Method for preparing molybdenum disulfide (MoS2) nanosheet

A technology of molybdenum disulfide and nanosheets, which is applied in the fields of molybdenum sulfide, nanotechnology, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Adopt MoS 2 Powder (99%) and lithium carbonate (analytical purity) are used as raw materials. After the two are uniformly mixed at 1 mol: 42 mol, they are placed in an autoclave containing 40 ml of benzyl alcohol and sealed under high pressure. React in a high temperature furnace at 200°C for 48 hours. After natural cooling, it is washed with acetone and alcohol, and dried in vacuum to obtain an intermediate product. Take 0.2g of the intermediate product and put it in a mixture of 20ml DMF (dimethylformamide) and 10ml water, and ultrasonicate for 12h. The resulting dispersion is centrifuged for 30 minutes in a centrifuge with a rotating speed of 600rpm (revolutions per minute), and then clear. The liquid was centrifuged at 6000 rpm for 6 minutes, the obtained product was washed twice with 3% HCl, washed with ionized water to neutrality, and the final product was washed with alcohol several times, and dried in a vacuum drying oven to obtain the product. The transmission ...

Embodiment 2

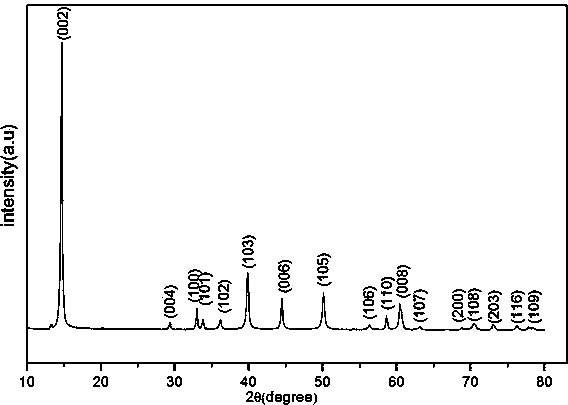

[0024] Adopt MoS 2 Powder (99%) and lithium carbonate (analytical purity) are used as raw materials. After the two are uniformly mixed at 1 mol: 42 mol, they are placed in an autoclave containing 40 ml of benzyl alcohol and sealed under high pressure. React for 48h in a high temperature furnace at 200°C. After natural cooling, it is washed with acetone and alcohol, and dried in vacuum to obtain an intermediate product. Take 0.55g of the intermediate product and put it into a mixture of 20ml dimethylformamide and 10ml water, ultrasonicate for 12h, and centrifuge the obtained dispersion with a centrifuge at 600rpm for 30 minutes, then take the clear liquid and centrifuge at 6000rpm for 6 minutes , The obtained product was washed twice with 3% HCl, washed with ionized water to neutrality, and the final product was washed with alcohol several times, and dried in a vacuum drying oven to obtain the product. Its X-ray diffraction pattern is as figure 2 .

Embodiment 3

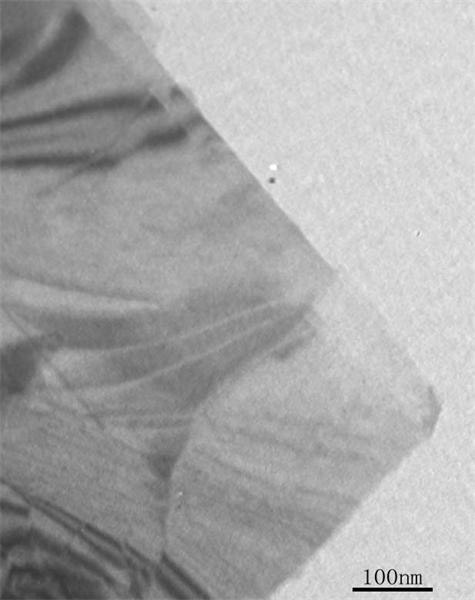

[0026] Adopt MoS 2 Powder (99%) and lithium carbonate (analytical purity) are used as raw materials. After the two are uniformly mixed at 1mol: 42mol, they are put into an autoclave containing 40ml benzyl alcohol and sealed under high pressure. React in a high temperature furnace at 200°C for 48 hours. After natural cooling, it is washed twice with acetone, twice with hydrochloric acid, then washed with deionized water to neutrality, finally washed with alcohol, and dried in vacuum to obtain the intermediate product. Take 0.04277g of the intermediate product into a mixture of 20ml of dimethylformamide and 10ml of water, and sonicate for 12h. Centrifuge at 500 rpm for 45 minutes, then take the clear liquid and centrifuge at 8000 rpm for 6 minutes. The product obtained is washed with deionized water several times, and finally dried with alcohol in a vacuum to obtain the product. The TEM picture is as follows image 3 , Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com