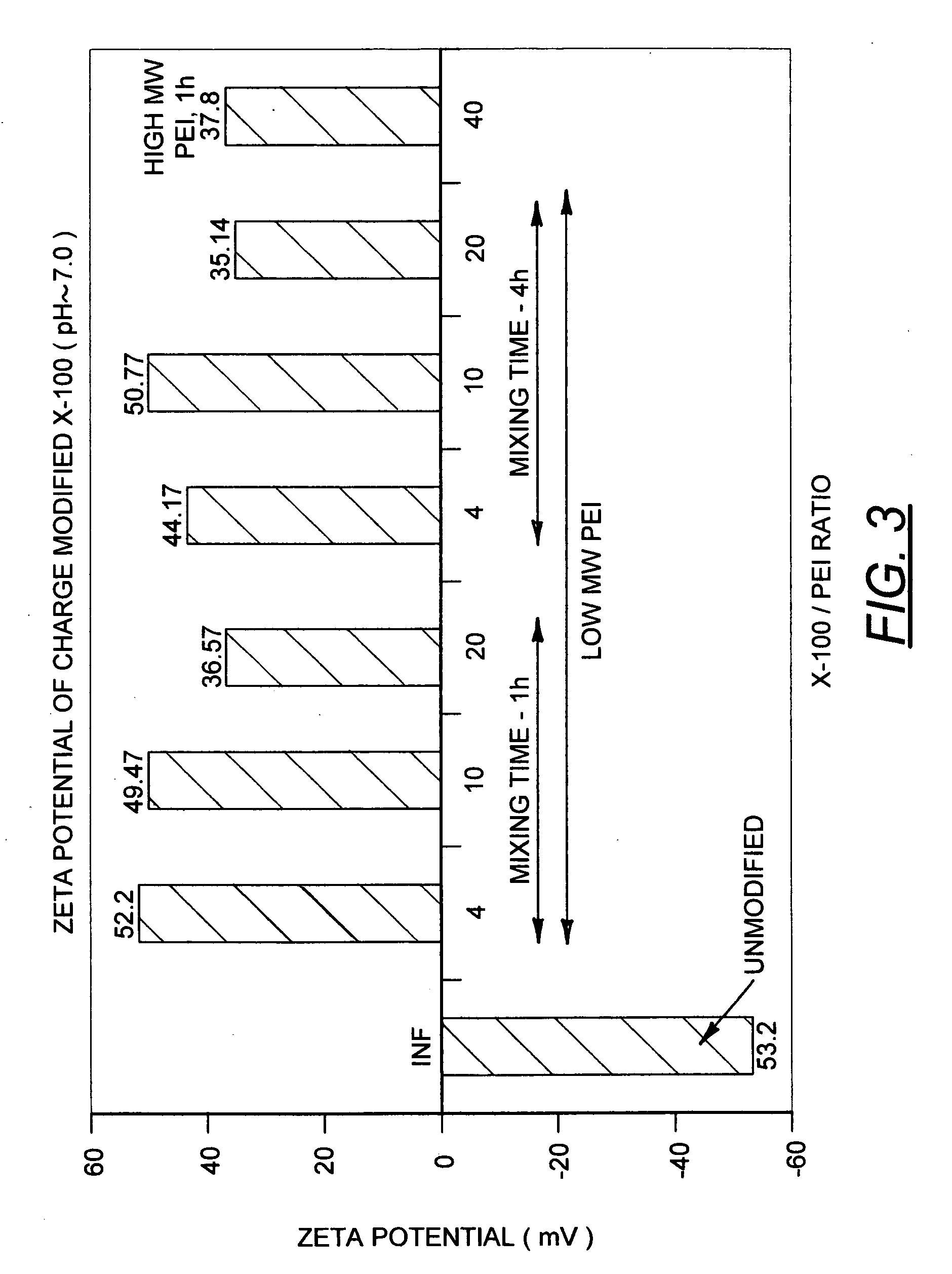

Compositions containing expandable microspheres and an ionic compound, as well as methods of making and using the same

InactiveUS20070044929A1Inorganic compound additionThin material handlingZeta potentialIonic strength

This invention relates to composition containing expandable microspheres and at least one ionic compound and having a zeta potential that is greater than or equal to zero mV at a pH of about 9.0 or less at an ionic strength of from 10−6 M to 0.1 M., as well as methods of making and using the composition.

Owner:INT PAPER CO

Foamed thermoplastic polyurethanes

InactiveUS7202284B1Improve cell structureExcellent surface appearanceCoatingsPolymer scienceMicrosphere

Process for the preparation of foamed thermoplastic polyurethanes characterized in that the foaming of the thermoplastic polyurethane is carried out in the presence of thermally expandable microspheres.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

Epoxy adhesive having improved impact resistance

InactiveUS6998011B2Increase resistanceImprove toughnessPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyolNitrile rubber

In the preparation of an improved adhesive composition, an epoxy-based prepolymer is obtained by the reaction of one or more epoxy resins with amino-terminated polyethers and / or carboxyl-terminated butadiene-nitrile rubbers. In one embodiment of the invention, both a solid epoxy resin and a liquid epoxy resin, each of which is a diglycidyl ether of a polyphenol such as bisphenol A, are used. The epoxy-based prepolymer is mixed with an acrylate-terminated urethane resin (preferably, one based on a polyol having a number average molecular weight of at least about 400) and a heat-activated latent curing agent to make an adhesive composition which can be pumpable at room temperature. Curable adhesives capable of expansion to about 100% with high impact resistance after curing may be obtained by inclusion of expanding agents such as expandable microspheres.

Owner:HENKEL KGAA

Composite foam made from polymer microspheres reinforced with long fibers

InactiveUS6864297B2Improved strain energy densityIncrease damage tolerancePolymer scienceMicrosphere

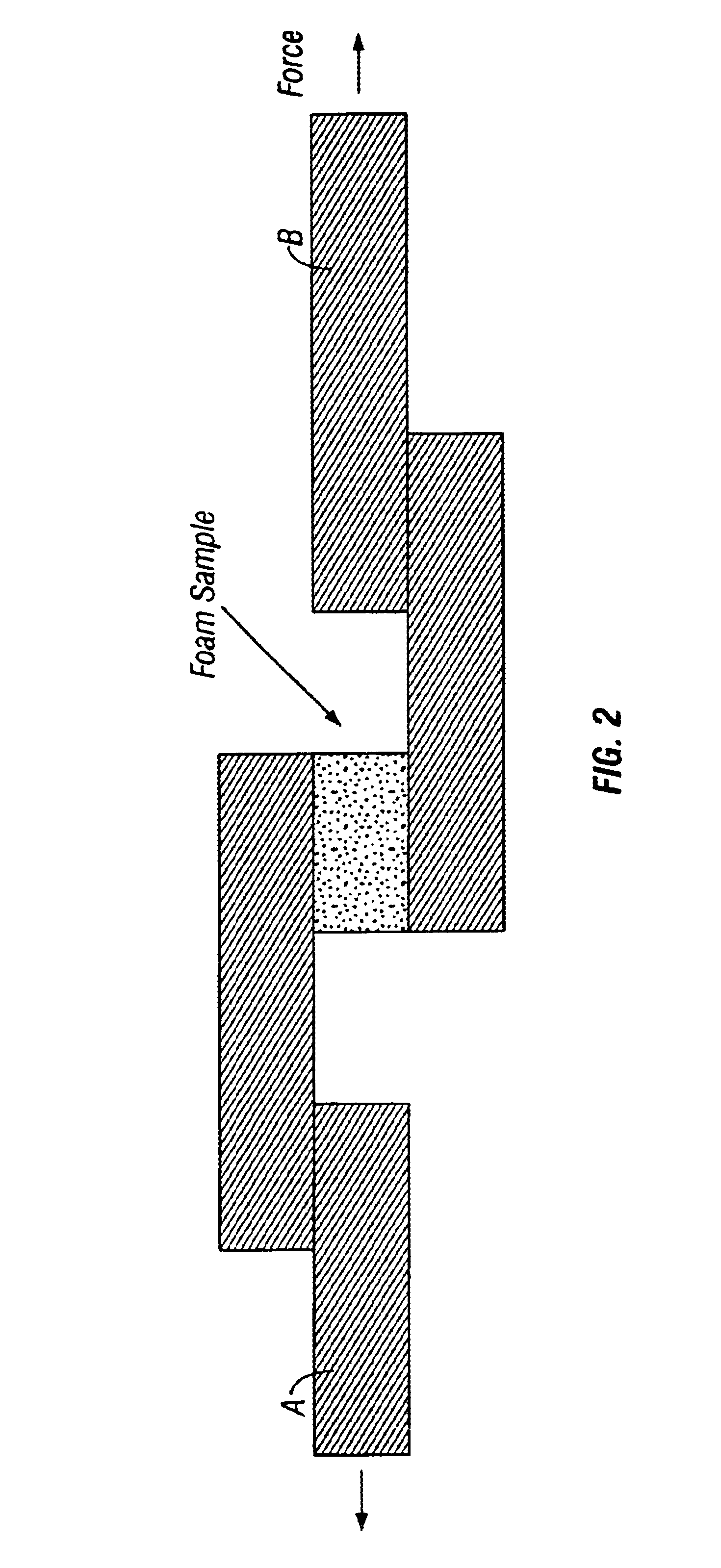

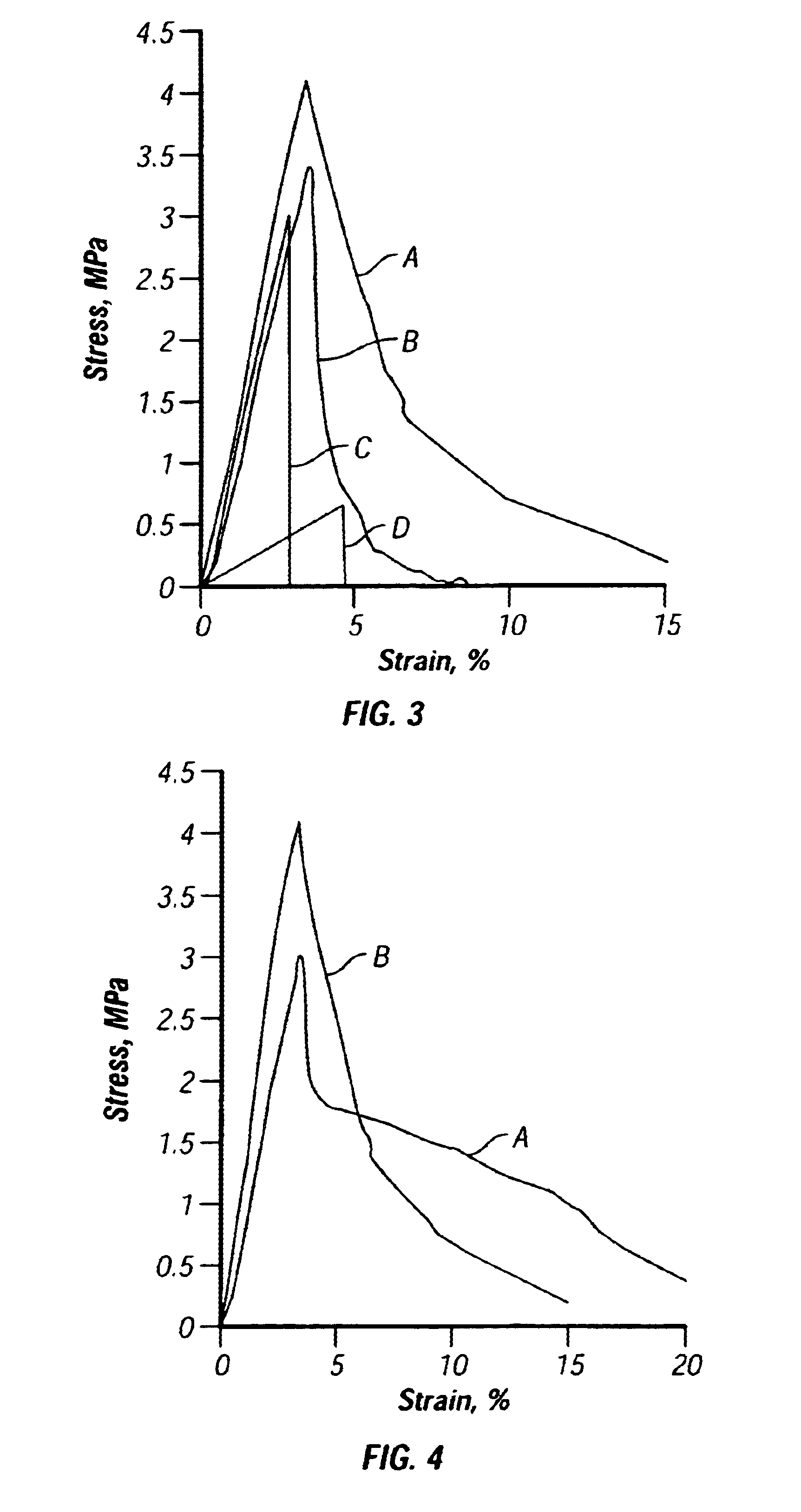

Composite foam based on expandable microspheres reinforced with fibers is described. Also disclosed are methods of making microsphere foam reinforced with fibers and methods of use thereof. The disclosure provides foam that performs equally and better than the performance of most thermoplastic foams commercially available.

Owner:UNIV OF SOUTHERN CALIFORNIA

Method for the production of expanded polymeric materials and expanded polymeric material obtained by the method

A method for the production of expanded polymeric materials; in particular for producing thermally insulating materials used in refrigerators. The method comprising the steps of providing a mixture of reagents based on isocyanate and polyol with the addition of expandable polystyrene-based microspheres, in which method the ratio by weight between the reagents and the expandable microspheres is between, about 7:1 and about 1:2.

