Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1619 results about "Revolutions per minute" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Revolutions per minute (abbreviated rpm, RPM, rev/min, r/min, or with the notation min⁻¹) is the number of turns in one minute. It is a unit of rotational speed or the frequency of rotation around a fixed axis.

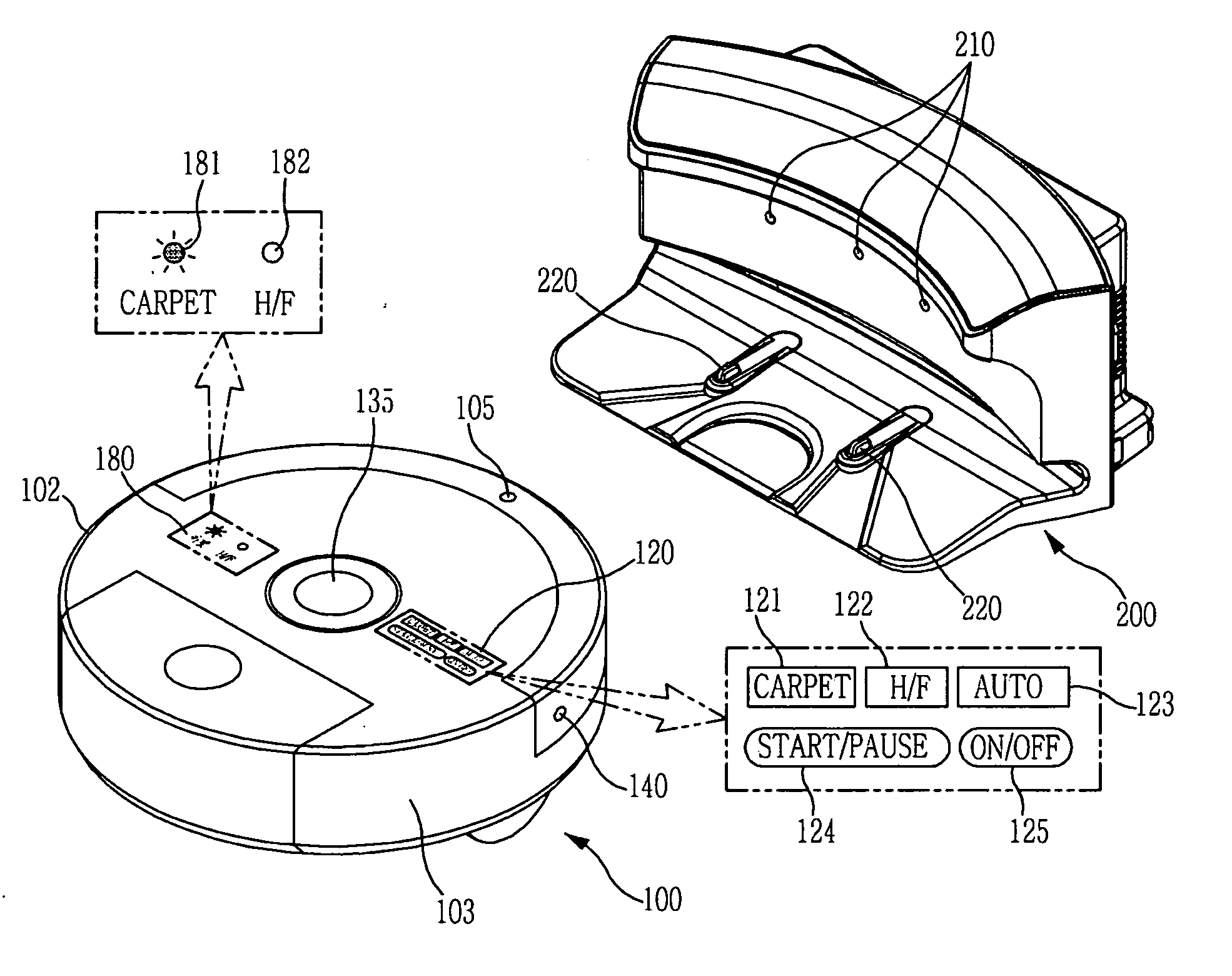

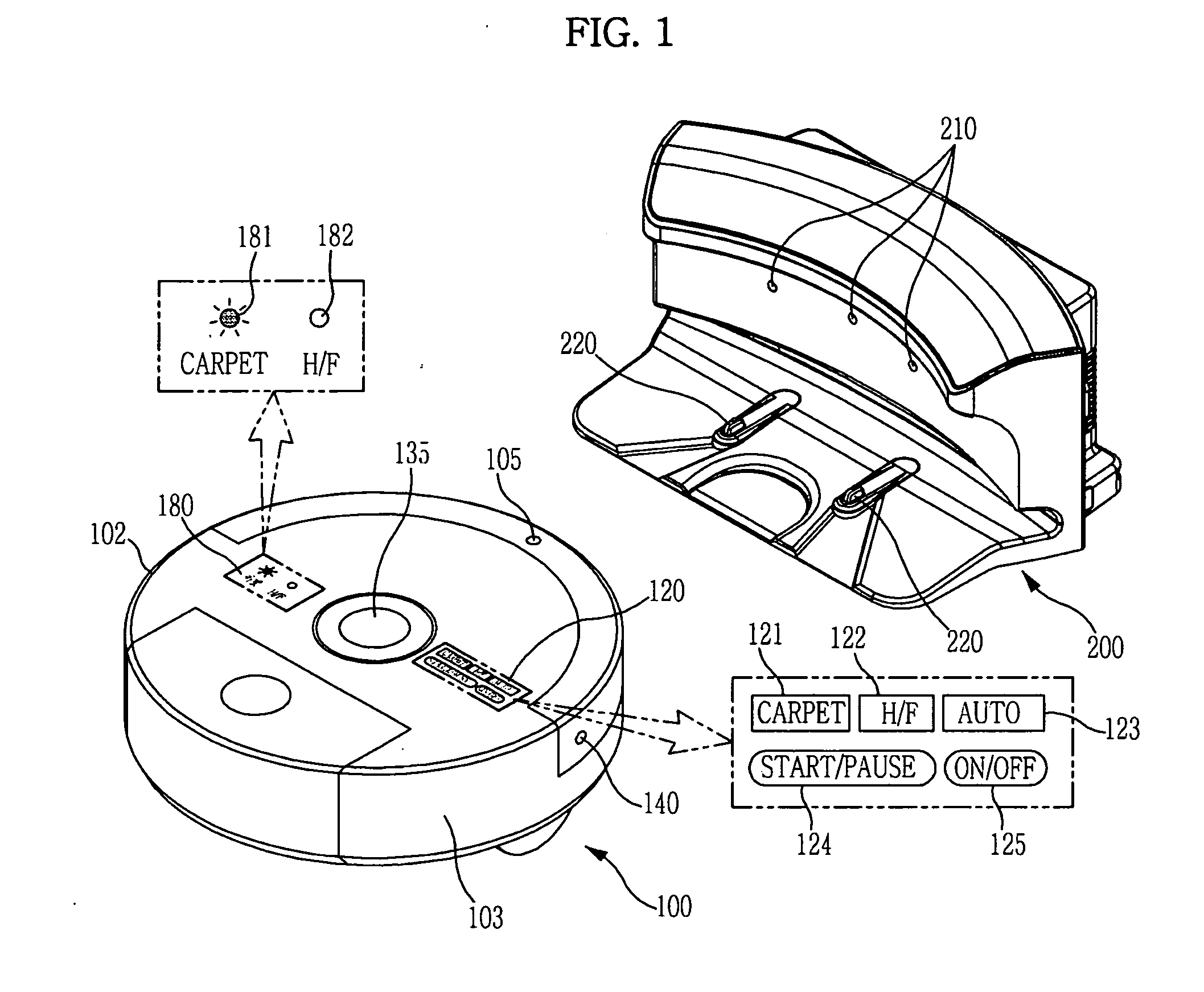

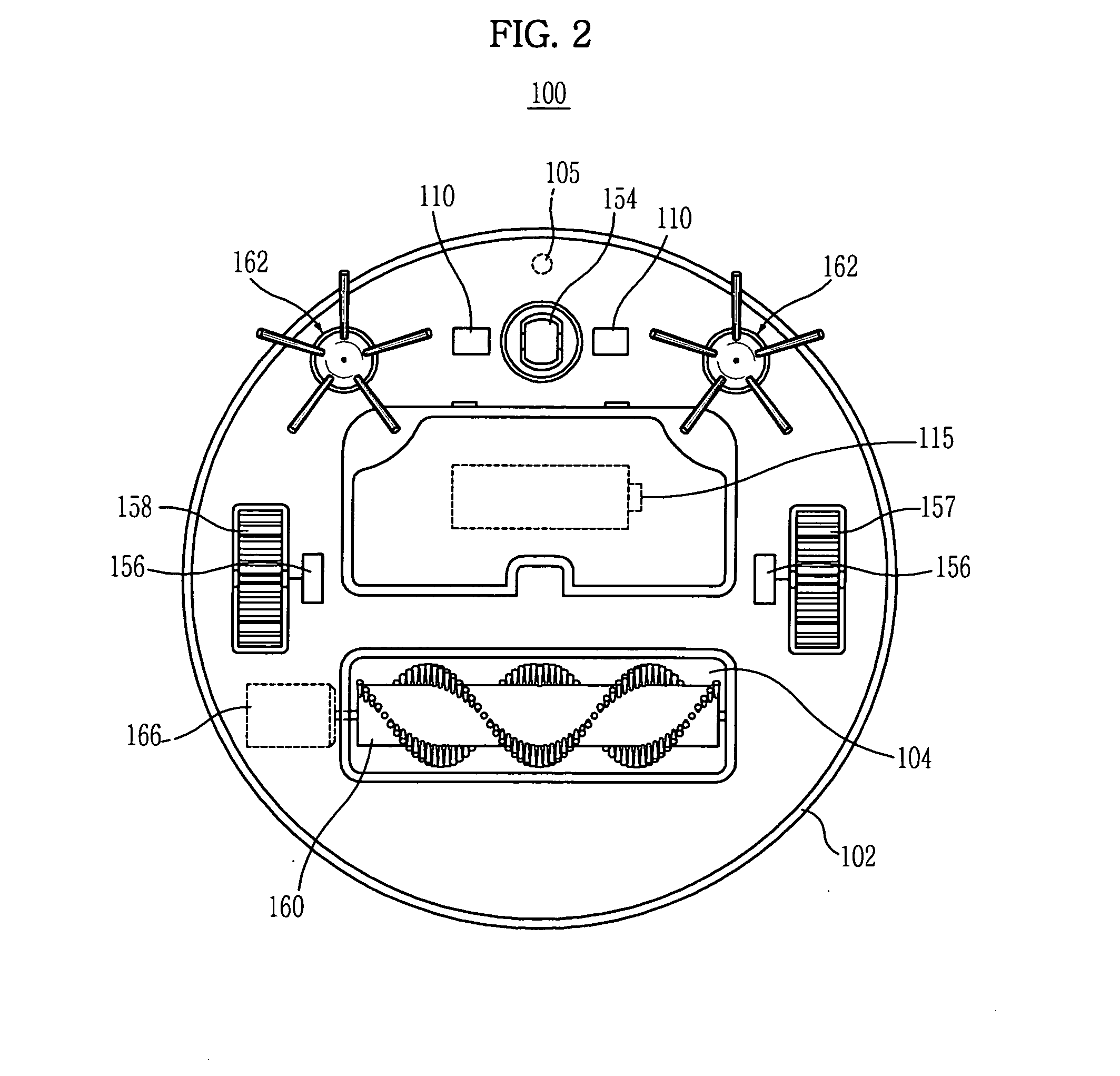

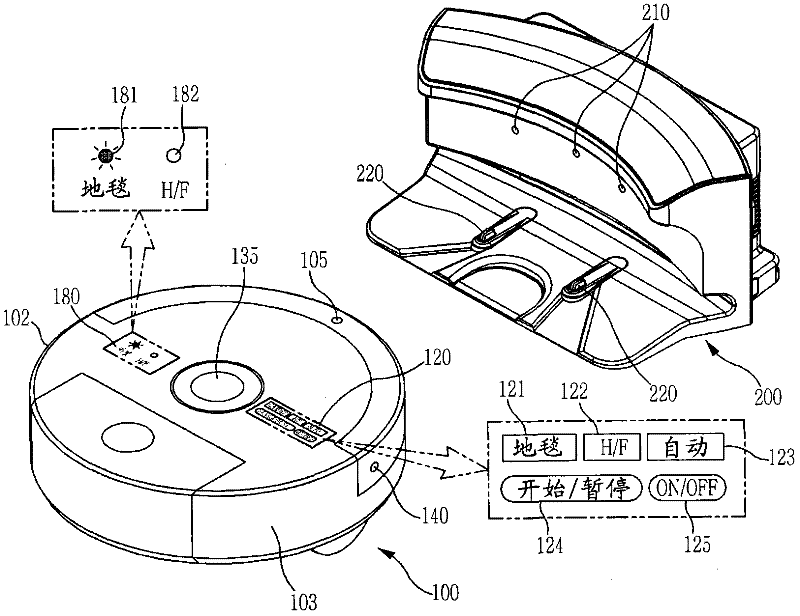

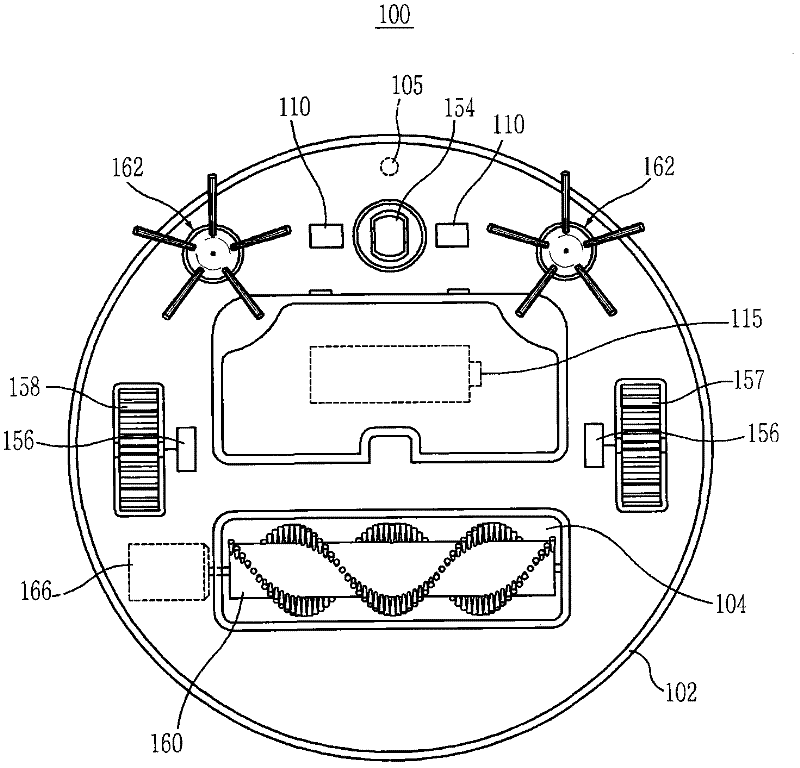

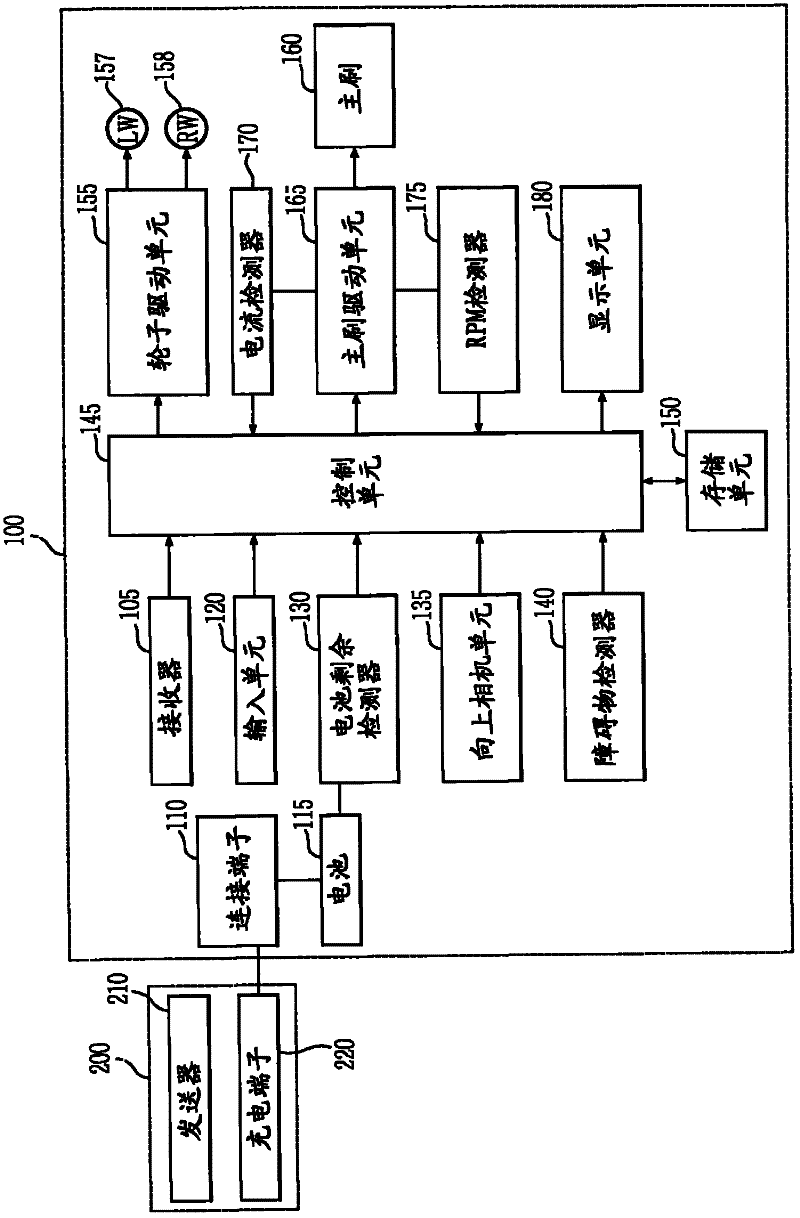

Robot cleaner and control method thereof

InactiveUS20120125363A1Avoid areaOperation is completedAutomatic obstacle detectionTravelling automatic controlMotor speedEngineering

A robot cleaner includes a main brush to sweep or scatter dust off a floor, a main brush motor to rotate the main brush, a Revolution Per Minute (RPM) detector to detect an RPM of the main brush motor, and a control unit to determine a type of floor according to the RPM of the main brush motor acquired by the RPM detector and control an operation of the robot cleaner based on the determined type of floor. A carpet mode to clean only a carpet area and a hard floor mode to clean a hard floor area excluding the carpet area are given based on detected information relating to the material of a floor, which enables partial cleaning with respect to a cleaning area selected by a user and adjustment in the number of cleaning operations or the intensity of cleaning according to the material of the floor.

Owner:SAMSUNG ELECTRONICS CO LTD

Microbial ecological traditional Chinese medicine preparation for livestock and poultry from fermentation production of multiple bacterials and fermentation method thereof

ActiveCN101401921ALow costImmunity exceedsFungiAnthropod material medical ingredientsHouttuyniaLactobacillus acidophilus

The invention relates to micro-ecological Chinese medicine preparation for livestock and poultry by adoption of multi-strain fermentation production and a fermentation method. The compositions of traditional Chinese medicines in a culture medium of the fermentation preparation include: radix astragali, radix codonopsitis, Atractylodes macrocephala, Poria cocos, liquorice, medicated leaven, hawkthorn, angelica, Chinese rhubarb, Scutellaria baicalensis, radix isatidis, cordate houttuynia, sicklesenna seeds, Schisandra chinensis, Gynostemma pentaphylla, phellodendron, dried orange peel, radix bupleuri, curcuma, honeysuckle, Chinese gall, purslane and Quisqualis indica. The fermentation method is as follows: a multi-strain solid state fermentation strain is adopted for fermentation; bacillus subtilis, bacillus natto, bacillus licheniformis, beer yeast, Candida wtilis, Aspergillus niger, lactobacillus plantarum, Lactobacillus acidophilus and bifidobacteria are purified and subjected to anaerobic fermentation under the conditions of a rotating speed of 180 revolutions per minute at a temperature is 32 DEG C for 48 to 72 hours till the pH value reaches 4.0. The micro-ecological Chinese medicine preparation has the advantages that the micro-ecological Chinese medicine preparation uses probiotics to ferment different Chinese medicine compositions, and is micro-ecological Chinese medicine preparation which completely replaces antibiotics and has the advantages of no residual medicine, disease prevention, growth promotion and low cost.

