Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5445results about How to "Achieve rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

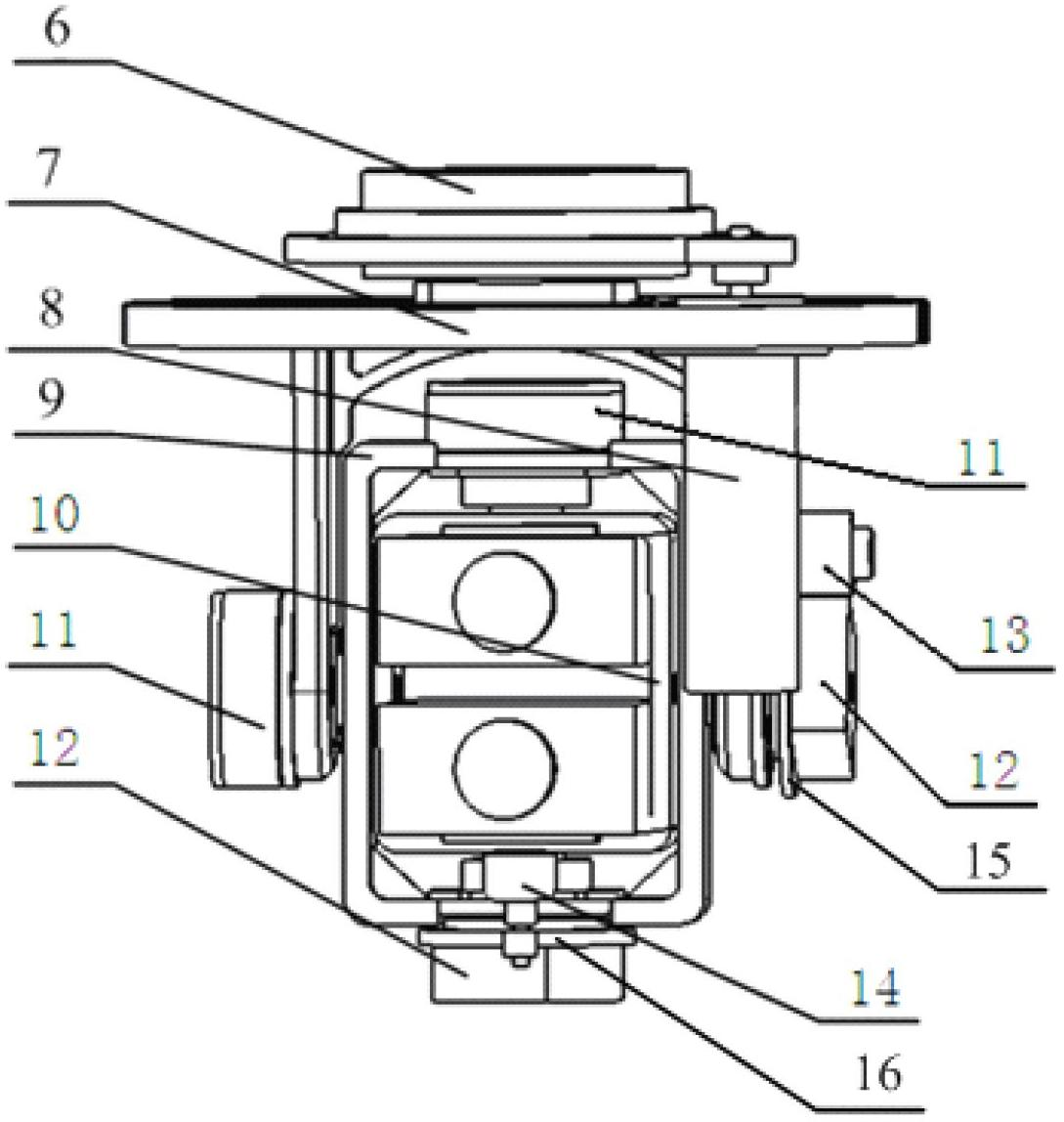

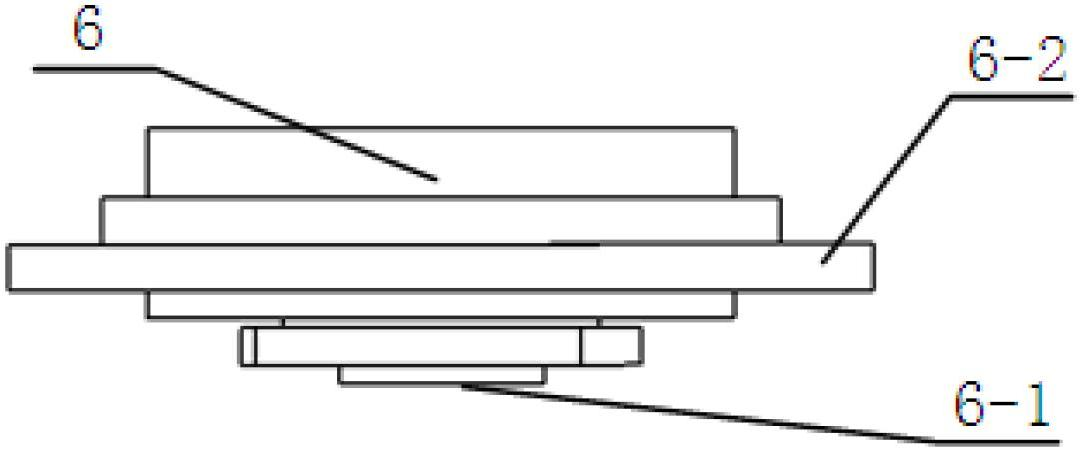

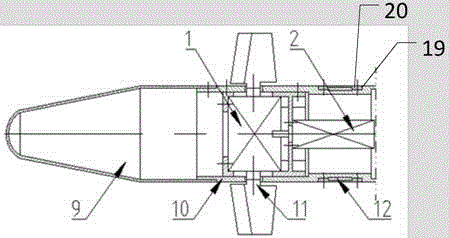

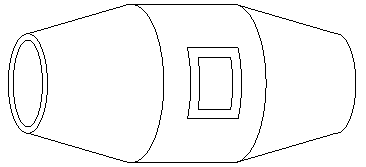

High voltage overhead transmission line line-inspection unmanned aerial vehicle photoelectric detection device

ActiveCN102694351AAchieve rotationPrecise Line Tracking TasksCable installation apparatusAircraftsNacelleEngineering

The invention relates to a high voltage overhead transmission line line-inspection unmanned aerial vehicle photoelectric detection device belonging to the technical field of power line inspection. The invention aims at solving the problem of single technology of the existing overhead transmission line line-inspection. The high voltage overhead transmission line line-inspection unmanned aerial vehicle photoelectric detection device mainly comprises an unmanned aerial vehicle, a GPS (global position system) inertial integrated attitude azimuth detection device, a damping device, a rotation detection nacelle, a ground data receiving processor and a controller. The high voltage overhead transmission line line-inspection unmanned aerial vehicle photoelectric detection device is characterized in that the GPS inertial integrated attitude azimuth detection device is arranged at the inner part of the unmanned aerial vehicle; the rotation detection nacelle is hung below the unmanned aerial vehicle by the damping device; a photoelectric stabilized platform is installed in the rotation detection nacelle; flexible combination of any two or more of a visible light camera, an ultraviolet ray imager and a full-digital dynamic thermal infrared imager and a laser ranging device are borne on the photoelectric stabilized platform; and the rotation detection nacelle is provided with a visible window. With the adoption of the high voltage overhead transmission line line-inspection unmanned aerial vehicle photoelectric detection device, a high voltage transmission line can be monitored, and a comprehensive and precise high voltage overhead transmission line line-inspection task is realized by combining interchange among a plurality of sensors.

Owner:CHANGCHUN UNIV OF SCI & TECH +1

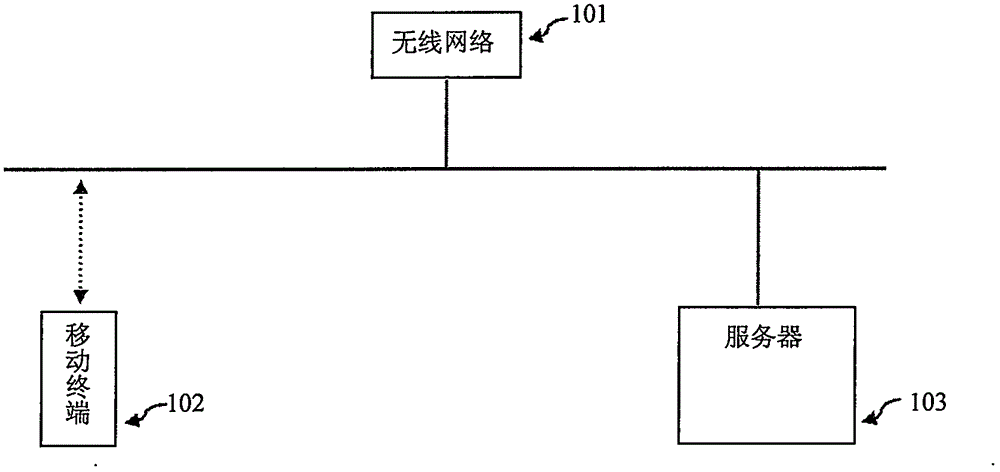

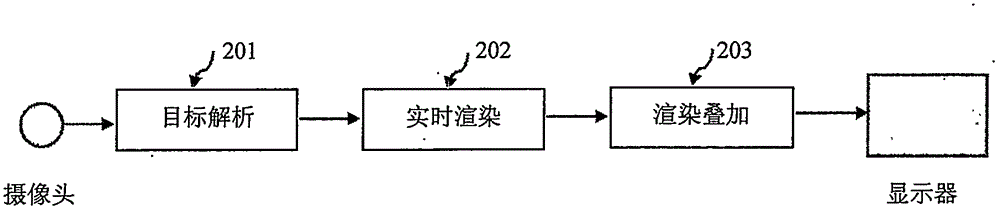

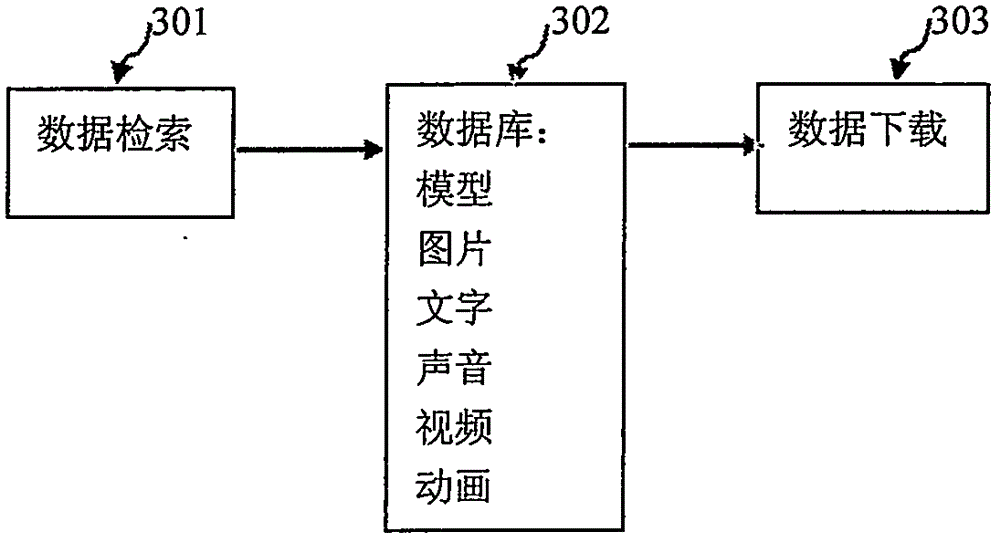

Real-time interaction reality augmenting system and method

The invention discloses a reality augmenting method. The reality augmenting method comprises the steps that a terminal obtains a current scene image through a camera, and detects a recognized target in the image to obtain data information in the recognized target; whether corresponding calling information exists in the terminal or not is checked, if yes, real-time rendering is directly carried out, and virtual information is superimposed on a terminal screen to be displayed in a scene; if the corresponding information does not exist, the information is uploaded to a server, the corresponding information is called from a database and downloaded to the terminal to be rendered in real time, and the effect of augmenting the reality is achieved. Meanwhile, movement, rotation and zooming of a virtual image can be controlled by moving the current scene or a terminal device.