Owner:WHIRLPOOL CORP

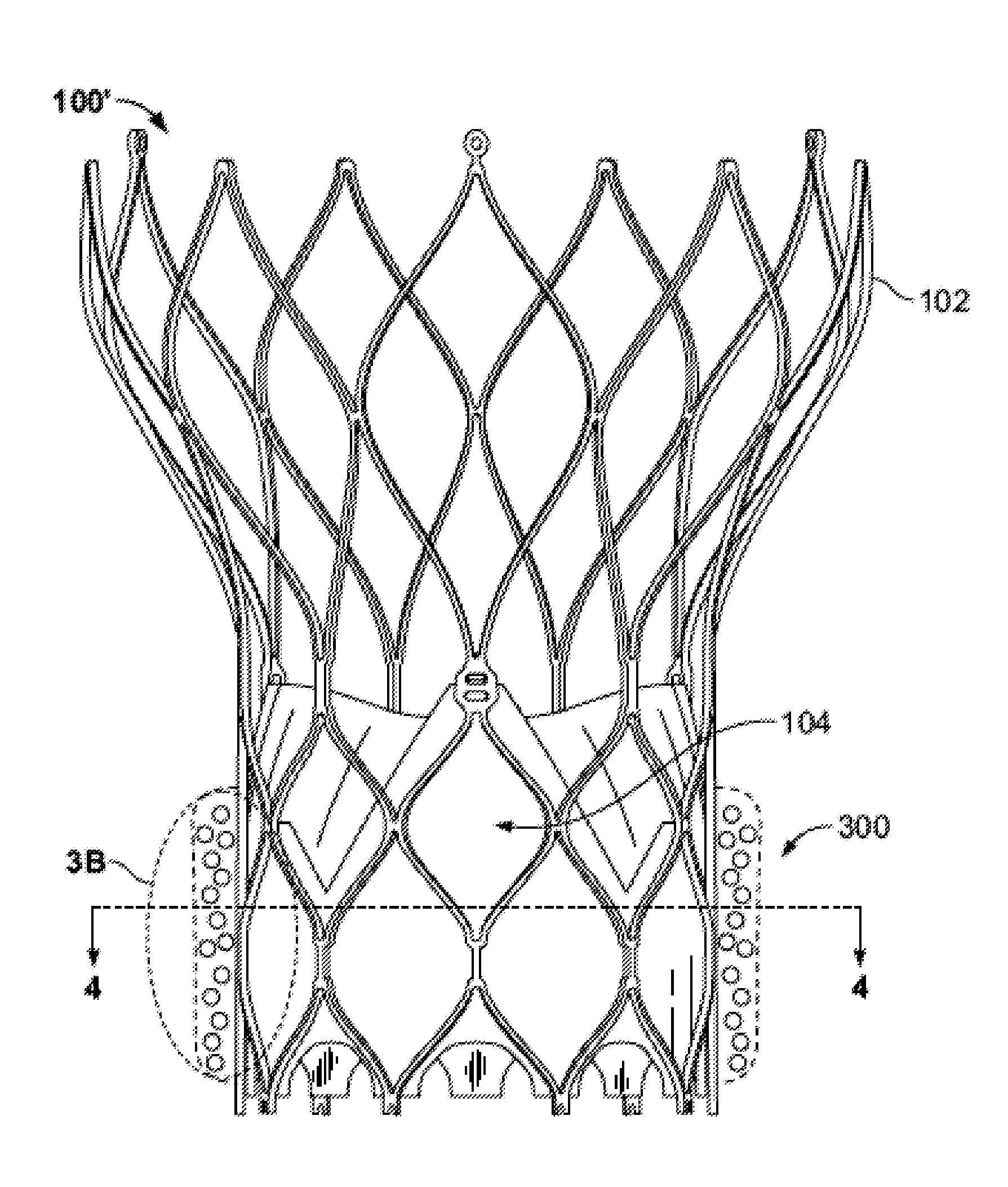

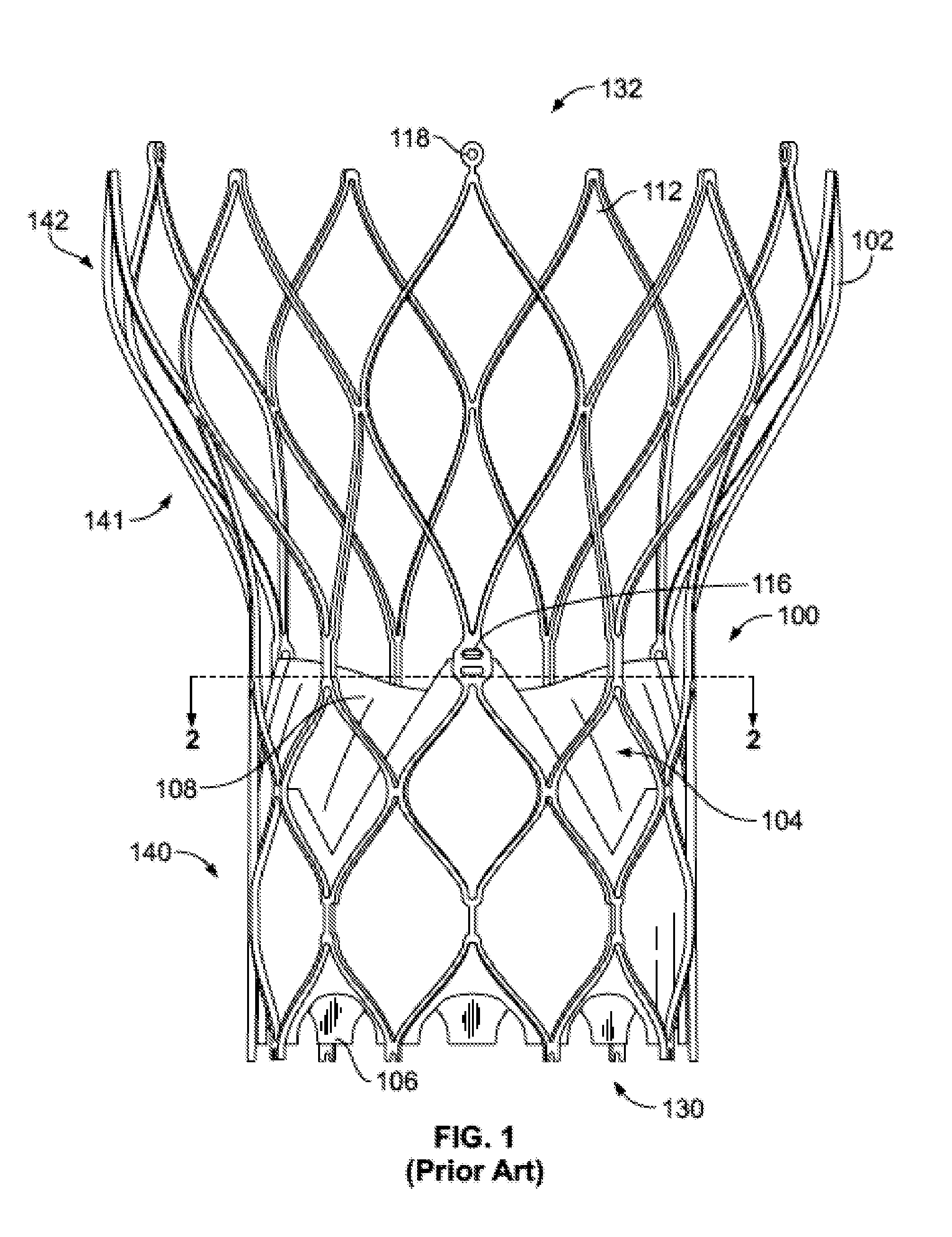

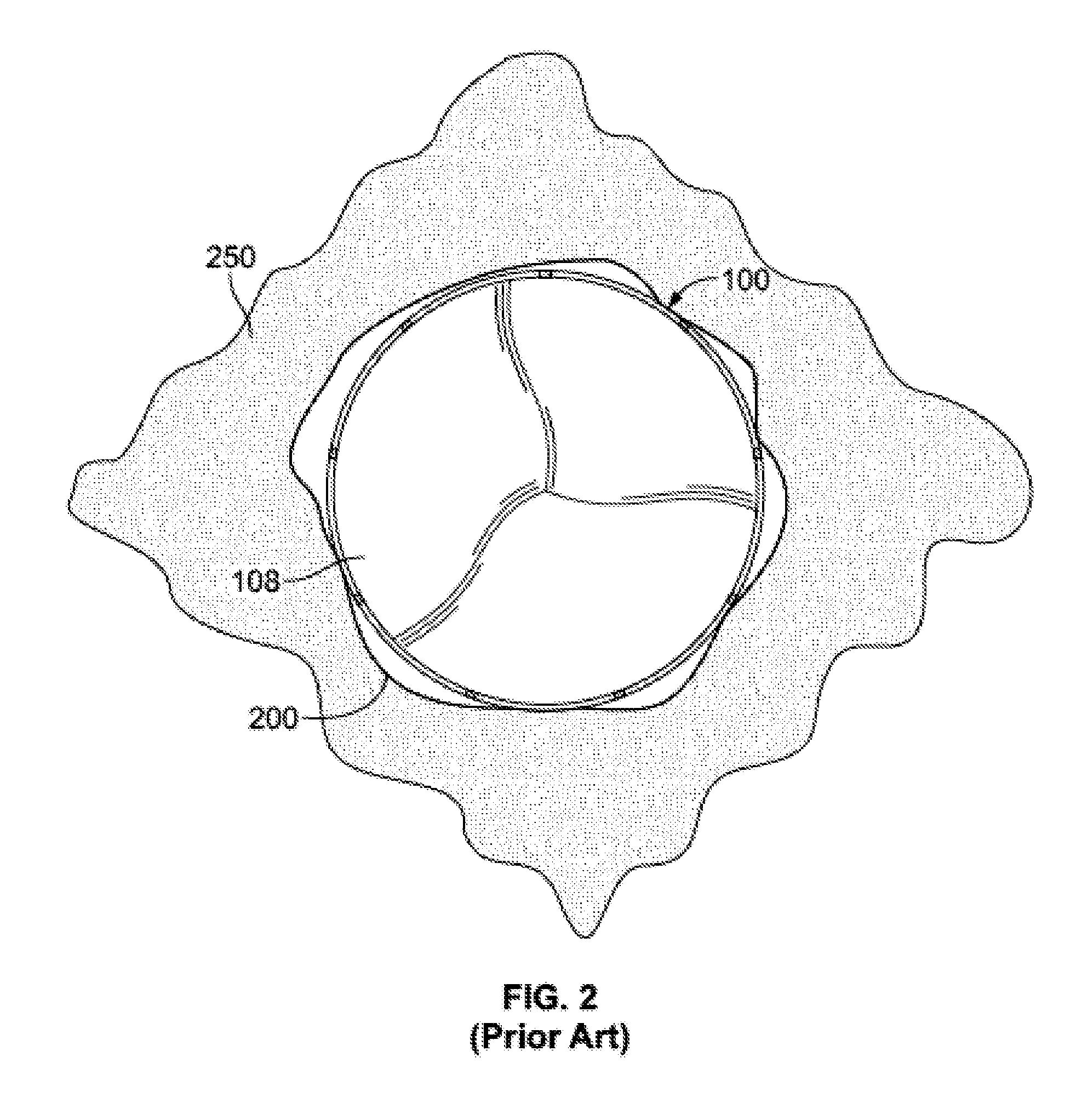

Prosthetic heart valve with expandable microspheres

A prosthetic heart valve includes a valve assembly mounted to an expandable stent. The prosthetic heart valve includes a cuff coupled to the stent. The cuff includes a pocket formed between an outer side and an inner side of the cuff. The pocket includes a plurality of biocompatible and irreversibly expandable microspheres. After implantation of the prosthetic heart valve into a patient, any gaps existing between the cuff and the native heart valve are exposed to bodily fluid, such as blood. The blood enters the pocket of the cuff through pores in the outer side of the cuff. The blood interacts with the microspheres, causing irreversible expansion of the microspheres. The microspheres expand to fill any gaps between the prosthetic heart valve and the native heart tissue, sealing the gaps and preventing leakage through the gaps.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