Owner:河南省龙腾高科实业有限公司

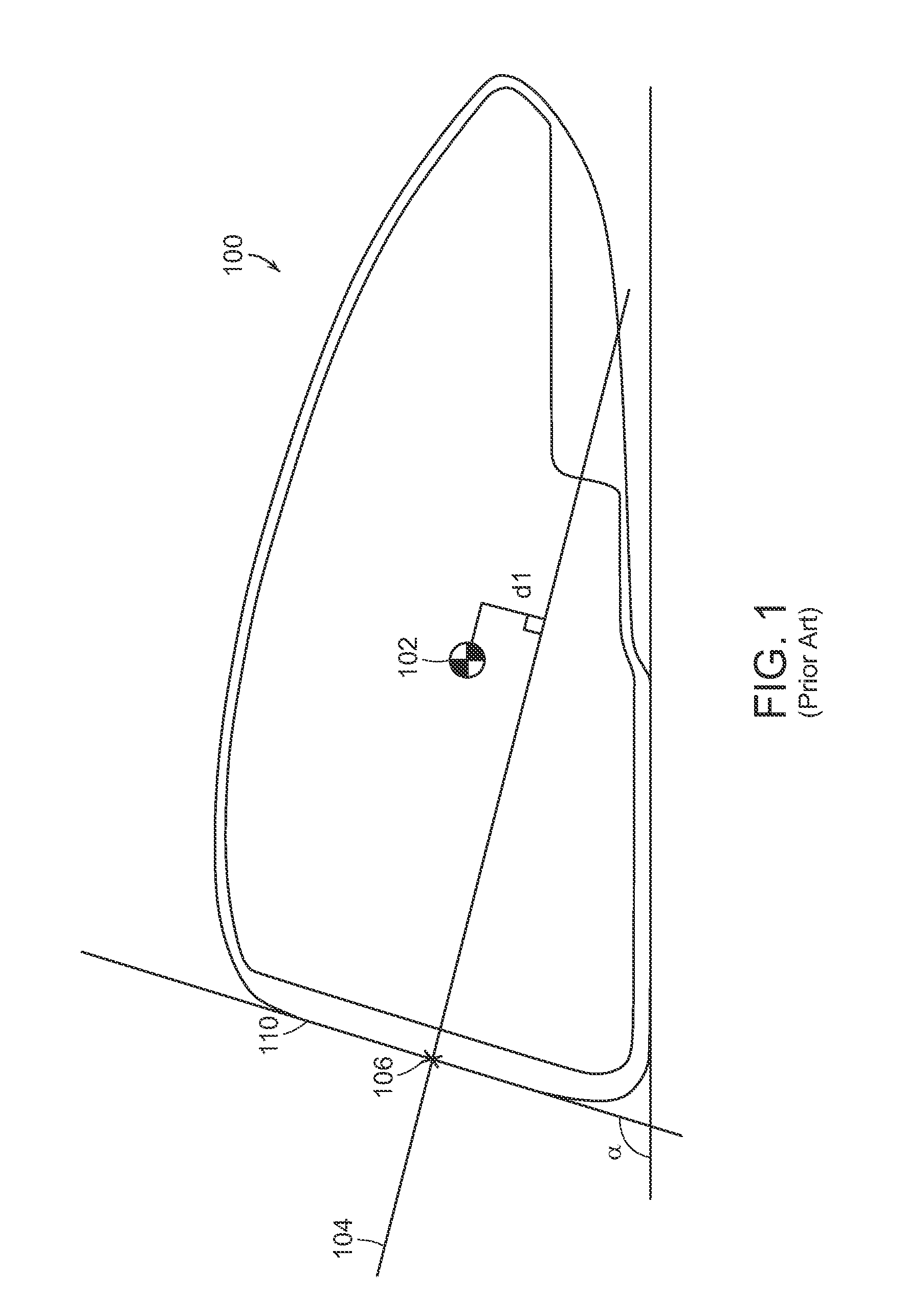

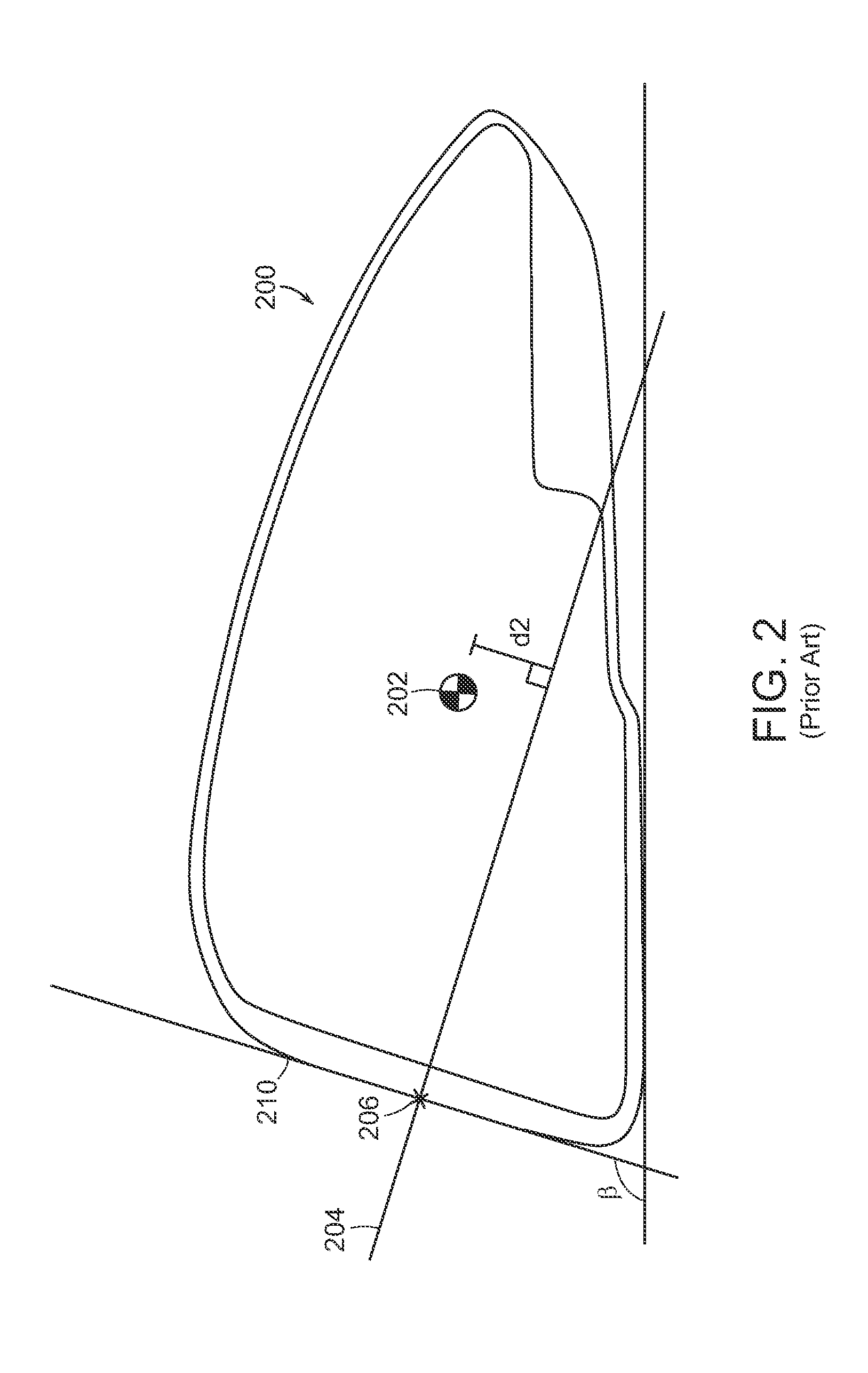

Golf club heads

A plurality of golf club heads wherein the difference in spin is minimized is disclosed herein. More specifically, the present invention discloses a plurality of fairway wood type golf club head with a volume of between about 110 cubic centimeters (cc) and about 250 cc, wherein the change in backspin between any two clubs within the plurality of metal wood type golf club heads is less than about 600 revolutions per minute (rpm). A plurality of golf clubs in accordance with the present invention may generally have all of its clubs maintain a center of gravity (CG) location that is less than about 8.0 mm away from a neutral axis of the golf club head regardless of the difference in loft of the specific golf club head within the plurality of golf club heads.

Owner:COBRA GOLF

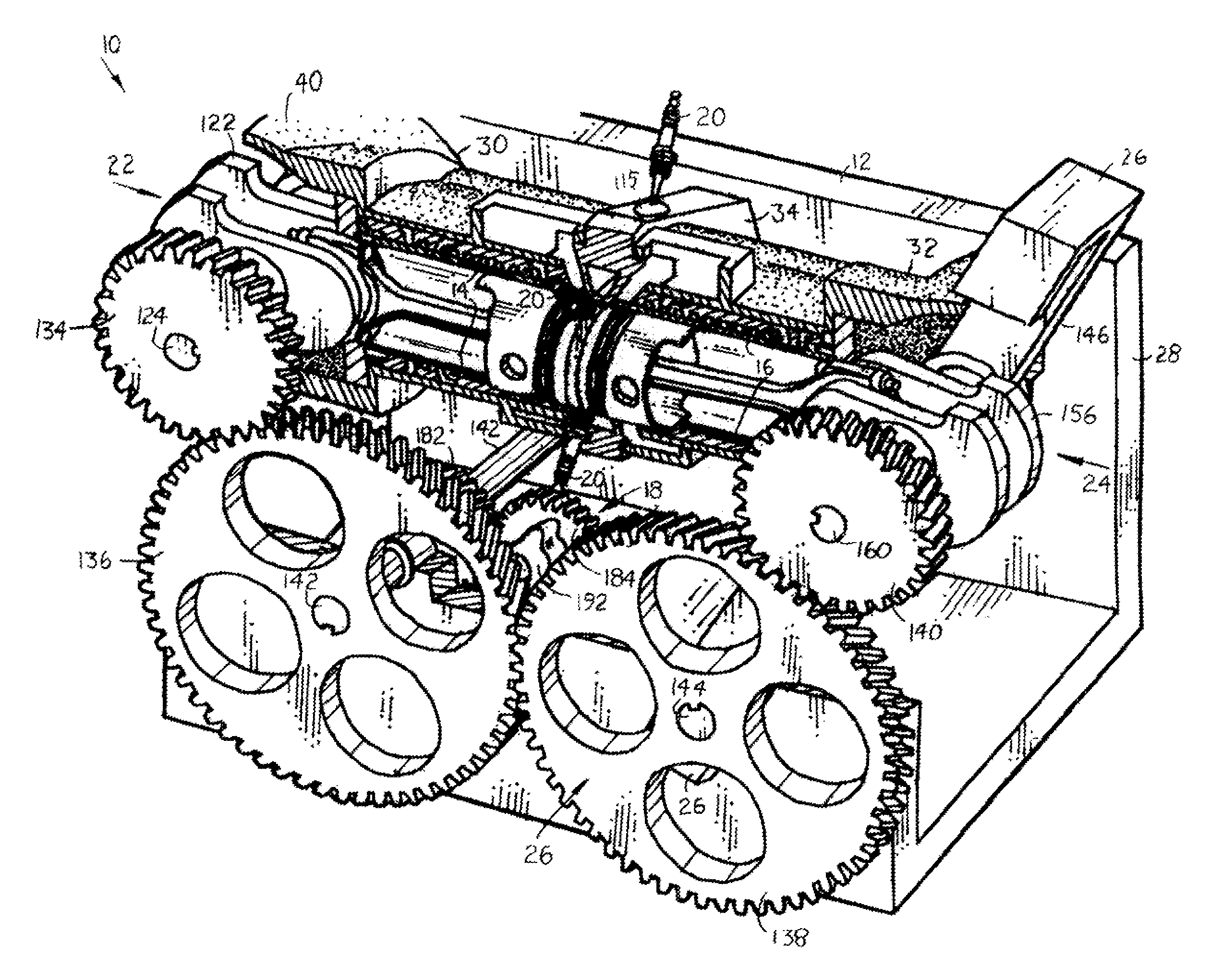

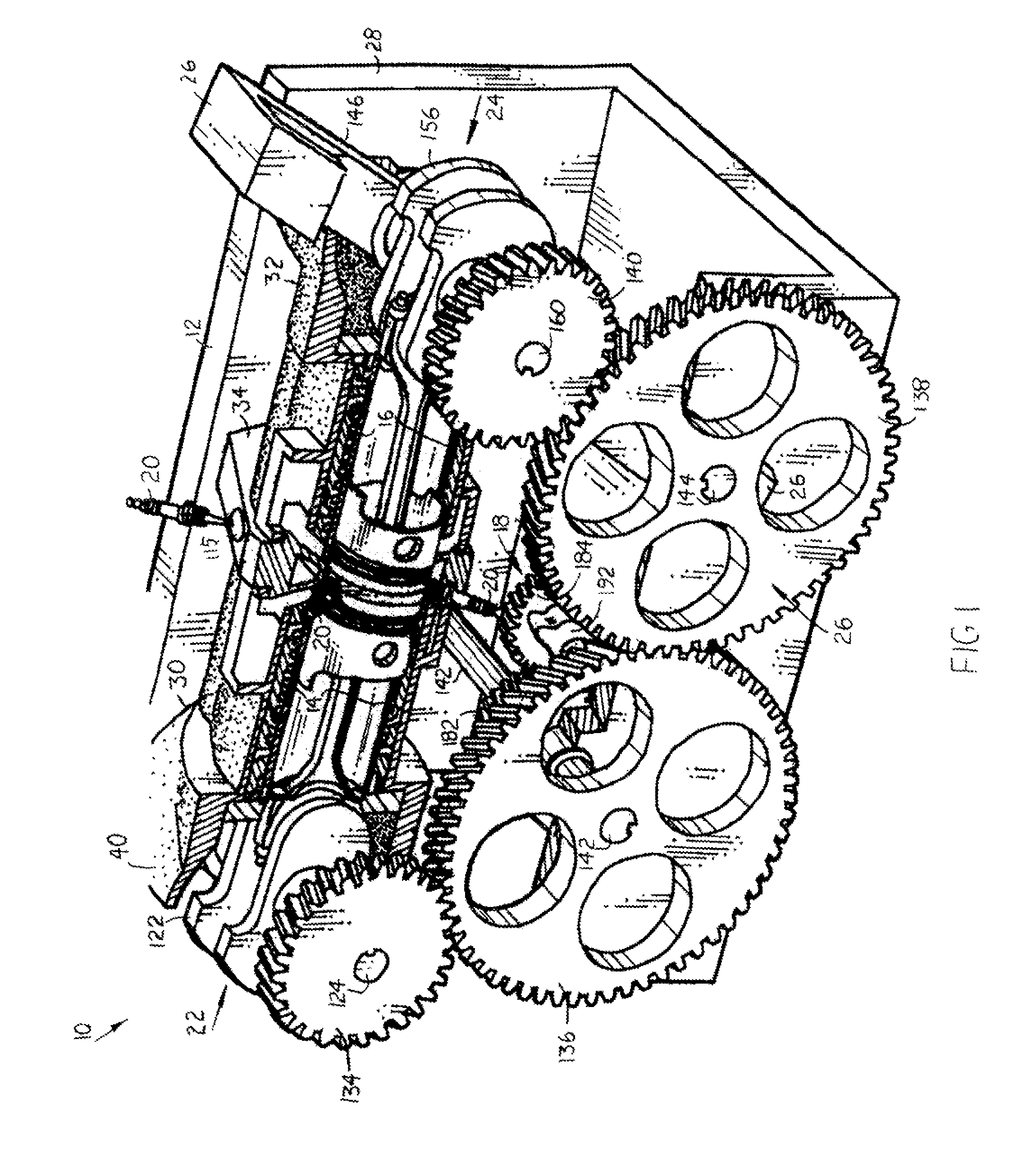

Internal combustion engine

InactiveUS7559298B2Assist in containment of heat energyReduce energy lossLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

An internal combustion engine is provided. Facing pistons eliminate a cylinder head, thereby reducing heat losses through a cylinder head. Facing pistons also halve the stroke that would be required for one piston to provide the same compression ratio, and the engine can thus be run at higher revolutions per minute and produce more power. An internal sleeve valve is provided for space and other considerations. A combustion chamber size-varying mechanism allows for adjustment of the minimum size of an internal volume to increase efficiency at partial-power operation. Variable intake valve operation is used to control engine power.