Owner:李成

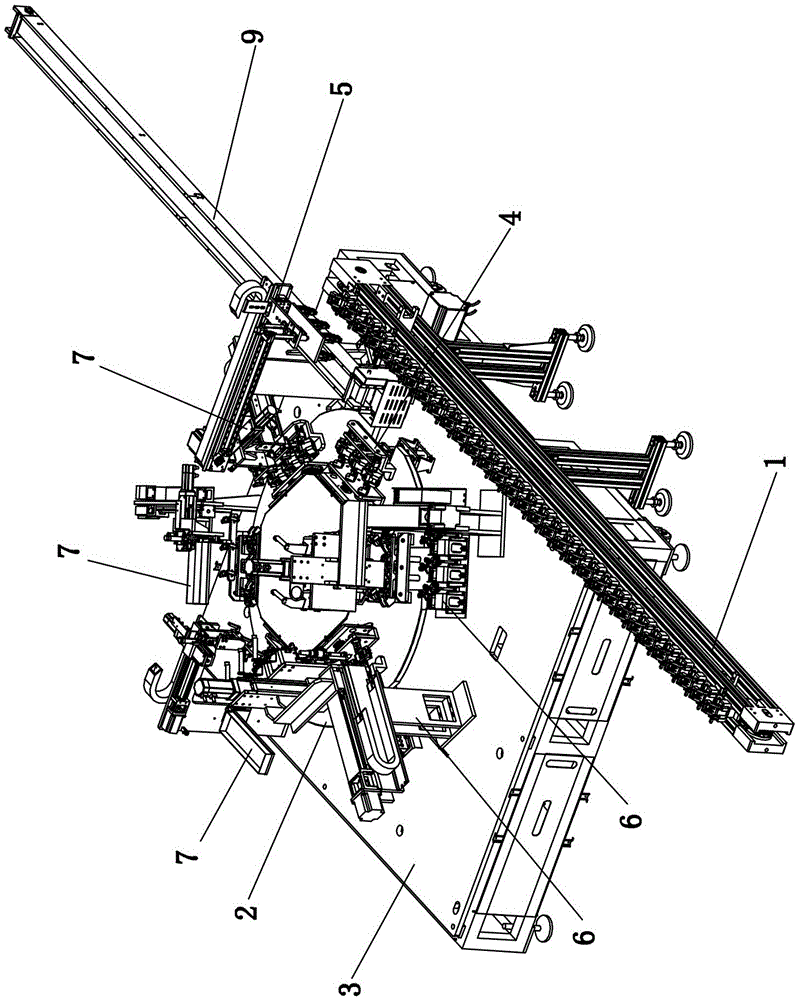

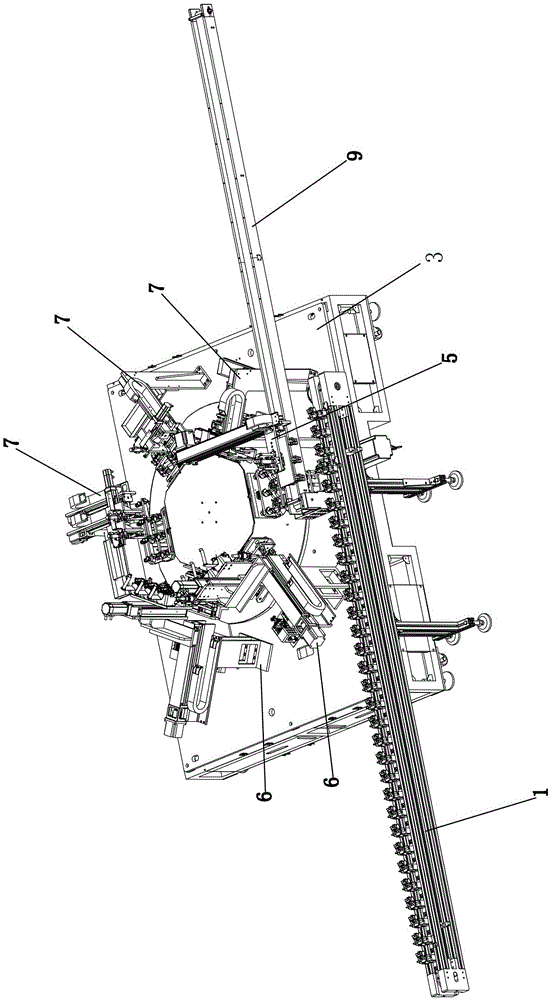

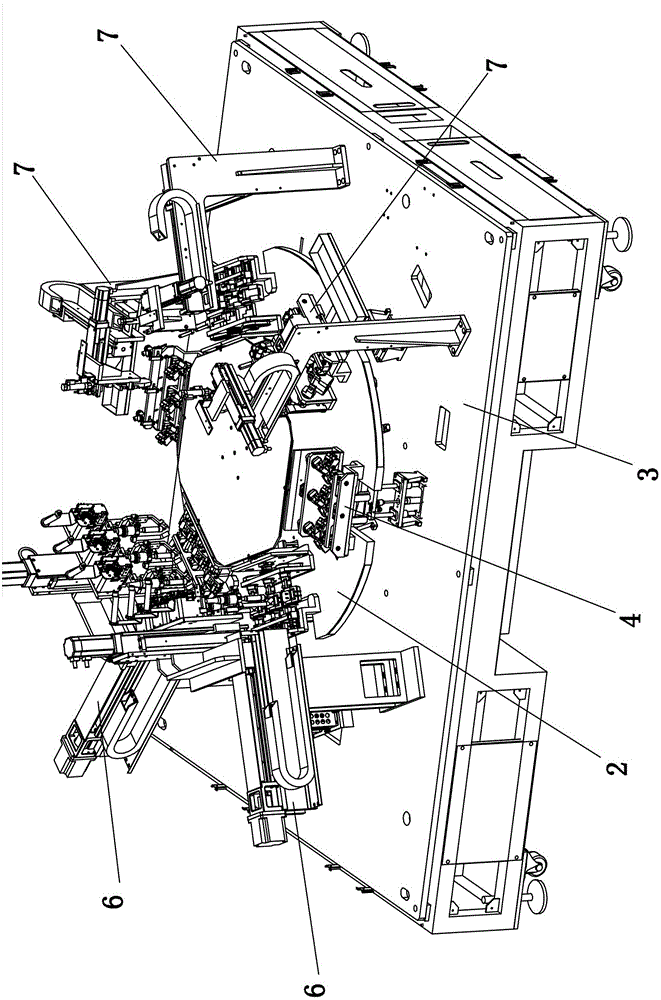

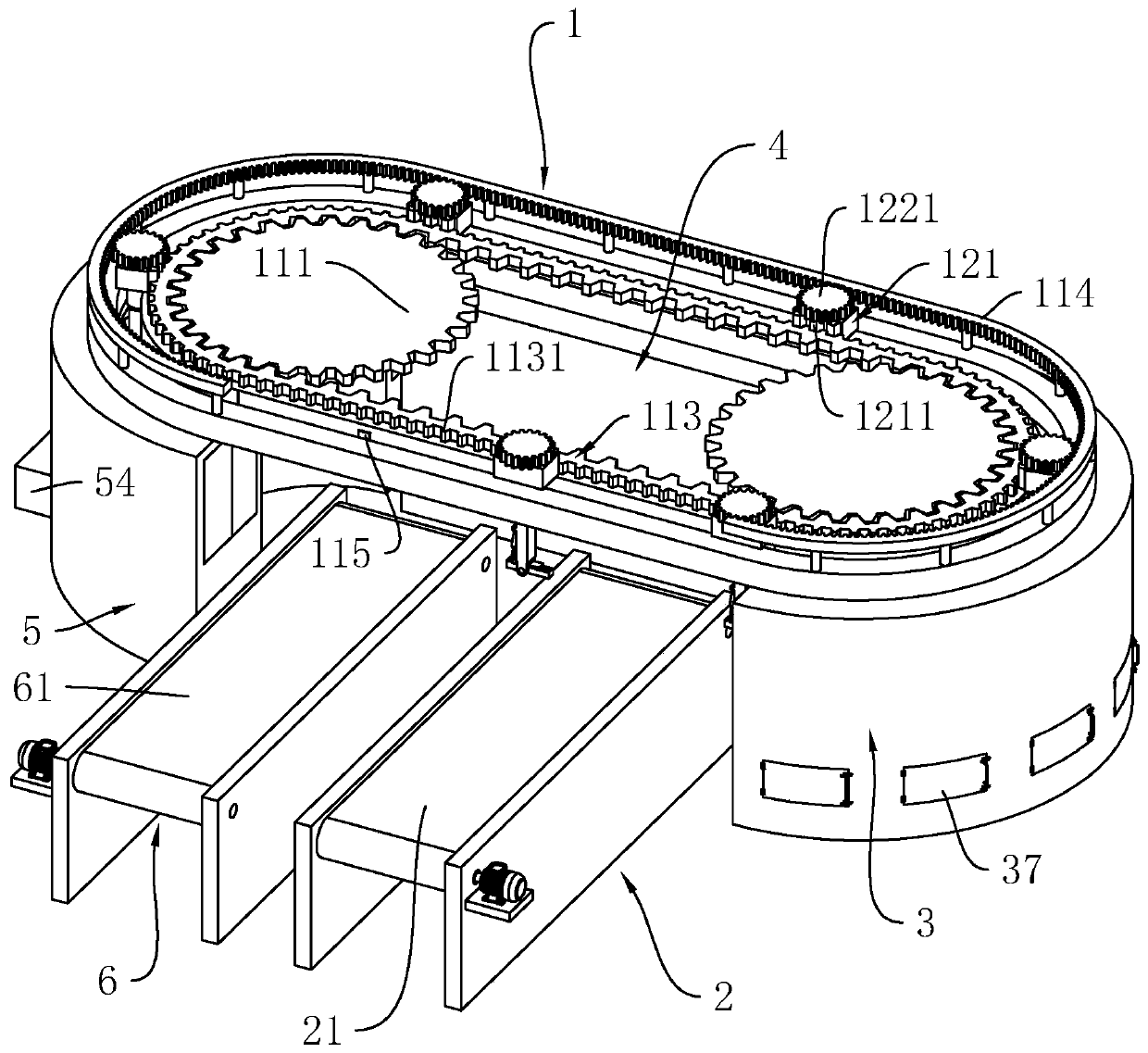

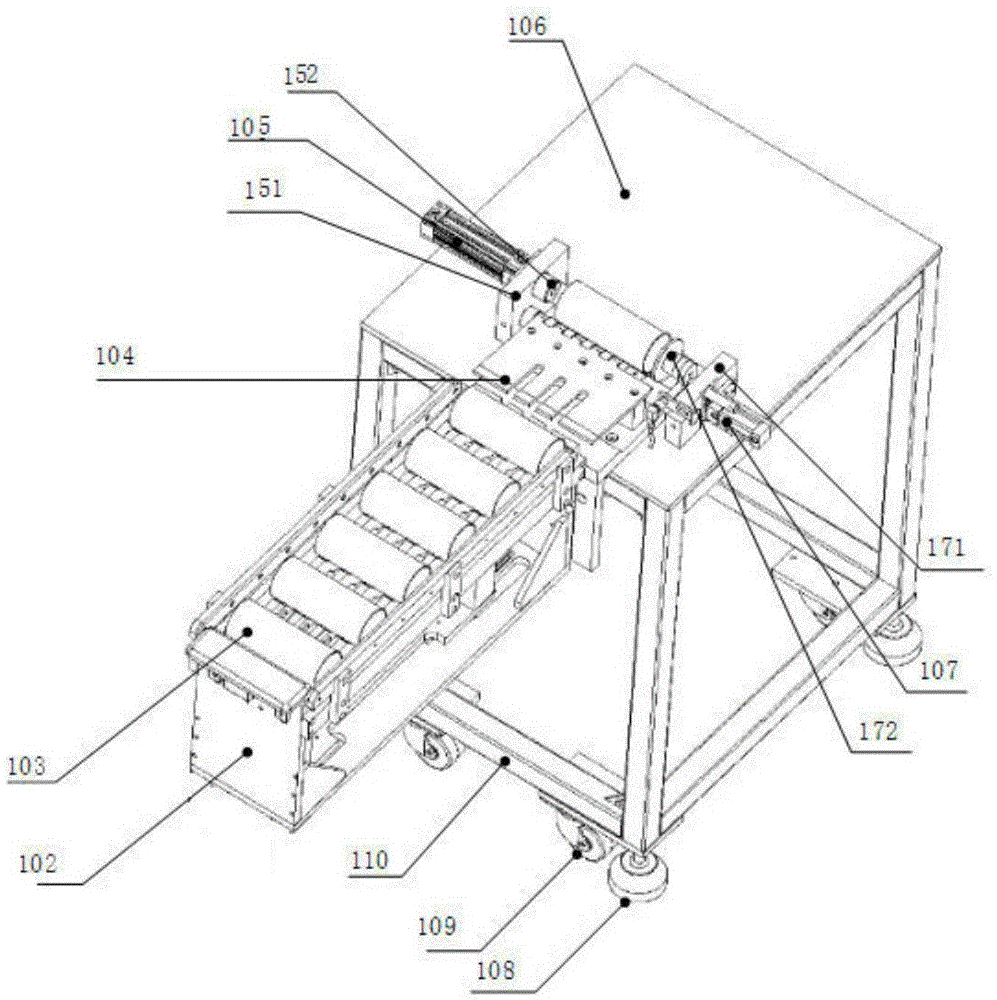

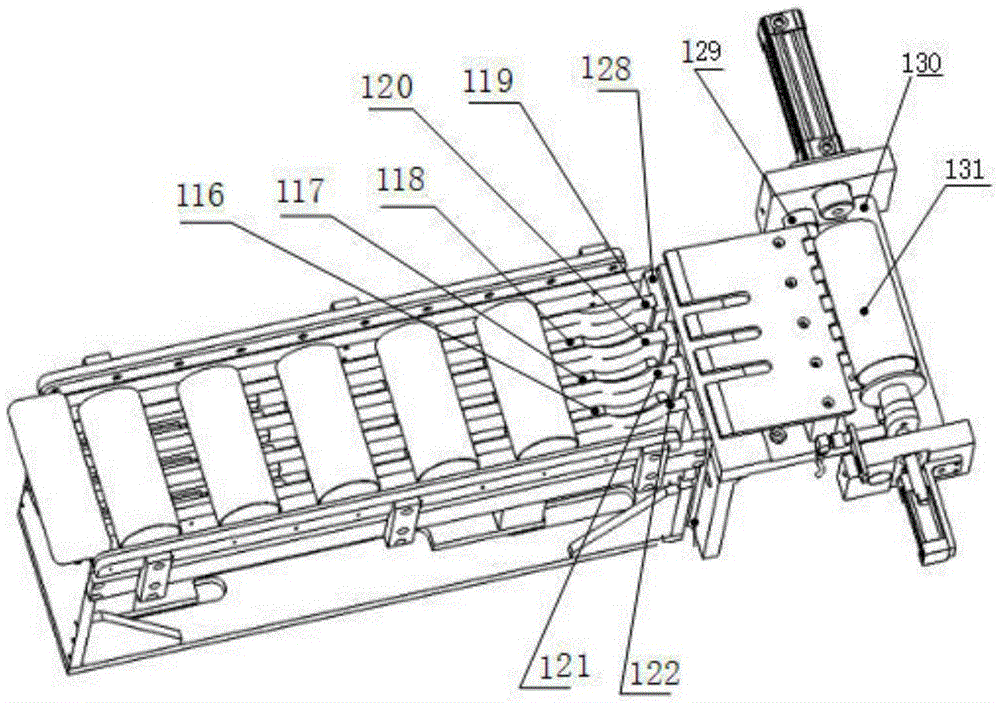

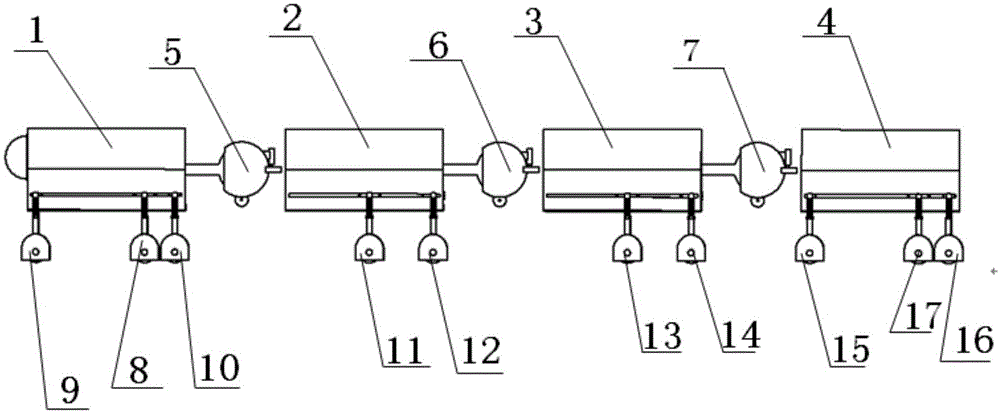

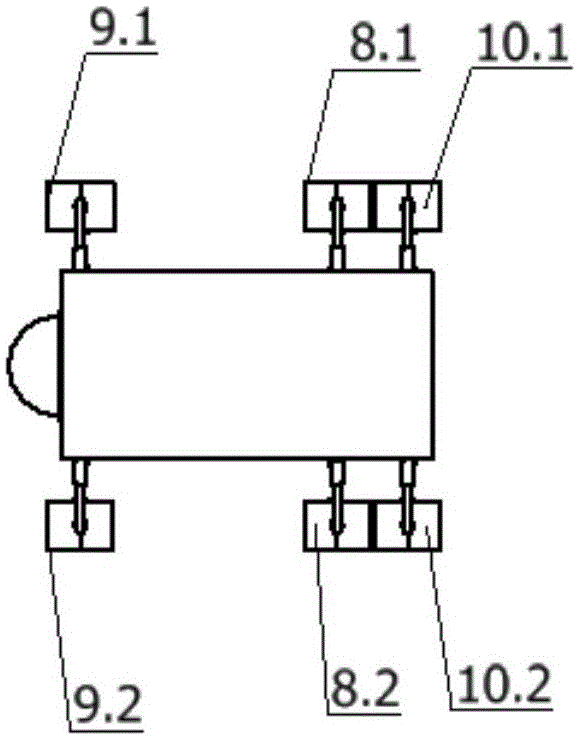

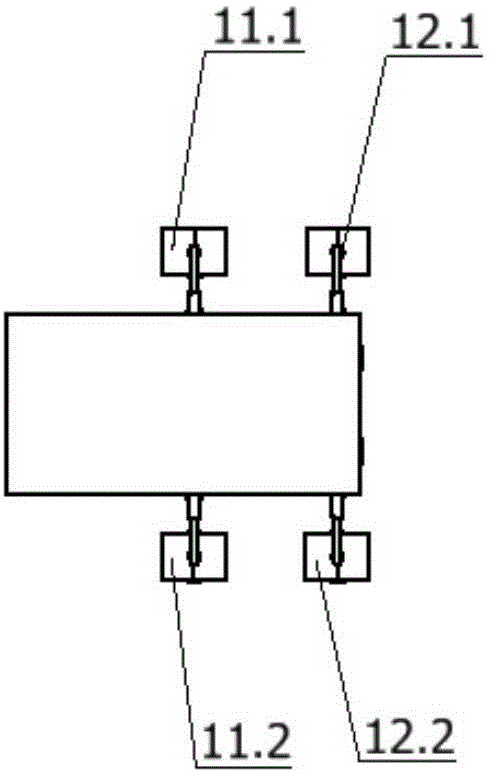

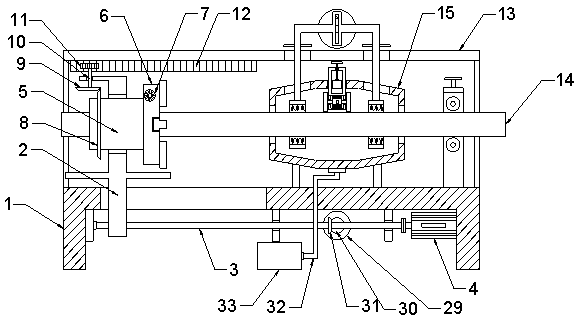

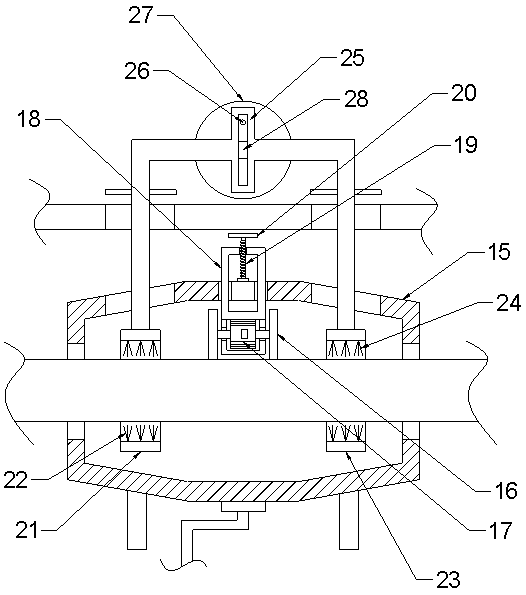

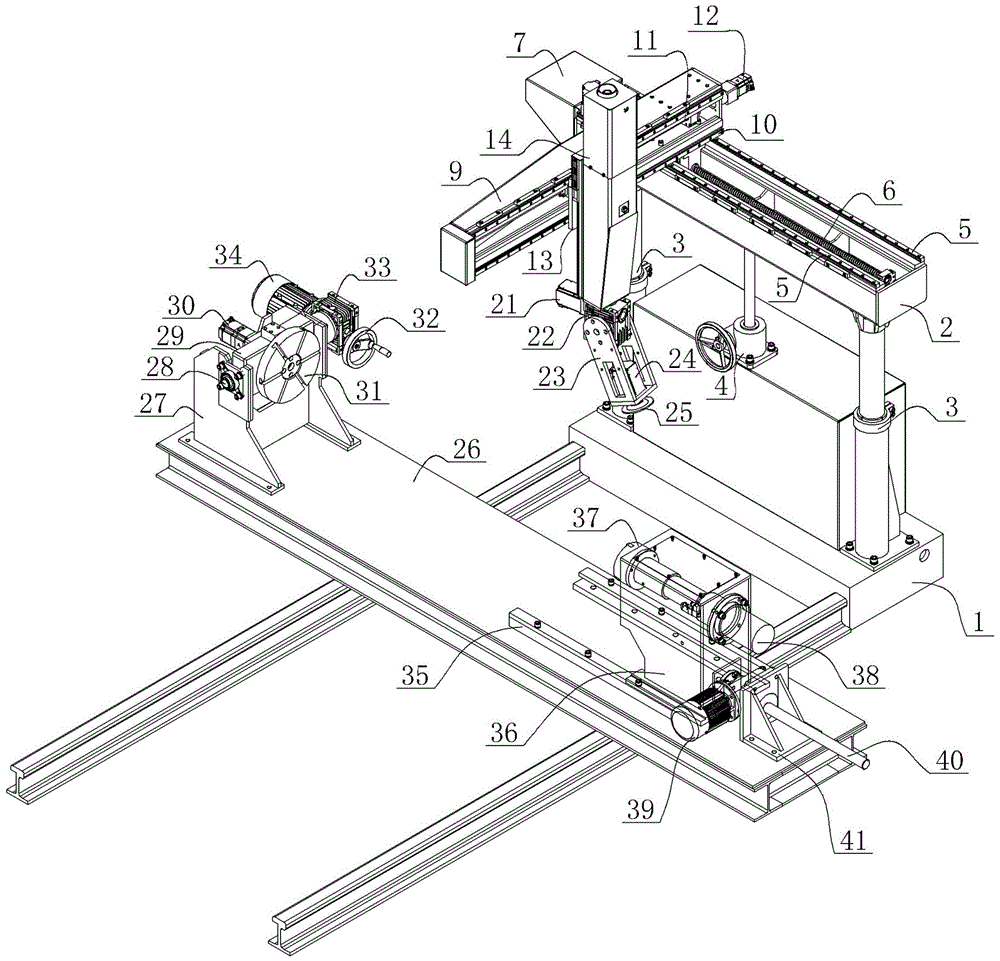

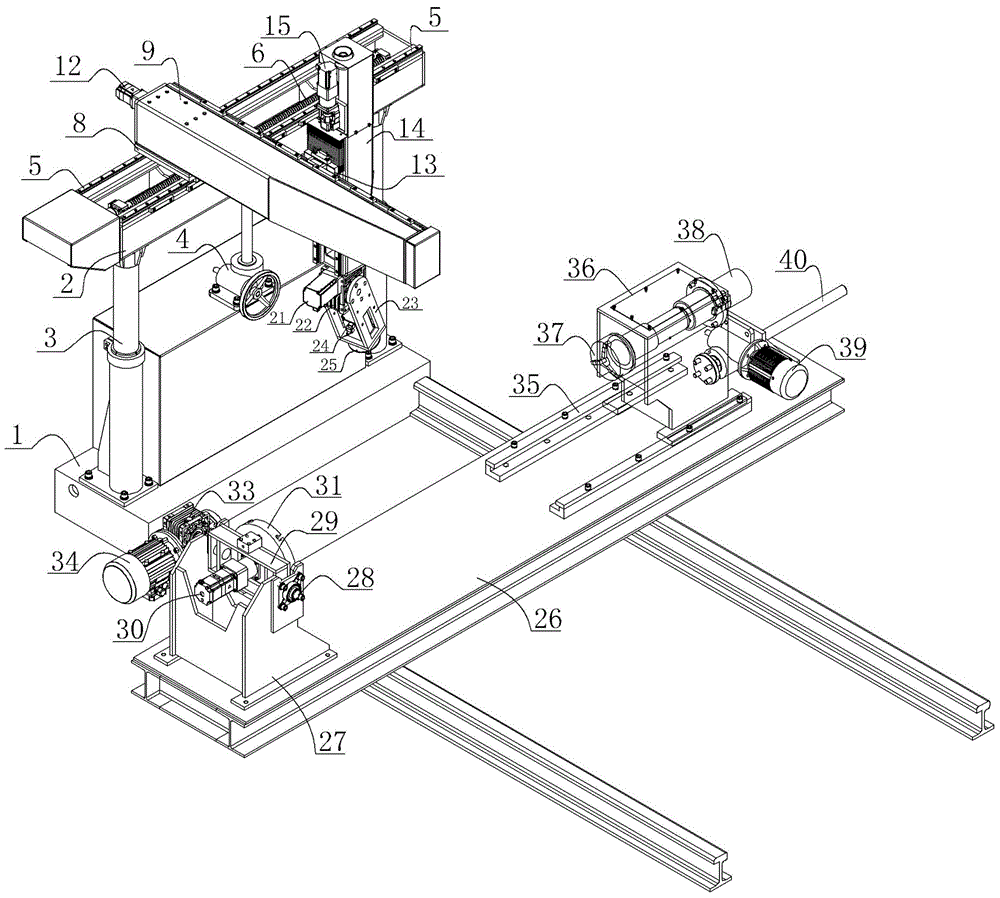

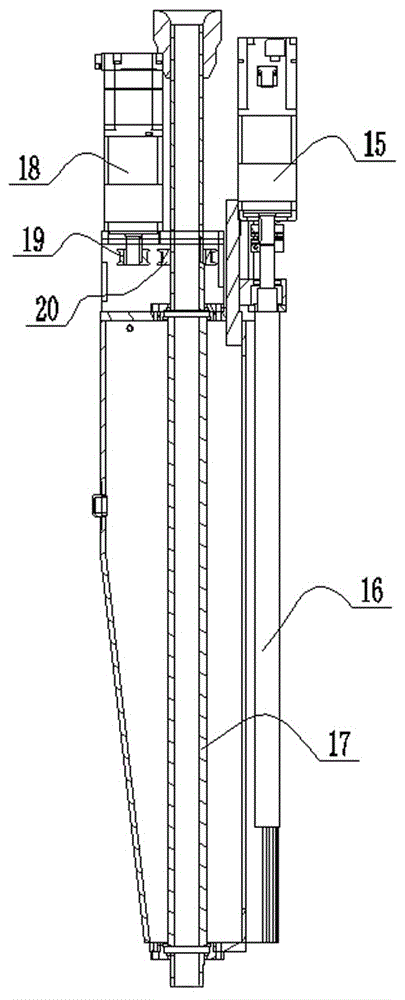

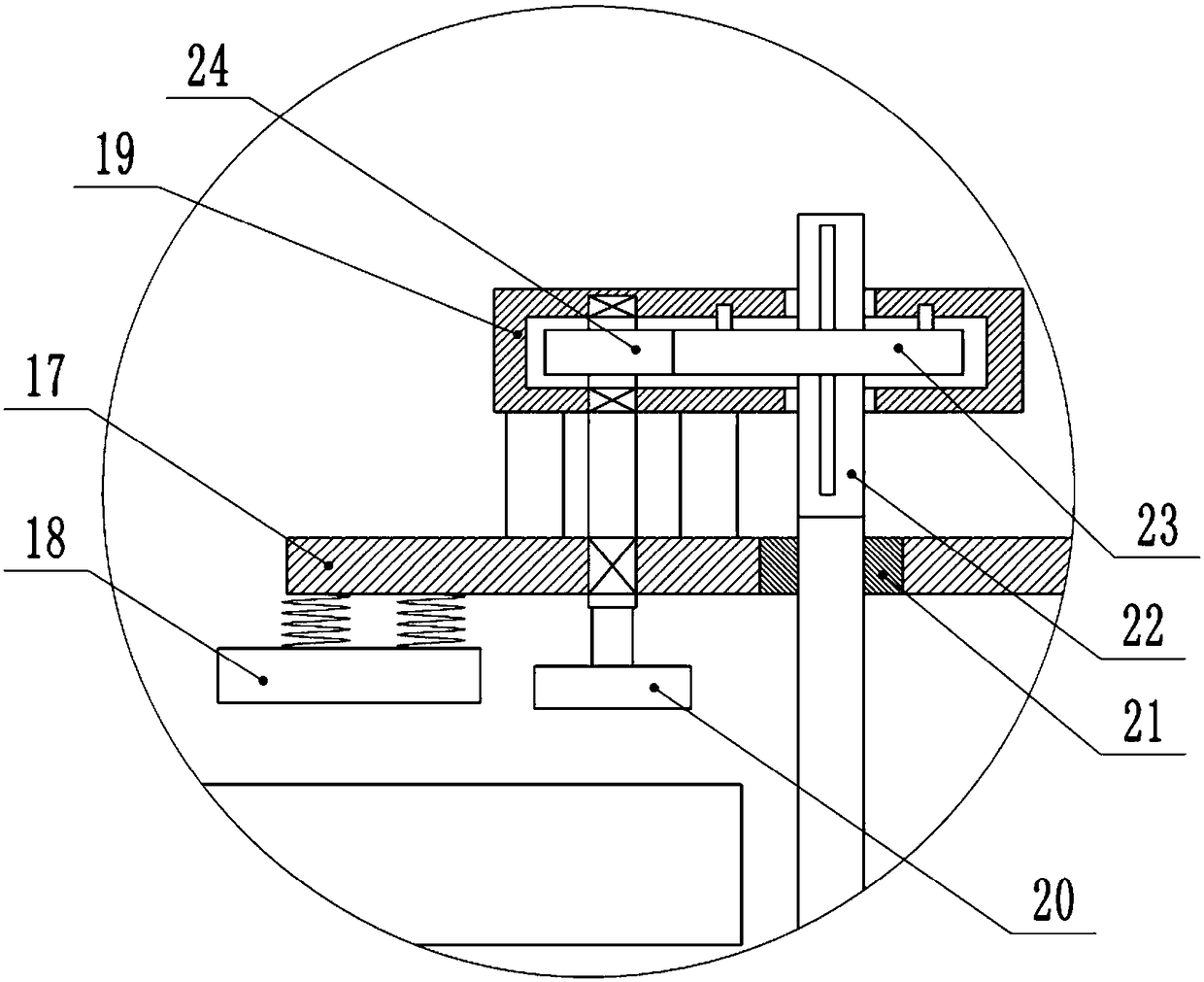

Power source automatic assembly production line and assembly process thereof

ActiveCN105583622ASave space costGuaranteed normal rotationLiquid surface applicatorsAssembly machinesProcess engineeringMachining

The invention discloses a power source automatic assembly production line and an assembly process thereof. The power source automatic assembly production line comprises a feeding mechanism, an assembly platform, a material conveying mechanism, welding mechanisms, adhesive dispensing mechanisms and a discharging mechanism. The feeding mechanism and the discharging mechanism are disposed on the two sides of the assembly platform correspondingly. A rotary plate is disposed in the middle of the assembly platform. Feeding and discharging stations and at least two machining stations are disposed at the edge of the rotary plate at intervals. The material conveying mechanism is disposed on the outer sides of the feeding and discharging stations. The welding mechanisms and the adhesive dispensing mechanisms are disposed on the outer sides of the machining stations. The assembly process of the power source automatic assembly production line includes the following steps that power sources are mounted and fixed inside jigs; jig loading and guiding are performed; feeding is prepared; feeding is conducted; the jigs are transferred to the machining stations; the power sources are machined; and discharging is performed. By means of the power source automatic assembly production line and the assembly process thereof, full-automatic guiding, feeding, machining and discharging are achieved, the multiple stations are combined, the power source assembly efficiency is improved, the machining accuracy is improved, and the reject ratio of products is decreased.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

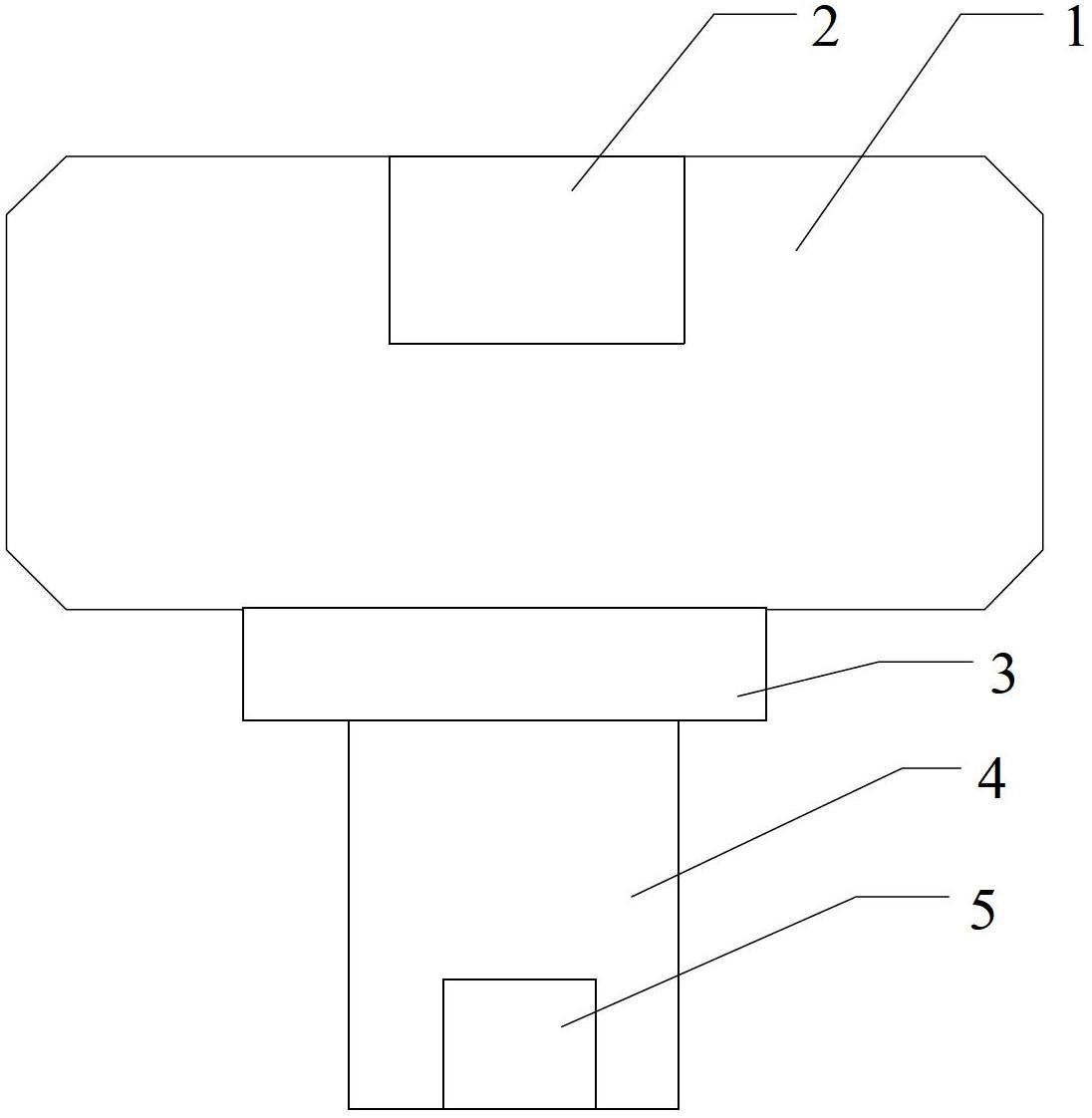

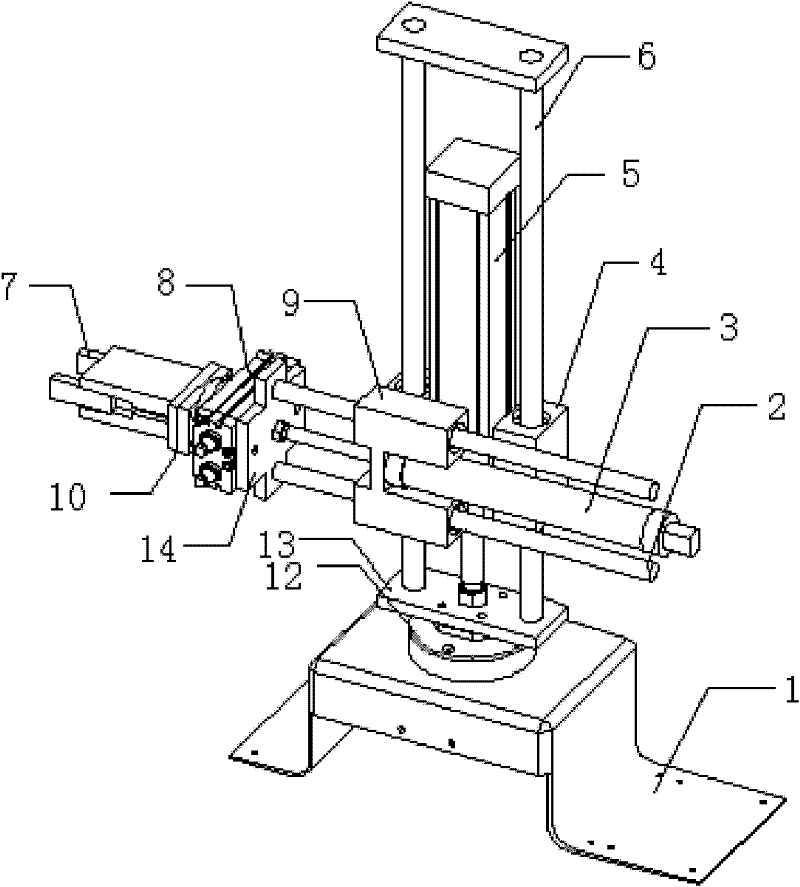

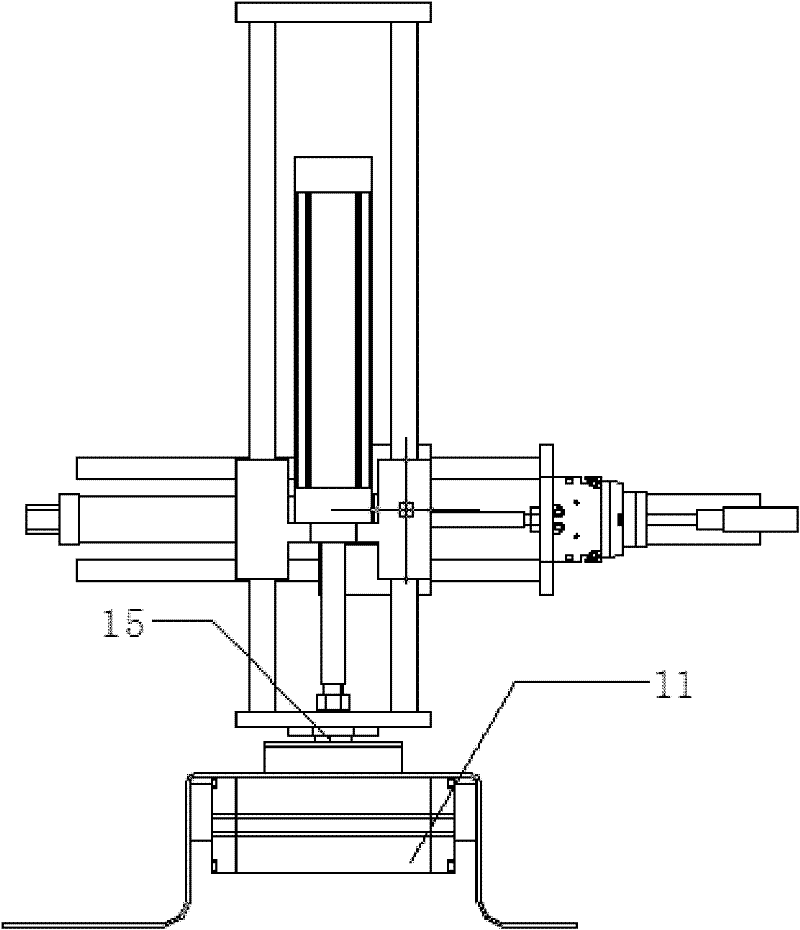

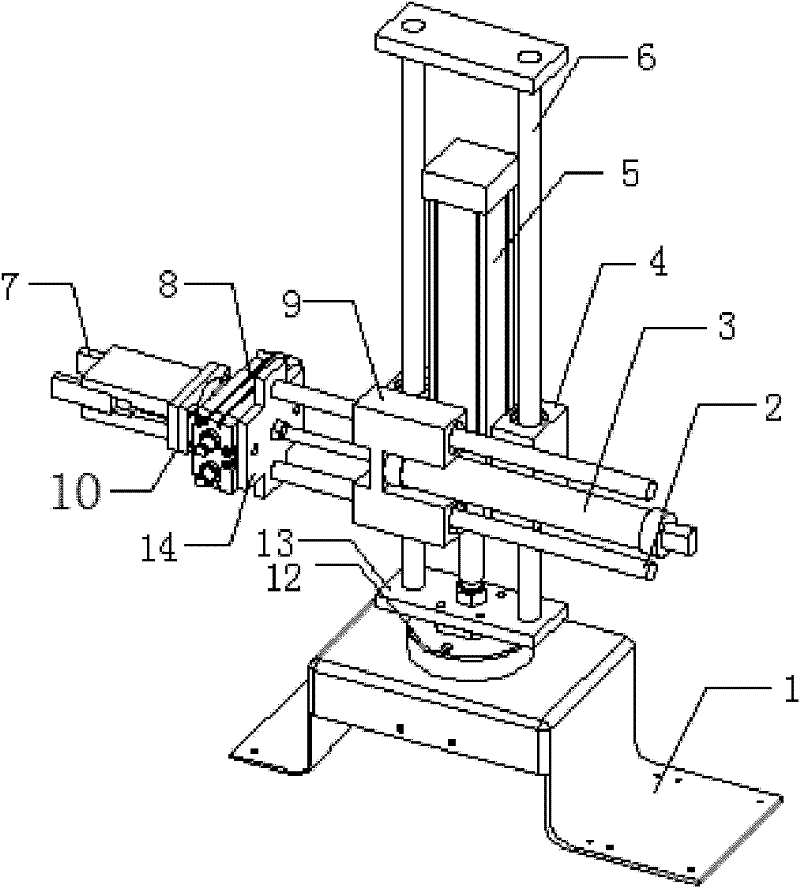

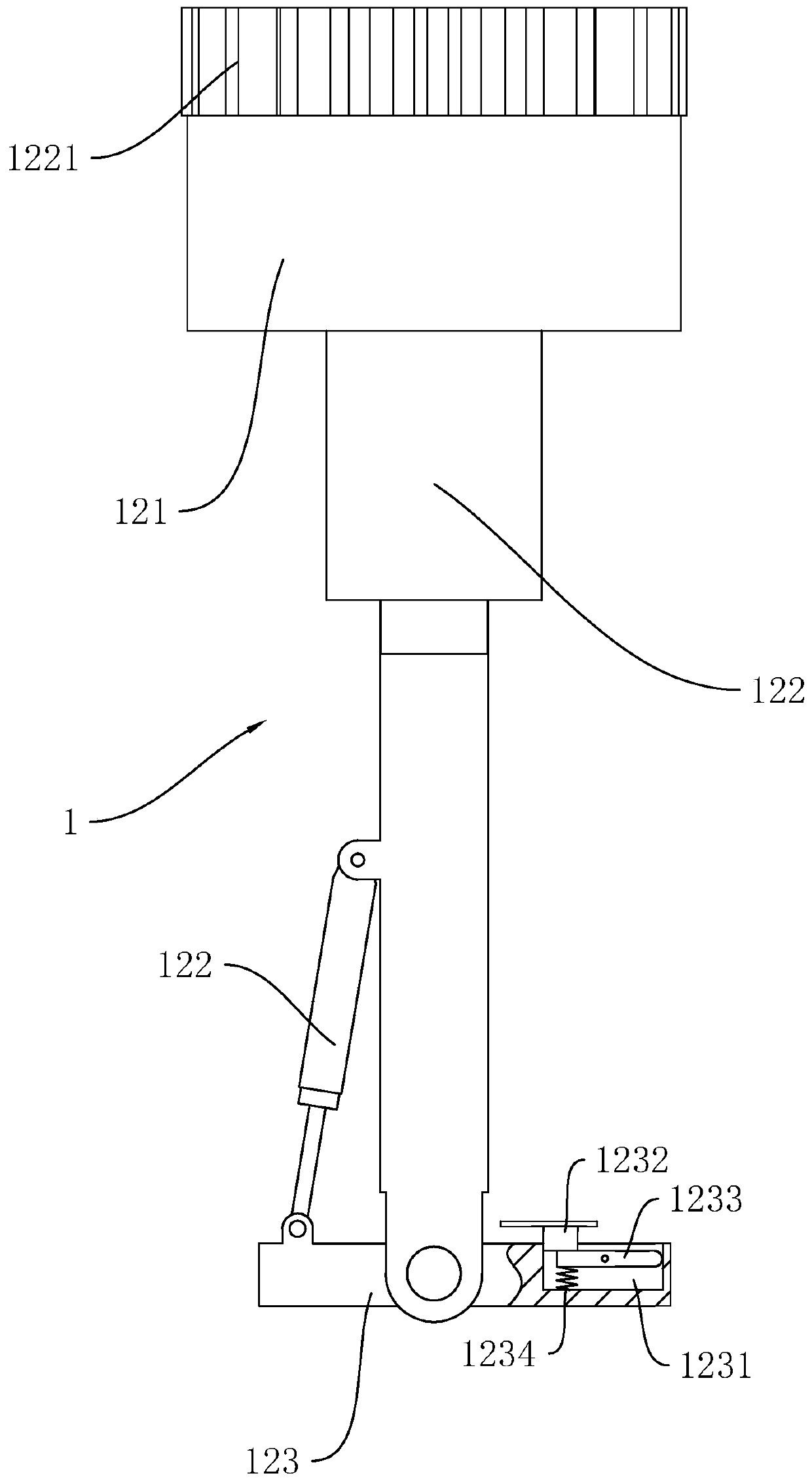

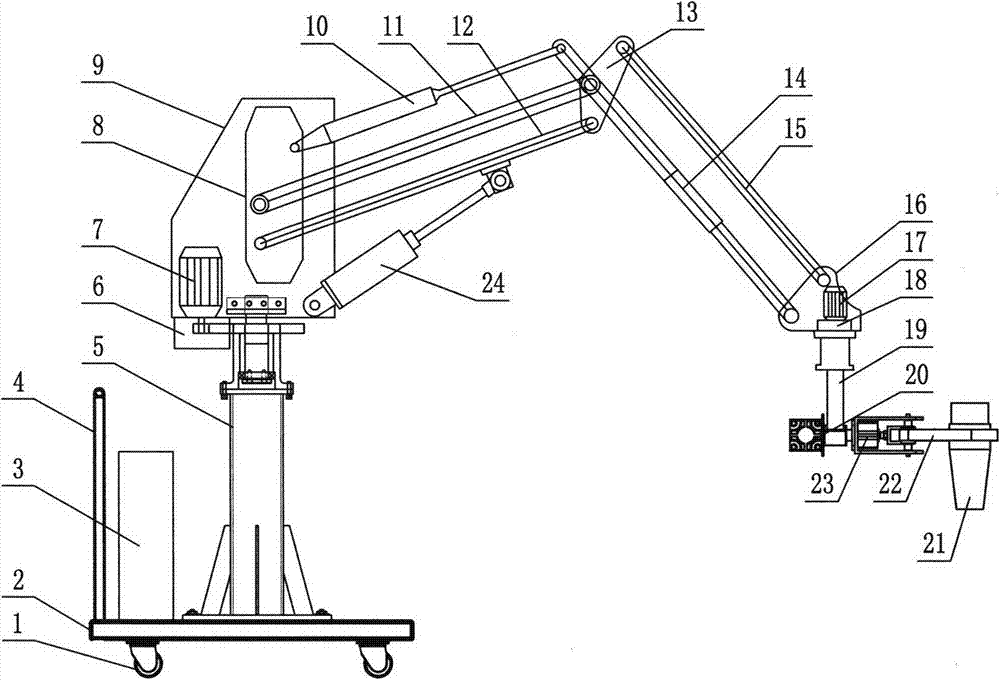

Four-degree-of-freedom pneumatic manipulator

InactiveCN102229143ASimple structureEasy to operateProgramme-controlled manipulatorMultiple formsDegrees of freedom

The invention discloses a four-degree-of-freedom pneumatic manipulator, which can realize motion of multiple forms and has the advantages of simple structure, convenience for operation and the like. The structure of the pneumatic manipulator consists of a metal plate base, a horizontal moving cylinder, a horizontal moving slide block, a horizontal moving guide rod, a vertical lifting cylinder, a vertical lifting slide block, a vertical lifting guide rod, an integral rotating cylinder, a bearing cover, a horizontal tray, a vertical tray, a rotating shaft and the like; the integral rotating cylinder is fixed below the metal plate base; the rotating shaft is fixed by the bearing cover, and the rotating shaft is connected with the vertical lifting cylinder through the horizontal tray; the vertical lifting guide rod is also fixed on the horizontal tray; the vertical lifting slide block is arranged on the vertical lifting guide rod, and the vertical lifting slide block is connected with the horizontal moving slide block; the horizontal moving slide block is arranged on the horizontal moving guide rod; the horizontal moving guide rod is fixed on the vertical tray; and the vertical tray is connected with the horizontal moving cylinder.