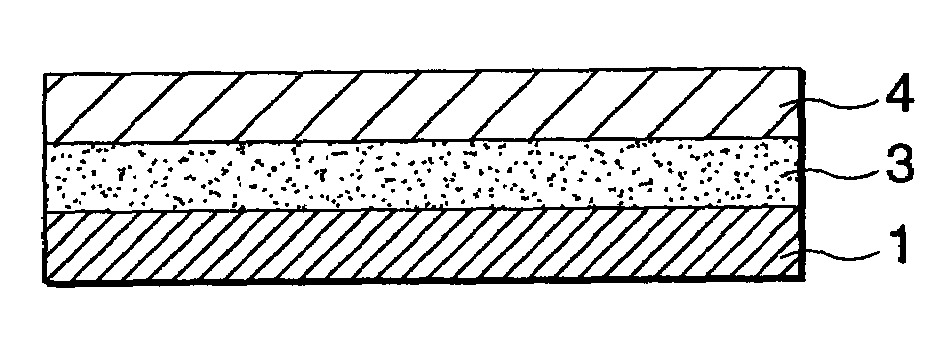

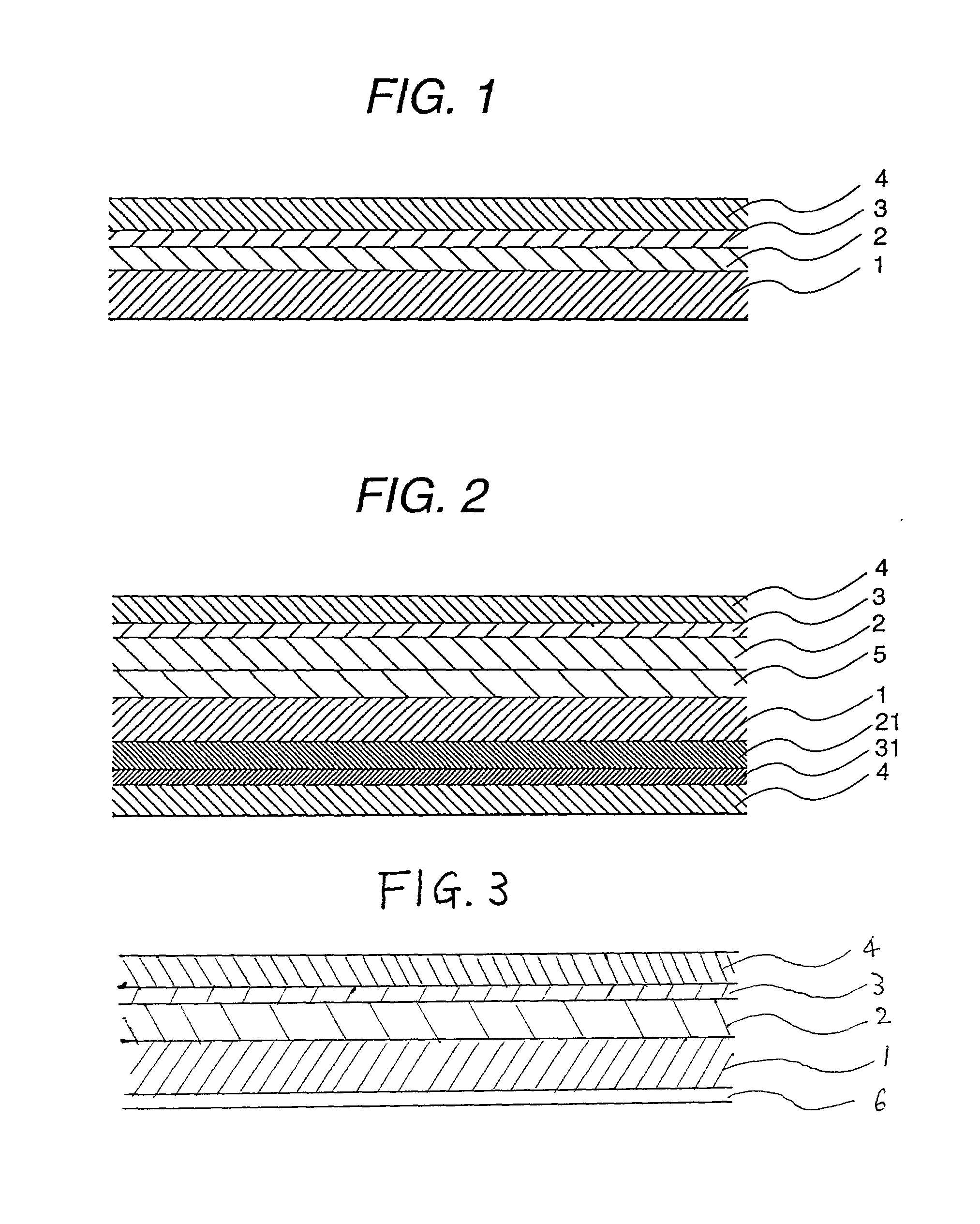

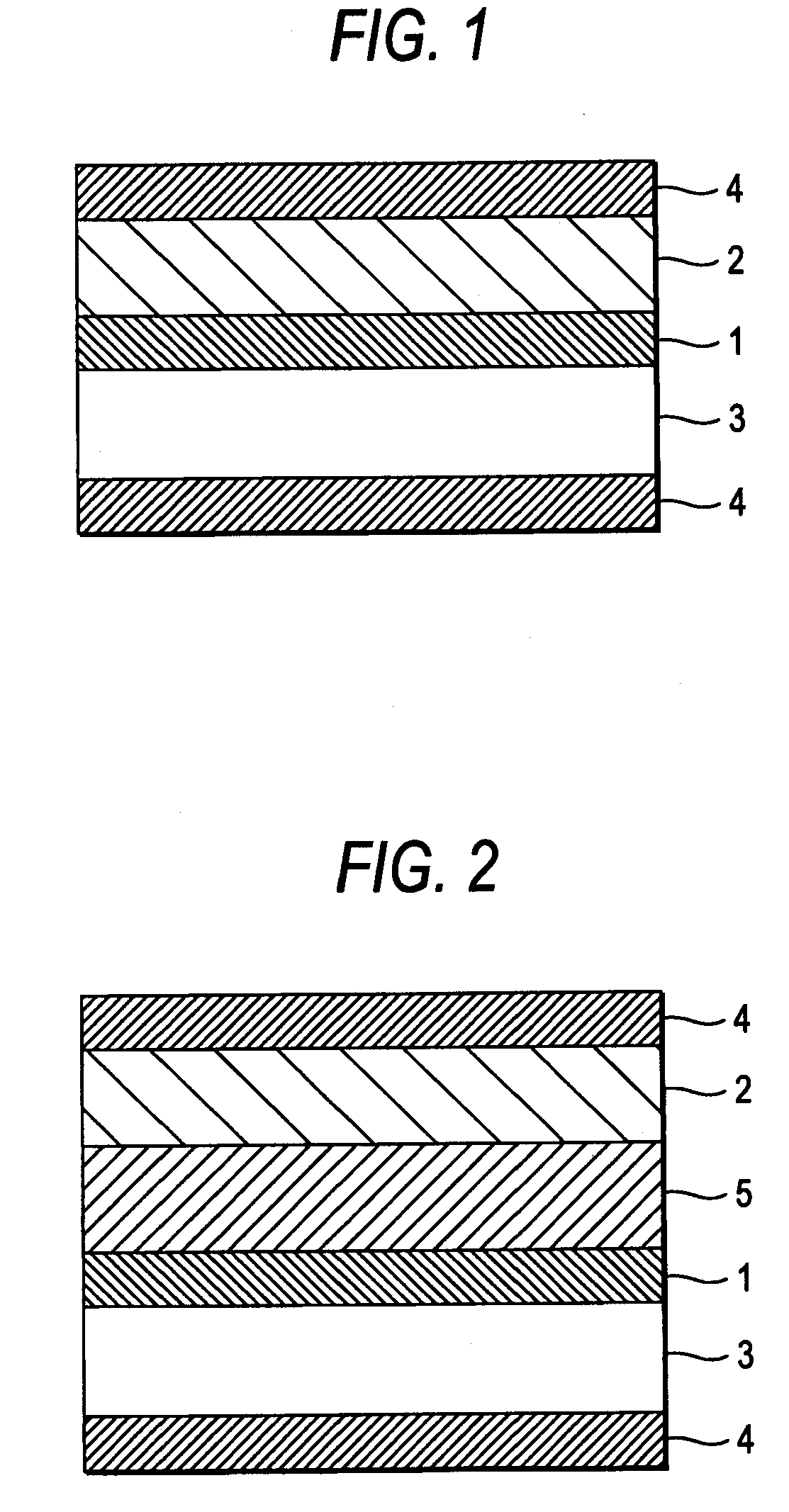

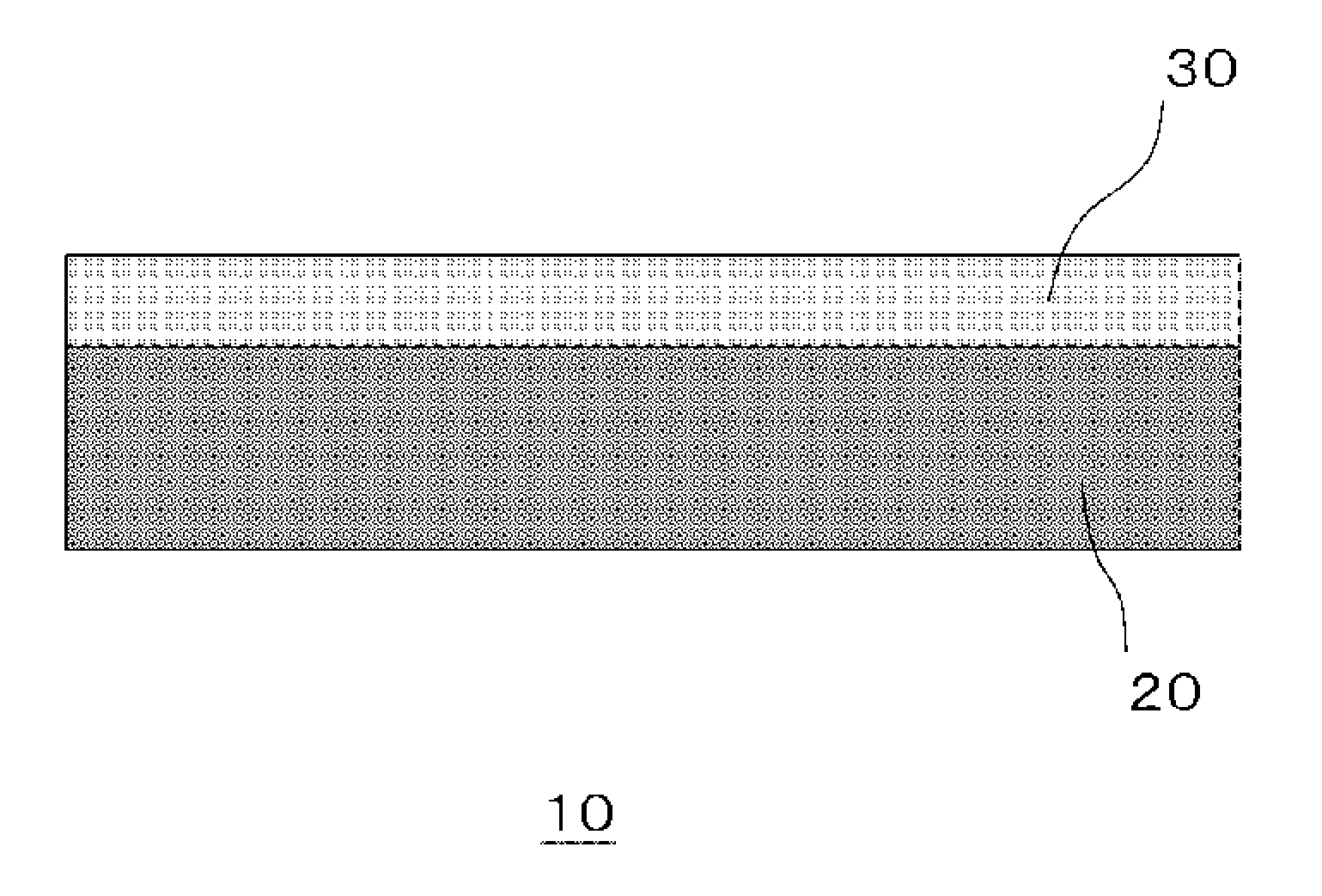

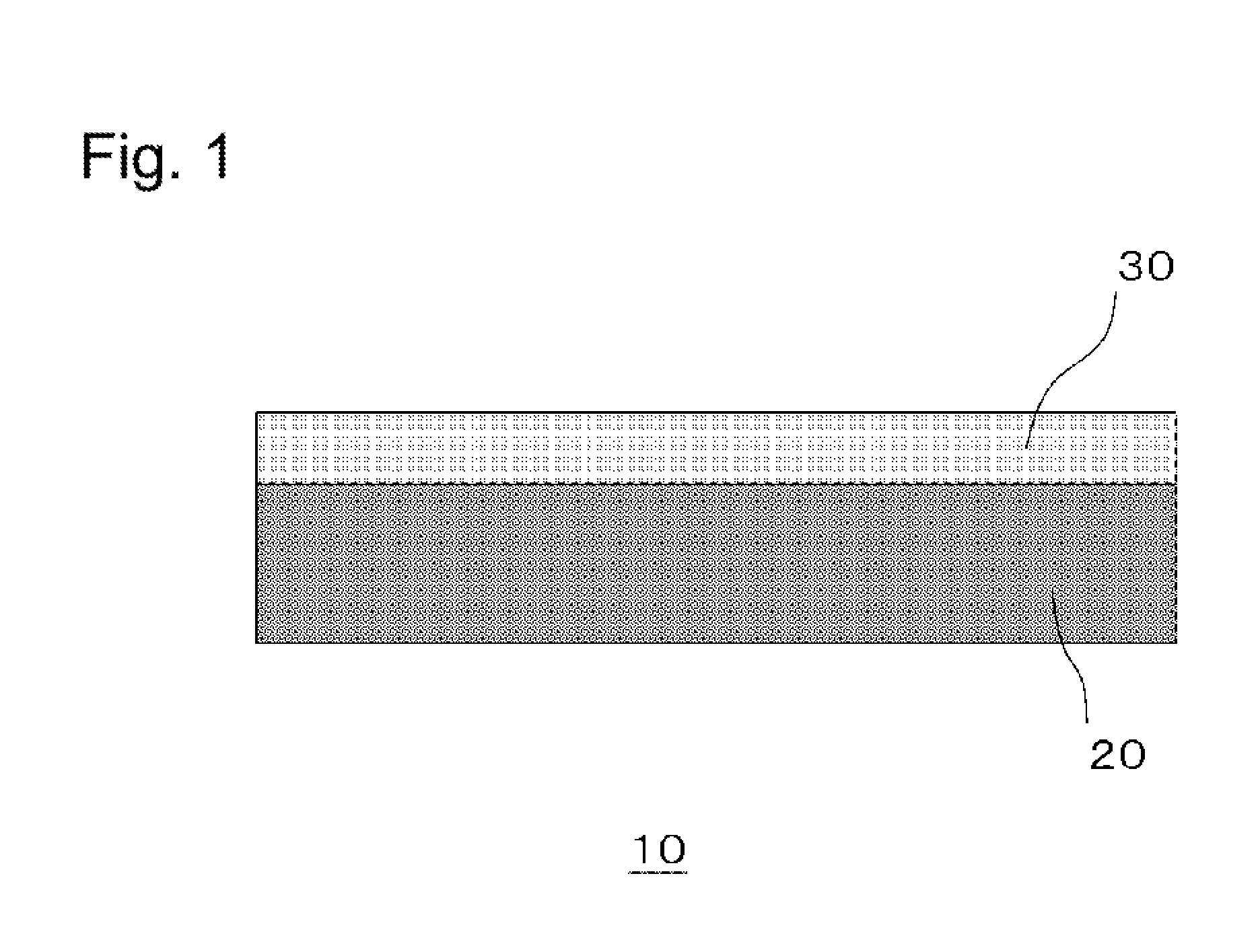

Heat-peelable pressure-sensitive adhesive sheet

InactiveUS6998175B2Avoid YieldAvoid breakingSynthetic resin layered productsSemiconductor/solid-state device manufacturingSurface resistivitySurface roughness

A heat-peelable pressure-sensitive adhesive sheet which, even when used for temporarily fixing electronic parts having poor resistance to static electricity, such as magnetic heads, is effective in preventing the yield of such electronic parts from being reduced by electrostatic breakage, while ensuring its functions of adhesiveness before heating and peelability after heating. The heat-peelable pressure-sensitive adhesive sheet comprises a substrate and formed on at least one side thereof a heat-expandable pressure-sensitive adhesive layer containing heat-expandable microspheres, wherein the heat-expandable pressure-sensitive adhesive layer has a surface resistivity of 1012 Ω / □ or lower. In this heat-peelable pressure-sensitive adhesive sheet, the heat-expandable pressure-sensitive adhesive layer before heating may have a center line average surface roughness of 2 μm or less and a maximum surface roughness of 5 μm or less. The adhesive sheet may have a rubber-like organic elastic layer interposed between the substrate and the heat-expandable pressure-sensitive adhesive layer.

Owner:NITTO DENKO CORP

Injectable and swellable microspheres for dermal augmentation

InactiveUS20020197326A1Improve water absorptionEasy CalibrationPowder deliveryMicrocapsulesMicrosphereBiocompatibility

The present invention relates to injectable compositions comprising biocompatible, swellable, hydrophilic, non-toxic and substantially spherical microspheres microspheres and a biocompatible carrier for use in dermal augmentation. The present invention further relates to methods of dermal augmentation, particularly for the treatment of skin contour deficiencies, using the injectable compositions.