Owner:CLEEVES ENGINES

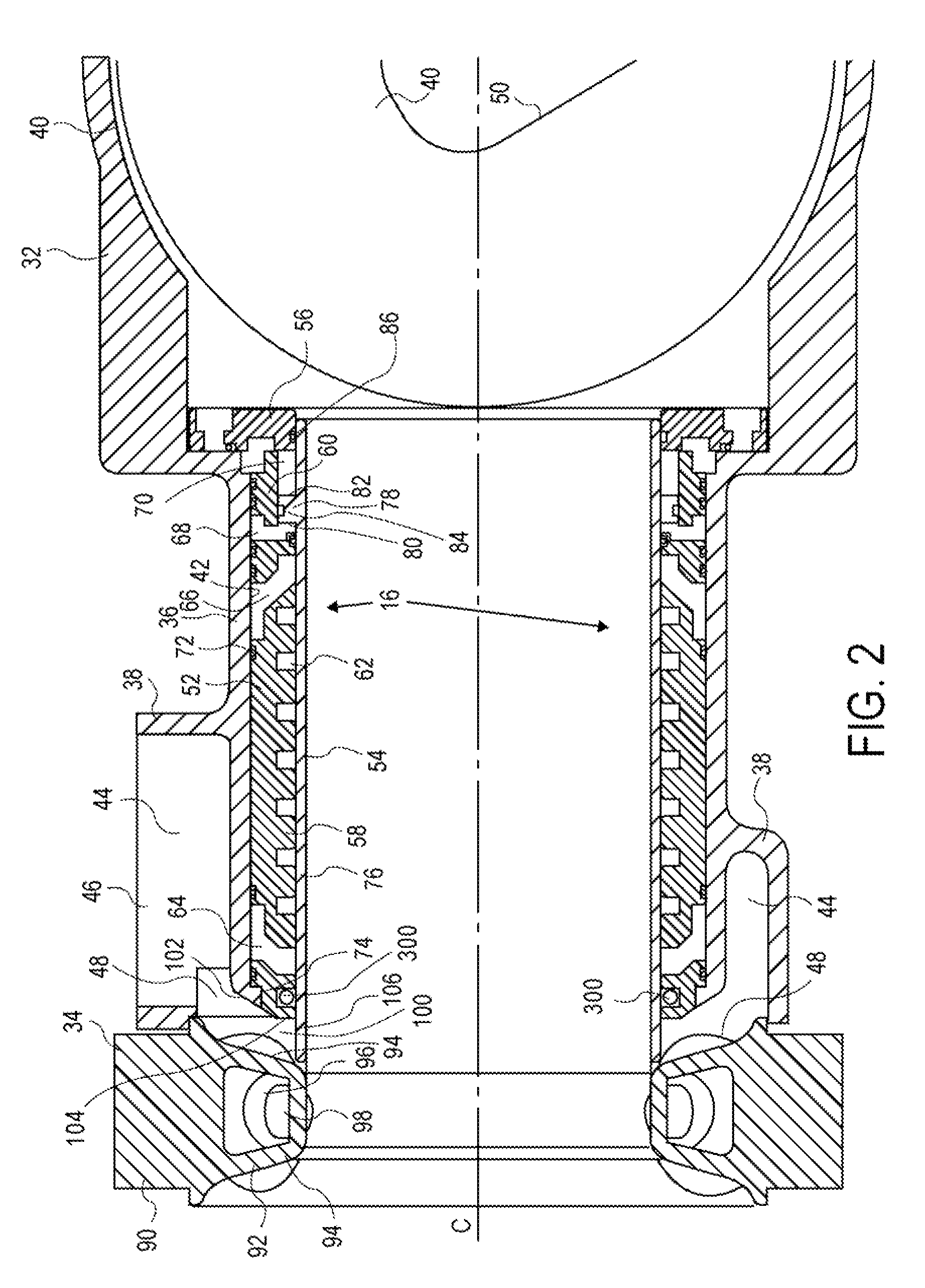

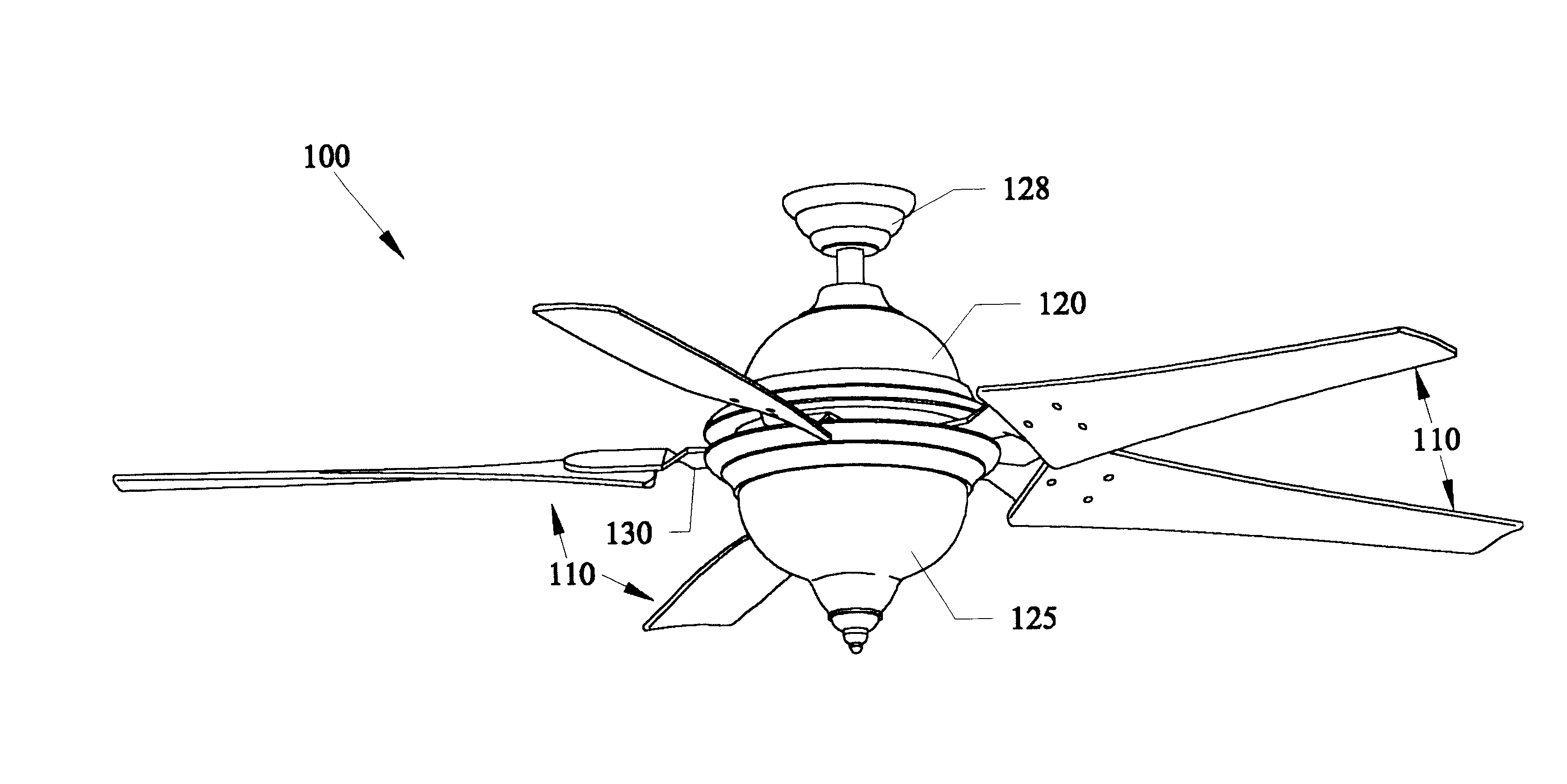

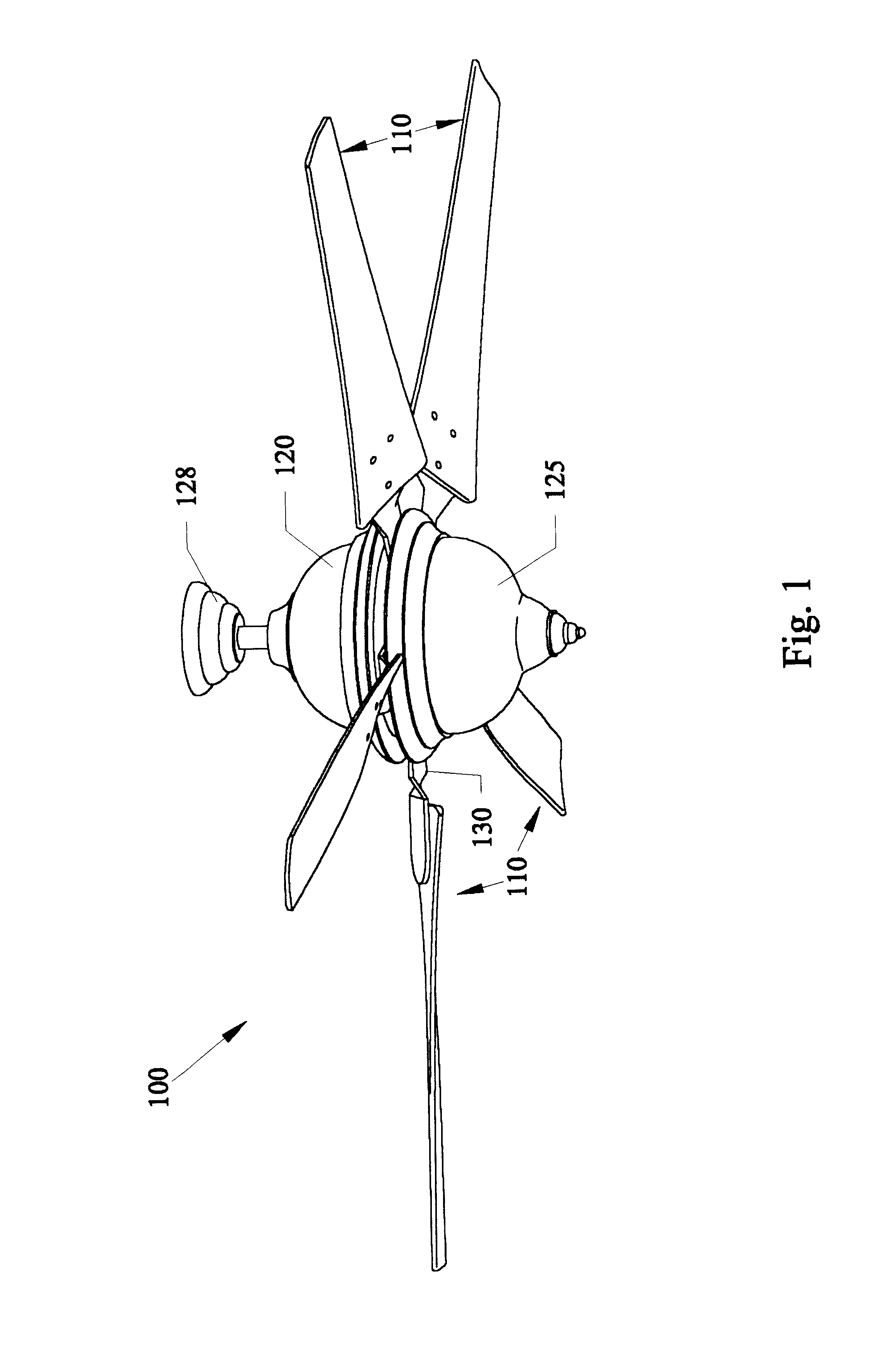

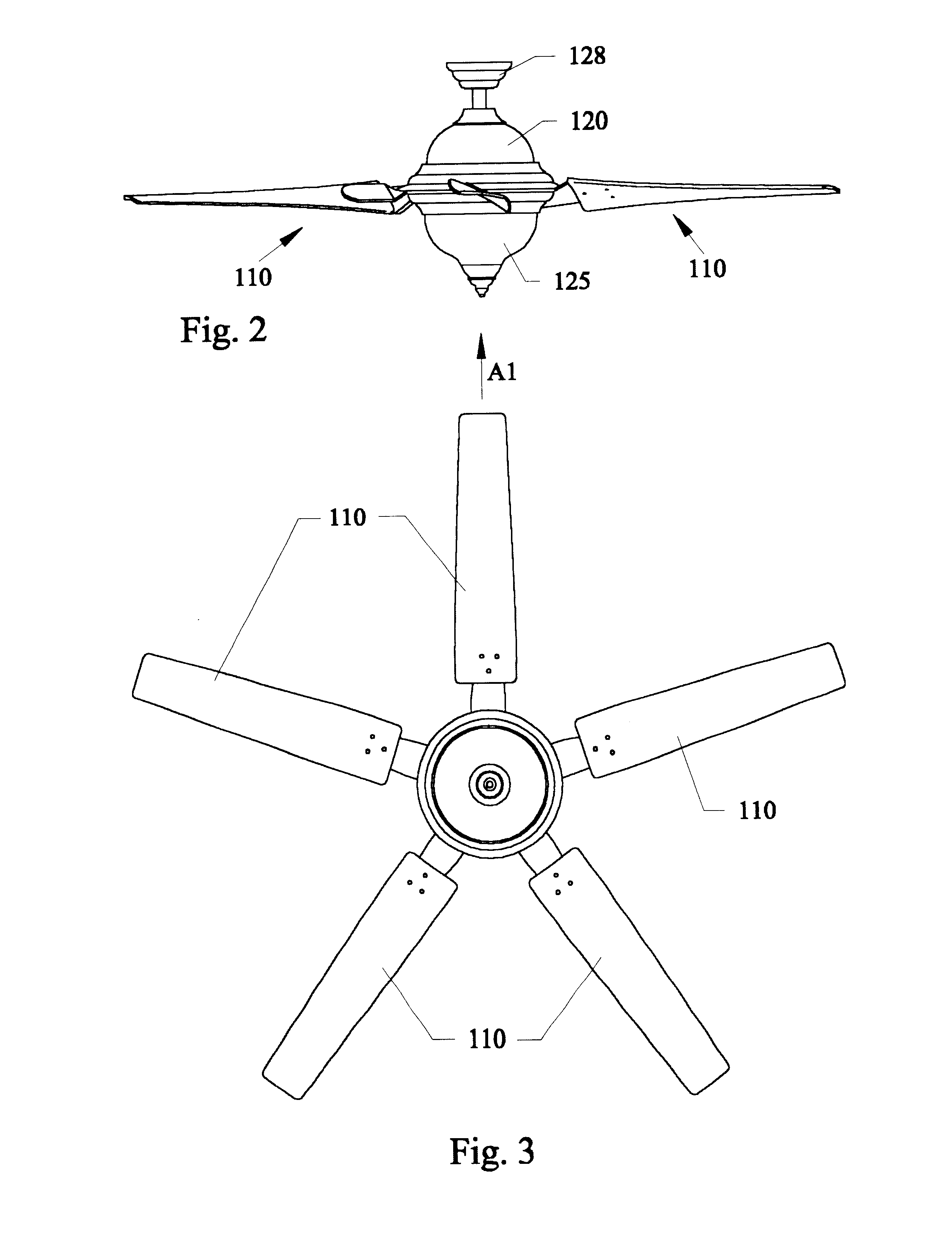

High efficiency ceiling fan blades

Ceiling fan blades for maximizing air flow at operational speeds of up to approximately 200 revolutions per minute(rpm). The blades have a positive twist at the tip ends of approximately 5 degrees to approximately 10 degrees parallel to the ceiling. The root end of the blades closest to the motor can have a positive twist exceeding that of the tip end and can be approximately 20 to approximately 35 degrees parallel to the ceiling. The ceiling fans can have individual blade lengths of approximately 20 inches and overall spans of up to approximately 52 inches and up to approximately 54 inches. Each embodiment can use three, four, and five blades, with the blades being made of injection molded plastic. and the like. The embodiments can include built in light kit domes.

Owner:UNIV OF CENT FLORIDA ADM 243

Sulfoxide pyrolid(in)one alkanolamine cleaner composition

InactiveUS6916772B2Organic detergent compounding agentsDetergent mixture composition preparationResistPhotoresist

The present invention relates to, inter alia, a composition for stripping photoresist from substrates comprising: about 5% to about 50% by weight of an alkyl substituted pyrrolidone, an alkyl substituted piperidone, or a mixture thereof, about 0.2% to about 20% of one or more alkanolamines, and about 50% to about 94% of a sulfoxide, sulfoxone, or mixture thereof. Advantageously, the composition can remove copper from a copper substrate at a rate of less than about 10 Å per minute when the substrate is immersed in the composition which is held at 70° C. for 30 minutes and rotated relative to the composition at about 200 revolutions per minute.

Owner:EKC TECH

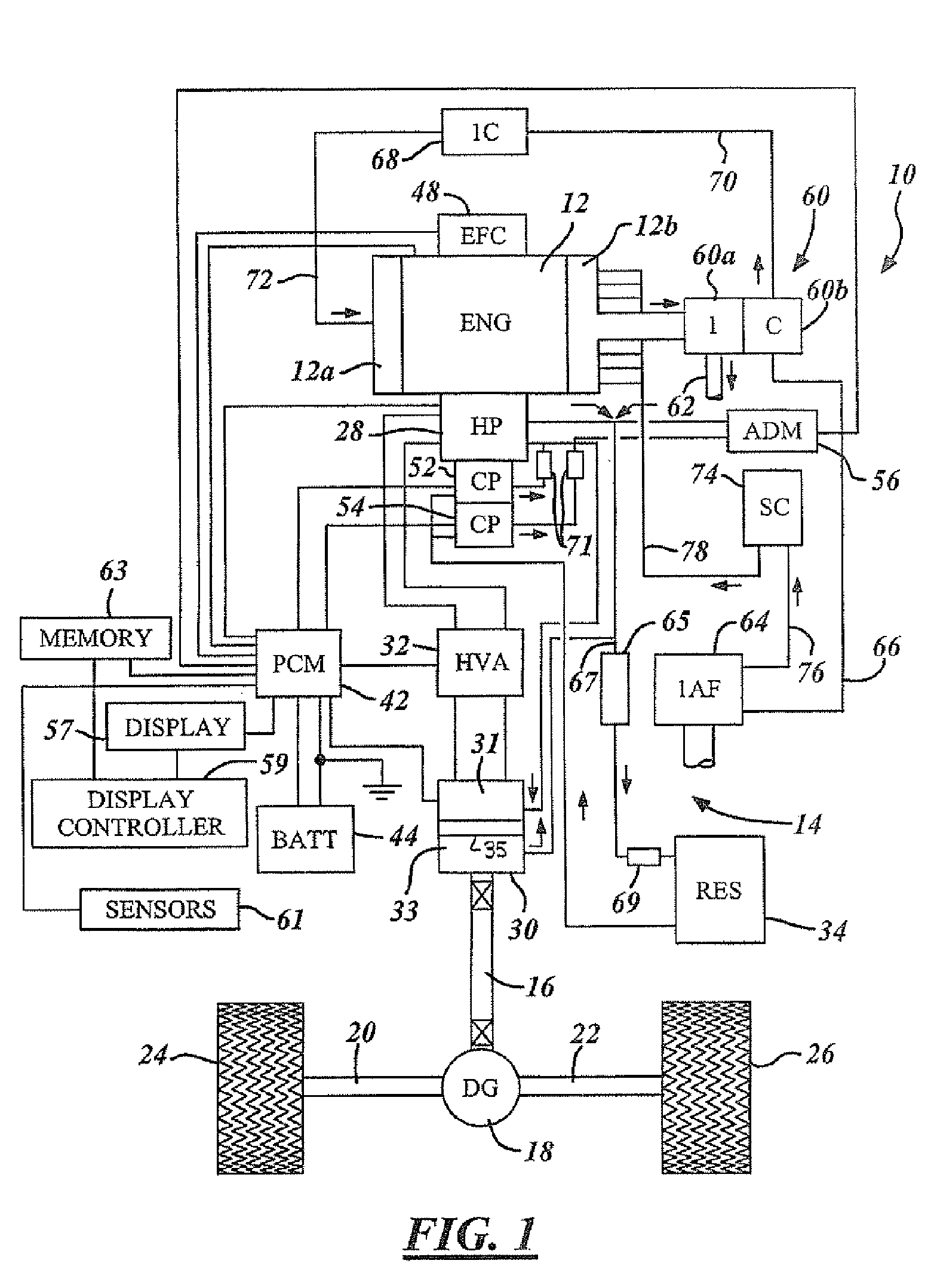

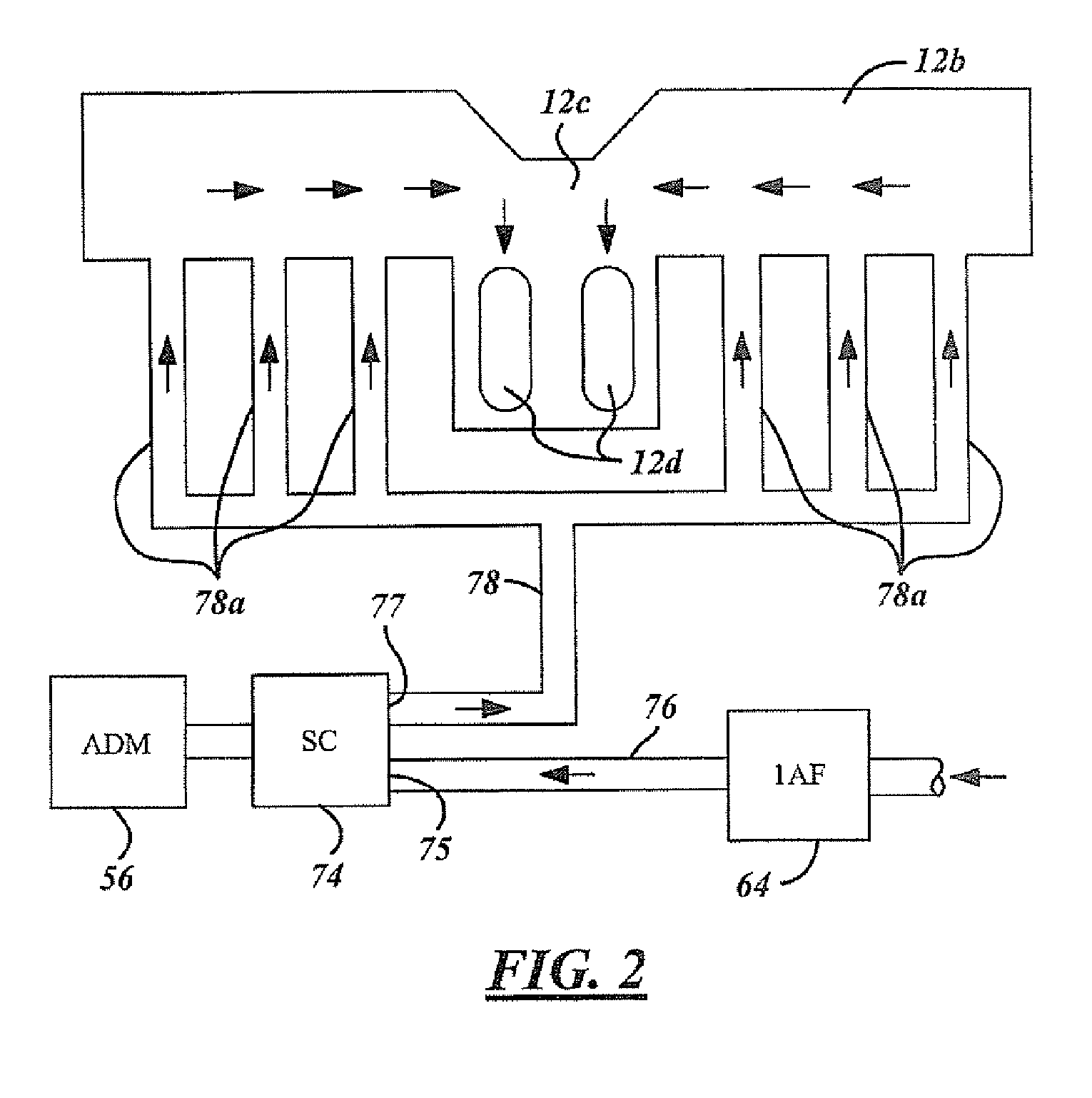

Continuous variable control methods for hydraulic powertrain systems of a vehicle

InactiveUS20060014608A1Efficient consumptionReduce speedGearing controlEngine controllersControl signalEngineering

A method of controlling a powertrain of a vehicle includes the generation of an engine torque versus engine revolutions per minute (RPM) reference for an engine. A current engine speed is determined. A fuel input signal and a continuous variable transmission control signal are generated in response to the engine torque versus engine RPM reference and the current engine speed to maintain an approximately constant engine speed for various engine loading conditions.

Owner:SUPERDRIVE

Method for preparing germinated brown rice milk beverage by compound lactobacillus fermentation

The invention provides a method for preparing germinated brown rice milk beverage by compound lactobacillus fermentation, which comprises the following steps of: preparing four lactobacillus direct-throwing fermentation agents such as lactobacillus rhamnosus, pediococcus acidilactici, streptococcus thermophilus and lactobacillus brevis; then soaking brown rice for 10 hours at 30 DEG C, and germinating for 12 hours at 2 DEG C to prepare germinated brown rice; adding 3 times water into the germinated brown rice, grinding milk by adopting colloid, gelatinizing and saccharifying the milk, adding 150 grams of direct-throwing fermentation agents into each ton of liquid rice milk, and performing standing fermentation for 6 hours at the temperature of between 38 and 40 DEG C; and centrifuging the liquid rice milk at 5,000 revolutions per minute, removing residue, adding xylitol according to the clear liquid volume for blending, filtering the liquid by using a hollow fiber membrane, performing ultrahigh-temperature instantaneous sterilization for 2 seconds at 143 DEG C, and filling the liquid with pillow-type package or tetra package to obtain a finished product.