Owner:于复生

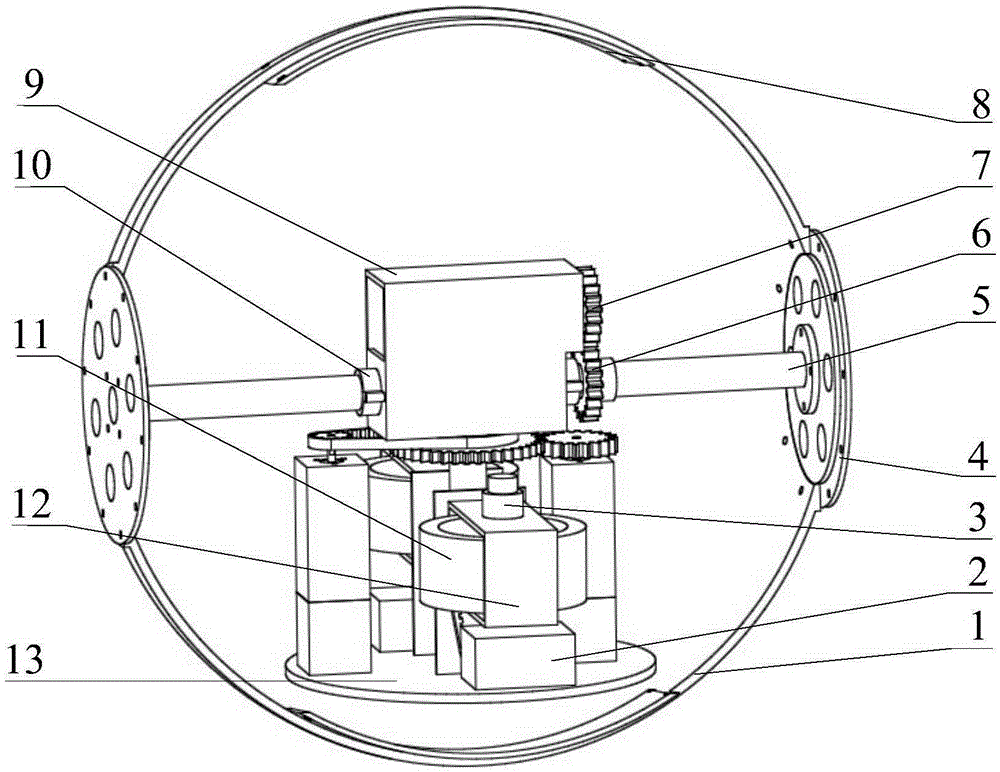

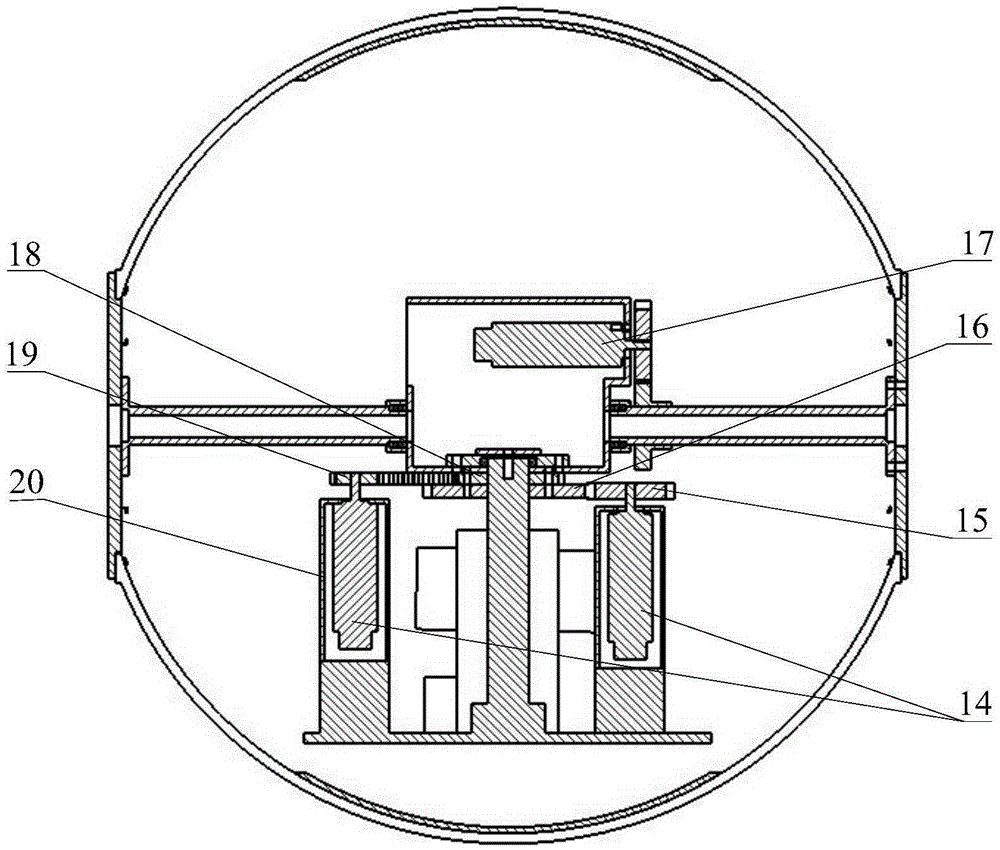

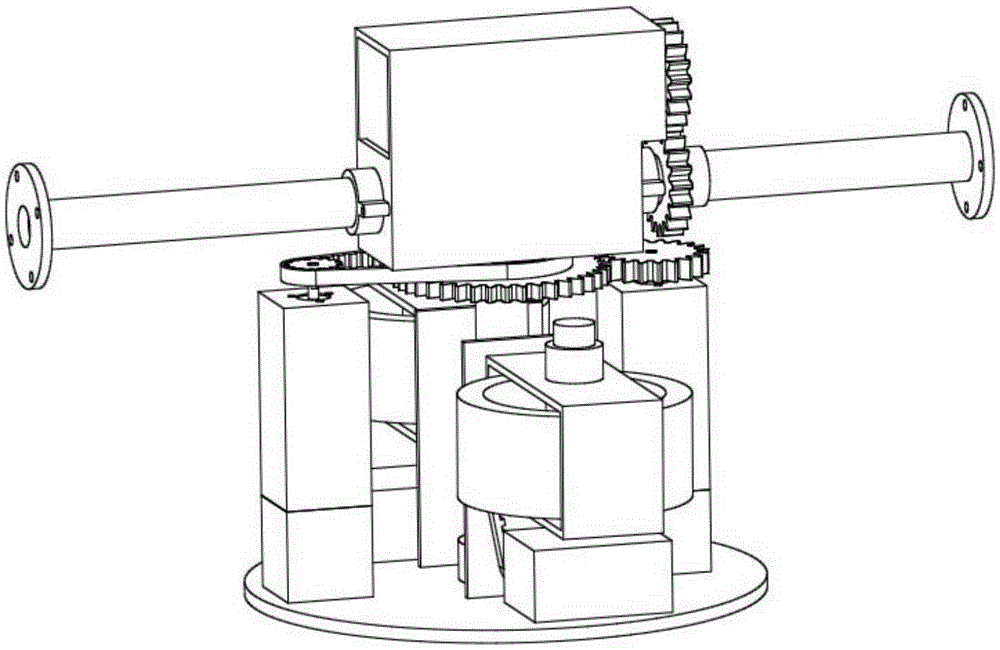

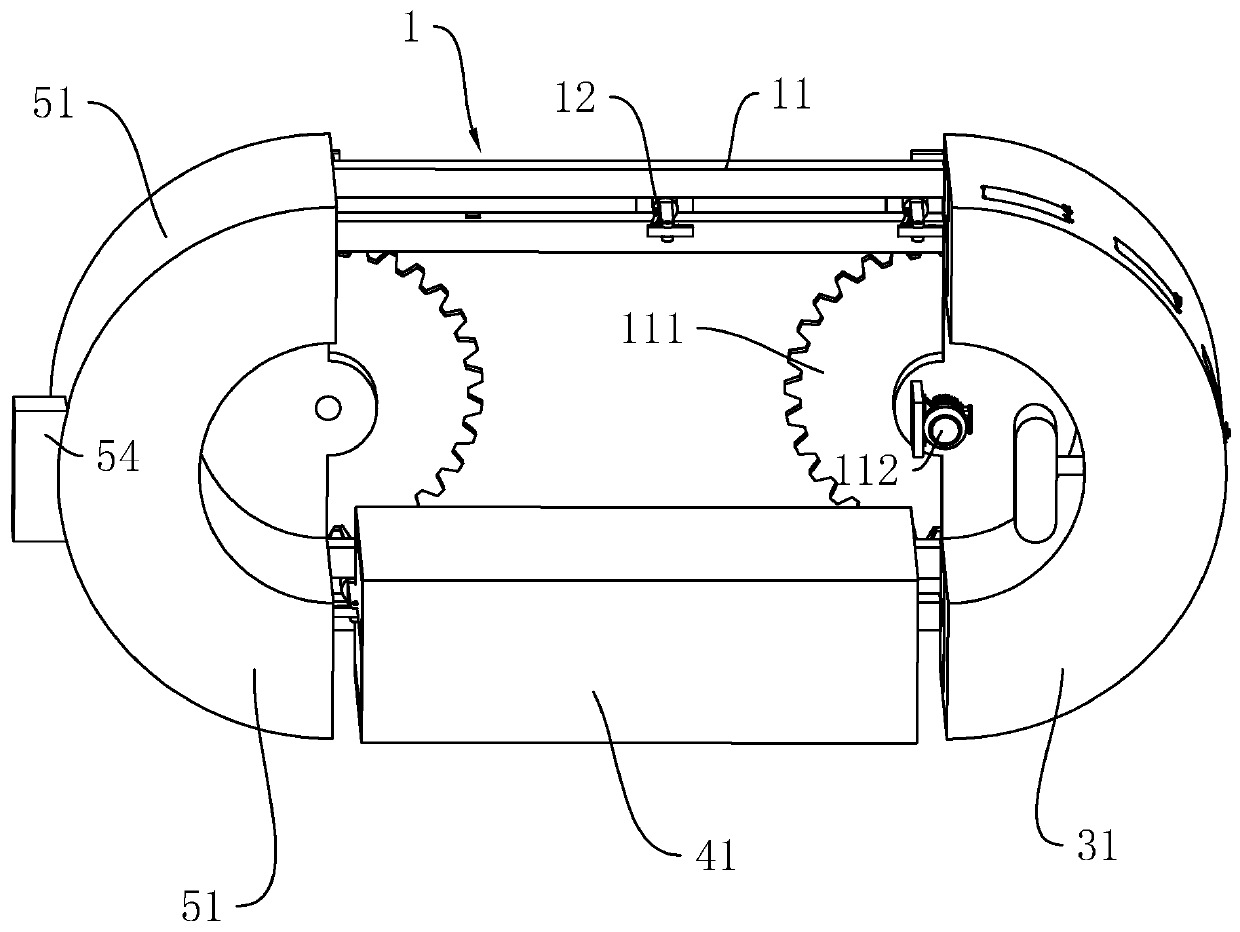

Spherical robot with in-situ rotation function carried with control moment gyro

The invention discloses a spherical robot with an in-situ rotation function carried with a control moment gyro. The robot is mainly composed of a homogeneous spherical shell, an advance driving mechanism, a steering mechanism, a control moment gyro mechanism, a heavy pendulum and the like. The steering mechanism is composed of two steering motors, a steering gear mechanism, a toothed belt wheel mechanism and the like. In-situ steering of the sphere is achieved through the cooperation of output torques of the two motors. Meanwhile, the robot is carried with the control moment gyro mechanism, and the control moment gyro mechanism is mainly composed of a flywheel, a flywheel rotation motor, a flywheel fixing frame, a frame rotation steering engine, the toothed belt wheel mechanism and the like; extra precession moment is provided through the precession effect of a gyro rotor which rotates at a high speed, so that the operation speed of the robot is higher, and the climbing and obstacle crossing capacity is improved. The spherical robot can steer in-situ and is high in operation speed, the movement rapidity and flexibility of the spherical robot are greatly improved, and the spherical robot has great application prospects.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Workpiece lifting spraying production line

The invention relates to a workpiece lifting spraying production line which comprises a lifting conveying device, a feeding station, a spray cleaning station, a spraying station, a drying station anda discharging station. The lifting conveying device comprises a conveying rail in the shape of a kidney-shaped ring, and multiple lifting frames arranged on the lower side of the conveying rail. The spray cleaning station comprises a spray cleaning box, and a first through groove for the lower ends of the lifting frames to be inserted into the spray cleaning box conveniently is formed in the upperside of the spray cleaning box. Multiple gas spraying guns capable of spraying gases to workpieces are arranged at the positions, corresponding to the lifting frame conveying track, of the two sidesof the spray cleaning box. A blanking groove is fixedly connected to the position, corresponding to the lower side of the lifting frame, of the spray cleaning box along the movement track of the lifting frame, and a cloth bag dust collecting bag with an opening formed in the upper end is arranged on the lower side of the blanking groove. A draught fan is fixedly connected to the position, corresponding to the lower side of the cloth bag dust collecting bag, of the spray cleaning box. First flexible dust blocking curtains are further fixedly connected to the two ends of the spray cleaning box.The workpiece lifting spraying production line has the beneficial effects that the workpieces can be automatically cleaned, the labor intensity is lowered, and the work efficiency is improved.

Owner:青岛欧轩机械有限公司

Three-dimensional ice form detection instrument

InactiveCN101865668ARealize horizontal acquisitionAvoid visual blind spotsUsing optical meansVision basedEngineering

The invention discloses a three-dimensional ice form detection instrument, which comprises externally purchase components such as a laser, a CCD camera, a step motor, a steering engine and the like. The three-dimensional ice form detection instrument also comprises a movement sub platform and a rotation sub platform, wherein the movement sub platform and the rotation sub platform are used for installing the externally purchase components, the movement sub platform is used for supporting the rotation sub platform to make the rotation sub platform move in the horizontal direction, and two guide rails arranged on the rotation sub platform can make the laser and the CCD camera be regulated to an angle satisfying the collection. The three-dimensional ice form detection instrument designed by the invention is based on the visual ice forms, can intuitively display the icing forms in an image mode, provides the visual technical solution scheme for researchers to accurately identify the three-dimensional ice forms and to obtain the dimension data of the ice forms, has important significance and practical value of the later stage study of influence of icing on the aircraft aerodynamic performance, and provides test verification detection measures for the three-dimensional ice forms obtained through calculation.

Owner:BEIHANG UNIV

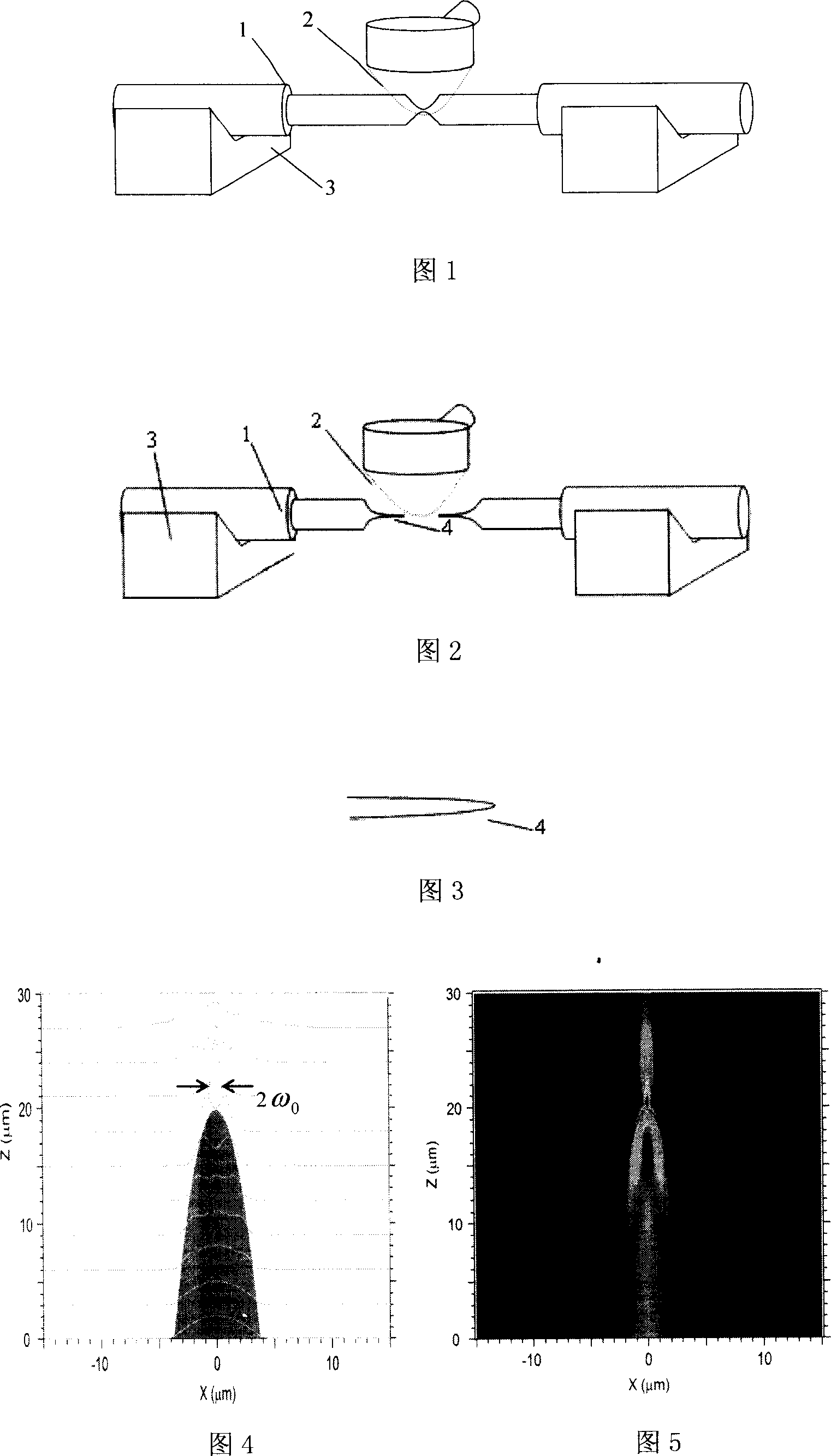

Melting and pulling method for manufacturing optical tweezers of parabolic microstructure single fiber

InactiveCN1963583ARealization of single-fiber optical tweezersProcessing conditions no special requirementsGlass making apparatusMaterial analysis by optical meansSingle fiberOptoelectronics

This invention provides one single fiber light nipper melt process method to catch and operate arc micro structure for micro object, wherein, it processes one end of light fiber with arc micro structure light fiber; other end of fiber is coupled to micro light; the laser is reflected from fiber needle to form focus field to form stable three dimensional position well to realize single fiber light nipper.

Owner:HARBIN ENG UNIV

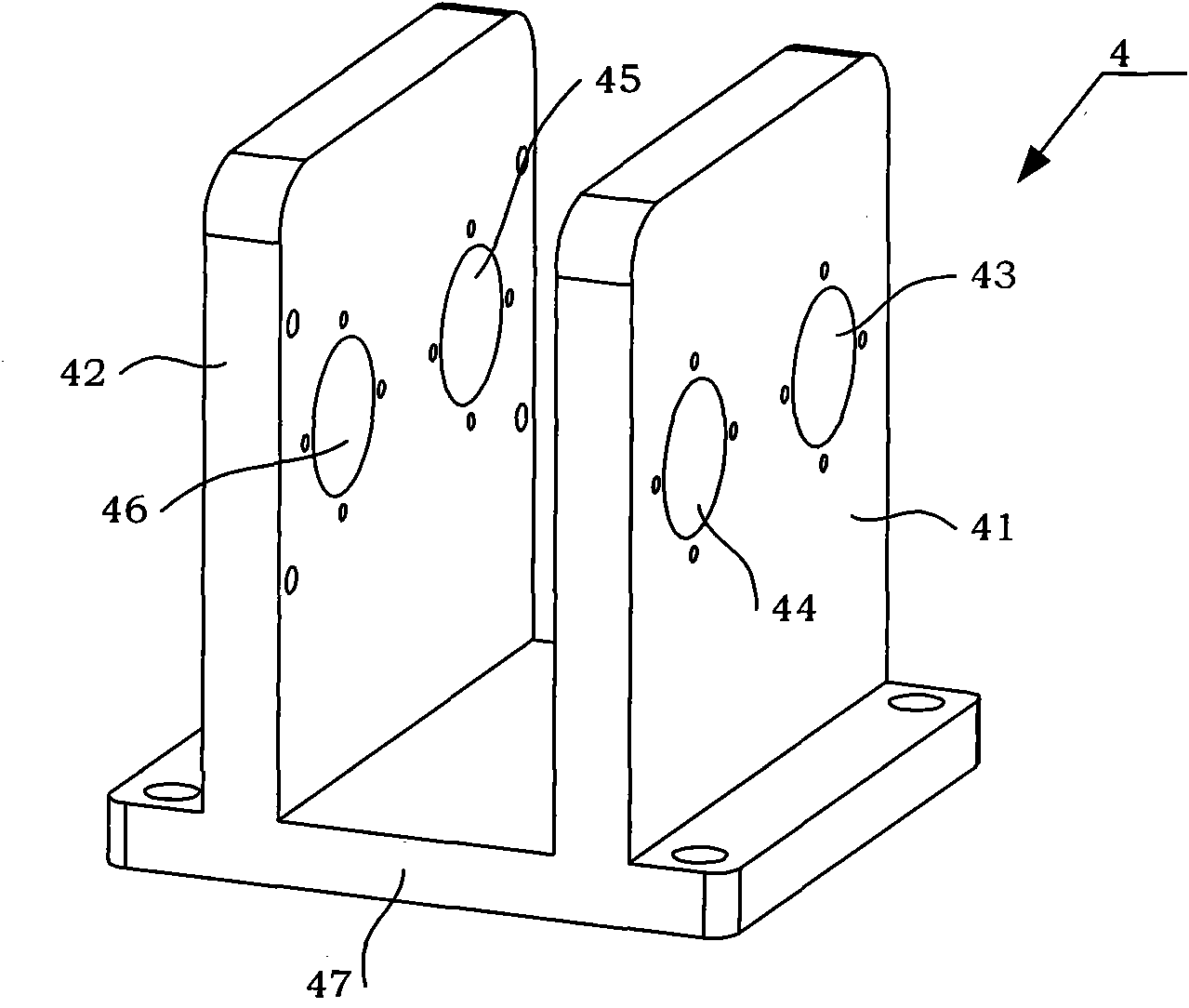

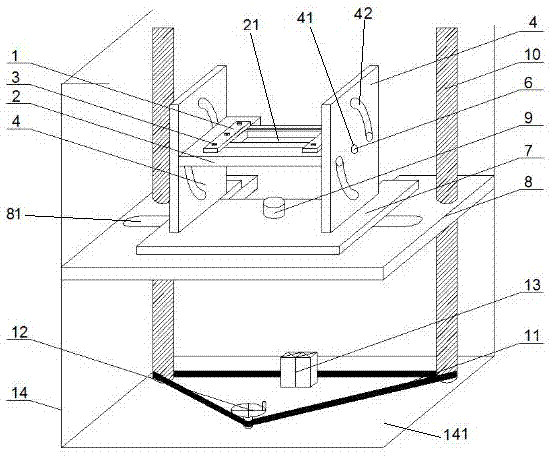

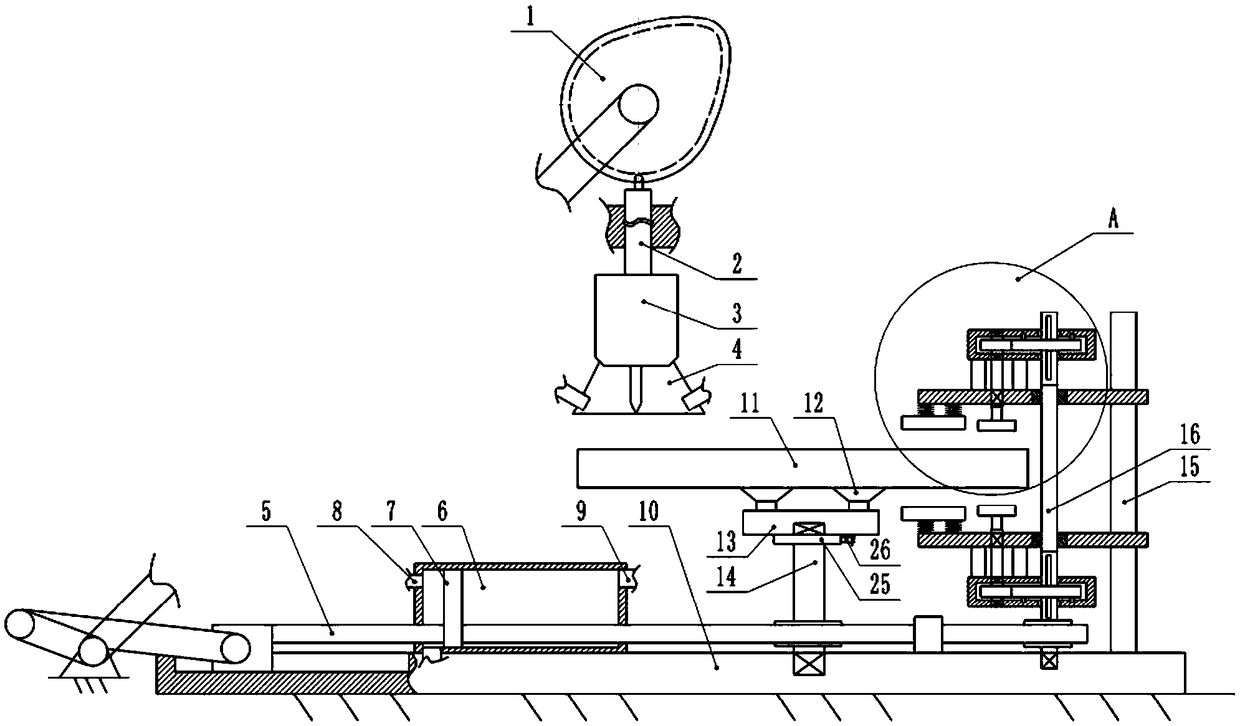

Plate clamper platform for falling weight impact test, and impact speed measurement method