Owner:BIOSPHERE MEDICAL INC

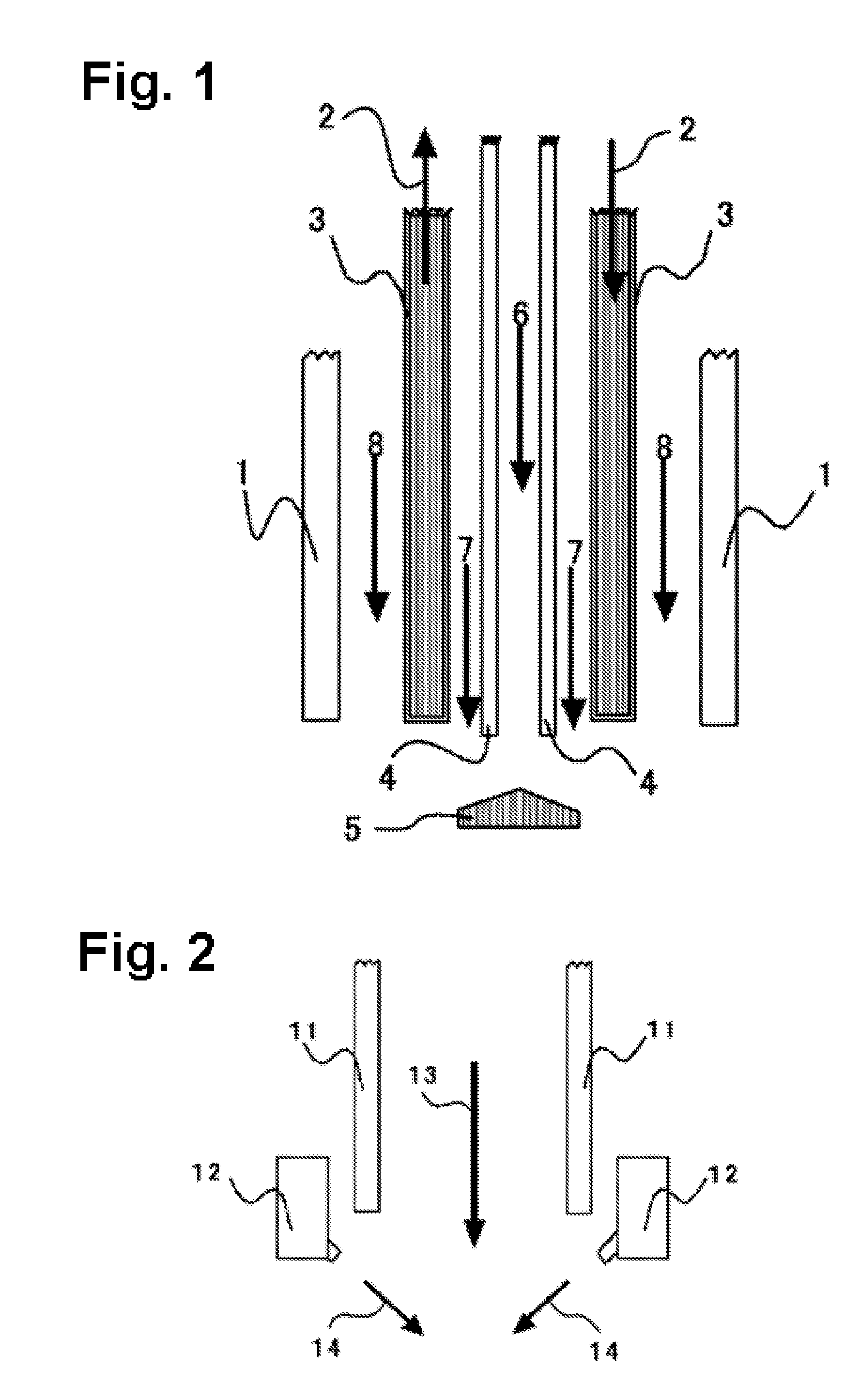

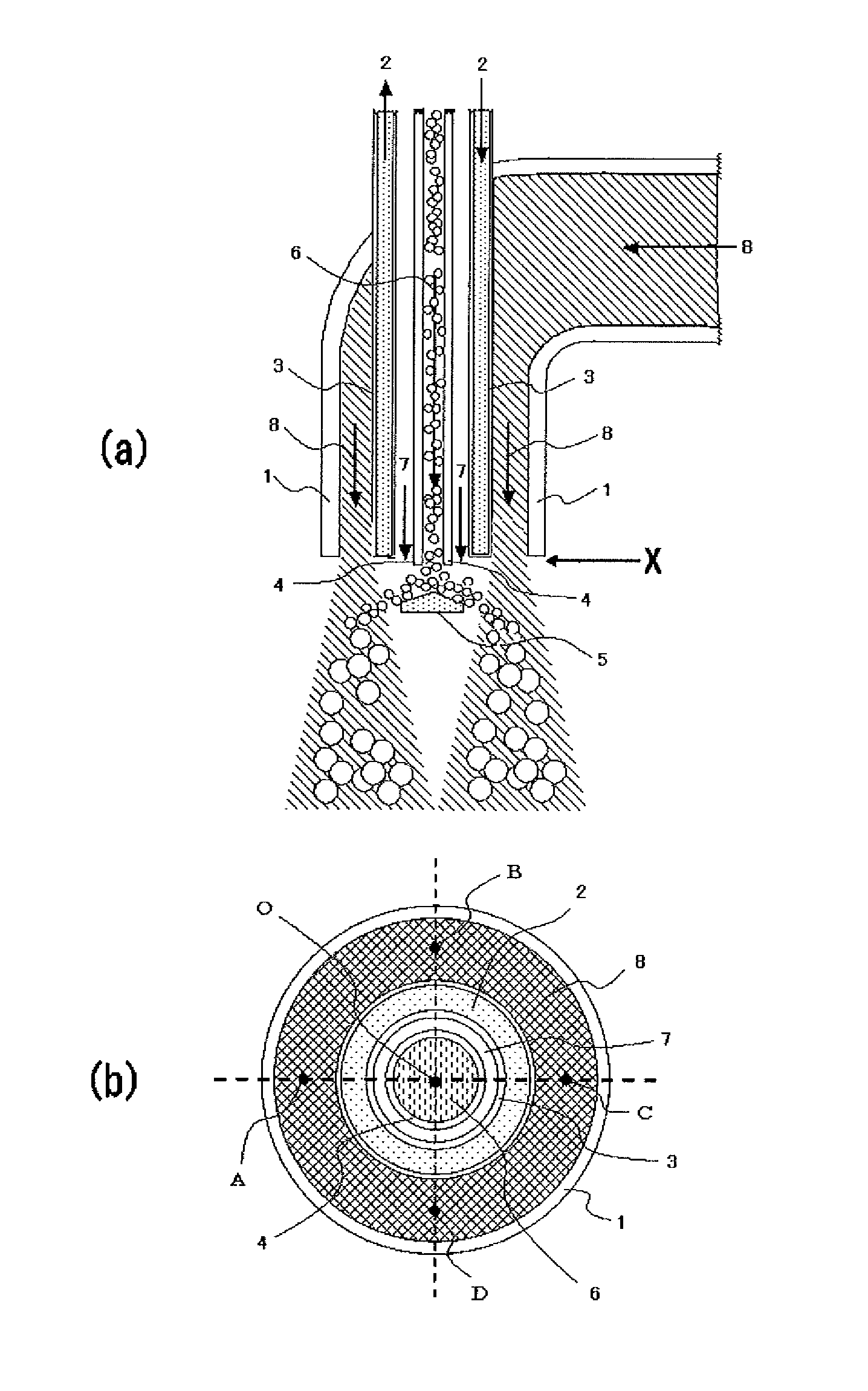

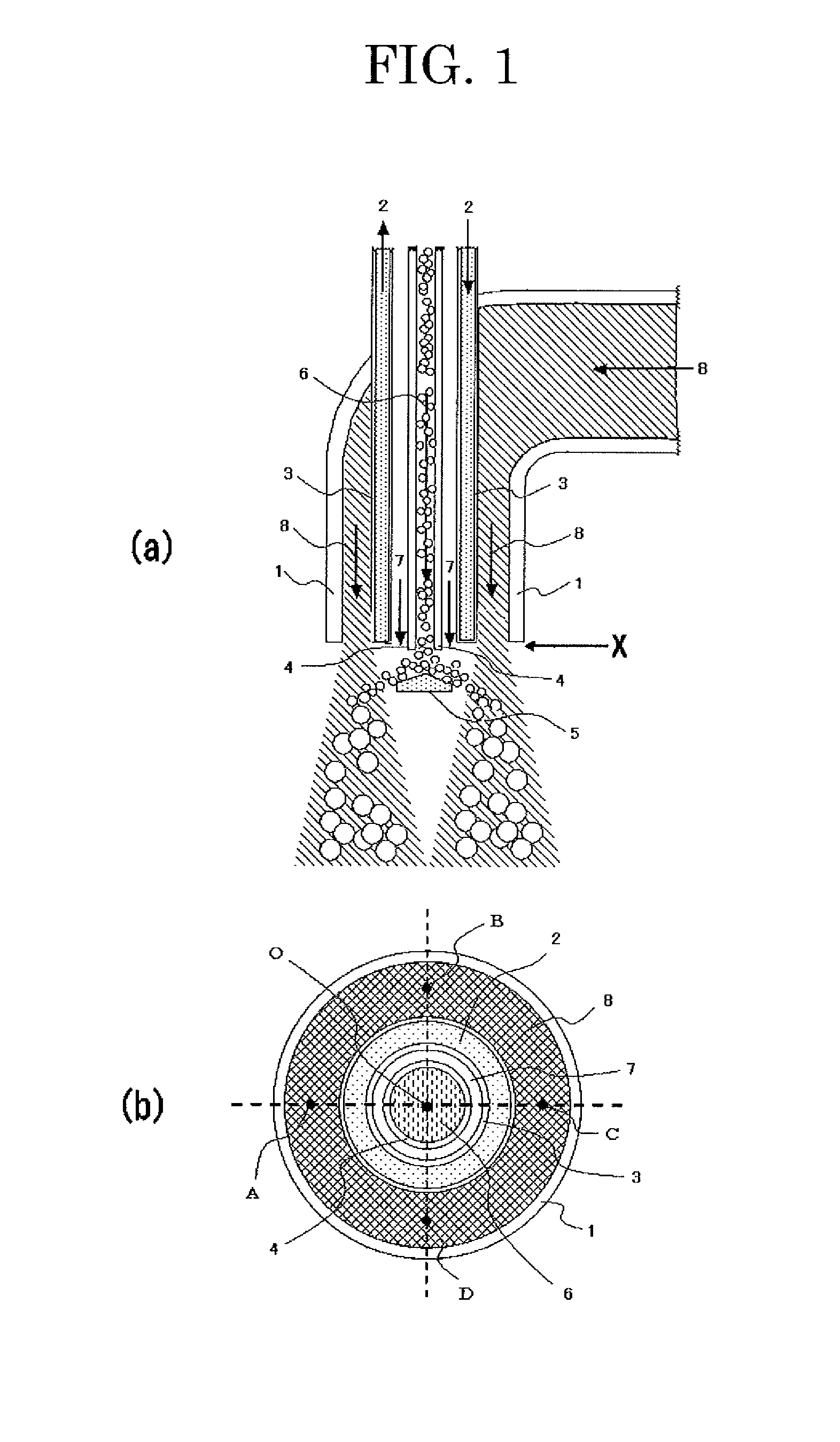

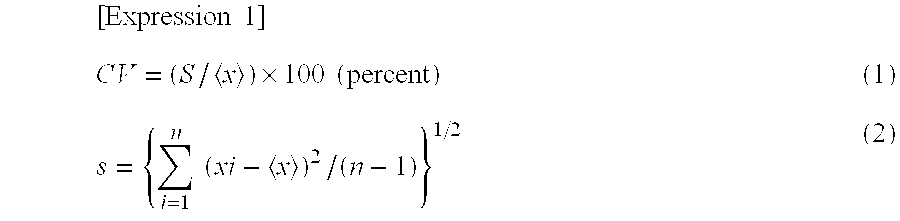

Thermally expanded microsphere, process for producing the same, thermally expandable microsphere and use thereof

ActiveUS20070154711A1Prevent hardeningAvoid shrinking inOther chemical processesSynthetic resin layered productsFoaming agentMicrosphere