Owner:黑龙江大荒春酒业有限公司

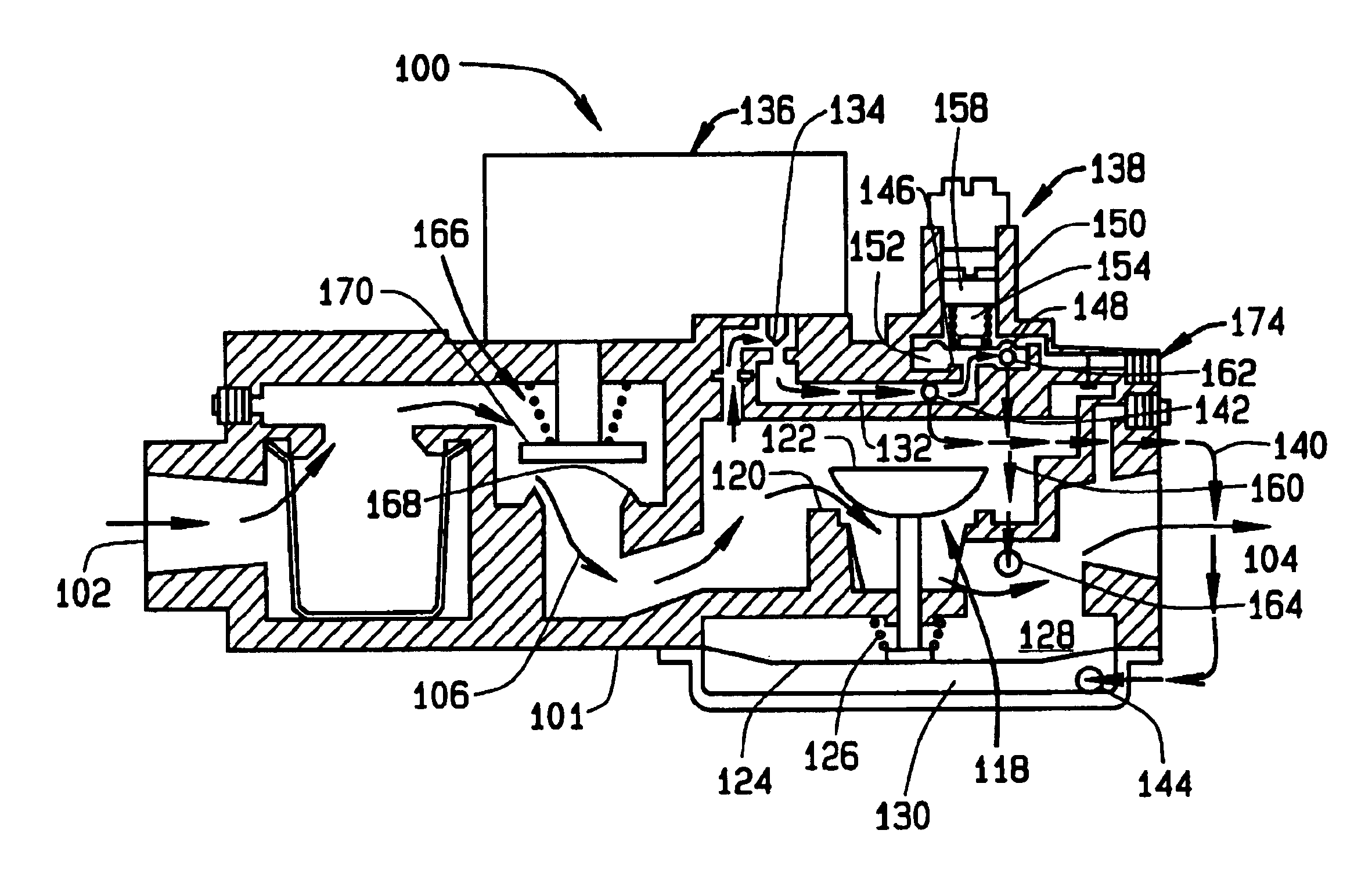

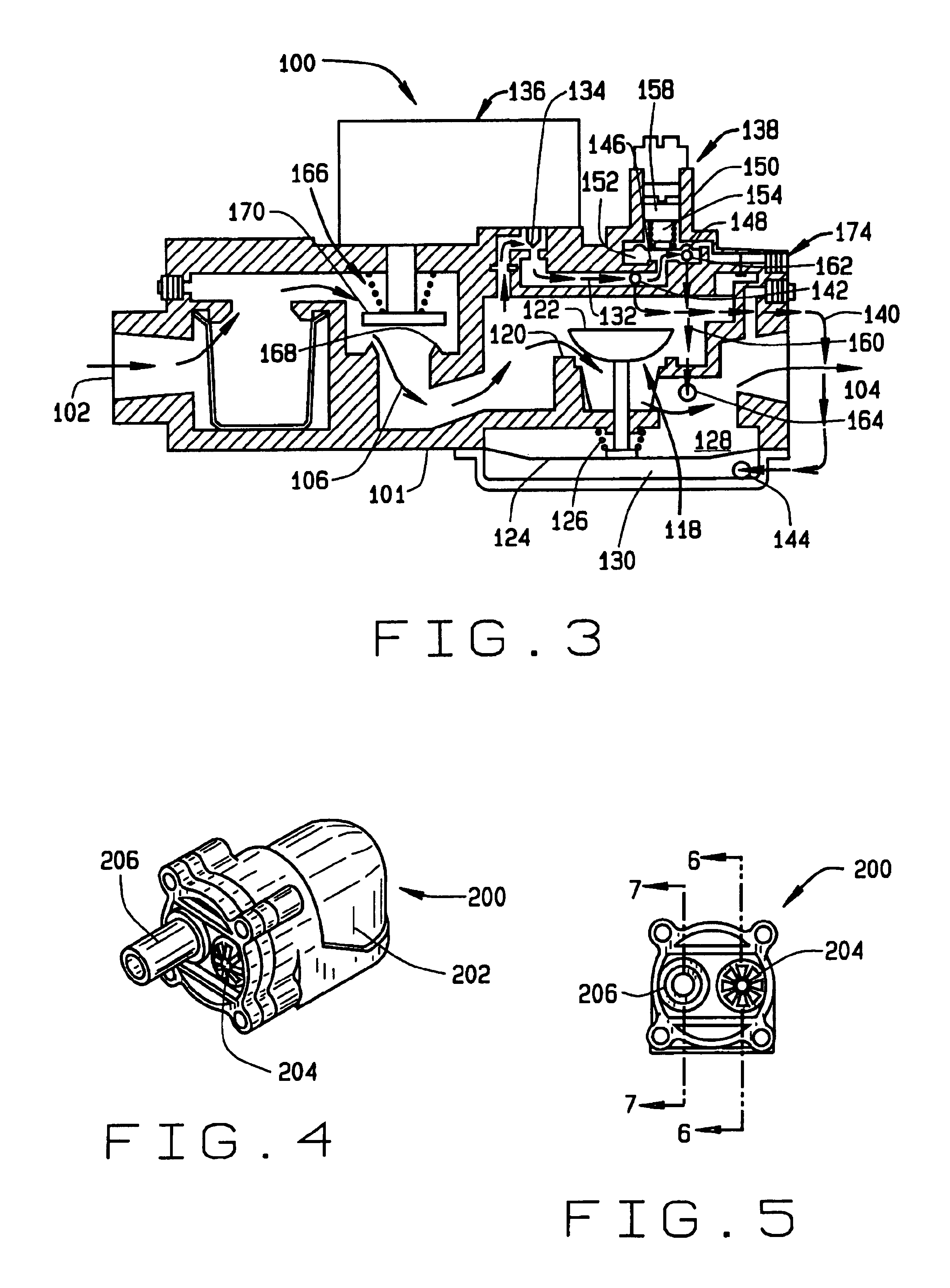

System and methods for modulating gas input to a gas burner

InactiveUS6918756B2Simply and reliably controlledLow costFluidized bed combustionFuel supply regulationMotor driveEngineering

An improved gas appliance having a burner, a gas valve through which the flow of combustion gas to the burner is controlled, and a motor driven blower that supplies combustion air to the burner. The improvement includes means for increasing gas flow through the gas valve as blower speed increases, and decreasing gas flow through the gas valve as blower speed decreases, based on a pressure signal generated independently of combustion air pressure. This improvement allows a constant ratio of gas to air to be maintained in the burner while a combustion flow rate varies dependent on the blower motor revolutions per minute. Thus input pressures of combustion can be controlled at low cost.

Owner:EMERSON ELECTRIC CO

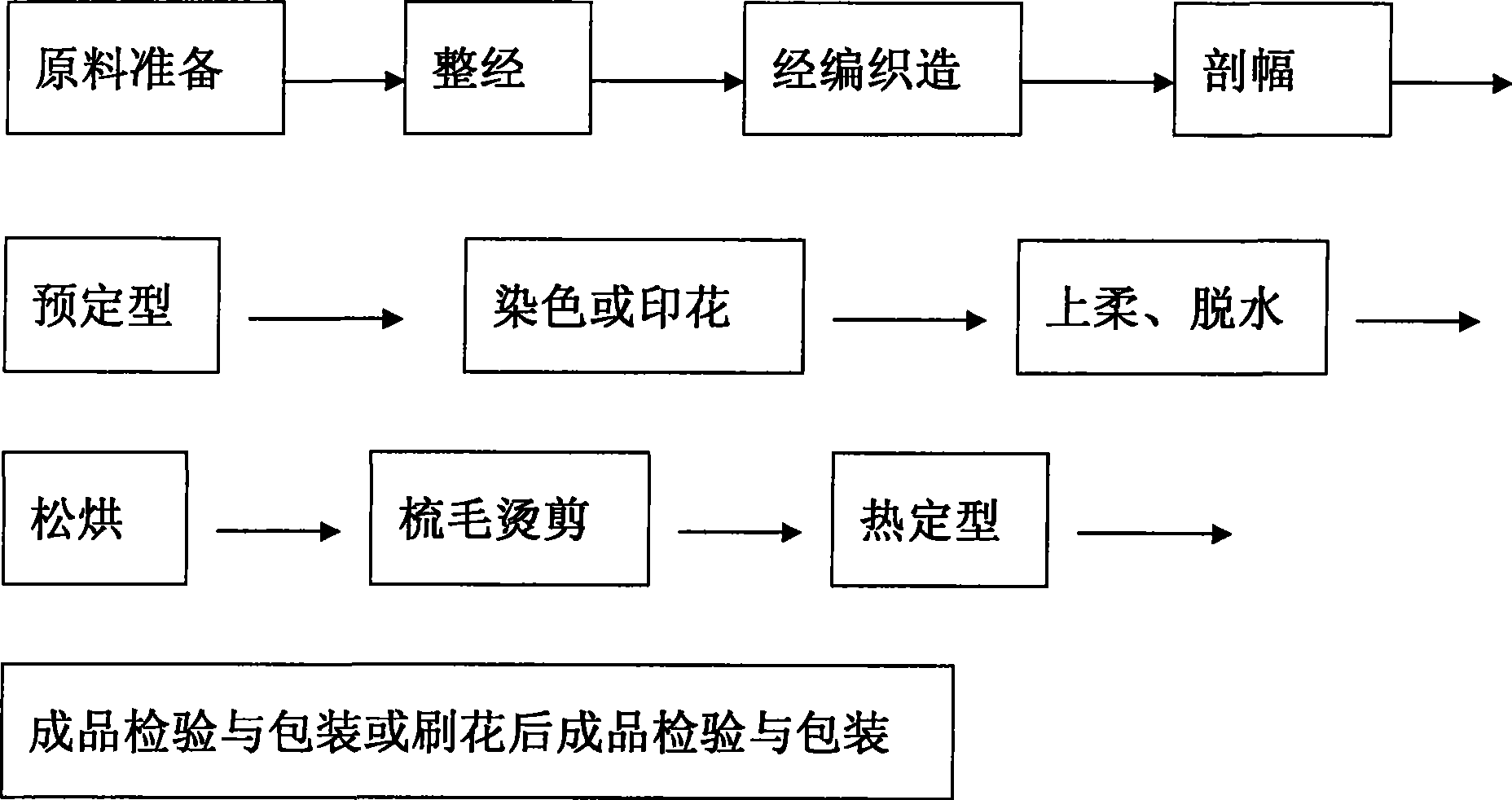

Processing method for full-cleansing woollen plush face fabric

InactiveCN101429703AHigh structural densitySoft feelWarp knittingHeating/cooling textile fabricsProduct inspectionPolyester

The invention relates to a processing method for a polyester plush fabric, which comprises the following processing steps: preparing raw materials; warping; warp knitting and weaving; slitting; pre-setting; dyeing or printing; lustring and dehydrating; baking; combing, scalding and shearing; heat shaping; and product inspection and packing, or product inspection and packing after pattern brushing, wherein the setting temperature for the pre-setting is between 190 and 230 DEG C; and in the pre-setting process, the tension of grey cloth is controlled, and the progression speed of controlling the grey cloth is 35 to 45 meters per minute, and the rotating speed of a blower is 1, 750 to 1, 900 revolutions per minute. The processing method has the advantages that the height of plush is increased to 5 to 30 millimeters, the plush is long and inflexible, and the plush surface is smooth and subtle, and the plush is soft and has good hand feel; the plush is straighter and can comb floating plush at the bottom; at the same time, resetting resulted from difference of fabric width and style caused by high-temperature ironing and cutting is reduced; by adopting warp knitting and weaving, a bottom tissue structure has high density and a bottom fabric tissue has good stability; and the step of pattern brushing makes patterns flexible and the fabrics extend from single toy fabrics to clothing fabrics.

Owner:CHANGSHU YATAIYA TEXTILE ADORN

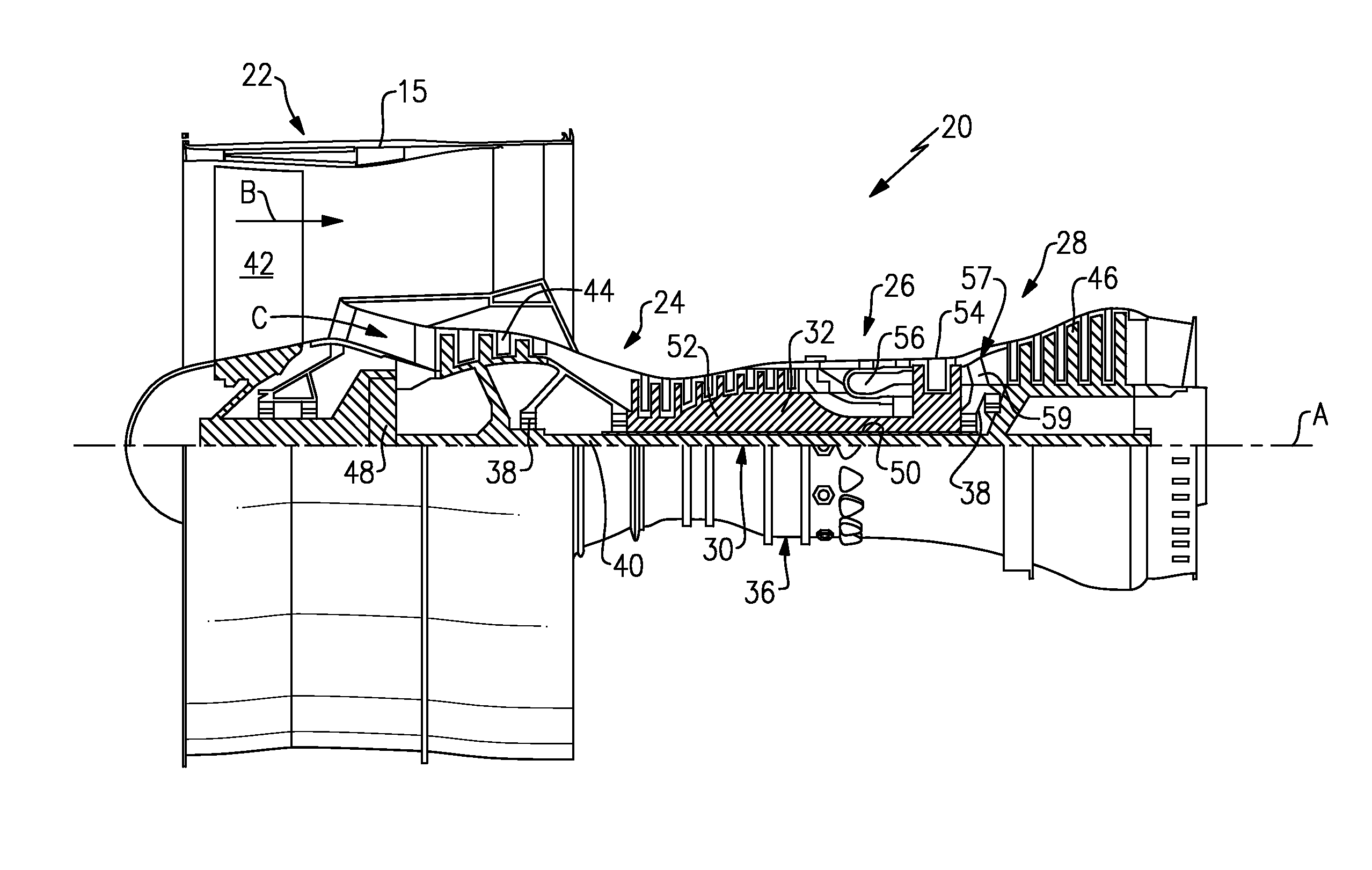

Low noise compressor rotor for geared turbofan engine

A gas turbine engine comprises a fan and a turbine section having a first turbine rotor. The first turbine rotor drives a compressor rotor. A gear reduction effects a reduction in the speed of the fan relative to an input speed from a fan drive turbine rotor. The compressor rotor has a number of compressor blades in at least one of a plurality of rows of the compressor rotor. The blades operate at least some of the time at a rotational speed. The number of compressor blades in at least one row and the rotational speed are such that the following formula holds true for at least one row of the compressor rotor:(the number of blades×the rotational speed) / (60 seconds / minute)≧5500 Hz; andthe rotational speed being in revolutions per minute.A compressor module and a method of designing a gas turbine engine are also disclosed.