PendingCN106940275ARealize multi-angle impactIncrease flexibilityDevices using optical meansStrength propertiesEngineeringLaser sensor

The invention discloses a plate clamper platform for a falling weight impact test, and an impact speed measurement method. The plate clamper platform comprises a clamper structure, a supporting lifting structure and a laser sensor, wherein the clamper structure comprises a plate clamping device, a multi-angle rotation device and a clamper bottom plate, the multi-angle rotation device comprises wall plates, wall plate bolts and a bottom plate bolt, each wall plate is provided with a central hole and two arc-shaped grooves, the two arc-shaped grooves are symmetrically arranged relative to the central hole, clamping plates can rotate along the arc-shaped grooves after the wall plate bolts are completely loosened, the supporting lifting structure comprises a platform and a lifting driving device, the clamper bottom plate can rotate by adopting the bottom plate bolt as the center and can slidably move along a straight strip hole, and the laser sensor is arranged below the weight tray positioned on the periphery of a hammer head. With the plate clamper platform and the impact speed measurement method of the present invention, the composite material plate specimen can be tightly clamped, the multi-angle impact on the specimen can be achieved, and the speed change during the drop hammer falling and impact process can be real-timely measured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

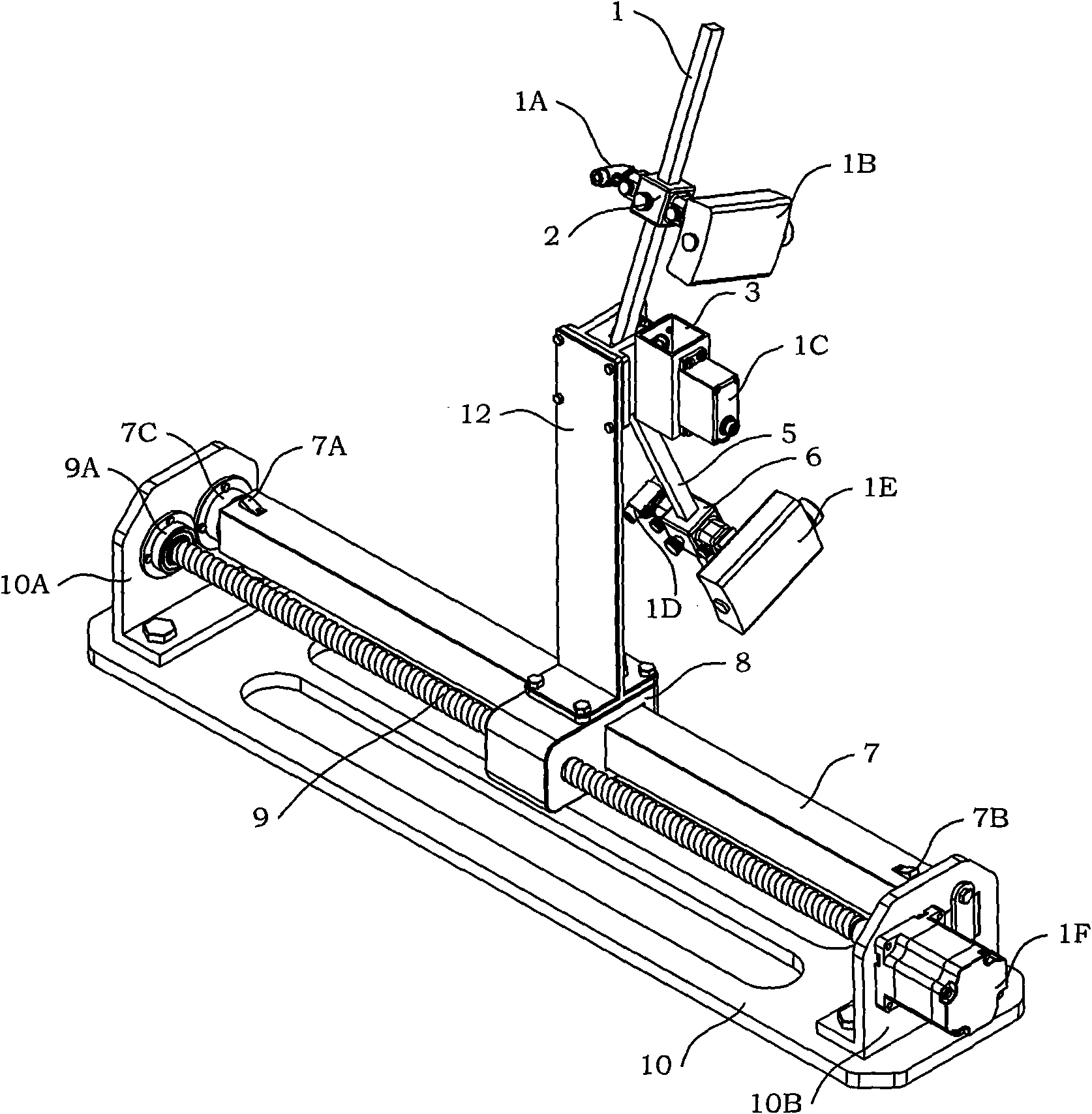

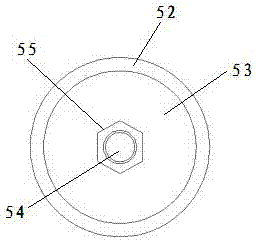

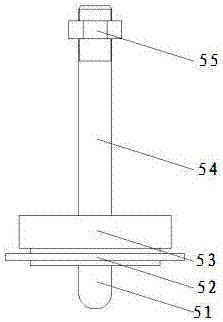

Accurate one-dimensional rotary and two-dimensional tilting table

InactiveCN101436436AImprove carrying capacityHigh adjustment accuracyInstrumental componentsPosition/direction controlEngineeringWork demand

Owner:TONGJI UNIV

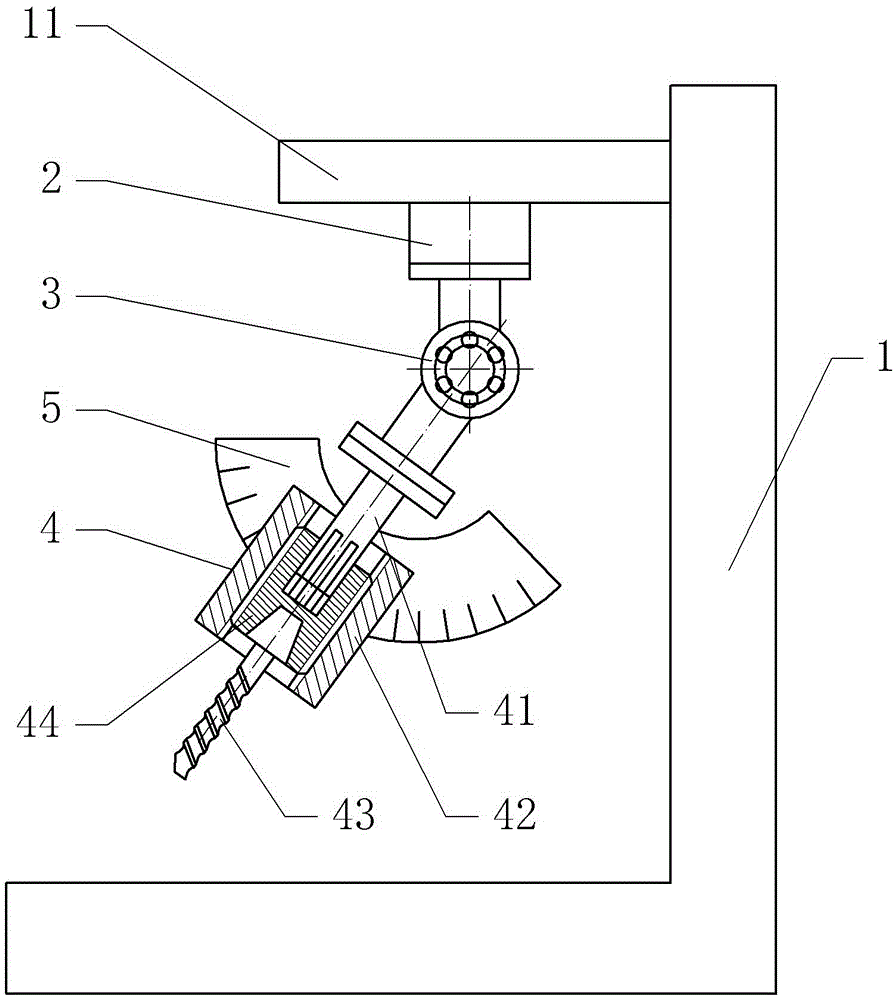

Drilling machine with variable-angle drill bit

InactiveCN105458321AAchieve rotationAchieve feedFeeding apparatusDriving apparatusDrive shaftUniversal joint

The invention discloses a drilling machine with a variable-angle drill bit and relates to a drilling device. The drilling machine with the variable-angle drill bit comprises a rack, a rotary seat, a drive portion and a drilling portion. The rotary seat is rotationally connected to the rack. The drilling portion comprises a transmission shaft, a sleeve, a feeding block and the drill bit. The sleeve is rotationally connected to the rack. An internal thread is arranged in the sleeve. An external thread is arranged on the feeding block. The feeding block is arranged in the sleeve and matched with the sleeve in a threaded manner. One end of the feeding block is provided with an internal spline. The drill bit is fixedly connected to the other end of the feeding block. The angle of the drill bit can be changed by rotating the sleeve. One end of the transmission shaft is connected with the spline in sliding fit with the feeding block. The transmission shaft is connected with the rotary seat through a universal joint so that variable-angle power transmission can be achieved. A fastening screw is arranged between the sleeve and the rack so that the sleeve can be fastened to the rack.

Owner:徐州致诚会计服务有限公司

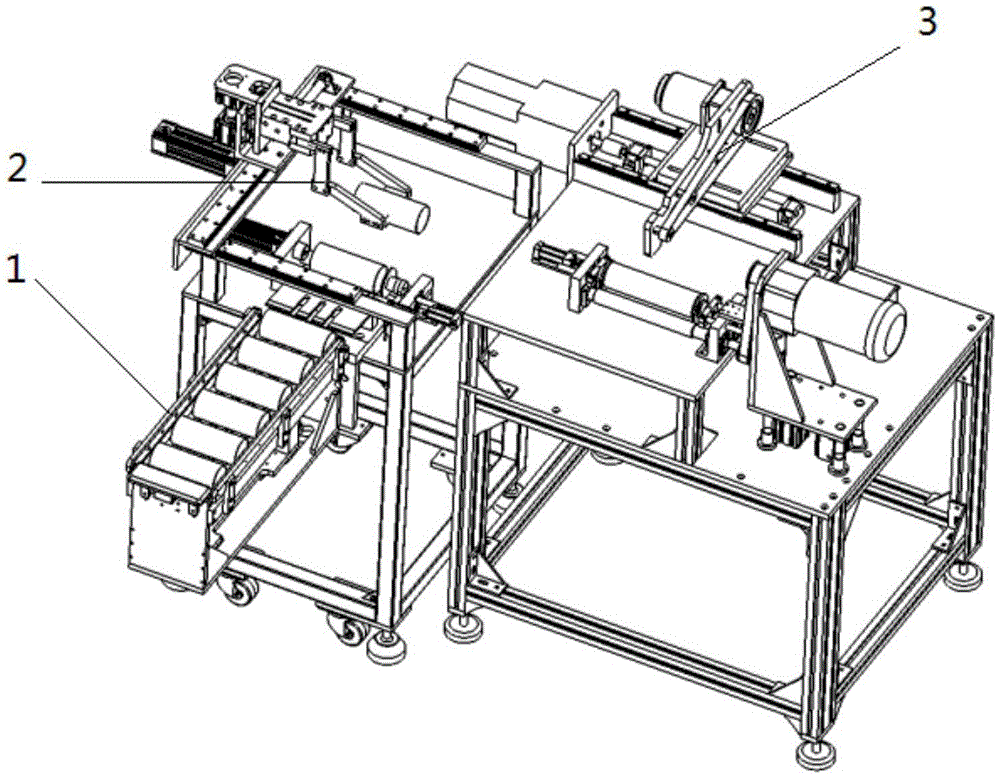

Automatic polishing system for cylindrical workpiece

ActiveCN105619213ARealize automatic deliveryIncrease the level of automationGrinding drivesBelt grinding machinesDrive wheelElectric machinery

The invention provides an automatic polishing system for a cylindrical workpiece. The automatic polishing system comprises a feeding mechanism, a feed mechanism and an outer circle polishing mechanism. The feeding mechanism comprises a feeding rack, a conveying table unit and a pressing unit, and the conveying table unit and the pressing unit are mounted on the feeding rack. The feed mechanism is mounted on a support face plate of the feeding mechanism and comprises a feed rack and a motion control unit mounted on the feed rack. The outer circle polishing mechanism comprises a polishing rack, a motion unit and a polishing unit, and the motion unit and the polishing unit are mounted on the polishing rack. The polishing unit comprises linear guide rails, a sliding base, a stepping motor support, a driving wheel, a lead screw, a servo motor, a sanding belt, a tensioning wheel, a driven wheel and a stepping motor. The automatic polishing system can completely replace manual operation, work efficiency is remarkably improved, manpower cost is reduced, and the automation level of an enterprise is improved; and all polishing parameters are precisely controlled, and the more stable and better polishing quality can be achieved.

Owner:LYNCWELL INNOVATION INTELLIGENT SYST ZHEJIANG CO LTD

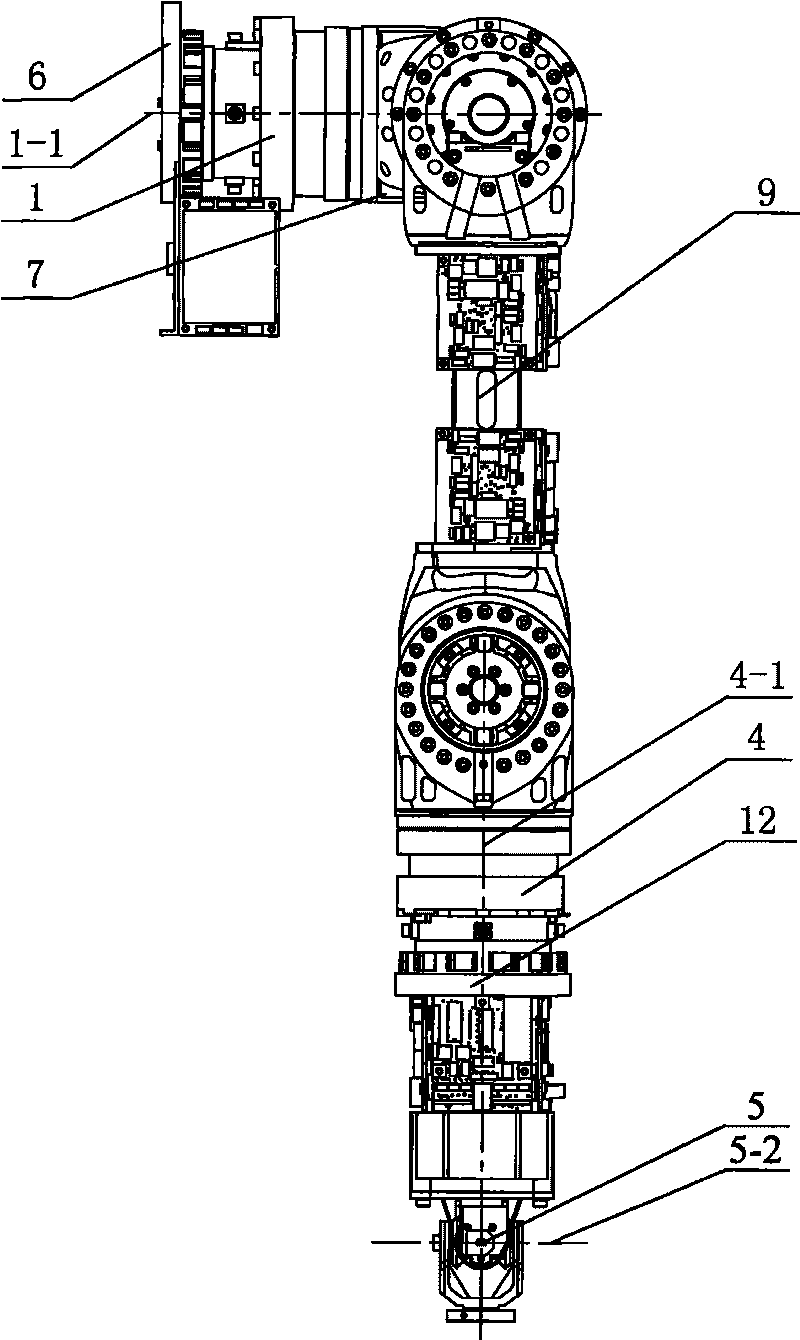

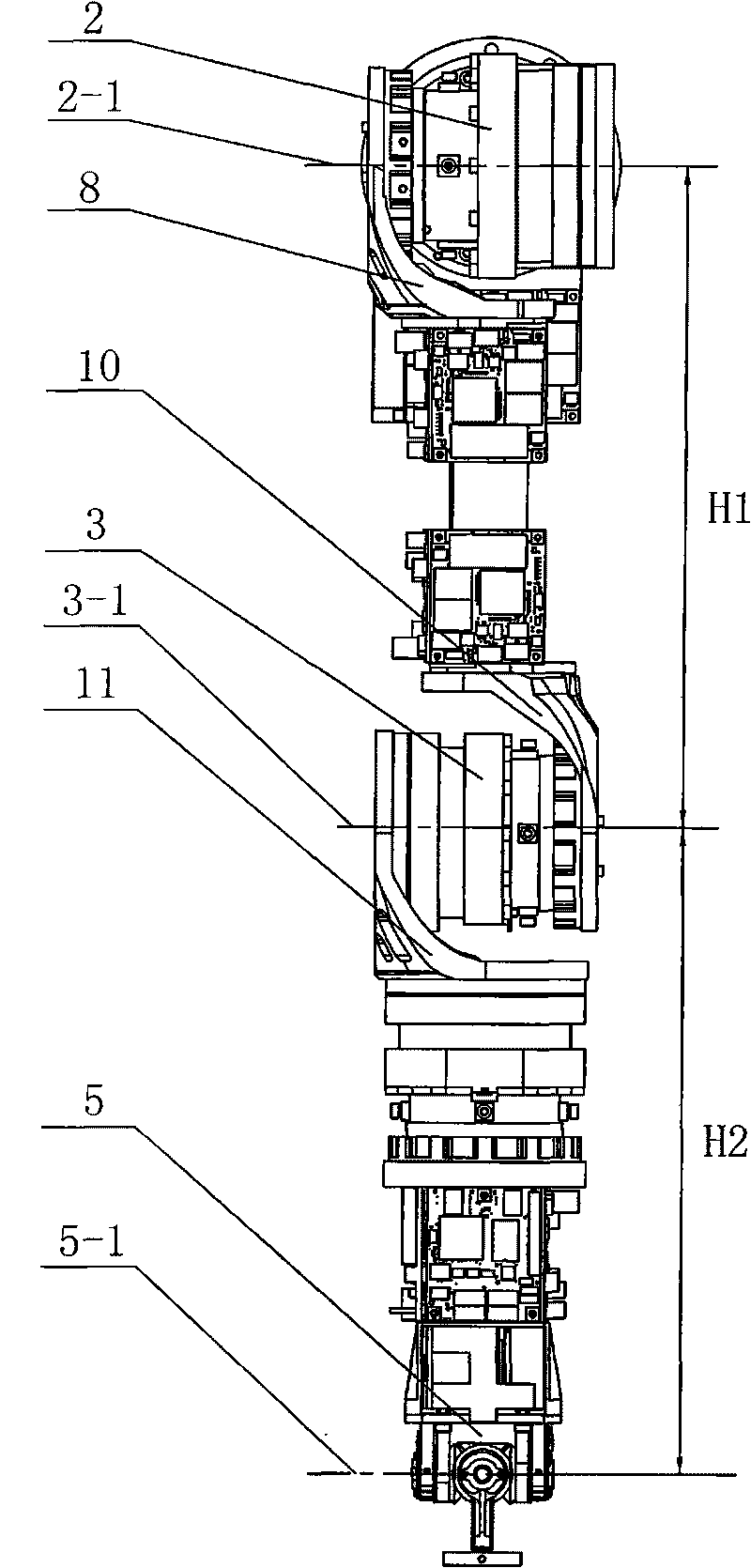

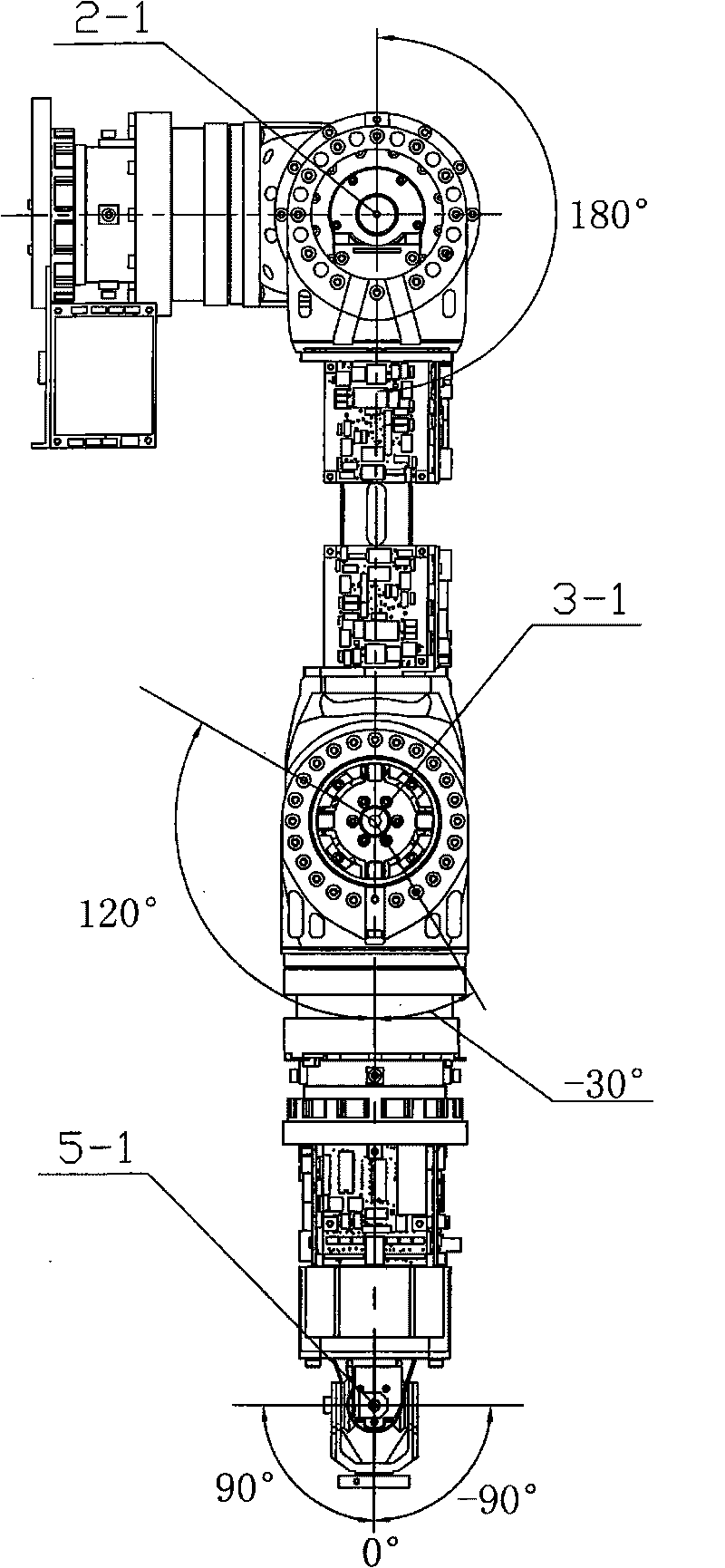

Nimble arm of six-DOF robot

InactiveCN101745913AAchieve rotationEnables serial electrical connectionProgramme-controlled manipulatorRobotic systemsEngineering

The invention discloses a nimble arm of six-degree of freedom (DOF) robot, relating to a robot arm, so as to solve the problems that the arm of the current robot has large weight and low integration level and the integration between a nimble arm and a robot system is limited. A first shoulder joint, which is connected with a base, is connected with a second shoulder joint through a connecting piece of the first shoulder joint; the second shoulder joint is connected with an upper arm through a connecting piece of the second shoulder joint; the upper arm is connected with a first elbow joint through a connecting piece of the first elbow joint; the first elbow joint is connected with a second elbow joint through a connecting piece of the second elbow joint which is connected with a front arm; the front arm is connected with a two-DOF wrist joint; the circuit board of the first shoulder joint is fixedly mounted on the base; the circuit board of the second shoulder joint and the circuit board of the first elbow joint are fixedly connected with the upper arm, and the circuit board of the second elbow joint and the circuit board of the wrist joint are fixedly mounted on the front arm. Wires are connected with the circuit boards of the first shoulder joint, the second shoulder joint, the first elbow joint, the second elbow joint and the wrist joint in sequence. The nimble arm has light weight, high integration and high reliability.

Owner:HARBIN INST OF TECH

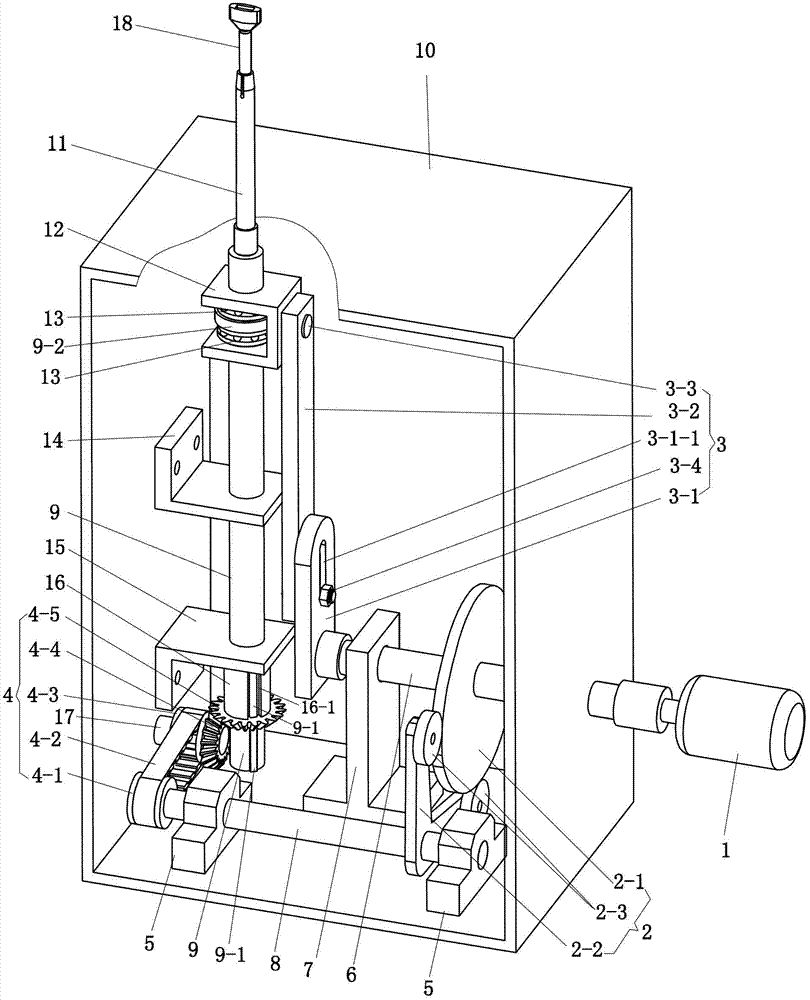

Motor stator coil winding machine

InactiveCN103199655AChange gear ratioAchieve rotationManufacturing dynamo-electric machinesLinear motionWinding machine

A motor stator coil winding machine comprises a box body, a driving motor, a power shaft and a main shaft, wherein a support frame and two support seats are fixed on a bottom board of the box body, the power shaft is supported by the support frame and the box body, the two support seats support a transmission long shaft, an upper installation seat and a lower installation seat are fixed on the box body, the middle portion of the main shaft is located in guide holes of the upper installation seat and the lower installation seat, a winding shaft is arranged at one end, extending upwards out of the box body, of the main shaft, a bushing is arranged at a position, extending downwards out of the lower installation seat, of the main shaft, the main shaft, the upper installation seat, the lower installation seat and the bushing are all in movable connection, the power shaft is driven by the driving motor and drives the transmission long shaft to rotate in positive and negative directions through a cam mechanism, the transmission long shaft drives the main shaft to rotate in positive and negative directions through a transmission mechanism with a bevel gear pair, a driven bevel gear is connected at the position, located below the bushing, of the main shaft, a connector is arranged at the upper portion of the main shaft, and a crank connection rod mechanism driving the main shaft to make linear motion back and forth is arranged between a power head and the connector. The motor stator coil winding machine can achieve narrow-notch and large-angle winding in a rotary mode.