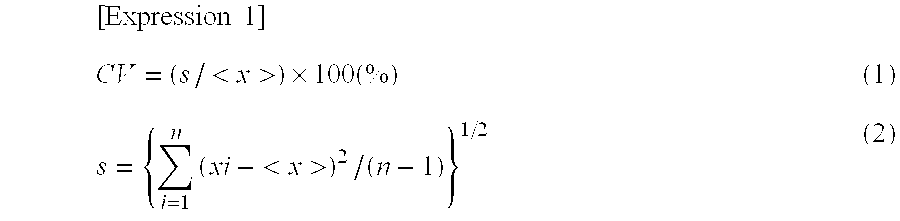

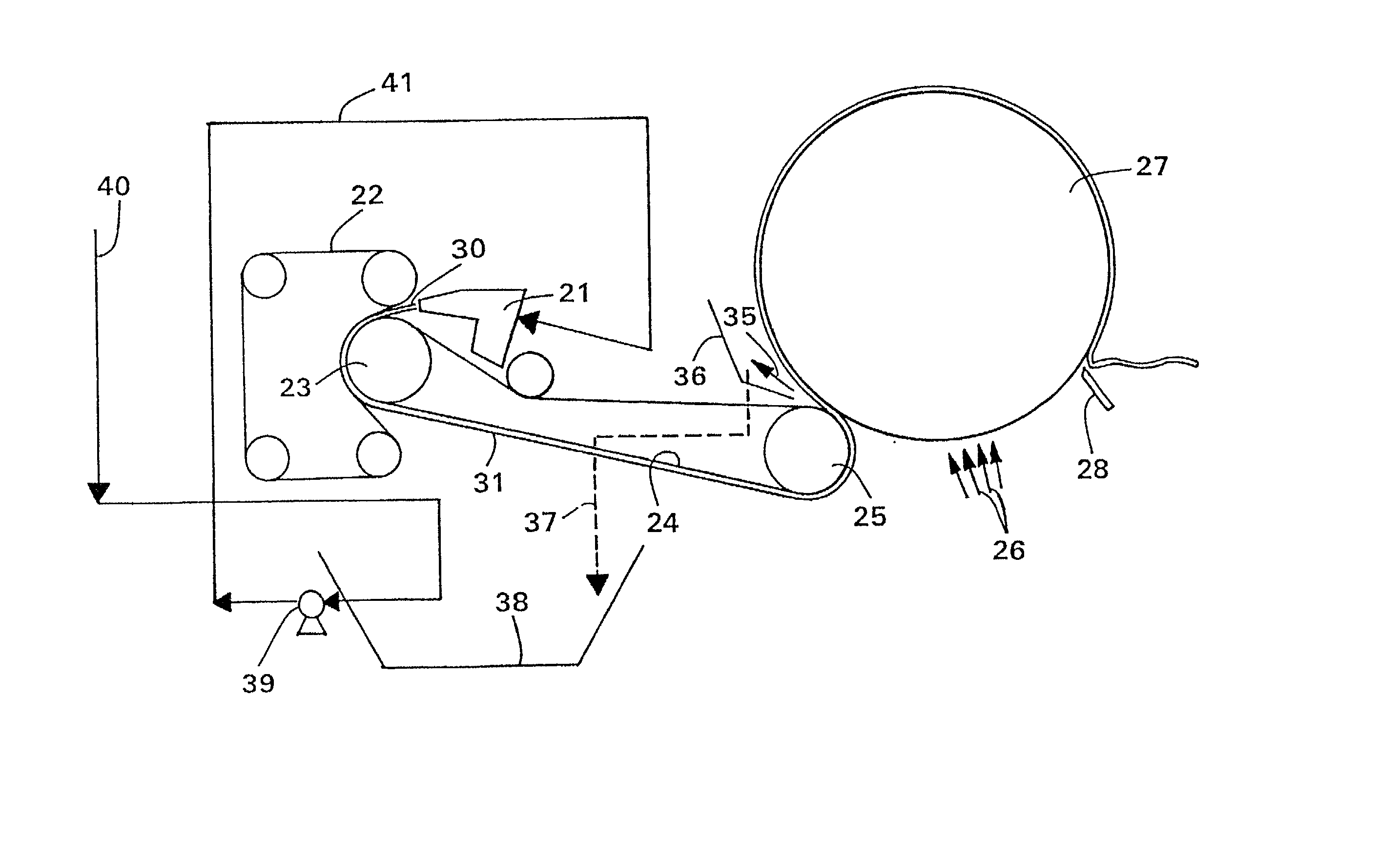

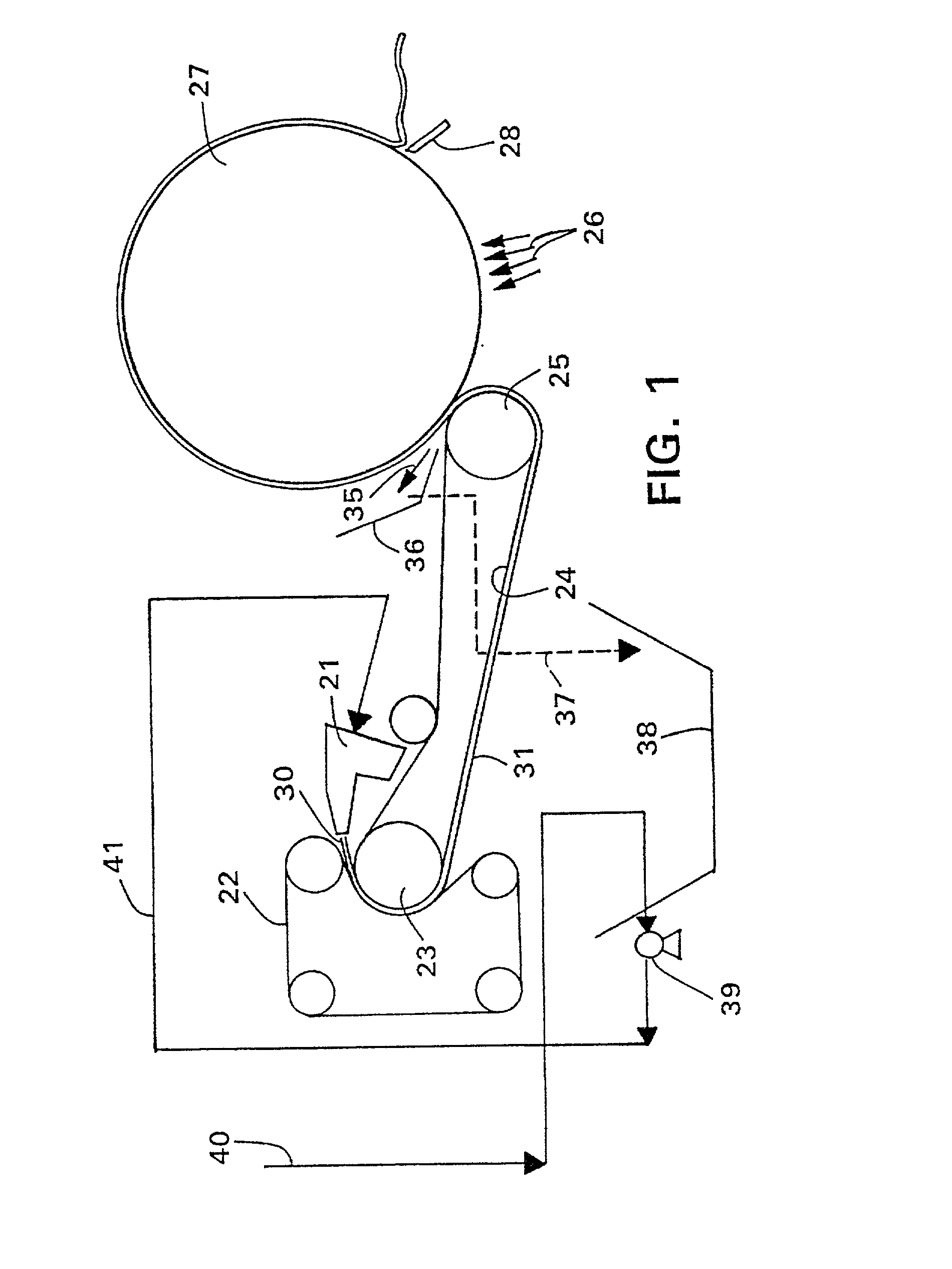

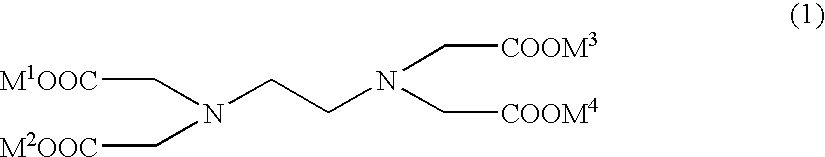

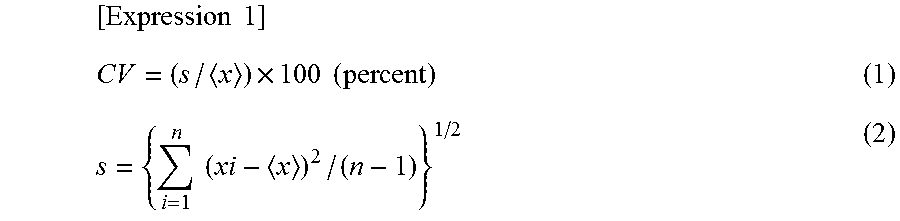

A production process for heat-expanded microspheres comprising the step of providing a gaseous fluid containing heat-expandable microspheres, which comprise shell of thermoplastic resin and a blowing agent encapsulated therein having a boiling point not higher than the softening point of the thermoplastic resin and have an average particle size from 1 to 100 μm, feeding the gaseous fluid through a gas-introducing tube having a dispersion nozzle on its outlet and being fixed inside a hot gas flow, and emitting a jet of the gaseous fluid through the dispersion nozzle; a step wherein the gaseous fluid is collided on a collision plate fixed under the dispersion nozzle so as to disperse the heat-expandable microspheres in the hot gas flow; and a step wherein the dispersed heat-expandable microspheres are heated in the hot gas flow at a temperature not lower than their expansion initiating temperature and thus expanded. The production process results in minimum difference in the variation coefficient of particle size distribution between the microspheres before and after heat-expansion, slight ratio of raw microspheres and slightly expanded microspheres contained in resultant heat-expanded microspheres, and suppressed formation of aggregated microspheres.

Owner:MATSUMOTO YUSHI SEIYAKU

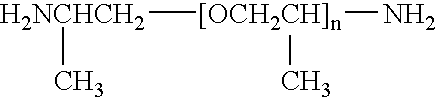

Opacity enhancement of tissue products with thermally expandable microspheres

InactiveUS20020104632A1Lose weightInorganic fibres/flakesNatural cellulose pulp/paperFiberMicrosphere

The present invention is generally directed to an opaque tissue product and a process for making the same. The tissue products of the present invention comprise thermally expandable microspheres which impart increased opacity to the tissues. The thermally expandable microspheres are added to a fiber furnish during the wet end of a manufacturing process for bath tissue, facial tissue, towels, or the like.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Heat-expandable microspheres, method for producing the same, and application thereof

ActiveUS20090149559A1High expansion rateIncreased durabilitySynthetic resin layered productsCellulosic plastic layered productsParticulatesFoaming agent

Heat-expandable microspheres include a shell of thermoplastic resin and a blowing agent encapsulated therein having a boiling point not higher than the softening point of the thermoplastic resin, have a maximum expanding ratio not lower than 50 times, and are thermally expanded into hollow particulates having a repeated-compression durability not lower than 75 percent. The method of producing the heat-expandable microspheres includes the steps of dispersing an oily mixture containing a polymerizable component and the blowing agent in an aqueous dispersing medium containing a specific water-soluble compound and polymerizing the polymerizable component contained in the oily mixture.