Owner:MTU AERO ENGINES GMBH

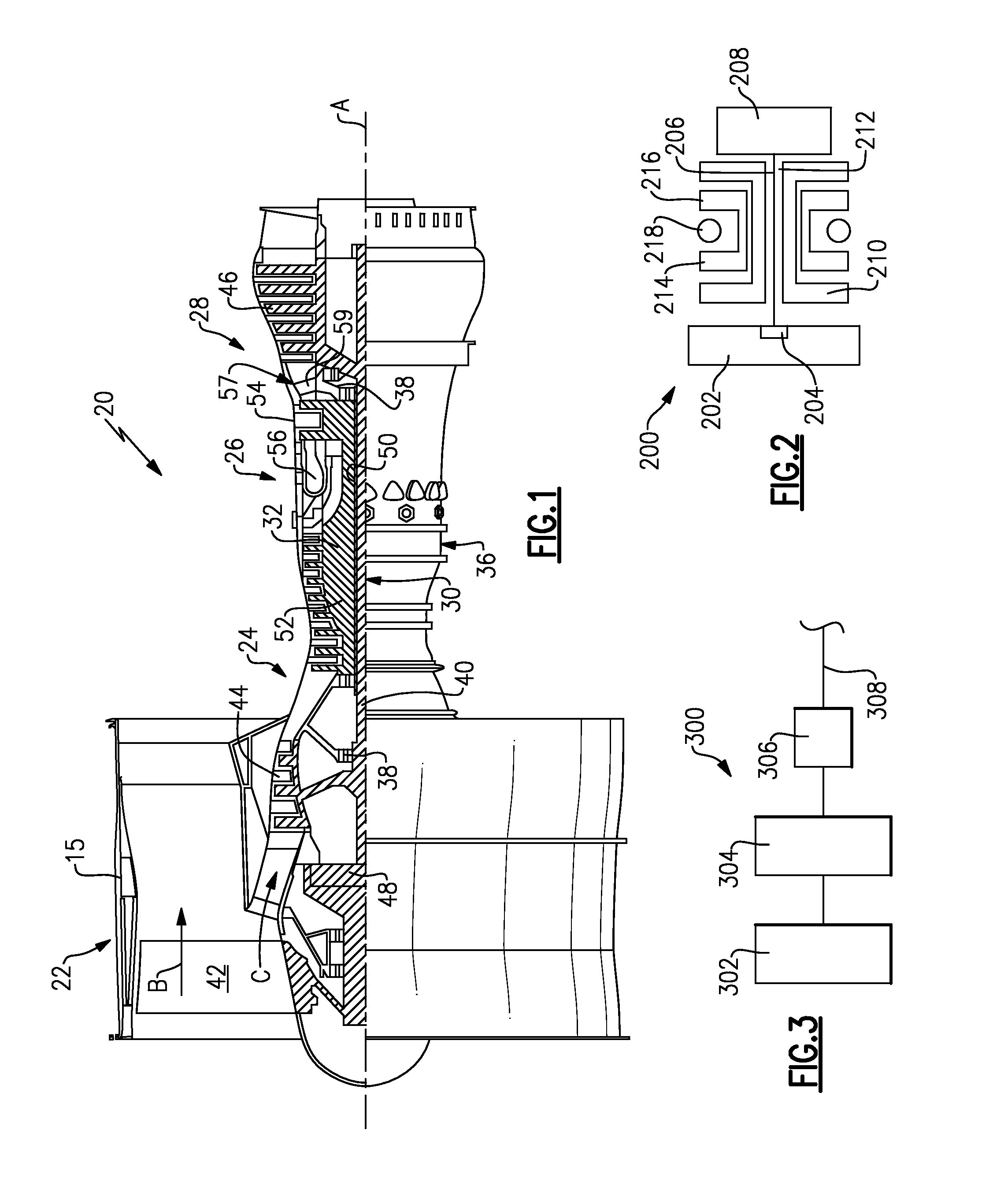

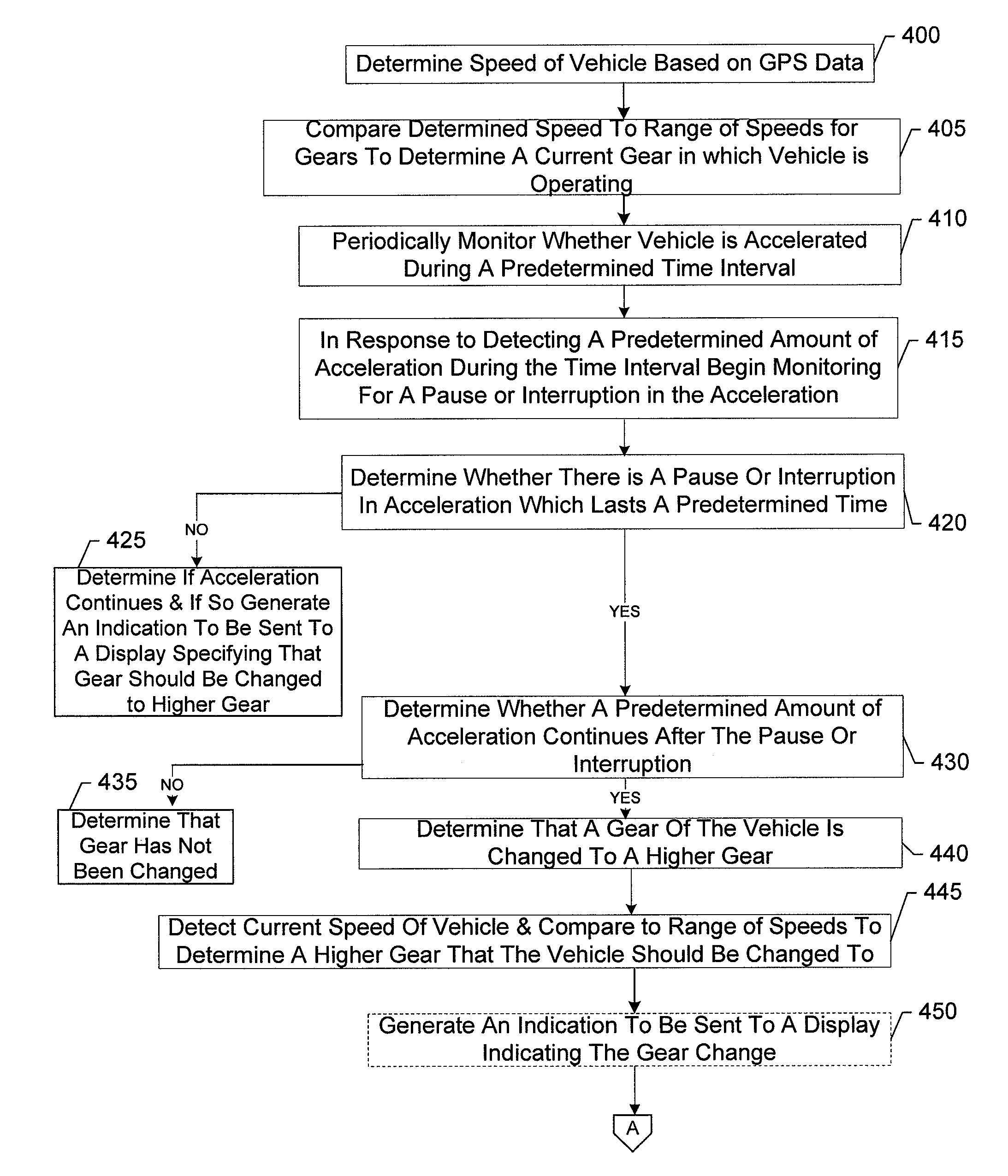

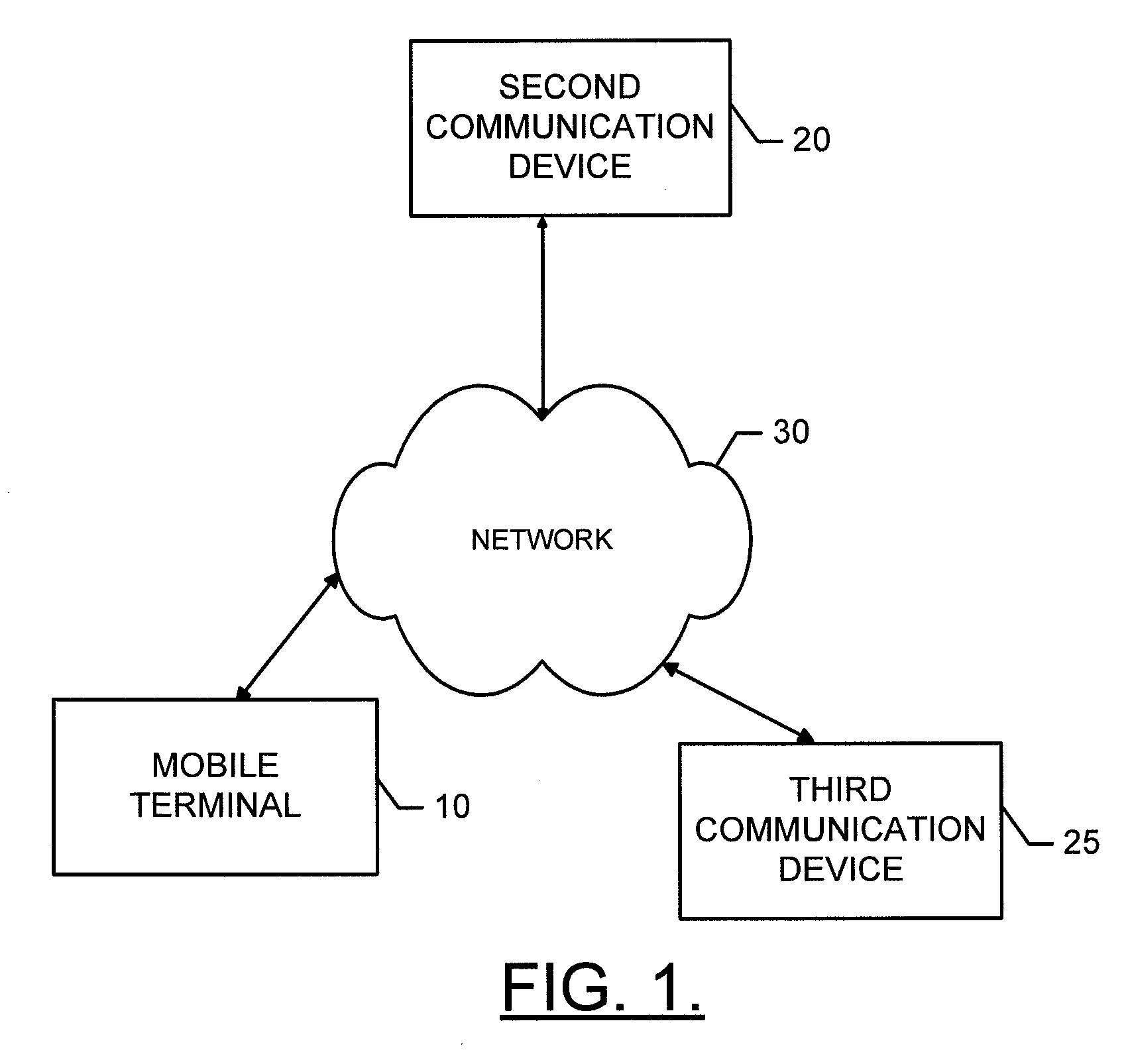

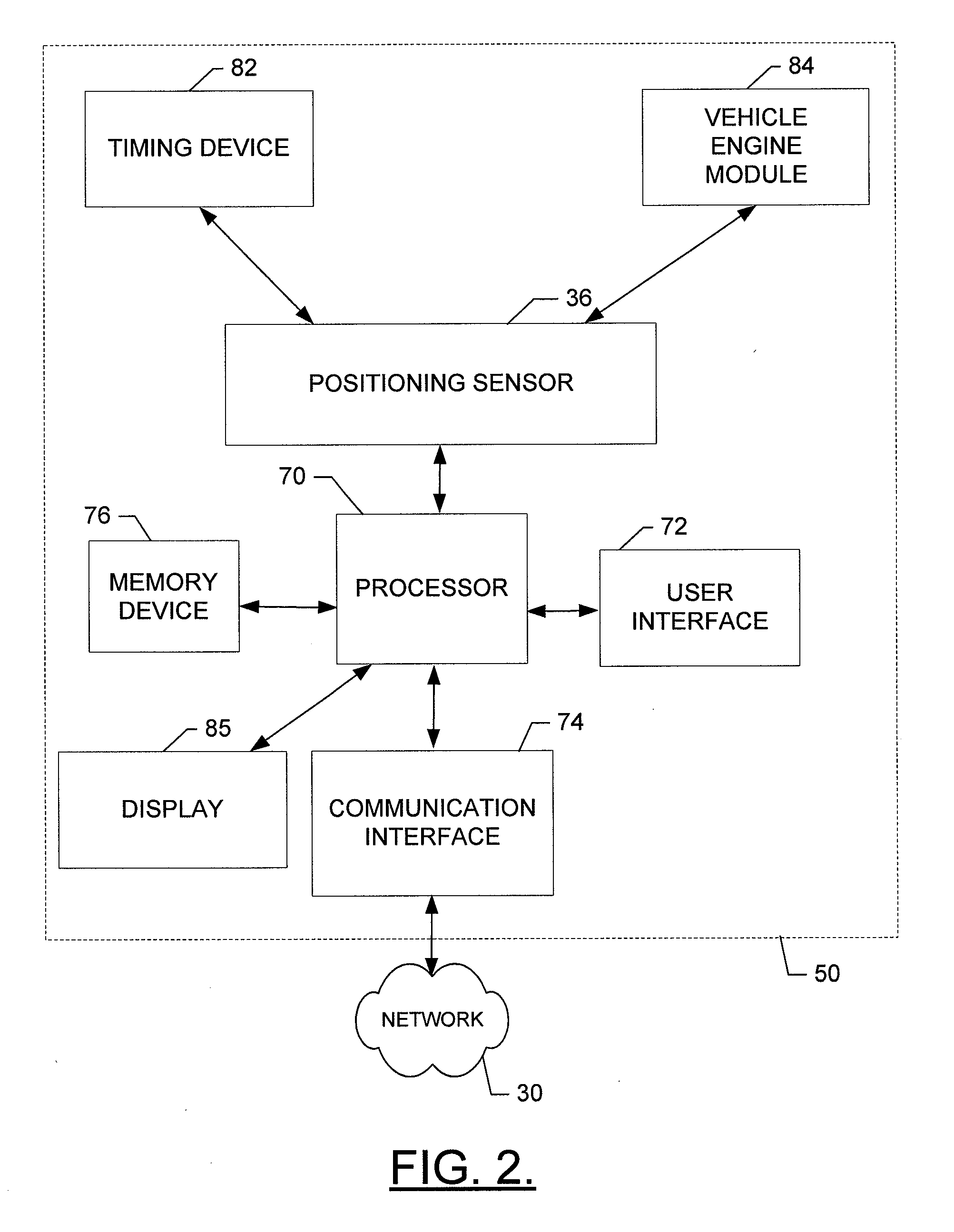

Method, apparatus and computer program product for determining vehicle engine revolutions per minute and gear position information using location information

InactiveUS20100305819A1Increased gas consumptionExcessive wearDigital data processing detailsExternal condition input parametersRevolutions per minuteComputer program

An apparatus for determining vehicle gear information and vehicle engine RPM data based in part on usage of location information may include a processor and a memory storing executable computer program code that causes the apparatus to at least perform operations including evaluating first location information identifying one or more positions of a vehicle at respective times in order to determine a speed of the vehicle. The computer program code may further cause the apparatus to compare the determined speed to a first range of speeds that correspond to gears of the vehicle and determine a current gear that the vehicle is operating in based at least in part on the determined speed corresponding to a speed in the first range of speeds associated with a gear. Corresponding computer program products and methods are also provided.

Owner:NOKIA CORP

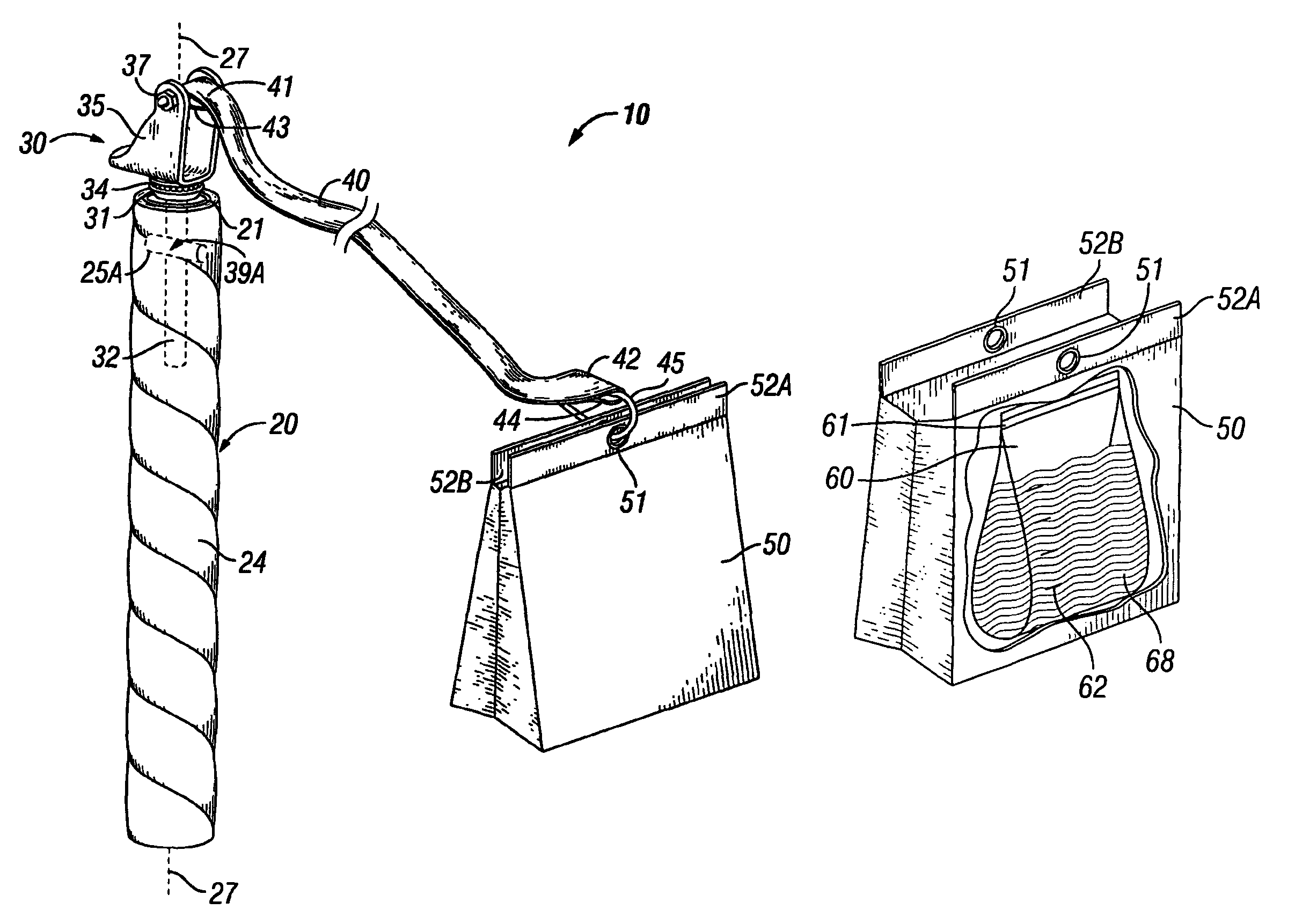

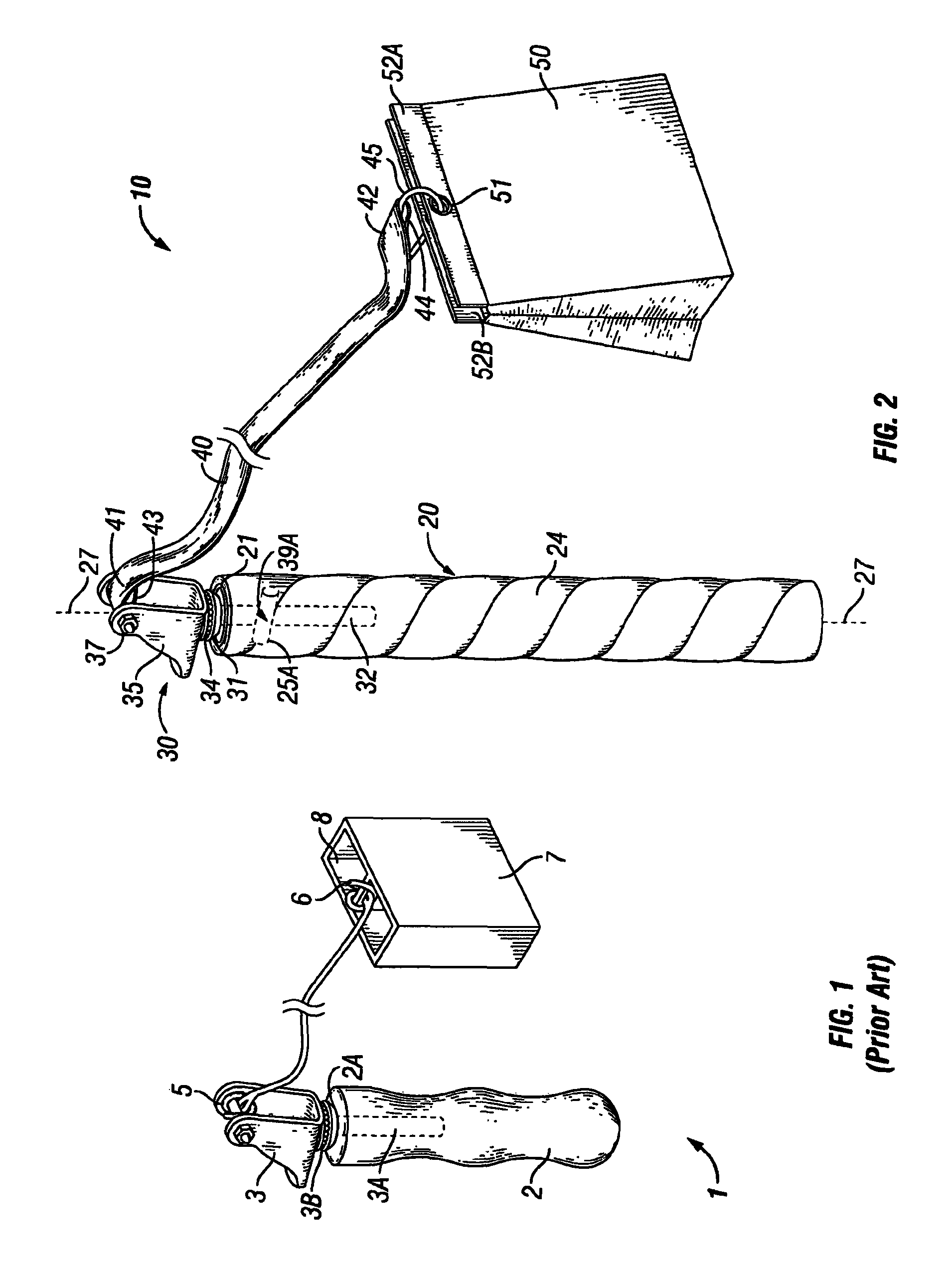

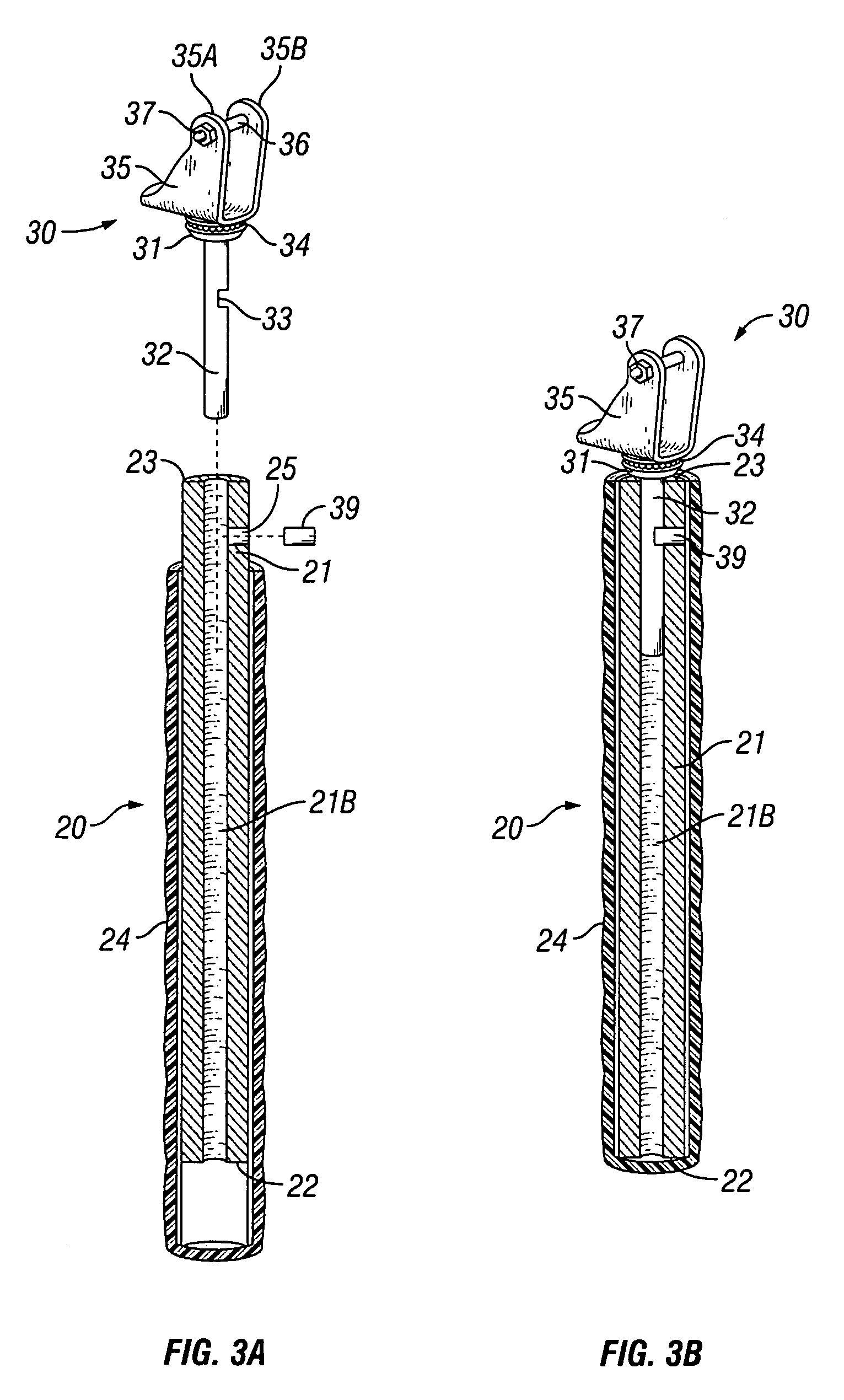

Portable exercise device

The present invention provides a compact, portable, centripetal force-driven exercise device. The device employs a handle equipped with a rotational member. One end of a strap is attached onto the rotational member; the other end to a soft bag. The soft bag, preferably of a heavy duty cloth or synthetic fiber construction, is capable of holding one or more water-refillable, reclosable plastic bags. The strap can have adjustable length. The soft bag itself is also capable of being filled with a desired amount of water. The handle preferably is covered on its exterior surface with a hand grip material. The user places the desired amount of contained water weight into the soft bag, holds the handle and swings the bag in an orbital pattern at a desired number of revolutions per minute to achieve the desired degree of centripetal force resistance to exercise, strengthen and condition the user's muscular system.