Owner:JIANGSU UNIV OF TECH

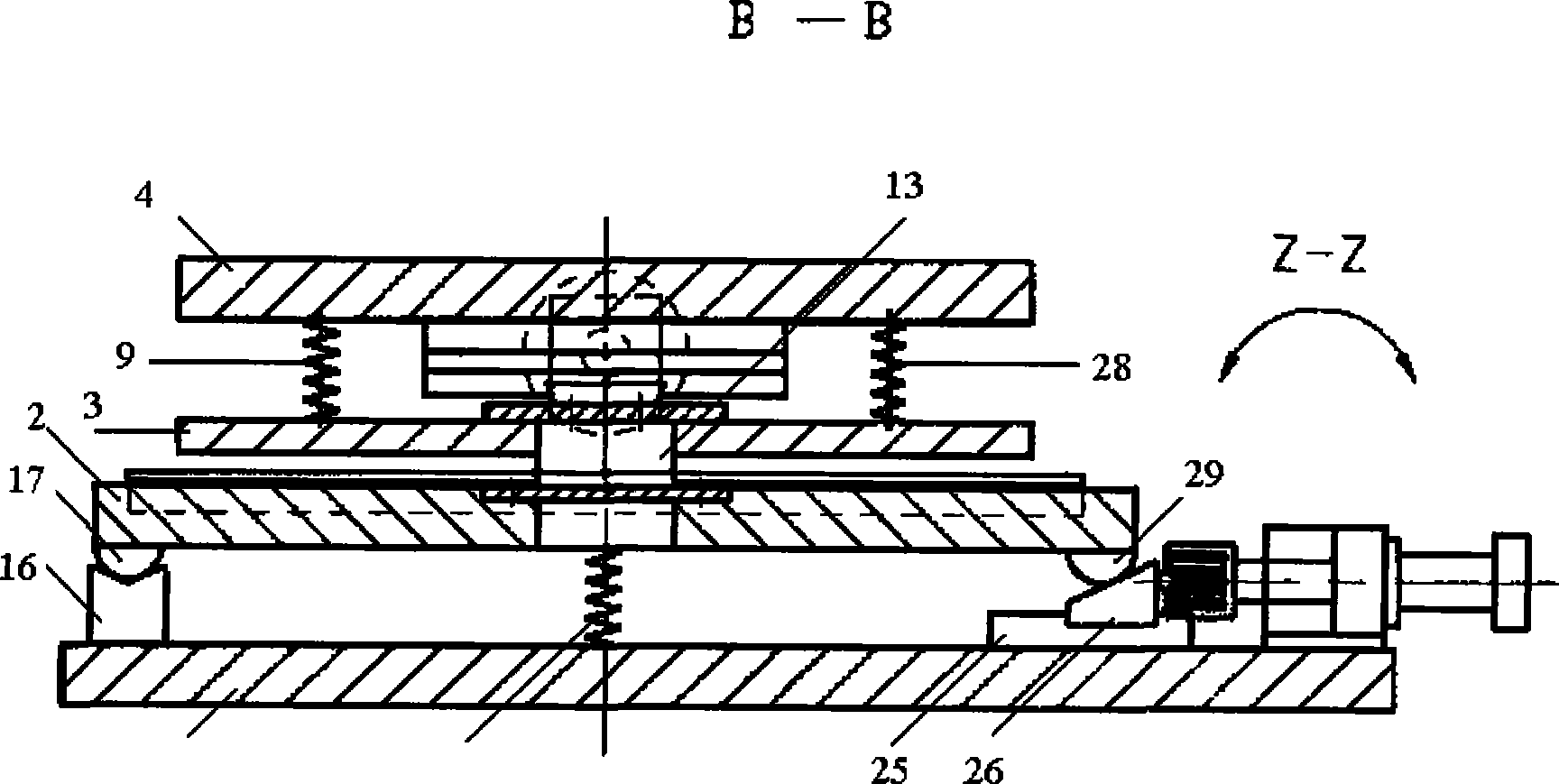

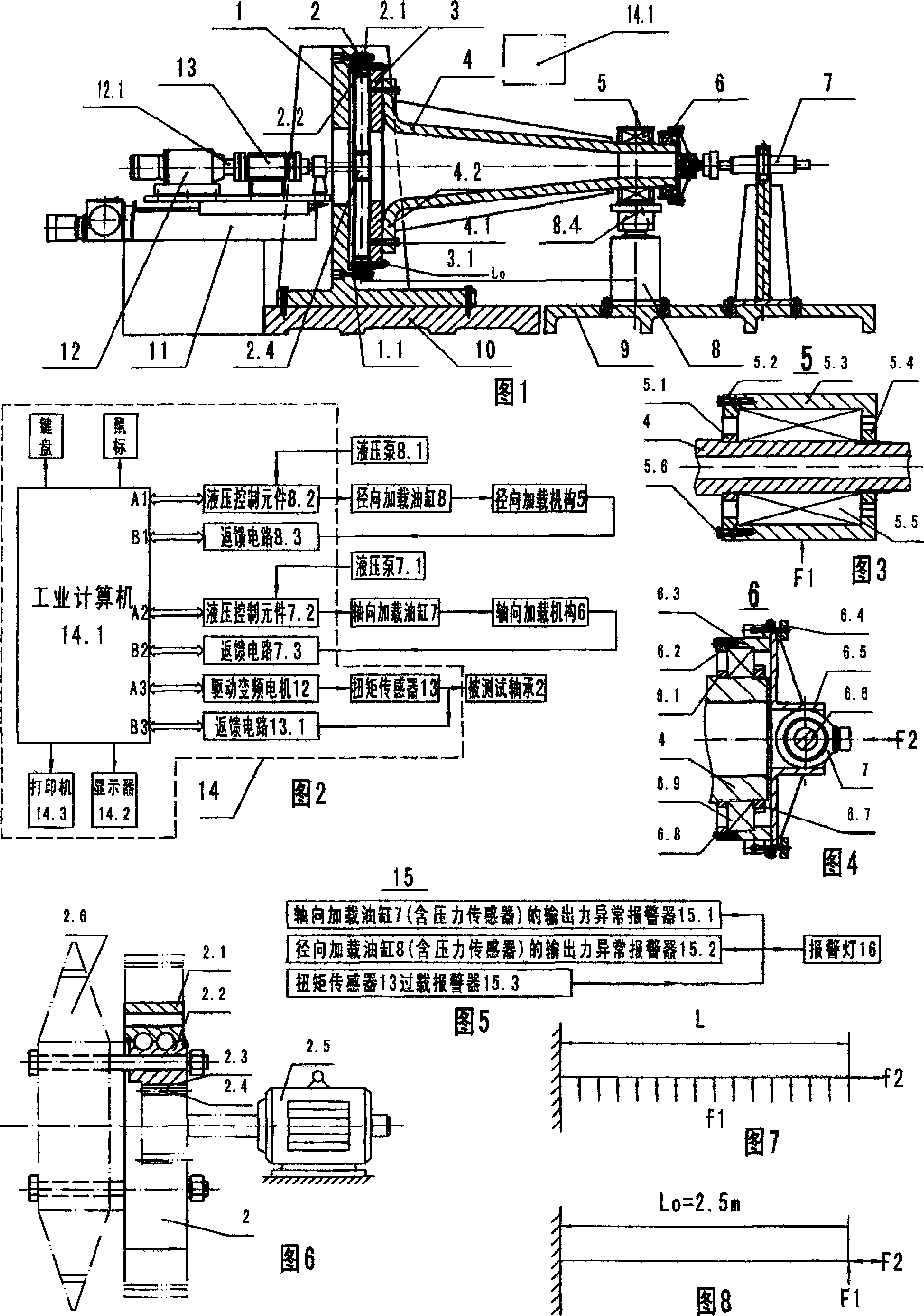

Megawatt level wind power generation oar-changing bearing friction torque numeric control testing machine and test approach

InactiveCN101256103ASmall sizeSimple structureMachine bearings testingEngine testingFriction torqueClosed loop

The invention provides a megawatt wind power generation adjustable blade bearing friction moment numerical control testing machine and a testing method. The tested bearing outer ring is fixed on the machine rack; a main axis is equipped, one end of the bearing inner ring is fixed on the bearing inner ring, the other end is equipped with a radial and axial loading mechanism, in which the radial and axial load cylinder are separately pressured, and is equipped with variable-frequency motor of torque sensor, the driving pinion is meshed with the tested bearing inner ring, which form the loading and transmission system. The testing machine is determined by force analysis and analog loading principle, which is reasonable and reliable, and has simple structure and small size. The closed-loop numerical control system, which is composed of an industrial computer, a hydraulic pressure control member, a hydro cylinder, a feedback element and other components, can realize overall monitor, data collection, analysis, process, and number and graph double output; the size, direction, variation period of the load are accurate, the curves of the load output and friction torque are intuitive, the testing process is highly automatic. And the invention can be matched with manual adjustment. The machine is shutdown automatically if any failure happens. The test provides data support for the bearing wind turbines, which assures that the machine can meet the test need after loading.

Owner:文鉴恒

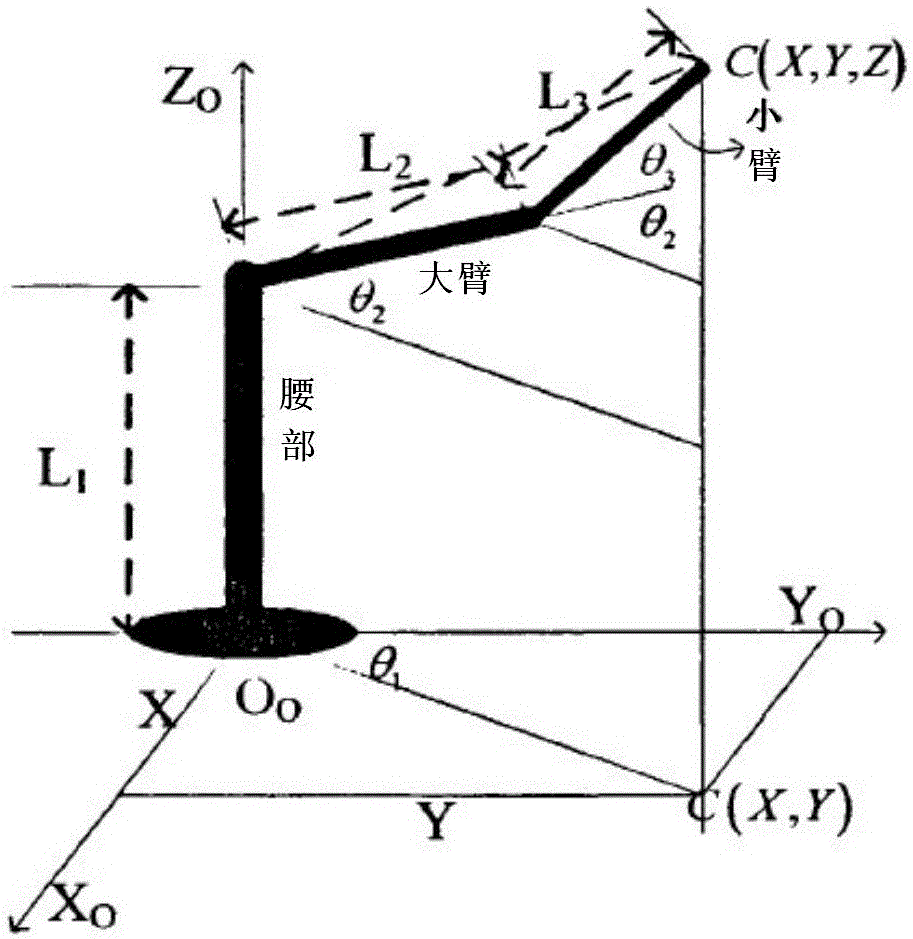

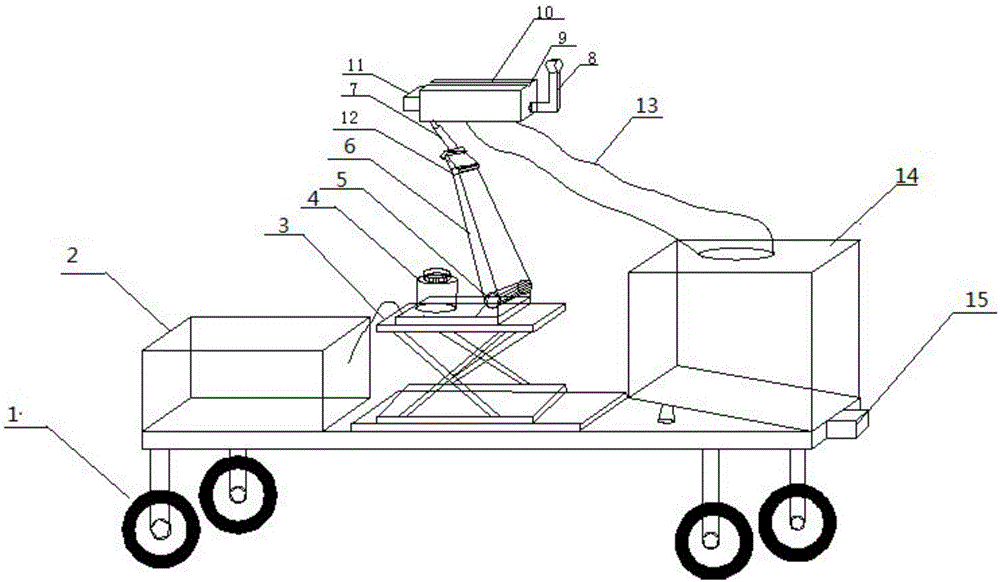

Wolfberry picking robot and control method thereof

InactiveCN105123127ARealize self-pickingRealize normal pickingPicking devicesControl mannerData acquisition

The invention discloses a wolfberry picking robot. A wolfberry picking robot system adopts a pinhole imaging technology and mainly comprises a data acquisition card and an analog-digital conversion module. A control method mainly adopts a fuzzy PID self-adaptive control way and is mainly used for controlling the vision. Hardware of the wolfberry picking robot mainly consists of a mechanical arm, a rotor structure, a picking head and various motors. By adopting the wolfberry picking robot, the automatic picking of wolfberry can be implemented, the manpower can be completely substituted, and the problem that the manual picking is subjected to the influence of the environment can be solved. The wolfberry picking robot is high in automation degree and high in picking efficiency.

Owner:BEIFANG UNIV OF NATITIES

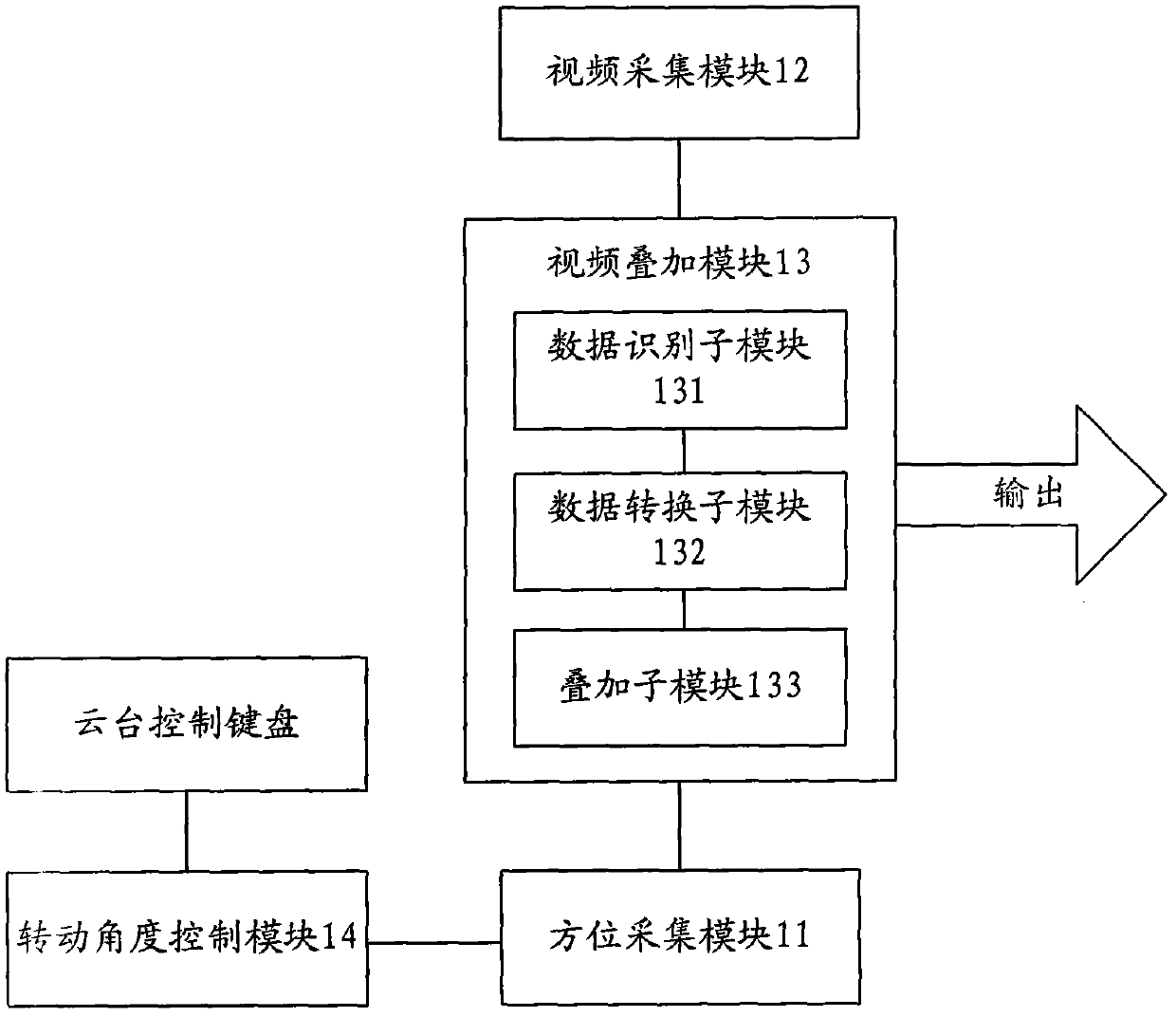

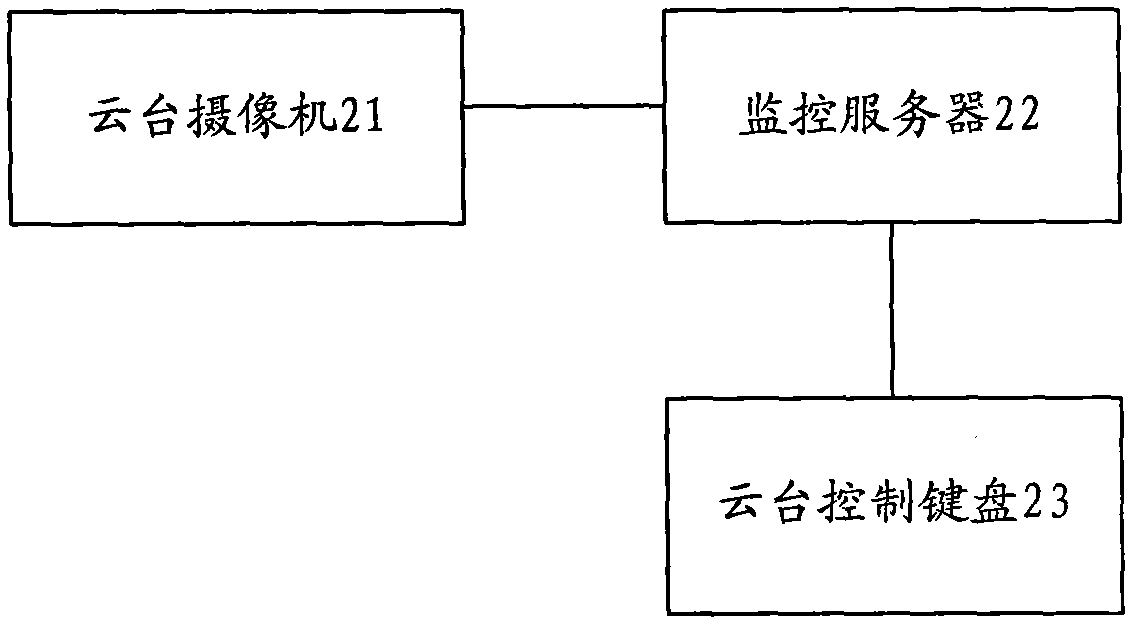

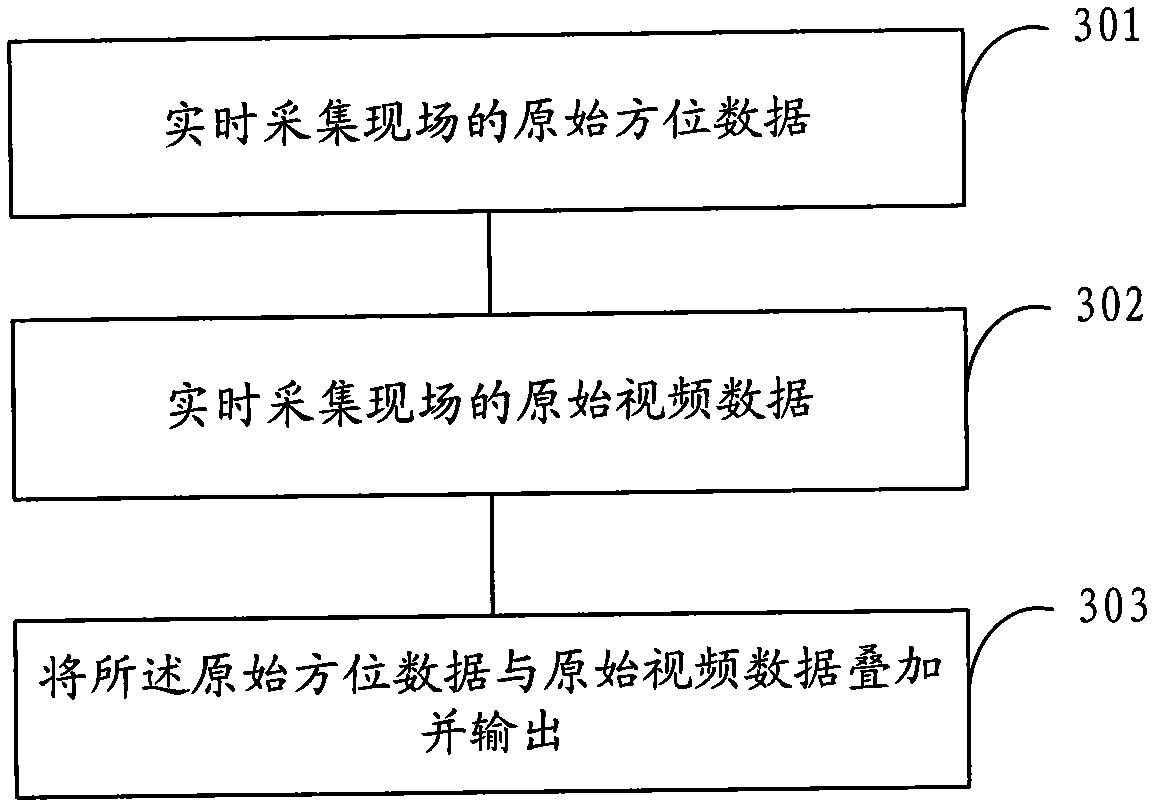

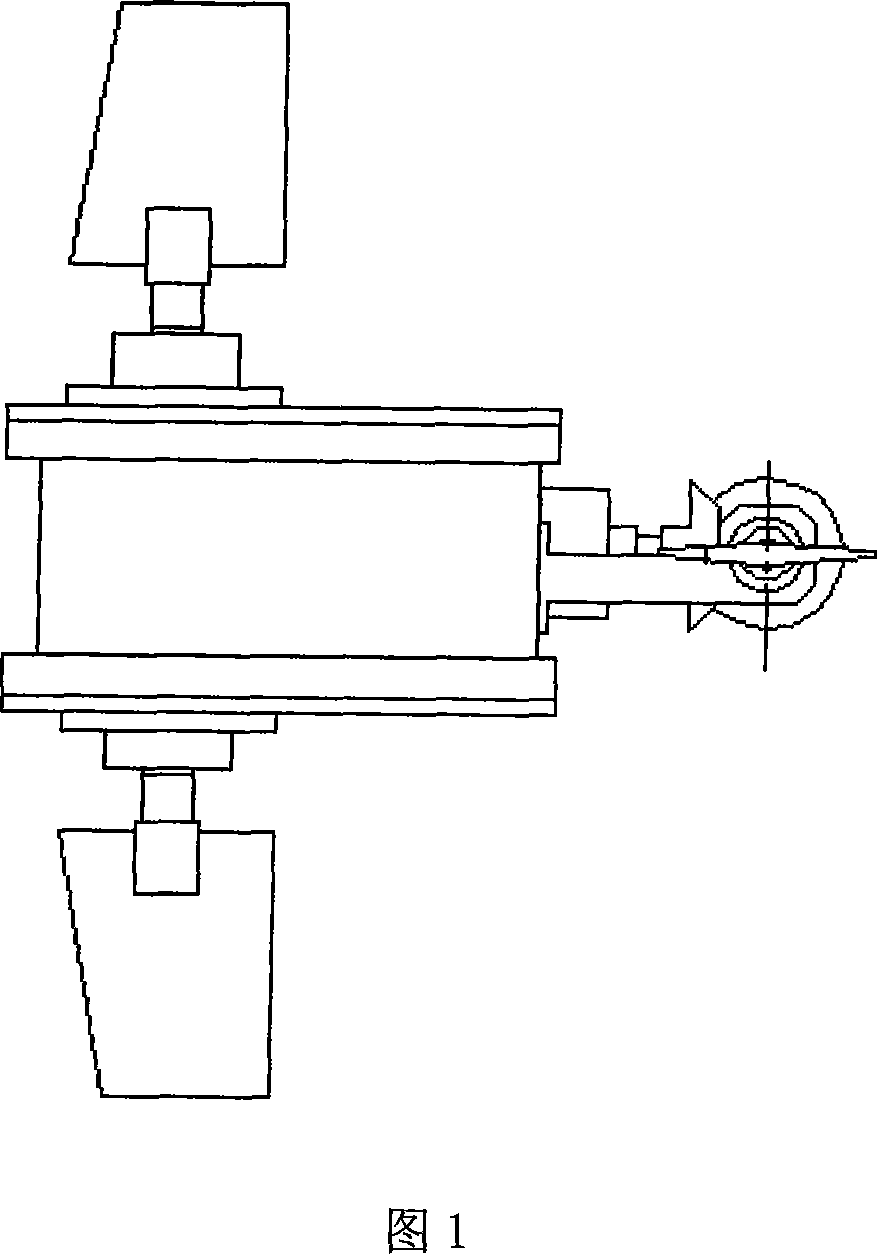

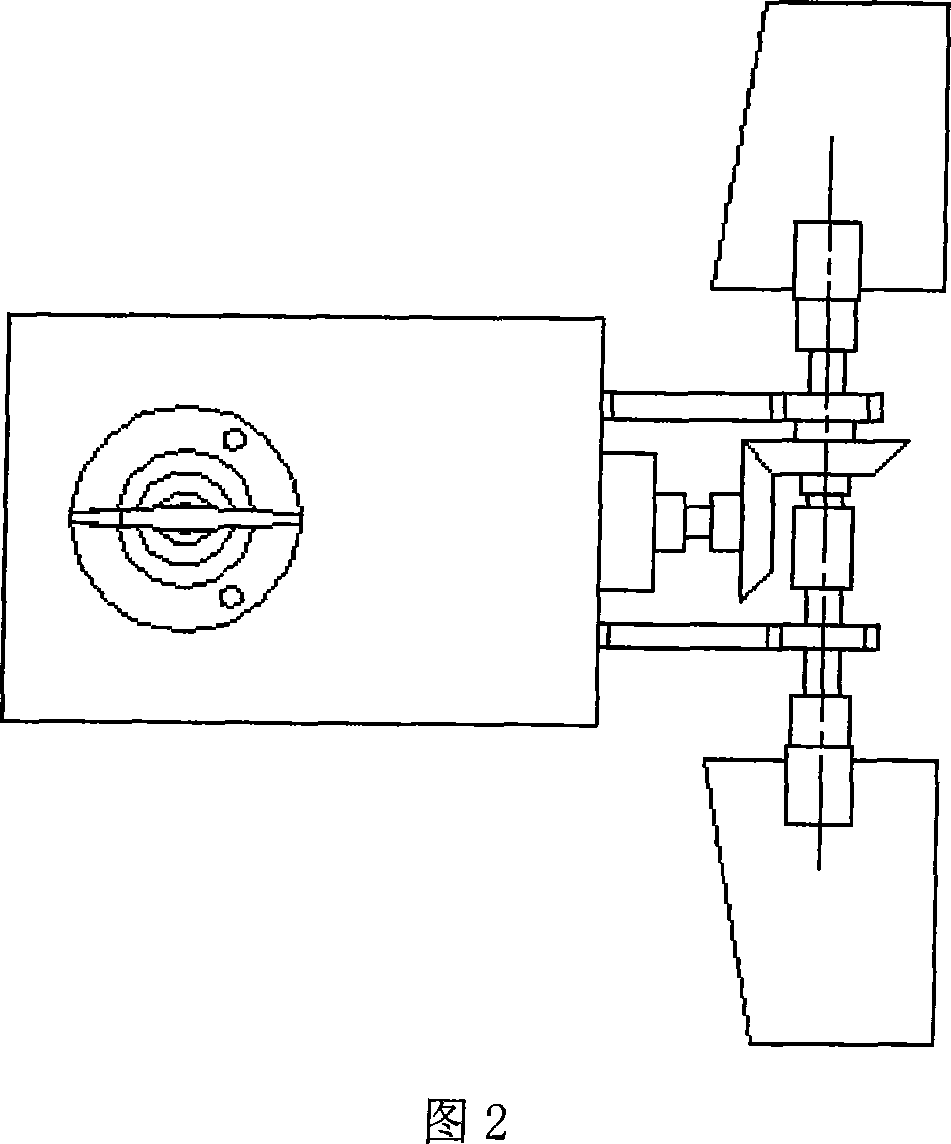

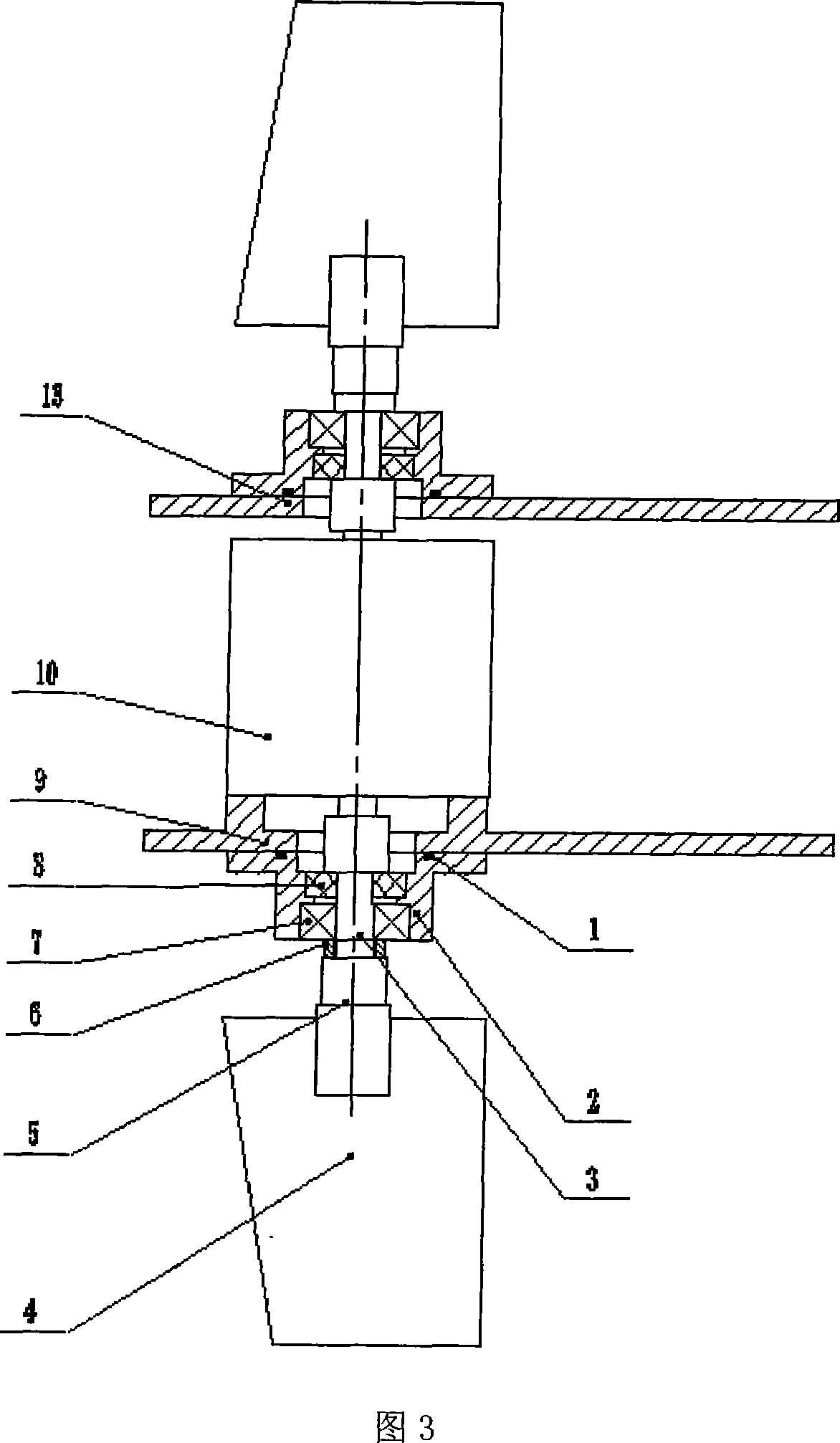

Cloud platform camera, cloud platform monitoring system and method for carrying out direction orientation