Owner:MATSUMOTO YUSHI SEIYAKU

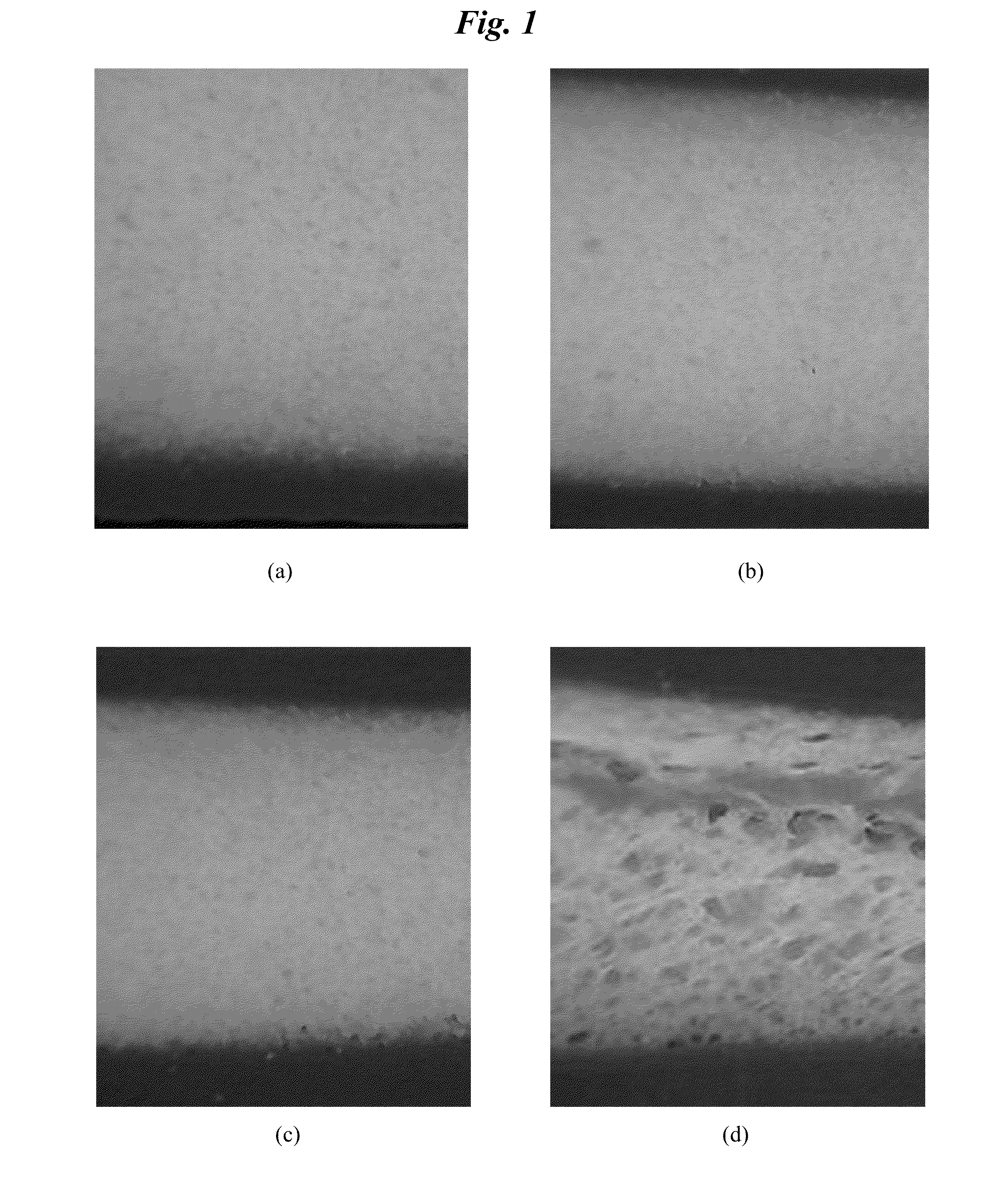

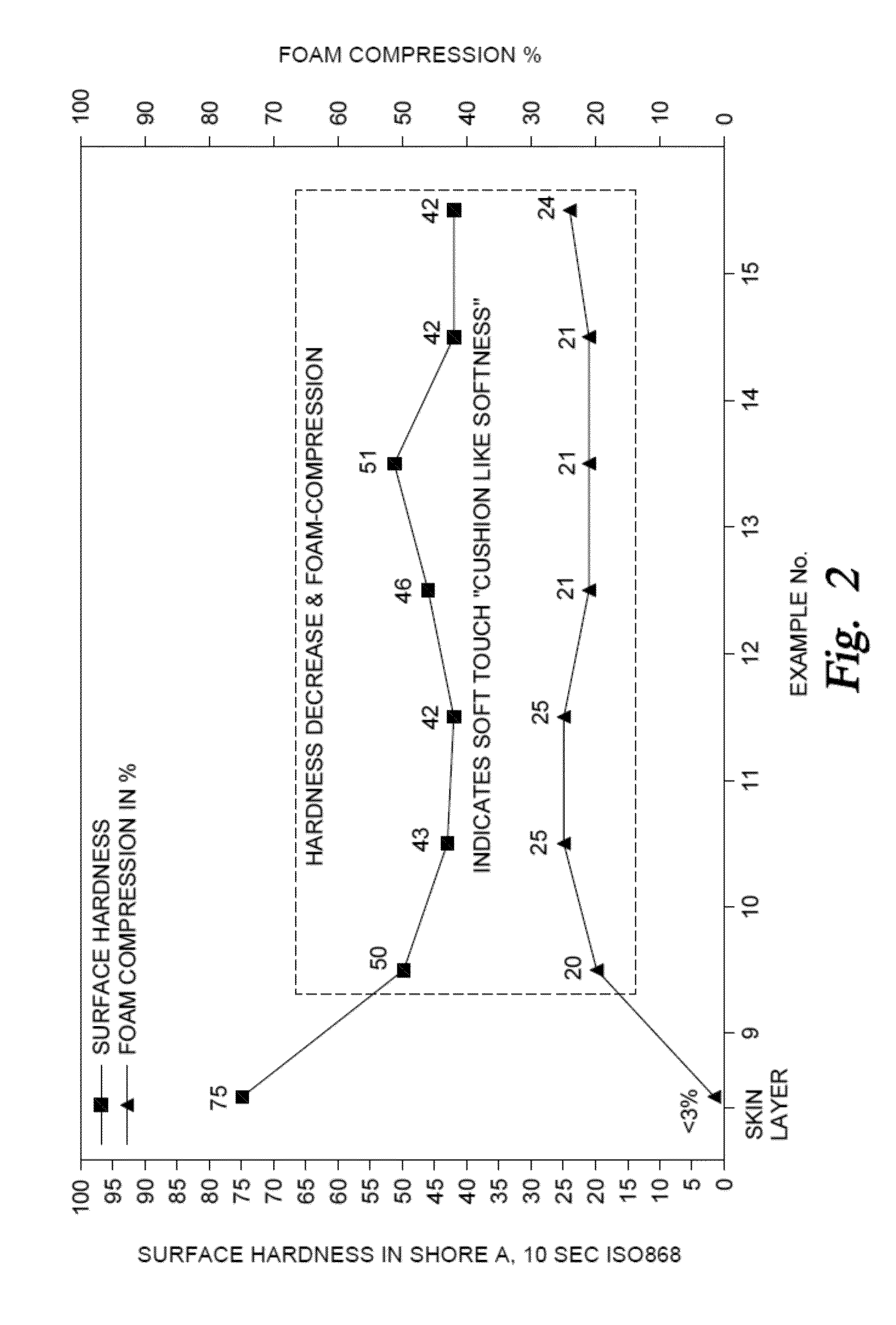

Composition, Foam and Article Made Therefrom

InactiveUS20130101826A1Balanced load deflectionBalanced elasticitySynthetic resin layered productsThin material handlingPolymer scienceLoad deflection

The present invention discloses a composition comprising a) a thermoplastic vulcanizate and b) a thermo-expandable microsphere comprising a polymer shell and a propellant encapsulated in said polymer shell based on the total weight of the composition. The composition is suitable for making foam with balanced load deflection and elasticity, including soft touch, reduced to low deflection, improved relaxation performance and low water absorption, replacing either soft paint or assembled constructions with foam sheets and meeting requirements in soft touch applications.

Owner:EXXONMOBIL CHEM PAT INC

Cut resistant paper and paper articles and method for making same

InactiveUS20050098286A1Reduce resistanceNon-fibrous pulp additionNatural cellulose pulp/paperMicrospherePapermaking

The specification discloses a method for making a paper material having a reduced tendency to cut human skin. The method includes providing a papermaking furnish containing cellulosic fibers and from about 0.5 to about 5.0 wt % by weight dry basis expandable microspheres, forming a paperboard web from the papermaking furnish, drying the web, and calendaring the web to a caliper of from about 11.0 to about 18.0 mils and a density ranging from about 7.0 to about 12.0 lb / 3000 ft2 / mil. Papers formed according to the method and articles formed therefrom are also disclosed.

Owner:INT PAPER CO

Resin-coated material and process for manufacturing same

InactiveUS20120015162A1Pleasant feelAccurate engravingRadiation applicationsPretreated surfacesPolymer resinPolyresin

A coated material includes a support covered with at least one layer of polymer resin, characterized in that the resin includes heat-expandable microspheres. A process for manufacturing the novel material, and also the use thereof in the binding and packaging fields and an article including the coated material are also described.

Owner:SOC DENDUCTION & DE FLOCKAGE

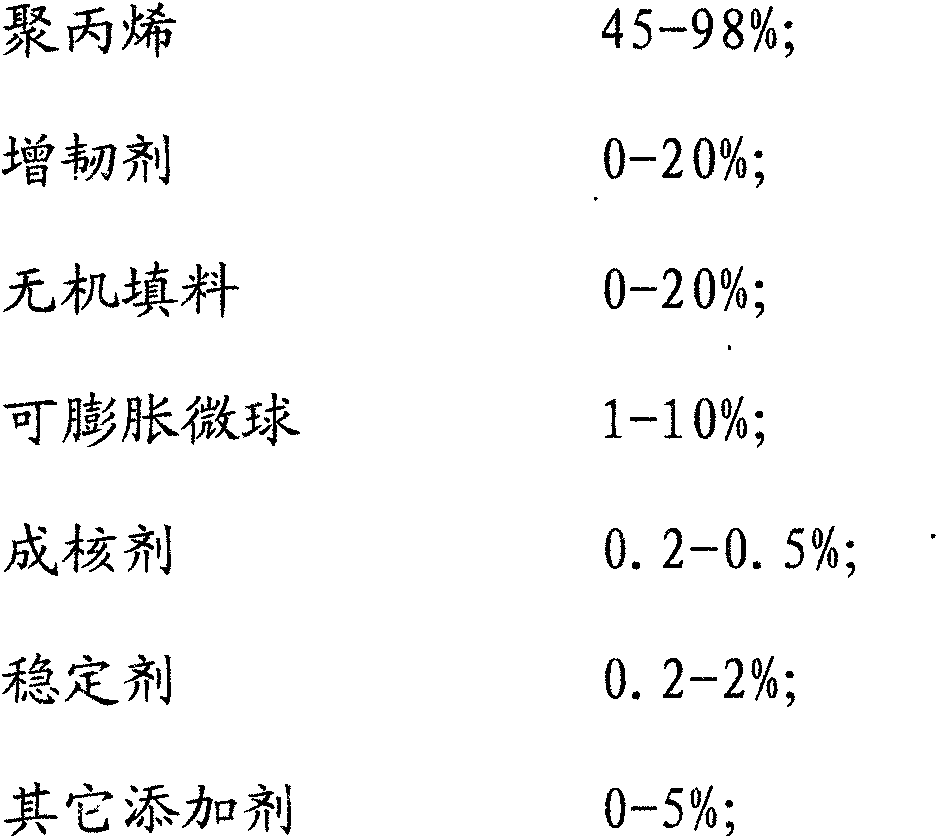

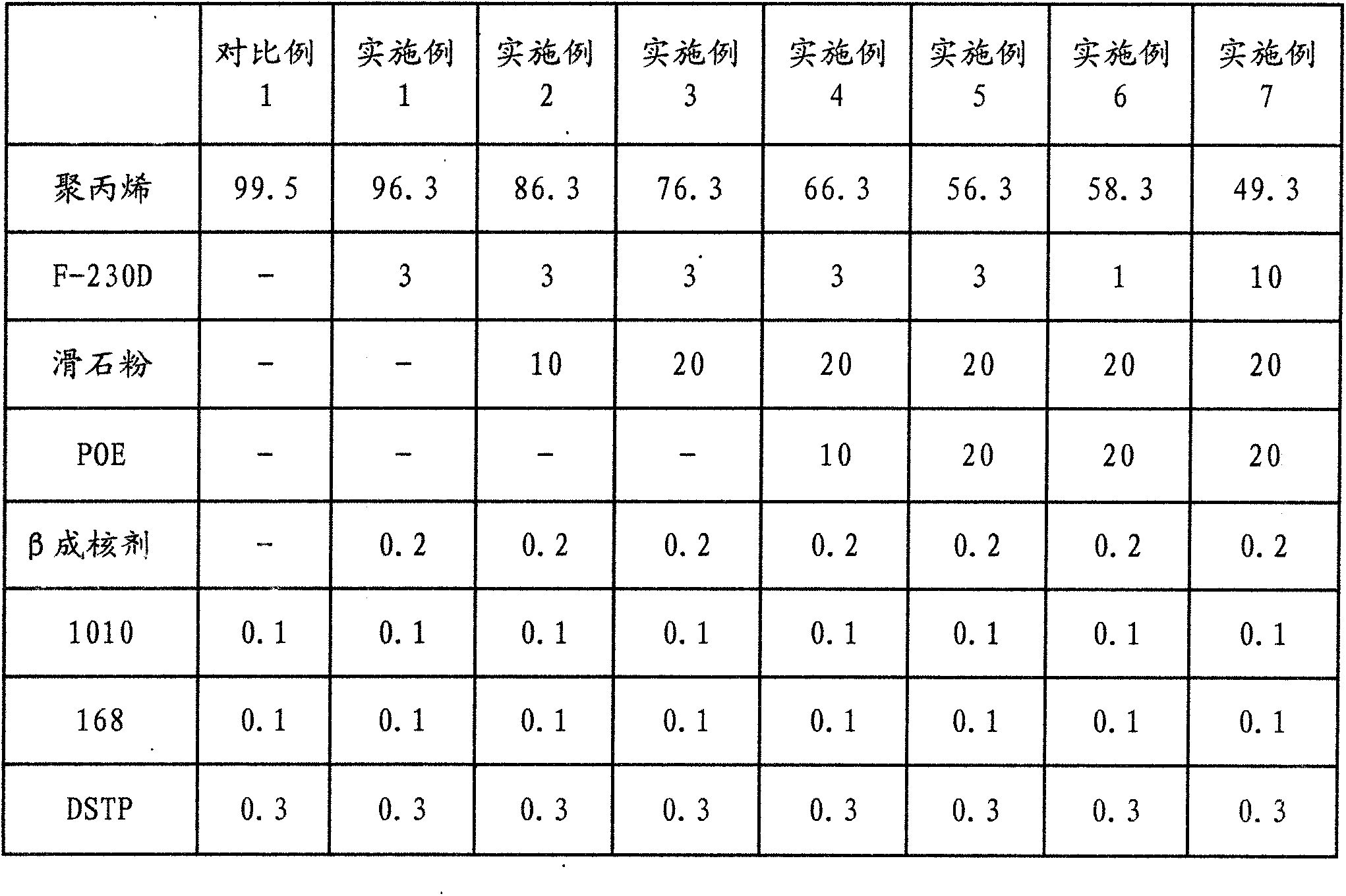

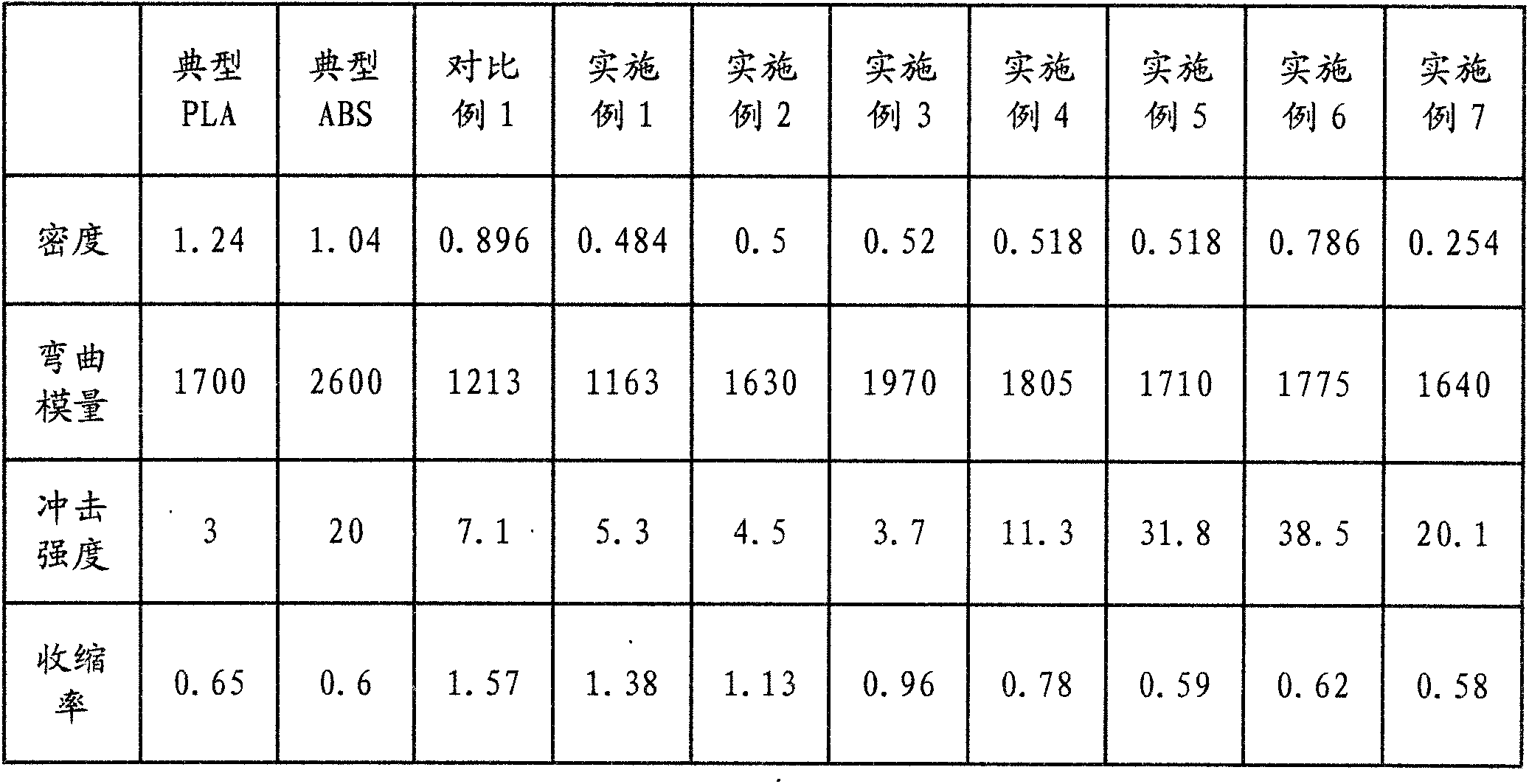

Ultra-low density polypropylene composite material capable of being used for 3D printing and preparation method thereof.