Owner:BOESCH DON E

Robot cleaner and control method thereof

InactiveCN102551591AAutomatic obstacle detectionTravelling automatic controlEngineeringUltimate tensile strength

A robot cleaner (100) includes a main brush (160) to sweep or scatter dust off a floor, a main brush motor to rotate the main brush, a Revolution Per Minute (RPM) detector to detect an RPM of the main brush motor, and a control unit to determine a type of floor according to the RPM of the main brush motor acquired by the RPM detector and control an operation of the robot cleaner (100) based on the determined type of floor. A carpet mode to clean only a carpet area and a hard floor mode to clean a hard floor area excluding the carpet area are given based on detected information relating to the material of a floor, which enables partial cleaning with respect to a cleaning area selected by a user and adjustment in the number of cleaning operations or the intensity of cleaning according to the material of the floor.

Owner:SAMSUNG ELECTRONICS CO LTD

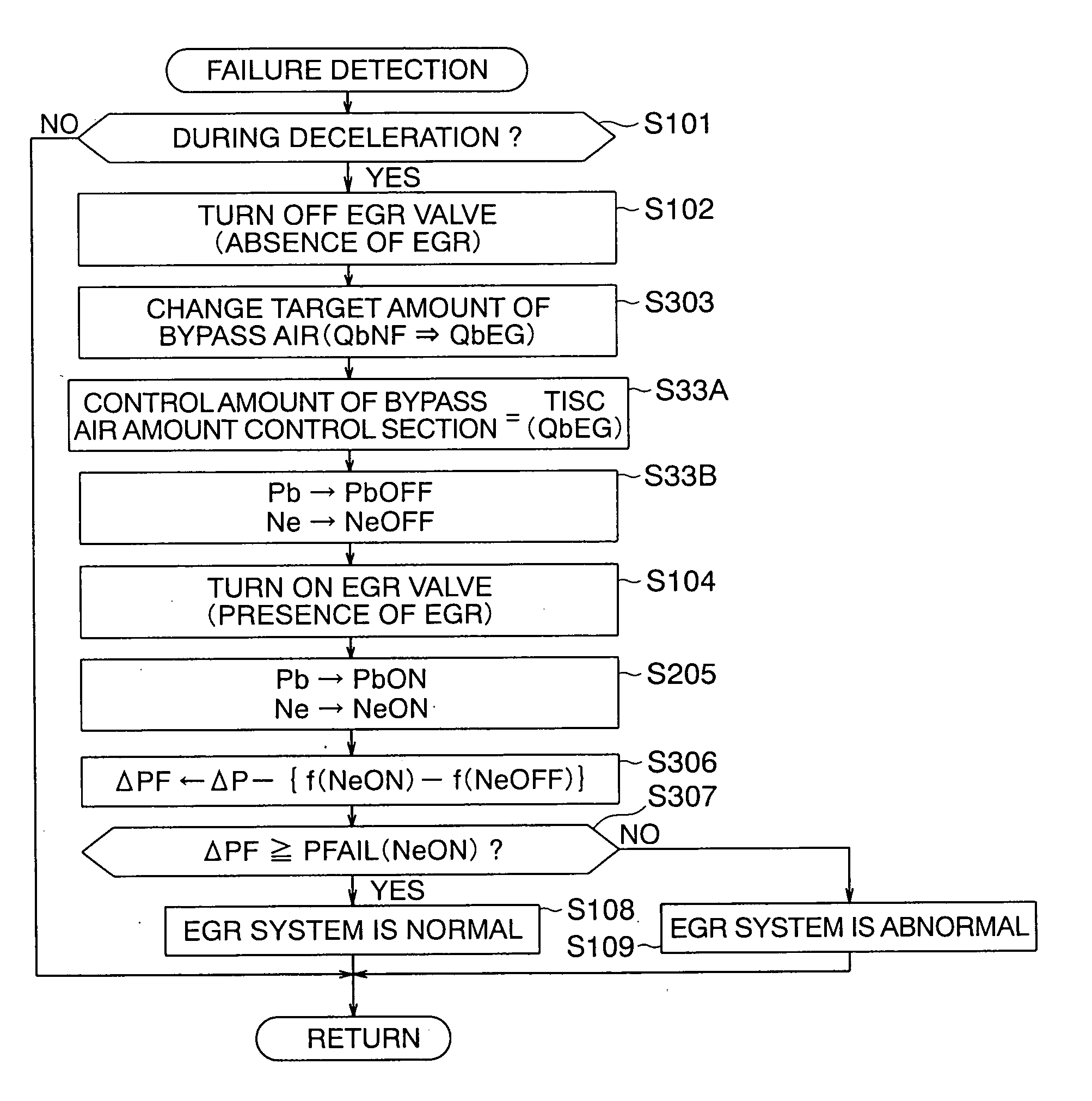

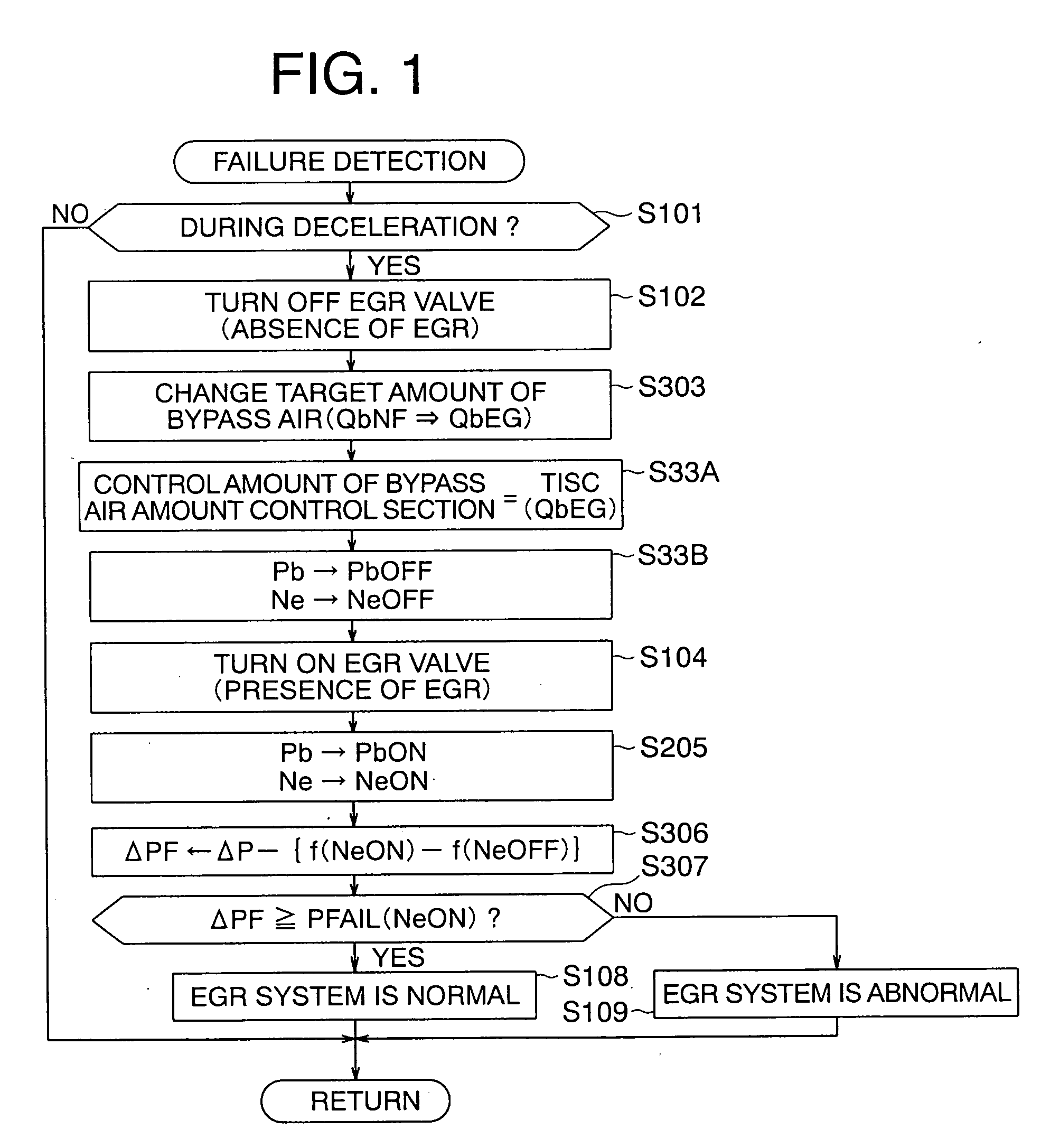

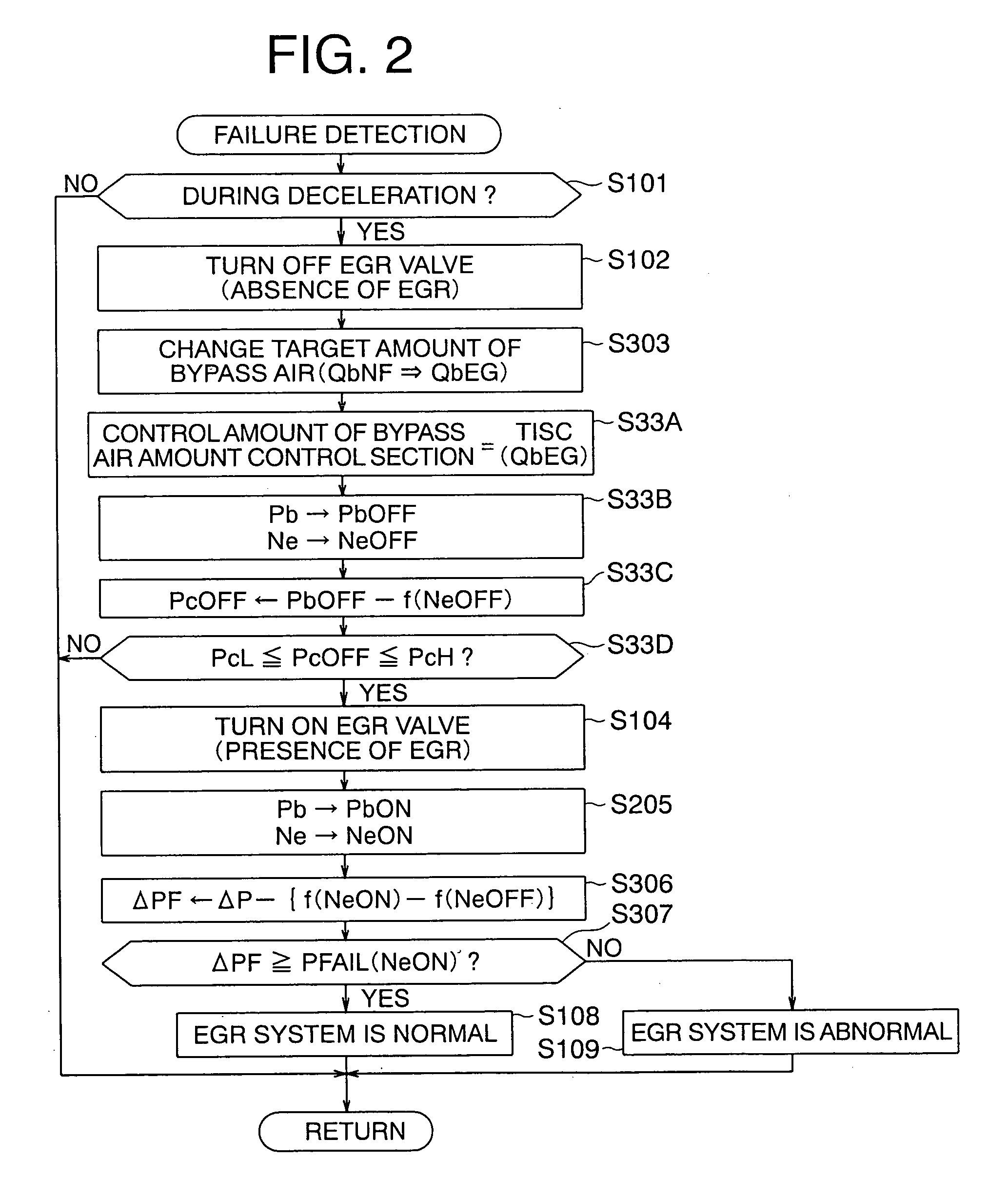

Control apparatus for an internal combustion engine

InactiveUS20070062499A1Highly reliable failure determinationDetermination failsElectrical controlNon-fuel substance addition to fuelIntake pressureRevolutions per minute

A control apparatus for an internal combustion engine can compensate for a variation of intake pressure resulting from various factors whereby a failure detection area can be expanded, and false detection can be prevented to enable failure determination for an EGR system with high reliability. The apparatus determines whether a vehicle is decelerating, forcedly opens and closes an EGR valve, and determines whether an EGR control device is in failure by comparing a pressure change index value based on intake pressures upon the forced opening and closing of the EGR valve with a failure determination value. The apparatus adjusts the intake pressure to a predetermined state before the EGR valve is forcedly opened and closed, whereby a failure determination can be always made based on the intake pressure whose variation was compensated for with the intake pressure becoming a predetermined characteristic to the number of revolutions per minute of the engine.

Owner:MITSUBISHI ELECTRIC CORP

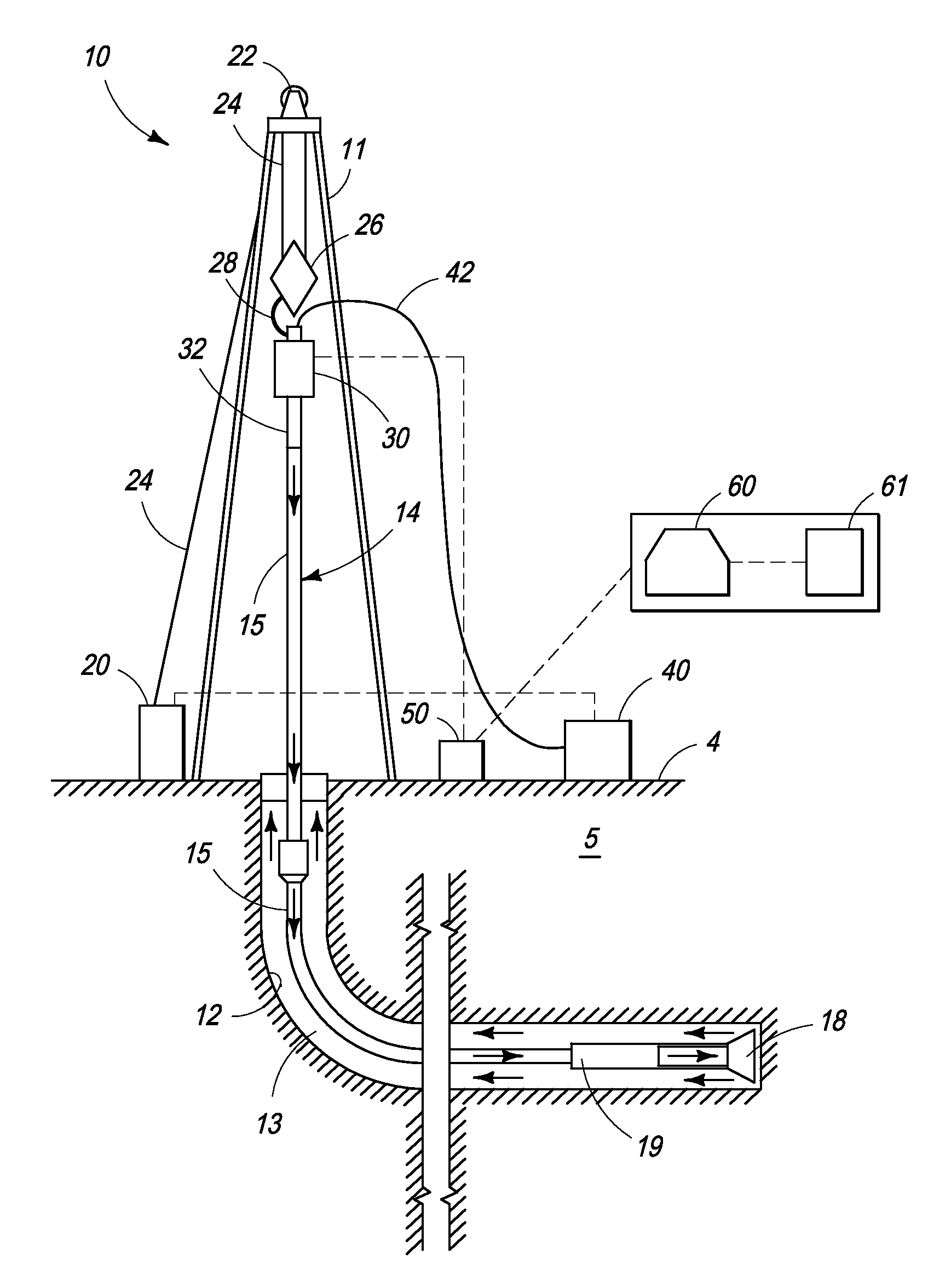

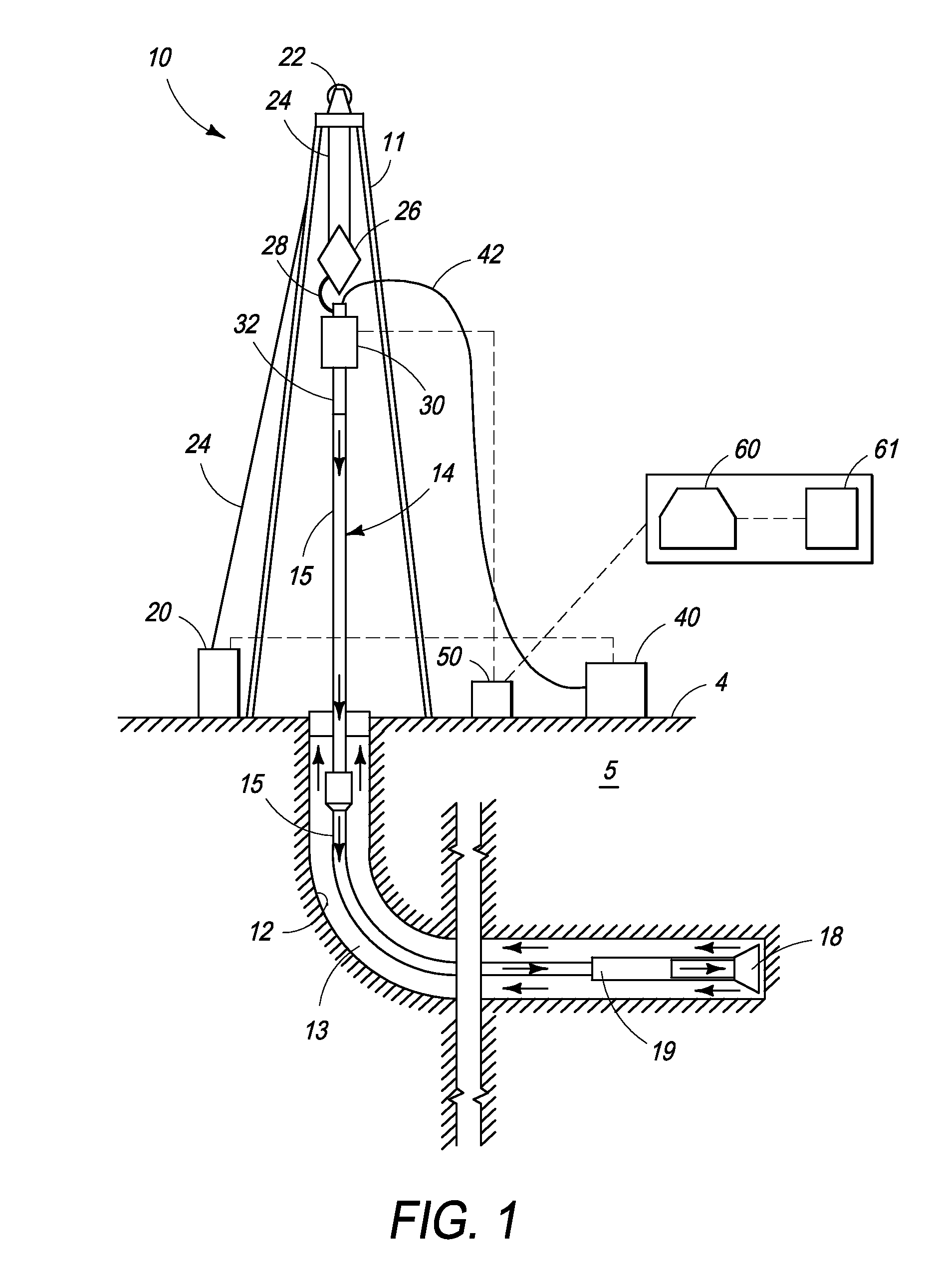

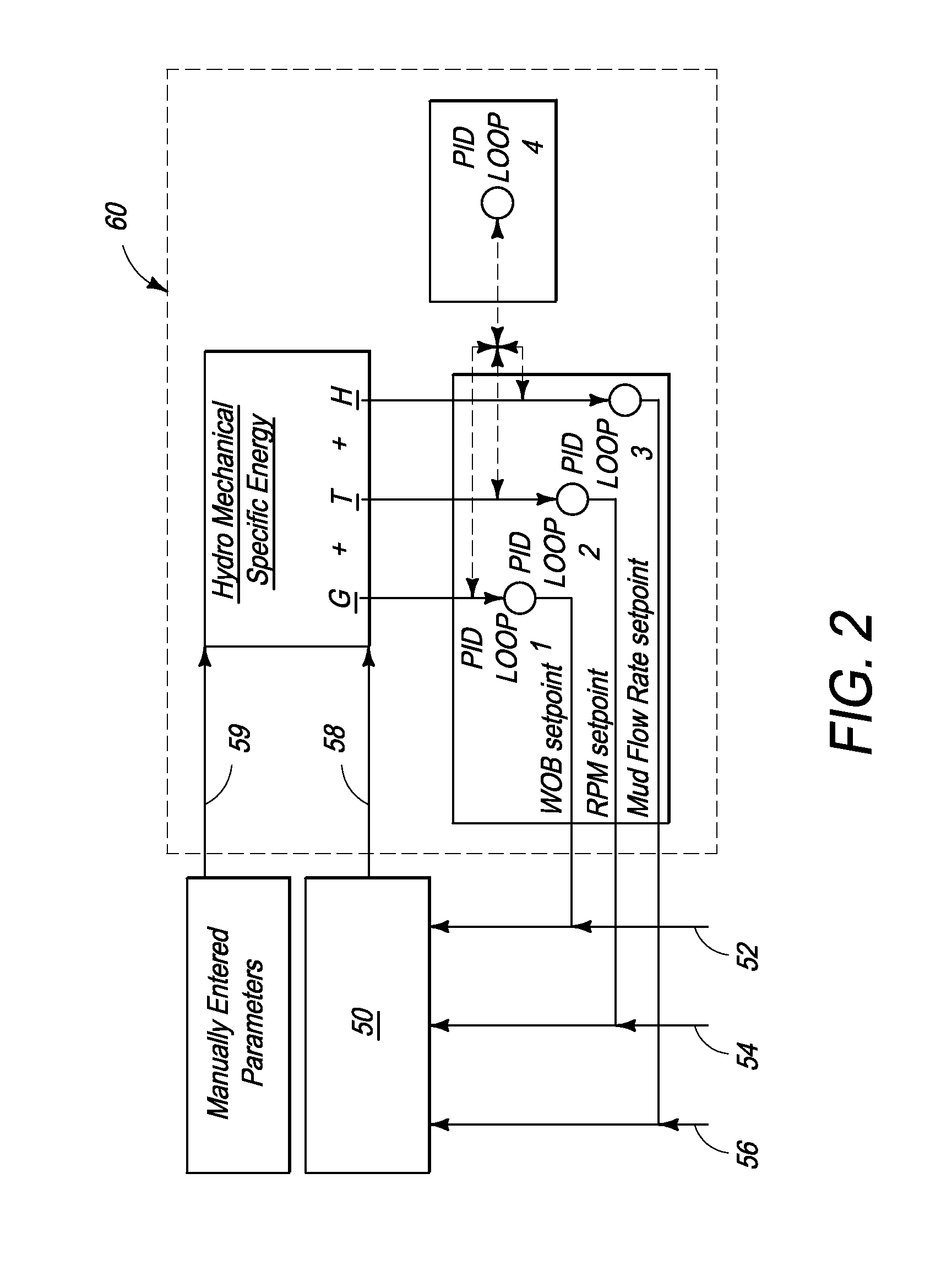

Processes and systems for drilling a borehole

InactiveUS20130146358A1Reduce the amount requiredWithout sacrificing rate of penetrationSurveyDrilling rodsReal-time dataEnergy reduction