InactiveCN102006456AAchieve rotationTelevision system detailsColor television detailsData displayComputer module

The invention discloses a cloud platform camera, a cloud platform monitoring system and a method for carrying out direction orientation by the cloud platform camera, which can solve the problem that the traditional cloud platform camera is controlled by operating personnel watching the rotating result via a monitor to confirm the rotating direction of the cloud platform. The cloud platform camera comprises: a direction collecting module, a video collecting module and a video superposing module, wherein the direction collection module is used for collecting spot original direction data in real time; the video collecting module is used for collecting spot original video data in real time; and the video superposing module is used for superposing and inputting the original direction data and the original video data. Therefore, both video images and the corresponding superposed three-dimensional direction data can be displayed on the monitor. Reference parameters can be provided by the cloud platform camera of the invention, therefore a monitoring user can rapidly orientate the specific position of a questionable object; even being unfamiliar with the monitoring scene, the operating personnel beside the monitor can recognize whether the present area displayed on the monitor needs attention or not according to the three-dimensional direction data displayed in real time.

Owner:VIMICRO CORP +1

Modular steering engine of ship underwater

The invention is concerned with the modularization steering engine for underwater sailing body, includes the steering module, the heaving steer module and the sealing box; sets the steer step motor and the heaving step motor in the sealing box; sets the steering module in front of the sealing box, the two steerings sets on the outputting axle of the steer step motor by the connecting axle of the steering; the heaving steer module is located at rear of the sealing box, the outputting power of the heaving step motor steers by the cone gear sub-steering to transfer to two heaving steering by the connecting axle of the heaving steering. The invention can achieve the simultaneous control of the steering and the heaving steering; the transmission is accurate by using the driving of step motor.

Owner:HARBIN ENG UNIV

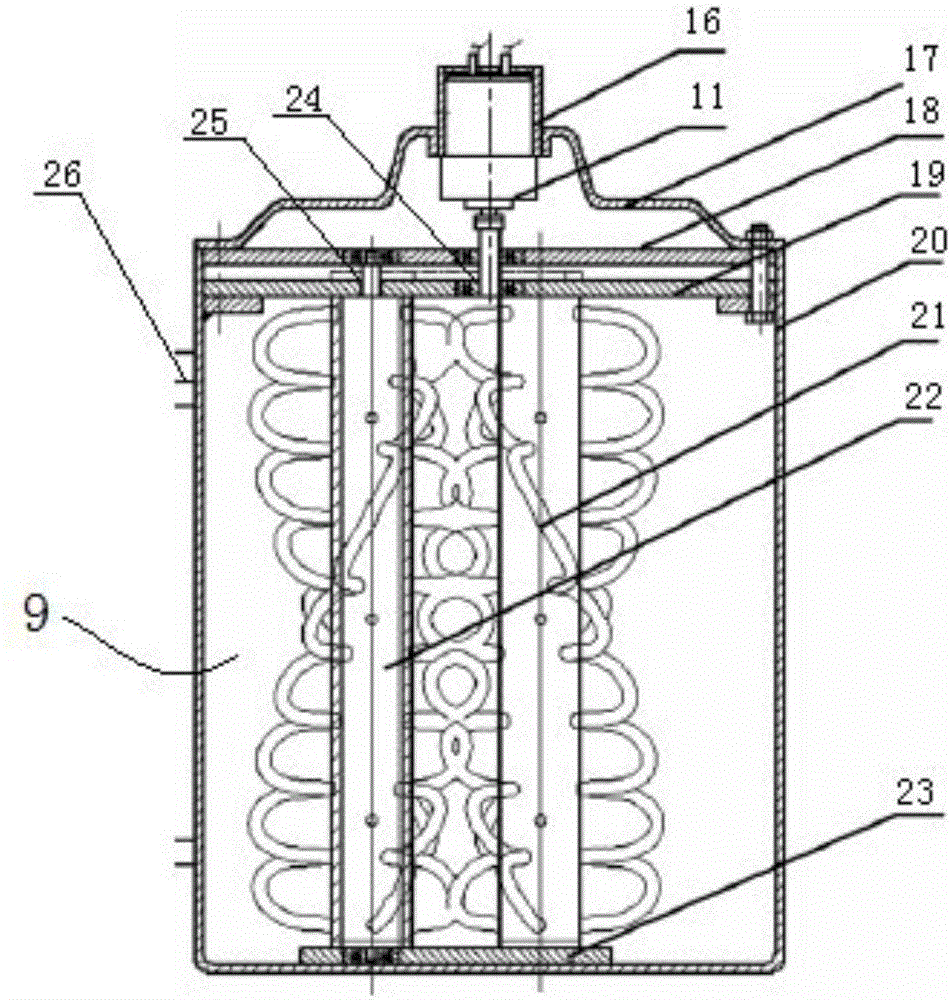

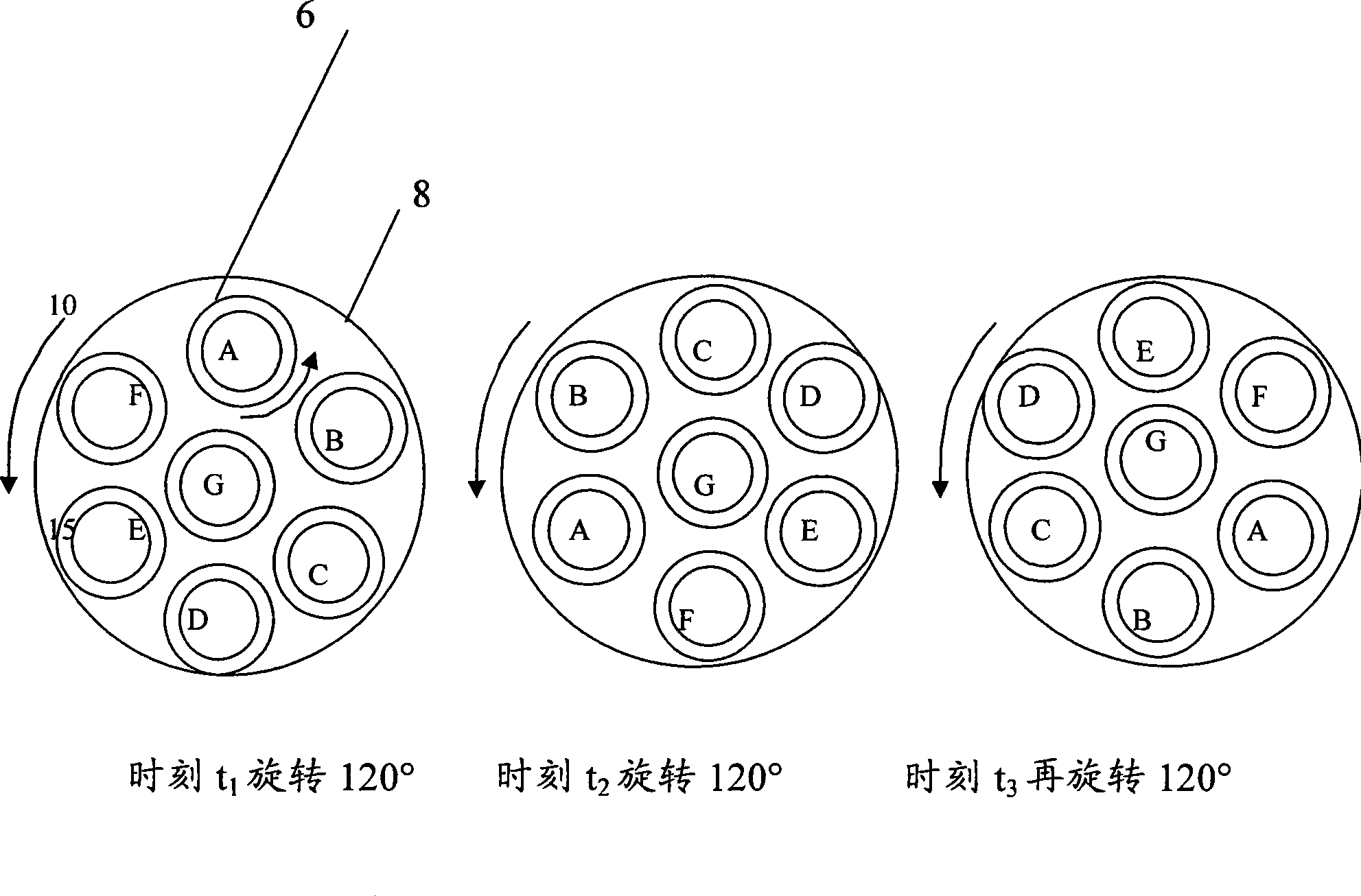

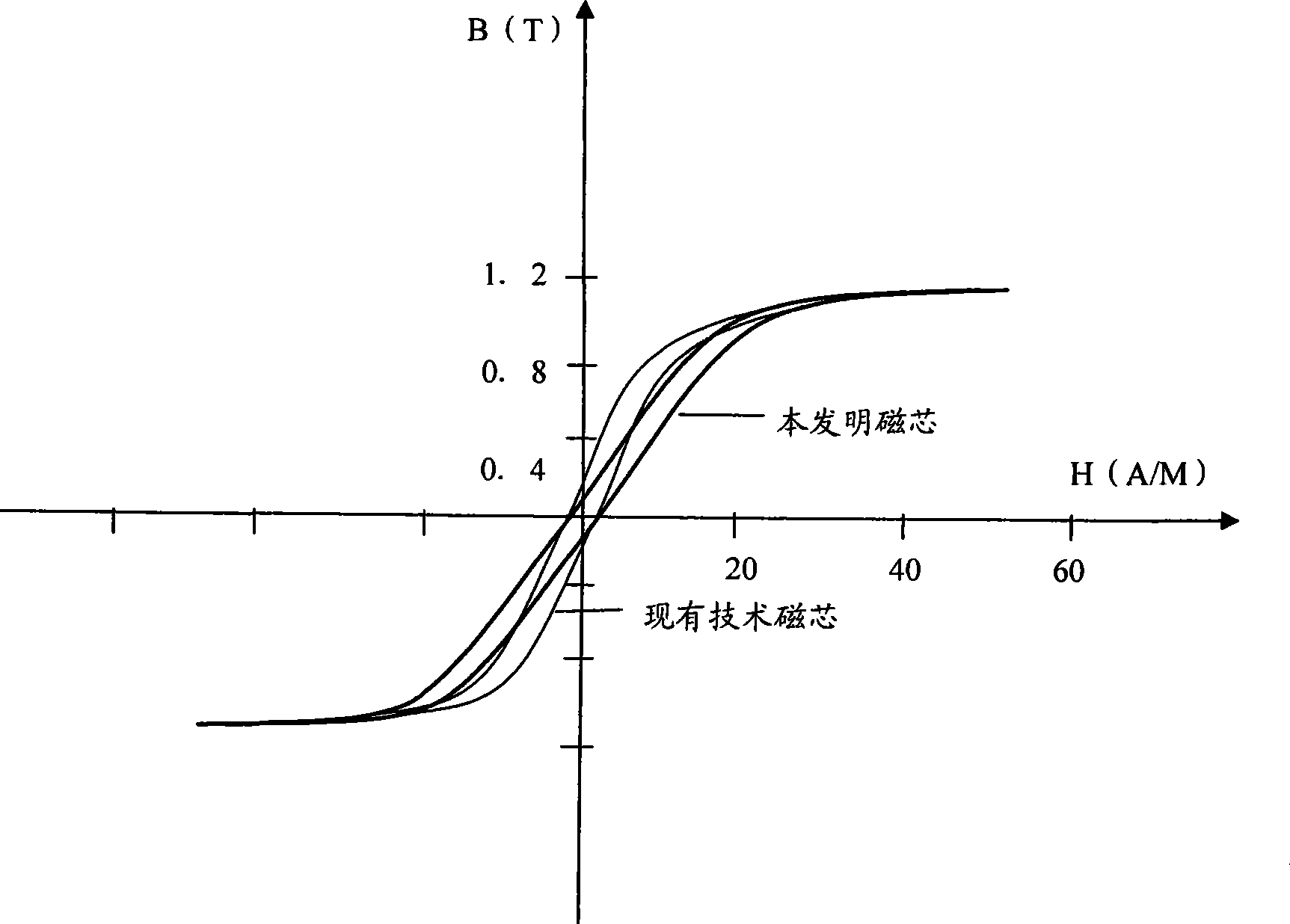

Iron based nanocrystalline magnet core for large power inverter power source and production method

ActiveCN101477868AGood tape making processReduce lossInorganic material magnetismTransformers/inductances magnetic coresPower inverterDownstream processing

The invention relates to a soft magnetic core used for a high-power inverter power supply, and a manufacturing method thereof. The magnetic core is made of an Fe-based amorphous nano-crystalline belt material through winding , and comprises components according to weight percentages as follows: 81%-85% of Fe, 0.01%-5% of Co, 7%-9% of Si, 1.5%-2.5% of B, 1%-2% of Cu, 4%-7% of M, and 0.001%-0.04% of M', wherein M is one or more of Nb, Mo, V, W and Ta, and M' is at least one of Al and Ti. The magnetic core is subjected to anneal in a protective atmosphere or a vacuum; when in anneal, the position of the magnetic core in a furnace is movable or rotatable, a holding temperature is 520-600 DEG C, the holding time is 1-2 hours, and a temperature rise speed is 100 DEG C per hour. The magnetic core manufactured by adopting the method has lower loss, better manufacturing technique properties, and good soft magnetic characteristics; moreover, the downstream processing after the heat treatment is applicable to various technique methods.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

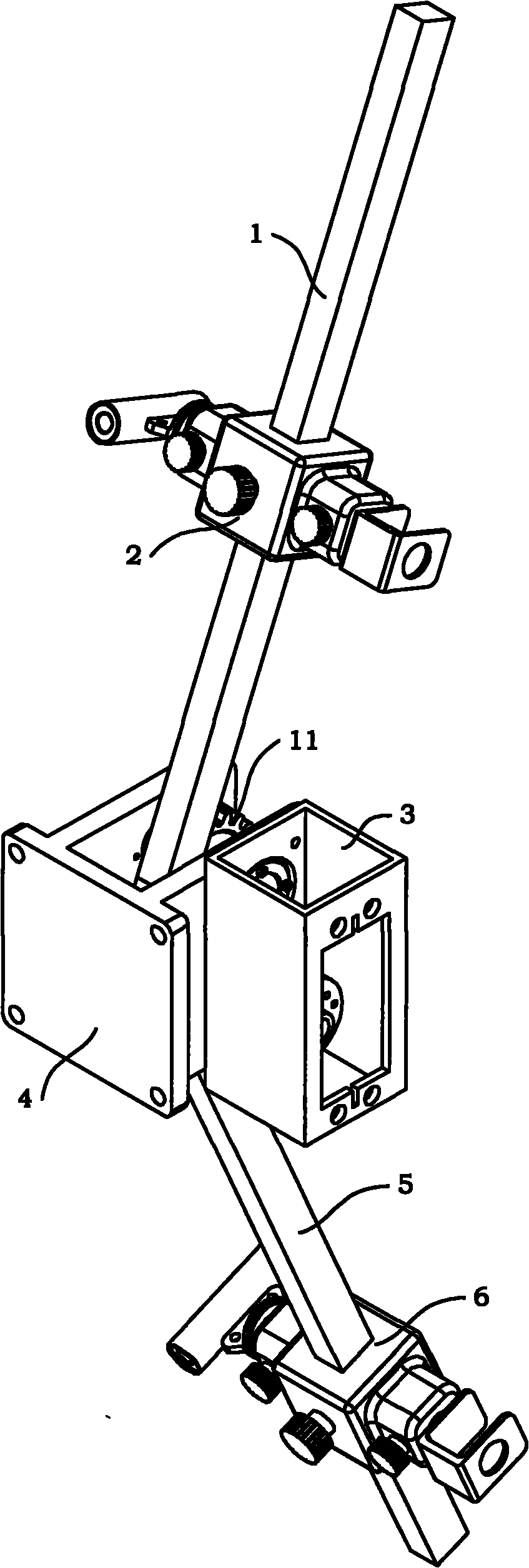

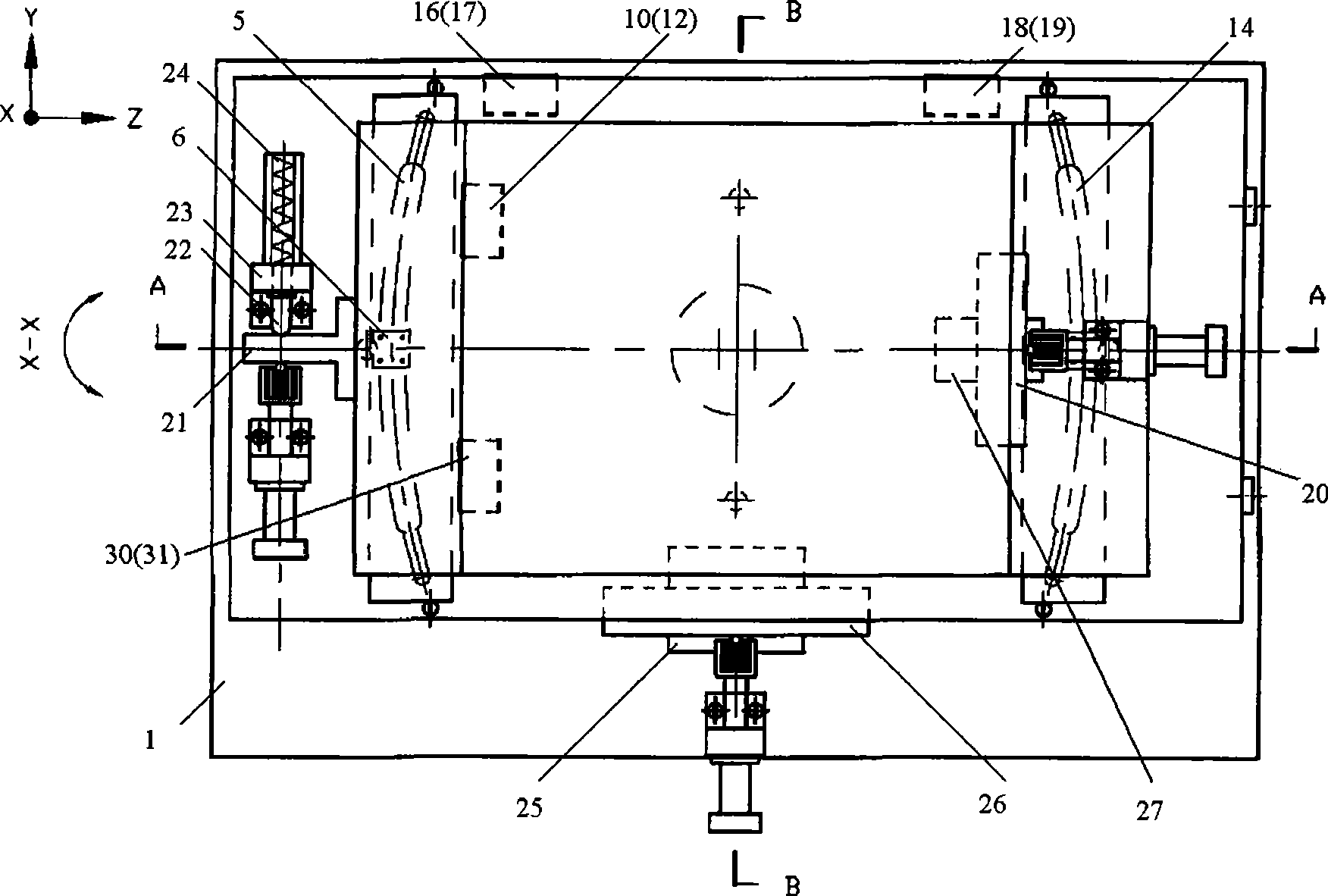

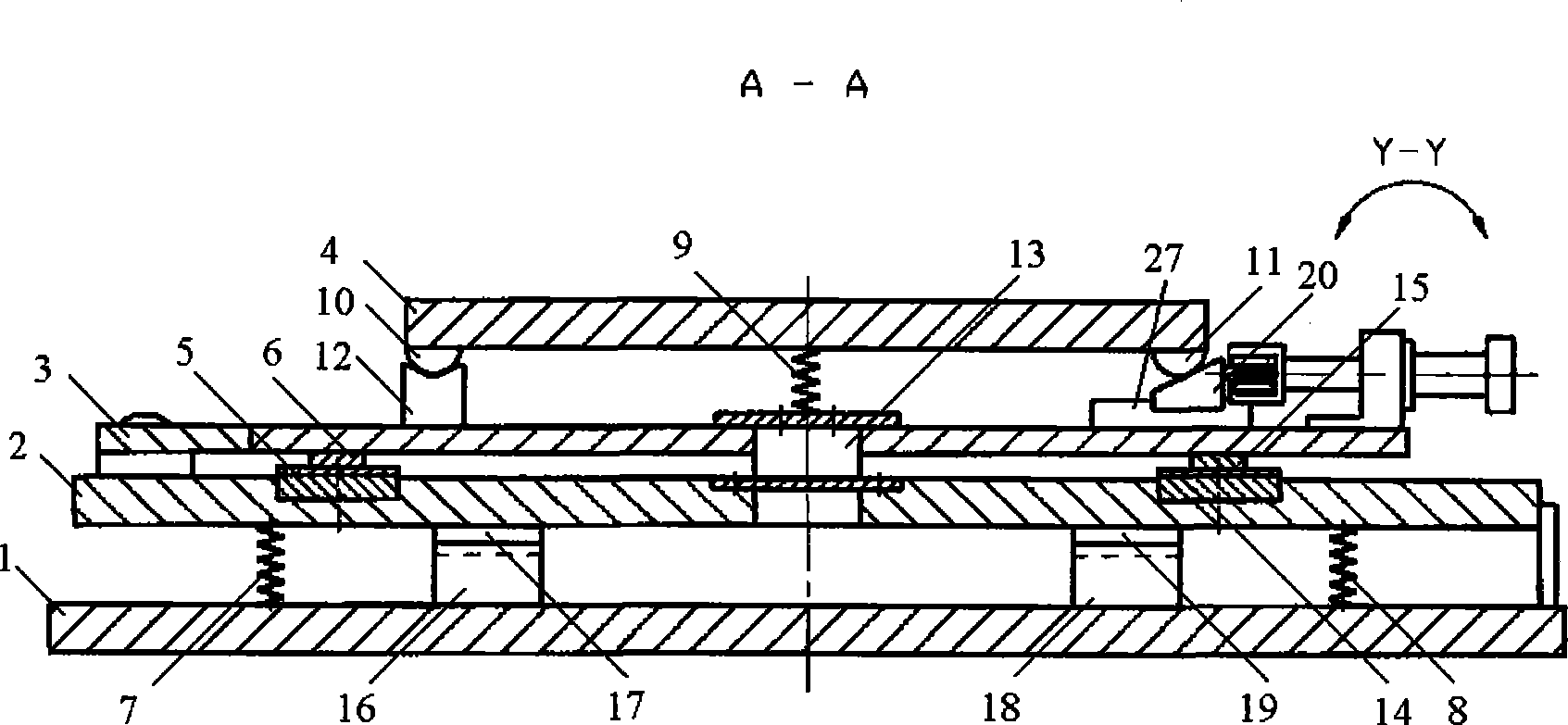

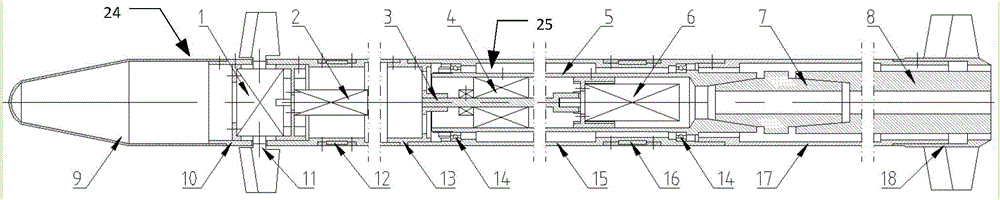

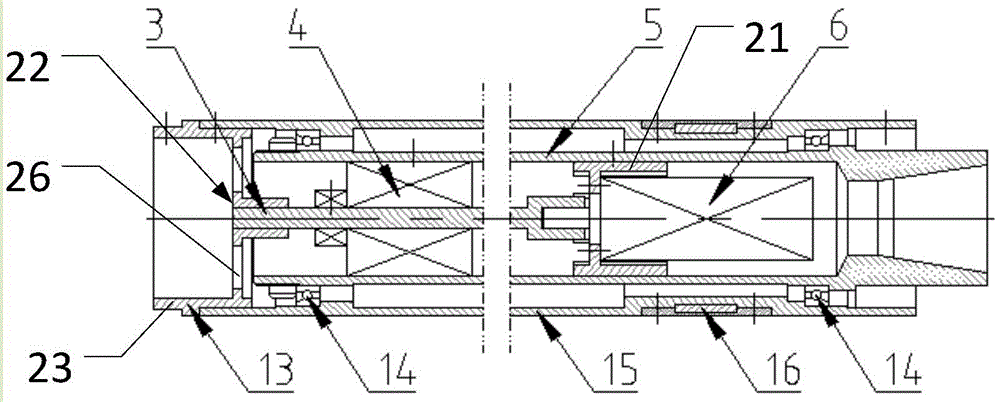

Wind tunnel dynamic force measurement test device for canard configuration rotating missile

InactiveCN105527068AAchieve rotationRealize measurementAerodynamic testingMeasurement testData acquisition