The invention relates to an ultra-low density polypropylene composite material capable of being used for 3D printing and a preparation method thereof. The polypropylene composite material comprises the following composition in percentage by weight: 45-98% of polypropylene, 0-20% of a toughening agent, 0-20% of an inorganic filler, 1-10% of expandable microspheres, 0.2-0.5% of a nucleating agent, 0.2-2% of a stabilizing agent and 0-5% of other additives. The preparation method comprises the steps of weighing the raw materials according the percentage by weight, putting the materials into a high-speed mixer and carrying out dry-blending for 3-15 minutes, adding the mixed raw materials into a twin-screw extruder, carrying out melt extrusion, cooling and granulating, wherein the temperature of a first zone, a second zone, a third zone and a fourth zone in the screw cylinder are all 170-190 DEG C, the temperature of the machine head is 170-190 DEG C and the rotation speed of the twin-screw extruder is 100-1000 revolutions per minute. The ultra-low density polypropylene composite material disclosed by the invention has the advantages of low shrinkage, no warping, ultra low density, high rigidity and high toughness and can also be well suitable for 3D printing.

Owner:温州科力塑业有限公司

Cut resistant paper and paper articles and method for making same

The specification discloses a method for making a paper material having a reduced tendency to cut human skin. The method includes providing a papermaking furnish containing cellulosic fibers and from about 0.5 to about 5.0 wt % by weight dry basis expandable microspheres, forming a paperboard web from the papermaking furnish, drying the web, and calendaring the web to a caliper of from about 11.0 to about 18.0 mils and a density ranging from about 7.0 to about 12.0 lb / 3000 ft2 / mil. Papers formed according to the method and articles formed therefrom are also disclosed.

Owner:INT PAPER CO

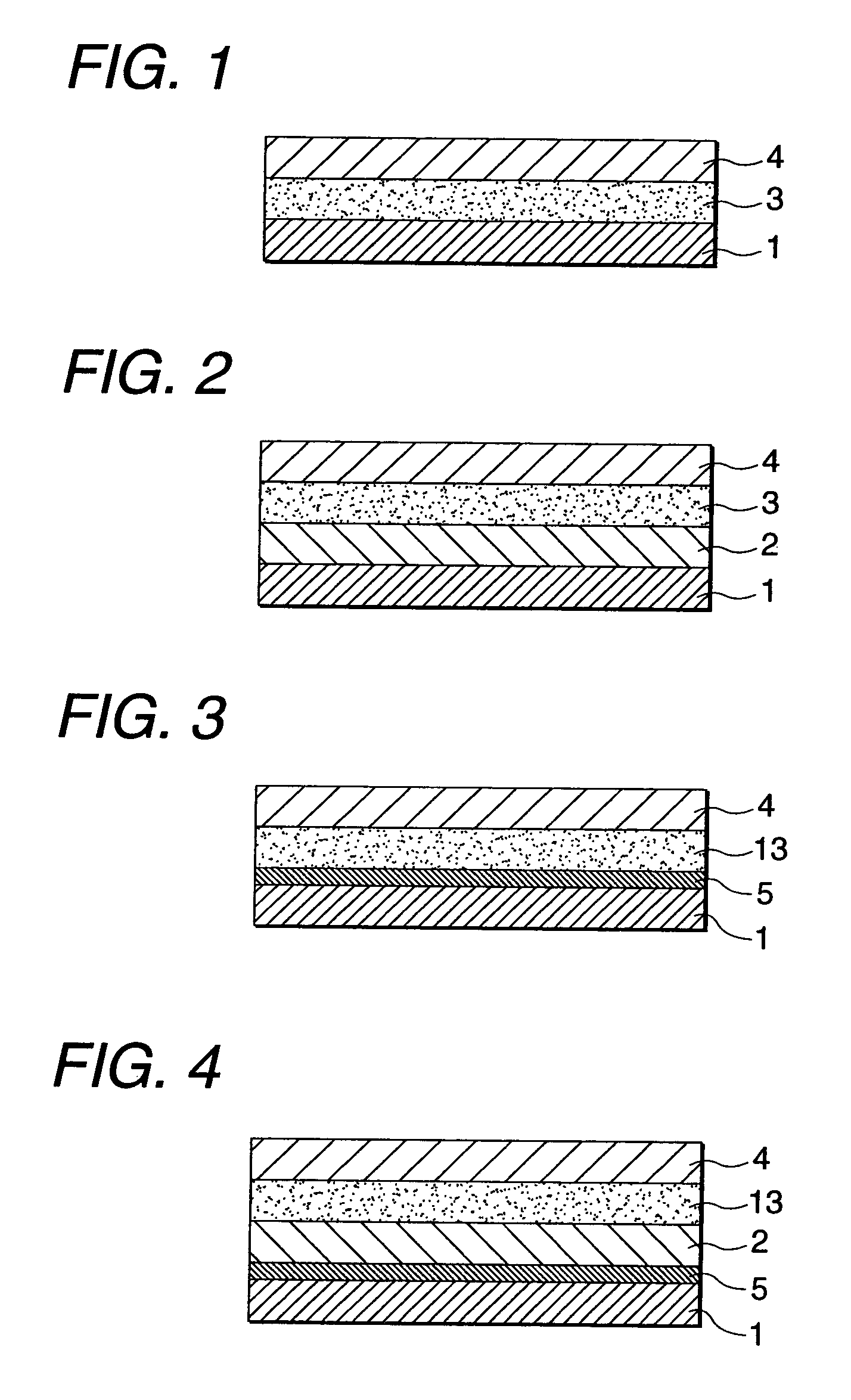

Heat-peelable pressure-sensitive adhesive sheet

InactiveUS20020192463A1Reduce pollutionIncrease in degree of contaminationSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorHeat treated

A heat-peelable adhesive sheet which shows small increase in the degree of contamination caused by a heat treatment for lowering an adhesive force is disclosed. The heat-peelable pressure sensitive adhesive sheet comprises a heat-expandable layer containing heat-expandable microspheres and expanding upon heating, and. a non-heat expandable pressure-sensitive adhesive layer formed on at least one side thereof. The heat-peelable pressure-sensitive adhesive sheet can achieve the desired adhesive properties such as an excellent adhesive force before heating and also show a quick lowering of the adhesive force upon heating. Further, it shows small increase in the degree of contamination due to the treatment for lowering the adhesive force. Due to those characteristics, the heat-peelable pressure-sensitive adhesive sheet is practically applicable to, for example, the production of electronic parts made of thinner semiconductor wafers.

Owner:NITTO DENKO CORP

Thermally expanded microspheres and a process for producing the same

ActiveUS20090280328A1Improve efficiencyImprove liquiditySynthetic resin layered productsCellulosic plastic layered productsVoid ratioMicrosphere

The present invention provides heat-expanded microspheres having high packing efficiency, and a production method thereof. The heat-expanded microspheres are produced by expanding heat-expandable microspheres, which comprise shell of thermoplastic resin and a blowing agent encapsulated therein having a boiling point not higher than the softening point of the thermoplastic resin and have an average particle size from 1 to 100 micrometer, at a temperature not lower than their expansion initiating temperature, and the heat-expanded microspheres result in a void fraction not higher than 0.70.

Owner:MATSUMOTO YUSHI SEIYAKU

Coated articles demonstrating heat reduction and noise reduction properties

Coated articles are provided comprising:(a) a substrate having two opposing surfaces;(b) a first curable film-forming composition applied to one surface of the substrate, the first curable film-forming composition comprising:(i) a resinous binder comprising a polyepoxide, a polyamideimide, a polyimide, and / or a polysiloxane;(ii) optionally, a curing agent having functional groups reactive with functional groups on the resinous binder in (a); and(iii) a metallic reflective pigment; and(c) a second curable film-forming composition applied to the opposing surface of the substrate, the second curable film-forming composition comprising:(i) a polyepoxide containing at least two epoxide groups per molecule;(ii) a thermoplastic polyester polymer;(iii) a curing agent having functional groups reactive with the epoxide groups in (c)(i);(iv) a mineral filler; and(v) microspheres comprising expandable microspheres and / or hollow microspheres.Coated articles provide heat reflection, heat insulation, vibration damping, and sound absorption.

Owner:PPG IND OHIO INC

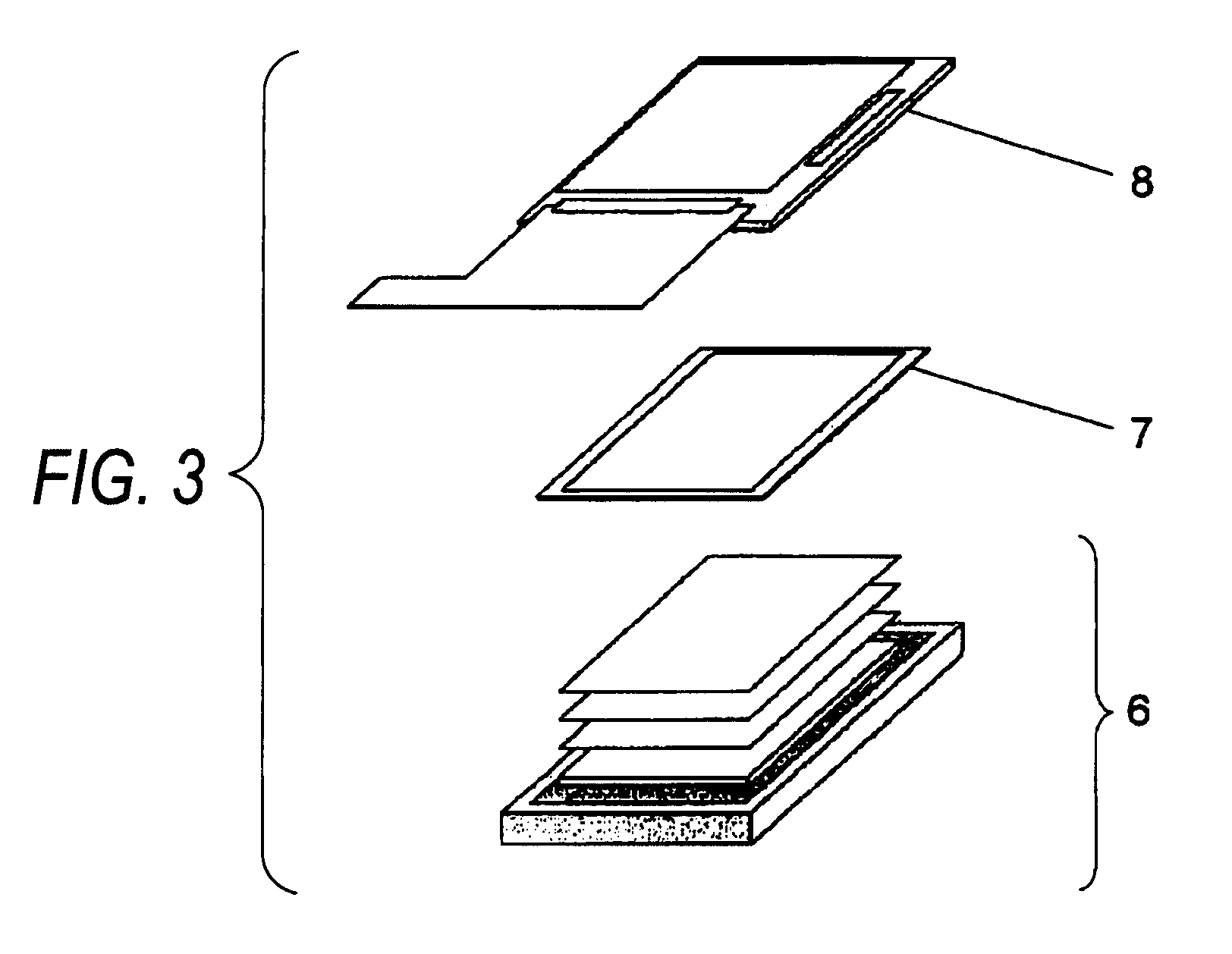

Double-sided pressure-sensitive adhesive sheet and liquid-crystal display

InactiveUS20100021668A1High adhesivenessExcellent peelabilityFilm/foil adhesivesLayered productsLiquid-crystal displaySheet film

The invention relates to a double-sided pressure-sensitive adhesive sheet for use in fixing a liquid-crystal display module unit to a backlight unit in a liquid-crystal display, the double-sided pressure-sensitive adhesive sheet including at least one heat-peelable pressure-sensitive adhesive layer containing heat-expandable microspheres. According to the double-sided pressure-sensitive adhesive sheet of the invention, since the pressure-sensitive adhesive layer has high adhesiveness and a liquid-crystal display module unit can be tenaciously fixed to a backlight unit with the pressure-sensitive adhesive sheet, excellent adhesion reliability can be attained. Furthermore, since this pressure-sensitive adhesive sheet can be easily made peelable by a heat treatment, it has excellent suitability for reworking.