Processes and systems for drilling a borehole wherein a gravitational energy term, a torsional energy term, a hydraulic energy term and a hydromechanical specific energy which is the sum thereof may be determined using real-time data and compared against corresponding setpoints. The hydraulic energy term may include a hydraulic energy reduction factor so as to account for the distance between the fluid nozzle of the drill bit and the rock and may include the kinematic viscosity of drilling fluid. One or more drilling parameters, such as weight on bit, revolutions per minute, drilling fluid flow rate, or combinations thereof, may be adjusted based upon such comparison to approximate the least amount of energy required to destroy and remove a given unit volume of rock. The setpoints may be changed manually or automatically at the direction of the user.

Owner:DISANTIS JOSEPH R

Micro-elastic memory face fabric and production process thereof

InactiveCN101338470APromote formationSuitable for mass productionWeft knittingLoomsEngineeringCompanion animal

The invention discloses micro-stretch memory fabric and a process thereof. The process comprises the selection of weaving equipment, warp and weft, weaving gray fabric, and dyeing and finishing. The invention is characterized in that the weaving equipment is a hydraulic loom or a jet loom; the warp is PTT memory filament or PET / 144F fine denier filament; the weft is PPT / PET compound blended fabric or PBT stretch yarn; and the quality ratio of the warp and the weft is 60 to 70 / 40 to 30. The gray fabric weaving adopts X55, CM800, T400 or the PBT stretch yarn of whole original weft supplier. Warp twisting is 6 to 8 twist / cm. Twisting speed is 8500 revolutions per minute. The temperature of setting twist is 75 DEG C and heat preservation lasts for an hour or scaling treatment lasts for 24 to 48 hours. The flow of the dyeing and finishing is as follows: open-width de-sizing, preshrinking, previous form definition, dying and subsequent form definition. The process of the micro-stretch improves the quality of a product, and reduces cost. In addition, the fabric has good elasticity and good size stability, and is comfortable to be wore and easy to be handled.

Owner:YANGZHOU JIYUAN TEXTILE +1

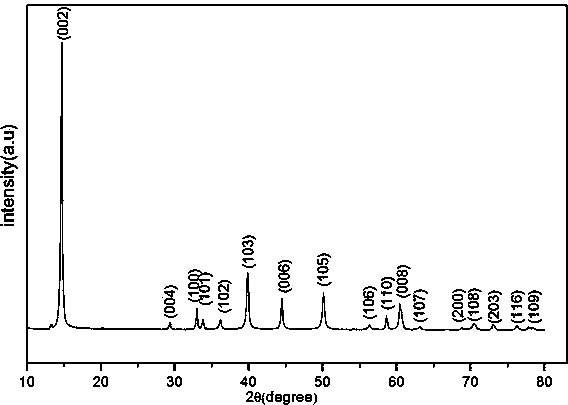

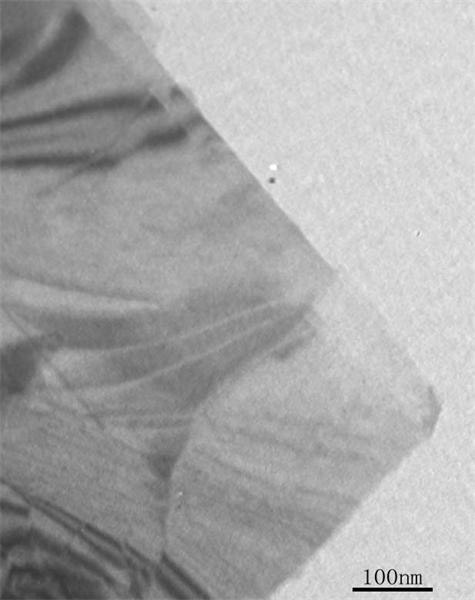

Method for preparing molybdenum disulfide (MoS2) nanosheet

The invention discloses a method for preparing a molybdenum disulfide (MoS2) nanosheet by two steps, namely a hydrothermal method and a liquid phase ultrasonic stripping method. The method disclosed by the invention is realized by the following technological steps: evenly mixing the bought MoS2 powder with lithium carbonate according to the molar ratio of 1: 42, putting the mixture into a high pressure kettle filled with 40ml of benzyl alcohol, and sealing; maintaining for 48 hours at the temperature of 200 DEG C; carrying out natural cooling and vacuum drying to obtain an intermediate product; putting 0.2-0.6g of intermediate product into mixed liquid of 20ml of dimethyl formamide and 10ml of water, and carrying out ultrasonic dispersion for 12 hours; centrifuging the obtained dispersed liquid for 30-45 minutes at the speed of 500-600rpm (revolutions per minute), and then centrifuging the supernatant liquid for 6 minutes at the speed of 6000-8000rpm; cleaning the product by 3% HCl for twice, and then cleaning the product by deionized water until the product is neutral; and finally, carrying out vacuum drying on the product to obtain the nano MoS2 sheet. The MoS2 nanosheet is stripped by the method disclosed by the invention. The method has the characteristics of being simple, easy to realize and popularize and suitable for large-scale industrial production.

Owner:XINJIANG UNIVERSITY

Preparation method of aroma rapeseed oil

ActiveCN102936531AStrong fragranceRetain nutrientsFatty-oils/fats refiningFatty-oils/fats productionScreening proceduresAdditive ingredient

The invention discloses a preparation method of aroma rapeseed oil, wherein the preparation method comprises the following main procedures: selecting rapeseeds, removing impurities, and removing macadam and clods, wherein the impurity content is smaller than 0.1% and the rapeseed content in the screen underflow is smaller than 0.5% after the screening procedure; frying the rapeseeds at 140-145 DEG C; squeezing the rapeseeds through a squeezer and controlling the thickness of an oil cake to be smaller than 1.5mm to obtain crude oil; primarily deslagging the squeezed crude oil through an oil clarifying box, and pumping the crude oil in a blade filter to be filtered, wherein the insoluble impurity in the filtered crude oil is smaller than 0.2%; obtaining clean crude oil, controlling the operation temperature at 65-70 DEG C and controlling the water temperature at 70-75 DEG C to perform hydration degumming; washing the clean crude oil twice by virtue of softened water, drying and dewatering at vapor pressure of 4-5 Mpa; stirring the clean crude oil at a rotating speed of 30 r / min (revolutions per minute), and cooling until the oil temperature is lower than 80 DEG C; and filtering the clean crude oil in a frame filter to obtain the aroma rapeseed oil. The prepared rapeseed oil generates full-bodied fragrance, and the nutrition ingredients and physiological active ingredients in the rapeseed oil are kept to the maximum.

Owner:YUNNAN ZHENWEI GREASE

Pigment ink for inkjet printing of high fastness textile and preparation method thereof

The invention discloses a pigment ink for inkjet printing of high fastness textile and a preparation method thereof. The ink comprises the following components by mass percent: 30-50% of pigment / branched polymer nano composite particle dispersoid, 10-50% of water soluble cosolvent, 1-5% of non-ionic surfactant, and the balance of deionized water. The preparation method comprises the following steps: sequentially adding the pigment / branched polymer nano composite particle dispersoid, a water-soluble cosolvent and a non-ionic surfactant into the deionized water in proportion, mixing uniformly, stirring by a stirrer at a speed of 500-1000rpm (revolutions per minute) for 20-40 minutes, regulating pH value of the ink to be 7-9, and filtering by virtue of a 500nm microfiltration membrane so as to obtain the coating ink. The ink needs no adhesive, the grain size of the pigment particle in the ink is less than 200nm, and the ink has good storage stability; after jet printing, the textile is baked so as to obtain good color fastness, thus improving the brightness.

Owner:JIANGSU GEMEIGAO DEV CO LTD

Thixotropic anaerobic adhesive

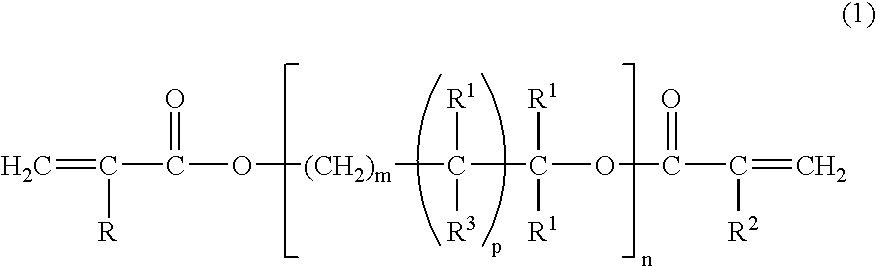

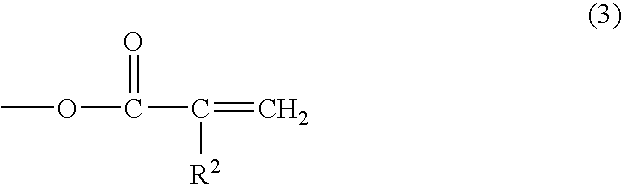

InactiveUS20060047046A1Material nanotechnologyOrganic non-macromolecular adhesiveVinyl etherParticulates

An anaerobic adhesive composition includes a monomer curable upon exclusion of oxygen. A peroxy polymerization initiator is present within the composition. The composition has a thixotrope imparting a thixotropic viscosity ratio in an uncured state of 8.2:1 to 11:1 as measured at rotation rates of 0.5 and 10 revolutions per minute. The thixotrope is composed of 3 to 50 total weight percent of inorganic particulate or 3 to 36 total weight percent of an organic compound. A process for forming an adhesive bond includes applying to a fastener an anaerobic adhesive composition that includes a polymerizable acrylate ester or vinyl ether, a peroxy polymerization initiator, and a thixotrope. The composition has a thixotropic viscosity ratio of between 8.2:1 and 11:1 for spindle rotation rates of 0.5 and 10.0 revolutions per minute. Tightening the fastener against a substrate induces viscosity breakdown and under the force to cure.

Owner:ILLINOIS TOOL WORKS INC

Macromolecule color masterbatch and preparation method thereof

The invention discloses a macromolecule color masterbatch which is composed of the following components in percentage by weight: a, 30-60% of carrier resin, b, 5-15% of pigment, c, 4-8% of dispersed lubricant, d, 1-3% of compatilizer and e, 15-25% of other additives. The component e comprises an antistatic agent, a protective agent, a heat stabilizer and an antibacterial agent. The preparation method comprises the following steps of: mixing each component in proportion and placing the mixture in a high-speed mixer; secondly, mixing for 5-20 minutes at the rotate speed of 1000-1500r / min (revolutions per minute); thirdly, carrying out melt blending by adopting a double-screw extruder or an internal mixer as the temperature is at 150-250 DEG C; and fourthly, shearing and mixing by a screw or a rotor as the rotate speed of the screw is 80-300r / min, finally extruding in the extruder, cooling, drying and pelleting to prepare the color masterbatch. The macromolecule color masterbatch has the advantages of anti-static electricity, invariant color, no color loss and uniform color and luster, and the process is clean and environmentally-friendly.

Owner:胡君

Special color master batch for refrigerator plate and preparation thereof

The invention discloses masterbatch special for a refrigerator plate and a preparation method thereof. The masterbatch comprises the following compositions by weight portion: 15 to 30 portions of carrier resin, 50 to 75 portions of titanium pigment, 0.1 to 5 portions of coloring agent, 0.5 to 20 portions of dispersing agent, 0.1 to 4 portions of stabilizer and 1 to 10 percent of processing agent. The preparation method comprises: firstly, mixing various compositions according to the proportion; secondly, mixing the various compositions in a high-speed kneader for 15 to 30 minutes or mixing the various compositions in a Banbury mixer for 20 to 60 minutes, and discharging and crushing a mixture, wherein the banburying temperature is between 170 and 230 DEG C; thirdly, fusing, mixing and granulating the mixture by a double-screw extruder, wherein the temperature of various areas of screws is between 190 and 230 DEG C, and the rotating speed of the screws is between 100 and 450 revolutions per minute; and fourthly, drying the mixture to obtain the masterbatch. The plate manufactured by the masterbatch special for the refrigerator plate is difficult to change color and crack, and has high finished product rate during plastic sucking.

Owner:常州市改性塑料厂有限公司

Process for recovering cobalt from cobalt based fischer-tropsch synthetic catalyst

InactiveCN101270420AEconomical and simpleShort processCobalt compoundsProcess efficiency improvementDifferential pressureEvaporation

A method of recycling Cobalt from Cobalt-based catalyst for F-T synthesis is carried out as follows, deionized water and waste Cobalt-based catalyst for F-T synthesis are added into a reaction vessel according to the weight ratio of 1 to 5:1, carbon monoxide is introduced into the reaction vessel till the differential pressure is at 0.5 to 5 Megapascal, then the reaction vessel is kept at the stirring speed of 50 to 700 revolution per minute and the heating temperature of 50 to 200 DEG C for constant temperature about 0.5 to 12 hours; Carbon monoxide is discharged from the reaction vessel after reducing temperature, water is discharged from the reaction vessel, alkali liquor is added into the water, then Cobalt is precipitated as Co(OH)2; Nitric acid is added into the precipitation for dissolving the precipitation, then Cobaltous nitrate is obtained after evaporation and crystallization. The method of recycling Cobalt from Cobalt-based catalyst for F-T synthesis has the advantages of the simple method, the environmental friendliness, and the high recovery efficiency and purity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Dynamic vulcanization thermoplastic elastomer material with excellent combination property and preparation thereof

The invention relates to a dynamic thermoplastic vulcanizate material TPV with superior comprehensive performance, which is characterized by comprising the following raw materials by weight percentage: 15 to 30 percent of polypropylene, 30 to 50 percent of ethylene propylene terpolymer, 5 to 20 percent of ethylene-octene copolymer, 1 to 10 percent of styrene elastomer, 10 to 20 percent of plasticizer, 1 to 5 percent of polyethylene wax, 0.5 to 2 percent of vulcanizing agent, 0.5 to 2 percent of accelerating agent, 0.1 to 0.5 percent of antioxidant and 0.1 to 0.5 percent of lubricant. The preparation method comprises: weighing the raw materials according to the weight percentage; placing all the raw materials into a high-speed mixer and mixing the raw materials for 2 to 5 minutes; discharging the raw materials; and placing the uniformly mixed raw materials into a screw compressor for extrusion and granulation, wherein the rotating speed of the screw compressor is between 180 and 600 revolutions per minute, and the temperature is between 160 and 200 DEG C. The invention has the characteristics that the prepared thermoplastic elastomer material has high elasticity, overcomes the defect of poor elasticity of the prior TPV, and can be used in situations with high elasticity requirement and oil resistance.

Owner:SHANGHAI SUNNY

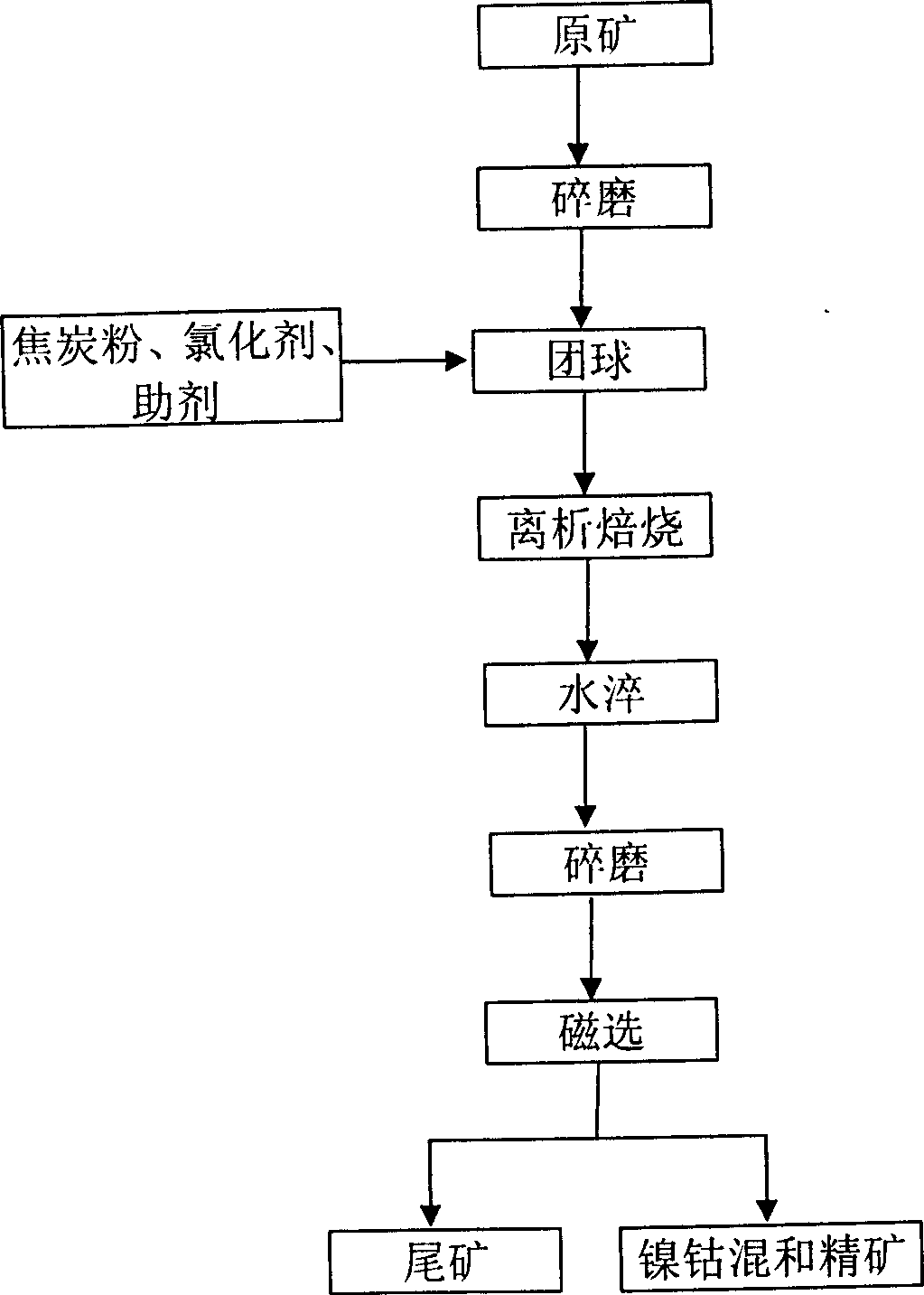

Method for recovering nickel and cobalt from nickel oxide ore and nickel silicide ore

InactiveCN1827799ASimple processShort investment cycleProcess efficiency improvementMagnetic separationSilicic acidCobalt

The invention relates the reclaiming nickel-to-cobalt method from nickel oxide ore and silicic acid nickel ore, comprising the following steps: milling the nickel oxide ore and silicic acid nickel ore to -200 mesh, adding 5-15% coke breeze, 10-30% chloration agent, and 0.1-1.0% adjuvant to make 5-15mm pellet, adopting chloridising separating and roasting, controlling the high temperature of rotary kiln at 1000-1300Deg.C and back kiln at 400-600Deg.C, the rotation rate of rotary kiln being 0.75-2 revolution per minute, time being 1-2 hours, then putting the product into magnet separator whose magnetic density is 1500-3000G, finally getting the cobalt-nickel ore, whose nickel grade is 5-15%, and recovery ratio is 80-85%, and whose cobalt grade is 0.3-1.7%, and recovery ratio is 70-80%.