The invention discloses a wind tunnel dynamic force measurement test device for a canard configuration rotating missile. The device comprises a tail supporting rod, a test missile model, a steering engine driving mechanism, a force measurement balance, a fixed sleeve, an autorotation driving mechanism and a data acquisition and processing system, wherein the test missile model has a cavity and is provided with a deflectable nose control; the steering engine driving mechanism drives the nose control to deflect, and is arranged in the front of the cavity; the fixed sleeve is arranged in the back of the cavity, the rear end of the fixed sleeve is connected to the front end of the force measurement balance, and the test missile model is rotationally sleeved outside the fixed sleeve; the autorotation driving mechanism is arranged inside the fixed sleeve, and a power output shaft extends out of a front opening of the fixed sleeve and drives the test missile model to rotate; and the data acquisition and processing system is in communication connection to the force measurement balance to receive force measurement data of the force measurement balance. The device realizes autorotation of the canard configuration rotating missile and deflection of the nose control, realizes measurement of aerodynamic force and torque, and is particularly suitable for force measurement test of large length-diameter ratio test missile models in 1.2m sub-trans-supersonic wind tunnels.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

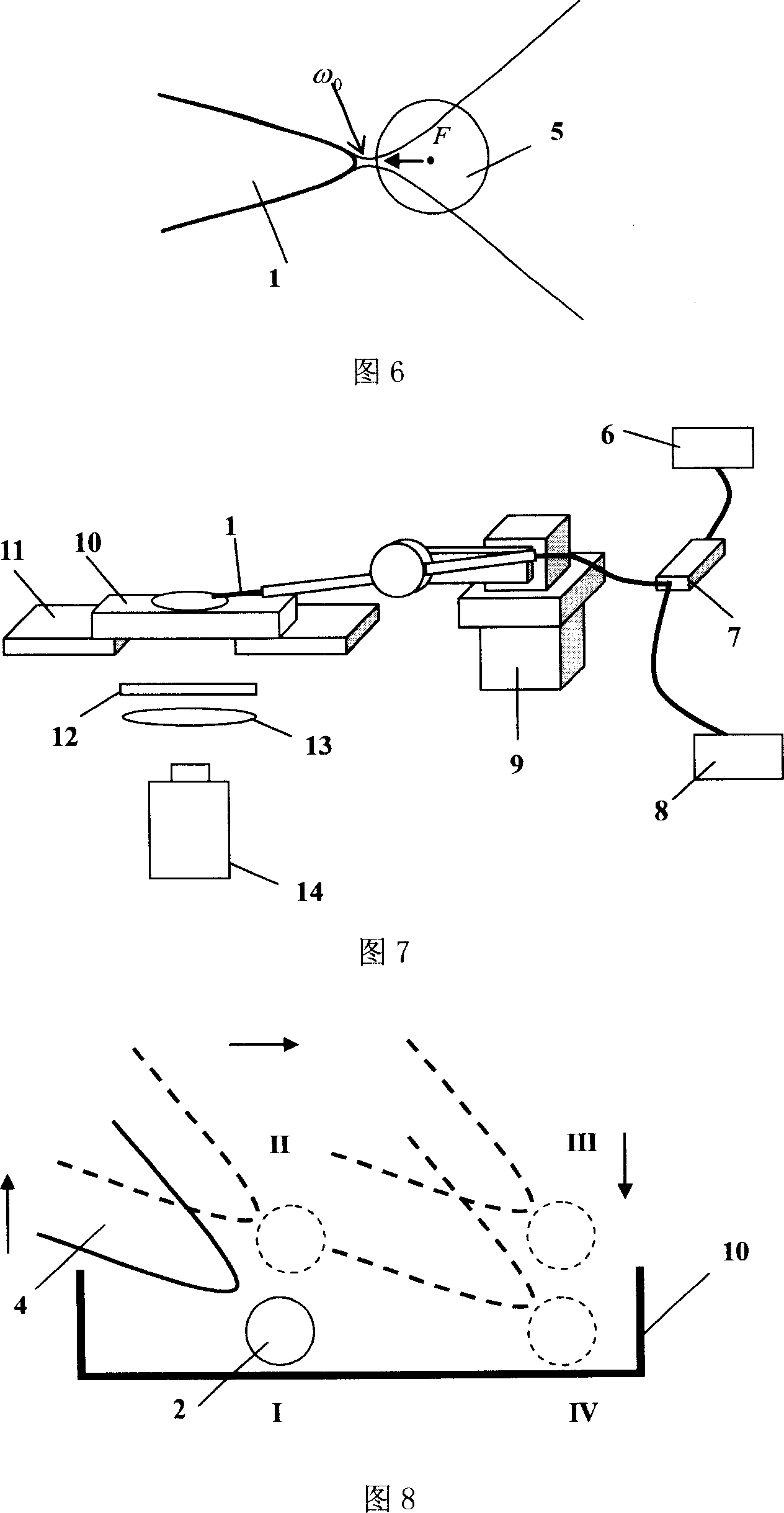

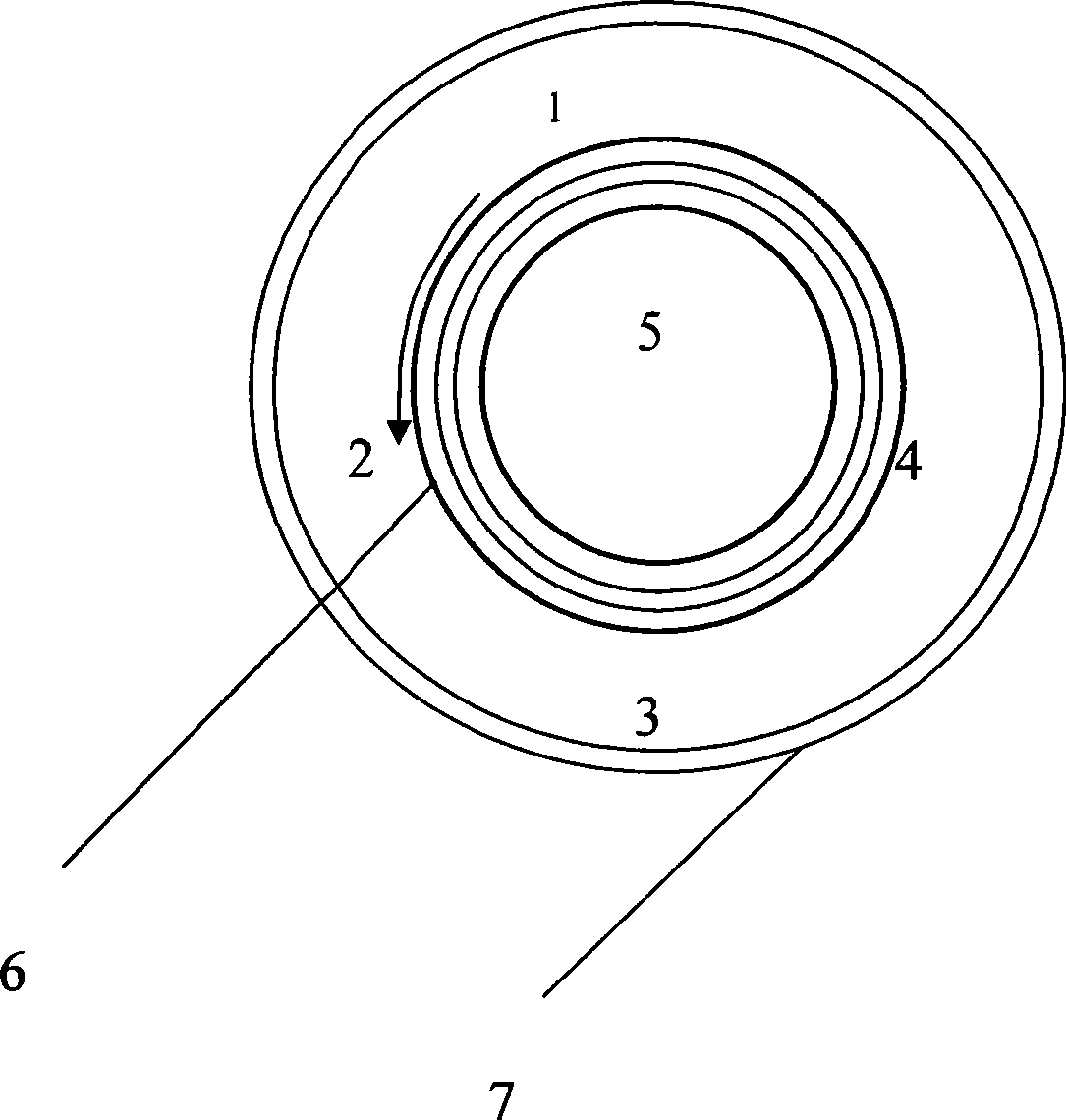

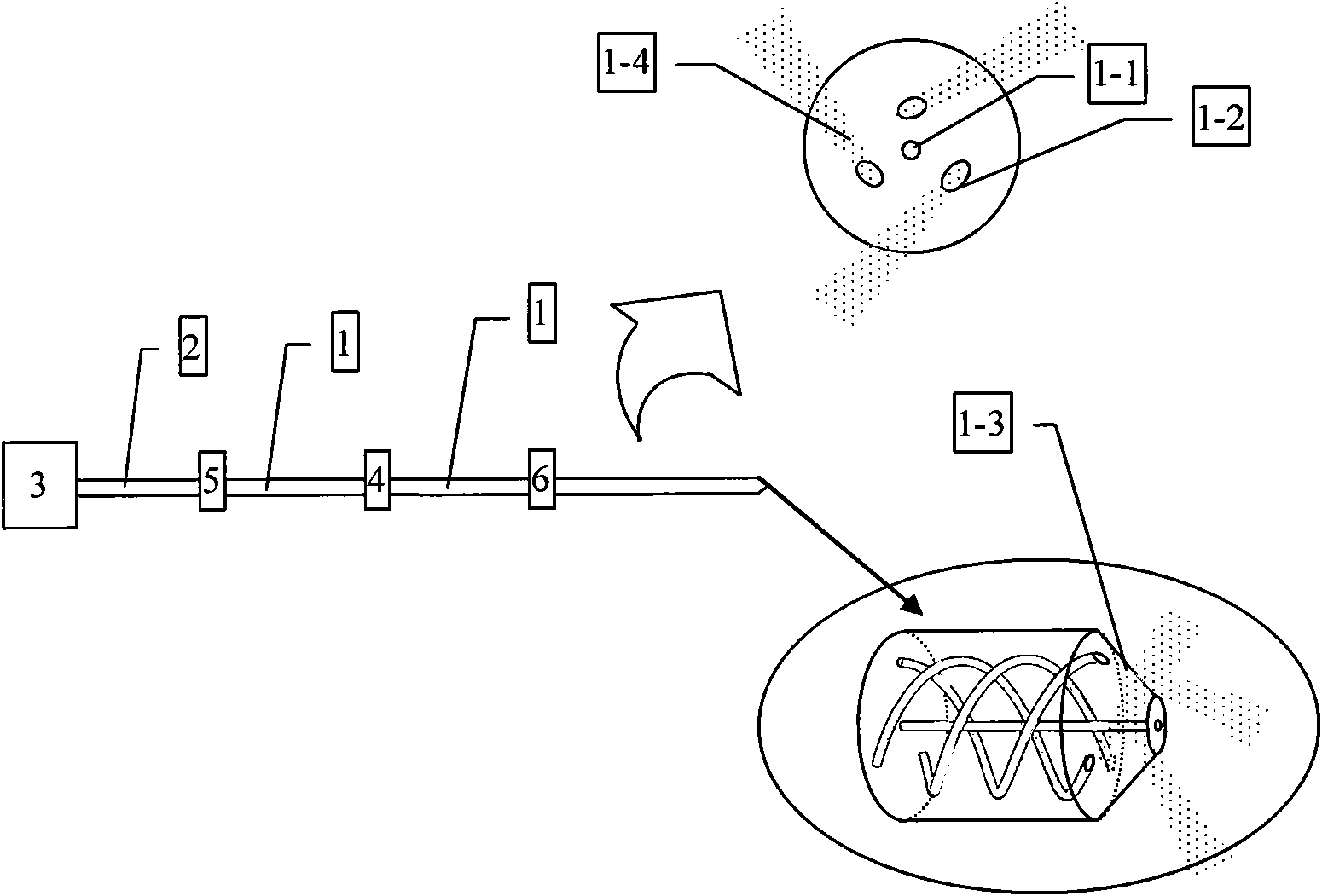

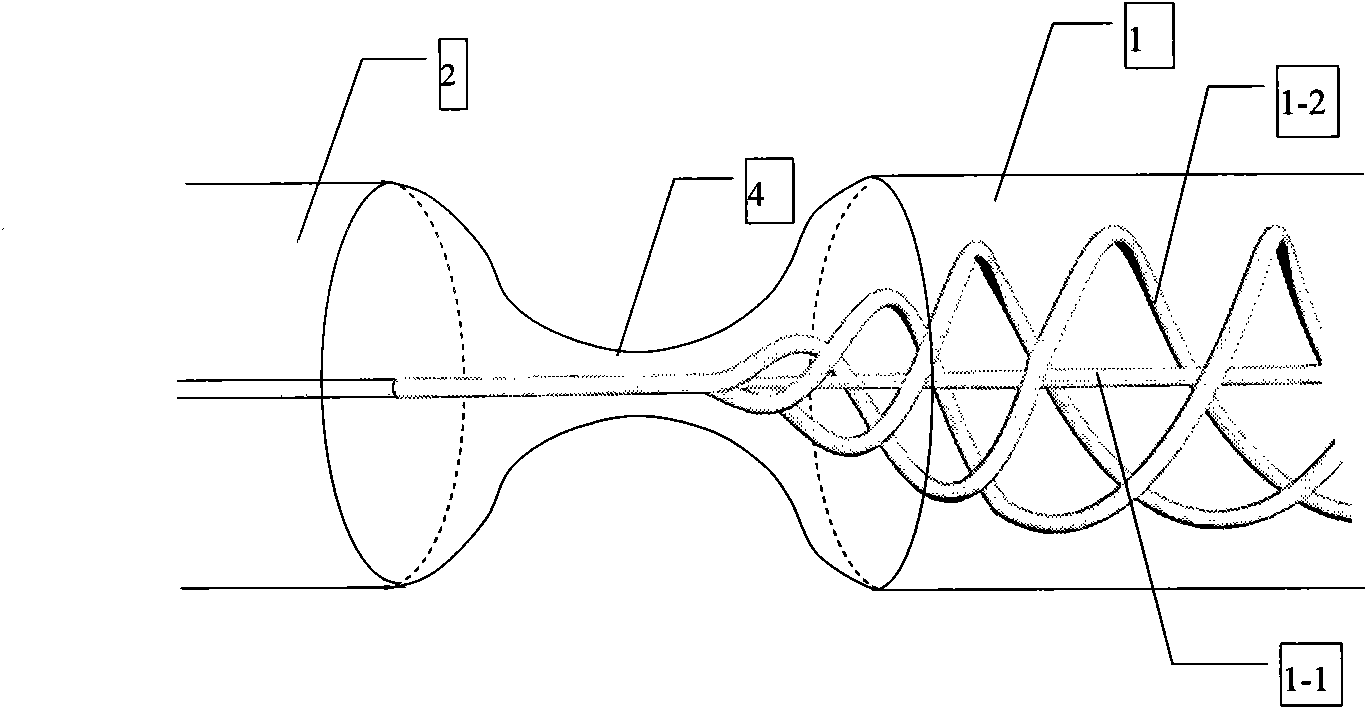

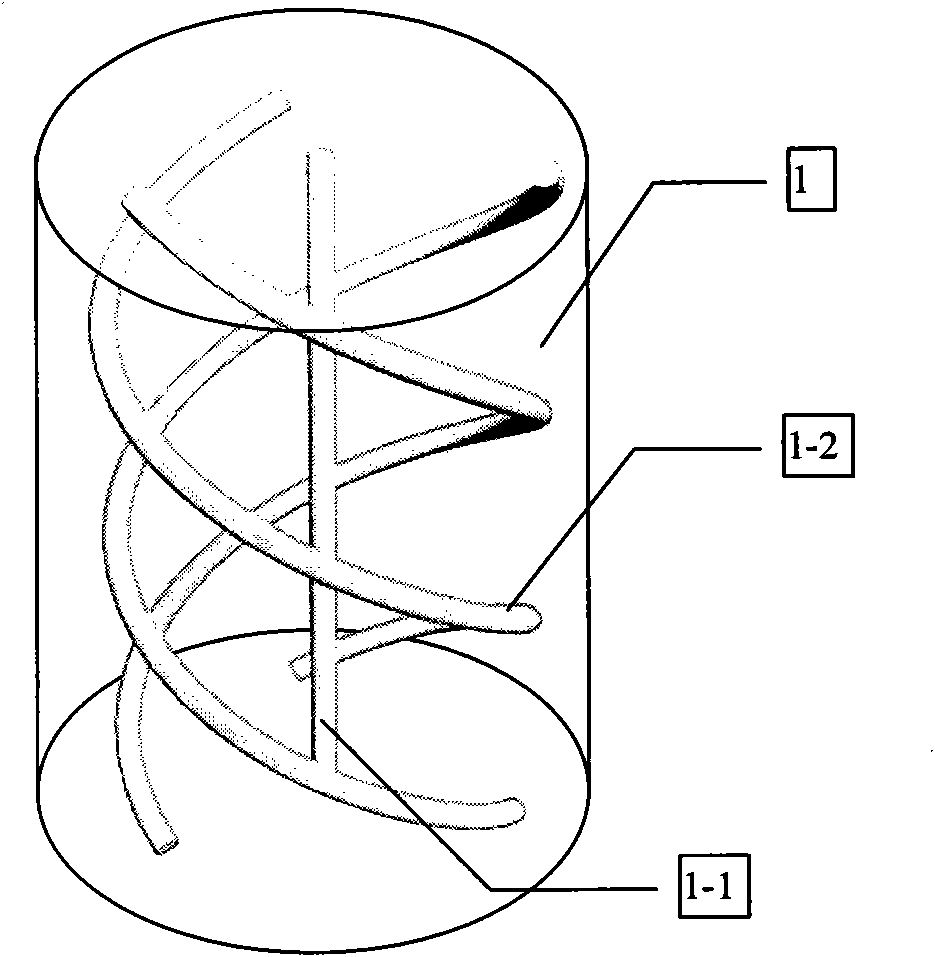

Satellite-type helical multi-core fiber optical micro-tweezers capable of achieving rotation of small particles and preparation method thereof

InactiveCN101881858AAchieve rotationCapture flexibleCladded optical fibreRadiation/particle handlingPhysical spaceEngineering

The invention provides satellite-type helical multi-core fiber optical micro-tweezers capable of achieving the rotation of small particles and a preparation method thereof. A laser source is connected with one end of a standard single-mode fiber, and the other end of the standard single-mode fiber is coupled with the satellite-type helical multi-core fiber by thermal-fused bi-conical taper to form a first thermal-fused bi-conical taper position; the satellite-type helical multi-core fiber is attached to an optical-path changing device, and the satellite-type helical multi-core fiber passing through the optical-path changing device is further subjected to the thermal-fused bi-conical taper operation to form a second thermal-fused bi-conical taper position; and the other end of the satellite-type helical multi-core fiber is prepared into a pyramidal shape in a processing manner of finely grinding. Therefore, the invention can save the physical space and greatly reduce the optical input power of the system, so as to reduce the damage on the particles to be trapped; the particles can be trapped in a more flexible, more accurate and adjustable manner; and the vortex-shaped optical trap can be naturally formed at the fiber end, thus achieving the rotation of the particles and the motor function of the operated particles.

Owner:HARBIN ENG UNIV

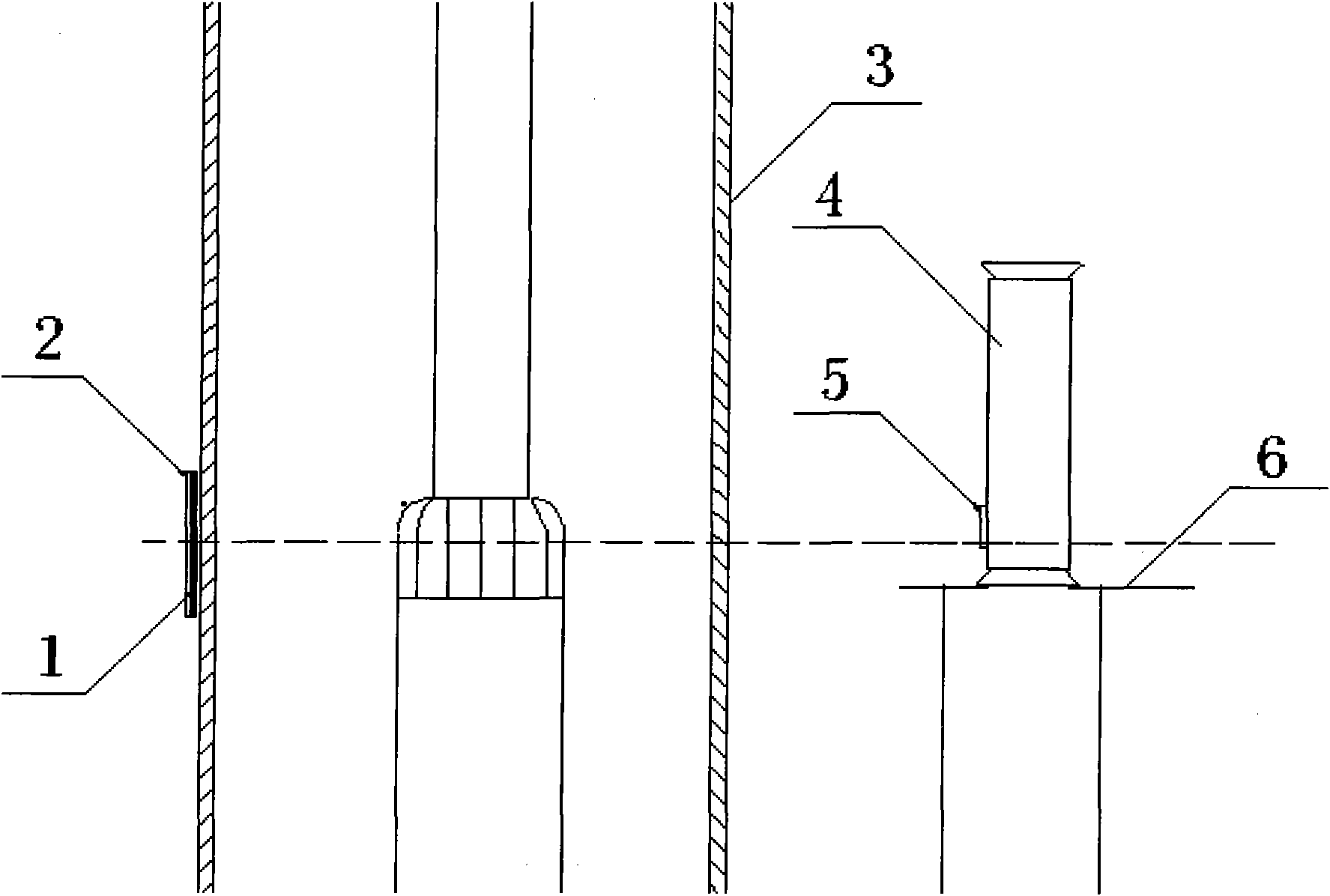

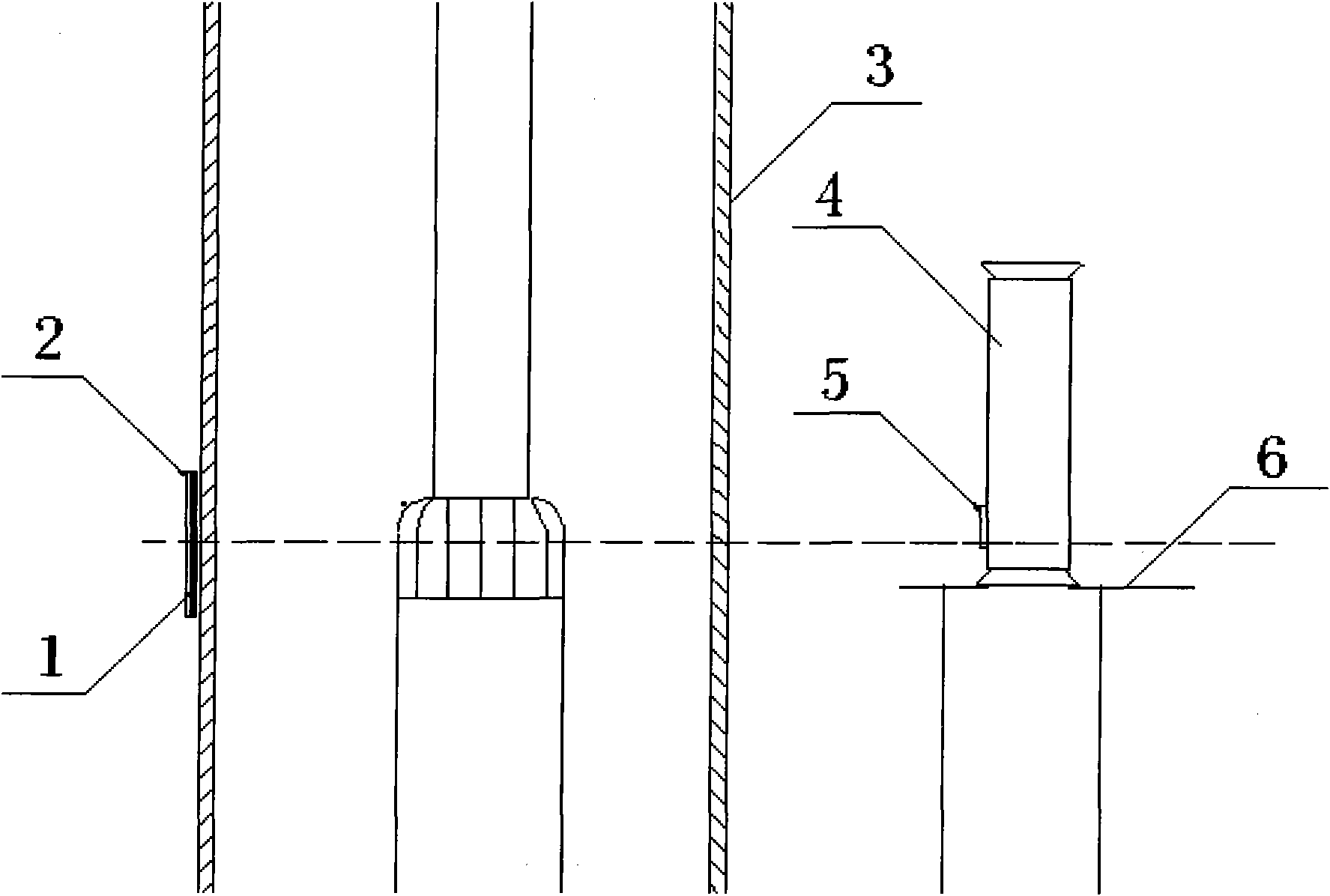

X-ray radiographic digital imaging detection method for power grid GIS (Geographic Information System) equipment

InactiveCN101839870AImprove work efficiencyLarge observable rangeMaterial analysis by transmitting radiationDigital imagingField conditions

The invention relates to a power grid equipment detecting technology, in particular to an X-ray radiographic digital imaging detection method for power grid GIS (Geographic Information System) equipment. The detection method comprises the following steps of: (1) fixing a part needing to be shot; (2) erecting an X-ray apparatus and placing an X-ray sensitization imaging plate; (3) connecting a cable between the X-ray apparatus and a console; (4) connecting a CR (Conditioned Reflex) digital image scanner and a computer by a special data line; (5) setting a shooting parameter of the X-ray apparatus according to the field condition; (6) starting a high-voltage emitting button of the console and carrying out radiographic shooting; (7) reading data to obtain a digital image picture; and (8) processing a shooting result by the computer. An X-ray radiographic digital imaging system of the GIS equipment directly reads data of an IP (Internet Protocol) imaging plate by adopting an advanced CR digital image scanning technology and converts the sensitizing image information on the IP imaging plate into a digital image signal; and compared with the traditional ray film needing a darkroom and the step of developing, the working efficiency is greatly improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID QINGHAI ELECTRIC POWER COMPANY

Nondestructive testing robot for pipes

ActiveCN105020537AAchieve rotationAvoid situations where a turn cannot be completedPigs/molesNondestructive testingEngineering

The invention discloses a nondestructive testing robot for pipes based on an electromagnetic principle, and belongs to the field of structural design. The nondestructive testing robot can adjust postures in real time to adapt to such conditions as pipe bending not beneficial to the climbing. The nondestructive testing robot is additionally provided with a magnetic absorbing device and a spherical connecting mechanism, so that the robot can climb in vertical pipes or bent pipes not beneficial to the climbing. The robot is stronger in pipe adaptability. The magnetic absorbing device is placed in a foot, and is connected with a spring; the spring is elongated and an electromagnet is absorbed on the pipe wall in electrification; and the spring is pulled back into the foot in power failure. Meanwhile, a flexible spring is mounted in the upper part in the foot, so that the foot has a certain adjusting capacity to adapt to the pipes with different diameters, and has a certain vibration reducing effect and obstacle crossing ability. When a leg is absorbed and fixed, the climbing action is finished by dint of relative actions of a body and the fixed leg. Through the absorption of the electromagnet, the electromagnet is absorbed on the pipe wall in electrification, the leg is fixed, and the body is advanced; and the electromagnet is pulled back into the leg by the spring in power failure, and the leg is movable.