Owner:NITTO DENKO CORP

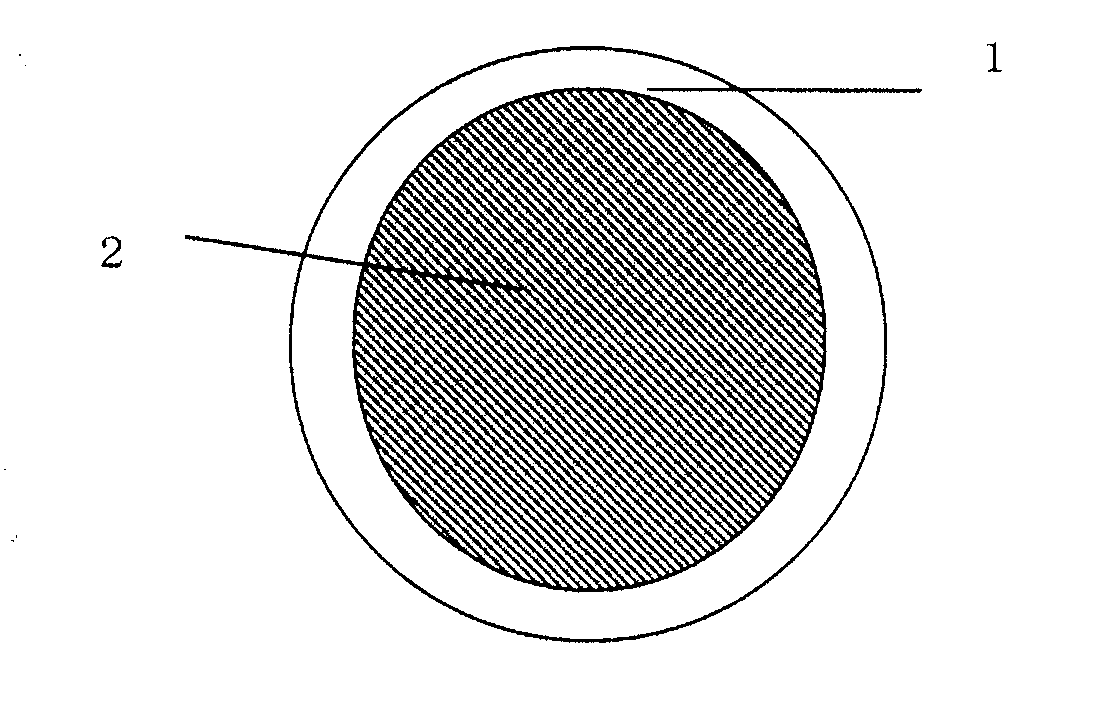

Thermally-Expandable Microspheres Having Good Foaming Characteristics and Uniform Microsphere Diameter and Methods of Preparing the Same

InactiveUS20110123807A1No lossSynthetic resin layered productsCellulosic plastic layered productsCross-linkFoaming agent

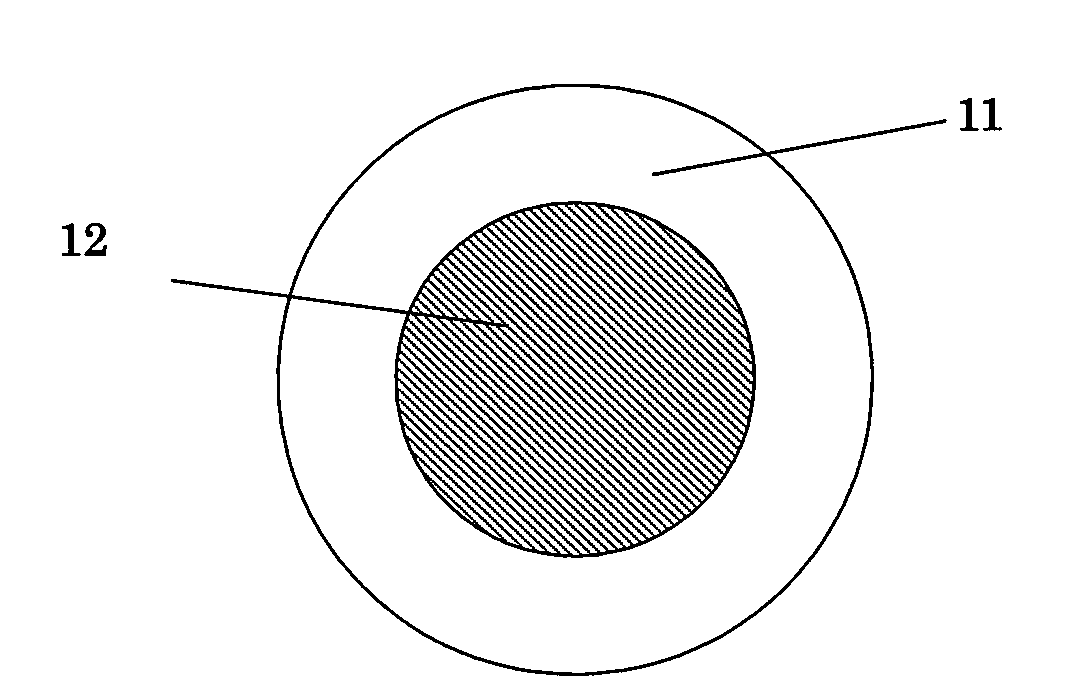

The present invention provides a thermally expandable microsphere having a core-shell structure comprising: a shell including a thermoplastic polymer and a long-chain crosslinking agent having a weight-average molecular weight between cross-linking sites of more than about 500; and a core including a foaming agent. The thermally expandable microsphere of the present invention can have excellent foaming characteristics and an even (uniform) microsphere diameter.

Owner:CHEIL IND INC

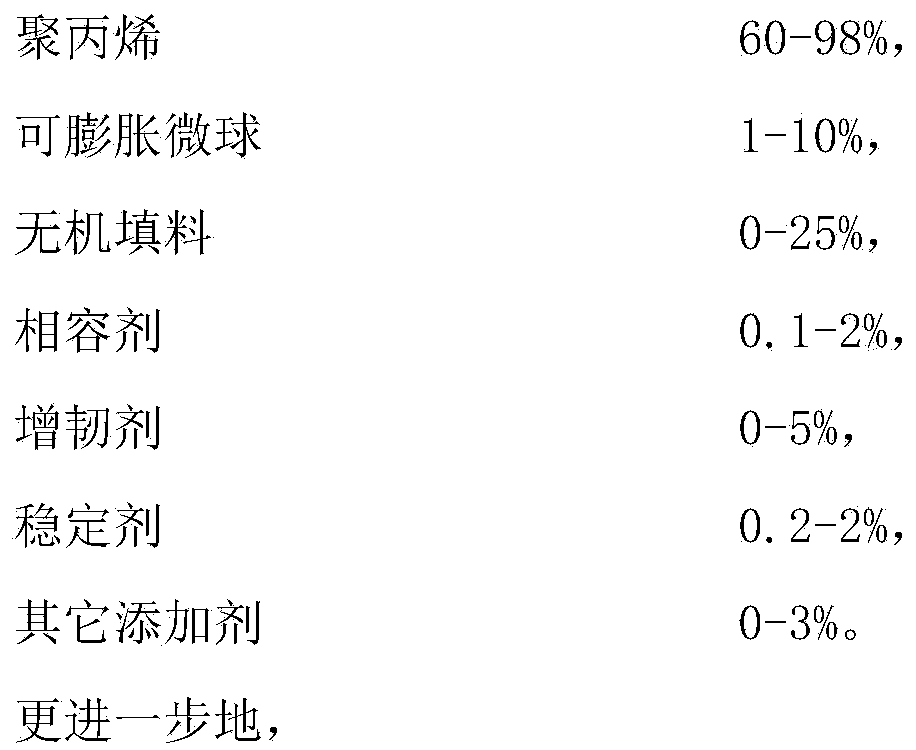

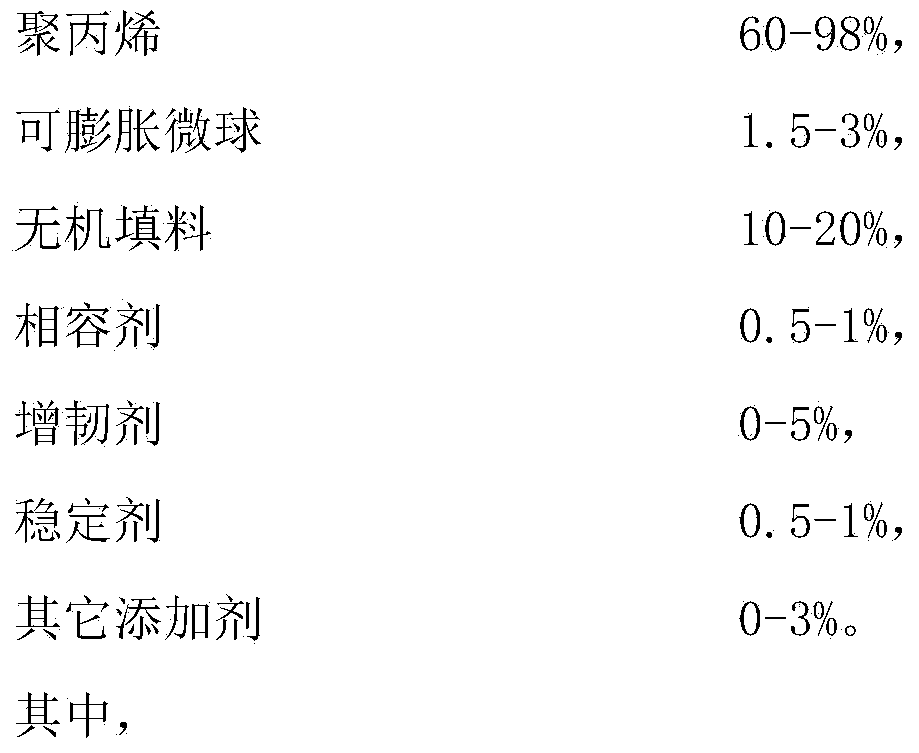

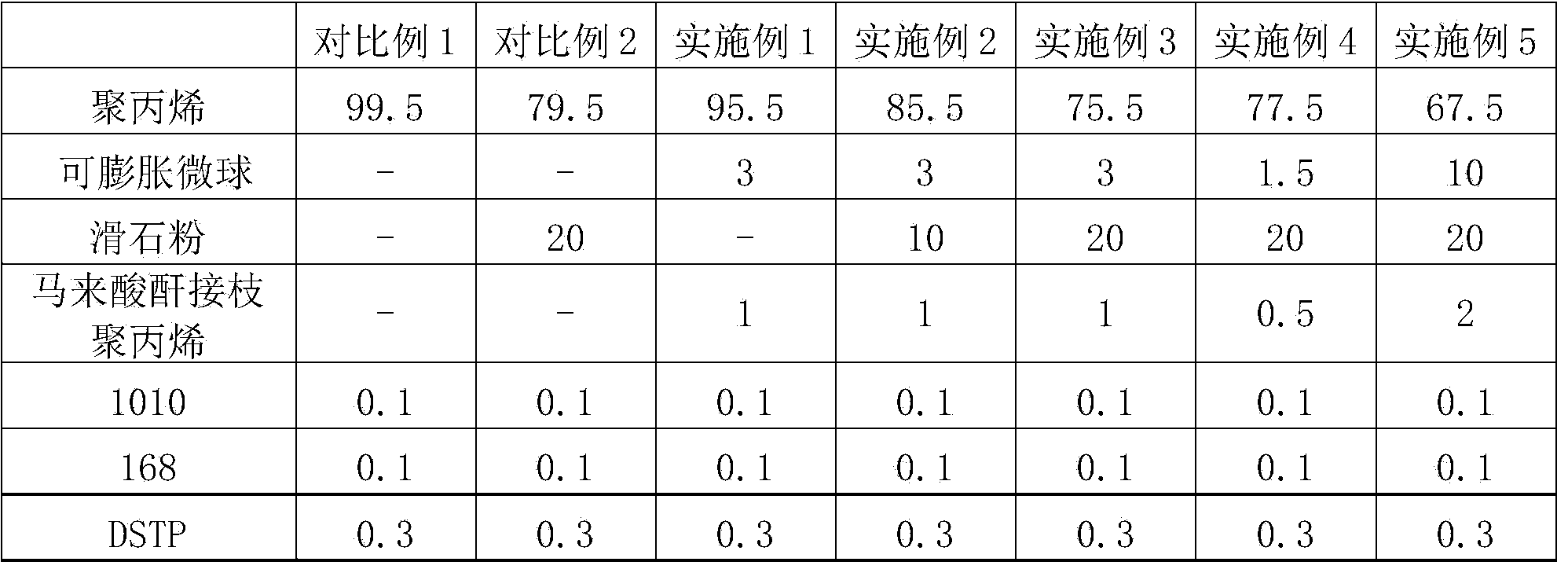

Expandable microsphere filling modified polypropylene composite material and preparation method thereof

InactiveCN103709509ALow densityMeet the requirements of lightweight developmentPolypropylene compositesPolymer science

The invention discloses an expandable microsphere filling modified polypropylene composite material and a preparation method thereof. The composite material is composed of the following raw materials in percentage by weight: 60-98% of polypropylene, 1-10% of expandable microsphere, 0-25% of inorganic filler, 0.1-2% of compatilizer, 0-5% of toughener, 0.2-2% of stabilizer and 0-3% of other additives. The expandable microsphere used as the auxiliary additive for processing polypropylene can lower the density of the composite material without excessively influencing other properties, so that the composite material conforms to the requirements for trends to light weight of the existing automobile parts, and has very low density and favorable comprehensive mechanical properties; and by adopting the sectional feeding mode, the expandable microsphere and other components can be added into the extruder at the downstream of the screw bolt, thereby maximally avoiding the influence on the shearing and dispersion process of the foamed microsphere, and further enhancing the properties of the composite material.

Owner:ZHEJIANG PRET NEW MATERIALS +2

Heat-expandable microspheres, process for producing the same, and application thereof

ActiveUS20100204349A1Improve good performanceHigh expansion rateSynthetic resin layered productsCellulosic plastic layered productsBoiling pointMicrosphere

Heat-expandable microspheres include a shell of thermoplastic resin and core material encapsulated in the shell. The core material include a blowing agent having a boiling point not higher than the softening point of the thermoplastic resin and a gas migration inhibitor having a boiling point higher than the softening point of the thermoplastic resin. The ratio of the gas migration inhibitor to the core material is at least 1 weight percent and below 30 weight percent. The average particle size of the heat-expandable microspheres ranges from 1 to 100 micrometers.

Owner:MATSUMOTO YUSHI SEIYAKU

Process for producing heat-expandable microspheres and application thereof

ActiveUS20160310924A1Good dispersionSmall particle sizeTransportation and packagingElectrode carriers/collectorsColloidal silicaLithium

A process for producing heat-expandable microspheres including a thermoplastic resin shell and a blowing agent encapsulated therein. The process includes the steps of dispersing a polymerizable component and the blowing agent in an aqueous dispersion medium having a pH of 7 or less and containing a fine-particle metal compound having a mean particle size ranging from 1.0 to 10 nm, and polymerizing the polymerizable component. The amount of the fine-particle metal compound ranges from 0.15 to 20 parts by weight to 100 parts by weight of the total amount of the polymerizable component and the blowing agent. Also disclosed are heat-expandable microspheres produced by dispersing a polymerizable component and a blowing agent in an aqueous dispersion medium containing colloidal silica and polymerizing the polymerizable component. Also disclosed is a composition containing the heat-expandable microspheres and a base component, a formed product, a slurry composition for use in forming a negative electrode of a lithium-ion secondary battery and a negative electrode.

Owner:MATSUMOTO YUSHI SEIYAKU

Pressure-sensitive adhesive composition and acrylic pressure-sensitive adhesive tape

InactiveUS20110250446A1Increase stickinessNon-macromolecular adhesive additivesLayered productsMeth-Metallic materials

A pressure-sensitive adhesive composition or an acrylic pressure-sensitive adhesive tape in which peeling-off property or tearing-off property occurring by heating is improved while the high adhesiveness to a metallic material is being maintained, will be provided. The pressure-sensitive adhesive composition contains: an acrylic polymer (A); a (meth)acrylic polymer (B) whose mass average molecular weight (Mw) is such that 1000≦Mw<30000; and a heat-expandable microsphere (C).

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com