Owner:KUNMING UNIV OF SCI & TECH +1

Fiberglass reinforced fire retardant engineering plastics and preparation method

The invention discloses glass fiber reinforced flame retardant engineering plastic and a preparation method thereof. Besides glass fiber, 30-70 parts of polycaprolactam, 8-30 parts of acrylonitrile-butadiene-styrol copolymer, 3-6 parts of compatilizer, 12-16 parts of flame retardant, 0.3-0.5 parts of antioxidant and 0.3-0.8 parts of lubricant are put in a high-mixing machine to blend for 2-5 minutes, then the blending material is put in a double screw extruder; meanwhile, 18-35 parts of glass fiber are put in the rear half section of the double screw extruder to mix together to be granulated and molded; wherein, the processing temperature is 180-245 DEG C and the screw speed is 240-560 revolutions per minute. The prepared glass fiber reinforced flame retardant engineering plastic is characterized by high size stability, large mechanical strength, excellent heat resistance, etc. The combustibility can reach UL94 V-0(1.6mm) level, thus expanding the application in electronics.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

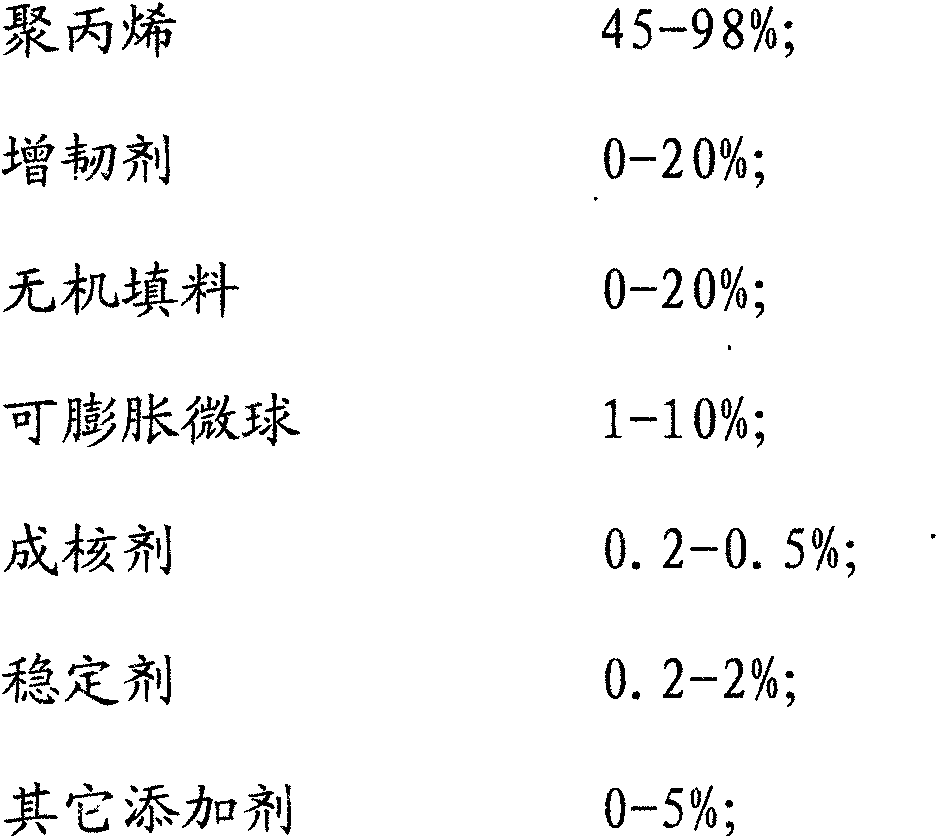

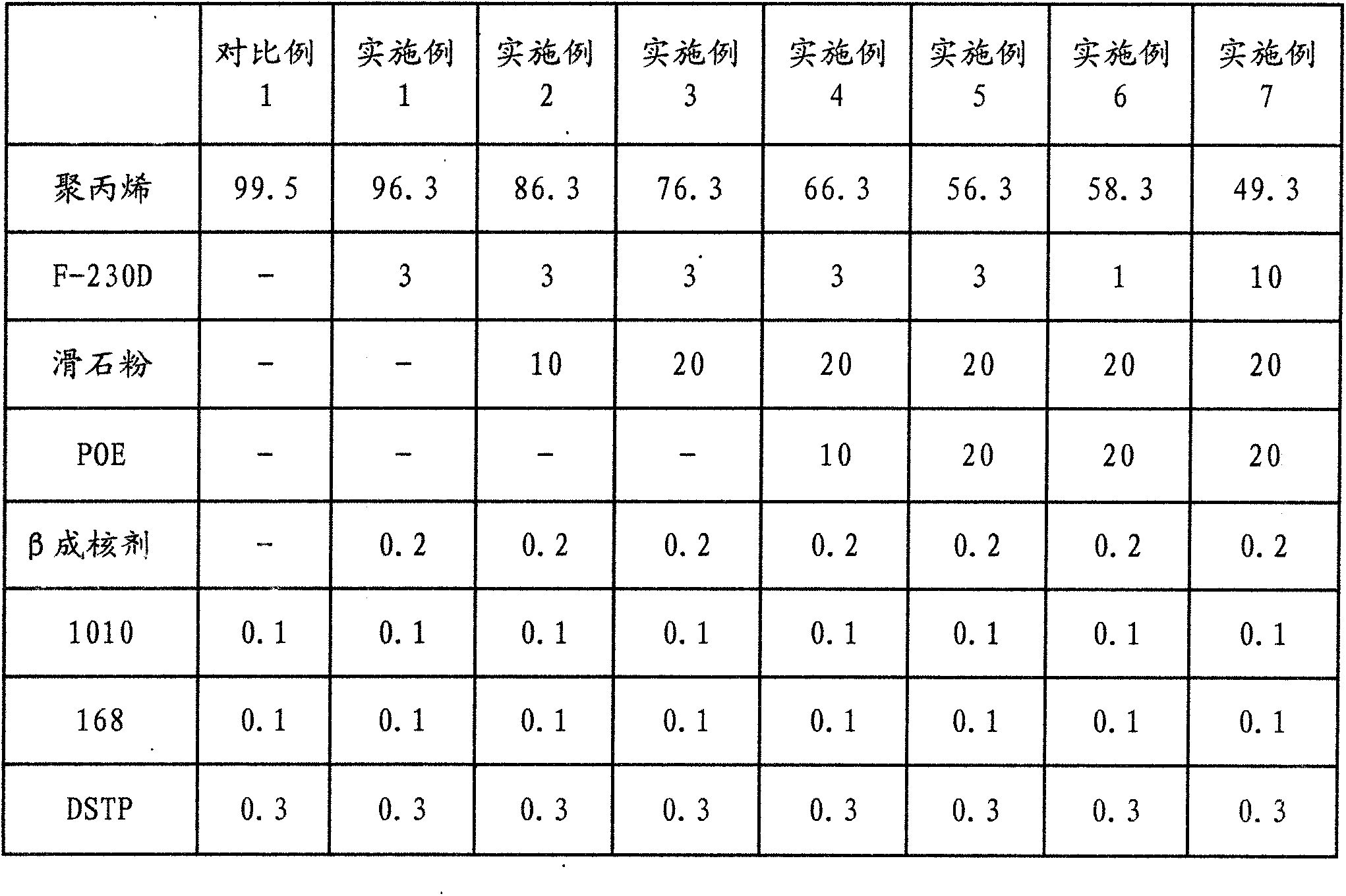

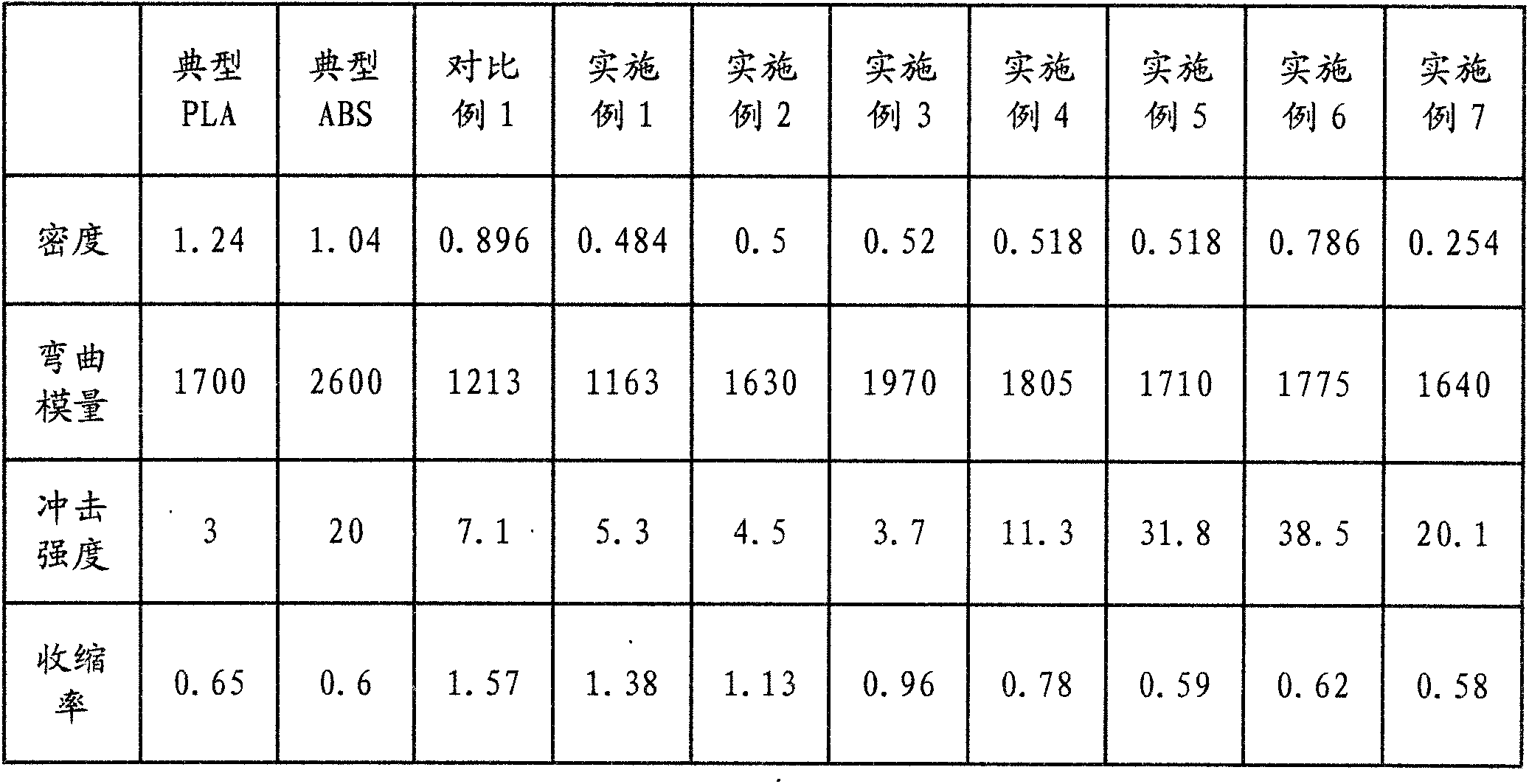

Ultra-low density polypropylene composite material capable of being used for 3D printing and preparation method thereof.

The invention relates to an ultra-low density polypropylene composite material capable of being used for 3D printing and a preparation method thereof. The polypropylene composite material comprises the following composition in percentage by weight: 45-98% of polypropylene, 0-20% of a toughening agent, 0-20% of an inorganic filler, 1-10% of expandable microspheres, 0.2-0.5% of a nucleating agent, 0.2-2% of a stabilizing agent and 0-5% of other additives. The preparation method comprises the steps of weighing the raw materials according the percentage by weight, putting the materials into a high-speed mixer and carrying out dry-blending for 3-15 minutes, adding the mixed raw materials into a twin-screw extruder, carrying out melt extrusion, cooling and granulating, wherein the temperature of a first zone, a second zone, a third zone and a fourth zone in the screw cylinder are all 170-190 DEG C, the temperature of the machine head is 170-190 DEG C and the rotation speed of the twin-screw extruder is 100-1000 revolutions per minute. The ultra-low density polypropylene composite material disclosed by the invention has the advantages of low shrinkage, no warping, ultra low density, high rigidity and high toughness and can also be well suitable for 3D printing.

Owner:温州科力塑业有限公司

Microemulsion polyunsaturated fatty acid product and preparation method thereof

The invention discloses a microemulsion polyunsaturated fatty acid product and a preparation method thereof, and belongs to the technical field of food ingredient production. The microemulsion polyunsaturated fatty acid product is a microemulsion product containing polyunsaturated fatty acid (PUFA), which can be uniformly and stably dispersed in a water-based food system. The method for preparing the microemulsion polyunsaturated fatty acid product comprises the following steps of: selecting common polyunsaturated fatty acid which can be used in foods to serve as a main functional component; and adding the polyunsaturated fatty acid into a mixed material consisting of edible surfactants, cosurfactants and water at the temperature of between 30 and 70 DEG C under the stirring condition (100 to 500 revolutions per minute) to prepare transparent or semitransparent emulsion with the droplet diameter between 5 and 100nm, which serves as a food strengthener for strengthening the polyunsaturated fatty acid in food processing.

Owner:JIANGNAN UNIV

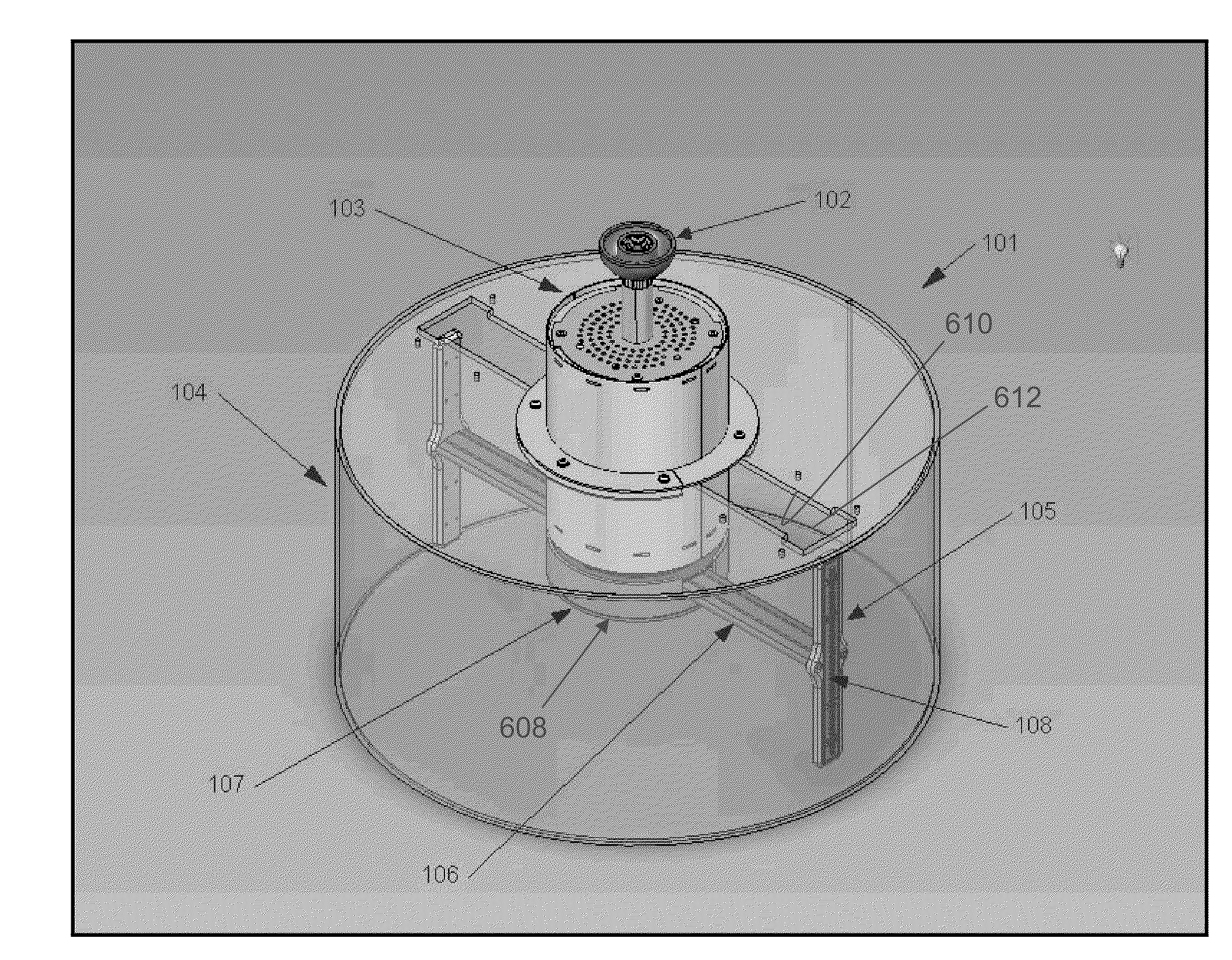

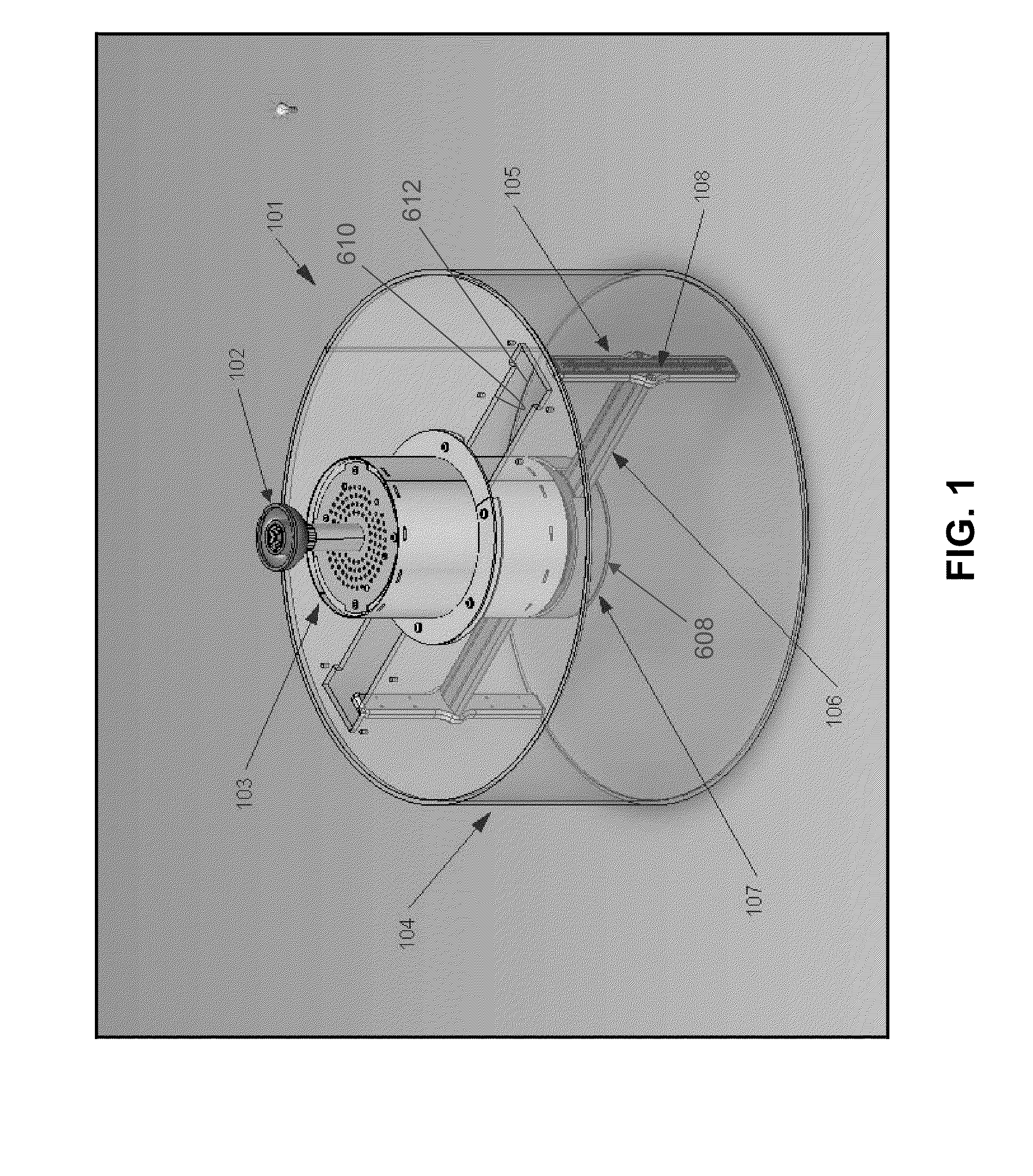

Method and apparatus for displaying digital data

A rotary display device comprising one or more vertical arrays of light-emitting diodes (LEDs) are rotated and energized at a controlled rate so as to project a 360 degree floating image. The displayed images are viewable from all angles (i.e., 360 degrees). The LEDs and associated control electronics are rotated at a desired speed, e.g., between about 720 and about 3600 revolutions per minute, by an AC or DC motor. Display content is either pre-loaded to the rotary display or transferred to the rotary display during device operation via a cellular telephone, Wi-Fi, Bluetooth, etc. connection. The electrical power for the system, including the LED array and the control electronics, is provided via a contact-less rotary transformer that functions independently of the rotation speed.

Owner:CABANAS MANUEL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com