Owner:河北航轮科技有限公司

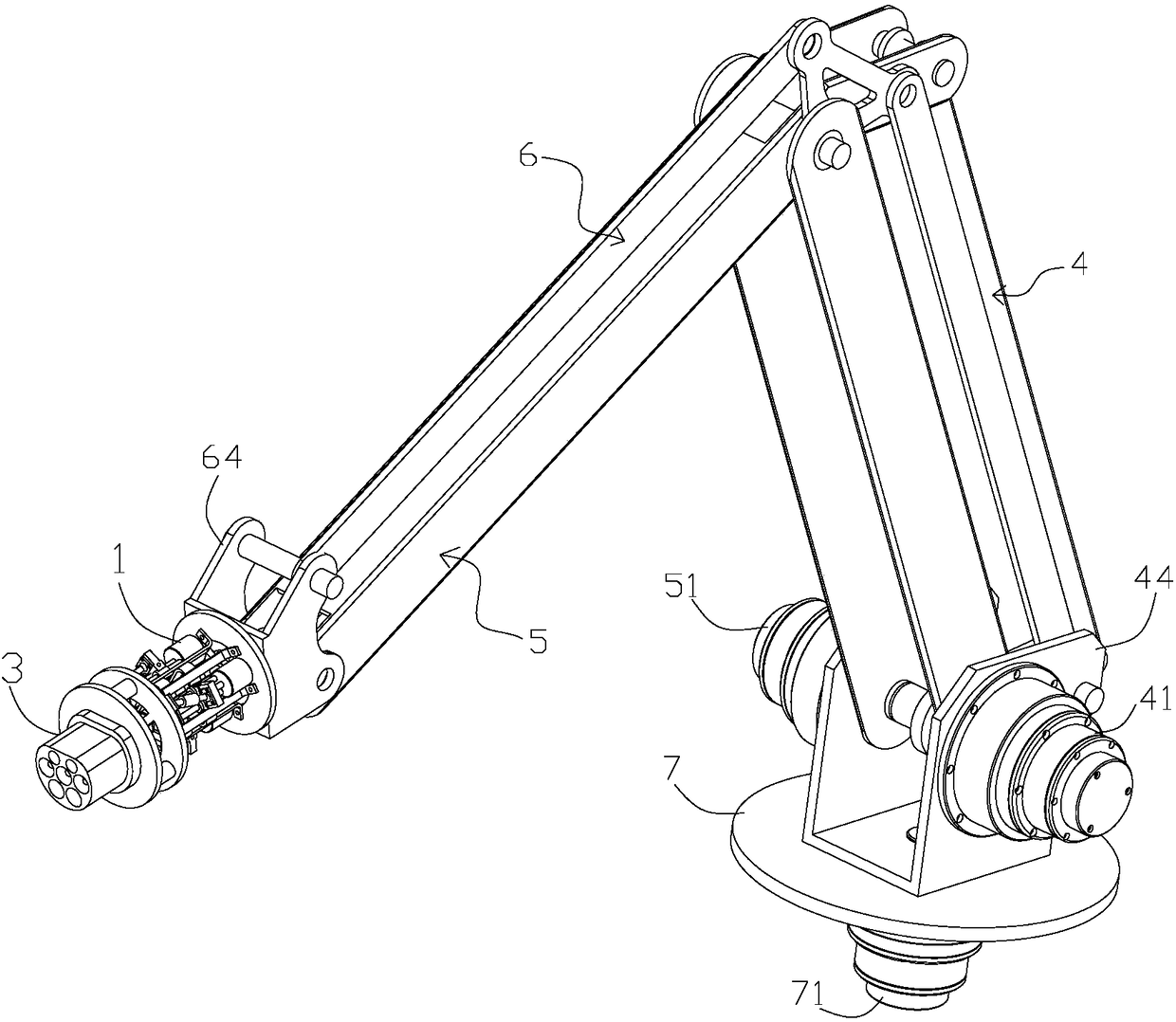

Intelligent 360-degree multi-dimensional mechanical arm of automobile equipment line

InactiveCN103495974AAchieve crawlingAchieve rotationProgramme-controlled manipulatorEngineeringMulti dimensional

The invention discloses an intelligent 360-degree multi-dimensional mechanical arm of an automobile equipment line, and relates to a mechanical arm. A large side plate is provided with a pressure energy accumulator, one end of a composite lifting arm I and one end of a composite lifting arm II are respectively connected with the pressure energy accumulator, the other end of the composite lifting arm I and the other end of the composite lifting arm II are connected with a connecting plate I, one end of a lifting air cylinder is connected with the large side plate, the other end of the lifting air cylinder is connected with the composite lifting arm II, one end of a front-and-back swinging air cylinder is connected with the pressure energy accumulator, and the other end of the front-and-back swinging air cylinder is connected with a composite swing arm I. Due to the adoption of a pneumatic clamp device capable of being rotated by 360 degrees under servo control, material grabbing and rotating are achieved, clamping time is saved, and labor intensity of workers is reduced in the assembling process. Meanwhile, a sensor network and an advanced ARM microcontroller are adopted in the mechanical arm to achieve intelligent detection and digital fuzzy control, state sensing and intelligent feedback control of the assisting mechanical arm are achieved in the working process, and safety and the automation level of products are improved.

Owner:盐城市昱博汽车零部件有限公司

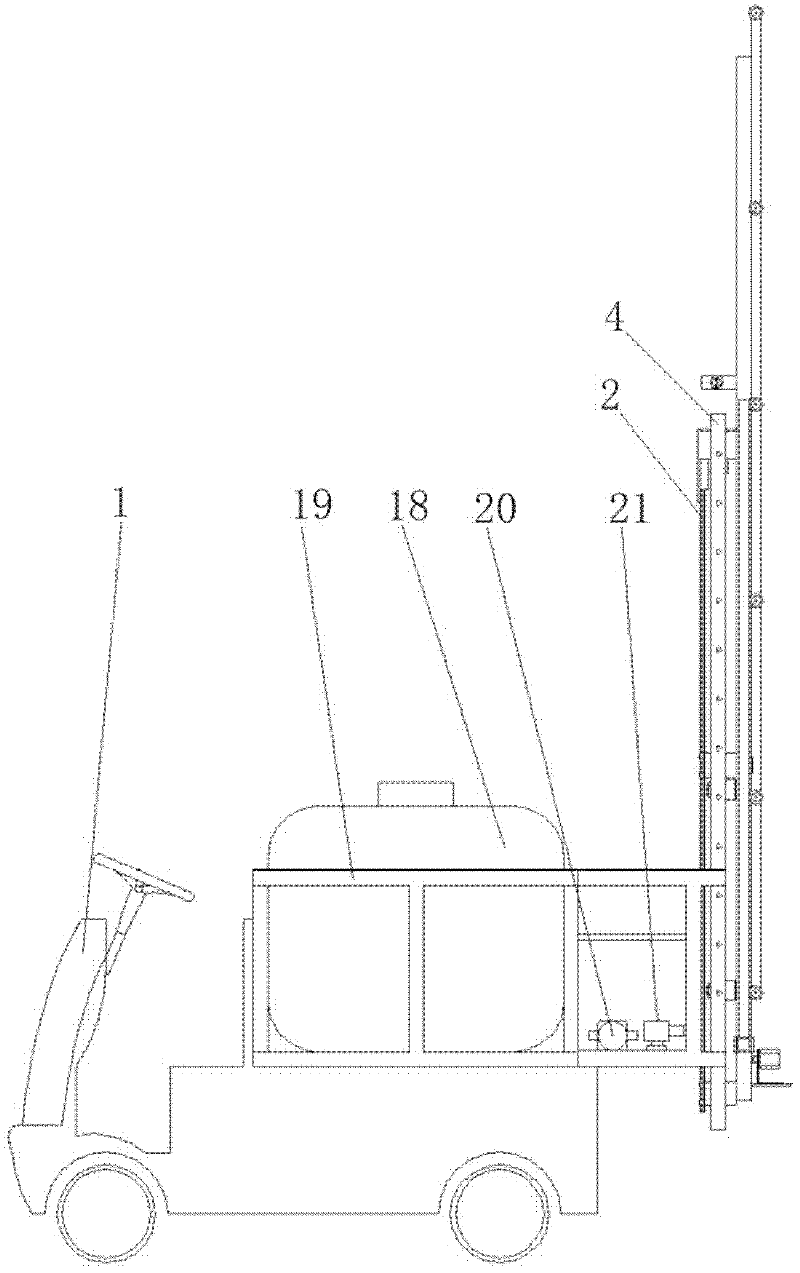

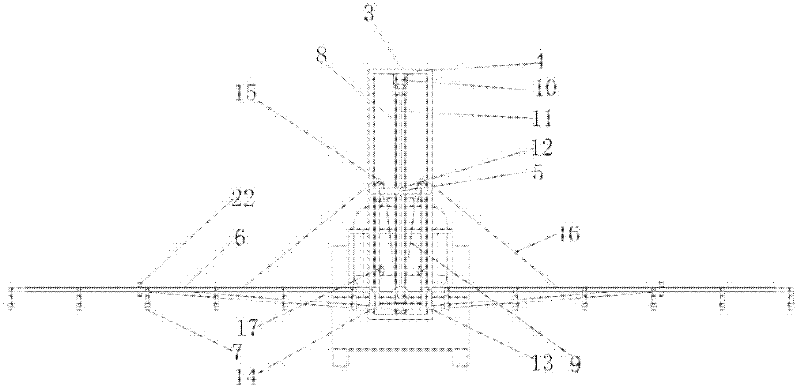

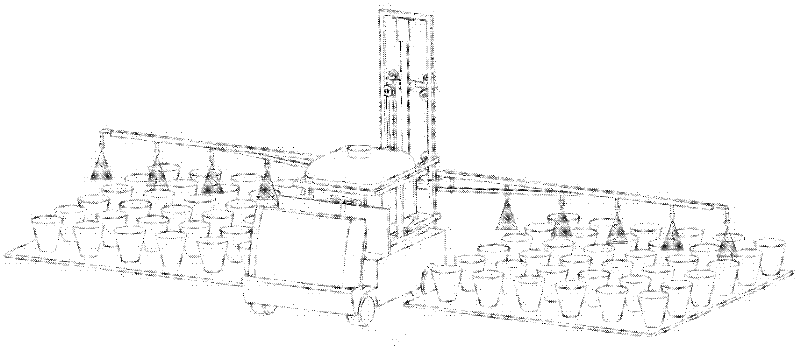

Automatic spraying machine

The invention discloses an automatic spraying machine, which relates to the technical field of equipment for plant protection and comprises a driving unit (1), a control unit (2), and a spray frame unit (2) loaded on the driving unit (1). The spray frame unit (1) comprises a fixed support (4), a movable support (5) and spray rod trusses (6), wherein the movable support (5) is mounted on the fixed support (4), the spray rod trusses (6) are symmetrically mounted on the movable support (5), and nozzles (7) are mounted on the spray rod trusses (6). The control unit (2) comprises a lifting unit (8) and a rotating unit (9), wherein the lifting unit (8) is used for controlling ascent and descent of the movable support (5), and the rotating unit (9) is used for controlling rotation of the spray rod trusses (6). The automatic spraying machine can be used for automatically spraying crops planted in different manners and for spraying crops planted in a tendril suspended manner and in a seedling bed manner, spraying efficiency is improved, and convenience is brought to users.

Owner:CHINA AGRI UNIV

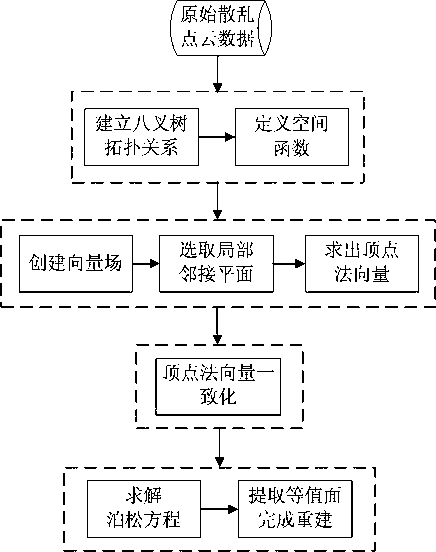

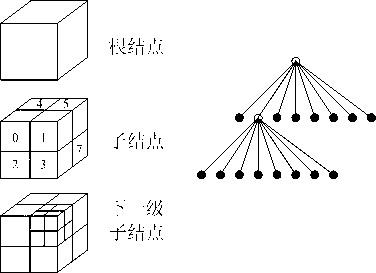

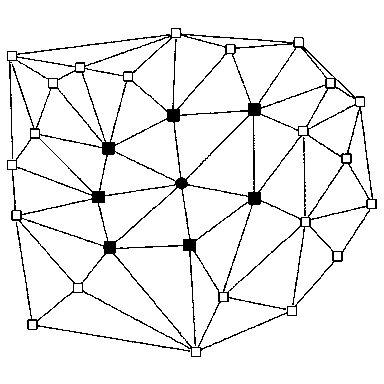

Curved planar reconstruction method for cardiac scattered-point cloud data

InactiveCN102999937AShow Spatial RelationshipsImprove security3D modellingDiseaseReconstruction method

The invention relates to the field of curved planar reconstruction, in particular to a curved planar reconstruction method for cardiac scattered-point cloud data. The curved planar reconstruction method for cardiac scattered-point cloud data includes the steps of firstly, defining the data representation form of acquired point cloud data, establishing octree topological relation, and defining a space function; secondly, establishing a vector field, selecting local adjacent planes, and determining vertex normal vectors according to an average of planar normal vectors of the local adjacent planes; thirdly, uniformizing the vertex normal vectors; and fourthly, solving a Poisson equation, extracting a contour surface by MC (marching cubes) algorithm according to an indicator function and gradient thereof, and reconstructing a cardiac three-dimensional surface model. By the curved planar reconstruction method for cardiac scattered-point cloud data, cardiac spatial position relation can be displayed visually and accurately, optional display, zooming, rotation and cutting in three dimensions can be achieved, cardiac diseases can be detected, computer diagnostic analysis for diseases such as arrhythmia and surgical accurate simulation are achieved, and safety and reliability in disease diagnosis are improved.

Owner:SHANGHAI HANPAN INFORMATION TECH

Steel pipe grinding device for machining

PendingCN109571162AAchieve rotationEasy to polishRevolution surface grinding machinesGrinding drivesBristleEngineering

The invention discloses a steel pipe grinding device for machining. The steel pipe grinding device comprises a base, a steel pipe and a rust removal barrel fixedly connected with the base. A moving frame is arranged above the base, a rotation barrel is embedded in the moving frame, and one side of the rotation barrel is fixedly connected with a three-jaw chuck. Symmetric grinding abrasive wheels are arranged at the middle position of the rust removal barrel. Through the arrangement of the rotation barrel embedded in the moving frame and rotationally connected with the moving frame, a bevel gear ring, a rolling gear and a rack plate, self-rotation during transverse steel pipe feeding is achieved, and subsequent steel pipe circumference face comprehensive grinding and scrubbing cleaning areconvenient. Through the arrangement of a swinging frame, a first rust removal brush barrel with steel wire bristles and a second rust removal brush barrel with soft bristles, the spindle-shaped rust removal barrel and an industrial dust collector are matched, so that iron scraps are conveniently collected in a centralized manner, and operation environment pollution is avoided.

Owner:HUNAN UNIV OF SCI & ENG

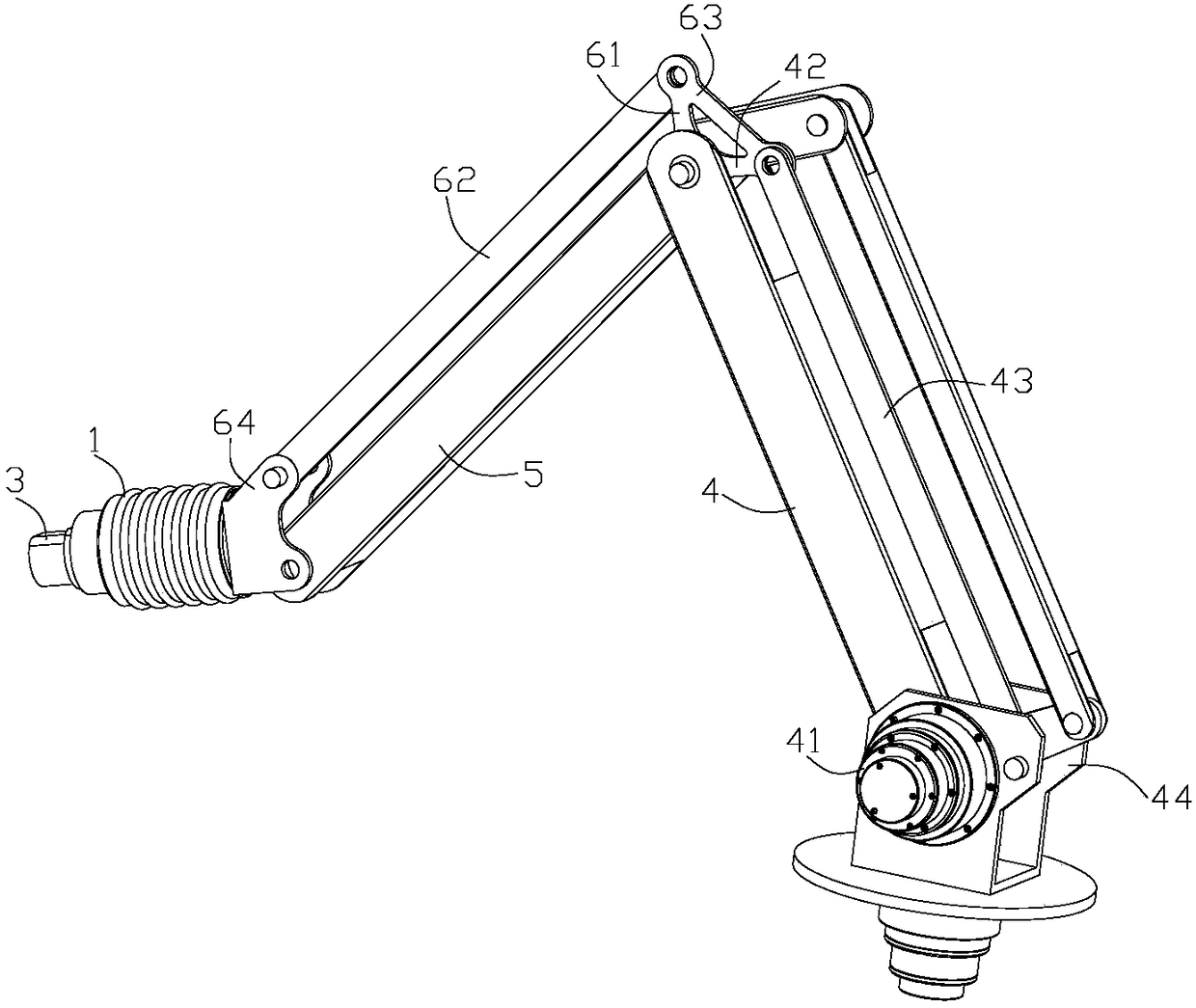

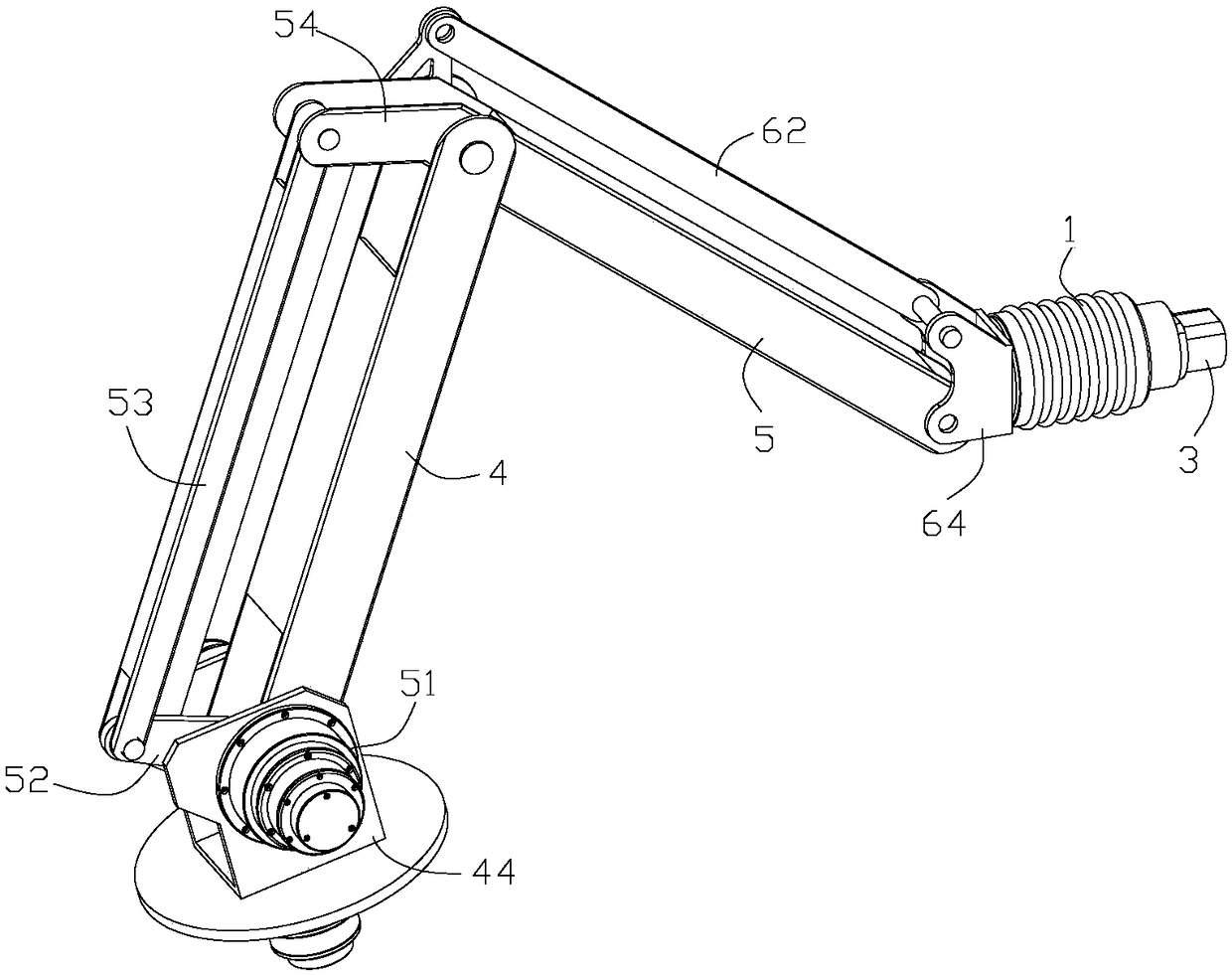

Charging robot and charging mechanical arm thereof

PendingCN108155700AAchieve rotationBatteries circuit arrangementsCharging stationsEngineeringElectric vehicle

The invention discloses a charging robot and a charging mechanical arm thereof. The charging mechanical arm comprises a moving arm and an adjusting arm, and the moving arm and the adjusting arm are connected with each other. The moving arm comprises at least two arm sections in a same moving plane, and each arm section is capable of rotating in the moving plane relative to the adjacent arm sectionto drive the adjusting arm in translational motion in the moving plane. The adjusting arm comprises a base, a mounting portion and an adjusting device, the mounting portion is used for being connected with a charging gun, and the adjusting device is used for driving the mounting portion to rotate around at least one of an X-axis, a Y-axis and a Z-axis relative to the base. By the charging adjusting arm, large-area movement of a charging gun in the moving plane can be realized while spatial rotation of the charging gun can be realized as well, a large moving space is available for the charginggun, the charging gun can be adjusted according to requirements to a position suitable for an electric vehicle to realize a charging process, adjusting the position through driving of the electric vehicle in a charging process is avoided, and convenience in implementation is achieved.

Owner:AUBO BEIJING ROBOTICS TECH CO LTD

Multi-axis linkage polishing device

ActiveCN106078396ARealize three-dimensional motionAchieve rotationEdge grinding machinesGrinding carriagesRotational axisEngineering

The invention discloses a multi-axis linkage polishing device which comprises a chassis, an X-axis motion mechanism, a Y-axis motion mechanism, a Z-axis motion mechanism, an R-axis motion mechanism, a W-axis motion mechanism, a V-axis motion mechanism, a polishing mechanism and a workpiece clamping mechanism. The W-axis motion mechanism is composed of a W-axis motor, a speed reducer and a swing arm, the speed reducer is fixed to the lower end of a rotary shaft, the output end of the W-axis motor is connected with the input end of the speed reducer, and the swing arm is fixed to an output shaft of the speed reducer. The polishing mechanism is composed of a polishing motor and a polishing head, the polishing motor is fixed to the swing arm, and the polishing head is fixed to an output shaft of the polishing motor. The multi-axis linkage polishing device achieves multistage linkage, different positions of a workpiece to be polished can be polished, the problem that the labor intensity is high during manual polishing is solved, work efficiency is improved, the beneficial effect is remarkable, and the multi-axis linkage polishing device is suitable for application and popularization.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

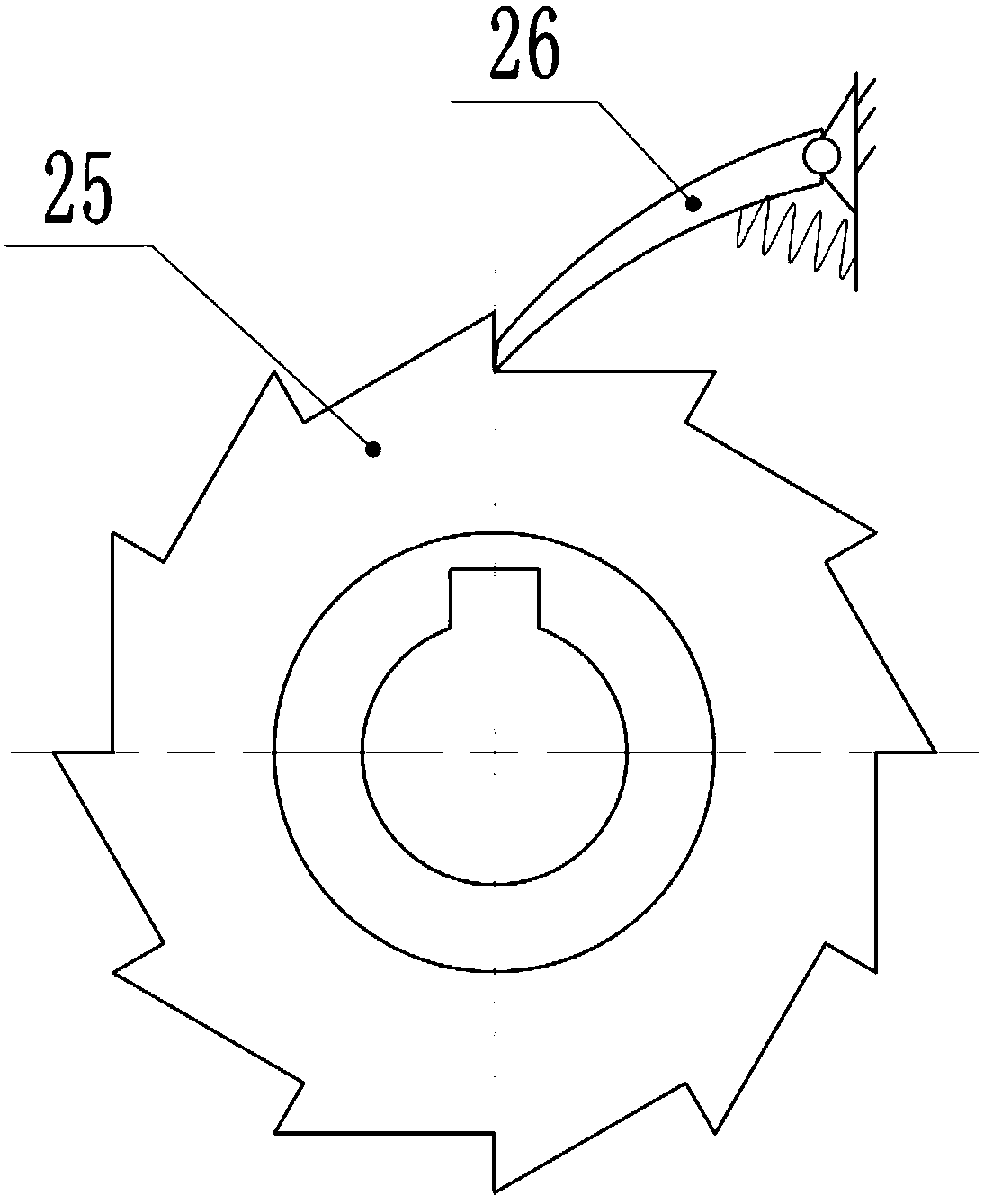

Board punching device

PendingCN108638225AEvenly punchedRealize Angle SwitchingEdge grinding machinesGrinding carriagesPunchingGear wheel

The invention belongs to the technical field of wood processing equipment, and particularly discloses a board punching device. The board punching device comprises a machine frame. A rotary table is arranged on the machine frame, a punching mechanism and a power mechanism are arranged on the upper portion of the machine frame, and the power mechanism drives the punching mechanism to ascend and descend. A crank and sliding block mechanism is arranged on the machine frame, a push rod which is fixedly connected with a sliding block is connected to the machine frame in a sliding mode, and an intermittent mechanism which drives the rotary table to conduct one-way intermittent rotation is connected between the push rod and the rotary table. A clamping mechanism is further arranged on the machineframe, and comprises a supporting rod. Two supporting plates are connected to the supporting rod in a sliding mode. A two-way lead screw is connected to the machine frame in a rotating mode, the two supporting plates are matched with the two-way lead screw through nuts, and the two-way lead screw and the push rod are connected through a gear and rack pair. Clamping plates and polishing discs are arranged on the inner sides of the two supporting plates, and transmission mechanisms which are used for driving the polishing discs to rotate are connected between the polishing discs and the two-waylead screw. By the adoption of the scheme, automatic rotation and clamping of a board are achieved in the drilling process, the working efficiency is high, and the labor intensity of workers is reduced.

Owner:重庆哲骁装饰工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com